Page 1

COMMON VENT SYSTEM

Features and Benefits

The Common Venng System provides for longer vent lengths and fewer wall or roof penetraons than

convenonal single-unit venng. CVent provides the necessary components for both combuson air and exhaust

and is made by Ubbink, the same supplier for Rinnai's innovave line of concentric venng. CVent ulizes a CSAcered and tested polypropylene venng material. The various secons are self locking and sealing and can be

pushed together without use of cement or glue. CVent can only be used with Rinnai’s RU98 condensing water

heaters.

For combuson air venng, Rinnai’s Common Venng System ulizes both CVent components and, if necessary for

extended vent runs, schedule 40 PVC.

The CVent Common Venng System can be used with up to 8 water heaters with a 41 foot equivalent vent length,

however if used with 7 or fewer units, the maximum equivalent vent length extends to 100 feet.

Advanced features include a precision-made check valve to prevent exhaust gases from penetrang non-operang

water heaters, avoiding negave impacts on combuson and reliability, as well as joint sockets designed to prevent

condensate from gathering in gaps and degrading gaskets.

The current version of CVent is made of polypropylene (PPtl) and is only for U.S. installaons.

Model Applicability

The common vent system is CSA cered (ANSI Z21.10.3, Gas Water Heaters Standards) for use only with the

Rinnai tankless condensing water heater RU98i (REU-KB3237FFUD-US).

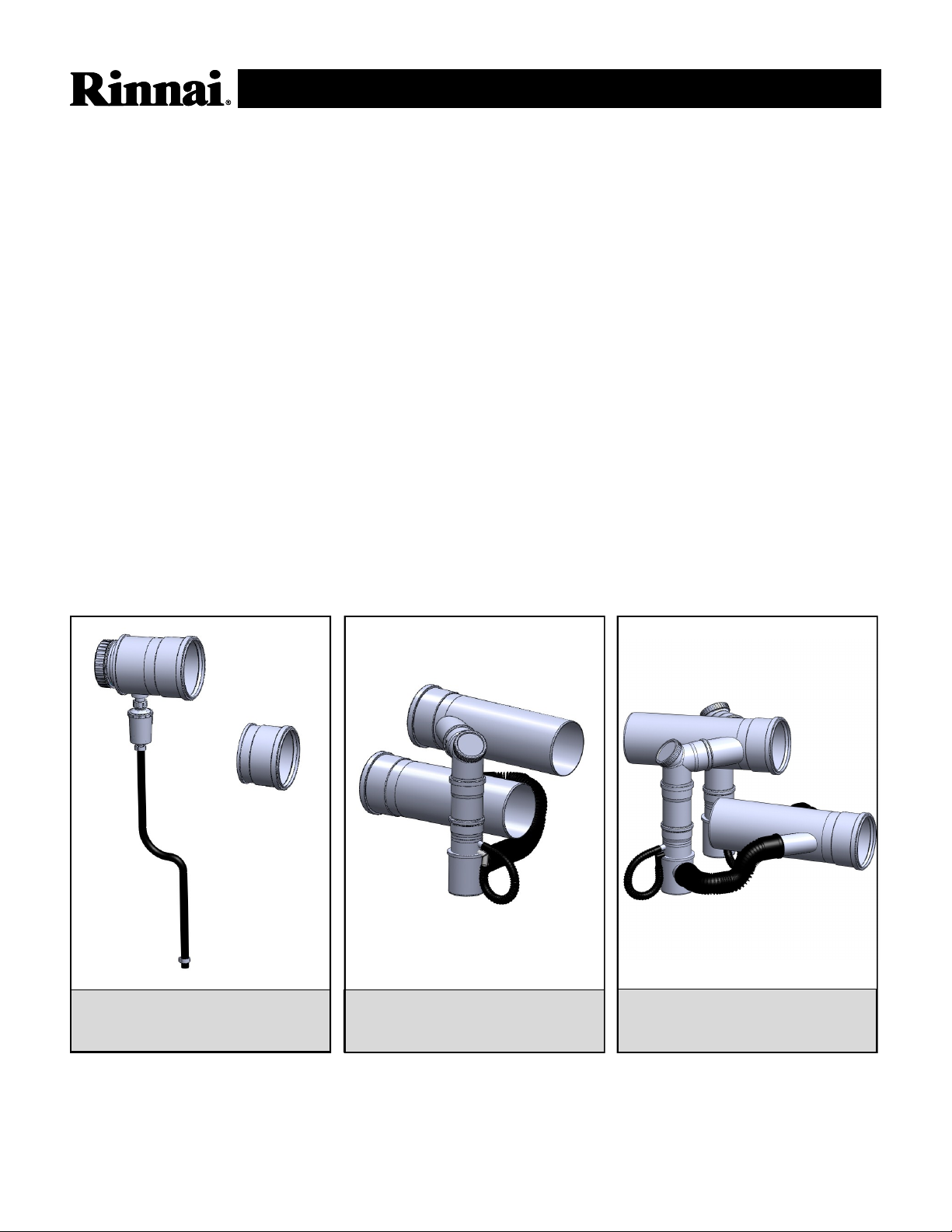

#790006 Cvent Starter Kit (Back-

2Back or InLine)

Rinnai Corporation • 103 International Drive • Peachtree City, GA 30269 • Toll-Free: 1-800-621-9419 • Fax: 678-829-1666 • www.rinnai.us

1 SP-CV-02 (2/13)

#790007 CVent InLine Kit

(Combustion Air & Exhaust)

#790008 CVent Back-2-Back Kit

(Combustion Air & Exhaust)

Page 2

COMMON VENT SYSTEM

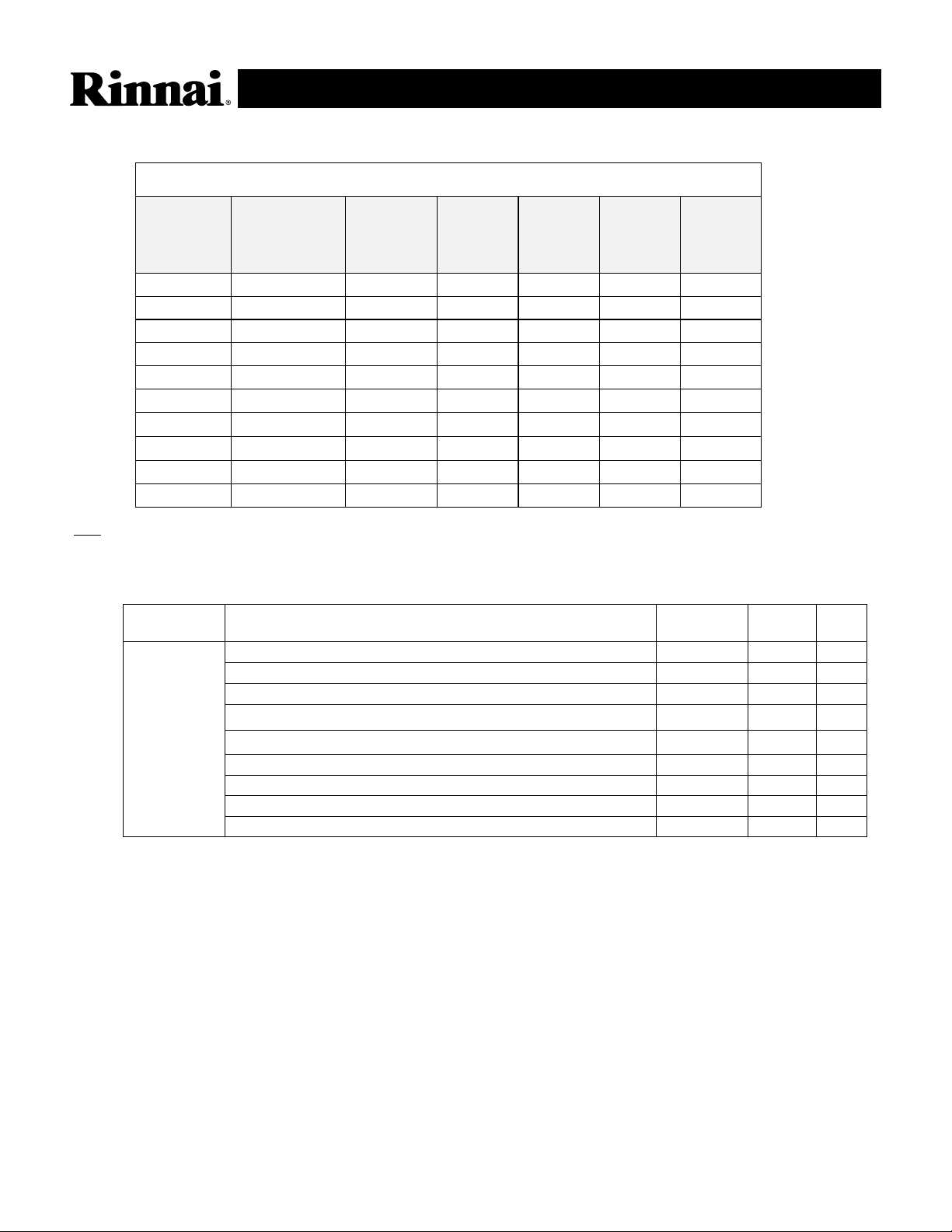

When ordering the CVent components and the Tankless Rack System (TRS) together, please use the following

table and part numbers.

CVent Components for the TRS

Back to

back Add-

on Kit

790008

18” Extension

790020

Part No. Configuration

For No. of

Water

Heaters

CVent

Starter Kit

790005

CVent

InLine Kit

790007

CV8IL4 in-line 4 1 4

CV8IL5 in-line 5 1 5 2

CV8IL6 in-line 6 1 6 2

CV8IL7 in-line 7 1 7 2

CV8IL8 in-line 8 1 8 2

CV8BB4 back-to-back 4 1 2

CV8BB5 back-to-back 5 1 1 2

CV8BB6 back-to-back 6 1 3

CV8BB7 back-to-back 7 1 1 3 2

CV8BB8 back-to-back 8 1 4 2

Key: CV = common vent; 8 = 8 inch diameter; IL/BB= in-line/back-to-back; 4/5/6/7/8 = no. of water heaters

When ordering the CVent exhaust components on their own, please use the following table and part nos.

Length/

Rinnai PN Description Ø Diameter

790005 CVent STARTER KIT, 8-inch For Back-2-Back or InLine

KIT COMPONENTS:

CVENT ENDPIECE (EXHAUST) W/ CLEANOUT & CONDEN-

CVENT COMBUSTION AIR ENDPIECE, D8

CVENT CONDENSATE TRAP (32mm Connection)

CVENT DRAIN HOSE

CVENT DRAIN HOSE CLAMP, L48

UBBINK INSTALLATION INSTRUCTIONS

CENTROCERIN LUBRICANT

8" 1

8” 1

1

48” 1

2

1

1

Other Qty.

Rinnai Corporation • 103 International Drive • Peachtree City, GA 30269 • Toll-Free: 1-800-621-9419 • Fax: 678-829-1666 • www.rinnai.us

2 SP-CV-02 (2/13)

Page 3

COMMON VENT SYSTEM

Parts / Kits

Length/

Rinnai PN Description Ø Diameter

790007

790008

790001

790002 CVent 8-in Flat Roof Flashing

790003 CVent 8-in Pitched Roof Flashing

790004 Cvent 8-in Wall Termination Kit (Combustion Air & Exhaust)

CVent InLine Kit, 8-in Header Kit For InLine Cumbustion Air & Exhaust

KIT COMPONENTS:

CVENT COLLECTOR, 1 CONNECTION, D8 X L20 X D4 (Exhaust)

CVENT ELBOW D4 X 87° WITH CLEANOUT

CVENT EXTENTION, D4 X L18

CVENT APPLIANCE ADAPTER, CHECK VALVE AND HOSE TRAP

CVENT COMBUSTION AIR COLLECTOR, 1 CONNECTION, D8 X L20 X D3

CVENT COMBUSTION AIR FLEX FITTING, D3

CENTROCERIN LUBRICANT

CVent Back-2-Back Kit, 8-in Header Kit For Back-2-Back Combustion Air

and Exhaust

KIT COMPONENTS:

CVENT COLLECTOR, 2 CONNECTION, D8 X L20 X D4 X D4 (Exhaust)

CVENT ELBOW D4 X 87° WITH CLEANOUT

CVENT EXTENSION, D4 X L18

CVENT APPLIANCE ADAPTER WITH CHECK VALVE AND HOSE TRAP

CVENT COLLECTOR, 2 CONNECTION, D8 X L20 X D3 X D3 (Combustion Air)

CVENT COMBUSTION AIR FLEX FITTING, D3

CENTROCERIN LUBRICANT

Cvent 8-in Roof Termination Kit

CVENT 8-IN ROOF TERMINATION

PP-PVC ADAPTER (For Combustion Air PVC Transition)

CENTROCERIN LUBRICANT

CVENT FLAT ROOF FLASHING

CVENT PITCHED ROOF FLASHING, INCLUDING STORM COLLAR

WALL TERMINATION + STAINLESS STEEL GRATE + WALL PLATE (2pc)

CENTROCERIN LUBRICANT

8" X 4” 20" 1

4" 87° 1

4" 18" 1

5” X 4” X 3” 1

8” X 3” 20” 1

3” 24” 1

8" 20" 1

4" 87° 2

4" 18” 2

5” X 4” X 3” 10" 2

8” X 3” 20” 1

3” 24” 2

8" 1

8" 1

1

8" 1

8" 1

8" 3' 1

1

Other Qty.

1

1

Rinnai Corporation • 103 International Drive • Peachtree City, GA 30269 • Toll-Free: 1-800-621-9419 • Fax: 678-829-1666 • www.rinnai.us

3 SP-CV-02 (2/13)

Page 4

Parts / Kits

Rinnai PN Description Ø Diameter Length/Other

COMMON VENT SYSTEM

790020 CVent Extension, D8 x L18 8" 18"

790021 CVent Extension, D8 x L39 8" 39"

790022 CVent Elbow D8 x 45degree (2 in a box) 8" 45°

790023 CVent Elbow D8 x 90degree 8" 87°

790024 CVent 8-in Brackets 8"

790025 Centrocerin lubricant

790035 CVent Extension, D4 x L18 4" 18"

790028 CVent Extension, D4 x L39 4" 39"

790029 CVent Elbow D8 x 90degree Vertical Support 8"

790030 CVent 8-in Chase Cover 8"

790031 CVent 8-in Vent Distancer, stainless steel 8"

790034 CVent 8-in Vent Rain Cap 8"

790032 Inverter Coupling Kit with condensate trap 8"

780037 Combustion Air PVC Adapter Kit 8"

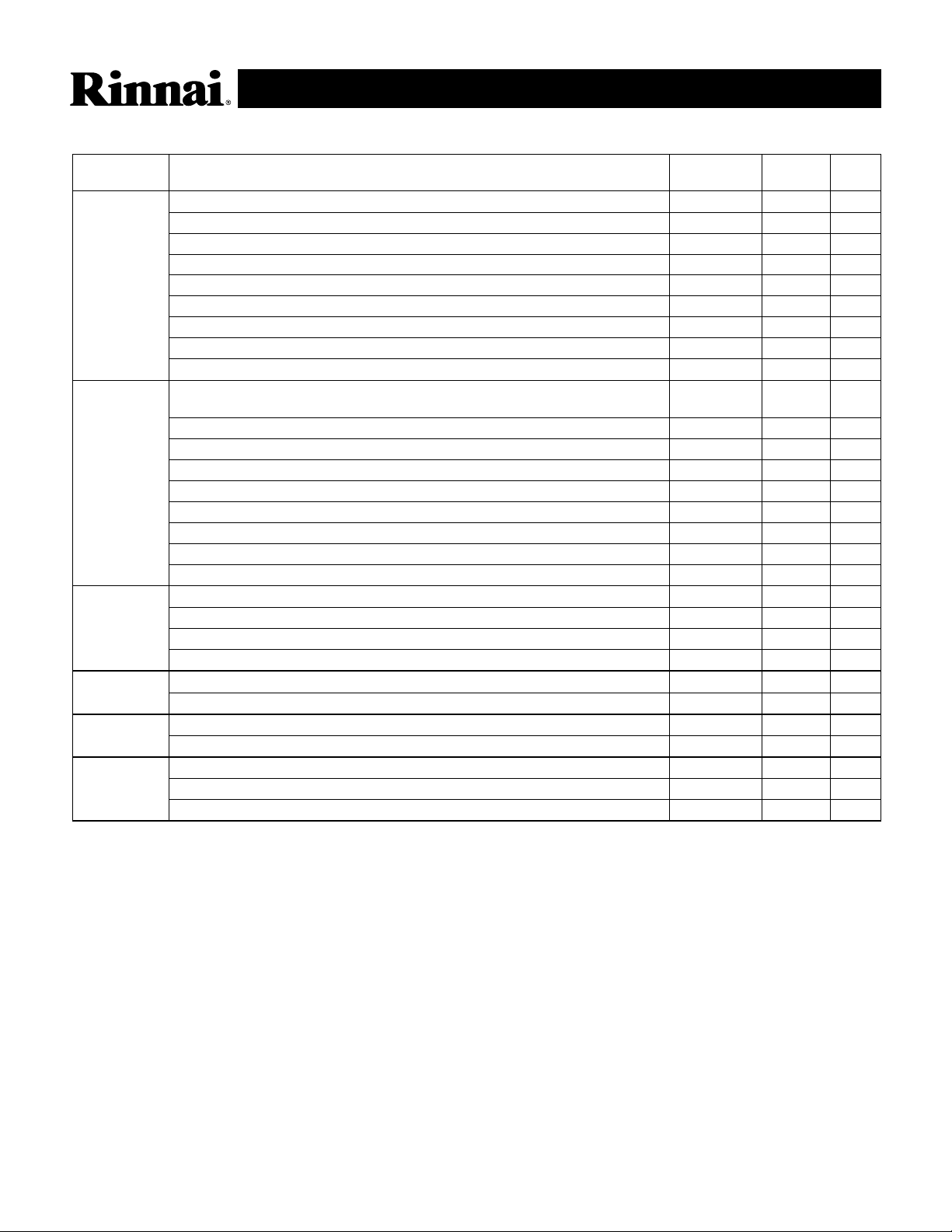

Maximum Equivalent Vent Length

When determining equivalent exhaust and intake vent

lengths add:

• 6 feet for each 90° elbow

• 3 feet for each 45° elbow

• 3 feet for the termination

Number of water

heaters

1 to 7 5 ft 15 ft 100 ft 100 ft

8 5 ft 15 ft 41 ft 41 ft

*Approved exhaust and intake diameter is 8 inches.

Minimum Equivalent Vent Length Maximum Equivalent Vent Length

Exhaust* Intake* Exhaust* Intake*

• Add any vent extension lengths which are added

within the header due to increased spacing of the

water heaters

• Header kits have already been counted and do

not need to be added.

De-Rate

Water heaters using CVent will automatically de-rate according to the table below.

Number of

water

heaters

1 0% 199,000 3.0 0.42 15,200

2 1% 394,000 3.1 0.42 30,400

3 1.5% 588,000 3.1 0.42 45,600

4 2% 780,000 3.1 0.42 60,800

5 2.5% 970,000 3.2 0.45 76,000

6 3% 1,158,000 3.2 0.45 91,200

7 3.5% 1,344,000 3.2 0.45 106,400

8 4% 1,528,000 3.2 0.45 121,600

Rinnai Corporation • 103 International Drive • Peachtree City, GA 30269 • Toll-Free: 1-800-621-9419 • Fax: 678-829-1666 • www.rinnai.us

4 SP-CV-02 (2/13)

Percent

De-rated

Total BTU Rate

Manifold Pressure

Maximum

Rate “W.C.

Minimum

Rate “W.C.

Btu’s at

Minimum Rate

(without MSB)

Btu’s at

Minimum Rate

(with MSB)

15,200

Page 5

790005 CVENT STARTER KIT

8-Inch For Back–2-Back or InLine (Combustion Air & Exhaust)

COMMON VENT SYSTEM

NO QTY DESCRIPTION

1 1

2 1 CVENT COMB AIR ENDPIECE D8

3 1 CVENT CONDENSATE TRAP (32mm Connection)

4 1 CVENT DRAIN HOSE

5 2 CVENT DRAIN HOSE CLAMP

6 1 UBBINK INSTALLATION INSTRUCTION

7 1 CENTROCERIN LUBRICANT

CVENT ENDPIECE (EXHAUST) W/ CLEANOUT & CONDENSATE DRAIN (32mm)

790007 CVENT INLINE KIT

2

1

Qty. 1

Qty. 1

7

5

3

Qty. 1

Qty. 2

Qty. 1

4

8-Inch Header Kit For InLine (Combustion Air & Exhaust)

Qty. 1

1 5

Ø4”

2 4

Qty. 1

3 6

NO QTY DESCRIPTION

1 1 CVENT COLLECTOR, 1 CONNECTION, D8 X L20 X D4 (Exhaust)

2 1 CVENT ELBOW D4 X 87° WITH CLEANOUT

3 1 CVENT EXTENTION, D4 X L18

4 1 CVENT APPLIANCE ADAPTER, CHECK VALVE AND HOSE TRAP

5 1 CVENT COMB. AIR COLLECTOR, 1 CONNECTION, D8 X L20 X D3

6 1 CVENT COMB AIR FLEX FITTING, D3

7 1 CENTROCERIN LUBRICANT

Rinnai Corporation • 103 International Drive • Peachtree City, GA 30269 • Toll-Free: 1-800-621-9419 • Fax: 678-829-1666 • www.rinnai.us

5 SP-CV-02 (2/13)

7

Qty. 1

Ø3”

Qty. 1 Qty. 1

Qty. 1

Page 6

COMMON VENT SYSTEM

790008 CVENT BACK-2-BACK KIT

8-Inch Header Kit For Back-2-Back (Combustion Air & Exhaust)

NO QTY DESCRIPTION

1 1 CVENT COLLECTOR, 2 CONNECTION, D8 X L20

2 2 CVENT ELBOW D4 X 87° WITH CLEANOUT

3 2 CVENT EXTENSION, D4 X L18

4 2

5 1

6 2 CVENT COMB. AIR FLEX FITTING, D3

7 1 CENTROCERIN LUBRICANT

CVENT APPLIANCE ADAPTER WITH CHECK

VALVE AND TRAP

CVENT COMB. AIR COLLECTOR, 2 CONNECTION,

D8 X L20 X D3

Qty. 1

1 5

Qty. 2

Ø4”

Ø4”

2 4

Qty. 2

3 6

7

Qty. 1

Qty. 2

Qty. 2

Ø3”

Ø3”

Rinnai Corporation • 103 International Drive • Peachtree City, GA 30269 • Toll-Free: 1-800-621-9419 • Fax: 678-829-1666 • www.rinnai.us

6 SP-CV-02 (2/13)

Page 7

CVent Terminaon Clearances

Vertical Termination

There should be a minimum of 36 inches between exhaust

terminations in multiple common vent installations.

COMMON VENT SYSTEM

36” MINIMUM INSIDE

EDGE TO INSIDE EDGE

12” OVER MAX.

SNOW LEVEL OR

24” WHICHEVER

IS GREATER

EXHAUST - CVent

INTAKE - PVC

Clearances of Brackets

All supports such as wall brackets on the

external façade or spacer blocks in a

shaft must be assembled in a maximum

distance of 78 in (2 m). Where there is a

bend, additional spacer blocks or wall

brackets can be planned before and after

the bend, depending on the local

situation.

Freestanding Components

Components, which are assembled

freestanding vertical (roof termination)

with a length of more than 59 in (1.5 m),

must, depending on the amount of wind

and snow level expected, be additionally

secured to the building with guys or

braces.

Intake Material

The materials described below can only be used on the combustion air vent. The Ubbink Polypropylene CVent can

be used on both the combustion air and exhaust. Field supplied PVC/CPVC material can only be used on the

combustion air side and MUST NOT be used for the exhaust.

Approval Codes for Installation

Item Description Flue Material United States

PVC Schedule 40 ANSI/ASTM D1785

Plastic Vent and/or combustion air

components

PVC - DWV ANSI/ASTM D2665

CPVC Schedule 40 ANSI/ASTM F441

PVC ANSI/ASTM D2564

Plastic pipe cement and primer

CPVC ANSI/ASTM F493

Options for Combustion Air Vent:

•For extended Combustion Air vent runs, PVC can be used between the Intake Header and Termination.

•Use Combustion Air PVC Adapter Kit (Part #: 780037) when transitioning from the PP intake header to

extended PVC combustion air vent runs. .

Rinnai Corporation • 103 International Drive • Peachtree City, GA 30269 • Toll-Free: 1-800-621-9419 • Fax: 678-829-1666 • www.rinnai.us

7 SP-CV-02 (2/13)

Page 8

COMMON VENT SYSTEM

CVent Termination Clearance

This appliance along with the CVent Common Vent System is certified with the Cvent 8-in Wall

Termination Kit,(790004) mounted in the orientation shown below.

Horizontal Termination

The exhaust and combustion air terminations must

follow these clearances:

[1] 12 inch minimum vertically from bottom of exhaust

termination to top of intake termination.

[2] 12 inch minimum vertically from bottom of

combustion air termination to ground or anticipated

snow line.

[3] From edge of exhaust termination to edge of

combustion air termination:

Minimum of 36 inches

Maximum of 20 feet

[4] 36 inch minimum from multiple exhaust CVents

There should be a minimum of 36 inches between

exhaust terminations in multiple common vent

installations.

Vertically

Combustion

Air Vent

Combustion

Air Vent

Vertically

The vent (exhaust & combustion air) terminations must

be in the same pressure zone and face the same

direction.

NOTE: During colder weather when the exhaust tem-

perature is much hotter than the outside air, the

exhaust fumes condense producing water vapor. As a result a plume of water vapor may be

seen leaving the exhaust.

EXHAUST

VENT

MAXIMUM 20’

MINIMUM 36”

COMBUSTION

AIR

VENT

Rinnai Corporation • 103 International Drive • Peachtree City, GA 30269 • Toll-Free: 1-800-621-9419 • Fax: 678-829-1666 • www.rinnai.us

8 SP-CV-02 (2/13)

Loading...

Loading...