Riello GS10 Installation, Use And Maintenance Instructions

Manuel d’entretien

Installation, use and maintenance instructions

Instrucciones para la instalación, uso y mantenimiento

Montage und Bedienungsanleitung

2902721 (0)

Gas-Gebläsebrenner

Brûleur gaz à air soufflé

Forced draught gas burner

Quemador de gas de aire soplado

CODE - CÓDIGO

MODELL - MODELE - MODEL - MODELO TYP - TYPE - TIPO

3755426

GS10 554T1

D

F

GB

E

Einstufiger Betrieb

Fonctionnement à 1 allure

One stage operation

Funcionamiento de una llama

2721

1

GB

INDEX

1. BURNER DESCRIPTION

Gas burner with one stage working.

1.1 BURNER EQUIPMENT

Insulating gasket . . . . . . . . . . . . . No. 1 Screws and nuts for flange to be fixed to boiler . . . No. 4

Cable grommet . . . . . . . . . . . . . . No. 1 Screw for fixing the cover . . . . . . . . . . . . . . . . . . . No. 1

Hinge . . . . . . . . . . . . . . . . . . . . . . No. 1 7 pin plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . No. 1

1. BURNER DESCRIPTION . . . . . . . . . . . 1

1.1 Burner equipment . . . . . . . . . . . . . . . . . 1

2. TECHNICAL DATA . . . . . . . . . . . . . . . . 2

2.1 Technical data . . . . . . . . . . . . . . . . . . . . 2

2.2 Overall dimensions . . . . . . . . . . . . . . . . 2

2.3 Working field . . . . . . . . . . . . . . . . . . . . . 2

3. INSTALLATION. . . . . . . . . . . . . . . . . . . 3

3.1 Boiler fixing . . . . . . . . . . . . . . . . . . . . . . 3

3.2 Probe-electrode positioning . . . . . . . . . . 4

3.3 Gas feeding line . . . . . . . . . . . . . . . . . . 4

3.4 Electrical wiring . . . . . . . . . . . . . . . . . . . 5

3.4.1 Standard electrical wiring . . . . . . . . . . . 5

3.4.2 Electrical wiring with gas leak control

device . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. WORKING . . . . . . . . . . . . . . . . . . . . . . . 6

4.1 Combustion adjustment . . . . . . . . . . . . . . 6

4.2 Combustion head setting. . . . . . . . . . . . . 6

4.3 Air damper setting . . . . . . . . . . . . . . . . . . 7

4.4 Combustion check. . . . . . . . . . . . . . . . . . 7

4.5 Air pressure switch . . . . . . . . . . . . . . . . . 7

4.6 Burner start-up cycle . . . . . . . . . . . . . . . . 8

4.7 Start-up cycle diagnostics . . . . . . . . . . . . 8

4.8 Operating fault diagnostics . . . . . . . . . . . 9

5. MAINTENANCE . . . . . . . . . . . . . . . . . . . 9

6. FAULTS / SOLUTIONS . . . . . . . . . . . . . . 10

1 – Air damper actuator

2 – Air dampers

3 – 7 pole socket for electrical supply

and control

4 – 6 pole socket for gas train

5 – Cable grommet

6 – Screw for fixing the cover

7 – Air pressure switch

8 – Control box

9 – Reset button with lock-out lamp

■

The burner meets protection level of IP 40, EN 60529.

■

CE marking according to Gas Appliance directive 90/396/EEC; PIN 0063AP6680.

According to directives: EMC 89/336/EEC, Low Voltage 73/23/EEC, Machines 98/37/EEC and

Efficiency 92/42/EEC.

■

Gas train according to EN 676.

NOTE

The cable grommet (5) and the screw for fixing the cover (6) supplied with the

burner, must be fitted to the same side of the gas train.

Fig. 1

D4181

6

5 3

2

19

8

7

4

2721

2

GB

2. TECHNICAL DATA

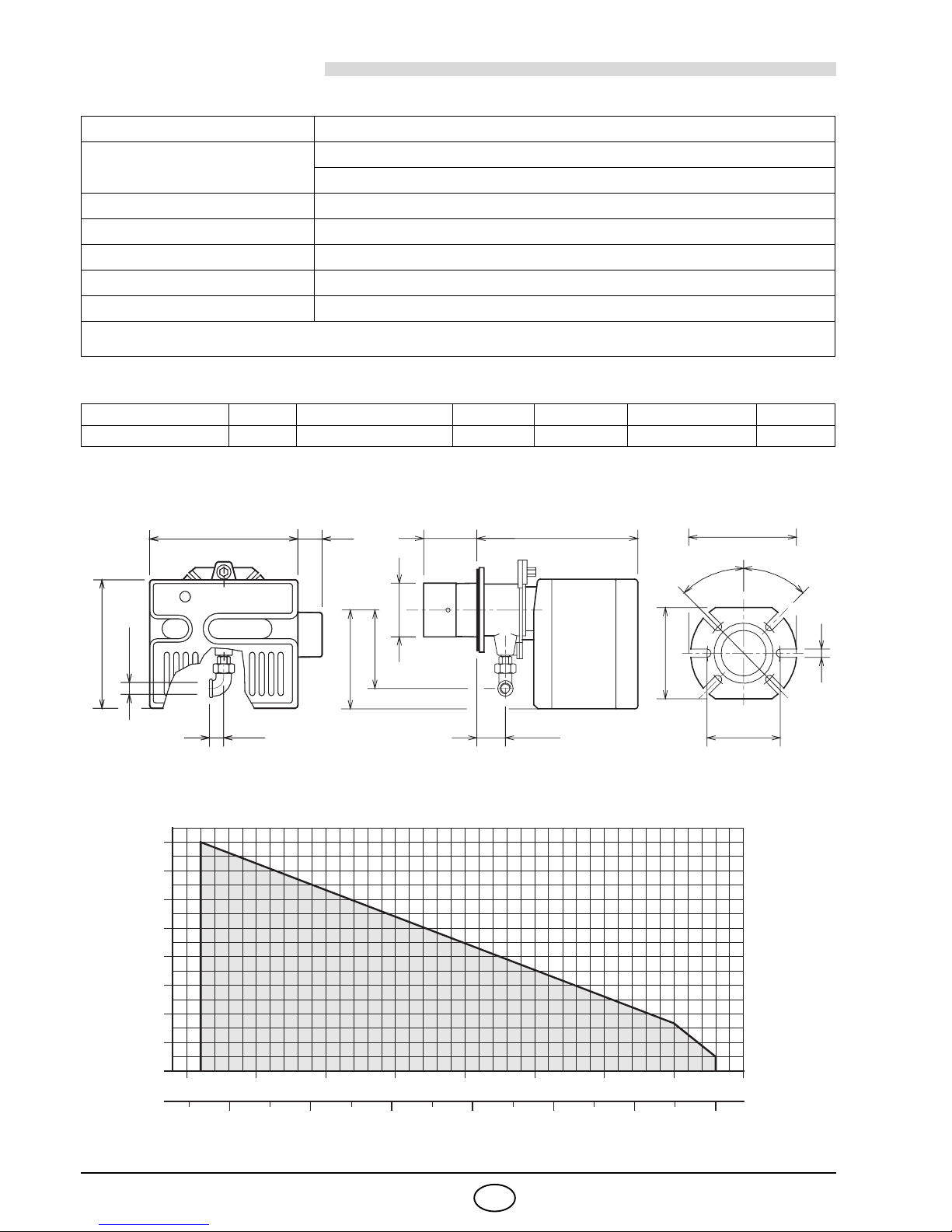

2.1 TECHNICAL DATA

For gas family 3 (LPG) ask for separate kit.

2.2 OVERALL DIMENSIONS

2.3 WORKING FIELD

(as EN 676)

Thermal power (1) 42 – 116 kW - 36,000 – 100,000 kcal/h

Natural gas

(Family 2)

Net heat value: 8 – 12 kWh/Nm

3

- 7,000 – 10,340 kcal/Nm

3

Pressure: min. 16 mbar - max. 100 mbar

Electrical supply Single phase, 230 V

±

10% ~50Hz

Motor 230V / 0.7A

Capacitor 2

µF

Ignition transformer

Primary 230V / 1.8 A - Secondary 8 kV / 30 mA

Absorbed electrical power 0.13 kW

(1) Reference conditions:

Temp. 20°C - Barometric pressure 1013 mbar – Altitude 0 m above sea level.

COUNTRY FR DK - AT - GR - SE - IT LU DE GB - IE - ES - PT NL

GAS CATEGORY II2Er3P II2H3B/P II2E3B/P II2ELL3B/P II2H3P II2L3B/P

■

Combustion head extension, supplied separately.

FlangeBurner

305 110 346 185

33 61

45°

36

ø 105

262

160

Rp 3/4

204

142

■

170

D4201

130

11

45°

Thermal power

D5256

0.8

0

0.2

0.4

0.6

40,000 50,000 60,000 70,000

kcal/h

1206050 70 80 kW

1.0

110

80,000

1.2

90 100

90,000

1.4

40

1.6

100,000

Pressure in the combustion

chamber – mbar

2721

3

GB

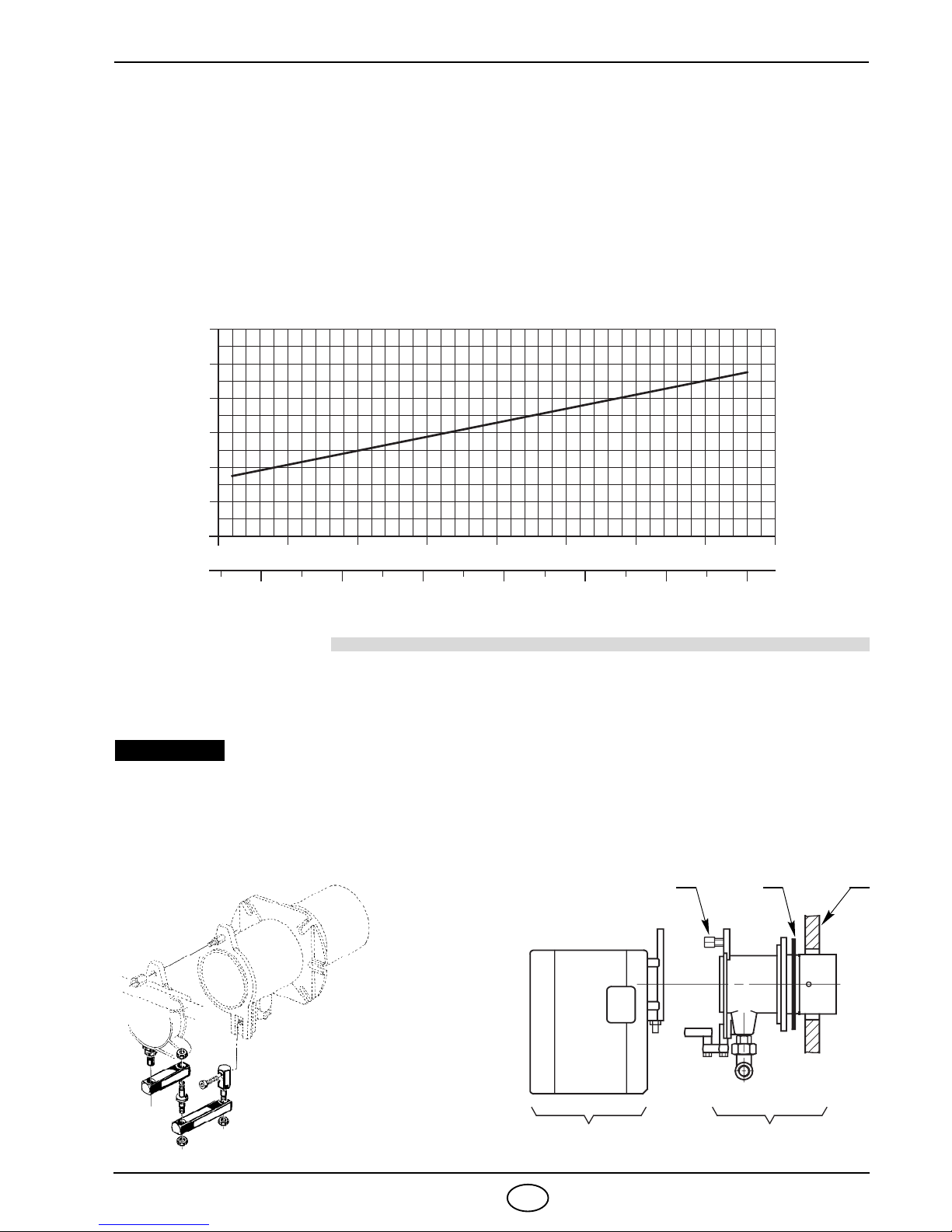

TEST BOILER

The working field has been defined according to EN 676 standard.

COMMERCIAL BOILERS

The burner-boiler matching is assured if the boiler conforms to EN 303 and the combustion chamber dimensions are similar to those shown in the diagram EN 676. For applications where the boiler does not conform to

EN 303, or where the combustion chamber is much smaller than the dimensions given in EN 676, please consult the manufacturers.

CORRELATION BETWEEN GAS PRESSURE AND BURNER OUTPUT

To obtain the maximum output, a gas head pressure of 5.8 mbar is measured (M2, see chapter 3.3, page 4) with

the combustion chamber at 0 mbar using gas G20 with a net heat value of 10 kWh/Nm

3

(8,570 kcal/Nm3).

3. INSTALLATION

THE BURNER MUST BE INSTALLED IN CONFORMITY WITH LEGISLATION AND LOCAL STANDARDS.

3.1 BOILER FIXING

4

1

2

3

5

6

7

Gas pressure in the

combustion head – mbar

40,000 50,000 60,000 70,000 kcal/h

1206050 70 80 kW

Thermal power

D5257

110

80,000

90 100

90,000

40

100,000

S7392

1 3 2

A B

D6323

HINGE

ASSEMBLY

Boiler door must have a max. thickness of 90 mm,

refractory lining included.

If thickness is greater (max. 150 mm), a combustion

head extension must be fitted, which is supplied

separately.

IMPORTANT

■

Separate the combustion-head assembly

from the burner body by removing nut (1) and

removing group (A).

■

Fix the head assembly group (B) to the boiler

(2) inser t the supplied insulating gasket (3).

Loading...

Loading...