RIDGID TS3612 Owner's Manual

76

2:1(560$18$/

)RU<RXU6DIHW\

5HDGDOOLQVWUXFWLRQVFDUHIXOO\

6DYHWKLVPDQXDOIRUIXWXUH

UHIHUHQHFH

,1&+&2175$&725

6(5,(6%(/7'5,9(6$:

Part No. SP6461 Printed in U.S.A.

Table of Contents

Section Page

Table of Contents ..........................................2

Safety Instructions For Table Saw ................3

Safety Signal Words ..................................3

Before Usi ng The Saw ............................... 3

When Installing Or Moving The Saw ............ 4

Before Each Use ........................................... 4

To Reduce the Risk of Injury From Jams, Slips Or

Thrown Pieces (Kickbacks Or Throwbacks) ..5

Plan Ahead To Protect Your Eyes, Hands,

Face and Ears ............................................ 6

Whenever Sawblade Is Spinning ................. 7

Additional Safety Instructions For: Ripping ... 8

Additional Safety Instructions For: Crosscut . 9

Additional Safety Instructions For

Herc-U-Lift™ Caster System: ................... 9

Glossary of Terms for Woodworking ............. 9

Motor Specifications and Electrical

Requirements ......................................... 11

Power S upply an d Motor Specifications ..11

General Electrical Connections ...............11

Changing Motor Voltage ..........................13

Motor Thermal Overload Protector .......... 14

Wire Sizes ................................................ 14

Unpacking and Checking Contents .............15

Tools Needed ........................................... 15

Unpac king ..... ........... ........ ........... ............ .. 1 5

List of Loose Parts .................................... 16

Herc-U-Lift™ Caster Carton .....................17

Loose Parts ............................................... 17

Assemb ly ..... ........... ............ ........... ........ ......17

Installing Handwheels ...............................17

Assemb lin g Le g Sta nd ..............................1 8

Mountin g You r Saw ......... ......................... 19

Assemb lin g Ta ble Extens i on s . .... .... .... ......20

Checking Table Insert ...............................21

Checking Heeling Adjustment or Parallelism

of Sawblade to Miter Gauge Groove ......22

Checki ng Blade Tilt, or Squareness of Blade

to Table ..................................................24

Checking Tilt Mechanism ..........................25

Assembling Herc-U-Lift™ Caster System . 26

Assembly Tips .......................................... 26

Upper Assembly ....................................... 26

Lower Assembly ....................................... 27

Assembling Herc-U-Lift™ Caster System to

Saw ........................................................28

Installation Instructions ............................. 28

Operation of Herc-U-Lift™ Caster System 29

Installing Front Rip Fence Guide Bar ........30

Installing Rear Fence Guide Bar ............... 31

Adjus tin g Rip Fence G uide Bars . .............. 32

Installing Spacer Bar .................................33

Rip Fence Alignment Adjustment .............34

Rip Fence Lock Lever Adjustment ............34

Adjus tin g Fenc e Ind icat or ....... ..................35

Installing Blade Guard .............................. 35

Aligning Blade Guard ................................36

ection Page

S

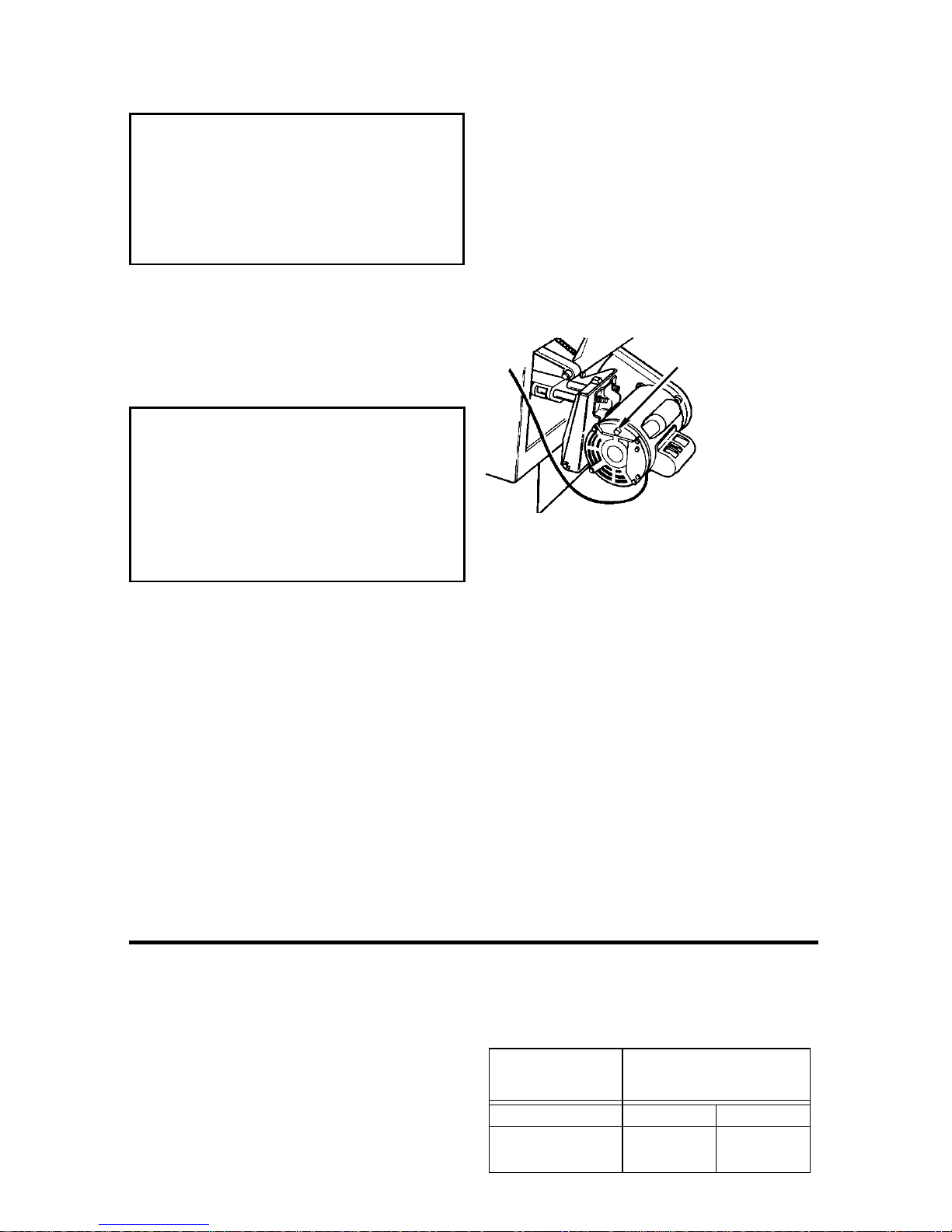

Mounting the Motor ...................................37

Installing Belt ............................................38

Installing Belt Guard ................................. 38

Mounting Switch and End Caps ................ 39

Securing Electrical Cords .........................40

Installing Guide Bar End Caps ..................40

Getting to Know Your Table Saw ................ 41

Additional Safety Instructions When Using Zero

Clearanc e Inse rt ... ... .... ............................43

Remove the Existing Metal Insert..............43

Installing Zero Clearance Insert/S awblade 43

Installing Zero Clearance Insert/Dado Blades44

Operation Tips ..........................................45

Safety Instructions for Basic Saw Operations 48

Before Each Use .........................................48

To Reduce the Risk of Injury From Jams, Slips Or

Throw n Pi eces (Kic kba cks Or Thro w backs ) 48

Plan Ahead To Protect Your Eyes, Hands,

Face and Ears ..........................................49

Whenever Sawblade Is Spinning ............. 50

Work Feed Devic e s ............. ........................ 51

Attaching Wood Face Board .....................51

Push Block . .... .... .... ................................... 52

Auxiliary Fe nce .. .... ... .... ............................53

Fence Extension........................................54

Basic Saw Operations ................................. 55

Using the Miter Gauge ..............................55

Additional Safety Instructions for Crosscutting 55

Crosscu tting ....... ........... ........ ........... ......... 55

Repetitive Crosscutting .............................56

Miter Crosscutting .....................................57

Bevel Crosscutting ....................................57

Compoun d Cros scu tti ng ........................... 57

Using the Rip Fence .................................58

Additional Safety Instructions for Rip Cuts 58

Ripping ... ........ ........ ....... .... ........ ....... ........ . 59

Bevel Ripping Narrow Work ......................60

Using Featherboards for Thru-Sawing ......61

Using Featherboards for

Non Thru-Sawing ....................................61

Resawing .................................................. 62

Using Carbide Tipped Blades ...................63

Dadoing ....................................................63

Rabbeting .................................................64

Ploughing and Molding .............................64

Molding ..................................................... 65

Adjustmen ts .. .... .... .... ................................... 66

Miter Gauge .............................................. 66

Maintaining Your Table Saw ....................... 67

Maintenance ............................................. 67

Lubrication ................................................ 68

RIDGID Recommends the Following

Accessories ............................................ 68

Troublesh ootin g ........ ....... ........ ....... .... ........ .69

General .. ................................................... 69

Motor .. .... .... ............................................... 70

Repair Parts ................................................72

2

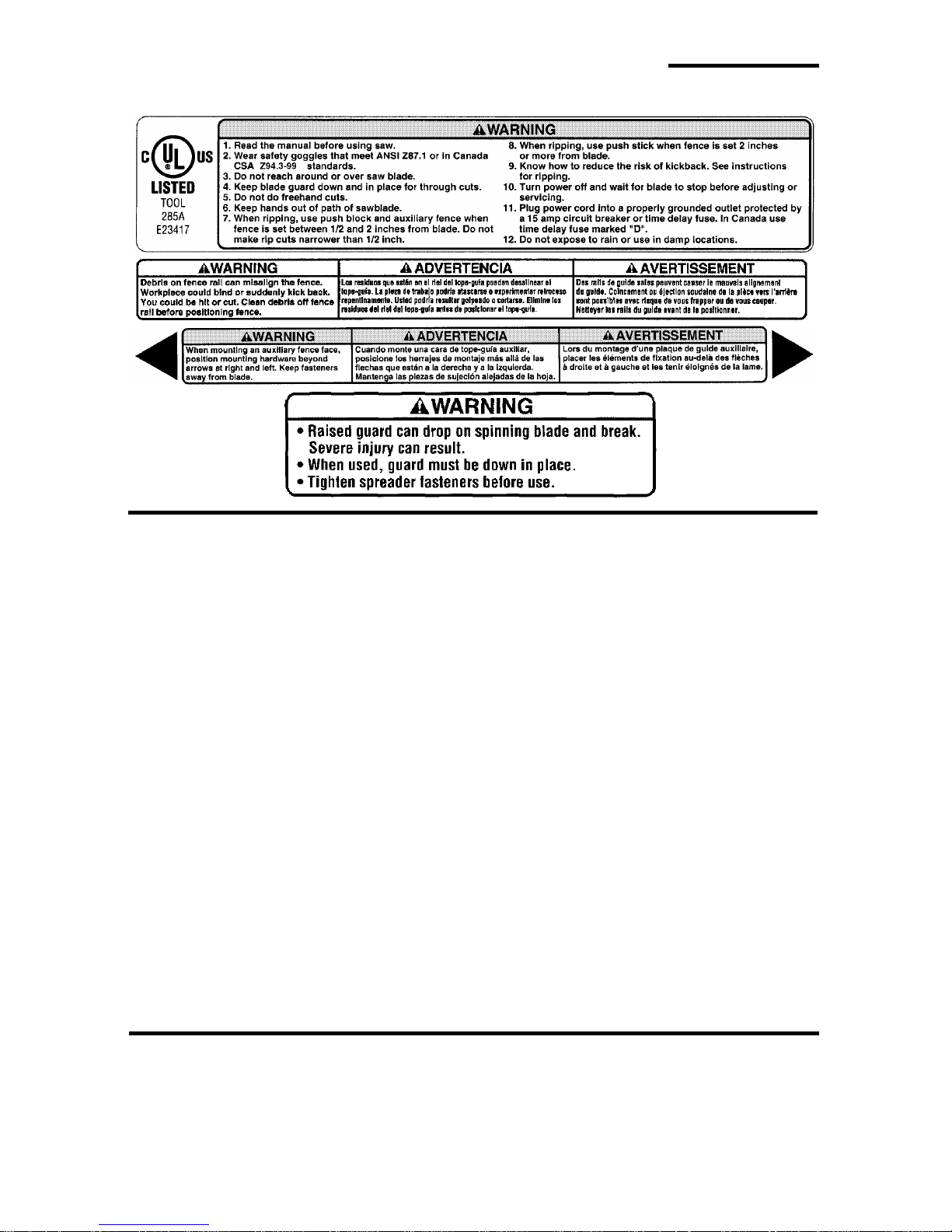

Safety Instructions For Table Saw

Safety is a combination of common sense, staying alert and know ing how

your table saw works. Read this manual to understand this table saw.

Safety Signal Words

DANGER: means if the safety infor-

mation is not followed someone will

be seriously injured or killed.

WARNING: means if the safety information is not followed someone

Before Using The Saw

WARNING: Some dust created by

power sa ndin g, s awi ng, gri ndi ng,

drilling, and other construction

activities contains chemica ls

known (to the State of California)

to cause cancer, birth defects or

other rep r od uc ti v e harm. Some

examples of these chemicals are:

Lead from lead-bases pain ts

• Crystalline silica from bricks

and cement and other mason ry

produc ts , and

• Arsenic and chromium from

chemically-treate d lumber.

Y o ur risk from these exposures

varies , depending on how often

you do th is type of work. To

reduce your exposure to these

chemicals: work in a well ventilated area, and work with

approved safety equipment,

such as those dust masks that

are specially designed to filter

out microscopic particles.

could be seriously injured or killed.

CAUTION: means i f th e safety infor-

mation is not followed someone may

be injured.

WARNING: To reduce the risk of

mistakes that could cause serious, per ma nent injury, do not

plug the tabl e saw in unti l the fo llowing steps have been satisfactorily completed.

• Completely assemble and align saw

(See “Assembly” section).

• Learn the use and function of the

ON-OFF switch, blade guard,

spreader, anti-kickback device,

miter gauge, rip fence, table insert,

blade elevation and blade tilt controls (See “Getti ng to Know Your

Table Saw” section).

• Review and underst and all safety

instructions and operating procedures in this manual.

• Review the maintenance methods

for this saw ( See “Maintaining Your

Table Saw” section)).

3

Safety Instructions For Table Saw (continued)

• Find and read all the warning labels found on the saw (shown below).

When Installing Or Moving The Saw

Reduce the Risk of Dangerous

Environment.

• Use the saw in a dry, indoor place

protected from rain.

• Keep work area well lighted.

• Use recommended accessori es.

Consult the owner’s manual for recommended accessories. The use of

improper accessories may cause

risk of injury to persons.

To reduce the risk of injury from

unexpected saw movement.

• Bolt or clamp the saw to firm level

surface where there is plenty of

room to handle and properly support

the workpiece (See “Assembly-

Mounting Your Saw” section).

• Support the saw so the table is level

and the saw does not rock.

• When using a table extension longer

• Put the saw where neither operator

• To reduce the risk of injury from

• Never St and On Tool. Serious

than 12" attached to any side of the

saw, bolt the saw to a stationary surface or prop up the outer end of the

extension from the floor or bench

top to keep the saw from tipping.

nor bystanders must stand in line

with the sawblade.

electrical shock, make sure your fingers do not touch the plug’s metal

prongs when plugging in or unplugging the saw.

injury could occur if the tool tips or

you accidentally hit the cutting tool.

Do not store anything above or near

the tool where anyone might stand

on the tool to reach them.

Before Each Use

Inspect your saw.

• To reduce the risk of injury from

accidental starting, turn the switch

off, unplug the saw, and remove the

switch key before raising or removing the guard, changing the cutting

tool, changing the setup, or adjusting anything. Make sure switch is in

4

OFF position before plugging in.

• Check for alignment of moving

parts, binding of moving parts,

breakage of parts, saw stability, and

any other conditions that may affect

the way the saw works.

• If any part is missing, bent or broken

in any way, or any electrical part

does not work properly , turn the saw

off and unplug the saw.

• Replace damaged or missing parts

before using the saw again.

• Use the sawblade guard, spreader

and anti-kickback pawls for any

comes through the top of the workpiece). Make sure the anti-kickback

pawls work properly. Make sure the

spreader is in line with sawblade

(See “Assembly-Aligning Blade

Guard” section).

• Rem ove adjusting keys and

wrenches. Form a habit of checking

for and removing keys and adjusting

wrenches from table top before turning saw on.

• Make sure all clamps and locks are

tight and no parts have excessive

play.

thru-sawing (whenever the blade

To Reduce the Risk of Injury From Jams, Slips Or Thrown Pieces

(Kickbacks Or Throwbacks)

Inspect Your Blade.

• Choose the right blade or cutting

accessory for the material and the

type of cutting you plan to do.

• Use The Right Tool. Don’t force tool

or attachment to do a job it was not

designed for.

• Never use grinding wheels, abrasive

cutoff wheels, friction wheels (metal

cutting blades) wire wheels or buffing wheels. They can fly apart

explosively.

• Cut only wood, wood like or plastic

materials. Do not cut metal.

• Choose and inspect your cutting

tool carefully:

- To reduce the risk of cutting tool

failure and thrown shrapnel (broken pieces of blade), us e only 10”

or smaller blades or other cutting

tools marked for speeds of 5000

rpm or higher.

- Always use unbroken, balanced

blades designed to fit this saw’s 5/8

inch arbor.

- When thru-sawing (making cuts

where the blade comes through

the workpiece top), always use a

10 inch diameter blade. This keeps

the spreader closest to the blade.

- Do not over tighten arbor nut. Use

arbor wrenches to “snug” it

securely.

- Use only sharp blades with properly set teeth. Consult a professional blade sharpener when in

doubt.

- Keep blades clean of gum and

resin.

- Never use the saw without the

proper blade insert.

Inspect your work area

• Keep work area clean.

• Cluttered areas and benche s invite

accidents. Floor must not be slippery from wax or sawdust.

• To reduce the risk of burns or other

fire damage, never use the saw

near flammable liquids, vapors or

gases.

• To reduce the risk of injury, don’t do

layout, assembly, or setup work on

the table while blade is spinning. It

could cut or throw anything hitting

the blade.

5

Safety Instructions For Table Saws (continued)

Plan your work

• Use the right tool. Don’t force tool or

attachment to do a job it was not

designed for.

Inspect your workpiece.

• Make sure there are no nails or foreign objects in the part of the workpiece to be cut.

• When cutting irregularly shaped

workpieces, plan your work so it will

not slip and pinch the blade:

• A piece of molding for example,

must lie flat or be held by a fixture or

jig that will not let it twist, rock or slip

while being cut. Use jigs or fixtures

where needed to prevent workpiece

from shiftin g .

• Use a different, better suited type of

tool for work that can’t be made stable.

Plan your cut

• To reduce the risk of kickbacks and

throwbacks - when a part or all of

the workpiece binds on the blade

and is thrown violently back toward

the front of the saw:

• Never cut Freehand . Always use

either a rip fence, miter gauge or fixture to position and guide the work,

so it won’t twist or bind on the blade

and kick back.

• Make sure there’s no debris

between the workpiece and its supports.

• Use extra caution with large, very

small or awkward workpieces.

• Use extra supports (tables, saw

horses, blocks, etc.) for any workpieces large enough to tip when not

held down to the table top. Never

use another person as a substitute

for a table extension, or as additional support for a workpiece that is

longer or wider than the basic saw

table, or to help feed, support or pull

the wor kpiece.

• Never confine the piece being cut

off, that is, the piece not against the

rip fence, miter gauge or fixture.

Never hold it, clamp it, touch it, or

use length stops against it. It must

be free to move. If confined, it could

get wedged against the blade and

cause a kickback or throwback.

• Never cut more than one workpiece

at a time.

• Never turn your table saw “ON”

before clearing everything except

the workpiece and related support

devices off the table.

Plan Ahead To Protect Your Eyes, Hands, Face and Ears

Dress for safety

• Do not wear loose clothing, gloves,

neckties or jewelry (rings, wrist

watches). They can get caught and

draw you into moving parts.

• Wear nonslip footwear.

• Tie back long hair.

• Roll long sleeves above the elbow.

• Noise levels vary widely. To reduce

the risk of possible hearing damage,

wear ear plugs or muffs when using

table saw for hours at a time.

• Any power saw can throw foreign

objects into the eyes. This can result

in permanent eye damage. Always

wear safety goggles, not glasses

complying with ANSI Z87.1 (or in

Canada CSA Z94.3-99) shown on

package. Everyday eyeglasses

have only impact resistant lenses.

They are not safety glasses. Safety

goggles are available at many local

6

retail stores. Glasses or goggles not

in compliance with ANSI or CSA

could seriously hurt you when they

break.

• For dusty operations, wear a dust

mask along with safety goggles.

Plan the way you will push the

workpiece through.

• Never pull the workpiece through.

Start and finish the cut from the front

of the table saw.

• Never put your fingers or hands in

the path of the sawblade or other

cutting tool.

• Never reach in back of the cutting

tool with either hand to hold down

workpiece, support the workpiece,

remove wood scraps, or for any

other reason.

• To reduce the risk of hand positions

where a sudden slip could cause fingers or hand to move into a sawblade or other cutting tool.

• Don’t overreach. Always keep good

footing and balance.

• Push the workpiece against the

rotation of the blade, never feed

materi al into the cutting t ool from th e

rear of the saw.

• Always push the workpiece all the

way past the sawblade.

• As much as possible, keep your

face and body to one side of the

sawblade, out of line with a possible

kic kback or thr o w b ack.

• Set the cutting tool as low as possible for the cut you’re planning.

Reduce the Risk of Accidental

Starting

• Make sure switch is “OFF” before

plugging saw into a power outlet.

Whenever Sawblade Is Spinning

WARNING: Don’ t allow familiarity

(gain ed f rom f requent use of

your table saw) to cause a careless mistake. Always remember

that a careless fraction of a second is enough to cause a severe

injury.

• Before actually cutting with the saw,

watch it while it runs for a short

while. If it makes an unfamiliar noise

or vibrates a lot, stop immediately.

Turn the saw off. Unplug the saw.

Do not restart until finding and correcting the problem.

• Make sure the top of the arbor or

cutting tool turns toward the front of

the saw.

Keep Children Away.

• Make sure bystande rs are clear of

the table saw and workpiece.

Don’t Force Tool.

• Let the blade reach full speed

before cutting.

• It will do the job better and safer at

its designed rate.

• Feed the workpiece into the saw

only fast enough to let the blade cut

without bogging down or binding.

Before freeing jammed material.

• Turn switch “OFF”.

• Wait for all moving parts to stop.

• Unplug the saw.

• Check blade, spreader and fence

for proper alignment before starting

again.

• Keep all visitors a safe distance

from the table saw.

7

Safety Instructions For Table Saws (continued)

• To reduce the risk of throwback of

cut off pieces.

• Use the guard assembly.

T o remove loose pieces beneath or

trapped inside the guard.

• Tur n saw “OFF”.

• Remove switch key.

• Wait for blade to stop before lifting

the guard.

Additional Safety Instructions For:

Rip Type Cuts.

• Never use the miter gauge when ripping.

• Use a push stick whenever the

fence is 2 inches or more from the

blade.

• When thru-sawing, use an auxiliary

fence and push block whenever the

fence must be between 1/2 and 2

inches from the blade.

• Never thru-saw rip cuts narrower

than 1/2 inch. (See “Basic Saw

Operations-Ripping and Bevel Ripping” sections.)

• Never rip anything shorter than 10”

long.

• When using a push stick or push

block, the trailing end of the board

must be square. A push stick or

block against an uneven end could

slip off or push the work away from

the fence.

• A Featherboard can help guide the

workpiece. (see ”Basic Saw Operation-Using Featherboards for ThruSawing.” section)

• Always use featherboards for any

non thru rip type cuts. (See “Basic

Saw Operations - Using Featherboards for Non-Thru Sawing” section).

Before Leaving The Saw.

• Turn the saw off.

• Wait for blade to stop spinning.

• Unplug the saw.

• Make workshop child-proof. Lock

the shop. Disconnect master

switches. Remo ve the yellow swi tch

key. Store it away from children and

others not qualified to use the tool.

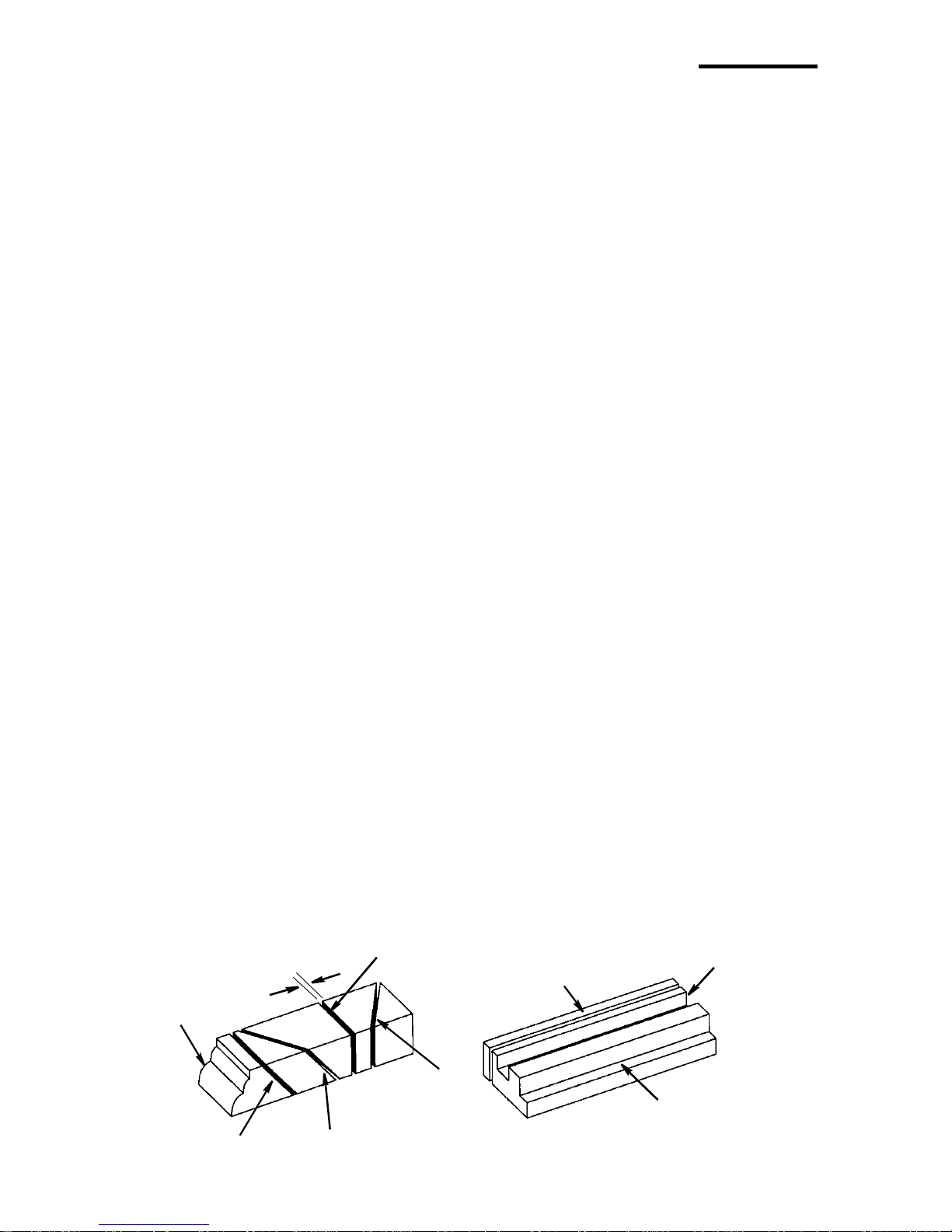

Featherboard

See “Work Feed Devices” section for

Material and Dimensions

Before Starting.

• To reduce the risk of kickbacks and

slips into the blade, make sure the

rip fence is parallel to the sawblade.

• Before thru-sawing, check the antikickback pawls. The pawls must

stop a kickback once it has started.

Replace or sharpen anti-kickback

pawls when points become dull.

(See “Maintaining Your Table Saw Anti-Ki ckb ack Pa wls” section.)

• Plastic and com position (like hardboard) materials may be cut on your

saw. However, since these are usually quite hard and slippery, the antikickback pawls may not stop a kickback. Therefore, be especially careful in your setup and cutting

procedures.

While Thr u-sa wing.

• To reduce the risk of kickbacks and

slips into the blade, always push forward on the section of the workpiece between the sawblade and

the rip fence. Never push forward on

the piece being cut off.

8

Additional Safety Instructions For:

Crosscut Type Cuts.

• Never use the rip fence when crosscutting.

• An auxiliary wood facing attached to

the miter gauge can help prevent

workpiece twisting and throwbacks.

Attach it to the slots provided. Make

the facing long enough and big

enough to support your work. Make

sure, however, it will not interfere

with the sawblade guard.

Before Starting

• Use jigs or fixtures to help hold any

piece too small to extend across the

full length of the miter gauge face

during the cut. This lets you properly

hold the miter gauge and workpiece

and helps keep your hands away

from the blade.

While Cutting

• To reduce the risk of blade contact,

always hold the miter gauge as

shown in “Basic Saw Operations Using The Miter Gauge”.

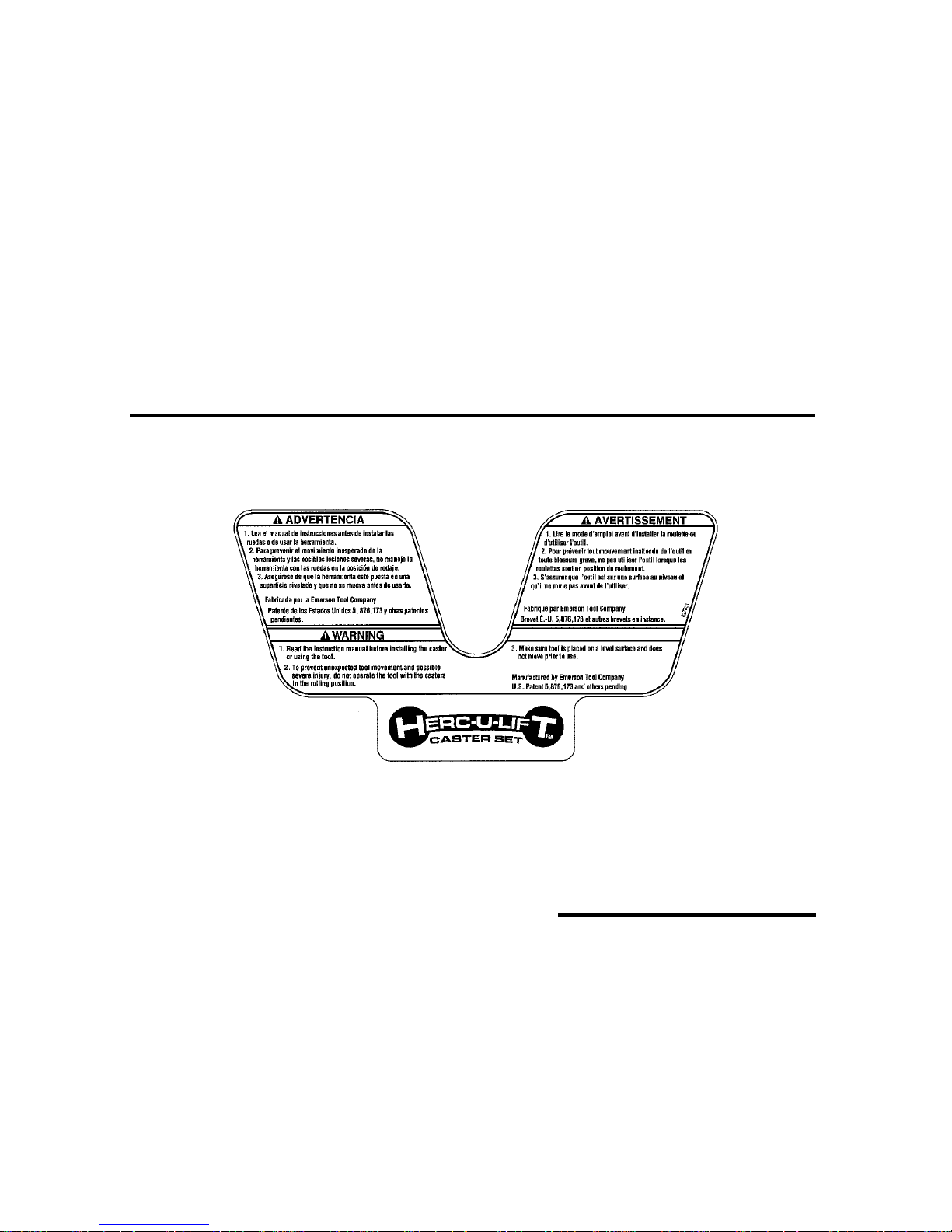

Additional Safety Instructions For Herc-U-Lift™ Caster System:

Before Using the Caster System

Read the following warning located on the plate assembly:

To reduce the risk of injury from

unexpected tool movement.

• Check to make sure tool does not

move prior to use. If tool moves,

adjust all four leveler feet to support

Glossary of Terms for Woodworking

Anti-Kickback Pawls

Device which, when properly maintained,

is designed to stop t he workpiece from

being thrown towar ds the front of the saw

at the operator during ripping operation.

Arbor

The shaft on which a cutting tool is

mounted.

Bevel Cut

An angle cutting operation made through

the tool.

• Put the tool on a firm level surface

where there is plenty of room to

handle and properly support the

workpiece.

the face of the workpiece.

Compound Cut

A simultan eous bevel and mite r crosscutting operation.

Crosscut

A cutting opera tion made across t he width

of the workpiece.

Dado

A non thru cut which produces a square

sided notc h or trough in the workpiece.

9

Glossary of Terms for Woodworking (continued)

Featherboard

A device which can help guide workpieces during ri p type operation.

Freehand

Performing a cut without the use of fence

(guide), mit er gauge, fix ture, hold down or

other proper device to prevent the workpiece from twisting during the cutti ng

operation. Twisting of the workpiece can

cause it to be thrown.

Gum

A sticky, sap based residue from wood

products.

Heel

Misalignmen t of the sawblade such that

the blade is n ot parallel t o the mit er gaug e

groove.

Kerf

The amount of material removed by the

blade in a through cut or the slot produced

by the bl ade in a nonthrough or par tial cut.

Kickback

An uncontrolled grabbing and throwing of

the workpiece ba ck t oward t he front of t he

saw.

Leading End

The end of the workpiece whi ch, during a

rip type operati on, is pushed into the cutting tool first.

Miter Cut

An angle cutting operation made across

the width of the workpiece.

Molding

A non through cut which produces a special shape in the work piece used for join-

ing o r decor a tion.

Ploughing

Grooving with the grain the length of the

workpiece, using the f ence. (A type of

non-through cut.)

Push Stick

A device used to feed th e workpiece

through the saw during narrow ripping

type opera tions which helps keep the

operator’s hands well away from the

blade.

Push Block

A device used for ri pping type operation s

too narro w to allow use of a push stick.

Rabbet

A notch in the edge of a workp iece. (A

type of non-through cut)

Resin

A sticky, sap based substance that has

hardened.

Revolutions Per Minute (RPM)

The number of tur ns com pleted by a spinning object in one minute.

Rip Cut

A cutting oper atio n along th e length o f the

workpiece.

Sawblade Path

The area of the workpiece or table top

directly in line with either the travel of the

blade or the part of the workpiece which

will be, or has been, cut by the blade.

Set

The distan ce that the tip of the sawblade

tooth is bent (or set) outward from the

face of the blade.

Molding

Bevel Cut

Kerf

Compound

Cut

Cross Cut

Miter Cut

10

Rip Cut

Dado or

Ploughing

Rabbet

Throw-Back

Trailing End

Throwing of pieces i n a mann er si m il ar to

a kickback.

Thru-Sawing

Any cutting operation where the blade

extends completely thr ough the thickness

of the workpiece.

The workpi ece end l ast cu t by the blade i n

a ripping operation.

Workpiece

The it em on which the cutti ng operation is

being performed. The surfaces of a workpiece are commonly referred to as fa ces,

ends, and edges.

Motor Specifications and Electrical Requirements

Power S upply and Mot or

Specifications

WARNING: To reduce the risk of

electrical hazards, fire hazards or

damage to the tool, use proper

circuit protection. Your tool is

wired at the factory for operation

using the voltage shown. Connect tool to a power line with the

appropriate voltage and a 15amp branch circuit. Use a 15amp time delay type fuse or circuit breaker. T o reduce the risk of

shock or fire, if power cord is

worn or cut, or damage d in any

way, have it replaced im m ed iately.

The A-C motor used on this tool is a

capacitor start, capacitor run non-reversible type, having the following specifications. It is wired at the factory for

operation on 110-120v AC, 60 Hz. service.

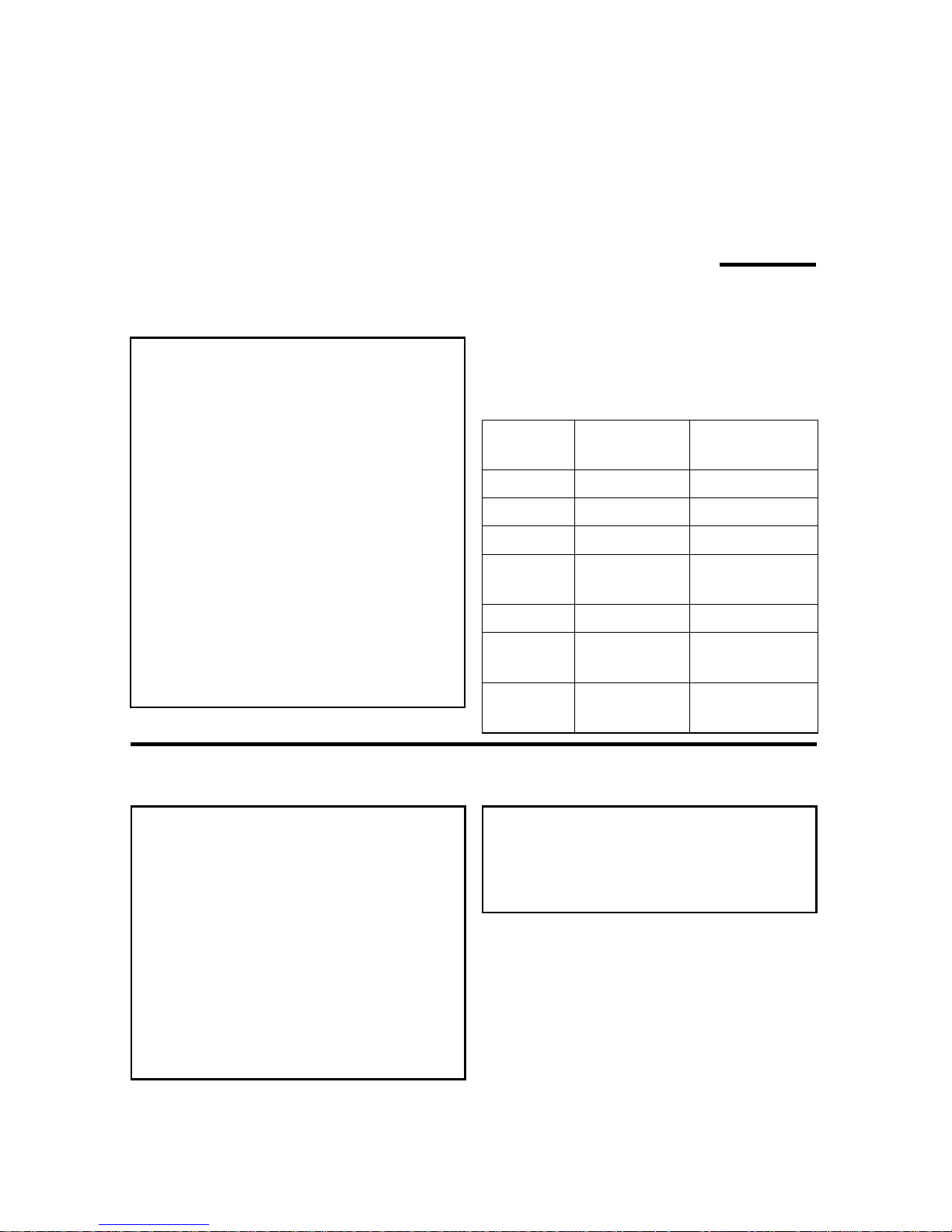

Wired for

120V

Rated H.P 1-1/2 1-1/2

Voltage 110-120 220-240

Amperes 13 6.5

Hertz

(Cycles)

Phase Single Single

RPM 3450 2875 (50 Hz)/

Rotation of

Shaft

60 50/60

Clockwise Clockwise

Wired for

240V

3450 (60 Hz)

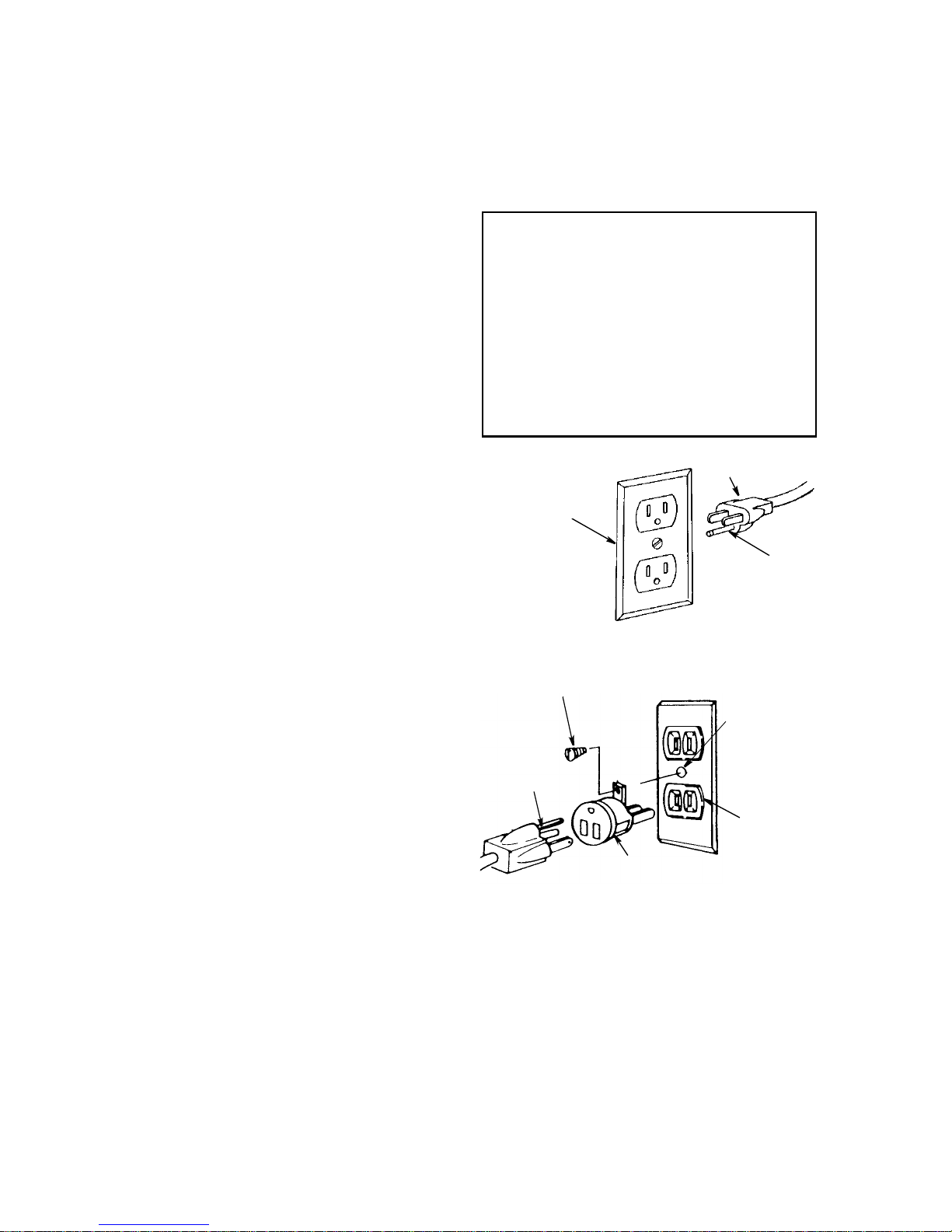

General Electrical Connections

DANGER: To reduce the risk of

electrocution:

1. Use only identical replacement parts when servicing.

Servicing should be performed by a qualified service

technician.

2. Do not use in rain or where

floor is wet.

This tool is intended for

indo or residenti al use only.

WARNING: Do not permit fingers

to touch the terminals of plug

when installing or removing the

plug to or from the outlet.

11

Motor Spec ifica tions a nd Electr ical Re qu iremen ts ( contin ued )

110-120 Volt, 60 Hz. Tool Information

The plug supplied on your tool may not fit

into the outlet you are planning to use.

Your local electrical code may require

slightly di fferent power cord plug connections. If the se differences exist refer to

and make the proper adj ustments per

your local code before your tool is

plugged in and turned on.

In the event of a malfunction or breakdown, grounding provides a path of least

resistance for electric current to reduce

the risk of electric shock. This tool is

equipped with an electric cord having an

equipment-g rounding conductor and a

grounding plug, as shown. The plug must

be plugged into a matching outlet that is

properly installed and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will

not fit the outlet, have the pr oper outlet

installed by a qual ified electrician.

A temporary adapt er may be used to connect this plug to a 2-prong outlet as

shown if a properly grounded three prong

outlet is not available. This tempor ary

adapter should be used only until a properly grounded three prong outlet can be

installed by a qual ified electrician. The

green colored rigid ear, lug or the like,

extending from the adapter must be connected to a permanent ground such as a

properly grounded outlet box.

Improper connec tion of the equipmentgrounding co nductor can r esult in a ri sk of

electric shock. The conductor with insulation having an outer surface that is green

with or without yell ow str ipes is the equipment-groundi ng conductor. If rep air or

replacement of the electric cord or plug is

necessary, do not connect the equi pmentgrounding cond uctor to a live terminal.

If the grounding instructions are not com-

pletely understood, or if you ar e in doubt

as to whether the tool is properly

grounded check with a qualified ele ctr ician or service personnel.

WARNING: If not properly

grounded, this tool can cause an

electrical shock, particularly

when used in damp locations, in

proximit y to pl um bi ng, or out of

doors. If an electrical shock

occurs there is the potential of a

secondary hazard, suc h as your

hands contacting the sawblade.

Properly

Grounded

3-Prong Outlet

Grounding Lug

3-Prong

Plug

Adapter

NOTE: The adapter il lustrated is for use

only if you already have a properly

grounded 2-prong outlet.

NOTE: In Canada the use of a temporary

adapter is not permitted by the Canadian

Electrical Code.

3-Prong Plug

Grounding

Prong

Make sure this

Is Connected

to a Known

Ground

2-Prong

Outlet

12

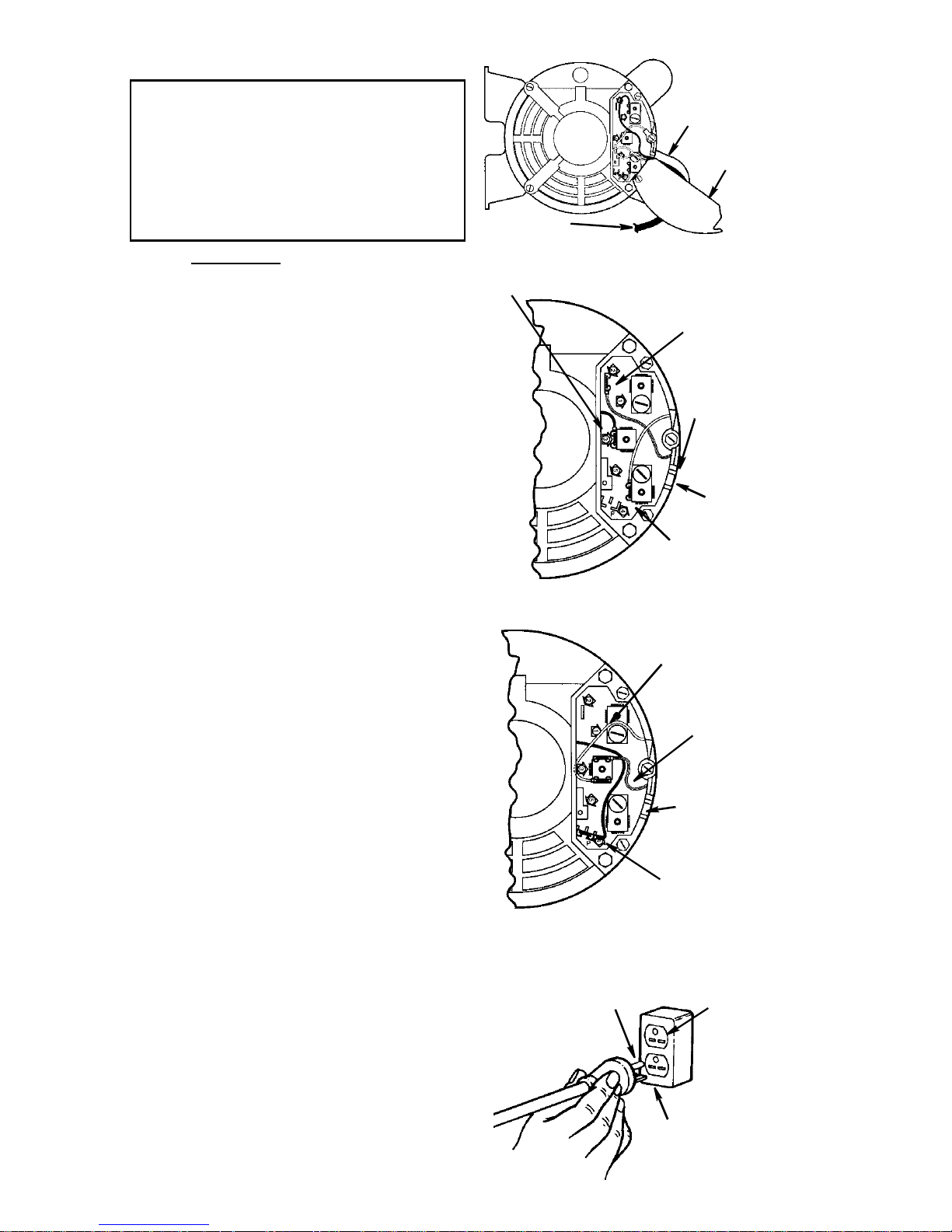

Changing Motor Voltage

WARNING: Electric shock can

kill. To reduce the risk of shock,

never connect plug to power

source outlet until all assembly

steps are completed. Unplug saw

before making or changing any

connections.

NOTE: Power cord lead connections for

110/120 volt and 220/240 volt applications

are the same. This will show how to

change the internal motor wiring to convert

saw from a 120V to a 240V application.

1. Open the motor connector box cover

located on the end of motor using a flat

blade screwdr iver to loosen screws.

2.From the factory this motor is connected

for 120V usage. F or 240V usage:

a. Remove the brown motor lead from

terminal #3 and attach it to the “P”

(parking position) plastic terminal.

NOTE: This brown lead is not

required for the 240 volt application

and is “parked” in the plastic “P” terminal to keep it insulated. Be sure the

brown lead is attached securely to

the “P” terminal holde r.

b. Remove the yellow motor lead from

terminal #4 and attach it to terminal #3.

c. Remove the red motor lead from termi-

nal #2 and attach it to terminal #3.

d. Cut off the 120 volt power cord plug

and replace it with a (3 blade) 240 volt

15 amp U.L. listed plug. (See illustration of 240V plug & receptacle.) Connect the power cord white and black

leads, respectively, to the “hot” plug

blade terminals and connect the power

cord green grounding wire to the plug

ground prong terminal.

3. Close motor connec to r box bein g s ure t hat

the power cord is seated in the strain rel ief

groove and t ight en bo x cover screws .

4.Plug your saw into a 220-2 40V, 15amp,

3 blade recept acle.

5. Make certain the receptacle is connected

to a 240V A.C. power supply through a

240V branch circuit having at least a 15

amp capacity and protected by a 15 amp

time-delay fuse or circuit breaker.

To Switch

Box

Brown Motor

Lead On

Terminal #3

220/240 Volt Connection

Power

Cord

Connector

Box Cover

110/120 Volt Connection

(As Received From Factory)

Red Motor

Lead on

Terminal #2

NOTE: Power

Cord Not

Shown For

Clarity

Cord Exit/

Strain Reli ef

Groove

Yellow Motor Lead

On Terminal #4

Yellow Motor

Lead on

Terminal #3

Red Motor

Lead on

Terminal #3

Cord Exit/

Strain Relief

Groove

Brown Motor

Lead on

Terminal “P”

(Plastic)

Grounding

Prong

Grounded

Outlet Box

220-240V

15 Amp 3 Blade

Receptacle

13

Motor Spec ifica tions a nd Electr ical Re qu iremen ts ( contin ued )

Motor Thermal Overload Protector

CAUTION: To reduce the risk of

motor damage, this motor should

be blown out or vacuumed frequently to prevent sawdust

buildup which will interfere with

normal motor ventilation .

Y ou r saw is equi pped wit h a manual-r eset

thermal-overload protector designed to

open the power line circuit when the

motor temperature exceeds a safe level,

when motor is overload ed or when a lo w

voltage condition exists.

WARNING: To reduce the risk of

thrown objects or blade contact

from unexpected starting. If the

protector stops the saw motor,

immediately turn the saw switch

“OFF”, remove the key and allow

motor time to cool.

1.After cooling to a safe operating tem-

peratur e, t he overload protector can be

reset by pushing the red button on the

end of the motor. If the red button will

not click into place immediatel y, the

motor is still too hot and must be

allowed to cool for a while longer.

The time required for the motor to cool

may be equal to the length of time the

saw was used before the thermal overload protector opened. NOTE: An audible click wil l indicate the protector is

reset, push hard to hear the click.

2. As soon as the r ed button is rese t, the s aw

may be star ted an d ope ra ted nor mall y.

3.Frequent “blowing” of fuses or tri pping

of circuit breakers may result i f:

a.Motor is overloaded - Overloading

can occur if you feed too rapidly or if

saw is misaligned.

b. Motor circuit is fused differently from

recommendations - Always follow

instructions for the proper fuse/breaker.

Do not use a fuse/breaker of greater

capacity without consulting a qualified

electrician.

Manu al R es et

Button

c. Low voltage - Although the motor is

designed for operation on the voltage

and frequency specified on motor

nameplate, normal loads will be handled safely on voltage not more than

10% above or below the nameplate

voltage. Heavy loads, however, require

that voltage at motor terminals equals

the voltage specified on nameplate.

4.Most motor troubles may be traced to

loose or incorrect connections, overloading, reduc ed input vol tage (s uch as

small size wire in the supply circuit) or

to overly long supply circuit wire.

Always check t he connect i ons, th e load

and the supply circuit whenever motor

fails to perform satisfactorily. Check

wire sizes and length with the Wire Size

Chart below.

Wire Sizes

NOTE: Make sure the proper extension

cord is used and is in good condition.

The use of any extension cord will cause

some loss of power. To keep this to a minimum and to prevent ove rheating and

motor burn-ou t, use the t able shown to

determine the mini mum wire size (A.W .G.)

extension cord.

Use only 3-wire extension cords which have

3-prong grounding type plugs and 3-prong

receptacles which accept the tool’s plug.

Extension

Cord Length

110-120V 220-240V

0-25 Ft.

26-50 Ft.

14

Gauge

(A.W.G.)

14

12

18

18

Unpacking and Checking Contents

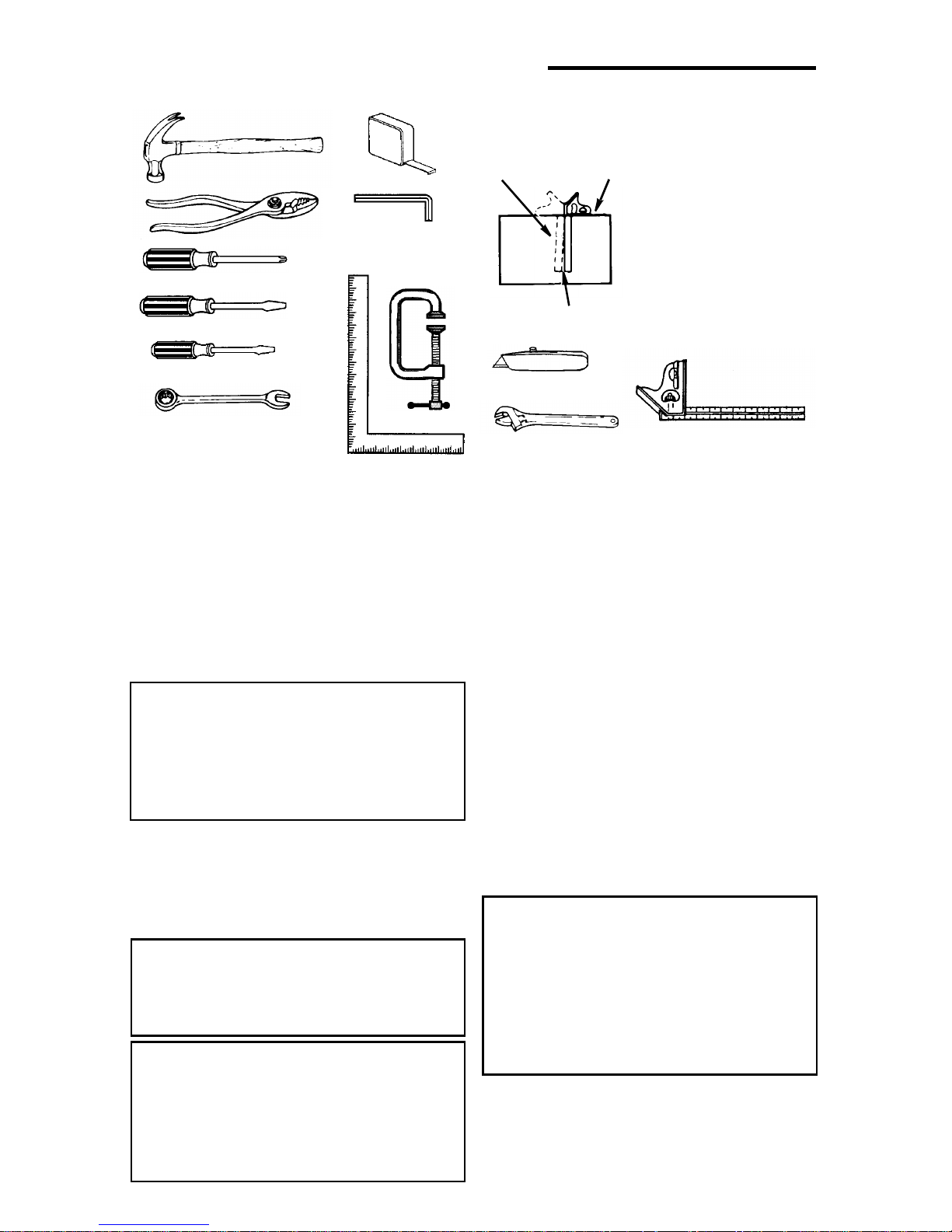

Tools Needed

Combination Square must be true. Check

it’s accuracy as shown below.

Draw light line on

Hammer

Ta pe Rule

board along edge

Select the straight edge of

3/4” thick board. This edge

must be perfectly straight.

Pliers

Phillips Screwdriver

Medium Screwdriver

Small Screwd river

Combination Wrenches

3/8 In., 7/16 In., 1/2 In.,

9/16 In., 3/4 In., 11/16 In.

Hex “L” Wrenches

2.5m m, 1/ 8 In .,

5/32 In., 3/16 In.

C Clamp

Framing Square

Unpacking

1.Sep ara t e saw an d a ll par t s f rom pac k ing

materials and check each one wit h the

illustration and the “List of Loose Parts”

to make certain all items are accounted

for , before discarding any packing material. Call 1-800-4-RIDGID or E-mail us at

inf o@ridgidwoodworking .com if any

parts are damaged or m issing.

WARNING: If any parts are missing, do not attempt to assemble

the table saw, plug in the power

cord or turn the switch on until

the missing parts are obtained

and are installed correctly.

2.Remove the protective oil that is

applied to the t able top and edges of

the table and tabl e exte nsions. Use a ny

ordinary household type grease and

spot remover.

WARNING: To reduce the risk of

fire or health hazard, never use

gasoline, naptha, or similar

highly volatile solvents.

WARNING: The saw is heavy. To

reduce the risk of back injury , get

help to lift the saw. Hold the saw

close to your body. Bend your

knees so you can lift with your

legs, no t your back.

NOTE: The square and

straight edge ar e us ed to

align the saw. They must

be accurate if the saw is

to be a ligned properly.

Should be no gap or overlap here when

square is flipped over in dotted position.

Utility Knife

Adjustable Wrench

Combination

Square

3.Apply coa t of paste wax t o the table and

table extensions.

NOTE: Before beginni ng assembly:

• Check that all parts are included. If you

are missing any part, do not assemble

the saw.

• Sometimes small parts can get los t i n

packaging mate rial. Do not throw away

any packaging unt il saw is put together.

Check packaging for missing parts

before contacting RIDGID.

• A complete parts list (Repair Parts) is at

the end of the manual. Use th is list to

identify the part number of the missing

part.

NOTE: At the begin ning of each ass embly

sectio n items such as nuts and bolts are

shown actual size.

WARNING: For your own safety,

never connect plug to power

source outlet until all assembly

steps are complete, and you

have read and understand the

safety and operating instructions.

15

Unpacking and Checking Contents (continued)

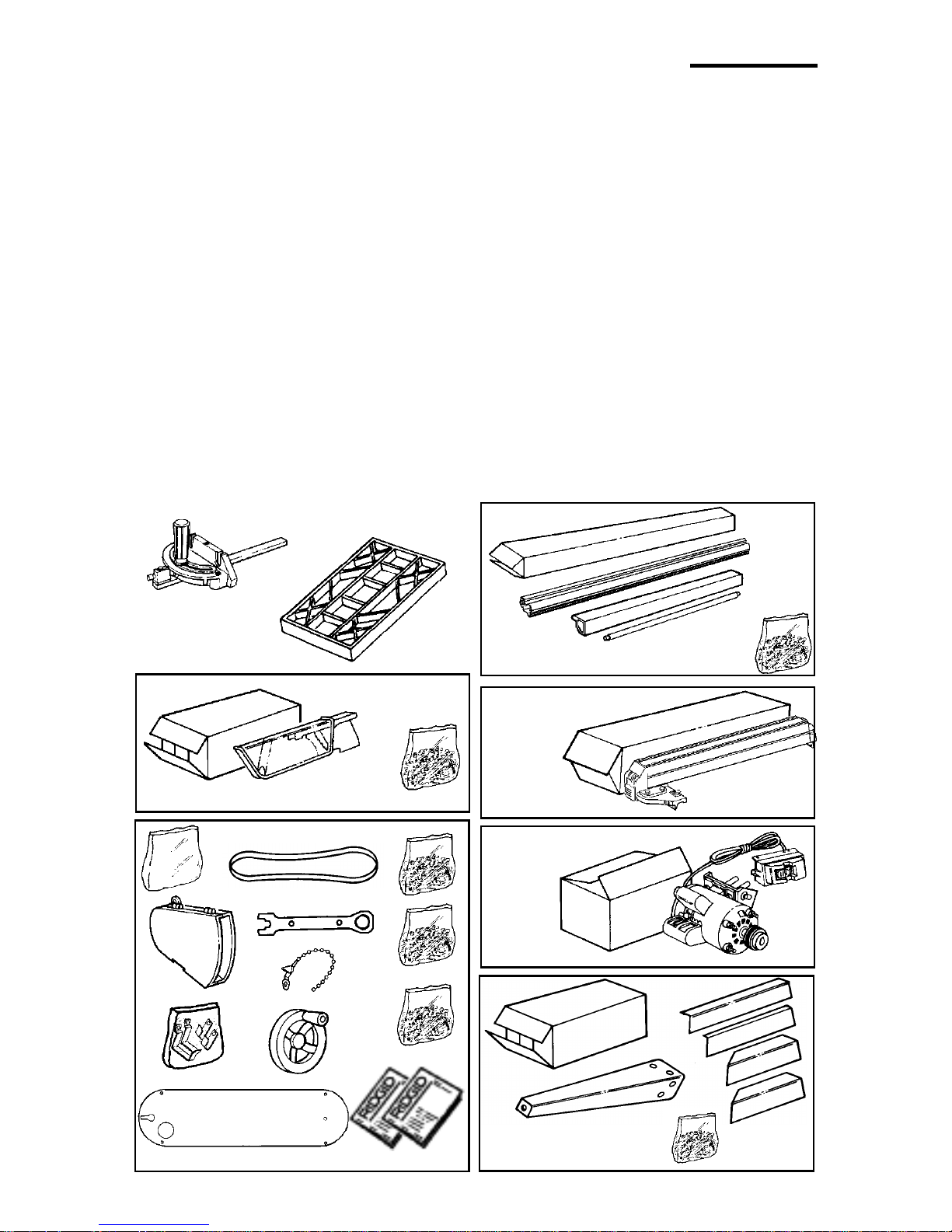

List of Lo ose P art s

Item Part Na me Qty.

A Mite r Ga ug e.....................................1

B Table Extension...............................2

Blade Guard Carton Containing:

C Blade Guard ..................... .. .......... .. .1

D Blade Guard Parts Bag......... .......... .1

Large Parts Bag Containing:

E Belt Guard .......................................1

F S to rage Hook Ba g ... .. ......................1

G Drive Belt .. ... ....................................1

H Blade Wrench............................ .. ....1

J Wire Tie ...........................................2

K Handwheel .......................................2

L Trim P a rt s B a g.. .. ... ..........................1

M Ta bl e Ex te n si o n Pa rts Bag ..............1

N Miscellaneous Parts Bag.................1

P Owners Manual (English)...... ..........1

Q Owners Manual (Spanish)...............1

DD Zero Clearance Table Insert ............1

Item Part Name Qty.

Fence Guide Bar Carton Containing:

R Front Fence Guide Bar.................... 1

S Re a r F e nce Gu i de Bar .... ................ 1

T Guide Bar Parts Bag .......................1

U Rod Support...... ............ .......... ........1

Rip Fence Carton Containing:

V Ri p F e nce.... ... ................................. 1

Motor Carton Containing:

W Motor/Switch Assembly...................1

Leg Stand Carton Containing:

X Leg .................................................. 4

Y Leg Brace (Long)..... .. ......................2

Z Leg Brace (Short)........................... .2

AA Si de Stringer ... .. ............................... 2

BB End Stringer (one w/label)...............2

CC Leg Stand Parts Bag........................1

A

Blade Guard Carton

G

E

H

J

B

C

D

M

R

S

Fence Guide Bar Carton

(Service #509469)

Rip Fence Carton

L

Motor Ca rton

U

T

V

W

F

DD

Large Parts Bag

K

N

Y

Z

P

Q

X

CC

Leg Stand Carton

16

AA

BB

Herc-U-Lift™ Caster Carton

Item Description Qty.

A Channel Rear .................................1

B Tube U-Bo lt 1 9- 5 /8 " L ong ......... .......1

C Tube Support 17-1/4" Long .............1

D Plate Assemb ly... ... .. ........................1

Loose Part s

AB C

Item Description Qty.

E Tube Front 13-7/8" Long ................ .2

F Caster Swivel 3" .............................. 4

G Tube Rear 27" Lon g ..... ...................2

H Bag Loose Parts..............................1

DE

G

Item G packed separately in

main table saw box

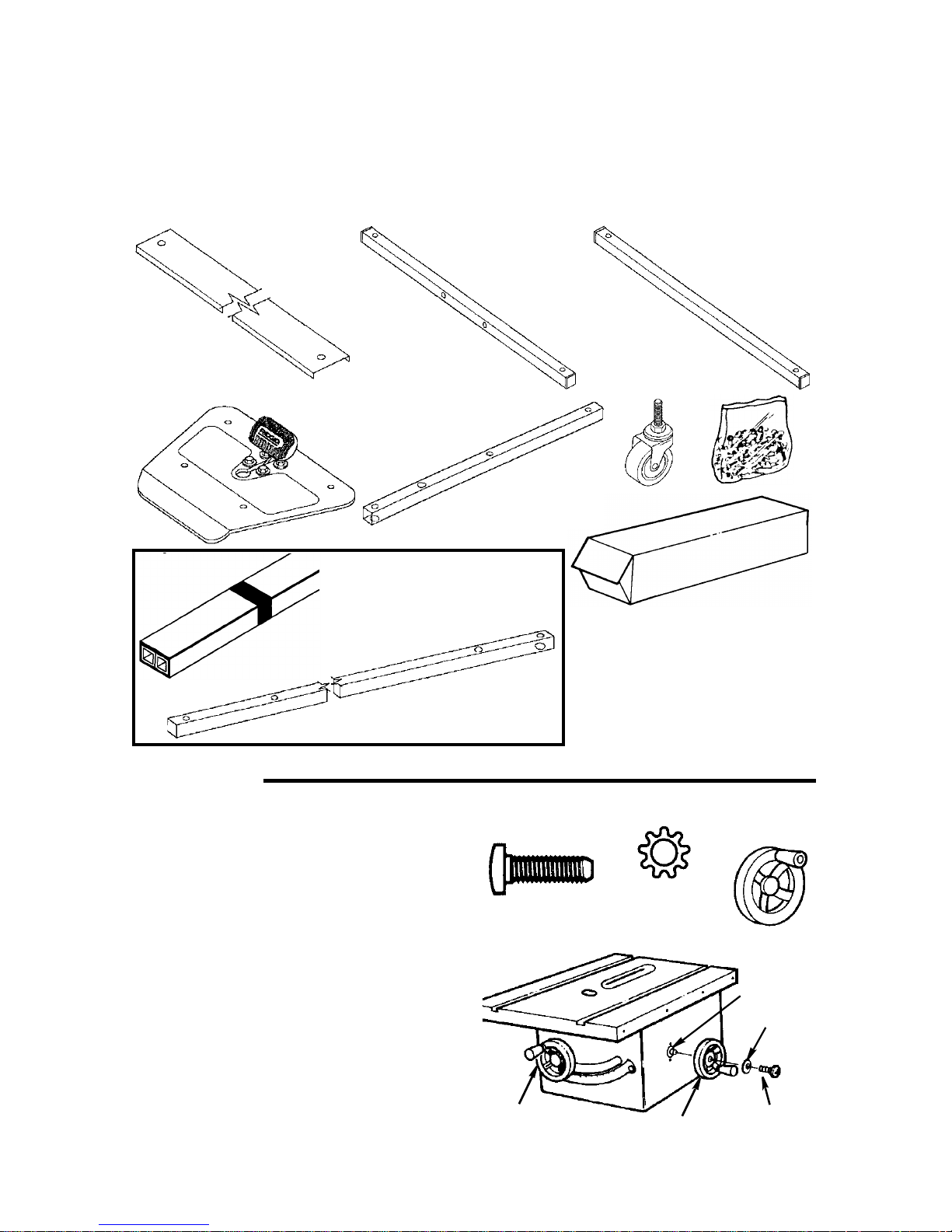

Assembly

Installing Handwheels

1.From the bag labeled “Miscellaneous”

remove only th e following hardware:

2 Pan Head Screws, 10 - 32 x 5/8" long

2 Lockwashers, #10 External Type

From among the loos e parts f ind the fol-

lowing:

2 Handwheels

2.Line up flat spots on shaft and hand-

wheel, push han dwheel onto shaft.

Install screw and lockwasher to lock

handwheel on shaf t. Repeat for the

other handwheel.

10-32 x 5/8

Pan Head Screw

Elevation

Handwheel

F

#10 Ext er na l

Lockwasher

Bevel

Handwheel

H

Handwheel

Shaft

Lockwasher

Pan Head

Screw

17

Assembly (continued)

Assembling Leg Stand

1. Locate the carton containing the leg

stand.

Remove all parts from packing material.

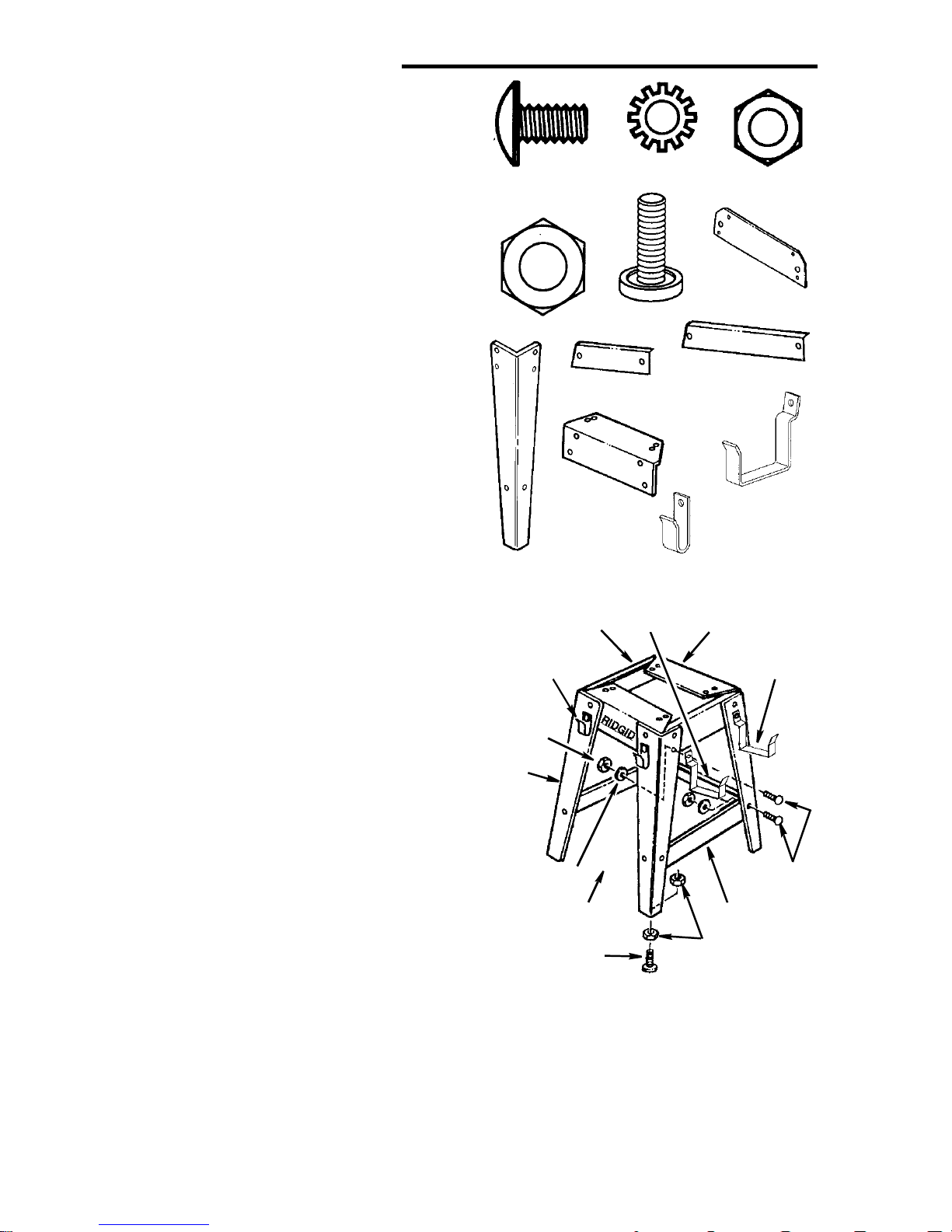

2.From the bag labeled “Legs” remove

the followi ng hardware:

22 Truss Head Screws, 1/4-20 x 1/2”

long

22 Lockwashers, 1/4” External Type

22 Hex Nuts, 1/4-20

4 Leveling Feet

8 3/8-16 Hex Nut

From leg stand carton find the following:

4Legs

2 End Stringers

2 Side St ringers

3 Leg Braces (Two Long , One Short )

3. From amon g the loos e pa r ts f in d t h e f o l lowing:

2 Miter Gauge Storage Hooks

2 Rip Fence Storage Hooks

4.Assemble the l egs as shown.

Insert the truss head screws through

the holes in the legs, then through the

holes in the side and end stringers.

Attach miter gauge and rip fence storage hooks as shown.

Legs must be assembled on top of

stringers

5.Instal l t he lockwashers. Screw on the

nuts hand tight.

6.Insert the truss head screws t hrough

the holes in the l egs, then through the

holes in the leg br aces. Place short leg

brace on opposite side of RIDGID logo

as shown.

7.Instal l t he lockwashers. Screw on the

nuts but do not tighten until completely

assembled.

8.Instal l levelin g feet through holes in bottom of l egs as sho wn. Adjust fee t all t he

way up to bottom of leg.

9. Once you have completed the entire

assembly process, move saw to desired

loc ati o n a nd ad j ust t he f o ur l e vel in g f e et

1/4-20 x 1/2 In

Truss Head

Screw

3/8-16 Hex Nu t

End String ers

Leg

Side Stringers

Miter Gauge

Storage Hook

1/4-20

Hex Nut

Legs

Lockwasher

Herc-U-Lift

System Will Be

Installed Here

Leveling Foot

1/4 In External

Lockwasher

Leveling Foot

Leg Brace

(Short)

Miter Ga u g e

Storage Hooks

Leg Brace

(Short)

Stringer

Leg Br as es

(Long)

Rip Fence

Storage Hooks

End Stringers

Rip Fence

Storage Hook

Tru ss H e ad

Leg Brace

(Long)

3/8-16

Hex Nuts

to support the tool as follows:

a.With 9/16" wrench loosen bottom nut.

b. Back off top nut by hand.

c. Raise or lower foot by adjusting bottom

nut using 9/16" wrench.

d. Snug top nut against inside of leg by

hand.

e. Tighten all four bottom nuts using 9/16"

wrench.

18

1/4-20

Hex Nut

Side

Screw

Mount i ng Your Saw

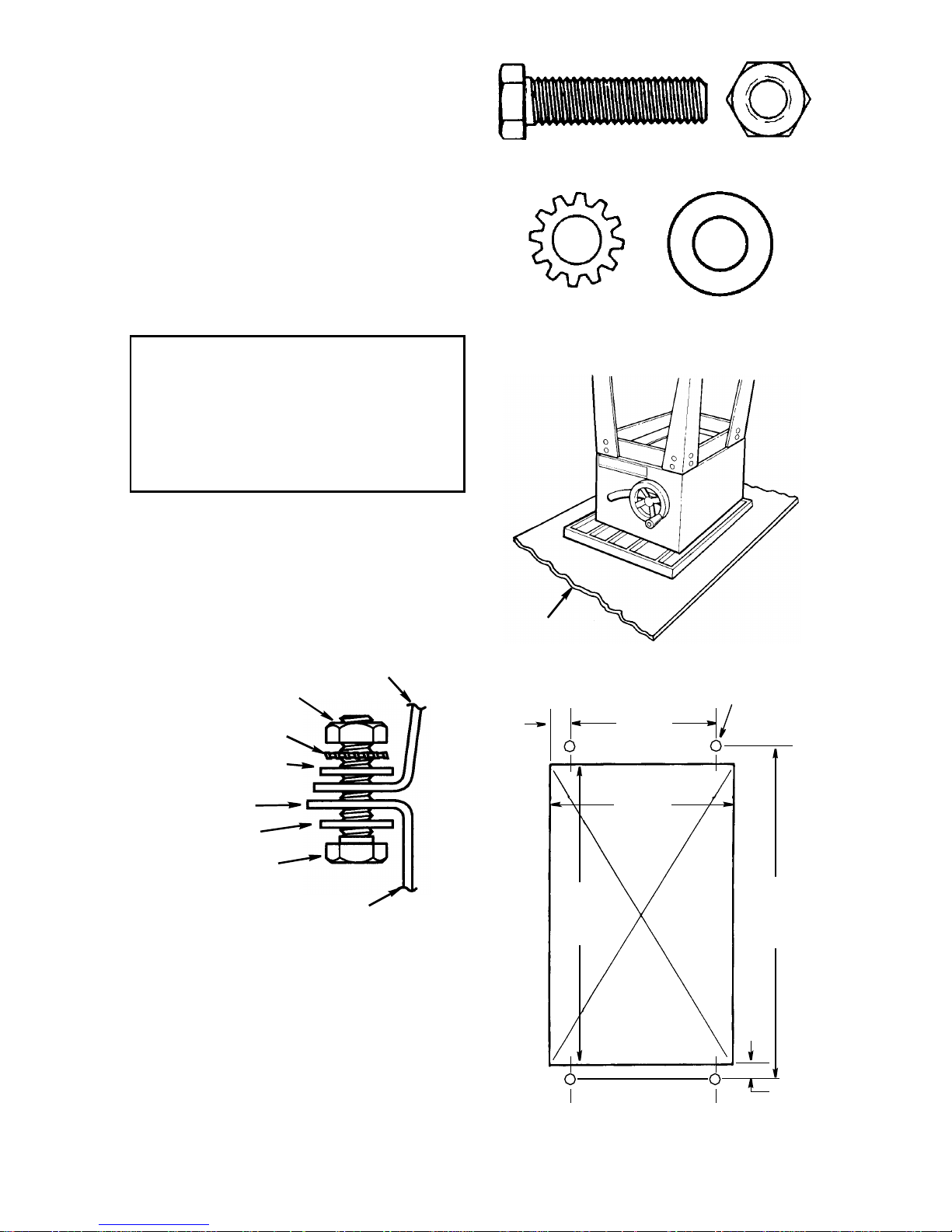

1.From the bag labeled “Legs” remove

the followi ng hardware:

4 Hex Head Screws, 5/16-18 x 1-1/4"

Long

4 Hex Nuts , 5/ 1 6- 1 8

4 Lockwashers, 5/16" External Type

8 Flat Washers, 11/32 x 11/16 x 1/16

2.Place the saw upside down onto a

smooth piece of cardboard or heavy

paper, on the floor , so the saw i s rest ing

on the table top.

WARNING: The saw is heavy. To

reduce the risk of back injury , get

help to lift the saw. Hold the saw

close to your body. Bend your

knees so you can lift with your

legs, no t your back.

3.Place legs on saw so that holes in saw

base and leg set line up and trim label

is facing front.

4.Install screw, washers, lockwasher and

nut as shown.

5.Tighten all leg assembly and mounting

hardw a re at th is time .

5/16-18 x 1-1/4 In

Hex Head Screw

5/16 In External

Lockwasher

Cardboard

5/16-18

Hex Nut

11/3 2 I. D.

Flat Washer

Leg Set

Hex Nut

Lockwasher

Flat Washer

End Stiffener

Flat Washer

Hex Head Screw

Saw Base

Bench Mounting

If you do not use the legset and mount the

saw on a bench, make sure that there is

an opening in the top of the bench the

same size as the openi ng in the bottom of

the saw so that the sawdust can drop

through. Recommended working height is

33 to 37 inches from the top of the saw

table to the floo r.

Moun ting Holes

7/8

+

15-3/4

+

NOTE: All dimensions in inches

11-1/4

13

Bench

Opening

Front of Saw

7/16 Dia.

+

16-3/4

+

1/2

19

Assembly (continued)

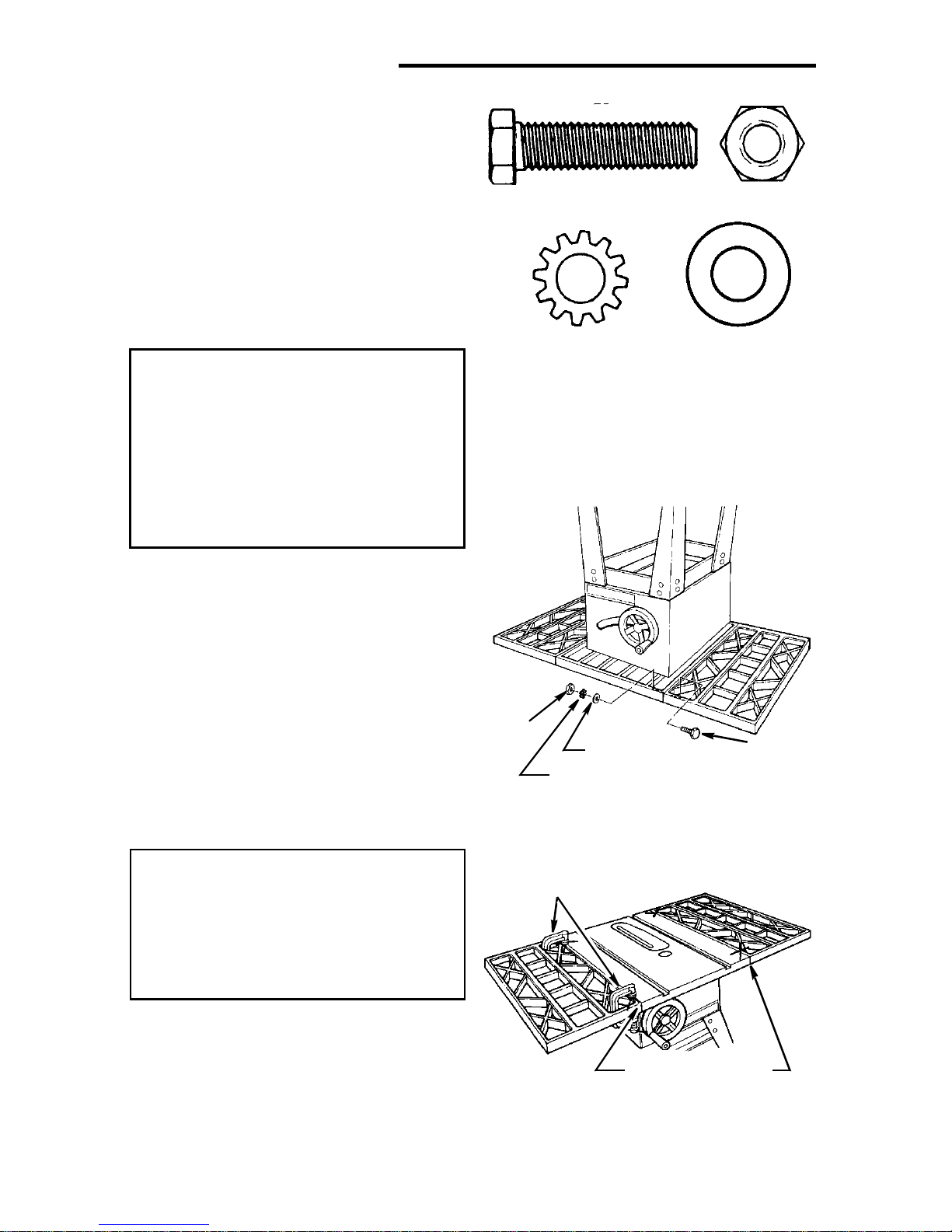

Assembling Table Extensions

1.From the bag labeled “Table Extensions” remove the following hardware:

(Quantity indicated is for two extensions)

8 Hex Head Screws, 5/16-18 x 1-1/4"

Long

8 Flat Washers, 11/32 x 11/16 x 1/16

8 Lockwashers, 5/16" External Type

8 Hex Nuts , 5/ 1 6- 1 8

NOTE: Assemble with saw upside down.

WARNING: Stock table extensions must be installed. They

help support the fence gu i de

bars. An unsupported guide bar

can twist. Twisted guide bars can

misalign fence. A misaligned

fence can cause binding or kickback. You could be hit or cut.

5/16-18 x 1-1/4 In

Hex Head Screw

5/16 In External

Lockwasher

5/16-18

Hex Nut

11/32 I.D.

Flat Washer

2. Insert four (4) 5/16-18 x 1 in. long screws

through the holes in each extension.

3.Positi on extension against ta ble so

screws extend through hole in table.

4.Instal l f lat washers, lockwasher, and

nuts on the screws. With a 1/2 " wrench ,

snug the four nuts just enough to take

the play out between the table and

extension. Do not tighten.

5.Repeat steps 1-4 to install the othe r

extension.

6.Stand saw upri ght on legs. Roll saw

over onto front then up onto feet.

WARNING: The saw is heavy. To

reduce the risk of back injury , get

help to lift the saw. Hold the saw

close to your body. Bend your

knees so you can lift with your

legs, no t your back.

7.Line up the front edge of extensi on with

the front edge of the table. At the spots

marked “X” in the drawing, tigh ten a “C”

Clamp over the edge of table and

extensi on. Use a combination squar e to

check the alignmen t o f the f ront a nd top

edges nearest the “X”’s. Tighten the

two corner nuts only wi th a 1/2" wrench.

Nut

Lockwasher

Flat Washer

“C” Clamps

Align Fron t Edge s

NOTE: This assembl y may also be done

without the use of a “C” Clamp.

Hex

Screw

20

WARNING: Table extensions

must be installed. Front edge of

table and extensions must be

lined up . An unev en front edge

can twist the fence guide bar.

Twisted guide bars can misalig n

fence. A misaligned fence can

cause binding or kickback. You

could be hit or cut.

8. Tighten a “C” clamp over the edge of

table and extension at the center until

the extension is even with the table surface as shown. Tighten the two center

nuts with a 1/2" wrench.

9. Re peat s teps 7 an d 8 to align th e othe r

extension.

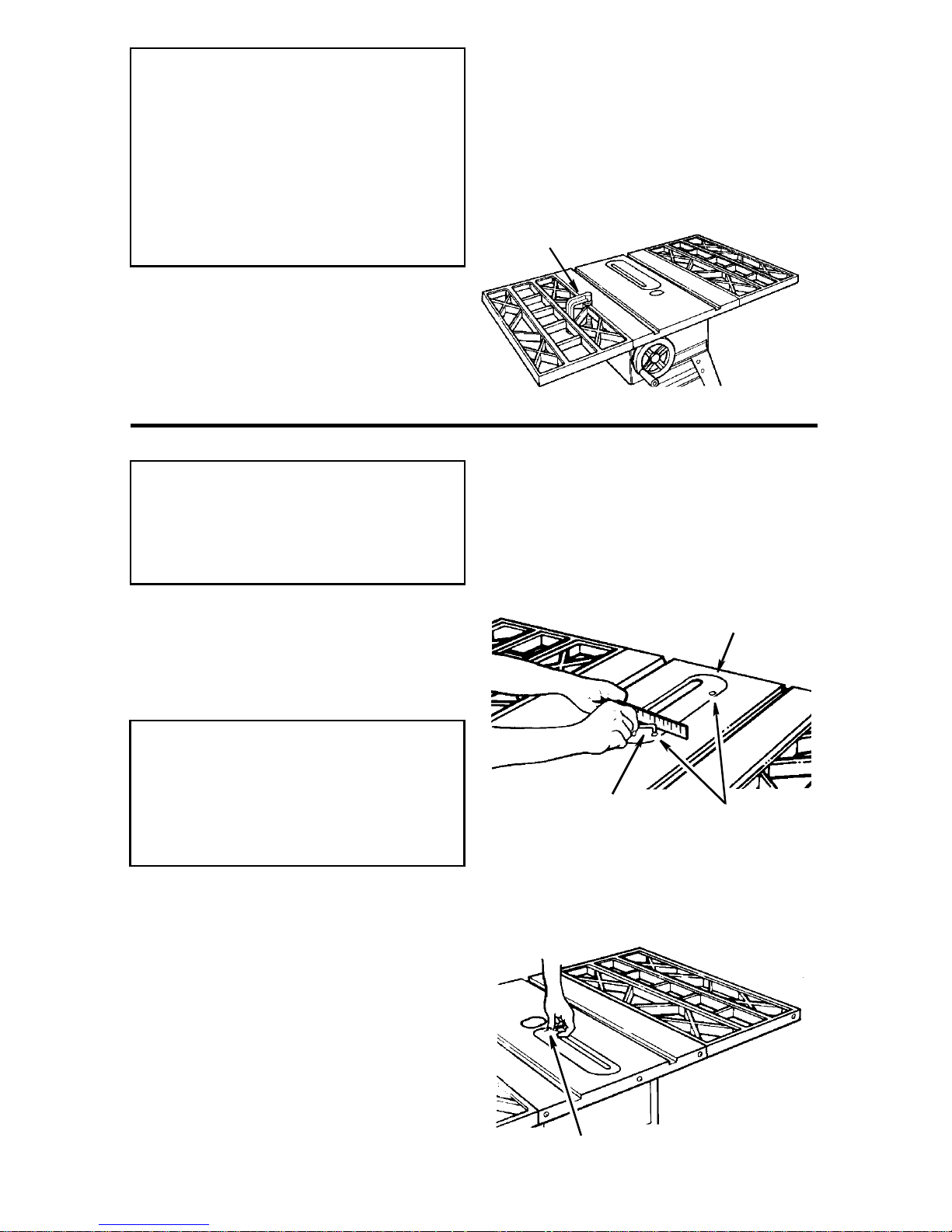

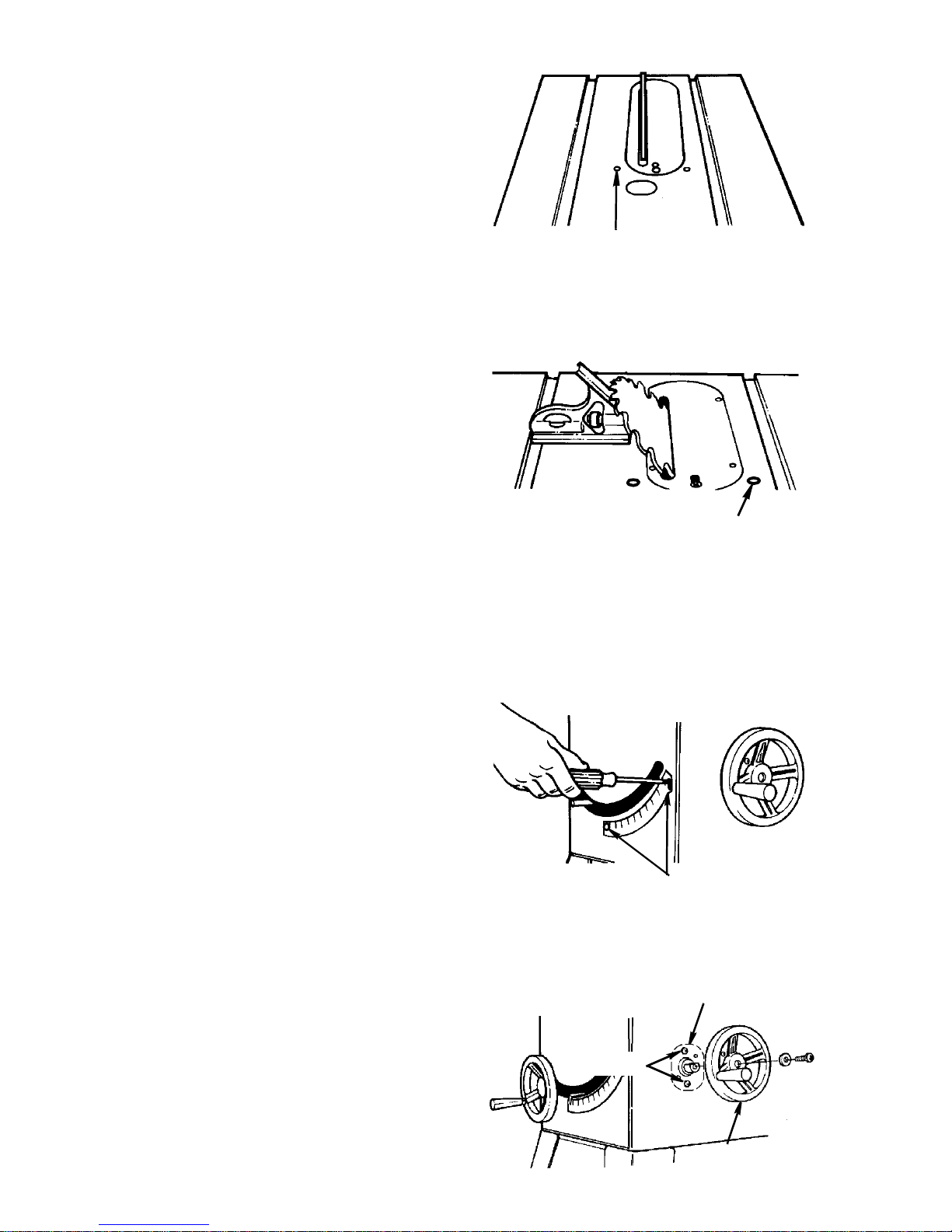

Checking Table Insert

WARNING: To reduce the risk of

injury from accidental start, make

sure switch is “OFF” and plug is

not connected to power source

outlet.

“C” Clamp

1.Insert should be flush with table top.

Check as shown. Loosen flat head

screw that holds insert and adjust the

four set screws as necessary. Tighten

flat head screw. Do not tighten screw to

the point where it bends the insert.

CAUTION: Insert must be even

with the table surface. Inserts too

high or l ow c an l et th e wor k pi ec e

“snag” or catch on uneven

edges. Workpiece could twist

and kickback.

2.To rem ove insert.

a.Make sure saw is off and unplugged.

b. Loosen flat head screw.

c. Lift insert from front end, and pull

toward fr o nt o f saw.

d. T o replace insert.

e. Make sure saw is off and unplugged.

f. Place insert into insert opening in table

and push toward rear of saw to engage

spring clip and until keyslot in insert will

drop over flat head screw. Tighten

screw .

g. Do not tighten screw to the point where

it bends the insert.

21

3/32 In.

Hex “L” Wrench

Fla t Head

Screw

Table I nsert

Set Screws

Assembly (continued)

Checking Heeling Adjustment or Parallelism of Sawblade to Miter Gauge

Groove

While cutting, the material mus t move in a

straight line parallel to the sawblade.

Therefore, both the miter gauge groove

and the rip fence must be parallel to the

sawblade.

WARNING: The blade must be

parallel to the miter gauge

groove. Misaligned b lades cou ld

bind on workpiece. Workpiece

could suddenly kickback. You

could be cut or hit.

To check for parallelism:

1.Raise blade to approximately 3" depth

of cut.

2.Mark an “X” on one tooth.

3.Place the head of a combination

square in the left miter gauge groove.

Rotate the blade so that the tooth

marked with an “X” is at the front and

adjust the blade of the square so that

it just touches the tip of the marked

tooth. Lock the square at this setting.

NOTE: Hold the head of the combina ti on

square firmly aga inst the edge of the miter

gauge groove during all measurements.

If the sawblade is not parallel to the miter

gauge groove, the blade will bind at one

end of the cut. This is known as “Heeling”.

WARNING: To reduce the risk of

injury from accidental start, make

sure switch is “OFF” and plug is

not connected to power source

outlet.

Sawblade

Combination

Square

Miter Gauge

Groove

4.Move the square to the rear of the

blade. Rotate the blade so the marked

tooth is at the rear and see if the

marked tooth again touches the blade

of the square.

5.If the marked tooth touches the square

at th e f ront a nd at the re ar of the s awblade, the blade is parallel to miter

gauge slot. The parallelism is correct.

Proc ee d to the “Checking Blade Tilt, or

Squareness of Blade to Table”.

6. If square does not touch the marked

tooth at the re ar an d front equa lly (gap

is greater that 0.015 inch–thickness o f

4 pages from Ow ners Manual) or t ooth

interferes with square, the m echanism

underneath must be adjusted to make

the blade parallel to the miter gauge

groove.

22

7. Tighten the tilt lock handle located at

the front of the saw.

8.Loosen the three mounting screws

that hold the front trunnion and the

three mounting screws that hold the

rear trunnion using a 9/16" wrench.

The front center trunnion bolt can be

accessed through the slot for the tilt

lock handle in the fr ont of the saw .

9. Check position of the sawblade in

the table insert slot. There should be

a minimum of 1/8" between the right

edge of the slot and the blade

(vie wed from re ar of sa w). Adj ust by

moving the front trunion. Secure by

lightly tightening the front trunion

center bolt.

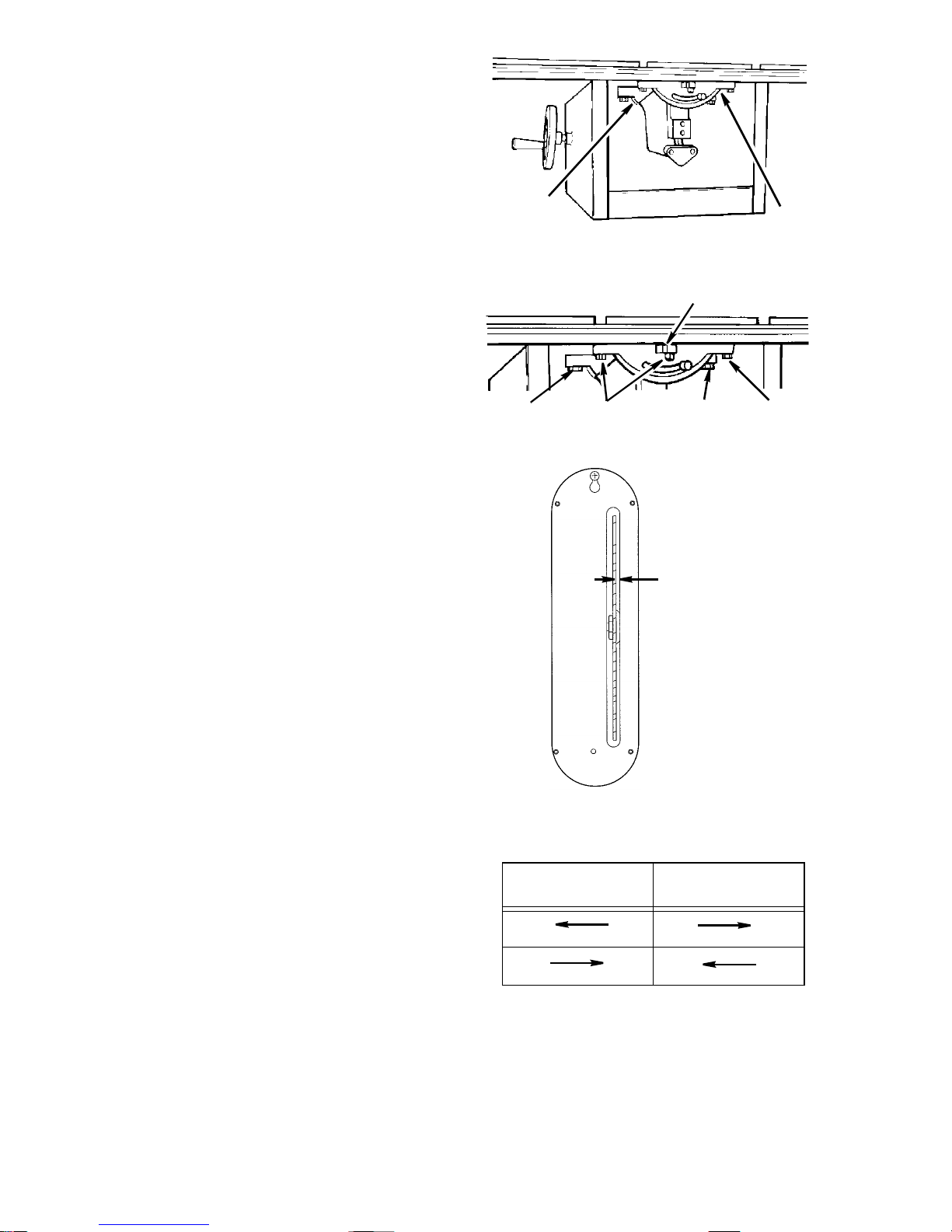

10.Standing at the rear of the saw, determine which direction the rear of the

sawblade must move to make it parallel to the miter slot. To move the rear

of the blade to the right - turn the

micr o ad jus t lev er to t he le ft. To move

the rear of the blade to the left - turn

the micro adjust lever to the right.

11. Using the micro adjust lever move the

rear of the blade in the desired direction. Repeat steps 3 and 4 until blade

is parallel to miter gauge slot.

12.Securely tighten all six screws on the

rear and front trunnion using a 9/16"

wrench.

13.Recheck the marked blade tooth at

the front and rear position to insure

that the adjustment has not moved.

14.If the adjustment moved, loosen the

five bolts (all except front center) and

repeat steps 11-12.

15.When the adjustment is correct

securely tighten all six bolts on the

front and rear trunnion.

NOTE: Maintain a minimum 1/8 inch

clearance between the right side of the

blade and the table in sert (viewed from

rear of saw). T his in sur es clear ance when

the blade is beveled.

Front

Trunnion

Eccentric

Front

Trunnion

Screws

Rear

Trunnion

Screws

Front

Trunnion

Screws

1/8" Minimum

Clearance

Rear of

Saw

To Move Blade Move Lever

Rear

Trunnion

Lever

Rear

Trunnion

Screws

23

Assembly (continued)

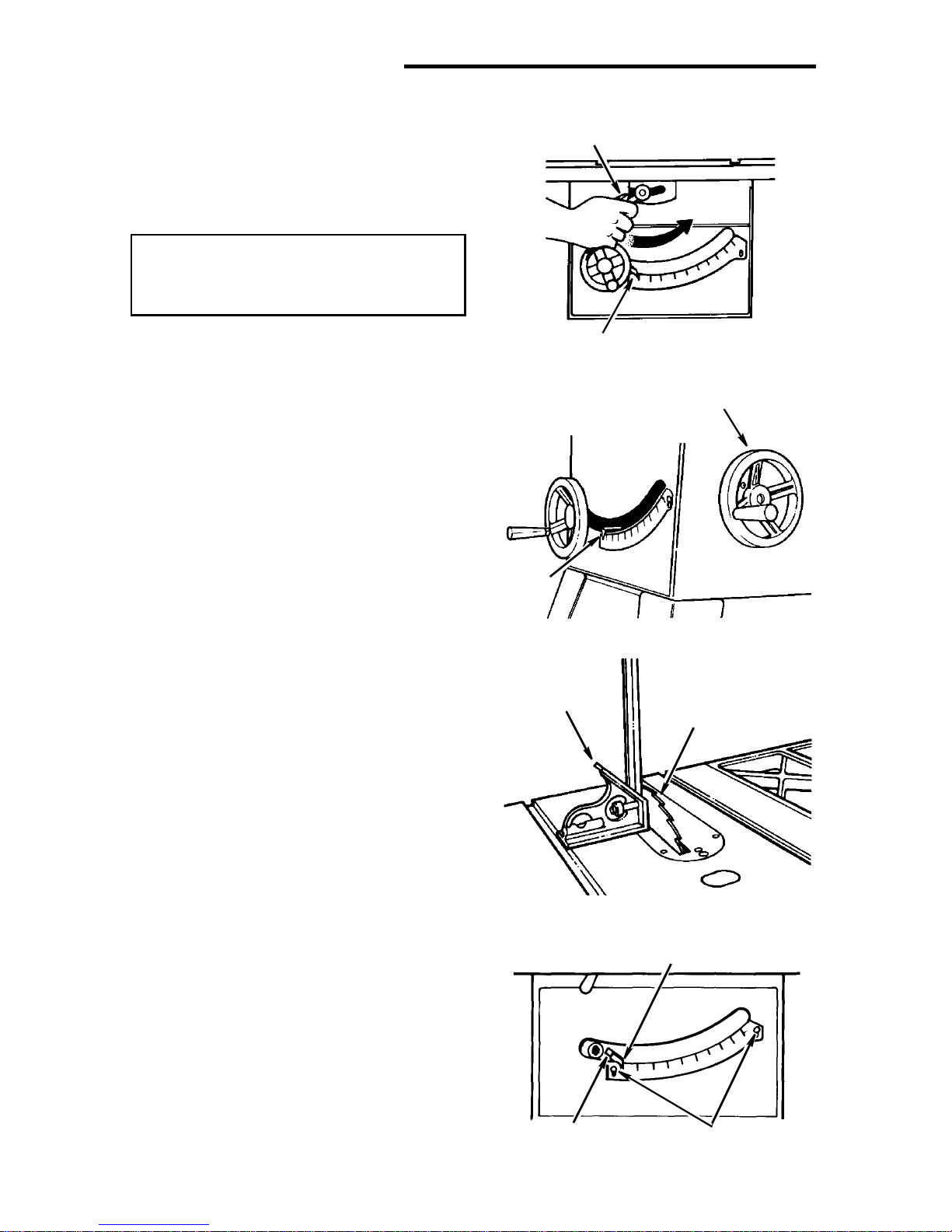

Checking Blade Tilt, or Squareness

of Bla de to Table

When the bevel pointer i s pointing directly

to the “0” mark on the bevel scale, the

sawblade should make a square cut 90°

to the table.

WARNING: For your own safety,

turn switch “OF F” and remove

plug from po we r source outl et.

Tilt Lock Handle

To check for squareness, 90° position:

1.Raise blade to 3" depth of cut .

2.Operate the tilt lock handle (counter-

clockwise) to loosen t he tilt clamp

screw.

NOTE: Handle is spring loaded for

engagement with screw head - must be

pushed inward for disengagement

whenever necessary to obtain a new

grip on screw head. Always position

handle in downward position to prevent

binding when tilting the blade.

3.Rotate tilt handwheel clockwise a few

turns to til t bl ade. Now, r otate handwheel counterclockwise until it stops.

Blade should now be square with table

and pointer should point to “0”.

4.Place the square against blade. Mak e

sure square is not touching the tip of

one of the saw teeth.

Bevel Poin ter

Tilt Handwhe el

Pointer

Square

Blade

A.If blade is square to table

1.Check pointer. If pointer does not

point to t he “0” mark on the bevel

scale.

a. Remove elevation handwheel.

b. For gross adjustments bend the

pointer to align with the zero

mark. For fine adjustments

loosen the screw and adjust the

pointer using a medium screwdriver.

c. Install elevation handwheel.

Adjusting Screw

24

Pointer

Pointer at

0° Position

Scale Adjusting

Screw

B.If blade is not square to table...the

90° stop screw must be adjusted.

1.Use a 3/16" hex “L” wrench to

unscrew the 90° stop screw until it

is flush with the top of the table.

2.Turn tilt handwheel clockwise one

turn, then turn handwheel counter clockwise until blade is square

with table.

3.Screw 90° stop screw in until the

sawblade starts to move. Check

once again for squareness and

readjust screw, i f necessary.

4.Check pointer as described in step

A.

To check for alignment, 45° Position

1.Tilt blade to left as far as it will go.

2.Place an accurate square against

blade. Make sur e square is not touching the tip of one of the saw teeth.

A.If blade is 45° to table;

1.Check pointer. If pointer does not

point to the 45° mark on the scale,

the scale must be adjusted.

a. Remove elevation handwheel.

b. Loosen two screws on scale

and adjust scale up or down

until pointe r points to 45° mark.

c. Install elevation handwheel.

B. If blade is not 45° to table, stop

screw and scale mus t be adjusted .

1.Use a 3/16" hex “L” wrench to

unscrew the 45° stop screw until it

is flush with the top of the table.

2. Turn tilt handwheel until blade is

45° to the table.

3.Screw 45° stop screw in until the

sawblade starts to move. Check

once again and readjust screw, if

necessary.

4.Check pointer as described in step

A above.

Checking Tilt Mechanism

With tilt lock handle loosened, the handwheel should turn freely without binding.

The turning friction can be adjusted by

tightening or loosening the screws in the

bearing retainer.

NOTE: Tilt handwheel must be removed

to adjust. When adjusting the screws in

the bearing retai ner, hold the nut inside

using a 3/8 inch wrench.

90°

Stopscrew

45°

Stopscrew

Scale Screws

Retainer Bearing

(Inside Base)

Screws

Tilt

Handwheel

25

Assembly (continued)

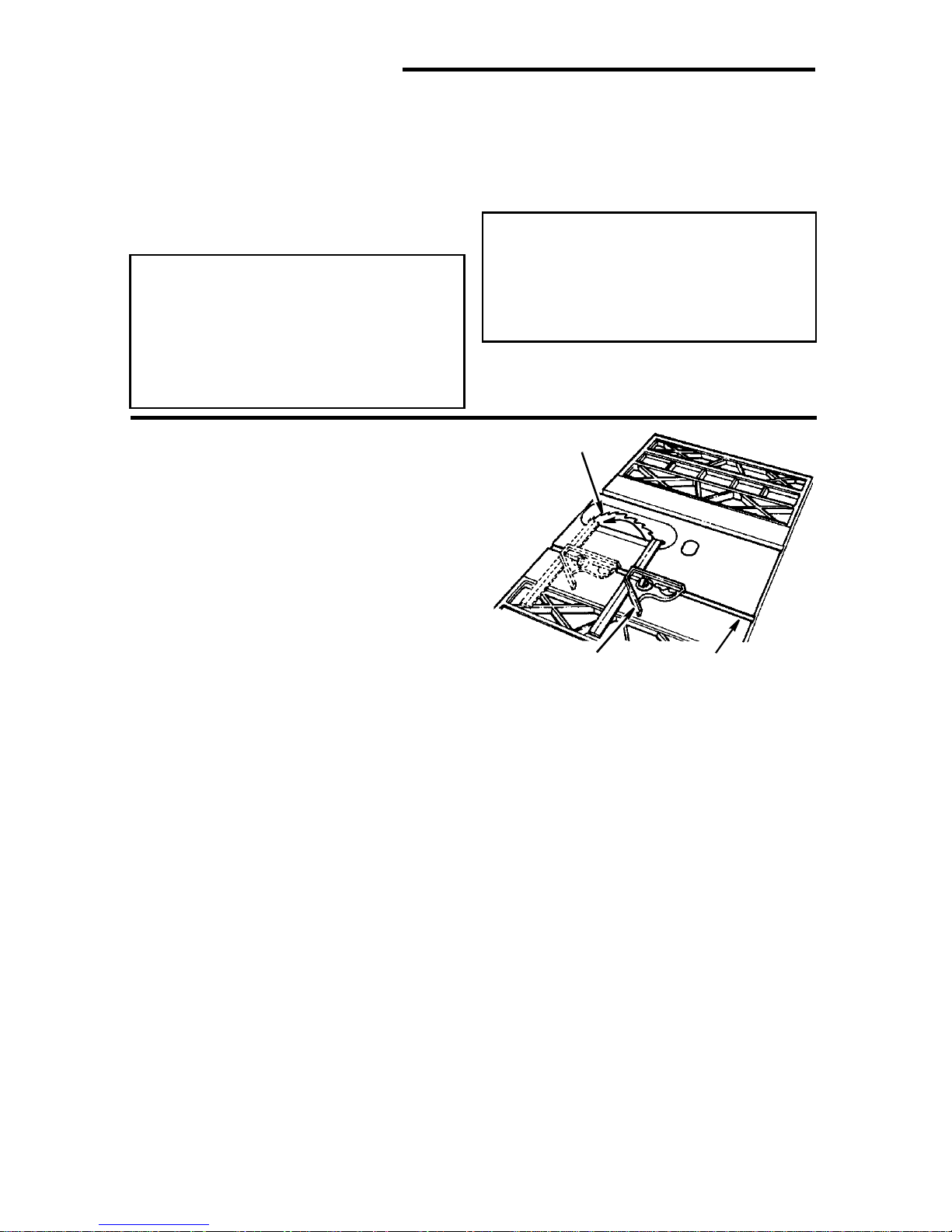

Assembling Herc-U-Lift™ Caster

System

Assembly Tips

1.The caster set consi sts of an upper and

lower as s e mb ly.

2.First put the upper and lower assembly

together following instructions below.

3.Loosely assemble all nut and screw

connecti ons. After mount ing the ass emblies on the t able saw, adjust frames on

center, and then securely tighten all fasteners.

4.When assembl ing the frames, Tube

Rear (27" long) and Tube Front (13-7/8"

long) must be assembled so the la rge

hole faces down towards the floor. See

the illust ration before assembling.

Hex Head Screw w/Washer

1/4-20 x 1-1/2

Upper Assembly

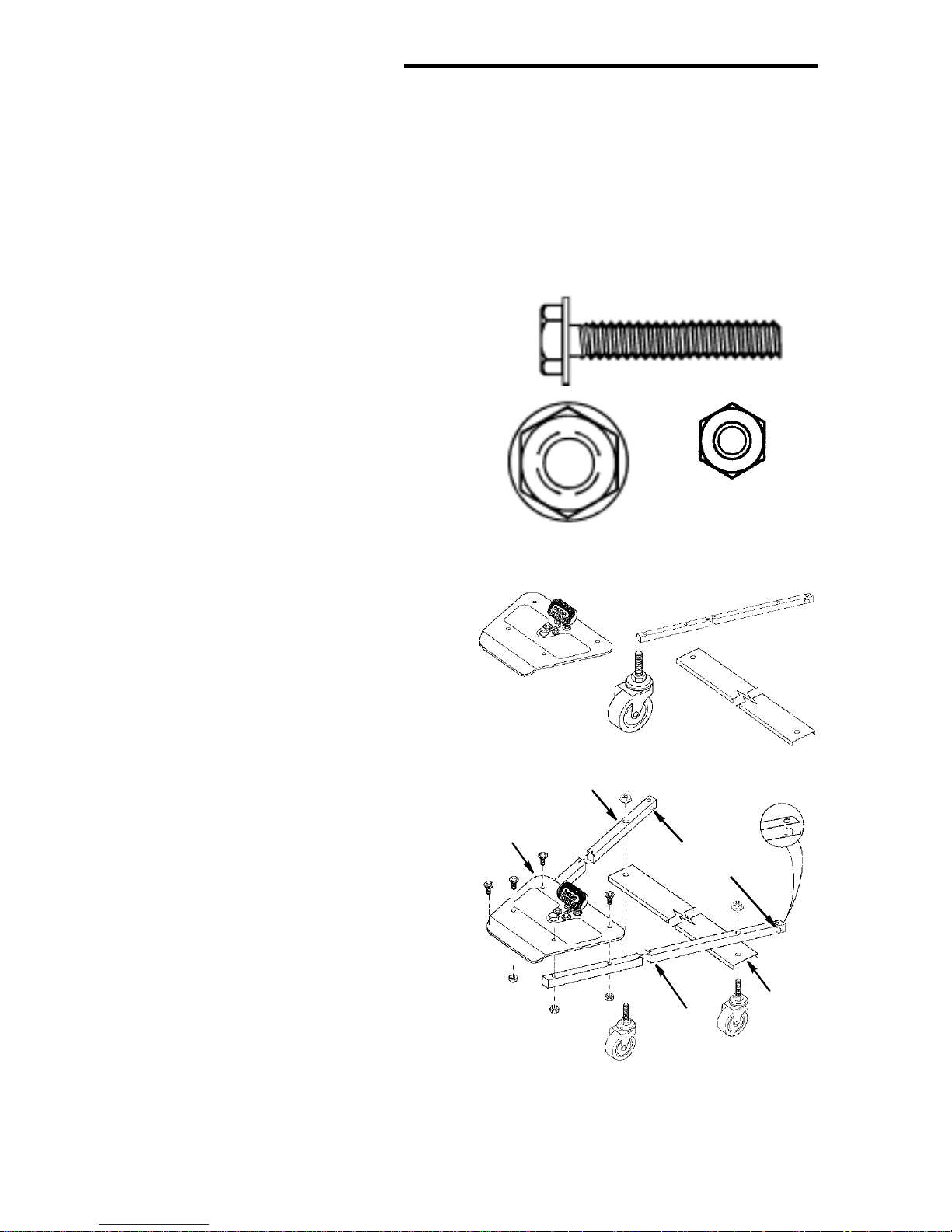

1.From bag of loose par ts remove the following hardware:

*4Hex Head Screw w/Washer, 1/4-20 x

1-1/2

*2Hex Nuts w/Serrated Flange 7/16

*4Lock Nuts 1/4-20

*Items marked with asterisk (*) are

shown actual size.

2.From the loose par ts find the following :

1 Plate Ass e m bly

2 Tube Rear (27" Length)

1 Channel Rear

2Casters

3.Assemble T ube Rear (2 7 inc h leng th) to

each side of the Plate Assembly as

shown using fou r each 1/4-20 x 1-1/2

hex head screw and lock nut. Loosely

assemble at this time.

NOTE: The larger hole at the end of the

tube, opposite the plate assembly,

must face down.

4.Align r ear chann el wit h holes in the rear

tubes as shown. Assemble caster

through channel and tube as shown.

Fasten with 7/ 16 n ut as shown . Lo osely

assemble at this time.

7/16 Hex Nut

w/Serrated Washer

Plate Assembly

Tube Rear

Plate

Assembly

Caster

1/4-20

Lock Nut

Tube Rear

Channel Rear

Large Hole

Facing Dow n

Tube

Rear

Channel

Rear

26

Loading...

Loading...