Page 1

Utility Pump

OPERATOR’S

MANUAL

• Pour français voire page 7

• Para ver el castellano vea

la paginá 15

TP-250

WARNING!

Read this operators Manual

carefully before using this

tool. Failure to understand

and follow the contents of

this manual may result in

electrical shock, fire and/or

serious personal injury.

Page 2

TP-250 Utility Pump

Table of Contents

Recording Form for Pump Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

General Safety Information

Work Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Electrical Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Personal Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specific Safety Information

Pump Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Description And Specifications

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Pump Assembly And Installation

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Adjustment and Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Suggested Parts Replacement Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Service And Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

Ridge Tool Company

ii

Page 3

TP-250 Utility Pump

Record Serial Number from product decal below.

TP-250 Utility Pump

Serial No.

Page 4

TP-250 Utility Pump

Ridge Tool Company

2

General Safety Information

Safety is a combination of common sense, staying alert

and understanding how your utility pump works.

Safety Signal Words

means if the safety information is not

followed someone will be seriously injured or killed.

means if safety information is not fol-

lowed someone could be seriously injured or killed.

means if safety information is not fol-

lowed someone may be injured.

indicates important information, that if

not followed, may cause damage to the equipment or

flooding .

Read and understand all instructions. Failure to follow all instructions listed below

may result in fatal electric shock,fire, property damage, and/or serious personal injury.

SAVE THESE INSTRUCTIONS!

Work Area

• Do not operate pump in explosive atmospheres,

such as in the presence of flammable liquids,

gases, or dust. Pump motors create sparks which

may ignite the dust or fumes.

• Keep by-standers, children, and visitors away

while installing pump. Distractions can result in

mistakes.

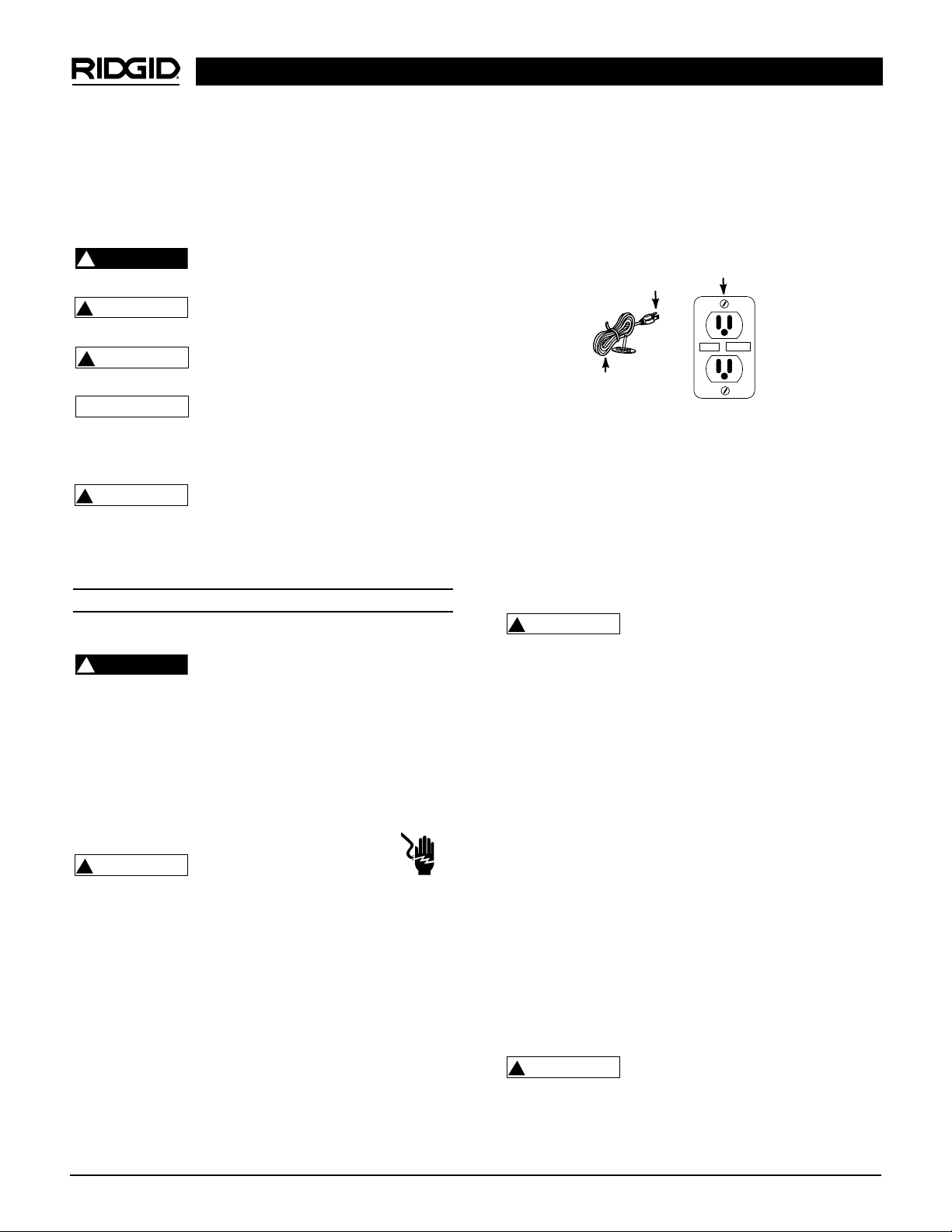

Electrical Safety

• This pump must be plugged into an outlet,

properly installed, and grounded in accordance

with all applicable codes and ordinances. Never

remove the grounding prong or modify the plug

in any way. Do not use any adapter plugs.

Check with a qualified electrician if you are not

sure the outlet is grounded. If the pump should

electrically malfunction or break down, grounding

provides a low resistance path to carry electricity

away from the user.

• Electrical wiring must be performed by a quali-

fied electrician. Improper wiring could result in

fatal electrical shock.

• Do not abuse cord. Never use the cord to carry

the pump or pull the plug from an outlet. Keep

cord away from heat, oil, sharp edges, or moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electrical

shock.

• Before using, test the Ground Fault Circuit

Interrupter (GFCI) to insure it is operating correctly. AGFCI reduces the risk of electrical shock.

• Do not use an extension cord.This increases the

risk of electrical shock. If necessary, install a properly grounded outlet closer to the pump.

Personal Safety

• Stay alert, watch what you are doing, and use

common sense when installing this pump. Do

not attempt to install this pump while tired or

under the influence of drugs, alcohol or medications. A moment of inattention may result in

serious personal injury.

• Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts.

Loose clothes, jewelry, or long hair can be caught

in moving parts.

• Do not overreach. Keep proper footing and bal-

ance at all times. Proper footing and balance

enables better control in unexpected situations.

• Use safety equipment. Always wear eye protec-

tion. Dust mask, non-skid safety shoes and hard

hat must be used for appropriate conditions.

Service

• Pump service must be performed only by qualified repair personnel. Service or maintenance

performed by unqualified repair personnel could

result in injury and may void the warranty.

d

Figure 1

!

DANGER

!

WARNING

!

CAUTION

!

NOTICE

!

WARNING

!

DANGER

!

WARNING

Grounding

Blade

Power

Cord

Grounde

Outlet

RESET

TEST

!

WARNING

!

WARNING

Page 5

TP-250 Utility Pump

Ridge Tool Company

3

• When servicing a pump, use only identical

replacement parts. Follow instructions in the

Maintenance Section of this manual. Use of

unauthorized parts or failure to follow maintenance

instructions may create a risk of electrical shock or

injury and may void the warranty.

Specific Safety Information

Risk of electric shock. This pump

is supplied with a grounding-type plug. To reduce

risk of electric shock be certain that it is connected only to a properly grounded, grounding-type

receptacle.

For your own safety, before assembling and operating

this unit, read this operators manual carefully and

completely. Learn the operation, application, and

potential hazards peculiar to this unit.

Call the Ridge Tool Company, Technical Service

Department at (800) 519-3456 if you have any questions.

Utility Pump Safety

• Do not use to pump flammable or explosive flu-

ids such as gasoline, fuel oil, kerosene, solvents, thinners, etc. Do not use in a flammable

and/or explosive atmosphere. Pump should

only be used to pump clear water. Improper use

could result in personal injury and/or death.

• If there is water or moisture on the floor,do not

walk on wet area until all power is turned off. If

the shut-off box is in the basement, call an

electrician. Failure to follow this warning could

result in fatal electrical shock.

• Always disconnect the power source before

attempting to install, service, relocate, or maintain the pump. Never handle a pump or pump

motor with wet hands or when standing on a

wet or damp surface or in water when the

pump is connected to power. Failure to follow

this warning could result in personal injury and/or

death.

Description and Specifications

Description

The Submersible Utility Pump is designed for nonautomatic use in water. The unit is equipped with an 8

foot, 3-prong grounding type power cord with a GFCI

plug. The motor is oil filled and sealed for cooler operation. The discharge fitting is designed for convenient

attachment to a garden hose.

• This pump is not designed to handle salt water,

brine, laundry discharge, or any other application

which may contain caustic chemicals and/or foreign materials. This pump is not suitable for use

with aquatic life. Pump damage or failure could

occur if used in these applications and will void the

warranty.

Specifications

Motor:

Type. . . . . . . . . . . . . . . . . . . . Shaded Pole

Rating . . . . . . . . . . . . . . 115V, Single Phase

1/4 HP, 4.8 amp

Pump:

1/4 HP . . . . . . . . . . . . . . 1100 GPH @ 0 Ft.

Installation:

Pump Down Level . . . . . . . . . . . . . 1/8 inch

Liquid Temperature Range. . . 40˚F to 120˚F

Discharge Size . . . . . 3/4 inch Garden Hose

Pump Installation

• Pump should only be used to pump clear

water.Do not use to pump fluids such as gasoline, fuel oil, or kerosene. Do not use in a flammable or explosive atmosphere. Improper use

could result in personal injury and/or death.

To prevent property damage, serious injury ,or death, proper installation of the pump

is required. The following procedures should be

followed:

• Always disconnect the power source before

attempting to install, service,relocate, or maintain the pump. Never handle a pump or pump

motor with wet hands or when standing on wet

or damp surface or in water when pump is connected to power source.

!

WARNING

!

NOTICE

!

DANGER

!

WARNING

!

DANGER

!

WARNING

Page 6

TP-250 Utility Pump

Ridge Tool Company

4

1. This pump has been designed to attach to a standard garden hose. Thread the female end of the

garden hose to the discharge on the pump.

2. To reduce leakage between the pump and the

hose, place a hose washer (not included) on the

garden hose before installing to the pump.

3. For best pump performance, unwind the hose

before starting the pump. This will help remove

any kinks or binds in the hose and allow the unit to

pump with less restriction.

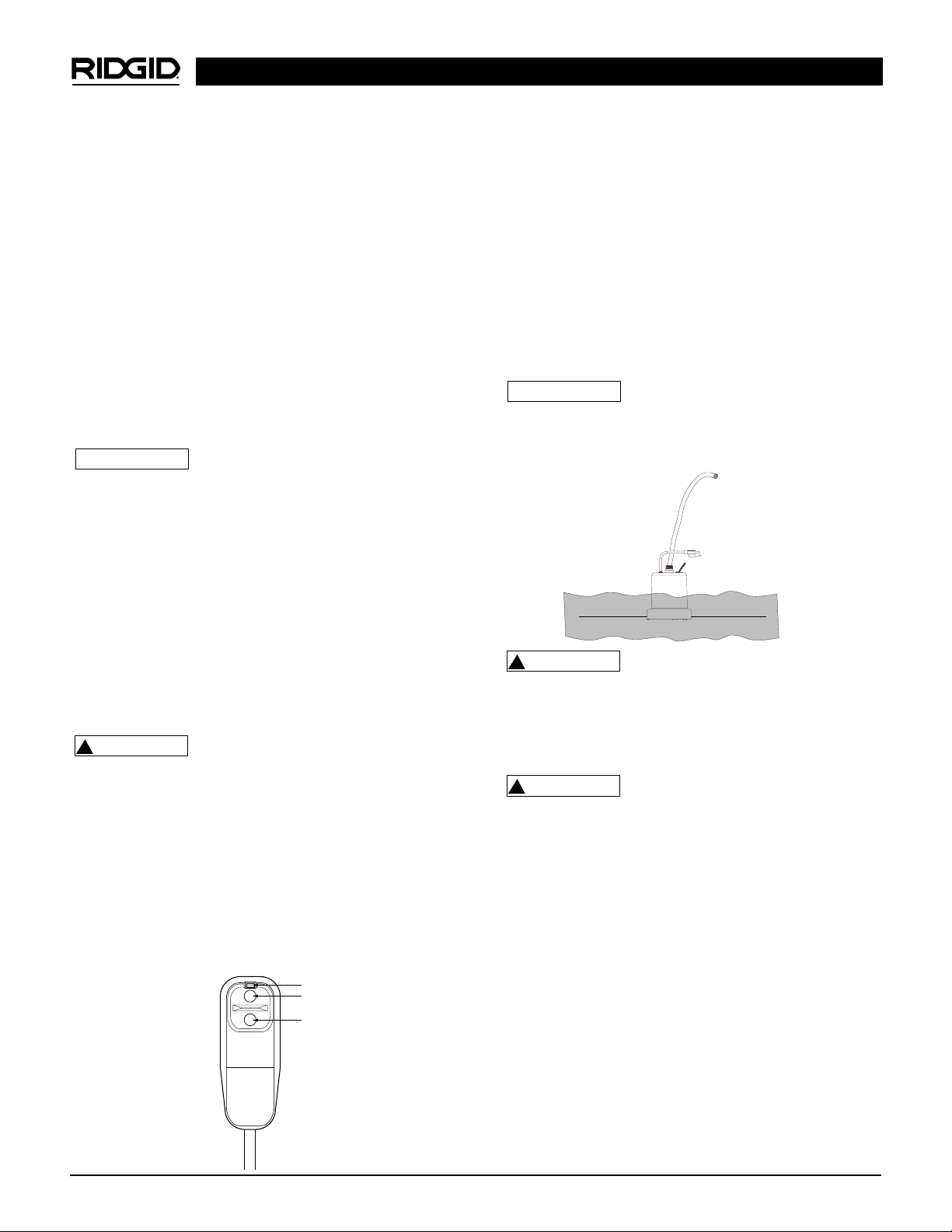

4. Place pump on a hard surface in the water. Do not

set the pump directly on mud or sand surfaces.

This will cause the inlet screen to clog.

Do not place pump directly on clay,

gravel, or any loose or sandy surfaces. These surfaces

contain small stones or sand that may clog or damage

the pump. This could result in pump failure causing

flooding and property damage.

5. The water level must be at least 1/2 inch for the

pump to operate. Water levels less than 1/2 inch

will not allow the impeller to contact water and no

water will be pumped.

6. Inspect the power cord and GFCI plug for damage.

If the plug is missing the grounding prong or the

cord is damaged, do not install the pump until the

cord has been replaced.

• Never cut off grounding prong or use an adapter.

• Before using, test the Ground Fault Circuit

Interrupter (GFCI) to insure it is operating correctly.

7. Plug the power cord into a grounded 115-volt AC

power outlet. Make sure the electrical outlet is

grounded and is rated for at least 15 amps. The

pump will start operating as soon as the power

cord is plugged into the power outlet. The indicator on the GFCI should be RED.

8. Press the TEST button. The RED indicator should

disappear.

9. Press RESET button. The indicator should be

RED. Do not use the pump if the indicator is not

RED.

10. The pump will remove water down to 1/8 inches of

the surface the pump was placed on.

11. The pump should be unplugged once the water

has reached the 1/8 inch height, or pump will run

dry.

Do not allow pump to run dry. The

shaft seal depends on water for lubrication. Operating

the pump without water will damage the shaft seal and

cause pump failure.

When routing electrical cord protect

cord from sharp objects, hot surfaces, oils, and chemicals. Do not kink cord; replace any damaged cord

immediately.

Maintenance Instructions

Always disconnect the electrical

supply or unplug the pump before attempting to

install, service, relocate, or perform any maintenance. If the po wer source is out of sight, lock and

tag in the open (OFF) position to prevent unexpected power application. Failure to do so could

result in fatal electrical shock. Only a qualified

technician should repair this unit. Improper repair

could result in fatal electrical shock.

1. Check the operation of the Ground Fault Circuit

Interrupter (GFCI) each time the pump is used.

2. Keep pump inlet clean and free of all foreign

objects. Inspect inlet at beginning of each use.

3. The motor housing is completely sealed and

requires no service. Disassembly of the motor

housing or alteration of the power cord could

result in fatal electrical shock.

Red Light

Reset Button

Test Button

!

NOTICE

!

NOTICE

!

WARNING

Red Light

Reset Button

Test Button

!

WARNING

!

WARNING

Page 7

TP-250 Utility Pump

Ridge Tool Company

5

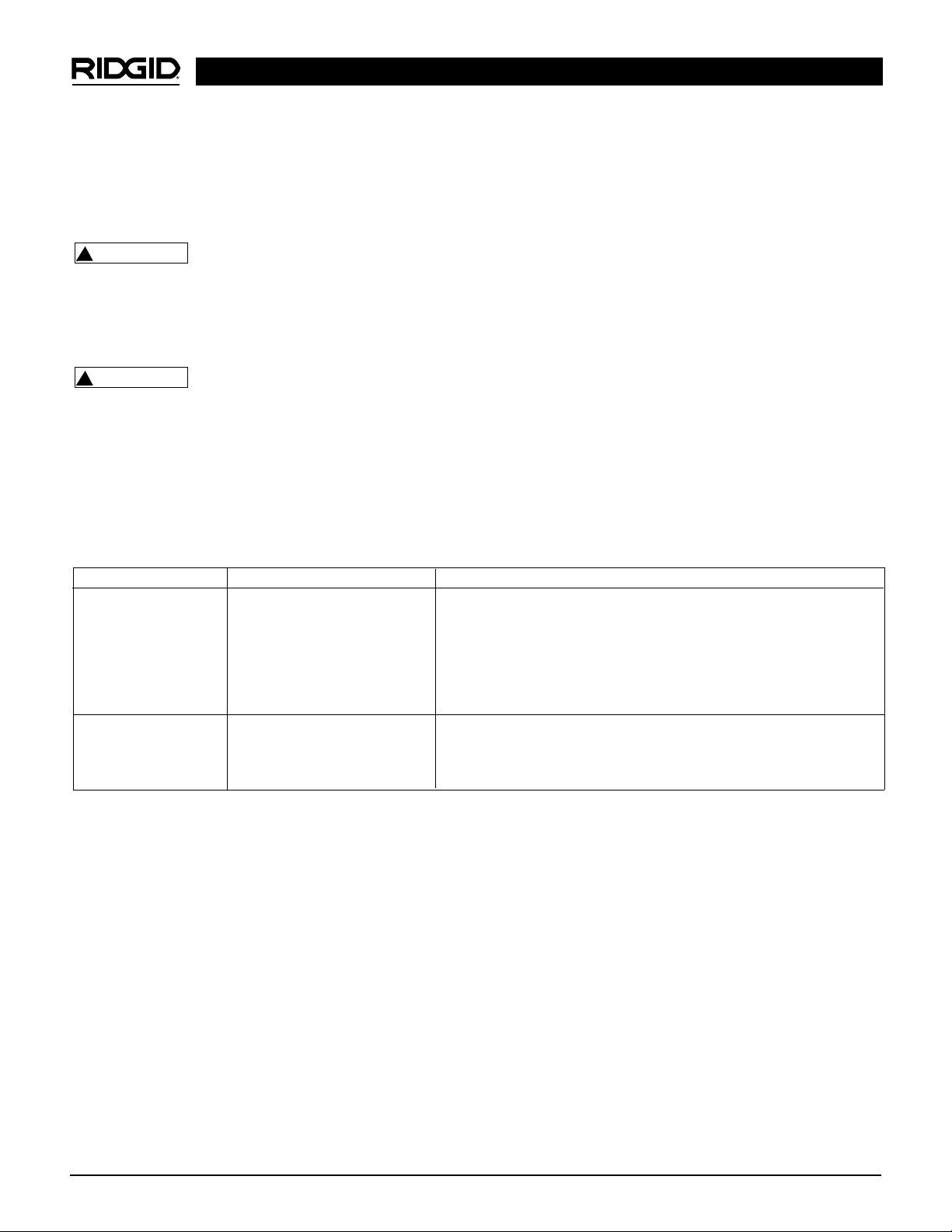

Suggested Part Replacement Schedule

Replace motor every 5 years. See page 6 for RIDGID

cat. 90202.

SERVICE AND REPAIR

Service and repair work on this

pump must be performed by qualified repair personnel.

Pump should be taken to a RIDGID Independent

Authorized Service Center or returned to the factory.

All repairs made by RIDGID service facilities are warranted against defects in material and workmanship.

When servicing this pump, only identical RIDGID replacement parts should be used.

Failure to follow these steps may create a risk of flooding, property damage, fatal electrical shock, or other

serious injury.

If you have any questions regarding the service or

repair of this machine, call or write to:

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44036-2023

Tel: (800) 519-3456

E-Mail: TechService@ridgid.com

For name and address of your nearest Independent

Authorized Service Center, contact the Ridge Tool

Company at (800) 519-3456 or http://www.ridgid.com

TROUBLESHOOTING CHART

Symptom

Pump will not start or

run

Pump starts but

delivers little or no flow

Possible Cause(s)

1. Blown fuse or breaker

2. Low line voltage

3. Worn motor

4. Impeller not rotating

5. GFCI

6. Thermal Protector open

1. Inlet screen clogged

2. Low line voltage

3. Restriction in discharge hose

4. Discharge lift too high

Corrective Action

1. If blown, replace with the proper sized fuse or reset the breaker.

2. If voltage is under 108 volts, check wiring size.

3. Replace motor or pump.

4. If impeller will not turn, disconnect pump from power source, remove

volute cover and remove blockage.

5. Test GFCI, replace if worn.

6. Motor locked up, replace motor (RIDGID Cat. 90202).

1. Clean debris from screen.

2. If voltage is under 108 volts, check wiring size.

3. Unwind garden hose, remove any kinks or restrictions in hose.

4. Water level to end of garden hose is 25 ft. or greater.

!

WARNING

!

WARNING

Page 8

TP-250 Utility Pump

Ridge Tool Company

6

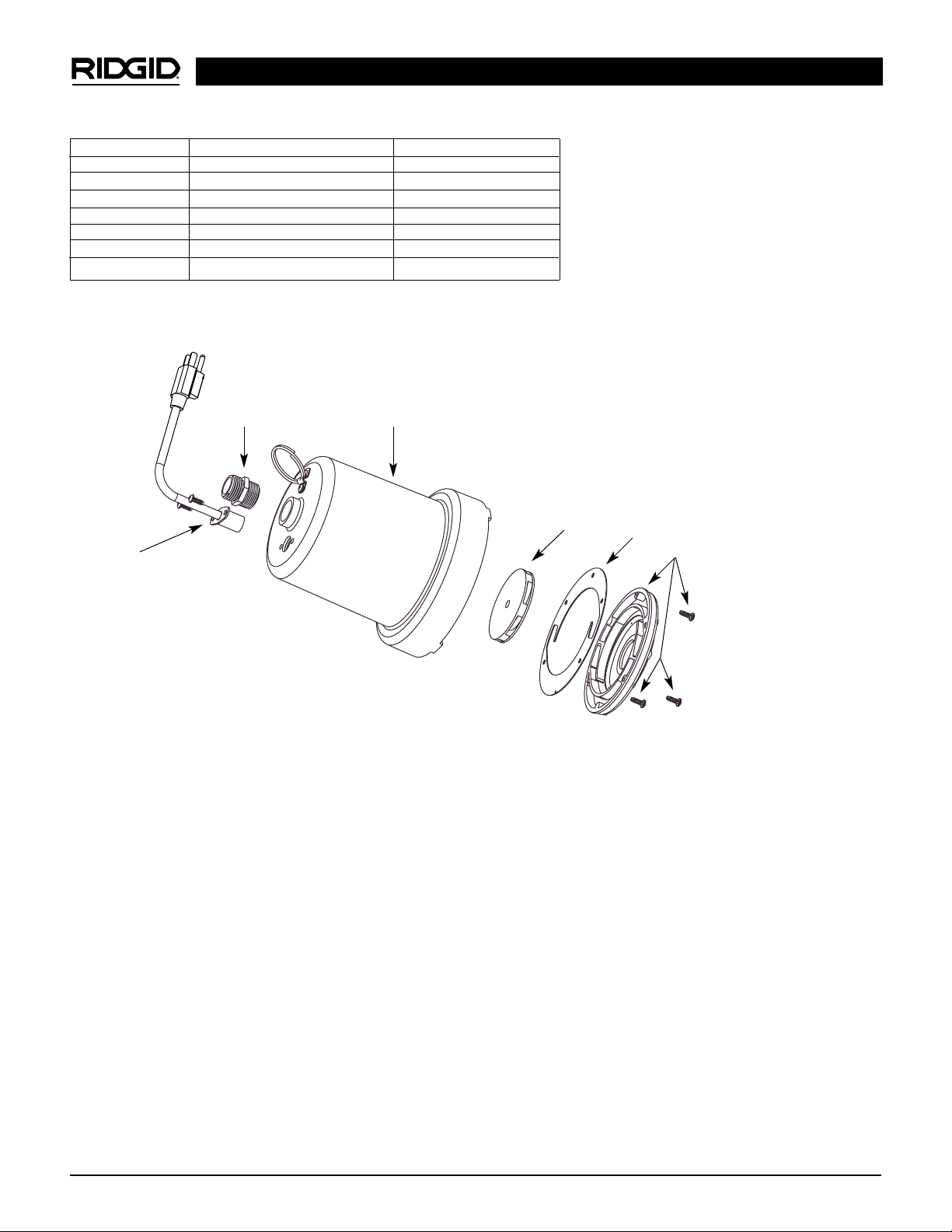

Figure

1

2

3

4

5

6

Not Shown

Description

Power Cord Kit

Discharge Fitting Kit

Outer Housing with O-ring Kit

Impeller Kit

Volute Gasket Kit

Volute Cover with screen Kit

Motor Kit

Cat. Number

90172

90177

90182

90187

90192

90197

90202

1

2

3

4

5

6

Page 9

Pompe utilitaire TP-250

Enregistrez le numéro de série de la décalcomanie du produit ci-après

Pompe utilitaire TP-250 Utility

No. de série

Page 10

Pompe utilitaire TP-250

Table des matières

Formulaire d’enregistrement du numéro de série de la pompe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Informations générales de sécurité

Aire de travail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Sécurité électrique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Sécurité personnelle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Information de sécurité spécifique

Sécurité de pompe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Description et spécifications

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Spécifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation et assemblage de la pompe

Assemblage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

Ajustement et test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

Instructions d’entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Suggestions d’horaire de remplacement des pièces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Service et réparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Dépannage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Couverture arrière

Ridge Tool Company

8

Page 11

Pompe utilitaire TP-250

Ridge Tool Company

9

Informations générales de

sécurité

La sécurité est un mélange de sens commun, vigilance et

compréhension du fonctionnement de votre pompe utilitaire.

Termes de sécurité

signifie que si l’information de

sécurité n’est pas respectée, une personne sera grièvement

blessée ou tuée.

signifie que si l’information de

sécurité n’est pas respectée, une personne pourrait être

grièvement blessée ou tuée.

signifie que si l’information de

sécurité n’est pas respectée, une personne pourrait être

blessée

.

indique de l’information

importante qui non respectée pourrait endommager

l’équipement ou inonder.

Lire et comprendre toutes

les instructions. Le non-respect de toutes les instructions ci-après pourrait mener à un choc électrique mortel, un incendie, des dommages à la propriété et/ou de

graves blessures.

CONSERVER CES INSTRUCTIONS !

A

ire de travail

• Ne faites pas fonctionner la pompe dans des atmo-

sphères explosives telles qu’en présence de liquides, gaz ou poussière inflammables. Les moteurs

de pompe créent des étincelles qui pourraient

enflammer la poussière ou les fumées.

• Gardez les spectateurs, les enfants et les visiteurs

loin en installant la pompe. Des distractions peuvent

mener à des erreurs.

Sécurité électrique

• Cette pompe doit être branchée dans une

prise, installée correctement et mise à la terre conformément à tous les codes et ordonnances applicables. Ne retirez jamais la broche de masse et ne modifiez pas la fiche. N’utilisez pas de fiches d’adaptateur. Vérifiez auprès d’un électricien qualifié si vous

n’êtes pas certain que la prise soit mise à la terre. Si

la pompe à une défaillance électrique ou cesse de fonctionner, la masse offre une voie de faible résistance pour

éloigner l’électricité de l’usager.

• Le câblage électrique doit être effectué par un élec-

tricien qualifié. Tout mauvais câblage peut mener à un

choc électrique mortel

.

• N’abusez pas du cordon. Ne l’utilisez jamais pour

transporter la pompe ou pour retirer la fiche de la

prise. Gardez le cordon loin de la chaleur, de l’huile,

bords tranchants ou pièces mobiles. Remplacez

immédiatement les cordons endommagés car ils

augmentent le risque de choc électrique.

• Avant d’utiliser, testez le disjoncteur différentiel

(DD) pour vous assurer qu’il fonctionne correctement.. Un DD réduit le risque de choc électrique.

• N’utilisez pas de rallonge car cela augmente le risque

de choc électrique. Si nécessaire, installez une prise à

la terre plus près de la pompe.

Sécurité personnelle

• Restez vigilant, regardez ce que vous faites et

utilisez du sens commun en installant cette pompe

N’essayez pas de l’installer fatigué ou sous l’influence de drogues, d’alcool ou de médicaments. Un

moment d’inattention peut provoquer de graves

blessures.

• Habillez-vous correctement. Ne portez pas de vêtements amples ni de bijoux. Attachez les cheveux

longs. Gardez les cheveux, vêtements et gants loin

des pièces mobiles car ils peuvent se prendre dans les

pièces mobiles.

• Ne vous penchez pas trop. Posez bien les pieds et

assurez-vous de ne jamais perdre l’équilibre car cela

vous permet de mieux contrôler les situations inattendues.

• Utilisez de l’équipement de sécurité. Portez toujours

une protection oculaire. Utilisez des masques

antipoussières, des souliers de sécurité antidérapants et

un casque protecteur selon le cas.

Service

• L’entretien de la pompe doit être effectué seulement

par un personnel d’entretien qualifié. L’entretien et la

réparation par une personne non qualifiée pourraient

provoquer des blessures et annuler la garantie.

d

Figure 1

Broche de

masse

Prise mise

à terre

Cordon

!

DANGER

!

AVERTISSEMENT

!

ATTENTION

AVIS

!

AVERTISSEMENT

!

DANGER

!

AVERTISSEMENT

Grounde

Outlet

RESET

TEST

Power

Cord

Grounding

Blade

!

AVERTISSEMENT

!

AVERTISSEMENT

Page 12

Pompe utilitaire TP-250

Ridge Tool Company

10

• En faisant le service de la pompe, utilisez seulement

des pièces de rechange identiques. Suivez les

instructions sous la section d’entretien de ce

manuel. Utilisez des pièces non-autorisées ou le non-

respect des instructions d’entretien peut annuler la

garantie

.

Information de sécurité spécifique

Risque de choc électrique.

Cette pompe est alimentée par une prise mise à la terre.

Pour réduire les risques de choc électrique, assurezvous qu’elle soit branchée seulement à une prise mise à

la terre correctement

.

Pour votre propre sécurité, avant d’assembler et de faire

fonctionner l’appareil, lisez attentivement et en entier ce

manuel des opérations. Apprenez l’application d’opération et

les dangers possibles de cet appareil-ci.

Appelez les services techniques de Ridge Tool Company au

(800) 519-3456 si vous avez des questions.

Sécurité de la pompe utilitaire

• N’utilisez pas pour pomper des fluides inflamma-

bles ou explosifs tels qu’essence, fuel, kérosène,

solvants, diluants, etc. N’utilisez pas dans une

atmosphère inflammable et/ou explosive. La pompe

doit seulement servir pour pomper de l’eau claire.

Une mauvaise utilisation peut mener à des blessures

personnelles et/ou à la mort.

• S’il y a de l’eau ou de l’humidité sur le sol ou sur le

plancher près de la pompe, ne marchez pas dessus

avant de couper le courant. Si la boîte d’arrêt est

dans le sous-sol, appelez un électricien. Le non-

respect de cet avertissement pourrait mener à un choc

électrique mortel.

• Coupez toujours la source de courant avant d’es-

sayer d’installer, de réparer, de replacer ou de faire

l’entretien de la pompe. Ne manipulez jamais une

pompe ou son moteur avec les mains mouillées ou

debout sur une surface mouillée ou humide ou dans

l’eau. Le non-respect de cet avertissement pourrait

mener à une blessure et/ou à la mort.

Description et spécifications

Description

La pompe utilitaire submersible est conçue pour une utilisation non-automatique de l’eau. L’appareil est doté d’un cordon mis à la terre à 3 broches de 8 pieds (2,4 m) avec une

prise à DD.

Le moteur est rempli d’huile et scellé pour

une opération de refroidissement. Le raccord de

décharge est conçu pour une fixation pratique à un tuyau

d’arrosage

.

• Cette pompe n’est pas conçue pour traiter l’eau salée, la

saumure, les refoulements de lavage ou toute autre

application pouvant contenir des produits chi-miques

caustiques et/ou des matières étrangères. Cette pompe

ne convient pas pour la vie aquatique. La pompe peut

être endommagée ou manquer si utilisée pour ces applications et cela annulera la garantie.

Spécifications

Moteur :

Type. . . . . . . . . . . . . . Enroulement à courtterme

Calibre . . . . . . . . . . . . . . . . . . Monophase 115V

1/4 HP, 4,8 A

Pompe :

1/4 HP . . . . . . . . . . . . . . . . . . 1100 gal/h @ 0 pi

Installation :

Niveau d’évacuation . . . . . . . . . 1/8 po (0,32 cm)

Plage de température liquide 40˚F à 120˚F

Taille de décharge . . . . . 3/4 po tuyau d’arrosage

Installation de la pompe

• La pompe ne doit servir que pour pomper de l’eau

claire. Ne l’utilisez pas pour des fluides tels

qu’essence, fuel ou kérosène ni dans une atmosphère inflammable ou explosive. Toute mauvaise

utilisation de la pompe pourrait causer des blessures

et/ou la mort.

Pour éviter les dom-

mages à la propriété, les blessures graves ou la mort, il faut

installer la pompe correctement et suivre ces procédures :

• Coupez toujours la source de courant avant d’essayer d’installer, de réparer, de replacer ou de faire

l’entretien de la pompe. Ne manipulez jamais une

pompe ou son moteur avec les mains mouillées ou

debout sur une surface mouillée ou humide ou dans

l’eau lorsque la pompe est sous tension.

!

AVERTISSEMENT

AVIS

!

DANGER

!

AVERTISSEMENT

!

DANGER

!

AVERTISSEMENT

Page 13

Pompe utilitaire TP-250

Ridge Tool Company

11

1. Cette pompe est conçue pour se fixer à un tuyau d’arrosage standard. Enfilez l’extrémité femelle du tuyau

d’arrosage à la décharge de la pompe.

2. Pour réduire les fuites entre la pompe et le flexible,

placez une rondelle de flexible (non fournie) sur le tuyau

d’arrosage avent d’installer la pompe.

3. Pour la meilleure performance, étirez le flexible avant de

lancer la pompe. Ceci aidera à retirer le tortillement ou

les coudes du flexible et laissera l’appareil pomper avec

moins de restriction.

4. Placez la pompe sur une surface dure dans l’eau. Ne

placez pas la pompe directement dans la boue ou dans

les surfaces de sable. Ceci bloquera le tamis de l’entrée.

Ne placez pas directement

sur l’argile, le gravier ou toutes surfaces lâches ou sablonneuses car elles contiennent de petites roches ou du sable

qui pourraient bloquer ou endommager la pompe provoquant

une défaillance et donc une inondation et des dommages à

la propriété

.

5. Le niveau d’eau doit être au moins 1/2 po (1,27 cm) pour

que la pompe fonctionne. Les niveaux d’eau de moins

de 1/2 po (1,27 cm) ne permettront pas au rotor d’entrer

en contact avec l’eau et aucune eau ne sera pompée.

6. Inspectez le cordon et la fiche du DD pour tout dommage. Si la fiche manque, la broche de masse ou le

cordon est endommagé, n’installez pas la pompe avant

de réparer le cordon.

• Ne coupez jamais la broche de masse et n’utilisez pas

d’adaptateur

.

• Avant d’utiliser, testez le disjoncteur différentiel (DD)

pour vous assurer qu’il fonctionne correctement.

7. Branchez le cordon dans une prise mise à la terre de 115

V de c.a. Assurez-vous que la prise est mise à la terre

et d’un calibre d’au moins 15 A. La pompe démarrera

dès que le cordon sera branché. Le voyant du DD

devrait être ROUGE.

8. Appuyez sur le bouton TEST. Le voyant ROUGE

devrait disparaître.

9. Appuyez sur le bouton RESET. Le voyant devrait être

ROUGE. N’utilisez pas la pompe s’il ne l’est pas.

10. La pompe retirera l’eau jusqu’à 1/8 po (0,32 cm) de la

surface sur laquelle se trouve la pompe.

11 . La pompe doit être débranchée lorsque l’eau atteint 1/8

po (0,32 cm) de hauteur ni pomper à sec.

Ne laissez pas la pompe

fonctionner à sec. L’étanchéité de l’arbre dépend de l’eau

pour sa lubrification. Faire fonctionner la pompe sans eau

endommagera l’étanchéité de l’arbre et provoquera la défaillance de la pompe.

En acheminant le cordon,

protégez-le des objets tranchants, surfaces chaudes, huiles

et produits chimiques. Ne tordez pas le cordon, remplacez

immédiatement tout cordon endommagé

.

Instructions d’entretien

Coupez toujours le courant

ou débranchez la pompe avant d’essayer d’installer,

répa-rer, replacer ou entretenir l’appareil. Si la source de

courant est hors de vue, verrouillez et étiquetez en position ouverte (OFF) pour éviter toute application

imprévue de courant. Sinon, cela pourrait mener à un

choc électrique mortel. Seul un technicien qualifié

devrait réparer cet appareil. Toute mauvaise réparation

peut mener à un choc électrique mortel

.

1. Vérifiez l’opération du disjoncteur différentiel (DD)

chaque fois qu’on l’utilise.

2. Gardez l’entrée de la pompe propre et sans objets

étrangers

. Inspectez au début de chaque utilisation.

3. Le logement du moteur est complètement scellé et ne

peut être réparé. Démontez le logement du moteur ou

modifier le cordon d’alimentation peut mener à un choc

électrique mortel.

Voyant rouge

Reinitialiser

Bouton de test

AVIS

AVIS

!

AVERTISSEMENT

!

AVERTISSEMENT

Red Light

Reset Button

Test Button

!

AVERTISSEMENT

Page 14

Pompe utilitaire TP-250

Ridge Tool Company

12

Suggestions d’horaire de remplacement

des pièces

Remplacez le moteur tous les 5 ans. Voir la page 13 du cat.

RIDGID 90202.

Service et réparation

Le travail de service et réparation de cette pompe doit être effectué par un personnel

qualifié. La pompe doit être apportée à un centre de service

autorisé indépendant RIDGID ou retournée à l’usine. Toutes

les réparations effectuées dans des installations de service

Ridge sont garanties contre les défauts de matériau et main

d’oeuvre.

En réparant cette pompe,

seules des pièces de rechange identiques doivent être utilisées sinon cela pourrait créer un risque d’inondation, de

dommages à la propriété, de choc électrique mortel.

Si vous avez des questions au sujet du service ou des réparations de cet appareil, appelez ou écrivez à

:

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44036-2023

Tél : (800) 519-3456

Courriel : TechService@ridgid.com

Pour le nom et l’adresse de votre centre de service autorisé

indépendant le plus près, contactez la Ridge Tool Company

au (800) 519-3456 ou http://www.ridgid.com

TABLEAU DE DÉPANNAGE

Symptôme

Pompe ne démarre

pas ou ne tourne pas

Pompe démarre, mais

livre peu ou aucune

eau

Cause(s) Possible(s)

1. Fusible ou disjoncteur grillé

2. Faible tension de ligne

3. Moteur usé

4. Rotor ne tourne pas

5. DD

6. Protecteur thermqiue ouvert

1. Tamis d’entré bloqué

2. Faible tension de ligne

3. Restriction dans le flexible

de décharge

4. Décharge se lève trop haut

Mesure corrective

1. Si grillé, remplacez avec la bonne taille de fusible ou réinitialisez

le disjoncteur.

2. Si la tension est sous 108 volts, vérifiez la taille des fils.

3. Remplacez le moteur.

4.

Si le rotor ne tourne pas, retirez le couvercle du volute et retirez le blocage.

5. Testez le DD, remplacez-le si usé.

6. Le moteur est verrouillé, remplacez le moteur (trousse du moteur

RIDGID cat. 90207)

1. Nettoyez les débris du tamis d’entrée

2. Si la tension est sous 108 volts, vérifiez la taille des fils.

3. Étirez le flexible d’arossage, retirez tous les tortillements ou

restrictions.

4. Le niveau de l’eau jusqu’à la fin du flexible de décharge et de 25

pi ou plus.

!

AVERTISSEMENT

!

AVERTISSEMENT

Page 15

Pompe utilitaire TP-250

Ridge Tool Company

13

Figure

1

2

3

4

5

6

Non illustré

Description

Trousse de cordon

Trousse de raccord de décharge

Trousse de log. ext. avec joint stat.

Trousse de rotor

Trousse de joint stat. de volute

Trousse couver volute avec tamis

Trousse de moteur

Numéro de cat.

90172

90177

90182

90187

90192

90197

90202

1

2

3

4

5

6

Page 16

Pompe utilitaire TP-250

Ridge Tool Company

14

Page 17

Bomba de uso general

TP-250

Anote el Número de serie indicado abajo en la calcomanía del producto.

Bomba de uso general TP-250

No. de serie

Page 18

Bomba de uso general TP-250

Índice

Formulario de registro para el número de serie de la bomba . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Información general sobre seguridad

Área de trabajo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Seguridad eléctrica . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Seguridad personal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Mantenimiento y reparación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Información específica sobre seguridad

Aspectos de seguridad de la bomba . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Descripción y especificaciones

Descripción . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Especificaciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Instalación de la bomba

Para armar la bomba . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-19

Instalación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-19

Ajustes y pruebas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-19

Instrucciones de mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Programa recomendado para el recambio de piezas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Servicio y reparación. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Corrección de fallas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Garantía . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Contraportada

Ridge Tool Company

16

Page 19

Bomba de uso general TP-250

Ridge Tool Company

17

Información general de

seguridad

La seguridad es una combinación de sentido común, mantenerse alerta y comprender cómo funciona su bomba de uso

general.

Palabras de señales de seguridad

significa que si no se sigue la

información de seguridad, alguien sufrirá graves lesiones o

la muerte.

significa que si no se sigue la

información de seguridad, alguien podría sufrir graves

lesiones o la muerte

.

significa que si no se sigue la

información de seguridad, alguien puede lesionarse

.

indica información importante,

que si no se sigue, puede causar daños al equipo o inundaciones

.

Lea y comprenda todas las

instrucciones. Pueden ocurrir descargas eléctricas,

incendios, daños materiales y/o graves lesiones personales, si no se siguen todas las instrucciones indicadas a

continuación.

¡CONSERVE ESTAS INSTRUCCIONES!

Área de trabajo

• No opere la bomba en atmósferas explosivas como,

por ejemplo, en presencia de líquidos, gases o

polvos inflamables. Los motores de la bomba generan

chispas que pueden incendiar el polvo o los gases.

• Mantenga a los transeúntes, niños y visitantes lejos

del sitio de instalación cuando vaya a instalar la

bomba. Las distracciones pueden ocasionar errores

.

Seguridad eléctrica

• Esta bomba debe conectarse a una toma de corriente

correctamente instalada y ponerse a tierra en conformidad con todas las ordenanzas y códigos aplicables. Nunca elimine la espiga de puesta a tierra ni

modifique el enchufe de ninguna manera. No use

enchufes adaptadores. Consulte a un electricista calificado si no está seguro de que la toma esté puesta

a tierra. Si la bomba sufre un desperfecto eléctrico o se

avería, la puesta a tierra proporciona una ruta de baja

resistencia para llevar la electricidad lejos del usuario

.

• La distribución del cableado eléctrico debe ser real-

izada por un electricista calificado. El cableado incorrecto puede acarrear descargas eléctricas fatales

.

•

No maltrate el cordón. Nunca use el cordón para

transportar la bomba ni tire del cordón para

desconectar el enchufe. Mantenga el cordón lejos

del calor, aceite, bordes cortantes o piezas móviles,

Reemplace inmediatamente los cordones dañados.

Los cordones dañados aumentan el peligro de descargas eléctricas

.

• Antes de usarlo, pruebe el interruptor (GFCI) para

asegurarse de que esté funcionando correctamente.

Un interruptor GFCI reduce el riesgo de descargas eléctricas

.

•

No use un cordón de extensión. El cordón de exten-

sión aumenta el riesgo de descargas eléctricas. De ser

necesario, instale una toma de corriente con una puesta correcta a tierra más cerca de la bomba

.

Seguridad personal

• Manténgase alerta, atento a lo que esté haciendo y

actúe con sentido común al instalar esta bomba. No

intente instalar esta bomba si está cansado o bajo el

efecto de drogas, alcohol o medicamentos. Un solo

momento de descuido puede ocasionar graves lesiones

personales

.

•

Vístase correctamente. No use ropas sueltas ni

joyas. Sujete el cabello largo. Mantenga su cabello,

sus ropas y sus guantes lejos de las piezas móviles.

La ropa suelta, las joyas o el cabello largo pueden

quedar atrapados entre las piezas móviles

.

•

No se estire excesivamente. Mantenga un equilibrio

apropiado con los pies bien firmes en el suelo. Una

buena postura de los pies y un buen equilibrio permiten

tener un mejor control en situaciones inesperadas

.

•

Use los equipos de seguridad. Use siempre protección para los ojos. También se deben usar zapatos

antirresbalantes de seguridad, mascarilla antipolvo y

casco en las condiciones apropiadas

.

d

Figure 1

Espiga de

puesta a tierra

Toma con pues-

ta a tierra

Cordón

eléctrico

!

PELIGRO

!

ADVERTENCIA

!

PRECAUCION

AVISO

!

ADVERTENCIA

!

PELIGRO

Grounding

Blade

Power

Cord

Grounde

Outlet

RESET

TEST

!

ADVERTENCIA

!

ADVERTENCIA

Page 20

Bomba de uso general TP-250

Ridge Tool Company

18

Mantenimiento y reparación

• El mantenimiento y la reparación de la bomba

deben estar a cargo de personal calificado únicamente. Si estas tareas son realizadas por personas

inexpertas podrían ocurrir graves lesiones y la anulación de la garantía.

• Al reparar una bomba, use sólo piezas idénticas de

repuesto. Siga las instrucciones en la Sección de

mantenimiento de este manual. Si no usa las piezas

autorizadas o no sigue las instrucciones de mantenimiento, puede crear riesgos de severas descargas

eléctricas o lesiones y anular la garantía.

Información específica de

seguridad

Riesgo de descargas eléctricas. Esta bomba trae un enchufe con puesta a tierra.

Para reducir el riesgo de descargas eléctricas, asegúrese

de conectarlo a una toma de corriente con puesta correcta a tierra

.

Por su propia seguridad, antes de armar y operar esta

unidad, lea cuidadosamente todo el Manual del Operador.

Aprenda cómo funciona y se aplica esta unidad, así como

sus riesgos peculiares.

Si tiene alguna pregunta, comuníquese con el Departamento

de Servicios Técnicos de Ridge Tool Company llamando al

(800) 519-3456.

Aspectos de seguridad de la bomba de

uso general

• No use la bomba para bombear líquidos inflamables

o explosivos como gasolina, petróleo combustible

(fueloil), queroseno, solventes, diluyentes, etc. No la

use en una atmósfera inflamable o explosiva. Esta

bomba sólo debe usarse para bombear agua limpia.

El uso inadecuado puede causar graves lesiones y/o la

muerte

.

•

Si hay agua o humedad en el piso o el suelo cerca

de la bomba, no camine sobre el área húmeda hasta

que se haya desconectado todo el suministro eléctrico. Si la caja de desconexión está en el sótano,

llame a un electricista. Si no sigue esta advertencia

podrían producirse graves descargas eléctricas

.

• Desconecte siempre la fuente de alimentación eléc-

trica antes de intentar instalar, reparar, reubicar o

dar mantenimiento a la bomba. Nunca maneje una

bomba o un motor de bomba con las manos

húmedas o parado sobre una superficie húmeda o

mojada o en el agua cuando la bomba esté conectada al suministro eléctrico. Si no se respeta esta adver-

tencia podrían ocurrir graves lesiones personales o la

muerte

.

Descripción y especificaciones

Descripción

Esta bomba sumergible para uso general está diseñada para

usarla en forma no automática en el agua. La unidad está

equipada con un cordón eléctrico de 8 pies de largo (2.40 m)

con 3 espigas, puesta a tierra y un enchufe con interruptor

de circuito de tierra accidental (GFCI). Ell motor está lleno de

aceite y está sellado herméticamente para funcionar a

menor temperatura. El accesorio de descarga está diseñado

para conectarlo sin problemas a una manguera de jardín.

• Esta bomba no está diseñada para manejar agua sala-

da, salmuera, descargas de lavandería u otras aplicaciones que puedan contener agentes químicos cáusticos y/o materiales extraños. Esta bomba no es adecuada para usarla con fauna acuática. La bomba puede

dañarse o averiarse, si se usa en estas aplicaciones y

esto causará la anulación de la garantía.

Especificaciones

Motor:

Tipo. . . . . . . . . . . . . . . . . . . . . . . Polo protegido

Capacidad nominal . . . . . . . . . 115V, monofásica

1/4 HP, 4.8 amps

Bomba:

1/4 HP . . . . . . . . . . . . 1100 GPH @ a cero pies.

Instalación:

Nivel inferior de bombeo . . . . . . . . . . . . 1/8 inch

Gama de temperaturas . . . . . . . . . 40˚F a 120˚F

Tamaño de descarga: Manguera de jardín de 3/4”

Instalación de la bomba

• Esta bomba sólo debe usarse para bombear agua

limpia. No use esta bomba para bombear líquidos

como gasolina, petróleo combustible (fueloil) o

queroseno. No la use en atmósferas inflamables o

explosivas. El uso incorrecto podría ocasionar

lesiones personales y/o la muerte

.

Para prevenir daños materiales, graves lesiones o muerte, se requiere la instalación

correcta de la bomba. Por tanto, deben seguirse estos procedimientos:

!

ADVERTENCIA

!

ADVERTENCIA

!

!

PELIGRO

ADVERTENCIA

AVISO

!

PELIGRO

!

ADVERTENCIA

Page 21

Bomba de uso general TP-250

Ridge Tool Company

19

• Desconecte siempre la fuente de alimentación eléctrica

antes de intentar instalar, reparar, reubicar o dar mantenimiento a la bomba. Nunca maneje la bomba o el motor

de la bomba con manos húmedas o si usted está de pie

sobre una superficie mojada o húmeda o en agua cuando la bomba esté conectada al suministro eléctrico

.

1. Esta bomba está diseñada para conectarse a una

manguera normal de jardín. Enrosque el extremo hembra

de esta manguera al punto de descarga en la bomba.

2. Para reducir las fugas entre la bomba y la manguera,

coloque una arandela de manguera (que no se incluye)

en la manguera de jardín antes de instalar la bomba.

3. Para obtener un mejor rendimiento de la bomba, desenrrolle la manguera antes de poner en marcha la bomba.

Esto ayudará a eliminar las partes dobladas y torcidas de

la manguera, permitiendo que la unidad bombee con

menos restricciones.

4. Coloque la bomba en el agua sobre una superficie

resistente. No coloque la bomba directamente en superficies lodosas o arenosas. Esto ocasionará la obstrucción

del filtro en el punto de entrada de la bomba.

No use la bomba directamente sobre arcilla, grava o en ninguna superficie de material suelto o arenoso. Estas superficies contienen piedrecitas

o arena que pueden obstruir o dañar la bomba. Esto podría

ocasionar daños a la bomba, inundaciones y daños materiales.

5. Para que la bomba pueda funcionar, el nivel del agua

debe estar al menos a 1/2 pulg. Los niveles de agua de

menos de 1/2 pulg. no permitirán que el rotor entre en

contacto con el agua y así no podrá bombear agua.

6. Revise el cordón y el enchufe GFCI para detectar

cualquier daño. Si el enchufe no tiene la espiga de puesta a tierra o el cordón está dañado, no instale la bomba

hasta que haya recambiado el cordón o el enchufe.

• Nunca corte una espiga de puesta a tierra ni use un

adaptador.

•

Antes de usarlo, pruebe el interruptor (GFCI) para asegurarse de que esté funcionando correctamente.

7. Enchufe el cordón de suministro eléctrico en una toma de

corriente alterna de 115 voltios con puesta a tierra.

Asegúrese de que la toma de corriente esté puesta a tierra y tenga capacidad nominal al menos para 15 amperios.

La bomba comenzará a funcionar tan pronto como el

cordón eléctrico se enchufe en la toma de corriente. El

indicador en el interruptor GFCI debe estar de color

ROJO.

8. Presione el botón de pruebas TEST. El indicador rojo

deberá desaparecer.

9. Presione el botón de reposición RESET. El indicador

debe estar de color ROJO. No use la bomba si el indicador no está de color ROJO.

10. La bomba debe remover el agua situada a 1/8 de pulgada de la superficie en la que se colocó la bomba.

11. La bomba debe desconectarse una vez que el agua se

ha reducido hasta quedar sólo a 1/8 de pulgada sobre la

superficie, si esto llega a pasar la bomba se quedará

funcionando en seco, dañándose.

No permita que la bomba

funcione en seco. El sello hermético del eje necesita agua

para su lubricación. El funcionamiento de la bomba sin agua

dañará el sello hermético del eje y ocasionará averías en la

bomba.

Cuando vaya a tender el

cordón de alimentación eléctrica, protéjalo contra objetos cortantes, superficies calientes, aceites y agentes químicos. No

doble ni tuerza el cordón; reemplace inmediatamente un

cordón dañado.

Instrucciones de mantenimiento

Desconecte siempre el

suministro eléctrico o desenchufe la bomba antes de

intentar instalar, reparar, reubicar o realizar cualquier

tarea de mantenimiento. Si la fuente de alimentación

eléctrica no está visible, bloquee y etiquete la posición

abierta (en posición OFF de apagado) para prevenir la

aplicación inesperada del suministro eléctrico. De no

hacerlo así, usted puede sufrir una descarga eléctrica

fatal. Sólo un electricista calificado debe intentar reparar

esta unidad. La reparación inadecuada puede ocasionar

descargas eléctricas fatales.

Luz roja

Botón de reposición

Botón de prueba

AVISO

AVISO

!

ADVERTENCIA

Red Light

Reset Button

Test Button

!

ADVERTENCIA

!

ADVERTENCIA

Page 22

Bomba de uso general TP-250

Ridge Tool Company

20

1. Compruebe el funcionamiento del Interruptor de circuito

de tierra accidental (GFCI) cad vez que use la bomba.

2. Mantenga limpio y libre de todo objeto extraño el punto

de entrada de la bomba. Revise el punto de entrada

antes de cada uso.

3. La caja del motor está completamente sellada y no

requiere mantenimiento. Desarmar la caja del motor o

alterar el cordón eléctrico puede ocasionar descargas

eléctricas fatales.

Programa recomendado de

recambio de piezas

Reemplace el motor cada 5 años. Vea en la página 21 el

número 90202 de Cat. RIDGID.

SERVICIO Y REPARACIÓN

Las tareas de mantenimiento

y reparación en esta bomba deben ser realizadas por personal calificado de reparaciones. La bomba debe llevarse a

un Centro Autorizado de Servicio RIDGID independiente o

enviarse a la fábrica. Todas las reparaciones realizadas en

los centros de servicio RIDGID están garantizadas contra

defectos en materiales y mano de obra.

Al dar mantenimiento a esta

bomba, sólo deben usarse piezas idénticas de repuesto

marca RIDGID. Si no se respetan estas advertencias, habrá

riesgos de inundaciones, daños materiales, descargas eléc-

tricas fatales u otras graves lesiones.

Si usted tiene alguna pregunta respecto al servicio o

reparación de esta máquina, llame o escriba a:

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44036-2023

Tel: (800) 519-3456

E-Mail: TechService@ridgid.com

Si desea conocer el nombre y la dirección del Centro

Autorizado de Servicio independiente más cercano a

su domicilio, comuníquese con Ridge Tool Company

llamando al (800) 519-3456 o visite nuestra página de

Internet en: http://www.ridgid.com

CUADRO DE CORRECCIÓN DE FALLAS

Síntoma

La bomba no arranca

ni funciona.

La bomba funciona

pero suministra poca o

nada de circulación de

agua

Causa(s) posible(s)

1. Interruptor o fusible quemado

2. Bajo voltaje de línea

3. Motor desgastado

4. El rotor no está girando

5. Interruptor GFCI

6. Protector térmico abierto

1. El filtro del punto de entrada

de la bomba está taponado

2. Bajo voltaje de línea

3. Restricciones en la manguera

de descarga.

4. La altura de descarga es

excesiva.

Medida correctiva

1. Si se quemó el fusible, reemplácelo con un fusible de tamaño

apropiado o reajuste el interruptor.

2. Si el voltaje está por debajo de 108 voltios, revise el calibre del

cable.

3. Reemplace el motor o la bomba.

4. Si el rotor no gira, desconecte la bomba de su fuente de alimentación eléctrica, retire la tapa de volutas y elimine el bloqueo.

5. Pruebe el GFCI, cámbielo si está gastado.

6. Motor bloqueado, reemplacelo (kit de motor, # de Cat. RIDGID

90202).

1. Retire desechos que obstruyen el filtro de entrada.

2. Si el voltaje está por debajo de 108 voltios, revise el calibre del cable.

3. Desenrrolle la manguera de descarga, enderece las partes

dobladas o torcidas.

4. El nivel del agua al extremo de la manguera de descarga es de 25

pies (7.5 m) o más.

!

ADVERTENCIA

!

ADVERTENCIA

Page 23

Bomba de uso general TP-250

Ridge Tool Company

21

Figura

1

2

3

4

5

6

No se muestra

Descripción

Kit de cordón eléctrico

Kit de accesorio de descarga

Caja externa con kit de anillos en O

Kit del rotor

Kit de empaquetaduras de volutas

Tapa de volutas con kit de filtro

Kit del motor

Number de Cat.

90172

90177

90182

90187

90192

90197

90202

1

2

3

4

5

6

Page 24

Printed in U.S.A. 7/00

320900-005 7/00

Ridge Tool Subsidiary

Emerson Electric Co.

Ridge Tool Company

400 Clark Street

Elyria, Ohio 44036-2023

What is covered

RIDGID

®

tools are warranted to be free of defects in workmanship and material.

How long coverage lasts

This warranty lasts for the lifetime of the RIDGID

®

tool. Warranty coverage ends when the

product becomes unusable for reasons other than defects in workmanship or material.

How you can get service

To obtain the benefit of this warranty, deliver via prepaid transportation the complete product to RIDGE TOOL COMPANY, Elyria, Ohio, or any authorized RIDGID

®

INDEPENDENT SERVICE CENTER. Pipe wrenches and other hand tools should be returned to the place of purchase.

What we will do to correct problems

Warranted products will be repaired or replaced, at RIDGE TOOL’S option, and returned at no

charge; or, if after three attempts to repair or replace during the warranty period the product

is still defective, you can elect to receive a full refund of your purchase price.

What is not covered

Failures due to misuse, abuse or normal wear and tear are not covered by this warranty.

RIDGE TOOL shall not be responsible for any incidental or consequential damages.

How local law relates to the warranty

Some states do not allow the exclusion or limitation of incidental or consequential damages,

so the above limitation or exclusion may not apply to you. This warranty gives you specific

rights, and you may also have other rights, which vary, from state to state, province to

province, or country to country.

No other express warranty applies

This FULL LIFETIME WARRANTY is the sole and exclusive warranty for RIDGID

®

products.

No employee, agent, dealer, or other person is authorized to alter this warranty or make any

other warranty on behalf of the RIDGE TOOL COMPANY.

FULL LIFETIME

WARRANTY

Against Material Defects

& Workmanship

Qué cubre

Las herramientas RIDGID están garantizadas contra defectos de la mano de obra y de los

materiales empleados en su fabricación.

Duración de la cobertura

Esta garantía cubre a la herramienta RIDGID durante toda su vida útil. La cobertura de la

garantía caduca cuando el producto se torna inservible por razones distintas a las de defectos en la mano de obra o en los materiales.

Cómo obtener servicio

Para obtener los beneficios de esta garantía, envíe mediante porte pagado, la totalidad del

producto a RIDGE TOOL COMPANY, en Elyria, Ohio, o a cualquier Servicentro Independiente

RIDGID. Las llaves para tubos y demás herramientas de mano deben devolverse a la tienda

donde se adquirieron.

Lo que hacemos para corregir el problema

El producto bajo garantía será reparado o reemplazado por otro, a discreción de RIDGE TOOL,

y devuelto sin costo; o, si aún resulta defectuoso después de haber sido reparado o sustituido tres veces durante el período de su garantía, Ud. puede optar por recibir un reembolso por

el valor total de su compra.

Lo que no está cubierto

Esta garantía no cubre fallas debido al mal uso, abuso o desgaste normal. RIDGE TOOL no se

hace responsable de daño incidental o consiguiente alguno.

Relación entre la garantía y las leyes locales

Algunos estados de los EE.UU. no permiten la exclusión o restricción referente a daños incidentales o consiguientes. Por lo tanto, puede que la limitación o restricción mencionada anteriormente no rija para Ud. Esta garantía le otorga derechos específicos, y puede que, además,

Ud tenga otros derechos, los cuales varían de estado a estado, provincia a provincia o país a

país.

No rige ninguna otra garantía expresa

Esta GARANTIA VITALICIA es la única y exclusiva garantía para los productos RIDGID. Ningún

empleado, agente, distribuidor u otra persona está autorizado para modificar esta garantía u

ofrecer cualquier otra garantía en nombre de RIDGE TOOL COMPANY.

Ce qui est couvert

Les outils RIDGE

®

sont garantis contre tous vices de matériaux et de main d’oeuvre.

Durée de couverture

Cette garantie est applicable durant la vie entière de l’outil RIDGE

®

. La couverture cesse dès lors que

le produit devient inutilisable pour raisons autres que des vices de matériaux ou de main d’oeuvre.

Pour invoquer la garantie

Pour toutes réparations au titre de la garantie, il convient d’expédier le produit complet en port payé

à la RIDGE TOOL COMPANY, Elyria, Ohio, ou bien le remettre à un réparateur RIDGID

®

agréé. Les

clés à pipe et autres outils à main doivent être ramenés au lieu d’achat.

Ce que nous ferons pour résoudre le problème

Les produits sous garantie seront à la discrétion de RIDGE TOOL, soit réparés ou remplacés, puis

réexpédiés gratuitement; ou si, après trois tentatives de réparation ou de remplacement durant la

période de validité de la garantie le produit s’avère toujours défectueux, vous aurez l’option de

demander le remboursement intégral de son prix d’achat.

Ce qui n’est pas couvert

Les défaillances dues au mauvais emploi, à l’abus ou à l’usure normale ne sont pas couvertes par

cette garantie. RIDGE TOOL ne sera tenue responsable d’aucuns dommages directs ou indirects.

L’influence de la législation locale sur la garantie

Puisque certaines législations locales interdisent l’exclusion des dommages directs ou indirects, il

se peut que la limitation ou exclusion ci-dessus ne vous soit pas applicable. Cette garantie vous

donne des droits spécifiques qui peuvent être éventuellement complétés par d’autres droits prévus

par votre législation locale.

Il n’existe aucune autre garantie expresse

Cette GARANTIE PERPETUELLE INTEGRALE est la seule et unique garantie couvrant les produits

RIDGID

®

. Aucun employé, agent, distributeur ou tiers n’est autorisé à modifier cette garantie ou à

offrir une garantie supplémentaire au nom de la RIDGE TOOL COMPANY.

FULL LIFETIME

WARRANTY

Against Material Defects

& Workmanship

FULL LIFETIME

WARRANTY

Against Material Defects

& Workmanship

Loading...

Loading...