Page 1

73

23(5$725·60$18$/

µ7+,&.1(66

3/$1(5

WARNING: To reduce the risk of

injury, the user must read and

understand the operator’s manual

before using this product.

Part No. SP6452 Printed in Taiwan

SAVE THIS MANUAL FOR

FUTURE REFERENCE

Page 2

Table of Contents

Section Page

Table of Contents ..................................2

Safety Instructions for

Thickness Planer ...............................3

Safety Symbols ...................................... 3

Before Using The Thickness Planer ... 3

When Installing Or Moving The

Thickness Planer ...............................4

Before Each Use ....................................5

To Reduce The Risk Of Injury From

Jams, Slips Or Thrown Pieces ..........5

Plan Ahead To Protect Your Eyes,

Hands, Face and Ears .......................5

Inspect Your Workpiece ......................6

Whenever Thickness Planer Is

Running .............................................6

Before Leaving The

Thickness Planer ...............................7

Glossary of Terms for Woodworking ..... 7

Motor Specifications and Electrical

Requirements ....................................8

Power Supply and Motor

Specifications ....................................8

General Electrical Connections ..........8

110-120 Volt, 60 Hz. Tool Information 8

Motor Safety Protection ......................9

Thermal Overload Protector ............. 10

Wire Sizes ......................................... 10

Unpacking and Checking Contents ..... 11

Tools Needed ................................... 11

Unpacking .........................................11

List of Loose Parts ............................11

Assembling Legset ..............................12

Assembling Upper and

Lower Legs ......................................13

Assembling Lower Stiffeners ............ 13

Assembling Upper Stiffeners ............ 14

Mounting The Thickness Planer ..........15

Mounting on Legset ..........................15

Mounting Thickness Planer on

Supplied Legset ...............................15

Mounting Thickness Planer on

Other Legsets or Work Benches ..... 15

Section Page

Portable Applications ........................15

Work Bench Applications .................. 15

Installing the Handwheel Knob ............ 16

Alignment (Adjustments) ..................... 16

Extension Assembly Alignment ........ 16

Adjusting the Thickness Indicator ..... 16

Getting to Know Your

Thickness Planer ............................. 17

Safety Instructions for Basic Thickness

Planer Operations ............................... 18

Before Using The Thickness Planer . 18

Before Each Use .............................. 18

Plan Ahead To Protect Your Eyes,

Hands, Face and Ears .................... 18

Inspect Your Workpiece ................... 19

Whenever Thickness Planer Is

Running ........................................... 19

Basic Thickness Planer Operations .... 20

Before You Begin ............................. 20

Reduce Damage To Knives .............. 21

Preparing the Work ........................... 21

Carriage Lock ................................... 21

Carriage Lock Adjustment ................ 22

Elevation Handwheel ........................ 22

Feeding the Work ............................. 22

Material Removal Indicator ............... 23

Preset Thickness Stops

(Repeat-A-Cut) ................................ 23

Thickness Stop (Repeat-A-Cut)

Adjustment ...................................... 23

Checking for Worn Knives ................ 24

Maintenance ........................................24

Lubrication ........................................ 24

Cleaning the Knives .......................... 24

Cleaning The Feed Rollers ............... 24

Motor Ventilation ............................... 24

Changing Brushes ............................ 25

Replacing Knives .............................. 25

Accessories ......................................... 26

Wiring Diagram .................................... 26

Troubleshooting ...................................27

Repair Parts ........................................ 28

Notes ................................................... 34

2

Page 3

Safety Instructions for Thickness Planer

The purpose of safety symbols is to

attract your attention to possible

dangers. The safety symbols, and the

explanations with them, deserve your

careful attention and understanding.

The safety warnings do not by

themselves eliminate any danger.

The instructions or warnings they give

are not substitutes for proper accident

prevention measures.

Safety Symbols

DANGER: indicates an imminently

hazardous situation which, if not

Before Using The Thickness Planer

avoided, will result in death or serious

injury.

WARNING: indicates a potentially

hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION: indicates a potentially

hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also be used to

alert against unsafe practices that

may cause property damage.

WARNING: Some dust created

by power sanding, sawing, grinding,

drilling, and other construction

activities contains chemicals known

(to the State of California) to cause

cancer, birth defects or other reproductive harm. Some examples of

these chemicals are:

• Lead from lead-bases paints,

• Crystalline silica from bricks and

cement and other masonry products, and

• Arsenic and chromium from

chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do

this type of work. To reduce your

exposure to these chemicals: work

in a well ventilated area, and work

with approved safety equipment,

such as those dust masks that are

specially designed to filter out

microscopic particles.

WARNING: To reduce the risk

of mistakes that could cause serious, permanent injury, do not plug

the thickness planer in until the following steps have been satisfactorily completed.

• Completely assemble and align

thickness planer. (See “Assembly”

and “Alignment” sections.)

• Learn the use and function of the

on-off switch, cutter guard, elevation

hand wheel, outfeed table and

infeed table (see “Getting to Know

Your Thickness Planer” section

within.)

• Review and understand all safety

instructions and operating procedures in this manual.

• Review the maintenance methods

for this thickness planer. (See

“Maintenance” section within).

WARNING: Do not attempt to use the tool until you have read thorough-

ly and understand completely the operator’s manual. Pay close attention to

the safety rules, including Dangers, Warnings, and Cautions. If you use this

tool properly and only for what it is intended, you will enjoy years of safe, reliable service.

3

Page 4

Safety Instructions for Thickness Planer (continued)

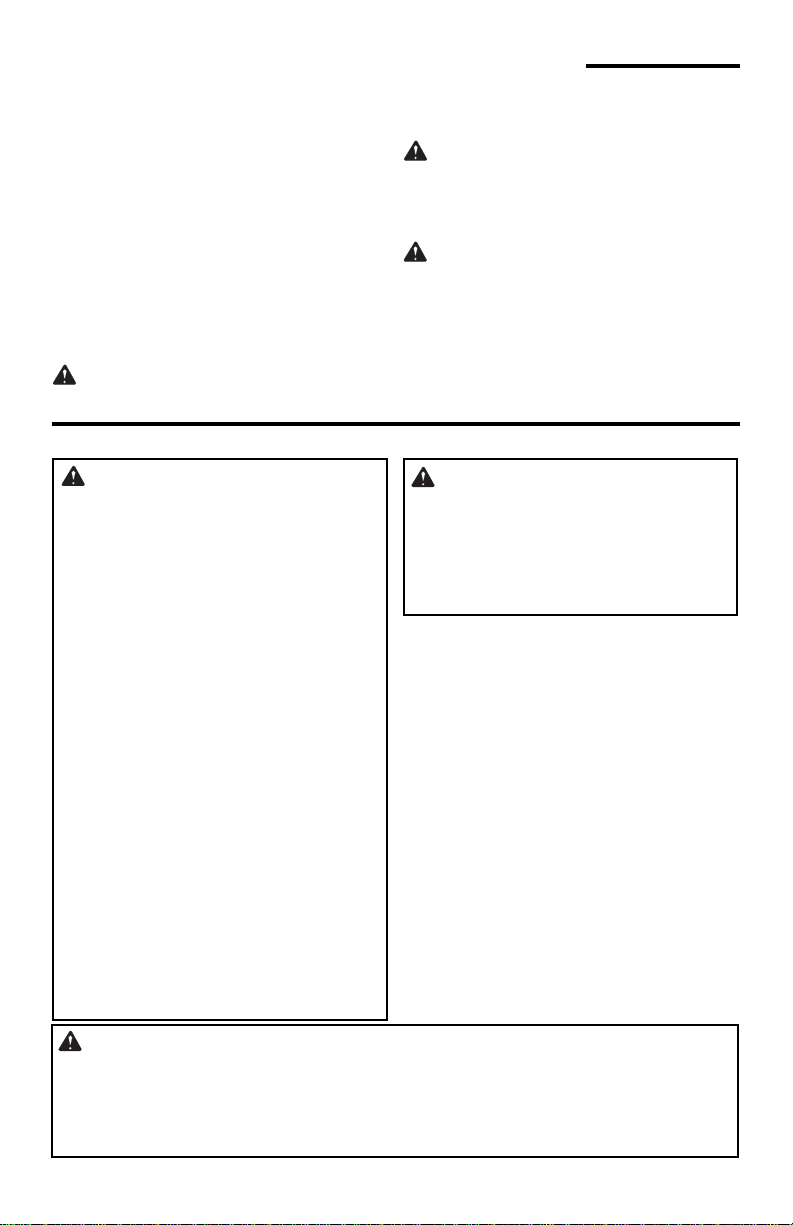

• Find and Read the following labels on the thickness planer:

When Installing Or Moving The Thickness Planer

• Before moving the thickness planer,

turn off and unplug the power cord.

• To reduce the risk of back injury, get

help when you need to lift the thickness planer.

Avoid Dangerous Environment.

• Use the thickness planer in a dry,

indoor place protected from rain.

• Keep work area well lighted.

• Place the thickness planer so neither

the user nor bystanders are forced to

stand in line with the wood. Thrown

debris could injure people in its path.

• Place the thickness planer where there

is room for moving the workpiece

through the entire cut.

To reduce the risk of injury from

unexpected thickness planer

movement:

• Put the thickness planer on a firm

level surface where there is plenty

of room for handling and properly

supporting the workpiece.

• Support the thickness planer so the

tables are level and the thickness

planer does not rock.

• Bolt or clamp the thickness planer to

the table/bench if it tends to slip,

walk, slide or tip over during work

such as planing long, heavy boards.

• Never Stand On Tool. Serious

injury could occur if the tool tips or

you accidentally hit the cutting tool.

Do not store anything above or near

the tool where anyone might stand

on the tool to reach them.

T o reduce the risk of injury or

death from electrical shock:

Make sure your fingers do not touch

the plug’s metal prongs when plugging or unplugging the thickness

planer.

4

Page 5

Before Each Use

Inspect your thickn ess planer.

• Disconnect The Thickness Planer

to reduce the risk of injury from accidental starting before changing the

setup, changing the blade or adjusting anything.

Check For Damaged Parts. Check

for:

• Proper alignment of moving parts,

• Damaged electric cords,

• Binding of moving parts,

• Broken parts,

• Stable mounting,

• Other conditions that may affect the

way the thickness planer works.

Before each use, make sure area

under the cutter head and feed rollers

is clear.

If any part of this thickness planer is

missing, bent, or broken in any way,

or any electrical parts don’t work, turn

the thickness planer off and unplug it.

Replace damaged, missing, or failed

parts before using the thickness

planer again.

To reduce possibility of thrown

pieces, make sure the knives are

properly installed and the knife lock

screws are tight.

Use sharp knives. Dull or knicked

knives tend to “pound” and chew at

the wood, causing kickbacks.

Replace dull or damaged planer

knives.

Make sure the dust chute is in place.

Keep Guards In Place, in working

order, and in proper adjustment.

Maintain Tools With Care. Keep the

thickness planer clean for best and

safest performance. (See “Maintenance” section) DON’T lubricate any

part of the thickness planer while the

knives are rotating.

To Reduce The Risk Of Injury From Jams, Slips Or Thrown Pieces

• Use Only Recommended Accessories. (See “Accessory” section).

Consult this Operator’s manual for

recommended accessories. Follow

the instructions that come with the

accessories. The use of improper

accessories may cause injury to

persons.

• Keep Work Area Clean. Cluttered

areas and benches invite accidents. Floor must not be slippery.

To reduce the risk of burns or other

fire damage, never use the thickness

planer near flammable liquids, vapors

or gases.

Plan Ahead To Protect Your Eyes, Hands, Face and Ears

Know Y our Thickness Planer. Read

and understand the operator’s manual and labels affixed to the tool.

Learn its applications and limitations

as well as the specific potential hazards peculiar to this tool.

To reduce the risk of injury from accidental contact with moving parts,

don’t do layout, assembly, or setup

work on the thickness planer while

any parts are moving.

Reduce the Risk of Accidental

Starting. Make sure switch is “OFF”

before plugging thickness planer into

a power outlet.

Plan your work.

Use the right tool. Don’t force planer

to do a job it was not designed to do.

NOTE: Advises you of information or

instructions vital to the operation or

maintenance of the equipment.

5

Page 6

Safety Instructions for Thickness Planer (continued)

Dress For Safety

Any power tool can throw foreign

objects into the eyes. This can result

in permanent eye damage. Wear

safety goggles (not glasses) that

comply with ANSI Z87.1 (or in Canada CSA Z94.3-99) shown on package. Everyday eyeglasses have only

impact resistant lenses. They are not

safety glasses. Safety goggles are

available at many local retail stores.

Glasses or goggles

not in compliance

with ANSI or CSA

could seriously hurt

you when they

break.

• Do not wear loose clothing, gloves,

Inspect Your Workpiece

• Make sure there are no nails or foreign objects in the part of the workpiece to be planed.

• Use quality lumber. Knives last

longer and cuts go smoother on

good wood.

• Do not plane undersized wood.

Boards which are thinner than 1/8"

neckties or jewelry (rings, wrist

watches) They can get caught and

draw you into moving parts.

• Wear nonslip footwear.

• Tie back long hair.

• Roll long sleeves above the elbow.

• Noise levels vary widely. To reduce

the risk of possible hearing damage,

wear ear plugs or muffs when using

thickness planer for hours at a time.

• For dusty operations, wear a dust

mask along with safety goggles.

Keep hands at least (8") 20cm from

the outfeed. Don’t grip board tightly or

pull board. A sudden kickback could

pull hand into cutters.

Keep hands away from moving parts.

or shorter than 12" could split while

being planed.

• Plane boards (12”) 30cm or longer

only. Short boards can jam or split

and cause dangerous kickbacks.

• Use for solid wood and wood products only. Do not plane metals, plastics or laminated materials.

Whenever Thickness Planer Is Running

WARNING: Don't allow familiar-

ity (gained from frequent use of

your thickness planer) to cause a

careless mistake. A careless fraction of a second is enough to cause

a severe injury.

Before starting to plane a board,

watch the thickness planer while it

runs. If it makes an unfamiliar noise

or vibrates a lot, stop immediately.

Turn the thickness planer off. Unplug

the thickness planer. Do not restart

until finding and correcting the problem.

Plan the way you will hold the

workpiece from start to finish:

• Avoid awkward operations and

hand positions where a sudden slip

could cause fingers or hand to move

into the knives.

• Don’t Overreach. Keep good foot-

ing and balance.

• Do not force the cut. Slowing or

stalling the motor will overheat it.

Allow the automatic feed to function

properly.

• Support workpiece. Do not allow

the board to hang from the planer.

6

Page 7

• Never use another person as a sub-

stitute for a table extension, or as

additional support for a workpiece

that is longer or wider than the basic

thickness planer table or to help

feed, support or pull the workpiece.

Take Precautions Against Kickback.

Do not permit anyone to stand or

cross in line with the path of the board

through the thickness planer. A kickback or thrown debris will travel in this

direction.

Keep Children Away. Keep all visi-

ness planer. Make sure bystanders

are clear of the thickness planer and

workpiece.

Let the blade reach full speed before

planing.

Turn switch off and unplug tool before

inspecting, adjusting or repairing the

planer.

Before freeing jammed material:

• Turn switch “OFF”.

• Wait for all moving parts to stop.

• Unplug the thickness planer.

tors a safe distance from the thick-

Before Leaving The Thickness Planer

Never Leave Tool Running Unattended. Turn power off. Wait for all

moving parts to stop.

Make workshop child-proof. Lock

the shop. Remove yellow switch key

and store away from tool. Disconnect

master switches. Store away from

children and others not qualified to

use the tool.

WARNING:

The operation of any power tool can result in foreign objects being thrown

into your eyes, which can result in severe eye damage. Before beginning tool

operation, always wear safety goggles of safety glasses with side shields

and a full face shield when needed. We recommend Wide Vision Safety

Mask for use over eyeglasses or standard safety glasses with side shields.

Always wear eye protection which is marked to comply wtih ANSI Z87.1.

Look for this symbol to point out important safety precautions. It

means attention!!! Your safety is involved.

Glossary of Terms for Woodworking

Bed - The combination of infeed and outfeed table surfaces which support the

workpiece during a cutting operation.

Cutter Head - The cutter head is a rotating piece with two adjustable knives. The

cutter head removes material from the

workpiece.

Depth of cut - A term used to indicate

how deep into the workpiece the cutter

knives will cut.

Gum - A sticky, sap based residue from

wood products.

Infeed Table - The section of the thickness planer upon which the workpiece is

placed before being pushed into the cutter

head.

Kickback - An uncontrolled grabbing and

throwing of the workpiece back toward the

operator by the rotating cutter head.

Leading End- The end of the workpiece

which is pushed into the cutter head first.

Outfeed Table - The section of a thickness planer which supports the workpiece

after it passes under the cutter head.

SAVE THESE INSTRUCTIONS

7

Page 8

Glossary of Terms for Woodworking (continued)

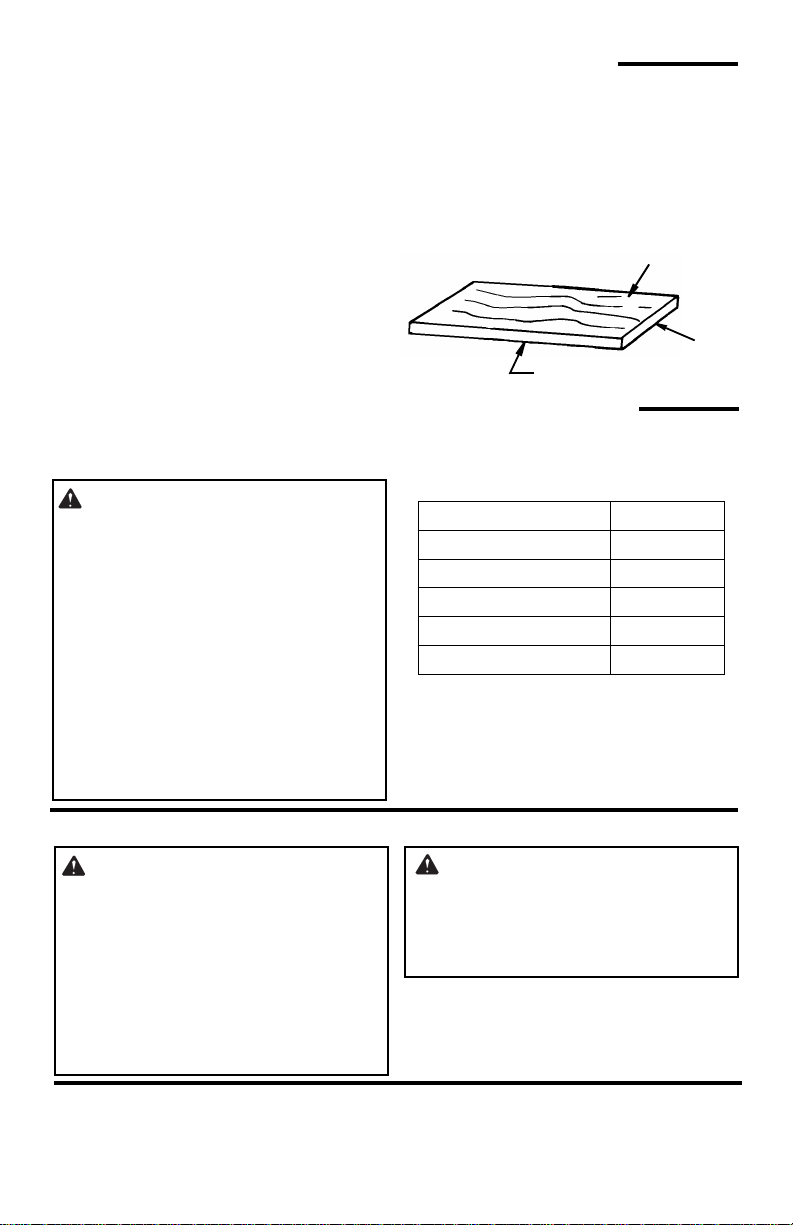

Face

Planing - Removing wood from the wid-

est surface or face of a board so as to

make it flat and smooth.

Resin - A sticky, sap based substance

that has hardened.

Revolutions Per Minute (RPM) - The

number of turns completed by a spinning

object in one minute.

Snipe - The localized variation in workpiece thickness.

Throw-Back -

Throwing of pieces in a manner similar to

a kickback.

Trailing End

The workpiece end last cut by the knives.

Workpiece

The item on which the cutting operation is

being performed. The surfaces of a workpiece are commonly referred to as faces,

ends and edges.

Edge

Motor Specifications and Electrical Requirements

Power Supply and Motor Specifications

W ARNING: To reduce the risk of

electrical hazards, fire hazards or

damage to the tool, use proper circuit protection. Your tool is wired at

the factory for operation using the

voltage shown. Connect tool to a

power line with the appropriate voltage and a 15-amp branch circuit.

Use a 15-amp time delay type fuse

or circuit breaker. To reduce the risk

of shock or fire, replace power cord

immediately if it is worn, cut, or

damaged in any way.

The A-C motor used on this tool is an universal non-reversible type, having the following specifications:

Voltage 110-120

Amperes 15

Hertz (Cycles) 60

Phase Single

Cuts per minute-CPM 18,000

Rotation of Shaft Clockwise

End

General Electrical Connections

DANGER: To reduce the risk of

electrocution:

1. Use only identical replacement

parts when servicing. Servicing

should be performed by a qualified service technician.

2. Do not use in rain or where floor

is wet. This tool is intended for

indoor use only.

110-120 Volt, 60 Hz. Tool Information

NOTE: The plug supplied on your tool

may not fit into the outlet you are planning

WARNING: To reduce the risk

of electrical shock do not permit

fingers to touch the terminals or

plug when installing or removing

the plug to or from the outlet.

If power cord is worn or cut, damaged in

any way, have it replaced immediately.

to use. Your local electrical code may

require slightly different power cord plug

8

Page 9

connections. If these differences exist

refer to and make the proper adjustments

per your local code before your tool is

plugged in and turned on.

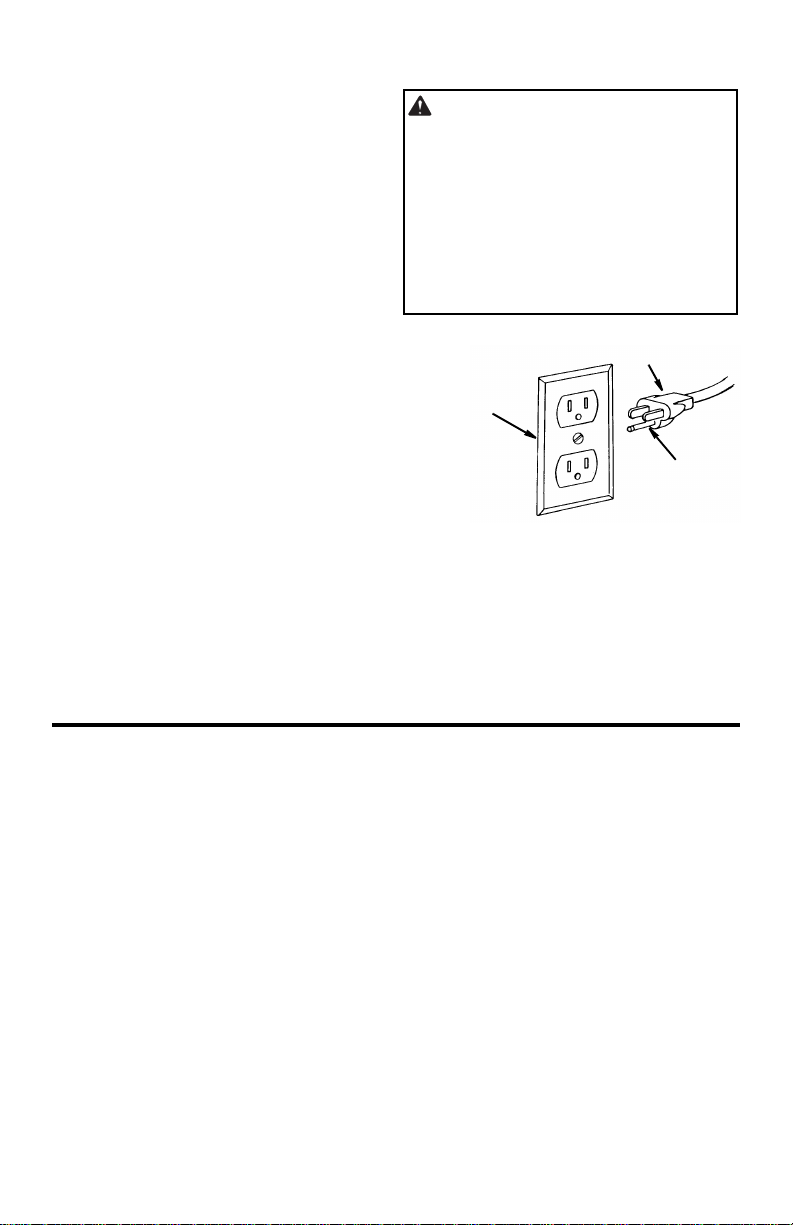

In the event of a malfunction or breakdown, grounding provides a path of least

resistance for electric current to reduce

the risk of electric shock. This tool is

equipped with an electric cord having an

equipment grounding conductor and a

grounding plug, as shown. The plug must

be plugged into a matching outlet that is

properly installed and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will

not fit the outlet, have the proper outlet

installed by a qualified electrician.

Improper connection of the equipment

grounding conductor can result in a risk of

electric shock. The conductor with insulation having an outer surface that is green

with or without yellow stripes is the equipment grounding conductor. If repair or

replacement of the electric cord or plug is

necessary, do not connect the equipmentgrounding conductor to a live terminal.

If the grounding instructions are not completely understood, or if you are in doubt

as to whether the tool is properly

grounded check with a qualified electrician or service personnel .

WARNING: If not properly

grounded, this tool can cause an

electrical shock, particularly when

used in damp locations, in proximity

to plumbing, or out of doors. If an

electrical shock occurs there is the

potential of a secondary hazard,

such as your hands contacting the

knives.

Properly

Grounded

3-Prong Outlet

3-Prong Plug

Grounding

Prong

Motor Safety Protection

IMPORTANT: To reduce the risk of motor

damage, this motor should be blown out

or vacuumed periodically to keep sawdust

from interfering with normal motor ventilation.

1. Connect this tool to a power source

with the appropriate voltage for your

model and a 15-amp branch circuit with

a 15-amp time delay fuse or circuit

breaker. Using the wrong size fuse can

damage the motor.

2. If the motor won’t start, turn off the

power switch immediately and unplug

the tool. Check the cutter head to make

sure it turns freely. If the head is free,

try to start the motor again. If the motor

still does not start, refer to the "Troubleshooting Chart."

9

Page 10

Motor Specifications and Electrical Requirements (continued)

r

3. Fuses may "blow" or circuit breakers

may trip frequently if:

a. Motor Is Overloaded-Overloading

can occur if you feed too rapidly or

make too many start/stops in a short

time.

b. Line voltages should not be more

than 10% above or below the nameplate voltage. For heavy loads, however, the voltage at motor terminals

must equal the voltage specified for

your model.

c. Improper or dull cutter knives are

used.

Thermal Overload Protector

This planer is equipped with a thermal

overload protector device which will automatically “trip” and cause the planer to

shut down if the planer is overheating due

to continuous heavy cutting.

The planer overload protector can only be

reset manually by the user after the

planer had been allowed to adequately

cool. Allow 15-30 minutes.

NOTE: Do not continuously use the thickness planer set at maximum depth of cut

(1/8") and at full 13" width of cut. Continuous use at maximum cutting capacity will

damage your motor.

4. Most motor troubles may be traced to

loose or incorrect connections, overload, low voltage (such as small size

wire in the supply circuit) or to overly

long supply circuit wire. Always check

the connections, the load and the supply circuit whenever motor doesn’t work

well. Check wire sizes and length with

the Wire Size Chart.

Should the overload protector “trip”:

1. Turn switch off.

2. Raise carriage and remove board.

3. Wait 15-30 minutes.

4. Push in on the reset button.

5. If motor has cooled, button will remain

in.

Thermal Overload Protecto

Wire Sizes

NOTE: Make sure a proper extension

cord is used and it is in good condition.

The use of any extension cord will cause

some loss of power. To keep this to a minimum and to prevent overheating and

motor burn-out, use the table below to

determine the minimum wire size

(A.W.G.) extension cord.

Reset Button

Use only 3-wire extension cords which

have 3-prong grounding type plugs and 3pole receptacles which accept the tools

plug.

Extension Cord

50-100 Ft.

10

Length

0-50 Ft.

Wire Sizes Required

for (A.W.G.)

14

10

Page 11

Unpacking and Checking Contents

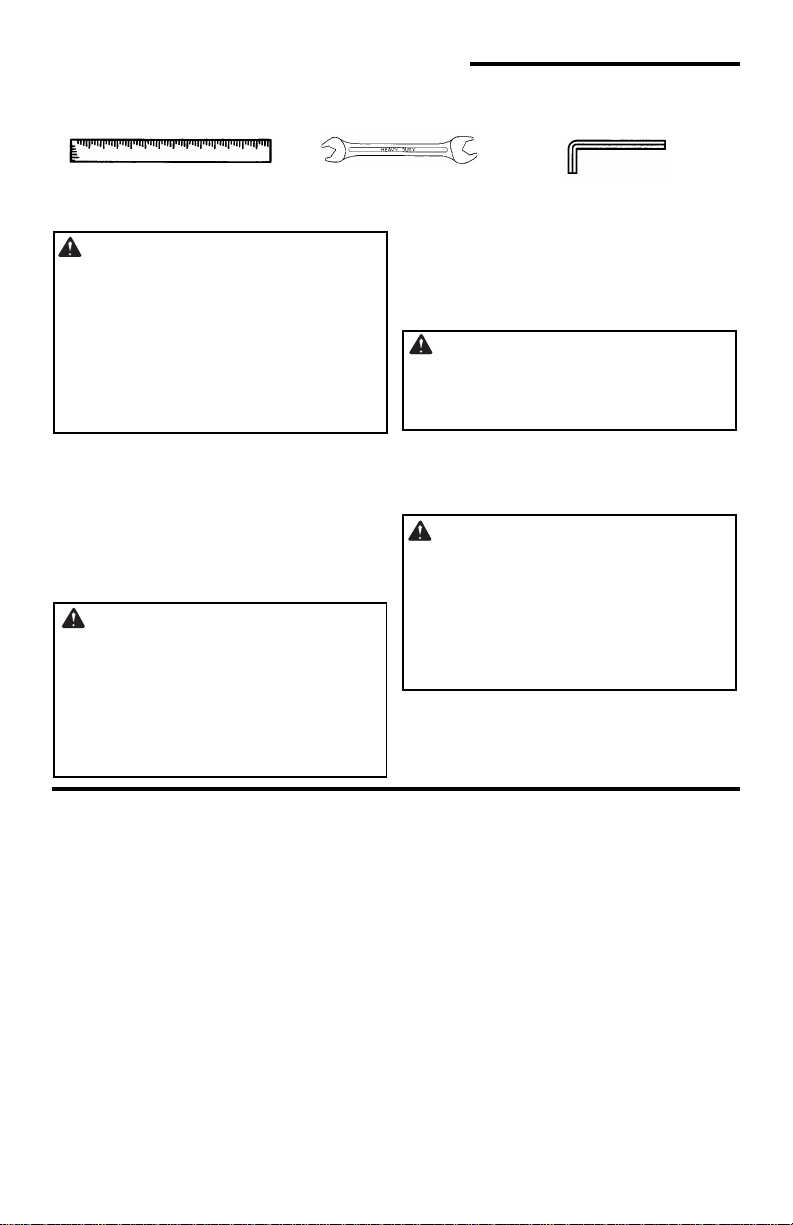

Tools Needed

Tools Required for Alignment

Straightedge

Wrench 8mm/10mm

Unpacking

W ARNING: To reduce the risk of

injury from unexpected starting or

electrical shock, do not plug the

power cord into a source of power

during unpacking and assembly.

This cord must remain unplugged

whenever you are working on the

thickness planer.

Your thickness planer, is shipped complete in one box.

NOTE: Every RIDGID 13" thickness

planer is tested at the factory to insure its

performance. You may see a small

amount of wood dust and chips on your

new planer.

WARNING: If any part is miss-

ing or damaged, do not plug the

thickness planer in until the missing

or damaged part is correctly

replaced. To reduce the risk of electric shock, use only identical

replacement parts.

Hex “L” Wrench 4mm

Remove the protective oil that is applied

to all unpainted metal surfaces. Use any

ordinary household type grease and spot

remover.

WARNING: To reduce the risk of

fire or toxic reaction, never use gasoline, naptha or similar highly volatile solvents.

Apply a coat of paste wax to the table.

Wipe all parts thoroughly with a clean, dry

cloth.

WARNING: For your own safety,

never connect plug to power source

outlet until all assembly steps are

complete, and you have read and

understand the safety and operating instructions.

List of Loose Parts

NOTE: Before beginning assembly, check

that all parts are included. If you are missing any part, do not assemble the thickness planer. Call 1-866-539-1710 to get

the missing part. Sometimes small parts

can get lost in packaging material. Do not

throw away any packaging until thickness

planer is put together. Check packaging

for missing parts before contacting

RIDGID.

11

Page 12

Unpacking and Checking Contents (continued)

L

Bolt

The following parts are included:

Item Description Qty

A Thickness Planer ...........................1

B * Magnetic Knife Handling Tool ........ 1

C * Hex “L” Wrench 4mm ....................1

D * Open End Wrench 8mm/10mm..... 1

E Replacement Blades/Blade Case .. 1

(stored under rear table)

F Operator’s Manual .........................1

G Bag of Loose Parts ........................1

(Contains the following items)

H Handle............................................1

A

Item Description Qty

J Screw M5 x 0.8-10......................... 1

K Switch Key.....................................1

L Upper Leg...................................... 4

M Lower Leg......................................4

N Long Upper Stiffener...................... 2

P Long Lower Stiffener...................... 2

Q Short Upper Stiffener ..................... 2

R Short Lower Stiffener..................... 2

S Foot ............................................... 4

T Hardware pack, Legset Hardware. 1

* Supplied in “Tool Box”

B

E

F

L

M

N

Assembling Legset

1. Locate the following parts:

4 Lower Legs

4 Upper Legs

2 Long Upper Stiffeners

2 Short Upper Stiffeners

2 Long Lower Stiffeners

2 Short Lower Stiffeners.

2. From the leg set hardware bag find the

following:

4Feet

32 Carriage Bolts M8 x 1.25

32 Hex Flanged Nuts M8 x 1.25

NOTE: Hardware not shown actual size.

C

D

P

Q

R

Lower Leg

ong Upper

Stiffener

Short Upper

H

Stiffener

G

J

K

S

T

Upper Leg

Long Lower

Stiffener

Short Lower

Stiffener

12

Foot

Flange Nut

Page 13

Assembling Upper and Lower Legs

t

L

r

1. Locate the following parts and hard-

ware:

8 Cariage Bolts M8 x 1.25

8 Hex Flanged Nuts M8 x 1.25

4 Upper Legs

4 Lower Legs

4Feet

2. Position the lower leg inside the upper

leg as shown. Place a bolt only through

the bottom hole of the upper leg and

through the bottom hole of the lower

leg. Attach a nut but only finger tighten.

3. Repeat for other three leg assemblies.

4. Asemble foot to bottom of lower leg.

Repeat for other three leg assemblies.

Carriage Bolts

M8 x 1.25

Upper Leg

Nut

Bolt

Bottom

Hole

Foot

Hex Flanged Nut

M8 x 1.25

Lower Leg

Upper Leg

Bottom

Hole

Nu

Bolt

Lower

Leg

Assembling Lower Stiffeners

1. Locate the following parts and hard-

ware:

8 Carriage Bolts M8 x 1.25

8 Hex Flanged Nuts M8 x 1.25

2 Long Lower Stiffeners

2 Short Lower Stiffeners

Carriage Bolts

M8 x 1.25

ong Lower

Stiffener

13

Hex Flanged Nut

M8 x 1.25

Short Lowe

Stiffener

Page 14

Assembling Legset (continued)

e

er

S

N

Long

r

Assembling Lower Stiffeners (cont.)

2. Assemble the lower stiffeners to the

legs as shown. Finger tighten the nuts.

Make sure:

a. The long and short lower stiffeners fit

inside the legs.

b. The short stiffeners must be assem-

bled on opposite sides of the leg set.

(The same for the long stiffeners.).

Assembling Upper Stiffeners

1. Locate the following parts and hardware:

16Carriage Bolts M8 x 1.25

16Hex Flanged Nuts M8 x 1.25

2 Long Upper Stiffeners

2 Short Upper Stiffeners

Nut

Stiffener

Carriage Bolts

M8 x 1.25

Carriag

Bolt

Short

Lower

Hex Flanged Nut

M8 x 1.25

2. Assemble the upper stiffeners to the

legs as shown. Finger tighten nuts.

Make sure:

a. The long upper stiffeners go over the

short upper stiffeners. Make sure the

stiffeners go inside the legs.

b. The short upper stiffeners go oppo-

site each other, same as the long

upper stiffeners.

c. The planer mounting holes in the top

of the legset are aligned.

3. Go back and tighten all nuts.

Long Upper

Stiffener

Carriage

Short Upp

Stiffener

Upper

Stiffene

Bolt

ut

hort Upper

Stiffener

Short

Long

Lower

Stiffener

Lower

Stiffener

14

Page 15

Mounting The Thickness Planer

Mounting on Legset

W ARN ING: To reduce the risk of injury from unexpected planer movement:

a. Unplug electric cord.

b. To reduce the risk of back injury, hold the tool close to your body when

lifting. Bend your knees so you can lift with your legs, not your back. Lift

by using the hand-hold areas at each side of the bottom of the base or by

the carrying handles.

c. Place the planer so other people cannot stand behind it. Thrown debris

could injure people in its path.

d. Place the planer on a firm, level surface where there is plenty of room for

handling and properly supporting the workpiece.

e. Bolt or clamp the planer to its support.

Mounting Thickness Planer on Supplied Legset

1. Locate 4 hex screws M8 x 1.25 and the

remaining 4 flange nuts and 4 washers

in parts bag.

2. Position leg set at the desired location .

3. Mount the thickness planer as shown

with provided hardware. Only finger

tighten nuts at this time.

If necessary shift the leg set to adjust for

slightly unlevel floor. Securely tighten all

hardware.

Mounting Thickness Planer on Other Legsets or Work Benches

Place the planer in the desired location on

either a workbench or other recommended leg set. The base of the planer

has eight mounting holes. Four smaller

holes for “drywall” screws are labeled B.

Four larger holes for bolts are labeled A

(see illustration). Place a bolt through the

larger holes. Attach a washer and nut and

securely tighten.

Portable Applications

To mount the planer to a 3/4” piece of plywood, use 4, 1/4" bolt holes or

wall screw holes. The mounting board can

then be clamped down to prevent it from

tipping.

the 4 dry-

Work Bench Applications

Mount as specified in portable applications. Check for workpiece clearances to

front and rear of planer.

Mounting Board or Work Surface

A

B

B

15

A

A

A

B

B

Page 16

Installing the Handwheel Knob

1. Locate the handwheel knob and screw

in the loose parts bag.

2. Use the hex “L” wrench from the tool

box to remove the screw from the center of the handwheel and remove the

handwheel from the unit.

3. Place the screw through the back of the

handwheel and secure the screw to the

knob on the front of the handwheel.

4. Place the handwheel back on the elevation shaft and reinstall the screw in

the center of the handwheel.

Alignment (Adjustments)

Extension Assembly Alignment

WARNING: To reduce the risk of

injury from unexpected starting or

electrical shock, do not plug the thickness planer in. The power cord must

remain unplugged whenever you are

adjusting or aligning the thickness

planer.

NOTE: Align only one extension at a time.

Elevate the motor enough to give a proper

view of the table body and clearance of

the knives.

WARNING: Knives are

extremely sharp and could seriously injure your hands or arms.

1. Place a straight edge across table body

and over infeed extension as shown.

Screw

M5 x 0.8-10

Loosen locking nut and adjust each

side of the table until the straightedge

touches the outer edge of table extension. Tighten the locking nuts.

2. Repeat step 1 for outfeed extension.

Planer

Table Body

Knob

~

Table

Locking

Nut

Straightedge

Extension

Adjusting the Thickness Indicator

The elevation indicator is preset at time of

manufacture. To check indicator select a

piece of stock at least 12" long and 3/4"

thick. Set planer to 11/16" and run stock

through planer. Measure wood after planing and if necessary, loosen screws to

adjust elevation indicator to agree with

measurement.

16

Page 17

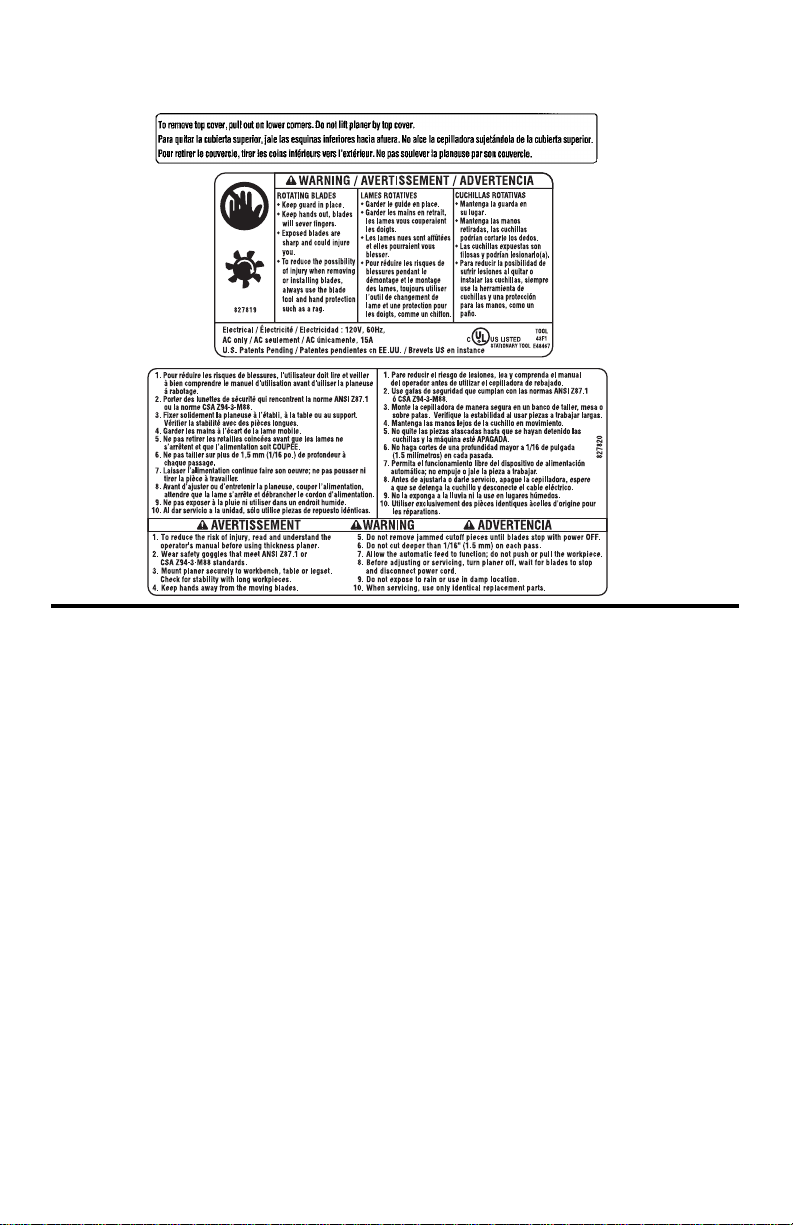

Getting to Know Your Thickness Planer

1

13

e

11 Brush

0 Thermal Reset

Protector

9 On-Off

Switch

8

Infeed

Table

Cap

7 Material Removal

Indicator

1. Rule. Quickly check the thickness of a

workpiece.

2. Carriage Lock. Firmly “locks” the cut-

ter head assembly to help minimize

snipe.

3. Elevation Handwheel. Raises or low-

ers the cutter head for the desired cut.

Each full revolution of the elevation

handwheel will raise or lower the cutter head 1/16"

4. Preset Thickness Stops. Limits cut-

ter head to predetermined thickness.

5. Elevation Indicator. Indicates the

height the cutter head is from the

table.

6. Mounting Holes. Reduces the risk of

injury from unexpected planer movement. Smaller holes are for “drywall”

screws, larger holes for bolts, nuts

and washers.

7. Material Removal Indicator. Indi-

cates how much material is being

removed.

8. Infeed Table. Supports and guides

the workpiece at the start of a cut.

9. On/Off Switch. Lockable, has remov-

able yellow key which helps to pre-

1 Rule

6 Mounting

Holes

2 Carriage Lock

5 Elevation

Indicator

12 Dust Chute

Knob(s)

Cord Storag

Wrap

3 Elevation

Handwheel

14 Tool

Storage

4 Preset

Thickness

Stops

vent unauthorized use.

15 Outfeed

Table

10.Thermal Reset Protector. Opens the

power line circuit when the motor temperature exceeds a safe level, when

the motor is overloaded, or when a

lower voltage condition exists.

11. Brush Caps. Provides access to

inspect or replace carbon motor

brush.

12.Dust Chute Knobs. Used to attach

dust chute and cover the cutter head.

13.Cord Storage Wrap.

14.Tool Storage. Contains tools and

instructions for changing knives.

15.Outfeed Table. Supports and guides

the workpiece at the end of a cut.

Replacement knives stored under outfeed table.

16.Cutter Head. (Not illustrated) Rotat-

ing cylinder which holds knives.

Located under dust chute.

17.Cutter Head Lock. (Not illustrated)

Red lever, located to the left end of

the cutter head. Automatically activated when dust chute is removed.

17

Page 18

Safety Instructions for Basic Thickness Planer Operations

Before Using The Thickness Planer

W ARNING: To reduce the risk of

mistakes that could cause serious,

permanent injury, do not plug the

thickness planer in until the following steps are completed.

• Completely assemble and align

thickness planer. (See “Assembly”

and “Alignment” sections).

Before Each Use

Inspect your thickness planer.

• Disconnect the thickness planer. To

reduce the risk of injury from accidental starting, unplug the thickness

planer, before changing the setup,

changing the blade or adjusting anything.

Check for Damaged Parts. Check

for:

• Proper alignment of moving parts,

• Damaged electric cords,

• Binding of moving parts,

• Broken parts,

• Stable mounting,

• Other conditions that may affect the

way the thickness planer works.

Before each use, make sure area

under the cutter head and feed rollers

is clear.

If any part of this thickness planer is

missing, bent, or broken in any way,

or any electrical parts don’t work, turn

the thickness planer off and unplug it.

• “See Getting To Know Your thickness Planer” section.

• Review and understand all safety

instructions and operating procedures in this manual.

• Review the maintenance methods

for this thickness planer. (See

“Maintenance” Section).

Replace damaged, missing, or failed

parts before using the thickness

planer again.

To reduce possibility of throwing

pieces, make sure the knives are

properly installed and the knife lock

screws are tight.

Use sharp knives. Dull or knicked

knives tend to “pound” and chew at

the wood, causing kickbacks.

Replace dull or damaged planer

knives.

Make sure the deflector or dust collector is in place.

Keep Guards in Place, in working

order, and in proper adjustment.

Maintain Tools With Care. Keep the

thickness planer clean for best and

safest performance. Follow instructions for lubricating. DON’T lubricate

any part of the thickness planer while

the knives are rotating.

Plan Ahead To Protect Your Eyes, Hands, Face and Ears

Know Your Thickness Planer. Read

and understand the operator’s manual and labels affixed to the tool.

Learn its application and limitations

as well as the specific potential haz-

ards peculiar to this tool.

To reduce the risk of injury from acci-

dental contact with moving parts,

don’t do layout, assembly, or setup

work on the thickness planer while

18

Page 19

any parts are moving.

Reduce The Risk Of Accidental

Starting. Make sure switch is “OFF”

before plugging thickness planer into

a power outlet.

Plan your work.

Dress For Safety

Any power tool can throw foreign

objects into the eyes. This can result

in permanent eye damage. Wear

safety goggles (not glasses) that

comply with ANSI Z87.1 (or in Canada CSA Z94.3-99) shown on package. Everyday eyeglasses have only

impact resistant lenses. They are not

safety glasses. Safety goggles are

available at many local retail stores.

Glasses or goggles not in compliance

with ANSI or CSA could seriously hurt

you when they break.

• Do not wear loose clothing, gloves,

neckties or jewelry (rings, wrist

watches). They can get caught and

draw you into moving parts.

• Wear nonslip footwear.

• Tie back long hair.

• Roll long sleeves above the elbow.

• Noise levels vary widely. To reduce

the risk of possible hearing damage,

wear ear plugs or muffs when using

thickness planer for hours at a time.

• For dusty operations, wear a dust

mask along with safety goggles.

Keep hands at least 20cm (8") from

the outfeed. Don’t grip board tightly or

pull board. A sudden kickback could

pull hand into cutters.

Keep hands away from moving parts.

Inspect Your Workpiece

• Make sure there are no nails or foreign objects in the part of the workpiece to be planed.

• Use quality lumber. Knives last

longer and cuts go smoother on

good wood.

• Do not plane undersized wood.

Boards which are too thin or too

short could split while being planed.

• Plane boards (12”) 30cm or longer

only. Short boards can jam or split

and cause dangerous kickbacks.

• Use for solid wood and wood products only. Do not plane metals, plastics or laminated materials.

Whenever Thickness Planer Is Running

WARNING: Don't allow familiar-

ity (gained from frequent use of

your thickness planer) to cause a

careless mistake. A careless fraction of a second is enough to cause

a severe injury.

Before starting to plane a board,

watch the thickness planer while it

runs. If it makes an unfamiliar noise

or vibrates a lot, stop immediately.

Turn the thickness planer off. Unplug

the thickness planer. Do not restart

until finding and correcting the problem.

19

Page 20

Safety Instructions for Basic Thickness Planer

y

Operations (continued)

Plan the way you will hold the

workpiece from start to finish:

• Avoid awkward operations and

hand positions where a sudden slip

could cause fingers or hand to move

into the knives.

• Don’t Overreach. Keep good foot-

ing and balance.

• Do not force the cut. Slowing or

stalling the motor will overheat it.

Allow the automatic feed to function

properly.

• Support workpiece. Do not allow

the board to hang from the planer.

• Never use another person as a sub-

stitute for a table extension, or as

additional support for a workpiece

that is longer than the basic thickness planer table or to help feed,

support or pull the workpiece.

T a ke Precautions Against Kickback. Do not permit anyone to stand

or cross in line with the path of the

board through the thickness planer. A

kickback or thrown debris will travel in

this direction.

Keep Children Away. Keep all visi-

tors a safe distance from the thickness planer. Make sure bystanders

are clear of the thickness planer and

workpiece.

Let the blade reach full speed before

planing.

Turn switch off and unplug tool before

inspecting, adjusting or repairing the

planer.

Before freeing jammed material:

• Turn switch “OFF”.

• Wait for all moving parts to stop.

• Unplug the thickness planer.

Basic Thickness Planer Operations

Before You Begin

1. Locate the planer where it is intended

to be used. Take into consideration the

length of wood you would normally

plane allowing ample room for infeed

and outfeed operations.

WARNING: Before turning

switch on make sure the dust chute

is correctly installed. The ON-OFF

switch has a locking feature. This

feature is intended to prevent unauthorized use by children and others.

2. Locate the yellow On-OFF switch key

from parts bag. Insert into the switch.

3. To turn planer on, stand to either side of

the planer, never in line with the opening. Insert finger under the switch and

lift key up.

4. To turn planer off push key down.

Never leave the planer until the cutting

head has come to a complete stop.

5. To lock switch in “OFF” position simply

remove the key when in the off position.

Always lock the switch “OFF” when

planer is not in use. Remove key and

keep it in a safe place. Also, in the

event of power failure (all of your lights

go out) turn switch off, lock it by remov-

20

Yellow

On-Off

Switch Ke

Thermal Overload Protector

Reset Button

Page 21

ing the key. This will prevent the planer

from starting up again when the power

comes back on.

Reduce Damage To Knives

The thickness planer is a precision wood

working machine and should be used on

quality lumber.

Do not plane dirty boards, dirt and small

stones are abrasive and will wear the

blade.

Remove nails and staples. The planer

should only cut wood.

Preparing the Work

The thickness planer works best when the

lumber has at least one flat surface.

Use a hand plane or jointer to define a flat

surface.

Twisted or severely warped boards can

jam the planer, rip lumber in half to reduce

the magnitude of the warp.

The work should be fed with the grain,

sometimes the grain will switch directions

in the middle of the cut. If possible, cut the

board in the middle before planing so the

grain direction is correct.

6. Refer to “Thermal Overload Protection”

section for proper use.

Avoid Knots. Heavy cross grain makes

the knots hard, also, they can come loose

and jam the blade.

WARNING: Any particle that

may encounter the planer knives

may be thrown from the planer creating the risk of severe injury.

WARNING: Do not plane a

board which is less than 12" long,

the force of the cut could split the

board and cause a kickback resulting in serious personal injury.

Carriage Lock

The carriage lock (see “Getting To Know

Your Thickness Planer” section) helps to

minimize “snipe” by locking the cutter

head position. Snipe is a change in thickness at either end of the board, caused by

an uneven force on the cutter head when

work is entering or leaving the planer.

Pushing the carriage lock to the left will

release the cutter head assembly. Set

planer to the correct thickness (see

below) and then push the carriage lock to

the right. This will lock the cutter head

assembly in place and help to minimize

snipe.

A snipe may occur when boards are not

supported properly (see “Extension

Assembly Alignment” section).

In a few instances it is impossible to elimi-

nate “snipe”. A slight snipe may still be

noticed. Snipe is more apparent when

deeper cuts are being taken.

To avoid snipe when planing more than

one board of the same thickness, butt the

boards together end to end so they follow

each other closely through the planer.

21

Page 22

Basic Thickness Planer Operations (continued)

Carriage Lock Adjustment

The carriage lock is preadjusted at the

factory. If the carriage lock lever does not

tighten when moved to the lock position,

follow the steps below to adjust.

1. Remove the switch key and unplug the

unit from the wall outlet.

2. Remove the top cover for visibility.

3. Use the hex wrench provided and

remove the screw in the center of the

handwheel. Note the position of the

carriage lock lever.

4. Pull the carriage lock lever straight out.

This will disengage the carriage lock

lever from the mating lock nut.

5. Slightly rotate the carriage lock lever

counterclockwise and reengage the

Elevation Handwheel

W ARNING: To reduce the risk of

electrical shock, unwrap cord from

cord storage before raising or lowering carriage.

Turn the elevation handwheel (see “Getting to Know Your Thickness Planer” sec-

carriage lock lever teeth onto the lock

nut.

Example: If your carriage lock is at a 2

o’clock position before adjustment,

move the lever counterclockwise to a 1

o’clock position.

6. Turn the lock lever clockwise to the lock

position to assure it is tightening (force

to the push the lever is increasing).

Then turn the lever counterclockwise to

the unlock position to assure it

becomes very loose in the unlocked

position. If the lock lever is not tightening in the lock position then repeat

steps 5 & 6.

7. Replace the handwheel, secure the

screw with the hex wrench and reinstall

the top cover.

tion), to set the planer for the correct

depth of cut. The surface the planer will

produce will be smoother if a shallower

depth of cut is used. Each full revolution

of the elevation handwheel will raise or

lower the cutter head 1/16".

Feeding the Work

The feed rate refers to the rate at which

the lumber travels through the planer.

The planer feed is automatic, it will vary

slightly depending on the type of wood cut

and depth of cut.

The operator is responsible for aligning

the work so it will feed properly.

Stand to one side of the planer infeed

table.

Lift the work to the infeed extension by

grasping the edges of the board at

approximately the middle of the length.

Boards longer than 24" should have additional support from free standing material

stands.

Rest the board end on the infeed support

extension and direct the board into the

planer.

Push slightly on the board and allow the

automatic feed to take the board. Release

the board and allow the automatic feed to

function properly. Do not push or pull on

the workpiece.

WARNING: To avoid serious

personal injury do not stand directly

in line with the front or rear of the

planer, when an object is thrown

from the planer it will travel in this

direction.

Move to the rear and receive the planed

lumber by grasping it in the same manner

as it was fed.

Do not grasp any portion of the board

which has not gone past the outfeed

extension.

Repeat this operation on all the boards

which need to be the same thickness.

22

Page 23

NOTE: An assistant must follow the same

precaution as the operator.

The surface that the planer will produce

will be smoother if a shallower depth of

cut is used. See “Material Removal Indicator”.

Feed the work in the direction of the grain.

Wood fed against the grain may result in a

chipped splintered surface. If this occurs

try feeding the other end of the board in

first.

Material Removal Indicator

Indicates the amount of material being

removed on each pass through the

planer. Up to 1/8" max. Make sure the

workpiece is under the Material Removal

Indicator label on the front of the tool.

Recommended maximum depth of cut per

pass through planer:

• 1/8" for material 0-6" in width

• 1/16" for material 6-13" in width

NOTE: Do not continuously use the thick-

ness planer set at maximum depth of cut

(1/8") and at full 13" width of cut. Continuous use at maximum cutting capacity will

damage your motor.

Preset Thickness Stops (Repeat -A -Cu t)

These stops are for repetitive planing to

preset thickness. Planing a workpiece to

one of these common thicknesses can be

easily accomplished:

1. Raise carriage to greater than 1-3/4".

2. Slide the knob to the desired thickness

setting.

3. Turn the elevation handle until the carriage contacts the thickness stop.

4. Lock the carriage lock.

5. Plane the workpiece and check the

thickness. If the thickness is incorrect

follow the adjustment steps below.

Thickness Stop (Repeat-A-Cut) Adjustment

1. Pull the Repeat-A-Cut knob straight

out to remove.

2. Remove the screw on the right side of

the Repeat-A-Cut scale and remove

the cover.

3. Measure the height from the base to

the cutter head knife tip. This can be

done with a scrap piece of board — 11/2" for example.

4. Use the elevation handwheel to adjust

the height to the known thickness piece

of scrap, then remove the piece of

scrap without moving the handwheel.

5. Make sure the Repeat-A-Cut is on the

1-1/2" setting and loosen the lock nut

on the adjustment bolt. Adjust the bolt

to come in full contact with the step

block and tighten the lock nut.

6. Replace the Repeat-A-Cut cover and

secure it with the screw.

23

Page 24

Basic Thickness Planer Operations (continued)

7. Replace the knob.

8. Plane a workpiece and check its thickness. Repeat procedure, if necessary.

Checking for Worn Knives

The condition of knives will affect the precision of the cut.

Observe the quality of the cut the planer

produces to check the condition of the

knives.

Dull knives will tear, rather than sever

wood fibers, and produce a fuzzy appearance.

A raised ridge will occur when dull knives

pound on wood that has a varying density.

If a raised ridge is produced running the

length of the workpiece, the knives have

been nicked. If the nick is small, shift one

knife to the right and the other to the left.

(see “Replacing Knives” section).

For knives replacement and installation

refer to “Replacing Knives” section.

Maintenance

The planer will operate best if it is kept in

good condition. Keep the unit adjusted as

described in the “Operation” section. Also,

the knives must be kept clean and sharp

to ensure the quality of cut and efficiency

of operation. Knives are “double edged”.

When one side becomes dull they may be

turned over and the opposite edge used.

W ARNING: To reduce the risk of

injury from unexpected starting or

electrical shock. Make certain that

the unit is disconnected from the

power source, before attempting to

service, or remove any component.

Lubrication

Motor and cutter head bearings are

sealed and need no lubrication. Height

adjustment guides and elevation screws

should be cleaned of debris and greased

when needed.

Occasionally apply a few drops of light

machine oil to the four support rods to

keep the carriage sliding smooth.

Cleaning the Knives

Gum and pitch will collect on knives and

cause excess friction when working.

Knives will overheat and wear at an accelerated rate. Remove knives and clean

with a gum and pitch remover to keep

knives clean.

Cleaning The Feed Rollers

Excessive gum, pitch and sawdust can

reduce friction of the rubber rollers. Use

alcohol to wipe the rollers.

Motor Ventilation

Check the motor vents periodically while

planing and clear away any sawdust to

avoid motor heating.

Nut

Bolt

24

Page 25

Changing Brushes

W ARNING: To reduce the risk of

electrical shock, fire or injury, use

only parts identical to those identified in the parts list. Reassemble

exactly as original assembly to

reduce the risk of electrical hazards.

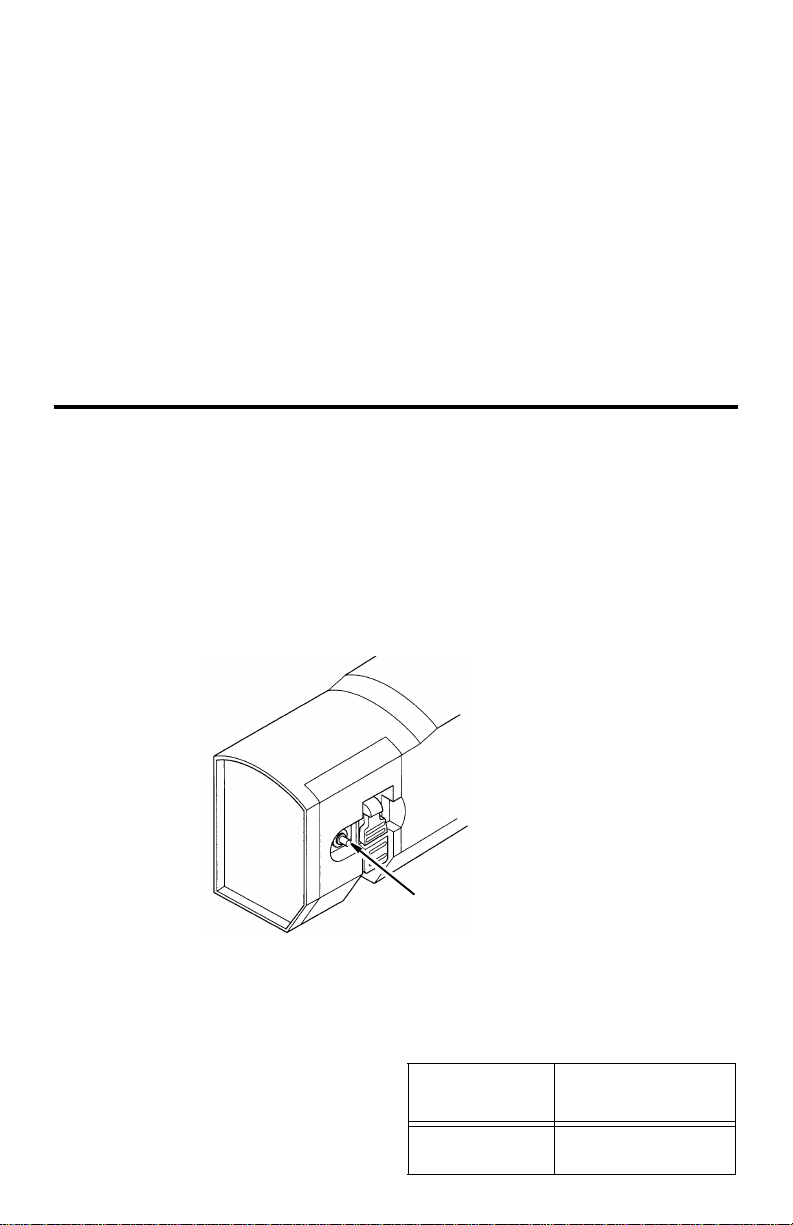

Replacing Knives

Your thickness planer is supplied with

double edged knives. Knives should be

replaced or turned 180° to the unused

edges whenever they become dull or

nicked. Keeping a spare set of knives on

hand is recommended. Knives should

always be replaced as a matched set.

WARNING: Exposed knives are

sharp and could injure you. To

reduce the possibility of injury protect your hands with gloves or shop

rag and use the knife tool when

removing or installing knives.

1. Be sure the switch key is removed and

the unit is unplugged from the wall

receptacle.

2. For easier access to the cutter head/

knife assembly remove the upper

cover. See illustration.

3. Loosen the two dust chute knobs and

remove the dust chute.

NOTE: When dust chute is removed

the cutter head lock will engage when

the head is rotated. Do not operate

thickness planer without the dust

chute in place, or your planer will be

damaged

4. Rotate the cutter head until the lock

The carbon brushes furnished will last

approximately 50 hours of running time or

10,000 on/off cycles. Replace both carbon

brushes when either brush has less than

1/4" length of carbon remaining. To

inspect or replace first unplug the planer.

Then turn the brush caps counterclockwise to remove. To reassemble reverse

the procedure. Tighten the brush caps

snugly but do not overtighten.

engages. This will correctly position a

knife and its seven knife lock screws.

WARNING: To reduce the risk of

injury from accidental contact with

the exposed knife, when turning the

knife lock screws, lay a folded shop

rag over the knife or wear a glove.

5. Carefully loosen all seven knife locking screws.

NOTE: Move wrench left to right to

loosen screws.

6. Use the notched end of the Magnetic

Knife Handling Tool to remove the

knife by hooking the notch over the

end of the knife and pulling straight

out.

7. Use the magnet on the Magnetic Knife

Handling Tool to help remove the

knife.

8. If you are changing to the second

edge of the knife, rotate the knife “end

for end” keeping the same flat side

down. This will correctly position the

knife to reinstall. Look closely at the

cutter head side view making sure the

knife is installed as pictured. Knives

should be cleaned of gum and pitch

before reinstalling.

25

Page 26

Maintenance (continued)

r

W ARNING: To reduce the risk of

thrown blades and other cutter

head parts make sure the knife lock

bar containing the seven knife lock

screws is positioned as shown in

the cutter head side view picture.

9. Push the installed knife in firmly.

Visually check that the knife edge

is parallel to the cutter head slot.

10. Tighten the seven (7) knife locking

screws.

NOTE: Move wrench right to left to

tighten.

11. To rotate the cutter head to the next

knife, release the cutter head lock.

Hold down on the red lock lever

located on the left side and rotate the

cutter head.

12. Release the red lock lever and continue to rotate the cutter head until it

locks. This should correctly position

the second knife.

13. Repeat procedures 5 through 10 for

the second knife.

14. Check that all knife lock screws are

tight and reinstall the dust chute.

Knife Lock Screws

Knife Lock Ba

Accessories

Do not use any accessory unless you

have received and read complete instructions for its use.

Wiring Diagram

Switch

Black

White

Green

Power Cord

Motor Lead

Grounding Wire

Power Tool Universal Legset....... AC9910

Dust Collector.............................. AC8640

Replacement Knives ................... AC8630

Over Load

Motor Lead

Motor

26

Page 27

Troubleshooting

Problem Possible Cause Remedy

Snipe

(Gouging at

ends of board)

Fuzzy Grain 1. Planing wood with a

Torn Grain 1. Too heavy a cut

Rough Raised

Grain

Uneven Depth

Cut Side to

Side

Cutter head

Elevation

Adjusts with

Difficulty

Board Thickness Does Not

Match Depth of

Cut Scale

Chain Jumping 1. Sprockets worn

Motor does not

start

Dust chute is

blocked

1. Dull knives

2. Inadequate support of

long boards

3. Lumber not butted

properly

4. Extensions misaligned

high moisture content

2. Knives cutting against

grain

3. Dull knives

1. Dull knives

2. Too heavy a cut

3. Moisture content too

high

1. Blade projection not

uniform

1. Elevation screws dirty

2. Gears or screws worn

3. Friction between casing and covers

1. Indicator not set correctly

2. Knife projection incorrect

2. Chain worn

1. Switch malfunction

2. Overload protector

tripped

3. Supply fuse opens

4. Brushes worn

5. Other

1. Build up of resin under

dust chute

2. Large debris

1. Replace knives per instructions (See

“Replacing Knives” section)

2. Support long boards

3. Butt end to end each piece of stock

as boards pass through planer

4. Adjust extension supports

1. Remove high moisture content from

wood by drying

1. Review “Depth of Cut” section

2. Review “Feeding the Work” section

3. Replace knives per instructions

1. Replace knives per instructions

2. Review “Depth of Cut”

3. Dry the wood or use dried wood

1. Check that end of knife is fully

seated in the cutter head.

1. Clean and lubricate elevation screws

2. Replace

3. Clean, lubricate

1. Adjust indicator/securely tighten

2. Set knife projection correctly (See

“Replacing Knives” section).

1. Replace sprockets

2. Replace chain

1. Have a qualified electrician replace

the ON/OFF switch.

2. Turn power switch off. When planer

temperature adequately cools (allow

15-30 minutes) press overload protector reset button.

3. Replace fuse with a 15 amp time

delay fuse, or circuit breaker.

4. See “Maintenance” section, ”Changing Brushes

5. Get authorized service.

1. Clean dust chute and exhaust area.

2. Clear debris.

27

Page 28

Repair Parts

RIDGID parts are available on-line at www.ridgidparts.com

10

15

14

13

5

Parts List for 13" Thickness Planer

Model No. TP13002

Figure 1

21

20

83

22

29

28

6

12

29

32

23

33

34

30

39

82

24

17

18

19

25

26

16

27

31

40

41

45

42

35

46

43

47

44

48

49

27

50

49

58

10

51

52

57

53

54

55

56

4

3

78

11

80

79

36

76

37

18

2

84

1

85

9

8

7

81

36

77

88

38

74

75

56

71

70

69

87

27

68

62

61

63

73

64

66

60

59

86

65

67

72

28

Page 29

Repair Parts

RIDGID parts are available on-line at www.ridgidparts.com

Parts List for 13" Thickness Planer

Model No. TP13002

Figure 1

Always order by Part Number - Not by Key Number

Key

Part No. Description

No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

820380-6

827681

827713

827841

827682

827741

817453-1

827769

827720

820379-6

827717

827719

827726

827766

827724

827754

827721

821065-2

827723

827699

827716

820379-9

827695

827753

827926

813312-6

821102-1

827697

827932

827930

827931

827750

827770

827759

827768

820240-3

827704

827767

827738

827678

827725

827751

827737

820240-6

AC8630

Scr Hex Soc Butt Hd

M6 x 1.0-20

Cap Left

Scale Length

Cover Upper

Cap Right

Pad Upper

Ring Retaining C17

Worm Gear L.H.

Plate Lock Left

*Scr Hex Soc Cap M5 x 0.8-12

Sleeve

Plate Lock Right

Shaft Transmission

Washer 21.5 x 24 x 1

Nut Lock M17 x 2.0

Support

*Washer 12 x 16 x 1

*Scr Soc Set Cup Pt M5 x 0.8-8

Worm Elevation

Handle

Knob Snipe

*Scr Hex Soc Cap M5 x 0.8-10

Chute Dust

Knob Chute

Cover Shroud

*Scr Pan Hd M4 x 0.75-6

*Washer 4.2 x 10 x 0.9

Manifold Air

Gasket Rear

Gasket Right

Gasket Left

Cover

Worm Gear R.H.

Bushing

Screw Elevating R.H.

*Scr Pan Hd M5 x 0.8-6

Plate Dust Chute

Clamp Cord

Spring /Plunger

Frame Upper

Block Support

Lock Cutter Head

Spacer Cutter Head Lock

*Scr Pan Hd M5 x 0.8-12

†Knife Planer

Key

Part No. Description

No

827711

46

827785

47

818654-9

48

827714

49

818469-6

50

827787

51

827793

52

827788

53

827789

54

827786

55

820722-5

56

827680

57

813249-76

58

821151-4

59

813164-6

60

827729

61

827817

62

827739

63

820401-2

64

827733

65

827734

66

827746

67

813312

68

827701

69

827732

70

827762

71

813314-8

72

820257-1

73

827784

74

828677

75

820379-8

76

820379-5

77

827773

78

827772

79

827794

80

817453-4

81

820383-4

82

828027-1

83

828027

84

820383-5

85

821065-1

86

827763

87

SP6452

88

Bar Knife Lock

Screw Knife Lock

*Key 5 x12mm

Collar Knife

*Scr Hex Soc Cap M4 x 0.75-8

Pulley Cutter head

Belt Drive

Nut Hex M6 x 2.0 L.H.

Pulley Motor

Retainer Bearing

Bearing Ball 6203ZZ

Head Cutter (Includes Collar

knife, Retainer Bearing, Bearing Ball and Gear Pinion)

Pin Spring 3 x 8mm

*Screw Hex Hd M5 x 0.8-26

*Nut Hex M5 x 0.8

Rod Step

Nut Special M10 x 1.5

Indicator Depth

Scr Pan Hd M3 x 0.5-16

Rod Pointer Elevating

Spring Coil

Cover Pointer

Scr Pan Cr M4 x 0.75-10

Housing Pointer

Pointer

Nut

Lockwasher Ext Tooth M5

Scr Pan Hd TY TT M5 x 0.8-8

Gear Pinion

Gear Box Asm

*Scr Hex Soc Cap M5 x 0.8-35

*Scr Hex Soc Cap M5 x 0.8-30

Spacer 15 x 20 x 7

Sprocket

Chain

Ring Retaining Ext STW15

Lockwasher M5

Scr Hex Soc Hd Lock M5

Scr Hex Soc Hd Lock

M5x0.8-12

Lockwasher M6

Scr Soc Set Cup Pt M5 x 0.8-5

Bushing 4.2 x 11 x 3

Operator’s Manual

8.5X19X0.8

* Standard Hardware Item - May be purchased locally.

† These replacement parts are available where you purchased your Planer.

29

Page 30

Repair Parts

0

3

RIDGID parts are available on-line at www.ridgidparts.com

Parts List for 13" Thickness Planer

Model No. TP13002

Figure 2

2

19

See Figure

18

26

10

25

27

29

28

30

31

17

9

5

8

7

5

4

2

3

2

1

54

6

4

5

2

10

8

6

58

55

5

9

11

12

13

53

10

51

52

16

15

29

14

50

21

22

59

23

24

40

29

49

41

35

48

41

36

29

28

40

42

44

46

32

37

38

39

34

33

45

43

51

39

47

56

57

30

Page 31

Repair Parts

Parts List for 13" Thickness Planer Model No. TP13002

RIDGID parts are available on-line at www.ridgidparts.com

Cover Side RH

Scale Thickness

Part No. Description

827703

827715

3132333435363738394041424344454647484950515253545556575859

No

Key

Figure 2

Always order by Part Number - Not by Key Number

Spring Coil 7.62x15.75x0.7

Ball Steel

Block Guard

Block Step

Knob Step

Pin Step Block

Spring Flat

Base

Bolt Adjustment

Nut Hex Special M10 x 1.5

Pad Base

Table Front

Nut Lock M10 x 1.5

Rod Support

Cover Side Left

* Scr Pan Hd Ty “TT” M5 x 0.8-8

827718

820257-1

Holder Tool

827684

827771

827760

823742-1

827698

827700

827743

* Nut Hex M6 x 1.0

827730

813164-7

* Scr Pan Hd M5 x 0.8-10

820240-1

827736

827677

827752

827817

* Scr Hex M6 x 1.0-25

827742

821388-3

828028

* Nut Hex M12 x 1.75

813164-10

817449-4

Tool Knife

Wrench Box M8 & M10

Cover Tool Box

Scr Hex Soc Cap M5x0.8-8

* Wrench Hex “L” 4mm

827748

827757

827756

827927

820379-1

Rod Pivot

827728

Ring Retaining

Sprocket

Chain

Part No. Description

817453-4

827772

827794

123456789

No

Key

Spring Coil Left

Block Bearing

827758

827790

Plate Retainer Left

Roller Outfeed

827791

827693

Spring Coil Right

Plate Retainer Right

Roller Infeed

Worm Gear L.H.

Screw Elevating L.H.

Rail Guide

Plate Wear

Table Rear

827705

827694

827688

Case Knife (Knives not included)

827764

* Scr Hex Soc Cap M5 x 0.8-10

* Washer 5.5 x 19 x 2

827755

827792

820379-9

827692

827765

827722

827735

101112131415161718192021222324252627282930

* Washer M8 x 23 x 2

* Screw Hex Hd M8 x 1.25-20

* Scr Pan Hd Ty “TT” M5 x 0.8-6

821063-0

813310

820257-3

Plate Stiffener

Spring Torsion

827928

827744

Plate Side Guard

827731

Cover Side Right

Hub Handwheel

827679

827696

31

Knob Handwheel

Screw Hex Soc.Fl Hd M6 x 1.0-12

* Scr Hex Soc Cap M5 x 0.8-15

* Lockwasher M5

827749

820379-2

820383-4

827929

* Standard Hardware Item - May be purchased locally.

Page 32

Repair Parts

RIDGID parts are available on-line at www.ridgidparts.com

12

21

Parts List for 13" Thickness Planer

Model No. TP13002

Figure 3

1

3

14

4

13

12

15

32

2

23

22

20

16

19

Ke

y

Part No. Description

No.

1

827808

2

827799

3

820240-7

4

827689

5

827740

6

827890

7

827809

8

827811

9

827810

10

821065-3

11

826463-4

12

820383-4

* Standard Hardware Item - May be purchased locally.

† These replacement parts are available where you purchased your Planer.

16

17

18

Always order by Part Number - Not by Key Number

Cord w/plug

Guard Cord

* Screw Pan Hd

M5 x 0.8-20

Housing Switch

Gasket Foam

Motor

(Includes Brushes)

Holder Brush

Brush

Cap Brush

* Screw Hex Soc Set

M5 x 0.8-12

Label RIDGID

* Lockwasher M5

5

6

11

Ke

y

Part No. Description

No.

13

14

15

16

17

18

19

20

21

22

23

827812

820257-1

827807

827806

827708

826347

AC1000

827797

827798

827765

820240-5

Lead Ground

* Screw Pan Hd

Ty “TT” M5 x 0.8-8

Rod Motor Pivot

Switch Reset

Bezel Switch

Switch Locking

† Key Switch

Screw Special

Clamp Cord

* Washer 5.5 x 19 x 2

* Screw Pan Hd

M5 x 0.8-30

9

8

7

10

(Includes Nut)

Page 33

Repair Parts

2

RIDGID parts are available on-line at www.ridgidparts.com

Parts List for 13" Thickness Planer

Model No. TP13002

Figure 4 - Legstand

11

11

11

8

9

1

11

1

5

3

4

6

7

10

9

9

3

3

6

7

6

7

2

4

3

5

6

7

Always order by Part Number - Not by Key Number

Key

Part No. Descripti on

No.

1

829635

2

829636

3

829634

4

829637

5

829638

6

829633

7

829632

* Standard Hardware Item - May be purchased locally

Stiffener Upper Long

Stiffener Upper Short

Leg Upper

Stiffener Lower Long

Stiffener Lower Short

Leg Lower

Foot

33

Key

No.

8

9

10

11

813310-10

829631

821063-2

821103

Part No. Description

Screw Hex

M8 x 1.25-65

Nut Hex Flanged

M8 x 1.25

Washer

M8 x 16 x 1.6

Bolt Cup Sq Neck

M8 x 1.25

Page 34

Notes

34

Page 35

Notes

35

Page 36

RIDGID¨ HAND HELD AND STATIONARY POWER TOOL

LIMITED THREE YEAR WARRANTY AND 90-DAY

SATISFACTION GUARANTEE POLICY

This product is manufactured by One World Technologies, Inc.,