RIDGID SuperFreeze SF-2300, SuperFreeze SF-2500 Operator's Manual

• Français – 13

• Castellano – pág. 27

WARNING!

Read this Operator’s Manual

carefully before using this tool.

Failure to understand and follow the contents of this manual

may result in extensive property damage and/or serious

personal injury.

SF-2300/SF-2500 Manual

SuperFreeze

®

Pipe Freezing Units

ii

Table of Contents

Recording Form for Machine Serial Number..............................................................................................................1

Safety Symbols..............................................................................................................................................................2

General Safety Rules

Work Area Safety........................................................................................................................................................2

Electrical Safety ..........................................................................................................................................................2

Personal Safety ..........................................................................................................................................................2

Power Tool Use and Care ..........................................................................................................................................3

Service ........................................................................................................................................................................3

Pipe Freezing Unit Safety Warnings............................................................................................................................3

Description, Specifications and Standard Equipment

Description ..................................................................................................................................................................3

Specifications..............................................................................................................................................................4

Standard Equipment ..................................................................................................................................................4

Icons ..............................................................................................................................................................................4

Pre-Operation Inspection ............................................................................................................................................5

Machine and Work Area Set-Up ..................................................................................................................................5

Capacities for Copper Tube &Steel Pipe ....................................................................................................................6

Operating Instructions..................................................................................................................................................8

Freezing Times ..........................................................................................................................................................9

Cleaning ........................................................................................................................................................................9

Accessories ................................................................................................................................................................10

Machine Storage..........................................................................................................................................................10

Service and Repair......................................................................................................................................................10

Disposal ......................................................................................................................................................................10

Troubleshooting..........................................................................................................................................................11

Lifetime Warranty ........................................................................................................................................Back Cover

*Original Instructions - English

SuperFreezer®Pipe Freezing Units

SuperFreeze®Pipe Freezing Units

Record Serial Number below and retain product serial number which is located on control panel.

Serial

No.

SuperFreeze

®

Pipe Freezing Units

SF-2300/SF-2500

2

SuperFreezer®Pipe Freezing Units

General Safety Rules

WARNING

Read all safety warnings and all instructions. Failure

to follow the warnings and instructions may result

in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE!

Work Area Safety

• Keep your work area clean and well lit. Cluttered or

dark areas invite accidents.

• Do not operate tools in explosive atmospheres,

such as in the presence of flam mable liquids,

gases, or dust. Tools create sparks which may ignite

the dust or fumes.

• Keep children and by-standers away while operat-

ing a tool. Distractions can cause you to lose control.

Electrical Safety

• Grounded tools must be plugged into an outlet

properly installed and grounded in accordance

with all codes and ordinances. Never remove the

grounding prong or modify the plug in any way. Do

not use any adapter plugs. Check with a qualified

electrician if you are in doubt as to whether the outlet is properly grounded. If the tool should electrical-

ly malfunction or break down, grounding provides a low

resistance path to carry electricity away from the user.

• Avoid body contact with grounded surfaces such

as pipes, radiators, ranges and refrigerators. There

is an increased risk of electrical shock if your body is

grounded.

• Do not expose the equipment to rain or wet con-

ditions. Water entering a tool will increase the risk of

electrical shock.

• Do not abuse the cord. Never use the cord for car-

rying, pulling or unplugging the tool. Keep cord

away from heat, oil, sharp edges or moving parts.

Replace damaged cords immediately. Dam aged or

entangled cords increase the risk of electric shock.

• When operating a tool outside, use an outdoor

extension cord marked “W-A” or “W”. These cords

are rated for outdoor use and reduce the risk of electric shock.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a tool. Do not use a

tool while you are tired or under the influence of

drugs, alcohol, or medication. A mo ment of inat-

tention while operating tools may result in serious

personal injury.

• Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

Safety Symbols

In this operator’s manual and on the product, safety symbols and signal words are used to communicate important safety information. This section is provided to improve understanding of these signal words and symbols.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE indicates information that relates to the protection of property.

This symbol means read the operator’s manual carefully before using the equipment. The operator’s manual contains

important information on the safe and proper operation of the equipment.

This symbol means always wear safety glasses with side shields or goggles when handling or using this equipment to reduce

the risk of eye injury.

This symbol indicates the risk of frostbite from a cold surface.

This symbol indicates the risk of electrical shock.

NOTICE

DANGER

WARNING

CAUTION

3

SuperFreeze®Pipe Freezing Units

• Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power

tool in unexpected situations.

Tool Use and Care

• Do not force the tool. Use the correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it is designed.

• Do not use tool if the switch does not turn it ON

and OFF. Any tool that cannot be controlled with the

switch is dangerous and must be repaired.

• Disconnect the plug from the power source before

making any adjustments, changing accessories, or

storing the tool. Such preventive safety measures

reduce the risk of starting the tool accidentally.

• Store idle tools out of the reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

• Maintain the tools. Check for misalignment or bind-

ing of moving parts, breakage of parts and any

other condition that may affect the tool’s operation.

If damaged, have the tool re paired before use.

Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by

the manufacturer for your model. Accessories that

may be suitable for one tool, may become hazardous

when used on another tool.

Service

• Have your tool serviced by a qualified repair person using only identical replacement parts. This will

ensure that the safety of the tool is maintained.

Pipe Freezing Unit Safety

Warnings

WARNING

This section contains important safety information

that is specific to this tool.

Read these precautions carefully before using the

SuperFreeze units to reduce the risk of electrical shock or other serious injury.

SAVE THESE INSTRUCTIONS!

The SuperFreeze®units include space in the unit to keep

this manual with machine for use by the operator.

• This tool is used to freeze a water plug inside

cop per, steel or other thermally conductive metallic tubes or pipes. Do not use on plastic pipe or

tube. Follow instructions on proper use. Other uses

may increase the risk of injury.

• Do not touch the freeze heads while frosted. Touch -

ing the freeze heads while frosted can cause frostbite.

Wear gloves if handling during use.

• Before opening piping system, test to confirm

that the ice plugs are fully formed and stable.

Opening the piping system before a complete plug is

frozen or allowing the plug to thaw while the system is

open could cause burns, electric shock or other serious

injury or result in flooding or other property damage.

• Do not twist, kink or pull hoses. Do not open

refrig erant piping. This can lead to refrigerant leaks

and cause frostbite, asphyxiation and other serious

injury. If a leak occurs, leave the area until the refrigerant dissipates.

The EC Declaration of Conformity (890-011-320.10) will

accompany this manual as a separate booklet when

required.

If you have any question concerning this RIDGID®product:

– Contact your local RIDGID distributor.

– Visit www.RIDGID.com or www.RIDGID.eu to find

your local RIDGID contact point.

– Contact Ridge Tool Technical Service Department at

rtctechservices@emerson.com, or in the U.S. and

Canada call (800) 519-3456.

Description, Specifications and

Standard Equipment

Description

The RIDGID®SuperFreeze®Pipe Freezing Units are used

to freeze plugs in water piping systems to allow maintenance without shutting down or draining the system. The

units are self-contained refrigeration units that circulate

refrigerant to the aluminum freeze heads. The freeze

heads, attached to the piping system, can freeze a plug in

metallic tubing or pipes. Once the work is complete, the

SuperFreeze unit is turned OFF and the ice plugs melt,

returning the system to operation.

The SuperFreeze units do not use CO2or Nitrogen, and do

not require the release of refrigerants. They use specially

designed compressors with overload protection. The SF2500 also includes quick restart capabilities. The freeze

head hoses are leak free flexible rubber. The units are

enclosed in a portable carry case.

4

SuperFreezer®Pipe Freezing Units

Figure 2 – SF-2300 SuperFreeze Unit

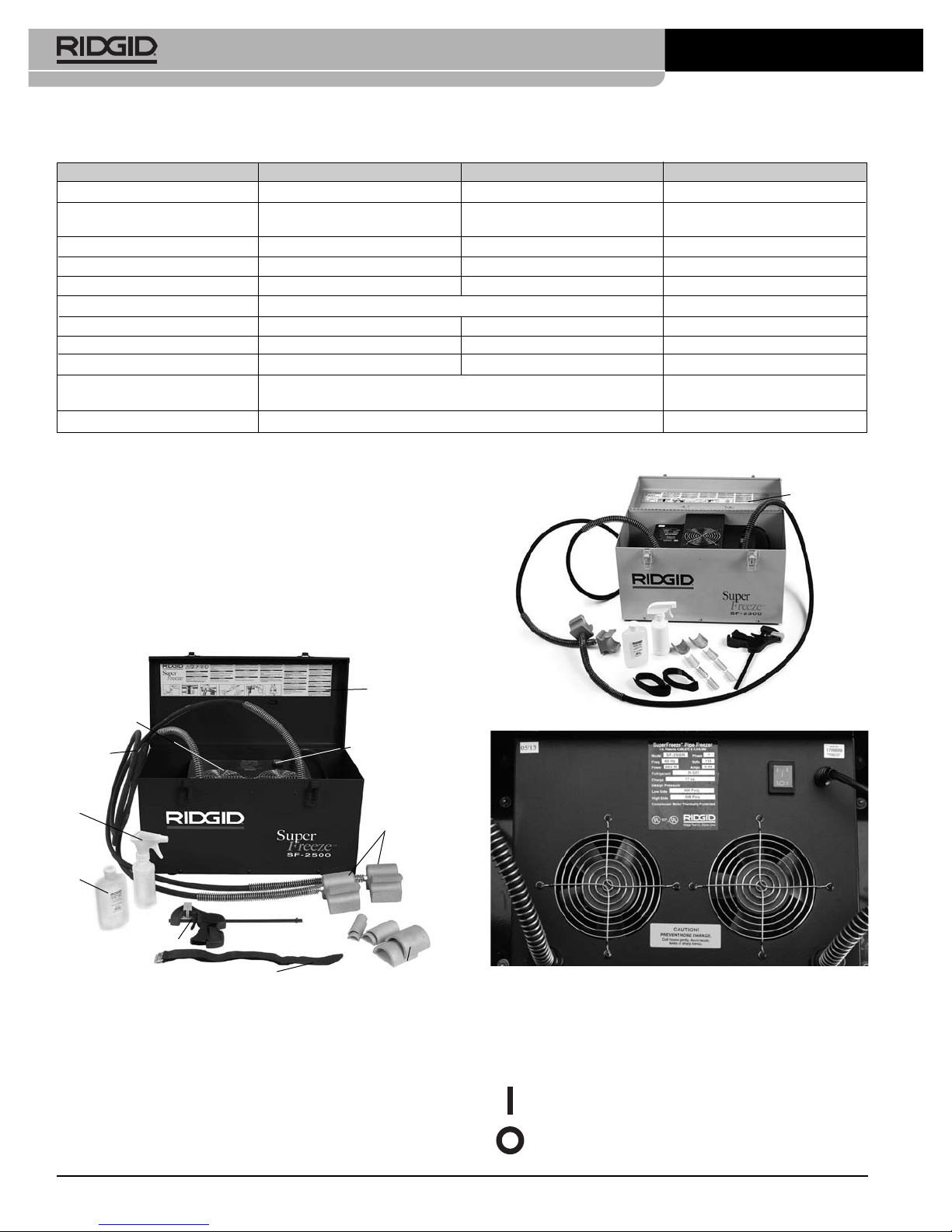

Figure 3 – Unit Serial Number

The machine serial number is located on the control

panel. An additional decal is supplied that indicates the

month and year of manufacture. (05 = Month, 13 = Year)

Icons

Specifications

Standard Equipment

All SuperFreeze pipe freezing units come with the following:

• Two Velcro Straps with D-Ring

• Quick Grip Clamp

• Freeze Gel

• Water Spray Bottle

• Operator’s Manual

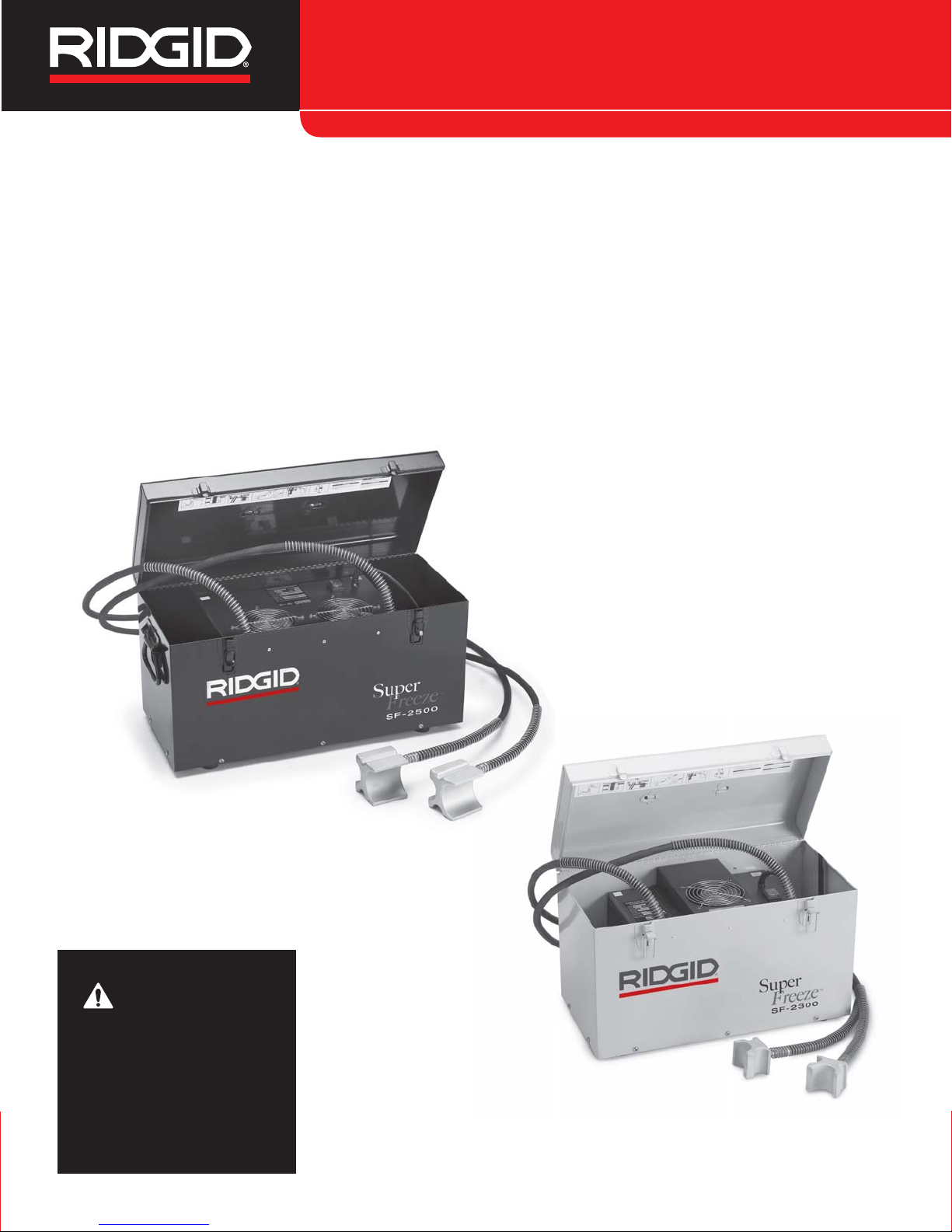

Figure 1 – SF-2500 SuperFreeze Unit

Parameter\Model SF-2500, 115V SF-2500, 230V SF-2300, 230V

Capacity: Copper Tube

1

/2to 21/2inch CTS 12 to 54 mm DN* 12 to 42 mm DN

Capacity: Steel Pipe

1

/2to 1 inch

#1

/2to 2 inch

1

/2to 11/4inch

#

(15 to 25 mm) (15 to 50 mm) (15 to 32 mm)

Hose Length 8.5 ft (2.6 m) 8.5 ft (2.6 m) 6.5 ft (2 m)

Hose Span 17 ft (5.2 m) 17 ft (5.2 m) 13 ft (4 m)

Refrigerant R-507 R-507 R-507

Compressor Type Rotary, Hermetic, Low Back Pressure Reciprocating

Motor Power 627 W 505 W 296 W

Fan Motor Power 2 × 18 W 2 × 17 W 17 W

Electric Supply 115 V, 1 Ph, 60 Hz 230 V, 1 ph, 50 Hz 230 V, 1 ph, 50 Hz

Dimension 24

1

/2× 11 × 141/2inch 21 × 101/2× 13 inch

(633 x 279 x 368) (533 x 267 x 330)

Weight 69 lb (31 kg) 58 (26 kg)

#

The freeze head cavities on these units are specifically sized for copper tube sizes. They may be used on steel pipe sizes with adherence to the instructions.

* The freeze head cavities on these units are specifically sized for steel pipe sizes. They may be used on copper tube sizes with adherence to the instructions.

Power ON

Power OFF

Label

ON/OFF (I/O)

Switch

Freeze

Heads

Hoses

Condenser

Spray

Bottle

Bushings

Freeze

Gel

Quick Grip Clamp

Velcro Strap

Label

Machine and Work Area Set-Up

WARNING

Set up the pipe freezing units and work area according to these procedures to reduce the risk of burns,

electrical shock and other injuries and prevent

machine damage.

1. Check work area for:

• Adequate lighting.

• Flammable liquids, vapors or dust that may ignite. If

present, do not work in area until sources have

been identified and corrected. The Pipe Freezing

Units are not explosion proof and can cause sparks.

• Clear, level, stable, dry location for all equipment

and operator.

• Properly grounded electrical outlet of the correct

voltage. A three-prong or GFCI outlet may not be

properly grounded. If in doubt, have outlet inspected by a licensed electrician.

• Clear path to electrical outlet that does not contain

any potential sources of damage for the power cord.

• Clear path for access to the work area.

2. Inspect the system and determine if the Pipe Freezing

Unit will work.

• Determine the system fluid – the unit will only work on

systems containing water. Know what additives are

in the water. Additives can change liquid freeze temperature and make freezing difficult or impossible.

• Determine the system material and size – the unit

will only work on metallic piping systems. For pipe

and tube material and size

see Specifications

.

• Determine the system water temperature and air

temperature in the area of the desired plug. If

temperatures exceed

up to 1" (25 mm) sizes – 110°F (43°C)

1

1

/4" (32 mm) and 11/2" (42 mm) sizes – 90°F (32°C)

2" (54 mm) and larger sizes – 80°F (27°C)

The water/air must be cooled to below these temperatures for the SuperFreeze unit to be used.

• Determine if there is flow in the system – the pipe

freezing unit will not work on flowing water. If there

is flow in the section of pipe to be frozen, the flow

needs to be stopped by shutting a valve, turning

OFF a circulating pump, or other appropriate means.

5

SuperFreeze®Pipe Freezing Units

This product is used to freeze ice plugs in

water piping systems. The ability to freeze plugs is

dependant on a wide variety of factors as discussed in

this manual. Depending upon the exact set of circumstances, this product may not work in all cases.

Pre-Operation Inspection

WARNING

Before each use, inspect your pipe freezing unit

and correct any problems to reduce the risk of serious injury from electrical shock and other causes

and prevent unit damage.

1. Make sure that the pipe freezing unit is unplugged and

the ON/OFF switch is in the OFF position.

2. Clean any oil, grease or dirt from all equipment and

controls. This aids inspection and control of the unit.

3. Inspect the pipe freezing units for the following:

• Inspect the cord and plug for damage or modifi-

cation.

• Proper assembly, maintenance and completeness.

• Any broken, worn, missing, misaligned or binding

parts.

• Presence and readability of the warning label.

(See Figures 1 and 2.)

• Any other condition, which may prevent safe and

normal operation.

If any problems are found, do not use the pipe freezing unit until the problems have been repaired.

4. Check the hoses to the freeze heads for cracks, kinks,

breaks or other issues. The hoses can be coiled and

flexed when not frosted. Care must be taken not to

twist or kink hoses. This prevents hose damage.

5. Inspect the fan grille and louvers into the condenser

housing to make sure that nothing is blocking the airflow. Lack of airflow through the unit can cause performance issues or damage the unit.

6. With dry hands, plug cord into properly grounded outlet, Move the switch to ON position. Confirm that the

compressor motor starts and that the fan runs. Move

the switch to OFF position and unplug the unit.

NOTICE

Model Freeze Head Copper Tube (CTS) Steel Pipe#Cavity Req’d Bushing

1

/2"—4—

3

/4"

1

/2" 2 Cat. #69712

1"

3

/4"2 —

1

1

/4" 1" 3 Cat. #70652

1

1

/2"—3—

2" — 1 Cat. #69717

2

1

/2"—1—

1

4

3

2

6

SuperFreezer®Pipe Freezing Units

• Determine if the piping is filled with water. A plug

cannot be frozen into partly filled pipes.

• Determine where the piping system needs to broken for the work that needs to be done.

• Locate piping system shut-off valves or determine

other methods to shut off system fluid flow to be

used in case of emergency.

3. Determine location for freeze plug(s).

• The location must allow access for at least one

freeze head. If only a single plug is required, it is

preferred that there be enough space for both

freeze heads. Freeze heads should not contact

more than one pipe.

• If the system will be soldered, brazed, welded, or

other heat adding processes performed, the freeze

plug(s) must be located as far away from the repair

as possible. Excess heat can prematurely thaw the

ice plug and allow water to flow while the system is

open. The freeze plugs should be a minimum of one

foot (0.3 m) away from the heat for each inch (25

mm) of diameter for steel pipe or tube. For all other

materials, the plug should be at least three feet

(0.9 m) away for each inch of pipe or tube diameter.

• Ice plugs must be more than one foot (0.3 m) away

from end caps, elbows, closed valves, other ice

plugs or similar obstructions. Placing an ice plug

closer can cause splitting of the pipe or tube.

• Do not place ice plugs closer than 5 feet (1.5 m)

from a circulating hot water (water hotter than

ambient air but cooler than 100°F (38°C)) main for

pipe sizes 1" (25 mm) and smaller or closer than 8

feet (2.4 m) from a circulating hot water main 1

1

/4"

(30 mm) or larger. Plugs placed closer to a circu-

lating hot water main can prevent plug formation

or can cause plug thawing.

4. Prepare the freeze plug locations. Remove all insulation and coatings from the pipe down to bare metal. If

needed, remove any corrosion with a wire brush.

Coatings and corrosion insulate the pipe and can

slow or prevent the freezing process.

5. Place the unit so that freeze heads can reach desired

plug points. Locate SuperFreeze on a solid, level surface, in an upright position. If the unit is not upright and

level, it can cause damage to the compressor. Make

sure the air inlet/outlet to condenser are not blocked.

Blocked condenser openings will slow or prevent the

freezing process. Be sure to locate the pipe freezing

unit away from where the repair will occur and not

under the freeze heads. This will help prevent the

entry of water into the freezing unit and help prevent

electrical shock.

6. Uncoil the hoses to the freeze heads. Use care not to

twist or kink the hoses, this can damage the hose

and prevent proper operation.

7. Choose the appropriate freeze head cavity for the

size of pipe or tube to be frozen. The capacities for

copper tube and steel pipe are listed in the chart that

follows. Adapter bushings are required in some applications. If using on pipe or tube other than listed

sizes, the pipe/tube diameter cannot be smaller than

the freeze head/bushing diameter -1/8" (3.2 mm).

8. Apply freeze gel to the freeze head cavity. If using end

adapter or bushings, apply freeze gel between the

freeze head and the adapter and to the adapter surface that contacts the pipe. The freeze gel improves

Capacities for Copper Tube and Steel Pipe

Model Freeze Head Copper Tube (DN)* Steel Pipe Cavity End Adapter

22 mm

1

/2" (15 mm) — Cat. #68837

28 mm

3

/4" (20 mm) — Cat. #72427

35 mm 1" (25 mm) 4 —

42 mm 1

1

/4" (32 mm) 2 —

1

1

/2" (40 mm) 1 —

2" (50 mm) 3 —

1

4

3

2

SF-2500,

230V European Model

(68832)

* See Specifications

* See Specifications

SF-2500,

115V Domestic (68967)

and 230V Domestic

Export (68962)

Forming a single freeze plug with freeze heads

positioned opposite to each other and using freeze

gel and quick grip clamp is the preferred method

for use on more difficult applications (higher temperatures, larger pipe sizes, etc.). If two freeze

plugs are required in a difficult application, it may

be necessary to use two pipe freezing units, one

for each plug.

• Two freeze plug applications – When two separate

freeze plugs are required to isolate a section of the

system, one freeze head is attached at each point

(Figure 6)

. Tightly secure the freeze heads to the

pipe with either Quick Grip clamp or Velcro straps.

If using the Quick Grip clamp do not over tighten

the clamp and deform the pipe.

Figure 6 – Two Freeze Plug Application

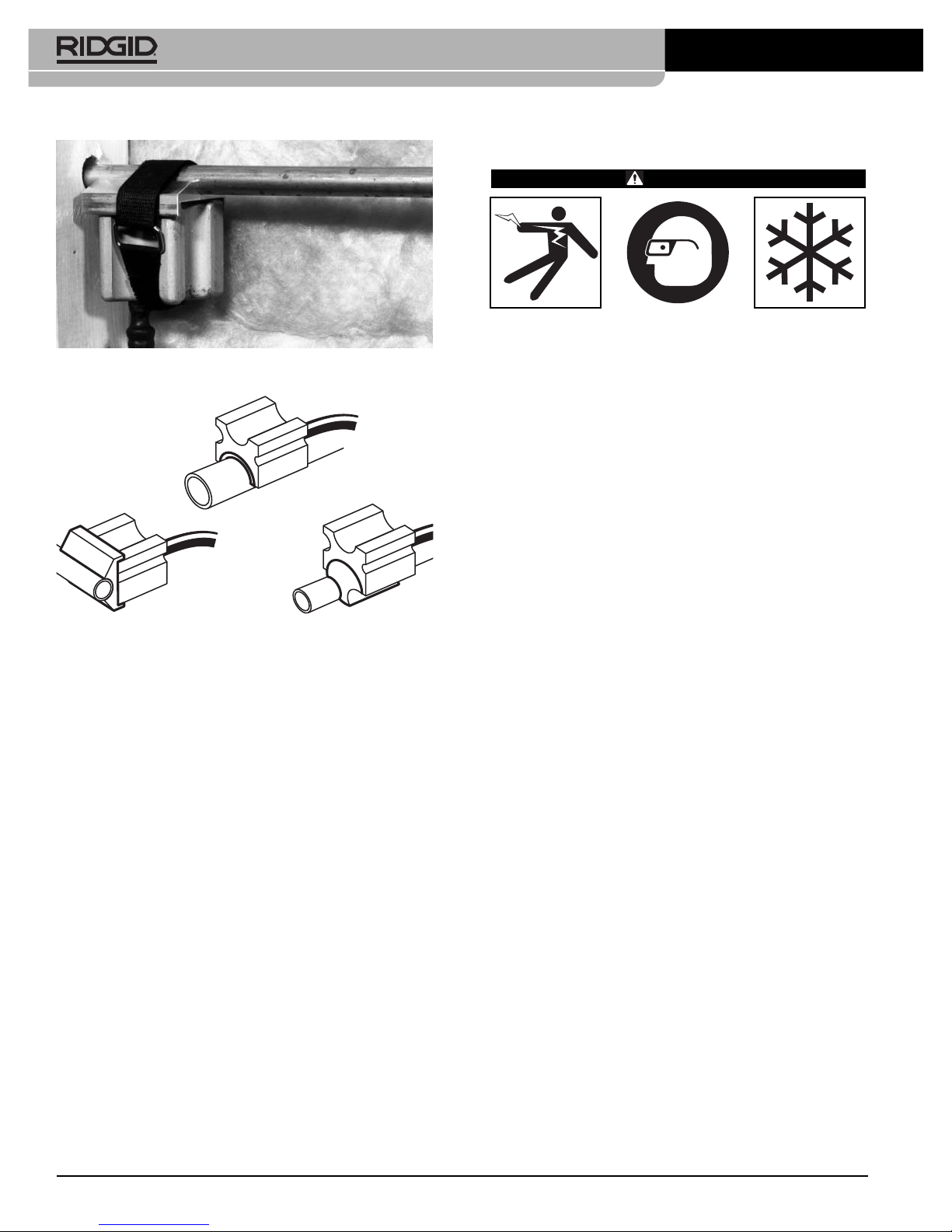

• If the standard freeze head cannot be used, adap ters are available. Freeze gel (if being used) is

applied to the back of the adapter and to the surface that contacts the tube. Tightly secure the

freeze heads to the tube with either the Quick

Grip clamp or the Velcro straps. If using the Quick

Grip clamp do not over tighten the clamp and

deform the tube.

See Figure 7.

7

SuperFreeze®Pipe Freezing Units

the thermal conductivity between the freeze head

and the pipe and decreases the time required to

freeze a plug. If no freeze gel is available, use the

spray bottle to spray water generously before and

during the pipe freezing process.

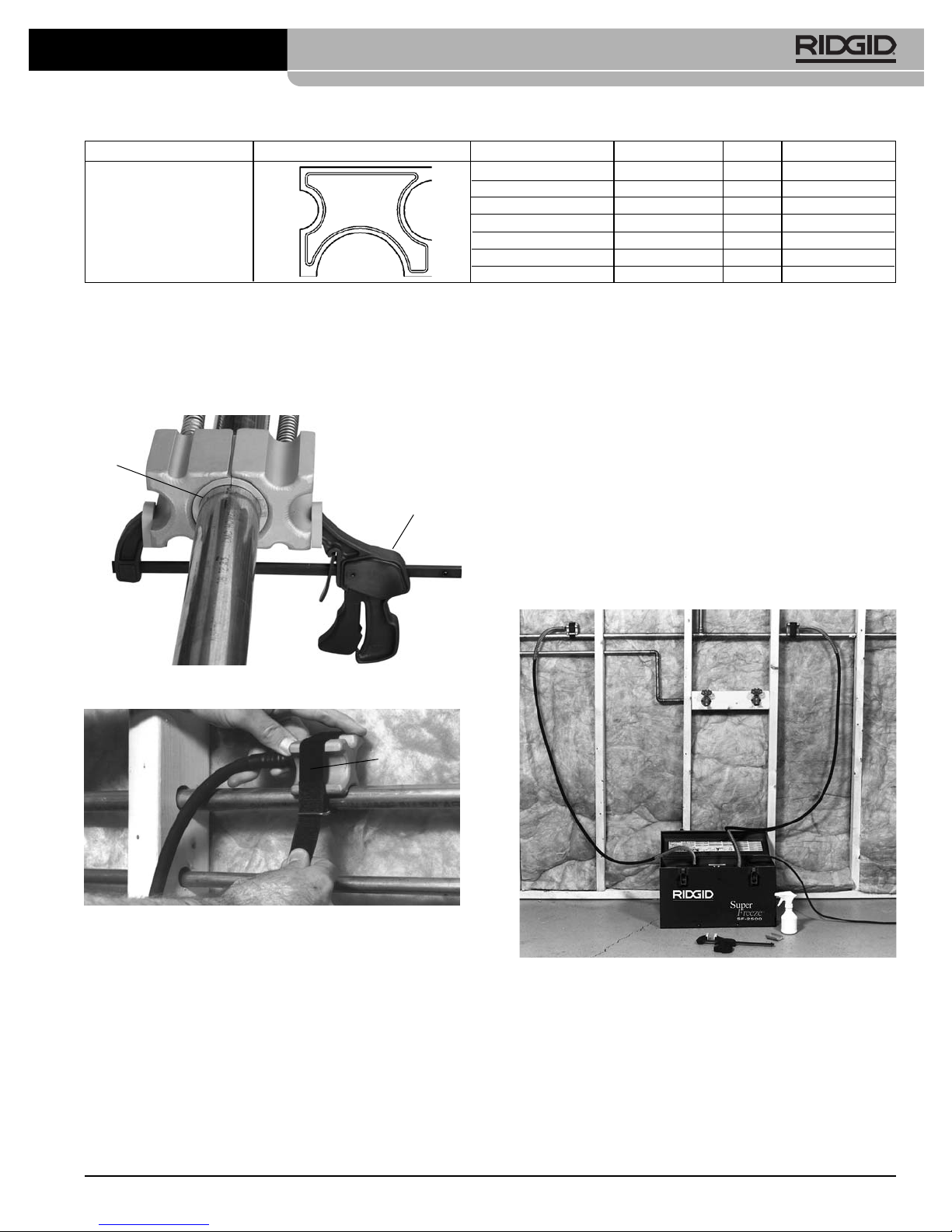

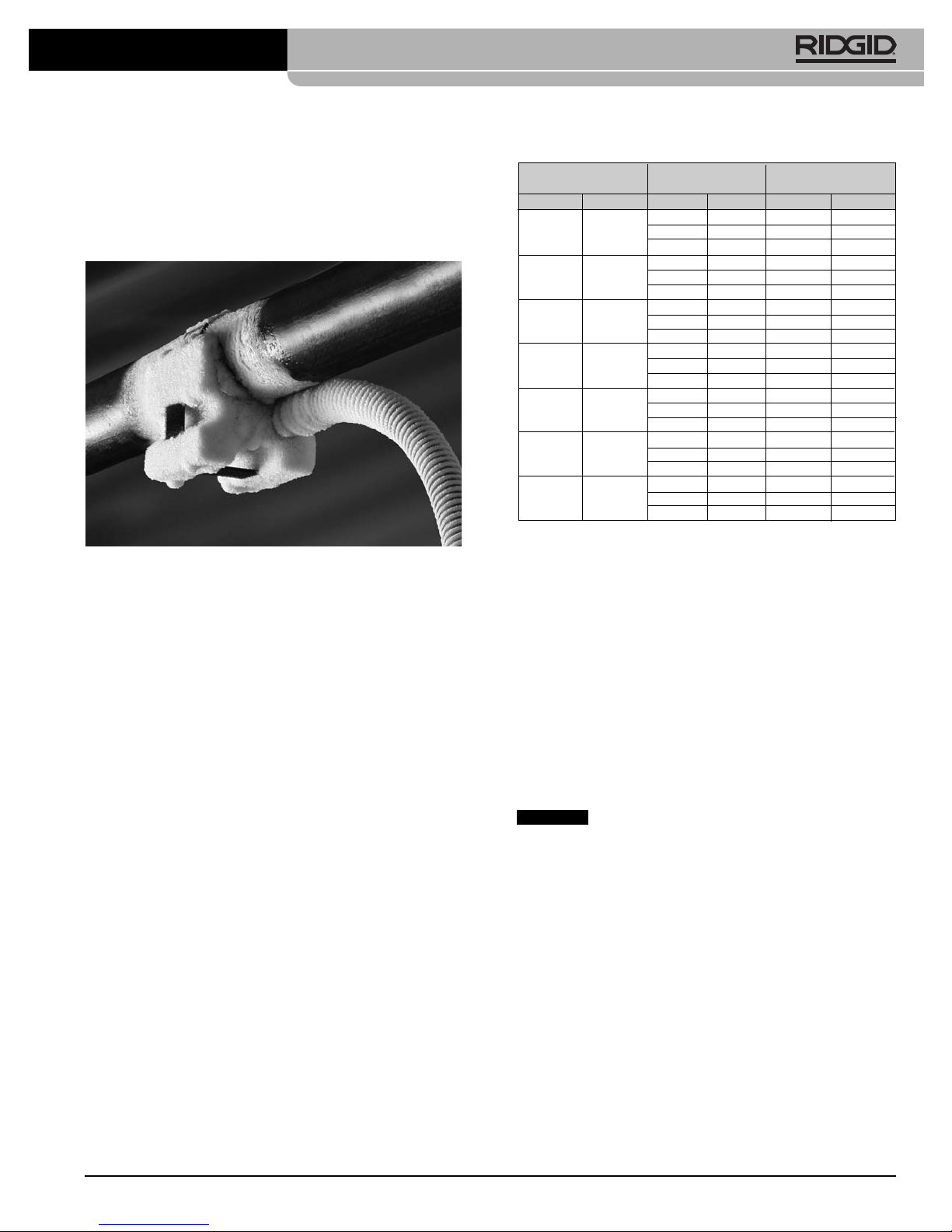

Figure 4 – Attaching Freeze Heads Using Quick Grip

Clamp

Figure 5 – Applying Freeze Head with Velcro Strap

9. Attach the freeze heads to the pipe.

• Single freeze plug applications – In single freeze

plug applications, both freeze heads should be

applied opposite each other to form the plug. This

will decrease the time required to freeze the plug.

Use the Quick Grip clamp

(Figure 4)

or Velcro

Strap

(Figure 5)

to secure the freeze heads to the

pipe. If using the Quick Grip clamp do not over

tighten the clamp and deform the pipe.

Model Freeze Head Copper Tube (DN)#Steel Pipe Cavity Req’d Bushing

12 mm — 1 42838

15 mm — 1 42853

18 mm — 1 —

22 mm

1

/2" (15 mm) 3 42843

28 mm

3

/4" (20 mm) 3 —

35 mm 1" (25 mm) 2 42833

42 mm 1

1

/4" (32 mm) 2 —

3

2

1

SF-2300,

230V European Model

(41078)

Bushings

Quick Grip

Clamp

Velcro Strap

* See Specifications

8

SuperFreezer®Pipe Freezing Units

Figure 7 – Freeze Head with End Adapter Attached with

Velcro Strap

Figure 8 – Freeze Heads with Various Adapters

10. Run cord along previously identified clear path. With

dry hands, plug the SuperFreeze into the previously

identified properly grounded outlet. If the power cord

is not long enough, use an extension cord that

• Is in good condition.

• Has a three prong plug similar to that supplied

on the Pipe Freezing Unit.

• Is rated for outdoor use and contains a W or W-A

in the cord designation (i.e. SOW), or complies with

H05VV-F, H05RN-F types or IEC type design

(60227 IEC 53, 60245 IEC 57).

• Has sufficient wire size (16 AWG (1.5 mm

2

) for 50'

(15.2 m) or less, 14 AWG (2.5 mm2) for 50' – 100'

(15.2 m – 30.5 m) long). Undersized wires can

overheat, melting the insulation or causing a fire or

other damage.

Operating Instructions

WARNING

Before opening system, test to confirm that the ice

plugs are fully formed and stable. Opening the piping

system before a complete plug is frozen or allowing

the plug to thaw while the system is open could

cause burns, electric shock or other serious injury or

result in flooding or other property damage. Make

sure the machine is properly set up and do not allow

the Pipe Freezing Unit to shut OFF during use.

The freeze heads and hoses get extremely cold

and can cause frostbite if touched during operation.

Wear gloves if handling during use.

Always wear eye protection to protect your eyes

from dirt and other foreign objects. Always wear

appropriate protective equipment for the piping

contents.

Follow operating instructions to reduce the risk of

injury from burns, frostbite, electrical shock and

other causes.

1. Make sure that machine and work area is properly set

up and that the work area is free of bystanders and

other distractions.

2. Turn the machine ON.

3. Allow the machine to run for 2-3 minutes. Freeze

heads should start to frost. Use spray bottle to spray

water between freeze heads and pipe. The water

will freeze and fill any gaps between the freeze head,

pipe and any adapters used. This improves thermal

conductivity and will improve freeze times, while gaps

between the freeze head and pipe will prevent freeze

plug formation. Make sure that any dripping water

does not cause a hazard. If freeze gel was used,

then water spray may not be necessary.

If the freeze heads do not become cold and covered with ice and frost after approximately 7 minutes, turn the unit OFF for 3 minutes and restart. If the

freeze heads still do not become cold, see the

“Troubleshooting”

section.

4. Once the freeze heads are frozen to the pipe, allow

the ice plug to form. If the ambient temperature is

high, but not above 100°F (38°C), the freeze heads

can be wrapped with pipe insulation or other insulation

to improve freeze times.

9

SuperFreeze®Pipe Freezing Units

Do not leave the unit unattended. Pipes can freeze

and split during the freezing process and monitoring

can minimize the hazard and damage. If for some reason the power to the freezing unit is interrupted, turn

the ON/OFF switch to OFF and do not restart for at

least 30 seconds to prevent compressor damage.

Figure 9 – Freeze Head Frozen to Pipe

Time to freeze a fully formed ice plug depends on a

variety of factors, including water temperature, ambient temperature, distance from heat sources, pipe size

and wall thickness, pipe material, number of freeze

heads, quality of contact between freeze heads and

pipe, and other conditions. The following table of

freeze times is based on water temperature being the

same as ambient temperature, use on copper tube,

use of freeze gel and use of two freeze heads. Freeze

times for steel pipe will be longer. Freeze times for

other less optimal conditions may be double those

shown or greater. Freeze times are only provided

as a general guide.

5. Carefully test the system to make sure that the plugs

are complete and there is no flow before opening

the system. This can be done by opening a valve

downstream of the plug and verifying that there is no

flow. Another method is to use a saddle tap valve

(similar to those used to install icemakers) to pierce a

copper tube and check for water flow. If there is flow,

close the system and continue the freezing process.

Wait at least five more minutes after confirmation that

there is no water flow to proceed with opening the

system for work. On high temperature applications,

water temperature over 90°F (32°C) but below 100°F

(38°C), wait at least 15 minutes. Do not shut OFF the

freezing unit.

6. Once the ice plug has been completely formed and

enough time has passed since confirmation that there

is no flow in the pipe, the pipe can be opened. When

opening the system, be prepared for the possibility of

liquid coming out of the line and wear proper protective equipment in case a plug fails. Be sure to follow

the guidelines in the set up section for distance from

plug to heating of system for soldering, brazing, etc.

Do not shut OFF the freezing unit while making

repairs. This will help insure that the plug does not

melt while the system is open.

7. When the repair is complete and system is closed,

shut OFF and unplug pipe freezing unit, and allow ice

and frost to melt off the freeze heads and hoses.

Do not try to remove the freeze heads from

the pipe or coil the hoses until they are completely

thawed. This can result in damage to the hoses and

freeze heads. If freeze heads and hoses must be

removed more quickly, a heat gun can be used to thaw

them.

Cleaning

After each use, clean the freeze heads with a soft cloth.

Clean the condenser fan grilles to remove dirt. Wipe

frost/water from the fully thawed freeze heads and hoses.

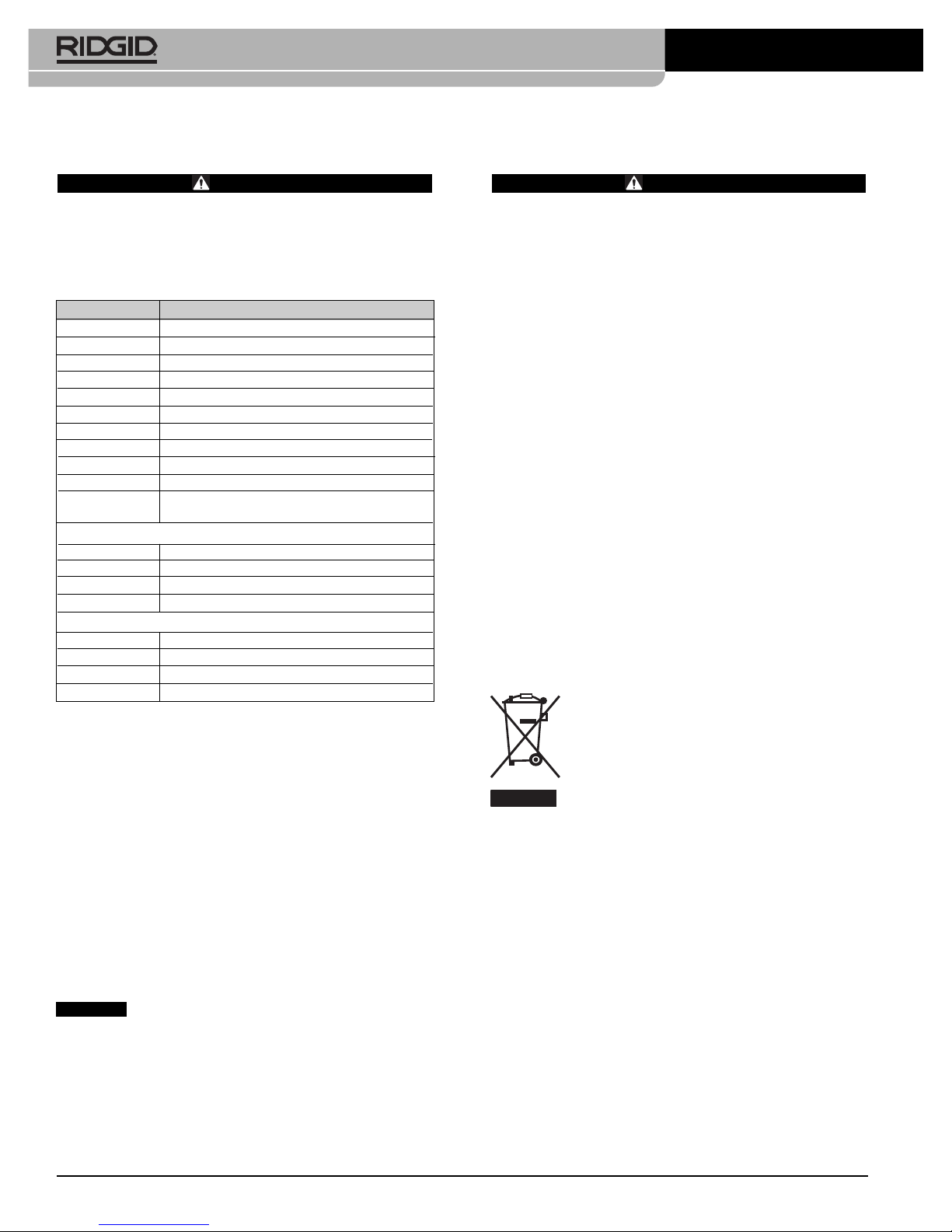

Freezing Times

Nominal Copper Ambient/Water Approx. Freezing Times

Tube Diameter Temperature (Minutes)

CTS Inches DN mm °F °C SF-2500 SF-2300

70 21 6 5

1

/

2

15 80 26 8 6

90 32 10 8

70 21 8 6

3

/

4

22 80 26 10 8

90 32 13 10

70 21 10 10

12880261312

90 32 16 15

70 21 12 NA

11/

4

35 80 26 15 NA

90 32 19 NA

70 21 19 21

11/

2

42 80 26 22 26

90 32 28 42

70 21 23 NA

254802625NA

90 32 28 NA

70 21 40 NA

21/

2

80 26 51 NA

90 32 55 NA

NOTICE

10

SuperFreezer®Pipe Freezing Units

Accessories

WARNING

To reduce the risk of serious injury, only use accessories specifically designed and recommended for

use with the SuperFreeze Pipe Freezing Units such

as those listed below. Other Accessories suitable

for use with other tools may be hazardous when

used with the Pipe Freezing Units.

Further information on accessories specific to the tool

can be found in the RIDGID Catalog and online at

www.RIDGID.com or www.RIDGID.eu.

Machine Storage

The RIDGID SuperFreeze Pipe Freezing Units must be

stored in a dry secure, locked area, out of the reach of children and people unfamiliar with the Units.

Wipe frost/water from the fully thawed freeze heads and

lines. Coil the hose in the adjacent compartment. Do not

cross the hoses. The aluminum freeze heads should be

protected from impact, sharp objects and rough handling.

Do not store the pipe freezing unit in a vehicle. Excessive vibration and shock can damage the

unit. Firmly secure the unit when transporting.

Service and Repair

WARNING

Improper service or repair can make the SuperFreeze

Pipe Freezing Units unsafe to operate.

RIDGID SuperFreeze Pipe Freezing units contain refrigerant which requires certified service people. Service

and repair of the SuperFreeze Pipe Freezing Units must

be performed by a RIDGID Independent Authorized

Service Center.

For information on your nearest RIDGID®Independent

Service Center or any service or repair questions:

• Contact your local RIDGID distributor.

• Visit www.RIDGID.com or www.RIDGID.eu to find

your local RIDGID contact point.

• Contact Ridge Tool Technical Service Department at

rtctechservices@emerson.com or in the U.S. and

Canada call (800) 519-3456

Disposal

Parts of the RIDGID SuperFreeze Pipe Freezing Units

contain valuable materials and can be recycled. There are

companies that specialize in recycling that may be found

locally. Dispose of the components in compliance with all

applicable regulations. Contact your local waste management authority for more information.

For EC Countries: Do not dispose of electrical equipment with household waste!

According to the European Guideline 2002/ 96/ EC for Waste Electrical and Electronic

Equipment and its implemen tation into nation-

al legislation, electrical equipment that is no

longer usable must be collected separately and disposed

of in an environmentally correct manner.

NOTICE

Catalog No. Description

For SF-2500:

69712 SF-2500R

3

/4" CTS Bushings (set of 2)

70652 SF-2500R 1

1

/4" CTS Bushings (set of 2)

69717 SF-2500R 2" CTS Bushings (set of 2)

68857 SF-2500R

1

/2" End Adapters (set of 2)

68862 SF-2500R

3

/4" CTS End Adapters (set of 2)

68837 SF-2500R 22 mm End Adapters (set of 2)

72427 SF-2500R 28 mm End Adapters (set of 2)

72422 Set of 2 End Adapters

3

/4" Fe (28 mm)

66986 Set of 2 End Adapters 12 mm to 16 mm

65976 Set of 2 End Adapters

3

/8" Fe (18 mm),

1

/2" Fe (22 mm)

For SF-2300:

42838 12mm Bushings (set of 2)

42853 15mm Bushings (set of 2)

42843 22mm Bushings (set of 2)

42833 35mm Bushings (set of 2)

For SF-2500 and SF-2300:

65942 Quick Grip Clamp

69707 Velcro Straps (set of 2)

74946 RIDGID Freeze Gel

60776 Spray Bottle, 8 oz. (0.25 liter)

11

SuperFreeze®Pipe Freezing Units

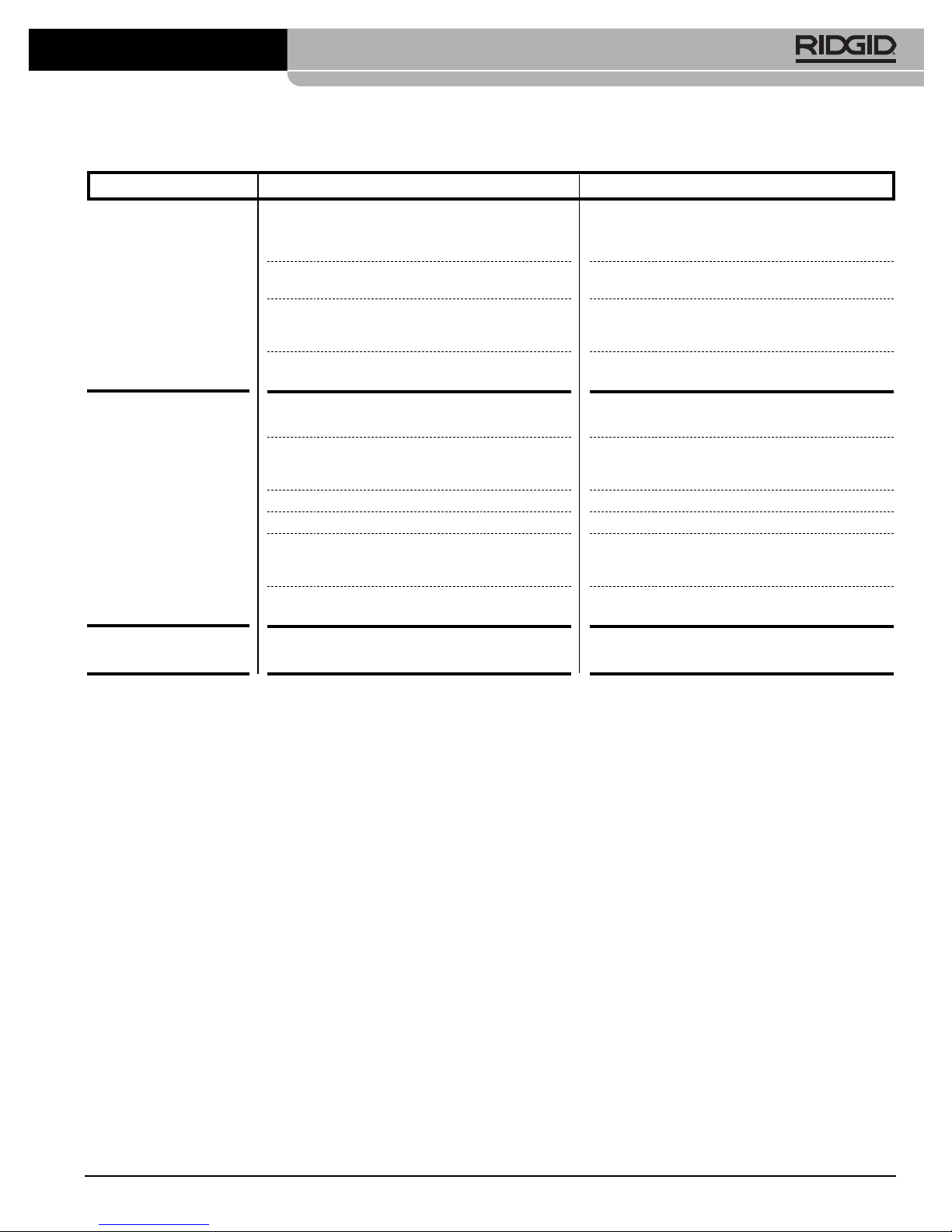

PROBLEM POSSIBLE REASONS SOLUTION

Freeze heads do not become frost-covered after

7 minutes.

The freeze heads get

cold and frost covered

but the pipe will not

freeze.

Tripping of the unit.

Troubleshooting

Unit has been stored in a cold location; unit has

not been used for long time.

No power supply.

No air circulation to the condenser unit.

Pipe Freezing unit has lost its charge.

Water flow in the pipe.

Poor contact between heads and pipe.

Pipe is not completely full of water.

System is filled with something other than water.

Water temperature is too high.

Air temperature is too high.

Overloading of the compressor.

If freeze heads are not cold and frost-covered

after 7 minutes, turn the unit OFF. Keep the unit

OFF for 3 minutes, and then restart.

Make sure of proper power supply without any interruption & compressor fan running.

Check that there is unrestricted air circulation to

the condenser unit. Check the condenser unit’s

inlet air ports and clean.

Contact Technical Service Department at Ridge

Tool

(see Service and Repair)

.

Check for water flow. If this exists, stop the flow.

Use the water spray bottle or freeze gel to build

an ice bridge and provide the contact for heat

transfer. The slightest air gap will prevent freezing

Make sure system is full of water.

Pipe freezing unit will not work.

Allow the system to cool off or freeze heads are

too close to circulating main, stop flow in circulating main.

After freeze head is frozen to pipe, wrap with insulation.

The compressor is thermally protected; it will take

time for automatic restart.

Loading...

Loading...