RIDGID SP-330, SP-500, SP-330D, SSP-1000 Operator's Manual

SP-330

Submersible

SP-330D

Sump Pump

SP-500

SSP-1000

OPERATOR’S

MANUAL

• Pour français voire page 11

• Para ver el castellano vea

la paginá 21

W ARNING!

Read this operators Manual

carefully before using this

tool. Failure to understand

and follow the contents of

this manual may result in

electrical shock, fire and/or

serious personal injury.

SP-330, SP-330D, SP-500, SSP-1000 Submersible Sump Pumps

Table of Contents

Recording Form for Pump Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

General Safety Information

Work Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Personal Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specific Safety Information

Submersible Pump Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Description and Specifications

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Performance Curve and Performance Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Pump Installation

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Suggested Part Replacement Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Service and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Lifetime Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

ii

Ridge Tool Company

SP-330, SP-330D,

SP-500, & SSP-1000

Submersible Sump Pumps

SP-330, SP-330D, SP-500, and SSP-1000 Submersible Sump Pumps

Record Serial Number From Product Decal Below

Serial

No.

351411-005 1/10

SP-330, SP-330D, SP-500, SSP-1000 Submersible Sump Pumps

General Safety Information

Safety is a combination of common sense, staying alert

and understanding how your sump pump works.

Safety Signal Words

means if the safety information is not

followed someone will be seriously

injured or killed.

means if safety information is not

followed someone could be

seriously injured or killed.

means if safety information is not

followed someone may be injured.

indicates important information, that

if not followed, may cause damage

to the equipment or fl ooding.

Read and understand all

instructions. Failure to follow all

instructions listed below may result in fatal electric

shock, fi re, property damage, and/or serious

personal injury.

SAVE THESE INSTRUCTIONS!

Work Area

• Do not operate pump in explosive atmospheres,

such as in the presence of flammable liquids,

gases, or dust. Pump motors create sparks

which may ignite the dust or fumes.

• Do not abuse cord. Never use the cord to carry

the pump or pull the plug from an outlet. Keep

cord away fr om heat, oil, sharp edges, or moving

parts. Replace damaged cords immediately.

Damaged cords increase the risk of electrical

shock.

• Pump must be plugged into an outlet receptacle

that includes a Ground Fault Circuit Interrupter

(GFCI). In the event of current leakage, a GFCI will

trip, thus reducing the risk of serious injury or death

from electrical shock.

Grounded

Grounding

Blade

Power

Cord

Outlet

TEST

RESET

Figure 1

• Before using, test the Ground Fault Circuit

Interrupter (GFCI) to insure it is operating

correctly. A GFCI reduces the risk of electrical

shock.

• Do not use an extension cord. This increases

the risk of electrical shock. If necessary, install a

properly grounded outlet closer to the pump.

Personal Safety

• Keep by-standers, children, and visitors away

while installing pump. Distractions can result in

mistakes.

Electrical Safety

• This pump must be plugged into

an outlet, properly installed, and grounded

in accordance with all applicable codes and

ordinances. Never remove the grounding prong

or modify the plug in any way. Do not use any

adapter plugs. Check with a qualified electrician

if you are not sure the outlet is grounded. If

the pump should electrically malfunction or break

down, grounding provides a low resistance path to

carry electricity away from the user.

• Electrical wiring must be performed by a

qualified electrician. Improper wiring could result

in fatal electrical shock.

2

• Stay alert, watch what you are doing, and use

common sense when installing this pump. Do

not attempt to install this pump while tired

or under the influence of drugs, alcohol or

medications. A moment of inattention may result

in serious personal injury.

• Dress properly. Do not wear loose clothing

or jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts.

Loose clothes, jewelry, or long hair can be caught

in moving parts.

• Do not overreach. Keep proper footing and

balance at all times. Proper footing and balance

enables better control in unexpected situations.

• Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety shoes and

hard hat must be used for appropriate conditions.

Ridge Tool Company

SP-330, SP-330D, SP-500, SSP-1000 Submersible Sump Pumps

Service

• The motor is oil filled and sealed for cooler

running. Allow 2 hours for the motor to cool

before servicing. Hot oil is under pressure and

could result in severe burns.

• Pump service must be performed only by

qualified repair personnel. Service or maintenance

performed by unqualified repair personnel could

result in injury and may void the warranty.

• When servicing a pump, use only identical

replacement parts. Follow instructions in the

Maintenance Section of this manual. Use of

unauthorized parts or failure to follow maintenance

instructions may create a risk of electrical shock or

injury.

NOTE! Disassembly of the motor will void warranty.

Specifi c Safety Information

Risk of electric shock. This

pump is supplied with a grounding-type plug. To

reduce risk of electric shock be certain that it is

connected only to a properly grounded, groundingtype receptacle that is protected by a GFCI.

For your own safety, before assembling and operating

this unit, read this operators manual carefully and

completely. Learn the operation, application, and

potential hazards peculiar to this unit.

Call the Ridge Tool Company, Technical Services

Department at 1-877-9RIDGID if you have any questions.

is in the basement, call an electrician. Failure

to follow this warning could result in fatal electrical

shock.

• Always disconnect the power source before

attempting to install, service, relocate, or maintain the pump. Never handle a pump or pump

motor with wet hands or when standing on wet

or damp surface or in water. Failure to follow

this warning could result in personal injury and/or

death.

• Pump motor is equipped with automatic reset-

ting thermal protector that could restart unexpectedly. Disconnect power source when servicing

pump.

• Do not modify float or position float switch

so that pump will operate continuously. Pump

is not designed for continuous operation, this will

reduce performance and life of the pump.

• Do not hang pump by handle for permanent

installation. This minimizes twisting which can

lead to damage during pump operations.

Description and Specifi cations

Description

The submersible pump is designed for home sump

operations only. The unit is equipped with an 8 foot,

3-prong grounding type power cord. The motor has an

automatic reset thermal protector to prevent burnouts

due to overloading or clogging. The pump is designed

to automatically maintain water level between factory

preset points.

The SSP-1000 is provided with a solid-state electronic

water level control. When water is detected, the pump

will start automatically.

The sensor is designed to run the pump a minimum of

4 seconds and a maximum of 16 seconds.

Submersible Pump Safety

• Do not use to pump flammable or

explosive fluids such as gasoline, fuel oil, kerosene, solvents, thinners etc. Do not use in a

flammable and/or explosive atmosphere. Pump

should only be used to pump clear water . Improper

use could result in personal injury and/or death.

• If there is water or moisture on the floor or

ground near the pump, do not walk on wet area

until all power is turned off. If the shut-off box

salt water, brine, laundry discharge, or any other

application which may contain caustic chemicals and/

or foreign materials. This pump is not suitable for use

with aquatic life. Pump damage or failure could occur

if used in these applications and will void the warranty.

Do not use for sewage or effl uent applications.

a battery back-up system be used. Power outages,

excessive w ater fl ow, G.F.C.I. tripping and primary pump

wear can cause fl ooding. A battery back-up system

reduces this risk. Contact your Ridge Tool distributor.

Ridge Tool Company

This pump is not designed to handle

It is strongly recommended that

3

SP-330, SP-330D, SP-500, SSP-1000 Submersible Sump Pumps

Specifi cations

Motor:

Type . . . . . . . . . . . . . . . . . . . 1/3 HP & 1/2 HP

Shaded Pole

1HP Split Phase

Rating . . . . . . . . . . . . . . . . . . 120V, Single Phase

1/3 HP, 9.5 Amps

1/2 HP, 10 Amps

1HP, 9.8 Amps

Pump

1/3 HP . . . . . . . . . . . . . . . . . 3100 GPH @ 0 Ft.

1/2 HP . . . . . . . . . . . . . . . . . 4400 GPH @ 0 Ft.

1HP . . . . . . . . . . . . . . . . . . . 5400 GPH @ 0 Ft.

Liquid temperature range . . .40F to 120F

Model Cut-in Cut-out

SP-330 & SP-500 9 inches 4 inches

SP-330D 10-13 inches 4-7 inches

SP-1000 7 inches 3 inches

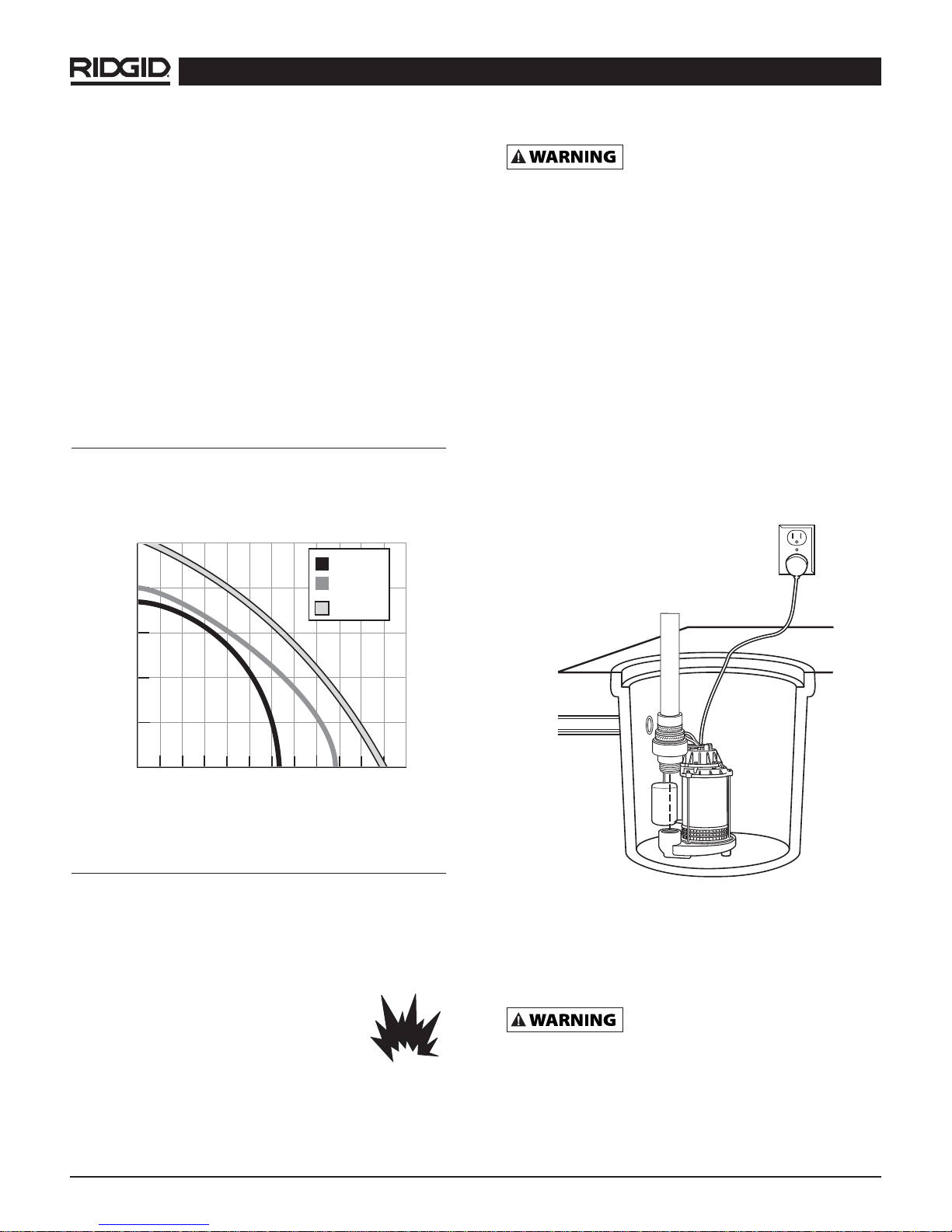

Performance Curve

25

SP-300

SP-300D

20

15

SP-500

SSP-1000

To prevent property damage,

serious injury, or death, proper installation of

the pump is required. The following procedures

should be followed:

• Pump must be plugged into an outlet receptacle

that includes a Ground Fault Circuit Interrupter

(GFCI) (Figure 1).

• Always disconnect the power source before

attempting to install, service, relocate, or maintain the pump. Never handle a pump or pump

motor with wet hands or when standing on wet

or damp surface or in water.

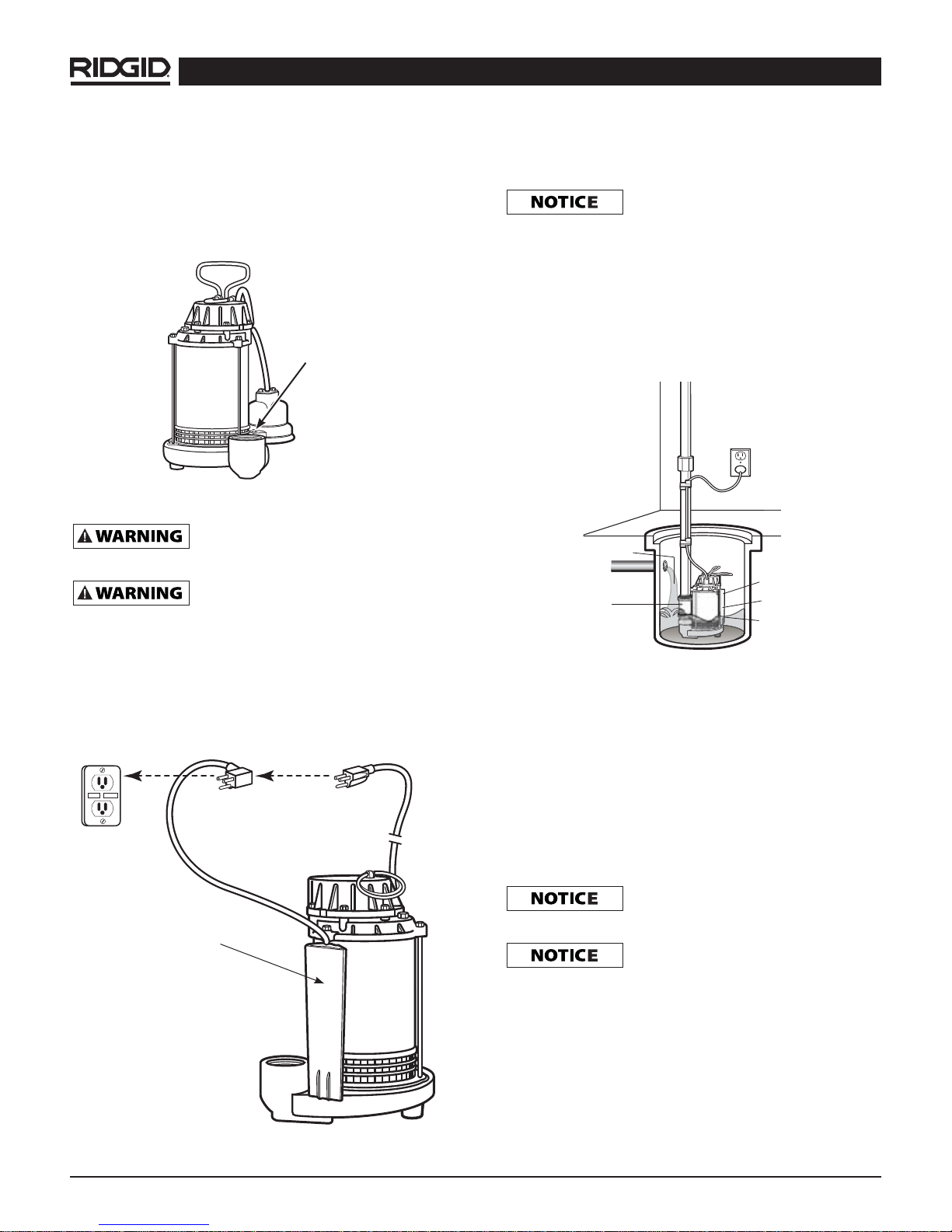

Installation

1. Construct a sump pit from concrete, steel, or

plastic that is at least 24" deep and at least 11"

in diameter (Figure 2). If the sump already exists,

make sure it is the proper size.

10

Discharge (Feet)

5

0

1000 2000 3000 4000 5000 6000

Gallons Per Hour

Performance Chart

Discharge Head 0' 5' 10' 15'

SP-330 Gallons/Hour 3100 3000 2700 1680

SP-330D Gallons/Hour 3100 3000 2700 1680

SP-500 Gallons/Hour 4400 4100 3200 2000

SSP-1000 Gallons/Hour 5400 4860 4200 3360

Pump Installation

• Pump should only be used to pump

clear water. Do not use to pump

fluids such as gasoline, fuel oil,

or kerosene. Do not use in a flammable or explosive atmosphere. Improper use

could result in personal injury and/or death.

Figure 2 – Submersible Pump Installation

2. Make sure the electrical outlet is grounded and

is rated for 115 volts and at least 15 amps. The

outlet must be protected by a Ground Fault Circuit

Interrupter (GFCI).

Use of a grounded receptacle that

is protected by a GFCI reduces risk of a fatal electrical

shock.

3. Inspect the power cord and plug for damage. If the

plug is missing the grounding prong or the cord is

damaged, do not install the pump until the cord

has been replaced.

4

Ridge Tool Company

SP-330, SP-330D, SP-500, SSP-1000 Submersible Sump Pumps

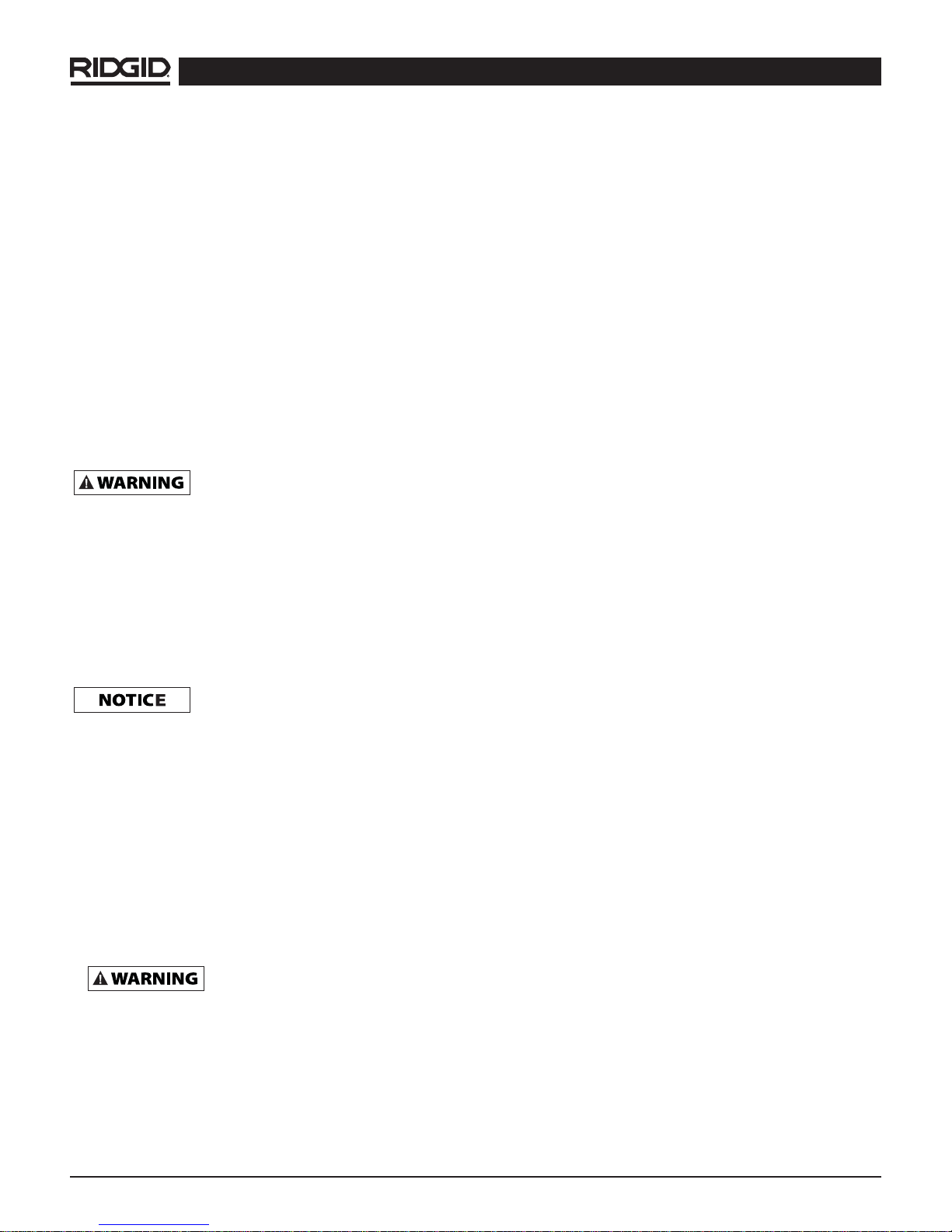

(SP-330D Diaphragm Switch Only)

4. Remove the two fasteners in the cast iron volute

near the discharge area. Align the hole with the

diaphragm switch and replace the fasteners without over tightening (Figure 3).

Attach switch

with screws (2)

provided

Figure 3 – Diaphragm Switch

Never cut off grounding prong or

use an adapter.

Support pump and piping when

assembling and after installation. Failure to do so

could cause piping to break or pump to fail, which

could result in property damage and/or personal injury.

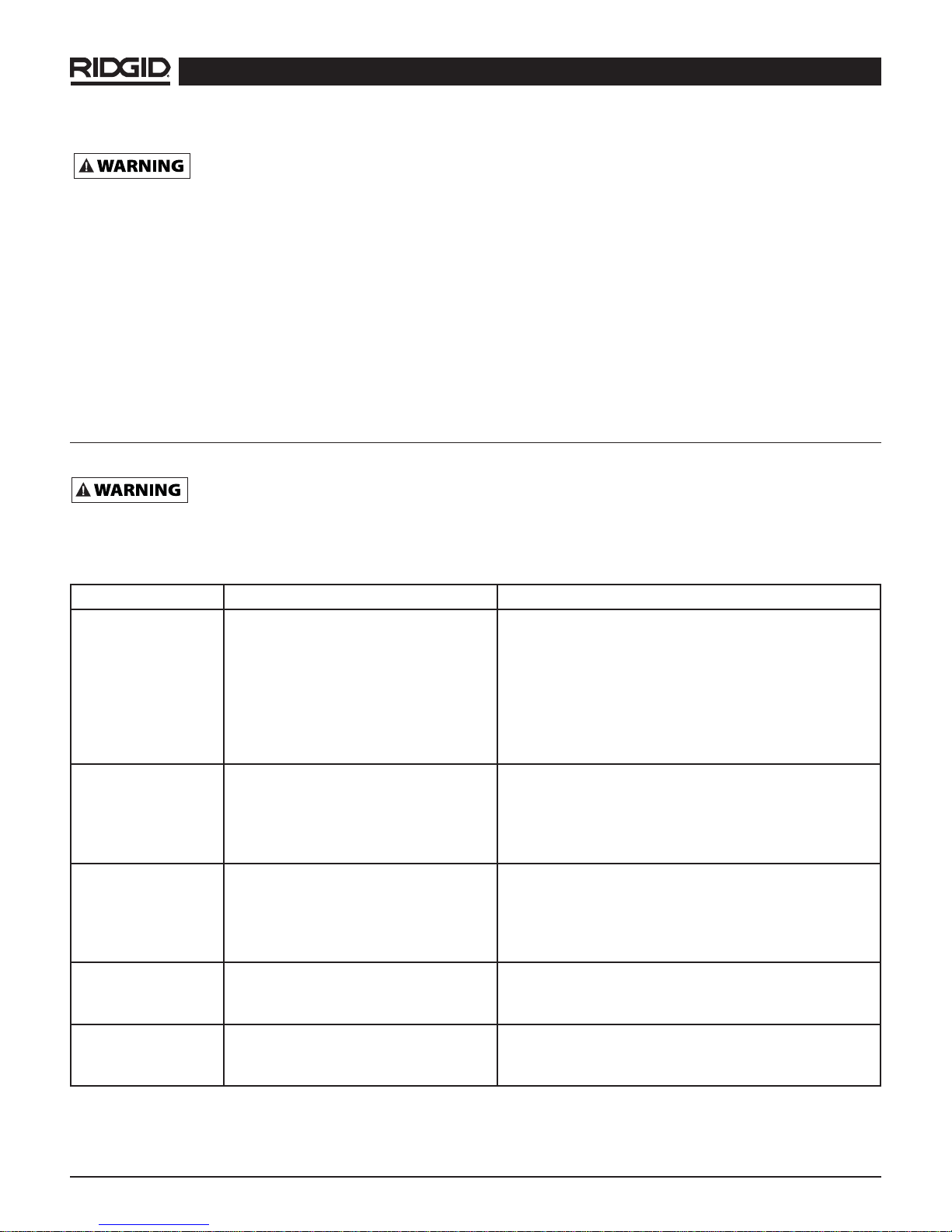

(SSP-1000 Solid-State Water Sensor only)

5. Insert the pump power cord plug directly into the

back of the Solid-State Water Sensor cord plug

(Figure 4).

RESET

TEST

6. Set pump into sump. Locate the pump on a solid

level surface.

Do not place directly on clay, gravel,

or any loose or sandy surfaces. These surfaces

contain small stones or sand that may clog or damage

the pump, which could result in pump failure causing

fl ooding and property damage.

(SSP-1000 Solid-State Water Sensor only)

• Position pump switch away from the inlet so the

switch is clear from incoming water. (See Figure 5)

DISCHARGE PIPE

GFCI PROTECTED

OUTLET

INCOMING

WATER

INLET PIPE

CHECK VALVE

@

ON

8”

SWITCH

OFF @

APPROX. 3”

Figure 5 – Inlet water fl ow

7. This pump has a 1-1/2" NPT discharge. If existing piping is 1-1/4" NPT, an adapter bushing (not

included) may be used. Do not use piping that is

less than 1-1/4" NPT. Piping that is too small will

result in reduced output.

8. A check valve is required in the discharge line to

prevent bac k-flow when the pump shuts off . It is best

to install the check-valve directly to the pump discharge. Thread a check valve into pump discharge.

Working surface of sensor to be kept free of

foreign material.

This will keep the pump

from cycling too often

Figure 4 – Solid-State Water Sensor

thread. Do not use pipe joint sealant.

temporary use only . Rigid PVC or metal pipe is required

for a permanent installation. If fl exible discharge hose is

temporarily used, make sure pump is secured in sump

pit to prevent mo v ement. Failure to secure pump could

allow pump movement and cause s witch interference

and prevent pump from starting or stopping. This could

result in fl ooding and property damage.

Ridge Tool Company

Be careful not to strip or cross-

Flexible discharge hose is intended f or

5

SP-330, SP-330D, SP-500, SSP-1000 Submersible Sump Pumps

IMPORTANT! Make sure there is adequate room

for fl oat switch to move freely during operation. A

1" minimum is required. Do not allow water infl ow

to affect fl oat.

9. Connect 1-1/4" diameter rigid pipe to rubber boot

on check valve (not included). Reverse boot for

1-1/2" diameter pipe. Tighten clamps.

10. For SP-330 and SP-500 pumps:

Insert the pump cord plug directly into a GFCI protected 115 volt grounded outlet (see Figure 1).

For SP-330D and SSP-1000 pumps:

Insert the switch cord plug into a GFCI protected

115 volt grounded outlet. Insert the pump cord

plug directly into the back of the switch cord plug

(see Figure 4).

When routing electrical cord protect cord from sharp objects, hot surfaces, oils,

and chemicals. Do not kink or tightly clamp cord;

replace any damaged cord immediately.

Testing

1. Fill sump pit with water.

2. While the pump is draining the pit, verify that the

discharge piping is carrying the water to a point at

least 15 feet away from the foundation.

The outside piping must be tilted

downward to drain. This helps prevent debris from

entering the discharge pipe, and also prevents trapped

water from freezing which can damage the pump.

3. Install sump pit cover (not included) to prevent

debris from clogging or damaging the pump.

(SSP-1000 Solid State Water Sensor only)

Sensor is designed to run the pump a minimum

of 4 seconds. If water is removed in less time, a

gurgling sound will be generated as air is ingested

into the pump. This will not damage the pump.

Maintenance Instructions

• The motor is oil filled and sealed for cooler

running. Allow 2 hour s for motor to cool before

servicing. Hot oil under pressure could result

in severe burns.

1. Check the operation of the Ground Fault Circuit

Interrupter (GFCI) on a monthly basis.

2. Keep pump inlet clean and free of all foreign

objects. Inspect at least once a year and clean

sump as needed.

3. Check pump for proper operation monthly by filling

sump with water until pump turns on.

4. Inspect all plumbing connections for any leaks or

looseness monthly.

(SSP-1000 Solid-State Water Sensor only)

5. Pump can be checked for proper operation by briefly removing pump power cord from the back of the

Solid-State W ater Sensor plug and inserting directly

into the grounded outlet. In this condition, the pump

will run continuously. Once pump operation is verified, replace pump power cord into the back of the

Solid-State Water Sensor plug (see Figure 3).

NOTE! Disassembly of the motor will void the

warranty.

Part Replacement Schedule

Failure to follow replacement schedule will void

lifetime warranty.

Replace pump switch every 2 years. See page 8 for

Ridgid catalog #.

Replace fl oat every 2 years. See page 8 for Ridgid

catalog #.

Replace stator every 5 years. See page 8 for Ridgid

Catalog number.

SSP-1000 uses a solid-state electronic control with no

moving parts (see Figure 3), therefore replacement is

not needed.

• Always disconnect the electrical supply or

unplug the pump before attempting to install,

service, relocate, or perform any maintenance.

If the power source is out of sight, lock and tag

in the open (OFF) position to prevent unexpected power application. Failure to do so could

result in fatal electrical shock. Only a qualified

technician should repair this unit. Improper

repair could result in fatal electrical shock.

6

Ridge Tool Company

SP-330, SP-330D, SP-500, SSP-1000 Submersible Sump Pumps

Service And Repair

• Service and repair work on this pump must be performed by qualified repair personnel. Pump should

be taken to a RIDGID Independent Authorized

Service Center or returned to the factory. All

repairs made by Ridge service facilities are warranted against defects in material and workmanship.

• When servicing this pump, only identical replacement parts should be used. Failure to follow these

steps may create a risk of flooding, property damage, fatal electrical shock, or other serious injury

and may also void your warranty.

If you have any questions regarding the service or

repair of this machine, call or write to:

Ridge Tool Compan y

Technical Service Department

400 Clark Street

Elyria, Ohio 44036-2023

E-Mail: TechService@ridgid.com

For name and address of your nearest Independent

Authorized Service Center, contact the Ridge Tool

Company at http://www.RIDGID.com

For Customer Support, call 1-877-9RIDGID.

Troubleshooting

Let the pump cool for a minimum of two hours before servicing because the pump contains hot oil under

pressure. Disconnect pump from power source before servicing.

TROUBLESHOOTING CHART

Symptom Possible Cause(s) Corrective Action

Pump will not start

or run

Pumps start and

stops too often

Pump will not shut

off or thermal protector turns off

Pump operates but

delivers little or not

water

Gurgling sound

from pump at end of

cycle

1. Blown fuse or breaker

2. Low line voltage

3. Worn motor

4. Worn switch

5. Impeller not rotating

6. Float obstruction

1. Backflow of water from piping

2. Defective switch

3. Dir ty Solid-State Water Sensor

(Model SSP-1000 only)

1. Dirty Solid-State Water Sensor

(Model SSP-1000 only)

2. Defective switch

3. Obstacle in piping

4. Float obstructed

1. Low line voltage

2. Plugged impeller

1. Air injested into pump

2. Time required for pumping is less

than 4 seconds

1. If blown, replace with proper sized fuse or reset

breaker.

2. If voltage is under 108 volts, check wiring size.

3. Replace motor or pump.

4. Replace switch.

5. If impeller will not turn, remove housing and

remove blockage.

6. Make sure float moves freely up and down.

1. Install or replace check valve.

2. Replace switch (SP-330, SP-330-D, SP-500

Only).

3. Clean sensor face / see Maintenance steps

1. Clean sensor face / see Maintenance steps

2. Replace switch.

3. Remove pump and clean pump and piping.

4. Make sure float moves freely up and down.

1. If voltage is under 108 volts, check wiring size.

2. Clean out impeller.

1. Wipe off surface of sensor (see Figure 4).

2. Additional run time will not damage pump.

Ridge Tool Company

7

SP-330, SP-330D, SP-500, SSP-1000 Submersible Sump Pumps

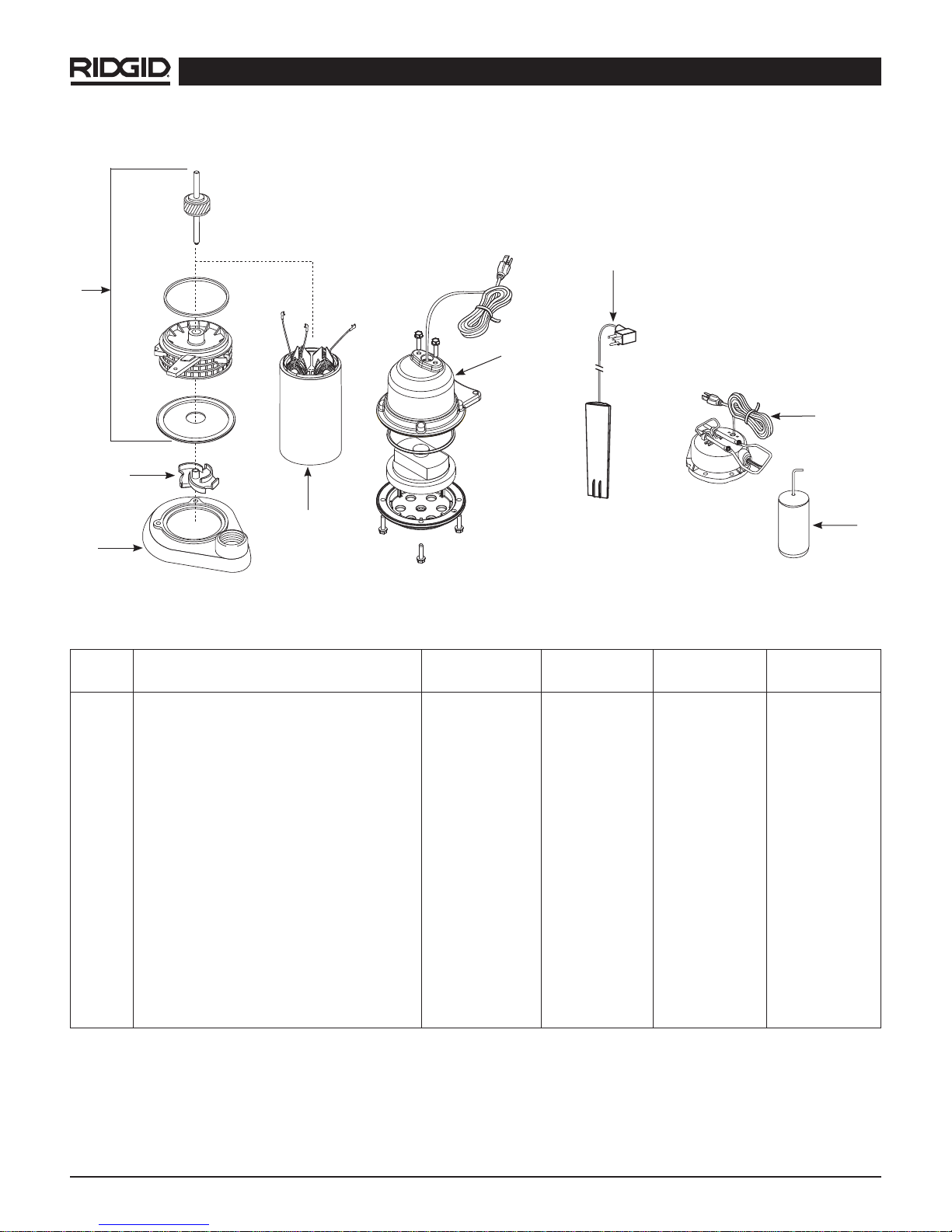

2b

4

2a

2

5

3

6

Figure Description RIDGID cat. #

SP330

1 Float Kit 88557 N/A 88557 N/A

2 Switch / Top Assembly 88562 N/A 88562 25138

2a Diaphragm Switch Assembly N/A 88567 N/A N/A

2b Solid-State Water Sensor N/A N/A N/A 25143

3 Stator 88577 88577 88582 25148

4 Lower Bracket / Rotor 88587 88587 88592 25153

5 Cast Iron Impeller 88597 88597 88597 25158

RIDGID cat. #

SP330D

RIDGID cat. #

SP500

RIDGID cat. #

SSP-1000

1

6 Cast Iron Volute 88602 90382 88602 88602

8

Ridge Tool Company

Loading...

Loading...