RIDGID SS1650 1 Owner's Manual

66

2:1(560$18$/

)RU<RXU6DIHW\

5HDGDOOLQVWUXFWLRQVFDUHIXOO\

,1&+9$5,$%/(

63(('6&52//6$:

Part No. SP6356 Printed in U.S.A.

Table of Contents

Section Page

Table of Contents ..................................2

Safety Instructions for Scroll Saw ..........2

Safety Signal Words ...........................2

Before Using The Saw .......................2

When Installing or Moving The Saw ...3

Before Each Use ................................3

Plan Ahead To Protect Your Eyes,

Hands, Face and Ears ......................4

Whenever Saw Is Running .................5

Before Leaving the Saw .....................5

Glossary of Terms for Woodworking .....6

Motor Specifications and Electrical

Requirements .................................... 6

Power Supply and Motor

Specifications ...................................6

General Electrical Connections ..........6

110-120 Volt, 60 Hz. Tool Information 7

Wire Sizes ..........................................8

Unpacking and Checking Contents 8

Tools Needed .....................................8

Unpacking .......................................... 8

List of Loose Parts .............................8

Getting to Know Your Scroll Saw ...........9

Alignment (Adjustments) ......................11

Changing the Table Bevel Angle ......11

To Adjust 90° Table Stop and Align the

Bevel Indicator ................................ 11

Adjusting Work Hold-down ...............12

Over Tensioning Or Under Tensioning

Blade ..............................................12

Section Page

Removing Pin End Blades ...............13

Installing 5" Pin End Blades .............14

Removing Plain End Blades ............15

Installing 5" Plain End Blades ..........16

Dust Blower .....................................17

Blade Guard .....................................17

Sawdust Collection Port ...................17

Mounting the Scroll Saw ......................18

Workbench Applications ..................18

Safety Instructions for Basic Saw

Operations ................ ..... ...... ...... ..... .19

Before Each Use ..............................19

Plan Ahead To Protect Your Eyes,

Hands, Face And Ears ...................19

Whenever Saw Is Running ..............20

Before Leaving The Saw .................21

Basic Saw Operations .........................21

General Instructions .........................21

Making Interior Scroll Cuts ...............21

Choice of Blade and Speed .............22

Maintenance ........................................ 23

General ............................................ 23

Motor/Electrical ................................ 23

Arm Bearings .................................. .23

Troubleshooting ...................................24

Wiring Diagram ....................................25

Repair Parts ........................................26

Safety Instructions for Scroll Saw

Safety is a com bination of common

sense, staying alert and knowing how

Safety Signal Words

DANGER: mean s if the s afe ty inf ormation

is not followed someone will be seriously

injured or killed.

WARNING: means if the safety information is not followed someone could be

Before Using The Saw

WARNING:

mistakes that could cause serious

permanent injury, do not plug the

saw in until the follow ing step s are

completed.

To reduce the risk of

your scroll saw works. Read this manual

to understand this saw.

seriously injured or killed.

CAUTION: means if the safety informa-

tion is not followed someone may be

injured.

• Completely assemble and align saw

(see “Assembly and Alignment” sections

within).

2

• Learn the use and function of the speed

control ON-OFF knob, bevel lock knob ,

blade holders, blade support, hold down,

tension knob, and blade guard. (See “Getting to Know Your Scroll Saw” section.)

• Read the warning label below, which is found on the base of the saw.

• Review and understand all safety

instructions and opera ting p roc edures in

this manual.

• Review the maintenance methods for

this saw. (See “Maintenance” section.)

When Installing or Moving The Saw

To Reduce the Risk of Dangerous Environment. Use the saw in a dry indoor

place, protected from rain. Keep work

area well lighted .

To reduce the risk of injury from unexpected saw movement:

• Turn saw off and unplug cord before

moving the saw.

• Place the saw on a firm level surface

where there is plenty of room for handling and properly supporting the workpiece.

• Support the saw so the t ab le is le v e l and

the saw does not rock.

• Bolt the saw to the work surface if it

tends to slip, walk, or slide during opera-

tions like cutting long heavy boards, or

when using an auxiliary table.

To reduce the risk of injury or death

from electrical shock:

• Ground the saw. This saw has an

approved 3 conductor cord and a 3prong grounding type plug. Use only 3wire, grounded outlets rated 120 volts,

15 amperes (amps). The green conductor in the cord is the grounding wire. To

reduce the risk of electrocution, NEVER

connec t the green wire to a live terminal.

• Make sure your fingers do not touch the

plug’s metal prongs when plugging or

unplugging the saw.

Before Each Use

Inspect your saw.

Disconnect The Saw. To red uce the risk

of injury from accidental starting, unplug

the saw, turn the switch off and lock out

the switch before changing the setup,

removing covers, guards or blade.

Check For Damaged Parts. Check for:

• Ali gnment of moving parts.

• Binding of moving parts.

• Broken parts.

• Stable mounting.

• A ny other cond ition that may affect the

way the saw works.

If any part is missing, bent or broken in

any way, or any electrical part doesn’t

work properly , turn the saw

the saw. Replace damaged, missing or

failed parts before using the saw again.

Keep Guard In Place and in working

order.

3

off and unplug

Safety Instructions for Scroll Saw (continued)

Maintain Tools with Care. Keep the saw

clean for best and safest performance. Follow instructions fo r lubricating.

To reduce the risk of injury from jams,

slips or thrown pieces

• Use Only Recommended Accessories. Follow the instructions that come

with the accessor ies. The use of

improper accessories may cause risk of

injury to person.

• Choose the right si z e a nd style bl ade for

the material and the type of cutting you

plan to do.

• Make s ure the blade teeth point downward, toward the table.

• Make sure the blade tension is properly

adjusted.

• Keep Work Area Clean. Cluttered areas

and benches invite accidents. Floor

must not be slippery.

To reduce the risk of burns or other fire

damage, never use the saw near flammable liquids, vapors or gases.

• Know Your Saw. Read and understand

the owners manual and labels affixed to

the tool. Learn its application and limitations as well as the specific potentia l

hazards peculiar to this tool.

• To reduce the risk of inju ry from a ccide ntal contact with moving parts, don't do

layout, assembly, or setup work on the

saw while any parts are moving.

• Reduce the Risk of Accidental Start-

ing. Make sure switch is "OFF" before

plugging saw into a power outlet.

Plan Your Work.

• Use The Right Tool. Don't force tool or

attachment to do a job it was not

designed for.

• Use this scroll saw to cut only wood,

woodlike products, plastics and nonferrous metals.

CAUTION: This saw is NOT

designed for cutting ferrous metals

like iron or steel. When cutting nonferrous metals (brass, copper and

aluminum, etc.), metal shavings can

react with wood dus t a nd start a fire.

To reduce the risk of fire:

• Remove all traces of wood dust

from on and around the saw.

• Remove al l metal shavings fr om on

or around the saw before sawing

wood again.

Plan Ahead To Protect Your Eyes, Hands, Face and Ears

Any power saw can throw foreign objects

into the eyes. This can cause permanent

eye damage . Alw a ys w ear saf e ty gogg les,

not glasses, complying with ANSI Z87.1

(or in Canada CSA Z94.3-99) shown on

package. Everyday eyeglasses have only

impact resistant lenses. They are not

safety glasses. Safety goggles are available at many loca l retail stores. Glasses

or goggles not in compl iance w ith ANSI or

CSA could seriously hurt you when they

break.

Dress for safety

• D o not wear l oose clothing, gloves,

neckties or jewelry (rings, wristwatches).

They can get caught and draw you into

moving parts.

• Wear nonslip footwear.

• Tie back long hair.

• Roll long sleeves above the elbow.

• Noise levels vary widely. To reduce the

risk of possible hearing damage, wear

ear plugs or muffs when using saw for

hours at a time.

• For dusty operations, wear a dust mask

along with the safety goggles.

Inspect Your Workpiece.

Make sure there are no nails or foreign

objects in the part of the workpiece to be cut.

4

Use extra caution with large, very

small or awkward workpieces

• Never use this tool to finish pieces too

small to hold by hand.

• Use extra supports (tables, saw horses,

blocks, etc.) for any workpieces large

enough to tip when no t hel d down to the

table top.

• Never use another person as a substitute for a table extension, or as additional support for a workpiece or to help

feed, support or pull the workpiece.

• When cutting irregularly shaped workpieces, p lan y our wo rk so it w ill not p inch

the blade. A piece of molding, for example, must lay flat or be held by a fixture

or jig that will not let it twist, rock or slip

while being cut.

• Properly support round material such as

dowel rods or tubing. They have a tendency to roll during a cut, causing the

blade to “bite”. To avoid this, always use

“V” blocks.

• Clear everything except the workpiece

and related su pport devices off the tab le

before turning the saw on.

Plan the way you will hold the workpiece from start to finish.

• Do not hand hold pieces so small that

your fingers will go under the blade

guard. Keep your hands away from the

blade.

• R educe th e Risk of awkward operations

and hand positions where a sudden slip

could cause fi ngers or h and to mo v e into

the blade.

• Don’t Overreach. Keep good footing

and balance.

• Keep your face and body to one side of

the blade, out of line with a possible

thrown piece if the blade should break.

Whenever Saw Is Running

WARNING:

(gained from frequent use of your

scroll sa w) cause a careless mi stake.

A careless fraction of a second is

enough to cause a severe injury.

• Before starting your cut, watch the saw

while it runs. If it makes an unfamiliar

noise or v ibra tes excessively, stop imme diately. Turn the saw off. Unplug the saw.

Do not restart until finding and correcting

the problem.

• Keep Children Awa y. Keep all vis itors a

safe distance from the saw. Make sure

bystanders are clear of the saw and

workpiece.

• Don’t Force T ool . It will do the job better

and safer at its designed rate. Feed the

workpi ece into the saw blade only fast

enough to le t it cut w ithout bogg ing dow n

or binding.

Don’t let familiarity

Before Freeing Any Jammed Material.

• Turn switch “OFF”

• Wait for all moving parts to stop.

• Unplug the saw .

When backing up the workpiece, the

blade may bind in the kerf (cut). T his is

usually caused by sawdust clogging

up the kerf. If this happens:

• Turn switch “OFF”.

• Wait for all moving parts to stop.

• Unplug the saw .

• With a flat blade screwdriver, turn motor

shaft by han d. Insert the screwd river into

the slotted end of motor shaft located at

the center of the motor housing. Do this

while backing up the w orkpie c e.

Before remo ving loose piec es from the

table, turn saw off and wait for all moving parts to stop.

Before Leaving the Saw

• Wait for all moving parts to stop.

• Make Workshop Child-proof . Unplug

the saw. Lock the workshop and ON/OFF

knob on the saw . Store the k ey a wa y from

children and others not qualified to use

the tool.

5

Glossary of Te rms f or Woodworking

Kerf - the slot cut by the blade.

Leading Edge - the edge of the work-

piece which is pushed into the blade first.

Sawblade Path - the area of the work-

piece directly in line with and moving

toward the sawblade edge.

Bevel - the ability to slant the table to

make angle cuts. An angle cutting operation through the face of the board.

Blade Tooth Set - the distance that the

edge of the s awb lade t ooth is bent (or set)

outward from the side of the blade.

Plain End Blade - blade ends are flat,

and are clamped in the blade holders.

Pin End Blade - blade ends contain a pin

oriented at 90° to the blade. Blade ends

are hooked into a groove in the blade

holder and clamped.

Trailing Edge - the workpiece edge last

cut by the sawblade.

Wo rkpiece - the item on which the cutting

operation is being performed.

Motor Specifications and Electrical Requirements

Power Supply and Motor Specifications

W ARNING

electrical hazards, fire hazards or

damage to the tool, use proper circuit

protection. Your tool is wired at the

factory for operation using the voltage shown. Connect tool to a power

line with the appropriate voltage and

a 15-amp branch circuit. Use a 15amp time delay type fuse or circuit

breaker . To reduce the risk of shock

or fire, if power cord is worn or cut, or

damaged in any way, have it r eplaced

immediately.

For replac ement motor and control board,

refer to parts list in this manual.

: To reduce the risk of

CAUTION: A direct current motor is

used in this saw. Changes to the

internal wiring will create a fire hazard and may also create a shock hazard.

This machine is equipped with a variable

speed motor having the following specifications:

Voltage 110-120

Amperes 1.2

Hertz (Cycles) 60

Phase Single

RPM 500-1700

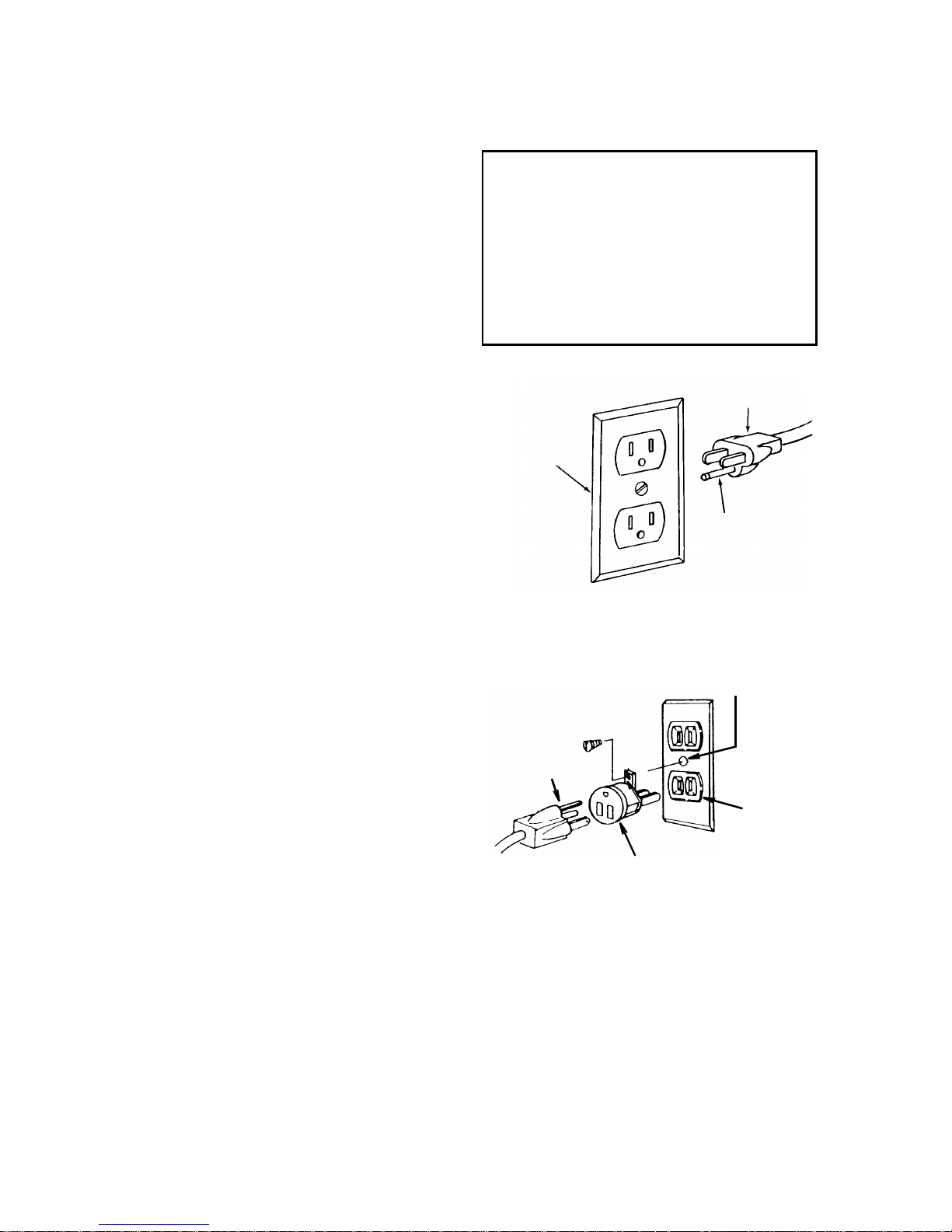

General Electrical Connections

DANGER:

electrocution:

• Use only identical replacement

parts when servicing. Servicing

should be performed by a qualified

service technician.

• Do not use in rain or where floor is

wet.

This tool is intended for indoor residential use only.

To reduce the risk of

Rotation of Shaft Clockwise

WARNING: Do not permit fingers to

touch the terminals of plug when

installing or removing the plug to or

from the outlet.

If power cord is worn or cut, or damaged

in any way, have it replaced immediately.

6

110-120 Volt, 60 Hz. Tool Information

NOTE: The plug supplied on your tool

may not fit in to the outlet y ou are planni ng

to use. Your local electrical code may

require slightly different power cord plug

connections. If these differences exist

refer to and m ake the proper adjustm ents

per your local code before you r tool is

plugged in and turned on.

In the event of a malfunction or breakdown, grounding provides a path of least

resistance for electric current to reduce

the risk of electric shock. This tool is

equipped with an electric cord having an

equipment grounding conductor and a

grounding plug, as shown. The plug must

be plugged into a matching outlet that is

properly installed and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will

not fit the outlet, have the proper outlet

installed by a qualified electrician.

A temporary adapter may be used to connect this plug to a 2-pole ou tlet, as sho wn,

if a properly grounded outlet is not available. This temporar y adapter should be

used only un til a p roperly grounded outlet

can be installed by a qualified electrician.

The green colored rigid ear, lug and the

like, extension from the adapter must be

connected to a permanent ground such

as a properly grounded outlet box.

Improper connection of the equipment

grounding c onductor c an resul t in a risk of

electric shock. The conductor with insulation having an outer surface that is green

with or without yellow stripes is the equipment grounding conductor. If repair or

replacement of the ele ctric cord or plug is

necessary, do not connect the equipmentgrounding conductor to a live terminal.

If the grounding instructions are not completely understood, or if you are in doubt

as to whether the tool is properly

grounded check with a qualified electrician or service personnel.

WARNING: If not properly

grounded, this tool can cause an

electrical shock, particularly when

used in damp locations, in proximity

to plumbing, or out of doors. If an

electrical shock occurs there is the

potential of a secondary hazard,

such as your hands contacting the

sawblade.

Properly

Grounded

Outlet

Green

Grounding Lug

3-Prong

Plug

Adapter

NOTE: The adapter illustrated is for use

only if you already have a properly

grounded 2-prong outlet.

NOTE: Use of a temporary adapter is not

permitted by the Canadian Electrical

Code.

3-Prong Plug

Grounding

Prong

Make sure this

Is Connected

to a Known

Ground

2-Prong

Outlet

7

Motor Specifications and Electrical Requirements (continued)

Wire Sizes

NOTE: Make sure the proper extension

cord is used and is in good condition.

The use of any extension cord will cause

some loss of power. To keep this to a minimum and to prevent overheating and

motor burn-out, use the table shown to

determine the minimum wire size

(A.W.G.) extension cord.

Use only 3-wire extension cords which have

3-prong grounding type plugs and 3-pole

receptacles which accept the tools plug.

Extension

Cord Length

26-50 Ft.

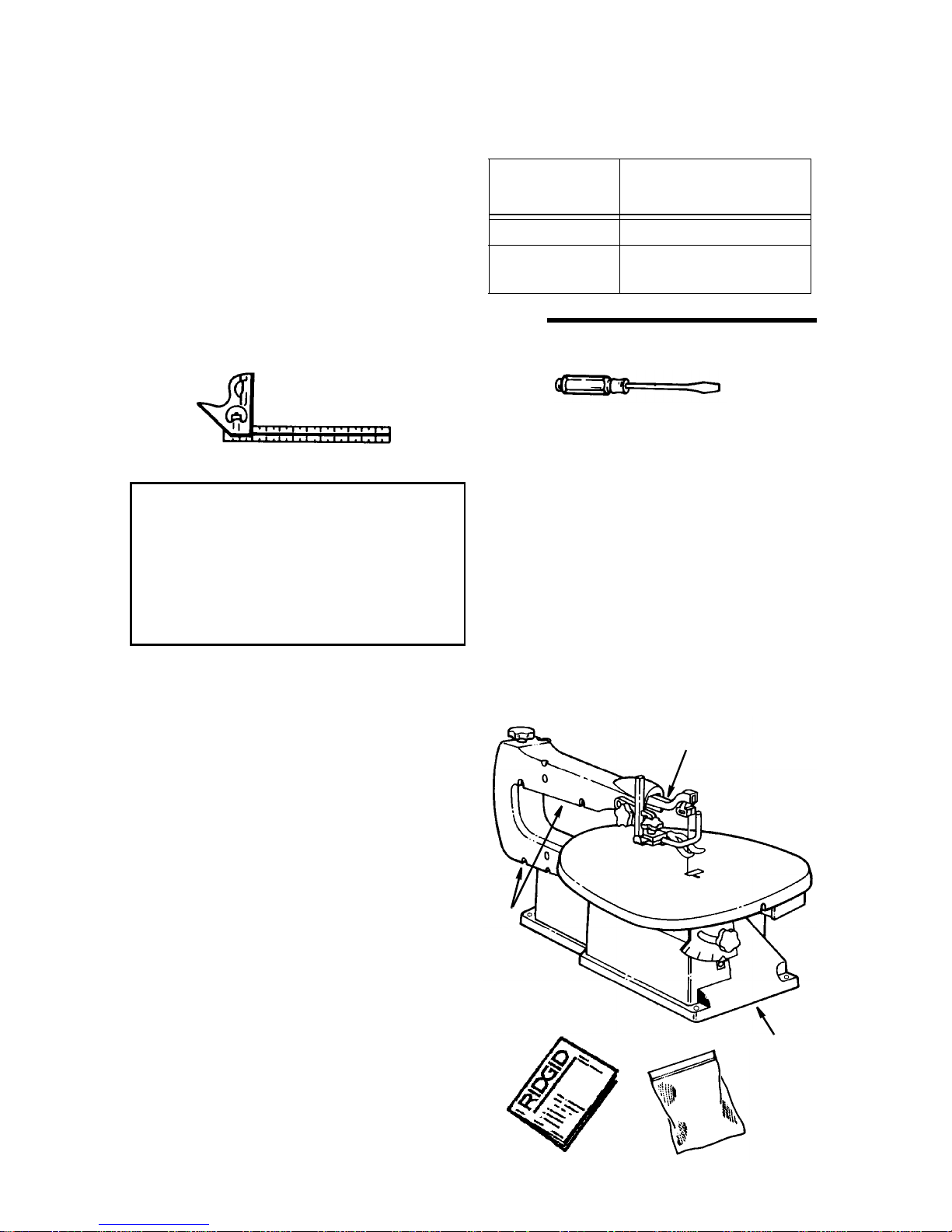

Unpacking and Checking Contents

Tools Needed

Combination Square

Unpacking

W ARNING

injury, from unexpected starting or

electrical shock, do not plug the

power cord into a power sour ce outlet

during unpacking and assembly. This

cord must remain unplugged whenever you are w orking on the saw.

Your scroll saw is fully assembled and

shipped complete in one box.

IMPORTANT: Never lift this saw by the

arm which holds th e blade or damage will

occur to your saw.

Separate all parts from packaging materials and check each item with illu stration

and "List of Loose Pa rts". Make certain all

items are accounte d f or bef ore dis cardi ng

any packaging material.

NOTE: If you are missing any part, call 1800-4-RIDGID or E -mail us at info@ridgidwoodworking.com to get the missing

part. Sometimes small parts can get lost

in packaging material. DO NOT throw

away any packaging until saw is put

together. Check packaging for missing

parts before contacting RIDGID. A complete parts list (Repair P a rts) is at the end

of the manual. Use the list to identify the

number of the missing part.

: To reduce the risk of

List of Loose Parts

Item Description Qty.

A 16" Scroll Saw

(Completely Assembled)............... 1

B Owner’s Manual............................. 1

C Loose Parts Bag containing:

Blade........................................1

NOTE: Hardwa re to mou nt th is sc rol l saw

to a bench is not supplied. See mounting

instructions for recommended hardware

size.

Lift

Here

B

0-25 Ft.

Medium Standard and

Phillips Screwdriver

A

Gauge

(A.W.G.)

110-120V

18

16

Do Not Lift Saw

By This Arm

Lift Here

C

8

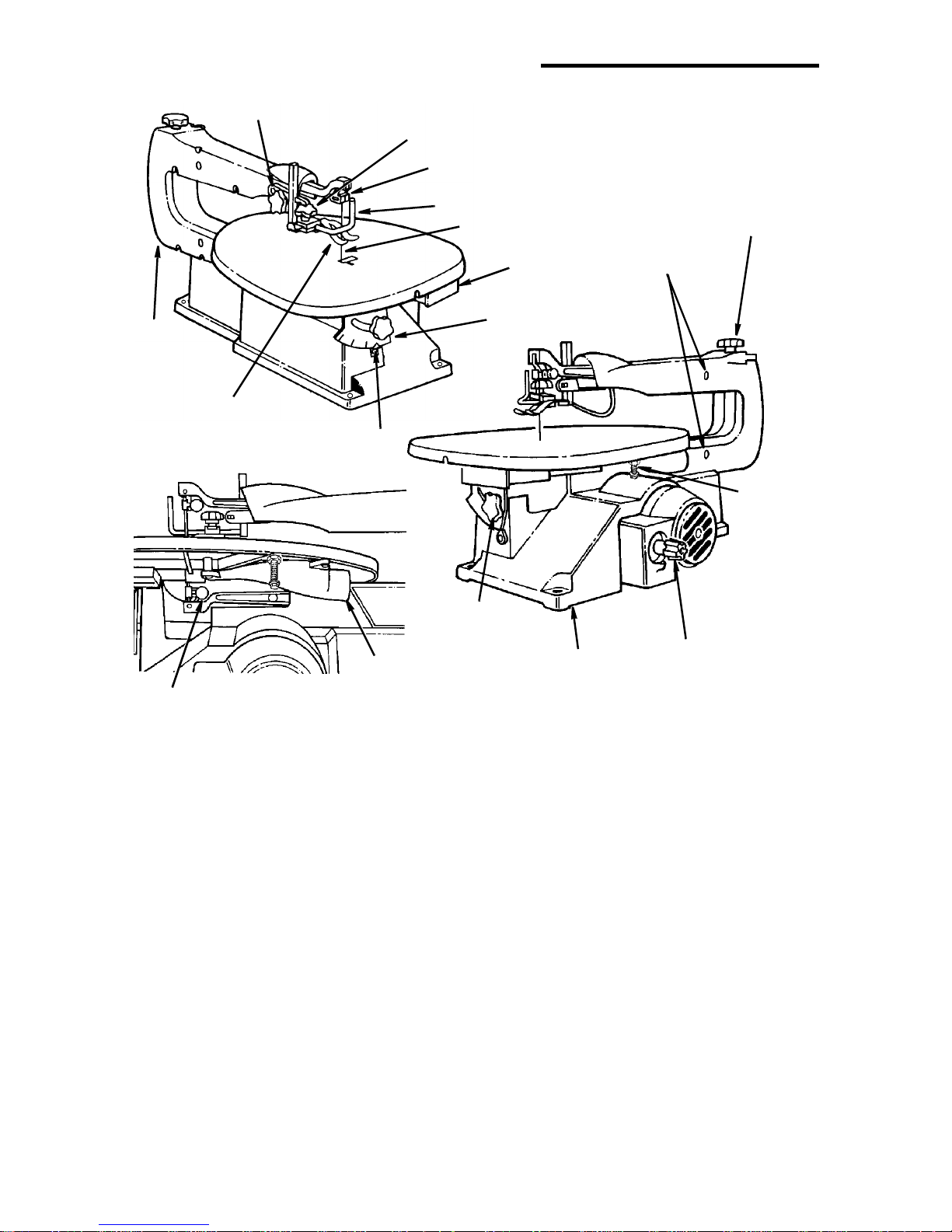

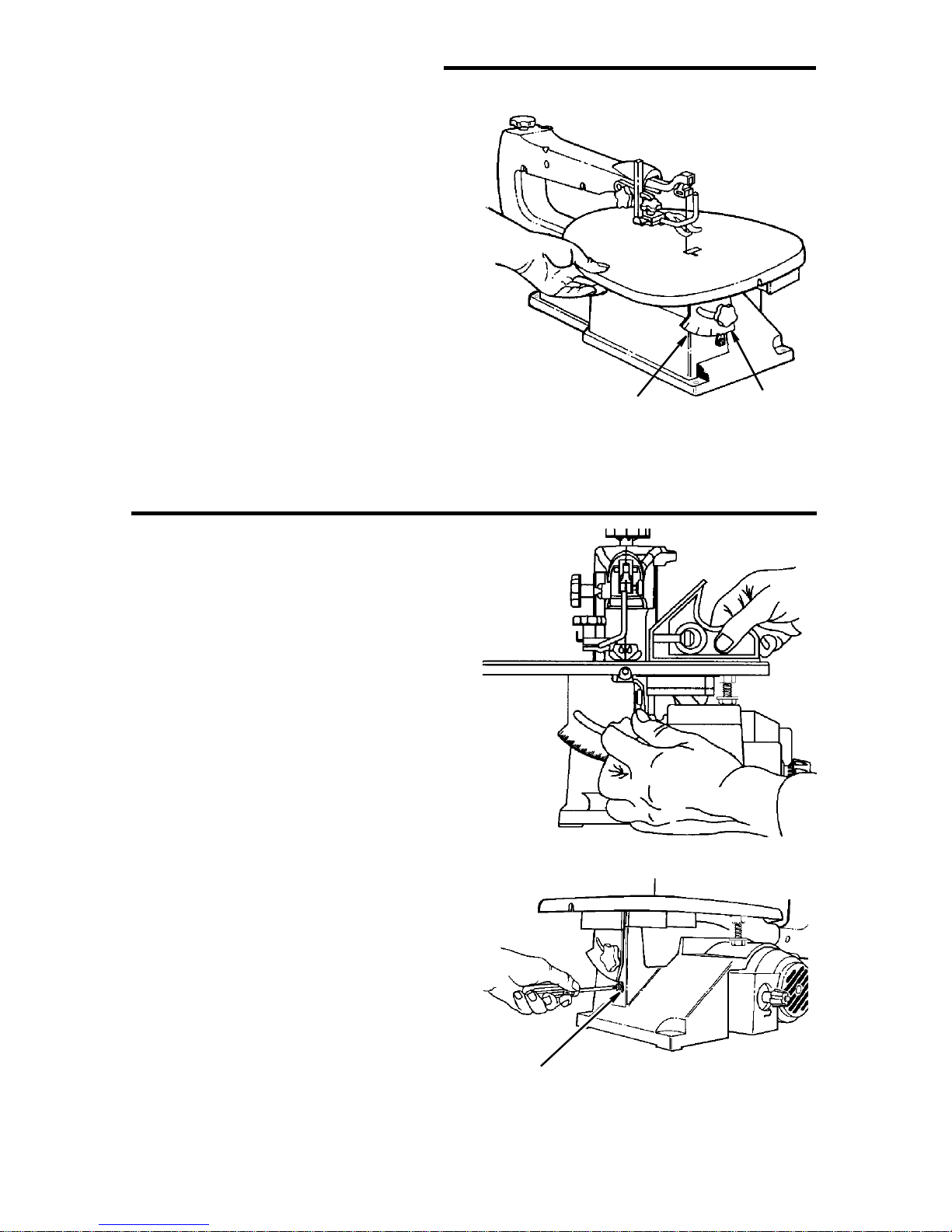

Getting to Know Your Scroll Saw

1 Height

Adjusting Knob

2 Blade Guard/Hold-Down Knob

3 Upper Blade Holder

Frame

(Lift Here)

8 Work Hold-Down Foot

and Blade Support

3 Lower Blade Holder

7 Bevel

Indicator

9 Sawdust

Collection

Port

4 Blade Guard

Blade

5 Storage

6 Bevel Scale

10 Table Bevel

Lock Knob

Drawer

(Lift Here)

Base

11 Blade

Tension Knob

Arm

Bearings

12 Table

Stop

13 Speed Control

On/Off Knob

1. Height Adjustment Knob - Allows

for vertical positioning of b lade guard/

hold down.

2. Blade Guard/Hold Down Knob -

Allows for secure angular positioning

of blade guard, work hold down and

sawdust bl ower.

3. Blade Holders - Retain and position

the blade.

4. Blade Guard - Defines area of mov-

ing blade.

5. Storage Drawer - For convenient

storage of pin and plain blades.

6. Bevel Scale - Shows angle table is

tilted for bevel cutting.

7. Bevel Indicator - Points to the

approximate angle of the blade in

relation to the table top.

8. Work Hold-Down and Blade Sup-

port - Provides added control of

workpiece, protection for operator

and support for the blade.

9. Sawdust Collection Port - Hook up

a wet/dry vac to help cont rol sa w dust.

10. Table Bevel Lock Knob - When

tightene d, this knob secur es table at

desired bevel angle. Loosening knob

allows the table to tilt up to 45° for

bevel cuts.

11. Blade Tension Knob - Tightening

the knob (c lo ckwi se) wi l l i n cre as e the

tension on the blade. Loosening it

(counterclockwise) will decrease the

tension.

12. Table Stop - Allows table to be tilted

and returned to accurate 90° stop.

9

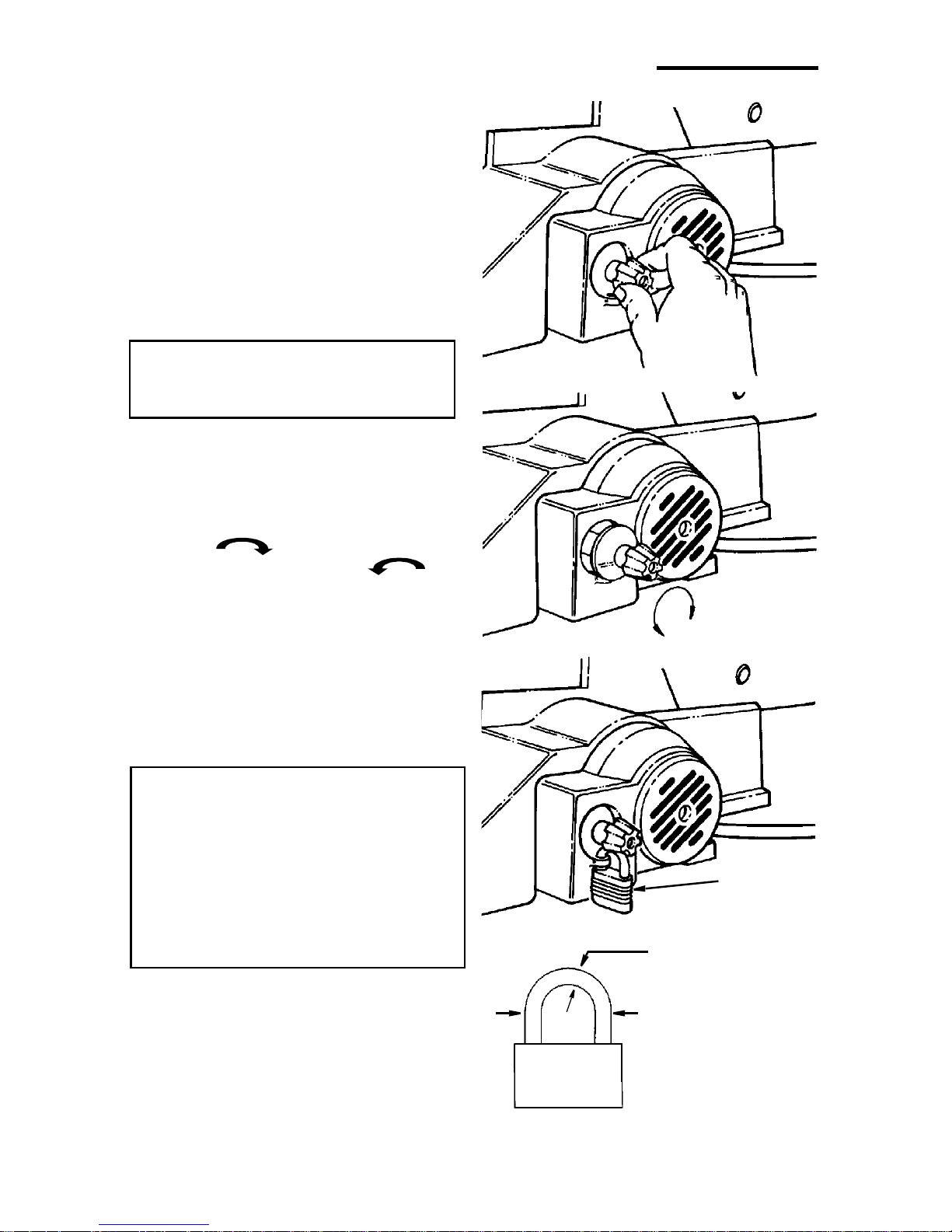

Getting to Know Your Scroll Saw (continued)

13. Speed Control/On-Off Knob - For

speed control setting, refer to the

“Choice of Blade and Speed” table.

The On-Off knob has a locking feature, This Feature Is Intended To

Help Prevent Unauthorized Use By

Children And Others.

• To turn machine “ON”, place fingers

on Speed Control/On-Off Knob and

pull out.

• To turn machine “OFF”, push in

Speed Control/On-Off Knob.

WARNING: Never lea ve the machine

unattended until it has come to a

complete stop.

The variable speed contr ol may be

adjusted to the approximate speeds identified on the control panel. Suggested

speeds are identified under “Choice of

Blade and Speed”. Turn the control knob

clockwise to increase strokes per

minute and counterclockwise to

reduce the strokes per minute.

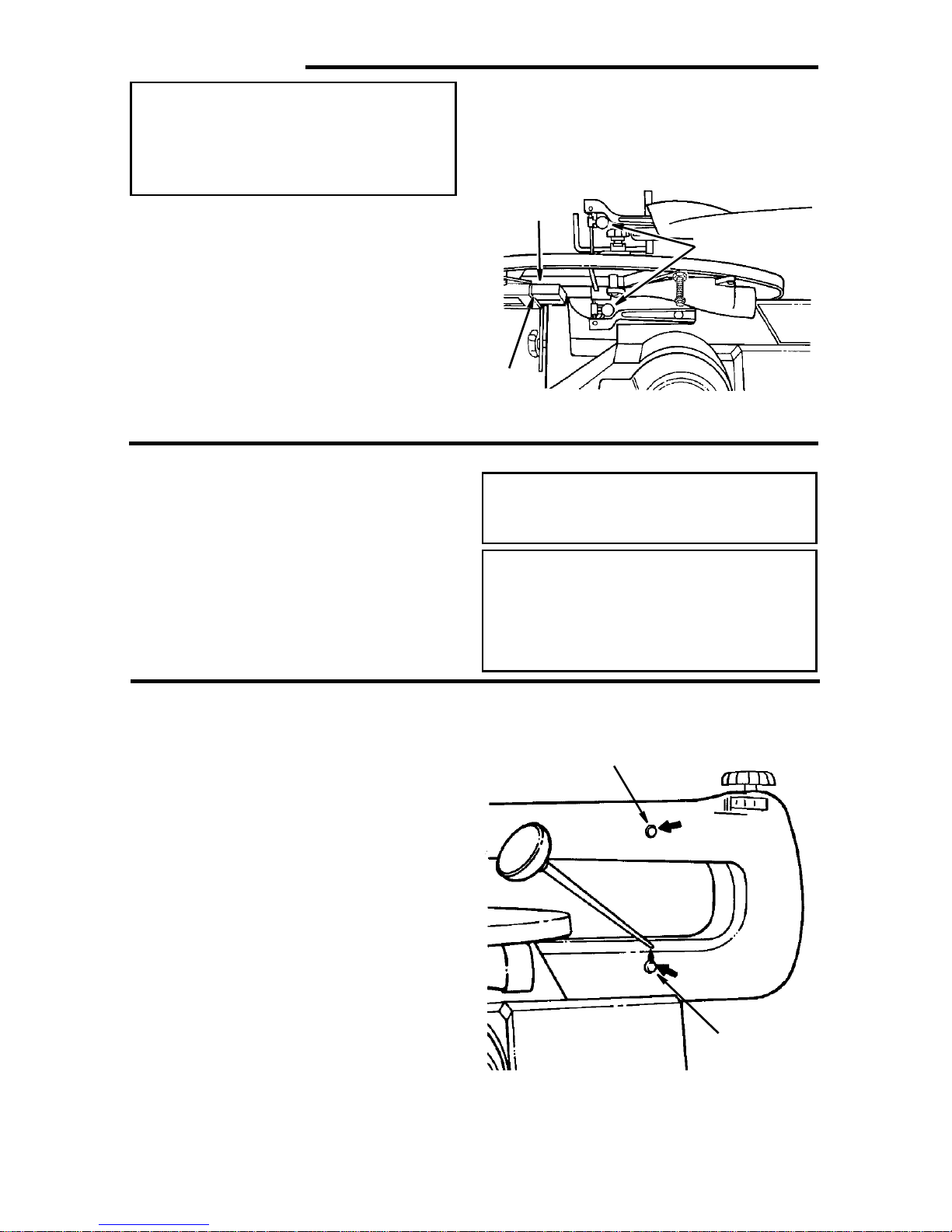

Rotate

Speed

Control

• To lock knob in “OFF” position, install

a padlock through the hole below

the knob as illustrated, and lock the

padlock. (Padlock is not supplied

with the saw.)

WARNING: For your own safety,

always push the knob “Off” when

machine is not in use. Also, in the

event of a power failure (all of your

lights go out), push knob “Off”.

“Lockout” your knob with a padlock

as shown. This will prevent the

machine from starting up again

when the power comes back on.

Install

Padlock

Through Hole

5/32 to 3/16 Inch

Approximate

Diameter

1 Inch Approximate

Approximate

Padlock Size

10

Alignment (Adjustmen ts)

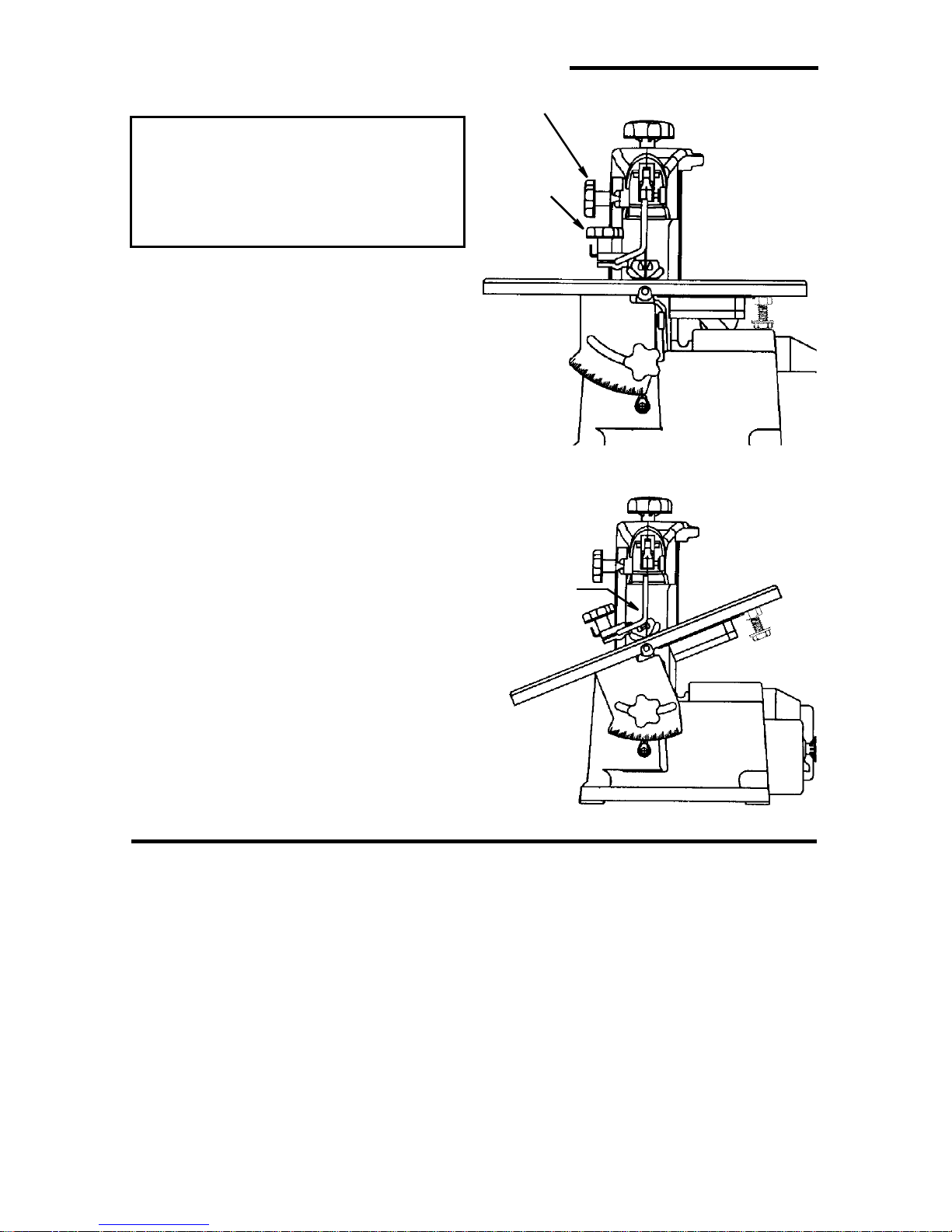

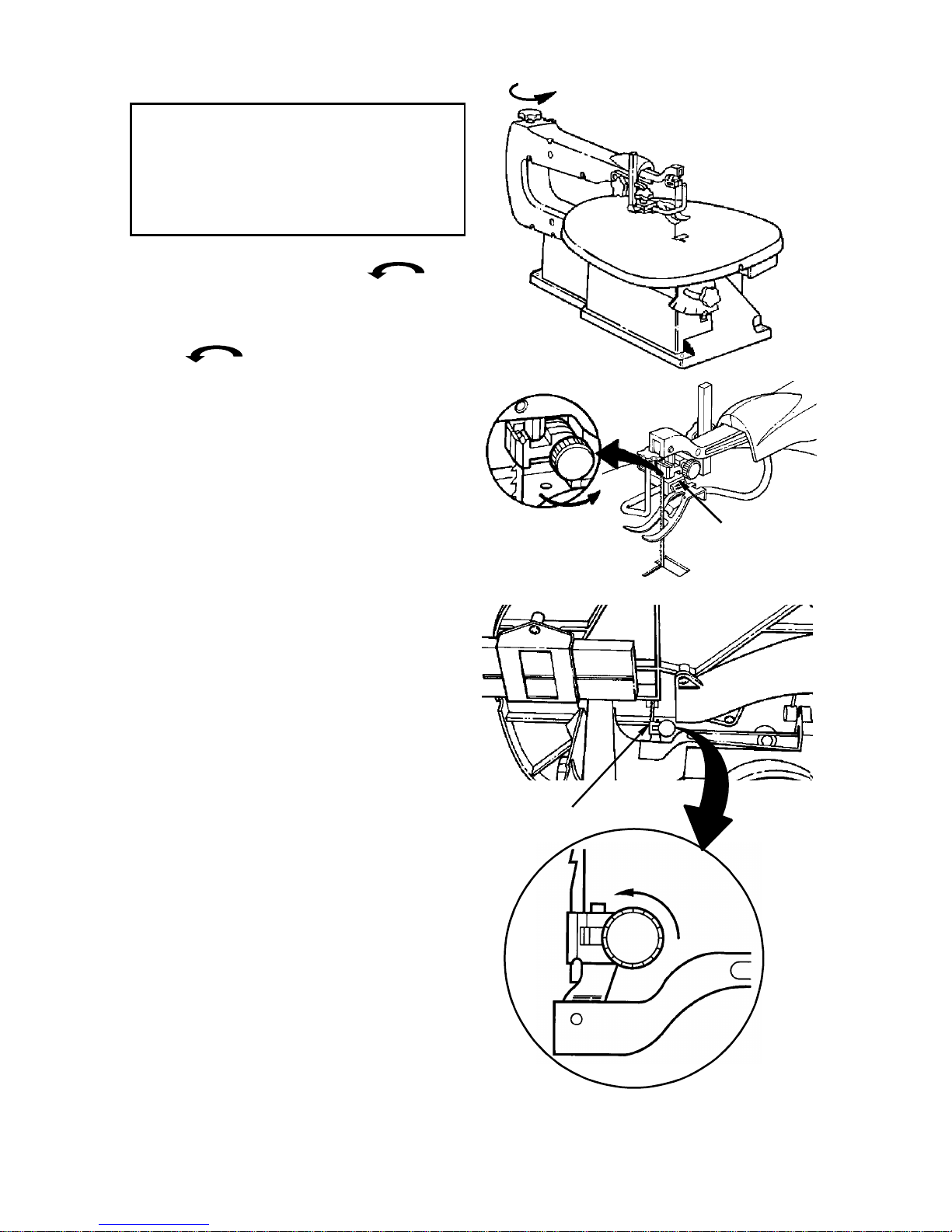

Changing the Table Bevel Angle

• The scroll saw w ork tabl e can be tilt ed to

the left for bevel cutting up to 45° from

the 0° or horizontal cutting position.

• A bevel s ca le a nd indicator are provided

under the work table as a convenient reference for setting the approximate table

angle for bevel cutting.

• A 90° table stop is provided under the

table to allow the table to be tilted and

returned to an accurate 90°.

NOTE: A scroll saw is a scroll curve cutting tool. It is not intended for making

precise angular cuts in wood. The indicator is provided to g ive approximate

angular readings. A precision protractor

or square should be used to measure a

more precise b l ade to t ab le ang ular lo ca tions.

Bevel

Scale

Bevel

Lock Knob

To Adjust 90° Table Stop and Align

the Bevel Indicator

• Loosen the table bevel lock knob and

use a small square to set the table at 90°

to the blade.

• Loosen the table stop jam nut and adjust

the stop bolt in or out to accurate 90°.

• Tig hten the jam nut.

• When there is no space between the

square and the b lade , hold tab le in pla ce

and tighten the bevel lock knob. The

table should now be approximately 90°

to the blade.

• Loosen the screw holding the bevel

scale pointer and adjust to 0°. Tighten

screw.

Remember, the bevel scale is a convenient guide but should not be relied

upon for precision.

Bevel

Pointer

11

Alignment (Adjustments) (continued)

Adjusting Work Hold-down

WARNING

injury from accidental starting,

always turn switch "OFF" and

unplug power cord from outlet

before removing or replacing the

blade.

The purpose of the work hold-do wn f oot is

to hold the work aga inst the tab le so that it

is less likely to lift with the up stroke of the

blade. It should lie flat on the workpiece

with the front prongs straddling the blade.

1.The work hold-down foot is attached to

the blade guard rod. The height of the

work hol d-down foot is ad justed by

loosening the height adjustment knob

and moving the guide post up or down.

The work hold-down foot is adjusted

front to back and left-to-right by loosening the hold-down knob located on the

bracket, as illustrated.

2.When the table is tilted, the work hold-

down foot can be adjusted by loosening

the height adjustment knob and adjusting the foot to the same angle as the

table. The work hold-down foot should

always be adjusted as close to the

blade as possible without touching it

and position ed directly on the surfa ce of

the workpiece.

NOTE: For most applications tightening

the hold down knob with your fingers is

adequate.

: To reduce the risk of

Height Adjustment Knob

Hold-Down

Knob

Adjust

Hold-Down

Foot to

Same Angle

as Table

Over Tensioning Or Under

Tensioning Blade

Too much or too little blade tension could

cause blades to break rapidly.

The thick er , h arder and more abr asiv e the

wood you are cutting, the more blades

you will have to use.

Blade breakage is caused by the following:

• Over tension or under tension.

• Twisting or bending the blade.

• Over use - blade life exhausted.

• Over Aggressive Feeding of the work-

piece into the blade by going too fast.

12

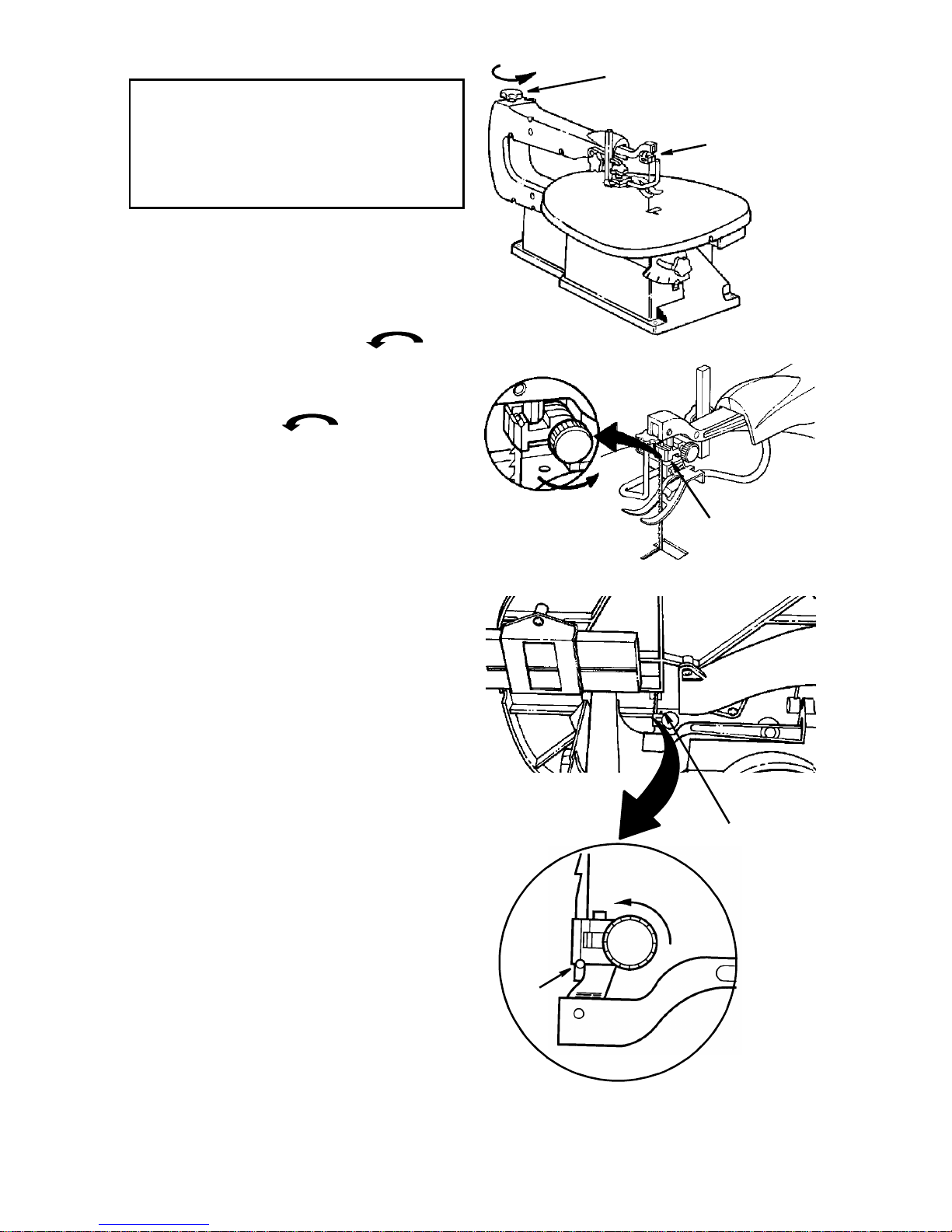

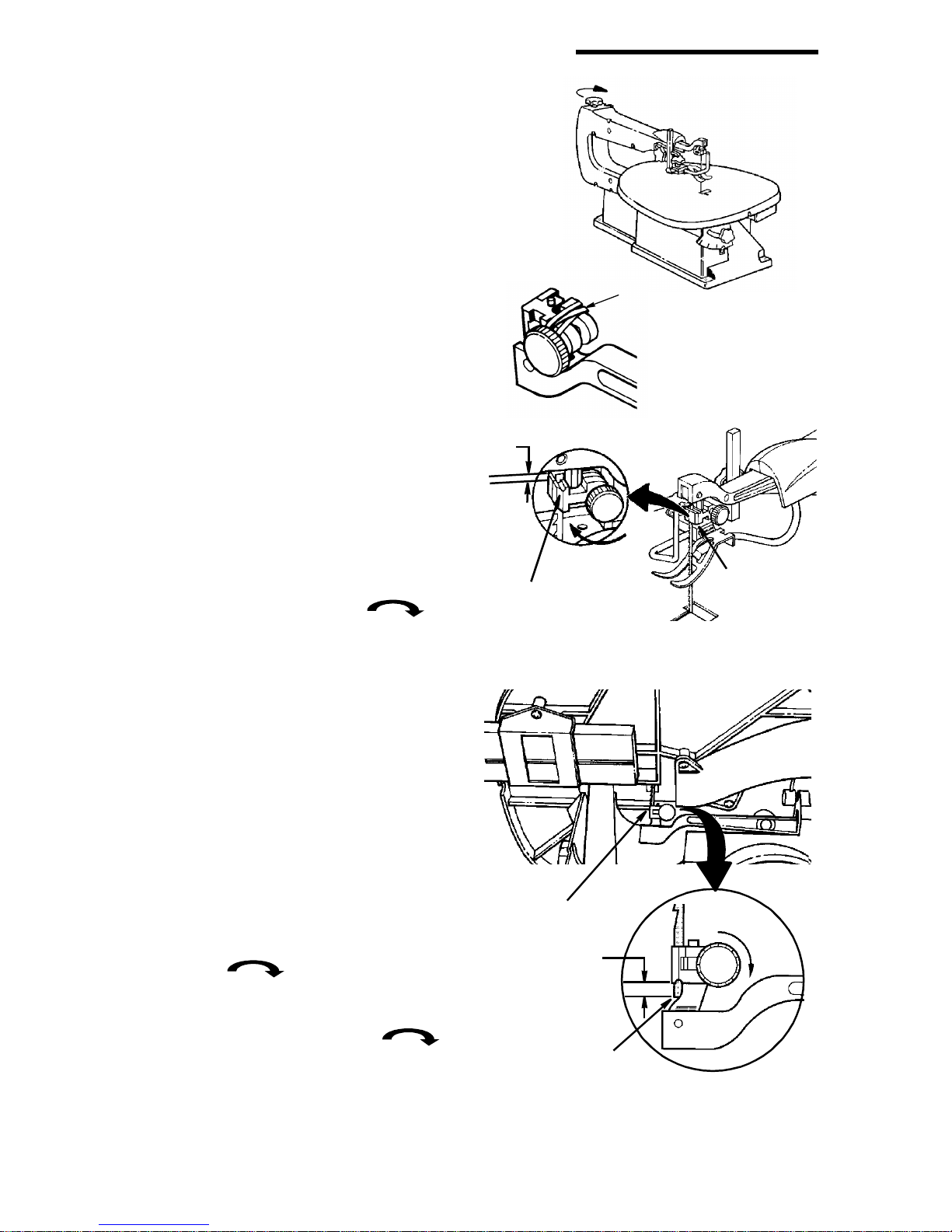

Removing Pin End Blades

WARNING

injury from accidental starting,

always turn switch "OFF" and

unplug power cord from outlet

before removing or replacing the

blade.

NOTE: Saw comes with 5" pin end blade

installed. If you are going to use 5" plain

end blades , re f er to the instructions under

“Installing Plain End Blades ”.

• Loosen tension on blade by turning tension knob counterclockwise at

least three full turns.

• Loosen upper and lower blade holder

knobs by turning the blade holder knobs

countercloc kwise about three full

turns. To make lower blade holder

access easier, tilt the table to 45°, and

raise the arms to the up position using a

screwdriver to rotate the motor shaft.

• Remove blade from the lower blade

holder by pushing down on the upper

arm, releasing the pin end blade from

the lower blade holder. Remove bl ade

from the upper blade holder by slightly

lifting up on the blade and pulling forward.

NOTE: The table can be tilted to 45° to

increase access and visibilit y to lower

blade holder area.

: To reduce the risk of

Tension Knob

Loosen

Blade

Upper Blade

Holder Knob

Upper

Blade

Holder

Lower Blade

Holder

Loosen

Pin

13

Alignment (Adjustments) (continued)

Installing 5" Pin End Blades

Pin end blade set up:

• Check that the blade tension knob is

loosened.

• Check that the upper and lower blade

holder knobs are loosened. Spread

blade holde r ja w s ope n usi ng fing ers.

NOTE: A rubber band looped around the

back of th e b lade h older wil l autom atica lly

open the jaws when the knobs are loosened which will make changing blades

easier.

• Install the blade through the opening in

the table with the teeth pointing down.

Engage the pin into the “V” notch of the

lower blade holder.

• Pull up on the blade and engage the

upper pin in the “V” notch of the upper

blade holder.

• Position the b l ade hol ders un til y ou a lign

the front face of the blade holders with

the vertical edge of the blade. Tighten

upper and lower blade holder knobs by

turning knobs clockwise until the jaws

close evenly against the blade.

NOTE: To prevent blade holder damage,

do not use pliers to tighten knob.

• Carefully tighten the blade tension by

turning the tension knob clockwise

just until you feel the sl ack in the

blade is removed.

• Check to see that the pins are properly

located in the V-notch slot. Turn the tension knob an additional two full turns

clockwise. This amount of blade tension

should do well for most cutting operations and blades, but may vary by up to

one turn depending on blade thickness

and blade type.

• Make sure the blade is properly

installed. Before applying power, rotate

the motor shaft by hand using a screwdriver in the motor shaft slot as shown.

Tighten

Rubber

Band

“V”-Notch

Pin

Tighten

“V”-Notch

Tighten

WARNING: To reduce the risk of

injury from thrown objects, remove

all tools from the saw.

Pin

14

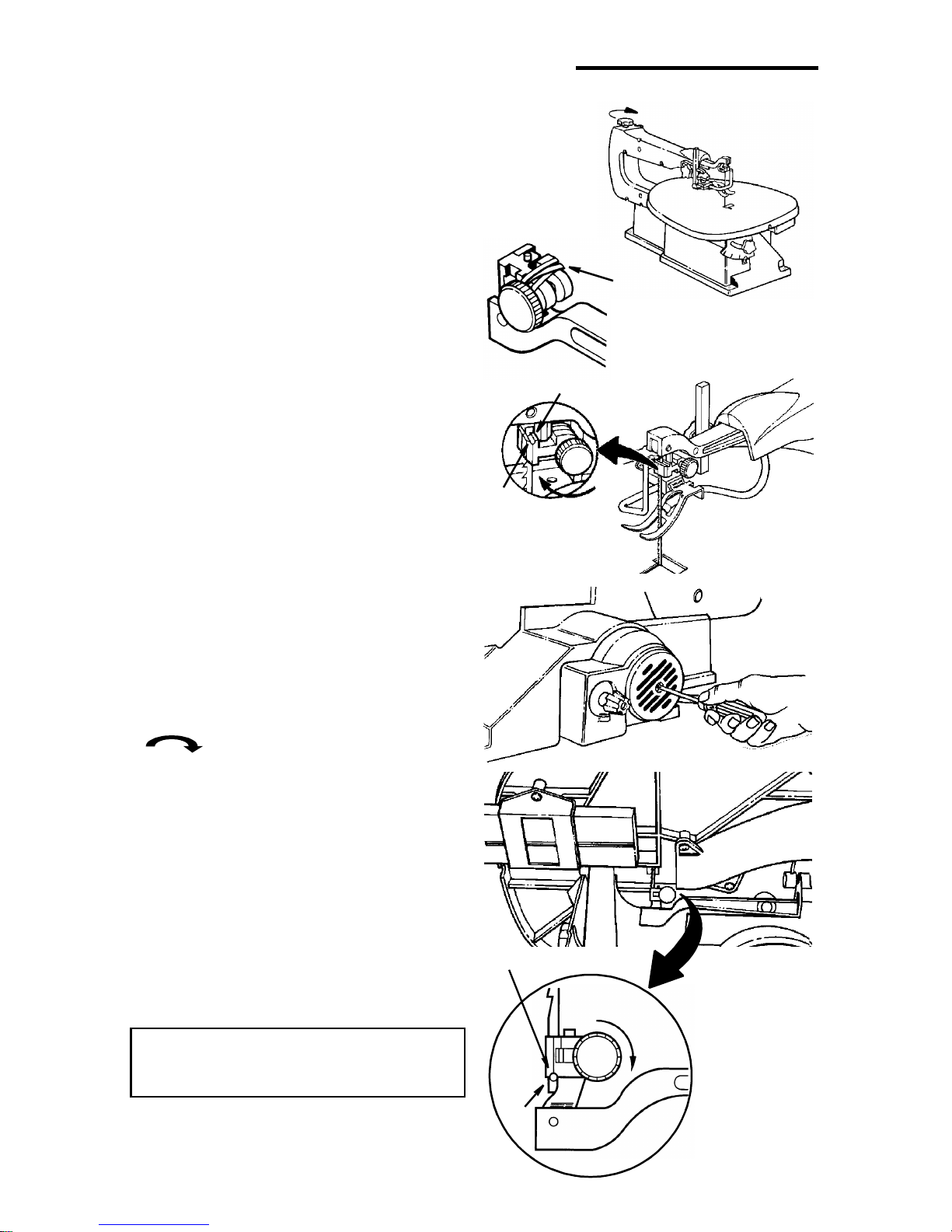

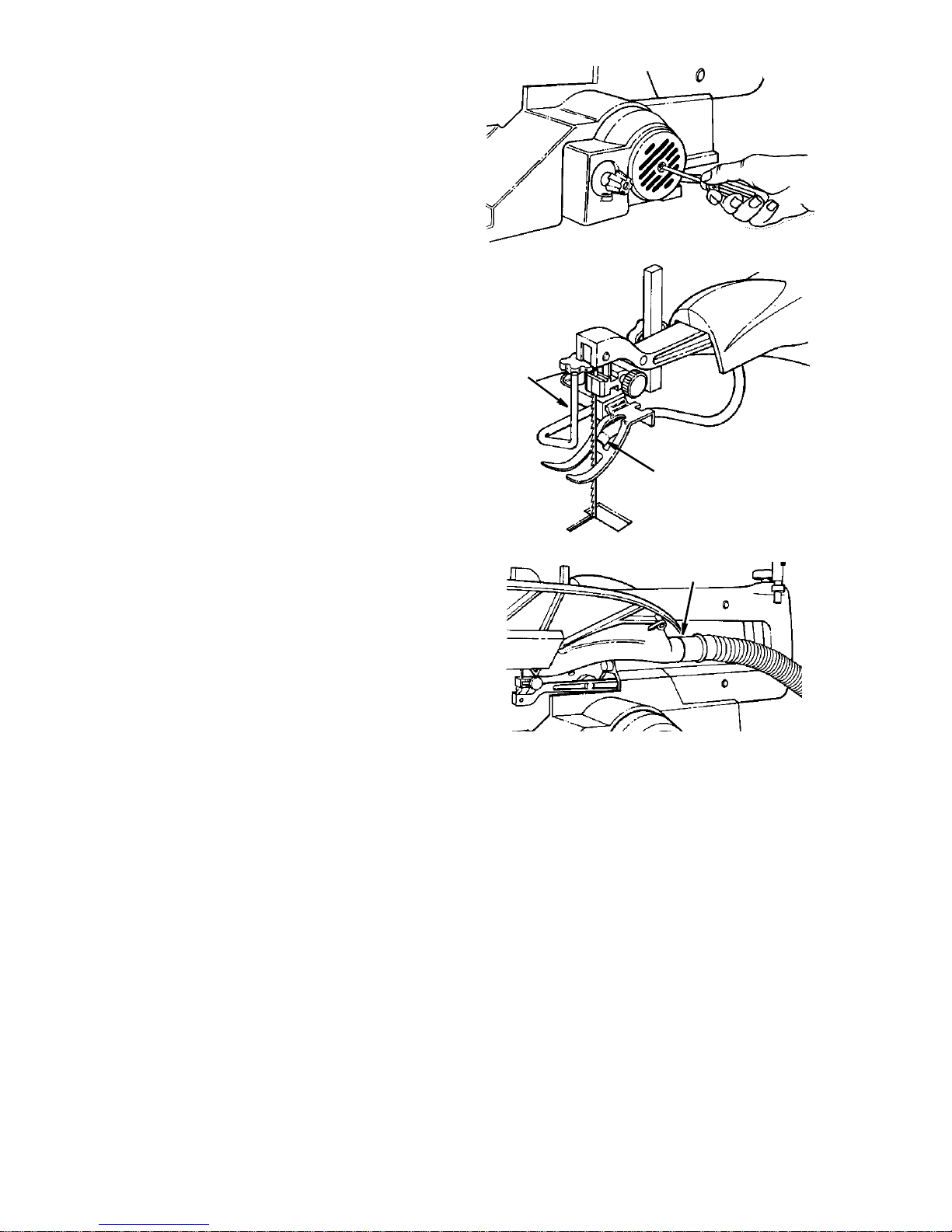

Removing Plain End Blades

WARNING

injury from accidental starting,

always turn switch “OFF” and

unplug power cord from outlet

before removing or replacing the

blade.

• Loosen tension on blade by turning tension knob counterclockwise at

least three full turns.

• Loosen the upper blade holder by turning the knob on the holder counterclockwise so the jaws open.

• Remove blade from upper blade holder.

• Loosen the lower blade holder knob in

the same wa y a s the uppe r blad e holder.

To make lower blade holder access easier, tilt the table to 45° and raise the

arms to the up position using a screwdriver to rotate the motor shaft.

• Remove blade from lower blade holder.

: To reduce the risk of

Loosen

Loosen

Upper

Blade

Holder

Lower Blade

Holder

Loosen

15

Alignment (Adjustments) (continued)

Installing 5" Plain End Blades

• Check that the blade tension knob is

loosened.

• Check that the upper and lower blade

holder knobs are loosened. Spread

blade holde r ja w s ope n usi ng fing ers.

NOTE: A rubber band looped around the

back of th e b lade h older wil l autom atica lly

open the jaws when the knobs are loosened which will make changing blades

easier.

NOTE: The table can be tilted to 45° to

increase access and visibilit y to lower

blade holder area.

• Install the blade through the hole in the

table and into the lower blade holder.

The blade tee th shoul d point down. Position the blade so that it is straight with

the front face of the blade holder and

blade end extends at least 1/8" below

the lower edge of the blade holder as

shown.

• Tighten the lower blade holder knob by

turning the knob clockwise

until the jaws close securely.

NOTE: To maintain blade holder clamping

force, keep finger knob threads cleaned

and oiled using all purpose household

machine (or motor) oil. To prevent blade

holder damage, do not use pliers to

tighten knob.

• Use the same procedure to install the

blade into the upper b lade holder . Bef ore

tightening the jaws using the upper

blade holder knob, adjust the position of

the blade, so that at least 1/8" extends

above the upper edge of the blade

holder as shown. Tighten the upper

blade holder knob by turning the knob

clockwise until the jaws close

securely.

• Carefully tighten the blade tension by turning the tension knob clockwise

until you feel the slack in the blade is

removed. Then turn the tension knob an

additional two turns. The number of turns

will be approximately two full turns, but

may vary by up to one turn depending on

blade thickness and blade type.

1/8"

Min.

Position Blade

As Shown

Lower Blade

Holder

1/8" Min.

Position Blade

As Shown

Rubber

Band

Tighten

Upper Blade

Holder

Tighten

16

• Make sure the blade is properly

installed. Before applying power, rotate

the motor shaft by hand using a screwdriver in the motor shaft as shown.

NOTE: To prevent blade holder damage,

do not use pliers to tighten knob.

Dust Blower

The dust blower wi ll direct air to the most

effecti ve point on t he cut ting line when the

hold down is adjusted. No adjustment is

necessary to the blower.

Blade Guard

The blade guard wil l alw a ys be po sitio ned

parallel to the blade. No adjustment is

necessary .

Sawdust Collection Port

The collection port will help to control

sawdust. Simply attach a 1-1/4" wet/dry

vac hose into the opening.

Blade

Guard

Dust Blower

Sawdust Collection

Port

17

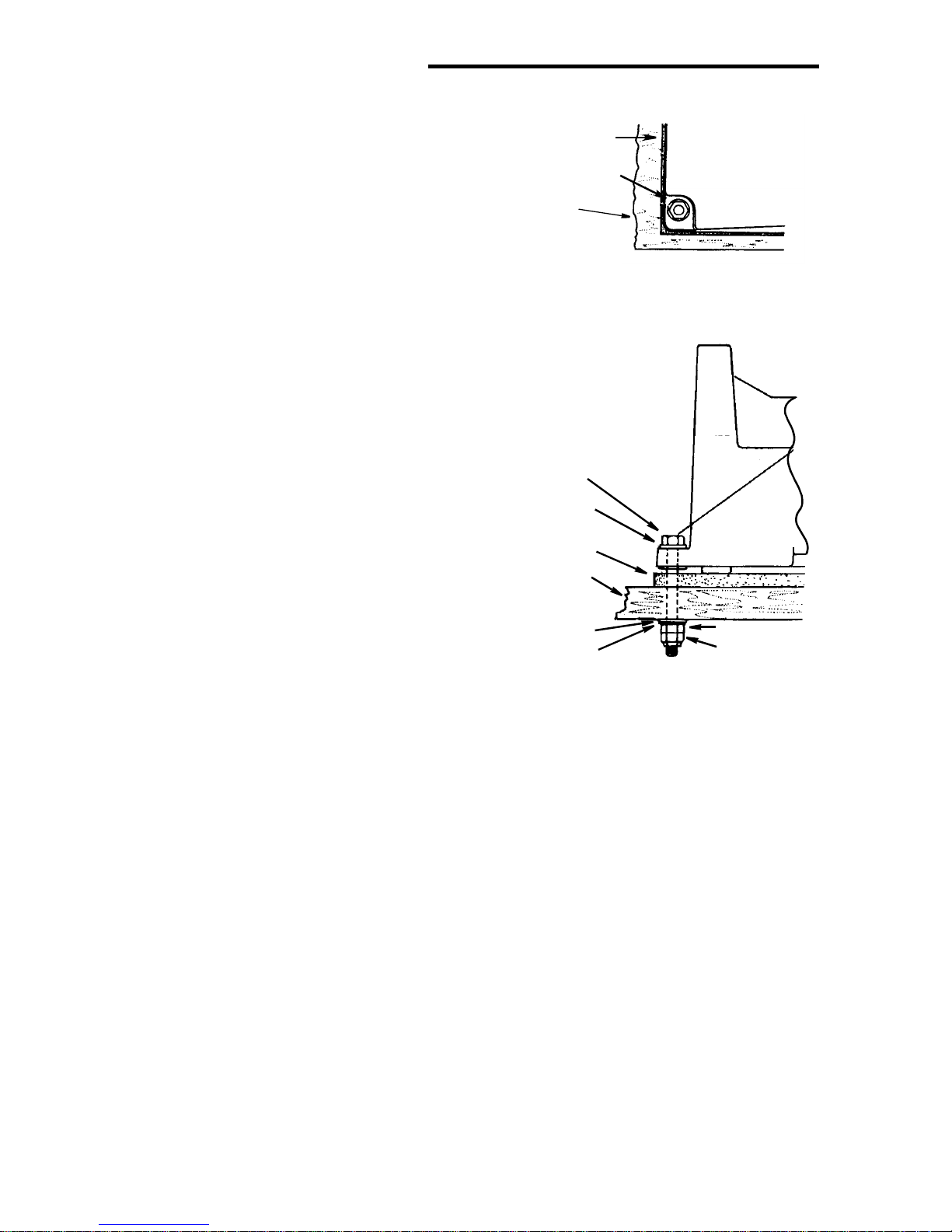

Mounting the Scroll Saw

Workbench Applications

• When mounting this saw to a w orkbench

a solid wood bench is preferred. A plywood bench will cause noise and vibration to be more noticeable.

• Hardware to mount this saw to a workbench is not supplied with the saw.

However, we recommend the hardware

used be not smaller than the following.

Description Qty.

Hex Head Screw,

1/4-20 x length required .................4

Flat Washers, 1/4 I.D. .................. ..... ..8

Lock Washers, 1/4 I.D.........................4

Hex Nuts, 1/4-20................................. 8

• A soft foam pad to place between your

scroll saw and workbench is not supplied with the saw. However, we highly

recommend the use of such a pad to

reduce noise and vibration.

Description Qty.

Soft foam pad such as carpet

padding, 24” x 12” x 1/2”..................1

Do NOT over tighten mounting bolts leave some cushion in the foam pad for

absorbing noise and vibration.

NOTE: Through normal use sawdust

accumulates under the unit. Frequently

clean sawdust from under the unit to prevent the linkage from bin ding, whic h could

overload and damage the motor.

Scroll Saw Base

Hex Head Screw

Workbench

Hex Head

Screw

Flat Washer

1/2" Foam Pad

(Optional)

Workbench

Flat Washer

Lockwasher

Top View

Side View

Hex Nut

Jam Nut

18

Safety Instructions for Basic Saw Operations

Before Each Use

Inspect your saw.

Disconnect The Saw. To reduce the risk

of injury from accidental starting, turn the

switch “OFF”, unplug the saw before

changing the setup, removing covers,

guards or blade.

Check Damaged Parts. Check for:

• Ali gnment of moving parts.

• Binding of moving parts.

• Broken parts.

• Stable mounting.

• Any other conditions that may affect the

way the saw works.

• If any part is missing, bent or broken in

any way, or any electrical part doesn’t

work properly, turn the saw off and

unplug the saw. Replace damaged,

missing or failed parts before using the

saw again. Keep Guard In Place and in

workin g order.

Maintain Tools With Care. Keep the sa w

clean for best and safest performance.

Follow instructions for lubricating.

• Use Only Recommended Accesso-

ries. Follow the instructions that come

with the accessor ies. The use of

improper accessories may cause risk of

injury to persons.

• Choose the right si z e a nd style bl ade for

the material and the type of cutting you

plan to do.

• Make s ure the blade teeth point down-

ward, toward the table.

• Make sure the blade tension is properly

adjusted.

• Keep Work Area Clean. Clu ttered areas

and benches invite accidents. Floor

must not be slippery.

To reduce the risk of burns or other fire

damage, never use the saw near flammable liquids, vapors or gases.

• Know Your Saw. Read and understand

the owners manual and labels affixed to

the tool. Lear n its appl ication s and limitations as well as the specific potential

hazards peculiar to this tool.

• To reduce the risk of inju ry from a ccide ntal contact with moving parts, don't do

layout, assembly or setup work on the

saw while any parts are moving.

• Reduce the Risk of Accidental Start-

ing. Make sure switch is “OFF” before

plugging saw into a power outlet.

Plan your work.

• Use The Right Tool. Don't force tool or

attachment to do a job it was not

designed to do.

• Use this scroll saw to cut only wood,

wood-like products, plastics and nonferrous metals.

CAUTION: This saw is NOT

designed for cutting ferrous metals

like iron or steel. When cutting nonferrous metals (brass, copper and

aluminum, etc.), metal sha vings ca n

react with wood dust and start a fire.

To reduce the risk of fire:

• Remove all traces of wood dust

from inside the saw.

• Remove all traces of metal dust

from on or around the saw before

sawing wood again.

Plan Ahead To Protect Your Eyes, Hands, Face And Ears

Any power saw can throw foreign objects

into the eyes. This can cause permanent

eye damage. Wear safety goggles, not

glasses complying with ANSI Z87.1 (or in

Canada CSA Z94.3-99) shown on package. Everyday eyeglasses have only

impact resistant lenses. They are not

safety glasses. Safety goggles are available at many local retail stores. Glasses

or goggles not in compli ance with AN SI or

CSA could seriously hurt you when they

break.

19

Safety Instructions for Basic Saw Operations (continued)

Dress for safety

• Do not wear loose clothing, gloves,

neckties or je welry (rings, wristw atches).

They can get caught and draw you into

moving parts.

• Wear non-slip footwear.

• Tie back long hair.

• Rol l long sleeves above the elbow.

• Noise levels vary widely. To reduce the

risk of possible hearing damage, wear

ear plugs or muffs when using saw for

hours at a time.

• For dusty operations, wear a dust mask

along with the safety goggles.

Inspect your workpiece.

Make s ure ther e are no n ails or foreign

objects in the part of the workpiece to be cut.

Use extra caution with large, very

small or awkward workpieces

• Never use this tool to finish pieces too

small to hold by hand.

• Use extra supports (tables, saw horses,

blocks, etc.) for any workpiece large

enough to tip when no t hel d down to the

table top.

• Never use another person as a substitute for a table extension, or as additional support for a workpiece or to help

feed, support or pull the workpiece.

• When cutting irregularly shaped workpieces, pl an y our w ork so it wil l not pin ch

the blade. A piece of molding, for example, must lay flat or be held by a fixture

or jig that will not let it twist, rock or slip

while being cut.

• Properly support round material such as

dowel rods or tubing. They have a tendency to roll during a cut, causing the

blade to "bite". To avoid this, always use

a "V" block.

• Clear everything except the workpiece

and related su pport devices off the tab le

before turning the saw on.

Plan the way you will hold the workpiece from start to finish.

• Do not hand hold pieces so small that

your fingers will go under the blade

guard. Keep your hands away from the

blade.

• R educe th e Risk of awkward operations

and hand positions where a sudden slip

could cause fi ngers or h and to mo v e into

the blade.

• Don’t Overreach. Keep good footing

and balance.

• Keep your face and body to one side of

blade, out of line with a possible thrown

piece if the blade shou ld brea k.

Whenever Saw Is Running

WARNING

(gained from frequent use of your

saw) cause a careless mistake. A

careless fraction of a second is

enough to cause a severe injury.

• Before starting your cut, watch the saw

while it runs. If it makes an unfamiliar

noise or vibrates a lot, s top i mm ed iat ely.

Turn the saw off. Unpl ug the saw. Do not

restart until finding and correcting the

problem.

• Keep Children Awa y. Keep all vis itors a

safe distance from the saw. Make sure

bystanders are clear of the saw and

workpiece.

• Don’t Force Tool. It will do the job better

and safer at its designed rate. Feed the

workpi ece into the saw blade only fast

enough to le t it cut w ithout bogg ing dow n

or binding.

: Don’t let familiarity

Before freeing any jammed material:

• Turn switch “OFF”.

• Wait for all moving parts to stop.

• Unplug saw.

When backing up the workpiece, the

blade may bind in the kerf (cut). T his is

usually caused by sawdust clogging

up the kerf. If this happens:

• Turn switch “OFF”.

• Wait for all moving parts to stop.

• Unplug saw.

• With a flat blade screwdriver, turn the

motor by hand while backing up the

workpiece.

Before remo ving loose piec es from the

table, turn saw off and wait for all moving parts to stop.

20

Before Leaving The Saw

• Wait for all moving parts to stop.

• Make Workshop Child-proof. Unplug

the saw. Lock the workshop and ON/

Basic Saw Operations

General Instructions

Please, read and understand the follow-

ing items about y our sc roll sa w before

attempting to use the saw.

• The saw does not c ut wood b y itself . You

allow the s aw to cut woo d b y guidi ng the

wood into the blade as it moves.

• The blade teeth cut wood only on the

down stroke.

• You must guide the wood into the blade

slowly because the teeth of the blade

are very small and the y can onl y remov e

wood when they are on the down stroke.

• There is a learning curve for each person who wants to use this saw. During

that period of time it is expected that

some blades will break until you learn

how to use the saw and receive the

greatest benefit from the blades.

• Best results are achieved when cutting

wood less than one inch thick.

• When cutting wood thic ke r than one inch

the user must guide the wood very, very

slowly int o th e blade and take extra care

not to bend or twist the blade while cutting in order to maximize blade life.

• Teeth on scroll saw blades wear out and

as such must be replaced frequently for

best cutting results. Scroll saw blades

generally stay sharp for 1/2 hour to 2

hours of cutting.

OFF knob on the saw. Store the key

away from children and others not qualified to use the tool.

• To get accurate cuts, be prepared to

compensate for blade’s tendency to follow the wood grain as you are cutting.

• This scroll saw is intended to cut wood,

wood-like products, plastics and nonferrous metals.

• When choosing a blade to use with your

scroll saw, consider the following carefully.

• Very fine, narrow blades should be

used to sc ro l l cu t in thi n wo od 1/ 4 in ch

thick or less.

• To cut wood over 1/4 inch thick, use

wider blades.

• Most blade packages state the size or

thickness of wo od which that blade is

intended to cut, and the radius, size of

curve, which can be cut with that

blade.

• Wi der blades can’t cut cur ves as tight

or small as thinner blades.

• Narrower blades work well only on

thinner wood material.

• This saw uses 5 inch long pin and plain

end type blades only.

• Blades wear faster when cutting plywood, which is very abra si ve, when sawing wood which is thicker than the 7/8

inch blade stroke, and when sawing

hardwood, or when side pressure is

placed on the blade.

Making Interior Scroll Cuts

• One of the features of this saw is that it

can be used to make scroll cuts on the

interior of a board without breaking or

cutting into the outline or perimeter of

the board.

WARNING: To reduce the risk of

injury from accidental starting,

always turn switch "OFF" and

remove plug from power so urce outlet before removing or replacing the

blade.

• T o make interior cuts in a board, remove

the scroll saw blade as explained in the

Assembly section.

• Drill a 1/4" or larger hole in the board in

which you will make interior cuts.

• Place the board on the saw table with

the hole in the board over the access

hole in the table.

• Install the blade through the hole in the

board and adjust blade tension.

21

Basic Saw Operations (continued)

• When finished making the interior scroll

cuts, simply remove the blade from the

blade holders, as described in the

Assembl y section, and remove the board

from the table.

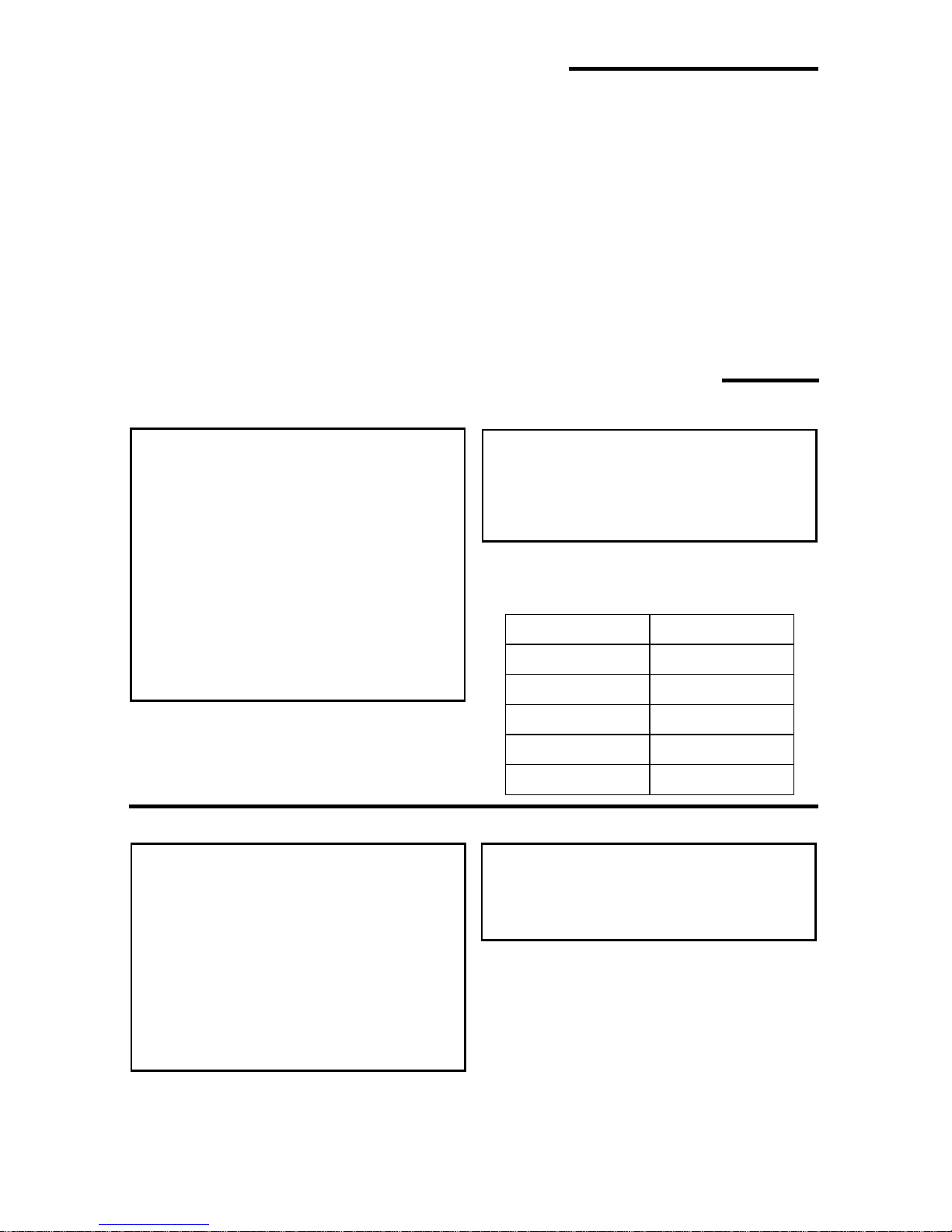

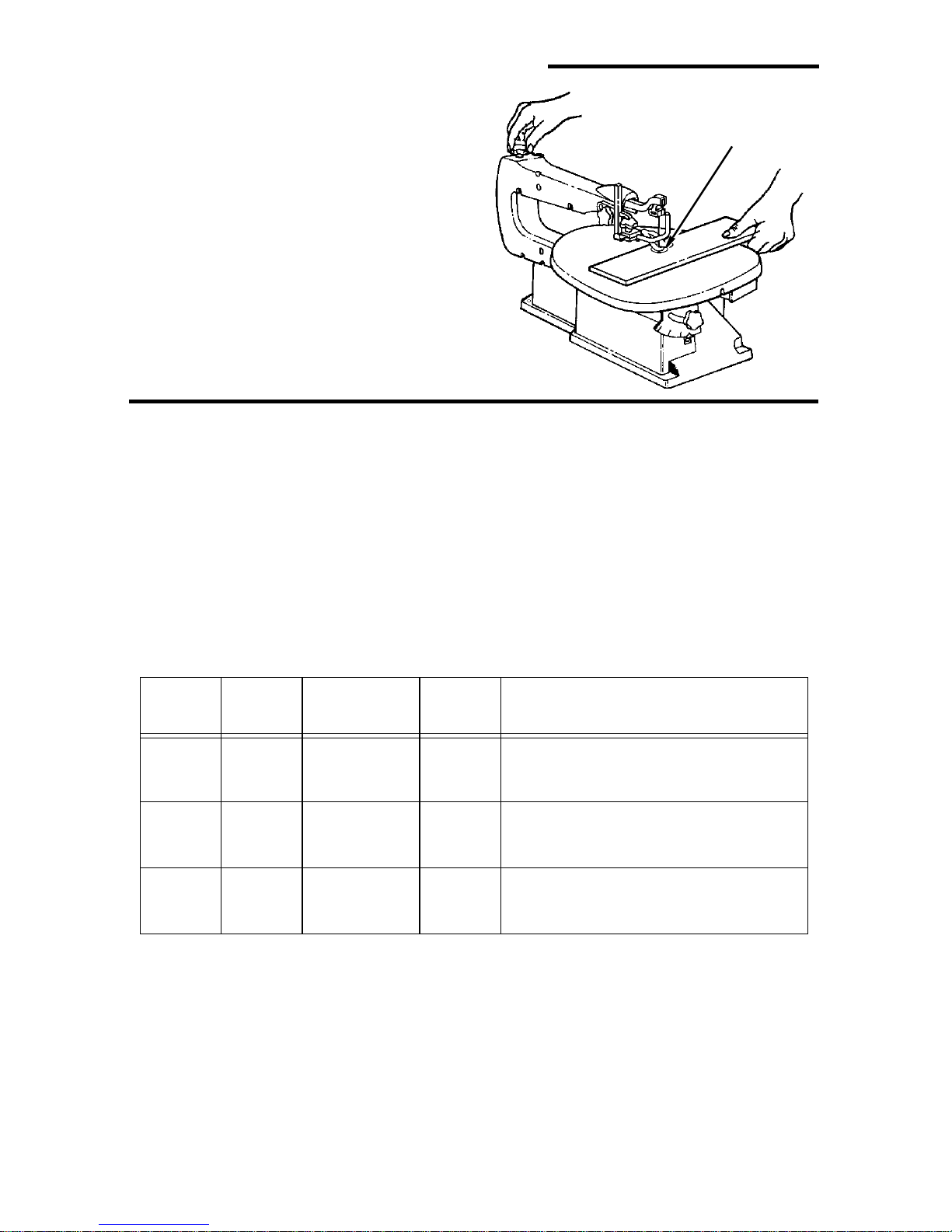

Choice of Blade and Speed

Install Blade Through

Hole In Board

Your scroll saw accepts a wide variety of

5" plain end and pi n end b lades . As a gen eral guide:

• Use a finer tooth blade for cutting thin

workpieces, when a smoother cut is

required for hard materials or when

using slow saw speeds.

• Use a coarser tooth blade for cutting

thicker workpieces, when making

straight cuts, for medium to soft materi-

Pin and Plain end Blades

Teeth/

Inch

20

15

12.5 .038" .016" 600-

11.5

10

Width Thickness Speed Application

.029"

.110"

.053"

.110"

.012"

.018"

.018"

.018"

500-600 Tight radius work; 3/32" to 1/8" wood

1200

12001700

als or when using faster saw speeds.

• Use a blade that will hav e at least 2 teeth

in the material at all times.

• Use thin, narrow blades for tight radius

work, and thick, wide blades for large

curves and straight cuts.

Listed below are examples of some

blades and their intended uses:

veneer, wood, bone, fiber, plastics,

non-ferro us me tals, etc.

Close radius cuttin g in materials 3/32" to

1/2" thick. Good f or hard and s oft wood,

bone, horn, plastics , etc.

For hard and s oft woods and wo odlike

products

3/16" and up.

22

Maintenance

WARNING: For your own safety,

push control knob “OFF” and

remove plug from power so urce outlet before mainta ining or lu brica ting

your saw.

General

An occasional coat of paste wax on the

work tab le will allo w the wood be ing cut to

glide smoothly across the work surface.

Drawer - Apply oil safe for plastic to

drawer and guide as necessary.

To maintain blade holder clamping force,

keep finger knob threads cleaned and

oiled using all purpose household

machine (or motor) oil.

Motor/Electrical

The motor bearings are permanently

lubricated and require no further lubrication.

Do not attempt to oil the moto r bearings or

service the motor internal parts.

Drawer

Oil Finger

Knob Threads

Oil

Here

WARNING: If the power cord is

worn, cut or damaged in any way,

have it replaced immediately.

WARNING: To reduce the risk of

fire or electrocution, reassemble

electric parts with only approved

service parts. Reassemble exactly

as originally assemb led.

Arm Bearings

Lubricate the arm bearings after 10 hours

of use. Re-oil after every 50 hours of use

or whenever there is a squeak coming

from the bearings.

• Turn saw on its side.

• Squirt a generous amount of SAE 30 oil

or household machine oil around the

shaft end and bronze bearing.

• Let the oil soak in overnight in this position.

• Next day repeat the above procedure for

the opposite side of the saw.

Arm

Bearing

Arm

Bearing

23

Troubleshooting

WARNING: For your own safety, turn switch “OFF”, and remove plug from

power source outlet before troubleshooting your scroll saw.

Problem Probable Cause Remedy Schedule

Breaking

Blades.

Plain end

blade slips

within blade

clamp

Motor will not

run.

1. Wrong tension

2. Over working blade.

3. Wrong blade application.

4. Twis ting blade in wood.

1. Blade clamp not tightened

2. Dirty finger knob

threads.

1. Damaged cord or plug.

2. Damaged motor or control board.

1. Adjust blad e tensio n per inst ruction s

under installing Pin End (Plain End)

Blades.

2. Reduce feed rate.

3. Use narrow blades for cutting thin

wood, wide blades for thicker wood.

4. Avoid side pressure on blade.

1. Tighten blade clamp.

2. Clean and oil threads.

3. Check position of blade in holder - 1/8"

beyond top and at front end of blade

holder.

1. Replace damaged parts before

using saw again.

2. Consult Authorized Service. Any

attempt to repai r this motor or c ontrol

board may create a HAZARD unless

repair is done by a qualified service

technician.

Vibration

NOTE: There

will always be

some vibration

present when

the saw is running because

of the blade

and arm

movement.

1. Improper mounting of

the saw.

2. Unsuitable mounting

surface.

3. Loose table

4. Loose motor mounting.

5. Resonance

1. See mounting instructions in this

manual for proper mounting technique.

2. The heavier your workbench is, the

less vibrat ion will occur. A plywood

workbench will not be as good a

work surface as the same size solid

lumber. Use common sense in

choosing a mounting surface.

3. Tighten table lock knob.

4. Tighten motor mounting screws.

5. Try different speed.

24

Wiring Diagram

WARNING: To reduce the risk of

fire or shock, use only recommended service parts and reassemble exactly as originally assembled.

Ground

Screw

(Black)

Smooth

Jacket

Switch

Cord w/Plug

Green

Ribbed

Jacket

(White)

White

Motor

Black

Control

Board

25

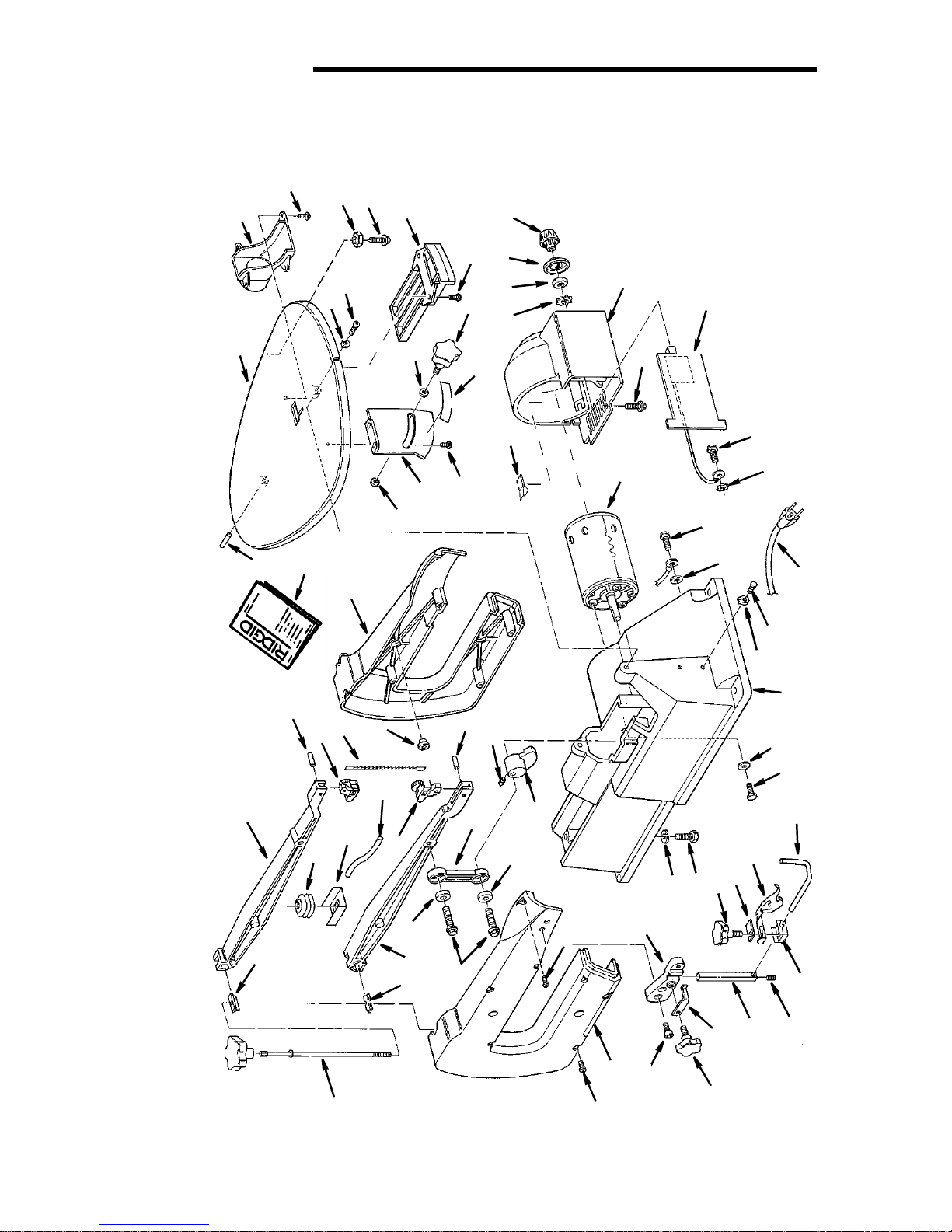

Repair Parts

RIDGID parts are available on-line at www.ridgidparts.com

3

2

1

14

63

6

7

8

5

4

9

12

13

57

15

3

16

17

10

18

11

24

3

19

25

21

20

22

23

22

23

26

27

28

34

38

29

23

30

35

36

37

Model No. SS16501

53

Parts List For RIDGID 16" Variable Speed Scroll Saw

52

54

62

55

56

51

61

58

60

59

48

49

50

54

45

48

46

44

43

42

41

40

31

32

10

10

39

33

47

7

26

Loading...

Loading...