RIDGID OL90150 User Manual

OL90150

OPERATOR’S MANUAL

WHEELBARROW

AIR

COMPRESSOR

To reduce the risk of injury, the user

must read and understand the

Operator’s Manual before using this

product.

IN614300AV 9/04 Printed in U.S.A.

!

WARNING:

Table of Contents

Section Page

Table of Contents . . . . . . . . . . . . . . . .2

Safety Instructions . . . . . . . . . . . . . . .3

Safety Signal Words . . . . . . . . . . . . .3

Before Using the Air

Compressor . . . . . . . . . . . . . . . . . . . .3

Spraying Precautions . . . . . . . . . . . .5

Breathable Air Warning . . . . . . . . . . .5

Warning Labels . . . . . . . . . . . . . . . . .6

Motor Specifications and Electrical

Requirements . . . . . . . . . . . . . . . . . . .7

Power Supply and Motor

Specifications . . . . . . . . . . . . . . . . . .7

General Electrical Connections . . . . .7

110-120 Volt, 60 Hz Tool

Information . . . . . . . . . . . . . . . . . . . .8

Extension Cords . . . . . . . . . . . . . . . .8

Changing Motor Voltage . . . . . . . . . .9

Thermal Overload Protector . . . . . .10

Glossary of Terms . . . . . . . . . . . . . .10

Unpacking and Checking

Contents . . . . . . . . . . . . . . . . . . . . . .11

Section Page

Installation . . . . . . . . . . . . . . . . . . . . .11

Getting to Know Your Air

Compressor . . . . . . . . . . . . . . . . . . .12

Operating Your Air Compressor . . .14

Moisture in Compressed Air . . . . . .14

Lubrication . . . . . . . . . . . . . . . . . . . .14

Operating Your Air Compressor . . .15

For Trouble-Free Operation . . . . . .16

Maintenance . . . . . . . . . . . . . . . . . . .17

Tank . . . . . . . . . . . . . . . . . . . . . . . . .18

Filter Removal, Inspection, and

Replacement . . . . . . . . . . . . . . . . . .18

Drive Belt . . . . . . . . . . . . . . . . . . . . .18

Storage . . . . . . . . . . . . . . . . . . . . . .19

Maintenance Schedule . . . . . . . . . .19

Troubleshooting . . . . . . . . . . . . . . . .20

Repair Parts . . . . . . . . . . . . . . . . . . .24

Warranty . . . . . . . . . . . . . . . . . . . . . .28

2

Safety Instructions

This manual contains information that is

very important to know and understand.

This information is provided for SAFETY

and to PREVENT EQUIPMENT PROBLEMS. To help recognize this information, observe the following symbols.

Safety Signal Words

Danger indicates

an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

Warning indicates

a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

Caution indicates a

potentially hazardous situation which, if not avoided,

MAY result in minor or moderate injury.

Notice indicates

important information, that if not followed, may cause damage to equipment.

Since air compressors and other components (material pump, spray gun, filters,

lubrications, hoses, etc.) used make up a

high pressure pumping system, the following safety precautions should be

observed at all times. Only persons well

acquainted with these rules of safe operation should be allowed to use the air

compressor.

1. Read instruction manuals for each

component carefully, before attempting to assemble, disassemble or

operate your particular system.

2. Wear safety glasses (meeting ANSI

Z87.1 or in Canada CSA Z94.3-99)

and use hearing protection when

operating the pump or unit. Everyday

glasses are not safety glasses.

3. Do not exceed pressure rating of any

component in system.

4. Protect material lines and air lines

from damage or puncture. Keep hose

and power cable away from sharp

objects, chemical spills, oil, solvents,

and wet floors.

5. Never point a spray gun at oneself or

any other person. Accidental discharge may result in serious injury.

6. Check hoses for weak or worn condition before each use, making certain

all connections are secure; do not

use if deficiency is found. Notify an

authorized service facility for examination or repair.

7. Release all pressures within system

slowly; dust and debris may be harmful.

Before Using the Air Compressor

All electrical work should be

done by a qualified (licensed or

certified) electrician. On a properly wired circuit, the black

wires supply a voltage potential

even when the unit is off.

Disconnect power and depressurize system before servicing

air compressor! (Turn pressure

regulator knob fully clockwise

after shutting off compressor.)

3

!

WARNING:

!

CAUTION:

!

DANGER:

!

WARNING:

NOTICE:

!

WARNING:

8. Follow all local electrical and safety

codes, as well as the National

Electrical Code (NEC) and the

Occupational Safety and Health Act

(OSHA).

9. Wiring and fuses should follow electrical codes, current capacity, and be

properly grounded.

10. Electric motors must be securely and

adequately grounded. See grounding

instructions and extension cord information in this manual.

11. Always disconnect power source

before working on or near a motor, or

its connected load. If power disconnect point is out-of-sight, lock it in the

open position and tag to prevent

unexpected application of power.

12. Guard all moving parts; keep visitors

away. Never allow children in work

area.

13. Use only a properly grounded outlet

that will accept a three pronged plug,

and wear shoes to prevent shock

hazards.

14. Be careful when touching exterior of

operating motor; it may be hot

enough to cause injury.

15. Protect power cable from coming in

contact with sharp objects.

16. Clean electrical or electronic equipment with an approved cleaning

agent, such as dry, nonflammable

cleaning solvent.

17. To avoid spontaneous combustion,

discard waste rags into approved

metal waste cans.

18. Never store flammable liquids or

gases in vicinity of compressor.

19. When spraying with solvent or toxic

chemicals, follow instructions provided by the chemical manufacturer.

20. Spray in a well ventilated area, to

keep fumes from collecting and causing health and fire hazards.

21. Do not spray in vicinity of open

flames or other places where a spark

can cause ignition. Do not smoke

when spraying paint, insecticides, or

other flammable substances.

22. Use a respirator when spraying.

23. NEVER reset safety valve or pressure switch. Keep safety valve free

from paint and other accumulations.

This provides safety against over

pressure.

24. Do regular maintenance; keep all

nuts, bolts, and screws tight, to be

sure equipment is in safe working

condition .

25. Keep cleaning rags and other flammable waste materials in a tightly

closed metal container and dispose of

later in the proper fashion.

26. Drain tanks of moisture after each

day’s use. If unit will not be used for a

while, it is best to leave drain cock

open until such time as it is to be

used. This will allow moisture to completely drain out and help prevent

corrosion of inside of tank.

27. Inspect tank yearly for rust, pin holes

or any other imperfections that could

cause it to become unsafe. NEVER

weld or drill holes in air tank.

28. Do not wear loose clothing or jewelry

that will get caught in the moving

parts of the unit.

Safety Instructions (continued)

4

1. Do not smoke when spraying paint,

insecticides, or other flammable substances.

2. Use a face mask/respirator when spraying and

spray in a well ventilated

area to prevent health and

fire hazards.

3. Do not direct paint or other sprayed

material at the compressor. Locate

compressor as far away from the

spraying area as possible to minimize

overspray accumulation on the compressor.

4. When spraying or cleaning with solvents or toxic chemicals, follow the

instructions provided by the chemical

manufacturer.

5

Spraying Precautions

Do not spray flammable materials in vicinity of open flame or

near ignition sources including

the compressor unit.

!

Breathable Air Warning

This compressor/pump is not equipped and should not be used “as

is” to supply breathing quality air. For any application of air for

human consumption, the air compressor/pump will need to be fitted

with suitable in-line safety and alarm equipment. This additional

equipment is necessary to properly filter and purify the air to meet

minimal specifications for Grade D breathing as described in

Compressed Gas Association Commodity Specification G 7.1 - 1966,

OSHA 29 CFR 1910. 134, and/or Canadian Standards Associations

(CSA).

DISCLAIMER OF WARRANTIES

In the event the compressor is used for the purpose of breathing air

application and proper in-line safety and alarm equipment is not

simultaneously used, existing warranties shall be voided, and

Campbell Hausfeld disclaims any liability whatsoever for any loss,

personal injury or damage.

WARNING:

!

DANGER:

Safety Instructions (continued)

6

Find and read all warning labels found on

the air compressor shown below

Warning Labels

0

DK724100AV 100

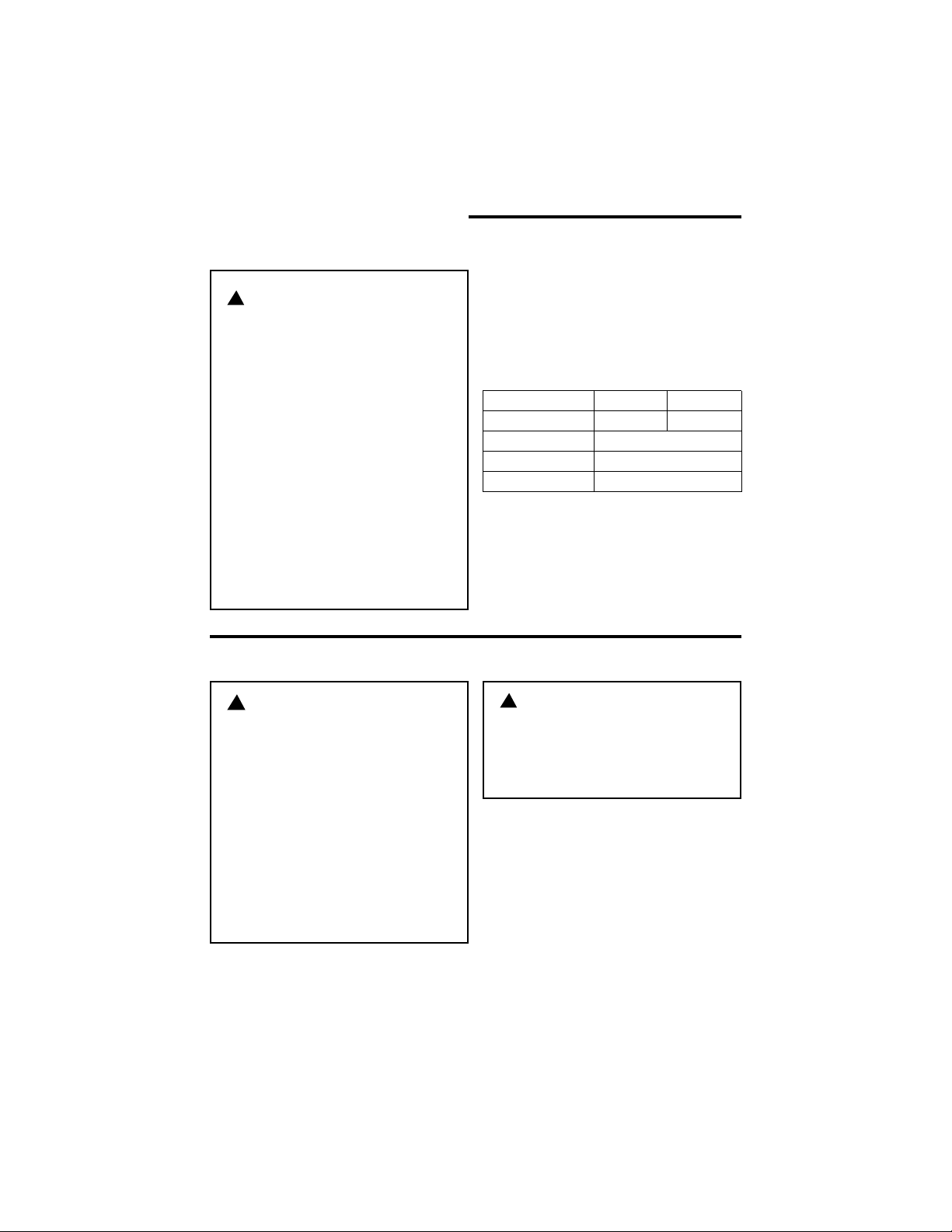

The A-C motor used on this compressor

is a capacitor start, capacitor run nonreversible induction type, having the following specifications. It is wired at the

factory for operation on 110V-120V AC,

60 Hz service.

Voltage 110-120 220-240

Amperes 15.0 7.5

Hertz (Cycles) 60

Phase Single

RPM 3450

Motor Specifications and

Electrical Requirements

7

Power Supply and Motor Specifications

To reduce the risk of electrical

hazards, fire hazards or damage

to the tool, use proper circuit

protection. Your tool is wired at

the factory for operation using

the voltage shown. Connect

tool to a power line with the

appropriate voltage and a 15amp branch circuit. Use a 15amp time delay type fuse or circuit breaker.To reduce the risk

of shock or fire, if power cord is

worn or cut, or damaged in any

way, have it replaced immediately.

!

General Electrical Connections

To reduce the risk of electrocution:

1. Use only identical replacement parts when servicing.

Servicing should be performed by a qualified technician.

2. Do not use in rain or where

floor is wet. This tool is

intended for indoor residential use only.

Do not permit fingers to touch

the terminals of plug when

installing or removing the plug

to or from the outlet.

WARNING:

!

DANGER:

!

WARNING:

8

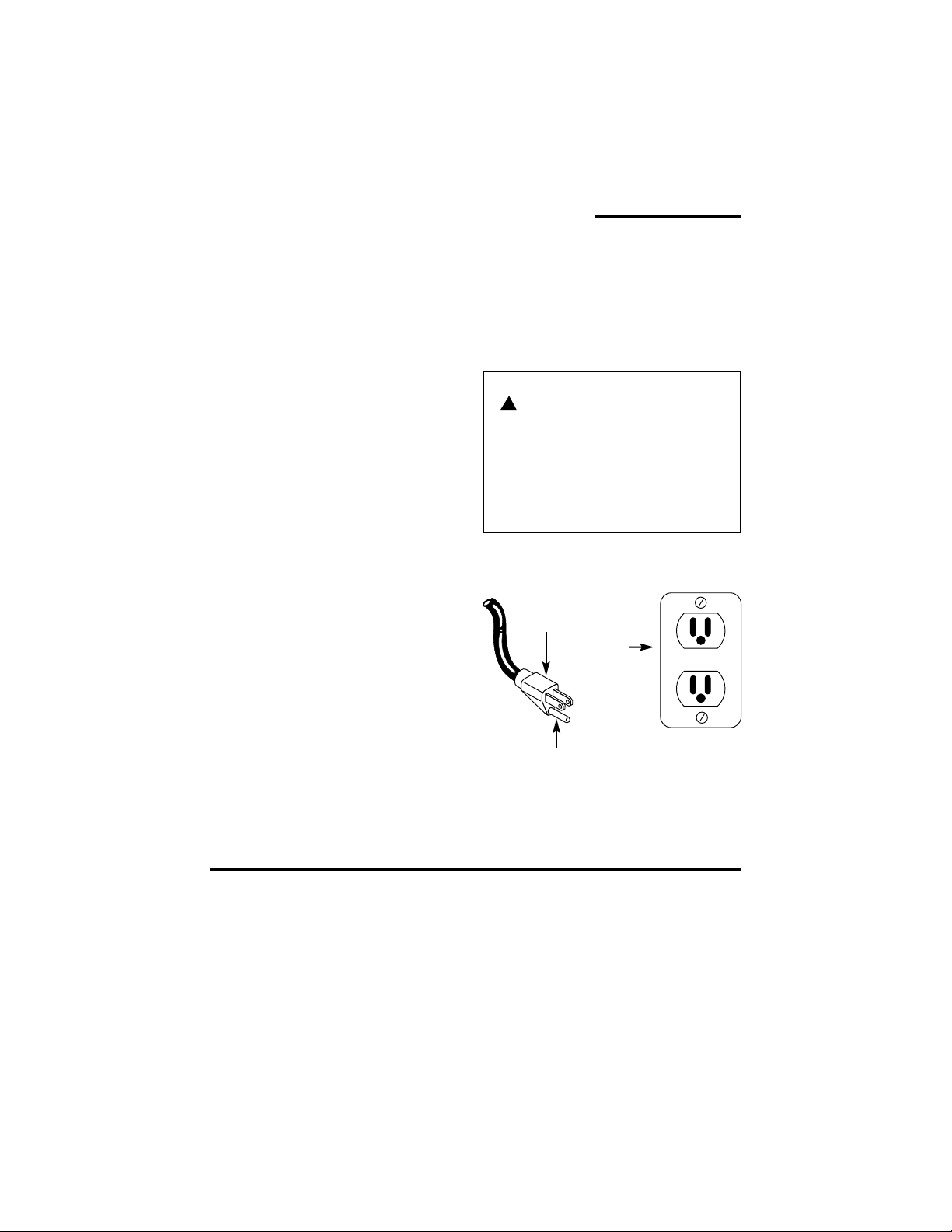

The plug supplied on your tool may not

fit into the outlet you are planning to use.

Your local electrical code may require

slightly different power cord plug connections. If these differences exist refer to

and make the proper adjustments per

you local code before your tool is

plugged in and turned on.

In the event of a malfunction or breakdown, grounding provides a path of least

resistance for electrical current to reduce

the risk of electric shock. This tool is

equipped with an electric cord having an

equipment-grounding conductor and a

grounding plug, as shown. The plug must

be plugged into a matching outlet that is

properly installed and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will

not fit the outlet, have the proper outlet

installed by a qualified electrician.

Improper connection of the equipmentgrounding conductor can result in a risk

of electric shock. The conductor with

insulation having an outer surface that is

green with or without yellow stripes is the

equipment-grounding conductor. If repair

or replacement of the electric cord or

plug is necessary, do not connect the

equipment-grounding conductor to a live

terminal.

If the grounding instructions are not completely understood, or if you are in doubt

as to whether the tool is properly grounded check with a qualified electrician or

service personnel.

Motor Specifications and

Electrical Requirements (continued)

110-120 volt, 60Hz Tool Information

If not properly grounded, this

tool can cause an electrical

shock, particularly when used

in damp locations, in proximity

of plumbing, or out of doors.

Grounding Prong

3-Prong Plug

Properly

Grounded

3-Prong

Outlet

Extension Cords

1. The air compressor should be located

where it can be directly plugged into

an outlet. An extension cord should

not be used with this unit.

2. To avoid loss of power and overheating, additional air hose must be used

to reach work area instead of extension cords.

!

WARNING:

TEST

RESET

9

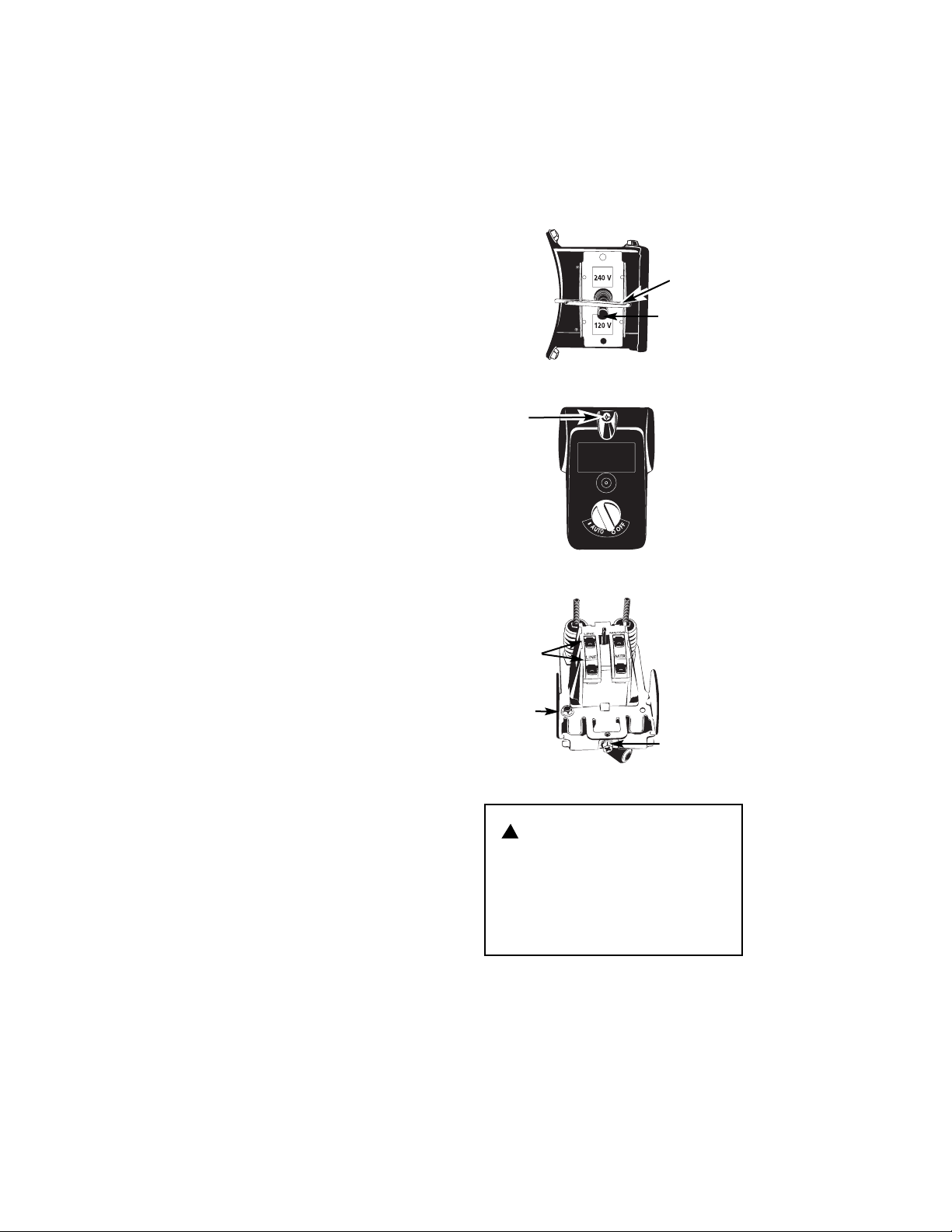

NOTE: The motor is prewired at the factory for 120V operation. Use the following procedure to change motor voltage to

240V.

1. Unplug the power cord before making

or modifying connections.

2. Remove the hitch pin.

3. Toggle the motor voltage selector

switch from 120V to 240V.

4. Install the hitch pin.

5. Unscrew the pressure switch cover

retaining screw and remove the pressure switch cover.

6. Remove the black and white wires

labeled ‘line’ and the green ground

wire. Loosen the screw for the strain

relief.

7. Install a 3 wire, 240 volt, 15 amp U.L.

listed cord (not provided). Be sure to

connect the white and black wires to

the terminals labeled ‘line’ and the

green ground wire to the ground terminal. Also tighten the strain relief

screw.

8. Install the pressure switch cover and

fasten the pressure switch cover

retaining screw.

The unit is now ready for 240 Volt operation.

Changing Motor Voltage

If not properly grounded, this

tool can cause an electrical

shock, particularly when used

in damp locations, in proximity

of plumbing, or out of doors.

Hitch pin

Motor

voltage

selector

switch

Line

terminals

Ground

terminal

Strain relief

screw

Pressure Switch

Pressure Switch Cover

Retaining

screw

!

WARNING:

Loading...

Loading...