RIDGID MS 1290 Owner's Manual

MS1290

OWNERS MANUAL

For Your Safety:

Read all instructions carefully

Save this manual for future

referenece

12 INCH DUAL BEVEL

SLIDE COMPOUND

MITER SAW

Part No. SP6463 Printed in Taiwan

Table of Contents

Section Page

Ta ble of Cont ents ...........................................2

Safety Instructions For Miter Saw ................3

Safety Signal Words ....................................3

Before Usi ng The Saw ..... .... ... .... .... .............3

When Installing Or Moving The Miter Saw ....4

Before Each Use .............................. ..............4

T o Reduce the Risk of Injury From Jams, Slips

Or Thrown Pieces ........................................5

Plan Ahead To Protect Y our Eyes, Hands, Face

and Ears ......................................................5

Dress For Safety ............................................6

Preparing to Make Cut ...................................6

Plan The Way You Will Hold The Workpiece

From Start To Finish. ...................................7

Whenever Saw Is Running ............................7

Before Leaving The Saw ...............................8

Glossary of Terms for Woodworking ...........8

Motor Specifications and Electrical Require-

ments ..........................................................9

Power Supply and Motor Specifications ......9

General Electrical Connections ...................9

110-120 Volt, 60 Hz. Tool Information .........9

Motor Saf ety P rote ctio n ... .... ... .... .... ...........10

Wire Sizes ..................................................10

Unpacking and Checking Contents ............11

Tools Needed ............................................11

Unpac king ..... ........... ........ ........... ............ ...11

List of Loose Parts .....................................11

Getting to Know Y our Miter Saw .................12

Assembly .......................................................13

Installing or Removing the Blade ...............13

Assembling Dust Bag ..................................15

Workpiece Clamp Installation ....................15

Four Basic Saw Controls .............................15

Alignment (Adjustments) .............................17

Miter Lo ck Lever Ad jus tm e nt ...... ...............20

Bevel Lock Lever Adjustment ....................20

Bevel Pivot Movement/Adjustment ............21

Mounting The Miter Saw ..............................22

Safety Instructions for Basic Saw

Opera tion s . .............................................23

Before Each Use .............................. ............23

T o Reduce the Risk of Injury From Jams, Slips

Or Thrown Pieces ......................................23

Plan A head To Pr otect Your Eyes , H ands,

Face and Ears ....... .... .... .... ......................24

Section Page

Dress For Safety ..........................................24

Preparing to Make the Cut ...........................25

Whenever Saw Is Running ................ ..........26

Before Leaving The Saw: ............................26

Basic Saw Operations ..................................27

Making Common Slide Compound Cuts ... 27

Slide Cutting ............................................. 27

Chop Cutting ............................................. 28

Body and Hand Pos it ion ... .... .... ... .... ......... 28

Miter Cut ................................................... 29

Miter Scale Usage ..................................... 29

Bevel Cut .................................................. 29

Sliding Fence ............................................ 29

Vernier Bevel Scale Operation: ................ 29

Compoun d Cut ... .... ... ................................ 30

Cutting Compound Miters on Picture Frames

and Boxes ............................................... 30

Cutting Bowed Material ............................. 30

Workpiece Clamp Usage .......................... 31

Workpiece Support ................................... 32

Auxiliary Fe nc e ...... ... .... ............................ 32

Rough Cutting A Dado .............................. 33

Helpful Hints When Cutting Compound

Miters ... ............ ........... ............ ........... ..... 3 3

Cutting Base Moldings .............................. 33

Cutting Crown Moldings ............................ 34

Two Methods of Cutting Crown Molding ... 34

Maintenance and Lubrication .....................38

Maintenance ............................................. 38

Lubrication ................................................ 39

Motor Belt Tension .................................... 39

Accessories ..................................................40

Recommen de d Ac cess o rie s ........ .... ......... 40

Basic Blade Requirements ....................... 40

Prohibited Accessories ................................40

Using Carbide Tipped Blades .....................40

Tr oubleshooting Guide ................................41

General .. ................................................... 41

Motor .. .... .... ............................................... 42

Wiring Diagram .............................................42

Troub le Shootin g of Br ak e by Qualified Ser -

vice Person Only .................................... 42

Notes ..............................................................43

Repair Parts ...................................................44

Notes ..............................................................50

2

Safety Instructions For Miter Saw

Safety is a combination of common sense, staying alert and knowing how

your miter saw works. Read this manual to understand this miter saw.

Safety Signal Words

DANGER: means if the safety infor-

mation is not followed someone will

be seriously injured or killed.

Before Using The Saw

WARNING: Some dust created by

power sa ndin g, s awi ng, gri ndi ng,

drilling, and other construction

activities contains chemicals

known (to the State of California)

to cause cancer, birth defects or

other rep r od uc ti v e harm. Some

examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks

and cement and other mason ry

products, and

• Arsenic and chromium from

chemically-treate d lumber.

Y o ur risk from these exposures

varies , depending on how often

you do th is type of work. To

reduce your exposure to these

chemicals: work in a well ventilated area, and work with

approved safety equipment,

such as those dust masks that

are specially designed to filter

out microscopic particles.

WARNING: means if the safety infor-

mation is not followed someone

could be seriously injured or killed.

CAUTION: means i f th e safety infor-

mation is not followed someone may

be injured.

lock lever, cover plate stop screw,

depth adjustment clamp and head

hold down, fence slide lock knobs

and workpiece clamp. (See “Getting to Know Your Miter Saw” section within.)

• Review and understand all safety

instructions and operating procedures in this manual.

• Review the maintenance methods

for this miter saw. (See “Maintenance” section within).

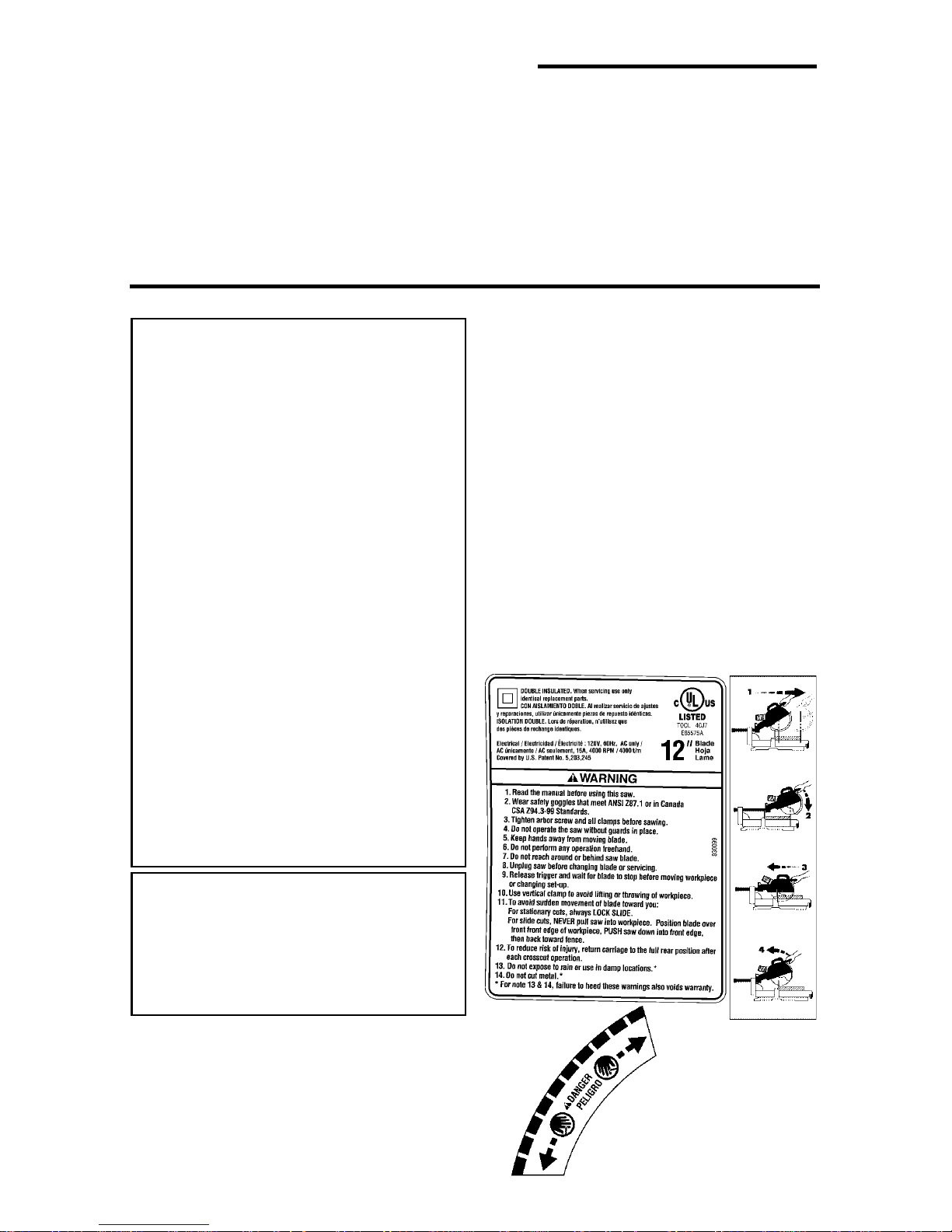

Find and read the following labels on

the miter saw.

WARNING: To reduce the risk of

mistakes that could cause serious, permanen t inju r y, do not

plug the miter saw in until the following steps have been satisfactorily completed.

• Co mpl etely assem ble and align

saw. (See “Assembly” and “Alignment” sections within.)

• L earn the use and function of the

ON-OFF switch, upper and lower

blade guards, miter lock lever , bevel

3

Safety Instructions for Miter Saws (continued)

When Installing Or Moving The Miter Saw

Before moving the saw , l ock th e

miter, bevel, slide and power head

posi t ion s . Un pl ug t h e pow er c or d.

To reduce the risk of back injury, get

help when you need to lift the saw.

Never carry the tool by the cord or

power head trigger handle. Damage

to insulation could cause an electric

shock. Damage to wire connections

could cause a fire.

Reduce the Risk of Dangerous

Environment. Use the miter saw in a

dry, location, protected from rain.

Keep work area well lighted.

Place the saw so neither the user nor

bystanders are forced to stand in line

with the blade. Thrown debris could

injure people in its path.

To reduce the risk of injury from

unexpected saw movement:

• Pla ce the miter saw on a firm level

surface where there is plenty of

room for handling and properly sup-

porting the workpiece.

• Support the miter saw so the tabl e is

level and the saw does not rock.

• Bolt, screw or clamp the saw to its

support.

• Never Stand On To ol. Serious

injury could occur if the tool tips or

you accidentally hit the cutting tool.

Do not store anything above or near

the tool where anyone might stand

on the tool to reach them.

To reduce the risk of injury or

death from electrical shock:

• Make sure your fingers do not touch

the plug’s metal prongs when plugging or unplugging the miter saw.

• This TOOL IS DOUBLE INSULATED to give you added protection. Double insulation does not take

the place of normal safety precautions when operating this tool. When

servicing this double insulated tool,

use only identical parts.

Before Each Use

Inspect your miter saw.

Disconnect The Miter Saw. To

reduce the risk of injury from accidental starting, unplug the saw , before

changing the setup, changing the

blade or adjusting anything.

Compare the direction of rotation

arrow on the guard to the direction

arrow on the blade. The blade teeth

should always point downward at the

front of the saw.

Tighten the arbor screw.

Tighten the cover plate stop screw.

Check For Damaged Parts. Check

for:

• Proper A lignment of moving parts,

• Damaged electric cords,

• Binding of moving parts,

• Broken parts,

• Stable mounting,

• Function of arm return spring and

lower guard: Push the arm all the

way down, then let it rise up until it

stops by itself. Check the lower

guard to see if it closed fully. If it did

not, follow the instructions in the

“Troubleshooting ” section.

• Smooth, solid movement of sliding

assembly.

• Other conditions that may affect the

way the miter saw works.

4

If any part of this m iter saw is missing,

bent, or broken in any way, or any

electrical parts don't work, turn the

saw off and unplug it. Replace damaged, missing, or failed parts before

using the saw again.

Keep Guards In Place, in working

order, and in proper adjustment.

Maintain Tools With Care. Keep the

miter saw clean for best and safest

performance. Follow instructions for

lubricating. DON’T put lubricants on

the blade while it’s spinning.

Remove Adjusting Keys And

Wrenches from tool before turning it

on.

To Reduce the Risk of Injury From Jams, Slips Or Thrown Pieces

• Use Only Recommended Accessories. (See “Accessory” section

within.) Consult this owner’s manual

for recommended accessories. Follow the instructions that come with

the accessories. The use of

improper accessories may cause

risk of injury to persons.

• Choose the right 12-inch diameter

blade for the saw and the material

you plan to cut.

• Mak e sure the blade is sharp,

undamaged and properl y aligned.

With the saw unplugged, push the

power head all the way down. Hand

spin the blade and check for clearance. Tilt the power head to 45

degrees left and right bevel and

repeat the check. If the blade hits

anything, make the adjustments

shown in “Alignment (Adjustments)”

section.

• Make sure the blade and arbor collars are clean.

• Make sure the collars' recessed

sides are facing the blade.

• Using the 1/4” hex end of combination wrench (supplied) or a 1/2-inch

box end wrench, make sure the left

hand thread arbor screw is firmly

tightened counterclockwise.

• Make sure all clamps and locks are

tight and there is no excessive play

in any parts.

• Keep Work Area Clean. Cluttered

areas and benches invite accidents.

Floor must not be slippery .

To reduce the risk of burns or other

fire damage, never use the saw near

flammable liquids, vapors or gases.

Plan Ahead To Protect Your Eyes, Hands, Face and Ears

Know Your Miter Saw. Read and

understand the owner ’s manual and

labels affixed to the tool. Learn its

applications and limitations as well as

the specific potential hazards peculiar

to this tool.

To reduce the risk of injury from accidental contact with moving parts,

don’t do layout, assembly, or setup

work on the miter saw while any parts

are moving.

To Reduce the Risk of Accidental

Starting. Make sure switch is “OFF”

before plugging miter saw into a

power outlet.

Plan your work.

Use The Right Tool. Don’t force tool

or attachment to do a job it was not

designed to do. Use a different tool

for any workpiece that can’t be held in

a solidly braced, fixed position.

5

Safety Instructions for Miter Saws (continued)

CAUTION: Because of the slid ing

action of this saw, this machine

is not designed for cutting metals. Use this miter saw to cut

only wood and wood like products. Other materials may shatter , bind on the blade, start fires

or create other dangers.

Dress F o r Safety

Any power tool can throw foreign

objects into the eyes. This can result

in permanent eye damage. Wear

safety goggles (not glasses) that

comply with ANSI Z87.1 (or in Canada CSA Z94.3-99) shown on package. Everyday eyeglas ses have only

impact resistant lenses. They are not

safety glasses. Safety goggles are

available at many local retail stores.

Glasses or goggles not in compliance

with ANSI or CSA could seriously hurt

you when they break.

Preparing to Make Cut

Do not wear loose clothing, gloves,

neckties or jewelry (rings, wrist

watches) They can get caught and

draw you into moving parts.

• Wear nonslip footwear.

• Tie back lon g ha ir.

• Roll long sleeves above the elbow.

• Noise levels vary widely. To reduce

the risk of possible hearing damage,

wear ear plugs or muffs when using

miter saw for hours at a time.

• For dusty operations, wear a dust

mask along with safety goggles.

Inspect Your Workpiece. Make sur e

there are no nails or foreign objects in

the part of the workpiece to be cut.

Plan your work to reduce the risk

of thrown pieces caused when the

workpiece binds on the blade and

is torn from your hands.

Plan how you will make the cut.

Always:

• Make sure the blade is not spinning.

• Raise the blade.

• Slide the saw out above the front

edge of the workpiece before starting saw, and

• Push the sawblade down on top of

the wood and back toward the rear

of the saw to make the cut.

DANGER: NEVER pull the saw

toward you during a cut. The

blade can sudden ly climb up on

top of the workpiece and force

itself toward you.

6

Plan The Way You Will Hold The Workpiece From Start To Finish.

• Avoid awkward operations and hand

positions where a sudden slip could

cause fingers or hand to move into

the blade.

• Don’t Overreach. Keep good footing and balance.

• Keep your face and body to one

side of sawblade, out of line with a

possible thrown piece.

• Cu t only one workpiece at a time.

• Never cut Freehand :

- Brace your workpiece solidly

against the fence and table top so

it will not rock or twist during the

cut.

-Make sure there’s no debris

between the workpiece and its

supports.

- Make sure no gaps between the

workpiece, fence and table will let

the workpiece shift after it is cut in

two.

• Keep the cut off piece free to move

sideways after it's cut off. Otherwise,

it could get wedged against the

blade and thrown violently.

• Clear everything except the workpiece and related support devices

off the table before turning the miter

saw on.

• Secu re Work . Use cl amps or a

vise to help hold the wor k wh en it’s

practical.

Use extra caution with large, very

small or awkward work pieces:

• Use extra supports (tables, saw

horses, blocks, etc.) for any workpieces large enough to tip when not

held down to the table top.

• Never use another person as a substitute for a table extension, or as

additional support for a workpiece

that is longer or wider than the basic

miter saw table or to help feed, support or pull the workpiece.

• Do n o t u s e th is saw to cut pieces

too small to let you easily hold the

work while you keep the thumb side

of your index (pointer) finger against

the outside edge of the fence.

• When cutting irregularly shaped

workpieces, plan your work so it will

not slip and pinch the blade and be

torn from your hands. A piece of

molding, for example, must lie flat

against the table or fence, or be held

by a fixture or jig that will not let it

twist, rock or slip while being cut.

• Properly support round material

such as dowel rods, or tubing. They

have a tendency to roll while being

cut, causing the blade to "bite." To

avoid this, always use a fixture

designed to properly hold your

workpiece.

Whenever Saw Is Running

WARNING: Don't al low familiarity

(gain ed f rom f requent use of

your miter saw) cause a careless

mistake. A careless fraction of a

second is enough to cause a

severe injury.

Before starting your cut, observe the

miter saw while it runs. If it makes an

unfamiliar noise or vibrates excessively , stop immediately. Turn the saw

off. Unplug the saw. Do not restart

until finding and correcting the problem.

Keep Children Away. Keep all visitors a safe distance from the miter

saw. Make sure bystanders are clear

of the miter saw and workpiece.

7

Safety Instructions for Miter Saws (continued)

Never confine the piece being cut

off. Never hold it, clamp it, touch it, or

use length stops against it while the

blade is spinning. It must be free to

move sideways on its own. If confined, it could get wedged against the

blade and be thrown violently.

Let the blade reach full speed

before cutting. T his will help avoid

thrown workpieces.

Don’t Force Tool. It will do the job

better and safer at its designed rate.

Feed the saw into the workpiece only

fast enough to let the blade cut without bogging down or binding.

Before Leaving The Saw

Never Leave Tool Running Unattended. Turn power off. Wait for all

moving parts to stop.

Make Workshop Child Proof. Install

a padlock through the hole provided

Before freeing jammed material:

• Turn miter saw “OFF” by releasing

trigger switch.

• Wait for all moving parts to stop.

• Unplug the miter saw.

After finishing a cut:

• Keep holding the power head down.

• Release the switch, and wait for all

moving parts to stop before moving

your hands or raising power head.

• If blade doesn’t stop within 6 seconds, unplug the saw and follow the

instructions in the Trouble Shooting

section for fixing the blade brake

before using the saw again.

in the trigger to prevent unauthorized

usage. Lock the shop. Disconnect

master switches. Store tool away

from children and others not qualified

to use the tool.

Glossary of Terms for Woodworking

Arbor

The shaft on which a cutt ing tool is

mounted.

Bevel Cut

An angle cutting operation made through

the face of the workpiece.

Compound Cut

A simultane ous bevel and miter cutting

operation.

Crosscut

A cutting operation m ade across the width

of the workpiece.

Dado

A non-through cut which produces a

square sided notch or

piece

Freehand

Doing a cut without holding the workpiece

against both the table and fence. Most

workpieces can be held down with your

trough in the work-

hand. Large or wide pieces should be

clamped to th e fence or table.

Gum

A sticky, sap based residue from wood

products.

Heel

Misalignment of the blade.

Kerf

The amount of material removed by the

blade in a throug h cut or the slot produc ed

by the blade in a nonthr ough or part ial cut.

Miter Cut

An angle cutting operation made across

the width of t he workpiece.

Offal

Unsecured pei ce of material aft er making

cut.

Resin

A sticky, sap based substan ce that has

hardened.

8

Revolutions Per Minute (RPM)

Workpiece

The number of turns comp let ed by a spinning object in one minute.

Sawblade Path

The area of the workpiec e or table top

directly in li ne with either the travel of the

blade or the part of the workpiece which

will be, or has been, cut by the blade.

Set

The distanc e that the tip of the sawblade

tooth is bent (or set) outward from the

face of the blade.

The it em on which t he cutting operation is

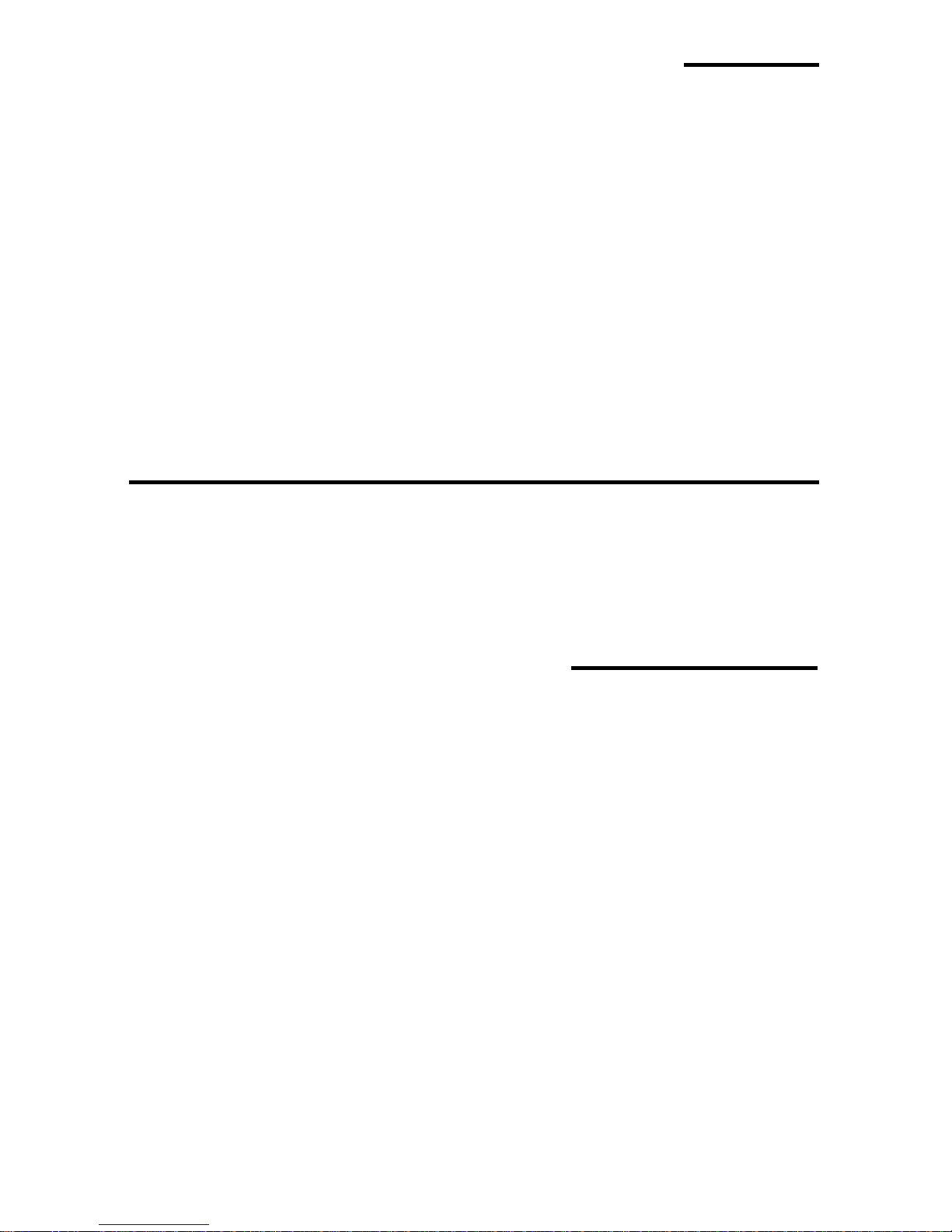

being performed. The surfaces of a workpiece are commonly referred to as fa ces,

ends, and edges.

Face

Edge

Motor Specifications and Electrical Requirements

Power Supply and Motor Specifications

WARNING: To reduce the risk of

electrical hazards, fire hazards

or damage to the tool, use

proper circuit protection. Your

tool is wired at the factory for

operation using the voltage

shown. Connect tool to a power

line with the appropri ate voltage

and a 15-amp branch circuit.

Use a 15-amp time delay type

fuse or circuit breaker. To

reduce the risk of shock or fire,

if pow er cord is wor n or cut, or

damaged in any way, have it

replaced immediately .

The A-C motor used on this tool is a nonreversi ble universal typ e, having the following spe cifications:

Voltage 120

Amperes 15

Hertz (Cycles) 60

Phase Single

RPM 4000

Shaft Rotation Clockwise

Brake Automatic

End

General Electrical Connections

DANGER: To reduce the risk of

electrocution:

1. Use only identical replacement

parts when servicing. Servicing should be performed by a

qualified service technician.

2.Do not use in rain or where

floor is wet.

110-120 Volt, 60 Hz. T ool Information

Double Insulated

The miter saw is double i nsulated to provide a double layer of insulation between

you and the tool’s electrical system. All

exposed metal part s are isolated from the

WARNING Do not permit fingers

to touch the terminals of plug

when installing or removing the

plug to or from the outlet.

If power cord is cut, or damaged in any

way, have it replaced immediately.

internal metal motor components with

protect ing insulation.

9

Motor Spec ifica tio ns and Electr ical Re qu iremen ts ( contin ued )

Polarized Plug

Y our uni t has a plug that looks like the one

shown on next page.

To reduce the risk of electrical shock, this

appliance h as a polar ized pl ug (one bla de

is wider than the other ). Thi s plug will fit in

a polarized out let onl y one way, if the plug

does not fit fully i n the outl et, reve rse plug.

If it still does not fi t, contact a qualified

electrici an to install the proper outlet. Do

not change the plug in any way.

Motor Safety Protection

1. Connect this too l t o a 120v, 15-amp

branch circui t with a 15-amp time delay

fuse or circui t breaker. Using the wrong

size fuse can damage the motor.

2. If the motor won't st art, release the trigger switch immediately. Unplug The

Tool. Check the saw blade to make

sure it turns freely . If the blade is free,

try to start the motor again. If the mo tor

still does not start, refer to the "Motor

Troubleshooting Char t."

3. If the motor sudden ly stalls while cutting wood, release the trigger switch,

unplug th e tool, and fre e the bla de from

the wood. The motor may now be

restarted and the cut finished.

4. Fuses may "blow" or circuit breakers

may trip frequently if:

WARNING: Double insulation

does not take the place of normal

safety precautions when operating this to o l .

a.Motor Is Overloaded-Overloading

can occur if you cut too rapidly or

make too many start/stops in a short

time.

b. Line voltages are more than 10%

above or below the nameplate voltage. For heavy loads, however, the

voltage at m ot o r t erm i na ls m ust equal

the voltage specified on nameplate.

c. Improper or dull saw blades are used.

5. Most motor troubles may be traced to

loose or incorrect connections, overload, low voltage (such as small size

wire in the supply cir cuit) or to overly

long supply circuit wire. Always check

the connections, the load and the supply ci rcuit whe never motor do esn't wor k

well. Check wire sizes and length with

the Wire Size Chart below.

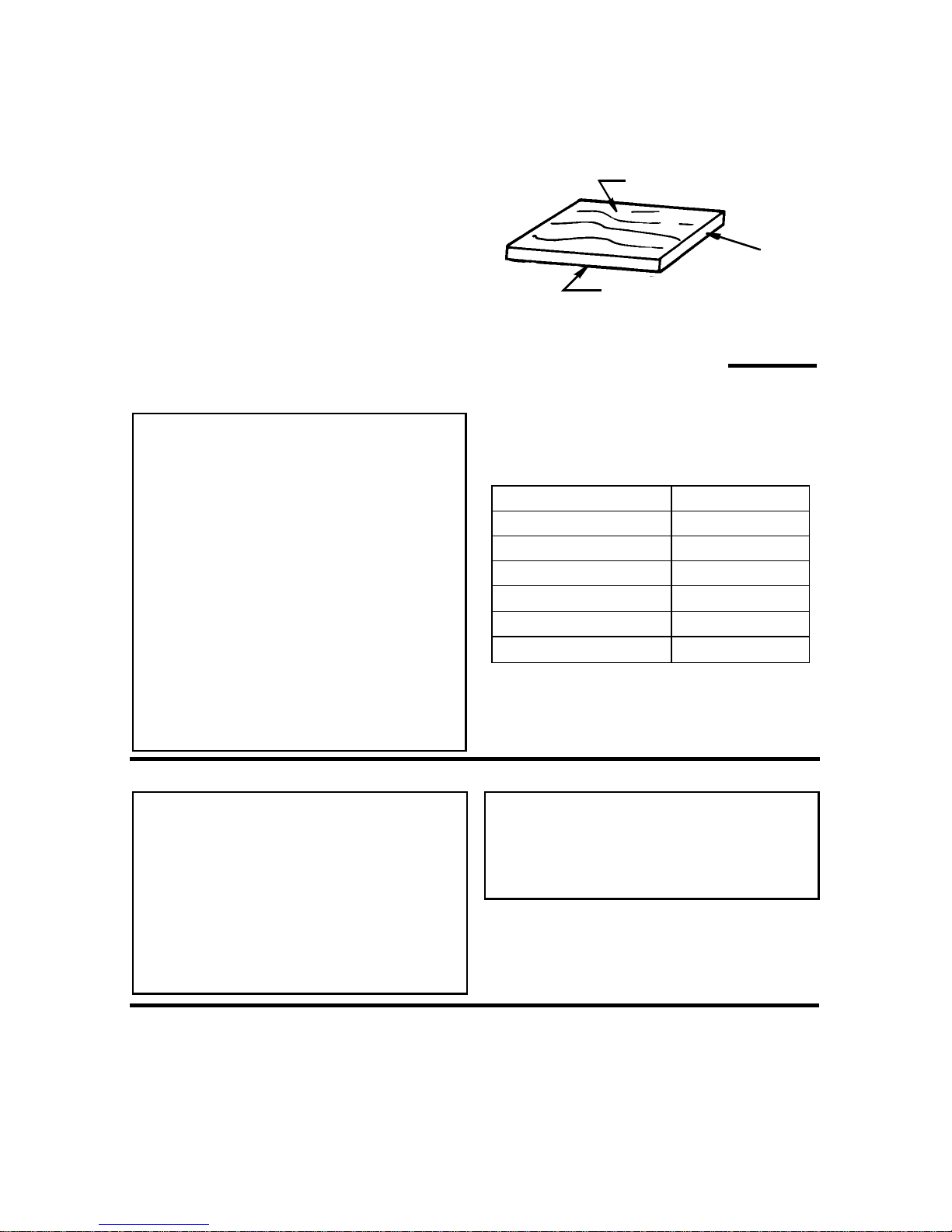

Wire Sizes

NOTE: Make sure the proper extension

cord is used and is i n good condition. The

use of any extension cord will cause

some loss of power. To keep this to a minimum and to prevent ove rheating and

motor burn-ou t, use the t able below to

determine the m inimum wire size (A.W .G.)

extension cord.

For circuits that are farther tha n 100 feet

away from electrical service box, the wire

size must be i ncreased proportionately in

order to deliver ample voltag e to the saw

motor.

Extension Cord

Length

110-120V

0-2 5 F t.

26-50 Ft.

10

Wire Sizes

Required for 120V

(A.W.G.)

14

12

Unpacking and Checking Contents

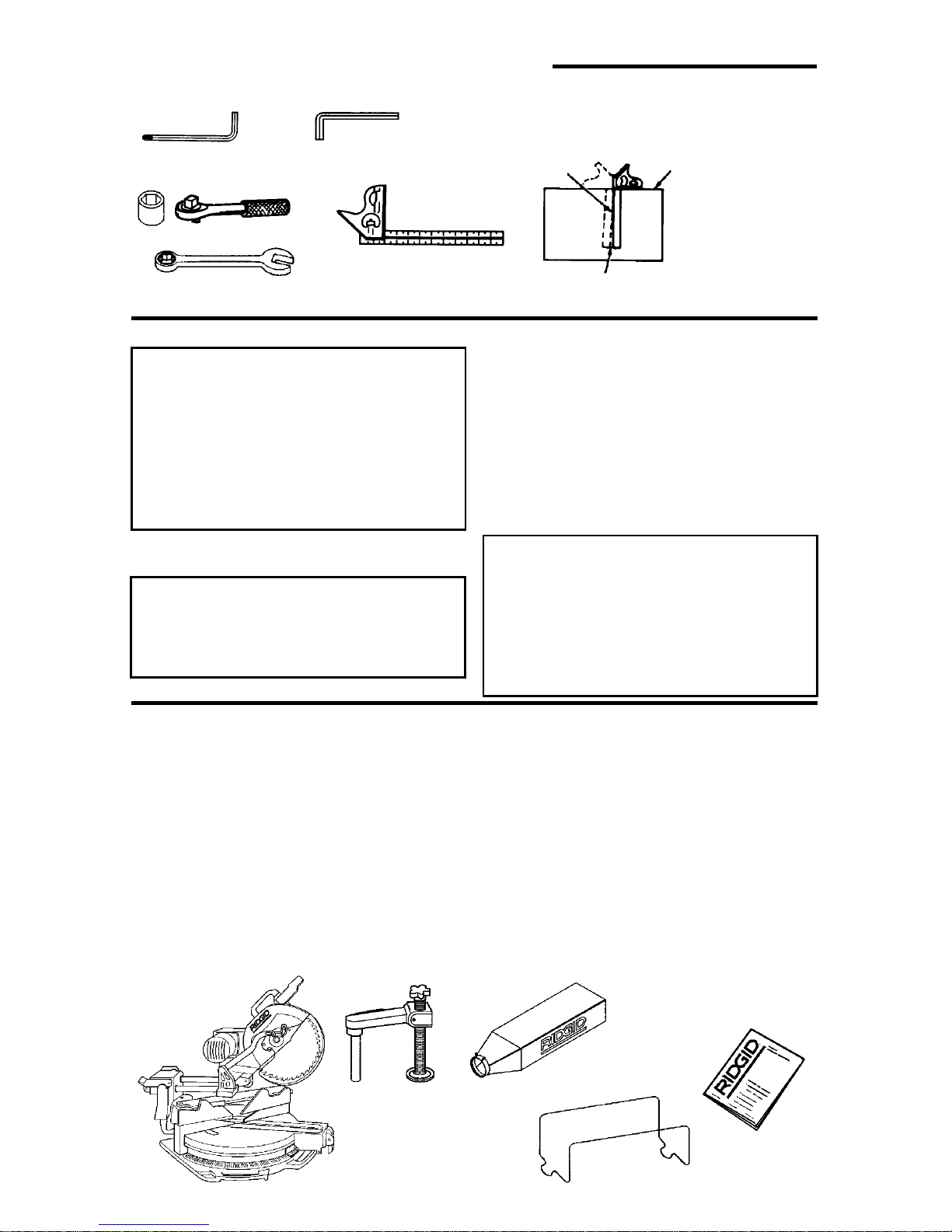

Tools Needed

Combination Square Must be True

Hex “L” Wrench

1/4" (supplied)

19 mm Socket

Combination

Unpacking

Draw Light

Hex “L” Wrench

4mm, 5mm, 6mm

Combination Square

12mmWrench (2)

Line on Board

Along thi s Edge

Should be no Gap or Overlap when Square

is Flipped Over in Dotted Position

Straight Edge of

Board 3/4" Thick

This Edge Must

be Perfectly

Straight

WARNING: To reduce the risk of

injury from unexpected starting

or electrical shock, do not plug

the power cord into a power

source outlet during unpacking

and assembly. This cord must

remai n un pl ug ged when eve r yo u

are working on the saw.

This Miter Saw is shipped complete in

one box.

WARNING: Although compact,

this saw is he avy. To reduce th e

risk of back injury, get help whenever you have t o lift the saw.

List of Lo ose P arts

NOTE: Before beginni ng assembly, check

that all parts are included. If you are missing any part , do not assem ble the saw. Email us at info@ridgidwoodworking.com if

any parts are damaged or missing.

Sometimes small parts can get lost in

packaging material. Do not throw away

any packaging until saw is put together.

Check packaging for missing parts before

contacting RIDGID. A complete parts list

1. Before removing the mit er saw from t he

carton tighten the slide lock knob to

guard against sudden movement.

2. Remove the miter saw from the carton by

lifting the saw with the carrying handle.

3. Place the saw on a secure, stationary

work surface and look the saw over

carefully.

WARNING: If any part is missing

or damaged, do not plug the saw

in until the m issing or dama ge d

part is correctly replaced. To

avoid electric shock, use only

identical replacement parts when

servicing double insulated tools.

(Repai r Part s) is at the end of the manual.

Use the list to identify the number of the

mis sing par t .

The following parts are incl uded:

Part or Assembly Qty.

A Basic Saw Assembly .......................... 1

B Workp ie ce Cl a mp ... ................. ........... 1

C Dust Bag............................................. 1

D Dust Bag Frame.................................. 1

E Owne rs M a nua l................................... 1

A

B

C

E

D

11

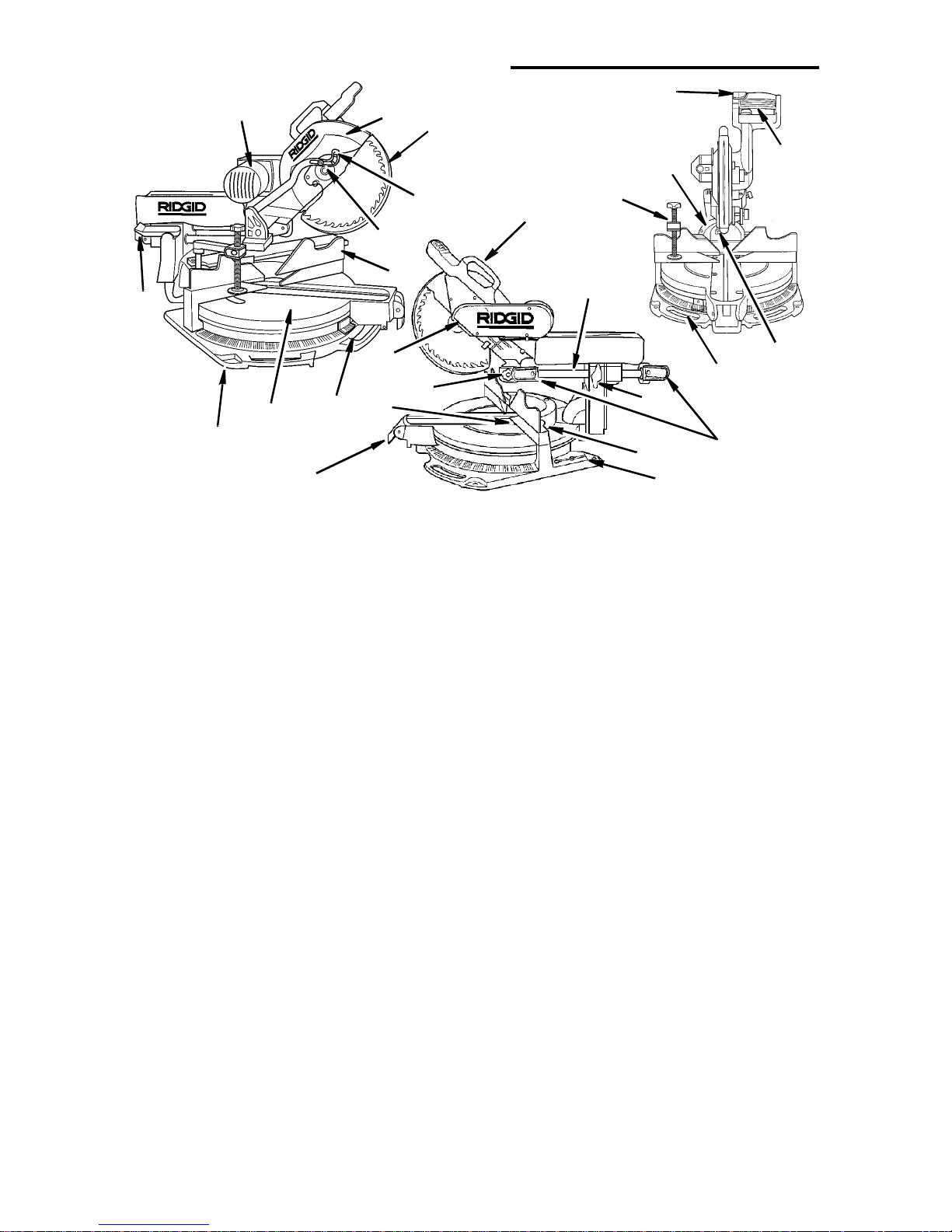

Getting to Know Your Miter Saw

1

10

7

8

16

1.Warn ing Label

2.Upper Blade Guard - Supports the

motor , handle, switch, blade an d lower

guard.

3. Lower Blade Guard - The bl ade gua rd

helps protect your hands from the

blade in the raised position. To reduce

the risk of binding on the workpiece, it

retracts as the blade is lowered.

4.Cover Plate - Holds the lower guar d

and is attached to upper guard. Prevents the arbor screw from backing

out when properly attached with the

cover plate stop screw.

5.Cover Plate Stop Screw - When this

screw is loosened, the cover plate is

rotated to the rear, allowing for blade

removal/replacement.

6.Sliding Fence(s) - Fen ce(s) slide lef t/

right to provi de ma ximum support for

the workpiece.

7. Table - Sits in base, supports pivot

and allows for approx imately 62° mit er

left and right.

8.Base - Supports table, holds accessories and allows for work bench or leg

set mounting.

9. Miter Indicator - Indicates the angle

(miter) the bl ade is set at.

10.Bevel Lock Lever - Locks the miter

20

2

3

25

5

11

24

21

4

6

12

19

18

9

17

13

23

22

26

14

15

saw at a desired bevel angle.

11.Top Carrying Handle - Convenient

way to transport saw.

12. Slide T u be(s) - Allow the blade to slide

for cutting various workpiece widths.

13.Slide Lock Knob - Prevent s th e saw’s

sliding motion by locking the carriage

in place.

14.Slide Fence Lock Knob - Locks

fence at cor rect cutting position.

15.Combination Wrench - 1/4" Hex “L”

wrench.

16.Miter Lock Lever/Miter Index

Thumbwheel - The miter lock lever

securely locks the saw at a desired

miter angle. Index points have been

provided at 0°, 15°, 22.5°, 31.6° (Crown

molding), 45°, 60° Left and Right.

17.The Repeat-A-Cut ™ - Surfac e allows

pencil marks to be made and easily

erased for duplicate cuts.

18.Depth Adjustment Clamp and Head

Hold Down - Limits the saw’s down-

ward trave l f or use when cutting

dadoes and locks the saw in the lowered position for compact storage.

19.Arbor Lock Pin - Allows the user to

keep blade f rom rotating while ti ghtening or loosening arbor during blade

replacement or removal.

12

20. S w i tc h In te rlock Bu tton - Prevents

trigger switch from being accidentally

engaged.

21.On/Off Trigger Switch - To prevent

the trigger from being accidentally

engaged, a lock- off but ton i s prov ided.

To start the tool, pres s in the switch

interlock button and squeeze the tri gger. Release the trigger t o stop the

miter saw. Inst all a padlock through

the hole in the tr igger to prevent unauthorized use.

22.Bevel Index Pin - This pin provides

indexes at 0° and 22.5 °, CM, and 45°

left and right.

Assembly

WARNING: For your own safety,

never connect plug to power

source outlet until all assembly

steps are complete, and you

have read and understood the

safety and operational instructions.

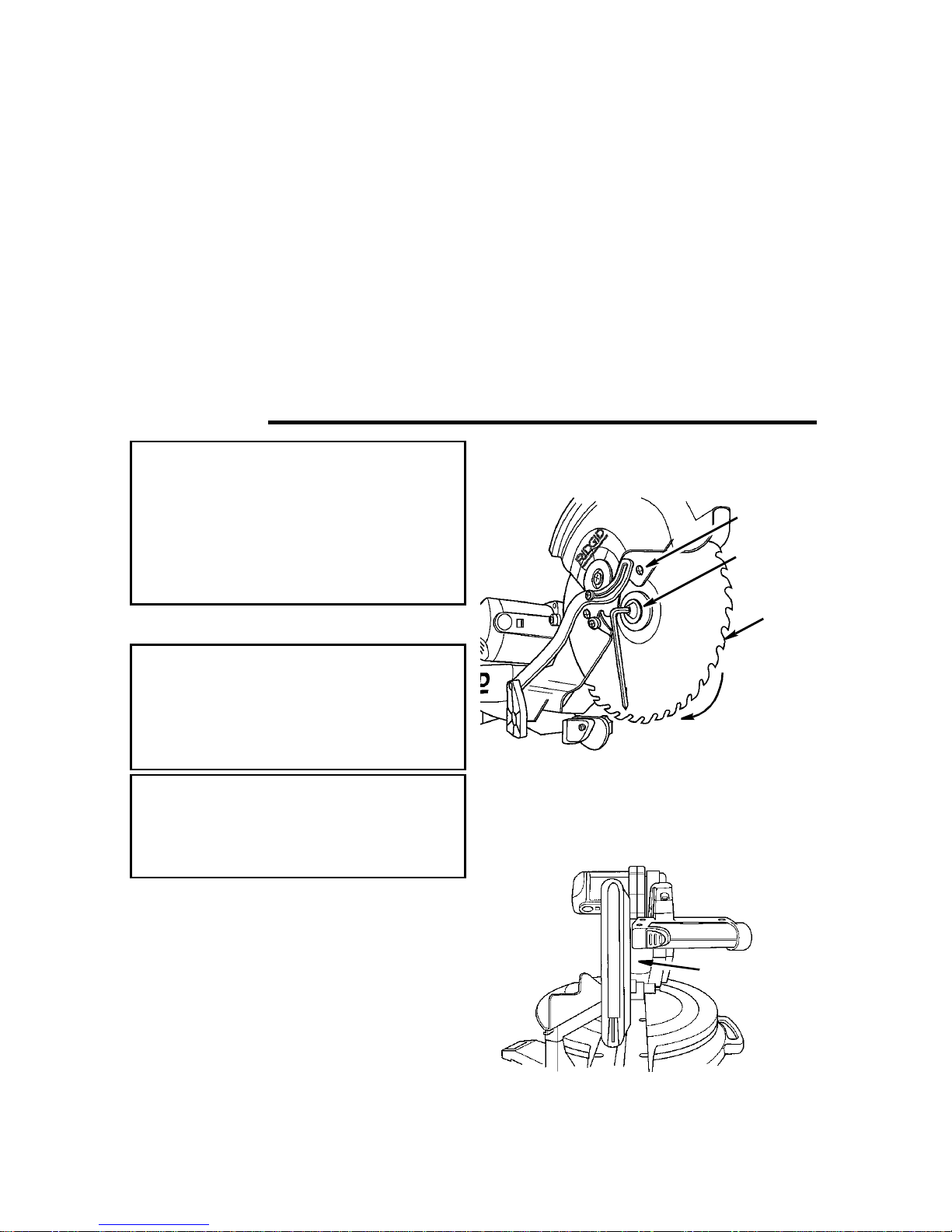

Installing or Removing the Blade

23.Front Carry Handles - Convenient

way to transport the saw.

24.Workpiece Clamp - Helps to h old

workpiece in position for precise cutting. Quick release allows easy movement for workpiece width adjustment.

Pin of clamp fit s in either hole in rear

at fence.

25.Bevel Indicator - Indicates the angle

(bevel) the blade is set.

26.Cord Wrap Brackets

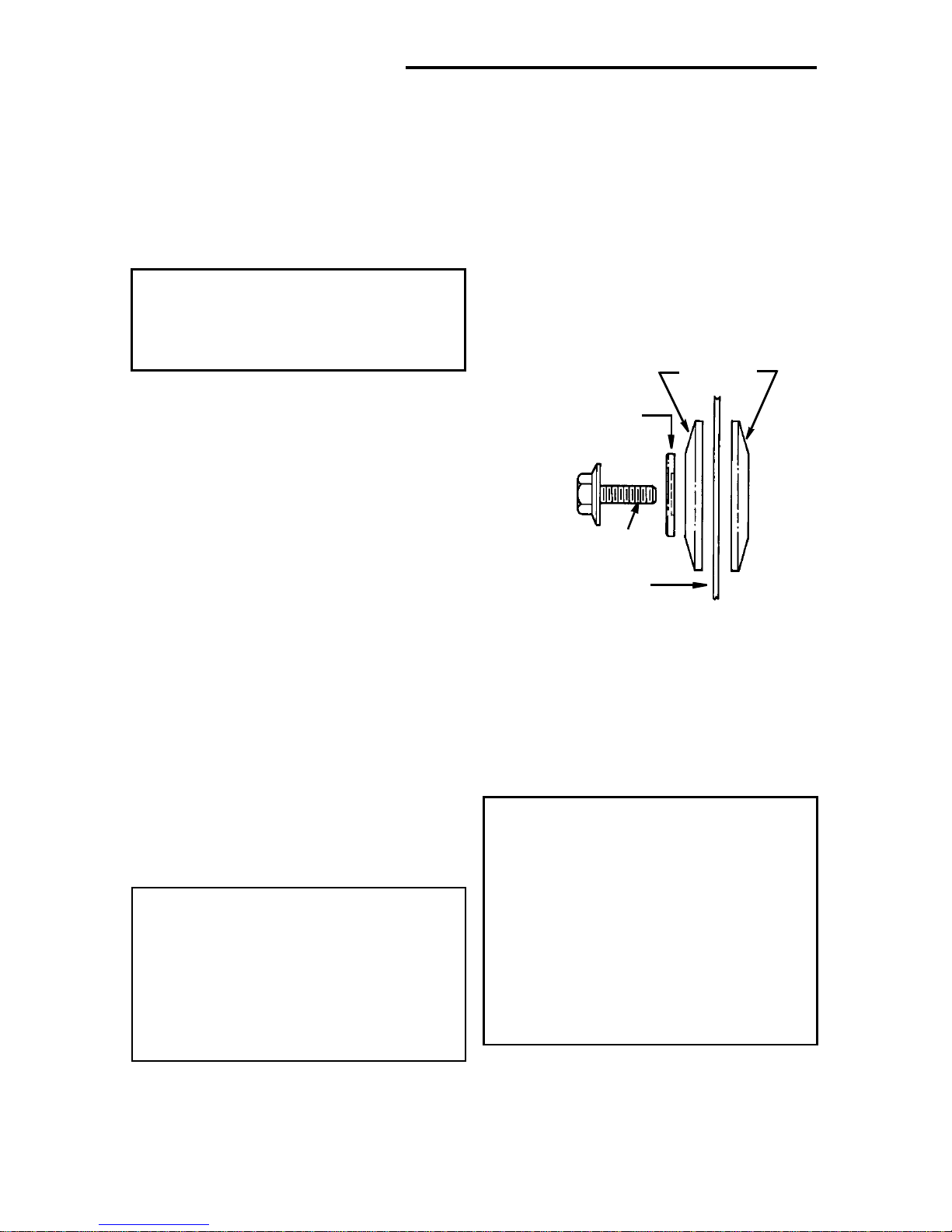

Coverplate

Stop

Screw

Arbor

Screw

Blade

WARNING: To reduce the risk of

injury from a thrown workpiece

or thrown pieces of blade, do not

use a blade larger or smaller than

12" diameter.

WARNING: To reduce the risk of

injury fro m unexpected starting,

unplug the saw whenever you are

removing or installing the blade.

1.Unplug the saw from the outlet. Cutting head is up.

2.Rotate t he lower blade g uar d by hand.

Loosen, but do not remove, the cover

plate stop sc rew u sing t he Phil lip s en d

of combination wrench.

3.Lift the lower guard up and tilt the

lower guard asse mb ly back so the

arbor screw is exposed.

4.Fit 1/4” hex end of combination tool in

arbor screw or use 1/2” box end

wrench.

n

e

s

o

o

L

5.Press the arbor lock and hold it in

firmly while turning the wrench clockwise. The arbor lock will engage after

some turning of the wrench.

Arbor Lock

NOTE: The arbor screw has a left hand

thread. This hel ps prevent unwanted

looseni ng of the arbor screw during normal operat ion.

13

Assembly (continued)

6. Remove the arbor screw, arbor

washer, outer blade collar, and the

blade.

NOTE: Pay attention to pieces removed,

noting their pos ition and direction they

face (see illustration). Wipe the blade collars clean of any sawd ust bef ore inst all ing

the new blades.

CAUTION: To reduce the risk of

cuts from extremely sharp teeth:

Wear gloves when installing or

removing sawblade.

See cautions in “Using Carbide Tipped

Blades” section concerning inspection,

use, and selection of carbide tipped and

other sawblades.

7.Install the new 12" blade (see recommended accesso ry l ist). Make sure

the rotation arrow on the blade

matches the clockwise rotation arrow

on the upper guard. The blade teeth

should always point downward at the

front of the saw.

8.Instal l the outer blade collar, blade

washer and arbor screw. Press the

arbor lock and turn the combination

wrench or the 1/2" wrench counter

clockwise to sec ure the bl ade. Tighten

arbor screw usin g modera te force, but

do not overtighten.

9.Lower the lower blade guard until the

slot in cover plate rests all the way

down on the cover plate stop screw.

Tight en the scr ew with the Phi llip s en d

of the combination wrench.

DANGER: Never use saw without

guard cover plate securely in

place. It keeps the arbor screw

from falling out if it accidentally

loosens, and prevents the spinning blade from coming off the

machine.

10.Be sure the arbor lo ck is released so

the blade turns freely.

Blade

Collars

Blade

Washer

(Hollowed Side

Toward Blade)

Arbor screw

(Left Hand Thread)

Sawblade

NOTE: The arbor lock can be damaged

by improper use. If the arbor lock will not

hold, lower the blade down on to a scrap

piece of wood pos it ioned against the

fence. Th is wi ll serve as an alter nate locking means.

WARNI NG: Make sure the collars

are clean and properly arran ged .

After installing a new blade,

make sure the blade clears the

table slot at the 0° and 45° bevel

positions. Lower the blade into

the table slot and check for any

contact with the base or turn

table structure. If blade contacts

table, seek authorized service.

If blade contacts insert, refer to “Alignment“section for adjustme nt.

14

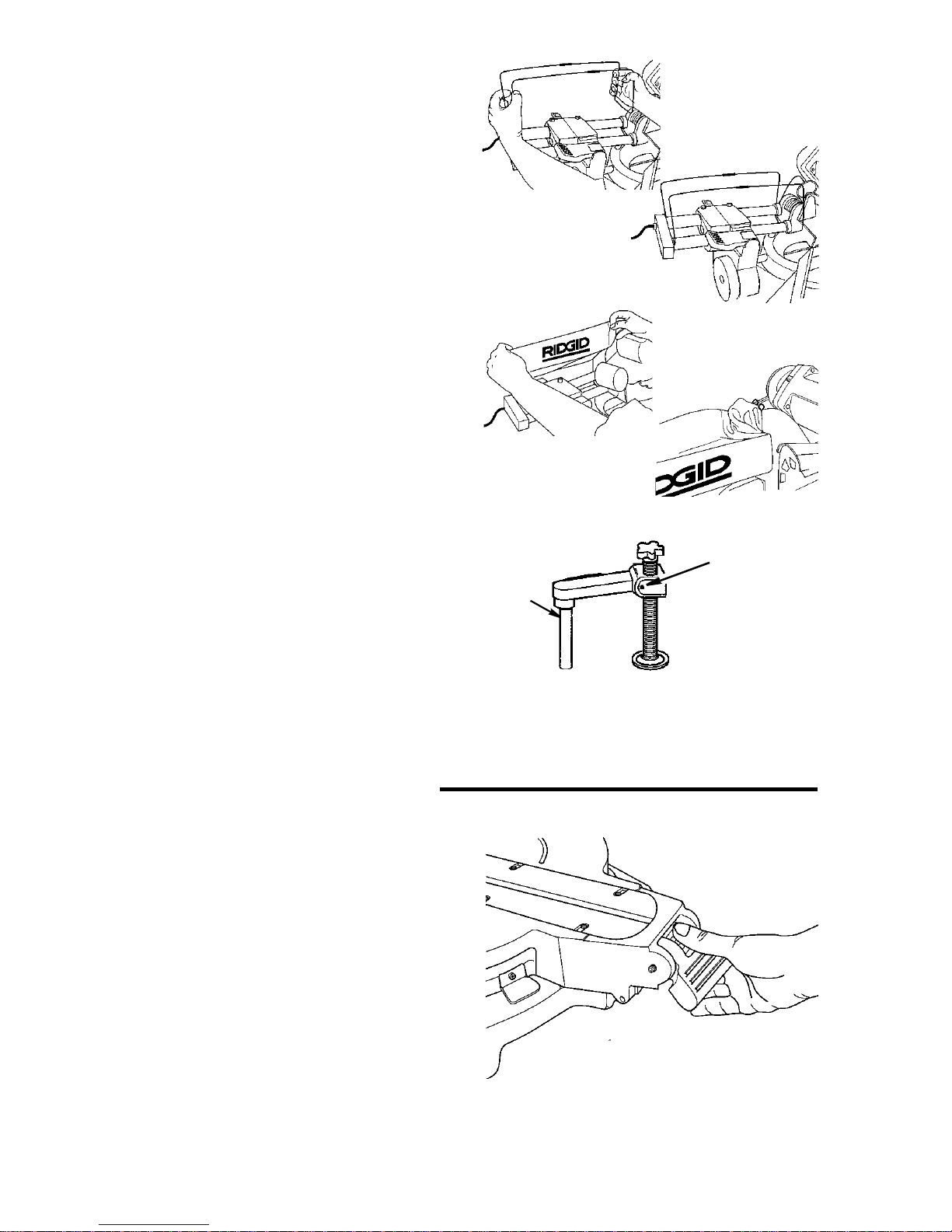

Assembling Dust Bag

1. Locate the dust bag fram e and cloth

dust bag.

2. Clip the dust bag frame in place on the

slide tubes as shown.

3. Slide the cloth dust bag over the dust

bag frame.

4. Connect the dust elbow t o the dus t port

on the upper blade guard.

5. Clamp dust bag onto elbo w.

NOTE: If connecting a 2-1/2" wet/dry vac

hose to the saw, do not attach the dust

bag frame, dust bag and elbow to the

saw. Connect the wet/dry vac hose

directly to the dust port on the upper blade

guard.

Workpiece Clamp Installation

The workpiec e clamp is used to help hold

the workpiece in the correct cutting position. It may be used on either the left side

of the miter saw or the right side. Before

turning the saw on make sure the workpiece clamp does not int erfere with the

cutting action of the saw.

1. Align pin in clamp shaft with keyway in

fence. In sert clamp shaft and rot ate.

Four Basic Saw Controls

In order to properly adjust and align the

Sliding Compound Miter Saw there are

four basic controls that must be understood.

1. Miter lock lever and miter index wheel

To change the miter setting of the

blade:

a. Raise the miter lock lever .

b. Rotate the miter index wheel partial ly

downward to disengage the current

index and engage the next index.

c. Rotate the miter index wheel com-

pletely downward to bypass all mit er

indexes.

d. Turn the tabl e to the desired miter

setting and lock the miter lock lever.

Clamp

Support

Shaft

Quick Rele a se

Button

15

Four Basic Saw Controls (continued)

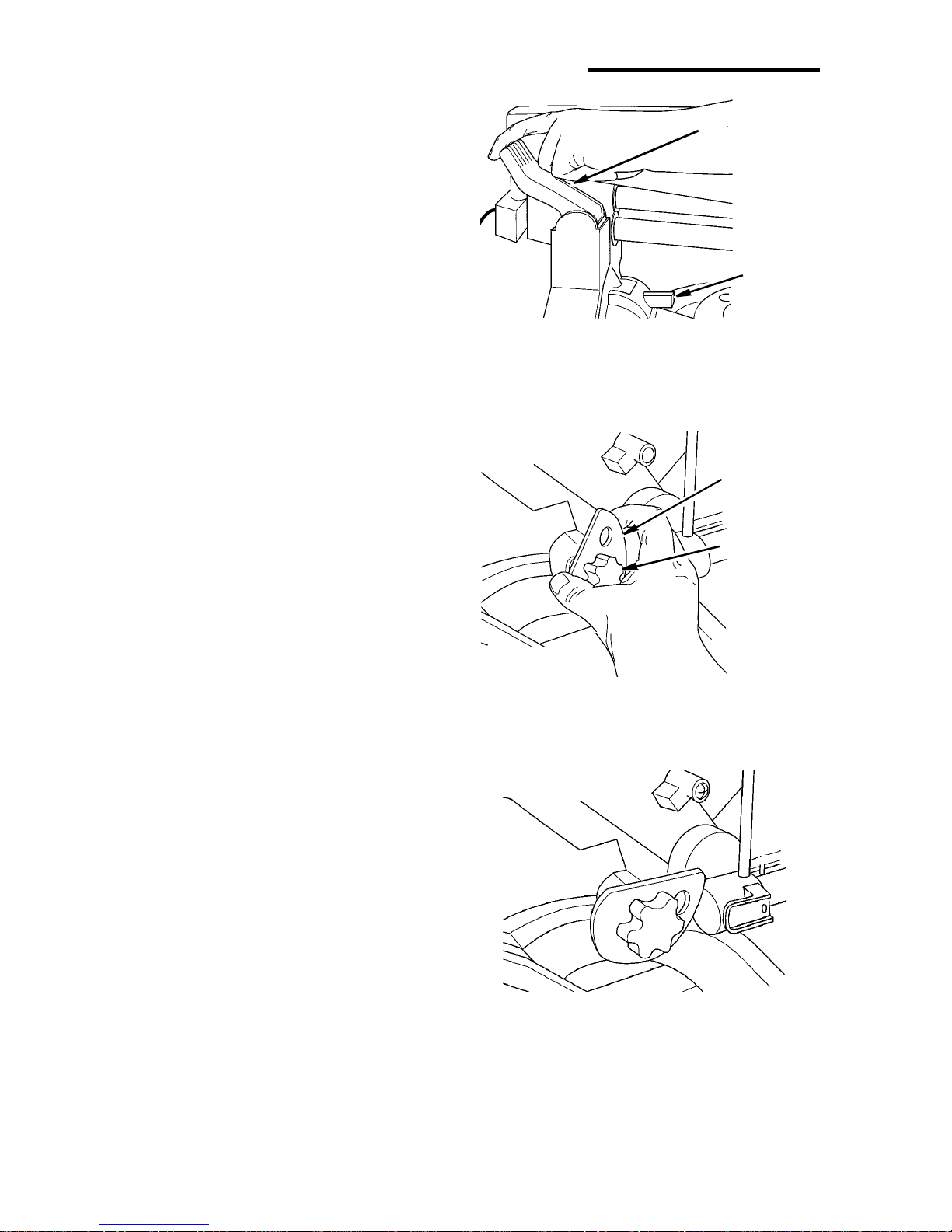

2. B e vel lo c k le v e r/i n de x pin

To change the bevel setting of the

blade:

a. Pull the bevel lock lever for w ard.

Then rotate the bevel index pin

downward. This will allow the blade

to be tilted and at the same time “bypass” the preset bevel indexes.

b. To engage the pr eset bevel indexe s,

rotate the bevel lock index pin up.

c. Engage bevel index pin and/or bevel

lock lever before cutting.

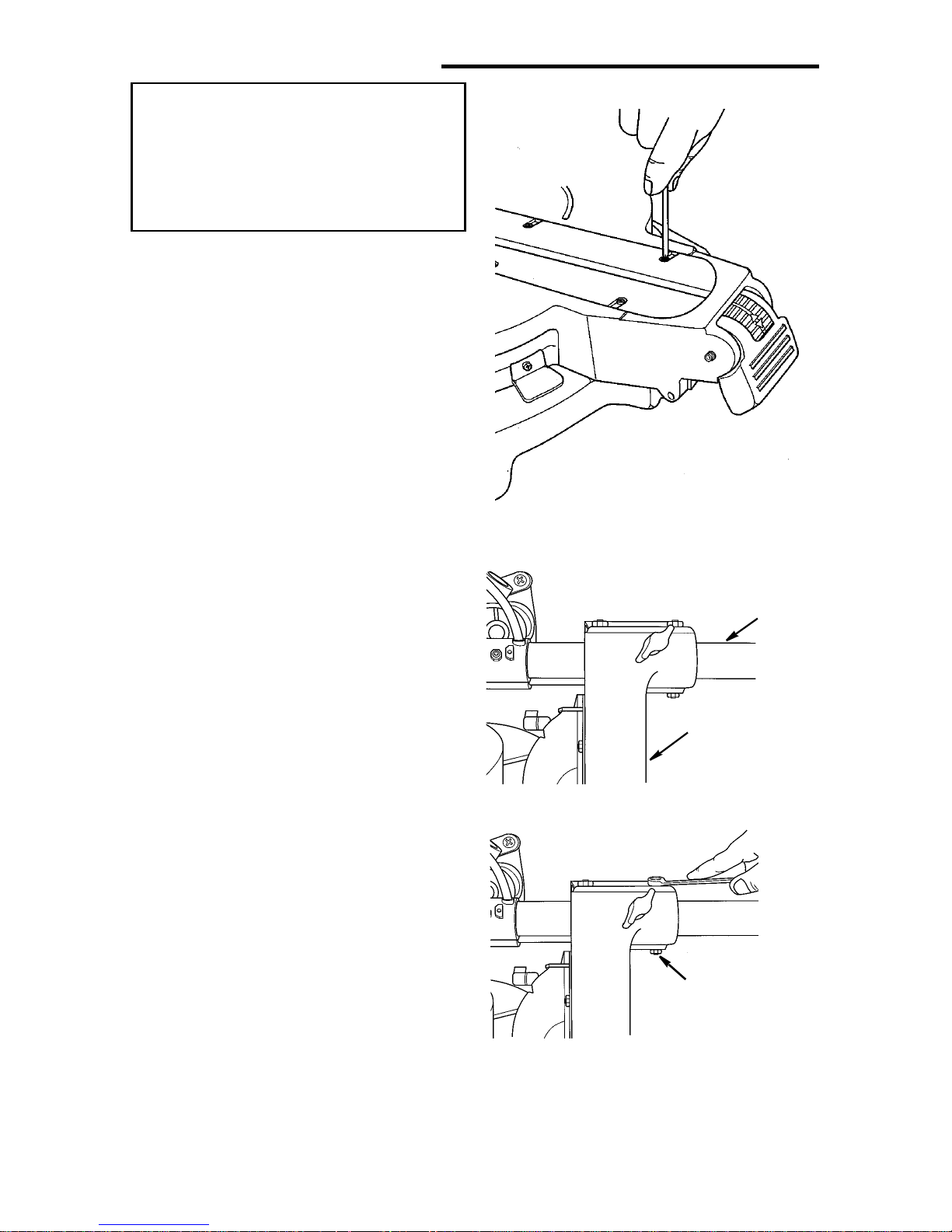

3. Depth Adjustment Cam and Head Hold

Down

To release the blade -

a. While applying light downward pres-

sure on the handle, pull the depth

adjustment cam to th e right, then

raise the blade.

NOTE: It is not necessary to loosen

depth adjustment knob.

b. Rotate the depth adjustment cam so

the flat on the cam is facing upward.

NOTE: Head Hold Down is for transport and storage purposes only. No

cutting operations should take place

while hold down is engaged.

To lock the blade in the lower posit ion.

a. Pull the depth adjustment cam to the

right and lower the blade into the

table.

b. Rotate the depth adjustment cam

until slot engages pin on upper

guard.

4. Slide lock knob

Turn the slide lock knob counterclockwise to loosen and clock wis e to tight en.

Loosening t he knob will allow the powerhead to sl ide back and forth. Tightening the knob will lock the powerhead in

place.

Bevel Loc k

Lever

Bevel Index

Pin

Depth

Adjustment

Cam

Depth

Adjustment

Knob

16

Alignment (A dju stm ents)

WARNING: To reduce the risk of

injury from unexpected starting

or electrical shock, do not plug

the saw in. The power cord must

remai n un pl ug ged when ev er y ou

are working on the saw.

Step One: Repositioning Zero Clearance Blade Insert

The zero cleara nce blade insert needs to

be repositioned so it is temporarily out of

the way when aligning the blade. It may

be replaced after the blade is aligned.

1. Loosen the three screws that secure

the zero cle arance blade insert on one

side of the blade.

2. Slide the zero clearance insert away

from the blade as far as possi b l e .

3. Retighten the three screws.

4. Repeat steps 1-3 for the opposite side

of the blade.

Step Two: Slide T ube Adju stment

1. Plac e the powerhead in the 0° miter/ 0°

bevel index and lock head in lower position.

2. Check to see that the blade is approxi-

mately centered between the two zero

clearance blade inserts. Also check for

play between the rig ht slide rai l and the

pivot assembly.

3. If adjustment is required loos en the jam

nuts on all four gib screws as shown.

4. Loosen the top two gib screws.

5. Tighten or loosen the lower two gib

screws as required to center the blade

between the zero clearance inser ts.

6. Tighten the lower two jam nut s.

7. To minimize play in the slide tubes

gradually tighten the top t wo gib

screws while at t he sam e ti m e sli ding

the powerhead back and forth. Tighten

the top jam nuts.

Slide Rail

Pivot

Assembly

Gib Screw

17

Loading...

Loading...