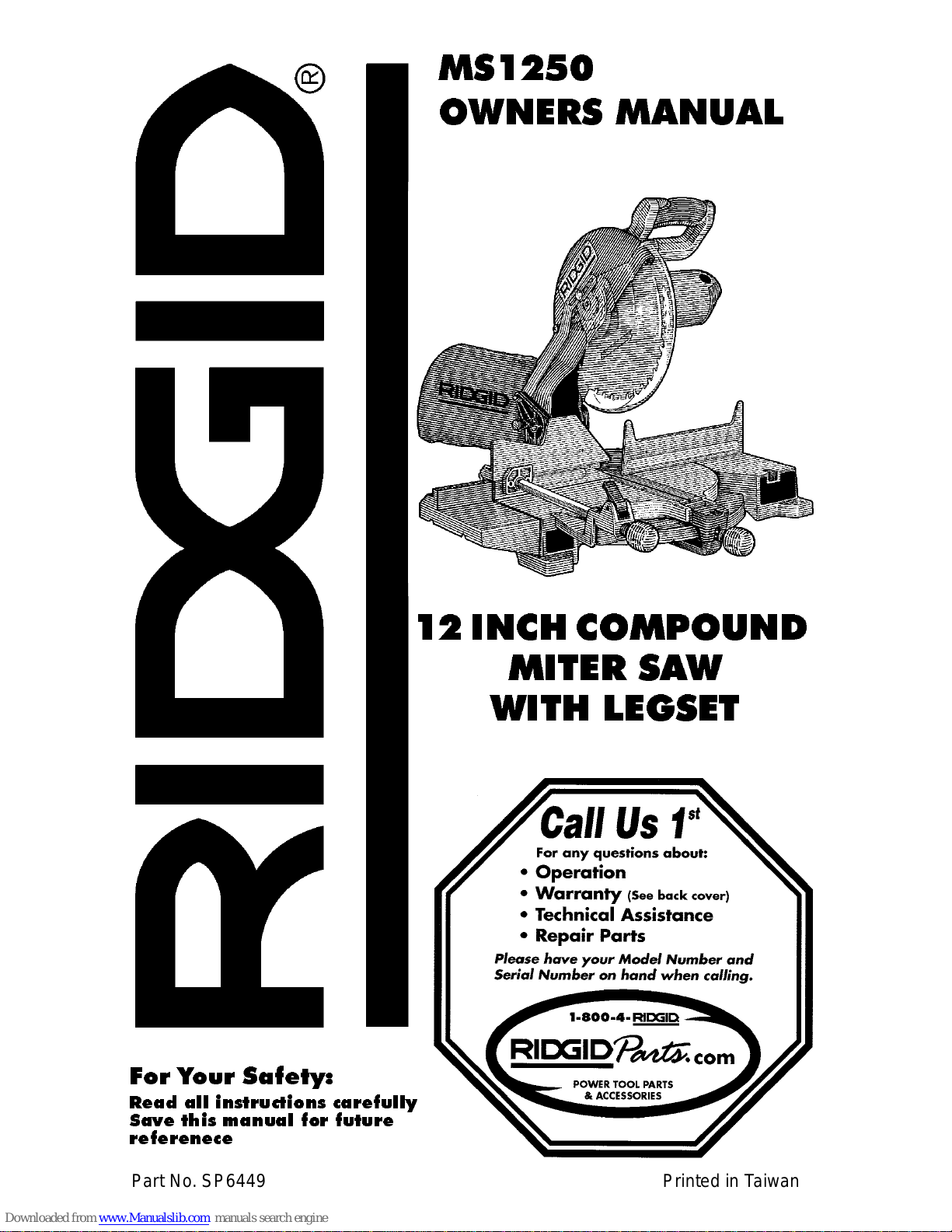

RIDGID MS1250 Owner's Manual

MS1250

OWNERS MANUAL

For Your Safety:

Read all instructions carefully

Save this manual for future

referenece

12 INCH COMPOUND

MITER SAW

WITH LEGSET

Part No. SP6449 Printed in Taiwan

Table of Contents

Section Page

Table of Contents .......................................... 2

Safety Instructions For Miter Saw ................. 2

Safety Signal Words ................................... 2

Before Using The Saw ............................... 3

When Installing Or Moving The Miter Saw .3

Before Each Use ........................................ 4

To Reduce the Risk of Injury From Jams,

Slips Or Thrown Pieces ............................ 4

Plan Ahead To Protect Your Eyes, Hands,

Face and Ears .......................................... 5

Dress For Safety ........................................ 5

Preparing to Make Cut ............................... 6

Whenever Saw Is Running ......................... 7

Before Leaving The Saw ............................7

Glossary of Terms for Woodworking ............. 8

Motor Specifications and Electrical

Requirements ........................................... 8

Power Supply and Motor Specifications ..... 8

General Electrical Connections .................. 9

110-120 Volt, 60 Hz. Tool Information .........9

Motor Safety Protection .............................. 9

Wire Sizes ................................................ 10

Unpacking and Checking Contents ............. 10

Tools Needed ........................................... 10

Unpacking ................................................ 10

List of Loose Parts ................................... 10

Assembly .....................................................1 2

Assembling and Aligning the

Table Extension ...................................... 12

Attaching Dust Elbow and Dust Bag .........12

Installing or Removing the Blade ............. 13

Getting to Know Your Miter Saw ................. 14

Alignment (Adjustments) ...............................16

Step One: Blade Square to Table

(Bevel Alignment) .....................................16

Assembling Leg Set .................................... 18

Attaching Feet ..........................................18

Mounting The Miter Saw ............................. 19

Mounting Saw on Supplied Legset ........... 19

Mounting Saw on Other Legsets or Work

Benches .................................................1 9

Portable Applications ............................... 19

Section Page

Safety Instructions for Basic Saw

Operations .............................................. 20

Before Each Use ........................................ 20

To Reduce the Risk of Injury From Jams,

Slips Or Thrown Pieces ..........................20

PlanAhead To Protect Your Eyes, Hands,

Face and Ears ........................................21

Dress For Safety ...................................... 21

Preparing to Make the Cut ....................... 21

Whenever Saw Is Running .......................23

Before Leaving The Saw: .........................23

Basic Saw Operations .................................24

Body and Hand Position ...........................24

Miter Scale Usage ....................................24

Sliding Fence ...........................................25

Miter Cut ...................................................25

Bevel Cut ..................................................25

Compound Cut .........................................26

Cutting Compound Miters on

Picture Frames and Boxes .....................26

Cutting Bowed Material ............................ 26

Workpiece Support ..................................27

Auxiliary Fence .........................................27

Cutting Base Moldings .............................27

Cutting Crown Moldings ...........................28

Two Methods of Cutting Crown Molding ..28

Maintenance and Lubrication ......................30

Maintenance .............................................30

Lubrication ................................................ 30

Accessories .................................................31

Prohibited Accessories ..............................31

Basic Blade Requirements ....................... 31

Using Carbide Tipped Blades ......................31

Troubleshooting Guide ................................32

General ....................................................32

Motor ........................................................ 33

Wiring Diagram ............................................33

Trouble Shooting of Brake by Qualified

Service Person Only ...............................33

Repair Parts ................................................34

Notes ...........................................................42

Safety Instructions For Miter Saw

Safety is a combination of common sense, staying alert and knowing how

your miter saw works. Read this manual to understand this miter s aw.

Safety Signal Words

DANGER: means if the safety infor-

mation is not followed someone wi ll

be seriously injured or killed.

WARNING: means if the safety infor-

mation is not followed someone

could be seriously injured or killed.

CAUTION: means if the safety infor-

mation is not followed someone may

be injured.

2

Before Us ing The Saw

WARNING: Some dust created by

power sanding, sawing, grinding,

drilling, and other construction

activities contains chemicals

known (to the S tate of Cal i fornia)

to cause cancer, birth defects or

other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-bases paints,

• Crystalline silica from bricks

and cement and other masonry

products, and

• A rsenic and chromium from

chemically-treated lumber.

Your risk from these exposures

varies, depending on how often

youdothistypeofwork.To

reduce your exposure to these

chemicals: work in a well ventilated area, and work with

approvedsafety equipm ent, such

as those dust m asks that are

specially designed to filter out

microscopic particles.

WARNING: To reduce the risk of

mistakes t hat could cause seri ous, permanent injury, do not

plug the miter saw in until the following s teps have been satisfactorily completed.

• Completelyassemble andalign saw.

(See “As se mbly” and “Alignment”

sections within.)

• Learn the use and f unc tio n of the

ON-OFF switch, upper and lower

blade guards, handle latch, bevel

clamp, cover plate stop screw, and

fence clamps. (See “Getting to

Know Your Miter Saw” section

within.)

• Review and understand all safety

instructions and operating procedures i n this manual.

• Review the maintenance methods

for this miter saw. (See “Maintenance” section within).

Find and read the following labels on

the miter saw:

When Installing Or Moving The Miter Saw

Beforemoving the saw, lockthe miter,

bevel and power head po sitions.

Unplug the power cord.

To reduce the risk of back injury, get

help when you need to lift the saw.

Never carry t he tool by t he co rd or

power head trigger handle. Damage

to insulation could cause an electric

shock. Da mag e to wire connections

couldcauseafire.

ReducetheRiskofDangerous

Environment. Use the miter saw in a

dry, indoor place prot ec te d from rain.

Keep work area well li ghted.

Place the saw s o neither the us er nor

bystanders are forced to stand in line

with the blade. T hrown debris could

injure people in its path.

3

Safety Instructions for Miter Saws (continued)

To reduce the risk of injury from

unexpected saw m ovem ent:

• Place the miter saw on a firm level

surface whe re there is plenty of

room for handling and properly sup porting theworkpiece.

• Support t he miter saw so the table is

level and the saw does not rock.

• Bolt, screw or clamp t he saw to its

support.

Before E ach Use

Inspect your mi ter saw.

Disconnect The Miter Saw.To

reduce the risk of injury from accidental starting, unp lug the saw, before

changing the setup, changing the

blade or adjusting anything.

Compare the direction of rotation

arrow on the guard to the direction

arrow on the blade. The blade teeth

should always point downward at the

front of the s aw.

Tighten the arbor screw.

Tighten the cover plate stop screw.

Check For Damage d Parts. Check

for:

• Proper Alignment of moving parts,

• Damag ed electric co rds,

• Binding of moving parts,

• Broken parts,

• Stable mounting,

• Never Stand On Tool. Serious

injury could occur if the tool tips or

you accident ally hit the cutting tool.

Do not store anything above or near

the tool where anyone might stand

on the tool to reach them.

To reduce the risk of injury or

death from electrical sho ck:

• Make sure your fingers do not touch

the pl ug’s metal prongs when plugging or unplugging the miter saw.

lower guard: Push the arm all the

way down, then let it rise up until it

stops by itself. Check the lower

guard to see if it closed fully. If it did

not, follow the instructions in t he

Trouble Shooting section.

• Other conditions that may affect the

way the miter saw works.

If any part of this mitersaw is missing, bent, or broken in any way, or any

electrical parts don't work, turn the

saw off and unplug it. Replace damaged, m iss ing, or failed parts before

using the saw again.

Keep G uards In Place,inworking

order, and in proper adjustment.

Maintain Tools With Care. Keep the

miter saw clean for best and safest

performance. Follow instructions for

lubricating. DON’T put lubricants on

the blade while it’s spinning.

• Function of arm ret urn spring and

To Reduce the Risk of Injury From Jams, Slips Or Thrown Pieces

• Use Only Recommended A c cessories. (See “Accessory” section

within.) Consult this Owner’s manual

for recommended acc es s ories. Follow the instructions that come with

the accessories. The use of

Remove Adjusting Keys And

Wrenches from tool before turning it on.

improper accessories may cause

risk of injury to pers ons.

• Choos e the right 12-inch diamet er

blade for t he material and t he type

of cutting you plan to do.

4

• Make sure the blade is shar p,

undamaged and properly aligne d.

With the saw u nplugged, push t he

power-head all the way down. Hand

spin the blade and che ck for clearance.

• Make sure the blade and arbor collars are c lean.

• Make sure the collars' recessed

sides are facing the blade.

• Using the 1/4” hex end of combination wrench (supplied) or a 1/2-inch

box end wrench, make s ure the left

hand thread arbor screw is firm ly

tightened counterclockwise.

• Make sure all clamps and locks are

tight and there is no excessive play

in any parts.

• Keep Work Area Cle an. Cluttered

areas and benches invite accidents.

Floor must not be slippery.

To reduce the risk of bur ns or other

fire damage, never use the saw near

flammable liquid s, vapors or gases.

Plan Ahead To Protect Your Eyes, Hands, Face and Ears

Know Your Miter Saw. Read and

understand the owner’s manual and

labels affixed to the tool. Lear n its

applications and limitations as well as

the specificpotential hazards pecul iar

to this tool.

To red uce the ri sk of injury from accidental contact with moving parts,

don’t do layout, assembly, or setup

work on the miter saw while any parts

are moving.

To Reduce the Risk of Accidental

Starting. Make sure switch is “O FF”

before plugg ing miter saw into a

power outlet.

Plan your work.

Use The Right Tool. Don’t force tool

or attachment to do a job it was not

designed to do. Use a different tool

forany workpiece that can’t be held in

a solidly braced, fixed position.

CAUTION: This machine is n ot

designed for cutting ferrous metals (steel , iron and iron b ased

metals). Use this miter saw to cut

only wood, wood like products or

soft me tals like aluminum. Other

material may shatter, bind on the

blade, o r create oth er dan gers.

CAUTION: W hen cutting any metals, sparks or hot fragments

could cause a fire . To reduce the

risk of this, disconnect any dust

collecting bag or hose from the

miter saw, and remove all traces

of wood dust from inside dust

traps i n the miter saw.

Dress For Safety

Any power tool can throw foreign

objects into t he eyes. This c an res ult

in permanent eye damage. Wear

safety goggl es (not glasses ) that

comply with A NSI Z87.1 (or in Canada CSA Z94.3-99) shown on package. Everyday eyeglasses have only

impact resistant lens es. They are not

safety glasses. Safety goggles are

available at many local retail stores.

Glasses or goggles not in compliance

with ANSI or CSA could seriously

hurt you when they break.

Do no t wear loose clothing, gloves,

neckties or jewelry (rings, wrist

watches) T hey can get caught and

draw you into moving parts.

5

Safety Instructions for Miter Saws (continued)

• Wear nonslip footwear.

• Tie back long hair.

• Roll long sleeves above the el bow.

• Noise levels vary widely. To reduce

the risk of possible hearing damage,

Preparing to Make Cut

WARNING: If planning to cut aluminum or other non-ferrous metals: Under adverse conditions,

the blade can grab and throw the

workpiece suddenly and unexpectedly. To reduce the ri sk of

injury, follow all applicable safety

instructions, as you normally

would, and:

• Use only sawblades specifically recommended for non-ferrous metal cutting.

• Do not cut metal workpieces

that must be hand held. U se

auxiliary clamps or other

equipment as neede d.

• Cut non-ferrous metals only if

you are experienced or under

the supervi sio n of an experienced person.

Inspect Your Workp iece. Make sure

there are no nails or foreign objects in

the part of the workpiece to be cut.

Plan your work to r e duce the risk

of thrown pieces caused w hen th e

workpiece binds on the blade and

is torn from your hands.

Plan the way you will hold the workpiece from start to finish.

wear ear plugs or muffs when using

miter s aw for hours at a time.

• For dusty operations, wear a dust

mask along with s afety goggles.

Don’t Overreach. Keep good footing

and balance.

Keep your face and body to one side

of sawblade, out of line with a possiblethrownpiece.

Cut only one workpie ce at a time.

Never cut Freehand:

• Brace your workpiece solidly

against the fence and table top so it

will not rock or twist during the cut.

• Make sure there’s no debris

between t he workpiece and its supports.

• Make sure no gaps between the

workpiece, fence and table will l et

the workpiece shift after it is cut in

two.

• Keep the c ut o ff piece free to move

sideways afterit's cut off.Otherwise,

it could get wedged against the

blade and thrown v iol ent ly.

• Clear everything except t he wo r k piece and related support devices

off the table before turning the miter

saw on.

• Secure Work. Use clamps or a vi se

to hel p hold the work when it’s practical.

Avoid awkward operations and hand

positions where a sudden slip could

cause fingers or hand to move into

the blade.

Use extra cautio n wi th larg e, very

small or awkward workpieces:

• Us e extra s upports (tables, saw

horses, blocks, etc.) for any workpieces l arge enough to tip when not

held down to the table t op.

6

• Never use another person as a substitute for a table extension, or as

additional support for a work piece

that is longer or wider than the bas ic

miter saw table or to help feed, sup port or pull the workpiece.

not slip and pinc h the blade and be

torn from your hands. A pie ce of

molding, for example, must lie flat

against t he table or fence, or be held

by a fixture or jig that will not let it

twist, rock or slip while being cut.

• Do not use this saw to c ut pieces

too small to let you easily hold the

workwhileyoukeepthethumbside

of your index (pointer) finge r against

the outside edge of the fence.

• When cutting irregularly shaped

workpieces, plan your work so it will

Whenever Saw Is Running

WARNING: Don't allow familiarity

(gained from frequent u se of

your miter saw) cause a carele ss

mistake. A careless frac t io n of a

second is enough to cause a

severe injury.

Before starting your cut, watch the

miter saw while it runs. If it makes an

unfamiliar noise or vibrates a lot, stop

immediately. Turn the saw o ff. Unplug

the saw. Do not restart until finding

and correcting the problem .

Keep Children Away. Keep all visitors a safe distance from the miter

saw. Make sure bystanders are cl ear

of the miter saw and workpiece.

Never confine the piece being cut

off. Never hold it, clamp it, touch it, or

use length stops against it while the

blade is spinning. It must be free t o

move sideways on its own. If confined, it could get wedged against the

blade and be th rown violently.

• Properly support round material

such as dowel rods, or tubing. They

have a t endency t o roll while being

cut, causing the blade to "bite." To

avoid this, always use a fixture

designed to properly hold your

workpiece.

Let the blade reach full speed

before cutting. This will help avoid

thrown workpieces.

Don’t Force Tool. It will do the job

better and safer at its designed rate.

Feed the saw into the work piece only

fast enough to let t he blade cut without bogging down or binding.

Before free in g jammed m aterial:

• Turn miter saw “OFF” by releasing

trigger switch.

• Wait for all moving parts to stop.

• Unplug the mi ter saw.

After finishing a cut:

• Keep holding the power head down.

• Release t he switch, and wait for all

moving parts to stop before moving

your hands or raising power head.

• If blade doesn’t stop within 6 seconds, unplug the saw and follow the

instructions in the Trouble Shooting

section for fixing the blade brake

before using the saw again.

Before Leaving The Saw

Never Leave Tool Running Unattended. Turn power off. Wait for all

moving parts to stop.

Make Workshop Child Proof. Install

a padlock through t he hole provided

in the trigg er to prevent unauthorized

usage. Lock the shop. Disconnect

master switches. Store tool awayfrom

children and ot hers no t qualified to

use the tool.

7

Glossary of Terms for Woodworking

Arbor

The shaft on which a cutting tool is

mounted.

Bevel Cut

An angle c utting operation m ade through

the face of the workpiece.

Compound Cut

A simultaneous bevel and miter cutting

operation.

Crosscut

A cutting operation madeacrossthewi dth

of the workpiece.

Freehand

Doing a cut without holding the workpiece

against both the table and fence. Most

workpieces can be held down with your

hand. Large or wide pieces should be

clamped to the fence or table.

Gum

A sticky, sap based residue from wood

products.

Heel

Misalignment of the blade.

Kerf

The amount of material removed by the

bladein a throughcutor the slot produced

by the bladei n a nonthrough or partial cut.

Miter Cut

An angle cutting operation made across

the width of the workpiece.

Resin

A sticky, sap based substance that has

hardened.

Revolutions Per Minute (RPM)

The number of turns completed by a spinning object in one minute.

Sawblade Path

The area of the workpiece or table top

directly in line with either the travel of the

blade or the part of the workpiece which

will be, or has been, cut by the blade.

Set

The distance that the tip of the sawblade

tooth is bent (or set) outward from the

face of the blade.

Workpiece

The item on which t he cutting operation is

being performed. The surfaces of a workpiece are commonly referred to as faces,

ends, and edges.

Face

End

Motor Specifications and Electrical Requirements

Power Supply and Motor Specifications

WARNING: To reduce the risk of

electrical hazards, fire hazards

or damage to the tool, use

proper circuit protection. Your

tool is wired at the factory for

operation using the voltage

shown. Connect tool to a power

line with the appropriate voltage

and a 15-amp branch circuit. Use

a 15-amp time delay type fuse or

circuit breaker. To reduce the

risk of shock or fire, if power

cord is worn or cut, or damaged

in any way, have it replaced

immediately.

Edge

TheA-Cmotorusedonthistoolisauniversal non-reversible type, having the following specifications:

Voltage 120

Amperes 15

Hertz (Cycles) 60

Phase Single

RPM 4000

Shaft Rotation Clockwise

Brake Automatic

8

General Electrical Connections

DANGER: To reduce the risk of

electrocution:

1.Use only identical replacement

parts when servicing. Servicing

should be performed by a qualified service technician.

2.Do not use in rain or where

floor is wet.

This tool is intended for indoor

residential use only.

110-120 Volt, 60 Hz. Tool Information

Double I nsulated

The miter saw is double insulated to provide a double thickness of insulation

between you and the tool’s electrical system. All exposed metal parts are isolated

fromt he internal metal motor components

with protecting insulation.

Polarized Plug

Your unit has a plug that looks like the one

shown.

To reduce the risk of electrical shock, this

appliancehas a polarizedplug (one blade

is wider t han the other).This plug will fit in

a polarizedoutlet only one way, if the plug

does not fit fully in the outlet, reverseplug.

If i t still does not fit, contact a qualified

electrician to install the proper outlet. Do

not change the pl ug in any way.

WARNING: Double insulation

does not take the place of norm al

safety precautions when operating this tool.

Motor Safety Protection

1. Connect this tool to a 120v, 15-amp

branch circuit with a 15-amp time delay

WARNING Do not permit fingers

to touch the terminals of plug

when installing or removing the

plug to or from the outlet.

If power cord is cut, or damaged in any

way, have it replaced immediately.

fuse or circuit breaker. Using the wrong

size fuse can damage the motor.

1. If the motor won't start, release the trigger switch immediately. Unplug The

Tool. Check the saw blade to m ake

sure it turns freely. If the blade is free,

try t o start the motor again. If the motor

still does not star t, refer to the "Motor

Trouble-Shooting Chart."

2. If the motor suddenly stalls while cutting wood, release the t rigger switch,

unplug the tool, and free the blade from

the wood. The m otor may now be

restarted and the cut finished.

3. Fuses may "blow" or circuit breakers

may trip frequently if:

a.Motor Is Overloaded-Overloading

can occur if you feed too rapidly or

make too many start/stops in a short

time.

b. Line voltages are more than 10%

above or below the nameplate voltage. For heavy loads, however, the

voltage at motor terminals must equal

the voltage specified on nameplate.

c. Improperor dull saw blades are used.

4. Most motor troubles may be traced to

loose or incorrect connections, overload, low voltage (such as small size

wire in the supply circuit) or to overly

long supply circuit wire. Always check

the connections, the load and the supply circuitwhenevermotordoesn't work

well. Check wire sizes and length with

the Wire Size Chart below .

9

Motor Specifications and Electrical Requirements (con’t.)

Wire Sizes

NOTE: Make sure the proper extension

cord is used and is in good condition. The

use of any extension cord will causesome

loss of power. To keep this to a minimum

and to prevent overheating and motor

burn-out, use the table below to determine the minimum wi re size A.W.G.)

extension cord.

For circuits that are farther than 100 feet

away from electrical service box, the wire

size must be increased proportionately in

order to deliver ample voltage to the saw

motor.

Extension Cord

Unpacking and Checking Contents

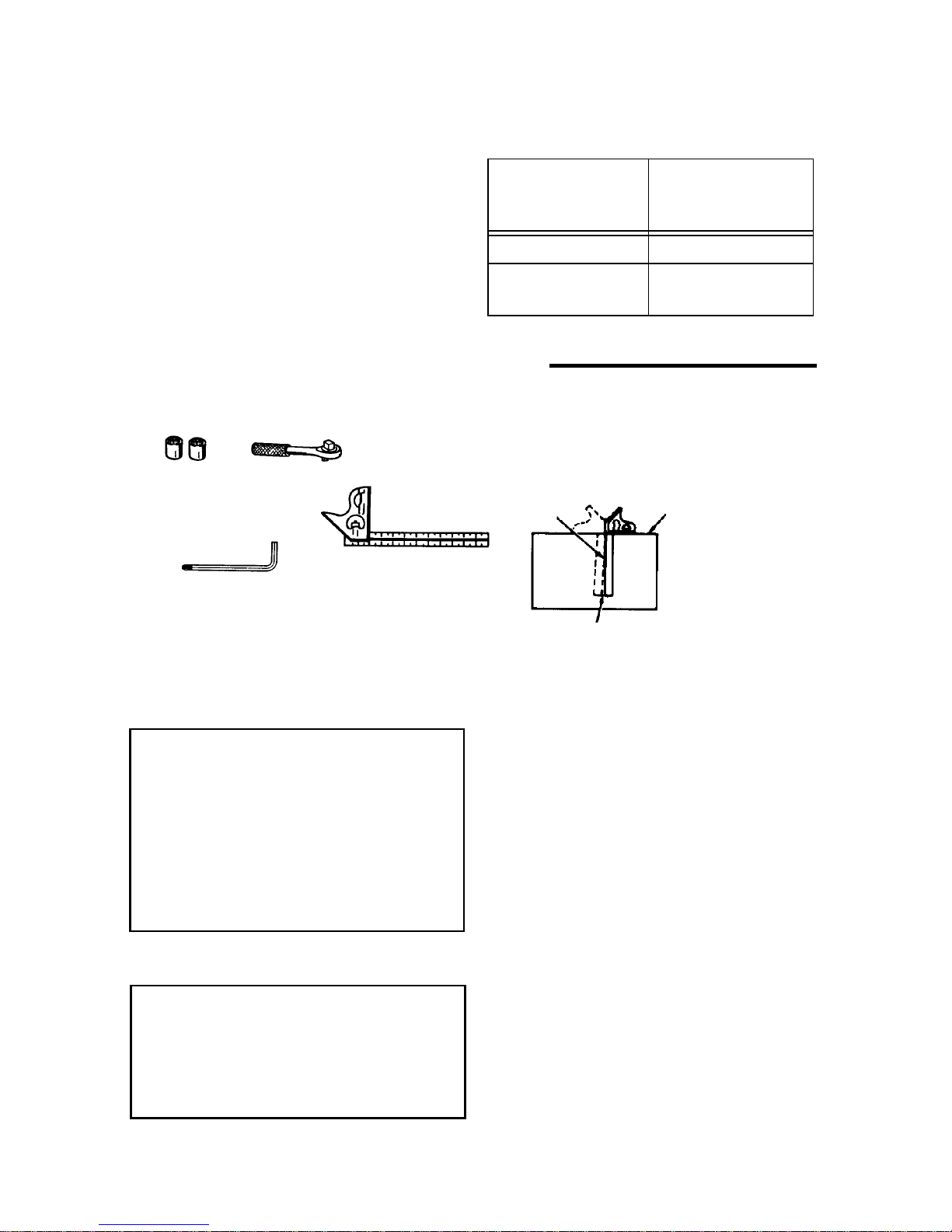

Tools Needed

Combination Square Must be True

Draw Light

3/4" or 19mm, 12mm

Socket

and Socket Wrench

Combination Square

Combination Wrench,

1/4" Hex “ L” W rench

with #2 Phillips tip

(supplied)

Line on Board

Along this Edge

Should be no Gap or Overlap when Square

is Flipped Over i n Dotted Position

Length

110-120V

0-25 Ft.

26-50 Ft.

Wire Sizes

Requiredfor120V

(A.W.G.)

14

12

Straight Edge of

Board 3/4" Thick

This Edge Must

be Perfectly

Straight

Unpacking

WARNING: To reduce the risk of

injury from un expected starting

or electrical shock, do no t plug

the power cord into a power

source outlet during unpacking

and assembly. This cord must

remain unplugged whenever you

are working on the saw.

ThisMi ter Saw is shipped completein one

box.

WARNING: Although co m pact,

this saw is heavy. To reduce the

risk of back injury, get help

whenever you have to lift the

saw.

1. Remove t he miter saw from the carton

by lifting the saw with the carrying handle.

1. Place the saw on a secure, stationary

work surface and look the saw over

carefully.

List of Loose Parts

NOTE:Before beginning assembly, check

that all parts are included. If you are missing any par t, do not assemble t he saw. Emailus atinfo@ridgidwoodworking.comif

any p arts are damaged or missing.

Sometimes small parts can get lost in

packaging material. Do not t hrow away

any packaging until saw i s put together.

Check packaging for missing parts before

contacting RIDGID. A complete parts list

(RepairParts) is at the end of the m anual.

Use the list to identify the number of the

missing part.

10

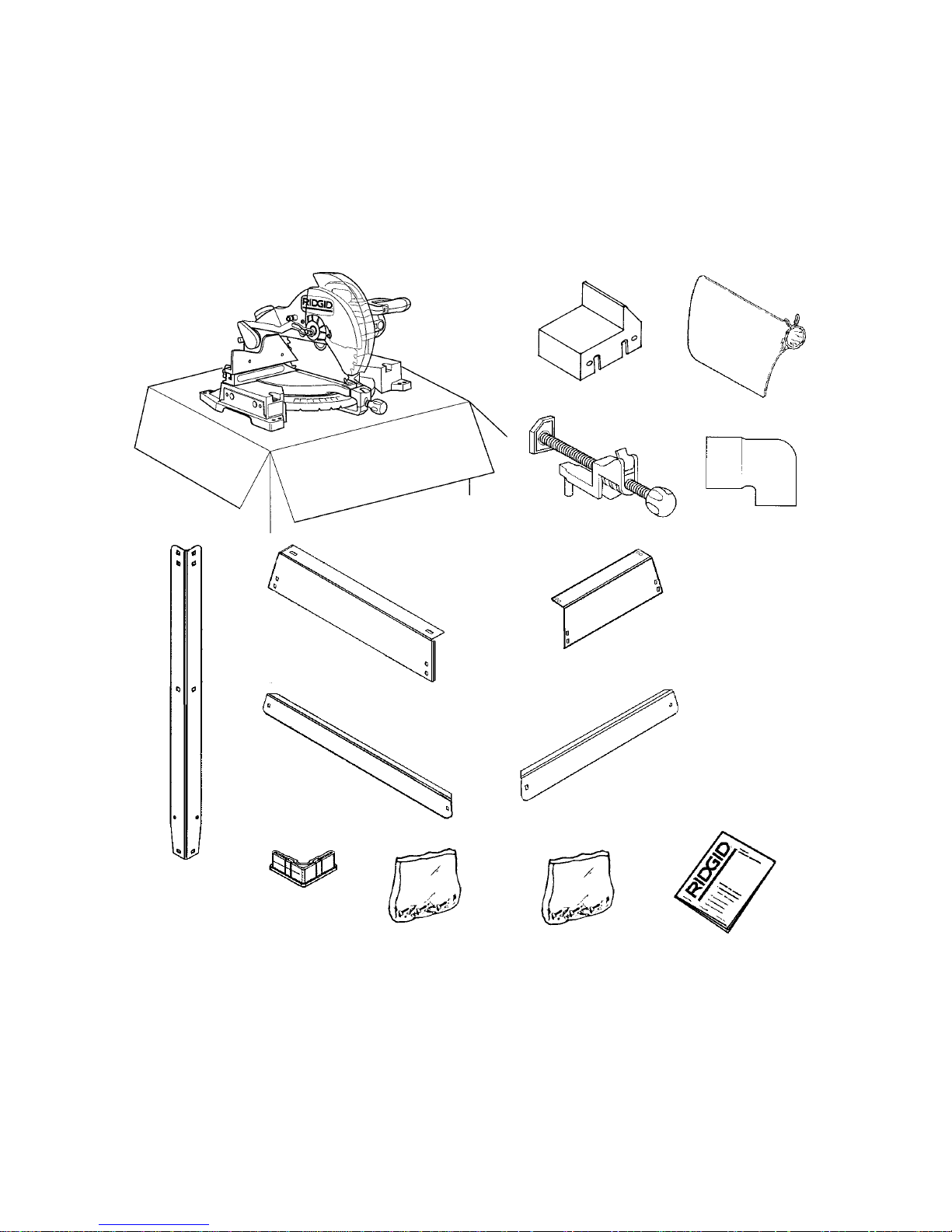

The following parts are included:

Part or Assembly Qty.

A Basic Saw Assembly...........................1

B Table Extension...................................1

C Dust Bag .............................................1

D Work Clamp ........................................1

E Dust Elbow..........................................1

F Leg ......................................................4

G Long U pper Stiffeners.........................2

A B C

Part or Assembly Qty.

H Shor t U pper Stiffeners........................2

J Long Lower Stiffeners.........................2

K Short Lower Stiffeners ........................2

L Foot (In Parts Bag) ............................. 4

MBag, Extension Hardware ................... 1

N Bag, Legset Hardware........................ 1

O Owners Manual................................... 1

DE

FG H

JK

LM N O

11

Assembly

WARNING: For your own safety,

never connect plug to power

source outlet until all assembly

steps are complete, and you

have read and u nderstood the

safety and o perational instructions.

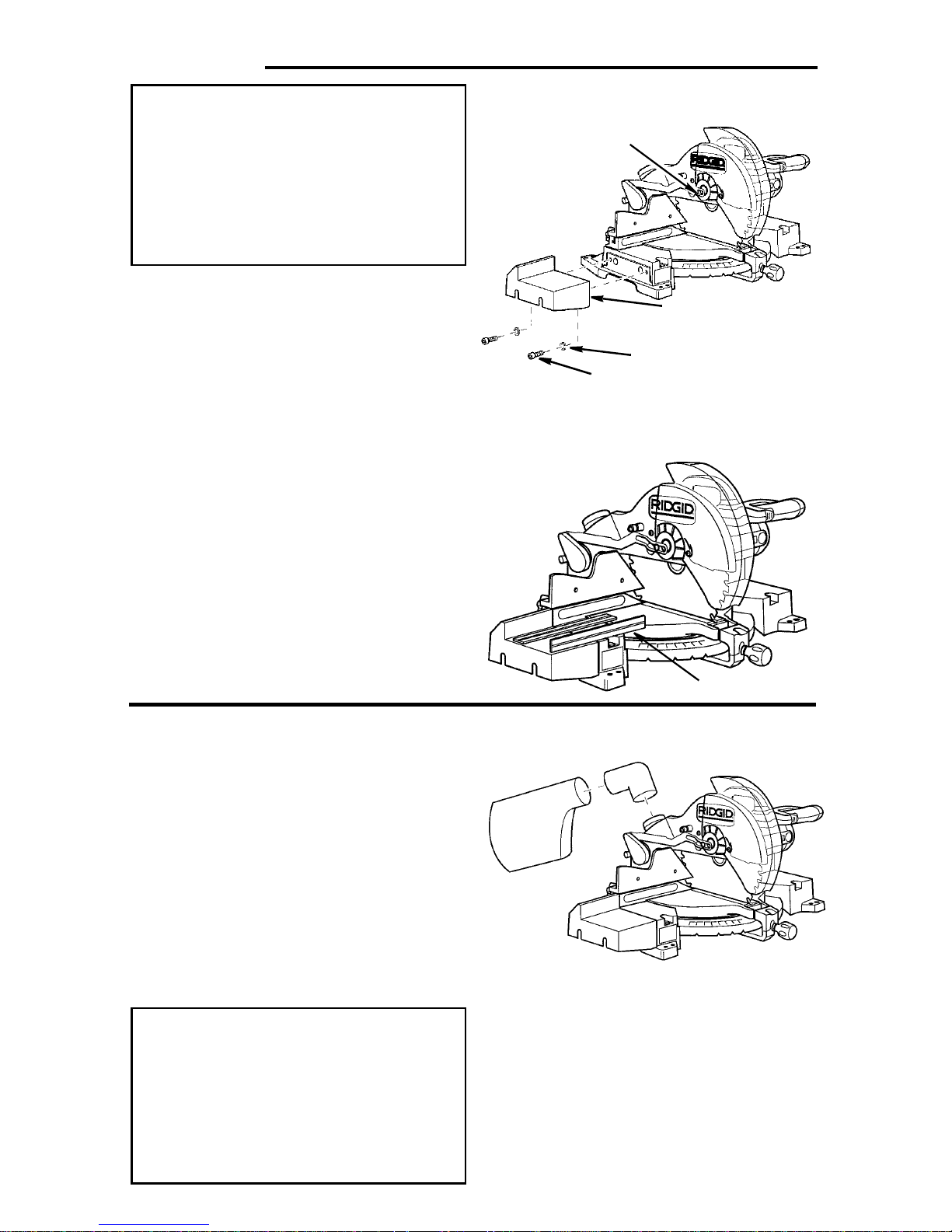

Assembling and Aligning the Table

Extension

1. Locate the table extension. Locate the

bag assembly with the two cap screws

and two washers.

1. Place the two bolts and washers

throughthe holes in the table extension

and fasten onto the end of the table.

Finger tighten only.

2. Use a straight edge to align the table

extension to both the fence and base of

the saw as shown.

3. Using the 1/4" hex end of combination

wrench securely tighten the two cap

screws.

Lock Pin

Table Extension

Washer

Cap Screws

Attaching Dust Elbow and Dust

Bag

Place t he dust elbow into the 2-1/2 inch

dust port at the rear of the saw.

To attach the dust bag squeezethe spring

clamp on the bag and place it over the

dust elbow.

If desired a 2-1/2 inch wet/dry vac hose

may be inser ted into the dust port or into

the elbow.

If desired, the dust bag may be attached

directly to dust por t on saw.

WARNING: To reduce the risk of

injury from thrown sawdust and

wood chips, never operate saw

without dust bag, dust elbow, or

vac hose installed. Always direct

elbow away from bystanders and

operator.

Straightedge

12

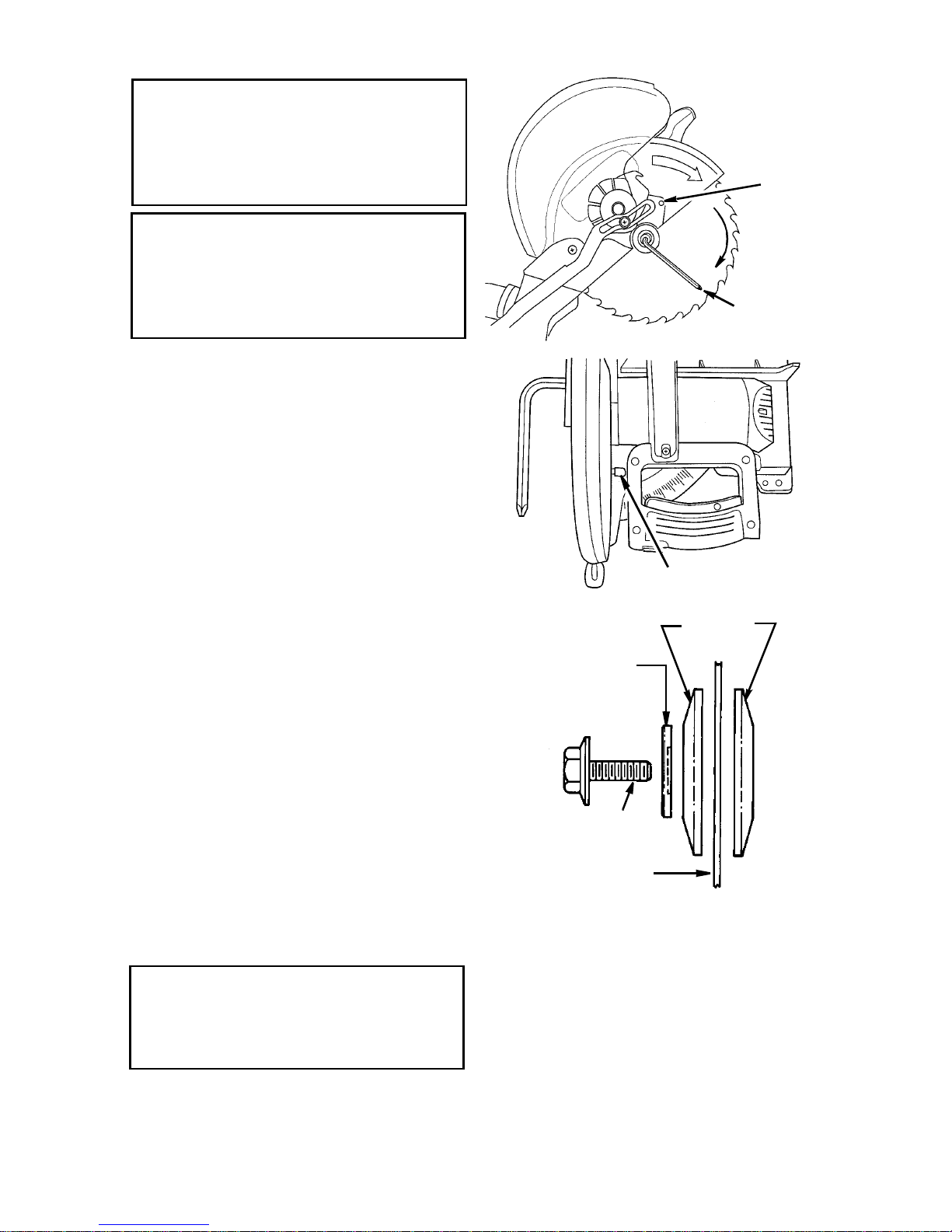

Installing or Removing the Blade

WARNING: To reduce the risk of

injury from a thrown workpiece

or thrown piec es of blade, do not

use a blade larg er or smaller than

12" diameter.

WARNING: To reduce the risk of

injury from un expected starting,

unplug the saw whenever you

are removing or installing the

blade.

1.Unplug the saw from the outlet.

2. Rotate the lower plastic guard by

hand. Loosen, but do not remove, the

cover plate stop screw using the Phillips end of c ombination wrench.

3.Lift the lower guard up and tilt the

lower guard assembly back so the

arbor screw is exposed.

4.Find the arbor lock between the upper

guard and the miter saw handle. Fit 1/

4” hex end of combination tool in arbor

screw or use 1/2” box end wrench.

5.Press the arbor lock and hold i t in

firmly while turning the wrench clockwise. The arbor lock will engage after

some turning of the wrench.

NOTE: The arbor screw has a left hand

thread. This helps prevent unwanted

loosening of the arbor screw during normal operation.

6. Remove the arbor screw, arbor washer,

outer blade collar , and the blade.

NOTE: Pay attention to pieces removed,

noting their position and direction they

face (see illustration). Wipe the blade collars clean of any sawdust before installing

the new blades.

CAUTION: To reduce the risk o f

cuts from extremely sharp teeth:

Wear gloves when instal ling or

removing saw blade.

See cautions in “Using Carbide Tipped

Blades” section concerning inspection,

use, and selection of carbide tipped and

other sawblades.

Stop

Screw

Loosen

Arbor Lock

Blade

Blade

Washer

(Hollowed Side

Toward Blade)

Arbor screw

(Left Hand Thread)

Sawblade

7.Install the new 12" blade (see recommended accessory list). Make sure

the rotation arrow on the blade

matches the clockwise rotation arrow

on the upper guard.

8.Install the outer blade collar, blade

washer and arbor screw. Press t he

arbor l ock and turn the combination

wrench or the 1/2" wrench counter

clockwise to secure the blade. Tighten

arbor screw using moderate force, but

do not overtighten.

Collars

13

Assembly (continued)

9.Lower the lower blade guard until the

slot in cover plate rests all the way

down on the cover plate stop screw.

Tighten the screw with the Phillips end

of the combination wrench.

DANGER: Never use saw withou t

guard cover pl ate securely in

place . It keeps the arbor screw

from falling out if it accidentally

loosens, and prevents the spinning blade from coming off the

machine .

10.Be sure the arbor lock is released so

the blade turns freely.

NOTE: The arbor lock can be damaged

by improper use. If the arbor lock will not

hold, lower the blade down on to a scrap

piece of wood positioned against the

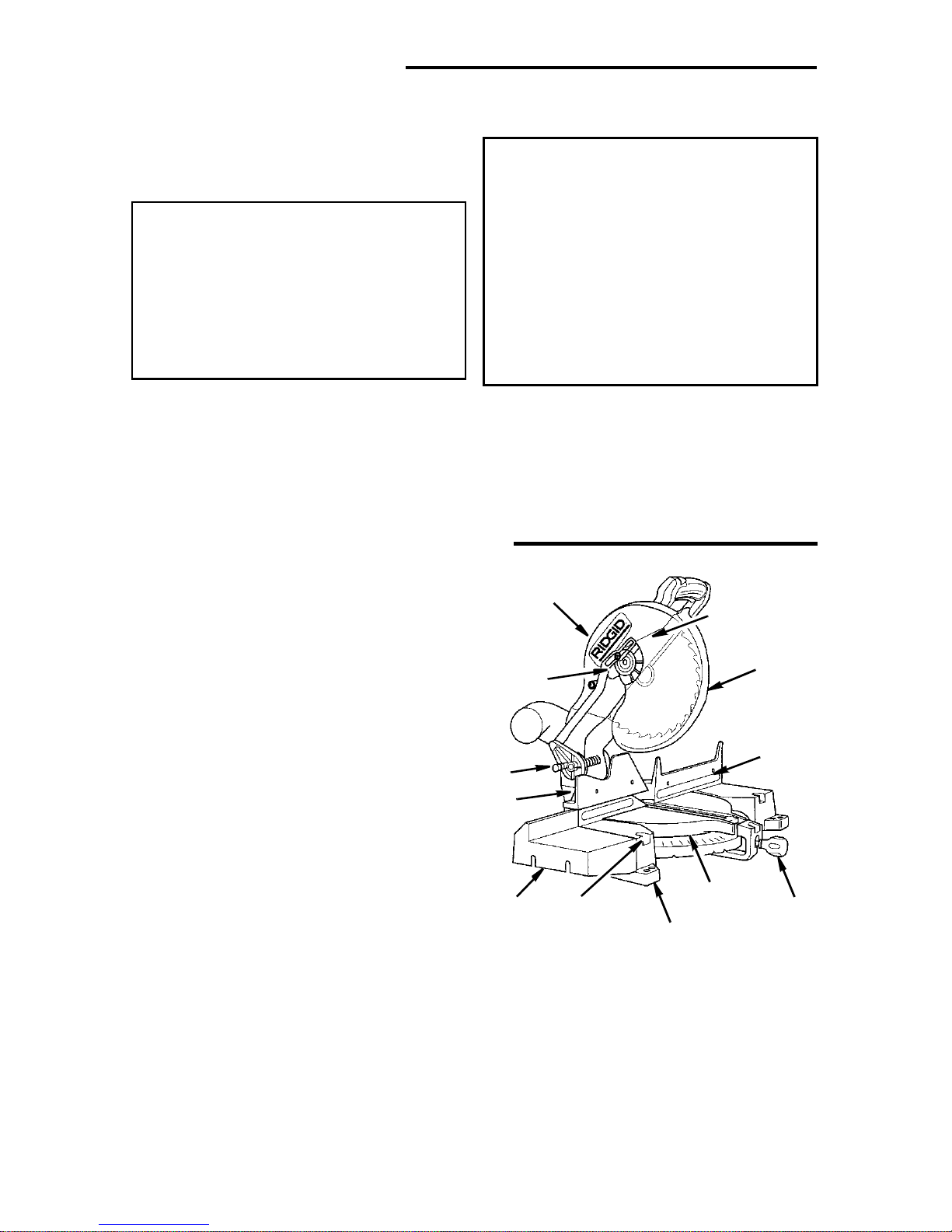

Getting to Know Your Miter Saw

fence. This will serve as an alternate locking means.

WARNING: Make sure th e collars

are clean and properly arranged.

After installing a new blade,

make sure the blade clears the

table slot at the 0° and 45° bevel

positions. Lower the blade into

the table slot and check for any

contact with the b ase or turn

table structure. If blade contacts

table, seek authorized service.

1.Lower Blade Guard - The blade

guard helps protect your hands from

the blade in the raised position. To

reduce the risk of binding on the workpiece, it retracts as the blade is lowered.

2.The Repeat-A-Cut™ - Surface allows

pencil marks to be made and easily

erased for duplicate cuts.

3.Miter Lock Knob - The miter lock

handle securely locks the miter saw at

a desired miter angle. Index points

have been provided on right and left

for 0, 15°, 22.5°, crown molding (CM)

and 45°.

4. Table - Sits in base, supports pivot

and allows for approximately 49° miter

left and right.

5.Base - Supports table, holds accessories and allows for work bench or leg

set mounting.

6. Left Extension Table - Helps to support long workpieces.

7. Sliding Fence - Slides left/right to

provide maximum support for the

workpiece.

10

9

Cover Plate

Stop Screw

1

2

8

7

~

(21-Clamp

6

Mounting Hole)

8.Lock Pin - The miter saw can be

lockedintheloweredpositionforcompact storage.

9.Cover Plate - Holds the lower guard

and is attached to upper guard. Prevents the arbor screw from backing

out when properly fastened.

10.Upper Blade Guard - Supports the

motor, handle, switch, blade and lower

guard.

4

3

5

14

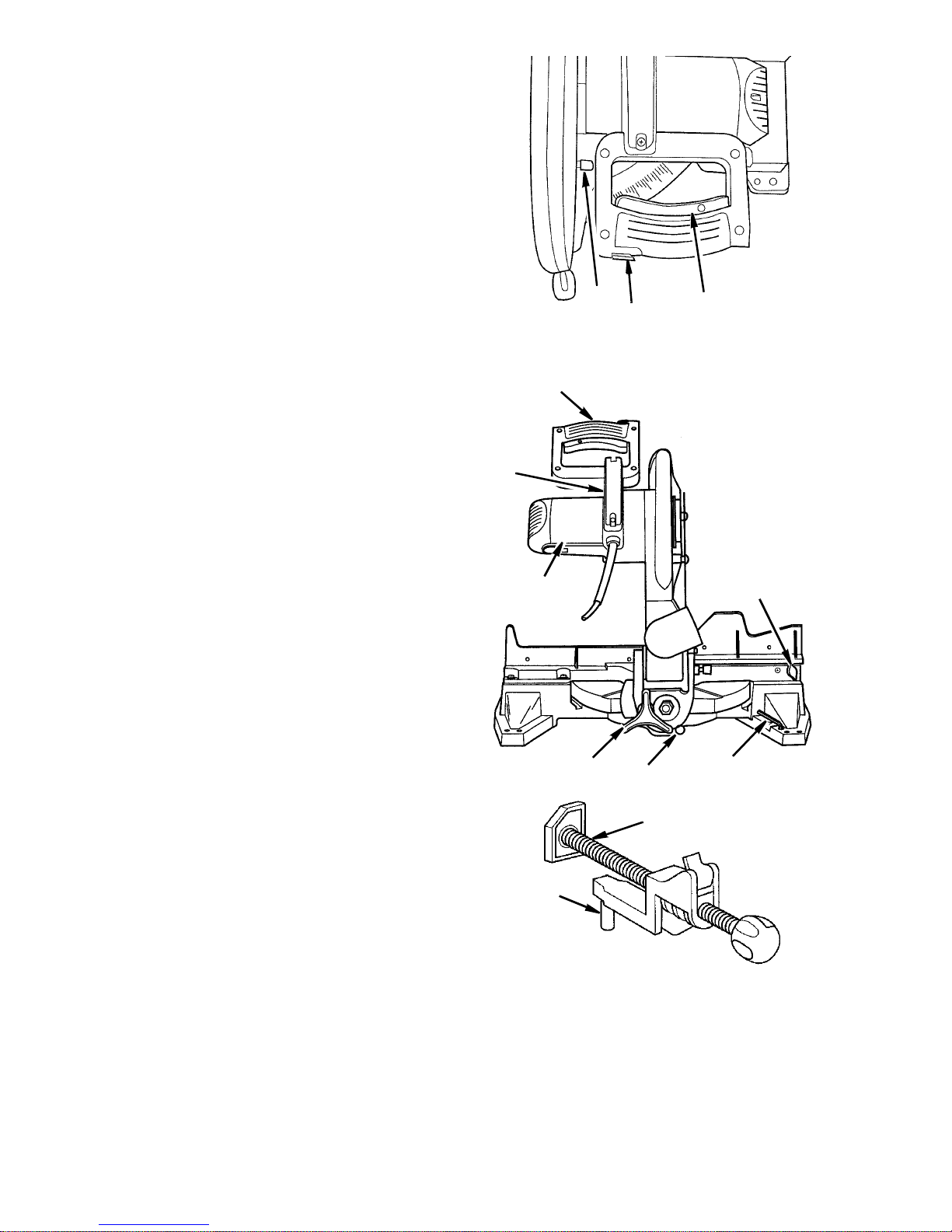

11.Arbor lock - Allows the user to keep

blade from rotating while tightening or

loosening arbor screw during blade

replacement or removal.

12.Switch Interlock Button - Prevents

trigger switch from being accidentally

engaged.

13.On/Off Trigger Switch - To start the

tool, depress switch interlock button

with right thumb or palm of ei ther hand

and then squeeze the trigger. Release

the trigger to stop the miter saw. Install

padlock through the hole in the trigger

to prevent unauthorized use.

14.Sliding Fence Locking Knob - Locks

fence at correct cutting position.

15.Combination Wrench - Used for 1/4"

hex and Phillips head screw adjustments.

16.Bevel Index Pin - This three position

pin provides a 0° and crown molding

bevel stop when pushed all the way in.

Inthemiddlepositiona0°and45°

bevel stop is pr ovided. Pull the pin all

the way out and the stops can be

over-ridden allowing -2° to 47° bevel

capacity.

17.Bevel Lock Knob - Locks the miter

saw at a desired bevel angle.

18.Warning Label

19.Carrying Handle - This handle is built

into the unit to move it from one location to another. Before attempting to

pick up the unit by the carrying handle

always lock the miter saw power head

in the down position using the lock pin.

Make sure the miter lock and bevel

lock knobs are tight.

20.Miter Saw Handle - The saw handle

contains the tr igger switch with a padlock, l ocking hole to prevent unauthorized use. The blade is lowered into

the workpiece by pushing down on the

handle. The saw will return to its

upright position when the handle is

released, unless the handle lock pin is

engaged.

11

12

13

FrontofSaw

20

19

18

17

16

14

15

21

Pin

21.Workpiece Clamp - Helps to hold

workpiece in position for precise cutting. Quick release allows easy movement for workpiece wi dth adjustment.

Pin of clamp fits in either hole in front

of base.

15

Alignment (Adjustments)

WARNING: Cut material can b e

thrown. Eyes can be perm anently

damaged. Wear your safety goggles.

Spring

NOTE:Before this saw is aligned or used,

a kerf must be cut into the table i nsert at

0° bevel. Our Quality Control Audit Procedure requiresus to cut through the inser ts

before they leave our factory.

To cut through an uncut insert:

1. Plug in the power cord.

1. Tur n the saw on by actuatingthe trigger

switch.

2. Lower the blade to full depth while cut-

ting through the table insert.

3. Release the trigger switch and allow

the blade to come to a complete stop.

4. Repeat this procedure at 45° bevel.

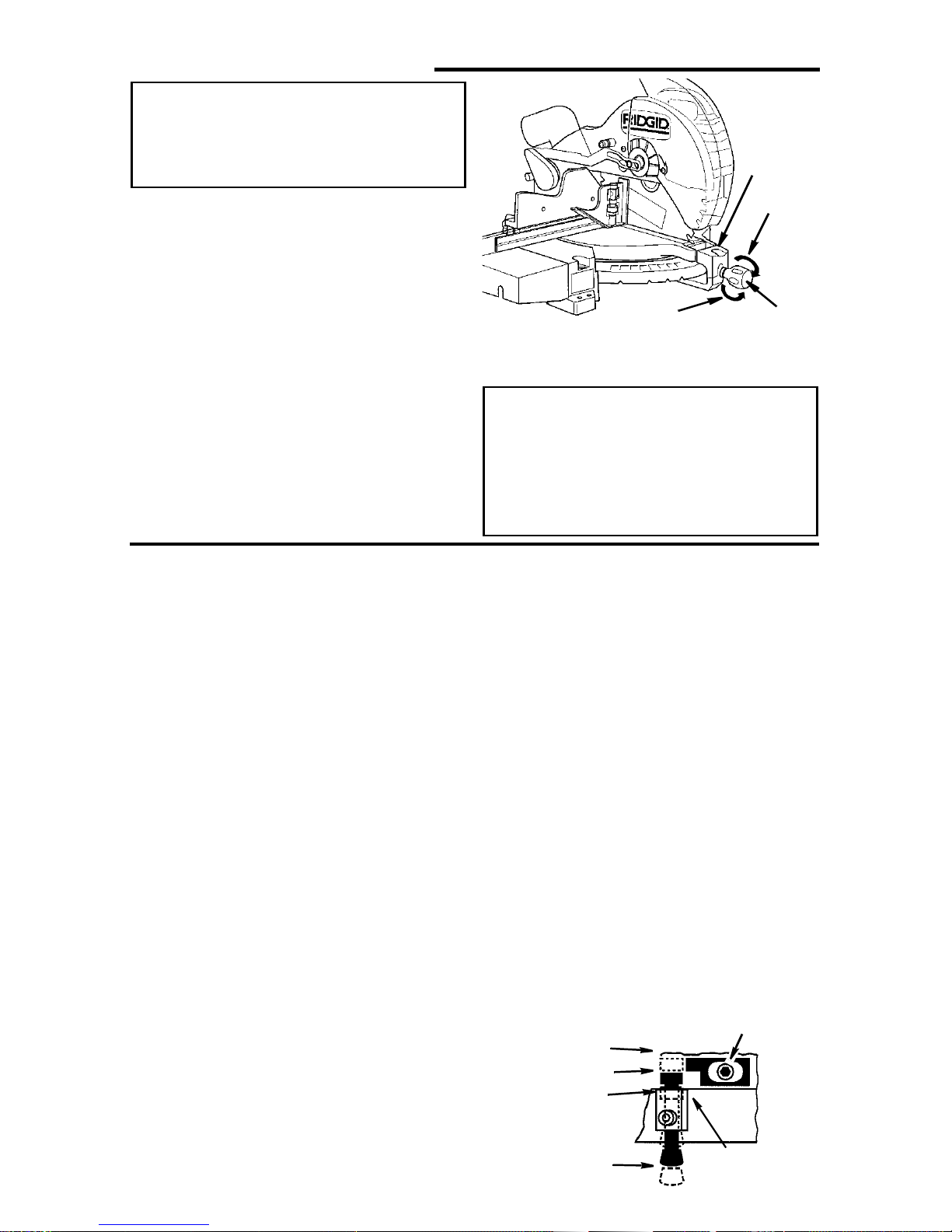

Step One: Blade Square to Table (Bevel Alignment)

NOTE: The miter saw was assembled,

aligned, and inspected before shipment.

Alignment should be checked and any

adjustments made to insure accurate cuts.

1. Check miter lock knob setting. The

miter lock knob should be at the 0°

position. To reset the miter angle, turn

the miter lock knob counter clockwise

and press down the indexspring, move

to 0° miter and retighten knob.

2. Lower the blade and engage the lock

pin.Use a combination squareto check

blade squareness to table. If the blade

does not contact the full length of the

square,(see illustration) follow the

alignment procedure.

a. Loosen bevel lock knob.

b. Grasping carrying handle, move the

cutting head left or right until blade

makes contact with the full length of

the square.

NOTE: If you cannot get to 0° bevel,the

bevel stop may be in your way. Adjust the

bevelstop(SeeStepd)soyoumay

achieve 0° bevel.

c. Tighten the bevel lock knob.

d. Loosen the 0° bevel stop mounting

Tighten

Loosen

5. Unplug the power cord before starting

alignment procedure.

Handle

WARNING: To reduce the risk of

injury from unexpected starting

or ele ctrical shock, do not plug

the saw in. The power cord must

remain unplugged whenever you

are working on the saw.

screw and push the stop against the

pin. Retighten the stop mounting

wrench. Sl ide the indicator under the

Phillipsheadscrewtolineupexactly

with the 0° bevel mark on the bevel

scale. Retighten the indicator screw.

e. Loosen bevel lock knob and tilt the

power head to 45° bevel and check

the 45° bevel stop. The bevel indicator should be on the 45° mark, the

45° bevel stop should be in full contact with the 45° bevel stop screw ,

and the blade should contact the full

length of the square. This adjustment

sets the 45° and crown molding

stops.

3. If adjustmentis necessary, repeatsteps

2a - 2d for the 45°/crown molding bevel

stop.

Bevel Stop

Mounting Screw

0°, CM Index

0°, 45° Index

By-Pass

Index/

By-Pass P in

16

Bevel Index

Mechanism

Step Two: Blade Square to Fence

(Miter Alignment)

WARNING: To reduce the risk of

injury from un expected starting

or electrical shock, do no t plug

the saw in. The power cord must

remain unplugged whenever you

are working on the saw.

Adjust Bl ade Square to Fence:

1. Lower the blade and engage the lock

pin. Use a combination square. Place

the square against the fence and next

to the blade as illustrated. Locate the

square properly so it does not contact

the set in t he teeth of sawblade, giving

an inaccurate reading. The sawblade

should contact the full l ength of the

square.

1. If blade contacts full length of square,

no alignment is necessary, skip a-f

below. If blade is not square to the

fence, follow the al ignment procedure.

a. Loosen miter lock knob a half turn.

The saw power head should still be

secured in the lowered position by

the lock pin.

Miter

Indicator

Miter Arm

Cap Head Screws

CAUTION: To keep from losing control of the unit, steady the base with

one hand while loosening the two

bolts with the other hand.

b. With the unit securely resting on a

large stable surface, tilt the unit by

lifting up on one side or the other of

the base. Using combination wrench

supplied, loosen the two miter arm

cap head screws on the underside of

the turn table.

c. Return the saw to its normal resting

position. Make sure the miter lock

knob is loose but do not release the

index spring.

d. Use the miter saw knob to move the

table so that the blade contacts the

full length of t he square. Watch out

fort ooth set. Turn the miter lock knob

clockwise to lock saw square to

fence.

e. Tilt saw as in Step b and tighten cap

head screws.

f. Recheck blade squareness to fence

and readjust if necessary.

Adjust Miter S cale Indicator

1. Through the hole in front of t he table

insert, loosen the Phillips screw that

holds the Vernier indicator in place.

1. Reposition the indicator to align it with

0° mark, and retighten screw.

17

Alignment (Adjustments) (continued)

Step Three: Pivot Adjustment

NOTE: This adjustment was made at the

factory and normally does not require

readjustment.

Arm Pivot M ovement

1. Make sure the see through lower guard

is rotated closed and is resting against,

or very close to,the r ubber stops. If not,

see “Lubrication” section.

Bevel Pivot Movement/Adjustment

Check that miter saw bevels easily by

looseningthe bevell ock handleand tilting

the power head to the left. NOTE: At least

one thread of the pivotbolt should stick

out past the hex lock nut.

1. If movement is tight or there is loose-

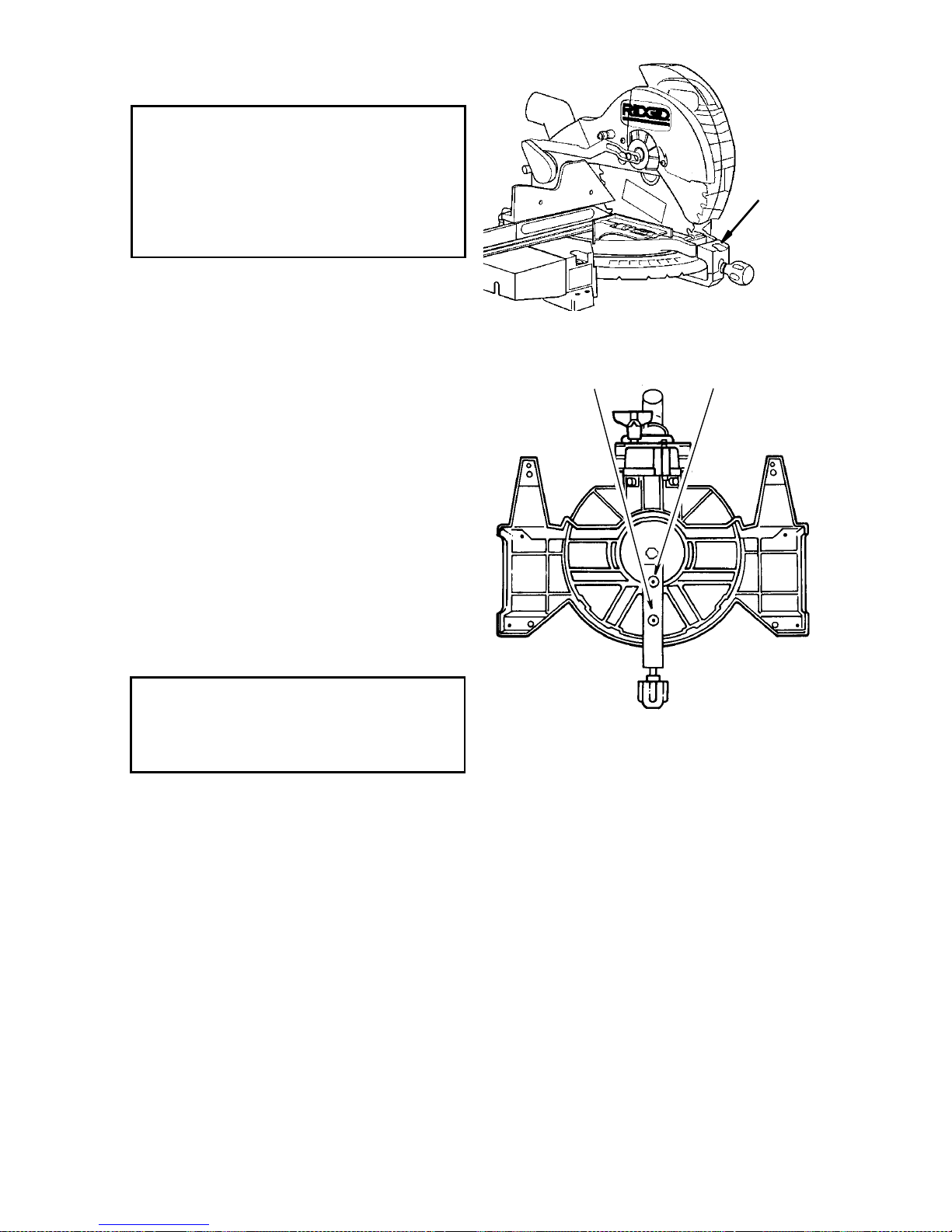

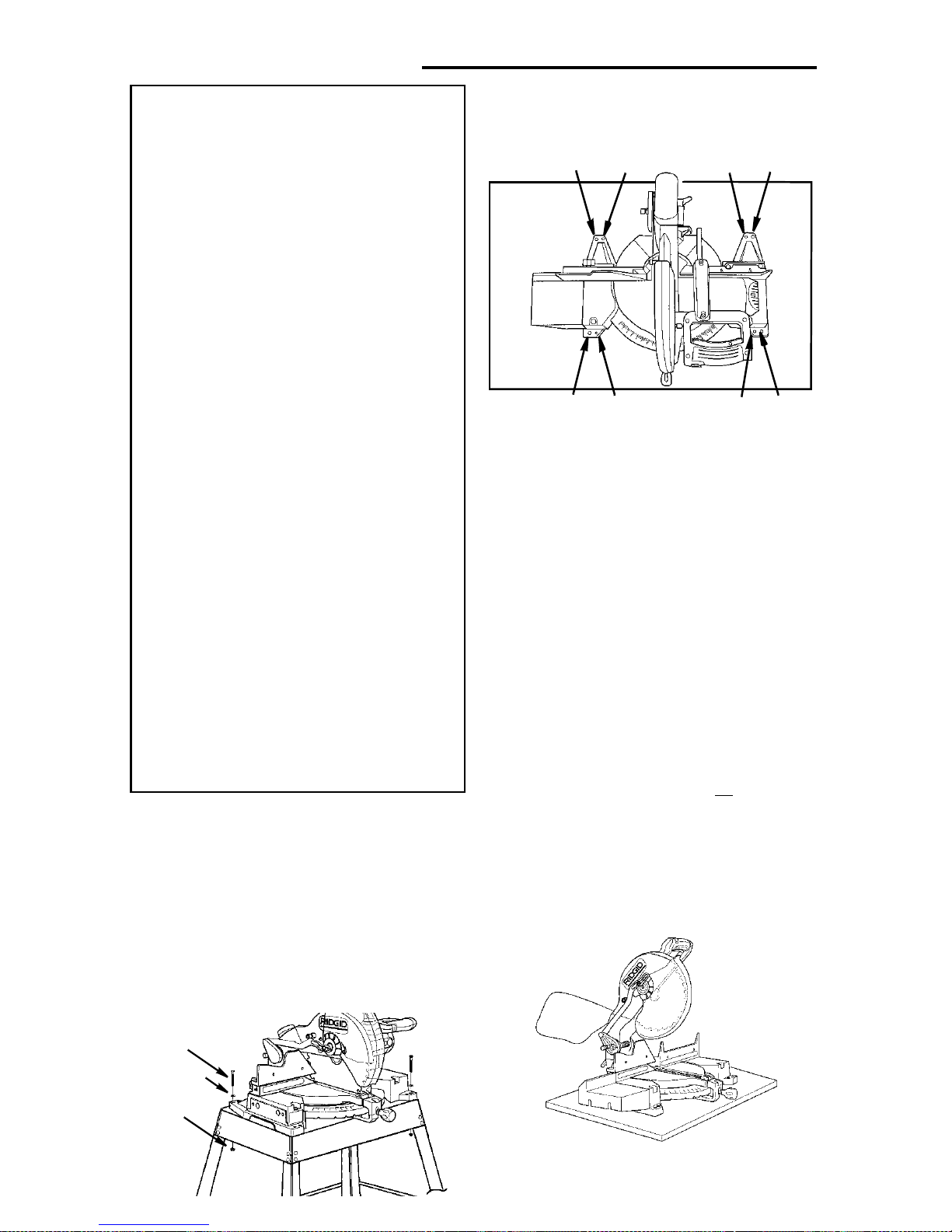

Assembling Leg Set

1. Locate the following parts:

4 Legs

2 Long Upper Stiffeners

2 Short Upper Stiffeners

2 Long Lower Stiffeners

2 Short Lower Stiffeners.

2. From the leg set hardware bag find the

following:

4 Feet

24Carriage Bolts 5/16-18 x 5/8

24Flange Nuts 5/16-18

NOTE: Hardware not shown actual size.

3. Assemble the stand as shown. Make

sure the legs go inside the upper stiffeners. Make sure the legs go outside

the lower stiffeners. Make sure the long

upperstiffenersgo overthe short upper

stiffeners.

4. Only finger tighten nuts at this time.

ness in the pivot, do the following

adjustment procedure:

a. Loosen t he bevel lock handle.

b.Turnthehexlocknutwitha3/4"or

19mm socket and socket wrench.

Recheck bevel movement of the miter

saw. Readjust if necessary.

Leg

Long Upper

Stiffener

Short Upper

Stiffener

Foot

Short UIpper

Stiffener

Leg

Long Lower

Stiffener

Bolt

Short Lower

Stiffener

Flange Nut

Long Upper

Stiffener

18

Long Lower

Stiffener

Foot

Short Lower

Stiffener

Mounting The Miter Saw

WARNING: To reduce the risk of

injury from un expected saw

movement:

a.Before moving the saw, lock the

miter and bevel knobs and lock

the power head in the lower

position. Unplug electric cord.

b.Toreducetheriskofback

injury , hold the tool close to

your body when lifting. Bend

your knees so you can lift with

your legs, not your back. Lift by

using the hand-hold areas at

each side of the bottom of the

base or by the carrying handle .

c.Never carry the miter saw by

the power cord or the trigger

grip of the plastic handle. Carrying the tool by the power

cord could cause damage to

the insulation or the wire connections resulting in electric

shock or fire.

d.Place the saw so other people

cannot stand b ehind it. Thrown

debris could injure people in

its path.

e.Place the saw on a firm, level

surfacewherethereisplentyof

room for handling and properly

supporting the workpiece.

f. Support the saw so the table is

level and the saw does not rock.

g.Boltor clamp the saw toitssupport.

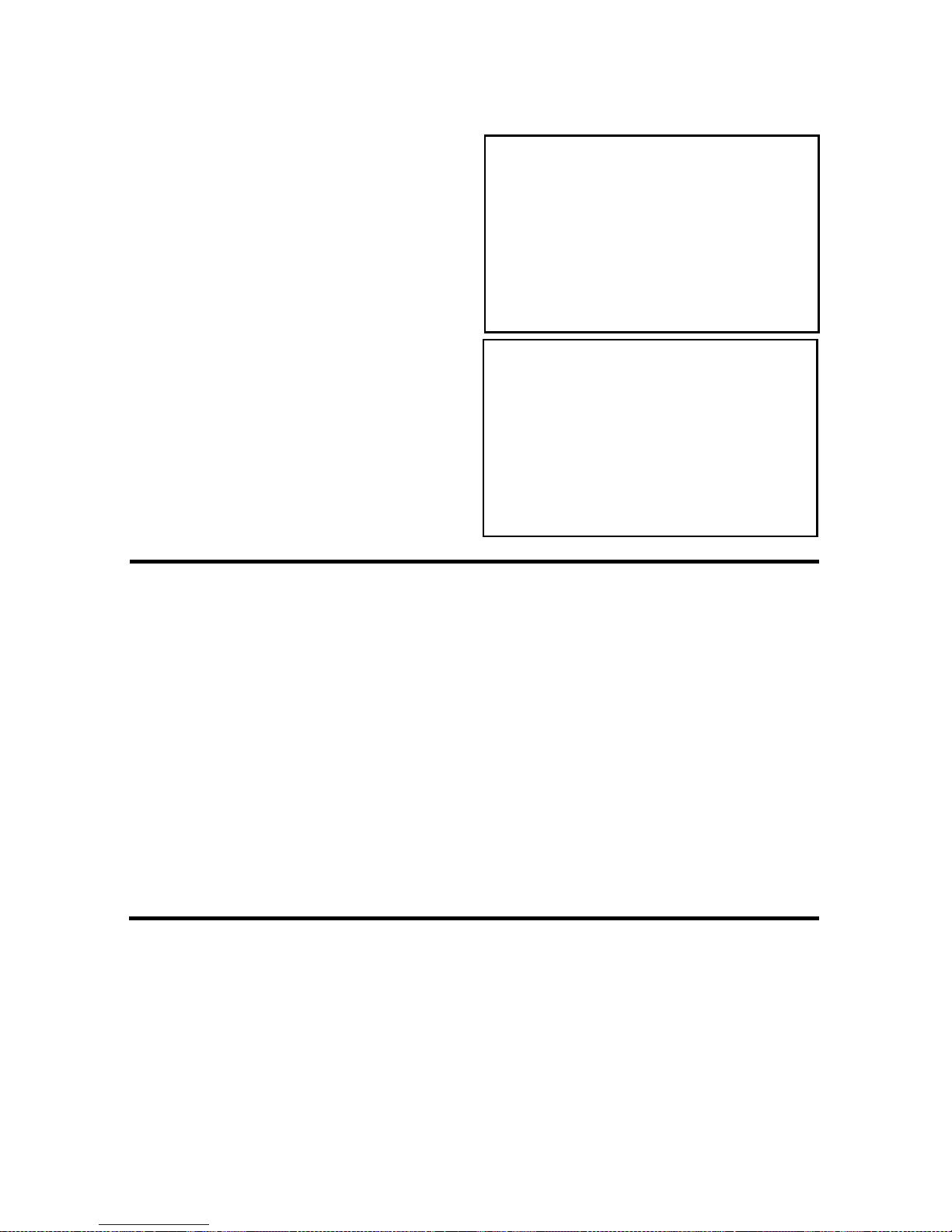

Mounting Saw on Supplied Legset

1. Locate 4 bolts,4 washers and 4 nuts in

parts bag.

2. Position leg set at the desired location .

3. Mount the miter saw as shown wi th provided hardware. Only finger tighten

nuts at this time.

4. If necessary shift the leg set to adjust

for slightly unlevel floor.Securely

tighten all hardware.

Mounting Saw on Other Legsets or

Work Benches

B

Mounting Board or Work Surface

Place the saw in the desired location

either on a work bench or other recommended leg set. The base of the saw has

eight holes to mount the miter saw. Four

smaller holes for “drywall” screws are

labeled A. Fourholes for bolts are labeled

B (seeillustration).If t he sawis tobe used

in one location, permanently fasten it to

the work bench or leg set.

NOTE: When mounted on a large flat surface, t he miter saw table is 3 1/2" high. A

finished 4x4 or a supported 2x4 on edge

can be used as work support extension.

A

ABBA

B

A

Portable Applications

To mount the saw to a 3/4” piece of plywood, use 4, 1/4" bolt holes or

wallscrew holes. The mounting board can

then be clamped down t o prevent i t from

tipping. Plywood mount also helps protect

saw from damage during the rough handling associated with portable miter saw

usage.

the 4 dry-

Bolt

Washer

Nut

19

Safety Instructions for Basic Saw Operations

Before Each Use

Inspect your saw.

Disconnect The Miter Saw. To

reduce the risk of injury from accidental starting, unp lug the saw, before

changing the setup, changing the

blade or adjusting anything.

Compare the direction of rotation

arrow on the guard to the direction

arrow on blade. The blade tee th

should always point downward at the

front of the s aw.

Tighten the arbor screw.

Tighten the cover plate stop screw.

Check Damaged Par t s. Check for:

• Alignment of moving parts,

• Damag ed electric co rds,

• Binding of moving parts,

• Broken parts,

• Stable mounting

• Function of arm ret urn spring and

lower guard: Push the arm all the

way down, then let it rise up until it

stops by itself. Check the lower

guard to see if it closed fully. If it did

not, follow the instructions in t he

Trouble Shooting section.

• Other conditions that may affect the

way the miter saw works.

Keep G uards In Place,inworking

order, and in proper adjustment.

If any part of this m iter saw if missing,

bent, or broken in any way, or any

electrical par ts don’t work, turn the

saw off and unplug it. Replace damaged, m iss ing, or failed parts before

using the saw again.

Maintain Tools With Care. Keep the

miter saw clean for best and safest

performance. Follow instructions for

lubricating. DON’T put lubricants on

the blade while it’s s pinning.

Remove Adjusting Keys And

Wrenches from tool before turning it

on.

To Reduce the Risk of Injury From Jams, Slips Or Thrown Pieces

• Use Only Recommended A c cessories. (See “Accessory” section

within.) Consult this Owner’s manual

for recommended acc es s ories. Follow the instructions that come with

the accessories. The use of

improper accessories may cause

risk of injur y to person s.

• Choose the right 12-inch diame ter

blade for the material and the t y pe

of cutting you plan to do.

• Make sure the blade is shar p,

undamaged and properly aligne d.

With the saw u nplugged, push t he

power-head all the way down. Hand

spin the blade and che ck for clearance.

• Make sure the blade and arbor col-

lars are clean.

• Make sure the collars' recessed

sides are facing the blade.

• Us ing 1/4” hex end of combination

wrench (supplied) or 1/2-inch box

end wrench, make sure the arbor

screw is firmly tightened.

• Make sure all clamps and locks are

tight and there is no excessive play

in any parts.

• Keep work area clean. Cluttered

areas and benches invite accidents.

Floor must not be slippery.

To reduce the risk of bur ns or other

fire damage, never use the miter saw

near flammable liquids, vapors or

gases.

20

Plan Ahead To Protect Your Eyes, Hands, Face and Ears

Know your miter saw. Read and

understand the owner’s manual and

labels affixed to the tool. Lear n its

application and limitations as well as

the specificpotential hazards pecul iar

to this tool.

To red uce the ri sk of injury from accidental contact with moving parts,

don’t do layout, assembly, or setup

work on the miter saw while any parts

are moving.

Reduce the Risk of Accidental

Starting. Make sure switch is “O FF”

before plugg ing miter saw into a

power outlet.

Plan your work.

Use The Right Tool. Don’t force tool

or attachment to do a job it was not

designed to do. Use a different tool

forany workpiece that can’t be held in

a solidly braced, fixed position.

CAUTION: This machine is n ot

designed for cutting ferrous metals (steel , iron and iron b ased

metals). Use this miter saw to cut

only wood, wood like products or

soft me tals like aluminum. Other

material may shatter, bind on the

blade, o r create oth er dan gers.

CAUTION: W hen cutting any metals, sparks or hot fragments

could cause a fire . To avoid this,

disconnect any dust collecting

bag or hose from the miter saw,

and remove all traces of wood

dust from inside dust traps in the

miter saw.

Dress For Safety

The operation of any powermiter saw can

throw foreign objects into the eyes. This

can result in permanent eye damage.

Wear safety goggles (not glasses) that

comply wi th ANSI Z87.1 (or in Canada

CSA Z94.3-99) shown on package.

Everyday eyeglasses have only impact

resistant lenses. They are not safety

glasses.Safety goggles ar e available at

many local retail stores. Glasses or goggles not in compliance with ANSI or CSA

could ser iously hurt you when they break

• Do not wear loose clothing, gloves,

neckties or jewelry (rings, wrist

Preparing to Make the Cut

Inspect Your Workp iece. Make sure

there are no nails or foreign objects in

the part of the workpiece to be cut.

Plan your work to avoid thrown

pieces caus ed when the workpiece

binds on the blade and is torn from

your hands.

Plan the way you will hold the work-

watches) T hey can get caught and

draw you into moving parts.

• Wear nonslip footwear.

• Tie back long hair.

• Roll long sleeves above the elbow.

• Noise levels vary widely. To reduce

the risk of possible heari ng d amage,

wear ear plugs or muffs when using

miter s aw for hours at a time.

• For dusty operations, wear a dust

mask along with s afety goggles.

piece from start to finish.

Avoid awkward operations and hand

positions where a sudde n slip could

cause f ingers or hand to move into

the blade.

Don’t Overreach. Keep good footing

and balance.

21

Safety Instructions for Basic Saw Operations (con’t.)

Keep your face an d body to one side

of sawblade, out of line with a possible throwback.

Cut only one workpiece at a time.

Never cut Freehand:

• Brace your workpi ec e solidly

against the fence and ta ble top so it

will not rock or twist during the cut.

• Make sure there’s no debris

between the workpiece and its supports.

• Make sure no gaps between the

workpiece, fence and table will let

the workpiece shift after it is cut in

two.

•Keepthecutoffpiecefreetomove

sidewaysafter it'scutoff.Otherwise,

it could get wedged against the

blade and c ould be thrown violently.

• Clear everything except the wor kpiece and related support devises

off the table before turning the miter

saw on.

• Secure Work. Use clamps or a vise

to help hold t he work wh en it’s practical.

Use extra caution with large , ver y

small or awkward workpieces:

• Use extra supports (t ables, saw

horses, blocks, etc.) forany workpieces large enough to tip when not

held down to the table top.

• Never use another person as a substitute for a table extension, or as

additional support for a work piece

that is longer or wider than the bas ic

miter saw table or to help feed, sup port or pull the workpiece.

too small to let you easily hold the

work while you keep the thumb side

of your index (pointer) finger against

the outside edge of the fence.

• When cutting irregularly shap ed

workpieces, pl an your work so it will

not slip and pinc h the blade and be

torn from your hands. A pie ce of

molding, for example, must lie flat or

be held by a fixture or jig that will not

let it twist, rock or slip while being

cut.

• Properly support round material

such as dowel rods, or tubing. They

have a t endency t o roll while being

cut, causing the blade to "bite." To

avoid this, always use a fixture

designed to properly hold your

workpiece.

WARNING: If planning to cut aluminum or other non-ferrous metals: Und er adverse conditions,

thebladecangrabandthrowthe

workpiece suddenly and unexpectedly. To reduce the risk of

injury ,follow all applicable safety

instructions, as you nor mally

would, and:

• Use only sawblades specifi-

cally recom m ended for non-ferrous metal cutting.

• D o not cut m etal workpieces

that must be hand held. Use

auxiliary clamps or other

equipment as needed.

• Cut non-ferrous metals only if

you are experienced or under

the supervisi on of an experienced person.

• Do not use this saw to c ut pieces

22

Whenever Saw Is Running

WARNING: Don't allow familiarity

(gained from frequent u se of

your miter saw) cause a carele ss

mistake. A careless frac t io n of a

second is enough to cause a

severe injury.

Before starting your cut, watch the

miter saw while it runs. If it makes an

unfamiliar noise or vibrates a lot, stop

immediately. Turn the saw o ff. Unplug

the saw. Do not restart until finding

and correcting the problem .

Keep Children Away. Keep all visitors a safe distance from the miter

saw. Make sure bystanders are cl ear

of the miter saw and workpiece.

Never confine the piece being cut

off. Never hold it, clamp it, touch it, or

use length stops against it while the

blade is spinning. It must be free t o

move sideways on its own. If confined, it could get wedged against the

blade and th rown violently.

Let the blade reach full speed

before cutting. This will help reduce

the risk of a thrown workpiece.

Don’t Force Tool. It will do the job

better and safer at its designed rate.

Feed the saw into the work piece only

fast enough to let t he blade cut without bogging down or binding.

Before free in g jammed m aterial:

• Turn miter saw “OFF” by releasing

trigger switch.

• Wait for all moving parts to stop.

• Unplug the mi ter saw.

After finishing a cut:

• Keep holding the power head down.

• Release t he switch, and wait for all

moving parts to stop before moving

your hands or raising power head.

• If blade doesn’t stop within 6 seconds, unplug the saw and follow the

instructions in the Trouble Shooting

section for fixing the blade brake

before using the saw again.

Before Leaving The Saw:

Never Leave Tool Running Unattended.Turnpoweroff.Waitforall

moving parts to stop.

Make workshop child-proof. Install

a padlock through t he hole provided

in the trigg er to prevent unauthorized

usage. Lock the shop. Disconnect

master switches. Store tool awayfrom

children and ot hers no t qualified to

use the tool.

23

Basic Saw Operations

WARNING: For your convenient

use, your saw has a blade brake .

The brake is not a safety device.

Never rely on it to replace proper

use of the guard on your saw. If

the blade does not stop within 6

seconds, unplug the saw and follow the instructions in the Trouble Shooting section for fixing

the brake before using saw

again.

Body and Hand Position

• Never place hands near cutting area.

Place hand at least 4" from path of

blade.

• Hold workpiece firmly to the fence to

prevent movement toward the blade.

• When holding the workpiece to t he left

side of the blade, always use your left

hand. Use your right hand to hold the

workpiece to the right side of the blade.

• Before making a cut, make a “dry r un”

with the power off so you can see the

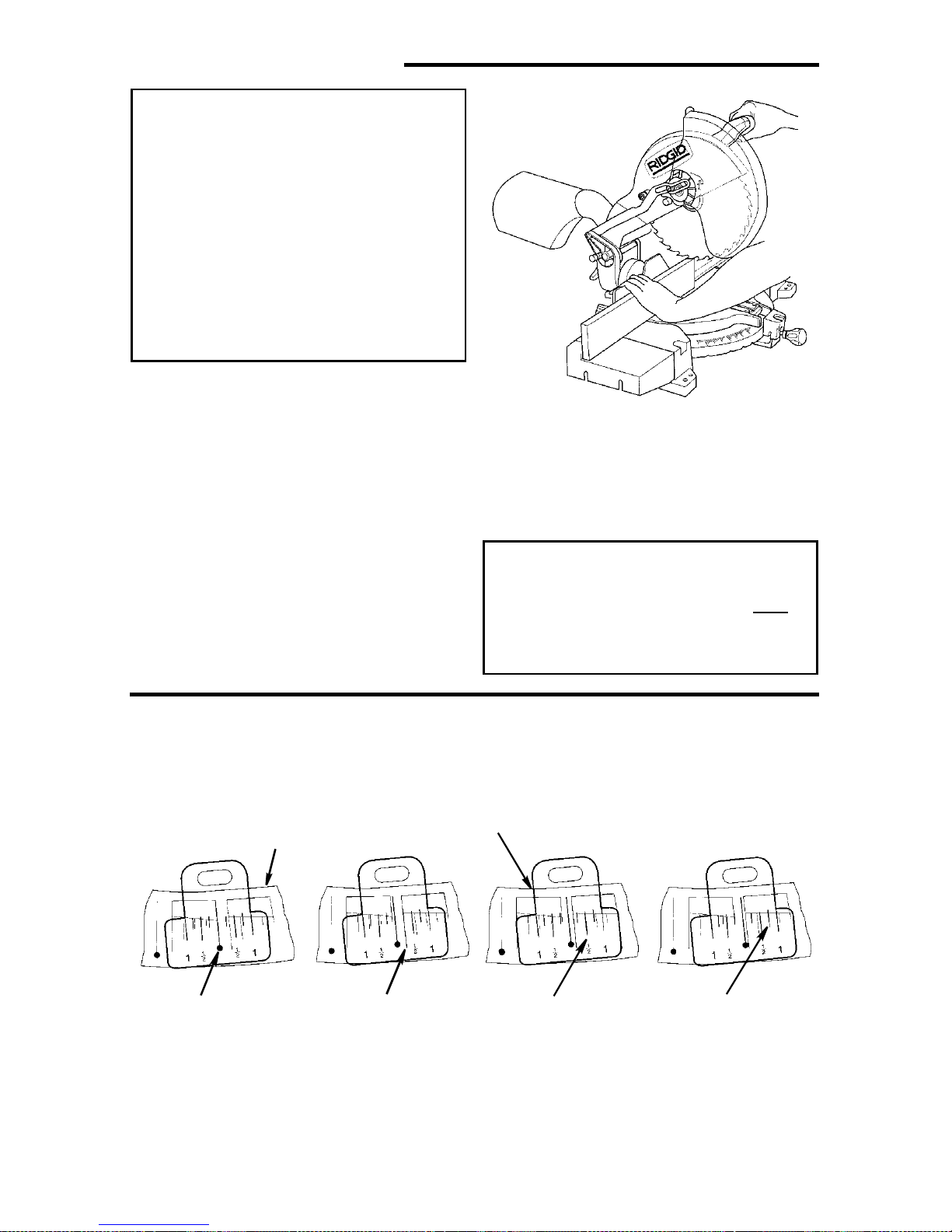

Miter Scale Usage

Vernier Miter Scale Operation:

The Vernier miter scale can quickly and

Miter Scale

5°

5-1/4°

path of the blade.

• Keep hands in position until trigger has

been released and the blade has completely stopped.

WARNING: Do not try to cut

short pieces, you cannot properly support the workpiece and

keep your hold down hand the

required distance from the blade.

accurately help the user to adjust the saw

to any 1/4° increment as illustrated below.

Vernier

Miter Indicator

5-1/2°

5-3/4°

Indicator over

5° scale mark

1/4° Indicator line

over 6° scale mark over 7° scale mark

1/2° Indicator line

24

3/4° Indicator line

over 8° scale mark

Sliding Fence

When beveling the blade to the left t he

fence may have to be repositioned.

Loosen the fence locking knob and slide

the fence to the left. Adjust the fence as

close to the guard and link as possible to

provide maximum suppor t for the workpiece. Securely tighten knob and make a

dry run with the saw off to check for clearance between the fence and guard. Af ter

completing bevelcut(s) remembert o slide

the fence back t o the right.

Miter Cut

When a miter cut is required, loosen miter

lock knob, depress the index spring and

move the saw to the desired angle.

Retighten miter lock knob.Move with the

handle to the miter angle to make the cut.

Bevel Cu t

When a bevel cut is required, loosen

bevel lock knob. Tilt the blade to desired

bevel angle. Retighten bevel lock knob.

Stand to the left side of the handle to

make the cut.

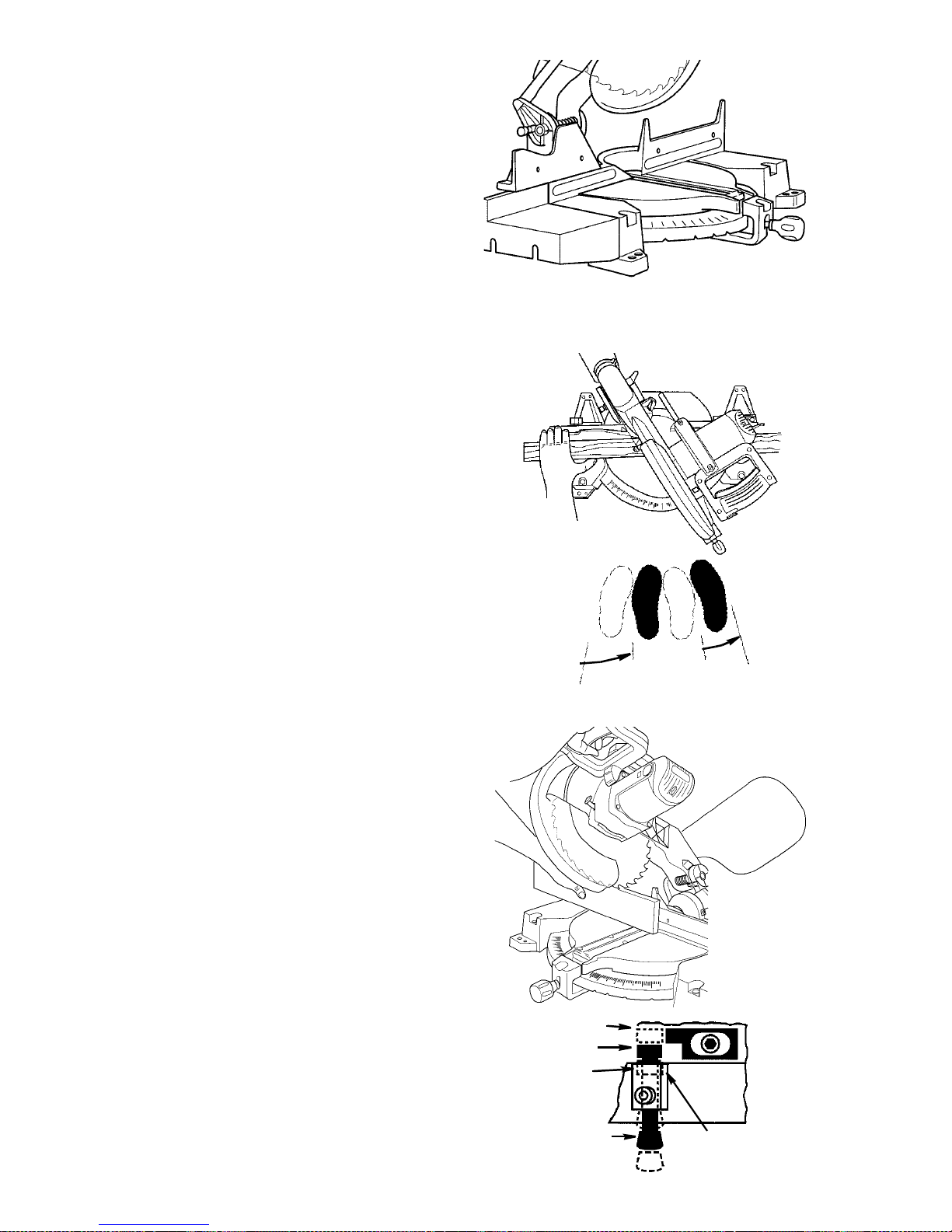

The bevel stop pin, foundat the rear of the

saw, has three positions as shown. For

most cuts the 0 - 45° middle position is

used. Push the pin all the way i n to utilize

the 0 - CM position when cutting crown

molding. Pull the pin all the way out to

allow the bevel adjustment to go beyond

the 0° and 45° stops.

Move Feet

With Miter

Saw

0°, CM Index

0°, 45° Index

By-Pass

25

Index/

By-Pass Pin

Bevel Index

Mechanism

Basic Saw Operations (continued)

Compound Cut

When a compound cut i s required, select

the desired bevel and miter positions.

Move with the handleto the miter angle t o

make the cut.

Cutting Compound Miters on

PictureFramesandBoxes

A compound miter is a cut requiring both

a miter setting and bevel setting. A compound miter is used for making frames or

boxes that have sloping sides and are

wide at one end and narrow at the opposite end. Compound miters are “tricky” to

makebecause the mitersetting and bevel

setting are directly related to each other.

Every time the miter setting is changed

the bevel setting must also be adjusted;

likewise every adjustment to bevel

requires a corresponding adjustment to

miter. Because it may take several tries to

obtain the desired angle, it is advisable to

make test cuts on a scrap piece of material.

Compound Cut Box

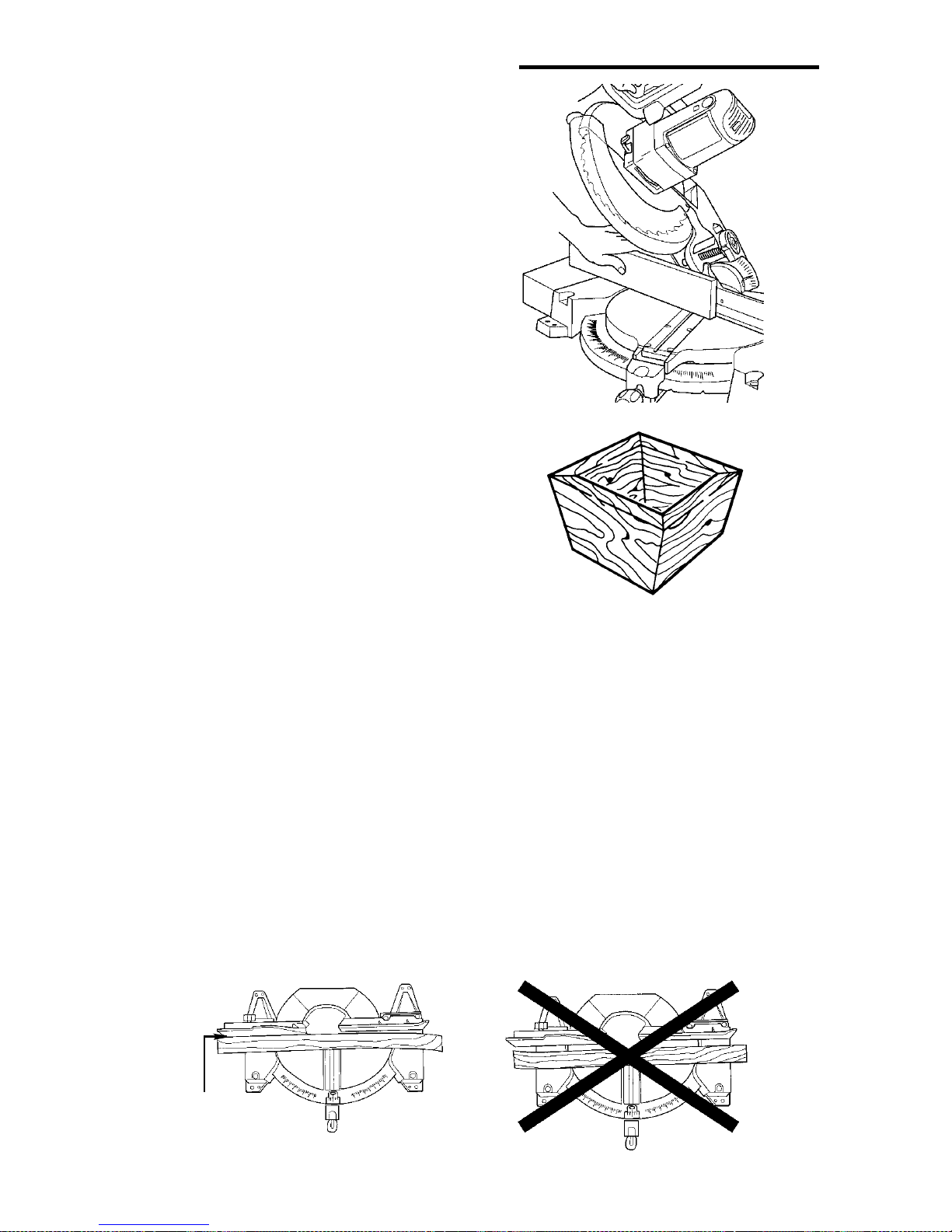

Cutting Bowed Material

Before cutting a workpiece, check to

make sure it is not bowed. If it is bowed

the workpiece must be positioned and cut

as illustrated. Do not position workpiece

incorrectly or try to cut the workpiecewith-

Hold workpiece tight

against fence so

thereisnogap

Correct

out the support of the fence.This will

cause pinching of the workpiece on t he

blade. The workpiece could suddenly

jump or move and your hand could hit the

blade.

Incorrect

26

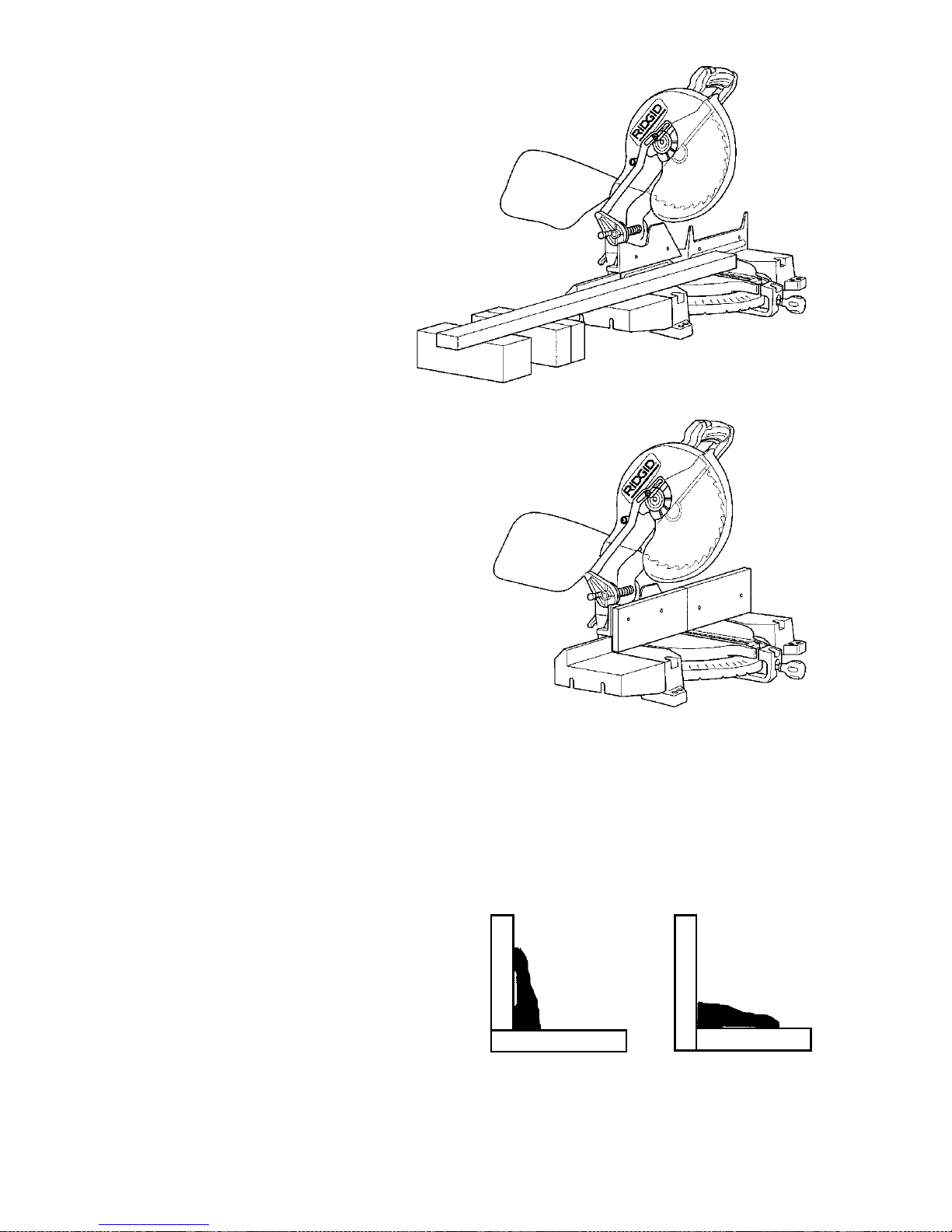

Workpiece Support

Long pieces need extra supports. The

supports should be placed along the

workpiece so the workpiece does not sag

and your hand holding the workpiece is

positioned4” or more from the blade path.

The support should let the workpiece

lay flat on the base and work table

during t he cutting operation.

NOTE: When mounted on a large flat surface, t he miter saw table is 3 1/2” high. A

finished 4x4 or a supported 2x4

on edge can be used as work support extension.

Auxiliary Fence

Certain unusual cuts may benefit from a

fence face extension due to the size and

position of the workpiece. Holes are provided in the fence to attach an auxiliary

fence. Get a straight piece of wood typically1/2 inch thick by 4-1/4 inches high by

23-1/2 or 28 inches long. To attach auxiliary fence, place the piece of wood on the

miter saw fence. Mark the hole locations

from the backside of the miter saw fence.

Drill .200”-.250” holes, then countersink

the holes on front of wood to receive #10

flat head screws. Attach the auxiliary

fence securely and make a full depth cut.

This wi ll create the blade slot. Check for

interference between the auxiliary fence

and lower blade guard. Correct any interference before proceeding. The auxiliary

fenceisusedwiththesawinthe0°bevel

position. If a bevel cut is desired, the auxiliary fence will have to be removed.

Cutting Base Moldings

Base moldings and many other moldings

can be cut on a miter saw. The set up of

the saw depends on your molding and

your application as shown. Always make

sure moldings rest firmly against fence

and table.

F

e

n

c

e

Miter Saw Table

(Miter at 45° (Miter at 0°,

Bevel at 0°) Bevel at 45°)

27

F

e

n

c

e

Miter Saw Table

Cutting Base Molding

Loading...

Loading...