Standard and Mini

SeeSnake

®

Diagnostic Equipment

OPERATOR’S

MANUAL

• Français – Page23

• Castellano – paginá 47

KD-200

KD-325

KD-100-Mini

KD-200-Mini

KD-200-Color

KD-325-Color

KD-100 Mini-Color

KD-200 Mini-Color

W ARNING!

Read this Operator’s Manual

carefully before using this

tool. Failure to understand

and follow the contents of

this manual may result in

electrical shock, fire and/or

serious personal injury.

UL/CSA Certified

Kollmann

Table of Contents

Recording Form for Machine Model and Serial Number ...........................................................................................1

General Safety Information

Work Area Safety........................................................................................................................................................2

Electrical Safety...........................................................................................................................................................2

Battery Precautions..................................................................................................................................................2

Personal Safety...........................................................................................................................................................2

Tool Use and Care......................................................................................................................................................3

Service ........................................................................................................................................................................3

Specific Safety Information

Tool Safety..................................................................................................................................................................4

Description, Specifications and Standard Equipment

Description ..................................................................................................................................................................4

System Components................................................................................................................................................4

Specifications..............................................................................................................................................................7

Standard Equipment....................................................................................................................................................8

Set-Up and Operation

Equipment Set-up........................................................................................................................................................8

Connections ................................................................................................................................................................8

Operation.....................................................................................................................................................................8

Pre-Checks..................................................................................................................................................................9

Mechanical Checks..................................................................................................................................................9

Electrical Checks......................................................................................................................................................9

SeeSnake Cable CountIR........................................................................................................................................9

At the Job Site...........................................................................................................................................................10

Transportation & Storage ...........................................................................................................................................12

Maintenance and Cleaning

Preventative Maintenance.........................................................................................................................................12

Corrective Maintenance ............................................................................................................................................13

Locating Faulty Components.....................................................................................................................................14

Options......................................................................................................................................................................15

Installing the SeeSnake Centering Guides................................................................................................................17

Appendix A – Installing the Standard SeeSnake Wheels ........................................................................................19

Service and Repair ......................................................................................................................................................20

Troubleshooting ..........................................................................................................................................................21

Lifetime Warranty..........................................................................................................................................Back Cover

Ridge Tool Companyii

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

SeeSnake®Camera Reel

Record Serial Number below and retain product serial number which is located on nameplate.

Serial

No.

Kollmann

Standard and Mini SeeSnake

®

Diagnostic Equipment

KD-200

KD-325

KD-100-Mini

KD-200-Mini

KD-200-Color

KD-325-Color

KD-100 Mini-Color

KD-200 Mini-Color

UL/CSA Certified

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

Ridge Tool Company2

General Safety Information

WARNING! Read and understand all instructions. Failure

to follow all instructions listed below may

result in electric shock, fire, and/or serious

personal injury.

SAVE THESE INSTRUCTIONS!

Work Area Safety

• Keep your work area clean and well lit. Cluttered

benches and dark areas may cause accidents.

• Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away

while operating tool. Distractions can cause you

to lose control.

• Do not let visitors contact the tool or extension

cord. Such preventative measures reduce the risk

of injury.

Electrical Safety

• Grounded tools must be plugged into an outlet,

properly installed and grounded in accordance with

all codes and ordinances. Never remove the grounding prong or modify the plug in any way. Do not use

any adapter plugs. Check with a qualified electrician

if you are in doubt as to whether the outlet is properly grounded. If the tool should electrically malfunction

or break down, grounding provides a low resistance

path to carry electricity away from the user.

• Avoid body contact with grounded surfaces such

as pipes, radiators, ranges and refrigerators. There

is an increased risk of electrical shock if your body is

grounded.

• Do not expose electrical tools to rain or wet con-

ditions. Water entering a tool will increase the risk of

electrical shock.

• Do not abuse cord. Never use the cord to carry the

tool or pull the plug from an outlet. Keep cord

away from heat, oil, sharp edges, or moving parts.

Replace damaged cords immediately. Damaged

cords increase the risk of electrical shock.

• When operating a power tool outside, use an out-

door extension cord marked “W-A” or “W

”

. These

cords are rated for outdoor use and reduce the risk of

electrical shock.

• Connect the tool to an AC power supply that

matches the name plate specification. Incorrect

voltage supply can cause electrical shock or burns.

• Use only three-wire extension cords which have

three-prong grounding plugs, and three-pole receptacles which accept the tools plug. Use of other

extension cords will not ground the tool properly and increase the risk of electrical shock.

• Use proper extension cords. (See chart.) Insufficient

conductor size will cause excessive voltage drop and

loss of power.

• Keep all electrical connections dry and off the

ground. Do not touch plugs or tool with wet hands.

This reduces the risk of electrical shock.

Battery Precautions

• Use only the size and type of battery specified.

• Be sure to install the battery with the correct po-

larity as indicated in the battery compartment.

• Recharge batteries with charging units specified by

the battery manufacturer. Using an improper charger

can overheat and rupture the battery.

• Properly dispose of the battery. Exposure to high

temperatures can cause the battery to explode,

so do not dispose of in a fire. Some countries have

regulations concerning battery disposal. Please follow all applicable regulations.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use tool while tired or under the influence of drugs,

alcohol, or medications. A moment of inattention

while operating power tools may result in serious personal injury.

• Dress properly. Do not wear loose clothing or jew-

elry. Contain long hair. Keep your hair, clothing, and

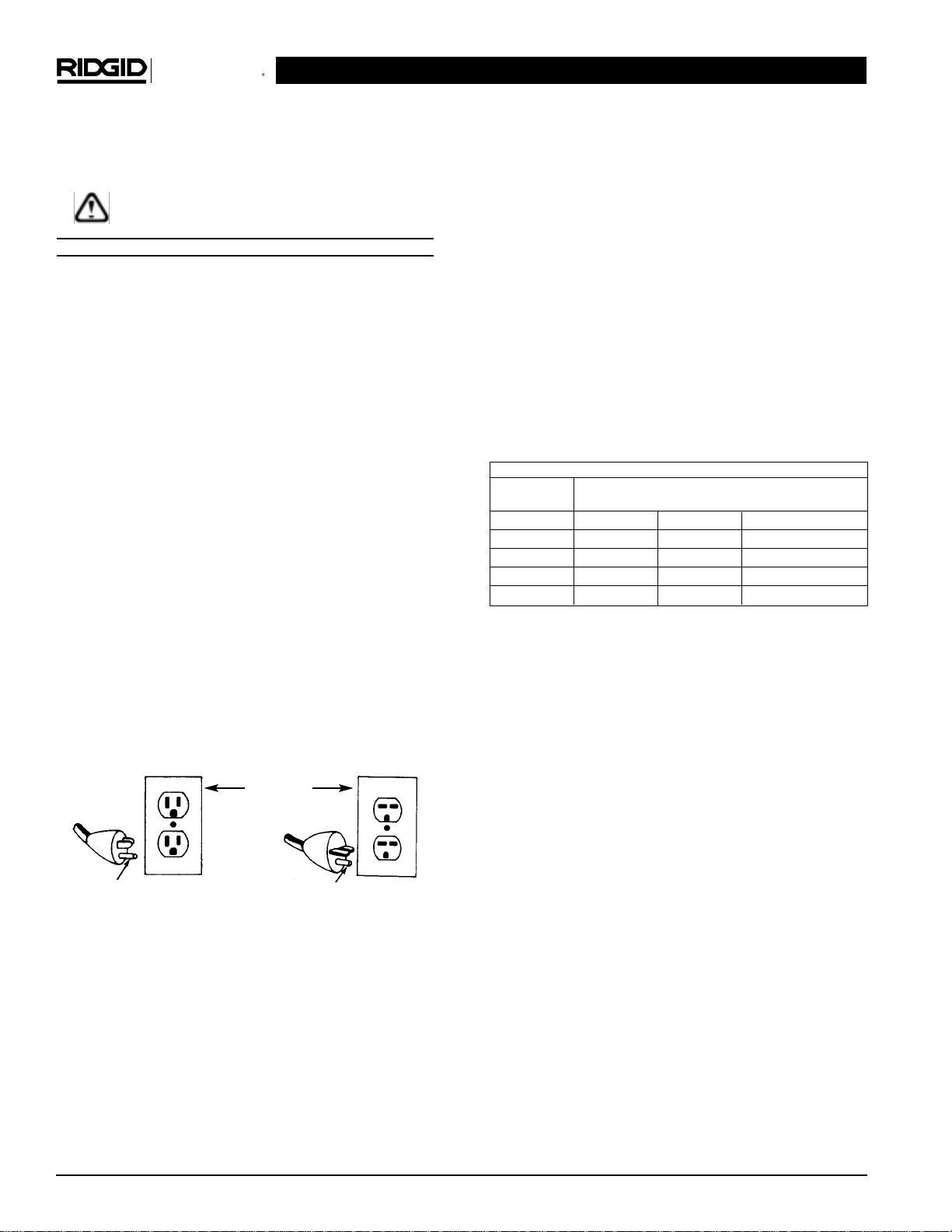

Grounding pin

Cover of

grounded

outlet box

Grounding pin

Minimum Wire Gauge for Extension Cord

Nameplate

Amps Total Length (in feet)

0 – 25 26 – 50 51 – 100

0 – 6 18 AWG 16 AWG 16 AWG

6 – 10 18 AWG 16 AWG 14 AWG

10 – 12 16 AWG 16 AWG 14 AWG

12 – 16 14 AWG 12 AWG

NOT RECOMMENDED

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

Ridge Tool Company 3

gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts.

• Avoid accidental starting. Be sure switch is OFF

before plugging in. Carrying tools with your finger on

the switch or plugging in tools that have the switch on

invites accidents.

• Do not overreach. Keep proper footing and balance

at all times. Proper footing and balance enables better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection.

Dust mask, non-skid safety shoes, hard hat, or hearing

protection must be used for appropriate conditions.

• Gloves should always be worn for health and

safety reasons. Sewer lines are unsanitary and may

contain harmful bacteria.

• Heed warnings. All warnings on the product and in

the Operator’s Manual should be adhered to.

• Use proper accessories. Do not place this product

on any unstable cart or surface. The product may fall

causing personal injury and/or damage to the product.

• Prevent object and liquid entry. Never spill liquid of

any kind on the product. Never push objects of any

kind into this product through openings as they may

touch dangerous voltage points or short to parts that

could result in a fire or electrical shock.

NOTE! Check to make sure pipe not electrically hot.

In some cases ground circuits may be returned

to cast iron pipes causing them to be electrically

charged. As sections of pipe joined with shielded

hub-less connections or compression gaskets

may be electrically isolated, care should be

taken to check the entire length on any pipe

you are going to inspect.

Tool Use and Care

• Do not use tool if switch does not turn it ON or

OFF. Any tool that cannot be controlled with the switch

is dangerous and must be repaired.

• Store idle tools out of the reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

• Maintain tools with care. Properly maintained tools

are less likely to cause injury.

• Check for misalignment or binding of moving

parts, breakage of parts and any other condition

that may affect the tool’s operation. If damaged,

have the tool serviced before using. Many accidents

are caused by poorly maintained tools.

• Use only accessories that are recommended by the

manufacturer for your tool. Accessories that may be

suitable for one tool may become hazardous when

used on another tool.

• Inspect tool and extension cords periodically and

replace if damaged. Damaged cords increase the risk

of electrical shock.

• Keep handles dry and clean; free from oil and

grease. Allows for better control of the tool.

• Store tools in dry place. Such measures reduce the

risk of electrical shock.

• Protect against lightning. For added protection for

this product during a lightning storm, or when it is

left unattended and unused for long periods of time,

unplug it from the wall outlet. This will prevent damage

to the product due to lightning and power surges.

• Protect against excessive heat. The product should

be situated away from heat sources such as radiators,

heat registers, stoves or other products (including amplifiers) that produce heat.

• Provide adequate ventilation. Slots and openings

in the cabinet are provided for ventilation and to ensure

reliable operations of the product. These openings

must not be blocked or covered. This product should

not be placed in a built-in installation such as a rack or

bookcase unless proper ventilation is provided or the

manufacturer’s instructions have been adhered to.

Service

• Tool service must be performed only by qualified

repair personnel. Service or maintenance performed

by unqualified repair personnel could result in injury.

• When servicing a tool, use only identical replace-

ment parts. Follow instructions in the Maintenance

Section of this manual. Use of unauthorized parts or

failure to follow maintenance instructions may create a

risk of electrical shock or injury.

• Follow instructions for lubricating and changing

accessories. Accidents are caused by poorly maintained tools.

• Provide proper cleaning. Unplug this product from the

wall outlet before cleaning. Do not use liquid cleaners

or aerosol cleaners. Use a damp cloth for cleaning.

• Conduct a safety check. Upon completion of any

service or repair of this product, ask the service technician to perform safety checks to determine that the

product is in proper operating condition.

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

Ridge Tool Company4

nents removed. Exposure to internal parts increases

the risk of injury.

• Do not place the camera control unit in water or

on a wet surface. Water entering the housings will increase the risk of electrical shock.

• Do not use as a chair or table. Do not drop or

shock. Can result in damage to the unit which increases the risk of electrical shock.

• Product and cart should be moved with care. Quick

stops, excessive force and uneven surfaces may cause

the product and cart combination to overturn.

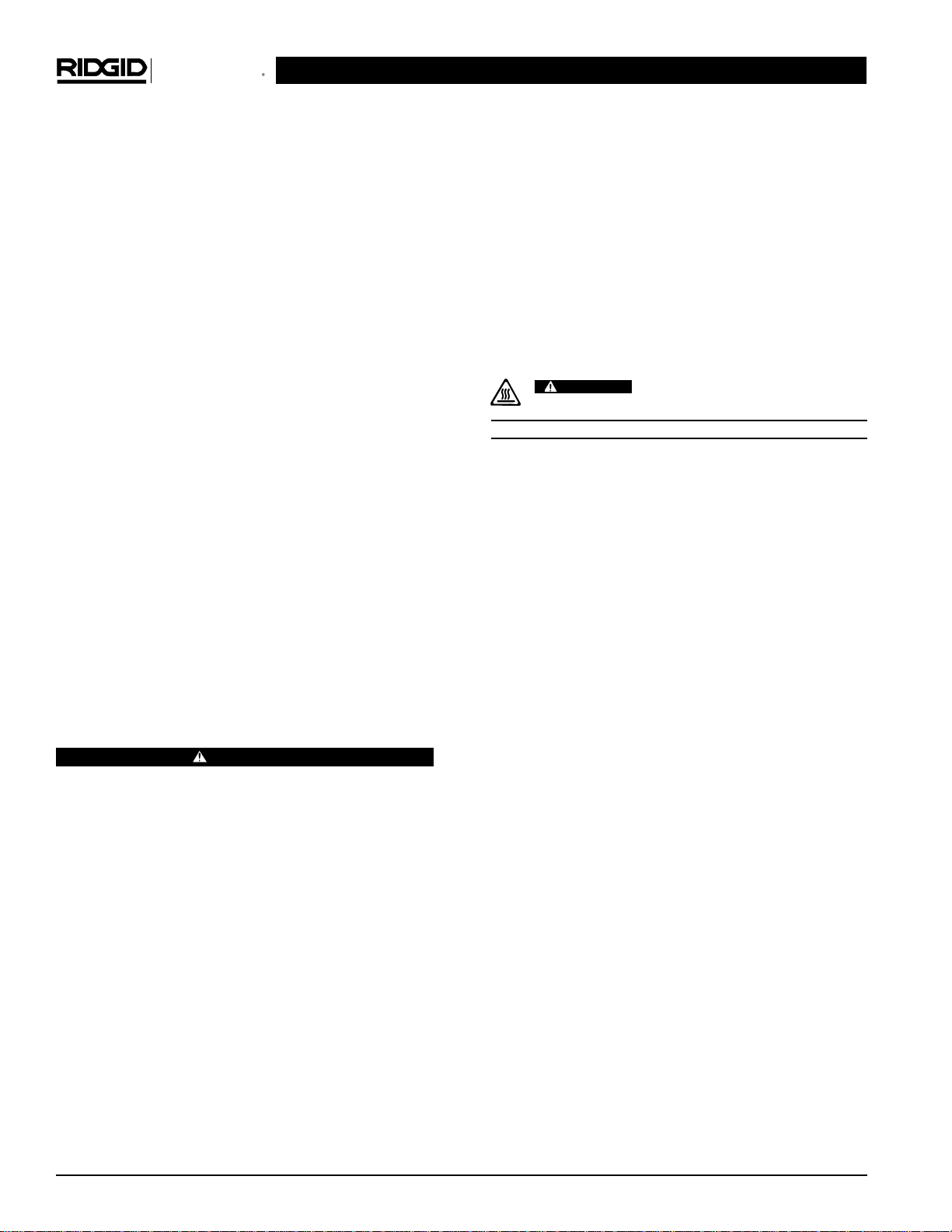

Camera head can get HOT! Turn

OFF camera while not in use.

SAVE THESE INSTRUCTIONS!

Description, Specifications and

Standard Equipment

Description

The RIDGID/Kollmann SeeSnake pipe inspection system is a powerful set of tools that helps you locate and

diagnose problems in drain and sewer systems. The

SeeSnake family of diagnostic equipment includes

Standard and Mini camera reels, a choice of camera

control, video display and recording options, and a locating system to help you quickly pinpoint problems under

ground. Every component in the SeeSnake system has

been engineered and tested to ensure rugged and reliable

operation on the kinds of jobs you encounter every day.

SeeSnake pipe inspection cameras are ideal for inspecting 2″ to 12″ (Standard SeeSnake) and 11/4″ to 8″ (Mini

SeeSnake) drain lines. Their flexible camera heads can negotiate multiple hard 90° bends. The fiberglass-reinforced

push cable is flexible enough to easily travel through

bends, yet stiff enough to push the camera head up to 325′

(Standard SeeSnake) and 200′ (Mini SeeSnake).

System Components

The SeeSnake pipe inspection system contains the following four sub assemblies: Camera Head, Reel/Frame,

Camera Control Unit and a Locating System. Please

take a moment to learn the following details and the

functions of each of these components. (Figures 1 - 9)

1) Camera Head

The camera head has adjustable lighting elements and

a highly scratch-resistant sapphire window (Lens Port).

This coupled with the stainless steel armoring allows

the camera to withstand repeated battering in cast iron

pipes. The Camera is rated to a water depth of 330′.

• Damage to the product that requires service.

Unplug this product from the wall outlet and refer servicing to qualified service personnel under any of the

following conditions:

• When the power cord or plug is damaged;

• If liquid has been spilled, or object have fallen into

product.;

• If product has been exposed to rain or water;

• If product does not operate normally by following the

operating instructions;

• If the product has been dropped or damaged in any

way.

• When the product exhibits a distinct change in per-

formance.

If you have any questions regarding the service or repair

of this machine, call or write to:

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44035-6001

Tel: (800) 519-3456

E-mail: TechServices@ridgid.com

On the Web: www.ridgid.com

or www.seesnake.com

In any correspondence, please give all the information

shown on the nameplate of your tool including model

number, voltage and serial number.

Specific Safety Information

WARNING

Read this operator’s manual carefully before using

this Diagnostic Equipment. Failure to understand

and follow the contents of this manual may result in

electrical shock, fire and/or serious personal injury.

Call the Ridge Tool Company, Technical Service Department at (800) 519-3456 if you have any questions.

Tool Safety

• Before using, test the Ground Fault Circuit Interrupter (GFCI) provided with the power cord to

ensure it is operating correctly. GFCI reduces the

risk of electrical shock.

• Extension cords are not recommended unless they

are plugged into a Ground Fault Circuit Interrupter

(GFCI) found in circuit boxes or receptacles. The

GFCI on the camera control unit power cords will not

prevent electrical shock from the extension cords.

• Do not operate the system with electrical compo-

CAUTION

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

Ridge Tool Company 5

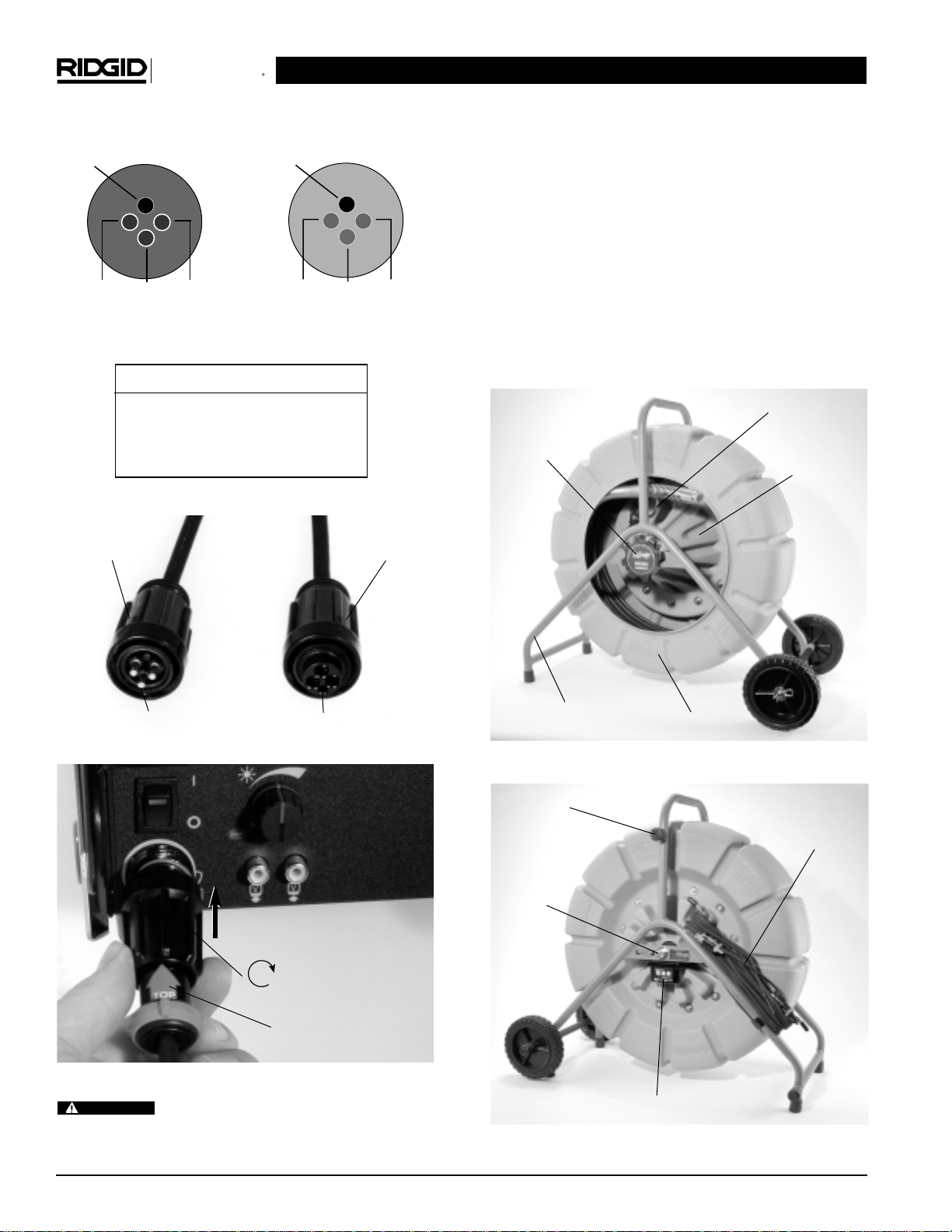

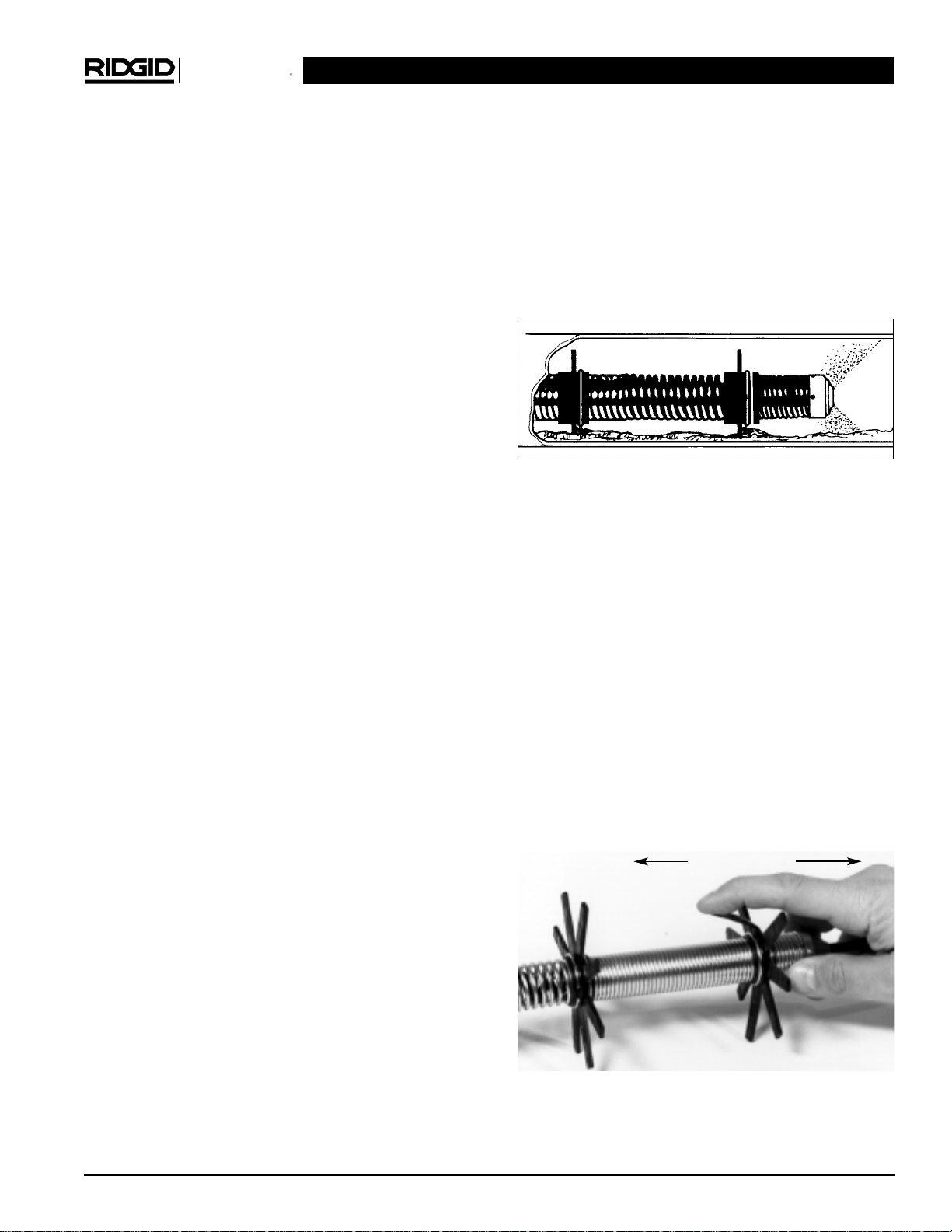

Figure 1 – Camera Head

LED – Light Emitting Diode. Solid-state light that, unlike

an incandescent lamp does not have a fragile filament.

LED Window – The donut shaped window that covers

and protects the LEDs from abrasion.

Spring Assembly – Flexible stainless steel spring and

associated components that hold the camera to the

push cable. It provides a flexible transition from camera

to push cable, and protects the terminations within the

spring. (Figure 2)

Figure 2 – Camera Head and Spring Assembly

Safety Cables – Stainless steel cables (two) within the

spring assembly. They connect between the push cable

termination and the locking sleeve, attaching to the

connector at the back of the camera head. These prevent the spring from over-extending when pulling the

camera out of a pipe, and ensure the connection to

the camera is never stressed.

Locking Sleeves – This device is found at the rear of

the camera within the spring (Figure 3), and with the

connectors on the cable hub (dry end), and both ends of

the system cable (Figure 5). The camera locking sleeve

holds the connector in place and serves as an anchor for

the safety cables. This device is unscrewed from the

back of the camera to detach the connector from it.

The other locking sleeves help ensure a solid connection

at the cable “dry end,” hub, or CCU. The locking sleeves

are turned or twisted, but the connectors are never

twisted – just pulled straight apart.

Figure 3 – Camera Head and Locking Sleeve

In-Line Transmitter – If you’re planning to pinpoint the

problem in a line, you will want a SeeSnake®In-Line

Transmitter, which is sold as an option.

Figure 4 – Standard (Top) and Mini In-Line Transmitters

(Optional Accessory)

Spanner Wrench – One piece wrench used to engage the

end of the spring and hold it while removing the camera

head. (See “Removing Camera Head” in the Corrective

Maintenance section.)

Centering guides – Installed over the spring, guides can

help you see the top of larger diameter pipes more

clearly and raise the camera head out of water or sediment that may obscure the lens. (See Page 15.)

Connectors – All the “plugs” in the system that connect

the camera, push cable, hub, System Cable and Camera

Control Unit. These are the connectors that have guide

pins (male) and guide sockets (female) and an outer

locking sleeve to ensure the connectors are securely

mounted. These connectors ARE NOT to be confused

with 120 volt (or 230V) AC outlet plugs, or any video/

audio jacks. Every SeeSnake System connector in the

system is waterproof and uses a standardized pin pattern, which allows you to plug components into one

another for easy troubleshooting. Refer to Figures 1

through 3.

Camera Housing

Sapphire

Window

LED

Window

Push Cable

Centering Guides

Camera Head

Spring Assembly

Safety Cables (2 Cables

Inside Spring Assembly)

Locking Sleeve

Figure 4 – Connector Functions

Figure 5 – Connectors on SeeSnake System Cable

Figure 6 – Joining Connectors

Bending or twisting the connectors will

lead to premature failure. Do Not bend or twist connectors!

Twist only the locking sleeve!

2) Reel/Frame

Push Cable – terminates right behind the spring. It has

a high-strength fiberglass core that’s stiff enough to

push long distances and flexible enough to negotiate tight

turns. The tough outer jacket resists abrasion and Kevlar

braid provides added strength.

Reel – The push cable is stored in the molded gray drum,

which is rust and dent-proof and keeps waste water off

your customers’ carpets. Mercury-free slip rings inside

the drum’s hub provide a rotating electrical connection between the drum and frame and allow operation at any

angle (i.e. rooftops).

Figure 7 – Reel Front

Figure 8 – Reel Back

Ridge Tool Company6

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

Outer Locking

Sleeve

Outer Locking

Sleeve

Pin - Male Connector

Female Connector

Pin/Socket Function

1 ..........................Neutral

2 ..........................+12 VDC

3 ..........................Video Signal

Male Connector Pins

Female Connector

Sockets

Guide

#1

#3

#2

Guide

#1

#3

#2

1 – Push Straight In

Until Fully Seated

2 – Turn Sleeve

Clockwise

Red Arrow Indicates

Top of Connector

Guide Hoop

Frame

Drum

Brake

Hub

SeeSnake

System Cable

CountIR

Back Feet

Axle

WARNING

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

Ridge Tool Company 7

4) Locating System (optional)

This consists of a miniaturized transmitter and a handheld receiving unit. The transmitters operate at the

industry-standard of 512Hz, are extremely durable, require no batteries for operation and do not interfere with

camera’s ability to go through turns. Optional receiving

units are available with either an analog readout or a digital display with push-button depth calculation.

Figure 10 – Pointer XL and Pointer Hand Held Locators

(Optional Accessory)

Specifications

Line Capacity

B&W Mini SeeSnake:....11/4″ to 8″ (32 to 200 mm)

Color Mini SeeSnake:....11/2″ to 8″ (38 to 200 mm)

B&W SeeSnake:............2″ to 12″ (50 to 300 mm)

Color SeeSnake:...........2″ to 12″ (50 to 300 mm)

Max. Cable Length

Mini SeeSnake:.............200′ (61 m)

SeeSnake:.....................325′ (99 m)

Reel & Frame Weight

Mini SeeSnake:.............24.5 lbs. (11.1 Kg) with 200′

cable

Standard SeeSnake:.....43 lbs. (19.5 Kg) with 325’

cable

Reel & Frame Diameter

Mini SeeSnake:...............20 x 11 x 23″ (51 x 28 x 58 cm)

SeeSnake:.......................32 x 14 x 30″ (81 x 36 x 76 cm)

Power Source:...............120V/60 Hz, 230V/50 Hz, or

12VDC, depending on CCU

Camera Type:................EIA/C C I R (B & W ) o r NTSC/PAL

(color) video format

Frame – A sturdy, powder coated metal structure that the

reel is mounted to. The frame has a second set of feet on

the back side of the reel, allowing the system to rest on

its back (open-end-up) for greater stability.

The guide hoop on the frame helps the push cable

feed in and out of the drum properly, and the brake

knob lets you adjust the amount of drag on the cable for

maximum control. (Figure 7)

The CountIR measures the distance the cable has traveled inside the pipe and can also display the day, date,

time, and up to 33 pages of user defined text information.

The SeeSnake System Cable stores on the frame and

provides the connection between the reel and the camera control unit. (Figure 8)

Figure 9 – Camera Control Unit (CCU) - Consult Your

Camera Control Unit Manual for Operating

Instructions.

3) Camera Control Unit (CCU)

This unit provides power to the camera reel and system

accessories. It also provides a control that adjusts the

camera’s lighting and activates the In-Line transmitter.

These range from a unit without a built-in monitor (Power

Pack) to sophisticated units with color monitors and

audio and video recording capability. Units may be powered by any 120 volt AC source (or 230 volts in some

countries - this requires a different camera control unit

than the 120 volt) or 12VDC, and some include rechargeable batteries. (Figure 9)

Pointer

KD-4510

Pointer XL

KD-4550

Ridge Tool Company8

Push Cable Diameter

Mini SeeSnake:.............0.315 in. (.8 cm)

Standard SeeSnake:.....0.43 in. (1.1 cm)

Camera Size & Weight

B&W Mini SeeSnake:....1.75 x 1 in., 1.5 oz.

(4.4 cm x 2.5 cm, .042 kg)

Color Mini SeeSnake:....2 x 1.26 in., 3.07 oz.

(5.1 cm x 3.2 cm, .087 kg)

B&W SeeSnake:............1.84 x 1.37 in., 2.82 oz

(4.68 cm x 3.48 cm, .08 kg)

Color SeeSnake:...........2.17 x 1.69 in., 4oz.

(5.5 cm x 4.3 cm, .113 kg)

Depth Rating: ................All cameras waterproof to

330′ (100 m)

Camera Resolution

B&W Mini SeeSnake:....400 HTVL

Color Mini SeeSnake:....330 HTVL

B&W SeeSnake:............400 HTVL

Color SeeSnake:...........330 HTVL

Lighting

B&W Mini SeeSnake:....15 Red LED’s

Color Mini SeeSnake:....30 White LED’s

B&W SeeSnake:............35 Red LED’s

Color SeeSnake:...........45 White LED’s

Environmental

Rating:...........................IPx4

Operating Environment

Temperature..............32° F to 104° F (0°C to 40°C)

Altitude ......................Up to 6560 ft. (2000 m)

Transient

Over voltage..............Installation Categories II

(1500V Phase to Earth)

Pollution Degree 2

Standard Equipment

• Camera Reel with Push Cable

• Camera Head

• Cable CountIR

• Centering Guides (standard and ball-type)

• C-Rings (for holding Centering Guides onto spring

assembly)

• SeeSnake System Cable

• Universal Spanner Wrench (for Camera Head removal)

• Pair of Plastic Coated Gloves

• SeeSnake Instructional Video

• Operator’s Manual

Set Up and Operation

Equipment Setup

1. For Standard SeeSnake reels, install the wheels as

described in appendix A.

2. Place the reel so the push cable is easy to manage

as you push the camera through the line. Three to

five feet from the access point seems to work best.

3. Set up the Camera Control Unit (CCU) so its monitor screen is easy to see and it’s controls are easy to

reach during use. In brightly lit areas, point the monitor screen away from bright light sources and/or

use the monitor’s sun shade to reduce glare.

4. Adjust the reel’s brake so the drum turns easily

when you pull cable from the reel, but stops turning

when you stop pulling the cable; if the drum turns too

easily, excess cable could wind out of the reel.

Connections

1. Plug the Camera Control Unit into an AC outlet and

reset the GFCI if necessary.

2. Unwrap the SeeSnake System Cable from its holder

on the reel frame and plug its connector into the

matching connector on the CCU. To join the connectors, align the guide pin to the guide socket,

push the connector straight in and tighten the outer

locking sleeve. (Figure 6)

NOTE! Twist only the locking sleeve! Never bend or

twist the connector! Bending or twisting the connector will lead to premature failure. When

unplugging you may wiggle a little, if necessary, but do not bend or twist.

Operation

1. Place the camera head into the reel’s guide hoop as

shown in Figure 4, and turn the CCU’s power ON.

You should see the words “SeeSnake CountIR” and

a version number on the monitor screen. Leave the

camera head in the guide hoop until this start-up

screen disappears (approx. 15 sec.). If you do not

see an image on the monitor, check to make sure its

power is turned on.

2. Put the camera head into the access point and adjust

the camera’s lighting with the Dimmer/Transmitter

control.

3. Turn the CountIR’s display modes ON or OFF as desired. If you want to measure distance, reset its

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

Ridge Tool Company 9

distance display to zero as described in the CountIR

section.

4. Adjust the monitor’s picture controls as necessary.

5. To record the inspection, refer to the operator’s

guide for the CCU you are using.

6. If you are using a Mini SeeSnake with the optional InLine Transmitter installed, you can activate it by

rotating the Dimmer/Transmitter control knob counterclockwise fully until it clicks into position.

NOTE! There is no need to activate the Standard

SeeSnake In-Line Transmitter; it is always transmitting when the system is powered ON.

Pre-Checks

These Pre-Checks are needed before using the system for

the first time. The operator should be aware of these and

make periodic checks throughout the life of the unit.

Mechanical Checks

1. Rotate the reel brake to a position that allows you to

easily pull cable from the reel, yet stops immediately

when you are not retrieving cable. For transport,

add more friction to the brake. (Tighten)

2. Grasp the spring assembly in one hand, and the

camera head in the other. Ensure the spring is tightened ONLY to the point where the cut end of it is as

far as it can go in the camera head’s threads. If it is

under tightened, you should be able to physically

screw the spring a little farther onto the camera’s

threads. Be careful not to over tighten. If it is over

tightened, the cut end of the spring will “crawl” up and

over the threads. If this occurs, follow the procedures in the “Maintenance - Removing the Camera

Head” section to properly seat the spring using the

spanner wrench provided.

3. Check to see that the connector at the end of the

push cable is fully seated into the connector attached to the cone-shaped portion of the hub (inside

the reel). Likewise, check that the system cable is

completely plugged into the hub. Periodically inspect these connectors for good connections as the

system is used. Be sure the locking sleeves on the

connectors are tightened.

Electrical Checks

The system should always produce a crisp picture that is

free of noise and lines. Sometimes, especially during

cold-weather conditions, it can take a moment for the system to heat up before it will produce the optimum picture.

Otherwise, check that connectors are fully engaged and

follow these guidelines:

1. With the system energized, look to see that an even

amount of light is coming from the LEDs. Place the

camera in the reel, and give it a good spin while

watching your monitor to test the slip ring. If you do not

get a stable picture, call RIDGE Tool Technical

Service at 800-519-3456.

2. If your CCU has a VCR, refer to its owner’s manual for

operating instructions.

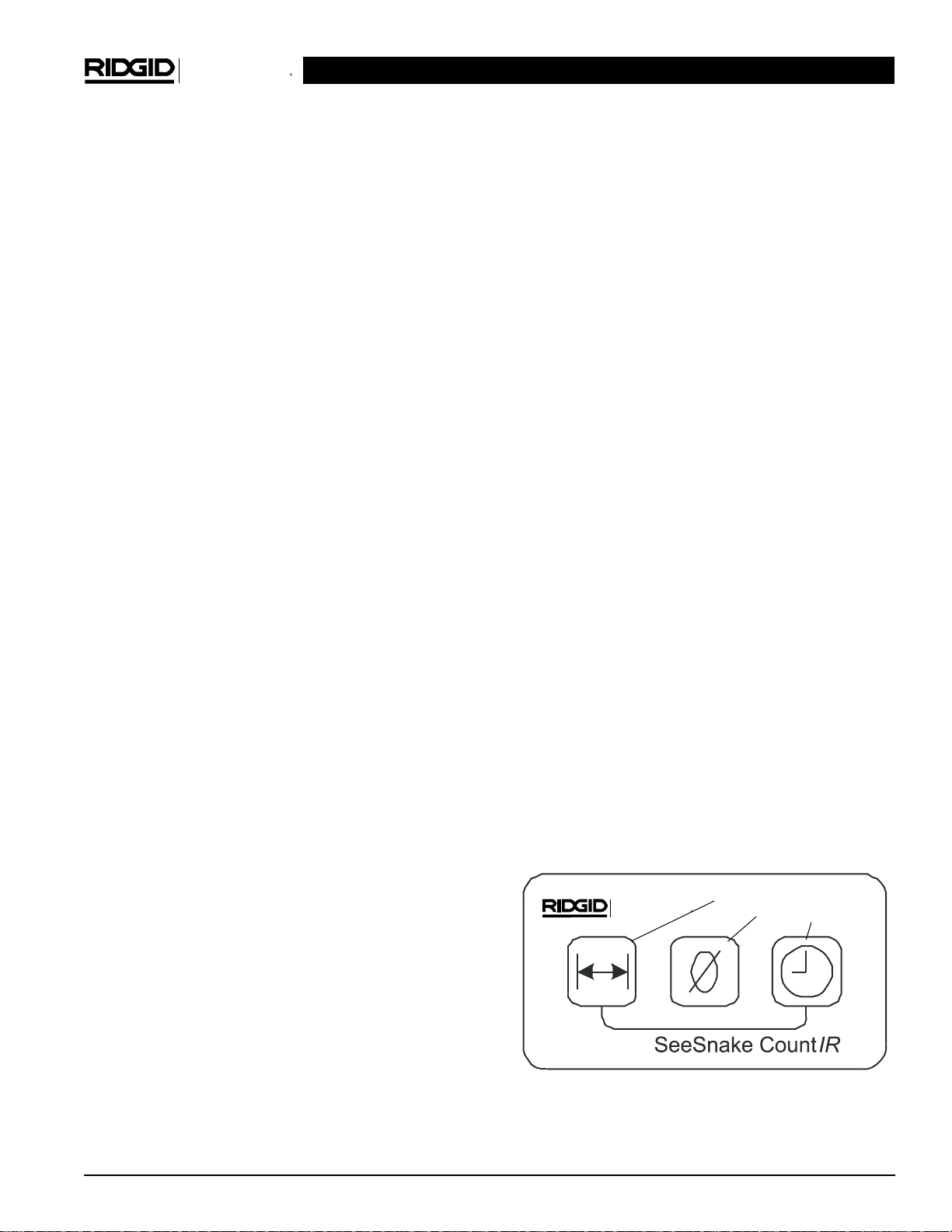

SeeSnake Cable CountIR

The CountIR is located under the axle on the closed side

of the drum and measures distance by counting drum rotations as you push the camera through the line. The

CountIR superimposes the distance reading, date/time

and user-defined text messages over the video. Please

read the CountIR owner’s guide for complete operating

and battery replacement instructions.

Keypad Button Description

(Figure 11)

Distance Button

Push to turn the distance display ON and OFF.

Clock Button

Push to cycle through the Date/Time display options:

• Date with Time

• Date Only

• Time Only

• Date/Time OFF

Zero Button

Push to reset the distance display to zero. This allows

you to measure:

• The distance from the access point to the cam-

era’s current position

• The distance between any two points in the line.

Figure 11

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

Distance

Clock

Zero

Kollmann

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

Ridge Tool Company10

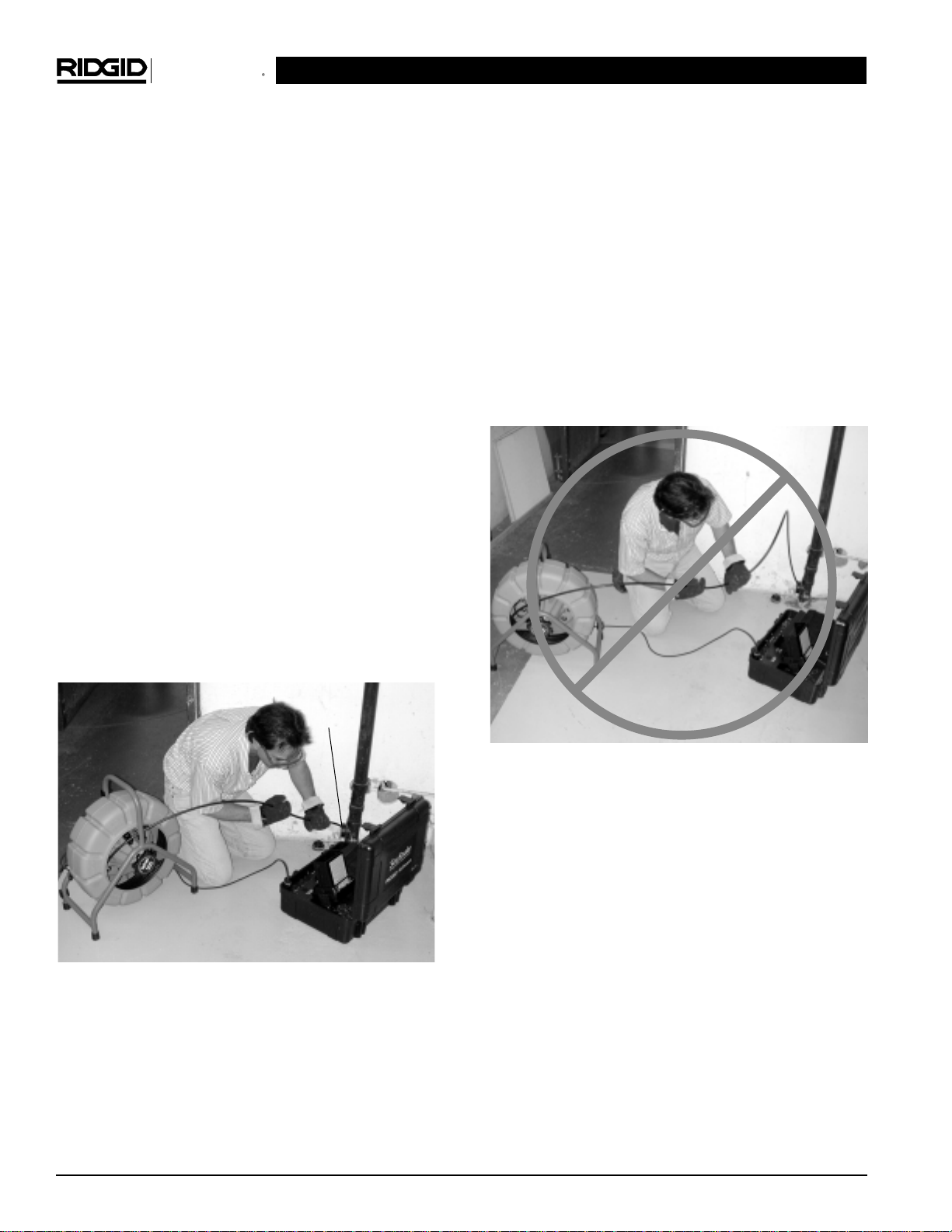

At the Job Site

1. The camera can almost always be pushed farther

when grip-style rubber gloves are worn. It is much

easier to get a grip on dirty push cable, and the

gloves also keep sludge off the hands.

2. Properly positioning the equipment and pushing of

the cable will save time, be more comfortable, and

minimize the potential for equipment damage. Refer

to Figures 12 and 13.

a.Set the monitor in an area where it is unlikely to

fall, and where it can be viewed while you are

pushing the camera. A good location is right next

to the cleanout or entry point. Be sure to keep it

from getting wet.

b.Set the reel about 3′ to 5′ (1-2 meters) from the

entry. This will provide ample cable to grasp and

will develop momentum without having a lot of

slack dragging on the ground. Slack can be alleviated by putting friction on the reel using the

brake. If it is set correctly, push cable will only

come off the reel when you pull on it.

c.When pushing, the end of your stroke should be as

close to the entry as possible. Standing too far back

with an excess of cable between your hands and the

entry may cause the cable to fold on itself outside the

entry and damage the cable (Figure 12).

Figure 12

d.Folding the push cable on the sharp edge of an

entry can cause it to snap. Extreme caution must

be used to minimize the chance of bending the

push cable on sharp corners. This can cause push

cable failure, and all operators should be aware of

this. If the camera just does not seem to want to go

any farther, DO NOT FORCE THE CAMERA! If an-

other entry is available, try it or run water down the line

as explained below. See Figure 13.

NOTE! Hands should be close to the line opening. DO

NOT catch the cable on the edge of an entry and

continue to push.

3. Always try to run water down the pipe undergoing

inspection. This will keep the system much cleaner,

and allow you to push noticeably farther with less

friction. This will also help you locate the bottom of the

pipe. This can be accomplished by feeding a hose

with a small amount of flow into the entry or occasionally flushing a toilet that drains to the pipe. If the

water is preventing you from seeing an area of importance, temporarily turn it off.

Figure 13 – Improper Pushing of Cable

4. When inspecting a pipe, it is usually necessary to

give a little extra push in the bends. Back the cam-

era head approximately 8″ from the bend, if

necessary, and give it a quick push, “popping” the

camera through a turn, using the least amount of

force required. Try to be as gentle as possible, and do

not hammer or snap the camera head through corners. After some practice, you may learn that the

best way to inspect a section of pipe is to push the

camera through quickly, then draw the camera back

home slowly and evenly. It is always easier to control

the camera when pulling than when pushing.

5. Make sure the sapphire window is clean prior to

entry. Some users claim that a slight film of detergent

on the lens minimizes the possibility of grease sticking

to the port. If necessary, take advantage of any standing water in the pipe to wash the front of the camera

by jiggling it in the water.

Keep hands

close to

entry

DO NOT PUSH

CABLE IN THIS

MANNER!

Ridge Tool Company 11

6. Take advantage of the lighting to keep track of

where the camera is headed. If the particular pipe

you are inspecting is easier to evaluate with other than

the maximum lighting, periodically maximize the lighting (using the dimmer knob) to get a look at what lies

ahead. Be aware of any obstructions, such as a

crushed section of pipe or excessive hard build-up,

that may prevent retrieval of the camera.

7. When you place the camera head into the pipe re-

member, as the materials of pipe vary, it will be

necessary to adjust the lighting settings to maximize picture quality. For example, white PVC pipe

requires less lighting than black ABS. As experience

is gained with the system, operators will learn that

slight adjustments in these settings can highlight

problems within a pipe. Always use the minimum illumination required to prevent excessive heat build-up

and to maximize picture quality.

8. Adjustment of the contrast and brightness set-

tings on the monitor, as well as the light dimmer

after the camera is within the pipe, can greatly increase picture quality. This is particularly important

when your customer is supervising, and when making

recordings.

Figure 14 – Improper Use of Camera to Clear Obstructions

WARNING

Do not clear obstructions with the camera head!

This may cause premature failure to your camera

head. The SeeSnake

®

is a diagnostic tool that identifies problems. Other tools should be used to

make effective repairs. It should never be used to

clear obstructions. See Figure 14.

9. Whenever possible, lay the system on its back feet

for even greater stability. This is also preferred

when on a rooftop (entry through a roof vent), overhead entry, or hillside. See Figure 15.

Figure 15 – Reel Can Be Positioned On Its Back for

Greater Stability

10. If local 120V (or 230V) AC power for the monitor is

not available, you can operate the system using a

voltage converter that plugs into your vehicle’s

cigarette lighter. They convert your vehicles 12 volt

DC to 120 volts (or 230V) AC.

11. The system can travel through multiple 45 and 90

degree bends and wyes. Do not, however, try to

force it through a P-trap or Tee if there is a large

amount of resistance.

12. If you are planning to use line locating equipment

with your camera, be sure to use only SeeSnake

®

in-line transmitters. The SeeSnake®transmitter is

specifically designed for years of service, and does not

interfere with the camera’s ability to travel bends.

Taping a non-SeeSnake®transmitter to the push

cable will interfere with the camera’s ability to negotiate bends and endanger the transmitter - as well as

the camera head - to getting hung-up in the line.

13. Do not attempt to remove or store push cable on

the reel solely by turning the reel itself. Release the

brake enough so that you can manually push or pull

cable from the reel and wind or unwind it. If for some

unusual reason the drum should not turn, do not try to

pull the push cable out of the reel. This will force the

cable to collapse down around the hub causing unnecessary stress on the cable.

14. Be careful in Tee-entries not to fold the camera

back on itself, this could cause the camera to

stick.

The camera head can get HOT!

When finished with your inspection, or if taking a

prolonged break in the middle of the inspection,

turn off the system.

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

CAUTION

Ridge Tool Company12

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

15. If the camera sits in a pipe, or any enclosed environment, heat will build-up. This may lead to the camera

head overheating which will cause fuzzy lines to appear on the monitor. In the event this happens, turn off

the system, remove the camera from the pipe (or

enclosed environment) and let the camera head cool

for 10 to 15 minutes. Running water into the line will

also help cool the camera head. Always use the minimum illumination required to maximize picture quality

and to avoid excessive heat build-up.

16. In the very unlikely event that you encounter

problems with your system during a job, the system is designed to let you troubleshoot faulty

components at the job site. The procedures are

covered in the “Locating Faulty Components” section

below. One tip that may help you finish the job: if

you isolate the problem to the hub, you can disconnect

the push cable at the dry-end, remove all the cable

from the drum and pay out all the cable in a convenient location. Disconnect the system cable at the

back side of the hub and connect the dry-end push

cable connector to the system cable connector.

Although this may be inconvenient, it will allow you to

finish the job. When disconnecting and joining the

connectors, be sure to pull/push the connectors

straight until fully unseated/seated. Never twist

connectors. Twist only the locking sleeves.

17. Ask customers what is in the line, or what the line

is used for, prior to putting the camera into the

line. Avoid lines containing harsh solvents, chemicals,

an electrical charge and excessive heat.

NOTE! Never use solvents to clean any part of the sys-

tem.

NOTE! See the Video Tape that came with your system

for valuable Tips and Tricks on how to handle

different situations.

Transportation & Storage

1. Slip the camera into the reel with the rest of the push

cable. Turn the brake clockwise enough so that the

reel does not rotate unless you manually turn it.

2. Unplug the SeeSnake System Cable from the CCU by

turning the locking sleeve counter clock wise and

then pulling the connectors straight out from each

other. Wrap the cable loosely onto its storage hooks

located on the frame.

3. If space allows, the reel/frame should be laid on its

back during transportation and use. You will notice that

there is a second set of feet (three) on the back of the

reel where the System Cable is stored. If there is

not enough space to lay the system on its back,

stand it up and run a strap or cord through the frame

and secure it to the vehicle.

4. Close the sunshade over the screen of the monitor

and stow the line (power) cord.

5. Keep spare parts, tools, and this operator’s manual

secure in a work bag to protect them when not in use.

6. When possible, keep the system stored in a cool, safe

place. Pointing the camera into the sun or a high

powered light source can damage the imaging chip.

Maintenance and Cleaning

Preventative Maintenance

Camera Head

1. The camera head requires little maintenance, other

than keeping the LED ring and sapphire window

clean. Use a soft nylon brush, mild detergent, and

rags and sponges from the camera head up to (but

not including) the CCU.

2. When cleaning the camera, do not use scraping

tools as they may permanently scratch these areas.

NEVER USE SOLVENTS to clean any part of the

system. Substances like acetone and other harsh

chemicals can cause cracking of the LED ring, which

could affect waterproofing.

3. As you use the system more and more, you may be

surprised to find that scratches on the LED ring will

have a minimal effect on the performance of the

lighting. DO NOT sand the LED ring to remove

scratches, as it is part of the watertight housing.

4. Another good way to extend the life of the camera is

to avoid removing obstructions from pipe with the

camera head. See Figure 14.

Spring Assembly

The spring assembly is the area where foreign matter is

most likely to accumulate. Within the spring is the splice

between the push cable and a connector. Should sharp

objects or harsh chemicals be allowed to remain in this

area for long periods, they may wear on these components. Stretch the spring end-to-end as far as the internal

safety cables allow to check this area. Stretch again

and stir in a bucket of warm water and mild detergent to

flush this area.

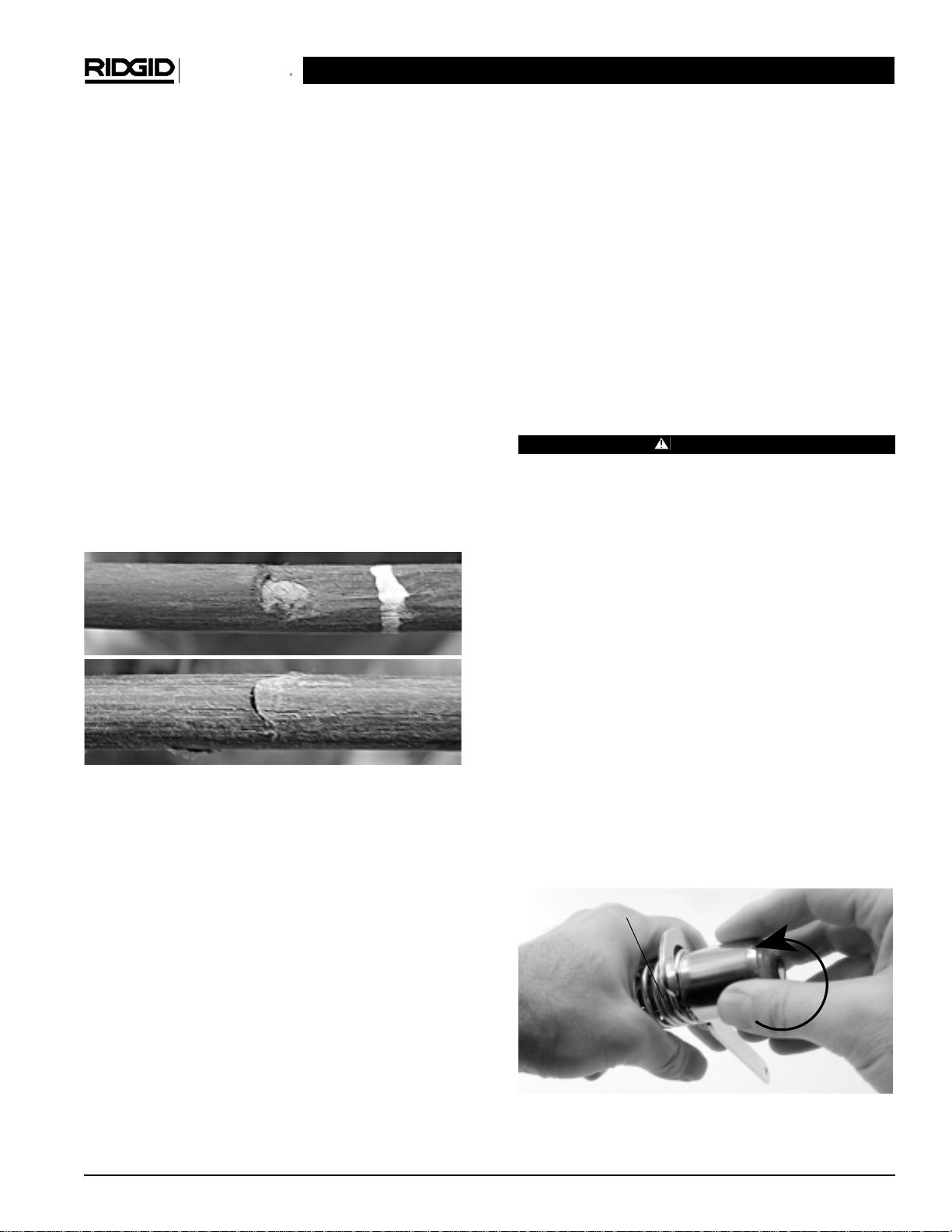

Push Cable, Reel/Frame

The push cable and reel/frame require almost no maintenance. (Of course, a clean system will last longer and

be more impressive to your customers.) It is important,

however, to keep the push cable clean to spot any excessive cuts or abrasions, while making it much easier to

grasp and push.

NOTE! Whenever you are retrieving push cable into the

reel, an excellent way to cut down on cable grime

is to run it through a rag in the last hand that

touches the cable as it enters the reel.

1. For thorough cleaning, stand the reel upright and fill

the bottom of the drum with lukewarm water and a

mild detergent. Spin the drum to loosen the grime.

Remove the water, pull out the cable, and run a rag

over the cable as you feed it back into the drum.

NOTE! Never fill the drum while the unit is tipped on its

back. Water can enter the hub and damage the

slip rings.

2. Visually inspect the cable for cuts and abrasions as

you feed it back into the drum. If the outer jacket is cut

or abraded through to the yellow Kevlar beneath, the

cable should be replaced or repaired (re-terminated).

(See Figure 16)

Figure 16 – Outer Jacket Abraded Through to Kevlar

Braid

3. In most cases it’s best to service a damaged cable as

soon as possible, but there may be some exceptions (when a cable is old and worn or when a

retermination repair would remove too much cable, for

example). Call Ridge Tool Technical Services to discuss your situation and develop an appropriate plan

of action.

NOTE! A damaged cable will absorb water and allow it to

“wick” along the inside. When the cable is reterminated, the entire wet portion of cable must be cut

off to allow for a proper termination onto a dry

section of the cable. Although the system may remain operable for a long period of time with

damaged (wet) cable, continued use may result

in significantly more cable being cut off when a repair is finally needed.

4 . In an emergency you may wrap the damaged area of

cable with duct or automobile hose tape to help min-

Ridge Tool Company 13

imize the amount of water entering the cable. This is

not a fix and should only be used in an emergency (if

your cable becomes damaged during an inspection

and you need to complete the job, for example).

Camera Control Unit

The CCU requires a little more care. The same is true for

any monitor in the field. Unlike the rest of the system, the

CCU’s are not waterproof. Clean them with a damp cloth,

and ensure foreign matter does not get into any cooling

vents. Always avoid dropping or shocking these components. See your CCU Manual for complete instructions.

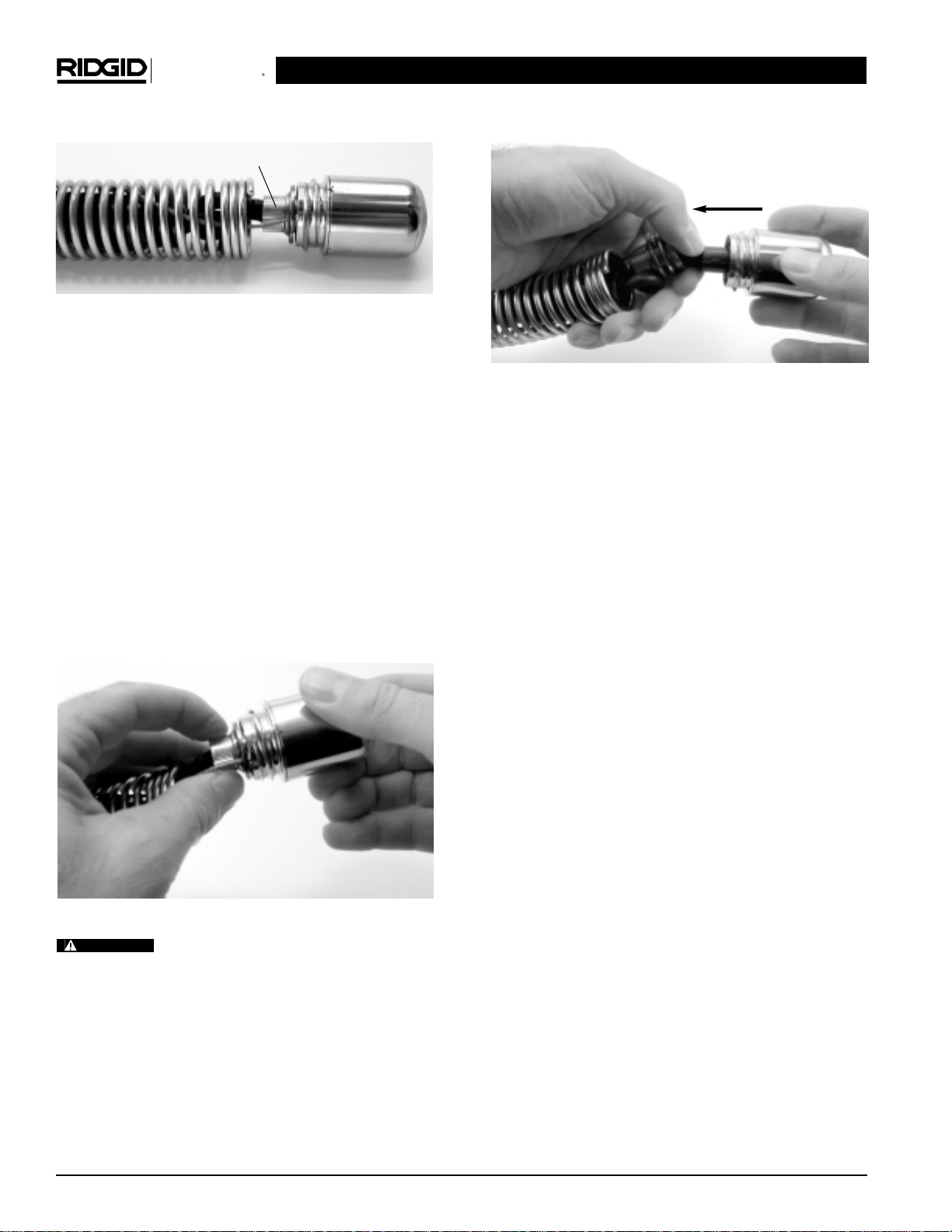

Corrective Maintenance

Removing Camera Head

WARNING

Before removing the camera head for the first

time, be sure to read the following instructions.

Bending or twisting the camera head connectors

will lead to premature failure and is not covered by

warranty. Do not bend or twist connectors! Twist

only the Locking Sleeves. If you need additional assistance, please call RIDGE Tool’s Technical

Service 800-519-3456 before proceeding.

The system has been designed so that the camera head

can be removed for troubleshooting. To remove the

camera head, the procedure below must be followed:

1. Pay out enough cable to place the camera and spring

assembly on a work bench or other convenient work

area. Set the brake to prevent the reel from spinning.

2. Locate the spanner wrench that was provided with the

system and hook the cut end of the spring (directly behind the camera head) with the business end of the

spanner. The hand holding the spanner wrench should

remain still while turning the camera off the spring with

the other hand. See Figure 17. The camera should

now be hanging by its locking sleeve and safety cables. See Figure 18.

Figure 17 – Using Spanner Wrench to Loosen Spring

Assembly on Camera Housing

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

Spanner Wrench

On Cut Edge

of Spring

Hold Wrench While

Turning Camera

Ridge Tool Company14

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

Figure 20 – Unplugging the Camera’s Connector. Pull

the Connector Straight Out. NEVER TWIST

THE CONNECTOR!

Re-Installing Camera Head

1. Lay out enough cable to lay the spring assembly on a

convenient work area and tighten the brake.

2. Plug the connector and locking sleeve into the camera

head, making sure that the guide pins/sockets are

aligned. Be sure to fully seat the connectors without

any twisting.

3. Once the connectors are fully seated, grasp the camera head with one hand and turn the ribbed portion of

the locking sleeve to screw it into the back of the

camera. Be sure not to let the safety cables twist

more than one rotation. The design minimizes the

chance of this happening; however, it may be necessary to hold the safety cables in such a manner that

when you turn the locking sleeve, you aren’t turning

the safety cables.

IMPORTANT! Do Not twist the camera head or coil cord!

Turn only the locking sleeve!

4. Once the locking sleeve is tight into the back of the

camera, and the safety cables are parallel to each

other, install the spring assembly onto the threads on

the camera housing exterior. To do this, turn the camera head one rotation in the counter clockwise direction

until the threads properly align; then rotate the camera

head clockwise onto the spring assembly. This method

will help keep the safety cables from twisting inside the

spring. Be sure to use only your hands (i.e. no tools)

when screwing the camera onto the spring.

NOTE! The camera head will be properly mounted when

the end of the spring is snug between the camera

and the thread (not so far that it begins to raise off

the threads) and you cannot manually unscrew

the camera.

Locating Faulty Components

The basic idea in troubleshooting the system is to use the

camera head to eliminate suspected components. Here

Figure 18 – Camera Head Separated From Spring

Assembly

3. Grasp the ribbed portion of the locking sleeve with one

hand and the camera with the other. Rotate the ribbed

portion of the sleeve (counter-clockwise when camera

is viewed from the rear) to unscrew it from the camera

housing threads while holding the camera head still

with the other hand. If the locking sleeve is difficult to

turn, get it started with a pair of pliers whose jaws have

been wrapped in electrical tape to prevent scarring the

locking sleeve. Do not crush or deform the locking

sleeve by exerting excessive pressure. Be sure not to

let the safety cables twist more than one rotation.

The design minimizes the chance of this happening;

however, it may be necessary to hold the safety cables in such a manner that when you turn the locking

sleeve, you aren’t turning the safety cables. See

Figure 19.

Figure 19 – Removing Camera Head From Locking Sleeve

DO NOT TWIST THE CAMERA! TWIST ONLY

THE LOCKING SLEEVE!

4. When the locking sleeve is completely unscrewed

from the camera housing female threads, the connector should automatically disengage from the

camera. If this does not occur, grab the locking sleeve

and connector in one hand, the camera head in the

other, and pull them straight out of the back of the

camera. DO NOT twist the connectors! Be sure to

separate connectors by pulling straight! See Figures

19 and 20.

Locking Sleeve

WARNING

Ridge Tool Company 15

are the areas we will try to isolate the fault to: camera

head, reel/frame, systems cable, CCU. As an example

assume that the symptom is NO VIDEO, NO LIGHTS.

1. Remove the camera from the spring assembly. See

CORRECTIVE MAINTENANCE, “Removing Camera

Head’ section above.

2. With the system set up for operation, plug the camera

head directly into the connector on the CCU where the

system cable is usually connected. Turn on the system

and check the monitor for a picture. If there is a good

picture with proper lighting, the problem is somewhere between the system cable and the spring

assembly. Proceed to step 4. If there is no picture, the

problem is probably in the camera head or CCU.

3. To virtually eliminate the monitor, play a tape on your

monitor with a VCR through the video-in jack on your

monitor (VCR - video-out; monitor - video-in). If you get

a good picture, it is almost certain the problem is in the

camera head. The CCU is more complicated to troubleshoot, so contact RIDGE Tool Technical Service at

800-519-3456.

4. Plug the system cable into the connector on the CCU.

Unplug the other end of the system cable from where

it plugs into the reel-hub by unscrewing the locking

sleeve and pulling the connectors straight out, and

plug the camera head into this end. Turn on the system

and check the monitor. If you get the video and lights

back, the problem is likely in the push cable or hub. If

there is no picture, the system cable is the likely fault.

5. Once you suspect a component, contact RIDGE Tool

Technical Service at 800-519-3456. We will establish

a plan of action to get your system back on line. One

tip that may help you finish the job: if you isolate the

problem to the hub, you can disconnect the push

cable at the dry-end, remove all the cable from the

drum and pay out all the cable in a convenient location. Disconnect the system cable at the back side of

the hub and connect the dry-end push cable connector to the system cable connector. Although this

may be inconvenient, it will allow you to finish the

job. When disconnecting and joining the connectors,

be sure to pull/push the connectors straight together

until fully seated. Never twist connectors. Twist only

the locking sleeves.

6. For additional troubleshooting suggestions, please

refer to Chart 1 at the end of the manual.

Options

Centering Guides

The centering guides are designed to help center the

camera in various sized pipes, and also help keep the

camera out of the bottom sludge. Picture quality is improved as they help position the camera towards the

middle of the pipe. This allows the camera to see an

equal amount of the pipe wall in all directions. Centering

guides also help in larger pipes by bringing the camera

closer to the pipe’s center and raising the camera out of

the sludge that is often found below the water line.

Keeping the camera off the bottom of the pipe keeps the

front of the camera cleaner, longer. See Figure 21.

Figure 21 – With centering guides installed, the camera can

see an equal amount of pipe wall in all directions. They also keep the camera out of sludge,

improving vision and wear on the camera.

It is recommended that guides be used whenever possible as they protect the camera from wear and tear.

However, if you are having trouble going further in a

particular pipe, try it without the guides. The best advice

is to experiment with local conditions and decide what is

best for the given job. For example, you may find that

placing two centering guides near the front end of the

camera may bias the camera head upward. This could be

beneficial if you need to see the top of the pipe during

your inspection.

Centering guides should be pre-strained prior to use

for increased flexibility. To do this, bend the spikes back

and forth a few times before use. It is best if you gently

bend the spikes slowly from the tip (not the base) in

one direction, then in the other. See Figure 22.

Figure 22 – Pre-stress tabs by placing your finger at the

top of the spike and slowly pushing the spike

90 degrees. Repeat in the other direction.

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

Bend 90° Slowly!

Ridge Tool Company16

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

The centering guide assembly consists of two parts - the

steel c-ring and the plastic centering guides. See Figure 23.

Figure 23 – The Centering Guide Assembly Components.

You should generally use 3 guide assemblies.

To Install the Centering Guide Assemblies:

1. Position the c-rings onto the spring assembly. This

can be accomplished by either placing the c-rings: a)

onto the push cable just behind the tapered end of the

spring assembly; or b) sliding them over the camera

head. Either method works well. If you use method a),

be sure to open the ring far enough to avoid “scarring”

the cable. See Figure 24. Regardless of the method,

place all c-rings onto the spring assembly before installing the first centering guide. You will need 2

c-rings for each centering guide, and 3 centering

guide assemblies generally work best in applications. However, we recommend you experiment to

find the best methods for local conditions.

Figure 24 – To place the c-rings onto the cable, pull the

c-rings with four fingers to open the ring far

enough to slip over the cable without touching the cable. Slide the c-rings onto the

spring assembly. Another method is to

place them over the camera head.

2. Place the centering guide over the spring assembly. You will notice the centering guide has a cut

through one side so the guide can be opened to

slide over the spring assembly.

3. Position the cut side of the centering guide 180 degrees from the opening in the c-rings. See Figure 25.

Figure 25 – Position the cut side of the guide 180 degrees

from the c-ring openings.

4. Press the closed portion of the c-ring into the grooved

portion of the centering guide. The C-ring will snap in

place. Repeat with other c-ring on the other side of the

centering guide. See Figure 26.

Figure 26 – Press the closed portion of the c-ring into

the groove of the centering guide. Repeat

on the opposite side of guide.

To Remove the Centering Guide Assemblies:

1. You will need a flat blade screw driver. Place the

flat tip of the screwdriver between the c-ring and the

base of the spike. Pry or snap the ring off. Repeat on

the other c-ring. See Figure 27.

Figure 27 – Place flat tip of screwdriver between c-ring

and base of spike and snap c-ring off the

groove.

Press

Press

(underneath)

Opening of C-Ring is 180°

from Centering Guide cut side

Cut side of

Centering Guides

Pull C-Ring

Open

C-Ring

Centering Guide

Figure 30

2. Place the sleeves over the spring between the ball

guide and camera head with the locking tabs pointed

toward the guide ball (Figure 31).

Figure 31

3. Slide ball guide over the sleeves until the locking

tabs engage with the rear of the ball guide (Figure 32).

Figure 32

Ridge Tool Company 17

2. Remove the centering guide, and then slide the c-rings

off the cable. Be sure to open the c-rings far enough

to avoid “scarring” the cable. An alternative method is

to slide the c-rings over the camera head.

Installing the SeeSnake Centering

Guides

The SeeSnake snap-on pipe guide consists of the following parts (Figure 28):

• 1 ball guide

• 1 top sleeve (with alignment pins)

• 1 bottom sleeve (with alignment slots)

Figure 28

Installation

1. Place the ball guide over the SeeSnake camera

spring with the orientation arrow heads pointing toward

the camera (Figure 29 and Figure 30).

Figure 29

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

Point Arrows

Toward Camera

Orientation Arrows

Alignment Pins Locking Tabs

Locking Tab

Ridge Tool Company18

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

Adjustment

If necessary, adjust the guide’s position on the spring by

turning the guide (Figure 33).

Figure 33

Removal

Depress the locking tab on both sleeves simultaneously, either with fingers (Figure 34) or with channel

lock pliers, and slide the ball guide off the sleeves

(Figure 35).

Figure 34

Figure 35

Ridge Tool Company 19

Appendix A – Installing the

Standard SeeSnake Wheels

Figure 36 – Parts of the Axle and Wheel Assembly

Figure 37 – Mounting the Axle to the Frame

Figure 38 – The side of the Wheel with Six Spokes

Should Face Inward

Figure 39 – The Washer and Retaining Pin Hold the Axle

and Wheels in Place

Figure 40 – Wheels Fully Assembled. Notice that the

Retaining Pin is on the same side as the

Hand Brake

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

Ridge Tool Company20

Service and Repair

WARNING

Tool should be taken to a RIDGID Independent Authorized

Service Center or returned to the factory. All repairs made

by Ridge service facilities are warranted against defects in

material and workmanship.

If you have any questions regarding the service or repair

of this machine, call or write to:

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44035-6001

Tel: (800) 519-3456

E-mail: TechServices@ridgid.com

For name and address of your nearest Independent

Authorized Service Center, contact the Ridge Tool

Company at (800) 519-3456 or http://www.ridgid.com

or www.seesnake.com

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

Ridge Tool Company 21

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

PROBLEM PROBABLE FAULT LOCATION

Garbled or jumbled video

Lights, but no video

No video, no camera

lights

Video, but no lights

White screen

Noisy Picture – vertical

stripes on Monitor

screen

Chart 1 Troubleshooting

Horizontal or Vertical hold need adjustment

75 Ohm-High Z switch in wrong position (older CCUs)

Fault within camera, cables, or CCU

SeeSnake System cable connected when playing back VCR

Monitor Contrast and/or Brightness is turned down

Break in video carrying conductor (pin/socket #3) between Camera and CCU

Fault within camera or CCU

CCU or monitor screen switch is turned OFF

SeeSnake System Cable not fully plugged in, or loose connection in system

Fault in any sub-assembly

Dimmer turned down

Fault within camera head, LED section

Contrast and/or Brightness is improperly set

Camera exposed to excessive light

Camera Head overheated

If further assistance is needed, please

call RIDGE Tool Technical Service at

(800) 519-3456. Additional information

may be available at www.ridgid.com or

www.seesnake.com

Ridge Tool Company22

Standard and Mini SeeSnake Diagnostic Equipment

Kollmann

Kollmann

SeeSnake

®

standard et Mini

SeeSnake

®

Matériel de sondage

SeeSnake

®

KD-200

KD-325

KD-100-Mini

KD-200-Mini

KD-200-Couleur

KD-325-Couleur

KD-100 Mini/Couleur

KD-200 Mini/Couleur

Homologué UL/CSA

Caméra sur enrouleur SeeSnake

®

Inscrivez ci-dessous le numéro de série de la plaque signalétique l’appareil pour future référence.

N° de

série :

Table des matières

Fiche d’enregistrement des numéros de modèle et de série de l’appareil............................................................23

Consignes générales de sécurité

Sécurité du chantier ..................................................................................................................................................25

Sécurité électrique.....................................................................................................................................................25

Précautions visant la batterie.................................................................................................................................25

Sécurité personnelle..................................................................................................................................................26

Utilisation et entretien de l’appareil ...........................................................................................................................26

Service après-vente ..................................................................................................................................................27

Consignes de sécurité particulières

Sécurité de l’appareil.................................................................................................................................................27

Description, spécifications et accessoires de base

Description ................................................................................................................................................................28

Composants du système........................................................................................................................................28

Spécifications............................................................................................................................................................31

Accessoires de base.................................................................................................................................................32

Installation et fonctionnement

Préparation du matériel.............................................................................................................................................32

Connexions ...............................................................................................................................................................32

Fonctionnement.........................................................................................................................................................33

Vérifications préalables.............................................................................................................................................33

Contrôles mécaniques............................................................................................................................................33

Contrôles électriques..............................................................................................................................................33

Compteur de distance SeeSnake CountIR ............................................................................................................33

Vérifications sur chantier...........................................................................................................................................34

Transport et stockage.................................................................................................................................................37

Entretien et nettoyage

Entretien préventif.....................................................................................................................................................37

Entretien correctif......................................................................................................................................................38

Dépistage des composants défectueux ....................................................................................................................39

Options......................................................................................................................................................................40

Installation du guide-tube à emboîtement SeeSnake................................................................................................42

Annexe A – Montage des roues sur le SeeSnake Standard....................................................................................44

Service après-vente et réparations............................................................................................................................45

Troubleshooting ..........................................................................................................................................................46

Garantie à vie ...........................................................................................................................................Page de garde

Ridge Tool Company24

Matériel de sondage SeeSnake Standard et Mini SeeSnake

Kollmann

Ridge Tool Company 25

Matériel de sondage SeeSnake Standard et Mini SeeSnake

Kollmann

Consignes générales de sécurité

MISE EN GARDE ! Familiarisez-vous avec l’ensemble des

instructions. Le respect des consignes

suivantes vous permettra d’éviter les

risques de choc électrique, d’incendie

et de blessure corporelle grave.

CONSERVEZ CES INSTRUCTIONS !

Sécurité du chantier

• Gardez le chantier propre et bien éclairé. Les établis encombrés et les locaux mal éclairés sont une

invitation aux accidents.

• N’utilisez pas d’appareils électriques dans un mi-

lieu explosif tel qu’en présence de liquides, de

gaz ou de poussières inflammables. L’appareil pro-

duit des étincelles qui pourraient provoquer la

combustion des poussières et vapeurs.

• Gardez les tiers, les enfants et les visiteurs à

l’écart lorsque vous utilisez un appareil électrique.

Les distractions peuvent vous faire perdre le contrôle

de l’appareil.

• Ne laissez pas les visiteurs entrer en contact avec

l’appareil ou la rallonge électrique. De telles mesures

préventives réduisent les risques d’accident.

Sécurité électrique

• Les appareils électriques avec terre doivent être

branchés sur une prise avec terre appropriée et

conforme aux normes en vigueur. Ne jamais enlever la barrette de terre ou tenter de modifier la

fiche d’aucune manière. Ne jamais utiliser d’adaptateurs de prise. Consultez un électricien qualifié

en cas de doute sur la bonne mise à la terre de la

prise. Dans le cas d’une panne ou d’une défaillance

électrique de l’appareil, la terre assure un passage de

faible résistance qui éloigne le courant électrique de

l’opérateur.

• Evitez d’entrer en contact avec les objets reliés à la

terre, tels que les canalisations, les radiateurs, les

cuisinières et les réfrigérateurs. Le contact avec

des masses augmente les risques de choc électrique.

• N’exposez pas les appareils électriques à la pluie

ou aux endroits mouillés. Toute pénétration d’eau à

l’intérieur de l’appareil augmentera les risques de choc

électrique.

• Ne maltraitez pas le cordon électrique de l’ap-

pareil. Ne jamais porter l’appareil par son cordon

électrique, ni tirer sur celui-ci pour débrancher

l’appareil. Gardez le cordon à l’abri des sources de

chaleur, de l’huile, des angles tranchants et des

pièces mobiles. Remplacez immédiatement tout

cordon endommagé. Les cordons endommagés aug-

mentent les risques de choc électrique.

• A l’extérieur, utilisez une rallonge électrique portant

l’indication “W-A” ou “W”. Ce type de cordon est

prévu pour être utilisé à l’extérieur et réduit les risques

de choc électrique.

• Branchez l’appareil sur une alimentation à courant

alternatif qui correspond aux spécifications de la

plaque signalétique. Une tension inadaptée risque de

provoquer des chocs ou brûlures électriques.

• Utilisez exclusivement des rallonges électriques

équipées d’une fiche avec barrette de terre et d’une

prise compatible avec la fiche de l’appareil. L’utili-

sation d’autres types de rallonge n’assurera pas la

mise à la terre de l’appareil et augmenterait les risques

de choc électrique.

• Utilisez la section de rallonge appropriée (voir le

tableau). Une section de conducteurs insuffisante entraînera des pertes de charge excessive et un manque

de puissance.

• Gardez toutes connexions électriques au sec et

surélevées. Ne touchez pas les fiches électriques

ou l’appareil avec les mains mouillées. Cela ré-

duira les risques de choc électrique.

Précautions visant la batterie

• Utilisez exclusivement la taille et le type de batterie

préconisé.

• Faites attention de bien respecter la polarité de la

batterie indiquée dans le logement à batterie.

• Utiliser le type de chargeur préconisé par le fabri-

cant de la batterie lors de sa recharge. L’utilisation

Barrette de terre

Cache-prise

avec

terre

Barrette de terre

Section minimale des fils conducteurs des rallonges

Ampères indiqués

sur la plaque Longueur totale (en pieds)

signalétique