Page 1

'3

2:1(5·60$18$/

,1&+)/22502'(/

'5,//35(66

)RU<RXU6DIHW\

5HDGDOOLQVWUXFWLRQVFDUHIXOO\

6DYHWKLVPDQXDOIRUIXWXUH

UHIHUHQHFH

Part No. SP6431 Printed in China

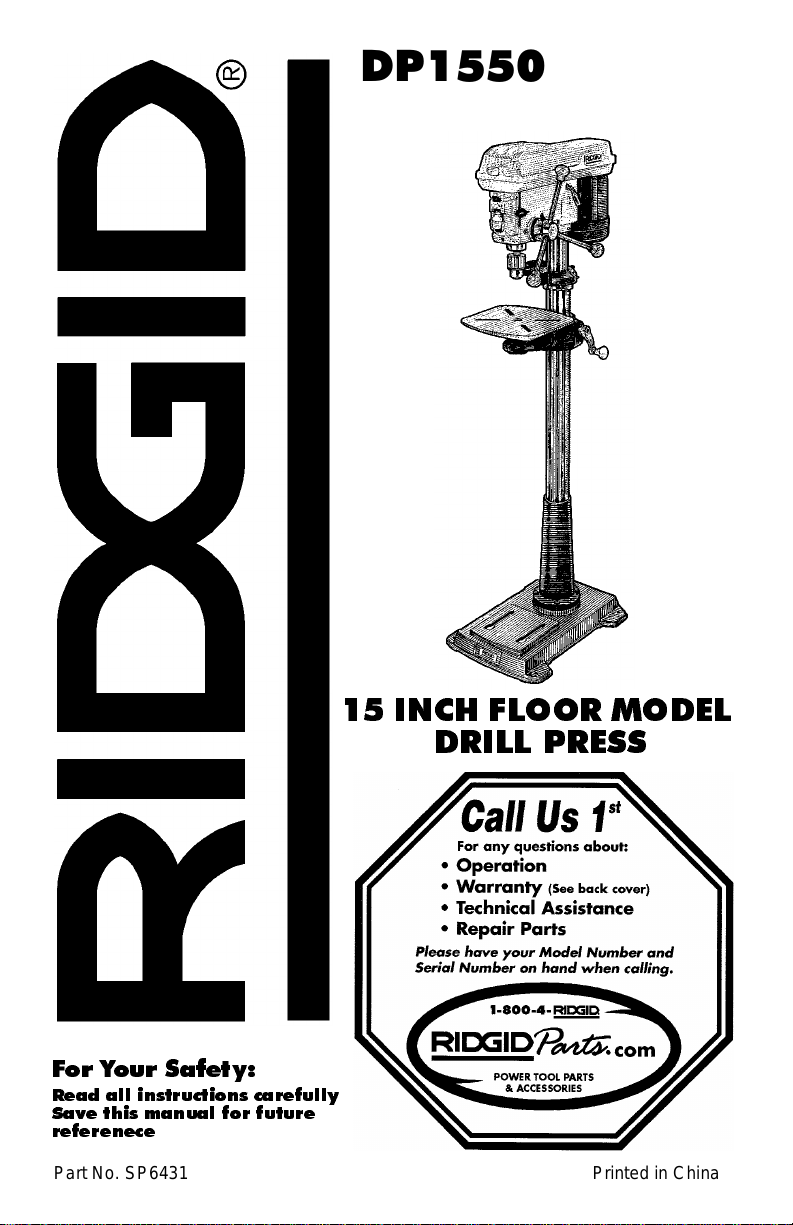

Page 2

Repair Parts

Parts List for RIDGID 15" Drill Press

Model No. DP15500

Figure 1

1

2

22

21

7

4

4

6

4

19

18

13

14

17

16

Always order by Part Number - Not by Key Number

Key

Part No. Description

No.

829775

1

828814

2

828812

3

828932

4

828813

5

828811

6

816439-4

7

828919

8

817358-1

9

820241-5

10

* Standard hardware item - may be purchased locally.

Guard Upper

Link - Rear

Clamp - Rear Link

* Screw Pan Hd

M5.5 x 1.8-12

Link - Front

Clamp - Front Link

Belt Poly V 27"

Pulley Asm - Idler

* Screw Rd Hd Wash

M6 x 1.0

* Lockwasher Ext M6

15

14

13

9

10

Key

Part No. Description

No.

828818

11

828816

12

817537

13

817530

14

817536

15

821734

16

828849

17

821742

18

829688

19

816439-5

20

828820

21

828821

22

3

4

5

8

9

10

12

Pulley Asm - Motor

Guard Lower

Ring Retaining

Bearin g B all 2 0 mm

Spacer

Insert P u lley

Pulley Spindle

Nut Pulley

Cap Spindle

Belt Poly V 25"

Latch

Spring Latch

20

11

35

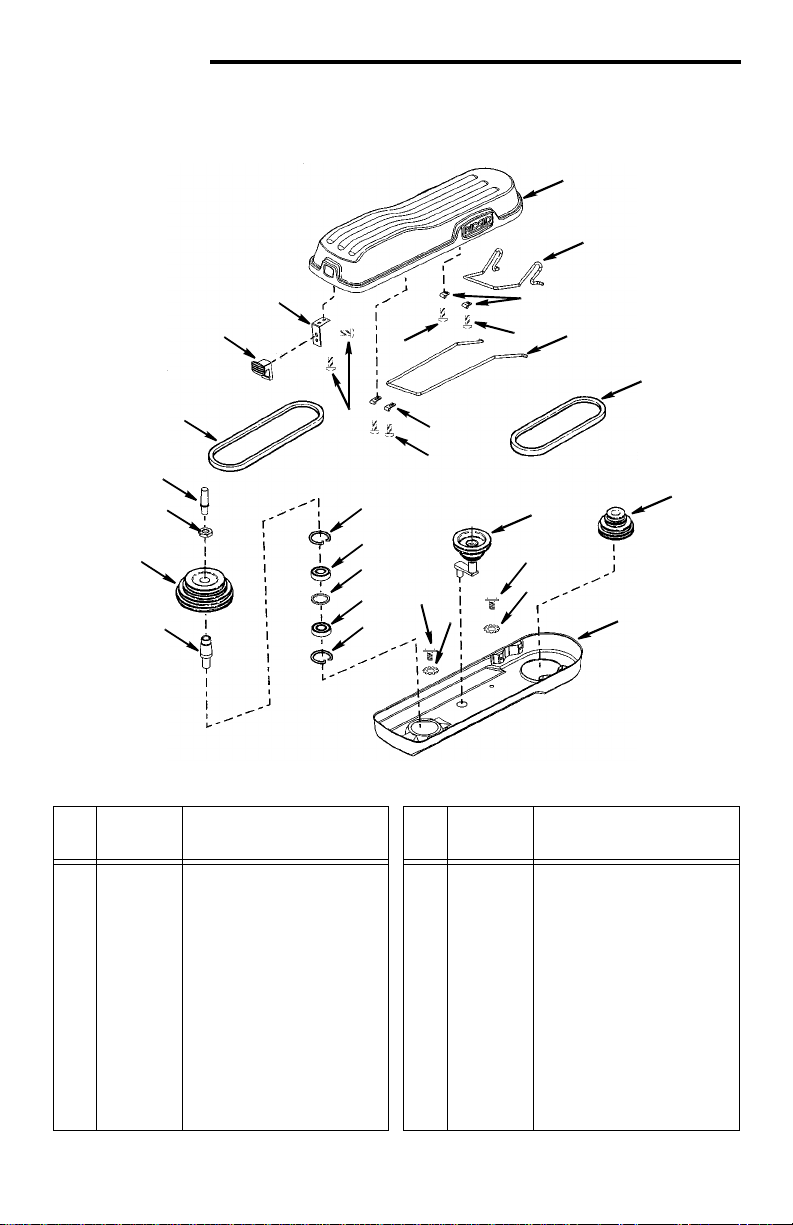

Page 3

36

49

55

48

56

50

52

28

51

37

41

27

42

36

43

Parts List for RIDGID 15" Drill Press

Model No. DP15500

Figure 2

13

14

29

53

40

34

33

35

39

15

25

38

35

12

22

Repair Parts

11

6

78

9

10

3

2

16

18

17

21

1

5

3

4

47

46

45

44

30

54

43

26

25

32

31

24

20

20

23

19

Page 4

Repair Parts

Always order by Part Number -- Not by Key Number

Parts List for RIDGID 15" Drill Press

Model No. DP15500

Figure 2

Key

Part No. Description

No.

828929

1

820381-2

2

821063-2

3

828940

4

824026-7

5

817336-1

6

820383-8

7

820236-9

8

817495

9

817516

10

817330

11

828941

12

SP6431

13

817317

14

820381-4

15

817320

16

817494

17

821750

18

828904

19

826445

20

826441

21

817300

22

829590

23

828876

24

816743-4

25

826057

26

828880

27

821738-3

28

828917

29

* Standard hardware item - may be purchased locally.

• Any attempt to repair t his motor may create a hazard unless repair is done by a qualified service tec hnician.

Repair service is avai lable at your nearest Author ized Service Center.

• Motor

* Screw Hex Hd.

M8 x 1.25-20

* Washer M8 x 16 x 1.6

Cord Motor

* Nut Hex M8 x 1.25

Mount Motor

* Lockwasher 12mm

* Nut Hex M12 x 1.75

Support Motor Bracket

Support Motor Bracket

Connector Wire

Cord w/Plug

Owners Manual

Lever Adjustin g

* Screw Hex Hd.

M8 x 1.25-16

Knob Motor Adjusting

Handle Belt Tension

Screw Hex Soc. Set

M10 x 1.5-12

Hub Asm.

Rod

Knob

Guide Scale

Ring Depth Stop

Scale Depth

* Screw Pan Cr

M4 x 0.7 x 8

Pointer

Spring Asm.

* Nut Hex M12 x 1.5-8

Pin Stop

Key

Part No. Description

No.

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

828877

828963

820240-6

829595

820244

817343

828928

820378

820294

829689

829826

810506-3

829803

820241-4

828921

820240

829787

826122

829597

829597-1

828923

829690

820236-8

817308

820240-3

813317-6

813317-8

Holder Key Chuck

Lens Assembly

* Screw Pan Hd.

M5 x 0.8-12

Socket Bulb Asm.

* Screw Pan Hd.

M6 x 1.0-12

Lock Depth Screw

Bearing Pinion Shaft

Screw Soc Cap

M4 x 0.7-10

Washer Foam

Clamp Cord

Head Asm.

Tie Wire

Screw Hex Hd. Gnd.

M5 x 0.8

Lockwasher Ext. M5

Box Switch Asm.

* Screw Pan Hd.

M5 x 0.8-16

Switch Locking

Key Switch

Lead 3" Black

Lead 3" White

Switch Rocker

Washer 12mm ID Plain

* Nut Hex M10 x 1.5

Screw Sl. Set Fl Pt

* Screw Pan Hd

M5 x 0.8-6

Wrench Hex “L” 3mm

Wrench Hex “L” 5mm

37

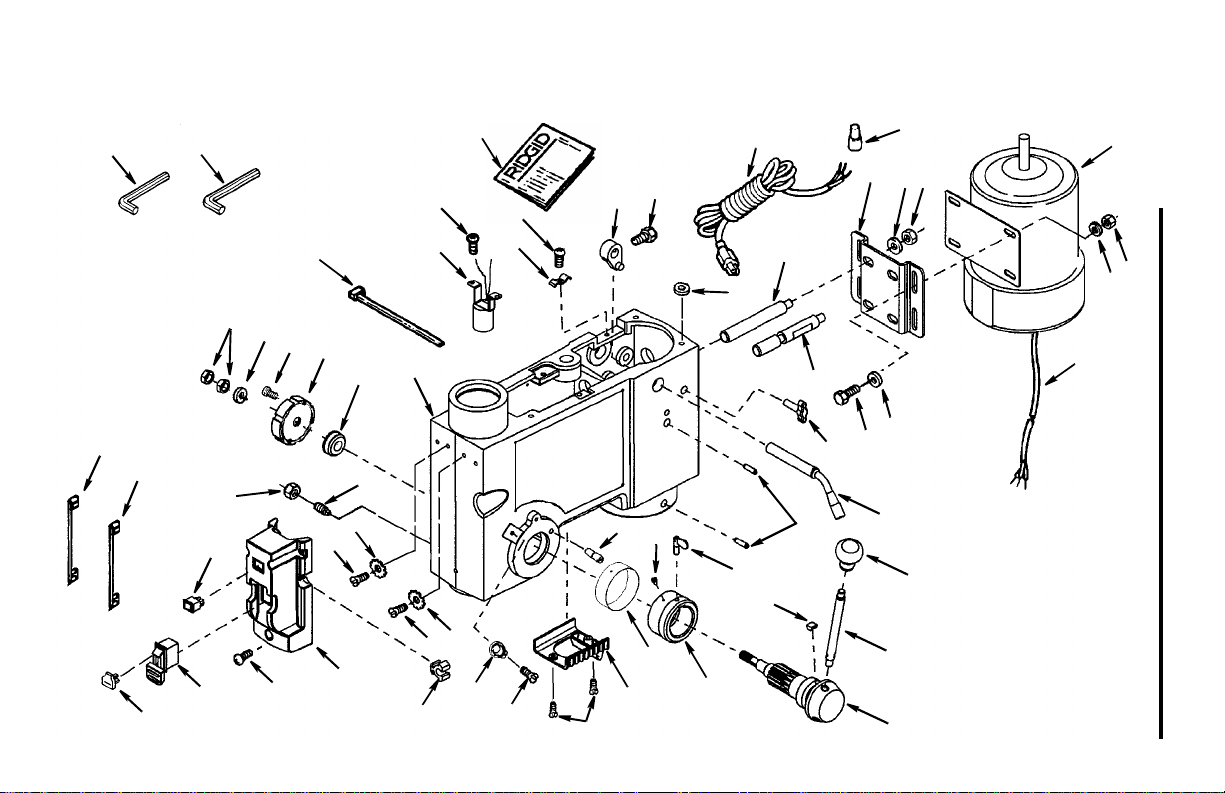

Page 5

Repair Parts

Parts List for RIDGID 15" Drill Press

Model No. DP15500

Figure 3

10

1

2

3

4

5

9

6

8

7

Always order by Part Number - Not by Key Number

Key

Part No. Description

No.

1

2

3

4

5

817309

817310

817311

813480

817535

Lock Nut M17 x 1.0

Ring Locking

Washer

Bearing Ball 17mm

Gasket Quill

38

Key

Part No. Description

No.

Tube Quill

Key Chuck

Chuck

Spindle

Bearin g B all

10

6

7

8

9

828875

817339

817340

828908

817529

Page 6

Repair Parts

21

20

Parts List for RDIGID 15" Drill Press

Model No. DP15500

Figure 4

20

1

19

2

18

5

6

22

17

16

15

13

2

23

Key

Part No. Description

No.

817478

1

820245

2

821861-2

3

826439

4

821880

5

828927

6

821881-1

7

828870

8

813164-6

9

821754

10

828961

11

* Standard hardware item - may be purchased locally.

14

Collar Rack

* Screw Hex Soc. Set

M6 x 1.0-10

Support Table

w/Indicator

Crank (Includes Set

Screw)

Tube Column

Rack

Support Column

Tray, Back

Nut Hex M5

* Screw Hex Hd.

M10 x 1.5-40

Base

39

Key

No.

12

13

14

15

16

17

18

19

20

21

22

23

821750

817288

817290-3

821732

817777-3

817294-2

817350

817349

10251002

828871

828903

826438

3

4

7

12

2

10

11

Part No. Description

* Screw Hex Soc. Set

M10 x 1.5-12

Pin Gear

Clamp Table

Screw Hex Hd.

M16 x 2.0-35

Arm Table w/Scale

Clamp Column

Gear Helical

Worm Elevation

* Screw Pan Hd Cr

M5 x 0.8-60

Tray, Front

Table

Wrench Hex 24mm

8

9

Page 7

Maintenance

k

Maintenance

WARNING: For your o wn safety,

turn switch “OFF” and remove

plug from po we r so urce outlet

before maintain ing or lubr icatin g

your drill press.

A coat of automotive type paste wax

applied to the table and column will help

to keep the surfaces clean.

WARNING: To reduce the risk of

shock or fire hazard, if the power

cord is worn or cut, or da maged

in any way, have it replaced

immediately.

Wiring Diagra m

Lubrication

All of the ball bearings are packed with

grease at the factory. They require no further lubrication.

Periodically lubricate the table elevation

mechanism, the splines (grooves) in the

spindle, and the rack (teeth of the quill).

See “Getting to Know Your Drill Press”.

To

Motor

B

White

e

r

G

Cord w/Plug

l

a

c

k

Motor Cord

n

e

Socket Asm Bulb

White

Green

Green

White

Black

Switch Locking

Black

Lead 3" White

White

Black

Switch Rocker (Lig ht)

(On/Off)

Top

Troubleshooting

WARNING: For yo ur own safety, turn switch “OFF” and always remove

plug from power source outlet befo re tr oubleshoot i ng .

Consult your Authoriz ed Service Center if for any rea son motor wil l not run.

Trouble

Noisy Operation 1. Incorrect belt tension.

Probable Cause Remedy

1. Adjust tension. See “Installing and

Tensioning Belt” section.

2. Dry spindle.

2. Lubricate sp indle. See “Lubrication”

section.

3. Loose spindle pulley

3. Checking tightness of ret aining nut

on pulley, and tighten if necessary.

4. Loose motor pulley

4. Tighten set screws in pulleys.

33

Lead

3"

Blac

Loading...

Loading...