RIDGID DP1550 Owner's Manual

'3

2:1(5·60$18$/

)RU<RXU6DIHW\

5HDGDOOLQVWUXFWLRQVFDUHIXOO\

6DYHWKLVPDQXDOIRUIXWXUH

UHIHUHQHFH

,1&+)/22502'(/

'5,//35(66

Part No. SP6431 Printed in China

Table of Contents

Section Page

Table of Contents ..........................................2

Safety Instructions For Drill Press .................2

Safety Signal Words ..................................2

Before Usi ng The Dril l Pr ess ..................... 3

When Installing Or Moving The Drill Press .... 3

Before Each Use . ... .... .... ............... ................ 4

Use Only Accessories Designed For This Drill

Pres s To Reduce The R is k of S eri ous Injur y

From Thrown Broken Parts Or Work Pieces .4

Plan Ahea d To Protec t Your Eyes , Hands, Fa ce

and Ears ........................................................ 6

Glossary of Terms .........................................7

Motor Specifications and Ele c trical

Requirements ........................................... 7

110-120 Volt, 60 Hz. Tool Information ........8

Motor Saf ety Pr otec tio n ... .... ... .... ................ 9

Unpacking and Checking Contents .............10

Tools Needed ...........................................10

Unpac king ..... ........... ........ ........... ............ .. 1 0

List of Loose Parts .................................... 11

Loose Parts in Box and Bag .....................11

Location and Function of Controls ...............12

Assemb ly ..... ........... ............ ........... ........ ......13

Assembly of Base/Column ........................13

Installing The Table ..................................14

Installing the Storage Tray ........................14

Installing the Head .................................... 15

Pulley Alignment and Speed Adjustment ..16

Tensioning Belt .........................................17

Installing Feed Handles ............................ 17

Installing the Drill Chuck ........................... 17

Installing Light Bulb ................................... 19

Section Page

Adjusting the Table Square To Head ........19

Bevel Scale ...............................................19

Conv erting F rom Righ t Hand Oper ation to Left

Hand Operation ...................................... 20

Quill Return Spring ...................................22

Adjusting Belt Latch Guard........................23

Getting To Know Your Drill Press ................24

Spindle Speed in R.P.M. ...........................25

Drilling to a Spe ci fic Dept h .... .... ................27

Another Way - Depth Scale ...................... 27

Locking Chuck at Desired Depth ..............28

Removing Chuck and Arbor ......................28

Safety Instructions for Basic Drill Press

Operation ......... ........... ........ ........... .........29

Plan Ahead To Prot ect Your Eyes, Hands, Fa ce

and Ears ......................................................29

Use Only Accessories Designed For This Dr ill

Press To Reduce the Risk of Serious Injury

From Thrown Broken Parts Or Work Pieces 30

Basic Drill Press Operation .........................30

Installing Drills ...........................................30

Positioning Table and Workpiece ............. 31

Tilting Ta ble ... .... .... ........... .... .... ... .... ......... 32

Hole Location ............................................32

Feeding .. ............ ....... ............ ........... ......... 32

Mainte nance ......... ............... ............... ......... 33

Maintenance ............................................. 33

Lubrication ................................................ 33

Wiring Diagram ............................................33

Troublesh ootin g ........ ....... ........ ....... .... ........ .33

Repair Parts ................................................35

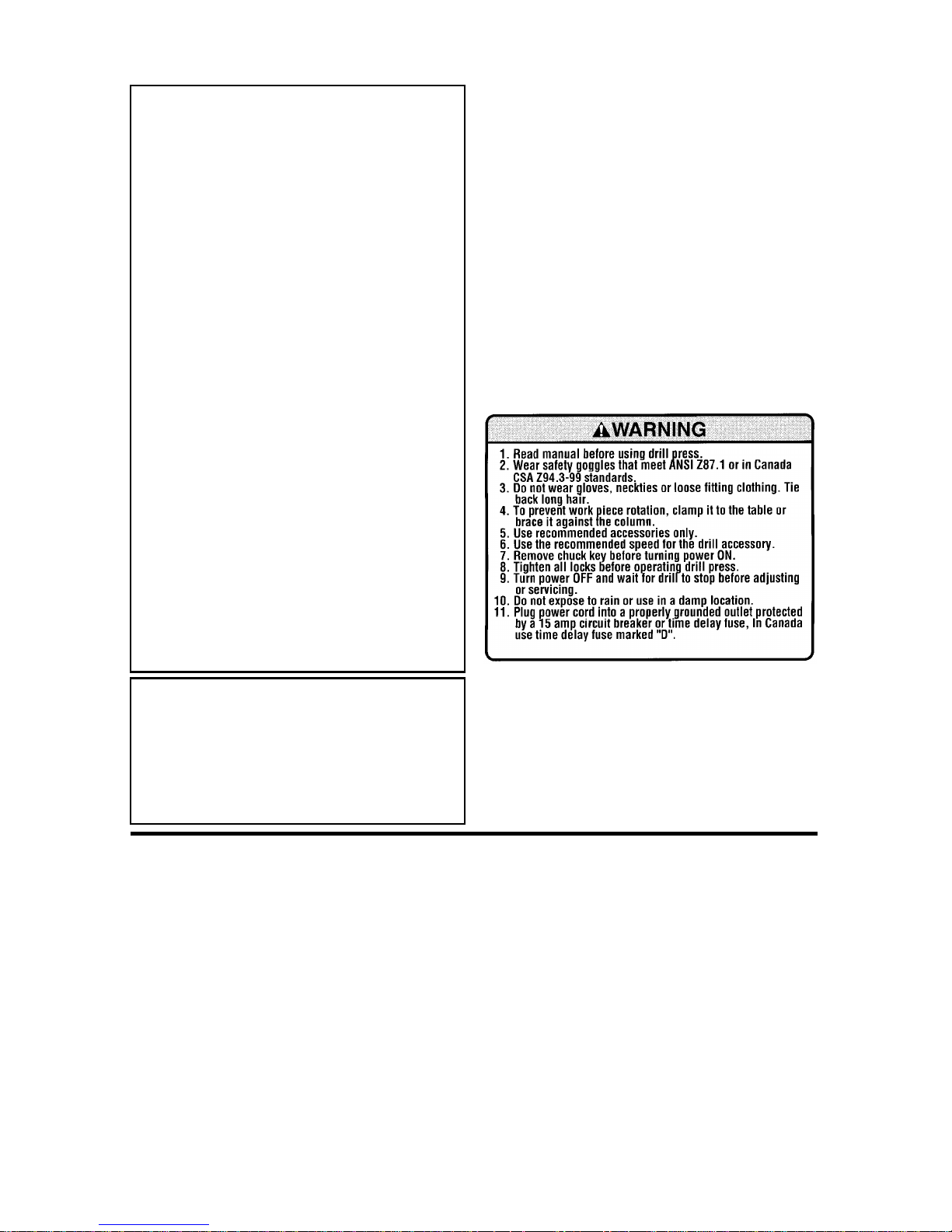

Safety Instructions For Drill Press

Safety is a combination of common sense, staying alert and know ing how

your drill press works. Read thi s manual to understan d this drill pr ess .

Safety Signal Words

DANGER: means if the safety informa-

tion is not followed someone will be

seriously injured or killed.

WARNING: means if the safety infor-

mation is not followed someone

could be seriously injured or killed.

CAUTION: means if the safety infor-

mation is not followed someone may

be injured.

2

Before Using The Drill Press

WARNING: Some dust created by

power sa ndin g, s awi ng, gri ndi ng,

drilling, and other construction

activities contains chemica ls

known (to the State of California)

to cause cancer, birth defects or

other rep r od uc ti v e harm. Some

examples of these chemicals are:

• Lead from lead-bases pain ts,

• Crystalline silica from bricks

and cement and other mason ry

produc ts , and

• Arsenic and chromium from

chemically-treate d lumber.

Y o ur risk from these exposures

varies , depending on how often

you do th is type of work. To

reduce your exposure to these

chemicals: work in a well ventilated area, and work with

approved safety equipment, such

as those dust masks that are

specially designed to filter out

microscopic particles.

• Completely assemble and align drill

press (See “Assembly” section).

• Learn the use and function of the

ON-OFF switch. (See “Getting to

Know Your Drill Press” section).

• Review and understand all safety

instructions and operating procedures in this manual.

• Review the maintenance methods

for this drill press (See “Maintenance” section).

• Find and read all the warning labels

found on the drill press (shown

below).

WARNING: To reduce the risk of

mistakes that could cause serious, permanen t inju r y, do not

plug the drill press in until the

following steps have been satisfactorily completed.

When Installing Or Moving The Drill Press

Reduce the Risk of Dangerous

Environment.

• Use the drill press in a dry, indoor

place protected from rain.

• Keep work area well lighted.

• Use recom me nded accessori es.

The use of improper accessories

may cause risk of injury to persons.

To reduce the risk of injury from

unexpected drill press movement.

If there is any tendency of the drill

press to tilt or move during any use,

bolt it to the floor. Make sure and

leave adequate room to fully open the

belt guard. If the workpiece is too

large to easily support with one hand,

provide an auxiliary support .

• To reduce the risk of injury from

electrical shock, make sure your fingers do not touch the plug’s metal

prongs when plugging in or unplugging the drill press.

3

Safety Instructions For Drill Press (continued)

• Ne ver Stand On Tool. Serious

injury could occur if the tool tips or

you accidentally hit the cutting tool.

Before Each Use

Inspect your drill press.

• To reduce the risk of injury from

accidental starting, turn the switch

off, unplug the drill press, and

remove the switch key before raising

the guard, changing the cutting tool,

changing the setup, or adjusting

anything. Make sure switch is in

OFF position before plugging in.

• Check for alignment of moving

parts, binding of moving parts,

breakage of parts, drill pr ess stabil ity, and any other conditions that

may affect the way the drill press

works.

Do not store anything above or near

the tool where anyone might stand

on the tool to reach them.

• If any part is missing, bent or broken

in any way, or any electrical part

does not work properly, turn the drill

press off and unplug the drill press.

• Replace damaged or missing parts

before using the drill press again.

• Remove adjusting keys and

wrenches. Form a habit of checking

for and removing keys and adjusting

wrenches from table top before turning drill press on.

• Make sure all clamps and locks are

tight and no parts have excessive

play.

Use Only Accessories Designed For This Drill Press To Reduce

The Risk of Serious Injury From Thrown Broken Parts Or Work

Pieces

• W hen cutting large diame ter holes:

- Clamp the workpiece firmly to the

table. Otherwise the cutting may

grab and spin it at high speed.

- Use only one piece, cup -type, hole

cutters.

- Do not use fly cutters or m ulti-part

hole cutters as they can come

apart or become unbalanced in

use.

- Keep speed below 1500 R.P.M.

• Drum sanders must never be oper-

ated on this drill press at a speed

greater than 1800 R.P.M.

• Do not insta ll or use a ny d r ill t ha t

exceeds 7” in length or extends 6”

below the chuck jaws. They can

suddenly bend outward or break.

rotary planers on this drill press.

Kickback

• Kickback is the grabbing of the

workpiece by the rotating tool. The

workpiece can be thrown at a very

high speed in the direction of rotation. This Can Cause Serious

Injury . To reduce the possibility of

injury from kickback:

- Clamp the workpiece firmly to the

table whenever possible.

- Buffing or sanding wheels or

drums should be co ntacted on the

side moving away from you, not the

side moving toward you.

- Use only recommended accessories and follow the instructions supplied with the accessory.

• Do not use wire wheels, router bits,

shaper cutters, circle (fly) cutter s or

4

This drill press has 12 speeds as

listed below:

250 RPM 990 RPM

340 RPM 1550 RPM

390 RPM 1620 RPM

510 RPM 1900 RPM

600 RPM 2620 RPM

650 RPM 3100 RPM

See inside of guard for specific placement of belt on pulleys.

• To reduce the risk of injury from

parts thrown by the spri ng, fo l lo w

instructions exactly as given and

shown in adjusting spring tension of

quill.

• To prevent the workpiece from being

torn from your hands, spinning of

the tool, shattering the tool or being

thrown, always properly support

your work so it won’t shift or bind on

the tool:

Think Safety

Safety is a combination of operator

common sense and alertness at all

times when the drill press is being

used.

WARNING: Do not allow familiarity ( gained f rom fre quent use of

your drill press) to become commonplace. Always remem b er

that a careless fraction of a second is sufficient to inflict severe

injury.

Plan Your Work

• Don’t force the tool. It will do the job

better and safer at the rate for which

it was designed.

• Use the right tool. Don’t force tool or

attachment to do a job it was not

designed to do.

• If any part of your drill press is missing, malfunctioning, has been dam aged or broken...such as the motor

switch, or other operating control, a

safety device or the power cord, turn

the drill press off and unplug it until

the particular part is properly

repaired or replaced.

• Never place your fingers in a position where they could contact the

drill or other cutting tool if the workpiece should unexpectedly shift or

your hand should slip.

- Always position backup material

(use beneath the workpiece) to

contact the left side of the column.

- Whenever possible, position the

workpiece to contact the left side of

the column - If it is t oo short or the

table is tilted, clamp solidly to the

table. Use table slots or clamping

ledge around the outside edge of

the table.

- When using a drill press vise,

always fasten it to a table.

- Never do any work “Freehand”

(hand holding workpiece rather

than supporting it on the table),

except when polishing.

- Securely lock head to column,

table support to column and table

to table support before operating

drill press.

- Never move the head or table while

the tool is running.

- Before starting the operation, jog

the motor switch to make sure the

drill or other cutting tool does not

wobble or cause vibration.

- If a workpiece overhangs the table

suc h th at it will fal l o r ti p if not he ld,

clamp it to the table or provide auxiliary support.

- Use fixtures for unusual operations

to adequately hold, guide and position workpiece.

5

Safety Instructions For Drill Press (continued)

- Use the spindle speed recommended for the specific operation

and workpiece material - check the

inside of the be lt guard for drilli ng

information; for accessories, refer

to the instructions provided with

the accessories.

• Ne ver climb on the drill press table,

it could break or pull the entire drill

press down on you.

• Turn the motor switch off and put

away the switch key when leaving

the drill press.

• To reduce the risk of injury from

thrown work or tool contact, do not

perform layout, assembly or setup

work on the table while the cutting

tool is rotating.

• Don’t overreach. Keep proper footing and balance at all times.

• Maintain tools with care. Keep tools

sharp and clean for best and safest

performance. Foll ow instr uction s fo r

lubricating and changing accessories.

Plan Ahead To Protect Your Eyes, Hands, Face and Ears

Dress for safety

• Do not wear loose clothing, gloves,

neckties or jewelry (rings, wrist

watches). They can get caught and

draw you into moving parts.

• Wear nonslip footwear.

• Tie back long hair.

• For dusty operations, wear a dust

mask along with safety goggles.

Reduce the Risk of Accidental

Starting.

• Make sure switch is “OFF” before

plugging drill press into a power outlet.

• Ro ll long sleeves above the elbow.

• Noise levels vary widely . To reduce

the risk of possible hearing damage,

wear ear plugs or muffs when using

drill press for hours at a time.

• Any power tool can throw foreign

objects into the eyes. This can result

in permanent eye damage. Always

wear safety goggles, not glasses

comply ing with AN S I Z87.1 (or in

Canada CSA Z94.3-99) shown on

package. Everyday eyeglasses have

only impact resistant lenses. They

are not safety glasses. Safety goggles are available at many local

retail stores. Glasses or goggles not

in compliance with ANSI or CSA

could seriously hurt you when they

break.

WARNI NG: Don’t all ow familiarity

(gained from frequent use of

your drill press) to cause a careless mistake. Always remember

that a careless fraction of a second is enough to cause a severe

injury .

Keep Children Away

• Keep all visitors a safe distance

from the drill press.

• Make sure bystanders are clear of

the drill press and workpiece.

Before Leaving The Drill Press

• Turn the drill press off.

• Wait for tool bit to stop spinning.

• Unplug the drill pres s .

• Make workshop child-proof. Lock

the shop. Disconnect master

switches. Remo ve the yellow swi tch

key. Store it away from children and

others not qualified to use the tool.

6

Glossary of Terms

Workpiece

The item on which the cutting operation is

being performed.

Drill Bit or Drill

The cutting tool used in the dr ill press to

make holes in a workpiece.

Backup Material

A piece of wood placed between the

workpiece and table...it prevents wood in

the workpiece from splintering when the

drill passes through the backside of the

workpice...also prevents drilling into the

table top.

Revolutions Per Minute (R.P.M.)

The number of turns completed by a spinning object in one minute.

Spindle Speed

The R.P.M. of the spi ndle.

Backlash

The amount of handle movement or play

bet w ee n adja c ent moving pa rts.

Motor Specifications and Electrical Requirements

Power Supply and Motor Specifications

WARNING: To reduce the risk of

electrical hazards, fire hazards or

damage to the tool, use proper

circuit protection. Your tool is

wired at the factory for operation

using the voltage shown. Connect tool to a power line with the

appropriate voltage and a 15-amp

branch circuit. Use a 15-amp time

delay type fuse or circuit breaker.

To reduce the risk of shock or

fire, if power cor d is wo rn or cut,

or damaged in any way, have it

replaced immediately .

The A-C motor used on this tool is a

totally enclosed fan cooled (TEFC) , induction nonreversible type, having the following specification s :

Rated H.P 1/2

Voltage 110-120

Amperes 8.0

Hertz (Cycles ) 60

Phase Single

RPM 1700

Rotation of Shaf t Clockwise

General Electrical Connections

DANGER: To reduce the risk of

electrocution:

1. Use only identical replacement

parts when servicing. Servicing should be performed by a

qualified service technician.

2. Do not use in rain or where

floor is w et.

This tool is intended for indoor

residential use only.

WARNING: Do not permit fingers

to touch the terminals of plug

when installing or removing the

plug to or from the outlet.

7

Motor Specifications and Electrical Requirements

(continued)

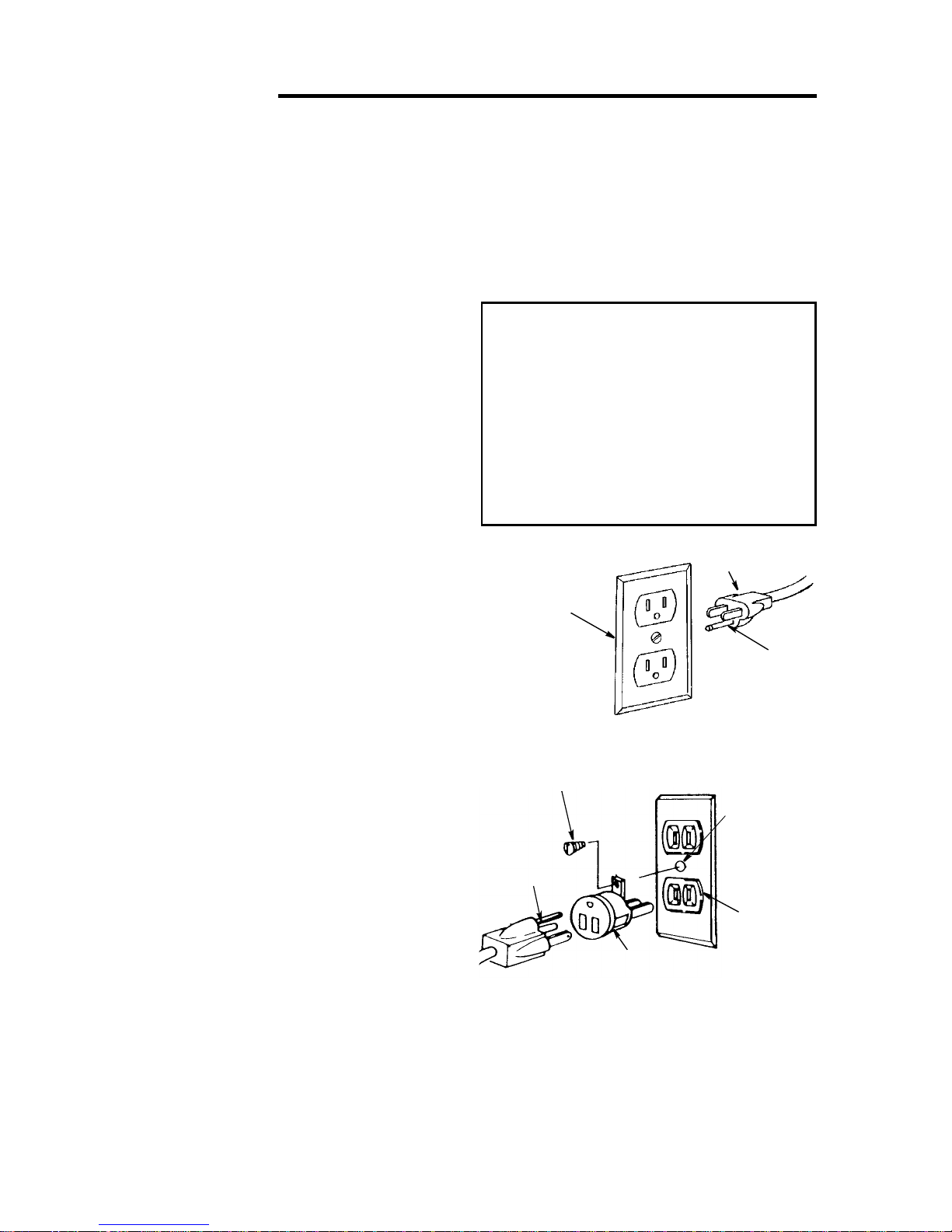

110-120 Volt, 60 Hz. T ool

Information

NOTE: The plug supplied on your tool

may not fit into the outlet you are planning

to use. Your local electrical code may

require slightly different power cord plug

connections. If these differences exist

refer to and make the proper adjustments

per your local code before your tool is

plugged in and turned on.

In the event of a malfunction or breakdown, grounding provides a path of least

resistance for electric current to reduce

the risk of electric shock. This tool is

equipped with an electric cord having an

equipment grounding conductor and a

grounding plug, as shown. The plug must

be plugged into a matching outlet that is

properly installed and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will

not fit the outlet, have the proper outlet

installed by a qual ified electrician.

A temporary adapter may be used to connect this plug to a 2-prong outlet, as

shown, if a properly grounded thr ee prong

outlet is not available. This temporary

adapter should be used only until a properly grounded three prong outlet can be

installed by a qualified electrician. The

green colored rigid ear, lug and the like,

extending from the adapter must be connected to a permanent ground such as a

properly grounded outlet box.

NOTE: In Canada the use of a temporary

adapter is not permitted by the Canadian

electrical code.

Improper connection of the equipment

grounding conductor can resul t i n a risk of

electric shock. The conductor with insulation having an outer surface that is green

with or without yellow stripes is the equipment grounding conductor. If repair or

replacement of the electric cord or plug is

necessary, do not connect the equipmentgrounding conductor to a live terminal.

If the grounding instructions are not completely understood, or if you are in doubt

as to whether the tool is properly

grounded check with a qualified electrician or ser vice personnel.

WARNING: If not properly

grounded, this tool can cause an

electrical shock, particularly

when used in damp locations, in

proximit y to plu m bi ng, or out of

doors. If an electrical shock

occurs there is the potential of a

secondary hazard, suc h as your

hands to hit the cutting tool.

Properly

Grounded

3-Prong Outlet

Grounding Lug

3-Prong

Plug

Adapter

NOTE: The adapter illustrated is for use

only if you already have a properly

grounded 2-prong outlet.

NOTE: In Canada the use of a temporary

adapter is not permitted by the Canadian

Electrical Code.

3-Prong Plug

Grounding

Prong

Make sure this

Is Connected

to a Known

Ground

2-Prong

Outlet

8

Motor Safety Protection

IMPORTANT: To avoid motor damage,

this motor should be blown out or vacuumed frequently to keep sawdust from

interfering wit h normal motor ventila ti on.

1. Connect this tool to a power source

with the appropriate voltage for your

model and a 15-amp branch circuit

with a 15-amp time delay fu se or circuit

breaker. Usin g the wrong size fuse can

damage the motor.

2. If the motor won’t start, turn the switch

off immediately and unplug the tool.

Check the quill to make sure it turns

freely. If the quill is free, try to start the

motor again. If the motor still does not

start, refer to the "Motor Troubleshooting

Chart."

3. Fuses may "blow" or circuit breakers

may trip frequently if:

a.Motor Is Overloaded-Overloading

can occur if you feed too rapidly or

make too many start/stops in a short

time.

b. Line voltages shoul d not be more than

10% above or below the nameplate

voltage. For heavy loads, however, the

voltage at motor t erminals must e qual

the voltage specified for your model.

c. Improper or dull drill bit is used.

4. Most motor troubles may be traced to

loose or incorrect connections, overload,

low voltage (such as small size wire in

the su pply circ uit) or to o verly l ong supply circuit wire. Always check the connectio ns, the loa d and the supply cir cuit

whenever motor doesn’t work well.

Check wire sizes and length with the

Wire Size Chart shown.

Wire Sizes

NOTE: Make sure the proper extension

cord is used and is in good condition.

The use of any extension cord will cause

some loss of power. To keep t his to a minimum and to prevent overheating and

motor burnout, use the table at right to

determine the minimum wire size

(A.W.G.) extension cord.

Use only 3-wire extension cords which

have 3-prong gr ounding type plugs and 3-

pole receptacles which accept the tools

plug.

Extension Cord

Length

0-25

25-50

Gauge

(A.W.G.)

16

14

9

Unpacking and Checking Contents

Combinati

Tools Needed

Draw Light

Medium Screwdriver

Adjustable Wr ench

Phil lip s S cr e wd river

Combination Square

Framing

Square

Line on Board

Along this Edge

Should be no Gap or Overlap when Square

is Flipped Over in D o tted Position

on Square Must be True

Straight Edge of

Board 3/4" Thick

This Edge Must be

Perfectly Straight

Unpacking

WARNING: For your own safety,

never connect plug to power

source outlet until all assembly

steps are complete, and you

have read and understoo d the

safety and operating instructions.

The Drill Press is shipped compl ete in one

box.

1. Sepa r ate al l “loose parts” from packing

materials and check each item with

illustration and “Table of Loose Parts.”

WARNING: To reduce the risk of

injury, if any parts are missing,

do not attempt to assemble the

drill press, plug in the power

cord, or turn the switch on until

the missing parts are obtained

and installed correctly.

2.Rem ove the pr otec tive oi l that is app lied

to the table and column. Use any ordinary household type grease and spot

remover.

WARNING: To reduce the risk of

fire or toxic reaction, never use

gasoline, naptha or similar

highly volatile solvents to

remove protective oil.

3. Apply a coat of paste wax to the table

and column to prevent rust. Wipe all

parts tho roughl y with a clean dry cloth.

NOTE: Make certain all items are

accounted for before discarding any packing material.

10

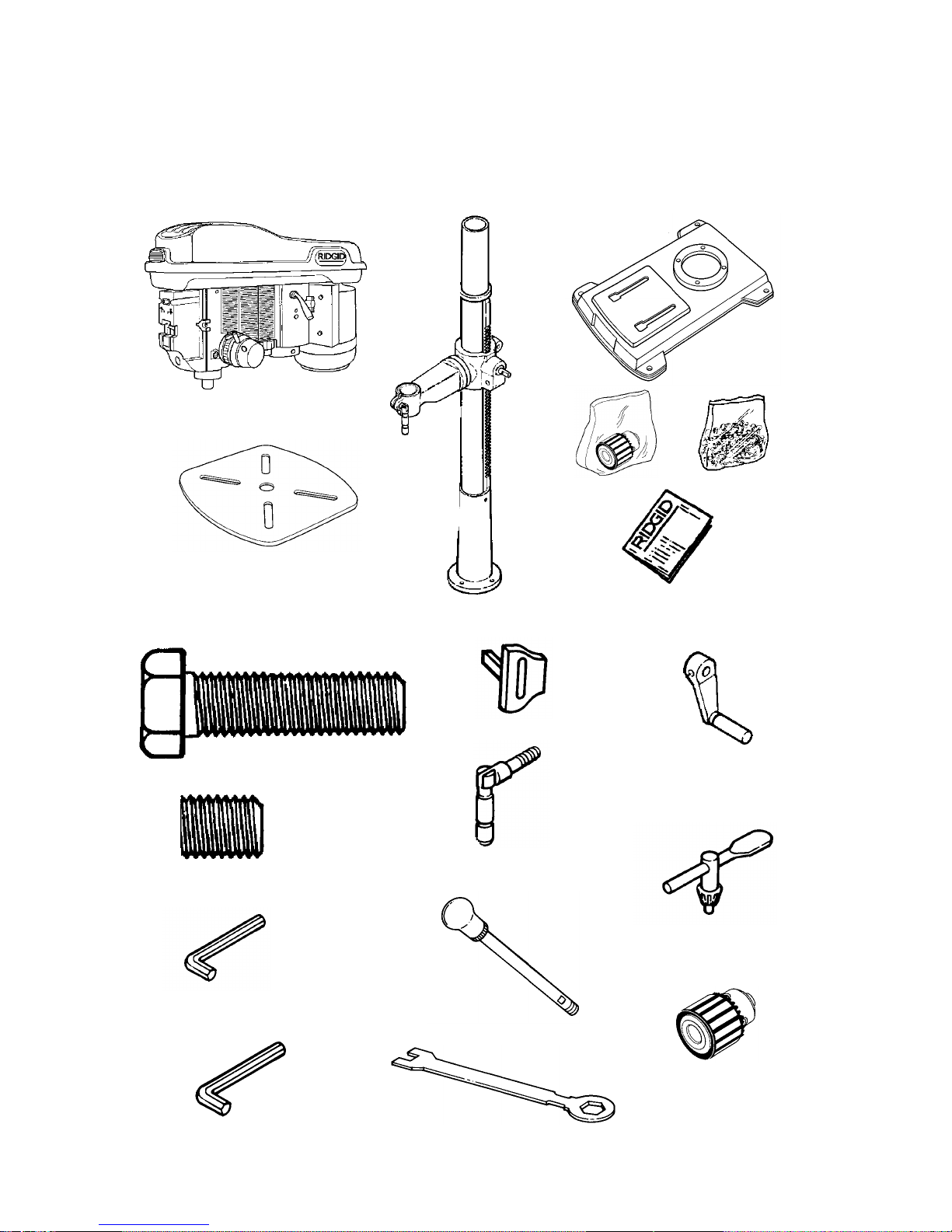

List of Lo ose P art s

Item Description Qty.

A Head A s m. ..... ..................................1

B Table.................................................1

C Column Support Ass em bly...............1

D Base .................................................1

A

C

E Bag Chuck .......................................1

F Bag of Loose Parts ..(Quantity vari es)

G Owne r s M a n ual................................ 1

D

B

Loose Part s

M10 x 1.5-40 Long

Hex Head Bolt (4)

E

Key Switch (1)

F

G

Crank

(With Set Screw) (1)

M10 x 1.5-12 Long

Hex Socket Set Screw (2)

M3 Hex “L” Wrench (1)

M5 Hex “L” Wrench (1)

Support Lock

Handle (1)

Chuck Key (1)

Feed Handle (3)

Chuck (1)

M24 Hex Box Wrench (1)

11

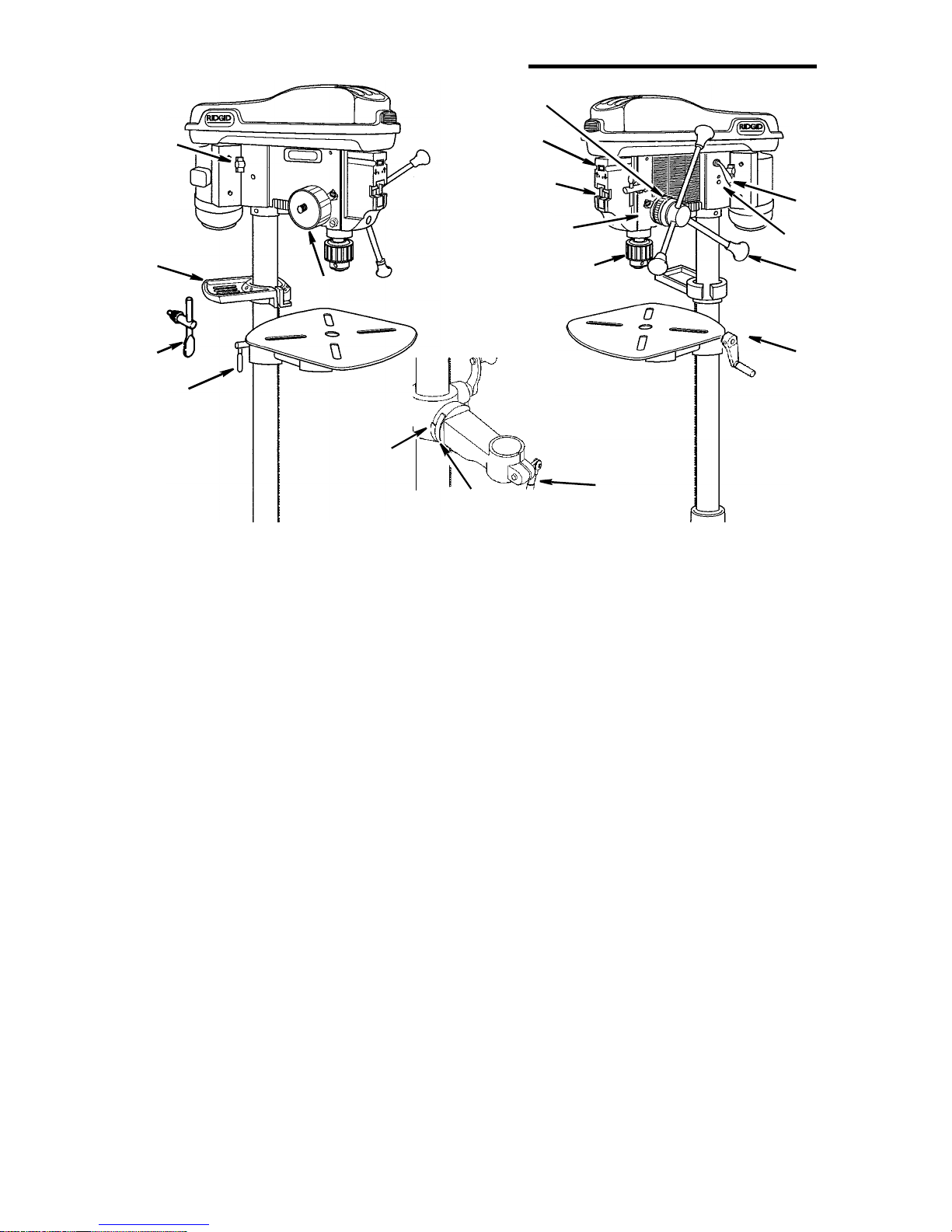

Location and Function of Controls

9

17

16

10

15

14

13

1. Belt Tension Handle...Turn handle

counterclockwise to apply tension to

belt, turn handle clockwise to release

belt tension.

2. Head Lock Set Screws...Locks the

head to the column. Always have

them locked in place while operating

the drill press.

3. Feed Handle...For moving the chuck

up or down. One or two of the handles may be removed if necessary

whenever the workpiece is of such

unusual shape that it interferes with

the handles.

4. Table Crank...Turn clockwise to ele-

vate table. Support lock must be

released before operating crank.

5. Chuck...Holds drill bit or other rec-

ommended accessory to perform

desired oper ati ons.

6. Depth Scale...Allows operator to

adjust drill press to drill to a desired

depth.

7. Drill “On-Off” Switch...Has locking

feature to prevent unauthorized and

possible hazardous use by children

and others.

8. Li ght “On-Off” Switch...Turns the

light on and off .

8

7

6

5

11

12

9. Depth Scale Lock...Locks the depth

scale at selected depth.

10. Spring Cap...Provides means to

adjust q uill s pr in g te nsio n .

11. Table Lock...Allows table to be

rotated in various positions and

locked.

12. T ab le Bevel Lock ...L ocks the table in

any position from 0°- 45°.

13. Bevel Scale...Shows degree table is

tilted for bevel operations. Scale is

mounted on side of arm.

14. Support Lock Handle...Tightening

locks tab le support to colum n. Always

have it locked in place while operating the drill press.

15. Chuck Key...Used to tighten drill in

the chuck and also to loosen the

chuck for drill removal.

16. Storage Tray...Conveniently holds

drill bits and other accessories.

17. Belt Tension Lock Handles...Tight-

ening handles locks motor bracket

support to maintain correct belt distance and tension.

Note and follow the saf ety warnings

and instructions that appear on the

panel on the right side of the head.

1

2

3

4

12

Assembly

WARNING: To reduce the risk of

injury from unexpected starting

or electrical shock, never connect plug to outlet until all

assembly steps are completed

and you rea d and unders ta nd al l

instructions.

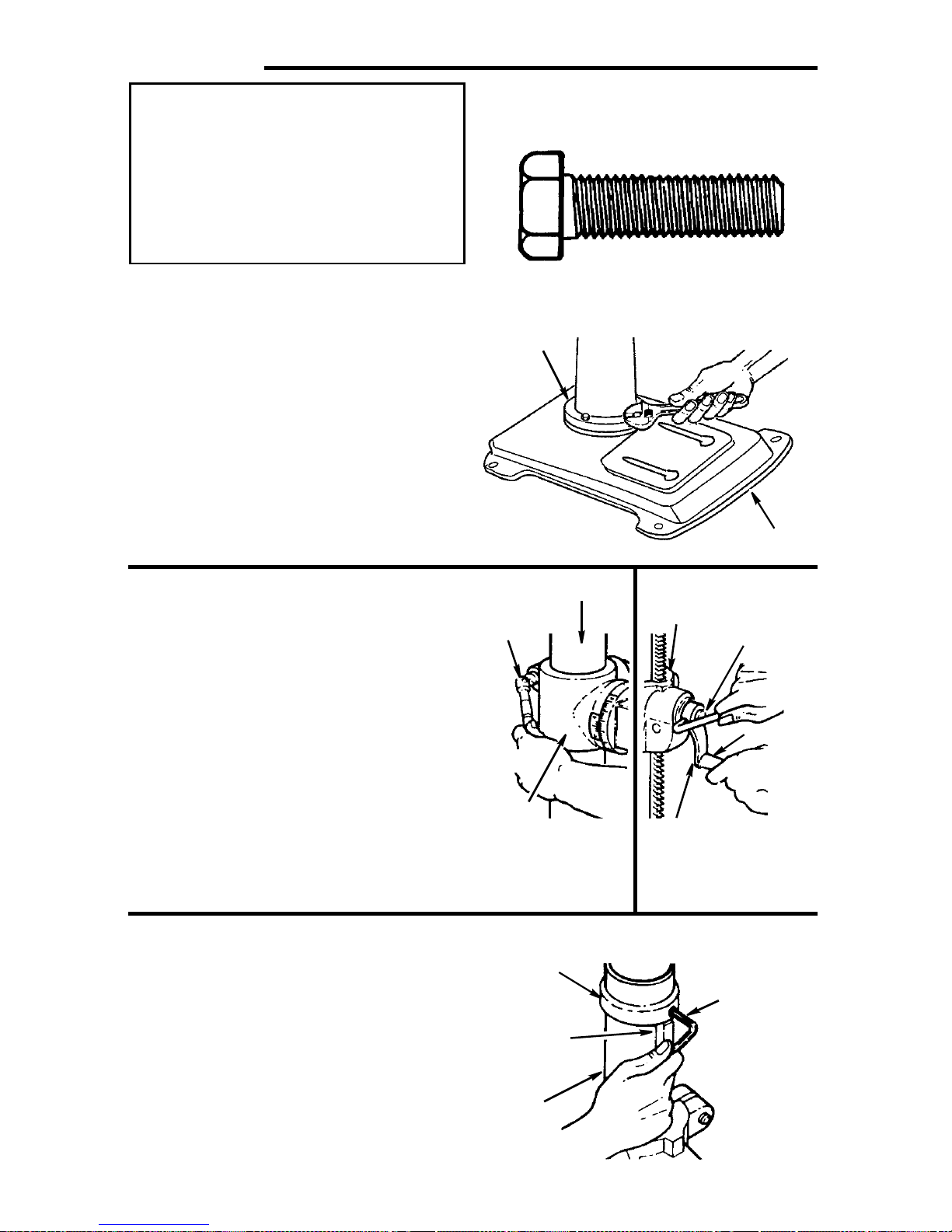

Assembly of Base/Column

10mm Dia. x 40mm

Hex Head Bolt (4)

1. Locate four ( 4) 10mm dia. x 40mm long

bolts among loose parts bag.

2. Po sition base on floor. Remove protec-

tiv e covering and discard.

3. Remove protective sleeve from column

tube and d iscard. Place co lumn ass embly on base, and align holes in column

support with holes in base.

4. Install a bolt in each hole through col-

umn sup port and base and t ighten with

adjustable wrench.

5. Locate table crank and support lock from

loose parts.

6.Install support lock from left side into

tabl e support and tighten by hand.

7. Ins tall ta ble cran k assem bly and ti ghten

set screw with a 3mm hex “L” wrench.

Do not o ver tighten. S et screw sh ould be

tighten ed against the flat section o f the

shaft.

Column

Support

Support

Lock

Column

Table

Support

Base

Elevation

Worm

Shaft

Handle

NOTE: To minimize crank backlash,

tighten support lock, rotate elevation

worm shaft clockwise, then assemble

crank tight against table support and

tighten set screw.

8. Check column collar for proper adjust-

ment. Collar should not be angled on the

column and it should be positioned so

rack will slide freely in collar when table

is rotated 360° around column tube. If

readjusted, only tighten set screw

enough to keep collar in place.

NOTE: To reduce the risk of column or

collar damage, do not overtighten set

screw.

Table

Support

Column

Collar

Column

13

Table

Crank

Do Not

Overtighten

Set Screw

Rack

Assembly (continued)

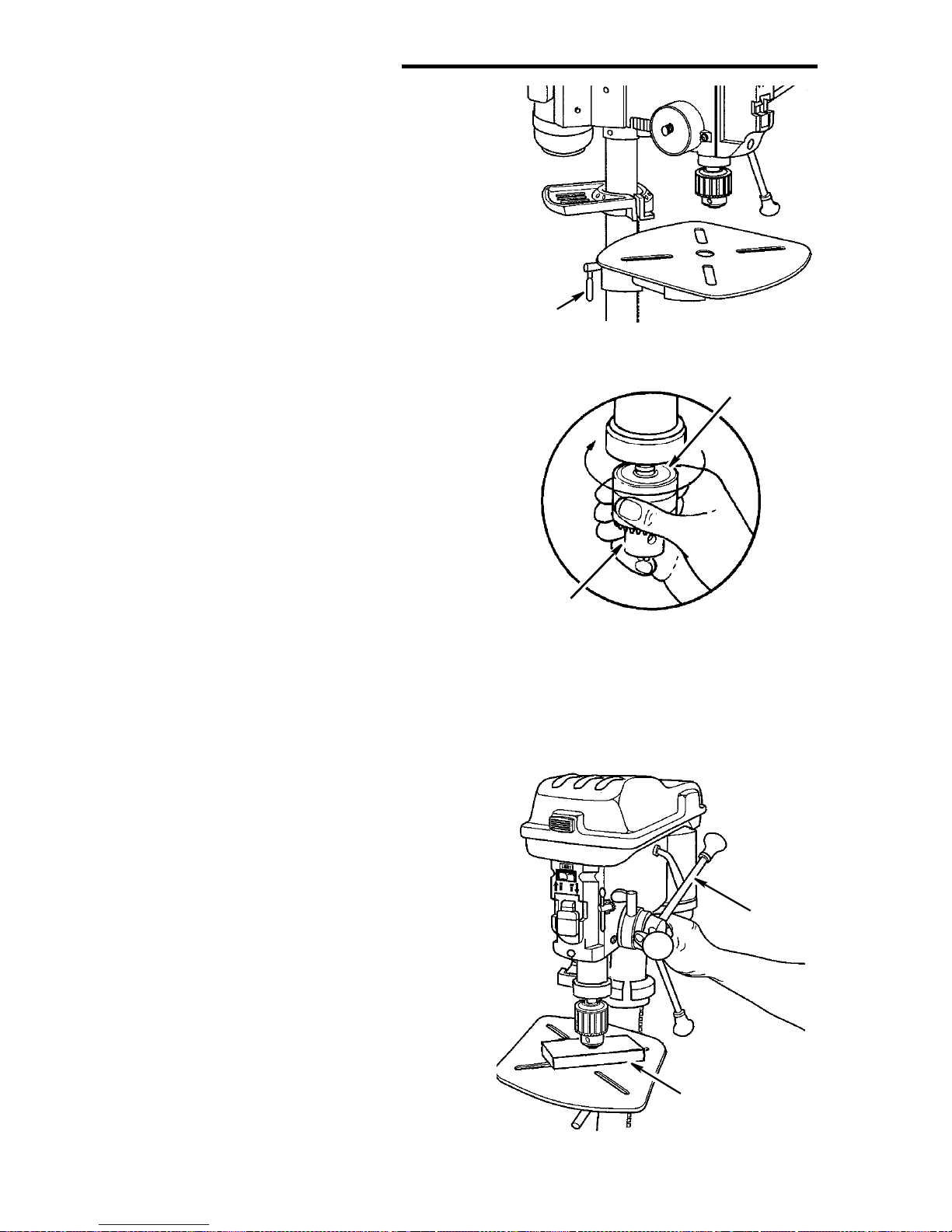

Installing The Table

1. Loosen support lock and raise table

support by turning table crank clockwise until support is at a working

height level. Tighten support lock.

2. Remove protective covering from table

and discard. Loosen table lock, place

table in table support and tighten table

lock (located under table) by hand.

NOTE: If table won’t fit into table support

easily, pry open table support with a flat

blade screwdr iver.

Support

Lock

Column

Table

Support

Support

Lock

Table

Support

Table

Crank

Rack

Table

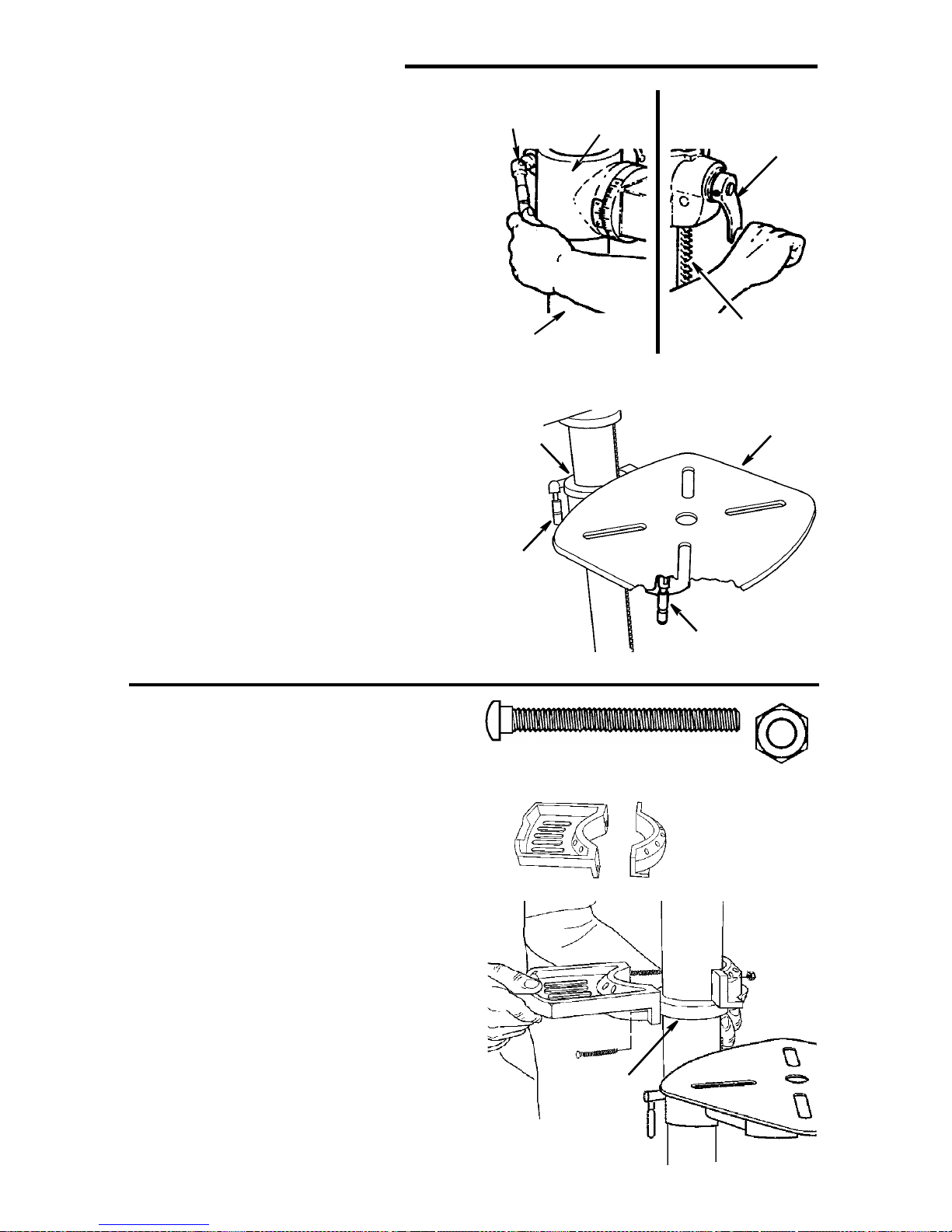

Installing the Storage Tray

1. Locate the two piece storage tray, (2)

two 5mm dia. x 60 mm long screw, and

(2) two 5 mm hex nuts.

2. Attach to the column as shown. Make

sure the storage tray is located above

the column collar. Be careful not to overtighten the nuts.

Pan Head Screw

5mm x 60mm

(Not Ac tu a l S iz e )

Storage Tray

Table

Lock

Hex Nut

5 mm

Column

Collar

14

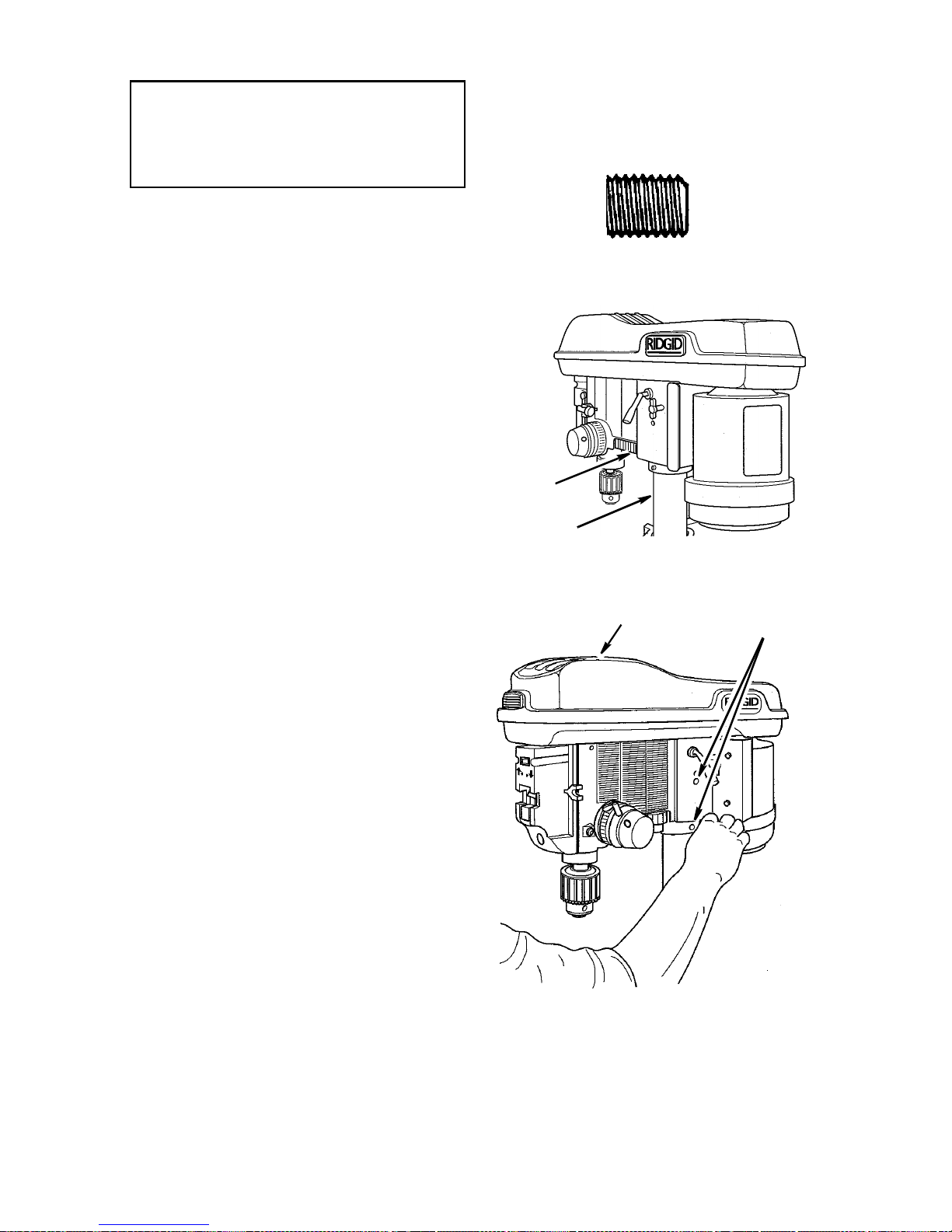

Installing the Head

CAUTION: The head assembly

weighs about 80 pounds. To

reduce the risk of back injury get

help to lift the head.

1. Locate (2) two 10mm dia. x 12mm long

set screws in loose parts bag.

2.Remove protective bag from head

assembly and discard. Carefully lift head

above col um n tube an d slide it onto co lumn making sure head slides down over

column as far as possible. Align head

with table and base.

10mm Dia. x 12mm

Set Screw

Head

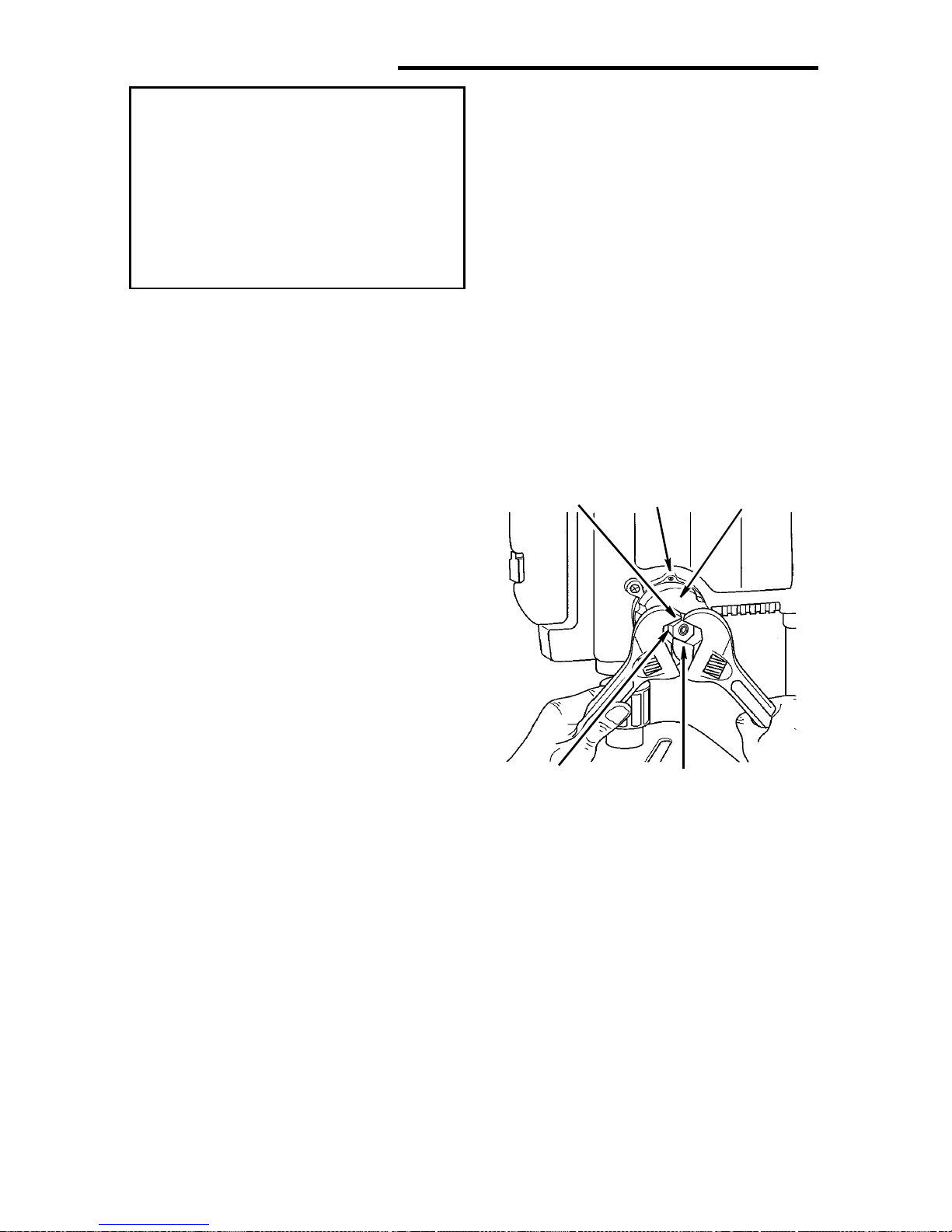

3.Install a set screw in each hole (as indi-

cated) on t he r ig ht s i de of th e head, and

using a 5mm hex “L” wrench, tighten the

two head lock set screws.

Column

Head

Head Lock

Set Screws

15

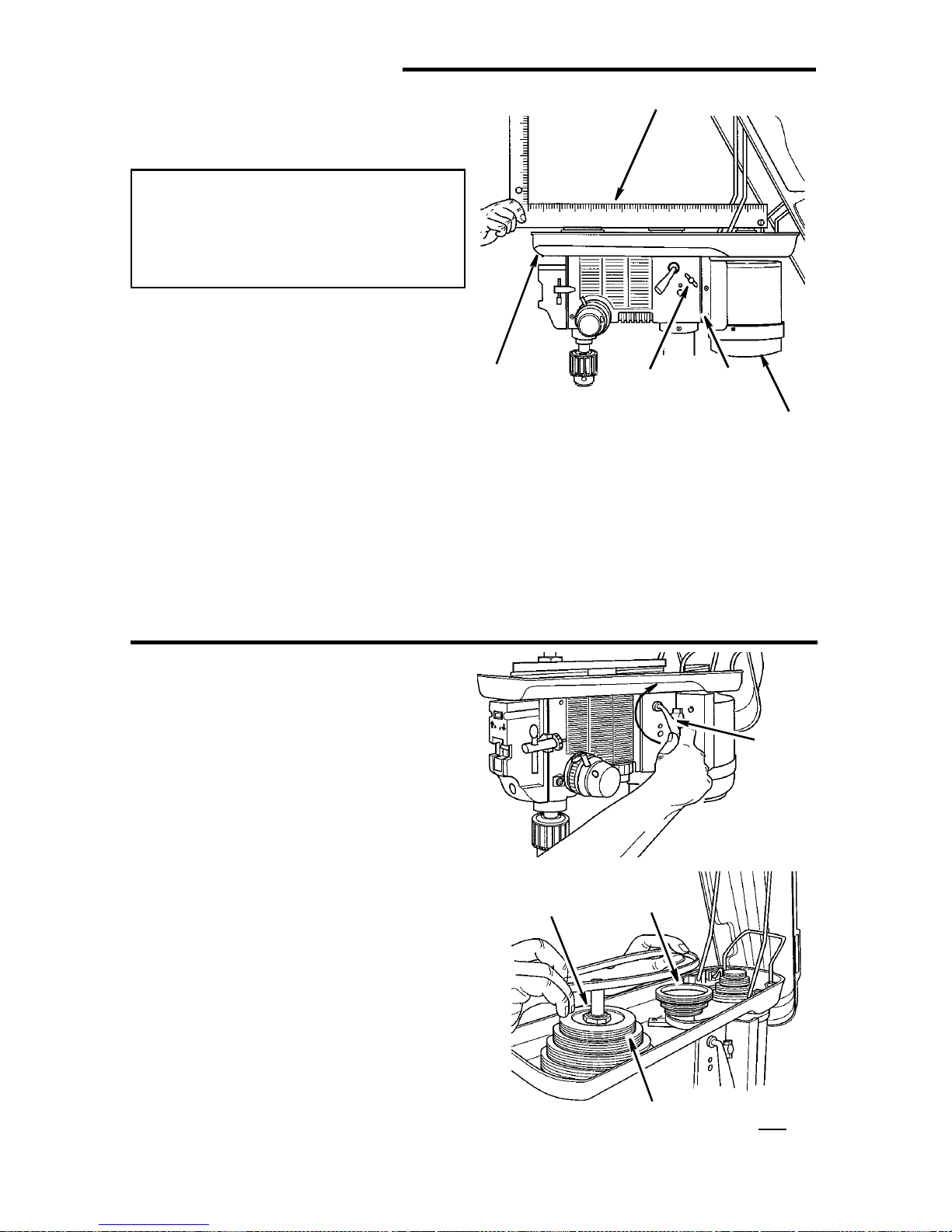

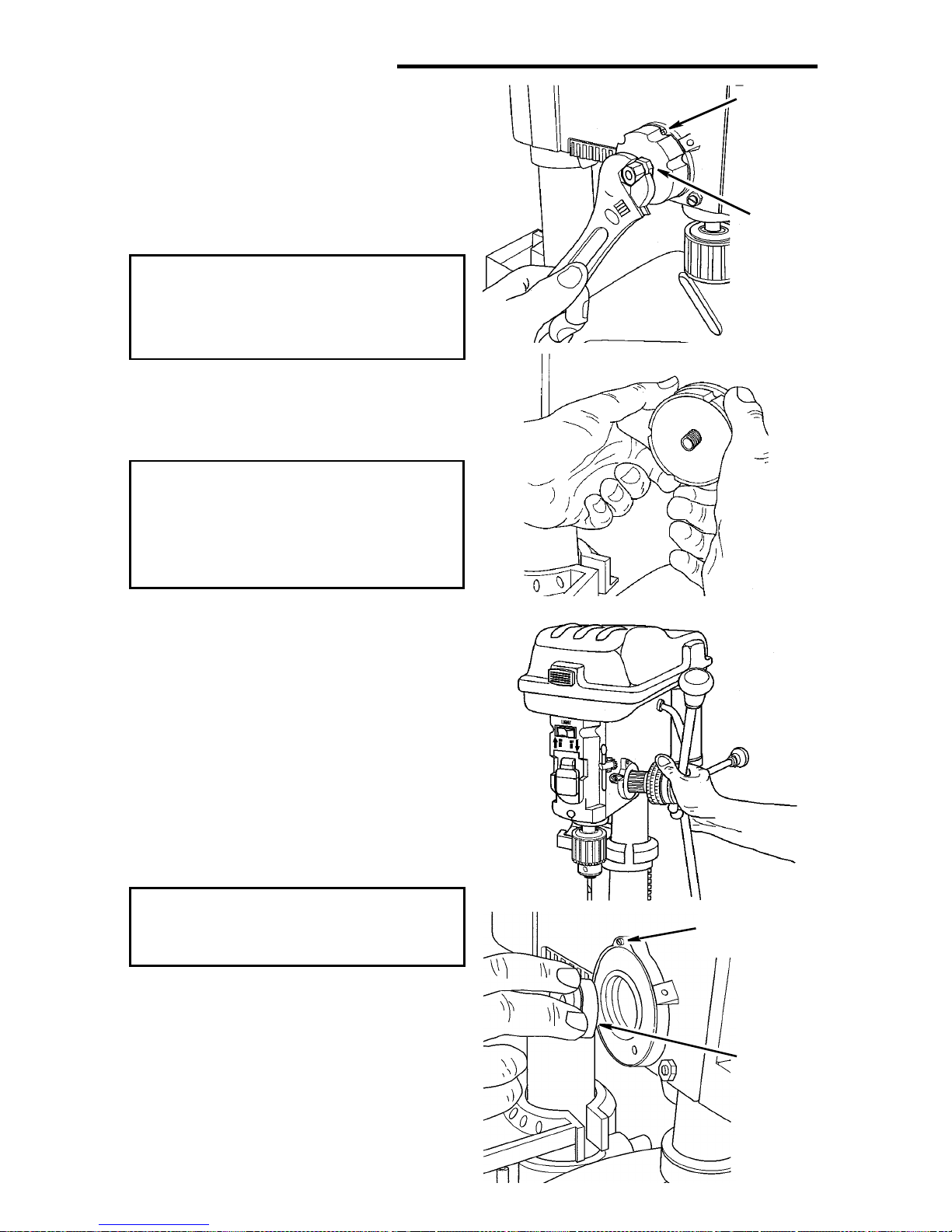

Assembly (continued)

Pulley Alignment and Speed

Adjustment

Checking Pulley(s) Alignment

WARNING: To reduce the risk of

injury due to accidental starting

always turn drill press off and

remove switch key before making belt adjustments.

Pulley alignment is set at the factory and

should not require further adjustment. If

the pulleys or motor are removed for service, follow the pulley alignment instructions below.

1. Place the idler pulley from loose parts

bag into the head as shown. Place

belts from loose parts bag on pulleys

following speed adjustment instructions below.

2.Place a straightedge such as a piece of

wood, metal, or framing square across

the top of pulle ys.

3. Th e top of all three pul leys sho uld touch

the straightedge.

Straightedge

Lower

Belt

Guard

4.If not:

• Loosen the motor mount nuts.

• Move the motor until the pulleys are

in line.

• Retighten the motor mount nuts.

NOTE: To avoid rattles or other noise,

motor frame must not touch lower belt

guard.

Belt

Tension

Lock

Handle

Motor

Mount

Nuts

Motor

Speed Adjustment

1. Release belt tension lock handles

located on each side of drill press head

by turning them counterclockwise.

2. Lo osen bel t tension b y turning belt ten-

sion handle clockwise.

3. Use speed chart inside belt guard to

choose speed for drilling operation.

Install belts in correct position for desired

speed. The longer of the two belts is

always position ed between the spin dle pulley and idler pulley.

IMPORTANT: Visu ally check t o m a ke sure

the fo ur r ibs on th e be l t are place d i nto t he

four pulley grooves.

Spindle

Pulley

Belt

Tension

Handle

Idler

Pulley

Properly aligned bel t shoul d not

touch the stepped surface on

the pulley

16

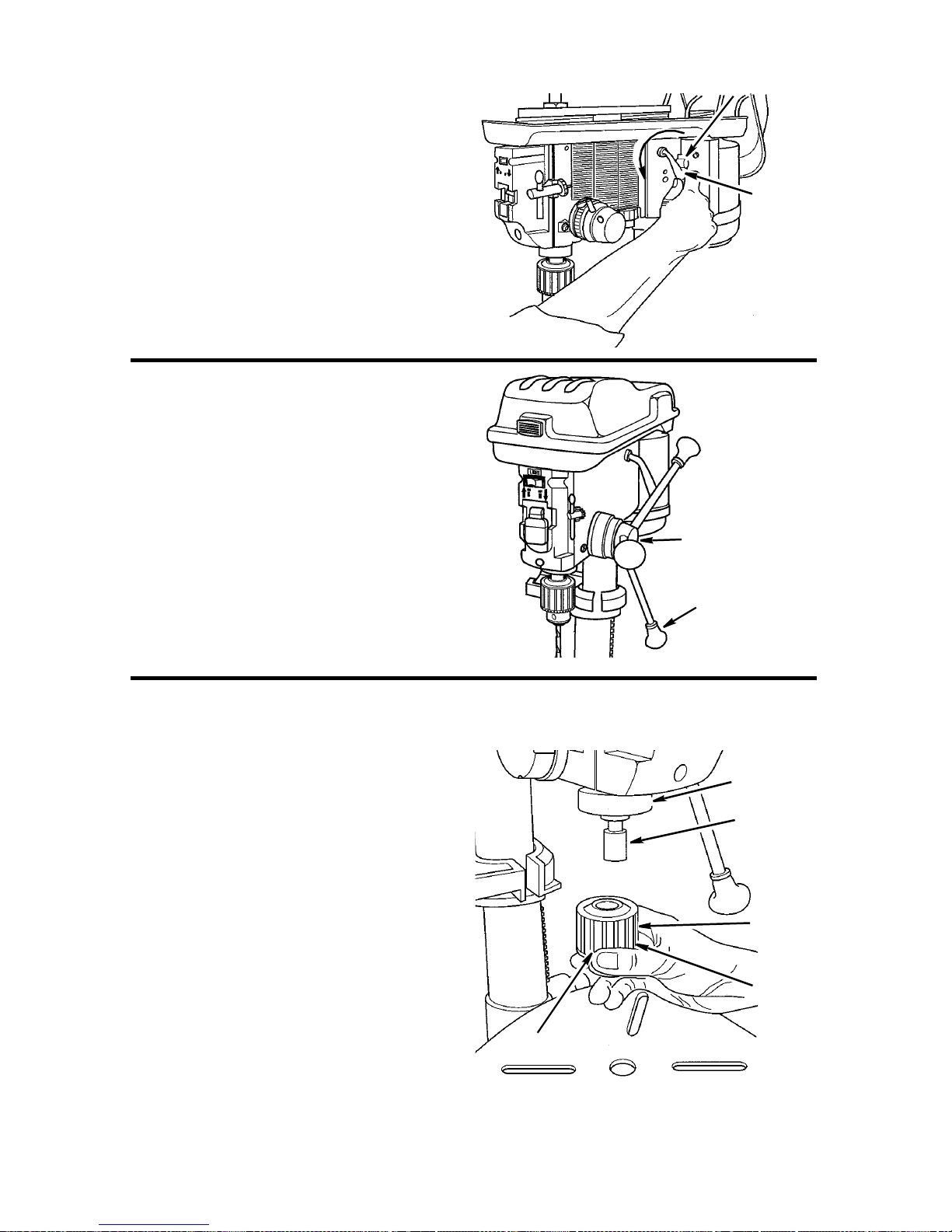

Tensioning Belt

1. Apply tension to belt by turning belt

tension handle counterclockwise until

belt deflects approximately 1/2 inch by

thumb pressure at its center.

2.T ighte n belt tension loc k handles.

NOTE: Over tensioning belt may cause

motor not to start or damage bearings.

3. If belt slips while drilling, readjust belt

tension. Also make sure the ribs in the

belt are aligned with groo ves in th e pulley.

Installing Feed Handles

1. Locate three (3) feed handles among

loose parts.

2.Screw the feed handles into the

threaded holes in the hub and tighten.

3. Tighten feed handles using the open

end of the M24 hex box wrench included

with drill press.

Belt Tension

Lock Handle

Belt

Tension

Handle

Tighten Using

M24 Wrench

Hub

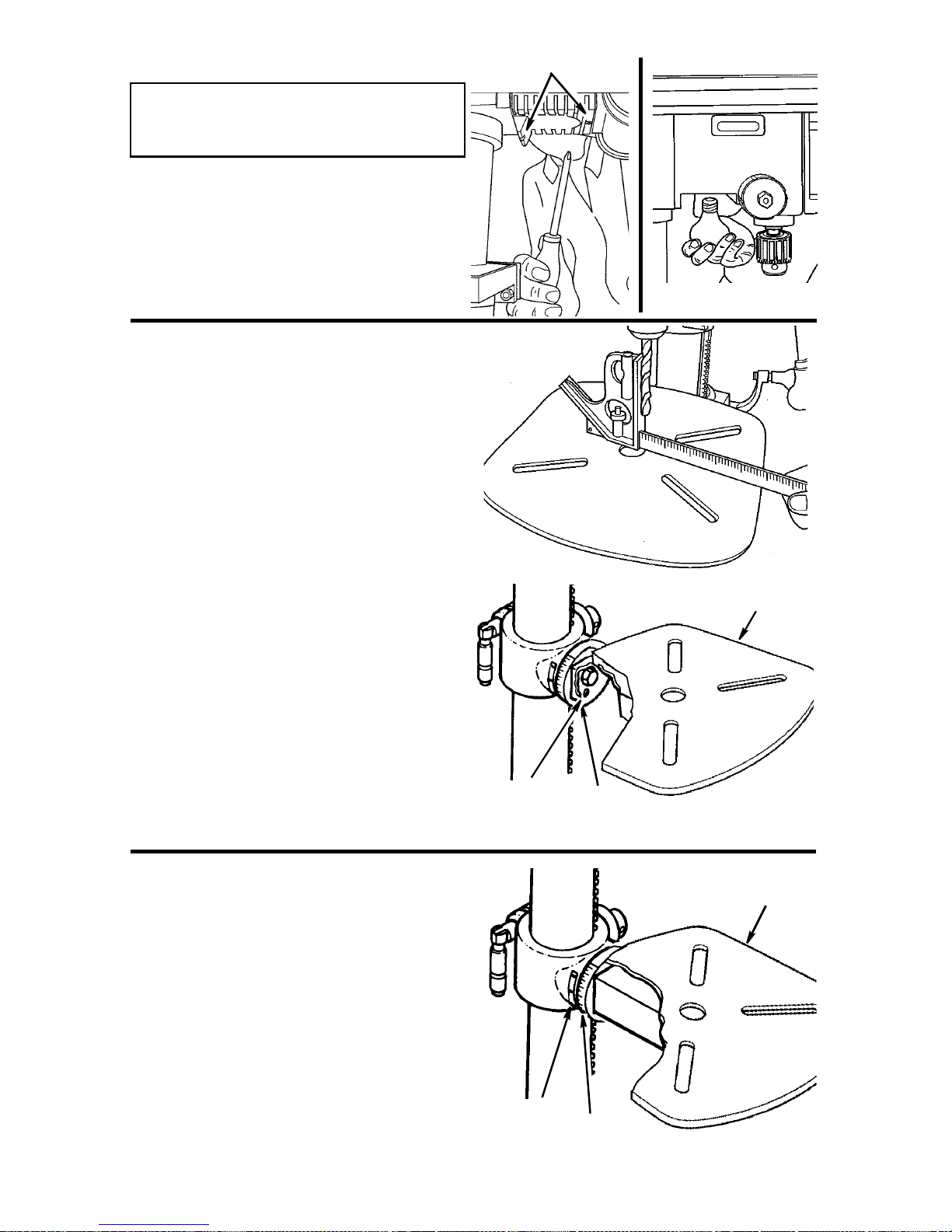

Installing the Drill Chuck

1. Clean the tapered surfaces on the

chuck and spindle with a clean cloth.

Make sure there are no foreign particles sticking to these surfaces. The

slightest pi ece of dirt on these sur faces

will prevent the arbor from seating

properly. This will cause the drill to

“wobble”.

2.Slide chuck into spindle of drill press.

3. Push up on chuck assembly as you

rotate it.

Feed

Handle

Quill

Spindle

Tapered

Surface

Arbor

Tapered

Surface

Chuck

Sleeve

Chuck Body

17

Assembly (continued)

4. Unlock support lock and raise table so

its about two (2) inches below tip of

chuck.

5. Turn chuck sleeve clockwise and open

jaws in chuck completely.

Support

Lock

Chuck

Sleeve

6.Place a piece of wood on table. Turn

feed handles counterclockwise and force

chuck against table until chuck is secure.

Chuck

Feed

Handle

Wood

18

Installing Light Bulb

WARNING: To reduce the risk of

electrical shock, unplug the tool

before install ing l ight bulb.

1. Remove the amber colored lens cover

by r e m o ving th e two Phi llips sc r ews.

2. Install a light bulb (not larger than 60

watt) into the socket inside the head.

3. Replace the lens cover.

Adjusting the Table Sq uare To

Head

NOTE: The combination square must be

“true”. See “Unpacking and Checking

Contents” section for method.

1. Insert precision round steel rod or

straight drill bit approximately 3” long

into chuck and tighten.

Remove Screws

2. W ith table raised to working h eight and

locked on column, place combination

square flat on table beside rod or bit.

3.If an ad jus tm ent i s nec e ss ary, loo se n th e

set screw under bevel lock with 3mm “L”

wrenc h, t h en l o osen the ta bl e b evel lock

bolt with the 24mm hex box wrench

(included). (This adjustment is located

under the table).

4.Align the table squ are to the rotor bit b y

rotati ng table until the squar e and rod o r

bit are in line.

5.Retighten table bevel lock.

6.Retighte n set screw.

Bevel Scale

NOTE: The bevel scale has been

included to provide a quick method for

beveling the table to approximate angles.

If precise accuracy is necessary, a

square, or other precision measuring tool

should be used to position the table.

1. To use the bevel scale do the f ollowing.

a.Loosen set screw and table bevel

lock (see step 3 above).

b. M ove table so desired angle on bevel

scale is straight across from zero line

on pointer.

c. Retighten table bevel lock and set screw.

Set

Screw

Pointer

Table

Table Bevel

Lock

Table

Scale

19

Assembly (continued)

Converting From Right Hand

Operation to Left Hand Operation

The drill press is shipped from the factory

with feed handles set-up for right hand

operation. However, if desired, the drill

press feed handles can be converted to

left hand operation.

WARNING: For your own safety

turn switch “OF F” and remove

plug from po we r source outl et

before making any adjustments.

1.To help keep the drill chuck from falling

on to the floor, place a piece of scrap

wood on top of the t able and r aise the

tabl e until it engages the ch uck.

CAUTION: Releasing the spring

assembly without proper support

of the chuck will allow the quill

assembly to drop on top of the

drill press table.

4mm Cap

Screw

M12

Nuts

2.Firmly hold spring housing against head

so it remains engaged with the 4mm

cap screw. Remove both M12 nuts and

M12 washer from the feed handle

assembly shaft.

3.Use both hands to firmly grasp the

spring assembly. Pull the spring

assembly slightly away from the drill

press, disengaging the spring housing

from the cap screw. While firmly holding the housing, allow the spring

assembly to unwind clockwise until

the spring tensi on is relieved.

CAUTION: To prevent injury, be

careful not to allow the spring

assem bl y t o rapi dl y un wi nd.

4.Remove the spring as sem bly.

5.Slide the feed handle assembly out

from the right si de of t he head.

6.Remove the bushing located on the

left of the head assembly as shown. It

may be necessary to tap this bushing

out from the right side. Reinstall this

bushing on the right side of the drill

press.

Remove 4mm

Cap Screws

Remove

Bushing

20

7.Remove the 4mm socket head cap

screw from the left side of the drill

press and install in the same position

on the right side of the drill press.

Tighten screw .

8.Remove the 6mm stop pin screw from

the right side of the drill press and

inst all in th e left side of the dri ll press

as shown. Ti ghten stop pin screw.

9. Install the feed handle assembly and

depth stop ring on the left side of the

drill p ress. With the chuck at its highest possible position, turn the depth

scale clockwise until it stops and

tighten the depth scale lock. This will

prevent the quill from dropping while

installing the spring.

10.Install the spr ing assembl y on the righ t

side of the drill press, making sure the

two housing screw heads face outwards. The center tab of the spring

must go in the slot on the feed handle

assembly.

If necessary, use a screwdriver to align

and keep spring centered during installation.

11. Replace M12 washer and screw the

outer and inner nuts back on the feed

handle assembly. Hold the spring

assembly in place and loosely assemble both nuts. See following page for

quill retur n spring adjustment.

12. Remove the depth scale and reposition so numbers are legi ble as shown.

13.Remove the depth scale indicator

from the right side of the drill press

and reinstall on the left side of the drill

press.

14.Remove the scrap wood from the

table top.

Install 6mm

Stop Screw

Right side housing screws

fa ce ou twa rd as show n

Install Feed Handle

Assembly

Remove Depth Scale

and Reposition

Install Depth

Scale

Indicator

21

Assembly (continued)

WARNING: For your own safety

turn switch “OF F” and remove

plug from po we r source outl et

before making any adjustments.

To reduce the risk of injury from

thrown parts due to spring

release, follow instructions carefully and wear eye goggles.

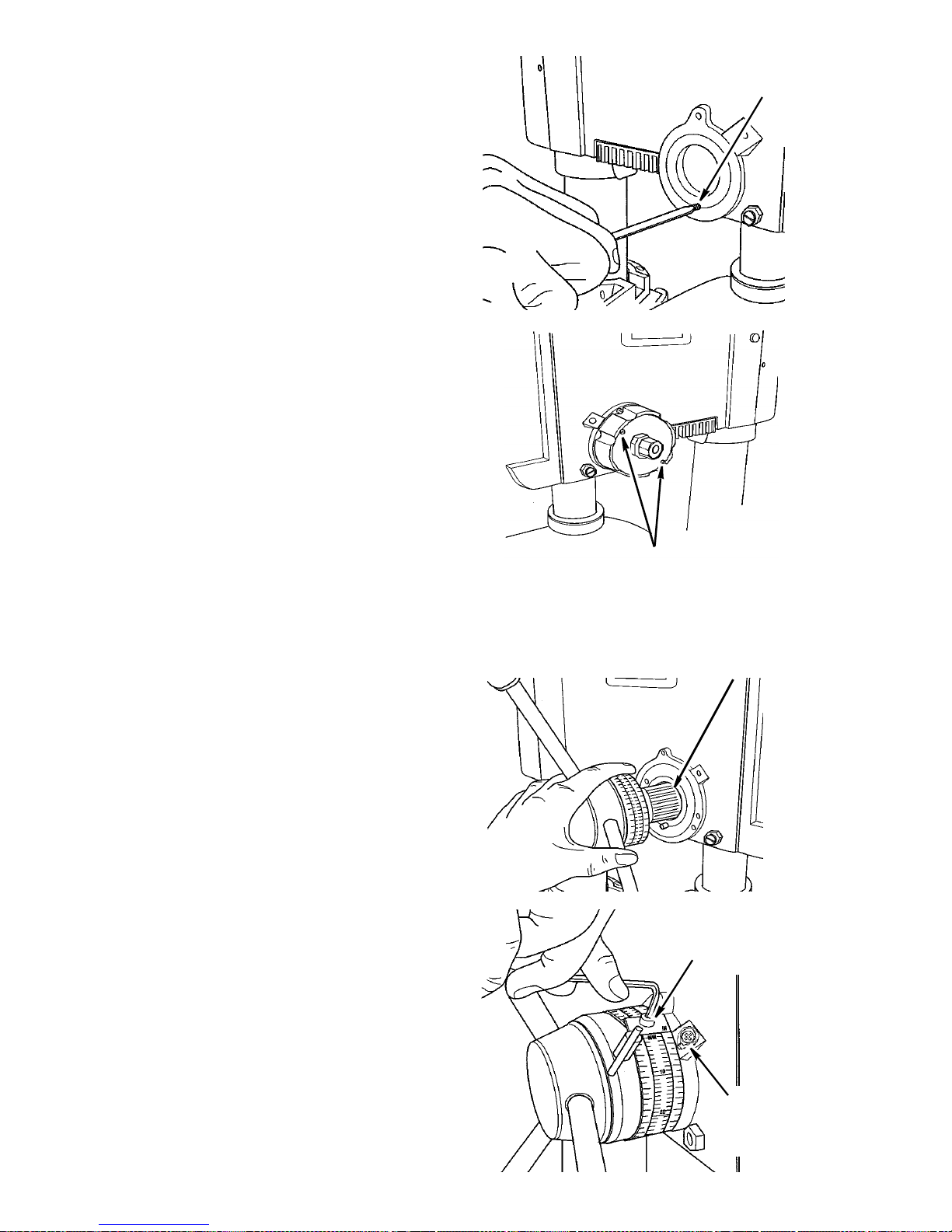

Quill Return Spri ng

NOTE: The return spring tension is set at

the factory and should not require further

adjustment.

If you switch ed your drill press from right

hand operation to left hand ope ration, follow the procedure below to adjust spring

tension.

1. With the chuck at its highest possible

position, turn the depth scale clockwise

until it stops and tighten the depth

scale lock. This will prevent the quill

from dropping while tensioning the

spring.

Notch

4 mm Cap

Screw

Spring

Cap

NOTE: For right hand operation (feed

handle on right side) turn the depth scale

counterclockwise until it stops and

tighten the depth scale lock.

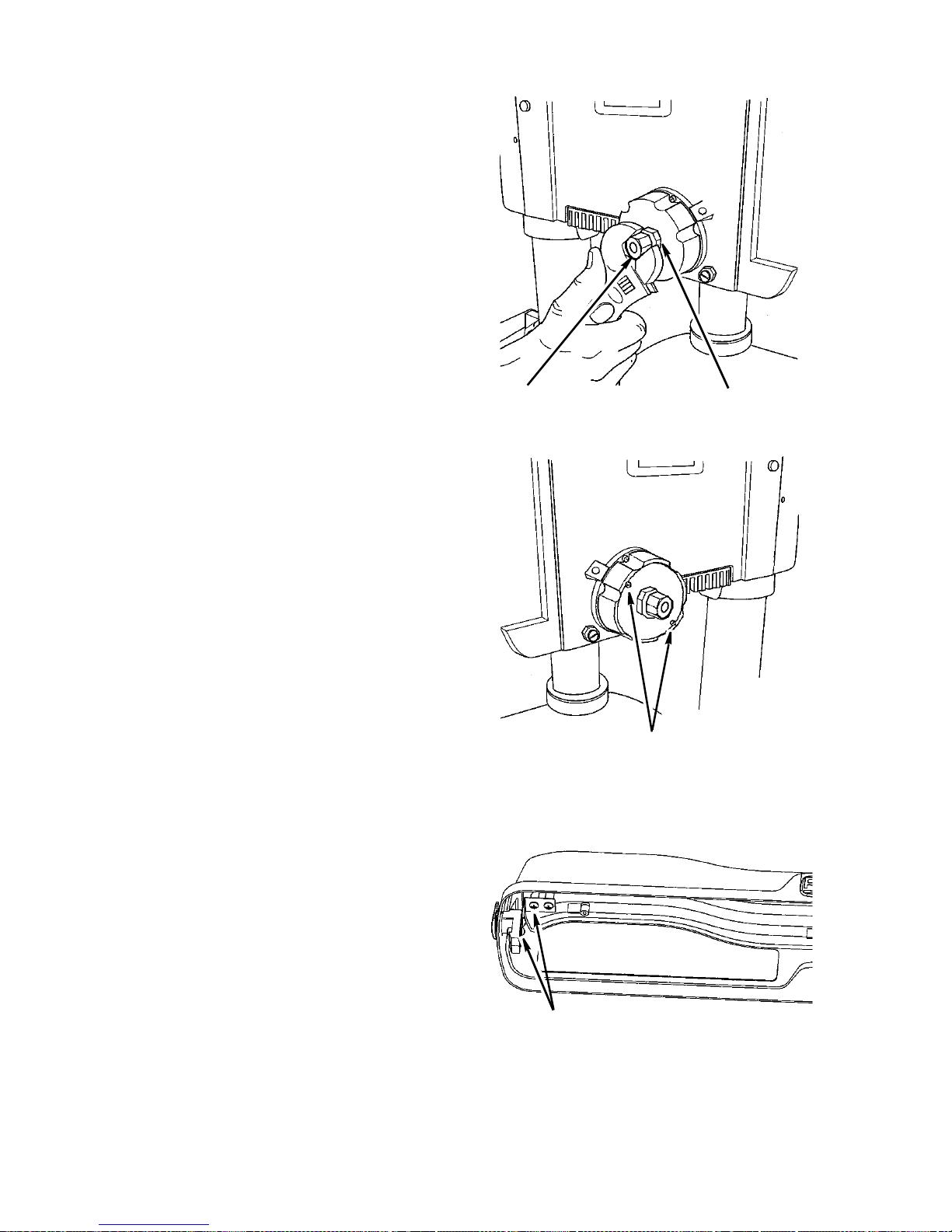

2.Check to make sure spring housing is

mounted correctly. When spring housing is placed on the right side (feed

handles mounted on left side), the

housing screws face out as shown.

When spring housing is placed on the

left side (feed handles mounted on

right side), the housing screws face

toward the head as shown .

3.Lower table for additional clearance.

4.Firmly hold the spring assembly

against the head keeping it engaged

with the 4mm cap screw while loosening and removing the outer nut only.

5.Loosen inner nut (approximately 1/4

inch) and disengage spring housing

from the 4mm cap screw. Using both

hands turn spring clockwise to the

next notch and engage with the 4mm

cap screw.

Nut (Outer)Nut (I nne r)

22

NOTE: For right hand operation (feed

handle on right side) turn spring counterclockwise to the next notch and engage

with the 4mm cap screw.

6.Finger tighten inner nut against spring

housing. Do not overtighten as this will

restric t qu ill move ment.

7.Loosen depth scale lock and check

quill return by rotating feed handles,

lowering quil l.

8.Proper tension is achieved when quill

returns gently to full up position when

released from 3/4” depth.

9.If there is not enough tension on

spring, repeat steps 5-8 moving only

one notch each time and checking

tension after each repetition .

10.After adjusting spring, replace outer

nut and tighten to inner nut. But do not

overtighten against inner nut.

11.Check quill movement to make sure it

is smooth and unrestricted. If movement is too tight, loosen outer nut and

slightly loosen inner nut until unrestricted. Retighten outer nut.

Left side housing screws

face towards head as shown

Nut (Out e r )

Nut (Inner)

Adjusting Belt Lat c h G uard

The button latch is adjusted at the factory

to be self latching when the pulley guard

lid is closed. If adjustment is needed,

loosen the two screws securing the latch

to the lid and move latch back until the lid

closes without depressing the button. The

button can also be adjusted up and down

to assure lid closes tight by loosening the

two screws in back of the latch button,

and moving the button up or down as

needed.

Right side housing screws

face outward as shown

Latch Adjusting Screws

23

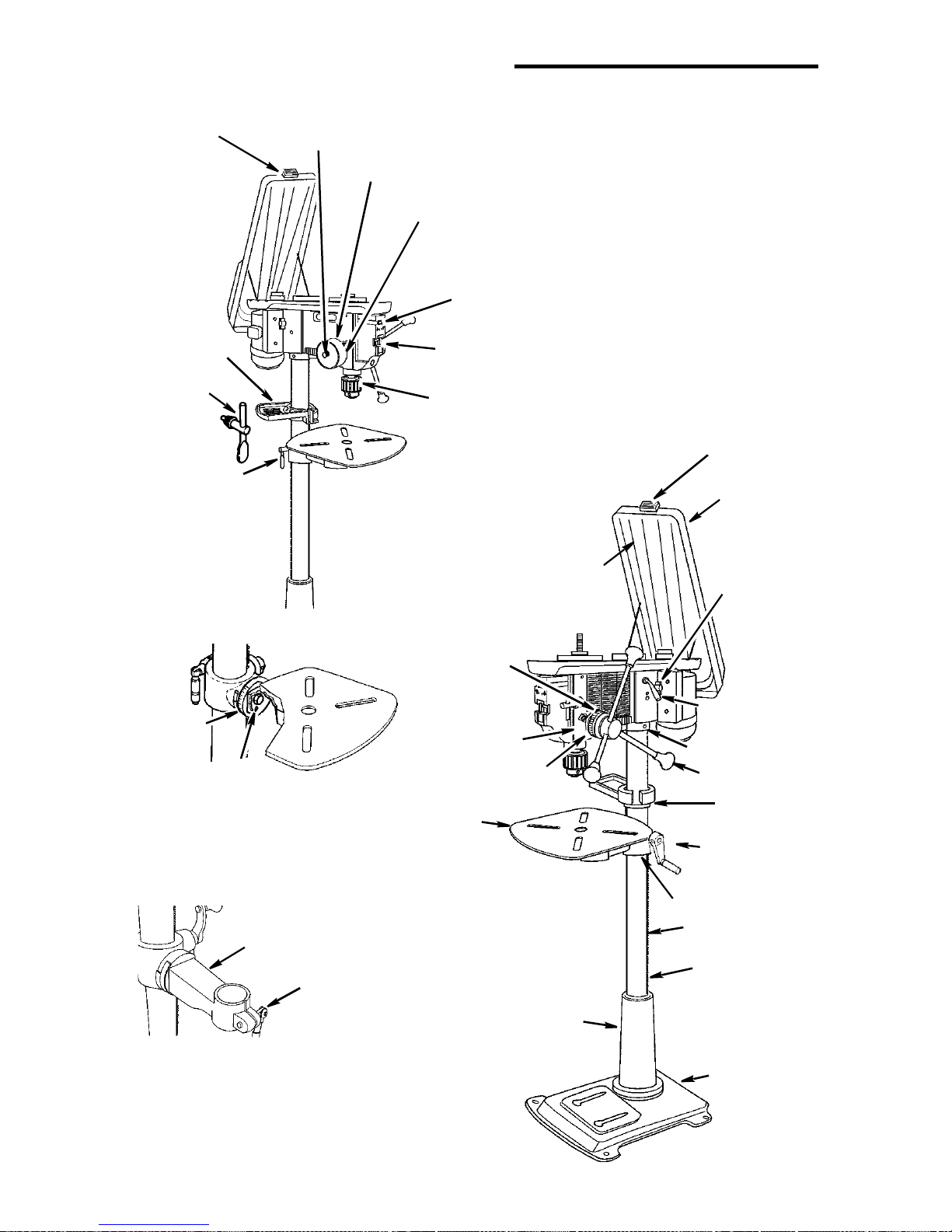

Getting To Know Your Drill Press

19 Belt Guard

Latch

27 Storage

Tray

26 Chuck

Key

25 Support

Lock

Feed Spring

Adjustment

Feed Spring

18 Spring

Cap

Light “On-O ff”

28 Drill “On-Off”

20 Chuc k

1 Drill Speed Table

(Inside B elt Gua r d)

Switch

Switch

19 Belt Guard Latch

2 Belt Guard

3 Belt Tension

Lock Handle

24 Bevel

Scale

22 Table Bevel

(Under Table)

Lock

21 Arm

23 Table

Lock

17

Depth Scale

Lock

16 Depth Scale

Indicator

14 Table

15 Depth

Scale

12 Column

Support

4 Belt Tension

Handle

5 Head Lock

6 Feed Handle

7 Column

Collar

9 Table Crank

8 Table Support

10 Rack

13 Column

11 Base

24

Loading...

Loading...