RIDGID DP1500 Owner's Manual

2:1(5·60$18$/

$VVHPEO\

2SHUDWLRQ

5HSDLU3DUWV

)RU<RXU6DIHW\

5HDGDOOLQVWUXFWLRQVFDUHIXOO\

48(67,21625&200(176"

&$//5,'*,'

Part No. SP6158 Printed in U.S.A.

'3

,1&+)/22502'(/

'5,//35(66

2

Table of Contents

Section Page

Table of Contents .......................................................... 2

Safety Instructions For Drill Press .................................2

Safety Signal Words ...................................................2

Before Using The Drill Press .......................................2

When Installing Or Moving The Drill Press ................. 3

Before Each Use .........................................................3

Use Only Accessories Designed For This Drill Press

To Reduce The Risk of Serious Injury From Thrown

Broken Parts Or Work Pieces. ...................................3

Plan Ahead To Protect Your Eyes, Hands, Face

and Ears .................................................................... 4

Glossary of Terms .........................................................5

Motor Specifications and Electrical Requirements ........5

Power Supply and Motor Specifications ..................... 5

General Electrical Connections ................................... 5

110-120 Volt, 60 Hz. Tool Information ........................5

Motor Safety Protection ..............................................6

Wire Sizes ...................................................................6

Unpacking and Checking Contents ............................... 7

Tools Needed .................. ...... ....... ...... ....... ...... ....... ..... 7

Unpacking ....................... ............................................7

List of Loose Parts ...................................................... 7

Loose Parts in Box and Bag ....................................... 8

Location and Function of Controls .................................9

Assembly .............. .......................................................10

Assembly of Base/Column ........................................10

Installing The Table ............... ....... ...... ....... ...... ....... ... 11

Installing the Head .................................................... 11

Pulley Alignment and Speed Adsjustment ................12

Tensioning Belt .........................................................12

Installing Feed Handles ............... ...... ....... ...... ..........13

Section Page

Installing the Chuck .................................................. 13

Installing Light Bulb ................................................... 15

Adjusting the Table Square To Head ........................ 15

Bevel Scale ................................................................. 15

Getting To Know Your Drill Press ................................ 16

Drilling to a Specific Depth ........................................ 19

Another Way - Depth Scale ...................................... 19

Locking Chuck at Desired Depth .............................. 19

Removing Chuck and Arbor ...................................... 20

Re-installing the chuck and arbor ............................. 21

Safety Instructions for Basic Drill Press Operation ...... 22

Plan Ahead To Protect Your Eyes, Hands, Face

and Ears ................................................................. 22

Use Only Accessories Des ign ed Fo r This Dri ll Pres s

To Reduce the Risk of Serious Injury From Thrown

Broken Parts Or Work Pieces. ................................. 22

Basic Drill Press Operation ......................................... 23

Installing Drills ........................................................... 23

Positioning Table and Workpiece ............................. 23

Tilting Table .............................................................. 24

Hole Location ............................................................ 24

Feeding .................... .............................................. ...24

Adjustments ................ ............. ............. ....... ............. ... 24

Quill Return Spring ............... ....... ...... ....... ...... ....... ... 2 4

Maintenance ......... ....................................... ................ 25

Maintenance ............................................................. 25

Lubrication ................................................................ 25

Wiring Diagram ............................................................ 25

Troubleshooting ................. ............. ............. ...... .......... 26

Repair Parts ................................................................ 27

Safety Instructions For Drill Press

Safety is a combinati on of comm on sense, staying alert and k nowin g how your dr ill pre ss works. Read this m anual to

understand this drill press.

Safety Signal Words

DANGER: means if the safety information is not followed

someone will be seriously injured or killed.

WARNING: means if the safety information is not followed

someone could be seriously injured or killed.

CAUTION: means if the safety informat ion is not followed

someone may be injured.

Before Using The Drill Press

WARNING: To reduce the risk of mistakes that

could cause serious, permanent injury, do not plug

the drill press in until the following steps have

been satisfactorily completed.

• Completely assemble and align drill press (See

“Assembly” section).

• Learn the use and function of the ON-OFF switch.

(See “Getting to Know Your Drill Press” section).

• Review and understand all safety instructions and

operating procedures in this manual.

• Review the maintenance methods for this drill press

(See “Maintenance” section).

• Find and read all the war ning labels found on the dr ill

press (shown at right).

3

When Installing Or Moving The Drill Press

Reduce the Risk of Dangerous Environment.

• Use the drill press in a dry, indoor place protected from

rain.

• Keep work area well lighted.

• Use recommended acce ssories. The use of improper

accessories may cause risk of injury to persons.

To reduce the risk of injury from unexpected drill

press movement.

If there is any tendency of the drill press to tilt or

move during any use, bolt it to the floor. If the workpiece is too large to easily support with one hand,

provide an auxiliary support.

• To reduce the r is k of inj ury from electr ic al shock, make

sure your fingers do not touch th e plug’s metal prongs

when plugging in or unplugging the drill press.

• Never Stand On Tool. Serious injury could occur if the

tool tips or you acciden tally hit the cutting to ol. Do not

store anything above or near the tool where anyone

might stand on the tool to reach them.

Before Each Use

Inspect your drill press.

• To reduce the risk of injury from accidental starting,

turn the switch off, unplug the dr ill press, and remove

the switch key before raising the guard, changing the

cutting tool, ch anging the setup, or adju sting anyth ing.

Make sure switch is in OFF position before plugging in.

• Check for alignment of moving parts, binding of moving

parts, breakage of parts, drill press stabi lity, and any

other conditions that may affect the way the drill press

works.

• If any part is missing, ben t or br oken in any wa y, or any

electrical part does not work properly, turn the drill

press off and unplug the drill press.

• Replace damaged or missing parts before using the

drill press again.

• Remove adjusting keys and wrenches. Form a hab it o f

checking for and removing keys and adjusting

wrenches from table top before turning drill press on.

• Make sure all clamps and locks are tight and n o par ts

have excessive play.

Use Only Accessories Designed For This Drill Press To Reduce The Risk of Serious Injury

From Thrown Broken Parts Or Work Pieces

• When cutting large diameter holes:

- Cla mp the workpiece firmly to th e table. Otherwise

the cutting may grab and spin it at high speed.

- Use only one piece, cup-type, hole cutters.

- Do not use fly cutters or multi-pa rt hole cutters as

they can come apart or become unbalanced in use.

- Keep speed below 1500 R.P.M.

• Drum sanders must never be operated on this drill

press at a speed greater than 1800 R.P.M.

• Do not install or use any drill tha t exceeds 7” in length

or extends 6” below the chuck jaws. They can suddenly bend outward or break.

• Do not use wire wheels, router bits, shaper cutters, circle (fly) cutters or rotary planers on this drill press.

Kickback

• Kickback is the grabbing of the workpiece by the rot ating tool. The workpiece can be thrown at very high

speed in the direction of rotation. This Can Cause

Serious Injury. To reduce the possibi lity o f inj ur y fr om

kickback:

• Clamp the workpiece fir mly to the table whenever possible.

• Buffing or sanding wheels or drums should be contacted on the side moving away from you, not the side

moving toward you.

• Use only recommended accessories and follow the

instructions supplied with the accessory.

This drill press has 12 speeds as listed below:

250 RPM 990 RPM

340 RPM 1550 RPM

390 RPM 1620 RPM

510 RPM 1900 RPM

600 RPM 2620 RPM

650 RPM 3100 RPM

See inside of guard for specific placement of belt on

pulleys.

Think Safety

Safety is a combination of operator commo n sense and

alertness at all times when the drill press is being used.

WARNING: Do not allow familiarity (gained from

frequent use of your drill press) to become commonplace. Always remember that a careless fraction of a second is sufficient to inflict severe injury.

Plan Your Work

• Don’t force the tool. It will do the job better and safer at

the rate for which it was designed.

• Use the right tool. Don’t force tool or attachment to do

a job it was not designed to do.

• If any part of your drill press is missing, malfunctioning,

has been damaged or broken...such as the motor

switch, or other operating control, a safety device or

the power cord, turn the drill press off and unplug it

until the particular part is properly repaired or

replaced.

• Never place your fingers in a position where they could

contact the drill or other cutting tool if the workpiece

should unexpectedly shift or your hand should slip.

4

Safety Instructions For Drill Press (continued)

• To reduce the risk of injury from parts thrown by the

spring, follow instr uctions exactly as g iven and shown

in adjusting spring tension of quill.

• To prevent the workpiece from being torn from your

hands, spinning of the tool, shattering the tool or being

thrown, always properly suppor t your work so it won’t

shift or bind on the tool:

- Always position backup material (use beneath the

workpiece) to contact the left side of the column.

- Whenever possible, position the workpiece to con-

tact the left side of the column - If it is too short or the

table is tilted, clamp solidly to the table. Use table

slots or clamping ledge aroun d the outside edge of

the table.

- When using a drill press vise, always fasten it to a

table.

- Never do any work “Freehand” (hand holding work-

piece rather than suppor ting it on the table), except

when polishing.

- Securely lock head to column, table suppor t to col-

umn and table to table support before operating drill

press.

- Never move the head or table whil e the tool is run-

ning.

- Before starting the operation, jog the motor switch to

make sure the drill or other cutting tool does not

wobble or cause vibration.

- If a workpiece overhangs the table such that it will

fall or tip if not held, clamp it to the table or provide

auxiliary support.

- Use fixtures for unusual operations to adequately

hold, guide and position workpiec e.

- Use the spindle speed recommended for the specific

operation and workpiec e material - c heck the inside

of the belt guard for dril ling i nformat ion; for acce ssories, refer to the instructions provided with the accessories.

• Never climb on the drill pres s table, it could break or

pull the entire drill press down on you.

• Turn the moto r switch off and put away the switch key

when leaving the drill press.

• To reduce the risk of injur y from thrown work or tool

contact, do not perform layout, assembly or setup work

on the table while the cutting tool is rotating.

• Don’t overreach. Keep proper footing and balance at

all times.

• Maintain tools with care. Keep tools shar p and clean

for best and safest performance. Follow instructions for

lubricating and changing accessories.

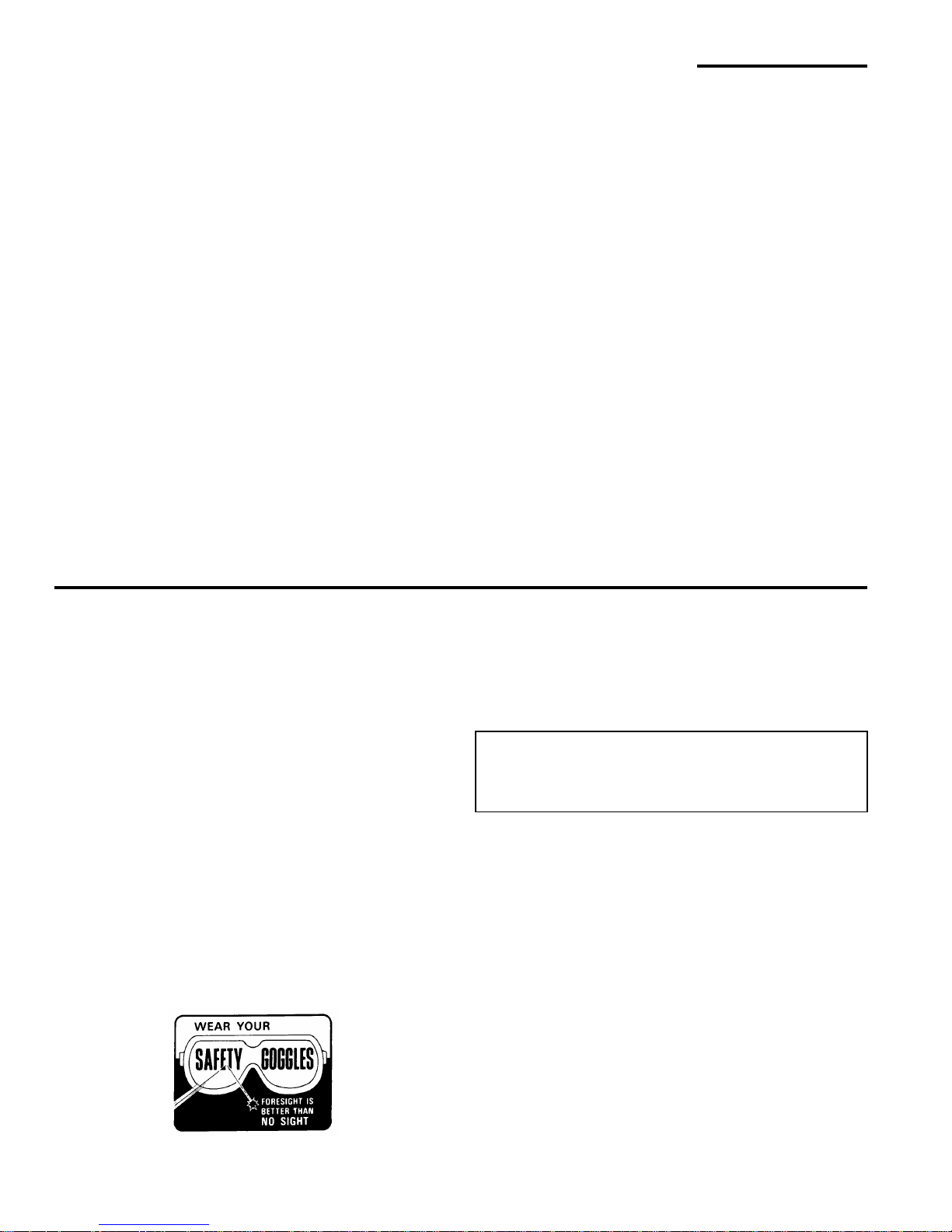

Plan Ahead To Protect Your Eyes, Hands, Face and Ears

Dress for safety

• Do not wear loose clothing, gloves, neckties or jewelry

(rings, wrist watch es). They can get caught and draw

you into moving parts.

• Wear nonslip footwear.

• Tie back long hair.

• Roll long sleeves above the elbow.

• Noise levels vary widely. To red uce the r i sk of poss ible

hearing damage, wear ea r plugs or muffs when using

drill press for hours at a time.

• Any power tool can throw foreign objects into the eyes.

This can result in permanent eye damage. Always

wear safety goggles, not glasses complyi ng with ANS I

Z87.1 (or in Canada CSA Z94-3-M88) shown on package. Everyday eyeglasses have only impact resist ant

lenses. They are not safety glasses. Safety goggles

are available at many local retail stores. Glasses or

goggles not in compliance with ANSI or CSA could

seriously hurt you when they break.

• For dusty operations, wear a dust mask along with

safety goggles.

Reduce the Risk of Accidental Starting.

• Make sure switch is “OFF” before plugging drill press

into a power outlet.

WARNING: Don’t allow familiarity (gained from frequent use of your drill press) to cause a careless

mistake. Always remember that a carel ess fr action

of a second is enough to cause a severe injury.

Keep Children Away

• Keep all visitors a safe distance from the drill press.

• Make sure bystanders are clear o f the drill press and

workpiece.

Before Leaving The Drill Press

• Turn the drill press off.

• Wait for tool bit to stop spinning.

• Unplug the drill press.

• Make workshop child-proof. Lock the shop. Disconnect

master switches. Remove the yellow switch key. St ore

it away from children and others not qualified to use

the tool.

5

Glossary of Terms

Workpiece

The item on which the cutting operation is being performed.

Drill Bit or Drill

The cutting tool used in th e dri ll pres s to make holes in a

workpiece.

Backup Material

A piece of wood placed between the workpiece and

table...it prevents wood in the workpiece from splinter ing

when the drill passes thro ugh the backside of the workpice...also prevents drilling into the table top.

Revolutions Per Minute (R.P.M.)

The number of turns comp leted by a spinning object in

one minute.

Spindle Speed

The R.P.M. of the spindle.

Backlash

The amount of handle movement or play between adjacent moving parts.

Motor Specifications and Electrical Requirements

Power Supply and Motor Specifications

WARNING: To reduce the risk of electrical hazards,

fire hazards or damage to the tool, use proper circuit protection. Your tool is wired at the factory for

operation using the voltage shown. Connect tool

to a power line with the appropriate voltage and a

15-amp branch circuit. Use a 15-amp time delay

type fuse or circuit breaker. To reduce the risk of

shock or fire, if power cord is worn or cut, or damaged in any way, have it replaced immediately.

The A-C motor used on this tool is an induction nonreversible type, ha vin g the f ollo win g specifica tions:

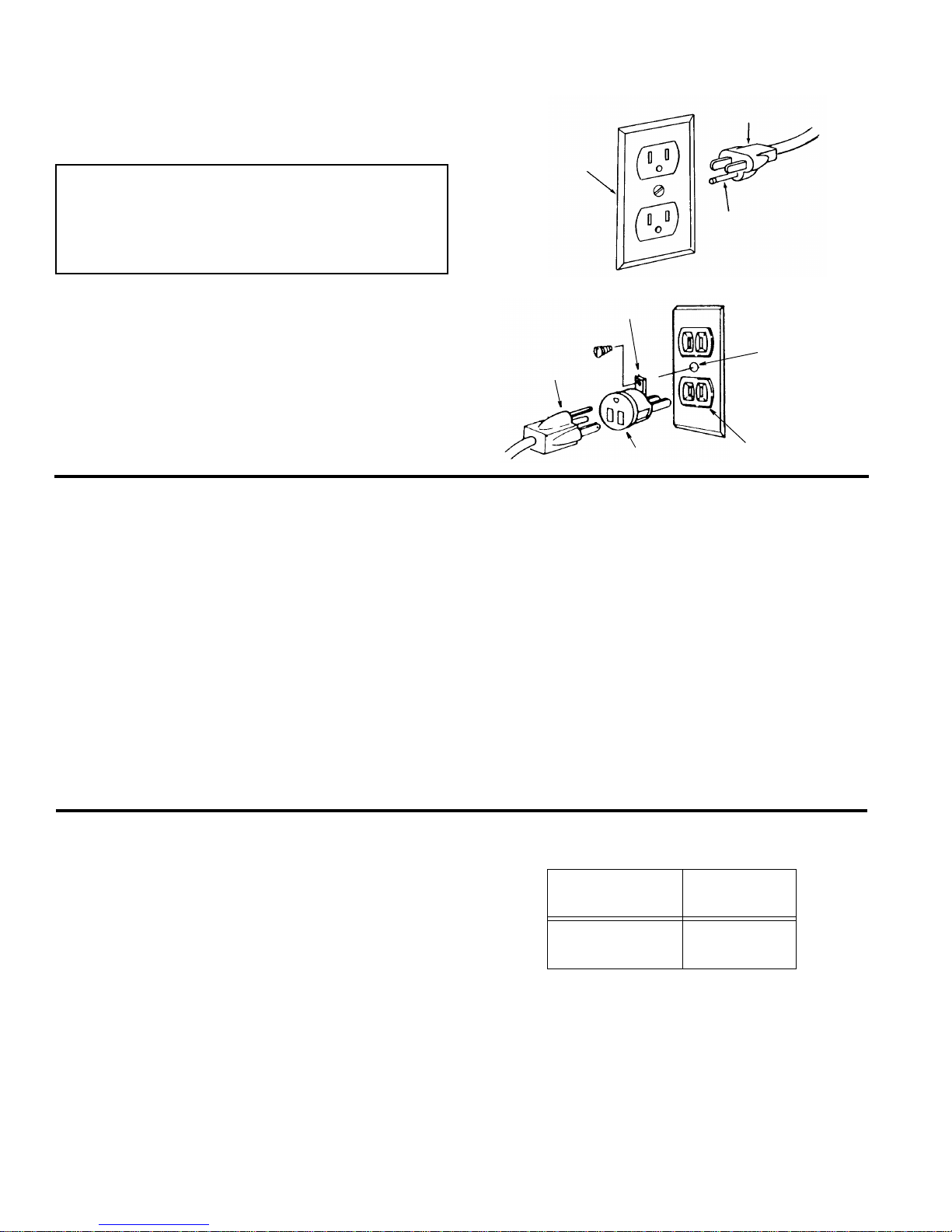

General Electrical Connections

DANGER: To reduce the risk of electrocution:

1. Use only identical replacement parts wh en servicing. Servicing should be performed by a

qualified service technician.

2. Do not use in rain or where floor is wet.

This tool is intended for indoor residential use

only.

WARNING: Do not permit fingers to touch the terminals of plug when installing or removing the

plug to or from the outlet.

110-120 Volt, 60 Hz. Tool Information

NOTE: The plug supplied on your tool may not fit into the

outlet you are plannin g to use. Your local electr ical code

may require slightly different power cord plug connections. If these differences exist refer to and make the

proper adjustments per your local code before your tool is

plugged in and turned on.

In the event of a malfunction or breakdown, grounding

provides a path of le ast resistance for electric curre nt to

reduce the risk of electric shock. This tool is equipped

with an electric cord having an equipment grounding conductor and a grounding plug, as shown. The plug must be

plugged into a mat ching outlet that is properly installed

and grounded in accordance with all local codes and

ordinances.

Do not modify the plug pr ovide d. I f i t wi ll not fi t the ou tle t,

have the proper outlet installed by a qualified electrician.

A temporary ad apte r m ay be used t o co nne ct this plug to

a 2-prong outlet, as shown, if a prope rly grounded three

prong outlet is not available. This temporary adapter

should be used only until a properly grounded three

prong outlet can be installed by a qualified electrician.

The green colored rigid e ar, lug and the like, extending

from the adapter must be connected to a permanent

ground such as a properly grounded outlet box.

NOTE: In Canada the use of a temporar y adapter is not

permitted by the Canadian electrical code.

Improper connection of the equipment grounding conductor can result in a r isk of electri c shock. The conductor with insulation having an outer surface that is green

with or without yellow stripe s is the equipmen t grounding

conductor. If repair or replacemen t of the electr ic cord or

plug is necessary, do not connect the equipme nt- grounding conductor to a live terminal.

Rated H.P

1/2

Voltage 110-120

Amperes 8.2

Hertz (Cycles) 60

Phase Single

RPM 1725

Rotation of Shaft

Clockwise

6

Motor Specifications and Electrical Requirements (continued)

If the grounding instructions are not completely understood, or if you are in doubt as to whether the tool is properly grounded check with a qualified electrician or service

personnel.

WARNING: If not properly grounded, this tool can

cause an electrical shock, particularly when used

in damp locations, in proximity to plumbing, or out

of doors. If an electrical shock occurs there is the

potential of a secondary hazard, such as your

hands to hit the cutting tool.

NOTE: The adapter illustrated is for use only if you already

have a p r ope rly gr o und ed 2- p rong ou tl et.

NOTE: In Canada the use of a temporary adapter is not

permitted by t he Canad ian Ele c trical C ode.

Motor Safety Protection

IMPORTANT: To avoid motor damage, this moto r should

be blown out or vacuumed frequently to keep sawdust

from interfering with normal motor ventilation.

1. Connect this tool to a power source with the approp riate voltage for your model and a 15-amp branch circuit

with a 15-amp time de lay fuse or ci rcu it breaker. Using

the wrong size fuse can damage the motor.

2. If the motor won’t start, turn th e switch off immediately

and unplug the tool. Check the quill to make sure it

turns freely. If the quill is free, try to start the motor

again. If the motor still does not start, refer to the

"Motor Troubleshooting Chart."

3. Fuses may "blow" or circuit breakers may trip frequently if:

a. Motor Is Ove rloaded-Overloading c an occur if you

feed too rapidly or make too many star t/stops in a

short time.

b. Line voltages should not be more than 1 0% above

or below the nameplate voltage. For heavy loads,

however, the voltage at motor term inals must equal

the voltage specified for your model.

c. Improper or dull drill bit is used.

4. Most motor troubles may be traced to loose or incorrect connections, overload, low voltage (such as small

size wire in the supp ly circuit) or to overly long supply

circuit wire. Always check the connections, the load

and the supply circuit whenever motor doesn’t work

well. Check wire sizes and l ength with the Wire Size

Chart shown.

Wire Sizes

NOTE: Make sure the proper extension cord is used and

is in good condition.

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent overheating and motor burnout, use the table at right to determine the minimum wire size (A.W .G.) extension cord.

Use only 3-wire extension cords which have 3-prong

grounding type plugs and 3-pole receptacles which

accept the tools plug.

Properly

Grounded

Outlet

3-Prong Plug

Grounding

Prong

Grounding Lug

3-Prong

Adapter

2-Prong

Outlet

Make sure this

Is Connected

Ground

Plug

Green

to a Known

Extension Cord

Length

Gauge

(A.W.G.)

0-25

25-50

16

14

7

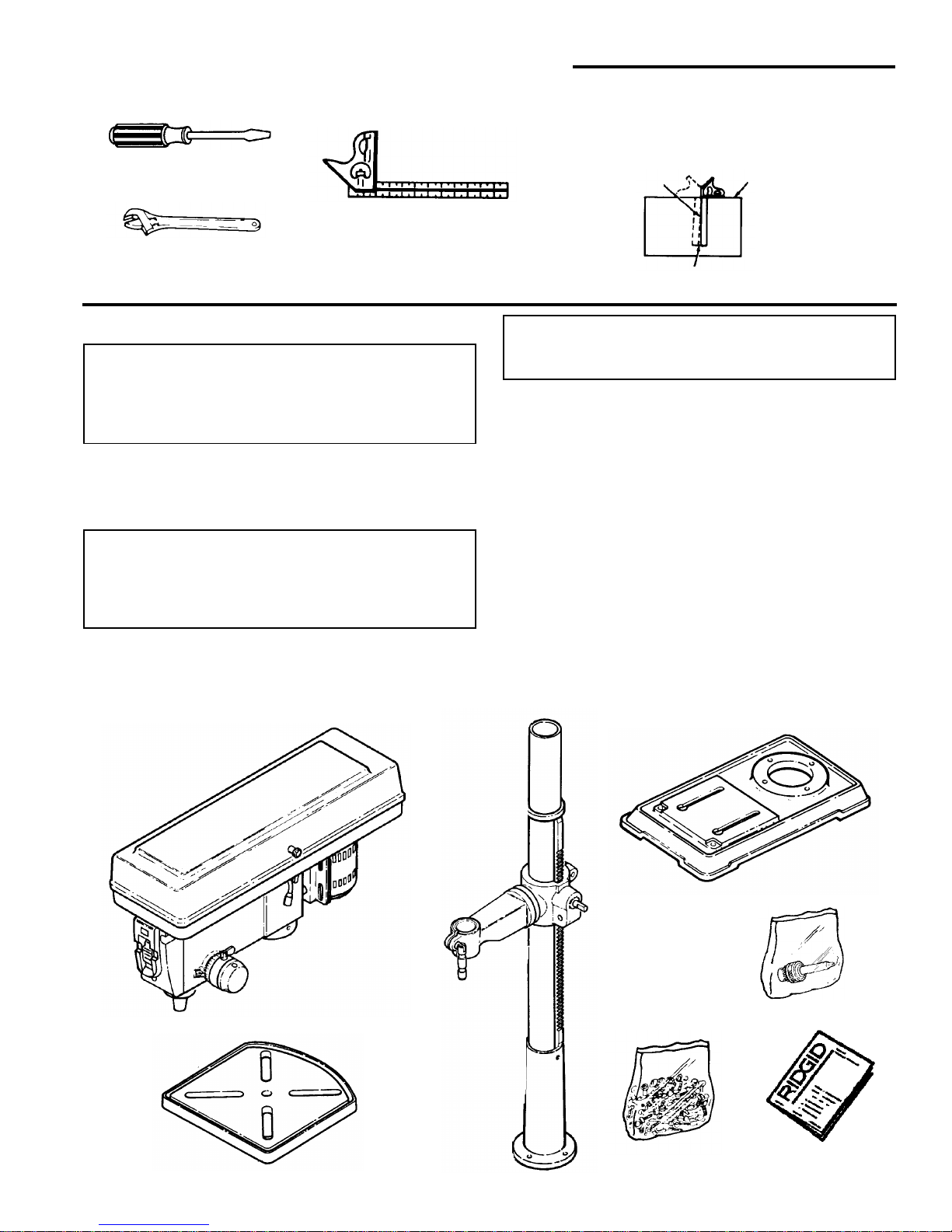

Unpacking and Checking Contents

Tools Needed

Unpacking

WARNING: To reduce the risk of injury from unexpected starting or electrical shock, do not plug the

power cord into a source of power. This cord must

remain unplugged whenever you are working on

the drill press.

The Drill Press is shipped complete in one box.

1. Separate all “loos e parts” from packing ma terials and

check each item with illustration and “Table of Lo ose

Par t s.”

WARNING: To reduce the risk of injury, if any parts

are missing, do not attempt to assemble the drill

press, plug in the power cord, or turn the switch on

until the missing parts are obtained and installed

correctly.

2. Remove the protective oil that is applied to the table

and column. Use any o rdinary h ousehold type grease

and spot remover.

WARNING: To reduce the risk of fire or toxic reaction, never use gasoline, naptha or similar highly

volatile solvents to remove protective oil

3. Apply a coat of pa ste wax to the table and column to

prevent rust. Wipe all parts thoroughly with a clean dry

cloth.

NOTE: Make cer tain all items are accounted for, before

discarding any packing material.

List of Loose Parts

Item Description Qty.

A Head Asm. .........................................................1

B Table...................................................................1

C Column Support Assembly.................................1

D Base...................................................................1

E Bag Chuck/Arbor Assembly ...............................1

F Bag of Loose Parts.............................................1

G Owners Manual..................................................1

Combination Square

Combination Square Must be True

Draw Light

Line on Board

Along this Edge

Straight Edge of

Board 3/4” Thick

This Edge Must be

Perfectly Straight

Should be no Gap or Overlap when Square

is Flipped Over in Dotted Position

Medium Screwdriver

Adjustable Wrench

A

B

D

E

G

F

C

8

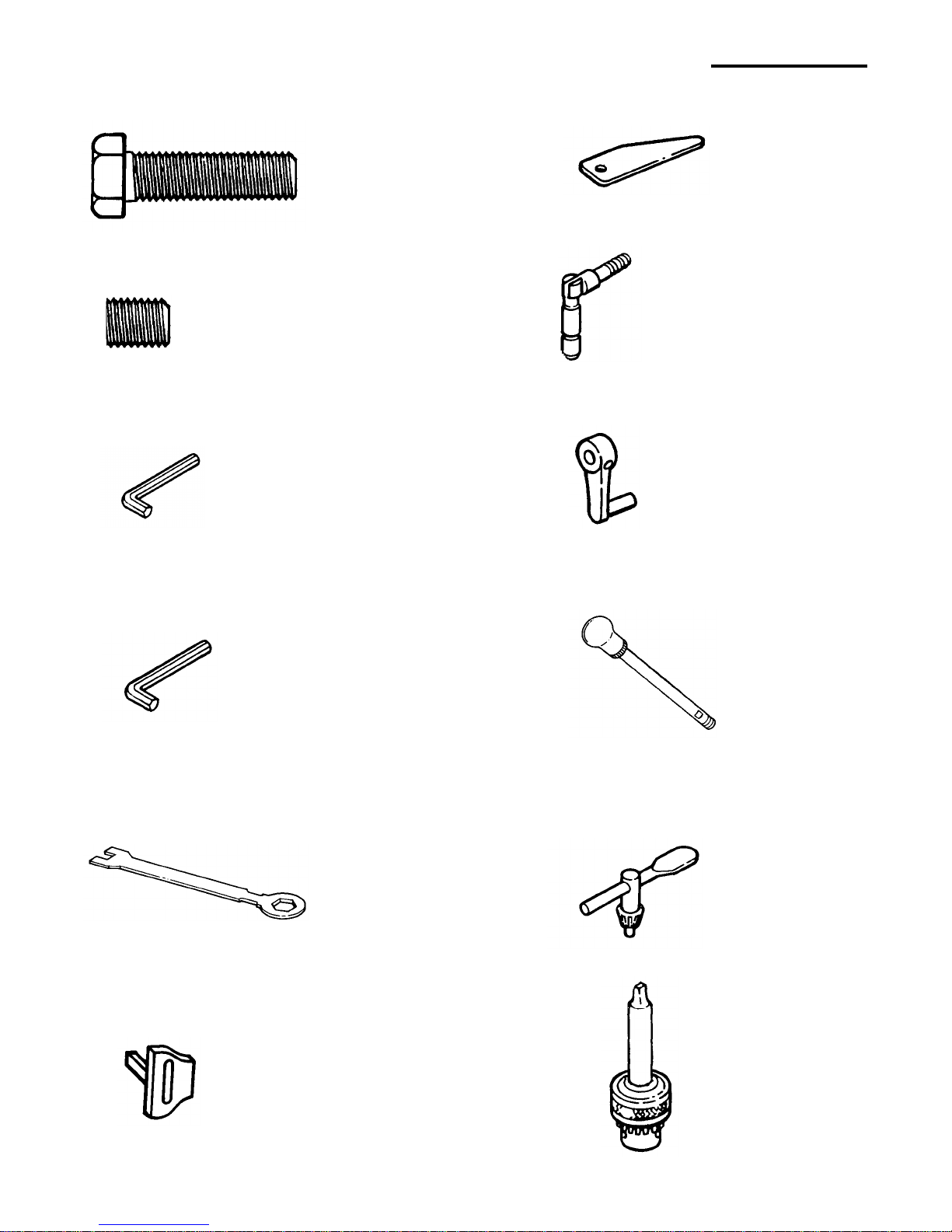

Unpacking and Checking Contents (continued)

Loose Parts in Box and Bag

M10 x 1.5-40 Long

Hex Head Bolt (4)

(With Set Screw) (1)

Crank

M10 x 1.5-12 Long

Hex Socket Set Screw (2)

Chuck Key (1)

Chuck/Arbor (1)

M5 Hex “L” Wrench (1)

M24 Hex Box

Wrench (1)

Key Drift (1)

Key-Switch (1)

M3 Hex “L” Wrench (1)

Feed Handle (3)

Support Lock Handle (1)

Assembly

9

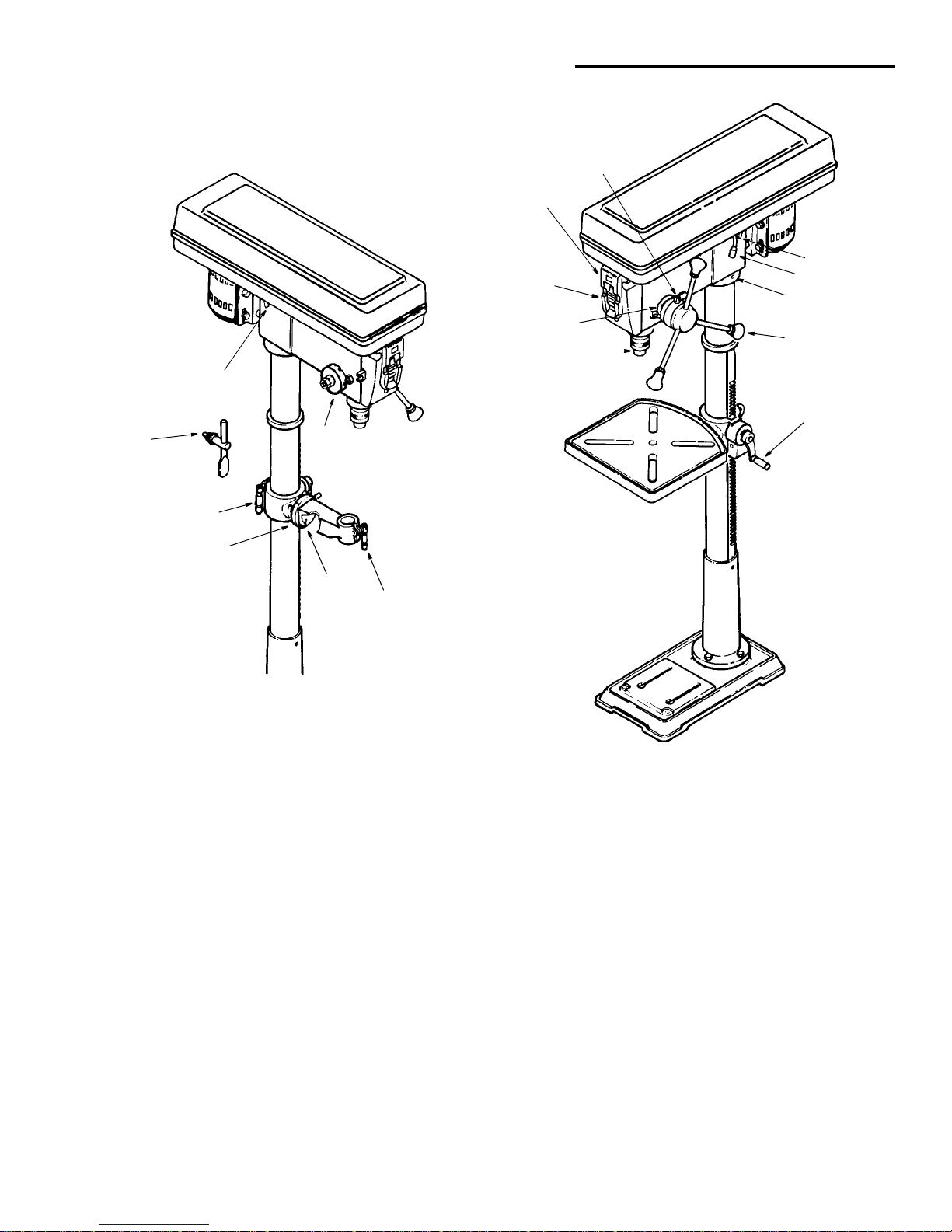

Location and Function of Controls

1. Belt Tension Lock Handles...Tightening handles

locks motor bracket support to maintain correct bel t

distance and tension.

2. Belt Tension Handle...T urn handle counterclockwise

to apply tension to belt, turn handle clockwise to

release belt tension.

3. Head Lock Set Screws...Locks the head t o the column. Always have them locked in place while operating the drill press.

4. Feed Handle...For moving the chuck up or down.

One or two of the handl es may be removed if ne cessary whenever the workpiece is of such unusual

shape that it interferes with the handles.

5. Table Crank...Tur n clockwise to elevate table. Support lock must be released before operating crank.

6. Chuck Key...Used to tighten drill in the chuck and

also to loosen the chuck for drill removal.

7. Chuck...Holds dr ill bit or oth er recomme nded acces sory to perform desired operations.

8. Depth Scale ...A llows operator to ad just dr ill pres s to

drill to a desired depth.

9. Drill “On-Off” Switch...Has locking feature to pre-

vent unauthorized and possible hazardous use by

children and others.

10. Light “On-Off” Switch...Turns the light on and off.

11. Depth Scale Lock...Locks the depth scale at

selected depth.

12. Spring Cap...Provides means to adjust quill spring

tension.

13. Table Lock...Allows table to be rotated in various

positions and locked.

14. Table Bevel Lock...Locks the table in any position

from 0°- 45°.

15. Bevel Scale...Shows degree table is tilted for bevel

operations. Scale is mounted on side of arm.

16. Suppor t Lock H andle...Tightening locks table support to column. Always have it locked in place while

operating the drill press.

Note and follow the safety warnings and instructions

that appear on the panel on the right side of the head.

1

12

13

14

15

16

Ta ble Remo ved

for Clarity

2

3

4

5

6

7

8

9

10

11

1

10

Assembly

WARNING: To reduce the risk of injury from unexpected starting or electrical shock, never connect

plug to outlet until all assembly steps are completed and you read and understand all instructions.

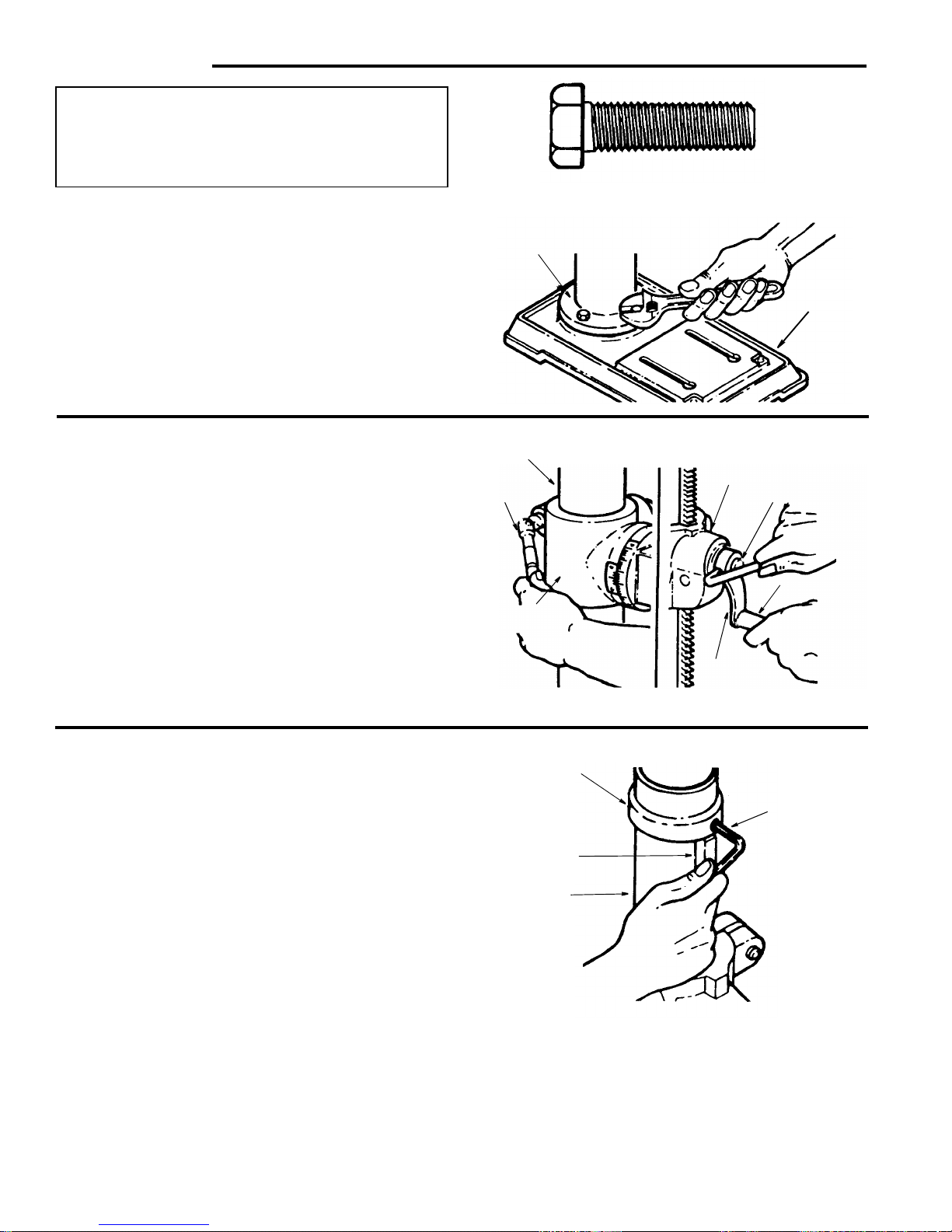

Assembly of Base/Column

1. Locate four (4) 10mm di a. x 40mm long bolts among

loose parts bag.

2. Po siti on b ase on f loo r. Remove prot ect iv e co v eri ng and

discard.

3. Remove protective sleeve from column tube and discard. Place column as sem bly on bas e, and align hol es

in column support with holes in base.

4. Install a bolt in each hole throug h column suppor t and

base and tighten with adjustable wrench.

5. Locate table crank and support lock in loose parts box.

6. Install support lock from left side into table support and

tighten by hand.

7. Install table crank asse mbly and tighten set screw with

a 3mm hex “L” wrench. Do no t overtighten. Se t screw

should be tightened against the flat section of the

shaft.

NOTE: To minimi ze crank backla sh, tig hten s upport lock,

rotate elevation worm shaft clockwise, then assemble

crank tight against table support and tighten set screw.

8. Check column collar for proper adjustment. Collar

should not be angle d on the column and it shoul d be

positioned so rack will slide freely in collar when table

is rotated 360° ar oun d col um n tube. If readjusted, only

tighten set screw enough to keep collar in place.

NOTE: To reduce the risk of column or collar damage, do

not overtighten set screw.

Column

Support

Base

Column

Support

Lock

Table

Support

Table

Support

Elevation

Worm Shaft

Handle

Table

Crank

10mm Dia. x 40mm

Hex Head Bolt (4)

Column

Collar

Rack

Column

Do Not

Overtighten

Set Screw

Loading...

Loading...