Page 1

OPER

0.0°

A

TOR’S MANUAL

UNIVERSAL DIGITAL MITER GAUGE

DMG9015

W

ARNING:

To reduce the risk of injury, the user must read and understand the operator’s manual before using this product.

Thank you for buying a RIDGID product.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Page 2

TABLE OF CONTENTS

n General Safety Instructions ........................................................................3

Safety Symbols ...................................................................................3

Damage Prevention and Information Messages .........................................................3

Safety Precautions for Operations .................................................................... 3

Service Safety .................................................................................... 3

n Unpacking and Checking Contents .................................................................4

Unpacking .......................................................................................4

List of Contents ..................................................................................4

n Getting to Know Your Digital Miter Gauge ...........................................................5-6

Main Parts ....................................................................................... 5

Technical Specications ............................................................................ 6

n Operation ......................................................................................7-9

To Install Batteries ................................................................................ 7

Attach the Fence to the Miter Gauge Head .............................................................7

Choose the Proper Gauge Bar Attachment ............................................................. 8

Adjust the T-slot Washer to the Correct Position .........................................................8

Turn the Digital Miter Gauge On and Off ............................................................... 9

Flip the Display ................................................................................... 9

Calibrate the Digital Miter Gauge to the Table-Saw-Blade Assembly .........................................9

Audio Feedback .................................................................................. 9

n Application ...................................................................................10-12

Cut Wood at Any Angle with ±0.1º Accuracy ...........................................................10

Use the Precision Fence Accessories ................................................................ 10

Set the Table-Saw-Blade Tilt Angle .................................................................. 11

n Maintaining Your Digital Miter Gauge ............................................................... 13

n Troubleshooting ................................................................................ 13

n Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2

Page 3

GENERAL SAFETY INSTRUCTIONS

The purpose of safety symbols is to attract your attention to

possible dangers. The safety symbols and the explanations

with them deserve your careful attention and understanding.

The symbol warnings DO NOT, by themselves, eliminate

any danger. The instructions and warnings they give are no

substitutes for proper accident prevention measures.

Safety Symbols

SAFETY ALERT SYMBOL:

Indicates DANGER, WARNING, OR CAUTION; may be

used in conjunction with other symbols or pictographs.

DANGER:

Failure to obey this safety warning WILL result in death

or serious injury to yourself or to others. Always follow

the safety precautions to reduce the risk of fire, electric

shock, and personal injury.

WARNING:

Failure to obey this safety warning CAN result in

death or serious injury to you or to others. Always

follow the safety precautions to reduce the risk of

fire, electric shock, and personal injury.

CAUTION:

Failure to obey this safety warning MAY result in personal injury to yourself or to others or property damage.

Always follow the safety precautions to reduce the risk

of fire, electric shock, and personal injury.

Damage Prevention and Information

Messages

WARNING:

Always keep the miter fence away from the blade

when guiding the workpiece with this digital miter

gauge. Serious personal injury may result if the

metal fence comes in contact with the blade.

WARINING:

Before setting blade-tilt angle, make sure that the table

saw switch is in the OFF position and the plug is not

connected to a power source. Serious personal injury

may result if the saw is started by accident.

Safety Precautions for operations

•Do not use this tool for any purpose other than those out-

lined in this manual. This could result in serious injury.

•Keep the tool dry, and do not use it in the rain.

•Avoid dropping the tool and other causes of impact on the

tool.

•Remove the batteries if the device will not be used for

several days.

•Always dispose of the used batteries according to your

local ordinance; do not incinerate the batteries.

•Thedigitalmitergauge must be calibrated before using it

to set up cuts or set the saw blade angle.

Service Safety

Do not attempt to repair or disassemble the Digital Miter

Gauge. If unqualied persons attempt to repair this product,

serious injury may occur. Any repair required should be performed only by authorized service personnel.

These inform the user of important information and/or instructions that could lead to equipment or other property

damage if they are not followed. Each message is preceded

by the word “NOTE,” as in the example below:

NOTE: Equipment and/or property damage may result if

these instructions are not followed.

WARNING:

Be sure to read and understand all safety instructions

in this manual and the manual for your power tool, including all safety alert symbols, such as “DANGER,”

“WARNING,” and “CAUTION,” before using this Digital

Miter gauge. Failure to follow all instructions listed below and in the instructions for your power tool may result in electric shock, fire, and/or serious personal

injury.

3

Page 4

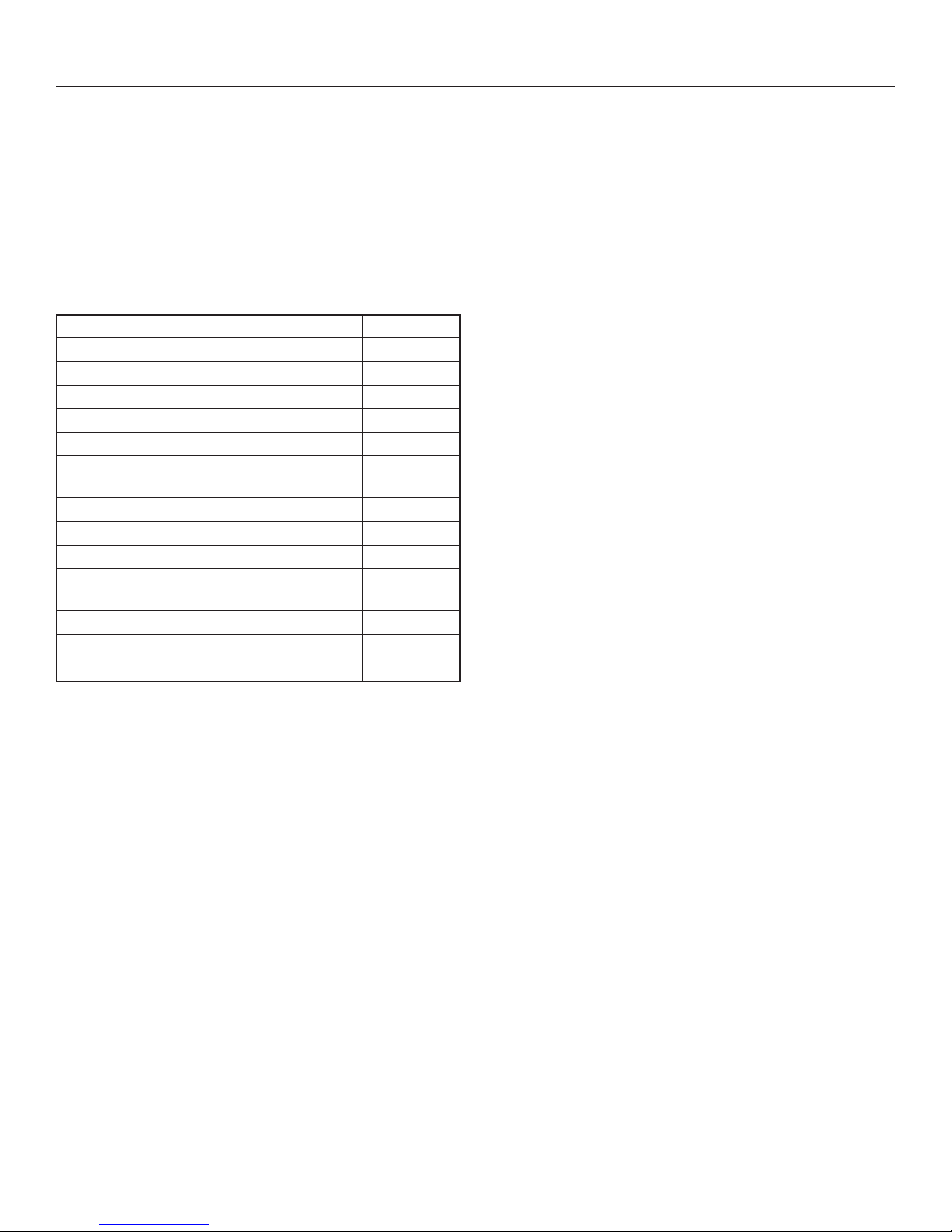

UNPACKING AND CHECKING CONTENTS

The Digital Miter Gauge comes in one box. Do not discard

any packing materials until all of the contents are accounted

for.

Separate all the parts from the packing materials. Refer to

the”List of Contents” and Fig. 1 to make certain that all the

items are accounted for before discarding any packing material. Call the RIDGID Service Center if any parts are damaged or missing.

List of Loose Parts

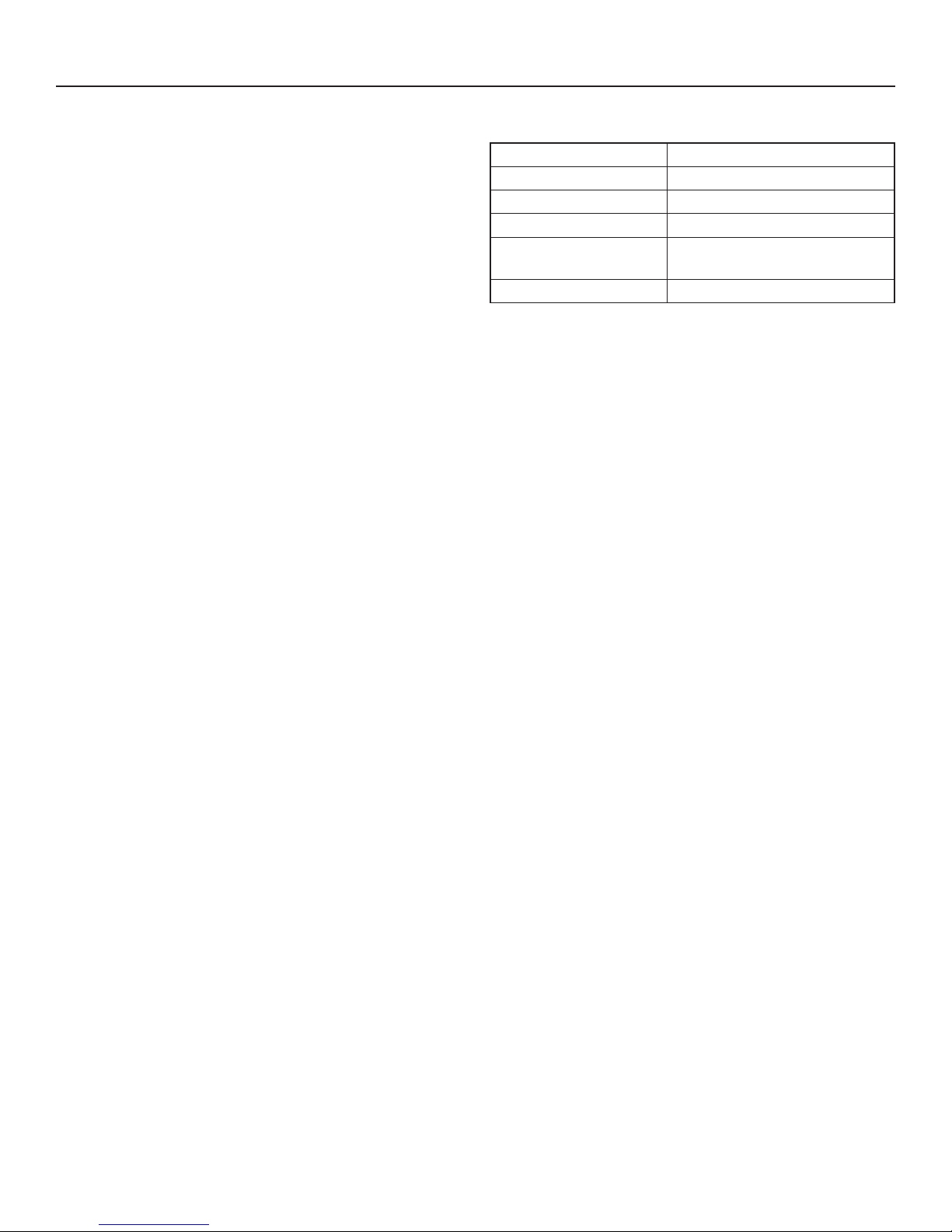

Part Name QuaNtity

Digital Miter Gauge 1

Miter Fence 1

Micro-adjust Gauge 1

Flip Stop Gauge 1

Precision Stop Gauge 1

1/4” Gauge bar attachment (installed on the

gauge bar)

1/8” Gauge bar attachment 1

Magnetic blade attachment 1

Hex wrench 1

T-slot washer for 3/8” depth slot (installed

on the gauge bar)

T-slot washer for 1/2” depth slot 1

Screw for Deep T-slot washer 1

AAA Batteries 2

1

1

4

Page 5

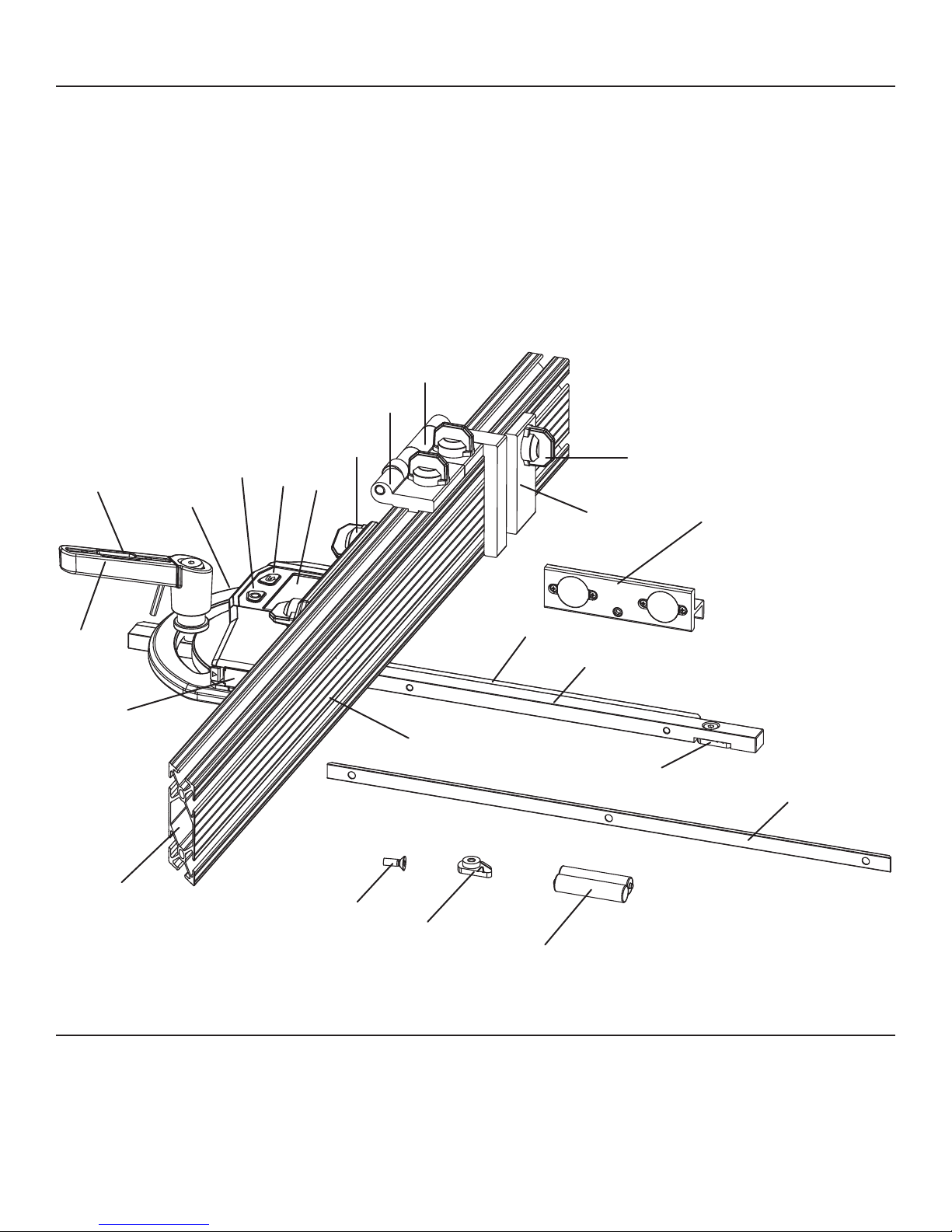

GETTING TO KNOW YOUR DIGITAL MITER GAUGE

The digital miter gauge is a smart tool that increases efciency in woodworking projects. It was designed by a professional

woodworker for woodworkers. It sets crosscut angles and table saw blade angles from -50° to +50° with ±0.1° accuracy in

a matter of seconds. For use with all bench, portable, and stationary table saws with 1/2", 5/8", and 3/4" slots and 5/8", 3/4",

and 7/8" T-Slots with the slot depth of 3/8" or 1/2".

Main parts

10

9

5

2

3

8

1

7

6

21

4

16

14

12

20

19

18

11

5

13

15

17

Fig. 1

5

Page 6

GETTING TO KNOW YOUR DIGITAL MITER GAUGE

1. Machined Miter Gauge head

2. Power button: press to turn on the digital miter gauge;

press again to ip the display;

3. ZERO Button: calibrates the current angle as 0.0 de-

gree.

4. LCD Screen: large LCD display with blue back lighting

for easy reading.

5. Fence-Lock Knobs: secures the miter fence to the mi-

ter gauge head; secures the stop gauges to the miter

fence.

6. Battery Compartment: for two AAA batteries.

7. Soft Grip Locking Handle: locks and unlocks the miter

gauge head.

8. Hex Wrench: used to loosen or tighten the screws on

gauge bar attachments, magnetic blade attachment

and T-slot washer.

9. Micro-adjust Gauge: designed to be used in any of the

fence grooves, it can be used as a micro adjust for the

ip stop or a positive stop gauge.

10. Flip-Stop Gauge: a multi-use gauge that can be used in

any fence groove and as a solid stop gauge.

11. Precision Stop Gauge: For accurate repetitive cuts.

12. Miter Fence: guides the workpiece for cutting at the se-

lected angle.

13. Magnetic Blade Attachment: attaches to the 1/2” miter

gauge bar for blade -tilt adjustment.

14. 1/2” Miter Gauge Bar: ts all bench, portable, and sta-

tionary tools with a standard 1/2” miter gauge slot.

15. T-slot Washer for 3/8” depth slot: ts in T-slot tables of

bench, portable, and stationary tools with a slot depth

of 3/8”.

16. 1/4” Gauge Bar Attachment: attaches to the 1/2” miter

gauge bar to t all bench, portable, and stationary table

saws with 3/4” slot.

17. 1/8” Gauge Bar Attachment: attaches to the 1/2” miter

gauge bar to t all bench, portable and stationary table

saws with 5/8” slot.

18. Batteries

19. T-slot Washer for 1/2” depth slot: ts in T-slot tables of

bench, portable, and stationary tools with a slot depth

of 1/2”.

20. Screw for Deep T-slot Washer

21. Mitered end: permits precise miter cuts close to the

end of the miter fence.

Technical Specifications

Battery 2 “AAA” 1.5V batteries

Miter angle range -50° to +50°

Blade tilt angle range -50° to +50°

Accuracy ±0.1°

Optimum Operating

Temperature Range

Weight 3.67 lbs ( 1.67 kg)

32°F to 104°F (0°C to 40°C)

6

Page 7

OPERATION

TO INSTALL BATTERIES

This digital miter gauge uses two ”AAA” batteries.

Fig. 2

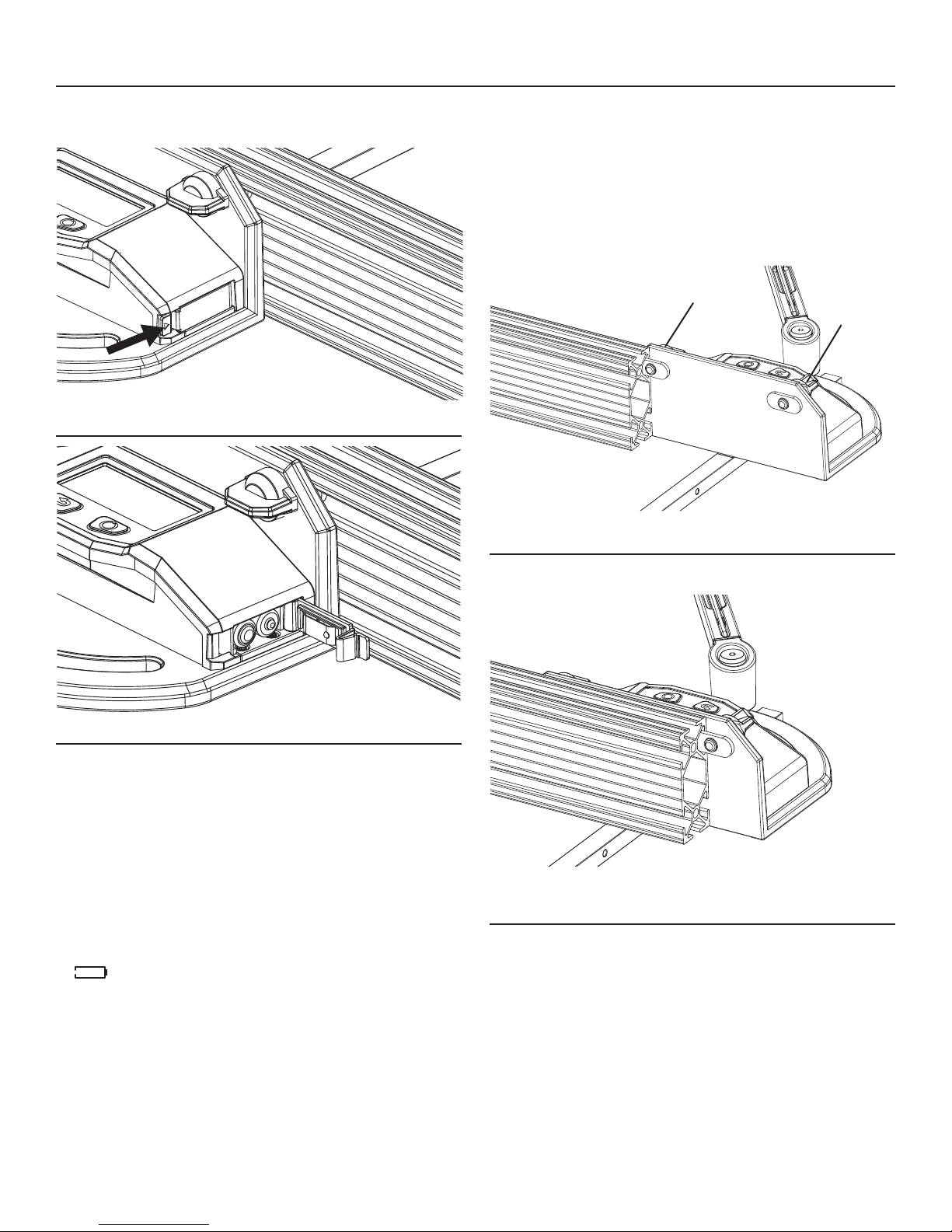

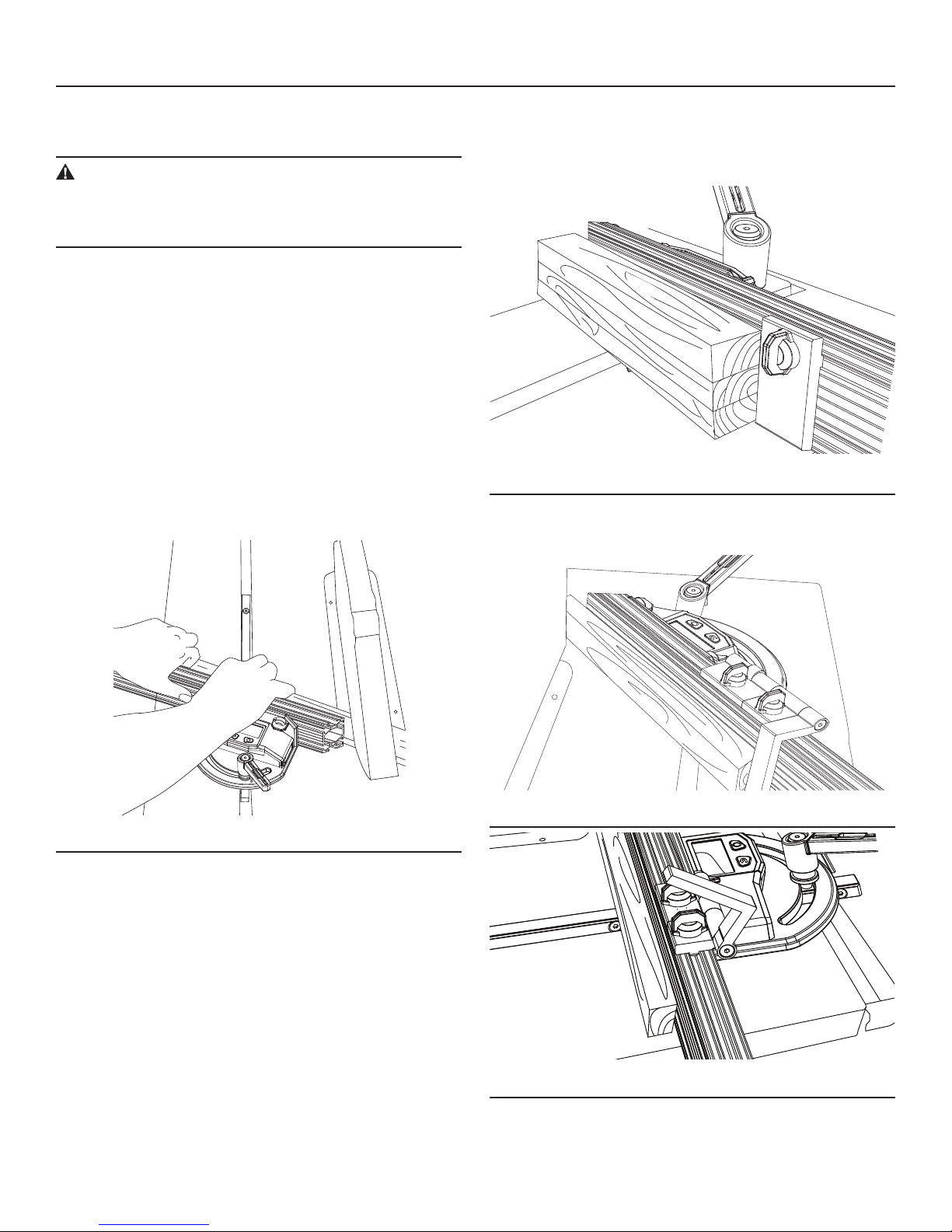

ATTACH THE FENCE TO THE MITER GAUGE HEAD

The fence has a mitered end to permit precise miter cuts

close to the end of the miter fence. Always position this

end to right side of the miter head. Refer to location 21 in

Fig. 1.

1. Loosen the fence-lock knobs (5 in Fig. 1) to release

both lock blocks so they may be inserted into the slot

in the fence.

fence-lock knob

fence-lock

knob

Fig. 4

Fig. 3

1. Open the battery cover as indicated by the arrow on the

cover (Fig. 2).

2. Insert two new “AAA”alkaline batteries according to the

polarity indicators in the battery compartment(Fig. 3). Be

sure the polarity (+/-) is correct!

3. Close the cover and lock it securely in place.

NOTE:

•Replacethebatterieswhenthebatteryindicatoronthe

display indicates that the batteries are fully depleted:

" ".

•Removethebatteriesfromthedigitalmitergaugewhenit

is not used for extended periods.

•The2AAAbatteriesshouldmatcheachotherinbrand

and type.

•Donotmixoldandnewbatteries.

•Removedepletedbatteriesimmediately,anddisposeof

them according to your local ordinance.

•Neverdisposeofbatteriesinre.

2. Align the rst lock block with the slot in the fence and

slide it into place (Fig. 4).

Fig. 5

3. Continue to slide the second lock block into place

(Fig.5).

4. Move the fence to the desired position.

5. Turn the fence-lock knobs clockwise to lock the fence.

7

Page 8

OPERATION

1/2” gauge bar

1/8” gauge bar

attachment

1/4” gauge bar

attachment

1/2” slot 5/8” slot 3/4” slot

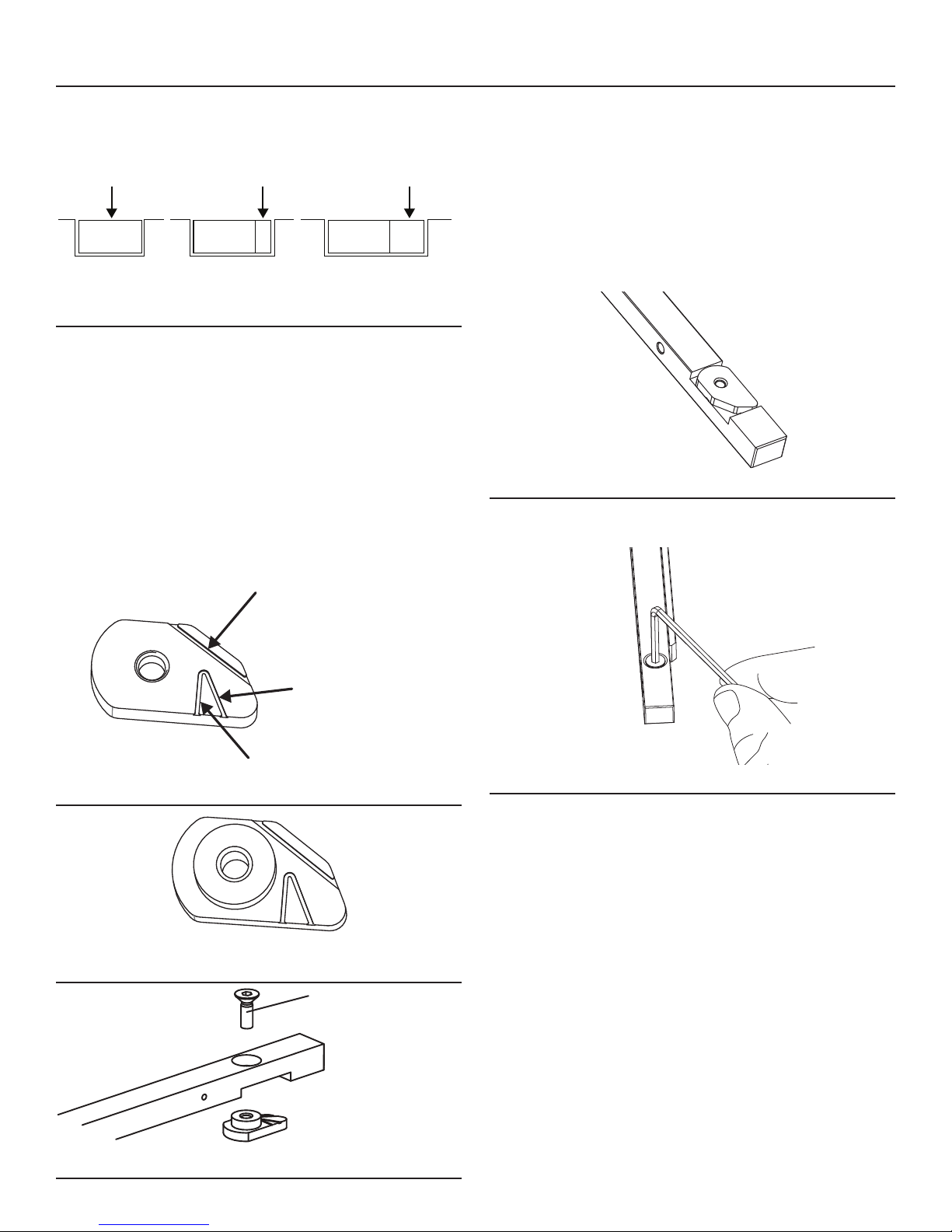

CHOOSE THE PROPER GAUGE BAR ATTACHMENT

Fig. 6

The gauge bar attachments adapt the universal gauge bar

to t in standard 1/2”, 5/8” or 3/4” miter gauge slots. The

universal gauge bar ts a 1/2” slot. Using the hex wrench

and the screws provided, attach a 1/8” gauge bar attachment on the side to t in a 5/8” slot; attach a 1/4” gauge

bar attachment on the side to t in a 3/4” slot. Please refer

to Fig. 6.

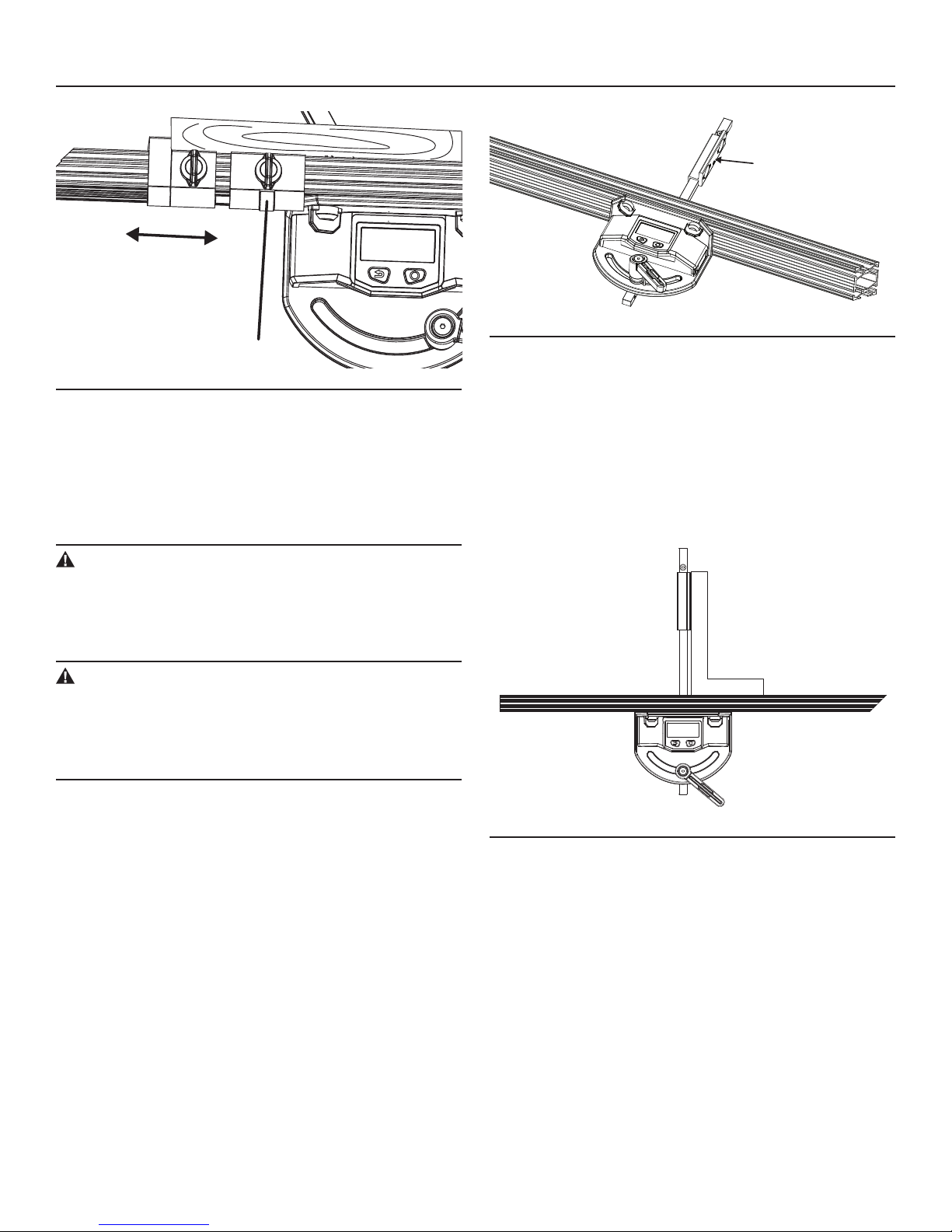

ADJUST THE T-SLOT WASHER TO THE CORRECT POSITION

Adjust the T-slot washer to allow the gauge bar to t in the

slots of T-slot tables and non T-slot tables on bench, portable, and stationary tools.

The 3/8” T-slot washer (Fig. 7a) is attached to the front side

of the gauge bar (Fig. 8). Use this washer for T-slots that

are 3/8” deep. For T-slots that are ½” deep, remove the

3/8” washer and attach the ½” T-slot washer (Fig. 7b & Fig.

7c).

There are three indicating lines on each washer (Fig. 7a);

use these lines to guide you as you turn the washer to a

specied position to it t a standard 5/8”, 3/4” or 7/8” Tslot table.

Fig. 8

To t non T- slot tables, keep the two sides of the T-washer

aligned with the gauge bar, as shown in Fig. 8.

Indicating line for

5/8" T-slot

Indicating line for

3/4" T-slot

Indicating line for

7/8" T-slot

Long screw for deep

T-slot washer

Fig. 7a

Fig. 7b

Fig. 9

To t a T-slot table:

1. Loosen the screw on the T-slot washer with the hex

wrench (Fig. 9).

Fig. 7c

8

Page 9

OPERATION

°

0‘0

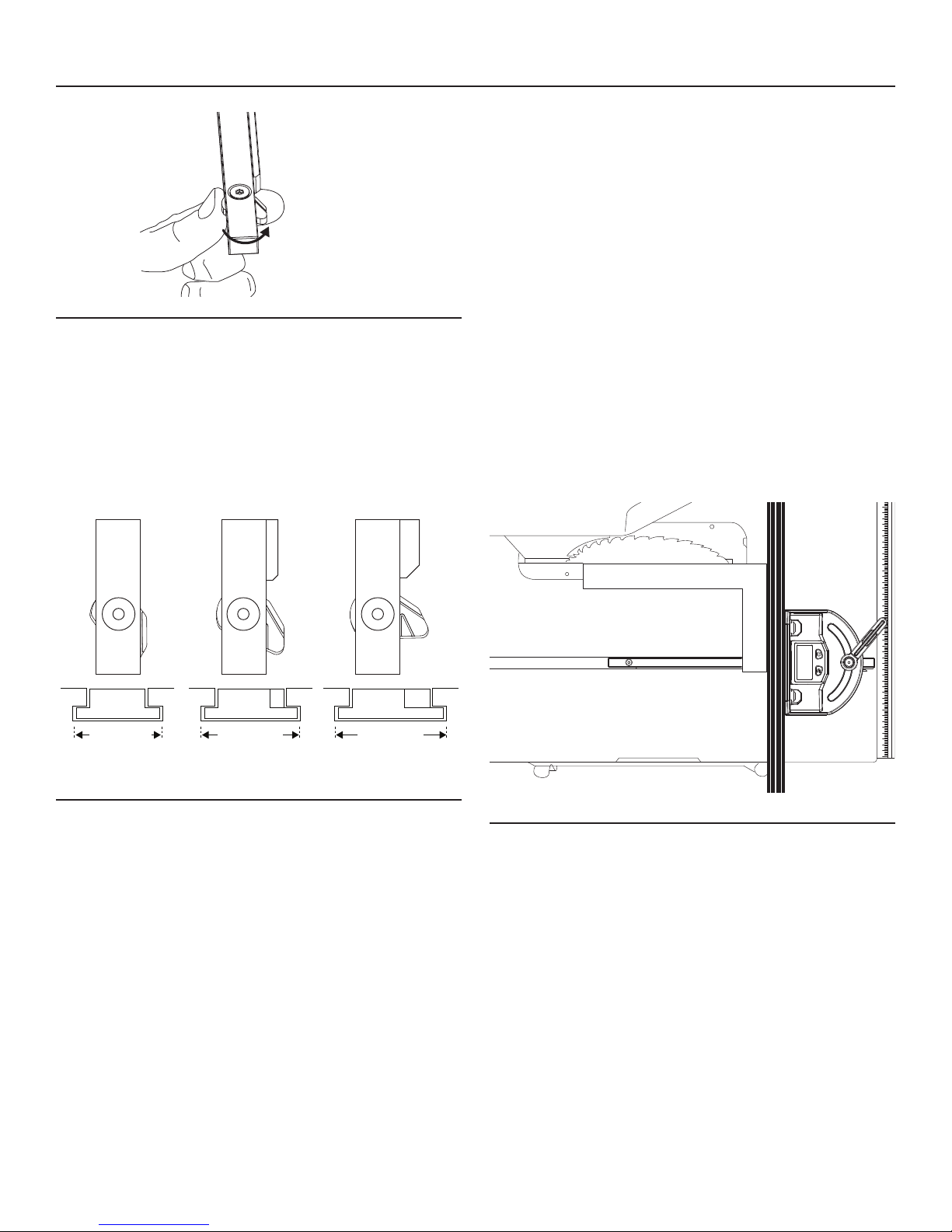

7/8” T-slot3/4” T-slot5/8” T-slot

a b c

Fig.10

2. Turn the T-slot washer counter-clockwise and align the

indicating line with the edge of the gauge bar (Fig. 10 and

Fig. 11).

Fig. 11(a) shows the position of the T-slot washer to t a

standard 5/8” T-slot table.

Fig. 11(b) shows the position of the T-slot washer to t a

standard 3/4” T-slot table.

Fig. 11(c) shows the position of the T-slot washer to t a

standard 7/8” T-slot table.

CALIBRATE THE DIGITAL MITER GAUGE TO

THE TABLE-SAW BLADE ASSEMBLY

(Carpenter’s square, available separately, required)

NOTE:

•Alwayscalibratethedigitalmitergaugetoyourtablesaw

before using this miter gauge to guide a cut. Failure to

perform the calibration may result in an inaccurate cutting.

•Oncethedigitalmitergaugehasbeencalibratedtoyour

table saw, no additional calibration is needed with subsequent use on the same table saw, unless the miter gauge

was calibrated to other table saws or carpenter’s square

after the rst calibration.

1. Slide the gauge bar into the groove on the T-slot in the

table or place the bar in the groove on a non T-slot table.

2. Fully raise the table-saw blade.

3. Loosen the locking handle.

4. Turn the miter gauge on.

3. Tighten the screw again with the hex wrench.

TURN THE DIGITAL MITER GAUGE ON AND

OFF

1. Press the Power button to turn on the tool.

2. Press the Power button for about 3 seconds to turn off

the tool.

3. The digital miter gauge will automatically turn itself off 5

minutes after the user stops moving the miter gauge

head.

FLIP THE DISPLAY

After the digital miter gauge is turned on, briey press the

Power key to ip the display.

Fig.11

Fig.12

5. Place a carpenter’s square rmly against the blade and

the miter fence (Fig. 12).

6. Press the Zero button for 2 seconds; the LCD will display

0.0º. The miter gauge is now calibrated to your table saw.

You may proceed to use the digital miter gauge for angle

cutting.

AUDIO FEEDBACK

During operation, the digital miter gauge produces an audible “click” as it swivels to the left or to the right. This feature

alerts the operator that the digital miter gauge is working

properly.

9

Page 10

APPLICATION

°

0’52

CUT WOOD AT ANY ANGLE WITH ±0.1º ACCURACY

WARNING:

Always keep the miter fence away from the blade when

guiding the cut with this digital miter gauge. Serious

personal injury may result if the metal fence is cut.

NOTE:

Before making any cuts, the digital miter gauge must rst be

calibrated.

1. Fit and calibrate the digital miter gauge to the table as

described in the preceding section, "CALIBRATE THE

DIGITAL MITER GAUGE TO THE TABLE-SAW-BLADE

ASSEMBLY.”

2. With the miter gauge bar securely in the table groove, turn

the digital miter gauge on.

3. Unlock the locking handle.

4. Swivel the miter gauge head to the desired angle, as indi-

cated in the display, and then tighten the locking handle.

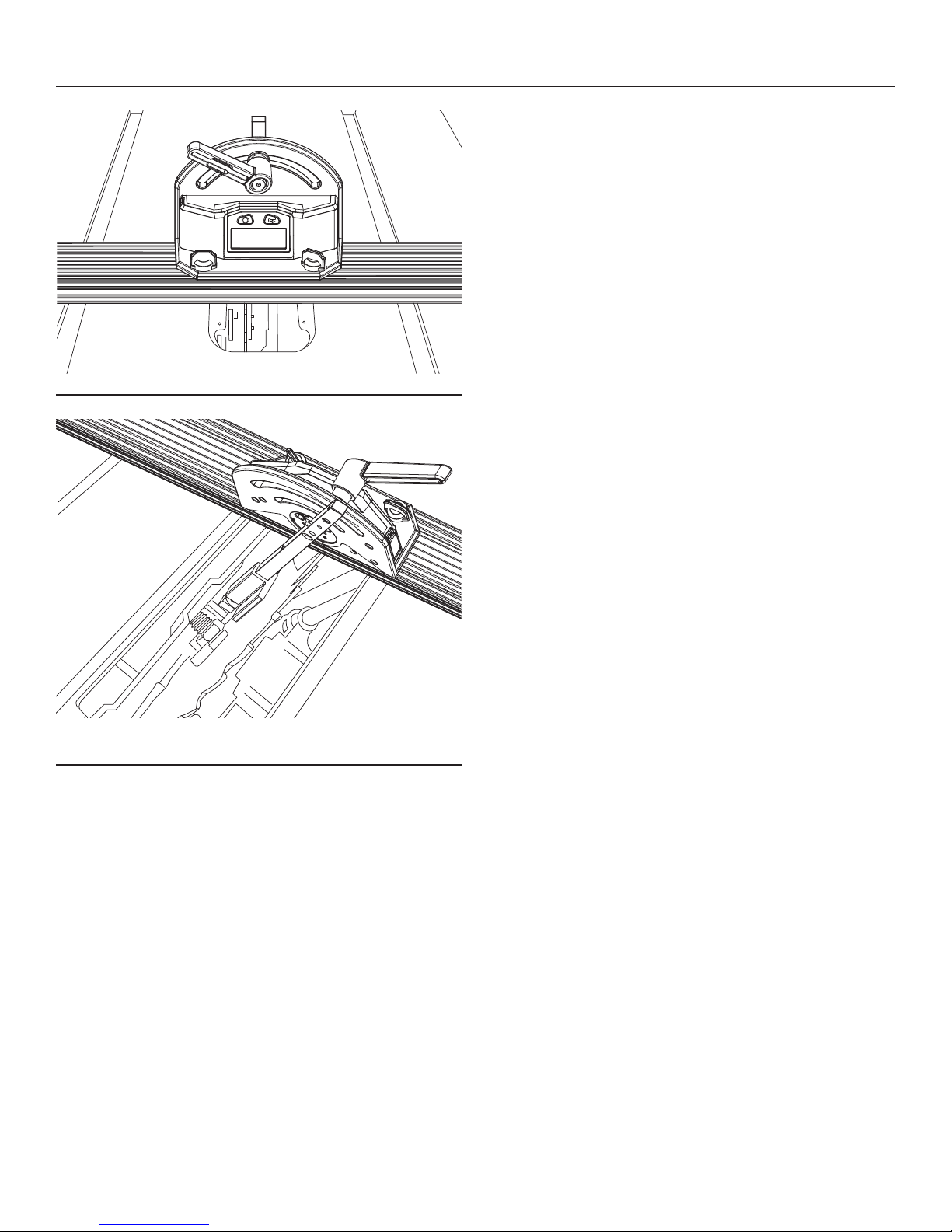

USE THE PRECISION FENCE ACCESSORIES

This digital miter gauge offers a variety of precision fence

accessories which will allow the user to fully utilize the miter

gauge capabilities.

Fig.14

The precision stop gauge is designed for vertical precision;

it allows the user to cut multiple pieces with one pass, as

shown in Fig. 14.

5. Securely place the workpiece against the miter fence and

begin crosscutting, following the operating instructions

for the table saw (Fig. 13).

Fig.15

Fig.13

Fig.16

The Flip Stop Gauge is a multiuse gauge, which can be used

in the top fence groove and as a solid stop gauge. To cut a

long workpiece, just ip it back, there is no need to detach it

from the fence (Fig. 15 and 16).

10

Page 11

APPLICATION

45,0°

0.0°

0.0°

Orient the magnets to

the correct side

Fig.18

Micro-adjust screw

Fig.17

The Micro-adjust Gauge is designed to be used in any of the

fence grooves; it can be used as a micro-adjust for the ip

stop or as a positive stop gauge. To adjust the ip stop

gauge, rst lock the micro-adjust gauge on the fence with

the lock knob, then turn the micro-adjust screw to move the

ip stop gauge left or right (Fig. 17).

SET THE TABLE-SAW BLADE TILT ANGLE

WARNING:

Before setting blade-tilt angle, make sure that the table-saw switch is in the OFF position and the plug is

not connected to a power source. Serious personal injury may result if the saw is accidentally started.

WARNING:

Remove the hex wrench from the locking handle and

put it in a safe place.

Serious personal injury may result if the hex wrench falls

into the table saw.

The magnetic blade attachment properly ts only the 1/2”

gauge bar, so detach any gauge bar attachment that is on

the gauge bar.

Use the magnetic blade attachment for table saw blades

that bevel to either the the left or the right.

1. Use the 1/8-in. hex wrench (included) to loosen the setscrew in the magnetic blade attachment in the counterclockwise direction.

2. For table saw blades that tilt "left," the magnets on the

attachment need to be oriented to the right side of the

gauge bar, as in Fig. 18. For table saw blades that tilt

"right," the magnets need to be oriented to the left side of

the gauge bar.

3. Tighten the setscrew.

4. Loosen the locking handle clockwise.

Fig.19

5. Place a carpenter’s square rmly against the magnetic

attachment and the miter fence. Press the Power button

to turn the digital miter gauge on. Press the Zero button

for 2 seconds to calibrate the gauge: the LCD will display

0.0º (Fig. 19).

6. Remove the table-saw insert.

7. Lower the table-saw blade to its lowest setting.

8. Loosen the fence-lock knobs and slide the miter gauge

head to the middle of the miter fence. Retighten the fencelock knobs.

11

Page 12

APPLICATION

0.0°

Fig.20

9. Lower the gauge bar into the table-saw-blade assembly

opening and allow the magnets to attach to the blade.

Always position the magnetic blade attachment close to

the center of the blade to keep the gauge bar from contacting the lower guard. Do not tighten the locking handle

(Fig. 20 and 21).

NOTE:

Be careful not to place the magnets near or on the saw blade

teeth.

10. Set the blade tilt angle by using your table saw controls

to adjust the blade to the desired angle, as indicated in

the miter-gauge display. If desired, ip the display by

briey pressing the Power button again.

NOTE:

In the process of moving the blade, ensure that the magnets

are always attached to the blade. If the magnets separate

from the blade, an inaccurate setting will result.

11. Remove the miter gauge and replace the table-saw in-

sert according to the table saw’s instruction manual before beginning to cut.

Fig.21

12

Page 13

MAINTENANCE

This tool has been designed to be a low-maintenance tool. However, in order to maintain its performance, you must always follow these simple directions.

•Avoidexposingthetooltoshock,continuousvibration,orextremehotorcoldtemperature.

•Storethetoolindoorsandinasafeplace.

•Alwayscleanthetoolwithaclean,softcloth.Ifnecessary,slightlymoistentheclothwithpurealcoholoralittlewater.

•Checkthebatteriesregularlytoavoiddeterioration.Alwaysremovethebatteriesfromthetoolifitisnotgoingtobeused

for an extended period of time.

•Replacethebatterieswhenthebatteryicondisplayedonthescreenindicatesthattheyarefullydepleted:" ".

•Donotattempttochangeanypartoftheunit.

•ToolservicemustbeperformedonlybyqualiedRepairCenter.Serviceormaintenanceperformedbyunqualiedper-

sonnel could result a risk of injury.

TROUBLESHOOTING

TROUBLE PROBABLE CAUSE SOLUTION

Batteries are installed incorrectly. Reinstall batteries with correct polarity.

The LCD screen will not turn

on.

The LCD display does not

operate correctly.

Inaccurate cutting angle or tilt

setting.

Battery voltage is low.

The LCD screen is damaged Take tool to the Service Center.

Batteries are depleted. Replace with new batteries.

The digital miter gauge was not calibrated to your table saw.

Replace with new batteries when the empty

battery icon appears on LCD.

Ensure that your miter gauge has been calibrated to the table saw prior to use

13

Page 14

NOTES

14

Page 15

RIDGID® DIGITAL MITER GAUGE

LIMITED THREE YEAR WARRANTY AND

90 DAY SATISFACTION GUARANTEE POLICY

America, Inc. All warranty communications should be directed to 1-800-4-RIDGID

(1-800-474-3443).

90-Day Satisfaction Guarantee Policy

During the rst 90 days after the date of purchase, if you are dissatised with the

performance of this RIDGID® tool for any reason, you may return the tool to the

dealer from which it was purchased for a full refund or exchange. To receive a

replacement tool you must present proof of purchase and return all original equipment packaged with the original product. The replacement tool will be covered by

the limited warranty for the balance of the three year warranty.

What is covered under the Limited Three Year Warranty

This warranty covers all defects in workmanship or materials in this RIDGID® tool

for the three year period from the date of purchase. This warranty is specic to

this tool. Warranties for other RIDGID® products may vary.

Important:

To speed up the warranty process, log onto the RIDGID® website at www.ridgid.com

or call 1-800-4-RIDGID within 30 days of purchase to register your Ridgid® tool and

validate your warranty. Please keep a copy of your receipt for your records and to

make a claim on your warranty.

What is not covered

This warranty applies only to the original purchaser at retail and may not be transferred. This warranty only covers defects arising under normal usage and does not

cover any malfunction, failure or defect resulting from misuse, abuse, neglect,

sentations or promises as to the quality or performance of its power tools other than

those specically stated in this warranty.

Additional Limitations

To the extent permitted by applicable law, all implied warranties, including warranties of or are dis-

claimed. Any implied warranties, including warranties of merchantability or tness

for a particular purpose, that cannot be disclaimed under state law are limited to

sible for direct, indirect, incidental or consequential damages. Some states do not

allow limitations on how long an implied warranty lasts and/or do not allow the exclusion or limitation of incidental or consequential damages, so the above limitations may not apply to you. This warranty gives you specic legal rights, and you

may also have other rights which vary from state to state.

© 2007 RIDGID, INC.

Model No. DMG9015

Serial No. _____________________

The model and serial numbers may be found on a plate attached to the saw at

the rear of the tile saw base. You should record both model and serial number

in a safe place for future use.

Questions or comments? Call:

1-800-4-RIDGID (1-800-474-3443) or go on-line at www.ridgid.com.

Please have your Model Number and Serial Number on hand when calling.

15

Page 16

MANUEL DE L’OPÉRATEUR

0.0°

JAUGE À ONGLETS NUMÉRIQUE

UNIVERSELLE

DMG9015

CONSERVEZ CE MANUEL POUR VOUS Y

RÉFÉRER ULTÉRIEUREMENT

MISE EN GARDE :

Pour réduire le risque de blessures, le consommateur doit lire et comprendre le manuel de l’opérateur avant d’utiliser ce

produit.

Merci d’avoir acheté un produit RIDGID.

CONSERVEZ CE MANUEL POUR VOUS Y RÉFÉRER ULTÉRIEUREMENT

Page 17

TABLE DES MATIÈRES

n Instructions de sécurité générales. . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Symboles de sécurité. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Message d’information et de prévention des dommages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Précautions de sécurité relative à l’utilisation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Sécurité concernant l’entretien. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

n Déballage et vérification du contenu. . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Déballage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Liste du contenu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

n Se familiariser avec votre jauge à onglets numérique. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Pièces principales. . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Caractéristiques techniques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

n Fonctionnement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-9

Installation des piles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... . . .7

Fixer le guide à la tête de la jauge à onglets. . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . 7

Choisir la bonne attache pour la barre de la jauge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Régler la rondelle pour rainure en T à la bonne position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . .8

Allumer et éteindre la jauge à onglets numérique. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Basculer l’afchage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Calibrer la jauge à onglets numérique sur l’assemblage de lame et de scie de table. . .. . . . . . . . . . . . . . . . 9

Rétroaction audio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

n Application. . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

Couper le bois à un angle quelconque avec une précision de ±0,1o. . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . .10

Utiliser l’accessoire de guide de précision. . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Déterminer l’angle d’inclinaison de l’assemblage de lame et de scie de table. . . . . . . . . . . . . . . . . . . . . . . 11

n Entretenir votre jauge à onglets numérique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

n Dépannage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

n Garantie. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2

Page 18

PRÉCAUTIONS DE SÉCURITÉ GÉNÉRALES

Les symboles de sécurité ont pour objectif d’attirer votre

attention sur les dangers possibles. Les symboles de

sécurités et leurs explications méritent toute votre

attention et compréhension.Les avertissements

N’éliminent PAS par eux même tout danger. Les

instructions et les avertissements donnés ne représentent

aucun substitut pour les mesures appropriées de

prévention d’accident.

Symboles de sécurité

LES SYMBOLES D’ALERTE À LA SÉCURITÉ :

Indique un DANGER, un AVERTISSEMENT ou une MISE

EN GARDE; ils peuvent être utilisés avec d’autres symboles ou pictographes.

DANGER :

À défaut d’obéir à cet avertissement de sécurité

vous CAUSERA, à vous ou d’autre personnes, la

mort ou des blessures graves. Toujours suivre les

precautions de sécurité afin de réduire les risques

d’incendie, de choc électrique et de blessure individuelle.

tions de sécurité dans ce manuel et le manuel pour

voutre outil électrique, y compris tous les symboles

d’alerte à la sécurité, tels que « DANGER », « AVERTISSEMENT » et « MISE EN GARDE ». Ne pas suivre

toutes les instructions indiquées ci-dessous et celles

de votre outils électrique peut causer un choc électrique, un incendie ou une blessure grave.

MISE EN GARDE :

Toujours tenir le guide à onglets éloigné de la lame,

lorsque la pièce à travailler est guidée avec cette jauge

à onglets numérique. Si le guide métallique entre en

contact avec la lame, cela peut entraîner des blessures

corporelles graves.

AVERTISSEMENT :

Avant de determiner l’angle d’inclinaison de la lame,

s’assurer que l’interrupteur de la scie est en position

ARRÊT et que la prise n’est pas branchée dans une

source d’alimentation. Si la scie est activée par accident, cela peut entraîner des blessures corporelles

graves.

MISE EN GARDE :

Ne pas obléir à cet avertissement de sécurité PEUT

vous causer, à vous ou d’autre personnes, la mort

ou des blessures graves. Toujours suivre les precautions de sécurité afin de réduire les risques

d’incendie de choc électrique et de blessure corporelle.

MISE EN GARDE :

À défaut d’béir à cet avertissement de sécurité

POURRAIT vous causer, à vous ou d’autre personnes, des blessures graves ou des dommages

matériels.Toujours suivre les precautions de sécurité afin de réduire les risques d’incendie, de choc

électrique et de blessure individuelle.

MESSAGES D’NFORMATION ET PRÉVENTION DES

DOMMAGES

Ils informent l’utilisateur des informations importantes ou des instructions qui pourraient endommager l’équipement ou d’autres biens matériels si

elles ne sont pas suivies. Chaque message est précédé par le mot « REMARQUE », comme le montre

l’exemple suivant :

Précautions de sécurité relative à l’utilisation

• Ne pas utiliser cet outil pour tout autre but que ceux

indiqués dans ce manuel. Cela pourrait occasionner des

blessures graves.

• Maintenir l’outil sec et ne pas l’utiliser sous la pluie.

• Éviter de faire tomber l’outil et de provoquer d’autres

causes d’impact sur l’outil.

• Retirer les piles si l’appareil ne servira pas pendant

plusieurs jours.

• Toujours jeter les piles usagées selon votre arrêté local;

ne pas incinérer les piles.

• La jauge à onglets numérique doit être calibrée avant

son utilisation an de congurer les coupes et l’angle

pour la lame de la scie.

Mesures de sécurité relatives à l’entretien

Ne pas tenter de réparer ou désassembler la jauge à onglets numérique. Si une personne non qualiée essaie de réparer ce produit, cela peut êntraîner des blessures graves.

Toute réparation nécessaire doit être effectuée uniquement

par un membre autorisé de l’équipe d’entretien.

Remarque : L’équipement ou les biens matériels peuvent être endommagés si ces instructions ne sont pas

suivies.

MISE EN GARDE :

Avant d’utiliser cette jauge à onglets numérique,

s’assurer de bien lire et comprendre toutes les instruc-

3

Page 19

DÉBALLAGE ET VÉRIFICATION DU CONTENU

La jauge à onglets numérique est contenue dans une

seule boîte. Ne pas jeter les matériaux d’emballage avant

d’avoir vérié que tout le contenu est présent.

Séparer toutes les pièces et les matériaux d’emballage.

Consulter la « liste du contenu » et la Figure 1 pour

s’assurer que toutes les pieces sont présentes avant de

jeter les matériaux d’emballage.

Appeler le centre de service RIDGID si des pièces sont

endommagées ou manquantes.

Liste des pièces en vrac

NOM DE LA PIÈCE QUANTITÉ

Jauge à onglets numérique

Guide à onglets

Jauge micro-réglable

Jauge d’arrêt à bascule

Jauge d’arrêt de précision

Attache de la barre de jauge de 1/4 po

(installée sur la barre de jauge)

Attache de la barre de jauge de 1/8 po

Attache de lame magnétique

Clé hexagonale

Rondelle à rainure en T pour rainure de

3/8 po (installée sur la barre de jauge)

Rondelle à rainure en T pour rainure de

1/2 po

Vis pour rondelle à rainure en T

profonde

Piles AAA

1

1

1

1

1

1

1

1

1

1

1

1

2

4

Page 20

SE FAMILIARISER AVEC VOTRE JAUGE À ONGLETS

NUMÉRIQUE

La jauge à onglets numérique est un outil intelligent qui améliore l’efcacité des projets du travail du bois. Elle a été

conçue par un travailleur du bois professionnel pour les travailleurs du bois. Elle permet de déterminer les angles de

coupe en travers et les angles pour la lame de la scie de -50° à +50° avec une précision de ±0,1° en quelques secondes.

La jauge est destinée à une utilisation avec toutes les scies d’établi, portatives et xes dotées de rainures de 1/2, 5/8 et

3/4 po et de rainures en T de 5/8, 3/4 et 7/8 po avec une profondeur de rainure de 3/8 ou 1/2 po.

Pièces principales

10

9

5

2

3

8

1

7

6

21

4

16

14

12

20

19

18

11

5

13

15

17

Fig. 1

5

Page 21

SE FAMILIARISER AVEC VOTRE JAUGE À ONGLETS

NUMÉRIQUE

20. Vis pour rondelle à rainure en T profonde.

1. Tête usinée de la jauge à onglets.

2. Bouton d’alimentation : appuyer pour allumer la jauge

à onglets numérique; appuyer de nouveau pour

basculer l’afchage.

3. Bouton ZÉRO : calibre l’angle actuel à 0,0 degré.

4. Écran ACL : large écran ACL avec un rétroéclairage

bleu pour une lecture facile.

5. Boutons de blocage du guide : sécurise le guide à

onglets sur la tête de la jauge à onglets; sécurise les

jauges d’arrêt sur le guide à onglets.

6. Compartiment à piles : pour deux piles AAA.

7. Poignée de blocage à prise douce : verrouille et

déverrouille la tête de la jauge à onglets.

8. Clé hexagonale : utilisée pour serrer ou desserrer les

vis sur les attaches de la barre de jauge, l’attache de

lame magnétique et la rondelle à rainure en T.

9. Jauge micro-réglable : conçue pour servir dans les

fentes du guide; elle peut être utilisée comme un

micro-réglage pour la jauge d’arrêt à bascule ou

d’arrêt xe.

10. Jauge d’arrêt à bascule : une jauge à usage multiple

qui peut servir dans les fentes du guide et comme

jauge d’arrêt solide.

11. Jauge d’arrêt de précision : pour des coupes

répétitives précises.

12. Guide à onglets : guide la pièce à travailler pour la

coupe à l’angle choisie.

13. Attache de lame magnétique : se xe à la barre de la

jauge à onglets de 1/2 po pour le réglage de

l’inclinaison de la lame.

14. Barre de la jauge à onglets de 1/2 po : convient à tous

les outils d’établi, portatifs et xes avec une rainure

standard de 1/2 po pour la jauge à onglets.

15. Rondelle à rainure en T pour rainure de 3/8 po :

convient aux tables à rainure en T pour les outils

d’établi, portatifs et xes avec profondeur de rainure

de 3/8 po.

16. Attache de la barre de jauge de 1/4 po : se xe à la

barre de la jauge à onglets de 1/2 po pour le réglage

de l’inclinaison de la lame.

17. Attache de la barre de jauge de 1/8 po : se xe à la

barre de la jauge à onglets de 1/2 po pour le réglage

de l’inclinaison de la lame.

18. 1,5 V

19. Rondelle à rainure en T pour rainure de 1/2 po :

convient aux tables à rainure en T pour les outils

d’établi, portatifs et xes avec profondeur de rainure

de 3/8 po.

21. Bout à onglets : permet des coupes à onglets précises

à l’extrémité du guide à onglets.

Fiche technique

Pile 2 piles « AAA » de 1,5 V

Intervalle d’angles à

onglets

Intervalle d’angles de

l’inclinaison de la lame

Précision ±0.1°

Intervalle de

températures de

fonctionnement optimal

Poids : 1,67 kg (3,67 lb)

-50° à +50°

-50° à +50°

0°C à 40°C (32°F à 104°F)

6

Page 22

FONCTIONNEMENT

INSTALLATION DES PILES

Cette jauge à onglets numérique utilise deux piles « AAA ».

Fig. 2

• Retirer immédiatement les piles vides et les jeter selon

votre arrêté local.

• Ne jamais jeter des piles dans le feu.

FIXER LE GUIDE À LA TÊTE DE LA JAUGE À ONGLETS

Le guide possède un bout à onglets an de permettre des

coupes à onglets précises proches de l’extrémité du guide

à onglets. Toujours placer ce bout sur le côté droit de la

tête à onglets. Consulter l’emplacement 21 sur la Fig. 1.

1. Desserrer les boutons de blocage du guide

(emplacement 5 sur la Fig. 1) an de relâcher les deux

boutons de blocages pour les insérer dans la rainure.

Bouton de

blocage du guide

Bouton de

blocage du

guide

Fig. 3

1. Ouvrir le couvercle de piles comme l’indique la èche

sur le couvercle (Fig. 2).

2. Insérer deux nouvelles piles alcalines « AAA » selon les

indications de polarité dans le compartiment à piles

(Fig. 3). S’assurer que la polarité (+/-) est correcte!

3. Fermer le couvercle et le verrouiller bien en place.

REMARQUE :

• Remplacer les piles lorsque le voyant de pile sur

l’afchage indique qu’elles sont entièrement vides :"

• Retirer les piles de la jauge à onglets numérique

lorsqu’elle n’est pas utilisée pendant une longue

période.

• Les deux piles AAA doivent être de même marque et

catégorie.

• Ne jumelez pas de vieilles piles avec des neuves.

Fig. 4

2. Aligner le premier bouton de blocage sur la rainure du

guide, puis le glisser en place (Fig. 4).

".

Fig. 5

3. Continuer de glisser le deuxième bouton de blocage

en place (Fig. 5).

4. Placer le guide à la position souhaitée.

5. Tourner les boutons de blocage du guide vers la

droite pour verrouiller le guide.

7

Page 23

Barre de jauge de 1/2 po

Attache de la

barre de jauge de 1/8 po

Attache de la

barre de jauge de 1/4 po

1/2” slot 5/8” slot 3/4” slot

FONCTIONNEMENT

CHOISIR LA BONNE ATTACHE POUR LA

BARRE DE LA JAUGE

Fig. 6

Les attaches de la barre de jauge s’adaptent à la barre de

jauge universelle pour convenir aux rainures standards de

1/2, 5/8 ou 3/4 po de la jauge à onglets. La barre de jauge

universelle convient à une rainure de 1/2 po. En utilisant la

clé hexagonale et les vis fournies, xer une attache de la

barre de jauge de 1/8 po sur le côté pour convenir à une

rainure de 5/8 po; xer une attache de la barre de jauge

de 1/4 po sur le côté pour convenir à une rainure de 3/4

po. Consulter la Fig. 6.

RÉGLER LA RONDELLE POUR RAINURE EN T

À LA BONNE POSITION

Régler la rondelle pour rainure en T an que la barre de

jauge puisse convenir aux rainures des tables avec et

sans rainures en T pour les outils d’établi, portatifs et

xes.

Vis longue pour

rondelle à rainure

en T profonde

Fig. 7c

La rondelle à rainure en T de 3/8 po (Fig. 7a) est xée à

l’avant de la barre de jauge (Fig. 8). Utiliser cette rondelle

pour les rainures en T d’une profondeur de 3/8 po. Pour

les rainures en T d’une profondeur de 1/2 po, retirer la

rondelle de 3/8 po et xer la rondelle à rainure en T de 1/2

po (Fig. 7b et Fig. 7c).

Trois lignes d’indication existent sur chaque rondelle (Fig.

7a);utiliser ces lignes comme guides lorsque vous tournez

la rondelle sur une position précise pour convenir à une

table à rainure en T standard de 5/8, 3/4 ou 7/8 po.

Ligne d’indication pour

rainure en 7/8" T-slot

Ligne d’indication pour

rainure en 5/8" T-slot

Ligne d’indication

pour rainure en 3/4"

T-slot

Fig. 7a

Fig. 7b

Fig. 8

Pour convenir à des tables sans rainures en T, garder les

deux côtés de la rondelle en T alignés sur la barre de

jauge, comme indiqué à la Fig. 8.

Fig. 9

Pour convenir à une table avec rainures en T :

1. Desserer la vise sur la rondelle à rainure en T à l’aide de

la clé hexagonale (Fig. 9).

8

Page 24

7/8” T-slot3/4” T-slot5/8” T-slot

a b c

°

0‘0

FONCTIONNEMENT

Fig. 10

2. Tourner la rondelle à rainure en T vers la gauche, puis

aligner la ligne d’indication sur le bord de la barre de

jauge (Fig. 10 et Fig. 11).

La Fig. 11(a) indique la position de la rondelle à rainure en T

pour convenir à une table standard à rainure en T de 5/8 po.

La Fig. 11(b) indique la position de la rondelle à rainure en

T pour convenir à une table standard à rainure en T de 3/4

po.

La Fig. 11(c) indique la position de la rondelle à rainure en

T pour convenir à une table standard à rainure en T de 7/8

po.

CALIBRER LA JAUGE À ONGLETS NUMÉRIQUE SUR L’ASSEMBLAGE DE LAME ET

DE SCIE DE TABLE

(équerre de charpente obligatoire, disponible séparément)

REMARQUE :

• Toujours calibrer la jauge à onglets numérique sur votre

scie de table avant de l’utiliser pour guider une coupe. À

défaut de réaliser le calibrage peut provoquer une coupe

inexacte.

• Une fois la jauge à onglets numérique calibrée sur votre

scie de table, aucun calibrage n’est nécessaire pour une

utilisation ultérieure sur la même scie, à moins que la

jauge à onglets n’ait été calibrée sur d’autres scies de

table ou sur une équerre de charpente après le premier

calibrage.

1. Glisser la barre de jauge dans la fente sur la table avec

rainures en T ou placer la barre dans la fente sur une

table sans rainures en T.

2. Élever entièrement la lame de la scie de table.

3. Desserrer la poignée de blocage.

4. Allumer la jauge à onglets.

3. Serrer à nouveau la vis à l’aide de la clé hexagonale.

ALLUMER ET ÉTEINDRE LA JAUGE À ONGLETS NUMÉRIQUE

1. Appuyer sur le bouton d’alimentation pour allumer

l’outil.

2. Appuyer sur le bouton d’alimentation pendant 3

secondes environ pour éteindre l’outil.

3. La jauge à onglets numérique s’éteindra

automatiquement 5 minutes après que l’utilisateur

arrête de bouger la tête de la jauge à onglets.

BASCULER L’AFFICHAGE

Une fois la jauge à onglets numérique allumée, appuyer

brièvement sur le bouton d’alimentation pour basculer

l’afchage.

Fig. 11

Fig. 12

5. Placer une équerre de charpente fermement contre la

lame et le guide à onglets (Fig. 12).

6. Appuyer sur le bouton Zéro pendant 2 secondes;

l’écran ACL s’afchera. 0.0o. La jauge à onglets est

maintenant calibrée sur votre scie de table. Vous

pouvez continuer l’utilisation de la jauge à onglets

numérique pour la coupe oblique.

RÉTROACTION AUDIO

Lors du fonctionnement, la jauge à onglets numérique

émet un « clic » sonore, lorsqu’elle pivote sur la gauche ou

la droite. Cette caractéristique avertit l’opérateur du bon

fonctionnement de la jauge à onglets numérique.

9

Page 25

APPLICATION

°

0’52

COUPER LE BOIS À UN ANGLE

QUELCONQUE AVEC UNE PRÉCISION DE

±0,1°

MISE EN GARDE :

Toujours tenir le guide à onglets éloigné de la lame, lorsque la coupe est guidée avec cette jauge à onglets numérique. Si le guide métallique est coupé, cela peut

entraîner des blessures corporelles graves.

REMARQUE :

Avant d’effectuer une coupe, la jauge à onglets numérique

doit être tout d’abord calibrée.

1. Convenir et calibrer la jauge à onglets numérique à la

table, comme le décrit la section précédente «

CALIBRER LA JAUGE À ONGLETS NUMÉRIQUE SUR

L’ASSEMBLAGE DE LAME ET DE SCIE DE TABLE ».

2. Une fois la barre de jauge bien xée dans la fente de la

table, allumer la jauge à onglets numérique.

3. Déverrouiller la poignée de blocage.

4. Pivoter la tête de la jauge à onglets vers l’angle

souhaitée, comme l’indique l’afchage, puis serrer la

poignée de blocage.

Fig. 14

La jauge d’arrêt de précision est conçue pour une

précision verticale;elle permet à l’utilisateur de couper

plusieurs pièces en un seul passage, comme le montre la

Fig. 14.

Fig. 13

5. Bien mettre en place la pièce à travailler contre le guide

à onglets et commencer la coupe en travers, en suivant

les instructions de fonctionnement pour la scie de table

(Fig. 13).

UTILISER L’ACCESSOIRE DE GUIDE DE PRÉCISION

Cette jauge à onglets numérique offre une variété

d’accessoires de guide de précision, qui permettent à

l’utilisateur d’utiliser au maximum les capacités de la

jauge.

Fig. 15

Fig. 16

La jauge d’arrêt à bascule est une jauge à usage multiple

qui peut servir dans la fente supérieure du guide et

comme jauge d’arrêt solide.

Pour couper une longue pièce à travailler, simplement la

retourner; il n’est pas nécessaire de la detacher du guide

(Fig. 15 et 16).

10

Page 26

45,0°

0.0°

0.0°

0.0°

APPLICATION

Vist micro-réglable

Fig. 17

La jauge micro-réglable est conçue pour servir dans les

fentes du guide; elle peut être utilisée comme un micro-

réglage pour la jauge d’arrêt à bascule ou d’arrêt xe.

Pour régler la jauge d’arrêt à bascule, verrouiller d’abord la

jauge micro-réglable sur le guide à l’aide du bouton de

blocage, puis tourner la vis micro-réglable pour déplacer la

jauge d’arrêt à bascule vers la gauche ou la droite (Fig. 17).

DÉTERMINER L’ANGLE D’INCLINAISON DE

L’ASSEMBLAGE DE LAME ET DE SCIE DE TABLE

1. Utiliser la clé hexagonale de 1/8 po (incluse) pour

desserrer les vis de l’attache de lame magnétique en

les tournant vers la gauche.

2. Pour les lames de scie de table qui s’inclinent vers la «

gauche », les aimants de l’attache doivent être orientés

vers le côté droit de la barre de jauge, comme indiqué à

la Fig. 18. Pour les lames de scie de table qui s’inclinent

vers la « droite », les aimants de l’attache doivent être

orientés vers le côté gauche de la barre de jauge.

3. Serrer les vis.

4. Desserrer la poignée de blocage en la tournant vers la

droite.

MISE EN GARDE :

Avant de determiner l’angle d’inclinaison de la lame,

s’assurer que l’interrupteur de la scie est en position

ARRÊT et que la prise n’est pas branchée dans une

source d’alimentation. Si la scie est activée par accident, cela peut entraîner des blessures corporelles

graves.

MISE EN GARDE :

Retirer la clé héxagonale de la poignée de blocage et la

placer dans un lieu sûr.

Si la clé hexagonale tombe dans la scie de table, cela

peut entraîner des blessures corporelles graves.

Comme l’attache de lame magnétique convient

uniquement à la barre de jauge de 1/2 po, détacher toute

attache qui se trouve sur la barre de jauge.

Utiliser l’attache de lame magnétique pour les lames de scie

de table qui taillent en biseau vers la gauche ou la droite.

Orienter les aimants vers le bon

côté

Fig. 19

5. Placer une équerre de charpente fermement contre

l’attache de lame magnétique et le guide à onglets.

Appuyer sur le bouton d’alimentation pour allumer la

jauge à onglets numérique. Appuyer sur le bouton Zéro

pendant 2 secondes pour calibrer la jauge : l’écran ACL

s’afchera0.0o (Fig. 19).

6. Retirer la garniture de la scie de table.

7. Abaisser la lame de la scie de table à sa conguration

la plus basse.

8. Desserrer les boutons de blocage du guide et glisser la

tête de la jauge à onglets dans le milieu du guide à

onglets. Reserrer les boutons de blocage du guide.

Fig. 18

Fig. 20

11

Page 27

APPLICATION

Fig. 21

9. Abaisser la barre de jauge dans l’ouverture de

l’assemblage de lame et de scie de table, puis laisser

les aimants se xer à la lame.Toujours placer l’attache

de lame magnétique près du centre de la lame an

d’empêcher la barre de jauge d’entrer en contact avec

la protection inférieure. Ne pas serrer la poignée de

blocage (Fig. 20 et 21).

REMARQUE :

Faire attention à ne pas placer les aimants à proximité ou

sur les dents de la lame de la scie.

10. Déterminer l’angle d’inclinaison de la lame à l’aide des

commandes de la scie de table an de régler la lame à

l’angle souhaité, comme l’indique l’afchage de la

jauge à onglets. Le cas échéant, basculer l’écran en

réappuyant brièvement sur le bouton d’alimentation.

REMARQUE :

Lors du déplacement de la lame, s’assurer que les

aimants sont toujours xés à la lame. Si les aimants se

détachent de la lame, une conguration inexacte aura lieu.

11. Retirer la jauge à onglets et replacer la garniture de la

scie de table selon le manuel d’instruction

correspondant avant de commencer la coupe.

ENTRETIEN

Cet outil a été conçu en vue d’un faible entretien. Toutefois, an de maintenir sa performance, vous devez toujours suivre

ces directions simples.

• Éviter d’exposer l’outil à un choc, une vibration continue ou des temperatures chaudes ou froides extrêmes.

• Conserver l’outil à l’intérieur et dans un lieu sûr.

• Toujours nettoyer l’outil avec un linge doux et propre. Le cas échéant, humidier légèrement le linge avec de l’alcool

pur ou un peu d’eau.

• Vérier les piles régulièremet pour éviter une détérioration. Toujours retirer les piles de l’outil, s’il ne sera pas utilisé

pendant une longue période.

• Remplacer les piles lorsque le voyant de pile afché à l’écran indique qu’elles sont entièrement vides :"

• Ne pas tenter de changer une pièce de l’unité.

• L’entretien de l’outil doit être effectué uniquement par un centre de réparation qualié. L’entretien ou la maintenance

réalisée par une personne non qualiée peut causer un risque de blessure.

".

DÉPANNAGE

PROBLÈME CAUSE POSSIBLE SOLUTION

Les piles sont mal installées. Réinstaller les piles selon la bonne

polarité.

L’écran ACL ne s’allume pas.

Le voltage des piles est faible. Remplacer par des piles neuves

lorsque le voyant de piles vides

apparaît sur l’écran ACL.

L’écran ACL ne fonctionne pas

correctement.

La conguration de l’inclinaison et de

l’angle de coupe est inexacte.

L’écran ACL est endommagé. Amener l’outil au centre

d’entretien.

L’énergie des piles est épuisée. Remplacer les piles défraîchies par

des piles neuves.

La jauge à onglets numérique n’a

pas été calibrée sur votre scie de

table.

12

S’assurez-vous que la jauge à

onglets a été calibrée sur la scie

de table avant l’utilisation.

Page 28

NOTES PERSONNELLES

13

Page 29

JAUGE À ONGLETS NUMÉRIQUE RIDGID

POLITIQUE DE GARANTIE DE SATISFACTION DE 90 JOURS ET

GANRANTIE LIMITÉE DE TROIS ANS

Ce produit est fabriqué sous licence de Ridgid, Inc. par Chervon North America,

Inc.America, Inc. Toute communication concernant la garantie doit être transmise

à 1-800-4-RIDGID (1-800-474-3443).

Politique de garantie de satisfaction de 90 jours

Au cours des 90 premiers jours suivant la date d’achat, si vous n’êtes pas

satisfait de la performance de cet outil Ridgid pour quelque raison que ce soit,

vous pouvez retourner l’outil chez le détaillant d’origine de cet achat pour obtenir

un remboursement complet ou un échange. Pour recevoir un outil de

remplacement, vous devez présenter une preuve d’achat et retourner l’emballage

d’origine et le produit d’origine. L’outil de remplacement sera couvert pour la

période résiduelle de la garantie de trois ans.

Ce qui est couvert par la garantie limitée de trois ans

Cette garantie couvre tous les défauts de fabrication et de matériaux de cet outil

Ridgid pour une période de trois ans à compter de la date d’achat.

Cette garantie ne s’applique qu’à cet outil. Les garanties pour les autres produits

Ridgid peuvent être différentes.

IMPORTANT :

Pour accélérer le processus de garantie, visiter le site Internet de RIDGID® en

allant au www.ridgid.com ou appeler au 1-800-4-RIDGID dans les 30 jours

suivant l’achat pour enregistrer votre outil Ridgid® et valider votre garantie.

Veuillez conserver une copie de votre reçu pour vos dossiers et lorsque vous

demandez une réclamation au titre de votre garantie.

Éléments non couverts

Cette garantie ne s’applique qu’à l’acheteur d’origine au détail et n’est pas

transférable.Cette garantie ne couvre que les défauts provenant d’un usage

normal et ne couvre pas les mauvais fonctionnements, les pannes ou les défauts

occasionés par une mauvaise utilisation, un abus, une négligence, une altération

ou une modication. Chervon North America Inc. ne fait aucune garantie,

représentation ou de promesses quant à la qualité ou la performance de ses

outils électriques autres que celles expressément énoncées dans la présente garantie.

Autres Restrictions

Dans la mesure permise par la loi applicable, toutes les garanties implicites, y

compris les garanties de QUALITÉ MARCHANDE ou D’ADAPTATION À UN

USAGE PARTICULIER, sont déclinées.Toute garantie implicite, y compris les

garanties de qualité marchande ou d’adéquation à un usage particulier, qui ne

peut pas être exclue en vertu de la législation des provinces est limitée à trois

ans à compter de la date d’achat. Chervon North America Inc. n’est pas

responsable dommages de directs, indirects, accessoires ou consécutifs.

Certaines provinces ne permettent pas de limitations sur la durée d’une garantie

implicite et/ou ne permettent pas l’exclusion ou la limitation des dommages

fortuits ou consécutifs, de sorte que les limitations ci-dessus peuvent ne pas

s’appliquer à vous. Cette garantie vous donne des droits spéciques, et vous

pouvez également avoir d’autres droits qui varient d’une province à l’autre.

© 2007 RIDGID, INC.

No de modèle DMG9015

No de série _____________________

Les numéros de modèle et de série se trouvent sur une plaque attachée à la

scie à l’arrière de la base de scie en tuile. Vous devez noter les numéros de

modèle et de série et les placer dans un endroit sûr pour référence ultérieure.

Des questions ou des commentaires? Appelez au :

1-800-4-RIDGID (1-800-474-3443) ou en ligne au www.ridgid.com.

Veuillez avoir en mains votre numéro de modèle et numéro de série lorsque

vous appelez © 2007 ridgid, inc.

14

Page 30

MANUAL DEL OPERADOR

0.0°

MEDIDOR DE CORTE ANGULAR

DIGITAL UNIVERSAL

DMG9015

Advertencia:

Para reducir el riesgo de lesiones, el usuario debe leer y comprender el manual del operador antes de utilizar este producto.

Gracias por comprar un producto RIDGID.

CONSERVE ESTE MANUAL PARA CONSULTARLO EN EL FUTURO

Page 31

TABLA DE CONTENIDO

n INSTRUCCIONES GENERALES DE SEGURIDAD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Símbolos de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Mensajes de información y prevención de daños . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Precauciones de seguridad para las operaciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Seguridad en la reparación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Desembalaje y vericación del contenido . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Desembalaje . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Listado del contenido . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Empiece a familiarizarse con su medidor de corte angular digital . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Partes principales . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Especicaciones técnicas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

n FUNCIONAMIENTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Para instalar las baterías . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Sujete la guía al cabezal del medidor de corte angular . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Elija el accesorio de barra del medidor que corresponda . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ajuste la arandela de ranura en T en la posición correcta . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Encienda y apague el medidor de corte angular digital . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Voltee el display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Calibre el medidor de corte angular digital al montaje de hoja-sierra-mesa . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Respuesta de audio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

n Aplicación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

Corte madera a un ángulo cualquiera con una exactitud de ±0,1º . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Utilice los accesorios de guía de precisión . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fije el ángulo del inclinación de hoja-sierra-mesa . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mantenimiento de su medidor de corte angular digital . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

SOLUCIÓN DE PROBLEMAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Garantía . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . 14

2

Page 32

INSTRUCCIONES GENERALES DE SEGURIDAD

El propósito de los símbolos de seguridad es llamar su

atención respecto de posibles peligros. Los símbolos de

seguridad y las explicaciones que los acompañan

merecen su total atención y comprensión. Las

advertencias de símbolos, en sí mismas, NO eliminan

ningún peligro. Las instrucciones y advertencias que

brindan no sustituyen a las medidas para prevención de

accidentes que correspondan.

Símbolos de Seguridad.

SÍMBOLO DE ALERTA DE SEGURIDAD:

Indica PELIGRO, ADVERTENCIA O PRECAUCIÓN; se

puede utilizar junto con otros símbolos o pictografías.

PELIGRO:

Ignorar esta advertencia de seguridad TENDRÁ como

resultado la muerte o una lesión grave para usted o

para los demás. Respete siempre las precauciones de

seguridad a fin de reducir el riesgo de incendio, descarga eléctrica y lesiones personales.

ADVERTENCIA:

Ignorar esta advertencia de seguridad PUEDE TENER

como resultado la muerte o una lesión grave para usted o para los demás.

Respete siempre las precauciones de seguridad a fin

de reducir el riesgo de incendio, descarga eléctrica y

lesiones personales.

PRECAUCIÓN:

Ignorar esta advertencia de seguridad PODRÍA TENER

como resultado una lesión personal para usted o para

terceros, o daños a los bienes. Respete siempre las

precauciones de seguridad a fin de reducir el riesgo

de incendio, descarga eléctrica y lesiones personales.

Información y prevención de daños Mensajes

instrucciones de su herramienta eléctrica, se podrían

producir descargas eléctricas, incendios y/o lesiones

personales graves.

ADVERTENCIA:

Mantenga siempre la guía de corte angular alejada de

la hoja cuando guíe la pieza de trabajo con este medidor de corte angular digital. Se podrían producir lesiones personales graves si la guía de metal entra en

contacto con la hoja.

ADVERTENCIA:

Antes de fijar el ángulo de inclinación de la hoja,

asegúrese de que el interruptor de la sierra de mesa

está en posición APAGADO (OFF) y el enchufe no está

conectado a una fuente de electricidad. Se podrían

producir lesiones personales graves si la sierra se activara por accidente.

Precauciones de seguridad para las operaciones

• No utilice esta herramienta para un propósito distinto de

los que se describen en este manual. Esto podría

producir lesiones graves.

• Mantenga la herramienta seca y no la utilice en la lluvia.

• Evite dejar caer la herramienta y otras causas de

impacto sobre la misma.

• Quite las baterías si el dispositivo no se va a utilizar

durante varios días.

• Siempre deseche las baterías usadas de conformidad

con lo establecido en las ordenanzas municipales; no

incinere las baterías.

• El medidor de corte angular digital se debe calibrar

antes de usarlo para jar los cortes o jar el ángulo de la

hoja de la sierra.

Estos mensajes informan al usuario sobre datos y/o instrucciones importantes que, en caso de no respetarse,

podrían tener como resultado daños a los equipos u otros

bienes. Cada mensaje es precedido por la palabra

“NOTA”, como en el ejemplo a continuación.

NOTA: Si no se respetan estas instrucciones, se podrían

causar daños a los equipos y/o bienes.

ADVERTENCIA:

Asegúrese de leer y comprender todas las instrucciones de seguridad en este manual y el manual correspondiente a su herramienta eléctrica, incluidos

todos los símbolos de alerta de seguridad, tales como

“PELIGRO”, “ADVERTENCIA” y “PRECAUCIÓN”, antes

de usar este medidor de corte angular digital. Si no se

respetan todas las instrucciones a continuación y las

Seguridad en la Reparación

No intente reparar o desarmar el medidor de corte angular

digital. Si personas no calicadas intentan reparar este

producto, podrían producirse lesiones graves. Toda

reparación que sea necesaria debe ser realizada por

personal del servicio técnico autorizado.

3

Page 33

DESEMBALAJE Y VERIFICACIÓN DEL CONTENIDO

El medidor de corte angular digital viene en una caja. No

descarte ningún material de embalaje hasta dar cuenta de

todo el contenido.

Separe todas las partes del material de embalaje.

Remítase al “Listado del contenido” y a la Fig. 1 para asegurarse de dar cuenta de todos los artículos antes de

descartar el material de embalaje.Llame al Centro de

Reparación RIDGID si están dañadas o faltan algunas de

las partes.

Listado de partes sueltas

NOMBRE DE LA PARTE CANTIDAD

Medidor de corte angular digital 1

Guía de corte angular 1

Medidor de microajuste 1

Medidor de retén de vuelta 1

Medidor de retén de precisión 1

Accesorio de barra del medidor de 1/4”

(instalado en la barra del medidor)

Accesorio de barra del medidor de 1/8” 1

Accesorio de hoja magnética 1

Llave hexagonal 1

Arandela de ranura en T para ranura de

profundidad de 3/8” (instalada en la barra

del medidor)

Arandela de ranura en T para ranura de

profundidad de 1/2”

Tornillo para arandela de ranura en T profunda

Baterías AAA 2

1

1

1

1

4

Page 34

EMPIECE A FAMILIARIZARSE CON SU MEDIDOR DE CORTE

ANGULAR DIGITAL

El medidor de corte angular digital es una herramienta inteligente que incrementa la eciencia en proyectos de trabajos

con madera. Fue diseñado por un trabajador de la madera profesional destinado para trabajadores de la madera. Fija

ángulos de corte transversal y ángulos de hoja de sierra de mesa desde -50º hasta +50º con una exactitud de ±0,1° en

cuestión de segundos. Para uso con todas las sierras de mesa de banco, portátiles y jas, con ranuras de 1/2”, 5/8” y

3/4”, y ranuras en T de 5/8”, 3/4” y 7/8” con una profundidad de ranura de 3/8” o 1/2”.

Partes principales

10

9

5

2

3

8

1

7

6

21

4

16

14

12

11

5

13

15

17

20

19

18

Fig. 1

5

Page 35

EMPIECE A FAMILIARIZARSE CON SU MEDIDOR DE CORTE

ANGULAR DIGITAL

1. Cabezal del medidor de corte angular torneado.

2. Botón de Energía (Power): presiónelo para encender el

medidor de corte angular; presiónelo otra vez para dar

vuelta el display.

3. Botón CERO (ZERO): calibra el ángulo actual como de

0,0 grados.

4. Pantalla LCD: display LCD grande con iluminación de

fondo azul para facilitar la lectura.

5. Perillas de bloqueo de guía: asegura la guía de corte

angular al cabezal del medidor de corte angular;

asegura los medidores de retén a la guía de corte

angular.

6. Compartimento para baterías: para dos baterías AAA.

7. Mango de bloqueo con empuñadura suave: bloquea y

desbloquea el cabezal del medidor de corte angular.

8. Llave hexagonal: se utiliza para aojar o ajustar los

tornillos en los accesorios de barra del medidor, el

accesorio de hoja magnética y la arandela de ranura

en T.

9. Medidor de microajuste: diseñado para utilizarlo en

cualquiera de las hendiduras de la guía, se puede usar

como un microajuste para el retén de vuelta o un

medidor de retén positivo.

10. Medidor de retén de vuelta: un medidor de usos

múltiples que se puede utilizar en cualquier hendidura

de la guía o como un medidor de retén sólido.

11. Medidor de retén de precisión: Para cortes repetitivos

exactos.

12. Guía de corte angular: guía la pieza de trabajo para el

corte al ángulo seleccionado.

13. Accesorio de hoja magnética: se sujeta a la barra del

medidor de corte angular de 1/2” para el ajuste de

inclinación de la hoja.

14. Barra del medidor de corte angular de 1/2”: se adapta

a todas las herramientas de banco, portátiles y jas

con una ranura de medidor de corte angular estándar

de 1/2”.

15. Arandela de ranura en T para ranura con profundidad

de 3/8”: encaja en mesas de ranura en T de

herramientas de banco, portátiles y jas con una

profundidad de ranura de 3/8”.

16. Accesorio de barra del medidor de 1/4”: se sujeta a la

barra del medidor de corte angular de 1/2” para el

ajuste de inclinación de la hoja.

17. Accesorio de barra del medidor de 1/8”: se sujeta a la

barra del medidor de corte angular de 1/2” para el

ajuste de inclinación de la hoja.

18. Baterías.

19. Arandela de ranura en T para ranura con profundidad

de 1/2”: encaja en mesas de ranura en T de

herramientas de banco, portátiles y jas con una

profundidad de ranura de 3/8”.

20. Tornillo para arandela de ranura en T profunda.

21. Extremo cortado angularmente: permite cortes

angulares precisos cerca del extremo de la guía de

corte angular.

Especificaciones Técnicas

Batería 2 baterías “AAA” de 1,5V

Rango de ángulo de corte

angular

Rango de ángulo de incli-

nación de la hoja

Exactitud ±0.1°

Rango de temperatura de

funcionamiento óptima

Peso 3,67 lbs ( 1,67 kg)

-50º a +50º

-50º a +50º

32°F a 104°F (0°C a 40°C)

6

Page 36

DEL CAJÓN

PARA INSTALAR LAS BATERÍAS

Este medidor de corte angular digital utiliza dos baterías

“AAA”.

Fig. 2

SUJETE LA GUÍA AL CABEZAL DEL MEDIDOR DE

CORTE ANGULAR

La guía cuenta con un extremo cortado angularmente

para permitir cortes angulares precisos cerca del extremo

de la guía de corte angular. Coloque siempre este extremo

a la derecha del cabezal de corte angular. Remítase a la

ubicación 21 en la Fig. 1.

1. Aoje las perillas de bloqueo de guía (5 en la Fig. 1)

para liberar ambos topes de bloqueo de manera que

se puedan insertar en la ranura en la guía.

Perilla de bloqueo de guía

Perilla de

bloqueo de

guía

Fig. 3

1. Abra la tapa de la batería como se indica mediante la

echa sobre la tapa (Fig. 2).

2. Inserte dos baterías alcalinas “AAA” nuevas de

acuerdo con los indicadores de polaridad en el

compartimento de baterías (Fig. 3). ¡Asegúrese de que

la polaridad (+/-) sea correcta!

3. Cierre la tapa y trábela de modo seguro.

NOTA:

• Reemplace las baterías cuando el indicador de baterías

en el display muestre que las baterías están totalmente

agotadas:"

• Quite las baterías del medidor de corte angular digital

cuando no se utiliza durante largos períodos.

• Las 2 baterías AAA deben ser iguales en cuanto a la

marca y el tipo.

• No mezcle baterías nuevas y viejas.

• Quite las baterías agotadas de inmediato, y deséchelas

de conformidad con lo dispuesto en las ordenanzas

municipales.

• Nunca deseche baterías en el fuego.

".

Fig. 4

2. Alinee el primer tope de bloqueo con la ranura en la

guía y deslícelo para colocarlo en su lugar (Fig. 4).

Fig. 5

3. Continúe deslizando el segundo tope de bloqueo

para colocarlo en su lugar. (Fig. 5).

4. Mueva la guía hasta la posición deseada.

5. Gire las perillas de bloqueo de guía en el sentido de

las agujas del reloj para bloquear la guía.

7

Page 37

DEL CAJÓN

barra del medidor

de 1/2"

accesorio de barra del

medidor de 1/8"

accesorio de barra del

medidor de 1/4"

1/2” slot 5/8” slot 3/4” slot

ELIJA EL ACCESORIO DE BARRA DEL MEDIDOR QUE CORRESPONDA

Fig. 6

Los accesorios de barra del medidor se adaptan a la barra

del medidor universal para encajar en ranuras de medidor

de corte angular estándares de 1/2”, 5/8” o 3/4”. La barra

de medidor universal encaja en una ranura de 1/2”.

Usando la llave hexagonal y los tornillos provistos, sujete

un accesorio de barra del medidor de 1/8” al costado

para encajar en una ranura de 5/8”; sujete un accesorio

de barra del medidor de 1/4” al costado para encajar en

una ranura de 3/4”. Por favor, remítase a la Fig. 6.

AJUSTE LA ARANDELA DE RANURA EN T EN

LA POSICIÓN CORRECTA

Ajuste la arandela de ranura en T para permitir que la

barra del medidor encaje en las ranuras de las tablas de

ranura en T y tablas de ranura no en T en herramientas de

banco, portátiles y jas.

Tornillo largo para

arandela de ranura

en T profunda

Fig. 7c

La arandela de ranura en T de 3/8" (Fig. 7) se sujeta al

frente de la barra del medidor (Fig. 8). Utilice esta arandela

para ranuras en T con una profundidad de 3/8". Para

ranuras en T con una profundidad de 1/2", quite la

arandela de 3/8" y sujete la arandela para ranura en T de

1/2" (Fig. 7b y Fig. 7c).

Hay tres líneas indicadoras en cada arandela (Fig. 7a);

utilice estas líneas para guiarse a medida que gira la

arandela a una posición especíca para adaptarse a una

tabla de ranura en T estándar de 5/8", 3/4” o 7/8".

Línea indicadora para

ranura en T de 5/8”

Línea indicadora para

ranura en T de 3/4”

Línea indicadora para

ranura en T de 7/8”

Fig. 7a

Fig. 7b

Fig. 8

Para adaptar tablas de ranura no en T, mantenga los dos

lados de la arandela en T alineados con la barra del

medidor, como se muestra en la Fig. 8.

Fig. 9

Para adaptarse a una tabla de ranura en T:

1. Aoje el tornillo sobre la arandela de ranura en T con

la llave hexagonal (Fig. 9).

8

Page 38

DEL CAJÓN

°

0‘0

7/8” T-slot3/4” T-slot5/8” T-slot