Page 1

• Français – 11

• Castellano – pág. 23

WARNING!

Read this Operator’s Manual

carefully before using this tool.

Failure to understand and follow the contents of this manual

may result in extensive property damage and/or serious

personal injury.

Press Tool

OPERATOR’S

MANUAL

CT400

Page 2

Ridge Tool Companyii

CT400 Press Tool

Table of Contents

Recording Form for Machine Serial Number..............................................................................................................1

General Safety Information

Work Area...................................................................................................................................................................2

Electrical Safety..........................................................................................................................................................2

Personal Safety...........................................................................................................................................................2

Tool Use and Care......................................................................................................................................................2

Service........................................................................................................................................................................3

Specific Safety Information

Press Tool Safety........................................................................................................................................................3

Description and Specifications

Description..................................................................................................................................................................3

Specifications..............................................................................................................................................................4

Inspecting the Pressing Tool, Jaw Sets and Press Rings.........................................................................................4

Attaching Pressing Jaws..............................................................................................................................................4

Tool and Work Area Set-Up..........................................................................................................................................5

Operating Instructions For Use Of Jaw Sets

Preparing the Joint......................................................................................................................................................5

Pressing the Fitting.....................................................................................................................................................5

Inspecting the Press Connection................................................................................................................................6

Operating Instructions For Use Of Press Rings

Preparing the Joint......................................................................................................................................................7

Pressing the Fitting.....................................................................................................................................................7

Inspecting the Press Connection................................................................................................................................7

Accessories...................................................................................................................................................................8

Maintenance Instructions

(CT400) Daily Cleaning and Lubrication ....................................................................................................................8

Jaws and Press Rings ................................................................................................................................................8

Required Maintenance at RIDGID Authorized Service Center ..................................................................................8

Storage ......................................................................................................................................................................8

Service and Repair........................................................................................................................................................9

Troubleshooting............................................................................................................................................................9

Lifetime Warranty .........................................................................................................................................Back Cover

Page 3

CT400 Press Tool

CT400 Press Tool

Record Serial Number below and retain product serial number which is located on nameplate.

Serial

No.

Page 4

Ridge Tool Company2

CT400 Press Tool

General Safety Information

WARNING! Read and understand all instructions. Failure

to follow all instructions listed below may

result in electric shock, fire, and/or serious

personal injury.

SAVE THESE INSTRUCTIONS!

Work Area Safety

• Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

• Do not operate tools in explosive atmospheres,

such as in the presence of flammable liquids,

gases, or dust. Power tools create sparks which may

ignite the dust or fumes.

• Keep by-standers, children, and visitors away

while operating a tool. Distractions can cause you to

lose control.

Electrical Safety

• Double Insulated tools are equipped with a polarized plug (one blade is wider than the other). This

plug will fit in a polarized outlet only one way. If the

plug does not fit fully in the outlet, reverse the

plug. If it still does not fit, contact a qualified electrician to install a polarized outlet. Do not change

the plug in any way. Double Insulation eliminates

the need for the three wire grounded power cord and

grounded supply system.

• Avoid body contact with grounded surfaces such

as pipes, radiators, ranges and refrigerators. There

is an increased risk of electrical shock if your body is

grounded.

• Do not expose power tools to rain or wet condi-

tions. Water entering a tool will increase the risk of

electrical shock.

• Do not abuse cord. Never use the cord to carry the

tools or pull the plug from an outlet. Keep cord

away from heat, oil, sharp edges or moving parts.

Replace damaged cords immediately. Damaged

cords increase the risk of electrical shock.

• When operating a tool outside, use an outdoor

extension cord marked “W-A” or “W”. These cords

are rated for outdoor use and reduce the risk of electrical shock.

• Use proper extension cords. (See Chart) Insufficient

conductor size will cause excessive voltage drop, loss

of power and overheating.

Personal Safety

• Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use tool while tired or under the influence of

drugs, alcohol, or medications. A moment of inat-

tention while operating power tools may result in

serious personal injury.

• Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, clothing,

and gloves away from moving parts. Loose clothes,

jewelry, or long hair can be caught in moving parts.

• Avoid accidental starting. Be sure switch is OFF

before plugging in. Carrying tools with your finger on

the switch or plugging in tools that have the switch ON

invites accidents.

• Remove adjusting keys or wrenches before turn-

ing the tool ON. A wrench or a key that is left attached

to a rotating part of the tool may result in personal

injury.

• Do not overreach. Keep proper footing and bal-

ance at all times. Proper footing and balance enables

better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protec-

tion. Dust mask, non-skid safety shoes, hard hat, or

hearing protection must be used for appropriate conditions.

Tool Use and Care

• Use clamp or other practical way to secure and

support the workpiece to a stable platform. Holding

the work by hand or against your body is unstable and

may lead to loss of control.

• Do not force tool. Use the correct tool for your

application. The correct tool will do the job better and

safer at the rate for which it is designed.

• Do not use tool if switch does not turn it ON or

OFF. Any tool that cannot be controlled with the

switch is dangerous and must be repaired.

• Disconnect the plug from the power source before

making any adjustments, changing accessories, or

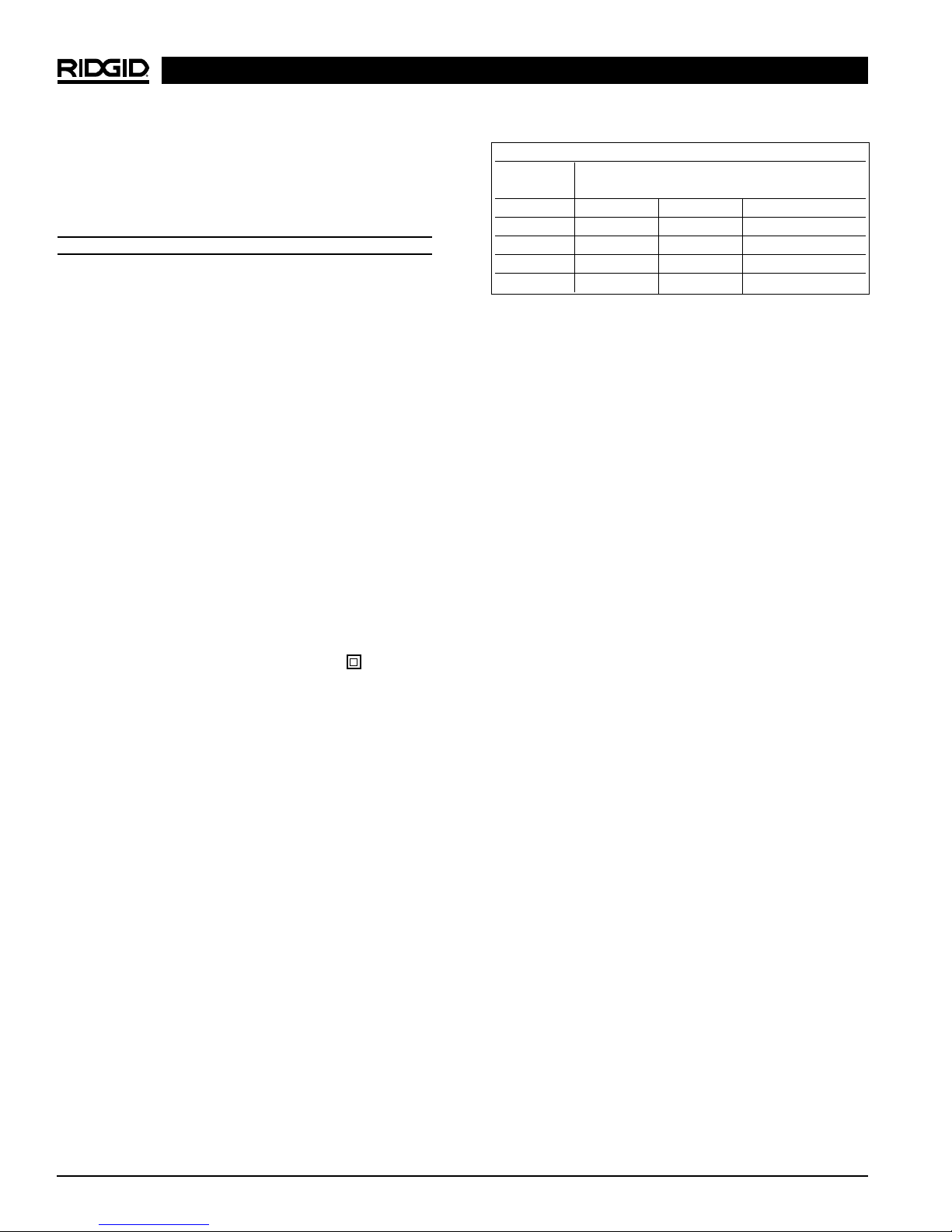

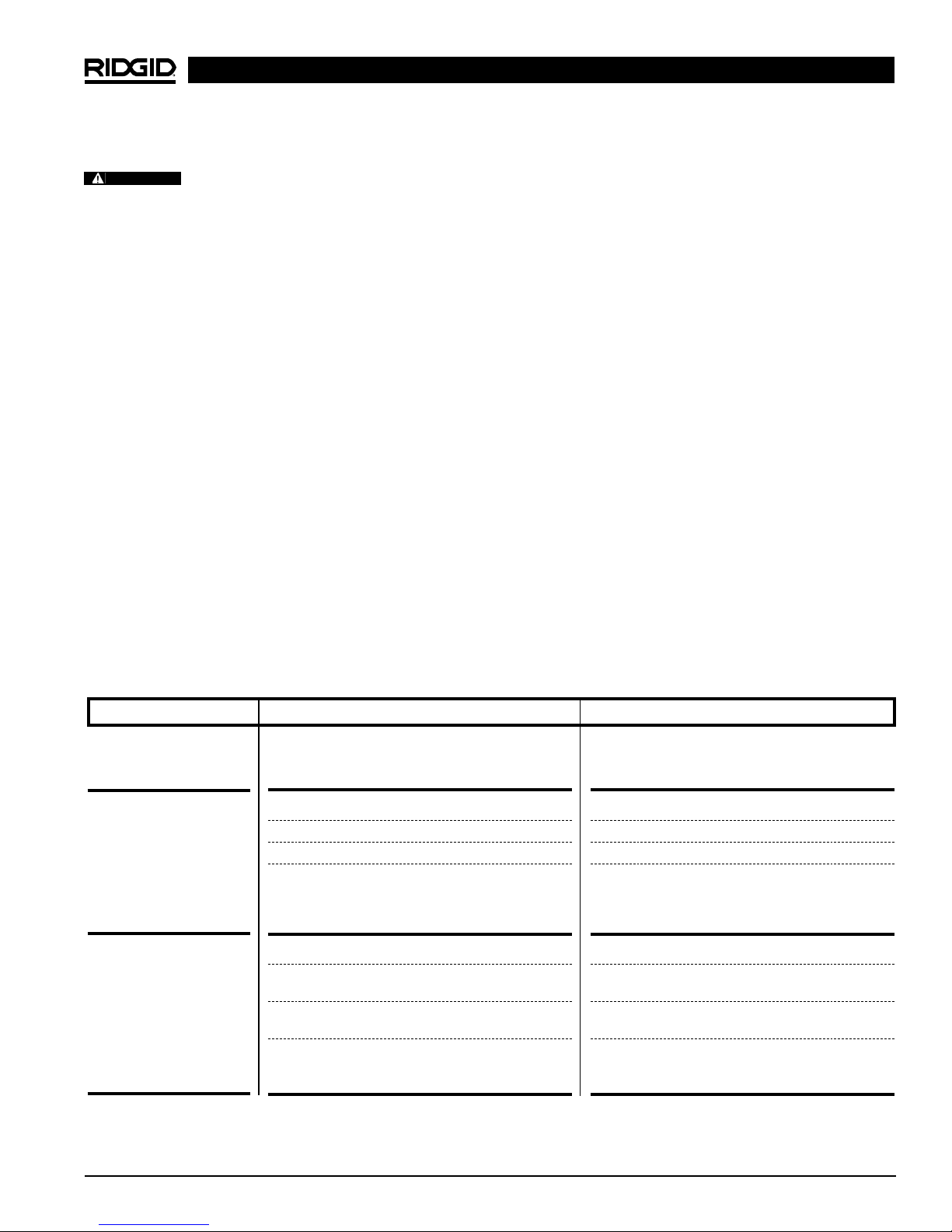

Minimum Wire Gauge for Extension Cord

Nameplate

Amps

Total Length (in feet)

0 – 25 26 – 50 51 – 100

0 – 6 18 AWG 16 AWG 16 AWG

6 – 10 18 AWG 16 AWG 14 AWG

10 – 12 16 AWG 16 AWG 14 AWG

12 – 16 14 AWG 12 AWG

NOT RECOMMENDED

Page 5

storing the tool. Such preventive safety measures

reduce the risk of starting the tool accidentally.

• Store idle tools out of the reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

• Check for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may affect the tool’s operation. If damaged,

have the tool serviced before using. Many acci-

dents are caused by poorly maintained tools.

• Use only accessories that are recommended by

the manufacturer for your model. Accessories that

may be suitable for one tool may become hazardous

when used on another tool.

• Keep handles dry and clean; free from oil and

grease. Allows for better control of the tool.

Service

• Tool service must be performed only by qualified

repair personnel. Service or maintenance performed

by unqualified repair personnel could result in injury.

• When servicing a tool, use only identical replace-

ment parts. Follow instructions in the Maintenance

Section of this manual. Use of unauthorized parts or

failure to follow maintenance instructions may create a

risk of electrical shock or injury.

Specific Safety Information

WARNING

Read this Operator’s Manual carefully before using

the RIDGID CT400 Press Tool. Failure to understand and follow the contents of this manual may

result in extensive property damage, severe personal injury, or death.

Call the Ridge Tool Company, Technical Service Department at (800) 519-3456 if you have any questions.

Press Tool Safety

• Only use the CT400 Press Tool with RIDGID jaws

or RIDGID press rings. Other uses or modifying the

CT400 Press Tool for other applications may damage

the press tool, damage the jaws and/or cause personal

injury.

• Keep your fingers and hands away from jaws or

press rings and actuator during pressing cycle.

Your fingers or hands can be crushed, fractured or

amputated if they become caught between the jaws,

Ridge Tool Company 3

CT400 Press Tool

press rings or actuator or between these components

and any other object.

• Do not use the CT400 if the finger guards are damaged or missing. Properly installed guards (Figure 1)

are necessary to protect your fingers and hands from

becoming crushed or amputated by the rollers and

jaws.

• Never remove the drop guard. Replace drop guard

if it is damaged or broken. The drop guard (Figure 1)

protects the tool handle if the tool is dropped. If the drop

guard is missing and the tool is dropped, the motor

housing may crack and expose live electrical wires.

• Never attempt to repair a damaged jaw set. A jaw

that has been welded, ground, drilled or modified in

any manner can shatter during pressing resulting in

serious injury. Discard the entire damaged jaw set.

Replace with a new jaw set. Never replace individual

components except for damaged jaw return springs.

Please call Ridge Tool Company, Technical Service

for availability.

• Never attempt to repair a damaged press ring or

actuator. A press ring set component that has been

welded, ground, drilled or modified in any manner can

shatter during pressing, resulting in serious injury.

Discard the entire damaged press ring assembly or

actuator assembly. Replace with a new press ring or

actuator. Never replace individual components except

for press ring and actuator return springs. Please call

Ridge Tool Company, Technical Service for availability.

• Never use tool with a power cord, switch or motor

housing that is damaged. Using a tool with a dam-

aged cord, cracked motor housing or broken switch

can result in electric shock and severe injury.

Selection of appropriate materials and joining

methods is the responsibility of the system designer and/or installer. Before any installation is attempted, careful

evaluation of the specific service environment, including

chemical environment and service temperature, should be

completed.

Description and Specifications

Description

The CT400 Press Tool, when used with appropriate

jaw sets, is designed to mechanically press fittings onto

tubing to create a water-tight and permanent seal. When

the switch on the CT400 is depressed, an internal electric motor powers a hydraulic pump which forces fluid into

the cylinder of the tool, forcing the ram forward and

applying thousands of pounds of pressing force onto specially designed press fittings.

CAUTION

Page 6

Ridge Tool Company

The entire cycle duration is approximately four (4) seconds.

Once the cycle begins to deform a fitting, it will automatically continue until completion. A hydraulic release button

is provided to allow the removal of the jaw set or press ring

from the tubing in the event of a power or system failure

during pressing.

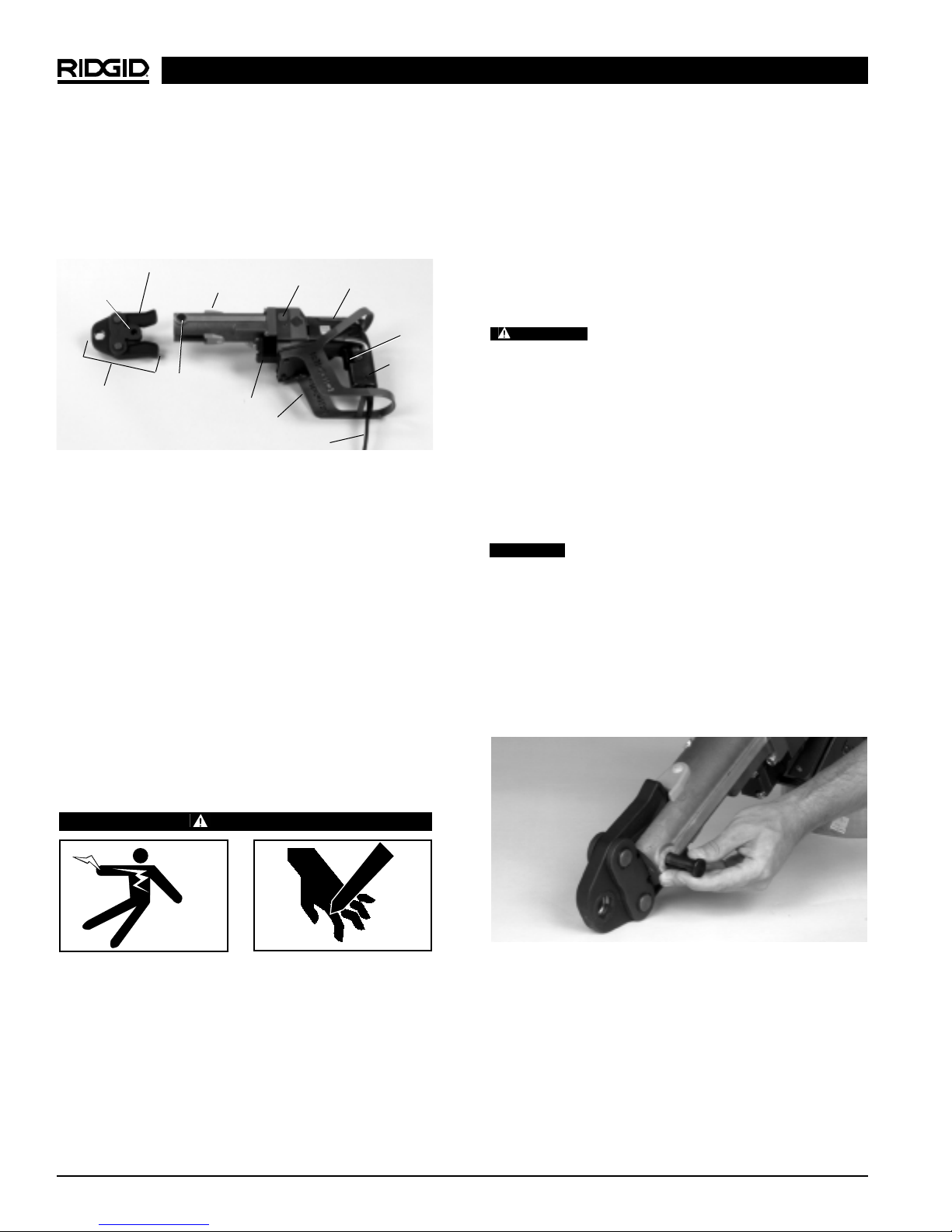

Figure 1 – CT400 Press Tool and Standard Series Jaw Set

Specifications

CT400 Press Tool:

Motor

Voltage ...................120V, Single Phase AC 60 Hz

Amperage...............5.2A

Weight ....................15.6 lbs. (7 Kg)

Ram Force ....................7,200 lbs. (32kN)

Operating Temperature

Range............................15°F to 120°F (-10°C to 50°C)

Inspecting the Press Tool, Jaw

Sets and Press Rings

WARNING

To prevent electrocution and serious injury, inspect

the CT400 Press Tool, jaw sets and press rings.

Never use the CT400, a jaw set, actuator arm or

press ring with damaged or missing parts. The following inspection procedures should be performed

on a daily basis:

1. Make sure the CT400 Press Tool is unplugged.

2. Inspect the motor housing, switch, power cord and plug

for damage. Check for damage such as cracks in the

motor housing, cut or frayed cords and exposed wires.

3. To avoid a crushing injury, make sure both of the finger guards and the drop guard are securely in place.

4. Inspect the jaw sets, press rings and actuator arm. If

dirty, refer to Fitting Systems operator's manual for

cleaning instructions. Failure to clean jaws or press

rings can result in an improper connection that can

lead to extensive property damage. If any cracks are

found, discard the damaged assemblies and obtain

replacement.

Always discard the entire assembly. Never

replace individual components except for press ring and

jaw/actuator return springs. Failure to replace the entire

assembly may result in component failure and serious

injury.

5. Clean any oil, grease or dirt from the tool handles.

This reduces the risk of the tool slipping from your grip.

Attaching Pressing Jaws

or Actuator

Only use RIDGID Standard Series Jaw sets

or actuators. Use with the RIDGID jaw or ring and fitting

system intended for the specific tubing material you are

installing. Use of other jaw sets or press rings will result in

an improper seal that could result in extensive property

damage.

1. Make sure the CT400 Press Tool is unplugged.

2. Pull the jaw set mounting pin to its most open position

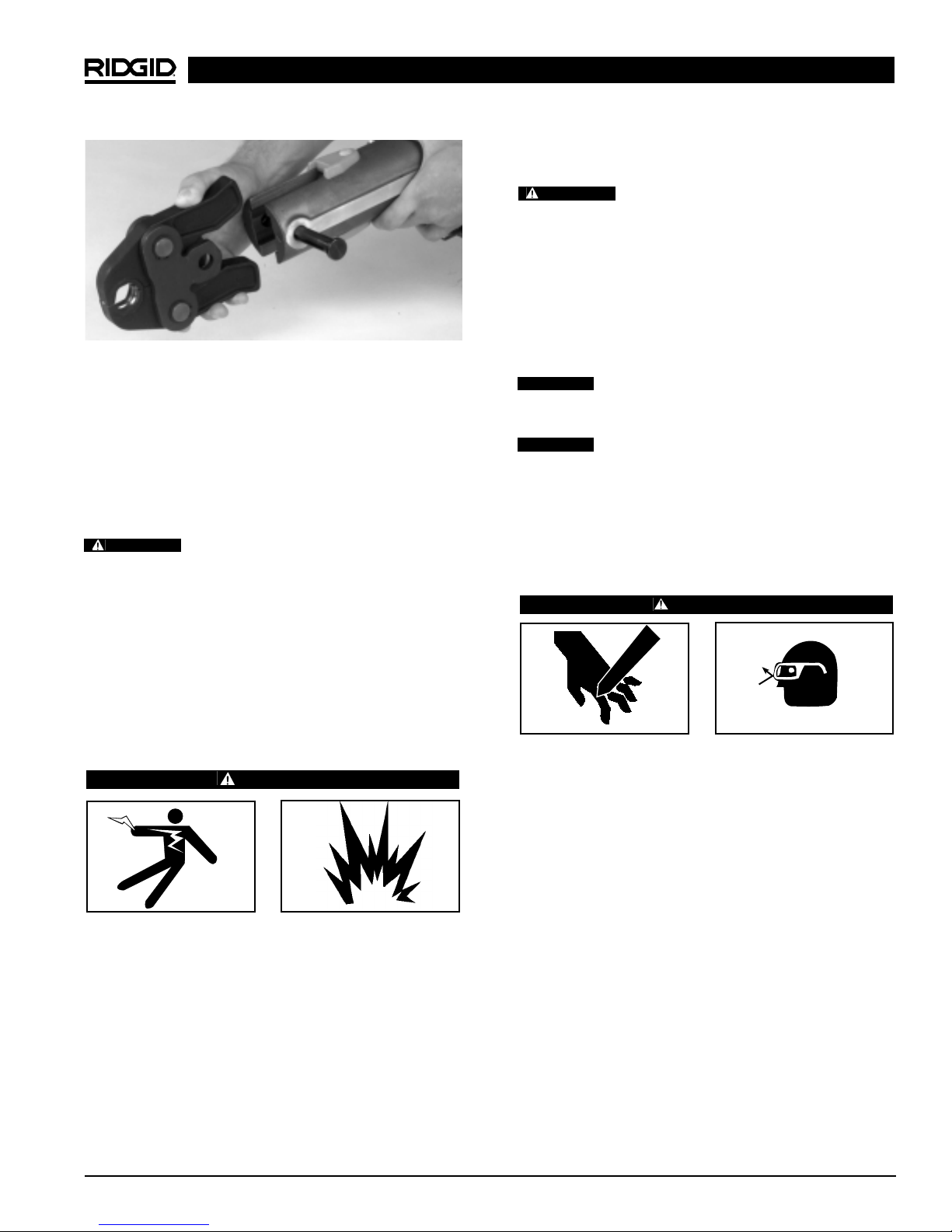

(Figure 2).

Figure 2 – Pulling The Jaw Set Mounting Pin Out

3. If press tool contains a jaw set or press ring actuator,

slide it out of the press tool.

CT400 Press Tool

4

Hydraulic

Release Valve

Finger Guard

Standard

Series Jaw Set

Jaw Arm

Jaw Mounting

Pin

Power Cord

Motor Housing

Switch

Handle

Drop Guard

Jaw

Sideplate

Pump

WARNING

CAUTION

Page 7

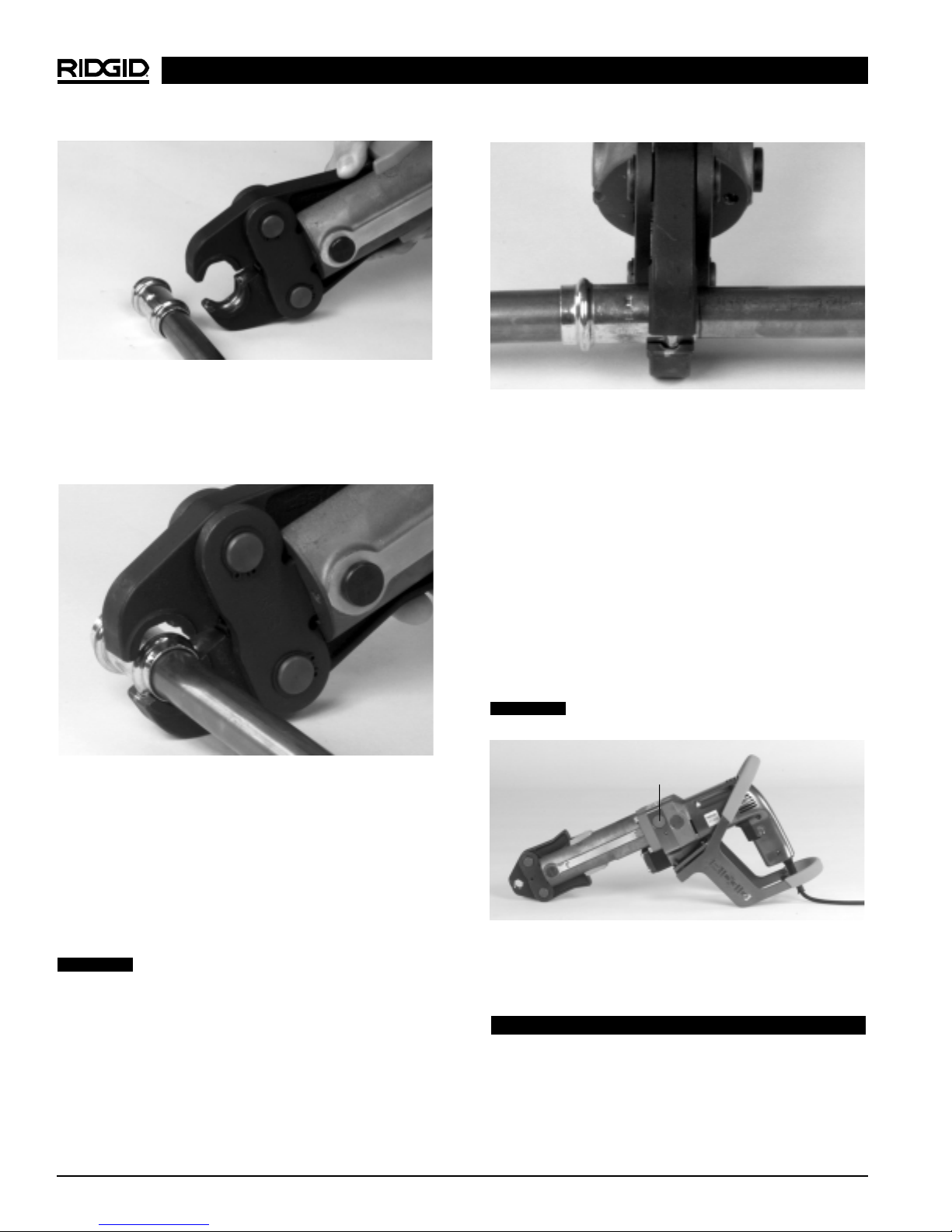

Figure 3 – Sliding Jaw Set Into CT400

4. Select the standard series jaw set or actuator that corresponds to the fitting system and tubing size. Inspect

the jaw set. If dirty, clean jaw sets. Refer to Maintenance Section for cleaning instructions. Failure to

clean jaws can result in an improper connection that

can lead to extensive property damage. If any cracks

are found, discard the damaged jaw set and obtain

replacement.

A jaw that has been welded, grounded,

drilled or modified in any manner can shatter during

pressing, resulting in sharp flying objects, severe injury

or death. Discard and replace damaged jaw sets.

5. Slide the jaw set into the press tool (Figure 3).

6. Push the jaw set mounting pin until it clicks.

NOTE! The CT400 will not work unless the pin is fully

engaged.

Tool and Work Area Set-Up

WARNING

To prevent serious injury, proper set-up of the press

tool and work area is required. The following procedures should be followed:

1. Check work area for:

• Adequate lighting

• Clear path to the electrical outlet that does not

contain any sources of heat or oil, sharp edges or

moving parts that may damage electrical cord.

• Flammable liquids, vapors or dust that may ignite.

2. Plug the Press Tool into the electrical outlet, making

sure to position the power cord along the clear path

CT400 Press Tool

Ridge Tool Company 5

selected earlier. If the power cord does not reach the

outlet, use an extension cord in good condition.

To avoid electric shock and electrical

fires, never use an extension cord that is damaged or

does not meet the following requirements:

• The cord is rated as “W” or “W-A” if being used

outdoors.

• The cord has sufficient wire thickness (16 AWG

below 50′/14 AWG 50′-100′). If the wire thickness is

too small, the cord may overheat, melting the cord’s

insulation or causing nearby objects to ignite.

Use of extension cords in excess of 100

feet is not recommended. May result in low voltage

condition that will cause the tool to malfunction.

Do not use the CT400 Press Tool at temperatures below 15°F (-10°C) or above 120°F (50°C).

Tool could malfunction resulting in an improper seal

that can lead to extensive property damage.

Operating Instructions For Use

With Jaw Sets

WARNING

The CT400 is designed for use only with RIDGID jaw

sets, actuators and press rings. Use the jaw and fitting system intended for the specific tubing material

you are installing.

Keep fingers and hands away from jaws, press

rings and actuator arms during pressing cycle.

Always wear eye protection to protect your eyes

from dirt and other foreign objects.

Preparing the Joint

1. See the appropriate press system operator's manual for proper joint preparations prior to pressing.

Pressing the Fitting With Scissor Jaw Set

1. Plug the CT400 Press Tool into electrical outlet.

2. Make sure the tubing is inserted to the proper depth in

fitting as specified in fitting system operator's manual.

3. Squeeze jaw arms to open the jaw set (Figure 4).

WARNING

WARNING

CAUTION

CAUTION

Page 8

Figure 4 – Opening The Scissor-Style Jaw Set

3. Place open jaws around the fitting. Make sure the contour of the jaw set is properly aligned with the contour

of the fitting as specified in press system operator's

manual (Figure 5).

Figure 5 – Placing Scissor-Style Jaw Set Around Fitting

4. Make sure the tool is square to the tubing and depress

the switch (Figure 6). The pressing cycle takes about

four (4) seconds. Once a press cycle begins and the

rollers contact the jaw arms, the tool will lock-on and

automatically complete the press cycle. Releasing

the trigger will not stop the tool once the pressing

process has begun. This assures consistent, repeatable press integrity.

To avoid pinch point injuries, keep fingers

away from jaws.

CT400 Press Tool

Ridge Tool Company6

Figure 6 – CT400 Square To Tubing

NOTE! If the tool beeps after the press cycle is completed,

the tool should be sent to a RIDGID Authorized

Service Center for required maintenance. When the

tool begins beeping, it is designed to run an additional 2000 cycles and then will automatically stop

operating.

NOTE! In the event of a tool or power failure, the jaw set can

be reopened by firmly depressing the hydraulic release valve button to retract the rollers and squeezing the jaw arms together (Figure 7). Be sure to

repress the fitting taking care to orient the jaw on the

fitting in its original position.

5. After cycle is complete, squeeze jaw arms to open the

jaw set.

6. Remove the CT400 Press Tool and jaws from tube.

Avoid sharp edges that may have formed on

the fitting during the pressing operation.

Figure 7 – Using Hydraulic Release Valve Button

(If Needed)

Inspecting the Press Connection

CAUTION

• If the CT400 or jaw set malfunctions and does not

completely press the fitting, be sure repress the

fitting taking care to orient the jaw on the fitting in its original position.

1. Inspect the pressed fitting. Look for the following:

• misaligned tubes

CAUTION

CAUTION

Hydraulic

Release Valve

Page 9

• not fully inserted tubes, double check depth marks

• incorrect jaw alignment with the fitting

If one or more of these problems are found then a

new section of tubing and a new fitting will have to be

prepared, inserted and pressed.

2. Test system in accordance with normal practice and

local codes.

Operating Instructions For Use

Of Press Rings

Preparing the Joint

1. See appropriate fitting system operator's manual for

proper joint preparations prior to pressing with press

rings.

Pressing The Fitting with Press Rings

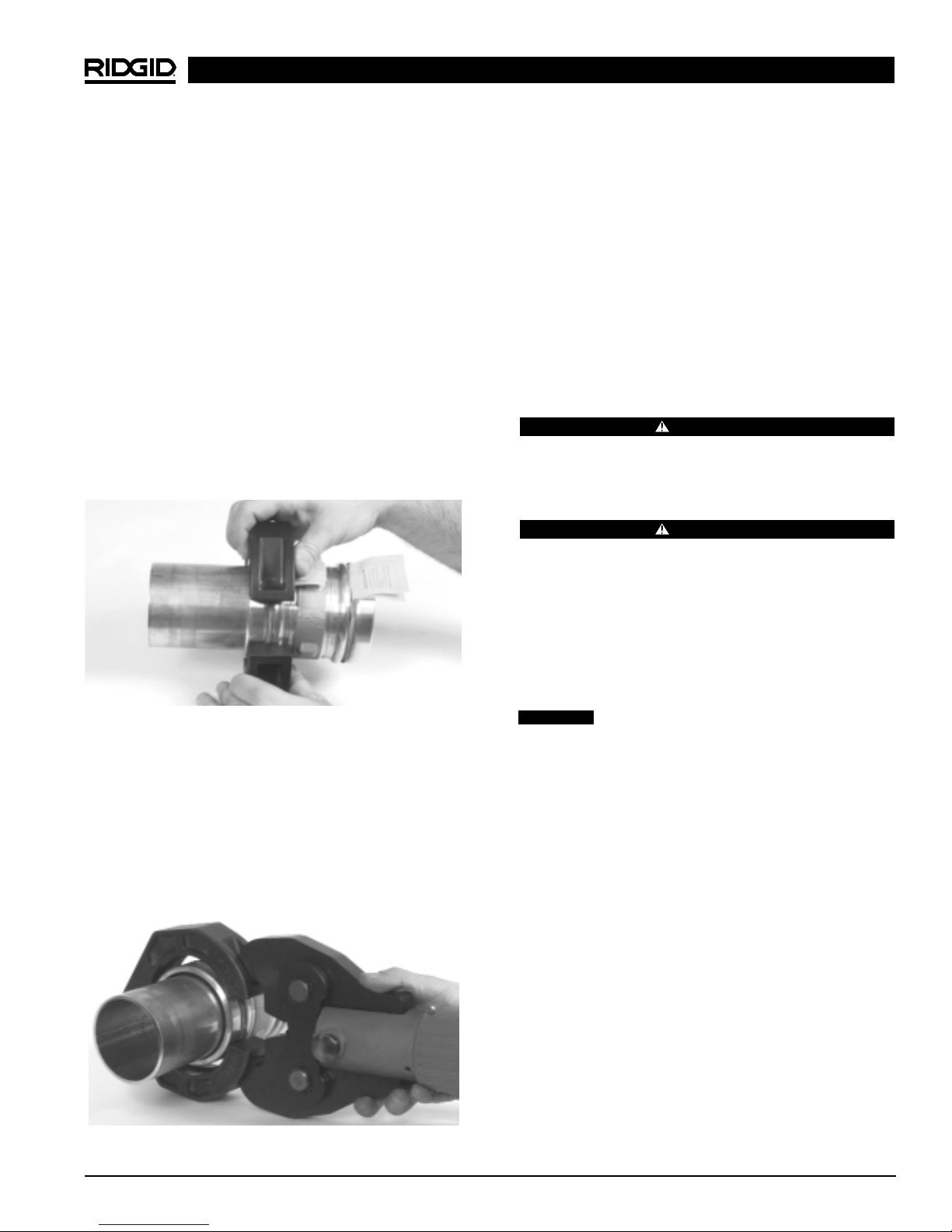

Figure 8 – Installing Press Ring Onto Fitting

1. Make sure, the tubing is inserted to the proper depth

in fitting, as specified in fitting systems operator's

manual.

2. Plug the CT400 Press Tool into electrical outlet.

3. Open the press ring and place at right angles onto the

fitting. Align ring with fitting according to fitting system

operator's manual. Recheck insertion depth before

completing pressing process.

Figure 9 – Attaching Ring Actuator To Press Ring

CT400 Press Tool

Ridge Tool Company 7

4. Confirm the actuator in the tool is the appropriate

actuator for use with the press ring being used.

Squeeze actuator arms to open actuator assembly.

Engage ring actuator ends into actuator pockets in the

press rings. Make sure actuator ends are fully engaged in pockets.

5. Depress the tool trigger switch. The pressing cycle

takes about four (4) seconds. Once a press cycle

begins and the rollers contact the actuator arms, the

tool will lock-on and automatically complete the press

cycle. Releasing the trigger will not stop the tool once

the pressing process has begun. This assures consistent, repeatable press connection integrity.

WARNING

Do not attempt to hang tool and ring actuator from

press ring. Tool could unexpectedly drop causing

serious injury or death.

WARNING

To avoid pinch point injuries, keep fingers away

from actuators or press rings during pressing.

6. After cycle is complete, squeeze actuator arms to

open and separate actuator from press ring. Remove

press ring from fitting by manually grasping ring halves

and opening assembly.

Inspecting the Press Connection

If the CT400 or ring jaw set malfunctions during a pressing cycle, the fitting should be replaced or

re-pressed per fitting system operator's manual.

1. Inspect the pressed fitting. Look for the following:

• Excessive misalignment of tubes.

• Tubes that are not fully inserted.

• Incorrect press ring alignment with the fitting.

• If one or more of these problems are found, then a

new section of tubing and a new fitting will have to

be prepared, inserted and pressed.

2. Test system in accordance with normal practice and

local codes.

3. See Fitting Systems operator's manual for specific

inspection criteria.

CAUTION

Page 10

Accessories

WARNING

Ridge Tool Company provides jaw sets and ring sets

for use on various fitting systems. Use only RIDGID

jaw or ring sets which have been designed to press

the specific fitting system and tubing material you are

installing. For a complete listing of available RIDGID

jaw and ring sets, contact Ridge Tool Company or an

authorized RIDGID distributor.

Fittings:

Refer to fitting systems operator's manual for a list of

available fittings for each specific fitting system.

Maintenance Instructions

WARNING

Make sure press tool is unplugged from power

source before performing maintenance or making

any adjustment.

CT400 Press Tools

Daily Cleaning and Lubrication

1. Wipe the tool with a clean dry cloth.

2. Inspect the jaw mounting pin and lubricate the pin with

silicone lubricant, as needed.

Jaws and Press Rings

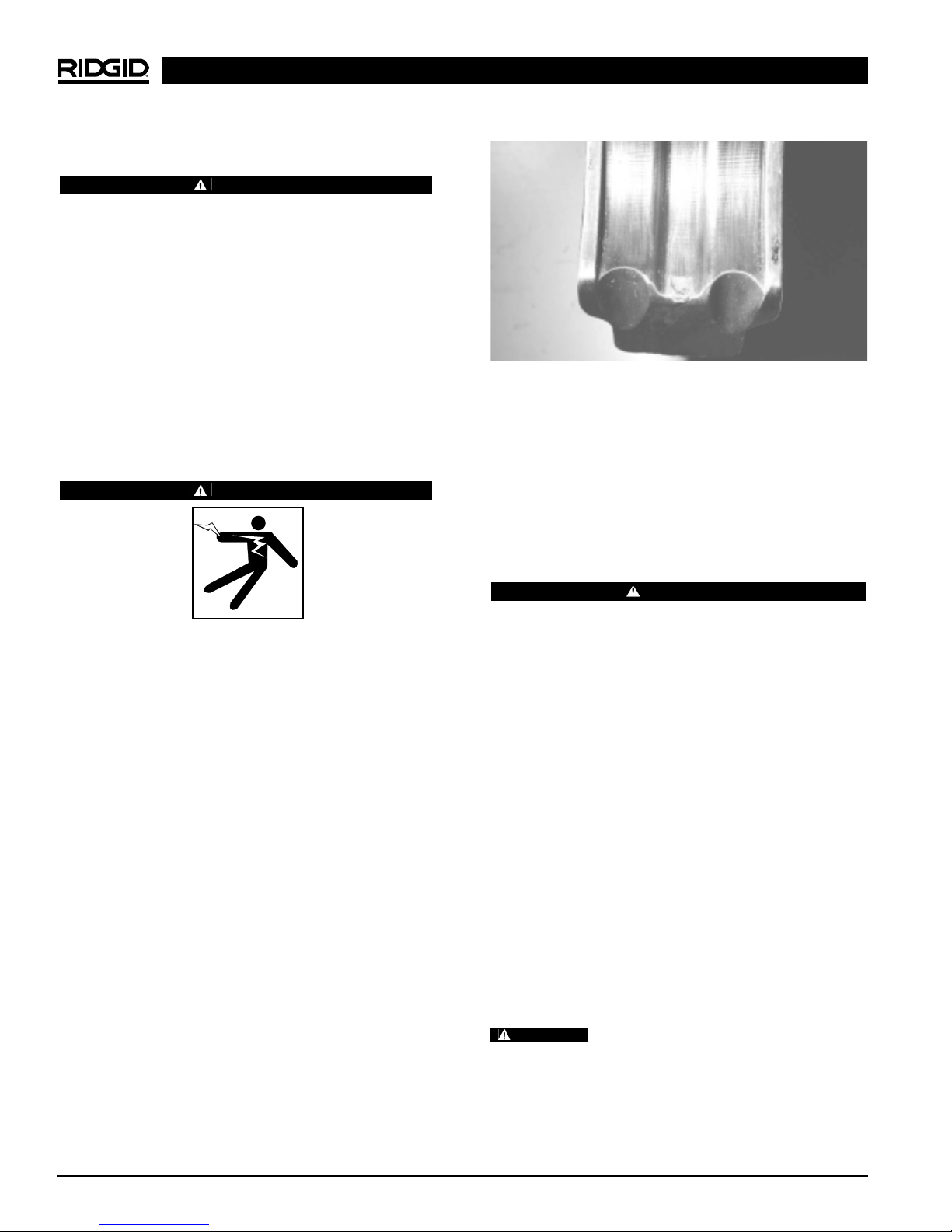

1. Inspect the inside diameter of jaws and press rings

daily. If rusty, dirty or if there is evidence of fitting

material building up on the jaw or ring inside diameter,

(fitting material build-up is most likely to occur near the

tips of scissor style jaws as shown in Figure 10) clean

with fine grade ScotchBrite®(ScotchBrite®is a registered trademark of 3M Company) metal polishing

pads (or equivalent), steel wool or a steel bristle wire

brush.

NOTE! Emery cloth, sandpaper or other similar abrasive

materials should not be used since they may damage critical press jaw dimensions.

Figure 10 – Fitting Material Build-Up Requiring Cleaning

2. Pivot pins on jaws, press rings and actuators should

be cleaned and lubricated at least once a year with a

general purpose “wheel bearing” type grease. A light

coating on the pins and bores is sufficient.

3. Jaws, actuator arms, sideplates and press rings

should be visually inspected daily for obvious cracks

or other signs of wear or damage. If cracks are visible

in any parts, they should be discarded and replaced.

WARNING

A press ring or actuator component that has been

welded, ground, drilled or modified in any manner

can shatter during pressing, resulting in sharp flying

objects, severe injury or death. Discard and replace

damaged jaws, press rings or ring actuators.

4. Check return springs in press jaws, rings and ring

actuators with each use. Jaws and ring actuators

should open and close freely with only moderate finger

effort required.

Required Maintenance at RIDGID

Authorized Service Center

After 20,000 cycles, the tool will beep to indicate that it is

time for maintenance and recalibration. The tool will not

run if it is not maintained within 2,000 more cycles after the

beeping begins.

Storage

Place the tool and jaws in its carrying case. The CT400

pressing tool should be stored above 15°F (-10°C) and

below 120°F (50°C).

Store the carrying case in a dry, secured,

locked area that is out of reach of children and people

unfamiliar with the CT400 Press Tool. The tool is dangerous in the hands of untrained users.

CT400 Press Tool

Ridge Tool Company8

WARNING

Page 11

If you have any questions regarding the service or repair

of this machine, call or write to:

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44035-6001

Tel: (800) 519-3456

E-mail: TechServices@ridgid.com

For name and address of your nearest Independent

Authorized Service Center, contact the Ridge Tool Company at (800) 519-3456 or http://www.ridgid.com

CT400 Press Tool

Ridge Tool Company 9

Service and Repair

Service and repair on this CT400 Press

Tool must be performed by a RIDGID Authorized Service

Center. The tool fasteners have been marked to indicate if service has been performed by unauthorized

individuals. Improper service or repair may lead to extensive property damage, serious injury or death.

For any repairs or maintenance, contact the Ridge Tool

Company, Technical Service Department at (800) 5193456 or www.ridgid.com for nearest authorized service

center.

WARNING

SYMPTOM POSSIBLE REASONS SOLUTION

Tool beeps after a pressing cycle is completed.

Tool will not run when

switch is depressed.

The pressed connections

produced are not

complete.

Troubleshooting

Scheduled maintenance/recalibration required.

Tool is not plugged into an electrical outlet.

Jaw set mounting pin is not properly engaged.

The electrical cord is damaged.

Scheduled maintenance/recalibration is required.

Used wrong jaw set for the tube size or material.

The tool was not square to the tube.

Jaw contour was not aligned with the fitting contour.

Tool is in need of repair.

Contact Ridge Tool Company, Technical Service

Department at (800) 519-3456 for nearest authorized service center.

Plug tool into an electrical outlet.

Push the mounting pin until it is fully inserted.

Inspect the electrical cord and replace if necessary.

The tool will beep when it is time for the scheduled

maintenance/recalibration. If it is not serviced after

2,000 more cycles, it will not run until the maintenance/recalibration is performed.

Install the correct jaw set.

Redo the joint using new tube and fitting and make

sure that the tool is square to the tube.

Redo the joint using new tube and fitting and make

sure that the tool is square to the tube.

Contact Ridge Tool Company, Technical Service

Department at (800) 519-3456 for nearest authorized service center.

Page 12

CT400 Press Tool

Ridge Tool Company10

Page 13

Sertisseuse CT400

Sertisseuse CT400

Notez ci-dessous le numéro de série qui se trouve sur la plaque signalétique de l’appareil

N° de

série :

Page 14

Ridge Tool Company12

Sertisseuse CT400

Table des matières

Fiche d’enregistrement du numéro de série de l’appareil.......................................................................................11

Consignes générales de sécurité

Sécurité du chantier..................................................................................................................................................13

Sécurité électrique....................................................................................................................................................13

Sécurité individuelle..................................................................................................................................................13

Utilisation et entretien de l’appareil...........................................................................................................................14

Service après-vente..................................................................................................................................................14

Consignes de sécurité spécifiques

Sécurité de la sertisseuse.........................................................................................................................................14

Description et spécifications

Description................................................................................................................................................................15

Spécifications............................................................................................................................................................15

Inspection de la sertisseuse, des jeux de mâchoires et des bagues de sertissage.............................................15

Montage des mâchoires de sertissage .....................................................................................................................16

Préparation de l’appareil et du chantier....................................................................................................................16

Utilisation des mâchoires

Préparation du joint...................................................................................................................................................17

Sertissage du raccord...............................................................................................................................................17

Inspection du raccord serti........................................................................................................................................18

Utilisation des bagues de sertissage

Préparation du joint...................................................................................................................................................18

Sertissage du raccord...............................................................................................................................................19

Inspection du raccord serti........................................................................................................................................19

Accessoires.................................................................................................................................................................19

Entretien

Nettoyage et lubrification quotidiens de la CT400 ....................................................................................................20

Mâchoires et bagues de sertissage..........................................................................................................................20

Révisions obligatoires par un centre de service RIDGID autorisé............................................................................20

Stockage...................................................................................................................................................................20

Service après-vente et réparations............................................................................................................................21

Dépannage...................................................................................................................................................................22

Garantie à vie...........................................................................................................................................Page de garde

Page 15

Sertisseuse CT400

Ridge Tool Company 13

Consignes générales de sécurité

MISE EN GARDE ! Familiarisez-vous complètement avec

l’ensemble des instructions. Le non-respect de ces consignes augmenterait

les risques de choc électrique, d’incendie et/ou de graves blessures corporelles.

CONSERVEZ CES INSTRUCTIONS !

Sécurité du chantier

• Maintenez le chantier propre et bien éclairé. Les

établis encombrés et le manque d’éclairage sont à

l’origine de nombreux accidents.

• N’utilisez pas d’appareils électriques en présence

de combustibles tels que les liquides, gaz ou poussières inflammables. Les appareils électriques pro-

duisent des étincelles capables d’enflammer les poussières et les émanations combustibles.

• Ecartez les curieux, les enfants et les visiteurs

lorsque vous utilisez un appareil électrique. Les dis-

tractions éventuelles peuvent vous faire perdre le

contrôle de l’appareil.

Sécurité électrique

• Les appareils à double isolation sont équipés de

fiches polarisées dont l’une des deux barrettes

est plus large que l’autre. Cette fiche ne peut être

introduite dans une prise polarisée que dans un

sens. Si la fiche ne s’introduit pas complètement

dans la prise, inversez-la. Si la fiche refuse toujours

de s’introduire, demandez à un électricien d’installer une prise polarisée. Ne tentez pas de modifier la fiche de manière quelconque. La double iso-

lation élimine le besoin d’un cordon d’alimentation a

trois fils (2+T) et d’un secteur d’alimentation avec terre.

• Evitez tout contact avec les masses telles que

tuyauteries, radiateurs, cuisinières ou réfrigérateurs. Les risques de choc électrique augmentent

lorsque votre corps est en contact avec une masse.

• N’exposez pas les appareils électriques à la pluie

ou aux intempéries. Toute pénétration d’eau à l’in-

térieur d’un appareil électrique augmente les risques de

choc électrique.

• Ne maltraitez pas le cordon électrique de l’appareil.

Ne jamais porter l’appareil par son cordon électrique, ni tirer sur celui-ci pour débrancher l’appareil. Gardez le cordon à l’abri des sources de chaleur, de l’huile, des angles tranchants et des pièces

mobiles. Remplacez immédiatement tout cordon

endommagé. Les cordons endommagés augmentent

les risques de choc électrique.

• Lorsque vous utilisez l’appareil à l’extérieur, uti-

lisez une rallonge électrique portant la désignation

“W-A” ou “W”. Ce type de rallonge est prévu pour

être utilisé à l’extérieur et réduit les risques de choc

électrique.

• Utilisez la section de rallonge appropriée (voir

tableau). Une section de conducteurs insuffisante

provoquerait une perte de tension excessive, un

manque de puissance et la surchauffe de l’appareil.

Sécurité individuelle

• Soyez attentif, concentrez-vous sur ce que vous

faites et faites preuve de bon sens lorsque vous

utilisez un appareil électrique. N’utilisez pas ce

type d’appareil lorsque vous êtes fatigués ou

lorsque vous prenez des médicaments, de l’alcool

ou des produits pharmaceutiques. Un instant d’inat-

tention peut entraîner de graves lésions lorsque l’on

utilise un appareil électrique.

• Habillez-vous de manière appropriée. Ne portez

pas de vêtements amples ou de bijoux. Attachez

les cheveux longs. Gardez vos cheveux, vos vêtements et vos gants à l’écart du mécanisme. Les

vêtements amples, les bijoux et les cheveux longs

peuvent s’entraver dans le mécanisme.

• Evitez les risques de démarrage accidentel. As-

surez-vous que l’appareil est éteint avant de le

brancher. Le fait de porter l’appareil avec un doigt sur

la gâchette est une invitation aux accidents.

• Enlevez les clés de réglage avant de mettre l’ap-

pareil en marche. Un dispositif de réglage laissé sur

un mécanisme rotatif de l’appareil peut s’avérer dangereux.

• Ne vous mettez pas en porte-à-faux. Maintenez

une bonne assise et un bon équilibre à tous moments. Une bonne assise et un bon équilibre vous

permettent de mieux contrôler l’appareil en cas

d’imprévu.

• Utilisez les équipements de sécurité appropriés.

Section minimale des fils conducteurs des rallonges

Ampères indiqués

sur la plaque Longueur totale (en pieds)

signalétique

0 à 25 26 à 50 51 à 100

0 à 6 18 AWG 16 AWG 16 AWG

6 à 10 18 AWG 16 AWG 14 AWG

10 à 12 16 AWG 16 AWG 14 AWG

12 à 16 14 AWG 12 AWG

Déconseillé

Page 16

Sertisseuse CT400

Ridge Tool Company14

Portez systématiquement des lunettes de sécurité.

Un masque à poussière, des chaussures de sécurité,

le casque et/ou une protection auditive doivent être

portés selon les conditions d’utilisation.

Utilisation et entretien de l’appareil

• Utilisez un serre-joint ou autre moyen pratique

pour arrimer la pièce à une plate-forme stable.

Tenir la pièce dans la main ou contre le corps risque

est instable et risque de vous en faire perdre le contrôle.

• Ne forcez pas l’appareil. Utilisez un appareil qui

soit adapté au travail prévu. L’outil approprié assur-

era un meilleur travail et une meilleure sécurité s’il est

utilisé au régime prévu.

• N’utilisez pas un appareil si sa gâchette ne permet

pas de le mettre en marche ou de l’arrêter. Tout

appareil qui ne peut pas être contrôlé par sa gâchette

est dangereux et doit être réparé.

• Débranchez l’appareil avant de le régler, de changer d’accessoires ou de le stocker. De telles mesures

préventives limitent les risques de démarrage accidentel de l’appareil.

• Rangez les appareils non utilisés hors de la portée

des enfants et des personnes non initiées. Ces

appareils sont dangereux entre les mains de personnes non initiées.

• Examinez l’appareil pour signes de mauvais alignement ou de grippage des mécanismes ou autres

conditions qui pourraient entraver son fonctionnement. Le cas échéant, il sera nécessaire de faire

réparer l’appareil avant de vous en servir. De nom-

breux accidents sont le résultat d’un appareil mal

entretenu.

• N’utilisez que les accessoires recommandés par le

fabricant pour votre appareil particulier. Des acces-

soires prévus pour un certain type d’appareil peuvent

être dangereux lorsqu’ils sont montés sur un autre.

• Gardez les poignées de l’appareil propres, sèches

et dépourvues d’huile ou de graisse. Cela vous

permettra de mieux le contrôler.

Service après-vente

• Toutes réparations de l’appareil doivent être confiées à un réparateur qualifié. La réparation ou

l’entretien de l’appareil par du personnel non qualifié

peut entraîner des lésions corporelles.

• Lors de la réparation de l’appareil, utilisez exclusivement des pièces de rechange identiques à

celles d’origine. Suivez les instructions de la section “Entretien” du mode d’emploi. L’utilisation de

pièces de rechange non homologuées et le nonrespect des consignes d’entretien peut créer un risque

de choc électrique ou de lésion corporelle.

Consignes de

sécurité spécifiques

MISE EN GARDE !

Lisez soigneusement ce mode d’emploi, ainsi que le

manuel d’utilisation de la sertisseuse soigneusement avant d’utiliser la sertisseuse RIDGID type

CT400. Le non-respect des consignes ci-devant

augmenterait les risques de dégâts matériels et

d’accidents graves, voire éventuellement mortels.

Veuillez adresser toutes questions éventuelles aux services techniques de la Ridge Tool Company en composant le (800) 519-3456.

Sécurité de la sertisseuse

• N’utilisez la sertisseuse CT400 qu’avec des mâchoires et bagues de sertissage RIDGID. Toute

autre application ou modification de la sertisseuse

CT400 risque d’endommager la sertisseuse et les

mâchoires, et/ou provoquer des lésions corporelles.

• Eloignez vos doigts et vos mains des mâchoires,

des bagues de sertissage et de l’actionneur durant

le cycle de sertissage. Les doigts et les mains peu-

vent être écrasés, brisés ou amputés en cas de prise

dans les mâchoires, les bagues de sertissage, l’actionneur ou entre ces composants et tout autre objet.

• Ne pas utiliser la CT400 si ses protège-doigts sont

endommagés ou absents. Correctement installés

(Figure 1), les protège-doigts empêcheront vos doigts

et vos mains d’être écrasés ou amputés par les galets

et les mâchoires.

• Ne jamais enlever le carter pare-chocs. Remplacez

le carter s’il est endommagé. Le carter pare-chocs

(Figure 1) protège la poignée de l’appareil en cas de

chute. Si l’appareil tombe sans son carter pare-chocs,

le bâti du moteur risque d’être fissuré et exposer des

conducteurs électriques sous tension.

• Ne jamais tenter de réparer des mâchoires endommagées. Toute mâchoire qui a été soudée, meulée,

percée ou modifiée d’une manière quelconque risque

d’éclater en cours de sertissage et provoquer de

graves lésions corporelles. Remplacez d’office toute

mâchoire endommagée. Ne jamais tenter de remplacer ses composants, mis à part les ressorts de

rappel de mâchoire. Veuillez contacter les services

Page 17

Sertisseuse CT400

Ridge Tool Company 15

techniques de la Ridge Tool Company pour vous

assurer de leur disponibilité.

• Ne jamais tenter de réparer des bagues de sertissage ou d’actionneurs endommagés. Toute bague

de sertissage qui a été soudée, meulée, percée ou

modifiée d’une manière quelconque risque d’éclater en

cours de sertissage et provoquer de graves lésions

corporelles. Remplacez d’office toute bague de sertissage endommagée. Ne jamais tenter de remplacer

ses composants, mis à part les ressorts de rappel

de bague de sertissage. Veuillez contacter les services

techniques de la Ridge Tool Company pour vous

assurer de leur disponibilité.

• Ne pas utiliser d’appareil dont la gâchette ou le bâti

est endommagé. L’utilisation d’un appareil dont le

bâti est fissuré ou la gâchette est abîmée augmenterait

les risques de choc électrique et de lésion corporelle

grave.

La sélection des matériaux et des

méthodes de raccordement appropriés est la responsabilité du bureau d’études et/ou de l’installateur. Avant

toute tentative d’installation, il convient d’effectuer une

étude approfondie du milieu d’utilisation spécifique, y

compris du milieu chimique et des températures d’utilisation.

Description et spécifications

Description

La sertisseuse CT400, équipée des mâchoires ou bagues

de sertissage appropriées, assure le sertissage mécanique des raccords de tuyau afin de produire une étanchéité permanente. Lorsqu’on appui sur la gâchette de la

CT400, son moteur électrique interne active une pompe

hydraulique qui sert à actionner le cylindre de l’appareil et

faire avancer son piston pour envoyer des milliers de

pieds de force de sertissage sur des raccords spécialement prévus.

La durée complète du cycle de sertissage est d’environ

quatre (4) secondes. Dès que le cycle de sertissage est

entamé, il ne s’arrêtera que lorsqu’il est terminé. Un bou-

ton de décompression est prévue pour permettre le retrait

du jeu de mâchoires ou de la bague de sertissage en cas

de panne d’électricité en cours de sertissage.

Figure 1 – Sertisseuse CT400 avec jeu de mâchoires

série Standard

Spécifications

Sertisseuse CT400 :

Moteur

Tension...................120V, CA monophasé, 60 Hz

Ampères.................5,2A

Poids.......................7 kg (15,6 livres)

Poussée ........................32 kN (7200 livres)

Température

opérationnelle................-10°C à 50°C (15°F à 120°F)

Inspection de la sertisseuse,

des jeux mâchoires et des

bagues de sertissage

MISE EN GARDE !

L’inspection préalable de la sertisseuse CT400,

des jeux de mâchoires et des bagues de sertissage permettra d’éviter les risques d’électrocution

et les accidents graves. Ne jamais utiliser de CT400,

jeux de mâchoires, actionneur ou bague de sertissage endommagés ou incomplets. Les procédures

d’inspection suivantes devraient être appliquées

quotidiennement :

1. Assurez-vous que la CT400 est débranchée.

2. Examinez le bâti, la gâchette et le cordon d’alimentation de l’appareil pour signes de dégâts. Examinez

le bâti pour signes de fissuration et le cordon d’alimentation pour signes de coupure, d’effilochage ou de

conducteurs exposés.

Détendeur

Protège-doigts

Jeu de

mâchoires série

Standard

Bras de mâchoire

Axe de mâchoires

Cordon d’alimentation

Bâti moteur

Gâchette

Poignée

Carter pare-chocs

Platine latérale

de mâchoire

Pompe

AVERTISSEMENT

Page 18

Sertisseuse CT400

Ridge Tool Company16

3. Assurez-vous que les protège-doigts et le carter

pare-chocs sont correctement attachés afin d’éviter

les risques d’écrasement des doigts.

4. Examinez les jeux de mâchoires, les bagues de sertissage et le bras de l’actionneur. Nettoyez les élé-

ments encrassés. Reportez-vous manuel du fabricant

du système de sertissage pour les consignes de

nettoyage correspondantes. Des mâchoires ou bagues de sertissage encrassées risquent de nuire à

l’étanchéité des raccords et occasionner d’importants dégâts matériels. Remplacez systématiquement

tout ensemble fissuré.

Jetez systématiquement l’ensemble

au complet. Ne jamais remplacer de composants individuels, autres que les ressorts de rappel des bagues de

sertissage, des mâchoires ou de l’actionneur. Tout remplacement partiel des composants risque d’endommager

l’appareil et provoquer un accident grave.

5. Eliminez toutes traces d’huile, cambouis ou crasse

des poignées de l’appareil. Cela empêchera l’appareil

de s’échapper d’entre vos mains.

Montage des mâchoires de

sertissage et de l’actionneur

N’utilisez que des jeux de mâchoires

ou actionneurs RIDGID série Standard. Utilisez le système

de mâchoires et raccords RIDGID prévu pour le type de

matériau à installer. L’utilisation de tout autre jeu de mâ-

choires ou bagues de sertissage produira une mauvaise

étanchéité qui pourrait occasionner d’importants dégâts

matériels.

1. Assurez-vous que la CT400 est débranchée.

2. Tirez l’axe de montage du jeu de mâchoires au max-

imum (Figure 2).

Figure 2 – Retrait de l’axe de montage du jeu de

mâchoires

3. Si un jeu de mâchoires ou actionneur de bagues de

sertissage est déjà monté sur la sertisseuse, retirez-

le.

Figure 3 – Insertion du jeu de mâchoires dans la

CT400

4. Sélectionnez le jeu de mâchoires ou actionneur qui

correspond à la section du tube. Examinez le jeu de

mâchoires. Nettoyez-le s’il est encrassé. Reportez-

vous au manuel du fabricant du système de sertissage pour les consignes de nettoyage. Des mâchoires

encrassées risquent de nuire à l’étanchéité des rac-

cords et d’occasionner d’importants dégâts matériels.

Remplacez systématiquement tout jeu de mâchoires

fissuré.

Toute mâchoire qui a été soudée,

meulée, percée ou modifiée d’une manière quelconque

risque d’éclater en cours de sertissage et provoquer de

graves lésions corporelles. Remplacez d’office tout jeu de

mâchoires endommagé.

5. Introduisez le jeu de mâchoires dans la sertisseuse

(Figure 3).

6. Repoussez l’axe de montage du jeu de mâchoires

jusqu’à ce qu’il s’enclenche.

NOTA ! La CT400 ne fonctionnera que lorsque l’axe est

complètement engagé.

Préparation de l’appareil et

du chantier

MISE EN GARDE !

La préparation appropriée de la sertisseuse et du

chantier permettra d’éviter les accidents grave.

Les procédures suivantes sont d’application :

1. Examinez les locaux pour :

• Suffisamment d’éclairage

MISE EN GARDE

AVERTISSEMENT

MISE EN GARDE

Page 19

Sertisseuse CT400

Ridge Tool Company 17

• Un passage dégagé jusqu’à la prise de courant,

dépourvu de sources de chaleur, d’huile, d’arêtes

tranchantes et de mécanismes qui pourraient

endommager le cordon d’alimentation.

• La présence de liquides, vapeurs ou poussières

combustibles qui risqueraient de s’enflammer.

2. Branchez la sertisseuse sur la prise électrique prévue

en faisant attention de suivre le passage dégagé

sélectionné. Si le cordon d’alimentation de l’appareil

n’arrive pas jusqu’à la prise, utilisez une rallonge

électrique qui n’est pas endommagée.

Afin d’éviter les risques de choc et

d’incendie électrique, ne jamais utiliser de rallonge électrique endommagée ou qui ne répond pas aux critères

suivants :

• La rallonge doit être du type « W » ou « W-A » si

elle est utilisée à l’extérieur.

• La rallonge doit avoir des conducteurs de section

suffisante (16 AWG en dessous de 50 pieds, 14

AWG de 50 à 100 pieds). Une section de conducteur insuffisante risque de faire surchauffer la

rallonge, fondre sa gaine et provoquer un incendie.

L’utilisation de rallonges électriques

de plus de 100 pieds de long est déconseillée, car cela

risque d’occasionner des pertes de charge suffisantes

pour nuire au bon fonctionnement de l’appareil.

N’utilisez pas la sertisseuse CT400 à

des températures inférieures à -10°C (15°F) ou supérieures à 50°C (120°F). L’appareil risquerait de mal

fonctionner et produire des sertissages de mauvaise

qualité qui pourraient occasionner d’importants dégâts

matériels.

Consignes d’utilisation avec

jeux de mâchoires

MISE EN GARDE !

La CT400 n’est compatible qu’avec les jeux de

mâchoires, actionneurs et bagues de sertissage

RIDGID de la série Standard. Utilisez le système de

mâchoires et de raccords RIDGID prévu pour le

type de tuyauterie à installer.

Ecartez vos doigts et vos mains des mâchoires,

des bagues de sertissage et des bras d’actionneur

durant le cycle de sertissage. Portez systématiquement une protection oculaire afin de protéger

vos yeux contre la projection de débris.

Préparation du joint

1. Reportez-vous aux instructions du manuel concernant

le système de raccord utilisé pour les consignes de

préparation du joint avant sertissage.

Sertissage du raccord avec un jeu de

mâchoires à ciseaux

1. Branchez la sertisseuse CT400 sur une prise de

courant.

2. Vérifiez la profondeur d’insertion du tube dans le

raccord selon les instructions du manuel concernant

le système de raccord utilisé.

3. Comprimez les bras de mâchoires afin d’ouvrir le

jeu de mâchoires (Figure 4).

Figure 4 – Ouverture du jeu de mâchoires à ciseaux

3. Positionnez les mâchoires ouvertes sur le raccord.

Assurez-vous que le pourtour du jeu de mâchoires

s’aligne correctement autour du bourrelet de joint

du raccord selon les indications du manuel concernant le système de raccord utilisé (Figure 5).

Figure 5 – Positionnement du jeu de mâchoires à

ciseaux sur le raccord

4. Assurez-vous que l’appareil se trouve d’équerre par

MISE EN GARDE

AVERTISSEMENT

AVERTISSEMENT

Page 20

Sertisseuse CT400

Ridge Tool Company18

rapport au tuyau, puis appuyez sur la gâchette (Figure

6). Le cycle de sertissage durera environ quatre (4)

secondes. Dès qu’un cycle de sertissage commence

et que les galets arrivent en contact avec l’actionneur,

l’appareil se verrouillera et complétera le cycle automatiquement. Le fait de lâcher la gâchette n’arrêtera

pas l’appareil lorsque le cycle de sertissage a déjà

commencé. Cela assure une intégrité de sertissage

constante et reproductible.

Evitez risques de pincement des

doigts en les éloignant des mâchoires.

Figure 6 – Sertisseuse CT400 à l’équerre du tube

NOTA ! Si l’appareil commence à émettre des bips sonores

en fin de cycle de sertissage, il sera nécessaire de

le faire réviser chez un centre de service RIDGID

agréé. Lorsque l’appareil commence à émettre des

bips sonores, il continuera à fonctionner pendant

20.000 cycles supplémentaires, puis cessera de

fonctionner automa-tiquement.

NOTA ! En cas de panne de l’appareil ou panne de courant,

le jeu de mâchoires peut être ouvert en appuyant

fermement sur le bouton de détente qui permet

de ramener les galets et comprimer les bras de

mâchoire (Figure 7). N’oubliez pas de sertir le raccord à nouveau en faisant attention de respecter la

position originale des mâchoires.

5. En fin de cycle, comprimez les bras de mâchoire

pour ouvrir le jeu de mâchoires.

6. Retirez la sertisseuse du tube.

Evitez les bavures qui risquent d’être

laissées sur les bords du raccord lors de son sertissage.

Figure 7 – Utilisation du bouton de détente (si néces-

saire)

Inspection des raccords sertis

AVERTISSEMENT

• En cas d’anomalie de fonctionnement de la CT400

ou du jeu de mâchoires qui empêcherait le sertissage intégral du raccord, il sera nécessaire

de sertir le raccord à nouveau en faisant attention

de bien aligner la mâchoire sur le raccord dans sa

position d’origine.

1. Examinez le raccord serti, et notamment pour les

anomalies suivantes :

• Tubes désaxés

• Tubes partiellement déboîtés; vérifiez à nouveau

les marques de profondeur d’insertion

• Mauvais alignement des mâchoires vis-à-vis du

raccord

Le (ou les) cas échéant(s), il sera nécessaire de

préparer d’installer et de sertir une nouvelle longueur

de tube et un nouveau raccord.

2. Vérifiez l’étanchéité du système selon les règles de

l’art et les normes en vigueur.

Le sertissage des raccords à

l’aide de bagues de sertissage

Préparation du joint d’étanchéité

1. Consultez le manuel du système de raccord utilisé

pour les consignes de préparation des joints d’étan-

chéité avant le sertissage à l’aide des bagues de

sertissage.

Bouton de détente

AVERTISSEMENT

AVERTISSEMENT

Page 21

Sertisseuse CT400

Ridge Tool Company 19

Utilisation des bagues de sertissage

Figure 8 – Positionnement de la bague de sertissage sur

le raccord

1. Assurez-vous que le tube atteint la profondeur d’insertion indiquée dans le manuel du système de raccord.

2. Branchez la sertisseuse CT400 sur la prise de

courant.

3. Ouvrez la bague de sertissage et positionnez-la bien

d’équerre sur le raccord. Alignez la bague sur le rac-

cord selon les instructions du manuel du système de

raccord correspondant. Vérifiez à nouveau la profondeur d’insertion avant d’effectuer le sertissage.

Figure 9 – Montage de l’actionneur à bagues sur la

bague de sertissage

4. Vérifiez que l’actionneur utilisé est compatible avec la

bague de sertissage. Ouvrez l’actionneur complètement en comprimant ses bras. Engagez les griffes de

l’actionneur à bagues dans les poches de la bague de

sertissage. Vérifiez que les griffes s’engagent complètement.

5. Appuyez sur la gâchette de l’appareil. Le cycle de ser-

tissage durera environs quatre (4) secondes. Dès

qu’un cycle de sertissage a commencé et que les

galets entrent en contact avec les bras de l’actionneur, l’appareil sera verrouillé et complétera automatiquement le cycle de sertissage. Le fait de lâcher

la gâchette n’arrêtera pas l’appareil lorsque le cycle de

sertissage a déjà commencé. Cela assure une

intégrité de sertissage constante et reproductible.

MISE EN GARDE !

Ne tentez pas de suspendre l’appareil avec actionneur de bagues à partir de la bague de sertissage.

L’appareil risque de tomber subitement et occasionner des blessures graves ou mortelles.

MISE EN GARDE !

Eloignez vos doigts des actionneurs et des bagues

de sertissage durant le processus afin d’éviter les

risques de pincement.

6. En fin de cycle, comprimez les bras de l’actionneur

pour ouvrir et séparer l’actionneur de la bague de sertissage. Retirez la bague de sertissage du raccord en

l’ouvrant manuellement.

Inspection du joint d’étanchéité

En cas d’anomalie au niveau du fonctionnement de la CT400 ou de la bague de sertissage

durant un cycle de sertissage, le raccord devra être soit

remplacé, soit serti à nouveau selon les consignes du fabricant du système de raccord.

1. Examinez le raccord serti pour les anomalies suivantes :

• Désalignement excessif des tubes.

• Tubes déboîtés.

• Mauvais alignement de la bague de sertissage

sur le raccord.

• En présence d’une ou plusieurs de ces anomalies, il

sera nécessaire de préparer, assembler et sertir

une nouvelle longueur de tube et un nouveau raccord.

2. Testez le système selon les règles de l’art et les

normes en vigueur.

3. Consultez le manuel du système de sertissage concerné pour les critères de vérification applicables.

Accessoires

MISE EN GARDE !

La Ridge Tool Company offre des jeux de mâchoires

et de bagues pour une variété de systèmes de raccords. N’utilisez que les jeux de mâchoires et bagues

spécifiquement prévus pour le sertissage du type et

de la nature des raccords et tubes utilisés. Pour un

répertoire global des jeux de mâchoire et de bagues

RIDGID disponibles, consultez la Ridge Tool Company ou un distributeur RIDGID autorisé.

AVERTISSEMENT

Page 22

Sertisseuse CT400

Ridge Tool Company20

2. Les axes de pivotement des mâchoires doivent être

nettoyés et lubrifiés au moins une fois par an avec de

la graisse à roulements traditionnelle. Une légère

couche sur les axes et leurs logements suffit.

3. Les mâchoires, les bras d’actionneur, les platines

latérales et les bagues de sertissage doivent être

examinés quotidiennement pour signes de fissuration

apparents ou autres signes d’usure ou de détérioration. En cas de fissures apparentes, l’élément en

question doit être remplacé.

MISE EN GARDE !

Un composant de bague de sertissage ou d’actionneur qui a été soudé, meulé, percé ou modifié d’une

manière quelconque risque d’éclater en cours de

sertissage et provoquer des lésions corporelles

graves ou mortelles. Remplacez d’office les mâchoires, bagues de sertissage et actionneurs

endommagés.

4. Examinez les ressorts de rappel des mâchoires,

bagues et actionneurs après chaque utilisation. Les

jeux de mâchoires doivent s’ouvrir et fermer du bout

des doigts sous effort modéré.

Révision obligatoire chez un centre de

service RIDGID agréé

Au bout de 20.000 cycles, l’appareil commencera à

émette des bips sonores pour indiquer qu’il est temps de

le faire réviser. L’appareil cessera de fonctionner s’il n’est

pas révisé au bout de 2.000 cycles suivant le début des

bips sonores.

Stockage

Rangez l’appareil et les mâchoires dans la mallette de

transport. La sertisseuse CT400 doit être stockée à une

température ambiante allant de -10°C (15°F) à 50°C

(120°F).

Stockez la mallette de transport dans

en endroit sec et sous clé, hors de la portée des enfants

et de ceux qui n’ont pas d’expérience avec la sertisseuse CT400. Cet appareil peut devenir dangereux entre

les mains d’un novice.

Raccords :

Reportez-vous au manuel du système de raccord concerné pour la liste des raccords disponibles dans chaque

système de raccord spécifique.

Entretien

MISE EN GARDE !

Assurez-vous que la sertisseuse est débranchée

avant toute intervention d’entretien ou de réglage.

Sertisseuses CT400

Nettoyage et lubrification quotidiens

1. Essuyez l’appareil avec un chiffon propre et sec.

2. Examinez l’axe de montage des mâchoires et, au

besoin, lubrifiez l’axe avec un lubrifiant aux silicones.

Mâchoires et bagues de sertissage

1. Examinez l’intérieur des mâchoires et des bagues de

sertissage quotidiennement. En présence de rouille,

de crasse ou de signes d’accumulation de résidus de

sertissage sur la surface interne des mâchoires ou

des bagues (surtout près des extrémités des mâ-

choires à ciseaux comme indiqué à la Figure 10),

nettoyez-les à l’aide de tampons de curage métal-

liques ScotchBrite®(ScotchBrite®est une marque de

fabrique de 3M Company) ou similaire, de paille de fer

ou d’une brosse métallique.

NOTA ! Les matériaux abrasifs (toile d’émeri, papier verre,

etc.) ne doivent pas être utilisés car ils risquent

d’endommager les surfaces d’attaque des mâchoires

Figure 10 – Accumulation de résidus de sertissage

nécessitant le nettoyage des mâchoires

MISE EN GARDE

Page 23

Service après-vente

et réparations

Le service après-vente et la réparation de la CT400 doivent être confiés à un centre de

service RIDGID autorisé. La visserie de l’appareil a été

marquée pour témoigner d’éventuelles interventions non

autorisées. Toute intervention ou réparation mal effectuée

risque d’occasionner d’importants dégâts matériels ou

de des lésions graves et potentiellement mortelles.

Pour toutes réparations ou révisions, veuillez consulter les

services techniques de la Ridge Tool Company en composant le (800) 519-3456, ou consulter son site Internet :

www.ridgid.com pour obtenir les coordonnées du centre

de service autorisé le plus proche.

Veuillez adresser toutes questions concernant l’entretien

ou la réparation de cette machine aux coordonnées

suivantes :

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44035-6001

Tél. : (800) 519-3456

E-mail: TechServices@ridgid.com

Pour obtenir les coordonnées du centre de service autorisé le plus proche, appelez la Ridge Tool Company au

(800) 519-3456, ou allez à http://www.ridgid.com

Sertisseuse CT400

Ridge Tool Company 21

MISE EN GARDE

Page 24

Sertisseuse CT400

Ridge Tool Company22

SYMPTOME POSSIBLES SOLUTION SOLUTION

L’appareil émet des bips

sonores en fin de cycle

de sertissage.

L’appareil ne fonctionne

pas lorsqu’on appui sur

la gâchette.

Les sertissages obtenus

ne sont pas étanches.

Dépannage

Besoin de révision/calibrage obligatoire.

L’appareil est débranché.

L’axe des mâchoires n’est pas engagé à fond.

Le cordon d’alimentation est endommagé.

Besoin de révision obligatoire.

Jeu de mâchoires inadapté à la section ou

composition du tube utilisé.

Appareil tenu en faux équerre par rapport au tube.

Redan des mâchoires non aligné sur le pourtour du

raccord.

L’appareil a besoin d’être réparé.

Contacter les services techniques de la Ridge Tool

Company en composant le (800) 519-3456 pour

les coordonnées du centre de service agréé le plus

proche.

Brancher l’appareil

Pousser l’axe à fond.

Examiner et/ou remplacer le cordon d’alimentation.

L’appareil émettra des bips sonores lorsqu’il est

nécessaire de le réviser ou de le calibrer à nouveau,

faute de quoi, il cessera de fonctionner au bout de

20.000 cycles supplémentaires en attendant sa

révision ou son calibrage.

Monter le jeu de mâchoires approprié.

Remplacer le raccord et le tube en faisant attention

de tenir l’appareil à l’équerre.

Remplacer le raccord et le tube en faisant attention

de tenir l’appareil à l’équerre.

Consulter les services techniques de la Ridge Tool

Company en composant le (800) 519 3456 pour

obtenir les coordonnées du centre de service agréé

le plus proche.

Page 25

Selladora CT400

Selladora CT400

A continuación apunte y retenga el número de serie de la máquina que se encuentra en su

placa de características.

No. de

serie

Page 26

Ridge Tool Company24

Selladora CT400

Índice

Ficha para apuntar el Número de Serie del aparato ................................................................................................23

Información general de seguridad

Seguridad en la zona de trabajo...............................................................................................................................25

Seguridad eléctrica...................................................................................................................................................25

Seguridad personal...................................................................................................................................................25

Uso y cuidado del aparato........................................................................................................................................26

Servicio.....................................................................................................................................................................26

Información específica de seguridad

Seguridad de la Selladora.........................................................................................................................................26

Descripción, especificaciones y equipo estándar

Descripción...............................................................................................................................................................27

Especificaciones.......................................................................................................................................................27

Inspección de la Selladora, de los juegos de mordazas y aros selladores...........................................................27

Montaje de las mordazas o del accionador..............................................................................................................28

Preparación del aparato y de la zona de trabajo......................................................................................................28

Instrucciones de funcionamiento con el uso de mordazas

Preparación de la junta.............................................................................................................................................29

Selladura del acoplamiento o fitting..........................................................................................................................29

Inspección de la junta sellada...................................................................................................................................30

Instrucciones de funcionamiento con el uso de aros selladores

Preparación de la junta.............................................................................................................................................30

Selladura del acoplamiento o fitting..........................................................................................................................30

Inspección de la junta sellada...................................................................................................................................31

Accesorios...................................................................................................................................................................31

Instrucciones de mantenimiento

Limpieza y lubricación diarias (CT 400)....................................................................................................................32

Mordazas y aros selladores......................................................................................................................................32

Mantenimiento obligatorio en un Servicentro Autorizado RIDGID............................................................................32

Almacenaje...............................................................................................................................................................32

Servicio y reparaciones..............................................................................................................................................32

Detección de averías...................................................................................................................................................33

Garantía vitalicia..................................................................................................................................carátula posterior

Page 27

Selladora CT400

Ridge Tool Company 25

Información general de seguridad

¡

ADVERTENCIA! Lea y comprenda todas las instrucciones.

Pueden ocurrir choques eléctricos, incendios y/o lesiones personales graves si

no se siguen todas las instrucciones detalladas a continuación.

¡

GUARDE ESTAS INSTRUCCIONES!

Seguridad en la zona de trabajo

• Mantenga su área de trabajo limpia y bien alumbrada. Los bancos de trabajo desordenados y las

zonas oscuras son el origen de numerosos accidentes.

• No haga funcionar aparatos motorizados en presencia de combustibles tales como líquidos, gases

o polvos inflamables. Los aparatos eléctricos generan

chispas que pueden inflamar el polvo o las emanaciones combustibles.

• Al hacer funcionar una máquina, mantenga apartados a los curiosos, niños y visitantes. Las distrac-

ciones pueden hacerle perder el control del aparato.

Seguridad eléctrica

• Los aparatos con doble aislamiento vienen provistos de un enchufe polarizado: una de sus clavijas es más ancha que la otra. Este enchufe puede

introducirse en un tomacorriente polarizado de

una sola manera. Si el enchufe no entra completamente en el tomacorriente, inviértalo. Si todavía

no cabe, recurra a un electricista calificado para

que instale un tomacorriente polarizado. No modifique el enchufe de manera alguna. El doble ais-

lamiento elimina la necesidad de contar con un

cordón de suministro de tres alambres y conexión a

tierra, y de un suministro conectado a tierra.

• Evite el contacto con artefactos conectados a tierra tales como cañerías, radiadores, estufas o cocinas y refrigeradores. Aumenta el riesgo de que

se produzca un choque eléctrico cuando su cuerpo

ofrece conducción a tierra.

• No exponga los aparatos motorizados a la lluvia o

a condiciones mojadas. Cuando agua penetra en un

aparato a motor, aumenta el riesgo de que se produzca

un golpe eléctrico.

• No maltrate el cordón eléctrico del aparato. Nunca

transporte el aparato tomándolo de su cordón

eléctrico ni lo jale para desenchufarlo del tomacorriente. Mantenga el cordón lejos del calor, aceite,

bordes cortantes o piezas movibles. Recambie un

cordón dañado inmediatamente. Un cordón en mal

estado aumenta el riesgo de que se produzca un

choque eléctrico.

• Al hacer funcionar un aparato motorizado a la

intemperie, emplee un cordón de extensión fabricado para uso exterior y rotulado “W-A” o “W”.

Estos cordones han sido diseñados para su empleo al

aire libre y reducen el riesgo de que se produzca un

choque eléctrico.

• Use cordones de extensión apropiados (vea la

tabla). Una dimensión insuficiente del conductor

causará una caída excesiva del voltaje, pérdida de

potencia y recalentamiento.

Seguridad personal

• Manténgase alerta, preste atención a lo que está

haciendo y use sentido común cuando trabaje

con un aparato motorizado. No lo use si está

cansado o se encuentra bajo la influencia de drogas, alcohol o medicamentos. Sólo un breve des-

cuido mientras hace funcionar un aparato a motor

puede resultar en lesiones personales graves.

• Vístase adecuadamente. No lleve ropa suelta ni joyas. Contenga el cabello largo. Mantenga cabello,

ropa y guantes apartados de las piezas en movimiento. La ropa suelta, las joyas o el pelo largo

pueden engancharse en la piezas móviles.

• Evite la puesta en marcha no intencional del apara-