Page 1

Combo

Roll

Groover

GB p.1

FR p.23

ES p.47

DE p.70

NL p.92

IT p.114

PT p.136

SV p.158

DA p.180

FI p.202

NO p.224

RU p.246

HR p.268

RO p.290

CZ p.312

HU p.334

EL p.356

PL p.378

TU p.400

SL p.422

SK p.444

SB p.466

RIDGE TOOL COMPANY

Page 2

975

Combo Roll Groover

Page 3

975 Combo Roll Groover

Table of Contents

Safety Symbols..............................................................................................................................................................2

General Safety Rules

Work Area Safety........................................................................................................................................................2

Electrical Safety..........................................................................................................................................................2

Personal Safety ..........................................................................................................................................................3

Tool Use and Care......................................................................................................................................................3

Service........................................................................................................................................................................3

Specific Safety Information

Roll Groover Safety ....................................................................................................................................................4

Roll Groover Safety When Used With A Power Drive/Threading Machine ................................................................4

Roll Groover Safety When Used In Place ..................................................................................................................4

Description, Specifications and Standard Equipment

Description..................................................................................................................................................................4

Specifications..............................................................................................................................................................5

Standard Equipment ..................................................................................................................................................5

Roll Groover Inspection................................................................................................................................................5

Machine and Work Area Set-Up For Power Driven Applications

Mounting The 975 Combo Groover Onto A RIDGID 300 Power Drive ......................................................................7

Mounting The 975 Combo Groover Onto A RIDGID 300 Compact Threading Machine ............................................7

Completing Set Up......................................................................................................................................................8

Pipe Preparation ........................................................................................................................................................9

Pipe Set Up In Roll Groover......................................................................................................................................10

Operating The 975 Combo Roll Groover With A Power Drive/Threading Machine

Setting/Measuring The Groove Diameter ................................................................................................................10

Forming The Roll Groove..........................................................................................................................................11

Setting The Groove Diameter For Copper Tubing....................................................................................................12

975 Combo Roll Groover Tracking Tips....................................................................................................................12

Machine and Work Area Set Up For In Place Applications

Pipe Preparation ......................................................................................................................................................14

Mounting The Roll Groover To The Pipe..................................................................................................................14

Operating The 975 Combo Roll Groover In Place

Setting/Measuring The Groove Diameter ................................................................................................................15

Forming The Roll Groove..........................................................................................................................................16

Maintenance Instructions

Lubrication ................................................................................................................................................................16

Cleaning....................................................................................................................................................................17

Changing Roll Sets ..................................................................................................................................................17

Accessories ................................................................................................................................................................18

Machine Storage..........................................................................................................................................................18

Service and Repair......................................................................................................................................................18

Table I. Standard Roll Groove Specifications ..........................................................................................................19

Table II. Pipe Maximum and Minimum Wall Thickness............................................................................................19

Table III. Copper Roll Groove Specifications............................................................................................................20

Troubleshooting ....................................................................................................................................................20-21

Lifetime Warranty ........................................................................................................................................Back Cover

1

Ridge Tool Company

Page 4

975 Combo Roll Groover

Safety Symbols

In this operator’s manual and on the product, safety symbols and signal words are used to communicate important safety information. This section is provided to improve understanding of these signal words and symbols.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER

WARNING

CAUTION

NOTICE

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE indicates information that relates to the protection of property.

This symbol means read the operator’s manual carefully before using the equipment. The operator’s manual contains

important information on the safe and proper operation of the equipment.

This symbol means always wear safety glasses with side shields or goggles when handling or using this equipment to reduce

the risk of eye injury.

This symbol indicates the risk of fingers and hands being crushed between the groove rolls.

This symbol indicates the risk of hands, fingers, legs, clothes and other objects catching and/or wrapping on rotating shafts

causing crushing or striking injuries.

This symbol indicates that a drill, impact tool, or other power tool should not be used to drive this device when used in place.

This symbol indicates the risk of machine tipping, causing striking or crushing injuries.

This symbol means always use a foot switch when using a threading machine/power drive.

This symbol means wear a hard hat when working overhead to reduce the risk of head injury.

General Safety Rules

WARNING

Read and understand all instructions. Failure to follow all

instructions listed below may result in electric shock, fire,

and/or serious personal injury.

SAVE THESE INSTRUCTIONS!

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Work Area Safety

• Keep your work area clean and well lit. Cluttered or

dark areas invite accidents.

• Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

• Keep children and by-standers away while oper-

ating a power tool. Distractions can cause you to lose

control.

• Keep floors dry and free of slippery materials

such as oil. Slippery floors invite accidents.

• Guard or barricade the area when work piece ex-

tends beyond machine. A guard or barricade that

provides a minimum of three (3) feet clearance around

the work piece will reduce the risk of entanglement.

Electrical Safety

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce

risk of electric shock.

• Avoid body contact with earthed or grounded sur-

faces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electrical shock

if your body is earthed or grounded.

• Do not expose power tools to rain or wet condi-

tions. Water entering a power tool will increase the risk

of electrical shock.

2 Ridge Tool Company

Page 5

975 Combo Roll Groover

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or enta ngled cords i ncrease

the risk of electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric shock.

• If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of an GFCI reduces the

risk of electric shock.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol, or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

• Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

• Prevent unintentional starting. Ensure the switch

is in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energizing power tools that have the switch

on invites accidents.

• Remove any adjusting key or wrench before turn-

ing the power tool on. A wrench or a key left attached

to a rotating part of the power tool may result in personal injury.

Tool Use and Care

• Do not force tool. Use the correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it is designed.

• Do not use tool if the switch does not turn it ON

and OFF. Any tool that cannot be controlled with

the switch is dangerous and must be repaired.

• Disconnect the plug from the power source and/or

the battery pack from the tool before making any

adjustments, changing accessories, or storing

tools. Such preventive safety measures reduce the risk

of starting the tool accidentally.

• Store idle tools out of the reach of children and

do not allow persons unfamiliar with the tool or

these instructions to operate the tool. Tools are

dangerous in the hands of untrained users.

• Maintain tools. Check for misalignment or binding

of moving parts, breakage of parts and any other

condition that may affect the tool’s operation. If

damaged, have the tool repaired before use. Many

accidents are caused by poorly maintained tools.

• Use only accessories that are recommended for

your tool. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to

control.

• Keep handles dry and clean; free from oil and

grease. Allows for better control of the tool.

Service

• Have your tool serviced by a qualified repair person using only identical replacement parts. This will

ensure that the safety of the tool is maintained.

Specific Safety Information

• Do not overreach. Keep proper footing and balance at all times. This enables better control of the

power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewelry. Keep your hair, clothing, and gloves away

from moving parts. Loose clothes, jewelry, or long

hair can be caught in moving parts.

• If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

Ridge Tool Company 3

WARNING

This section contains important safety information

that is specific to this tool.

Read these precautions carefully before using the

975 Combo Roll Groover to reduce the risk of serious personal injury.

SAVE THESE INSTRUCTIONS!

Contact Ridge Tool Technical Service Department at

(800) 519-3456 or techservices@ridgid.com if you have

any questions.

Page 6

975 Combo Roll Groover

Roll Groover Safety

• Do not wear loose clothing. Keep sleeves and

jackets buttoned. Do not reach across the machine

or pipe. Clothing can be caught by the pipe or other

rotating parts, resulting in entanglement and serious

injury.

• Keep hands away from grooving rolls. Do not

groove pipe shorter than specified. Do not wear

loose fitting gloves. Fingers can be crushed between

groove rolls or between groove roll and pipe.

• Keep hands away from ends of pipe. Do not reach

inside pipe. Burrs and sharp edges can catch and cut.

Fingers can be crushed between groove rolls or

between groove roll and pipe.

• Properly prepare and handle pipe. Burrs and sharp

edges can catch and cut.

• Properly support the pipe. This will help to prevent

the tipping of the pipe and equipment.

• Read and understand this operator’s manual, the

appropriate power drive or threading machine

operator’s manual, the fitting manufacturer’s installation instructions and the instructions for any

other equipment used with this tool before operating the RIDGID®975 Combo Roll Groover. Failure

to follow all instructions may result in property damage

and/or serious personal injury.

• Always wear appropriate personal protective equip-

ment while setting up and using the RIDGID 975

Combo Roll Groover. Appropriate personal protective

equipment always includes eye protection and may

include equipment such as tight fitting leather gloves,

steel toed footwear, and a hardhat.

• Only use roll groover to groove pipe of recom-

mended sizes and types according to these instructions. Other uses or modifying the roll groover for

other applications may increase the risk of injury.

Roll Groover Safety When Used With A

Power Drive/Threading Machine

• Only use the RIDGID 300 Power Drive or the 300

Compact Threading Machine with this 975 Combo

Roll Groover. Use of other power sources will result in

improper set up and could cause tipping or other

issues.

• Do not use this roll groover with a power drive or

threading machine that does not have a foot

switch. Never block a foot switch so that it does

not control the power drive. A foot switch provides

better control by letting you shut off the power drive

motor by removing your foot. If clothing should become

caught in the machine and power is maintained to

the motor, the clothing will be pulled into the machine.

This machine has high torque and can cause the

clothing to bind around your arm or other body parts

with enough force to crush or break bones or cause

striking or other injuries.

• One person must control both the grooving pro-

cess and the foot switch. Do not operate with more

than one person. In case of entanglement, the oper-

ator must be in control of the foot switch.

• Only use power drives and threading machines

with a rotational speed of 57 rpm or less. Higher

speed machines increase the risk of injury.

• Be sure the roll groover is properly set up and

secured to the power drive/threading machine.

Be sure the machine, stand, groover and pipe are

stable. This will help prevent tipping of the equip-

ment and pipe.

Roll Groover Safety When Used In Place

• Only drive manually when used for in place applications. Do not use powered devices (such as

drills or impact tools) to drive the roll groover

when used in place. Use of powered devices can

damage the Groove and increase the risk of injury.

• When working overhead, all personnel should

wear hard hats and be clear of the area below.

Prevents serious injuries if roll groover, pipe or other

objects fall.

Description, Specifications and

Standard Equipment

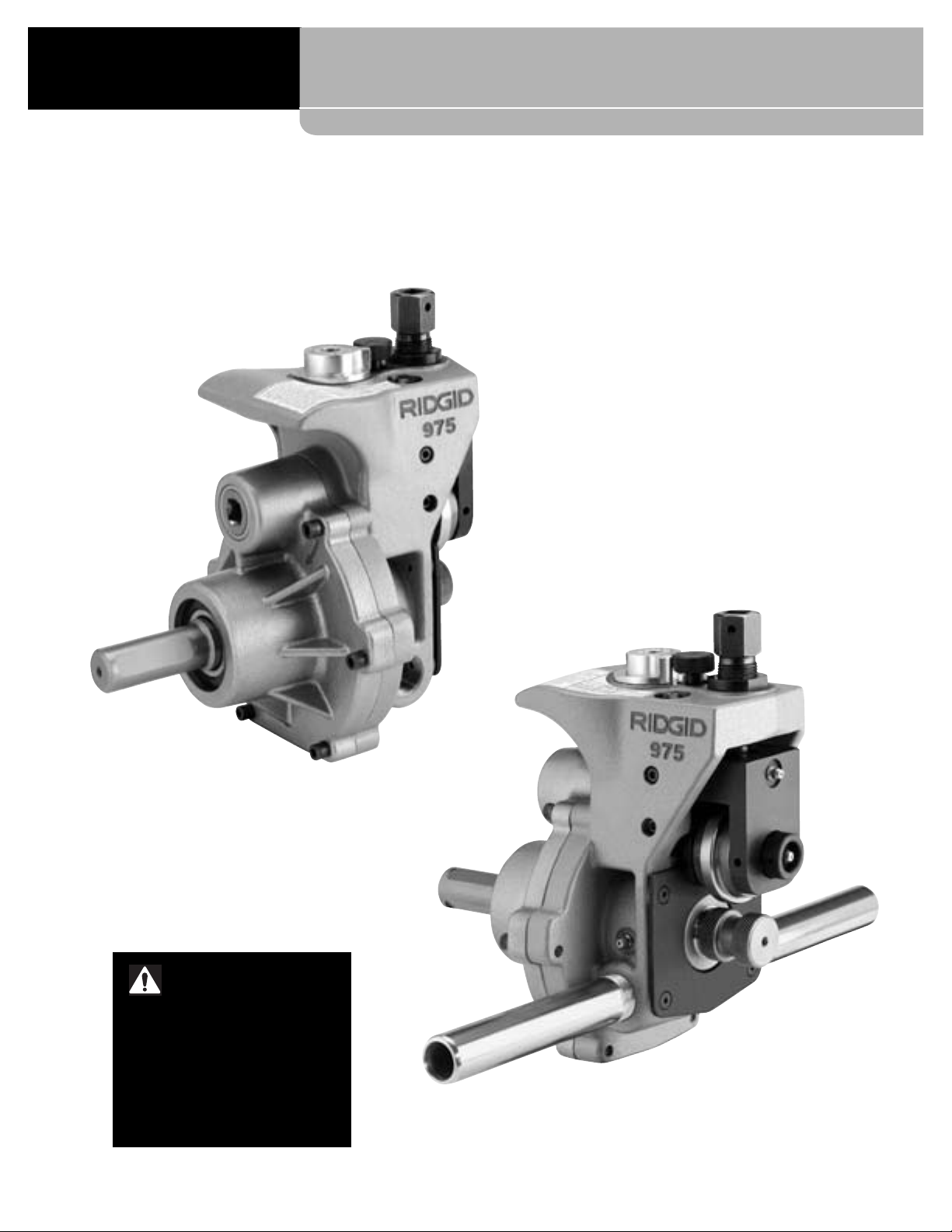

Description

The RIDGID®975 Combo Roll Groover forms rolled

grooves in steel, aluminum and PVC pipe and will groove

11/4" to 6" diameter pipe, schedule 10 and schedule 40. It

is also designed to groove 11/4" to 6" schedule 10 and 11/4"

to 2" schedule 40 stainless steel pipe. It can also be

adapted for 2" - 8" Type K, L,M and DWV copper tube with

a roll set change. The grooves are formed by mechanically

advancing a grooving roll into the pipe which is supported

by a drive roll. The only adjustment necessary is for the

depth of the groove.

The unit is specifically designed to be used either in place

or with the RIDGID Model 300 Power Drive (38 and 57

RPM Models). With the appropriate adapter (cat. #67662),

the unit can work with the RIDGID Model 300 Compact

Threading Machine. The 975 Combo Roll Groover includes

a patented groove depth gauge to aid in groove set up and

patented features to improve tracking during use.

Ridge Tool Company4

Page 7

975 Combo Roll Groover

The 975 Combo Roll Groover is a portable unit intended

for occasional use on the job site and should not be used

for high volume work or for production work in a pipe fabrication shop.

NOTICE

When properly used, the Model 975 Combo

Roll Groover makes grooves 2" - 6" that are dimensionally

within the specifications of AWWA C606-06. Selection

of appropriate materials and joining methods is the responsibility of the system designer and/or installer. Before any

installation is attempted, careful evaluation of the specific

service environment, including chemical environment and

service temperature, should be completed.

Specifications

Capacity ........................11/4" – 6" Schedule 10 and

Schedule 40 Steel Pipe

With Roll Change: 2"- 8" Copper Tube, Type K, L ,M & DWV

Groove Diameter

Adjustment ....................Adjusting Screw And Groove

Depth Gauge

Actuation .......................Feed Screw with 1/2" Ratchet

Wrench

Power Drive Mounting...RIDGID 300 Power Drive (38

and 57 RPM Model Only)

RIDGID 300 Compact Thread-

ing Machine (with adapter)

Weight............................27.6 lbs.

The 975 Combo Roll Groover is protected under U.S. and

International patents, including patents 6,272,895 and

6,591,652.

Standard Equipment

11/4" – 6" Schedule 10 & 40 Groove and Drive Rolls

Ratchet Wrench (1/2" Drive) with Button Release

Locking Extension Drive

Support Arms

Integral Index Depth Gauge

Roll Groover Inspection

WARNING

Before each use, inspect your roll groover and

correct any problems to reduce the risk of serious

injury from crushing injuries and other causes and

prevent roll groover damage.

Do not use this roll groover with a power drive/threading machine that does not have a foot switch.

1. If the roll groover is installed on a power drive or

threading machine, make sure that the machine is

unplugged and that the REV/OFF/FOR switch is in the

OFF position. Inspect and maintain the power drive/threading machine as directed in the machine’s operator’s manual. Failure to properly inspect and maintain

equipment can result in serious injury and property

damage. Make sure that that a foot switch is present

and properly operating. Do not use this roll groover

without a foot switch.

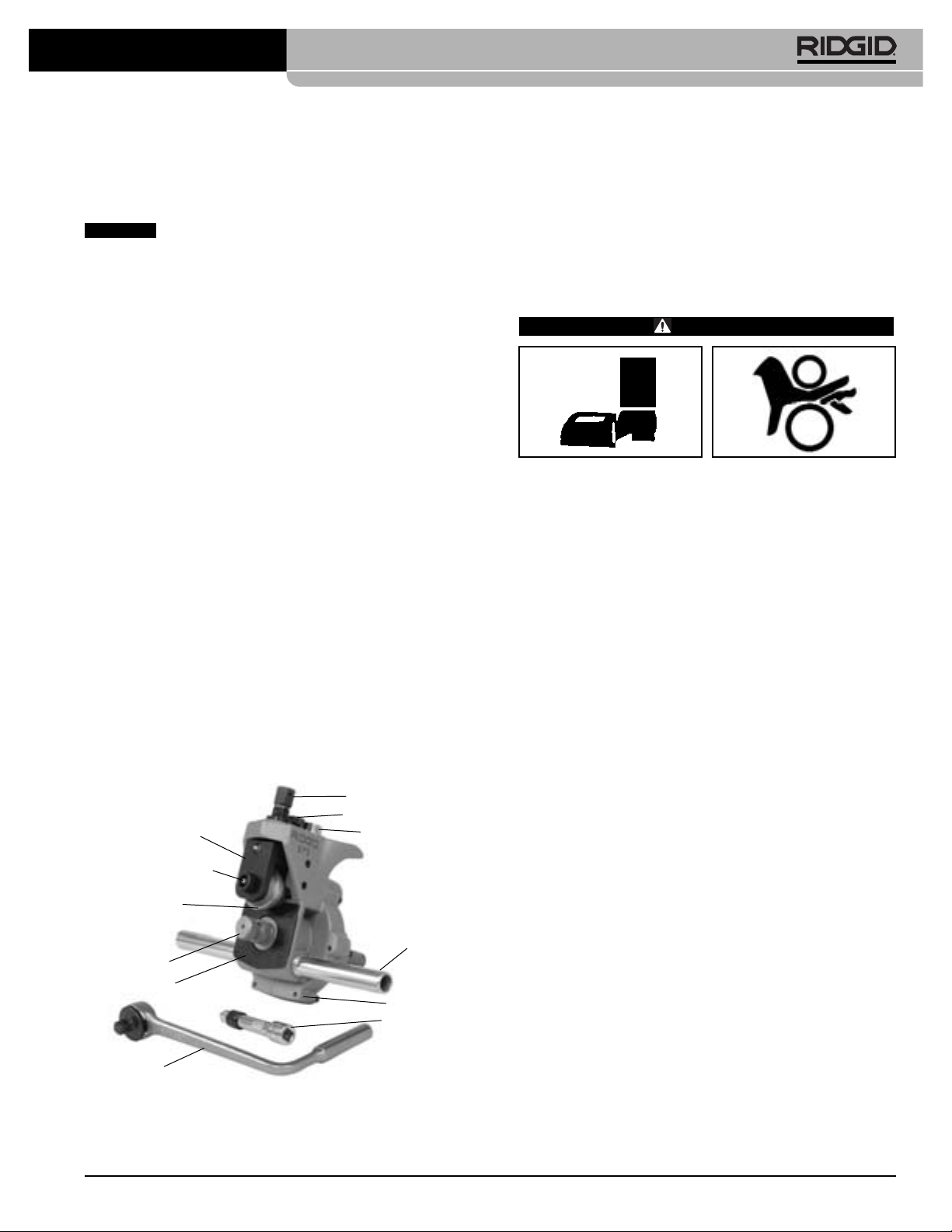

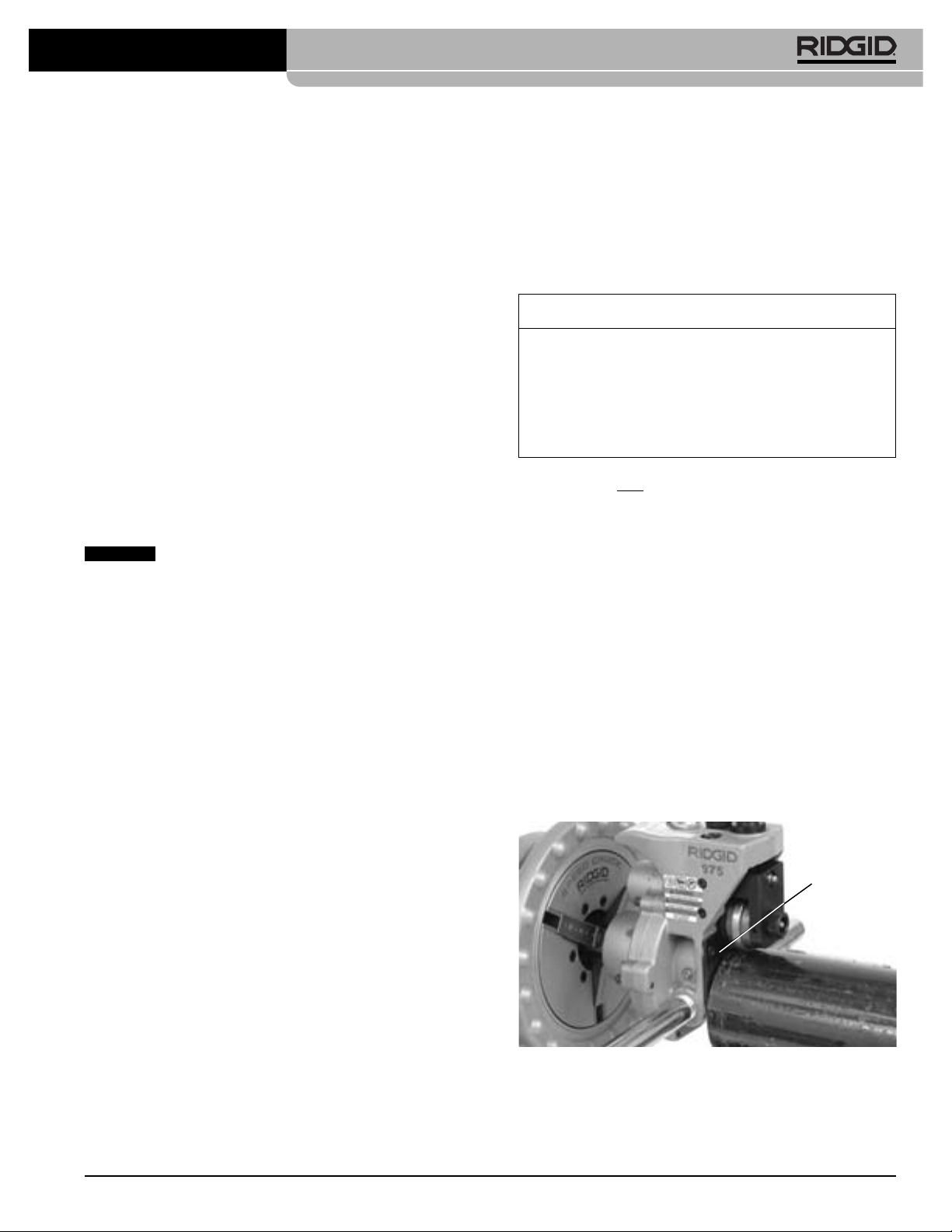

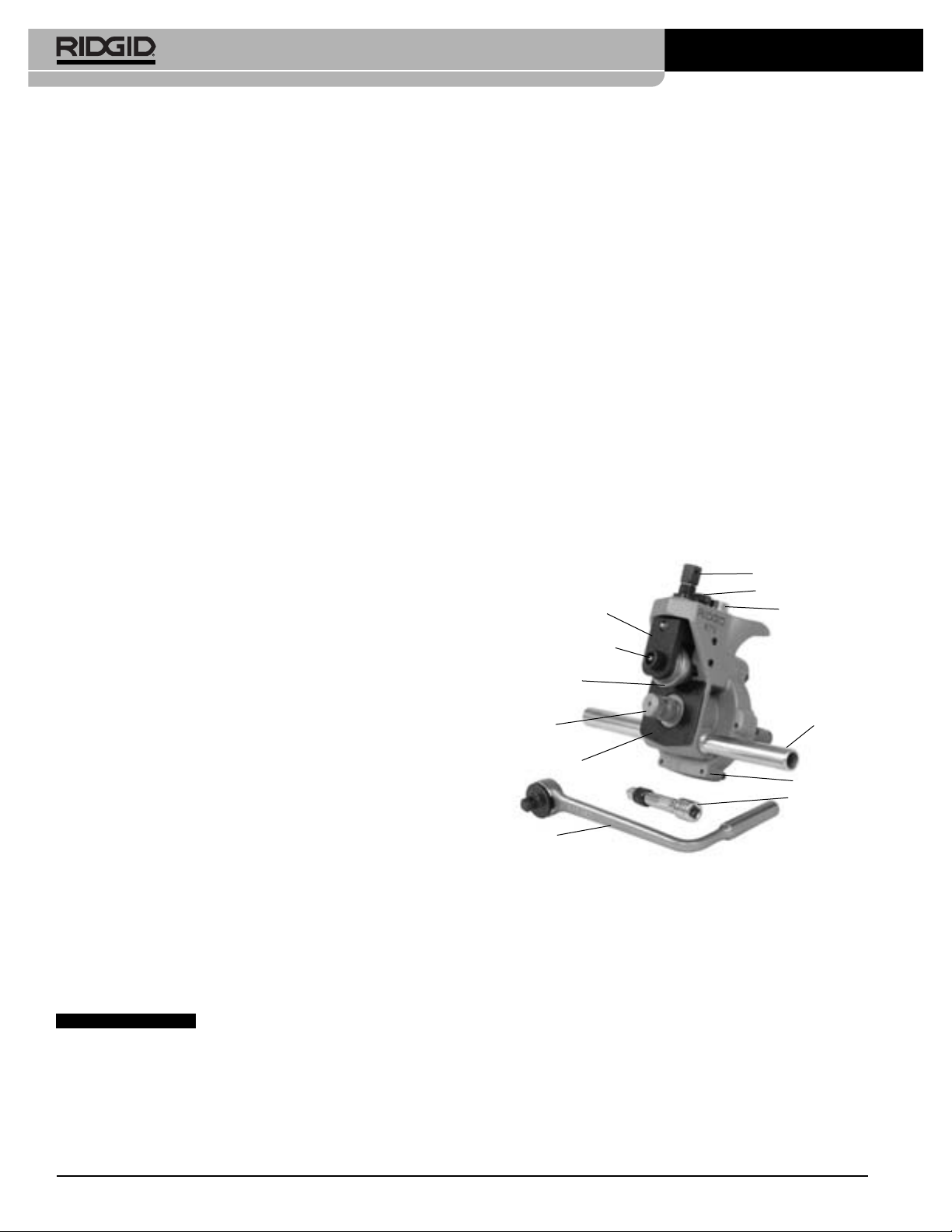

Slide Block

Groove Roll Shaft

Groove Roll

Drive Shaft

Cover Plate

Ratchet

Figure 1 – 975 Combo Roll Groover

Feedscrew

Adjusting Screw

Groove Depth

Gauge

Support Arm

Base

Extension

Ridge Tool Company 5

2. Clean any oil, grease or dirt from the roll groover,

including the carry handle, and the ratchet used to

activate the roll groover. This reduces the risk of

injury due to the groover or ratchet slipping from your

grip during use and allows easier inspection.

3. Make sure that the support arms are tight in the body

of the roll groover.

4. Inspect the roll groover for any broken, missing, misarranged or binding parts or any other condition that

may prevent the safe and normal operation. Make

sure that the groove roll and drive shaft turn freely.

5. Check that the warning label is present and firmly

attached.

See Figure 2

for the location of the warning

label.

6. If the drive shaft knurls are dirty, clean with a wire

brush. Dirty knurls can cause pipe slippage and tracking issues during grooving.

Page 8

975 Combo Roll Groover

7. Inspect the groove roll and drive shaft for cracks,

wear or other signs of damage. Damaged groove

rolls and drive shafts can cause pipe slippage, poor

quality grooves, or cause failure during use.

8. Inspect the ratchet and extension for proper operation.

Make sure that the ratchet operates smoothly and

consistently in both directions. Press the release button in the center of the ratchet head and install on the

feedscrew. The ratchet should firmly lock into position.

The ratchet should also lock securely into the extension and the extension should securely lock into the

manual drive square at the back of the roll groover.

This helps to prevent the ratchet and extension from

coming loose from the roll groover in use. If using a

different ratchet, wrench or extension that does not

lock to the roll groover, be aware that it could come

loose during use.

If any problems are found, do not use the machine

until the problems have been corrected.

9. Lubricate the roll groover per the maintenance instructions in this manual. Wipe any excess grease from the

roll groover.

10. If any other equipment is being used, inspect and

maintain to make sure it is functioning properly.

Machine and Work Area Set-Up

For Power Driven Applications

WARNING

Always wear eye protection to protect your eyes

against dirt and foreign objects. Wear steel toe

footwear to protect feet from tipping tools and

falling pipe.

Do not use this roll groover with a power drive or

threading machine that does not have a foot switch.

Never block a foot switch so that it does not control

the power drive. A foot switch provides better control by letting you shut off the power drive motor by

removing your foot. If clothing should become

caught in the machine and power is maintained to

the power drive motor, the clothing will be pulled

into the machine. This machine has high torque

and can cause the clothing to bind around your

arm or other body parts with enough force to crush

or break bones or cause striking or other injuries.

Set up the roll groover and the work area according

to these procedures to reduce the risk of injury

from electric shock, fire, machine tipping, entanglement, crushing and other causes, and prevent roll

groover damage.

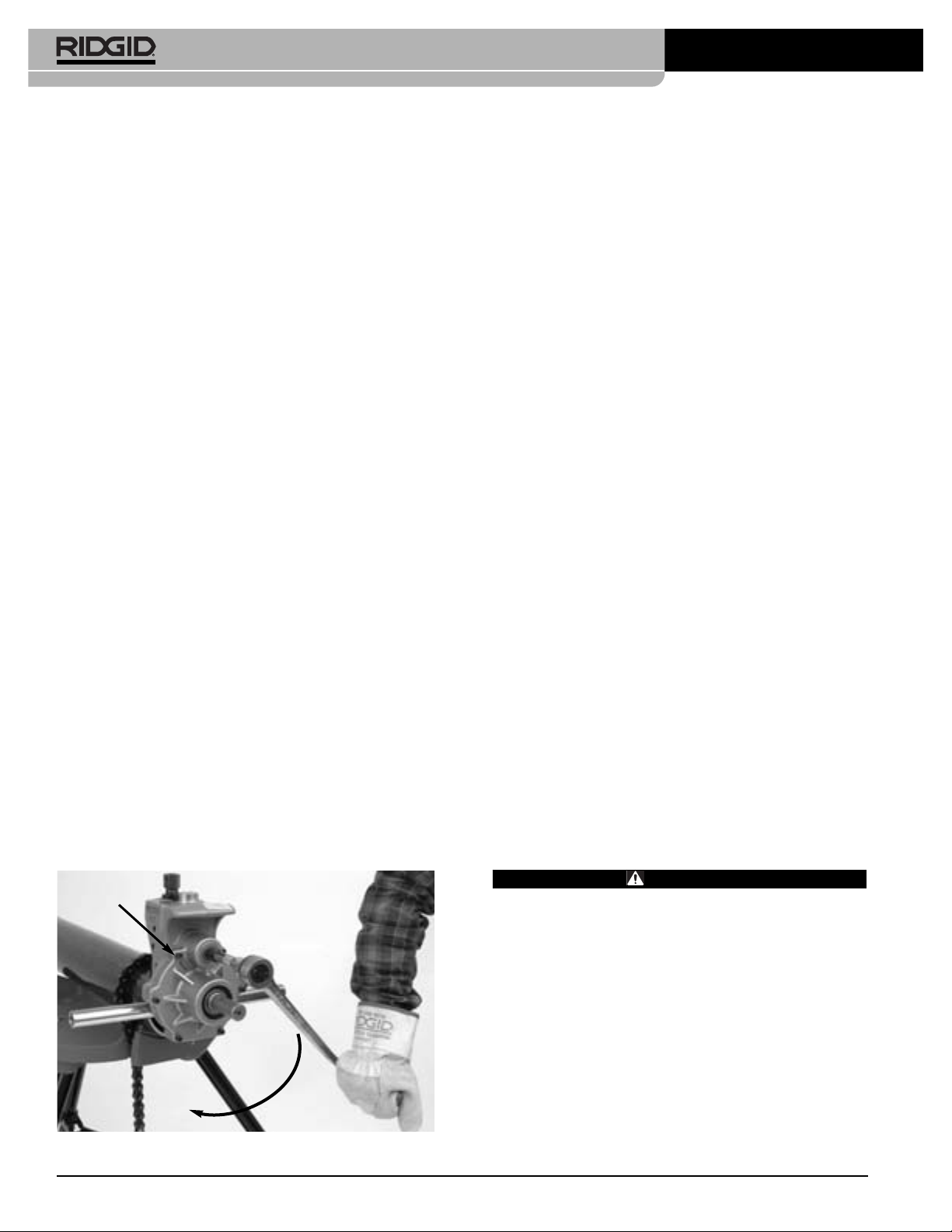

Warning Label

Figure 2 – 975 Combo Roll Groover Warning Label

Grease

Fittings

1. Locate a work area that has the following:

• Adequate lighting.

• No flammable liquids, vapors or dust that may

ignite. If present, do not work in area until sources

have been identified and corrected. Power Drives

and threading machines are not explosion proof,

and can cause sparks.

• Clear, level, stable and dry location for all of the

equipment and the operator. Do not use the equipment while standing in water.

• Properly grounded electrical outlet. A three prong

or GFCI outlet may not be properly grounded. If in

doubt, have outlet inspected by a licensed electrician.

• Clear path to the electrical outlet that does not

contain any potential sources of damage to the

power cord.

2. Clean up the work area prior to setting up any equipment. Always wipe up any oil that may be present.

3. Inspect the pipe to be grooved and confirm that the

975 Combo Roll Groover is the correct tool for the job.

The 975 Combo Roll Groover is designed to groove

schedule 10 and 40 steel, aluminum, and PVC pipe in

11/4" to 6" sizes. It is also designed to groove 11/4" to 6"

Ridge Tool Company6

Page 9

1

schedule 10 and 1

/4" to 2" schedule 40 stainless

steel pipe. With a roll set change, it can be used to

groove 2" - 8" Type K, L, M and DWV copper tube.

The 975 Combo Roll Groover can be used for in

place applications (pipe that is in place or mounted in

a vise) or with a RIDGID 300 Power Drive or 300

Compact Threading Machine for powered applications

on the job site. The 975 Combo Roll Groover is not

intended for production type applications.

Roll groovers for other applications can be found

by consulting the Ridge Tool catalog, on line at

www.RIDGID.com, or by calling Ridge Tool Technical

Services at 800-519-3456.

NOTICE

Use of roll sets (groove roll and driveshaft)

on both carbon and stainless steel pipe can lead to contamination of the stainless steel material. This contamination could cause corrosion and premature pipe failure. To

prevent ferrous contamination of stainless steel pipe, use roll

sets dedicated for stainless steel roll grooving. Alternately,

a stainless steel wire brush may be used to thoroughly

clean the roll set when switching between materials.

4. Make sure the power drive/threading machine has

been inspected per it’s manual. Confirm the presence

of a foot switch and make sure that the FOR/OFF/REV switch is in the OFF position. Set up the power

drive/threading machine as directed in it’s manual.

Make sure that the machine and stand are stable and

do not wobble.

5. Fully open the chuck of the power drive/threading

machine.

6. Confirm that the 975 Combo Roll Groover has been

inspected and has the appropriate roll set installed.

975 Combo Roll Groover

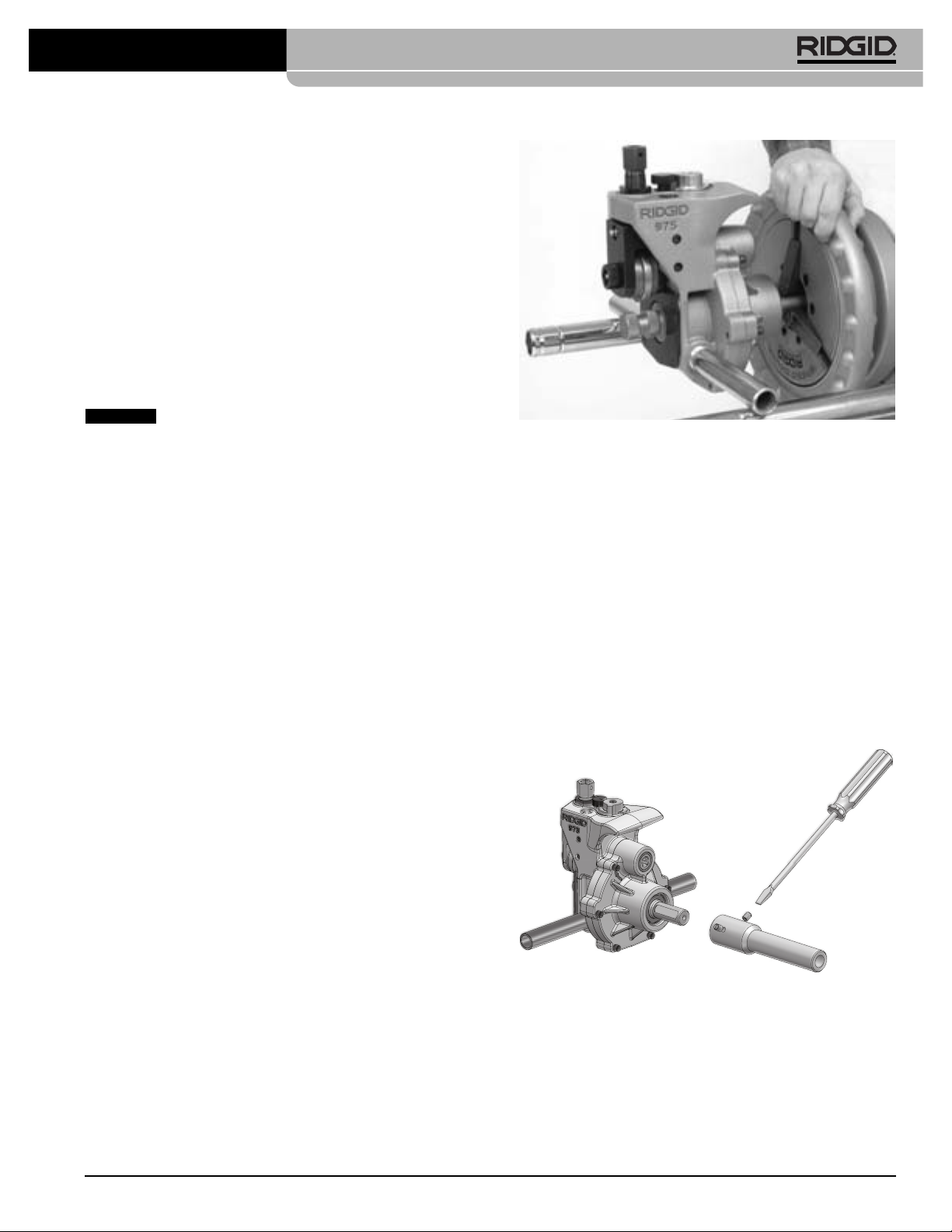

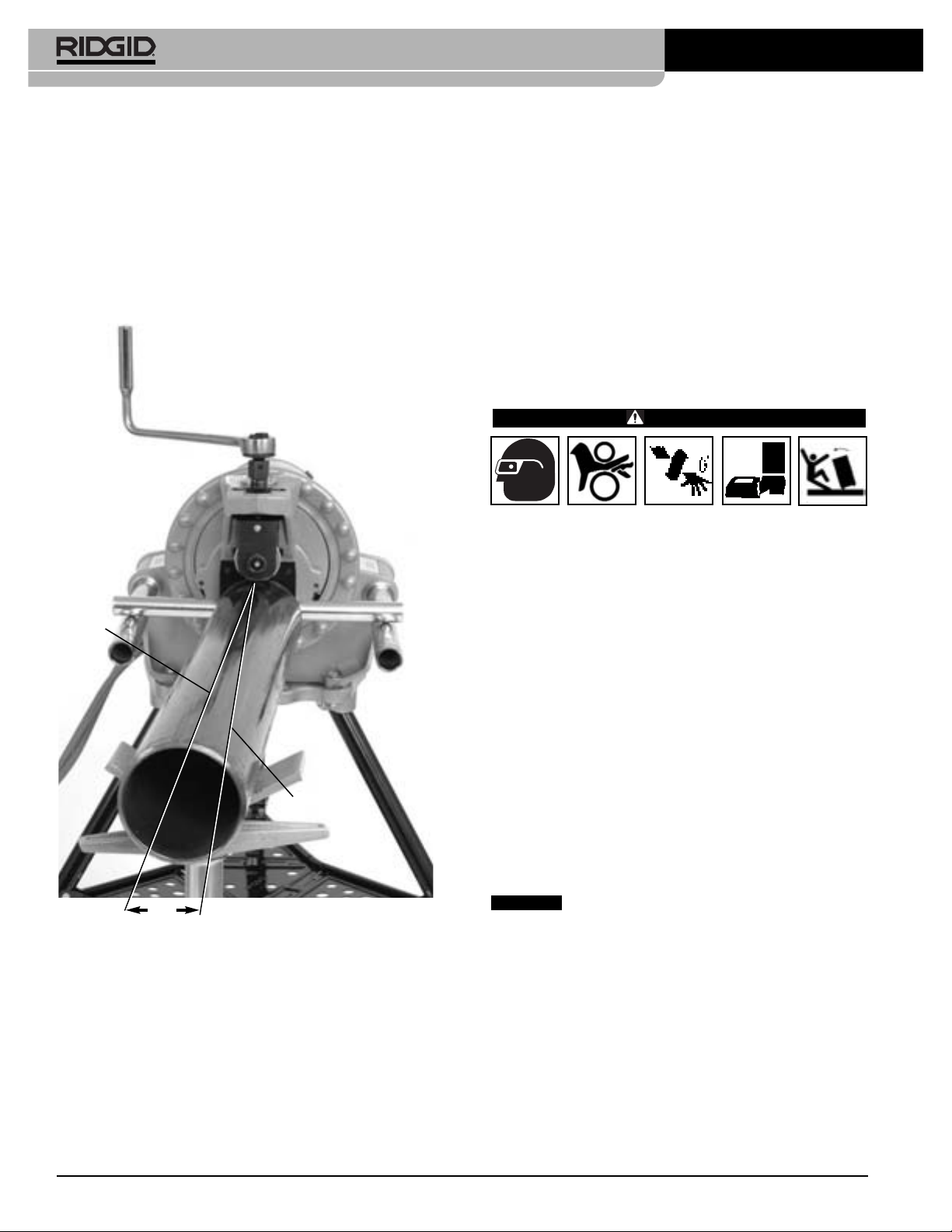

Figure 3 – Mounting 975 Combo Roll Groover Into 300

Power Drive Chuck

Mounting The 975 Combo Groover Onto A

RIDGID 300 Compact Threading Machine

When using the 975 Combo Roll Groover with a 300

Compact Threading Machine, an adapter kit (Catalog

Number 67662) must be used. This adapter kit properly

positions the 975 Combo Roll Groover relative to the

threading machine and stand and to allow the complete

range of sizes to be grooved. Do not try to use the 975

Combo Groover with any other threading machine, as tipping or other issues may result.

1. Install the drive bar adapter onto the roll groover

drive shaft

flats on the roll groover drive shaft and firmly tighten.

(See Figure 4)

. Align set screws with the

Mounting The 975 Combo Groover Onto

A RIDGID 300 Power Drive

1. If the power drive to be used is equipped with a carriage or other attachments, remove them from the

power drive. Make sure the power drive support

arms are fully forward and fixed in position.

2. Place the support arms of the roll groover onto the

support arms of the power drive and the end of the roll

groover driveshaft in the chuck of the machine. Close

and tighten the power drive chuck onto the flats of the

driveshaft. Make sure that the driveshaft is centered

in the chuck. Use repeated and forceful counterclockwise spins of the speed chuck hammerwheel to

securely grip the driveshaft

(Figure 3)

.

Ridge Tool Company 7

Figure 4 – Installing Drive Bar Adapter

2. Move carriage on the 300 Compact Threading Machine as close to the machine chuck as possible.

Move the cutter, reamer and die head in to the position away from the operator, so they are out of the

way. Position reamer cone inside of die head.

Page 10

975 Combo Roll Groover

3. Place the adapter bracket over the end of rails of the

300 Compact

(as shown in Figure 5)

and lock into

place with the attached pin

Figure 5 – Installing Adapter Bracket

4. Place the 975 support arms on the arms of the

adapter bracket with the drive bar adapter in the

chuck of the machine. Close and tighten the threading

machine chuck onto the drive bar adapter. Make

sure that the drive bar is centered in the chuck. Use

repeated and forceful counterclockwise spins of the

speed chuck hammerwheel to securely grip the drive

bar.

• Control the ON/OFF action of the foot switch and

quickly release the foot switch if needed.

• Have convenient access to the roll groover, pipe

and ratchet wrench without reaching over the roll

groover.

Figure 6 – 975 Combo Roll Groover Properly Mounted

On 300 Compact Threading Machine

Completing Set Up

1. Position the foot switch so that the operator can control the power drive/threading machine, the roll

groover and the pipe to be grooved. As shown in

Figure 6

• Stand facing the roll groover with access to (on the

, the position should allow the operator to:

same side as) the FOR/OFF/REV switch.

Figure 7 – Operator Position

2. Run the power cord along the previously identified

clear path. With dry hands plug the power drive into

the properly grounded outlet. Keep all connections dry

and off the ground. If the power cord is not long

enough use an extension cord that :

• Is in good condition

• Has a three prong plug similar to that on the power

drive

• Is rated for outdoor use and contains a W or W-A in

the cord designation (i.e. SOW)

• Has sufficient wire size (14 AWG for 25' or less, 12

AWG for 25' – 50' long). Undersized wires can

overheat, melting the insulation or causing a fire or

other damage.

3. Check the power drive/threading machine to make

sure that it is operating correctly:

• Move the switch to the FOR (Forward) position.

Press and release the foot switch. Confirm that

the driveshaft rotates in a counter-clockwise direction as you face the front chuck. If the unit does not

Ridge Tool Company8

Page 11

975 Combo Roll Groover

rotate in the correct direction or the foot switch does

not control the machine operation, do not use the

machine until it has been repaired.

• Depress and hold the foot switch. Check the rotational speed of the unit. Inspect the moving parts for

misalignment, binding, odd noises or any other

unusual conditions. Release foot switch. If the rotational speed exceeds 57 rpm, do not use the unit for

roll grooving. Higher speeds may increase the risk

of injury. If unusual conditions are found, do not use

the equipment until it has been repaired.

• Move the switch to the REV (reverse) position.

Press and release the foot switch. Confirm that

the driveshaft rotates in a clockwise direction as you

face the front of the chuck. If the unit does not

rotate in the correct direction, do not use the

machine until it has been repaired.

• Move the switch to the OFF position. With dry

hands unplug the machine.

Pipe Preparation

NOTICE

follow grooved coupling manufacturer’s specific recommendations for pipe end preparation. Failure to follow the

grooved coupling manufacturer’s recommendations may

lead to an improper connection and cause leaks.

1. Cut pipe to proper length. Be aware of the minimum

lengths of pipe that can be grooved for each size of

pipe

imum length increases the risk of injury from crushed

fingers and entanglement.

Make sure pipe end is cut square and free of burrs.

Burrs can catch or cut gloves or fingers during grooving. Cut off method and large burrs can effect the

quality of the groove made and the tracking of the

Groove. Do not attempt to groove pipe that has been

cut with a torch.

These are generalized instructions. Always

(See Chart A)

. Grooving pipe shorter than min-

2. Make sure to have appropriate support available for

the pipe you are going to be grooving.

Chart A

lists

the maximum length of pipe to be grooved using a

single pipe stand. Longer lengths of pipe should be

supported with at least two pipe stands. Failure to

properly support the pipe may allow the pipe or the

pipe and machine to tip and fall. Do not groove pipe

shorter than the minimum length.

Nom. Min. Max. Nom. Min. Max.

Size Length Length Size Length Length

1 8 36 4 8 36

1

4

/

1

1

2

1

/

2 8 36 6 O.D. 10 30

1

2

2

/

3 8 36

1

2

3

/

Chart A – Minimum/Maximum Pipe Length To Be Grooved

8 36 41/

8 36 5 8 32

8 36 6 10 28

8 36

With One Stand (All Dimensions In Inches)

2

8 32

3. Place the required pipe stands in front of the roll

groover. For lengths supported by a single stand, the

stand should be placed slightly more than half the

length of the pipe from the roll groover cover plate. For

lengths of pipe requiring more than one stand, the

stands should be placed 1/4of the pipe length from the

ends of the pipe. It may be appropriate to use more

stands in some situations. Stand height should be

adjusted so that the pipe can fit over the drive roll.

4. Make sure that the groove roll has been retracted

enough to allow the pipe to be placed over the drive

shaft. If needed, turn the feedscrew counter-clockwise

to raise the groove roll.

5. Place the pipe end over the driveshaft and set the

pipe down onto the pipe stand(s). Make sure the

pipe is stable.

2. All internal/external weld beads, flash, or seams must

be ground flush at least 2" back from the end of the

pipe. Do not cut flats into gasket seat area, this could

cause leaks.

3. Remove all scale, dirt, rust and other contaminants at

least 2" back from the end of the pipe. Contaminants

can clog the drive knurls and prevent proper driving

and tracking of the pipe while grooving.

Pipe Set Up In Roll Groover

1. Confirm that the power drive switch/threading machine is in the OFF position.

Ridge Tool Company 9

Cover Plate

Figure 8 – Placing Pipe Over Driveshaft and Flush To

Cover Plate

6. Adjust pipe and pipe stands so that the end of the

pipe is flush to the roll groover cover plate and that the

inside of the pipe contacts the top of the driveshaft

Page 12

975 Combo Roll Groover

(Figure 7)

. The centerline of the pipe and the centerline of the drive shaft should be parallel to one

another. One way to do this is to level both the pipe

and the power drive/threading machine.

7. Slightly offset the pipe and pipe stands approximately

1

/2degree (about 1" over at 10 feet from the roll groover) towards the operator. Proper alignment of the

pipe and roll groover helps to insure proper tracking

of the pipe while grooving.

Pipe

Center

Line

(See Figure 9.)

Drive Shaft

Center Line

away from the equipment and pipe. Guards or barricades should be used to create a minimum of three

(3) feet of clearance around the power drive and

pipe. This “safety zone” prevents others from accidentally contacting the machine or pipe and causing

tipping or becoming entangled in the rotating parts.

10. With dry hands, plug the machine into the properly

grounded outlet.

Operating The 975 Combo Roll

Groover With A Power

Drive/Threading Machine

WARNING

Do not wear loose clothing when operating the roll

groover. Keep sleeves and jackets buttoned. Do

not reach across the machine or pipe. Loose clothing can become entangled in rotating parts and

cause crushing injuries.

Keep hands away from grooving rolls. Do not groove

pipes shorter than specified. Do not wear loose

fitting gloves. Fingers can be crushed between

groove rolls or between groove roll and pipe.

Keep hands away from ends of pipe. Do not reach

inside pipe. Burrs and sharp edges can catch and

cut. Fingers can be crushed between groove rolls or

between groove roll and pipe.

Always wear eye protection to protect your eyes

against dirt and foreign objects. Wear steel toe

footwear to protect feet from tipping tools and

falling pipe.

Follow operating instructions to reduce the risk of

injury from crushing, tipping, striking and other

causes.

1

/2°

Figure 9 – Offsetting The Pipe 1/2° Towards Operator

(Exaggerated)

8. Turn the feedscrew clockwise to bring the groove

roll down in contact with the pipe outside diameter,

then turn the feedscrew one quarter additional turn.

The adjusting screw may need to be loosened (turned

counter-clockwise) to allow the groove roll to contact

pipe. The pipe and roll groover should be secure to

each other at this point.

9. Evaluate the work area and determine if any barriers

are required to keep people other than the operator

Setting/Measuring The Groove Diameter

NOTICE

groove should always be performed before the first

groove of the day or when changing pipe size, schedule

or material. Groove diameter setting gauges are approximate only and the groove diameter must be measured

to confirm proper size.

1. Confirm that the equipment and pipe is properly set

up. Improper pipe preparation can effect the accurate

set up of the groove depth gauge. The groove roll

should be touching the pipe.

2. Adjust the groove depth gauge so that the correct

step of the gauge is under the head of the adjusting

screw

Ridge Tool Company10

Due to differing pipe characteristics, a test

(Figure 10A).

The groove depth gauge is

Page 13

975 Combo Roll Groover

designed for use with pipe.

See “Setting The Groove

Diameter For Copper Tube” for use with copper tube.

3. Turn the adjusting screw clockwise until the head

touches the step of the depth gauge. Turn the groove

depth gauge to the grooving position

(Figure 10B).

the gauge is not in the grooving position it will prevent

grooving and may be damaged.

Figure 10A – Place Correct

Step of Gauge Under

Adjusting Screw Head

4. Prepare a test groove

Figure 10B – Gauge In

Grooving Position

(follow the steps for “Forming

the Roll Groove).

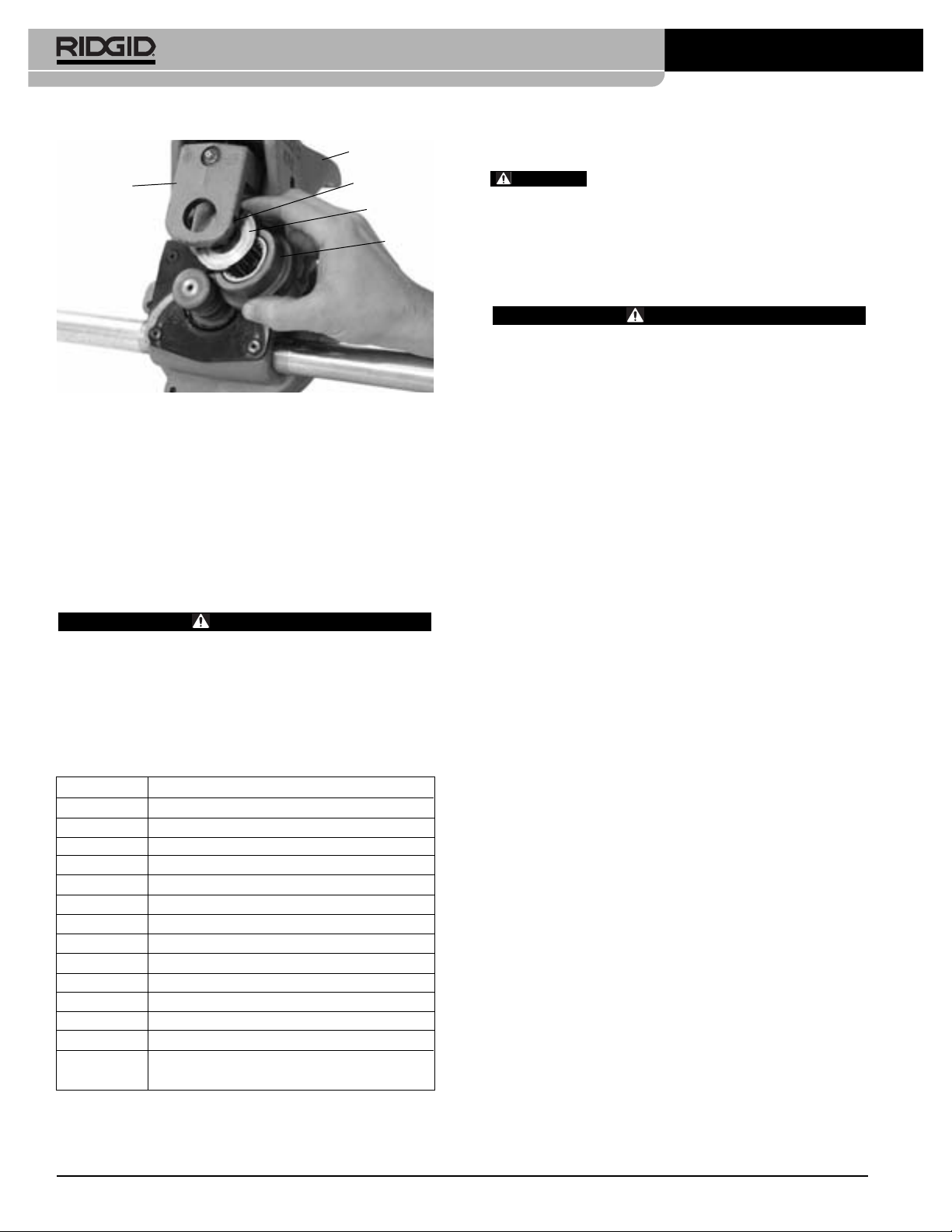

5. Measure the groove diameter. The best method for

measuring groove diameter is the use of a diameter

tape

(see Accessories Section)

. Snugly wrap the

diameter tape around the pipe in the groove. Make

sure that the tape sits flat in the bottom of the groove,

and read the groove diameter.

(See Figure 11.)

diameter, the adjusting screw must be repositioned to

give the correct groove diameter.

• To increase groove diameter, turn the adjusting

screw clockwise.

If

• To decrease groove diameter, turn the adjusting

screw counter-clockwise.

• Each 1/4turn of the adjusting screw changes the

groove diameter approximately 0.02".

7. Repeat steps 4-6 until the groove diameter is within

specifications. If the groove is too large, the groover

can be adjusted and the groove made smaller. If the

groove is too small, another groove will need to be

made. Proper groove diameter is important to insure

connection performance. Out of specification grooves

could cause joint failure.

Forming The Roll Groove

1. Confirm that the equipment and pipe are properly

set up.

Figure 11 – Checking Groove Diameter With A Diameter

Tape

6. Compare the measured groove diameter to the required groove diameter as shown in

Table I or III

or as

specified by the groove fitting manufacturer. If the

measured groove is outside of the required groove

Ridge Tool Company 11

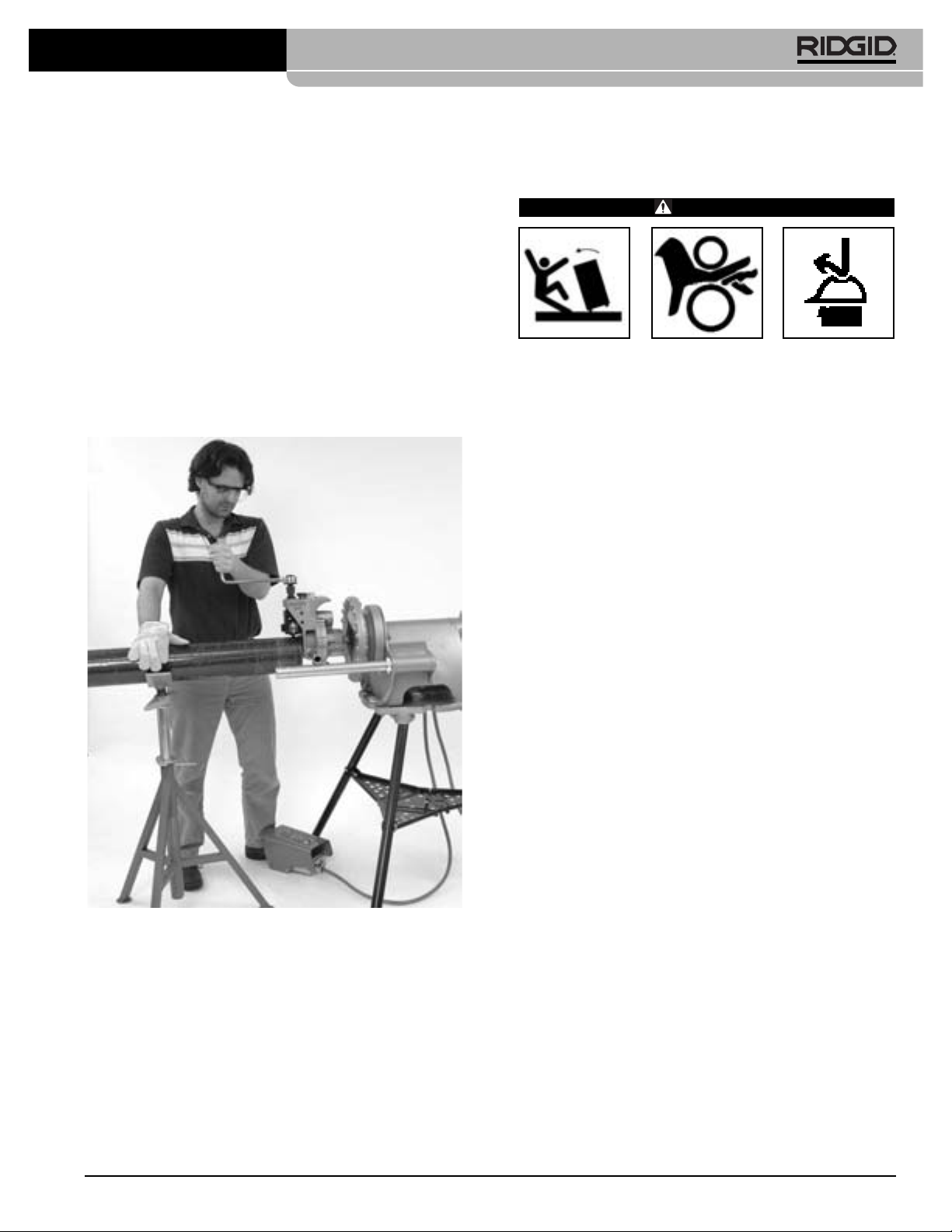

Figure 12 – Roll Groover Operating Position

2. Assume a proper operating position. Position the

power drive foot switch so that the operator can control the power drive, the roll groover and the pipe to be

grooved. As shown in

Figure 12

, the position should

allow the operator to:

Page 14

975 Combo Roll Groover

• Stand facing the roll groover with access to (on

the same side as) the FOR/OFF/REV switch.

• Control the ON/OFF action of the foot switch and

quickly release the foot switch if needed.

• Have convenient access to the groover and ratchet wrench without reaching over the roll groover.

• Place right hand on pipe being grooved if needed.

• Have good footing and proper balance.

3. Move the FOR/OFF/REV switch to the REV (reverse

position). Do not run the 975 Combo Roll Groover

in the FOR (forward). Because of the design of the

975 Combo Roll Groover, this will cause the pipe

to “spiral” out of the roll groove rolls and may

allow the pipe to fall.

4. Place one hand on the on the head of the ratchet/top

of the feedscrew and the other hand on the end of the

ratchet.

5. Press the foot switch to start the power drive. Watch

the pipe rotate and be sure that the face of the pipe

stays in contact with the cover plate of the roll groover.

If the pipe starts to move away from the roll groover

cover plate, release the foot switch to prevent the pipe

from spiraling off and falling. If needed, re-set up the

(see Pipe Set Up Section)

pipe

. If the pipe end is deformed, it will need to be cut off and a new groove

prepared.

6. As the pipe completes a full rotation, tighten the feedscrew another 1/4turn. Continue to monitor the pipe

end to make sure that it is in contact with the cover

plate. Do not tighten the feedscrew more than 1/

turn per pipe rotation. Aggressive tightening of the

feedscrew can cause excessive groove flare or cause

the pipe to spiral off the drive shaft.

7. Continue tightening the feedscrew

1

/4turn per pipe revolution until the head of the adjusting screw stops

against the top of the roll groover. Do not continue

tightening the feedscrew after the adjusting screw

reaches the top of the roll groover, this can damage

the adjusting screw. Allow the pipe to rotate at least

two more full rotations in this position to insure uniform

groove depth.

8. Release the foot switch and move the FOR/OFF/REV

switch to the OFF position.

9. Turn the feedscrew counter-clockwise and raise the

groove roll so that the pipe can be removed from

the machine.

10. Inspect the groove.

• Make sure that the groove is fully formed.

• Check the groove diameter and make sure it is

within specification.

• Check any other items required by the fitting manufacturer.

If any problems are found, the groove cannot be used.

Setting The Groove Diameter For

Copper Tubing

When using the 975 Combo Roll Groover for copper

tube, the groove depth gauge on the groover cannot be

used. It will give incorrect groove diameters.

1. Turn the feedscrew clockwise to bring the groove

roll down in contact with the pipe outside diameter,

then turn the feedscrew one quarter additional turn.

The adjusting screw may need to be loosened (turned

counter-clockwise) to allow the groove roll to contact

pipe. The pipe and roll groover should be secure to

each other at this point.

2. Make sure the groove depth gauge is in the grooving

position.

(Figure 10B)

3. Turn the adjusting screw until it is flush with the top

plate of the groover.

4. Find the diameter and type of pipe to be grooved on

Table B and back the adjusting screw off the top

plate the corresponding number of turns. For example, for 4" Sch. L copper, back the adjustment screw

11/4turns.

Depth Adjustment for Roll Grooving Copper Tubing

4

(Adjusting Screw Turns)

Dia. K L M DWV

7

2-2.5"

3" 11/

4" 11/

5" 11/

6" 113/

8" 21/

8

/

16

4

2

16

2

Chart B – Depth Adjustment for Roll Grooving Copper

Tubing

5.

Go to step 4 of “Setting/Measuring The Groove

11/

11/

11/

13/

23/

7

8

/

16

4

2

4

8

11/

11/

11/

13/

21/

5

8

/

16

4

2

4

8

11/

11/

11/

13/

21/

5

8

/

16

8

2

4

8

Diameter”.

975 Combo Roll Groover Tracking Tips

The main issue users encounter when roll grooving is the

pipe “spiraling” or “walking off” the driveshaft or not “tracking” properly. For good tracking, it is important that all of

the instructions are followed. If, even after following all

instructions, the pipe will not properly track, there are

several other options to improve tracking.

Ridge Tool Company12

Page 15

975 Combo Roll Groover

• Slightly increase the offset of the pipe towards the

operator (increase from 1/2degree to 1 degree)

(See

Figure 9).

• The operator may need to apply slight force on the

pipe while grooving to maintain tracking. This is usually only needed on shorter sections of pipe. To do

this, the operator should wear a leather glove in

good condition and cup their hand around the middle

of the pipe as shown in

Figure 13

. This may require

that the stand to which the power drive/threading

machine is mounted be fixed to the floor to prevent

movement during grooving. To prevent crushing

injuries, keep hand away from the groove roll and the

ends of the pipe, and do not groove pipe shorter

that recommended.

Machine and Work Area Set-Up

For In Place Applications

WARNING

Always wear eye protection to protect your eyes

against dirt and foreign objects. Wear steel toe

footwear to protect feet from tipping and falling

pipe and tools. When working in place, wear a hard

hat.

Set up roll groover and work area according to

these procedures to reduce the risk of injury from

machine tipping, crushing and other causes, and

prevent roll groover damage.

1. Locate a work area that has the following:

• Adequate lighting.

• No flammable liquids, vapors or dust that may ignite.

If present, do not work in area until sources have

been identified and corrected.

• Clear, level, stable and dry location with adequate

space for all of the equipment and the operator.

2. Clean up the work area prior to setting up any equipment. Always wipe up any oil that may be present.

Figure 13 – Applying Force To Pipe While Grooving To

• Additionally, see the

Maintain Tracking

Troubleshooting Section

for a

complete list of reasons for and solutions to tracking

issues.

3. Inspect the pipe to be grooved and confirm that the

975 Combo Roll Groover is the correct tool for the job.

The 975 Combo Roll Groover is designed to groove

schedule 10 and 40 steel, aluminum, and PVC pipe in

11/4" to 6" sizes. It is also designed to groove 11/4" to 6"

schedule 10 and 11/4" to 2" schedule 40 stainless

steel pipe. With a roll set change, it can be used to

groove 2" - 8" Type K, L, M and DWV copper tube.

The 975 Combo Roll Groover can be used for in

place applications (pipe that is in place or mounted in

a vise) or with a RIDGID 300 Power Drive or 300

Compact Threading Machine for powered applications

on the job site. The 975 Combo Roll Groover is not

intended for production type applications.

4. When grooving in place, make sure that there will be

enough space for the 975 Combo Roll Groover to fit

and be operated. The roll groover will orbit around the

solidly mounted pipe and requires:

• A minimum of 61/2" clear space around the pipe to

the be grooved

• A minimum of 21/2" pipe extending past an obstruc-

tion such as a wall

Ridge Tool Company 13

Page 16

975 Combo Roll Groover

• A minimum opening of 91/2" to fit the roll groover

onto the pipe

Roll groovers for other applications can be found

by consulting the Ridge Tool catalog, on line at

www.RIDGID.com, or by calling Ridge Tool Technical Services at 800-519-3456.

NOTICE

Use of roll sets (groove roll and driveshaft) on

both carbon and stainless steel pipe can lead to contamination of the stainless steel material. This contamination could cause corrosion and premature pipe failure.

To prevent ferrous contamination of stainless steel pipe,

use roll sets dedicated for stainless steel roll grooving.

Alternately, a stainless steel wire brush may be used to

thoroughly clean the roll set when switching between

materials.

Pipe Preparation

NOTICE

follow grooved coupling manufacturer’s specific recommendations for pipe end preparation. Failure to follow

the grooved coupling manufacturer’s recommendations

may lead to an improper connection and cause leaks.

1. If grooving in place on an existing piping, make sure

that the system has been depressurized and emptied

of contents. Know what the contents are and any

hazards associated with them.

2. Cut pipe to proper length.

Make sure pipe end is cut square and free of burrs.

Burrs can catch or cut gloves or fingers during grooving. Cut off method and large burrs can effect the

quality of the groove made and the tracking of the

Groove. Do not attempt to groove pipe that has been

cut with a torch.

These are generalized instructions. Always

Mounting The Roll Groover To The Pipe

1. Confirm that the 975 Combo Roll Groover has been

inspected and has the appropriate roll set installed.

Make sure that the support arms are tight in the body

of the roll groover or remove them completely for

better access in tight spaces. Next, install the ratchet

into the feedscrew and install the extension into the

manual drive square at the back of the roll groover.

Make sure both the ratchet and extension are securely installed.

2. Make sure that there is enough space between the

groove roll and drive shaft for the pipe wall. If needed,

turn the feedscrew counter-clockwise to retract the

groove roll.

3. Securely grasp the roll groover. Do not lift with the

ratchet. Place the driveshaft into the pipe and make

sure that the cover plate is tight to the end of the pipe

(Figure 14)

roll into contact with the outside of the pipe. Once the

feedscrew is hand tight, use the ratchet to tighten the

feedscrew an additional 1/4turn. Confirm that the roll

groover is securely attached to the pipe and the

cover plate is flush to the end of the pipe. If not,

repeat procedure. Always make sure groover is

secure when used in place to prevent it from falling.

. Tighten the feedscrew to bring the groove

3. All internal/external weld beads, flash, or seams must

be ground flush at least 2" back from the end of the

pipe. Do not cut flats into gasket seat area, this could

cause leaks.

4. Remove all scale, dirt, rust and other contaminants at

least 2" back from the end of the pipe. Contaminants

can clog the drive knurls and prevent proper driving

and tracking of the pipe while grooving.

5. Make sure that the pipe to be grooved is solidly

mounted. The pipe must be able to withstand the

weight of the roll groover (28 pounds), and the force

and torque required for grooving without moving.

For pipe that is in place, it may make sense to remove

the pipe and groove at a pipe vise. In other cases, it

may be necessary to add other temporary or permanent pipe supports. When using a pipe vise, make

sure that it is secure and will not tip during use. For

longer lengths of pipe, use appropriate pipe stands to

support the extra length.

Ridge Tool Company14

Cover Plate

Figure 14 – Holding the Roll Groover In Place While

Tightening the Feedscrew

Page 17

975 Combo Roll Groover

Operating The 975 Combo Roll

Groover In Place

WARNING

Only drive manually when used for in place applications. Do not use powered devices (such as drills

or impact tools) to drive the roll groover when used

in place. Use of powered devices can damage the

groover and increase the risk of injury.

Do not wear loose clothing when operating the roll

groover. Keep sleeves and jackets buttoned. Do

not reach across the machine or pipe. Loose clothing can become entangled in rotating parts and

cause crushing injuries.

Keep hands away from grooving rolls. Do not groove

pipes shorter than specified. Do not wear loose fitting gloves. Fingers can be crushed between groove

rolls or between groove roll and pipe.

Keep hands away from ends of pipe. Do not reach

inside pipe. Burrs and sharp edges can catch and

cut. Fingers can be crushed between groove rolls or

between groove roll and pipe.

Always wear eye protection to protect your eyes

against dirt and foreign objects. Wear steel toe footwear to protect feet from tipping tools and falling

pipe. When working in place, wear a hard hat.

Follow operating instructions to reduce the risk of

injury from crushing, tipping, striking and other

causes.

touches the step of the depth gauge. Turn the groove

depth gauge to the grooving position

(Figure 15B)

gauge is not in the grooving position it will prevent

grooving and may be damaged.

Figure 15A – Place Correct

Step of Gauge Under

Adjusting Screw Head

4. Prepare a test groove (

the Roll Groove)

.

Figure 15B – Gauge In

Grooving Position

follow the steps for “Forming

5. Measure the groove diameter. The best method for

measuring groove diameter is the use of a diameter

tape

(See Accessories Section)

. Snugly wrap the

diameter tape around the pipe in the groove. Make

sure that the tape sits flat in the bottom of the groove,

and read the groove diameter

(See Figure 16)

.

. If

Setting/Measuring The Groove Diameter

NOTICE

groove should always be performed before the first

groove of the day or when changing pipe size, schedule

or material. Groove diameter setting gauges are approximate only and the groove diameter must be measured to

confirm proper size.

1. Confirm that the equipment and pipe are properly

set up. Improper pipe preparation can effect the

accurate set up of the groove depth gauge. The

groove roll should be touching the pipe.

2. Adjust the groove depth gauge so that the correct step

of the gauge is under the head of the adjusting screw

(Figure 15A).

use with pipe.

Copper Tube” for use with copper tube

3. Turn the adjusting screw clockwise until the head

Due to differing pipe characteristics, a test

The groove depth gauge is designed for

See “Setting The Groove Diameter For

.

Ridge Tool Company 15

Figure 16 – Measuring The Groove Diameter With A

Diameter Tape

6. Compare the measured groove diameter to the required groove diameter as shown in

Table I or III

or as

specified by the groove fitting manufacturer. If the

measured groove is outside of the required groove

diameter, the adjusting screw must be repositioned to

give the correct groove diameter.

• To increase groove diameter, turn the adjusting

screw clockwise.

Page 18

975 Combo Roll Groover

• To decrease groove diameter, turn the adjusting

screw counter-clockwise.

• Each 1/4turn of the adjusting screw changes the

groove diameter approximately 0.02".

7. Repeat steps 4-6 until the groove diameter is within

specifications. If the first groove is too large, the

Groove can be adjusted and the groove made smaller. If the groove is too small, another groove will

need to be made. Proper groove diameter is important

to insure connection performance. Out of specification

grooves could cause joint failure.

Forming The Roll Groove

1. Confirm that the equipment and pipe are properly

set up.

2. Assume a proper operating position. Make sure that

your footing is good and you are well balanced.

3. Make sure that the feedscrew has been tightened 1/

turn.

4. Remove the ratchet from the feedscrew and securely install in the extension. (In close quarters applications, the extension does not need to be used.)

5. Turn the ratchet clockwise as viewed from the back of

the roll groover (this will match the arrows cast into the

back of the roll groover,

groover rotate and be sure that the cover plate of the

roll groover stays in contact with the end of the pipe.

If the roll groover starts to move away from the pipe

end, stop rotating the ratchet to prevent the roll

groover from spiraling off the pipe end and falling.

The roll groover support arms can be pushed on to

help bring the cover plate back in contact with the pipe

end. If needed, re-mount the roll groover to the pipe.

(see “Mounting Roll Groover to Pipe” section)

pipe end is deformed, it will need to be cut off and a

new groove prepared.

see Figure 17

). Watch the

. If the

6. Continue rotating the ratchet until the roll groover

completes at least a full rotation around the pipe.

Remove the ratchet from the extension and attach to

the feedscrew. Tighten the feedscrew another 1/

4

turn. Remove the ratchet from the feedscrew and

securely attach to the extension. Do not tighten the

feedscrew more than 1/4turn per pipe rotation. Aggressive tightening of the feedscrew can cause excessive groove flare and can cause the roll groover to

walk off the pipe. Continue rotating the ratchet to

drive the roll groover around the pipe while monitoring

the position of the cover plate to the end of the pipe.

7. Continue tightening the feedscrew 1/4turn per groove

revolution around pipe until the head of the adjusting

screw stops against the top of the roll groover. Do not

continue tightening the feedscrew after the adjusting

screw reaches the top of the roll groover, this can

damage the adjusting screw. Rotate the roll groover

4

at least two more full rotations around the pipe after

the adjusting screw reaches the top of the roll groover

to insure uniform groove depth.

8. Move the ratchet to the feedscrew. Securely grasp the

roll groover. Turn the feedscrew counter-clockwise

and retract the groove roll so that the roll groover can

be removed from the pipe. Do not drop the roll

groover.

9. Inspect the groove.

• Make sure that the groove is fully formed.

• Check the groove diameter and make sure it is

within specification.

• Check any other items required by the fitting man-

ufacturer.

If any problems are found, the groove cannot be used.

Maintenance Instructions

Turn

Figure 17 – Turning the Ratchet in the Direction of the

Arrows

WARNING

Make sure the power drive switch is in the OFF

position and the unplugged before performing any

maintenance or making any adjustments.

Lubrication

Lubricate the 975 Combo Roll Groover with a good general purpose grease once a month.

• Grease fittings are located on the side of the oper-

ator’s side of the base, the front of the slide block,

and the end of the groove roll shaft

Add grease until a small amount is pushed out.

• Apply a light coat of grease to the feedscrew.

Ridge Tool Company16

(See Figure 2).

Page 19

975 Combo Roll Groover

• The gear box of the 975 Combo Roll Groover is

greased for life and does not require the addition of

any grease unless the gear box is opened.

See Inspection Section for other information on maintenance.

Cleaning

Clean the driveshaft knurls with a wire brush on a daily

basis or more often if needed.

Changing Roll Sets

NOTICE

sure drive and groove roll markings match. Mismatched

parts can make improper grooves and cause leaks.

Remove the roll groover from the power drive or threading machine and place on a stable work bench.

Required Tools:

•

•3/32" Hex Wrench

• .070" External Retaining Ring Pliers

Removing and Installing Drive Roll

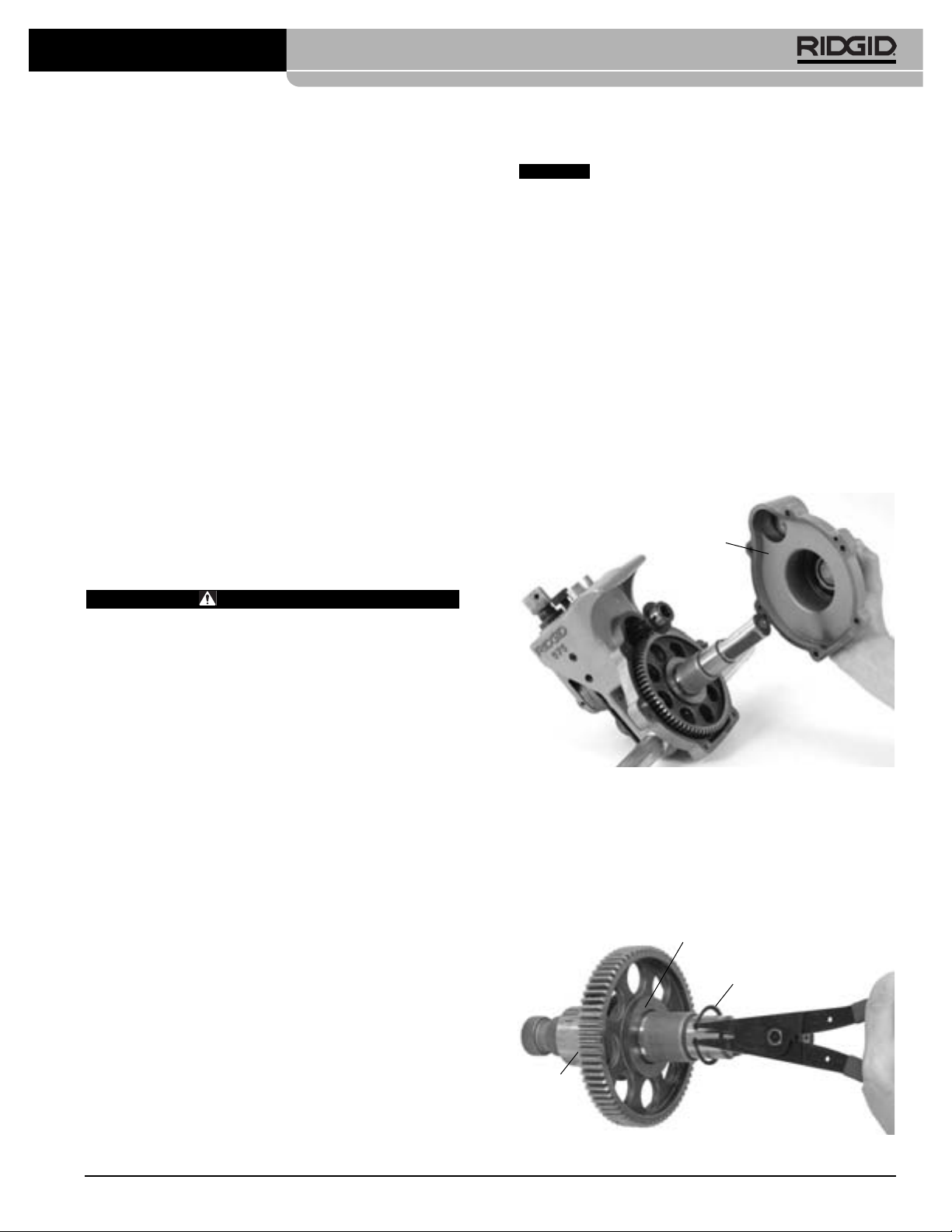

1. Remove 6 screws that hold rear cover to the housing.

2. Remove the rear cover

When changing roll set parts, always make

3

/8" Hex Wrench

(See Figure 18)

.

Gear

Retaining Ring

Thrust

Washer

Figure 19 – Removing Retaining Ring

6. Remove key and then thrust washer.

7. Slide thrust washer onto new driveshaft.

8. Insert key and install gear.

9. Install retaining ring into driveshaft groove.

10. Place driveshaft assembly into main housing.

11. Grease from the gearbox may have been lost during

the driveshaft change. Make sure the bearings and

gear teeth are coated sufficiently with a good general purpose grease.

12. Insert pinion and reinstall rear cover. Tighten screws

to 12-16 ft*lbs of torque.

Main Housing

Rear Cover

Figure 18 – Removing Rear Cover

3. Remove pinion.

4. Remove the driveshaft assembly out of the back of

the 975 Roll Groover.

5. Remove retaining ring from driveshaft and slide gear

off.

(See Figure 19.)

Driveshaft

Pinion

Thrust

Washer

Figure 20 – 975 Combo Roll Groover Parts Diagram

Key

Retaining

Ring

Gear

Screws

Rear Cover

Removing and Installing Groove Roll

1. Remove the setscrew that holds the groove roll shaft

in place.

2. Pull the groove roll shaft out of the slide block and

remove the groove roll and thrust washer.

3. Insert the thrust washer and new groove roll into the

slide block. Ensure that the internal retaining ring in

the groove roll is closest to the main housing, and that

the groove roll is between the thrust washer and

main housing.

Ridge Tool Company 17

Page 20

975 Combo Roll Groover

Main Housing

Slide

Block

Figure 21

Set Screw

Thrust

Washer

Groove

Roll

4. Replace the groove roll shaft and the set screw.

5. Visually inspect the alignment between the groove roll

and the drive roll. If they are not aligned, check orientation of groove roll and thrust washer.

6. Grease as directed in Lubrication Section of manual.

Accessories

WARNING

The following RIDGID products have been designed

to function with the 975 Combo Roll Groover. Other

accessories suitable for use with other tools may be

hazardous when used on the 975 Combo Roll

Groover. To reduce the risk of serious injury, only

use accessories specifically designed and recommended for use with the 975 Combo Roll Groover,

such as those listed in the chart.

Machine Storage

WARNING

out of reach of children and people unfamiliar with roll

groover equipment. This tool can cause serious injury in

the hands of untrained users.

Store the tool in a locked area that is

Service and Repair

WARNING

Improper service or repair can make machine

unsafe to operate.

The “Maintenance Instructions” will take care of most of

the service needs of this machine. Any problems not

addressed by this section should only be handled by an

authorized RIDGID service technician.

Tool should be taken to a RIDGID Independent Authorized Service Center or returned to the factory.

When servicing this machine, only identical replacement

parts should be used. Use of other parts may create a risk

of serious injury.

If you have any questions regarding the service or repair

of this machine, call or write to:

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44035-6001

Tel: (800) 519-3456

E-mail: TechServices@ridgid.com

For name and address of your nearest Independent

Authorized Service Center, contact the Ridge Tool Company at (800) 519-3456 or www.RIDGID.com

Cat. Number Description

41855 300 Power Drive, 115V 25-60Hz 38RPM

75075 300 Power Drive, 115V 23-60Hz 57RPM

42360 1206 Stand for 300 Power Drive

66947 300 Compact, 115V 50/60Hz 38RPM

73447 300 Compact, 115V 50/60Hz 52RPM

67662 Adapter Bracket for 300 Compact

67657 250 Folding Wheel Stand for 300 Compact

72037 460 Portable TRISTAND Chain Vise

56662 VJ-99 VHead High Pipe Stand

76822 Inch Diameter Tape

76827 Metric Diameter Tape

30708 Extension,

30703 Ratchet,

32833 Groove and Drive Rolls for 2" - 8" Copper

Tube Type K, L, M and DWV

1

/2" Drive, Locking

1

/2" Drive With 90° bend

Ridge Tool Company18

Page 21

975 Combo Roll Groover

Table I. Standard Roll Groove Specifications For Pipe of IPS Dimensions

NOTE! All Dimensions are in Inches.

NOM. PIPE MIN. GASKET GROOVE GROOVE NOM.

PIPE DIAMETER WALL SEAT WIDTH DIAMETER GROOVE

SIZE O.D. TOL. THK. +.015/-.030 +.030/-.015 O.D. TOL. DEPTH (Ref.) (2)

1

4

1

/

1.660 +.016 .065 .625 .344 1.535 +.000 .063

-.016 -.015

1

2

1

/

1.900 +.016 .065 .625 .344 1.775 +.000 .063

-.016 -.015

(1)

2

2.375

+

.024 .065 .625 .344 2.250 +.000 .063

-.016 -.015

1

(1)

2

2

/

2.875

+

.029 .083 .625 .344 2.720 +.000 .078

-.016 -.015

(1)

3

3.50

+

.030 .083 .625 .344 3.344 +.000 .078

-.018 -.015

1

(1)

2

3

/

4.00

+

030 .083 .625 .344 3.834 +.000 .083

-.018 -.015

(1)

4

4.50

+

.035 .083 .625 .344 4.334 +.000 .083

-.020 -.015

(1)

5

5.563

+

.056 .109 .625 .344 5.395 +.000 .084

-.022 -.015

(1)

6

6.625

+

.050 .109 .625 .344 6.455 +.000 .085

-.024 -.015

(1)As per AWWA C606-06

(2)Nominal Groove Depth is provided as a reference dimension only. Do not use groove depth to determine acceptability of a groove.

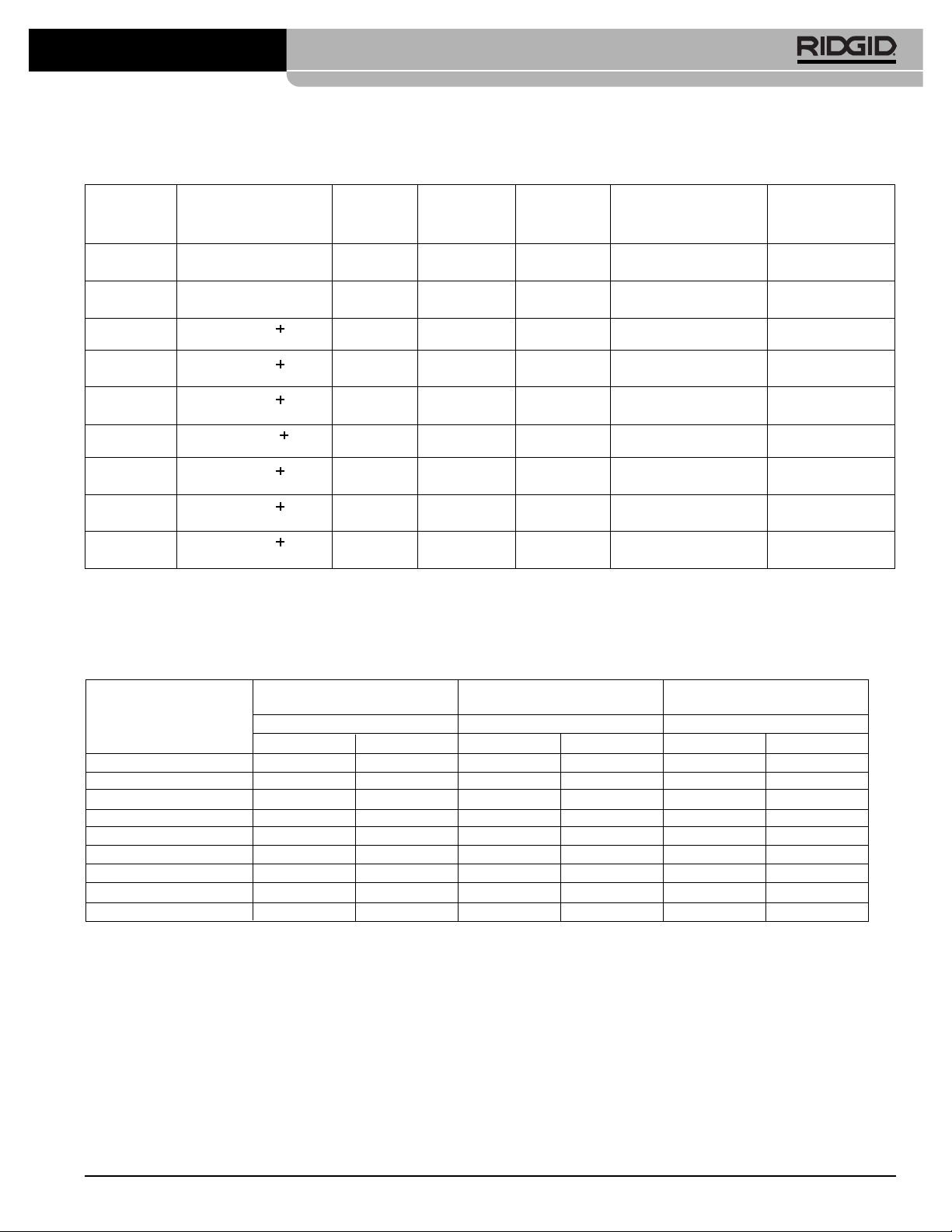

TA B C D

Table II. Pipe Maximum and Minimum Wall Thickness

NOTE! All Dimensions are in Inches.

CARBON STEEL OR STAINLESS STEEL

ALUMINUM PIPE OR TUBE PIPE OR TUBE PVC PIPE

Pipe Size

1

1

/4" .065 .140 .065 .140 .140 .140

1

1

/2" .065 .145 .065 .145 .145 .200

2" .065 .154 .065 .154 .154 .154

1

2

/2" .083 .203 .083 .188 .203 .276

3" .083 .216 .083 .188 .216 .300

1

3

/2" .083 .226 .083 .188 .226 .300

4" .083 .237 .083 .188 .237 .300

5" .109 .258 .109 .188 .258 .300

6" .109 .280 .109 .188 .280 .300

Wall Thickness Wall Thickness Wall Thickness

Min. Max. Min.

Max. Min. Max.

Ridge Tool Company 19

Page 22

975 Combo Roll Groover

Table III. Copper Roll Groove Specifications

1 2 345678

AB CDT

Nom. Tubing Outside Gasket Groove Groove Groove Min. Max.

Size Diameter O.D. Seat Width Dia. Depth Allow. Allow.

Inches A +.03 +.00 Ref.

Basic Tolerance ±0.03 –.000 –.02 Thick. Dia.

2" 2.125 ±0.002 0.610 0.300 2.029 0.048 DWV 2.220

21/2" 2.625 ±0.002 0.610 0.300 2.525 0.050 0.065 2.720

3" 3.125 ±0.002 0.610 0.300 3.025 0.050 DWV 3.220

4" 4.125 ±0.002 0.610 0.300 4.019 0.053 DWV 4.220

5" 5.125 ±0.002 0.610 0.300 5.019 0.053 DWV 5.220

6" 6.125 ±0.002 0.610 0.300 5.999 0.063 DWV 6.220

8" 8.125 +0.002/-0.004 0.610 0.300 7.959 0.083 DWV 8.220

1. Nominal Groove Depth is provided as a reference dimension. Do not use groove depth to determine groove acceptability.

1

Wall Flare

Troubleshooting

SYMPTOM POSSIBLE REASONS SOLUTION

Roll groove too narrow or

too wide.

Rolled groove not perpendicular to pipe axis.

Pipe will not track while

grooving/Groover will not

track on pipe while grooving.

Pipe flared at grooved end.

Grooving roll and/or driving shaft worn.

Pipe length not straight.

Pipe end not square with pipe axis.

Pipe and drive shaft not parallel.

Pipe axis not offset 1/2degree from driving roll axis.

Driving roll knurl plugged or worn flat.

Feedscrew not tight.

Turning ratchet wrong direction.

Inside of pipe has too much scale.

Excessive weld seam.

Not applying pressure to pipe.

Pipe end not square/deburr.

Feedscrew too tight.

Pipe and drive shaft not parallel.

Feedscrew too tight.

Replace grooving roll and/or drive shaft.

Use straight pipe.

Cut pipe end square.

Adjust stand to make pipe parallel.

Offset pipe 1/2degree.

Clean or replace drive roll.

Tighten feedscrew with ratchet for every

revolution as per directions.

Turn ratchet in proper direction.

Clean inside of pipe.

Grind weld seam flush 2" from end of pipe.

Apply pressure to pipe.

Properly prep end of pipe.

Only advance feedscrew in 1/4turn increments.

Adjust stand to make pipe parallel.

Only advance feedscrew 1/4 turn.

(See Figure 10.)

Ridge Tool Company20

Page 23

975 Combo Roll Groover

Troubleshooting

(continued)

SYMPTOM POSSIBLE REASONS SOLUTION

Pipe drifts back and forth

on driving roll axis while

grooving.

Pipe rocks from side to

side on driving roll while

grooving.

Groover will not roll

groove in pipe.

Groover will not roll

groove to required

diameter.

Pipe length not straight.

Pipe end not square with pipe axis.

Pipe stand is too close to end of pipe.

Pipe end flattened or damaged.

Hard spots in pipe material or weld seams harder

than pipe.

Grooving roll feed rate too slow.

Power drive speed exceeds 57 RPM.

Pipe supports stand not in correct location.

Maximum pipe wall thickness exceeded.

Pipe material too hard.

Adjustment screw not set.

Power drive does not supply required minimum

torque.

Maximum pipe diameter tolerance exceeded.

Depth adjustment screw not set correctly.

Pipe too hard.

Use straight pipe.

Cut pipe end square.

Move pipe stand in to match set-up Instructions.

Cut off damaged pipe end.

Use different pipe.

Feed grooving roll into pipe faster.

Reduce speed to 57 RPM.

Position pipe stand rollers correctly.

Check pipe capacity chart.

Replace pipe.

Set depth.

Use RIDGID No. 300, 38-RPM Power Drive.

Use correct diameter pipe.

Adjust depth setting.

Use different pipe.

Pipe slips on driving roll.

Groover will not rotate

pipe while grooving.

Pipe rises or tends to tip

Groover over backwards.

Grooving roll feed rate too slow.

Driving roll knurls plugged with metal or worn flat.

Power drive does not supply minimum required

torque.

Chuck not closed on drive shaft flats.

Pipe support stand not properly set up.

Feed grooving roll into pipe faster.

Clean or replace driving roll.

Use RIDGID No. 300, 38 RPM Power Drive.

Close chuck.

Properly set up stands.

Ridge Tool Company 21

Page 24

975 Combo Roll Groover

Ridge Tool Company22

Page 25

Rainureuse à galets mixte

975

AVERTISSEMENT

Lisez soigneusement ce manuel

avant d’utiliser l’appareil. Le

manque d’assimilation ou le nonrespect des consignes ci-devant

augmenteraient les risques de

choc électrique, d’incendie et/ou

de blessure corporelle grave.

Page 26

Rainureuse à galets mixte modèle 975

Table des matières

Symboles de sécurité ................................................................................................................................................25

Consignes générales de sécurité

Sécurité des lieux......................................................................................................................................................25

Sécurité électrique....................................................................................................................................................25

Sécurité individuelle..................................................................................................................................................26

Utilisation et entretien de l’appareil ..........................................................................................................................26