RIDGID Color SeeSnake KD-200 Color, Color SeeSnake KD-325 Color Operator's Manual

Color SeeSnake

™

Diagnostic Equipment

Patent Pending

Camera and Line Location

Products for Pipe Inspection

Kollmann

OPERATOR’S

MANUAL

• Pour français voire page 19

• Para el castellano vea la

página 39

KD-200 Color

KD-325 Color

WARNING!

For your own safety, read this

Operator’s Manual carefully

before assembling or operating

this unit.

SeeSnake™Diagnostic Equipment

Kollmann

Ridge Tool Company • Elyria, Ohio • U.S.A.ii

Table of Contents

Recording Form for Machine Model and Serial Number...........................................................................................1

General Safety Information

Work Area Safety.......................................................................................................................................................2

Electrical Safety..........................................................................................................................................................2

Personal Safety..........................................................................................................................................................2

Tool Use and Care.....................................................................................................................................................3

Service .......................................................................................................................................................................3

Specific Safety Information

Tool Safety.................................................................................................................................................................3

Description, Specifications and Standard Equipment

Description .................................................................................................................................................................3

Specifications.............................................................................................................................................................4

Standard Equipment...................................................................................................................................................5

Terms.............................................................................................................................................................................5

Set-Up, and Operation

SeeSnake Cable CountIR Standard Key Pad Usage.................................................................................................8

Key Pad Usage in Edit Mode .....................................................................................................................................8

Edit Menu Fields for Display and System Settings.....................................................................................................8

Battery Removal/Installation.......................................................................................................................................8

Possible Display Messages........................................................................................................................................9

To Install the Wheels Onto the Dolly..........................................................................................................................9

Models with Power Packs ..........................................................................................................................................9

Models with RIDGID/Kollmann SeeSnake Provided Monitor+VCRs...........................................................................9

Pre-Checks...............................................................................................................................................................10

At the Job Site..........................................................................................................................................................10

Maintenance

Preventative Maintenance........................................................................................................................................11

Corrective Maintenance ...........................................................................................................................................12

Removing the Camera Head.................................................................................................................................12

Locating Faulted Components ..............................................................................................................................13

Re-Installing Camera Head...................................................................................................................................13

Transportation and Storage......................................................................................................................................14

Options

Centering Guides .....................................................................................................................................................14

Pipe Location Transmitter ........................................................................................................................................15

Installing the Pipe Location Transmitter................................................................................................................15

Service and Repair .....................................................................................................................................................16

Troubleshooting Chart...............................................................................................................................................17

Lifetime Warranty.........................................................................................................................................Back Cover

Pipe Inspection Equipment

Record Serial Number below and retain product serial number which is located on nameplate.

Serial

No.

Kollmann

SeeSnake

™

Diagnostic Equipment

KD-200 Color

KD-325 Color

General Safety Information

WARNING! Read and understand all Instructions.

Failure to follow all instructions listed below

may result in electric shock, fire, and/or serious personal injury.

SAVE THESE INSTRUCTIONS!

Work Area Safety

1. Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

2. Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep by-standers, children, and visitors away

while operating a power tool. Distractions can

cause you to lose control.

4. Do not let visitors contact the tool or extension

cord. Such preventative measures reduce the risk

of injury.

Electrical Safety

1. Grounded tools must be plugged into an outlet,

properly installed and grounded in accordance

with all codes and ordinances. Never remove

the grounding prong or modify the plug in any

way. Do not use any adapter plugs. Check with

a qualified electrician if you are in doubt as to

whether the outlet is properly grounded. If the

tools should electrically malfunction or break down,

grounding provides a low resistance path to carry

electricity away from the user.

2. Avoid body contact with grounded surfaces

such as pipes, radiators, ranges and refrigerators. There is an increased risk of electrical shock

if your body is grounded.

3. Don’t expose power tools to rain or wet condi-

tions. Water entering a power tool will increase the

risk of electrical shock.

4. Do not abuse cord. Never use the cord to carry

the tools or pull the plug from an outlet. Keep

cord away from heat, oil, sharp edges, or moving parts. Replace damaged cords immediately.

Damaged cords increase the risk of electrical shock.

5. When operating a power tool outside, use an

outdoor extension cord marked “W-A” or “W”.

These cords are rated for outdoor use and reduce

the risk of electrical shock.

6. Connect the tool to an AC power supply that

matches the name plate specification. Incorrect

voltage supply can cause electrical shock or burns.

7. Use only three-wire extension cords which

have three-prong grounding plugs, and threepole receptacles which accept the tools plug.

Use of other extension cords will not ground the

tool and increase the risk of electrical shock.

8. Use proper extension cords. (See chart.) Insufficient conductor size will cause excessive voltage

drop and loss of power.

9. Keep all electrical connections dry and off the

ground. Do not touch plug with wet hands.

Reduces the risk of electrical shock.

Personal Safety

1. Stay alert, watch what you are doing, and use

common sense when operating a power tool.

Do not use tool while tired or under the influence of drugs, alcohol, or medications. A

moment of inattention while operating power tools

may result in serious personal injury.

2. Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts.

Loose clothes, jewelry, or long hair can be caught

in moving parts.

3. Avoid accidental starting. Be sure switch is OFF

before plugging in. Carrying tools with your finger

on the switch or plugging in tools that have the

switch ON invites accidents.

4. Do not overreach. Keep proper footing and bal-

ance at all times. Proper footing and balance

SeeSnake™Diagnostic Equipment

Kollmann

Ridge Tool Company • Elyria, Ohio • U.S.A.2

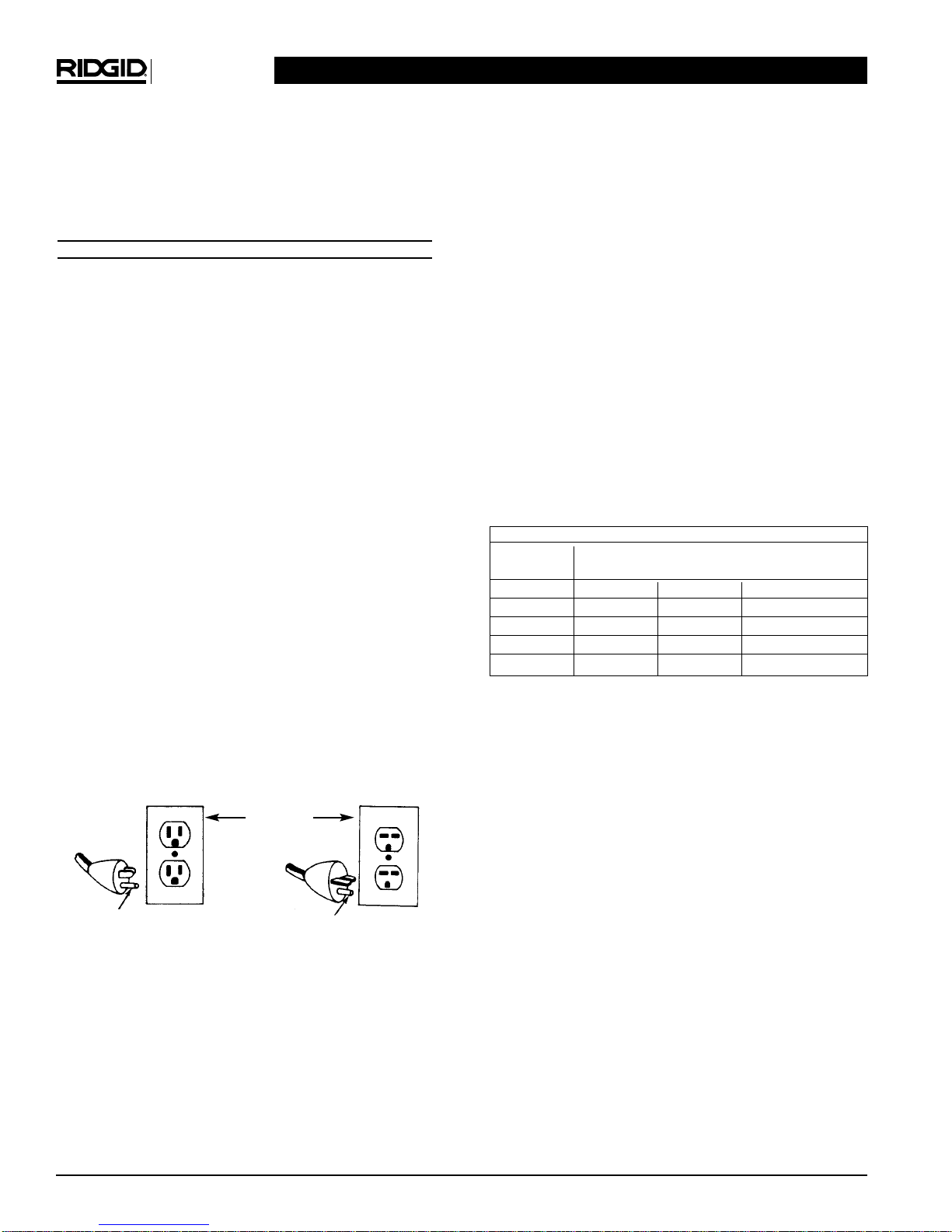

Minimum Wire Gauge for Cord Set

Nameplate

Amps

Total Length (in feet)

0 – 25 26 – 50 51 – 100

0 – 6 18 AWG 16 AWG 16 AWG

6 – 10 18 AWG 16 AWG 14 AWG

10 – 12 16 AWG 16 AWG 14 AWG

12 – 16 14 AWG 12 AWG

NOT RECOMMENDED

Grounding pin

Cover of

grounded

outlet box

Grounding pin

enables better control of the tool in unexpected situations.

5. Use safety equipment. Always wear eye protec-

tion. Dust mask, non-skid safety shoes, hard hat,

or hearing protection must be used for appropriate

conditions.

Tool Use and Care

1. Do not use tool if switch does not turn it ON or

OFF. Any tool that cannot be controlled with the

switch is dangerous and must be repaired.

2. Store idle tools out of the reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

3. Maintain tools with care. Properly maintained

tools are less likely to cause injury.

4. Check for breakage of parts, and any other con-

dition that may affect the tools operation. If damaged, have the tool serviced before using. Many

accidents are caused by poorly maintained tools.

5. Use only accessories that are recommended by

the manufacturer for your model. Accessories

that may be suitable for one tool may become hazardous when used on another tool.

6. Inspect tool and extension cords periodically

and replace if damaged. Damaged cords increase

the risk of electrical shock.

7. Keep handles dry and clean; free from oil and

grease. Allows for better control of the tool.

8. Store tools in dry place. Such measures reduce

the risk of electrical shock.

Service

1. Tool service must be performed only by qualified repair personnel. Service or maintenance

performed by unqualified repair personnel could

result in injury.

2. When servicing a tool, use only identical

replacement parts. Follow instructions in the

Maintenance Section of this manual. Use of

unauthorized parts or failure to follow maintenance

instructions may create a risk of electrical shock or

injury.

3. Follow instructions for lubricating and chang-

ing accessories. Accidents are caused by poorly

maintained tools.

Specific Safety Information

The Operator’s Manual contains specific safety information and instructions for your protection against

serious injuries including:

• Electrical shock or burns from contact with wires

or other electrical parts.

Read and follow the safety labels on machine!

Know the location and functions

of all controls before using system.

Tool Safety

1. Before using, test the Ground Fault Circuit

Interrupter (GFCI) provided with the power cord

to ensure it is operating correctly. GFCI reduces

the risk of electrical shock.

2. Extension cords are not recommended unless

they are plugged into a ground fault circuit

interrupter (GFCI) found in circuit boxes or

receptacles. The GFCI on the monitor power cord

will not prevent electrical shock from the extension

cords.

3. Do not operate the system with electrical enclo-

sures removed. Exposure to internal parts

increases the risk of injury.

4. Do not place the monitor and power pack in

water or on a wet surface. Water entering the

housings will increase the risk of electrical shock.

5. Do not use the monitor as a chair or table. Do

not drop or shock the monitor. Can result in

damage to the unit which increases the risk of electrical shock.

SAVE THESE INSTRUCTIONS!

Description, Specifications,

and Standard Equipment

Description

The RIDGID/Kollmann patent pending Color SeeSnake

Pipe Inspection Tool is ideal for inspecting 2″ to 8″ drain

lines. Its flexible camera head can negotiate multiple

hard 90° bends, and the fiberglass rod is flexible enough

to easily travel bends, yet stiff enough to push the camera head over 300′. The hardened stainless steel camera housing, sapphire crystal lens port (a material which

doesn’t scratch), waterproof connectors, and push rod

are built for long lasting use.

SeeSnake™Diagnostic Equipment

Kollmann

Ridge Tool Company • Elyria, Ohio • U.S.A. 3

SeeSnake™Diagnostic Equipment

Kollmann

Ridge Tool Company • Elyria, Ohio • U.S.A.4

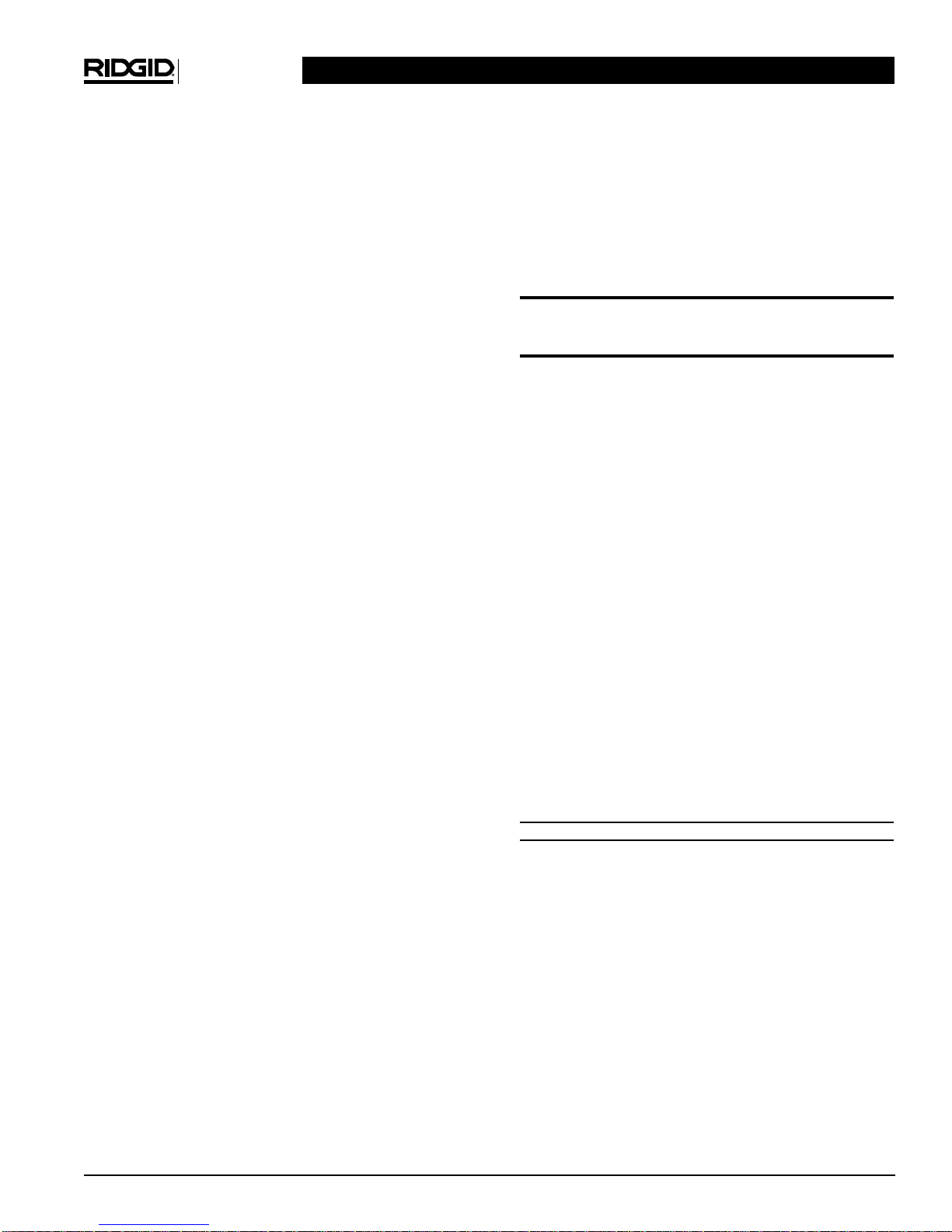

Figure 1 – Connectors

There are several pairs of these connectors in the

system: camera - push cable, push cable - hub, hub interconnect cord, interconnect cord - Monitor+VCR/

power pack. The above designations are always true

for these connectors. Guide pins are always a different color than circuit pins, and guide sockets are a different size than the other sockets. Align guide pins to

guide sockets, ensuring the remaining pins and sockets are aligned, and push straight together. To unplug,

pull straight out. Wiggle the connector a little, if necessary, but DO NOT bend or twist it!

Specifications

Line Capacity:..............2″ to 8″

Maximum Run:.............325′

Reel & Frame Weight:...43 lbs.

Reel & Frame Width:...15″

Reel Length:................30″

Power Source:.............120V/60 Hz or 230V/50 Hz

depending on model ordered,

(Converted to approximately

12V DC current to camera

head)

Camera Type:...............Color

Camera Size:................1.75″ x 2.12″

Camera Weight:...........4 oz.

Depth Rating:...............Waterproof to 330′

Camera Resolution: ....330 tvl

The system can be broken down into four sub-assemblies: camera head, reel/dolly, interconnect cord, and

Monitor

+

VCR/power pack. The Monitor+VCR/power

pack is powered by any 120 or 230 volt AC source. In

turn, they convert this power to ~12 volt DC to power

the camera head and LED lighting, as well as any

options in the system. Other than the controls found

on the Monitor+VCR/power pack for such things as

brightness, contrast, and LED lighting, the system has

no external buttons or dials.

The 12 volts DC for the camera (and options) is fed to

the reel through the interconnect cord that is stored on

the dolly. There are three conductors within this cable

that terminate to pins (male) and sockets (female) in

the connectors. See Figure 1 for a detailed description.

Pins/sockets #1 and #2 are the supply and return for

the 12 volts DC. Pins/sockets #3 are the return path for

the video signal generated by the camera back to the

monitor/ power pack. The connectors on this cable are

the same type that are found at the camera head, push

cable, and any options.

The interconnect cord plugs into the back side of the

reel into an area called the hub. Inside the hub, there

is a device called a slip ring, a kind of rotating electrical joint. The slip ring allows the reel to spin without

twisting the cables that enter/exit the reel, while allowing power and video signals to pass.

The push cable is connected to the slip ring by another connector inside the reel, on the cone-shaped portion. This is the “dry end” of the push cable. The

power and video signals travel within the push cable

to and from the camera head. At the “wet end” of the

push cable, a transition occurs from the stiff rod to a

flexible coil cord within the spring. This cord has

another connector that is held into the back of the

camera with a locking sleeve. There are also two

stainless steel safety cables within the spring which

prevent the spring from overstretching when pulling

the camera from pipe.

Once the 12 volt DC power enters the camera, it

passes through a circuit board that directs it to either

the actual video module, or the lights. There is also

some protective circuitry to minimize electronic failure.

The camera circuitry processes images it receives

through the sapphire window and converts it to a

standard video signal that returns to your monitor for

display. If you have a separate power pack, this signal

exits the pack through a video out jack to the monitor

you have chosen to use.

Pin/Socket Function

1 ..........................Neutral

2 ..........................+12 VDC

3 ..........................Video Signal

Male Connector

Female Connector

Guide

#1

#3

#2

Guide

#1

#3

#2

Standard Equipment

KD-200 – Unit with Monitor+VCR, 200′ of push rod,

color camera head, reel, wheel and frame assembly, and standard accessories which include:

• Operator’s Manual

• Cable CountIR

• 3″ and 6″ Centering Guides

• 6 Snap Rings (for Centering Guides)

• 1-Interconnect Cable

• 1 Spanner Wrench (for Camera Head removal)

• 1 Pair of Plastic Coated Gloves

KD-200P – Unit with power pack, 200′ of push rod,

color camera head, reel, wheel and frame assembly, and standard accessories.

KD-325 – Unit with Monitor+VCR, 325′ of push rod,

color camera head, reel, wheel and frame assembly, and standard accessories.

KD-325P – Unit with power pack, 325′ of push rod,

color camera head, reel, wheel and frame assembly, and standard accessories.

Terms

(Refer to Figures 2-11)

Brake Large black knob on dolly that controls the

spinning action of reel. The purpose of the brake is to

provide a slight drag on the reel to prevent freewheeling, resulting in excessive cable exiting the reel. The

brake is not intended to lock the reel.

Cable CountIR Device used to measure the distance

traveled by the SeeSnake.

Cable Guide The U-shaped metal bar above the

brake that the camera and push cable passes through

as it exits the reel.

Color Camera Head Contains a video camera module, LED board, and control and protective components for the video system. The camera is rated to a

water depth of 330 feet.

Centering Guides Small, plastic, star-shaped devices

that mount onto the spring assembly using snap rings.

3″ and 6″ in diameter, they center the camera and help

keep it off of the bottom (out of the sludge).

Connectors All the “plugs” in the system that connect the camera; push cable; hub; interconnect cable;

monitor/power pack. These are the connectors that

have guide pins (male) and guide sockets (female).

These connectors ARE NOT to be confused with 120

volt (or 230V) AC outlet plugs, or any video/audio

jacks. Refer to Figure 1.

Dimmer A small knob found on the front of Monitor+VCRs, and power packs. This allows control of

power to the LEDs to dim or brighten them as conditions vary in pipe. For example, white PVC pipe may

reflect too much light to the camera, making the picture

over-exposed (too bright). Similarly, black ABS pipe will

reflect much less light, making the picture underexposed (too dark). Adjustment of the dimmer allows fine

control of the LED lighting for an optimum picture.

Dolly Metal frame that the reel is mounted to. The

dolly has a second set of feet on the back side of the

reel, allowing the system to rest on its side (open-endup) for greater stability.

Hub The center, cone-shaped portion of the reel.

Within the hub is the slip ring and axle.

Interconnect Cable Thirty-three foot cord that plugs

between the output of the hub and the Monitor+VCR/

power pack. It is kept stored on the dolly, and left

plugged into the hub.

LED Light Emitting Diode. Solid-state light that, unlike

an incandescent lamp (a regular light bulb), does not

have a fragile filament.

LED Ring The polycarbonate (plastic), donut shaped

ring that protects the LEDs from abrasion.

Locking Sleeve This device is found at the rear of

the camera, within the spring. It holds the connector in

place and serves as an anchor for the safety cables.

This device is unscrewed from the back of the camera

to detach the connector from it.

Monitor

+

VCR RIDGID/Kollmann Monitor+VCRs

include a high resolution monitor, power pack and

VCR within them and have a dimmer knob to adjust

the LED brightness for varying pipe conditions. They

also include a sunshade, tilt stand, handle, AC cord

storage hooks, and hands-free microphone.

Power Pack This component is supplied with systems where a Monitor+VCR is not ordered. The power

pack converts 120 or 230 volt AC power from a wall

outlet to ~12 volts DC power to run the camera head

(video and lights), as well as any options. Its features

include a power switch, connector (female to interconnect cable), a dimmer, and a video out jack providing

a signal to your monitor.

Reel The gray plastic portion of the system that holds

the push cable and camera.

SeeSnake™Diagnostic Equipment

Kollmann

Ridge Tool Company • Elyria, Ohio • U.S.A. 5

SeeSnake™Diagnostic Equipment

Kollmann

Ridge Tool Company • Elyria, Ohio • U.S.A.6

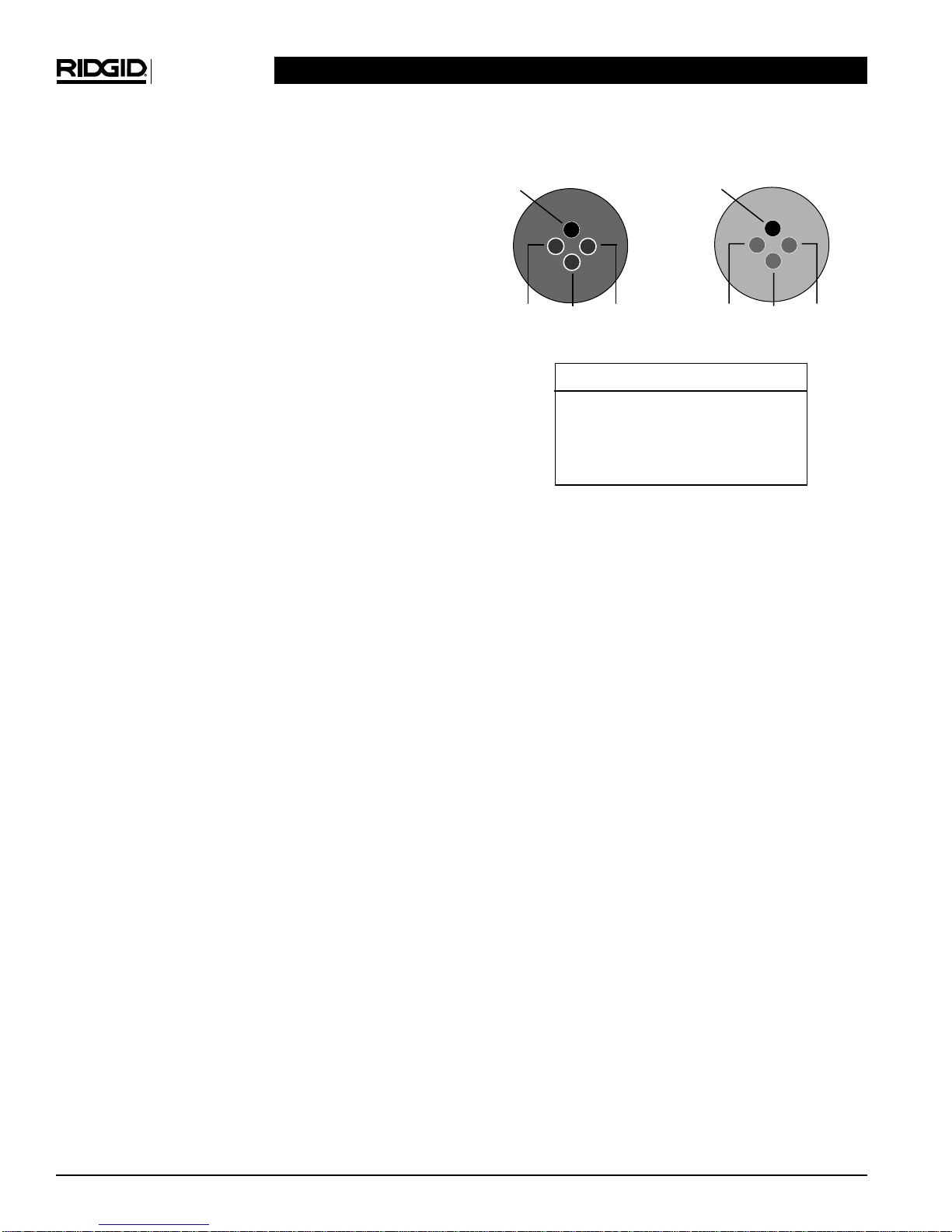

Figure 3 – Reel, Front

Figure 4 – Reel, Back

Safety Cables Stainless steel cables (two) within the

spring assembly that connect between the push cable

termination and the locking sleeve holding the connector at the back of the camera head. These prevent

the spring from over-extending when pulling the camera out of a pipe. Together, they provide over 800

pounds of breaking strength.

Sapphire Window The small, round port that the

camera “looks” through. This component is virtually

scratch-proof providing excellent video throughout the

life of the system.

Spanner Wrench One-piece wrench used to engage

the end of the spring when removing the camera

head. To remove the camera from the spring, you

must use a spanner wrench.

Spring Assembly Flexible stainless steel spring and

associated components that hold the camera to the push

cable, provides a flexible transition from camera to push

cable, and protects the terminations within the spring.

Sunshade This metal device is included on

Monitor+VCRs to protect the screen when system is

not in use (closed) and to optimize the picture in bright

sunlight (opened).

Tilt Stand Small kick stand on bottom of Monitor+VCR

helps raise the angle of the screen when the monitor is

sitting on the ground for easier viewing.

(Figures 2-11):

Figure 2 – Tilt Stand

Brake

Reel

Dolly

Interconnect Cable

Axle

Figure 5 – Wheel Set

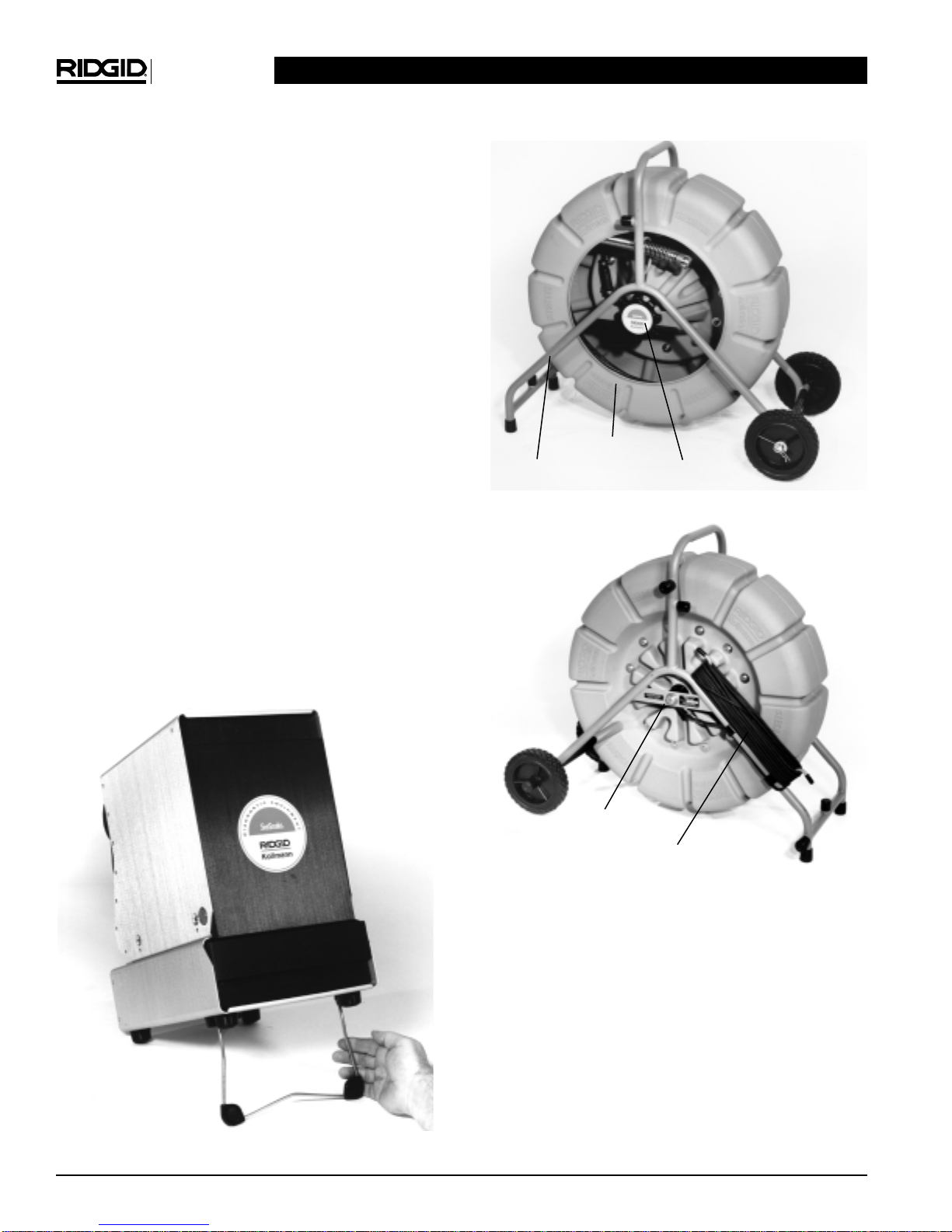

Figure 6 – Camera/Spring

Figure 7 – Camera Head

Figure 8 – Power Pack – Front

Figure 9 – Power Pack – Rear

Figure 10 – Color Monitor

+

VCR Back

All RIDGID/Kollmann Color Monitor+VCRs include an

integrated power supply with connector to reel, dimmer

sunshade, tilt stand, AC cord storage hooks, handle,

and hands-free microphone.

SeeSnake™Diagnostic Equipment

Kollmann

Ridge Tool Company • Elyria, Ohio • U.S.A. 7

Spring Assembly

Camera head

Centering Guide

LED Ring

Sapphire Window

Figure 11 – Color Monitor+VCR Front

The sunshade on this Color Monitor+VCR has been

locked open, and the tilt stand is engaged. Close the

sun shade whenever the Monitor+VCR is not in use.

Always adjust the settings below for each inspection

to ensure the optimum picture.

Set Up and Operation

SeeSnake Cable CountIR Standard Key

Pad Usage

Distance: Displays distance reading in lower right

hand corner of screen. To remove distance

reading press once, press again to show

distance reading.

Zero: Resets distance reading to zero.

Clock: Displays date and time. Press to choose

both, one, or none displayed. Press and

hold to display optional title field (see

description of title field below).

Key Pad Usage in Edit Mode

Press Distance and Clock simultaneously to get into

edit mode.

Distance: Functions as edit button. Press to cycle

through available options.

Zero: Functions as next button. Press to move to

next field.

Clock: Functions as exit button. Press to exit from

edit mode, saving any changes made.

Edit Menu Fields for Display and

System Settings

Time: Display choice...12 hr (AM/PM) or 24 hr

Date: Display choice...mm/dd/yy or dd/mm/yy

Units: Display choice...feet (ft) or meters (m)

Title: The title field is factory set to read

RIDGID/Kollmann, but can be changed to

display your company name or any

desired message of up to 18 characters.

(The edit button will scroll through optional

letters and symbols while the next button

will take you to the next title space until

you are through the 18 character field.)

Press Distance and Clock at same time to edit

SeeSnake type and cable length.

Cable Select the actual push cable length for

Length: your SeeSnake. The selection for length in

feet is from 50 to 325 in 5 foot increments.

The selection for length in meters is from

15 to 100 in 1 meter increments.

SeeSnake Select type of SeeSnake System, either

System: Mini or Standard.

Battery Removal/Installation

1. The CountIR uses a single Lithium CR-2032, 3 Volt

battery to maintain the memory of the Edit Configuration and also to power the clock module during system power down.

2. The battery is located inside the CountIR just below

the cabling connector. It is easily removed by using

a thumbnail or a small pair of needle nose pliers.

3. When the battery is removed all of the Edit Menu

Fields and System Settings are lost and will need

SeeSnake™Diagnostic Equipment

Kollmann

Ridge Tool Company • Elyria, Ohio • U.S.A.8

Distance

Clock

Zero

to be individually reentered. The battery should last

for approximately 5 years.

4. Before inserting a new CR-2032 battery, make

sure the polarity is correct. Insert the battery such

that the +(plus) side of the battery is towards the

top of the battery holder (this is also towards the

center of the CountIR).

Possible Display Messages

Error 1: Displayed when the CountIR reads a dis-

tance which is out of bounds. These

boundaries could be less than zero or a

length that is 40 feet greater than what the

system is configured for.

Error 2: Displayed when the system memory is not

set up. This can occur when the battery

needs to be replaced.

No Video: Displayed when the camera is disconnect-

ed. Once the camera is reconnected, the

screen is restored.

To Install the Wheels Onto the Dolly

NOTE! The rims of the wheels are flat on one side, con-

vex on the other. To make the wheel stance as

wide as possible (more stable), the flat edge

should face outward when the wheels are

mounted.

1. Position the axle so that the side with the rubber

foot is on the same side as the other two rubber

feet on the dolly frame. Slide one wheel onto the

axle with the flat edge facing outward.

2. Slide the axle and wheel through one frame mount

(on the side with the rubber feet), then through the

plastic spacer. Slide the axle through the other

frame mount.

3. Slide the second wheel onto the axle with the flat

edge facing outward. Slide the washer onto the

axle (outboard of the wheel); then insert the cotter

pin at the far end of the axle.

Models with Power Packs

1. Find the power button at the front of the power

pack, and make sure it is switched OFF. Plug the

power pack’s power cord into an approved outlet,

and press GFCI reset switch.

2. Unwrap the interconnect cable from its storage

hooks on the dolly. Plug the loose end of this cord

into the mating connector on the power pack, referring to Figures 1 and 8.

NOTE! Figure 1 demonstrates the proper way to plug

connectors together. This is true in all cases.

For example, the camera head will plug directly

into the back of the monitor/power pack, using

these guidelines.

3. Locate the small video cable that came with the

power pack. Plug either end of it into the small jack

on the power pack labeled video out. (These types

of connectors are called RCA jacks.) Most likely,

your monitor will have the same type of connector

for video in. (If not, it has a connector called a

BNC jack.)

4. Plug the remaining end of the video cable into the

monitor at the video in jack.

5. Turn the monitor ON, then the power pack. You

should now have a picture on the screen. If the picture doesn’t look perfect, you can adjust the contrast, brightness, and horizontal/vertical hold on

your monitor, as well as the brightness of the camera head LED lighting using the dimmer knob located on the front of the power pack.

NOTE! If you do not have a picture, make sure you have

followed the above steps correctly, checking to

see that the video cable is plugged in and the

120V source is actually working.

Models with RIDGID/Kollmann

SeeSnake Provided Monitor

+

VCRs

NOTE! Please refer to Monitor+VCR manual for com-

plete details.

1. Gather the reel/dolly and Monitor+VCR in a convenient area near a 120V or 230V AC power source.

2. Lift and open the black sunshade that covers the

screen of the Monitor+VCR.

NOTE! Figure 1 demonstrates the proper way to plug

connectors together. This is true in all cases.

For example, the camera head will plug directly

into the back of the monitor/power pack, using

these guidelines.

3. Unwrap the interconnect cord from its hooks located

on the back side of the dolly. Plug this cord into the

connector at the front of the monitor, referring to

Figure 1 for the proper way to make the connection.

4. Plug the power cord for the monitor into a standard

120 or 230 volt outlet.

5. Locate the power button at the lower-left, front of

the Monitor+VCR and depress it. In a few moments

you should have a picture. You may need to adjust

the brightness and contrast of the monitor. This can

be accomplished by adjusting the dials to the right

of the power button. The one represented by a sun

above it is the brightness, and the one with the par-

SeeSnake™Diagnostic Equipment

Kollmann

Ridge Tool Company • Elyria, Ohio • U.S.A. 9

tially-shaded circle above it is the contrast. You can

also dim or brighten the cameras lighting with the

dimmer knob, located on the lower-right, front of

the monitor.

NOTE! These adjustments will be more accurately made

when the camera is positioned in a section of

pipe. If the picture still does not look right, or

there just isn’t one, carefully review the above

steps to ensure they were properly followed.

Pre-Checks

Mechanical Checks

1. Check the cotter pin that holds the axle in place to

ensure it is fully engaged. The wheels should both

spin freely.

2. Rotate the reel brake to a position that allows you

to easily pull cable from the reel, yet stops immediately when you aren’t retrieving cable. For transport, add more friction to the brake.

3. Grasp the spring assembly in one hand, and the

camera head in the other. Ensure the spring is tightened ONLY to the point where the cut end of it is as

far as it can go in the camera head’s threads. If it is

undertightened, you should be able to physically

screw the spring a little farther onto the camera’s

threads. If it is overtightened, the cut end of the

spring will “crawl” up and over the threads. If this

occurs, follow the procedures in the “Maintenance –

Removing the Camera Head” section to properly

seat the spring using the spanner wrench provided.

4. Check to see that the connector at the end of the

push cable is fully seated into the connector

attached to the cone-shaped portion of the hub

(inside the reel). Likewise, check that the

Interconnect cable is completely plugged into the

hub. Periodically inspect these connectors for good

connections as the system is used.

Electrical Checks

The system should always produce a crisp picture that

is free of noise and lines. Sometimes, especially during cold-weather conditions, it can take a moment for

the system to heat up before it will produce the optimum picture. Otherwise, check that connectors are

fully engaged and follow these guidelines:

1. With the system energized, look to see that an

even amount of light is coming from the LEDs.

Place the camera in the reel, and give it a good

spin while watching your monitor.

2. Find a section of pipe that is 2-6 inches in diameter.

Roll a page of newspaper or business stationary

into the pipe and watch the monitor. The picture

should be clear and the lighting should be even on

the pipe walls. Try adjusting the contrast and

brightness, as well as the lighting (using the dimmer knob on the monitor/power pack) to obtain the

best picture. Remember, as the materials of pipe

vary, it will be necessary to adjust these settings to

maximize picture quality on different jobs. For

example, white PVC pipe requires less lighting than

Black ABS. As experience is gained with the system, operators will learn that slight adjustments in

these settings can highlight problems within a pipe.

At the Job Site

1. The camera can almost always be pushed farther when grip-style rubber gloves are worn. It

is much easier to get a grip on dirty push cable,

and the gloves also keep sludge off the hands.

2. Properly positioning the equipment before you

begin an inspection will save time, be more

comfortable, and minimize the potential for

equipment damage. Set the monitor in an area

where it is unlikely to fall, and where it can be

viewed while you are pushing the camera. A

good location is right next to the cleanout or entry

point. Be sure to keep it from getting wet.

3. Set the reel about 6 to 8 feet from the entry. This

will provide ample cable to grasp and develop

momentum without having a lot of slack dragging on

the ground. Slack can be alleviated by putting friction on the reel using the brake. If it is set correctly,

push cable will only come off the reel when you pull

on it.

4. Always try to run water down the pipe undergo-

ing inspection. This will keep the system much

cleaner, and allow you to push noticeably farther

with less friction. This can be accomplished by

feeding a hose with a small amount of flow into the

entry or occasionally flushing a toilet that drains to

the pipe. If the water is preventing you from seeing

an area of importance, temporarily turn it OFF.

5. When pushing, the end of your stroke should

be as close to the entry as possible. Standing

too far back, with an excess of cable between your

hands and the entry may cause the cable to fold on

itself outside the entry.

6. Folding the push cable on the sharp edge of an

entry can cause it to snap. Extreme caution

must be used to minimize the chance of bending the push cable on sharp corners. This is a

common cause of push cable failure, and all opera-

SeeSnake™Diagnostic Equipment

Kollmann

Ridge Tool Company • Elyria, Ohio • U.S.A.10

tors should be aware of this. If the camera just

doesn’t seem to want to go any farther, DON’T

FORCE IT! If another entry is available, try it.

7. When inspecting a pipe, it is usually necessary to

give a little extra push in the bends. Back up, if

necessary, and “pop” the camera through a turn

using the least amount of force required. Try to be

as gentle as possible, and don’t hammer or snap

the camera head through corners. After some practice, you may learn that the best way to inspect a

section of pipe is to push the camera through

quickly, then draw the camera back home slowly

and evenly. It is always easier to control the camera when pulling than when pushing.

8. Make sure the sapphire window is clean prior to

entry. Some users claim that a slight film of detergent on the lens minimizes the possibility of grease

sticking to the port. In any case, take advantage of

any standing water in the pipe to wash the front of

the camera by jiggling it in the water. Flushing the

pipe with water supplied by a hose or periodically

flushing a toilet can help keep the port clean and

improve performance by reducing cable friction.

9. Take advantage of the lighting to keep track of

where the camera is headed. If the particular pipe

you are inspecting is easier to evaluate with other

than the maximum lighting, periodically maximize

the lighting (using the dimmer knob on the monitor/power pack) to get a look at what lies ahead. Be

aware of any obstructions, such as a crushed section of pipe or excessive hard build-up, that may

prevent retrieval of the camera. Do not clear

clogged lines with the camera head!

10. Pipe materials and conditions vary. Adjustment of

the contrast and brightness settings, as well as the

light dimmer after the camera is within the pipe,

can greatly increase picture quality. This is particularly important when your customer is supervising,

and when making recordings.

11. Whenever possible, lay the system on its side feet

for even greater stability. This is also preferred when

on a rooftop (entry through a roof vent) or hillside.

12. The system can travel through multiple 45 and 90

degree bends and wyes. Do not, however, try to

force it through a P-trap or T if there is a large

amount of resistance.

13. Do not attempt to remove or store push cable on

the reel solely by turning the reel itself. Release the

brake enough so that you can manually push or

pull cable from the reel and wind or unwind it.

14. Be careful in T-entries not to fold the camera back

on itself, this could cause camera to stick.

NOTE! Some customers have reported success in con-

trolling camera entry into hard Ts using a “shoe

horn” made from a length of 1-inch copper pipe

of the necessary length to reach the T that has

been flattened and curved at the end. With this

device, you can position the curved portion into

the side of the T where entry is preferred and

guide the camera in the proper direction.

Maintenance

Preventative Maintenance

Camera Head

1. The camera head requires little maintenance, other

than keeping the LED ring and sapphire window

clean. Use a soft nylon brush, mild detergent, and

rags and sponges from the camera head up to (but

not including) the Monitor+VCR/power pack.

2. When cleaning the camera, do not use scraping

tools as they may permanently scratch these

areas. NEVER USE SOLVENTS to clean any part

of the system. Substances like acetone and other

harsh chemicals can cause cracking and crazing of

the LED ring, which could affect waterproofing.

3. As you use the system more and more, you may

be surprised to find that scratches on the LED ring

will have a minimal effect on the performance of

the lighting. Don’t sand the LED ring to remove

scratches, as it is part of the watertight housing.

4. Another good way to extend the life of the camera

is to avoid removing obstructions from pipe with the

camera head.

Spring Assembly

1. The spring assembly is the area where foreign matter is most likely to accumulate. Within the spring is

the splice between the push cable and a connector

(and maybe a sonde unit for a pipe location system). Should sharp objects or harsh chemicals be

allowed to remain in this area for long periods, they

may wear on these components. Stretch the spring

end-to-end as far as the internal safety cables

allow to check this area. Stretch again and stir in a

bucket of warm water and mild detergent to flush

this area.

Push Cable, Reel/Dolly

1. The push cable and reel/dolly require almost no

maintenance. (Of course, a clean system will last

longer and be more impressive to your customers.)

SeeSnake™Diagnostic Equipment

Kollmann

Ridge Tool Company • Elyria, Ohio • U.S.A. 11

It is important, however, to keep the push cable

clean to spot any excessive cuts or abrasions,

while making it much easier to grasp and push.

NOTE! Whenever you are retrieving push cable into the

reel, an excellent way to cut down on cable

grime is to run it through a rag in the last hand

that touches the cable as it enters the reel. For

an overhaul cleaning, lay the system on its side

feet and fill the reel with lukewarm water and a

mild detergent. Leave it overnight and spin it

occasionally. Remove the water prior to use and

run a rag over the cable.

Monitor+VCR/Power Pack

1. The Monitor+VCR and power pack requires a little

more care. The same is true for any monitor in the

field. Unlike the rest of the system, the

monitor/power pack aren’t waterproof. Clean them

with a damp cloth, and ensure foreign matter does

not get into any cooling vents. Always avoid dropping or shocking these components.

Corrective Maintenance

Removing Camera Head

The system has been designed so that the camera

head can be removed for troubleshooting, installing

the transmitter, or to use in a different application on a

separate cable. If you need additional assistance,

please call Ridge Tool’s Technical Service Group

at 800-519-3456.

1. Pay out enough cable to place the camera and

spring assembly on a work bench or other convenient work area. Set the brake to prevent the reel

from spinning.

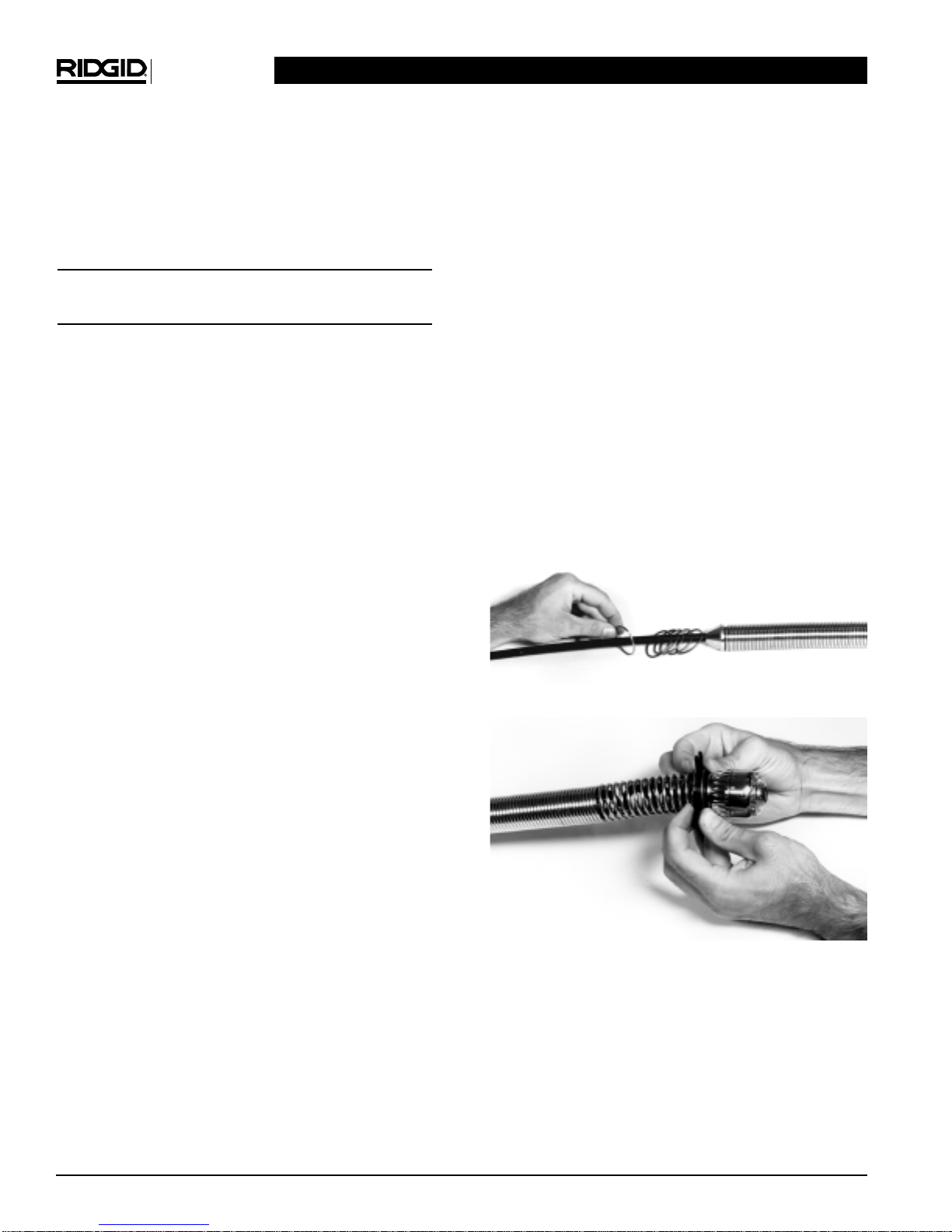

2. Remove taper ring. (Figures 12 and 13)

Figure 12

Figure 13

3. Locate the metal spanner wrench that was provided with the system and hook the cut end of the

spring (directly behind the camera head) with the

business end of the spanner and turn the camera

off the spring (Figure 14). The camera should now

be hanging by its locking sleeve and safety cables

(Figure 15).

4. Grasp the ribbed portion of the sleeve with one

hand and the camera and cables with the other.

Rotate the ribbed portion of the sleeve (counterclockwise when camera is viewed from the rear) to

unscrew it from the camera. If it is difficult to turn,

get it started with a pair of pliers (Figure 16).

5. When the sleeve is completely unscrewed, slide it

down the black cord so that the actual connector is

exposed. Grasp the connector in one hand and pull

it straight out of the back of the camera. Wiggling

the connector slightly, side-to-side, may help break

it free (Figure 17).

Figure 14

The spanner wrench is hooked into the end of the

spring. The camera is then rotated (counter-clockwise

when viewed from front) with the other hand.

SeeSnake™Diagnostic Equipment

Kollmann

Ridge Tool Company • Elyria, Ohio • U.S.A.12

Figure 15

Once the camera head is removed from the spring,

the locking sleeve can be seen holding the connector

to the back of the camera. The safety cables are

mounted to a rotating portion of the sleeve, which

helps prevent their twisting.

Figure 16

The locking sleeve has been removed by the camera

back by rotating it counter-clockwise (when viewing

the camera from the back). The connector is now all

that holds the camera on.

Figure 17

The camera head is now removed. Note that these

connectors are the same style as those found throughout the system.

Locating Faulted Components

The basic idea in troubleshooting the system is to use

the camera head to eliminate suspected components.

Here are the areas we will try to isolate the fault to: camera head, reel/dolly, interconnect cord, Monitor+VCR

power pack. As a scenario, we will assume that the

symptom is no video, no lights.

1. Remove the camera from the spring assembly.

2. With the Monitor

+

VCR power pack set up for operation, plug the camera head directly into the back of

the Monitor+VCR/power pack where the interconnect cable is usually connected. Turn on the system and check the Monitor+VCR for a picture. If

there is a good picture with proper lighting, the

problem is somewhere between the interconnect

cable and the spring assembly. Proceed to step 4.

If there is no picture, the problem is probably in the

camera head or Monitor+VCR power pack.

3. To virtually eliminate the Monitor+VCR, play a tape

on your Monitor+VCR with a VCR through the video

in jack at the rear (VCR – video out; Monitor+VCR –

video in). If you get a good picture, it is almost certain the problem is in the camera head. The power

pack is a little more complicated to troubleshoot, so

contact Ridge Tool Company if you suspect it is

faulted.

4. Plug the interconnect cable into the Monitor+VCR

and power pack. Unplug the other end of the interconnect cable from where it plugs into the reel-hub,

and plug the camera head into this end. Turn on

the system and check the monitor. If you get the

video and lights back, the problem is likely in the

push cable or hub. If there is no picture, the interconnect cable is the likely fault.

5. Once you suspect a component, contact Ridge Tool

Company Technical Services. We will establish a

plan of action to get your system back on line.

6. For additional troubleshooting suggestions, please

refer to Chart 1.

Re-Installing Camera Head

1. Lay out enough cable to lay the spring assembly

on a convenient work area and set the brake.

2. Plug the connector at the spring assembly into the

camera head, making sure that the guide pins/sockets are aligned.

3. Grasp the camera head and safety cables with one

hand and turn the ribbed portion of the locking

sleeve to screw it into the back of the camera.

IMPORTANT: Try not to tw ist the co rd or the c amera,

only the locking sleeve. If this is done

properly, the cord and safety cables will

not be twisted around each other when

you view them from between the windings

of the spring.

4. Once the locking sleeve is tight into the back of the

camera, thread the spring onto the camera and,

SeeSnake™Diagnostic Equipment

Kollmann

Ridge Tool Company • Elyria, Ohio • U.S.A. 13

using only your hands, screw the camera onto the

spring.

NOTE! The camera head will be properly mounted when

the end of the spring is snug between the camera and the thread (not so far that it begins to

raise off the threads and you cannot manually

unscrew the camera.)

If further assistance is needed, please

call Ridge Tool’s Technical Service

at 800-519-3456

Transportation & Storage

1. Slip the camera into the reel with the rest of the push

cable. Turn the brake clockwise enough so that the

reel does not rotate unless you manually turn it.

2. Unplug the interconnect cable from the Monitor+VCR/power pack and wrap it loosely onto its

storage hooks located on the dolly.

3. If space allows, the reel/dolly should be laid on its

side during transportation and use. You will notice

that there is a second set of feet (three) on the side

of the reel where the interconnect cable is stored. If

there is not enough space to lay the system on its

side, stand it up and run a strap or cord through the

dolly and secure it to the vehicle.

4. Close the sunshade over the screen of the

Monitor+VCR and wrap its outlet cord onto the

hooks provided at the rear.

5. Keep spare parts, tools, and the manual secure in

a work bag to protect them when not in use.

6. When possible, keep the system stored in a cool,

safe place. Leaving the camera pointed into the

sun or a high powered light source (when operating) can damage the imaging chip.

Options

Centering Guides: 3″ and 6″

The centering guides are designed to help center the

camera in various sized pipes, and also help keep the

camera out of the bottom sludge. Picture quality is

improved as they help position the camera towards

the middle of the pipe. This allows the camera to see

an equal amount of the pipe wall in all directions.

Do not assume that the guides are only helpful in 3″

and 6″ pipe! They also help in larger pipe by bringing

the camera closer to center and raising the camera

out of the sludge that is often found below the water

line. Keeping the camera off the bottom of the pipe

keeps the front of the camera cleaner, longer.

It is recommended that guides be used whenever possible (3″ and up) as they protect the system from wear

and tear. However, if you are having trouble going further in a particular pipe, try it without the guides. The

best advice is to experiment with local conditions and

decide what is best for the given job. One way to

increase their flexibility is to pre-strain them by bending the spikes back and forth a few times before use.

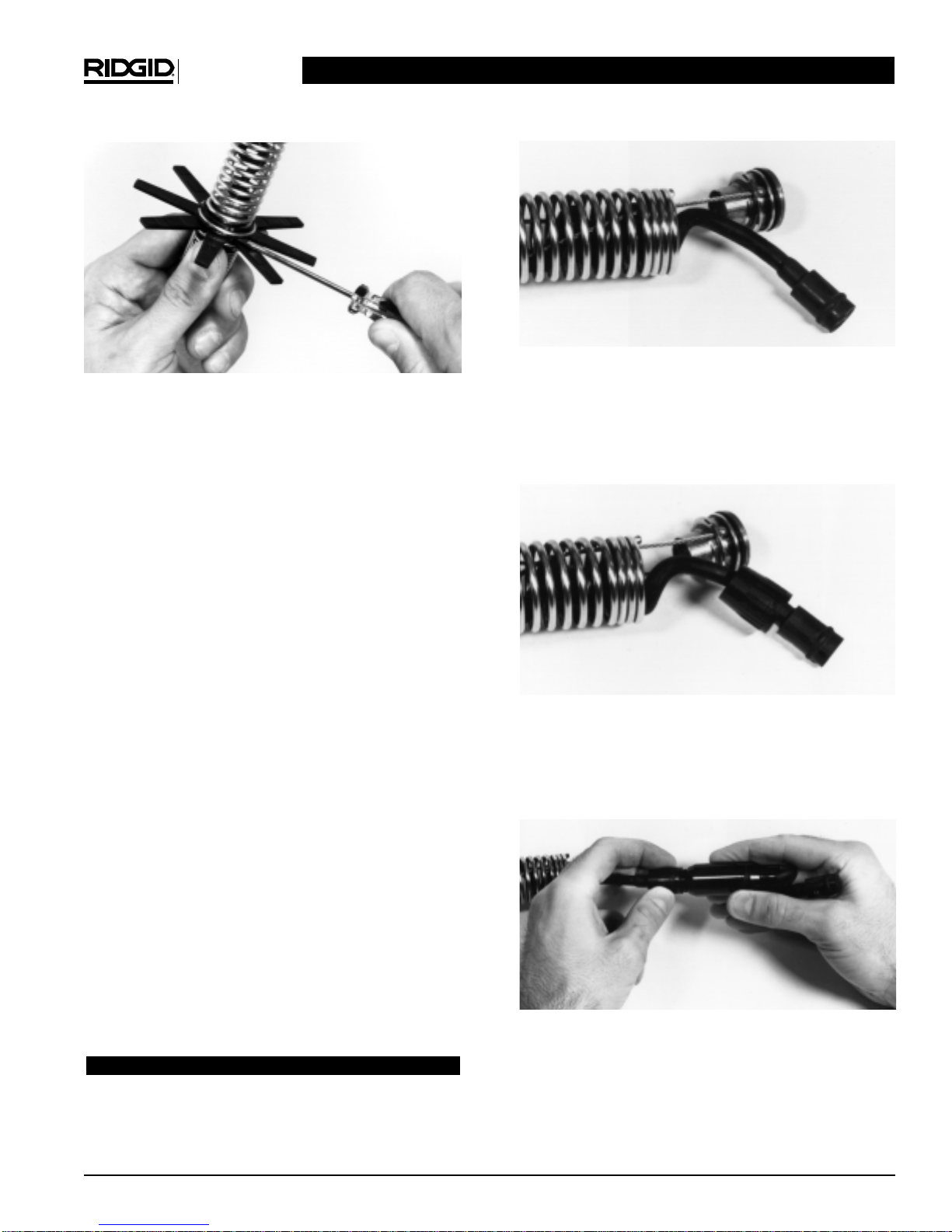

To install the guides, wind two metal snap rings per

guide into the push cable just like you would slip a key

onto a key ring (Figure 18). You should usually use 3

guides. Position each guide where you want it on the

spring, with one of snap rings on either side. Look for

grooves on either side of the spikes on the guide and

wind a snap ring into each groove to lock it onto the

spring (Figure 19). When it is time to remove them, lift

the edge of the snap rings out of the grooves with the

tip of a small screwdriver and unwind them from the

grooves (Figure 20). Slip the snap rings off the

spring/push cable and store them with the guides for

later use.

Figure 18

Figure 19

SeeSnake™Diagnostic Equipment

Kollmann

Ridge Tool Company • Elyria, Ohio • U.S.A.14

Figure 20

Pipe Location Transmitter

The pipe location transmitter allows the user to pinpoint the location and depth of the camera head

greater than 10 feet underground in cast iron pipe.

The transmitter emits a 512Hz signal that is sensed

by the receiver. The transmitter is designed to work

with manufacturer’s receivers who use 512Hz.

One of the great features of our transmitter is that it is

powered by the same power supplied to the camera

head. Once installed, it is always ready for use,

whether or not you choose to bring the receiver along

on the job. There are no batteries or extra cables

required, and the system still travels the hard 90

degree bends.

Installing the Pipe Location Transmitter

1. Remove the camera head from the spring assembly. (See Corrective Maintenance – Removing

Camera Head section.)

2. With the camera head removed, you can see that

the connector passes through the locking sleeve,

and that there is a rounded ridge on the connector

that prevents it from slipping out the rear of the locking sleeve. You want to carefully push the connector out the back of the locking sleeve (Figure 21).

Use a blunt object, such as the eraser-end of a pencil or a finger to push on it, while pulling on it from

the back. Don’t grasp the coil cord when pulling,

grasp the connector! You can lube the connector to

make it easier, if necessary. BE CAREFUL not to

damage the sockets of the connector by pushing on

it with a sharp object, like a screwdriver.

CAUTION

Be sure to use non-conductive lubricant. a silicone lubricant is suggested.

Figure 21

After removing the camera head, slip the coil connector out of its locking sleeve. Some silicone lubricant

makes removal much easier. Keep the stainless

cables untwisted by holding the sleeve and rotating

the ring on it that the cables are attached to.

Figure 22

On the transmitter, unscrew the plastic locking sleeve.

Place the plastic locking sleeve (leading with the

tapered end) over the coil connector. Again, some silicone lubricant makes this easier.

Figure 23

Push the coil connector onto the leads making sure

that it is fully seated. Screw the plastic locking sleeve

back onto the transmitter.

SeeSnake™Diagnostic Equipment

Kollmann

Ridge Tool Company • Elyria, Ohio • U.S.A. 15

Figure 24

When completed, grasp both ends of the spring

assembly and stretch it to draw the transmitter inside.

Check that the coil cord and stainless cables are situated properly. Push the camera-end of the transmitter

back through the locking sleeve using some silicone

lubricant, if necessary. Re-install the camera head.

3. On the transmitter, unscrew the plastic locking

sleeve. Place the plastic locking sleeve (leading

with the tapered end) over the coil connector

(Figure 22). Again lubricant makes this easier.

4. Plug the coil cord connector into the rear of the

transmitter, making sure that it is fully seated.

Screw the plastic locking sleeve back onto the

transmitter (Figure 23).

5. Carefully insert the transmitter into the spring

assembly ensuring that no cabling gets bent or

wedged between the transmitter and the spring

assembly. You can stretch the spring assembly,

end-to-end, to help draw the transmitter into it.

6. Push the female connector of the transmitter

through the metal locking sleeve (Figure 24). Use

some silicone lubricant on the exterior of the connector, if necessary.

7. The system should now look like it did when you

first removed the camera head, except the transmitter is within the spring assembly. Re-install the

camera head. (See Re-Installing Camera Head

section.)

8. Refer to the manual provided along with your

receiver for operation of the location equipment.

Service and Repair

If any maintenance is required other than that outlined,

the tool should be sent to a RIDGID Independent

Authorized Center or returned to the factory. All repairs

made by Ridge service facilities are warranted against

defects in material and workmanship.

If you have any questions regarding the operation or

function of this tool, call or write to:

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44036-2023

800-519-3456

If any correspondence, please give all information

shown on the nameplate of your tool including model

number, voltage, and serial number.

SeeSnake™Diagnostic Equipment

Kollmann

Ridge Tool Company • Elyria, Ohio • U.S.A.16

SeeSnake™Diagnostic Equipment

Kollmann

Ridge Tool Company • Elyria, Ohio • U.S.A. 17

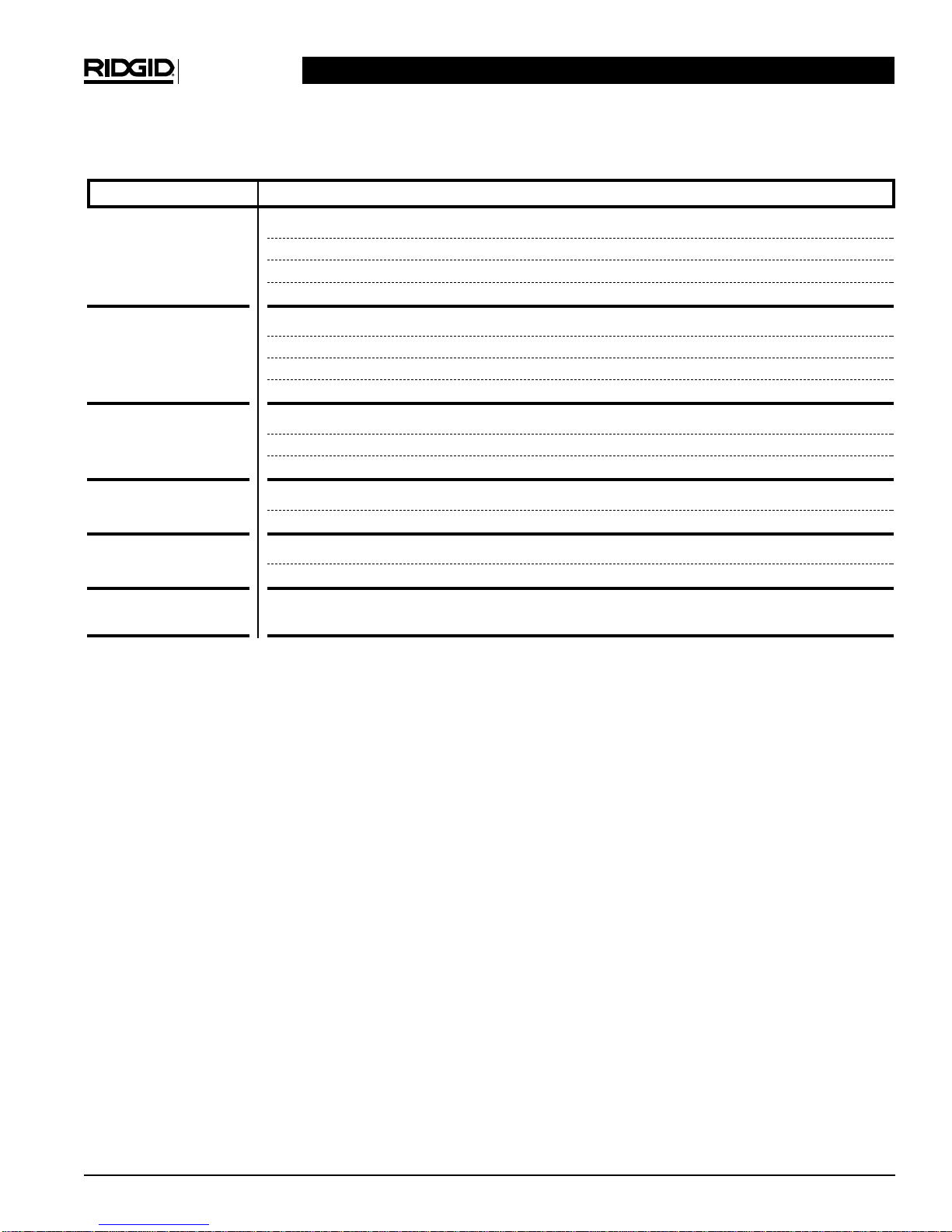

PROBLEM PROBABLE FAULT LOCATION

Garbled or jumbled

video

Lights, but no video

No video, no lights

Video, but no lights

White screen

Noisy picture – vertical

stripes on monitor screen

Chart 1 Troubleshooting

Horizontal or Vertical hold need adjustment

75 Ohm-High Z switch in opposite position

Fault within camera, cables , or monitor/power supply

Try to plug back from VCR into monitor with Interconnect cord plugged into monitor

Brightness turned down

Contrast or Brightness improperly set

Break in video carrying conductor (pin/socket #3) between monitor and camera

Fault within camera or monitor/power pack

Monitor/power pack not turned on

Interconnect cable not fully plugged in, or loose connection in system

Fault in any sub-assembly

Dimmer turned down

Fault within camera head, LED section

Camera exposed to excessive light

Contrast/Brightness improperly set

Camera head overheated

Loading...

Loading...