Page 1

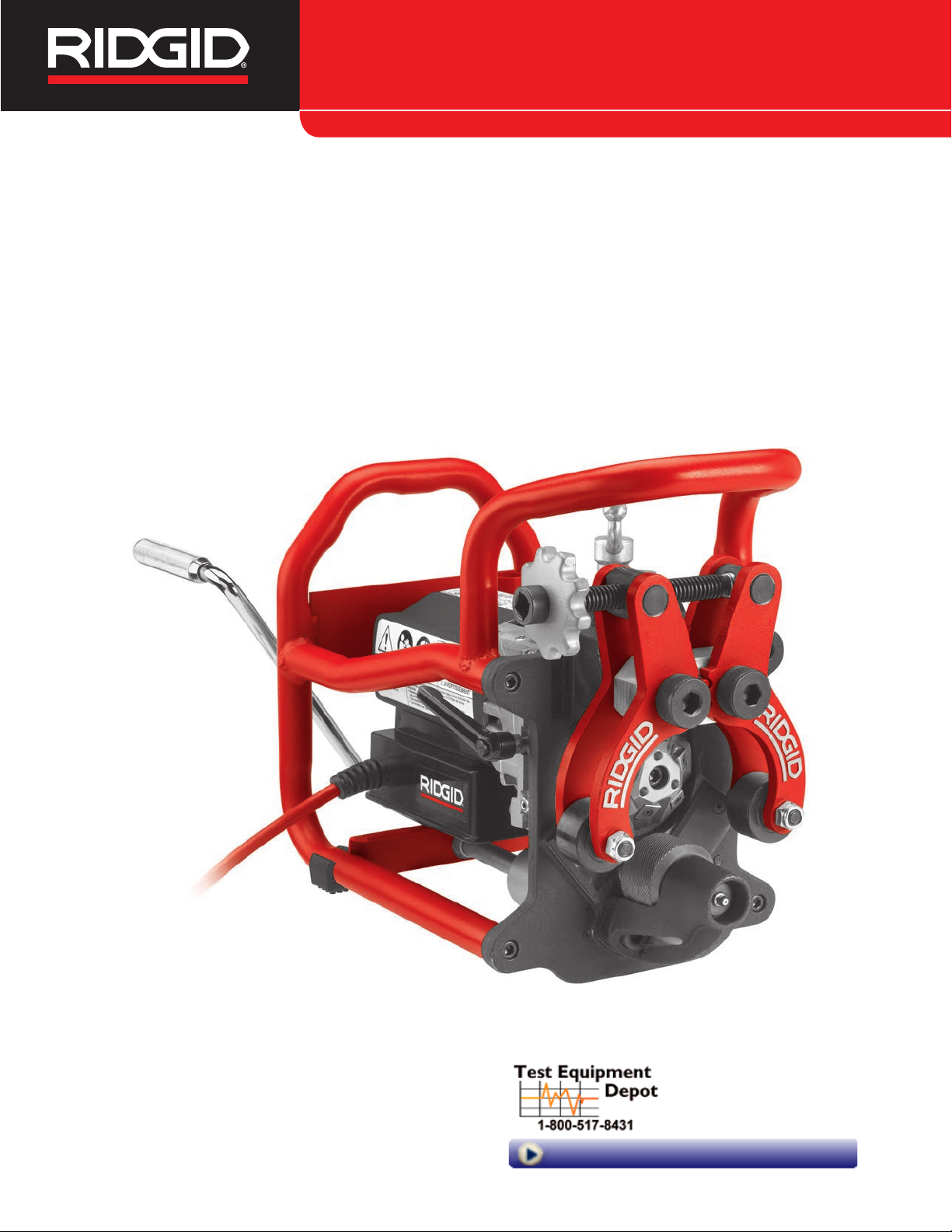

Model B-500Manual

Transportable Pipe

Beveller

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

Page 2

Model B-500 Transportable Pipe Beveller

Table of Contents

Recording Form For Machine Serial Number ............................................................................................................1

Safety Symbols..............................................................................................................................................................2

General Power Tool Safety Warnings

Work Area Safety ........................................................................................................................................................2

Electrical Safety ..........................................................................................................................................................2

Personal Safety ..........................................................................................................................................................3

Power Tool Use And Care ..........................................................................................................................................3

Service ........................................................................................................................................................................3

Specific Safety Information

Beveller Safety ............................................................................................................................................................4

Description, Specifications And Standard Equipment

Description ..................................................................................................................................................................4

Specifications..............................................................................................................................................................5

Standard Equipment ..................................................................................................................................................6

Icons ..........................................................................................................................................................................6

Pre-Operation Inspection..............................................................................................................................................6

Set-Up And Operating Instructions ............................................................................................................................7

Workpiece Preparation................................................................................................................................................7

Fixed Workpiece/Moving Beveller Set-up....................................................................................................................8

Fixed Beveller/Rotating Pipe Set-up ..........................................................................................................................8

Bevelling....................................................................................................................................................................10

Maintenance Instructions

Cleaning....................................................................................................................................................................14

Lubrication ................................................................................................................................................................14

Rotating/Replacing Cutter Inserts ............................................................................................................................14

Changing Cutter Heads ............................................................................................................................................15

Replacing Carbon Brushes ......................................................................................................................................15

Breaker......................................................................................................................................................................16

Wear Plates ..............................................................................................................................................................16

Gib Plate Adjustment ................................................................................................................................................16

Optional Equipment ....................................................................................................................................................16

Machine Storage..........................................................................................................................................................17

Service And Repair......................................................................................................................................................17

Disposal ......................................................................................................................................................................17

Lifetime Warranty ..........................................................................................................................................Back Cover

*Original Instructions - English

ii

Page 3

Model B-500

Transportable Pipe

Beveller

WARNING!

Read this Operator’s Manual

carefully before using this

tool. Failure to understand

and follow the contents of

this manual may result in

electrical shock, re and/or

serious personal injury.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

Model B-500 Transportable Pipe Beveller

Record Serial Number below and retain product serial number which is located on nameplate.

Serial

No.

Page 4

Model B-500 Transportable Pipe Beveller

Safety Symbols

In this operator’s manual and on the product, safety symbols and signal words are used to communicate important safety information. This section is provided to improve understanding of these signal words and symbols.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER

WARNING

CAUTION

NOTICE

NOTICE indicates information that relates to the protection of property.

This symbol means read the operator’s manual carefully before using the equipment. The operator’s manual contains

important information on the safe and proper operation of the equipment.

This symbol means always wear safety glasses with side shields or goggles and hearing protection while using this equipment

to reduce the risk of injury.

This symbol indicates the risk of electrical shock.

This symbol indicates the risk of hands, fingers or other body parts being cut by the rotating or moving parts.

This symbol indicates the risk of machine tipping, causing striking or crushing injuries.

This symbol indicates that a drill, impact tool, or other power tool should not be used to drive this device.

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

General Power Tool Safety

Warnings*

WARNING

Read all safety warnings, instructions, illustrations and specifications provided with this power

tool. Failure to follow all instructions listed below

may result in electric shock, fire and/or serious

injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE!

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

• Keep children and bystanders away while operat-

ing a power tool. Distractions can cause you to lose

control.

Electrical Safety

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adap ter

plugs with earthed (grounded) power tools. Un -

modified plugs and matching outlets will reduce risk of

electric shock.

• Avoid body contact with earthed or grounded sur-

faces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electrical shock

if your body is earthed or grounded.

Work Area Safety

• Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

• Do not operate power tools in explosive atmo-

spheres, such as in the presence of flam mable liquids, gases, or dust. Power tools create sparks which

may ignite the dust or fumes.

* The text used in the General Power Tool Safety Warnings section of this manual is verbatim, as required, from the applicable UL/CSA/EN 62841 standard. This

section contains general safety practices for many different types of power tools. Not every precaution applies to every tool, and some do not apply to this tool.

• Do not expose power tools to rain or wet condi-

tions. Water entering a power tool will increase the risk

of electrical shock.

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock.

2

Page 5

Model B-500 Transportable Pipe Beveller

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric shock.

• If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of a GFCI reduces

the risk of electric shock.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol, or medication. A mo -

ment of inattention while operating power tools may

result in serious personal injury.

• Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

• Prevent unintentional starting. Ensure the switch is

in the OFF-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energizing power tools that have the switch

ON invites accidents.

• Remove any adjusting key or wrench before turn-

ing the power tool ON. A wrench or a key left at tached to a rotating part of the power tool may result in

personal injury.

• Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power

tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewel ry. Keep your hair and clothing away from

moving parts. Loose clothes, jewelry, or long hair

can be caught in moving parts.

• If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

• Do not let familiarity gained from frequent use of

tools allow you to become complacent and ignore

tool safety principles. A careless action can cause

severe injury within a fraction of a second.

Power Tool Use And Care

• Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it is

designed.

• Do not use the power tool if the switch does not

turn it ON and OFF. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

• Disconnect the plug from the power source and/or

remove the battery pack, if detachable, from the

power tool before making any adjustments, changing accessories, or storing power tools. Such pre-

ventive safety measures reduce the risk of starting the

power tool accidentally.

• Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the pow er tool or these instructions to operate the power

tool. Power tools are dangerous in the hands of

untrained users.

• Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

• Keep cutting tools sharp and clean. Properly main-

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

• Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations dif-

ferent from those intended could result in a hazardous

situation.

• Keep handles and grasping surfaces dry, clean

and free from oil and grease. Slippery handles and

grasping surfaces do not allow for safe handling and

control of the tool in unexpected situations.

Service

• Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool is

maintained.

3

Page 6

Model B-500 Transportable Pipe Beveller

Specic Safety Information

WARNING

This section contains important safety information

that is specic to this tool.

Read these precautions carefully before using the

Model B-500 Transportable Pipe Beveller to re duce

the risk of electrical shock or other serious injury.

SAVE THESE INSTRUCTIONS!

Keep this manual with machine for use by the operator.

Beveller Safety

• Always wear appropriate eye protection and hearing

protection. Cutting tools can break or shatter. Cutting pro-

duces chips that can be thrown or fall into eyes. Cutting

produces high noise levels that over time can damage

your hearing.

• Always wear appropriate personal protective equip-

ment. Face shields, long sleeves, safety shoes, hard

hat, and other equipment as appropriate will reduce the

risk of injury.

• Do not wear loose clothing when operating ma -

chine. Keep sleeves and jackets buttoned. Do not

reach across machine. Clothing can be caught by the

machine resulting in entanglement.

• Keep bystanders clear of work area. Guard or bar-

ricade minimum of 6 feet (2 meter) around the working area. Chips or broken cutting tools can be thrown

and cause injury beyond immediate area of operation. A

guard or barricade that provides a clearance around the

work piece will reduce the risk of injury.

• Do not use power tools such as a drill or impact to

drive the beveller. Only drive beveller by hand.

Use of power to drive the beveller can increase the risk

of injury.

• Avoid breathing of dust created from pipe bevel-

ling. Some dust created may contain chemicals known

to cause cancer, birth defects or other serious personal

injury. Consider the pipe material and coatings when

determining appropriate respiratory protection, including things such as lead based paint.

Your risk from these exposures varies, depending on

how often you do this type of work and the concentration of dust. To reduce your exposure to these chemicals, work in a well ventilated area, and use respiratory

protection selected based on appropriate regulations

and standards, such as ANSI Z88.2 and OSHA.

• Do not modify beveller or use for any other pur-

pose. Other uses or modifying the beveller for other

applications may damage the tool, damage the attachments and/or cause personal injury.

• Read and understand these instructions and the

instructions and warnings for all equipment and

materials being used before operating this tool to

reduce the risk of serious personal injury.

The EC Declaration of Conformity (890-011-320.10) will

accompany this manual as a separate booklet when

required.

• One person must control the work process and the

beveller ON/OFF switch. Only the operator should be

in the work area when the machine is running. This

helps reduce the risk of injury.

• Properly support work piece and beveller. Make

sure the beveller is secure to the work piece. This

will reduce the risk of striking and crushing injuries

from tipping and falling pipe and equipment.

• Do not start the beveller with the cutter inserts

touching the work piece. Let the cutter head reach

full speed before carefully feeding it into the work

piece. The cutter may bind, walk or kickback if the tool

is started while in contact with the work piece.

• Keep hands away from rotating cutter head. Allow

parts to come to a complete stop before handling

the tool or pipe. This practice will reduce the chance

of entanglement in rotating parts.

4

Description, Specications And

Standard Equipment

Description

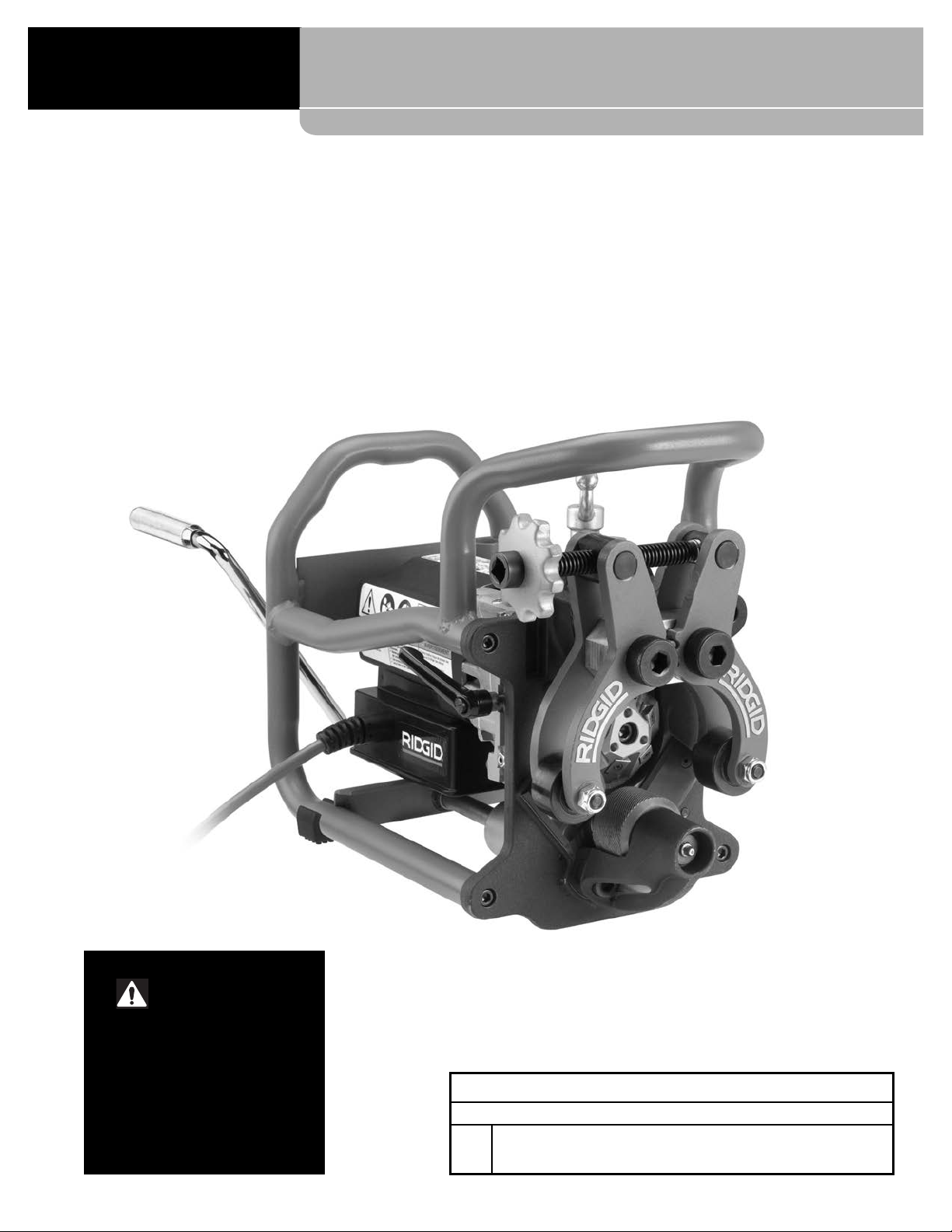

The RIDGID®Model B-500 Transportable Pipe Beveller is

used for bevelling most steel and stainless steel pipe

ends and plate edges on material up to 0.5" (13 mm)

thick in preparation for welding. Conical cutter heads with

replaceable cutter inserts (see Figure 24) are driven by a

motor/gearbox to pro duce 30°, 37.5°, or 45° bevels (with

the correct cutter head).

The bevel is formed in a single pass without the need of

any further dressing. No coolant or cutting oil is used.

Land width can be adjusted in approximately 1/32" (0.8

mm) increments from 0 to 0.188" (0 to 4.8 mm). The bev-

Page 7

Model B-500 Transportable Pipe Beveller

eller securely grips the work piece between guide rolls and

a drive roll. A detachable, hand crank is included to manually move the cutter head through the material being

bevelled. Indicator lights are supplied to give feedback on

proper cranking speed. The frame helps protect the motor/ gearbox and aids in beveller handling.

Land Width

Adjustment

Warning

Frame

Gage

Motor

Label

Clamp

Screw

Indicator

Lights

Hand Crank

Cutter Feed

Screw

ON/OFF Switch

Rotation

Decal

Instruction

Label

Drive

Shaft

Bevel

Angle

0.188" - 0.5" Max.

Figure 2 – Bevel Configuration

Specications

Capacity Diameter......Minimum – 4" IPS Pipe

Maximum – Flat Plate

Pipe Wall/Plate

Thickness...................Minimum – 0.188" (4.8 mm)

Maximum – 0.50" (12.7 mm)

Material thickness cannot vary by

more than 0.031" (0.8 mm)

Pipe/Plate

Orientation...................Horizontal (See Figure 6.)

Bevel Angles................37.5°, 30° and 45° (with Correct

Cutter Head)

Land

Width

Swing Arms

Guide

Rollers

Drive Roll

Gib Plate

Locking Screw

Figure 1 – Model B-500 Beveller

Face Plate

Breaker

Cutter Head

with Cutter

Inserts

Wear Plate

Land Width ..................0 to 0.188" (4.8 mm) in approxi-

mately 1/32" (0.8 mm) increments

Materials* ....................Most Steel, Stainless Steel

*Beveller cutting head and inserts are optimized for standard A53 mild

steel pipe. Reduced insert life can be expected on other materials.

*Ability to bevel depends on a variety of factors, including material

type, chemistry, hardness, amount of material being removed and

other factors. In some cases, bevels may not be able to be made or may

result in cutter insert damage. If there are any questions about the specific material to be bevelled, contact Ridge Tool Technical Services

Department.

No Load Operating

Speed N0.....................950/min

Motor:

Type ........................Universal

Horsepower ............1.2 HP

Rating .....................115V, 13 Amps, 50/60 Hz

230V, 6.5 Amps, 50/60 Hz

Dimensions:

Height .....................13.3" (33.8 cm)

Length.....................15.8" (40.1 cm)

Width.......................11.5" (29.2 cm)

Weight.....................52.5 lbs (23.8 kg) with Cutter

Head and Crank Handle

5

Page 8

Model B-500 Transportable Pipe Beveller

Standard Equipment

The RIDGID®Model B-500 Transportable Pipe Beveller

comes with:

• Cutter Head, with one set of six cutter inserts (In stalled)

• T15 Wrench for cutter Insert Screws

• Anti-Seize Grease for cutter Insert Screws

• 1" Spanner Wrench

•5/16" Hex Key

• Operator’s Manual

Figure 3 – Standard Equipment

Icons

Power ON

Power OFF

Figure 4 – Machine Serial Number

The Model B-500 Beveller serial number plate is located

on the side of the motor. The last 4 digits indicate the

month and year of manufacture.

NOTICE

lation, joining and forming methods is the responsibility of

the system designer and/or installer. Selection of improper materials and methods could cause system failure.

Stainless steel and other corrosion resistant materials

can be contaminated during installation, joining and forming. This contamination could cause corrosion and premature failure. Careful evaluation of materials and methods

Selection of appropriate materials and instal-

for the specific service conditions, including chemical and

temperature, should be completed before any installation

is attempted. (See NOTICE in Workpiece Preparation sec-

tion.)

Pre-Operation Inspection

WARNING

Before each use, inspect your beveller and correct

any problems to reduce the risk of serious injury

from electric shock, entanglement, crushing injuries

and other causes and prevent beveller damage.

1. Make sure that the beveller is unplugged and press

the OFF button.

2. Clean any oil, grease, dirt, or chips from the beveller, including the handles and controls. This aids

inspection and helps prevent the machine or control from slipping from your grip. Clean and maintain

the machine per the Maintenance Instructions.

3. Inspect the beveller for the following:

• Inspect the cord and plug for damage or modifica-

tion.

• Proper assembly, maintenance and completeness.

• Any broken, worn, missing, misaligned or binding

parts or other damage.

• Drive roll knurl is clean and in good condition. If

needed, clean with a wire brush. Worn or dirty drive

roll knurls can cause slippage or tracking issues in

use. Dirty rolls and knurls can cause ferrous contamination of stainless steel.

• Presence and readability of the warning and instruc-

tion labels (See Figure 1).

• Confirm fasteners and cutter head are secure.

• Confirm that drive shaft only turns in the clockwise

direction (as marked on decal).

• Inspect the cutting edges of the cutter inserts in the

cutter head for wear, deformation, chips or other

issues. Confirm that the cutter inserts are secure.

Dull, damaged or loose cutting inserts can damage

the tool, produce poor quality cut and increase the

risk of injury.

• Any other condition which may prevent safe and

normal operation.

If any problems are found, do not use the tool until the

problems have been repaired.

6

Page 9

Model B-500 Transportable Pipe Beveller

4. Inspect and maintain any other equipment being used

per its instructions to make sure it is functioning properly.

Set-Up And Operating

Instructions

WARNING

Always wear appropriate eye protection and hearing

protection. Cutting tools can break or shatter. Cut ting produces chips that can be thrown or fall into

eyes. Cutting produces high noise levels that over

time can damage your hearing.

Do not wear loose clothing when operating machine.

Keep sleeves and jackets buttoned. Do not reach

across machine. Clothing can be caught by the ma chine resulting in entanglement.

Keep bystanders clear of work area. Guard or barricade minimum of 6 feet (2 meter) around the working area. Chips or broken cutting tools can be thrown

and cause injury beyond immediate area of operation. A guard or barricade that provides a clearance around the work piece will reduce the risk of

injury.

One person must control the work process and the

Beveller ON/OFF switch. Only the operator should be

in the work area when the machine is running. This

helps reduce the risk of injury.

Properly support work piece and beveller. Make

sure the beveller is secure to the work piece. This

will reduce the risk of striking and crushing injuries

from tipping and falling pipe and equipment.

Do not start the Beveller with the cutter inserts

touching the work piece. Let the cutter head reach

full speed before carefully feeding it into the work

piece. The cutter head may bind, walk or kickback

if the tool is started while in contact with the work

piece.

Keep hands away from rotating cutter head. Allow

parts to come to a complete stop before handling the

tool or pipe. This practice will reduce the chance of

entanglement in rotating parts.

Do not use power tools such as a drill or impact to

drive the beveller. Only drive beveller by hand. Use of

power to drive the beveller can increase the risk of

injury.

Set-up and operate the beveller according to these

procedures to reduce the risk of injury from electric

shock, entanglement, striking, crushing and other

causes, and to help prevent machine damage.

1. Check work area for:

• Adequate lighting.

• Flammable liquids, vapors or dust that may ignite. If

present, do not work in area until sources have

been identified and corrected. The machine is not

explosion proof and can cause sparks.

• Clear, level, stable and dry place for all equipment

and operator.

• Properly grounded electrical outlet of the correct voltage. A three-prong or GFCI outlet may not be properly grounded. If in doubt, have outlet inspected

by a licensed electrician.

• Clear path to electrical outlet that does not contain

any potential sources of damage for the power cord.

2. When using the beveller, you will generally need to use

extension cords. Choose an extension cord that:

• Is in good condition.

• Has a grounded (earthed) plug like on the bev-

eller.

• Is rated for outdoor use.

• Has sufficient wire size. For extension cords up to 50'

2

(15.2 m) long use 14 AWG (1.5 mm

) or heavier. For

extension cords 50'-100' (15.2 m - 30.5 m) long

use 12 AWG (2.5 mm2) or heavier.

With dry hands, plug the extension cord into the outlet.

Run the extension cord along a clear path to the beveller. Keep all connections dry and off the ground.

Leave excess cord at the base of the machine to allow

for machine movement in the Fixed Workpiece/ Moving

Beveller configuration (see Figure 20A & B). Do not

plug the beveller in at this time.

3. Make sure all equipment has been properly inspected.

4. Keep bystanders clear of work area, set up guards or

barricades to create a minimum of 6 feet (2 m) of

clearance around the workpiece and beveller. This

helps to prevent bystanders from being struck by

chips during use.

Workpiece Preparation

Inspect the work piece to be bevelled and confirm that the

Model B-500 Beveller is a correct tool for the job. See

Specifications.

For pipe, the pipe end must be square within 0.062" (1.6

mm), see Figure 5. The beveller follows the cut on the end

of the pipe and does not square the end of the pipe. For

plate, the edge to be bevelled must be straight, without

curves. The bevelled edge will be no straighter than the initial cut. Bevelling non-square edges could cause tracking

issues and can affect the bevel quality.

7

Page 10

Model B-500 Transportable Pipe Beveller

Vertical

0.062"(1.6 mm) Max.

Figure 5 – Pipe Squareness Requirements

The beveller will work on displacement cut (cutting wheel),

saw cut or torch cut edges. Prior to bevelling, remove

torch cutting slag build up, pipe weld seams over 1/32"

(0.8 mm) high, large burrs and other debris on both sides

of the edge to be bevelled within 3" (75 mm) of the edge.

This allows the beveller to grip and drive on the material. It

may be necessary to remove oil or other coatings on the

material to be bevelled to ensure beveller tracking.

There must be at least 3" of unobstructed straight pipe or

flat plate from the edge to be bevelled for the beveller to

mount and drive on. Do not use on curved material, such

as elbows or other fittings.

NOTICE

To prevent ferrous contamination of stainless

steel, make sure that the drive and guide rolls are clean

and debris free. Thoroughly clean with a stainless steel

brush. Change inserts – use dedicated inserts for stainless

steel. Best practice is to dedicate a beveller for stainless

steel.

NOTICE

Do not use the beveller on material that is

connected to a welder. If the beveller is connected to a

workpiece during welding processes, it can damage the

beveller circuitry.

Horizontal

Figure 6 – Acceptable (4) and Unacceptable (6) pipe ori-

entations

Make sure that the work piece to be bevelled is solidly

mounted and stable. Work piece and support must be able

to withstand the weight of the beveller and the force and

torque required for bevelling without moving or turning.

When using a pipe vise, make sure that it is properly

sized and secured to prevent tipping during use. For

longer lengths of pipe, use appropriate pipe stands to

support extra length.

When used on flat plate, the beveller cannot be used

with in 6 inches of the end of the edge. Both guide rollers

must contact the plate to hold the beveller in place (See

Figure 16).

If bevelling in place, make sure that there is sufficient

room for the beveller to fit in place and move along work

piece.

Fixed Workpiece/Moving Beveller Set-Up

The beveller is designed for use on horizontal pipe and

plate. It may also be used for pipe ends above horizontal.

See Figure 6 for examples. Use in other orientations can

allow the beveller and chips to fall on the operator, and is

not allowed.

8

Fixed Beveller/Rotating Pipe Set-Up

With the Model TBM-36 Beveller Adapter (optional equipment) (See Figure 7) the B-500 Beveller is mounted on a

RIDGID 450 or 460 series TRISTAND chain pipe vise. The

beveller is held stationary in use while the pipe rotates,

increasing convenience and allowing shorter pieces of pipe

to be beveled. This can be used for pipe up to 36" (900

mm) in diameter.

10" Long

1/2" Extension

Figure 7 – TBM-36 Beveller Adapter

Page 11

Model B-500 Transportable Pipe Beveller

1. Inspect and set up the RIDGID®450 or 460 Series

Portable TRISTAND chain pipe vise as per its instructions. If desired, anchor the rear leg of the Portable

TRISTAND chain pipe vise for greater stability. Do not

anchor the front legs. Anchoring the front legs of the

stand can prevent slight stand movement needed

for good tracking.

2. Place the cylindrical body of the adapter in the V-jaw

of the vise as shown in Figure 8. Locate the key into

the slot of the vise jaw for proper positioning and

stability.

Hooks

Key

Slot

7. Make sure the stand and equipment are stable.

8. Install the supplied 10" long ½" drive extension in the

Beveller drive shaft (see Figure 10).

9. When beveling pipe less than 12" (300 mm) long and

less than 50 pounds (22 kg), as long as the beveller

and Portable TRISTAND Pipe Vise are stable and

secure, no pipe stand is needed to support the pipe.

Pipe is placed directly on the drive roll and secured

with the guide rolls (Figure 10).

Extension

Figure 8 – Mounting the Adapter on Vise

3 Place the vise chain over the body of the adapter

and securely tighten the chain to hold the adapter in

place.

4. Fully loosen the adapter hook knobs and move the

hooks outwards.

5. Securely grasp the beveller and place on the adapter

as shown in Figure 9.

Hooks

Figure 10 – Fixed Beveller, Pipe under 12" Long, under 50

Pounds

If beveling pipe longer than 12" (300 mm) or more than

50 lbs (22 kg), the pipe must be supported with appropriate pipe stands to reduce the risk of the pipe and

equipment tipping and falling. Stands must be equip ped with rollers to allow the pipe to rotate while beveling. Improper pipe supports or supporting the pipe by

hand can cause tipping or falling pipe and equipment.

Place the pipe stands in line with beveller drive roll.

Always use at least two pipe stands if possible. Pipe

upper inside diameter should be the same height or

up to 1/8" (3mm) higher than the upper edge of the

beveller drive roll prior to gripping (see Figure 11). Pipe

should be parallel to the beveller drive roll. Do not

place the inside diameter of the pipe lower than the

upper edge of the drive roll – this can decrease stability and tracking.

Figure 9 – Securing Beveller to Adapter

6. Move the hooks over the beveller frame and secure-

ly tighten the knobs (Figure 9).

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

9

Page 12

Wear Plate

Model B-500 Transportable Pipe Beveller

1/8" (3 mm) Max.

Pipe Wall

Drive Roll

See Figure 11

Beveller

Figure 11 – Fixed Beveller, Pipe Position relative to

Beveller Drive Roll (Cut Away Pipe - Prior To

Gripping)

Pipe

See Figure 11

Figure 13 – Fixed Beveller, Long Pipe, Multiple Pipe

Stands

The set-up and tracking of the pipe to Beveller can be

confirmed prior to bevelling. Following the bevelling instructions, but without turning machine ON, tighten the clamp

screw hand tight plus 3/4 turn to grip the pipe. Insert the

hand crank and rotate to drive the pipe around. Pipe end

should stay flush to wear plates (Figure 15B) as pipe

rotates. If not, the set-up will need to be adjusted.

Bevelling

The B-500 Transportable Pipe Beveller can be used in

two configurations, either with the work piece fixed and the

beveller moving along it (Fixed Workpiece/Moving Beveller)

or with the beveller fixed on the Model TBM-36 Beveller

Adapter and the pipe moving relative to the beveller (Fixed

Beveller/Rotating Pipe) See Set-Up information for these

configurations.

Figure 12 – Fixed Beveller, Short Pipe, One Pipe Stand

When used with short sections of the pipe and one

pipe stand, the pipe will be supported on the beveller

drive roll and the pipe stand (see Figure 12). When

used with longer pipes and multiple pipe stands, the

pipe will be supported on the stands, as shown in

Figure 13.

10

Due to differing material characteristics, a test bevel should

always be performed before the first bevel of the day or

when changing material type, material thickness, bevel

angle or land width.

A label is provided on the beveller motor with basic operation information. The label steps follow the steps of this

section. This label is not a substitute for operator’s manual which contains all of the information for proper use.

Figure 14 – Instruction Label

Page 13

Model B-500 Transportable Pipe Beveller

1. Confirm that the gib plate lock screw is loose.

2. Turn the cutter feed screw counter clockwise to fully

retract the cutter head (away from the drive roll).

3. Turn the clamp screw to open the swing arms to

position wide enough for mounting to work piece.

4. Bringing the beveller and workpiece together.

Fixed Workpiece/Moving Beveller

Confirm that the beveller and workpiece have been

properly set up.

Securely grasp the beveller and place on the pipe with

guide rollers on the outside diameter (guide rolls to the

side that gets the bevel for flat plate) and drive roll

inside the pipe (side away from the bevel). Make

sure the wear plates on the beveller are flush to the

end of the pipe or plate edge (Figure 15B). Do not hit

the pipe or plate with the Cutter Head to prevent

damage to the inserts. Hold beveller until secure to

work piece.

When used on flat plate, the beveller cannot be used

within 6 inches of the end of the edge. Both guide

rollers must contact the plate to hold the beveller in

place (See Figure 16).

6" (0.15 m)

Min.

Figure 16A – Beveller On Plate

Cutter Feed

Screw

Figure 15A – Placing Beveller on Pipe

Figure 15B – Wear Plate Flush To End of Pipe

Clamp

Screw

Gib Plate

Lock Screw

Wear

Plates

Figure 16B – Installing Beveller on Plate

Fixed Beveller/Rotating Pipe

Confirm that the beveller, pipe stands and pipe have

been properly set up (see Figures 10, 12 and 13).

Place the pipe over the beveller drive roll. Make sure

the wear plates on the beveller are flush to the end of

the pipe or plate edge. Do not hit the Cutter Head with

the workpiece to prevent damage to the inserts. Hold

pipe until secured by the beveller.

5. Tighten the clamp screw hand tight plus an additional

3

/4turn (270°) (Fi g ure 17) with the

supplied hand crank to grip the

material between the guide rollers

and the drive roll. Make sure that the beveller is secure

to the material and the beveller and material is stable.

Remove the hand crank. Do not leave the hand crank

on the clamp screw. Do not attempt to bevel unless the

pipe is secure to the beveller.

11

Page 14

Model B-500 Transportable Pipe Beveller

Figure 17A – Hand Tighten Clamp Screw

beveller power cord into a properly grounded outlet/extension. All indicator lights should be illuminated.

Assume a proper operating position (Figure 19).

• Stand at the back of the machine, facing the hand

crank with good access to the ON/OFF switch. In

case of emergency you must be able to turn the

machine OFF.

• Be sure you have good balance and do not have

to overreach.

Depress the ON button (I). After motor comes up to

speed, yellow indicator lights should be ON.

3/4 Turn

(270°)

Figure 17B – Tighten Clamp Screw Additional

3

/4Turn (270°)

6. Set the desired bevel land width (Figure 18) using

th e land w idth

adjustment gage. If

set to “0” there will

be no land on the

end of the pipe.

Land Width

Land Width

Adjustment

Adjustment

Gage

Each step on the

land width adjustment gage is ap proxi mately a 1/32"

(0.8 mm) different

from the ad jacent

Stop

Stop

(Shoulder

(Shoulder

Screw)

Screw)

Cutter

Cutter

Feed

Feed

Screw

Screw

step. (1 ~ 0.03" (0.8

mm) land width, 2 ~

0.06" (1.6 mm), etc.)

Move the needed

step of the gage so

it aligns under the

Figure 18 – Land Width

Adjustment Gage

Setting

head of the stop.

7. Confirm that the cutter head is fully retracted and not

in contact with the work piece. With dry hands, plug the

Figure 19 – Proper Operating Position

8. Using a smooth continuous clockwise rotation of the

cutter feed screw (Figure 18); engage the cutter head

into the work piece until the stop contacts the land

width adjustment gage. Do not use cutting oil or

coolant.

9. Tighten the gib plate locking screw to lock the cutter

head into position (Figure 15). If gib plate locking

screw is not securely tightened, the cutting inserts

could become damaged.

10. Insert the hand crank into the drive shaft or extension.

Using a controlled uninterrupted motion, start rotating

the hand crank in a clockwise direction to bevel

(Figure 20).

It is important to provide proper rotational speed to

prolong the life of the cutting inserts. Monitor the LED

indicator lights on the rear of the unit. Green indicates the proper speed. Yellow indicates that you

need to rotate the handle faster, Red indicates to

rotate the handle slower. (See Figure 21.)

The crank should only turn clockwise when viewed

from the back of the beveller. Do not drive the beveller

with a drill, impact or other power tool – drive by

hand only. Do not use cutting oil or coolant.

12

Page 15

In some cases, chips will build up between the work

piece and the guide rollers. In most cases, the guide

rollers will ride over the chips with no issue other

than a slight increase in cranking force. If the unit

binds or chips need to be removed during bevelling,

turn the tool off and unplug it prior to removing chips

or removing the pipe.

Model B-500 Transportable Pipe Beveller

Figure 20A – Bevelling Operation (Fixed Workpiece/Mov -

ing Beveller)

Indicator Lights

Figure 20B – Bevelling Operation (Fixed Workpiece/Mov -

ing Beveller)

Figure 20C – Bevelling Operation (Fixed Beveller/Rotating

Pipe)

Lights Illuminated Condition

Indicator Lights

All Plugged in, switch OFF

Two Yellow Crank speed too slow.

One Yellow/OneGreen

Two Green Optimum crank speed.

One Green/OneRed

Two Red Crank speed too fast.

Figure 21 – Indicator Lights

13

Page 16

Model B-500 Transportable Pipe Beveller

Continually monitor the cord position (moving beveller

only) and tracking of the beveller to the workpiece.

Make sure the cord stays clear of the cutter head. As

the bevel is formed, make sure that the wear plates

stay flush to the end of pipe or plate edge. Stop rotating the hand crank and press the OFF (O) button. If:

• The wear plates move away from the work piece.

• The cutters do not engage the work piece.

• The process needs to be stopped for any reason.

This will help prevent the beveller from tracking off the

work piece. Repeat procedure starting at step one to

continue bevel.

Continue rotating the crank until the bevel is complete.

Figure 22– Clean Drive Roll Knurls

11. When bevel is complete, press the OFF button (O)

and make sure the cutter head comes to a complete

stop. Unplug the beveller from the extension (Moving

Beveller Only).

12. Loosen the gib plate locking screw to unlock the cutter head.

13. Fully retract the cutter head using the cutter feed

screw.

14. Making sure that the beveller and workpiece are

secure, loosen the clamp screw to open the swing

arms to release work pipe.

15. Separate the beveller and work piece. Be careful of

sharp edges on the pipe. Be careful not to hit the

Cutter Head with the pipe to prevent damage to the

inserts.

Maintenance Instructions

WARNING

Make sure the beveller is unplugged and press the

OFF button before performing any maintenance or

making any adjustments.

Always wear eye protection.

Maintain beveller according to these procedures to

reduce the risk of injury from electrical shock,

entanglement and other causes.

Cleaning

After each use, wipe any chips off with a soft, clean,

cloth or brush, especially areas of relative motion such as

the swing arms, dovetail rails or feed screw. Clean any

dust and debris from the motor vents.

Clean drive roll knurl with a wire brush (Figure 22).

Lubrication

On a monthly basis (or more often if needed) lubricate all

exposed moving parts (such as feed screw, clamping screw

and pivot points) with a light lubricating oil. Wipe any excess

oil from exposed surfaces. Use an extreme pressure (“EP”)

lithium grease for the two grease fittings on the faceplate and

one grease fitting on the end of the drive roll. (See Figure

23.) Add grease until a small amount pushes out (at the

ends of the gib plate and the end of the drive knurl).

Grease

Fittings

Figure 23 – Grease Fittings

Rotating/Replacing Cutter Inserts

If the cutting edges are dull, worn or chipped, cutter inserts

will need to be rotated or changed. Increased cutting time is

an indication of cutter insert wear. Use care when handling inserts. Do not allow the inserts to touch each other or

any other hard surface, they can be chipped or damaged.

1. With the cord unplugged, open the swing arms using

the clamp screw. Inserts can be rotated/replaced with

cutter head on the beveller.

14

Page 17

Model B-500 Transportable Pipe Beveller

2. Using the supplied T15 insert wrench, remove the

screws and inserts from the cutter head. If needed,

use the spanner wrench to turn the cutter head

(Figure 24, 25A).

3. Inspect the insert mounting pockets and the insert

screws for damage. Do not use damaged parts. Make

sure mounting pockets are clean and free of debris.

4. Either install a new set of inserts or rotate the existing

inserts (cutter inserts have 4 cutting edges) to expose

an unused cutting edge in the cutting position. Do not

mix new and used cutting edges – all cutting edges

should be changed at the same time. Only use

RIDGID inserts and insert screws. Other inserts or

screws may cause injury or tool damage. Place a

small amount of anti-seize grease on the screw and reinstall. Securely tighten the screw with the supplied

wrench. Do not over tighten. When inserts are changed,

you may notice a slight amount of vapor or smoke

during the first few bevels. This is not a cause for concern.

4. Inspect mounting area and cutter head for damage or

debris. Do not use damaged parts.

5. When replacing the cutter head, make sure it sits

squarely on the spindle, with the slots in the cutter

head engaging the drive pins (Figure 25B). Securely

tighten socket head cap screw using the hex wrench

and spanner wrench supplied.

Figure 25A – Changing Cutter Heads

Figure 24 – Replacing Cutter Inserts

Changing Cutter Head

Cutter Heads need to be changed for different bevel angles.

Only use the RIDGID cutter heads made for the beveller,

Other cutter heads may cause injury or tool damage.

1. With the cord unplugged, open the swing arms using

the clamp screw. Insert the provided spanner wrench

in the holes on the end of the cutter head to prevent

rotation.

2. Using a 5/16" hex wrench, remove the socket head

cap screw that holds the Cutter Head in place (Figure

25A).

Slots

Pins

Figure 25B – Replacing Cutter Heads

Replacing Carbon Brushes

Check the motor brushes every six months and replace

when worn to less than 1/2" (13 mm).

1. To access the motor, remove the 4 bolts holding the

frame to the face plate and remove the frame (Figure 1).

2. Remove four screws holding the motor cover and

remove cover.

3. Using a pair of pliers, pull the motor brush housings

straight out. Disconnect the electrical connector. (See

Figure 26.)

3. Carefully remove the cutter head. Watch for sharp

edges.

15

Page 18

Model B-500 Transportable Pipe Beveller

Connector

Brush

Figure 26 – Brush Placement - Motor Cover Removed

Not Present In

All Versions

Insulator

Sheet

Brush

Connector

4a. Inspect brushes if less than 1/2" (13 mm) long, replace

brushes as a set.

b. Inspect the commutator for wear. If excessively worn,

have tool serviced.

5. Depress the brush into the holder and insert into the

motor housing. Firmly push down on brush housing

and make sure it snaps in place. Inspect to make

sure insulator sheets are properly positioned between

brush holder and housing. Attach the connector and

replace the motor cover.

6. Securely install the frame to the beveller.

Breaker

The beveller is equipped with a breaker (Figure 1) that will

trip with excessive current draw. If this should happen,

unplug the beveller. Using the instructions, remove the

beveller from the work piece and inspect for the beveller for

damage. If undamaged, press the breaker button to reset. If

the breaker will not reset, allow beveller to cool for 15 minutes. Resume process starting with Inspection.

Wear Plates

If wear plates wear more than 0.03" (0.8 mm), replace.

6. Lubricate the gib plates and cycle the cutter feed

screw through its range several times. The parts

should move smoothly with no looseness or binding.

If needed repeat the adjustment process.

Figure 27 – Gib Plate Adjustment

Optional Equipment

WARNING

To reduce the risk of serious injury, only use equipment specically designed and recommended for

use with the RIDGID Model B-500 Transportable

Pipe Beveller, such as those listed below.

Catalog

No. Description

48863 37

48858 30° Cutter Head

48868 45° Cutter Head

48873 Pack Of 6 Cutter Inserts

48883 Anti-Seize Grease – 1 Tube

48888 Torx Wrench T15/S7

48893 Spanner Wrench

48898 5/16" Hex Wrench

55023 Model TBM-36 Adapter

1

/2° Cutter Head

Gib Plate Adjustment

If experiencing excessive vibration or tracking issues, the

gib plate may need to be adjusted. To adjust:

1. Loosen the gib screw.

2. Place the cutter feed screw approximately at the middle of its travel.

3. Loosen the gib plate jam nuts with a

4. Using a 5/32" hex key, tighten the gib plate set screws

equally (same number of turns) until tight. Loosen

each set screw 1/2turn.

5. While holding set screws in place with the hex key,

tighten the jam nuts (Figure 27).

16

3

/8" wrench.

Page 19

Machine Storage

WARNING

must be kept indoors or well covered in rainy weather.

Store the machine in a locked area that is out of reach of

children and people unfamiliar with bevellers. This machine

an cause serious injury in the hands of untrained users.

c

The Model B-500 Transportable Beveller

Service And Repair

WARNING

Improper service or repair can make machine

unsafe to operate.

The “Maintenance Instructions” will take care of most of

the service needs of this machine. Any problems not addressed by this section should only be handled by an

authorized RIDGID service technician.

Tool should be taken to a RIDGID Independent

Service Center or returned to the factory. Only use

RIDGID service parts.

Model B-500 Transportable Pipe Beveller

Disposal

Parts of the Model B-500 Beveller contain valuable materials and can be recycled. There are companies that specialize in recycling that may be found locally. Dispose of the

com ponents in compliance with all applicable regulations. Contact your local waste management authority

for more information.

For EC Countries: Do not dispose of elec-

trical equipment with household waste!

According to the European Guideline 2012/ 19/ EU for Waste Electrical and Electronic

Equipment and its implemen tation into nation-

al legislation, electrical equipment that is no

longer usable must be collected separately and disposed

of in an environmentally correct manner.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

17

Loading...

Loading...