RIDGID 915 Operator's Manual

In Place

Roll Groover

OPERATOR’S

MANUAL

915

WARNING!

Read this Operator’s Manual

carefully before using this

tool. Failure to understand

and follow the contents of this

manual may result in serious

personal injury.

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

915 In Place Roll Groover

manufacturer for your model. Ac cessories that may

be suitable for one tool may become hazardous when

used on another tool.

• Keep handles dry and clean; free from oil and

grease. Allows for better control of the tool.

Service

• Tool service must be performed only by qualified

repair personnel. Service or maintenance performed

by unqualified repair personnel could result in injury.

• When servicing a tool, use only identical replace-

ment parts. Follow instructions in the Maintenance

Section of this manual. Use of unauthorized parts or

failure to follow maintenance instructions may create a

risk of injury.

Specific Safety Information

WARNING

SAVE THESE INSTRUCTIONS!

Ridge Tool Company

2

General Safety Information

WARNING! Read and understand all instructions. Failure

to follow all instructions listed below may

result in serious personal injury.

SAVE THESE INSTRUCTIONS!

Work Area Safety

• Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

• Keep bystanders, children, and visitors away while

operating a tool. Distractions can cause you to lose

control.

• Keep floors dry and free of slippery materials

such as oil. Slippery floors invite accidents.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a tool. Do not use tool

while tired or under the influence of drugs, alcohol,

or medications. A moment of inattention while oper-

ating tools may result in serious personal injury.

• Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, clothing,

and gloves away from moving parts. Loose clothes,

jewelry, or long hair can be caught in moving parts.

• Do not overreach. Keep proper footing and bal-

ance at all times. Proper footing and balance enables

better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection.

Dust mask, non-skid safety shoes, hard hat, or hearing

protection must be used for appropriate conditions.

Tool Use and Care

• Do not force tool. Use the correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it is designed.

• Store idle tools out of the reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

• Check for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may affect the tool's operation. If damaged,

have the tool serviced before using. Many acci-

dents are caused by poorly maintained tools.

• Use only accessories that are recommended by the

Read this operator’s manual carefully before using

t

he 915 Roll Groover. Failure to understand and

follow the contents of this manual may result in

serious personal injury.

Roll Groover Safety

• Keep fingers away from rolls when grooving

pipe. Keep Sleeves and jackets buttoned. They

can become pinched resulting in serious injury.

• Do not wear loose fitting gloves. Can become

caught in rolls resulting in serious injury.

• Handle pipe carefully and have all burrs removed

from ends. Eliminates the risk of cuts to fingers and

hands.

• When working overhead, all personnel should

wear hard hats and be clear of the area below.

Prevents serious injuries if roll groover or workpiece

falls.

• Groover is designed to manually roll groove pipe

and tubing. Other uses may result in injury.

• Do not use power activated devices to aid in rotat-

ing the groover. Using a tool in a manner not intended can result in injury.

Ridge Tool Company

3

Description, Specifications

and Equipment

Description

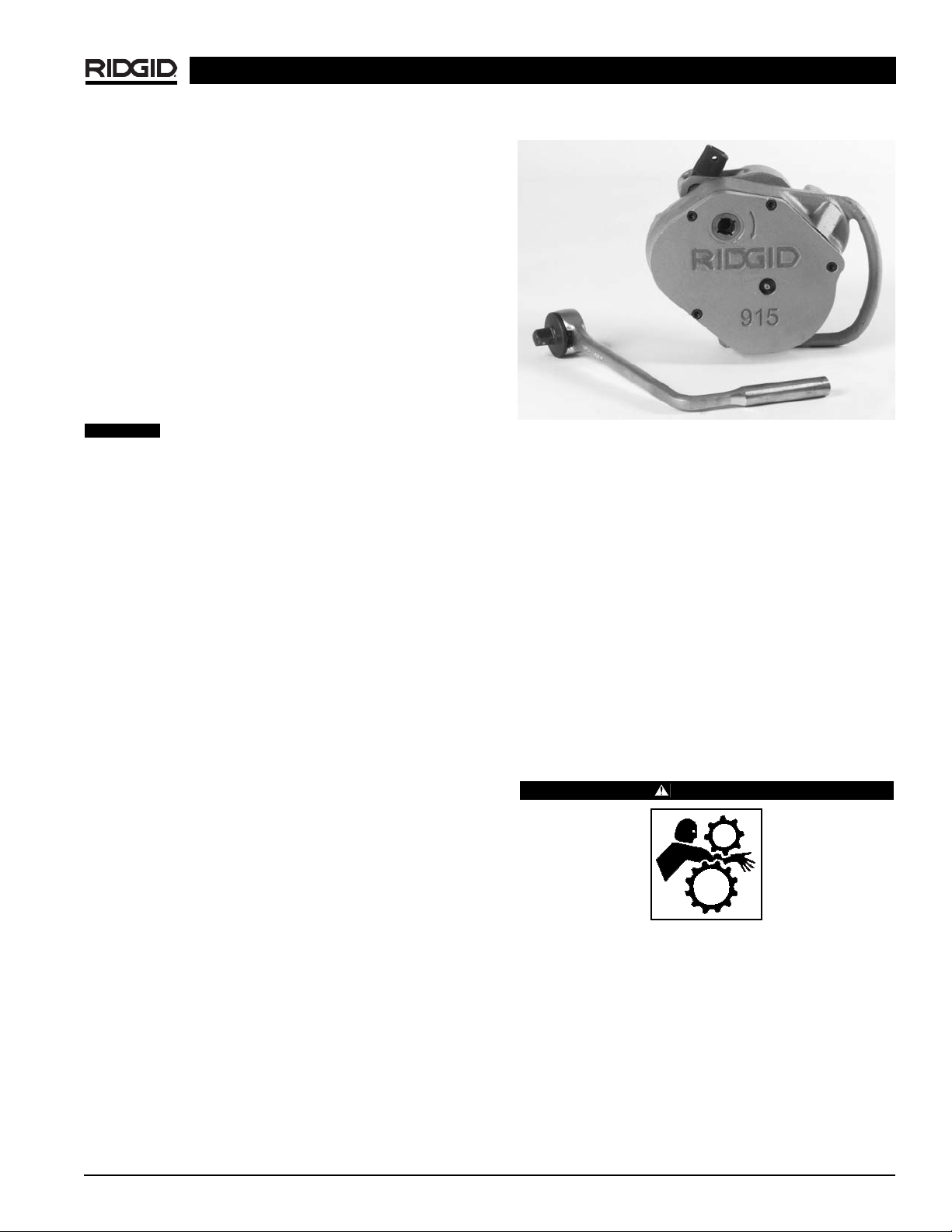

The RIDGID No. 915 Roll Groover is designed to manually form standard roll grooves on pipe or copper tube

that is installed. The 915 is lightweight, only 23 lbs., and

capable of grooving steel, stainless steel, PVC and aluminum pipe from 11/4″ to 12″ and 2″ to 8″ copper tube

(Type K, L, M, and DWV). The 1/2″ hand ratchet rotates

a feed screw that advances a groove roll into the

pipe/tube to form a groove that meets specifications

required for mechanical coupling systems, and also

drives the 915 around the pipe.

When properly used, the Model 915 Roll

Groover makes grooves that are dimensionally within the

specifications of AWWA C606-87. Selection of appropriate materials and joining methods is the responsibility of the system designer and/or installer. Before any

installation is attempted, careful evaluation of the specific

service environment, including chemical environment

and service temperature, should be completed.

Specifications

Capacity ........................Standard 2″ – 6″ Schedule 10

and 2″ – 31/2″ Schedule 40

Steel Pipe

Depth Adjustment..........Feed Screw with 1/2″ Female

Drive

Actuation........................Feed Screw with 1/2″ Ratchet

Wrench

Weight............................23 lbs.

With Roll Changes:

• 2″ – 8″ Copper Tube,

Type K, L, M, DWV

• 1

1

/4″ and 11/2Schedule 10 and 40 Steel/Stainless

Steel Pipe

• 4″ – 6″ Schedule 40

Steel/Stainless Steel Pipe

• 8″ – 12″ Schedule 10

Steel/Stainless Steel Pipe

(See Table II for Wall Thickness.)

Standard Equipment

Model 915......................Groove set for

2″ – 6″ Schedule 10 and

2″ – 31/2″ Schedule 40

1

/2″ Drive Ratchet w/button

release

Figure 1 – 915 Roll Groover

Accessories

• Groove set for 11/4″ to 11/2″ Schedule 10 & 40 pipe.

• Groove set for 4″ to 6″ Schedule 40 pipe.

• Groove set for 8″ – 12″ Schedule 10.

• Copper groove set for 2″ to 8″ Copper Tube

Type K, L, M, DWV.

• Carrying case for 915 and roll sets.

The 915 Roll Groover is a portable unit designed for occasional use on the jobsite and should not be used for high

volume work.

Roll Groover Inspection

WARNING

To prevent serious injury, inspect your Roll

Groover. The following inspection procedures

should be performed on a daily basis:

1. Inspect the Roll Groover for any broken, missing,

misarranged or binding parts as well as any other

conditions which may affect the safe and normal

operation of this equipment. If any of these conditions

are present, do not use the Roll Groover until any

problem has been repaired.

2. Lubricate the Roll Groover if necessary according

to the Maintenance Instructions.

915 In Place Roll Groover

CAUTION

Ridge Tool Company

4

3. Use groover rolls and accessories that are designed for

your Roll Groover and meet the needs of your application. The correct groover tools and accessories

allow you to do the job successfully and safely.

Accessories designed for use with other equipment

may be hazardous when used with this Roll Groover.

4. Clean any oil, grease or dirt from all handles and

controls. This reduces the risk of injury due to a tool or

control slipping from your grip.

5. Inspect the groove rolls to insure they are not damaged or worn. Worn groover rolls can lead to slippage

and poor quality grooves.

Roll Groover and

Work Area Set-Up

WARNING

To prevent serious injury,

proper set-up of the Groover and work area is

required. The following procedures should be followed to set-up the machine:

1. Insure work area has adequate lighting.

2. Clean up the work area prior to setting up any equipment. Always wipe up any oil that may be present.

3. Check the groove and drive rolls to insure they are the

correct size.

Use of roll sets on both carbon and stainless

steel pipe can lead to contamination of the stainless steel

material. This contamination could cause corrosion and

premature pipe failure. To prevent ferrous contamination, use roll sets dedicated for stainless steel grooving.

4. Make sure pipe/tube is secured and not free to rotate

prior to roll grooving.

• If pipe is not installed, use a bench vise or tristand

vise to secure the pipe. Pipe supports must be used

if pipe is greater than 36″ in length.

Failure to properly support the pipe can

result in the pipe falling.

Place vise and stands on a flat level surface. Be

sure the pipe, vise and stands are stable.

• If the pipe/tube is installed, care must be taken to

prevent pipe rotation or movement. Make sure that

the added weight and force required of the 915

can be supported by the pipe hangers and clamps.

Operating the 915 Roll Groover

WARNING

Do not wear loose clothing when operating a Roll

Groover. Keep sleeves and jackets buttoned.

Always wear eye protection to protect eyes from

dirt and other foreign objects. When working overhead, wear a hard hat and keep personnel clear of

area.

Keep hands away from grooving rolls. Do not wear

loose fitting gloves when operating groovers. Use

pipe stands to support pipe when using a pipe vise.

Unit to be hand driven only. Do not power with drill

or other types of units.

Pipe Preparation

1. Make sure pipe/tube end is cut square and free of

burrs. Do not attempt to groove pipe that has been cut

with a torch.

2. Pipe/tube out-of-roundness must not exceed the

total O.D. tolerances listed in the dimension specification

(Table 1).

NOTE! Determine out-of-roundness by measuring max-

imum and minimum outside dimensions at 90

degree increments. Compare minimum and

maximum numbers with pipe diameter column

in

Table 1

.

3. All internal or external weld beads, flash or seams

must be ground flush at least 2″ back from the pipe

end.

IMPORTANT! Do not grind flats on the pipe outside wall

where the coupling gasket seals (gasket

seat area).

4. The 915 Roll Groover will orbit around the pipe/tube.

Care must be taken that adequate space is provided

completely around material.

NOTE! The RIDGID 915 can roll groove pipe/tube with-

in 3

1

/2″ of a wall, ceiling or any other obstruction.

915 In Place Roll Groover

CAUTION

WARNING

Ridge Tool Company

5

915 Roll Groover Set-up

IMPORTANT! To confirm the proper groove depth, test

grooves should be performed and checked

with a Pi tape.

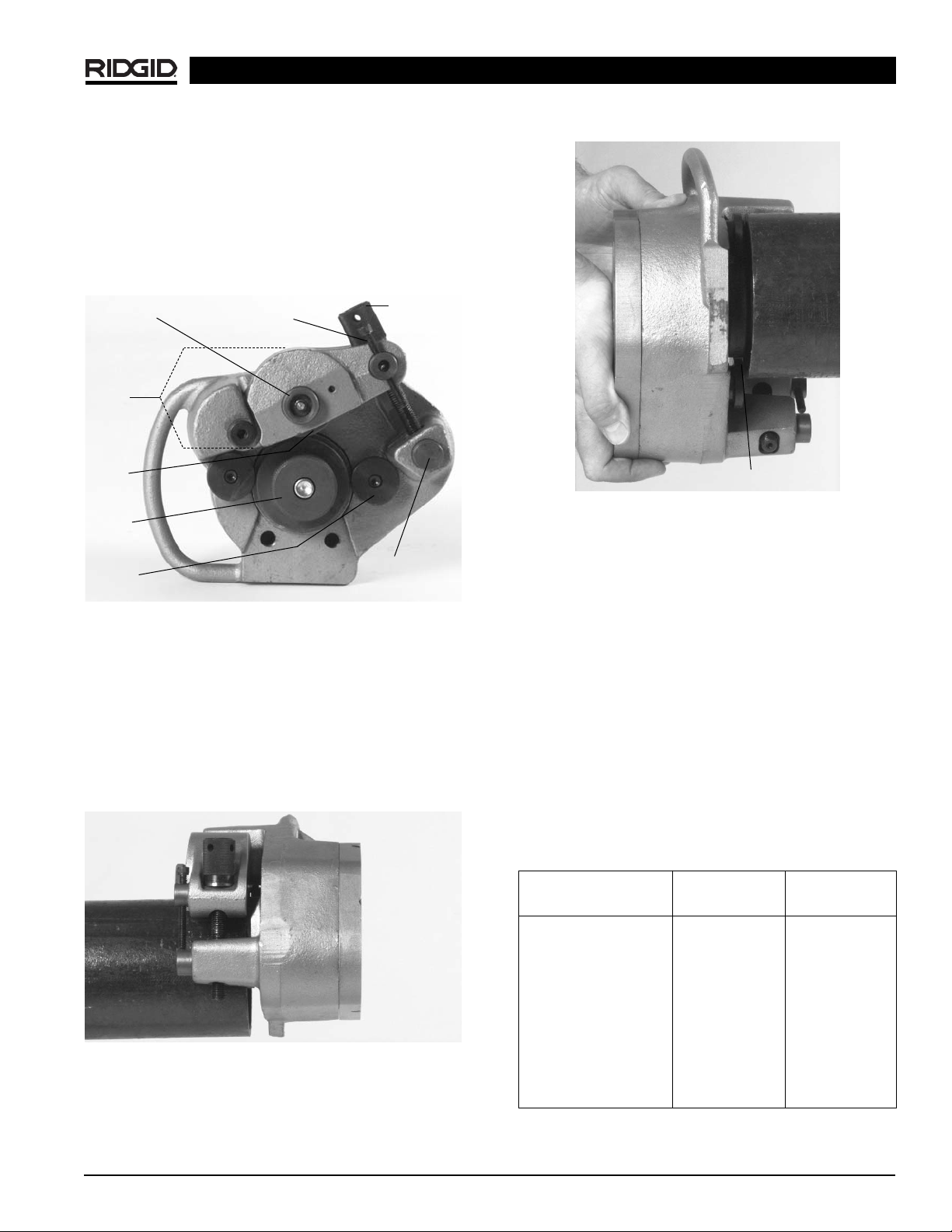

1. At a bench or on the ground, rotate the feed screw

counter clockwise to “open” the groove roll from

the drive roll

(Figure 2)

.

Figure 2 – “Open” Groove Roll from Drive Roll.

NOTE! Ensure that groove set specifications matches

pipe/tube capacity to be grooved. See drive roll

for capacity.

IMPORTANT! Do not attempt to groove copper tube with

the steel groove set. Also do not attempt to

groove steel with copper groove rolls.

2. Place 915 onto pipe/tube with feedscrew accessible

(Figure 3)

.

Figure 3 – Placing Groover on Pipe

3. Push 915 into pipe/tube until fully engaged. End of

pipe should contact the drive roll flange

(Figure 4)

.

Figure 4 – Pipe Contact with Drive Roll Flange

4. Rotate the feed screw clockwise by hand until tight.

915 should now be held in position on the pipe/tube.

Adjusting for Groove Depth

NOTE! The groove depth must be adjusted for each

pipe/tube diameter and wall thickness.

1. With feedscrew handtight, run depth adjustment

screw down until it touches the pivot nut.

2. Back the depth adjustment screw off the number of

turns indicated in

Chart 1 (For Steel/Stainless Steel,

For Copper See Chart 2. These are approximate settings only).

NOTE! The distance between the depth adjustment

screw and the pivot nut equals roll groove depth.

Adjustments up or down, with test grooves, will

ensure proper groove depths for couplings.

Chart 1 – Depth Adjustment for Steel/Stainless Steel

915 In Place Roll Groover

Groove Roll

Shaft

Feedscrew

Reaction

Arm

Groove

Roll

Drive

Roll

Stabilizer

Pads

Pivot

Nut

Depth

Adjustment

Screw

Drive Roll Flange

Steel/Stainless Steel Sch. 10 Sch. 40

Pipe Diameter Turns Turns

11/4″ 33/

4

4

11/2″ 33/

4

4

2″ 33/

4

4

21/2″ 43/

8

53/

8

3″ 43/

8

55/

8

4″ 45/

8

67/

8

6″ 57

1

/

2

8″ 6N/A

10″ 61/

4

N/A

12″ 71/

2

N/A

Loading...

Loading...