Page 1

460-6/460-12/40-A Instructions

WARNING

Read these instructions and the warnings and instructions for all equipment being used before using

RIDGID

®

stands to reduce the risk of serious person-

al injury.

• Always wear eye pr otection to reduce the risk of eye

injury .

• Support pipe with pipe stands. Failure to properly sup-

port the pipe can cause vise tipping, falling pipe, chain

breakage and serious injury.

Use of equipment for both carbon and stainless

steel pipe can lead to contamination of the stainless steel

mater

ial. This contamination could cause corrosion and premature pipe failure. To prevent ferrous contamination of stainless steel pipe, use dedicated equipment. Alternately, a stainless steel wire brush may be used to thoroughly clean the

equipment when switching between materials.

Description

RIDGID®TRISTAND®Pipe Vises are used to hold and work

pipe with either a chain or yoke vise. All are equipped with tool

hangers and a tray f or equipment storage during use, pipe benders for bending and adjusting pipe, and a jackscre w to help

stabilize the vise. The TRISTAND pipe vises easily fold for storage and transportation and allow adjustment of stand stiffness.

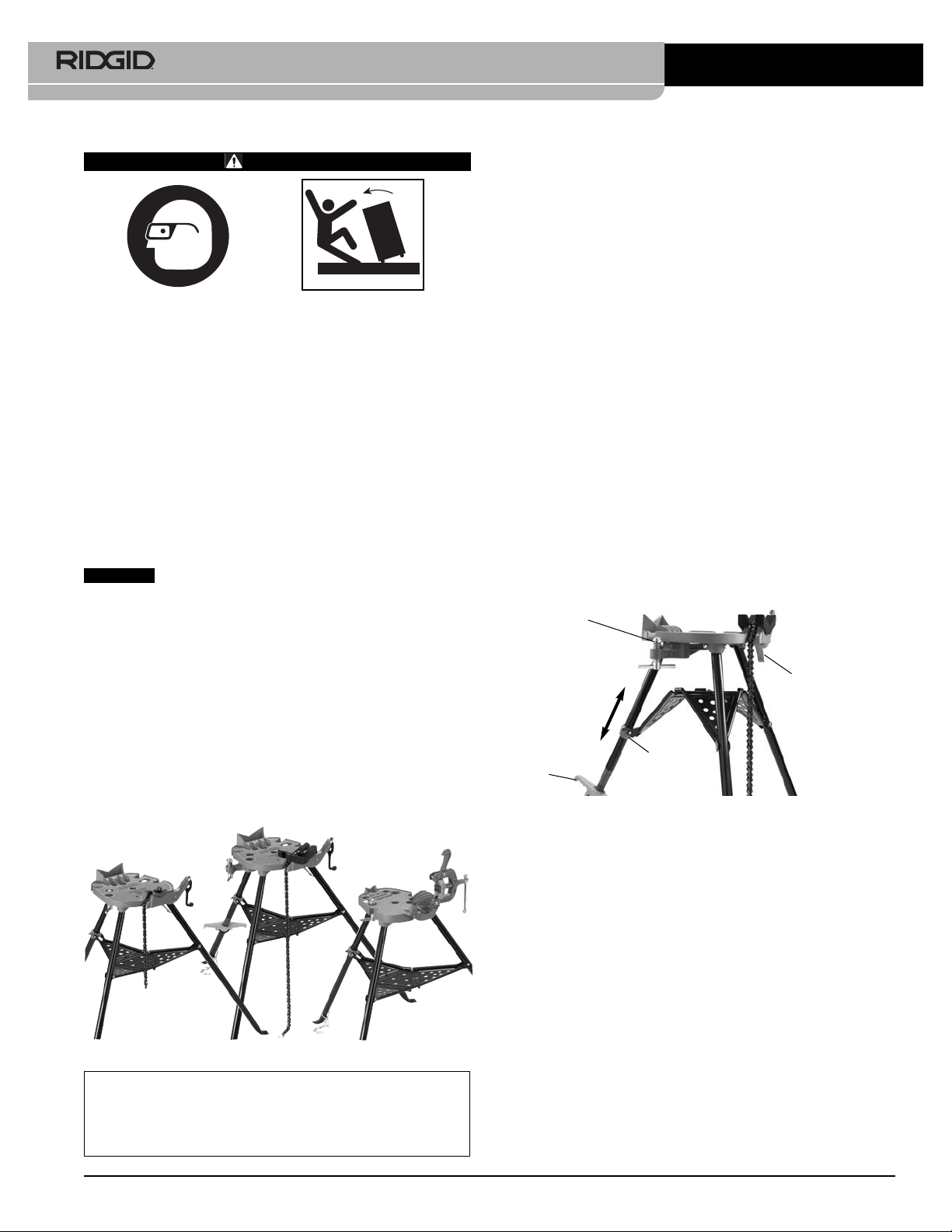

Figure 1 – RIDGID TRISTAND Pipe Vises

TRISTAND®Pipe Vise Instruction Sheet

Assembly

The yoke f or the 40-A can be assemb led to the base to open

to either side. Attach with supplied bolt and n ut.

Inspection/Maintenance

TRISTAND Pipe Vises should be inspected before each use f or

wear or damage that could affect the safe use of the vise.

Clean the vise to aid inspection and help prevent handles , etc.

from slipping from your grip. Make sure the vise is complete

and properly assembled. Clean the teeth of the ja w with a wire

brush to remove dirt. Replace jaw if teeth are w orn to prevent

pipe slippage. Inspect chain for any separation of links or

other damage. Link separation indicates the chain has been

overloaded and should be replaced. If any problems are

found, do not use the vise until the problems are corrected.

Lubricate all moving parts/joints as needed with a light lubricant

oil and wipe any excess oil from the stand.

TRISTAND Pipe Vise Set Up

and Operation

1. Locate a clean, level, stable location to set up the vise .

2. Place vise stand with feet on floor and open legs. Care fully push down on the center of the tray and lock into

position. Keep fingers and hands away from pinch points

to prevent injury.

3. A properly adjusted stand in good condition should sit

solidly with no significant looseness. To adjust:

a. Remove all objects (pipe, tools, etc.) from stand.

Care fully push up on the tray to unlock. Stay clear of

moving legs.

Figure 2 – Adjusting T ray Support (460-12)

b. Loosen the set screw on the rear tray support.

c. Move the rear tray support towards the vise to in -

crease stiffness, and away from the vise to decrease

stiffness.

d. Firmly tighten the set screw on the rear tray support.

Repeat above steps until properly adjusted. On worn

out stands, adjustment may not be possible .

4. The stand can be anchored for greater stability.

Jackscrew – Cut a length of 1" sch. 40 steel pipe to fit

between the jackscrew and a suitable overhead support (such as a structural beam or concrete floor). Firmly

tighten the jackscrew to hold the vise in place. As larger

loads are placed on the vise, the jackscrew may require

further tightening.

Anchoring the feet – Holes are provided in the leg feet to

fasten the stand to the floor. Always use this method

when using the stands with geared threaders and for

large, heavy pipe to prevent tipping.

5. Place pipe into vise. Tighten the vise to hold the pipe in

place. Do not drop the pipe on the vise or use handle ex -

RIDGID

®

6/11

999-998-462.10

REV. A

Printed in U.S.A.

EC37400

NOTICE

Pipe Size Weight

Capacity: Capacity

40-A TRISTAND Yoke Vise 1/8" to 2

1

/2" N/A

460-6 TRISTAND Chain Vise 1/8" to 6" N/A

460-12 TRISTAND Chain Vise 1/8" to 12" 1500 lbs

Jack Screw

Jack

Handle

Weld Ground

Connection

Increase

Stand Stiffness

Decrease

Set Screw

460-6

460-12

40-A

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 -

TestEquipmentDepot.com

Page 2

tensions when tightening the vise, this can damage the

vise.

Make sure the pipe and stand are stable f or the work to be

done. For best stability during use, keep the pipe end as

close to the vise as possible. Use appropriate pipe supports if the pipe extends past the base of the stand.

Failure to properly support the pipe can cause chain

breakage, vise tipping, falling pipe and serious injury.

When using the vise, do not over reach and maintain

proper footing and balance at all times. This allo ws better

control in unexpected situations.

6. Pipe Benders – to reduce the chance of kinking, bend

approximately 10 degrees at a time, moving the pipe

slightly in or out of the bender after each bend, until the

desired bend is formed.

7. Stand Leveling – The 460-12 TRISTAND pipe vise comes

standard with an adjustable rear leg that allows approximately +/-3 degrees angular adjustment for pipe leveling. With the pipe securely clamped in the vise, turn the

jack handle to adjust as desired. Le v eling of the stands can

also be accomplished with appropriate shims under the

feet of the stand. Alw a ys confirm that the stand is secure

and stable to prev ent shifting and tipping during use.

8. Welding Connection – The 460-6 and 460-12 TRISTAND

Pipe Vises include a welding ground connection point

under the vise,

see Figure 2

.

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

Loading...

Loading...