RIDGID 300 Compact, 1233 User Manual

Threading MachinesManual

300 Compact/1233

No Foot Switch

300 Compact

1233

• Français – 21

• Castellano – pág. 43

• CN – pág. 65

300 Compact/1233 Threading Machines

Table of Contents

Recording Form For Machine Serial Number..................................................................................................................................1

Safety Symbols ..................................................................................................................................................................................2

General Power Tool Safety Warnings

Work Area Safety ............................................................................................................................................................................2

Electrical Safety ..............................................................................................................................................................................2

Personal Safety ..............................................................................................................................................................................3

Tool Use And Care..........................................................................................................................................................................3

Service ............................................................................................................................................................................................3

Specific Safety Information

Safety Instructions for Transportable Threading Machines ............................................................................................................4

Description, Specifications And Standard Equipment

Description ......................................................................................................................................................................................4

Specifications ..................................................................................................................................................................................5

Standard Equipment ......................................................................................................................................................................6

Machine Assembly

Mounting on Stands ........................................................................................................................................................................6

Mounting on Bench ........................................................................................................................................................................6

Mounting on Pipe Legs ..................................................................................................................................................................6

Pre-Operation Inspection ..................................................................................................................................................................7

Machine and Work Area Set-Up........................................................................................................................................................7

Die Head Set-Up and Use

Removing/Installing Die Head ........................................................................................................................................................9

Quick-Opening Die Heads ..............................................................................................................................................................9

Inserting/Changing the Dies ........................................................................................................................................................9

Adjusting Thread Size ..................................................................................................................................................................9

Opening the Die Head at the End of the Thread..........................................................................................................................9

Self-Opening Die Heads ..............................................................................................................................................................10

Inserting/Changing the Dies ......................................................................................................................................................10

Adjusting Thread Size ................................................................................................................................................................10

Trigger Slide Adjustment............................................................................................................................................................10

Opening the Die Head at the End of the Thread........................................................................................................................10

Receding Self-Opening Die Heads ..............................................................................................................................................11

Inserting/Changing the Dies ......................................................................................................................................................11

Adjusting Thread Size ................................................................................................................................................................11

Adjusting Thread Length ............................................................................................................................................................11

Preparing the Die Head to Thread ............................................................................................................................................12

Opening the Die Head at the End of the Thread........................................................................................................................12

Operating Instructions

Cutting ..........................................................................................................................................................................................13

Reaming........................................................................................................................................................................................13

Threading Pipe..............................................................................................................................................................................14

Threading Bar Stock/Bolt Threading ............................................................................................................................................14

Left Hand Threading ....................................................................................................................................................................14

Removing Pipe from the Machine ................................................................................................................................................15

Inspecting Threads........................................................................................................................................................................15

Preparing Machine for Transport ..................................................................................................................................................16

Maintenance Instructions

Cleaning ........................................................................................................................................................................................16

Lubrication ....................................................................................................................................................................................16

Oil System Maintenance ..............................................................................................................................................................16

Replacing Cutter Wheel ................................................................................................................................................................17

Replacing Jaw Inserts ..................................................................................................................................................................17

Replacing Carbon Brushes ..........................................................................................................................................................17

Optional Equipment ........................................................................................................................................................................18

Thread Cutting Oil Information ......................................................................................................................................................18

Machine Storage ..............................................................................................................................................................................18

Service And Repair ..........................................................................................................................................................................18

Disposal ............................................................................................................................................................................................18

Troubleshooting ..............................................................................................................................................................................19

Lifetime Warranty ..............................................................................................................................................................Back Cover

*Original Instructions - English

ii

Threading Machines

300 Compact/1233

WARNING!

Read this Operator’s Manual

carefully before using this tool.

Failure to understand and follow the contents of this manual

may result in electrical shock,

re and/or serious personal

injury.

300 Compact

1233

300 Compact/1233 Threading Machines

Record Serial Number below and retain product serial number which is located on name plate.

Serial

No.

300 Compact/1233 Threading Machines

Safety Symbols

In this operator’s manual and on the product, safety symbols and signal words are used to communicate important safety information. This section is provided to improve understanding of these signal words and symbols.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER

WARNING

CAUTION

NOTICE

NOTICE indicates information that relates to the protection of property.

This symbol means read the operator’s manual carefully before using the equipment. The operator’s manual contains important information on the safe and proper operation of the equipment.

This symbol means always wear safety glasses with side shields or goggles when handling or using this equipment to reduce

the risk of eye injury.

This symbol indicates the risk of fingers, hands, clothes and other objects catching on or between gears or other rotating parts

and causing crushing injuries.

This symbol indicates the risk of fingers, legs, clothes and other objects catching and/or wrapping on rotating shafts causing

crushing or striking injuries.

This symbol indicates the risk of electrical shock.

This symbol indicates the risk of machine tipping, causing striking or crushing injuries.

This symbol means do not wear gloves while operating this machine to reduce the risk of entanglement.

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

General Power Tool Safety

Warnings

• Keep children and by-standers away while operating a power. Distractions can cause you to lose control.

WARNING

Read all safety warnings, instructions, illustrations and specifications provided with this power

tool. Failure to follow all instructions listed below

may result in electric shock, fire and/or serious

injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE!

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Work Area Safety

• Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

• Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

2

Electrical Safety

• Power tool plugs must match the outlet. Never

mod ify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools. Unmodi -

fied plugs and matching outlets will reduce risk of electric shock.

• Avoid body contact with earthed or grounded sur-

faces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electrical shock

if your body is earthed or grounded.

• Do not expose power tools to rain or wet condi-

tions. Water entering a power tool will increase the risk

of electrical shock.

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock.

300 Compact/1233 Threading Machines

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric shock.

• If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of a GFCI reduces

the risk of electric shock.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol, or medication. A mo -

ment of inattention while operating power tools may

result in serious personal injury.

• Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

• Prevent unintentional starting. Ensure the switch

is in the OFF-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energizing power tools that have the switch

ON invites accidents.

• Remove any adjusting key or wrench before turn-

ing the power tool ON. A wrench or a key left

attached to a rotating part of the power tool may result

in personal injury.

• Do not overreach. Keep proper footing and bal-

ance at all times. This enables better control of the

power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewelry. Keep your hair, and clothing away from

moving parts. Loose clothes, jewelry, or long hair

can be caught in moving parts.

for your application. The correct power tool will do the

job better and safer at the rate for which it is designed.

• Do not use power tool if the switch does not turn it

ON and OFF. Any power tool that cannot be controlled with the switch is dangerous and must be

repaired.

• Disconnect the plug from the power source and/or

the battery pack, if detachable, from the power

tool before making any adjustments, changing

accessories, or storing power tools. Such preven-

tive safety measures reduce the risk of starting the

power tool accidentally.

• Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

tool. Power tools are dangerous in the hands of

untrained users.

• Maintain power tools and accessories. Check for

misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the

power tool’s op er ation. If damaged, have the power

tool repaired before use. Many accidents are caused

by poorly maintained power tools.

• Keep cutting tools sharp and clean. Properly main-

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

• Keep handles and grasping surfaces dry, clean

and free from oil and grease. Slippery handles and

grasping surfaces do not allow for safe handling and

control of the tool in unexpected situations.

• Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into

account the working conditions and the work to be

performed. The use of the power tool for operations dif-

ferent from those intended could result in a hazardous

situation.

Service

• If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

• Do not let familiarity gained from frequent use of

tools allow you to become complacent and ignore

tool safety principles. A careless action can cause

severe injury within a fraction of a second.

Power Tool Use and Care

• Do not force power tool. Use the correct power tool

• Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool is

maintained.

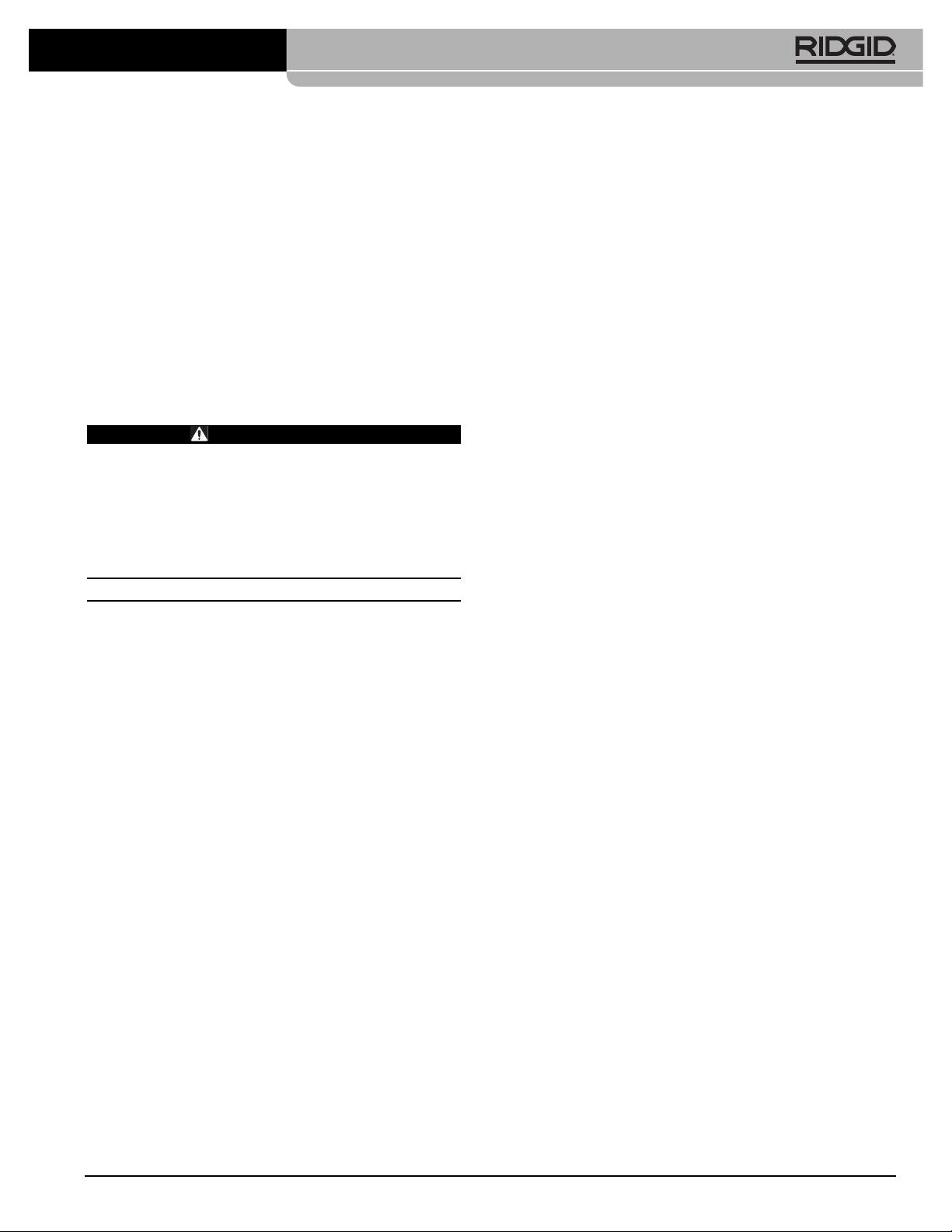

Specific Safety Information

WARNING

This section contains important safety information

that is specific to these tools.

Read these precautions carefully before using the

3

300 Compact/1233 Threading Machines

300 Compact/1233 Threading Machines to reduce

the risk of electrical shock or other serious injury.

SAVE THESE INSTRUCTIONS!

Keep this manual with machine for use by the operator.

Safety Instructions for Transportable

Threading Machines

This threading machine is not equipped with a foot switch.

Foot switches are required by standards in certain markets, such as the United States, Canada, Australia, the

European Union, Russia, Turkey and Saudi Arabia. Do not

use machines without foot switches if standards require

them. Foot switches improve operational convenience

and reduce risk. When foot switches are required, they

should be hardwired to the machine.

• Keep floor dry and free of slippery materials such as

oil. Slippery floors invite accidents.

• Restrict access or barricade the area when work

piece extends beyond machine to provide a minimum of one meter clearance from the work piece.

Restricting access or barricading the work area around

the work piece will reduce the risk of entanglement.

• Do not wear gloves. Gloves may be entangled by the

rotating pipe or machine parts leading to personal

injury.

• Do not use for other purposes such as drilling

holes or turning winches. Other uses or modifying this

machine for other applications may increase the risk of

serious injury.

a complete stop before touching the pipe. This

practice will reduce the chance of entanglement in

rotating parts.

• Do not use this machine to install or remove (make

or break) fittings, it is not an intended use of the

machine. This practice could lead to trapping, entan-

glement and loss of control.

• Keep covers in place. Do not operate the machine

with covers removed. Exposing moving parts increases the probability of entanglement.

• One person must control the work process and

ma chine operation. Only the operator should be in the

work area when the machine is running. This helps

reduce the risk of injury.

• Never reach into the machine front chuck or rear

centering head. This will reduce the risk of entanglement.

• Read and understand these instructions and the

instructions and warnings for all equipment and

materials being used before operating this tool to

reduce the risk of serious personal injury.

If you have any question concerning this RIDGID®product:

– Contact your local RIDGID®distributor.

– Visit www.RIDGID.com to find your local RIDGID

contact point.

– Contact Ridge Tool Technical Service Department

at rtctechservices@emerson.com, or in the U.S. and

Cana da call (800) 519-3456.

• This machine is used to cut, ream and thread pipe

per these instructions. Do not use with equipment

which require the use of a foot switch, such as geared

threaders or roll groovers.

• Secure machine to bench or stand. Support long

heavy pipe with pipe supports. This practice will

prevent tipping.

• Operate the machine from the operator control

(switch) side. Be sure you can control the switch at

all times. Operating the machine from the switch side

improves control and eliminates need to reach over the

machine. Switch control helps to reduce the risk of serious injury.

• Do not leave machine running unattended. Place

switch in OFF position when plugging in and not in use

to reduce the risk of entanglement.

• Keep hands away from rotating pipe and fittings.

Stop the machine before wiping pipe threads or

screwing on fittings. Allow the machine to come to

4

Description, Specifications

And Standard Equipment

Description

The RIDGID®Model 300 Compact and 1233 Threading

Machines are electric motor-driven machines that center

and chuck pipe, conduit and bolt stock and rotates it while

cutting, reaming and threading operations are performed.

Threading dies are mounted in a variety of available die

heads. An integral oiling system with adjustable flow rate

is provided to flood the work with thread cutting oil during

the threading operation.

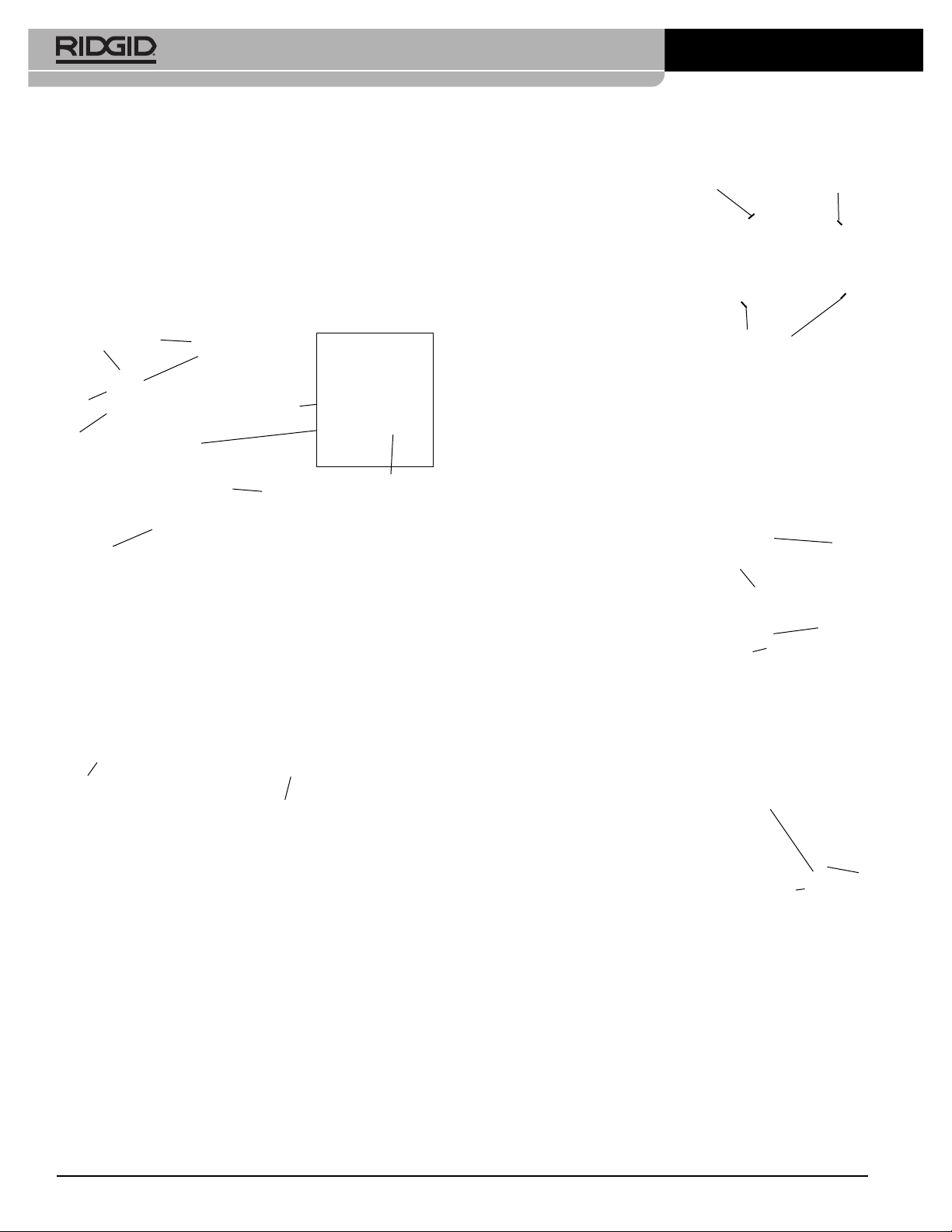

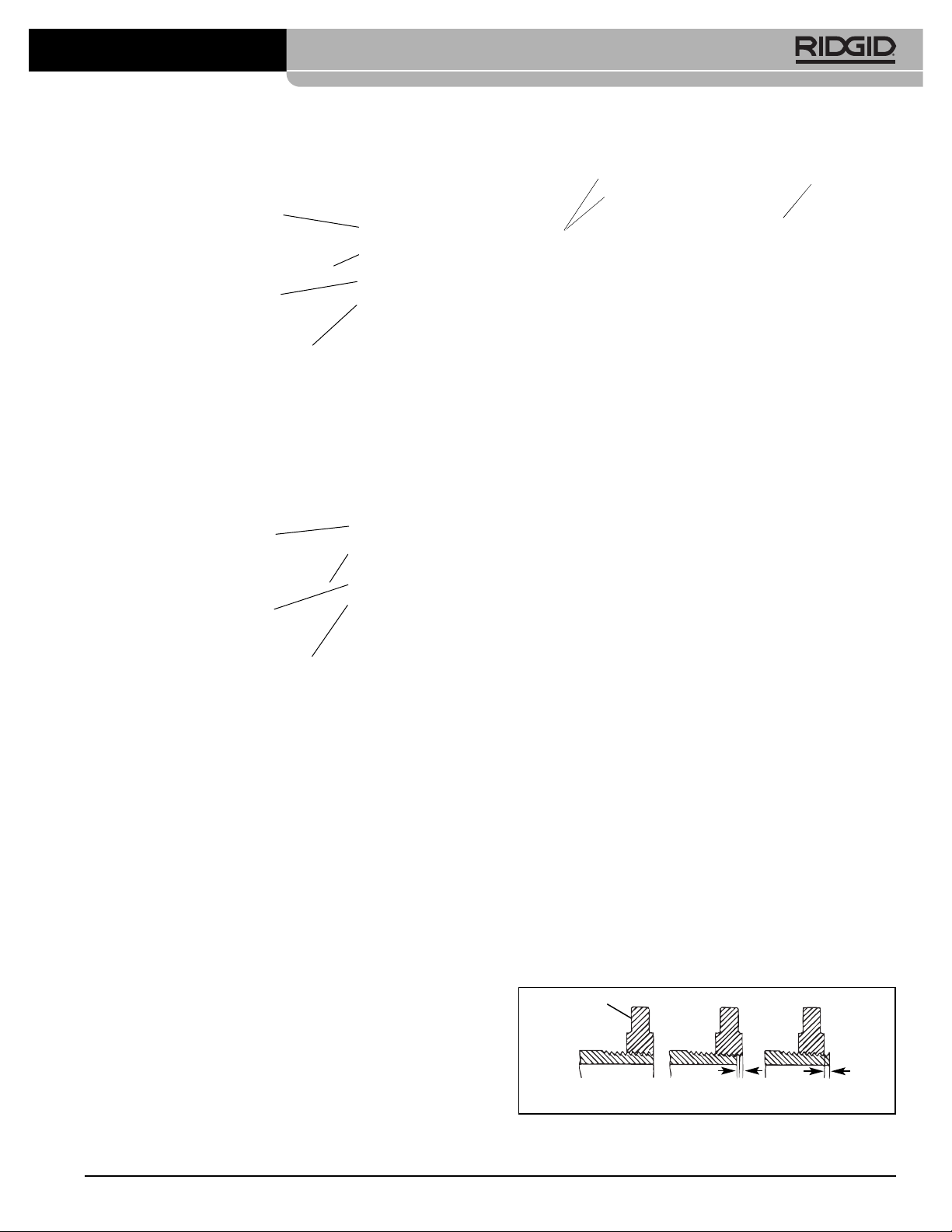

300 Compact/1233 Threading Machines

Rear

Centering

Device

Motor

Cover

Cutter

Chuck Jaw

Handwheel

REV/OFF/FWD

(2/0/1)

Switch

Warning

Hand

Hold

Label

Chip Tray

Quick Opening

Die Head

Carriage

Handwheel

Figure 1 – 300 Compact Threading Machine

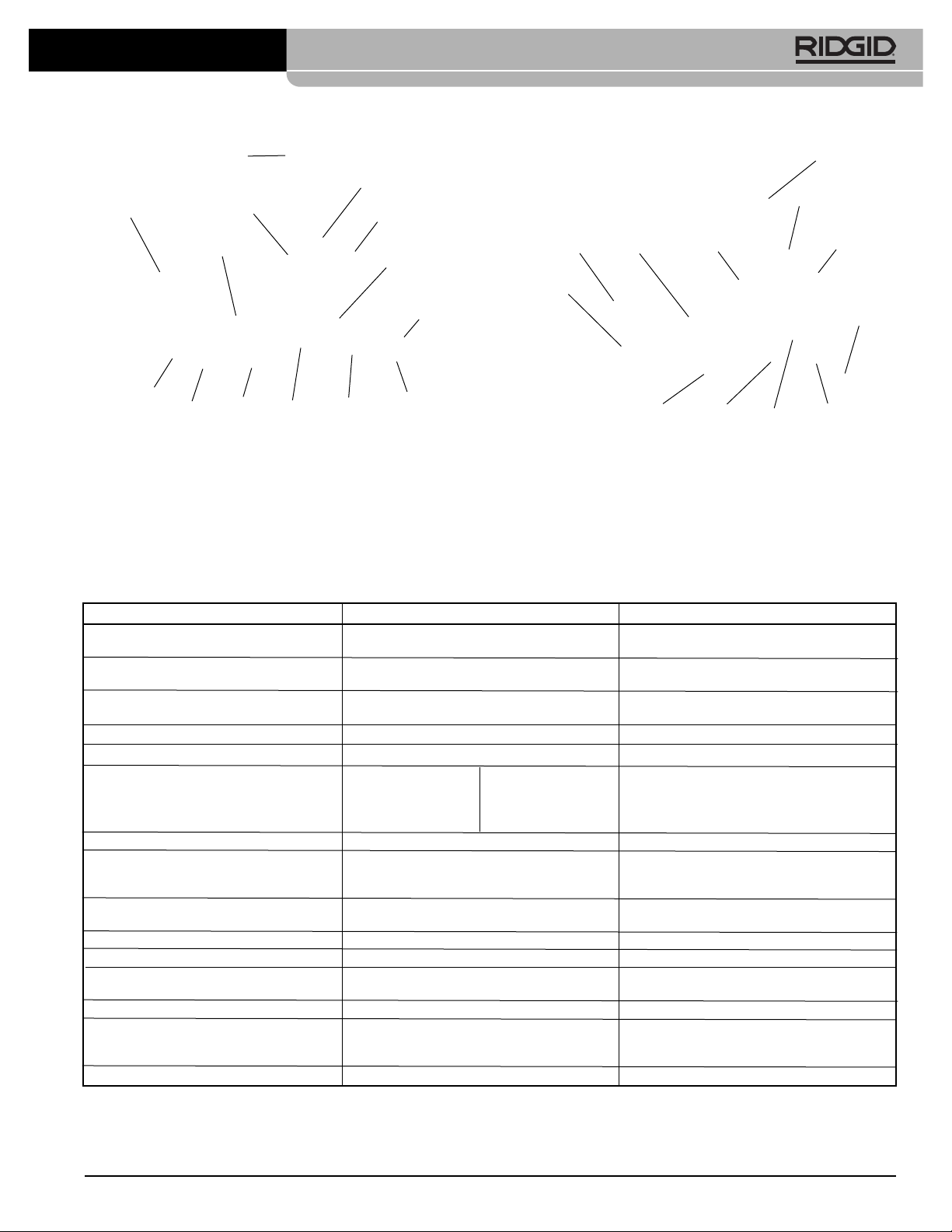

Specifications

Reamer

Carriage

Front

Hand

Hold

Oil

Drain

Rear

Centering

Device

Motor

Cover

(2/0/1)

Switch

Warning

Label

Chuck Jaw

Handwheel

Chip

Tray

REV/OFF/FWD

Figure 2 – 1233 Threading Machine

Carriage

No. 763

Cutter

Die

Head

No. 743

Reamer

Drain

Carriage

Handwheel

Oil

Parameter 300 Compact Threading Machine 1233 Threading Machine

Pipe Threading Capacity

1

/8to 2 inch (3 to 50 mm)

1

/8to 3 inch (3 to 80 mm)

(Nominal Pipe Size)

Bolt Threading Capacity

1

/4to 2 inch (6 to 50 mm)

3

/8to 2 inch (9,5 to 50 mm)

(Actual Stock Diameter)

Yes No

LH Threads (units with REV only)

Rated Motor Power (HP)

1

/2HP (0.37 kW)

1

/2HP (0.37 kW)

Motor Type Universal Motor, Single Phase Universal Motor, Single Phase

Electrical Information 36 RPM 52 RPM 115 V, 50/60 Hz, 15 AMP

115 V, 50/60 Hz, 12 AMP 115 V, 50/60 Hz, 18 AMP 230 V, 50/60 Hz, 8 AMP

230 V, 50/60 Hz, 8 AMP

1700 W 2100 W 1700 W

Operating Speed 36 RPM (52 RPM version available) 36 RPM

Rotary Type REV/OFF/FWD (2/0/1) switch Rotary Type REV/OFF/FWD (2/0/1) switch

Controls Some units use an OFF/ON Rocker Some units use an OFF/ON Rocker

Switch in place of the Rotary Switch. Switch in place of the Rotary Switch.

Front Chuck Hammer-Type with replaceable Hammer-Type with replaceable

Rocker-Action Jaw Inserts Rocker-Action Jaw Inserts

Rear Centering Device Scroll operated, rotates with Chuck Scroll operated, rotates with Chuck

Die Heads See RIDGID Catalog for available Die Heads See RIDGID Catalog for available Die Heads

1

Cutter Model 360,

/8" - 2" Full Floating, Model 763, 1⁄4" - 3",

Self Centering Cutter Self Centering Cutter

1

Reamer Model 344,

/8" - 2" Reamer Model 743, 1⁄4" - 3", 5-Fluted Reamer

Oil System Reservoir Capacity 3.2 qt (3 l), Reservoir Capacity 3.2 qt (3 l),

with integrated Gerotor Pump, with integrated Gerotor Pump,

adjustable flow rate adjustable flow rate

Weight (Unit with Oil and a Die Head) 147 lb (67 kg) 165 lb (75 kg)

5

300 Compact/1233 Threading Machines

Standard Equipment

Refer to the RIDGID catalog for details on equipment

supplied with specific machine catalog numbers.

The Threading Machine serial number plate is located on

the end of the base or the back of the base. The last 4 digits indicate the month and year of the manufacture (06 =

June, 14 = 2014).

Figure 3 – Machine Serial Number

NOTICE

lation, joining and forming methods is the responsibility of

the system designer and/or installer. Selection of improper materials and methods could cause system failure.

Stainless steel and other corrosion resistant materials

can be contaminated during installation, joining and forming. This contamination could cause corrosion and premature failure. Careful evaluation of materials and methods

for the specific service conditions, including chemical and

temperature, should be completed before any installation

is attempted.

Selection of appropriate materials and instal-

Mounting on Stands

The Threading Machines can be mounted on various

RIDGID Threader Stands. Refer to RIDGID catalog for

stand information and to the respective Stand Instruction

Sheet for mounting instructions.

Mounting on Bench

The machines can be mounted on a level, stable bench.

To mount the unit on a bench, use four 1/4" - 20 UNC bolts

in holes provided at each corner of the machine base.

Base hole spacing is 12.25" × 18" (311 mm x 457 mm).

Tighten securely.

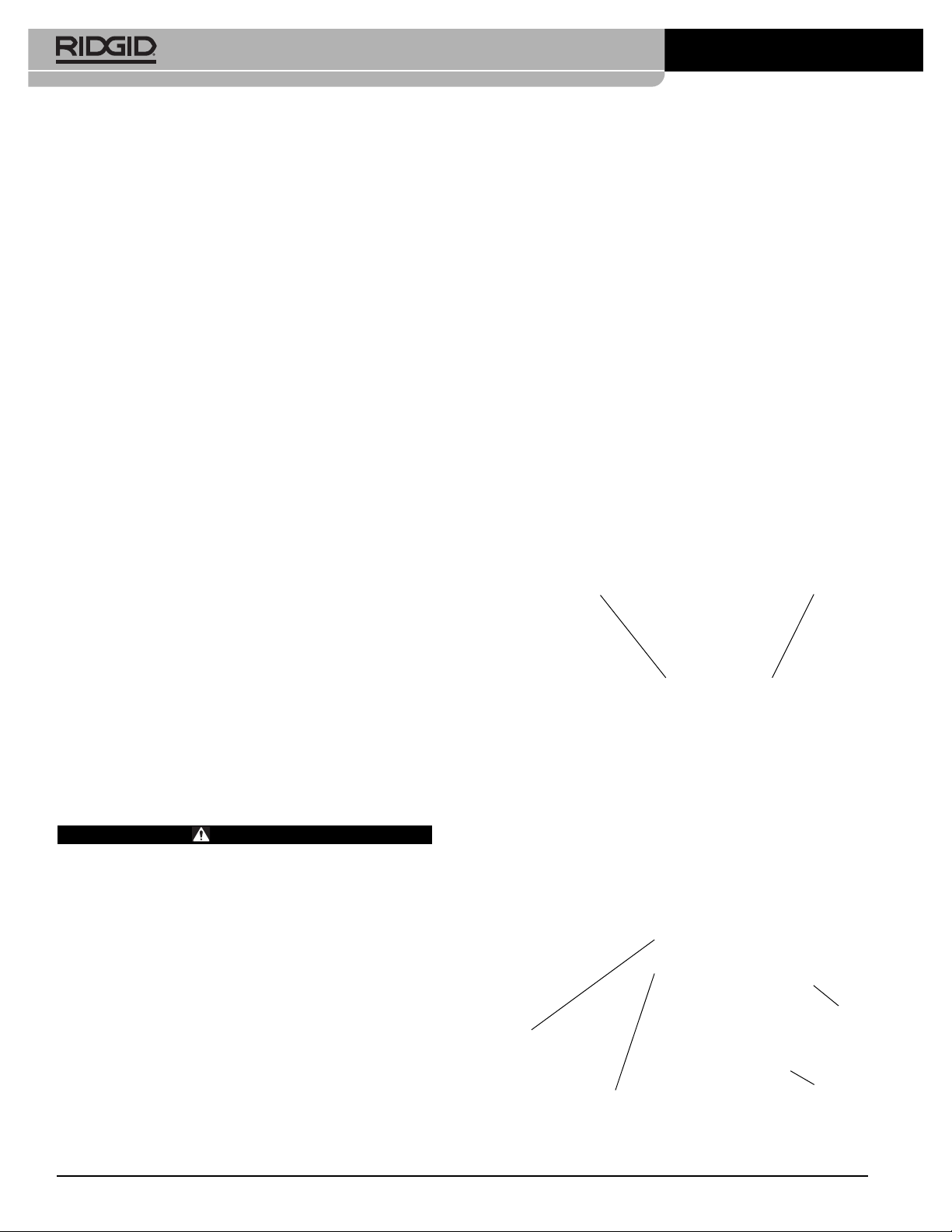

Mounting on Pipe Legs

Four equal lengths of 1" (25 mm) pipe can be used as a

stand for both the machines. Pipes cut to 33" (0.84 m)

length will place the machine rails approximately 36"

(0.91 m) off the ground. Fully insert the pipes into leg sockets provided on the underside of the base at the corners. Secure with four provided 10 mm hex bolts through

the base. See Figure 4.

Machine Assembly

WARNING

To reduce the risk of serious injury during use, follow these procedures for proper assembly.

Failure to mount the threading machine to a stable

stand or bench may result in tipping and serious

injury.

REV/OFF/FWD switch should be OFF and machine

unplugged before assembly.

Use proper lifting techniques. The RIDGID 300

Compact weighs 147 lb (67 kg) and the 1233 weighs

165 lb (75 kg).

6

Secure

Legs with

Hex Bolts

Figure 4 – Threading Machine Mounted On Pipe Legs

300 Compact/1233 Threading Machines

Pre-Operation Inspection

WARNING

Before each use, inspect your threading machine

and correct any problems to reduce the risk of

serious injury from electric shock, crushing injuries

and other causes, and to help prevent threading

machine damage.

1. Make sure that the threading machine is unplugged

and the REV/OFF/FWD switch is in OFF position.

2. Clean any oil, grease or dirt from the threading

machine, including the handles and controls. This

aids inspection and helps prevent the machine or

control from slipping from your grip. Clean and maintain the machine per the maintenance instructions.

3. Inspect the threading machines for the following:

• Condition of the cords and plug for damage or

modification.

• Proper assembly, maintenance and completeness.

• Any broken, worn, missing, misaligned or binding

parts or other damage.

• Confirm that the REV/OFF/FWD switch is in good

condition and cycles smoothly.

• Presence and readability of warning labels (Fi -

gures 1 & 2).

• Condition of the dies, cutter wheel and reamer cut-

ting edges. Dull or damaged cutting tools increase

required force, produce poor results and increase

the risk of injury.

• Any other condition which may prevent safe and

normal operation.

If any problems are found, do not use the threading

machine until the problems have been repaired.

4. Inspect and maintain any other equipment being

used per its instructions to make sure it is functioning

properly.

Machine and Work Area Set-Up

WARNING

Set up the Threading Machine and the work area

according to these procedures to reduce the risk of

injury from electric shock, machine tipping, entanglement, crushing and other causes, and to help prevent threading machine damage.

Restrict access or barricade the area when work

piece extends beyond machine to provide a minimum of one meter clearance from the work piece.

Restricting access or barricading the work area

around the work piece will reduce the risk of

entanglement.

Secure machine to stable stand or bench. Properly

support pipe. This will reduce the risk of falling

pipe, tipping and serious injury.

1. Check work area for:

• Adequate lighting.

• Flammable liquids, vapors or dust that may ignite.

If present, do not work in area until source is identified, removed or corrected, and area is completely

ventilated. The threading machine is not explosion

proof and can cause sparks.

• Clear, level, stable, dry location for all equipment

and operator.

• Good ventilation. Do not use extensively in small,

enclosed areas.

• Properly grounded electrical outlet of the correct

voltage. Check the machine serial plate for required

voltage. A three-prong or GFCI outlet may not be

properly grounded. If in doubt, have outlet inspected by a licensed electrician.

2. Inspect the pipe to be threaded and associated fittings. Determine the correct equipment for the job, see

specifications. Do not use to thread anything other

than straight stock. Do not thread pipe with fittings or

other attachments. This increases the risk of entanglement.

3. Transport equipment to work area. See Preparing

Machine for Transport for information.

4. Confirm equipment to be used has been properly

inspected and assembled.

5. Confirm that the REV/OFF/FWD switch is in the OFF

position.

7

300 Compact/1233 Threading Machines

6. Check that the correct dies are in the die head and

are properly set. If needed, install and/or adjust the

dies in the die head. See Die Head Set-Up and Use

section for details.

7. Swing the cutter, reamer and die head away up

away from the operator. Make sure they are stable

and will not fall in the work area.

8. If pipe will extend past the chip tray in the front of the

machine or more than 2' (0.6 m) out of the rear of the

machine, use pipe stands to support the pipe and prevent the pipe and threading machine from tipping or

falling. Place the pipe stands in line with machine

chucks, approximately 1/3of distance from end of the

pipe to the machine. Longer pipe may need more

than one pipe stand. Only use pipe stands designed

for this purpose. Improper pipe supports or supporting the pipe by hand can cause tipping or entanglement injuries.

9. Restrict access or set-up guards or barricades to

create a minimum of 3' (1 m) clearance around the

threading machine and pipe. This helps prevent nonoperators from contacting the machine or pipe and

reduces the risk of tipping or entanglement.

the switch to the OFF position. Repeat for REV

position – chuck should rotate clockwise. If the

threading machine does not rotate in the correct

direction do not use the machine until it has been

repaired.

• Move the switch to the FWD position. Inspect the

moving parts for misalignment, binding, odd noises

or any other unusual conditions. Move the switch to

the OFF position. If any unusual conditions are

found, do not use the machine until it has been

repaired.

• Place die head in the use position. Move the switch

to the FWD position. Check for oil flow through

the die head. Move the switch to the OFF position.

The oil flow can be adjusted with the control valve

on carriage (Figure 5). Clockwise rotation decreas-

es flow and counterclockwise increases flow. Do not

adjust while the machine is running.

-

+

10. Check the level of RIDGID Thread Cutting Oil. Re move the chip tray and oil pan liner; see that the filter

screen assembly is fully submerged in oil. See Oil

System Maintenance. If the machine is equipped

with the drip tray, make sure it properly placed to

direct oil dripping off the die head into the chip tray

(see Figure 5).

11. With the REV/OFF/FWD switch in OFF position, run

the cord along a clear path. With dry hands, plug

the power cord into the properly grounded outlet.

Keep all connections dry and off the ground. If the

power cord is not long enough use an extension

cord that:

• Is in good condition.

• Has a three-prong plug like on the threading

machine.

• Is rated for outdoor use and contains a W or W-A in

the cord designation (e.g. SOW).

• Has sufficient wire size. For extension cords up to

50' (15.2 m) long use 14 AWG (2.5 mm2) or heavier.

For extension cords 50'-100' (15.2 m - 30.5 m) long

use 12 AWG (2.5 mm2) or heavier.

12. Check the threading machine for proper operation.

With hands clear:

• Move the REV/OFF/FWD switch to the FWD posi-

tion. Chuck should rotate counter-clockwise when

viewed from the carriage end (see Figure 23). Move

Control

Control

Valve

Valve

Figure 5 – Adjusting Oil Flow

Drip Tray

13. Confirm the REV/OFF/FWD switch is in OFF position,

and with dry hands unplug the machine.

Die Head Set-Up and Use

The 300 Compact and 1233 Threading Machines can

be used with a variety of RIDGID Die Heads to cut pipe

and bolt threads. Information is included here for QuickOpening, Self-Opening and Receding Self-Opening Die

Heads (1233 only). See the RIDGID catalog for other

available die heads.

Die Heads using Universal Dies for pipe require one set of

dies for each of the following pipe size ranges: (1/8"), (1/4"

and 3/8"), (1/2" and 3/4") and (1" through 2"). NPT/NPSM dies

must be used in NPT die heads and BSPT/BSPP dies

must be used n BSPT die heads – The size bar is marked

for each.

8

300 Compact/1233 Threading Machines

Die heads using Mono or Bolt dies require a dedicated set

of dies for each specific thread size. High speed dies

are recommended for use on 52 rpm machines.

See the RIDGID catalog for dies available for your die

head.

Always cut a test thread to confirm proper thread size after

changing/adjusting the dies.

Removing/Installing Die Head

Insert/remove Die Head Post into mating hole in carriage. When fully inserted, the Die Head will be held in

place. When it is installed, the Die Head can be pivoted on

post to align it with pipe or it can be swung up and out of

the way to allow use of cutter or reamer.

Quick-Opening Die Heads

Quick opening die heads include Model 811A and 531/532

Bolt. Quick opening die heads are manually opened and

closed for user specified thread length.

Washer Tongue

Size Bar

Throwout Lever

Link

Clamp Lever (Hex Nut

on Mono Dies)

Post

3. Loosen clamp lever

(Hex nut on Mono die

Indicator

Line

heads) approximately

three turns.

4. Lift tongue of washer out of slot in size

Indicator

Line

bar. Move washer to

end of slot (Figure 8).

5. Remove dies from the

die head.

Figure 8 – Inserting Dies

6. Insert appropriate dies into the die head, numbered

edge up until the in di cator line is flush with the edge of

the die head (see Figure 8). Numbers on the dies

must correspond with those on the die head slots.

Always change dies as sets – do not mix dies from different sets.

7. Move link index mark to align with desired size mark

on size bar. Adjust die insertion as needed to allow

movement. Washer tongue should be in slot to left.

8. Tighten clamp lever (Hex nut on Mono die heads).

Adjusting Thread Size

1. Install the die head per the Threading Machine instructions and move the die head into threading position.

Dies

Hole for Locking Pin (LH Die Heads)

Figure 6 – Quick-Opening Die Head

Inserting/Changing the Dies

1. Place the die head with numbers facing up.

2. Move throwout lever to OPEN position (Figure 7).

Throwout

Lever

Open

Figure 7 – Open/Closed Lever Position

Throwout

Lever

Closed

2. Loosen clamp lever (Hex nut on Mono die heads).

3. Start with link index mark a ligned with desired size

mark on size bar. On Mono

and Bolt die heads, set link

mark at line in size bar. For

Link

Index

Mark

“Under”

bolt threads with Universal

die head, set all bolt dies at

BOLT line on size bar (Fi -

gure 9).

Size

4. If thread size needs to be ad justed, set the link index mark

Bar

“Over”

slightly off the mark on size

bar in the direction of OVER

(larger dia meter thread, less

Figure 9 – Adjusting

Thread Size

turns of fitting engagement) or UNDER (small er thread

diameter, more turns of fitting engagement) mark ings.

5. Tighten clamp lever.

Opening the Die Head at the End of the Thread

At the end of the thread:

• Pipe Threads – End of threaded pipe is flush with the

end of the number 1 die.

• Bolt Threads – Thread the desired length – watch

closely for any interference between the parts.

9

300 Compact/1233 Threading Machines

Move the throwout lever to the OPEN position, retracting

dies.

Self-Opening Die Heads

The Model 815A Die Heads are self-opening die heads.

For 1/2" through 2" pipe sizes, a trigger can be used to open

the die head when the thread is complete. For 1/8" to 3/8"

sizes, bolt and straight threads, and if desired for the

other sizes, the die head is manually opened when the

thread is complete.

Roll Pin

Index

Line

Lock

Screw

Throwout

Lever

Figure 10 – Universal Self-Opening Die Head

Inserting/Changing the Dies

1. Place the die head with numbers facing up.

2. Make sure the trigger assembly is released and die

head OPEN by pulling the trigger slide away from the

die head. Stay clear of the spring loaded Throwout

Lever while releasing trigger assembly.

Throwout

Lever

Open

Figure 11 – Open/Closed Position

3. Loosen clamp lever ap proximately six full turns.

4. Pull lock screw out of size bar slot so roll pin will

bypass slot. Position size bar so that the index line on

lock screw is a ligned with the RE MOVE DIES mark.

5. Remove dies from the die head.

6. Insert appropriate dies into the die head, numbered

edge up until the indicator line is flush with the edge of

the die head (see Fi gure 12). Num bers on the dies

must cor res pond with those on the die head slots.

Always change dies as sets – do not mix dies from different sets.

“Remove Dies” Mark

Size Bar

Trigger

Assembly

Clamp Lever

Throwout

Lever

Closed

Trigger

Slide

7. Move size bar so in dex

line on lock screw is a ligned with desired size

Indicator

Line

Indicator

Line

mark. Adjust die insertion

as needed to allow movement.

8. Make sure roll pin points

to ward REMOVE DIES

mark.

9. Tighten the clamp lever.

Indicator Line

Figure 12 – Inserting Dies

Adjusting Thread Size

1. Install the die head per the Thread ing Machine Instruc tions and move the die head into threading position.

2. Loosen clamp lever.

3. Position size bar so index line on lock screw is aligned

with desired size mark on size bar.

4. If thread size needs to be ad justed, set the lock screw index

line slightly off the mark on size

bar in the direction of OVER

Lock

Screw

Index

Line

“Over”

(larger dia meter thread, less

turns of fitting engagement) or

UNDER (smaller thread dia meter, more turns of fitting en gagement) markings.

5. Tighten clamp lever.

Size

Bar

Figure 13 – Adjusting

“Under”

Thread Size

Trigger Slide Adjustment

Position the Trigger Slide for the size of pipe being threaded (see Figure 14).

1

•

/2" and 3/4" – End of pipe should

hit foot of Trigger Slide.

1" thru 2"

pipe hit

this

surface

• 1" to 2" – End of pipe should hit

the shank of the Trigger Slide.

For

•1/8", ¼" and 3/8" pipe

• Longer or shorter threads

• Bolt threading

1

/2" and 3/4"

pipe hit this

surface

Figure 14 – Setting

Trigger

Slide

the

Trigger

Push trigger slide up and out of the way. Die head must be

opened manually.

Opening the Die Head at the End of the Thread

When using trigger it will contact the end of pipe, causing

the die head to automatically open. Stay clear of the

spring loaded Throwout Lever when it releases.

To open the die head manually (with trigger slide up), at

the end of the thread:

• Tapered Pipe Threads – End of pipe is flush with

the end of the number 1 die.

10

300 Compact/1233 Threading Machines

• Bolt and Straight Threads – Thread the desired

length – watch closely for any interference between

the parts.

Move the throwout lever to the OPEN position, retracting

dies.

Receding Self-Opening Die Heads

The Model 728 and 928 receding self-opening die heads

are used on 1233 threading machine for 21/2" and 3" pipe

sizes. A trigger is used to open the die head when the

thread is complete, and is adjustable to change thread

length.

Back

Size Bar

Adjustment

“Change

Ball

Ball

Detent

Detent

Nuts

Dies”

Arrow

Adjuster

Knob

Figure 15 – Receding Self-Opening Die Head

Front

Adjuster

Slide

Trigger

Cam Plate

Inserting/Changing the Dies

1. Place the die head with numbers facing up.

2. Pull back on adjuster knob on die head and fully

open die head by sliding cam plate in direction of

CHANGE DIES arrow on cam plate.

4. Pull back on adjuster knob and rotate cam plate to

desired size setting.

5. Engage adjuster knob into slot.

Adjusting Thread Size

1. Loosen the adjustment nut for the desired pipe size.

2. When setting for new dies, start with the adjusting

slide index line aligned with the size mark on the size

bar.

3. If thread size needs to be adjusted, set the index line

slightly off the mark on the size bar in the + direction

(larger thread diameter, less

turns of fitting engage ment)

or in the - direction (smaller

thread diameter, more turns

of fitting engagement) as

shown on the size bar.

4. Tighten the adjustment nut.

Adjusting Thread Length

1. Loosen the screw on bot-

+

-

Size

Bar

Adjustment

Slide Index

Line

tom trigger.

2. For short threads, shift the

bottom trigger towards the

machine spindle. For long

Adjustment

Nut

Figure 17 – Adjusting

Thread Size

threads, shift it away from the spindle (see Figure 18

– factory settings shown). Long threads are typically

preferred in Far East and short threads in Europe. Set

as desired.

3. Re-tighten the screw.

For Long

Threads

For Short

Threads

Top Trigger

Figure 16 – Inserting Dies

3. Remove dies from die head.

Insert appropriate dies into the die head, numbered

edge up. Numbers on the dies must correspond with

those on the die head slots (see Figure 16). The die

slots have a ball detent that engages with the groove

on dies when properly installed. Always change dies

as sets – do not mix dies from different sets.

Groove

Bottom

Trigger

Top Trigger Hole

Location

Figure 18 – Adjusting Thread Length

Short Threads Long Threads

11

300 Compact/1233 Threading Machines

Preparing the Die Head to Thread

Lower the die head down into the threading position.

Firmly push on adjusting slide to set/close the die head

(Figure 19).

Figure 19 – Closing the Receding Die Head

Opening the Die Head at the End of the Thread

The die head trigger will contact end of pipe causing the die

head to automatically open.

Operating Instructions

Do not use this machine to make or break (tighten

or loosen) fittings. This can cause striking or crushing injuries.

One person must control the work process and

machine operation. Only the operator should be in

the work area when the machine is running. This

helps reduce the risk of injury.

Follow operating instructions to reduce the risk of

injury from entanglement, striking, crushing and

other causes.

1. Make sure that machine and work area is properly set

up and that the work area is free of bystanders and

other distractions. The operator should be the only

person in the area while the machine is operated.

The cutter, reamer and die head should be up away

from the operator, do not place in the operating position. Make sure they are stable and will not fall. Fully

open the chucks of the threading machine.

2. Insert pipe shorter than 2' (0,6 m) from the front of the

machine. Insert longer pipes through either end so

that the longer section extends out beyond the rear of

the Threading Machine. Confirm that pipe stands

are properly placed.

3. If needed, mark the pipe. Place pipe so that the area

to be cut or end to be reamed or threaded is approximately 4" (100 mm) from the front of the chuck. If closer, the carriage may strike the machine during the

threading and damage the machine.

WARNING

Operate the machine from the operator control

(switch) side. Be sure you can control the switch at

all times. Operating the machine from the switch

side improves control and eliminates need to reach

over the machine. Switch control helps to reduce

the risk of serious injury.

Do not leave machine running unattended. Place

switch in OFF position when plugging in and not in

use to reduce the risk of entanglement.

Do not wear gloves or loose clothing. Keep sleeves

and jackets buttoned. Loose clothing can become

entangled in rotating parts and cause crushing and

striking injuries.

Keep hands away from rotating pipe and parts.

Stop the machine before wiping threads or screwing on fittings. Do not reach across the machine or

pipe. To prevent entanglement, crushing or striking

injuries, allow machine to come to a complete stop

before touching the pipe or machine chucks.

Do not wear gloves. Gloves may be entangled by

the rotating pipe or machine parts leading to personal injury.

4. Turn the rear centering device counterclockwise

(viewed from rear of machine) to close down onto

pipe. Make sure that the pipe is centered in the inserts.

This improves pipe support and gives better results.

Close

Figure 20 – Chucking Pipe

Open

5. Turn the front chuck handwheel counterclockwise

(viewed from front of machine) to close down onto

pipe. Make sure that the pipe is centered in the inserts.

12

300 Compact/1233 Threading Machines

Use repeated and forceful counterclockwise spins of

the handwheel to secure the pipe in front chuck.

6. Assume a proper operating position to help maintain

control of the machine and pipe (See Figure 21).

• Stand on the REV/OFF/FWD switch side of the

machine with convenient access to the tools and

switch. Be sure you can control the switch at all

times. Do not turn the machine ON yet.

• Be sure that you have good balance and do not

have to overreach.

Cutting

1. Open cutter by turning the feed screw counterclockwise. Lower the cutter into cutting position over the

pipe. Use the carriage handwheel to move the cutter

over the area to be cut, and align the cutter wheel with

the mark on the pipe. Cutting threaded or damaged

sections of pipe can damage the cutter wheel.

2. Tighten the cutter feed screw handle to bring the

cutter wheel firmly in contact with the pipe while

keeping the cutter wheel aligned with the mark on the

pipe.

3. Move the REV/OFF/FWD switch to the FWD position.

4. With both hands, grasp the pipe cutter feed handle.

5. Tighten the feed screw handle one-half turn per rotation of the pipe until the pipe is cut. More aggressive

tightening of the handle reduces cutter wheel life

and increases pipe burr formation. Do not support the

pipe by hand. Let the cut off piece be supported by

the threading machine carriage and pipe stand.

Figure 21 – Operating Position

Figure 22 – Cutting Pipe with Cutter

6. Move the REV/OFF/FWD switch to the OFF position.

7. Raise cutter into position up away from operator.

Reaming

1. Move the reamer into reaming position. Make sure

that it is securely positioned to prevent it from moving

during use.

2. Move the REV/OFF/FWD switch to the FWD position.

3. With both hands, grasp the carriage handwheel.

4. Turn carriage handwheel to move the reamer to the

end of the pipe. Apply slight pressure to the handwheel to feed the reamer into pipe to remove the

burr as desired.

13

300 Compact/1233 Threading Machines

FWD (1) REV (2)REV (2)

handwheel to start the die head onto the pipe. Once

the die head starts threading the pipe, no more force

is required on the carriage handwheel.

6. Keep your hands away from the rotating pipe. Make

sure the carriage does not hit the machine. When the

thread is complete, open the die head. Do not run

machine in Reverse (REV) with dies engaged.

7. Move the REV/OFF/FWD switch to the OFF position.

8. Turn the carriage handwheel to move the die head

past the end of the pipe. Raise the die head into

position up away from the operator.

Figure 23 – Reaming Pipe with Reamer, Machine Rotation

5. Move the REV/OFF/FWD switch to the OFF position.

6. Move the reamer up away from the operator.

Threading Pipe

Due to differing pipe characteristics, a test thread should

always be performed before the first thread of the day or

when changing pipe size, schedule or material.

1. Lower the die head into the threading position. Con firm that the dies are correct for the pipe being threaded and properly set. See the “Die Head Set-Up and

Use” section for information on changing and adjusting dies.

9. Remove the pipe from the machine and inspect the

thread. Do not use the machine to tighten or loosen fittings on the thread.

Threading Bar Stock/Bolt Threading

Bolt threading is similar to the pipe threading process. The

stock diameter should never exceed the thread major

diameter.

When cutting bolt threads, the correct dies and die head

must be used. Bolt threads may be cut as long as needed, but make sure the carriage does not hit the machine.

If long threads are required:

1. At the end of carriage travel, leave the die head

closed, and move the REV/OFF/FWD switch to the

OFF position.

2. Open the chuck and move the carriage and workpiece

to the end of the machine.

3. Re-chuck the rod and continue threading.

Left Hand Threading

Cutting left hand threads is similar to the right hand

threading process. Left hand threading is possible with 300

Compact threading machine with REV/OFF/FWD switch

only. To cut left hand threads, left hand die heads and dies

are required.

Figure 24 – Threading Pipe (811-A Quick Opening Die

Head shown)

2. Close the die head.

3. Move the REV/OFF/FWD switch to the FWD position.

4. With both hands, grasp the carriage handwheel.

Confirm cutting oil flow through the die head.

5. Turn carriage handwheel to move the die head to the

end of the pipe (Figure 24). Apply slight force to the

14

1. Change the oil pump connections to allow oil flow

when the machine is run in reverse (REV). See Figure

25. Be sure to return the connections to their original

configuration when returning to right hand threading.

Always replace cover before use.

Pump In (REV)

From Filter

300 Compact/1233 Threading Machines

Pin

Holes

Holes

Pin

Pump Out (FWD)

To Carriage

Figure 25A – Oil Pump Connections for Left Hand

Threading (Switch in REV)

Pump Out (FWD)

From Filter

Pump In (REV)

To Carriage

Figure 25B – Oil Pump Connections for Right Hand

Threading (Switch in “FWD”)

Figure 25C – Cover in Place

2. Place a 5/16" pin 2" long through the holes in carriage

rest and left hand die head to retain in place (see

Figure 26).

Figure 26 – Retaining LH Die Head in Place

Removing Pipe from the Machine

1. With the REV/OFF/FWD switch in the OFF position

and the pipe stationary, use repeated and forceful

clockwise spins of the handwheel to loosen the pipe

in the chuck. Open the front chuck and the rear-centering device. Do not reach into chuck or centering

device.

2. Firmly grip the pipe and remove from the machine.

Carefully handle the pipe as the thread may still be hot

and there may be burrs or sharp edges.

Inspecting Threads

1. After removing the pipe from the machine, clean the

thread.

2. Visually inspect thread. Threads should be smooth

and complete, with good form. If issues such as

thread tearing, waviness, thin threads, or pipe out-ofroundness are found, the thread may not seal. Refer

to the Troubleshooting Chart for help in diagnosing

these issues.

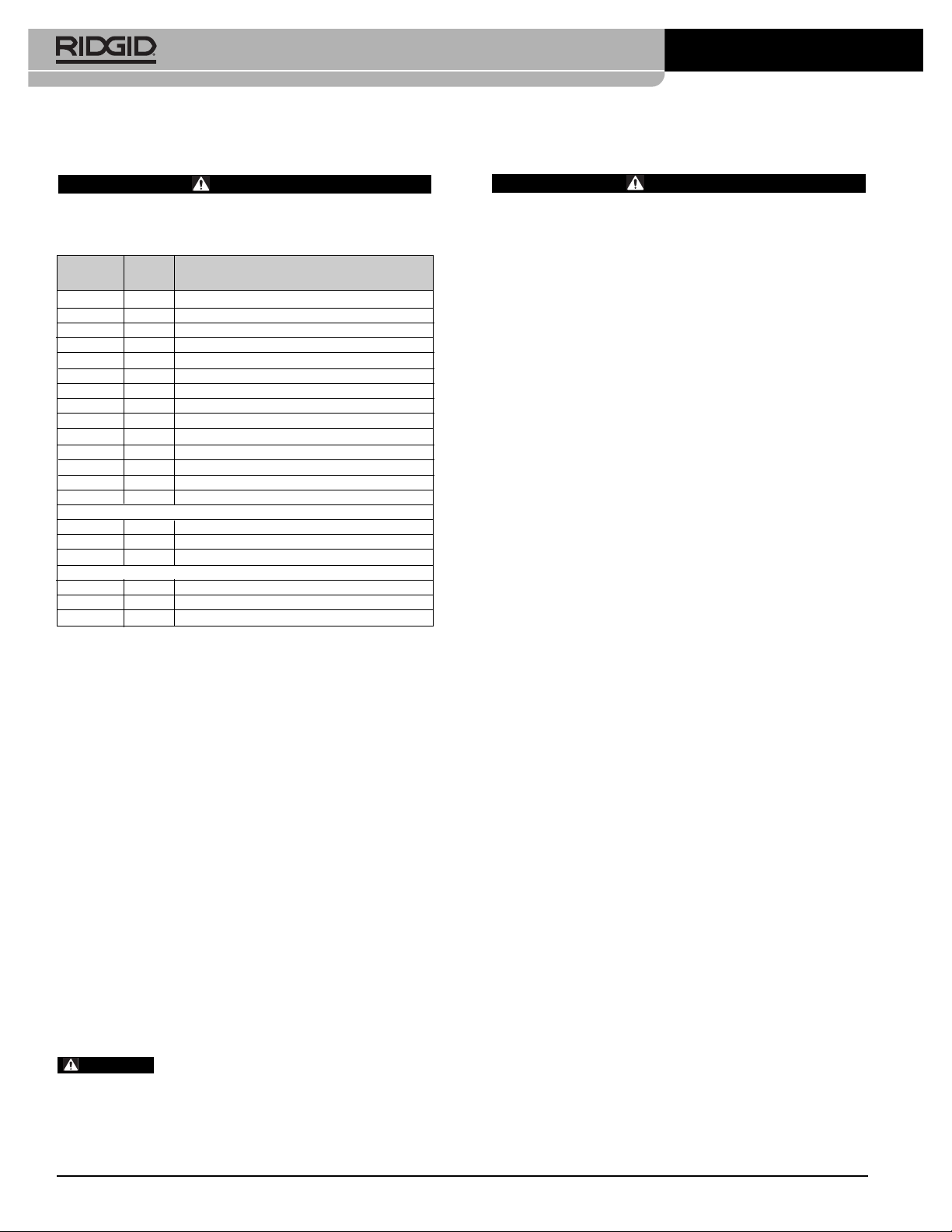

3. Inspect the size of the thread.

• The preferred method of checking thread size is

with a ring gauge. There are various styles of ring

gauges, and their usage may differ from that shown

here.

• Screw ring gauge onto the thread hand tight.

• Look at how far the pipe end extends through the

ring gage. The end of the pipe should be flush with

the side of the gauge plus or minus one turn. If

thread does not gauge properly, cut off the thread,

adjust the die head and cut another thread. Using a

thread that does not gauge properly can cause

leaks.

Ring

Gauge

Flush

(Basic Size)

One Turn Large

(Maximum Size)

One Turn Small

(Minimum Size)

Figure 27 – Checking Thread Size

15

300 Compact/1233 Threading Machines

• If a ring gauge is not available to inspect thread

size, it is possible to use a new clean fitting representative of those used on the job to gauge thread

size. For 2" and under NPT threads, the threads

should be cut to obtain 4 to 5 turns to hand tight

engagement with the fitting and for BSPT it should

be 3 turns. For 21/2" to 3" NPT threads the hand tight

engagement should be 5.5 to 6 threads, and for

BSPT it should be 4 threads.

4. See “Adjusting Thread Size” under “Die Head Set-

Up and Use” heading to adjust thread size.

5. Test the piping system in accordance with local codes

and normal practice.

Preparing Machine for Transport

1. Make sure that the REV/OFF/FWD switch is in the

OFF position and the cord is unplugged from the

outlet.

2. Clean the chips and other debris from the chip tray.

Remove or secure all equipment and material from

the machine and stand prior to moving to prevent

falling or tipping. Clean up any oil or debris on the

floor.

If the jaw inserts do not grip and need to be cleaned, use

a wire brush to remove any build up of pipe scale, etc.

Lubrication

On a monthly basis (or more often if needed) lubricate all

exposed moving parts (such as carriage rails, cutter

wheels and rollers, cutter feed screw, jaw inserts and

pivot points) with a light lubricating oil. Wipe any excess oil

from exposed surfaces.

Clean the lubrication points to remove dirt and prevent

contamination of the oil or grease. Lubricate on a monthly basis.

300 Compact: Use a grease gun to add a Lithium EP

(Extreme Pressure) grease through the grease fittings in

the lubrication points.

1233: Fill the lubrication points with lubricating oil. Press

the ball in the lubrication point to allow the oil to reach

bearings.

3. Place the cutter, reamer and die head in the operating position.

4. Coil up the power cord.

5. If needed, remove the machine from the stand. Use

proper lifting techniques, be aware of the machine

weight. Machine is equipped with four hand grips at

corners. Use care in lifting and moving.

Maintenance Instructions

WARNING

Make sure that the REV/OFF/FWD switch is in the

OFF position and the machine is unplugged before

performing any maintenance or making any adjustments.

Always wear eye protection.

Maintain threading machine according to these

procedures to reduce the risk of injury from electrical shock, entanglement and other causes.

Cleaning

After each use, empty the threading chips from the chip

tray and wipe out any oil residue. Wipe oil off exposed surfaces, especially areas of relative motion like the carriage rails.

Lubrication Points

Figure 28 – Lubrication Points

Oil System Maintenance

Keep the oil filter screen clean for sufficient oil flow. Oil filter screen is located in the bottom of oil reservoir. Loosen

the screw that secures filter to base, remove filter from oil

line and clean. Do not operate machine with oil filter

screen removed.

Filter

Screen

Oil Drain

Chip Tray

Oil Pan

Liner

16

Figure 29 – Filter Screen Assembly

Replace thread cutting oil when it becomes dirty or contaminated. To drain the oil, position a container under drain

plug at end of reservoir and remove plug. Follow all local

laws and regulations when disposing of oil. Clean build up

from the bottom of the reservoir. Use RIDGID Thread Cut ting Oil for high quality threads and maximum die life. See

the Specification section for reservoir oil capacity.

The oil pump should self-prime if the system is clean. If it

does not, this indicates that the pump is worn and should

be serviced. Do not attempt to prime the pump.

Replacing Cutter Wheel

If the cutter wheel becomes dull or broken, push cutter

wheel pin out of frame and check for wear. Replace pin if

worn and install new Cutter Wheel (see catalog). Lubricate

pin with light lubricating oil.

Replacing Jaw Inserts

If Jaw inserts are worn out and do not grip pipe, they need

to be replaced.

300 Compact/1233 Threading Machines

Motor Cover

Brush Cap

1. Place screwdriver in insert slot and turn 90 degrees in

either direction. Remove insert (Figure 30).

2. Place insert sideways on locking pin and press down

as far as possible (Figure 30).

PRESS

DOWN

Screw Driver

Insert

To Remove

Figure 30 – Replacing Jaw Inserts

Locking

To Replace

Pin

‘

Teeth

3. Hold insert down firmly, and with screwdriver, turn so

teeth face up.

Replacing Carbon Brushes

Check motor brushes every 6 months. Replace when

worn to less than 1/2".

Figure 31 – Removing Motor Cover/Changing Brushes

3. Unscrew brush caps. Remove and inspect brushes.

Replace when worn to less than 1/2". Inspect the commutator for wear. If excessively worn, have machine

serviced.

4. Re-install brushes/install new brushes. Reassemble

unit. Install all covers before operating machine.

1. Unplug the machine from power source.

2. Loosen the two motor cover screws and remove

motor cover at rear of machine.

17

300 Compact/1233 Threading Machines

Optional Equipment

WARNING

To reduce the risk of serious injury, only use equipment specifically designed and recommended for

use with the RIDGID Threading Machines.

Catalog Model

No. No. Description

97075 815A 1/8" - 2" NPT, Self-Opening, RH Die Head

97065 811A 1/8" - 2" NPT, Quick-Opening, RH Die Head

97080 815A 1/8" - 2" BSPT, Self-Opening, RH Die Head

45322 815A 1/8" - 2" BSPT, Self-Opening, RH EUR. RT

97070 811A 1/8" - 2" BSPT, Quick-Opening, RH Die Head

97045 531 1/4" - 1" Bolt, Quick-Opening, RH/LH Die Head

97050 532 11/4" - 2" Bolt, Quick-Opening, RH/LH Die Head

67657 250 Folding Wheel Stand

58077 250 Folding Wheel Stand

92457 100A Universal Leg & Tray Stand

92462 150A Universal Wheel & Tray Stand

92467 200A Universal Wheel & Cabinet Stand

51005 819 Nipple Chuck, 1/2" - 2" NPT

68160 819 Nipple Chuck, 1/2" - 2" BSPT

For 300 Compact Only

84537 816 1/8" - 3/4" Semi-Automatic Die Head

84532 817 1" - 2" Semi-Automatic Die Head

67662 — 916 Groover Adapter Bracket

For 1233 Only

54437 728 21/2" - 3" NPT, Receding Self-Opening, RH Die Head

93562 928 21/2" - 3" BSPT, Receding Self-Opening, RH Die Head

— 419 Nipple Chuck

For a complete listing of RIDGID equipment available for the 300 Compact or 1233 Threading

Machine, see the Ridge Tool Catalog online at

www.RIDGID.com or call Ridge Tool Technical

Service Department (800) 519-3456, from the U.S.

and Canada.

Service And Repair

WARNING

Improper service or repair can make machine

unsafe to operate.

The Maintenance Instructions will take care of most of the

service needs of this machine. Any problems not ad dressed by this section should only be handled by an

authorized RIDGID service technician.

Tool should be taken to a RIDGID Independent Service

Center or returned to the factory. Only use RIDGID service

Parts.

For information on your nearest RIDGID Independent

Service Center or any service or repair questions:

• Contact your local RIDGID distributor.

• Visit www.RIDGID.com or to find your local RIDGID

contact point.

• Contact Ridge Tool Technical Service Department at

rtctechservices@emerson.com, or in the U.S. and

Canada call (800) 519-3456.

Disposal

Parts of the Threading Machine contain valuable materials and can be recycled. There are companies that

specialize in recycling that may be found locally. Dispose

of the components and any waste oil in compliance with

all applicable regulations. Contact your local waste management authority for more information.

Thread Cutting Oil Information

Read and follow all instructions on the threading oil label

and Safety Data Sheet (SDS). Specific information about

RIDGID Thread Cutting Oils, including Hazard Identi fi ca tion,

First Aid, Fire Fighting, Accidental Release Measures,

Handling and Storage, Per sonal Protective Equipment,

Disposal and Transportation, is included on the container

and SDS. SDS is available at www.RIDGID.com or by

contacting Ridge Tool Technical Service Department at

(800) 519-3456 in U.S. and Canada or rtctech servic es@em erson.com.

Machine Storage

WARNING

indoors or well covered in rainy weather. Store the machine

in a locked area that is out of reach of children and people

unfamiliar with threading machines. This machine can

cause serious injury in the hands of untrained users.

18

The Threading Machines must be kept

300 Compact/1233 Threading Machines

Troubleshooting

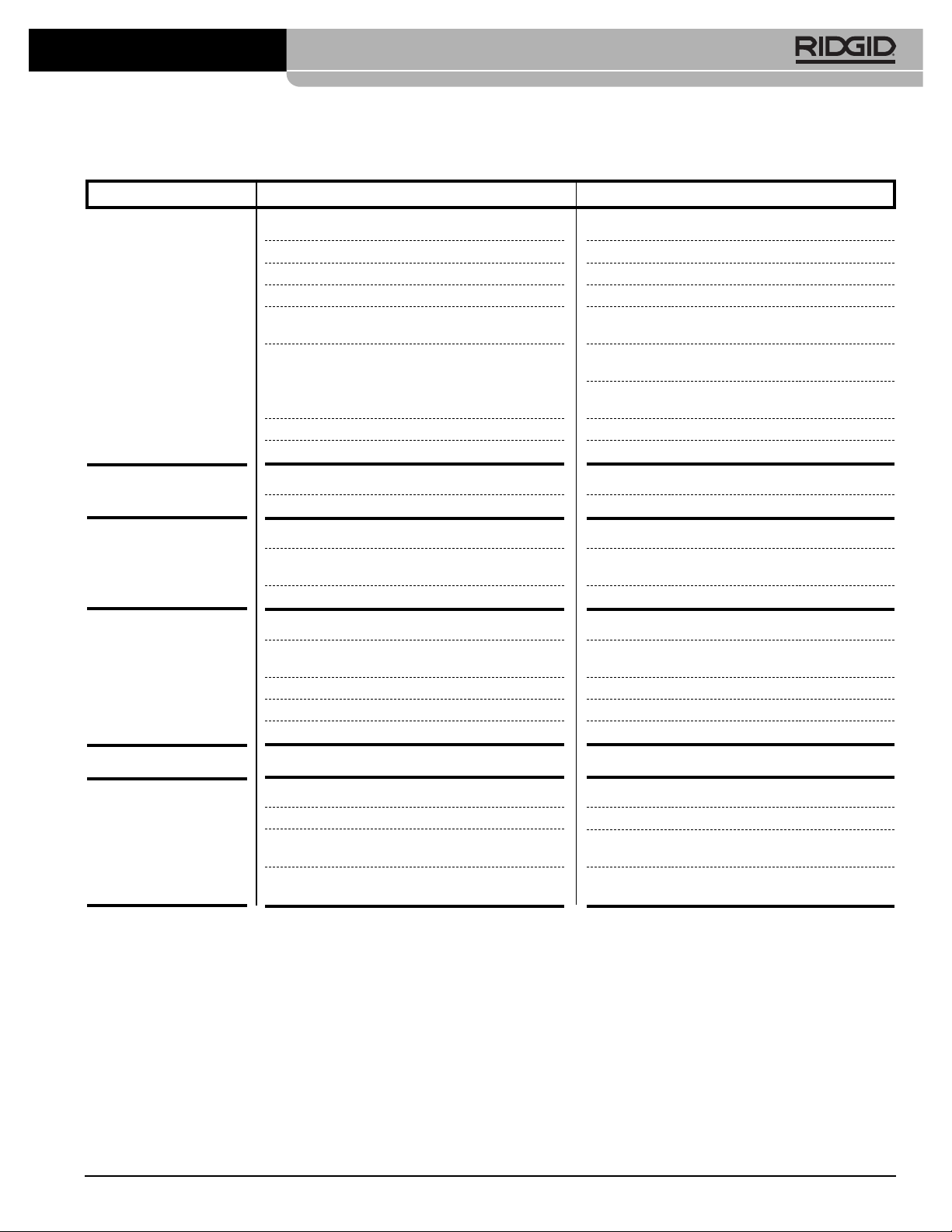

PROBLEM POSSIBLE REASONS SOLUTION

Torn threads.

Out-of-round or crushed

threads.

Thin threads.

No cutting oil flow.

Damaged, chipped or worn out dies.

Incorrect cutting oil.

Insufficient cutting oil.

Dirty or contaminated oil.

Die head not properly aligned with pipe.

Improper pipe.

Die head not properly set.

Carriage not moving freely on rails.

Die head set undersize.

Pipe wall thickness too thin.

Dies inserted into head in wrong order.

Forcing carriage feed handle during threading.

Die head cover plate screws are loose.

Low or no cutting oil.

Machine set up for Left Hand Threading.

Oil Screen Plugged.

Oil flow rate not properly set.

Die head not in the threading (DOWN) position.

Replace dies.

Only use RIDGID®Thread Cutting Oil.

Check oil flow rate and adjust as needed.

Replace the RIDGID®Thread Cutting Oil.

Clean chips, dirt or other foreign material from

between die head and carriage.

Recommend using with black or galvanized steel

pipe.

Pipe wall too thin – use schedule 40 or heavier

pipe.

Adjust die head to give proper size thread.

Clean and lubricate carriage rails.

Adjust die head to give proper size thread.

Use schedule 40 or heavier pipe.

Put dies in proper position in die head.

Once dies have started thread, do not force carriage feed handle. Allow carriage to self-feed.

Tighten screws.

Fill oil reservoir.

Reverse the oil pump hoses (see section on Left

Hand Threading).

Clean Screen.

Adjust oil flow rate.

Move die head to the threading position.

Machine will not run.

Pipe slips in jaws.

Motor brushes worn out.

Jaw inserts loaded with debris.

Jaws inserts worn out.

Pipe not properly centered in jaw inserts.

Chuck not tight on pipe.

Replace brushes.

Clean jaw inserts with wire brush.

Replace jaw inserts.

Make sure pipe is centered in jaw inserts, use the

rear centering device.

Use repeated and forceful counterclockwise spins of

the handwheel to secure the pipe in front chuck.

19

300 Compact/1233 Threading Machines

20

Fileteuses

300 Compact et 1233

AVERTISSEMENT

Familiarisez-vous avec le mode

d’emploi ci-présent avant d’utiliser

l’appareil. Tout manquement aux

consignes avancées dans ce ma nuel augmenterait les risques de

choc électrique, d’incendie et/ou

de blessure grave.

300 Compact

1233

Fileteuses 300 Compact et 1233

Enregistrez ici le numéro de série indiqué sur la plaque signalétique de l’appareil pour future référence

N° de

série

Fileteuses 300 Compact et 1233

Table des matières

Fiche d’enregistrement du numéro de série de la machine ........................................................................................................21

Symboles de sécurité ......................................................................................................................................................................23

Consignes de sécurité générales visant les appareils électriques

Sécurité des lieux..........................................................................................................................................................................23

Sécurité électrique ........................................................................................................................................................................23

Sécurité individuelle ......................................................................................................................................................................24

Utilisation et entretien des appareils ............................................................................................................................................24

Service après-vente ......................................................................................................................................................................25

Consignes de sécurité spécifiques

Sécurité des fileteuses transportables ..........................................................................................................................................25

Description, caractéristiques techniques et équipements de base

Description ....................................................................................................................................................................................26

Caractéristiques techniques..........................................................................................................................................................26

Equipements de base ..................................................................................................................................................................27

Montage des machines

Montage sur support ....................................................................................................................................................................27

Montage sur établi ........................................................................................................................................................................27

Montage sur jambages tubulaires ................................................................................................................................................27

Inspection préalable ........................................................................................................................................................................28

Préparation de la machine et du chantier......................................................................................................................................28

Préparation et utilisation des têtes de filière

Dépose et montage des têtes de filière ........................................................................................................................................30

Têtes de filière à ouverture rapide ................................................................................................................................................30

Installation et remplacement des filières ....................................................................................................................................31

Réglage du pas de filetage ........................................................................................................................................................31

Ouverture de la tête de filière en fin de filetage ........................................................................................................................30

Têtes de filière à ouverture automatique ......................................................................................................................................31

Installation et remplacement des filières ....................................................................................................................................31

Réglage du pas de filetage ........................................................................................................................................................32

Ouverture de la tête de filière en fin de filetage ........................................................................................................................32

Têtes de filière rétractables à ouverture automatique ..................................................................................................................32

Installation et remplacement des filières ....................................................................................................................................33

Réglage du pas de filetage ........................................................................................................................................................33

Réglage de la longueur de filetage ............................................................................................................................................33

Préparation de la tête de filière ..................................................................................................................................................33

Ouverture de la tête de filière en fin de filetage ........................................................................................................................34

Consignes d’utilisation

Coupe............................................................................................................................................................................................35

Alésage ........................................................................................................................................................................................35

Filetage des tuyaux ......................................................................................................................................................................36

Filetage des ronds et boulons ......................................................................................................................................................36

Filetage à gauche..........................................................................................................................................................................36

Retrait des tuyaux de la machine..................................................................................................................................................37

Contrôle des filetages ..................................................................................................................................................................37

Préparation de la machine au transport ........................................................................................................................................38

Consignes d’entretien

Nettoyage......................................................................................................................................................................................38