Page 1

Model Z-P2

Machine Codes: M257

Field Service Manual

April, 2015

Page 2

Page 3

Important Safety Notices

Responsibilities of the Customer Engineer

Customer Engineer

Maintenance shall be done only by trained customer engineers who have completed service training for

the machine and all optional devices designed for use with the machine.

Reference Material for Maintenance

• Maintenance shall be done using the special tools and procedures prescribed for maintenance of

the machine described in the reference materials (service manuals, technical bulletins, operating

instructions, and safety guidelines for customer engineers).

• In regard to other safety issues not described in this document, all customer engineers shall strictly

obey procedures and recommendations described the "CE Safety Guide".

• Use only consumable supplies and replacement parts designed for use of the machine.

Before Installation, Maintenance

Shipping and Moving the Machine

• Work carefully when lifting or moving the machine. If the machine is heavy, two or more customer

engineers may be required to prevent injuries (muscle strains, spinal injuries, etc.) or damage to the

machine if it is dropped or tipped over.

• Personnel moving or working around the machine should always wear proper clothing and

footwear. Never wear loose fitting clothing or accessories (neckties, loose sweaters, bracelets,

etc.) or casual footwear (slippers, sandals, etc.) when lifting or moving the machine.

• Always unplug the power cord from the power source before you move the product. Before you

move the product, arrange the power cord so it will not fall under the product.

Power

• Always disconnect the power plug before doing any maintenance procedure. After switching off

the machine, power is still supplied to the main machine and other devices. To prevent electrical

1

Page 4

shock, switch the machine off, wait for a few seconds, then unplug the machine from the power

source.

• Before you do any checks or adjustments after turning the machine off, work carefully to avoid

injury. After removing covers or opening the machine to do checks or adjustments, never touch

electrical components or moving parts (gears, timing belts, etc.).

• After turning the machine on with any cover removed, keep your hands away from electrical

components and moving parts. Never touch the cover of the fusing unit, gears, timing belts, etc.

Installation, Disassembly, and Adjustments

• After installation, maintenance, or adjustment, always check the operation of the machine to make

sure that it is operating normally. This ensures that all shipping materials, protective materials, wires

and tags, metal brackets, etc., removed for installation, have been removed and that no tools

remain inside the machine. This also ensures that all release interlock switches have been restored

to normal operation.

• Never use your fingers to check moving parts causing spurious noise. Never use your fingers to

lubricate moving parts while the machine is operating.

Special Tools

• Use only standard tools approved for machine maintenance.

• For special adjustments, use only the special tools and lubricants described in the service manual.

Using tools incorrectly, or using tools that could damage parts, could damage the machine or

cause injuries.

During Maintenance

General

• Before you begin a maintenance procedure:

1) Switch the machine off,

2) Disconnect the power plug from the power source,

3) Allow the machine to cool for at least 10 minutes.

• Avoid touching the components inside the machine that are labeled as hot surfaces.

2

Page 5

Safety Devices

• Never remove any safety device unless it requires replacement. Always replace safety devices

immediately.

• Never do any procedure that defeats the function of any safety device. Modification or removal of

a safety device (fuse, switch, etc.) could lead to a fire and personal injury. Always test the

operation of the machine to ensure that it is operating normally and safely after removal and

replacement of any safety device.

• For replacements use only the correct fuses or circuit breakers rated for use with the machine. Using

replacement devices not designed for use with the machine could lead to a fire and personal

injuries.

Organic Cleaners

• During preventive maintenance, never use any organic cleaners (alcohol, etc.) other than those

described in the service manual.

• Make sure the room is well ventilated before using any organic cleaner. Use organic solvents in

small amounts to avoid breathing the fumes and becoming nauseous.

• Switch the machine off, unplug it, and allow it to cool before doing preventive maintenance. To

avoid fire or explosion, never use an organic cleaner near any part that generates heat.

• Wash your hands thoroughly after cleaning parts with an organic cleaner to contamination of

food, drinks, etc. which could cause illness.

• Clean the floor completely after accidental spillage of silicone oil or other materials to prevent

slippery surfaces that could cause accidents leading to hand or leg injuries. Use "My Ace" Silicone

Oil Remover (or dry rags) to soak up spills. For more details, please refer to Technical Bulletin

"Silicone Oil Removal" (A024-50).

Lithium Batteries

• Always replace a lithium battery on a PCB with the same type of battery prescribed for use on that

board. Replacing a lithium battery with any type other than the one prescribed for use on the board

could lead to an explosion or damage to the PCB.

• Never discard used batteries by mixing them with other trash. Remove them from the work site and

dispose of them in accordance with local laws and regulations regarding the disposal of such

items.

3

Page 6

Power Plug and Power Cord

• Before serving the machine (especially when responding to a service call), always make sure that

the power plug has been inserted completely into the power source. A partially inserted plug could

lead to heat generation (due to a power surge caused by high resistance) and cause a fire or other

problems.

• Always check the power plug and make sure that it is free of dust and lint. Clean it if necessary. A

dirty plug can generate heat which could cause a fire.

• Inspect the length of the power cord for cuts or other damage. Replace the power cord if

necessary. A frayed or otherwise damaged power cord can cause a short circuit which could lead

to a fire or personal injury from electrical shock.

• Check the length of the power cord between the machine and power supply. Make sure the power

cord is not coiled or wrapped around any object such as a table leg. Coiling the power cord can

cause excessive heat to build up and could cause a fire.

• Make sure that the area around the power source is free of obstacles so the power cord can be

removed quickly in case of an emergency.

• Make sure that the power cord is grounded (earthed) at the power source with the ground wire on

the plug.

• Connect the power cord directly into the power source. Never use an extension cord.

• When you disconnect the power plug from the power source, always pull on the plug, not the

cable.

After Installation, Servicing

Disposal of Used Items

• Never incinerate used toner or toner cartridges.

• Toner or toner cartridges thrown into a fire can ignite or explode and cause serious injury. At the

work site always carefully wrap used toner and toner cartridges with plastic bags to avoid spillage

before disposal or removal.

• Always dispose of used items (developer, toner, toner cartridges, OPC drums, etc.) in accordance

with the local laws and regulations regarding the disposal of such items.

4

Page 7

• To protect the environment, never dispose of this product or any kind of waste from consumables at

a household waste collection point. Dispose of these items at one of our dealers or at an

authorized collection site.

• Return used selenium drums to the service center for handling in accordance with company policy

regarding the recycling or disposal of such items.

Points to Confirm with Operators

At the end of installation or a service call, instruct the user about use of the machine. Emphasize the

following points.

• Show operators how to remove jammed paper and troubleshoot other minor problems by

following the procedures described in the operating instructions.

• Point out the parts inside the machine that they should never touch or attempt to remove.

• Confirm that operators know how to store and dispose of consumables.

• Make sure that all operators have access to an operating instruction manual for the machine.

• Confirm that operators have read and understand all the safety instructions described in the

operating instructions.

• Demonstrate how to turn off the power and disconnect the power plug (by pulling the plug, not the

cord) if any of the following events occur: 1) something has spilled into the product, 2) service or

repair of the product is necessary, 3) the product cover has been damaged.

• Caution operators about removing paper fasteners around the machine. They should never allow

paper clips, staples, or any other small metallic objects to fall into the machine.

Special Safety Instructions for Toner

Accidental Physical Exposure

• Work carefully when removing paper jams or replacing toner bottles or cartridges to avoid spilling

toner on clothing or the hands.

• If toner is inhaled, immediately gargle with large amounts of cold water and move to a well

ventilated location. If there are signs of irritation or other problems, seek medical attention.

• If toner gets on the skin, wash immediately with soap and cold running water.

• If toner gets into the eyes, flush the eyes with cold running water or eye wash. If there are signs of

irritation or other problems, seek medical attention.

• If toner is swallowed, drink a large amount of cold water to dilute the ingested toner. If there are

signs of any problem, seek medical attention.

5

Page 8

• If toner spills on clothing, wash the affected area immediately with soap and cold water. Never use

hot water! Hot water can cause toner to set and permanently stain fabric.

Handling and Storing Toner

• Toner, used toner, and developer are extremely flammable.

• Never store toner, developer, toner cartridges, or toner bottles (including empty toner bottles or

cartridges) in a location where they will be exposed to high temperature or an open flame.

• Always store toner and developer supplies such as toner and developer packages, cartridges, and

bottles (including used toner and empty bottles and cartridges) out of the reach of children.

• Always store fresh toner supplies or empty bottles or cartridges in a cool, dry location that is not

exposed to direct sunlight.

Toner Disposal

• Never attempt to incinerate toner, used toner, or empty toner containers (bottles or cartridges).

Burning toner can explode and scatter, causing serious burns.

• Always wrap used toner and empty toner bottles and cartridges in plastic bags to avoid spillage.

Follow the local laws and regulations regarding the disposal of such items.

• Dispose of used toner and toner cartridges at one of our dealers or at an authorized collection site.

Always dispose of used toner cartridges and toner bottles in accordance with the local laws and

regulations regarding the disposal of such items.

Safety Instructions for this Machine

Prevention of Physical Injury

1. Before disassembling or assembling parts of the machine and peripherals, make sure that the

machine and peripheral power cords are unplugged.

2. The plug should be near the machine and easily accessible.

3. Note that some components of the machine and the paper tray unit are supplied with electrical

voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off or open while the

main switch is turned on, keep hands away from electrified or mechanically driven components.

6

Page 9

5. If the [Start] key is pressed before the machine completes the warm-up period (the [Start] key starts

blinking red and green ), keep hands away from the mechanical and the electrical components as

the machine starts making copies as soon as the warm-up period is completed.

6. The inside and the metal parts of the fusing unit become extremely hot while the machine is

operating. Be careful to avoid touching those components with your bare hands.

7. To prevent a fire or explosion, keep the machine away from flammable liquids, gases, and

aerosols.

Health Safety Conditions

1. Always replace the ozone filters with the specified types at the proper intervals.

2. Toner and developer are non-toxic, but if you get either of them in your eyes by accident, it may

cause temporary eye discomfort. Try to remove with eye drops or flush with water as first aid. If

unsuccessful, get medical attention.

Observance of Electrical Safety Standards

1. The machine and its peripherals must be installed and maintained by a customer service

representative who has completed the training course on those models.

2. The NVRAM on the system control board has a lithium battery which can explode if replaced

incorrectly. Replace the NVRAM only with an identical one. The manufacturer recommends

replacing the entire NVRAM. Do not recharge or burn this battery. Used NVRAM must be handled

in accordance with local regulations.

Safety and Ecological Notes for Disposal

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly when exposed to an

open flame.

2. Dispose of used toner, developer, and organic photoconductors in accordance with local

regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do not put more than 100

batteries per sealed box. Storing larger numbers or not sealing them apart may lead to chemical

reactions and heat build-up.

• The danger of explosion exists if a battery of this type is incorrectly replaced.

• Replace only with the same or an equivalent type recommended by the manufacturer. Discard used

batteries in accordance with the manufacturer's instructions.

7

Page 10

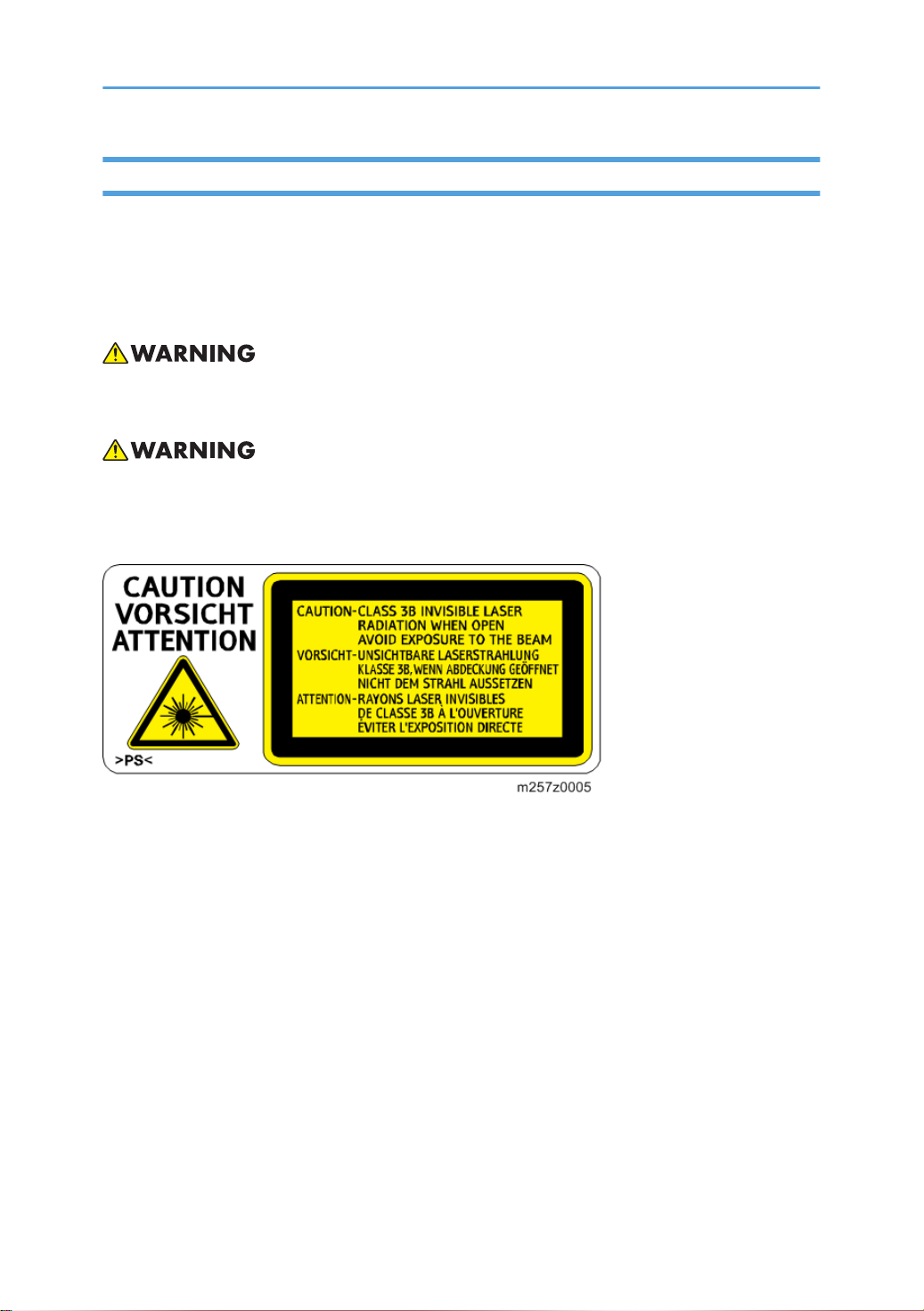

Laser Safety

The Center for Devices and Radiological Health (CDRH) prohibits the repair of laser-based optical units

in the field. The optical housing unit can only be repaired in a factory or at a location with the requisite

equipment. The laser subsystem is replaceable in the field by a qualified Customer Engineer. The laser

chassis is not repairable in the field. Customer engineers are therefore directed to return all chassis and

laser subsystems to the factory or service depot when replacement of the optical subsystem is required.

• Use of controls, or adjustment, or performance of procedures other than those specified in this

manual may result in hazardous radiation exposure.

• WARNING: Turn off the main switch before attempting any of the procedures in the Laser Optics

Housing Unit section. Laser beams can seriously damage your eyes.

• CAUTION MARKING:

8

Page 11

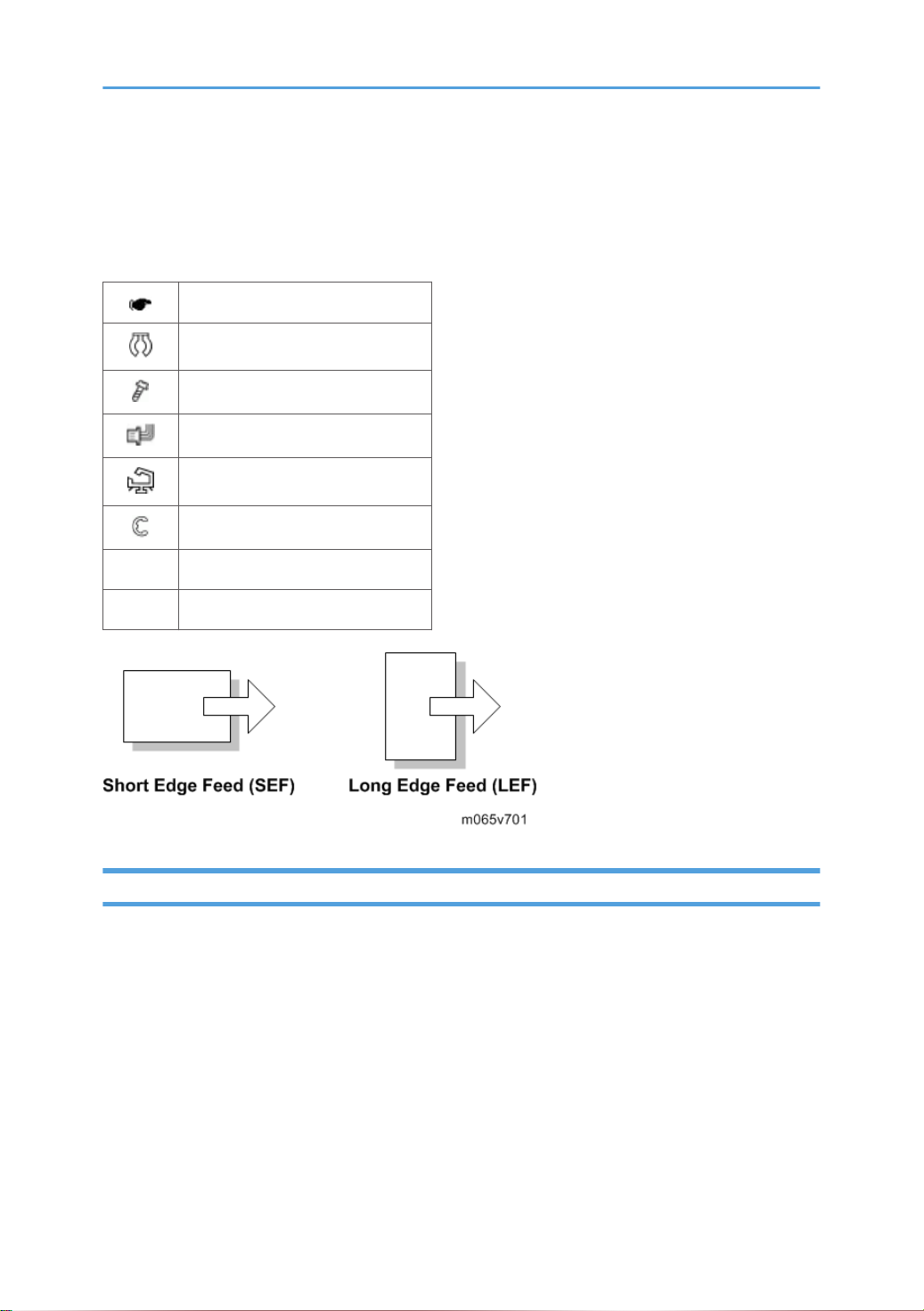

Symbols, Abbreviations and Trademarks

This manual uses several symbols and abbreviations. The meaning of those symbols and abbreviations

are as follows:

See or Refer to

Clip ring

Screw

Connector

Clamp

E-ring

SEF Short Edge Feed

LEF Long Edge Feed

Trademarks

Microsoft®, Windows®, and MS-DOS® are registered trademarks of Microsoft Corporation in the

United States and /or other countries.

PostScript® is a registered trademark of Adobe Systems, Incorporated.

PCL® is a registered trademark of Hewlett-Packard Company.

Ethernet® is a registered trademark of Xerox Corporation.

PowerPC® is a registered trademark of International Business Machines Corporation.

Other product names used herein are for identification purposes only and may be trademarks of their

respective companies. We disclaim any and all rights involved with those marks.

9

Page 12

TABLE OF CONTENTS

Important Safety Notices................................................................................................................................... 1

Responsibilities of the Customer Engineer.................................................................................................... 1

Customer Engineer................................................................................................................................ 1

Reference Material for Maintenance...................................................................................................1

Before Installation, Maintenance..................................................................................................................1

Shipping and Moving the Machine..................................................................................................... 1

Power......................................................................................................................................................1

Installation, Disassembly, and Adjustments.........................................................................................2

Special Tools..........................................................................................................................................2

During Maintenance...................................................................................................................................... 2

General.................................................................................................................................................. 2

Safety Devices........................................................................................................................................3

Organic Cleaners..................................................................................................................................3

Lithium Batteries......................................................................................................................................3

Power Plug and Power Cord................................................................................................................ 4

After Installation, Servicing............................................................................................................................4

Disposal of Used Items..........................................................................................................................4

Points to Confirm with Operators......................................................................................................... 5

Special Safety Instructions for Toner.............................................................................................................5

Accidental Physical Exposure...............................................................................................................5

Handling and Storing Toner................................................................................................................. 6

Toner Disposal....................................................................................................................................... 6

Safety Instructions for this Machine...............................................................................................................6

Prevention of Physical Injury................................................................................................................. 6

Health Safety Conditions...................................................................................................................... 7

Observance of Electrical Safety Standards.........................................................................................7

Safety and Ecological Notes for Disposal...........................................................................................7

Laser Safety.....................................................................................................................................................8

Symbols, Abbreviations and Trademarks.........................................................................................................9

Trademarks..................................................................................................................................................... 9

1. Product Information

Specifications....................................................................................................................................................21

Machine Configuration....................................................................................................................................22

10

Page 13

Machine Configuration............................................................................................................................... 22

Guidance for Those Familiar with Predecessor Products.............................................................................. 23

Different Points from Previous Products...................................................................................................... 23

Overview.......................................................................................................................................................... 24

Mechanical Component Layout................................................................................................................. 24

Paper Path.................................................................................................................................................... 25

Drive Layout..................................................................................................................................................26

2. Installation

Installation Requirements................................................................................................................................. 29

Environment..................................................................................................................................................29

Machine Level..............................................................................................................................................30

Machine Space Requirements....................................................................................................................30

Power Requirements.................................................................................................................................... 31

Optional Unit Combinations............................................................................................................................32

Machine Options.........................................................................................................................................32

Controller Options....................................................................................................................................... 32

Printer Installation............................................................................................................................................. 33

Installation Procedure..................................................................................................................................33

Unpacking........................................................................................................................................... 33

Installing the toner............................................................................................................................... 37

Loading Paper..................................................................................................................................... 38

Turning Power On............................................................................................................................... 40

Selecting the Panel Display Language.............................................................................................. 41

Printing the Test Page.......................................................................................................................... 42

Settings Relevant to the Service Contract..........................................................................................42

Meter Click Charge..................................................................................................................................... 42

Moving the Machine................................................................................................................................... 45

Transporting the Machine........................................................................................................................... 45

Paper Feed Unit (M384).................................................................................................................................46

Caster Table (M393).......................................................................................................................................48

Accessory Check..........................................................................................................................................48

Installation Procedure..................................................................................................................................49

For Installing the Caster Table (M393) Only................................................................................... 49

11

Page 14

For Installing with the Paper Feed Unit (M384)............................................................................... 53

Tray Heater.......................................................................................................................................................57

Component Check.......................................................................................................................................57

Tray Heater (Mainframe)............................................................................................................................ 58

Tray Heater (Optional Unit)........................................................................................................................62

Component Check.............................................................................................................................. 62

For Installing the Tray Heater in M384.............................................................................................63

For Installing the Securing Bracket.....................................................................................................69

Controller Options............................................................................................................................................72

Overview...................................................................................................................................................... 72

I/F Card Slots......................................................................................................................................72

SD Card Slots...................................................................................................................................... 73

Installation Procedure for USB Device Server Option Type M12........................................................... 73

Component Check.............................................................................................................................. 73

Interface Board Surface......................................................................................................................74

Installation Procedure......................................................................................................................... 74

What Do the LED Indications Mean?................................................................................................ 78

IP Address Setting................................................................................................................................79

SD Card Appli Move...................................................................................................................................80

Overview............................................................................................................................................. 80

Outline of SD Card Appli Move........................................................................................................ 80

Move Exec...........................................................................................................................................81

Undo Exec........................................................................................................................................... 82

3. Preventive Maintenance

Maintenance Tables........................................................................................................................................ 83

4. Replacement and Adjustment

Notes on the Main Power Switch................................................................................................................... 85

Push Switch...................................................................................................................................................85

Characteristics of the Push Switch (DC Switch).................................................................................85

Shutdown Method...............................................................................................................................86

Forced Shutdown................................................................................................................................ 86

Before You Start............................................................................................................................................... 87

Special Tools.................................................................................................................................................... 88

12

Page 15

Tools..............................................................................................................................................................88

Exterior Covers................................................................................................................................................. 89

Left Cover......................................................................................................................................................89

Right Cover...................................................................................................................................................90

Rear Cover................................................................................................................................................... 91

When Reinstalling the Rear Cover.....................................................................................................91

Top Cover.....................................................................................................................................................92

When Reinstalling the Top Cover...................................................................................................... 93

Operation Panel...........................................................................................................................................93

Inner Left Upper Cover................................................................................................................................ 94

Inner Left Front Cover.................................................................................................................................. 95

Inner Left Rear Cover................................................................................................................................... 96

Inner Left Lower Cover.................................................................................................................................96

Inner Right Front Cover................................................................................................................................97

Inner Right Rear Cover................................................................................................................................ 99

Laser Optics....................................................................................................................................................100

Caution Decal Locations...........................................................................................................................100

Laser Unit....................................................................................................................................................100

Before removing the old laser unit...................................................................................................100

Recovery procedure for no replacement preparation of laser unit.............................................. 101

Removing the laser unit.................................................................................................................... 101

After installing a new laser unit........................................................................................................102

Laser Unit Fan............................................................................................................................................ 104

When installing the laser unit fan.................................................................................................... 104

LDU Shutter Motor.....................................................................................................................................105

Image Creation..............................................................................................................................................106

PCDU (Photo Conductor and Development Unit)...................................................................................106

When installing a new PCDU.......................................................................................................... 107

Waste Toner Bottle....................................................................................................................................110

Toner Supply Tube.................................................................................................................................... 111

Toner Supply Motor.................................................................................................................................. 117

Toner Collection Motor.............................................................................................................................118

Waste Toner Bottle Full Sensor.................................................................................................................120

13

Page 16

Waste Toner Bottle Set Sensor.................................................................................................................120

RFID CPU Board........................................................................................................................................121

RFID Board.................................................................................................................................................122

Development Fan...................................................................................................................................... 123

When installing the development fan..............................................................................................124

Image Transfer............................................................................................................................................... 125

ITB (Image Transfer Belt) Unit...................................................................................................................125

Image Transfer Belt....................................................................................................................................127

When Installing the Image Transfer Belt......................................................................................... 132

ITB Contact Motor.....................................................................................................................................133

ITB Contact Sensor....................................................................................................................................134

ID Sensor Board........................................................................................................................................ 136

After installing a new ID sensor board............................................................................................138

Paper Transfer................................................................................................................................................140

PTR (Paper Transfer Roller) Unit............................................................................................................... 140

When Installing the PTR Unit............................................................................................................140

PTR Contact Motor.................................................................................................................................... 141

PTR Contact Sensor................................................................................................................................... 142

Temperature/Humidity Sensor.................................................................................................................143

Drive Unit........................................................................................................................................................145

Gear Unit................................................................................................................................................... 145

When installing the gear unit........................................................................................................... 151

Toner Supply Fan...................................................................................................................................... 151

When installing the toner supply fan...............................................................................................152

Toner Supply Fan Base.................................................................................................................... 152

Drum Motor: CMY.................................................................................................................................... 152

Development Motor: CMY....................................................................................................................... 153

ITB Unit/ Drum-K/ Development-K Motor............................................................................................. 154

Development Clutch: K............................................................................................................................. 154

Fusing/Paper Exit Motor.......................................................................................................................... 155

Front Door Sensor..................................................................................................................................... 155

Motors with Bracket.................................................................................................................................. 156

Registration Motor.....................................................................................................................................158

14

Page 17

Paper Feed Motor..................................................................................................................................... 159

Vertical Transport Motor...........................................................................................................................160

Drum Phase Sensor: CMY........................................................................................................................ 161

Drum Phase Sensor: K...............................................................................................................................161

Drive Unit Fan............................................................................................................................................ 162

When installing the drive unit fan.................................................................................................... 163

Fusing..............................................................................................................................................................164

Fusing Unit..................................................................................................................................................164

When installing the fusing unit......................................................................................................... 164

Cleaning Unit.............................................................................................................................................164

Pressure Roller Fusing Lamp......................................................................................................................165

Pressure Roller............................................................................................................................................168

When Reinstalling the Pressure Roller.............................................................................................170

Heating Roller Fusing Lamp......................................................................................................................170

Fusing Belt.................................................................................................................................................. 175

Fusing, Heating and Tension Roller......................................................................................................... 177

When Reinstalling the Fusing Roller................................................................................................ 177

Heating Roller Thermostat.........................................................................................................................178

Heating Roller Thermistor..........................................................................................................................179

Pressure Roller Thermistor......................................................................................................................... 180

Pressure Roller Thermostat........................................................................................................................ 181

Thermopile................................................................................................................................................. 181

Paper Feed..................................................................................................................................................... 183

Separation Roller.......................................................................................................................................183

Pick-up and Paper Feed Rollers............................................................................................................... 183

Paper Feed Unit.........................................................................................................................................184

Registration Sensor....................................................................................................................................186

Vertical Transport Sensor..........................................................................................................................187

Paper Height Sensor 1..............................................................................................................................188

Paper Height Sensor 2..............................................................................................................................189

Paper Lift Sensor........................................................................................................................................ 190

Paper End Sensor...................................................................................................................................... 191

Paper Feed Sensor.................................................................................................................................... 192

15

Page 18

Tray Lift Motor............................................................................................................................................194

Tray 1 Set Sensor...................................................................................................................................... 195

Paper Size Sensor Board..........................................................................................................................197

Cleaning the Paper Dust Container......................................................................................................... 197

Paper Exit........................................................................................................................................................198

Paper Exit Unit........................................................................................................................................... 198

Paper Exit Sensor.......................................................................................................................................200

Inverter Sensor...........................................................................................................................................203

Paper Overflow Sensor.............................................................................................................................204

Fusing Exit Sensor......................................................................................................................................205

Inverter Motor............................................................................................................................................206

Fusing Cooling Fan....................................................................................................................................206

When installing the fusing cooling fan............................................................................................207

Upper Cover Sensor................................................................................................................................. 207

Duplex Unit.....................................................................................................................................................208

Duplex Unit................................................................................................................................................ 208

By-pass Tray Unit.......................................................................................................................................210

Duplex Entrance Sensor............................................................................................................................212

Duplex Exit Sensor.................................................................................................................................... 214

Fusing Entrance Sensor.............................................................................................................................215

Duplex/By-pass Motor.............................................................................................................................216

By-pass Paper End Sensor........................................................................................................................220

By-pass Feed Roller, Friction Pad.............................................................................................................221

HVPS: D......................................................................................................................................................224

Fusing Fan.................................................................................................................................................. 225

When installing the fusing fan..........................................................................................................226

Electrical Components...................................................................................................................................227

Boards........................................................................................................................................................ 227

HDD (Option)............................................................................................................................................ 229

Disposal of HDD Units......................................................................................................................230

Reinstallation..................................................................................................................................... 231

Controller Board........................................................................................................................................231

When installing the new controller board...................................................................................... 232

16

Page 19

Bridge Board............................................................................................................................................. 233

PSU............................................................................................................................................................. 234

Controller Box............................................................................................................................................235

BCU............................................................................................................................................................ 238

When installing the new BCU..........................................................................................................239

Removing the BCU with bracket......................................................................................................240

HVPS: T1T2 Board.................................................................................................................................... 241

HVPS: CB Board........................................................................................................................................242

DC Switch Board.......................................................................................................................................244

NVRAM Replacement Procedure............................................................................................................ 245

NVRAM on the BCU........................................................................................................................ 245

NVRAM on the Controller................................................................................................................246

Adjustments.................................................................................................................................................... 248

Gamma Adjustment...................................................................................................................................248

Summary............................................................................................................................................248

Adjustment Procedure.......................................................................................................................250

5. System Maintenance Reference

Service Program Mode.................................................................................................................................253

Service Mode Operation......................................................................................................................... 253

Accessing the Required Program.................................................................................................... 253

Inputting a Value or Setting for a Service Program....................................................................... 253

Exiting Service Mode....................................................................................................................... 253

Remarks......................................................................................................................................................254

Display on the Control Panel Screen.............................................................................................. 254

Bit Switch Programming............................................................................................................................ 256

Service SP Mode Tables............................................................................................................................... 258

SP1-XXX (Service Mode)..........................................................................................................................258

Engine SP Mode Tables: SP1000................................................................................................................271

SP1-XXX (Feed)......................................................................................................................................... 271

Engine SP Mode Tables - SP2000...............................................................................................................297

SP2-XXX (Drum).........................................................................................................................................297

Engine SP Mode Tables - SP3000...............................................................................................................397

SP3-XXX (Process)..................................................................................................................................... 397

17

Page 20

Engine SP Mode Tables - SP4000...............................................................................................................419

Engine SP Mode Tables - SP5000...............................................................................................................420

SP5-XXX (Mode)....................................................................................................................................... 420

Engine SP Mode Tables - SP6000...............................................................................................................472

Engine SP Mode Tables - SP7000...............................................................................................................473

SP7-XXX (Data Log).................................................................................................................................. 473

Engine SP Mode Tables - SP8000...............................................................................................................504

SP8-xxx: Data Log2.................................................................................................................................. 504

Input Check/ Output Check......................................................................................................................... 531

Input Check Table..................................................................................................................................... 531

Printer.................................................................................................................................................531

Table 1: Paper Size Switch (Tray 1)............................................................................................... 534

Table 2: Paper Height Sensor..........................................................................................................535

Output Check Table.................................................................................................................................. 535

Printer.................................................................................................................................................535

Test Pattern Printing........................................................................................................................................542

Test Pattern Printing....................................................................................................................................542

Firmware Update...........................................................................................................................................544

Type of Firmware.......................................................................................................................................544

SD Card Firmware Updating....................................................................................................................544

Before You Begin..............................................................................................................................544

File Arrangement.............................................................................................................................. 545

Update Procedure............................................................................................................................ 546

Error Handling.................................................................................................................................. 547

Power Failure.................................................................................................................................... 548

Handling Firmware Update Errors...........................................................................................................548

Error Message Table........................................................................................................................548

NVRAM Data Upload/Download.............................................................................................................. 550

Uploading NVRAM Data......................................................................................................................... 550

Downloading NVRAM Data.................................................................................................................... 551

Address Book Upload/Download.............................................................................................................. 552

Information List...........................................................................................................................................552

Download.................................................................................................................................................. 552

18

Page 21

Upload....................................................................................................................................................... 553

Capturing the Debug Logs............................................................................................................................ 554

Overview....................................................................................................................................................554

Types of debug logs that can be saved..........................................................................................554

Operation Log Security.................................................................................................................... 555

Storing the Debug Logs with SD Card.....................................................................................................556

Retrieving Debug Logs.............................................................................................................................. 556

Procedure for Retrieving the Debug Log.........................................................................................556

SP Text Mode (Saving SMC List to SD Card)..............................................................................................558

Overview....................................................................................................................................................558

SP Text Mode....................................................................................................................................558

Procedure...................................................................................................................................................558

File Names of the Saved SMC Lists......................................................................................................... 559

Error Messages..........................................................................................................................................560

DIP Switches...................................................................................................................................................561

Controller Board........................................................................................................................................561

6. Troubleshooting

SC Tables....................................................................................................................................................... 563

Service Call Conditions.............................................................................................................................563

Summary............................................................................................................................................563

SC1xx: Scanning.......................................................................................................................................564

SC 2xx: Exposure......................................................................................................................................564

SC3xx: Image Processing – 1..................................................................................................................571

SC4xx: Image Processing - 2...................................................................................................................576

SC5xx: Paper Feed and Fusing................................................................................................................581

SC6xx: Device Communication............................................................................................................... 595

SC8xx: Overall System.............................................................................................................................599

SC9xx: Miscellaneous.............................................................................................................................. 609

Process Control Results..................................................................................................................................612

Developer Initialization Result.................................................................................................................. 612

Process Control Self-Check Result............................................................................................................613

Vsg Adjustment Result.......................................................................................................................615

Line Position Adjustment Result................................................................................................................. 615

19

Page 22

Troubleshooting Guide..................................................................................................................................617

Blank Print...................................................................................................................................................617

All-black Print.............................................................................................................................................617

Missing CMY Color...................................................................................................................................618

Light Print.................................................................................................................................................... 618

Repeated Spots or Lines on Prints............................................................................................................ 618

Dark Vertical Line on Prints....................................................................................................................... 620

White Horizontal Lines or Bands..............................................................................................................620

Missing Parts of Images............................................................................................................................ 621

Dirty Background.......................................................................................................................................621

Partial CMY Color Dots............................................................................................................................ 621

Dark Irregular Streaks on Prints................................................................................................................621

CMY Color Irregular Streaks....................................................................................................................622

Ghosting.....................................................................................................................................................622

Unfused or Partially Fused Prints.............................................................................................................. 622

Image Skew............................................................................................................................................... 623

Background Stain......................................................................................................................................623

No Printing on Paper Edge.......................................................................................................................624

Image not centered when it should be.................................................................................................... 624

Jam Detection.................................................................................................................................................625

Paper Jam Display.....................................................................................................................................625

Jam Codes and Display Codes................................................................................................................625

Paper Size Code...............................................................................................................................627

Electrical Component Defects.......................................................................................................................628

Sensors....................................................................................................................................................... 628

Optional Paper Feed Unit................................................................................................................632

Blown Fuse Conditions..............................................................................................................................633

Power Supply Unit............................................................................................................................ 633

LEDs............................................................................................................................................................ 634

INDEX...........................................................................................................................................................635

20

Page 23

1. Product Information

Specifications

See "Appendices" for the following information:

• "General Specifications"

• "Supported Paper Sizes"

• "Software Accessories"

• "Optional Equipment"

21

Page 24

1. Product Information

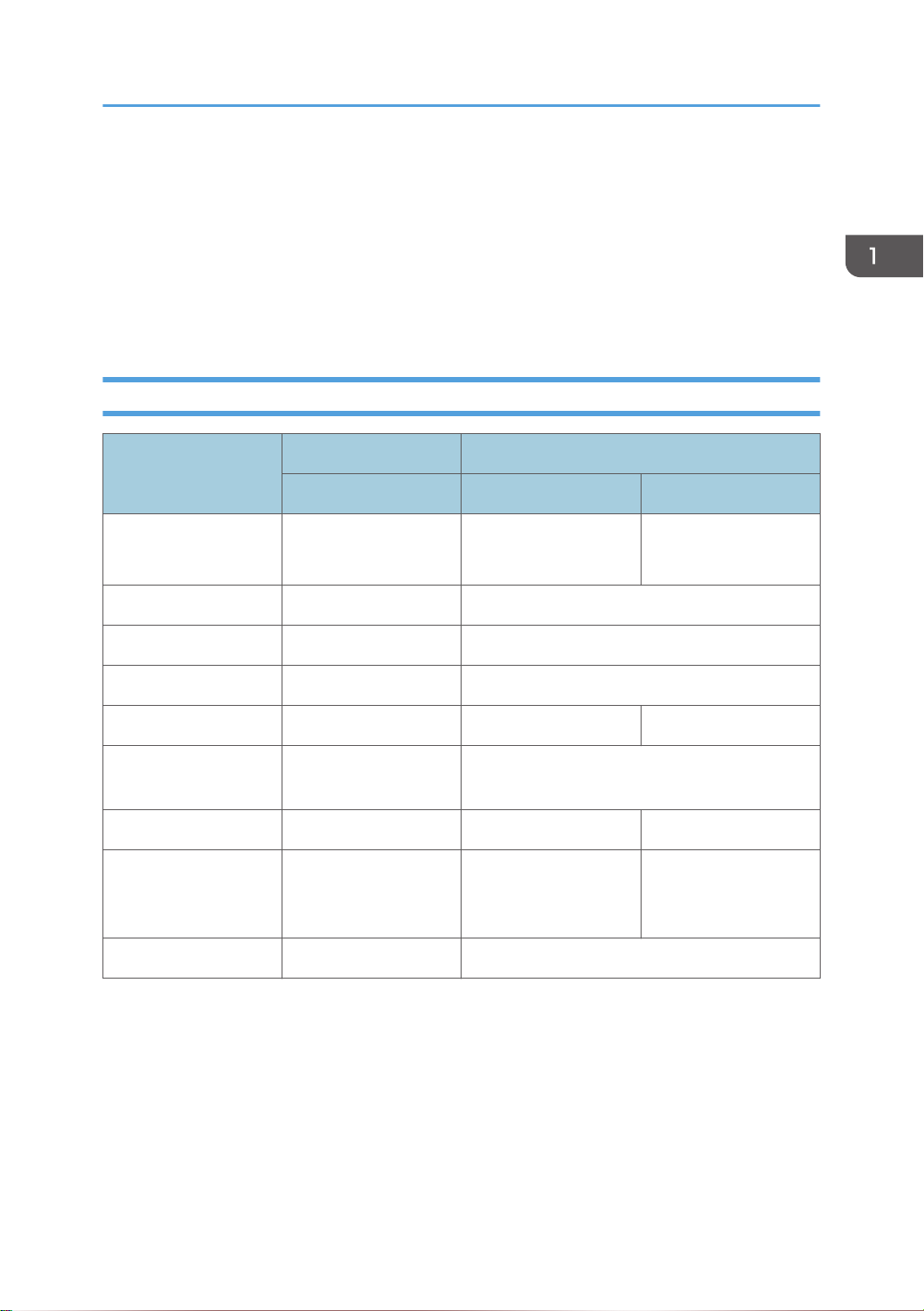

Machine Configuration

Machine Configuration

Item Machine Code Remarks

SP C440DN M257

Paper Feed Unit PB1020 M384

Caster Table Type C M393 Common with Z-P1 (M065/ M066)

Hard Disk Drive Option Type P7 M479-00

IEEE802.11 Interface unit Type

O

IEEE1284 Interface Board Type

A

USB Device Server Option Type

M12

Camera Direct Print Card Type

P7

VM CARD Type P7 M479-08

IPDS Unit Type P7 M479-01, -02, -03

Direct Print Option Type P7 M479-05, -06, -07

M417

B679-17

D3A7

M479-04

Up to three tray units can be installed.

Common with Z-P1 (M065/ M066)

Common with Z-P1 (M065/ M066)

22

SD CARD SET FOR FONT TYPE

D FOR MFP

D641-54

Page 25

Guidance for Those Familiar with Predecessor Products

Guidance for Those Familiar with Predecessor

Products

The Z-P2b (M257) is similar to the Z-P1a (M065) and P1b (M066) models.

If you have experience with those products, the following information will be of help when you read this

manual.

Different Points from Previous Products

New Predecessor Models

M257 M065 M066

PPM

Controller Type GW+ GW

Power Switch DC Switch AC Switch

Light Detection Sensor Available Not available

HDD Option Option Standard

Additional network

interface port

ELP-NX Option Option Standard

Data Overwrite

Security Unit and HDD

Encryption Unit

Log-storing function Available Not available

LT: 42 ppm,

A4: 40 ppm

Option Not available

On board SD card SD card

LT: 37 ppm,

A4: 35 ppm

LT: 42 ppm,

A4: 40 ppm

23

Page 26

1. Product Information

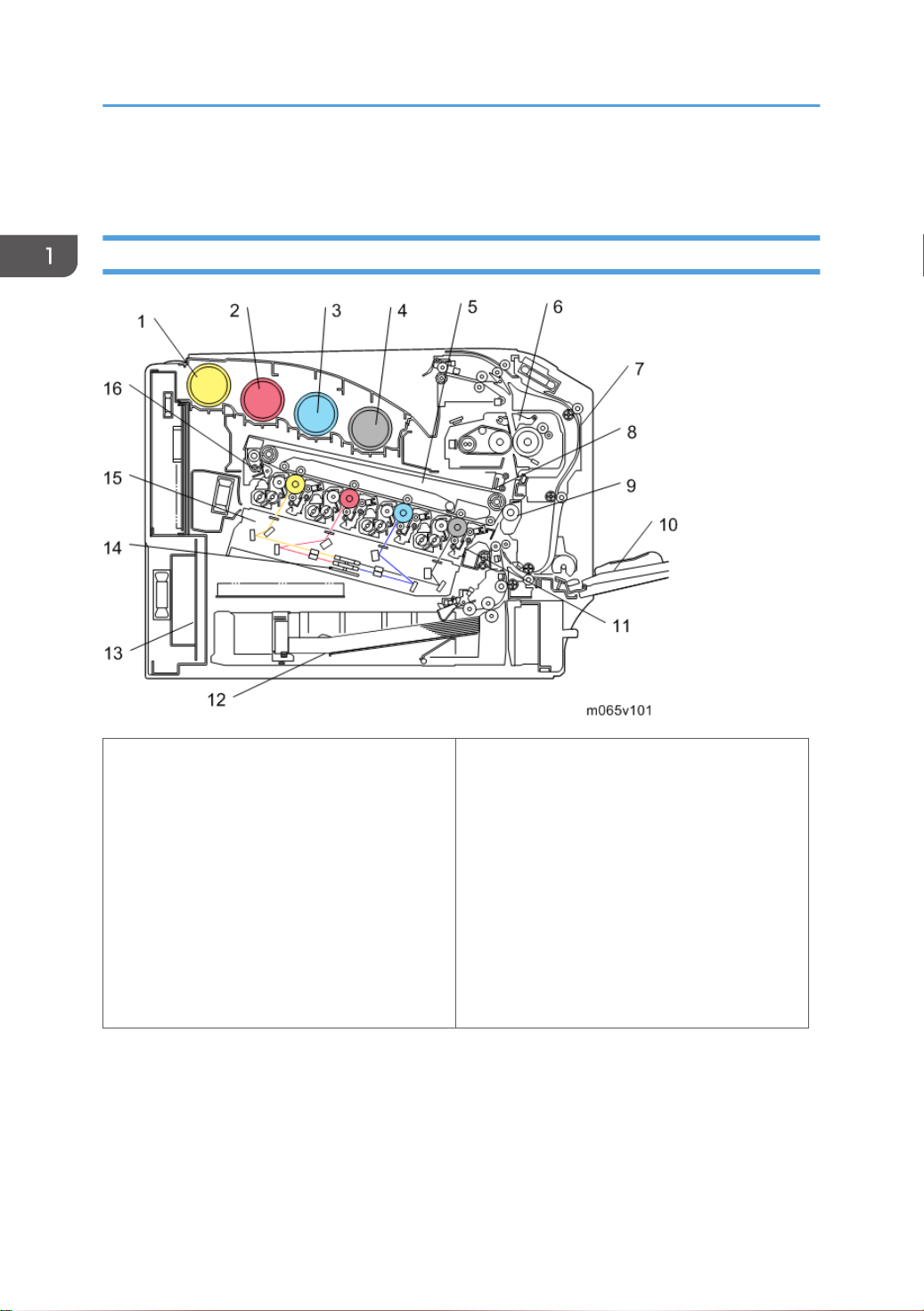

Overview

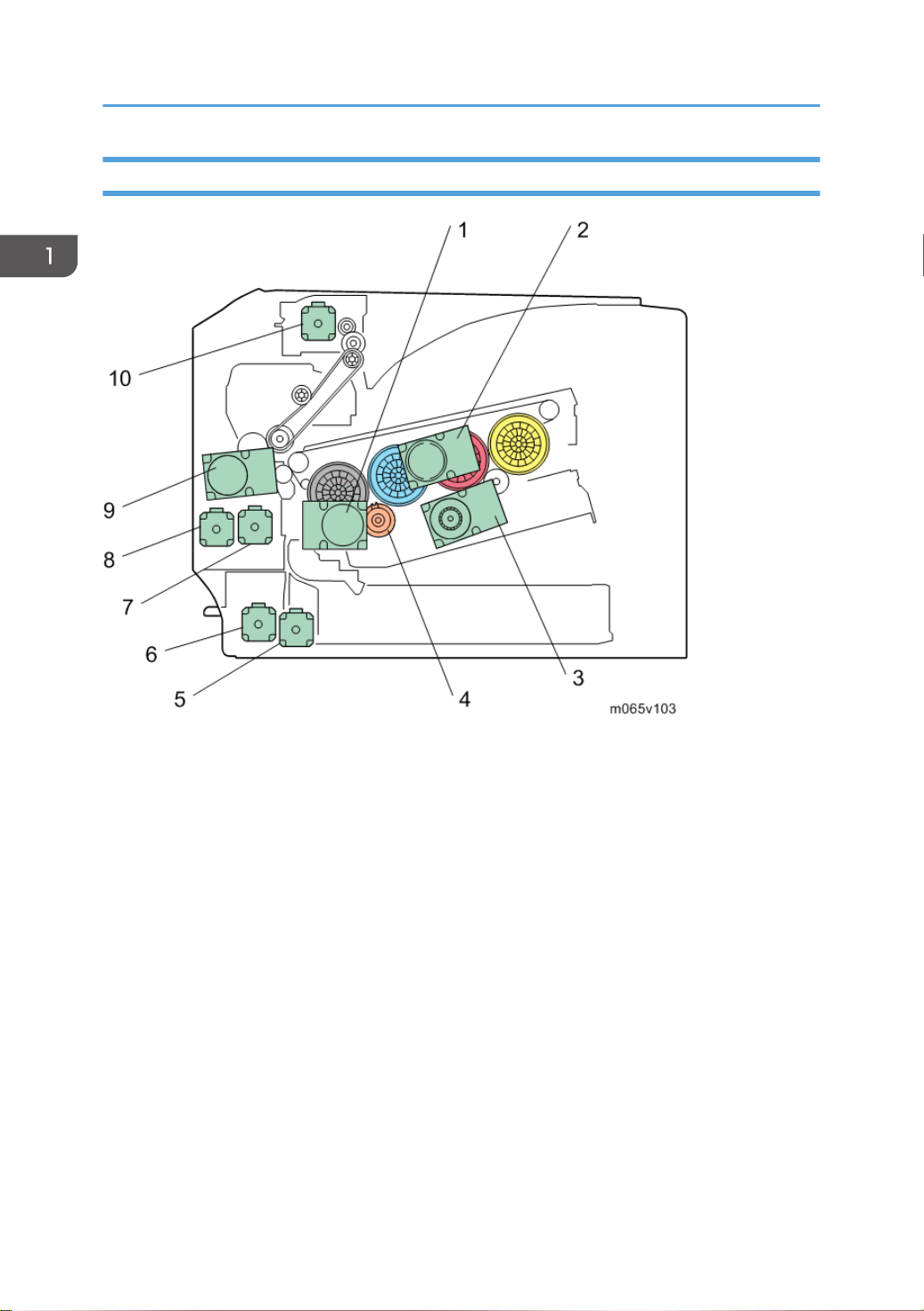

Mechanical Component Layout

24

1. Toner Bottle [Y]

2. Toner Bottle [M]

3. Toner Bottle [C]

4. Toner Bottle [K]

5. ITB (Image Transfer Belt) Unit

6. Fusing Unit

7. Duplex Unit

8. ID Sensor

9. PTR (Paper Transfer Roller)

10. By-pass Tray

11. PCDU (Photo Conductor Development Unit)

12. Standard Paper Feed Tray (Tray 1)

13. PSU (Power Supply Unit)

14. Polygon Mirror Motor

15. LDU

16. ITB (Image Transfer Belt) Cleaning Unit

Page 27

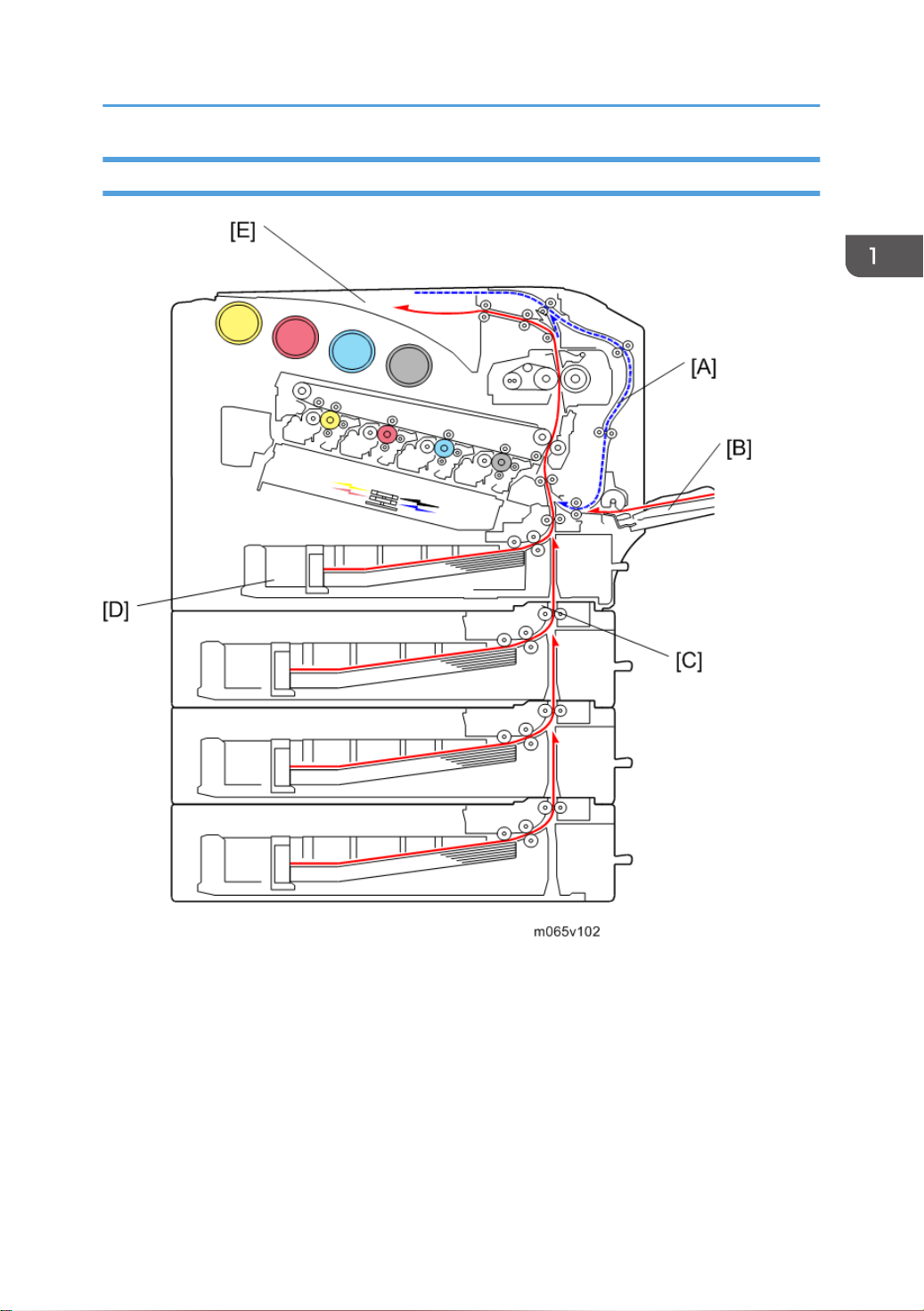

Paper Path

Overview

[A]: Duplex Unit

[B]: By-pass Tray

[C]: Optional Paper Feed Trays (Trays 2, 3, and 4)

[D]: Standard Paper Feed Tray (Tray 1)

[E]: Standard Paper Exit Tray

25

Page 28

1. Product Information

Drive Layout

26

1. ITB Unit/ Drum-K/ Development-K Motor:

This controls the OPC for black, development unit for black, and ITB unit.

2. Drum Motor: CMY:

This controls the OPCs for cyan, magenta, and yellow.

3. Development Motor: CMY:

This controls the color development units (cyan/ magenta/ yellow).

4. Development Clutch: K:

This controls the drive power to the development unit for black.

5. Paper Feed Motor:

This controls the paper feed mechanisms (tray 1).

6. Vertical Transport Motor:

This controls the vertical transport roller.

7. Registration Motor:

This controls the registration rollers.

8. Duplex/By-pass Motor:

Page 29

This controls the duplex entrance, relay, exit, and by-pass feed rollers.

9. Fusing/ Paper Exit Motor:

This controls the fusing unit and paper exit rollers.

10. Inverter Motor:

This controls the inverter roller.

Overview

27

Page 30

1. Product Information

28

Page 31

2. Installation

Installation Requirements

Environment

1. Temperature Range: 10°C to 32°C (50°F to 89.6°F)

2. Humidity Range: 15% to 80% RH

3. Ambient Illumination: Less than 1500 lux (do not expose to direct sunlight)

4. Ventilation: 3 times/hr/person or more

5. Do not let the machine get exposed to the following:

1) Cool air from an air conditioner

2) Heat from a heater

6. Do not install the machine in areas that are exposed to corrosive gas.

7. Install the machine at locations lower than 2,000 m (6,500 ft.) above sea level.

8. Install the machine on a strong, level base. (Inclination on any side must be no more than 5 mm.)

9. Do not install the machine in areas that get strong vibrations.

29

Page 32

2. Installation

Machine Level

Front to back: Within 5 mm (0.2")

Right to left: Within 5 mm (0.2")

Machine Space Requirements

• This machine, which uses high voltage power sources, can generate ozone gas. High ozone

density is harmful to human health. Therefore, the machine must be installed in a well-ventilated

room.

A: Over 500 mm (19.7")

B: Over 20 mm (0.8")

C: Over 100 mm (4.0")

D: Over 700 mm (27.6")

Above the machine: Over 350 mm (13.8")

Put the machine near the power source with the clearance.

30

Page 33

Power Requirements

• Insert the plug firmly in the outlet.

• Do not use an outlet extension plug or cord.

• Ground the machine.

1. Input voltage level:

120 V to 127 V, 60 Hz: More than 12 A

220 V to 240 V, 50 Hz/60 Hz: More than 8 A

2. Permissible voltage fluctuation: NA: ±8.66 %/ EU: ±10 %

3. Do not put things on the power cord.

Installation Requirements

31

Page 34

2. Installation

Optional Unit Combinations

Machine Options

U: User installation, C: CE installation

No. Options Remarks

1 Paper Feed Unit PB1020 (M384) U/C Up to x 3

User: For installing on the

table

CE: For installing on the

floor

2 Caster Table Type C (M393) C Install the caster table if

the machine is on the

floor.

Controller Options

U: User installation, C: CE installation

No. Options Remarks

1 Hard Disk Drive Option Type P7 (M479) U -

2 IEEE1284 Interface Board Type A (B679-17) U

4 USB Device Server Option Type M12 C

5 Camera Direct Print Card Type P7 U

6 VM CARD Type P7 U

7 IPDS Unit Type P7 U

8 XPS Direct Print Option Type P7 U

9 SD CARD SET FOR FONT TYPE D FOR MFP(D641-54) U

I/F slot3 IEEE802.11 Interface unit Type O (M417) U

SD slot 1

32

Page 35

Printer Installation

Printer Installation