Page 1

®

RICOH GROUP COMPANIES

C218

SERVICE MANUAL

PN: RCSM3600

Page 2

®

®

SERVICE MANUAL

C218

RICOH GROUP COMPANIES

Page 3

Page 4

C218

SERVICE MANUAL

PN: RCSM3600

Page 5

Page 6

It is the reader's responsibility when discussing the information contained within this

document to maintain a level of confidentiality that is in the best interest of Ricoh

Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH CORPORATION.

All product names, domain names or product illustrations, including desktop images,

used in this document are trademarks, registered trademarks or the property of their

respective companies.

They are used throughout this book in an informational or editorial fashion only and for

the benefit of such companies. No such use, or the use of any trade name, or web

site is intended to convey endorsement or other affiliation with Ricoh products.

2000 RICOH Corporation. All rights reserved.

Page 7

Page 8

WARNING

The Service Manual contains information regarding

service techniques, procedures, processes and

spare parts of office equipment distributed by

Ricoh Corporation. Users of this manual should be

either service trained or certified by successfully

completing a Ricoh T echnical Training Program.

Untrained and uncertified users utilizing

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property or loss of warranty

protection.

Ricoh Corporation

Page 9

Page 10

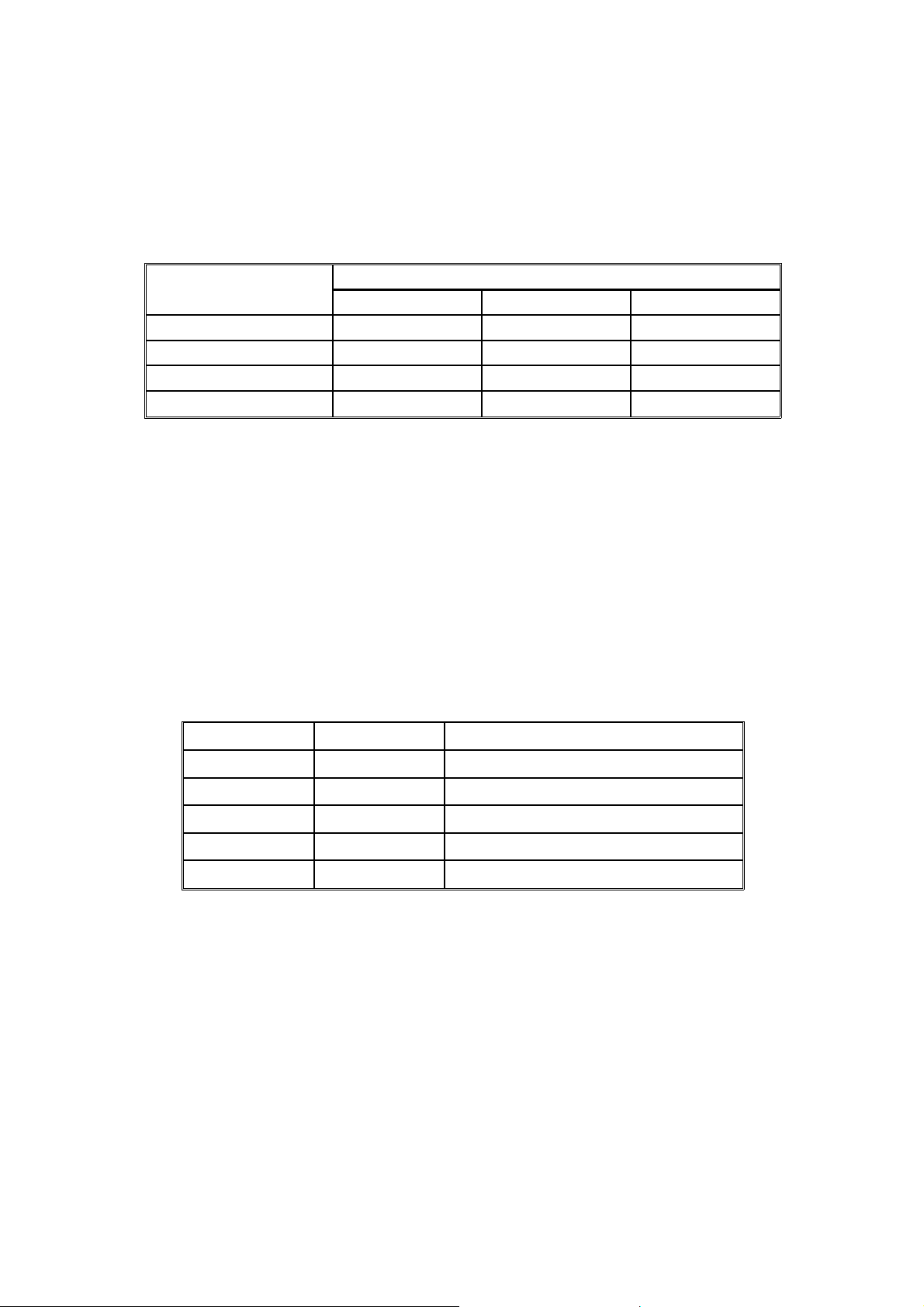

LEGEND

PRODUCT CODE COMPANY

GESTETNER RICOH SAVIN

C218 5380 VT3600

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

* 9/94 Original Pr in ti n g

Page 11

Page 12

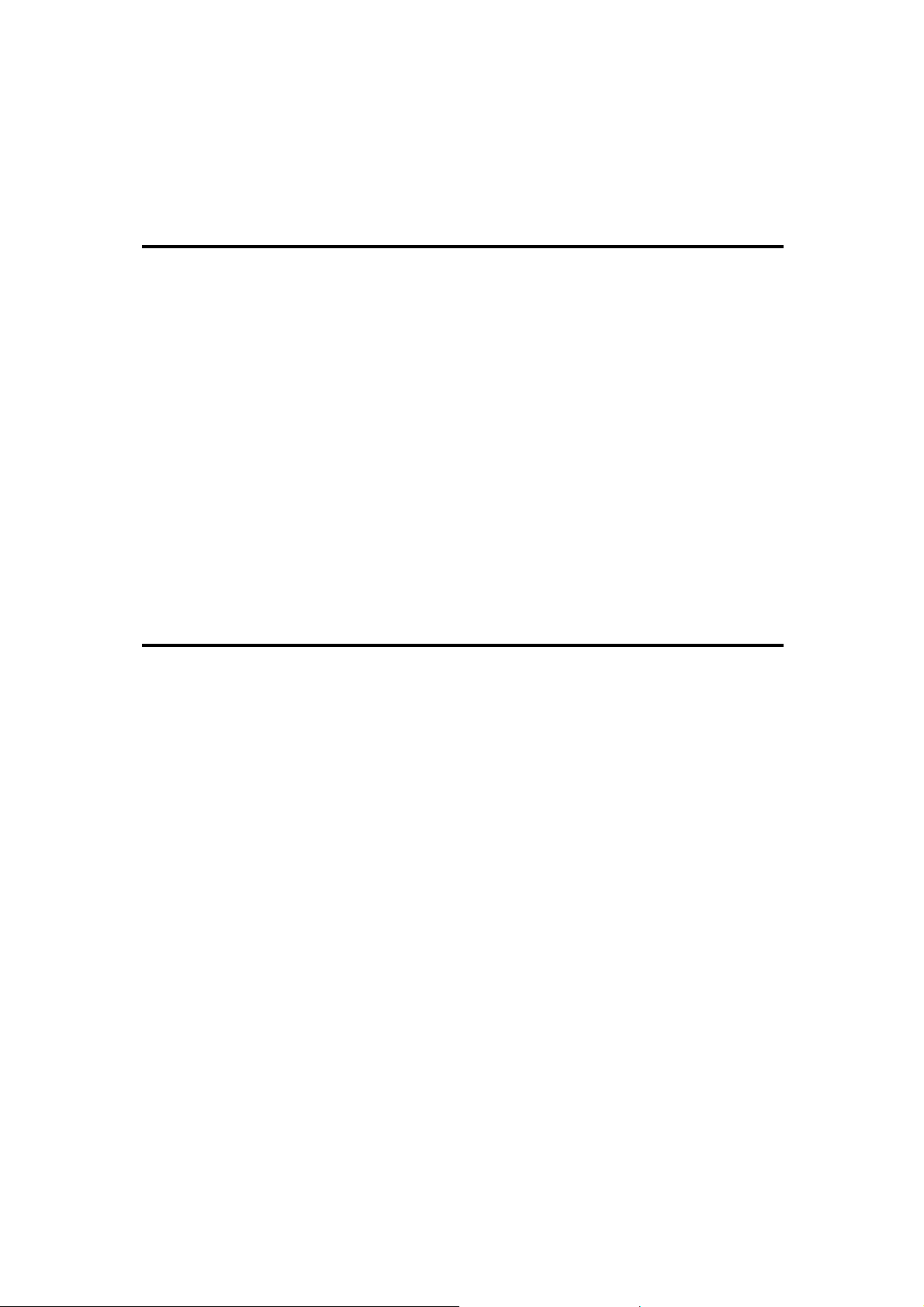

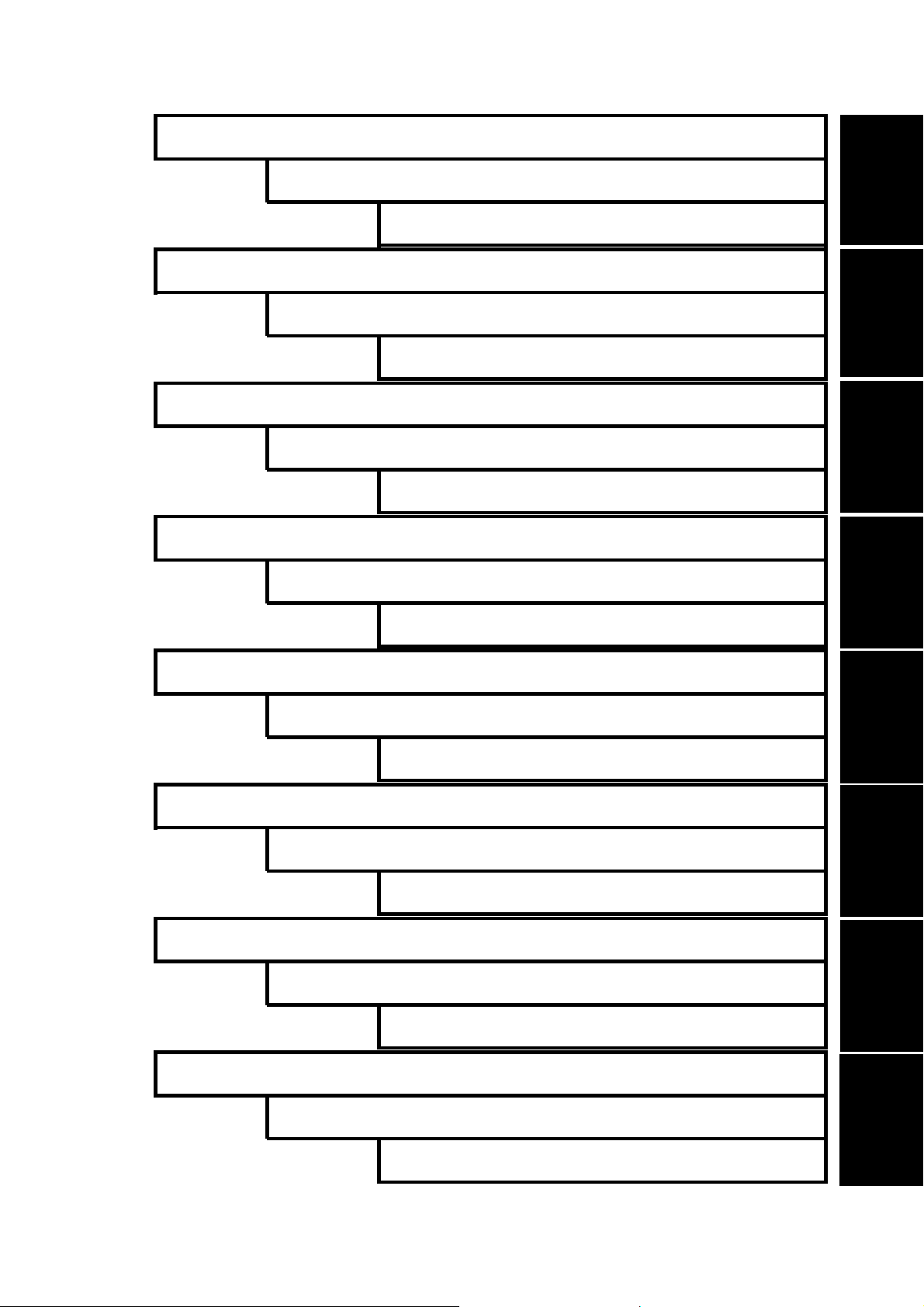

Table of Contents

OVERALL MACHINE INFORMATION

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. GUIDE TO COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . 1-4

3. OPERATION PANEL. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4. PRINTING PROCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

5. MECHANICAL COMPONENT LAYOUT. . . . . . . . . . . . . 1-9

6. ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . 1-10

7. ELECTRICAL COMPONENT DESCRIPTIONS . . . . . . 1-14

8. DRIVE LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

DETAILED SECTION DESCRIPTIONS

1. MASTER EJECT SECTION. . . . . . . . . . . . . . . . . . . . . . . 2-1

1.1 OVERALL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.2 MASTER EJECT ROLLER ROTATING MECHANISM . . . . . . . . 2-2

1.3 MASTER EJECT ROLLER DRIVE MECHANISM . . . . . . . . . . . . 2-3

1.4 MASTER EJECT CLAMPER MECHANISM . . . . . . . . . . . . . . . . 2-5

1.5 PRESSURE PLATE UP/DOWN MECHANISM . . . . . . . . . . . . . . 2-6

1.6 ELECTRICAL TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

1.7 CIRCUIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2. SCANNER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.1 OVERALL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.2 SCANNER MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.3 PLATEN COVER POSITION DETECTION . . . . . . . . . . . . . . . . 2-17

2.4 ELECTRICAL TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.5 CIRCUIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

SM i C218

Page 13

3. MASTER FEED SECTION. . . . . . . . . . . . . . . . . . . . . . . 2-22

3.1 OVERALL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

3.2 MASTER CLAMPER OPENING MECHANISM. . . . . . . . . . . . . 2-23

3.3 MASTER FEEDING MECHANISM . . . . . . . . . . . . . . . . . . . . . . 2-24

3.3 MASTER WRAPPING MECHANISM. . . . . . . . . . . . . . . . . . . . . 2-25

3.4 CUTTER MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

3.5 ELECTRICAL TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

3.6 CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

4. PAPER FEED SECTION. . . . . . . . . . . . . . . . . . . . . . . . 2-31

4.1 OVERALL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

4.2 PAPER FEED ROLLER/UPPER SEPARATION

ROLLER MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

4.3 FEED ROLLER PRESSURE MECHANISM . . . . . . . . . . . . . . . 2-33

4.4 PAPER SEPARATION MECHANISM . . . . . . . . . . . . . . . . . . . . 2-34

4.5 SEPARATION ROLLER PRES SURE

RELEASE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

4.6 SEPARATION PLATE PRES SURE

RELEASE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

4.7 PAPER RETURN MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . 2-39

4.8 SECOND FEED ROLLER MECHANISM. . . . . . . . . . . . . . . . . . 2-40

4.9 PAPER TABLE SIDE ADJUSTMENT MECHANISM. . . . . . . . . 2-43

4.10 PAPER TABLE UP/DOWN MECHANISM . . . . . . . . . . . . . . . . 2-44

4.11 PAPER SIZE DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

4.12 ELECTRICAL TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

4.13 CIRCUIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

5. PRINTING SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

5.1 OVERALL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

5.2 PAPER DETECTING AND PRINTING

PRESSURE ON/OFF MECHANISM . . . . . . . . . . . . . . . . . . . . . 2-52

C218 ii SM

Page 14

5.3 PRINTING PRESSURE ON/O FF

MECHANISM FOR A4/LT DRUM . . . . . . . . . . . . . . . . . . . . . . . 2-53

5.4 PRINTING PRESSURE RELEASE MECHANISM. . . . . . . . . . . 2-54

5.5 CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

6. DRUM SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-56

6.1 OVERALL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-56

6.2 DRUM ROTATION MECHANISM . . . . . . . . . . . . . . . . . . . . . . . 2-5 7

6.3 DRUM LOCK MECHANISM 1 . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

6.4 DRUM LOCK MECHANISM 2 . . . . . . . . . . . . . . . . . . . . . . . . . . 2-59

6.5 DRUM LOCK MECHANISM 3 . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

6.6 DRUM CONNECTION MECHANISM . . . . . . . . . . . . . . . . . . . . 2-61

6.7 INK SUPPLY MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-62

6.8 INK KNEADING MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . 2-63

6.9 DRUM MASTER DETECTION. . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

6.10 DRUM TYPE IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . 2-65

6.11 INK DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-66

6.12 CIRCUIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-68

7. DELIVERY SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-70

7.1 OVERALL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-70

7.2 EXIT PAWL DRIVE MECHANISM. . . . . . . . . . . . . . . . . . . . . . . 2-71

7.3 VACUUM UNIT DRIVE MECHANISM. . . . . . . . . . . . . . . . . . . . 2-72

7.4 PAPER EXIT PAWL AIR PUMP MECHANISM . . . . . . . . . . . . . 2-73

7.5 WING GUIDE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-74

7.6 PAPER DELIVERY TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-75

7.6.1 Master Eject Unit Lock Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-75

7.6.2 Paper Delivery Table Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-76

7.7 ELECTRICAL TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-77

7.8 CIRCUIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-78

SM iii C218

Page 15

8. IMAGE POSITIONING SECTION . . . . . . . . . . . . . . . . . 2-79

8.1 OVERALL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-79

8.2 IMAGE POSITIONING MECHANISM . . . . . . . . . . . . . . . . . . . . 2-80

8.3 CIRCUIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-81

9. IMAGE PROCESSING. . . . . . . . . . . . . . . . . . . . . . . . . . 2-82

9.1 CCD (CHARGE COUPLED DEVICE) . . . . . . . . . . . . . . . . . . . 2-82

9.2 A/D CONVERSION PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-84

9.2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-84

9.2.2 Inversion and Amplification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-85

9.2.3 A/D Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-86

9.2.4 Reference Data Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-89

9.3 IMAGE PROCESSING PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-95

9.3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-95

9.3.2 MTF Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-97

9.3.3 Main Scan Magnification And Image Shift Processing. . . . . . . . . . . . . . . 2-100

9.3.4 Binary Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-102

9.3.5 Photo Data Compensation Processing . . . . . . . . . . . . . . . . . . . . . . . . . . 2-103

9.3.6 Half-tone Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-105

9.3.7 Make-up Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-110

9.4 PLOTTER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-123

9.4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-123

9.4.2 Thermal Head Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-124

9.4.3 Thermal Head Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-126

9.4.4 Thermal Head Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-129

10. OTHERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-131

10.1 INTERLOCK SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-131

10.2 MONITOR INDICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-132

10.2.1 Cover Open Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-132

10.2.2 Key Counter Indicator: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-132

10.2.3 Master Eject Box Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-133

C218 iv SM

Page 16

10.2.4 Ink Supply Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-133

10.2.5 Master Supply Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-134

10.2.6 Paper Supply Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-134

10.2.7 Master Eject Error Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-135

10.2.8 Paper Misfeed Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-135

10.2.9 Paper Delivery Error Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-135

10.2.10 Paper Wrap Message 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-136

10.2.11 Paper Wrap Message 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-136

10.2.12 Master Clamp Error Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-136

10.2.13 Original Misfeed Indication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-137

10.2.14 Other Guidance Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-138

10.2.15 Other Monitor Indications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-139

10.3 MASTER PLOTTING AND PRINTING AREA . . . . . . . . . . . . 2-140

10.4 PAPER MISFEED DETECTION . . . . . . . . . . . . . . . . . . . . . . 2-144

10.5 PROTECTION FROM OVERCURRENT. . . . . . . . . . . . . . . . 2-145

INSTALLATION

1. INSTALLATION REQUIREMENTS. . . . . . . . . . . . . . . . . 3-1

1.1 ENVIRONMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.2 ACCESS TO THE MACHINE. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1.3 POWER SOURCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1.4 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

1.5 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

1.5.1 MAIN BODY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

1.6 COLOR DRUM UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

1.6.1 Key Counter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

SERVICE TABLES

1. SERVICE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.1 MAINTENANCE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.1.1 Lubrication Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

SM v C218

Page 17

1.1.2 User’s Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

1.1.3 Table of Periodic Inspection (every 6 months). . . . . . . . . . . . . . . . . . . . . . . 4-4

1.1.4 Table of Periodic Inspection (every 12 months). . . . . . . . . . . . . . . . . . . . . . 4-4

1.2 TABLE OF SERVICE CALL CODES. . . . . . . . . . . . . . . . . . . . . . 4-6

1.3 TABLE OF DIP SW, LED, VR, TP (ON THE MAIN CONTROL PCB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

1.3.1 DIP SW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

1.3.2 Photodiode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

1.3.3 VR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

1.3.4 TP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

1.4 EXPECTED LIFE OF PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

1.5 SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

2. SERVICE PROGRAM MODE . . . . . . . . . . . . . . . . . . . . 4-11

2.1 SERVICE PROGRAM MODE OPERATION . . . . . . . . . . . . . . . 4-11

2.1.1 Service Program Mode Access Procedure (for engineers) . . . . . . . . . . . . 4-11

2.1.2 Service Program Mode Access Procedure (for users). . . . . . . . . . . . . . . . 4-12

2.1.3 Change Adjustment Values or Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

2.2 SERVICE PROGRAM TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

2.3 THERMAL HEAD TEST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

2.4 COMMAND SHEET CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

2.5 INPUT/OUTPUT CHECK MODE . . . . . . . . . . . . . . . . . . . . . . . . 4-30

2.5.1 Input Check Mode Access Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

2.5.2 Output Check Mode Access Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

2.5.3 Input Check Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

2.5.4 Output Check Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

2.6 USER CODE MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

2.6.1 User Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

2.6.2 How To Use a User Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

3. DRUM/MASTER INTERCHANGEABILITY. . . . . . . . . . 4-37

REPLACEMENT AND ADJUSTMENT

1. EXTERIOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

C218 vi SM

Page 18

1.1 EXTERIOR COVERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

2. SCANNER SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

2.1 ADJUSTING THE SCANNER POSITION . . . . . . . . . . . . . . . . . . 5-2

2.2 FLUORESCENT LAMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

2.3 A/D CONVERSION PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

2.4 SCANNER TIMING BELTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

3. OPTICS SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

3.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

3.2 PREPARATION FOR ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . 5-7

3.3 ADJUSTING THE REDUCTION RATIO

(MOIRE ADJUSTMENT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5- 8

3.4 ADJUSTING THE FOCUS (MTF ADJUSTMENT) . . . . . . . . . . . 5-8

3.5 ADJUSTING THE READING START POSITION IN

THE MAIN SCAN DIRECTION . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

3.6 ADJUSTING THE SCAN LINE POSITION . . . . . . . . . . . . . . . . . 5-9

3.7 ADJUSTING THE SHADING PLATE . . . . . . . . . . . . . . . . . . . . 5-10

3.8 ADJUSTING THE WHITE LEVEL AND BLACK LEVEL . . . . . . 5-10

4. MASTER FEED SECTION . . . . . . . . . . . . . . . . . . . . . . 5-11

4.1 ADJUSTING THE THERMAL HEAD POSITION . . . . . . . . . . . . 5-11

4.2 THERMAL HEAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5. IMAGE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.1 SUB SCAN MAGNIFICATION ADJUSTMENT . . . . . . . . . . . . . 5-13

5.2 IMAGE CENTER ADJUSTMENT (Side to Side) . . . . . . . . . . . . 5-13

5.3 SCANNER LEADING EDGE REGISTRATION ADJUSTMENT 5-14

6. MASTER FEED SECTION. . . . . . . . . . . . . . . . . . . . . . . 5-15

6.1 ADJUSTING THE THERMAL HEAD VOLTAGE . . . . . . . . . . . . 5-15

6.2 ADJUSTING THE BELT TENSION . . . . . . . . . . . . . . . . . . . . . . 5-16

6.3 ADJUSTING THE RIGHT AND LEFT CUTTER SWITCHES . . 5-17

SM vii C218

Page 19

6.4 CUTTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

6.5 THERMAL HEAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

6.6 THERMAL HEAD DRIVE PCB. . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

7. MASTER EJECT SECTION. . . . . . . . . . . . . . . . . . . . . . 5-21

7.1 ADJUSTING THE MASTER EJECT SENSOR . . . . . . . . . . . . . 5-21

7.2 ADJUSTING THE MASTER EJECT SOLENOID. . . . . . . . . . . . 5-22

7.3 ADJUSTING THE AIR KNIFE MOTOR SAFETY SWITCH . . . . 5-23

7.4 MASTER EJECT UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

7.5 MASTER EJECT SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

7.6 MASTER EJECT BELT/ROLLER . . . . . . . . . . . . . . . . . . . . . . . 5-26

8. PAPER FEED SECTION . . . . . . . . . . . . . . . . . . . . . . . . 5-27

8.1 ADJUSTING THE PAPER TABLE OPEN SWITCH . . . . . . . . . 5-27

8.2 ADJUSTING THE PAPER TABLE HEIGHT . . . . . . . . . . . . . . . 5-28

8.3 ADJUSTING THE SEPARATION PLATE

RELEASE SOLENOID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

8.4 ADJUSTING THE PAPER FEED ROLLER PRESSURE . . . . . 5-31

8.5 ADJUSTING THE LOWER GUIDE PLATE . . . . . . . . . . . . . . . . 5-33

8.6 ADJUSTING THE UPPER SECOND FEED ROLLER. . . . . . . . 5-34

8.7 ADJUSTING THE SEPARATION

PLATE PRESSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

8.8 ADJUSTING THE FEED-LENGTH OF THE

PAPER FEED ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

8.9 ADJUSTING THE CLEARANCE OF THE PAPER

FEED SECTOR GEAR STOPPER . . . . . . . . . . . . . . . . . . . . . 5-37

8.10 ADJUSTING THE CLEARANCE OF THE SECOND

FEED ROLLER SECTOR STOPPER . . . . . . . . . . . . . . . . . . . 5-38

8.11ADJUSTING THE FEED-LENGTH OF THE

SECOND FEED ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

8.12 ADJUSTING THE FEED TIMING OF THE

SECOND FEED ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-40

8.13 PAPER FEED ROLLER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

C218 viii SM

Page 20

8.14 PAPER FEED ROLLER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

8.15 UPPER SEPARATION ROLLER . . . . . . . . . . . . . . . . . . . . . . . 5-44

8.16 SEPARATION PLATE RELEASE SOLENOID AND

PAPER RETURN MOTOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-45

8.17 SEPARATION PLATE/LOWER SEPARATION ROLLER . . . . 5-46

9. PRINTING SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

9.1 ADJUSTING THE CLEARANCE OF THE PAPER

DETECTING ARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

9.2 ADJUSTING THE PRESS ROLLER POSITION 1. . . . . . . . . . . 5-48

9.3 ADJUSTING THE PRE SS ROLLER POSITION 2

(FOR THE A4/LT DRUM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-49

9.4 ADJUSTING THE PRESSURE TIMING . . . . . . . . . . . . . . . . . . 5-50

9.5 ADJUSTING THE PRINTING PRESSURE . . . . . . . . . . . . . . . . 5-51

9.6 ADJUSTING THE CLEARANCE OF THE

PRINTING PRESSURE SOLENOID . . . . . . . . . . . . . . . . . . . . . 5-52

9. PRESS ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-53

10. DRUM SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-54

10.1 ADJUSTING THE MAIN DRIVE BELT TENSION . . . . . . . . . . 5-54

10.2 ADJUSTING THE DRUM MASTER DETECTION

SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-55

10.3 ADJUSTING THE PRINTING SPEED . . . . . . . . . . . . . . . . . . . 5-56

10.4 ADJUSTING THE DRUM STOPPER. . . . . . . . . . . . . . . . . . . . 5-57

10.5 ADJUSTING THE DRUM LOCK SOLENOID . . . . . . . . . . . . . 5-58

10.6 ADJUSTING THE MASTER FEED CLAMPER CAM . . . . . . . 5-59

10.7 ADJUSTING THE MASTER EJECT CLAMPER CAM. . . . . . . 5-60

10.8 ADJUSTING THE POSITIO N OF THE

INK DETECTING PIN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-61

10.9 ADJUSTING THE CLEARANCE OF THE

DOCTOR ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-62

10.10 ADJUSTING TH E INK ROLLER WITH THE

DRUM UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-63

SM ix C218

Page 21

10.11 ADJUSTING THE POSITION OF THE

INK SUPPLY SOLENOID. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-64

10.12 ADJUSTING INK DETECTION . . . . . . . . . . . . . . . . . . . . . . . 5-65

10.13 SCREEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-66

10.14 DRUM DRIVE BELT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-67

11. DELIVERY SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . 5-71

11.1 ADJUSTING THE FIRST PAPER EXIT SENSOR . . . . . . . . . 5-71

11.2 ADJUSTING THE SECOND PAPER EXIT SENSOR . . . . . . . 5-72

11.3 ADJUSTING THE CLEARANCE OF THE EXIT PAWL . . . . . . 5-73

11.4 ADJUSTING THE EXIT PAWL TIMING. . . . . . . . . . . . . . . . . . 5-74

11.5 ADJUSTING THE PAPER EXIT PAWL AIR PUMP . . . . . . . . 5-75

11.6 TRANSPORT UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-76

11.7 DELIVERY BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-77

11.8 TRANSPORT VACUUM FAN AND PAPER

EXIT SENSORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-78

12. IMAGE POSITIONING SECTION . . . . . . . . . . . . . . . . 5-79

12.1 ADJUSTING THE IMAGE POSITION . . . . . . . . . . . . . . . . . . . 5-79

TROUBLESHOOTING

1. ELECTRICAL COMPONENT TROUBLE . . . . . . . . . . . . 6-1

2. TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

2.1 IMAGE TROUBLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

2.2 PAPER FEED TROUBLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

TAPE MARKER

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

2. BASIC OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

2.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

2.2 DRIVE AND CUTTING MECHANISM . . . . . . . . . . . . . . . . . . . . . 7-3

C218 x SM

Page 22

2.3 MANUAL CUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

3. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

3.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

3.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

4. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . 7-8

4.1 CUTTER REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

4.2 CUTTER HOME POSITION SENSOR REPLACEMENT . . . . . . 7-9

4.3 TAPE CUT LENGTH ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . 7-10

DOCUMENT FEEDER

1. OVERALL MACHINE INFORMATION . . . . . . . . . . . . . . 8-1

1.1 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

1.2 MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . 8-1

1.3 ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . 8-2

2. SECTIONAL DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . 8-3

2.1 DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

2.2 PAPER FEED AND SEPARATION . . . . . . . . . . . . . . . . . . . . . . . 8-4

2.3 ORIGINAL SIZE DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

2.4 ADF OPEN/CLOSE DETECTION . . . . . . . . . . . . . . . . . . . . . . . . 8-5

2.5 ADF POSITION DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

2.6 ELECTRICAL TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

2.6.1 ADF (Before Scanning) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

2.6.2 ADF Scanning Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

2.6.3 Plotting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

2.7 CIRCUIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

2.8 ORIGINAL MISFEED DETECTION . . . . . . . . . . . . . . . . . . . . . . 8-12

3. INSTALLATION PROCEDURE. . . . . . . . . . . . . . . . . . . 8-13

3.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

SM xi C218

Page 23

4. REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

4.1 ADF COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

4.2 ADF UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

4.3 SEPARATION ROLLER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

4.4 PICK-UP ROLLER AND FEED ROLLER. . . . . . . . . . . . . . . . . . 8-19

4.5 TRANSPORT ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

4.6 ORIGINAL REGISTRATION SENSOR . . . . . . . . . . . . . . . . . . . 8-21

4.7 ADF POSITION SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

4.8 ORIGINAL SET SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

4.9 SCAN LINE SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

4.10 ORIGINAL EXIT SENSOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

4.11 ADF MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-25

5. ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

5.1 PICK-UP TORQUE AND SHUTTER TORQUE

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

5.2 SEPARATION ROLLER PRESSURE ADJUSTMENT . . . . . . . 8-27

5.3 SEPARATION TORQUE ADJUSTMENT . . . . . . . . . . . . . . . . . 8-28

5.4 ORIGINAL SKEW ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . 8-28

5.5 ADF HEIGHT ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 8-29

5.6 IMAGE SCAN MAGNIFICATION ADJUSTMENT . . . . . . . . . . . 8-30

5.7 IMAGE CENTER ADJUSTMENT (Side to side) . . . . . . . . . . . . 8-30

5.8 SCANNER LEADING EDGE REGISTRATION

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-31

PRIPORT CONTROLLER INSTALLATION GUIDE

1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

1.1 SYSTEM REQUIREMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

1.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

1.3 PARTS LISTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

C218 xii SM

Page 24

9.5 CABLING BETWEEN PCRIP-10 AND COMPUTER. . . . . . . . . . 9-8

A. IBM AND COMPATIBLES - PARALLEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

B. IBM AND COMPATIBLES - SERIAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

C. MACINTOSH COMPUTERS - APPLETALK STANDARD . . . . . . . . . . . . . . . . 9-9

9.6 SYSTEM VERIFICATION AND DEFAULT

CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

9.7 CABLE PIN-OUT DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

A. PARALLEL INTERFACE, PIN-OUT CONNECTIONS . . . . . . . . . . . . . . . . . . 9-12

B. PARALLEL INTERFACE CABLE, PIN ASSIGNMENTS . . . . . . . . . . . . . . . . 9-12

C. SERIAL INTERFACE CABLE, PIN-OUT CORRECTIONS . . . . . . . . . . . . . . 9-13

D. SERIAL INTERFACE CABLE, PIN ASSIGNMENTS . . . . . . . . . . . . . . . . . . . 9-13

9.8 RAM UPGRADE PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . 9-14

PRIPORT CONTROLLER USER’S GUIDE

9.9 REGULATORY NOTICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21

9.10 TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21

9.11 HARDWARE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

9.12 PRIPORT CONTROLLER CONFIGURATION . . . . . . . . . . . . 9-24

9.13 CONFIGURATION OF IBM PC AND COMPATIBLES . . . . . . 9-24

9.14 CONFIGUTATION OF MACINTOSH COMPUTERS. . . . . . . . 9-28

9.15 APPLICATION SOFTWARE SET-UP . . . . . . . . . . . . . . . . . . . 9-29

9.16 PRIPORT CONTROLLER OPERATION . . . . . . . . . . . . . . . . . 9-30

9.17 COMMONLY ASKED QUESTIONS. . . . . . . . . . . . . . . . . . . . . 9-31

9.18 TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-34

9.19 APPENDIX A - DIAGNOSTIC STATUS PAGE . . . . . . . . . . . . 9-37

9.20 PARTS CATALOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-39

BULLETINS

SM xiii C218

Page 25

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the printer and peripherals,

make sure that the power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers

off or open while the main switch is turned on, keep hands away from

electrified or mechanically driven components.

HEALTH SAFETY CONDITIONS

1. If you get ink in your eyes by accident, try to remove with eye drops or

flush with water as first aid. If unsuccessful, get medical attention.

2. If you ingest ink by accident, induce vomiting by sticking finger down

throat or by giving soapy or strong salty water to drink.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The printer and its peripherals must be installed and maintained by a

customer service representative who has completed the training course

on those models.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Dispose of replaced parts in accordance with local regulations.

2. Used ink and master should be disposed of in an environmentally safe

manner and in accordance with local regulations.

-- CAUTION --

The RAM pack has a lithium battery which can explode if handled

incorrectly. Replace only with same RAM pack. Do not recharge or burn

this battery. Used RAM packs must be handled in accordance with local

regulations.

Page 26

Page 27

OVERALL MACHINE INFORMATION

PRIPORT CONTROLLER INSTALLATION GUIDE

DETAILED SECTION DESCRIPTIONS

PRIPORT CONTROLLER USER’S GUIDE

INSTALLATION

TAB POSITION 1

TAB POSITION 2TAB POSITION 3TAB POSITION 4

SER VICE T ABLES

REPLACEMENT AND ADJUSTMENT

TROUBLESHOOTING

TAPE MARKER C532

TAB POSITION 5TAB POSITION 6

DOCUMENT FEEDER C532

TAB POSITION 7

TAB POSITION 8

Page 28

Page 29

OVERALL MACHINE

INFORMATION

Page 30

Page 31

1. SPECIFICATIONS

Configuration: Desk top

Master Processing: Digital

Printing Process: Fully automatic one-drum stencil system

Original Type: Sheet/Book

Original Scan Area

Size:

Reduction Ratio: LT version: 93%, 77%, 74%, 65%

Enlargement Ratio: LT version: 155%, 129%, 121%

Image Mode: Line/Photo/Sharpen

Zoom: From 50% to 200% in 1% steps

Color Printing: Drum unit replacement system (red, blue, green and brown)

Master Feed/Eject: Roll master automatic feed/eject

Leading Edge

Margin:

Print Paper Size: Maximum: 325 mm x 447 mm (12.7" x 17.5")

Printing Area: Maximum:

Print Paper Weight: 47.1 g/m

Printing Speed: 60, 75, 90, 105, 120

First Print Time: 38 s/A3/DLT (with "L" drum)

Paper Feed Table

Capacity:

Paper Delivery

Table Capacity:

Power Source: 120 V, 60 Hz, 4.1 A (for

Power

Consumption:

Weight: 128 kg (282.2 lb)

Maximum: 307 mm x 432 mm (12.0" x 17.0")

A4 version: 93%, 87%, 82%, 71%

A4 version: 141%, 122%, 115%

8 ± 3 mm (0.32" ± 0.12")

Minimum: 90 mm x 148 mm (3.6" x 5.8")

290 mm x 412 mm (11.4" x 16.2")

at 23°C/65% RH (A3/DLT drum)

Maximum:

290 mm x 204 mm (11.4" x 8.0")

at 23°C/65% RH (A4/LT drum)

sheets/minute (5 steps)

35 s/A4/LT (lengthwise with "L"

drum)

26 s/A4/LT (with "S" drum)

1000 sheets (75 g/m

1000 sheets (75 g/m

N.America)

220/240 V, 50 Hz, 2.1 A

(for Europe, Asia)

120 V, 60 Hz, 374 W (for

N.America)

220/240 V, 50 Hz, 380 W

(for Europe, Asia)

Cabinet: 23.5 kg (51.8 lb)

2

to 209.3 g/m2 (12.5 lb to 55.6 lb)

2

, 20 lb)

2

, 20 lb)

Overall

Machine

Information

SM 1-1 C218

Page 32

Dimensions

(W x D x H):

Original Scanning

Time:

Pixel Density: 400 dpi

Master Eject Box

Capacity:

Paper Separation: Friction roller/center separation

Feed Table Side

Plate Movement

Distance:

Paper Feed Roller

Pressure:

Separation Roller

Pressure:

Separation Plate

Pressure:

Side Registration:

Vertical

Registration:

Paper Table

Raising/Lowering

Speed:

Ink Supply: Automatic ink supply system

Press Roller

Pressure:

Paper Delivery: Air knife/vacuum delivery

Delivery Side Plate

Movement

Distance:

Print Counter: 7 digits

Noise Emission: Less than 74 dB

Stored: 719 x 698 x 644 mm

(28.3" x 27.5" x 25.4")

Set up: 1331 x 698 x 644 mm

(52.4" x 27.5" x 25.4")

Cabinet: 1331 x 698 x 1070 mm

(52.4" x 27.5" x 42.1")

3 ms/line

50 masters with "L" drum

90 masters with "S" drum

system

88 mm to 336 mm (3.46" to 13.2")

Normal position 300 g

Thick paper position 600 g

Normal position 125 g

Weak position 50 g

Weak 10 g

Normal 20 g

Strong 1 40 g

Strong 2 60 g

±

10 mm

±

20 mm

22 mm/s (50 Hz)

26 mm/s (60 Hz)

12.5 ± 0.5 kg

80 mm to 327 mm (31.5" to 12.9")

Printing (Average):

60 rpm less than 64 dB

90 rpm less than 67 dB

120 rpm less than 72 dB

C218 1-2 SM

Page 33

Supplies: Master

Thermal master 320 mm width

225 masters/roll

Master length 540 mm/master

Max run length 2000 prints

Ink

800 cc ink pack (black)

500 cc ink pack

(red, blue, green, brown)

Overall

Machine

Information

SM 1-3 C218

Page 34

2. GUIDE TO COMPONENTS

Original Holder

A convenient place for

holding originals while

operating the mach i ne .

Platen Cover

Lower this cover over

an original before

printing.

Original Table Release Lever

Use to open the original table

unit when installing the master.

Feed Roller Pressure

Lever

Use to adjust the contact

pressure of the paper feed

roller according to paper

thickness.

Separation Roller

Pressure Levers

Use to adjust the

separation roller

pressure to prevent

double feed.

Paper Feed Table

Set blank paper on this

table for printing.

Front Door

Open for access to

the inside of the

machine.

Paper Feed Table

Down Key

Press to lower the

paper feed table.

Paper Feed Side

Plates

Use to prevent pa pe r

skew.

Side Plate Fine

Adjustment Dial

Use to shift the

paper feed table

sideways

C218 1-4 SM

Page 35

Master Eject Unit Open

Button

Press to remove misfed

paper or a misfed master.

Main Switch

Use to turn the

power on or off.

Master Eject

Container Cover

Open when removing

the master eject box.

Paper Delivery

Side Plates

Use to align the

prints on the

paper delivery

table.

Paper Delivery End

Plate

Use to align the

leading edge of prints

larger than A4, 8

1/2

" x

11".

Small Size Paper Delivery

End Plate

Use to align the l ea di n g ed ge

of prints that are A4, 8

1/2

" x

11" or smaller.

Original Table

Place the origina l s

on this table.

Master Cut Button

Press this button to cut

the master paper

leading edge after

installing a new master

roll.

Pressure Release

Lever

Use to install the

master roll.

Operation Panel

Operator controls

and indicators ar e

located here.

Drum Rotation

Button

Press to replace

the drum.

Drum Unit Lock

Lever

Lift to unlock and

pull out the drum

unit.

Drum Unit

The master is wrapped

around this unit.

Overall

Machine

Information

Paper Delivery Table

Completed prints are

delivered here.

SM 1-5 C218

Ink Holder

Set the ink cartridge in

this holder.

Page 36

3. OPERATION PANEL

– Keys and Indicators –

54 3 2 1

6 7 8 9 10 11 12 13

1. Reset key Press to reset error indicators.

2. Directional

Magnification key

3. Image Shift key Press to shift the image.

4. Contrast key Press to select the desired contrast according to

5. Screen key Press to select the desired grade of screening to

6. Make Up key Press to use the make-up function.

7. Combine 2 Originals

key

8. Im age Density key Press to make prints darker or ligh te r.

9. Image Mode key Press to select line mode, photo mode or sharpen

10. Zoom keys Press to alter the reproductions ratio in 1%

11. Reduce/Enlarge key Press to reduce or enl ar g e th e im ag e.

12. Full Size key Press to make prints the same size as the original.

Press to enter the horizontal or vertical

magnification for copies, using the number keys.

the type and quality of the original.

be applied to the image according to the type and

quality of the original.

Press to combine two originals onto one print

image.

image mode according to the type and quality of

the original.

increments from 50 % to 200 %.

13. Auto Cycle key Use to automatically pro c ess mast er s an d m ake

prints.

C218 1-6 SM

Page 37

18 17 16 15 14

19 20 21 22 23 24 25 26 27 28

Overall

Machine

Information

14. Clear Modes key

15. Program key

16. Enter key

17. Counter

18. Monitors

19. Speed keys

20. Image Position key

21. Memory/Class

Indicators

22. Number keys

23. Memory/Class key

24. Clear key

Press to cancel all previously ent ered settings and

modes.

Press to input or recall user programs.

Press to input information into memory.

Displays the number of prints entered. While

printing, it shows the number of copies left to print.

Light or blink when a non-standard condition

occurs within the machine.

Press to adjust the rot at ion spee d of the drum

according to the type of image and printing paper.

Press to shift the image forwards or backwards on

the print paper.

Shows the number entered in memory mode or

class mode.

Press to enter the number of prints.

Press to select group printing in memory mode or

class mode.

Press to change the number set in the counter.

Also use to change make-up mode. This key can

be used only after the machine stops operation.

25. Stop key

26. Proof key

27. Print Start key

28. Master Making key

SM 1-7 C218

Press to stop the machine operation. The

machine will continue operation when the Print

Start key or Master Making key is pressed.

Press to make trial prints or extra prints.

Press to start printing.

Press to make a master.

Page 38

4. PRINTING PROCESS

3

2

4

1

6

7

5

1. Master Ejecting: Ejects the used master that was wrapped

around the drum i nt o th e m ast er eje c t bo x.

2. Original: The original is placed onto the exposure glass.

3. Scanning: Scans the original image with the CCD through

the mirrors and the lens while moving the lamp

across the original.

4. Master Feeding: Converts the imag e sign al r ea d by th e CC D

into digital signal s an d sen ds th em to the

thermal head to plo t ho les on the ma ste r. The

new master is the n wr ap pe d ar o un d th e dr u m .

5. Paper Feeding: Feeds the paper to the drum section.

6. Printing: Presses the paper fed from the paper feed

section against the dr u m . This tr a nsf er s th e i nk

through the dru m scre en , th e m ast er an d on to

the paper.

7. Paper Delivering: Peels the printed paper off the drum with the

exit pawl and air knife and ejects the paper

onto the paper delivery table.

C218 1-8 SM

Page 39

5. MECHANICAL COMPONENT LAYOUT

30

29

28

27

26

25

24

23

3231

20

2122

19

123456

18

17

141516

13

7

8

9

10

11

12

Overall

Machine

Information

1. Drum Unit

2. Lens

3. CCD

4. Reverse Roller

5. Master Feed Roller

6. Platen Roller

7. Thermal Head

8. Master Roll

9. Plotter Unit

10. Upper Separation Roller

11. Paper Feed Roller

12. Paper Table

13. Separation Plate

14. Lower Separation Roller

15. 2nd Feed Roller

16. Doctor Roller

17. Press Roller

18. Ink Roller

19. Paper Exit Pawl Air Pump

20. Paper Exit Pawl

21. Transport Unit

22. Paper Delivery Table

23. Master Eject Box

24. 2nd Eject Roller

25. 1st Eject Roller

26. Master Eject Unit

27. 3rd Mirror

28. 1st Mirror

29. 2nd Mirror

30. Reflector

31. Fluorescent Lamp

32. Exposure Glass

SM 1-9 C218

Page 40

6. ELECTRICAL COMPONENT LAYOUT

35

3333

31

34

32

37

36

30

40

39

29

27

6

9

8

7

38

1

2

3

24

4

5

10

11

12

13

15

14

28

26

25

23

22

21

20

19

17

16

18

C218 1-10 SM

Page 41

1. Scanner Motor

2. Fluorescent Lamp Stabilizer

3. CCD PCB

4. Platen Cover Position Sensor

5. A/D Conversion PCB

6. Original Sensor

7. ADF Set Sensor

8. Scanner Home Position Sensor

9. Fluorescent Lamp

10. Scanner Unit Safety Switch

11. Paper Return Motor

12. Paper Table Down Button

13. Paper End Sensor

14. Paper Width Sensor

15. Paper Table Open Switch

16. Paper Table Safety Switch

17. Paper Detection PCB

(Paper Length Sensor)

18. Cassette Size Detection PCB

19. Paper Table Height Sensor

22. Transformer

23. Paper Table Lower Limit Sensor

24. Main PCB

25. Printing Pressure Sensor

26. Front Door Safety Switch

27. Power Supply Unit

28. Vacuum Fan Motor

29. 1st Paper Exit Sensor

30. Drum Detection Switch

31. 2nd Paper Exit Se nsor

32. Circuit Breaker

33. Delivery Table Open Switch

34. Main Switch

35. Interlock Switch

36. Air Knife Motor Safety Switch

37. Drum Rotation Switch

38. Drum Rotati on LED

39. Total Counter

40. Operation Pa ne l

Overall

Machine

Information

20. Image Processing PCB

21. Separation Plate Release

Solenoid

SM 1-11 C218

Page 42

58

60

45

62

63

64

56

61

57

59

55

54

53

52

51

50

49

48

44. Ink Supply Solenoid

45. Drum Lock Solenoi d

46. Master Eject Unit Safety Switch

47. 2nd Drum Positio n Se nso r

48. Noise Filter

49. Printing Pressure Solenoid

50. Main Motor

51. Drum Rotati on Sensor

(Pulse Generator)

52. Paper Table Drive Motor

44

46

47

55. AC Drive PCB

56. Master Eject Clamper Solenoid

57. Image Position Sensor

58. Master Feed Clamper Solenoid

59. Ink Detection PCB

60. Master Cut Button

61. Image Positioning Motor

62. Drum Unit Safety Switch

63. 1st Drum Position Sensor

64. Drum Master Det ect i on Sens or

53. Paper Table Drive Motor

Capacitor

54. Paper Feed Solenoid

C218 1-12 SM

Page 43

81

77

76

78

79

75

74

80

82

65

66

69

70

71

67

68

Overall

Machine

Information

73

65. Pressure Plate Motor

66. Lower Pressure Plate Sensor

67. Upper Pressure Plate Sensor

68. Full Master Detection Sensor

69. Master Eject Senso r

70. Master Eject Sol en oid

71. Air Knife Motors

72. Master Eject Box Switch

73. Master Eject Mot or

74. Thermal Head Drive PCB

72

76. Cutter Motor

77. Master End Senso r

78. Right Cutter Switch

79. Thermal Head

80. Master Buckle Senso r

81. Master Feed Motor

82. Left Cutter Switch

SM 1-13 C218

Page 44

7. ELECTRICAL COMPONENT DESCRIPTIONS

Index No. Name Function

Motors

* ADF

option

11 Paper Return Motor Returns paper to the paper table when

28 Vacuum Fan Motor Provides suction so paper is held firmly

Original Transport

Motor

Transports the original to the scanner

section.

the paper table is lowered.

on the transport belt.

* ADF

option

50 Main Motor Drives paper feed, drum, pr i nt ing and

52 Paper Table Drive

61 Image Positioning

65 Pressure Plate Motor Raises and lowers the pressure plate.

71 Air Knife Motors Rotates the fan to separate the paper

73 Master Eject Motor Sends used master into the master

76 Cutter Motor C uts the master.

81 Master Feed Motor Feeds the mast er to the drum .

1 Scanner Motor Transports the lamp across the original

Solenoids

21 Separation Plate

44 Ink Supply Solenoid Releases the spring clutch to turn on

45 Drum Lock Solenoid Prevents the drum unit from being

ADF Drive Motor Feeds the original to the scanne r

section.

paper delivery unit components.

Raises and lowers the paper table.

Motor

Changes the timing between the paper

Motor

Release Solenoid

feed roller and the drum to adjust the

vertical image po siti o n.

leading edge fr om th e dr u m .

eject box.

Releases the separation plate when the

paper table is lo w ered.

activate the ink supply pump.

removed during the printi ng run.

49 Printing Pressure

Solenoid

54 Paper Feed Solenoid Releases the sector gears to feed the

56 Master Eject

Clamper Solenoid

* ADF Option - Refer to Section 8.

C218 1-14 SM

Engages the pressure ON/OFF lever

when a paper misfeed occurs.

paper.

Opens the master clamper to eject the

master.

Page 45

Index No. Name Function

58 Master Feed

Clamper Solenoid

70 Master Eject

Solenoid

Opens the master clamper to clamp the

master.

Presses the lower master eject roller

against the drum surface.

Sensors

*ADF

option

Original Registration

Sensor

Informs the CPU when the original

activates the sensor. Also, detect s the

original misfeed.

*ADF

option

Scan Line Sensor Informs the CPU when the original

activates the sensor. Also, detect s

original misfeeds.

*ADF

option

*ADF

option

Original Exit Sensor Informs the CPU when the original exits

the ADF.

Original Width

Informs the CPU of the original width.

Sensor

13 Paper End Senso r Informs the CPU if the paper is set on

the paper table.

14 Paper Width Sensor Informs the CPU of the paper width.

19 Paper Table Height

Sensor

Informs the CPU if the paper table is at

the paper feed position.

Overall

Machine

Information

23 Paper Table Lower

Limit Sensor

25 Printing Pressure

Sensor

29 1st Paper Exit

Sensor

31 2nd Paper Exit

Sensor

47 2nd Drum Positio n

Sensor

51 Drum Rotat i on

Sensor

57 Image Position

Sensor

63 1st Drum Position

Sensor

* ADF

ADF Cover Sensor Detects when the ADF cover is opened.

option

Informs the CPU if the paper table is at

the lowest position.

Informs the CPU if printing pressure is

applied. Also, detects paper misfeeds.

Detects paper misfeeds.

Detects paper misfeeds.

Checks the position of the drum.

Supplies timing pulses to the CPU

based on the main motor speed.

Informs the CPU of the image position.

Checks the position of the drum.

* ADF Option - Refer to Section 8.

SM 1-15 C218

Page 46

Index No. Name Function

* ADF

option

4 Platen Cover

64 Drum Master

66 Lower Pressure

67 Upper Pressure

68 Full Master

Original Set Sensor Detects when an original is inserted

into the ADF

Detects when the platen cover is

Position Sensor

opened more than 25°

Informs the CPU if the master is on the

Detection Sensor

drum.

Informs the CPU if the pressure plate is

Plate Sensor

at the lower limit position.

Informs the CPU if the pressure plate is

Plate Sensor

at the upper limit position.

Informs the CPU when the master eject

Detection Sensor

box is full of masters.

69 Master Eject Sensor Detects used master misfeeds.

77 Master End Sensor Informs the CPU if the plotter unit runs

out of master roll.

80 Master Buckle

Sensor

Informs the CPU if the master is

buckling.

Switches

9 Scanner Unit Safety

Switch

Cuts off the power line of the main and

paper table drive motors when the

scanner unit is open.

12 Paper Table Down

Button

Informs the CPU to turn on the paper

table drive motor to lower the paper

table.

15 Paper Table Open

Switch

Checks whether the paper table is

opened correctly or not.

16 Paper Table Safety

Switch

Stops lowering the paper table to

prevent catching fingers under it. Cuts

the AC power line.

26 Front Door Safety

Switch

Cuts off the power line of the paper

table drive motor when the front door is

open.

30 Drum Detection

Switch

33 Delivery Table Open

Switch

Checks whether the drum unit is set

correctly or not.

Checks whether the delivery table is

opened correctly or not.

34 Main Switch Turns the power on or off.

* ADF Option - Refer to Section 8.

C218 1-16 SM

Page 47

Index No. Name Function

35 Interlock Switch Disables the front door, paper table,

master eject unit, and scann er un it

safety switches.

36 Air Knife Motor

Safety Switch

Cuts off the power line of the paper

table drive motor whe n th e m ast er ej e ct

unit is open.

37 Drum Rotat i on

Switch

Informs the CPU to rotate the drum at

10 rpm.

Overall

Machine

Information

*ADF

option

46 Master Eject Unit

ADF Safety Switch Cuts the power line of the paper table

drive motor off when the ADF is open.

Cuts off the power line of the paper

Safety Switch

table drive motor whe n th e m ast er ej e ct

unit is open. (Also, cuts off the power

line of the main motor in the 220/240 V

version machines.)

60 Master Cut Button Informs the CPU to cut the master

paper leading edge.

62 Drum Unit Safety

Switch

72 Master Eject Box

Switch

Checks whether the drum unit is set

correctly or not.

Checks whether the master eject box is

set correctly.

78 Right Cutter Switch Detects when the cutter position is far

right (non-operation side).

82 Left Cutter Switch Detects when the cutter position is far

left (operation side).

*ADF

ADF Set Switch Detects when the ADF unit is opened

option

Printed Circuit Board

3 CCD PCB Converts light intensity into an electrical

signal.

5 A/D Conversion PCB Converts the analog signal into a digital

signal.

17 Paper Detection

PCB

18 Cassette Size

Detection PCB

20 Image Processing

PCB

Detects the size of the paper set on the

table.

Detects the size of the cassette set on

the table.

Controls the image proces sing

performance.

24 Main PCB Controls all machine functions both

directly and throu gh other boards.

55 AC Drive PCB Controls the AC component by relays.

* ADF Option - Refer to Section 8.

SM 1-17 C218

Page 48

Index No. Name Function

59 Ink Detection PCB Controls the ink supply.

74 Thermal Head Drive

PCB

Supplies the power to t he the rm al he ad

according to the signal from the

scanner section.

Counters

39 Total Counter Keeps track of the total number of

prints made.

Others

2 Fluorescent Lamp

Stabilizer

Stabilizes the power supplement to the

fluorescent lamp.

22 Transformer Steps down the wall voltage.

27 Power Supply Unit Provides power for all DC components.

32 Circuit Breaker Cuts the AC line off.

38 Drum Rotat ion LED Turns to green fr om r ed wh en the dr um

stops to the home po sition.

9 Fluorescent Lamp Applies light to the original for exposure.

48 Noise Filter Filters electrical noise on the AC power

input lines.

53 Paper Table Drive

Motor Capacitor

75 Reverse Roller

Magnetic Clutch

Protects the AC drive PCB from

induced current.

Stops the reverse roller turning while

the master buckle sensor i s OFF.

79 Thermal Head Plots the master usin g he at .

C218 1-18 SM

Page 49

8. DRIVE LAYOUT

20

19

18

17

16

21

1

2

Overall

Machine

Information

3

4

5

6

7

8

9

15

1. Scanner Belt

2. Scanner Motor

3. Image Position Motor

4. Master Eject Motor

5. Drum Drive Gear

6. Drum Unit Gear

7. Drum Drive Pulley

8. Main Drive Belt

9. Transport Belt

10. Printing Pressure Pulley

11. Printing Pressure Gear

14

13

12. Idle Gear

13. Idle Pulley

14. Main Motor

15. Paper Table Drive Motor

16. Paper Feed Cam Gear

17. Master Feed Motor

18. Timing Belt

19. Platen Roller Gear

20. Master Transport R olle r Gea r

21. Reverse Roller Gear

12

11

10

SM 1-19 C218

Page 50

Page 51

DETAILED SECTION

DESCRIPTIONS

Page 52

Page 53

1. MASTER EJECT SECTION

1.1 OVERALL

At the end of the printing cycle, th e use d mast er rema ins wrap pe d aro und

the drum to prevent the ink on the drum surface from drying. When the

Master Making key is pressed to make a new master, the used master is

then ejected from the drum.

The master is pulled off the drum, by the eject rollers and is fed into the

master eject box. A pressure plate compacts the used master.

[A]

•

Drum [B] rotates in reverse

(opposite to printing direction).

•

Master eject rollers [A] rotate.

[C]

•

[B]

Lower eject roller [C] is pressed

against the drum .

[E]

[D]

•

The trailing edge of the master

Drum

[F]

curls off the drum and pass es

between the uppe r [E] and lower

[F] eject rollers, and the master [D]

is dumped into the master eje ct

[G]

box [G].

Detailed

Section

Descriptions

SM 2-1 C218

[H]

[I]

•

The pressure plate [H] compacts

the ejected master [I].

Page 54

1.2 MASTER EJECT ROLLER ROTATING MECHANISM

[I]

[J]

[H]

[G]

[A]

[B]

[E]

[F]

[B]

[C]

[D]

[E]

[F]

When the original i s set an d th e Mast er M akin g key is presse d, the mai n

motor starts turning at 30 rpm in the reverse direction. The drum will rotate in

the reverse direction (ccw ) (compared with the printing rotations).

At this time, if the drum m ast er de tection sensor detects a mast er on the

drum, the master eject motor [A] starts rotating . Drive is transmitted to gear

[E] and to the uppe r fir s t eje c t r oll e r s [G] through the timin g belt [B] and gears

[C] and [D]. Gear [F] drives the lower first eject rollers [H]. The belts [I]

transmit drive from th e fi rs t ej ect rol l ers to t he upp er an d low e r second fe ed

rollers [J].

(If the drum master detection sensor detects no master on the drum when

the Master Making key is pressed, the machine skips the master eject

process and goes directly to the master making process.)

After the master eje c t pro c ess is com ple te d, the dr um r et urn s to i ts ho me

position. The master eject rollers then stop rotating.

The model VT3600 has five rollers on each eject roller shaft. The roller shafts

can feed up to A3/DLT sized masters.

C218 2-2 SM

Page 55

1.3 MASTER EJECT ROLLER DRIVE MECHANISM

[A]

[B]

[E]

[F]

[G]

[D]

[C]

Detailed

Section

Descriptions

[H]

The drum position is dete cte d by th e fi rs t [G] and secon d [H] dr um po si tio n

sensors. When the drum reaches its home position, the first drum position

sensor [G] is activated by the interrupter [F] at the rear side of the drum.

To eject the master, the drum turns in the reverse direction (CCW) (oppos ite

to the printing direct ion). When the drum is 70° from the home position, the

master eject solenoid [A] turns on and the supporter [C] rotates

counterclockwise on the upper eject roller shaft [D]. This forces the lower first

eject rollers [E] against the drum surface.

The drum will momentarily stop its reverse rotation for 150 milliseconds,

when the trailing edge of the master is about 5 millimeters from the master

rollers to ensure the com p l et ion of th e m ast er eje c t pro c ess.

As the drum turns, the curled trailing edge of the master [B] passes between

the upper and lower first eject rollers. The first eject rollers then peel the

master from the dr u m .

SM 2-3 C218

Page 56

[A]

[B]

[C]

[D]

When the drum is 109 degrees from the home position, the master eject

solenoid [A] turns off, separating the lower first eject rollers [C] from the

surface of the drum.

When the ejected master passes between the upp er and lower first eject

rollers, the master eject sensor [B] is actuated. The master is then dumped

into the master eject bo x [D].

C218 2-4 SM

Page 57

1.4 MASTER EJECT CLAMPER MECHANISM

[G]

[F]

Rear side of

machine

[B]

[A]

[E]

Detailed

Section

Descriptions

[C]

When the drum rot at es 30 6 de gr e es ( in th e r eve r se di r e ctio n) pa st th e home

position, the master eject clamper solenoid [A] turns on and lever [B] will

rotate counterclockwise as shown. This moves the cam [D] inside the drum.

The drum rotation will bring the clamper sector gear [E] against the cam [D].

Gear [F] will rotate counterclockwise as it engages the clamper sector gear,

thus opening the master clamper [G]. The opened master clamper will

releases the master from the drum.

The drum will continue to turn until the interrupter at the rear side of the drum

moves 13 degrees past the first drum position sensor. The main motor will

then turn off. Half a second later, the master eject clamper solenoid [A] turns

off and spring [C] pulls cam [D] back to its init ial position. The drum then

rotates forward to its home position.

[D]

SM 2-5 C218

Page 58

1.5 PRESSURE PLATE UP/DOWN MECHANISM

[B]

[M]

[C]

[L]

[D]

[A]

[K]

[I]

[J]

[Pressure Plate Down]

When the interrupter at the rear side of the drum interrupts the first drum

position sensor (this means the end of the master eject process), the

pressure plate motor [B] starts rotating. This drives gear [H] clockwise by

means of gears [C], [D], [E], and [F].

Pin [I] on gear [H] moves the link [G ] down until the link interrupter [L]

interrupts the lower pressure plate sensor [J]. Spring [M] pulls down on the

pressure plate and th e ejected master in the master eject box is compressed

by the pressure plate [A].

[E]

[F]

[G]

[H]

If the full master detection sensor [K] does not turn on when the pressure

plate goes down, the master eject box is filled with ejected masters. In this

case, the Master Full indicator will blink, and the machine will stop after a

new master is wrapped around th e drum.

Reset the Master Full indicator by turning the Master Eject Box switch OFF

and ON (Remove and insert this box). This will prevent the master full

indicator from being reset without removing the ejected masters from the

box. When the Master Full indicator is blinking, the Master Making key will

not work, but the Print Start key and Proof key function correctly.

C218 2-6 SM

Page 59

[A]

[B]

[G]

[C]

[D]

[F]

[E]

[Pressure Plate Up]

When the master has been wrapped around the drum in the master making

process and the master cutter leaves the home position to cut the master,

the pressure plate motor [B] starts rotating to raise the pressure plate.

When the pressure plate motor [B] turns, the gear [C] is driven through the

relay gears. The pin [F] on the gear in the link [D] rises and lifts the left end of

the link, thus raisin g th e pr e ssur e plate.

The gear [C] continues turning until the interrupter [G], which is installed onto

the front end of the pressure plate, blocks the upper pressure plate sensor

[A]. At this time, the master eject motor [B] will stop and the pressure plate

will be held in the upper position.

Detailed

Section

Descriptions

[Pressure Plate Motor Lock Detection]

To prevent the pressure plate motor from locking the error indicator, "E-12"

will light up on the operation display panel if any of the following conditions

occur:

1. The upper [A] or lower [E] pressure plat e sen sor rem a i ns act ivated for

more than 4 seconds after th e pr e ssur e plat e m ot or sta rts tu r nin g.

2. The lower pressure plate sensor [E] is not activat ed wit hi n 8 secon ds of

the pressure plate motor starts turning even though the upper pressure

plate sensor [A] is de- act iv at ed .

3. The upper pressure plate sensor [A] is not activated within 8 seconds of

the pressure plate motor starts turning even though the lower pressure

plate sensor [E] is de- act iv at ed .

SM 2-7 C218

Page 60

1.6 ELECTRICAL TIMING

T1

First Drum Position Sensor

Second Drum Position Sensor

Main Motor Reversing

30 rpm

Main Motor Forwarding

Master Eject Motor

T2

Master Eject Solenoid

Master Eject Clamper Solenoid

X1

T1: When the Master Making key is

pressed, the main motor and

master eject motor will start turning.

At the same time, the paper table

drive motor will start to lift the paper

table to the paper f ee d po siti o n.

T2: When the drum rotates X1 degrees

past the first drum po siti o n sen sor

actuation positio n (dr u m home

position), the mast er eject solenoid

is energized. This will press the

lower eject rollers against the drum

surface. The master eject solenoid

is de-energized when the drum

rotates X2 degrees more.

306°

X2

T4

13°

30 rpm

T3

500 msec

0°

0°

70°

39°

The drum rotation angles X1 and

X2 depend on the drum type. This

machine has two types of drums:

one is the A3/DLT dru m (st an da r d) ,

and the other is the A4/LT drum

(optional). X1 and X2 for eac h drum

are as follows:

Drum Type A3/DLT A4/LT

X1 (degree) 70 174

X2 (degree) 39 55

C218 2-8 SM

Page 61

T3: When the drum rotates 306

degrees past the home po si tio n, the

master eject clamper sole no i d is

energized.

T4: When the drum rotates 13 degrees

past the drum home position, the

drum stops rotating.

500 milliseconds later (the drum

completely stops during this

period), the mast er eje c t clam p er

solenoid is de-energized and the

drum starts rotating forward. The

drum then returns to its home

position. The master ej e ct process

is now over.

Soon after this, the machine wll

start feeding a new master and the

drum will start rotating in reverse to

begin the master making process.

13°

0°

0°

306°

Detailed

Section

Descriptions

SM 2-9 C218

Page 62

First Drum Position Sensor

Master Eject Solenoid

Print key on

Misfeed Indicator Lights

39° 18°

50° 50°

Sensor ON Check

70°

Drum Rotation

Reverse Reverse

Master Eject Sensor

Master Eject Motor

68°

Foward

[Master Eject Misf e ed Det e ction]

The misfeed indicator for the master eject section blinks in the following

cases:

Case 1: The master eject sensor is not activated and the drum has turned

50 an additional degrees (still in reverse and after de-activation of

the master eject solenoid). The machine will know that the eject

rollers have failed to catch the master. The dru m re tu rns 68

degrees (by rotating in the forward direction, the printing direc tion)

to repeat the master eje c t pro c ess on e mor e ti me. The m ast er

eject solenoid is agai n ene rgi ze d w hil e the drum tu r ns an ot he r 18

degrees (in the reverse direction) to try to catch the c urled edge of

the master.

If the master ejec t sen sor ag ain fai ls to det ect the master, the drum

will return to its home position and the misfeed indicator will blink.

Case 2: The drum finishes its rotation for th e m ast er eje c tin g pr o cess an d

retuns to the home position, but the master eject sensor does not

turn off. This means that the master is still in between the master

eject rollers, the misfeed indicator will blink.

C218 2-10 SM

Page 63

1.7 CIRCUIT

[A]

[B]

[C]

[D]

1

2

3

1

2

3

1

2

3

CN101

-24

-23

-22

-27

-26

-25

-30

-29

-28

-17

-16

-19

-18

Main PCB

5V

GND

5V

GND

5V

GND

5V

LED DRIVE

5V

24V

24V

FU101

FU102

GND

CN103

-21

-10

-20

-11

-19

-12

-25

-6

CN101

-20

-21

SOL

M

M

SOL

[E]

[F]

[G]

[H]

[I]

Detailed

Section

Descriptions

Component

Name

Upper Pressure

Plate Sensor [A]

Lower Pressure

Plate Sensor [B]

Full Master Detection

Sensor [C]

In/Out Main PCB Description

CN No. Signal Level

In 101-23 Signal goes High when the pressure

0V

In 101-26 Signal goes High when the pressure

0V

5V

plate is at the highest position.

5V

plate is at the lowest position.

In 101-29 Signal goes High when the interrupter

5V

0V

of the pressure plate passes through

the sensor. (Master full detection in the

master eject box.)

Master Eject

Sensor [D]

In TP104

101-18

0.7V

Signal goes High when the sensor

3V

detects the master. This is a pulse

signal.

Sensor LED [D] Out 101-16 Pulse signal goes to Low and the LED

Master Eject So-

Out 103-10 Signal goes Low when the solenoid

lenoid [E]

Master Eject Mo-

Out 103-11 Signal goes Low when the motor turns

tor [F]

Pressure Plate

Out 103-12 Signal goes Low when the motor turns

Motor [G]

Master Eject

Out 103- 6 Signal goes Low when the solenoid

Clamper Sole-

5V

3.5V

24V

24V

24V

24V

3 msec

lights when the main switch is turned

600

µ

sec

on.

0V

turns on.

0V

on.

0V

on.

0V

turns on.

noid [H]

Master Eject

Box Switch [I]

In 101-20 Signal goes Low when the master eject

5V

0V

box is installed.

SM 2-11 C218

Page 64

2. SCANNER

2.1 OVERALL

A book type scanner is used in the model VT3600. There are 2 modes for

scanning originals.

Platen Cover Mod e: The ori g i nal is pla c ed on th e exp osu re gl a ss, an d th e

scanner motor drives the scanner to across the original.

Optional ADF Mode: Wh en an op tio na l Docum e nt Feed er is insta l led , th e

original is fed across the exposure glass. The scanner move s 24 mm away

from the CCD and then remains still as it scans the original. The scanner will

return to the home positio n when the scanning is finished.

[I]

[H]

[G]

[F]

[E]

The light from the fluorescent lamp [A] is reflected from the original, by the

first [B], second [F], and third [E] mirrors and goes through the lens [D] into

the CCD [C].

In the Platen Cover Mode, the CCD measures the reflector light off the white

plate [H] on the back of the original scale [I] each time before scanning to

obtain a standard white level before the original is scanned. The standard

white level data is used to correct distortion. The scanner is in the home

position when it measures the white level.

[A]

[C]

[B]

[D]

[G]: Reflector

In the ADF mode, as the scanner moves 24 mm, the CCD will then measure

the white plate installed on the ADF.

C218 2-12 SM

Page 65

[A]

[B]

[C]

[F]

[D]

[E]

[Light Source]

A high frequency (15 kHz) fluorescent lamp [D] is used as a light source for

high speed reading. The light is reflected off the original at two angles, direct

and reflected. The reflector mirror [F] is used to prevent shadows from the

edges of cut-and-paste originals from appearin g as lines on the printed

copies. The original guide plate [C] blocks part of the direct light from the

fluorescent lamp to ensure that the light intensity of both the direct light and

reflected light the same. A heater [E] is wrapped around the fluorescent

lamp. The lamp will turn on for one minute when the main switch is turned on

to quickly raise the lamp temperature. This will prevent a loss in light intensity

that would occur if the lamp temperature were too low.

Detailed

Section

Descriptions

[Platen Cover]

The CCD reads the reflected light off the platen cover [A] to obtain a