Page 1

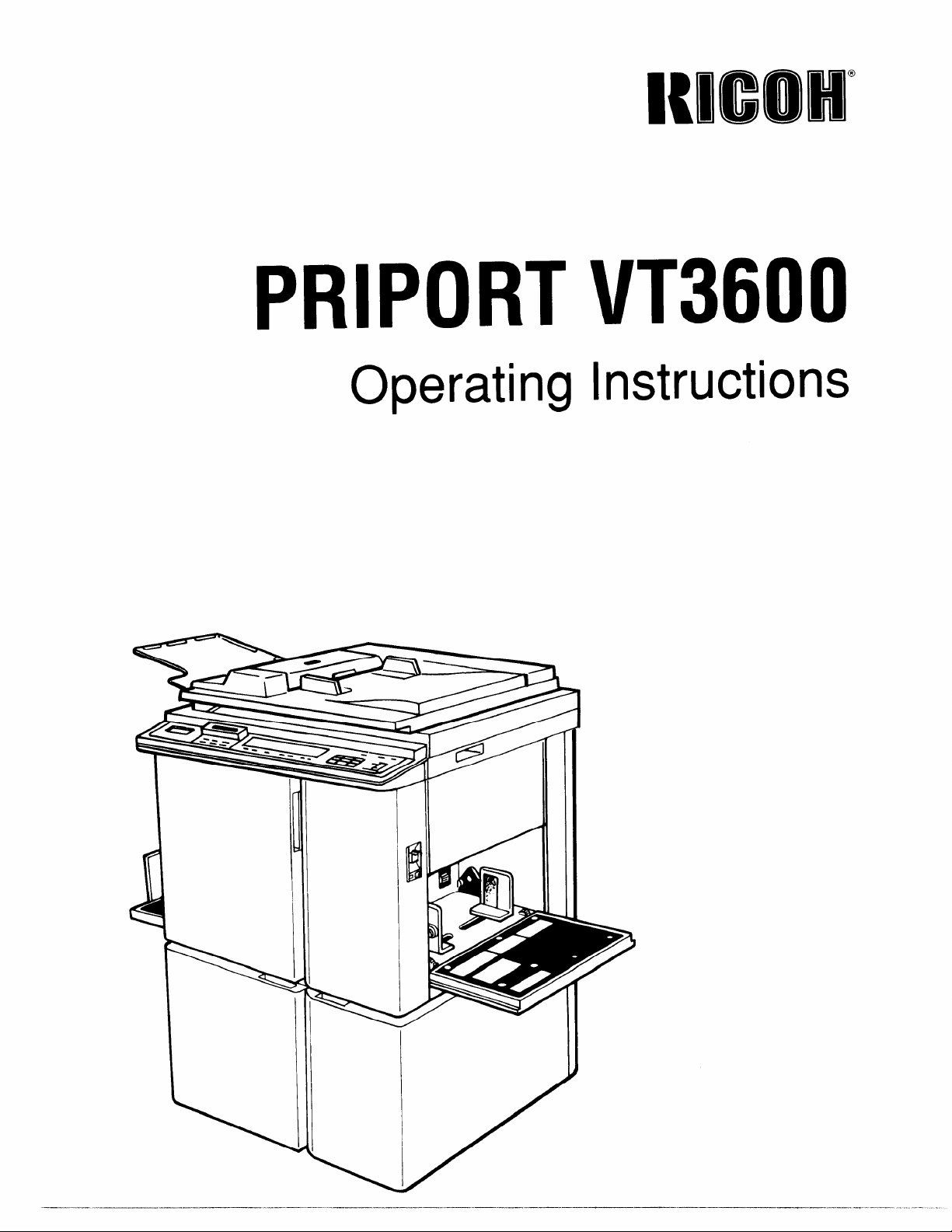

PRIPORT VT3600

Operating Instructions

-——~— —..——.

Page 2

For good print quality, Ricoh recommends that you use genuine Ricoh master

and ink.

#

I

Ricoh shall not be responsible for any damage or expense that may result from

the use of parts other than genuine Ricoh parts in your Ricoh office product.

Power Source: 120V , 60Hz , more than 4.1A

Please make sure to connect the power cord to a power source as above. For

s about power connection, see page 6.

Power Comsuption: Master Making : 374W

Note: Some of the illustrations may be slightly different from your machine,

I

Printing : 372W

1

,

..—..——————

_—.—

@ Copyright 1994

Ricoh Co., Ltd.

——------

Page 3

Safety During Operation

INTRODUCTION

INTRODUCTION

This manual contains detailed instructions on the operation and care of this

machine. To get the maximum versatility from this machine, all operators should

read and follow the instructions in this manual. Please keep this manual in a

handy place near the machine.

SAFETY INFORMATION

When using your machine, the following safety precautions should always be

followed.

Safety During Operation

In this manual, all safety messages are identified by

“Caution”. These words mean the following:

the words “WARNING” and

WARNING:

Important information to alert you to a situation

injury and damage to your property if instructions

Caution:

Important information on how to

avoid a situation that might cause

-

WARNING -

prevent damage to

minor injuty.

that might cause

are not followed.

your equipment, or how to

serious

IJ Do not modify or replace any parts other than the ones specified in this

manual.

Since some parts of the machine are supplied with high voltage, touch

CJ

on/y the parts specified in this manual.

IJ Do not operate the machine without covers. You might get your fingers

caught in the machine, or the machine might be damaged because of

something, such as dust, getting inside it.

IJ Since some parts of the machine are sharp and might cause injury,

touch only the parts

Caution –

–

I_JWhile copying, do not

CIWhile copying, do not

specified in this manual.

turn off the main switch.

open the door.

i

Page 4

SAFETY INFORMATION

IJ While copying, do not unplug the power cord.

~ While copying, do not move the machine.

CJKeep corrosive liquids, such as acid, off the machine.

CJDo not allow paper clips, staples, or other small objects to fall inside the

machine.

#Open and close the door and covers softly.

fJ Do not put anything except originals or command sheets on the machine.

n Do not spill liquid on the machine.

~ When you open or close the door or cover, don’t let go of them.

~ When you open or close the platen cover or optional document feeder, be

careful not to pinch your fingers between the platen cover or document feeder

and the back cover.

IJ If you clean rubber parts with benzine, wipe them with a dry cloth afterwards.

General Safety Information

General Safety Information

~ Always turn the machine off when you have finished printing for the day.

u When the machine will

cord.

CI If the machine must be transported by vehicle, please contact your service

representative.

not be used for long periods, disconnect the power

..

Page 5

Chapter I

.

Page 6

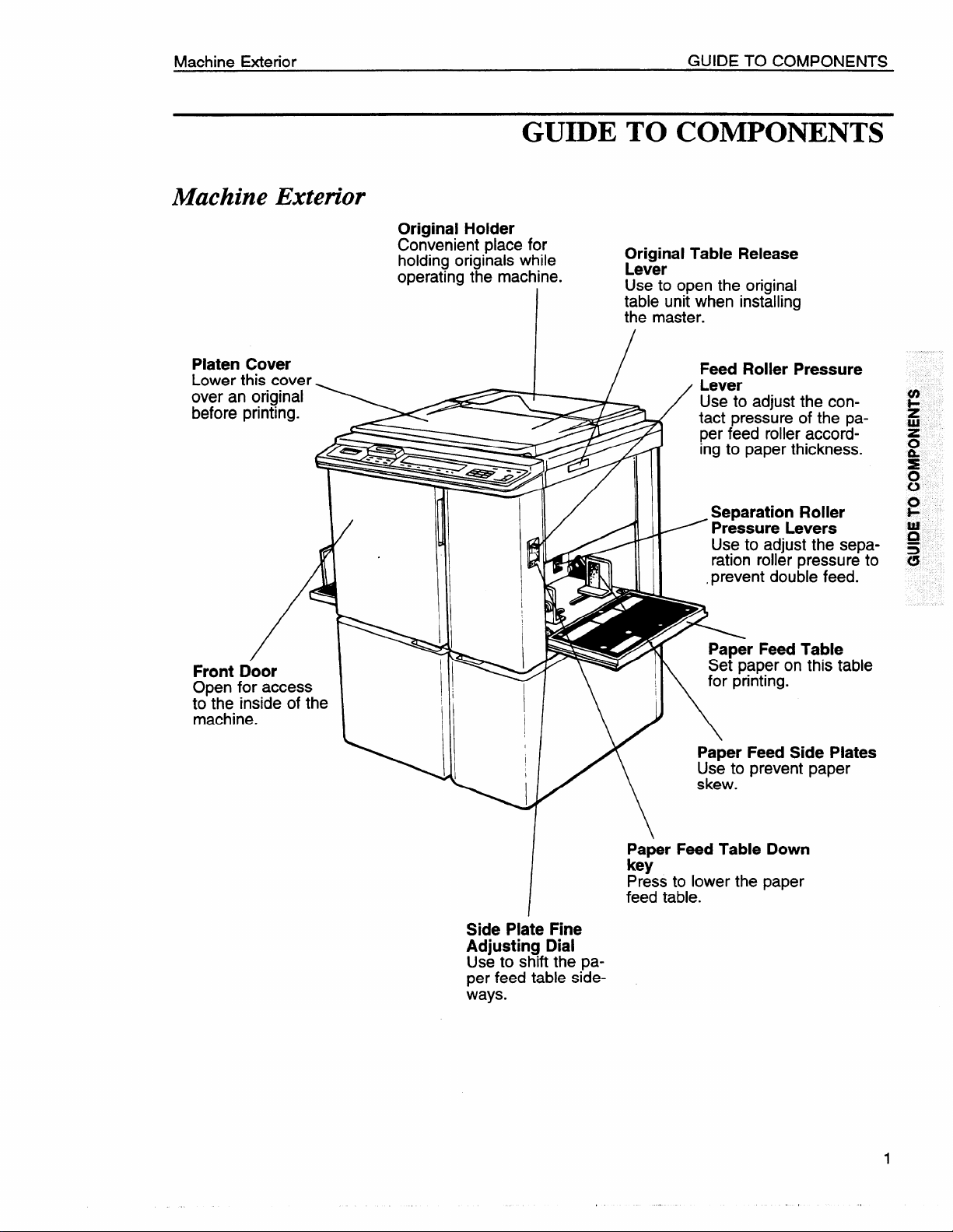

Machine Exterior

Machine Exterior

GUIDE TO COMPONENTS

Original Holder

Convenient place for

holding originals

operating the machine.

while

I

GUIDE TO COMPONENTS

Original Table Release

Lever

Use to open the original

table unit when installing

the master.

Platen Cover

Lower this cover

over an original

before printing.

Front Door

Open for access

too::i$eside of the

.

Feed Roller Pressure

Lever

Use to adjust the con-

/

tact pressure of the pa-

per feed roller according to paper thickness.

Separation Roller

= Pressure Levers

Use to adjust the separation roller pressure to

,prevent double feed.

r Feed Table

aper on this table

..

W \ !1 \ ‘orpr’nt’ng”

I

1

I

\

Paper Feed Side Plates

Use to prevent paper

skew.

/

Side Plate Fine

Adjusting Dial

Use to shift the paper feed table sideways.

Paper Feed Table Down

key

Press to lower the paper

feed table.

Page 7

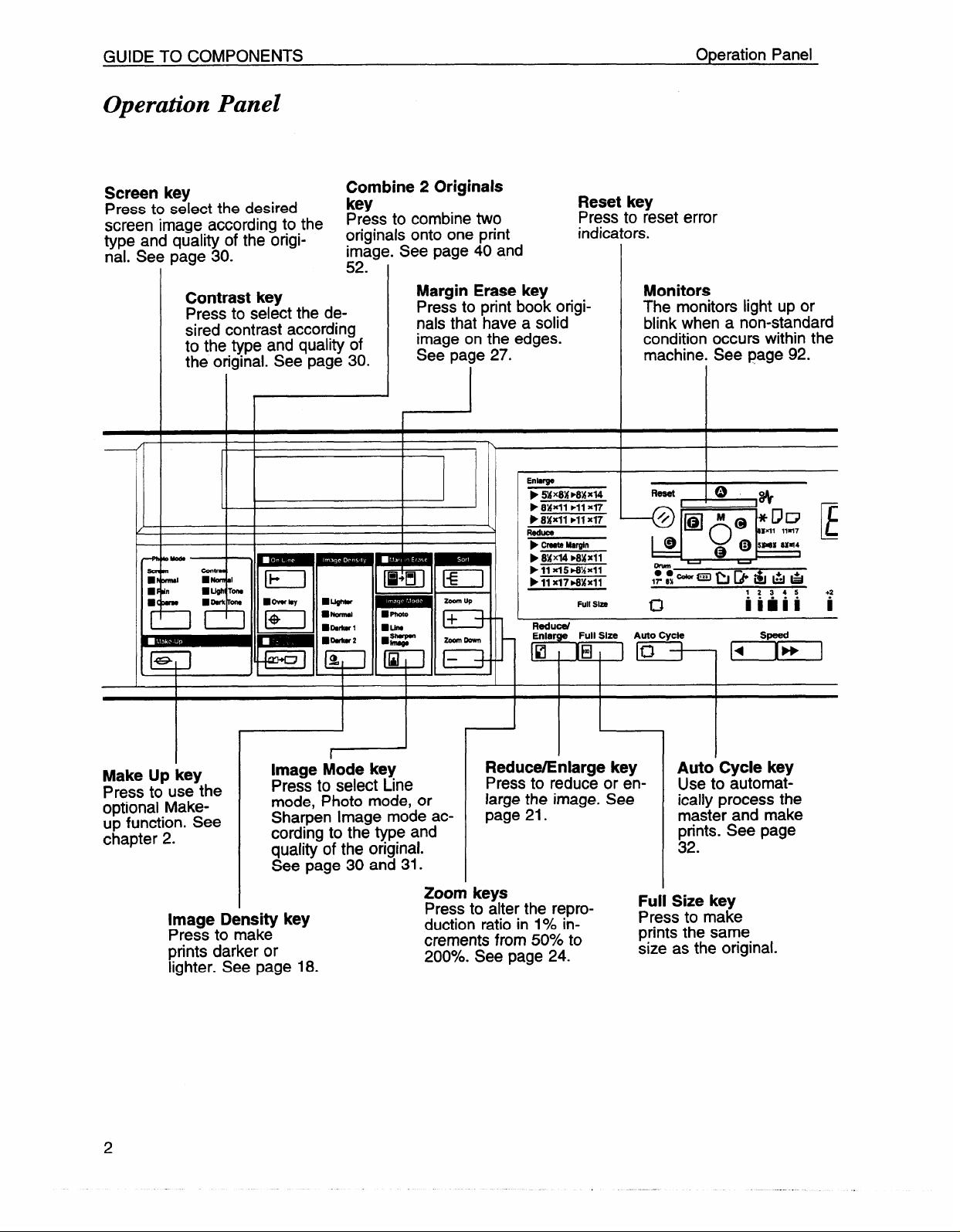

GUIDE TO COMPONENTS Operation Panel

Operation Panel

Screen key

Press to select the desired

screen image according to the

type and quality of the origi-

nal. See page 30.

Contrast key

Press to select the desired contrast according

to the type and quality of

the original. See page 30.

Combine 2 Originals

key

Press to combine two

originals onto one print

image. See page

co

ad.

Margin Erase key

Press to print book originals that have a solid

image on the edges.

See page 27.

40 and

Reset key

Press to reset error

indicators.

Enhrge

wx8xmAJd4

p

p 8XXll ➤11 x~

➤ 84Jfll ➤11 X17

Reduce

➤ Create M8rgln

➤ 8XX14 ➤8XX11

P 11 X15*%X11

➤ 11 X17 MMX11

Full Slzo

Monitors

The monitors light up or

blink when a non-standard

condition occurs within the

machine. See page 92.

E

+2

i

I

I

Make Up key

Press to use the

optional Makeup function. See

chapter 2.

Image Density key

Press to make

prints darker or

lighter. See page 18.

I

I

r

Image Mode key

Press to select Line

mode, Photo mode, or

Sharpen Image mode according to the type and

aualitv of the original.

See page 30 and 31.

I

w

I

I

Zoom keys

Press to alter the reproduction ratio in 1940increments from

200?40.See page 24.

I

Reduce/Enlarge key

Press to reduce or enlarge the image. See

page 21.

50’%0to

El

1

Auto Cycle key

Use to automatically process the

master and make

prints. See page

32.

Size key

Full

Press to make

prints the same

size as the original.

db

Page 8

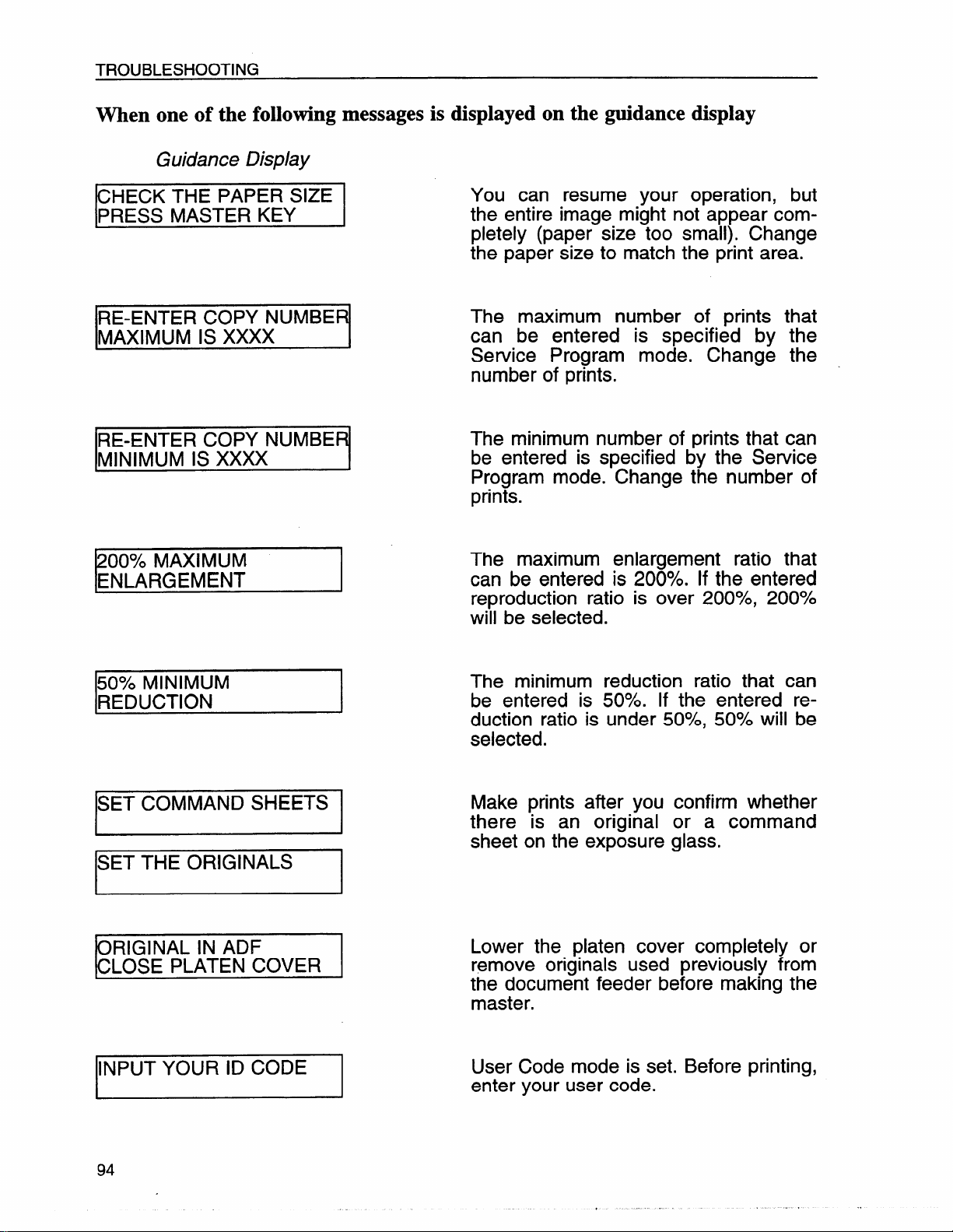

TROUBLESHOOTING

When one of the following messages is displayed on the guidance display

Guidance Display

CHECK THE PAPER SIZE

PRESS MASTER KEY

RE-ENTER COPY NUMBER

MAXIMUM IS XXXX

IRE-ENTER

lMINIMUM IS xxxx

200% MAXIMUM

ENLARGEMENT

cow NumERl

You can resume your operation, but

the entire image might not appear completely (paper size too small). Change

the paper size to match the print area.

The maximum number of prints that

can be entered is specified by the

Service Program mode. Change the

number of prints.

The minimum number of prints that can

I

be entered is specified by the Service

Program mode. Change the number of

prints.

The maximum enlargement ratio that

can be entered is 200940. If the entered

reproduction ratio is over 200?4, 200%

will be selected.

50?40 MINIMUM

REDUCTION

ISET COMMAND SHEETS I

SET THE ORIGINALS

ORIGINAL IN ADF

CLOSE PLATEN COVER

INPUT YOUR ID CODE

I

The minimum reduction ratio that can

be entered is 50?40. If the entered reduction ratio is under 50?4, 50?40will be

selected.

Make prints after you confirm whether

there is an original or a command

sheet on the exposure glass.

Lower the platen cover completely or

remove originals used previously from

the document feeder before making the

master.

User Code mode is set. Before printing,

enter your user code.

94

Page 9

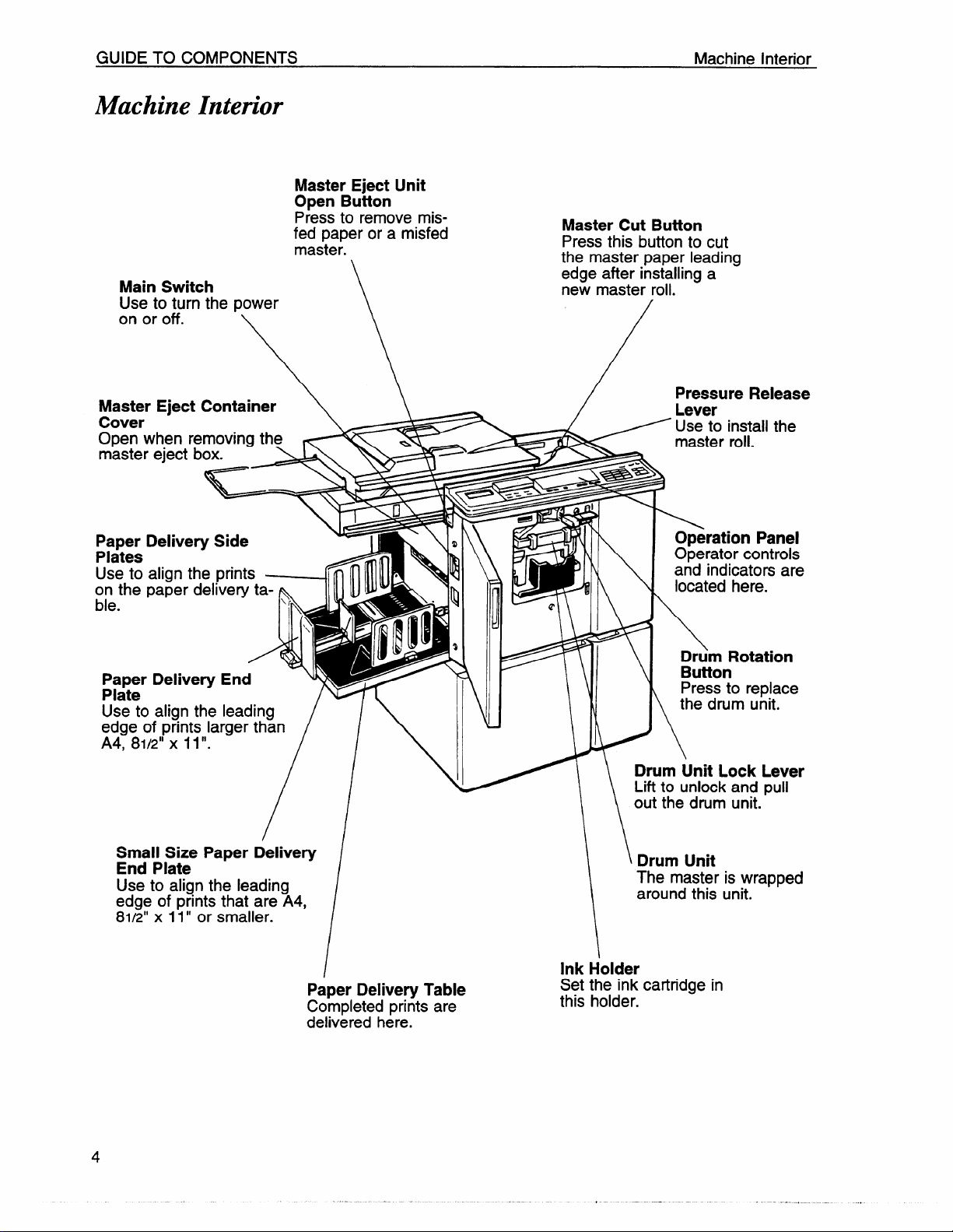

GUIDE TO COMPONENTS

Machine Interior

Main Switch

Use to turn the power

on or off.

Master Eject Unit

Open Button

P~essto remove misfed paper or a misfed

master.

\

Machine Interior

Master Cut Button

Press this button to cut

the master paper leading

edge after installing a

new master roil.

Master Eject Container

\\

Cover

Open when removing the

master eject box.

Paper Delivery Side

Plates

Use to align the prints

on the paper delivery ta-

ble.

Paper Delivery End

Plate

Use to align the leading

edge of prints larger than

A4, 81/2” x 11”.

Small Size Paper Delivery

End Plate

Use to align the leading

edge of prints that are A4,

81/2” x 11” or smaller.

*’

T&

\r

4

ll

//

70!

IN

/

m> q ‘$ ‘ \

‘

~\

/ ,njo,?,nzrapped

!JI”k‘N

Pressure Release

Lever

Use to install the

master roll.

Operation Panel

111’d’

Operator controls

and indicators are

located here.

\

Drum Rotation

Button

Press to replace

the drum unit.

Drum Unit Lock Lever

Lift to unlock and pull

out the drum unit.

Paper Delivery Table

Completed prints are

delivered here.

Set the ink cartridge in

this holder.

Page 10

INSTALLATION REQUIREMENTS

Power Connection

Power Connection

IJ Connect the power cord to an appropriate power source (as described inside

of the front cover).

n Make sure the plug is firmly inserted in the outlet.

CI

Avoid multiwiring.

~ Do

CI Make sure that the wall-outlet is near the machine and easily accessible,

not pinch the power cord.

Page 11

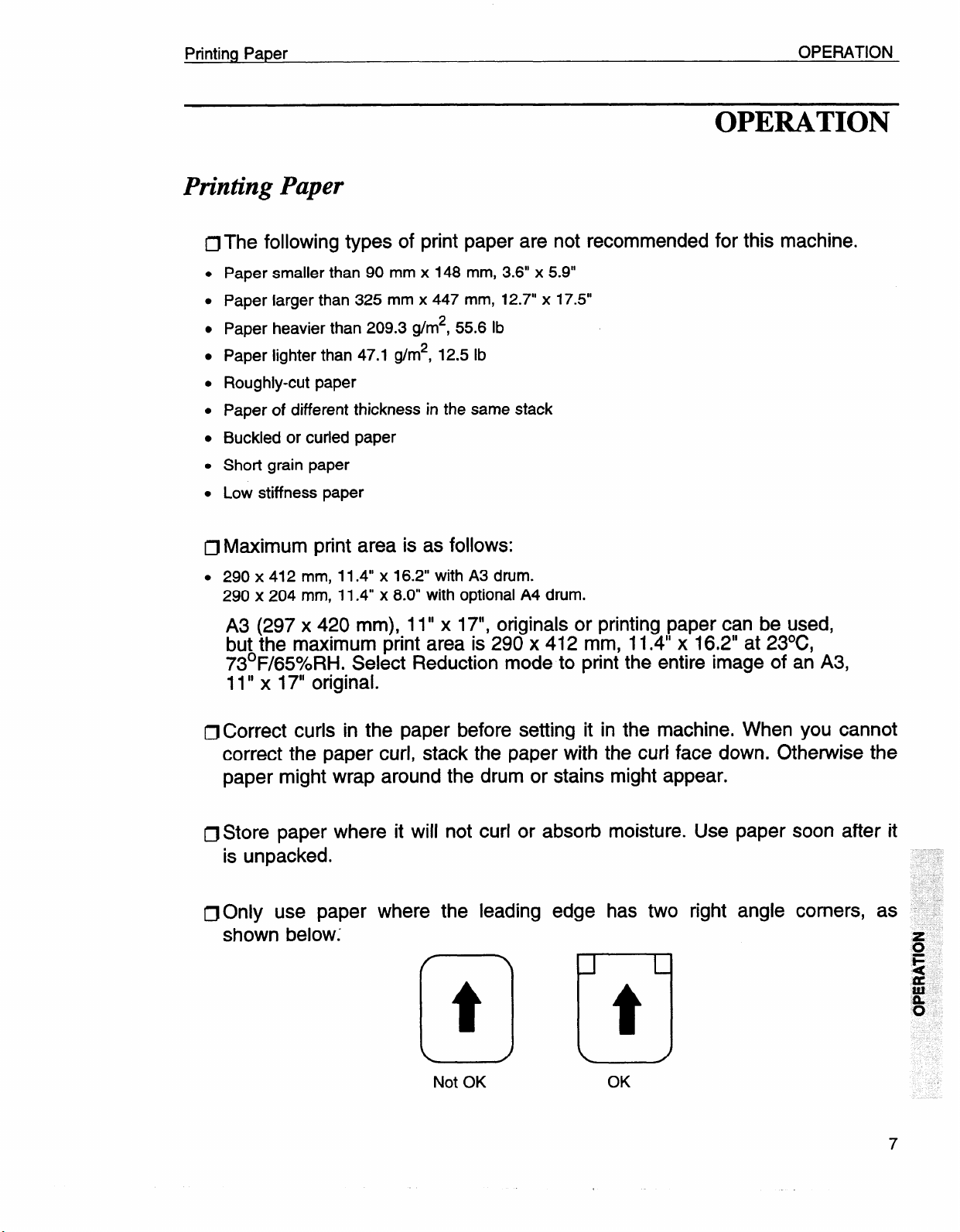

Printing Paper OPERATION

OPERATION

Printing Paper

fJ

The following types of print paper are not recommended for this machine.

●

Paper smaller than 90 mm x 148 mm, 3.6” x 5.9”

●

Paper larger than 325 mm x 447 mm, 12.7” x 17.5”

●

Paper heavier than 209.3 g/m2, 55.6 lb

●

Paper lighter than 47.1 g/m2, 12.5 lb

●

Roughly-cut paper

●

Paper of different thickness in the same stack

●

Buckled or curled paper

●

Short grain paper

●

Low stiffness paper

n Maximum print area is as follows:

.

290 x412 mm, 11.4” x 16.2” with A3 drum.

290 x 204 mm, 11.4” x 8.0” with optional A4 drum.

A3 (297 x 420 mm), 11” x 17“, originals or printing paper can be used,

but the maximum print area is 290 x412 mm, 11.4” x 16.2” at 23°C,

73°F/65YoRH. Select Reduction mode to print the entire image of an A3,

11” x 17“ original.

IJ Correct curls in the paper before setting it in the machine. When you cannot

correct the paper curl, stack the paper with the curl face down. Otherwise the

paper might wrap around the drum or stains might appear.

IJ Store paper where it will not curl or absorb moisture. Use paper soon after it

is unpacked.

n Only use paper

shown below;

where the leading

edge has two

right angle comers,

Not OK

t

El

OK

Page 12

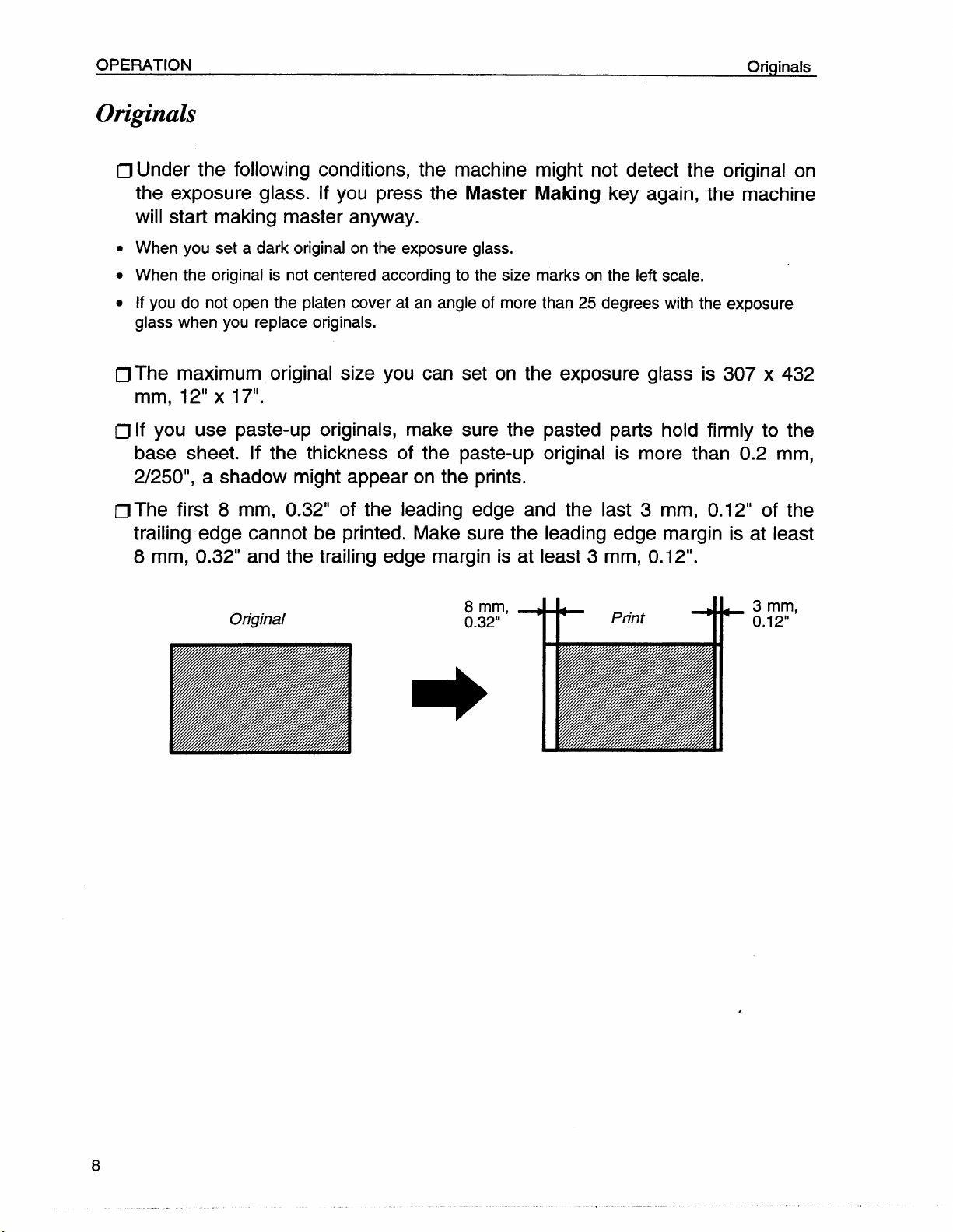

OPERATION

Originals

Originals

~

Under the following conditions, the machine might not detect the original on

the exposure glass. If you press the Master Making key again, the machine

will start making master anyway.

●

When you set a dark original on the exposure glass.

●

When the original is not centered according to the size marks on the left scale.

●

If you do not open the platen cover at an angle of more than 25 degrees with the exposure

glass when you replace originals.

The maximum original size you can set on the exposure glass is 307 x 432

n

mm, 12” x 17”.

~ If you use paste-up originals, make sure the pasted parts hold firmly to the

base sheet. If the thickness of the paste-up original is more than 0.2

2/250”,

IJ The first 8 mm, 0.32” of the leading edge and the last 3 mm, 0.12“ of the

trailing edge cannot be printed. Make sure the leading edge margin is

8 mm, 0.32” and the trailing edge margin is at least 3 mm, 0.1 2“.

a shadow might appear on the prints.

at least

mm,

Original

8 mm,

0.32”

*

Print

*

3 mm,

0.12”

Page 13

Preparation For Printing

Preparation For Printing

OPERATION

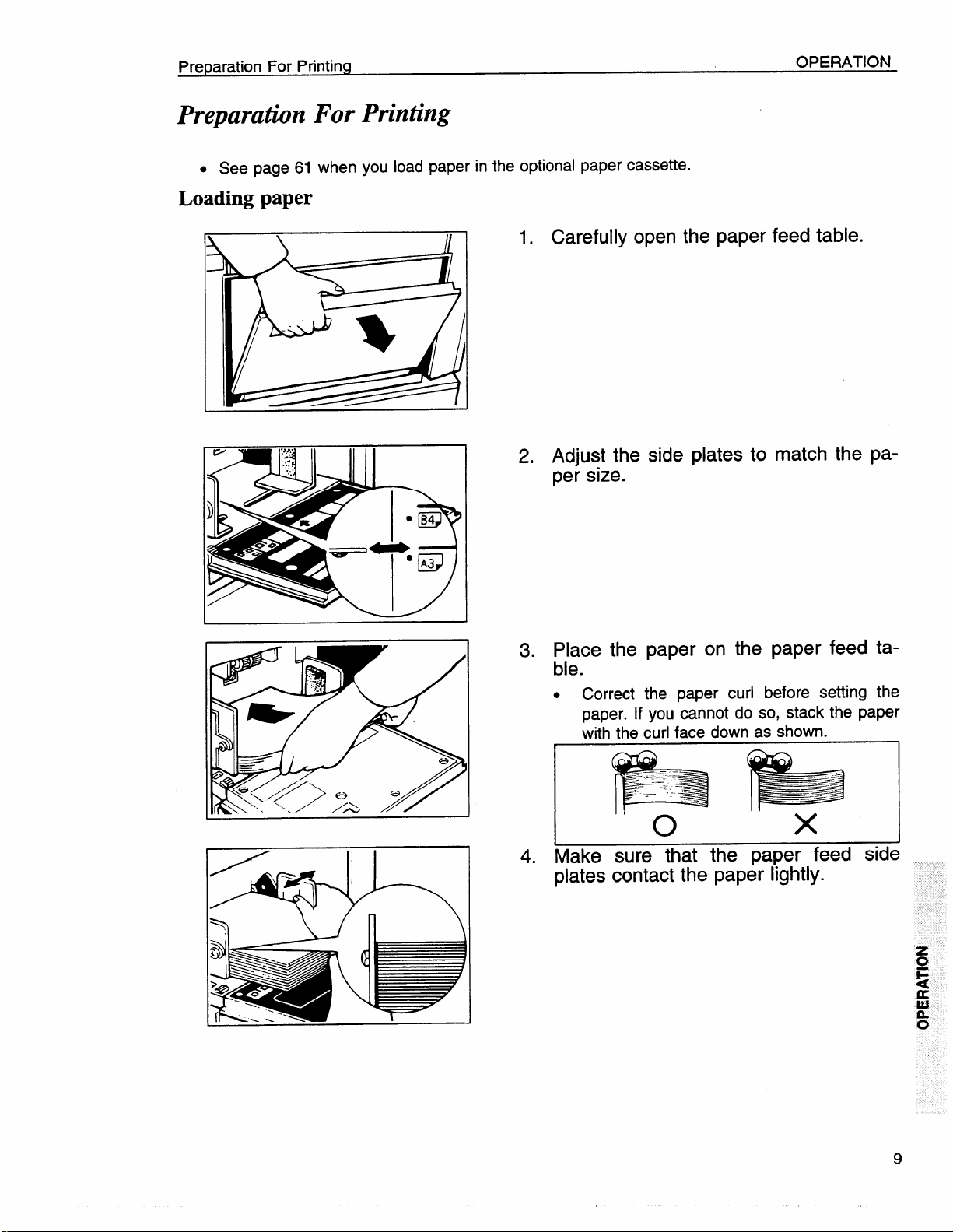

. See page 61 when you load paper in the

Loading paper

w

)

P~

:s .....

.. .

. .+

.:: .

. ..

..

m

-00

e

-- . *3

● B4

Q

D

optional

paper cassette.

1. Carefully open the paper feed table.

2. Adjust the side plates to match the paper size.

3. Place the paper on the paper feed ta-

ble.

.

Correct the paper curl before setting the

paper. If you cannot do so, stack the paper

with the curl face down as shown.

&q

Make sure that the paper feed side

4.

plates contact the paper lightly.

z

u

F

4

&

a.

o

Page 14

OPERATION

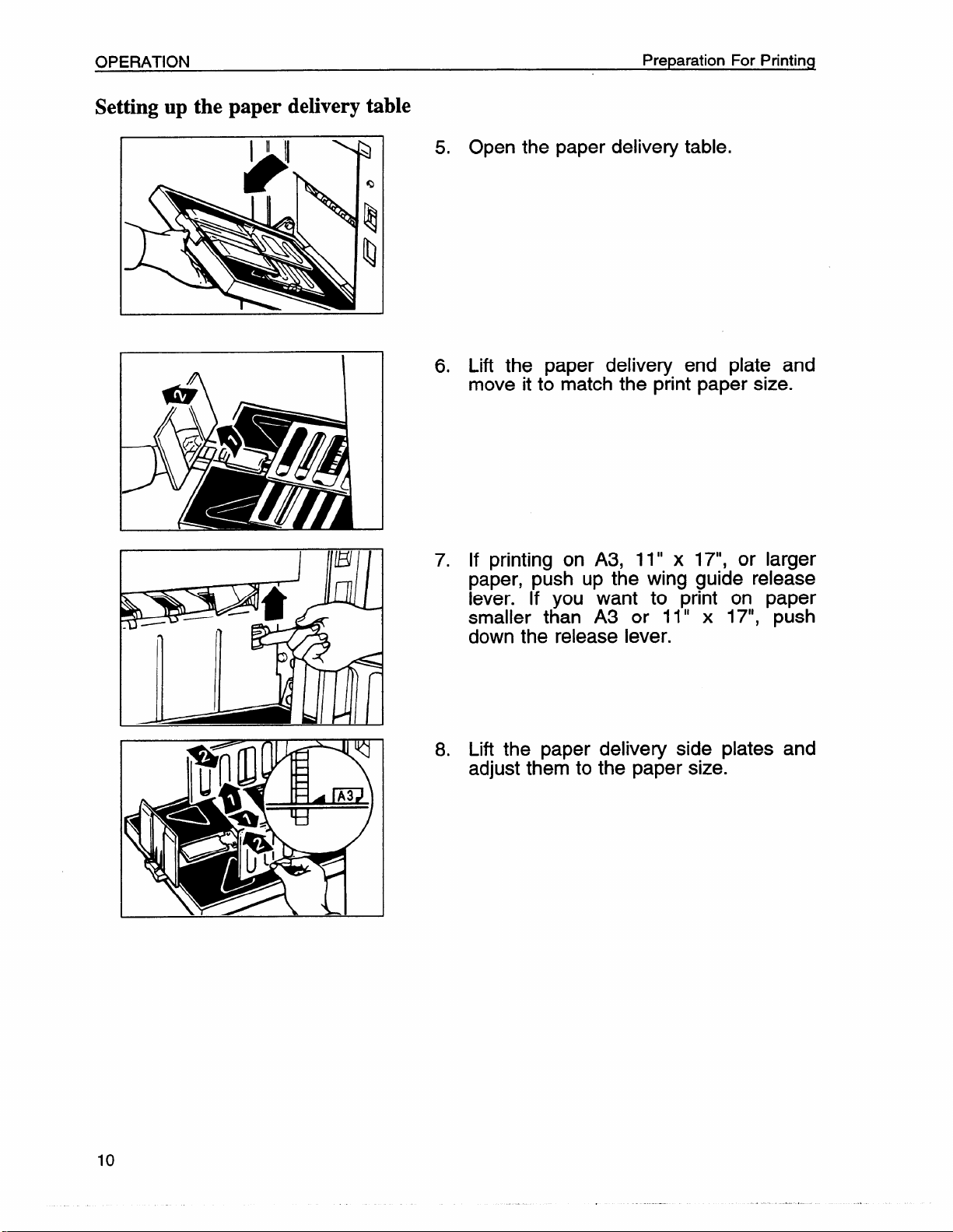

Setting up the paper delivery table

Preparation For Printing

5. Open the paper delivery table.

6. Lift the paper delivery end plate and

move it to match the print paper size.

I WI I

7. If printing on A3, 11” x 17“, or larger

paper, push up the wing guide release

lever. If you want to print on paper

smaller than A3 or 11” x 17“, push

down the release lever.

8. Lift the paper delivery side plates and

adjust them to the paper size.

Page 15

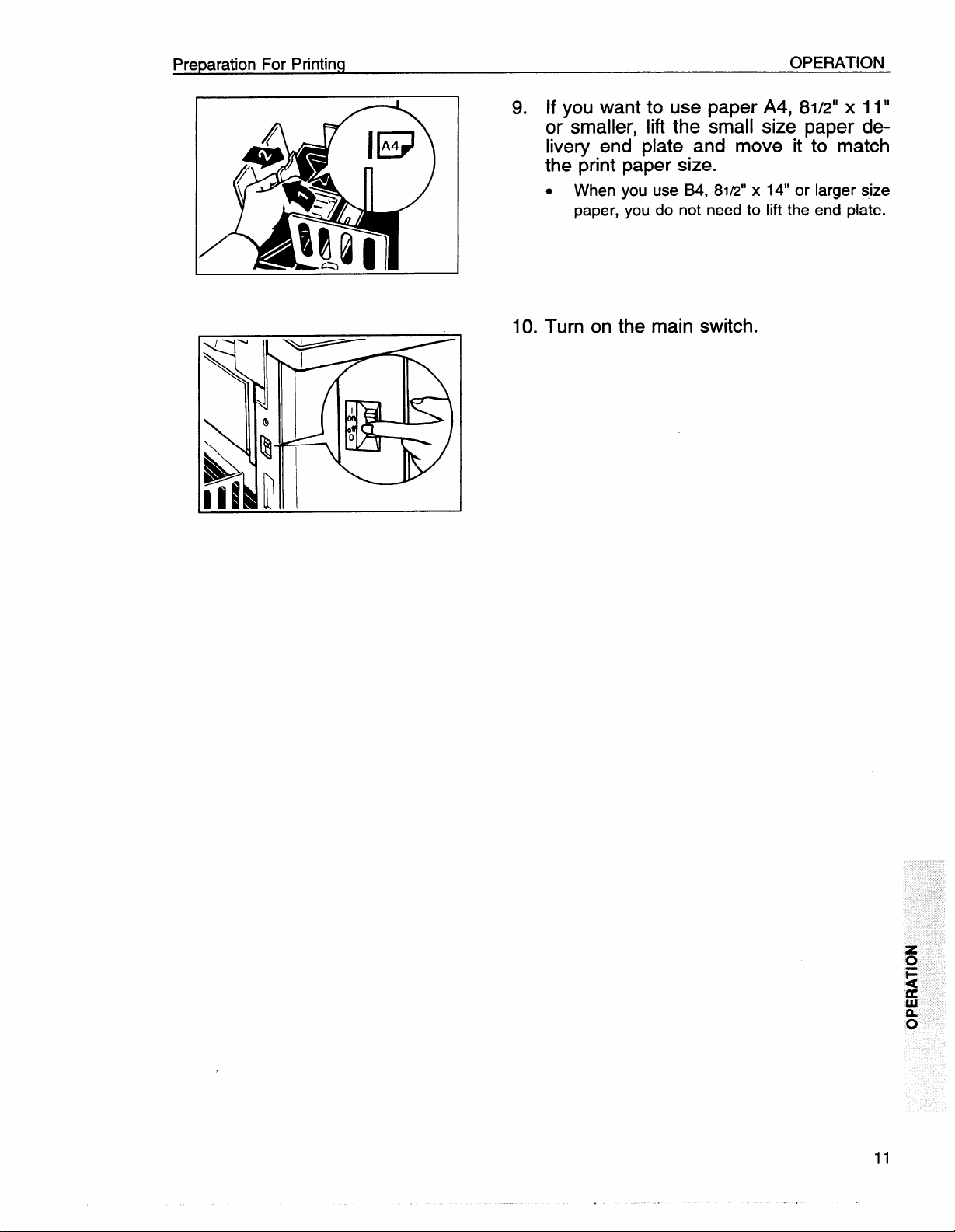

Preparation For Printing

OPERATION

9. If you want to use paper A4, 8112”x 11”

or smaller, lift the small size paper de-

livery end plate and move it to match

the print

.

When

paper,

paper size.

you use B4, 8112”x 14“ or

you do not need to lift the

larger size

end plate.

10. Turn on the main switch.

Page 16

OPERATION

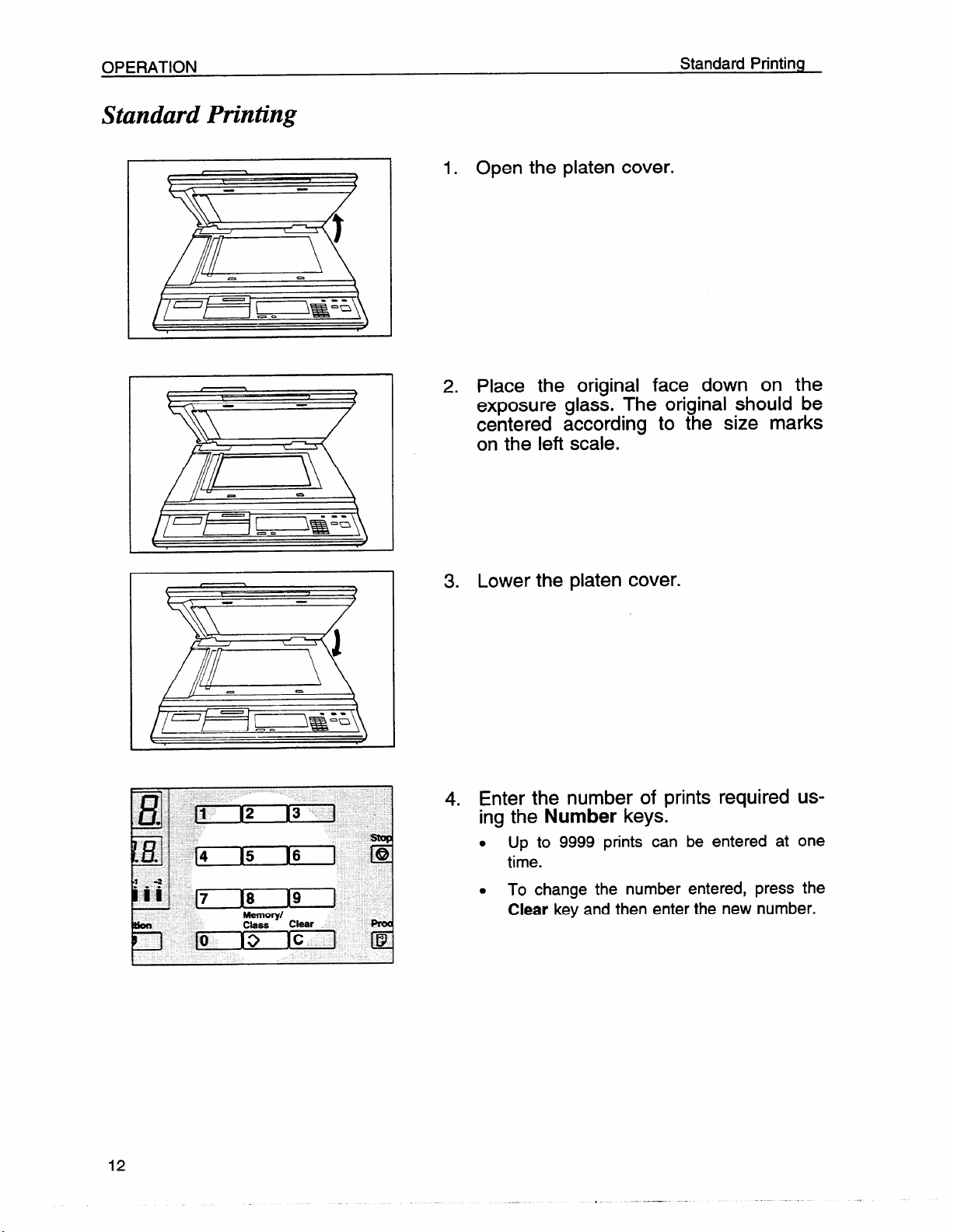

Standard Printing

Standard Printing

1

1. Open the platen cover.

2. Place the original face down on the

exposure

glass. The original should be

centered according to the size marks

on the left scale.

3.

Lower the platen cover.

4. Enter the number of prints required using the Number keys.

. Up to 9999 prints can be entered at one

time.

. To change the number entered, press the

Clear key and then enter the new number.

Page 17

Standard Printing

OPERATION

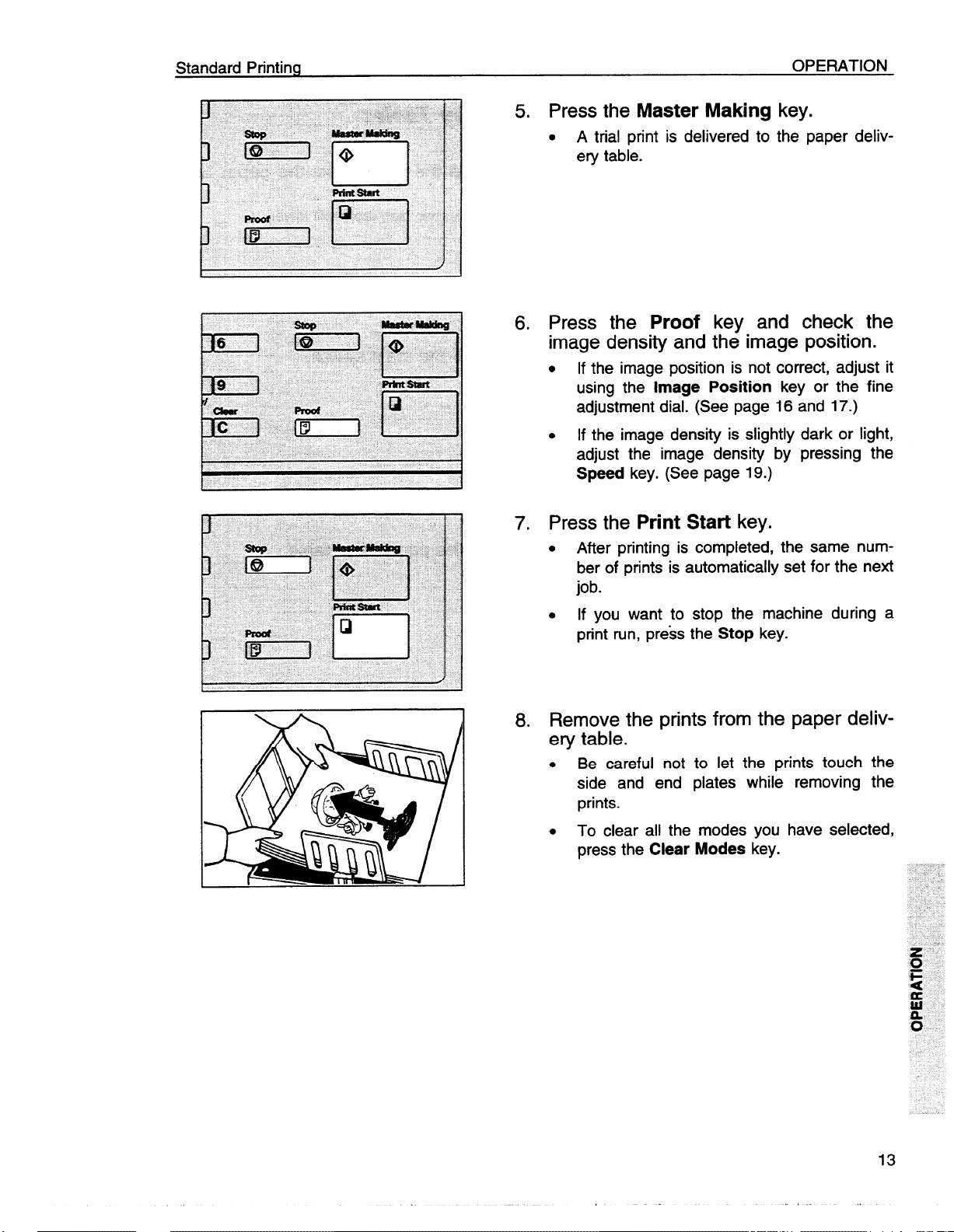

5. Press the Master Making key.

. A trial print is delivered to the paper deliv-

ery table.

6. Press the Proof key and check the

image density and the image position.

● Ifthe image position is not correct, adjust it

using the

adjustment dial. (See page 16 and 17.)

. If the image density is slightly dark or light,

adjust the image density by pressing the

Speed key. (See page 19.)

Image Position key or the fine

7. Press the Print Start key.

● After printing is completed, the same num-

ber of prints is automatically set for the next

job.

you want to stop the machine during a

. If

print run, press the

Stop key.

8. Remove the prints from the paper delivery table.

. Be careful not to let the prints touch the

side and end plates while removing the

prints.

. To clear all the modes you have selected,

press the

Clear Modes key.

13

,,

Page 18

OPERATION

Restoring Paper Feed And Paper Delivery Tables

Restoring Paper Feed And Paper Delivery Tables

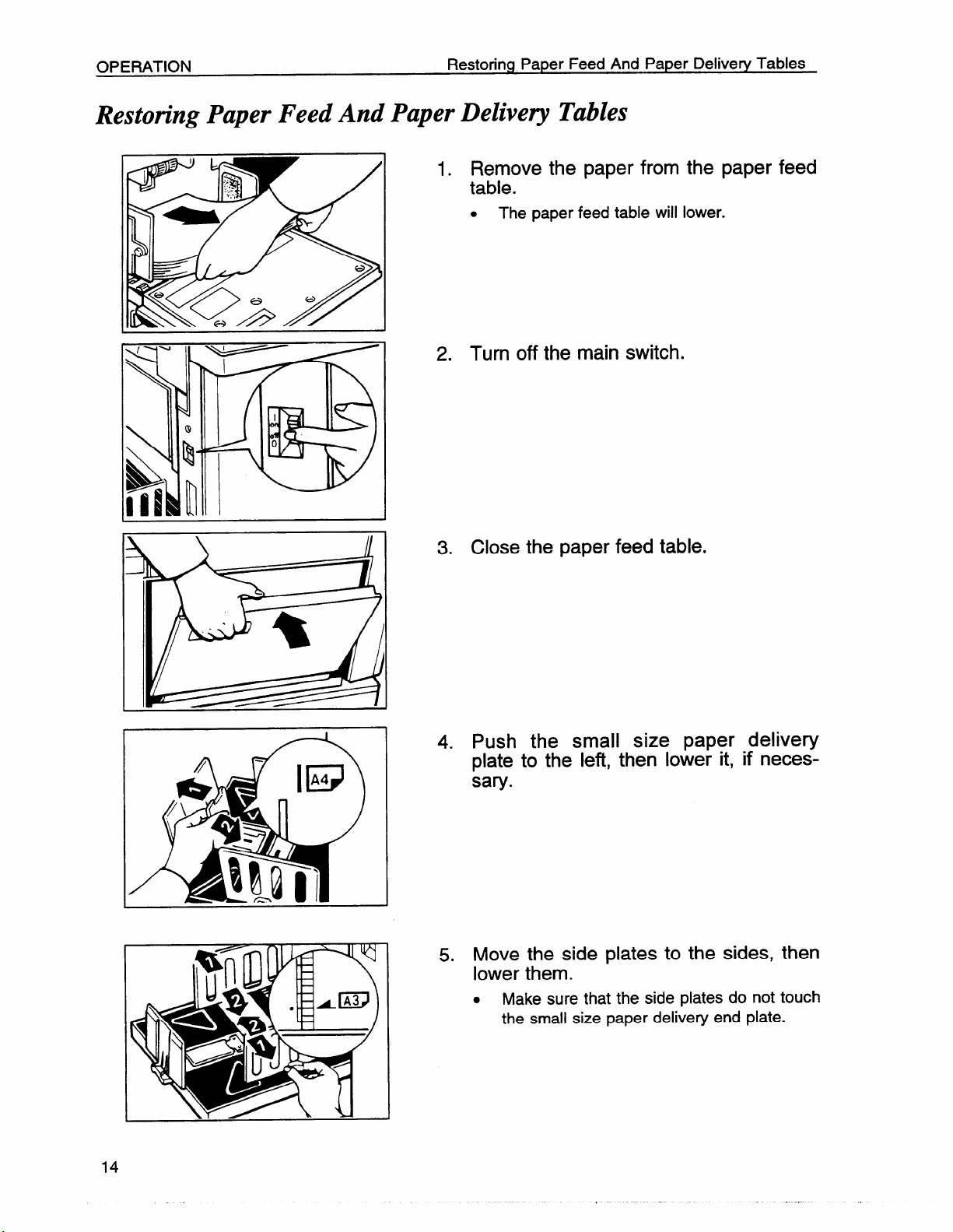

1. Remove the paper from the paper feed

table.

.

The paper feed table will lower.

2. Turn off the main switch.

3. Close the paper feed table.

4. Push the small size paper delivery

plate to the left, then lower it, if necessary.

5. Move the side plates to the sides, then

lower them.

.

Make sure that the side plates do not touch

the small size paper delivery end plate.

Page 19

Restoring Paper Feed And Paper Delivery Tables

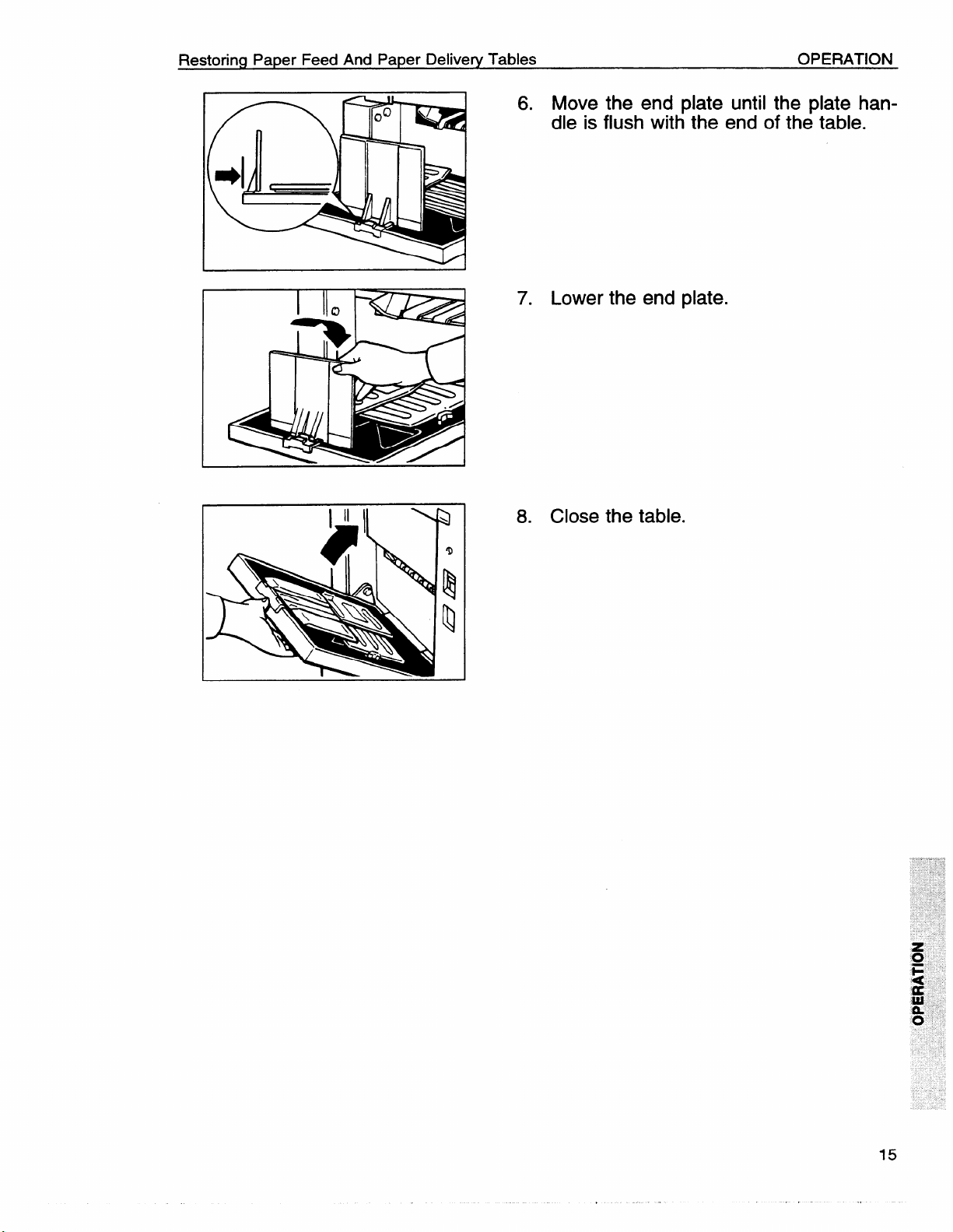

6. Move the end plate until the plate han-

I

7. Lower the end plate.

OPERATION

dle is flush with the end of the table.

8. Close the table.

Page 20

OPERATION

Adjusting The Image Position

A&usting

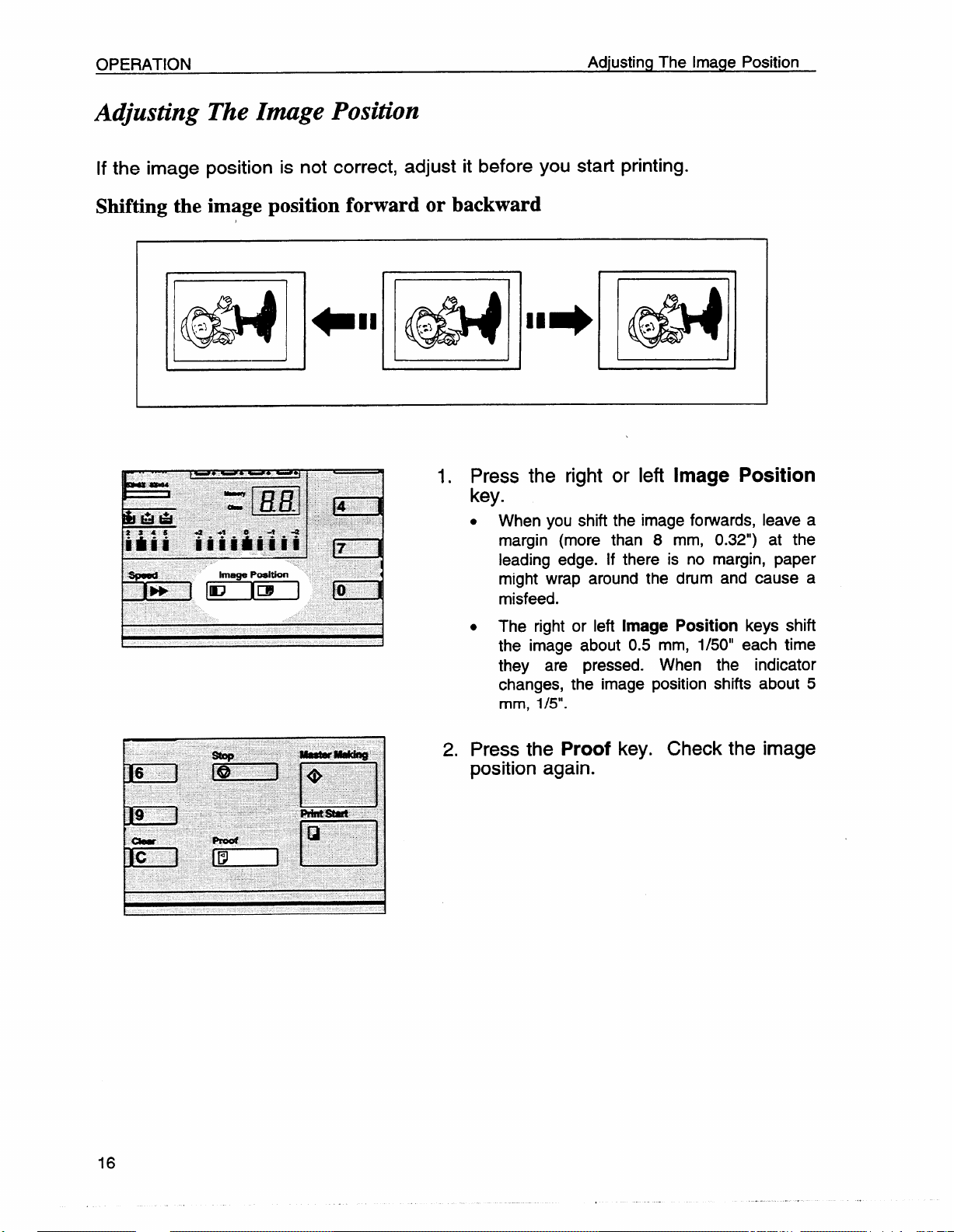

If the image

Shifting the

The Image Position

position is not correct, adjust it before you start printing.

image position forward or backward

1. Press the right or left Image Position

key.

. When you shift the image forwards, leave a

margin (more than 8 mm, 0.32”) at the

leading edge. If there is no margin, paper

might wrap around the drum and cause a

misfeed.

. The right or left

the image about 0.5 mm, 1/50” each time

they are pressed.

changes, the image position shifts about 5

mm, 1/5”.

Image Position keys shift

When the indicator

2. Press the Proof key. Check the image

position again.

Page 21

Adjusting The Image Position

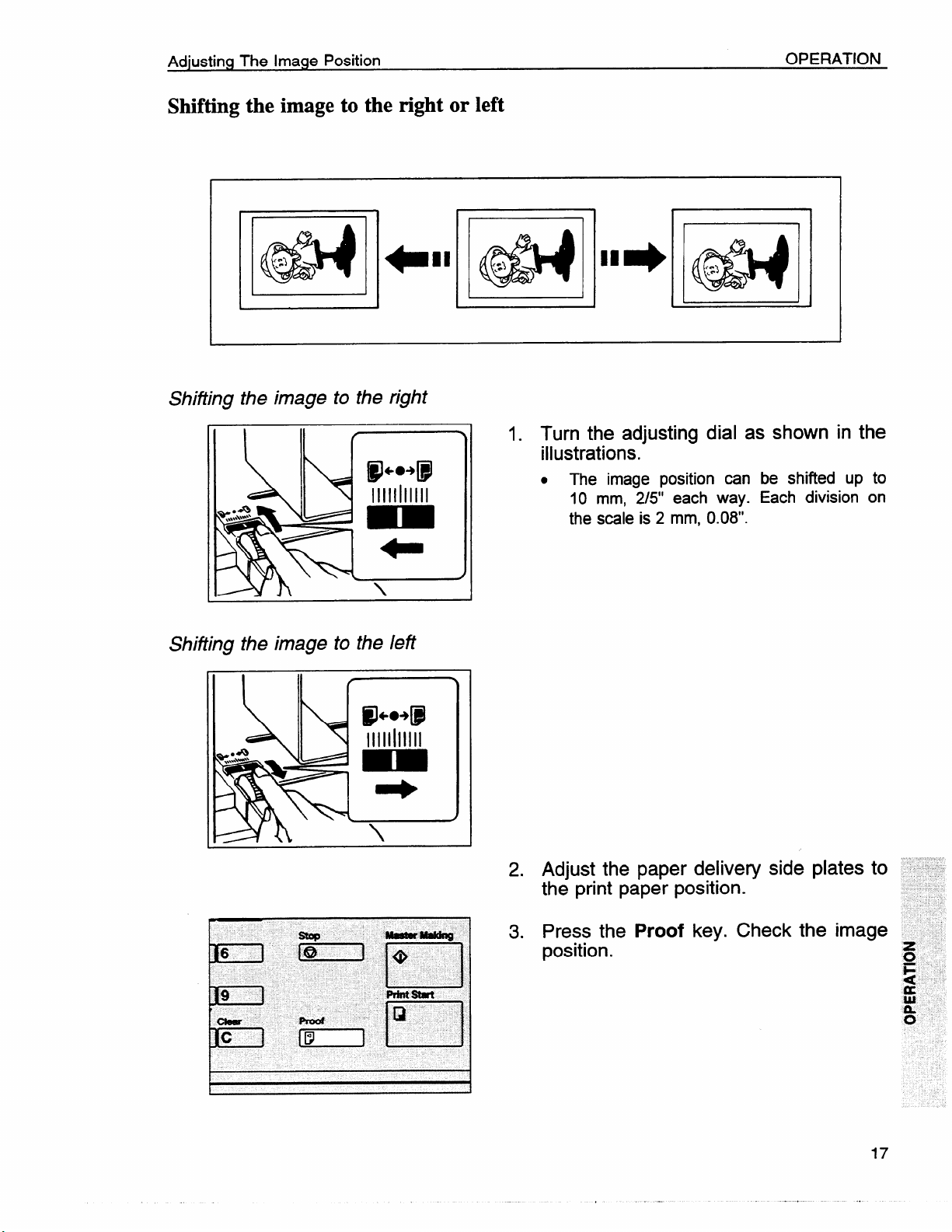

Shifting the image to the right or left

OPERATION

I

Shiiting the image to the right

@J+.+@

11111111111

L

Shifting the image to the left

IP-49

11111111111

d

1. Turn the adjusting dial as

illustrations.

. The image position can be shifted up to

10 mm, 2/5” each way. Each division on

the scale is 2 mm, 0.08”.

1

in the

Adjust the paper delivery side plates to

2.

the print paper position.

3.

Press the

Proof key. Check

position.

Page 22

OPERATION

Adjusting The Image Density

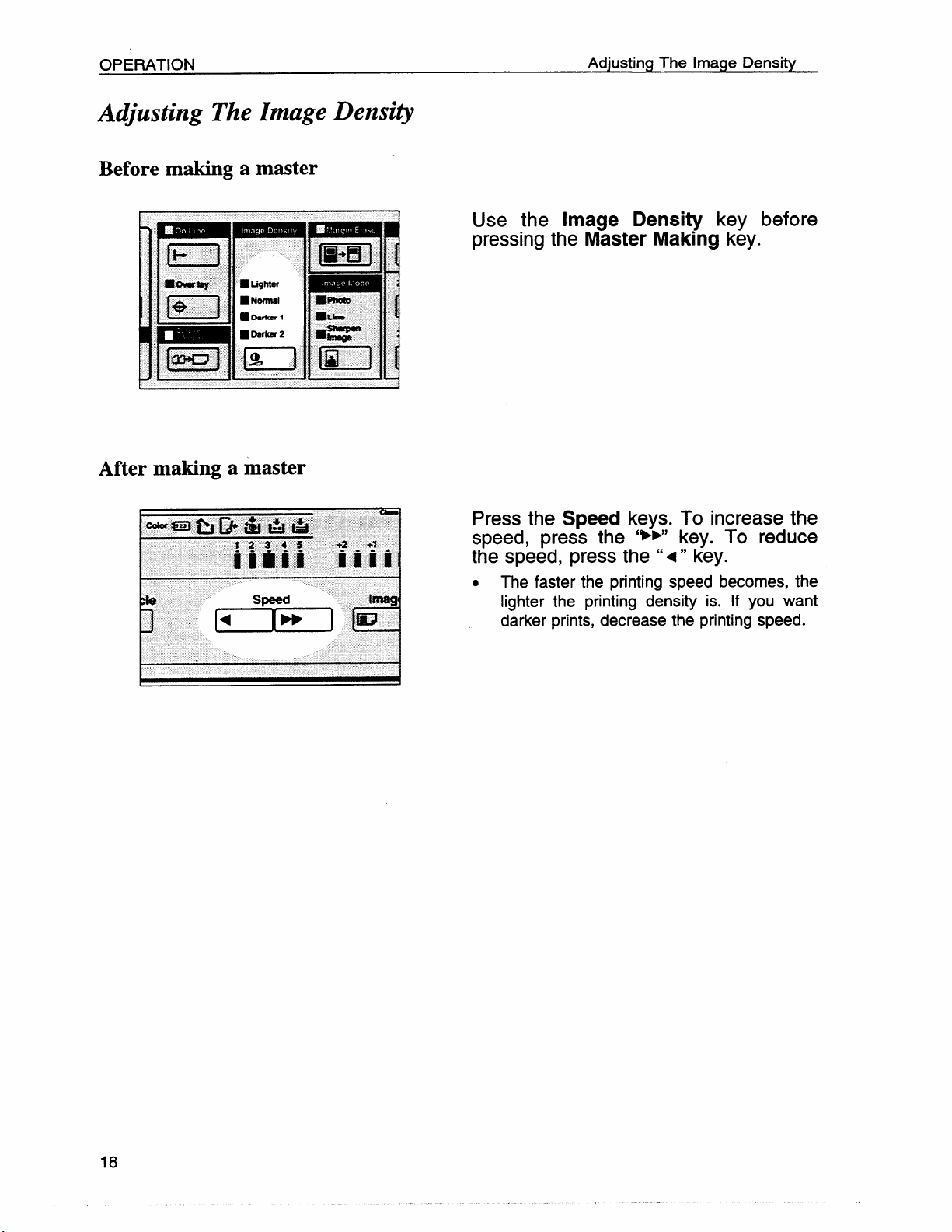

Before making a master

Adjusting The Image Density

B

ti

mvawe

13E2 ::R’, :s”

IziEEl [’1 gz’-l

iDDnl

u

■ LigMtn

gDarkw2

After making a master

Use the Image Density key before

pressing the

m

n

a=

Press the

Master Making key.

Speed keys. To increase the

speed, press the ‘*~” key. To reduce

the speed, press the “4” key.

. The faster the printing speed becomes, the

lighter the printing density is. If you want

darker prints, decrease the printing speed.

Page 23

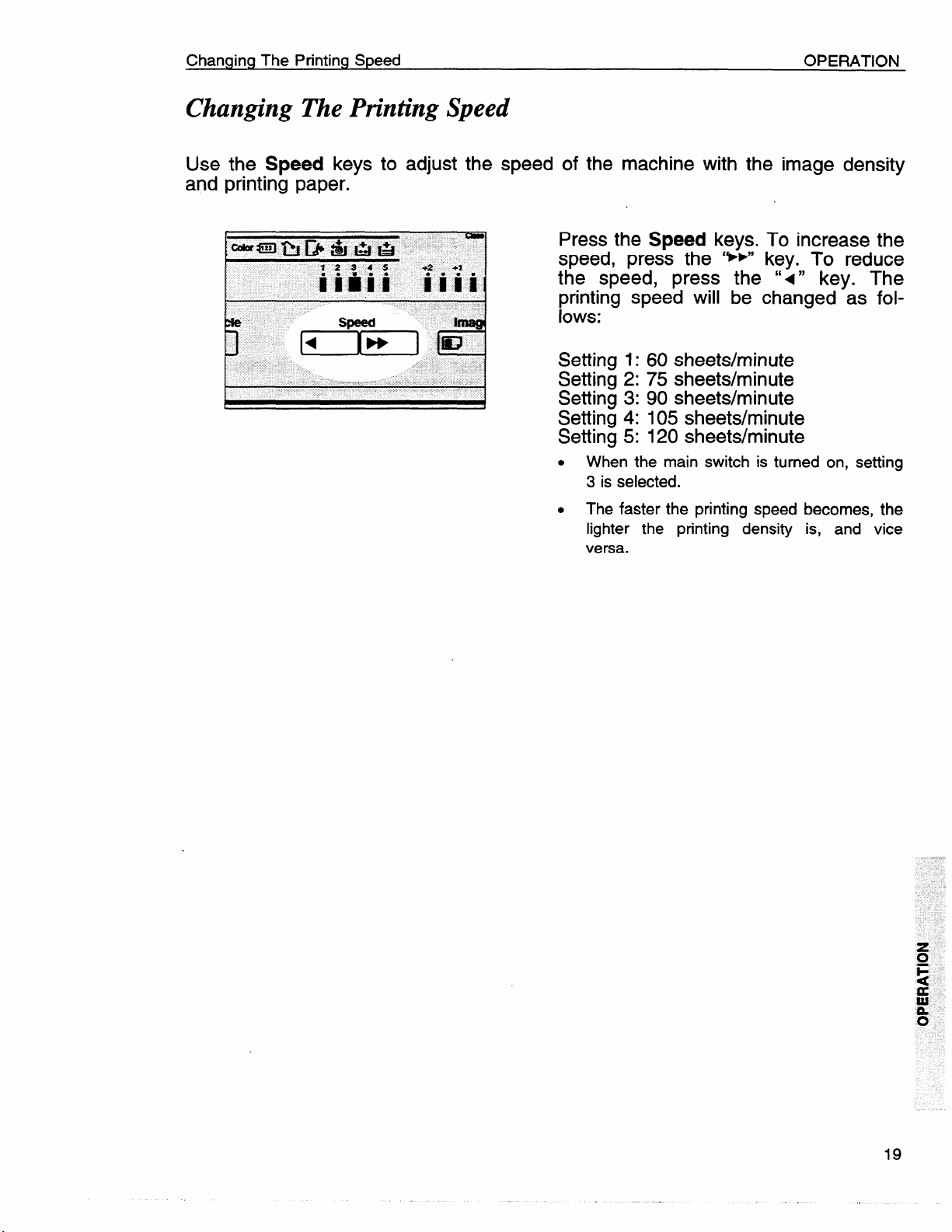

Changing The Printing Speed

Changing The Printing Speed

OPERATION

Use the Speed keys

and printing paper.

to adjust the speed of the machine with the image density

Press the

Speed keys. To increase the

speed, press the ‘**” key. To reduce

the speed, press the “<” key. The

printing speed will be changed as follows:

Setting 1:60 sheets/minute

Setting 2:75 sheets/minute

Setting 3:90 sheets/minute

Setting 4:105 sheets/minute

Setting 5:120 sheets/minute

. When the main switch is turned on, setting

3 is selected.

. The faster the printing speed

lighter the printing density

versa.

becomes, the

is, and vice

Page 24

OPERATION

Stopping The Machine During A Printing Run

Stopping The Machine During A Printing Run

When you want to stop the machine during a print run and print the next

original

1. Press the Stop key.

2. Set the new original.

3. Re-enter

press the

the number of prints and

Master Making key.

When you want to change the number of prints entered or to check the completed prints

1. Press the Stop key.

2. Change the number

the completed prints.

.

When you change the number of prints,

you can re-enter the number using the

Number keys after pressing the Stop key.

Press the Print Start key.

3.

of prints or check

Page 25

Reduce/Enlarge Printing

Reduce/Enlarge Printing

OPERATION

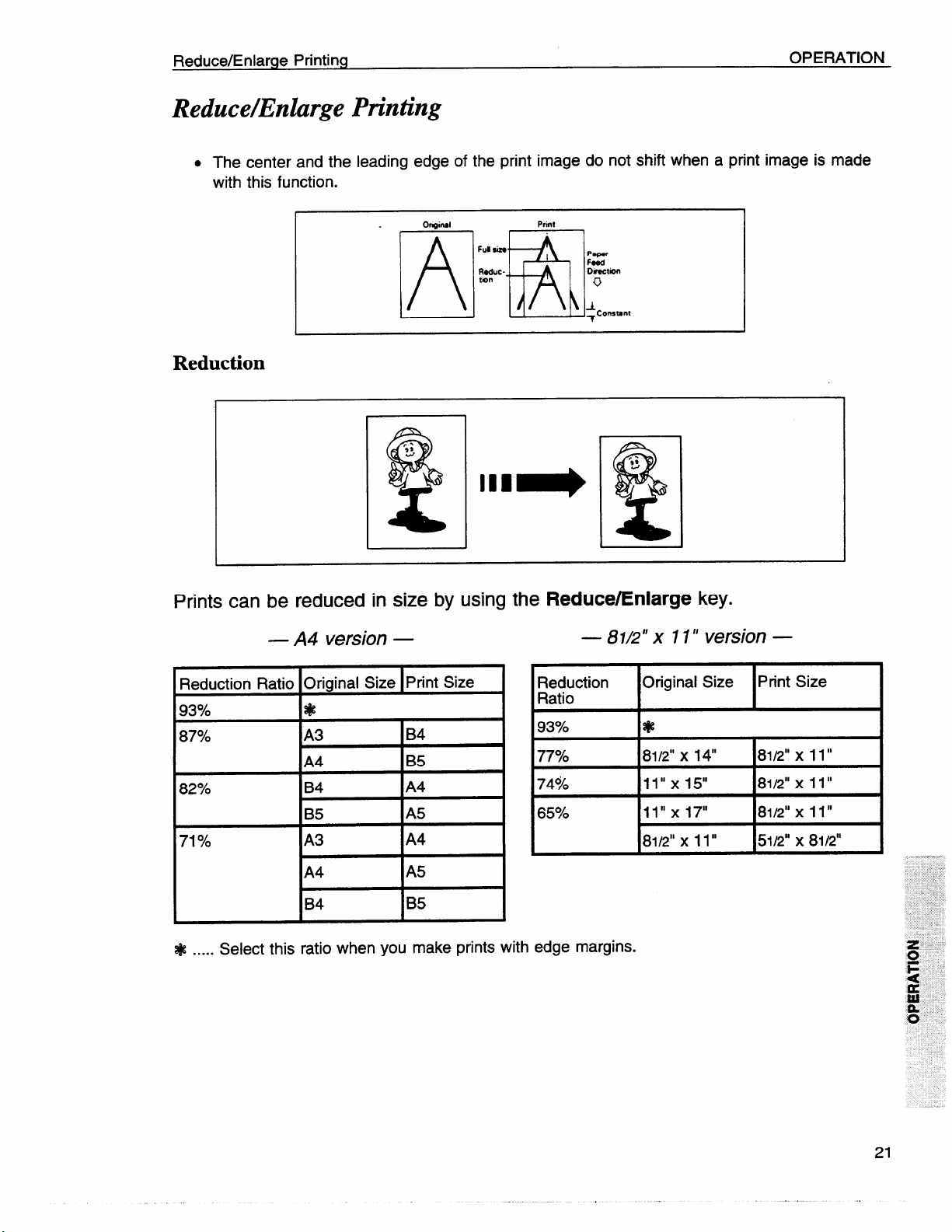

● The

with

center and the

this function.

leading

edge of the print image do lot shift when a print image is made

Print

t

A

Full siz,

Ro8uctm

R

P8fmr

Feed

Chmction

0

-L

Consmnt

~

Reduction

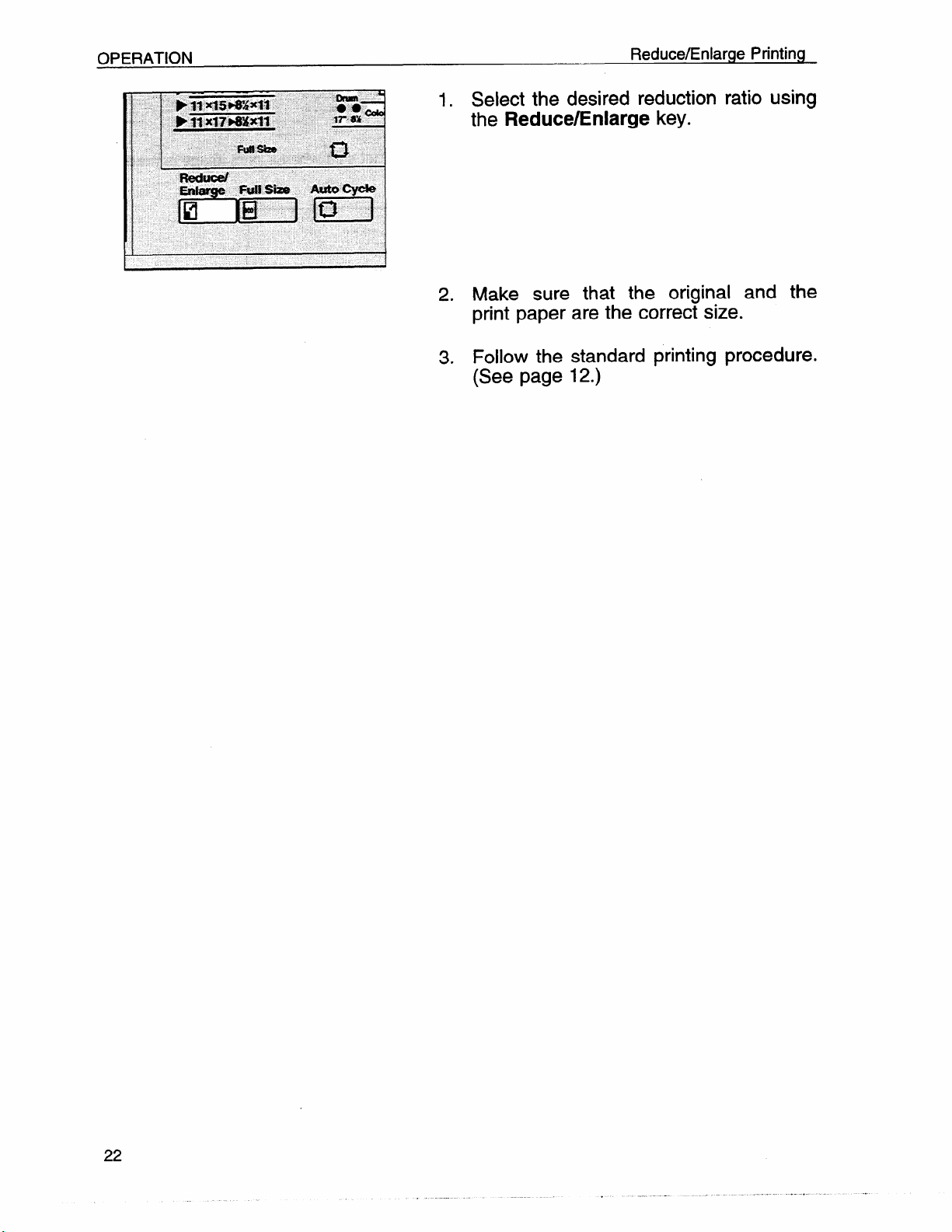

Prints can be reduced in size by using the Reduce/Enlarge key.

— A4 version —

Reduction Ratio

93%

87940

I

i?--E--

82%

71%fO

Select this ratio when you make prints with edge margins.

.....

*

B4

A4

B4

IA4

A5

I

IB5

— 81/2” x 11” version —

Reduction Original Size

Ratio

93%

7770

7490 11’’ XI5° 8112”x 11”

65?40

*

X 14“

81/2”

11” x 17” 8112”x 11”

L

8112”x 11” 51/2” x 81/2t’

Print Size

81/2” X 11“

Page 26

Reduce/Enlarge Printing

1. Select the desired reduction ratio using

the

Reduce/Enlarge key.

2. Make sure that the original and the

print paper are the correct size.

3. Follow the standard printing procedure.

(See page 12.)

Page 27

Reduce/Enlarge Printing

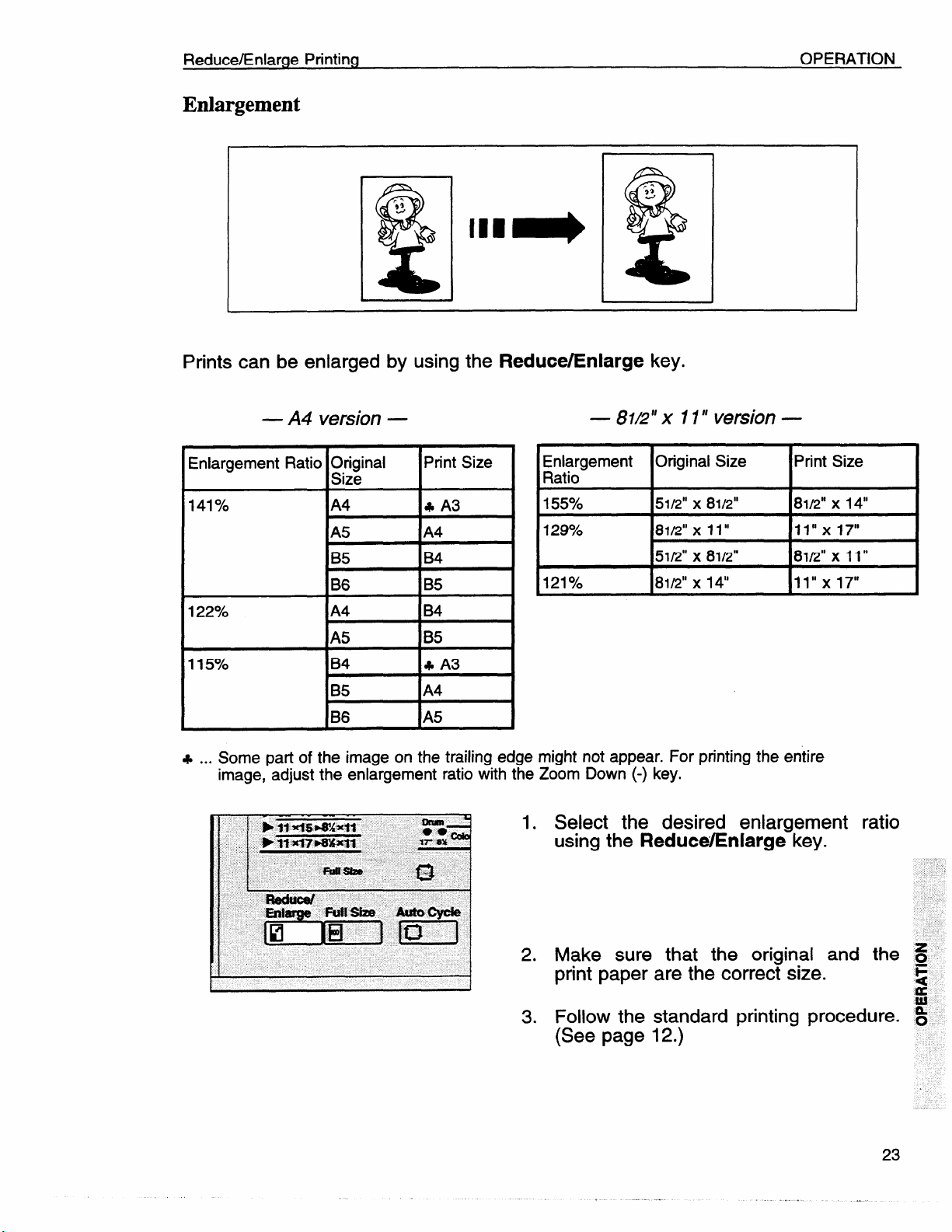

Enlargement

Prints can be enlarged by using the Reduce/Enlarge key.

OPERATION

— A4 version —

Enlargement Ratio O&inal

I

141Yo

122%-0

115?40

...

Some patt of the image on the trailing ed! Ie might not appear. For printing the entire

+

image, -adjust the enlargement ratio

IA4

tA5 1A4

B5

B6

A4

A5

IB4

IB5

IB6

Print Size

I

B4

B5

B4

B5

k A3

IA4

with 1

~a~igement Original Size

155?40 51/2” x 8112”

129% 81/2”

121?40 81/2” x 14“

]e Zoom Down (-) key.

— 81L?”x 11” version —

x 11” 11’’ XI7°

51/2” x 81/2”

1. Select the desired enlargement ratio

using the

ReduceEnlarge key.

Print Size

8112”x 14“

8112”x 11”

11’’ X17°

2. Make sure that the original and the S

print paper are the correct size.

3. Follow the standard printing procedure. ~

(See page 12.)

F

s

Page 28

OPERATION

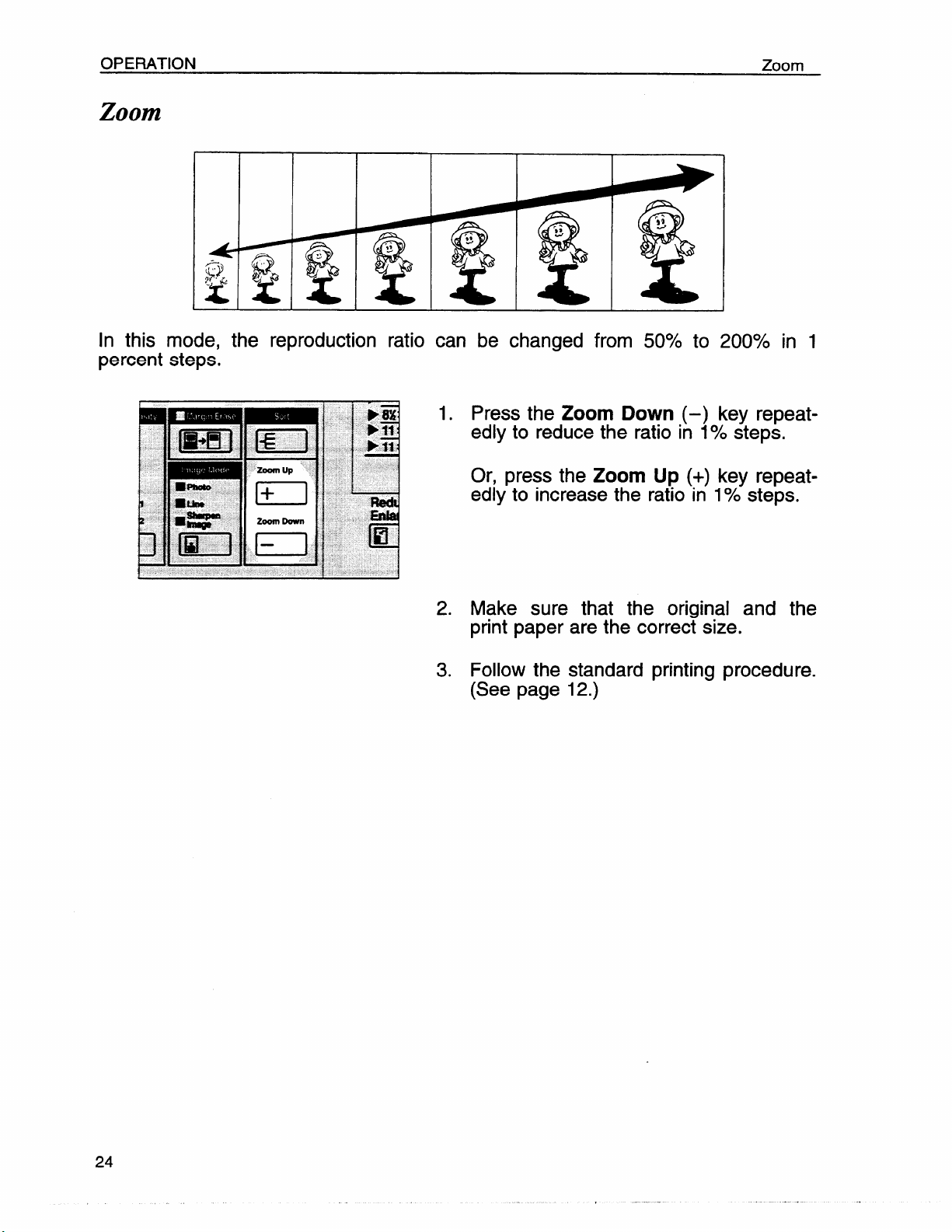

Zoom

Zoom

In this mode, the reproduction ratio can be changed from 50% to 200’XO in 1

percent steps.

1. Press the Zoom Down

edly to reduce the ratio

Or, press the

edly to increase the ratio in

2.3.Make sure that the original and the

print paper are the correct size.

Follow the standard printing procedure.

(See page 12.)

Zoom Up (+)

(–) key repeat-

in 10/0steps.

key repeat-

1?40steps.

Page 29

Erasing Center And Edge Margins

OPERATION

Erasing Center And Edge Margins

I

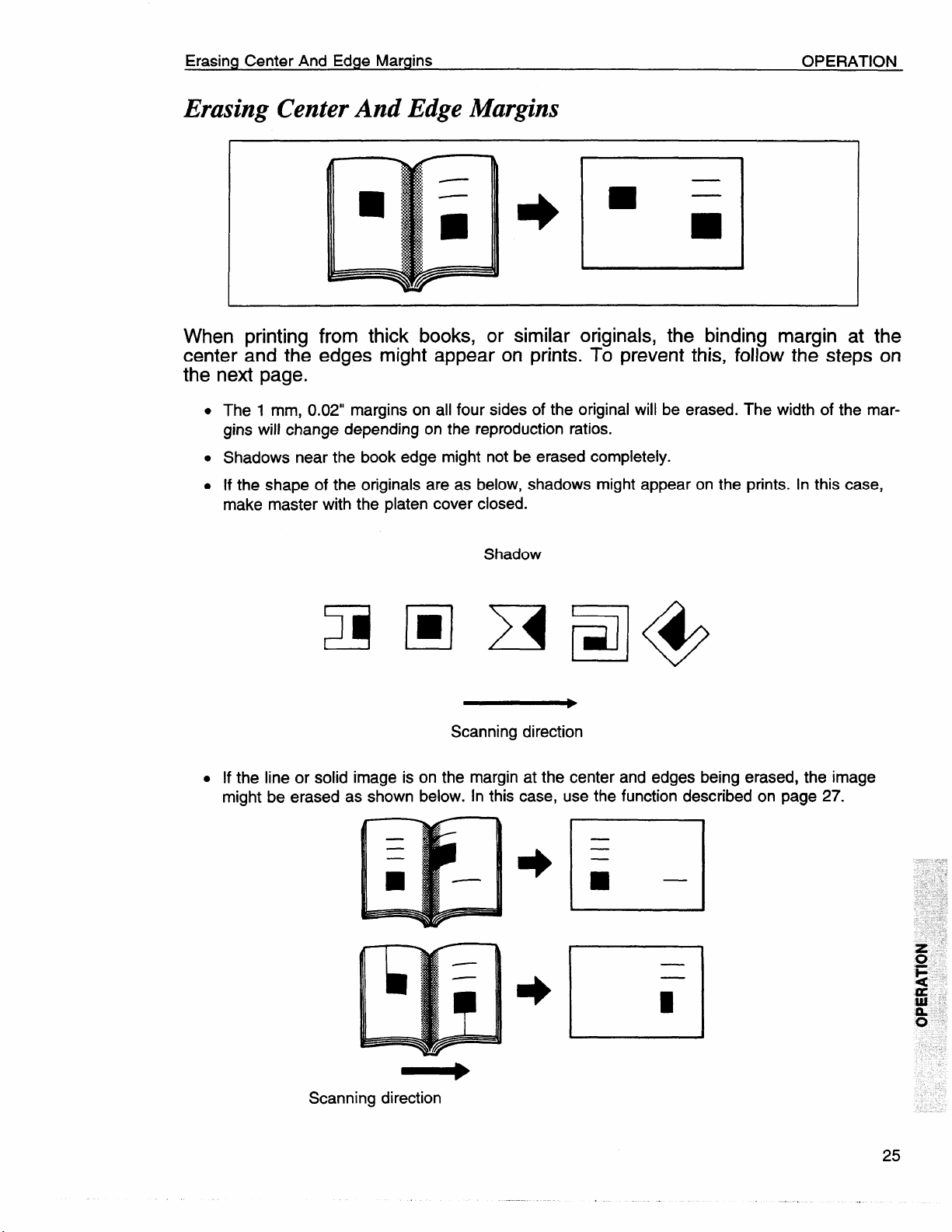

When printing from thick books, or similar originals, the binding margin at the

center and the edges might appear on prints. To prevent this, follow the steps on

the next page.

.

The 1 mm, 0.02” margins on all four sides of the original will be erased. The width of the margins will change depending on the reproduction ratios.

. Shadows near the book edge might not be erased completely.

. If the shape of the originals are as

make master with the platen cover

L

. If the line or solid image is on the margin at the center and edges being erased, the image

might be erased as shown below. In this case, use the function described on page 27.

1

J

below, shadows might appear on the prints. In this case,

closed.

Shadow

J

~F=l@

Scanning direction

t 1

b

—

El

Scanning direction

Page 30

OPERATION

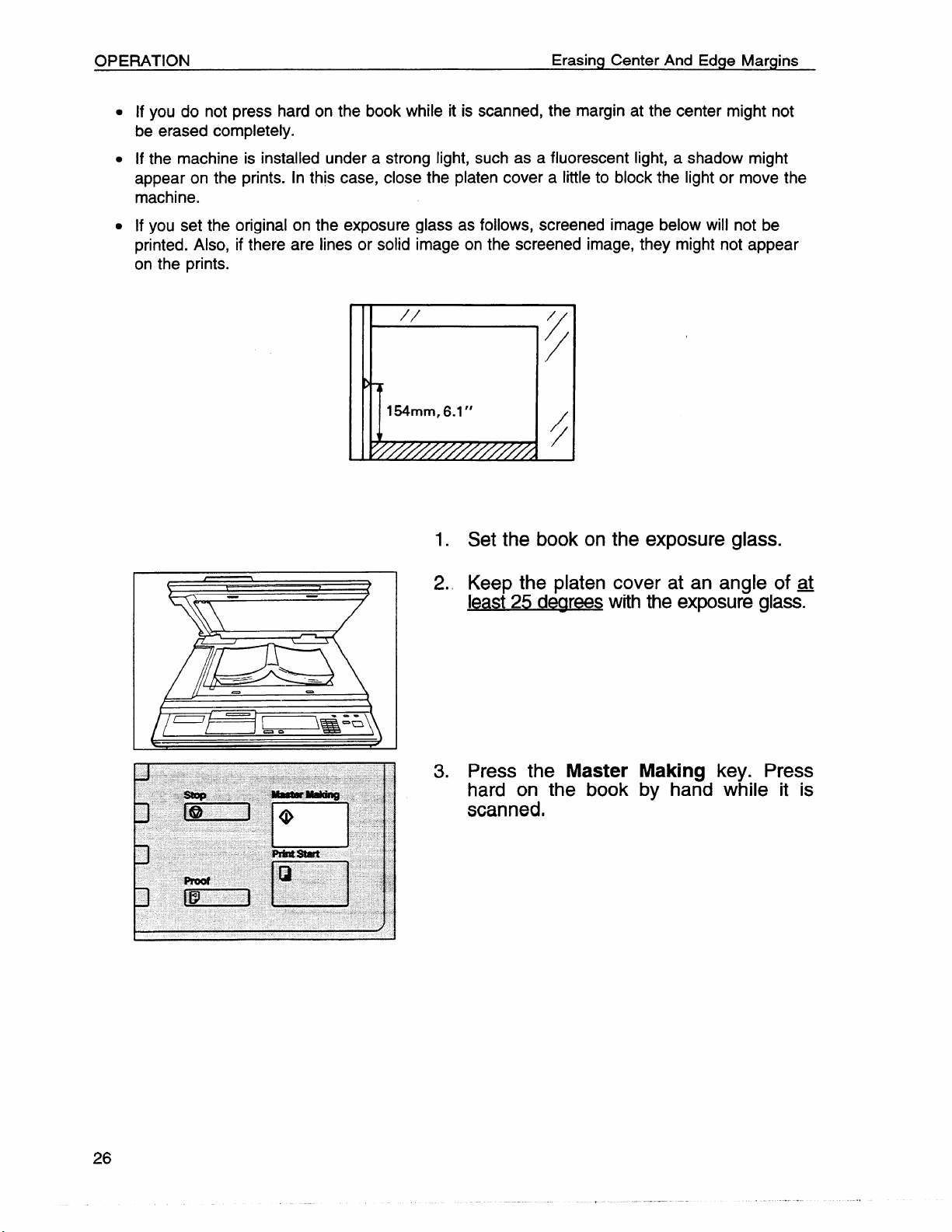

●

If you do not press hard on the book while it is scanned, the margin at the center might not

Erasing Center And Edge Margins

be erased completely.

●

If the machine is installed under a strong light, such as a fluorescent light, a shadow might

appear on the prints. In this case, close the platen cover a little to block the light or move the

machine.

●

If you set the original on the exposure glass as follows, screened image below will not be

printed. Also, if there are lines or solid image on the screened image, they might not appear

on the prints.

I

1.

Set the book on the exposure glass.

Keep the platen cover at an angle of ~

2.

least 25 dearees

Press the

3.

with the exposure glass.

Master Making key. Press

hard on the book by hand while it is

scanned,

Page 31

Erasing Center And Edge Margins

OPERATION

If you reproduce originals that have solid images at the edges, erasing the binding

and edge shadows will also erase solid images at the edge. To reproduce the

solid image, follow the steps below.

1. Set the original on the exposure glass.

4. The following message will appear on

the display. The paper size and direction will be changed by pressing the

Zoom key.

SCROLL BY ZOOM KEY

(YYY x XXXmm)

5. When you reach the desired paper size

and direction, press the

Then, make the master.

Enter key.

27

Page 32

OPERATION

Printing On Thick Or Thin Paper

Printing On Thick Or Thin Paper

When you make prints on

to 52.3 g/m2, 12.5 to 13.9

Printing on thick paper

thick (127.9 to 209.3 g/m2, 34.0 to 55.6 lb) or thin (47.1

lb) paper, do the following steps.

1. Push the pressure lever (A) down.

.

In the case of paper smaller than B5, 51/2”

x 81/2” and heavier than 127.9 g/m2 (34.0

lb), move the feed roller pressure lever to

the standard position.

2, Push the pressure levers (B) down.

.

There are two pressure levers (B). Make

sure that both levers are down.

● If dog-eared or wrinkled prints are deliv-

ered, push the levers up.

I VW

3. Pull the release lever up.

Page 33

Printing On Thick Or Thin Paper

Printing on thin paper

OPERATION

1. Set the side pads (move the side pad

levers to the right).

2. Pull the pressure lever (A) up.

I Ilfwl

3. Push the pressure levers

●

If dog-eared or wrinkled

ered, push the levers up.

. There are two pressure levers (B). Make

sure that both

4. Set the wing

match the print

levers are down.

guide release lever to

paper size.

(B) down.

prints are deiiv-

29

.,

Page 34

OPERATION

Photo Mode Printing

Photo Mode Printing

Original

Photo mode

Line mode

When printing a photograph or a color original, select Photo mode.

●

Moire patterns may occur when screened originals are printed.

●

When printing originals with letters and photos using Photo mode, the image of the letters

will be light. Select Line mode for letter areas and Photo mode for photo areas in the op-

1. Press the Image Mode key to select

Photo mode.

2. Press the

Image Density key to adjust

the image density.

3. Adjust the screen image by pressing

the

Screen key, if necessary.

Adjust the contrast by pressing the

Contrast key, if necessary.

4. Follow the standard printing procedure.

(See page 12.)

Page 35

Sharpen Image Mode Printing

OPERATION

Sharpen Image Mode Printing

When the original is mostly made up of bold lines and characters, this mode

keeps the image sharp.

Press the Image Mode key to select

1.

Sharpen Image mode.

111=11 I

Press the

2.

the image

3. Follow the standard printing procedure.

(See page 12.)

Image Density key to adjust

density.

31

Page 36

OPERATION

Printing From Several Originals At Once

Printing From Several Originals At Once

the Auto Cycle key to process masters and make prints at one stroke.

Use

●

When you use the optional document feeder, it is not necessary to place originals one by

one. AHoriginals are fed and prints are completed after you press the Master Making key.

●

If you use the optional tape dispenser, the tape dispenser drops a strip of paper onto the top

of the paper stack after the last page of each printing set is fed out to the paper delivery table. This marks the end of each printing group.

1. Set the original face down on the exposure glass.

.

You can set up to 20 originals into the optional document feeder.

2. Enter the number of prints required using the

3. Press the

Number keys.

Master Making key. Check

the image position on the trial print.

4. Press the Auto Cycle key.

s

The Auto Cycle indicator will light.

●

If you press the Auto Cycle key, you cannot make trial prints by pressing the Proof

key.

Page 37

Printing From Several Originals At Once

OPERATION

f%?’

5. If you use the optional tape dispenser,

turn on the power switch of the tape

dispenser.

Press the

6.

. If you set originals into the document

feeder, originals are fed and prints are

completed automatically.

7. Repeat steps 1 to 3 until all originals

are printed.

. After the last page of each set is fed out to

the paper delivery table, the optional tape

dispenser drops a strip of paper on the top

of the paper stack. The next cycle begins.

Print Start key.

33

Page 38

OPERATION

Group Printing From The Same Original (Class Mode)

Group Printing From The Same Original (Class Mode)

Use the Memory/Class key to make sets of prints from the same original. The

same number of prints is made for each set.

●

The optional tape dispenser automatically feeds out strips

ing groups on the paper delivery table.

●

Up to 20 sets of prints can be selected for one original.

1. Press the Memory/Class key to light

the Class indicator.

2. Set the original face down on the exposure glass.

of paper which

separate the print-

3. With the

Number keys, enter the num-

ber of prints for each set to be made

from the original.

Page 39

Group Printing From The Same Original (Class Mode)

4. Press the Enter key.

OPERATION

5. With the

Number keys, enter the de-

sired number of sets.

. The maximum number of sets that can be

made is 20.

6. Turn on the power switch of the optional tape dispenser.

7. Press the

Master Making key. Check

the image position by making prints

with the

. If the image position is not correct, adjust it

Proof key.

using the image Position key (See page

16) or the side plate fine adjusting dial.

(See page 17.)

35

.,

Page 40

OPERATION

Group Printing From The Same Original (Class Mode)

Press the Print Start key.

8.

. After the last page of each printing set is

fed out to the paper delivery table, the tape

dispenser drops a strip of paper on the top

of the paper stack.

●

If the power switch of the optional tape dispenser is turned off or the tape dispenser is

not installed in your machine, the group

printing cycle stops after each set is delivered. Remove the set of prints from the paper delivery table and press the Print Start

key to start the next group printing cycle.

Page 41

Group Printing From Different Originals (Memory Mode)

OPERATION

Group Printing From Dijjferent Originals (Memory Mode)

Use the Memory/Class key .to make sets of prints from different originals.

With the optional document feeder, you can set several originals and make prints of all of

them at once. For detail, see page 53.

The optional tape dispenser automatically feeds out strips of paper which separate the printing groups on the paper delivery table.

1. Press the Memory/Class key to light

the Memory indicator.

2. With the

Number keys, enter the de-

sired number of prints for the first origi-

nal.

3. Press the

Enter key. This stores the

number of prints to be made for the

first original in memory 1.

. When the number of prints in each set is

the same, it is not necessary to input the

number of prints for each group in memory.

Simply select the Auto Cycle mode and enter the desired number of prints once.

37

,,

Page 42

OPERATION Group Printing From Different Originals (Memory Mode)

4. With the Number keys, enter the num-

ber of prints for the second original.

5. Press the

number of prints

second original in

6. Repeat steps 4 and 5 for each

.

The number of prints can be

memory for 1 to 15 originals.

Enter

key. This stores the

to be made for the

memory 2.

original.

stored in

7. Press the Enter key again. The mem-

o~ returns to memory 1.

●

If you store the number of prints for 15

originals, the memory number returns to 1.

It is not necessary to press the Enter key.

8. Set the first original face down on the

exposure glass.

.

Set originals one sheet at a time in order

that you store in memory.

38

—a.

[

/

c

9. Press the

the image

(See page

Master Making key. Check

position on the trial prints.

12).

Page 43

Group Printing From Different Originals (Memory Mode)

10.

Turn on the power switch of the optional tape dispenser.

OPERATION

11.

Press the

c

If you press the Auto Cycle key, you cannot make trial prints by pressing the Proof

key.

Press the Print Start key.

12.

.

After the first set is fed to the paper deliv-

ery table, the tape dispenser drops a strip

of paper on the top of the paper stack.

After the first set is completed, set the

13.

Auto Cycle key.

second original on the exposure glass

and press the

Master Making key.

14.

Repeat step 13 until you have finished

printing.

.,

39

Page 44

OPERATION

Combine 2 Originals

Combine 2 Originals

You can print 2 separate originals on a single sheet of paper. The following tables

list the combinations that can be used when combining two originals.

A4 version —

Paper Size

Y

A3 lengthwise

B4 lengthwise

A4 lengthwise

B5 lengthwise

A5 lengthwise

— BI\z” x 11” version

Paper Size

11” x 17“ lengthwise

81/2”x 14“lengthwise

8112° x 11” lengthwise

51/2” x 81/2”lengthwise

A4

sideways

100?40 I 11570

87% I 1OOYO

71 ‘%0

6170 I 71%

50% I 57?40

Original Size 8112”x 11”

B5

sideways

I

I 82%

I 50?40 I 65%

A5

sideways sideways

B6

I

141% I 163?40

12270 1 14170

100%

sideways sideways

100?40 129?40

77?40

I 115%

5112”x 8112”

100?40

A6

sideways

200?40

173%

141%

122!!40

100?40

Page 45

Combine 2 Originals

OPERATION

D If the first original is wider than the maximum allowable width for combined

prints, the Combine 2 Originals mode will be canceled automatically after the

first original is on the master. The following table gives the maximum aHow-

able combined print width for each print paper size.

Maximum allowable original width for

combining

1210mm

I 182 mm

I 148 mm

I 105 mm

I 178 mm, 7.0”

140 mm, 5.5”

108 mm, 4.3”

prints

actual original width x magnification ratio

I

I

I

I

I

I

I

Maximum

Print paper size

A3

B4

A4 lengthwise

B5 Iermthwise I 128 mm

A5 Ienathwise

11’’XI7° I 216 mm, 8.5”

81I2”x 14”

81/2”x 11” length-

wise

51/2” x 81/2” length-

wise

allowable original width =

~Any image closer than 8 mm, 0.32” to the leading edge of the first original will

not be printed. Also, any image closer than 4 mm, 0.16” to the leading edge

of the second original will not be printed. When the image is too close to the

leading edge, use a copy of the original with the image shifted at least 8 mm,

0.32” for the first original (4 mm, 0.16” for the second original) from the leading edge.

~You can select a different kind of image settings for the first and second

original.

~ When you use the optional document feeder with this function, see page 52.

,,

41

Page 46

OPERATION

Combine 2 Originals

1. Set the

the top

first original face down and with

toward the operating side.

. The first original will be printed on the lead-

ing part of print.

,

2. Enter the number of prints using the

Number keys.

L

.“l

3. Check the print paper size and the reproduction ratio.

4.

Press the Combine 2 Originals key.

.

The Combine 2 Originals indicator will

light.

5. Press the Master Making key.

Page 47

Combine 2 Originals

OPERATION

6. The beeper sounds after the first oriainal is on the master. Set the

original face down and with

seco;d

the top

toward the operating side.

7. Press the

Making key.

8. Check the image position of trial prints

and press the

Print Start key.

43

.,

Page 48

OPERATION

User Program

User Program

This User Program function allows you to

job setups. -

How to input a user program

1.

2.

3.

store and recall

up to 5 frequently used

Select and enter the job settings you

want to store

Press the Program key.

.

Numbers already containing a program are

displayed on the guidance display.

in memory.

Enter “O”using the Number keys.

4.

Press the

●

The program numbers (1-5) will be dis-

played in the guidance display.

s

If a user program has been protected, that

program number will not appear in the display. For changing a protected user program, see page 46.

●

If all the user programs have been protected, the machine returns to the ready

condition.

Enter key.

Page 49

User Program

OPERATION

5. Enter one of the program numbers displayed on the guidance display using

the

Number keys.

. Make sure that the previous job setup

stored under the selected program number

are overwritten.

6. Press the Enter key.

45

Page 50

OPERATION

User Program

How to protect a program

If you want to prevent someone from writing over your program, do the following

procedure.

1. While pressing the

Reset key and Stop

key simultaneously, press the Program

key.

2. Enter “1” using the

3. Press the

●

The numbers of the programs which are

not protected will be displayed in the guidance display.

Enter key.

Number keys.

“,,”C-..?.—?.-?--”---- ,’——

.———-j

i

Iielm

4. using the Number keys, enter the

number of the program that you wish to

protect.

5. Press the

Enter key.

Page 51

User Program

How to remove user program protection

1. While pressing the Reset key and Stop

2.

OPERATION

key simultaneously, press the Program

key.

Enter “O”using the

Number keys.

3.

Press the Enter key.

●

If no program number is protected, the ma-

chine returns to the ready condition.

4.

Using the Number keys, enter the

number of the program that you

remove protection from.

5.

Press the

Enter key.

wish to

47

,!

Page 52

How to access a user program

User Program

1. Press the Program key.

.

Numbers already containing a program are

displayed on the guidance display.

2. Using the Number keys, enter the

number of the program that you wish to

access.

3. Press the

.

All stored job settings are recalled.

Enter key.

Page 53

Printing Using The Optional Document Feeder

OPTIONAL FUNCTIONS

OPTIONAL FUNCTIONS

Printing Using The Optional

Guide to document feeder component

ADF Unit Open Lever

Use to open the ADF unit.

Original Tray

Originals used to make

masters are delivered

the master “making =

position.

\ ‘hrna’scorrect’y”

#

e!!

Document Feeder

Original Guides

Adjus! these guides to position

I

I

I

I

49

.,

Page 54

OPTIONAL FUNCTIONS

Printing Using The Optional Document Feeder

Originals

D The following types of originals are not recommended for use with the docu-

ment feeder. Set the originals on the exposure glass.

●

Originals heavier than 127.9 g/m2, 34 lb

●

Originals lighter than 40.7 g/m2, 10.8 lb

●

Carbon coated originals

●

Damaged originals

●

Originals with glue on them

●

Originals with perforated for ring binders

●

Book originals

●

Originals written with a pencil or ball-point pen

●

Originals smaller than 90 mm x 140 mm, 3.6” x 5.6”

●

Originals larger than 307 mm x 432 mm, 12.0” x 17.0”

●

Folded, curled, creased originals

●

Bound, stapled, or clipped originals

n If you use paste-up originals, make

sure the pasted parts hold firmly to the

base sheet. If the thickness of the paste-up original is more than 0.2 mm,

1/1 25”, a shadow might appear on the prints.

~ The first 8 mm, 0.32”, of the leading edge and the last 2 mm, 0.08”, of the

trailing edge cannot be printed. Make sure the leading edge margin is at least

8 mm, 0.32”, and the trailing edge margin is at least 2 mm, 0.08”.

Original

8 mm, -

0.32”

Print

t- it-

2 mm,

0.08”

Page 55

Printing Using The Optional Document Feeder

OPTIONAL FUNCTIONS

Setting originals into the document feeder

.

If you set one original into the document feeder while another original is still on the exposure

glass, the original set into the document feeder will be scanned first.

1. Set the original tray.

2. Adjust the original

guides to the size of

the originals.

Insert the originals face down in the

3.

document feeder until it stops.

● Do not insert different size originals at the

same time.

. Approximately 20 originals can be inserted

at one time.

● The guides must fit snugly against both

sides of the stack.

4. Set the required image settings and

press the Master Making key.

●

If the next original has been set in the

document feeder before the machine stops,

that original is fed automatically and a trial

print is delivered to the paper delivery table

after the print of the first original is completed. Check the image position of the trial

print of the next original. (See page 16.)

51

,,

..

Page 56

OPTIONAL FUNCTIONS Printing Using The Optional Document Feeder

Combine 2 originals with the document feeder

.

Refer to page 40 for details about the Combine 2 originals funtion.

1. Insert the 2 originals face down and

with the top toward the operation side.

.

The first original fed will be printed on the

leading part of print.

2*

Enter the number of prints using the

Number keys.

3. Check the print paper size and the reproduction ratio.

4. Press the

5. Press the

.

After the first original is on the master, the

second original is fed.

. If you set only one original, the beeper

sounds after the first original is on the master. Set the second original and press the

Master Making key.

●

If you set only 2 originals, the Combine 2

Originals mode will be canceled after the

second original is on the master.

Combine 2 Originals key.

Master Making key.

Page 57

Printing Using The Optional Document Feeder

OPTIONAL FUNCTIONS

Group printing from different originals with the document feeder (Memory

mode)

.

To prevent original misfeed, do not set originals of different sizes.

. Do not set more than 15 originals at one time.

1. Follow steps 1 to 7 of page 37 and 38. *

2. Set the originals face down into the ~

document feeder.

● The originals are fed from the bottom of the

stack. Make sure that the originals are set

in the correct sequence with the first original on the bottom.

3. Press the Master Making key. Check

the image position on the trial prints.

(See page 16.)

m

z

o

i=

o

z

z

o

o

4. Turn on the power switch of the optional tape dispenser.

5. Press the

.

The Auto Cycle indicator will light.

. In Auto Cycle mode, printing starts auto-

matically after a trial print is delivered.

Auto Cycle key.

53

,,

Page 58

OPTIONAL FUNCTIONS

Printing Using The Optional Document Feeder

6. Press the Print Start key.

● After the last page of each set is

the paper delivery table, the tape

drops a strip of paper on the top

per stack. The next cycle begins.

fed out to

dispenser

of the pa-

Page 59

Color Printing Using The Optional Color Drum

OPTIONAL FUNCTIONS

Color Printing Using The Optional Color Drum

I

Color drum units (red, blue, green, and brown) are available as options in addition

to the standard black unit. For making color prints, a separate drum unit is

necessary for each color.

How to make color mints

*

Changing the drum unit for color

1. Make sure

lights.

2. Follow the

(See page

that the Color Print indicator

standard printing procedure.

12.)

printing

1. Open the front door.

NI& “1

2. Make sure that the lamp of the drum

rotation button is green. If this lamp is

red, press the drum rotation button until

the beeper sounds and the lamp turns

green.

55

Page 60

OPTIONAL FUNCTIONS

Color Printing Using The Optional Color Drum

3. Lift the lock lever until it locks in position.

4. Pull out the drum unit handle while

pressing the release bar inside the

green handle.

. If you cannot pull out the drum unit even

when the lamp of the drum rotation button

is green, push the drum unit handle, then

pull out the drum unit.

5. Hold the rail on the drum and slide out

the drum while pulling the release towards you.

6. Remove the drum unit from the machine while holding the upper drum

stay.

Caution: Be careful not to let the drum

unit fall.

Page 61

Color Printing Using The Optional Color Drum

OPTIONAL FUNCTIONS

7. Insert

guide

8. Slide

the color drum unit along the

rail.

in the drum unit until

unit locks in position.

9. Lower the drum unit lock lever.

the drum

10. Close the front door.

.

Make sure that the Cover Open indicator

turns off, and the Color Drum indicator

lights.

57

,,

Page 62

OPTIONAL FUNCTIONS

Color Printing Using The Optional Color Drum

Printing in two colors

After printing in one color, you can print in another color on the same side of the

print.

.

You cannot print in two colors at one time.

. Leave the printsfor a while before printing on them again. This lets the ink dry.

1. Prepare the two originals. Set the first

original on the exposure glass.

FI+H”+J

L

I 1 I I I

2. Enter the number of prints using the

Number keys.

3. Press the Master Making key.

● The original is fed, and the trial print is de-

livered to the paper delivery table. Check

image position. (See page 16.)

the

4. Press

the Print Start key.

5. Remove the prints from the paper delivery table and set them on the paper

feed table again as shown in the illustration.

Page 63

Color Printing Using The Optional Color Drum

OPTIONAL FUNCTIONS

6. Exchange the drum unit. (See page

---

7. Set the second original and press the

Master Making key. Check the image

position. (See page 16.)

8. Press the Print

Start key.

59

.

Page 64

OPTIONAL FUNCTIONS

Changing The Drum Size

Changing The Drum Size

To save costs on master rolls, you can shorten the length of each master by

changing to an optional smaller drum.

Printing area (at 23°C/730F, 65 % RH):

Max. 290 x 412 mm (1 1.4” x 16.2”) with A3 drum

Max. 290 x 204 mm (1 1.4” x 8.0”) with an optional A4 drum

Master cut length:

A3 drum

Optional A4 drum 11::

n To change the drum unit, follow the same procedure as “Changing the drum

unit for color printing”. (See page 55.)

320 mm x 540 mm, 12.5” x 21.2”, 225 masters/roll

320 mm x 332 mm, 12.5” x 13“, 370 masterslroll

Page 65

Printing Using The Optional Paper Cassette

OPTIONAL FUNCTIONS

Printing Using The Optional Paper Cassette

#The

If you always use 2 or more paper sizes, it is easy to change the paper size by ~

using the paper cassette. Set the paper you use most on the paper feed table and ~

set other paper in the cassette. You can use B4, A3,

paper in the A3 cassette, and B5, A4, or 81/2” x

Replenishing paper

The Load Paper indicator (l&J)lights when the paper cassette runs out of paper.

optional paper cassettes are not sold in some areas.

81/2”x 14“, or 11” x 17“ +

11” paper in the A4 cassette.

1. To remove the cassette cover, raise

both sections of the cover to the verti-

cal position, then pull the cover up and

out from its holders.

m

z

Q

z

o

&

~

2. Insert paper into the cassette,

care to align the sheets.

3. To replace the cover, fold both

sections toaether and insert the

as shown i;to the holders on the sides

of the cassette.

taking

cover

cover

61

Page 66

OPTIONAL FUNCTIONS

Printing Using The Optional Paper Cassette

4. Remove the paper from the paper feed

table.

.

The paper feed table will lower.

5. Adjust the feed roller pressure lever,

separation roller pressure levers and

wing guide release lever according to

the type of the paper. (See page 28.)

6. Adjust the side plates to the paper cassette size.

7. Using both hands, insert the cassette in

the machine and open the front section

of the cover, as shown.

8. Push the cassette forward until it stops.

Re-adjust the guide plates to the cas-

sette size.

●

If the side pads are positioned right, move

them to the left.

Page 67

Printing Using The Optional Paper Cassette

Removing the paper cassette

OPTIONAL FUNCTIONS

1. Press the Paper Feed Table Down ~

key. Pull out the cassette to the middle Q

of the paper feed

table and close the

cassette cover.

. To prevent paper

keep the cassette

ing the cassette.

from falling out, always

cover closed when mov-

63

Page 68

OPTIONAL FUNCTIONS Printing Using The Optional Paper Cassette

Changing the paper size

1. To remove the cassette cover, lift both

sections to the vertical position and pull

the cover up and out from its holders.

2. Turn the cassette upside down.

3. Loosen the 6 screws fixing the guide

plate at the right, left, and rear sides.

4. Slide the guide plates to the desired

position and tighten the screws.

Page 69

Printing Using The Optional Paper Cassette

A3 size paper cassette

OPTIONAL FUNCTIONS

5. Insert the sensor actuator in the slot

that corresponds to the cassette setting

(refer to the cassette size decal).

Examp/e: A3 printing

A4 size paper cassette

t

Example: A4 lengthwise printing

. If only one sensor actuator is required, be careful not to lose the other one.

65

Page 70

CHANGING DEFAULT SEVING,S

CHANGING DEFAULT SETTINGS

Printing needs may vary. To suit your application, you can adjust the setting for

certain functions. Functions that can be adjusted are as follows:

L

Minimum print quantity setting (SP # 10)

Specifies the minimum number of prints (O to 9999) that can be input with the

Number keys.

Example:

If

you specify 20 as the minimum number of prints,

runs of 20 or more copies will be accepted,

runs of less than 20 copies will not be accepted.

2.

Maximum print quantity setting (# 11)

Specifies the maximum number of prints (O to 9999) that can be input with the

Number keys.

3.

Fixed magnification ratio adjustment (#12 to # 19)

Adjusts any of the 8 fixed magnification ratios. The new fixed magnification

ratio is displayed on the guidance display by pressing the Reduce/Enlarge

key on the control panel.

4.

Beeper ON/OI?I?setting (# 20)

Turns the key beeper on or off.

5.

Optional key counter adjustment (# 21)

The key counter (option) usually counts the number of copies made regardless

of the number of masters used. For accounting purposes, it is possible for the

key counter to be incremented by a value between O and 50 whenever a new

master is used.

Example:

The key counter is adjusted to increase by 20 for each master fed. If 100

copies have

increase by 120.

been made and the master is replaced, the key counter will

Page 71

CHANGING DEFAULT SEITINGS

6.

Default mode selection

Specifies settings to which the machine defaults at power on. This can be done

for the following:

Image mode (3 possible settings) —

Image density level (4 possible settings)

Auto cycle mode (selects or deselects) —

Memory or Class mode (specifies one or the other) — #44

Make-up mode background pattern selection (# 46)

7.

This function can be used only when you have the optional Make-up function,

Specifies the default make-up mode background pattern that is selected

when the Make-up key is pressed.

8.

Skip paper feed setting (# 82)

If you find the back of prints are dirty, you can increase the time between

two prints. This gives you the chance to remove prints one by one from the

paper delivery table or insert one sheet of paper between two prints. With

the default setting, one sheet of paper is fed while the drum rotates once.

However, you can change the setting so that one sheet of paper is fed

each time the drum rotates two to five times. If you set the drum to rotate

two or five times each time one sheet of paper is fed, you can use 590 mm,

23.2”, or shorter paper.

The maximum length of paper is 447 mm, 17.5”. If you use paper longer than

447 mm, 17.5”, completed prints will not be delivered to the paper delivery

table properly, so receive them by hands.

#40

—# 41

# 43

9.

Auto Reset mode setting (# 83)

Sets the auto reset time (3 or 5 minutes). The machine automatically returns to

the default settings if no keys are pressed during this time period. This mode

can also be turned off.

10.

Auto combine 2 originals mode selection (# 84)

Select the Combine 2 originals mode as the default setting.

11.

Adding the master compression process at power on (# 85)

The master is always compressed after it is ejected into the master eject box, in

order to get a few more masters in the box. With this function, it takes 6 or 7

seconds for the machine to become ready when you turn on the main switch.

12.

Resettable total counter display/reset

Displays the total number of masters and copies —

Clears the resettable total counter —# 114

#113

67

Page 72

CHANGING DEFAULT SETTINGS

13.

Paper size detection selection (# 142)

The machine determines the print area size according to the reproduction ratio

and the size of paper set on the paper feed table. If you are making prints on

non-standard paper and the original image does not entirely appear on the

print, then set paper size detection not work. You can turn width or length

detection off separately.

14.

Original width detection selection (# 143)

The machine determines the print area size according to the size of the

original. If you are making prints using originals of a non-standard size and the

image does not entirely appear on the print, then set original detection not

work.

Erase margins adjustment area (# 160 to # 170)

15.

Margins erased by pressing the Margin Erase key can be adjusted.

Page 73

How To Access Setvice Programs

CHANGING DEFAULT

SET17NGS

How To Access Service Programs

The items described in the previous pages can be set by following this procedure.

1.

Press the keys on the operation panel

in the following order:

Clear Modes key

(1)

(2) Clear key

(3) Enter key.

● The sp-mode display appears on the guid-

ance display.

2.

Using the Number keys, enter the de-

sired sewice program number (listed

the service program table – see page

71).

in

When you leave the Service Program

3.

mode, press the Clear Modes key.

69

Page 74

CHANGING DEFAULT SEITINGS

How To Change Adjustment Values Or Modes

How To Change Adjustment Values Or Modes

1. After entering the desired setvice program number, press the Enter key.

The value or mode set at the factory

will be displayed at the end of the second line on the guidance display.

2. Enter the desired value or mode using

the Number keys.

3. Press the Enter key to store the desired value or mode.

4. When you leave the Setvice

mode, press the Clear Modes

Program

key.

Page 75

Service Program Table

Service Program Table

CHANGING DEFAULT SEITINGS

v: A4 version

SP No.

10.

11.

Minimum Print

Quantity

Maximum Print

Quantity

12.

13.

Fixed

Magnification

14.

‘

Ratio

Adjustment

15.

16.

17.

Mode

+; 8f~” x 11” version

Function

Sets the minimum print

quantity that can be

entered.

Sets the maximum print

quantity that can be

entered.

Adjusts a fixed

magnification ratio.

A4 version:

from A4 to A3

81n” x 11“

from

x 14“

Adjusts a fixed

magnification ratio.

A4 version:

from A4 to B4

84/2” x 11“ version:

from 8@’ x ll”to ll”X

17“

Adjusts a fixed

magnification

version:

A4

from B4 to A3

81/2” x 11” version:

from 81/2”x 14” to 11“ x

17“

Adjusts the full size

magnification ratio.

Adjusts the create

margin magnification

ratio.

Adjusts a fixed

magnification ratio.

version:

A4

from

81/2”x 11” version:

from 81/2”x 14” to 81/2”

x 11”

version:

51n” x 81/2”to 81/2”

ratio.

A3 to B4

Adjustment

Value

oto 9999

oto 9999

50 to 200%

50 to 200%

50 to 200%

50 to 200%

50 to 200!40

50 to 200%

0

9999

v: 141!40

+: 155%

v: 122’XO

●: 129%

v: 115?40

+: 121!40

100?40

93!!40

V: 87’XO

+: 77°h

Reference

Page 66-1

Page 66-2

Page 66-3

71

Page 76

CHANGING DEFAULT SEITINGS

Service Proaram Table

SP No.

18.

19.

20.

21.

40.

41.

43.

44.

46.

82.

83.

84.

85.

113.

Mode Function

Adjusts a fixed

magnification ratio. 4: 74?40

A4 version:

from B4 to A4

81/2” x 11” version:

Fixed

from 11“ x 15” to 81/2”x

Adjustment

Value

50 to 200%

Magnification 11”

Ratio

Adjustment

Beeper

Adjusts a fixed

magnification ratio.

A4 version:

from A3 to A4

81/2” x 11” version:

from 11“ x 17” to 81/2” x

,,,,

Turns the beeper ON or

OFF. 1: Yes

Prints/Master Adjusts the ratio of

cost

Image Mode

masters to prints for

accounting

purposes.

Specifies the image

Default Setting mode at power on.

50 to 200?40 v: 71°h

O:No

oto 50

O: Photo

1: Line

2: Sharpen

Image Density Specifies the image O:Light

Default Setting density at

Auto Cycle

Mode Default Cycle mode is selected 1: Yes

Memory/Class Specifies Memory or

Mode Default Class mode at power on.

Setting

Make-Up Specifies which make-up 1 to 40

Background background pattern is

Pattern Default selected when the Make-

Setting Up key is pressed.

Skip Feed Selects the feed interval. 1: Normal

Interval

Auto Reset

Time

Auto Combine Selects the auto

2 combine mode.

Adding the Sets the used masters to

master be compressed at power 1: Yes

compression on.

Resettable Used to display the total

Total Master/ number of masters and

Copy Counter copies. (This counter can

Specifies whether Auto

at power on.

Specifies the auto reset

time.

be reset.)

power on.

1: Standard

2: Dark

3: Darker

O:No

O: Class

1: Memory

51 to 90

101 to 140

150to 190

O: No back-

ground

pattern

1 sheet

fed every 1

t05 drum

rotations

O: No

1:3 min.

2:5 min.

O: No

1: Yes

O: No.

v: 82’!!40

+ : 65%

o

0

1

1

o

1

0

1

o

o

o

o

Page 66-3

Page 66-4

Page 66-5

Page 67-6

Page 67-6

Page 67-6

Page 67-6

Page 67-7

Page 67-8

Page 67-9

Page 67-10

Page 67-11

Page 67-12

Page 77

Service Program Table CHANGING DEFAULT SEITINGS

SP No. Mode

114.

120.

121.

122.

123.

124.

142.

143.

Clear

Resettable total masterlcopy counter.

Total

Master/Copy

Counter

User Code

Mode

User Code

Count

Clear User

Code Count

Total User Displays the total

Code Count

Clear Total

Code code counter.

User

Count

Paper Size Selects paper size O: Yes

Detection detection. 1: Width

Original Size Specifies whether O: No

Detection

Function

Clears the resettable

Selects user

Displays the number of

masters and copies

made in each

Clear each user code

counter. 1: Yes

number of masters and

copies

codes.

Clears the total user O: No

original size detection is

done.

code mode. O:No

user code.

for all the 20 user

Adjustment

Value

O:No

1: Yes

1: Yes

O:No

1: Yes

detection

2: Length

detection

3: No

detection

1: Yes

~e:

o

o

1

o

o

o

o

o

~eferen~e

Page 67-12

Page 75

Page 78

Page 79

Page 80

Page 81

Page 68-13

Page 68-14

73

.,

Page 78

CHANGING DEFAULT SETTINGS

Semite Program Table

SP

No.

160.

161.

162.

163.

164.

165.

166.

167.

168.

169.

170.

Mode Function Adjustment

Value

Erase

Margins

Adjustment

Area

Adjust the erase center

and edges area for an A3,

11” x 17“ oriqinal.

Adjust the erase center

and edges area for a B4,

81/2”x 14“ original.

Adjust the erase center

and edges area for an A4

lengthwise, 81/2” x 11”

lengthwise oriainal.

Adjust the erase center

and edges area for an A4,

81/2” x 11” original.

Adjust the erase center

and edges area for a 65

lengthwise, 51/2”x 81/2:’

Ienqthwise original.

Adjust the erase center

and edges area for a B5,

51/2” x 81/2” original.

Adjust the erase center

and edges area for an A5

lengthwise ori~inal.

Adjust{the erase center

and edges area for an A5

Driqinal.

Adjust the erase center

and edges area for an A6

Ienqthwise ori~inal.

Adjust the erase center

and edges area for an A6

ori~inal.

Adjust the erase center

and edges area for a

~maller than A6 original.

(50 -307

(50 -432

mm) x

mm)

Factorv

Settinti

v:289

+ :271

V :249 X 360

+ :208

V :202

+ :208

V:289 X 206

+ :271

v:174 X 253

+:132x212

v:249 X 178

+ :208 X 136

v:140 X 206

* :50 x 50

V:202 x 144

0:50 x 50

V:97 X144

$:50 x 50

V:140 x 101

0:50 x 50

v:92 X 144

0:50 x 50

X 416

X 428

X 352

X 293

X 275

X 212

Reference

Page 68-14

Page 79

User Code

CHANGING DEFAULT SEITINGS

User Code

With the user code function, operators must input an authorized code before the

machine will operate. The machine

under each code. In this

mode, the following 20 user codes (fixed) can be used to

keeps track of the number of prints made

access the machine:

382, 191, 182, 173, 164, 155, 146, 137, 128, 119,

482, 291, 282, 273, 264, 255, 246, 237, 228, 219

~ To prevent unauthorized users from accessing the machine, note down these

codes and then black out the codes from this manual.

How to enable user code mode (# 120)

The following procedure explains how to enable user code mode. This must be

done before a user code can be input.

1.

Press the keys in the following order:

(1) Clear Modes key

(2) Clear key

(3) Enter key.

Enter “120” using the Number

2.

and press the Enter key.

Enter “1” (Yes) using the Number keys

3.

and press the Enter key.

keys

75

Page 80

4. Specify the Auto Reset time.

Enter “1” (3 minutes) or “2” (5 minutes)

using the Number keys and

press the

Enter key.

5. Press the Clear Modes key to leave

SeNice Program mode.

76

Page 81

User Code

How to use user code mode

CHANGING DEFAULT SEITINGS

1. Input your assigned 3-digit user code

using the Number keys, then press the

Enter key.

2. Make your prints.

3. After you have finished, press the Stop

key while pressing the Clear Modes

key.

.

This prevents others from using your user

code to make prints.

● If you do not follow this step, the machine

will returns to the condition that you should

input your user code before making prints

after auto reset time.

77

.,

.,

Page 82

CHANGING DEFAULT SETTINGS

How to check the user code counter (# 121)

1. Press the keys in the following order:

(1)

(2) Clear key

(3) Enter key.

2. Enter “121” using the Number keys

and

The number of masters and prints

made under the

displayed in the guidance display.

User Code

Clear Modes key

press the Enter key.

user code “382” will be

3. Continue pressing the Enter key to display the number of masters and prints

made under your user codes.

4. Press the Clear Modes key to leave

Service Program

mode.

Page 83

User Code

How to clear the user code counter (# 122)

.

lfyouwant toclear every user code counter, seepage 81.

1.

2.

CHANGING DEFAULT SEl17NGS

Press the keys in the following order:

(1) Clear Modes key

(2) Clear key

(3) Enter key.

Enter “122”

using the Number

and press the Enter key.

keys

3. Keep pressing the Enter key until the %

desired user code is displayed.

4. Enter “1” using the Number keys and

press the Enter key.

5. Press the Clear Modes key to leave

Service Program mode.

g

s

o

79

Page 84

CHANGING DEFAULT SETTINGS

User Code

How to check the total number of masters and prints made under all user

codes (# 123)

1.

Press the keys in the following order:

(1) Clear Modes key

(2) Clear key

(3) Enter key.

2. Enter “123” using the Number keys

,

and press the Enter key.

● The total number of masters and prints

made under all user codes will be displayed

in the guidance display.

3. Press the Clear Modes key to leave

Service Program mode.

Page 85

User Code

How to clear the user code total counter (# 124)

1. Press the keys in the following order:

Clear Modes key

(1)

(2) Clear key

(3) Enter key.

2. Enter “124” using the Number keys

and

press the Enter key.

CHANGING DEFAULT SETHNGS

m

a

~

E

%

~

3

g

M

3. Enter “1” using the Number keys and ~

press the Enter key.

4. Press the Clear Modes key to leave

Service Program mode.

:

z

2

u

81

.

Page 86

REPLENISHING SUPPLIES

Loading Paper

On The Paper Feed Table

REPLENISHING SUPPLIES

Loading Paper On The Paper Feed Table

The Load Paper indicator (I&l) lights when the paper feed table runs out of paper.

1. Press the Stop key.

.

This step is necessary

pause a print run to replenish paper.

only if you want to

2. Press the Lower Paper Feed Table

key.

.

The paper feed table will lower without the

key being pressed when the printing paper

runs out.

. The top sheet might remain between the

feed rollers. In this case, remove the top

sheet.

3. Load paper on the paper feed table.

.

Release the pads of the feed side plates

before loading paper. Reset the pads after

paper is set.

. Correct the paper curl before setting the

paper.

4. Press the Print Start key to resume

printing.

82

Page 87

Loading Paper On The Paper Feed Table

Changing the paper size

REPLENISHING SUPPLIES

1. Remove the paper from the paper feed

table.

.

The paper feed tray will lower.

2. Adjust the paper feed side plates to

match the paper size.

3. Place the paper on the paper feed

ble.

.

Correct any paper curl before setting

paper.

. Make sure that the side plates contact

paper lightly.

4. Adjust the side plates

plate and if necessary,

and the end

the small size

end plate at paper delivery.

. Make sure that the wing guide release lever

positionscorrectly to match the paper size.

ta-

the

the

83

Page 88

REPLENISHING SUPPLIES Supplying Ink

Supplying Ink

The Add Ink indicator (@) lights when it is

1.

NF&”

2. Lower the ink holder and remove the

3. Remove the cap of the new ink car-

time to supply ink.

Open the front door.

used ink cartridge.

tridge.

4. Insert the new cartridge into the ink

holder. Return the ink holder to its original position until it clicks.

. Always supply ink of the same color.

Page 89

Supplying Ink

REPLENISHING SUPPLIES

5. Close the front door.

6. Press the Reset key.

.

The machine will start idling to supply ink to

the drum. It will then stop when the correct

amount of ink reaches the drum.

85

Page 90

REPLENISHING SUPPLIES

Master Roll Replacement

Master Roll Replacement

1. Open the original table.

.

Lift the original table release lever and slide

the original table all the way to the left.

2. Lift the pressure release lever in the

direction of the arrow to release the

feed roller pressure.

3. Remove the used master roll and pull

out both spools. Then, insert both

spools into a new master roll.

. When the Master End indicator lights, it is

necessary to replace the master roll even if

some master remains on the old roll.

4. The new master roll must be positioned

as shown in the illustration.

Page 91

Master Roll Replacement

REPLENISHING SUPPLIES

Insert the master from its roll under the

5.

arrow mark (1) until the leading edge

comes out the other side of the steel

cover.

Return the Pressure release

6.

lever to its

original position.(2)

.

Rotate the spools backward to take up any

slack in the master.

Press the master cut button to cut the

7.

leading edge of the master roll.

After the beeper sounds, remove the

8.

cut-off portion of the master roll.

. Remove the cut-off master completely to

prevent master misfeed.

Return the original table to its original

9.

position.

87

Page 92

REPLENISHING SUPPLIES

Placing A New Roll Of Tape In The Tape Dispenser (Option)

Pkzcing A New Roll Of Tape In The Tape Dispenser (Option)

#

Make sure that the main switch is turned on and the tape power switch is off.

1. Open the cover of the tape dispenser.

2. As shown,

.

Make sure that the tape is installed in the

proper direction. If it is

direction, the tape dispenser will not work

correctly.

put the roll in the dispenser.

not in the correct

3. Feed the leading edge of the roll in the

dispensing slot until it stops.

. Push the tape as far as possible through

the slot.

4. Turn on the power switch of the tape

dispenser.

Page 93

Placing A New Roll Of Tape In The Tape Dispenser (Option)

5. Press the manual cut button to trim off

the leading edge of the tape.

REPLENISHING SUPPLIES

89

Page 94