Page 1

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYS ICAL INJURY

1. Before disassembling or asse mblin g pa rts of the print er and pe riph erals,

make sure that the power co rd is unp lug ge d.

2. The wall outlet should be near the copier an d easily accessible.

3. If any adjustment or operat ion check ha s to be made with exterior covers

off or open while the main switch is turned on, keep han ds awa y from

electrified or mechanically driven components.

HEALTH SAFETY CONDITIONS

1. If you get ink in your eyes by accident, try to remove it with eye drop s or

flush with water as first aid. If unsuccessful, get medical attention.

2. If you ingest ink by accident, induce vomiting by sticking a finger down

your throat or by giving soapy or strong salty water to drink.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The printer and its peripherals must be installed and mainta ine d by a

customer service represent at ive who has completed the training course

on those models.

CAUTION

I

The RAM board has a lithium battery which can explode if handle d

incorrectly. Replace only with the same type of RAM boar d. Do not

recharge or burn this battery. Use d RAM boards must be handled in

accordance with local re gulations.

SAFETY AND ECOLOGICAL NOTES FOR DISP OS AL

1. Dispose of replaced parts in acco rda nce with local regulations.

2. Used ink and masters should be disp ose d of in an envionmentally safe

manner and in accordance with local regulations.

3. When keeping used lithium bat te ries (fro m t he ma in con tro l boa rds) in

order to dispose of them late r, do not store more than 100 batteries (from

the main control boards) per sealed box. Sto ring larger numbers or not

sealing them apart may lead to chemica l react ions and heat build-up.

Page 2

SECTION 1

OVERALL MACHINE

INFORMATION

Page 3

15 July 1995 SPECIFICATIONS

1. SPECIFICATIONS

Configuration: Table-top

Master Processing: Digital

Printing Process: Fully automatic one-drum stencil syste m

Original Type: Sheet /B oo k

Original Size: Maximum 307 mm x 432 mm (12.0" x 17.0")

Reproduction Ratios: LT version 93%, 77%, 74%, 65%

A4 version 93%, 87%, 82%, 71%

Image Mode: Line, Photo, Line/Photo

Color Printing: Drum unit replacement system

(Red, Blue, Green, Bro wn, Yello w, Pu rple ,

Navy, and Maroon)

Master Feed/Eject: Roll master, automatic feed/eject

Leading Edge Margin: 5 mm (0.2")

Trailing Edge Margin: 3 mm (0.12")

Printer Paper Size: Maximum 297 mm x 432 mm (11.6" x 17.0")

Minimum 90 mm x 148 mm (3.6" x 5.8")

Printing Area: Maximum 250 mm x 355 mm (9.8" x 14.0") at

23°C/65%RH

Print Paper Weight: 47.1 g/m2 to 209.3 g/m2 (12.5 lb to 55.6 lb)

Printing Speed: 60, 75, 90, 105, 120 sheets/minute (5 steps)

First Copy Time

(Trial Print):

Second Copy Time

(First Printout):

Paper Feed Table Capacity: 1,000 sheets (80g/m2, 20 lb)

Paper Delivery Table

Capacity:

Power Source: 120 V, 50/60 Hz, 3.6 A (for N. America)

Less than 20 s (B4, 81/2 x 14")

17 ± 1 s (A4, 81/2" x 14")

Less than 22 s (B4, 81/2" x 14")

19 ± 1s (A4, 81/2" x 14")

1,000 sheets (66.3 g/m2, 17.6 lb)

840 sheets (80g/m2, 20lb)

220/240 V, 50/6 0 Hz, 1.6 A (for Europe, Asia )

1-1

Page 4

SPECIFICATIONS 15 July 1995

Power Consumption: 120 V, 50/60 Hz, 380 W (for N. America)

220/240 V, 50/60 Hz, 360 W (for Europe, Asia)

Weight: 120 V version: 121 kg (266.5 lb)

220/240 V version: 121 kg (266.5 lb)

Cabinet: 23.5 kg (51.8 lb)

Dimensions (W x D x H): Trays closed: 719 x 698 x 644 mm

(28.3" x 27.5" x 25.4")

Trays open: 1331 x 698 x 666 mm

(52.4" x 27.5" x 26.2")

Cabinet: 719 x 630 x 426 mm

(28.3" x 24.8" x 16.8")

Original Scanning Time: 2.5 ms/line

Pixel Density: 300 dpi

Master Eject Box Capacity: More than 50 masters under low temp era tu re

More than 60 masters at 23 °C, 73°F

More than 60 masters under high temperature

Paper Separation: Friction roller/center separation system

Feed Table Side Plate

88 mm to 336 mm (3.46" to 13.2")

Movement:

Side Registration:

Vertical Registration:

±10 mm

±20 mm

Ink Supply: Automatic ink supply system

Paper Delivery: Air knife/vacuum delivery

Print Counter: 7 digits

Master Counter: 6 digits

Supplies: Master Thermal master 280 mm width

Master roll 257 masters/roll

(VT-II M master)

Master length 480 mm/1 master

Max run length 2000 prints

Ink 1000 cc ink pack (black)

600 cc ink pack

(Red, Blue, Green, Bro wn, Yello w,

Purple, Navy, Maroon)

1-2

Page 5

15 July 1995 GUIDE TO COMPONENTS

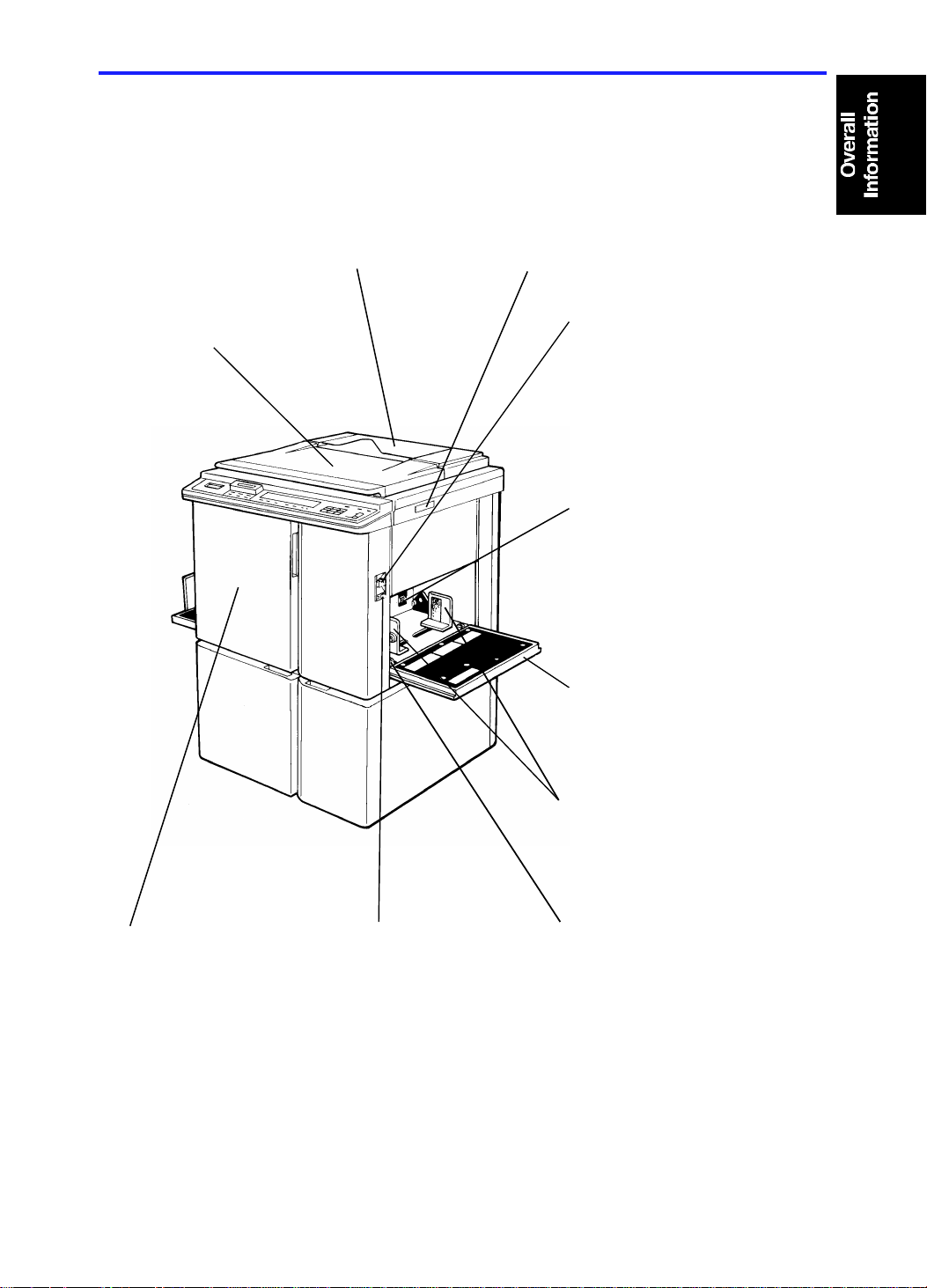

2. GUIDE TO COMPONENTS

Original Holder

A convenient place for

holding originals while

operating the mach ine.

Platen Cover

Lower this cover over

an original before

printing.

Original Table Release Lever

Use to open the original tab le

unit when installing the master.

Feed Roller Pressure

Lever

Use to adjust the contact

pressure of the paper fe ed

roller according to paper

thickness.

Separation Roller

Pressure Lev er s

Use to adjust the

separation roller

pressure to prevent

double fe ed.

Front Door

Open for access to

the inside of the

machine.

Paper Feed Table

Down Key

Press to lower the

paper feed table.

Paper Feed Table

Set blank paper o n th is

table for printing.

Paper Feed Side

Plates

Use to prevent paper

skew.

C222V501.img

Side Plate Fine

Adjustment Dial

Use to shift the

paper feed table

sideways

1-3

Page 6

GUIDE TO COMPONENTS 15 July 1995

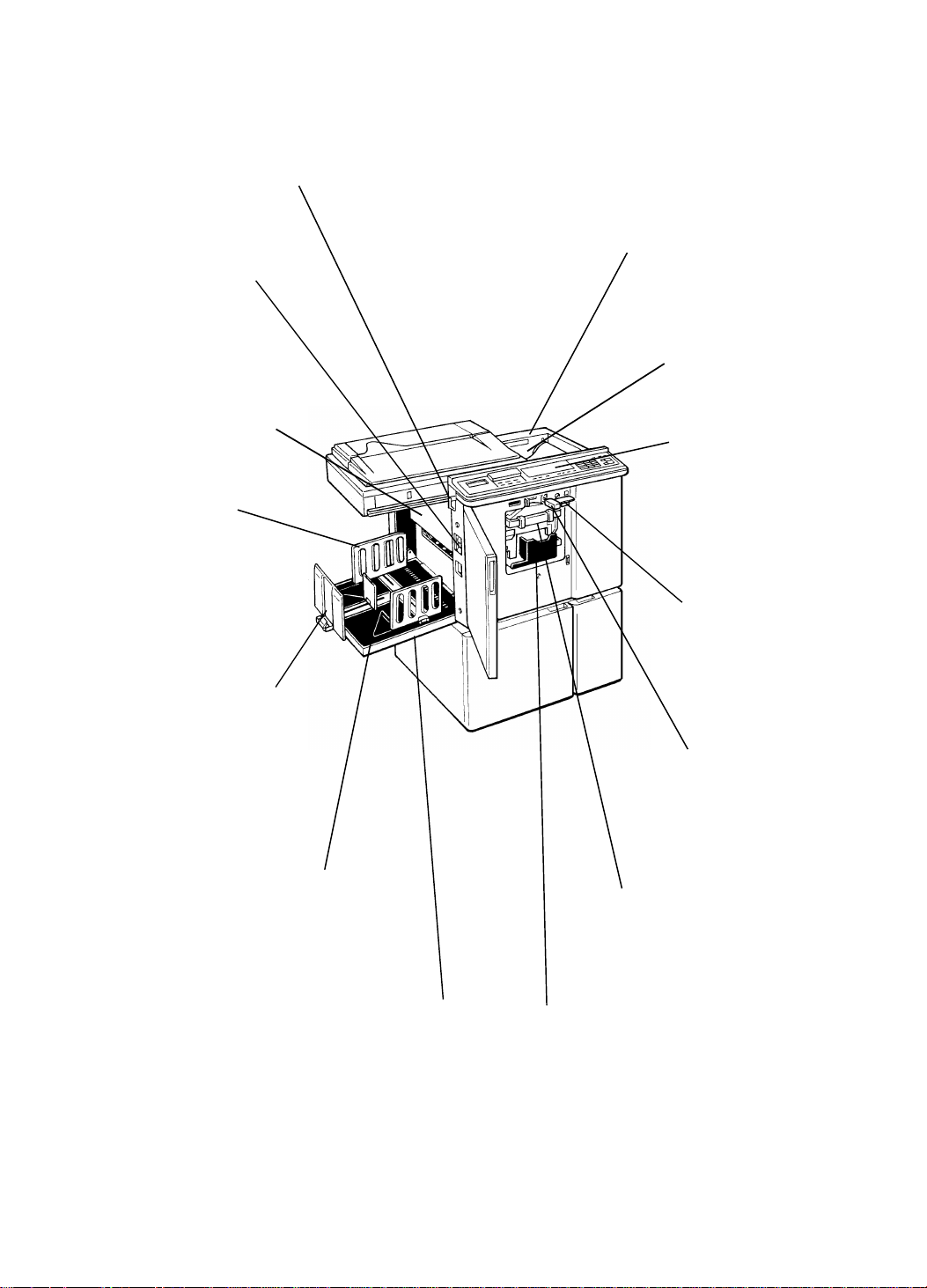

Master Eject Unit Open

Button

Press to remove misfed

paper or a misfed master.

Master Cut Button

Press this button to cut

the master paper

leading ed ge after

Main Switch

Use to turn the

power on or off.

Master Eject

Container Cover

Open when

installing a new master

roll.

Pressure Release

Lever

Use to install the

master roll.

removing the

master eject box.

Operation Panel

Operator controls

Paper Deliver y

Side Plates

and indicators are

located here.

Use to align the

prints on the

paper delivery

table.

Drum Rotation

Button

Press to replace

the drum.

Paper Deliver y En d

Plate

Use to align the

leading edges of

prints larger than A4,

81/2" x 11".

Small Size Paper Delivery

End Plate

Use to align the leading

edges of prints that are A4 ,

81/2" x 11" or smaller.

C222V502.img

Drum Unit

The master is wrapped

around this unit.

Drum Unit Lock

Lever

Lift to unlock and

pull out the drum

unit.

Paper Deliver y Tabl e

Completed prints are

delivered here.

1-4

Ink Holder

Set the ink cartridge in

this holder.

Page 7

5

6

13

7

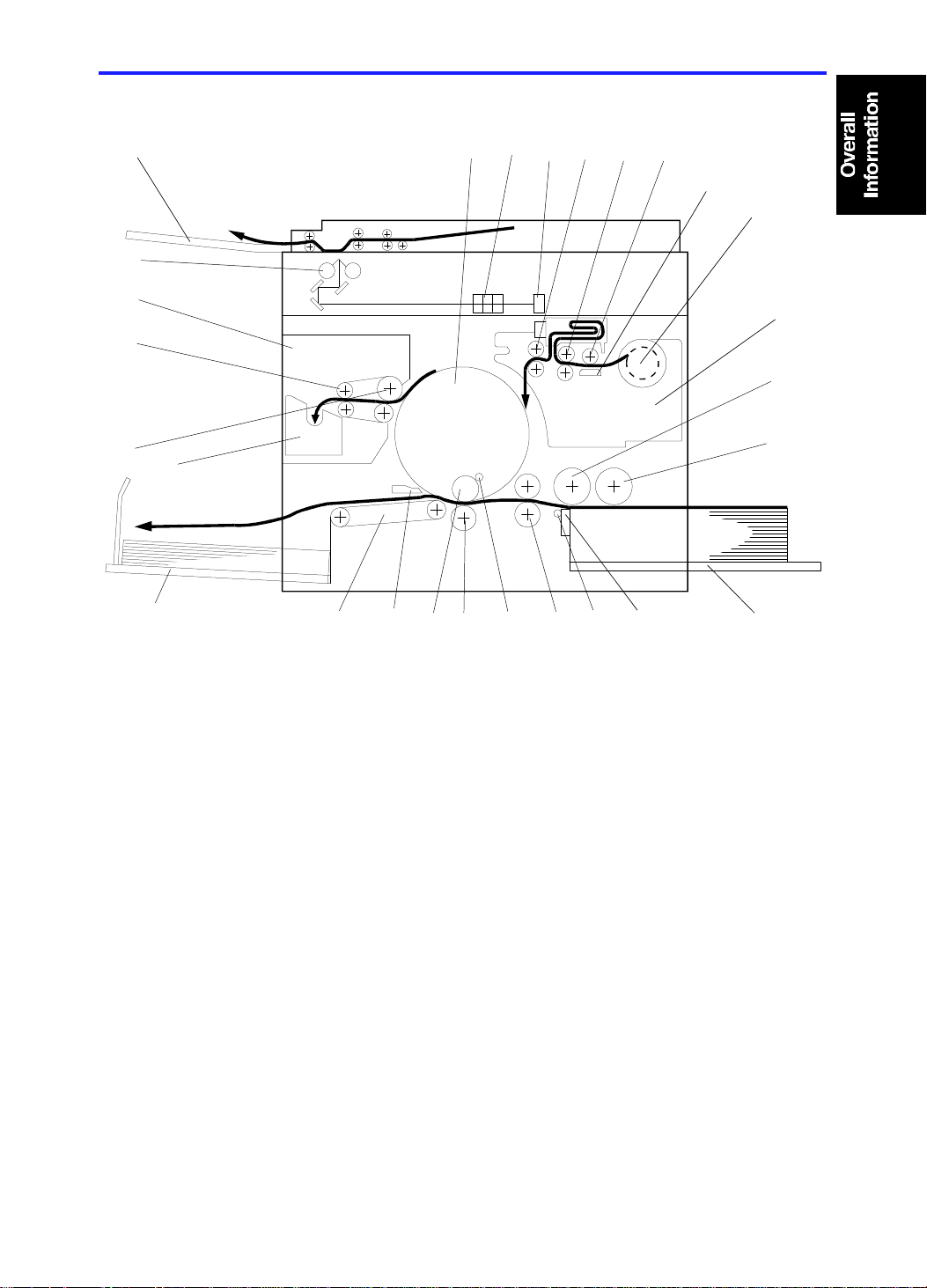

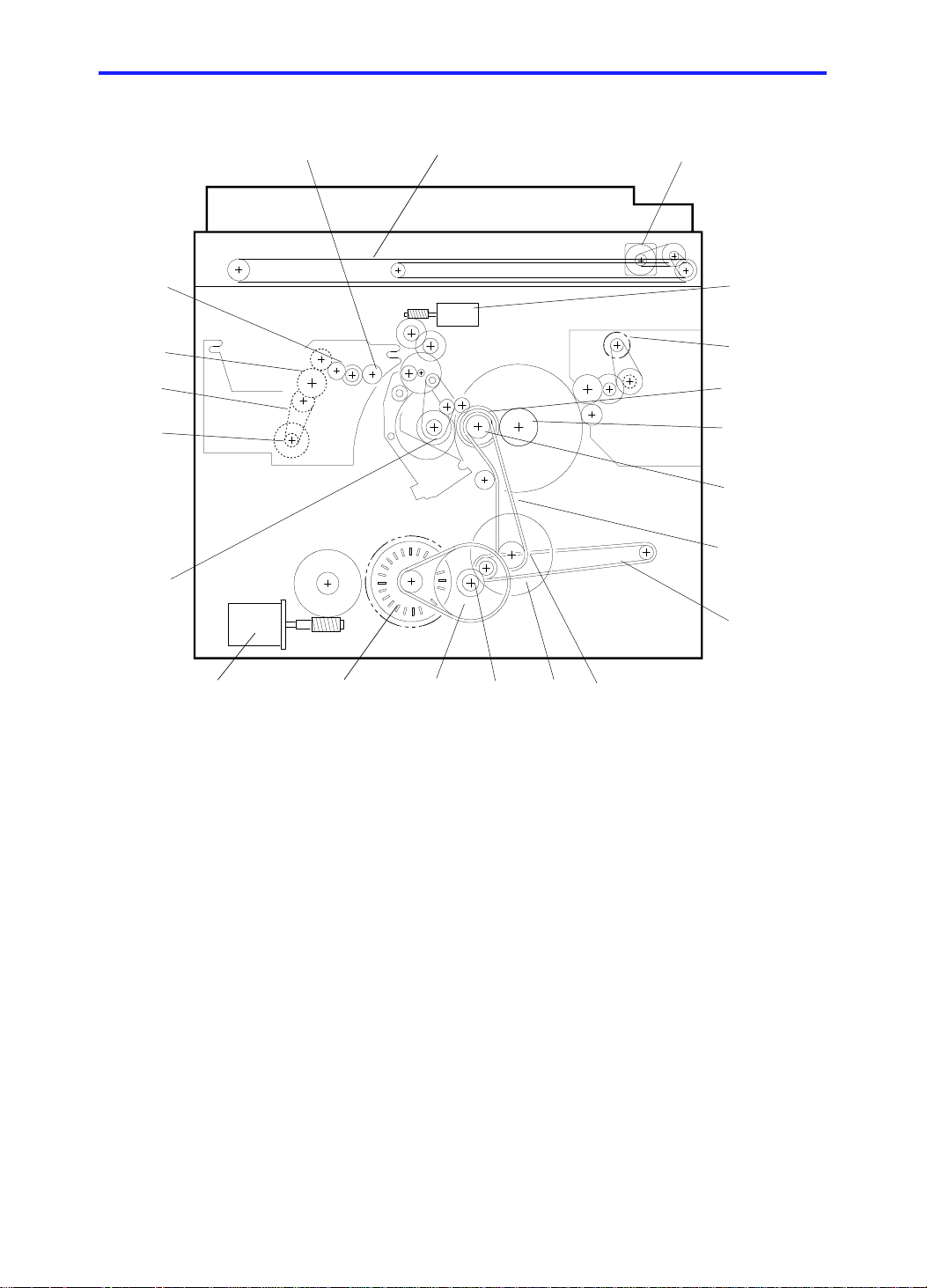

15 July 1995 MECHANICAL COMPONENT LAYOUT

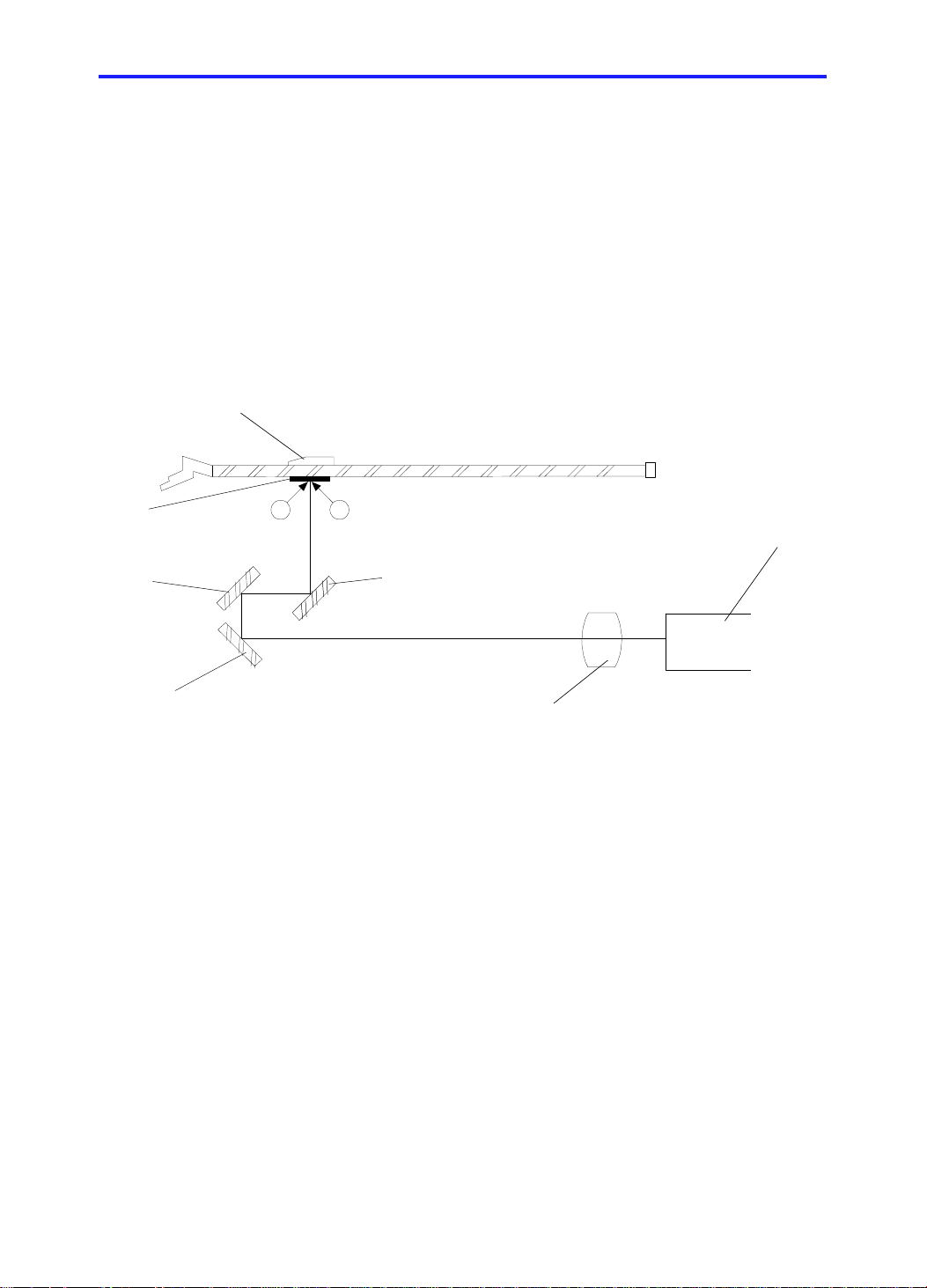

3. MECHANICAL COMPONENT LAYOUT

26

25

24

23

27

21

22

19

1234

1820

17

8

9

10

11

141516

12

1. Drum Unit

2. Lens

3. CCD

4. Reverse Roller

5. Master Feed Roller

6. Platen Roller

7. Thermal Head

8. Master Roll

9. Master Making Unit

10. Upper Separation Roller

11. Paper Feed Roller

12. Paper Table

13. Separation Pla te

14. Lower Separation Roller

C222V500-1.wmf

15. 2nd Feed Roller

16. Doctor Roller

17. Press Roller

18. Ink Roller

19. Paper Exit Pawl

20. Transport Unit

21. Paper Delivery Table

22. Master Eject Box

23. 1st Eject Roller

24. 2nd Eject Roller

25. Master Eject Unit

26. Exposure Lamps

27. Original Exit Tray

1-5

Page 8

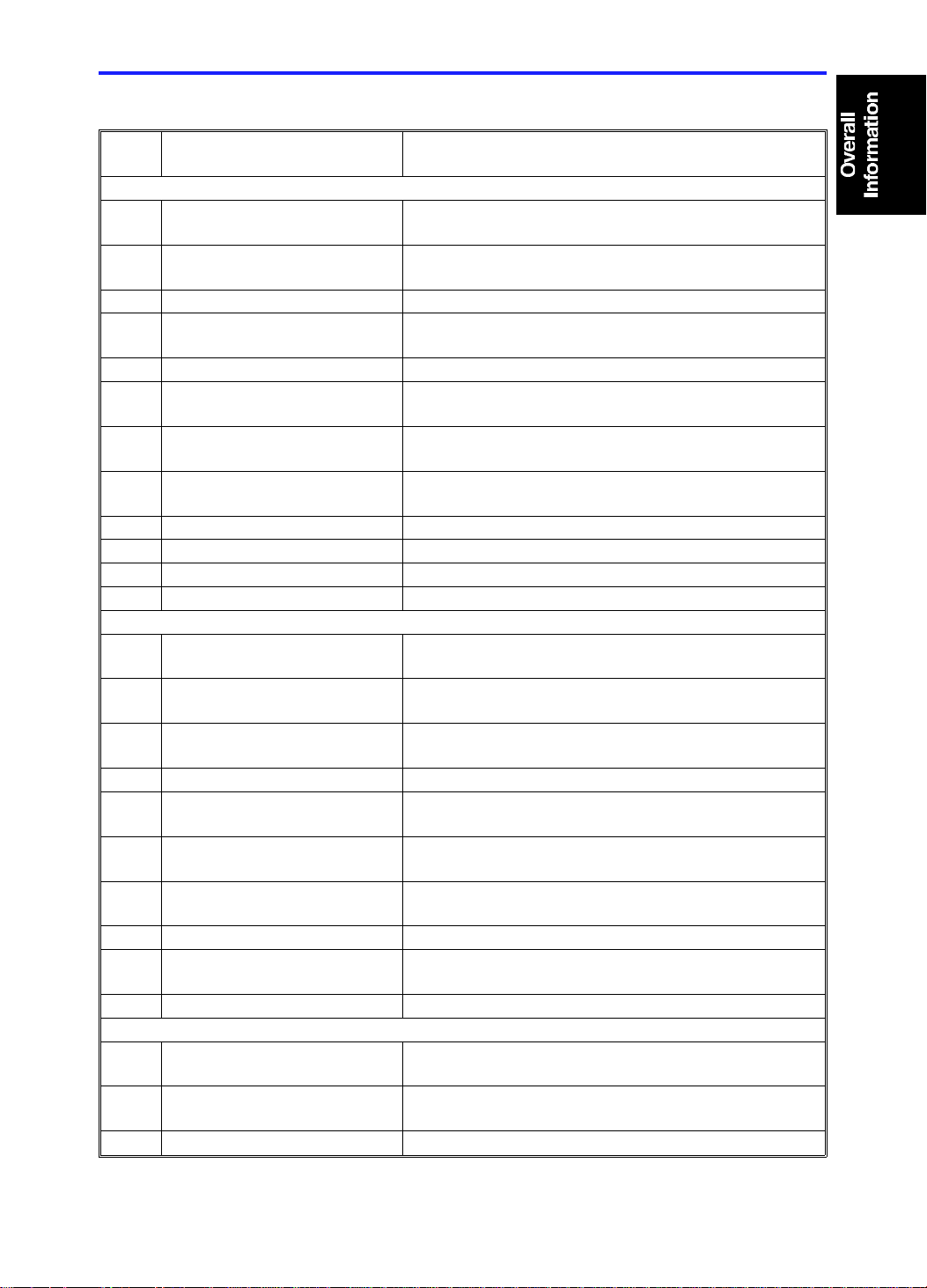

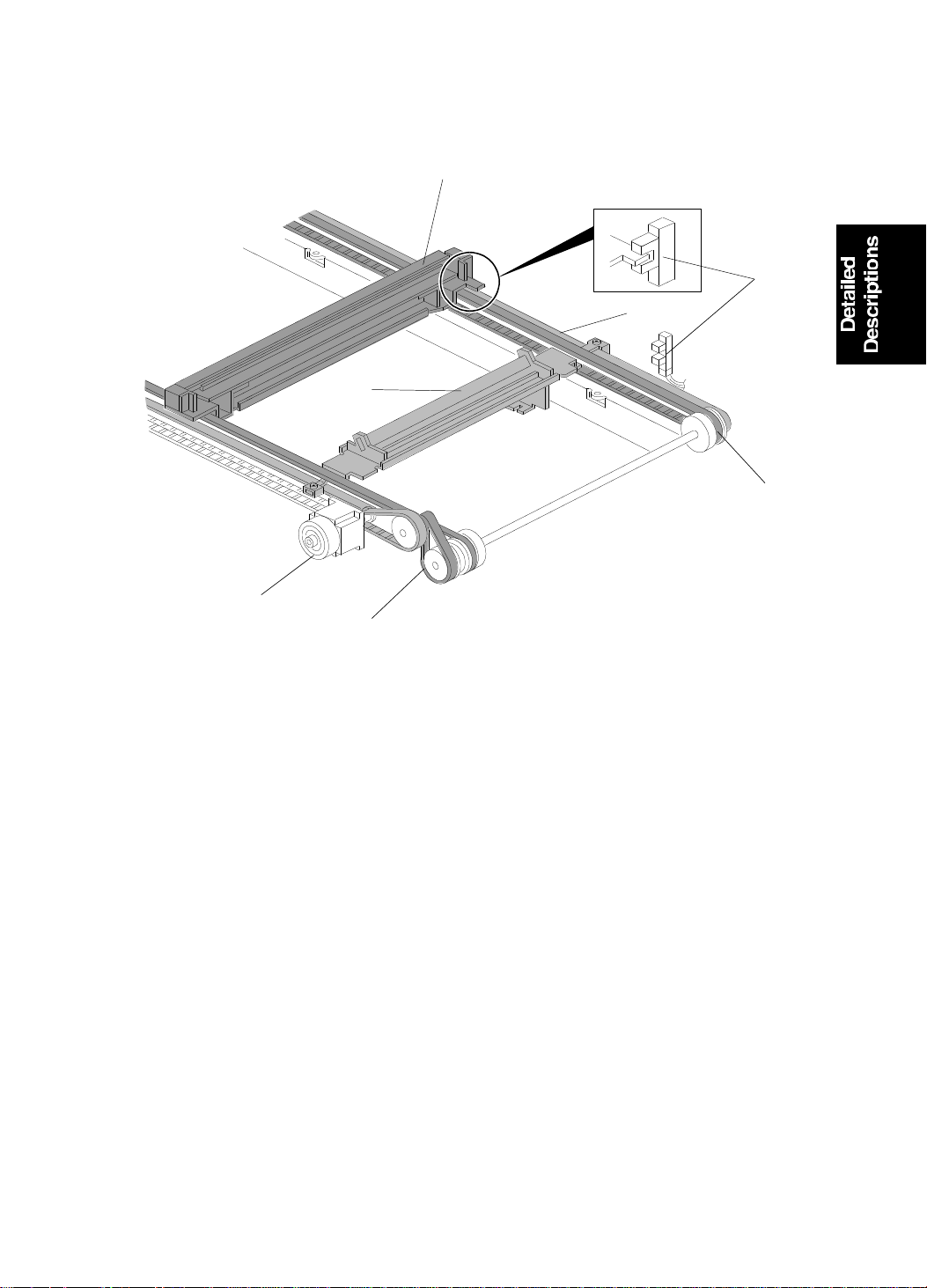

DRIVE LAYOUT 15 July 1995

4. DRIVE LAYOUT

21

1

20

19

18

17

2

3

4

5

6

7

8

16

9

15 14

1. Scanner Belt

2. Scanner Motor

3. Image Position Motor

4. Master Eject Motor

5. Drum Drive Gear

6. Drum Unit Gear

7. Drum Drive Pulley

8. Main Drive Belt

9. Transport Belt

10. Printing Pressure Pulle y

11. Printing Pressure Gear

13

C222V504.wmf

12

11 10

12. Idle Gear

13. Idle Pulley

14. Main Motor

15. Paper Table Drive Motor

16. Paper Feed Cam Gea r

17. Master Feed Motor

18. Timing Belt

19. Platen Roller Gear

20. Master Transport Roller Gear

21. Reverse Roller Gear

1-6

Page 9

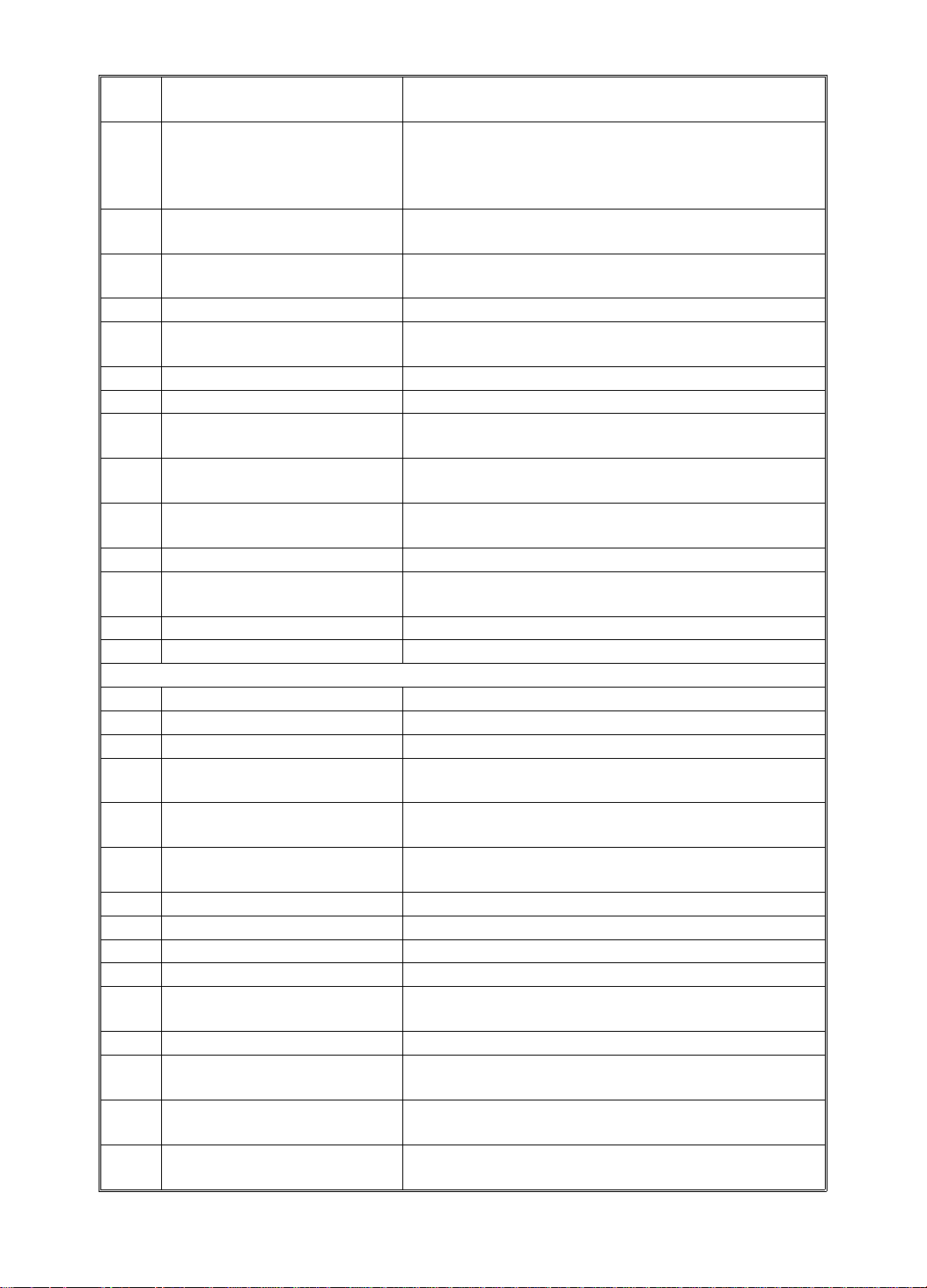

15 July 1995 ELECTRICAL COMPONENT DESCRIPTIONS

5. ELECTRICAL COMPONENT DESCRIPTIONS

INDEX

No.

Motors

15 Vacuum Fan Motor Provides suction so that paper is held firmly on the

35 Main Motor Drives paper feed, drum printing, and paper delivery

38 Paper Table Drive Motor Raises and lowers the paper feed table.

44 Image Positioning Motor Changing the relative timing of the paper feed roller

49 Master Feed Motor Feeds the master to the drum.

51 Master Buffer Fan Motor Provides suction so that the master is stored in the

52 Pressure Plate Motor Raises and lowers the pressure plate in the master

58 Air Knife Motor Drives the fan to separate the paper’s leading edge

60 Master Eject Motor Sends the used master into the master eject box.

62 Cutter Motor Drives the mechanism that cuts the master.

68 Scanner Motor Drives the 1st and 2nd scanners.

Solenoids

29 Ink Supply Solenoid Releases the spring clutch to activate the ink supply

30 Master Press Sheet Solenoid Inserts the mylar sheet between the press roller and

34 Printing Pressure Solenoid Engages the pressure on/off lever when a paper

37 Paper Feed Solenoid Releases the sector gears to feed the paper.

40 Detection Pin Release

Solenoid

45 Master Feed Clamper

Solenoid

46 Drum Lock Solenoid Prevents the drum unit from being removed during a

47

Master Eject Clamper Solenoid Open the master clamper to eject the master.

57 Master Eject Solenoid Presses the lower master eject roller against the

NAME FUNCTION

transport belt.

unit components.

and the drum to adjust the vertical image position.

master box during the master eject operation.

eject mechanism.

from the drum.

pump.

the drum during a quality start operation.

misfeed occurs.

Releases the detection pin arm to apply printing

pressure during a quality start operation.

Open the master clamper to catch the master during

master feed.

printing run.

drum surface.

Switches

1 Scanner Unit Safety Switch Cuts off the power line of the main and paper table

drive motors when the scanner unit is open.

2 Paper Table Down Button Instructs the CPU to turn on the paper table drive

motor to lower the paper table.

5 Paper Table Open Switch Checks whether the paper table is opened or not.

1-7

Page 10

ELECTRICAL COMPONENT DESCRIPTIONS 15 July 1995

INDEX

No.

7 Paper Table Safety Switch Stops lowering the paper feed table to prevent users

12 Front Door Safety Switch Informs the CPU when the front door is open, and

18 Test Switch Disables the front door, paper table, master eject

20 Main Switch Turns the power on or off.

21 Air Knife Motor Safety Switch Cuts off the power line of the air knife motor when

26 Drum Rotation Button Instructs the CPU to rotate the drum at 10 rpm.

27 Drum Unit Safety Switch Checks whether the drum unit is set correctly or not.

28 Master Eject Unit Safety

Switch

43 Master Cut Button Instructs the CPU to feed a short strip of master

50 Left Cutter Switch Detects when the cutter position is at the far left

59 Master Eject Box Switch Checks whether the master eject box is set properly.

64 Right Cutter Switch Detects when the cutter position is at the far right

74 ADF Set Switch Detects if the optional document feeder is closed.

NAME FUNCTION

from catching their fingers under it, by cutting the ac

power. It also closes when the paper feed table is

closed.

cuts off the power line to the paper table drive motor.

unit, and scanner unit safety switches.

the master eject unit is open.

Cuts off the power line when the master eject unit is

open.

paper and cut the master paper.

(operation side).

(non-operation side).

Sensors

3 Paper End Sensor Informs the CPU if there is paper on the paper table.

4 Paper Width Sensors Informs the CPU of the printer paper width.

6 Paper Length Sensor Informs the CPU of the printer paper length.

8 Paper Table Height Sensor Informs the CPU if the paper table is at the paper

feed position.

11 Paper Table Lower Limit

Sensor

13 Printing Pressure Sensor Informs the CPU if printing pressure is applied. Also,

14 1st Paper Exit Sensor Detects paper misfeeds.

17 2nd Paper Exit Sensor Detects paper misfeeds.

31 2nd Drum Position Sensor Checks the position of the drum.

33 1st Drum Position Sensor Checks the position of the drum.

36 Drum Rotation Sensor Supplies timing pulses to the CPU based on the

48 Drum Master Sensor Informs the CPU if there is a master on the drum.

53 Lower Pressure Plate Sensor Informs the CPU if the pressure plate in the master

54 Upper Pressure Plate Sensor Informs the CPU if the pressure plate in the master

55 Full Master Box Sensor Informs the CPU whether the master eject box is full

Informs the CPU if the paper table is at the lowest

position.

detects paper misfeeds.

main motor speed.

eject mechanism is at the lower limit position.

eject mechanism is at the upper limit position.

of masters or not.

1-8

Page 11

15 July 1995 ELECTRICAL COMPONENT DESCRIPTIONS

INDEX

NAME FUNCTION

No.

56 Master Eject Sensor Detects used master misfeeds.

63 Master End Sensor Informs the CPU when the master roll in the master

making unit runs out.

65 Master Buckle Sensor Informs the CPU if the master is buckling.

70 Platen Cover Position Sensor Detects when the platen cover or the optional

document feeder is opened more than 25 degrees

above the exposure glass.

73 Original Sensor Detects if an original is placed on the exposure glass.

75

Scanner Home Position Sensor Informs the CPU when the 1st scanner is at home

position.

Printed Circuit Boards

9 Main Control PCB Controls all machine functions both directly and

through other boards.

41 AC Drive PCB Controls the ac components using relays.

42 Ink Detection PCB Informs whether ink is present in the drum.

69 CCD PCB Converts light intensity into an electrical signal.

72 A/D Conversion PCB Converts analog signals into digital signals.

Counters

22 Master Counter Keeps track of the total number of masters made.

23 Total Counter Keeps track of the total number of prints made.

Others

10 Transformer Steps down the wall voltage.

16 Power Supply Unit Provides power for all dc components.

19 Circuit Breaker Cuts the ac line off.

24 Operation Panel Interfaces the CPU and the operator.

25 Drum Rotation LED Turns to green from red when the drum stops at the

home position.

32 Noise Filter Filters out electrical noise from the ac power input

line.

39 Paper Table Drive Motor

Protects the ac drive PCB from induced current.

Capacitor

61 Reverse Roller Clutch Transfers drive to the reverse roller.

65 Thermal Head Creates the master using heat.

67 Xenon Lamp Illuminates the original.

71 Xenon Lamp Stabilizer Stabilizes the power supplied to the xenon lamp.

1-9

Page 12

Master

Making/

Master

Feed

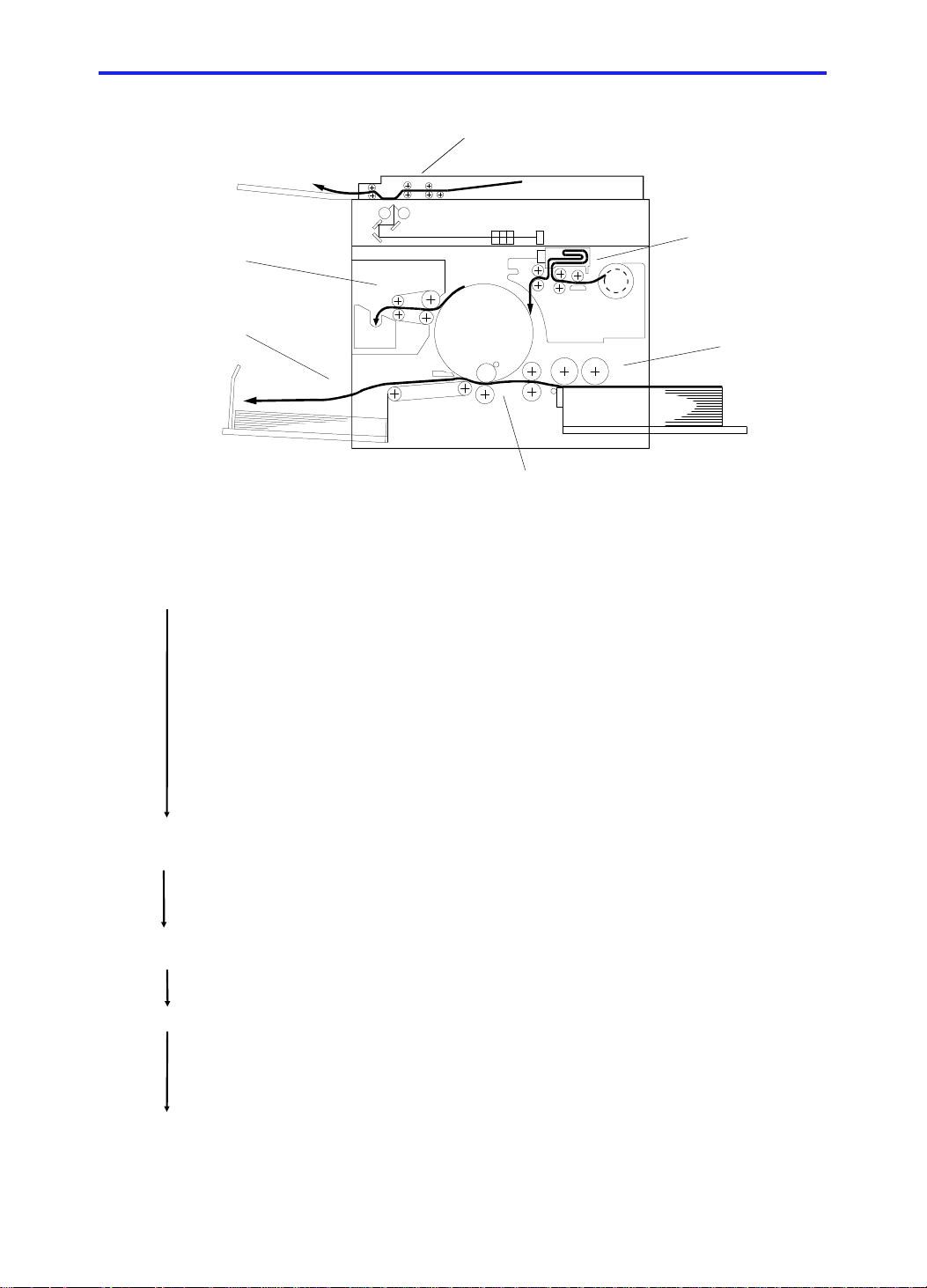

PRINTING PROCESS 15 July 1995

6. PRINTING PROCESS

Master

Ejection

Paper

Delivery

1. Master Ejection/

Scanning/

Master Making:

At the start of the print ing run, the machine

ejects the used master wrapped around the

drum into the master eject box.

Scanning

Printing

Shown with

optional ADF

attached

Paper

Feed

C222V500.wmf

At the same time, the machine scans the

original on the exposure glass (reflected light

goes to the CCD via the mirrors and the lens.

The scanned image is tran sfe rred to the master

using a thermal head.

While the old master is still being ejected, the

new master is stored in a box.

2. Master Feed: After the old master has been eject ed , th e ne w

master is fed to the drum and wrapped around

it. At the same time, the master is cut of f fro m

the roll.

3. Paper Feed: I nd ividu al she et s of pa per are fe d to the drum.

4. Printing: The paper fed from the paper fee d mech anism

is pressed onto the drum. This transfers ink to

the printer paper through the drum screen and

the master.

5. Paper Delivery: The exit pawl and air knife peel off the printout,

and the printout is ejected onto the paper

delivery table.

1-10

Page 13

SECTION 2

DETAILED SECTION

DESCRIPTIONS

Page 14

15 July 1995 MASTER EJECT

1.

MASTER EJECT

1.1 OVERALL

At the end of the printing cycle, the use d master remains wrapped around the

drum to prevent the ink on th e drum surface from drying. Whe n th e Master

Making key is pressed to make a new master, the used master is ejected

from the drum.

The master is pulled off the drum, then it goes through the eje ct rolle rs and

into the master eject box. A pressure plate then compacts the used master.

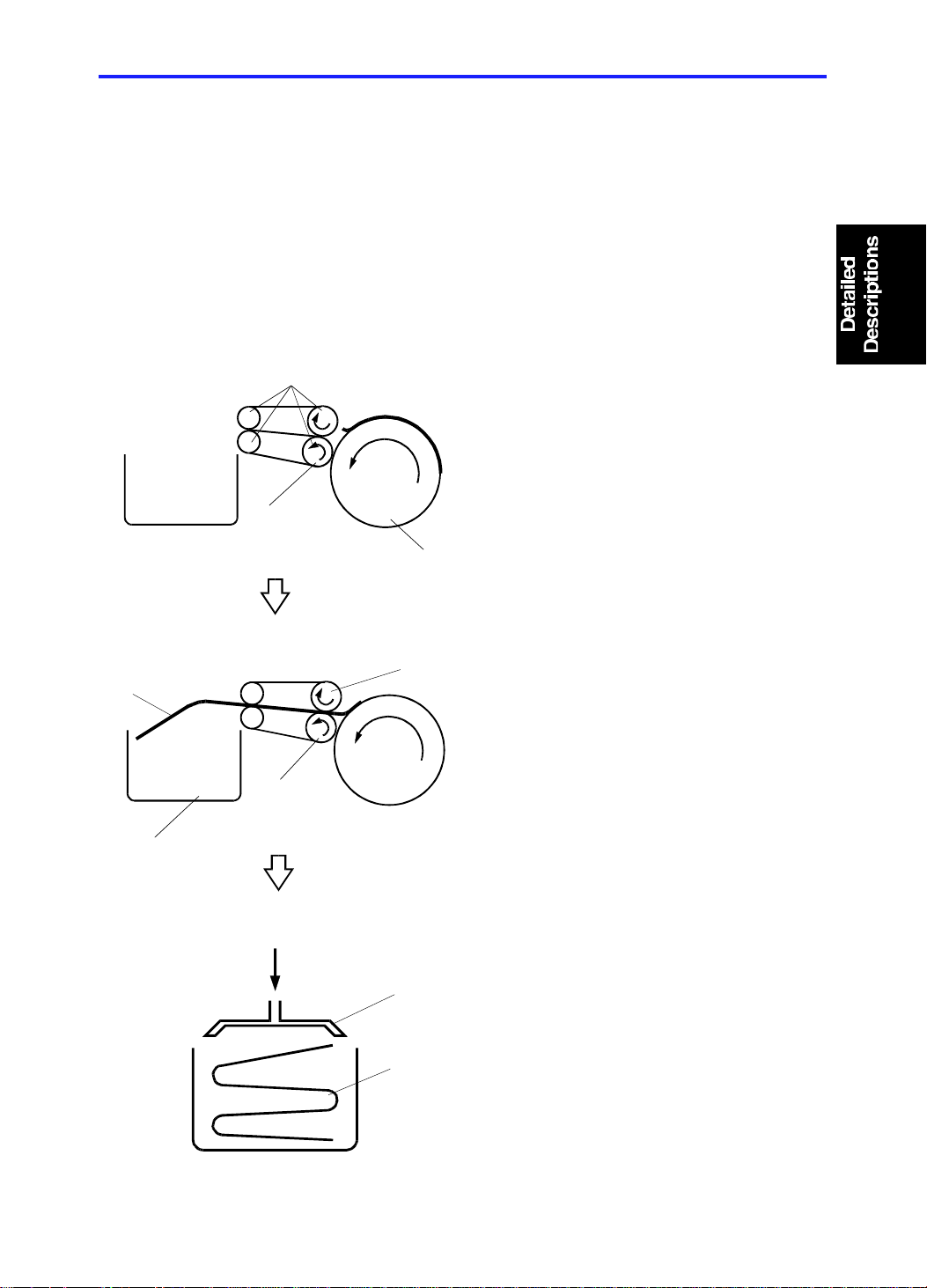

[D]

[G]

[C]

[A]

[F]

[B]

C222D505.wmf

[E]

Drum

•

The drum [B] rotates in reverse

(opposite to the printing direction).

•

The master eject rollers [A] rotate.

•

The lower eject roller [C] is

pressed against the drum.

•

The trailing edge of the master,

which curls up from the drum,

passes between the upper [E] and

lower [F] eject rollers, and the

master [D] is peeled off th e dru m

and dumped into the mast er eje ct

box [G].

C222D506.wmf

C222D507.wmf

[H]

[I]

•

The pressure plate [H] compa cts

the ejected master [I].

2-1

Page 15

MASTER EJECT 15 July 1995

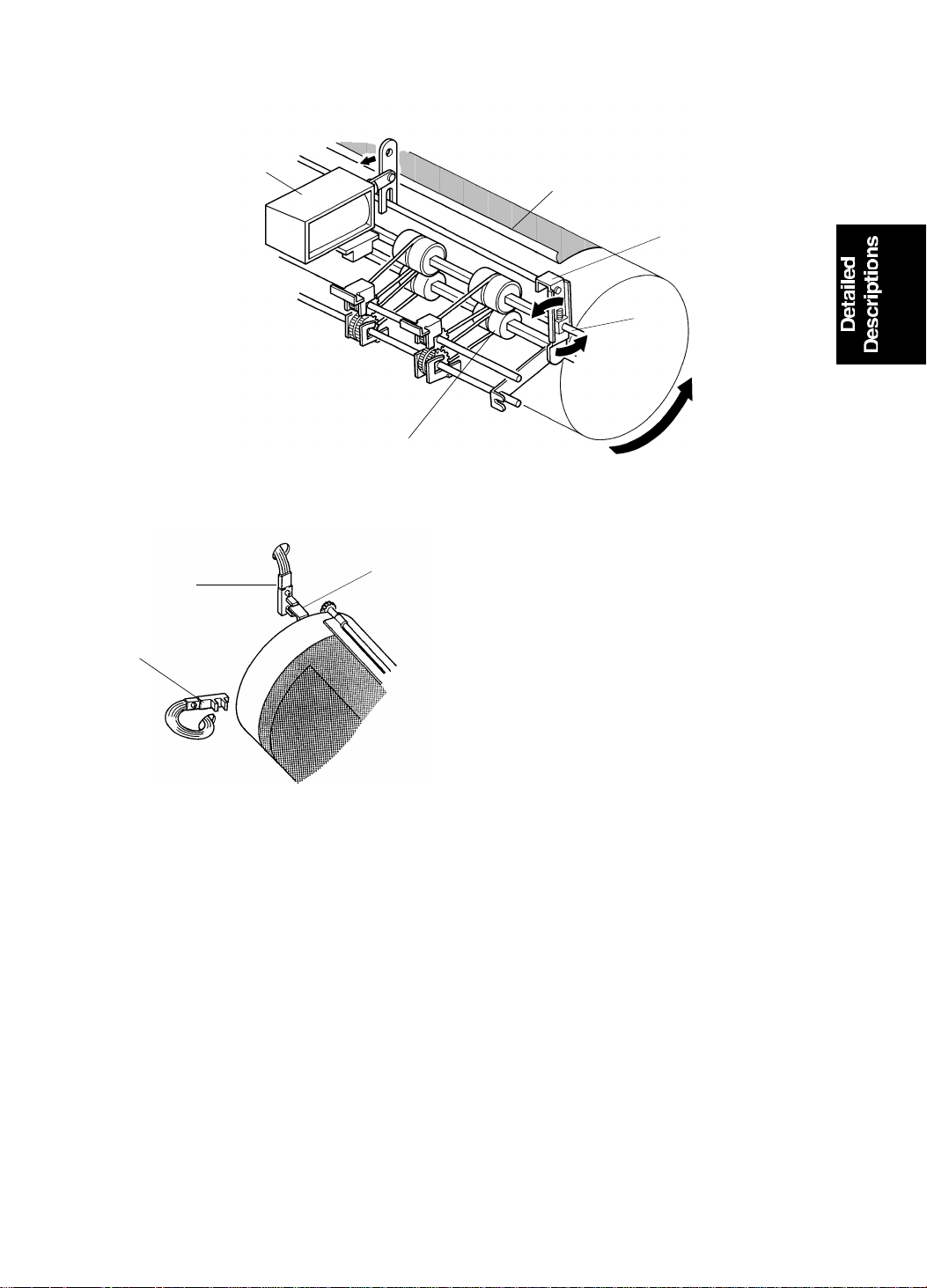

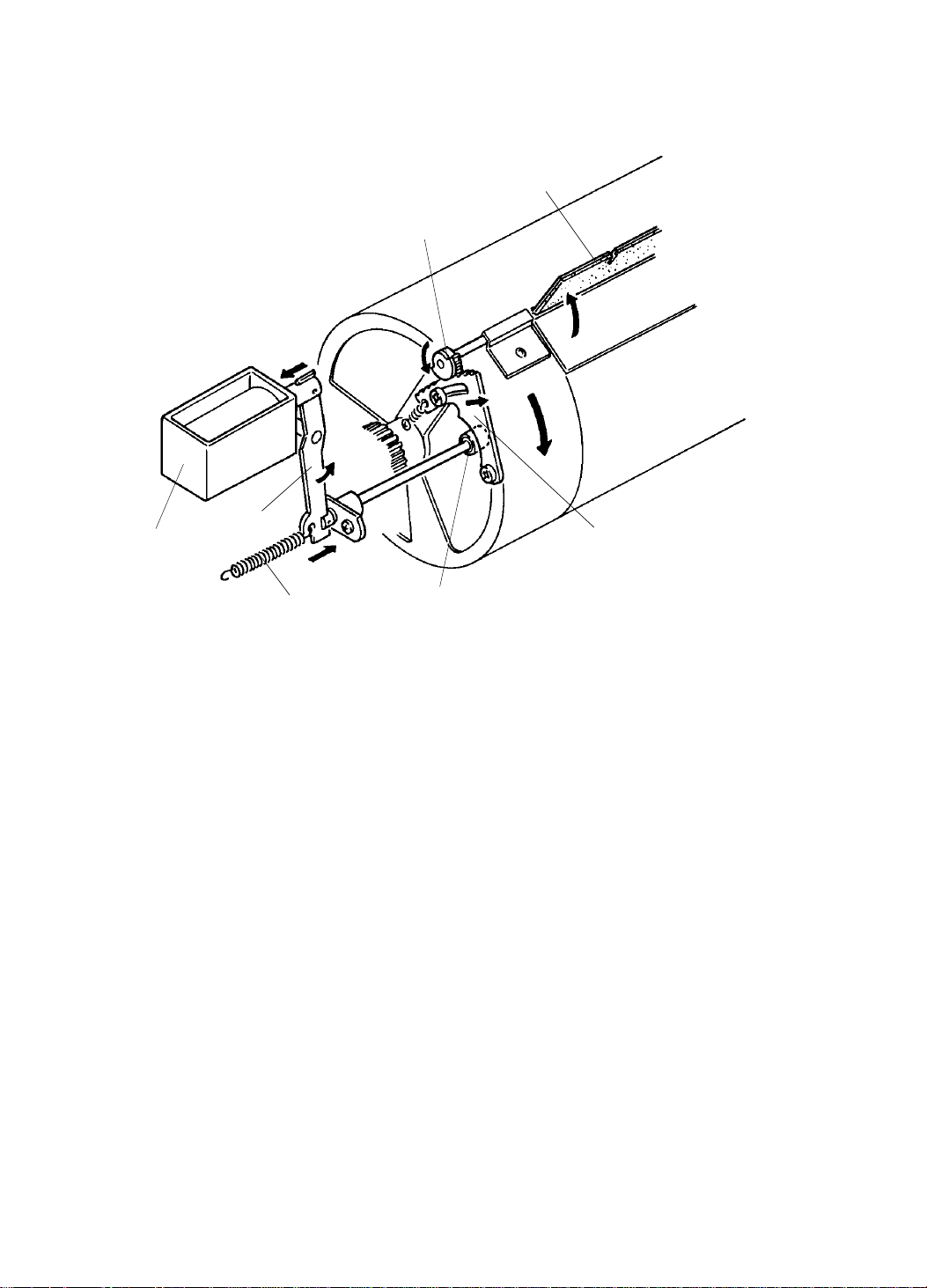

1.2 MAS TER E JE CT ROLLE R ROTATI O N MECHANIS M

[I]

[J]

[H]

[G]

[A]

[B]

[E]

[F]

[B]

[C]

[D]

[E]

[F]

C222D511.img

When an original is in place and the Mast er Making key is pressed, the main

motor starts turning at 20 rpm in re verse . As a resu lt, the drum also turns in

reverse (compared with the rotation direct ion for prin ting).

At this time, if the drum master sensor detects a master on the drum, the

master eject motor [A] starts rotating. Drive is transmitted to gear [E] and to

the upper first eject rollers [G] through the timing belt [B] and gears [C] and

[D]. Gear [F] drives the lower first eject rollers [H] . The belts [I] transmit drive

from the first eject rollers to the upper and lower second eject rolle rs [ J].

(If the drum master sensor det ect s no mast er on the drum whe n th e Mast er

Making key is pressed, the machine skips the master eject process and goes

directly to the master making process.)

After the master eject process is completed, the drum returns to its home

position. The master eject rollers then stop rotating.

This model has four rollers on each eject roller shaft.

2-2

Page 16

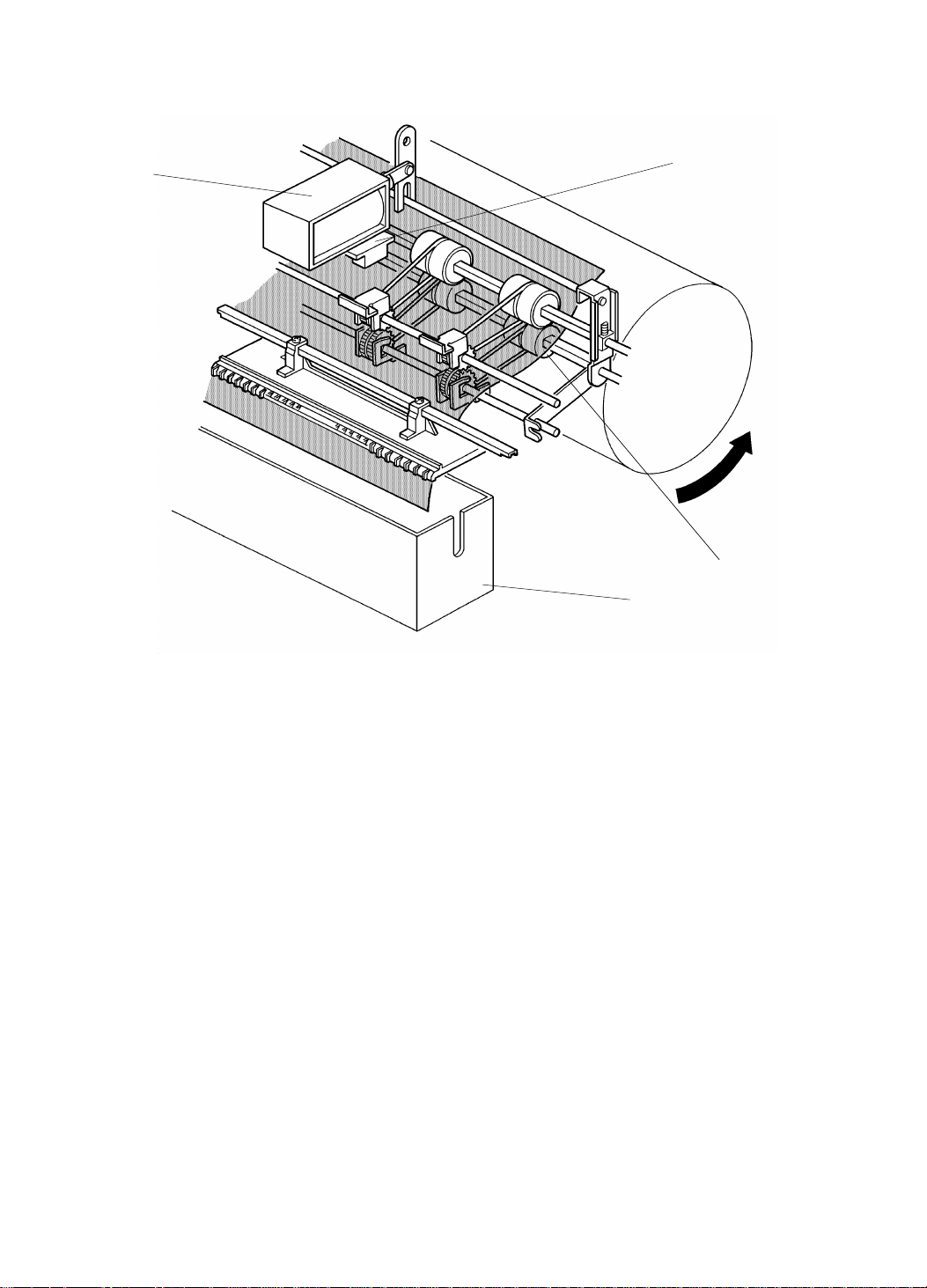

[D]

15 July 1995 MASTER EJECT

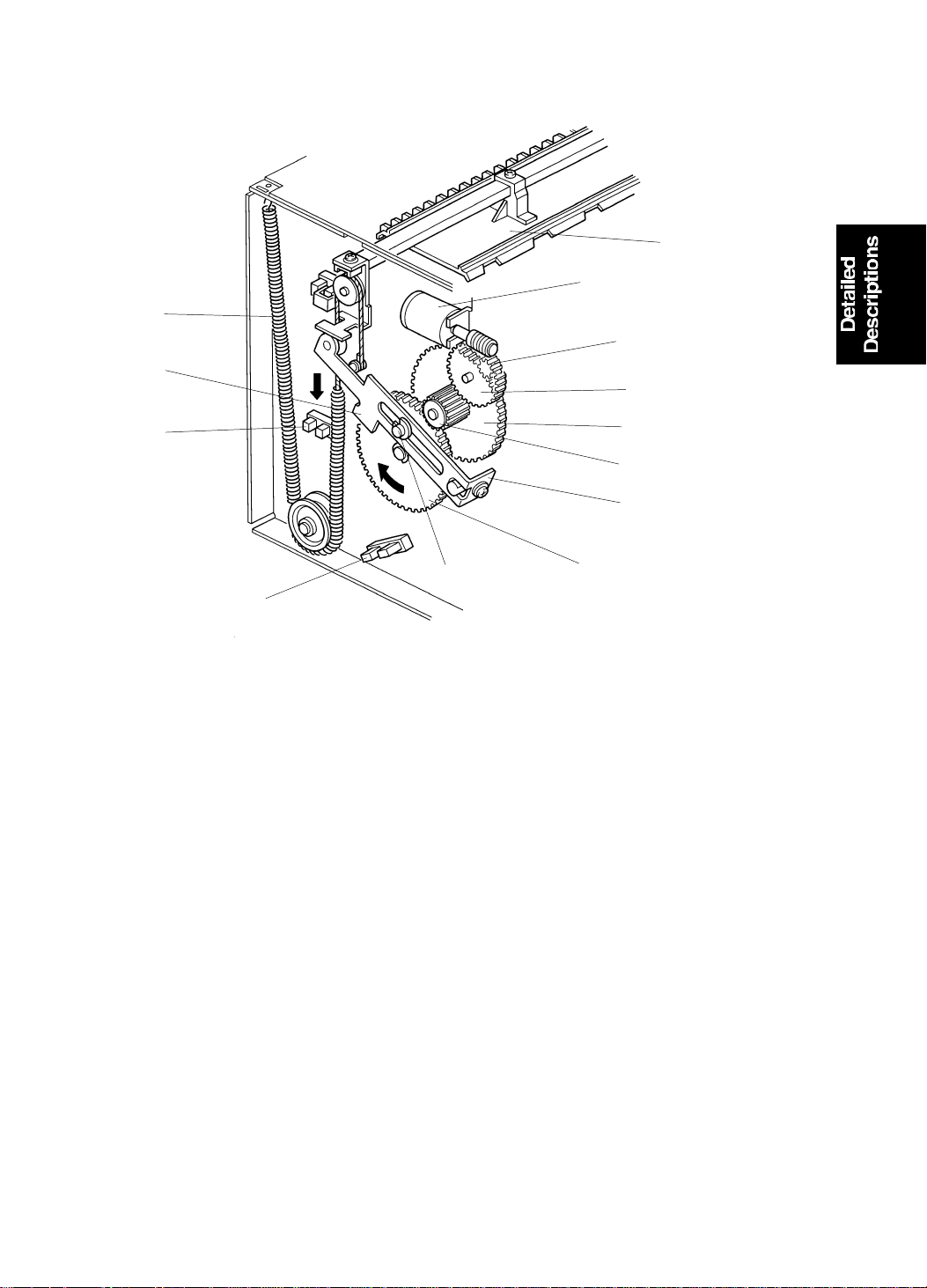

1.3 MASTER EJECT ROLLER DRIVE MECHANISM

[H]

[G]

[A]

[B]

[C]

[E]

C222D508.img

[F]

C222D510-1.img

The drum position is detected by th e first [G] and secon d [H] drum position

sensors. When the drum reach es its ho me position, the first drum position

sensor [G] is activated by the interrupter [F] on the rear side of th e drum.

To eject the master, the drum turns in reverse (opposite to the printing

direction). When the drum is 22° past the 2nd drum position sen sor, the

master eject solenoid [A] turns on and the suppo rte r [C] rotates

counterclockwise on the upper eject roller shaft [D]. This forces the lower first

eject roller [E] against the dru m.

As the drum turns, the curled trailing edge of the master [B] passes be twe en

the upper and lower first eject rollers. The first eje ct rolle rs the n peel the

master from the drum.

2-3

Page 17

[B]

[D]

MASTER EJECT 15 July 1995

[A]

[C]

C222D509.img

When the drum is 63° past the 2nd drum posit ion se nso r, the master eject

solenoid [A] turns off , sep ara ting the lower first eject rollers [C] from the drum.

Shortly after the lead ing edge of the ejected master h as passed between the

upper and lower first eject rollers, the master eje ct sen sor [B ] is a ctiva ted.

The master is then dumped into th e mast er eject box [D].

2-4

Page 18

15 July 1995 MASTER EJECT

Master Eject Misfeed Dete ction

The misfeed indicator for the master eject mechanism blinks in the fo llowing

cases:

Case 1: The drum has turned 11 3 de gre es past the 2nd drum position

sensor, and the master eject sen sor is still n ot activa te d. The CPU

determines that the eject rollers ha ve fa iled to cat ch th e master. So

the drum returns 70 degrees (in the printing dire ctio n) to repeat the

master eject process. The master eject solenoid is again energized

while the drum turns another 21 deg ree s to try to catch the master.

C222D512.wmf

If the master eject sensor once again fails to detect the master,

then the drum returns to its home position and the misfee d

indicator blinks.

Case 2: The drum finishes its rotation for the master ejecting pro cess an d

returns to the home position, but the master eject sensor does not

turn off. This means that the master is still in between the master

eject rollers, and the misfeed indicator blin ks.

2-5

Page 19

[G]

MASTER EJECT 15 July 1995

1.4 MAS TER E JE CT CLAMPE R MECHANI S M

[F]

[B]

[A]

[E]

[C]

[D]

C222D513.img

When the drum has rotate d 21 4 de gre es (in reverse) past the 2nd drum

position sensor, the mast er eject clamper solenoid [A] turns on and lever [B ]

moves counterclockwise a short way as shown. This moves the cam [D]

inside the drum. Drum rotatio n brings the clamper sector gear [E] against the

cam [D]. Gear [F] turns count erclo ckwise as it en ga ges the clamper sector

gear, thus opening the maste r clampe r [G] . This rele ases the master from the

drum.

The drum keeps on turning until the interrupter at the rear of the drum has

gone 17 degrees past the first drum position sensor. Then, the main mot or

turns off. Half a second later, the master eject clamper solenoid [A] turns off

and spring [C] pulls cam [D] back to its initia l posit ion . The drum then rotates

forward to its home position .

2-6

Page 20

[A]

[C]

[D]

[E]

[F]

[G]

15 July 1995 MASTER EJECT

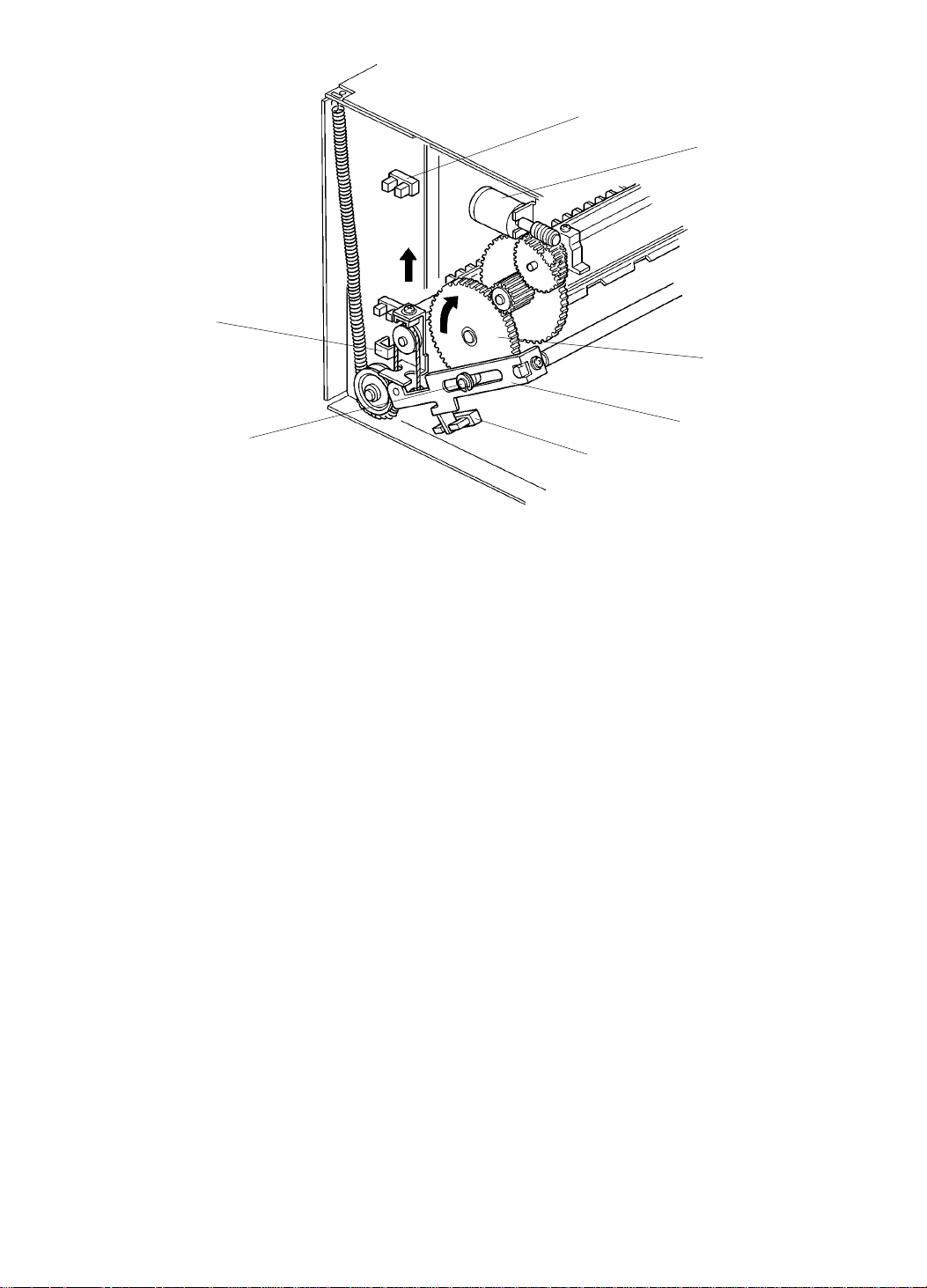

1.5 P RESSURE PLATE UP/DOWN MECHANISM

[B]

[M]

[L]

[K]

[I]

[H]

[J]

Pressure Plate Down

C222D514.img

When the interrupter at the rear of the drum interrupts the first drum position

sensor (this happens at th e en d of the master eject process), th e pre ssure

plate motor [B] starts. This drives gear [H] clockwise by mea ns of gears [C],

[D], [E], and [F].

Pin [I] on gear [H] moves link [G] down until the link interrupter [L] interrupts

the lower pressure plate sensor [J] . Sp ring [M] pulls down on the pressure

plate and the ejecte d master in the master eject box is compresse d by the

pressure plate [A].

If the master box full sensor [K] does not turn on when the pressu re plate

goes down, it means the master eje ct box is fille d with eject ed masters. In

this case, the master eject bo x full ind icator blinks, and the machine stop s

after a new master is wrapped around the drum.

The indicator goes out after t he master eject box switch has been turned off

and on. Then the maste r box fu ll se nso r is che cked aga in af ter one master

has been fed. This is to prevent the indicator from being reset without

removing the ejected masters from the box. When the indicato r is blin king ,

the Master Making key does not work, but the Print Start key and Proof key

work so that the master curre nt ly o n th e dru m ca n be used for printing.

2-7

Page 21

[B]

[D]

MASTER EJECT 15 July 1995

[A]

[G]

[C]

[F]

[E]

C222D515.img

Pressure Plate Up

When the master has been wrapped around the drum in the master making

process and the master cutter leaves the home position to cu t th e master, the

pressure plate moto r [B] starts rotating to raise th e pressure plate.

When the pressure plate motor [B] turns, the gear [C] is driven through the

relay gears. The pin [F] on the gear inserted into the link [D] rises and lift s the

left end of the link, thus raising the pressure plate.

The gear [C] continues turnin g until th e int erru pt er [G ] at the fron t en d of the

pressure plate blocks the upper pressu re pla te senso r [ A] . At this time , th e

master eject motor [B] stop s and the pressu re pla te is held in th e up pe r

position.

Pressure Plate Motor Lock Detection

To prevent the pressure plate motor from locking, "E-12" light s up on the

operation display panel under the following conditions:

1. When the lower pressure plate sen sor [E ] is not activa te d with in 8

seconds after the pressure plate motor starts to lower th e pressure plate.

2. When the upper pressure plat e sensor [A] is not activated with in 4

seconds after the pressure plate motor starts to raise th e pressure plate.

2-8

Page 22

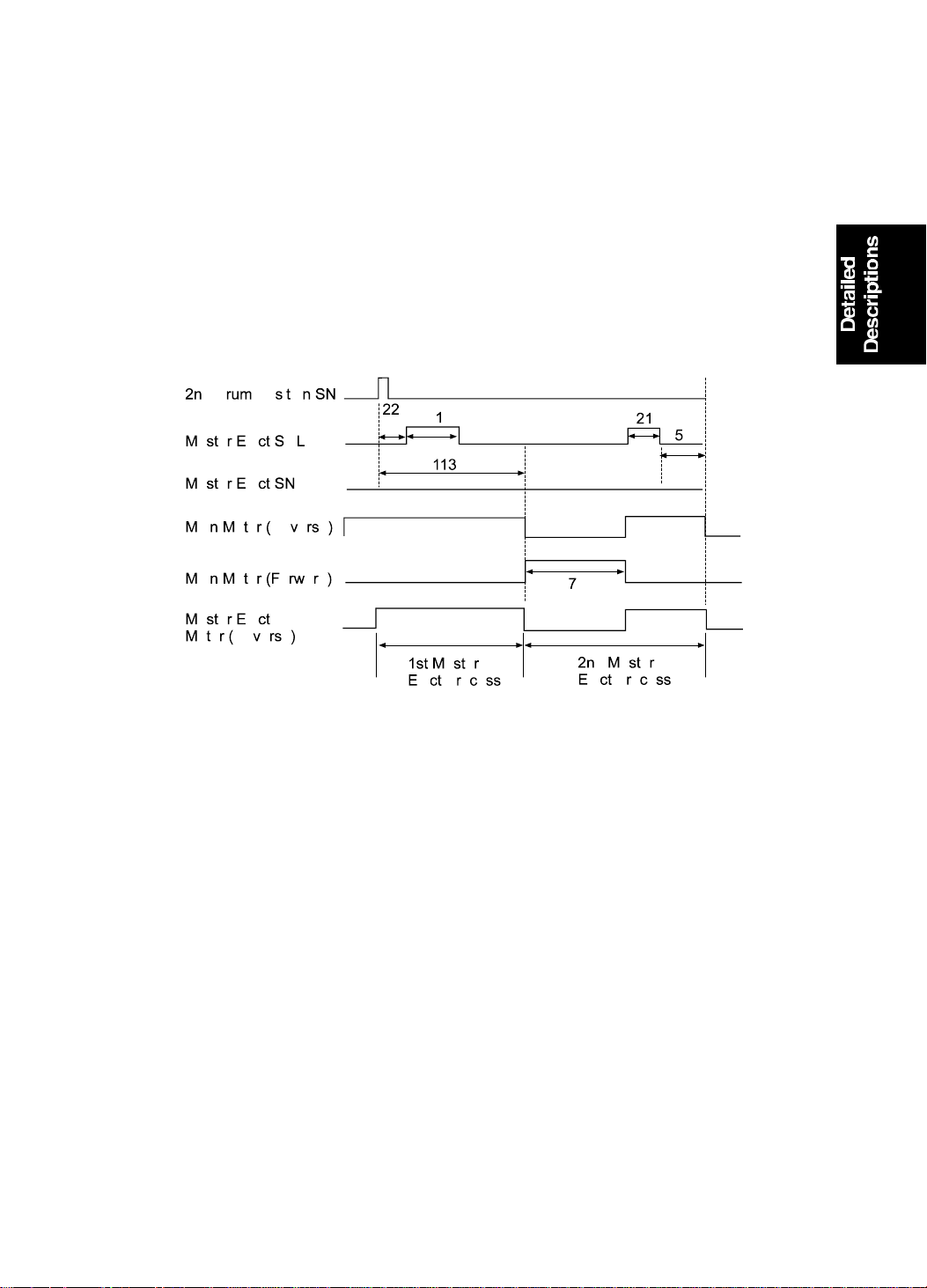

22 rpm

15 July 1995 MASTER EJECT

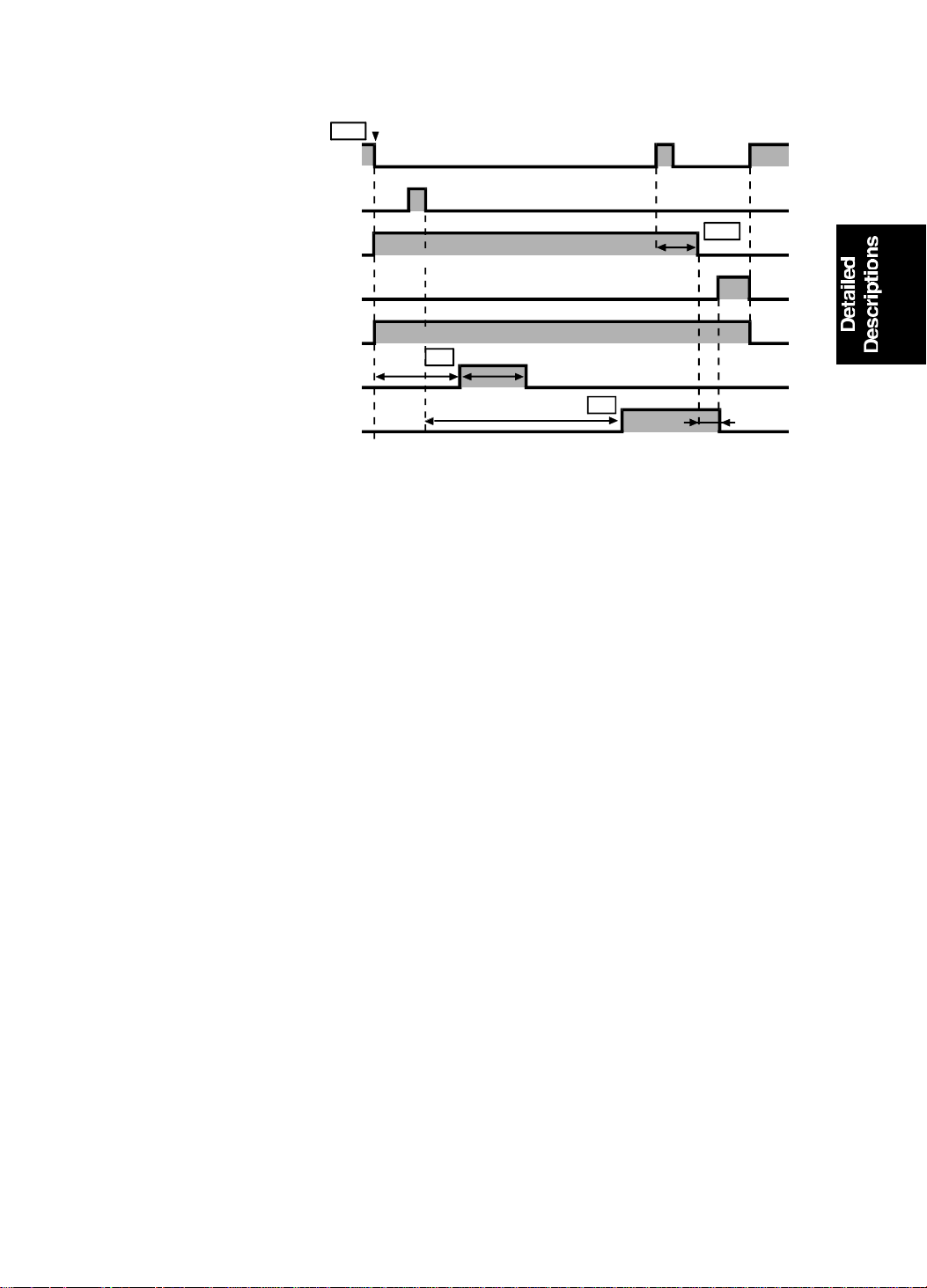

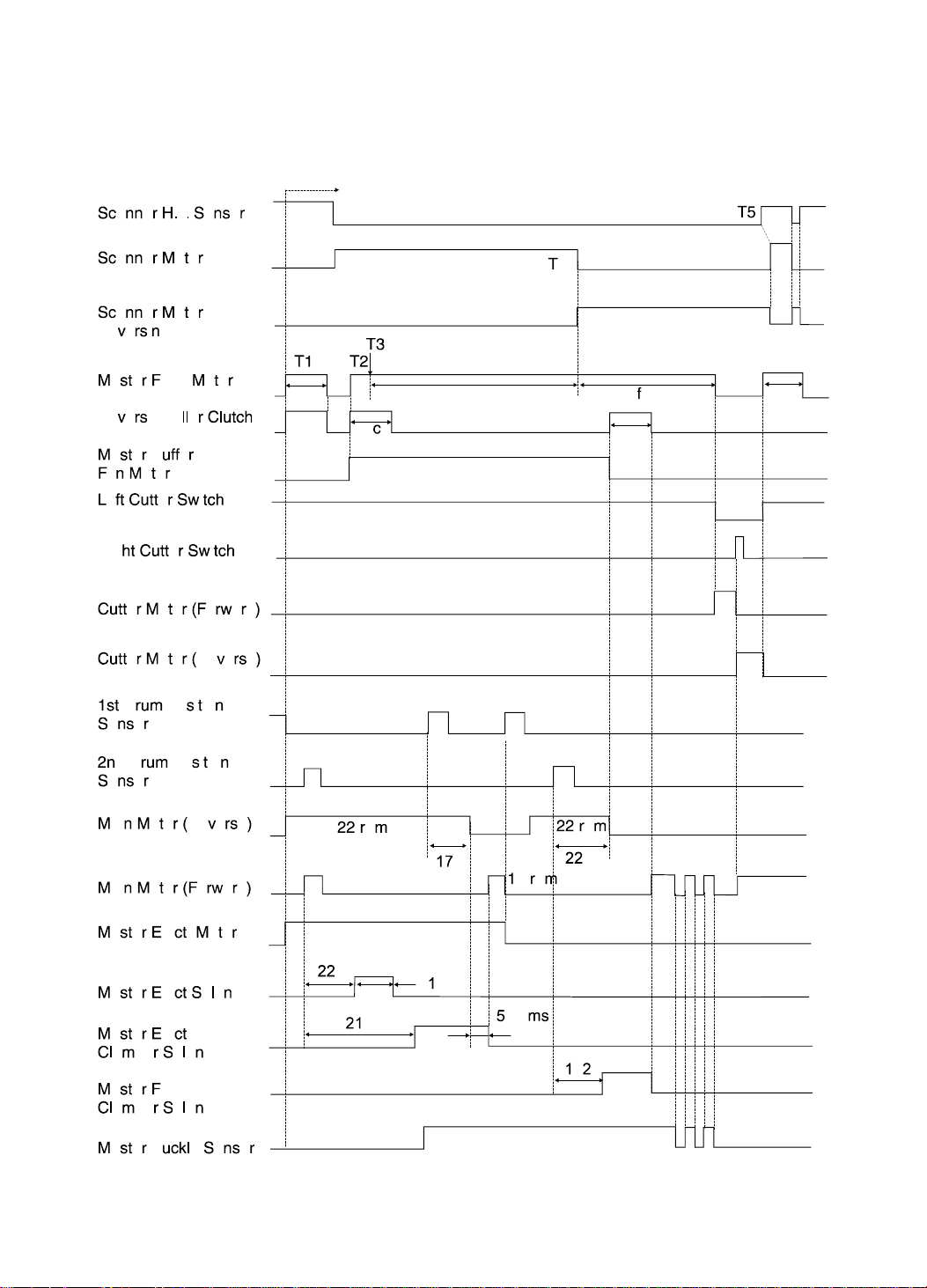

1.6 E LECTRI CAL TI MI NG

T1

First Drum Position Sensor

Second Drum Position Sensor

Main Motor (Reverse)

Main Motor (Forward)

Master Eject Motor

Master Eject Solenoid

Master Eject Clamper Solenoid

22 rpm 17°

T2

22°

41°

214°

T3

T4

500 ms

C222D516.wmf

T1: When the Master Making key is p resse d, the main mot or an d mast er

eject motor start. At the same time, the paper table drive motor starts to

lift the paper table to the paper feed position.

T2: When the drum has rotated 22 degrees past the 2n d dru m posit ion

sensor actuation position, the master eject solenoid is energ ized . This

presses the lower eject rollers against th e dru m surface. The master eject

solenoid is de-energized when the drum has rotated 41 degrees more.

T3: When the drum has rotated 214 degree s past the 2nd drum position

sensor, the master eject clamper solenoid is energized.

T4: When the drum has rotated 17 degrees past the drum home position, the

drum stops rotating.

500 milliseconds later (the drum complet ely stops during this period), the

master eject clamper solenoid is de-e ne rgize d an d th e drum starts

rotating forward. The dru m the n ret urn s to its home po sitio n. The mast er

eject process is now over.

Soon after this, the mach ine starts feeding a new maste r t o th e dru m f rom

the new master storage box, and the drum starts rotating in reverse to

open the clamper and begin the mast er makin g process.

2-9

Page 23

SCANNER 15 July 1995

2.

SCANNER

2.1 OVERALL

A book type scanner is used for the #C222 model. There are two mod es for

scanning originals.

Platen Cover Mode: The original is placed on the exposure glass, and the

scanner motor drives the scanner to scan the original.

ADF Mode: When an optional Documen t Fee de r is installed, the original is

fed onto the exposure gla ss. The scann er move s 22 mm away from the CCD

and remains still as it scans the original. The scanner comes back to the

home position when the scanning is finished.

[G]

[F]

[E]

The light from the xenon lamps [A] is reflected from the orig ina l by the first

[B], second [F], and third [E] mirrors t hro ug h th e lens [D] to the CCD [C].

[I]

[A]

[A]

[B]

[D]

[C]

C222D517.wmf

In the Platen Cover Mo de , th e CCD re ad s the white plate [G] on the back of

the original scale [I] each time be fo re scanning to obtain a standa rd white

level. The standard white data are used to corre ct dist ortion. The scanner is

at its home position when it rea ds th e white level.

In the ADF mode, as the scanner move s 22 mm, th e CCD read s the wh ite

plate installed on the ADF.

2-10

Page 24

15 July 1995 SCANNER

2.2 S CANNER ME CHANI SM

[B]

Front Side

[E]

[D]

[C]

[F]

Rear Side

[A]

[G]

C222D518.wmf

The scanner motor [A] (a stepper motor) drives the scanners. The first

scanner [B], which consists of the expo sure lamp an d th e first mirror, is

driven by the first scanner belt [F]. The seco nd scann er [C] , which consists of

the second and third mirrors, is drive n by th e second scanner belt [D]. Both

scanners move along the gu ide rails.

The timing belt [G] moves t he secon d scanner at half the speed of th e first

scanner. This is to maintain the focal distance between th e orig inal and the

lens during scanning.

The scanner home position is detected by the scanne r home position sensor

[E]. In the Platen Cover Mod e, the scann er scan s the origin al on the

exposure glass for the full A3 leng th, then returns until the scanner home

position sensor is activated . In the ADF Mode , th e scan ne r moves 22 mm

backwards (away from the CCD), to scan the original which is fed by the

ADF. When the master making process is finished and the ADF motor st ops,

the scann e r goes back to th e home positi on.

2-11

Page 25

SCANNER 15 July 1995

2.3 P LATEN CO VER POSITION DETECTION

[B]

[A]

C222D519.wmf

When the platen cover is opene d ab ou t 25 deg rees, the platen cover posit ion

sensor [A] is deactivat ed . Whe n this sensor is deactivated, th e original sensor

[B] is able to detect the original on the exposure glass.

If no original is detected, th e Mast er Makin g key will b e deact ivated. This is to

prevent wasting of the maste r tha t wou ld occur when a master is made

without an original.

When an original is placed on th e exposure glass and the Master Ma king ke y

is pressed with the platen cover opened more than 25 degrees (as the platen

cover position sensor is deactivate d), the shadow erase function is enabled.

2-12

Page 26

15 July 1995 SCANNER

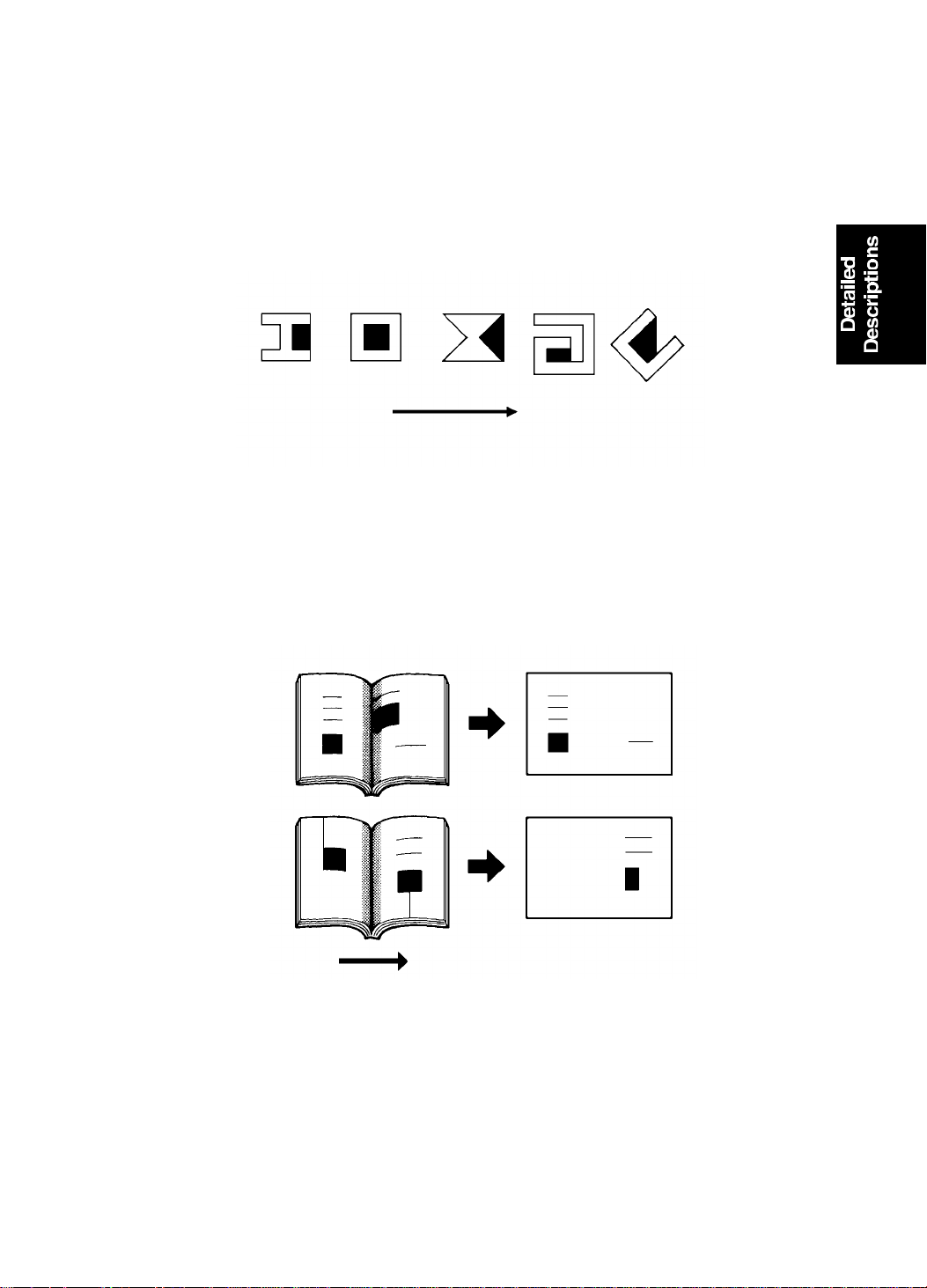

Notes regarding the shadow erase function

•

Margins of 1 mm [0.02"] on all four side s of th e orig ina l will be erase d. Th e

width of the margins will change depending on the rep rod uction ratios.

•

Shadows near the edge of a book might not be erased completely.

•

If the shape of the orig inal is as shown below, shadows might appe ar on

the prints. In this case, make the master with the platen cover closed.

Shadow

Scanning directio n

C222D520.img

•

If there is a line or solid image on the margin at the center or at the ed ge s

being erased, parts of the image might be erased as shown be low.

Scanning directio n

C222D521.img

2-13

Page 27

SCANNER 15 July 1995

2.4 E LECTRI CAL TI MI NG

2.4.1 Platen Mode

2-14

C222D522.wmf

Page 28

15 July 1995 SCANNER

Master Feed Lengths

a: 20 mm

b: 1 mm

c: 7.5 mm

d: 18.9 mm

e: 355 mm

f: 62.5 mm

g: 40 mm

The timing chart shows how scan ning takes place at the same time as

master ejection and master making.

T1: When the master making key is p resse d, the main mot or starts reverse

rotation at 22 rpm. At the same time , the mast er fe ed moto r and the

reverse roller clutch turn on to feed th e master 20 mm. Then they switch

off, and the scanner motor tu rns on shortly afterwards.

T2: When the scanner h as move d 17 mm fro m the home position, the master

feed motor, master buckle fan motor, and the reverse roller clut ch tu rn on.

T3: The thermal head starts to make the new mast er whe n the master has

been transported 1mm.

T4: When 355 mm (the maximum scan length) has been scanned the

scanner motor starts reversing to return the scanne r t o th e ho me position.

T5: After the scanner home position sensor has been actuated, the scanner

motor rotates forward the n reve rses to stop the sca nner at the correct

home position.

2-15

Page 29

SCANNER 15 July 1995

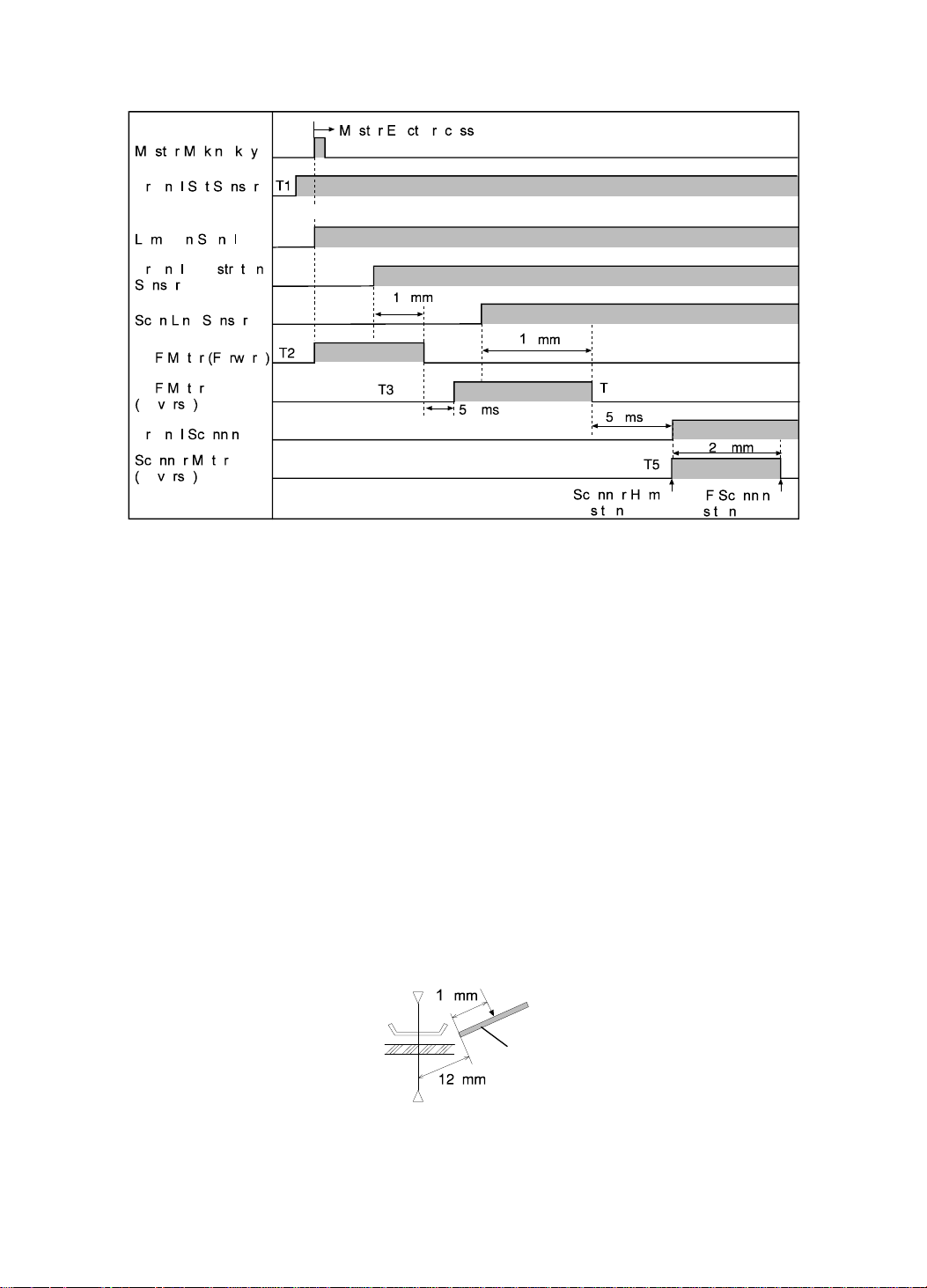

2.4.2 ADF Mode

C222D611.wmf

The above timing chart shows scan ne r timing when an optio na l ADF has

been installed.

T1: When originals are inse rte d in th e ADF un it, the origin al set senso r is

activated.

T2: When the Master Makin g key is pressed, the ADF motor rotates the

pickup roller and the feed roller to feed the bot to m origin al into the ADF.

T3: The ADF motor stops rotating clockwise when the origin al has bee n fed

14.0 millimeters after the original registration sensor was activated. After

50 milliseconds, the ADF motor starts rotating counterclockwise to rotate

the 1st original transport roller.

T4: The ADF motor stops again when th e orig ina l has be en fed 18 millimeters

after the scan line sensor wa s activa te d. The ADF motor waits until the

master eject process is finished.

Scan Line Sensor On

Original

ADF Scanning Position

C222D610.wmf

T5: 50 miliseconds later, the ADF motor starts reversing to bring the scanner

to the ADF scanning position.

2-16

Page 30

15 July 1995 MASTER FEED

3.

MASTER FEED

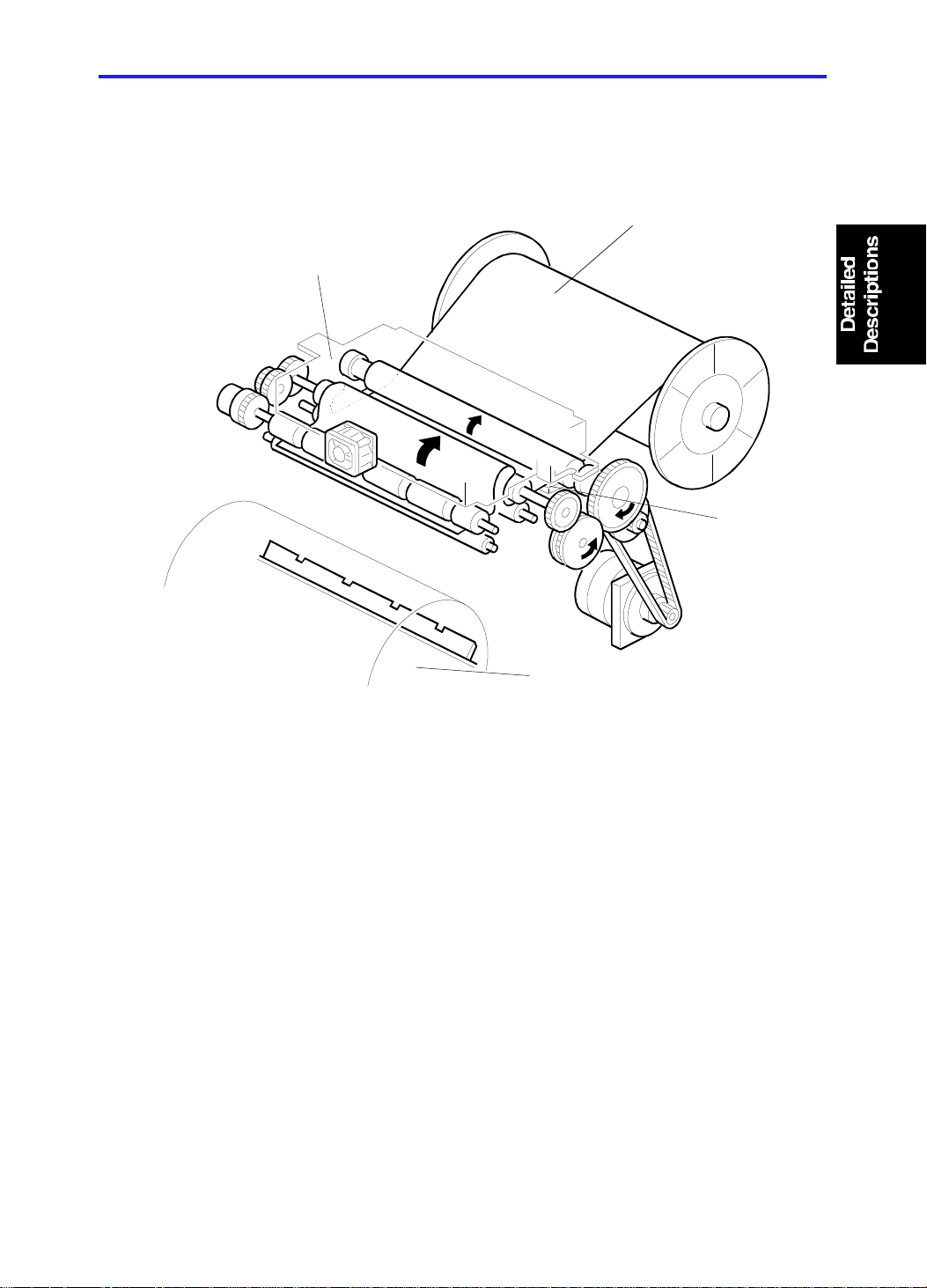

3.1 OVERALL

[A]

[D]

[B]

[C]

C222D500-1.wmf

The thermal head [B] burns the imag e (scan ned by th e CCD) onto th e mast er

[A] as it is being fed to the dru m [ C]. Th e use d master is ejected at the same

time that the new master is printed, and the new master is stored in the

master box [D] until the old master ha s bee n comp let ely eje cted. The master

is then clamped to and wrapped around the drum.

The master box mechanism reduce s the amou nt of time neede d to ma ke a

new master, because the new mast er can be mad e at the same time tha t the

old one is fed out.

2-17

Page 31

MASTER FEED 15 July 1995

3.2 MASTER FEED CLAMPER OPENING MECHANISM

[A]

[B]

[C]

C222D512-2.img

[G]

[F]

[H]

[D]

[E]

C222D526.img

After the master eject pro cess is finished and the interrupter [A] is positio ned

in the first drum position senso r [B] , th e main moto r turns on and the drum

starts rotating (22 rpm) in reverse (opposite to the printing direction).

When the drum has turned 162 degrees past the actuation position of the

second drum position senso r [C], the master feed clamper solenoid [D] turn s

on, and the cam [H] moves inside the drum.

When the drum has turned another 58 degrees, the sector gear [F] rotate s

upwards as it contacts the cam [H] . This en ga ges the secto r gea r wit h gear

[E], which turns counterclockwise to open the clamper [G]. At the same time,

the drum stops and the clamper remains open to cat ch and clamp the

master’s leading edge.

2-18

Page 32

[A]

15 July 1995 MASTER FEED

3.3 MASTER FEED MECHANISM

[D]

[B]

[C]

[E]

C222D500-2.wmf

C222D501.wmf

To minimize the first print time, the maste r ma king proce ss starts just after

the master making key is pressed.

When the master making key is pressed , th e drum starts rotating in reverse

to eject the master that is wrapped aro und th e dru m. At the same time , th e

master feed motor [A] sta rts tu rning and the reverse roller clutch [B] is

energized.

When the master has been transported 20 mm, the master feed roller and the

reverse roller clutch stop. They sta rt ag ain just af ter original scanning starts.

When the master has been transported a further 7.5 mm (when the leading

edge is 6 mm past the reverse roller [C]), the reverse roller clutch is turned off

but the master feed mot or continues to rotate. As a re sult , the master leading

edge stays at 6 mm past the reverse roller, and the ma ste r buckles up behind

the reverse roller. Until the drum comes to the maste r fee d positio n, the new

2-19

Page 33

MASTER FEED 15 July 1995

master fed by the master feed motor during the eject process is stored in the

master box [D]. The suction provided by the master buffer fan motor [E] helps

to bring the master into the box.

The main results of this mechanism are:

•

A much greater length of new mast er can be made be fore it starts to be

wrapped around the drum.

•

The new master can start to be mad e much earlier during the machine ’s

operation cycle, saving time.

The master buffer fan mot or tu rns on when maste r ma king starts, and it stays

on until the reverse roller starts feeding the master again to be caught by the

master clamp on the drum.

2-20

Page 34

15 July 1995 MASTER FEED

3.4 MASTER WRAPPING MECHANISM

[B]

[A]

[B]

[E]

[C]

[D]

C222D502.wmf

[C]

[D]

C222D503.wmf

When the drum stops at the master feed position (at this time , th e mast er

clamper is open), the reverse rolle r clutch [A] turns on again. When the

master has been transported 18.9 mm and the master leading edge has

reached the master clampe r, th e reverse roller clutch and the master feed

clamper solenoids turn off . The maste r le ad ing edg e is clampe d by th e

master clamper.

After the master clamper catches the master leading edge, the drum rot at es

at 22 rpm while the master buckle sensor [B ] is o n. The mast er fe ed motor

continues to feed the master at this sta ge . The drum pulls t he master faster

than the master feed motor feeds it, so the maste r b uckle senso r will

deactivate eventually. When this happen s, the main moto r stops unt il the

sensor is activated by the maste r buckle again. In this way, the master is

wrapped around the drum keeping a buckle between the reverse ro ller [C]

and the master feed roller [D]. This buckle prevents the master that is still

2-21

Page 35

MASTER FEED 15 July 1995

under the thermal hea d fro m being pulled; if a long master is bein g made, this

will adversely affect copy quality.

When the new master is finished, th e mast er fe ed spee d incre ase s (t o 4

times the master making speed) and the maste r cutter cuts the master when

the appropriate length of ma ste r has be en transported.

Even if a master eject jam occurs, the master making operation continues.

When a master eject jam is detecte d, the machin e stops after master making

and cutting is done (during th is period, the new master is stored in the master

box [E]). When the reset key is pressed after the jammed master is remove d,

the reverse roller clutch turns on to tra nsp ort the maste r t o the mast er

clamper, and the master clamp er clamp s t he lead ing edg e. The drum rotates

at 22 rpm to wrap the master.

2-22

Page 36

15 July 1995 MASTER FEED

3.5 CUTTER MECHANISM

[A]

[E]

[C]

[D]

[A]

[B]

[B]

C222D527.img

[F]

[G]

C222D528.img

After the master makin g pro cess is finished, the master feed mo to r turns off

and the cutter motor [A] sta rts tu rnin g.

The cutter motor [A] starts turning in reverse (see the arrows) when the cutter

holder [B] pushes the left cutt er switch at th e front (o peration side) end of the

cutter rail; this is the cutter holder home position. This drives the cutt er ho lde r

[B] toward the rea r (non -operation side) by means of the gear/pulley [C] and

the wire [D] on which the cutter h old er [B ] is f ixed .

When the cutter holder reaches the rear end of the cutter rail and pushes the

right cutter switch, the cutter moto r [A] changes its rota tio n dire ctio n, and the

cutter holder [B] start s mo ving toward the front. The cutt er motor [A] stops

turning when the cutter ho lde r [B] is back at its home po sitio n an d pu she s the

left cutter switch. The ma ste r cutting process is now finished.

While the cutter hold er [B] is traveling to the rear, th e roller [E] in the cutter

holder is turning clockwise because it to uch es th e cut te r rail. The roller [E]

rotates the cutter blade [F] as ind icat ed by the arrow. Th e master is b et wee n

the blade and blade plat e [G] and as the cutter moves, it cuts th e master. The

blade plate also serves as a lower guide plat e for the master.

After the master cuttin g process is finished, the master is fed anoth er 40

millimeters and the master feed process is finished.

2-23

Page 37

MASTER FEED 15 July 1995

3.6 ELECTRICAL TIMING

2-24

C222D609.wmf

Page 38

15 July 1995 MASTER FEED

Master Feed Lengths

a: 20 mm

b: 1 mm

c: 7.5 mm

d: 18.9 mm

e: 355 mm

f: 62.5 mm

g: 40 mm

– Master Feed –

T1: When the master making key is p resse d, the main mot or starts reverse

rotation at 22 rpm. At the same time , the mast er fe ed moto r and the

reverse roller clutch turn on to feed th e master 20 mm. Then they switch

off, and the scanner motor tu rns on shortly afterwards.

T2: When the scanner mo to r h as move d 17 mm fro m the home position, the

master feed motor, master buffer fan mot or, and the reverse roller clutch

turn on.

T3: The thermal head starts when the maste r h as been tran spo rted 1 mm.

T4: When the master has b een transported 479.5 mm, the maste r f ee d mot or

stops. At the same time, the cutter motor starts rotating to cut the ma ste r.

When the right cutter switch is actuated, th e cutte r moto r start s reversing.

When the left cutter switch is actuat ed , th e cut te r moto r stop s.

T5: When the left cutter switch is actuated, the master feed motor start s

again to feed the master 40 mm.

– Master Wrapping –

T6: After the master eject operation is finished, the ma in mot or rot at es in

reverse at 22 rpm. The main motor stop s when the drum has ro ta te d 22 0

degrees.

T7: When the drum has rotated 162 degree s past the 2nd drum position

sensor, the master feed clamper solenoid turns on.

T8: When the drum stop s at the master feed position, the master buffer

fan motor turns off. At the same time the reverse roller clutch is

de-energized. When the master has been transport ed 18. 9 mm, th e

reverse roller clutch and the master f eed clamp er solenoid turn off.

T9: When the master has b een clamped, the main motor start s ro ta ting to

wrap the master around the drum. The motor rotat es at 22 rpm only when

the master buckle sensor is activate d.

2-25

Page 39

PAPER FEED 15 July 1995

4. PAPER FEED

4.1 OVERALL

[A]

[B]

[F]

[C]

[D]

[E]

C222D602.img

This mechanism uses a center separation system, which consists of the

separation plate [F], up per se paration roller [B], and lower separa tio n rolle r

[E]. Because of the sepa rat ion system, if a few sheets of pape r are picke d up

from the paper stack (on the paper ta ble) by the paper feed roller [A], only

one sheet of paper is transported to the second upper feed rolle r [C] and

second lower feed roller [D].

2-26

Page 40

15 July 1995 PAPER FEED

4.2 PAPER FEED ROLLER/UPP ER SEPARATION ROLLER

MECHANISM

[A]

[C]

[B]

[M]

[L]

[K]

[D]

[E]

[F]

[J]

Viewed from the

non-operation side

[I]

[H]

[G]

C222D603.img

The main motor drives the pape r fee d roller ca m [C], wh ich move s the secto r

gear back and forth. The secto r gea r [J] rotates the paper feed roller [M] an d

the upper separation rolle r [A] . A on e-wa y clutch inside gear [H] prevents the

rollers from rotating in reve rse during the return half of the sector gea r

movement cycle. The cam ro ta tes once per sheet of paper.

When the paper feed solenoid [G] turn s on, it pulls th e link [F] away fro m the

sector gear to allow it to rotate. When the cam roller [D] is at the widest part

of the paper feed roller cam [C], the sector stopper [E] drops away in a

counterclockwise direction as a cleara nce is formed between the stopper and

pin [I]. Then, the cam roller [D] on the sector gear is able to move along the

surface of the cam [C]. The solenoid [G] stays on during the copy cycle.

When the narrowest part of the paper feed roller cam [C] is rotating away

from the cam roller [D] and the wide st pa rt is app roa chin g, the sector gear [J]

turns clockwise and the gear [H] is turned counterclockwise. The rotation of

the gear [H] is transmitted to the uppe r sepa rat ion ro ller sha ft [B] , an d the

upper separation roller [A] turns coun terclockwise. At the same time, the

pulley [K] on the upper separation roller shaft [B] turns, and the belt [L]

rotates the paper feed roller [M] counterclockwise to feed the print ing paper.

When the narrowest part of the paper feed roller cam [C] appro ach es th e

cam roller [D] again, the sector gear [J] turns cou nt erclo ckwise and the gear

[H] is turned clockwise. However, a one-wa y clutch inside the gear [ H]

prevents the upper separa tio n [A] and paper feed rollers [M] from turn ing .

2-27

Page 41

PAPER FEED 15 July 1995

4.3 FEED ROLLER PRESSURE MECHANISM

[B]

[C]

[A]

C222D606.wmf

The feed roller assembly rot at es freely around its shaft, and th e weight of the

feed roller assembly [C] presses the paper feed roller down on the paper

stacked on the pap er table.

The spring [A] pulls the feed roller assembly upwards. When the feed

pressure lever [B] is moved up , th e tension in spring [A] increase s,

weakening the feed roller pre ssure .

The paper feed pressure can be chan ge d, and has th ree possible settings

(this is a user-level adjustment). In a new machin e, the feed pre ssure lever is

in the middle position. Whe n th ick p aper is used and paper is often not fed,

push down the feed pressure lever. The feed roller pressure will increase.

When thin paper is used and paper multi-feed often occurs, push up the lever

to decrease the feed roller pre ssure .

2-28

Page 42

[C]

15 July 1995 PAPER FEED

4.4 PAPER SEPARATION MECHANI SM

[A]

[B]

[D]

[A]

[C]

[E]

[G]

[F]

[D]

C222D604.img

Pressure from spring [F] ho lds th e separation plate [G] aga inst the upp er

separation roller. A rubber pa d on top of the sep ara tio n pla te allows only a

few sheets of paper to reach the lowe r sepa rat ion roller. If too many sheets of

paper are fed to the lower separation roller at the same time , th e lowe r

separation roller may not be able to separate the sheets; it can separate only

two or three sheets of pap er.

Springs pull lever [A] and this push es up the lower separation roller [E]. Then

this roller presses the sheets to be fed again st th e uppe r sepa rat ion roller [B].

Also, the lower separation roller does not turn in the paper feeding direction.

(It turns in the opposite direction due to the one-way clutch bearings [D]

provided on both right and left sepa rat ion le vers [A ]. ) Wh en two or more

sheets of paper are fed, a brake force is applied to the lowe r shee ts of pap er

due to the friction between the paper and the lower separatio n rolle r. The n,

the sheets are sepa rated and one sheet of pap er is f ed to the second feed

rollers.

The pressure between the upper and lower sep aration rollers can be

adjusted by changing the right and left separation pressure adjusting levers

[C] as follows (this is a user-level adjustment):

Levers Up: Separation pressure decreases.

Levers Down: Standard position.

When dog-eared or wrinkled prints are delivered, the separation pressure

should be decreased.

2-29

Page 43

PAPER FEED 15 July 1995

Fig. 2

"E"

Fig. 1

[C]

[A]

[B]

[A]

[C]

[D]

View from "E"

C222D523.img

[F]

[G]

C222D524.img

The lower separation roller [C] turn s slight ly (see the arrow in Fig. 2) due to

the one-way clutch bearings when pa pe r passe s through the roller. The lower

separation roller [C] and its shaf t [D] are pushed down slightly by the paper

[B] when the upper separatio n rolle r [ A] is feeding the paper (Fig.1). Just

when the paper is fed out from the rollers, the lower separation roller [C] and

its shaft [D] spring back again st rolle r [ A] (Fig. 2). This ro ta tes the lower

separation roller and ensure s tha t it will wear eve nly.

Four paper guide rollers [G] are th ere to red uce curl in the paper’s leading

edge, and to feed the pap er smoo thly to the guide plates. Th ere are four

marks on the bracket [F] correspo nd ing to th e roller positions as shown in the

lower diagram.

2-30

Page 44

15 July 1995 PAPER FEED

[A]

[B]

C222D529.img

[C]

C222D530.img

The side pads [A] in the fron t an d rear paper side guides preven t multiple

feed. These are especia lly u sef ul when thin paper is used. After ad justing the

paper side plates to the prop er pa pe r width (so that they touch the pap er

lightly), move the front and rea r sid e pad levers to the right (as viewed from

the operation side of the machine). Normally, the pressure from the side pads

should be released by moving the levers to the left.

The separation plate pressure can be adjust ed to mat ch the type of paper

being used. The plate which sup po rts the pre ssure plate spring [B] can be

moved up or down by turning th e eccentric cam shaft [C] (this is a

service-level adjustment only).

If multiple paper feed freq ue ntly occurs, the plate should be move d up .

If paper misfeeds frequently, the plat e should be moved down.

2-31

Page 45

PAPER FEED 15 July 1995

4.5 SEPARATION ROLLER PRESSURE RELEASE

MECHANISM

[A]

[B]

[C]

[D]

[E]

C222D605.img

When printing is finished or a misfe ed occurs, the paper table drive motor

rotates for 500 milliseconds to lower the paper ta ble . The paper on the paper

table moves down from the pape r fee d roller [ D] and the paper feed bracket

[A] is pulled down by its own weight.

At this time, the shaft [B] pushes down the left separation lever [C] and this

moves the lower separation roller [E] slightly downward.

This mechanism makes it easier to remo ve pape r caug ht bet wee n th e up pe r

and lower separation rollers.

2-32

Page 46

15 July 1995 PAPER FEED

4.6 SECOND FEED ROLLER MECHANIS M

[A]

[J]

[B]

[I]

[H]

[C]

[D]

[E]

[G]

[F]

[K]

C222D531.img

Drive Mechanism

The main motor drives the lowe r secon d feed roller cam [A], which moves the

sector gear [C] back and fort h. The sect or ge ar [C] ro ta te s the lower second

feed roller [I]. A one-way clutch inside the feed roller gear [E] prevents the

roller from rotating in reve rse during the return half of the sector gea r

movement cycle. The cam ro ta tes once per sheet of paper.

When the paper feed solenoid [G] turn s on, it pulls link [F] , th e 1st paper fe ed

roller sector gear stopper [H], an d th e 2n d fe ed roller sector gear stopper [K].

The bearing [J] on the sect or ge ar moves along the cam surface. Whe n the

widest part of the cam come s to th e be arin g [J], the stopper [B] is relea sed

from the sector gear as a clearance is formed between the pin of the secto r

gear [D] and th e stopper [K].

When the feed roller gear turns counterclockwise, its rot at ion is not

transmitted to the lower second feed roller due to the one-way clut ch bearing

in the gear.

When the narrowest part of the second feed roller cam moves away from the

bearing [J], the sector gear turns counterclockwise and the feed roller gear

turns clockwise. As the rotation of the feed roller gear is tra nsmit ted to the

lower second feed roller, the lowe r second feed roller turns clockwise to feed

the paper to the drum.

2-33

Page 47

PAPER FEED 15 July 1995

[B]

[A]

[C]

[G]

[H]

[F]

[A]

[D]

[E]

C222D542.img

Release Mechanism

This mechanism releases the uppe r seco nd feed rolle rs [B] from the lower

one [G] after the press roller and the drum catch the paper leading edge.

The mechanism is made up of several parts. First , a cam which tran smits

motion to a sector gea r [ F]; the n another cam [E] that is part of th e sect or

gear. This cam pushes a bearing [D], which causes the lever [H] attached to

this bearing to turn the upper feed ro ller sha ft [C] so th at the upper rolle rs

contact the lower rollers.

At the beginning of each cycle the upper and lower rollers are away fro m

each other. They come tog et he r halfway through the cycle and at th e en d of

the cycle they separate again.

At first, the rollers are sep arate, and the sector gear [F] is ready to start

moving clockwise. The bearing [D] on th e leve r [ H] is in cont act with the cam

[E] on the sector gear. As the gear turn s clo ckwise, it causes the cam to turn

the lever in the same direction (clockwise).

The lever then lowers the upper rolle r [B] . It doe s this by tu rnin g the roller’s

eccentric shaft [C]. The sha ft is a little off center, so when the shaft turns the

roller, the roller moves up or down.

2-34

Page 48

15 July 1995 PAPER FEED

When the cycle is halfway through, the sector gear has reached its maximum

clockwise position. Now the upper roller touche s the lower one and a pair of

springs [A] apply tension at each en d of the upp er rolle r. Until now the lower

roller has not turned.

At this point, the paper arrives from the first paper feed rollers. The lea din g

edge hits the two rollers and the paper buckles slightly. This ensu res th at the

paper will go into the rollers straight.

The lower roller now begins turnin g and feeds the paper to the drum section.

The sector gear is now turning cou nterclockwise, raising the upper roller. The

gear returns to its original position and the cycle is now over.

Service Note

The paper buckles slightly as the leading edge of the paper arrives from the

first paper feed rollers before the second paper feed rolle rs start to turn. The

second feed roller start timing can be adjust ed to cha nge th e leading edge

margin. See "Removal and Adju stme nt : Se cond Feed Roller Start Timing".

2-35

Page 49

PAPER FEED 15 July 1995

4.7 PAPER TABLE SIDE ADJUSTMENT MECHANIS M

[B]

[A]

[C]

[G]

[D]

[F]

[E]

C222D532.img

The shaft [D] of the fine adjustment dial [F] is threa de d. The inside of the

sleeve [E] is also thread ed . The sleeve is fixed to the paper table stay [B ]

through a bracket [A].

The paper table bracket [C] mounted under the table is fixe d to bot h en ds of

the adjustment dial shaft . Whe n th e adjust ment dial is turned clockwise, the

feed table bracket [C] and the paper table move to the right.

The indicator [G] fixe d to the bracket [A] shows how much the pap er table

has moved.

2-36

Page 50

15 July 1995 PAPER FEED

4.8 PAPER TABLE UP/DOWN MECHANISM

There are diagrams of this mecha nism on the following page.

The paper table is raised and lowere d by th e pa per t able drive motor.

The paper end sensor [E] (a reflective photosensor) is actuated when the

paper is placed on the paper ta ble. When the Print Start key is pre ssed , the

paper table drive motor [H] starts turning clockwise an d the worm gear [G ]

also turns. The worm wheel [F] turns clockwise and both gears [D] tu rn to

raise the racks [C].

As the paper table rises, the paper pushes against the paper feed roller [I] .

This raises the lever [J] which is mount ed on the pa per f eed bra cket . This

activates the paper table height sensor [K] (the phototransistor detects the

light from the photocoupler, which up to now was cut off by the lever), and

that causes the paper t ab le mot or [H] to turn off and stop raising the paper

table.

As printing proceeds and the paper level runs down, the lever [J] cuts off th e

light path in the photocoupler and the motor [H] turn s clockwise until th e

phototransistor is react ivat ed . As a resu lt, the top of th e pa per st ack is

constantly kept at the correct heig ht .

When no paper is present, the pap er en d sensor [E] is not activated and the

motor [H] turns counterclockwise to lower th e paper table. The paper table is

lowered until the actuator [A] (fixed to the front rack) interrupts the lower limit

sensor [B].

When a misfeed occurs or printing is finished, the paper table motor [H] turns

counterclockwise for 500 milliseconds, slightly lowe ring the paper ta ble .

2-37

Page 51

[J]

[K]

PAPER FEED 15 July 1995

[C]

[D]

[A]

[E]

[C]

[D]

[B]

[F]

[G]

[H]

C222D533.img

[I]

C222D534.img

2-38

Page 52

15 July 1995 PAPER FEED

4.9 PAPER SIZE DETECTION

The machine determines the printing area of the ma ste r based on the

detected paper size and th e original length (which is detected during the

original scanning process). If th e original size is different from the paper size,

the machine compares the lengths of the original and the paper. The

master’s length will be the shorter of the two. Th e printing width of the master

is determined by the paper width.

Note: The determined master printing area is not changed if the paper on

the paper table is replaced with another size of paper during the

master making process.

The printing area of the maste r for ea ch dete cte d pa per size is as follows:

Paper Size Printing Area of the Master

Width (mm) Length (mm)

A3

B4

A4

A4-S

B5

B5-S

A5

DLT

LG

LT

LT-S

HLT

292

256

208

292

180

256

146

278

214

214

278

138

407

351

284

197

244

169

197

407

343

266

203

203

S: Sideways feed

The machine can only distingu ish sta nd ard sizes. If a non-standard paper

size or original size is used, the mach ine will dete rmine a stan dard size for

the non-standard sized paper or original. If the actua l paper size, the

non-standard sized paper, or the original is larg er than the determin ed paper

size, the excess area will not be tran sferred to the master. In such a case,

paper size detection can be can cele d using SP mode (no. 2-14) in orde r t o

obtain the entire image of the origin al. However, the press roller may become

contaminated with ink if the paper is smaller than the image on the maste r.

The ink will be transferred to the back side of th e prints when the next printin g

is done with larger paper.

2-39

Page 53

PAPER FEED 15 July 1995

Paper Size Detection for the Pape r Tabl e

[B]

[B]

[A]

[A]

[G]

C222D566.wmf

[F]

[E]

[D]

[C]

C222D536.img

The paper width det ection plate [A] behin d the front paper side guid e [B] has

several interrupters.

The front and rear paper sid e gu ide s ar e adjusted to the paper width.

Depending on which paper width sen sors ([C] [D] [E ] [F]; 4 photointerrupters)

are interrupted and whet he r t he pape r len gth sensor [G] (a reflective

photosensor) is activated, the machine determines the paper size as shown

in the table below.

Paper Size A4-S LT-S B5-S LT A4 B5 A5 HLT A3 DLT B4 LG

Paper Width Sensor-0 [C] o x o x x x o x x o o x o x

Paper Width Sensor-1 [D] x o o x x x o o o o x o o x

Paper Width Sensor-2 [E] x x o o o o o x x x x x o o

Paper Width Sensor-3 [F] x x x x x o o o o o x x x x

Paper Length Sensor [G] x x x x x x x x x x o o o o

x: Not blocked or Not activated, o: Blocked or Activat ed

S: Sideways feed

2-40

Page 54

Counter Reset

15 July 1995 PAPER FEED

4.10 ELECTRICAL TIMING

Stop key ON

30 ms

C222D537.wmf

500 ms

Paper Table Height Sensor

Paper Table Up Relay

(Table up)

Paper Table Brake Relay

First Drum Position Sensor

Second Drum Position Sensor

Paper Feed Solenoid

Vacuum Fan Motor

Air Knife Motor

Main Motor (Forward)

Paper Table Down Relay

Print key ON

15 ms

50 ms

T1: When paper is placed on th e pa pe r tab le an d the Print key is pressed, the

paper table moves up unt il the pap er ta ble height sensor is activated . 15

milliseconds after the height senso r is act ivat ed , th e paper t able brake

signal turns on for 50 milliseconds to apply bra king force to the paper

table drive motor to prevent th e pape r tab le fro m o verru nn ing .

T2: When the height sensor is activated, the vacuu m f an motor and air knife

motor turn on. At the same time, the drum (main moto r) starts turning

forward (this is the printin g dire ctio n).

T3: The paper feed solen oid is energized when the interrupter at the rear side

of the drum activate s the second drum position sensor.

T4: After the paper is fed, the top of the paper stack is a little lower and the

height sensor is de-activat ed . Whe n th e second drum position sensor is

activated, the paper table drive motor sta rts rot ating. This lifts the paper

table until the height sensor is re-activat ed (app roxima te ly 30

milliseconds after the motor starts). Whe n the heigh t sensor is

re-activated, the motor stops rotating.

T5: After the Stop key is pressed, the paper feed solen oid is de-energized the

next time that the second drum position sensor is activated. The coun te r

on the operation panel will be reset at this time.

T6: When the second drum positio n sen sor is aga in act ivated after one more

drum rotation, the vacuum fan motor and air knife mot or tu rn off. Then,

the drum rotates once more and stops at the first drum position act uatio n

position (the drum home position).

2-41

Page 55

[A]

[C]

PRINTING 15 July 1995

5. PRINTING

5.1 OVERALL

[B]

C222D538-1.img

In standby mode, the printing pressure roller is held away from the drum by

two devices, a solenoid (the printing pressure solenoid), and a mechanical

arm (activated by the paper detect ion feeler [A]).

At the start of printing, the printing pressure solenoid releases its hold on the

printing mechanism at poin t [C], and the paper feed soleno id turns on to

transfer drive from the main mot or to the paper fe ed mecha nism.

Soon after the paper has reached the second paper feed rolle r, the paper

detection feeler [A] is pushed down by the paper, which completely releases

the printing mechanism.

Printing pressure is then applie d (th e press ro ller [B ] to uch es th e dru m) to

transfer the ink from the master to the printer pa per.

If the machine is not used for more than 8 hours, a drum stroke ope rat ion is

done before the master wrapped around the drum is removed. This operation

minimizes the wasted prints before the image is stabilize d.

2-42

Page 56

15 July 1995 PRINTING

5.2 PAPER DETECTION AND PRINTING PRESSURE ON/OFF

MECHANISM

Rear View

[F]

Front View

[F]

[E]

[D]

[H]

[C]

[B]

[G]

[A]

C222D538-2.img

C222D540.img

During the printing process, the main motor turns the gear [A] and pressure

cam [B] clockwise.

When the widest part of th e pressure cam [B] reaches the be aring on the

pressure on/off lever [C], th e pape r det ect ion arm [D] separates from the

pressure on/off lever [C] . At this mome nt, if paper is being fed, the paper

presses down the paper detection feeler [E]. The n, the pap er de te ction arm

[D] turns clockwise to release the pressu re on/o ff le ver. As a result , th e

pressure on/off bea ring continues moving along the pressu re cam an d the

press roller [F] moves against the drum to apply p rint ing pressu re.

The printing pressure can be adju sted with the pressure spring [G].

The printing pressure sensor feeler [H] is away from the sensor while printing

pressure is applied.

2-43

Page 57

[E]

PRINTING 15 July 1995

5.3 PRINTING PRESSURE RELEASE MECHANISM

[A]

[B]

[G]

[H]

[C]

[D]

C222D538-3.img

[F]

[D]

C222D539.img

During normal operation , th e printing pressure solenoid [G] ene rgize s to

release the pressure on/ of f leve r [D] at the same time as the paper feed

solenoid energizes.

If a jammed sheet of paper in the printing sectio n pre sses do wn on the paper

detection feeler [A], the pressu re on/off lever [D] remains disengage d fro m

the paper detection arm [C]. Printing pre ssure will keep on bein g applie d to

the drum. If this printing pressure is still applied when an opera to r slides out

the drum unit to remove the jammed sheet, the drum surface and the press

roller could be damaged.

To prevent this, printing pressure is released from the drum if a paper

misfeed is detected. When a misfeed is detected, the print ing pressu re

solenoid [G] is de-en erg ized. Then, the drum rotates to the home position.

While the drum returns to the home position, the wide st pa rt of the pressure

cam [F] approach the bearing [E] . This move s the pressu re on/off lever [D]

clockwise, then the stopp er [H] eng ag es th e lever [D] (because the stopp er

[H] is pressed down by spring tensio n fro m the solen oid ). Thus, printing

pressure is released since th e leve r [D] is co nnected to the press roller [B].

2-44

Page 58

[B]

15 July 1995 PRINTING

5.4 QUALITY START OPERATION

[D]

[E]

C222D557.wmf

[C]

[C]

D222D558.wmf

If the main motor has been kept off for more than 8 hours, a drum stroke

operation is done before the master wrapped around the drum is removed.

This operation removes the dried ink with the ejected master to minimize th e

waste prints before the print image is stabilized.

[A]

When the master making key is pressed , th e master press sheet solenoid [A]

is energized. The master press she et mylar [B] is inserted between the drum

and the press roller [C]. At the same time, the det ect ion arm release solenoid

[D] is energized to relea se th e pa pe r detection arm [E]. Then, the ma in mot or

turns on and the press roller presses the mylar she et to stro ke the dru m

surface. The drum rotate s five times to stroke the master around the drum.

Then the master press sheet solenoid and the detection pin release solenoid

are de-energized and the master eject operation starts.

There is no paper in the paper path at this time to rele ase the paper detection

arm [E] so that printing pressure can be applied to the master press sheet

mylar [B], so the extra soleno id [D] was add ed to the mechanism.

2-45

Page 59

PRINTING 15 July 1995

5.5 ELECTRICAL TIMING

C222D556.wmf

T1: The main motor starts. At th e same time, the print ing pressu re sole no id

and the detection arm release solenoid turn on.

T2: When the drum has rotated 198 degree s f rom the ho me position, the

master press sheet solen oid turns on. The solenoid tu rns of f when the

drum has rotated a further 40 degrees.

T3: When the printin g pressure sensor turns on afte r t he master press sheet

solenoid has been energized (n-1) times, the printing pressure solenoid

and the detection arm release solenoid turn off.

The value of n depends on SP 3-7.

2-46

Page 60

[B]

15 July 1995 DRUM

6. DRUM

6.1 OVERALL

[C]

[A]

[F]

[E]

[D]

C222D541.wmf

[A]: Doctor Roller

[B]: Ink

[C]: Ink Roller

[D]: Press Roller

[E]: Pa per

[F]: Drum

Ink is supplied from the ink cartridge and is applied to the ink roller unif ormly.

The ink is then transferred to the print ing paper th rough the holes in the

master.

2-47

Page 61

[H]

DRUM 15 July 1995

6.2 DRUM ROTATION MECHANISM

[B]

[A]

[C]

[D]

[B]

[B]

[A]

[A]

[E]

[F]

[K]

[K]

C222D574.img

[J]

[I]

[G]

C222D575.img

The main motor (a dc moto r) [J], located under the rear side plate, turns the

drum either clockwise or counterclockwise throu gh belt [G] , then thro ugh

gears [F] and [E], then belt [D] , and pu lley [C] . The drive mechanism uses

helical gears because they turn more quietly.

Notice gear [A], th e last gea r of the drive, and gear [B] at the rear en d of the

drum: they each have a part cut out of the flange [K]. When the drum is in the

home position, the cutout pa rts mee t, and the drum unit can be pulled out.

Pulse disk [I] and sensor [H] on the main motor shaft monitor the dru m

rotation speed.

2-48

Page 62

15 July 1995 DRUM

6.3 DRUM LOCK MECHANISM 1

[E]

[C]

[A]

[B]

[C]

Fig. 3

[B]

[B]

[D]

[B]

[C]

[C]

C222D544.img

[D]

Fig. 1

[D]

Fig. 2

C222D543.img

When the drum unit is placed in th e mach ine, the arm [B] is pushed by the

lock pin [D] until the top of the arm [B ] is locked by the stoppe r [C]. This

completely locks the drum unit in th e mach ine (Fig . 1). At th e same time, the

top of the right stopper [C] turn s on the dru m d etection switch [E]. The switch

[E] tells the machine that the drum unit is in place (Fig. 3).

Pulling the lever [A] to th e operation side turns the stopper [C] clockwise and

disengages the arm [B]. Theref ore, the lock pin [D] of the main body is also

released from the arm [B ] du e to sp ring ten sion (Fig . 2).

2-49

Page 63

DRUM 15 July 1995

6.4 DRUM LOCK MECHANISM 2

[B]

[C]

[B]

[A]

[A]

C222D545.img

To prevent the drum from ro ta ting when the drum unit is slid out, the drum

stopper [A] drops into the drum lock [B]. This secures the drum [D].

[D]

When the drum unit is put back, the front side plate of the main body [C]

holds the drum stopper [A] out of the drum lock.

2-50

Page 64

[A]

[B]

15 July 1995 DRUM

6.5 DRUM LOCK MECHANISM 3

[B]

[C]

[D]

C222D546.img

C222D547.img

When the drum is pulled out, the drum sto pp er [B ] drops into the hole (see

the above diagram). This stops th e drum u nit from be ing pulle d out an y

further. Now, if the operat or pulls h andle [A], the drum unit won’t fall ou t.

When the operator pulls stopper release [D] in the direction of the arrow, the

drum stopper [B] is pushed up to the level of the drum rail cover [C]. This

allows the drum to be remove d.

2-51

Page 65

[E]

DRUM 15 July 1995

6.6 DRUM CONNECTION MECHANISM/DRUM LOCK

MECHANISM 4

[D]

[A]

[C]

[B]

[F]

C222D548.img

[D]

[H]

[G]

C222D549.img

When the drum release lever [A] in fro nt of th e mach ine is raised, the

connector [B] is push ed away fro m t he drum by th e bra cket [C] through the

link [D], and is disconnected. The bracke t [C] also pu she s the drum lock leve r

[F] to release the dru m lock allowing the drum to be removed. Wh ile th e drum

is away from its home position, the drum lock solenoid [G] is energized and

the stopper [H] locks the link [D] to preven t th e dru m from be ing pulle d out

during a print cycle. The sole no id is de-energized when the dru m stop s at the

home position (when the 1st drum position sensor is actuated).

2-52

Page 66

15 July 1995 DRUM

6.7 INK SUPPLY MECHANISM

[H]

[F]

[I]

[C]

[J]

[G]

[E]

[B]

[D]

C222D550.img

Ink is supplied from the ink cartridge [A ] to the ink ro ller by the ink pu mp [B ]

through four holes in th e drum shaft [C].

[K]

[A]

Drum rotation is transmitt ed thro ug h gear [D] to gear [E]. However, rotation is

not transmitted to gear [F] due to the sprin g clut ch [G].

When the amount of ink on the ink roller decrea ses an d th e ink de te ctor turns

on (see Ink Detection), the ink supply solenoid [H] turn s on and the ink supply

stopper [I] releases fro m the clutch sle eve allowin g th e ge ars [F] and [J] to

turn.

The pin [K] moves the pump shaft up and down as gear [J] rota te s.

Therefore, ink from th e ink cartridge is sucked into the pump . The pump then

pushes the ink out onto the ink roller throu gh the four holes in the drum shaft

[C].

One stroke of the ink pump occu rs fo r eve ry t wo rot ations of the drum.

2-53

Page 67

DRUM 15 July 1995

6.8 INK KNEADING MECHANISM

[C]

[A]

[D]

[A]

[E]

[B]

[C]

0.08 mm

[B]

[F]

C222D551.img

The ink kneading mechanism con sists of the ink roller [C] and the doctor

roller [B]. The ink roller [C] rotates with the drum and the docto r ro ller [B ]

ensures that the ink goes evenly to th e ink rolle r.

The ink roller [C] rotates with the drum this way: the dru m turn s a gear [A] ,