Page 1

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the printer and peripherals, make

sure that the power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off or

open while the main switch is turned on, keep hands away from electrified or

mechanically driven components.

HEALTH SAFETY CONDITIONS

1. If you get ink in your eyes by accident, try to remove it with eye drops or flush

with water as first aid. If unsuccessful, get medical attention.

2. If you ingest ink by accident, induce vomiting by sticking a finger down your

throat or by giving soapy or strong salty water to drink.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The printer and its peripherals must be installed and maintained by a customer

service representative who has completed the training course on those

models.

CAUTION

The RAM board has a lithium battery which can explode if handled

incorrectly. Replace only with the same type of RAM board. Do not

recharge or burn this battery. Used RAM boards must be handled in

accordance with local regulations.

ATTENTION

La carte RAM comporte une pile au lithium qui présente un risque

d'explosion en cas de mauvaise manipulation. Remplacer la pile

uniquement par une carte RAM identique. Ne pas recharger ni brûler cette

pile. Les cartes RAM usagées doivent être éliminées conformément aux

réglementations locales.

Page 2

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Dispose of replaced parts in accordance with local regulations.

2. Used ink and masters should be disposed of in an envionmentally safe manner

and in accordance with local regulations.

3. When keeping used lithium batteries (from the main control boards) in order to

dispose of them later, do not store more than 100 batteries (from the main

control boards) per sealed box. Storing larger numbers or not sealing them

apart may lead to chemical reactions and heat build-up.

Page 3

TABLE OF CONTENTS

1. OVERALL MACHINE INFORMATION .........................................1-1

1.1 SPECIFICATIONS................................................................................... 1-1

1.2 MAJOR DIFFERENCES BETWEEN THE C223 AND THE C228............. 1-4

2. DETAILED SECTION DESCRIPTIONS........................................2-1

2.1 MASTER EJECT...................................................................................... 2-1

2.2 MASTER FEED........................................................................................ 2-2

2.2.1 MASTER FEED MECHANISMS...................................................... 2-2

2.2.2 THERMAL HEAD PRESSURE RELEASE MECHANISM................ 2-4

2.3 PAPER FEED .......................................................................................... 2-5

2.3.1 PAPER FEED ROLLER................................................................... 2-6

2.3.2 PAPER SEPARATION PLATE........................................................ 2-7

2.4 PRINTING................................................................................................ 2-8

2.4.1 OVERVIEW..................................................................................... 2-8

Printing Pressure Cam........................................................................ 2-8

Paper Detection and Printing.............................................................. 2-8

Quality Start........................................................................................ 2-9

2.4.2 PAPER DETECTION AND PRINTING PRESSURE ON/OFF

MECHANISM ............................................................................... 2-10

2.5 IMAGE PROCESSING........................................................................... 2-11

2.5.1 OVERVIEW................................................................................... 2-11

2.5.2 MASTER MAKING ........................................................................ 2-12

2.5.3 THERMAL HEAD PROTECTION .................................................. 2-12

2.6 PAPER MISFEED DETECTION............................................................. 2-13

3. INSTALLATION............................................................................ 3-1

3.1 INSTALLATION REQUIREMENTS.......................................................... 3-1

3.1.1 OPTIMUM ENVIRONMENTAL CONDITIONS................................. 3-1

3.1.2 ENVIRONMENTS TO AVOID.......................................................... 3-2

3.1.3 POWER CONNECTION.................................................................. 3-3

3.1.4 ACCESS TO THE MACHINE .......................................................... 3-4

3.2 ACCESSORY CHECK............................................................................. 3-5

3.3 INSTALLATION PROCEDURE................................................................ 3-6

4. SERVICE TABLES.......................................................................4-1

4.1 SERVICE REMARKS............................................................................... 4-1

4.2 SERVICE TABLES................................................................................... 4-2

4.2.1 MAINTENANCE TABLES................................................................ 4-2

Lubrication Points............................................................................... 4-2

User's Maintenance............................................................................ 4-5

Periodic Inspection (every 6 months).................................................. 4-5

Periodic Inspection (every 12 months)................................................ 4-6

4.2.2 SERVICE CALL CODES................................................................. 4-7

Page 4

4.2.3 DIP SWITCHES, LEDS, VRS, TPS

(ON THE MAIN CONTROL PCB)................................................. 4-10

DIP Switches.................................................................................... 4-10

Photodiodes...................................................................................... 4-10

VRs................................................................................................... 4-11

TPs................................................................................................... 4-11

4.2.4 EXPECTED LIFE OF PARTS........................................................ 4-11

4.2.5 SPECIAL TOOLS.......................................................................... 4-12

4.3 SERVICE PROGRAM MODE................................................................. 4-13

4.3.1 SERVICE PROGRAM MODE OPERATION.................................. 4-13

Service Program Mode Access Procedure (for engineers)................ 4-13

Service Program Mode Access Procedure (for users) ...................... 4-14

Change Adjustment Values or Modes............................................... 4-14

4.3.2 SERVICE PROGRAM TABLE....................................................... 4-15

4.3.3 THERMAL HEAD TEST ................................................................ 4-32

4.3.4 COMMAND SHEET CHECK ......................................................... 4-33

4.3.5 INPUT/OUTPUT CHECK MODE................................................... 4-34

Input Check Mode Access Procedure............................................... 4-34

Output Check Mode Access Procedure............................................ 4-34

Input Check Table............................................................................. 4-35

4.3.6 USER CODE MODE...................................................................... 4-42

User Codes....................................................................................... 4-42

How To Use a User Code................................................................. 4-42

5. REPLACEMENT AND ADJUSTMENT ......................................... 5-1

5.1 MASTER FEED........................................................................................ 5-1

5.1.1 THERMAL HEAD VOLTAGE ADJUSTMENT.................................. 5-1

5.2 PAPER FEED .......................................................................................... 5-3

5.2.1 SECOND FEED ROLLER START TIMING...................................... 5-3

5.2.2 PAPER FEED ROLLER REMOVAL ................................................ 5-5

5.3 DELIVERY............................................................................................... 5-6

5.3.1 EXIT PAWL TIMING ADJUSTMENT............................................... 5-6

6. POINT TO POINT DIAGRAM (C228)............................................6-1

Page 5

SECTION 1

OVERALL MACHINE

INFORMATION

Page 6

29 January 1998 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Configuration: Table-top

Master Processing: Digital

Printing Process: Fully automatic one-drum stencil system

Original Type: Sheet/Book

Original Size: Maximum 307 mm x 432 mm (12.0" x

17.0")

Reduction Ratios: Inch version:

93%, 77%, 74%, 65%

Metric version:

93%, 87%, 82%, 71%

Enlargement Ratios: Inch version:

155%, 129%, 121%

Metric Version:

141%, 122%, 115%

Zoom: From 50% to 200% in 1% steps

Directional Magnification: Vertical: From 50% to 200% in 1% steps

Horizontal: From 50% to 200% in 1% steps

Overall

Information

Image Mode: Letter, Photo, Letter/Photo

Color Printing: Drum unit replacement system

(Red, Blue, Green, Brown, Yellow, Purple,

Navy, and Maroon)

Master Feed/Eject: Roll master, automatic feed/eject

Leading Edge Margin: 5 mm (0.2")

Trailing Edge Margin: 3 mm (0.12")

Print Paper Size: Maximum 297 mm x 432 mm

(11.6" x 17.0")

Minimum 90 mm x 148 mm (3.6" x 5.8")

Printing Area: A3 drum (original drum)

More than 290 mm x 412 mm

Optional A3 drum

More than 290 mm x 407 mm

Optional A4 drum

More than 290 mm x 204 mm

Print Paper Weight:

47.1 g/m

2

to 209.3 g/m2 (12.5 lb to 55.6 lb)

1-1

Page 7

SPECIFICATIONS 29 January 1998

Printing Speed: 60, 75, 90, 105, 120 sheets/minute

First Copy Time

(Master Process Time):

Second Copy time

(First Print Time):

Paper Feed Table Capacity:

Paper Delivery Table

Less than 46.0 seconds (A3)

Less than 37.0 seconds (A4)

Less than 48.0 seconds (A3)

Less than 39.5 seconds (A4)

2

1,000 sheets (80 g/m

1,000 sheets (80 g/m

, 20 lb)

2

, 20 lb)

Capacity:

Power Source: 120 V, 50/60 Hz: 3.6 A (for N. America)

220/240 V, 50/60 Hz: 2.0 A (for Europe,

Asia)

Power Consumption: 120 V, 50/60 Hz: 360 W (for N. America)

220/240 V, 50/60 Hz: 350 W (for Europe,

Asia)

Weight: 120 V version: 127 kg

220/240 V version: 127 kg

Cabinet: 23.5 kg

Dimensions (W x D x H):

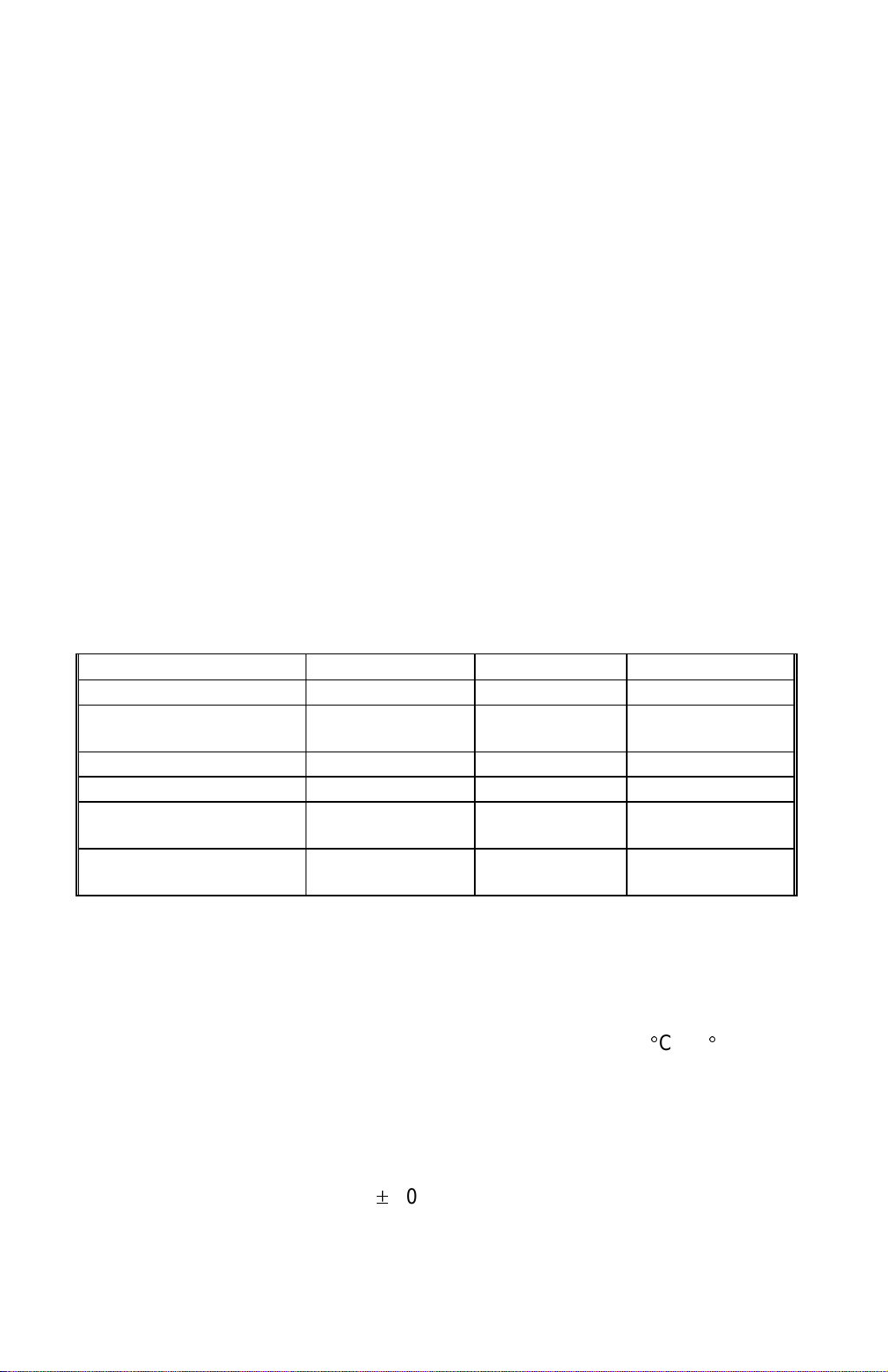

Width Depth Height

Stored 719 mm, 28.4" 698 mm, 27.5" 644 mm, 25.4"

Stored with document

feeder

Set up 719 mm, 28.4" 698 mm, 27.5" 644 mm, 25.4"

Set up with cabinet 719 mm, 28.4" 698 mm, 27.5" 1,070 mm, 42.2"

Set up with document

feeder

Set up with cabinet and

document feeder

719 mm, 28.4" 698 mm, 27.5" 666 mm, 26.3"

1,331 mm, 52.5" 698 mm, 27.5" 666 mm, 26.3"

1,331 mm, 52.5" 698 mm, 27.5" 1,092 mm, 43.0"

Original Scanning Time: 3.07 ms/line

Master Making Density: 600 dpi (CCD: 400 dpi)

Master Eject Box Capacity: More than 70 masters under low temperature

q

More than 100 masters at 23

C, 73qF and

over

Paper Separation: Friction roller/center separation system

Feed Table Side Plate

88 mm to 336 mm (3.46" to 13.2")

Movement:

Side Registration:

r

10 mm

Vertical Registration: More than +10 mm, -20 mm

1-2

Page 8

29 January 1998 SPECIFICATIONS

Ink Supply: Automatic ink supply system

Paper Delivery: Air knife/vacuum delivery

Print Counter: 7 digits

Supplies: Master Thermal master 320 mm width

370 masters/roll (with A4 drum)

250 masters/roll (with A3 drum)

(VT-6 master)

Max. run length 2000 prints

Ink 1000 cc ink pack (black)

600 cc ink pack

(Red, Blue, Green, Brown,

Yellow, Purple, Navy, Maroon)

Overall

Information

1-3

Page 9

MAJOR DIFFERENCES BETWEEN THE C223 AND THE C228 29 January 1998

1.2 MAJOR DIFFERENCES BETWEEN THE C223 AND

THE C228

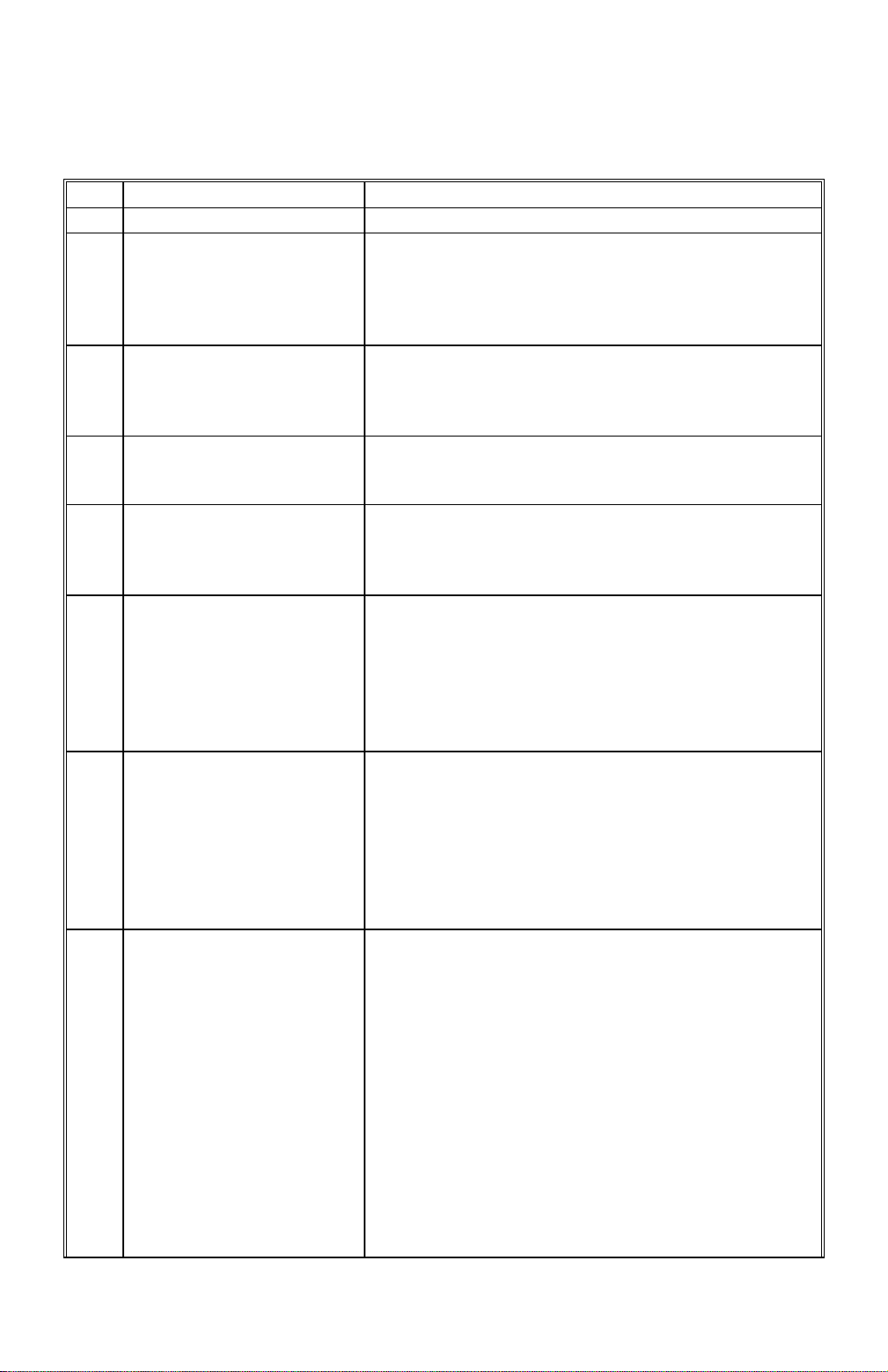

No. Item Details

1 Thermal Head A new 600 dpi thermal head is used.

2 Thermal Head Pressure

Release Mechanism

3 Improvements for Better

Master Feeding in the

Master Feed Unit

4 Paper Feed Roller The core of the paper feed roller has been changed

5 Paper Separation Plate The shape of the separation plate has been

6 Paper Feed Cam and

Printing Pressure Cam

7 Paper Detection System

for Starting Applying the

Printing Pressure

8 Master Eject Roller Grooves have been made in the lower master feed

The thermal head is pressed against the platen

roller only during the master making process. A

unique dc motor is used for this mechanism. For

details, refer to ‘Master Feed’ in the Detailed

Section Descriptions section.

The new master is thinner and has a smoother

surface. Some improvements have been made to

improve master feed. For details, refer to ‘Master

Feed’ in the Detailed Section Descriptions section.

to improve paper feed. For details, refer to ‘Paper

Feed’ in the Detailed Section Descriptions section.

changed for better paper feeding. For details, refer

to ‘Paper Feed’ in the Detailed Section Descriptions

section.

For better printing quality, the shape of the printing

pressure cam (the cam profile) has been changed.

Also, the shapes of the two paper feed rollers have

been changed in order to make the paper

registration more accurate. For details, refer to

‘Paper Feed’ and ‘Printing’ in the Detailed Section

Descriptions section.

For better printing, the printing pressure application

timing has been changed. Because of the strictly

controlled timing, a photocoupler (the paper

registration sensor) is used to detect when to start

applying the printing pressure. (The paper detection

feeler used in the C223 has been removed.) For

details, refer to ‘Printing’ in the Detailed Section

Descriptions section.

rollers to improve master feed. For details, refer to

‘Master Eject’ in the Detailed Section Descriptions

section.

1-4

Page 10

29 January 1998 MAJOR DIFFERENCES BETWEEN THE C223 AND THE C228

No. Item Details

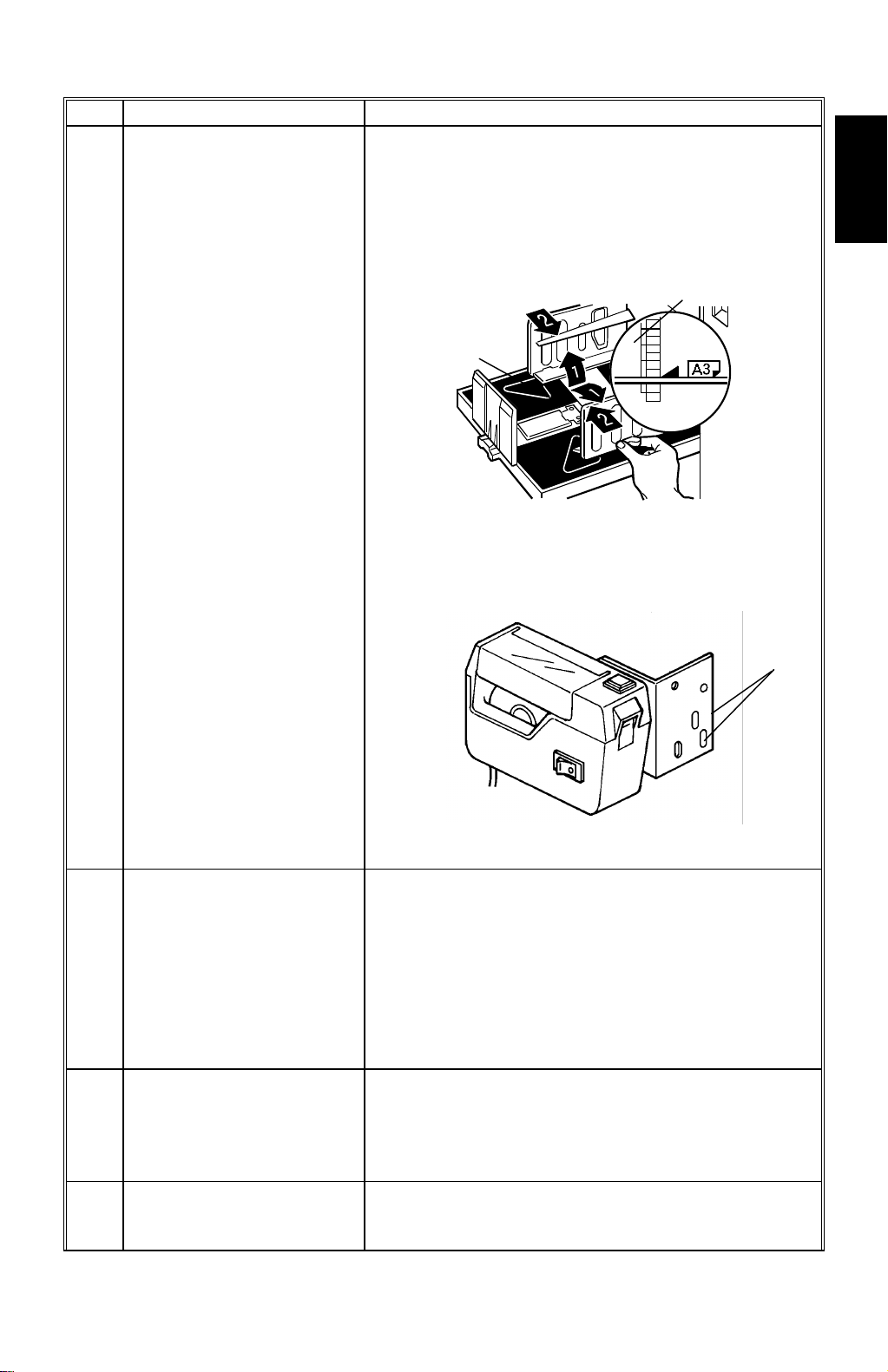

9 Paper Delivery Table The C228 uses a new paper delivery table. (This

table is also used for the recent C223 because of a

modification.) This new table has small guide plates

[A] on the front and rear side fences. The guide

plates stack the prints more evenly. The small

guide plates [B], on the bottom of each side fence,

keep the prints aligned in the center of the table

while the prints are being stacked.

[A]

[B]

C228V500.WMF

Due to the new paper delivery table design, the set

position of the optional tape marker is different from

that for the C223. Use the screw holes [C] shown

below.

Overall

Information

[C]

C532I504.PCX

10 Thermal Head Drive The voltage to the thermal heating elements in the

thermal head is different from that of the C223. The

DC/DC Converter Board which is newly added

supplies the voltage while using the same power

supply board as the C223.

Also, the thermal head drive board used in the

C223 has been removed. The function has been

built into the image processing board.

11 Image Shifting Mode The shift range in the backward direction in image

shifting mode has been changed from 15 mm to 10

mm. This is due to the changed printing pressure

application timing. (In the forward direction, it is 20

mm as before.)

12 Make-up Function The memory chips for the Make-up function, which

was an option for the C223, are built into the image

processing board.

1-5

Page 11

MAJOR DIFFERENCES BETWEEN THE C223 AND THE C228 29 January 1998

No. Item Details

13 New Replacement and

Adjustment Procedures

x

The thermal head voltage adjustment

procedure has been changed.

x

The adjustment standard for the second

feed roller start timing has been changed

from 177q to 144q.

x

A remark has been added to the paper

feed roller removal procedure.

x

The adjustment standard for the exit pawl

timing has been changed from 230 r 2q to

228 r 2q.

For details, refer to the Replacement and

Adjustment section.

14 New Master A new more heat-sensitive master is used to

improve the printing quality.

Due to the new master material, the capacity of the

master eject box has been increased.

Because the new master surface is slippery, the

new master roll is tightened with tape [A] as shown

below to prevent the roll from becoming loose. The

master roll installation method has been changed.

(For details, refer to ‘Installation Procedure’ in the

Installation section.)

[A]

C228V502.WMF

1-6

Page 12

29 January 1998 MAJOR DIFFERENCES BETWEEN THE C223 AND THE C228

No. Item Details

15 New SP Modes The default setting for the thermal head energy for

the economy mode (SP35-2) has been changed

from -35% to -30%. (In other words, the energy

used in economy mode has been increased.)

The following SP modes are new for the C228:

SP51: Clear Multi Copy

SP52: Compress W Start Key

SP78-1: Letter/Pht Mode [CS]

SP78-2: Clear/Original

SP51 and SP78 are accessible to users. SP78

Note:

also can be registered in CS mode.

- Functions -

SP51: Resets the Combine 2 Originals or

Combined Print function (if it has been set) after the

master making process. There are two options: 0:

No, 1: Yes. “0” is the default.

Overall

Information

16 New Input/Output Check

Mode

SP52: The masters in the master eject box can be

compressed every time the Master Making key is

pressed. There are two options: 0: No, 1: Yes. “0”

is the default.

If this mode is enabled, it reduces the

Note:

possibility of the master eject belts slipping off, which

tends to occur when the master box is full.

SP78-1: Select whether the reproduction of letter

mode areas is emphasized when Letter/Photo

mode is used. There are two options: 0: Standard,

1: Emphasized. “0” is the default.

SP78-2: Select whether the image mode (letter,

photo, or letter/photo) is to be returned to the

default setting when master making is finished.

There are two options: 0: No, 1: Yes. “0” is the

default.

The following are the new items for the Input/Output

Check Mode:

Input: 51 SN: Paper Registration

(Paper Registration Sensor)

Input: 52 SN: T. Head Position

(Thermal Head Pressure Release

Sensor)

Output: 42 MOTOR: T. Head Up/Down (Turns

on

the thermal head pressure release

motor.)

1-7

Page 13

SECTION 2

DETAILED SECTION

DESCRIPTIONS

Page 14

29 January 1998 MASTER EJECT

2. DETAILED SECTION DESCRIPTIONS

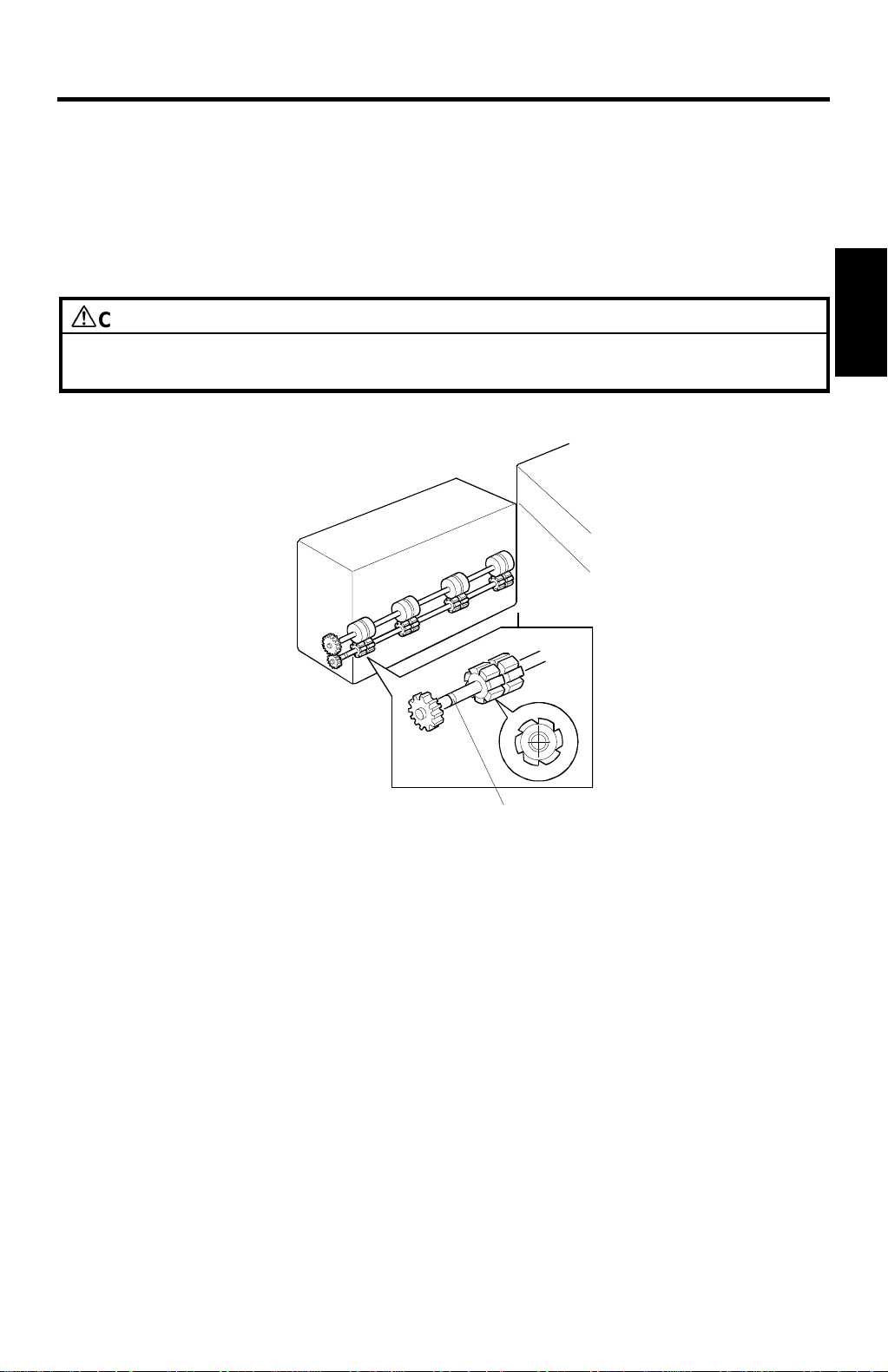

2.1 MASTER EJECT

Grooves have been added on the lower master eject rollers for better master

feeding.

CAUTION

The lower master eject roller must be installed the correct way around. The

groove [A] on the shaft (see the illustration) must be on the operation side.

Detailed

Descriptions

[A]

C228D501.WMF

2-1

Page 15

MASTER FEED 29 January 1998

2.2 MASTER FEED

2.2.1 MASTER FEED MECHANISMS

A 600 dpi thermal head and a new more heat-sensitive master is used to improve

the printing quality. The new master is thinner and has a smoother surface. The

following improvements are implemented to improve master feed.

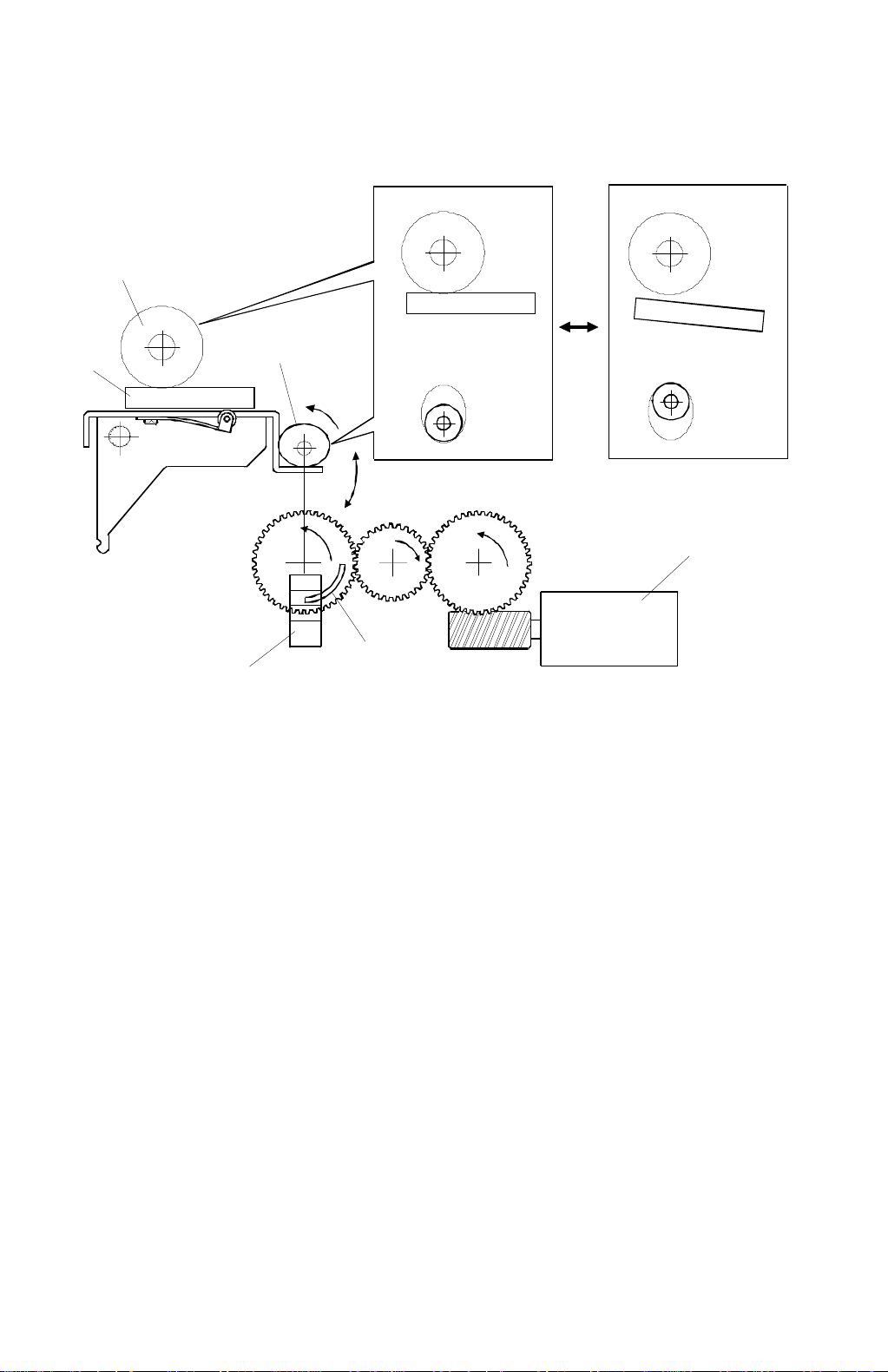

1. Three master buffer fan motors [A] are used instead of the one fan motor used

in the C223. This generates stronger suction to guide the master into the

master box [B].

[B]

[A]

[D]

[E]

[C]

C228D502.WMF

2. To ensure correct master feed, the material of the upper master feed roller [C]

has been changed to an anti-static rubber. (A sponge-like material was used

for the C223.)

The new master feed roller [C] rotates slightly faster than the platen roller [D].

This stretches the master on the thermal head (under the platen roller) and

makes sure that the master is made accurately. A torque limiter built into the

upper master feed roller gear can release the master feed force to prevent the

master from being damaged in this area.

Also, the counter roller [E] has been added to prevent the master from

wrapping around the upper master feed roller.

2-2

Page 16

29 January 1998 MASTER FEED

[B] [C]

[A]

[D]

C228D503.WMF

3. A metal master guide plate was used between the master feed roller and

reverse roller for the C223. This was good for grounding static electricity.

However, when static electricity is grounded, the master tends to stick to the

guide plate. As a thinner master is used for the C228, the guide plate [A] is

made of a plastic material. This prevents the master from being stuck on the

guide plate surface even if static electricity is generated. Also, ribs have been

added to the new guide plate to feed the master more smoothly.

4. Four strips of mylar [B] have been added to the surface of the master guide

plates. This can prevent the master from catching on the rollers under the

master feed and reverse rollers. Other strips of mylar are used in front of the

master feed roller [C] and after the platen roller [D].

NOTE:

These mylar strips must be carefully repositioned when the rollers are

reinstalled.

Detailed

Descriptions

2-3

Page 17

MASTER FEED 29 January 1998

2.2.2 THERMAL HEAD PRESSURE RELEASE MECHANISM

[B]

[B]

[B]

[A]

[A]

[C]

[C]

[A]

[C]

[D]

[F]

[E]

C228D504.WMF

The thermal head [A] is pressed against the platen roller [B] only during the master

making process. The thermal head position is moved up and down by changing

the position of the cam [C].

The cam position is changed by the thermal head pressure release motor [D] via

gears. The thermal head pressure release sensor [E] monitors the cam position.

The sensor, which is a photointerrupter, is interrupted by the shutter mounted on

the gear [F] as the pressure release motor turns to maintain the cam position.

2-4

Page 18

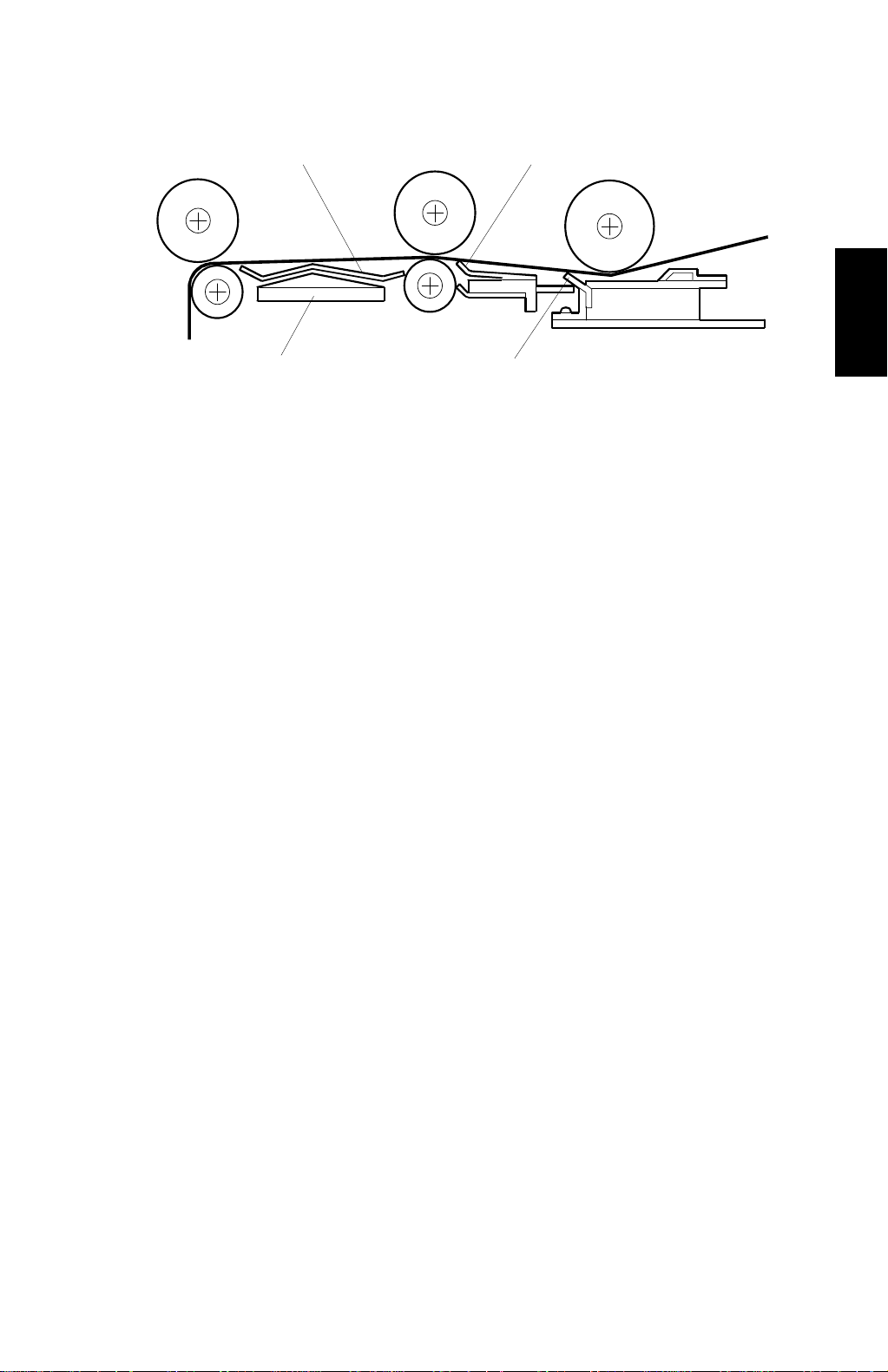

29 January 1998 PAPER FEED

2.3 PAPER FEED

To improve paper feed, especially for thin paper, the paper feed roller and the

separation plate have been changed.

In addition, the shapes of the two paper feed cams (the cam profiles) have been

changed in order to make the paper registration more accurate.

With the new cams, the leading edge of the paper reaches the second feed roller

faster than before. Then, the second feed roller can start feeding the paper earlier.

Thanks to this, the second feed roller can start feeding the paper at a lower

transportation speed. (The time that the paper reaches the press roller position is

still the same, but the acceleration from the second feed roller has become more

moderate.) As a result, the paper registration has become more accurate.

Since the timing for the second feed roller to start feeding the paper was

advanced, the paper detection feeler used in the C223 could not be used. A

photocoupler is used instead. For more details about this, refer to the Printing

section.

NOTE:

1) Due to the new cams, the adjustment values for second feed roller

operation are changed. For details, refer to ‘Feed Length of the Second

Feed Roller Adjustment‘ and ‘Second Feed Roller Start Timing

Adjustment‘ in the ‘Replacement and Adjustment’ section. (The ‘Feed

Length of the Paper Feed Roller Adjustment’ procedure is still the

same.)

2) The new paper feed cams cannot be used on the older models since

those models use the paper detection feeler.

Detailed

Descriptions

2-5

Page 19

PAPER FEED 29 January 1998

2.3.1 PAPER FEED ROLLER

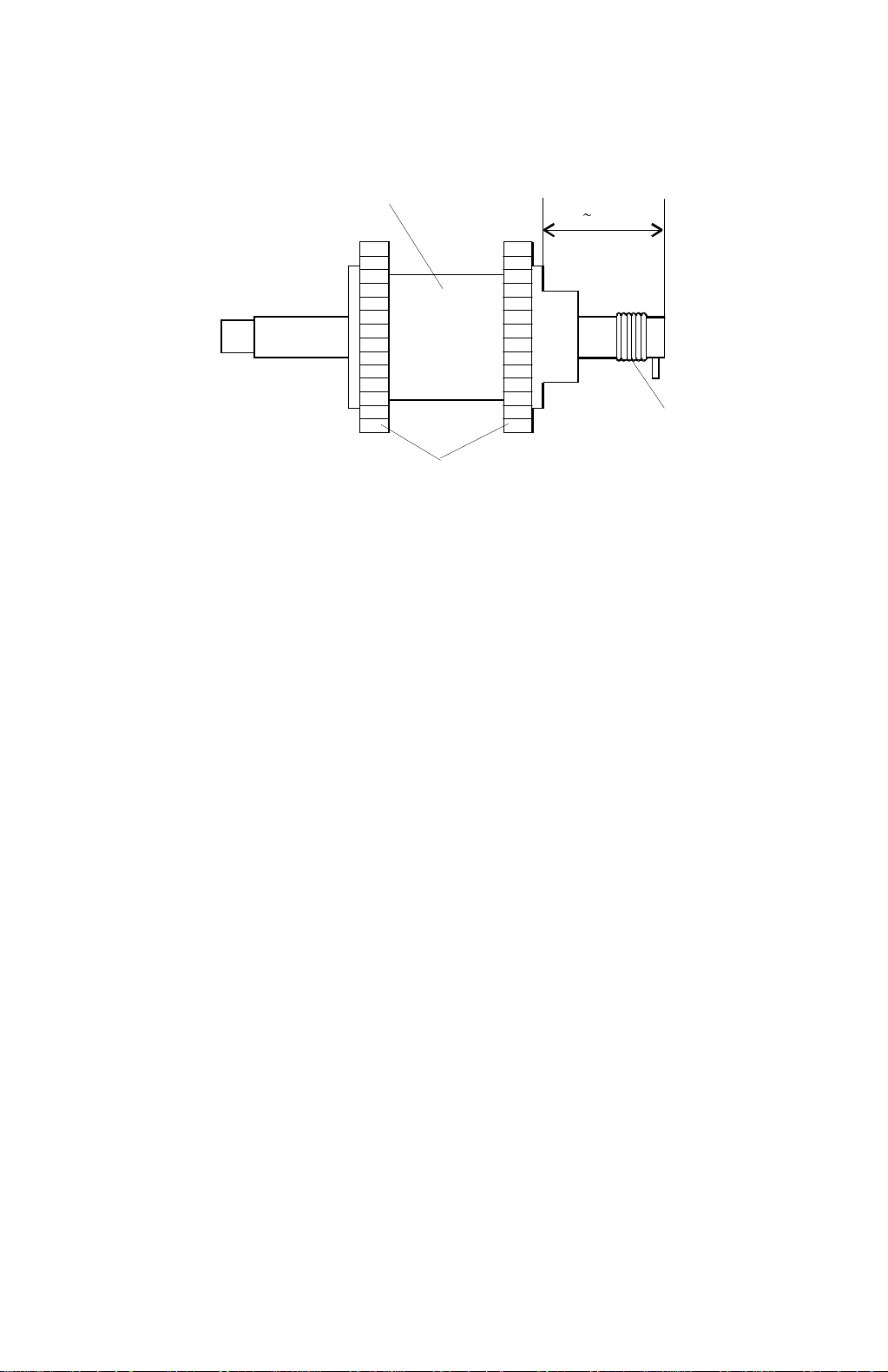

[B]

35.5

a

36.5 mm

[C]

C228D505.WMF

[A]

In this model, the two rubber rollers [A] on the core roller are separated. This helps

to prevent creasing of paper that can be caused by the narrower roller assembly of

the C223. (This was likely with very thin paper.)

The material of the core roller [B] was changed from plastic to metal for better

stiffness. As a result, to balance the weight of the whole paper feed roller unit, the

number of balancing weight plates on the feed roller bracket was reduced from

three to two.

Since the weight of the paper feed roller itself has increased, the roller tends to

overrun (it keeps on feeding paper) after the roller driving force stops. To prevent

this, a spring [C] which works as a brake has been added at the end of the shaft.

NOTE:

When servicing, make sure that the core roller is between 35.5 mm and

36.5 mm from the end of the shaft.

2-6

Page 20

29 January 1998 PAPER FEED

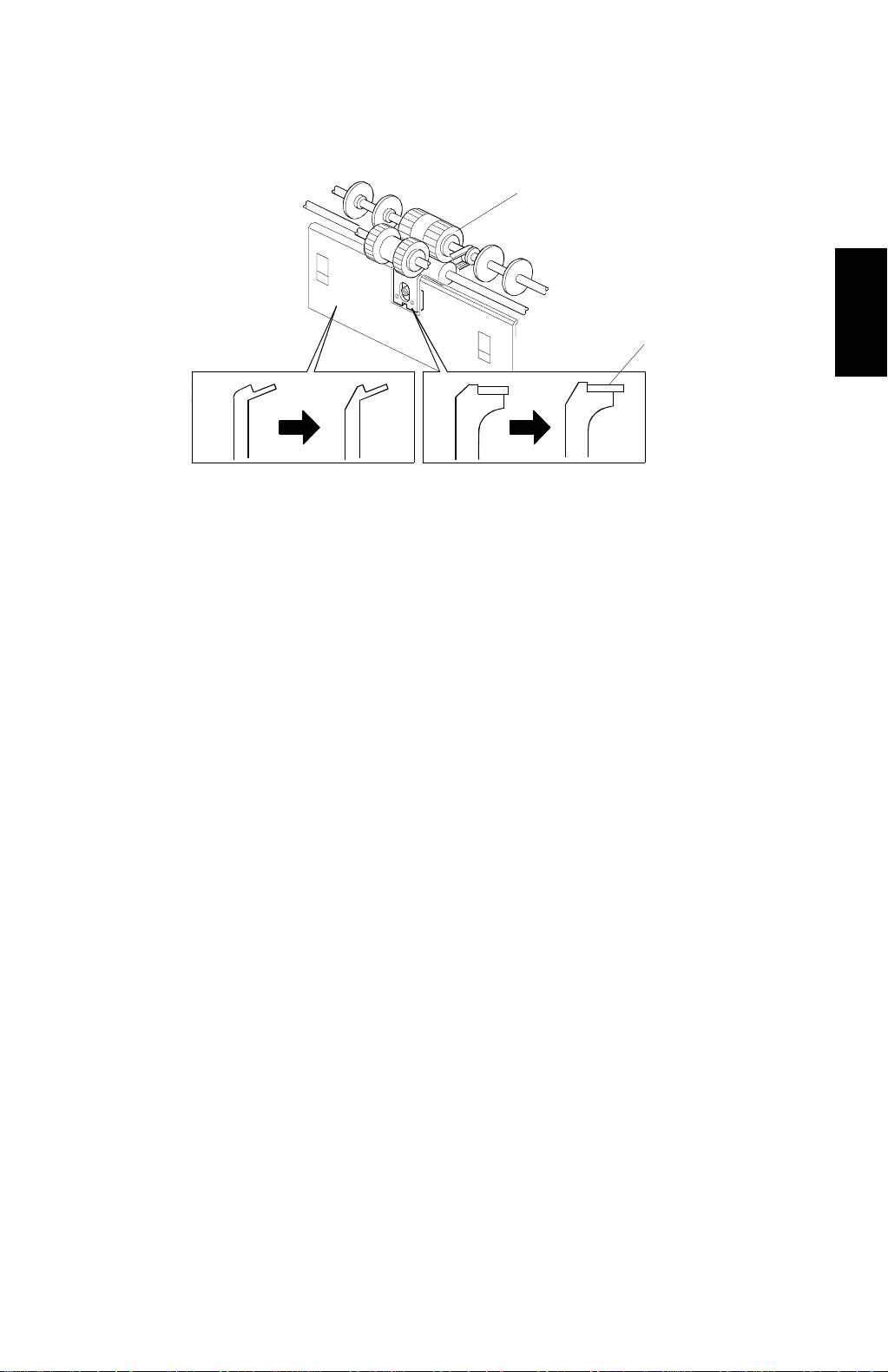

2.3.2 PAPER SEPARATION PLATE

[D]

[C]

[A]

[B]

C228D506.WMF

If the leading edge of paper stacked on the paper table curls downwards, it tends

to be caught by the separation plate and this causes a jam. The shape of the

separation plate [A] has been changed (see the diagram) to improve paper feed in

such a case.

For the same purpose, the shape of the upper edge of the entrance plate [B]

(which holds the separation plate) has been changed as shown.

The rubber part of the separation plate [C] has been lengthened to improve paper

feed, especially for thick paper. The lengthened rubber can guide the paper

leading edge to the upper separation roller [D] surface more precisely. Because of

this, the paper edge hits the upper separation roller more gently. This prevents the

paper leading edge from being damaged at the area where the separation plate

(the rubber part) contacts the upper separation roller surface. (This was likely with

thick paper.)

Detailed

Descriptions

2-7

Page 21

PRINTING 29 January 1998

2.4 PRINTING

2.4.1 OVERVIEW

Printing Pressure Cam

For better printing quality, the shape of the printing pressure cam (the cam profile)

has been changed.

The new cam applies printing pressure to the drum faster than before. The press

roller is pressed against the ink roller (the master and the drum screens are in

between) before the leading edge of the paper reaches this section.

In the C223, the press roller is pressed against the ink roller just when the paper

leading edge reaches this point. In this case, the paper leading edge is strongly

pressed against the master surface on the drum. Since the new master is thinner

and delicate, the paper leading edge tends to damage the master surface if the

same printing pressure cam is used, especially during a long printing run. (If the

master surface is damaged, ink will leak and transfer onto the paper.) The new

printing pressure cam can avoid this situation.

NOTE:

1) Because of the new printing pressure cam, the adjustment values

(angles) for printing pressure application timing and exit pawl operation

timing are changed. Refer to ‘Pressure Timing Adjustment’ and ‘Exit

Pawl Timing Adjustment’ in the ‘Replacement and Adjustment’ section.

2) The new printing pressure cam cannot be used in the older models.

Because of the new cam profile, the shift range in the backward

direction in image shifting mode has been changed from 15 mm to 10

mm. (In the forward direction, it is 20 mm as before.)

Paper Detection and Printing

In the C223, the paper detection feeler was used in order to prevent the press

roller from contacting the drum (without paper) and getting ink on it when a paper

misfeed occurred before the paper reached the press roller.

The paper detection feeler could be pressed downwards by paper since a gap

between the paper detection arm and the pressure on/off lever was created when

the widest part of the pressure cam reached the bearing on the pressure on/off

lever. With the earlier second feed roller start timing, this gap cannot be created.

Therefore, the same mechanism is not used. (The timing was changed to make

paper registration more accurate; see the Paper Feed section for details.)

NOTE:

Instead of the paper detection feeler, the registration sensor (a photocoupler) is

used. When the sensor detects the paper, the printing pressure solenoid energizes

to start applying the printing pressure. (In the C223, the printing pressure solenoid

was energized as soon as paper feed started.) The sensor is also used as a paper

jam detector.

For the details of the paper detection feeler operation, refer to the C223

Service Manual. (Section 5.2, ‘Paper Detection And Printing Pressure

On/Off Mechanism’ in the ‘Detailed Section Descriptions’ section.)

2-8

Page 22

29 January 1998 PRINTING

For more details about this mechanism, refer to the following ‘Paper Detection and

Printing Pressure On/Off Mechanism’ section.

Quality Start

The detection arm release solenoid which was used in the C223 has been

removed. Since the paper detection feeler has been removed, the detection arm

release solenoid is not necessary to start the drum stroke operation in the quality

start mode.

When the drum stroke operation starts, the printing pressure solenoid turns on.

This disengages the pressure on/off lever and starts applying the printing

pressure.

Detailed

Descriptions

NOTE:

For the details of the quality start mode operation, refer to the C223

Service Manual. (Section 5.4 ‘Quality Start Operation’ in the ‘Detailed

Section Descriptions’ section.)

2-9

Page 23

PRINTING 29 January 1998

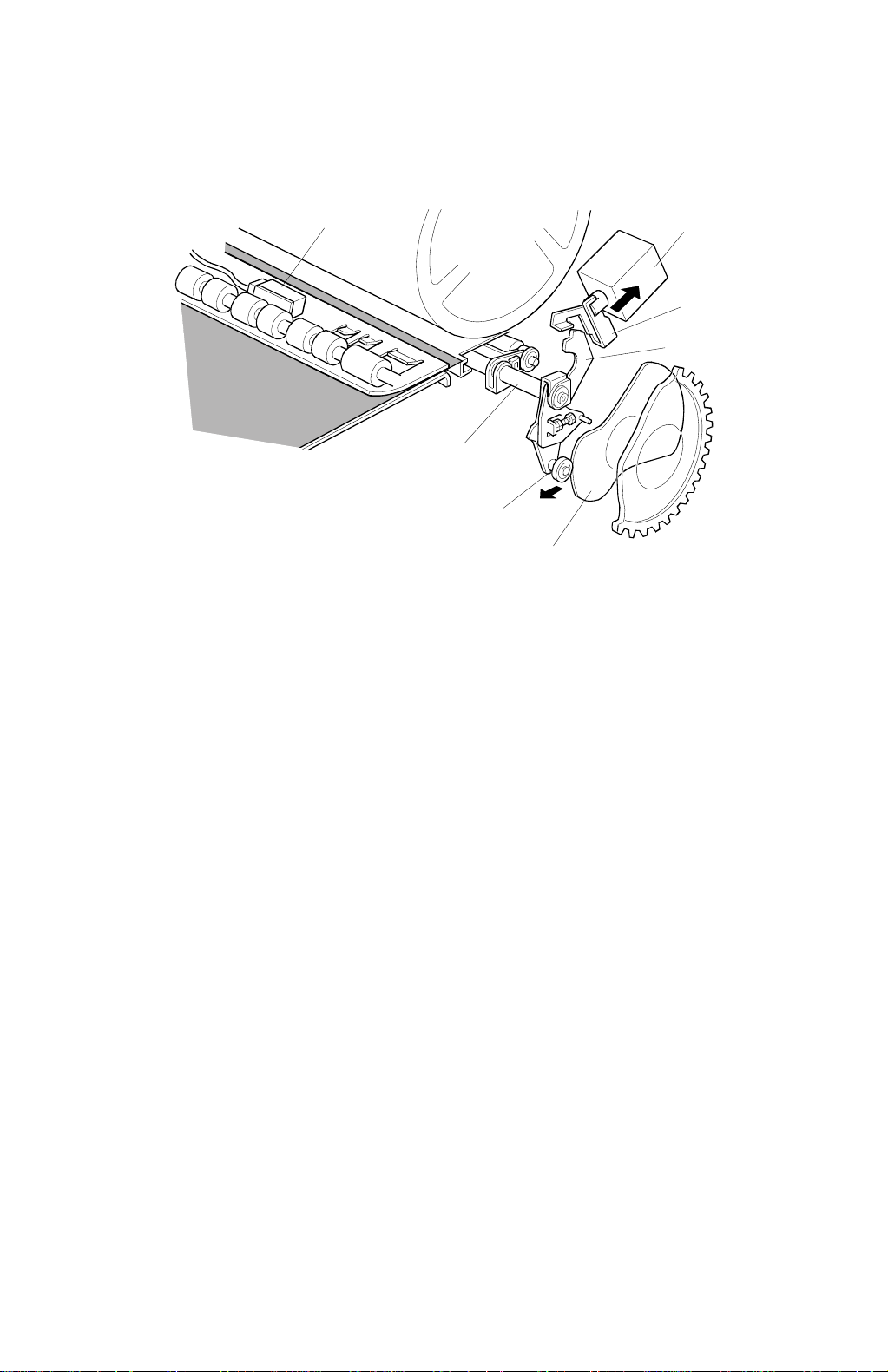

2.4.2 PAPER DETECTION AND PRINTING PRESSURE ON/OFF

MECHANISM

[A]

[B]

[C]

[D]

[E]

[G]

[F]

C228D507.WMF

When the paper is detected by the paper registration sensor [A], the printing

pressure solenoid [B] is energized. The stopper arm [C] then disengages the

pressure on/off lever [D]. The pressure on/off lever, which is connected to the end

of the press roller arm [E], starts moving when the printing pressure cam [F] starts

moving; the cam moves bearing [G], which is on the lever. The press roller is

pressed against the ink roller.

The printing pressure solenoid is de-energized when the printing pressure sensor

is activated; this is soon after it is energized. The stopper arm [C] returns and is

pressed against the pressure on/off lever, due to tension from a spring. (The

stopper arm just rides on the edge of the pressure on/off lever at this time.) To

finish applying the printing pressure, the bearing [G] on the pressure on/off lever is

pushed by the printing pressure cam and the lever turns clockwise, until it is

engaged by the stopper arm.

If the next sheet of paper is detected by the registration sensor within a certain

period, the printing pressure solenoid is again energized to disengage the pressure

on/off lever. The printing pressure for the next sheet of paper starts being applied.

If the registration sensor is not activated, the machine detects a paper misfeed

condition (Location B Misfeed). In this case, the printing pressure solenoid stays

de-energized and the printing pressure is not applied. This can prevent the press

roller contacting the drum (without paper) and getting ink on it because of the

paper misfeed.

NOTE:

In the C223, Location B Misfeed was detected when the printing pressure

sensor was not activated within a certain period.

2-10

Page 24

29 January 1998 IMAGE PROCESSING

2.5 IMAGE PROCESSING

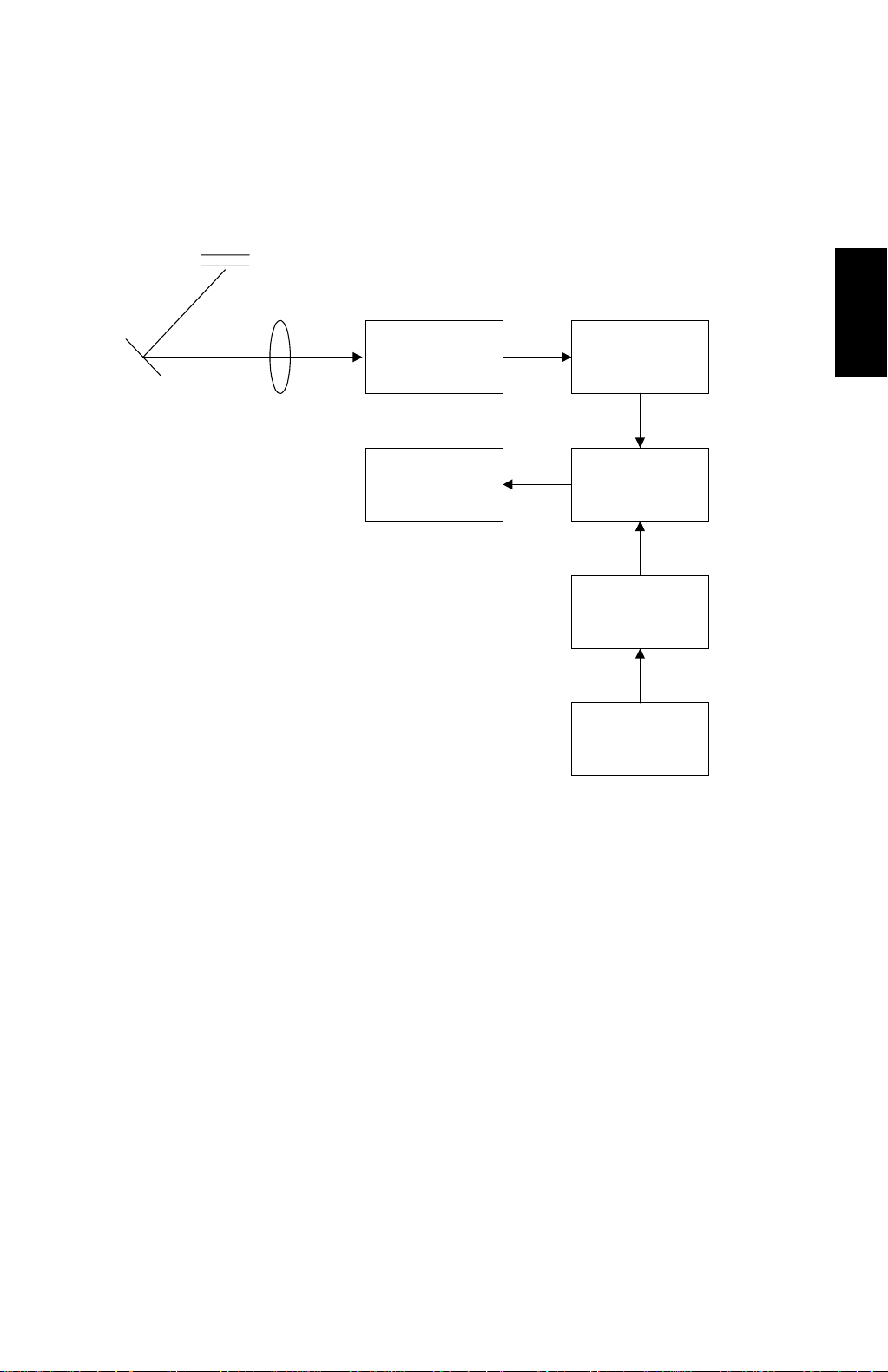

2.5.1 OVERVIEW

Analog signal

CCD PCB

Thermal Head

1-bit

A/D Conversion

PCB

6-bit

Image

Processing PCB

Main Control

PCB

Image Settings

Operation Panel

C228D508.WMF

Detailed

Descriptions

The light reflected from the original goes to the CCD, which converts the light

signal into an analog electrical signal. The analog signal is sent to the A/D

conversion PCB, where it is changed to 6-bit digital data. The 6-bit data is changed

to 1-bit data in the image processing PCB and it goes to the thermal head. The

thermal head drive circuit is built into the image processing PCB.

The 6-bit to 1-bit conversion procedure depends on the image settings on the

operation panel.

2-11

Page 25

IMAGE PROCESSING 29 January 1998

2.5.2 MASTER MAKING

The operation of the thermal head is just like that of the C223, except that the

thermal head drive circuit has been built into the image processing board.

The new 600 dpi thermal head is used with the new more heat-sensitive master.

The specifications of the thermal head are as follows:

z

Density of Thermal Heating Elements: 600 dpi

z

Number of Thermal Heating Elements: 7168 dots

z

Maximum Master Making Width: 303.45 mm

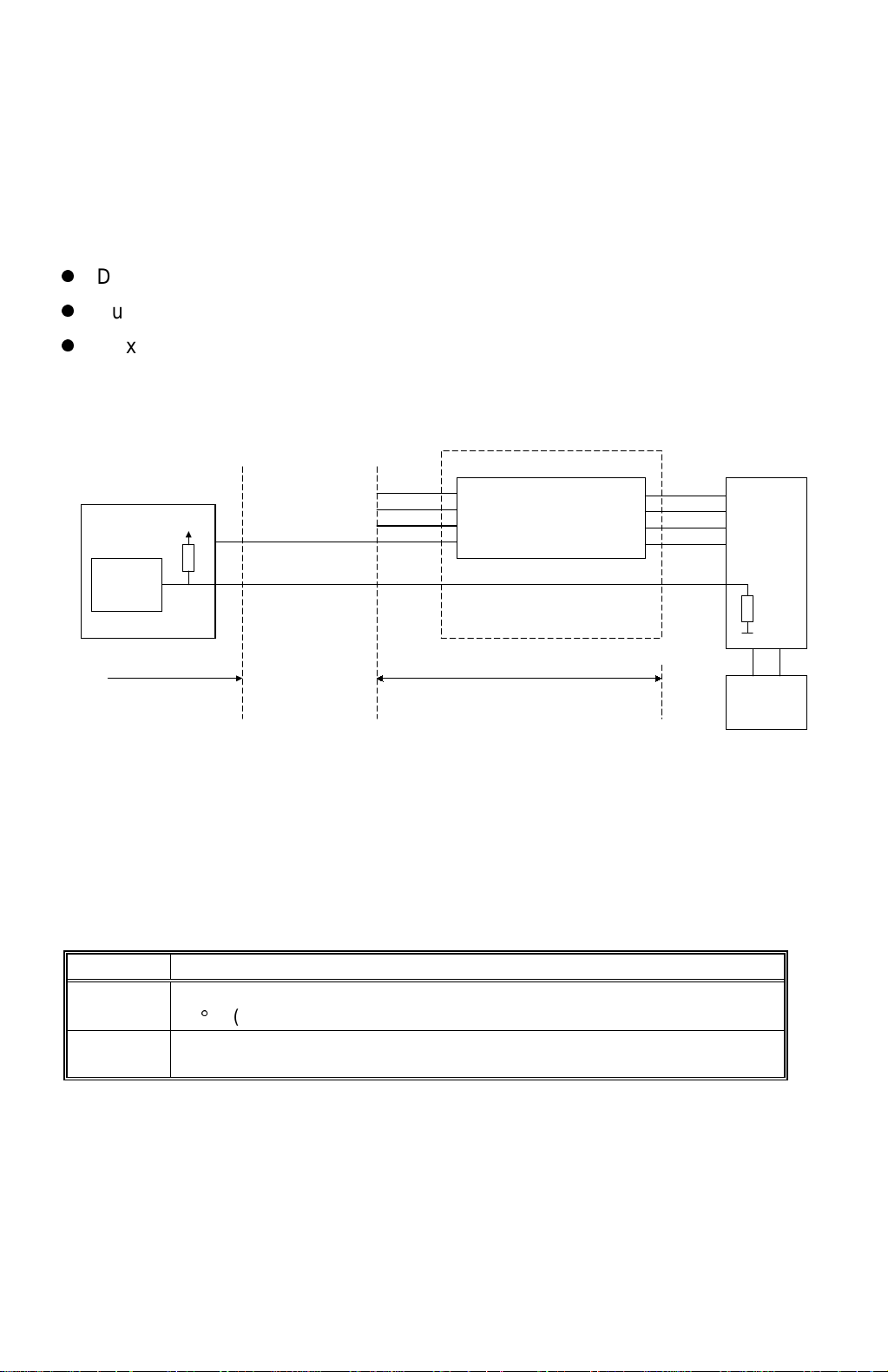

2.5.3 THERMAL HEAD PROTECTION

Pulse Generator

Circuit

A/D

Conversion

Circuit

Main Control PCB

CN111-A8 CN404-A8

CN111-A1 CN404-A1

/ P:CLK

/ P:LSYNC

/ P:DATA

/ ENLPLS

Thermal Head Drive Circuit

Gate Array

Image Processing PCB

DI1~4

Thermal Head

CK1~4

LAT1~4

STB1~4

Thermistor

C228D509.WMF

DC/DC

Converter

PCB

The thermistor on the thermal heat prevents it from overheating when continuously

processing a solid image.

The CPU checks for abnormal conditions when the Master Making key is pressed,

and indicates an SC code on the operation panel under the following conditions:

SC Code Conditions

E-04 The thermistor on the thermal head detected a temperature of over

54qC. (CN111-A1 is below 1.17 volts.)

E-09 The thermistor is open, or related connectors are not connected.

(The signal level between CN111-A1 and GND is over 4.9 volts.)

2-12

Page 26

29 January 1998 PAPER MISFEED DETECTION

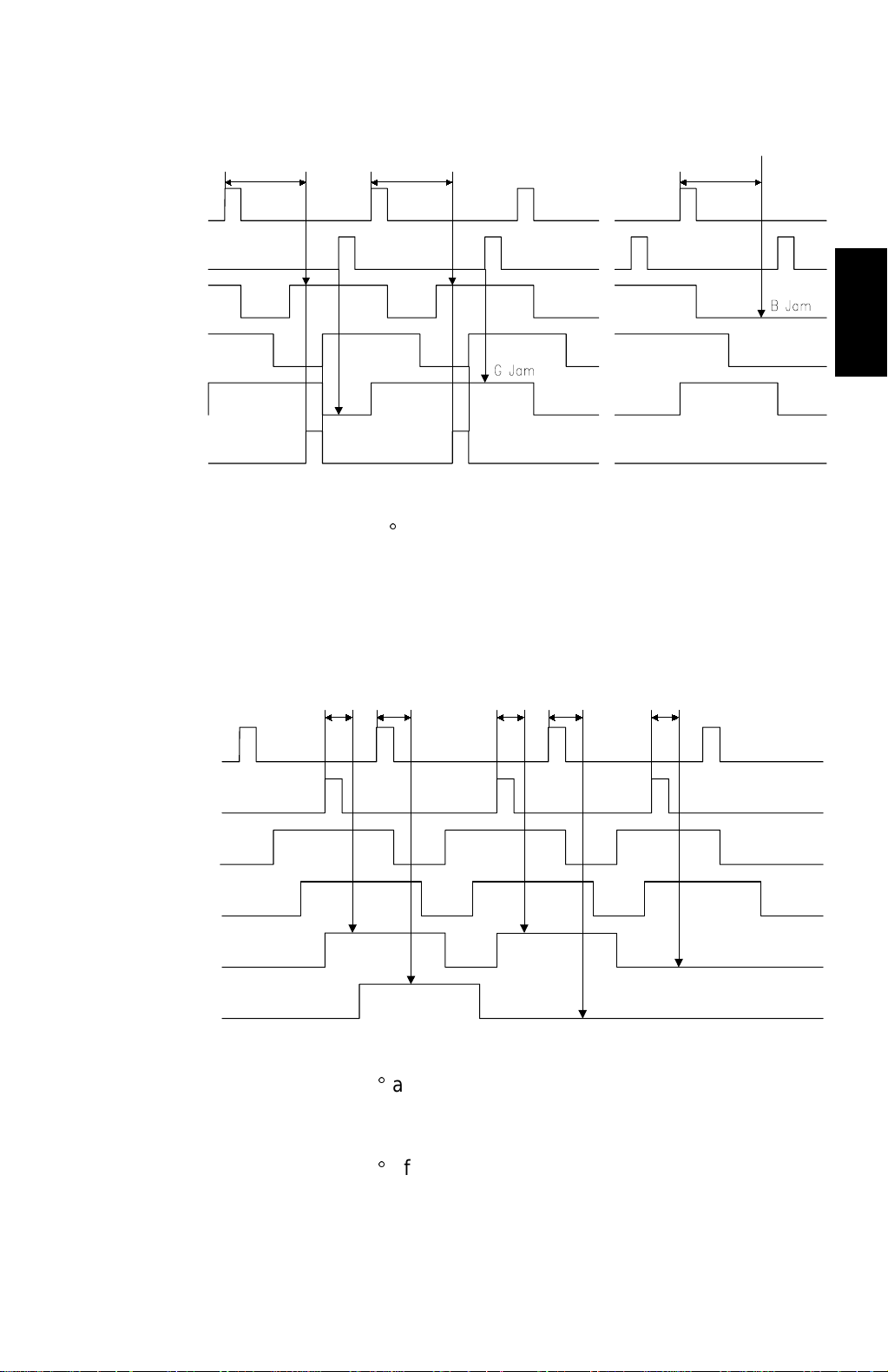

2.6 PAPER MISFEED DETECTION

175°

1st Drum Position Sensor

2nd Drum Position Sensor

Paper Registration Sensor

Printing Pressure Sensor

2nd Paper Exit Sensor

Printing Pressure Solenoid

175°

175°

C228D510.WMF

[a] When the drum has rotated 175q after activating the 1st drum position sensor,

if the paper registration sensor is still OFF, a paper misfeed (Location B jam) is

detected.

[b] When the 2nd drum position sensor turns on, if the 2nd paper exit sensor

remains ON, a paper misfeed (Location G jam) is detected.

Detailed

Descriptions

20° 25° 25° 20°

1st Drum Position Sensor

2nd Drum Position Sensor

Paper Registration Sensor

Printing Pressure Sensor

1st Paper Exit Sensor

2nd Paper Exit Sensor

20°

BE Jam

E Jam

C228D511.WMF

[c] When the drum has rotated 20q after activating the 2nd drum position sensor, if

the 1st paper exit sensor is still OFF, a paper misfeed (Location BE jam) is

detected.

[d] When the drum has rotated 25q after activating the 1st drum position sensor, if

the 2nd paper exit sensor is still OFF, a paper misfeed (Location E jam) is

detected.

2-13

Page 27

SECTION 3

INSTALLATION PROCEDURE

Page 28

29 January 1998 INSTALLATION REQUIREMENTS

3. INSTALLATION

3.1 INSTALLATION REQUIREMENTS

3.1.1 OPTIMUM ENVIRONMENTAL CONDITIONS

Installation

Temperature

Humidity

C223I518.PCX

10 to 30qC

(50 to 86qF)

20 to 90 % RH The machine must be level within

On a strong and level base.

5 mm (13/64") both front to rear

and left to right.

C223I519.PCX

3-1

Page 29

INSTALLATION REQUIREMENTS 29 January 1998

3.1.2 ENVIRONMENTS TO AVOID

Locations exposed to direct

C223I520.PCX

Dusty areas.

C223I521.PCX

sunlight or strong light (more than

1,500 lux).

C223I523.PCX

C223I525.PCX

Areas with corrosive gases. Locations directly exposed to cool air

from an air conditioner or reflected

heat from a space heater. (Sudden

temperature changes from low to

high or vice versa may cause

condensation within the machine.)

3-2

Page 30

29 January 1998 INSTALLATION REQUIREMENTS

3.1.3 POWER CONNECTION

C223I524.PCX

Securely connect the power cord

to a power source.

Make sure that the wall outlet is

near the machine and easily

accessible.

Make sure the plug is firmly

inserted in the outlet.

C223I516.PCX

Voltage must not fluctuate more than

10%.

Installation

C223I515.PCX

C223I517.PCX

Avoid multiwiring. Do not pinch the power cord.

3-3

Page 31

INSTALLATION REQUIREMENTS 29 January 1998

(

)

3.1.4 ACCESS TO THE MACHINE

Place the machine near a power source, providing clearance as shown below.

Paper Delivery

Table

More than 60 cm

(23.7”)

20 cm (8.0”)

Paper

Feed

Table

More than 60 cm

(23.7”)

More than 60 cm

23.7”

C223I526.WMF

3-4

Page 32

29 January 1998 ACCESSORY CHECK

3.2 ACCESSORY CHECK

Make sure that you have the following accessories.

1. Operating Instructions (except for -27 models)

2. NECR (-17, -27 models only)

3. End Plate Prop

4. Decal - Mode

5. Decal - Key Top Cover (OEM machines only)

6. Model Name Plate (OEM machines only)

7. Decal - Master Set (-27 models only)

Installation

3-5

Page 33

INSTALLATION PROCEDURE 29 January 1998

3.3 INSTALLATION PROCEDURE

[A]

[A]

C223I501.PCX

CAUTION

C223I500.PCX

Do not hold the scanner unit when pushing the machine or the scanner unit

safety switch may be damaged.

1. Place the machine on the table.

NOTE:

The screw holes in the bottom plate of the machine must line up with

the screw holes in the table.

[A]

2. Remove the strips of tape [A] securing the covers and units shown above.

[B]

[D]

[C]

C223I502.PCX

3. Open the front door and slide out the drum unit [B].

4. Open the master clamper and remove the clamp [C].

5. Open the paper feed table and remove the cardboard cover [D] protecting the

paper feed roller.

3-6

Page 34

29 January 1998 INSTALLATION PROCEDURE

6. Slide the scanner unit to the left (as seen from the operation side) and remove

the two strips of tape securing the master box.

[G]

[F]

[H]

[E]

C223I503.PCX

C223I504.PCX

7. Open the paper delivery table and remove the strip of tape [E] protecting the

end fence.

8. Remove the cardboard [F] under the scanner unit.

9. Open the scanner unit and change the position of screws [G] from the transport

position to the operating position.

10. Open the doors (2 strips of tape [H]) of the optional table and take out the

plastic bag containing 2 screws.

Installation

3-7

Page 35

INSTALLATION PROCEDURE 29 January 1998

[B]

[A]

[C]

C223I505.wmf

11. Raise the front side of the machine and position the base pad [A] under the

machine. Then raise the rear side of the machine and position the other base

pad [B] under the machine.

12. Secure the machine to the table with the two screws [C] packed with the table.

3-8

Page 36

29 January 1998 INSTALLATION PROCEDURE

13. Open the paper feed table [A] and neatly

stack some printing paper on the table.

14. Slide the paper feed side plates [B] gently up

against the paper stack.

[B]

C223I506.PCX

[A]

15. Open the paper delivery table [C] and adjust

the position of the end plate [D] and the side

plates [E] to match the printing paper size.

Refer to the paper size scale on the table.

[D]

16. Install the ink cartridge [F].

1) Open the front door and lower the ink

holder [G].

2) Remove the ink cartridge cap.

3) Insert the ink cartridge in the ink holder

and raise the ink holder to the original

position.

4) Close the front door.

[C]

[E]

Installation

C228v000-2.WMF

[F]

C223I508.PCX

[G]

17. Slide the scanner unit all the way to the left,

and take the master spools [H] out.

3-9

[H]

C223I514.wmf

Page 37

INSTALLATION PROCEDURE 29 January 1998

18. Install the master roll.

1) Take out the master roll from the plastic bag.

NOTE:

x

Firmly grasp the master roll

since it is very slippery.

x

Do not remove the strip of

the tape holding the master

roll till step 5 below.

C228I500.WMF

[A]

2) Attach a spool [A] to each end of the

master roll [B].

3) Push the pressure release lever [C] to the

C228V002-2.WMF

[C]

left.

4) Set the master roll in the machine as shown

in the illustration.

5) Remove the tape holding the master roll as

shown to the right.

NOTE:

x

Hold the spools by hand to

C228I501.PCX

remove the tape easier.

[B]

x

It is better to remove the

tape completely, but leave

any parts that remain on the

spools or in the core.

6) Insert the leading edge of the master roll

under the platen roller.

7) Return the pressure release lever to the

original position.

8) Plug in the power cord and turn on the main

switch.

9) Press the master cut button.

10) Open the master box cover and remove the

cut strip of master paper.

NOTE:

Check that the paper on the master roll is not bent or creased.

11) Close the scanner unit.

3-10

C228I502.WMF

Page 38

29 January 1998 INSTALLATION PROCEDURE

[A]

C223I512.PCX

19. Idle the machine to distribute ink on the drum.

1) Press the Reset key while holding down the "0" key on the operation panel.

<

2) If

blinks on the operation panel when the machine stops, press the Reset

key again.

Installation

20. Make some test prints to check the machine.

1) Raise the platen cover and place an original face down on the exposure

glass [A]. Make sure the original is flush with the left scale and aligned with

the proper paper size marks.

2) Press the Master Making key.

3) Select the lowest print speed (1) with the Speed key and press the Print

Start key. Make prints at this speed until the print image density stabilizes.

NOTE:

1) Usually, about 30 prints need to be made before the image fully

stabilizes.

2) Check the image quality after the print image density is stabilized.

3-11

Page 39

INSTALLATION PROCEDURE 29 January 1998

21. If necessary, change the language for the LCD guidance as follows:

1) Turn the main switch off and unplug the machine.

2) Remove the right front cover (4 screws).

3) Change the DIPSW 102-1, 2, 3 settings. The following table shows the

setting for each language.

DPS102 LCD Display

123

ON ON OFF English (Default)

OFF OFF ON German

ON OFF ON French

OFF ON ON Spanish

ON ON ON Italian

4) Reinstall the right front cover (4 screws).

3-12

Page 40

SECTION 4

SERVICE TABLES

Page 41

29 January 1998 SERVICE REMARKS

4. SERVICE TABLES

4.1 SERVICE REMARKS

1. If a circuit breaker or a fuse opens, check and remove the cause of the

overcurrent before resetting the breaker or replacing the fuse.

2. If the thermal head or the power supply unit is replaced, thermal head voltage

adjustment is required.

3. Do not touch the edge of the cutter blade with bare hands.

4. Be careful not to drop the master eject unit when removing the eject unit guide

shaft.

5. If the paper feed guide plate is removed, make sure that the guide plates do

not touch the lower second feed roller when putting back the guide.

6. When putting back the lower separation roller, make sure that the front and

rear separation levers move smoothly.

7. If the slowest speed is faster than 60 rpm, the sorter cannot keep up with the

machine and a TS sorter jam might occur.

8. Do not energize the master feed and master eject clamper solenoids for longer

than 10 seconds.

Tables

Service

9. When adjusting the ink roller gap, check the gap at the right, center, and left

positions.

10. The ink detection adjustment should be made under normal conditions (20

C/65%RH).

11. When removing the pressure cam drive gear, do not loosen the two deeply

recessed bolts.

12. If the main drive belt has been removed, check the relationships between the

drum drive gear, printing pressure cam, and the paper feed cams after

replacing the belt. Adjust if necessary.

13. Do not keep on pressing the Image Position key if the image position sensor is

broken or removed. The plastic gears between the metal gears may break.

4-1

Page 42

SERVICE TABLES 29 January 1998

4.2 SERVICE TABLES

4.2.1 MAINTENANCE TABLES

Lubrication Points

Lubricate after removing adhering ink and paper dust at yearly intervals.

Section Lubrication Point Type Location

Drive Speed Reduction Gears of

the Main Motor

Gears of the Drum Drive

Shaft

Image

Positioning

Paper Feed Paper Feed Sector Gear (Fig.1- J)

Drum Drum Drive Gear Grease (Shell

Printing

Pressure

Master Eject Master Pressure Plate

Paper Exit Air Pump Drive Gears (Fig. 6-T)

ADF Bearings for the Feed Roller

Others Edge of Each Cam Grease (Shell

Spiral Track of the Cam Gear (Fig.1- K)

Second Feed Sector Gear (Fig.1- F)

Gear of the Paper Feed Cam

Shaft

Paper Table Slide Groove Both front and rear

Paper Table Drive Gear (Fig.1- G)

Bearings for the Upper

Separation Roller Shaft

Bearings for the Paper Feed

Roller Shaft

Master Clamper Sector Gear (Fig.3- O)

Master Clamper Pinion Gear (Fig.3- P)

Ink Pump Drive Gear (Fig.3- M)

Between Printing Pressure

Arm [Q] and Printing

Pressure Stay [Q']

Pressure Spring Link (Fig.1- C)

Grooves

Rounded Ends of the Master

Pressure Plate Drive Arms

Inside of the Air Pump Piston Grease

Shaft

Grease

(Shell Albania

No.2)

Motor oil

(SAE No.20)

Albania No. 2)

Grease

(Shell Albania

No. 2)

(Mobil Ep-1)

Motor oil

(SAE No. 20)

Albania No. 2)

(Fig.1- E)

On the inside and

outside of the

frame (Fig.1- B)

(Fig.1- A)

(Fig.1- H)

(Fig.1- I)

(Fig.2- L)

(Fig.3- N)

Both front and rear

(Fig.4- Q)

Both front and rear

(Fig.5- S)

(Fig.5- R)

(Fig. 6-U)

Both front and rear

(Fig. 7-V)

(Fig.1- D)

4-2

Page 43

29 January 1998 SERVICE TABLES

[Fig1]

[D]

[J]

[I]

[H]

[G]

[K]

[A]

[F]

C223M500.PCX

[B]

[C]

[D]

[E]

[Fig2]

Tables

Service

[O]

[L]

C223M501.PCX

[Fig 3]

[P]

[M]

[N]

C223M502.PCX

4-3

Page 44

SERVICE TABLES 29 January 1998

[Fig 4]

[Q’]

[Fig 5]

[R]

[Q]

C223M503.PCX

[S]

[Fig 6]

[U]

[T]

C223M509.PCX

C223M504.PCX

[Fig 7]

4-4

[V]

C223M510.WMF

Page 45

29 January 1998 SERVICE TABLES

User's Maintenance

Advise the customer to clean each item regularly. Clean the following items at

every EM call if necessary.

Section Cleaning Point Cleaner Interval

Optics Original Platen Cover Cloth and water

Exposure Glass Cloth and glass cleaner

Paper Feed Paper Feed Roller Cloth and soap and

water

Paper End Sensor Dry cloth

Paper Length Sensor

Printing Press Roller Cloth and soap and

water

ADF Original Feed Rollers

At every EM call

Periodic Inspection (every 6 months)

Section Item Standard Procedure

Optics Original Platen Cover Wipe off stains using a soft cloth

moistened with ethyl alcohol.

Exposure Glass Wipe with a dry cloth.

Paper Feed Paper Feed Roller Wipe off ink and paper powder using a

cloth moistened with ethyl alcohol.

Upper and Lower

Second Feed Rollers

Upper and Lower

Separation Rollers

Printing Press Roller

ADF Pick-up Roller

Feed Roller

Separation Roller

Wipe off paper powder using a cloth

moistened with water.

Tables

Service

4-5

Page 46

SERVICE TABLES 29 January 1998

Periodic Inspection (every 12 months)

Section Item Standard Procedure

Optics Back side of the

Exposure Glass

Mirrors Use a blower brush.

Xenon Lamps Wipe with a dry cloth.

Master Eject Upper and Lower Master

Eject Rollers

Drum Inside and outside of the

Drum

Ink Holder

Master Making Platen Roller Wipe off paper powder using a cloth

Others First and Second Paper

Exit Sensors

Master Eject Sensor

Drum Master Sensor

Wipe with a dry cloth.

Wipe off ink and paper powder using a

cloth moistened with ethyl alcohol.

Wipe off built-up ink and paper powder

using a cloth moistened with ethyl

alcohol.

moistened with water.

Check the performance of all the

sensors. Remove stains from the

sensors using a dry cloth.

4-6

Page 47

29 January 1998 SERVICE TABLES

4.2.2 SERVICE CALL CODES

Code Problem Possible Causes

Main Body

E-01 Neither the right nor the left cutter

switch turns off within 3 seconds of the

cutter motor starting.

E-02 Malfunction in the paper table drive

section.

1. The paper table lower limit sensor or

paper table height sensor does not

turn on within 7 seconds.

2. The LCT tray drive motor does not

stop within 25 seconds.

3. The upper limit sensor does not turn

or within 8 seconds after the LCT

cassette bottom plate drive motor

starts.

E-04 The temperature of the thermal head is

greater than 54qC when the Master

Making key is pressed

E-05

E-06

E-09 The signal level between CN104-A1

E-10 The CPU detects an abnormality in the

E-11 Encoder output does not change within

Malfunction in the image shifting

section.

The drum rotation sensor detects an

incorrect motor speed.

and GND is over 4.9 volts.

pulse signals from the image

processing PCB. These pulses

determine the energy to be applied to

the thermal heating elements.

3 seconds of the main switch being

turned on or the Clear Mode key being

pressed.

1) Drive wire cut

2) Drive section malfunction

3) Defective cutter switch

1) Drive worm gear broken

2) Mounting screw of the

worm gear broken

3) No power supply

1) Excessive thermal head

temperature

2) Thermistor short

1) Image position sensor

connector disconnected

2) Defective image position

sensor

1) Drum lock

2) No power supply

1) The thermistor is open.

1) Defective thermistor

2) Related connectors are

not.

1) Defective image position

motor

2) No power supply

Tables

Service

4-7

Page 48

SERVICE TABLES 29 January 1998

Code Problem Possible Causes

E-12 1. The upper or lower pressure plate

sensor remains activated for more

than 4 seconds after the pressure

plate motor starts turning.

2. The lower pressure plate sensor is

not activated within 8 seconds of the

pressure plate motor starting to turn

even though the upper pressure

plate sensor is de-activated.

3. The upper pressure plate sensor is

not activated for more than 8

seconds after the pressure plate

motor starts to turn even though the

lower pressure plate sensor is deactivated.

E-13 1. During scanner initialization:

The home position sensor

remains activated for more than 4

seconds.

The home position sensor is not

activated within 2 seconds.

2. The home position sensor is not

activated within 7 seconds when the

scanner returns after finishing

making the master or scanning.

Pressure plate drive

mechanism malfunction.

1) Defective home position

sensor

2) Scanner motor lock

E-14 EMF sorter communication error.

Sorters

E-21 The 1st transport motor speed is

abnormal.

E-26 The 1st sorter helical wheel H.P.

sensor status does not change even if

the bin shift motor drive signal is

applied.

The bin shift motor rotation sensor

status does not change even if the bin

shift motor drive signal is applied.

E-27 The 1st sorter jogger bar H.P. sensor

status does not change even if the

jogger bar motor drive signal is applied.

1) Defective 1st transport

motor

2) Defective 1st transport

motor rotation sensor.

1) Defective bin shift motor

2) Defective helical wheel

H.P. sensor

3) Defective bin shift motor

rotation sensor

1) Defective jogger bar

motor

2) Defective jogger bar H.P.

sensor

4-8

Page 49

29 January 1998 SERVICE TABLES

Code Problem Possible Causes

E-28 The 1st sorter staple position switch or

staple unit movement switch status

does not change even if the staple unit

shift motor drive signal is applied.

E-29 The 1st transport sort mode position

sensor or the 1st transport non-sort

mode position sensor status does not

change even if the delivery table motor

drive signal is applied.

E-34 The 2nd transport motor rotation sensor

speed is abnormal.

E-36 The 2nd sorter helical wheel H.P.

sensor status does not change even if

the bin shift motor drive signal is

applied.

The bin shift motor rotation sensor

status does not change even if the bin

shift motor drive signal is applied.

E-37 The 2nd sorter jogger bar H.P. sensor

status does not change even if the

jogger bar motor drive signal is applied.

E-38 The 2nd sorter staple position sensor or

staple unit movement sensor status

does not change even if the staple unit

shift motor drive signal is applied.

1) Defective staple unit shift

motor

2) Defective jogger bar H.P.

sensor

3) Defective staple unit

movement switch

1) Defective 1st transport

sort mode position

sensor

2) Defective 1st transport

non-sort position sensor

3) Defective delivery table

motor

1) Defective 2nd transport

motor

2) Defective 2nd transport

motor rotation sensor

1) Defective bin shift motor

2) Defective helical wheel

H.P. sensor

3) Defective bin shift motor

rotation sensor

1) Defective jogger bar

motor

2) Defective jogger bar H.P.

sensor

1) Defective staple unit shift

motor

2) Defective jogger bar H.P.

sensor

3) Defective staple unit

movement switch

Tables

Service

4-9

Page 50

SERVICE TABLES 29 January 1998

4.2.3 DIP SWITCHES, LEDS, VRS, TPS (ON THE MAIN CONTROL

PCB)

DIP Switches

DIP Switch Function Remarks

DIP SW101 Do not use. Must be off at all times.

DPS 102 LCD Display

123

ON ON OFF English

OFF OFF ON German

ON OFF ON French

OFF ON ON Spanish

ON ON ON Italian

OFF OFF OFF For Japanese Machines

ON OFF OFF

OFF ON OFF

DPS 102 ON OFF

4 DFII (Type 50) Also see SP8. DFI

5 Print and master counters

increment by two counts when

the A3 drum is used (NRG

setting). Also, see SP86.

6 Inch version A4 version

NOTE:

The DF setting can be changed using SP8. When the memory clear

Print and master counters

increment by one regardless of

the drum size.

(SP60) is performed, the SP8 setting depends on the DPS102-4

setting. Later, if the SP mode is changed but not the DPS, the SP

mode setting takes priority. This note also applies to DPS 102-5.

Photodiodes

LED Component Remarks

LED101 1st Paper Exit Sensor When paper is detected, the LED lights.

LED102 Drum Master Sensor When a master is on the drum, the LED

lights.

LED103 2nd Paper Exit

Sensor

LED104 Master Eject Sensor When a master is under the master eject

LED105 Ink Detection When ink is present, the LED lights.

LED106 Main Motor When the main motor turns on, the LED

When paper is detected, the LED lights.

sensor, the LED lights.

lights.

4-10

Page 51

29 January 1998 SERVICE TABLES

VRs

VR Function

VR101 1st Paper Exit Sensor Adjustment

VR102 Drum Master Sensor Adjustment

VR103 2nd Paper Exit Sensor Adjustment

VR104 Master Eject Sensor Adjustment

VR105 Adjustment for Drum Speed 5 (120 rpm)

VR106 Adjustment for Drum Speed 1 (60 rpm)

TPs

TP Function

TP101 1st Paper Exit Sensor Voltage

TP102 Drum Master Sensor Voltage

TP103 2nd Paper Exit Sensor Voltage

TP104 Master Eject Sensor Voltage

TP105 Ink Detection Voltage

TP106 Drum Rotation Sensor Voltage

TP107 GND

Tables

Service

4.2.4 EXPECTED LIFE OF PARTS

Section Part Description Expected Life

Scanner Xenon Lamp 15,000 originals

Master Feed/Master

Making

Drum Drum Cloth Screen 2 years or 1,200,000 prints

Paper Feed Paper Feed Rubber Side Plate 2 years or 1,200,000 prints

Printing Press Roller 2 years or 1,200,000 prints

Delivery Transport Belt 2 years or 1,200,000 prints

Thermal Head

Reverse Roller

Platen Roller 30,000 masters

Upper Master Feed Roller 1 year or 30,000 masters

Paper Feed Roller 6 months or 300,000 prints

Upper Separation Roller 1 year or 600,000 prints

Lower Separation Roller 2,000,000 prints

2nd Feed Roller Brake Belt 1,000,000 prints

2nd Feed Roller Gear 1,000,000 prints

Separation Plate 1 year or 600,000 prints

30,000 masters

30,000 masters

4-11

Page 52

SERVICE TABLES 29 January 1998

4.2.5 SPECIAL TOOLS

Description Part Number

Test Chart R-21 99992131

Resolution Chart A0129110

Drum Gauge C2009001

Image Shifting Gauge C2009002

4-12

Page 53

29 January 1998 SERVICE PROGRAM MODE

4.3 SERVICE PROGRAM MODE

4.3.1 SERVICE PROGRAM MODE OPERATION

The service program (SP) mode is used to check electrical data, change modes,

or change adjustment values.

Service Program Mode Access Procedure (for engineers)

All service program modes can be accessed with this procedure.

1. Press the following keys on the operation panel in the following order:

Case 1:

a) Clear Modes key

b) Clear key

c) Combine 2 Originals key

d) Enter key

Case 2:

a) Turn off the power switch

b) Press the Enter key, Stop key, and Clear key simultaneously

c) Turn on the power

Tables

Service

2. The following is displayed on the LCD when the SP mode is accessed.

SP—MODE

PROGRAM No. 0

3. Using the number keys, enter the desired SP mode number (listed in the

service program table.)

NOTE:

4. To cancel the SP mode, press the Clear Modes key.

The SP mode number can be shifted up or down by pressing the Zoom

key ("+" or "-").

4-13

Page 54

SERVICE PROGRAM MODE 29 January 1998

Service Program Mode Access Procedure (for users)

This procedure allows users to access only the service program modes that are

marked with an asterisk in the service program table.

1. Press the following keys on the operation panel in the following order:

a) Clear Modes key

b) Clear key

c) Enter key

2. The following is displayed on the LCD when the SP mode is accessed.

SP—MODE

PROGRAM No. 0

3. Using the number keys, enter the desired SP mode number (listed in the

service program table).

4. To cancel the SP mode, press the Clear Modes key.

Change Adjustment Values or Modes

1. After entering the desired SP mode number, press the Enter key. The current

value or mode will be displayed on the LCD (at the end of the second line).

2. Enter the desired value or mode using the number keys (listed in the service

program table).

Use the Memory/Class key to toggle between + and -.

3. Press the Enter key to store the desired value or mode.

4. To cancel the SP mode, press the Clear Modes key.

4-14

Page 55

29 January 1998 SERVICE PROGRAM MODE

4.3.2 SERVICE PROGRAM TABLE

*: Accessible by a customer<_>**: Can be registered in CS mode

j

: A4 version i: LT version

No. Display Function Data Factory

Setting

1 On line Enables On Line key

operation.

2 FDC Type 10 Used only in Japan 0: No

3 Key Counter Enables key counter

operation.

4 Key Card Used only in Japan. 0: No

5 EMF Sorter Selects the number of

sorters.

7-1 DS/TS Sorter Enables TS20A/B

operation.

7-2 Auto Reset Time Specifies the auto

reset time.

8 ADF Select Informs the machine if

DF Unit Type 50 is

installed.

*10. Min. Print Limits the minimum

print quantity that can

be entered.

*11 Max. Print Limits the maximum

print quantity that can

be entered.

*12

j

: A4 o A3

Mag. Ratio

i

HLT o LG

Mag. Ratio

*13

j

: A4 o B4

Mag. Ratio

i

LT o DLT

Mag. Ratio

*14

j

: B4 o A3

Mag. Ratio

i

LG o DLT

Mag. Ratio

*15 Full Size Adjusts the full size

Adjusts the fixed

magnification ratio.

j

: From A4 to A3

i

: From 51/2" x 81/2"

to 81/2" x 14"

Adjusts the fixed

magnification ratio.

j

: From A4 to B4

i

From 51/2" x 81/2"

to 11" x 17"

Adjusts the fixed

magnification ratio.

j

: From B4 to A3

i

From 81/2" x 14" to

11" x 17"

magnification ratio.

0: No

1: Yes

1: Yes

0: No

1: Yes

1: Yes

0: No sorters

1, 2, 3, 4, or 5:

Sorters present

0: No

1: Yes

0: No

1-5: min.

0: DF1 (or no

DF)

1: DF2 (type 50)

0 to 9999 0

0 to 9999 9999

50 to 200%

50 to 200%

50 to 200%

50 to 200% 100%

0

0 Keep at 0.

0

0

0 Input 1 to 5 to

0 If "1" is selected

0

0

j

: 141%

i

: 155%

j

: 122%

i

: 129%

j

: 115%

i

: 121%

Comments

indicate the

number of

sorters.

in 7-1, the

machine goes to

Auto Reset

Time setting

mode.

Tables

Service

4-15

Page 56

SERVICE PROGRAM MODE 29 January 1998

No. Display Function Data Factory

Setting

*16 Page Margin Adjusts the create

margin magnification

ratio.

*17

*18

*19

*20 Buzzer On Turns the beeper ON

*21 Prints/Master

22 Read Image Area Not used - 0 Not used

*23 Online Paper

25 Sorter Feed

26-1 Sorter Priority Determines the sorter

26-2 0: 1st/2nd

: A3 o B4

j

Mag. Ratio

: LG o LT

i

Mag. Ratio

: B4 o A4

j

Mag. Ratio

: ** o LT

i

Mag. Ratio

: A3 o A4

j

Mag. Ratio

: DLT o LT

i

Mag. Ratio

Cost

Size

Speed

1: 2nd/1st

2. 1st

3. 2nd

Adjusts the fixed

magnification ratio.

: From A3 to B4

j

: From 81/2" x 14" to

i

81/2" x 11"

Adjusts the fixed

magnification ratio.

: From B4 to A4

j

: From 11" x 15" to

i

81/2" x 11"

Adjusts the fixed

magnification ratio.

: From A3 to A4

j

: From 11" x 17" to

i

81/2" x 11"

or OFF

Adjusts the cost ratio

of masters to prints for

accounting purposes.

Used only in Japan 0: A6

Determines the

transport belt speed in

the TS sorter.

priority.

Determines the sorter

priority when "1" is

selected in SP26-1.

50 to 200% 93%

50 to 200%

50 to 200%

50 to 200%

0: No

1: Yes

0 to 50 0 The set number

1: A5

0: -20%

1: -15%

2: -10%

3: -5%

4: +5%

5: +10%

6: +15%

7: +20%

8: +25%

9: +30%

10: 0%

0: Normal

1: Others

0: 1st sorter first

1: 2nd sorter first

2: 1st sorter only

3: 2nd sorter only

: 87%

j

: 77%

i

: 82%

j

: 74%

i

: 71%

j

: 65%

i

0

0 Not used

10

0

0 If "2" or "3" is

Comments

(0 to 50) is

automatically

added to the key

counter each

time a master is

used.

selected, only

one sorter is

used.

4-16

Page 57

29 January 1998 SERVICE PROGRAM MODE

No. Display Function Data Factory

Setting

27 Auto Staple Off Specifies whether the

staple unit is disabled.

28 Max. Print/Bin Specifies the

sort/stack number

limit.

**29 Pht Bckgrnd

Correct

30 Sub Scan Mag.

Adjust

31 MTF Level Adjusts the MTF level. 0: Low

32 Image Density

Rank

33 Lead Edge

Margin

34 Line/Pht Mode

Level

34-1 Contrast Select the contrast

Determines whether

the original

background correction

is done in Photo mode.

Adjusts the sub-scan

magnification.

In line mode, adjusts

the image density

level.

Adjusts the lead edge

margin.

Use to adjust the

threshold level for

separating line areas

and photo areas in the

Line/Photo mode.

setting for changing

the threshold for line

and photo.

0: Staple mode

enabled.

1: Staple mode

disabled.

1 to 50 sheets 50

0: Correction is

not done.

1: Correction is

done.

-1.9 to +1.9% (0) The factory

1: Standard

2: High

3: Maximum

0: Light

1: Standard

2: Dark

4 to 10 mm 5 mm

0: Change the

threshold setting

1: Returns the

setting to default

0: Standard

1: Light

2: Dark

0

0

1

1

0 If "0" is selected

Comments

setting depends

on the machine.

in this mode, the

machine goes to

34-1.

Depending on

the number

selected in this

mode, the

machine goes to

34-1-0, 34-1-2,

or 34-1-3.

Tables

Service

34-1-0 Std

(setting for the

Standard tone)

Adjust the threshold

level to distinguish line

and photo areas for

the Standard tone

setting in the

Line/Photo mode.

There are four

numbers and each

represents the

threshold value for an

image density. Input

the required value for

the one that is blinking,

then press Enter to

move the next one.

4-17

Lt: 0 to 63

Std: 0 to 63

Dk: 0 to 63

Dkr: 0 to 63

Lt: 18

Std: 16

Dk: 22

Dkr: 22

If "0" is selected

in 34-1, the

machine goes to

this mode.

Page 58

SERVICE PROGRAM MODE 29 January 1998

No. Display Function Data Factory

Setting

34-1-1 Lt

(setting for the

Light tone)

34-1-2 Dk

(setting for the

Dark tone)

35 Head Energy

Adjust

35-1 Head Energy

Adjust (Normal)

35-2 Head Energy

Adjust (Economy)

36 Sub Scan Mag.

Adjust (ADF)

37 Shadow Erase

Level

37-0 Line Adjusts the shadow

37-1 Contrast (Photo) Selects the contrast

Adjust the threshold

level to distinguish line

and photo areas for

the Light tone setting

in the Line/Photo

mode.

Adjust the threshold

level to distinguish line

and photo areas for

the Dark tone setting

in the Line/Photo

mode.

Selects normal mode

or Economy mode for

changing the thermal

head energy.

Adjusts the thermal

head energy for the

normal mode.

Adjusts the thermal

head energy for the

Economy mode.

Adjusts the ADF subscan magnification.

Selects the image

mode for adjusting the

threshold level for

shadow erase.

erase threshold level

for Line mode.

There are four

numbers and each

represents the

threshold value for an

image density. Input

the required value for

the one that is blinking,

then press Enter to

move the next one.

setting for adjusting

the threshold level for

shadow erase in Photo

mode.

Lt: 0 to 63

Std: 0 to 63

Dk: 0 to 63

Dkr: 0 to 63

Lt: 0 to 63

Std: 0 to 63

Dk: 0 to 63

Dkr: 0 to 63

0: Normal mode

1: Economy

mode

0 to -99 (%) 7

0 to -99 (%) 30

-1.9 to 1.9 % 0 0.1 % steps

0: Line

1: Photo

2: Returns the

settings to the

defaults

Lt: 0 to 63

Std: 0 to 63

Dk: 0 to 63

Dkr: 0 to 63

0: Standard

1: Light

2:Dark

Lt: 16

Std: 14

Dk: 14

Dkr: 14

Lt: 8

Std: 10

Dk: 14

Dkr: 14

Lt: 27

Std: 19

Dk: 15

Dkr: 10

Comments

Depending on

the number

selected in this

mode, the

machine goes to

35-1 or 35-2.

If "0" or "1" is

selected in this

mode, the

machine goes to

37-0 or 37-1.

Depending on

the number

selected in this

mode, the

machine goes to

37-1-0, 37-1-1

or 37-1-2.

4-18

Page 59

29 January 1998 SERVICE PROGRAM MODE

No. Display Function Data Factory

Setting

37-1-0 Std (setting for

the normal tone)

37-1-1 Lt (setting for the

light tone)

37-1-2 Dk (setting for

the dark tone)

38 ADF Scan Line

Adjust

39 Image Center

Adjustment

39-0 Image Center

Adjustment:

Scanner

39-1 Image Center

Adjustment:

ADF

*40 Original Specifies the image

*41 Image Density Specifies the image

42 Print Speed Specifies the printing

*43 Auto Cycle Mode Specifies whether Auto

Adjusts the shadow

erase threshold for the

Normal contrast

setting in Photo mode.

There are four

numbers and each

represents the

threshold value for an

image density. Input

the required value for

the one that is blinking,

then press Enter to

move the next one.

Adjusts the shadow

erase threshold for the

Light Tone contrast

setting in Photo mode.

Adjusts the threshold

value for shadow

erase of the Dark tone

contrast in Photo

mode.

Adjusts the ADF

scanning start

position.

Adjusts the center

position of copies in

the ADF and platen

modes.

Adjusts the center

position of copies in

platen mode.

Adjusts the center

position of copies in

ADF mode.

mode at power-up.

density at power-up.

speed at power-up.

Cycle mode is selected

at power-up.

Lt: 0 to 63

Std: 0 to 63

Dk: 0 to 63

Dkr: 0 to 63

Lt: 0 to 63

Std: 0 to 63

Dk: 0 to 63

Dkr: 0 to 63

Lt: 0 to 63

Std: 0 to 63

Dk: 0 to 63

Dkr: 0 to 63

-4.9 to 4.9 mm 0 0.1 mm steps

0: Scanner

1: ADF

-4.9 to 4.9 mm 0 0.1 mm steps

-4.9 to 4.9 mm 0 0.1 mm steps

0: Photo

1: Line

2: Line/Photo

0: Light

1: Standard

2: Dark

3: Darker

0: 60 rpm

1: 75 rpm

2: 90 rpm

3: 105 rpm

4: 120 rpm

0: No

1: Yes

Lt: 24

Std: 15

Dk: 11

Dkr: 4

Lt: 31

Std: 24

Dk: 15

Dkr: 9

Lt: 12

Std: 7

Dk: 5

Dkr: 2

Comments

See remarks

(1).

0 See remarks

(2).

1

1

2

0

Tables

Service

4-19

Page 60

SERVICE PROGRAM MODE 29 January 1998

No. Display Function Data Factory

Setting

*44 Memory/Class

Mode

45 Std. Image

Position

*46 Make Up Specifies the initial

47 Contrast Specifies the initial

48 Photo Specifies the initial

*50 Directional Mag.

Mode

*51 Clear Multi Copy Resets the Combine 2

52 Compress W

Start Key

60 Clear All Memory Returns all SP modes

61 Clear Memory /

Except SP 30, 36,

38, 39

70 Original Feed

Jam (A)

Specifies the initial job

memory feature

(Memory or Class

mode) at power-up.

Specifies the image

position at power-up

make-up background

pattern when the

Image Make-up mode

is selected.

contrast when the

Photo mode is

selected.

screen when the Photo

mode is selected.

Selects which is used

to input directional

magnifications:

reproduction ratios or

vertical and horizontal

lengths.

originals or Combined

Print function (if it has

been set) after the

master making

process.

The master

compression for the

master eject box is

carried out always

when the Master

Making key is pressed.

to the default settings.

Returns all SP modes

to the default settings

except for SP No. 30,

36, 38 and 39

Displays the total