Page 1

CONTENTS

1. OVERALL MACHINE INFORMATION

1. SPECIFICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. GUIDE TO COMPONENTS AND THEIR FUNCTION . . . . . . . . . . . . 1-4

3. OPERATION PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

4. PRINTING PROCESS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

5. MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . 1-11

6. ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . 1-12

7. ELECTRICAL COMPONENT DESCRIPTIONS. . . . . . . . . . . . . . . . 1-16

8. DRIVE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Page 2

CONTENTS

2. SECTIONAL DESCRIPTION

1. MASTER EJECT SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.1 OVERALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.2 MASTER EJECT ROLLER ROTATING MECHANISM . . . . . . . . . . . . . . . . . . . . 2-2

1.3 MASTER EJECT ROLLER DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . 2-3

1.4 MASTER EJECT CLAMPER MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

1.5 PRESSURE PLATE UP/DOWN MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

1.6 ELECTRICAL TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

1.7 CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2. SCANNER/OPTICS SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.1 OVERALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.2 ORIGINAL FEED MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.3 ORIGINAL FEED DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.4 ORIGINAL SIZE DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.5 ELECTRICAL TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.6 CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

3. MASTER FEED SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

3.1 OVERALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

3.2 MASTER CLAMPER OPENING MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

3.3 MASTER FEEDING MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

3.4 MASTER WRAPPING MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

3.5 CUTTER MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

3.6 ELECTRICAL TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

3.7 CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

4. PAPER FEED SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

4.1 OVERALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

4.2 PAPER FEED ROLLER/UPPER SEPARATION ROLLER MECHANISM . . . . . 2-40

4.3 FEED ROLLER PRESSURE MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Page 3

4.4 PAPER SEPARATION MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

4.5 SEPARATION ROLLER PRESSURE RELEASE MECHANISM . . . . . . . . . . . . 2-45

4.6 SEPARATION PLATE PRESSURE RELEASE MECHANISM. . . . . . . . . . . . . . 2-46

4.7 PAPER RETURN MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

4.8 SECOND FEED ROLLER MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

4.9 PAPER TABLE SIDE ADJUSTMENT MECHANISM . . . . . . . . . . . . . . . . . . . . . 2-51

4.10 PAPER TABLE UP/DOWN MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

4.11 PAPER SIZE DETECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

4.12 ELECTRICAL TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-57

4.13 CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

5. PRINTING SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-59

5.1 OVERALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-59

5.2 PAPER DETECTING AND PRINTING PRESSURE ON/OFF MECHANISM. . . 2-60

5.3 PRINTING PRESSURE ON/OFF MECHANISM FOR A4/LT DRUM . . . . . . . . . 2-61

5.4 PRINTING PRESSURE RELEASE MECHANISM. . . . . . . . . . . . . . . . . . . . . . . 2-62

5.5 CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-63

6. DRUM SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

6.1 OVERALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

6.2 DRUM ROTATION MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-65

6.3 DRUM LOCK MECHANISM 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-66

6.4 DRUM LOCK MECHANISM 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-67

6.5 DRUM LOCK MECHANISM 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-68

6.6 DRUM LOCK MECHANISM 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-69

6.7 INK SUPPLY MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-70

6.8 INK KNEADING MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-71

6.9 DRUM MASTER DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-72

6.10 DRUM TYPE IDENTIFICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-73

6.11 INK DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-74

6.12 CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-76

7. DELIVERY SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-78

7.1 OVERALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-78

7.2 EXIT PAWL DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-79

Page 4

7.3 VACUUM UNIT DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-80

7.4 PAPER EXIT PAWL AIR PUMP MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . 2-81

7.5 WING GUIDE MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-82

7.6 PAPER DELIVERY TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-83

7.6.1 Master Eject Unit Lock Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-83

7.6.2 Paper Delivery Table Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-84

7.7 CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-85

7.8 ELECTRICAL TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-86

8. IMAGE POSITIONING SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-88

8.1 OVERALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-88

8.2 IMAGE POSITIONING MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-89

8.3 CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-90

9. IMAGE PROCESSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-92

9.1 CCD (CHARGE COUPLED DEVICE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-92

9.2 A/D CONVERSION PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-94

9.2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-94

9.2.2 Inversion and Amplification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-95

9.2.3 A/D Conversion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-96

9.2.4 Reference Data Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-99

9.3 IMAGE PROCESSING PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-105

9.3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-105

9.3.2 MTF Correction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-107

9.3.3 Main Scan Magnification and Ima ge Shi ft Proc essing . . . . . . . . . . . . . . . 2-110

9.3.4 Binary Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-112

9.3.5 Photo Data Compensation Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-113

9.3.6 Half-tone Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-115

9.3.7 Make-up Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-120

9.4 PLOTTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-133

9.4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-133

9.4.2 Thermal Head Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-135

9.4.3 Thermal Head Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-136

9.4.4 Thermal Head Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-139

Page 5

10. OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-141

10.1 INTERLOCK SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-141

10.2 MONITOR INDICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-142

10.2.1 Cover Open Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-142

10.2.2 Key Counter Indicator: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-142

10.2.3 Master Eject Box Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-143

10.2.4 Ink Supply Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-143

10.2.5 Master Supply Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-144

10.2.6 Paper Supply Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-144

10.2.7 Master Eject Error Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-145

10.2.8 Paper Misfeed Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-145

10.2.9 Paper Delivery Error Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-145

10.2.10 Paper Wrap Message 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-146

10.2.11 Paper Wrap Message 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-146

10.2.12 Master Clamp Error Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-146

10.2.13 Original Misfeed Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-147

10.2.14 Other Guidance Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-148

10.2.15 Other Monitor Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-149

10.3 MASTER PLOTTING AND PRINTING AREA . . . . . . . . . . . . . . . . . . . . . . . . 2-150

10.4 PAPER MISFEED DETECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-154

10.5 PROTECTION FROM OVERCURRENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-155

Page 6

CONTENTS

3. INSTALLATION

1. INSTALLATION REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.1 ENVIRONMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.2 ACCESS TO THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1.3 POWER SOURCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

2. ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3. INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.1 MAIN BODY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2 PAPER CASSETTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.3 COLOR DRUM UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.4 KEY COUNTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Page 7

CONTENTS

4. SERVICE TABLES

1. SERVICE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.1 MAINTENANCE TABLES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.1.1 Lubrication Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.1.2 User’s Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

1.1.3 Table of Periodic Inspection (every 6 months) . . . . . . . . . . . . . . . . . . . . . . . 4-4

1.1.4 Table of Periodic Inspection (every 12 months) . . . . . . . . . . . . . . . . . . . . . . 4-4

1.2 TABLE OF SERVICE CALL INDICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

1.3 TABLE OF DIP SW, LED, VR, TP (ON THE MAIN CONTROL PCB) . . . . . . . . . 4-8

1.3.1 DIP SW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

1.3.2 Photodiode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

1.3.3 VR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

1.3.4 TP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

1.4 EXPECTED LIFE of PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

1.5 SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

2. SERVICE PROGRAM MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

2.1 SERVICE PROGRAM MODE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

2.1.1 Service Program Mo de Access Procedure (for engineers). . . . . . . . . . . . . 4-11

2.1.2 Service Program Mo de Access Procedure (for user s) . . . . . . . . . . . . . . . . 4-11

2.1.3 Change Adjustment Values or Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

2.2 SERVICE PROGRAM TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

2.3 THERMAL HEAD TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

2.4 COMMAND SHEET CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

2.5 INPUT/OUTPUT CHECK MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

2.5.1 Input Check Mode Access Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

2.5.2 Output Check Mode Access Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

2.5.3 Input Check Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

2.5.4 Output Check Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Page 8

2.6 USER CODE MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

2.6.1 User Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

2.6.2 How To Use a User Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Page 9

CONTENTS

5. REPLACEMENT AND ADJUSTMENT

1. EXTERIOR SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.1 EXTERIOR COVERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

2. SCANNER SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

2.1 ADJUSTING THE TENSION OF THE ORIGINAL FEED ROLLER DRIVE BELT 5-3

2.2 ADJUSTING THE ORIGINAL PRESSURE SOLENOID. . . . . . . . . . . . . . . . . . . . 5-4

2.3 EXPOSURE GLASS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

2.4 EXPOSURE LAMP/HEATER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

2.5 ORIGINAL REGISTRATION SENSOR/2ND ORIGINAL SENSOR . . . . . . . . . . . 5-7

2.6 ORIGINAL FEED ROLLERS/PULL-OUT ROLLERS . . . . . . . . . . . . . . . . . . . . . . 5-8

3. OPTICS SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

3.1 OVER VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

3.2 ADJUSTING THE REDUCTION RATIO (MOIRE ADJUSTMENT) . . . . . . . . . . 5-11

3.3 ADJUSTING THE FOCUS (MTF ADJUSTMENT) . . . . . . . . . . . . . . . . . . . . . . . 5-12

3.4 ADJUSTING THE READING START POSITION IN THE MAIN SCAN

DIRECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

3.5 ADJUSTING THE SCAN LINE POSITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

3.6 ADJUSTING THE SHADING PLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

3.7 ADJUSTING THE WHITE LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

4. MASTER FEED SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

4.1 ADJUSTING THE THERMAL HEAD VOLTAGE . . . . . . . . . . . . . . . . . . . . . . . . 5-17

4.2 ADJUSTING THE BELT TENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

4.3 ADJUSTING THE RIGHT AND LEFT CUTTER SWITCHES. . . . . . . . . . . . . . . 5-19

4.4 CUTTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

4.5 THERMAL HEAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

4.6 THERMAL HEAD DRIVE PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5. MASTER EJECT SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

5.1 ADJUSTING THE MASTER EJECT SENSOR. . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Page 10

5.2 ADJUSTING THE MASTER EJECT SOLENOID . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5.3 ADJUSTING THE AIR KNIFE MOTOR SAFETY SWITCH . . . . . . . . . . . . . . . . 5-25

5.4 MASTER EJECT UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.5 MASTER EJECT SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

5.6 MASTER EJECT BELT/ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

6. PAPER FEED SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

6.1 ADJUSTING THE PAPER TABLE OPEN SWITCH . . . . . . . . . . . . . . . . . . . . . . 5-29

6.2 ADJUSTING THE PAPER TABLE HEIGHT. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

6.3 ADJUSTING THE SEPARATION PLATE RELEASE SOLENOID . . . . . . . . . . . 5-31

6.4 ADJUSTING THE PAPER FEED ROLLER PRESSURE . . . . . . . . . . . . . . . . . . 5-33

6.5 ADJUSTING THE LOWER GUIDE PLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

6.6 ADJUSTING THE UPPER SECOND FEED ROLLER . . . . . . . . . . . . . . . . . . . . 5-36

6.7 ADJUSTING THE SEPARATION PLATE PRESSURE . . . . . . . . . . . . . . . . . . . 5-37

6.8 ADJUSTING THE FEED-LENGTH OF THE PAPER FEED ROLLER . . . . . . . 5-38

6.9 ADJUSTING THE CLEARANCE OF THE PAPER FEED SECTOR GEAR

STOPPER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

6.10 ADJUSTING THE CLEARANCE OF THE SECOND FEED ROLLER SECTOR

STOPPER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-40

6.11 ADJUSTING THE FEED-LENGTH OF THE SECOND FEED ROLLER . . . . . 5-41

6.12 ADJUSTING THE FEED TIMING OF THE SECOND FEED ROLLER . . . . . . 5-42

6.13 PAPER FEED ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

6.14 PAPER FEED ROLLER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-45

6.15 UPPER SEPARATION ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-46

6.16 SEPARATION PLATE RELEASE SOLENOID AND PAPER RETURN MOTOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

6.17 SEPARATION PLATE/LOWER SEPARATION ROLLER . . . . . . . . . . . . . . . . 5-48

7. PRINTING SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-49

7.1 ADJUSTING THE CLEARANCE OF THE PAPER DETECTING ARM . . . . . . . 5-49

7.2 ADJUSTING THE PRESS ROLLER POSITION 1 . . . . . . . . . . . . . . . . . . . . . . . 5-50

7.3 ADJUSTING THE PRESS ROLLER POSITION 2 (FOR THE A4/LT DRUM) . . 5-51

7.4 ADJUSTING THE PRESSURE TIMING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-52

7.5 ADJUSTING THE PRINTING PRESSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-53

7.6 ADJUSTING THE CLEARANCE OF THE PRINTING PRESSURE SOLENOID 5-54

7.7 PRESS ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-55

Page 11

8. DRUM SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-56

8.1 ADJUSTING THE MAIN DRIVE BELT TENSION . . . . . . . . . . . . . . . . . . . . . . . 5-56

8.2 ADJUSTING THE DRUM MASTER DETECTION SENSOR . . . . . . . . . . . . . . . 5-57

8.3 ADJUSTING THE PRINTING SPEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-58

8.4 ADJUSTING THE DRUM STOPPER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-59

8.5 ADJUSTING THE DRUM LOCK SOLENOID . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-60

8.6 ADJUSTING THE MASTER FEED CLAMPER CAM . . . . . . . . . . . . . . . . . . . . . 5-61

8.7 ADJUSTING THE MASTER EJECT CLAMPER CAM . . . . . . . . . . . . . . . . . . . . 5-62

8.8 ADJUSTING THE POSITION OF THE INK DETECTING PIN. . . . . . . . . . . . . . 5-63

8.9 ADJUSTING THE CLEARANCE OF THE DOCTOR ROLLER . . . . . . . . . . . . . 5-64

8.10 ADJUSTING THE INK ROLLER WITH THE DRUM UNIT . . . . . . . . . . . . . . . . 5-65

8.11 ADJUSTING THE POSITION OF THE INK SUPPLY SOLENOID. . . . . . . . . . 5-66

8.12 ADJUSTING INK DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-67

8.13 SCREEN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-68

8.14 DRUM DRIVE BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-69

9. DELIVERY SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-73

9.1 ADJUSTING THE FIRST PAPER EXIT SENSOR . . . . . . . . . . . . . . . . . . . . . . 5-73

9.2 ADJUSTING THE SECOND PAPER EXIT SENSOR . . . . . . . . . . . . . . . . . . . . 5-74

9.3 ADJUSTING THE CLEARANCE OF THE EXIT PAWL . . . . . . . . . . . . . . . . . . . 5-75

9.4 ADJUSTING THE EXIT PAWL TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-76

9.5 ADJUSTING THE PAPER EXIT PAWL AIR PUMP . . . . . . . . . . . . . . . . . . . . . 5-77

9.6 TRANSPORT UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-78

9.7 DELIVERY BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-79

9.8 TRANSPORT VACUUM FAN AND PAPER EXIT SENSORS . . . . . . . . . . . . . . 5-80

10. IMAGE POSITIONING SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . 5-81

10.1 ADJUSTING THE IMAGE POSITION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-81

Page 12

CONTENTS

6. TROUBLESHOOTING

1. ELECTRICAL COMPONENT TROUBLE. . . . . . . . . . . . . . . . . . . . . . 6-1

2. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

2.1 IMAGE TROUBLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

2.2 PAPER FEED TROUBLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Page 13

CONTENTS

7. ELECTRICAL DATA

1. INK DETECTING CIRCUIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

2. CCD CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

3. TAPE MARKER CIRCUIT (OPTION). . . . . . . . . . . . . . . . . . . . . . . . . 7-3

4. PAPER SIZE DETECTION CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

5. AC DRIVE CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

6. POWER SUPPLY CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7. THERMAL HEAD DRIVE CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

8. A/D CONVERTER CIRCUIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

9. MAIN BOARD CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

10. OPERATION PANEL CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Page 14

CONTENTS

8. TAPE MARKER

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. BASIC OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

2.1 OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

2.2 DRIVE AND CUTTING MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

2.3 MANUAL CUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

3. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

3.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

3.2 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

4. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 8-10

4.1 CUTTER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

4.2 CUTTER HOME POSITION SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . 8-11

4.3 TAPE CUT LENGTH ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Page 15

SECTION 1

OVERALL MACHINE INFORMATION

Page 16

1 December 1993

1. SPECIFICATIONS

Configuration: Desk top

Master Processing: Digital

Printing Process: Fully automatic one drum stencil system

Original Type: Sheet

Original Size: Maximum 307 mm x 432 mm (12.0" x 17.0")

Minimum 90 mm x 140 mm (3.6" x 5.5")

Reproduction Ratios: LT version 93%, 77%, 74%, 65%

A4 version 93%, 87%, 82%, 71%

Enlargement Ratio: LT version 155%, 129%, 121%

A4 version 141%, 122%, 115%

Image Mode: Line/Photo

Color Printing: Drum unit replacement system

(red, blue, green and brown)

Master Feed/Eject: Roll master automatic feed/eject

Leading Edge Margin: 10 mm (0.39")

Print Paper Size: Maximum 325 mm x 447 mm (12.7" x 17.5")

Minimum 90 mm x 148 mm (3.6" x 5.8")

Printing Area: Maximum 290 mm x 405 mm (11.4" x 15.9") at

20°C/65% RH

Print Paper Weight: 50 g/m

2

to 215 g/m2 (13.3 lb to 57.19 lb)

Printing Speed: 40, 60, 80, 100, 120 sheets/minute (5 steps)

First Print Time: 39 sec./A3/DLT (with "L" drum)

36 sec./A4/LT (with "L" drum)

29 sec./A4/LT (with "S" drum)

Paper Feed Table Capacity: Table mode: 1,000 sheets (66 g/m

Cassette mode: 500 sheets (66 g/m

2

Paper Delivery Table

500 sheets (66 g/m

, 17.6 lb)

2

, 17.6 lb)

2

, 17.6 lb)

Capacity:

Power Source: 110 V, 60 Hz, 5.5 A (for Taiwan)

120 V, 60 Hz, 4.8 A (for N.A.)

220/240 V, 50/60 Hz, 2.7 A (for Eu., Asia)

1-2

Page 17

1 December 1993

Power Consumption: 110 V, 60 Hz, 385 W (for Taiwan)

120 V, 60 Hz, 385 W (for N.A.)

220/240 V, 50/60 Hz, 443 W (for Eu., Asia)

Weight: 110 V version: 110 kg (242.5 lb)

120 V version: 110 kg (242.5 lb)

220/240 V version: 116 kg (255.7 lb)

Cabinet: 23.5 kg (51.8 lb)

Dimensions (W x D x H): Stored: 735 x 698 x 599 mm

(29.0" x 27.5" x 23.5")

Set up: 1331 x 698 x 616 mm

(52.4" x 27.5" x 24.2")

Cassette mode: 1386 x 698 x 616 mm

(54.6" x 27.5" x 24.2")

Cabinet: 719 x 630 x 426 mm

(28.3" x 24.8" x 16.8")

ADF Original Capacity: 20 sheets (66 g/m

2

, 17.6 lb) or 1.8 mm height

Original Scanning Time: 3 ms/1 line

Original Guide Movement

90 mm to 310 mm (3.54" to 12.2")

distance:

Original Feed Speed: 21.4 mm/sec (while master processing)

87.8 mm/sec (not master processing)

Pixel Density: 400 dpi

Master Eject Box Capacity: 50 masters with "L" drum

70 masters with "S" drum

Paper Separation: Friction roller/center separation system

Feed Table Side Plate

88 mm to 336 mm (3.46" to 13.2")

Movement Distance:

Paper Feed Roller Pressure: Normal position 300 g

Thick paper position 600 g

Separation Roller Pressure: Normal position 125 g

Weak position 50 g

Separation Plate Pressure: Weak 10 g

Normal 20 g

Strong 1 40 g

Strong 2 60 g

Side Registration:

Vertical Registration:

±10 mm

±20 mm

1-3

Page 18

1 December 1993

Paper Table Raising/

Lowering speed:

22 mm/sec (50 Hz)

26 mm/sec (60 Hz)

Ink Supply: Automatic ink supply system

Press Roller Pressure:

13 ± 1 kg

Paper Delivery: Air knife/vacuum delivery

Delivery Side Plate

80 mm to 327 mm (31.5" to 12.9")

Movement distance:

Print Counter: 7 digits

Supplies: Master Thermal master 320 mm width

Master roll 225 masters/1 roll

Roll diameter

Master length 535 mm/1 master

Max run length 2000 prints

Ink 800 cc ink pack (black)

500 cc ink pack (red, blue, green, blown)

1-4

Page 19

1 December 1993

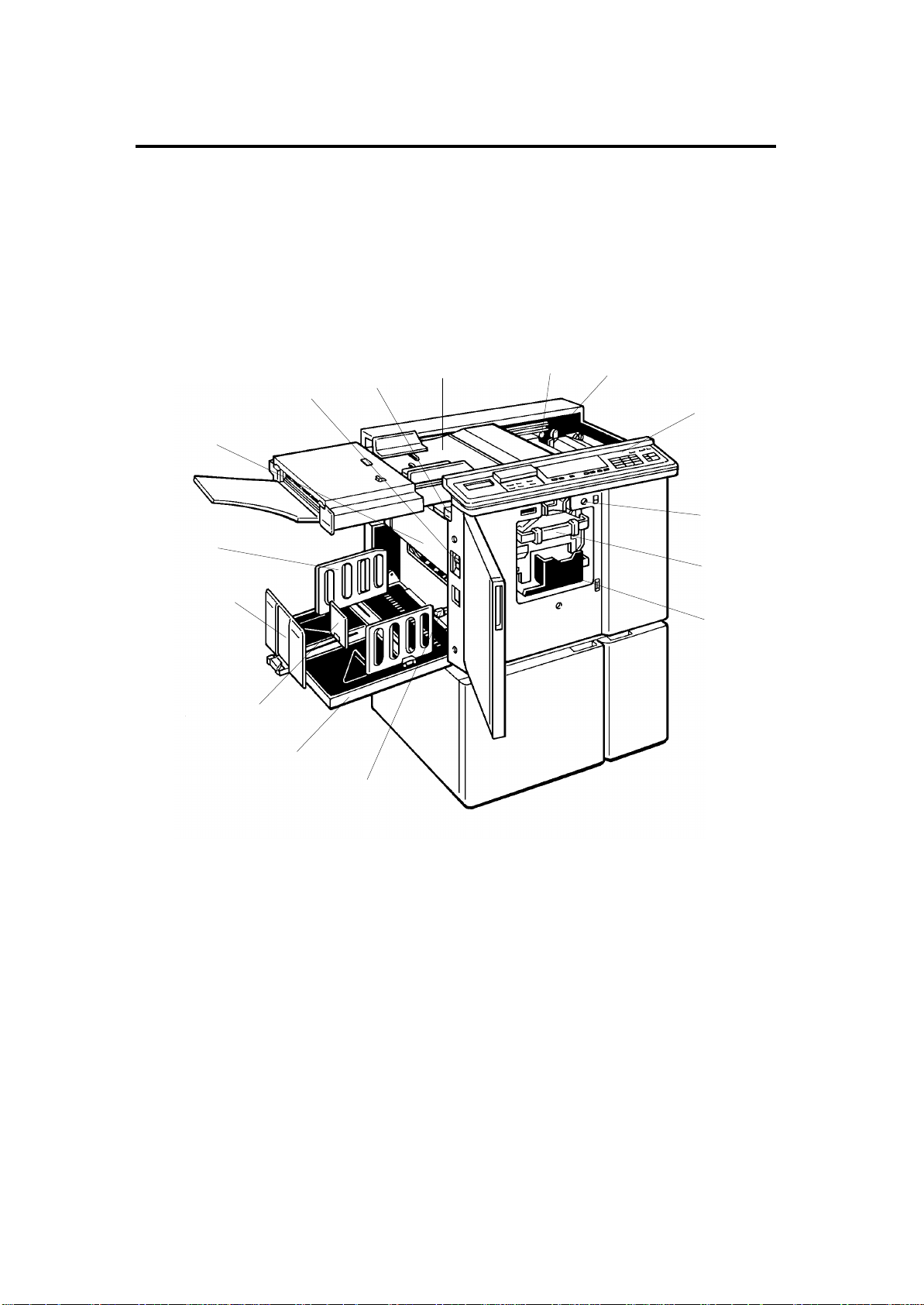

2. GUIDE TO COMPONENTS AND THEIR FUNCTION

7

8

9

10

11

12

6

13

5

14

4

15

3

2

1

1-5

Page 20

1 December 1993

No. Name Function

1. Wing Guide Release

Use to aid paper stack of large size paper.

Lever

2. Paper Delivery Table

3. Small Size Paper

Delivery End Plate

(for smaller than A4)

4. Paper Delivery End

Plate

(for larger than A4)

5. Paper Delivery Side

Plate

6. Master Eject Box

Cover

7. Main Switch

8. Master Eject Unit Open

Button

9. Original Table

10. Master Cut Button

Completed prints are delivered here.

Use to align the leading edge of prints that are

A4/LT or smaller.

Use to align the leading edge of prints larger

than A4/LT.

Use to align the prints on the paper delivery

table.

Open when removing the master eject box.

Use to turn the power on or off.

Press to remove misfed paper or a misfed

master.

Place the originals on this table.

Press this button to cut the master paper

leading edge after installing a new master roll.

11. Pressure Release

Lever

12. Operation Panel

13. Drum Rotation Button

14. Drum Unit

15. Ink Holder

Use to install the master roll, or to clean the

thermal head.

Operator controls and indicators are located

here.

Press to rotate the drum manually.

The master paper is wrapped around this unit.

Set the ink cartridge in this holder.

1-6

Page 21

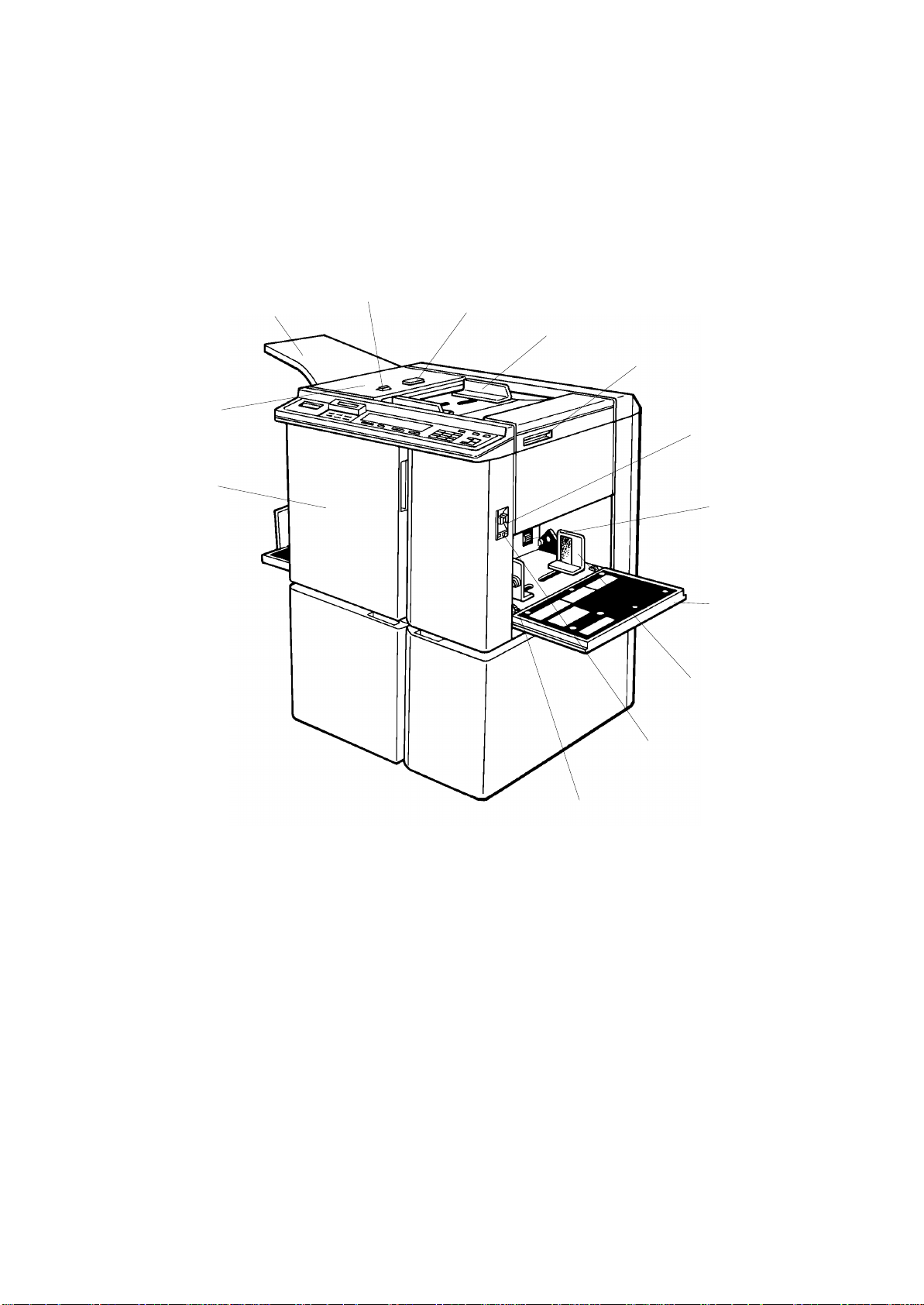

1 December 1993

17

16

18

19

20

21

22

23

24

25

26

1-7

27

28

Page 22

1 December 1993

No. Name Function

16. Front Door

Open for access to the inside of the machine.

17. ADF Unit

18. Original Tray

19. ADF On/Off Select

Switch

20. ADF Unit Open Button

21. Original Guides

22. Original Table Release

Lever

23. Feed Roller Pressure

Lever

24. Separation Roller

Pressure Lever

25. Paper Table

Feeds the original to the scanning position

automatically.

Originals used to make master(s) are delivered

to this tray.

When setting originals one sheet at a time, set

this switch to the off position.

Use to open the ADF unit.

Adjust these guides to position the originals

correctly.

Use to open the original table unit to the left for

master installation.

Use to adjust the contact pressure of the paper

feed roller according to paper thickness.

Use to adjust the separation roller pressure to

prevent double feed.

Set paper on this table for printing.

26. Paper Feed Side Plate

27. Paper Table Down

Button

28. Side Registration Fine

Adjusting Dial

Use to prevent paper skew.

Press to lower the paper table.

Use to shift the paper table sideways.

1-8

Page 23

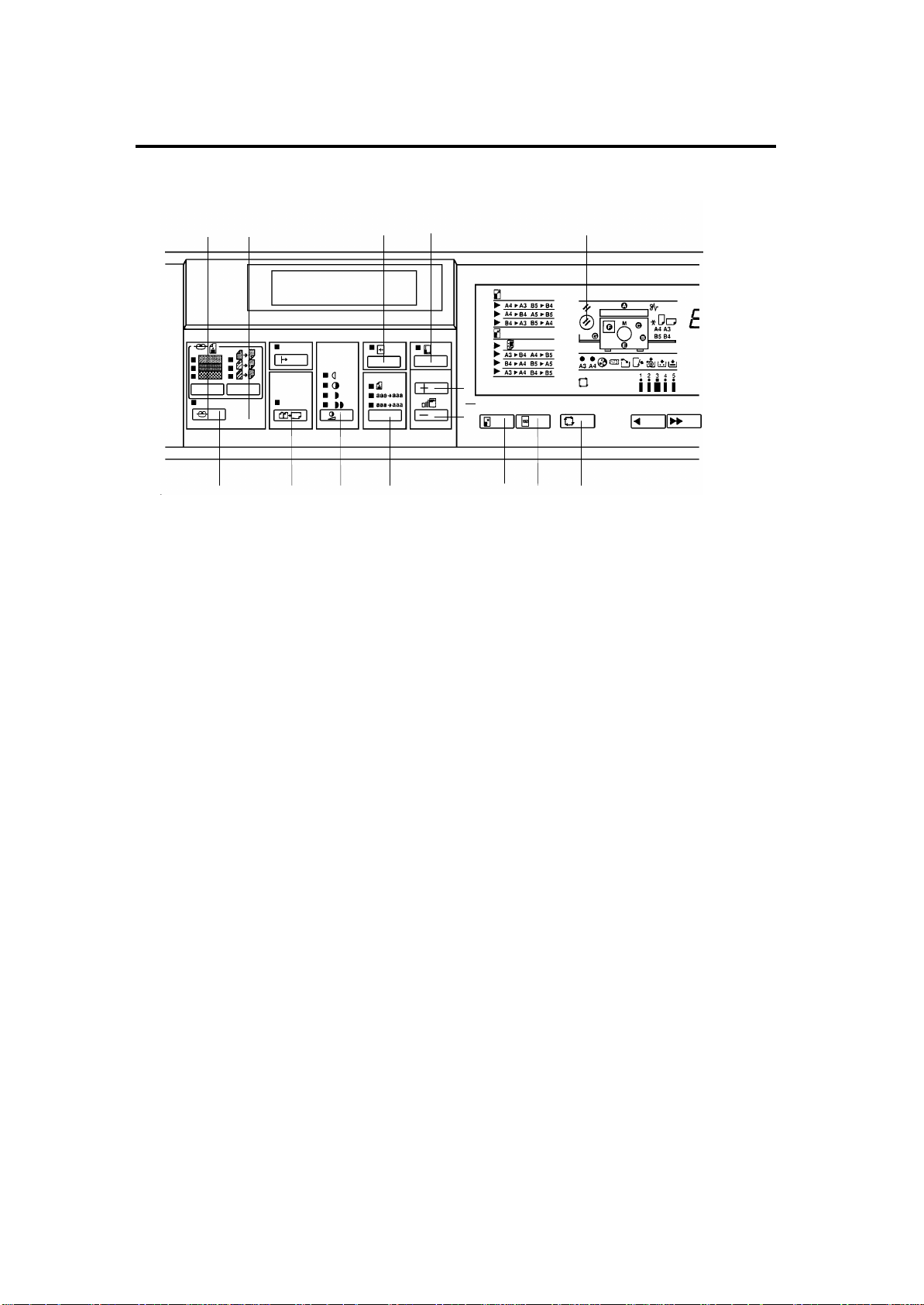

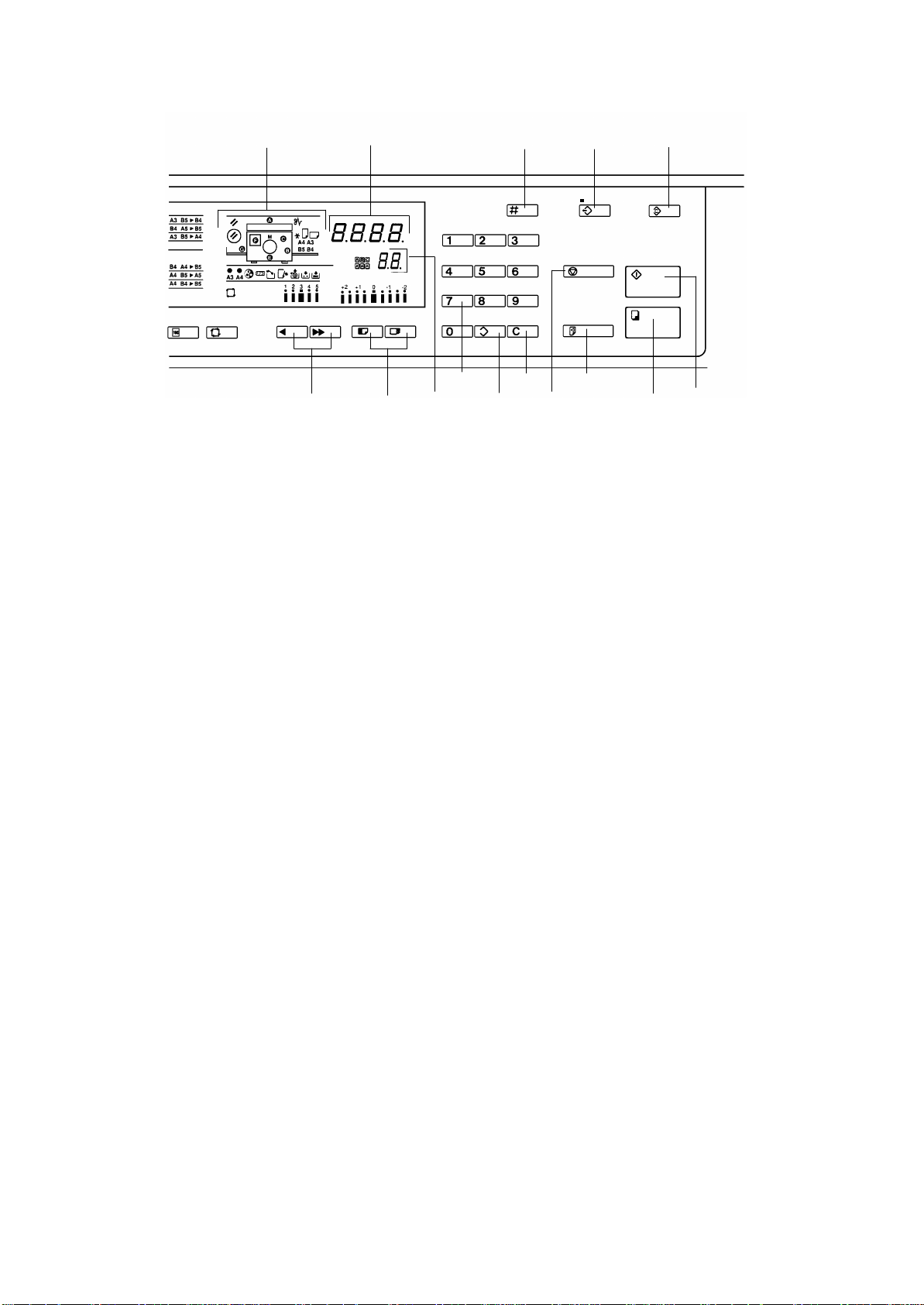

3. OPERATION PANEL

– Keys and Indicators –

1 December 1993

54

6789

1. Reset key

2. Directional

Magnification key

3. Image Shift key

32 1

10 11 12 13

Press to reset error indicators.

Press to enter the horizontal or vertical

magnification for copies, using the number keys.

Press to shift the image.

4. Contrast key

5. Screen key

6. Make Up key

7. Combine 2 Originals

key

8. Image Density key

9. Image Mode key

10. Zoom keys

11. Reduce/Enlarge key

12. Full Size key

13. Auto Cycle key

Press to select the desired contrast according to

the type and quality of the original.

Press to select the desired grade of screening to

be applied to the image according to the type and

quality of the original.

Press to use the make-up function.

Press to combine two originals onto one print

image.

Press to make prints darker or lighter.

Press to select line mode, photo mode or sharpen

image mode according to the type and quality of

the original.

Press to alter the reproductions ratio in 1%

increments from 50% to 200%.

Press to reduce or enlarge the image.

Press to make prints the same size as the original.

Use to automatically process masters and make

prints.

1-9

Page 24

1 December 1993

18

19 20

14. Clear Modes key

15. Program key

16. Enter key

17. Counter

17 16 15 14

22

21

Press to cancel all previously entered settings and

modes.

Press to input or recall user programs.

Press to input information into memory.

Displays the number of prints entered. While

printing, it shows the number of copies left to print.

232425

26

27 28

18. Monitors

19. Speed keys

20. Image Position key

21. Memory/Class

Indicators

22. Number keys

23. Memory/Class key

24. Clear key

25. Stop key

26. Proof key

27. Print Start key

Light or blink when a non-standard condition

occurs within the machine.

Press to adjust the rotation speed of the drum

according to the type of image and printing paper.

Press to shift the image forwards or backwards on

the print paper.

Shows the number entered in memory mode or

class mode.

Press to enter the number of prints.

Press to select group printing in memory mode or

class mode.

Press to change the number set in the counter.

Also use to change make-up mode. This key can

be used only after the machine stops operation.

Press to stop the machine operation. The machine

will continue operation when the Print Start key or

Master Making key is pressed.

Press to make trial prints or extra prints.

Press to start printing.

28. Master Making key

Press to make a master.

1-10

Page 25

4. PRINTING PROCESS

1

1 December 1993

23

4

7

6

5

1. Master Ejecting: Ejects the used master wrapped around the

drum into the master eject box.

2. Original Feeding: Transports the original to the scanner section.

3. Scanning: Scans the original image with the CCD through

the mirror and the lens while feeding the

original.

4. Master Feeding: Converts the image signal read by the CCD into

digital signals and sends them to the thermal

head to plot holes on the master. The master

then wraps dround the drum.

5. Paper Feeding: Sends paper separately to the drum section.

6. Printing: Presses the paper fed from the paper feed

section to the drum. This transfers the ink to the

print through the drum screen and the master.

7. Paper Delivering: Peels the printed paper with the exit pawl and

air knife and ejects the paper onto the paper

delivery table.

1-11

Page 26

1 December 1993

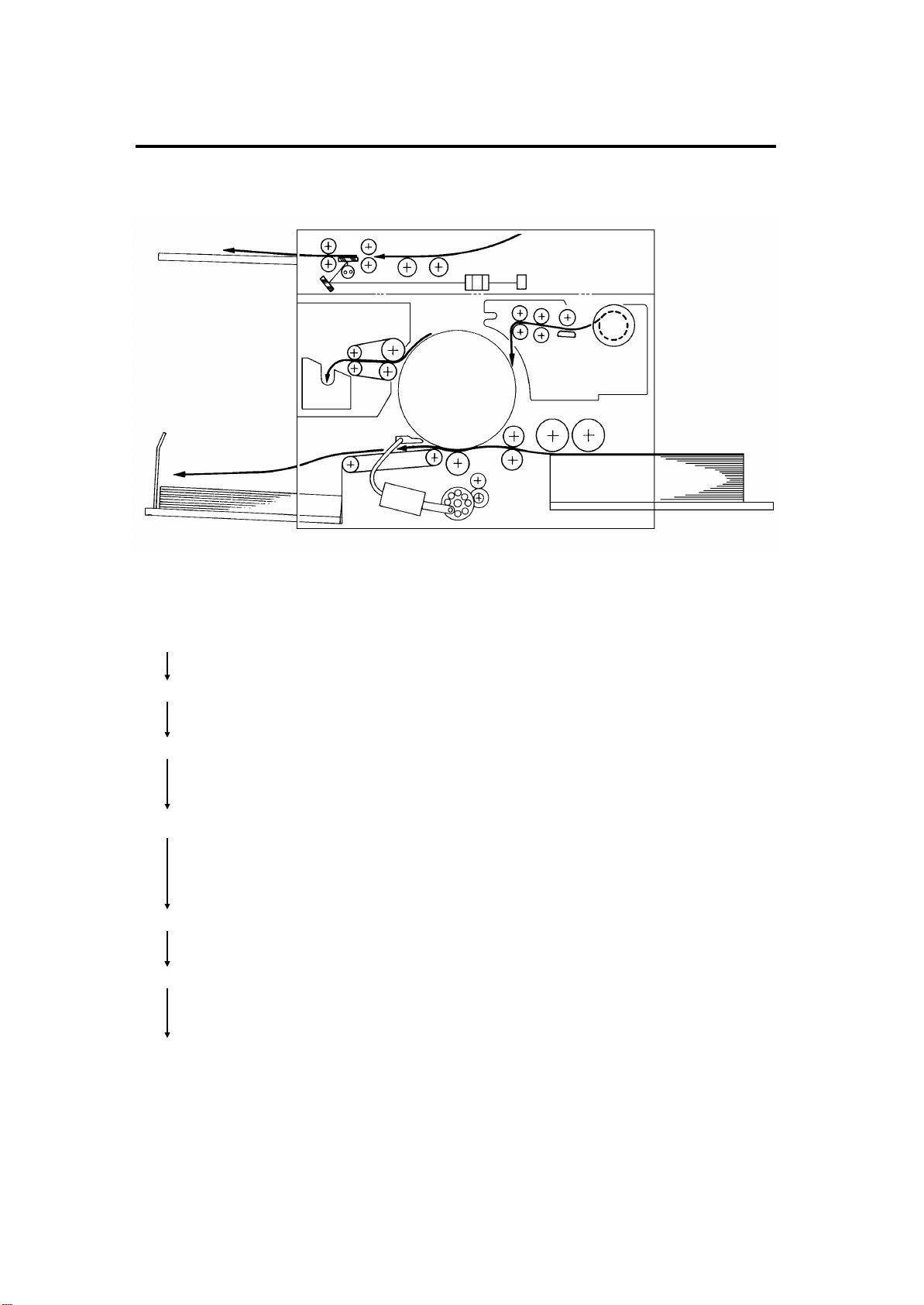

5. MECHANICAL COMPONENT LAYOUT

123456

3433323130

28

27

26

25

29

24

23

19

7

8

9

10

11

13

18202122

17

141516

12

1. Drum Unit

2. Lens

3. CCD

4. Reverse Roller

5. Master Feed Roller

6. Platen Roller

7. Thermal Head

8. Master Roll

9. Plotter Unit

10. Upper Separation Roller

11. Paper Feed Roller

12. Paper Table

13. Separation Plate

14. Lower Separation Roller

15. 2nd Feed Roller

16. Doctor Roller

17. Press Roller

18. Ink Roller

19. Paper Exit Pawl Air Pump

20. Paper Exit Pawl

21. Transport Unit

22. Paper Delivery Table

23. Master Eject Box

24. 1st Eject Roller

25. 2nd Eject Roller

26. Master Eject Unit

27. Mirror

28. Fluorescent Lamp

29. Original Exit Tray

30. 2nd Original Transport Roller

31. Exposure Glass

32. 1st Original Transport Roller

33. Original Feed Roller

34. Pull-out Roller

1-12

Page 27

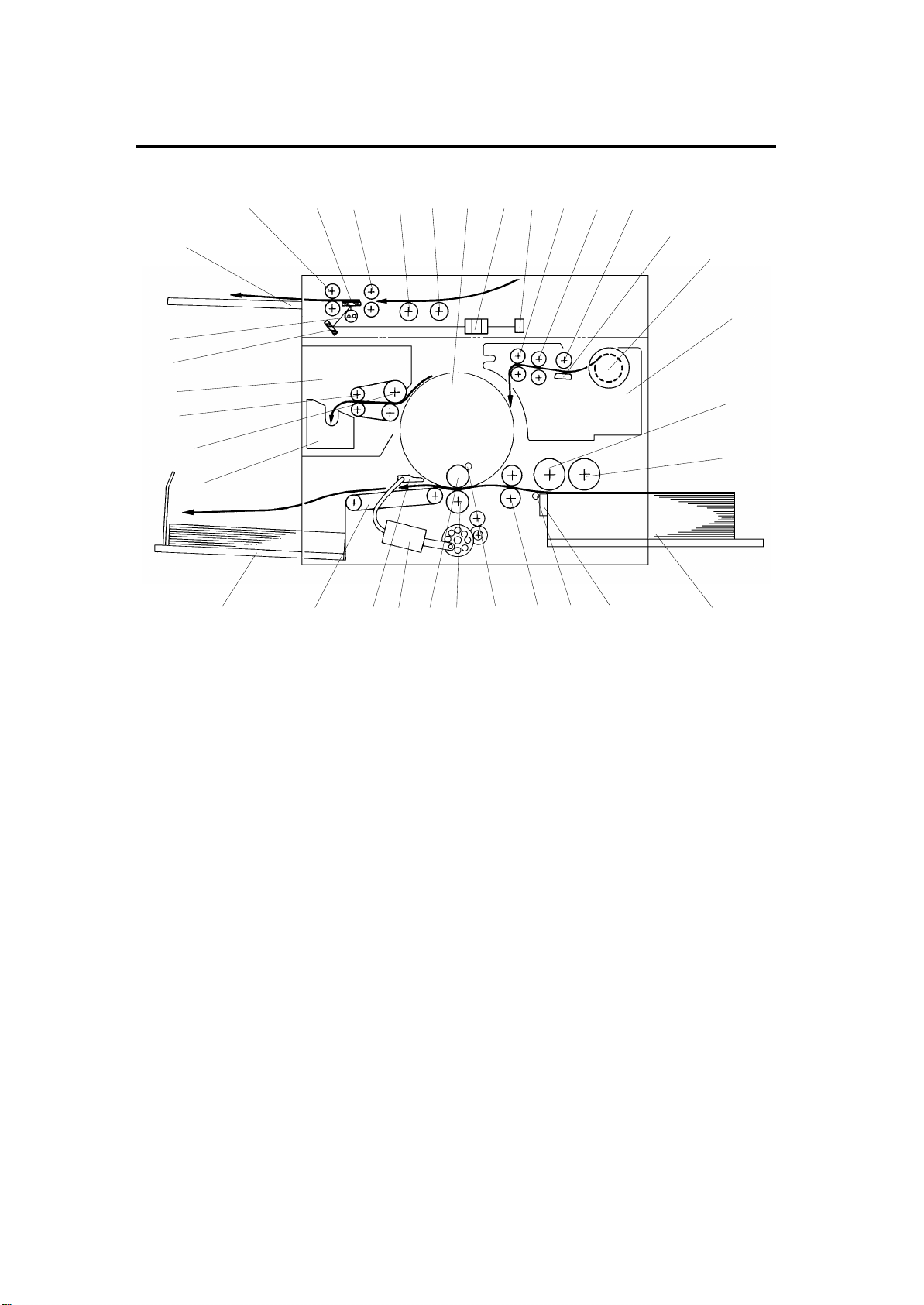

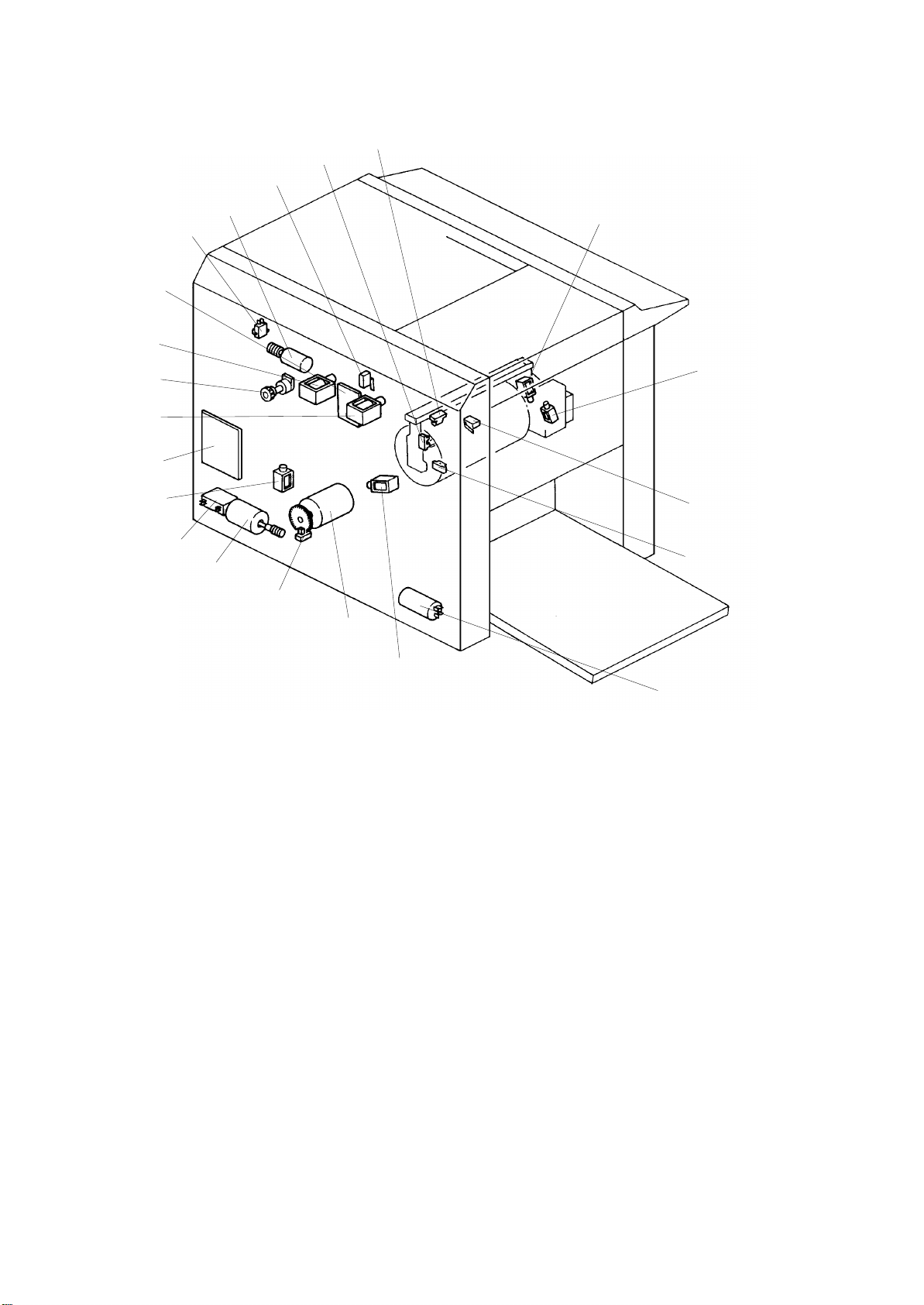

6. ELECTRICAL COMPONENT LAYOUT

1 December 1993

2

1

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

34

5

6

7

8

9

10

11

12

13

14

15

16

25

24

23

22

1-13

21

20

19

17

18

Page 28

1 December 1993

1. Original Registration Sensor

2. 2nd Original Sensor

3. 1st Original Sensor

4. Original Transport Motor

5. Original Pressure Solenoid

6. Fluorescent Lamp Stabilizer

7. Original Width Sensor

8. CCD PCB

9. Scanner Unit Safety Switch

10. A/D Conversion PCB

11. Paper Return Motor

12. Paper Table Down Button

13. Paper End Sensor

14. Paper Width Sensor

22. Transformer

23. Paper Table Lower Limit Sensor

24. Main PCB

25. Printing Pressure Sensor

26. Front Door Safety Switch

27. Power Supply Unit

28. Vacuum Fan Motor

29. 1st Paper Exit Sensor

30. Drum Detection Switch

31. 2nd Paper Exit Sensor

32. Circuit Breaker

33. Delivery Table Open Switch

34. Main Switch

35. Interlock Switch

15. Paper Table Open Switch

16. Paper Table Safety Switch

17. Paper Detection PCB

(Paper Length Sensor)

18. Cassette Size Detection PCB

19. Paper Table Height Sensor

20. Image Processing PCB

21. Separation Plate Release

Solenoid

36. Air Knife Motor Safety Switch

37. Drum Rotation Switch

38. Drum Rotation LED

39. Total Counter

40. Operation Panel

41. ADF Safety Switch

42. ADF Drive Motor

43. Fluorescent Lamp

1-14

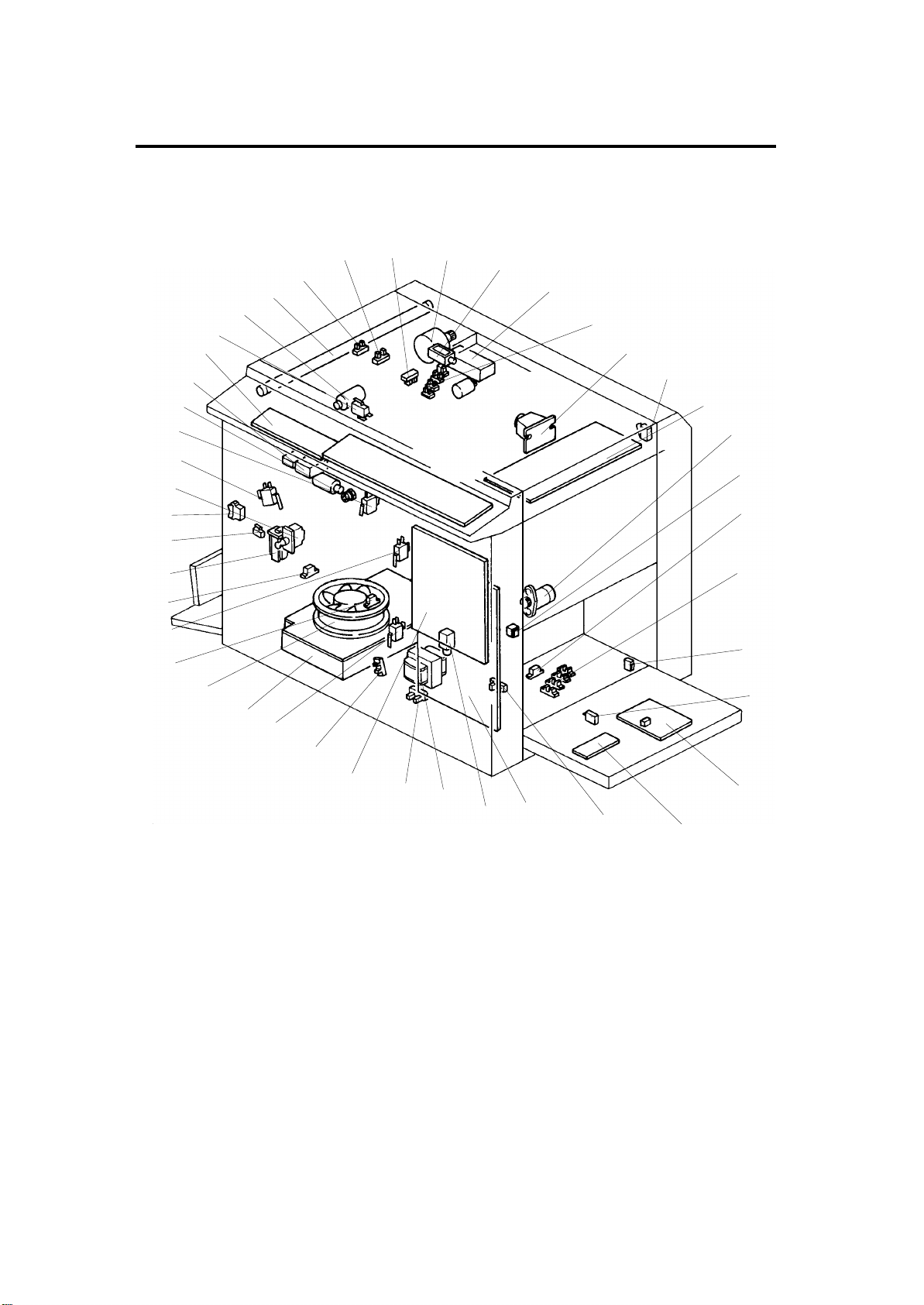

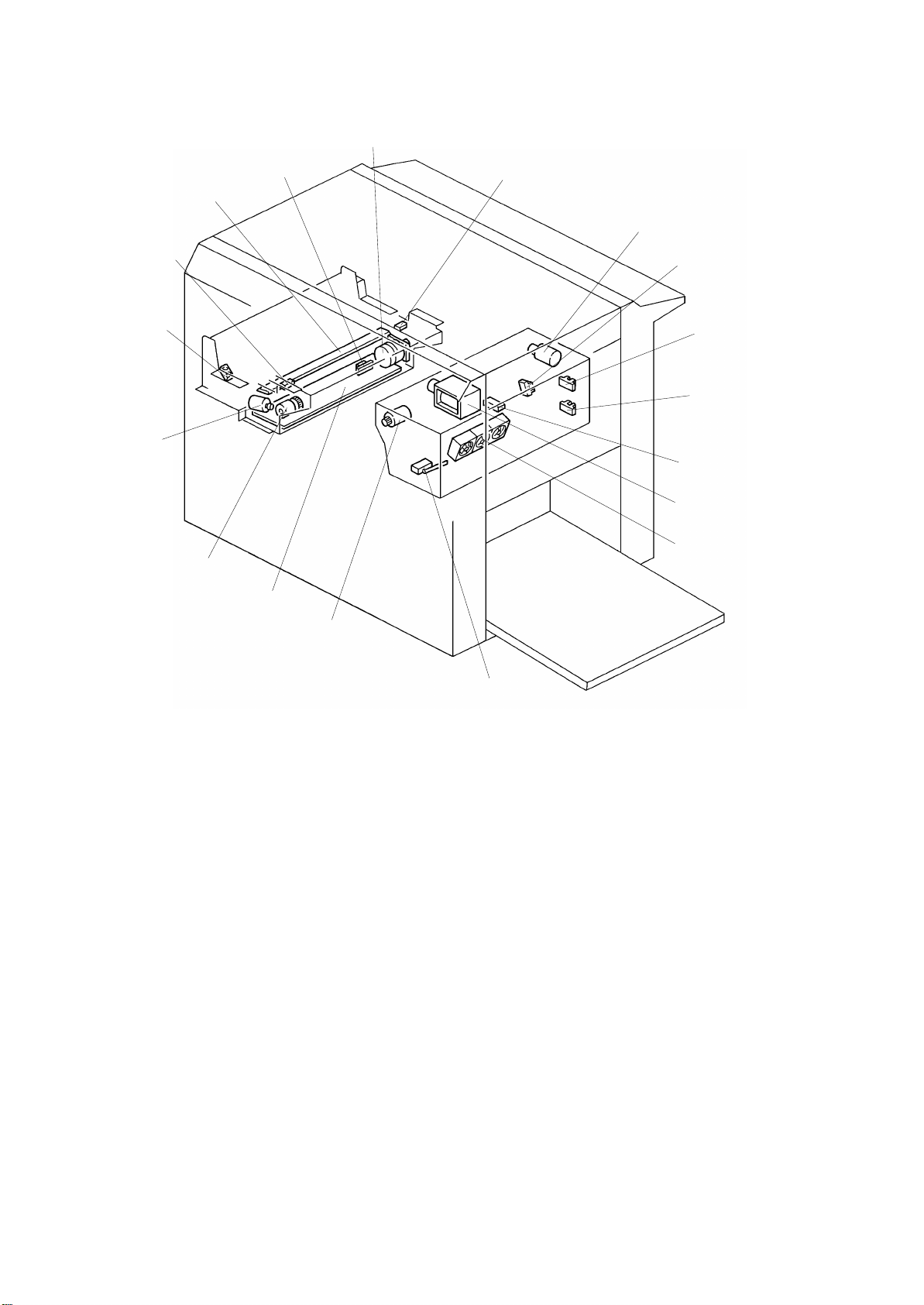

Page 29

1 December 1993

58

57

56

59

55

54

53

60

52

61

63

64

62

44

45

46

47

51

50

49

44. Ink Supply Solenoid

45. Drum Lock Solenoid

46. Master Eject Unit Safety Switch

47. 2nd Drum Position Sensor

48. Noise Filter

49. Printing Pressure Solenoid

50. Main Motor

51. Drum Rotation Sensor

(Pulse Generator)

52. Paper Table Drive Motor

53. Paper Table Drive Motor

Capacitor

48

54. Paper Feed Solenoid

55. AC Drive PCB

56. Master Eject Clamper Solenoid

57. Image Position Sensor

58. Master Feed Clamper Solenoid

59. Ink Detection PCB

60. Master Cut Button

61. Image Positioning Motor

62. Drum Unit Safety Switch

63. 1st Drum Position Sensor

64. Drum Master Detection Sensor

1-15

Page 30

1 December 1993

77

76

78

79

75

74

80

81

82

65

66

67

68

69

70

71

73

65. Pressure Plate Motor

66. Lower Pressure Plate Sensor

67. Upper Pressure Plate Sensor

68. Full Master Detection Sensor

69. Master Eject Sensor

70. Master Eject Solenoid

71. Air Knife Motors

72. Master Eject Box Switch

73. Master Eject Motor

74. Thermal Head Drive PCB

72

75. Reverse Roller Magnetic Clutch

76. Cutter Motor

77. Master End Sensor

78. Right Cutter Switch

79. Thermal Head

80. Master Buckle Sensor

81. Master Feed Motor

82. Left Cutter Switch

1-16

Page 31

1 December 1993

7. ELECTRICAL COMPONENT DESCRIPTIONS

Index No. Name Function

Motors

4 Original Transport

Motor

11 Paper Return Motor Returns paper to the paper table when

28 Vacuum Fan Motor Provides suction so paper is held firmly

42 ADF Drive Motor Feeds the original to the scanner

50 Main Motor Drives paper feed, drum, printing and

Transports the original to the scanner

section.

the paper table is lowered.

on the transport belt.

section.

paper delivery unit components.

52 Paper Table Drive

Motor

61 Image Positioning

Motor

65 Pressure Plate Motor Raises and lowers the pressure plate.

71 Air Knife Motors Rotates the fan to separate the paper

73 Master Eject Motor Sends used master into the master

76 Cutter Motor Cuts the master.

81 Master Feed Motor Feeds the master to the drum.

Solenoids

5 Original Pressure

Solenoid

21 Separation Plate

Release Solenoid

44 Ink Supply Solenoid Releases the spring clutch to turn on

Raises and lowers the paper table.

Changes the timing between the paper

feed roller and the drum to adjust the

vertical image position.

leading edge from the drum.

eject box.

Presses the original pressure plate

down on the originals.

Releases the separation plate when the

paper table is lowered.

activate the ink supply pump.

45 Drum Lock Solenoid P revents the drum unit from being

removed during the printing run.

49 Printing Pressure

Solenoid

54 Paper Feed Solenoid Releases the sector gears to feed the

Engages the pressure ON/OFF lever

when a paper misfeed occurs.

paper.

1-17

Page 32

1 December 1993

Index No. Name Function

56 Master Eject

Clamper Solenoid

58 Master Feed

Clamper Solenoid

Opens the master clamper to eject the

master.

Opens the master clamper to clamp the

master.

70 Master Eject Solenoid Presses the lower master eject roller

against the drum surface.

Sensors

1 Original Registration

Sensor

Informs the CPU when the original

activates the sensor. Also, detects the

original misfeed.

2 2nd Original Sensor Informs the CPU when the original

activates the sensor. Also, detects

original misfeeds.

3 1st Original Sensor Informs the CPU if the original is set in

the ADF mode.

7 Original Width Sensor Informs the CPU of the original width.

13 Paper End Sensor Informs the CPU if the paper is set on

the paper table.

14 Paper Width Sensor Informs the CPU of the paper width.

19 Paper Table Height

Sensor

23 Paper Table Lower

Limit Sensor

25 Printing Pressure

Sensor

Informs the CPU if the paper table is at

the paper feed position.

Informs the CPU if the paper table is at

the lowest position.

Informs the CPU if printing pressure is

applied. Also, detects paper misfeeds.

29 1st Paper Exit Sensor Detects paper misfeeds.

31 2nd Paper Exit

Detects paper misfeeds.

Sensor

47 2nd Drum Position

Checks the position of the drum.

Sensor

51 Drum Rotation

Sensor

57 Image Position

Supplies timing pulses to the CPU

based on the main motor speed.

Informs the CPU of the image position.

Sensor

63 1st Drum Position

Checks the position of the drum.

Sensor

1-18

Page 33

Index No. Name Function

64 Drum Master

Detection Sensor

66 Lower Pressure

Plate Sensor

67 Upper Pressure

Plate Sensor

Informs the CPU if the master is on the

drum.

Informs the CPU if the pressure plate is

at the lower limit position.

Informs the CPU if the pressure plate is

at the upper limit position.

1 December 1993

68 Full Master Detection

Sensor

Informs the CPU when the master eject

box is full of masters.

69 Master Eject Sensor Detects used master misfeeds.

77 Master End Sensor Informs the CPU if the plotter unit runs

out of master roll.

80 Master Buckle

Sensor

Informs the CPU if the master is

buckling.

Switches

9 Scanner Unit Safety

Switch

Cuts off the power line of the main and

paper table drive motors when the

scanner unit is open.

12 Paper Table Down

Button

Informs the CPU to turn on the paper

table drive motor to lower the paper

table.

15 Paper Table Open

Switch

16 Paper Table Safety

Switch

Checks whether the paper table is

opened correctly or not.

Stops lowering the paper table to

prevent catching fingers under it. Cuts

the AC power line.

26 Front Door Safety

Switch

Cuts off the power line of the paper

table drive motor when the front door is

open.

30 Drum Detection

Switch

Checks whether the drum unit is set

correctly or not.

33 Delivery Table Open

Switch

Checks whether the delivery table is

opened correctly or not.

34 Main Switch Turns the power on or off.

35 Interlock Switch Disables the front door, paper table,

master eject unit, and scanner unit

safety switches.

36 Air Knife Motor

Safety Switch

Cuts off the power line of the paper

table drive motor when the master eject

unit is open.

1-19

Page 34

1 December 1993

Index No. Name Function

37 Drum Rotation Switch Informs the CPU to rotate the drum at

10 rpm.

41 ADF Safety Switch Cuts the power line of the paper table

drive motor off when the ADF is open.

46 Master Eject Unit

Safety Switch

Cuts off the power line of the paper

table drive motor when the master eject

unit is open. (Also, cuts off the power

line of the main motor in the 220/240 V

version machines.)

60 Master Cut Button Informs the CPU to cut the master

paper leading edge.

62 Drum Unit Safety

Switch

72 Master Eject Box

Switch

Checks whether the drum unit is set

correctly or not.

Checks whether the master eject box is

set correctly.

78 Right Cutter Switch Detects when the cutter position is far

right (non-operation side).

82 Left Cutter Switch Detects when the cutter position is far

left (operation side).

Printed Circuit Board

8 CCD PCB Converts light intensity into an electrical

signal.

10 A/D Conversion PCB Converts the analog signal into a digital

signal.

17 Paper Detection PCB Detects the size of the paper set on the

table.

18 Cassette Size

Detection PCB

20 Image Processing

PCB

Detects the size of the cassette set on

the table.

Controls the image processing

performance.

24 Main PCB Controls all machine functions both

directly and through other boards.

55 AC Drive PCB Controls the AC component by relays.

59 Ink Detection PCB Controls the ink supply.

74 Thermal Head Drive

PCB

Supplies the power to the thermal head

according to the signal from the

scanner section.

1-20

Page 35

1 December 1993

Index No. Name Function

Counters

39 Total Counter Keeps track of the total number of

prints made.

Others

6 Fluorescent Lamp

Stabilizer

Stabilizes the power supplement to the

fluorescent lamp.

22 Transformer Steps down the wall voltage.

27 Power Supply Unit Provides power for all DC components.

32 Circuit Breaker Cuts the AC line off.

38 Drum Rotation LED Turns to green from red when the drum

stops to the home position.

43 Fluorescent Lamp Applies light to the original for exposure.

48 Noise Filter Fi lters electrical noise on the AC power

input lines.

53 Paper Table Drive

Motor Capacitor

75 Reverse Roller

Magnetic Clutch

Protects the AC drive PCB from

induced current.

Stops the reverse roller turning while

the master buckle sensor is OFF.

79 Thermal Head Plots the master using heat.

1-21

Page 36

1 December 1993

8. DRIVE LAYOUT

20

19

18

17

16

21

3

4

5

6

7

8

9

15 14 13 12 11

1. Reverse Roller Gear

2. Image Position Motor

3. Original Transport Motor

4. Master Eject Motor

5. Drum Drive Gear

6. Drum Unit Gear

7. Drum Drive Pulley

8. Main Drive Belt

9. Transport Belt

10. Printing Pressure Pulley

10

11. Printing Pressure Gear

12. Idle Gear

13. Idle Pulley

14. Main Motor

15. Paper Table Drive Motor

16. Paper Feed Cam Gear

17. Master Feed Motor

18. Timing Belt

19. Platen Roller Gear

20. Master Transport Roller Gear

1-22

Page 37

SECTION 2

SECTIONAL DESCRIPTION

Page 38

1 December 1993

1. MASTER EJECT SECTION

1.1 OVERALL

At the end of the printing cycle, the used master remains wrapped around the

drum to prevent the ink on the drum surface from drying. When the Master

Making key is pressed to make a new master, the used master is ejected

from the drum.

The master is pulled off the drum, then it goes through the eject rollers and

into the master eject box. A pressure plate then compacts the used master.

[D]

[G]

[C]

[A]

[F]

Drum

[E]

[B]

•

Drum [B] rotates in reverse

(opposite to printing direction).

•

Master eject rollers [A] rotate.

•

Lower eject roller [C] is pressed

against the drum.

•

The trailing edge of the master

curls off the drum and passes

between the upper [E] and lower

[F] eject rollers, and the master [D]

is dumped into the master eject

box [G ].

[H]

•

The pressure plate [H] compacts

the ejected master [I].

[I]

2-2

Page 39

1 December 1993

1.2 MASTER EJECT ROLLER ROTATING MECHANISM

[I]

[J]

[H]

[G]

[A]

[B]

[E]

[F]

[B]

[C]

[D]

[E]

[F]

When the original is set and the Master Making key is pressed, the main

motor starts turning at 30 rpm in reverse. So now the drum also turns in

reverse (compared with the printing rotations).

At this time, if the drum master detection sensor detects a master on the

drum, the master eject motor [A] starts rotating. Drive is transmitted to gear

[E] and to the upper first eject rollers [G] through the timing belt [B] and gears

[C] and [D]. Gear [F] drives the lower first eject rollers [H]. The belts [I]

transmit drive from the first eject rollers to the upper and lower second feed

rollers [J].

(If the drum master detection sensor detects no master on the drum when the

Master Making key is pressed, the machine skips the master eject process

and goes directly to the master making process.)

After the master eject process is completed, the drum returns to its home

position. The master eject rollers then stop rotating.

This model has five rollers on each eject roller shaft. The roller shafts can

feed up to A3/DLT sized masters.

2-3

Page 40

1 December 1993

1.3 MASTER EJECT ROLLER DRIVE MECHANISM

[H]

[G]

[A]

[B]

[C]

[D]

[E]

[F]

The drum position is detected by the first [G] and second [H] drum position

sensors. When the drum reaches its home position, the first drum position

sensor [G] is activated by the interrupter [F] at the rear side of the drum.

To eject the master, the drum turns in reverse (opposite to the printing

direction). When the A3/DLT drum is 70° from the home position, the master

eject solenoid [A] turns on and the supporter [C] rotates counterclockwise on

the upper eject roller shaft [D]. This forces the lower first eject roller [E]

against the drum.

As the drum turns, the curled trailing edge of the master [B] passes between

the upper and lower first eject rollers. The first eject rollers then peel the

master from the drum.

2-4

Page 41

1 December 1993

[A]

[B]

[C]

[D]

When the A3/DLT drum is 109 degrees from the home position, the master

eject solenoid [A] turns off, separating the lower first eject rollers [C] from the

drum.

When the ejected master passes between the upper and lower first eject

rollers, the master eject sensor [B] is actuated. The master is then dumped

into the master eject box [D].

2-5

Page 42

1 December 1993

Print key on

First Drum Position Sensor

Master Eject Solenoid

Sensor ON Check

70°

Drum Rotation

Reverse Reverse

Master Eject Sensor

Master Eject Motor

Misfeed Indic at or Light s

39° 18°

50° 50°

68°

Foward

[Master Eject Misfeed Detection]

The misfeed indicator for the master eject section blinks in the following

cases:

Case 1: The master eject sensor is not activated and the drum has turned

50 degrees more (still in reverse and after de-activation of the

master eject solenoid). The machine knows that the eject rollers

have failed to catch the master. So the drum returns 68 degrees (in

the printing direction) to repeat the master eject process once

again. The master eject solenoid is again energized while the drum

turns another 18 degrees to try to catch the master.

If the master eject sensor once again fails to detect the master,

then the drum returns to its home position and the misfeed

indicator blinks.

Case 2: The drum finishes its rotation for the master ejecting process and

retuns to the home position, but the master eject sensor does not

turn off. This means that the master is still in between the master

eject rollers, the misfeed indicator blinks.

2-6

Page 43

1.4 MASTER EJECT CLAMPER MECHANISM

[G]

[F]

1 December 1993

[B]

[A]

[C]

[D]

[E]

When the drum rotates 306 degrees (in reverse) past the home position, the

master eject clamper solenoid [A] turns on and lever [B] rotates

counterclockwise as shown. This moves the cam [D] inside the drum. Drum

rotation brings the clamper sector gear [E] against the cam [D]. Gear [F] turns

counterclockwise as it engages the clamper sector gear, thus opening the

master clamper [G]. This releases the master from the drum.

The drum keeps on turning until the interrupter at the rear side of the drum

goes 13 degrees past the first drum position sensor. Then, the main motor

turns off. Half a second later, the master eject clamper solenoid [A] turns off

and spring [C] pulls cam [D] back to its initial position. The drum then rotates

forward to its home position.

2-7

Page 44

1 December 1993

1.5 PRESSURE PLATE UP/DOWN MECHANISM

[B]

[M]

[C]

[L]

[D]

[A]

[K]

[E]

[F]

[G]

[I]

[H]

[J]

[Pressure Plate Down]

When the interrupter at the rear side of the drum interrupts the first drum

position sensor (this means the end of the master eject process), the

pressure plate motor [B] starts rotating. This drives gear [H] clockwise by

means of gears [C], [D], [E], and [F].

Pin [I] on gear [H] moves link [G] down until the link interrupter [L] interrupts

the lower pressure plate sensor [J]. Spring [M] pulls down on the pressure

plate and the ejected master in the master eject box is compressed by the

pressure plate [A].

If the full master detection sensor [K] does not turn on when the pressure

plate goes down, it means the master eject box is filled with ejected masters.

In this case, the Master Full indicator blinks, and the machine stops after a

new master is wrapped around the drum.

Reset the Master Full indicator by turning the Master Eject Box switch OFF

and ON. This is to prevent the master full indicator from being reset without

removing the ejected masters from the box. When the Master Full indicator is

blinking, the Master Making key does not work, but the Print Start key and

Proof key work.

2-8

Page 45

1 December 1993

[A]

[B]

[G]

[C]

[F]

[D]

[E]

[Pressure Plate Up]

When the master has been wrapped around the drum in the master making

process and the master cutter leaves the home position to cut the master, the

pressure plate motor [B] starts rotating to raise the pressure plate.

When the pressure plate motor [B] turns, the gear [C] is driven through the

relay gears. The pin [F] on the gear inserted into the link [D] rises and lifts the

left end of the link, thus raising the pressure plate.

The gear [C] continues turning until the interrupter [G], installed in the front

end of the pressure plate, blocks the upper pressure plate sensor [A]. At this

time, the master eject motor [B] stops and the pressure plate is held in the

upper position.

[Pressure Plate Motor Lock Detection]

To prevent the pressure plate motor from locking, "E-12" lights up on the

operation display panel under the following conditions:

1. The upper [A] or lower [E] pressure plate sensor remains activated for

more than 4 seconds after the pressure plate motor starts turning.

2. The lower pressure plate sensor [E] is not activated within 8 seconds of

the pressure plate motor starts turning even though the upper pressure

plate sensor [A] is de-activated.

3. The upper pressure plate sensor [A] is not activated within 8 seconds of

the pressure plate motor starts turning even though the lower pressure

plate sensor [E] is de-activated.

2-9

Page 46

1 December 1993

1.6 ELECTRICAL TIMING

T1

First Drum Position Sens or

Second Drum Position Sensor

Main Motor Reversing

30 rpm

Main Motor Forwarding

Master Eject Motor

T2

Master Eject Solenoid

Master Eject Clamper Solenoid

X1

306°

T1: When the Master Making key is

pressed, the main motor and

master eject motor start turning. At

the same time, the paper table drive

motor starts turning to lift the paper

table to the paper feed position.

T2: When the drum rotates X1 degrees

past the first drum position sensor

actuation position (drum home

position), the master eject solenoid

is energized. This presses the lower

eject rollers against the drum

surface. The master eject solenoid

is de-energized when the drum

rotates X2 degrees more.

X2

T4

13°

30 rpm

T3

500 msec

0°

0°

70°

39°

The drum rotation angles X1 and

X2 depend on the drum type. This

machine has two types of drums:

one is the A3/DLT drum (standard),

and the other is the A4/LT drum

(optional). X1 and X2 for each drum

are as follows:

Drum Type A3/DLT A4/LT

X1 (degree) 70 137

X2 (degree) 39 50

2-10

Page 47

1 December 1993

T3: When the drum rotates 306

degrees past the home position, the

master eject clamper solenoid is

energized.

T4: When the drum rotates 13 degrees

past the drum home position, the

drum stops rotating.

500 milliseconds later (the drum

completely stops during this period),

the master eject clamper solenoid is

de-energized and the drum starts

rotating forward. The drum then

returns to its home position. The

master eject process is now over.

Soon after this, the machine starts

feeding a new master and the drum

starts rotating in reverse to begin

the master making process.

13°

0°

306°

0°

2-11

Page 48

1 December 1993

-24

-23

-22

-27

-26

-25

-30

-29

-28

-17

-16

-19

-18

0V

0V

0V

Main PCB

5V

GND

5V

GND

5V

GND

5V

LED DRIVE

5V

5V

CN103

-21

24V

24V

FU101

FU102

GND

-10

-20

-11

-19

-12

-25

-6

CN101

-20

-21

SOL

M

M

SOL

plate is at the hi ghest position.

5V

plate is at the lowest position.

5V

of the pressure pla te passes through

the sensor. (M ast er fu l l det ect i on in the

[E]

[F]

[G]

[H]

[I]

1.7 CIRCUIT

[A]

[B]

[C]

[D]

Component

Name

Upper Pressure

Plate Sensor [A]

Lower Pressure

Plate Sensor [B]

Full Master

Detection

Sensor [C]

CN101

1

2

3

1

2

3

1

2

3

In/Ou t Main P C B Description

CN No. Signal Level

In 101-23 Signal goes High when t he pr essure

In 101-26 Signal goes High when t he pr essure

In 101-29 Signal goes High when t he i nter r upt er

master eject box.)

Master Eject

Sensor [D]

Sensor LED [D] Out 101-16 Pulse signal goes to Low and the LED

Master Eject

Solenoid [E]

Master Eject

Motor [F]

Pressure Plate

Motor [G]

Master Eject

Clamper

In TP104 Signal goes High when the sensor

0V

3 msec

5V

3.5V

Out 103-10 Signal goes Low when the soleno i d

Out 103-11 Signal goes Low when the motor turn s

Out 103-12 Signal goes Low when the motor turn s

Out 103-6 Signal goes Low when the solenoid

24V

24V

24V

24V

3V

detects the master. This is a pulse

signal.

lights when the main switch is turned on.

600

sec

µ

0V

turns on.

0V

on.

0V

on.

turns on.

0V

Solenoid [H]

Master Eject

Box Switch [I]

In 101-20 Signal goes Low when the m aster eject

5V

0V

box is installed.

2-12

Page 49

2. SCANNER/OPTICS SECTION

2.1 OVERALL

1 December 1993

[A]

[G]

Thermal Head

[F]

[E]

Thermal Head

Drive PCB

Operation Panel

PCB

[D]

[B]

[C]

A/D Conversion

PCB

Image Proccessing

PCB

Main PCB

The first original [A] at the bottom of the stack on the original table is

separated from the other originals by the original feed rollers [E] and the

separation blade [B], and is fed onto the exposure glass [F].

The light of the fluorescent lamp [G] is reflected from the original and goes

through the lens [D]. The light is changed to an electrical signal in the CCD

(Charge Coupled Device) [C].

The electrical signal from the CCD is converted into an 8-bit digital signal in

the A/D conversion PCB. Then the upper 6 bits of the 8 bits are used in the

image processing PCB.

The binary circuit in the image processing PCB produces 1-bit data (white or

black) from the 6-bit data and sends it to the thermal head dri ve PCB.

The thermal head plots image data on the master and is driven through the

thermal head drive PCB.

2-13

Page 50

1 December 1993

[A]

[B]

[C]

[F]

[D]

[E]

[Light Source]

A high frequency (15 kHz) fluorescent lamp [D] is used as a light source for

high speed reading. The light is reflected at two angles using a mirror [F].

This prevents shadows from the edges of cut-and-paste originals from

appearing on the original [B]. The original guide plate [C] blocks part of the

direct light from the fluorescent lamp to make the light intensity of both the

direct light and reflected light the same. A heater [E] is wrapped around the

fluorescent lamp. The lamp stays on for one minute when the main switch is

turned on to quickly raise the lamp temperature. This prevents a loss in light

intensity that would occur if the temperature were too low.

[Platen Cover]

The CCD reads the platen cover [A] to obtain a standard white level before

the original is read. The standard white data are used to correct for distortion

such as bright or dull spots in the light path (lamp, reflectors, exposure glass,

mirrors, lens, and CCD).

2-14

Page 51

1 December 1993

Fluorescent

Lamp

CN608

-1

[D]

-2

-3

[C]

-4

Original

Scanning

Signal

Main PCB

CN601

-A13

+5V

+24V

4.3K

TH601

110K

[B]

[A]

24K

A/D Conversion PCB

Q605

10K

5

6

18K

+

7

_

IC

Q602

[Lamp Heater]

The thermistor [C] mounted in the lamp heater maintains the lamp

temperature at about 40°C.

Lamp

Heater

If the lamp temperature drops too low, the voltage at [B] goes High. This is

because the resistance of thermistor [C] increases, causing the voltage at

IC-pin 7 (operational amplifier) to go High. Q602 then turns on and the lamp

heater [D] is energized. If the lamp temperature rises, the voltage at [B]

becomes less than that at IC-pin 6. This causes IC-pin 7 to go Low, which

turns off the lamp heater.

Thermistor TH601 in the A/D conversion PCB monitors the temperature

inside the machine. If the temperature is low, the increased resistance of

TH601 drops the voltage at [A] and the control temperature of the heater

thermistor (heater ON/OFF temperature) is raised slightly. If the temperature

is high, the control temperature is lowered slightly.

If Q605 turns on, the voltage at [B] becomes 0 volt and the lamp heater turns

off. Q605 is turned on when the original scanning signal (active low) is sent

from the main PCB. Consequently, the heater is always off during the original

scanning process.

2-15

Page 52

1 December 1993

[A]

[B]

[C]

[Lens]

The lens assembly [B] consists of 6 lenses to transfer the image to the

photoelectric elements of the CCD. It is possible to adjust the focus by

moving the lens assembly.

[Shading Plate]

Compared with the ends, the middle of the lamp is too bright. To correct this,

a shading plate [A] is placed in front of the lens. This blocks some of the light

and distributes it more uniformly.

[CCD (Charge Coupled Device)]

The CCD [C] is a solid-state device similar to a photodiode array, but unlike a

photodiode array, a CCD can read one complete scan line at a time. The

CCD produces an analog signal which is converted into a digital signal in the

A/D conversion PCB.

2-16

Page 53

2.2 ORIGINAL FEED MECHANISM

1 December 1993

[A]

[C]

[B]

[D]

[E]

[L]

[F]

[K]

[I]

[H]

[G]

[J]

[J]: Fluorescent Lamp

[K]: Exposure Glass

[L]: 2nd Original Transport Rollers

Two original feed modes can be selected by the ADF ON/OFF select switch.

[ADF Mode]

The originals [A] set on the original table are detected by the 1st original

sensor [E]. When the Master Making key is pressed, the original pressure

plate [D] presses the originals down. The pull-out rollers [F] start moving the

lowest original forward at the same time. The lowest original is separated

from the other originals by the original feed rollers [G] and the separation

blade [C].

350 milliseconds after the 2nd original sensor [H] detects the original, the 1st

original transport rollers [B] start rotating. The rollers stop after the original

activates the original registration sensor [I]. The 1st original transport rollers

start rotating again after the drum section completes the preparation for the

master making.

[SADF Mode]

The separation blade [C] and the original pressure plate [D] are released in

the SADF mode. The original on the original table is fed to the original

reading position one second after the 2nd original sensor [H] detects the

original.

[Original Misfeed Detection]

The original misfeed indicator blinks in the following conditions:

1. The 2nd original sensor is not activated within 3 seconds after the ADF

drive motor turns on.

2. The original registration sensor is not activated within 3.5 seconds after

the 2nd original sensor is activated.

2-17

Page 54

1 December 1993

2.3 ORIGINAL FEED DRIVE MECHANISM

[A]

[L]

[K]

[J]

[I]

[H]

[G]

[B]

[C]

[D]

[E]

[F]

[M]

[N]

[M]

[B]

[O]

[P]

[E][B]

[E]

The original transport rollers [A] are driven by the original transport motor [C],

which is a stepper motor. The original feed rollers [B] are driven by the ADF

drive motor [F] (dc motor) through a series of gears [G] to [L]. The pull-out

rollers [E] are driven by the ADF motor through a drive belt [D].

The original pressure plate [P] is pressed down on the originals by the

original pressure solenoid [O]. The separation blade [M] is moved up and

down by the ADF ON/OFF select switch [N].

2-18

Page 55

2.4 ORIGINAL SIZE DETECTION

1 December 1993

[F]

[E]

[D]

[C]

[A]

[B]

[A]

[B]

The original width detection plate [A] installed behind the rear original guide

[B] has 4 photointerrupters.

The front and rear original guides are adjusted according to the original width.

Depending on which original size sensors are interrupted, the machine

determines the original width as shown in the below table. The original size

sensors are 4 photointerrupters.

Original Size* A3 DLT B4 LT/LG A4 B5 A5 HLT

Original Size Sensor - 3 [C] o x o x x o x x o

Original Size Sensor - 2 [D] x o o x x o o o o

Original Size Sensor - 1 [E] x x o o o o x x x

Original Size Sensor - 0 [F] x x x x o o o o o

x: Non-blocked, o: Blocked

* All of the above original sizes are for lengthwise feed.

2-19

Page 56

1 December 1993

The machine also checks the paper size on the paper feed table (both the

length and width).

When the paper width is smaller than the original width (multiplied by the

reproduction ratio), the machine indicates "Check paper size" on the

operation display for 3 seconds when the Master Making key is pressed. If

the operator ignores the indication and presses the Master Making key again,

the machine goes ahead with normal processing.

If the original size is different from the paper size, the machine compares the

length of the original and paper. The master’s length will be the shorter of the

two. The machine runs the same procedure for the width. (The original length

is detected by scanning the original.)

2-20

Page 57

2.5 ELECTRICAL TIMING

1 December 1993

First Drum Positi on

Sensor

Second Drum Position

Sensor

First Original Sensor

Master Motor Key

Main Motor Reversing

Lamp On Signal

ADF Drive Motor

Original Pressure

Solenoid

Second Original Sensor

Original Registration

Sensor

Original Transport Motor

T1

Master Eject Process Master Making Process