Page 1

RICOH PRIPORT

VT3600/2600

SERVICE MANUAL

Page 2

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYS ICAL INJURY

1. Before disassembling or asse mblin g pa rts of the print er and pe riph erals,

make sure that the power cord is unplu gged .

2. The wall outlet should be near the copier an d easily accessible.

3. If any adjustment or operat ion check ha s to be made with exterior covers

off or open while the main switch is turned on, kee p ha nds away from

electrified or mechanically drive n comp on ents.

HEALTH SAFETY CONDITIONS

1. If you get ink in your eyes by accident, try to remove with eye drops or

flush with water as first aid. If unsuccessful, get medical attent ion.

2. If you ingest ink by accident, induce vomiting by sticking finger down

throat or by giving soapy or strong salty water to drink.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The printer and its peripherals must be installed and mainta ine d by a

customer service represen tative who has completed the training course

on those models.

SAFETY AND ECOLOGICAL NOTES FOR DISP OS AL

1. Dispose of replaced parts in acco rda nce with local regulations.

2. Used ink and master should be disp ose d of in an environmentally safe

manner and in accordance wit h loca l regu lat ions.

– CAUTION –

The RAM pack has a lithium battery which can explode if handled

incorrectly. Replace only with same RAM pa ck. Do not recharge or burn

this battery. Used RAM packs must be handled in accordance with local

regulations.

Page 3

SECTION 1

OVERALL MACHINE INFORMATION

Page 4

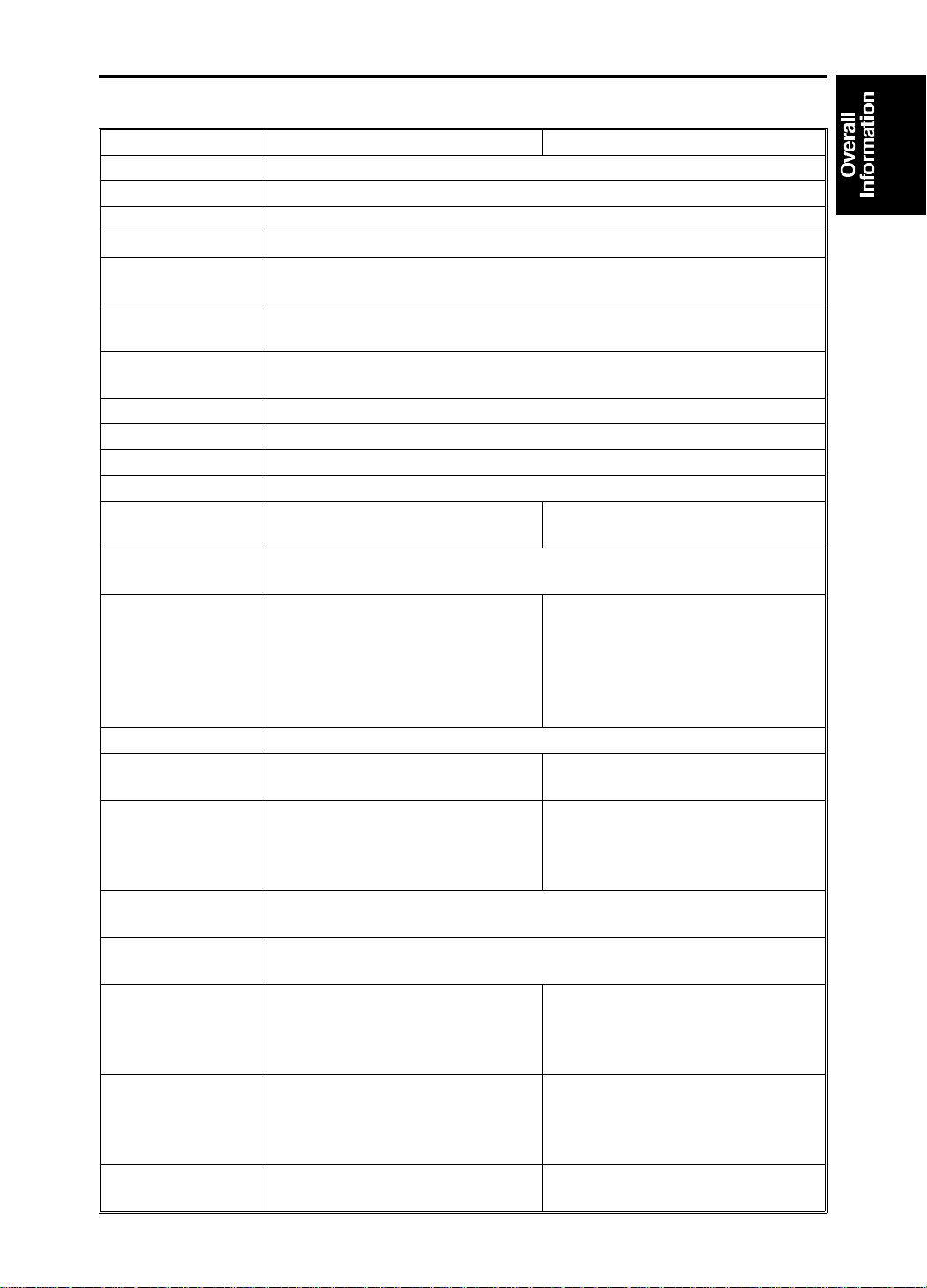

15 July 1994 SPECIFICATIONS

1. SPECIFICATIONS

C218 Model C219 Model

Configuration: Desk top

Master Processing: Digital

Printing Process: Fully automatic one-drum stencil system

Original Type: Sheet/Book

Original Scan Area

Size:

Reduction Ratio: LT version: 93%, 77%, 74%, 65%

Enlargement Ratio: LT version: 155%, 129%, 121%

Image Mode: Line/Photo/Sharpen

Zoom: From 50% to 200% in 1% steps

Color Printing: Drum unit replacement system (red, blue, green and brown)

Master Feed/Eject: Roll master automatic feed/eject

Leading Edge

Margin:

Print Paper Size: Maximum: 325 mm x 447 mm (12.7" x 17.5")

Printing Area: Maximum:

Print Paper Weight: 47.1 g/m

Printing Speed: 60, 75, 90, 105, 120 sheets/minute

First Print Time: 38 s/A3/DLT (with "L" drum)

Paper Feed Table

Capacity:

Paper Delivery

Table Capacity:

Power Source: 120 V, 60 Hz, 4.1 A (for

Power

Consumption:

Weight: 128 kg (282.2 lb)

Maximum: 307 mm x 432 mm (12.0" x 17.0")

A4 version: 93%, 87%, 82%, 71%

A4 version: 141%, 122%, 115%

8 ± 3 mm (0.32" ± 0.12") 5 ± 3 mm (0.20" ± 0.12") mm

Minimum: 90 mm x 148 mm (3.6" x 5.8")

Maximum:

290 mm x 412 mm (11.4" x 16.2")

at 23°C/65% RH (A3/DLT drum)

Maximum:

290 mm x 204 mm (11.4" x 8.0") at

23°C/65% RH (A4/LT drum)

(5 steps)

35 s/A4/LT (lengthwise with "L"

drum)

26 s/A4/LT (with "S" drum)

1000 sheets (75 g/m

1000 sheets (75 g/m

N.America)

220/240 V, 50 Hz, 2.1 A

(for Europe, Asia)

120 V, 60 Hz, 374 W (for

N.America)

220/240 V, 50 Hz, 380 W

(for Europe, Asia)

Cabinet: 23.5 kg (51.8 lb)

2

to 209.3 g/m2 (12.5 lb to 55.6 lb)

2

, 20 lb)

2

, 20 lb)

250 mm x 355 mm (9.8" x 14.0") at

23°C/65% RH (for Europe, Asia)

Maximum:

210 mm x 355 mm (8.3" x 14.0") at

23°C/65% RH (For N.America)

60, 75, 90, 110, 130 sheets/minute

(5 steps)

36 s/B4 (with "M" drum)

33 s/A4 (lengthwise)

120 V, 60 Hz, 3.6 A (for

N.America)

220/240 V, 50 Hz, 2.0 A

(for Europe, Asia)

120 V, 60 Hz, 325 W (for

N.America)

220/240 V, 50 Hz, 322 W

(for Europe, Asia)

120 kg (265.0 lb)

Cabinet: 23.5 kg (51.8 lb)

1-1

Page 5

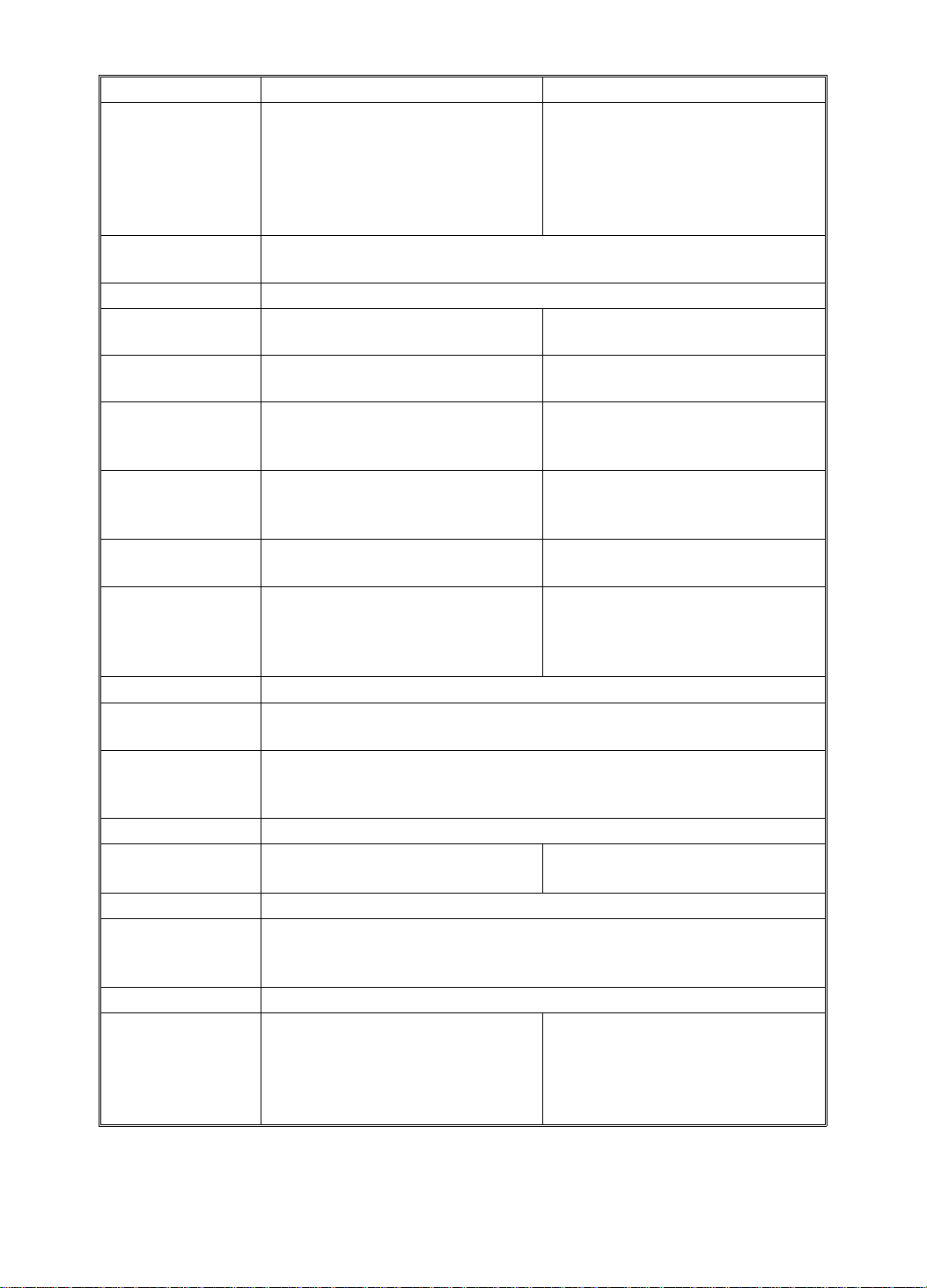

SPECIFICATIONS 15 July 1994

C218 Model C219 Model

Dimensions

(W x D x H):

Original Scanning

Time:

Pixel Density: 400 dpi

Master Eject Box

Capacity:

Paper Separation: Friction roller/center separation

Feed Table Side

Plate Movement

Distance:

Paper Feed Roller

Pressure:

Separation Roller

Pressure:

Separation Plate

Pressure:

Side Registration:

Vertical

Registration:

Paper Table

Raising/Lowering

Speed:

Ink Supply: Automatic ink supply system

Press Roller

Pressure:

Paper Delivery: Air knife/vacuum delivery

Delivery Side Plate

Movement

Distance:

Print Counter: 7 digits

Noise Emission: Less than 74 dB

Stored: 719 x 698 x 644 mm

(28.3" x 27.5" x 25.4")

Set up: 1331 x 698 x 644 mm

(52.4" x 27.5" x 25.4")

Cabinet: 1331 x 698 x 1070 mm

(52.4" x 27.5" x 42.1")

3 ms/line

50 masters with "L" drum

90 masters with "S" drum

system

88 mm to 336 mm (3.46" to 13.2") 88 mm to 336 mm (3.46" to 13.2")

Normal position 300 g

Thick paper position 600 g

Normal position 125 g

Weak position 50 g

Weak 10 g

Normal 20 g

Strong 1 40 g

Strong 2 60 g

±10 mm

±20 mm

22 mm/s (50 Hz)

26 mm/s (60 Hz)

12.5 ± 0.5 kg 10.5 ± 0.5 kg (for B4 drum)

80 mm to 327 mm (31.5" to 12.9")

Printing (Average):

60 rpm less than 64 dB

90 rpm less than 67 dB

120 rpm less than 72 dB

Stored: 719 x 698 x 644 mm

(28.3" x 27.5" x 25.4")

Set up: 1331 x 698 x 644 mm

(52.4" x 27.5" x 25.4")

Cabinet: 1331 x 698 x 1070 mm

(52.4" x 27.5" x 42.1")

35 masters

Friction roller/center separation

system

Thin paper position 250 g

Normal position 400 g

Thick paper position 550 g

Normal position 125 g

Weak position 50 g

Weak 10 g

Normal 20 g

Strong 1 40 g

Strong 2 60 g

10.0 ± 0.5 kg (for LG drum)

Printing (Average):

60 rpm less than 64 dB

90 rpm less than 69 dB

130 rpm less than 74 dB

1-2

Page 6

15 July 1994 SPECIFICATIONS

C218 Model C219 Model

Supplies: Master

Thermal master 320 mm width

225 masters/roll

Master length 540 mm/master

Max run length 2000 prints

Ink

800 cc ink pack (black)

500 cc ink pack

(red, blue, green, brown)

Master

Thermal master 280 mm width

250 masters/roll

(VT-ΙΙ M master)

Thermal master 240 mm width

250 masters/roll

(VT-ΙΙ S master)

Master length 480 mm/master

Max run length 2000 prints

Ink

800 cc ink pack (black)

500 cc ink pack

(red, blue, green, brown)

1-3

Page 7

DIFFERENCES BETWEEN THE #C210 MODEL AND #C218/C219 MODELS 15 July 1994

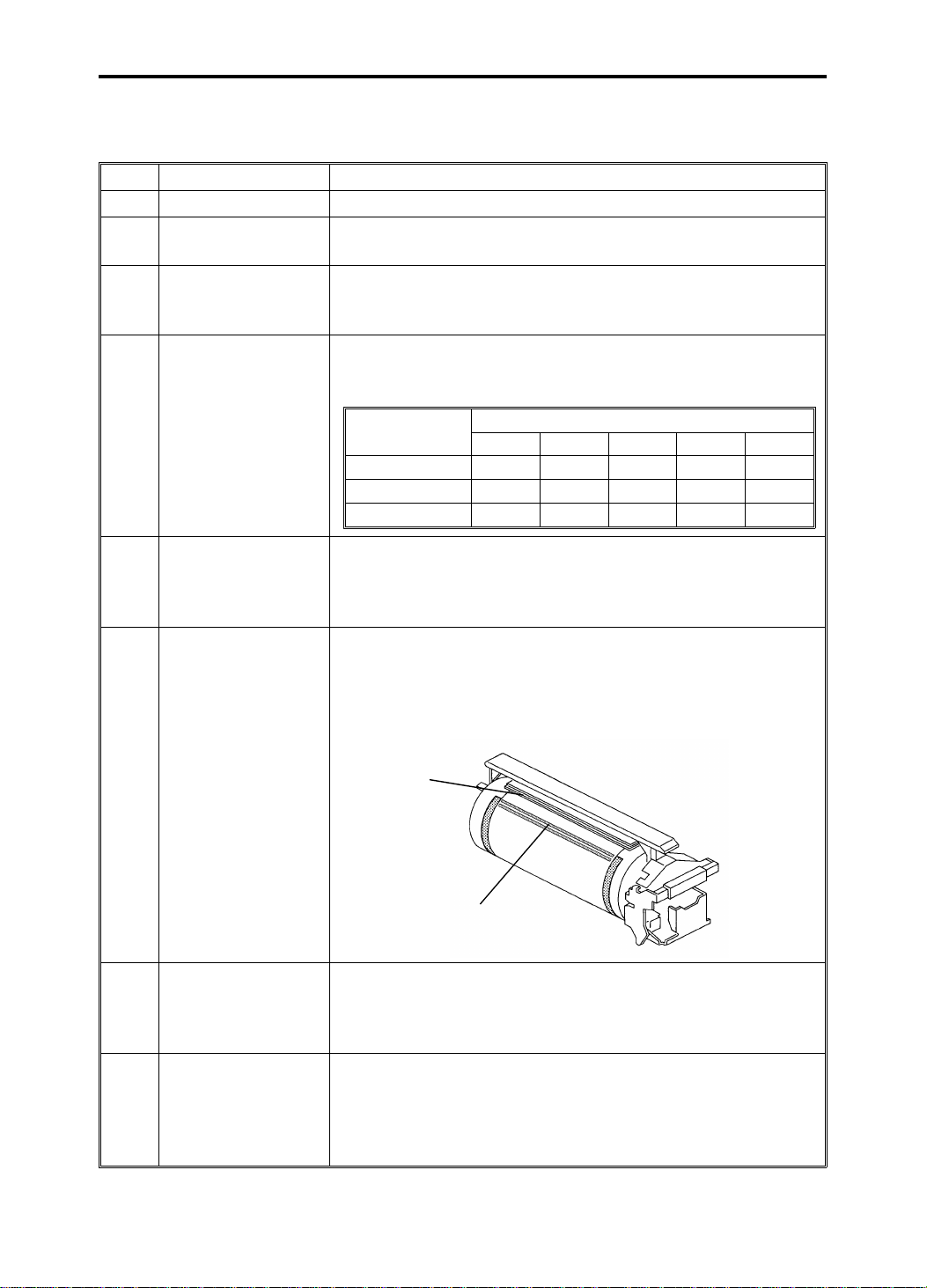

2. DIFFERENCES BETWEEN THE #C210

MODEL AND #C218/C219 MODELS

No. Item Remarks

1 Scanner A book type scanner is used (A3 size exposure glass).

Operation Panel The image shift key has been changed to the margin erase

2

Thermal Head The thermal elements used in C218/219 models are finer than

3

Printing Speed The print speed of 40 cpm is not used in C218 /C219 models.

4

key, which is a new feature added for the C218/C219 models.

those used in the C210 model. This is to reduce ink set-off on

the back sides of copies.

This reduces ink set-off, which is most likely to occur at low

printing speeds.

Model

C210 40 60 80 100 120

C218 60 75 90 105 120

C219 60 75 90 110 130

12345

Printing Speed

Drum Connector To ensure drum connection, a drum lock lever is added inside

5

Drum The rubber strip [A] has been added to the master clamper

the front door. To remove the drum from the machine, the

drum release lever must be pulled up to disconnect the drum

connector.

and the master stopper [B] (2 strips for C218, 1 strip for C219)

has been added to the surface of the drum.

This is to reduce master slipping when a high volume is

printed from the same master.

[A]

6

[B]

Ink Detection Board The location of the ink detection board has been changed

7

Paper Feed Table The paper table and the delivery table open/close detection is

8

from the upper side to the right side of the drum shaft. The ink

type switch which was not used (it was always set to the oil

type setting) has been removed.

done separately to enable paper table lowering regardless of

whether the delivery table is open or closed (C218 model).

Delivery table open/close detection is not available for the

C219 model.

1-4

Page 8

92

15 July 1994 DIFFERENCES BETWEEN THE #C210 MODEL AND #C218/C219 MODELS

SP Mode (Thermal

Paper Mode)

9

SP Mode (Sensor

Voltage)

10

Make-up Mode The image make-up mode has been made into an option. To

11

The following item is a difference only for the #C218 model.

Photo Mode The Photo Data Compensation Processor has been changed

12

The following items are differences only for the #C219 model.

Original Size

13

Detection

Paper Return

14

Mechanism

Paper Feed The paper feed pressure can be adjusted in three steps for

15

Wing Guide

16

(Delivery)

17 Air Knife Motor The number of air knife motors has been changed from 3 to 2.

Second Feed Roller The number of rollers on the second feed roller shafts has

18

Master Eject Roller The number of rollers on the master eject roller shafts has

19

To test the thermal head, SP Mode 92 has been added to

make a test print on the thermal paper without the master

clamp process.

SP-MODE

PROGRAM

SP modes 135 to 138 have been added to indicate the sensor

voltage on the operation display.

SP Mode No. 135: First Paper Exit Sensor

SP Mode No. 136: Second Paper Exit Sensor

SP Mode No. 137: Master Eject Sensor

SP Mode No. 138: Drum Master Detection Sensor

enable this mode, the IPU board must be replaced.

For the C218 model, up to 4 command sheets can be given

for an original.

For the C219 model, up to 2 command sheets can be given

for an original.

to improve image quality in the Photo mode.

The original size detection is eliminated for the C219 model.

The paper return mechanism has been eliminated for the

C219 model.

the C219 model.

The wing guide adjustment mechanism has been eliminated

for the C219 model.

been changed from 5 to 3.

been changed from 5 to 4.

Thermal Paper Mode

0: No 1: Yes 1

1-5

Page 9

GUIDE TO COMPONENTS 15 July 1994

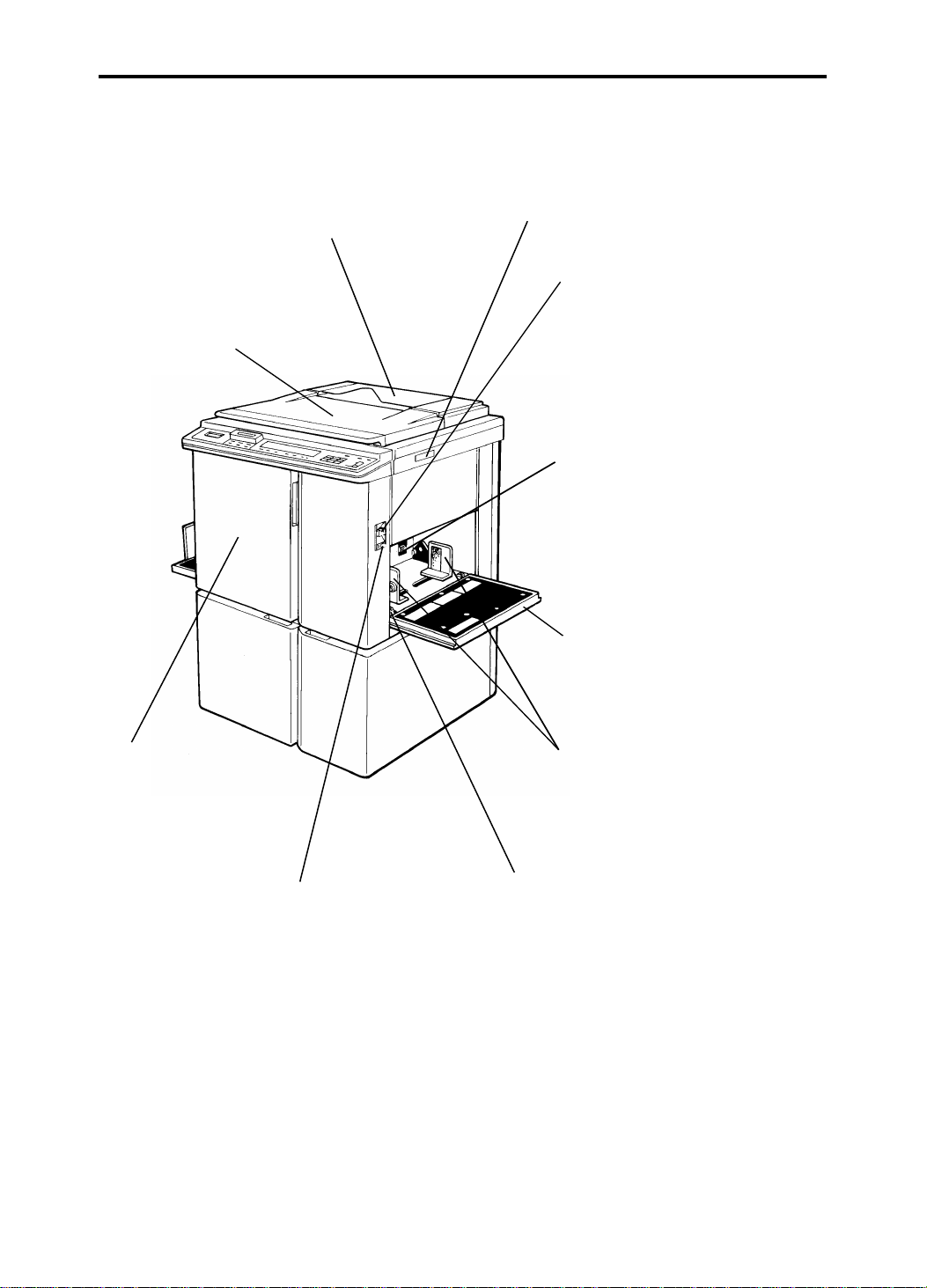

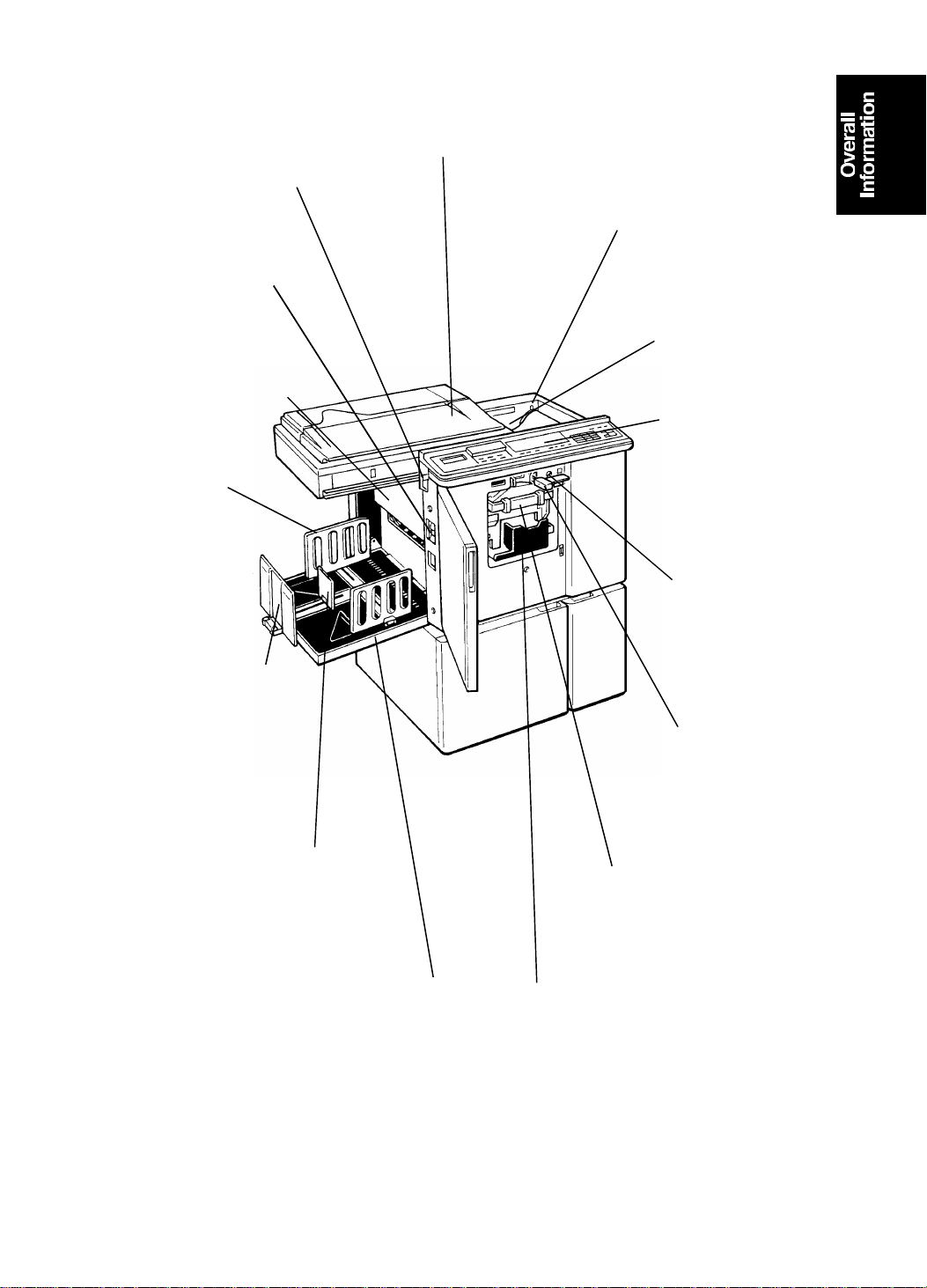

3. GUIDE TO COMPONENTS

Original Holder

A convenient place for

holding originals while

operating the mach ine.

Platen Cover

Lower this cover over

an original before

printing.

Original Table Release Lever

Use to open the original tab le

unit when installing the master.

Feed Roller Pressure

Lever

Use to adjust the contact

pressure of the paper fe ed

roller according to paper

thickness.

Separation Roller

Pressure Levers

Use to adjust the

separation roller

pressure to prevent

double feed.

Paper Feed Table

Set blank paper on this

table for printing.

Front Door

Open for access to

the inside of the

machine.

Paper Feed Table

Down Key

Press to lower the

paper feed table.

Paper Feed Side

Plates

Use to prevent paper

skew.

Side Plate Fine

Adjustment Dial

Use to shift the

paper feed table

sideways

1-6

Page 10

15 July 1994 GUIDE TO COMPONENTS

Master Eject Unit Open

Button

Press to remove misfed

paper or a misfed master.

Main Switch

Use to turn the

power on or off.

Master Eject

Container Cover

Open when removing

the master eject box.

Paper Deliver y

Side Plates

Use to align the

prints on the

paper delivery

table.

Paper Deliver y E nd

Plate

Use to align the

leading edge of prints

larger than A4, 81/2" x

11".

Small Size Paper Delivery

End Plate

Use to align the leading edge

of prints that are A4, 81/2" x

11" or smaller.

Original Table

Place the originals

on this table.

Master Cut Button

Press this button to cut

the master paper

leading ed ge after

installing a new master

roll.

Pressure Release

Lever

Use to install the

master roll.

Operation Panel

Operator controls

and indicators are

located here.

Drum Rotation

Button

Press to replace

the drum.

Drum Unit Lock

Lever

Lift to unlock and

pull out the drum

unit.

Drum Unit

The master is wrapped

around this unit.

Paper Deliver y Tabl e

Completed prints are

delivered here.

1-7

Ink Holder

Set the ink cartridge in

this holder.

Page 11

15

5

3

2

16

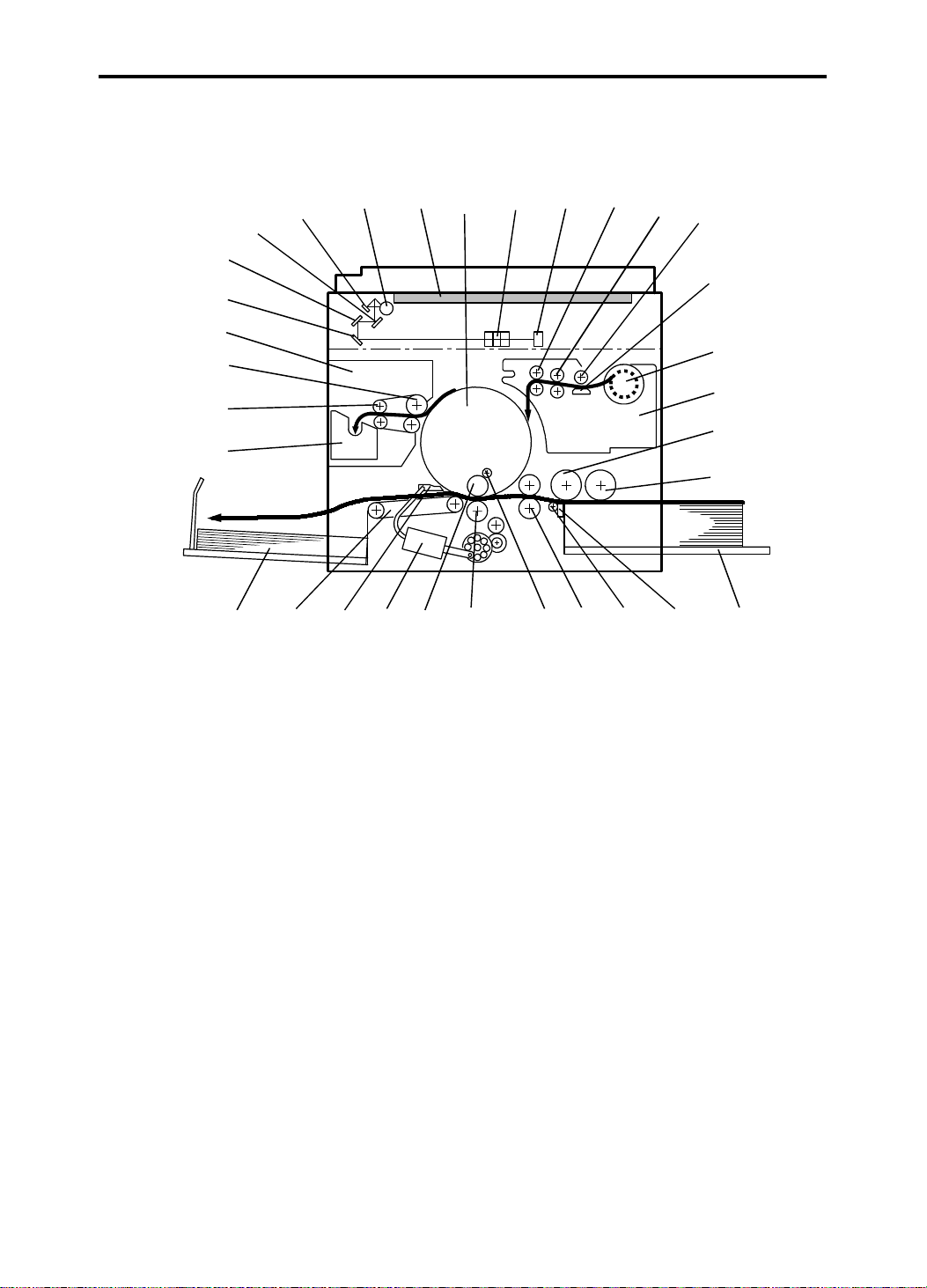

MECHANICAL COMPONENT LAYOUT 15 July 1994

4. MECHANICAL COMPONENT LAYOUT

30

29

28

27

26

25

24

23

2122

1. Drum Unit

2. Lens

3. CCD

4. Reverse Roller

5. Master Feed Roller

6. Platen Roller

7. Thermal Head

8. Master Roll

9. Plotter Unit

10. Upper Separation Roller

11. Paper Feed Roller

12. Paper Table

13. Separation Plat e

14. Lower Separation Roller

15. 2nd Feed Roller

16. Doctor Roller

31

20

32

19

18

1

17

17. Press Roller

18. Ink Roller

19. Paper Exit Pawl Air Pump

20. Paper Exit Pawl

21. Transport Unit

22. Paper Delivery Table

23. Master Eject Box

24. 2nd Eject Roller

25. 1st Eject Roller

26. Master Eject Unit

27. 3rd Mirror

28. 2nd Mirror

29. 1st Mirror

30. Reflector

31. Fluorescent Lamp

32. Exposure Glass

4

14

13

6

7

8

9

10

11

12

1-8

Page 12

543

15 July 1994 ELECTRICAL COMPONENT LAYOUT

5. ELECTRICAL COMPONENT LAYOUT

1

9

2

8

7

6

1. Scanner Motor

2. Fluorescent Lamp Stab ilizer

3. CCD PCB

4. Platen Cover Position Sensor

6. Original Sensor

7. ADF Set Sensor

8. Scanner Home Position Sensor

9. Fluorescent Lamp

5. A/D Conversion PCB

COMPONENT DESCRIPTIONS

Index No. Name Function

1

4

Scanner Motor Drives the scanner (1st and 2nd).

Platen Cover

Position Sensor

Detects when the pla ten cover is

opened ab out 25° above the exposure

glass.

6

Original Sensor Detects if an original is placed on the

exposure glass.

7

ADF Set Sensor Detects when the optional document

feeder is closed.

8

Scanner Home

Position Sensor

Informs the CPU when the 1st scanner

is at the home position.

1-9

Page 13

2

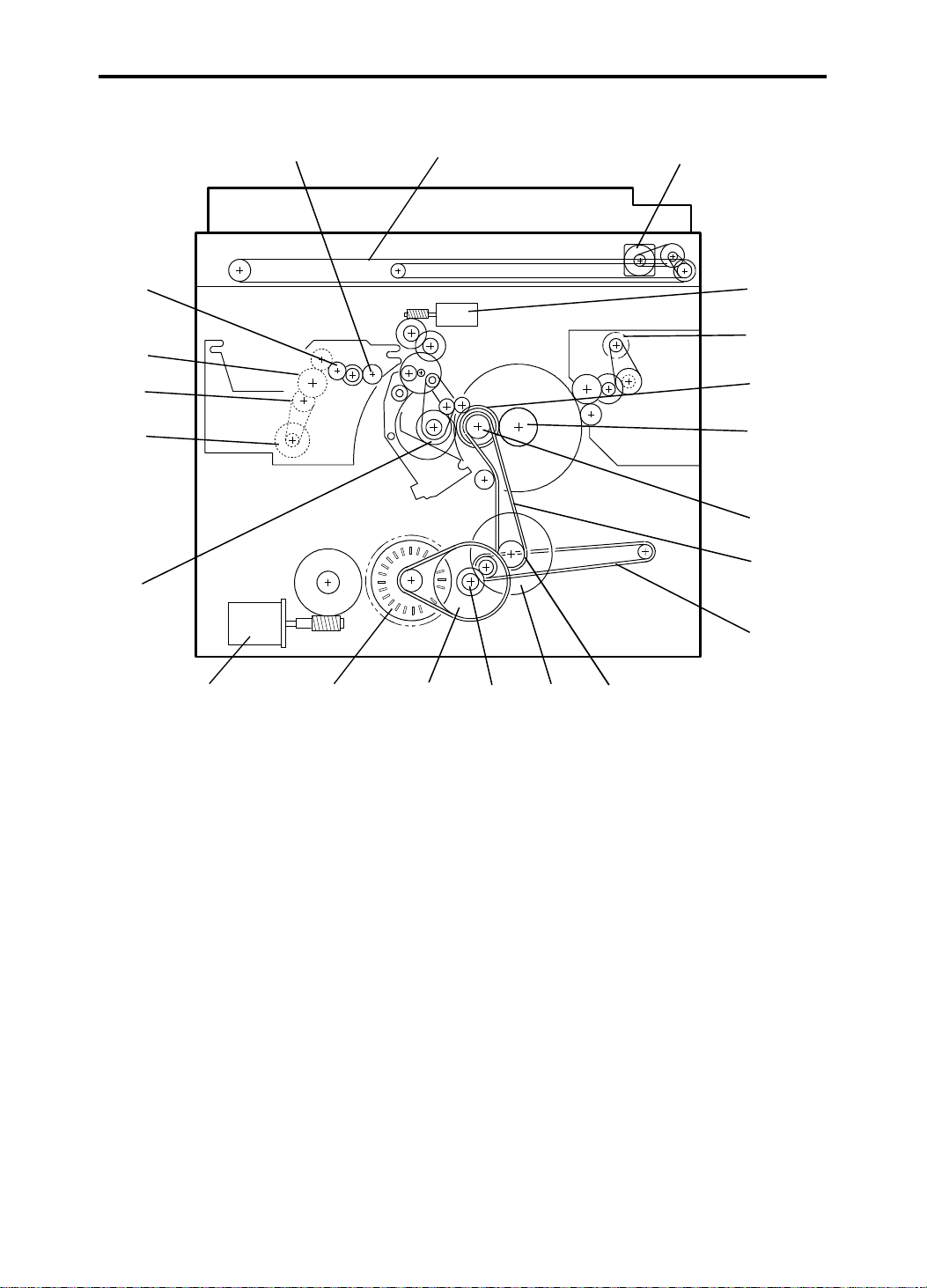

DRIVE LAYOUT 15 July 1994

6. DRIVE LAYOUT

20

19

18

17

16

21

1

3

4

5

6

7

8

9

15

1. Scanner Belt

2. Scanner Motor

3. Image Position Motor

4. Master Eject Motor

5. Drum Drive Gear

6. Drum Unit Gear

7. Drum Drive Pulley

8. Main Drive Belt

9. Transport Belt

10. Printing Pressure Pulle y

11. Printing Pressure Gear

14

13 12

12. Idle Gear

13. Idle Pulley

14. Main Motor

15. Paper Table Drive Motor

16. Paper Feed Cam Gea r

17. Master Feed Motor

18. Timing Belt

19. Platen Roller Gear

20. Master Transport Roller Gear

21. Reverse Roller Gear

11

10

1-10

Page 14

SECTION 2

DETAILED SECTION

DESCRIPTIONS

Page 15

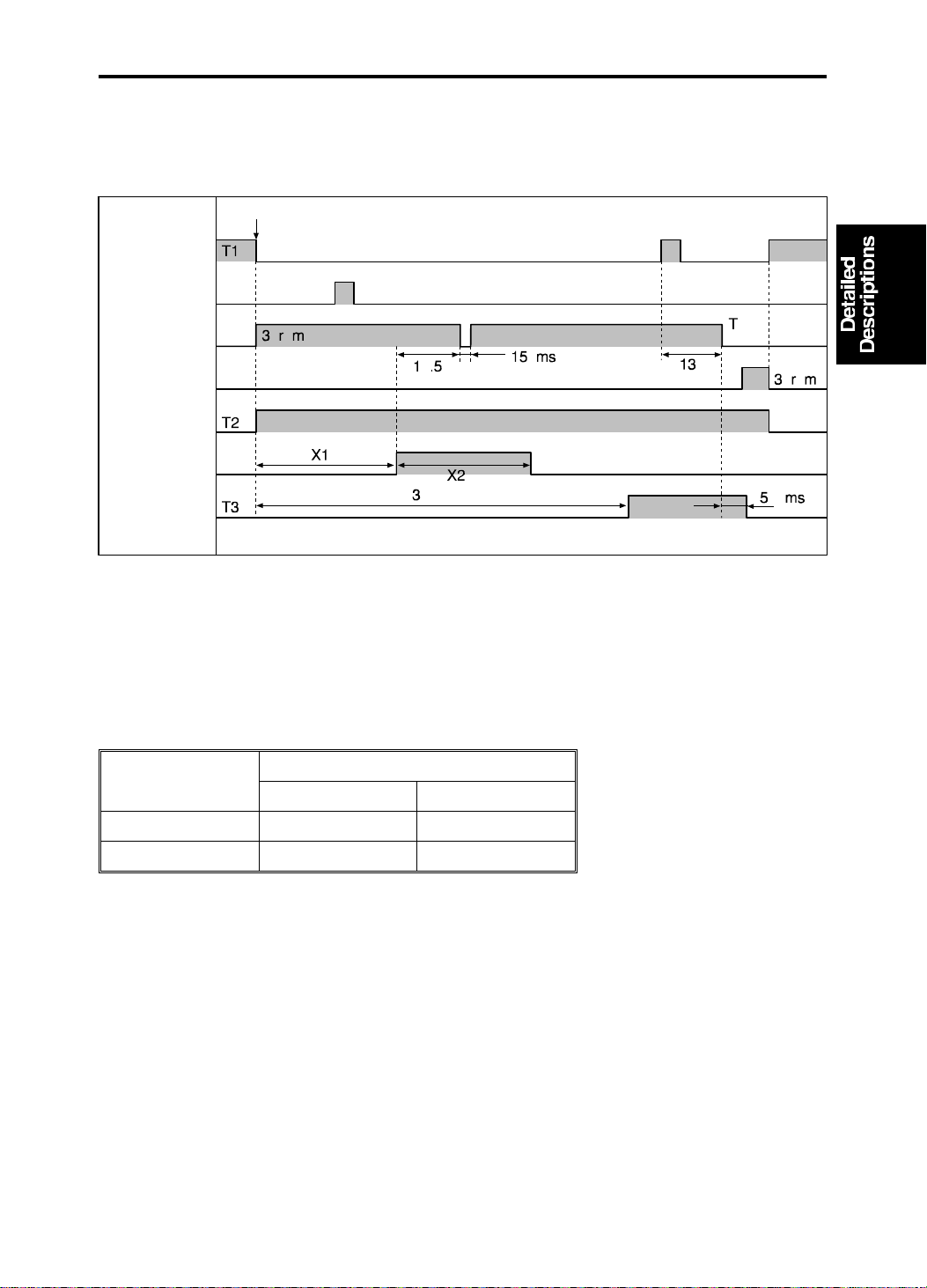

15 July 1994 MASTER EJECT

1. MASTER EJECT

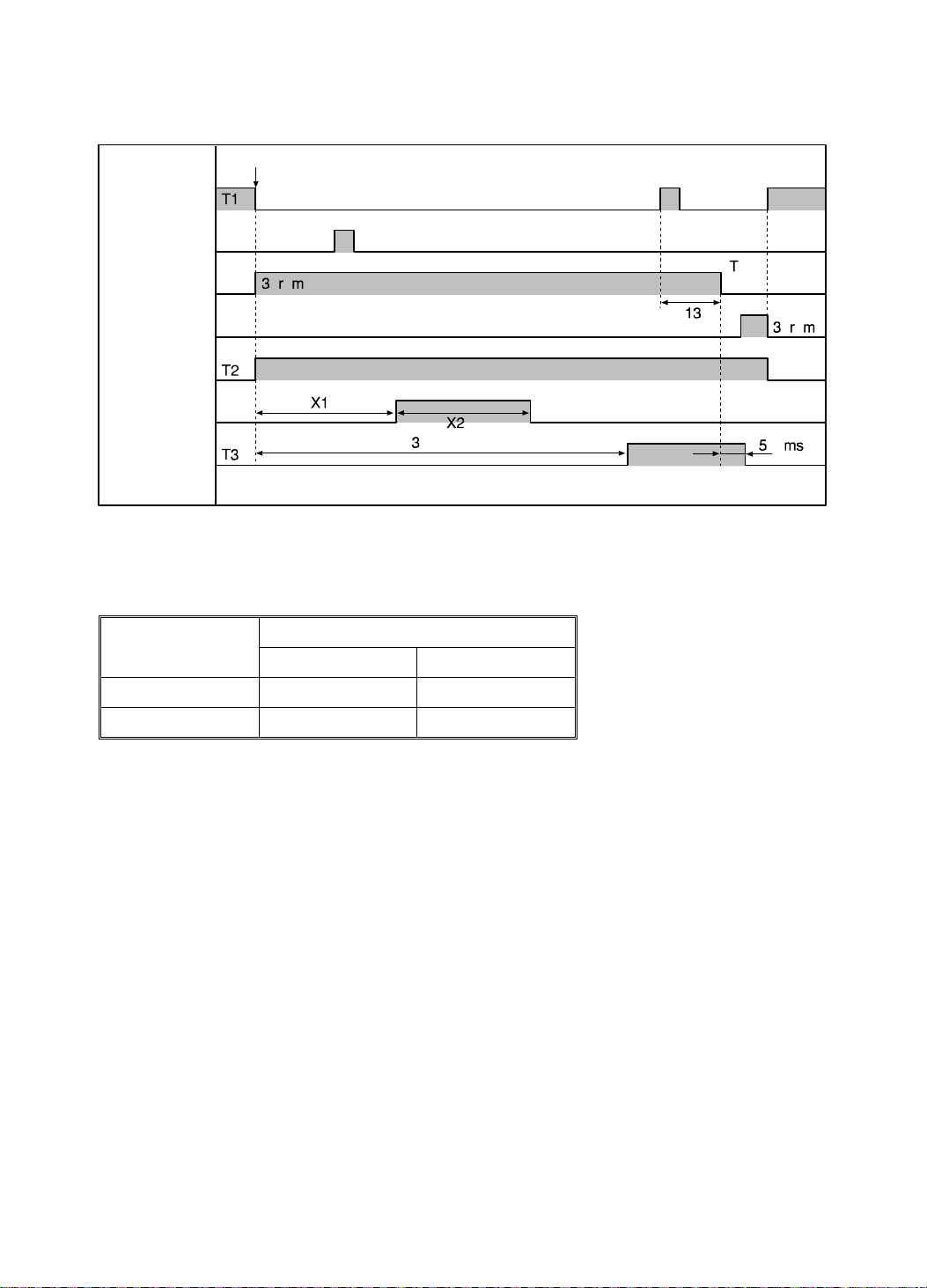

1.1 ELECTRICAL TIMING: #C21 8 MODELS

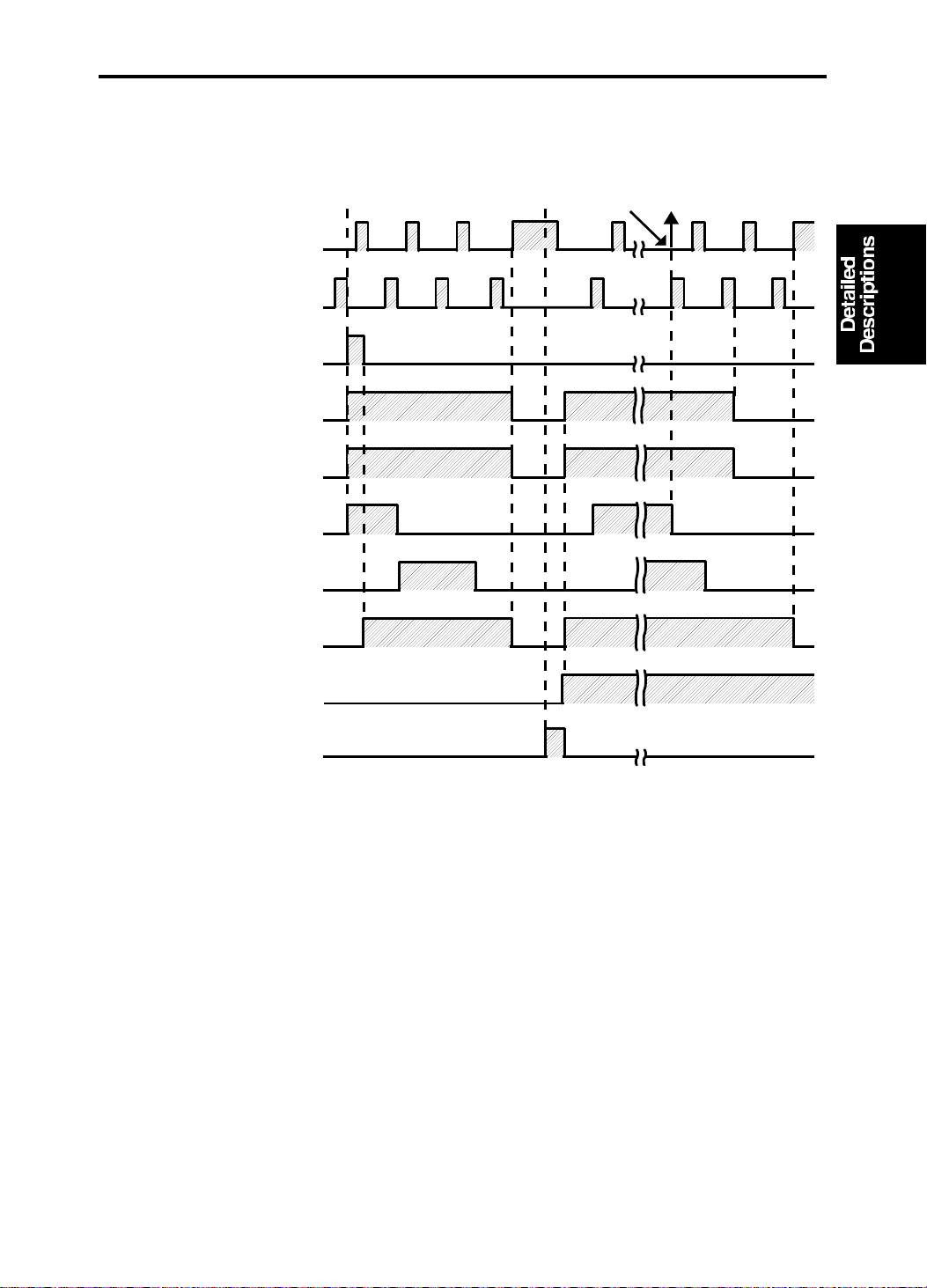

First Drum

Position Senso r

Second Drum

Position Senso r

Main Motor

Reversing

Main Motor

Advancing

Master Eject

Motor

Master Eject

Solenoid

Master Eject

Clamper

Solenoid

The drum stops its reverse rotation for 150 ms when the tra iling edge of the

master is about 5 millimeters away from th e mast er eject rollers to ensure

that the master eject process is successf ul (only for #C218 models).

Drum Type

#C218 Models

A3/DLT A4/LT

X1 (degrees) 70 174

X2 (degrees) 39 55

2-1

Page 16

MASTER EJECT 15 July 1994

1.2 ELECTRICAL TIMING: #C21 9 MODELS

First Drum

Position Senso r

Second Drum

Position Senso r

Main Motor

Reversing

Main Motor

Advancing

Master Eject

Motor

Master Eject

Solenoid

Master Eject

Clamper

Solenoid

Drum Type

#C219 Models

B4 LG

X1 (degrees) 85 85

X2 (degrees) 55 55

2-2

Page 17

[D]

15 July 1994 SCANNER

2. SCANNER

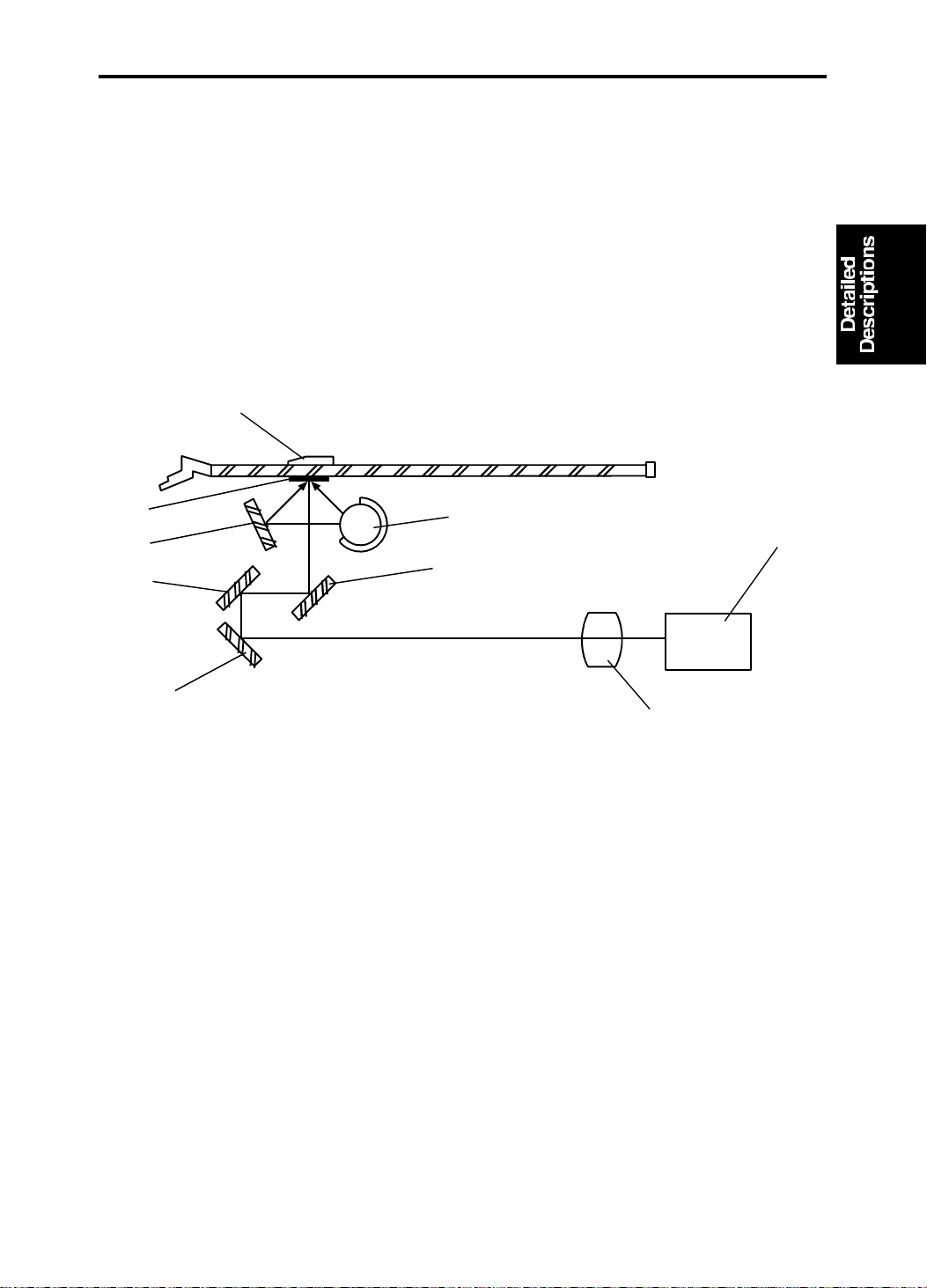

2.1 OVERALL

A book type scanner is used for the #C218/#C219 mod els. There are 2

modes for scanning origina ls.

Platen Cover Mode: The original is placed on the exposu re glass, and the

scanner motor drives the scanner to scan the original.

ADF Mode: When an optional Docu men t Fee de r is installed, the original is

fed onto the exposure gla ss. The scann er move s 24 mm away from the CCD

and remains still as it scans the original. The scanner comes back to the

home position when the scanning is finished.

[H]

[G]

[F]

[E]

The light from the fluoresce nt lamp [A ] is re fle cte d fro m t he origin al, by the

first [B], second [F], and th ird [E ] mirrors an d goes th rou gh the lens [D] into

the CCD [C].

[I]

[A]

[C]

[B]

[G]: Reflector

In the Platen Cover Mo de , th e CCD re ad s the white plate [H] on the back of

the original scale [I] each time be fo re scanning to obtain a standa rd white

level. The standard white data are used to corre ct dist ortion. The scanner is

at its home position when it rea ds th e white level.

In the ADF mode, as the scanner move s 24 mm, th e CCD read s the wh ite

plate installed on the ADF.

2-3

Page 18

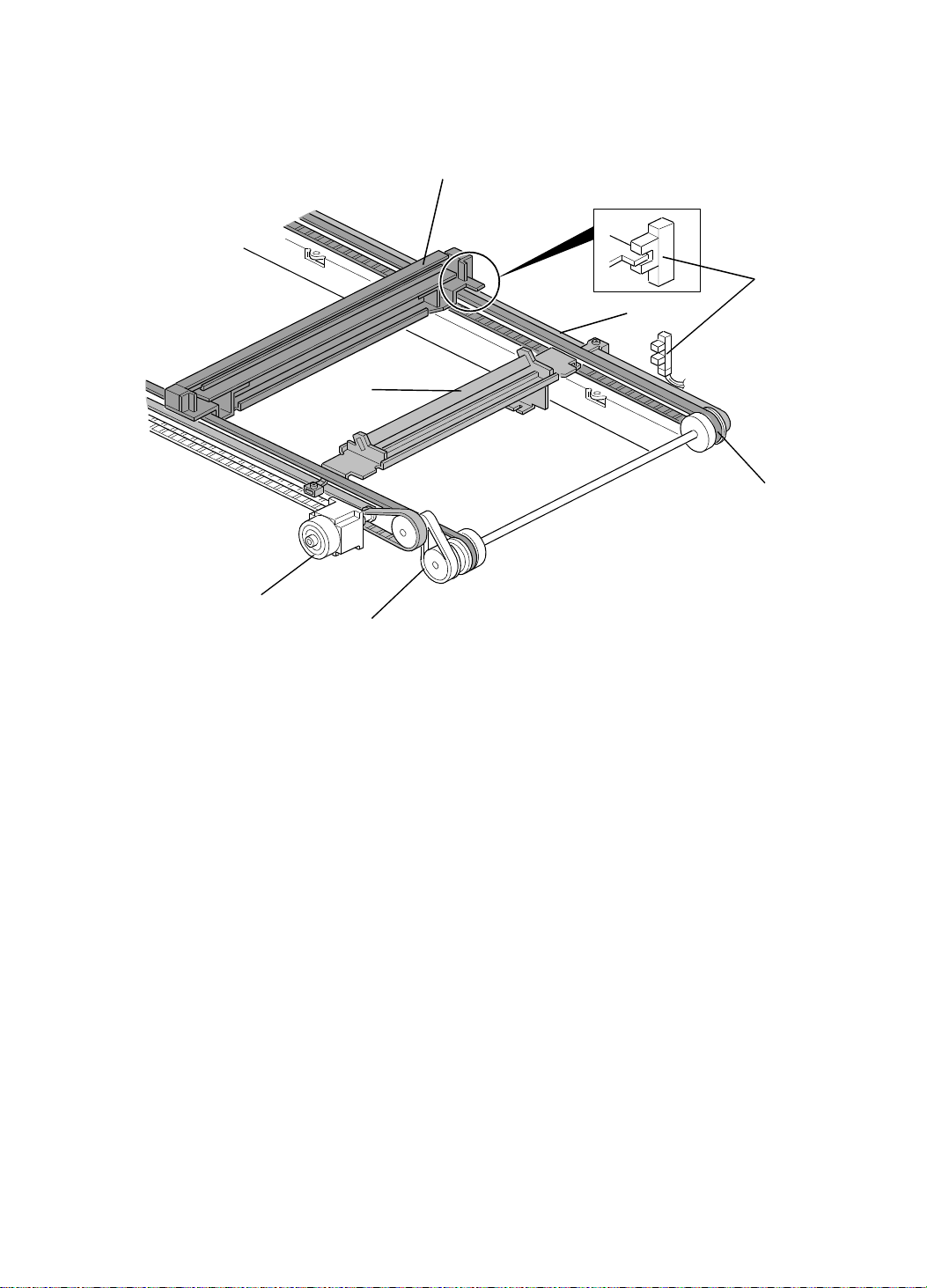

SCANNER 15 July 1994

2.2 SCANNER MECHANISM

[B]

[Front Side]

[E]

[D]

[C]

[F]

[Rear Side]

[A]

[G]

A stepper motor is used fo r the scann er motor [A] to drive the scanners. The

first scanner [B], which consist s of th e exp osu re lamp and the first mirror, is

driven by the first scanner belt [F]. The seco nd scann er [C] , which consists of

the second and the th ird mirror, is driven by the second scanner belt [D] . Bo th

scanners move along the gu ide rails.

The timing belt [G] moves t he secon d scanner at half the velocity of the first

scanner. This is to maintain the focal distance between th e orig inal and the

lens during scanning.

The scanner home position is detected by the home positio n sensor [E]. In

the Platen Cover Mode, the scanner scans the original on the exposure glass

for the full A3 lengt h, then returns until the scann er ho me po sitio n sensor is

activated. In the ADF Mod e, the scanner moves 24 mm backwards (away

from the CCD), to scan the original which is fed by the ADF. When the

master making process is finishe d and the ADF motor stops, the scanner

goes back to the home position.

2-4

Page 19

15 July 1994 SCANNER

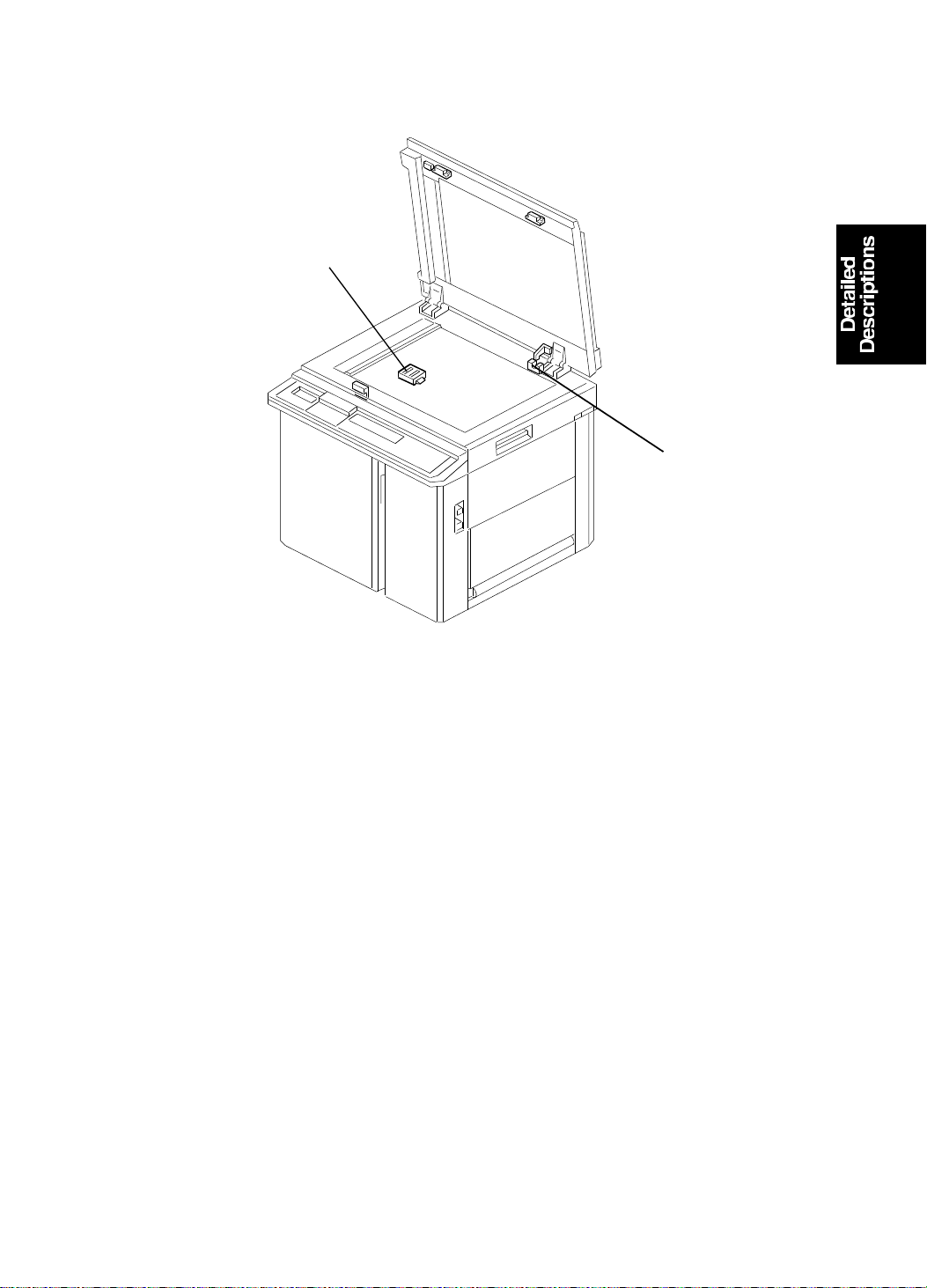

2.3 PLATEN COVER POSITI ON DETECTION

[B]

[A]

When the platen cover is opene d ab ou t 25 deg rees, the Platen Cover

Position Sensor [A] is deactiva ted. When this sensor is deactivate d, the

Original Sensor [B] is able to det ect the origin al on the expo sure glass.

When the Platen Cover Position Sensor is deactivat ed and the Origin al

Sensor detects no original on the expo sure glass, the machin e indicates

"SET THE ORIGINALS" on the operat ion displa y. This is t o pre ven t wast ing

of the master that wo uld occur whe n the Master Making key is pressed with

no original placed on the exposure glass.

When the original is placed on the expo sure glass and the Master Making

key is pressed with the pla te n cover opened more than 25 degrees (a s the

Platen Cover Position Senso r is deact ivat ed ), th e shadow erase function is

enabled.

2-5

Page 20

SCANNER 15 July 1994

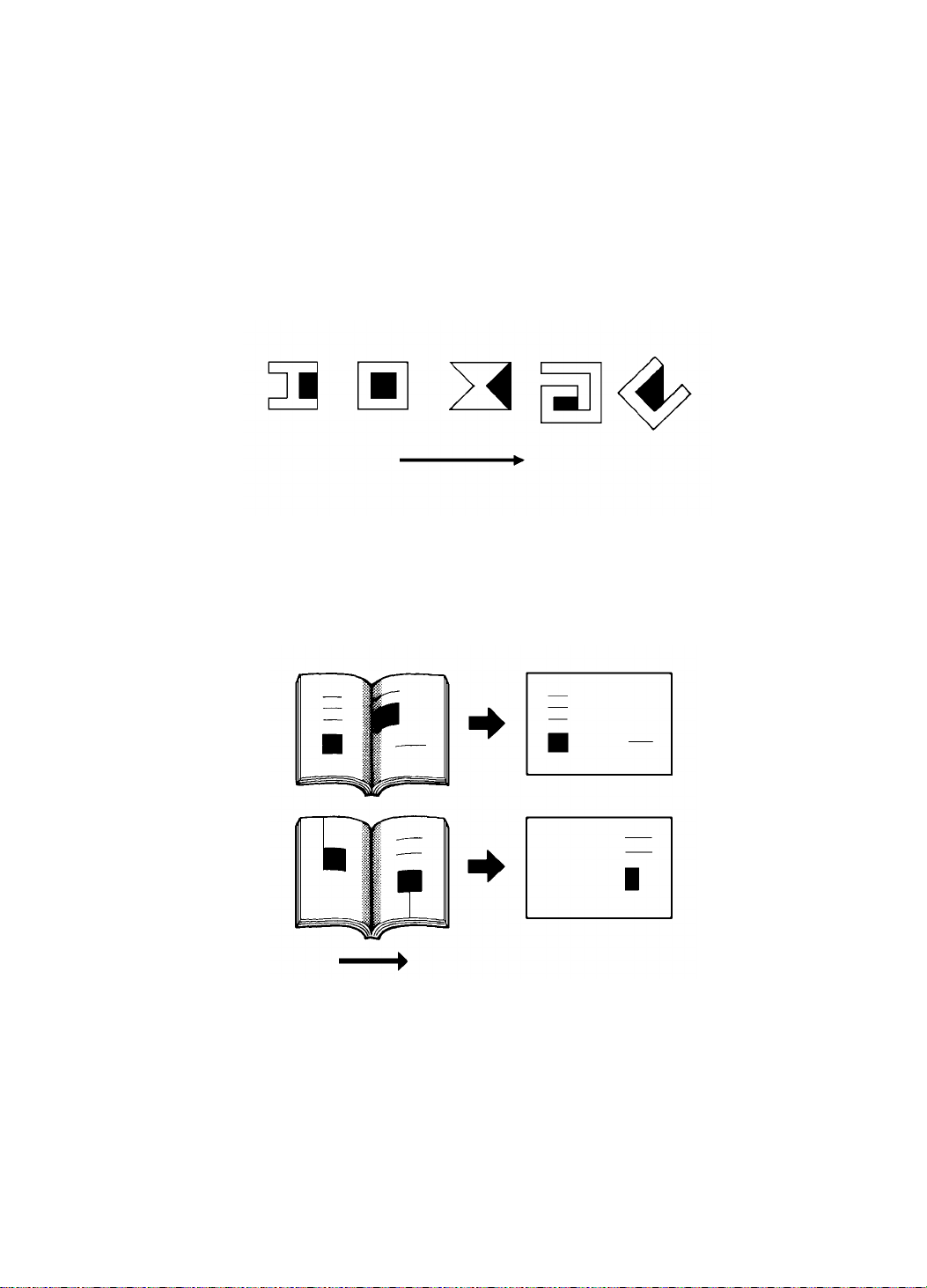

Notes regarding the shadow erase function:

• Margins of 1 mm, 0.02" on all four sides of the original will be erased. The

width of the margins will change depending on the rep rod uction ratios.

• Shadows near the book edge might not be erased complet ely.

• If the shape of the originals are as sho wn be low, shadows might appear

on the prints. In this case, make the master with the platen cover clo sed .

Shadow

Scanning directio n

• If a line or solid image is on the margin at the center and at the edges

being erased, the image might be erased as shown below.

Scanning directio n

2-6

Page 21

Scanner HP

15 July 1994 SCANNER

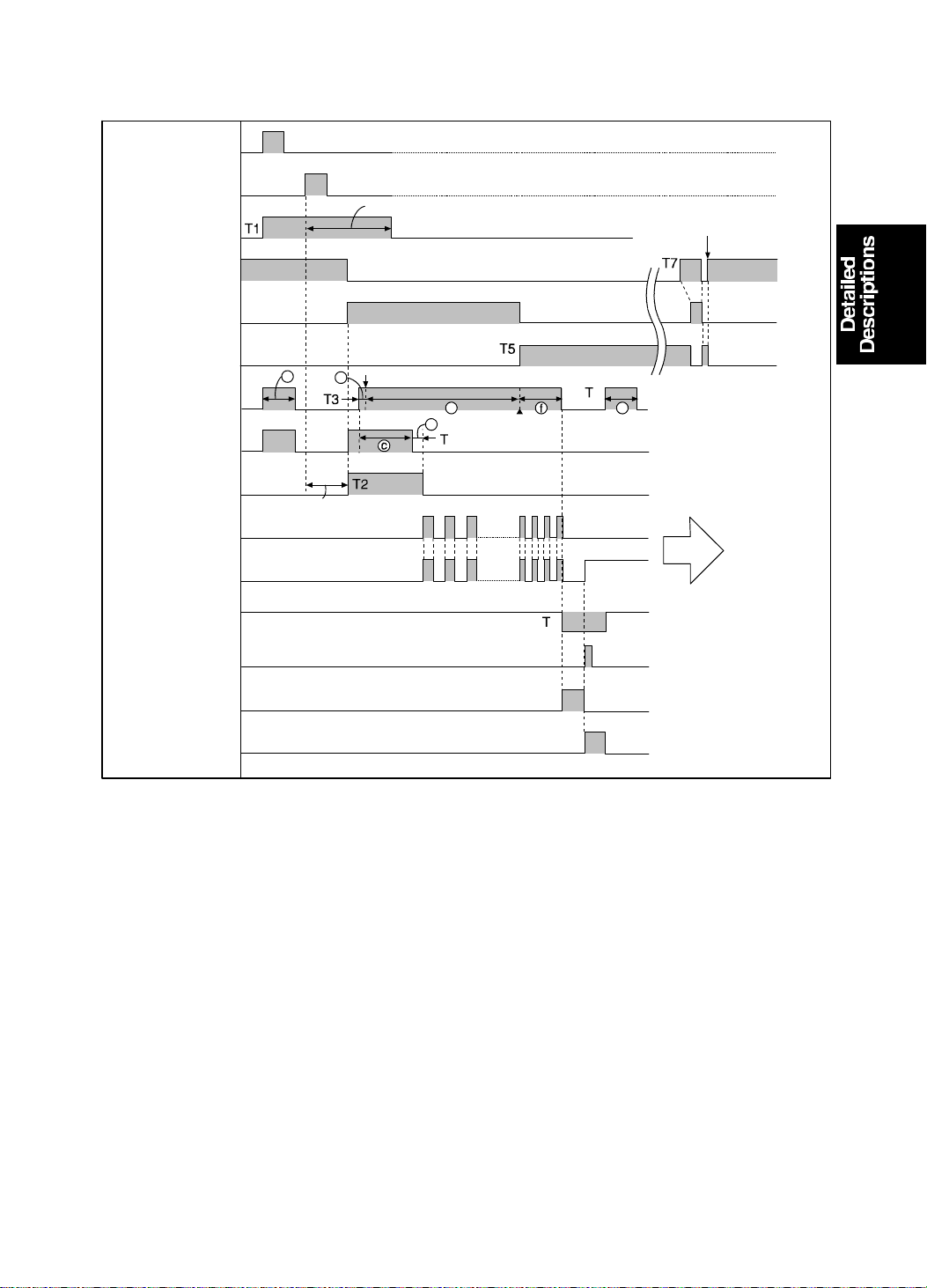

2.4 ELECTRICAL TIMING

First Drum

Position Sensor

Second Drum

Position Sensor

Main Motor

Reversing

Scanner Home

Position

Scanner Motor

Scanner Motor

Reversing

Master Feed

Motor

Reverse Roller

Clutch

Master Feed

Clamper Solenoid

160° of Drum Rotation

Buckle Sen sor

Main Motor

Advancing

Left Cutter

Switch

Right Cutter

Switch

218.5° of Drum Rotation

Plotting Start

Plotting Max.

To Trial Print

Cutter Motor

Cutter Motor

Reversing

For C218 model a: 21.5 mm b: 0.9 mm For C219 model a: 18.5 mm b: 1.0 mm

e: 412 mm f: 60 mm e: 359 mm f: 61 mm

g: 40 mm c: 38 mm g: 40 mm c: 41 mm

d: 5 mm d: 5 mm

T1: After the master eject process is completed, the main moto r st art s

reverse rotation at 30 rpm. At th e same time, the master feed motor and

the reverse roller magnetic clutch tu rn on to feed the ma ste r 21. 5

millimeters (18.5 mm for the C219 model).

T2: The master feed clamp er sole no id is e ne rgize d when the drum rotates

160 degrees past the second drum position sensor (162 degrees for the

C219 model). At the same time, th e reve rse roller magnetic clutch is

turned on and th e scanner motor starts t o rot ate.

2-7

Page 22

SCANNER 15 July 1994

T3: When the scanner has move d 20 millimeters from its home position (17

mm for the C219 model), the master starts to be fed. When the maste r

has been fed 0.9 millimeters (1.0 mm for the C219 model), the thermal

head starts plotting on the mast er.

The leading edge is zero when the sca nner is 12 millimet ers from its

home position. The leading edge margin can be adjusted within the rang e

of 4 to 10 millimeters by SP mode No.33.

T4: When the master has been fed 38 millimeters (41 mm for C219 models),

the reverse roller magnetic clutch tu rns of f. Then the master is fed 5

millimeters more and the master feed clamper solenoid is de-energized to

close the master clamper. The master is fed in the same way as in #C210

models. The original transp ort and the maste r f eed mot ors speed up once

the master plotting is done. The master feeding lengths for plotting are:

For #C218 models

412 millimeters: A3/DLT dru m

204 millimeters: A4/LT dru m

For #C219 models

355 millimeters: for both B4 and LG drums

T5: When the scanner has scanned the fu ll scanning length (the sa me len gth

as the master feeding length), the scanner motor starts its reve rse

rotation to bring back th e scanner to the home position.

T6: The master feed mot or stops when the master has been fe d 53 4.4

millimeters (479.5 mm for the C219 model). At the same time, the cut te r

motor starts rota tin g to cut the master. The cutter motor changes its

rotation direction when th e cut ter h old er pu she s the right cutt er switch.

The cutter motor st ops wh en the cutt er ho lder goes back to the home

position to activate the left cutter switch (the same wa y as in #C210

models).

When the right cutter switch is activated, the drum starts rotatin g to go

back to its home position . Whe n the left cutter switch is activa te d (when

the cutter comes back to it s home position), the master fe ed motor turns

on again to feed the master 40 millimeters.

T7: When the scanner moto r st ops it s reverse ro ta tio n, the scanner motor

rotates forward until th e scanner home position sensor is activat ed .

2-8

Page 23

[D]

[E]

15 July 1994 SCANNER

2.5 CIRCUIT

[A]

[B]

[C]

AD Conversion PCB

Image Processing PCB Main PCB

Scanner Motor

Component

Name

Fluorescent

Lamp [A]

Fluorescent

Lamp [A]

Original Sensor

[B]

Scanner HP

Sensor [C]

Platen Cover

Position Sensor

[D]

ADF Set Sensor

[E]

I/O

A/D Conversion PCB

CN No. Signal Level

Out 601-b10

Out 608-3

In 602-4

In 602-2

In 605-B9

In 602-8

0V

24V

0V

0V

0V

5V

Description

5V

Signal goes high when the lamp on

signal turns on.

Signal goes low when the lamp on

signal turns on.

0V

5V

Signal goes high when the sensor

detects an original.

5V

Signal goes high when the sensor

detects an original.

Signal goes high when the sensor

5V

detects an original.

Signal goes low when the lead

switch is turned on.

0V

2-9

Page 24

[E]

DRUM 15 July 1994

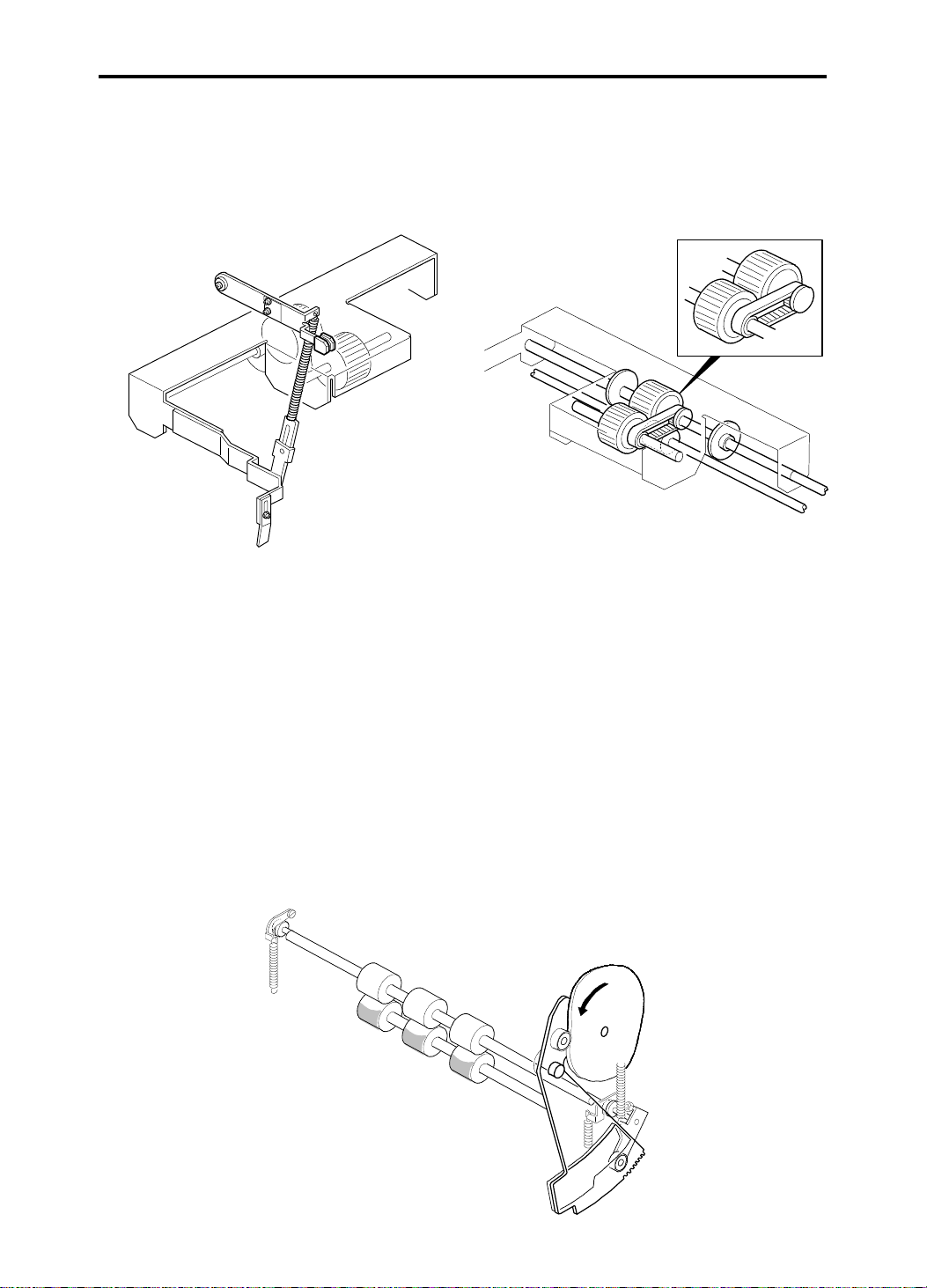

3. DRUM

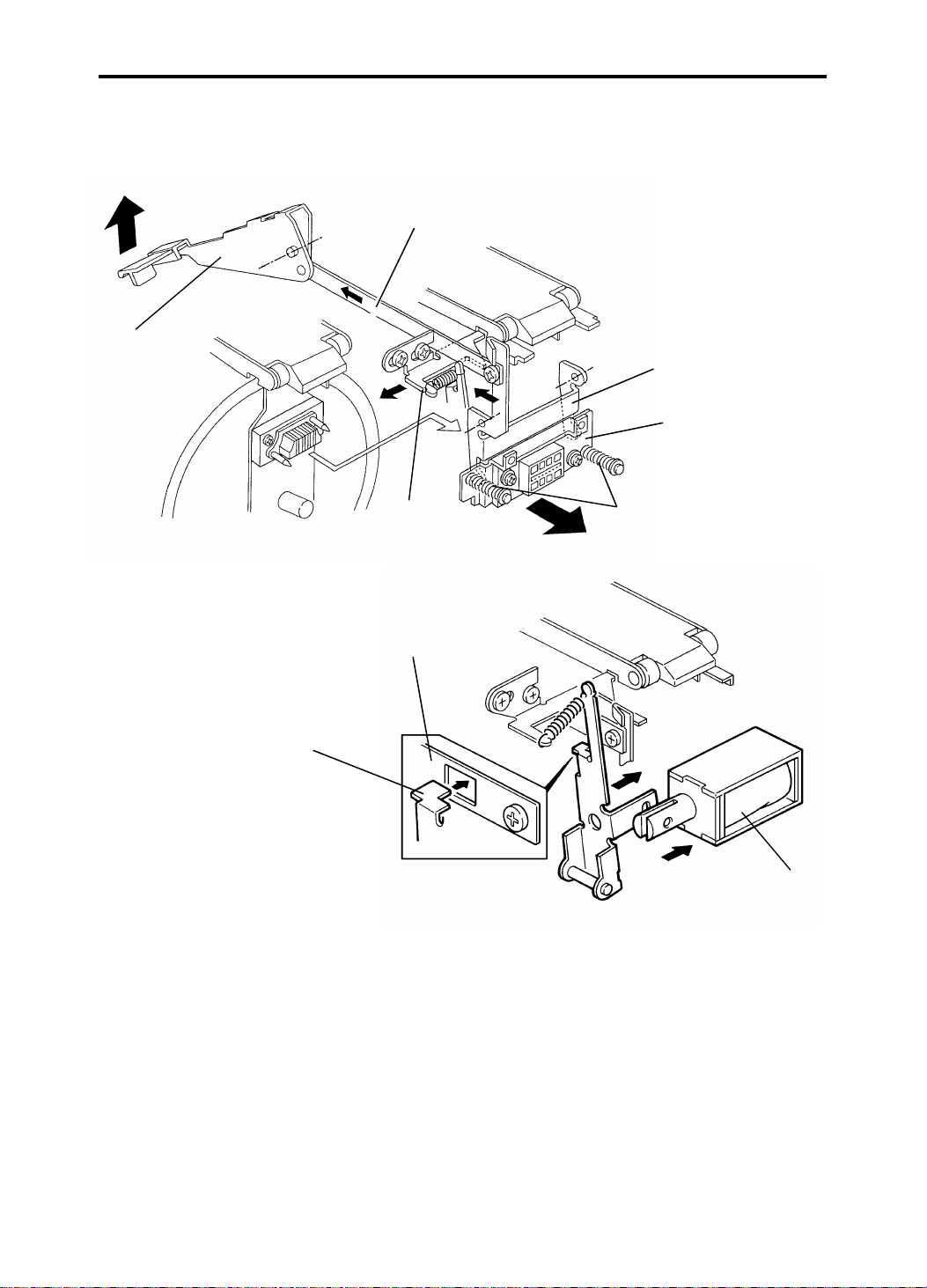

3.1 DRUM CONNECTION MECHANISM

[D]

[A]

[C]

[B]

[F]

[D]

[H]

[G]

When the drum release lever [A] in fro nt of th e mach ine is raised, the

connector [B] is push ed away fro m t he drum by th e bra cket [C] through the

link [D], and is disconnected. The bracke t [C] also pu she s the drum lock leve r

[F] to release the dru m lock allowing the drum to be removed. Wh ile th e drum

is away from its home position, the drum lock solenoid [G] is energized and

the stopper [H] locks the link [D] to preven t th e dru m from be ing pulle d out.

The solenoid is de-energized when the drum stops at th e ho me po sitio n

(when the 1st drum position senso r is act uated).

2-10

Page 25

15 July 1994 DRUM

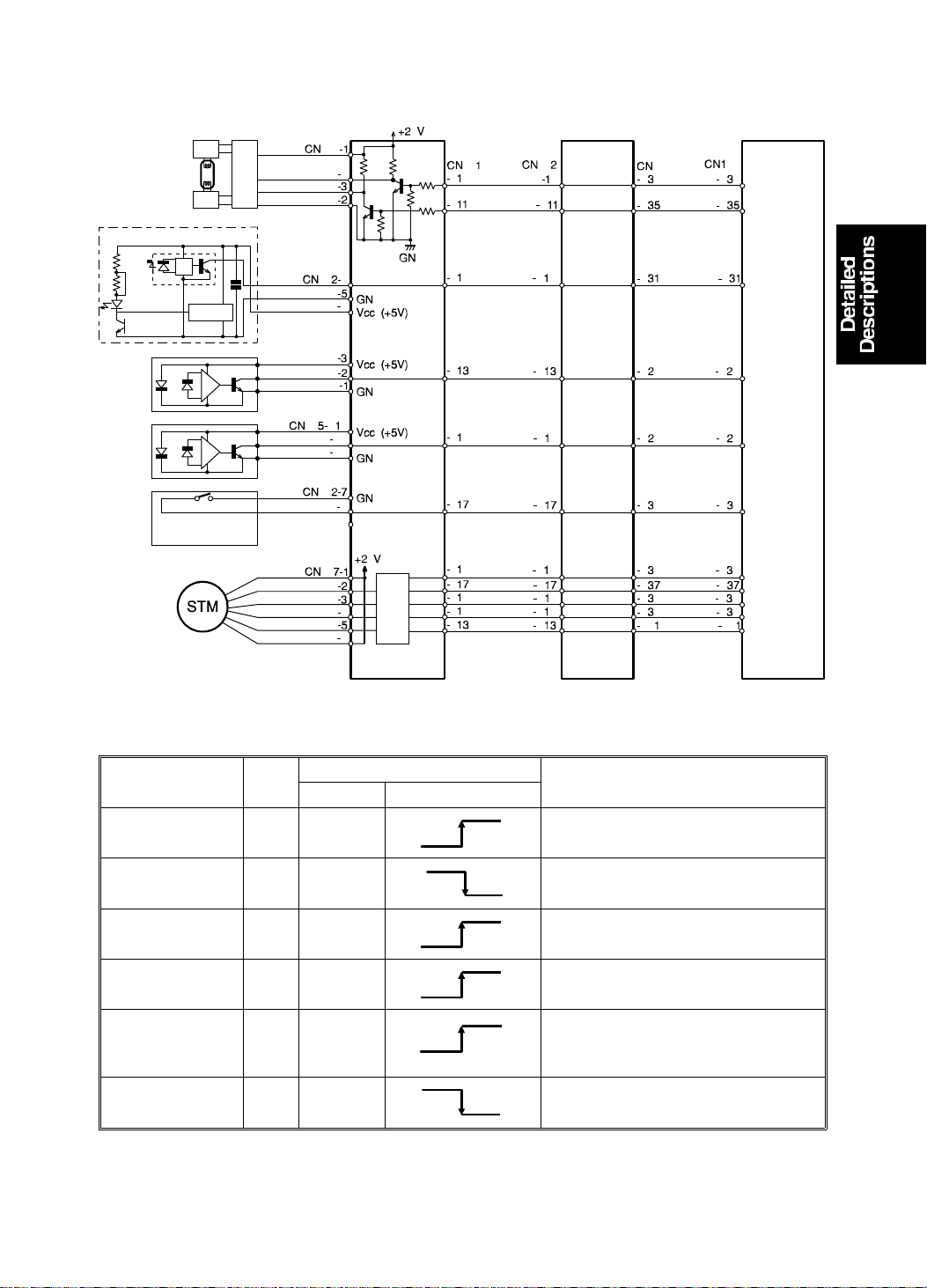

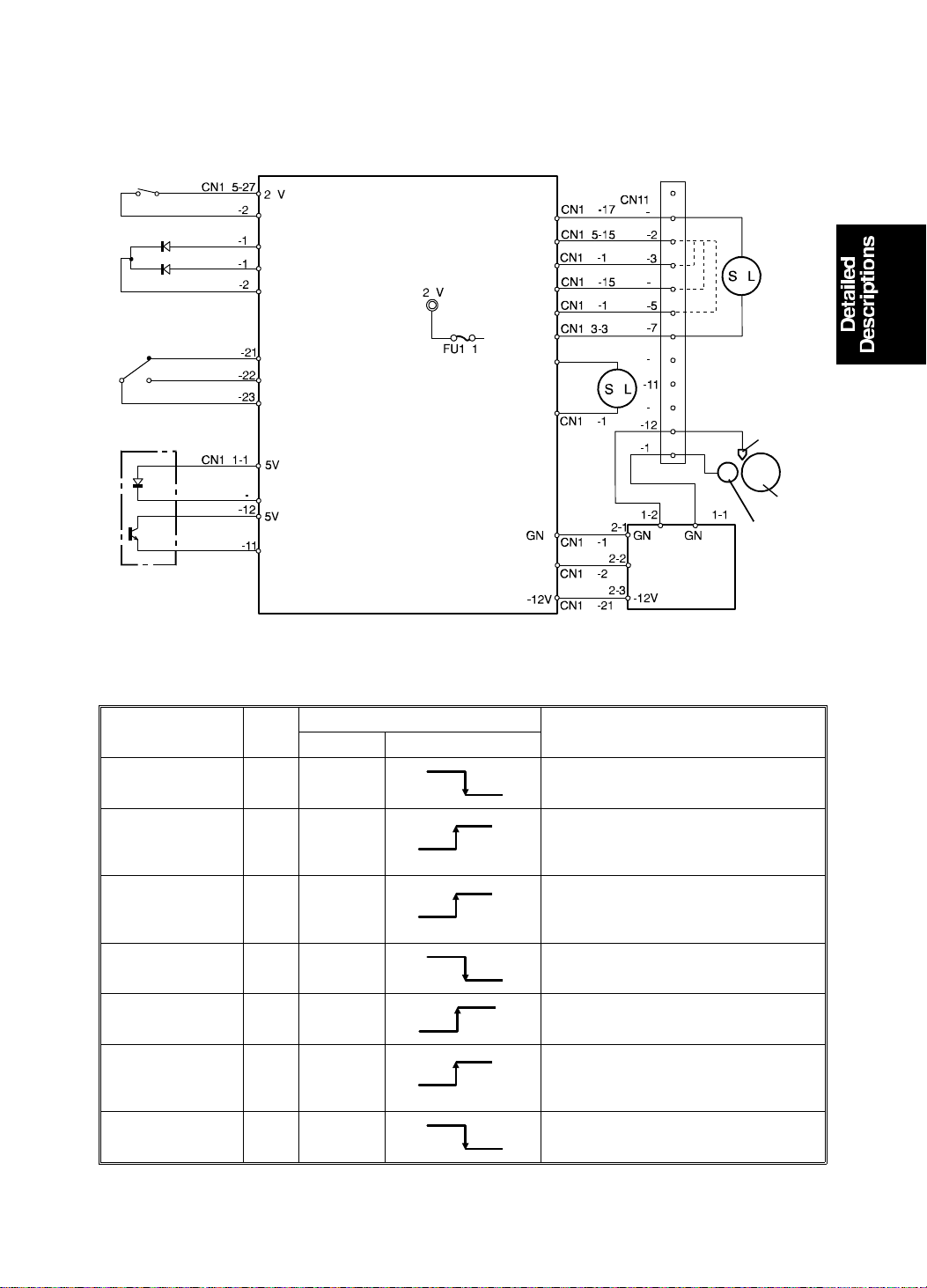

3.2 CIRCUIT FOR #C218 MODE LS

Main PCB

[A]

(Drum Unit Connector)

[B]

Common

[C]

Common

[D]

LED Drive

Component

Name

Drum Detection

Switch [A]

I/O

CN No. Signal Level

In 105-26

Drum Rotation

LED (Red) [B] Out 105-18

Drum Rotation

LED (Green) [B] Out 105-19

Drum Rotation

Button (N.C.) [C]

Drum Rotation

Button (N.O.) [C]

In 105-21

In 105-22

Drum Master

Detection

In TP102

Sensor [D]

Ink Supply

Solenoid [E]

Out 104-17

Main PCB

24V

0V

0V

24V

0V

0V

24V

[F]

(Drum Unit

Frame)

Ink Detection PCB

Description

Signal goes Low when the drum

0V

unit is slid out.

Signal goes High when the drum is

2.8V

not in the home position. (The LED

lights red.)

Signal goes High when the drum is

2.8V

in the home position. (The LED

lights green.)

Signal goes Low when the button

is pressed.

0V

24V

Signal goes High when the main

switch is turned on.

The voltage between TP102 and

2.5V

ground becomes more than 2 volts

when a master is on the drum.

Signal goes Low when the

solenoid is energized.

0V

[E]

Ink

Detecting Pin

[G]

Ink Roller

Doctor Roller

2-11

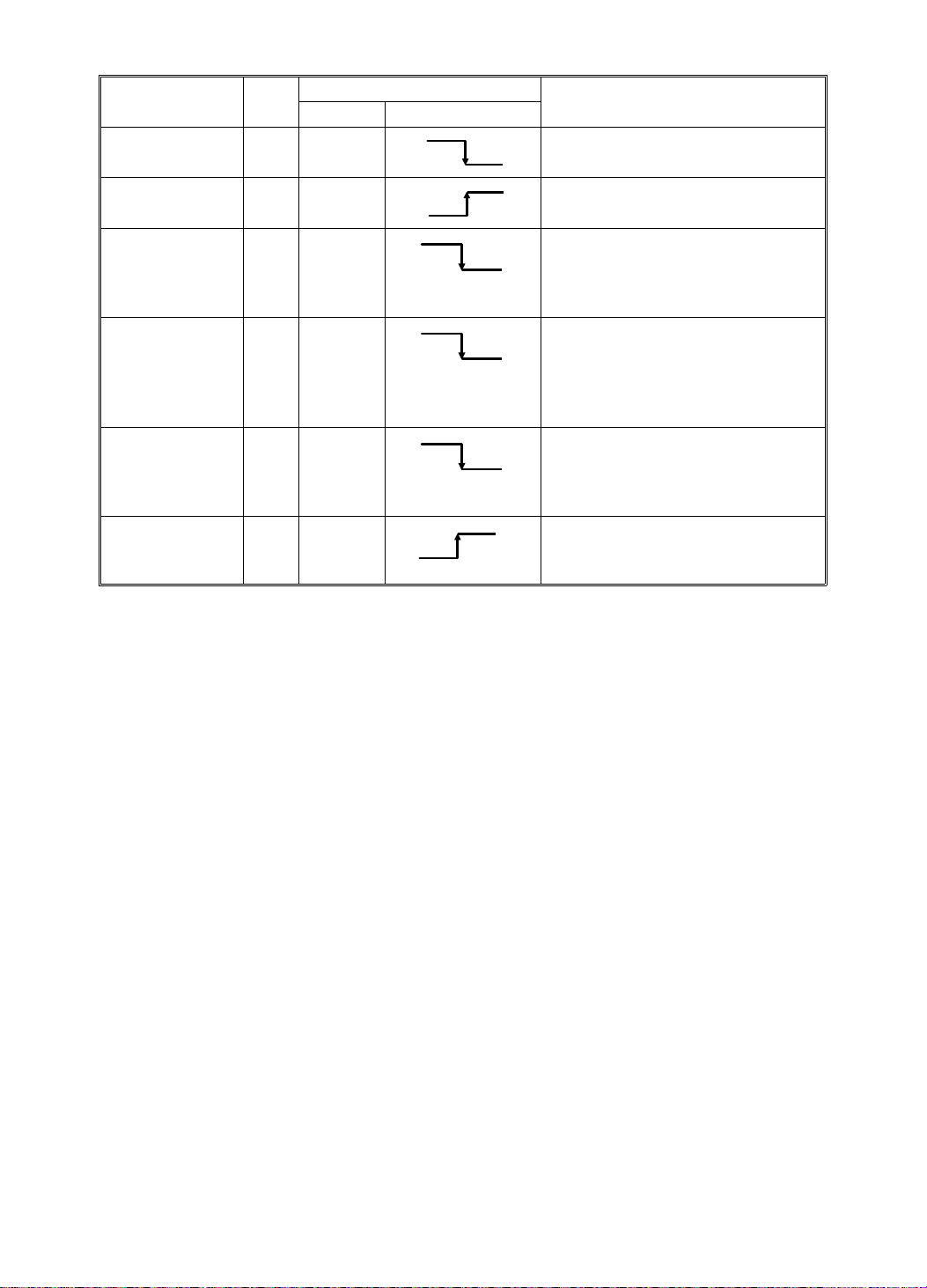

Page 26

DRUM 15 July 1994

Component

Name

Drum Lock

Solenoid [F]

Ink Detection [G]

I/O

Out 104-18

In

Color Drum

Detection [H]

In 104-14

Drum Size

Detection [H]

In 104-15

A4/LT Drum

Detection [H]

In 104-16

Drum Unit

Safety Switch Out

Main PCB

CN No. Signal Level

24V

104-20

(TP105)

-12V

5V

5V

5V

118-7

(Drum

Unit)

0V

Description

Signal goes Low when the

solenoid is energized.

0V

0V

Signal goes High when there is no

ink.

Signal goes Low when the color

drum is installed. (CN118-2 and -3

0V

are shorted.) The Color Drum

indicator will light.

Signal goes Low when the drum is

installed. (CN118-2 and -4 are

0V

shorted.) The A3 or DLT Drum

indicator will light when CN118-2

and -5 are open.

Signal goes Low when the A4/LT

drum is installed. (CN118-2 and -5

0V

are shorted.) The A4 or LT Drum

indicator will light.

CN118-7 of the drum unit

24V

connector becomes 24 volts when

the drum unit is set.

2-12

Page 27

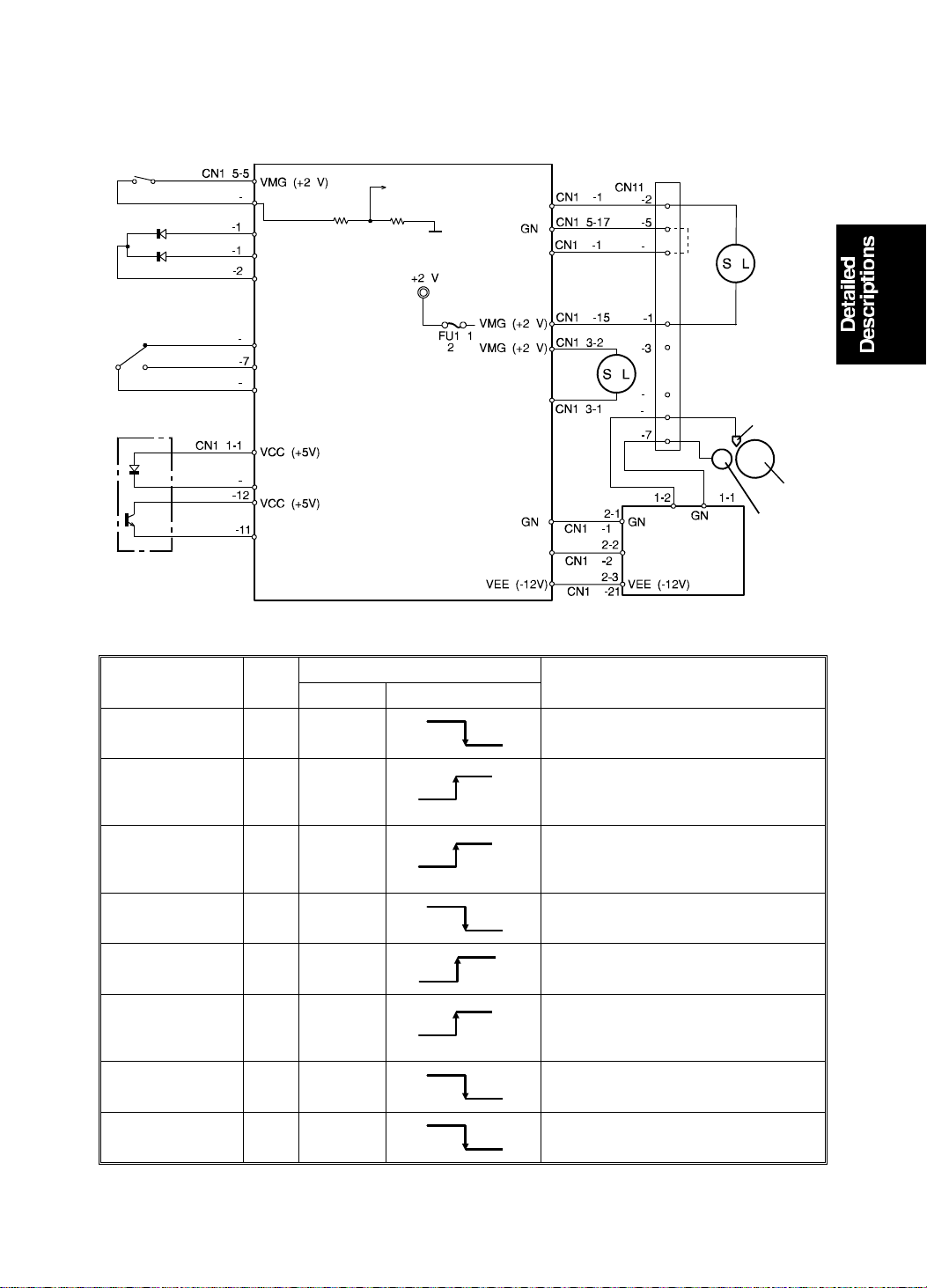

15 July 1994 DRUM

3.3 CIRCUIT FOR #C219 MODE LS

[A]

[B]

[C]

[D]

Main PCB

(Drum Unit Connector)

[E]

Common

[F]

Common

LED Drive

(Drum Unit

Frame)

Ink Detection PCB

Ink

Detecting Pin

[G]

Ink Roller

Doctor Roller

Component

Name

Drum Detection

Switch [A]

I/O

CN No. Signal Level

In 105-4

Drum Rotation

LED (Red) [B] Out 105-18

Drum Rotation

LED (Green) [B] Out 105-19

Drum Rotation

Button (N.C.) [C]

Drum Rotation

Button (N.O.) [C]

In 105-8

In 105-7

Drum Master

Detection

In TP102

Sensor [D]

Ink Supply

Solenoid [E]

Drum Lock

Solenoid [F]

Out 104-16

Out 103-19

Main PCB

24V

0V

0V

24V

0V

0V

24V

24V

Description

Signal goes Low when the drum

unit is slid out.

0V

Signal goes High when the drum is

2.8V

not in the home position. (The LED

lights red.)

Signal goes High when the drum is

2.8V

in the home position. (The LED

lights green.)

Signal goes Low when the button

0V

is pressed.

24V

Signal goes High when the main

switch is turned on.

The voltage between TP102 and

2.5V

ground becomes more than 2 volts

when a master is on the drum.

Signal goes Low when the

solenoid is energized.

0V

Signal goes Low when the

solenoid is energized.

0V

2-13

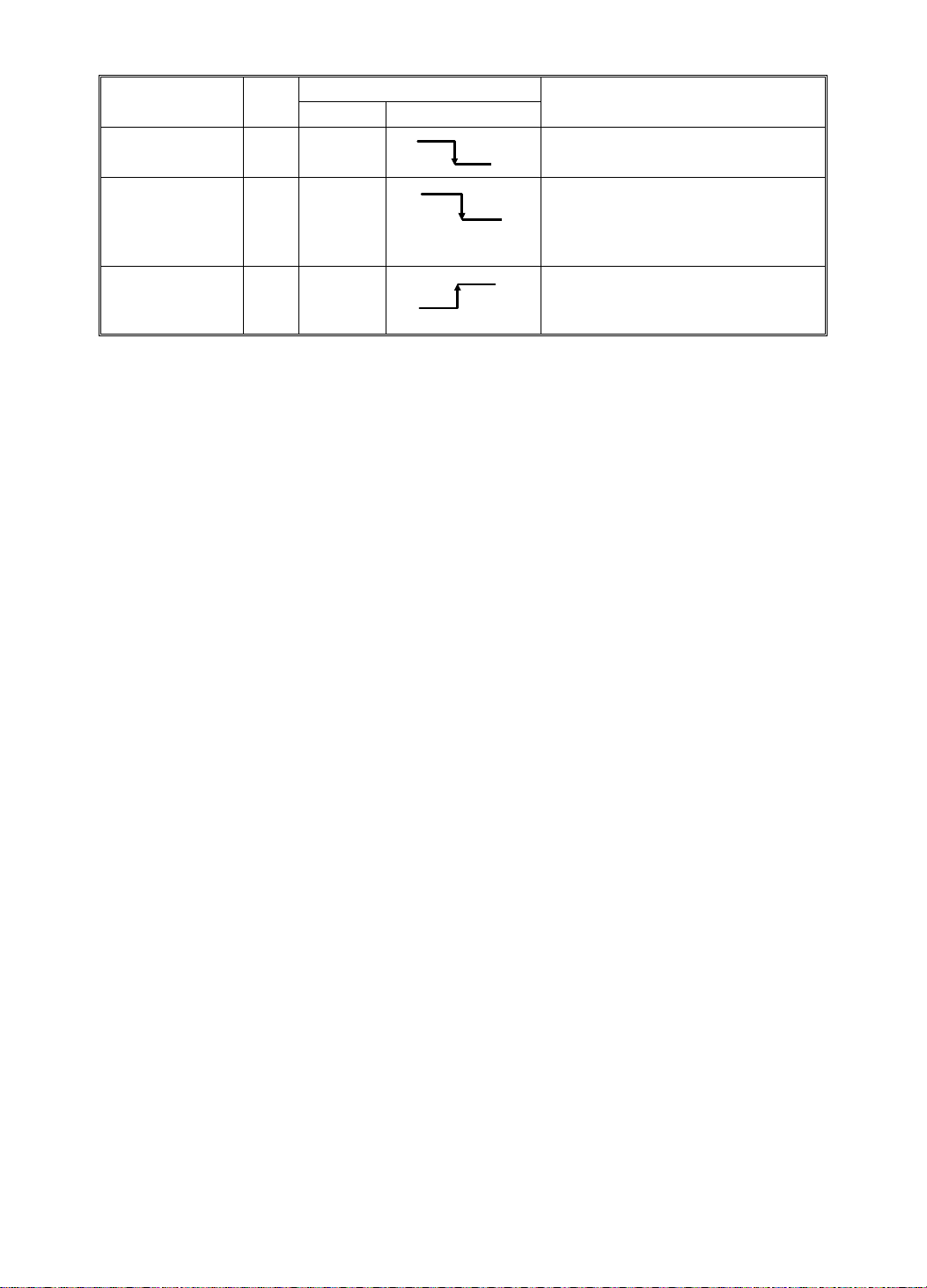

Page 28

DRUM 15 July 1994

Component

Name

Ink Detection [G]

I/O

In

Color Drum

Detection [H]

In 104-18

Drum Unit

Safety Switch Out

Main PCB

CN No. Signal Level

104-20

(TP105)

0V

5V

118-7

(Drum

Unit)

0V

Description

Signal goes Low when there is no

-12V

ink.

Signal goes Low when the color

drum is installed. (CN118-5 and -6

0V

are shorted.) The Color Drum

indicator will light.

CN118-7 of the drum unit

24V

connector becomes 24 volts when

the drum unit is set.

2-14

Page 29

Counter "0"

15 July 1994 DELIVERY

4. DELIVERY

4.1 ELECTRICAL TIMING

1st Drum Position Sensor

2nd Drum Position Sensor

Cutter Motor

Cutter Motor ON Print Key ON

Stop Key

ON

T2

Vacuum Fan Motor

Air Knife Motors

Paper Feed Solenoid

Printing Pressure Sensor

Main Motor

Paper Table Height Sensor

Paper Table Drive Motor

T1

T1: The cutter motor, vacuum fan motor, and air knife motors turn on.

The main motor turns o n whe n th e cutter motor stops rotating.

T2: The vacuum fan motor and the air knife motors turn off when the printing

• The on/off timing for the vacuum fan motor, air knife motors a nd the main

pressure sensor is deactivated and the 1st drum positio n sensor is

activated.

motor is different from the #210 model.

2-15

Page 30

DELIVERY 15 July 1994

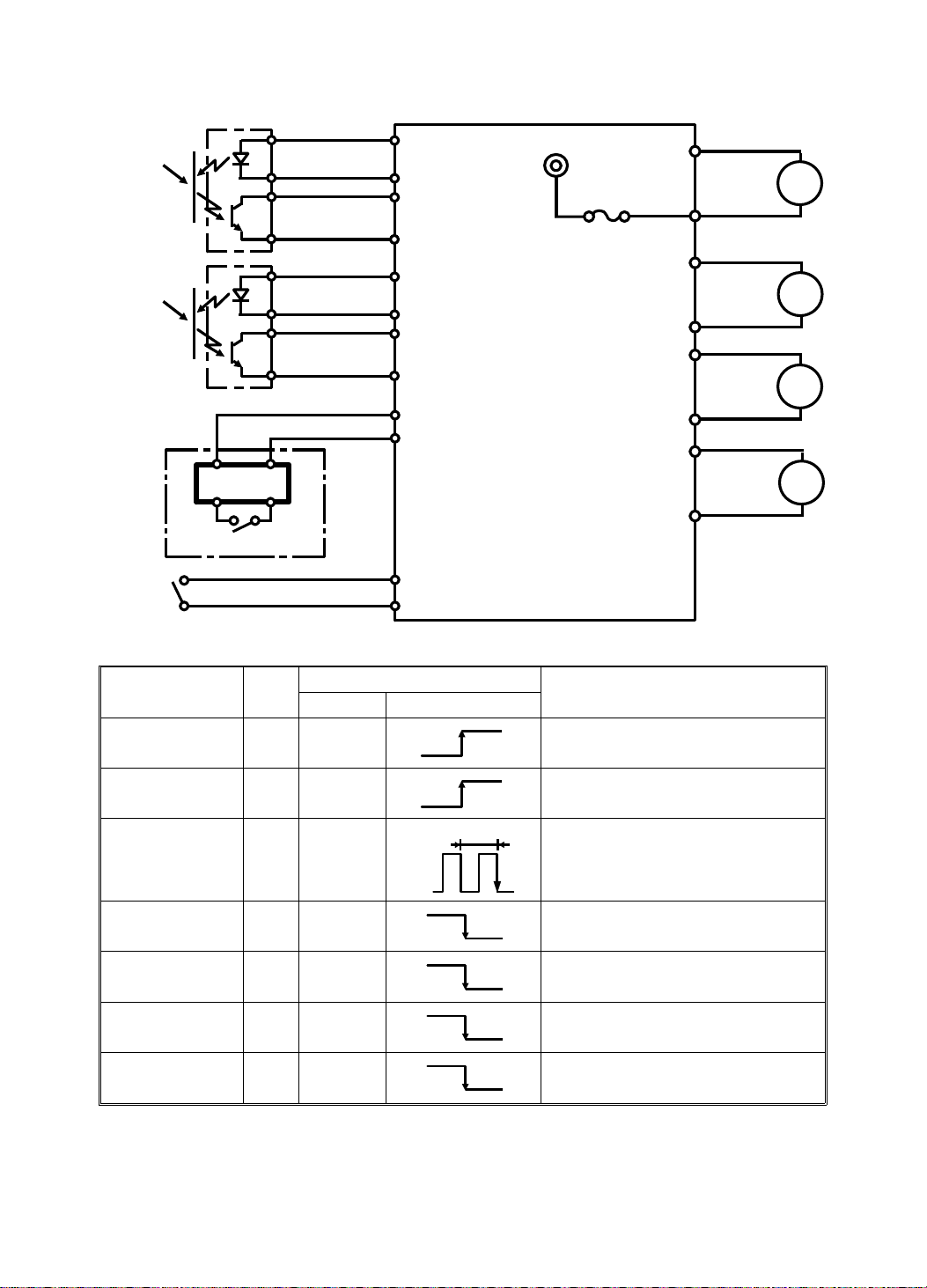

4.2 CIRCUIT FOR #C218 MODE LS

[A]

[B]

A

K

C

E

A

K

C

E

CN101-2

CN102-7

CN102-12

-1

-4

-3

-6

-5

-8

-7

+5V

+5V

+5V

+5V

GND

24V

FU101

2A

CN103

-9

-22

-13

-18

-14

-17

-15

-16

[D]

M

[E]

M

[F]

M

[G]

M

Paper Table

CN102-26

GND

-25

[C] Delivery Table

Main PCB

Component

Name

1st Paper Exit

Sensor [A]

2nd Paper Exit

Sensor [B]

Delivery Table

Open Switch [C]

Vacuum Fan

Motor [D]

Air Knife Motor

[E]

Air Knife Motor

[F]

Air Knife Motor

[G]

I/O

CN No. Signal Level

In TP101

In TP103

In 102-25

Out 103-9

Out 103-13

Out 103-14

Out 103-15

Main PCB

0V

0V

7.5V

0V

26V

26V

26V

26V

5 msec

Description

3V

Signal goes High when the paper

is on the sensor.

3V

Signal goes High when the paper

is on the sensor.

Pulse signal goes to Low when the

delivery table is opened.

Signal goes Low when the motor is

energized.

0V

Signal goes Low when the motor is

energized.

0V

Signal goes Low when the motor is

energized.

0V

Signal goes Low when the motor is

0V

energized.

The paper table and the delivery table open/ close detection is done

separately to enable paper table lowerin g reg ard less of whethe r the delive ry

table is open or closed.

2-16

Page 31

15 July 1994 DELIVERY

4.3 CIRCUIT FOR #C219 MODE LS

CN103

-8

-7

-14

-13

-12

-11

[D]

M

[E]

M

[F]

M

[A]

[B]

A

K

C

E

A

K

C

E

CN101-2

CN105-22

-23

-1

-4

-3

-6

-5

-8

-7

+5V

+5V

+5V

+5V

GND

24V

FU101

2A

[C] Paper Table

Main PCB

Component

Name

1st Paper Exit

Sensor [A]

2nd Paper Exit

Sensor [B]

Paper Table

Open Switch [C]

Vacuum Fan

Motor [D]

Air Knife Motor

[E]

Air Knife Motor

[F]

I/O

CN No. Signal Level

In TP101

In TP103

In 105-22

Out 103-8

Out 103-12

Out 103-14

Main PCB

0V

0V

7.5V

0V

26V

26V

26V

5 msec

Description

3V

Signal goes High when the paper

is on the sensor.

3V

Signal goes High when the paper

is on the sensor.

Pulse signal goes to Low when the

paper table is opened.

Signal goes Low when the motor is

energized.

0V

Signal goes Low when the motor is

energized.

0V

Signal goes Low when the motor is

energized.

0V

Delivery table open/close detection is not available for the #219 model.

2-17

Page 32

CHANGES ONLY FOR C219 MODELS 15 July 1994

5. CHANGES ONLY FOR C219 MODELS

The following items have been chang ed only for the #C21 9 mod el.

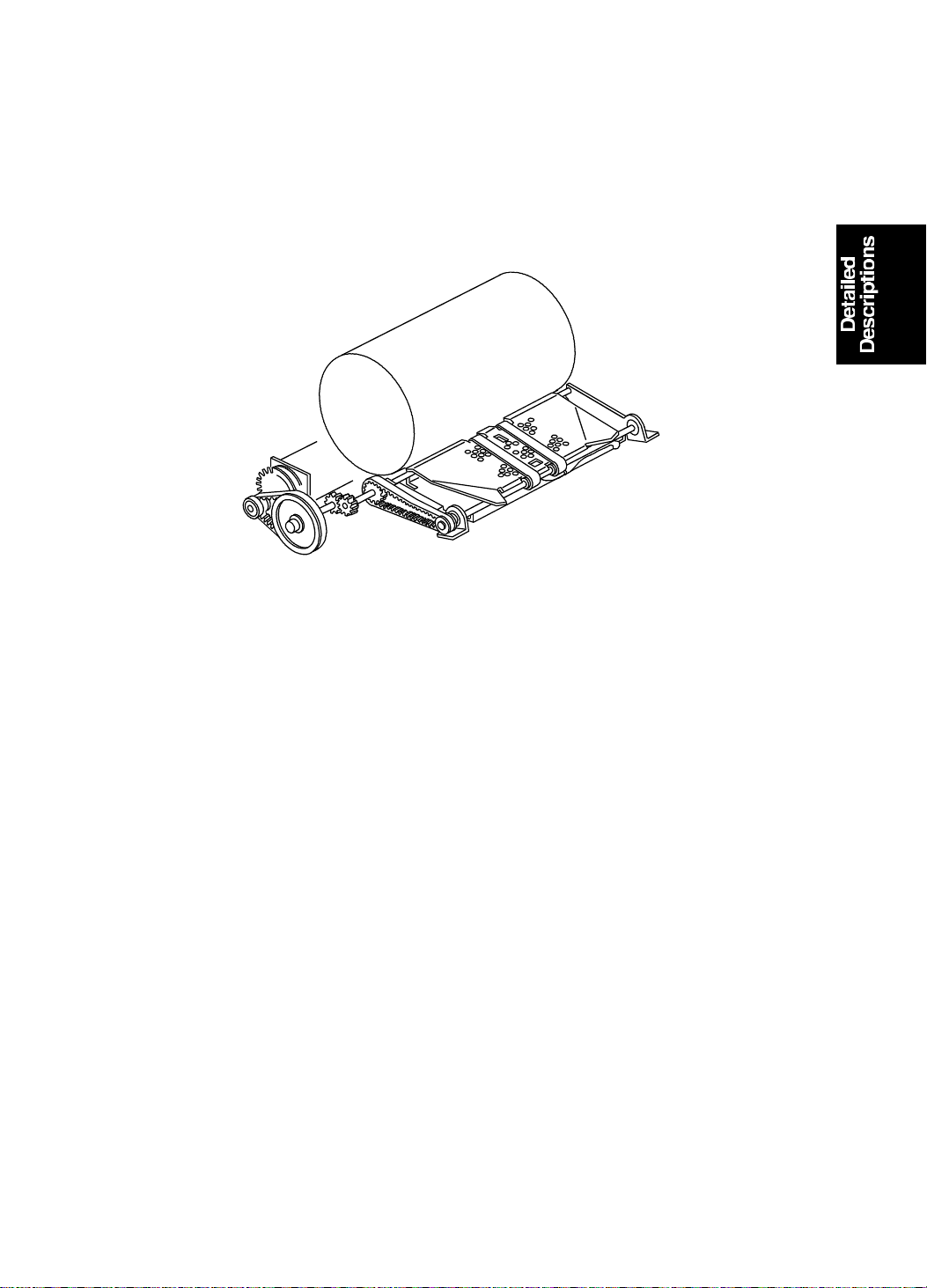

5.1 PAPER FEED

• The paper return mechanism has been eliminated.

• The Feed Roller pressure can be adjusted in 3 steps.

• The feed pressure lever on the feed roller asse mbly has bee n elimin at ed .

• The rubber material for the Paper Feed Roller and the Separation Roller

has been changed to improve longevity, and ensu re stable friction.

• The Paper Feed Roller shaft has been changed to a light-weight material.

Therefore, the torque limiter in the Paper Fee d Rolle r, which was there to

prevent the roller from over-runnin g, has been elimina te d.

• The number of rollers on the second feed roller shaf ts ha s been cha ng ed

from 5 to 3.

2-18

Page 33

15 July 1994 CHANGES ONLY FOR C219 MODELS

5.2 DELIVERY

• The number of transport belts has been changed from 3 to 2.

• The wing guide has been eliminated for the #C219 model.

2-19

Page 34

SECTION 3

INSTALLATION

Page 35

15 July 1994 INSTALLATION PROCEDURE

1. INSTALLATION PROCEDURE

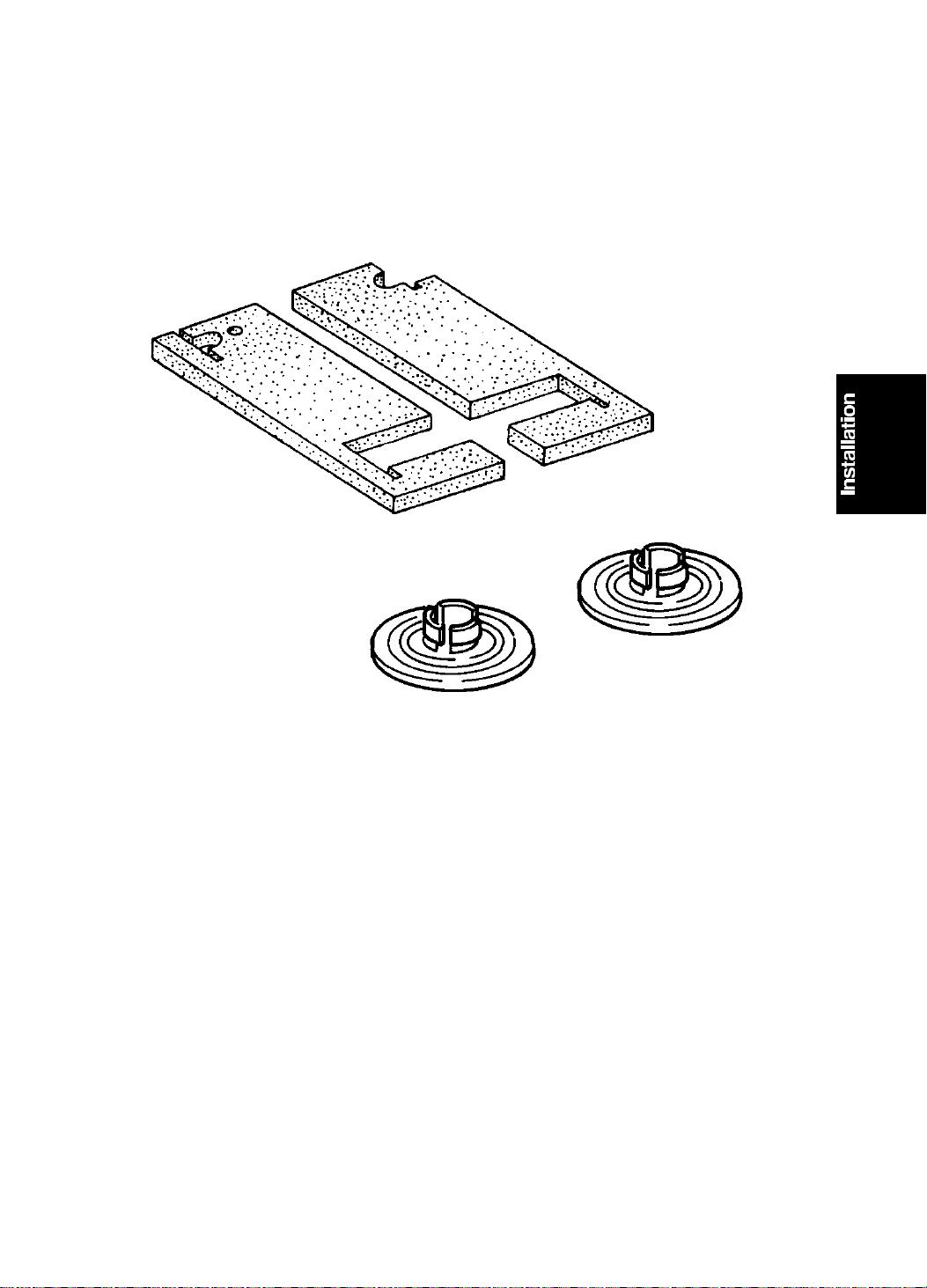

1.1 ACCESSORY CHECK

Make sure that you have all the accesso ries liste d below.

[A]

(Only for the C218 mode l)

[B]

A. Base Pad (Only for the C218 model)................................................2

B. Master Spool......... .. .................... .. .............................. .. ....................2

Operating Instructions

3-1

Page 36

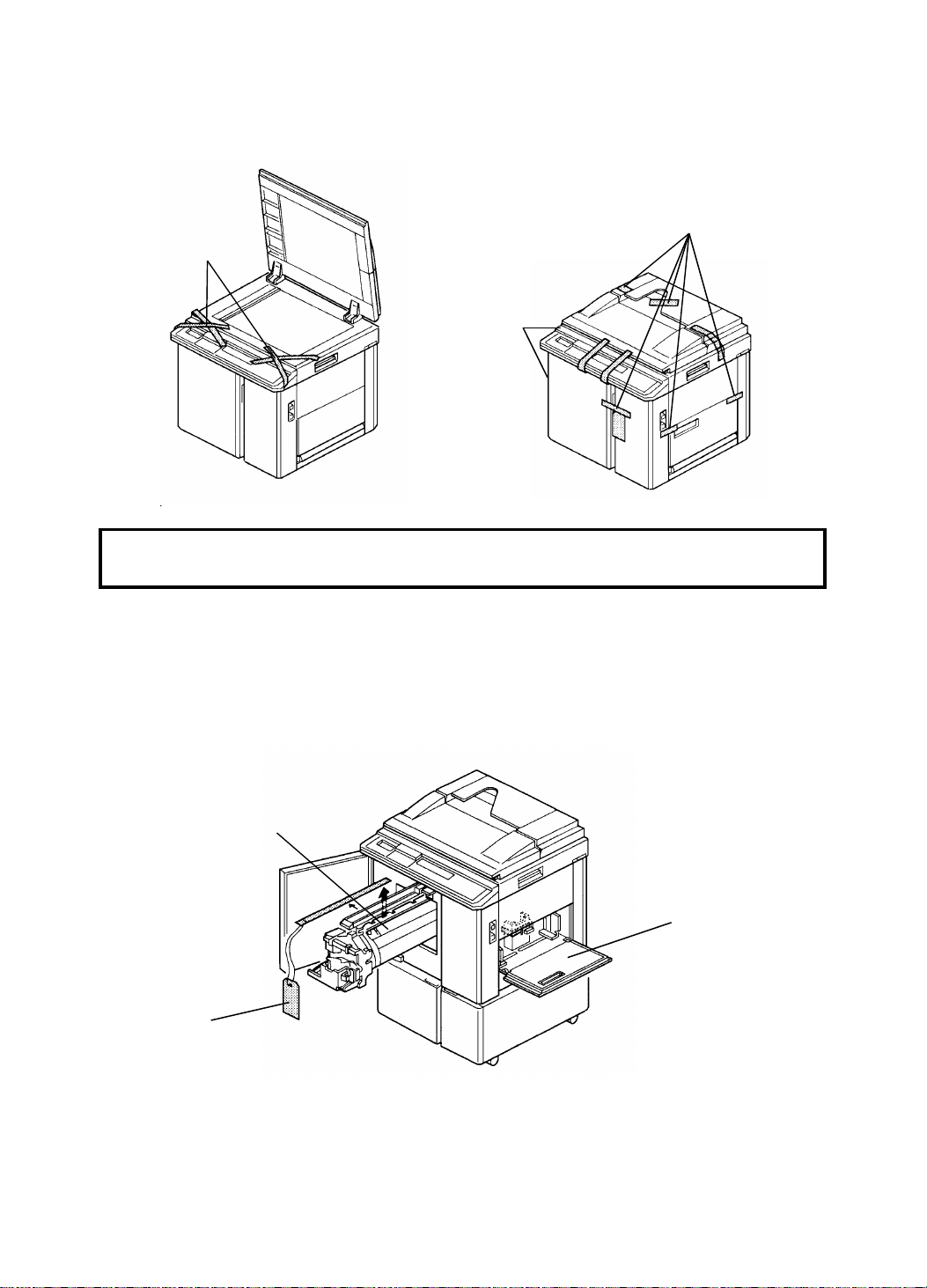

[A]

[D]

INSTALLATION PROCEDURE 15 July 1994

2. INSTALLATION PROCEDURE

MAIN BODY

[A]

[A]

CAUTION: Do not hold the scanner unit when pushing the machine or

the scanner unit safety switch may be dam age d .

1. Place the machine on the table.

NOTE: The screw holes in th e bo ttom plate of the machine must line up

with the screw holes in the table.

2. Remove the strips of tape [A ] securing the covers and units shown ab ove .

[B]

[C]

3. Open the front door and slide out the drum unit [B].

4. Open the master clamper an d remo ve the clamp [C].

5. Open the paper feed ta ble and remove the cardboard cove r [ D] pro te cting

the paper feed roller.

3-2

Page 37

[F]

15 July 1994 INSTALLATION PROCEDURE

[G]

[H]

[E]

6. Open the paper delivery table and remove th e strip of tape [E] prot ect ing

the end fence .

7. Remove the cardboard [F] under the scanner unit.

8. Open the scanner unit and chan ge the posit ion of screws [G ] from

transport position to opera ting position.

9. Open the doors (2 strips of tape [H]) of the option al ta ble and take out the

plastic bag containing 2 screws.

3-3

Page 38

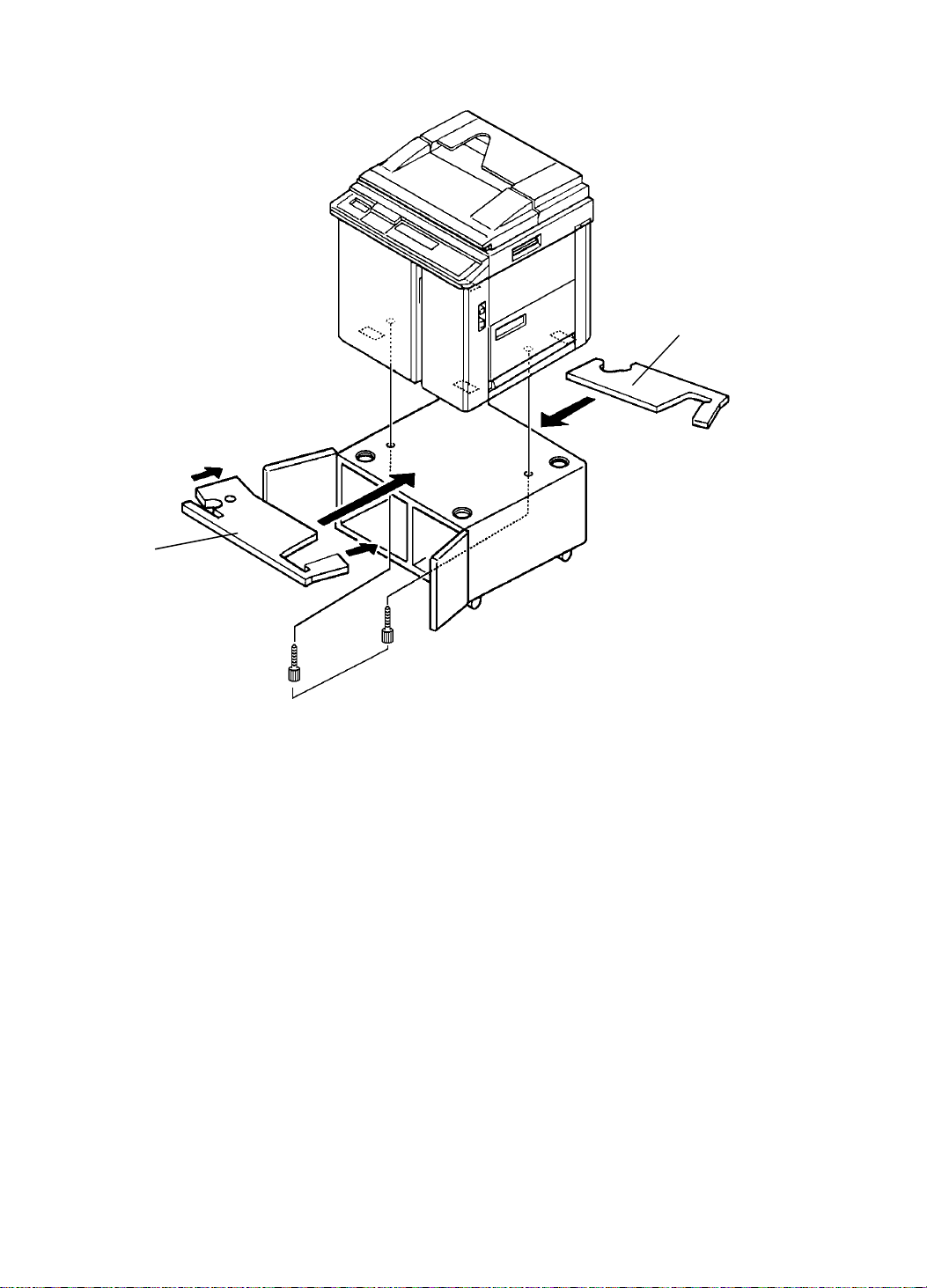

INSTALLATION PROCEDURE 15 July 1994

[B]

[A]

[C]

10. Raise the front sid e of t he machine and position the base pa d [A] under

the machine. Then raise the rear side of the machine and position the

other base pad [B] under the machine. (This procedure is necessa ry o nly

for the C218 model.)

11. Secure the machine to the table with the two scre ws [C] pa cked wit h th e

table.

NOTE: Make sure the ma chin e legs fit through the cutouts in the base

pads.

3-4

Page 39

15 July 1994 INSTALLATION PROCEDURE

12. Open the paper feed table [A]

and neatly stack the printing

paper on the ta ble.

13. Slide the paper feed side plates

[B] gently u p against the pa per

[A]

stack.

[B]

14. Open the paper delivery table

[C] and adjust the position of

the end plate [D] an d th e side

plates [E] according to the

printing paper size. Refer to the

paper size scale on the table.

15. Install the ink cartridg e [F] .

a. Open the front door and

lower the ink holder [G].

b. Remove the ink cartridge

cap.

c. Insert the ink cartridge in the

ink holder and raise the ink

holder to the origina l posit ion.

d. Close the front door.

[E]

[D]

[C]

[F]

[G]

3-5

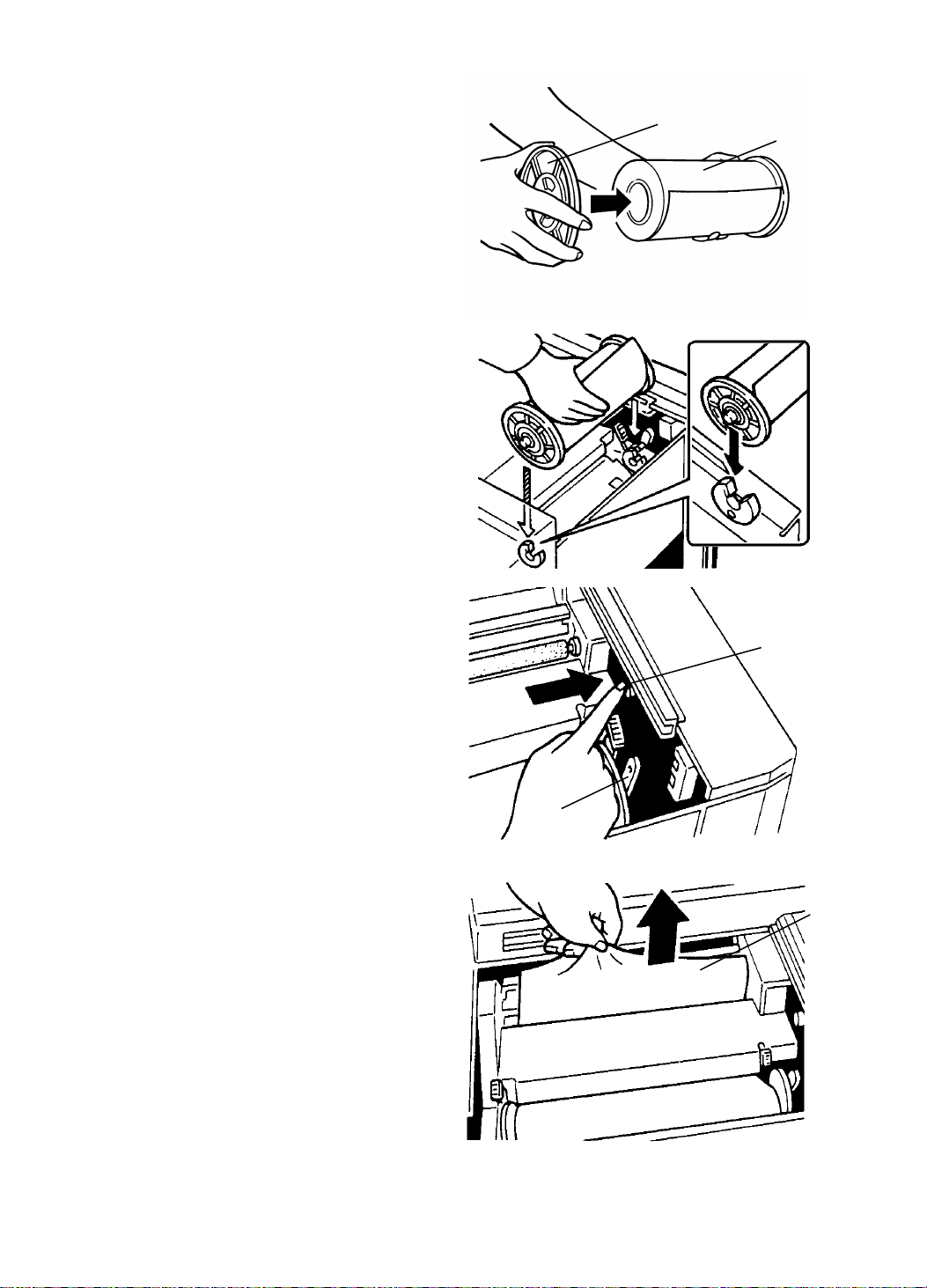

Page 40

[A]

INSTALLATION PROCEDURE 15 July 1994

16. Install the master roll.

a. Slide the scanner unit all the

way to the left.

b. Attach a spool [A] to each

end of the master roll [B].

c. Push the pressure relea se

lever [C] to the left.

d. Set the master roll i n the

machine as shown in the

illustration.

e. Insert the leading edge of

the master roll under the

platen roller.

f. Return the pressure release

lever to the original position.

g. Plug in the power cord and

turn on the main switch.

h. Press the master cut butto n

[D].

[B]

[D]

i. Remove the cut strip [E] of

master paper.

NOTE: Confirm that the paper on

the master roll is not bent

or creased.

j. Close the scanner unit.

[C]

[E]

3-6

Page 41

15 July 1994 INSTALLATION PROCEDURE

[A]

[D]

[F]

[B][E]

[C]

17. Idle the machine to distribute ink on the drum.

a. Press the Reset key [A] while hold ing down the "0" key [B] on the

operati on panel.

b. If blinks on the operation pane l wh en the ma chin e stops, press the

Reset key again.

17. Make some test prints to check the machine.

a. Raise the platen cove r a nd place the origin al fa ce do wn on the

exposure glass [C]. Make sure the origin al is f lush with the left scale

and aligned with the proper paper size marks.

b. Press the Master Making key [D] .

c. Select the lowest print speed (1) with the Speed key [E] and press the

Print Start key [F]. Make prin ts at this spe ed unt il the print image

density stabilizes.

NOTE: 1. Usually, about 100 prints are made before the imag e fully

stabilizes.

2. Check the image qualit y aft er the print image density is

stabilized.

3-7

Page 42

SECTION 4

SERVICE TABLES

Page 43

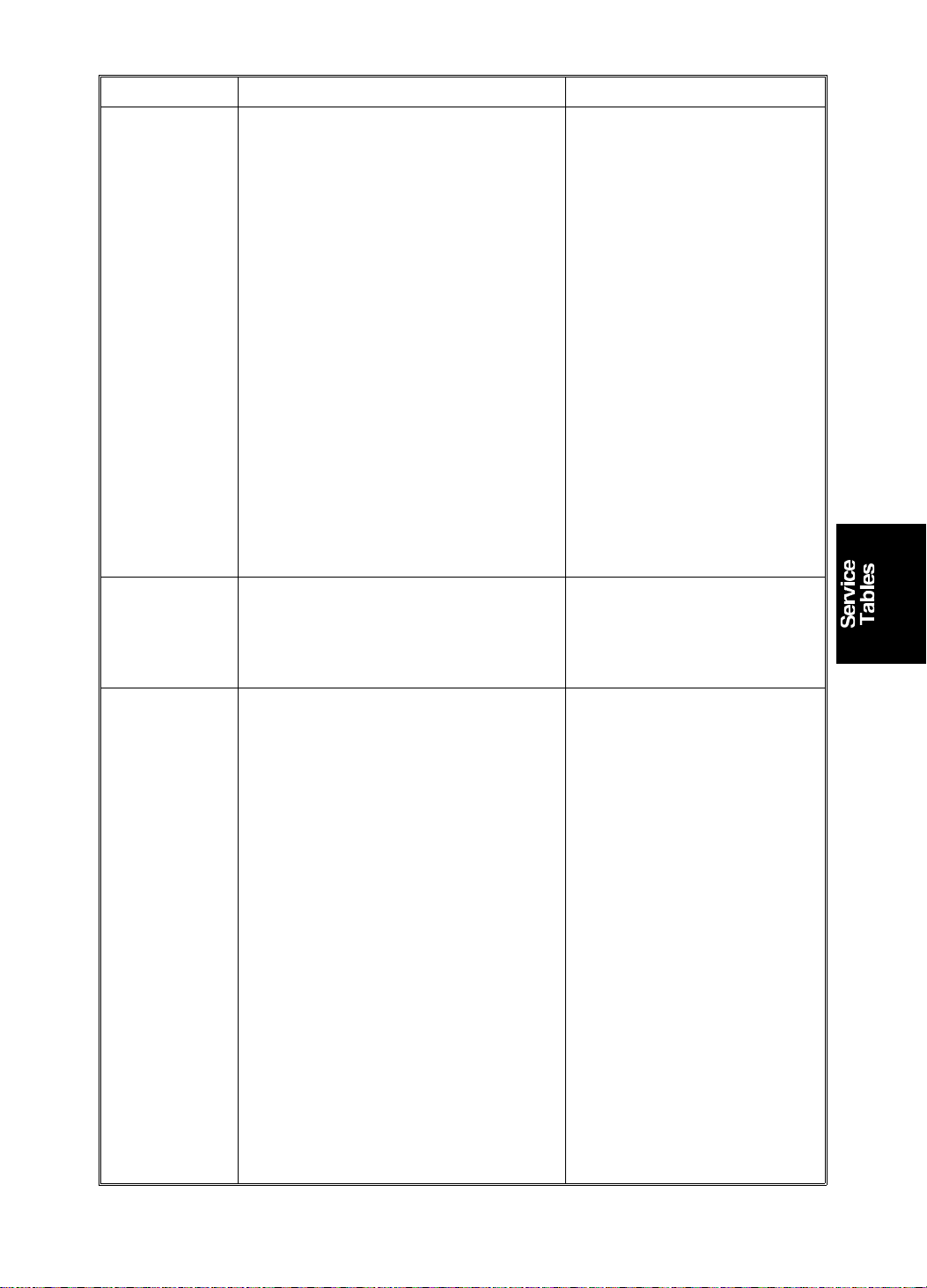

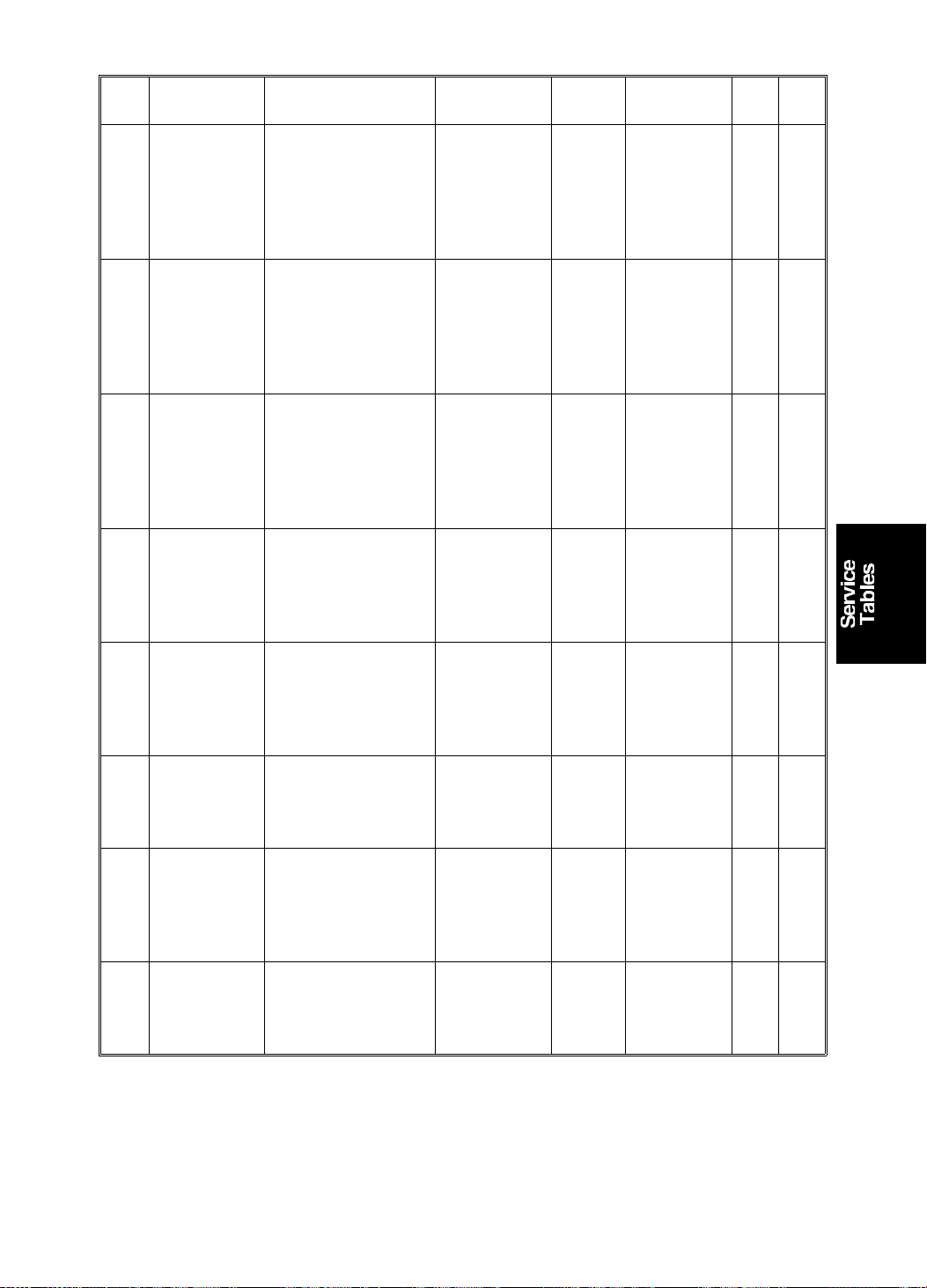

15 July 1994 SERVICE TABLES

1. SERVICE TABLES

1.1 MAINTENANCE TABLES

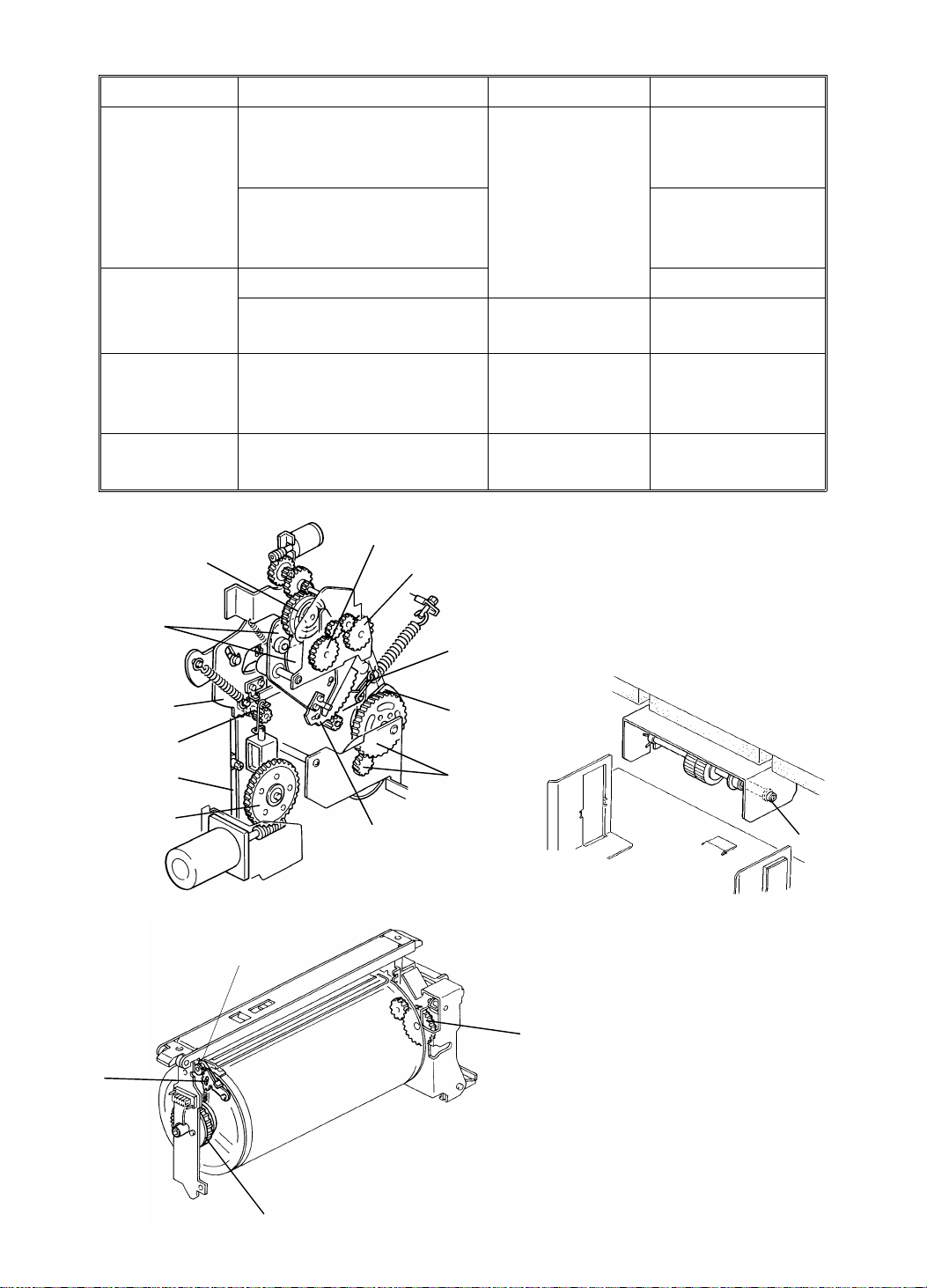

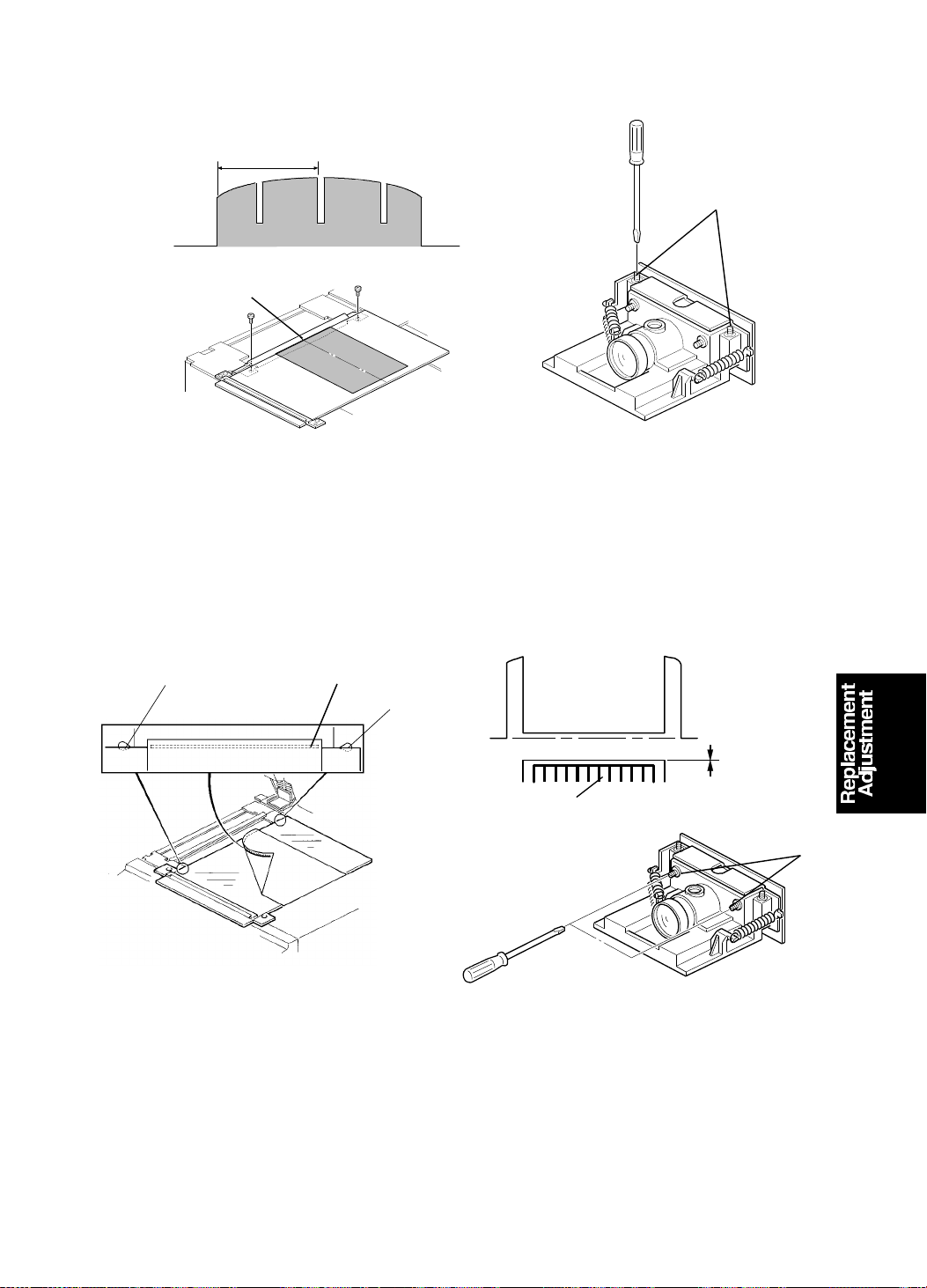

1.1.1 Lubrication Points

Lubricate after removin g ad hering ink and paper dust at yearly intervals.

Section Lubrication Point Type Location

Drive Speed Reduction Gear s

of the Main Motor

Gears of the Drum Drive

Shaft

Grease (Shell

Albania No. 2)

(Fig.1- E)

Inside and

outside of the

machine

(Fig.1- B)

Image

Positioning

Paper Feed Paper Feed Sector Gear (Fig.1- J)

Drum Drum Drive Gear Grease (Shell

Spiral Track of the Cam

Gear

Second Feed Sector

Gear

Gear of the Paper Feed

Cam Shaft

Paper Table Slide

Groove

Paper Table Drive Gear (Fig.1- G)

Bearings for the Upper

Separation Roller Shaft

Bearings for the Paper

Feed Roller Shaft

Master Clamper Sector

Gear

Master Clamper Pinion

Gear

Motor oil (SAE

No. 20)

Albania No. 2)

(Fig.1- K)

(Fig.1- F)

(Fig.1- A)

Both front side

and rear side

(Fig.1- H)

(Fig.1- I)

(Fig.2- L)

(Fig.3- N)

(Fig.3- O)

(Fig.3- P)

Printing

Pressure

Ink Pump Drive Gear (Fig.3- M)

Printing Pressure Arm

and Printing Pressure

Stay

Pressure Spring Link (Fig.1- C)

4-1

Both front side

and rear side

(Fig.4- Q)

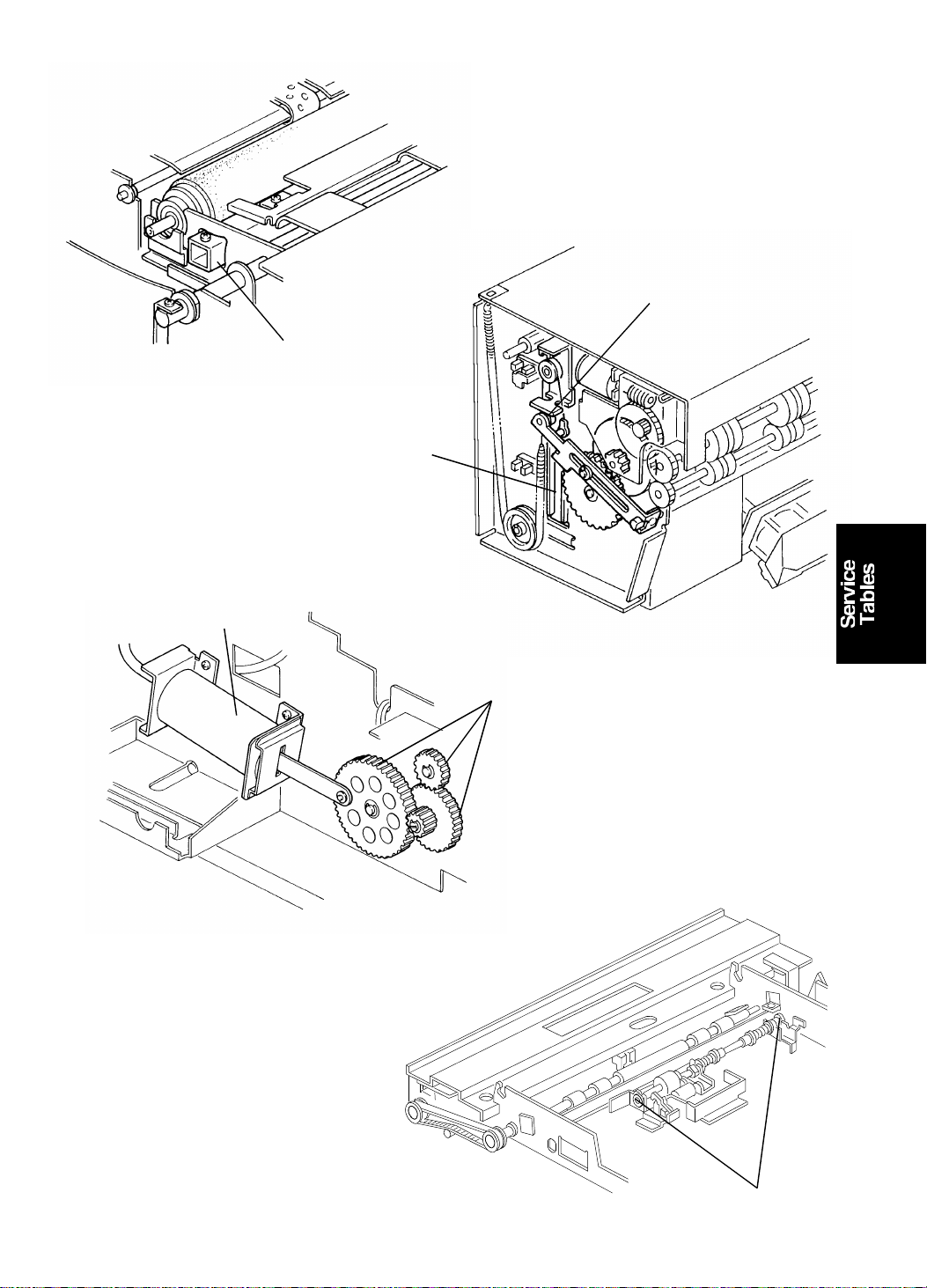

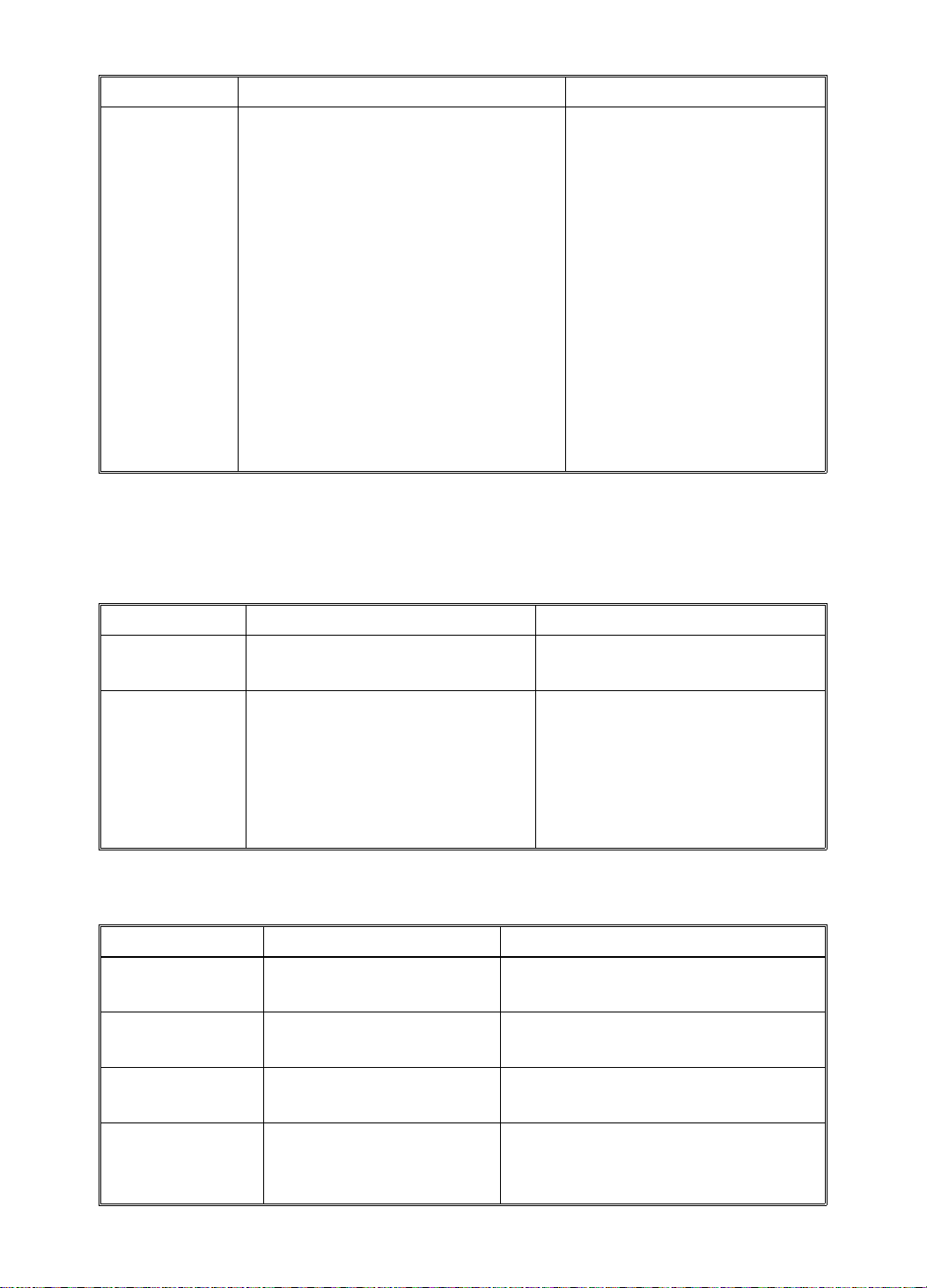

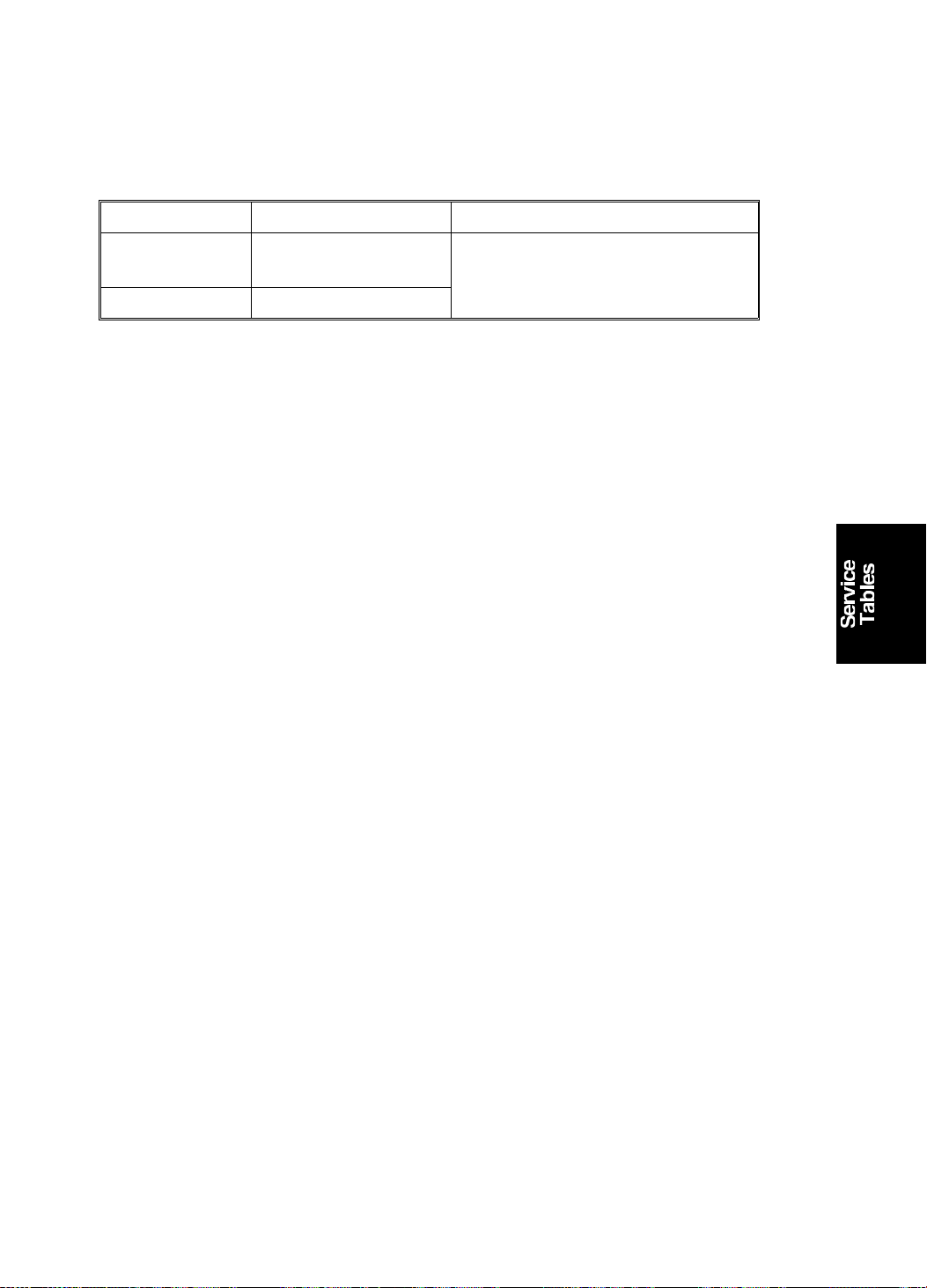

Page 44

SERVICE TABLES 15 July 1994

Section Lubrication Point Type Location

Master Eject Master Pressure Plat e

Grooves

Grease (Shell

Albania No. 2)

Both front side

and rear side

(Fig.5- S)

Edges of the Master

(Fig.5- R)

Pressure Plate Drive

Arms

Paper Exit Air Pump Drive Gears (Fig.6- T)

Inside of the Air Pump

Piston

ADF Bearings for the Feed

Roller Shaft

Grease (Mobil

Ep-1)

Motor oil (SAE

No. 20)

(Fig.6- U)

Both front and

rear side

(Fig.7- V)

Others Edge of Ea ch C a m Grease (Shell

(Fig.1- D)

Albania No. 2)

[Fig 1]

[K]

[D]

[A]

[B]

[C]

[Fig 2]

[O]

[Fig 3]

[J]

[I]

[H]

[G]

[P]

[F]

[D]

[E]

[L]

[M]

[N]

4-2

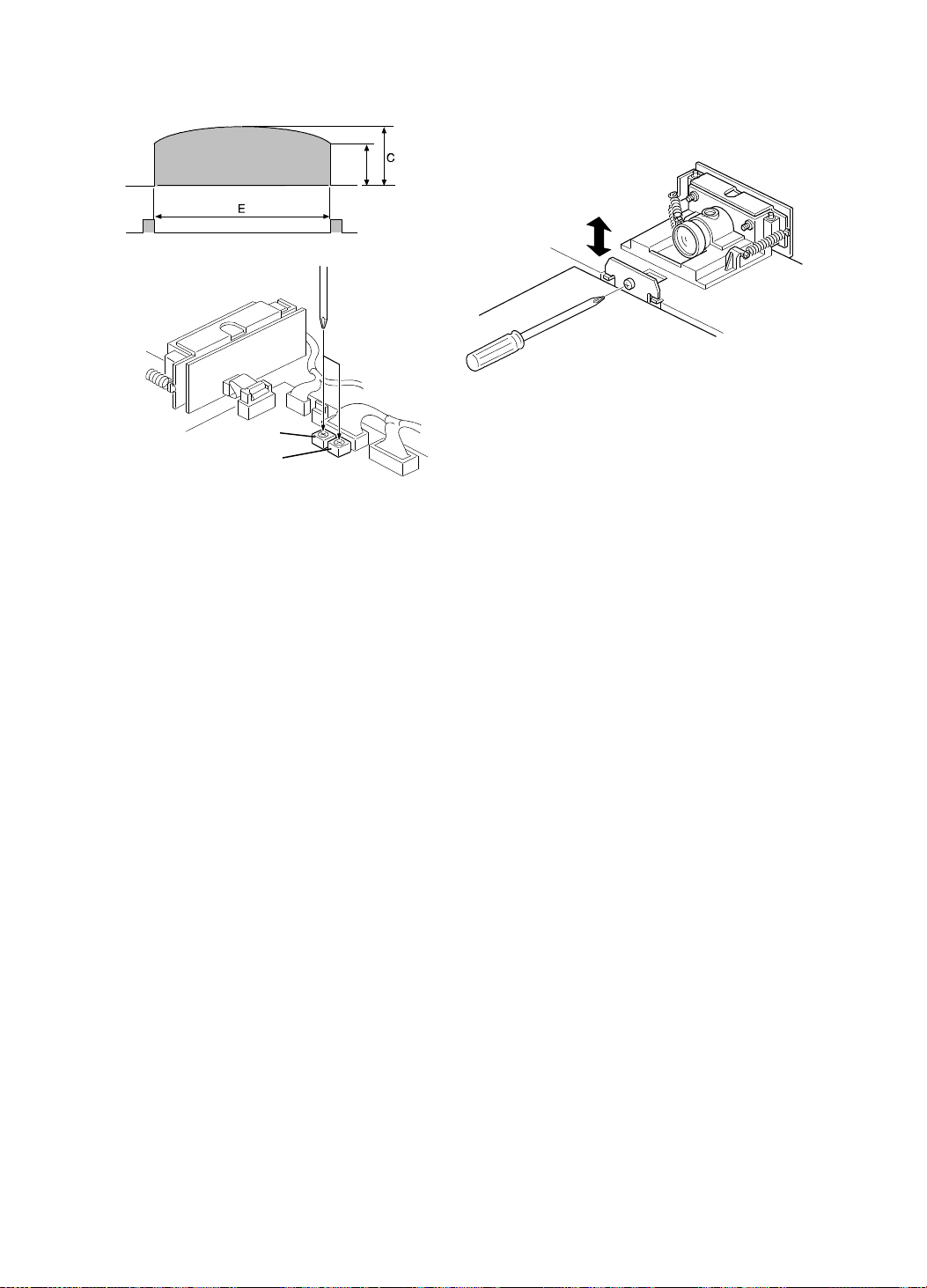

Page 45

[Fig 7]

[Fig 5]

15 July 1994 SERVICE TABLES

[Fig 4]

[R]

[Q]

[S]

[Fig 6]

[U]

[T]

[V]

4-3

Page 46

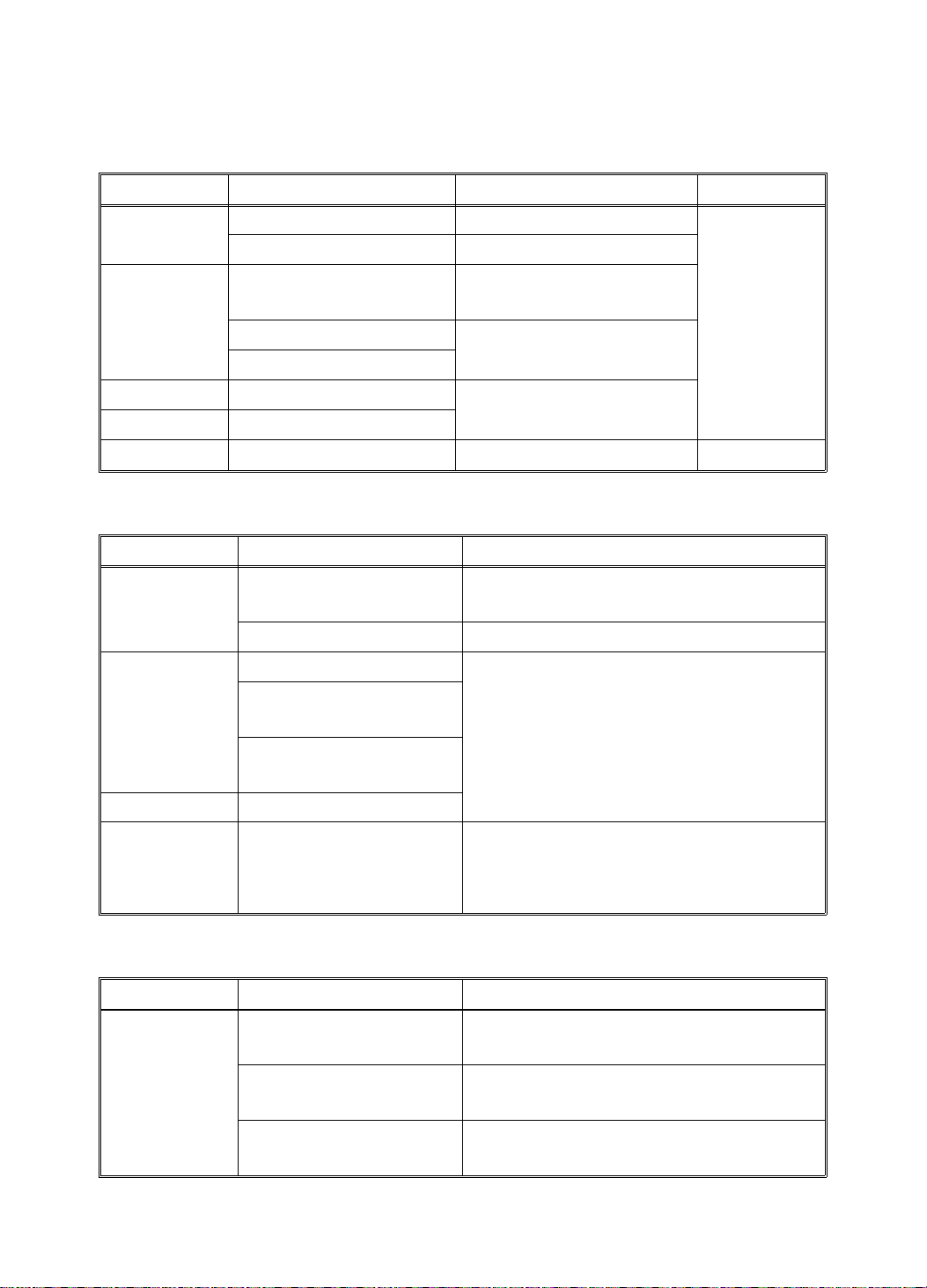

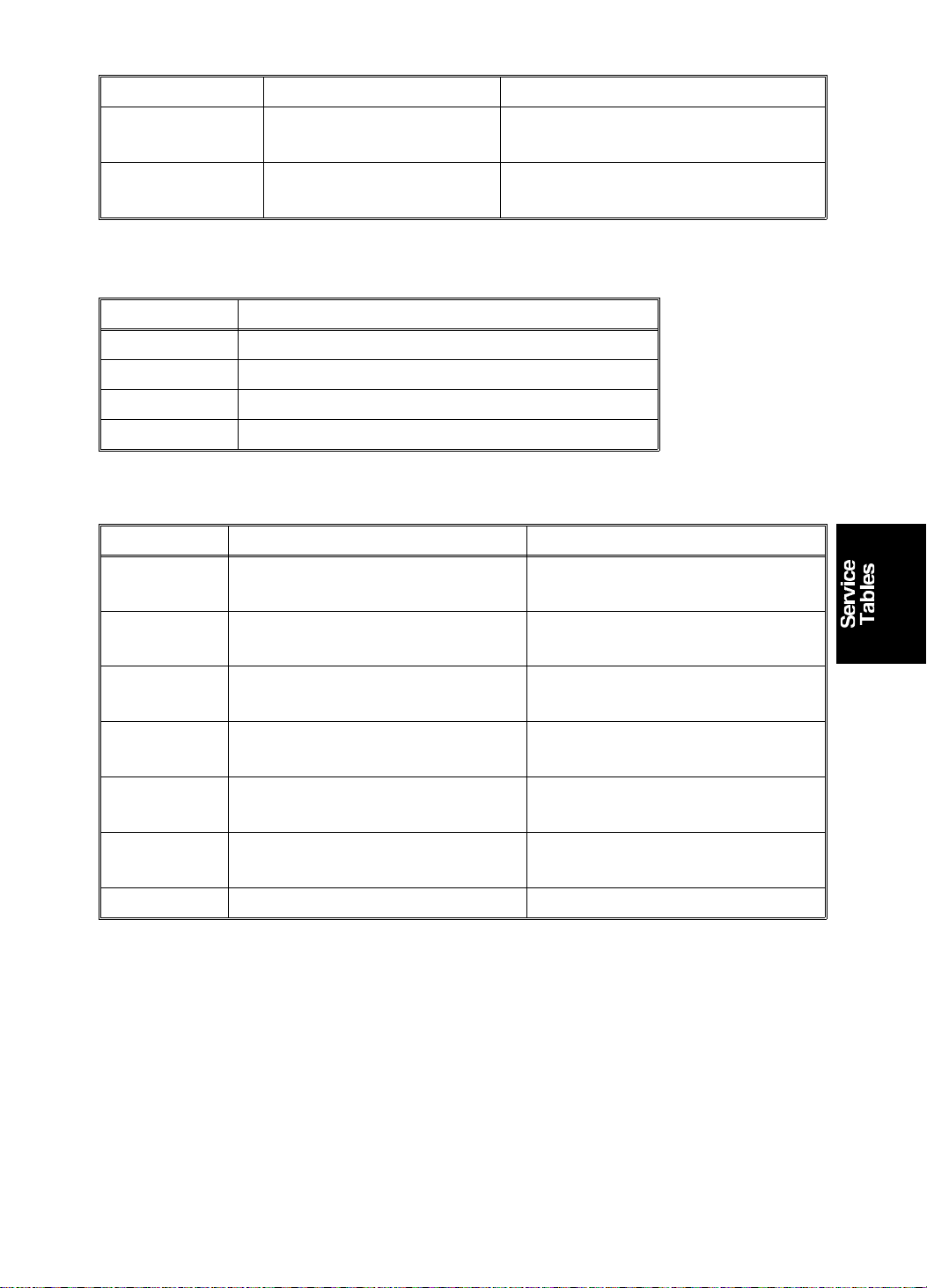

SERVICE TABLES 15 July 1994

1.1.2 User’s Maintenance

Advise the customer to clean each item regularly. Clean the followin g ite ms

at every EM call if necessary.

Section Cleaning Point Cleaner Interval

Optics Original Platen Cover Cloth and water

Exposure Glass Cloth and glass cleaner

Paper Feed Paper Feed Roller Cloth and soap and

water

Paper End Sensor Dry cloth

At every

EM call

Paper Length Sensor

Printing Pre ss Roller Cloth and soap and

ADF Original Feed Rollers

water

Plotter Thermal Head Thermal head cleaner 500 masters

1.1.3 Table of Periodic Inspection (every 6 months)

Section Item Standard Procedure

Optics Original Platen Cover Wipe off the stains using a soft cloth

moistened with ethyl alcohol.

Exposure Glass Wipe with a dry cloth.

Paper Feed Paper Feed Roller Wipe off the ink and paper powder

Upper and Low e r

Second Feed Rollers

using a cloth moistened with ethyl

alcohol.

Upper and Low e r

Separation Rollers

Printing Press Roller

ADF Pick-up Roller

Feed Roller

Wipe off paper powder using a cloth

moistened with water.

Separation Roller

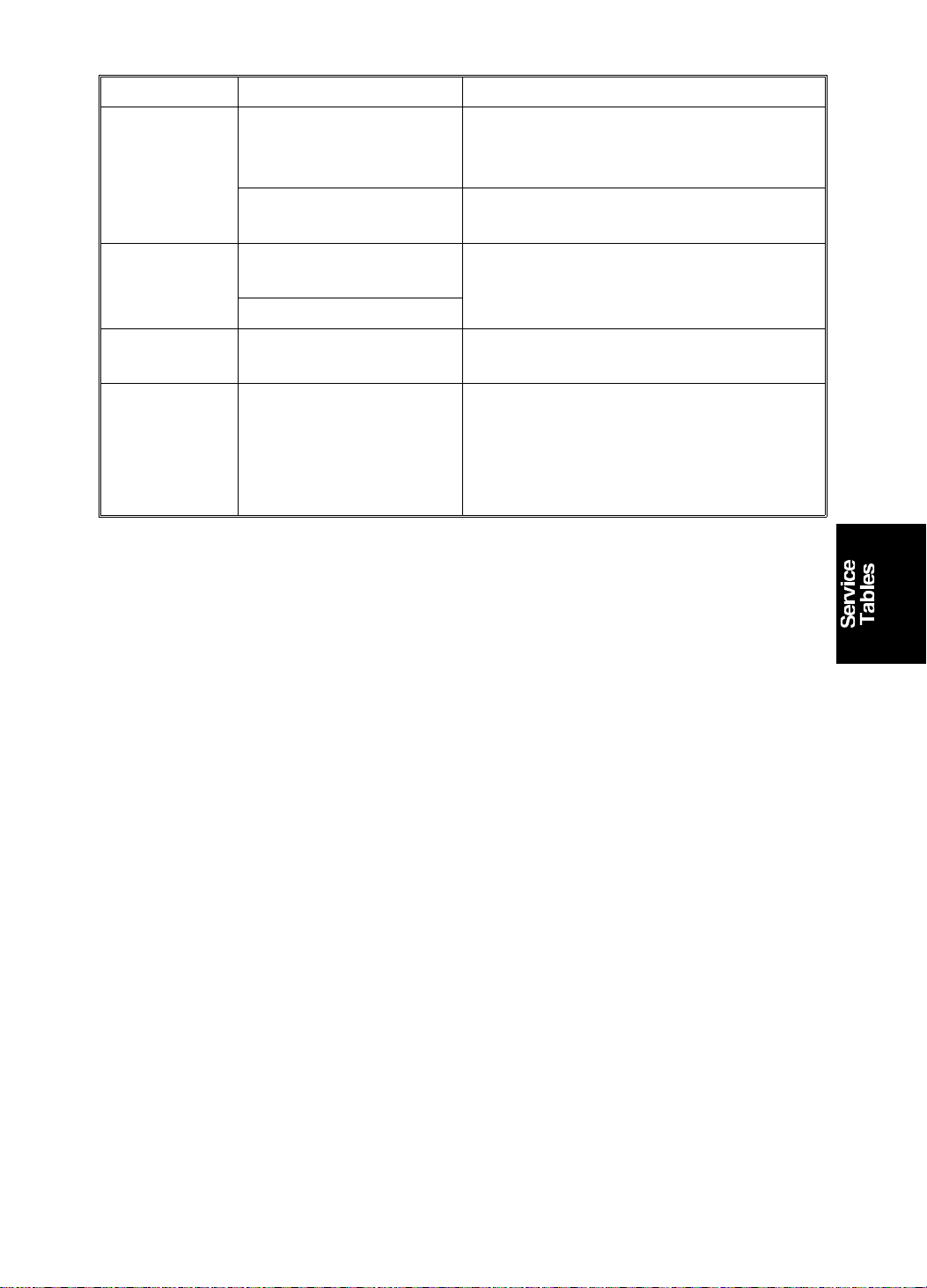

1.1.4 Table of Periodic Inspection (every 12 months)

Section Item Standard Procedure

Optics Back side of the

Wipe with a dry cloth.

Exposure Glass

Back side of the

Use a blower brush.

Mirror and Sub Mirror

Back side of the

Wipe with a dry cloth.

Fluorescent Lamp

4-4

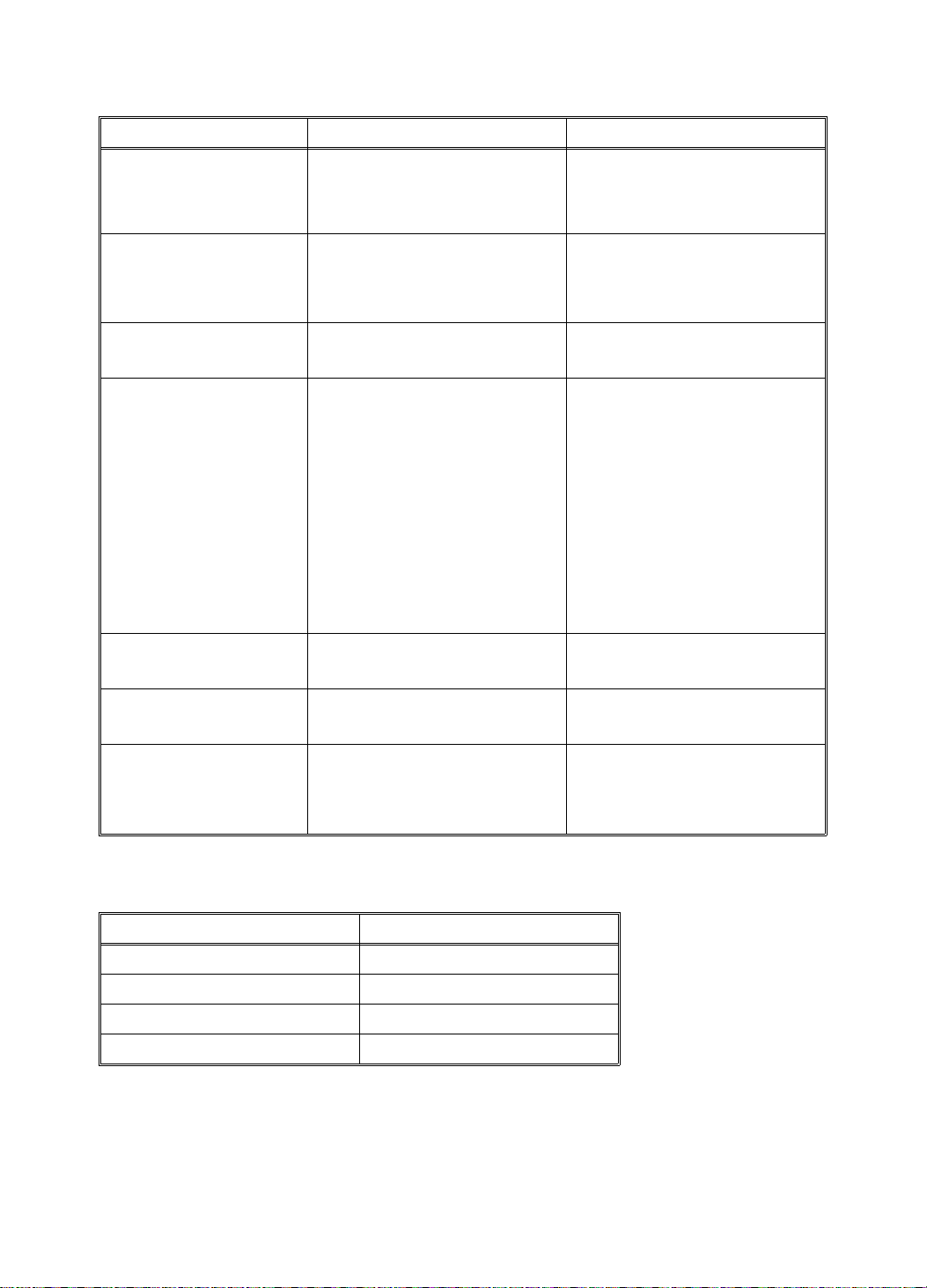

Page 47

15 July 1994 SERVICE TABLES

Section Item Standard Procedure

Master Eject Upper and Lower

Master Eject Rollers

Wipe off the ink and paper powder

using a cloth moistened with ethyl

alcohol.

Master Eject Box Wipe off the ink using a cloth

moistened with ethyl alcohol.

Drum Inside and outside of

Drum

Ink Holder

Wipe off the built up ink and paper

powder using a cloth moistened with

ethyl alcohol.

Plotter Platen Roller Wipe off the paper powder using a

cloth moistened with water.

Others First and Second

Paper Exit Sensors

Master Eject Sensor

Check the performance of all the

sensors. Remove the stains from the

sensors using a dry cloth.

Drum Master

Detection Sensor

4-5

Page 48

SERVICE TABLES 15 July 1994

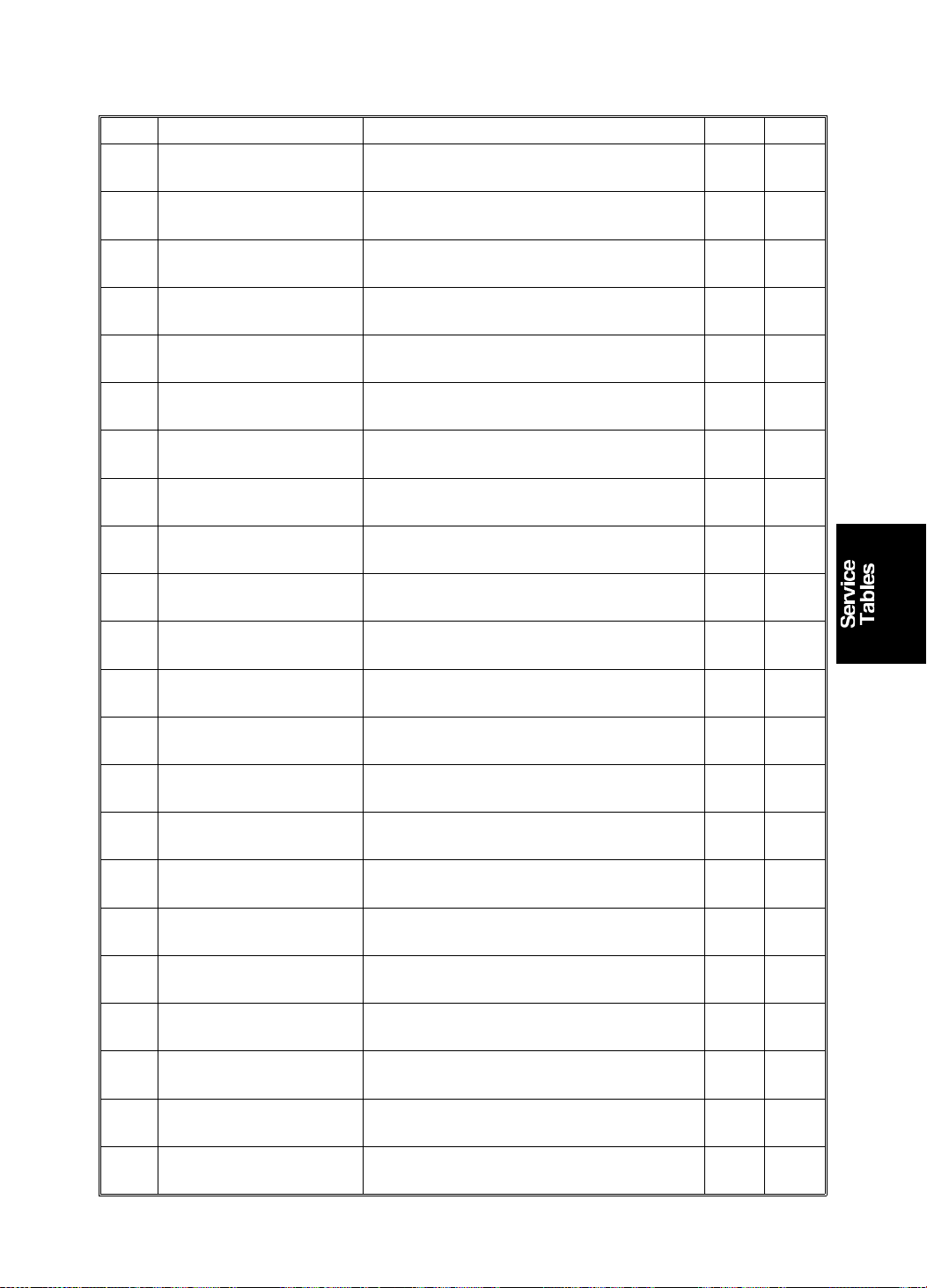

1.2 TABLE OF SERVICE CALL CODES

Code Problem Possible Causes

E-01 Neither th e righ t no r t he left

cutter switch turns off within 3

seconds of the cutter motor

starting.

E-02 Malfunction in the paper table

drive section.

The lower limit sensor or paper

table height sensor does no t turn

on within 7 seconds.

E-04 Temperat ure of th e thermal head

is greater than 54°C when th e

Master Making key is pressed.

E-05 Malfunction in the image shifting

section.

E-06 The drum rota tion sensor detects

an incorrect motor speed.

1) Drive wire cut

2) Drive section

malfunction

3) Defective cutter switch

1) Drive worm gear

broken

2) Mounting screw of the

worm gear broken

3) No power supply

1) Excessive thermal

head temperature

2) Thermistor short

1) Image position sensor

connector

disconnected

2) Defective image

position sensor

1) Drum lock

2) No power supply

E-07 Malfunction in the program.

When the main switch is turned

on, "E-07" lights up if the ROM is

defective.

E-08 Temperature of th e power sup ply

unit is greater than 85°C when

the Master Making key is

pressed.

E-09 The signal level between

CN109-A8 and GND is over 4.9

volts.

Defective ROM

Excessive power supply

unit temperature

1) Thermistor open.

2) Related connectors

are not connected

(Main PCB CN109-A8,

image processing

PCB CN404-B8/

CN403-22, or thermal

head drive PCB

CN705-22/ CN703-10).

4-6

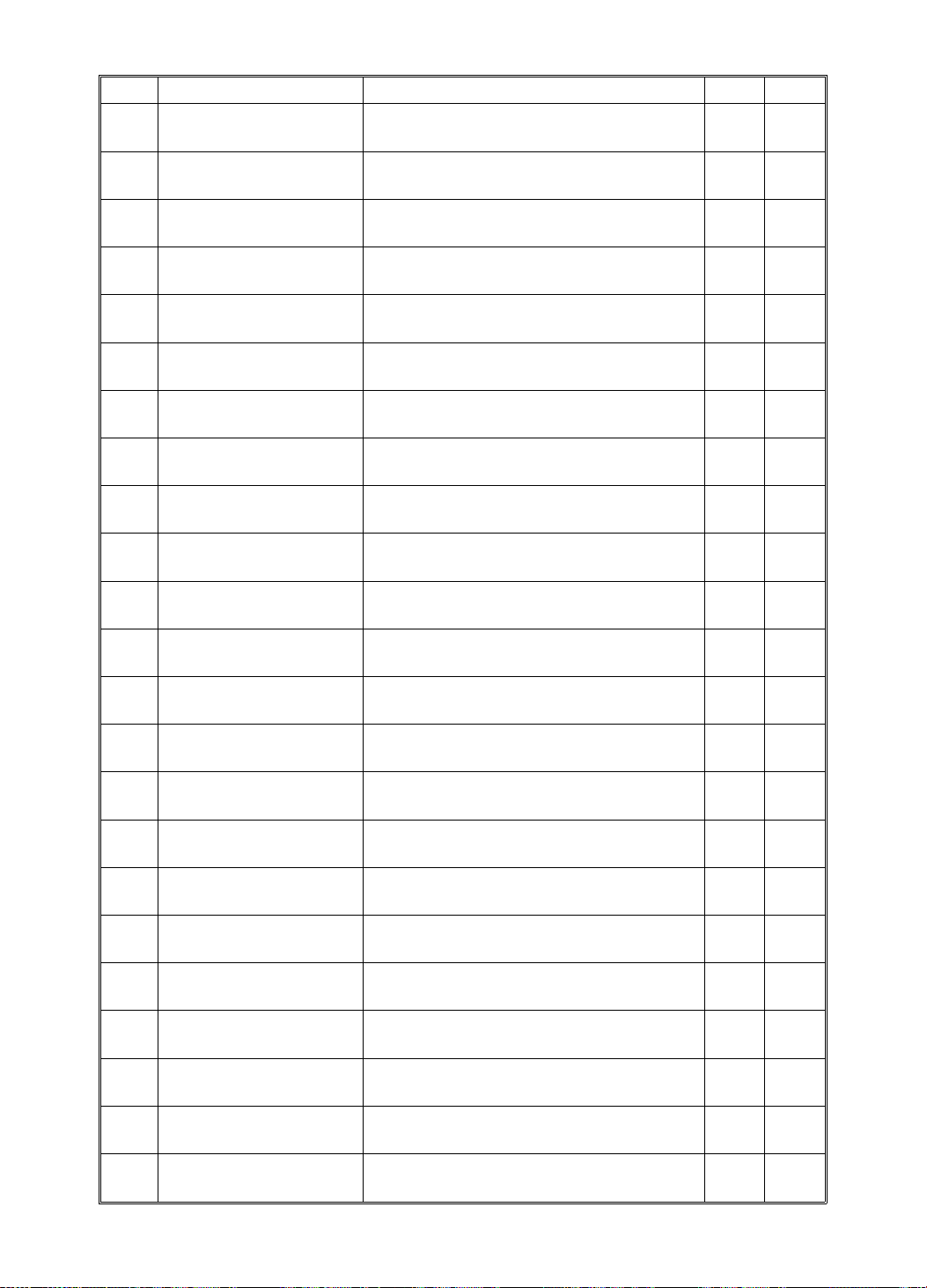

Page 49

15 July 1994 SERVICE TABLES

Code Problem Possible Causes

E-10 The CPU detects an abnormality

in the pulse from the thermal

head drive PCB (ENR 1 to 4).

This pulse determines th e en erg y

applied to the therma l hea ting

elements.

E-11 Encoder output does no t change

within 3 seconds of the main

switch being turned on or the

Clear Mode key being pressed.

1) Defective thermistor

2) Related connectors

are not connected

(Main PCB CN109-A7,

image processing

PCB CN404-B7/

CN403-20, or thermal

head drive PCB

CN705-20).

3) No power supply for

ICs (Vcc) from power

supply unit to image

processing PCB

(disconnection of

image processing

PCB CN701-7/14, or

power supply unit

CN503-12/13).

1) Defective image

position motor

2) No power supply

E-12 1. The upper or lower pressure

plate sensor remains

activated for more th an 4

seconds after the pressu re

plate motor starts turning.

2. The lower pressure plate

sensor is not activated within

8 seconds of the pressure

plate motor starting to turn

even though the upper

pressure plate sensor is

de-activated.

3. The upper pressure plate

sensor is not activated for

more than 8 seconds after the

pressure plate motor starts to

turn even thoug h th e lower

pressure plate sensor is

de-activated.

Pressure plate drive

mechanism malfunction.

4-7

Page 50

SERVICE TABLES 15 July 1994

Code Problem Possible Causes

E-13 While the scanne r is going back

to the home position:

- The home position sensor

remains activated for more

than 4 seconds.

- The home position sensor is

not activated within 2

seconds.

- The home position sensor is

not activated within 7

seconds when the scanner

returns after finishing

making the master or

scanning.

1) Defective Home

Position Sensor

2) Scanner Motor Lock

1.3 TABLE OF DIP SW, LED, VR, TP (ON THE MAIN

CONTROL PCB)

1.3.1 DIP SW

No. DIP SW Function Remarks

DIP SW101 — Not used.

Must be OFF.

DIP SW102 Sets the initial setting for the

counter to incremen t by two

counts per print when the A3

drum is used. (This setting

can be changed by SP mode

No.86)

1.3.2 Photodiode

No. LED Component Remarks

LED101 1st Paper Exit Sensor When paper is detected, th e

LED102 Drum Master Detection

Sensor

LED103 2nd Paper Exit Sensor When paper is detected, the

LED104 Master Eject Sensor When the master is under the

Turn on to make the initial

setting for the counter

increment by two counts.

Normal: OFF for Ricoh/

AB Dick

ON for NRG

LED lights.

When the master is on the drum,

the LED lights.

LED lights.

master eject sensor, th e LE D

lights.

4-8

Page 51

15 July 1994 SERVICE TABLES

No. LED Component Remarks

LED105 Ink Detection When ink is present, the LED

lights.

LED106 Main Motor When the main motor turns on,

the LED lights.

1.3.3 VR

No. VR Function

VR101 1st Paper Exit Sensor Adjustment

VR102 Drum Master Detection Sensor Adjustment

VR103 2nd Paper Exit Sensor Adjustment

VR104 Master Eject Sensor Adjustment

1.3.4 TP

No. TP Function Standard Voltag e

TP101 1st Paper E xit Sensor Voltage ON: More than 2 V

OFF: 0.9 V

TP102 Drum Master Detection

Sensor Voltage

ON: More than 2 V

OFF: 0.9 V

TP103 2nd Paper Exit Sensor Voltage ON: More than 2 V

OFF: 0.9 V

TP104 Maste r Eject Sensor Voltage ON: More than 2 V

OFF: 0.9 V

TP105 Ink Detection Voltage ON (ink is present): 0 V

OFF: – 12 V

TP106 Drum Rotation Sensor Voltage ON: 0 V

OFF: 5 V

TP107 GND

4-9

Page 52

SERVICE TABLES 15 July 1994

1.4 EXPECTED LIFE O F PARTS

Section Part Description Expected Life

Scanner Fluorescent La mp 15,000 originals

1st and 2nd Lower

Original Transport Rollers

Plotter/Master Feed Thermal Head 30,000 masters

Platen Roller 30,000 masters

Upper Master Feed Roller 1 year or 30,000 masters

Drum Drum Tetron Screen 2 years or 1,200,000

Paper Feed Paper Feed Rubbe r S ide

Plate

Paper Feed Roller 6 months or 300,000

Upper Separation Roller 1 year or 600,000 prints

Lower Separation Roller 2,000,000 prints

2nd Feed Roller Brake

Belt

Separation Plate 1 year or 600,000 prints

Printing Press Roller 2 years or 1,200,000

Delivery Transport Belt 2 years or 1,200,000

1 year or 60,000 originals

prints

1,200,000 prints

prints

1,000,000 prints

prints

prints

ADF Pick-up Roller 60,000 originals

Original Feed Roller 3 0,00 0 originals

Separation Roller 60,000 originals

1.5 SPECIAL TOOLS

Description Part Number

Test Chart R-21 99992131

Resolution Chart A0129110

Drum Gauge C2009001

Image Shifting Gauge C2009002

4-10

Page 53

15 July 1994 SERVICE PROGRAM MODE

2. SERVICE PROGRAM MODE

2.1 SERVICE PROGRAM MODE OPERATION

The service program (SP) mode is used to check electrical data, change

modes, or change adjust men t values.

2.1.1 Service Program Mode Access Procedure (for engineers)

All service program modes can be accessed with this procedure.

1. Press the following keys on the operation panel in the following order:

Case 1:

a) Clear Modes key

b) Clear key

c) Combine 2 Originals key

d) Enter key

Case 2:

a) Turn off the power switch

b) Press the Enter key, Stop key, and Clear key simult an eo usly

c) Turn on the power

2. The following is displayed on the LCD when the SP mode is acce ssed .

SP–MODE

PROGRAM No. 0

3. Using the number keys, enter the desired SP mode number (listed in the

service program table.)

NOTE: The SP mode nu mb er can be shifted up or down by pressing the

Zoom key ("+" or "–").

4. To cancel the SP mode, press the Clea r Mo des key.

4-11

Page 54

SERVICE PROGRAM MODE 15 July 1994

2.1.2 Service Program Mode Access Procedure (for users)

This procedure allows users to access only the service pro gra m modes tha t

are marked with an asterisk in the service program table.

1. Press the following keys on the operation panel in the following order:

a) Clear Modes key

b) Clear key

c) Enter key

2. The following is displayed on the LCD when the SP mode is acce ssed .

SP–MODE

PROGRAM No. 0

3. Using the number keys, enter the desired SP mode number (listed in the

service program table).

4. To cancel the SP mode, press the Clea r Mo des key.

2.1.3 Change Adjustment Values or Modes

1. After entering the desire d SP mode number, press the Enter key. The

value or mode set at the factory will be displayed on the LCD (at the end

of the second line).

2. Enter the desired value or mode using the number keys (listed in the

service program table).

3. Press the Enter key to sto re th e de sired value or mode.

4. To cancel the SP mode, press the Clea r Mo des key.

4-12

Page 55

15 July 1994 SERVICE PROGRAM MODE

2.2 DIFFERENCE IN SP MODE S BETWEEN THE #C210

MODEL AND THE #C218/C219 MO DELS

2.2.1 NEW SP MODES

SP mode No.5 Setting the number of EMF sorters.

SP mode No. 24 Character Emphasis setting. (Only for the C219 model.)

SP mode No. 36 Sub-scan magnification adjustment (ADF mode).

SP mode No. 37 Threshold value adjustment for shadow erase.

SP mode No. 38 ADF scan line adjustment

SP mode No. 39 Image center adjustment.

SP mode No. 84 Initial mode for Combine 2 Originals.

SP mode No. 85 Master full detection at power-up.

SP mode No. 86 Counter setting for the A3 drum. (Only for the C218 model.)

SP mode No. 87 Mode setting for Memory mode.

SP mode No. 88 Setting the print mode.

SP mode No. 92 Thermal Paper Mode.

SP mode No. 93 Shadow erase area check.

SP mode No. 95 Scanner free run mode.

SP mode No. 96 ADF original feed test mode.

SP mode No. 115 ADF mode counter.

SP mode No. 116 Platen mode counter.

SP mode No. 117 Color drum counter.

SP mode No. 118 Each paper size counter.

SP mode No. 119 All total counter clear mode.

SP mode No. 135 1st paper exit sensor voltage.

SP mode No. 136 2nd paper exit sensor voltage.

SP mode No. 137 Master eject sensor voltage.

SP mode No. 138 Drum master sensor voltage.

SP mode No. 142 Paper size detection On/Off.

SP mode No. 147 ADF set detection On/Off.

SP mode No. 160 to

170

Margin erase dimension settings.

2.2.2 ELIMINATED SP MODES

SP mode No. 50 Settings for directional magnification mode.

SP mode No. 109 Directional magnification counter.

SP mode No. 112 Clear Total Master/Print counter.

4-13

Page 56

SERVICE PROGRAM MODE 15 July 1994

2.3 SERVICE PROGRAM TABLE

*: Accessible by a customer ♥: A4 version ♦: LT version

No. Display Function Data Factory

Setting

1. On line Enables On Line

key operation.

2. FDC Type 10 Used only in Japan 0: No

0: No

1: Yes

0OO

0 Keep at 0. O O

1: Yes

3. Key Counter Enables key

counter operation.

4. Key Card Used only in Japan. 0: No

0: No

1: Yes

0OO

0OO

1: Yes

5. EMF Sorter Selects the number

of sorters.

0: No sorters

1, 2, 3, 4, or

0 Input 1 to 5

5: Sorters

present

*10. Min. Print Limits the minimum

0 to 9999 0 O O

print quantity that

can be entered.

*11. Max. Print Limits the maximum

0 to 9999 9999 O O

print quantity that

can be entered.

*12.

*12.

*13.

*14.

♥: A4 → A3

Mag. Ratio

♦: HLT → LG

Mag. Ratio

♥: B5 → B4

Mag. Ratio

♦: HLT → LG

Mag. Ratio

♥: A4 → B4

Mag. Ratio

♦: LT → DLT

Mag. Ratio

♥: B4 → A3

Mag. Ratio

♦: LG → DLT

Mag. Ratio

Adjusts the fixed

magnification ratio.

♥: From A4 to A3

♦: From 5

1/2" to 81/2" x 14"

8

1/2" x

Adjusts the fixed

magnification ratio.

♥: From B5 to B4

♦: From 5

1/2" to 81/2" x 14"

8

1/2" x

Adjusts the fixed

magnification ratio.

♥: From A4 to B4

♦: From 5

1/2" to 11" x 17"

8

1/2" x

Adjusts the fixed

magnification ratio.

♥: From B4 to A3

♦: From 8

1/2" x 14"

50 to 200%

50 to 200%

50 to 200%

50 to 200%

♥:

141%

♦:

155%

♥:

141%

♦:

155%

♥:

122%

♦:

129%

♥:

115%

♦:

121%

to 11" x 17"

*14.

♥: B5 → A4

Mag. Ratio

♦: LG → DLT

Mag. Ratio

Adjusts the fixed

magnification ratio.

♥: From B5 to A4

♦: From 8

1/2" x 14"

50 to 200%

♥:

115%

♦:

121%

to 11" x 17"

Comments C218 C219

OO

to indicate

the number

of sorters.

O

O

OO

O

O

4-14

Page 57

15 July 1994 SERVICE PROGRAM MODE

No. Display Function Data Factory

Setting

*15. Full Size Adjusts the full size

50 to 200% 100% O O

magnification ratio.

*16. Page Margin Adjusts the create

50 to 200% 93% O O

margin

magnification ratio.

*17.

*18.

♥: A3 → B4

Mag. Ratio

♦: LG → LT

Mag. Ratio

♥: B4 → A4

Mag. Ratio

♦: ** → LT

Mag. Ratio

Adjusts the fixed

magnification ratio.

♥: From A3 to B4

♦: From 8

to 8

1/2" x 14"

1/2" x 11"

Adjusts the fixed

magnification ratio.

♥: From B4 to A4

♦: From 11" x 15"

50 to 200%

50 to 200%

♥: 87%

♦: 77%

♥: 82%

♦: 74%

to

1/2" x 11"

8

*19.

♥: A3 → A4

Mag. Ratio

♦: DLT → LT

Mag. Ratio

Adjusts the fixed

magnification ratio.

♥: From A3 to A4

♦: From 11" x 17"

50 to 200%

♥: 71%

♦: 65%

to

1/2" x 11"

8

*19.

♥: B4 → B5

Mag. Ratio

♦: DLT → LT

Mag. Ratio

Adjusts the fixed

magnification ratio.

♥: From B4 to B5

♦: From 11" x 17"

50 to 200%

♥: 71%

♦: 65%

to

1/2" x 11"

8

*20. Buzzer On Turns the beeper

ON or OFF

*21. Prints/Master

Cost

Adjusts the ratio of

masters to prints.

0: No

0OO

1: Yes

0 to 50 0 The set

For accounting

purposes.

22. Read Image

Not used

—

0 Not used O O

Area

*23. Online

Paper Size

*24. Character

Emphasis

Used only in Japan 0: A6

1: A5

Use this to make

text more clear

when using Photo

mode.

0: No

1: Slightly

High

2: High

0 Not used O

0O

Comments C218 C219

OO

OO

O

O

OO

number (0

to 50) is

automatically

added to

the key

counter

each time a

master is

used.

4-15

Page 58

SERVICE PROGRAM MODE 15 July 1994

No. Display Function Data Factory

Setting

30. Sub Scan

Mag. Adjust

31. MTF Level Adjusts the MTF

32. Image

Density Rank

33. Lead Edge

Margin

35. Head

Energy

Adjust

36. Sub Scan

Mag. Adjust

(ADF)

37 Shadow

Erase Level

37-0 Line Use to adjust the threshold value for shadow erase in Line

37-1 Photo Use to adjust the threshold values for each of the contrast

37-1-0Std (Normal) Adjusts the shadow

37-1-1Lt (Light

Tone)

Adjusts the

sub-scan

magnification.

level.

In line mode,

adjusts the image

density level.

Adjusts the lead

edge margin.

Adjusts the thermal

head energy.

Adjusts the ADF

sub-scan

magnification.

Use to adjust the

threshold levels for

shadow erase in

the various image

modes.

mode. There are four numbers. Each represents the

threshold value for an image density. Input the required

value for the one that is blinking, then press Enter to move

on to the next one.

The lower the value, the darker the printout will be. The

factory settings are 27 for Light, 23 for Standard, 21 for

Dark, and 17 for Darker.

settings for shadow erase in Line mode. There are three

sub-menus to choose from. These are 0: Standard

(Normal), 1: Light Tone, and 2: Dark Tone (see below).

erase threshold

level for the Normal

contrast setting in

Line mode

Adjusts the shadow

erase threshold

level for the Light

Tone contrast

setting in Line mode

–1.9 to

+1.9%

0: Low

1: Standard

2: High

3: Maximum

0: Light

1: Standard

2: Dark

4 to 10 mm 8 mm O O

0 to –99% –7% 1% steps O O

-1.9 to 1.9% 0 0.1% steps O O

0: Line

1: Photo

2: Clear

Defaults

31: Light

25: Standard

17: Dark

15: Darker

Defaults

31: Light

25: Standard

17: Dark

15: Darker

(0) The factory

Comments C218 C219

setting

depends on

the

machine.

1OO

1OO

OO

OO

OO

OO

OO

OO

4-16

Page 59

15 July 1994 SERVICE PROGRAM MODE

No. Display Function Data Factory

Setting

37-1-2Dk (Dark

Tone)

37-2 Clear Returns all the

38. ADF Scan

Line Adjust

39 Image

Center

Adjustment

39-0 Image

Center

Adjustment:

Scanner

39-1 Image

Center

Adjustment:

ADF

*40. Original Specifies the image

*41. Image

Density

42. Print Speed Specifies the

*43. Auto Cycle

Mode

Adjusts the shadow

erase threshold

level for the Dark

Tone contrast

setting in Line mode

settings for SP

mode 37 to the

defaults.

Adjusts the ADF

scanning start

position.

Adjusts the center

position of copies in

the ADF and platen

modes.

Adjusts the center

position of copies in

platen mode.

Adjusts the center

position of copies in

ADF mode.

mode at power-up.

Specifies the image

density at power-up.

printing speed at

power-up.

Specifies whether

Auto Cycle mode is

selected at

power-up.

Defaults

17: Light

13: Standard

7: Dark

3: Darker

-4.9 to 4.9

mm

0: Scanner

1: ADF

-0.9 to 0.9

mm

-4.9 to 4.9

mm

0: Photo

1: Line

2: Sharpen

0: Light

1: Standard

2: Dark

3: Darker

[C218 model]

0: 60 rpm

1: 75 rpm

2: 90 rpm

3: 105 rpm

4: 120 rpm

[C219 model]

0: 60 rpm

1: 75 rpm

2: 90 rpm

3: 110 rpm

4: 130 rpm

0: No

1: Yes

0 0.1 mm

0See

0 0.1 mm

0 0.1 mm

1OO

1OO

2OO

0OO

Comments C218 C219

OO

OO

OO

steps

See

remarks (1).

OO

remarks (2).

OO

steps

OO

steps

4-17

Page 60

SERVICE PROGRAM MODE 15 July 1994

No. Display Function Data Factory

Setting

*44. Memory/Class

Mode

45. Std. Image

Position

*46. Make Up Specifies the initial

47. Contrast Specifies the initial

48. Photo Specifies the initial

60. Clear All

Memory

70. Original

Feed Jam

(A)

71. Paper Feed

Jam (B)

72. Paper Wrap

Jam

(E)/(B)(E)

73. Paper

Delivery

Jam (G)

74. Master Feed

Jam (C)

Specifies the initial

job memory feature

(Memory or Class

mode) at power-up.

Specifies the image

position at power-up

make-up

background pattern

when the Image

Make-up mode is

selected.

contrast when the

Photo mode is

selected.

screen when the

Photo mode is

selected.

Returns all SP

modes to the

factory settings.

Displays the total

number of original

jams.

Displays the total

number of paper

feed jams.

Displays the total

number of times

that paper has

wrapped around the

drum.

Displays the total

number of paper

delivery jams.

Displays the total

number of master

feed jams.

0: Class

1: Memory

0: –20 mm

1: –15 mm

2: –10 mm

3: –5 mm

4: 0 mm

5: +5 mm

6: +10 mm

7: +15 mm

8: +20 mm

1 to 40

51 to 90

101 to 140

150 to 190

0: Standard

1: Light

2: Dark

0: Standard

1: Fine

2: Coarse

0: No

1: Yes

1OO

4OO

0 0: No

0OO

0OO

0OO

0OO

0OO

0OO

0OO

0OO

Comments C218 C219

OO

background

pattern is

selected.

4-18

Page 61

15 July 1994 SERVICE PROGRAM MODE

No. Display Function Data Factory

Setting

75. Master

Delivery

Jam (F)

76. Clear Jam

Counters

81. Proof Print

No.

*82.-1Skip Feed

No.

-2 Long Sheet Specifies whether a

*83. Auto Reset

Time

*84. Auto

Combine 2

Orig.

*85. Initial Full

Check

86. A3 Drum 2

Count Up

Displays the total

number of master

delivery jams.

Clears all jam

counters.

Specifies how many

trial prints are made

after making the

master.

Selects the feed

interval.

long sheet is used.

Specifies the auto

reset time.

Specifies the initial

mode for Combine

2 Originals.

Specifies whether

master full

detection is made

at power-up.

Specifies whether

the counter

increments by two

counts per print

when the A3 drum

is used.

0OO

0: No

1: Yes

0 to 2 sheets 1 O O

1 to 5 1 1: Normal

0: No

1: Yes

0: No

1: 3 min.

2: 5 min.

0: Normal

1: Auto (Two

identical

images are

made if the

Master

Making key

is pressed

once.)

0: No

1: Yes

0: No

1: Only the

master

counter

2: Both the

master and

the copy

counter

0OO

0 Displays

0OO

0OO

0OO

0

Ricoh,

AB Dick

2

NRG

Comments C218 C219

OO

operation

2 to 5: One

sheet fed

every two

to five drum

rotations

OO

only when

no. 2, 3, 4,

or 5 are

selected in

82-1.

See

Remarks (3)

O

4-19

Page 62

SERVICE PROGRAM MODE 15 July 1994

No. Display Function Data Factory

Setting

87. Memory Print Specifies the print

mode when in

Memory mode.

88 Auto

Memory/

Class

90. Thermal

Head Test

91. Command

Sheet Check

92. Thermal

Paper Mode

93. Erase Area

Check

95.

Scanner

-1

Free Run

-2 Scanner

Free Run

96. ADF Original

Feed Check

100. Combine 2

Originals

Count

101. Make Up

Count

Specifies the print

mode.

Selects the

background pattern

for the copy made

in the thermal head

test; performs the

test.

Prints the command

sheet image

(designated area)

together with the

original image.

Use this mode to

test the thermal

head.

Checks the erase

area.

Selects free running

of the scanner.

Carries out the

scanner free run.

(The speed can be

changed: see

remarks (8).)

Carries out the ADF

original feed check.

(The speed can be

changed; see

remarks (9).)

Displays the total

number of masters

made in Combine 2

Original mode.

Displays the total

number of masters

made in Make-up

mode.

0: Normal

(Memory

Print Mode)

1: Stack

Mode

0: Normal

1: Auto

Class

(Memory)

Print

1 to 40

51 to 90

101 to 140

150 to 190

0: No

1: Yes

0: No

1: Yes

0: No

1: Yes

0: With the

lamp off

1: With the

lamp on

Start with

the Print

Start key.

Stop with the

Stop key.

Start with

the Print

Start key.

Stop with the

Stop key.

0See

0See

7 See the

0 See the

0See

0See

0See

0OO

0OO

Comments C218 C219

OO

Remarks (4)

OO

Remarks (5)

OO

Thermal

Head Test

section.

Command

Sheet

Check

section.

Remarks (6)

Remarks (7)

Remarks (8)

Displays by

pressing #,

after

selecting 0

or 1 in 95-1.

See

Remarks (9)

(Only

one

patte

rn)

OO

OO

OO

OO

OO

OO

4-20

Page 63

15 July 1994 SERVICE PROGRAM MODE

No. Display Function Data Factory

Setting

102. Make Up

Photo Count

103. Area Mask

Count

104. On line

Count

105. Overlay

Count

106. Enlarge

Count

107. Reduction

Count

108. Zoom Count Displays the total

110. Power On

Time

111. Total Count Displays the total

*113. Resettable

Count

*114. CLR Reset

table Count

115. ADF Mode

Count

Displays the total

number of masters

made in Make-up

Photo mode.

Displays the total

number of masters

made with the

Margin Erase key.

Displays the total

number of masters

made in On Line

mode.

Used only in Japan. 0 O O

Displays the total

number of masters

made in Fixed

Enlargement mode.

Displays the total

number of masters

made in Fixed

Reduction mode.

number of masters

made in Zoom

mode.

Displays the total

amount of time the

machine has been

turned on.

number of masters

and prints.

Used by the

customer to display

the total number of

masters and prints.

Clears the

resettable total

master/print

counters.

Displays the total

number of sheets

fed in the ADF

mode.

0: No

1: Yes

0OO

0OO

0OO

0OO

0OO

0OO

0 xxxxx Hour

0 M: Master

0 M: Master

0OO

0OO

Comments C218 C219

OO

xx Min.

xx Sec.

OO

count

P: Print

count

OO

count

P: Print

count

4-21

Page 64

SERVICE PROGRAM MODE 15 July 1994

No. Display Function Data Factory

Setting

116. Platen Mode

Count

117. Color Drum

Count

118. Paper Size

Count

119. CLR All

Total Count

*120.

User Code

-1

Mode

-2 Auto Reset

Time

*121. UC Count Displays the total

*122. Clear UC

Count

*123. Total UC

Count

*124. Clear Total

UC Count

130. Input Check

Mode

131. Output

Check Mode

Displays the total

number of originals

set in platen mode.

Displays the total

number of prints

when using the

color drum.