Page 1

INTRODUCTION

INTRODUCTION

This manual contains detailed instructions on the operation and maintenance of this machine. To get the maximum versatility from this machine, all

operators should carefully read and follow the instructions in this manual.

Please keep this manual in a handy place near the machine.

Please read the next section before using this machine. It contains important information related to USER SAFETY and PREVENTING EQUIPMENT

PROBLEMS.

SAFETY INFORMATION

When using your machine, the following safety precautions should always

be followed.

Safety During Operation

In this manual, the following important symbols are used:

R WARNING:Ignoring this warning could cause serious injury

or even death.

R CAUTION: Ignoring this caution could cause injury or

damage to property.

Examples Of Indications

R Symbols R means a situation that requires you take care.

q Do NOT carry out the operation represented by the symbol m.

This example means "Do not take apart".

r Symbols ● means you MUST perform this operation.

This example means "You must remove the wall plug".

i

Page 2

SAFETY INFORMATION

R WARNINGS:

Only connect the machine to the power source described on

the inside front cover of this manual. Avoid multi-wiring as

m

m

q

it could cause an electric shock or a fire.

Avoid using an extension cord. Make sure the wall outlet is

near the machine and freely accessible so that in event of an

emergency it can be unplugged easily.

Do not damage, break or make any modifications to the

power cord. Do not place heavy objects on it, pull it hard or

bend it more than necessary. These actions could cause an

electric shock or fire.

Do not remove any covers or screws other than those

specified in this manual. Some parts of the machine are at a

high voltage and could give you an electric shock. When the

machine needs to be checked, adjusted or repaired, contact

your service representative.

Do not take apart or attempt any modifications to this

machine. There is a risk of fire, electric shock, explosion or

loss of sight.

r

m

r

ii

If the machine looks damaged or breaks down, smoke is

coming out, there is a strange smell or anything looks

unusual, immediately turn off the main power switch then

unplug the power code from the wall. Do not continue using

the machine in this condition. Contact your service representative.

Do not put any metal objects or containers holding water

(e.g. vases, flowerpots, glasses) on the machine. If the

contents fall inside the machine a fire or electric shock could

occur.

If any metal, liquid or foreign matter falls into the machine,

turn off the main switch and unplug the main power cord.

Contact your service representative. Do not keep using the

machine with a fault or defect.

Page 3

Do not plug or unplug the power cord with wet hands or an

m

electric shock might occur.

RCAUTIONS:

When you move the machine, unplug the power cord from

r

t

m

r

the wall outlet to avoid fire or electric shock.

When you pull out the plug from the socket, grip the plug to

avoid damaging the cord and causing fire or electric shock.

Keep the machine away from humidity and dust. A fire or

an electric shock might occur.

Do not place the machine on an unstable or tilted surface.

If it topples over it could cause injury.

When the machine will not be used for a long time, unplug

the power cord.

SAFETY INFORMATION

o

R

If you use this machine in a confined space, make sure there

is a continuous air turnover.

This machine has been tested for safety using this supplier’s

parts and consumable. We recommend you only use these

specified supplies.

iii

Page 4

SAFETY INFORMATION

iv

Page 5

TABLE OF CONTENTS

TABLE OF CONTENTS

GUIDE TO COMPONENTS...........................................................................1

Machine Exterior .........................................................................................1

Machine Interior .......................................................................................... 3

Operation Panel ..........................................................................................5

INSTALLATION REQUIREMENTS...............................................................8

Optimum Environmental Conditions ............................................................8

Environments To Avoid ...............................................................................8

Access To The Machine ............................................................................8

Power Connection ......................................................................................9

OPERATION ...............................................................................................10

Printing Paper ............................................................................................10

Originals ......................................................................................................11

Preparation For Printing ..............................................................................12

Standard Printing ........................................................................................ 16

Restoring Paper Feed And Paper Delivery Tables ....................................19

Adjusting The Image Position .....................................................................21

Adjusting The Image Density .....................................................................23

Changing The Printing Speed ...................................................................24

Stopping The Machine During A Print Run ................................................25

Reduction/Enlargement Printing (Reduce/Enlarge) ...................................27

Erasing Center And Edge Margins (Edge Erase/Center Erase) ...............31

Erasing Edge Margins (Edge Erase) ..........................................................34

Erasing The Shadow Of Pasted Originals (Paste Shadow Erase) ............36

Printing On Thick Or Thin Paper ...............................................................38

Photo Mode Printing (Type of Original) ....................................................40

Ink Saving (Economy Mode) ......................................................................42

Making Half-tone Prints (Tint Mode) ..........................................................43

Printing From Several Originals At Once (Auto Cycle) ..............................45

Printing With A Programmed Number Of Prints For Each Class

(One Touch Class Mode) ........................................................................47

v

Page 6

TABLE OF CONTENTS

Combine 2 Originals ................................................................................ 63

Skip Feed Printing (Skip Feed Mode) ....................................................... 71

User Program ............................................................................................ 73

Printing Of Secret Documents (Security Mode) ......................................... 79

Recovering The Image Density (Quality Start) ........................................... 80

OPTIONAL FUNCTIONS .............................................................................82

Printing Using The Optional Document Feeder ......................................... 82

Color Printing Using The Optional Color Drum ........................................ 88

CHANGING DEFAULT SETTINGS (SERVICE PROGRAM MODE) .........94

How To Access Service Programs ........................................................... 94

How To Change Settings of Service Programs ......................................... 95

Service Program Menu ............................................................................... 102

User Codes ................................................................................................. 109

REPLENISHING SUPPLIES ........................................................................116

Loading Paper On The Paper Feed Table ................................................ 116

Supplying Ink .............................................................................................. 119

Master Roll Replacement ........................................................................... 121

Placing A New Roll Of Tape In The Tape Dispenser (Option) ................ 124

DAILY MAINTENANCE.................................................................................126

Exposure Glass ......................................................................................... 126

Platen Cover .............................................................................................. 126

Separation Roller (Optional Document Feeder) ....................................... 127

Paper Feed Roller (Paper Feed Table) ..................................................... 127

TROUBLESHOOTING ..................................................................................128

When The Misfeed Indicator (Y) Is Lit ...................................................... 131

When The Supply/Exchange Indicators Are Lit ......................................... 150

When Other Indicators Are Lit..................................................................... 152

When The Prints Are Not Delivered In A Neat Stack, Or The Prints Are

Thrown Over The Paper Delivery Table ..................................................... 152

Poor Printing ............................................................................................... 153

vi

Page 7

TABLE OF CONTENTS

OPERATION NOTES....................................................................................158

General Cautions ......................................................................................... 158

Print Paper ................................................................................................... 160

Originals ....................................................................................................... 160

COMBINATION CHART ..............................................................................161

SPECIFICATIONS ........................................................................................162

Main Frame ................................................................................................. 162

Document Feeder (Option) ...........................................................................165

Consumables .............................................................................................. 166

vii

Page 8

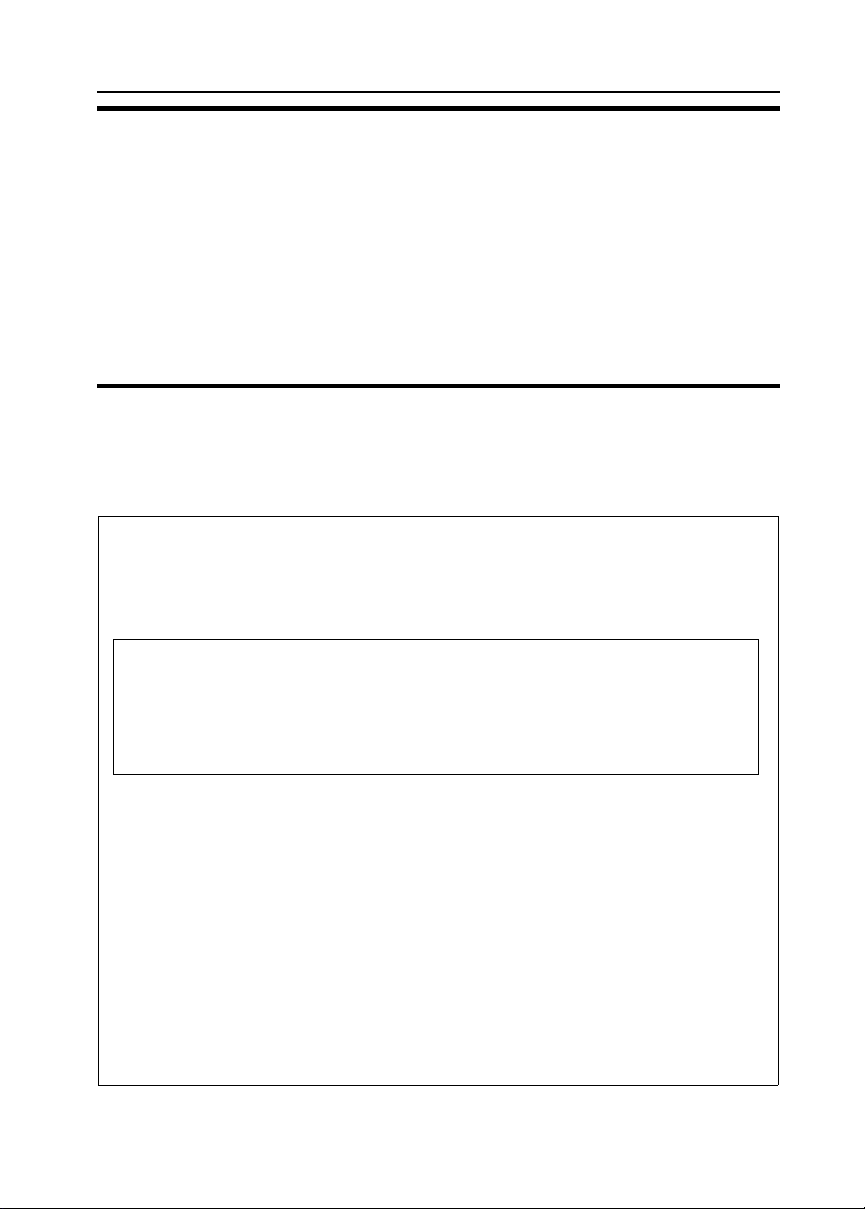

GUIDE TO COMPONENTS

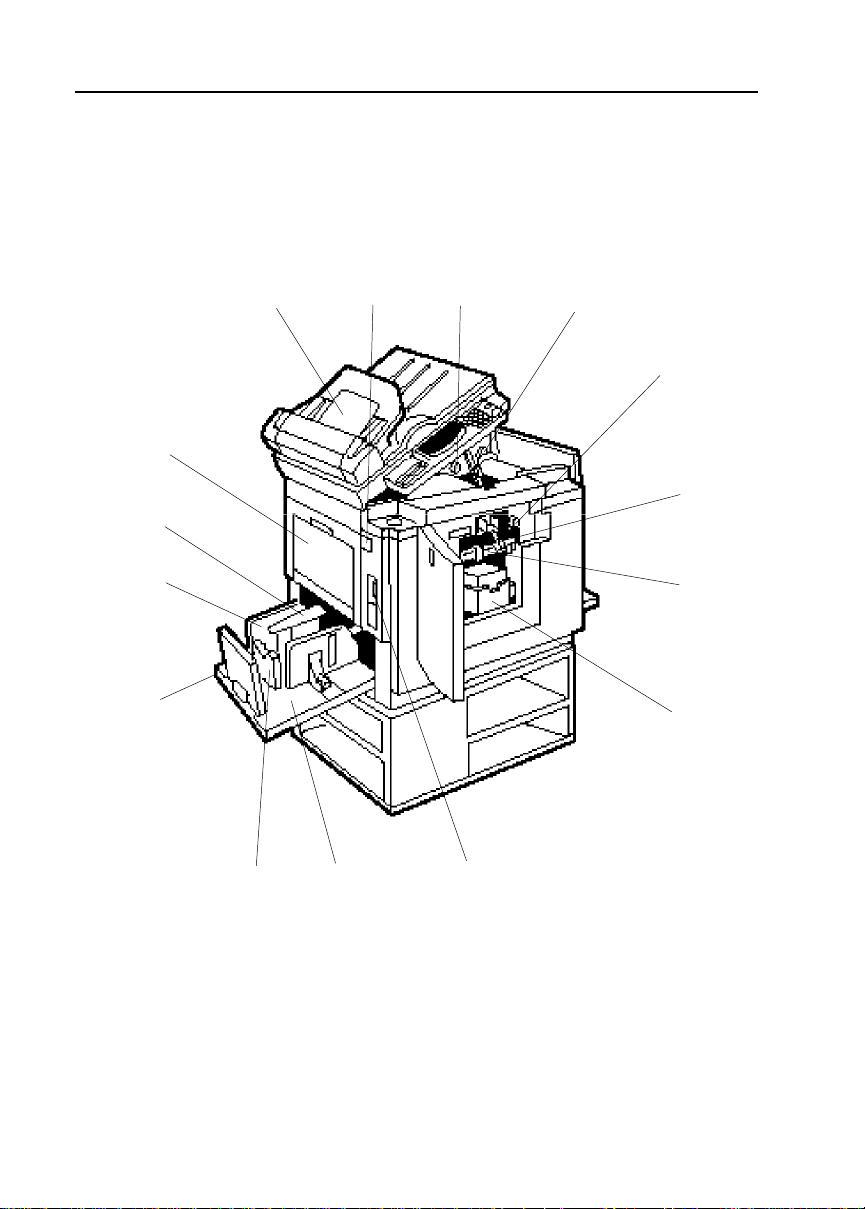

Machine Exterior

GUIDE TO COMPONENTS

10

1

2

3

4

5

6

7

8

9

1

Page 9

GUIDE TO COMPONENTS

GUIDE TO COMPONENTS

1. Operation panel Operator controls and indicators are located

here. ☛ See pages 5 ~ 7.

2. Platen cover Lower this cover over an original before printing.

3. Original table

release lever

4. Feed roller

pressure lever

5. Separation roller

pressure lever

6. Paper feed side

Use to open the original table unit when installing

the master.

Use to adjust the contact pressure of the paper

feed roller according to paper thickness.

Use to adjust the separation roller pressure to

prevent double feed.

Use to prevent paper skew.

plates

7. Paper feed table Set paper on this table for printing.

8. Side plate fine

Use to shift the paper feed table sideways.

adjusting dial

9. Front cover Open to access to the inside of the machine.

10. Plate Flip over when you use One Touch Class func -

tion. ☛ See page 47.

2

Page 10

GUIDE TO COMPONENTS

Machine Interior

15

14

13

12

1

2 3

4

5

6

7

8

11

3

10

9

Page 11

GUIDE TO COMPONENTS

GUIDE TO COMPONENTS

1. Document feeder

(Option)

2. Master eject unit

open button

Original inserted into the document feeder are individually and automatically fed onto and re moved from the exposure glass. ☛ See page 82.

Press to remove misfed paper or a misfed master.

3. Master cut button Press this button to cut the master leading edge

after installing a new master roll.

4. Pressure release

Use to install the master roll.

lever

5. Drum rotation

Press to rotate the drum unit.

button

6. Drum unit lock

Lift to unlock and pull out the drum unit.

lever

7. Drum unit The master is wrapped around this unit.

8. Ink holder Set the ink cartridge in this holder.

9. Main switch Use to turn the power on or off.

10. Paper delivery table Completed prints are delivered here.

11. Small size paper

delivery end plate

12. Paper delivery end

plate

13. Paper delivery side

Use to align the leading edge of prints that are

A4, 81/2" x 11" or smaller.

Use to align the leading edge of prints larger

than A4, 81/2" x 11".

Use to align the prints on the paper delivery table.

plate

14. Wing guides When printing on thin or small size paper, lift

these guides. ☛ See page 15.

15. Master eject

Open when removing the master eject box.

container cover

❐ Other options: Color Drums (red, blue, green, brown, yellow, purple, navy,

maroon, orange and teal)

Tape Dispenser

Key Counter

Cabinet

4

Page 12

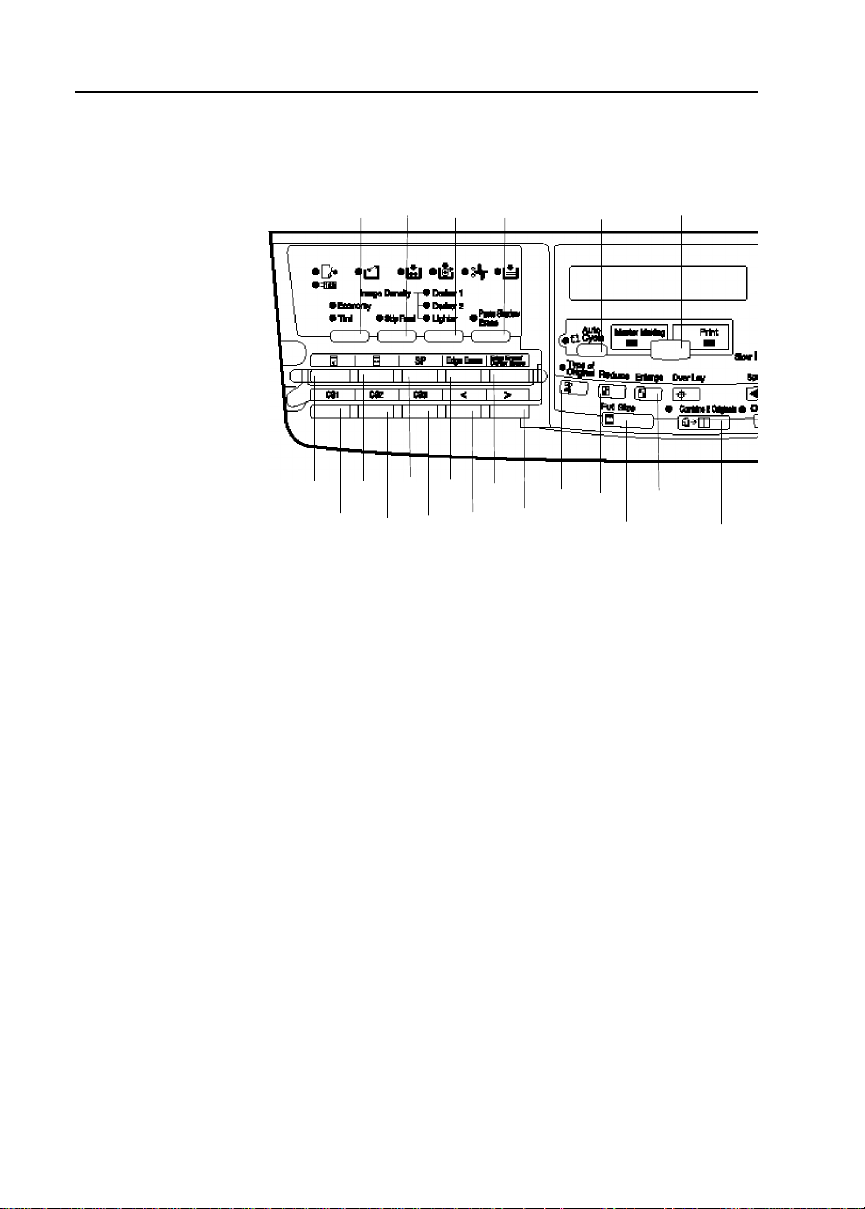

GUIDE TO COMPONENTS

Operation Panel

Keys

1. Economy/Tint key

☛ See pages 42 ~ 44.

2. Skip Feed key

☛ See page 71.

3. Image Density key

☛ See page 23.

20

6

19

21

1

2

3

4

7

12

8

9

13 14

10 11

15

16

10. Edge Erase key

☛ See page 34.

11. Edge Erase/Center Erase key

☛ See page 31.

12. 13. 14. CS mode keys

☛ See pages 97 ~ 101.

17

5

18

4. Paste Shadow Erase key

☛ See page 36.

5. Auto Cycle key

☛ See page 45.

6. Master Making/Print key

Press to select Master Making or

Print mode.

7. Security key

☛ See page 79.

8. Quality Start key

☛ See page 80.

9. SP mode key

☛ See page 94.

5

15. 16. Scroll keys

Press to select size and direction

of paper or original in Edge

Erase/Center Erase and Edge

Erase function.

Press to select the mode in Serv ice Program mode.

17. Type of Original key

☛ See page 40.

18. Reduce key

☛ See page 27.

19. Enlarge key

☛ See page 29.

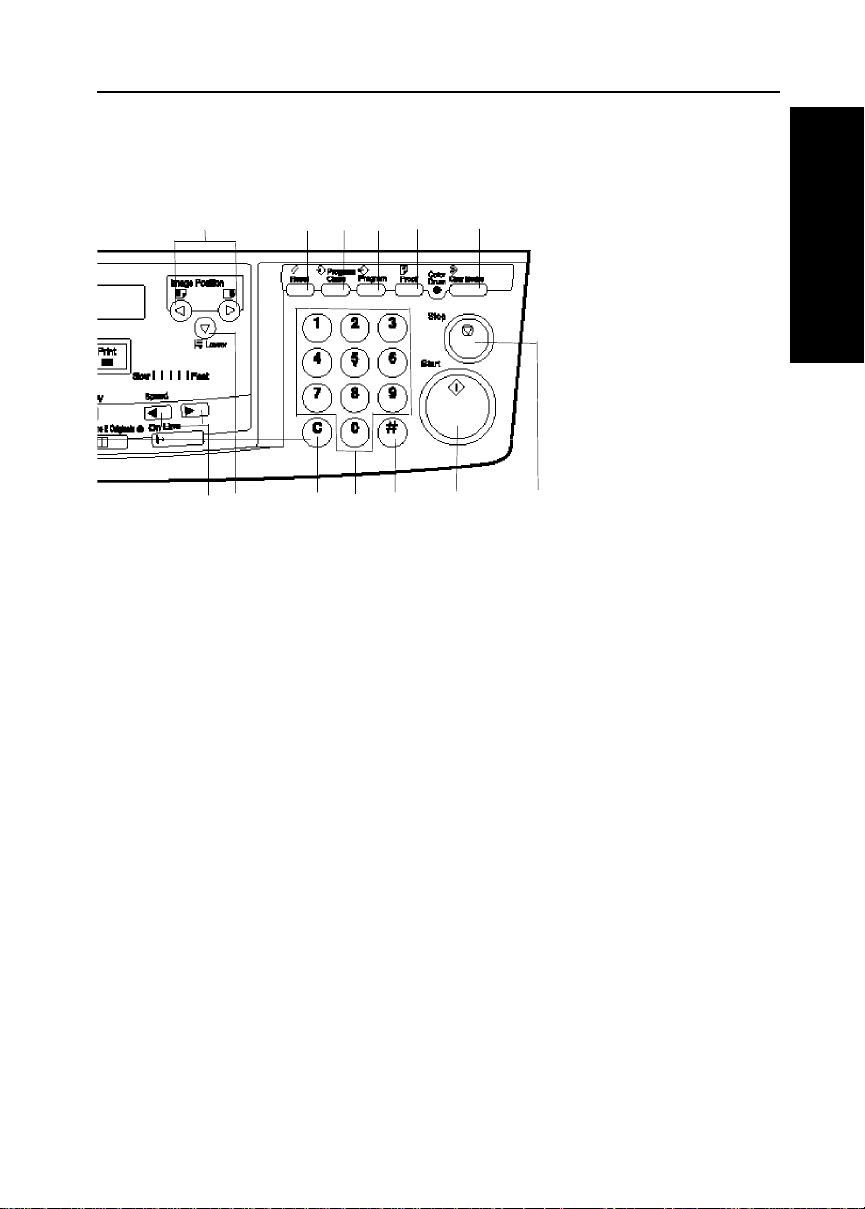

Page 13

GUIDE TO COMPONENTS

GUIDE TO COMPONENTS

22 23

28

29

30

20. Full Size key

Press to make full size prints.

21. Combine 2 Originals key

☛ See page 63.

22. Image Position keys

☛ See page 21.

23. Reset key

Press to reset the error indicators.

24. Program Class key

☛ See page 47.

25. Program key

☛ See page 73.

26. Proof key

Press to make proof prints.

24 25

31

32

27

26

33

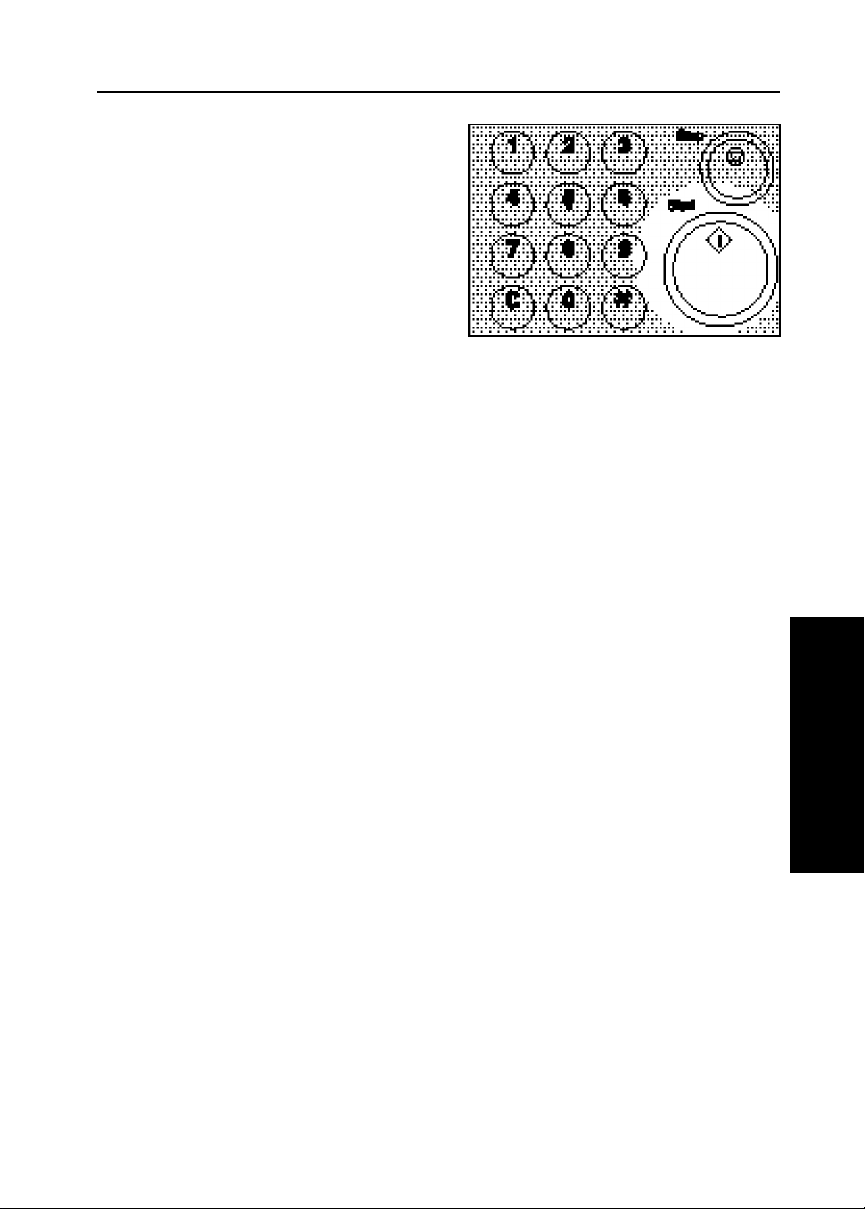

28. Speed keys

29. Lower key

30. Clear key

31. Number keys

32. Enter key

33. Start key

34

☛ See page 24.

Press to lower the paper feed ta ble.

Press to change the number set.

Press to enter the number of

prints and data.

Press to input data into memory.

Press to start making of a master

or printing.

27. Clear Modes key

Press to cancel all previously en tered settings.

34. Stop key

Press to stop the machine opera tion.

6

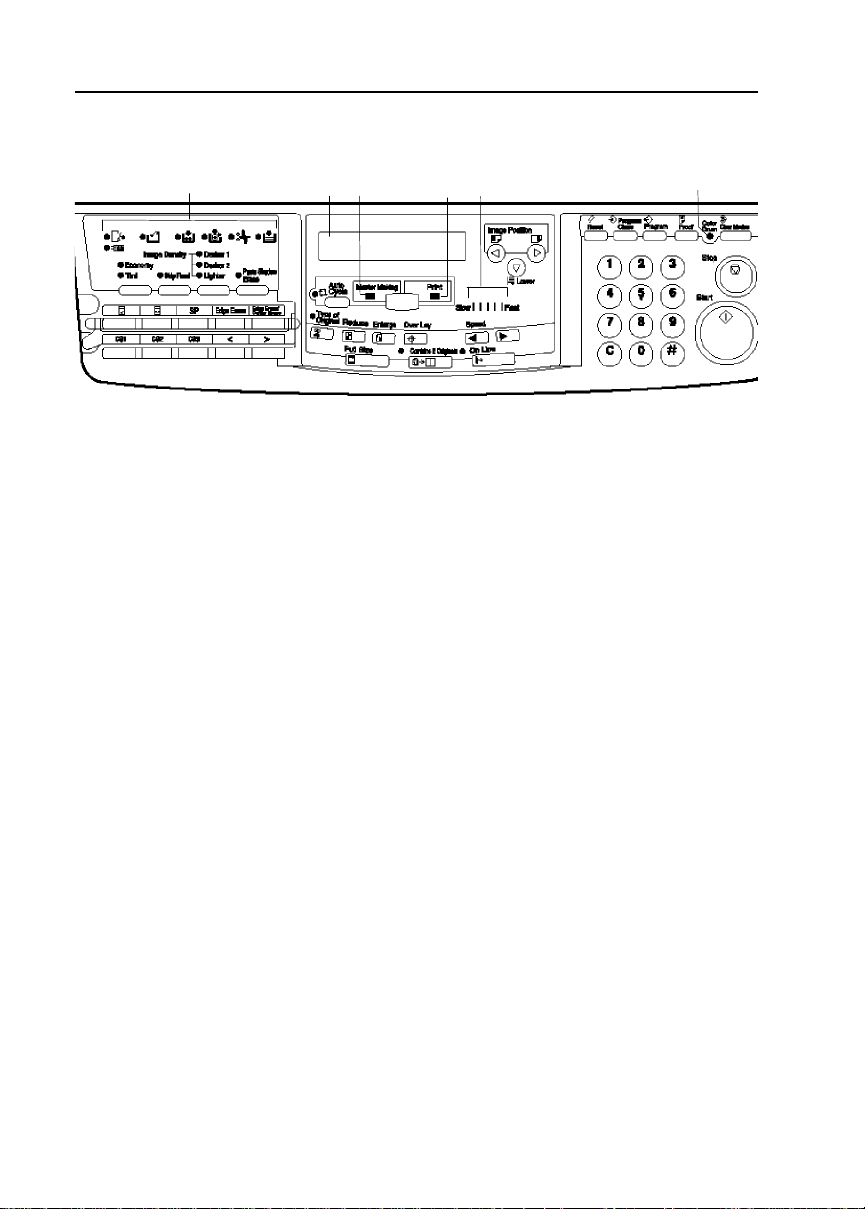

Page 14

GUIDE TO COMPONENTS

Indicators

1. Error indicators

These indicators are lit when a

non-standard condition occurs

within the machine. ☛ See page

128.

2. Guidance Display

Press to stop the machine opera tion.

3. Master Making indicator

This indicator is lit when Master

Making mode is selected.

1

3

2

4

5

4. Print indicator

This indicator is lit when Print

mode is selected.

5. Speed indicators

These indicators show the printing

speed that is selected. ☛ See

page 24.

6. Color Drum indicator

This indicator is lit when the op tional color drum unit is set. ☛

See page 88.

6

7

Page 15

INSTALLATION

REQUIREMENTS

INSTALLATION REQUIREMENTS

INSTALLATION REQUIREMENTS

The machine’s location should be carefully chosen because environmental

conditions can affect its performance.

Optimum Environmental Conditions

❐ Temperature: 10 - 30°C, 50 - 86 °F

❐ Humidity: Main frame: 20 - 90 % RH

Document feeder (option): 20 - 70 % RH

❐ A strong and level base (A sturdy desk and cabinet etc.).

❐ The machine must be level within 5 mm (13/64") both front to rear and left to

right.

❐ Make sure to locate this machine in a large well ventilated room that has an air

turnover of more than 30 m3/hr/person.

Environments To Avoid

❐ Direct sunlight or strong light (more than 1500 lux).

❐ Locations directly exposed to cool air from an air conditioner or heated air from

a heater. (Sudden temperature changes from low to high or vice versa may

cause condensation within the machine.)

❐ Dusty areas.

Access To The Machine

❐ Place the machine near a power source, providing clearance as shown.

More than 20 cm, 8.0"

More than 60 cm,

23.7"

Machine

More than 60 cm, 23.7"

More than 60 cm, 23.7"

8

Page 16

INSTALLATION REQUIREMENTS

Power Connection

WARNING:

R

Only connect the machine to the power source described on the

inside front cover of this manual.

Avoid multi-wiring as it could cause an electric shock or a fire.

Avoid using an extension cord. Make sure the wall outlet is near

the machine and freely accessible so that in event of an emergency

it can be unplugged easily.

Do not damage, break or make any modifications to the power cord.

Do not place heavy objects on it, pull it hard or bend it more than

necessary. These actions could cause an electric shock or fire.

CAUTION:

R

When you move the machine, unplug the power cord from the wall

outlet to avoid fire or electric shock.

When you pull out the plug from the socket, grip the plug to avoid

damaging the cord and causing fire or electric shock.

❐ Make sure the plug is firmly inserted in the outlet.

❐ Avoid multiwiring.

❐ Do not pinch the power cord.

9

Page 17

OPERATION

OPERATION

OPERATION

Printing Paper

❐ The following types of print paper are not recommended for this machine.

• Paper smaller than 90 mm x 148 mm, 3.6" x 5.9"

• Paper larger than 297 mm x 432 mm, 11.6" x 17.0"

• Paper heavier than 209.3 g/m2, 55.6 lb

• Paper lighter than 47.1 g/m2, 12.5 lb

(However, 45 g/m2, 11.9 lb paper may be used when the printing speed

is setting 1, 2 or 3 and the separation pressure levers are in the "Thick"

position.)

• Roughly-cut paper

• Paper of different thickness in the same stack

• Buckled or curled paper

• Short grain paper

• Low stiffness paper

❐ Correct curls in the paper before setting it in the machine. When you cannot

correct the paper curl, stack the paper with the curl face down. Otherwise the

paper might wrap around the drum or stains might appear.

❐ Store paper where it will not curl or absorb moisture. Use paper soon after it is

unpacked.

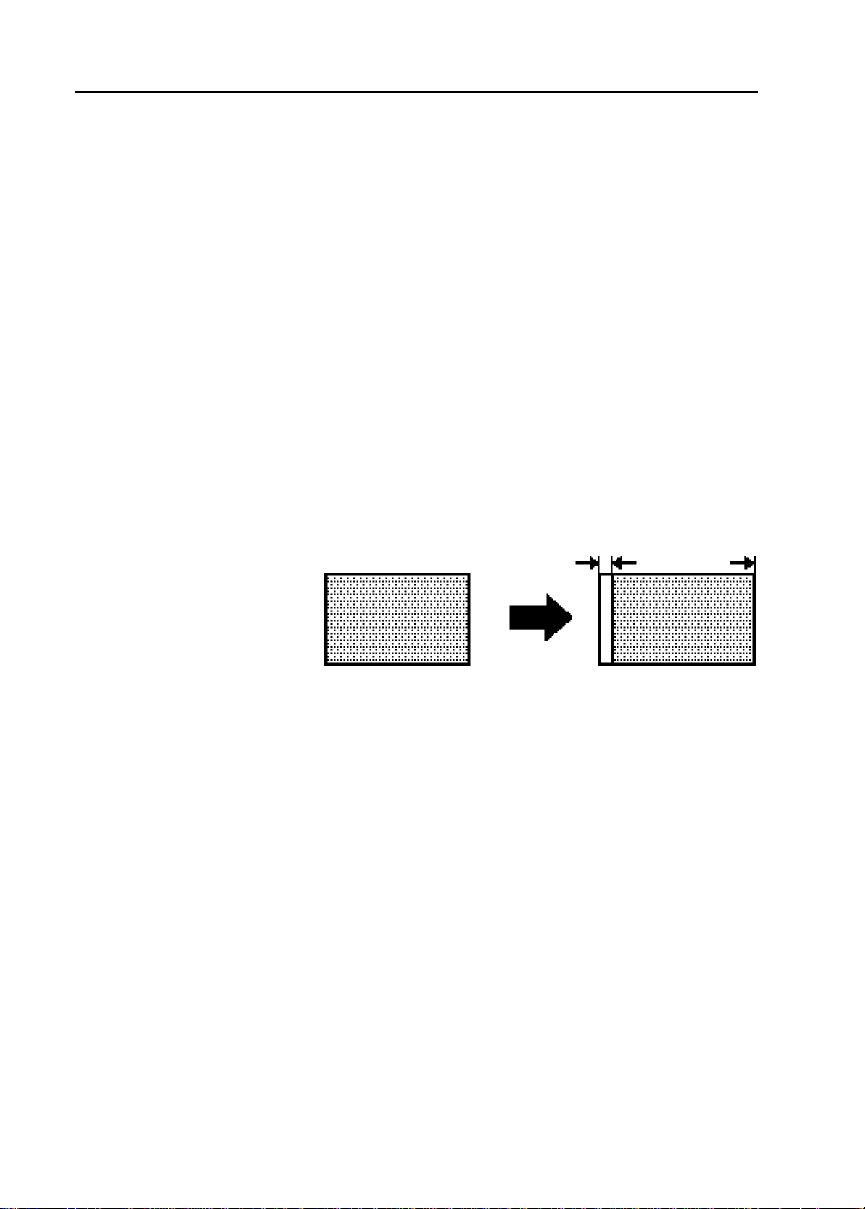

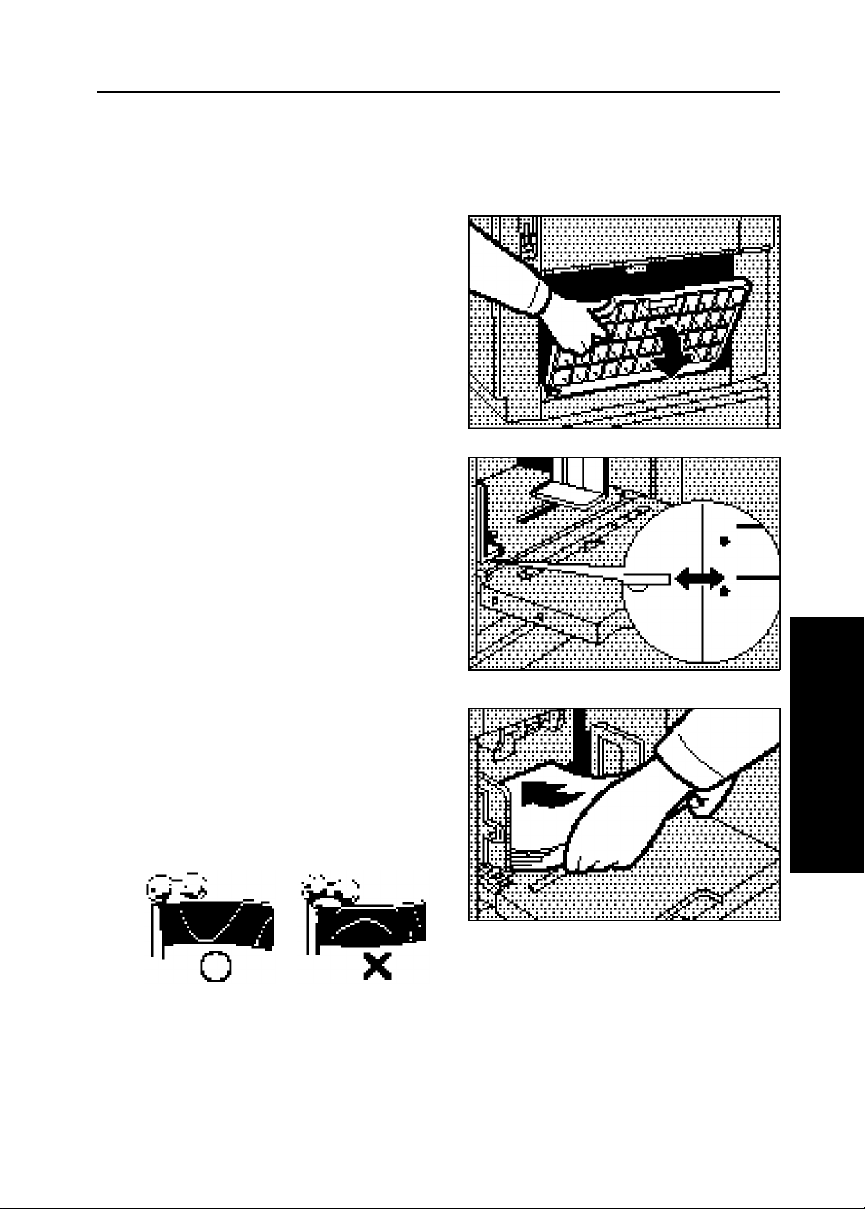

❐ Only use paper where the leading edge has two right angle corners, as shown

below.

Not OK

OK

10

Page 18

OPERATION

Originals

❐ Originals that can be set on the exposure glass are as follows:

• Maximum size: 257 x 364 mm, 10.2" x 14.4"

• Maximum total thickness: 30 mm, 1.1"

• Maximum total weight: 5 kg, 11.0 lb

❐ If you use paste-up originals, make sure the pasted parts hold firmly to the

base sheet and press the Paste Shadow Erase key. If the thickness of the

paste-up original is more than 0.1 mm and the space between the pasted parts

is less than 2 mm, 2/25", a shadow might appear on the prints.

❐ If you use originals that have bold letters or solid images at the leading edges,

you might get prints with dirty edges. In this case, insert the widest margin first,

or raise the printing speed.

❐ The first 5 mm, 0.2" of the leading edge cannot be printed. Make sure the

leading edge margin is at least 5 mm, 0.2".

Original

5 mm, 0.2"

Print

11

Page 19

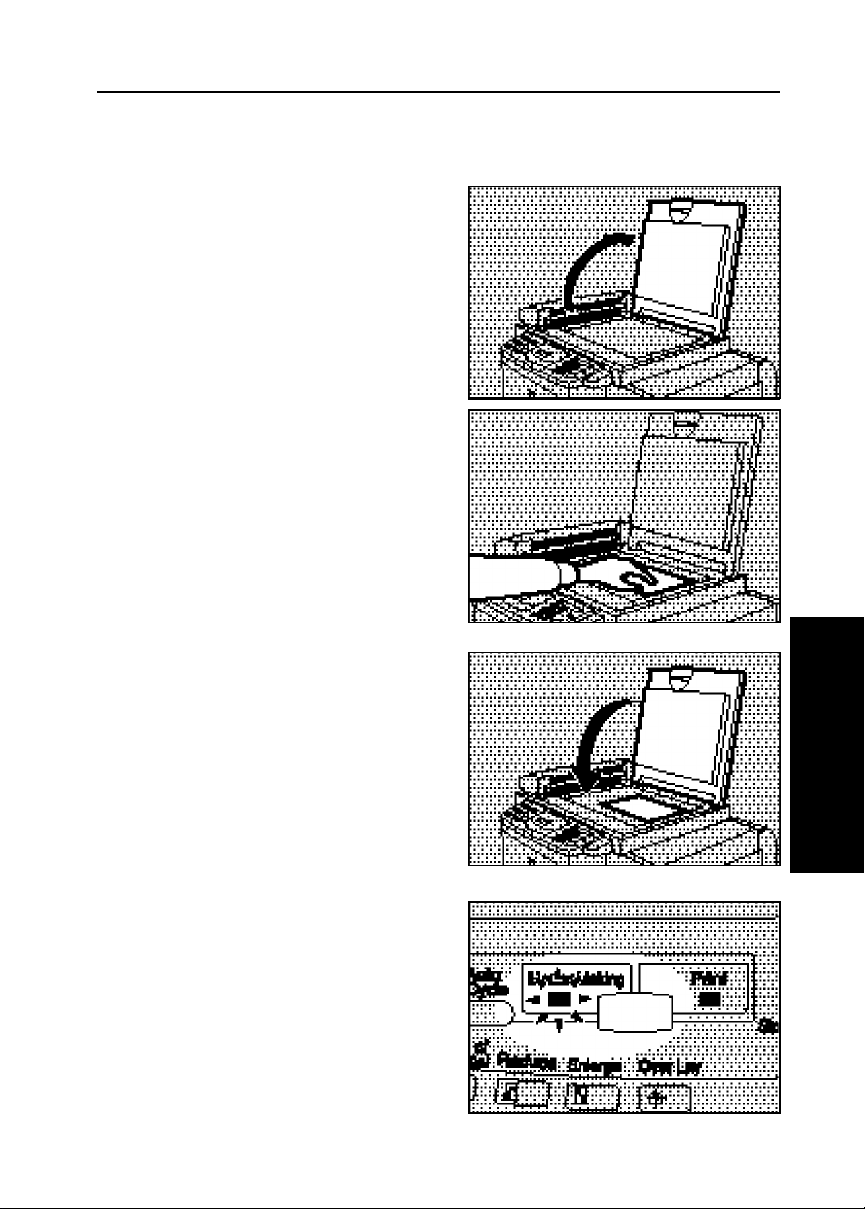

Preparation For Printing

OPERATION

Carefully open the paper feed ta-

1

ble.

❐ Keep hold the paper feed table until it

stops.

Adjust the side plates to match

2

the paper size.

OPERATION

Place the paper on the paper

3

feed table.

❐ Correct the paper curl before setting

the paper. If you cannot do so, stack

the paper with the curl face down as

shown.

12

Page 20

OPERATION

Make sure that the paper feed

4

side plates contact the paper

lightly.

Setting up the paper delivery table

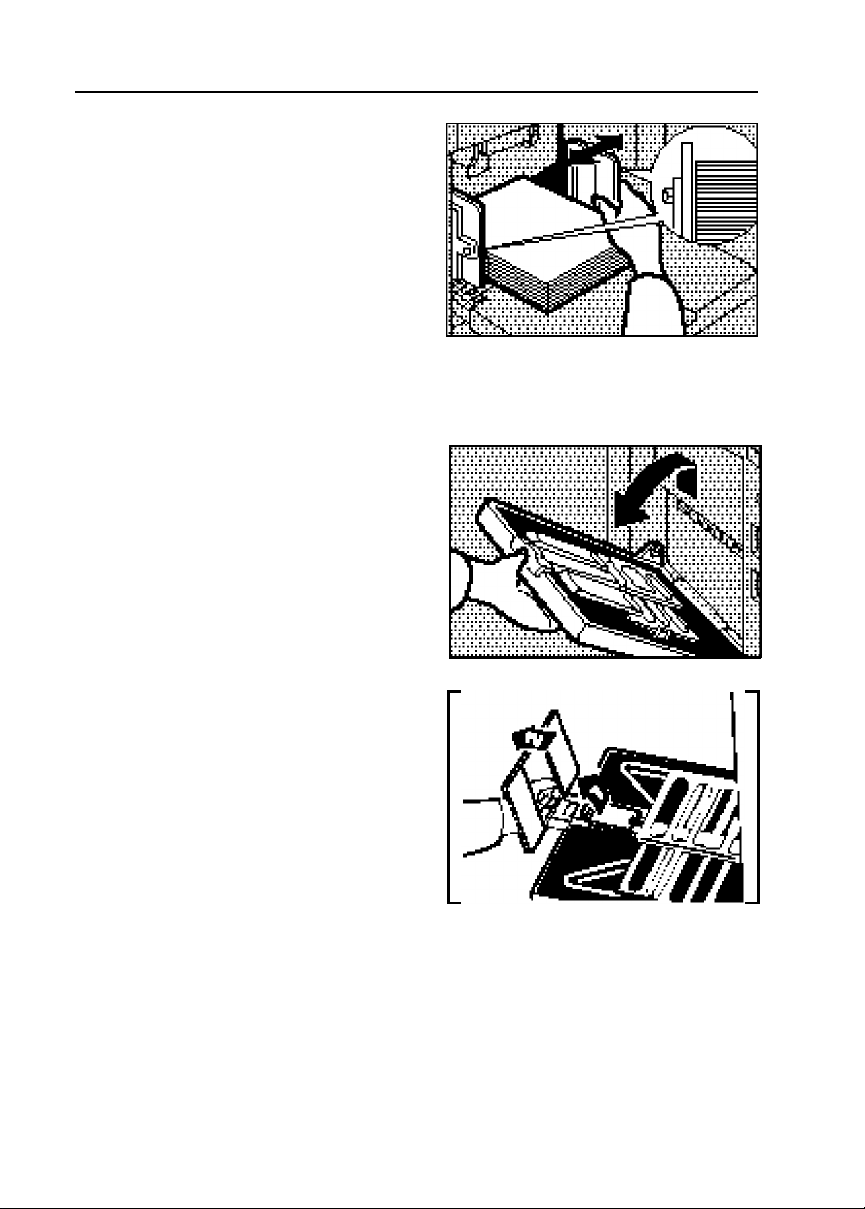

Lift up the paper delivery table a

5

little and then open it.

Lift the paper delivery end plate

6

and move it to match the print

paper size.

13

Page 21

Lift the paper delivery side plates

OPERATION

7

and adjust them to the paper

size.

If you want to use A4, 81/2" x 11"

8

or smaller paper, lift the small

size paper delivery end plate and

move it to match the print paper

size.

❐ When you use B4, 81/2" x 14" size

paper, you do not need to lift the

small size paper delivery end plate.

If necessary, lift the left and right

9

wing guides.

❐ If you find paper is not delivered

properly when printing on thin paper,

make sure the wing guides are up.

❐ When printing on paper thicker than

81.4 g/m2, 21.6 lb, do not lift up the

wing guides.

OPERATION

Turn on the main switch.

A

14

Page 22

OPERATION

Setting the small size end plate prop

If A4, 8

properly, set the small size end plate prop to the small size paper delivery

end plate.

1

2

" x 11" or smaller paper is not delivered to the paper delivery table

1/2

Set the small size end plate prop

to the small size paper delivery

end plate as shown in the illustration.

Slide the prop until it locks in position.

Adjust the main frame side of the

3

prop to match the paper size.

15

Page 23

Standard Printing

OPERATION

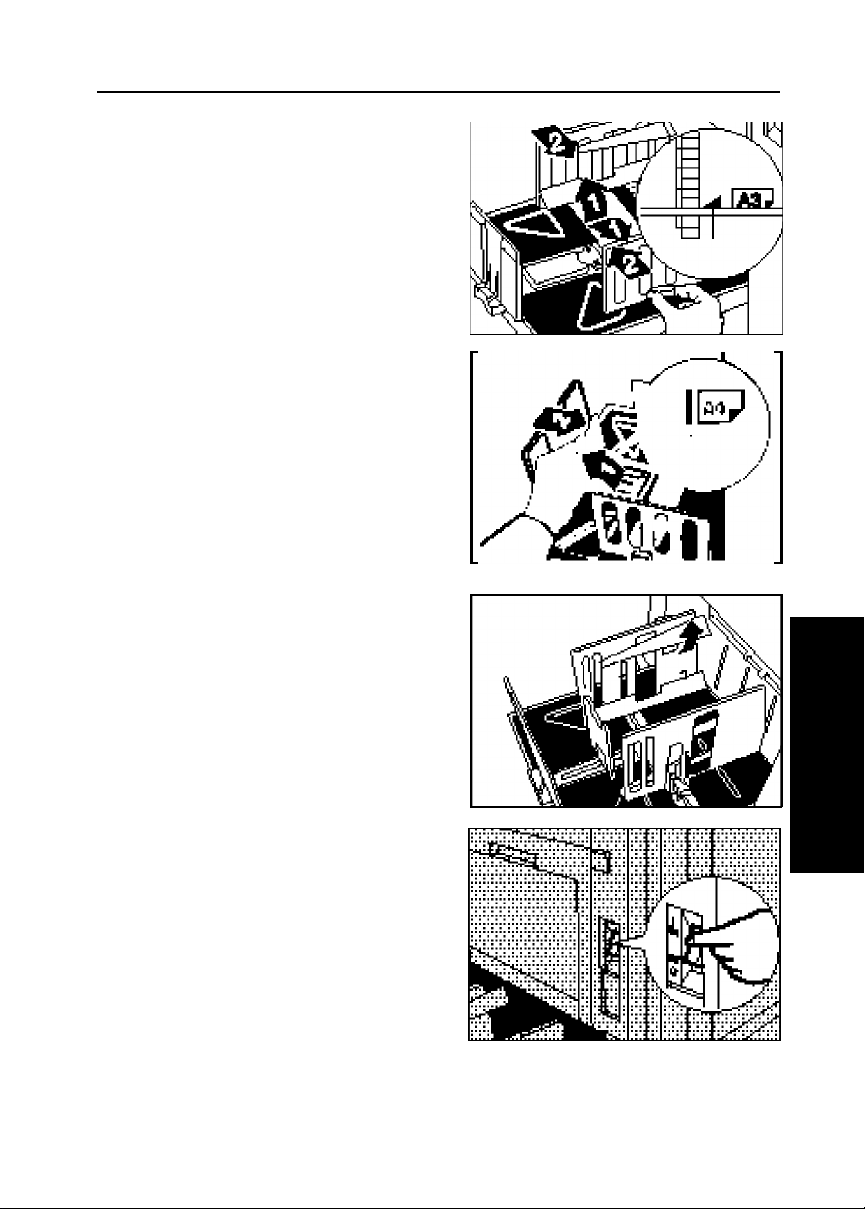

Open the platen cover.

1

Place the original face down on

2

the exposure glass. The original

should be centered according to

the size marks on the right scale.

OPERATION

Lower the platen cover.

3

Make sure the Master Making

4

indicator is lit. If not, press the

Master Making/Print key and select the Master Making mode.

16

Page 24

OPERATION

Press the Start key.

5

❐ A trial print is delivered to the paper

delivery table.

Press the Proof key and check

6

the image density and the image

position of the proof print.

❐ If the image position is not correct,

adjust it using the Image Position

keys or the fine adjustment dial.

(☛ See pages 21 and 22.)

❐ If the image density is slightly dark or

light, adjust the image density by

pressing the Speed keys. (☛ See

page 24.)

Enter the number of prints re-

7

quired using the Number keys.

❐ Up to 9999 prints can be entered at

one time.

❐ To change the number entered,

press the Clear key and then enter

the new number.

Make sure the Print indicator is

8

lit and then press the Start key.

❐ After printing is completed, the same

number of prints is automatically set

for the next job.

❐ If you want to stop the machine dur -

ing a print run, press the Stop key.

17

Page 25

Remove the prints from the paper

OPERATION

9

delivery table.

❐ To clear all the modes you have se -

lected, press the Clear Modes key.

OPERATION

18

Page 26

OPERATION

Restoring Paper Feed And Paper Delivery Tables

Remove the paper from the pa-

1

per feed table.

❐ The paper feed table will lower.

Turn off the main switch.

2

Close the paper feed table.

3

Push the small size paper deliv-

4

ery plate to the left, then lower it,

if necessary.

19

Page 27

Return the left and right wing

OPERATION

5

guides to their original positions,

if necessary.

Move the side plates to the sides,

6

then lower them.

❐ Make sure that the side plates do not

touch the small size paper delivery

end plate.

Move the end plate until the plate

7

handle is flush with the end of the

table.

OPERATION

Lower the end plate.

8

Close the table.

9

20

Page 28

OPERATION

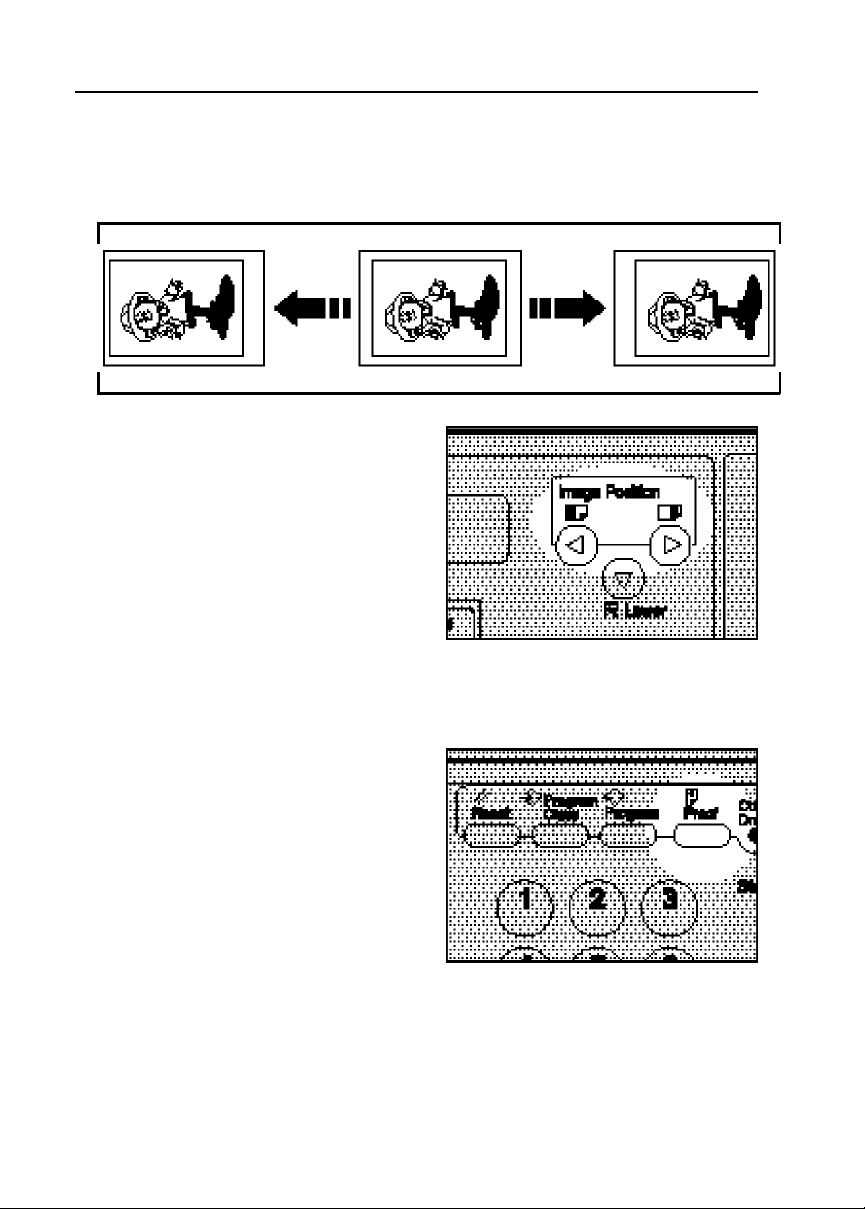

Adjusting The Image Position

Shifting the image position forward or backward

Press the right or left Image Po-

1

sition key.

❐ When you shift the image forwards,

leave a margin (more than 5 mm,

0.2") at the leading edge. If there is

no margin, paper might wrap around

the drum and cause a misfeed.

❐ The right or left Image Position keys

shift the image about 0.5 mm, 1/50"

each time they are pressed. When

the indicator changes, the image po sition shifts about 5 mm, 1/5".

Press the Proof key. Check the

2

image position again.

21

Page 29

Shifting the image to the right or left

OPERATION

OPERATION

Turn the side plate fine adjusting

1

dial as shown in the illustrations.

❐ The image position can be shifted up

to about 10 mm, 2/5" each way.

Each division on the scale is 2 mm,

0.08".

Adjust the paper delivery side

2

plates to the print paper position.

<Shifting the image to the right>

<Shifting the image to the left>

Press the Proof key. Check the

3

image position.

22

Page 30

OPERATION

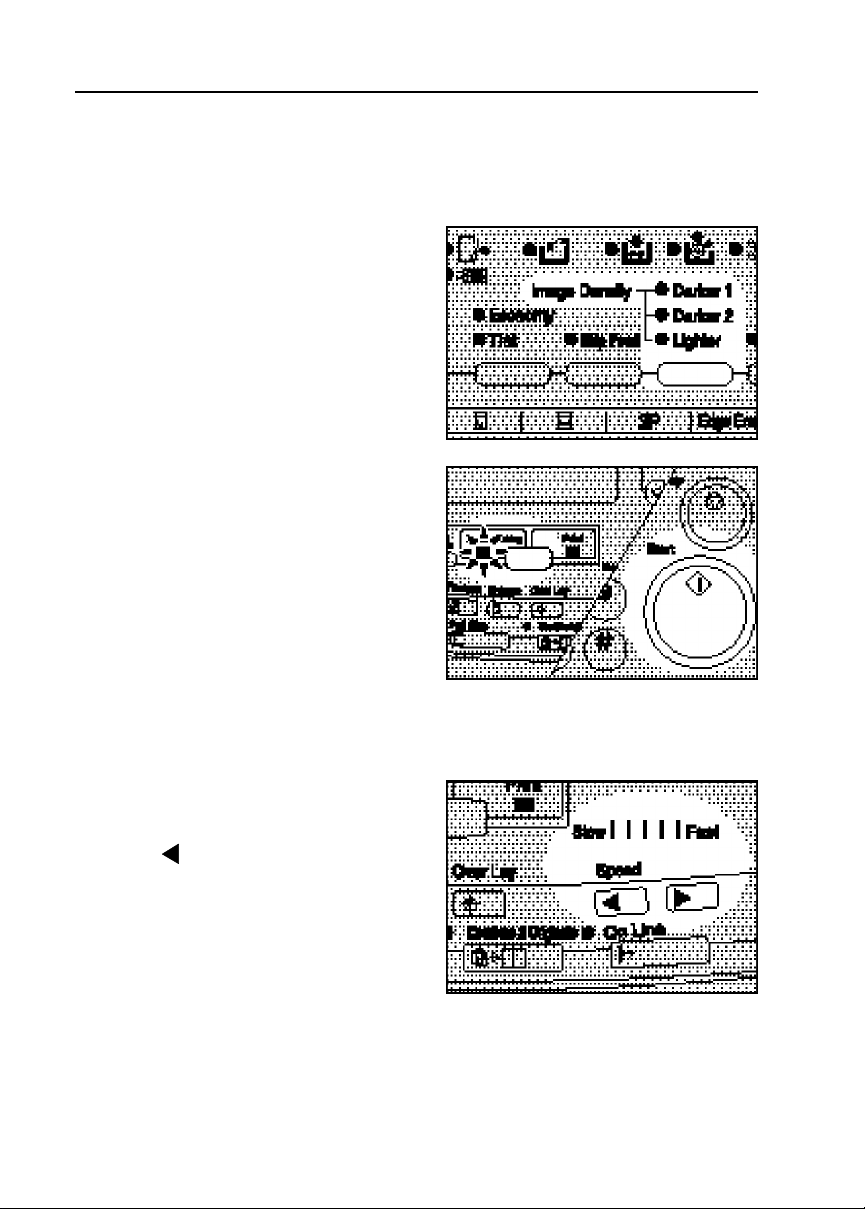

Adjusting The Image Density

Before making a master

Select the desired image density

1

using the Image Density key.

Make sure that Master Making in-

2

dicator is lit and then press the

Start key.

After making a master

Press the Speed keys. To in-

1

crease the speed, press the ‘‘ S ’’

key. To reduce the speed, press

the ‘‘ ’’ key.

❐ The faster the printing speed be -

comes, the lighter the printing density

is. If you want darker prints, decrease the printing speed.

23

Page 31

OPERATION

OPERATION

Changing The Printing Speed

Use the Speed keys to adjust the speed of the machine with the image

density and printing paper.

Press the Speed keys. To increase the speed, press the ‘‘ S ’’

key. To reduce the speed, press

the ‘‘ ’’ key. The printing speed

will be changed as follows:

Setting 1: 60 sheets/minute

Setting 2: 75 sheets/minute

Setting 3: 90 sheets/minute

Setting 4: 105 sheets/minute

Setting 5: 120 sheets/minute

❐ When the main switch is turned on,

Setting 3 is selected.

❐ The faster the printing speed be -

comes, the lighter the printing density

is, and vice versa.

24

Page 32

OPERATION

Stopping The Machine During A Print Run

When you want to stop the machine during a print run

and print the next original

Press the Stop key.

1

Press the Master Making/Print

2

key to select Master Making

mode.

Set the new original.

3

Press the Start key.

4

25

Page 33

OPERATION

OPERATION

When you want to change the number of prints entered

or check the completed prints

Press the Stop key.

1

Change the number of prints or

2

check the completed prints.

❐ When you change the number of

prints, you can re-enter the number

using the Number keys after pressing the Stop key.

Make sure that Print indicator is

3

lit and then press the Start key.

26

Page 34

OPERATION

Reduction/Enlargement Printing (Reduce/Enlarge)

❐ The center and the leading edge of the print image do not shift when a print im -

age is made with this function.

Reduction

Prints can be reduced in size by using the Reduce key.

---- Metric version ---- ---- Inch version ----

Reduction

Ratio

93 % *

87 %

82 %

71 %

Original

Size

A5 B6

A4 B5

B4 A4

B5 A5

A4 A5

B4 B5

Print Size

Reduction

Ratio

93 % *

77 % 81/2" x 14" 81/2" x 11"

74 % 10" x 14" 81/2" x 11"

65 % 81/2" x 11" 51/2" x 81/2"

Original

Size

* Select this ratio when you make prints with a lot of edge margins.

27

Print Size

Page 35

Select the desired reduction ratio

OPERATION

1

using the Reduce key.

❐ If you want to return the ratio to 100

%, press the Full Size key.

Make sure that the original and

2

the print paper are the correct

size.

Set your originals on the expo-

3

sure glass or in the optional

document feeder.

Make sure that Master Making

4

indicator is lit and then press the

Start key. Check the image position of the trial or proof print.

❐ If the image position is not correct,

adjust it using the Image Position

keys (☛ see page 21) or the side

plate fine adjusting dial ( ☛ see page

22).

OPERATION

Enter the number of prints re-

5

quired using the Number keys.

Make sure that the Print indicator

6

is lit and then press the Start

key.

28

Page 36

OPERATION

Enlargement

Prints can be enlarged by using the Enlarge key.

---- Metric version ---- ---- Inch version ----

Enlargement

Ratio

141 %

122 %

115 %

Original

Size

B5 B4

A5 A4

A4 B4

A5 B5

B5 A4

B6 A5

Print Size

Enlargement

Ratio

155 % 51/2" x 81/2" 81/2" x 14"

129 % 51/2" x 81/2" 81/2" x 11"

121 % 81/2" x 11" 11" x 15"

Original

Size

Print Size

29

Page 37

Select the desired enlargement

OPERATION

1

ratio using the Enlarge key.

❐ If you want to return the ratio to 100

%, press the Full Size key.

Make sure that the original and

2

the print paper are the correct

size.

Set your originals on the expo-

3

sure glass or in the optional

document feeder.

Make sure that Master Making

4

indicator is lit and then press the

Start key. Check the image position of the trial or proof print.

❐ If the image position is not correct,

adjust it using the Image Position

keys (☛ see page 21) or the side

plate fine adjusting dial ( ☛ see page

22).

OPERATION

Enter the number of prints re-

5

quired using the Number keys.

Make sure that Print indicator is

6

lit and then press the Start key.

30

Page 38

OPERATION

Erasing Center And Edge Margins (Edge Erase/Center Erase)

When printing from thick books, or similar originals, the binding margin at

the center and the edges might appear on prints. To prevent this, follow the

steps on the next page.

❐ As a default setting, the paper sizes and directions that can be used are as fol -

lows:

Metric version: B4 ;, A4 ;, A5 :, A5;, B5 :, B5 ;

Inch version: 81/2" x 14" ;, 8 1/2" x 11" ;, 5 1/2" x 8 1/2" ;, 51/2" x 81/2" :

If you want to use other size originals, you can register the size using Service

Program mode. ☛ See page 107.

❐ The margin width to be erased can be adjusted with Service Program mode.

☛ See page 107.

31

Page 39

Press the Edge Erase/Center

OPERATION

1

Erase key.

❐ To cancel this mode, press the Edge

Erase/Center Erase key again.

Press the "<" or ">" key to select

2

the paper size and direction.

When you reach the desired pa-

3

per size and direction, press the

Enter key.

OPERATION

Set the book on the exposure

4

glass.

32

Page 40

OPERATION

Make sure that Master Making

5

indicator is lit and then press the

Start key.

Check the image position of the

6

trial or proof print.

❐ If the image position is not correct,

adjust it using the Image Position

keys (☛ see page 21) or the side

plate fine adjusting dial ( ☛ see page

22).

Enter the number of prints using

7

the Number keys.

Make sure that Print indicator is

8

lit and then press the Start key.

33

Page 41

OPERATION

OPERATION

Erasing Edge Margins (Edge Erase)

If you want to erase edge margins of a book original, follow the steps below.

❐ As a default setting, the paper sizes and directions that can be used are as fol -

lows:

Metric version: B4 ;, A4 ;, A5 :, A5;, B5 :, B5 ;

Inch version: 81/2" x 14" ;, 8 1/2" x 11" ;, 51/2" x 8 1/2" ;, 51/2" x 81/2" :

If you want to use other size originals, you can register the size using Service

Program mode. ☛ See page 107.

❐ The margin width to be erased can be adjusted with Service Program mode.

☛ See page 107.

Press the Edge Erase key.

1

❐ To cancel this mode, press the Edge

Erase key again.

Press the "<" or ">" key to select

2

the paper size and direction.

When you reach the desired pa-

3

per size and direction, press the

Enter key.

34

Page 42

OPERATION

Set the book on the exposure

4

glass.

Make sure that Master Making

5

indicator is lit and then press the

Start key.

Check the image position of the

6

trial or proof print.

❐ If the image position is not correct,

adjust it using the Image Position

keys (☛ see page 21) or the side

plate fine adjusting dial ( ☛ see page

22).

Enter the number of prints using

7

the Number keys.

Make sure that Print indicator is

8

lit and then press the Start key.

35

Page 43

OPERATION

OPERATION

Erasing The Shadow Of Pasted Originals (Paste Shadow Erase)

If you want to erase the shadow of pasted originals, follow the steps below.

Set the original on the exposure

1

glass.

Press the Paste Shadow Erase

2

key.

Make sure that Master Making

3

indicator is lit and then press the

Start key.

36

Page 44

OPERATION

Enter the number of prints using

4

the Number keys.

Make sure that Print indicator is

5

lit and then press the Start key.

37

Page 45

OPERATION

OPERATION

Printing On Thick Or Thin Paper

Printing on thick paper

If your paper applied to "Thick" in the table below, perform the following

steps.

Size

Weight

209.3 g/m2, 55.6 lb Thick Standard

157.0 g/m2, 41.7 lb Thick Standard

127.9 g/m2, 34.0 lb Thick Standard

47.1 g/m2 ~ 105 g/m2,

12.5 lb ~ 28 lb

Push down the feed roller pres-

1

sure lever.

Push the separation roller pres-

2

sure levers up to the thick paper

position.

❐ There are two pressure levers. Make

sure that both levers are up.

B4 A4 B5

Standard

38

Page 46

OPERATION

Printing on thin paper

Set the side pads (move the side

1

pad levers to the right).

Position the feed roller pressure

2

lever to the Standard paper position.

Set the separation roller pressure

3

levers to the standard position.

❐ There are two pressure levers. Make

sure that both levers are down.

39

Page 47

OPERATION

OPERATION

Photo Mode Printing (Type of Original)

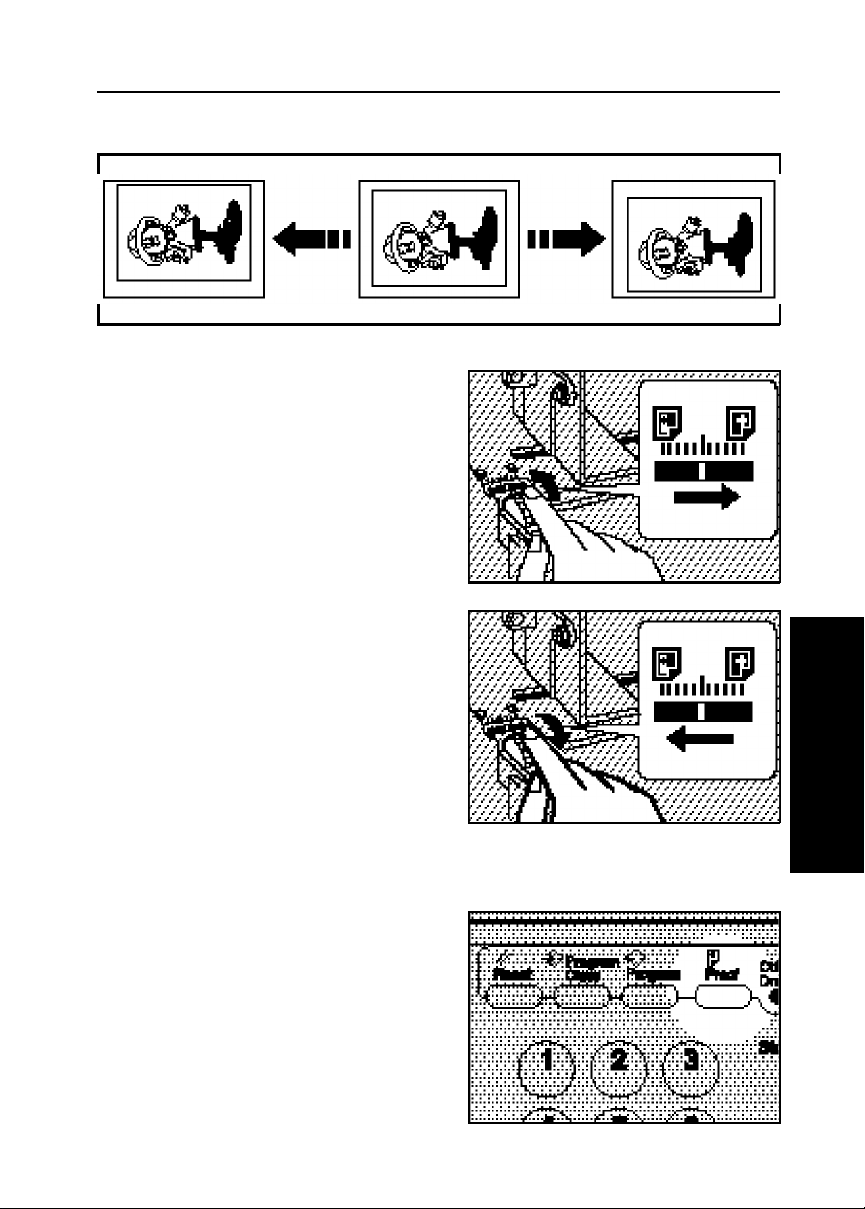

Original Photo mode Letter mode Letter/Photo mode

When printing a photograph or a color original, select Photo mode.

❐ Moire patterns may occur when screened originals are printed.

❐ When printing originals with both letters and photos using Photo mode, the im -

age of the letters will be light. Select Letter/Photo mode using the Type of

Original key.

Press the Type of Original key

1

to select Photo mode.

Press the Image Density key to

2

adjust the image density.

40

Page 48

OPERATION

Set your originals on the expo-

3

sure glass or in the optional

document feeder.

Make sure that the Master Mak-

4

ing indicator is lit and then press

the Start key. Check the image

position of the trial or proof print.

❐ If the image position is not correct,

adjust it using the Image Position

keys (☛ see page 21) or the side

plate fine adjusting dial ( ☛ see page

22).

Enter the number of prints using

5

the Number keys.

Make sure that the Print indicator

6

is lit and then press the Start

key.

41

Page 49

Ink Saving (Economy Mode)

OPERATION

When you want to save ink, select Economy mode.

❐ The printing density may be light in this mode.

Press the Economy/Tint key to

1

select Economy mode.

Set your originals on the expo-

2

sure glass or in the optional

document feeder.

Make sure that the Master Mak-

3

ing indicator is lit and then press

the Start key. Check the image

position of the trial or proof print.

❐ If the image position is not correct,

adjust it using the Image Position

keys (☛ see page 21) or the side

plate fine adjusting dial ( ☛ see page

22).

OPERATION

Enter the number of prints using

4

the Number keys.

Make sure that the Print indicator

5

is lit and then press the Start

key.

42

Page 50

OPERATION

Making Half-tone Prints (Tint Mode)

Press the Economy/Tint key to

1

select Tint mode.

Set your originals on the expo-

2

sure glass or in the optional

document feeder.

Make sure that the Master Mak-

3

ing indicator is lit and then press

the Start key. Check the image

position of the trial or proof print.

❐ If the image position is not correct,

adjust it using the Image Position

keys (☛ see page 21) or the side

plate fine adjusting dial ( ☛ see page

22).

Enter the number of prints using

4

the Number keys.

43

Page 51

Make sure that the Print indicator

OPERATION

5

is lit and then press the Start

key.

OPERATION

44

Page 52

OPERATION

Printing From Several Originals At Once (Auto Cycle)

Use the Auto Cycle key to process masters and make prints at one stroke.

❐ When you use the optional document feeder, it is not necessary to place origi -

nals one by one. All originals are fed and prints are completed after you press

the Start key.

❐ If you use the optional tape dispenser, the tape dispenser drops a strip of pa -

per onto the top of the paper stack after the last page of each printing set is

fed out to the paper delivery table. This marks the end of each printing group.

Set the original on the exposure

1

glass or in the optional document

feeder.

❐ You can set up to 30 originals into

the optional document feeder.

Press the Auto Cycle key.

2

❐ Both indicators of Master Making

mode and Print mode are lit.

❐ If you press the Auto Cycle key, you

cannot make proof prints by pressing

the Proof key.

Enter the number of prints using

3

the Number keys.

If you use the optional tape dis-

4

penser, turn on the power switch

of the tape dispenser.

45

Page 53

Press the Start key.

OPERATION

5

❐ If you set the originals into the op -

tional document feeder, originals are

fed and prints are completed automatically.

Repeat steps 1 through 5 until all

6

originals are printed when you set

originals on the exposure glass.

❐ After the last page of each set is fed

out to the paper delivery table, the

optional tape dispenser drops a strip

of paper on the top of the paper

stack. The next cycle begins.

OPERATION

46

Page 54

OPERATION

Printing With A Programmed Number Of Prints For Each Class (One Touch Class Mode)

1-1 1-2

2-1 2-2

1-3

2-3

2-4

What is One Touch Class mode?

This feature is useful for teachers who frequently make multiple print sets

for their classes, e.g. notes, handouts, tests etc.

Using a standard print function, the teacher would have to stand by the

machine entering the number of prints and pressing the Start key for each

class. However, One Touch Class mode allows you to program the number

of students in each class into the machine beforehand. Then, whenever you

need to make print sets for several classes, set your original, select the

classes who need prints and press the Start key. Print sets will be made

containing the correct number of prints for each class.

❐ If you have the Tape Dispenser option, print sets will be sent to the paper

delivery table separated by a slip of tape for easy separation. If you do not

have this option, the machine will stop after each set has been printed. In this

case, remove the stack from the paper delivery table and press the Start key to

start printing the next set.

❐ You can program student numbers for up to 9 grades with 10 classes in each,

giving a maximum of 90 classes. Each class can have up to 9999 students.

47

Page 55

OPERATION

OPERATION

Example:

Imagine a school with 4 grades and 6 classes in each grade. There are 27

students in every class in grades 1 to 3, and grade 4 has varying numbers

of students due to a high transfer rate. The information you need to program

in the machine might look like that shown in the table below:

Grade

Class

1 27 27 27 27 27 27

2 27 27 27 27 27 27

3 27 27 27 27 27 27

4 25 20 23 24 25 20

1 2 3 4 5 6

48

Page 56

OPERATION

Programming student numbers

Before you can use One Touch Class Mode, you need to program the

number of students in each class. Because classes are grouped into

grades, you must program one grade at a time.

There are two methods of programming a grade:

Simple: Use if all classes in a grade have the same number of

students. (saves entering the same number over and over

again)

Multi: Use if class student numbers vary.

❐ Note that to specify a grade, you need to use the One Touch Class keys. If you

cannot see the key you need, flip over the plate (see below).

One Touch Class keys

49

Page 57

OPERATION

OPERATION

Simple programming

In this example we will program student numbers for grade 1 of the table

shown on page 48.

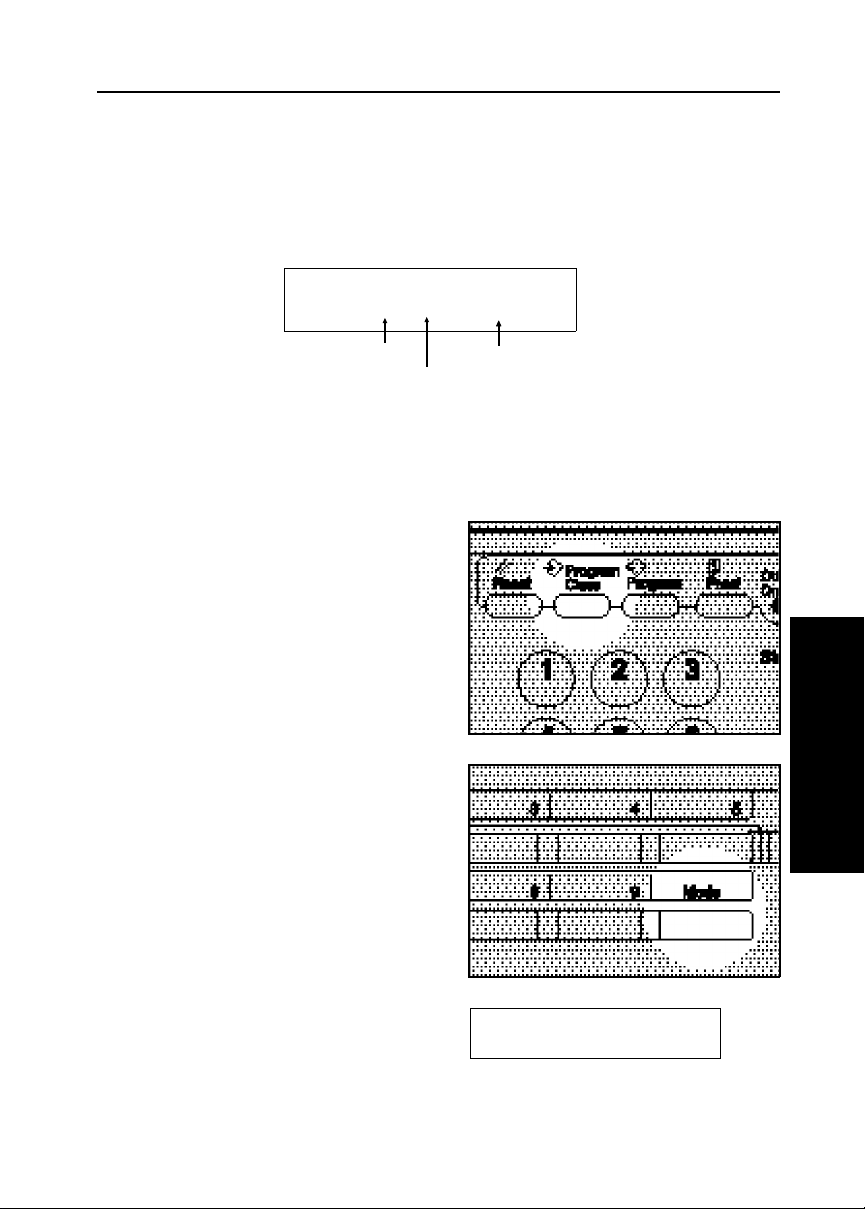

The information on the guidance display is in the format:

SET PROGRAM CLASS

SIMPLE X - (1 - YY) _ _ _ _

Grade

Number of classes in a grade

❐ If you want to clear any class numbers you have programmed, you need to

program each class number as "0".

Number of students in each class

Press the Program Class key.

1

Enter the grade you wish to pro-

2

gram with the One Touch Class

keys.

❐ E.g. to Program grade 1, press the

One Touch Class key 1.

❐ The guidance display will appear as

opposite.

SET PROGRAM CLASS

SIMPLE 1-(1-YY) _ _ _ _

50

Page 58

OPERATION

Enter the number of students per

3

class using the Number keys

then press the Enter key.

❐ E.g. press "2", "7" and "#" key.

❐ The guidance display will appear as

opposite.

❐ If you want to clear the class you

have programmed, enter "0" then

press the Enter key.

Enter the number of classes in

4

the 1st grade with the Number

keys then press the Enter key.

❐ E.g. press "6" and "#" key.

You now have two options:

5

❐ Program another grade: go to step 2.

❐ Finish programming: press the Clear

Modes key.

SET PROGRAM CLASS

SIMPLE 1 - (1 - YY) _ _ 2 7

51

Page 59

OPERATION

OPERATION

Multi-programming

In this example we will program student numbers for grade 4 of the table

shown on page 48.

The information on the guidance display is in the format:

SET PROGRAM CLASS

MULTI X - YY _ _ _ _

Grade

Class

❐ If you want to clear any class numbers you have programmed, you need to

program each class number as "0".

Press the Program Class key.

Number of students in a class

1

Press the Mode key to select

2

multi programming mode.

❐ The guidance display will appear as

opposite.

SET PROGRAM CLASS

MULTI X - 1 _ _ _ _

52

Page 60

OPERATION

Enter the grade you wish to pro-

3

gram.

❐ E.g. to program grade 4, press the

One Touch Class key 4.

❐ The guidance display will appear as

opposite.

Enter the number of students in

4

class 1 with the Number keys,

then press the Enter key.

❐ E.g. press "2", "5" and "#" key.

❐ The guidance display will show it is

ready for you to enter the next class.

❐ If you want to clear the class you

have programmed, enter "0" then

press the Enter key.

You now have three options:

5

❐ Program the remaining classes in

this grade: repeat steps 4 for all

classes.

❐ Program another grade: go back to

step 3.

❐ Finish programming: press the Clear

Modes key.

SET PROGRAM CLASS

MULTI 4 - 1 _ _ _ _

SET PROGRAM CLASS

MULTI 4 - 2 _ _ _ _

53

Page 61

OPERATION

OPERATION

Protecting One Touch Class settings

If you want to prevent someone from writing over your settings, you can

protect each grade.

While pressing the Reset and

1

Stop keys simultaneously, press

the Program Class key.

❐ The guidance display will appear as

opposite.

Enter "1" using the Number keys.

2

Press the Enter key.

3

❐ The grades which are not protected

will be displayed in the guidance display.

0 : CANCEL PROTECTION

1 : PROTECT NO. _

54

Page 62

OPERATION

Using the Number keys, enter

4

the grade that you want to protect.

Press the Enter key.

5

Cancelling protection

While pressing the Reset and

1

Stop keys simultaneously, press

the Program Class key.

❐ The guidance display will appear as

opposite.

Enter "0" using the Number keys.

2

55

0 : CANCEL PROTECTION

1 : PROTECT NO. _

Page 63

Press the Enter key.

OPERATION

3

❐ The grades which are protected will

be displayed in the guidance display.

❐ If no grade is protected, the machine

returns to the ready condition.

Using the Number keys, enter

4

the grade that you want to cancel

protection.

Press the Enter key.

5

OPERATION

56

Page 64

OPERATION

Making prints with One Touch Class mode

Example 1 -- making prints for all classes in a grade

The example describes how to make print sets for all classes in the 1st and

2nd grades.

Set the original on the exposure

1

glass or in the optional document

feeder.

Make sure that the Master Mak-

2

ing indicator is lit and then press

the Start key. Check the image

position of the trial or proof print.

❐ If the image position is not correct,

adjust it using the Image Position

keys (☛ See page 21) or the side

plate fine adjusting dial ( ☛ See page

22).

Enter the first grade you wish to

3

make prints for.

❐ E.g. to select grade 1, press the One

Touch Class key 1.

Press the Enter key.

4

57

Page 65

Enter the next grade you want to

OPERATION

5

make prints for.

❐ E.g. to select grade 2, press the One

Touch Class key 2.

Press the Enter key.

6

❐ To select more grades, just repeat

steps 5 and 6.

If you have the optional tape dis-

7

penser, switch it on.

OPERATION

58

Page 66

OPERATION

Make sure that the Print indicator

8

is lit and then press the Start

key.

❐ After the last page of each printing

set is fed out to the paper delivery

table, the tape dispenser drops a

strip of paper on the top of the paper

stack.

❐ If the power switch of the optional

tape dispenser is turned off or the

tape dispenser is not installed in your

machine, the machine stops after

each set is delivered. Remove the

set of prints from the paper delivery

table and press the Print Start key

to start printing the next set.

Example 2 -- making prints for selected classes

This procedure describes how to make prints for selected classes in different grades.

Set the original on the exposure

1

glass or in the optional document

feeder.

Make sure the Master Making

2

indicator is lit and then press the

Start key. Check the image position of the trial or proof print.

59

Page 67

Enter a grade number with the

OPERATION

3

One Touch Class keys.

❐ E.g. press the One Touch Class key

1.

Enter a class number with the

4

Number keys.

❐ E.g. press "2" key.

Press the Enter key.

5

OPERATION

You have three options:

6

❐ Select another class in this grade: go

to step 3

❐ Select another class from a different

grade: go to step 3

❐ Finish selecting classes: go to step 7

60

Page 68

OPERATION

If you have the optional tape dis-

7

penser, switch it on.

Make sure that the Print indicator

8

is lit and then press the Start

key.

❐ If you do not have the optional tape

dispenser, you will need to remove

the copies from the paper delivery

tray after each print set is finished,

then press the Start key to continue

printing.

61

Page 69

OPERATION

OPERATION

Checking how many prints will be made in One Touch

Class mode

If you want to find out the programmed class numbers before making prints,

do the following steps after step 6 (page 58) or step 5 (page 60):

Flip over the plate so you can

1

see the "<" and ">" keys.

Hold down the Reset and Stop

2

keys simultaneously and use the

"<" and ">" keys to scroll through

the classes.

❐ The machine will beep when you

reach the end or beginning of the list.

❐ If Print Program Class is set to "Last"

(see page 103), pressing the " <" key

shows classes from the last class

set.

4 - 1 25

Grade

Class

Number of students

in the class

62

Page 70

OPERATION

Combine 2 Originals

You can print 2 separate originals on a single sheet of paper. The following

tables list the combinations that can be used when combining two originals.

---- Metric version ----

Original Size

Paper Size

B4 ; 100 % 122 % 141 % ---A4 ; 82 % 100 % 115 % 141 %

B5 ; 71 % 87 % 100 % 122 %

A5 ; ---- 71 % 82 % 100 %

B5 : A5 : B6 : A6 :

---- Inch version ----

Original Size

Paper Size

81/2" x 14" ; 100%

81/2" x 11" ; 100%

51/2" x 81/2" ; 65%

❐ When you set an original on the exposure glass, the machine cannot detect the

original length. So you have to enter the original size with Edge Erase function.

❐ When you use the optional document feeder with this function, ☛ see page 85.

63

51/2" x 81/2" :

Page 71

OPERATION

OPERATION

❐ If the master length of the first original is longer than the maximum allowable

length or shorter than the minimum allowable length, Combine 2 Originals

mode is canceled. The following table gives the maximum and minimum allow able master length.

Master length = actual original length x Enlargement/Reduction ratio

Minimum Maximum

B4 drum model 91 mm, 3.6" 243 mm, 9.5"

A4 drum model 91 mm, 3.6" 198 mm, 7.7"

❐ Any image closer than 5 mm, 0.2" to the leading edge of the first original will

not be printed. Also, any image closer than 4 mm, 0.16" to the leading edge of

the second original will not be printed. When the image is too close to the

leading edge, use copies of the originals with the image shifted at least 5 mm,

0.2" for the first original (4 mm, 0.16" for the second original) from the leading

edge.

❐ You can select different kinds of image settings for the first and second original.

❐ Make sure that the paper feed side plates contact the paper lightly in the Com -

bine 2 Originals function. Otherwise, the two original images do not appear at

the proper position on the prints.

64

Page 72

OPERATION

Example 1: When using 100 % reproduction ratios

1st original size 2nd original size Paper size

Metric version

Inch version

Set the first original face down.

1

❐ The first original will be printed on the

leading part of the print.

Press the Combine 2 Originals

2

key.

B5 : B5 : B4 ;

51/2" x 81/2" : 51/2" x 81/2" : 81/2" x 11" ;

Press the Edge Erase key.

3

65

Page 73

Press the "<" or ">" key to select

OPERATION

4

the original size and direction.

When you reach the desired size

5

and direction (metric version: B5

:, inch version: 51/2" x 81/2" :),

press the Enter key.

Make sure that the Master Mak-

6

ing indicator is lit and then press

the Start key.

OPERATION

The beeper sounds after the first

7

original is on the master. Set the

second original face down.

66

Page 74

OPERATION

Make sure that the Master Mak-

8

ing indicator is lit and then press

the Start key. Check the image

position of the trial or proof print.

❐ If the image position is not correct,

adjust it using the Image Position

keys (☛ See page 21) or the side

plate fine adjusting dial. ( ☛ See page

22.)

Enter the number of prints re-

9

quired using the Number keys.

Make sure that the Print indicator

A

is lit and then press the Start

key.

67

Page 75

Example 2: When using enlarging or reducing ratios

OPERATION

1st original size 2nd original size Paper size

Metric version

Set the first original face down.

B6 : B5 : B4 ;

1

❐ The first original will be printed on the

leading part of the print.

Press the Combine 2 Originals

2

key.

OPERATION

Press the Edge Erase key.

3

68

Page 76

OPERATION

Press the "<" or ">" key to select

4

the original size and direction.

When you reach the desired size

5

and direction (metric version: B6

:), press the Enter key.

Press the Reduce or Enlarge

6

key to select the suitable reproduciton ratio to match the paper

size (metric version: 141 %).

Make sure that the Master Mak-

7

ing indicator is lit and then press

the Start key.

69

Page 77

The beeper sounds after the first

OPERATION

8

original is on the master. Set the

second original face down.

Make sure that the Master Mak-

9

ing indicator is lit and then press

the Start key. Check the image

position of the trial or proof print.

❐ If the image position is not correct,

adjust it using the Image Position

keys (☛ See page 21) or the side

plate fine adjusting dial. (☛ See page

22.)

Enter the number of prints re-

A

quired using the Number keys.

Make sure that the Print indicator

B

is lit and then press the Start

key.

OPERATION

70

Page 78

OPERATION

Skip Feed Printing (Skip Feed Mode)

If the back of prints are dirty, you can increase the time between two prints

using the Skip Feed key. In the default setting, when one sheet of paper is

fed the drum rotates once. However, you can select the number of rotations

of the drum. This gives you the chance to remove prints one by one from

the paper delivery table or insert one sheet of paper between two prints. If

you use this function, you can also use paper longer than 447 mm, 17.5" in

spite of the maximum length limitations of paper.

❐ The maximum length of paper in Skip Feed mode is 590 mm, 23.2".

❐ When you use paper longer than 447 mm, 17.5", completed prints will not be

delivered to the paper delivery table properly, so receive them by hand.

Set your originals on the expo-

1

sure glass or in the optional

document feeder.

Make sure that the Master Mak-

2

ing indicator is lit and then press

the Start key. Check the image

position of the trial or proof print.

❐ If the image position is not correct,

adjust it using the Image Position

keys (☛ See page 21) or the side

plate fine adjusting dial. ( ☛ See page

22.)

While pressing the Skip Feed

3

key, select the number of rotations of the drum while one sheet

of paper is fed, using the Num-

ber key.

❐ You can select from 1 to 9 rotations.

❐ The beeper sounds after you set the

number of rotations.

71

Page 79

Enter the number of prints using

OPERATION

4

the Number keys.

Make sure that the Print indicator

5

is lit and then press the Start

key.

OPERATION

72

Page 80

OPERATION

User Program

This User Program function allows you to store and recall up to 9 frequently

used job setups.

❐ The stored programs are not cleared when you turn off the main switch.

How to input a user program

Select and enter the job settings

1

you want to store in memory.

Press the Program key.

2

❐ The program menu is displayed on

the guidance display.

Enter "0" using the Number key.

3

Press the Enter key.

4

❐ The program numbers (1 to 9) will be

displayed in the guidance display.

❐ If a user program has been pro -

tected, that program number will not

appear in the display. For changing a

protected user program, ☛ see page

78.

❐ If all the user programs have been

protected, the machine returns to the

ready condition.

73

Page 81

Enter one of the program num-

OPERATION

5

bers displayed on the guidance

display using the Number keys.

❐ Make sure that the previous job set -

tings stored under the selected pro gram number are overwritten.

Press the Enter key.

6

OPERATION

74

Page 82

OPERATION

How to access a user program

Press the Program key.

1

❐ Numbers already containing a pro -

gram are displayed on the guidance

display.

Using the Number keys, enter

2

the number of the program that

you want to access.

Press the Enter key.

3

❐ All stored job settings are recalled.

Set your originals on the expo-

4

sure glass or in the optional

document feeder.

Make sure that the Master Mak-

5

ing indicator is lit and then press

the Start key.

75

Page 83

OPERATION

OPERATION

How to protect a program

If you want to prevent someone from writing over your program, do the

following procedure.

While pressing the Reset key

1

and Stop key simultaneously,

press the Program key.

Enter "1" using the Number key.

2

Press the Enter key.

3

❐ The numbers of the programs which

are not protected will be displayed in

the guidance display.

❐ If all the user programs have been

protected or no program is stored,

the machine returns to the ready

condition.

76

Page 84

OPERATION

Using the Number keys, enter

4

the number of the program that

you wish to protect.

Press the Enter key.

5

77

Page 85

How to remove user program protection

OPERATION

While pressing the Reset key

1

and Stop key simultaneously,

press the Program key.

Enter "0" using the Number key.

2

Press the Enter key.

3

❐ If not program number is protected or

no program is stored, the machine

returns to the ready condition.

OPERATION

Using the Number keys, enter

4

the number of the program that

you wish to remove protection

from.

Press the Enter key.

5

78

Page 86

OPERATION

Printing Of Secret Documents (Security Mode)

This function prevents others from making prints of secret documents using

its master.

Make your prints.

1

Press the Security key.

2

❐ If you press the Start key in Print

mode or press the Proof key after

finishing one print job, the beeper

sounds and you cannot make prints.

❐ You cannot cancel Security mode

even if you turn off the main switch.

❐ If you make the next master, Security

mode is canceled.

79

Page 87

OPERATION

OPERATION

Recovering The Image Density (Quality Start)

If the machine is not used for a long period of time, the image density might

decrease because the ink on the drum might dry. Printing quality can be

regained by making a few prints. The Quality Start function recovers the

image density quality by making a print with slow printing speed (20

sheets/minute). It prevents you from making extra prints.

❐ You can select how many times Quality Start mode is carried out for each

master making using Service Program mode. ☛ See page 105.

❐ When you set the Quality Start function, the bold letters or solid images may be

light.

❐ If you use the Quality Start function before 6 hours have passed after the last

operation, the image density may not be recovered earlier. However, it is con venient to use this function when you change drum unit and make prints before

6 hours have passed after the last operation.

Set your originals on the expo-

1

sure glass or in the optional

document feeder.

Press the Quality Start key.

2

Make sure that Master Making

3

indicator is lit and then press the

Start key.

80

Page 88

OPERATION

Enter the number of prints using

4

the Number keys.

Make sure that the Print indicator

5

is lit and then press the Start

key.

81

Page 89

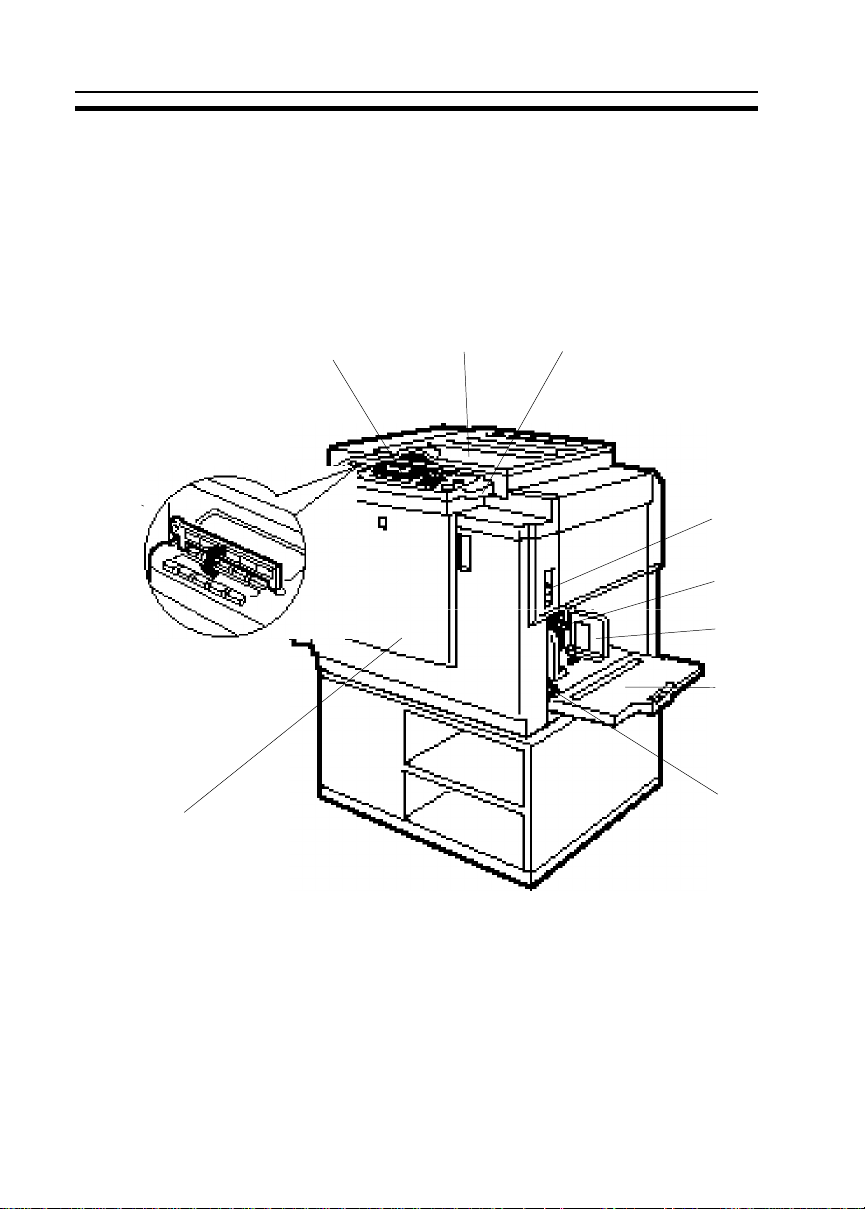

OPTIONAL FUNCTIONS

OPTIONAL FUNCTIONS

OPTIONAL FUNCTIONS

Printing Using The Optional Document Feeder

Guide to document feeder components

Original Guides

Adjust these guides

ADF Unit Open Lever

Use to open the ADF

unit.

to position the originals correctly.

Original Tray

Originals used to

make masters are

delivered to this

tray. ADF Unit

Feeds the original to

the master making

position.

82

Page 90

OPTIONAL FUNCTIONS

Originals

❐ The following types of originals are not recommended for use with the optional

document feeder. Set these types of originals on the exposure glass.

• Originals heavier than 90 g/m2, 23.9 lb (when setting a stack of originals)

• Originals lighter than 50 g/m2, 13.3 lb (when setting a stack of originals)

• Originals heavier than 120 g/m2, 31.9 lb (when setting one original at a time)

• Originals lighter than 40 g/m2, 10.6 lb (when setting one original at a time)

• Carbon coated originals

• Damaged originals

• Originals with glue on them

• Originals perforated for ring binders

• Book originals

• Originals written with a pencil or ball-point pen

• Originals smaller than 148 mm x 105 mm, 5.8" x 4.1"

• Originals larger than 257 mm x 364 mm, 10.2" x 14.4"

• Folded, curled, creased originals

• Bound, stapled, or clipped originals

• OHP transparencies

• Translucent paper

• Pasted originals

❐ If you use paste-up originals, make sure the pasted parts hold firmly to the

base sheet and press the Paste Shadow Erase key. If the thickness of the

paste-up original is more than 0.1 mm, and the space between the pasted parts

is less than 2 mm, 2/25", a shadow might appear on the prints.

❐ The first 5 mm, 0.2", of the leading edge cannot be printed. Make sure the

leading edge margin is at least 5 mm, 0.2".

Original

5 mm, 0.2"

Print

83

Page 91

OPTIONAL FUNCTIONS

OPTIONAL FUNCTIONS

Setting originals into the document feeder

❐ If you set one original into the document feeder while another original is still on

the exposure glass, the original set into the document feeder will be scanned

first.

Adjust the original guides to the

1

size of the originals.

Insert the originals face up in the

2

document feeder until it stops.

❐ Do not insert different size originals

at the same time.

❐ Approximately 30 originals can be in -

serted at one time in the document

feeder. The top original will be fed

first.

❐ The guides must fit snugly against

both sides of the stack.

Set the required image settings.

3

Make sure that Master Making

4

indicator is lit and then press the

Start key.

Make your prints.

5

84

Page 92

OPTIONAL FUNCTIONS

Combine 2 originals with the document feeder

❐ For details about Combine 2 Originals function, ☛ See page 63.

.

Insert the 2 originals face up.

1

❐ The top original will be printed on the

leading part of print.

Press the Combine 2 Originals

2

key.

Check the print paper size and

3

the reproduction ratio.

Enter the number of prints using

4

the Number keys.

Make sure that the Master Mak-

5

ing indicator is lit and then press

the Start key.

❐ After the first original is on the mas -

ter, the second original is fed.

❐ If you set only one original, the

beeper sounds after the first original

is on the master. Set the second

original and the desired image settings. Then, press the Start key.

85

Page 93

Make sure that Print indicator is

OPTIONAL FUNCTIONS

6

lit and then press the Start key.

OPTIONAL FUNCTIONS

86

Page 94

OPTIONAL FUNCTIONS

Printing with One Touch Class mode

❐ For details about One Touch Class mode, ☛ see page 47.

❐ To prevent original misfeed, do not set originals of different sizes.

❐ Do not set more than 30 originals at one time.

Set the originals face up into the

1

document feeder.

❐ The originals are fed from the top of

the stack. Make sure that the origi nals are set in the correct sequence

with the first original on top.

Follow the steps from 2 to 7 on

2

pages 57 ~ 58 or pages 59 ~ 61.

Press the Auto Cycle key.

3

❐ In Auto Cycle mode, printing starts

automatically after a trial print is de livered.

Make sure that the Print indicator

4

is lit and then press the Start

key.

❐ After the last page of each set is fed

out to the paper delivery table, the

tape dispenser drops a strip of paper

on the top of the paper stack. The

next cycle begins.

87

Page 95

OPTIONAL FUNCTIONS

OPTIONAL FUNCTIONS

Color Printing Using The Optional Color Drum

Color drum units (red, blue, green, brown, yellow, purple, navy, maroon,

orange and teal) are available as options in addition to the standard black

unit. For making color prints, a separate drum unit is necessary for each

color.

Making color prints

Make sure that the Color Drum

1

indicator is lit.

Make sure that Master Making

2

indicator is lit and then press the

Start key. Check the image position on the trial or proof print.

❐ If the image position is not correct,

adjust it using the Image Position

keys (☛ see page 21) or side plate

fine adjusting dial ( ☛ see page 22).

Make your prints.

3

88

Page 96

OPTIONAL FUNCTIONS

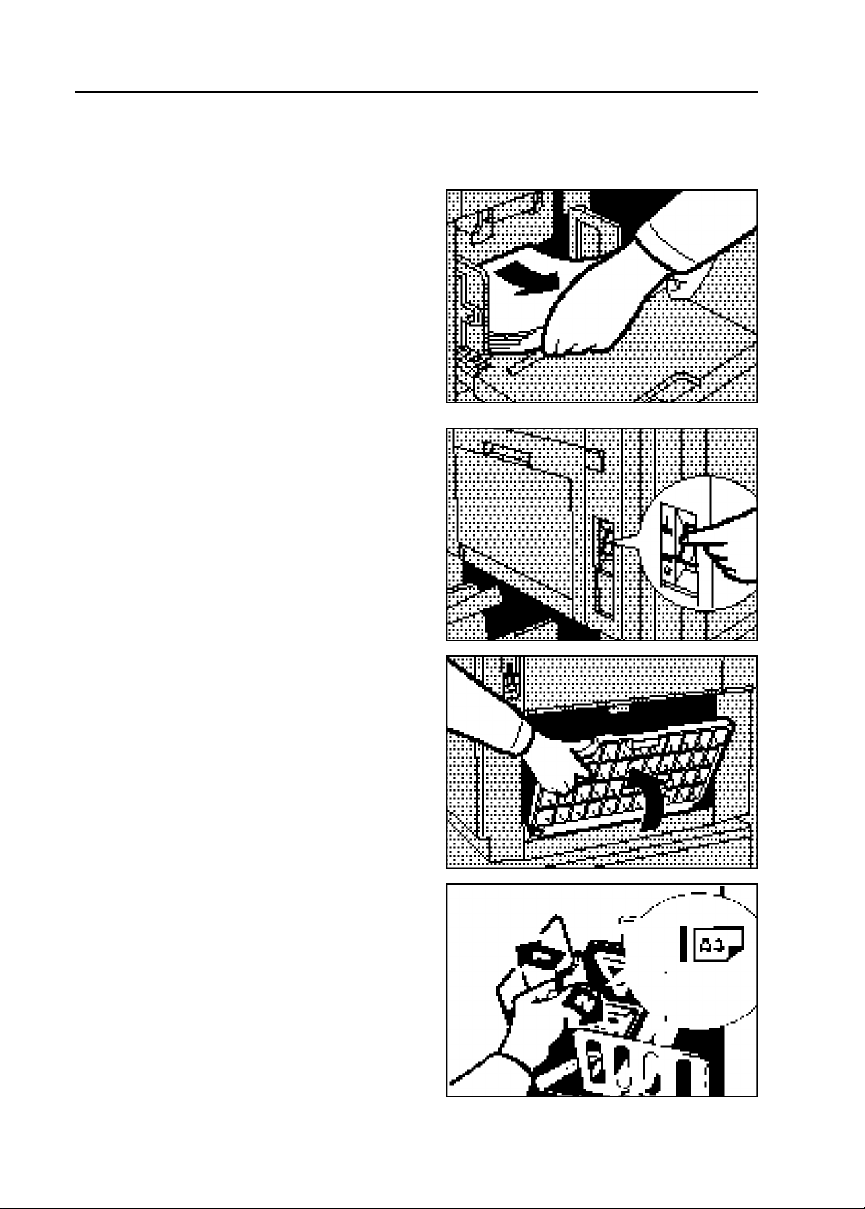

Changing the drum unit for color printing

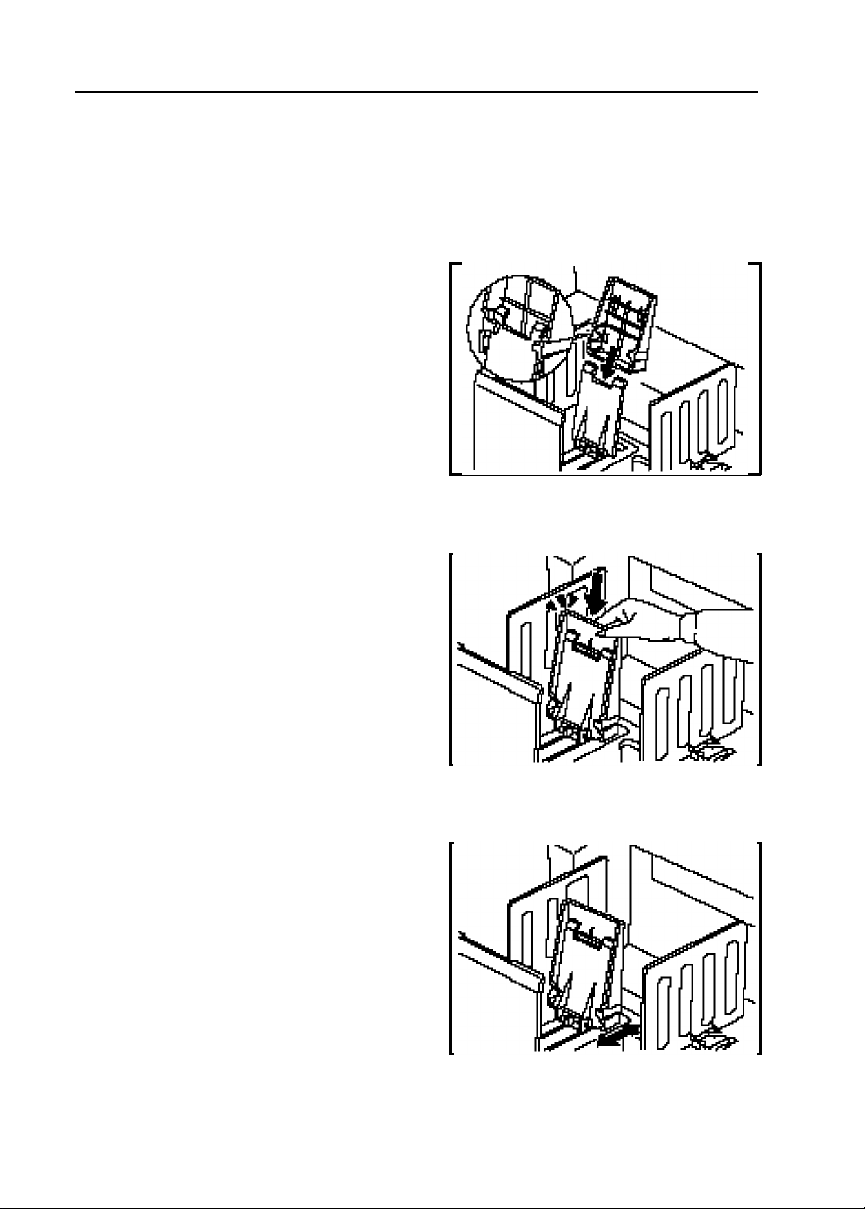

Open the front door.

1

.

Press the drum rotation button

2

until the beeper sounds.

Lift the lock lever until it locks in

3

position.

Pull out the drum unit handle

4

while pressing the release bar inside the green handle.

❐ If you cannot pull out the drum unit

even when the lamp of the drum ro tation button is green, push the drum

unit handle, then pull out the drum

unit.

89

Page 97

Hold the rail on the drum and

OPTIONAL FUNCTIONS

5

slide out the drum while pulling

the release towards you.

Remove the drum unit from the

6

machine while holding the upper

drum stay.

Note:

Be careful not to let the drum

unit fall.

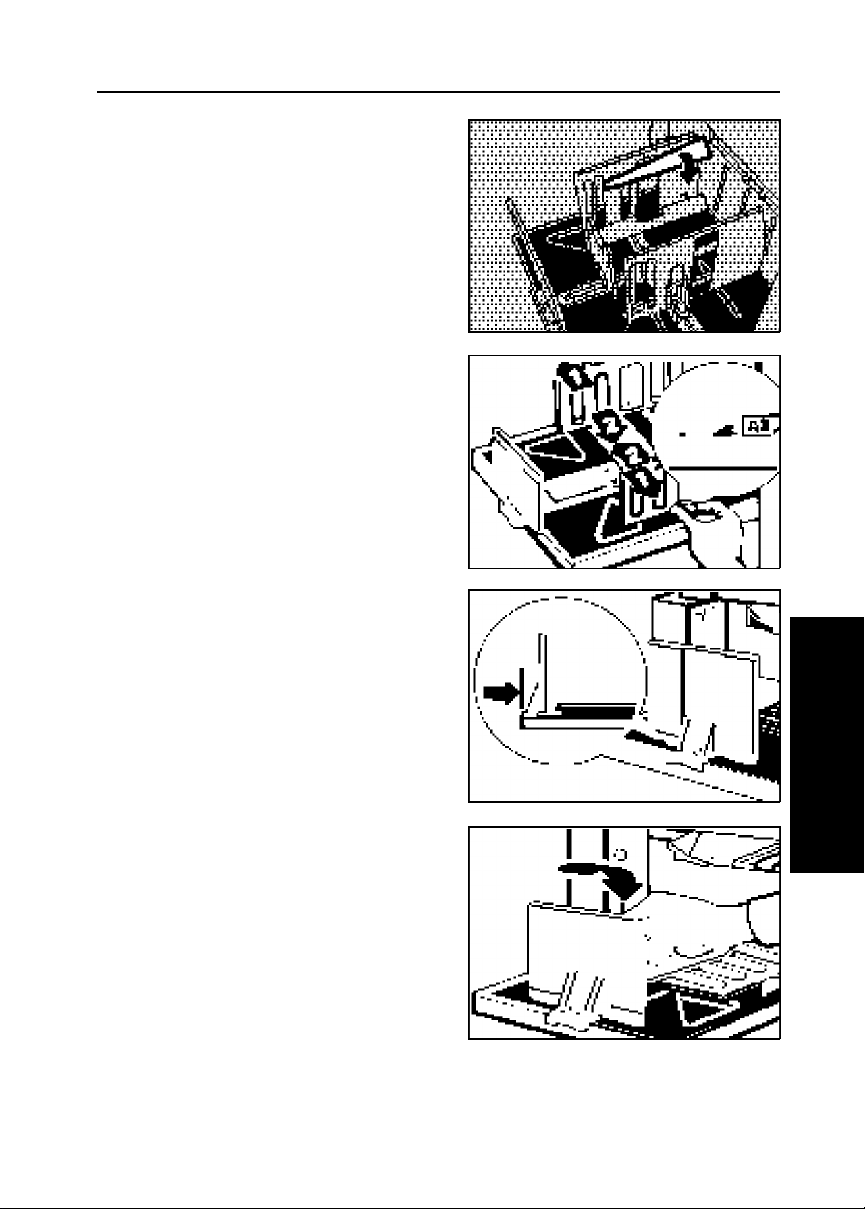

Insert the color drum unit along

7

the guide rail.

OPTIONAL FUNCTIONS

Slide in the drum unit until the

8

drum unit locks in position.

90

Page 98

OPTIONAL FUNCTIONS

Lower the drum unit lock lever.

9

Close the front door.

A

❐ Make sure that the Cover Open indi -

cator turns off, and the Color Drum

indicator lights.

91

Page 99

OPTIONAL FUNCTIONS

OPTIONAL FUNCTIONS

Printing in two colors

After printing in one color, you can print in another color on the same side of

the print.

❐ You cannot print in two colors at one time.

❐ Leave the prints for a while before printing on them again to let the ink dry.

Prepare the two originals. Set the

1

first original on the exposure

glass.

Make sure that Master Making

2

indicator is lit and then press the

Start key. Check the image position of the trial or proof print.

❐ If the image position is not correct,

adjust it using the Image Position

keys (☛ see page 21) or the side

plate fine adjusting dial ( ☛ see page

22).

Enter the number of prints using

3

the Number keys.

Make sure that Print indicator is

4

lit and then press the Start key.

92

Page 100

OPTIONAL FUNCTIONS

.

Remove the prints from the paper

5

delivery table and set them on

the paper feed table again as

shown in the illustration.

.

Exchange the drum unit. ☛ See

6

pages 89 ~ 91.

.

Set the second original. Make

7

sure that Master Making indicator is lit and then press the Start

key. Check the image position.

Make sure that Print indicator is

8

lit and then press the Start key.

93

Loading...

Loading...