Page 1

I{IIGOM

PRIPORTVT2130

OPERATINGINSTRUCTIONS

Ill

RICOH COMPANY, LTD.

p’

Page 2

Note to users in the United States of America

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Note to users in Canada

This digital Apparatus does not exceed the Class A limits for Radio

Frequency noise from Digital Apparatus set out in the Radio Interference

Regulations of the Canadian Department of Communications.

Remarque concernant Ies utilisateurs au Canada

Le present appareil numerique n’emet pas de bruits radioelectriques

depassant Ies Iimites applicable aux appareiis numeriques de la classe

A prescribes clans Ie R&glement sur Ie brouillage radioelectrique edicte

par Ie ministere des Communications du Canada.

Page 3

INTRODUCTION

The Ricoh Priport VT2130 is a stencil duplicator which is carefully

manufactured to exacting standards of high performance.

This manual contains detailed instructions on the operation and care of the

Priport VT21 30.

operators should read and follow the instructions in this manual. Please keep

this manual in a handy place near the machine.

1.

Wide range of reproduction ratios:

4 fixed reproduction ratios (100% plus 3 reduction ratios).

2.

2 single originals can be printed on one sheet of paper.

3.

5 mono color printing with optional drum units.

To get the maximum versatility from this machine, all

Page 4

TABLE OF CONTENTS

GUIDE TO COMPONENTS

1. Machine Exterior ........................ 2

2. Machine Interior

3.

Operation Panel

INSTALLATION REQUIREMENTS

1. Machine Environment ................. 8

2. Access to Machine .....................9

3. Power Connection ......................9

DO’S AND DON’TS

ORIGINALS ......................................0....

PRINTING PAPER

OPERATION

Preparation for Printing ............14

1.

2.

Setting the Originals ................. 16

Printing

3.

4.

Restoring Paper Feed and

Paper Delivery Tables ............... 18

..................................... 17

..........................

..........................

...............................

................................

4

6

10

11

13

12. Changing the Drum Unit for

Color Printing

13. Printing in Two Colors .............. 29

SPECIAL FUNCTIONS

1. Group Printing from the Same

Original

2.

Combine 2 Originals ................. 32

3. Various Run Lengths Using

the Same Master ....................... 34

4. Photo Mode Printing ................. 35

REPLENISHING SUPPLIES

1. Loading Paper

2. Supplying Ink

3. Master Roll Replacement .......... 38

MAINTENANCE

1. Thermal Head Cleaning ...........40

2. Platen Cover/Exposure Glass ..41

TROUBLESHOOTING

1. Indicators

............................

....................................

...........................

............................

..................................

27

30

36

37

42

5.

Adjusting the Image Position ...19

6.

Changing the Paper Size ..........21

7.

Printing on Thick or Thin

Paper

.........................................

8.

Printing on Postcard Size

Paper

.........................................

Various Originals

9.

10.

Changing the Printing Speed ...25

11.

To Stop the Machine During a

Printing Run

......................24

..............................

22

23

26

2. When the Misfeed (8%) Indicator

Lights

When the Supply/Exchange ~)

3

Indicator Lights ........................ 49

4

Other Indicators Light ............... 51

Poor Printing

5

MISCELLANEOUS

1. Operating Cautions ........----- 54

SPECIFICATION

........................................

................................

...................................

.-.

.............................

43

52

54

56

Page 5

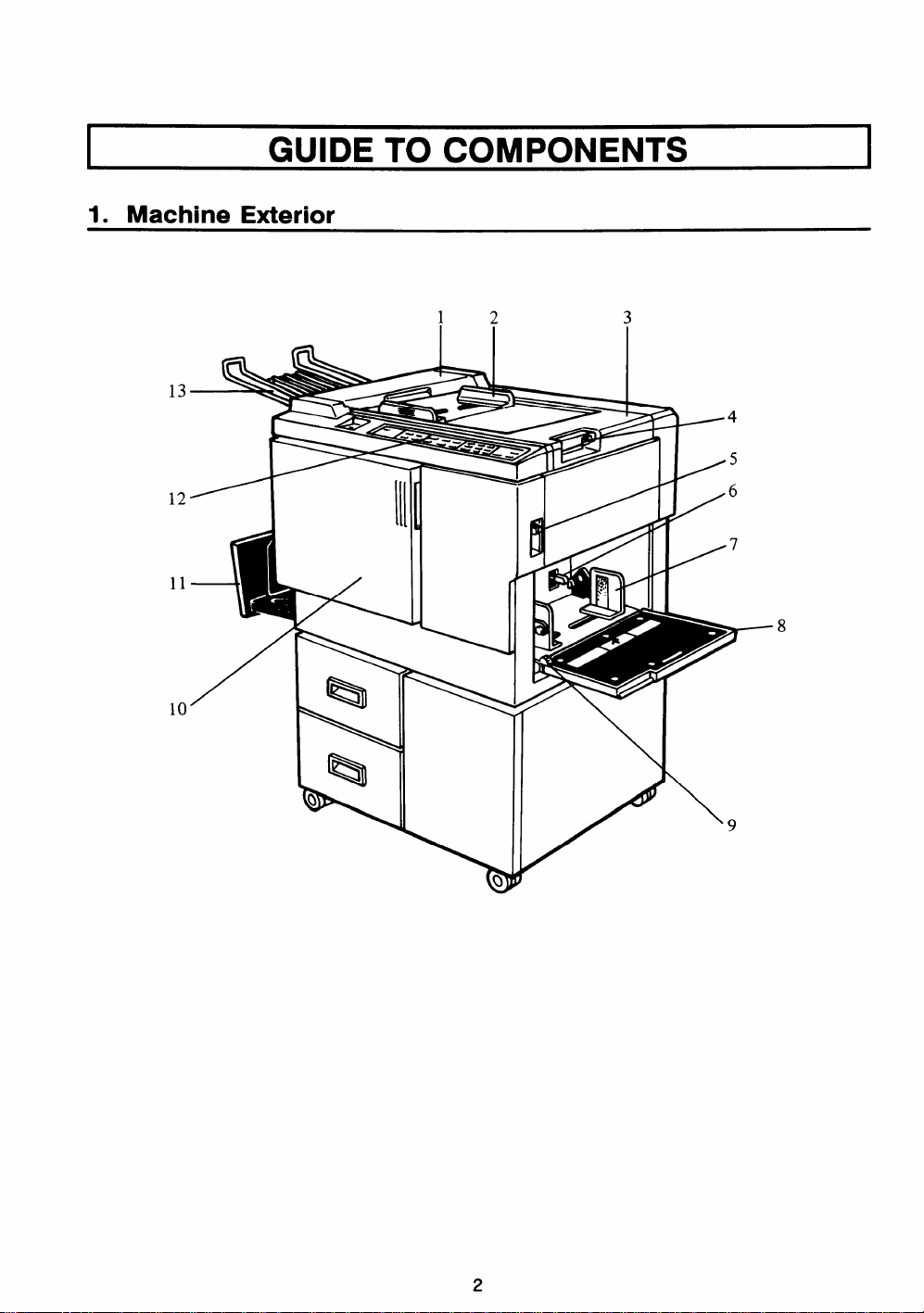

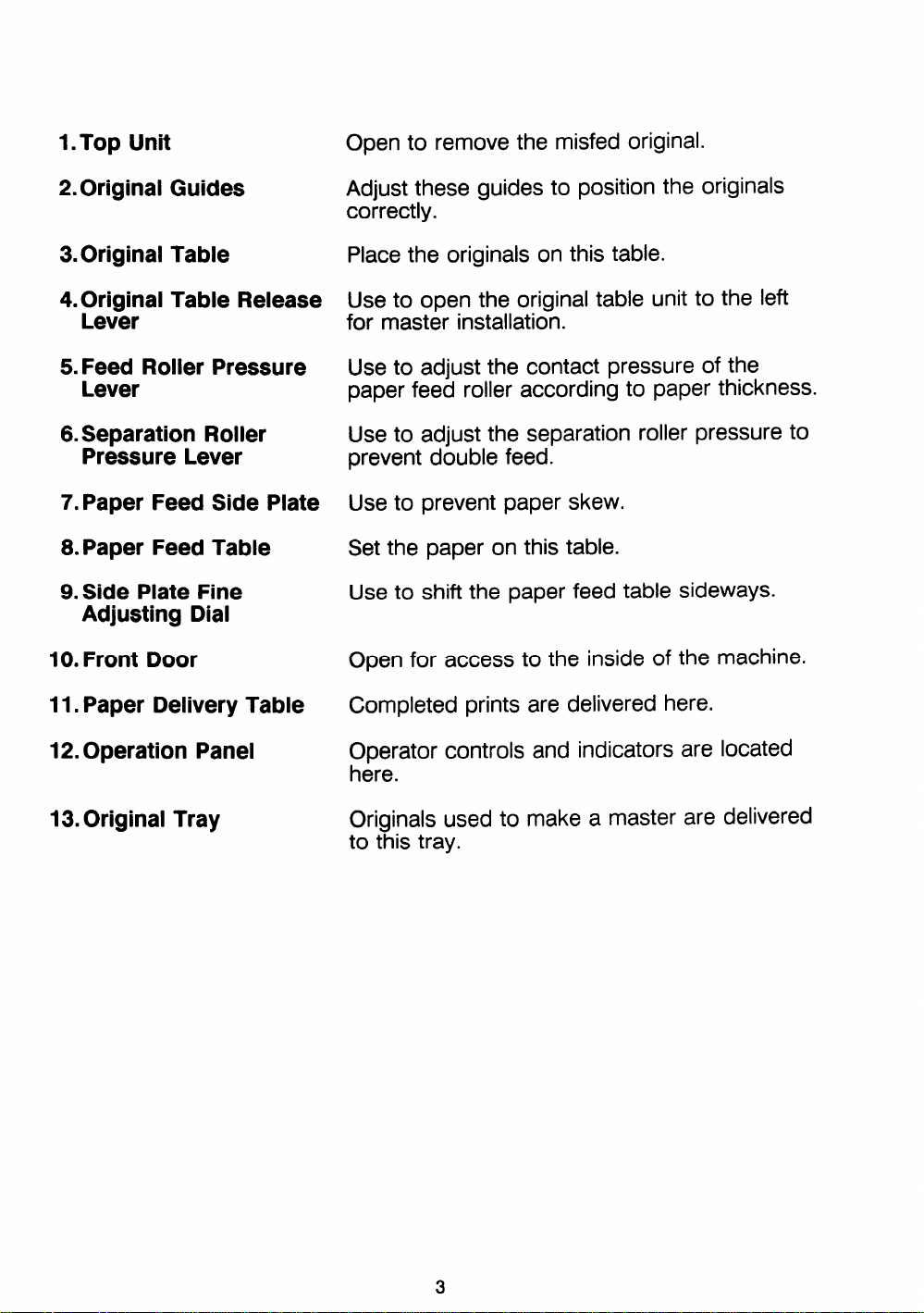

GUIDE TO COMPONENTS

1. Machine Exterior

12

1111

A!

b

3

5

6

1’

/

/7

8

p–

\

9

‘%

Q

Page 6

1.Top Unit

Open to remove the misfed original.

2.Original Guides

3.Original Table

4. Original Table Release

Lever

5.Feed Roller Pressure

Lever

6.Separation Roller

Pressure Lever

7. Paper Feed Side Plate

8.Paper Feed Table

9. Side Plate Fine

Adjusting Dial

10. Front Door

11. Paper Delivery Table

Adjust these guides to position the originals

correctly.

Place the originals on this table.

Use to open the original table unit to the left

for master installation.

Use to adjust the contact pressure of the

paper feed roller according to paper thickness.

Use to adjust the separation roller pressure to

prevent double feed.

Use to prevent paper skew.

Set the paper on this table.

Use to shift the paper feed table sideways.

Open for access to the inside of the machine.

Completed prints are delivered here.

12.Operation Panel

13.Original Tray

Operator controls and indicators are located

here.

Originals used to make a master are delivered

to this tray.

Page 7

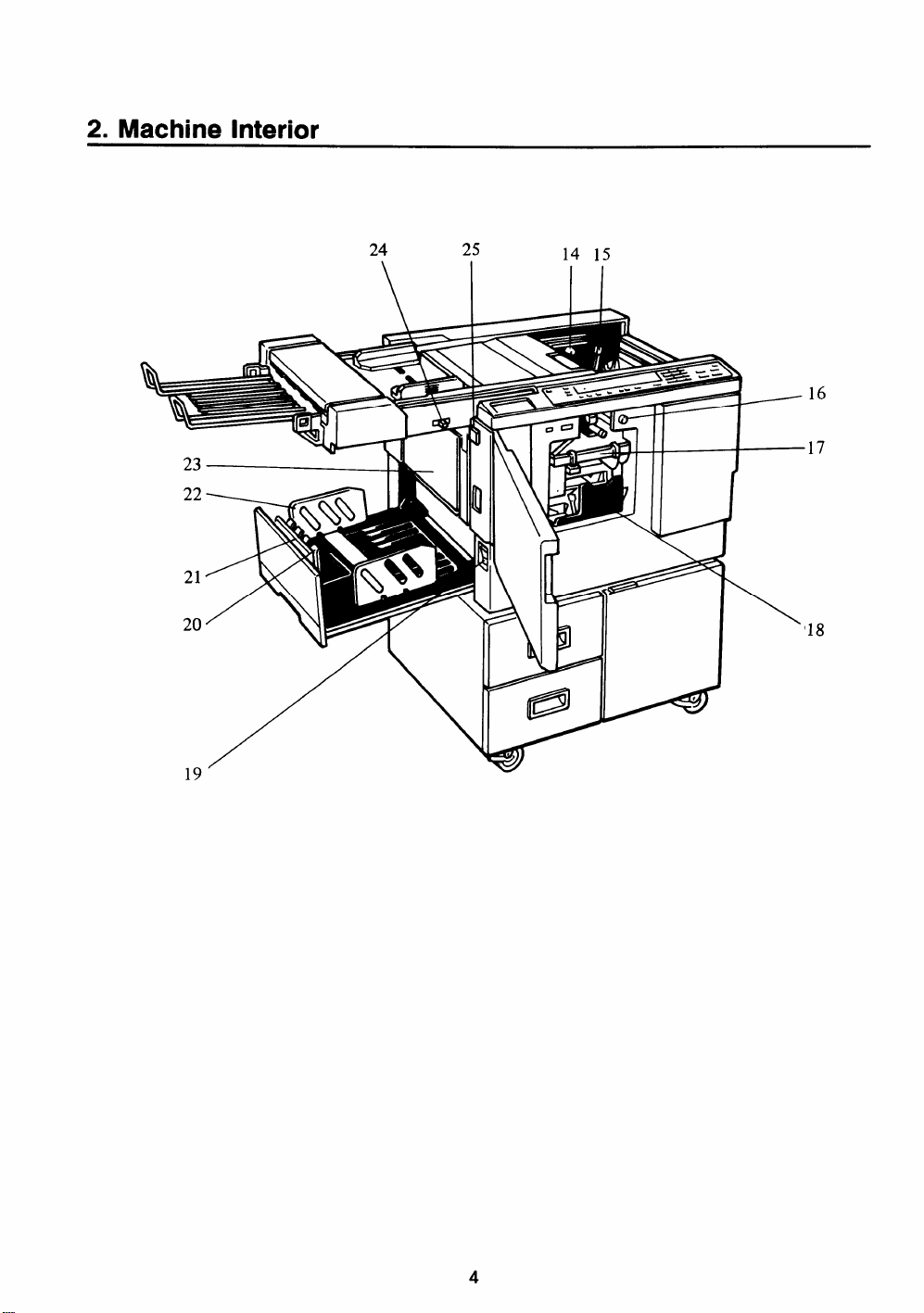

2. Machine Interior

19‘

24

25

14 15

Ii=

16

17

\

’18

4

Page 8

14. Master Cut Button

15.

Pressure Release Lever

Press this button to cut the master paper leading edge after installing a new master roll.

Use to install the master roll, or to clean the

thermal head.

16. Drum Rotation Button

17.Drum Unit

18. Ink Holder

19.Main Switch

20. Small Size Paper

Delivery End Plate

(for smaller than

81/2”x 1l“)

21. Paper Delivery End

Plate

(for larger than

81/2” x 1l“)

22. Paper Delivery Side

Plate

23. Master Eject Container

Cover

Press to replace the drum or to remove misfed

paper.

The master paper is wrapped around this unit.

Set the ink cartridge in this holder.

Use to turn the power on or off.

Use to align the leading edge of small-sized

(less than 81/2” x 11”) prints.

Use to align the leading edge of prints larger

than 81/2” x 1l“.

Use to align the prints on the paper delivery

table.

Open when removing the master eject box.

24.Printing Density Select

Switch

25.Master Eject Unit Open

Button

Use to select the printing density according to

the type and quality of the original.

Press to remove misfed paper or a misfed

master.

5

Page 9

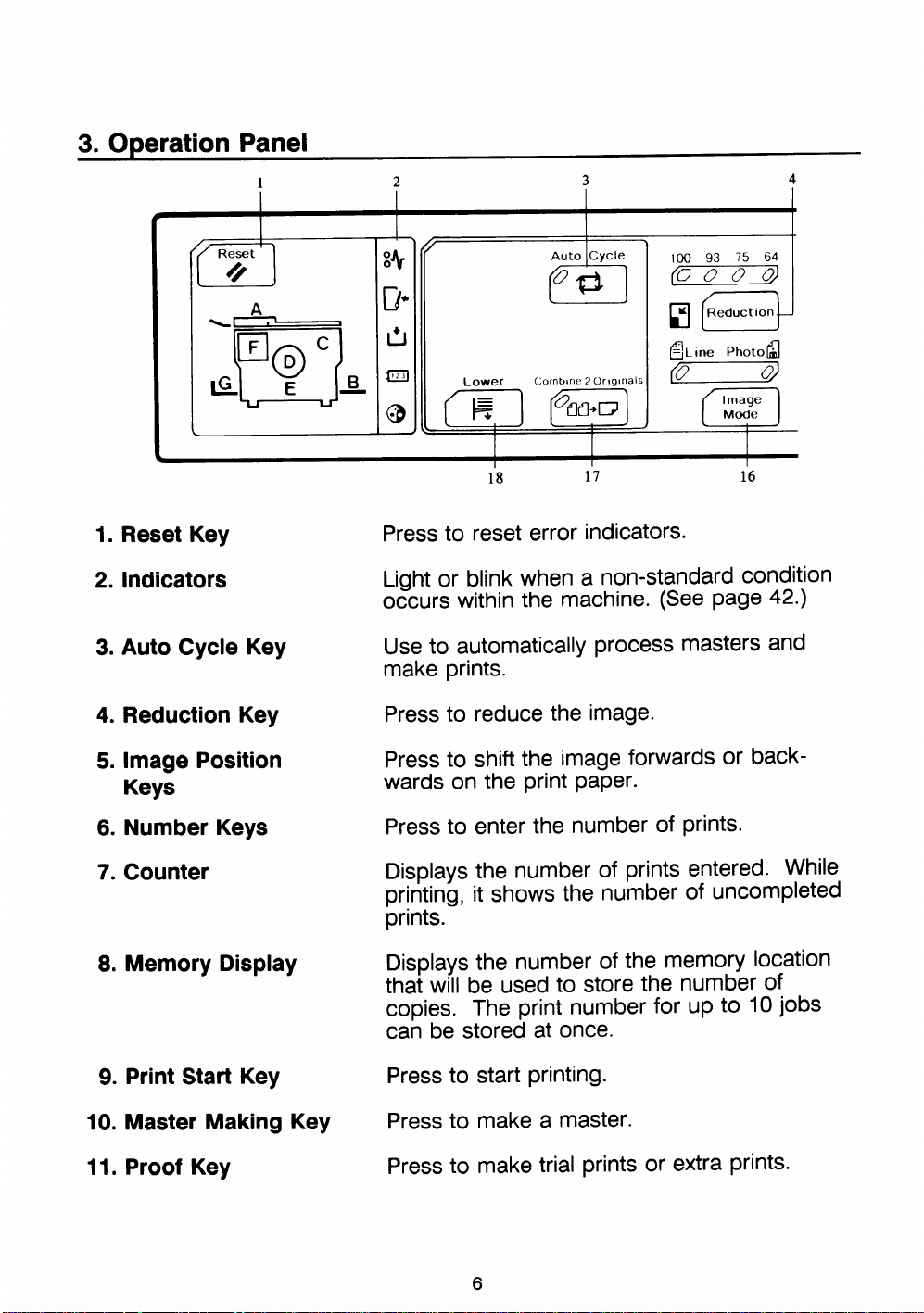

3. Operation Panel

1

r

I A

1. Reset Key

2. Indicators

3. Auto Cycle Key

2

t

3

I

1

Auto Cycle

OQ

1

IO(I 93 75 64

(0000)

4

m

(5

18

Cornblne 2 originals

17 16

Lower

Q%=%

Press to reset error indicators.

Light or blink when a non-standard condition

occurs within the machine. (See page 42.)

Use to automatically process masters and

make prints.

4. Reduction Key

5. Image Position

Keys

6. Number Keys

7. Counter

8. Memory Display

9. Print Start Key

10. Master Making Key

11. Proof Key

Press to reduce the image.

Press to shift the image forwards or back-

wards on the print paper.

Press to enter the number of prints.

Displays the number of prints entered. While

printing, it shows the number of uncompleted

prints.

Displays the number of the memory location

that will be used to store the number of

copies. The print number for up to 10 jobs

can be stored at once.

Press to start printing.

Press to make a master.

Press to make trial prints or extra prints.

6

Page 10

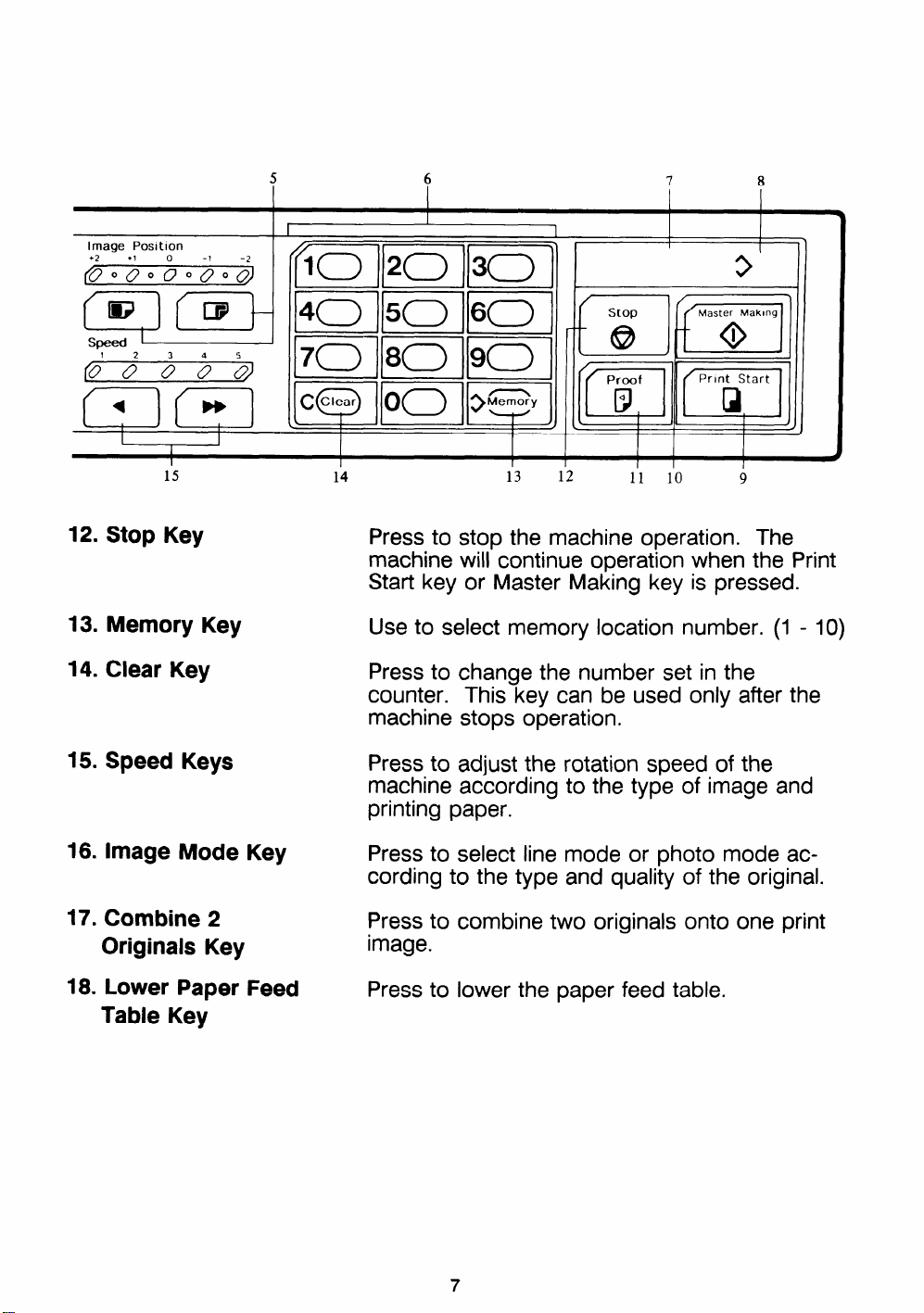

5

6

7 8

15

12. Stop Key

13. Memory Key

14. Clear Key

15.

Speed Keys

16.

Image Mode Key

17.

Combine 2

Originals Key

18.

Lower Paper Feed

Table Key

14

13 12

11 10

9

Press to stop the machine operation. The

machine will continue operation when the Print

Start key or Master Making key is pressed.

Use to select memory location number. (1 - 10)

Press to change the number set in the

counter. This key can be used only after the

machine stops operation.

Press to adjust the rotation speed of the

machine according to the type of image and

printing paper.

Press to select line mode or photo mode according to the type and quality of the original.

Press to

combine two originals onto

one print

image.

Press to

lower the paper feed table.

Page 11

INSTALLATION REQUIREMENTS

1. Machine Environment

The installation location should be carefully chosen because environmental

conditions greatly affect the performance of a machine.

I ml I

- Optimum environmental conditions -

Temperature:

●

10 – 30°c

(50 - 86”F)

Humidity:

●

Ventilation:

●

20 – 90% RH

Well-ventilated and wide room.

On a strong and level base (a

●

sturdy desk, etc.).

The machine must be level

●

within 5 mm (13/64”) both front

to rear and le~ to right.

- Environments to avoid Direct sunlight or strong light

●

Locations directly exposed to

●

the cool air from an air con-

ditioner or reflected heat from a

space heater. (Sudden temperature changes low to high or

vice versa may cause conden-

sation within the machine.)

Dusty areas.

●

8

Page 12

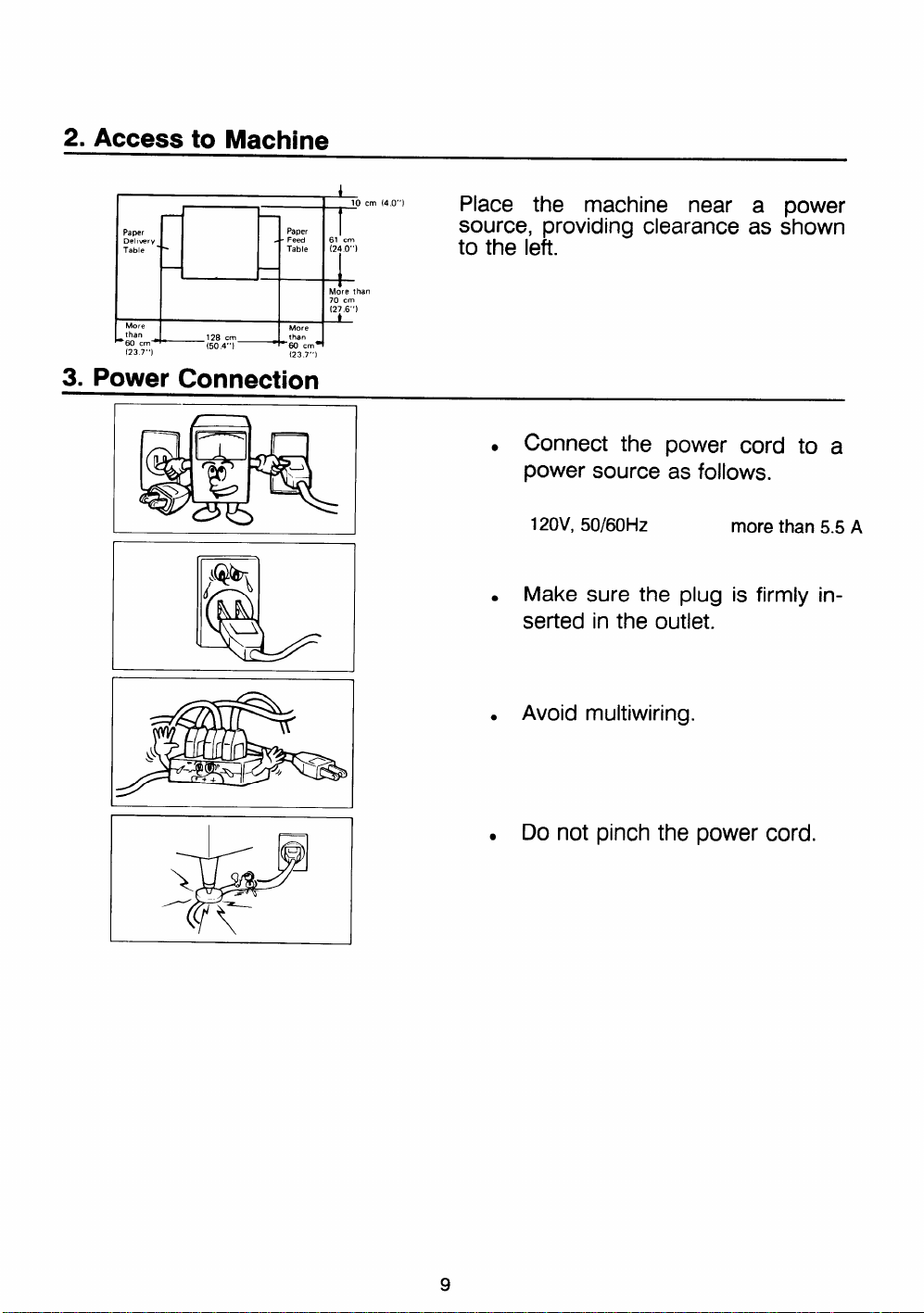

2. Access to Machine

Paper

Del, very

Table

c

than

60 cm”

(23 7“)

~

~

Paper

Feed

Table

(23 7’,1

3. Power Connection

I f

10 cm {4.0”)

I

61 cm

(24 O“)

I

+

More than

70 cm

(27 6“)

Place the machine near a power

source, providing

clearance as shown

to the left.

. Connect the

power source

120V, 50/60Hz

power cord to a

as follows.

more than 5.5 A

. Make sure the plug is firmly in-

serted in the outlet.

Avoid multiwiring.

●

. Do not pinch the power cord.

Page 13

I DO’S AND DON’TS

- Operating Cautions -

1.

While Printing :

- Do not turn off the main switch.

- Do not unplug the

Do not open the front cover.

-

- Do not move the machine.

2. Keep corrosive liquids, such as acid, off the machine.

Do not allow paper

3.

machine.

4. Always turn the machine off when

5. Do not touch print paper

appear on prints.

clips, staples, or other small objects to fall inside the

- General Cautions -

1.

Do not modify or replace any parts other than the ones specified in this

manual.

2. When the machine will not be used for long periods, disconnect the

power cord.

If the machine must be transported by vehicle, please contact your

3.

dealer.

4. Do not operate the machine with any covers off.

power cord.

you have finished printing for the day.

if your fingers are wet or oily; fingerprints may

I

10

Page 14

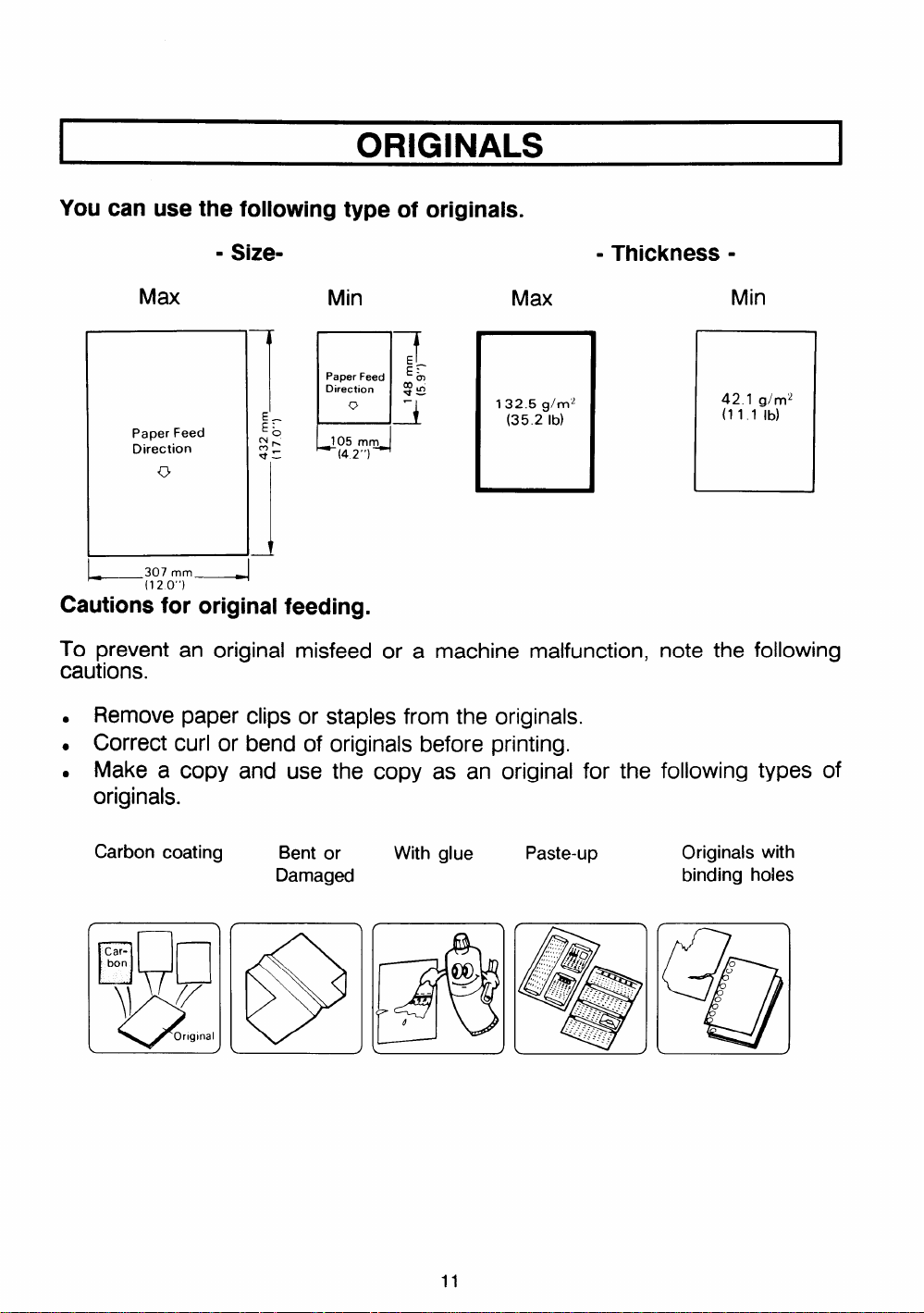

ORIGINALS

You can use the following type of originals.

- Thickness -

Max

Paper Feed

Direction

Min

7

Paper Feed

Direction _

0’

1

J05 mm

(4 2“)

-i

--l

Max

E:

:In

132.5 g/rnz

(35.2 lb)

Min

42.1 glmz

(11.1 lb)

u

—307 ““—

(120”)

Cautions for original feeding.

TO prevent an original misfeed or a machine malfunction, note the following

cautions.

. Remove paper clips or staples from the originals.

. Correct curl or bend of originals before printing.

. Make a copy and use the

originals.

copy as an original for the

following types of

Carbon coating

Car-

bon

LIJn

]] Y

o

Onglnal

@]

Bent or

Damaged

With glue

11

Paste-up

Originalswith

binding holes

.,,,

;,::’:’..:~$

,,

Q

,;.,;:,

?,,,:,

O@

;:?

.:

47

........ .

..... .. . ..

.....- .- .. ... .

. .......

.%5

..’..“”...”...

.----......,..

...

..

.... .

. . .. .. ..

...... ..

.-. .

...

. .

..-.$.:

- .-.

. ... ,.

Page 15

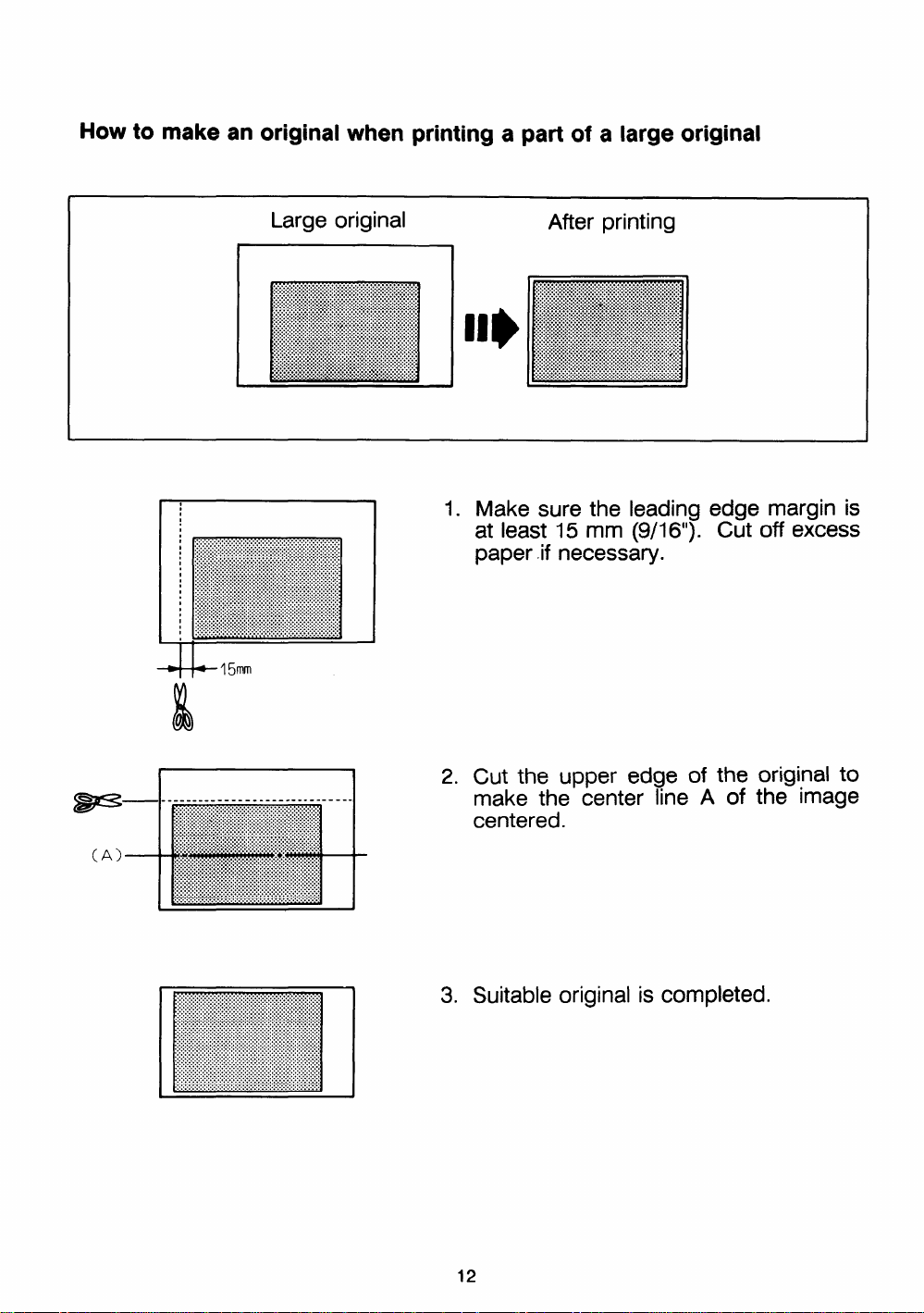

How to make an original when printing a part of a large original

1!

+15mm

Iii

Large original

After printing

1. Make sure the leading edge margin is

at least 15 mm (9/16“). Cut off excess

paper .if necessary.

2. Cut the upper edge of the original to

make the center line A of the image

centered.

3. Suitable original is completed.

12

Page 16

I

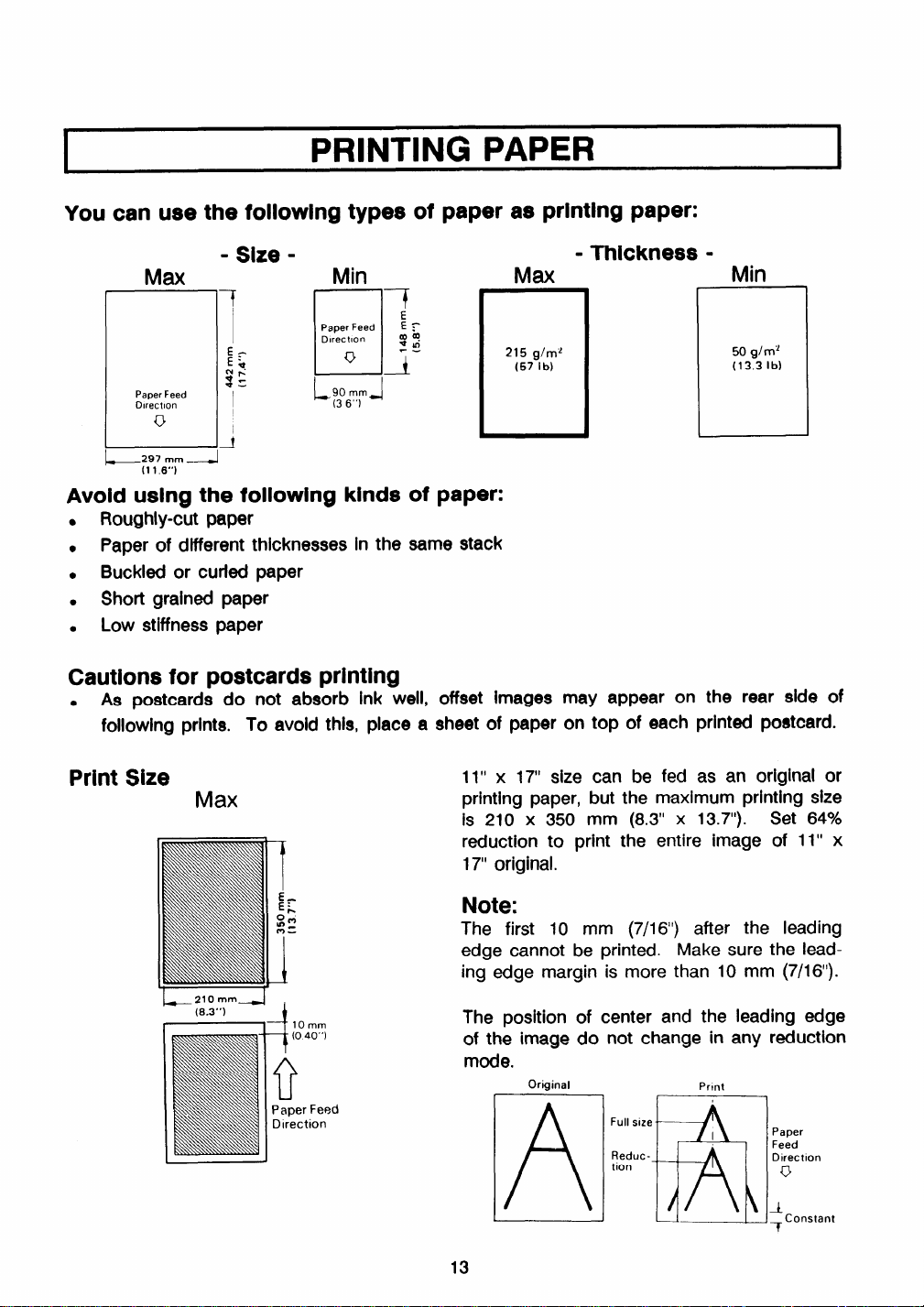

PRINTING PAPER

You can use the following types of paper as printing paper:

- Thickness -

Paper Feed

Dlrectlon

u

Min

17

Paper Feed E ~

Dlrect!on

u Y

J“

E

Max

215 g/mz

(57 lb)

I

Min

50 girl+

(13.3 lb)

r

Avoid using the foliowing kinds

. Roughly-cut paper

Paper of different thicknesses In the

.

. Buckled or curled paper

. Short grained paper

. Low stiffness paper

Cautions for postcards printing

● As postcards do not absorb ink weii,

foiiowing prints. To avoid this, piace a

Print Size

Max

~ ;;:,;

m_/

r

10mm

,4

of

same stack

offset images may appear on the rear side of

sheet of paper on top of each printed postcard.

11” x 17“ size can be fed as an original or

printing paper, but the maximum printing size

is 210 x 350 mm (8.3” x 13.7”). Set 64%

reduction to print the entire image of 11” x

17“ originai.

Note:

The first 10 mm (7/16“) after the ieading

edge cannot be printed. Make sure

ing edge margin is more than 10 mm (7/16”).

The position of center and the ieading edge

of the image

mode.

do not change in any reduction

Original

Print

the lead-

13

!_.---Y

l.J!!L_!j!+Constant

-T

Page 17

OPERATION

1. Preparation for Printing

1.

Open the

2.

Adjust the paper feed

match the paper size.

paper

carefully.

plates

to

3. Place the paper on the paper feed

table.

. Correct the paper curl before setting the

paper.

h b

o

4. Make sure that the paper feed side

plates contact the paper lightly.

x

14

Page 18

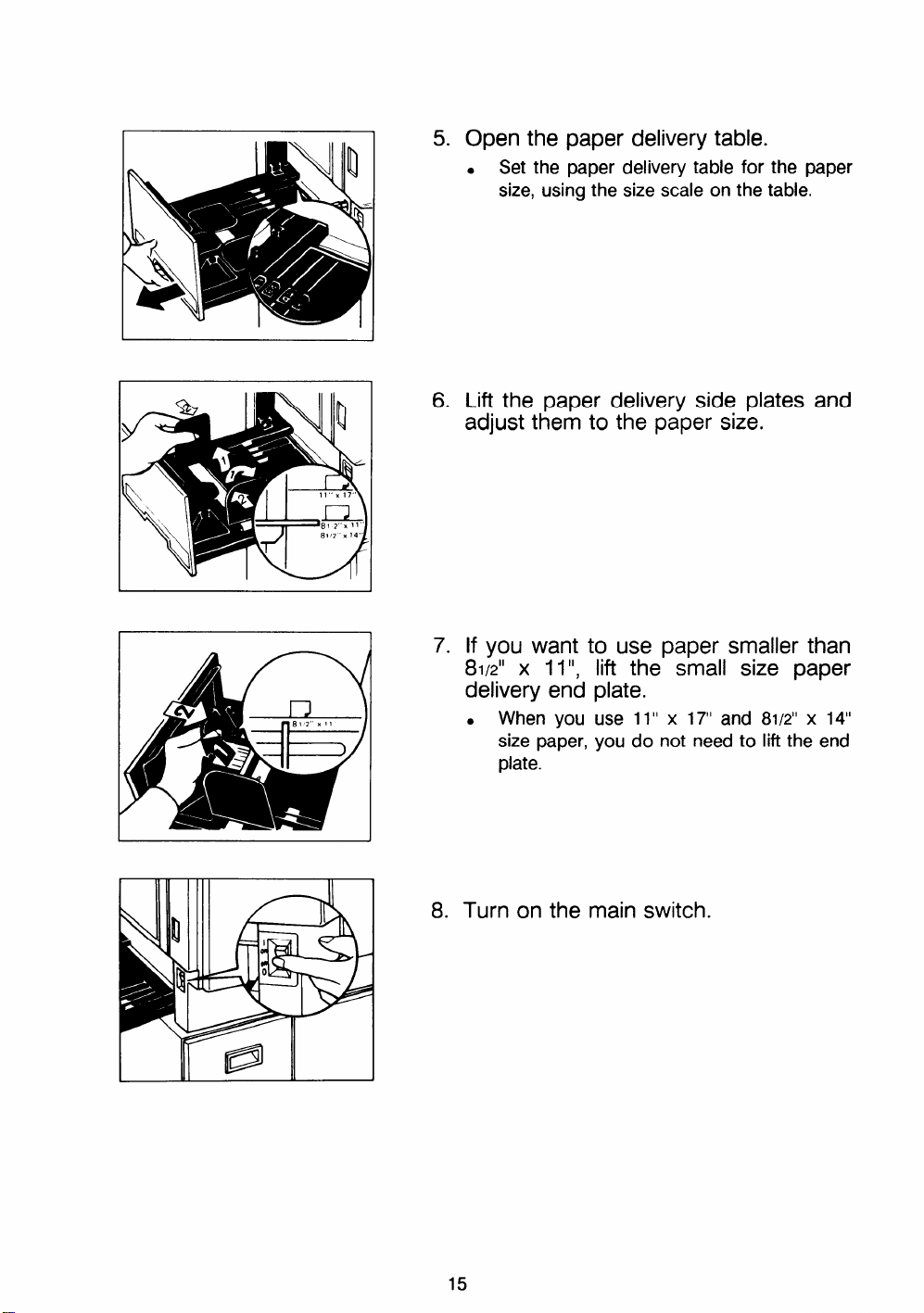

r I

5. Open the paper delivery table.

.

Set the paper delivery table for the paper

size, using the size scale on the table.

I

I 1

I

6. Lift the paper delivery side plates and

adjust them to the paper size.

7. If you want to use paper smaller than

81/2” x 11”, lift the small size paper

delivery end plate.

. When you use 11” x 17“ and 81/2”x 14“

size paper, you do not need to lift the end

plate.

8. Turn on the main switch.

15

Page 19

2. Setting the Originals

1. Adjust the original guides to the size

of the original.

I

1

2. Insert the original face down on the

original table until it stops.

.

Only one original can be set at a time.

3. Select the image

mode using the

Image Mode keys.

.

J

Use the line mode

printed matter.

. Use the photo mode when the original

contains photos or colored images.

The line mode is automatically selected

●

when the main switch is turned on.

4. If reduced prints are desired, set the

reproduction ratio using the

key.

tion

.

The reduction ratio will change as follows:

93% - 75V0+64%

● 11” x 17’ original cannot be printed in

100% mode. Select 64Y0.

when the original is

Reduc-

100% mode is automatically selected

●

when the main switch is turned on.

16

Page 20

3. Printina

If -4[ ■ 1

1. Enter the number of prints required

using the

1

.

Up to 9999 prints can be entered at one

time.

. To change the number entered, press the

Clear key and then enter the new number.

Number keys.

2. Press the Master Making key.

● The original is fed, and the trial print is

delivered to the paper delivery table.

Check the image position. (See page 19

to 20.)

3. Press the Print Start key.

.

The number of prints set in the counter

are made and the machine stops.

. The same number of prints are input auto-

matically after printing is completed.

. If the next original has been set in the

original table before the machine stops,

that original is fed automatically and a trial

print is delivered to the paper delivery

I

tray. Check the image position. (See page

19 to 20.)

4. Remove the prints from the paper

delivery table.

I

Page 21

4. Restoring Paper Feed and Paper Delivery Tabies

1. Remove the paper from the paper

feed table.

. The paper feed table will lower automat-

ically.

1 1

kill I

2. Return the paper feed table to its

original position.

3. Return the small size paper delivery

end plate to its original position

4. Return the paper delivery side plates

to their original position.

Make sure that the paper delivery side

●

plates do not touch the small size paper

delivery end plate.

5. Slide in the paper delivery table.

6. Turn off the main switch.

1

1

18

Page 22

5. Adjusting the Image Position

If the image position is not Correct, acfjust before you start printing.

- Shifting the image position forward

t

1

1 t I

1

L

1. Press the left Image Position key.

I

2. Press the Proof key.

- Shifting the image position backward

1. Press the right Image Position key.

When you shift the image forwards, leave

●

a margin (more than 10 mm/O.40”) at the

leading edge.

Check the

image position again.

+2 +1 o –’l –2

2. Press the Proof key. Check the

image position again.

Note:

● The left and right Image Position keys

shift the image about 1mm/O.04° each

time they are pressed.

● When the indicator changes from O to + 1

(-1 ), the image position shifts about

10mm/O.40” (-10mm/PO.40”).

19

Page 23

- Shifting the image to the right

m~m

—__.___.-_

1.

Press the Lower Paper Feed Table

key.

2.

Turn the side plate fine adjusting dial

as shown in the illustration.

.

You can shift the image position up to 10

mm from the center. Each division on the

scale is 2 mm.

Press the Proof key. Check the

3.

image position again.

If the image position is not set correctly,

●

do steps 1-3 again.

- Shifting the image to the left

I II (

Press the

1.

key.

Turn the side plate fine adjusting dial

2.

as shown in the illustration.

. You can shift the image position up to 10

mm from the center. Each division on the

scale is 2 mm.

Press the Proof key. Check the

3.

image position again.

. If the image position

do steps 1 -3 again.

Lower Paper Feed Table

is not set correctly,

20

Page 24

6. Changing the Paper Size

1. Remove the paper from the paper

feed table.

. The paper feed tray will lower automati-

cally.

2. Adjust the paper feed side plates to

match the paper size.

3. Place the paper on the paper feed

table.

. Correct the paper curl before setting the

paper.

b

!!!!!!s

4. Adjust the paper delivery side plates

and the paper delivery end plate. (See

page 15.)

.

Make sure that the paper feed side plates

contact the paper lightly.

o

x

21

Page 25

7. Printing on Thick or Thin Paper

When you make prints on thick or thin paper, do the following steps.

- Printing on thick paper

1. Push down the feed roller pressure

lever.

.

Thick paper : 132.5 to 215 g/m2 (35.2 to

57 lb)

. In the case of paper smaller than

S1/2’’x8l/2° and heavier than 132.5 g/m2

(35.2 lb), move the feed roller pressure

lever to the standard position.

2. Push the separation roller pressure

levers up to the thick paper position.

- Printing on thin paper

1. Set the side pads (Move the side pad

levers to the right).

.

Thin paper: lighter than 51.2 g/m2 (13.61b)

2. Make prints. (See page 14 to 17.)

22

Page 26

8. Printing on Postcard Size Paper

● AS postcards do not absorb ink well, offset images may appear on the rear side of

following prints. TO avoid th~, reduce the printing speed and place a sheet of paper on

top of each printed postcard.

Postcard size original

-

1.

I I

Place the postcard sized paper on the

paper feed table.

● Make sure that the paper feed side plates

—

contact the paper lightly.

2.

Set the original guides

to match the

postcard size original.

Insert the origin~ face down into the

3.

original table until it stops.

4.

Make the prints. (See page 14 to 17.)

The original is larger than postcard and the image is postcard size.

f 1 I

Paper Feed

D Irectlo n

x

1. Place the postcard size paper on the

paper feed table.

Make sure that the paper feed side plates

●

contact the paper lightly.

2. Cut the leading edge of the original as

shown in the illustration. Leave 15

mm/O.6’’(9/l6”) margin when you cut.

3. Insert the original face down into the

original table until it stops.

4. Make the prints. (See page 14 to 17.)

23

Page 27

9. Various Originals

If you want to make prints using a light or dark original, change the

printing density using the printing density select switch.

Light image originals –

Heavy image originals –

Change the printing density to a darker setting

Change the printing density to a lighter setting

NOTE:

. Makesure

Return the printing density select switch to its original position after printing.

●

I

that the printing density select switch clicks into position.

%“,,w 0..,,.

W,.nd.rdI

I

1.

Open the original table.

Lift the original table release lever and

●

slide the original table to the “ T “ mark.

2.

Adjust the printing density to match

the type and quality of the original

using the printing density select

switch.

Return the original table to its original

~ _~\>

WA- ““’’s’’’’’”O”’”’‘

‘m w

1

P,,.,, - 6.”,,,,

Y

\

I

3.

position.

Make the prints. (See page 14 to

4.

17.)

After printing, return the printing

sity select switch to the standard

tion.

24

den-

posi-

Page 28

10. Changing the Printing Speed

Use the Speed key to adjust the rotation Speed of the machine

according to the image densfiy and

printing paper.

1.

Press the Speed key. To increase

speed, press the “ F E “ key. To

reduce speed,

.

press the “ ● “ key. The

printing speed will be changed as follows:

Step 1

Step 2

Step 3

Step 4

Step 5

. When the main switch is turned on, step 3

(9o sheets/rein)

The faster the printing speed becomes,

S

the lighter the printing density is. If darker

prints are required, set the printing speed

lower.

60 sheets/rein

75 sheets/rein

90 sheets/rein

105 sheets/rein

120 sheets/rein

issd@d a@OrnatiCallY-

25

Page 29

11. To Stop the Machine During a Printing Run

[f you want to stop the machine during a print run and print the next

-original, do the following procedure.

1. Press the Stop key.

2. Set the new original.

3. Re-enter the number of prints and

press the

If you want to change the number of prints entered or to check the

completed prints.

1. Press the Stop key.

Change the number of prints or check

the completed prints.

.

When you change the number of prints,

you can re-enter the number using the

Number keys after pressing the Stop key.

Master Making key.

2. Press the Print Start key.

26

Page 30

12. Changing the Drum Unit for Color Printing

Color drum units Type VT2000-LG (red, blue, green, and brown) are

available as options in addition to the standard black.

For making color prints, a separate drum unit is necessary for each

color.

1. Open the front door.

Make sure that the lamp of the drum rota-

●

tion button lights. If this lamp is not lit,

press the drum rotation button until the

beeper sounds.

2. Pull out the drum unit handle while

pressing the release bar inside the

green handle.

3. Hold the rail on the drum and slide

out the drum while pressing the

release slide to the front.

4. Remove the drum unit from the

machine while holding the upper drum

stay.

Be careful not to let the drum unit fall.

●

27

Page 31

~ Insert the color drum unit alona the

guide rail.

6.

Slide in the drum unit until the drum

w-—

unit locks securely.

7.

Close the front door.

. Make

. If the Cover Open indicator does not turn

ly.

sure that the Cover Open indicator

turns off, and the Color Drum indicator

lights.

off, check that the drum unit is set correct-

28

Page 32

13. Printing in Two Colors

After printing in black, you can print in color on the same side of the

print.

You cannot print in two colors at one time.

●

Leave the printed paper for a while before secondary printing, in order to dry the ink on

●

the printed paper.

1.

Prepare the two originals.

Set the first original on the original

table.

F[rst

Orlglnal

H+m”

Second

orlglndl

Print

AP

Ss

2.

Enter the number of prints using

Number keys.

Press the Master Making key.

3.

The original is fed, and the trial print is

●

delivered to the paper delivery table.

Check the image position. (See page 19

20).

to

4.

Press the Print Start key.

5.

Remove the prints from the paper

delivery table and set them on the

paper feed table

the illustration.

Paper delwew table

eye

Exchange the drum unit. (See page

6.

again as shown in

27 to 28.)

7.

Set the second original and press the

Master Making key, Check the image

position. (See page 19 to

Press the Print Start key.

8.

20.)

the

29

Page 33

t

SPECIAL FUNCTIONS

1. Group Printing from the Same Original

Use the Memory key to make sets of prints from the same original. A

different number of prints can be made for each set.

The optional tape dispenser automatically feeds out strips of paper which separate the

●

printing groups on the paper delivery table.

1.

Turn on the main switch.

Enter the number of prints for the first

2.

L.—F--L--I

set using the

Number keys.

~

Ii==! Ir-11==\=== mEI\

‘n

3. Press the

Memory key.

The number for the first set is stored

in Memory 1.

4. Enter the number of prints for the

second set using the

5. Press the

Memory key. The number

Number keys.

for the second set is stored in

Memory 2.

Repeat the above procedure until you

complete the settings.

30

Page 34

6. Press the Memory key again. The

Memory returns to Memory 1.

.

You only need to press the Memory key

again if you have stored the print quantity

for less than 10 sets. The Memory auto-

matically returns

10th set is stored

to Memory 1 after the

in Memory.

7. Set the original

original table.

I

I

face down on the

8.Turn on the power switch of the optional tape dispenser.

9. Press the Master Making key.

Check the image position of the trial

prints. (See page 19 to 20.)

10. Press the Print Start key.

● After the last page of each printing set is

fed out to the delivery table, the tape dis-

penser drops a strip of paper onto the top

of the paper stack. This marks the end of

each printing set.

31

Page 35

2. Combine 2 Oriainals

YOU can print 2 separate Originals m a single sheet of paper.

Original (A)

Original (B)

Print

t

AB+

El

Orlglnal(A)

A+

El

Onglnal

(face side)

A

El

if you print 81/2” x 11” originals on one sheet of paper, set the reduction ratio to 75% or

●

640A. When using 81/2”x 11” originals, you cannot use this mode with 93?40or 100Y0i

. Use paper larger than the combined image area of the 2 originals.

CD

Orlglnal(A)

E!

Orlglnal

(reverse side)

+

El

1 .. . . . . . . . . . . . . . . . . . . . . . . . . . J

A

Print

B

AB

n

,

I

For Example:

Original

Ratio

100% 93%

75$Z0

64%

~

El+El - - @ ~

Hyou set an original larger than as shown in the following table, the Combine 2 originals

●

mode is canceled automatically.

~1

100$%0

93% :

~1

51/2” x 81/2”

51/2” x 81/2”

75Y0 + 81/2” x

64% +

81/2” x

32

~1

11“

11“

~1

Page 36

Set the first original face down and

1.

with the top toward the operating

side.

The first original fed will be printed on the

●

leading part of print.

Enter the number of prints using the

2.

Number keys.

Check the print paper size.

3.

4.

Press the Combine 2 Originals key.

.

The indicator of the Combine 2 Originals

key will light.

Press the Master Making key.

5.

Set the second original face down

6.

after master making for the first

original is finished and the beeper

sounds.

Press the Master Making key.

7.

Check the image position of trial

8.

prints and press the Print Start key.

33

Page 37

3. Various Run Lengths Using the Same Master

1. Set one original on the original table.

2. Enter the number of prints for the first

run using the Number keys.

f

Ill I I

3. Press the Master making key. Check

the image position of trial prints. (See

page 19 to 20.)

I

~(m,

start

Pr,”t

Prcd

19ci

[i]

!lm

4. Press the Print Start key.

5. Remove the prints from the paper

delivery table.

6. Press the Clear key to return the

counter to “O”.

7. Enter the number of prints for the

second run using the Number keys.

8. Press the Print Start key.

9. Remove the prints from the paper

delivery table.

10. Repeat steps 6-9 until printing is completed.

34

Page 38

4. Photo Mode Printing

When printing a photograph or a color original, select Photo Mode.

Original

. Striped patterns may

. When using originals

1(I

3

Photo mode Line mode

occur when meshed originals are printed.

with letters and photos, the image of the letters will be light.

1. Press the Image Mode key to select

Photo mode.

2, Press the Master Making key.

l—

11I

35

Page 39

REPLENISHING SUPPLIES

1. Loadina Pa~er

1. Press the Stop key.

.

This step is necessary only if you want

pause a print run to replenish paper.

2. Press the Lower Paper Feed Table

key.

● The paper feed table will lower automat-

ically when the printing paper runs out.

● When the paper feed table lowers, the top

sheet may remain between the feed

rollers. In this case, remove the top sheet

by hand.

3. Load paper on the paper feed table.

Release the pads of the feed side plates

●

before loading paper. Reset the pads after

paper is set.

4. Press the Print Start key to resume

printing.

36

Page 40

2. Supplying Ink

1. Open the front door.

2. Lower the ink holder and remove the

used ink cartridge.

—

3. Remove the cap of the new ink

cartridge and insert the new cartridge

into the ink holder. Return the ink

holder to its original position.

r

I

I

,

. Do not remove the seal [A].

. Supply the same color ink.

4. Close the front door.

5. Press the Reset key.

Ink will be supplied and the machine

will stop automatically.

37

Page 41

3. Master Roll Replacement

I

1. Open the original table.

Lift the original table release lever and

●

slide the original table to the “ Y “ mark.

2. Lift the pressure release lever in the

direction of the arrow to release the

feed roller pressure.

3. Remove the used master roll and pull

out both spools. Thenj insert both

spools into a new master roll (Type

VT-s).

. When the Master End indicator lights, it is

necessary to replace the master roll even

if some paper remains on the old roll.

4. The new master roll must be posi-

tioned as shown in the illustration.

38

Page 42

5. Insert the leading edge of the master

roll under the pressure roller. (1)

6. Return the pressure release lever to

its original position. (2)

● Rotatethe spools backwardto take up all

slackin the masterpaper.

/

/

7. Press the master cut button to cut the

leading edge of the master roll.

Warning: When the master cut button is

pressed, the master roll will rotate. Do not

touch the master roll.

I

8. After the beeper sounds, remove the

cut-off portion of the master roll.

●

Remove the cut-off master paper com-

pletely to prevent master misfeed.

I

9. Return the original table to its original

position until it stops.

39

Page 43

MAINTENANCE

1. Thermal Head Cleaning

Clean the thermal head when 2 master rolls have been used.

1. Turn off the main switch.

2. Open the original table. (See page

38.)

3. Move the pressure release lever in the

direction of the arrow. (See page 38.)

4. Loosen the screw knobs located on

both sides of the feed roller.

5. Grip both ends of the feed roller and

lift it straight up.

6. Clean the thermal head as follows.

I) Wipethe surfaceof the thermalheadwith

a damp cloth.

2) Cleanthe surfaceof thermal headseveral

times usingthe cleaner

solution. (The cleaner pen is stored in the

carton box as an accessory.)

3) Dry the surface of thermal head with a

clean dry cloth.

I

I

I

Warning: Make sure to replace the cap of

cleaner after using it.

I

. Replace the felt of the cleaner pen if it be-

comes ditty.

7. Install the feed roller

pen with cleaning

by reversing the

above procedure.

. Make sure to tighten

both sides

of the feed

the screw knobs on

roller.

40

Page 44

2. Platen Cover / Exposure Glass

To maintain a high copy quality, clean the following sections regularly.

Platen cover

I

7 rli

/

/

Exposure ~

Glass

1. Platen Cover / Exposure Glass

. Clean the platen cover and the exposure

glass with a soft cloth and a commercial

glass cleaner.

. Be careful not to touch the detect switch

(white).

41

Page 45

I

TROUBLESHOOTING

1. Indicators

[f a malfunction or a misfeed occurs within the machine, the following indicators will light.

Check the misfeed or malfunction location.

-

Open the top unit cover, remove original and reset. (See page 43.)

Remove the jammed paper and press the Reset key. (See page 44.)

Remove the jammed master and

Open the master eject unit and remove any jammed paper, then press

the Reset key. If the paper is stuck to the drum, pull out the drum unit

until the drum unit hits the drum stopper,

from the drum. (See page 46.)

1. If the paper is stuck to the drum, pull out the drum unit until the drum

unit hits the drum stopper, and remove the jammed paper from the

drum.

2. If the jam is in the paper feed section, the jammed paper may be

cleared at either the paper entrance or the paper exit side.

(See page 47.)

Open the master eject unit and remove the jammed master. Press Reset

key. If the jammed master is stuck to the drum, pull out the drum unit

and remove the misfed master. (See page 48.)

Open the master eject unit and remove the jammed paper. Press Reset

key. (See page 48.)

Check that the original is correctly placed and that the counter is set for

the required number of copies. (See page 49.)

Load paper. (See page 49.)

Load new master roll. (See page 49.)

Load new ink cartridge. (See page 50.)

1. Remove the used masters inside the master eject box.

2. Make sure the master eject box is replaced correctly. (See page 50.)

Check the setting of the original table, the front cover, the master eject

unit,the drum,the paperfeedtable, and the top unit. (Seepage 51.)

Colordrum is installed.(Seepage51.)

Setthe key counter.(Seepage51.)

pressthe Resetkey. (Seepage 45.)

and remove the jammed paper

I

If a service code

representative.

– E08) is displayed

(EO1

in the counter, please contact your service

42

Page 46

2. When the Misfeed (~) Indicator Lights

1. Open the top unit and

pull out the original.

Reset the original.

3.

k f-

1

Z. Close the top unit.

Press the Reset key.

prevent original misfeeds:

● Thin original

● Thick original

● Paste-up original

● Folded or damaged originals

● Originals larger than 11” x 17“

Press the Master

4.

Making key.

+

+

Make a copy

Make a

copy

+ Make a copy

+

+

Make a copy

Make a reduced copy

43

Page 47

When a sheet of paper is misfed:

1.

1

Remove the misfed

paper.

sure lever is in the

standard position, set

it in the thick paper

position.

3.

pads.

4.

If the separation roller

pressure lever is in

the standard position,

move it to the thick

paper position.

Press the Reset key.

5.

Press the Print Start

6.

key.

When two or

misfed:

-1

more sheets are

Remove the misfed

1.

sheets.

If the feed roller

2.If the feed roller prespressure lever is in

the thick paper position set it in the

standard position.

If the pad levers are

3.Release the side plate

positioned to the

left, move them to

the right.

If the separation

4.

roller pressure lever

is in the thick paper

position, move it to

the standard position.

Press the Reset key.

5.

Press the Print

6.

Start key.

To

prevent paper

●

Curled paper. +

. Post card and

thick paper.

feed jams:

Correct the curl.

Set the printing speed

+ slower than step 3.

(See page 25.)

, Paper edges ~ Shuffle the paper

stuck together

Page 48

1.

Slide the original table

to the left while pull-

ing up original table

release lever.

5.

Open the top unit

and slowly but firmly pull out the

original.

2.

Remove

the misfed ~

master.

3.

Slide the original table

to the original position.

If you could not

remove the misfed

master in step 2, take

out the drum and

remove the misfed

master from inside.

page27 and 28.)

(See

6.

Re-insert the

\

\

+

PI

I

*

original after closing the top unit.

I

I7.

Press

8.

Press the Master

he Reset key.

Making key.

45

Page 49

.

lb

————_

1.

Push the master eject

unit open button and

open the master eject

unit.

2.

Remove the misfed

paper.

I

3.

When paper is completely wrapped

around the drum, pull

out the drum unit until

the drum hits the

drum stopper, and

remove the misfed

paper from the drum.

4.

Close the front

cover and the

master eject unit.

Prints which have

5.

an image on the

leading edge tend

to wrap around the

drum easily. Shift

the image toward

to the trailing edge.

Press the Reset key.

6

Press the Print

7.

Start key. Use the

Proof key if necessary.

If the paper is curled or the Original has narrow leading edge margin,

the following action is necessary.

46

Page 50

c Misfeed in paper feed section

. Paper is wrapped around the drum.

Slowly but firmly pull

out the paper.

. When the misfed ~a~er is underneath the drum.

(Difficult to remov~ th’e paper from the paper feed section.)

_z //%?4 1. Pull out the drum until I

I the dru-rnUni hits - - I ~

the drum stopper and

remove the paper

from the paper exit

side.

● (Also difficult to

remove the paper from the paper exit section.)

1.

Take out the drum

unit. Remove the

misfed paper. (Refer

to page 27 to 28 for

the drum removal)

~1

P ,

.,.

v’

$,

,,

,1

m

When paper is com-

pletely wrapped

around the drum,

pull out the drum

unit until the drum

hits the drum stop-

per, and remove

the paper from the

drum.

2. When the image is

located on the lead-

ing edge, shift the

image to the trailing

edge by pressing

the right image position key.

2. Press the Reset key.

3. Press the Print

Start key. Use the

Proof key if necessary.

1

If the paper is curled or the original

the following action is necessary.

Curled Paper

. Curled Paper

Correct the curl.

[a

Load the paper with

the face curl down as

shown in the fiqure.

k

has narrow leading edge margin,

Narrow Leading Edge Margin Original

I

.-

47

Page 51

1.

Open the master eject

container cover and

remove the master

eject box.

2.

Remove the misfed

master from master

eject section.

3.

Reinstall the master

eject box and close

the master eject container cover.

. When the master eject box is full, remove the used masters from the box.

4. Press the Reset key.

5. Press the Print

Start key.

1.

Open the master eject

unit by pushing the

master eject unit open

button.

2.

Remove the misfed

paper.

3.

Close the master

eject unit.

. If misfeeds occur

thick paper position. (Refer to page 22 for details.)

while printing on thick paper, lift the wing guide release lever to the

48

4. Press the Reset key.

5. Press the Print

~ I Start kev.

t

II

Page 52

3. When the Supply/Exchange (fi) Indicator Lights

1.

Set the original.

2.

Input the number of

pfints using the Number keys,

Press the Master

3.

Making key.

1. Load paper on the

paper feed table. (See

page 36.)

1.

Slide the original

table to the left by pull-

ing up the original

table release lever.

Exchange the master

roll. (Refer to page 38

for details.)

Reset the original

table after replacing

the master roll.

2.

When the paper

end occurs during

a printing run,

press the Print Start

key again to

resume printing.

49

Page 53

1.

Open the front cover

and replace the ink

cartridge. (Refer to

page 37 for the

details.)

Press the Reset key.

2.

●

Ink is supplied to the

drum.

●

Press the Reset kev

again if the add ink indicator does not turn

off.

. When the master eject box is full, do the following:

3. When the add ink

indicator blinks

during repeat print-

ing, press the Print

Start key again to

resume printing.

1. Open the master eject

container cover.

. Incomplete master eject box

installation.

1.

Open the master eject

container cover.

Reinstall the master

2.

eject box.

●

Push the box so that

it is in contact with

the inside bracket.

Close the master

3.

eject container cover.

● No master

Take out the

2.

master eject box

and remove the

used masters.

Install the master

3.

eject box and close

the master eject

container cover.

Press the Reset key.

4.

eject box.

1.

Open the master

eject container

cover.

install the master

2.

eject box.

50

Page 54

4. Other Indicators Light

Make sure that the following

covers/units are closed.

1. Original Table

2. Front Cover

3. Master Eject Unit

4. Drum Unit

5. Paper Feed Table

(Make sure that the paper

feed table should be open

Insert the key counter.

When an error code (E-01

representative.

- E-08) is displayed, contact your service

51

Page 55

5. Poor Printina

Remove the drum

1.

unit. (Refer to page 27

to 28 for details.)

2.

Clean the pressure

roller with a clean

cloth.

Check following parts and clean them if necessary.

1) Platen cover (See page 41.)

2) Exposure glass (See page 41.)

3) Thermal head (See page 40.)

3. Clean the drum

with a clean cloth.

4. Install the drum

unit. (See page 27

to 28 for details.)

52

Page 56

Original

White print

incomplete print

Original

1. Pull out the drum unit.

2. Remove the master

from the drum.

1. Pull out the drum and

remove two masters.

Remove the paper

3.

that is adhered to

the drum.

4.

Set the original and

press the Master

Making key.

2.

Set the original and

press the Master

Making key.

53

Page 57

I

MISCELLANEOUS

1. Operating Cautions

1.

If there is no blank area or a solid image area on the leading edge of

the original, create a blank area because the paper may wrap around

the drum or the paper eject pawl may become dirty and cause black

line on prints.

2.

When the paper is curled, stack the paper with the curl face down,

otherwise the paper may wrap around the drum or stains may appear.

3.

Make sure to make a few trial prints to check the image position

cause the image position of the trial print

of the original.

4.

If the image registration is not consistent,

than step 3.

5.

The leading edge of the prints may become stained if the edge touches

the image of prints on the paper delivery table.

may not correspond with that

set the printing speed slower

I

be-

6.

In case of duplex or multicolor printing, leave the printed paper for a

while before the

paper. If this is not done, feed roller marks will appear on the print

image.

7.

If the machine is not used for a long period, the image

decrease because the ink on the drum may dry. Make extra prints until

the image density recovers.

8.

When the machine is used in

density may decrease. In this case, decrease the printing speed (1 or 2

steps).

9.

The ink of the print on the paper delivery table may stick to the back

side of the next print.

next printing in order to dry the ink on the printed

IOW temperature conditions, the image

54

density may

Page 58

10.

When making duplex prints, misdetection of paper wrapping may occur

because the paper delivery sensor detects the black area at the leading

edge of the back side. Keep more than 10mm/O.4° blank area at the

leading edge of the back side of the printing paper.

11.

Do not use the thermal head cleaner for anything but cleaning the thermal head.

Also, be Sure to read ttle cautions about the thermal head

cleaner, and be careful as this cleaner is an alcohol.

Take note of the following regarding the cleaner:

●

Do not take internally.

●

Do not breathe it.

●

Keep out of the reach of children.

●

If it comes in contact with skin, wash well with water.

●

Keep away from eyes. If it comes in contact with your eyes, wash well. If

irritation occurs, contact

Never place it whet’e it will be exposed to heat.

●

12.

When feeding 51/2’’x8l/2° paper in the sideways direction, the prints may

your doctor.

not stack correctly on the paper delivery table. In this case, push up the

wing guide release lever.

13.

Perform a test print using the Proof key as the first few prints may be

light.

14.

When the machine

is m and the power source is less than 90% of the

specified amount, printing quality will decrease. Therefore, make sure

the mains supply is at

15.

Such paper as postcards

ages may appear on the rear side of following prints.

originals will make offset image prints.

16.

AS various kinds and qualities of paper

wrapped around the drum and/or cause jams.

least 90% of the required amount.

do not absorb ink well. Therefore, offset im-

exist, Some paper may be

Solid

image

55

Page 59

SPECIFICATION

1

Configuration:

Master Processing:

Printing Process:

Original Type:

Image Mode:

Color Printing:

Master Feed/Eject:

Original Size:

Paper Size:

Paper Weight:

Printing Area:

Desk top

Digital

Full automatic one drum stencil system

Sheet

Line/Photo

Drum unit replacement system (red, blue,

green, and brown) (option)

Roll master automatic feed/eject

Maximum 307 mm x 432 mm (12.0” x 17.0”)

Maximum 297 mm x 442 mm (11.6” x 17.4”)

Minimum

so to 215 g/m2 (13.3 to 57 lb)

Maximum 210 mm x 350 mm (8.3” x 13.7”)

(at 20°C/65%RH)

90 mm x 148 mm (3.6” x 5.8”)

Reproduction Ratio:

Printing Speed:

Paper Feed Table

Capacity:

Paper Delivery Table

Capacity:

Power

Power Consumption:

Dimensions

(W XDXH):

Source:

10oyo + 935%0-) 75% + 64%

5 steps: 60, 75, 90, 105, 120 sheets/minute

1,000 sheets (66.3 g/m2/l 7.6 lb)

500 sheets (66.3 g/m2/l 7.6 lb)

120V, 50/60 Hz, 5.5A

120V version:

Printing:

Storing:

1279 x 607 x 656 mm

(50.4 x 23.9x 25.9 inches)

735 x 607 x 569 mm

(28.9 x 23.9x 22.4 inches)

56

430W

Page 60

120V version: 100 kg (220.4 lb)

Optional Equipment:

Consumables:

Name

Priport Master

Vr-s

Priport Ink-Black

Priport Ink-Red 500 cc/ pack

Priport Ink-Blue

Priport Ink-Green 500 cc/pack

Color drum unit type VT2000-LG

(red, blue,

Key counter

Tape marker type 20

Size

125m(41 O ft)/roll

2 Rolls/case per one roll.

green, and brown)

Remarks

250 masters can be made

Storage:

0-40°c, 10- 95$ZORH

500 cc/pack

5 packsl case

Environmental conditions:

5 packslcase

500 cclpack Storage:

5 packs/case

5 packslcase

10- 25°C, 20- 90YoRH

5- 40°c, 10- 95YORH

‘1

Priport Ink-Brown 500 cc/pack

5 packs/case

Thermal head

Cleaner

For good print quality, Ricoh recommends that you use genuine Ricoh ink and master,

Specifications are subject to change without notice.

Ricoh shall not be responsible for any damage or expense that may result from

the use of parts other than genuine Ricoh parts in your Ricoh office product.

Cleaner pen -1 pc Clean the thermal head

Replacement Felt

-1 Opts master

Cleaner Bottle -1 PC

using the cleaner when 2

rolls have been

used.

Loading...

Loading...