Page 1

RICOH PRIPORT VT 2000 SERIES

(VT2100/2130/2150/2300/2500)

SERVICE MANUAL

Page 2

SECTION 1

OVERALL MACHINE

INFORMATION

Page 3

28 February ’91

1. SPECIFICATIONS

VT2300/VT2500

Configuration: Desktop

Master processing: Digital

Printing process: Full automatic one drum stencil system

Original type: Sheet

Original size: Maximum 307 mm x 432 mm (12.0" x 17.0")

Minimum 90 mm x 140 mm (3.6" x 5.5")

Reproduction ratios: 3 Enlargement and 3 Reduction

LT Version A4 Version

Enlargement 141% 141%

127% 122%

115% 115%

Full Size 100% 100%

Reduction 93% 93%

75% 82%

64% 71%

Image mode: Line/Photo

Color Printing: Drum Unit replacement system

Master feed/eject: Roll master automatic feed/eject

Printing area: Maximum: 250 mm x 350 mm (9.8" x 13.7") at

20°C/ 65 % RH.

Leading edge margin:

± 3 mm at "0" position

10

Print paper size: Minimum: 90 mm x 148 mm (3.6" x 5.8")

Maximum: 325 mm x 447 mm (12.8" x 17.6")

Print paper weight: 50 g/m

2

to 215 g/m

2

Printing speed: 60, 75, 90, 105, 120 sheets/minute (5 steps)

1-1

Page 4

28 February ’91

First print time: 34.5 seconds (B4 size)

31.5 seconds (A4 Size)

2

Paper feed table

1000 sheets (66.3 g/m

/17.6 lb)

capacity:

2

Paper delivery table

500 sheets (66.3 g/m

/ 17.6 lb)

capacity:

Power source: 110V, 60 Hz.....................6.0A

120 V, 60 Hz....................5.5 A

220/240 V, 50/60 Hz........2.7 A

Power consumption: 110/120 V version: 430 W

220/240 V version: 470 W

Weight: 120 V version: 102 kg (224.8 lb)

220/240 V version: 107 kg (235.8 lb)

Optional Table: 26 kg (57.3 lb)

Dimensions:

(W x D x H)

Stored: 735 mm x 607 mm x 577 mm

(29.0" x 23.9" x 22.8")

Set up: 1279 mm x 607 mm x 656 mm

(50.4" x 23.9" x 25.9")

Table: 640 mm x 570 mm x 455 mm

(25.2" x 22.4" x 17.9")

2

ADF original capacity: 20 sheets (66 g/m

Original guide width

98 mm to 316 mm (38.6" to 12.44")

) or 1.8 mm height

settings:

Original scanning time: 3 ms/1 line

Original thickness: 0.05 mm to 0.8 mm

Original feed speed: 20.8 mm/second (When master processing)

41.7 mm/second (When not master processing)

Pixel density: 16 dots/mm

Master eject box

capacity:

25 masters (Normal condition)

20 masters (10°C/30% RH Condition)

Paper feeding: Friction roller/center separation system

1-2

Page 5

28 February ’91

Feed table side plate

88 mm to 330 mm (3.46" to 12.99")

width settings:

Paper feed roller

pressure:

Separation roller

pressure:

Side registration:

Vertical registration:

Normal position................250 g

Thick paper position.........550 g

Normal position................180 g

Weak position ..................70 g

± 10 mm (manual)

± 20 mm (mechanical)

Ink Supply: Automatic ink supply system

Press roller pressure:

± 0.3 kg

10

Paper Delivery: Air knife/vacuum delivery

Delivery side plate width

80 mm to 320 mm (3.15" to 12.6")

settings:

Print counter: 7 digits

Master counter: 6 digits

Supplies:

Priport Thermal master 280 mm width

Master VT-M:

(16 dots/mm)

Master roll 250 masters/1 roll

Roll diameter 130 mm

Master length 480 mm/1 master

Max run length 2000 prints

Ink Colors: Black, Red, Blue, Green, Brown

(500 cc/pack)

1-3

Page 6

28 February ’91

VT2100 Series (VT2100, VT2130, VT2150)

Configuration: Desk top

Master processing: Digital

Printing process: Full automatic one drum stencil system

Original type: Sheet

Original size: Maximum 307 mm x 432 mm (12.0" x 17.0")

Reproduction ratios: LT version: 100 %, 93 %, 75 %, 64 %

A4 version: 100 %, 93 %, 82 %, 71 %

Image mode: Line/Photo

Color printing: Drum unit replacement system

Master feed/eject: Roll master automatic feed/eject

Master processing area: VT2100: Maximum 256 mm x 354 mm

(10.1" x 13.9")

VT2130: Maximum 216 mm x 354 mm

(8.5" x 13.9")

VT2150: Maximum 216 mm x 287 mm

(8.5" x 11.3")

Printing area: VT2100: Maximum 250 mm x 350 mm

(9.8" x 13.7") at 20°C/65 % RH

VT2130: Maximum 210 mm x 350 mm

(8.3" x 13.7") at 20°C/65% RH

VT2150: Maximum 210 mm x 283 mm

(8.3" x 11.1") at 20°C/65% RH

Leading edge margin: 10 mm

Print paper size: Minimum 90 mm x 148 mm (3.6" x 5.8")

Maximum 297 mm x 442 mm (11.6" X 17.4")

Print paper weight: 50 g/m

2

to 215 g/m

2

Print speed: 60, 75, 90, 105, 120 sheets/minute (5 steps)

First print time: VT2100: 35 seconds (B4 size)

VT2130: 35 seconds (LG size)

VT2150: 31 Seconds (A4 size)

1-4

Page 7

Paper feed table capacity 1000 sheets (66.3 g/m2 / 17.6 lb)

2

Paper delivery table

500 sheets (66.3 g/m

/ 17.6 lb)

capacity:

Power source: 220/240V, 50/60 Hz.........2.7A

120V, 60 Hz.....................5.5 A

110V, 60 Hz.....................6.0 A

Power consumption: 110/120 V version: 430 W

220/240 V version: 470 W

Weight: 110/120 V version: 100 kg (220.4 lb)

220/240 V version 105 kg (233.7 lb)

Optional table: 26 kg (57.3 lb)

28 February ’91

Dimensions:

(W x D x H)

When stored: 735 mm x 607 mm x 569 mm

(29.0" x 23.9" x 22.4")

When set up: 1279 mm x 607 mm x 656 mm

(50.4" x 23.9" x 25.9")

Table only: 640 mm x 570 mm x 455 mm

(25.2" x 22.4 x 17.9")

Original guide

98 mm to 316 mm (38.6" to 12.44")

width-settings:

Original scanning time: 3 ms/1 line

Original thickness: 0.06 mm to 0.5 mm

Original feed speed: 20.8 mm/second

Pixel density: 16 dots/mm

Master eject box

capacity:

25 masters (at normal conditions)

20 masters (at 10°C/30 % RH)

Paper feeding: Friction roller/center separation system

Feed table side plate

width settings:

Paper feed roller

pressure:

Separation roller

pressure:

88 mm to 317 mm (3.46" to 12.48")

Normal position ...............250 g

Thick paper position.........550 g

Normal position................180 g

Weak position ..................70 g

1-5

Page 8

28 February ’91

Side registration:

Vertical registration:

Paper table raising /

lowering speed:

±10 mm (manual)

±20 mm (mechanical)

22 mm/second (50 Hz)

26 mm/second (60 Hz)

Ink supply: Automatic ink supply system

Pressure roller pressure:

± 0.3 kg

10

Paper delivery: Air knife/vacuum delivery

Delivery side plate

80 mm to 320 mm (3.15" to 12.6")

width settings:

Print counter: 7 digits

Master counter: 6 digits

Supplies:

Priport Master VT-M for VT2100:

(16 dots/mm) Thermal master 280 mm width

Master roll 250 masters/1 roll

Master length 480 mm/1 master

Max run length 2000 prints

Priport Master VT-S for VT2130/VT2150:

Thermal master 240 mm width

Max run length 2000 prints

VT2130: Master roll 250 masters/1 roll

Master length 480 mm/1 master

VT2150: Master roll 300 masters/1 roll

Master length 413 mm/1 master

Ink: 500 cc ink pack

Colors: Black, Red, Blue, Green, Brown

1-6

Page 9

---- MEMO ----

28 February ’91

1-7

Page 10

28 February ’91

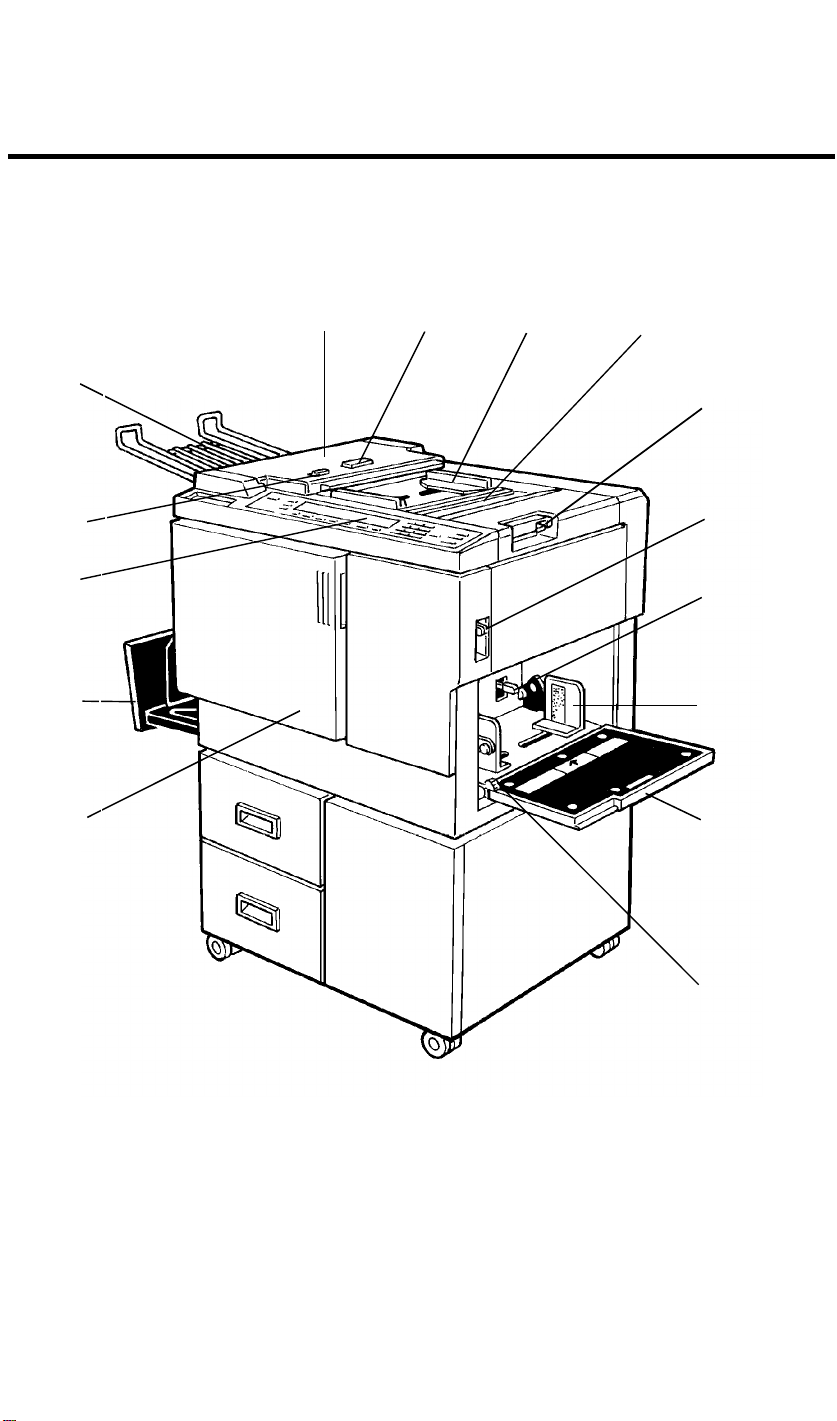

2. GUIDE TO COMPONENTS AND THEIR

FUNCTIONS

(Paper Feed Side)

15

14

13

12

11

1 2 3

4

5

6

7

8

9

1-8

10

Page 11

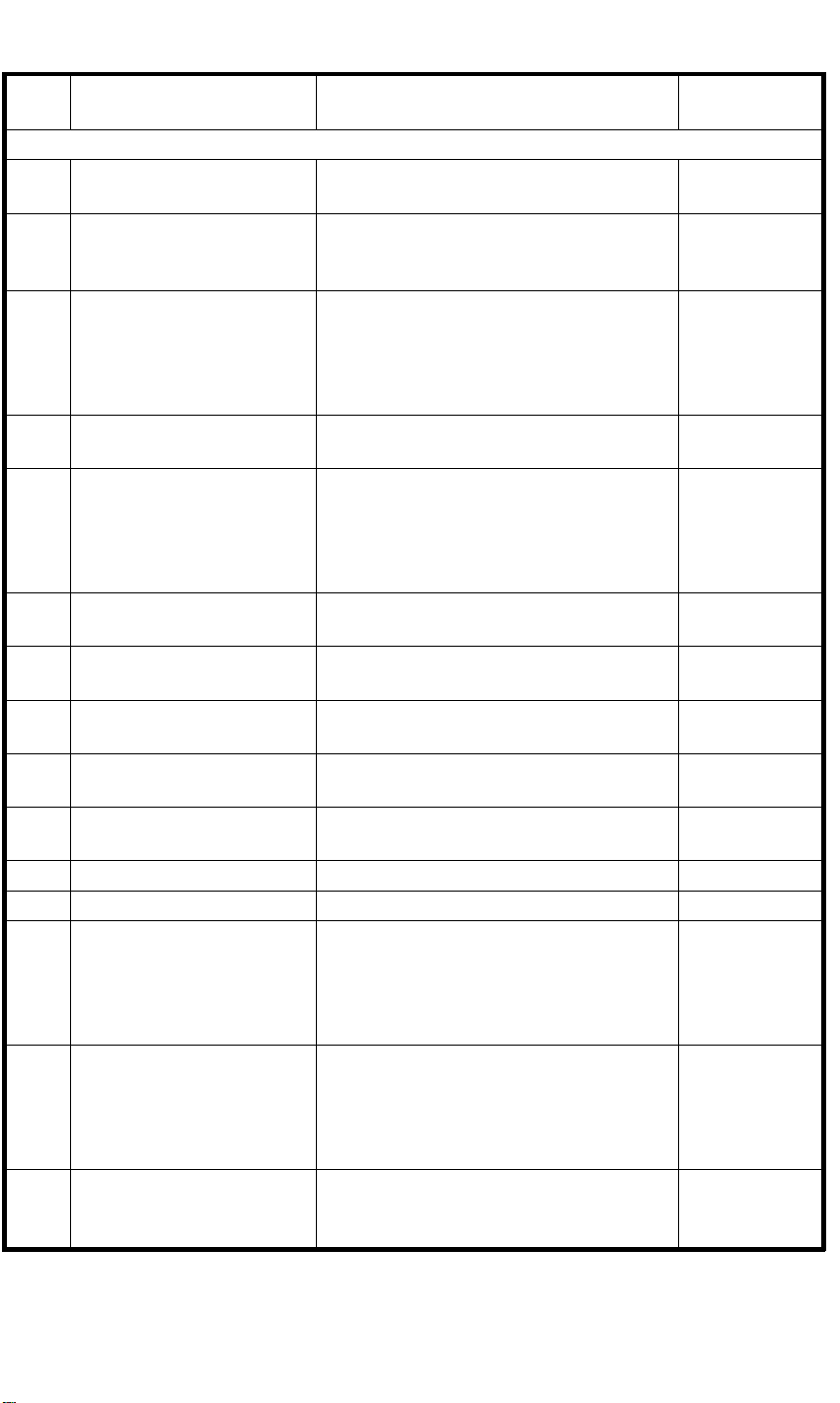

No. Name Function

28 February ’91

1. ADF Unit

(VT2300/2500)

2. ADF Unit Open

Feeds the original to the printing position

automatically.

Use to open the ADF unit.

Button

(VT2300/2500)

3. Original Guides Adjust these guides to position the originals

correctly.

4. Original Table Place the originals on this table.

5. Original Table

Release Lever

6. Feed Roller

Pressure Lever

7. Separation Roller

Pressure Lever

8. Paper Feed Side

Use to open the original table unit to the left for

master installation.

Use to adjust the contact pressure of the paper

feed roller according to paper thickness.

Use to adjust the separation roller pressure to

prevent double feed.

Use to prevent paper skew.

Plate

9. Paper Feed Table Set the paper on this table.

10. Side Plate Fine

Use to shift the paper feed table sideways.

Adjusting Dial

11. Front Door Open for access to the inside of the machine.

12. Paper Delivery Table Completed prints are delivered here.

13. Operation Panel Operator controls and indicators are located here.

14. ADF On/Off Select

Switch

When setting originals one sheet at a time, set this

switch to the Off position.

(VT2300/2500)

15. Original Tray Originals used to make a master are delivered to

this tray.

1-9

Page 12

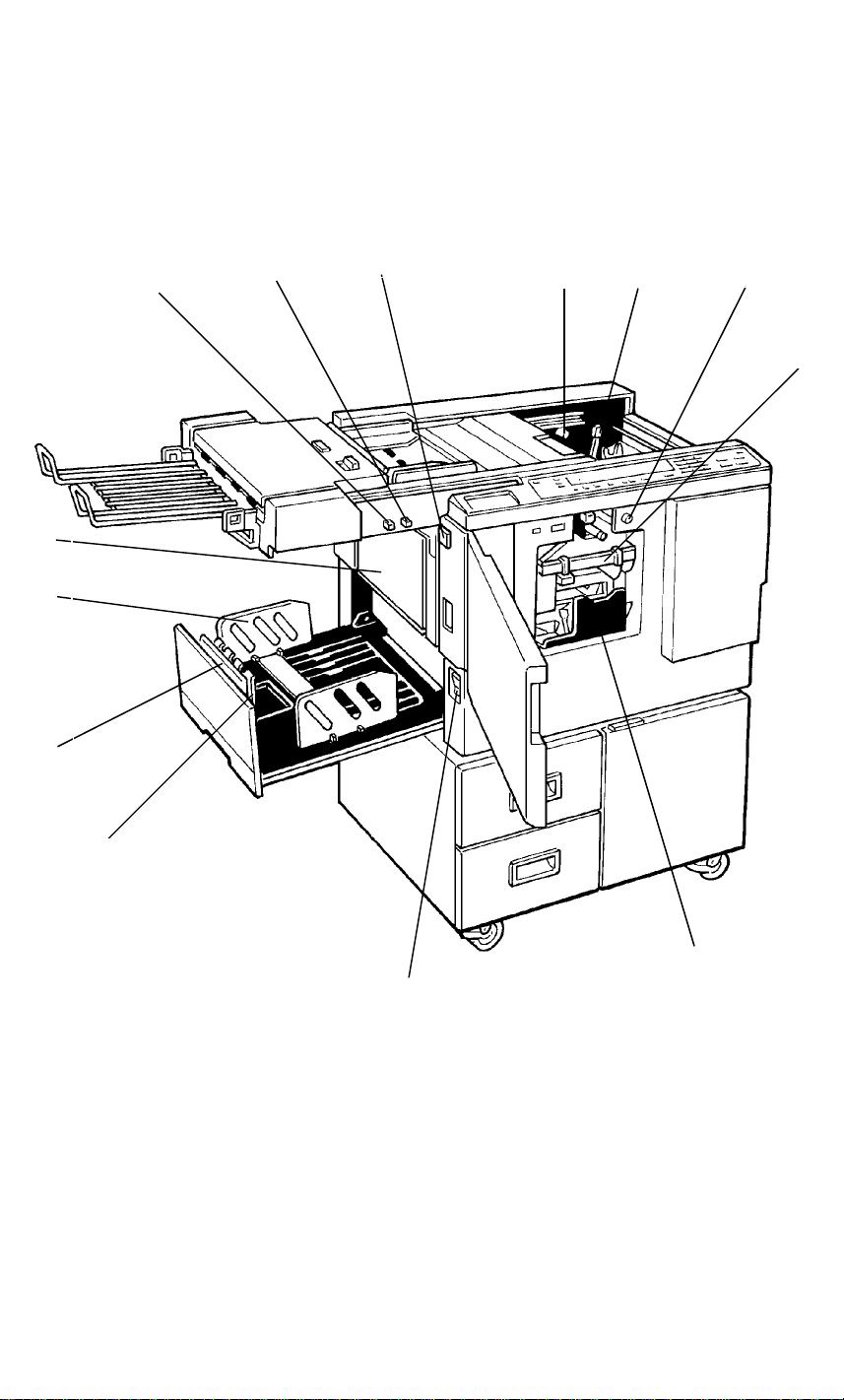

28 February ’91

(Paper Delivery Side)

25

24

23

26

27

28

16 17 18

19

22

20

21

1-10

Page 13

28 February ’91

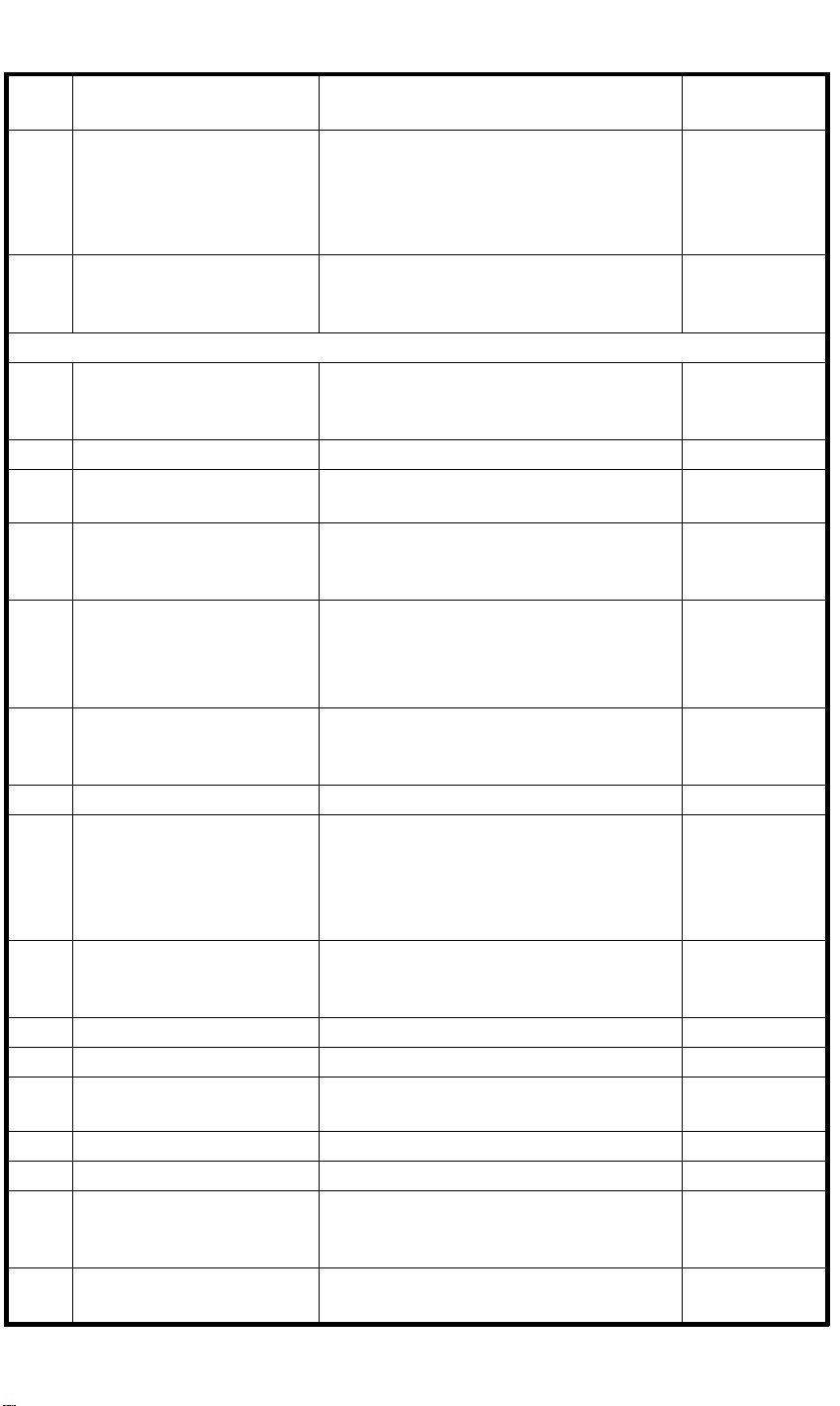

No. Name Function

16. Master Cut Button Press this button to cut the master paper leading

edge after installing a new master roll.

17. Pressure Release

Lever

18. Drum Rotating

Button

Use to install the master roll, or to clean the

thermal head.

Press to replace the drum or to remove misfed

paper.

19. Drum Unit The master paper is wrapped around this unit.

20. Ink Holder Set the ink cartridge in this holder.

21. Main Switch Use to turn the power on or off.

22. Small Size Paper

Delivery End Plate

Use to align the leading edge of small-sized (less

than A4/LT) prints.

(for smaller than

A4/LT)

23. Paper Delivery End

Plate (for larger

Use to align the leading edge of prints larger than

A4/LT.

than A4/LT)

24. Paper Delivery

Use to align the prints on the paper delivery table.

Side Plate

25. Master Eject

Open when removing the master eject container.

Container Cover

26. Memory/Class switch

Use to select memory or class mode.

(VT2300/2500)

27. Skip Paper Feed

Switch (VT2300/2500)

Printing Density

Select Switch

Use to adjust paper feed interval or a misted

master.

Use to select the printing density according to the

type and quality of the original.

(VT2100/2130/2150)

28. Master Eject Unit

Press to remove misfed paper or a misfed master.

Open Button

1-11

Page 14

28 February ’91

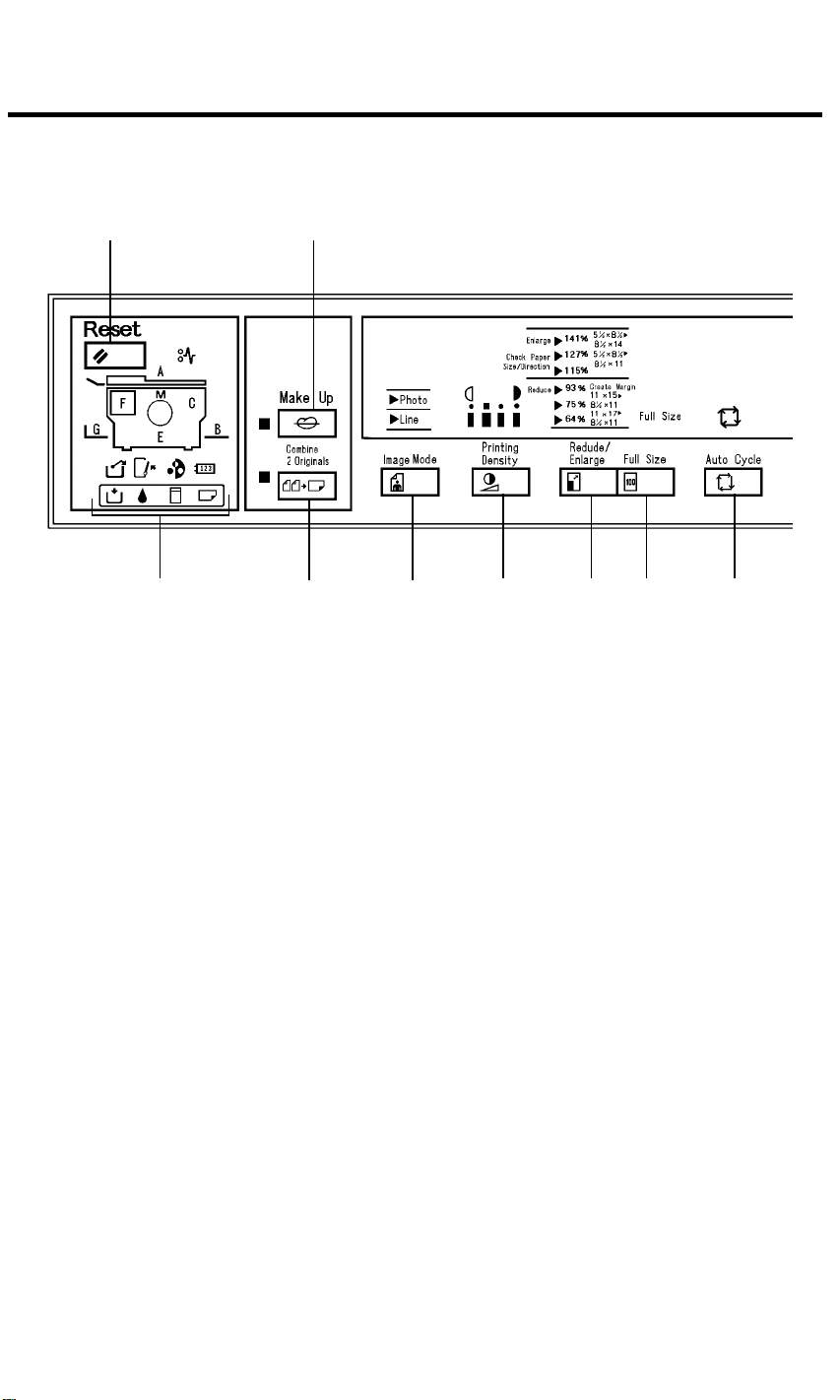

3. OPERATION PANEL

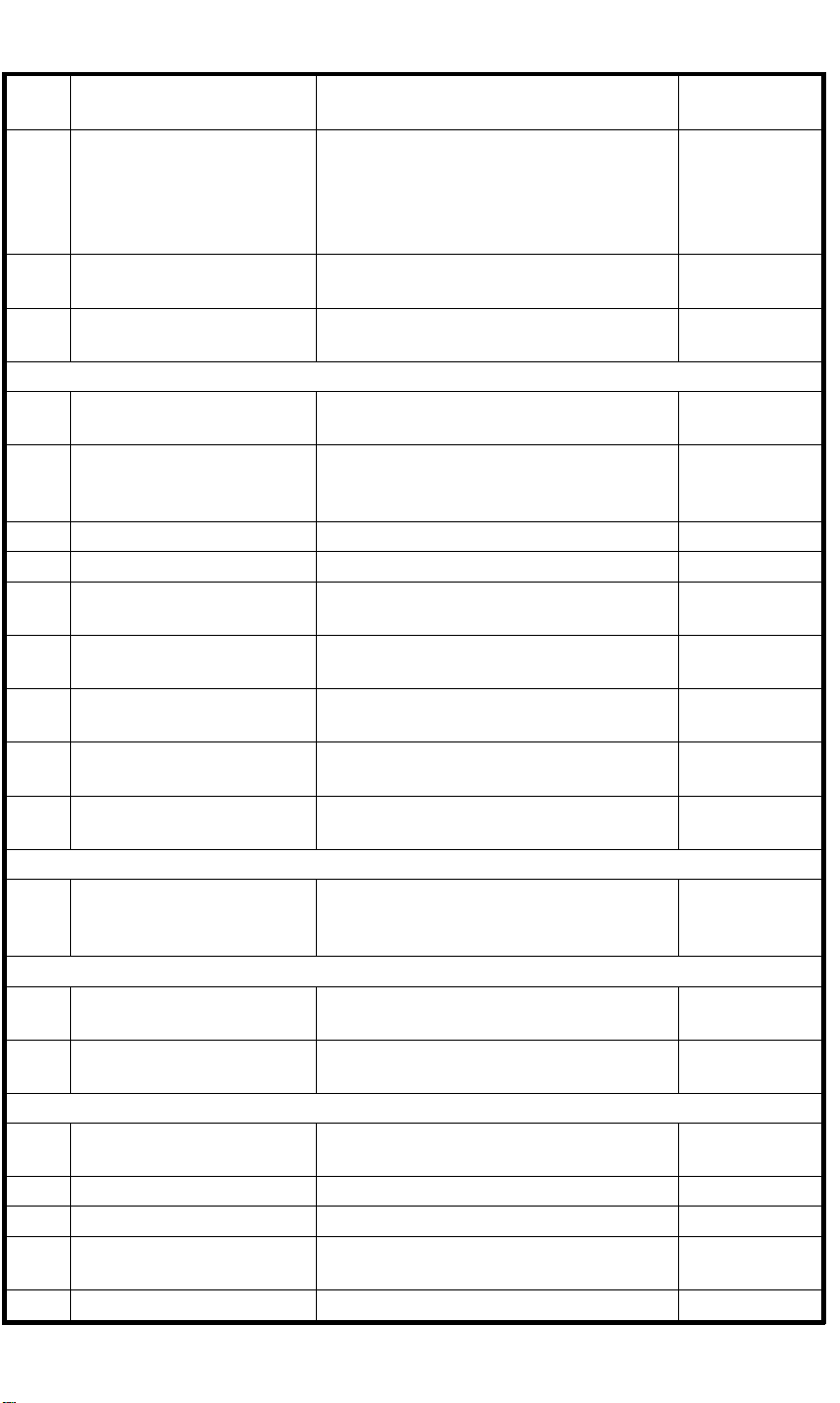

VT2300/VT2500

1

20

1. Reset Key Press to reset error indicators.

2. Make-up Key Press to use the make-up function (VT2500 only).

3. Number Keys Press to enter the number of prints.

4. Stop Key Press to stop the machine operation. The machine

5. Clear Modes Key Press to cancel all previously entered settings and

6. Master Making

Key

7. Print Start Key Press to start printing.

8. Proof Key Press to make trial prints or extra prints.

9. Clear Key Press to change the number set in the counter.

10. Memory/Class Key Use to select group printing in Memory mode or

11. Lower Paper Feed

Table Key

12. Image Position

Keys

2

16

19 18

will continue operation when the Print Start key or

Master Making key is pressed.

modes.

Press to make a master.

Also use to change the make-up mode (VT2500

only). This key can be used only after the machine

stops operation.

Class mode.

Press to lower the paper feed table.

Press to shift the image forwards or backwards on

the print paper.

15

1417

1-12

Page 15

28 February ’91

3

111213

910

4

5

8 7 6

13. Speed Keys Press to adjust the rotation speed of the machine

according to the type of image and printing paper.

14. Auto Cycle Key Use to automatically process masters and make

prints.

15. Full Size Key Press to make prints the same size as the original.

16. Reduce/Enlarge

Press to reduce or enlarge the image.

Key

17. Printing Density

Press to make prints darker or lighter.

Key

18. Image Mode Key Press to select line mode or photo mode according

to the type and quality of the original.

19. Combine 2

Originals Key

Press to combine two originals onto one print

image.

20. Monitors Light or blink when a non-standard condition

occurs within the machine.

1-13

Page 16

28 February ’91

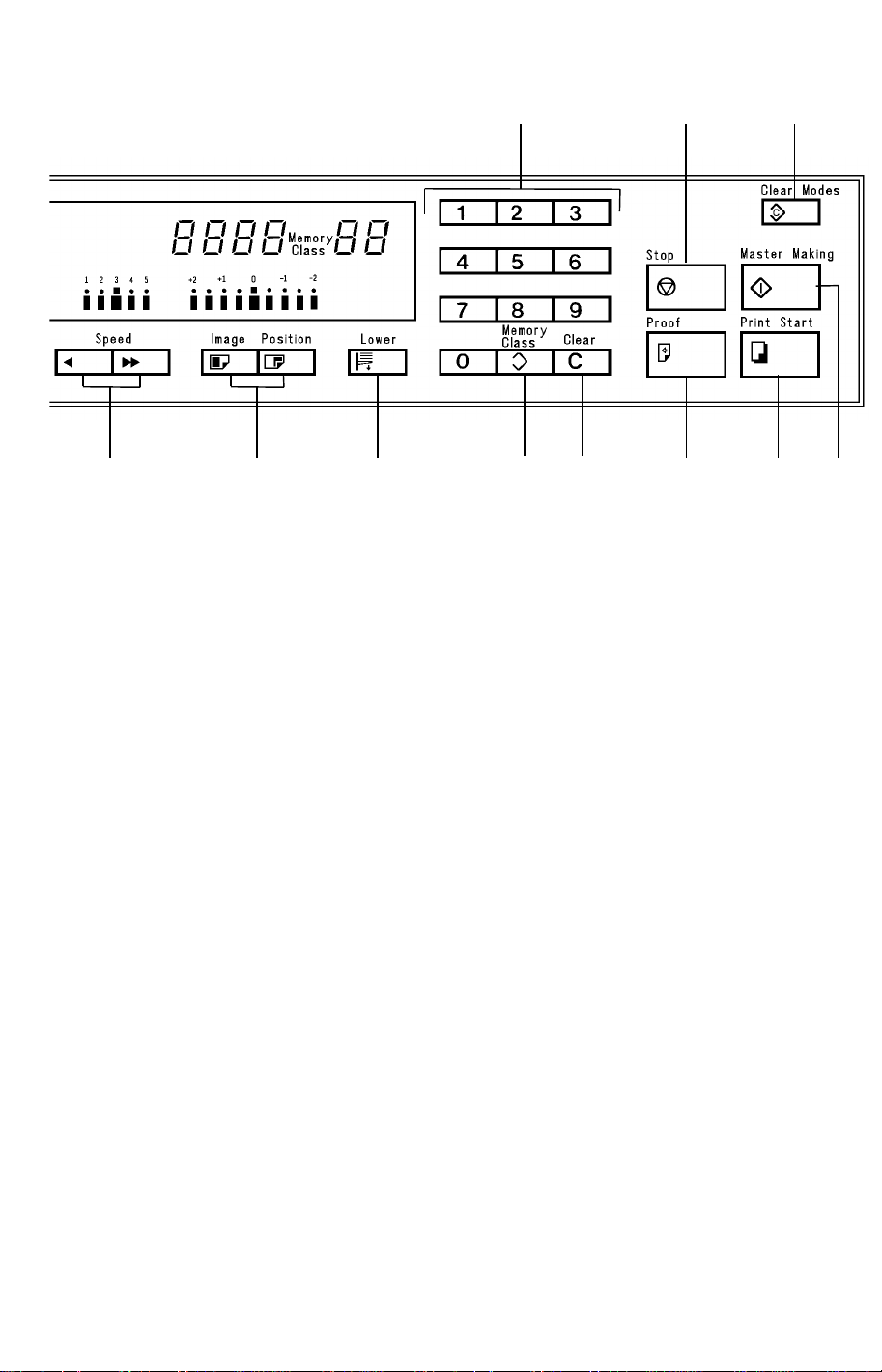

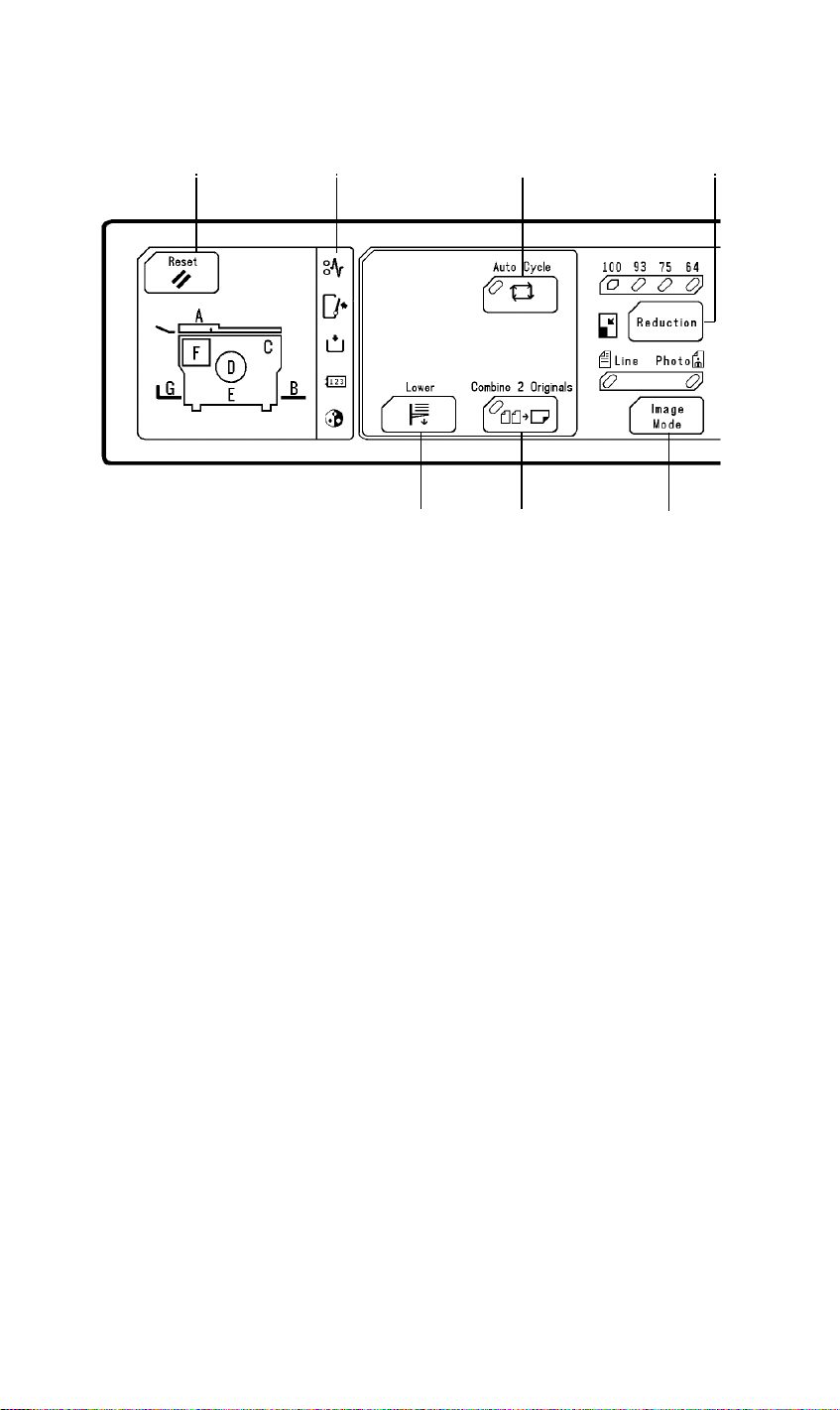

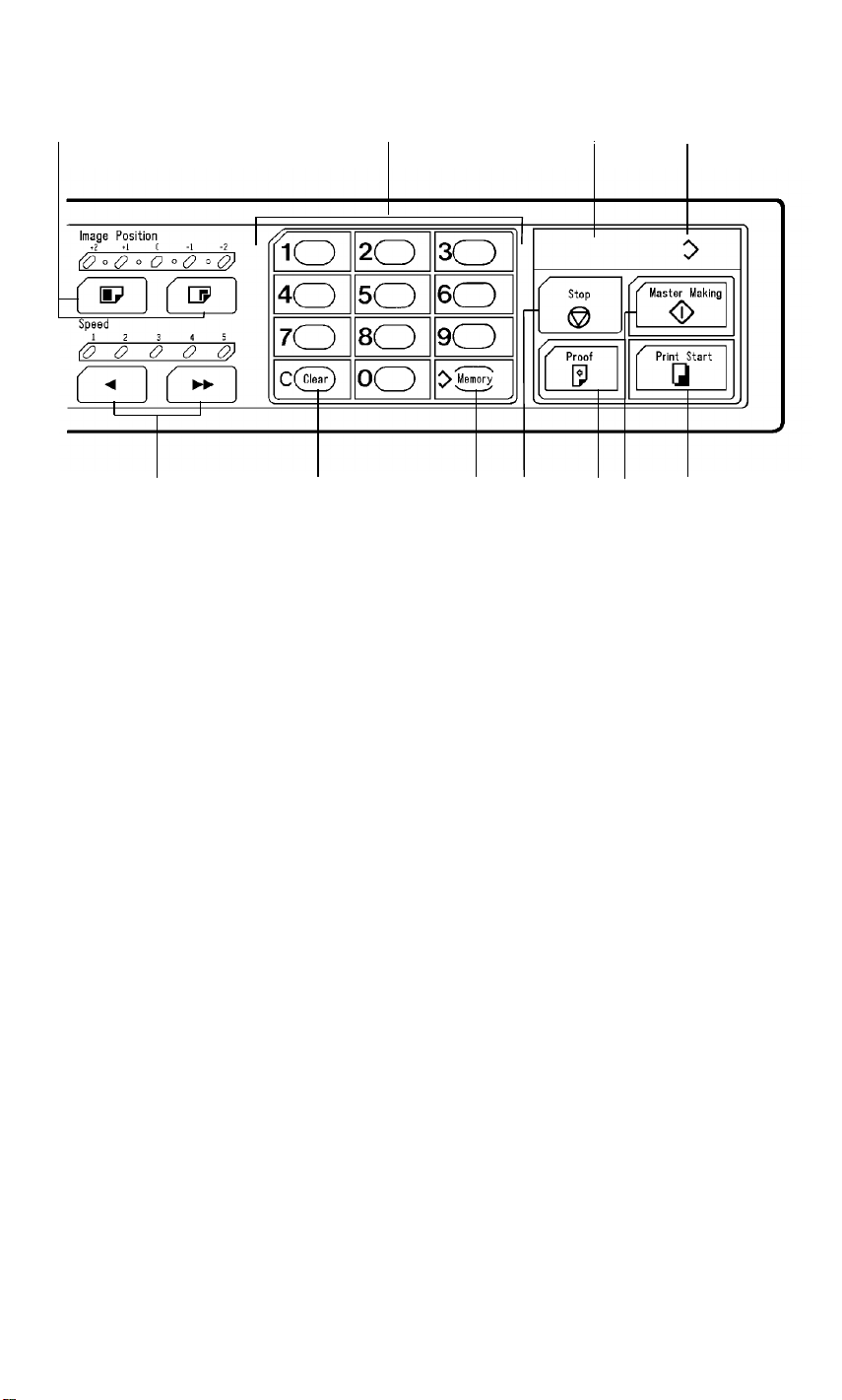

VT2100/VT2130/VT2150

1 2 3 4

18 17

16

1. Reset Key Press to reset error indicators.

2. Indicators Light or blink when a non-standard condition

occurs within the machine.

3. Auto Cycle Key Use to automatically process masters and make

prints.

4. Reduction Key Press to reduce the image.

5. Image Position

Keys

Press to shift the image forwards or backwards on

the print paper.

6. Number Keys Press to enter the number of prints.

7. Counter Displays the number of prints entered. While

printing, it shows the number of uncompleted

prints.

8. Memory Display Displays the number of the memory location that

will be used to store the number of copies. The

print number for up to 10 jobs can be stored at

once.

9. Print Start Key Press to start printing.

10. Master Making

Press to make a master.

Key

11. Proof Key Press to make trial prints or extra prints.

12. Stop Key Press to stop the machine operation. The machine

will continue operation when the Print Start key or

Master Making key is pressed.

1-14

Page 17

28 February ’91

5 6

15

14 13 12

7 8

1110

9

13. Memory Key Use to select memory location number.

14. Clear Key Press to change the number set in the counter.

This key can be used only after the machine stops

operation.

15. Speed Keys Press to adjust the rotation speed of the machine

according to the type of image and printing paper.

16. Image Mode Key Press to select line mode or photo mode according

to the type and quality of the original.

17. Combine 2

Originals Key

18. Lower Paper Feed

Press to combine two originals onto one print

image.

Press to lower the paper feed table.

Table Key

1-15

Page 18

28 February ’91

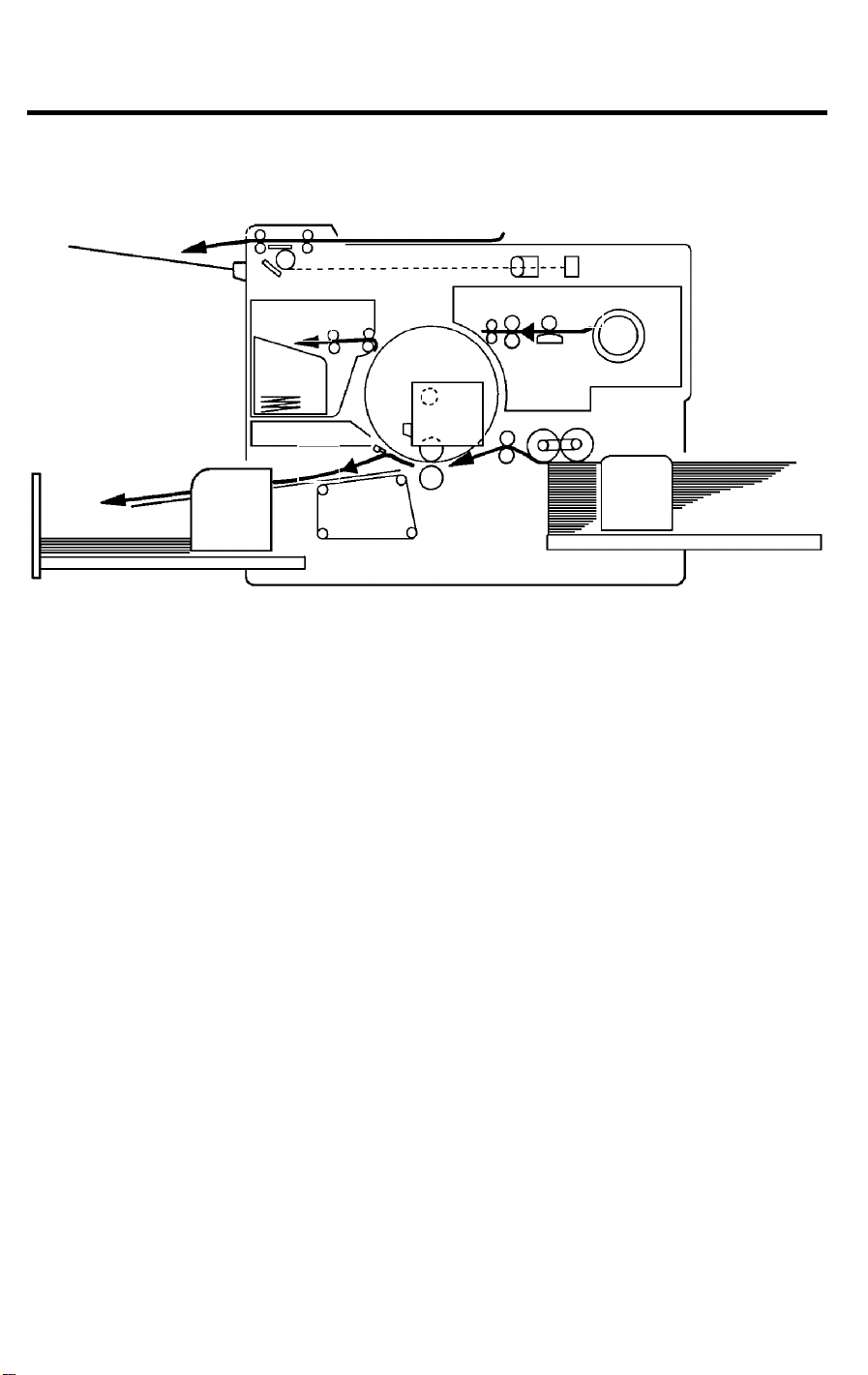

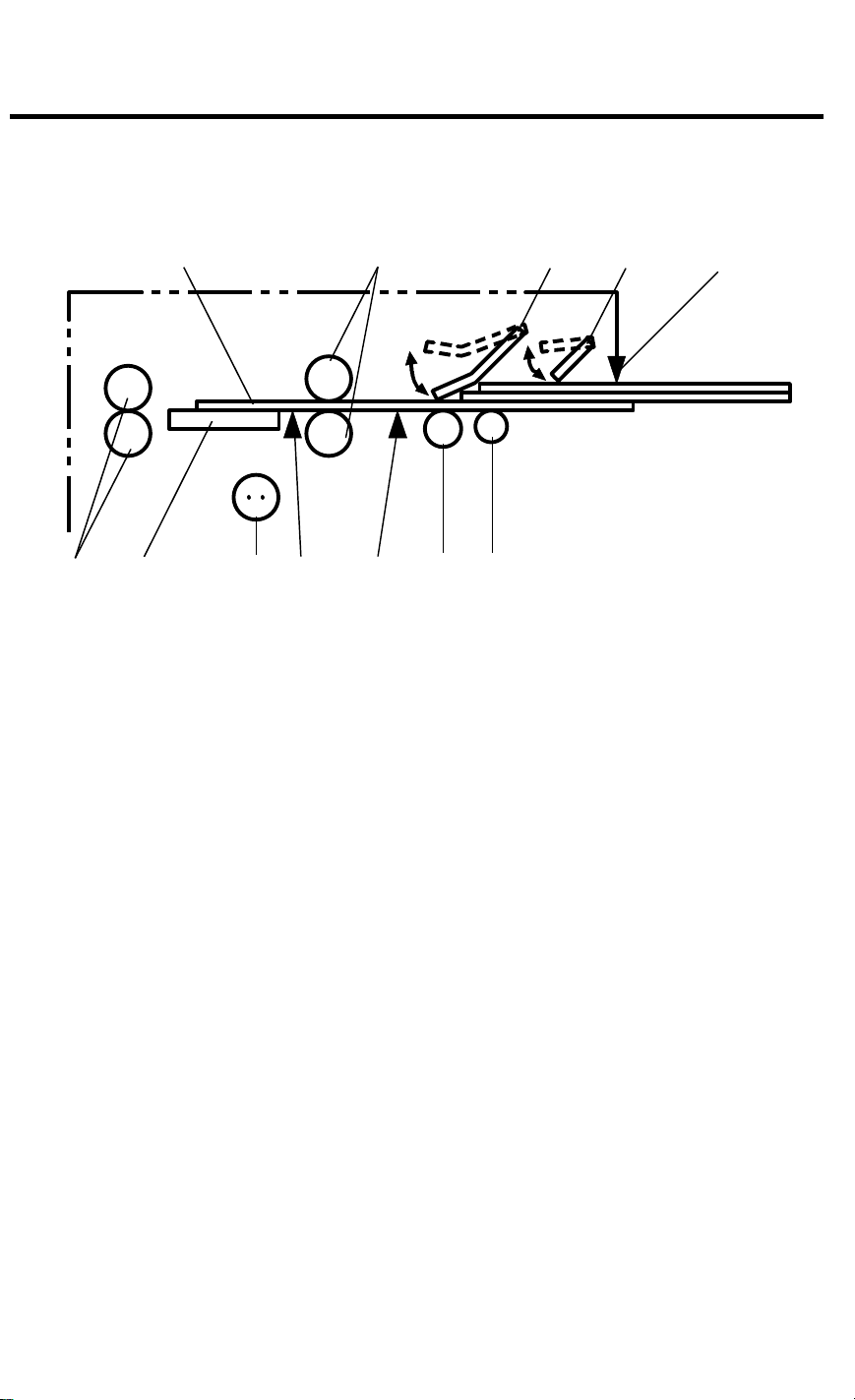

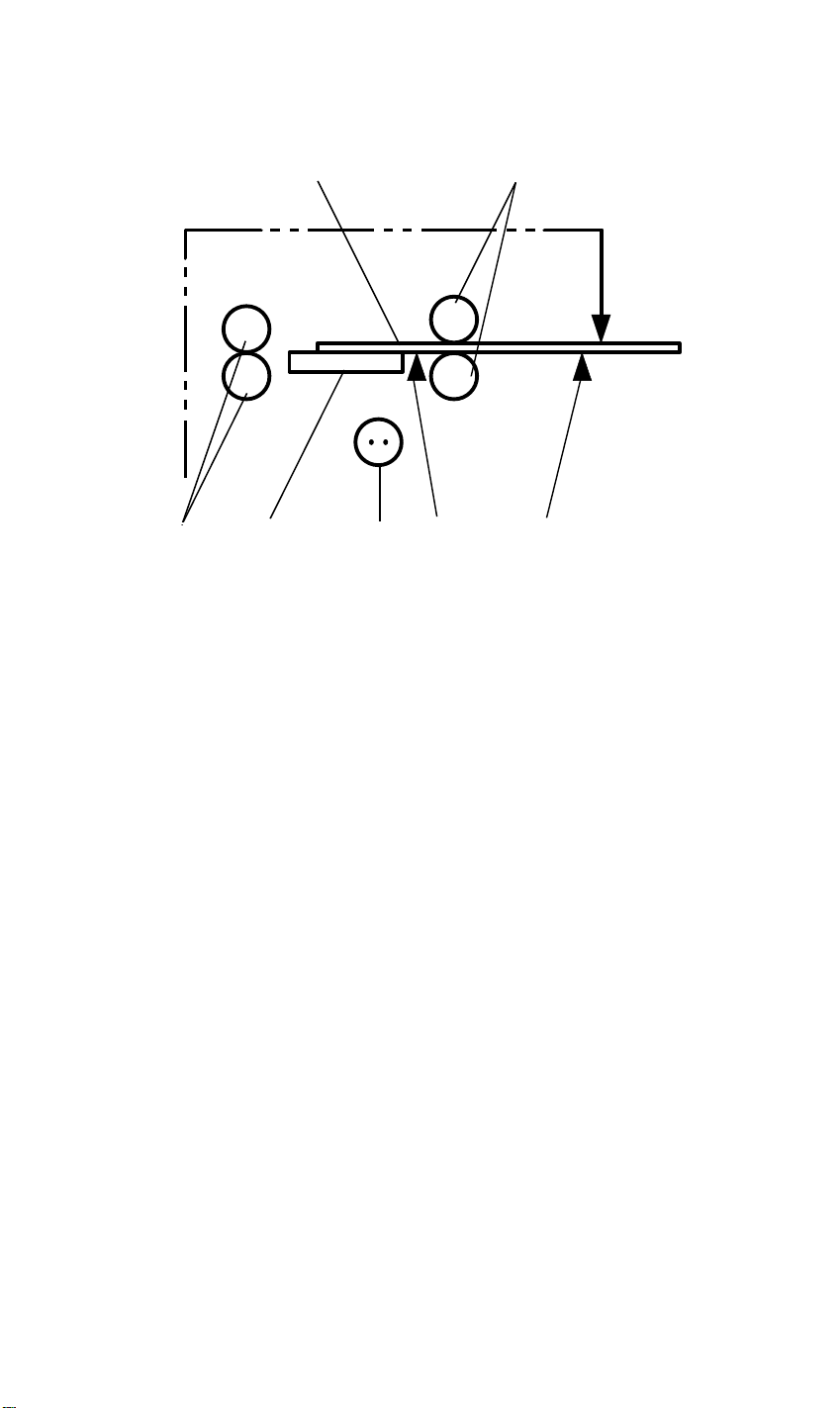

4. PRINTING PROCESS

2

1

6

4

5

1. Master Ejecting: Eject the used master wrapped around the drum

into the master eject box.

2. Scanning: Scan the original image by CCD through the mirror

and the lens while feeding the original.

3. Master Feeding: Convert the image signal read by CCD into the

digital signal and send it to the thermal head to

make holes on the surface of the master and then,

set the master around the drum.

4. Paper Feeding: Send paper to the drum section by using center

separation system consisting of the separation

plate and separation roller.

5. Printing: Press the paper fed from the paper feed section to

the drum to transfer the ink through drum screen

and the master.

6. Paper Delivering: Peel the printed paper with the Exit Pawl and Air

knife and eject the paper onto the paper delivery

table.

3

1-16

Page 19

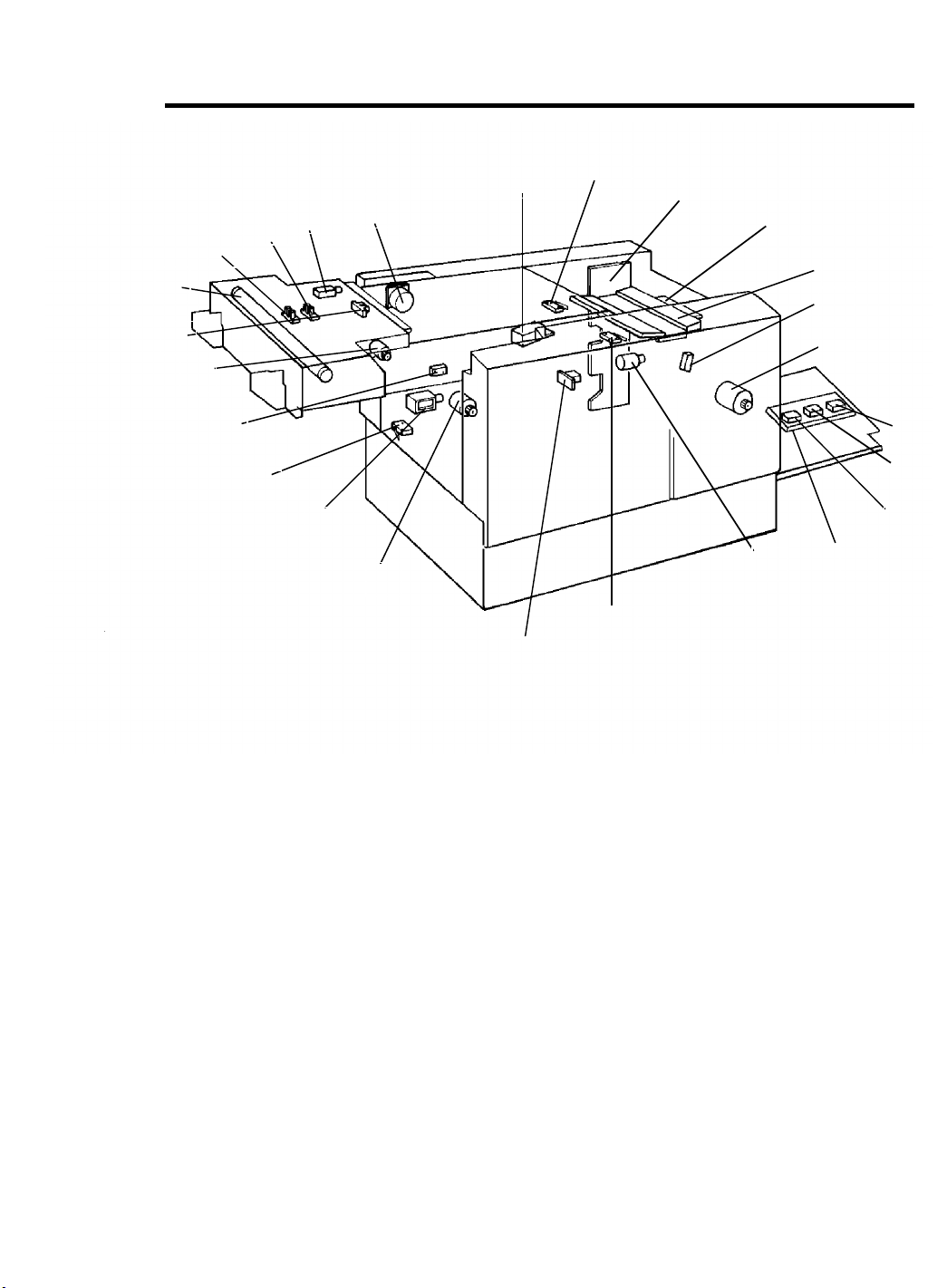

5. ELECTRICAL COMPONENT LAYOUT

28 February ’91

25

24

23

1

22

21

5

3

2

20

4

19

18

6

17

7

8

9

10

11

12

13

14

16

15

1. Original Registration Sensor

2. 2nd Original Sensor

3. Original Pressure Solenoid

(VT2300/VT2500)

4. Original Transport Motor

5. Fluorescent Lamp Stabilizer

6. Right Cutter Switch

7. Power Supply PCB

8. Thermal Head Drive Control PCB

9.Thermal Head

10. Master End Sensor

11. Master Feed Motor

12. Paper Size Detection Sensor 3

(VT2300/VT2500)

13. Paper Size Detection Sensor 2

(VT2300/VT2500)

14. Paper Size Detection Sensor 1

(VT2300/VT2500)

15. Paper Size Detection Board

(VT2300/VT2500)

16. Cutter Motor

17. Left Cutter Switch

18. Master Buckle Sensor

19. Master Eject Motor

20. Master Eject Solenoid

21. Master Box Switch

22. Master Eject Sensor

23. ADF Drive Motor (VT2300/VT2500)

24. 1st Original Sensor

(VT2300/VT2500)

25. Fluorescent Lamp

1-17

Page 20

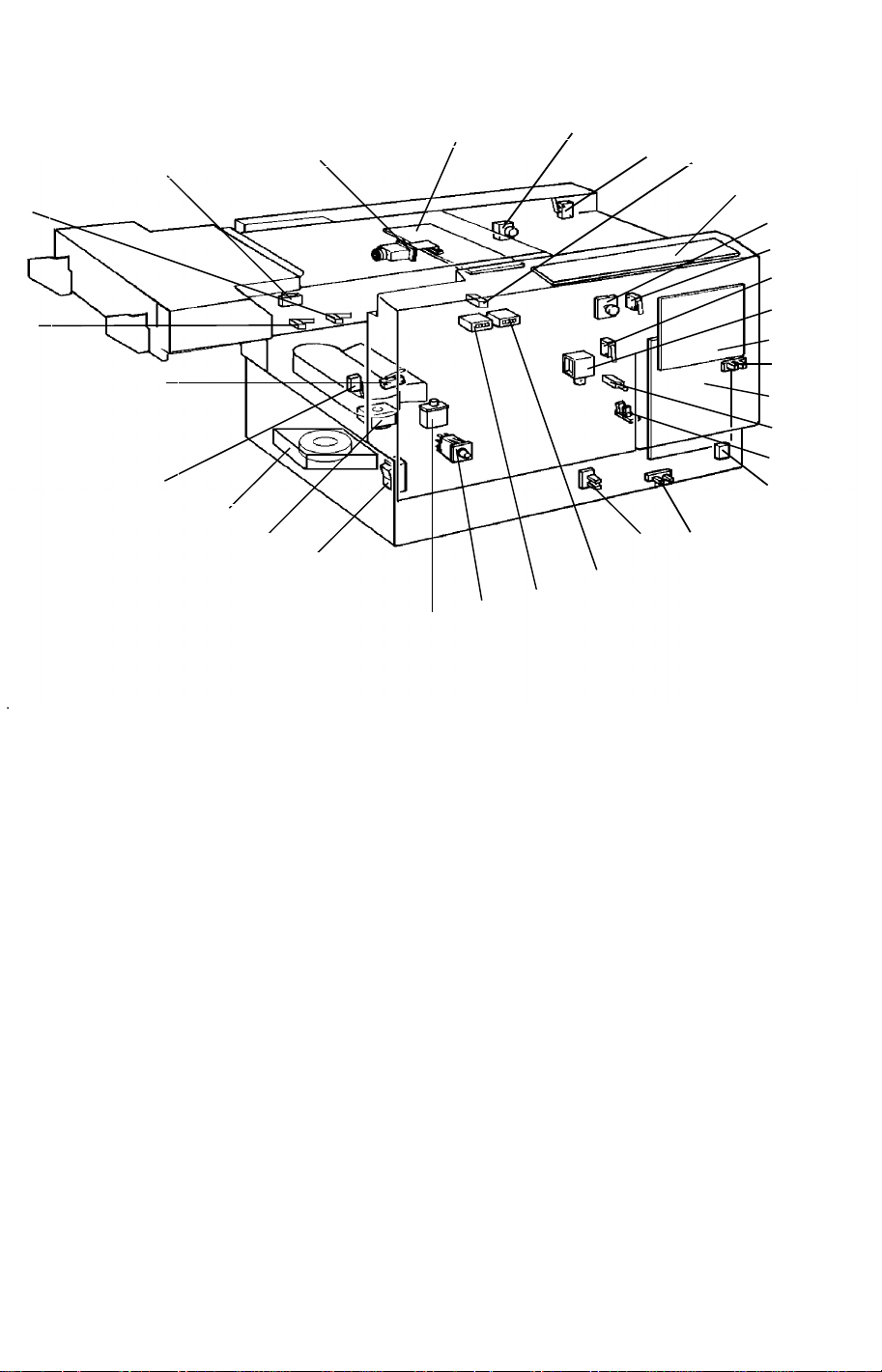

28 February ’91

27

26

28

29

30

31

32

33

34

42

41

35

36

40

37

39

26. Master Eject Clamper Solenoid

27. Ink Detection PCB

28. Master Feed Clamper Solenoid

29. Master Eject Unit Safety Switch

30. Image Shift Motor

31. Reverse Roller Solenoid

32. Encoder

33. 1st Drum Position Sensor

34. 2nd Drum Position Sensor

38

35. Paper Feed Solenoid

36. Paper Table Drive Motor

37. Drum Rotation Sensor

38. Main Motor

39. Printing Pressure Solenoid

40. AC Drive PCB

41. 1st Paper Exit Sensor

42. 2nd Paper Exit Sensor

1-18

Page 21

28 February ’91

71

70

69

68

72

67

66

43

65

64

44

63

62

45

61

46

47

48

49

50

51

52

53

54

55

56

57

58

5960

43. CCD PCB

44. A/D Conversion PCB

45. Master Cutter Switch

46. Scanner Safety Switch

47. Drum Master Detection Sensor

(VT2300/VT2500)

48. Operation Panel

49. Drum Rotation Switch

50. Front Door Safety Switch

51. Drum Safety Switch

52. Ink Supply Solenoid

53. Main Control Board

54. Paper Table Height Sensor

55. Image Processing PCB

56. Drum Lock Solenoid

57. Paper End Sensor

58. Paper Table Safety Switch

59. Paper Table Lower Limit Sensor

60. Printing Pressure Sensor

61. Copy Counter

62. Master Counter

63. Interlock Switch

64. Circuit Breaker

65. Main Switch

66. Air Knife Motor

67. Vacuum Motor

68. Full Master Detecting Switch

69. Pressure Plate Position Switch

70. Memory/Class Switch

(VT2300/VT2500)

71. Skip Paper Feed Switch

(VT2300/VT2500)

Printing Density Switch

(VT2100 /VT2130/VT2150)

72. A.D.F. Safety Switch

(VT2300/VT2500)

1-19

Page 22

28 February ’91

6. ELECTRICAL COMPONENT DESCRIPTIONS

INDEX

No.

Motors

4 Original Transport Motor Transports the original to the scanner

11 Master Feed Motor Feeds the master to the drum. E-3

16 Cutter Motor Cut the master. F-6

19 Master Eject Motor Sends used master into the master

23 ADF Drive Motor Feeds the original to the scanner

30 Image shift Motor Changes the timing between the paper

36 Paper Table Drive Motor Raises and lowers the paper table. F-5

38 Main Motor Drives paper feed, drum, printing and

66 Air Knife Motor Rotates the fan to separate the paper

67 Vacuum Motor Provides suction so paper is held firmly

Solenoids

3 Original Pressure Solenoid Presses the original pressure plate

20 Master Eject Solenoid Moves the master eject roller to contact

26 Master Eject Clamper

Solenoid

28 Master Feed Clamper

Solenoid

31 Reverse Roller Solenoid Releases the clutch to rotate the

35 Paper Feed Solenoid Releases the paper feed sector gear to

39 Printing Pressure Solenoid Moves the press roller against the drum. F-8

52 Ink Supply Solenoid Releases the spring clutch to activate

56 Drum Lock Solenoid Prevents removal of the drum unit

NAME FUNCTION P to P

LOCATION

section.

eject box.

section.

feed roller and the drum to adjust

vertical image position.

paper delivery unit components.

leading edge from the drum.

on the transport belt.

down on the originals.

the drum surface.

Opens the master clamp to eject the

master.

Opens the master clamp to clamp the

master.

reverse roller.

rotate the paper feed roller.

the ink supply pump.

unless the drum is at the original stop

position

(This solenoid can be used on the

VT2300/VT2500).

(VT2300/2500

(VT2300/2500

A-4

F-7

A-4

only)

F-8

F-4

F-7

F-5

A-4

only)

F-6

F-8

F-8

F-6

F-8

F-7

F-7

1-20

Page 23

28 February ’91

INDEX

No.

NAME FUNCTION P to P

LOCATION

Switches

6 Right Cutter Switch Detects when the cutter position is far

right.

17 Left Cutter Switch Detects when the cutter position is far

left.

21 Master Box Switch Checks whether the master eject box is

installed correctly or not.

(VT2300/2500)

(VT2100/2130

29 Master Eject Unit Safety

Switch

Checks whether the Master Eject Unit

is closed correctly or not.

45 Master Cut Switch Informs the CPU to cut the master

paper leading edge.

(VT2300/2500)

(VT2100/2130

46 Scanner Safety Switch Checks whether the scanner unit is

closed correctly or not.

49 Drum Rotation Switch Informs the CPU to rotate the main

motor at 10 rpm.

50 Front Door Safety Switch Checks whether the Front Door is set

correctly or not.

51 Drum Safety Switch Checks whether the drum unit is set

correctly or not.

58 Paper Table Safety Switch Checks whether the paper table is

opened correctly or not.

63 Interlock Switch Releases the cover safety functions. F-4

65 Main Switch Turns the power on or off. B-1

68 Full Master Detecting

Switch

Informs the CPU when the master eject

box is full of masters.

(VT2300/2500)

(VT2100/2130

69 Pressure Plate Position

Switch

Informs the CPU when the pressure

plate has reached the home position.

(VT2300/2500)

(VT2100/2130

70 Memory/Class Switch Selects Memory or Class mode. C-4

(VT2300/2500

F-6

F-6

F-7

F-6

/2150)

F-4

F-8

F-7

/2150)

F-4

A-6

F-4

B-6

F-4

F-7

F-6

/2150)

F-7

F-6

/2150)

only)

1-21

Page 24

28 February ’91

INDEX

No.

71 Skip Paper Feed Switch

(VT2300/VT2500)

Printing Density Switch

(VT2100 series)

72 ADF Safety Switch Check whether the ADF unit is set

Sensors

1 Original Registration

Sensor

2 2nd Original Sensor Detects when the original is set. A-3

10 Master End Sensor Informs the CPU when the plotter unit

12 Paper Size Detection

Sensor 3

13 Paper Size Detection

Sensor 2

NAME FUNCTION P to P

LOCATION

Adjusts paper feed interval to allow

time for user to remove prints.

Use to select the printing density

according to the type and quality of the

original.

correctly or not.

Informs the CPU when the original

leading edge reaches the exposure

glass.

runs out of master roll.

Detects the size of the paper set on the

paper table.

Detects the size of the paper set on the

paper table.

(VT2300/2500)

(VT2100/2130

(VT2300/2500

(VT2300/2500

(VT2300/2500

C-4

C-3

/2150)

B-4

only)

A-3

F-6

E-5

only)

E-5

only)

14 Paper Size Detection

Sensor 1

18 Master Buckle Sensor Detects the master buckle existence. F-6

22 Master Eject Sensor Detects when the used master is sent

24 1st Original Sensor Detects when the original is set in the

33 1st Drum Position Sensor Checks the position of the drum. F-8

34 2nd Drum Position Sensor Checks the position of the drum. F-8

37 Drum Rotation Sensor Supplies timing pulses to the main

41 1st Paper Exit Sensor Misfeed detector. A-5

42 2nd Paper Exit Sensor Misfeed detector. A-5

47 Drum Master Detection

Sensor

54 Paper Table Height

Sensor

Detects the size of the paper set on the

paper table.

into the master eject box.

ADF mode.

board.

Checks whether the master is on the

drum.

Detects when the paper table reaches

the paper feed position.

E-5

(VT2300/2500

only)

F-7

(VT2300/2500)

F-6

(VT2100/2130

/2150)

A-4

(VT2300/2500

only)

F-8

F-6

(VT2300/2500

only)

A-6

1-22

Page 25

28 February ’91

INDEX

No.

57 Paper End Sensor Informs the CPU when the paper table

59 Paper Table Lower Limit

Sensor

69 Printing Pressure Sensor Informs the CPU when the printing

Printed Circuit Board

7 Power Supply PCB Rectifies 100V AC input and supplies

8 Thermal Head Drive

Control PCB

27 Ink Detection PCB Control the ink supply. F-7

40 AC Drive PCB Controls the AC component by relays. E-5

43 CCD PCB Converts the light intensity into the

44 A/D Conversion PCB Converts the analogue signal into the

48 Operation Panel Controls the LED performance and

53 Main Control PCB Controls all machine functions both

55 Image Processing PCB Controls the master processing

Printed Circuit Board

15 Paper Size Detection

Board

Counters

61 Copy Counter Keeps track of the total number of

62 Master Counter Keeps track of the total number of

Others

5 Fluorescent Lamp

Stabilizer

9 Thermal Head Plots the master with heat. F-2

25 Fluorescent Lamp Applies light to the original for exposure. A-3

32 Encoder Converts 16 image positions to 4 bit

64 Circuit Breaker Cuts the ac line off. B-1

NAME FUNCTION P to P

LOCATION

runs out of paper.

Detects when the paper table reaches

the lowest position.

pressure is applied.

DC voltage.

Supplies the power to the Thermal

Head according to the signal from the

scanner section.

electrical signal.

digital signal.

monitors the key operation.

directly and through other boards.

performance.

Detects the size of the paper set on the

table.

copies made.

masters made.

Stabilizes the power supplement to the

Fluorescent Lamp.

data.

(VT2300/2500)

(VT2100/2130

(VT2300/2500

F-5

B-6

/2150)

A-6

A-6

D-1

E-2

A-2

B-3

A-8

C-6

C-3

E-5

only)

A-7

A-7

B-3

F-7

1-23

Page 26

28 February ’91

7. MECHANICAL COMPONENT LAYOUT

17 16 15 1413 109 8 7 6 5 4

18

19

20

21

22

23

24

1. Thermal Head

2. Platen Roller

3. Master Feed Roller

4. CCD

5. Lens

6. Reverse Roller

7. Ink Roller

8. Drum Unit

9. 1st Eject Roller

10. 2nd Eject Roller

1211

333231302928272625

21. Mirror

22. Master Eject Box

23. Exit Pawl

24. Air Knife

25. Delivery Table

26. Delivery Guide Plate

27. Vacuum Unit

28. Press Roller

29. Doctor Roller

30. 2nd Feed Roller

3

2

1

38

37

36

35

34

11. Original Pressure Plate

(2300/2500)

12. Pull-out Roller (2300/2500)

13. Separation Blade (2300/2500)

14. Original Feed Roller (2300/2500)

15. 1st Original Transport Roller

16. Exposure Grass

17. 2nd Original Transport Roller

18. Fluorescent Lamp

19. Original Exit Tray

20. Feed Sub Mirror

31. Lower Separation Roller

32. Separation Plate

33. Paper Feed Side Plate

34. Paper Feed Table

35. Paper Feed Roller

36. Upper Separation Roller

37. Ink Holder

38. Master Spool

1-24

Page 27

SECTION 2

SECTIONAL DESCRIPTION

Page 28

1. ORIGINAL FEED SECTION

1.1 OVERALL: VT2300/VT2500

[I] [G] [E] [B] [A]

28 February ’91

[J] [K] [L] [D] [C]

[J]: 2nd Original Transport Rollers

[K]: Exposure Glass

[L]: Fluorescent Lamp

There are two original feed modes in this model.

ADF Mode: The originals [I] set on the original table are detected by the

1st original sensor [A]. When the Master Making key is

pressed, the original pressure plate [B] presses the originals

down. The pull-out roller [C] starts moving the lowest original

forward at the same time. The lowest original is separated

from the other originals by the original feed roller [D] and the

separation blade [E]. When the 2nd original sensor [F] detects the original, the 1st original transport rollers [G] start

rotating. The rollers stop after the original activates the original registration sensor [H]. The 1st original transport rollers

start rotating again after the drum section completes the

preparation for the master making.

[F][H]

SADF Mode: The separation blade [E] is released in the SADF mode. The

original on the original table is fed to the starting position

when the 2nd original sensor [F] detects the original.

2-1

Page 29

28 February ’91

1.2 OVERALL: VT2100/VT2130/VT2150

[I] [G]

[J] [K] [L] [H] [F]

[J]: 2nd Original Transport Rollers

[K]: Exposure Glass

[L]: Fluorescent Lamp

[H]: Original Registration Sensor

The original [I] set on the original table is detected by the 2nd original

sensor [F]. At the same time, the 1st original transport rollers [G] and 2nd

original transport rollers [J] start rotating and feed the original to the original

start position where is 12 mm far from the guide plate. The original

transport rollers start rotating again after the drum section completes the

preparation for the master making.

2-2

Page 30

28 February ’91

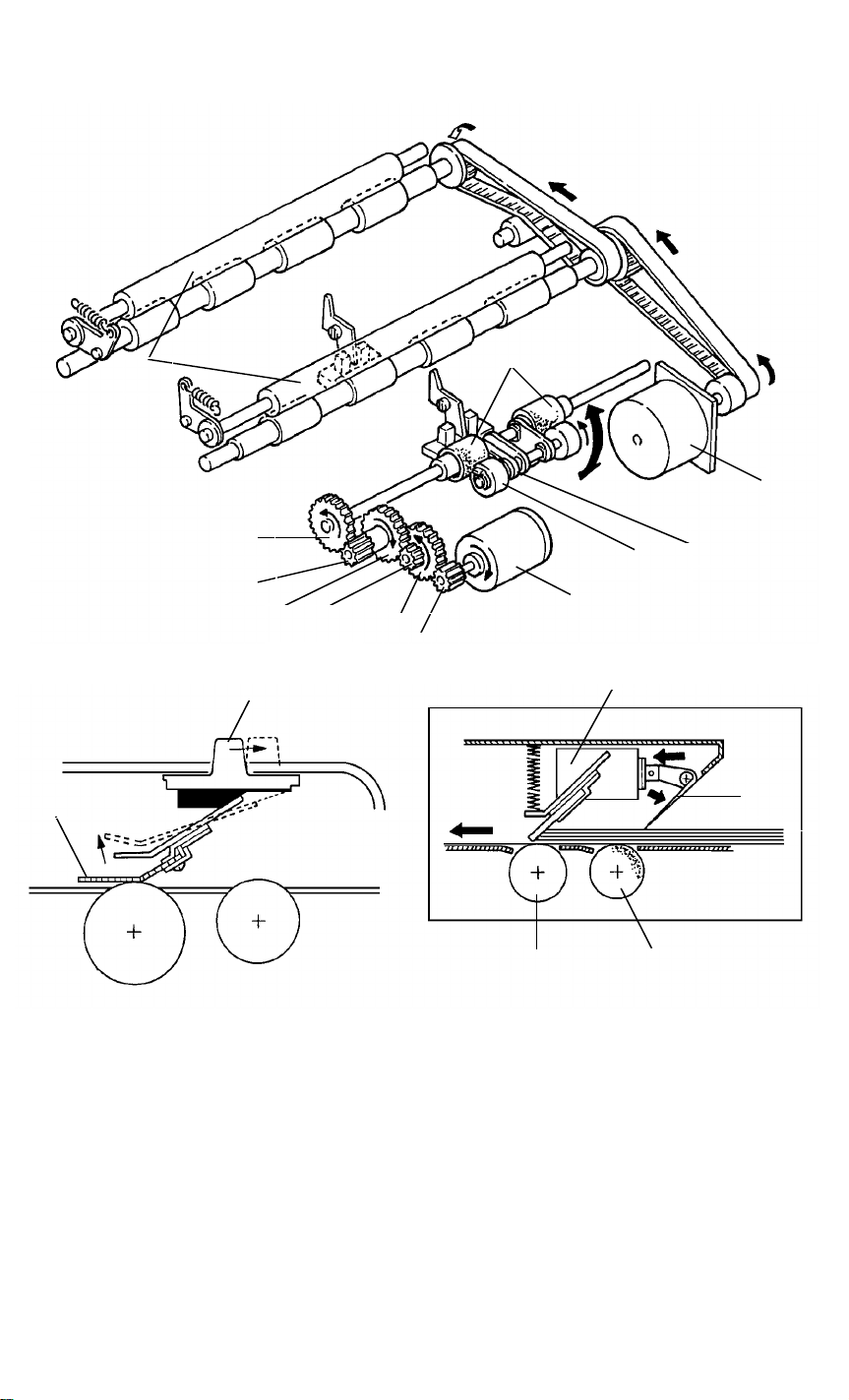

1.3 ORIGINAL FEED DRIVE MECHANISM: VT2300/VT2500

[J]

[A]

[B]

(f)

(e)

[C]

(c)(d)

(b)

[D]

[E]

(a)

[I]

[H]

[G]

[F]

[J] [D]

The original transport rollers [A] are driven by the original transport motor

[B], which is a stepper motor. The original feed rollers [J] are driven by the

ADF drive motor [C] through a series of gears [(a) to (f)]. The ADF drive

motor is a dc motor. The pull-out rollers [D] are driven by the ADF motor

through a drive belt [E].

The original pressure plate [F] is pressed down on the originals by the

original pressure solenoid [G]. The separation blade [H] is moved up and

down by the ADF ON/OFF select switch [I].

2-3

Page 31

28 February ’91

1.4 ORIGINAL FEED DRIVE MECHANISM: VT2100/VT2130

/VT2150

[G]

[F]

[I]

[H]

[A]

[B]

[E]

[D]

[C]

When the actuator [A] is pressed down by the original, the 2nd original

sensor [B] is activated and the original transport motor [C] starts rotating.

The rotation of the original transport motor is transmitted to belts [D] and [E]

to turn the lower first original transport roller and lower second original

transport roller. At the same time, both the upper original transport rollers

[F] contact the first and second lower original transport rollers due to

pressure from the springs [G]. The rollers rotate and the original is fed.

When the actuator [H] is pressed down by the original, the original

registration sensor [I] is activated and the original transport motor stops.

When the Master Making key is pressed, the original transport motor rotates

to read the original after the master eject process is finished.

The distance between the sensors is 50 millimeters. If the original

registration sensor is not activated within five seconds, "A" and

indications blink.

2-4

Page 32

1.5 ELECTRICAL TIMING: VT2300/VT2500

(One Original):

Insert Original

2nd Drum Position Sensor

Master Making Key

1st Original Sensor

Fluorescent Lamp

ADF Drive Motor

Original Pressure Solenoid

2nd Original Sensor

Original Registration Sensor

Original Transport Motor

Master Feed Motor

Read Command

T1

T2

T3

425 ms

T7

T4

Drum

Rotates

120°

T5

Original Feeds 25 mm

T6

Original

Feeds 14 mm

Master Feeds 438 mm

28 February ’91

T4:

Exposure Glass

Original Stop Position

12 mm

Scanning Position

16 mm

Original

Guide Plate

T1: When originals are inserted in the ADF unit, the 1st original sensor is

activated.

T2: When the Master Making key is pressed, the ADF drive motor starts

rotating and the pull-out roller and original feed roller feed the 1st

original. At the same time, the original pressure solenoid is energized

and the pressure plate presses the originals against the pull-out

rollers.

T3: When the 2nd original sensor detects the original, which is separated

by the separation blade and the original feed roller, the original

transport motor starts rotating and the transport rollers start rotating.

T4: One original is fed and when the original registration sensor detects

the original, the original transport motor stops the original position is

then as shown above.

T5: After the master eject process is finished and the second drum

position sensor is activated, the drum rotates 120 degrees more and

then the original transport motor turns on.

2-5

Page 33

28 February ’91

T6: After the original is fed 14 millimeters, master feeding and master

making start.

T7: The ADF drive motor and the original pressure solenoid are turned off

425 mseconds after the 2nd original sensor detects the original.

If 2nd original sensor is not activated within 2.3 seconds after

pressing the Master Making key, the Original Misfeed indicator (A +

) will start blinking.

2-6

Page 34

(Make-up mode): VT2500 only

Insert

Command

Sheet

Command Sheet Transportation

28 February ’91

Original

Transportation

Master Making Key

1st Original Sensor

Fluorescent Lamp

ADF Drive Motor

Original Pressure Solenoid

2nd Original Sensor

Original Registration Sensor

Original Transport Motor

Read Command

(Command Sheet)

Read Command (Original)

Make-up Key

T4:

T1

T0

T2

T3

41.6 msec

2 mm

Scanning Position

T4

16 mm

425 msec

Original Feeds

25 mm

Original Feeds

2 mm

Command Sheet

Guide Plate

Master Ejecting Start

425 msec

T5

T0: When the Make-up key is pressed, the fluorescent lamp turns on.

T1: When the original is inserted with a command sheet, the 1st original

sensor is activated.

T2: When the Master Making key is pressed, the ADF drive motor turns

on and the command sheet is fed by the pull-out rollers and the

original transport rollers. At the same time, the original pressure

solenoid is energized and the original pressure plate presses down

on the original and the command sheets.

T3: The original transport motor starts rotating when the 2nd original

sensor is activated by the command sheet.

T4: The reading command is output when the command sheet is fed

2mm past the scanning position.

T5: The original transport motor stops rotating when the command sheet

is fed 25 mm past the original registration sensor. At the same time,

the reading command turns off. The ADF drive motor and the original

pressure solenoid turn on at the same time and the original is fed.

2-7

Page 35

28 February ’91

1.6 ELECTRICAL TIMING: VT2100/VT2130/VT2150

Original Set Master Making Key "ON"

2nd Drum Position Sensor

2nd Original Sensor

Original Registration Sensor

Original Transport

Fluorescent Lamp

T1

T2

Drum Rotation Degree

o

120

T3

T5

Reading Command

Master Feed Motor

T2:

No Image Area:

10 mm

Scanning Position

NOTE: The original stops 12 millimeters

16 mm

away from the corner of the

12 mm14 mm

lower guide plate edge [A].

Original Feed

Length (14 mm)

[A]

T4

Master Feed Length

(438 mm VT2100/VT2130)

(371 mm VT2150)

T1: When the 2nd original sensor detects the original, the original

transport motor starts rotating.

T2: One original is fed and when the original registration sensor detects

the original, the original transport motor stops the original position is

then as shown above.

T3: After the master eject process is finished and the second drum

position sensor is activated, the drum rotates 120 degrees more and

then the original transport motor turns on.

T4: After the original is fed 14 millimeters, master feeding and master

making start.

T5: The master feed motor stays on until it feeds the master 437 mm.

The original transport motor stops when the master feeding stops. At

that time the fluorescent lamp also turns off.

2-8

Page 36

28 February ’91

1.7 CIRCUIT:

Original

Registration

Sensor

2nd Original

Sensor

Original

Transport Motor

M

Image

A/D

Conversion P.C.B.

1

3

2

1

3

2

5V

CN603-1

CN603-4

CN603-2

GND

CN603-3

CN601-13

CN601-11

CN601-25

(CN601-27)

CN601-17

CN601-18

CN601-19

CN601-20

CN601-21

Processing

P.C.B.

CN403-13

CN403-11

CN403-25

(CN403-27)

CN403-17

CN403-18

CN403-19

CN403-20

CN403-21

Fluorescent Lamp

VT2300/VT2500 only:

1st Original

Sensor

ADF

Drive Motor

Original Pressure

Solenoid

ADF Safety SW

M

SOL

Stabilizer

CN611-1

CN611-2

CN612-1

CN612-2

1

3

2

CN604

Red

-1

CN604

Yellow

-3

CN604-2

Black

CN607-3+5V

CN607-5 CN601-3

CN607-4 (GND)

CN607-6

CN607-7

CN607-1

CN607-2

CN607-8

CN607-9

24V

+24V

CN601

-15

GND

+5V

CN601-5

+24V

CN601-1

CN601-7

CN601-9

CN403-15

CN403-3

CN403-5

CN403-1

CN403-7 (IN)

CN403-9 (OUT)

2-9

Page 37

28 February ’91

1.8 OUTPUTS:

Signal Name I/O

A/D Conversion Board

CN No. Level

Fluorescent

Lamp O CN601-15

Reading

Command I

CN601-25

(CN601-27)

ADF Drive

Motor

(VT2300/VT2500)

I (CN607-6)

Original

Pressure SOL

(VT2300/VT2500)

O (CN607-2)

Original

Registration

O CN603-4

Sensor

2nd Original

Sensor I CN603-3

1st Original

Sensor

(VT2300/VT2500)

I (CN607-5)

0V

3V

24V

24V

7.5V

7.5V

0V

3V

0V

0V

0V

5 m

5 m

5V

Description

When the fluorescent lamp turns

on, the voltage of the CN601-15

is 3V.

When the CCD reads the original

the voltage of CN601-25

(CN601-27) is 0V.

When the ADF drive motor starts

rotating, the voltage of CN607-6

is 0V.

When the original pressure

solenoid is energized, the voltage

of CN607-2 is 0V.

When the original registration

sec

sensor is activated, the voltage of

0V

CN603-4 is 0V.

When the 2nd original sensor is

sec

activated, the voltage of CN603-3

0V

is 0V.

When the 1st original sensor is

activated the voltage of CN607-5

is 5V.

( ): VT2300/VT2500

2-10

Page 38

2. OPTICS/IMAGE PROCESSING

2.1 OVERALL

28 February ’91

[D]

Thermal Head

[E]

[F]

[C]

Thermal Head

Control

Operation Panel

[A]

A/D Converter

Image Processing

Main Board

[B]

[C]: Shading Plate

[D]: Mirror

[E]: Exposure Glass

[F]: Fluorescent Lamp

The light reflected from the original goes through the lens [A] and is

changed to an electrical signal in the CCD [B].

The electrical signal from the CCD is converted from an analog signal to a

digital signal in the A/D converter.

The converted digital image data is modulated and edited (VT2500) and is

sent to the thermal head control PCB.

2-11

Page 39

28 February ’91

2.2 LIGHT SOURCE

[B]

[D] [G]

[B]

[A][K]

[D] [C]

[F]

[A]

[E]

[H]

[I]

[J]

[G]: Exposure Glass

[H]: Lens

[I]: CCD

[J]: A/D Converter

[K]: Mirror

The high frequency fluorescent lamp [A] is used as a light source for the

high speed reading of 16 pixels/mm. The light exposes at two angles using

a sub mirror [B] to prevent the shades at the edges of paste-ups on the

original [C]. The original guide plate [F] blocks part of the direct light from

the fluorescent lamp to make the light intensity of both direct and reflected

light the same. A heater [E] is wrapped around the fluorescent lamp. It

prevents light intensity reduction due to low temperature.

<Fluorescent Lamp>

Form: 15.5 ∅ x 436 mm

Lamp Voltage : 59 ± 6 V

---- Platen Cover ----

The platen cover [D] is used as a standard white level reference to correct

for shading distortion.

2-12

Page 40

2.3 LENS

28 February ’91

Original

Surface

312.5∅

5 mm

404.179 mm

Exposure Glass

30.655 mm

[A]

29.895 mm

35∅ mm

[B]

[C]

This consists of 6 lenses, to transfer the image, correctly oriented, to the

photoelectric elements of the CCD. It is possible to adjust the focus by

moving the lens assembly [A].

<Lens>

Focal distance: 43 mm (43.05 ± 0.32 mm)

F No.: F4.5

The above illustration shows the layout to transfer the image from an A3

original (297 millimeter width) to the CCD [B].

<CCD>

Number of effective pixels: 5000 pixels

Reading length: 312.5 mm

Photo signal storage time: 3 msec.

The shading plate [C] corrects light intensity distortion. The light intensity is

low at the both ends of the lamp and is also low at the edge of the lens.

Therefore, the center light is cut to make the light intensity uniform.

2-13

Page 41

28 February ’91

2.4 CCD (Charge Coupled Device)

Shift Registor

Shift Gate

D

31

Shift Gate

Shift Registor

10

φ1E

13 14

S1 S2

D35D34D33D

32

9

1 8

SSφ10φ2Bφ2CRS

15

SSSSφ20

RS2

OS2

OS

RS1

OS1

OD φ2E

18

20

2

5

3

19 17 21

22

φ1Bφ1C

D18D19D

20

6

4

CCD (16 dots/mm) φ1E, φ2E Clock (Phase 1)

φ10, φ20 Clock (Phase 2)

Light

Energy

Shift

Electrode

01B : Final Clock (Phase 1)

02B : Final Clock (Phase 2)

SH : Shift Gate

Photo

Diode

Shift Register

Storage

Electrde

RS : Reset Gate

OS : Output Transistor source

OD : Output Transistor Drain

SS : Sub-straight (Ground)

IS : Input Source (Test Pin)

IG : Input Gate (Test Pin)

7

IS

12

SH

16

IG

This is a solid-state device similar to a photodiode array, but unlike a photodiode array, a CCD can read one complete scan line at a time. The CCD

produces an analog signal which is converted into a digital signal for image

processing.

2-14

Page 42

28 February ’91

2.4.1 Function

The principle circuit of each pixel in the CCD is shown above. The light

reflected from the original is absorbed in the photodiode and the capacitor

stores the charge corresponding to the light intensity.

The CCD is composed of many such pixel elements in series. The image

signal of each pixel element is stored in the shift register as a charge.

When the SH signal is input, the image signal stored in the shift register, is

output in serial as the OS signal.

SH : Shift Gate

The storage electrode charge in the exposure section is transmitted to the

shift register by the shift gate pulse.

φ1E, φ2E Clock (Phase 1)

This is the transmission clock for analog shift register 2 (even pixels).

φ10, φ20 Clock (Phase 2)

This is the transmission clock for analog shift register 1 (odd pixels).

The shift gate signal transmits the electrical charge in parallel to either

analog shift register 1 or 2 (odd or even pixels). At the same time, the photo

signal storage of the next scan line starts in the exposure section.

The transmission clocks serially shift the electric charge transmitted to the

shift register, which outputs it from the OS (output signal) terminal.

2-15

Page 43

28 February ’91

2.4.2 The Image Signal :

CCD Board

+12V

GND

CN801-2

RS

CN801-4

OS

CN801-6

1B

CN801-8

2B

CN801-12

20

CN801-14

10

CN801-16

2E

CN801-18

1E

CN801-20

SH

CN801-9, 10

CN801-1, 3, 5, 7, 11, 13, 15, 17, 19

CN602-1, 3, 5, 7, 11, 13, 15, 17, 19

CN602-2

CN602-4

CN602-6

CN602-8

CN602-12

CN602-14

CN602-16

CN602-18

CN602-20

CN602-9, 10

A/D Converter

A/D Converter

Input

Output

∅10, ∅1B, ∅1E (CN801-14, 6, 18)

∅20, ∅2B, ∅2E (CN801-12, 8, 16)

LSYNC (5,120)

{

SH

∅10, ∅1B, ∅1E

∅20, ∅2B, ∅2E

RS

OS

{

SH (CN801-20)

RS (CN801-2)

OS (CN801-4)

3 ms (5,120 Count)

4,096

Photo Signal Storage Time (3 ms)

Dummy

Pixels 32

Effective

Pixels

5,000

Dummy Pixels 4

Empty Data 84

5,120

Dummy Pixels:The dummy pixels generated by the area covered with alumi-

num film. The dummy pixels are used as the standard black

level.

The first 32 pixels read (D0 to D31) are dummy pixels. Pixels D32 to

D5,032 are the effective pixels (S1 to S5,000). After that there are four

more dummy pixels. Therefore, the total pixel count from the CCD, including

the dummy pixels, is 5,036.

As the image signal captured by the CCD is clocked out by the shift gate

every 3 ms (scan line period), there remains time for 84 transmission clock

pulses after all the image data from the CCD has been output. These clock

pulses, after all valid data have been clocked out, constitute empty data.

During this period, subscanning occurs.

2-16

Page 44

2.5 A/D CONVERSION BOARD

Outline: VT2100/VT2130/VT2150 Circuit

Original

28 February ’91

VPH

Peak

Hold

PKHTM

CCD

Board

Selector 1

80%

53%

6%

PHOTO SHMRT

OS

Selector 2

0

1

2

3

0

1

2

3

A B

Signal Conversion

Direct Current Clamp

Amplification

Counter

CK

LUF

4-bit A/D

Conversion

VH VL

Current

Voltage

Conversion

4 bit

Black Level

Correction

Image

Processing

P.C.B

4 bit

Shading

Distortion

Memory

8-bit D/A

Conversion

VR(+) VR (-)

Selector 2

0: Shading Distortion Correction in Photo mode

1: Shading Distortion Correction in Line mode

2: Line mode

3: Photo mode

The CCD reads the light of the fluorescent lamp reflected from the original.

The CCD and A/D conversion boards convert the analog signals into digital

signals which are transmitted to the image processing board.

2-17

Page 45

28 February ’91

2.5.1 CCD Output Signal Conversion, DC Clamping, Amplification:

VT2100/VT2130/VT2150 Circuit:

+12V

602-4

DCREST

OS

a

SH

Approx. 6V

OS

-12V

+12V

Q607

C669

DC Clamp

Switch

6V

IC628

4.7K

2.2K

IC624

2

_

6

3

+

b

1.7V 1.7V

(VT2300/VT2500:

VR600

R2

IC620

+

_

+5V

TP600

V0

c

IC624-6

Approx. 1.7V

(VT2300/VT2500: 1.4V)

SH

1.7V

(VT2300/VT2500: 1.4V)

DCREST

14 pixels

1). Signal Conversion

The CCD output (OS) varies according to the reflected light intensity and is

clipped at 6 volts. The output signal is then buffered, inverted and amplified.

2-18

Page 46

28 February ’91

2). DC Clamping

The OS signal is amplified by Q607. The dc clamping switch is turned

ON/OFF by the DCREST signal. The switch turns on when the CCD

produces black level (empty data) at the end of scanning and is off during

image scanning.

When the switch turns on, the black level signal is stored in capacitor C669.

When the switch turns off, the black level signal is input to IC624 pin 3

while the image signal is input to the IC624 pin 2.

The difference between the image signal and the black level signal is

amplified and output from the IC624.

This output signal from IC624 is amplified again in IC620. The signal then

goes in the A/D converter.

2-19

Page 47

28 February ’91

2.5.2 Peak Hold:

CCD Board A/D Conversion Board

CCD

Image

Processing

Board

Read

Write

S LSYNC

S CLK

OS

(CN403-27)

CN403-25

(CN403-29)

CN403-27

(CN403-31)

CN403-29

(CN403-33)

CN403-31

Inverter Amp

Timing

Signal

Generator

( ): VT2300/VT2500

Vo

PKHTM

PKHST

BLSET

SHMRT

A/D Conversion

SW2

Peak Hold

Circuit

A/D Conversion

VPH

This circuit holds, at different stages of image processing, the peak white

levels for both the original and the platen cover (standard white). The peak

white, or maximum, level is stored as charge on a capacitor. The peak hold

circuit is cleared by discharging the capacitor.

1). Platen Cover Peak Hold (Standard White)

The platen cover peak hold is used as standard white when processing

data to create the shading distortion data, which is later stored in memory.

This data is used to correct such distortions as bright or dull spots on the

lamp or variations in the CCD output. To create the platen cover peak hold

(standard white), the peak hold circuit stores the maximum level from five

scan lines of the platen cover.

2). Original Background Peak Hold

The maximum white level of the original, stored in the peak hold circuit, is

used to shift the threshold voltage of the D/A converter to match the original

background. An area of the original, 64 mm wide (from S2,048 to S3,072),

is read. This corresponds to a small size original.

3). Peak Hold Set Signal

The peak hold set signal (PKHST) clears the peak hold circuit. The peak

hold timing signal (PKHTM) turns on the analog switch (SW2) allowing the

image signal to be applied to the peak hold circuit.

2-20

Page 48

4) Peak Hold Signal Timing:

L. SYNC

CN403-29

(CN403-31)

Reading

CN403-25

(CN403-27)

Write Out

CN403-27

(CN403-29)

SHMRT

PKHST

PKHTM

5 lines

5 lines

A

BLSET

SW2

Correction Timing

P.H. Signal Input

Timing

ON OFF ON OFF

( ): VT2300/VT2500

A Section (Main Scanning)

LSYNC

PKHTM

0

Original Background

Peak Hold

2080 3140 4096 5120

1024

Image

Reading

Pixels (64 mm width in the middle)

Page 49

28 February ’91

2.5.3 Shading Distortion Correction:

Amp

Pixels Data

PKHTM SW2

Peak

Hold

Circuit

L. SYNC CN403-29

(CN403-31)

Read CN403-25

(CN403-27)

Write CN403-27

(CN403-29)

SHMRT

VPH

53%

B

1 X

Y1

Current/

Voltage

Convertor

VT2100/2130/2150: 1.7V

VT2300/VT2500: 1.4V

5 lines

VH

A/D

Converter

VL

D/A

Converter

VR(+)

4 bit Signal

Shading

Distortion

Memory

4 bit Signal

VR(-)

1.7V: VT2100/2130/2150

1.4V: VT2300/VT2500

SHMRT

PKHST

PKHTM

BLSET

( ): VT2300/VT2500

Shading Distortion Memory

Since the output of the CCD varies according to both the CCD and the

intensity of the fluorescent lamp, shading distortion is corrected electrically

as well as mechanically (shading plate).

2-22

Page 50

1). Shading Distortion Memory

White Peak Hold of Platen Cover

VPH

28 February ’91

VT2100/2130/2150: 1.7V

VT2300/2500: 1.4V

Memory

100%

53%

5,000 pixels

4 bits

When reading the white level of the platen cover, the peak hold (standard

white) is determined using the five scan lines.

The shading distortion data is stored in memory during the fifth scan line .

The potential difference between the output of each pixel and the 53% level

of the peak hold is converted by an A/D converter into 4-bit data. This data

is stored in a memory location corresponding to the pixel.

2). Shading Distortion Correction

White Peak Hold of Original Background

VPH

Correction Memory

100%

53%

VT2100/2130/2150: 1.7V

VT2300/2500: 1.4V

4 bits for

distortion memory

Fixed 4 bits

When reading the original, the distortion data corresponding (stored in

memory) to each pixel is converted from digital to analog, using the D/A

converter, and used as the reference voltage (VH) of the A/D converter.

The D/A converter is an 8-bit converter with 4 of its 8 bits fixed. This

ensures that the output of the D/A converter is always greater than 53% of

the reference voltage (VR+).

2-23

Page 51

28 February ’91

The reference (VR+) of the D/A converter is set to the peak hold of the

original background. Distortion correction is obtained by using the output

voltage of the D/A converter as the reference voltage (VH) of the A/D

converter; therefore, distortion correction also corrects for the original

background level.

For Example: If the light intensity at a certain pixel is very high, then a high

voltage level will be stored in the distortion memory location for that pixel.

When reading a document, that high voltage level is used as the reference

level (VH) of the A/D converter. Therefore, during conversion, the input level

from the pixel is compared to a high voltage by the A/D. This negates any

errors caused by the high light intensity at that pixel.

2-24

Page 52

2.5.4 Original Background Correction

VT2100/2130/2150: 1.7V

VT2300/2500: 1.4V

White Peak Hold of Platen Cover

VPH

28 February ’91

<Original background is lighter.>

Peak Hold of Original Background

VPH

53%

53%

<Original background is darker.>

Peak Hold of Original Background

VT2100/2130/2150: 1.7V

VT2300/2500: 1.4V

VPH

53%

VT2100/2130/2150: 1.7V

VT2300/2500: 1.4V

As the white peak hold of the original background is used as the reference

(VR+) of the D/A converter, the overall shading distortion correction level is

adjusted for the original background at the output of the D/A converter.

For Example, if the background level of the original is low, the reference

level (VH) of the D/A converter is low, causing the overall distortion

correction level to be low. Therefore, even though the light level from the

original background is low, it is being compared to a low reference level

(VH) which causes it to be detected as background, not image.

2-25

Page 53

28 February ’91

2.5.5 Black Level Correction (Line mode only)

Selector 1 0

1

2

3

4

5

6

Counter

CK

Amp.

VT2100/2130/2150: 1.7V

VT2300/2500: 1.4V

Selector 2

Y3

VS

4-bit A/D Conversion

LUF

VL

The black level correction compensates for the image density. Black level

correction is used only when in line mode.

The lower threshold level (VL) of the A/D converter is set according to a

high density original or a low density original.

At first, the black level reference of the A/D converter is set to 35% of the

original peak hold white level (PH) because the analog switch of selector-1

is set to the "0" position.

If while reading the original image the black level of the image is lower than

VL (PH x 35%), the A/D converter outputs the LUF signal.

The LUF signal is applied to selector 1 as a clock pulse. The LUF signal

increments the counter of selector 1 from 0 to 1. This changes the VL to

30% of PH. If the LUF signal is again applied to the counter of selector 1,

incrementing it from 1 to 2, the analog switch of selector 1 changes from 0

to 1.

The following table shows the number of clock pulses needed to increment

the analog switch of selector 1.

Counter (4 bit) Selector 1 Switching VL

0.1 SW 0 PH x 35 %

2.3 SW 1 PH x 30 %

4.5 SW 2 PH x 25 %

6.7 SW 3 PH x 20 %

8.9 SW 4 PH x 15 %

A.B SW 5 PH x 10 %

C.D SW 6 PH x 5 %

E.F SW 7 PH x 0 % (Black Level)

2-26

Page 54

2.5.6 A/D Conversion

28 February ’91

VH

(White Standard)

OS

4 bit A/D

Convertion

VT

(Black Standard)

65%

35%

VT2100/VT2130/VT2150 Circuit:

Amp

VPH of Platten/

Original

Background

VPH of Shading

Distortion

Memory

Black Level

Correction

Output of

Selector 1

SW

VPH x 80%

VPH x 53%

VPH x 6%

PHOTO

Back Ground (White Peak)

A B

Selector 2

0

1

2

X

3

0

1

Y

2

3

A B

A B

0

BAD1

1

2

3

BAD2

4

5

6

BAD3

7

8

9

BAD4

10

11

12

13

14

15

BAD1

BAD2

BAD3

BAD4

1

0

1

0

0

0

1

0

VS

VH

M1

M2

VL

A/D CONVERSION

SHMRT

PHOTO SHMRT

Selector 2 (X,

Y)

Shading Distortion Correction (Photo Mode) L L SW0 ON

Shading Distortion Correction (Line Mode) H L SW1 ON

Photo Mode L H SW2 ON

Line Mode H H SW3 ON

This circuit converts the analog input signal (VS) to a 4-bit digital signal

using both the white level reference (VH) and the black level reference (VL).

In each mode, the settings of the "X" and "Y" switches in Selector 2 are

automatically determined by the PHOTO and SHMRT signals as shown in

the above table.

2-27

Page 55

28 February ’91

VT2300/VT2500 Circuit:

Amp

Photo Mode

VPH of Shading

Distortion

Memory

VPH of Platten/

Original

Background

Black Level

Correction

Output of

Selector 1

Standard

Voltage: 1.4V

CN601-24

CN601-25

Density: 0

Density: 1

95%

80%

80%

70%

10%

10%

40%

40%

70%

40%

20%

Selector

3

2

1

0

3

2

1

0

Line Mode

Selector

3

2

1

0

3

2

1

0

A B

A B

X

Line/Photo

Selector 2

3

2

X

Y

53%

X

Y

1

0

3

2

Y

1

0

AB

PHOTO

SHMRT

VS

VH

M1

M2

VL

A/D CONVERSION

4 bit

Image

Signal

Line/Photo

PHOTO SHMRT

Selector 2 (X,

Y)

Shading Distortion Correction (Photo Mode) L L SW0 ON

Shading Distortion Correction (Line Mode) H L SW1 ON

Photo Mode L H SW2 ON

Line Mode H H SW3 ON

This circuit converts the analog input signal (VS) to a 4-bit digital signal

using both the white level reference (VH) and the black level reference (VL).

In each mode, the settings of the "X" and "Y" switches in Selector 2 are

automatically determined by the PHOTO and SHMRT signals as shown in

the above table.

2-28

Page 56

1). Shading Distortion Correction -- (Selector 2 Switch 1 ON)

28 February ’91

Peak Hold of

Platen Cover

VPH

VPH x53%

VT2100/2130/2150: 1.7V

VT2300/2500: 1.4V

(Black Level)

(Black Level)

Waveform of

Platen Cover

4-bit A/D

Conversion

When reading the platen cover to establish the shading distortion data, the

high reference voltage (VH) of the A/D converter is set to the peak hold

level and the low reference voltage (VL) is set to 53 % of the peak hold

level. Therefore, the potential difference between the output of each pixel

and the 53% level of the peak hold is converted by the A/D converter into

4-bit data. The shading distortion data for each pixel is stored in a memory

location corresponding to that pixel.

2). Original Reading

Peak Hold of

Background

VPH

VH

(Corrected Waveform)

VL (VPH x 35%~0%)

VT2100/2130/2150: 1.7V

VT2300/2500: 1.4V

(Black Level)

(Black Level)

a). Line Mode -- (Selector 2 Switch 3 ON)

The reference voltage (VH) of the A/D converter is set to the output of

the D/A converter (converted shading distortion data) for each pixel being read. Because the reference level of the D/A converter is set to the

original peak hold level, this corrects for shading distortion as well as

matching the output level to the original background.

Also, as described in "Black Level Correction", VL is set from 0% to

35% of the potential difference between 1.7 volts (VT2300/2500: 1.4

volts) and the peak hold of the original background. Black level

correction varies according to the original image density.

2-29

Page 57

28 February ’91

Peak Hold of Background

(Corrected Waveform X 80%)

VPH

VH (Corrected

Waveform x 80%)

VL (VPH x 6%)

VT2100/2130/2150: 1.7V

VT2300/2500: 1.4V

(Black Level)

(Black Level)

b). Photo Mode -- (Selector 2 Switch 2 ON)

The VH of the A/D converter is set to 80% of the potential difference

between 1.7 volts (VT2300/2500: 1.4 volts) and the output from the D/A

converter (converted shading distortion data). This corrects for shading

distortion as well as matching the output level to the original background because the reference level of the D/A converter is set to the

original peak hold level.

Also, VL is set to 6% of the potential difference between 1.7 volts

(VT2300/2500: 1.4 volts) and the peak hold level of the original.

2-30

Page 58

2.5.7 Printing Density Change

VT2100/VT2130/VT2150 Circuit in Line mode:

Image Signal

28 February ’91

Shading Distortion

Memory Correction

Signal

Selector 1

Output

Black Date

Correction

3

3

Selector 3

3

73%

5

67%

6

47%

1.7V

COM

A/D Converter

VH

VL

1

A/D

Converter

5V

A

B

C

LUF

VS

4 bit

Image

Signal

CN606-2

CN606-3

CN606-5

CN606-1

CN606-4

Gate

5

3

Printing

1

Density

S.W.

2

4

4 bit

Image

Signal

SW ON

(Terminal No.)

CN606

-2 -3 -5

Selector 3

MANUAL 1 1-2 H H L COM--3

MANUAL 2 2-3 H L H COM--5

Standard ---- H H H COM--1

MANUAL 3 4-5 L H H COM--6

The printing density can be changed by the printing density switch when in

the line mode. This switch changes the threshold level to 47 %, 67 %, or 73

% of the white level.

The selected threshold level enters port VL while the shading distortion

corrected image signal enters port VH of the A/D converter.

In manual printing density mode (Dark, Darker, and Lighter), the A/D

converter outputs either all "H" BAD signals (4 bit) or all "L" BAD signals (4

bit). This is determined by the LUF signal

When the image signal is lower than the threshold level, the LUF signal is

output from the A/D converter to make all BAD signals "H". Then the image

signal is output as a black.

When the image signal is higher than threshold level, LUF signal is not

output. Then the BAD signals are all "L".

2-31

Page 59

28 February ’91

VT2300/VT2500 Circuit in Line Mode:

VPH of Shading

Distortion

Memory

Black Level Correction

Output of Selector 1

Standard Voltage: 1.4

CN601-24

CN601-25

Density : 0

Density : 1

70%

40%

20%

Line Mode

Setector

3

2

1

0

3

2

Y

1

0

A B

X

PHTO

Line/Photo

Selector 2

3

Y

3

B

A

X

A/D Converter

SHMRT

The printing density (i.e. image density) can be changed with the Printing

Density key on the operation panel.

Line Mode Selector changes the threshold level of VH (White level

reference) and VL (Black level reference) according to the density signals

from CN 601-24 and CN 601-25.

VH

VL

4 bit

Image

Signal

The A/D converter converts the analog input signal to a 4-bit digital signal

using both the white reference level (VH) and the black reference level (VL).

The following table shows the VH and VL levels that vary according to the

combination of the density signals in Line mode.

Printing

Density

Density

Signal 0

(CN601-

24)

Density

Signal 1

(CN601-

25)

Line Mode Selector

ON Channel.

A/D Converter

VH VL

Darker 2 H H 0X, 0Y 100% 40%

Darker 1 L H 1X, 1Y 100% 20%

Standard H L 2X, 2Y 100% 0~35%

Lighter L L 3X, 3Y 70% 0%

2-32

Page 60

VT2300/VT2500 Circuit in Photo Mode:

Photo Mode

Selector

VPH of Shading Distortion

Memory

VPH of Platlen/

Original

Background

CN601-24

Density : 0

95%

80%

80%

70%

10%

10%

4%

4%

3

2

1

0

3

2

1

0

A B

X

Y

Selector 2

2

Y

2

A

B

28 February ’91

X

VH

M1

M2

VL

A/D Converter

4 bit

Image

Signal

CN601-25

Density : 1

(Low signal when in Photo mode)

PHTO

SHMRT

(Low signal when in Photo/Line mode)

The printing density (i.e. image density) can be changed with the Printing

Density key on the operation panel. This adjustment can also be done in

Photo mode to increase the image quality of photo originals.

Photo ode Selector changes the threshold level of VH (White level

reference) and VL (Black level reference) according to the density signals

from CN 601-24 and CN 601-25.

The A/D converter converts the analog input signal to a 4-bit digital signal

using both the white reference level (VH) and the black reference level (VL).

The following table shows the VH and VL levels that vary according to the

combination of the density signals in Photo mode.

Printing

Density

Density

Signal 0

(CN601-

24)

Density

Signal 1

(CN601-

25)

Photo Mode Selector

ON Channel.

A/D Converter

VH VL

Darker 2 H H 0X, 0Y 95% 10%

Darker 1 L H 1X, 1Y 80% 10%

Standard H L 2X, 2Y 80% 4%

Lighter L L 3X, 3Y 70% 4%

2-33

Page 61

28 February ’91

2.6 REDUCTION PROCESSING:

Original

Transport

M

A/D Converter

BAD 1

BAD 2

BAD 3

BAD 4

24V

Motor

Drive

Circuit

CN403-17

CN403-18

CN403-19

CN403-20

CN403-21

4 bit

Image

Data

ORF0 A

ORF0 B

ORF0 C

ORF0 D

ORF0 E

Image Processing PCB

Image Data

Reduction

Processing

Discard Timing

Drive

Pulse

Generator

Image

Processing

Timing Signal

Generator

( ): VT2300/VT2500

CN-NO Signal I/O FROM 100 % 93 %

105-19

105-20

(105-21)

Reduction 0

(Magnification 0)

Reduction 1

(Magnification 1)

(Magnification 2) (I)

I Main PCB H L H L

I Main PCB H H L L

(Main

PCB)

(H) (H) (H) (H)

( ): VT2300/VT2500

Main PCB

CN

105-19

CN

105-20

(CN

105-21)

82 %

[75%]

Reduction 0

(Mag. 0)

Reduction 1

(Mag. 1)

(Mag. 2)

71 %

[64%]

Reduction in the main scanning direction is performed by systematically

discarding the pixels and the reduction in the sub-scanning direction is

performed by changing the transportation speed of the original.

2.6.1 Main Scanning Reduction:

Reduction Mode Discarded Pixels Remaining Pixels

100 % 0 Pixels All Pixels

93 % 1/14 Pixels 13/14 Pixels (0.929)

82 % (A4 version) 3/11 Pixels 9/11 Pixels (0.818)

75 % (LT version) 1/4 Pixels 3/4 Pixels (0.75)

71 % (A4 version) 2/7 Pixels 5/7 Pixels (0.714)

64 % (LT version) 5/14 Pixels 9/14 Pixels (0.642)

When the reduction command is sent from the main board, the timing signal

generator sends the thinning timing control signal to the reduction

2-34

Page 62

28 February ’91

processing circuit. Some of the 4-bit image data from the A/D converter is

discarded according to the thinning timing control signal.

2.6.2 Movement:

Main scan direction: Examples (A4 version)

During the 71% reduction mode, 5 out of 7 pixels are used; 1 pixel is

discarded each cycle.

0 1 2 3 4 5 6 0 1

7 pixels

Before thinning

5 pixels

0 1 2 3 4 5 0 1 2

After thinning

(2nd and 5th pixels are removed.)

During the 82% reduction mode, 9 out of 11 pixels are used; 2 pixels are

discarded each cycle.

0 1 2 3 4 5 6 0 1

11 pixels

7 8 9 10

Before thinning

9 pixels

0 1 2 3 4 5 0 1 2

After thinning

36 7 8

(3rd and 8th pixels are removed.)

During the 93% reduction mode, 13 out of 14 pixels are used; 1 pixel is

discarded each cycle.

Before

0 1 2 3 4 5 6 11

14 pixels

7 8 9 10

12 13

thinning

6th pixels is removed.

13 pixels

After

0 1 2 3 4 5 010 12

9

116 7 8

thinning

2-35

Page 63

28 February ’91

2.6.3 Sub-scanning Reduction:

5V

E Phase

D Phase

Original Transort Motor

∅A CN605-1

∅B CN605-3

C Phase

A Phase

B Phase

CN605-1

CN605-2

CN605-3

CN605-4

CN605-5

CN605-6

CN605-7

CN605-8

CN605-9

CN605-10

0A

24V

0B

0C

0D

0E

Transort Motor

Drive Circuit

A/D Converter Image Processing PCB

t

0 1 2 3 4 5 6 7 8

CN403-17

CN403-18

CN403-19

CN403-20

CN403-21

9

10 11 12

Motor

Drive

Timing

Pulse

Generator

CK

Timing

Pulse

Generator

13

∅C CN605-5

∅D CN605-7

∅E CN605-9

1 line

(1/16 mm)

NOTE: The reduction ratio change is performed by changing the pulse

width "t".

2-36

Page 64

28 February ’91

Reduction

Ratio

100% 1.484 ms 674 ---- 0.742 ms 1348 ----

93% 1.378 ms 726

82% 1.214 ms 824

75% 1.112 ms 899

71% 1.060 ms 944

64% 0.950 ms 1053

Pulse Width PPS Pulse Width PPS

Original Transportation Command Sheet Transportation

674

= 0.928 0.689 ms 1451

726

674

=0.818 0.607 ms 1648

824

674

=0.74 0.556 ms 1798

899

674

=0.714 0.530 ms 1888

944

674

1053

=0.64 0.475 ms 2106

2 3 4 5 6 7 8 9 10 11 12 1310

A Phase

B Phase

1348

1451

1348

1648

1348

1798

1348

1838

1348

2106

=0.928

=0.818

=0.749

=0.714

=0.640

C Phase

D Phase

E Phase

When the reduction command is sent from the main board, the frequency of

the pulses from the pulse generator increases. The drive pulse generator

then increases the frequency of the motor drive pulses to increase the

motor rotation speed.

2-37

Page 65

28 February ’91

2.7 Enlargement Processing: VT2300/VT2500

In reduction processing, pixels are discarded according to the selected

reduction ratio. In enlargement processing, pixels are added.

Enlargement processing requires main scanning enlargement and

sub-scanning enlargement.

Main Scanning : Main scanning is performed by systematically

adding pixels according to the enlargement ratio.

Sub-Scanning : Sub-scanning is performed by changing the original

transportation speed according to the enlargement ratio.

2.7.1 Main Scanning Enlargement

When the magnification command is sent from the main control board

(CN402-19, 20, 21), the timing signal generator in the image processing

board sends the adding timing control signal. Pixels are added to the 4-bit