Page 1

IMPORTANT SAFETY NOTICES

+

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the printer and peripherals,

make sure that the printer power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. Note that some components of the printer are supplied with electrical

voltage even if the main switch is turned off.

4. If any adjustment or operation check has to be made with exterior

covers off or open while the main switch is turned on, keep hands away

from electrified or mechanically driven components.

HEALTH SAFETY CONDITIONS

1. If you get ink in your eyes by accident, try to remove it with eye drops or

flush with water as first aid. If unsuccessful, get medical attention.

2. If you ingest ink by accident, induce vomiting by sticking a finger down

your throat or by giving soapy or strong salty water to drink.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The printer and its peripherals must be installed and maintained by a

customer service representative who has completed the training course

on those models.

2. The RAM board has a lithium battery which can explode if handled

incorrectly. Replace only with the same type of RAM board. Do not

recharge or burn this battery. Used RAM boards must be handled in

accordance with local regulations.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Dispose of replaced parts in accordance with local regulations.

2. Used ink and masters should be disposed of in an envionmentally safe

manner and in accordance with local regulations.

3. When keeping used lithium batteries (from the main control boards) in

order to dispose of them later, do not store more than 100 batteries

(from the main control boards) per sealed box. Storing larger numbers

or not sealing them apart may lead to chemical reactions and heat

build-up.

Page 2

General Remarks

Each model code used in this manual represents the following models.

Model

Code

C207 SS955 1170/5270

C208 SS935 1160/5230

C210 VT3500 CP375/1280/5375 6720

C211 VT2100/

C212 VT2300 CP320/CP330/1260/5330

C213 VT2500

C215 VT2005 5323

C216 VT2105 CP325/1250/5325

C224 VT2200 CP327/1252/5327 6530 3200DNP

C226 VT2250/40 CP329(L)/1254(L)/5329(L) 6560 3250DNP

RICOH

Model

30/50

NRG Model A.B.Dick

CP310/CP315/1240/1241/1242/

5310/5315/5320

Model

SAVIN

Model

Page 3

SECTION 1

OVERALL MACHINE

INFORMATION

Page 4

1 November 1996 SPECIFICATIONS

1. SPECIFICATIONS

1.1 C226

Configuration: Desktop

Master processing: Digital

Printing process: Full automatic one-drum stencil system

Original type: Sheet/Book

Platen mode: Document Size:

Smaller than 257 x 364 mm [10.2" x 14.4"]

Thickness: Less than 30 mm

Weight: Less than 5 kg

ADF mode: Document Size

Length: 105 - 364 mm [4.1" - 16.5"]

Width: 148 - 364 mm [5.8" - 16.5"]

Overall

Information

Thickness:

0.05 to 0.2 mm [2 to 8 mils]

2

(equivalent to 50 - 90 g/m

)

0.04 to 0.4 mm [1.6 to 16 mils],

manually assisted

(equivalent to 40 - 120 g/m

2

)

Document Feed

Automatic feed, face up

ADF Capacity

30 sheets (using 20 lb paper)

Scanning method: Contact image sensor, with xenon lamp

Maximum scan width

256 mm [10.1"] ± 0.25%

1-1

Page 5

SPECIFICATIONS 1 November 1996

Reproduction ratios: U.S.A. Version Other Versions

Full Size 100% 100%

Reduction 65% 71%

74% 82%

77% 87%

93% 93%

Enlargement 121% 115%

129% 122%

155% 141%

Image mode: Letter, Photo, Letter/Photo

Color printing: Drum unit replacement system

Master feed/eject: Roll master automatic feed/eject

Printing area: M aximum: 250 mm x 355 mm (9.8" x 14.0") at

20°C/ 65 % RH.

(210 mm x 288 mm for the A4 drum model)

Leading edge margin:

5 ± 3 mm at the "0" position

Print paper size: Minimum: 90 mm x 148 mm (3.6" x 5.9")

Maximum: 297 mm x 432 mm (11.6" x 17.0")

2

Print paper weight: 47.1 g/m

to 209.3 g/m2 (12.5 lb to 55.6 lb)

Printing speed: 60, 75, 90, 105, 120 sheets/minute (5 steps)

First copy time: Platen mode:

Less than 26 seconds (B4 paper)

Less than 25 seconds (A4 paper)

ADF mode:

Less than 29 seconds (B4 paper)

Less than 28 seconds (A4 paper)

Second copy time: Platen mode:

Less than 28 seconds (B4 paper)

Less than 27 seconds (A4 paper)

ADF mode:

Less than 32 seconds (B4 paper)

Less than 31 seconds (A4 paper)

Paper feed table

capacity:

Paper delivery table

capacity:

2

1000 sheets (66.3 g/m

1000 sheets (66.3 g/m

/17.6 lb)

2

/17.6 lb)

(800 sheets when the small guide plates are

used.)

1-2

Page 6

1 November 1996 SPECIFICATIONS

Power source: 110/120 V, 60 Hz 4.5 A

220/240 V, 50/60 Hz 2.7 A

Maximum

power consumption:

110/120 V version: 325 W

220/240 V version: 340 W

Weight: 95 kg (209.4 lb)

Dimensions:

(W x D x H)

Trays closed: 685 mm x 625 mm x 620 mm

(27.0" x 24.6" x 24.4")

With ADF:

685 mm x 625 mm x 670 mm

(27.0" x 24.6" x 26.4")

Trays open: 1285 mm x 625 mm x 620 mm

(50.6" x 24.6" x 24.4")

With ADF:

(1285 mm x 625 mm x 670 mm

(50.6" x 24.6" x 26.4")

Pixel density: 300 dots/inch

Master eject box

capacity:

70 masters (Normal conditions)

60 masters (10°C/30%RH)

Paper feeding: Friction roller/center separation system

Overall

Information

Feed table side plate

88 mm to 330 mm (3.46" to 12.99")

width settings:

Paper feed roller

pressure:

Separation roller

pressure:

Side registration:

Vertical registration:

Normal position 300 g

Thick paper position 400 g

Normal position 180 g

Weak position 70 g

± 10 mm (manual)

± 20 mm (mechanical)

Ink supply: Automatic ink supply system

Press roller pressure:

10 ± 0.3 kg

Paper delivery: Air knife/vacuum delivery

1-3

Page 7

SPECIFICATIONS 1 November 1996

Delivery side plate width

90 mm to 320 mm (3.54" to 12.6")

settings:

Print counter: 7 digits

Master counter: 6 digits (Option)

Supplies:

Master for B4 model

Thermal master 280 mm width

Master roll 257 masters/roll

Roll diameter 130 mm

Max run length 2,000 prints

Master for A4 model

Thermal master 240 mm width

Master roll 290 masters/roll

Roll diameter 130 mm

Max run length 2,000 prints

Ink colors:

(600 ml/pack)

Black, Red, Blue, Green, Brown

Yellow, Purple, Navy, Maroon, Orange, Teal

1-4

Page 8

1 November 1996 SPECIFICATIONS

1.2 C224

Configuration: Desktop

Master processing: Digital

Printing process: Full automatic one-drum stencil system

Original type: Sheet

Original size: Maximum 307 mm x 432 mm (12.0" x 17.0")

Minimum 90 mm x 140 mm (3.6" x 5.5")

Reproduction ratios: VT Version A4 Version

Full Size 100% 100%

Reduction 93% 93%

75% 82%

64% 71%

Image mode: Line/Photo

Color printing: Drum unit replacement system

Master feed/eject: Roll master automatic feed/eject

Printing area: Maximum: 250 mm x 355 mm (9.8" x 13.9") at

20°C/ 65 % RH.

Overall

Information

Leading edge margin:

5 ± 3 mm at the "0" position

Print paper size: Minimum: 90 mm x 148 mm (3.6" x 5.8")

Maximum: 325 mm x 447 mm (12.7" x 17.5")

2

Print paper weight: 47.1 g/m

to 209.3 g/m2 (12.5 lb to 55.6 lb)

Printing speed: 60, 75, 90, 105, 120 sheets/minute (5 steps)

First copy time: Less than 35 seconds (B4)

Less than 32 seconds (A4)

Second copy time: Less than 38 seconds (B4)

Less than 35 seconds (A4)

2

Paper feed table

1,000 sheets (66.3 g/m

/17.6 lb)

capacity:

Paper delivery table

500 sheets (66.3 g/m

2

/ 17.6 lb)

capacity:

Power source: 110/120 V, 60 Hz 4.5 A

220/240 V, 50/60 Hz 2.7 A

1-5

Page 9

SPECIFICATIONS 1 November 1996

Maximum

power consumption:

110/120 V version: 280 W

220/240 V version: 280 W

Weight: 97kg (213.6 lb)

Dimensions:

(W x D x H)

Trays closed: 735 mm x 607 mm x 577 mm

(28.9" x 23.9" x 22.7")

Trays open: 1279 mm x 607 mm x 656 mm

(50.4" x 23.9" x 25.9")

2

ADF original capacity: 20 sheets (66 g/m

Original guide width

98 mm to 316 mm (38.6" to 12.44")

) or 1.8 mm height

settings:

Original scanning time: 2.5 ms/line

Original thickness: 0.05 mm to 0.8 mm

Original feed speed: 21.2 mm/second (When master processing)

33.9 mm/second (When not master processing)

Pixel density: 300 dots/inch

Master eject box

capacity:

70 masters (Normal condition)

60 masters (10°C/30% RH Condition)

Paper feeding: Friction roller/center separation system

Feed table side plate

88 mm to 330 mm (3.46" to 12.99")

width settings:

Paper feed roller

pressure:

Separation roller

pressure:

Side registration:

Vertical registration:

Normal position 300 g

Thick paper position 400 g

Normal position 180 g

Weak position 70 g

± 10 mm (manual)

± 20 mm (mechanical)

Ink supply: Automatic ink supply system

Press roller pressure:

10 ± 0.3 kg

Paper delivery: Air knife/vacuum delivery

Delivery side plate width

90 mm to 320 mm (3.54" to 12.6")

settings:

Print counter: 7 digits

1-6

Page 10

1 November 1996 SPECIFICATIONS

Master counter: 6 digits

Supplies:

Master: Thermal master 280 mm width

Master roll 257 masters/roll

Roll diameter 130 mm

Master length 480 mm/master

Max run length 2000 prints

Ink colors:

(600 ml/pack)

Black, Red, Blue, Green, Brown

Yellow, Purple, Navy, Maroon

Overall

Information

1-7

Page 11

SPECIFICATIONS 1 November 1996

1.3 C215/C216

Configuration: Desktop

Master processing: Digital

Printing process: Full automatic one drum stencil system

Original type: Sheet

Original size: Maximum 307 mm x 432 mm (12.0" x 17.0")

Minimum 90 mm x 140 mm (3.6" x 5.5")

Reproduction ratios: LT Version A4 Version

Full Size 100% 100%

Reduction 93% 93%

75% 82%

64% 71%

Image mode: Line/Photo

Color printing: Drum Unit replacement system

Master feed/eject: Roll master automatic feed/eject

Printing area: Maximum: 250 mm x 355 mm (9.8" x 13.9") at

20°C/ 65 % RH.

Leading edge margin:

5 ± 3 mm at "0" position

Print paper size: Minimum: 90 mm x 148 mm (3.6" x 5.8")

Maximum: 325 mm x 447 mm (12.8" x 17.6")

Print paper weight: 50 g/m

2

to 215 g/m

2

Printing speed: 60, 75, 90, 105, 120 sheets/minute (5 steps)

First print time:

Paper feed table

42 ± 3 seconds (B4 size)

1,000 sheets (66.3 g/m

2

/17.6 lb)

capacity:

Paper delivery table

500 sheets (66.3 g/m

2

/ 17.6 lb)

capacity:

Power source: 120 V, 60 Hz 3.0 A

220/240 V, 50/60 Hz 1.8 A

1-8

Page 12

1 November 1996 SPECIFICATIONS

Maximum

Power consumption:

120 V version: 300 W

220/240 V version: 300 W

Weight: C216–120 V version: 99 kg (217.8 lb)

C216–220/240 V version: 104 kg (228.8 lb)

C215–120 V version: 98 kg (215.6 lb)

C215–220/240 V version: 103 kg (226.6 lb)

Dimensions:

(W x D x H)

C216 Stored: 735 mm x 607 mm x 577 mm

(29.0" x 23.9" x 22.8")

C215 Stored: 735 mm x 607 mm x 569 mm

(29.0" x 23.9 " x 22.5")

Set up: 1279 mm x 607 mm x 656 mm

(50.4" x 23.9" x 25.9")

2

ADF original capacity:

20 sheets (66 g/m

) or 1.8 mm height

(C216)

Original guide width

98 mm to 316 mm (38.6" to 12.44")

settings:

Original scanning time: 5 ms/1 line

Original thickness: 0.05 mm to 0.8 mm

Overall

Information

Original feed speed: 16.9 mm/second (When master processing)

33.9 mm/second (When not master processing)

Pixel density: 300 dots/inch

Master eject box

capacity:

30 masters (Normal condition)

25 masters (10°C/30% RH Condition)

Paper feeding: Friction roller/center separation system

Feed table side plate

88 mm to 330 mm (3.46" to 12.99")

width settings:

Paper feed roller

pressure:

Separation roller

pressure:

Side registration:

Vertical registration:

Normal position 250 g

Thick paper position 550 g

Normal position 180 g

Weak position 70 g

± 10 mm (manual)

± 20 mm (mechanical)

Ink supply: Automatic ink supply system

Press roller pressure:

10 ± 0.3 kg

Paper delivery: Air knife/vacuum delivery

1-9

Page 13

SPECIFICATIONS 1 November 1996

Delivery side plate width

90 mm to 320 mm (3.54" to 12.6")

settings:

Print counter: 7 digits

Master counter: 6 digits

Supplies:

Master: Thermal master 280 mm width

Master roll 250 masters/1 roll

Roll diameter 130 mm

Master length 480 mm/1 master

Max run length 2,000 prints

Ink colors: (600 cc/pack) Black, Red, Blue, Green, Brown

1-10

Page 14

1 November 1996 SPECIFICATIONS

1.4 C212/C213

Configuration: Desktop

Master processing: Digital

Printing process: Full automatic one drum stencil system

Original type: Sheet

Original size: Maximum 307 mm x 432 mm (12.0" x 17.0")

Minimum 90 mm x 140 mm (3.6" x 5.5")

Reproduction ratios: 3 Enlargement and 3 Reduction

LT Version A4 Version

Enlargement 141% 141%

127% 122%

115% 115%

Full Size 100% 100%

Reduction 93% 93%

75% 82%

64% 71%

Image mode: Line/Photo

Overall

Information

Color Printing: Drum Unit replacement system

Master feed/eject: Roll master automatic feed/eject

Printing area: Maximum: 250 mm x 350 mm (9.8" x 13.7") at

20°C/ 65 % RH.

Leading edge margin:

10 ± 3 mm at "0" position

Print paper size: Minimum: 90 mm x 148 mm (3.6" x 5.8")

Maximum: 325 mm x 447 mm (12.8" x 17.6")

Print paper weight: 50 g/m

2

to 215 g/m

2

Printing speed: 60, 75, 90, 105, 120 sheets/minute (5 steps)

1-11

Page 15

SPECIFICATIONS 1 November 1996

First print time: 34.5 seconds (B4 size)

31.5 seconds (A4 Size)

2

Paper feed table

1000 sheets (66.3 g/m

/17.6 lb)

capacity:

Paper delivery table

500 sheets (66.3 g/m

2

/ 17.6 lb)

capacity:

Power source: 110V, 60 Hz..................6.0A

120 V, 60 Hz ................5.5 A

220/240 V, 50/60 Hz.....2.7 A

Power consumption: 110/120 V version: 430 W

220/240 V version: 470 W

Weight: 120 V version: 102 kg (224.8 lb)

220/240 V version: 107 kg (235.8 lb)

Optional Table: 26 kg (57.3 lb)

Dimensions:

(W x D x H)

Stored: 735 mm x 607 mm x 577 mm

(29.0" x 23.9" x 22.8")

Set up: 1279 mm x 607 mm x 656 mm

(50.4" x 23.9" x 25.9")

Table: 640 mm x 570 mm x 455 mm

(25.2" x 22.4" x 17.9")

ADF original capacity: 20 sheets (66 g/m

Original guide width

98 mm to 316 mm (38.6" to 12.44")

2

) or 1.8 mm height

settings:

Original scanning time: 3 ms/1 line

Original thickness: 0.05 mm to 0.8 mm

Original feed speed: 20.8 mm/second (When master processing)

41.7 mm/second (When not master processing)

Pixel density: 16 dots/mm

Master eject box

capacity:

25 masters (Normal condition)

20 masters (10°C/30% RH Condition)

Paper feeding: Friction roller/center separation system

1-12

Page 16

1 November 1996 SPECIFICATIONS

Feed table side plate

88 mm to 330 mm (3.46" to 12.99")

width

settings:

Paper feed roller

pressure:

Separation roller

pressure:

Side registration:

Vertical registration:

Normal position 250 g

Thick paper position 550 g

Normal position 180 g

Weak position 70 g

± 10 mm (manual)

± 20 mm (mechanical)

Ink Supply: Automatic ink supply system

Press roller pressure:

10 ± 0.3 kg

Paper Delivery: Air knife/vacuum delivery

Delivery side plate width

80 mm to 320 mm (3.15" to 12.6")

settings:

Print counter: 7 digits

Master counter: 6 digits

Overall

Information

Supplies:

Master Thermal master 280 mm width

Master roll 250 masters/1 roll

Roll diameter 130 mm

Master length 480 mm/1 master

Max run length 2,000 prints

Ink Colors: Black, Red, Blue, Green, Brown

(600 cc/pack)

1-13

Page 17

SPECIFICATIONS 1 November 1996

1.5 C211

Configuration: Desk top

Master processing: Digital

Printing process: Full automatic one drum stencil system

Original type: Sheet

Original size: Maximum 307 mm x 432 mm (12.0" x 17.0")

Reproduction ratios: LT version: 100 %, 93 %, 75 %, 64 %

A4 version: 100 %, 93 %, 82 %, 71 %

Image mode: Line/Photo

Color printing: Drum unit replacement system

Master feed/eject: Roll master automatic feed/eject

Master processing area: B4 model: Maximum 256 mm x 354 mm

(10.1" x 13.9")

LG model:Maximum 216 mm x 354 mm

(8.5" x 13.9")

A4 model: Maximum 216 mm x 287 mm

(8.5" x 11.3")

Printing area: B4 model: Maximum 250 mm x 350 mm

(9.8" x 13.7") at 20°C/65 % RH

LG model:Maximum 210 mm x 350 mm

(8.3" x 13.7") at 20°C/65% RH

A4 model: Maximum 210 mm x 283 mm

(8.3" x 11.1") at 20°C/65% RH

Leading edge margin: 10 mm

Print paper size: Minimum 90 mm x 148 mm (3.6" x 5.8")

Maximum 297 mm x 442 mm (11.6" X 17.4")

Print paper weight: 50 g/m

2

to 215 g/m

2

Print speed: 60, 75, 90, 105, 120 sheets/minute (5 steps)

First print time: B4 model: 35 seconds (B4 size)

LG model: 35 seconds (LG size)

A4 model: 31 Seconds (A4 size)

2

Paper feed table capacity 1000 sheets (66.3 g/m

Paper delivery table

500 sheets (66.3 g/m

/ 17.6 lb)

2

/ 17.6 lb)

capacity:

1-14

Page 18

1 November 1996 SPECIFICATIONS

Power source: 220/240V, 50/60 Hz......2.7 A

120V, 60 Hz..................5.5 A

110V, 60 Hz..................6.0 A

Power consumption: 110/120 V version: 430 W

220/240 V version: 470 W

Weight: 110/120 V version: 100 kg (220.4 lb)

220/240 V version 105 kg (233.7 lb)

Optional table: 26 kg (57.3 lb)

Dimensions:

(W x D x H)

When stored: 735 mm x 607 mm x 569 mm

(29.0" x 23.9" x 22.4")

When set up: 1279 mm x 607 mm x 656 mm

(50.4" x 23.9" x 25.9")

Table only: 640 mm x 570 mm x 455 mm

(25.2" x 22.4 x 17.9")

Original guide

98 mm to 316 mm (38.6" to 12.44")

width-settings:

Original scanning time: 3 ms/1 line

Original thickness: 0.06 mm to 0.5 mm

Original feed speed: 20.8 mm/second

Pixel density: 16 dots/mm

Overall

Information

Master eject box

capacity:

25 masters (at normal conditions)

20 masters (at 10°C/30 % RH)

Paper feeding: Friction roller/center separation system

Feed table side plate

88 mm to 317 mm (3.46" to 12.48")

width settings:

Paper feed roller

pressure:

Separation roller

pressure:

Side registration:

Vertical registration:

Paper table raising /

lowering speed:

Normal position ...........250 g

Thick paper position.....550 g

Normal position ............180 g

Weak position...............70 g

±10 mm (manual)

±20 mm (mechanical)

22 mm/second (50 Hz)

26 mm/second (60 Hz)

Ink supply: Automatic ink supply system

Pressure roller pressure:

10 ± 0.3 kg

1-15

Page 19

SPECIFICATIONS 1 November 1996

Paper delivery: Air knife/vacuum delivery

Delivery side plate

80 mm to 320 mm (3.15" to 12.6")

width settings:

Print counter: 7 digits

Master counter: 6 digits

Supplies:

Master for B4 model:

Thermal master 280 mm width

Master roll 250 masters/1 roll

Master length 480 mm/1 master

Max run length 2000 prints

Master for A4/LG model:

Thermal master 240 mm width

Max run length 2000 prints

LG model: Master roll 250 masters/1 roll

Master length 480 mm/1 master

A4 model: Master roll 300 masters/1 roll

Master length 413 mm/1 master

Ink: 600 cc ink pack

Colors: Black, Red, Blue, Green, Brown

1-16

Page 20

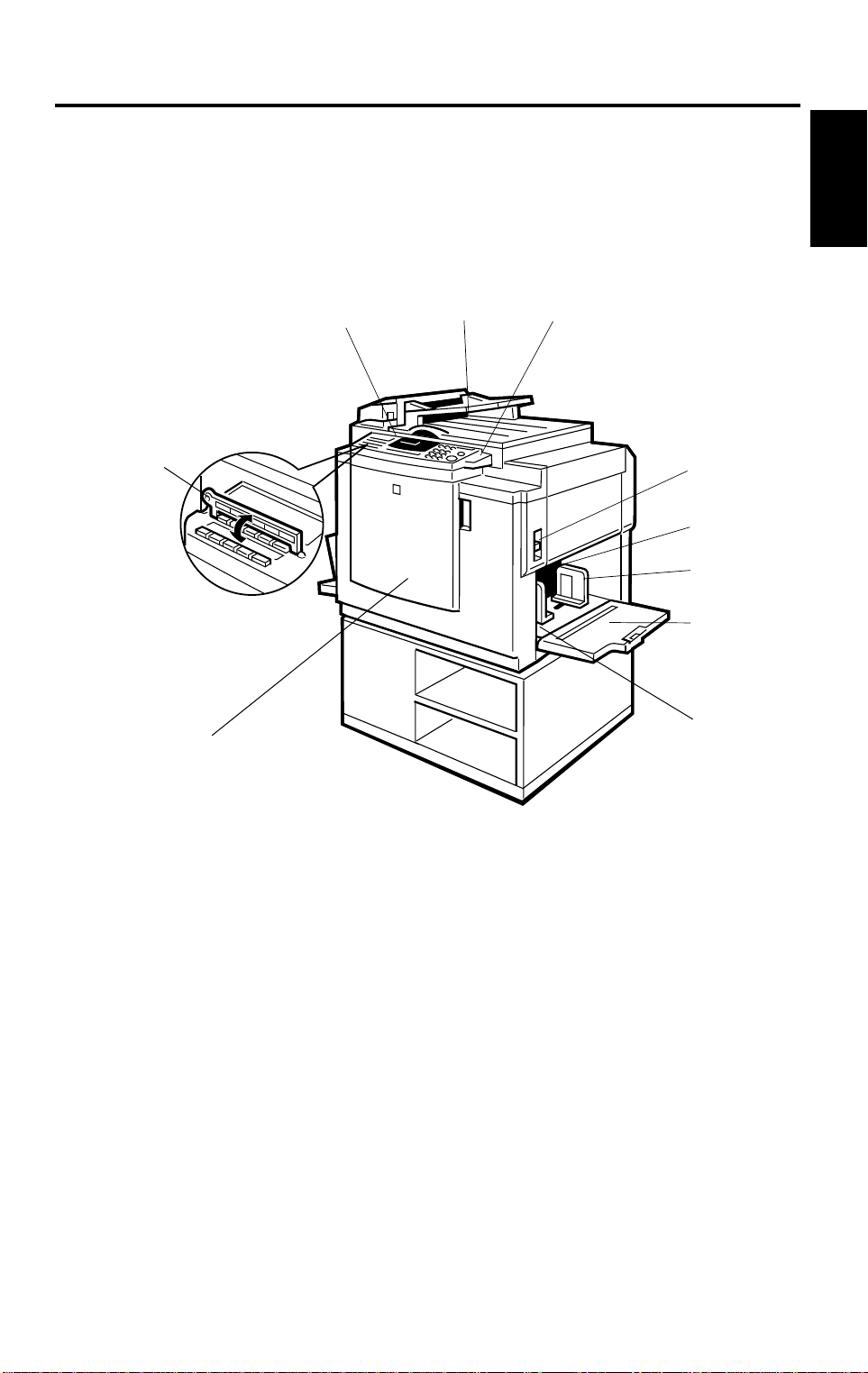

1 November 1996 GUIDE TO COMPONENTS AND THEIR FUNCTION: C226

2. GUIDE TO COMPONENTS AND THEIR

FUNCTION: C226

2.1 Machine Exterior

10

9

Overall

Information

1

2

3

4

5

6

7

8

1-17

Page 21

GUIDE TO COMPONENTS AND THEIR FUNCTION: C226 1 November 1996

1. Operation panel

2. Platen cover

3. Original table

release lever

4. Feed roller

pressure lever

5. Separation roller

pressure lever

6. Paper feed side

plates

7. Paper feed table

8. Side plate fine

adjusting dial

9. Front cover

Operator controls and i ndicators are locat ed here.

Lower this cover ove r an original before prin ting.

Use to open the original table unit when installing the master.

Use to adjust the contac t pressure of the paper fee d ro l ler

according to pa per th ickness.

Use to adjust the separa tion roller pressu re to prevent

double feed.

Use to prevent paper sk ew .

Set paper on this table fo r pri nti ng.

Use to shift the pape r feed table sidewa ys .

Open to access to the in side of the machine.

10.Plate

Flip over when you use One Touch Class fu nct ion.

1-18

Page 22

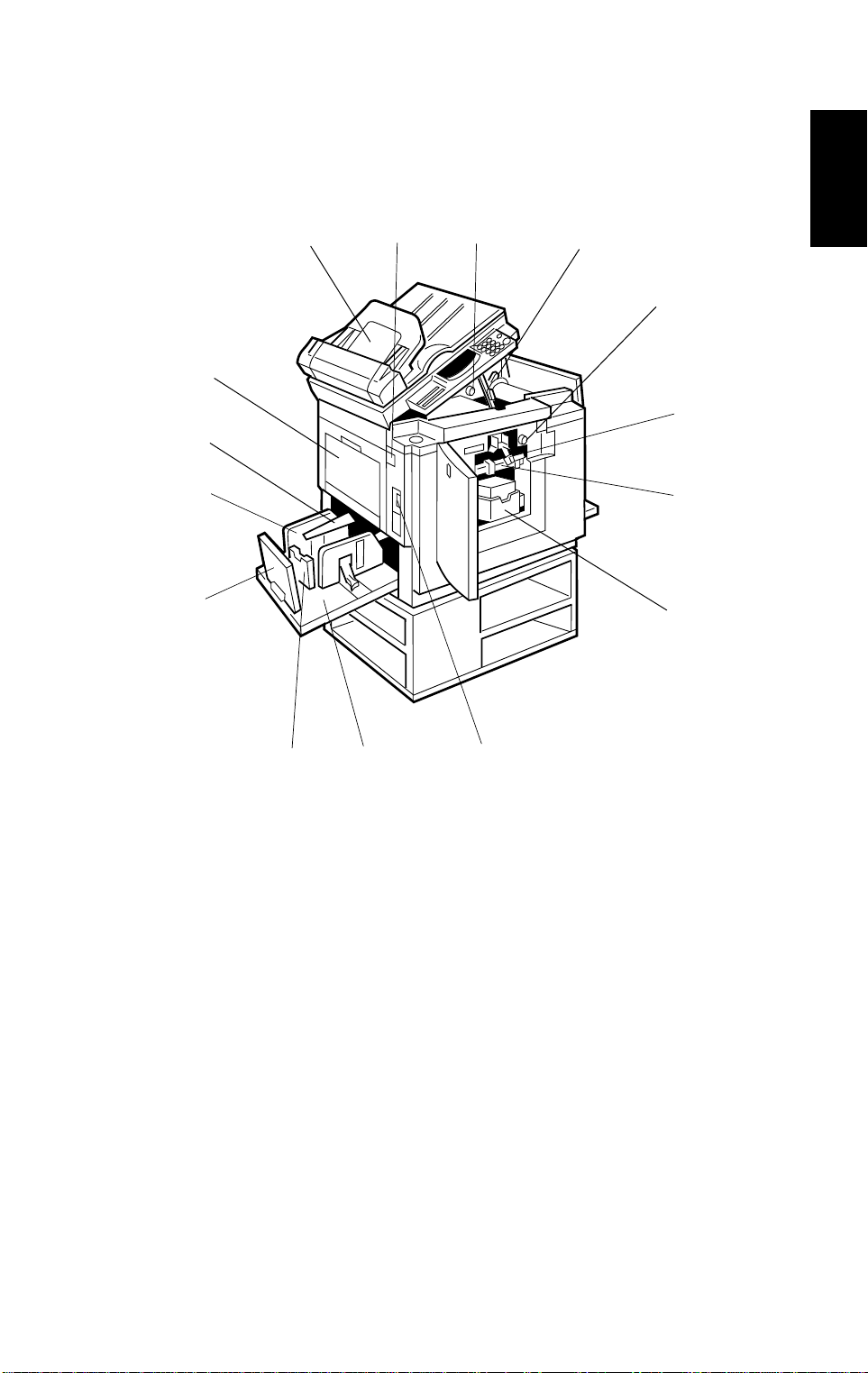

1 November 1996 GUIDE TO COMPONENTS AND THEIR FUNCTION: C226

2.2 Machine Interior

1

15

14

23

4

5

6

Overall

Information

13

12

11

10

7

8

9

1-19

Page 23

GUIDE TO COMPONENTS AND THEIR FUNCTION: C226 1 November 1996

1. Document feeder

(Option)

2. Master eject unit

open button

3. Master cut button

4. Pressure release

lever

5. Drum rotation

button

6. Drum unit lock

lever

7. Drum unit

8. Ink holder

9. Main switch

10.Paper delivery table

11.Small size paper

delivery end plate

Original inser ted i nt o th e doc um ent feeder are indivi d ual l y

and automatica ll y fed ont o and removed from t he ex posure

glass.

Press to remove mis fe d pap er or a m isf ed master.

Press this button to cut the m aster leading edge after

installing a new master roll.

Use to install the master roll.

Press to rotate the drum unit.

Lift to unlock and pull out the drum unit.

The master is wrapped around this unit.

Set the ink cartridge in this holder.

Use to turn the power on or of f.

Completed print s ar e deli vered here.

Use to align the leading edge of prints tha t are A4, 8

1/2

" x 11"

or smaller.

12.Paper delivery end

plate

13.Paper delivery side

plate

14.Wing guides

15.Master eject

container cover

Use to align the leading edge of prints larg er tha n A4, 8

1/2

11".

Use to align the prints on the paper delivery table.

When printing on th i n or sm al l size paper, lift these guides.

Open when remov ing t he m aster eject box.

" x

1-20

Page 24

1 November 1996 OPERATION PANEL: C226

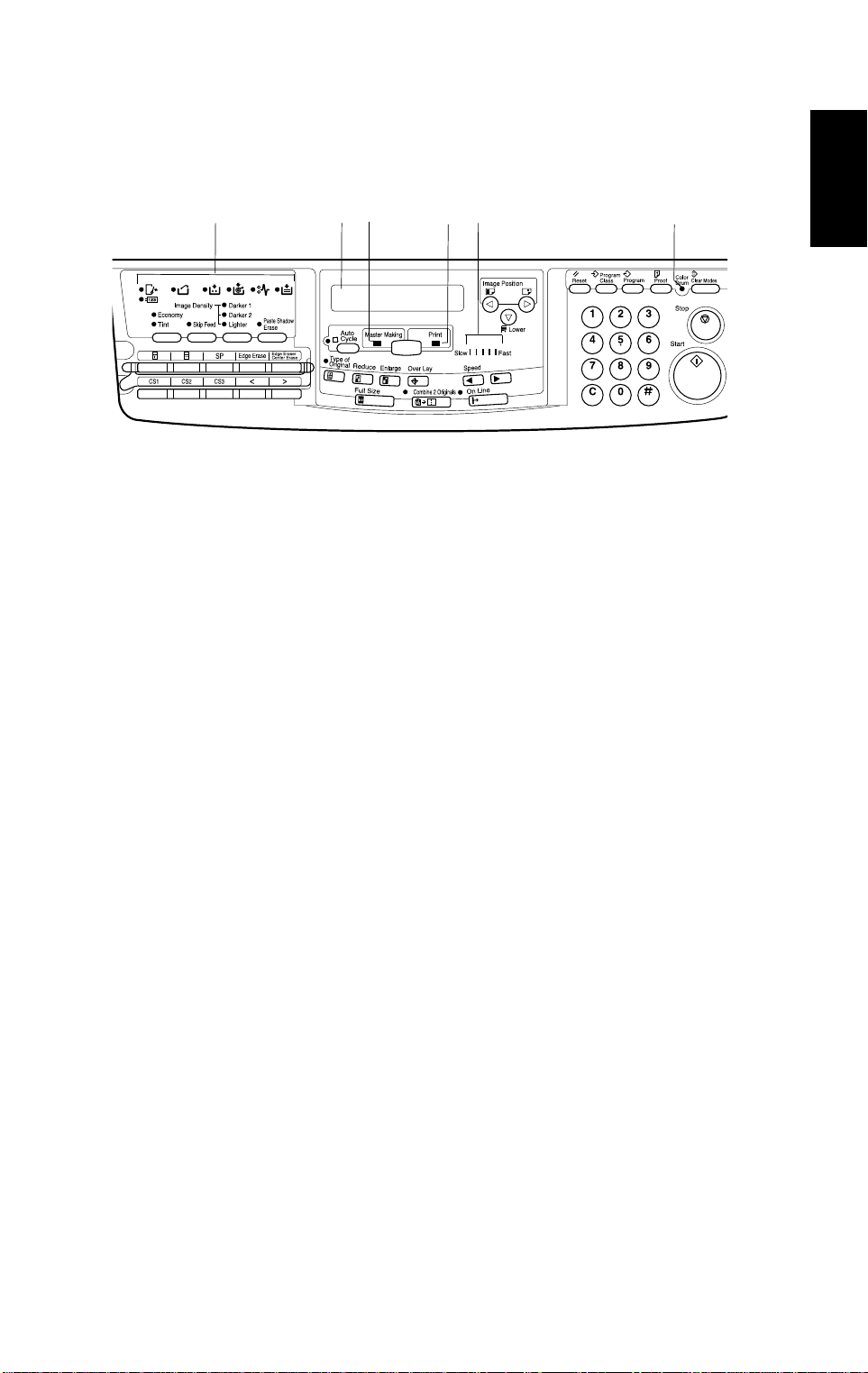

3. OPERATION PANEL: C226

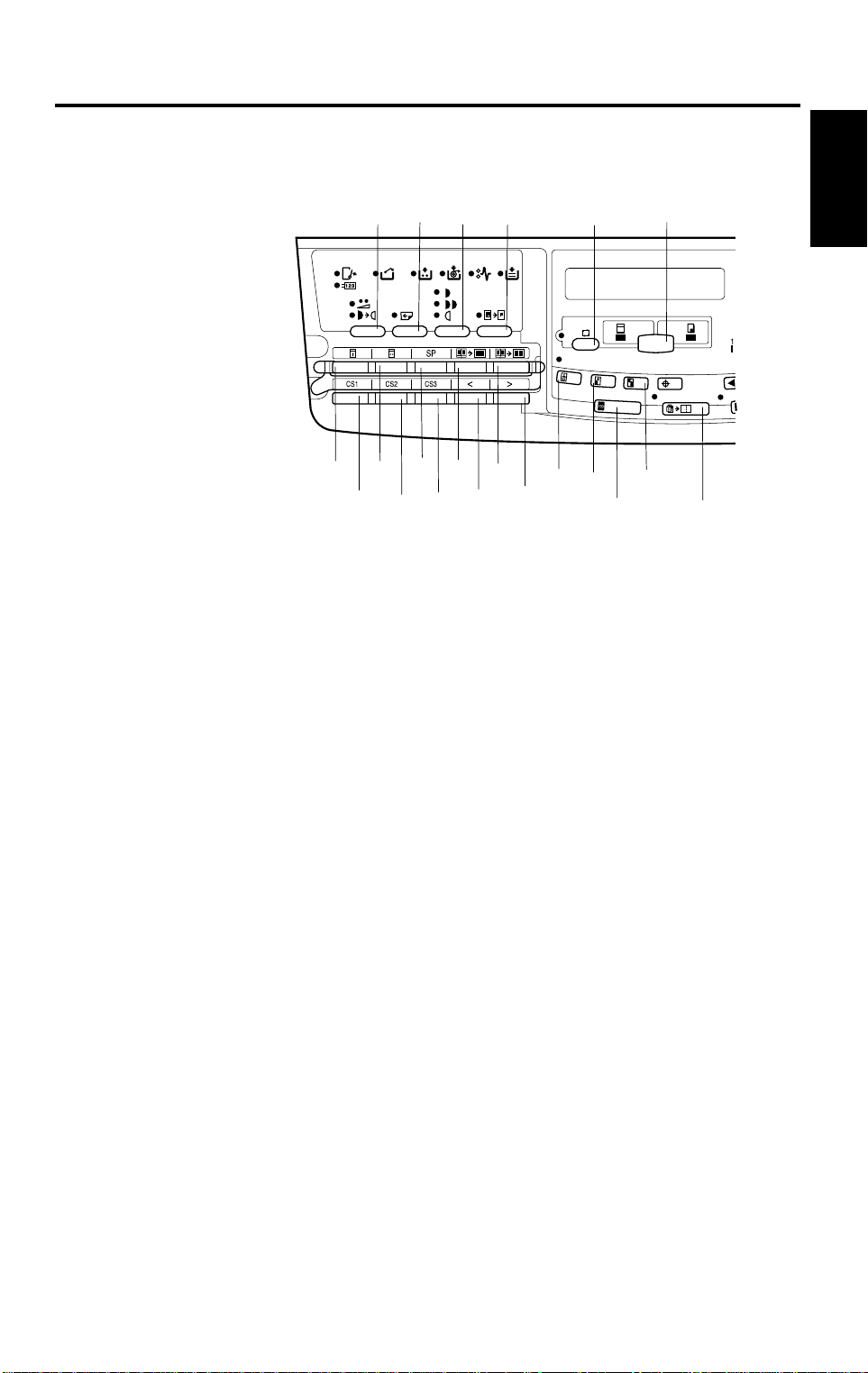

3.1 Keys

1

2

4

3

5

6

Overall

Information

7

1. Economy/Tint key

2. Skip Feed key

3. Image Density key

4. Paste Shadow Erase key

5. Auto Cycle key

6. Master Makin g/ Prin t key

Press to select Master Making or Print

mode.

7. Security key

8. Quality Start key

9. SP mode key

10. Edge Erase key

12

8

9

13 14

10 11

15

16

17

18

20

19

21

11. Edge Erase/Center Era se key

12. 13. 14. CS mode key s

15. 16. Scroll keys

Press to select si ze and direction

of paper or original in Edge

Erase/Center Erase and Edge

Erase function.

Press to select the mo de i n

Service Program mode.

17. Type of Original key

18. Reduce key

19. Enlarge key

1-21

Page 25

OPERATION PANEL: C226 1 November 1996

22

28

29

23

20. Full Size key

Press to make full size prints.

21. Combine 2 Orig in al s key

22. Image Position keys

23. Reset key

Press to reset the error indicators.

24. Program Class key

25. Program key

26. Proof key

Press to make proof prints.

27. Clear Modes key

Press to cancel all previously

entered settings.

28. Speed keys

30

24 25

31

27

26

32

33

29. Lower key

Press to lower the paper feed

table.

30. Clear key

Press to change the nu m ber set .

31. Number keys

Press to enter the number of

prints and data.

32. Enter key

Press to input data int o m em ory.

33. Start key

Press t o start ma king of a master

or printing.

34. Stop key

Press to stop the machine

operation.

34

1-22

Page 26

1 November 1996 OPERATION PANEL: C226

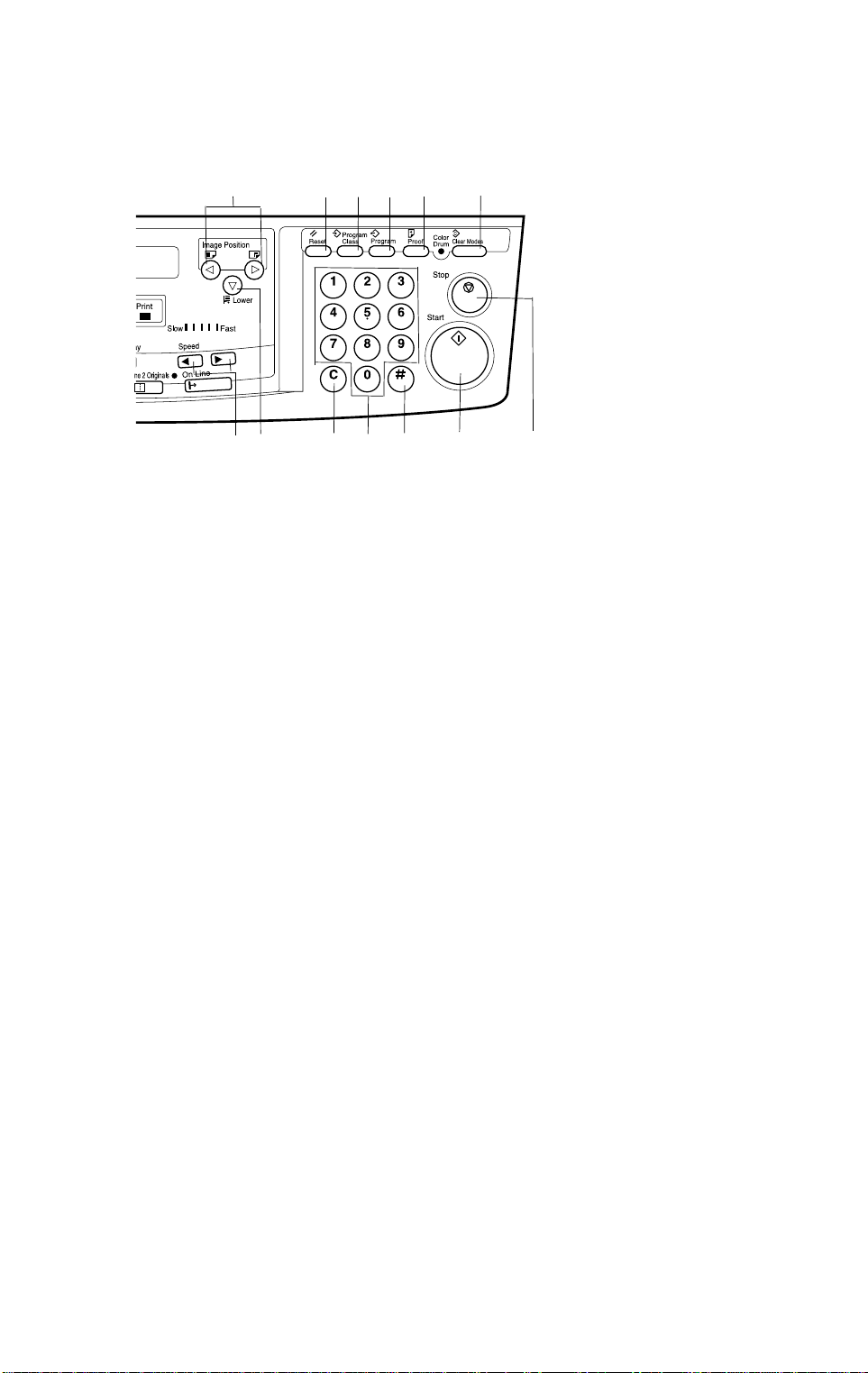

3.2 Indicators

1

1. Error indicators

These indicators are lit when a

non-standard condition occurs

within the machine.

2. Guidance Display

Press to stop the machine

operation.

3. Master Making indicator

This indicator is lit when Master

Making mod e is sel ected.

2

3

5

4

4. Print indicator

6

Overall

Information

This indicator is lit when Print

mode is selected.

5. Speed indicators

These indicators show the

printing speed that is selected.

6. Color Drum indicator

This indicator is lit when the

optional colo r drum unit is set.

1-23

Page 27

PRINTING PROCESS 1 November 1996

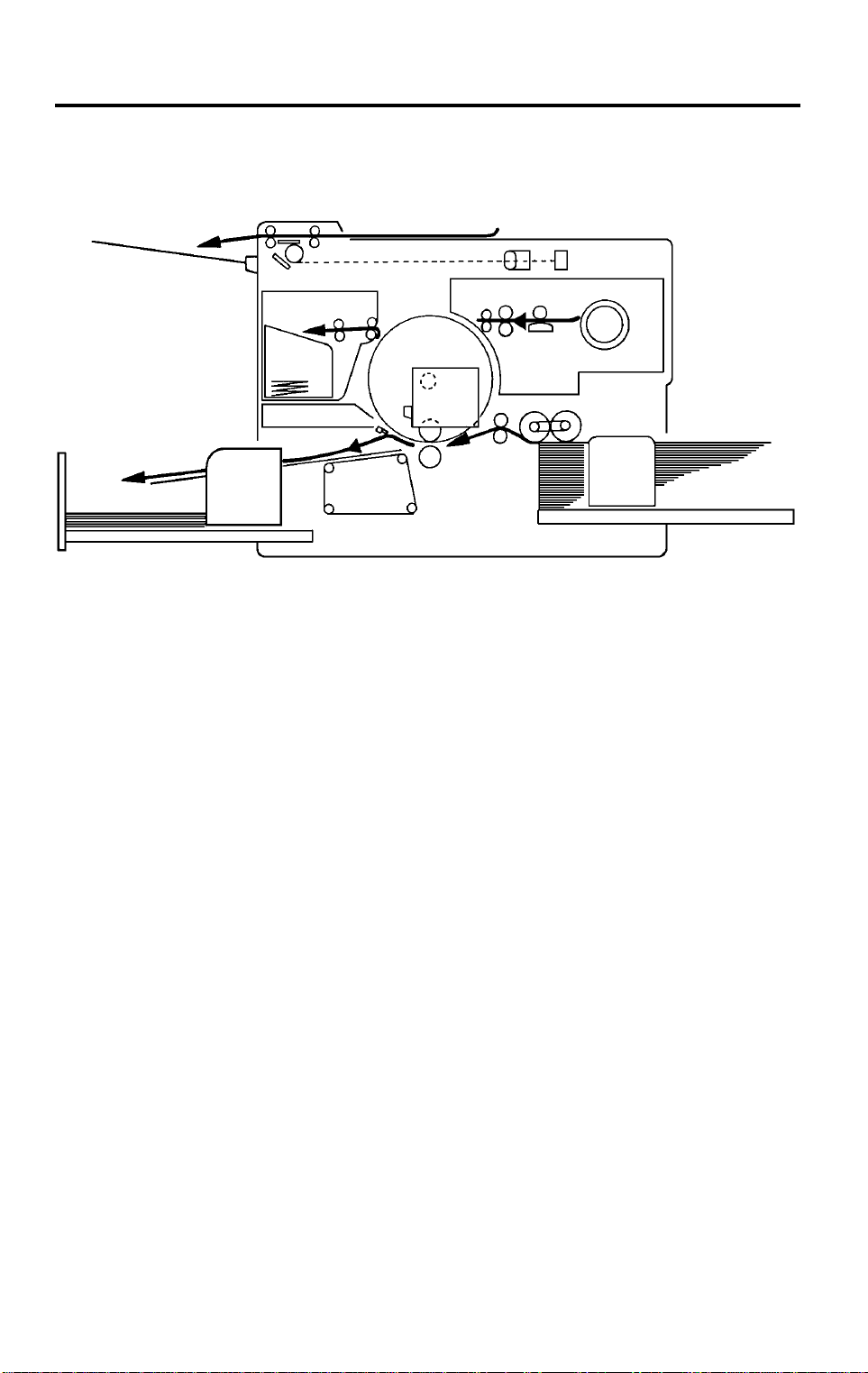

4. PRINTING PROCESS

2

1

6

4

5

1. Master Ejecting: Eject the used master wrapped around the

drum into the master eject box.

2. Scanning: Scan the original image by CCD through the

mirror and the lens while feeding the original.

3

3. Master Feeding: Convert the image signal read by CCD into the

digital signal and send it to the thermal head to

make holes on the surface of the master and

then, set the master around the drum.

4. Paper Feeding: Send paper to the drum section by using center

separation system consisting of the separation

plate and separation roller.

5. Printing: Press the paper fed from the paper feed section

to the drum to transfer the ink through drum

screen and the master.

6. Paper Delivering: Peel the printed paper with the Exit Pawl and

Air knife and eject the paper onto the paper

delivery table.

1-24

Page 28

1 November 1996 ELECTRICAL COMPONENTS LAYOUT

5. ELECTRICAL COMPONENTS LAYOUT

5.1 C226

5.1.1 ADF and Scaner

4

1

17

19

20

Overall

Information

6

9

13

21

22

25

1-25

28

Page 29

ELECTRICAL COMPONENTS LAYOUT 1 November 1996

Table

INDEX

NO.

Printed Circuit Board

1 OPU (Operation Pan el Uni t ) This boar d co nt ro l s the operation panel.

Contact Image Sens or and

Xenon Lamp

9

Motors

6 ADF Motor This stepper motor dri ves the scan ner .

4 Scanner Motor This stepper motor dr ives the book scanner.

Sensors and Switches

Document Sensor This detects the presence of a docu m ent i n th e

17

Scan Line Sensor This detects when a page i s app ro aching the auto

19

20 Not used

ADF Cover Switch This detects whether the ADF cover is open or

21

Scanner Home Positi on

28

Sensor

Platen Cover Sensor This detects wheth er the plat en cover is open or

25

22 ADF Swi t ch This detects whether th e ADF unit i s open or closed.

NAME FUNCTION

This sensor reads an d converts the light reflected

from the document in to an analog video sig nal. It

uses an RMLA (Roof Mi rror Lens Array) sensor un it.

The xenon lamp which illuminates the document is

contained in t his unit .

feeder.

shadi ng posit ion.

closed.

This detects when the image sensor is at home

position.

closed.

Others

13 Lamp Stabilizer This supplies power to the xenon lamp.

1-26

Page 30

1 November 1996 ELECTRICAL COMPONENTS LAYOUT

5.1.2 Main Body

39

63

Overall

Information

28

27

26

29

5

30

31

2

1

33

3

34

4

32

35

36

19

20

21

25

24

23

22

1-27

Page 31

ELECTRICAL COMPONENTS LAYOUT 1 November 1996

59

60

14

62

64

65

61

58

54

53

55

52

51

56

57

50

49

48

47

46

45 44

18

37

38

40

41

42

43

1-28

Page 32

1 November 1996 ELECTRICAL COMPONENTS LAYOUT

Table

INDEX

No.

Motors

Main Motor Drives paper feed, drum, printing and paper delivery

1

Vacuum Motor Provides suction so that paper is held f irm ly on the

4

20 Master Fe ed M ot or Feeds the master to the drum.

22 Pressure Pl at e M otor Raises and lower s the pr essure plate.

Air Knife Motor Rotates the fan to provide air to separate the paper

26

28 Master Ejec t Mot or Sends used masters into the mas te r eje ct box.

33 Cutter Motor Cuts the master.

Image Shift Motor Changes the timing bet ween the paper feed roller

60

64 Paper Table Drive Motor Raises and lowers the paper table.

Solenoids

Ink Supply Solenoid Releases the spr ing cl utch to activate the ink supply

21

29 Master Ejec t Solenoid Opens the master clamp to eject the master.

Paper Feed Solenoid Releases the paper feed sector gear to rotate the

51

52 Printing Pr ess ur e Sol enoid Moves the press roller against the drum.

Master Eject Clamper

56

Solenoid

Drum Lock Solenoi d Preven ts removal of the drum unit w hen the drum is

58

Master Feed Clamp er

59

Solenoid

NAME FUNCTION

unit component s.

transport belt.

leading edge from the dru m .

and the drum to adjust the ver t i cal i m age position.

pump.

paper feed roller .

Opens the master cl am p to eject the mast er .

not at the home positi on.

Opens the master cl am p to eject the mast er .

Overall

Information

Switches

Scanner Unit Safety Sw itc h Check w het her the scanner unit is set corre ct l y or

14

Plotter Cover Safety Sw itc h Check whether the co ver on t he plotter unit is closed

18

19 Left Cutter Switch Detects when the cutter position is at the far left.

Master Eject Box Switch Checks whether the master eject box is installed

27

32 Right Cutter Switch Detects when the cutter position is at the far right.

37 Front Doo r Safet y Swi tch Checks whether the front door is set correctly or no t.

38 Drum Safety Switch Checks whether the drum unit is set correctly or not.

Paper Table Safety Switch Checks whether the paper table is opened or not.

41

not.

correctly or not.

correctly or not.

1-29

Page 33

ELECTRICAL COMPONENTS LAYOUT 1 November 1996

INDEX

No.

Test Switch Releases the cover safety functions. (NOTE:)

47

Main Switch Turns the power on or off.

48

Master Eject Unit Safety

49

Switch (220V machines only)

Master Eject Unit Safety

55

Switch (115V machines only)

Master Cutter Switch Informs the CPU to cut the master paper leading

62

65 Drum Rotation Switch Informs the CPU to rotate the main motor at 10 rpm.

Sensors

3 1st Paper Exit Sen sor Detects misfeeds.

5 2nd Paper Exit Sensor Detects misfeeds.

Lower Pressure Plate Sensor Informs the CPU if the pressure plate is at the lower

23

Full Master Box Sensor Informs the CPU if the master eject box is full of

24

NAME FUNCTION

Checks whether the ma st er e ject uni t is cl osed

correctly or not. Cuts the ac power.

edge.

limit position.

used masters.

Upper Pressure Plate Sensor Informs the CPU if the pressure plate is at the upper

25

30 Master Ejec t Sen sor Det ects m aster eject jams.

34 Master Buc kle Sensor Detects master buckling.

Master End Sensor Informs the CPU when the plotter unit runs out of

35

Paper Table Height Sensor Detects when the paper table reaches t he paper

40

Paper Table Low er Limit

42

Sensor

43 Printing Press ur e Sensor Informs the CPU when print ing pr es sur e i s ap pl ied.

Paper End Sensor Informs the CPU when the paper table runs out of

44

50 Drum Rot ati on Sensor Supp l ies t i m ing pulses to the main boar d.

53 2nd Drum Posi ti on Sensor Checks the positi on of th e dr um .

57 1st Drum Posit i on Sensor Checks the position of the drum.

Printed Circuit Board

Main Control PCB Controls all machine functions both directly and

39

limit position.

master roll.

feed position.

Detects when the paper table reach e s the l ow est

position.

paper.

through other boards.

1-30

Page 34

1 November 1996 ELECTRICAL COMPONENTS LAYOUT

INDEX

No.

54 Ink Detection PCB Checks if the ink is present in the drum.

63 Power Suppl y PCB Rectifies 100 V ac input and supplies dc vol tage.

Counters

45 Copy Coun te r Keeps track of the total number of copies made.

46 Maste r Counter Keeps track of the total num ber of ma st er s m ade.

Others

2 Transformer Steps down the wall vol t ag e.

Reverse Roller Clutch Transfers master feed motor rotation to the reverse

31

36 Thermal H ead Burns the image onto the master.

61 Encoder Converts 16 image positions to 4 bit data.

NOTE:

1) The Master Eject Unit Safety Switch in the 220 V machines cannot

NAME FUNCTION

roller at proper timi ng.

be disabled by this test switch.

2) When you use this test switch, be sure to return it to home position

after servicing in order to recover the cover safety functions.

Overall

Information

1-31

Page 35

ELECTRICAL COMPONENTS LAYOUT 1 November 1996

5.2 C224

Electrical Component Layout

14

13

12

11

10

15

16

17

18

1

9

2

8

7

6

5

31

30

29

32

4

33

3

34

35

36

28

19

27

26

25

24

20

21

22

23

1-32

Page 36

1 November 1996 ELECTRICAL COMPONENTS LAYOUT

55

54

53

56

52

51

57

50

58

49

59

48

60

47

61

46 45

62

63

44

64

Overall

Information

65

66

37

38

39

40

41

42

43

1-33

Page 37

ELECTRICAL COMPONENTS LAYOUT 1 November 1996

Table

INDEX

No.

Motors

Main Motor Drives paper feed, drum, printing and paper delivery

1

Vacuum Motor Provides suction so that paper is held f irm ly on the

4

7 ADF Drive Motor Feeds the origin al to the original transp or t se ct i on.

12 Origina l Tra nsport Motor Transports the original to the scanner section.

20 Master Fe ed M ot or Feeds the master to the drum.

22 Pressure Pl at e M otor Raises and lower s the pr essure plate.

Air Knife Motor Rotates the fan to provide air to separate the paper

26

28 Master Ejec t Mot or Sends used masters into the mas te r eje ct box.

33 Cutter Motor Cuts the master.

Image Shift Motor Changes the timing bet ween the paper feed roller

60

64 Paper Table Drive Motor Raises and lowers the paper table.

Solenoids

Original Pressure Solenoid Presses the original pressure plate down on the

11

Ink Supply Solenoid Releases the spr ing cl utch to activate the ink supply

21

29 Master Ejec t Solenoid Opens the master clamp to eject the master.

Paper Feed Solenoid Releases the paper feed sector gear to rotate the

51

52 Printing Pr ess ur e Sol enoid Moves the press roller against the drum.

Master Eject Clamper

56

Solenoid

Drum Lock Solenoi d Preven ts removal of the drum unit w hen the drum is

58

Master Feed Clamp er

59

Solenoid

NAME FUNCTION

unit component s.

transport belt.

leading edge from the dru m .

and the drum to adjust the ver t i cal i m age position.

originals.

pump.

paper feed roller .

Opens the master cl am p to eject the mast er .

not at the home positi on.

Opens the master cl am p to eject the mast er .

Switches

Printing Density Switch Use to select the printing density corresponding to

6

14 ADF Safety Swit ch Check whether the ADF un it is se t co rrectly or not.

Fluorescent Lamp Safety

18

Switch

19 Left Cutter Switch Detects when the cutter position is at the far left.

Master Eject Box Switch Checks whether the master eject box is installed

27

32 Right Cutter Switch Detects when the cutter position is at the far right.

the type and quality of the ori gi n al .

Cuts the power for the fluorescent lamp when the

scanner is opene d.

correctly or not.

1-34

Page 38

1 November 1996 ELECTRICAL COMPONENTS LAYOUT

INDEX

No.

37 Front Doo r Safet y Swi tch Checks whether the front door is set correctly or no t.

38 Drum Safety Switch Checks whether the drum unit is set correctly or not.

41 Paper Table Safety Switch Checks whether the paper table is opened or not.

47 Test Switch Releases the cover safety functions. (NOTE:)

48 Main Switch Turns the power on or off.

Master Eject Unit Safety

49

Switch (220V machines only)

Master Eject Unit Safety

55

Switch (115V machines only)

Master Cutter Switch Informs the CPU to cut the master paper leading

62

65 Drum Rotation Switch Informs the CPU to rotate the main motor at 10 rpm.

Sensors

3 1st Paper Exit Sen sor Detects misfeeds.

5 2nd Paper Exit Sensor Detects misfeeds.

Original Regist r at i on Sen sor Detects misfeeds in the AD F, and synchronizes

9

10 2nd Orig inal Sensor Detects when the original comes to the feed position .

13 1st Original Sensor Detects when the original is set in the ADF mode.

Lower Pressure Plate Sensor Informs the CPU if the pressure plate is at the lower

23

Full Master Box Sensor Informs the CPU if the master eject box is full of

24

Upper Pressure Plate Sensor Informs the CPU if the pressure plate is at the upper

25

30 Master Ejec t Sen sor Det ects m aster eject jams.

34 Master Buc kle Sensor Detects master buckling.

Master End Sensor Informs the CPU when the plotter unit runs out of

35

Paper Table Height Sensor Detects when the paper table reaches t he paper

40

Paper Table Low er Limit

42

Sensor

43 Printing Press ur e Sensor Informs the CPU when print ing pr es sur e i s ap pl ied.

Paper End Sensor Informs the CPU when the paper table runs out of

44

50 Drum Rot ati on Sensor Supp l ies t i m ing pulses to the main boar d.

53 2nd Drum Posi ti on Sensor Checks the positi on of th e dr um .

57 1st Drum Posit i on Sensor Checks the position of the drum.

NAME FUNCTION

Checks whether the ma st er e ject uni t is cl osed

correctly or not. Cuts the ac power.

edge.

master feed with ori gi na l fee d.

limit position.

used masters.

limit position.

master roll.

feed position.

Detects when the paper table reach e s the l ow est

position.

paper.

Overall

Information

Printed Circuit Board

16 CCD PCB Converts light into an electrical signal.

17 A/D Convers i on PCB Converts analog signals into di gital signals.

1-35

Page 39

ELECTRICAL COMPONENTS LAYOUT 1 November 1996

INDEX

No.

Main Control PCB Controls all machine functions both directly and

39

54 Ink Detection PCB Checks if the ink is present in the drum.

63 Power Suppl y PCB Rectifies 100 V ac input and supplies dc vol tage.

Counters

45 Copy Coun te r Keeps track of the total number of copies made.

46 Maste r Counter Keeps track of the total num ber of ma st er s m ade.

Others

2 Transformer Steps down the wall vol t ag e.

8 Fluorescent Lam p Exposes the original.

15 Fluorescent Lamp Stabilizer Controls the exposure lamp.

Reverse Roller Clutch Transfers master feed motor rotation to the reverse

31

36 Thermal H ead Burns the image onto the master.

61 Encoder Converts 16 image positions to 4 bit data.

66 Operation Panel Interfaces the CPU and the oper at or .

NOTE:

1) The Master Eject Unit Safety Switch in the 220 V machines cannot

NAME FUNCTION

through other boards.

roller at proper timi ng.

be disabled by this test switch.

2) When you use this test switch, be sure to return it to home position

after servicing in order to recover the cover safety functions.

1-36

Page 40

1 November 1996 ELECTRICAL COMPONENTS LAYOUT

5.3 C215/C216

Electrical Component Layout

4

3

2

1

5

6

7

8

Overall

Information

9

20

19

10

18

17

16

15

14

13

12

11

36

37

35

38

34

33

32

31

21

22

23

24

25

26

27

28

29

30

1-37

Page 41

ELECTRICAL COMPONENTS LAYOUT 1 November 1996

39

40

41

42

43

44

45

46

65

64

63

62

61

60

59

58

57

56

55

47

48

49

50

51

52

53

54

1-38

Page 42

1 November 1996 ELECTRICAL COMPONENTS LAYOUT

Table

INDEX

No.

Motors

4 Original Transport Motor Transpor ts the original to the scanne r se ct ion.

10 Master Feed Motor Feeds the master to the drum.

11 Cutter Motor Cuts the master.

14 Master Eject Motor Sends used master into the master eject box.

18 ADF Drive Motor (C216) Feeds the original to the scanner section.

Image Shift Motor Changes the tim i ng between the paper fe ed r oll er

25

28 Paper Table Drive Motor Raises and lowers the pape r table.

Main Motor Drives paper feed, drum, printi ng and paper deliv er y

30

Air Knife Motor Rotates the fan to separate the paper leading edge

60

Vacuum Motor Provides suction so paper is held firmly on the

61

Solenoids

Original Pressure Solenoid

3

(C216)

Master Eject Solenoid Moves the master eject ro ll er to co ntact th e dr um

15

Master Eject Clamper

21

Solenoid

Drum Lock Sole noid Prevents remov al of the dru m uni t unl ess the drum is

22

Master Feed Clamper

23

Solenoid

24 Reverse Roller Solenoid Releases the clutch to rotat e t he r eve rs e ro l ler .

Paper Feed Solen oid Releases the paper feed sector gear to rotat e t he

27

32 Printing Pressure Solenoid Moves the press roller against the drum.

Ink Supply Soleno id Releases the spring clutch to activate the ink su ppl y

47

NAME FUNCTION

and the drum to adjust the vertical image position.

unit component s.

from the drum.

transport belt.

Presses the origi nal pr es sur e pl ate down on the

originals.

surface.

Opens the mast er clam p t o eject the master.

at the original st op position

Opens the ma st er clam p t o cl am p the master.

paper feed rolle r.

pump.

Overall

Information

Switches

6 Right Cutter Switc h Detects when the cutte r po sit i on is at th e fa r right .

12 Left Cutter Switch Detects when the cutter position is at the far left.

Master Box Switch Checks whether the master eject box is i ns ta l led

16

Master Eject Unit Safety

36

Switch

Master Cut Switch Informs the CPU to cut the master paper leading

41

correctly or not.

Checks whethe r the M as te r Eject Unit is closed

correctly or not.

edge.

1-39

Page 43

ELECTRICAL COMPONENTS LAYOUT 1 November 1996

INDEX

No.

Scanner Safety Switch Checks whether the scanner unit is closed correctly

42

44 Drum Rotation Switch Informs the CPU to rotate the main motor at 10 rpm.

45 Front Door Safety Switch Checks whether the Front Door is set correctly or not.

46 Drum Safety Switch Checks whethe r the dr um unit is set correctly or no t.

Paper Table Safet y Swi tch Checks whether the paper table is op ened correctly

52

57 Interlock Switch Releases the cover safety func tions.

59 Main Switch Turns the power on or off.

Full Master Detecting Switch Informs the CPU when the master eject box is full of

62

Pressure Plate Positio n

63

Switch

Printing Densit y Swi t ch Us e to sel ec t the pr i nti ng density accord ing t o th e

64

65 ADF Safety Switch (C216) Check whether the ADF unit is set cor r ect l y or not .

Sensors

Original Registration Sensor Informs the CPU when the original lea di ng edge

1

2 2nd Original Sensor Detects when the original is set.

Master End Sensor Informs the CPU when the pl ot ter un i t runs out of

9

13 Master Buckle Sensor Detects master buckles.

Master Eject Sensor Detects when the used master is sent into the

17

19 1st Original Sensor (C216) Detects when the original i s set in the ADF mode.

29 Drum Rotation Sensor Supplies timi ng pulses to the main board.

33 2nd Drum Position Sensor Checks the position of the dru m .

34 1st Paper Exit Sensor Detects misfeed.

35 2nd Paper Exit Sensor Detects misfeed.

37 1st Drum Position Sensor Checks the posi tio n of the dru m .

Paper Table Height Sensor Detects when the paper table rea ches the paper

49

Paper End Sensor Inform s t he CPU when the paper table runs out of

51

Paper Table Lowe r Limi t

53

Sensor

Printing Pressure Sen sor Informs the CPU when the prin tin g pr essure is

54

NAME FUNCTION

or not.

or not.

masters.

Informs the CPU when the pressure plat e has

reached the home position.

type and quality of th e or igi nal.

reaches the exposure glass.

master roll.

master eject box .

feed position.

paper.

Detects when the paper table reaches the lowest

position.

applied.

Printed Circuit Board

7 Power Supply PCB Rectifies 100V AC input and su ppl ies DC voltage.

1-40

Page 44

1 November 1996 ELECTRICAL COMPONENTS LAYOUT

INDEX

No.

31 AC Drive PCB Controls the AC component by relays.

38 Ink Detection PCB Control the ink supply.

39 CCD PCB Converts the light intensity into the electrical signal.

40 A/D Conversion PCB Converts the an al ogue signal into the di gital signal.

Operation Pan el Controls the LED perfor m anc e and monitors the key

43

Main Control PC B Controls all machine func tions both directl y and

48

50 Image Processing PCB Controls the master pr ocessing perform ance.

Counters

55 Copy Counter Keeps track of the tot al num ber of copies made.

56 Master Counter Keeps track of the total numb er of masters made.

Others

Fluorescent Lamp Stabilizer Stabilizes the power supplement to the fluorescent

5

8 Thermal Head Burns the image on to the master.

20 Fluorescent Lamp Exposes the original.

26 Encoder Converts 16 ima ge positions to 4 bit data.

58 Circuit Breaker Cuts the ac line.

NAME FUNCTION

operation.

through other bo ar ds.

lamp.

Overall

Information

1-41

Page 45

ELECTRICAL COMPONENTS LAYOUT 1 November 1996

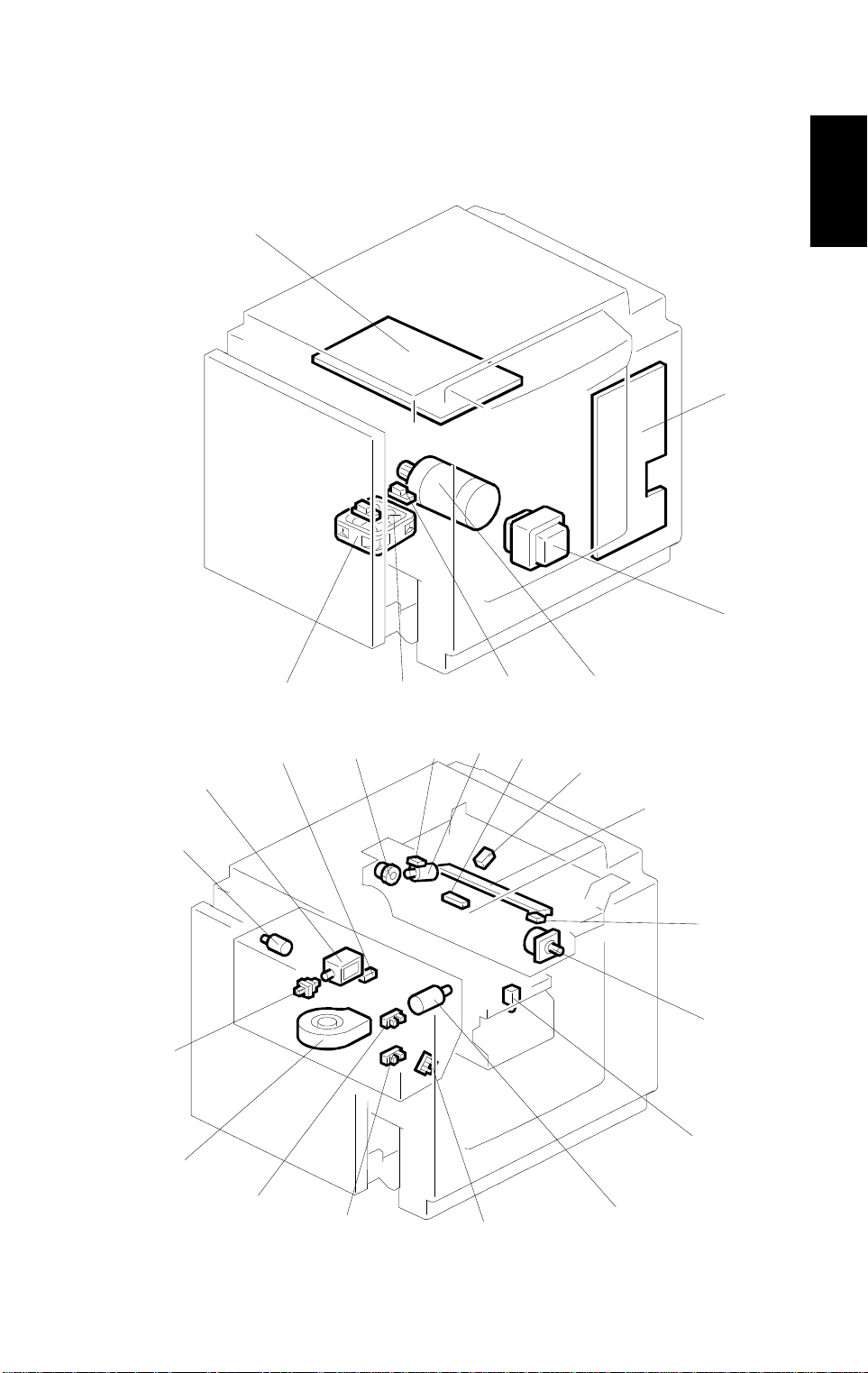

5.4 C211/C212/C213

Electrical Component Layout

25

24

23

1

22

21

5

3

2

4

6

7

8

9

10

11

12

13

14

20

19

18

16

17

15

1-42

Page 46

1 November 1996 ELECTRICAL COMPONENTS LAYOUT

42

41

26

27

28

29

30

31

Overall

Information

32

33

34

35

36

40

39

37

38

1-43

Page 47

ELECTRICAL COMPONENTS LAYOUT 1 November 1996

71

70

69

72

68

67

66

43

65

64

44

63

62

45

61

46

47

48

49

50

51

52

53

54

55

56

57

58

5960

1-44

Page 48

1 November 1996 ELECTRICAL COMPONENTS LAYOUT

Table

INDEX

No.

Motors

4 Original Transport Motor Transports the original to the scanner secti on.

11 Master Fe ed M ot or Feeds the master to the drum.

16 Cutter Motor Cut the master.

19 Master Eject Motor Sends used master into the mast er eject box.

ADF Drive Motor

23

(C212/C213 onl y)

Image shift Motor Changes the timing between the paper feed

30

36 Paper Table Drive Motor Raises and lowers the paper table.

Main Motor Drives paper feed, drum, printing and paper

38

Air Knife Motor Rotates the fan to separate the pap er leadi ng

66

Vacuum Motor Provides suc tion so paper is held firm l y on t he

67

Solenoids

Original Pressure Solenoid

3

(C212/C213 onl y)

Master Eject Solenoi d Moves the master eject rol ler to cont ac t the dr um

20

26 Master Eject Clamper Soleno i d Opens the master clamp to eject the ma ster .

28 Master Fe ed C lam per Solenoid Opens the master cl am p to clamp the master .

31 Reverse Rol l e r Solenoid Releases the clutch to rotate the rev er se r oll er .

Paper Feed Solenoid Releases the paper feed sector gear to rotate the

35

39 Printing Pr ess ur e Sol enoid Moves the press roller against the dr um .

Ink Supply Solenoid Releases the spring clu tc h to acti vat e the i nk

52

Drum Lock Solenoi d Prevents removal of the drum uni t unl ess the

56

NAME FUNCTION

Feeds the original to the scan ner section.

roller and the drum t o adjust vertical image

position.

delivery unit com ponents.

edge from the drum.

transport belt.

Presses the or i ginal pressure plate down on the

originals.

surface.

paper feed roller .

supply pump.

drum is at the original stop position

(This solenoi d can be used on the C21 2/ C 213).

Overall

Information

Switches

6 Right Cutter Switch Detects when the cutter position is far right.

Left Cutter Switch Detects when the cutter position is far left.

17

Master Box Switch Checks whether the master eject box is installed

21

correctly or not.

1-45

Page 49

ELECTRICAL COMPONENTS LAYOUT 1 November 1996

INDEX

No.

29

45

46

49

50

51

58

Master Eject Unit Safety Switch Checks whether the Master Eject Unit is closed

Master Cut Switch Informs the CPU to cut th e m aster paper leading

Scanner Safety Switch Checks whether the scanner unit is cl os ed

Drum Rotation Switch Informs the CPU to rotate the main motor at 10

Front Door Safety Switch Checks whether the Front Door is set correctly or

Drum Safety Switch Checks whether the drum unit is set correctly or

Paper Table Safety Switch Checks whether the paper table is opened

NAME FUNCTION

correctly or not.

edge.

correctly or not.

rpm.

not.

not.

correctly or not.

63 Interlock Switch Releases the cover safety functions.

65 Main Switch Turns the power on or off.

Full Master Detecting Switch Informs the CPU when the master eject box is

68

Pressure Plate Positi on Switch Informs the CPU when th e pr essure plate has

69

Memory/Class Switch

70

(C212/C213 onl y)

Skip Paper Feed Switch

(C212/C213)

71

Printing Density Switch

(C211)

ADF Safety Switch

72

(C212/C213 onl y)

full of master s.

reached the home position.

Selects Memory or Class mode.

Adjusts paper feed interval to allow time for user

to remove prints.

Use to select the printing density according to

the type and quality of the ori gi n al .

Check whether the ADF unit is set correctly or

not.

Sensors

Original Registration Sensor Informs the CPU when the original leading edge

1

reaches the expos ur e glass.

2 2nd Original Sensor Detects when the original is set.

Master End Sensor Informs the CPU when the plotter unit runs out of

10

Paper Size Detection Sensor 3

12

(C212/C213 onl y)

Paper Size Detection Sensor 2

13

(C212/C213 onl y)

Paper Size Detection Sensor 1

14

(C212/C213 onl y)

master roll.

Detects the size of the paper set on the paper

table.

Detects the size of the paper set on the paper

table.

Detects the size of the paper set on the paper

table.

18 Master Buckle Sensor Detects the master buckle existence.

Master Eject Sensor Detects when the used master is sent into the

22

master eject box.

1-46

Page 50

1 November 1996 ELECTRICAL COMPONENTS LAYOUT

INDEX

No.

1st Original Sensor

24

(C212/C213 onl y)

33 1st Drum Position Sensor Checks the position of th e dr um .

34 2nd Drum Position Sensor Chec ks t he position of the drum .

37 Drum Rotation Sensor Supplies timing pulses to the mai n boar d.

41 1st Paper Exit Sensor Misfeed detector.

42 2nd Paper Exit Sensor Misfeed detector.

Drum Master Detection Sensor

47

(C212/C213 onl y)

Paper Table Height Sensor Detects when the paper tabl e re aches the paper

54

Paper End Sensor Informs the CPU when the paper table runs out

57

Paper Table Lower Lim i t Sensor Detects when the paper table reaches the lowest

59

Printing Pressure Sens or Informs the CPU when th e pr int ing pr essure is

69

Printed Circuit Board

7 Power Supply PCB Rectifies 100V AC in put and supplies DC volt age.

Thermal Head Drive Control

8

PCB

27 Ink Detection PCB Control the ink supply.

40 AC Drive PCB Contr ols t he AC com ponent by relays.

CCD PCB Converts the light intensity into the electrical

43

A/D Conversion PCB Converts the analogue signal into the digital

44

Operation Pane l Controls the LED performance and moni t or s the

48

Main Control PCB Controls all machine functions both directly and

53

55 Image Processing PCB Controls the m aster processing performance.

NAME FUNCTION

Detects when the original is set in the ADF mode.

Checks whether the master is on the drum.

feed position.

of paper.

position.

applied.

Supplies the power to the Thermal Head

according to the sig nal fro m the scanner section.

signal.

signal.

key operation.

through other boards.

Overall

Information

Printed Circuit Board

Paper Size Detection Board

15

(C212/C213 onl y)

Counters

61 Copy Counter Keeps track of the total nu m ber of copi e s m ade.

Master Count er Keeps track of the total num ber of ma st er s made.

62

Detects the size of the paper set on the table.

1-47

Page 51

ELECTRICAL COMPONENTS LAYOUT 1 November 1996

INDEX

No.

Others

Fluorescent Lamp Stabilizer Stabilizes the power supplement to the

5

9 Thermal Head Plots the m ast er w ith heat .

25 Fluorescent Lamp Applies light to the orig i nal f or exposure.

32 Encoder Converts 16 image positions to 4 bit data.

64 Circuit Breaker C ut s th e ac li ne off.

NAME FUNCTION

Fluorescent Lamp.

1-48

Page 52

1 November 1996 MECHANICAL COMPONENT LAYOUT

6. MECHANICAL COMPONENT LAYOUT

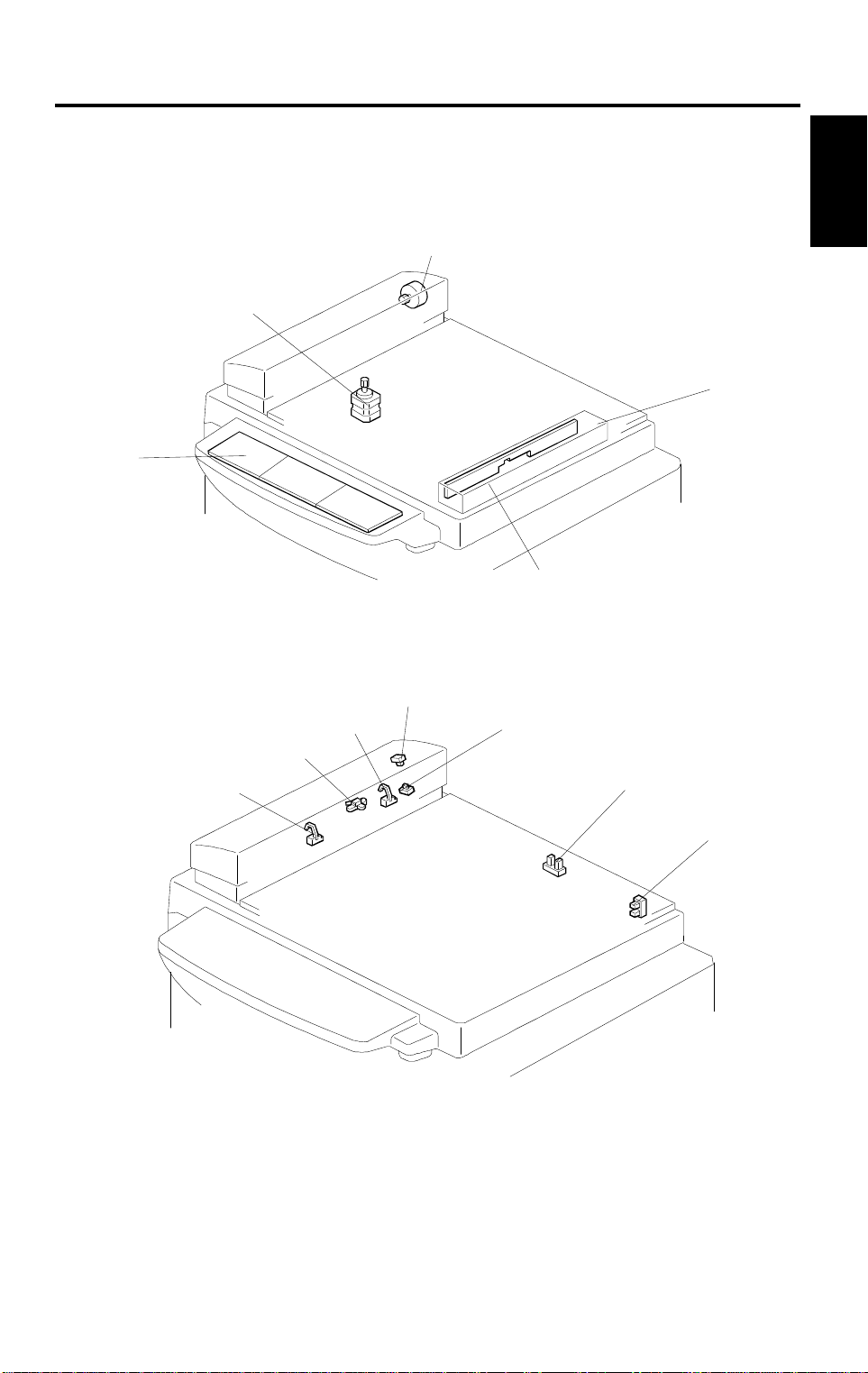

6.1 ADF AND SCANNER: C226 ONLY

43

2

No. Name Description

Scanner Contains a contact image sensor and a xenon lamp

1

2 R1 Roller Feed s the document throug h the scanner.

3 R0 Roller Feed s the document into the sc anner.

Separation roller Prevents more t han one sheet from feed i ng int o t he

4

5 Document Feed Roller Feeds the document into the scanner.

Pick-up Roller Picks up pages of the docu m ent from t he document

6

7 R2 Roller Feed s the document throug h the scanner.

Platen Cover This covers the original w hich was placed on the

8

9 Exposure Glass Book scanner reads the original on it.

6

5

7

8

9

1

driver.

scanner.

table one at a time.

exposure gla ss.

Overall

Information

1-49

Page 53

MECHANICAL COMPONENT LAYOUT 1 November 1996

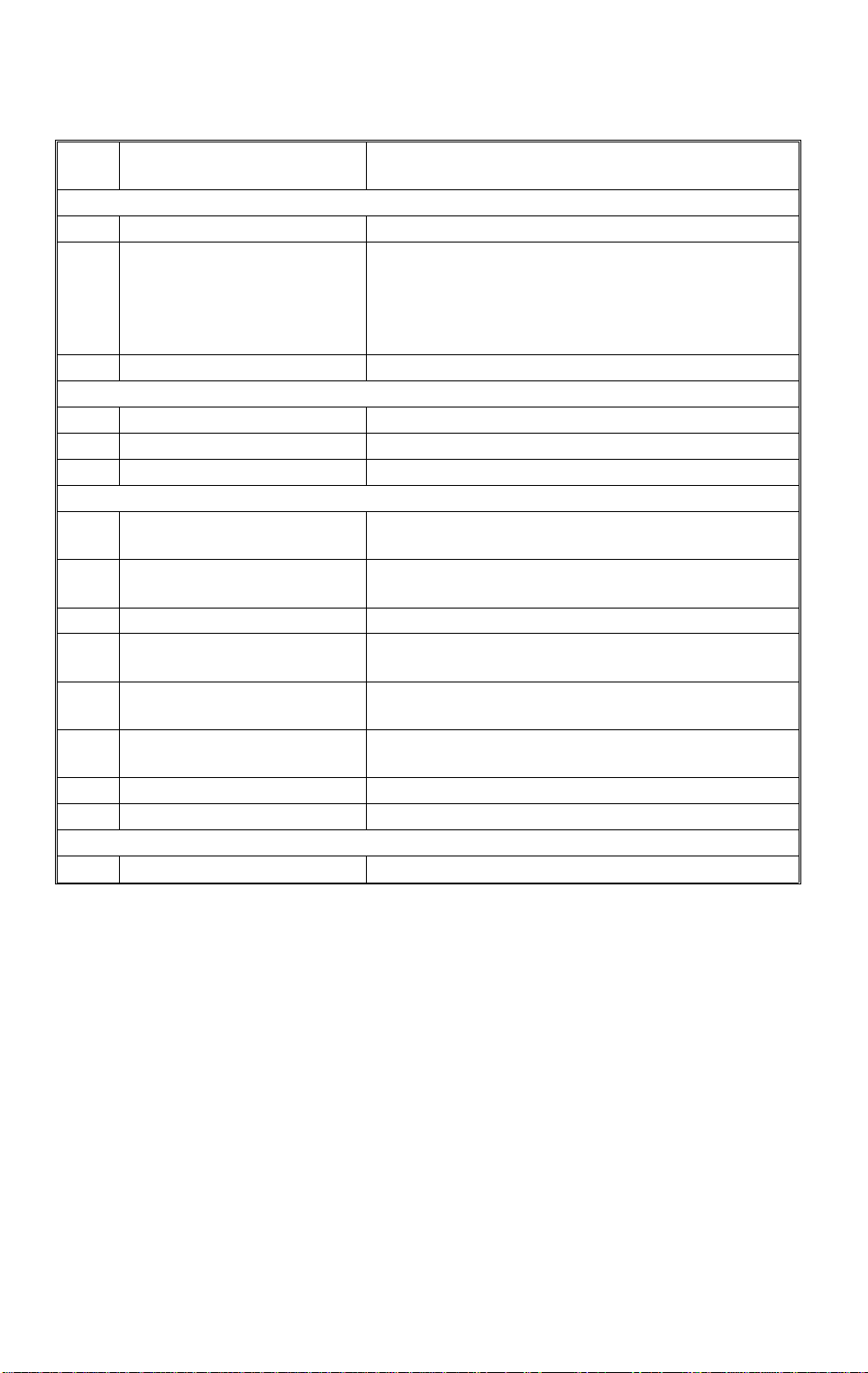

6.2 MECHANICAL COMPONENT LAYOUT

18

19

20

21

22

23

24

17 16 15 1413 109 8 7 6 5 4 3

1211

333231302928272625

2

1

38

37

36

35

34

1-50

Page 54

1 November 1996 MECHANICAL COMPONENT LAYOUT

1. Thermal Head

2. Platen Roller

3. Master Feed Roller

4. CCD (Except for C226)

5. Lens (Except for C226)

6. Reverse Roller

7. Ink Roller

8. Drum Unit

9. 1st Eject Roller

10. 2nd Eject Roller

11. Original Pressure Plate

(C212/C213/C216/C224)

12. Pull-out Roller

(C212/C213/C216/C224)

13. Separation Blade

(C212/C213/C216/C224)

14. Original Feed Roller

(C212/C213/C216/C224)

15. 1st Original Transport Roller

(Except for C226)

16. Exposure Grass

(Except for C226)

17. 2nd Original Transport Roller

(Except for C226)

18. Fluorescent Lamp

(Except for C226)

19. Original Exit Tray

(Except for C226)

20. Feed Sub Mirror

(Except for C226)

21. Mirror

22. Master Eject Box

23. Exit Pawl

24. Air Knife

25. Delivery Table

26. Delivery Guide Plate

27. Vacuum Unit

28. Press Roller

29. Doctor Roller

30. 2nd Feed Roller

31. Lower Separation Roller

32. Separation Plate

33. Paper Feed Side Plate

34. Paper Feed Table

35. Paper Feed Roller

36. Upper Separation Roller

37. Ink Holder

38. Master Spool

Overall

Information

1-51

Page 55

DIFFERENCES BETWEEN MODELS 1 November 1996

7. DIFFERENCES BETWEEN MODELS

7.1 C226 AND C224

No. Item Remarks

These units are commonly used in our facsimile products.

The C226 model use s a book type scanner. Th e C 224

model does not have this feature. The contact image

sensor remove s th e necessity of compl i cated adjustment s

1.

ADF, Scanner, and

Operation Pan el

needed for a CCD scanner.

A half-tone processor is used for image processing. This

processor is similar to those in higher level models. It

produces better co py quality half-tone i m ag es i n Photo

and Letter/Photo modes.

[A]

2. Paper Deli v er y Table

[B]

The C226 model use s a new paper delivery tabl e. This

table has newly added small guide plates [A] on each

front and rear side fenc e. The guide plates stack the

prints more evenly. The small guide plat es [B] , on the

bottom of each side fence keep the prints ali gned in the

center of the table while the copies are stacked.

Also, the paper stack ca pacity has been incre ased from

500 sheets to 1000 sheets.

[C]

Due to the the new paper del ivery table design, a new

auxiliary bracket [C] has been added for optional TAPE

MAKER installation. For details, refer to the "Tape Maker

Installation" section.

1-52

Page 56

1 November 1996 DIFFERENCES BETWEEN MODELS

No. Item Remarks

NOTE:

1) The small uppe r gu ide pl atesare needed w hen thin or

normal paper (80g/ m

2

or 20 lb. and thinner paper) is

used. The guide pla te is not needed for thicker pap er . If

the paper is too thick, it may be caught by the upper

guide plates. (Thick paper can be stacke d evenly

without the upper gui de plates.)

2) When the small up per gui d e pl at es are used, the paper

delivery table’s stack capacity reduces to about 750

sheets (dependin g on paper type). Close t he guide

plates to achieve th e maximum paper stack capacity.

3) The optional TAPE MAKER works with up to 500

sheets (dependin g on paper type).

Overall

Information

3. Main Control PCB

The C224 model’s A/D Co nve rs ion PC B is not used. The

function is now included in the Main Control PCB, which

is located beneath t he sc anner unit. Since the M ain

Control PCB was move d from t he op er at i onal side, the

Power Supply PCB was also moved from the

non-operation side of th e m achine to where the Main

Control PCB was located in the C224 model.

1-53

Page 57

DIFFERENCES BETWEEN MODELS 1 November 1996

No. Item Remarks

The following func tions were not used in the C 224 model:

– CS Mode

– SP Mode (User Accessible)

– Paste Shadow Erase Mod e (Unique to the C226

model)

– One Touch Clas s M ode (Uni que to the C226 model)

– Tint Mode (Unique to the C226 model)

– Program Mode

– Letter/Photo Mo de ( In addi ti on to the Letter and

Photo modes.)

– Quality Start Mode: See NOTE 1

4.

New Functions in

Operation

– Edge Erase Mode: See NO TE 2

– Edge Erase / Center Erase Mod e: See NO TE 2

NOTE:

1) In the Quality Start mo de, afte r the m aster making

process, one extra print (this can be set by the

operator from 0 to 3 print s) is m ade at the lowest

printing speed (20 cpm ) . Th e tri al pr i nt is m ade in the

same way as other models. As the default se tting, two

extra prints are made in the Quality Start m ode. The

Quality Start mode i s also used in some othe r models,

however, this meth od is unique to the C226 m odel.

2) In other models which use a book type sca nne r,

shadows near the edg es and the center of print s (wit h

the platen cover open) can be removed. In the C226, a

similar function is available as the Edge Erase/Center

Erase mode. Before using this fun cti on, th e pr int paper

size must be selected manually by the operator. Also.

the erasable margin widths for the edges and center

adjustable with a us er accessible SP mode.

The Edge Erase mode is t he sa m e as t he M ar gi n

Erase mode used in some other models that have a

book type scanner .

1-54

Page 58

1 November 1996 DIFFERENCES BETWEEN MODELS

7.2 BETWEEN C224 AND C211/C212/C213

No. Item Remarks

A CCD which corresponds to 300 dpi pixel density is used.

1. CCD

Number of Effective

Pixels:

Reading Lengt h: 309 mm

Photo Signal Storage: 2.5 ms

The thermal he ad and thermal head dr i ve cir cuit have

been changed corresponding to the 300 dpi pixel density

and the increased master feed speed.

3648 pixels

Overall

Information

2. Thermal Head

3.

Drum Ink Roller

Layout

Density of thermal

heating element s

Number of thermal

heating element s

Memory length 256 mm

To ensure paper separation from the drum , th e ink r ol l er

has been shifted towards the pap er feed table.

The distance L has be en changed from 5.0 mm t o 3. 5 m m

(same as the C21 6 m ode l ).

C211 model

[A]

L

L = 5.0 mm L’ = 3. 5 m m

NOTE:

The optional color dr um fo r the C224 model

is commonly used f or the C211 m odel.

(The distance L for th e color drum is

4.5 mm.)

[B]

300 dots/inch

3072 dots

C224 mode

l

[A]

[B]

L’

1-55

Page 59

DIFFERENCES BETWEEN MODELS 1 November 1996

No. Item Remarks

To ensure drum connection, a drum lo ck lever has been

added inside th e front door. To remove t he dr um fro m the

machine, the dru m rele ase lever must be pul l ed up to

disconnect the drum connector. (Same as the C216

model.)

4. Drum Connector

The location of th e i nk de te ct i on bo ar d has been changed

5. Ink Detecti on Board

6. Drum Shaft

7. Exit Pawl Air Pump

Main Board and

8.

9. Thermal Head Drive

12.

13. Air Knife Motor

14.

Image Processing

Board

Paper Table Drive

Motor

Pressure Plate

Position Sensors

from the upper si de to th e right side of the drum shaft. The

ink type switch (SW901), which was not used (always set

at oil type), has been removed. (Same as the C216 model.)

To supply ink to the i nk roller evenly , the second ink suppl y

hole (count from the front side) of the drum sh af t is

covered with a strip of tape.

(Same as the C216 mo del .)

To ensure paper separation from the drum , th e exit paw l

air pump system is standardized. (Same as the C216

model.) (Th e pum p system can opti onally be instal led in

models of the C21 1 ser i es .)

The main board and the image processing board have

been combin ed int o one board.

The thermal he ad dr i ve boar d has been remove d. The

function of the boa rd has been moved to the mai n board.

The thermal he ad voltage is directly appl ied from the

power supply un i t. The ma i n board applies the signal to the

PSU to supply thermal head voltage only dur i ng the master

making process. (Same as the C216 model.)

The paper table dr i ve mo to r ha s been changed from an ac

motor to a dc motor.

The air knife mot or has been changed from an ac mo to r to

a dc motor.

The pressure plate position swi tch and the full master

detecting swi tch have been elimina te d.

Three photo-i nt er ru pt er s, upper and lower press ur e pl ate

sensors and full m aster box sensor ar e used instead.

1-56

Page 60

1 November 1996 DIFFERENCES BETWEEN MODELS

No. Item Remarks

The master eje ct mo to r whi c h had two functions: (one i s t o

15.

16 Skip Feed

17.

18.

Pressure Plate

Motor

Economy Function

(New Function )

Security Mode

(New Function )

drive the exit rollers, the other is to drive the pressure

plate) has been replaced by two motors; the master eject

motor and press ur e pl ate m ot or . Du e to this modification ,

the master box capacity has be en increased.

A user can select from 2 t o 9 ro ta tio ns of th e dr um w hil e

one sheet of pape r is fed.

If "Economy mode" is selected on th e ope ration panel, a

lower thermal head energy is applied when a master is

made. As a result, the image will be lighter than normal

and ink consumption will be less.

"Secret mode" can be selected by changing DIP SW103-6.

If this mode is select ed, the Print key is disabled after

turning the m ai n swi t ch off and on. (Only the "M ast er

making key" is available.)

Overall

Information

1-57

Page 61

DIFFERENCES BETWEEN MODELS 1 November 1996

7.3 BETWEEN C215/C216 AND C211/C212/C213

No. Iter Remarks

The pixel densi t y of the C2 15/ C216 model is 300

dots/inch. Corresponding to this, the CCD used on the

C215/C216 model is the same as the one used on the

C201 model.

1. CCD

2. Thermal Head

Due to pixel density change, the thermal head has been

changed.

Number of effect ive

Pixels:

Reading Length: 309 mm

Photo Signal Storage: 5 ms

Density of thermal

heating element s

Number of thermal

heating element s

Memory length 256 mm

Applied voltage 19~24 V

3648pixels

300 dots/inch

3072 dots

3.

Drum Ink Roller

Layout

To ensure paper separation from the drum , th e ink r ol l er

has been shifted forw ar d t he paper feed table.

The distance L has be en changed from 5.0 mm t o 3. 5 m m .

C211 model

[A]

[B]

L

L = 5.0 mm L’ = 3.5 mm

NOTE:

The optional color dr um fo r the C215/C216 model

is commonly use d fo r t he C211 model.

(The distance L of the color drum is

4.5 mm)

C215/C216 model

[A]

[B]

L’

1-58

Page 62

1 November 1996 DIFFERENCES BETWEEN MODELS

To ensure drum connection, a drum lock lever is added

inside the front door. To remove the dr um from the

machine, the dru m rele ase lever must be pul l ed up to

discon nect th e drum con nector.

4. Drum Connector

The location of th e i nk de te ct i on bo ar d has been changed

5. Ink Detecti on Board

6. Drum Shaft

7. Exit Pawl Air Pump

8. Thermal Head Drive

from the upper si de to th e right side of the drum shaft. The

ink type switch (SW901), which was not used (always set

at oil type), has been removed.

To supply ink to the i nk roller evenly , the second ink suppl y

hole (count from the front side) of the drum sh af t is

covered with a strip of tape.

To ensure paper separation from the drum , th e exit paw l

air pump system is standardized. (The pump system can

optionally be installed on the C211/ C 212/C213 models .)

The thermal he ad dr i ve boar d has been remove d. The

function of the boa rd has been moved to the im age

processing boar d and the main boar d.

The thermal he ad voltage is directly appl ied from the

power supply unit. The main board applies signal to the

PSU to supply thermal head voltage only dur i ng the master

making process.

Overall

Information

1-59

Page 63

DIFFERENCES BETWEEN MODELS 1 November 1996

7.4 BETWEEN C207/C208 AND C211/C212/C213

No. Item Remarks

The heating elements used in the C211/C212/C213 ther m al head

are smaller tha n those used on the C207/C208 models. This

reduces ink set-off on the back sides of copies.

C207/C208 model

1

2

3

4Exterior

5

6

7

Thermal

Head

Thermal

Head Drive

Board

Power

Supply Board

Image

Processing

Board

Main

Harness

Drum Master

Sensor

The thermal hea d dr ive voltage has been decreased from 24 V to

16V because the sm all er heating element s in th e th er m al head

require less power.

The power supply boar d has been modified to output 16V to drive

the thermal head.

An ON/OFF switching circuit for the thermal head drive voltage

(VHD) has been add ed t o th e power supply board.

The design of the fron t co ver and the model name pr i nt ed on the

cover have been changed. This was done for marketing rea sons

and to ensure that the us er s do not confuse the C211/ C 21 2/ C 213

models with the C207/C208 models and use the wrong mast er ty pe.

(The new master is more sensitive.)

The C213 make-up control board has been eliminated because the

C213 image pro ces si ng boar d performs the Mak e- up function.

A VHD ON/OFF line has been added to the main har ness.

The drum master sensor has been chan ged to stabilize the sensor

sensitivity.

C211/C212/C213

model

1-60

Page 64

1 November 1996 DIFFERENCES BETWEEN MODELS

No. Item Remarks

The paper feed rol ler cam has been slightly modified as shown to

reduce the paper speed to 55% that of the C20 7/ C208 models.

(Extended outwa rd at po int [A].) Thi s reduces the nois e cau sed

when the paper leadi ng edge strikes the second feed roller .

Overall

Information

8

Paper Feed

Roller Cam

C207/C208 cam

C211/C212/C213 cam

[A]

The second feed cam has been modified sl ight l y as show n to

reduce the speed of the second feed roller to 40% that of the

C207/C208 model s. (Extended outwa rd at po int [A], moved in at

point [B].) This reduces the noise caused when the second fe ed

rollers turn and the paper [C] snaps as it is pull ed t aut .

[C]

9

Second

Feed Roller

Cam

C207/C208 cam

1-61

C211/C212/C213 cam

[A]

[B]

Page 65

DIFFERENCES BETWEEN MODELS 1 November 1996

No. Item Remarks

The shape of the C211 /C212/C213 press ur e cam has been modified

slightly as sh own t o decrease the pre ssure roller speed to 70% that

of the C207/C208 models. (A portion at po i nt [A] has be en shaved

off.) This reduces th e noi s e caused when the pres sur e r ol ler m oves

against the drum.

C207/C208 cam

10

Pressure

Cam

C211/C212/C2 13 cam

[A]

Rear Paper

Delivery

Side Plate

One of the air slots [B] cu t in t he r ear pap er del i ve ry side pl ate has

been enlarged so that tap e st rip s from t he optional tape dispenser

can be inserted thro ugh it.

C207/C208

11

12

Main Control

Board

C211/C212/C213

[B]

An ON/OFF control circ ui t for the th er m al head drive voltage (V HD )

has been added to th e m ain control board.

The drum master det ection circuit on the m ai n cont r ol boa rd has

been modified to accommodate the new drum master sensor.

1-62