Page 1

RICOH PRIPORT VT 2105

SERVICE MANUAL

Page 2

SECTION 1

OVERALL MACHINE

INFORMATION

Page 3

Overall

Information

1 October 1992 SPECIFICATIONS

1. SPECIFICATIONS

Configuration: Desktop

Master processing: Digital

Printing process: Full automatic one drum stencil system

Original type: Sheet

Original size: Maximum 307 mm x 432 mm (12.0" x 17.0")

Minimum 90 mm x 140 mm (3.6" x 5.5")

Reproduction ratios: LT Version A4 Version

Full Size 100% 100%

Reduction 93% 93%

75% 82%

64% 71%

Image mode: Line/Photo

Color printing: Drum Unit replacement system

Master feed/eject: Roll master automatic feed/eject

Printing area: Maximum: 250 mm x 355 mm (9.8" x 13.9") at

20°C/ 65 % RH.

Leading edge margin:

± 3 mm at "0" position

5

Print paper size: Minimum: 90 mm x 148 mm (3.6" x 5.8")

Maximum: 325 mm x 447 mm (12.8" x 17.6")

Print paper weight: 50 g/m

2

to 215 g/m

2

Printing speed: 60, 75, 90, 105, 120 sheets/minute (5 steps)

First print time:

Paper feed table

± 3 seconds (B4 size)

42

1000 sheets (66.3 g/m

2

/17.6 lb)

capacity:

2

Paper delivery table

500 sheets (66.3 g/m

/ 17.6 lb)

capacity:

Power source: 120 V, 60 Hz 3.0 A

220/240 V, 50/60 Hz 1.8 A

1-1

Page 4

SPECIFICATIONS 1 October 1992

Maximum

Power consumption:

120 V version: 300 W

220/240 V version: 300 W

Weight: 120 V version: 99 kg (217.8 lb)

220/240 V version: 104 kg (228.8 lb)

Dimensions:

(W x D x H)

Stored: 735 mm x 607 mm x 577 mm

(29.0" x 23.9" x 22.8")

Set up: 1279 mm x 607 mm x 656 mm

(50.4" x 23.9" x 25.9")

2

ADF original capacity: 20 sheets (66 g/m

Original guide width

98 mm to 316 mm (38.6" to 12.44")

) or 1.8 mm height

settings:

Original scanning time: 5 ms/1 line

Original thickness: 0.05 mm to 0.8 mm

Original feed speed: 16.9 mm/second (When master processing)

33.9 mm/second (When not master processing)

Pixel density: 300 dots/inch

Master eject box

capacity:

30 masters (Normal condition)

25 masters (10°C/30% RH Condition)

Paper feeding: Friction roller/center separation system

Feed table side plate

88 mm to 330 mm (3.46" to 12.99")

width settings:

Paper feed roller

pressure:

Separation roller

pressure:

Side registration:

Vertical registration:

Normal position 250 g

Thick paper position 550 g

Normal position 180 g

Weak position 70 g

± 10 mm (manual)

± 20 mm (mechanical)

Ink supply: Automatic ink supply system

Press roller pressure:

± 0.3 kg

10

Paper delivery: Air knife/vacuum delivery

Delivery side plate width

90 mm to 320 mm (3.54" to 12.6")

settings:

Print counter: 7 digits

Master counter: 6 digits

1-2

Page 5

Overall

Information

1 October 1992 SPECIFICATIONS

Supplies:

Priport Thermal master 280 mm width

Master VT- II - M:

(300 dots/inch)

Master roll 250 masters/1 roll

Roll diameter 130 mm

Master length 480 mm/1 master

Max run length 2000 prints

Ink colors: Black, Red, Blue, Green, Brown

(500 cc/pack)

1-3

Page 6

DIFFERENCE BETWEEN VT2000 SERIES AND VT2105 1 October 1992

2. DIFFERENCE BETWEEN VT2000 SERIES

AND VT2105

No. Iter Remarks

The pixel density of the VT2105 is 300 dots/inch.

Corresponding to this, the CCD used on the

VT2105 is the same as the one used on the

SS800 series.

1. CCD

2. Thermal Head

Number of effective

Pixels:

Reading Length: 309 mm

Photo Signal Storage: 5 ms

3648pixels

Due to pixel density change, the thermal head

has been changed.

Density of thermal

heating elements

Number of thermal

heating elements

Memory length 256 mm

Applied voltage 19~24 V

300 dots/inch

3072 dots

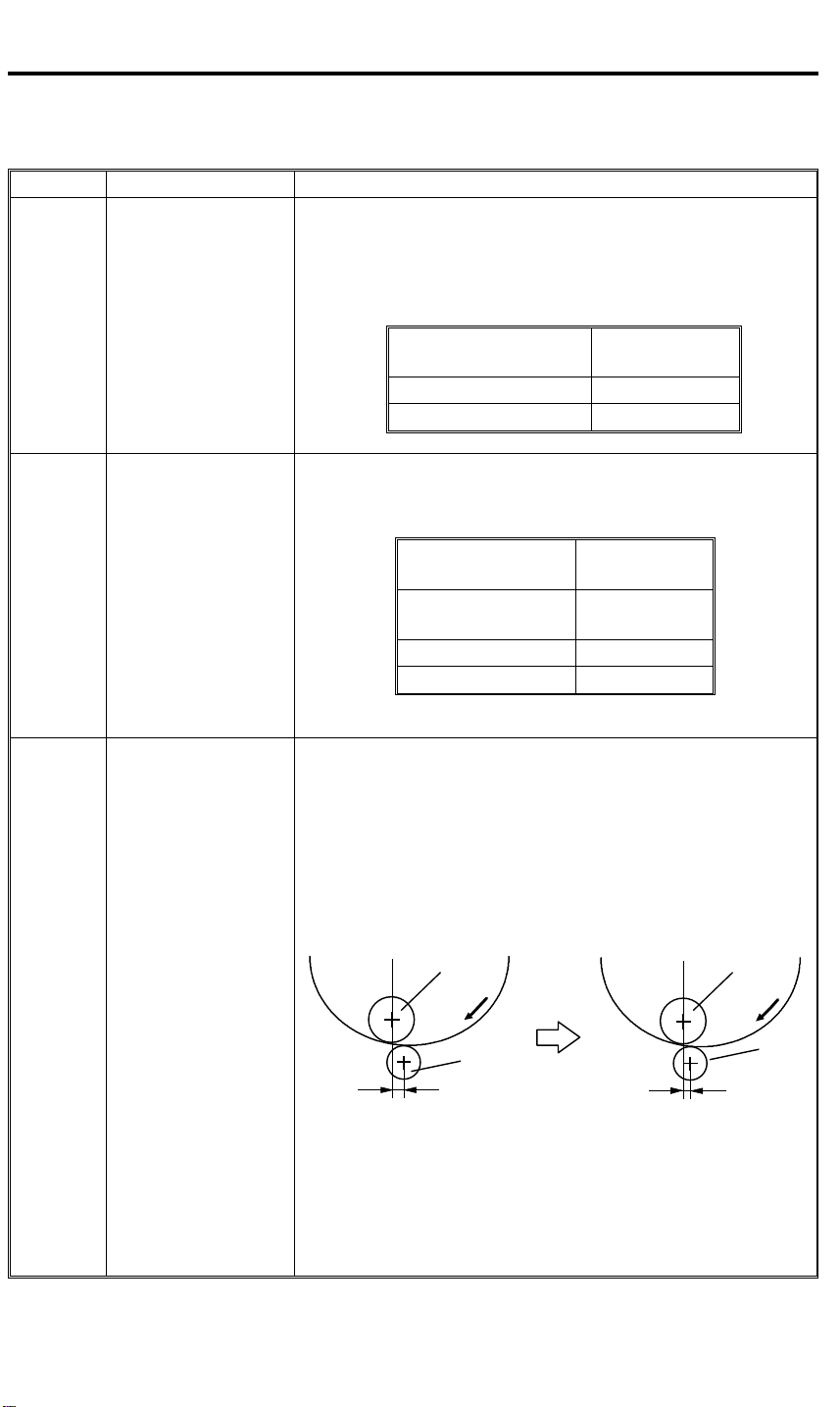

3.

Drum Ink Roller

Layout

To ensure paper separation from the drum, the

ink roller has been shifted forward the paper

feed table.

The distance L has been changed from 5.0 mm

to 3.5 mm.

VT2100 series VT2105

[A]

[B]

L

[A]

[B]

L’

L = 5.0 mm L’ = 3.5 mm

NOTE:The optional color drum for the VT2105

is commonly used for the VT2100 series.

(The distance L of the color drum is

4.5 mm)

1-4

Page 7

Overall

Information

1 October 1992 DIFFERENCE BETWEEN VT2000 SERIES AND VT2105

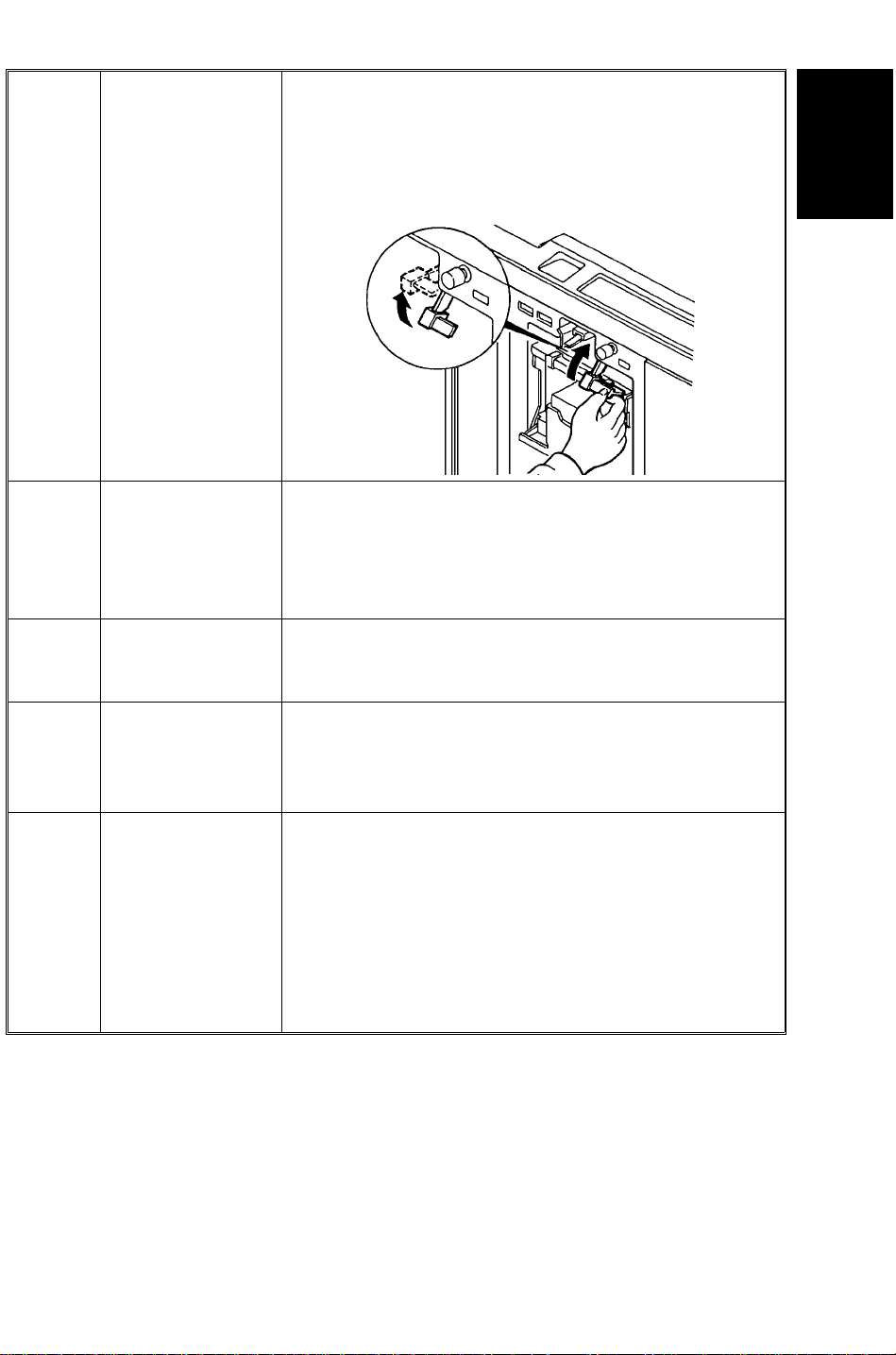

To ensure drum connection, a drum lock lever is

added inside the front door. To remove the drum

from the machine, the drum release lever must

be pulled up to disconnect the drum connector.

4. Drum Connector

The location of the ink detection board has been

changed from the upper side to the right side of

the drum shaft. The ink type switch (SW901),

which was not used (always set at oil type), has

5.

Ink Detection

Board

been removed.

To supply ink to the ink roller evenly, the second

6. Drum Shaft

ink supply hole (count from the front side) of the

drum shaft is covered with a strip of tape.

To ensure paper separation from the drum, the

7.

Exit Pawl Air

Pump

exit pawl air pump system is standardized. (The

pump system can optionally be installed on the

VT2000 series.)

The thermal head drive board has been

removed. The function of the board has been

moved to the image processing board and the

8.

Thermal Head

Drive

main board.

The thermal head voltage is directly applied from

the power supply unit. The main board applies

signal to the PSU to supply thermal head voltage

only during the master making process.

1-5

Page 8

ELECTRICAL COMPONENT DESCRIPTIONS 1 October 1992

3. ELECTRICAL COMPONENT

DESCRIPTIONS

INDEX

No.

Motors

4 Original Transport Motor Transports the original to the scanner section.

10 Master Feed Motor Feeds the master to the drum.

11 Cutter Motor Cuts the master.

14 Master Eject Motor Sends used master into the master eject box.

18 ADF Drive Motor Feeds the original to the scanner section.

25 Image Shift Motor

28 Paper Table Drive Motor Raises and lowers the paper table.

30 Main Motor

60 Air Knife Motor

61 Vacuum Motor

Solenoids

3 Original Pressure Solenoid

15 Master Eject Solenoid

Master Eject Clamper

21

Solenoid

22 Drum Lock Solenoid

Master Feed Clamper

23

Solenoid

24 Reverse Roller Solenoid Releases the clutch to rotate the reverse roller.

27 Paper Feed Solenoid

32 Printing Pressure Solenoid Moves the press roller against the drum.

47 Ink Supply Solenoid

Switches

6 Right Cutter Switch Detects when the cutter position is at the far right.

12 Left Cutter Switch Detects when the cutter position is at the far left.

16 Master Box Switch

Master Eject Unit Safety

36

Switch

NAME FUNCTION

Changes the timing between the paper feed roller

and the drum to adjust the vertical image position.

Drives paper feed, drum, printing and paper delivery

unit components.

Rotates the fan to separate the paper leading edge

from the drum.

Provides suction so paper is held firmly on the

transport belt.

Presses the original pressure plate down on the

originals.

Moves the master eject roller to contact the drum

surface.

Opens the master clamp to eject the master.

Prevents removal of the drum unit unless the drum

is at the original stop position

Opens the master clamp to clamp the master.

Releases the paper feed sector gear to rotate the

paper feed roller.

Releases the spring clutch to activate the ink supply

pump.

Checks whether the master eject box is installed

correctly or not.

Checks whether the Master Eject Unit is closed

correctly or not.

1-6

Page 9

Overall

Information

1 October 1992 ELECTRICAL COMPONENT DESCRIPTIONS

INDEX

No.

41 Master Cut Switch

42 Scanner Safety Switch

44 Drum Rotation Switch Informs the CPU to rotate the main motor at 10 rpm.

45 Front Door Safety Switch

46 Drum Safety Switch Checks whether the drum unit is set correctly or not.

52 Paper Table Safety Switch

57 Interlock Switch Releases the cover safety functions.

59 Main Switch Turns the power on or off.

62 Full Master Detecting Switch

Pressure Plate Position

63

Switch

64 Printing Density Switch

65 ADF Safety Switch Check whether the ADF unit is set correctly or not.

Sensors

1 Original Registration Sensor

2 2nd Original Sensor Detects when the original is set.

Master End Sensor

9

13 Master Buckle Sensor Detects master buckles.

17 Master Eject Sensor

19 1st Original Sensor Detects when the original is set in the ADF mode.

29 Drum Rotation Sensor Supplies timing pulses to the main board.

33 2nd Drum Position Sensor Checks the position of the drum.

34 1st Paper Exit Sensor Detects misfeed.

35 2nd Paper Exit Sensor Detects misfeed.

37 1st Drum Position Sensor Checks the position of the drum.

49 Paper Table Height Sensor

51 Paper End Sensor

Paper Table Lower Limit

53

Sensor

54 Printing Pressure Sensor

NAME FUNCTION

Informs the CPU to cut the master paper leading

edge.

Checks whether the scanner unit is closed correctly

or not.

Checks whether the Front Door is set correctly or

not.

Checks whether the paper table is opened correctly

or not.

Informs the CPU when the master eject box is full of

masters.

Informs the CPU when the pressure plate has

reached the home position.

Use to select the printing density according to the

type and quality of the original.

Informs the CPU when the original leading edge

reaches the exposure glass.

Informs the CPU when the plotter unit runs out of

master roll.

Detects when the used master is sent into the

master eject box.

Detects when the paper table reaches the paper

feed position.

Informs the CPU when the paper table runs out of

paper.

Detects when the paper table reaches the lowest

position.

Informs the CPU when the printing pressure is

applied.

1-7

Page 10

ELECTRICAL COMPONENT DESCRIPTIONS 1 October 1992

INDEX

No.

NAME FUNCTION

Printed Circuit Board

7 Power Supply PCB Rectifies 100V AC input and supplies DC voltage.

31 AC Drive PCB Controls the AC component by relays.

38 Ink Detection PCB Control the ink supply.

39 CCD PCB Converts the light intensity into the electrical signal.

40 A/D Conversion PCB Converts the analogue signal into the digital signal.

43 Operation Panel

48 Main Control PCB

Controls the LED performance and monitors the key

operation.

Controls all machine functions both directly and

through other boards.

50 Image Processing PCB Controls the master processing performance.

Counters

55 Copy Counter Keeps track of the total number of copies made.

56 Master Counter Keeps track of the total number of masters made.

Others

5 Fluorescent Lamp Stabilizer

Stabilizes the power supplement to the fluorescent

lamp.

8 Thermal Head Burns the image on to the master.

20 Fluorescent Lamp Exposes the original.

26 Encoder Converts 16 image positions to 4 bit data.

58 Circuit Breaker Cuts the ac line.

1-8

Page 11

SECTION 2

DETAILED SECTION

DESCRIPTION

Page 12

Detailed

Descriptions

1 October 1992 OPTICS

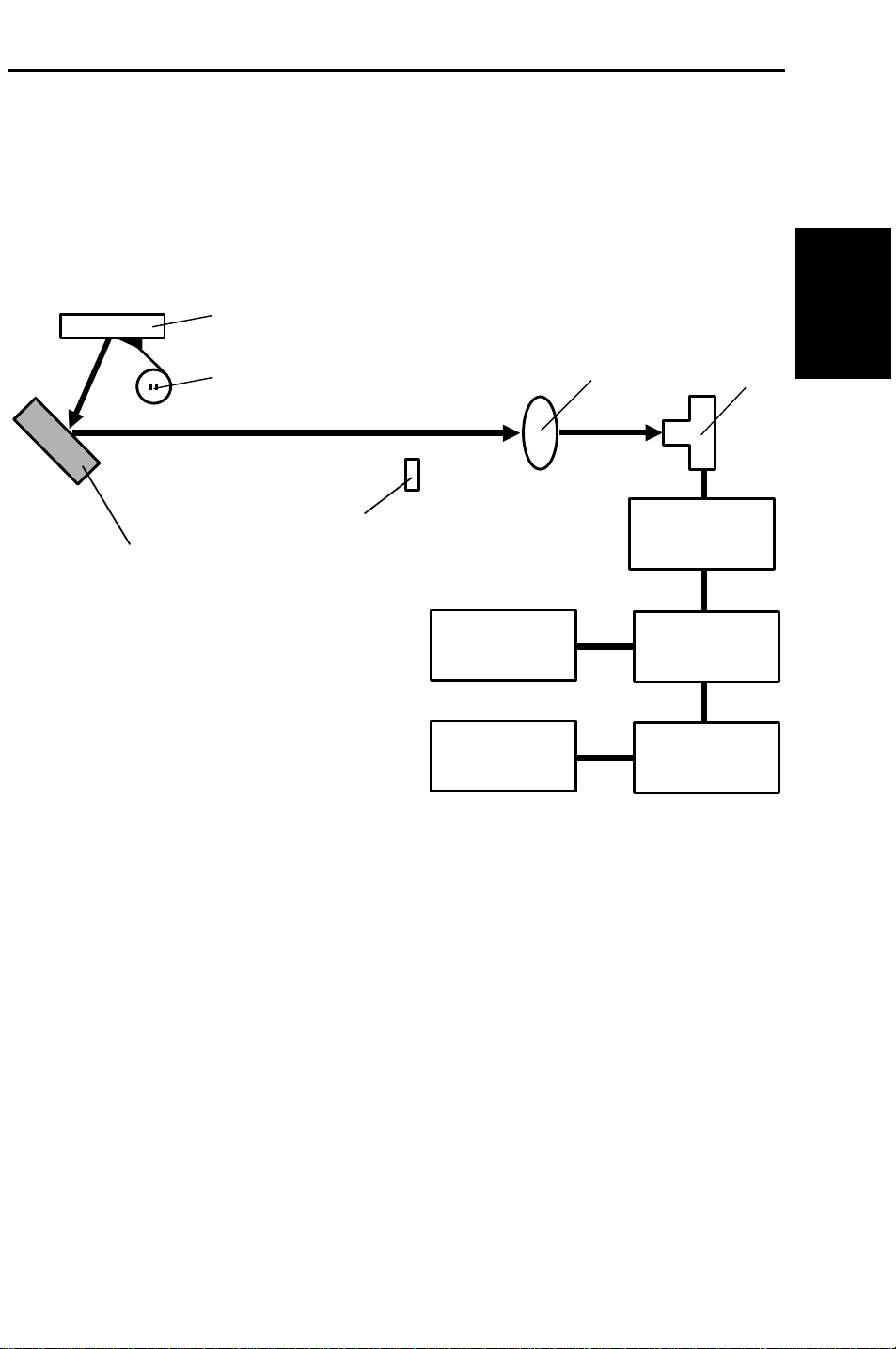

1. OPTICS

1.1 OVERALL

The CCD [A] used on the VT2105 is commonly used on the SS800 series.

Due to the pixel density difference between the VT2105 and SS800 series

(300 dots/inch and 12 dots/mm), the reduction ratio (lens [B] position) of the

VT2105 is different from the SS800 series.

[E]

[F]

[C]

[B]

A/D Converter

[D]

Thermal Head

Image

Processing

[C]: Shading Plate

[D]: Mirror

[E] Exposure Glass

Operation Panel

Main Board

[F]: Fluorescent Lamp

The thermal head drive board has been removed. The function of this board

has been moved to the image processing board and the main board.

[A]

2-1

Page 13

OPTICS 1 October 1992

1.2 CIRCUIT

Original

Registration

Sensor

2nd Original

Sensor

Original

Transport Motor

M

Image

A/D

Conversion P.C.B.

1

3

2

1

3

2

5V

CN603-1

CN603-4

CN603-2

GND

CN603-3

CN605

-1

-2

-3

-4

-5

-6

CN601-13

CN601-11

CN601-25

CN601-27

CN601-21

CN601-23

CN601-25

CN601-19

Processing

P.C.B.

CN403-13

CN403-11

CN403-25

CN403-27

CN403-21

CN403-23

CN403-25

CN403-19

Fluorescent Lamp

1st Original

Sensor

ADF

Drive Motor

Original Pressure

Solenoid

ADF Safety SW

M

SOL

Stabilizer

CN611-1

CN611-2

CN612-1

CN612-2

1

3

2

CN604

Red

-1

CN604

-3

Yellow

Black

CN604-2

CN607-3+5V

CN607-5 CN601-3

CN607-4 (GND)

CN607-6

CN607-7

CN607-1

CN607-2

CN607-8

CN607-9

24V

+24V

CN601

-15

GND

+5V

CN601-5

+24V

CN601-1

CN601-7

CN601-9

CN403-15

CN403-3

CN403-5

CN403-1

CN403-7 (IN)

CN403-9 (OUT)

2-2

Page 14

Detailed

Descriptions

1 October 1992 OPTICS

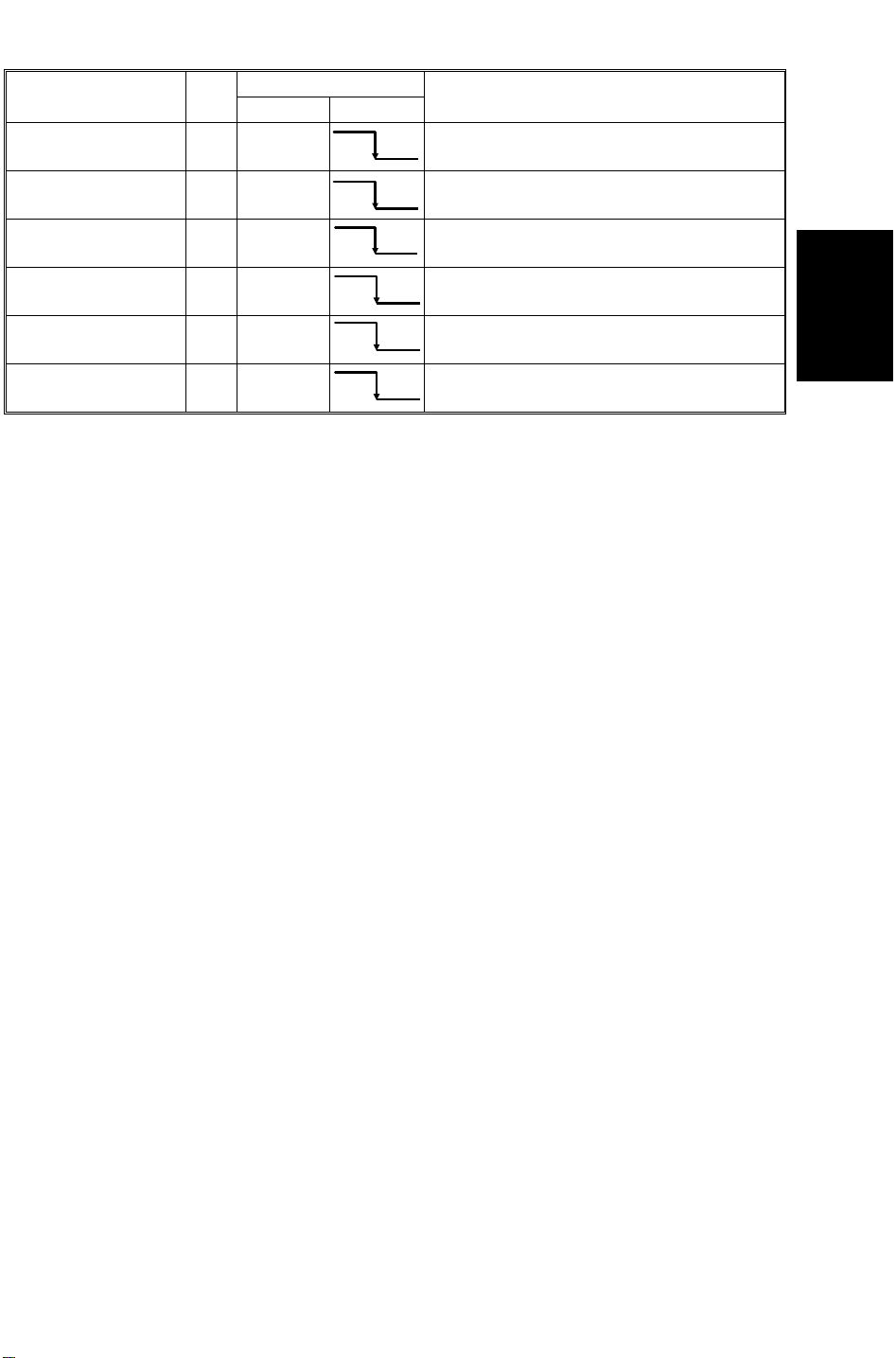

Component Name I/O

Fluorescent Lamp O 604-3

ADF Drive Motor O 607-6

Original Pressure

Solenoid

Original

Registration Sensor

2nd Original Sensor I 603-3

1st Original Sensor I 607-5

ID Conversion Board

CN No

O 607-2

I 603-4

24V

24V

24V

24V

24V

24V

Description

When the fluorescent lamp turns ON, the

0V

CN604-3 goes to 0V.

When the ADF drive motor starts rotating

0V

CN607-6 goes to 0V.

When the original pressure solenoid is

0V

energized, CN607-2 goes to 0V.

When the original registration sensor is

0V

activated, CN603-4 goes to 0V.

When the 2nd original sensor is

0V

activated, CN603-3 goes to 0V.

When the 1st original sensor is activated,

0V

CN607-5 goes to 0V.

2-3

Page 15

OPTICS 1 October 1992

1.3 THERMAL HEAD

CN104-34

ENL

CPU

CN105

-18

Thermistor

Temperature

detection

CN105

-19

ENLTRIG

CN402

-17

ENL

CN402

-15

CN402

-18

HERR

CN402

-19

STOROBE

STOROBE

CN504-2

CN404

-5

-7

-9

-11

-13

-15

-17

-19

-21

-23

-25

-1

-2

SEOH

Thermal

Guard

PSU

DATA

LATCH

CLOCK

STROBE1

STROBE2

STROBE3

STROBE4

STROBE5

STROBE6

STROBE7

STROBE8

Thermistor: IN

Thermistor: OUT

Thermal Head

Main Board

Image Processing

Board

(1) Specification

The VT2105 uses a 300 DPI thermal head.

Thermal head

• Memory lergth 256 mm

• Number of thermal head elements 3072 dots

• Density of thermal head elements 300 DPI

• Applied voltage 19~24 V

(2) Thermal Head Control

The thermal head drive board has been removed. The function of this

board has been moved to the image processing board and the main

board.

2-4

Page 16

Detailed

Descriptions

1 October 1992 OPTICS

ENLTRIG

ENL

Pulse width

The thermal head energy is controled by changing pulse width.

The pulse is controlled by the ENL signal from the main board corresponding

to ENLTRIG from the image processing board.

VHD

CNT

Main Board

CN504-1

CN104-33

Thermal

Head

Voltage

Circuit

PSU

VHD

CN505-1

VHD

CN505-3

GND

CN505-4

GND

CN505-5

CN701-1

CN701-2

CN701-3

CN701-4

Thermal Head

Thermal head voltage (VHD: 19V~24V) is applied from PSU only during the

master making process. This is controlled by the VHDCNT signal (CN104-33)

from the main board.

VHDCNT (CN104-33)

VHD (CN505-1)

(CN505-3)

0 V 19~24 V

5 V 0 V

2-5

Page 17

DRUM 1 October 1992

2. DRUM

2.1 DRUM CONNECTION MECHANISM

[D]

[A]

[C]

[B]

[F]

[E]

[E]

[D]

[H]

[G]

When the drum release lever [A] in front of the machine is raised, the

connector [B] is pushed away from the drum by the bracket [C] through the

link [D] to be disconnected. The connector moves only horizontally due to the

guidance of the shafts [E]. The bracket [C] also pushes the drum lock lever

[F] to release the drum lock allowing the drum to be removed.

While the drum is out of home position, the drum lock solenoid [G] is

energized and the stopper [H] locks the link [D] not to be pulled. The solenoid

is de-energized when the drum stops at the home position (1st drum home

position sensor is actuated).

2-6

Page 18

Detailed

Descriptions

1 October 1992 DRUM

2.2 CIRCUIT

Drum

Safety SW

Drum

Release

Solenoid

Drum

Rotation

SW

Ink Supply

Solenoid

Color

Drum

SOL

COM

NC

NO

SOL

Scanner

Safety SW

1

2

5

6

CN102-46

CN104-39

CN104-35

CN104-40

CN104-30

CN102-45

CN102-16

CN104-3

CN104-14

+24 V

Safety SW = IN

Safety SW = OUT

MSW: Drum Rotation

2 A

GND

SIG: Color Drum

24 V

Ink Petection

Pin

Component Name I/O

MSW: Drum

Rotation

ID Conversion Board

CN No

I 104-30

Ink Supply SOL O 102-16

Drum Release SOL O 104-35

Ink Detection PCB I 104-9

7

8

Ink Detection

Board

24V

0V

24V

24V

12V

CN102

-43

-9

-41

GND

Ink Detection

-12 V

Main Board

CN104

CN102

Description

When the drum rotation SW is pressed,

CN104-30 goes to 24V.

When the solenoid is turned on,

0V

CN102-16 goes to 0V.

When the drum position sensor 1 is

0V

deactuated, CN104-35 goes to 0V.

When there is no ink on the ink roller,

0V

CN104-9 goes to 0V.

2-7

Page 19

PAPER DELIVERY 1 October 1992

3. PAPER DELIVERY

3.1 EXIT PAWL AIR PUMP MECHANISM

[A]

[C]

[A]

[D]

[B]

[C]

The main motor drive is transmitted to the pump gear [A] through gears and a

timing belt [B]. The gear [A] rotates and drives the piston [C] back and forth.

The piston moves forward and pushes a jet of air out through the nozzle [D].

This jet of air helps separating the paper from the drum.

2-8

Page 20

SECTION 3

INSTALLATION

Page 21

Installation

1 October 1992 INSTALLATION PROCEDURE

1. INSTALLATION PROCEDURE

1. Make sure that you have all the accessories listed below.

(1) Original Exit Tray..................................................................... 1

(2) Right Tray Bracket .................................................................. 1

Left Tray Bracket..................................................................... 1

(3) Fixing Screws.......................................................................... 2

(4) Master Spools ......................................................................... 2

(5) Thermal Head Cleaner ...........................................................1

(6) Operating Instructions (USA and Asia version only)...............1

(7) NECR ..................................................................................... 1

(8) Installation Procedure (English)..............................................1

3-1

Page 22

INSTALLATION PROCEDURE 1 October 1992

[A]

2. Mount the machine on the optional table (2 screws packed with table).

3. Remove the tape and string securing the covers and units as shown on

the right.

a. Open the paper feed tray. Then remove the cushion plate [A] from the

paper feed roller section.

b. Open the master delivery unit. Then remove the tape securing the

paper delivery guide plate.

3-2

Page 23

Installation

1 October 1992 INSTALLATION PROCEDURE

4. Remove the protective sheet [A] from

the drum unit.

a. Open the front door.

b. Take out the drum unit.

c. Remove the protective sheet from

the master clamper.

d. Reinstall the drum unit in the

machine.

e. Push down the drum lock lever

[B].

[B]

[A]

5. Install the original exit tray [B].

a. Hook the right and left tray brackets

on the stepped screws.

b. Set the original exit tray on the

brackets.

c. Secure the brackets with fixing

screws.

[B]

3-3

Page 24

INSTALLATION PROCEDURE 1 October 1992

6. Loading Paper on the Paper Feed

Table

a. Open the paper feed table.

b. Stack the paper neatly on the paper

feed table.

c. Position the paper feed side plates

so that they lightly contact the paper

on both sides.

d. Position the paper delivery table for

the printing paper size, using the

scale on the table.

e. Position the paper delivery side

plate for the printing paper size,

using the scale on the table.

7. Installing the Master Roll

(Type VT-II-M)

a. While lifting the release lever, slide

the scanner unit to the left.

b. Attach a spool to each end of the

master roll.

c. Set the master roll in the machine.

NOTE: The vinyl side faces down.

d. Return the pressure release lever to

the original position.

e. Plug in the power cord and turn on

the main switch.

f. Press the Master Cut button.

g. Remove the cut master paper.

NOTE: Confirm that the master

paper is not bent or creased.

h. Close the scanner unit.

3-4

Page 25

Installation

1 October 1992 INSTALLATION PROCEDURE

8. Installing the Ink Cartridge

a. Open the front door and lower the

ink holder.

b. Remove the ink cartridge cap.

c. Insert the ink cartridge into the ink

holder and return the ink holder to

the original position.

d. Close the front door.

9. Idling

a. While holding down the "0" key on

the operation panel, press the

Reset key.

b. If + D blinks on the operation

panel, repeat the above procedure.

10. Test Printing

a. Adjust the original guide to match

the original size.

b. Set the original face down.

c. Input the desired number of prints

with the number keys and press the

Master Making key.

NOTE: With a new machine, the

master paper misfeed

indicator + F blinks

because there is no master

yet on the drum. Press the

Reset key, then press the

Master Making key.

d. After one sheet of paper is

delivered, make prints at the lowest

print speed (1) until the print image

density stabilizes. Use a test chart

to check for changes in the image

density.

e. Check the copy image after about

one hundred prints.

3-5

Page 26

SECTION 4

SERVICE TABLES

Page 27

Service

Tables

1 October 1992 MAINTENANCE TABLE

1. MAINTENANCE TABLE

The following VT2105 tables are identical to those from the VT2000 series.

• Lubrication Points

• User’s Maintenance

• Table of Periodic Inspection

1.1 TABLE OF SERVICE CALL INDICATIONS

Indication Trouble Possible cuses

Malfunction in cutter section:

E 01

E 02

E 03 Malfunction in the program.

E 04

E 05 Malfunction in the image shifting section:

E 06

E 07

E 08 Thermal head drive signal (ENL) is defective.

The cutter does not reach both right and left

cutter position switches within 2 seconds.

Malfunction in the paper table drive section:

The lower limit sensor or the paper table height

sensor status does not change even though the

paper table UP or Down signal is applied.

Temperature of the thermal head or the power

supply unit is high:

Temperature of the thermal head becomes

greater than 57°C or the temperature of the

power supply unit becomes greater than 85°C

when the machine is in stand-by condition.

Mechanical lock:

Drum rotation sensor detects that the drum

rotation speed is abnormal.

Malfunction in the program (PROM). When using

I/O check mode, "E 07" lights up if the ROM is

defective.

NOTE: When "E 03" is lit, access I/O check

mode to check if the PROM is defective.

1) Drive wire cut

2) Drive section malfunction

3) No power supply

1) Drive worm gear broken

2) Mounting screw of the

worm gear broken

3) No power supply

1) Defective PROM

2) Defective control PCB

1) Defective thermistor

2) Defective thermal head

3) Defective power supply

unit

1) Encoder connector of

the image shifting

sectiond is connected.

2) Defective encoder

1) Mechanical lock

2) Main motor failure

Defective ROM

Defective image

processing board.

4-1

Page 28

DIP SW, LED, VR, AND TP TABLES 1 October 1992

2. DIP SW, LED, VR, AND TP TABLES

2.1 DIP SW TABLE (ON THE MAIN BOARD)

No. DIP SW Function Remarks

Turn on to disable all cover safety switch

1 DP102--1 Cover Open

2 DP102--2 ADF Cover Open

3 DP101--1 Key Counter

4 DP101--2 Buzzer ON/OFF Turn on to sound the beeper. (Normal: OFF)

5 DP101--3 Initial Print

6 DP101--4 ADF Operation Turn on to kill the ADF function. (Normal: OFF)

7 DP101--5

8 DP101--6

9 DP101--7 Erase White Line

10 DP101--8

11 DP103--1

12 DP103--2

13 DP103--3

14 DP103--4 Mode Clear

15

DP103--5

DP103--6

Class/Memory

Selection

I/O Check

Procedure

Double Master

Compression

Reduction Ratio

Compensation

Reduction Ratio

Compensation

Reduction Ratio

Compensation

Skip Paper Feed

Setting

functions except ADF cover safety.

(Normal: OFF)

Turn on to disable the ADF cover safety switch

function. (Normal: OFF)

Turn on when installing the key counter.

(Normal: OFF)

ON: Makes two prints after making a master.

OFF: Makes one print after making a master.

(Normal: OFF)

To select class or memory function.

OFF: Class, ON: Memory. (Normal: ON)

Selects the I/O check mode access procedure.

(ON: Europe/Asia version, OFF: US version)

Turn on to erase the white line 60 mm from the

leading edge. (NOTE1) (Normal: OFF)

If this switch is ON, when the master making

key is pressed, masters in the master eject

box are compressed once before plotting

starts and detects if the master box is full.

(NOTE2) (Normal: OFF)

Used to adjust the reduction ratio in the

sub-scan direction.

Used to adjust the reduction ratio in the

sub-scan direction.

Used to adjust the reduction ratio in the

sub-scan direction.

If this switch is turned on, the blind key on the

operation panel is used as the clear mode key.

(Normal: OFF)

Setting these switches enables skip paper

feed mode. After setting these switches, the

blind key is used to access skip paper feed

mode. (NOTE3)

(Normal: 103-5 OFF, 103-6 OFF)

4-2

Page 29

Service

Tables

1 October 1992 DIP SW, LED, VR, AND TP TABLES

NOTE1 The shock wave from clamping might make a thin white line 60 mm

from the leading edge. This line is visible when the image is made

by photo mode. By turning on DPS 101-7, the reverse roller

solenoid ON timing is delayed to absorb the shock wave. However,

the above measure sometimes disturbs master registration (image

position on the master).

NOTE2 If the customer does not dispose of the ejected masters even

though full master is indicated (Turning off the main switch resets

full master condition), master eject jams or master eject belt might

slip off. Double master compression prevents the customer from

making a master when the master box is full. However, if this switch

is turned on, the master compression is performed twice for every

master made. This hastens parts wear and may cause trouble.

NOTE3 The following skip number can be selected by setting DIP SW 103-5

and 103-6.

DPS103

5 OFF ON OFF ON

6 OFF OFF ON ON

1 Sheet/

1 Rotation

1 Sheet/

3 Rotation

1 Sheet/

5 Rotation

If both DPS 103-4 (Mode Clear) and DPS 103-4/5 (Skip Paper Feed

Setting) are selected, Mode Clear mode is selected. (Skip Feed is

ignored.)

2.2 DIP SW TABLE (Image Processing Board)

No. DIP SW Function Remarks

1 DPS 400-1 Test Pattern

2 DPS 400-1 Dither Pattern

Turn off to access test pattern mode

(Normal: ON)

Used to change dither matrix

(ON: 4 x 4, OFF: 6 x 6)

2.3 LED TABLE

No. LED Function Remarks

1 LED 101 Main Motor ON When the main motor turns on, LED lights

2 LED 102

3 LED 103

4 LED 104 Ink Detection

1st Paper Exit

SN Detection

2nd Paper Exit

SN Detection

When paper is detected, LED lights

When paper is detected, LED light

When ink is detected, LED lights

NOTE: When the drum release lever is raised,

the drum connector is disconnected

and LED turns off.

1 Sheet/

8 Rotation

4-3

Page 30

DIP SW, LED, VR, AND TP TABLES 1 October 1992

2.4 VR TABLE (Main Board)

No. VR Function

1 VR 101 Main motor speed adjustment

2 VR 102 1st paper exit sensor adjustment

3 VR 103 2nd paper exit sensor adjustment

2.5 VR TABLE (AD Conversion Board)

No. VR Function

1 VR 600 White level adjustment

2 VR 601 Black level adjustment

2.6 TEST PIN TABLE (Main Board)

No. Test Pin Function Standard Voltage

1 TP 101 GND 0 V.

2 TP 102

3 TP 103

1st paper exit

sensor (PDLV)

1st paper exit

sensor (PROL)

ON: 5~10 V

OFF: 0 V

ON: 5V

OFF: 0 V

2.7 TEST PIN TABLE (A/D Conversion Board)

No. Test Pin Function

1 TP 600 GND

2 TP 601 Shift signal output (SH)

3 TP 602 CCD output (OS)

4 TP 603 Inverted and amplified CCD output

5 TP 604 Black level standard voltage output

4-4

Page 31

Service

Tables

1 October 1992 SERVICE PROGRAM TABLE: VT2105

3. SERVICE PROGRAM TABLE: VT2105

3.1 HOW TO ACCESS I/O CHECK MODE

1. A4 version:

Turn on the main switch while holding down the Print Start key, Stop key,

Clear key and Full Master Detection switch.

LT version:

Turn on the main switch while holding down the Print Start key, Stop key,

and Clear key.

2. Press the Memory/Class key to select either "Input" or "Output".

Memory indicator "1" Input

Memory Indicator "0" Output

4-5

Page 32

SERVICE PROGRAM TABLE: VT2105 1 October 1992

3.2 OUTPUT MODE:

COUNTER

INDICATION

0001-0

0002-0

0003-0

0004-0

0005-0

0006-0

0007-0

0008-0

0009-0

0010-0

0011-0

0012-0

0013-0

0014-0

0015-0

0016-0

0017-0

0018-0

0019-0

0020-0

0021-0

0022-0

0023-0

0024-0

0025-0

0026-0

0027-0

0028-0

0029-0

0030-0

0031-0

0032-0

0033-0

0034-0

0035-0

0036-0

OUTPUT

Turns on the drum (10 rpm).

Turns on the drum (30 rpm).

Turns on the drum (75 rpm).

Turns on the paper table drive motor (up).

Turns on the paper table drive motor (down).

Turns on the vacuum motor.

Turns on the master eject solenoid.

Turns on the master eject clamper opening solenoid.

Turns on the master feed clamper opening solenoid.

Turns on the reverse roller solenoid.

Turns on the paper feed solenoid and the printing pressure solenoid.

Turns on the ink supply solenoid.

Turns on the original transport motor.

Turns on the master feed motor.

Turns on the fluorescent lamp.

Master Process Command (photo LED ON)

Reverses the master eject motor (turn the eject rollers).

Turns on the master eject motor (pressure plate up/down).

Turns on the cutter motor (moves it from front to rear).

Turns on the cutter motor (moves it from rear to front).

Turns the image shifting motor in the (+) direction.

Turns the image shifting motor in the (--) direction.

Turns on the magnetic counter for paper.

Turns on the magnetic counter for master.

Turns on the drum reverse rotation relay.

Magnification ratio : 100% (LED ON)

Magnification ratio : 93% (LED ON)

Magnification ratio : 82% (A4 version)/ 75% (LT version) (LED ON)

Magnification ratio : 71% (A4 version)/ 64% (LT version) (LED ON)

Turns on the drum (10 rpm), the paper feed solenoid, and the printing

pressure solenoid.

Tape marker (option) feeds out strips of paper.

Turns on the ADF drive motor (Not used).

Turns on the ADF original pressure solenoid (not used).

Turns on the drum lock solenoid.

Outputs the thermal head voltage (VHS).

Simulates original transportation in ADF mode. (Fluorescent lamp and CCD

do not work.)

NOTE: 0001-0 to 0006-0 and 0030-0 are not activated when the safety

cover is open.

4-6

Page 33

Service

Tables

1 October 1992 SERVICE PROGRAM TABLE: VT2105

3.3 INPUT MODE:

COUNTER

INDICATION

0001-1

0002-1

0003-1

0004-1

0005-1

0006-1

0007-1

0008-1

0009-1

0010-1

0011-1

0012-1

0013-1

0014-1

0015-1

0016-1

0017-1

0018-1

0019-1

0020-1

0021-1

0022-1

0023-1

0024-1

0025-1

0026-1

0027-1

0028-1

0029-1

0030-1

0031-1

0032-1

0033-1

INPUT

SW: Master Eject Detection (Indicator lights when sensor ON)

SW: Pressure Plate Position (Indicator lights when switch ON)

SN: 2nd Original Detection (Indicator lights when sensor ON)

SN: Original Registration Detection (Indicator lights when sensor ON)

SN: 1st Drum Position Detection (Indicator lights when sensor ON)

SN: 2nd Drum Position Detection (Indicator lights when sensor ON)

SN: Master Detection (Indicator lights when master is set)

SN: Master Buckle Detection (Indicator lights when master appears)

SW: Left Cutter (Indicator lights when switch ON)

SW: Right Cutter (Indicator lights when switch ON)

SW: Master Eject Box (Indicator lights when switch ON)

SW: Full Master Detection (Indicator lights when switch ON)

SN: Paper End (Indicator lights when paper is set)

SN: Paper Table Low Limit (Indicator lights when sensor ON)

SN: Paper Table Height (Indicator lights when sensor ON)

SN: Pressure (Indicator lights when sensor ON)

SN: 1st Paper Exit (LED103) (Indicator lights when paper is present)

SN: 2nd Paper Exit (LED102) (Indicator lights when paper is present)

SW: Cover Safety/Drum Detection (Indicator lights when switch ON)

SN: Color Drum (Indicator lights when color

drum is set)

DIP SW-1 (DIP101-1) (Indicator lights when switch ON)

DIP SW-2 (DIP101-2) (Indicator lights when switch ON)

DIP SW-3 (DIP101-3) (Indicator lights when switch ON)

DIP SW-4 (DIP101-4) (Indicator lights when switch ON)

Not Used

SN: Ink Detection (Indicator lights when ink appears)

SN: Thermistor (Indicator lights when temp. is

standard)

Key: Proof (Indicator lights when key ON)

Key: Image Shift + (Indicator lights when key ON)

Key: Image Shift -- (Indicator lights when key ON)

SW: Drum Rotation (Indicator lights when switch ON)

SW: Master Manual Cut (Indicator lights when switch ON)

SN: 1st Original Detection (Indicator lights when sensor ON)

4-7

Page 34

TEST PATTERN IMAGE MODE 1 October 1992

4. TEST PATTERN IMAGE MODE

The purpose of this mode is to distinguish whether the cause of the image

problem is located before or after image processing.

Output image: The normal output of this test pattern image mode is one

of the dither matrix pattern as illustrated below.

Master processing length:

Main scan (Horizontal) direction: Full width of the thermal head

Sub-scan (Vertical) direction: Same as the vertical size of

the original set on the original

table.

Magnified Test Pattern Image

Test Pattern Image

Fluorescent Lamp

CCD

Original Feed

Motor

A/D Conversion

PCB

Test Pattern in

Line Mode

Image

Processing PCB

Master Feed

Motor

Test Pattern in

Photo Mode

BA

Thermal Head

This test pattern is generated by the image processing PCB.

[Example] Problem: Vertical white lines appear on the print.

Possible Cause 1 If the same problem appears on the output

image from the thermal head in test pattern

image mode, the cause should be in area

B, as shown above.

Possible Cause 2 If the output image from the thermal head is

correct in test pattern mode but the output

image in the normal mode is incorrect, the

cause should be in area A, as shown

above.

4-8

Page 35

Service

Tables

1 October 1992 TEST PATTERN IMAGE MODE

4.1 OPERATION: (To Enter Test Pattern Image Mode)

1) Remove the front cover.

2) Turn off DIP SW 400-1 on the image processing PCB only when the

power switch is off.

3) Turn on the main switch.

4) Press the Image Mode key to select the test pattern image.

Test pattern in line mode

Test pattern in photo mode

5) Set the original on the original table.

CAUTION: To prevent overheating of the thermal head, make the

original as short as possible. Any type of original is

suitable as the test pattern being used is in the image

processing PCB memory.

6) Press the Master Making key and make prints.

7) After completion of the test pattern image mode, turn on DIP SW 400-1.

4-9

Page 36

AVAILABLE OPTION/SUPPLY TABLE 1 October 1992

5. AVAILABLE OPTION/SUPPLY TABLE

O: Standard combination

∆: Usable under certain conditions

X: Cannot be used

VT2105

Masters Type 800 X

Type 900 X

VT-S X

VT-M X *NOTE1

VT-L X

VT-

ΙΙ-M

Inks Black O

Color (rd/bl/gn/br) O

VT-Black-800 X

Color Drums

Others Cassette B4 X

Color Drum

Color Drum Type 905

Color Drum VT2000-M O

Color Drum VT2000-LG X *NOTE3

Color Drum VT2000-S X *NOTE3

Color Drum VT3000-L X

Color Drum VT3000-S X

Cassette VT3000-L X

Cassette VT3000-S X

Tape Marker Type 20 O

Priport Table O

Priport Table VT3000 X

O

∆ *NOTE2

∆ *NOTE2

NOTES: 1. The VT-M master can be installed on the VT2105, however, a

weak image (sometimes image blank) will appear.

This is because the VT-

ΙΙ-M master is more sensitive than the

VT-M master.

2. The modified master clamper (P/N C2074948) must be installed.

3. The drum can be installed, however, the maximum image area is

limited according to the drum screen size.

4-10

Page 37

SECTION 5

REPLACEMENT AND

ADJUSTMENT

Page 38

Replacement

Adjustment

1 October 1992

1) The replacement and adjustment procedures not mentioned in the

following pages are identical to those of the VT2000 series.

2) The purpose and procedure of the following adjustments are identical to

those of the VT2000 series, however the adjusting value or VR is different.

•• PRINTING PRESSURE ADJUSTMENT

[A]

Adjust the clearance [A] to be 14 ± 0.5 mm by turning the adjusting belt [B].

•• PRINTING SPEED ADJUSTMENT

Adjust the drum speed by turning VR101 on the main board.

•• EXIT PAWL CLEARANCE ADJUSTMENT

Drum

0.5 + 0.2 mm

-0 mm

Adjust the exit pawl clearance so that the distance between the exit pawl and

the drum is between 0.5 and 0.7 mm.

•• FIRST PAPER EXIT SENSOR ADJUSTMENT

Adjust the 1st paper exit sensor sensitivity by turning VR103. Check the

sensor status with LED103.

•• SECOND PAPER EXIT SENSOR ADJUSTMENT

Adjust the 2nd paper exit sensor sensitivity by turning VR102. Check the

sensor status with LED102.

5-1

Page 39

OPTICS ADJUSTMENT 1 October 1992

1. OPTICS ADJUSTMENT

The method of the optics adjustment is the same as the VT2000 series.

However, the wave shape is not exactly same because the pixel density of

VT2105 is different from that of the VT2000 series.

Necessary Tools

1) Facsimile Text Chart R-21 (99992131)

2) Resolution Chart (A0129110)

3) Oscilloscope

1.1 PREPARATION FOR ADJUSTMENT

1. Remove the original table and the original table cover.

2. Connect the terminals of the oscilloscope to the following test pins on the

A/D conversion board.

Oscilloscope Text Pin

Channel 1 TP603

Channel 2 (Black level

standard voltage)

GND TP600

TP604

3. Access "I/O Check Mode".

• Turn on the main switch while holding the Print Start key, Stop key

and Clear key on the operation panel. ------ LT version

• Turn on the main switch while holding the Print Start key, Stop key,

Clear key and the full master detection switch. ------ A4 version

4. Set "15" in the copy counter using the number keys, and set "0" in the

memory/class display by pressing the memory/class key

5. Press the Print Start key to turn on the fluorescent lamp.

5-2

Page 40

Replacement

Adjustment

1 October 1992 OPTICS ADJUSTMENT

1.2 BLACK LEVEL ADJUSTMENT

TP603 wave shape

TP604 standard black level

TP604 standard black level

TP603 wave shape

Adjust VR601 so that the black level at TP603 is the same as the standard

black level (1.4 V

±0.03 V).

1.3 SHADING ADJUSTMENT

B

A

B/A ≥ 60%

Adjust the shading plate position so that the wave is shaped as shown above.

5-3

Page 41

OPTICS ADJUSTMENT 1 October 1992

1.4 SCAN LINE POSITION ADJUSTMENT

Set the test chart R-21 so that the 1 mm black line is positioned 16 mm away

from the edge of the lower original guide plate.

Adjust the CCD board position so that the shape of the wave is similar to the

above illustration.

1.5 READING START POSITION ADJUSTMENT

(In The Main Scan Direction)

L

L’

[E]

L = L’

[D]

Set the test chart so that the center line, located at the leading edge of the

test chart, is positioned above the original leading edge sensor actuator.

Then feed the test chart so that the center line can be read.

Adjust the CCD board position so that the above wave is displayed.

5-4

Page 42

Replacement

Adjustment

1 October 1992 OPTICS ADJUSTMENT

1.6 FOCUS ADJUSTMENT

B A

B

•

x 100 ≥ 20%

A

• Amplitude "B" (difference between white and black levels) must be a

maximum.

Position the resolution chart so that the 300 DPI section can be read. Adjust

the lens position so that the above wave appears.

1.7 REDUCTION RATIO ADJUSTMENT

Cross point

Position the resolution chart so that the 300 DPI section can be read. Adjust

the lens block position so that the cross points are less than 8.

5-5

Page 43

OPTICS ADJUSTMENT 1 October 1992

1.8 WHITE LEVEL ADJUSTMENT

2.0 ± 0.1 V

Adjust the VR600 on the AD conversion board so that the maximum level is

± 0.1 V.

2.0

1.9 IMAGE MAGNIFICATION IN THE SUB-SCAN DIRECTION ADJUSTMENT

Adjust the magnification ratio in the sub-scan direction using DIP103-1, 2, 3

on the main board, so that the printed image length is 100%

± 0.5% by

comparing the original image length.

--DIP SW/Correction Ratio--

DPS 103 Original Length

1 2 3

OFF OFF OFF 100%

OFF ON OFF 99.25%

OFF OFF ON 98.75%

OFF ON ON 98.25%

ON OFF OFF 100%

ON ON OFF 100.75%

ON OFF ON 101.25%

ON ON ON 101.75%

Print Image Length

X 100

5-6

Page 44

Replacement

Adjustment

1 October 1992 THERMAL HEAD VOLTAGE ADJUSTMENT

2. THERMAL HEAD VOLTAGE ADJUSTMENT

Purpose: To maintain master making quality and extend the lifetime of the

thermal head.

NOTE: This adjustment is always required when the thermal head or

power supply board is replaced.

1. Remove the rear cover of the machine.

2. Check the voltage noted on the decal, located on the thermal head.

(The voltage varies according to each thermal head.)

3. Access "I/ Check Mode".

• Turn on the main switch while holding the Print Start, Stop and Clear

keys. ------ LT version

• Turn on the main switch while holding the Print Start, Stop, Clear

keys and the full master detection switch. ------ A4 version

4. Input 35 in the copy counter using the number keys, and set "0" in the

Memory/Class display by pressing the Memory/Class key.

5. Press the Print Start key to apply the thermal head voltage.

6. While holding down the Print Start key , confirm that the voltage between

pins 2(VHD) and 4(GMD) on CN505 is at the level specified on the decal

(Within + 0 V ,-- 0.1 V).

7. If it is not, adjust VR202 on the power supply board.

5-7

Page 45

AIR PUMP TIMING ADJUSTMENT 1 October 1992

3. AIR PUMP TIMING ADJUSTMENT

[B]

[B]

[C]

Purpose: To ensure that the paper exit pawl air pump produces a jet of air

at the proper timing

[A]

[D]

1. Remove the rear cover.

2. Set the drum in the home position.

3. Confirm that the mark [A] on the pump drive gear [B] is right over the gear

shaft [C].

4. If incorrect, remove the support plate [D] (5 screws) and reposition the

gear.

5. Rotate the drum to the home position and confirm step 3 again.

5-8

Loading...

Loading...