Page 1

MODEL U-C1

(Machine Code: B051/B052)

SERVICE MANUAL

Page 2

!IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals, make sure

that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off or

open while the main switch is turned on, keep hands away from electrified or

mechanically driven components.

4. If a job has started before the copier completes the warm-up or initializing period,

keep hands away from the mechanical and electrical components because the

starts making copies as soon as the warm-up period is completed.

5. The inside and the metal parts of the fusing unit become extremely hot while the

copier is operating. Be careful to avoid touching those components with your bare

hands.

HEALTH SAFETY CONDITIONS

Toner is non-toxic, but if you get it in your eyes by accident, it may cause temporary eye

discomfort. Try to remove with eye drops or flush with water as first aid. If unsuccessful,

get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a customer

service representative who has completed the training course on those models.

2. The NVRAM on the Controller board has a lithium battery which can explode if

replaced incorrectly. Replace the NVRAM only with an identical one. Do not

recharge or burn this battery. Used NVRAM must be handled in accordance with

local regulations.

3. The danger of explosion exists if batteries on the FCU, MBU and JBIG are

incorrectly replaced. Replace only with the same or an equivalent type

recommended by the manufacturer. Discard used batteries in accordance with the

manufacturer’s instructions.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly when

exposed to an open flame.

2. Dispose of used toner, the maintenance unit which includes developer or the

organic photoconductor in accordance with local regulations. (These are non-toxic

supplies.)

3. Dispose of replaced parts in accordance with local regulations.

When keeping used lithium batteries in order to dispose of them later, do not put

more than 100 batteries per sealed box. Storing larger numbers or not sealing them

apart may lead to chemical reactions and heat build-up.

Page 3

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

!WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

!WARNING

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Optics Housing Unit section. Laser

beams can seriously damage your eyes.

CAUTION MARKING:

Page 4

Trademarks

Microsoft

®

, Windows®, and MS-DOS® are registered trademarks of Microsoft

Corporation in the United States and /or other countries.

PostScript

®

is a registered trademark of Adobe Systems, Incorporated.

PCL

®

is a registered trademark of Hewlett-Packard Company.

Ethernet

®

is a registered trademark of Xerox Corporation.

PowerPC

®

is a registered trademark of International Business Machines

Corporation.

Other product names used herein are for identification purposes only and may be

trademarks of their respective companies. We disclaim any and all rights involved

with those marks.

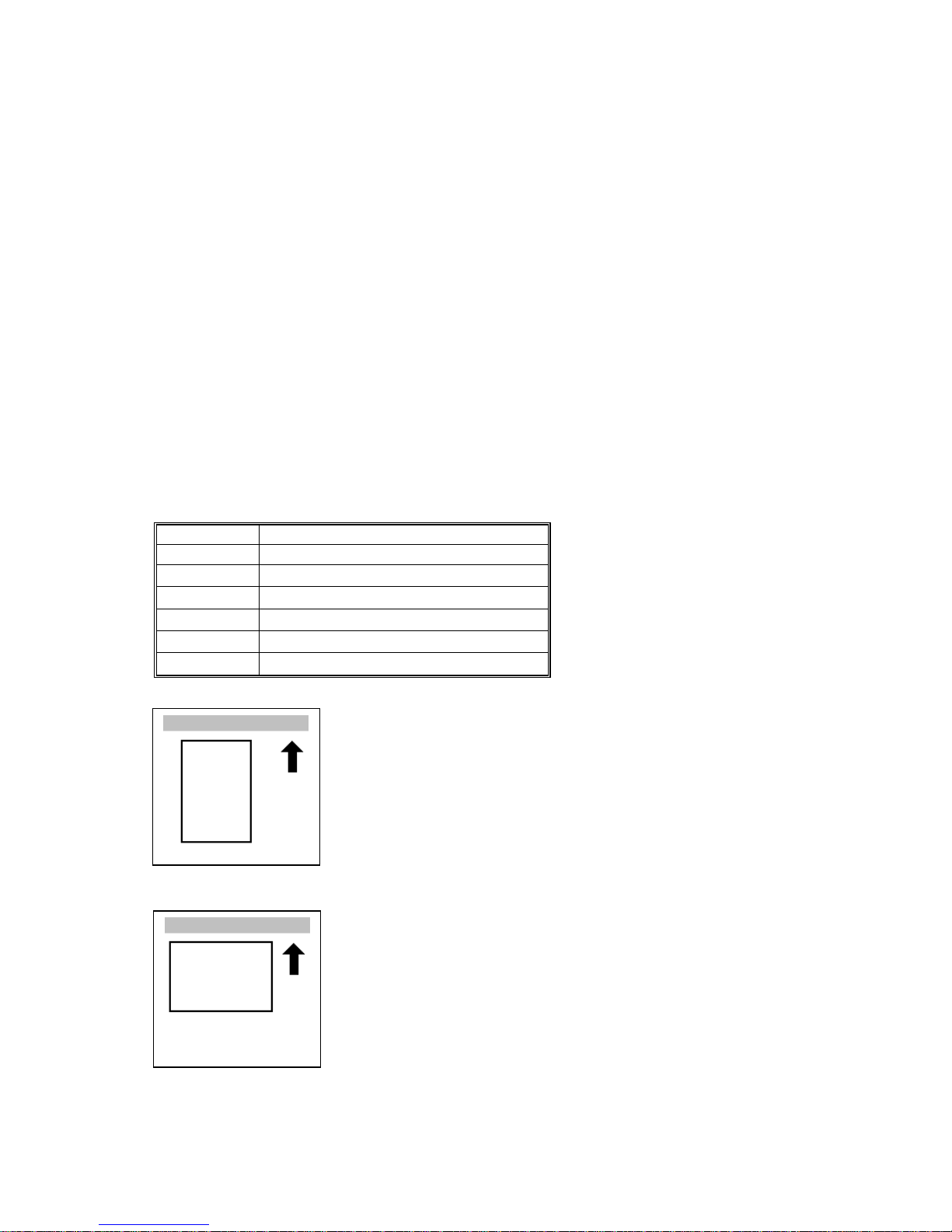

Conventions in this Manual

This manual uses several symbols.

Symbol What it means

☛ Refer to section number

!

See Core Tech Manual for details

"

Screw

#

Connector

$%

Clip ring

&%

E-ring

Lengthwise, SEF (Short Edge Feed)

Sideways, LEF (Long Edge Feed)

Page 5

i

TABLE OF CONTENTS

1. INSTALLATION...........................................................................1-1

1.1 INSTALLATION REQUIREMENTS...........................................................1-1

1.1.1 ENVIRONMENT .............................................................................. 1-1

1.1.2 MACHINE LEVEL............................................................................ 1-1

1.1.3 POWER REQUIREMENTS.............................................................. 1-2

1.1.4 SPACE REQUIREMENTS............................................................... 1-2

1.2 COPIER (B051/B052)............................................................................... 1-3

1.2.1 POWER SOCKETS FOR PERIPHERALS....................................... 1-3

1.2.2 INSTALLATION FLOW CHART....................................................... 1-4

1.2.3 ACCESSORY CHECK..................................................................... 1-5

1.2.4 INSTALLATION PROCEDURE........................................................ 1-6

1.3 PAPER TRAY UNIT (B456).................................................................... 1-13

1.3.1 ACCESSORY CHECK................................................................... 1-13

1.3.2 INSTALLATION PROCEDURE...................................................... 1-13

1.4 LCT (B457)............................................................................................. 1-17

1.4.1 ACCESSORY CHECK................................................................... 1-17

1.4.2 INSTALLATION PROCEDURE...................................................... 1-17

1.5 AUTO REVERSE DOCUMENT FEEDER (B386)................................... 1-21

1.5.1 ACCESSORY CHECK................................................................... 1-21

1.5.2 INSTALLATION PROCEDURE...................................................... 1-21

1.6 INTERCHANGE UNIT (B481)................................................................. 1-24

1.6.1 ACCESSORY CHECK................................................................... 1-24

1.6.2 INSTALLATION PROCEDURE...................................................... 1-25

1.7 1-BIN TRAY UNIT (B480)....................................................................... 1-26

1.7.1 ACCESORY CHECK..................................................................... 1-26

1.7.2 INSTALLATION PROCEDURE...................................................... 1-27

1.8 SHIFT TRAY........................................................................................... 1-30

1.8.1 COMPONENT CHECK.................................................................. 1-30

1.8.2 INSTALLATION PROCEDURE...................................................... 1-30

1.9 BY-PASS FEED UNIT (B490)................................................................. 1-33

1.9.1 ACCESSORY CHECK................................................................... 1-33

1.9.2 INSTALLATION PROCEDURE...................................................... 1-33

1.10 DUPLEX UNIT (B509).......................................................................... 1-35

1.10.1 ACCESSORY CHECK................................................................. 1-35

1.10.2 INSTALLATION PROCEDURE.................................................... 1-36

1.11 BRIDGE UNIT (B482) ........................................................................... 1-38

1.11.1 ACCESSORY CHECK................................................................. 1-38

1.11.2 INSTALLATION PROCEDURE.................................................... 1-38

1.12 1000-SHEET FINISHER (B408)........................................................... 1-41

1.12.1 ACCESSORY CHECK................................................................. 1-41

1.12.2 INSTALLATION PROCEDURE.................................................... 1-42

1.13 500-SHEET FINISHER (B458)............................................................. 1-45

1.13.1 ACCESSORY CHECK................................................................. 1-45

1.13.2 INSTALLATION PROCEDURE.................................................... 1-46

1.14 PLATEN COVER INSTALLATION........................................................ 1-48

Page 6

ii

1.15 MEMORY.............................................................................................. 1-49

1.16 KEY COUNTER INSTALLATION..........................................................1-51

1.17 ANTI-CONDENSATION HEATER........................................................ 1-53

1.18 TRAY HEATER..................................................................................... 1-54

1.19 TRAY HEATER (OPTIONAL PAPER TRAY UNIT) .............................. 1-55

1.20 TRAY HEATER (OPTIONAL LCT)........................................................ 1-57

2. PREVENTIVE MAIN TENANCE...................................................2-1

2.1 MAIN UNIT ............................................................................................... 2-1

2.1.1 OVERVIEW...................................................................................... 2-1

2.1.2 PM TABLE....................................................................................... 2-2

2.2 OPTIONAL UNIT PM TABLE.................................................................... 2-5

3. REPLACEMENT A ND ADJUSTMENT........................................ 3-1

3.1 SPECIAL TOOLS................................................................................ 3-1

3.2 FILTERS................................................................................................... 3-1

3.3 SCANNER UNIT....................................................................................... 3-2

3.3.1 EXPOSURE GLASS........................................................................ 3-2

3.3.2 APS SENSORS............................................................................... 3-2

3.3.3 LENS BLOCK ASSEMBLY.............................................................. 3-3

3.3.4 EXPOSURE LAMP STABILIZER..................................................... 3-5

3.3.5 SCANNER LAMP............................................................................. 3-5

3.3.6 SCANNER I/O BOARD.................................................................... 3-7

3.3.7 SCANNER MOTOR......................................................................... 3-7

3.3.8 FRONT SCANNER WIRE................................................................ 3-7

3.3.9 REAR SCANNER WIRE................................................................ 3-10

3.4 LASER UNIT........................................................................................... 3-12

3.4.1 CAUTION DECAL LOCATION....................................................... 3-12

3.4.2 LASER UNIT.................................................................................. 3-13

Adjusting for Image Skew .................................................................. 3-15

D-Phase Adjustment.......................................................................... 3-16

Laser Beam Pitch Adjustment............................................................ 3-17

3.4.3 POLYGONAL MIRROR MOTOR AND LSD...................................3-18

3.5 DEVELOPMENT UNIT........................................................................... 3-19

3.6 PHOTOCONDUCTOR UNIT (PCU)........................................................ 3-20

3.6.1 PCU ASSEMBLY........................................................................... 3-20

3.6.2 WASTE TONER BOTTLES........................................................... 3-21

3.6.3 CHARGE CORONA UNIT, GRID, WIRE, AND CLEANER............ 3-22

3.6.4 CHARGE CORONA WIRE CLEANER MOTOR............................ 3-23

3.6.5 OPC BELT CLEANING UNIT......................................................... 3-23

3.6.6 IMAGE TRANSFER BELT CLEANING UNIT................................. 3-23

3.7 PAPER TRANSFER UNIT...................................................................... 3-24

3.7.1 VERTICAL TRANSPORT UNIT..................................................... 3-24

3.7.2 TRANSFER ROLLER.................................................................... 3-24

3.8 FUSING/PAPER EXIT............................................................................ 3-25

3.8.1 FUSING UNIT................................................................................ 3-25

3.8.2 OIL SUPPLY UNIT......................................................................... 3-25

3.8.3 OIL SUPPLY PAD.......................................................................... 3-26

3.8.4 CLEANING ROLLER AND FUSING SPONGE ROLLER............... 3-26

Page 7

iii

3.8.5 OILING ROLLER AND OIL SUPPLY ROLLER.............................. 3-27

3.8.6 FUSING LAMPS............................................................................ 3-28

3.8.7 FUSING INNER UNIT.................................................................... 3-29

3.8.8 PRESSURE ROLLER THERMOFUSE.......................................... 3-29

3.8.9 HOT ROLLER STRIPPERS........................................................... 3-30

3.8.10 FUSING BELT UNIT AND PRESSURE ROLLER UNIT.............. 3-30

3.8.11 PRESSURE ROLLER, PRESSURE R OLLER G EAR,

AND CLEANING ROLLER........................................................... 3-31

3.8.12 PRESSURE ROLLER THERMISTOR......................................... 3-32

3.8.13 OIL ABSORBERS........................................................................ 3-33

3.8.14 PAPER EXIT/OVERFLOW SENSORS........................................ 3-34

3.9 PAPER FEED AND TRANSPORT ......................................................... 3-36

3.9.1 FEED ROLLER AND FRICTION PAD........................................... 3-36

3.9.2 REGISTRATION SENSOR............................................................ 3-37

3.9.3 PAPER FEED SENSOR 1............................................................. 3-40

3.9.4 PAPER NEAR-END SENSORS..................................................... 3-40

3.9.5 PAPER FEED SENSOR 2............................................................. 3-41

3.9.6 PAPER END SENSOR 1............................................................... 3-42

3.9.7 PAPER END SENSOR 2............................................................... 3-42

3.10 ELECTRICAL COMPONENTS............................................................. 3-43

3.10.1 EXHAUST FAN AND I/O BOARD................................................ 3-43

3.10.2 EX I/O BOARD............................................................................. 3-43

3.10.3 BICU BOARD AND CONTROLLER BOARD............................... 3-44

3.10.4 HDD............................................................................................. 3-45

3.10.5 HIGH VOLTAGE SUPPLY BOARD............................................. 3-45

3.10.6 POWER SUPPLY UNIT............................................................... 3-46

3.11 DRIVE UNITS....................................................................................... 3-47

3.11.1 DEVELOPMENT CLUTCHES...................................................... 3-47

K and Y Development Units............................................................... 3-47

C and M Development Units.............................................................. 3-47

3.11.2 DEVELOPMENT MOTOR............................................................ 3-48

3.11.3 MAIN MOTOR.............................................................................. 3-48

3.11.4 PCU GEAR BOX.......................................................................... 3-49

3.11.5 FUSING UNIT MOTOR................................................................ 3-49

3.11.6 PAPER FEED CLUTCH 1............................................................ 3-50

3.11.7 PAPER FEED MOTOR ................................................................ 3-50

3.11.8 PAPER FEED CLUTCH 2............................................................ 3-51

3.11.9 REGISTRATION CLUTCH........................................................... 3-51

3.11.10 OIL PUMP.................................................................................. 3-52

3.12 COPY ADJUSTMENT........................................................................... 3-53

3.12.1 PRINTING.................................................................................... 3-53

Registration - Leading Edge/Side-to-Side.......................................... 3-53

Blank Margin...................................................................................... 3-54

Main Scan Magnification.................................................................... 3-54

3.12.2 SCANNING.................................................................................. 3-55

Scanner Sub-Scan Magnification....................................................... 3-55

Scanner Leading Edge and Side-to-Side Registration....................... 3-55

Main Scan Dot Position Correction.................................................... 3-56

3.12.3 ARDF IMAGE ADJUSTMENT...................................................... 3-57

Page 8

i

v

ARDF Side-to-Side and Leading Edge Registration........................... 3-57

ARDF Skew Adjustment..................................................................... 3-58

3.13 COLOR ADJUSTMENT........................................................................ 3-59

3.13.1 AUTO COLOR CALIBRATION (ACC) ......................................... 3-59

3.13.2 PRINTER GAMMA CORRECTION.............................................. 3-60

Copy Mode......................................................................................... 3-60

Printer Mode....................................................................................... 3-64

3.14 SCANNER WHITE LEVEL ADJUSTMENT........................................... 3-66

White Level Check............................................................................. 3-66

White Level Adjustment..................................................................... 3-66

3.15 TOUCH SCREEN CALIBRATION........................................................ 3-69

4. TROUBLESHOOTIN G.................................................................4-1

4.1 SERVICE CALL........................................................................................ 4-1

4.1.1 SERVICE CALL CONDITIONS........................................................ 4-1

4.1.2 SC TABLE........................................................................................ 4-2

4.2 SELF-DIAGNOSTIC MODE.................................................................... 4-18

4.2.1 OVERVIEW.................................................................................... 4-18

4.2.2 DETAILED SELF-DIAGNOSTICS.................................................. 4-19

4.3 IMAGE TEST MODE .............................................................................. 4-20

4.3.1 OVERVIEW.................................................................................... 4-20

4.3.2 VPU TEST..................................................................................... 4-20

SP4-907-1: VPU Test Pattern: R........................................................ 4-20

SP4-907-2: VPU Test Pattern: G....................................................... 4-20

SP4-907-3: VPU Test Pattern: B........................................................ 4-20

4.3.3 IPU TEST....................................................................................... 4-20

SP4-904-1 Register Write/Read Check Result................................... 4-20

SP4-904-2 Image Path Check Result ................................................ 4-20

4.3.4 GAVD TEST................................................................................... 4-20

4.4 ELECTRICAL COMPONENT DEFECTS................................................ 4-21

4.4.1 SENSORS..................................................................................... 4-21

4.4.2 SWITCHES.................................................................................... 4-23

4.4.3 BLOWN FUSE CONDITIONS........................................................ 4-23

4.5 CHECK POINTS FOR IMAGE PROBLEMS AT REGULAR

INTERVALS............................................................................................ 4-24

5. SERVICE TABLES......................................................................5-1

5.1 SERVICE PROGRAM MODE................................................................... 5-1

5.1.1 SERVICE PROGRAM MODE OPERATION.................................... 5-1

Starting the SP mode........................................................................... 5-1

Quitting the SP mode........................................................................... 5-1

SP Mode Touch Screen....................................................................... 5-2

Copy Window for Test Printing............................................................. 5-3

Working on SP Mode Menus................................................................ 5-3

5.1.2 SP MODE TABLE............................................................................ 5-4

SP1-XXX: (Feed) ................................................................................. 5-4

SP2-XXX: (Drum)................................................................................. 5 -8

SP3-XXX: (Process)........................................................................... 5-21

SP4-XXX: (Scanner) .......................................................................... 5-25

Page 9

v

SP5-XXX: (Mode)............................................................................... 5 -29

SP6-XXX: (Peripherals) ..................................................................... 5-47

SP7-XXX: (Data Log)......................................................................... 5-50

SP9-XXX: (Etc.) ................................................................................. 5-62

5.1.3 TEST PATTERN PRINTING (SP5-955-1)...................................... 5-63

5.1.4 INPUT CHECK............................................................................... 5-64

Main Machine Input Check (SP5-803)............................................... 5-64

Table 1: Tray 1 and 2 Paper Size....................................................... 5-67

Table 2: By-pass Tray Paper Size...................................................... 5-67

Table 3: Optional Paper Tray Unit Paper Size................................... 5-67

Table 4: Optional Paper Tray Unit Paper Near End........................... 5-67

ARDF Input Check (SP6-007)............................................................ 5-68

Finisher Input Check (SP6-117)......................................................... 5-69

5.1.5 OUTPUT CHECK........................................................................... 5-70

Main Machine Output Check (SP5-804)............................................. 5-70

ARDF Output Check (SP6-008)......................................................... 5-73

Finisher Output Check (SP6-118)...................................................... 5-73

5.1.6 SMC DATA LISTS (SP5-990)........................................................ 5-74

5.1.7 ORIGINAL JAM HISTORY DISPLAY............................................. 5-74

Total Count......................................................................................... 5-74

Details on the Most Recent Jams....................................................... 5-74

5.1.8 COPY JAM HISTORY DISPLAY.................................................... 5-75

Total Count......................................................................................... 5-75

Details on the Most Recent Jams....................................................... 5-75

5.1.9 MEMORY ALL CLEAR (SP5-801)................................................. 5-76

Using a Flash Memory Card............................................................... 5-76

Without Using a Flash Memory Card ................................................. 5-77

5.1.10 APS OUTPUT DISPLAY (SP4-301)............................................. 5-78

5.2 PROGRAM DOWNLOAD....................................................................... 5-79

5.2.1 FIRMWARE................................................................................... 5-79

5.2.2 NVRAM DATA UPLOAD/DOWNLOAD.......................................... 5-80

Uploading NVRAM Data (SP5-824)................................................... 5-80

Downloading NVRAM Data (SP5-825)............................................... 5-81

5.3 SOFTWARE RESET............................................................................... 5-82

5.4 SYSTEM SETTINGS AND COPY SETTING RESET............................. 5-82

5.4.1 SYSTEM SETTING RESET........................................................... 5-82

5.4.2 COPIER SETTING RESET............................................................ 5-83

5.5 USER TOOLS......................................................................................... 5-84

5.5.1 HOW TO ENTER USER TOOLS................................................... 5-84

UP Mode Initial Screen: User Tools/Counter Display......................... 5-84

System Settings................................................................................. 5-84

Copier/Document Server Features..................................................... 5-84

Printer, Facsimile, Scanner Settings.................................................. 5-84

Inquiry................................................................................................ 5-84

Counter.............................................................................................. 5-85

5.6 DIP SWITCHES...................................................................................... 5-85

Page 10

vi

6. DETAILED SECTION DESCRIPTIONS.......................................6-1

6.1 OVERVIEW .............................................................................................. 6-1

6.1.1 MECHANICAL COMPONENTS....................................................... 6-1

6.1.2 PAPER PATH.................................................................................. 6-2

6.1.3 DRIVE COMPONENTS................................................................... 6-3

Layout.................................................................................................. 6-3

Drive Power Path................................................................................. 6-4

6.1.4 ELECTRICAL COMPONENTS........................................................ 6-5

Scanner Unit........................................................................................ 6-5

Image Transfer..................................................................................... 6-6

Paper Path........................................................................................... 6-7

Development Units............................................................................... 6-8

Boards.................................................................................................. 6-9

6.2 BOARD STRUCTURE............................................................................ 6-10

6.2.1 BLOCK DIAGRAM......................................................................... 6-10

6.2.2 CONTROLLER.............................................................................. 6-12

6.3 COPY PROCESS................................................................................... 6-14

6.4 PROCESS CONTROL............................................................................ 6-16

6.4.1 OVERVIEW.................................................................................... 6-16

6.4.2 PROCESS CONTROL STEPS...................................................... 6-16

Six Steps............................................................................................ 6-16

When is Process Control Done?........................................................ 6-16

Supplementary Information on Pr ocess Control................................. 6-17

6.5 SCANNING............................................................................................. 6-19

6.5.1 OVERVIEW.................................................................................... 6-19

6.5.2 SCANNER DRIVE ......................................................................... 6-20

Book Mode......................................................................................... 6-20

ARDF Mode ....................................................................................... 6-20

6.5.3 ORIGINAL SIZE DETECTION....................................................... 6-21

6.6 IMAGE PROCESSING ........................................................................... 6-23

6.6.1 OVERVIEW.................................................................................... 6-23

6.6.2 SBU BLOCK DIAGRAM................................................................. 6-24

Signal Processing .............................................................................. 6-24

A/D Conversion.................................................................................. 6-24

White Level Correction ....................................................................... 6-24

Others................................................................................................ 6-24

Black Level Correction....................................................................... 6-25

VPU Test Mode.................................................................................. 6-25

6.6.3 IMAGE PROCESSING .................................................................. 6-26

Shading Correction............................................................................ 6-26

Picture Element (Dot Position) Correction.......................................... 6-26

Scan Line Correction.......................................................................... 6-26

Scanner Gamma Correction (RGB Gamma Correction).................... 6-27

Filtering.............................................................................................. 6-27

ADS (Auto Image Density Selection) ................................................. 6-27

Image Separation............................................................................... 6-28

ACS (Auto Color Selection)................................................................ 6-28

Color Conversion ............................................................................... 6-29

Page 11

vii

Main Scan Magnification.................................................................... 6-29

Printer Gamma Correction................................................................. 6-30

Error Diffusion.................................................................................... 6-32

ASICs on the BICU Board Test.......................................................... 6-32

6.7 PHOTOCONDUCTOR UNIT (PCU)........................................................ 6-33

6.7.1 OVERVIEW.................................................................................... 6-33

6.7.2 CHARGE CORONA UNIT.............................................................. 6-34

Power Supply..................................................................................... 6-34

Grid and Wire Cleaning...................................................................... 6-34

Quenching.......................................................................................... 6-35

6.7.3 OPC BELT DRIVE......................................................................... 6-35

6.7.4 OPC BELT CLEANING UNIT......................................................... 6-36

Bottle Detection.................................................................................. 6-36

Waste Toner Collection...................................................................... 6-36

Drive................................................................................................... 6-37

6.7.5 IMAGE TRANSFER BELT UNIT.................................................... 6-37

Drive................................................................................................... 6-37

Belt Mark Detection............................................................................ 6-38

Transfer Roller................................................................................... 6-38

6.7.6 IMAGE TRANSFER BELT CLEANING UNIT................................. 6-39

Image Transfer Belt Cleaning............................................................. 6-39

Waste Toner Collection...................................................................... 6-39

Set Switch and Full Sensor................................................................ 6-39

Contact Mechanism ........................................................................... 6-40

Power Supply..................................................................................... 6-41

Drive................................................................................................... 6-41

6.8 LASER EXPOSURE............................................................................... 6-42

6.8.1 OVERVIEW.................................................................................... 6-42

6.8.2 POLYGON MIRROR MOTOR UNIT.............................................. 6-43

Speed................................................................................................. 6-43

6.8.3 SYNCHRONIZATION DETECTOR................................................ 6-43

6.8.4 LD UNIT......................................................................................... 6-43

6.8.5 LD SAFETY SWITCH.................................................................... 6-44

Front Door.......................................................................................... 6-44

Circuit................................................................................................. 6-44

Operation Panel Display and Switch Mechanism............................... 6-45

6.9 DEVELOPMENT..................................................................................... 6-46

6.9.1 OVERVIEW.................................................................................... 6-46

6.9.2 DEVELOPMENT UNIT .................................................................. 6-47

Replacing Units.................................................................................. 6-47

Memory Chip...................................................................................... 6-47

6.9.3 TONER SUPPLY MECHANISM.................................................... 6-48

Drive................................................................................................... 6-48

Rollers and Agitators.......................................................................... 6-49

Shutter ............................................................................................... 6-49

6.9.4 TONER END DETECTION............................................................ 6-50

Mechanism......................................................................................... 6-50

Toner Near-End Detection................................................................. 6-50

Toner End Detection.......................................................................... 6-51

Page 12

viii

Toner End Recovery.......................................................................... 6-51

6.9.5 DEVELOPMENT UNIT CONTACT MECHANISM......................... 6-52

Mechanism......................................................................................... 6-52

Reverse Rotation ............................................................................... 6-52

6.9.6 POWER SOURCE......................................................................... 6-53

Development, Toner Supply, and Doctor Rollers............................... 6-53

Doctor Roller...................................................................................... 6-53

6.10 PAPER FEED....................................................................................... 6-54

6.10.1 OVERVIEW.................................................................................. 6-54

Transport Speed................................................................................ 6-55

Friction Pad........................................................................................ 6-55

6.10.2 DRIVE MECHANISM................................................................... 6-55

Feed and Vertical Transport............................................................... 6-55

Registration........................................................................................ 6-55

6.10.3 PAPER LIFT................................................................................ 6-56

Lift Mechanism................................................................................... 6-56

Paper End/Near-End Detection.......................................................... 6-56

6.10.4 PAPER SIZE DETECTION.......................................................... 6-57

Mechanism......................................................................................... 6-57

Switch Pattern.................................................................................... 6-57

6.11 PAPER TRANSFER AND SEPARATION............................................. 6-58

6.11.1 OVERVIEW.................................................................................. 6-58

Jammed Paper Release..................................................................... 6-58

Image Transfer and Paper Separation............................................... 6-58

6.11.2 CONTACT/SEPARATION MECHANISM..................................... 6-59

Timing................................................................................................ 6-59

Mechanism......................................................................................... 6-59

6.11.3 POWER SUPPLY........................................................................ 6-60

Circuit................................................................................................. 6-60

Paper Transfer Roller Bias................................................................. 6-60

Discharge Plate.................................................................................. 6-60

Temperature/Humidity Control........................................................... 6-60

Roller Cleaning................................................................................... 6-61

6.12 IMAGE FUSING AND PAPER EXIT..................................................... 6-62

6.12.1 OVERVIEW.................................................................................. 6-62

6.12.2 DRIVE.......................................................................................... 6-63

6.12.3 FUSING UNIT COMPONENTS ................................................... 6-64

Fusing Belt......................................................................................... 6-64

Heating Roller Lamp .......................................................................... 6-64

Pressure Roller Lamp ........................................................................ 6-64

Pressure Roller Pawls........................................................................ 6-64

Fusing Bias........................................................................................ 6-65

Fusing Unit SCs................................................................................. 6-65

6.12.4 OIL SUPPLY................................................................................ 6-66

Oil Supply........................................................................................... 6-66

Oil Supply........................................................................................... 6-67

Oil End Detection and Recovery........................................................ 6-68

6.12.5 TEMPERATURE CONTROL....................................................... 6-69

6.12.6 ENERGY SAVER MODES........................................................... 6-70

Page 13

ix

Overview............................................................................................ 6-70

Panel Off Mode.................................................................................. 6-71

Low Power Mode............................................................................... 6-72

Auto Off Mode.................................................................................... 6-73

6.12.7 PAPER EXIT................................................................................ 6-74

Drive................................................................................................... 6-74

Paper Jam Detection.......................................................................... 6-74

6.12.8 PAPER OVERFLOW DETECTION.............................................. 6-74

PERIPHERALS

PAPER TRAY UNIT (B456)

1. REPLACEMENT AND ADJUSTMENT..................................B456-1

1.1 REAR COVER....................................................................................B456-1

1.2 PAPER FEED CLUTCHES.................................................................B456-1

1.3 LIFT MOTORS....................................................................................B456-2

1.4 PAPER FEED MOTOR.......................................................................B456-2

1.5 CONTROLLER BOARD......................................................................B456-2

1.6 PAPER FEED UNIT............................................................................B456-3

1.7 PICKUP, FEED, AND SEPARATION ROLLERS................................B456-4

1.8 UPPER LIMIT, PAPER END, AND RELAY SENSORS...................... B456-4

2. DETAILED DESCRIPTIONS.................................................B456-5

2.1 MECHANICAL COMPONENT LAYOUT.............................................B456-5

2.2 ELECTRICAL COMPONENT LAYOUT..............................................B456-6

2.3 PAPER FEED..................................................................................... B456-7

Paper Feed Mechanism.................................................................B456-7

Drive Path......................................................................................B456-7

2.4 PAPER SIZE DETECTION.................................................................B456-8

2.5 REVERSE ROLLER AND PICK-UP ROLLER RELEASE...................B456-9

2.6 PAPER LIFT.....................................................................................B456-10

2.7 PAPER HEIGHT AND END DETECTION........................................B456-11

Paper Height Detection................................................................B456-11

Paper End and Bottom Plate........................................................B456-12

LCT (B457)

1. REPLACEMENT AND ADJUSTMENT..................................B457-1

1.1 TRAY..................................................................................................B457-1

1.2 SENSORS..........................................................................................B457-2

Paper Height Sensors of Paper Storage Side................................B457-2

Left Fence HP Sensor/Paper End Sensor 2...................................B457-2

1.3 CHANGING THE TRAY SIZE.............................................................B457-3

1.4 TRAY LIFT MOTOR............................................................................B457-3

1.5 TRAY MOTOR .................................................................................... B457-4

1.6 MAIN BOARD..................................................................................... B457-4

Page 14

x

1.7 STACK TRANSPORT CLUTCH.........................................................B457-5

1.8 PAPER FEED CLUTCH......................................................................B457-5

1.9 PAPER FEED UNIT............................................................................B457-6

1.10 PICKUP, FEED, AND SEPARATION ROLLERS..............................B457-7

1.11 UPPER LIMIT, PAPER END 1, AND RELAY SENSORS................B457-7

2. DETAILED DESCRIPTIONS.................................................B457-8

2.1 MECHANICAL COMPONENT LAYOUT.............................................B457-8

2.2 ELECTRICAL COMPONENT LAYOUT..............................................B457-9

2.3 ELECTRICAL COMPONENT DESCRIPTIONS................................B457-10

2.4 PAPER FEED................................................................................... B457-11

2.5 SEPARATION ROLLER AND PICKUP ROLLER RELEASE............B457-12

2.6 TRAY LIFT........................................................................................B457-13

2.7 PAPER AMOUNT DETECTION ....................................................... B457-14

2.8 PAPER END DETECTION OF PAPER FEED SIDE.........................B457-15

2.9 PAPER STACK TRANSPORT..........................................................B457-16

AUTO REVERSE DOCUMENT FEEDER (B386)

1. REPLACEMENT AND ADJUSTMENT..................................B386-1

1.1 DF EXIT TABLE AND COVERS.........................................................B386-1

1.2 ORIGINAL FEED UNIT.......................................................................B386-2

1.3 LEFT COVER.....................................................................................B386-2

1.4 PICK-UP ROLLER..............................................................................B386-3

1.5 FEED BELT........................................................................................B386-3

1.6 SEPARATION ROLLER.....................................................................B386-4

1.7 ORIGINAL SET/ORIGINAL REVERSE SENSORS............................B386-4

1.8 ORIGINAL SIZE SENSORS, TRAILING EDGE SENSOR..................B386-5

1.9 ORIGINAL FEED DRIVE....................................................................B386-6

DF Feed Clutch..............................................................................B386-6

Pick-up Solenoid............................................................................B386-6

Transport Motor..............................................................................B386-6

DF Feed Motor...............................................................................B386-6

1.10 REGISTRATION SENSOR...............................................................B386-7

1.11 STAMP SOLENOID AND ORIGINAL EXIT SENSOR......................B386-8

2. DETAILED DESCRIPTIONS.................................................B386-9

2.1 MECHANICAL COMPONENT LAYOUT.............................................B386-9

2.2 ELECTRICAL COMPONENT LAYOUT............................................ B386-10

2.3 ELECTRICAL COMPONENT DESCRIPTION..................................B386-11

2.4 DRIVE LAYOUT ...............................................................................B386-12

2.5 ORIGINAL SIZE DETECTION..........................................................B386-13

2.6 MIXED ORIGINAL SIZE MODE........................................................B386-16

2.7 PICK-UP AND SEPARATION...........................................................B386-17

2.8 ORIGINAL TRANSPORT AND EXIT................................................B386-18

2.8.1 SINGLE-SIDED ORIGINALS...................................................B386-18

2.8.2 DOUBLE-SIDED ORIGINALS..................................................B386-19

2.8.3 ORIGINAL TRAILING EDGE SENSOR...................................B386-20

Page 15

xi

2.9 STAMP ............................................................................................. B386-21

2.10 TIMING CHART..............................................................................B386-22

2.11 CONDITION OF JAM DETECTION................................................B386-23

2.12 OVERALL ELECTRICAL CIRCUIT.................................................B386-24

3. SERVICE TABLES..............................................................B386-25

3.1 DIP SWITCHES................................................................................B386-25

INTERCHANGE UNIT (B418)

1. REPLACEMENT AND ADJUSTMENT..................................B481-1

1.1 EXIT SENSOR REPLACEMENT........................................................B481-1

2. DETAILED DESCRIPTION....................................................B481-2

2.1 MECHANICAL COMPONENT LAYOUT.............................................B481-2

2.2 ELECTRICAL COMPONENT AND DRIVE LAYOUT..........................B481-3

2.3 JUNCTION GATE MECHANISM........................................................B481-4

To the Exit Tray or Bridge Unit (for the Upper Tray on top of the Bridge

Unit, or the Finisher).......................................................................B481-4

To the 1-bin Tray............................................................................B481-4

To the Duplex Unit ......................................................................... B481-4

1-BIN TRAY UNIT (B480)

1. REPLACEMENT AND ADJUSTMENT..................................B480-1

1.1 PAPER SENSOR REMOVAL.............................................................B480-1

2. DETAILED DESCRIPTION....................................................B480-2

2.1 MECHANICAL COMPONENT LAYOUT.............................................B480-2

2.2 ELECTRICAL COMPONENT LAYOUT..............................................B480-3

2.3 ELECTRICAL COMPONENT DESCRIPTION....................................B480-3

2.4 BASIC OPERATION...........................................................................B480-4

SHIFT TRAY UNIT (B510)

1. REPLACEMENT AND ADJUSTMENT..................................B510-1

1.1 TRAY COVER REPLACEMENT.........................................................B510-1

1.1.1 TRAY COVER REMOVAL......................................................... B510-1

1.1.2 TRAY COVER ATTACHMENT..................................................B510-1

1.2 TRAY MOTOR AND HALF TURN SENSOR REPLACEMENT .......... B510-2

1.2.1 REPLACING THE TRAY MOTOR.............................................B510-2

1.2.2 REPLACING THE HALF TURN SENSOR ................................. B510-2

2. DETAILED DESCRIPTIONS.................................................B510-3

2.1 COMPONENT LAYOUT.....................................................................B510-3

2.2 BASIC OPERATION...........................................................................B510-4

2.3 PRIMARY MECHANISMS..................................................................B510-5

Page 16

xii

2.3.1 TRAY SHIFT..............................................................................B510-5

2.3.2 HALF TURN DETECTION.........................................................B510-6

BY-PASS TRAY UNIT (B490)

1. REPLACEMENT AND ADJUSTMENT..................................B490-1

1.1 PICKUP/FEED ROLLER.....................................................................B490-1

1.2 PAPER FEED CLUTCH......................................................................B490-2

1.3 REVERSE ROLLER...........................................................................B490-2

1.4 PAPER SIZE SENSOR BOARD.........................................................B490-3

2. DETAILED DESCRIPTIONS.................................................B490-4

2.1 MECHANICAL COMPONENT LAYOUT.............................................B490-4

2.2 PAPER FEED..................................................................................... B490-5

2.2.1 DRIVE........................................................................................B490-5

Power Source.................................................................................B490-5

Rollers............................................................................................B490-5

2.2.2 PAPER FEED MECHANISM.....................................................B490-6

Pickup Roller Mechanism...............................................................B490-6

Paper End Detection......................................................................B490-6

2.3 PAPER SIZE DETECTION.................................................................B490-7

DUPLEX UNIT (B509)

1. REPLACEMENT AND ADJUSTMENT..................................B509-1

1.1 EXTERIOR COVER............................................................................B509-1

1.2 ENTRANCE/EXIT SENSORS.............................................................B509-1

1.3 INVERTER MOTOR...........................................................................B509-2

1.4 CONTROLLER BOARD......................................................................B509-2

1.5 TRANSPORT MOTOR.......................................................................B509-2

2. DETAILED DESCRIPTIONS.................................................B509-3

2.1 OVERVIEW ........................................................................................B509-3

2.2 ELECTRICAL COMPONENT LAYOUT..............................................B509-4

2.3 DRIVE LAYOUT .................................................................................B509-5

2.4 DUPLEX PAPER FEED ORDER........................................................ B509-6

2.4.1 LONGER THAN A4/LT LEF....................................................... B509-6

2.4.2 UP TO A4/LT LEF......................................................................B509-7

2.5 REVERSE MECHANISM....................................................................B509-8

BRIDGE UNIT (B482)

1. REPLACEMENT AND ADJUSTMENT..................................B482-1

1.1 BRIDGE UNIT DRIVE MOTOR REPLACEMENT...............................B482-1

1.2 TRAY EXIT SENSOR REPLACEMENT.............................................B482-2

1.3 RELAY SENSOR REPLACEMENT....................................................B482-2

Page 17

xiii

2. DETAILED DESCRIPTIONS.................................................B482-3

2.1 MECHANICAL COMPONENT LAYOUT.............................................B482-3

2.2 DRIVE LAYOUT .................................................................................B482-4

2.3 ELECTRICAL COMPONENT LAYOUT..............................................B482-5

2.4 ELECTRICAL COMPONENT DESCRIPTION....................................B482-6

2.5 JUNCTION GATE MECHANISM........................................................B482-7

1000-SHEET FINISHER (B408)

1. REPLACEMENT AND ADJUSTMENT..................................B408-1

1.1 MAIN PCB ..........................................................................................B408-1

1.2 STAPLER UNIT..................................................................................B408-2

1.3 MOTORS............................................................................................B408-3

1.3.1 SHIFT MOTOR..........................................................................B408-3

1.3.2 STAPLER MOTOR....................................................................B408-3

1.3.3 UPPER TRANSPORT MOTOR AND EXIT MOTOR.................B408-4

1.3.4 LOWER TRANSPORT MOTOR................................................B408-4

1.4 MOTORS AND SENSORS.................................................................B408-5

1.4.1 PREPARATION.........................................................................B408-5

1.4.2 STACK HEIGHT SENSOR........................................................B408-6

1.4.3 STAPLER TRAY PAPER SENSOR...........................................B408-6

1.4.4 LOWER TRAY LIFT MOTOR.....................................................B408-7

1.4.5 STACK FEED-OUT MOTOR.....................................................B408-7

2. TROUBLESHOOTIN G...........................................................B408-8

2.1 JAM DETECTION...............................................................................B408-8

3. SERVICE TABLES................................................................B408-9

3.1 DIP SWITCH SETTINGS....................................................................B408-9

4. DETAILED DESCRIPTIONS...............................................B408-10

4.1 GENERAL LAYOUT.........................................................................B408-10

4.2 ELECTRICAL COMPONENT LAYOUT............................................ B408-11

4.3 ELECTRICAL COMPONENT DESCRIPTION..................................B408-13

4.4 DRIVE LAYOUT ...............................................................................B408-15

4.5 JUNCTION GATES...........................................................................B408-16

Upper Tray Mode.........................................................................B408-16

Sort/Stack Mode...........................................................................B408-16

Staple Mode.................................................................................B408-16

4.6 UPPER TRAY...................................................................................B408-17

4.7 LOWER TRAY UP/DOWN MECHANISMS.......................................B408-18

4.8 PAPER SHIFT MECHANISM ........................................................... B408-19

4.9 JOGGER UNIT PAPER POSITIONING MECHANISM ..................... B408-20

4.10 EXIT GUIDE PLATE.......................................................................B408-21

4.11 STAPLER MECHANISM.................................................................B408-22

4.12 STAPLER UNIT MOVEMENT MECHANISM..................................B408-23

4.13 PAPER FEED-OUT MECHANISM..................................................B408-24

Page 18

xi

v

500-SHEET FINISHER (B458)

1. REPLACEMENT AND ADJUSTMENT..................................B458-1

1.1 EXTERIOR .........................................................................................B458-1

Front Cover....................................................................................B458-2

1.2 ENTRANCE UPPER GUIDE/PAPER EXIT UNIT...............................B458-4

1.3 ENTRANCE LOWER GUIDE..............................................................B458-5

1.4 PAPER EXIT UNIT GEAR/PADDLE ROLLER SOLENOID................B458-5

1.5 STAPLER UNIT..................................................................................B458-6

1.6 JOGGER TRAY UNIT.........................................................................B458-6

1.7 PAPER EXIT SENSOR FEELER........................................................B458-7

1.8 MAIN MOTOR ....................................................................................B458-7

1.9 JOGGER MOTOR..............................................................................B458-8

1.10 CONTROL BOARD...........................................................................B458-8

1.11 OUTPUT TRAY UNIT.......................................................................B458-9

2. DETAILED DESCRIPTIONS...............................................B458-10

2.1 OVERALL MACHINE INFORMATION..............................................B458-10

2.1.1 COMPONENT LAYOUT..........................................................B458-10

Mechanical Component Layout....................................................B458-10

Drive Layout.................................................................................B458-11

2.1.2 ELECTRICAL COMPONENT LAYOUT...................................B458-12

2.1.3 ELECTRICAL COMPONENT DESCRIPTIONS.......................B458-13

2.2 DETAILED SECTION DESCRIPTIONS............................................B458-14

2.2.1 OUTPUT TRAY MECHANISM.................................................B458-14

Stack Height Detection.................................................................B458-14

Output Tray Up/Down Mechanism...............................................B458-15

2.2.2 PAPER FEED..........................................................................B458-16

Straight Feed Out Mode............................................................... B458-16

Shift Sorting Mode........................................................................B458-17

Stapling Mode..............................................................................B458-19

2.2.3 JAM CONDITIONS..................................................................B458-20

2.2.4 ERROR DETECTION...............................................................B458-20

SPECIFICATIONS

SPECIFICATIONS...................................................................... Spec-1

1. GENERAL SPECIFICATIONS (MAIN UNIT)........................................Spec-1

2. MACHINE CONFIGURATION.............................................................. Spec-3

2.1 SYSTEM COMPONENTS.............................................................Spec-3

2.2 OPTIONAL EQUIPMENT ............................................................. Spec-5

ARDF............................................................................................. Spec-5

Bridge Unit..................................................................................... Spec-5

By-pass Tray Unit...........................................................................Spec-6

Duplex Unit.....................................................................................Spec-6

Interchange Unit............................................................................. Spec-6

Page 19

x

v

LCT................................................................................................ Spec-7

Paper Tray Unit.............................................................................. Spec-7

Shift Tray Unit ................................................................................Spec-7

1-Bin Tray Unit............................................................................... Spec-8

500-Sheet Finisher......................................................................... Spec-8

1000-sheet Finisher ....................................................................... Spec-9

Upper Tray.....................................................................................Spec-9

Lower Tray.....................................................................................Spec-9

Page 20

26 July 2002 INSTALLATION REQUIREMENTS

1-1

Installation

1. INSTALLATION

1.1 INSTALLATION REQUIREMENTS

1.1.1 ENVIRONMENT

1. Temperature Range:

10°C to 32°C (50°F to 89.6°F) (humidity to be 54% at

32°C, 89.6°F)

2. Humidity Range:

15% to 80% Rh (temperature to be 27°C, 80.6°F at

80%)

3. Ambient Illumination: Less than 1,500 lux (keep the machine out of direct

sunlight.)

4. Ventilation: Air turnover of more than 30 m

3

/hr/person or more

5. Ambient Dust: Less than 0.10 mg/m

3

(2.7 x 10

– 6

oz/yd3)

6. Avoid exposing the machine to sudden temperature changes, which include:

1) Direct cool air from an air conditioner

2) Direct heat from a heater

7. Avoid installing the machine in areas that may be exposed to corrosive gas.

8. Install the machine at a location lower than 2,000 m (6,500 ft.) above sea level.

9. Install the machine on a strong, level base.

10. Avoid installing the machine in areas that may be subjecte d to strong vibration.

1.1.2 MACHINE LEVEL

Front to back: W ithin 5 mm (0.2") of level

Right to left: Within 5 mm (0.2") of level

Page 21

INSTALLATION REQUIREMENTS 26 July 2002

1-2

1.1.3 POWER REQUIREMENTS

!CAUTION

1. Insert the plug firmly in the outlet.

2. Avoid using an outlet extension plug or cord.

3. Ground the machine.

1. Input voltage level: 120 V, 60 Hz, More than 12 A

220 ∼ 240 V, 50/60 Hz, More than 8 A

110 V, 50/60 Hz, More than 13A

2. Permissible voltage fluctuation: ±10%

3. Do not put or place anything on the power cord.

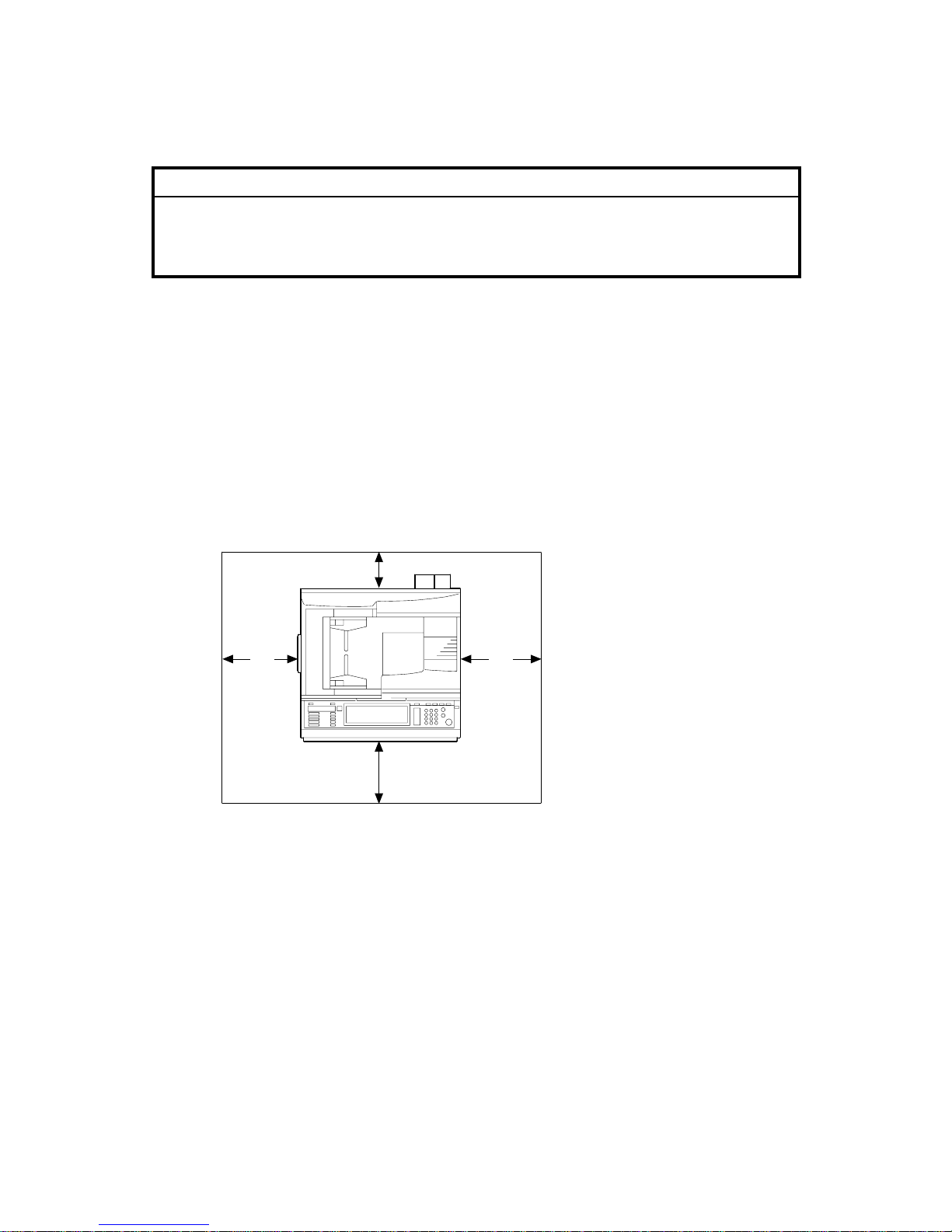

1.1.4 SPACE REQUIREMENTS

B051I126.WMF

A

: Over 100 mm (4")

B: Over 100 mm (4")

C: Over 550 mm (22")

D: Over 750 mm (29.6")

A C

B

D

Page 22

26 July 2002 COPIER (B051/B052)

1-3

Installation

1.2 COPIER (B051/B052)

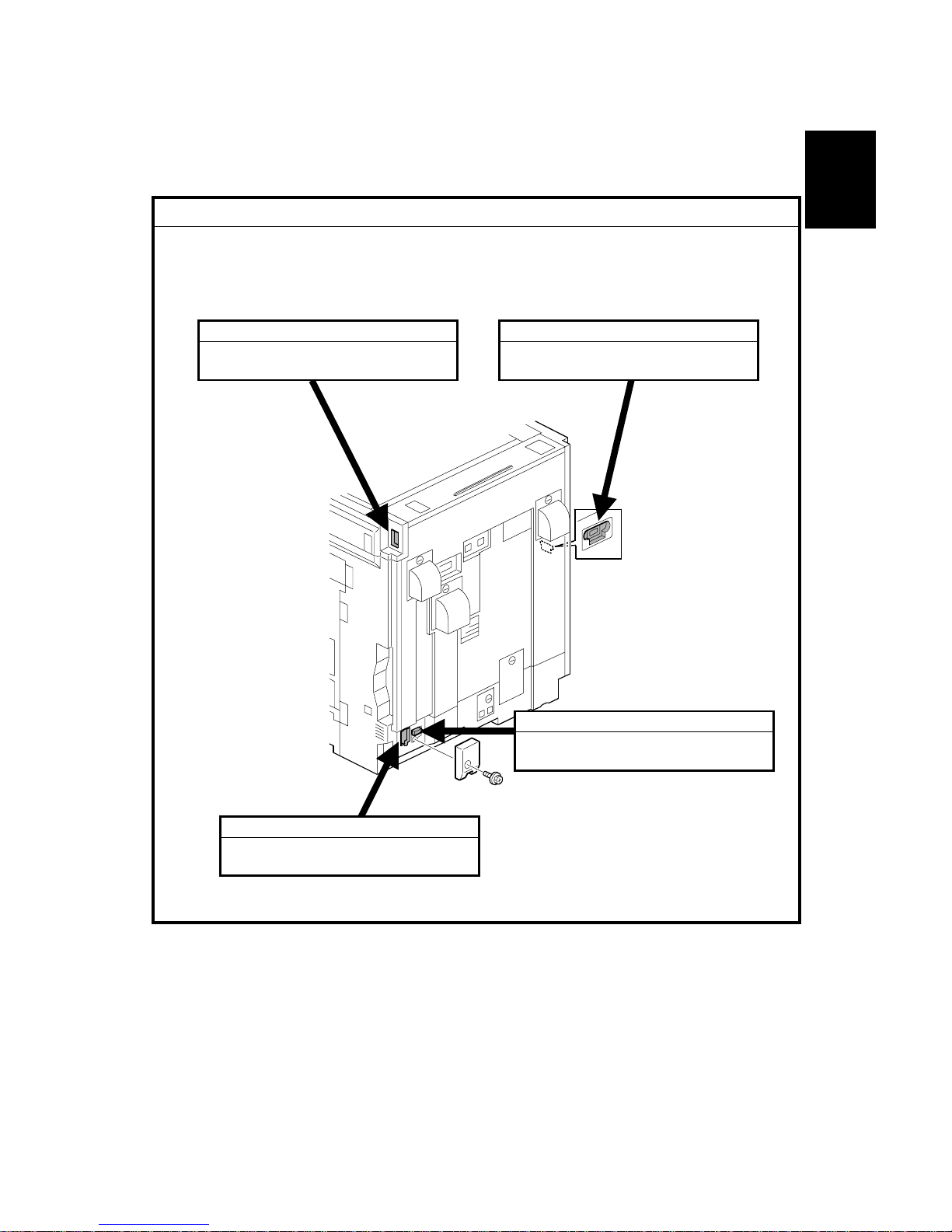

1.2.1 POWER SOCKETS FOR PERIPHERALS

!CAUTION

Rating voltage for peripherals.

Make sure to plug the cables into the correct sockets.

B051I130.WMF

1. ADF

1. Rating voltage output connector

for accessory Max. DC24 V

2. Finisher

1. Rating voltage output connector

for accessory Max. DC24 V

3. By-pass Tray

1. Rating voltage output connector

for accessory Max. DC24 V

4. Duplex Unit

1. Rating voltage output connector

for accessory Max. DC24 V

Page 23

COPIER (B051/B052) 26 July 2002

1-4

1.2.2 INSTALL ATION FLOW CHART

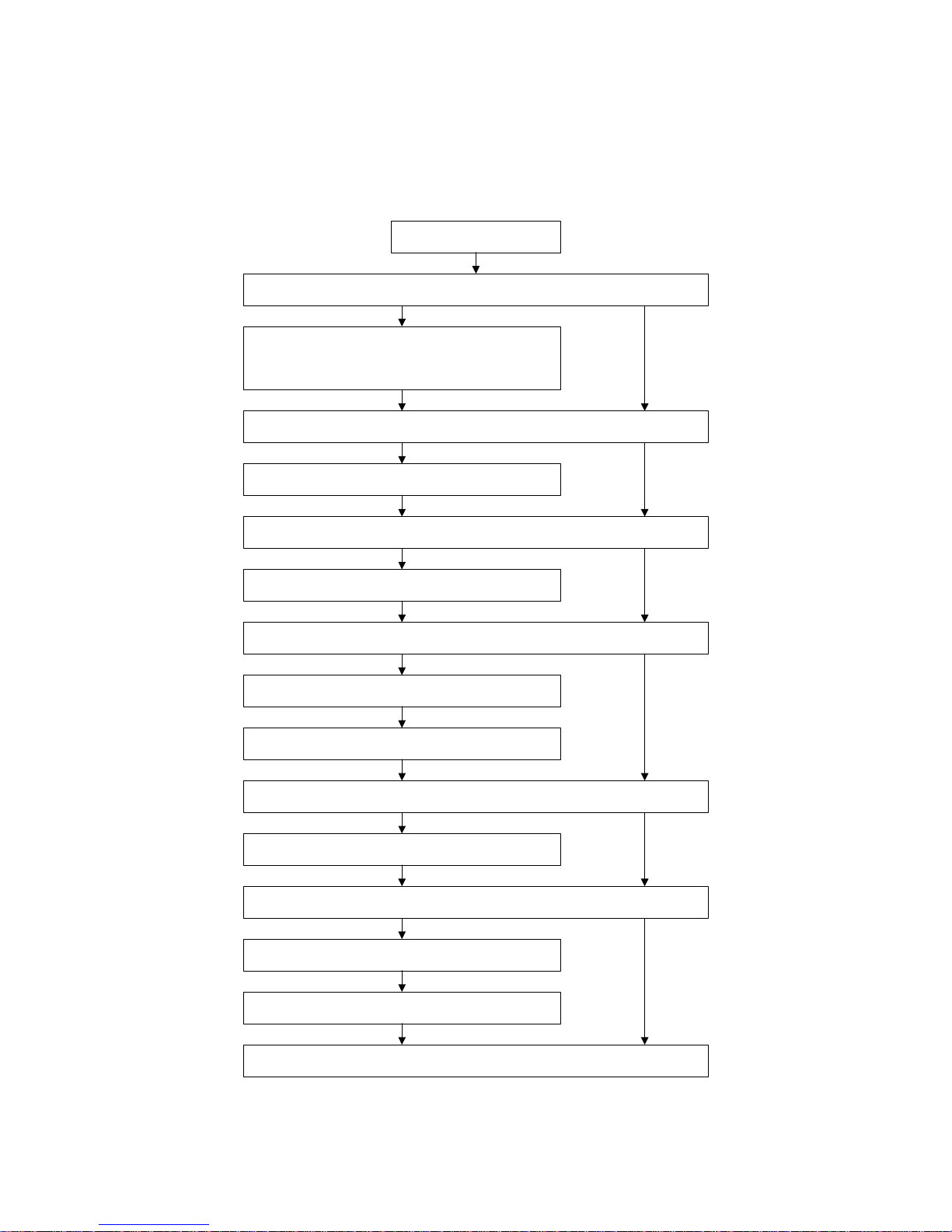

The following flow chart shows how to install the optional units more efficiently.

Unpack the copier

Place the copier on the Paper Tray Unit or LCT

Install the Paper Tray Unit or LCT

Install the copier

Install the Memory Unit

Install the By-pass Tray

Yes No

Yes No

Yes No

Install the Interchange Unit

Install the Duplex Unit and/or 1-bi n Tray U nit

Yes No

Install the Shift Tray

Yes No

Install the Bridge Unit

Install the Finisher

Yes No

Does the user require the Paper Tray Unit, LCT, or Finisher?

Does the user require the Memory Unit

Does the user require the By-pass Tray ?

Install the ARDF or Platen Cover (if required)

Does the user require the Duplex Unit and/or 1-bin Tray Unit ?

Does the user require the Shift Tray?

Does the user require the Finisher?

B051I500.WMF

Page 24

26 July 2002 COPIER (B051/B052)

1-5

Installation

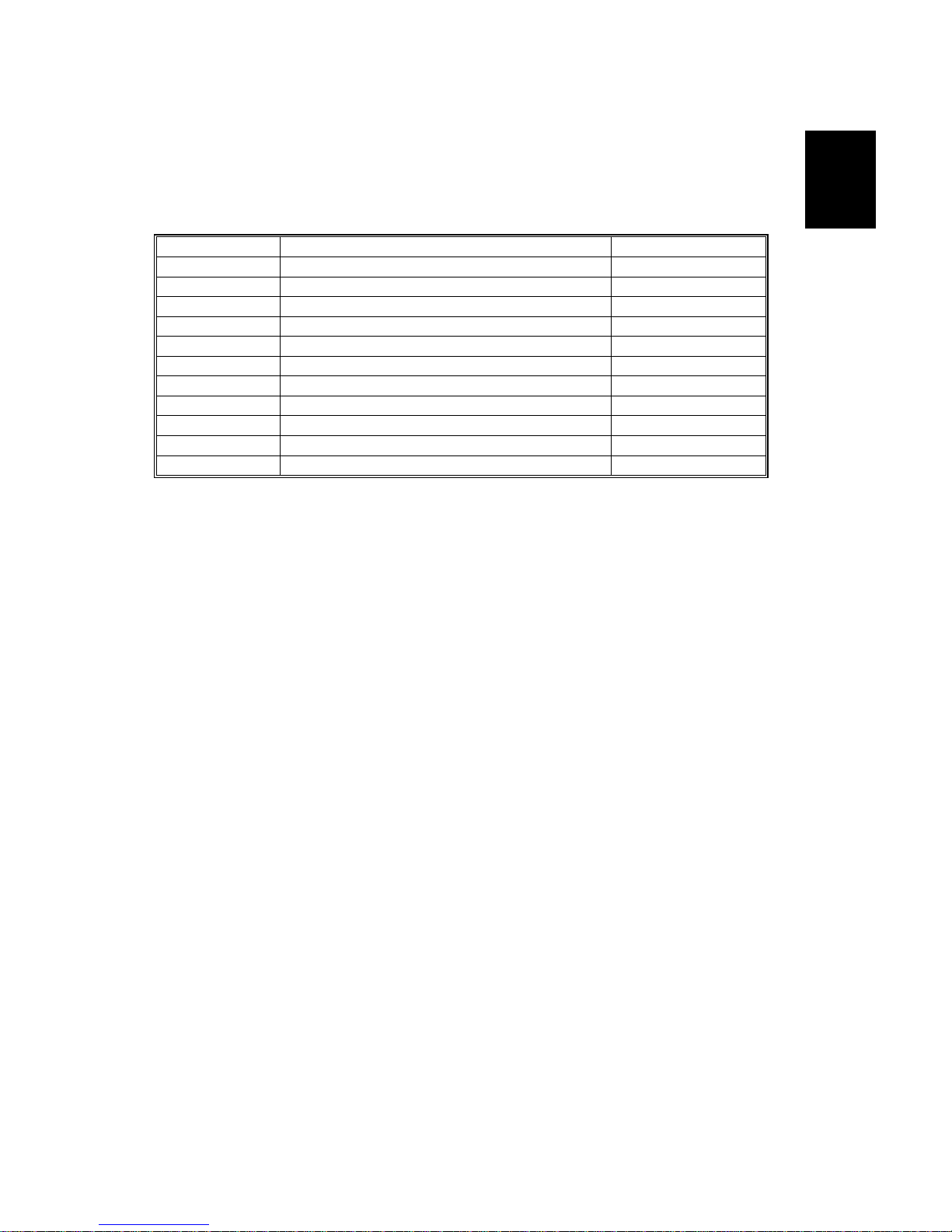

1.2.3 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

No. Description Q’ty

1 Paper Tray Decal 1

2 Model Name Decal 1

3 NECR 1

4 Factory Data Sheet 1

5 Filter Duct 3

6 Filter 3

7 Caution Decal – Power/Paper 1

8 Decal – Copy prohibit ion 1

9 Manual Holder 1

10 Operating Instructions – System Setting 1

11 Operating Instructions – C opy Reference 1

Page 25

COPIER (B051/B052) 26 July 2002

1-6

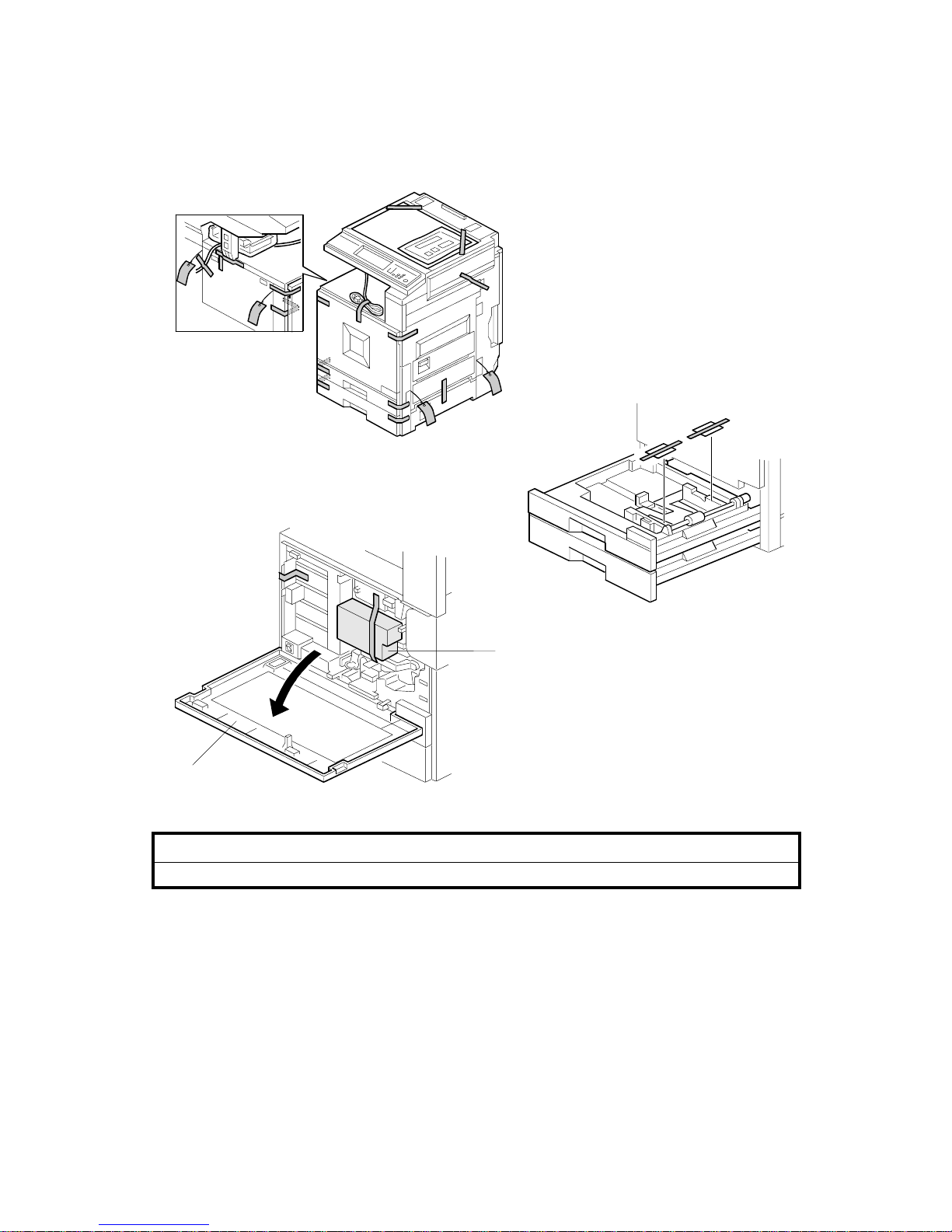

1.2.4 INSTALLATION PROCEDURE

!CAUTION

Unplug the machine power cord before starting the following procedure.

If the optional paper tray or the optional LCT will be installed at the same time,

place the copier on the paper tray unit or the LCT first, then install the copier and

the other options.

NOTE: Keep the shipping retainers after installing the machine. They will be

reused when the machine is moved to another location in the future.

1. Remove the tapes.

2. Open the front cover [A] and remove the shipping retainer [B].

B051I101.WMF

B051I138.WMF

B051I125.WMF

[A]

[B]

Page 26

26 July 2002 COPIER (B051/B052)

1-7

Installation

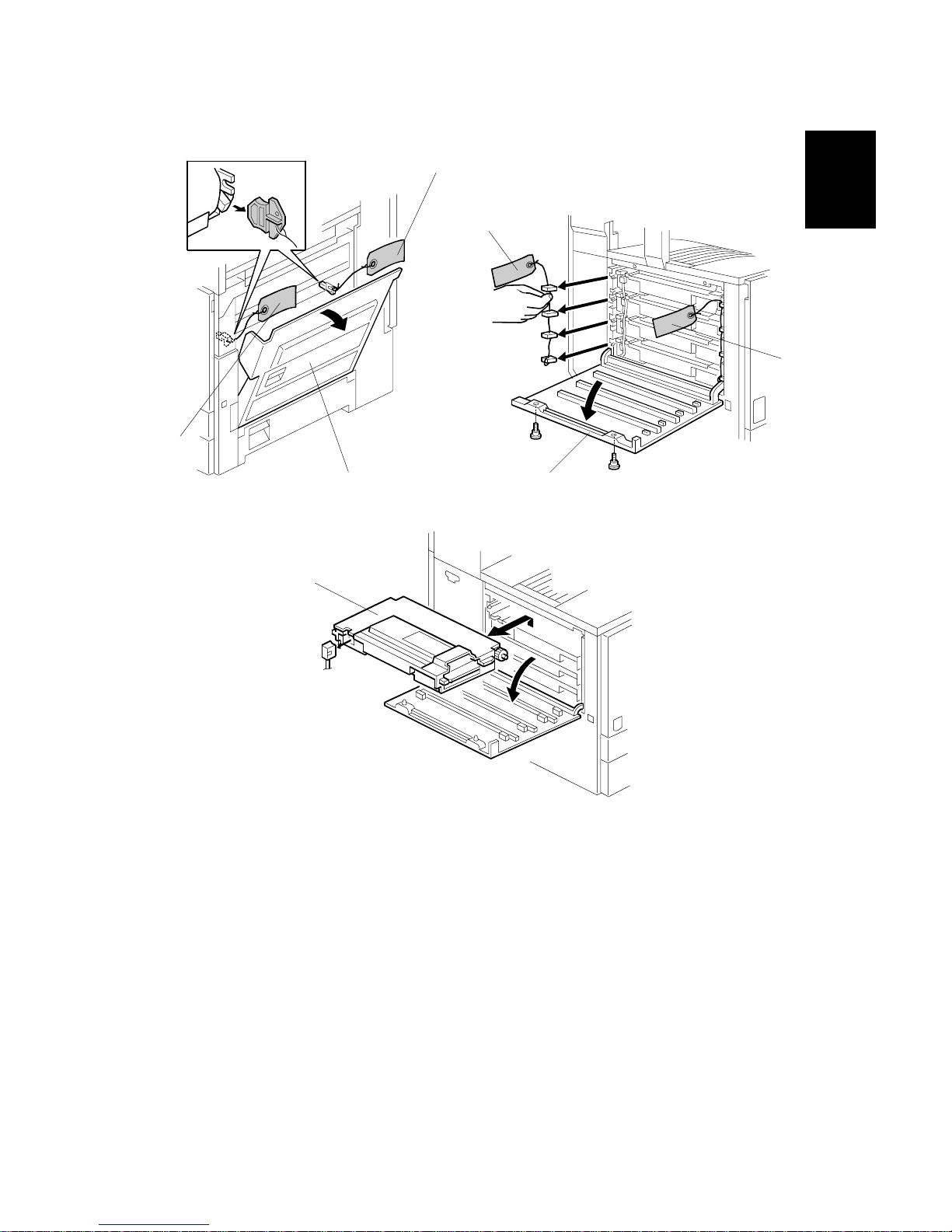

3. Open the right cover [A], and remove the red tags [B].

4. Open the left cover [C] (! x 2), and remove the red tags [D].

5. Pull out all development units [E] (" x 1 each).

B051I134.WMF

B051I124.WMF

B051I110.WMF

[C]

[D]

[D]

[A]

[B]

[B]

[E]

Page 27

COPIER (B051/B052) 26 July 2002

1-8

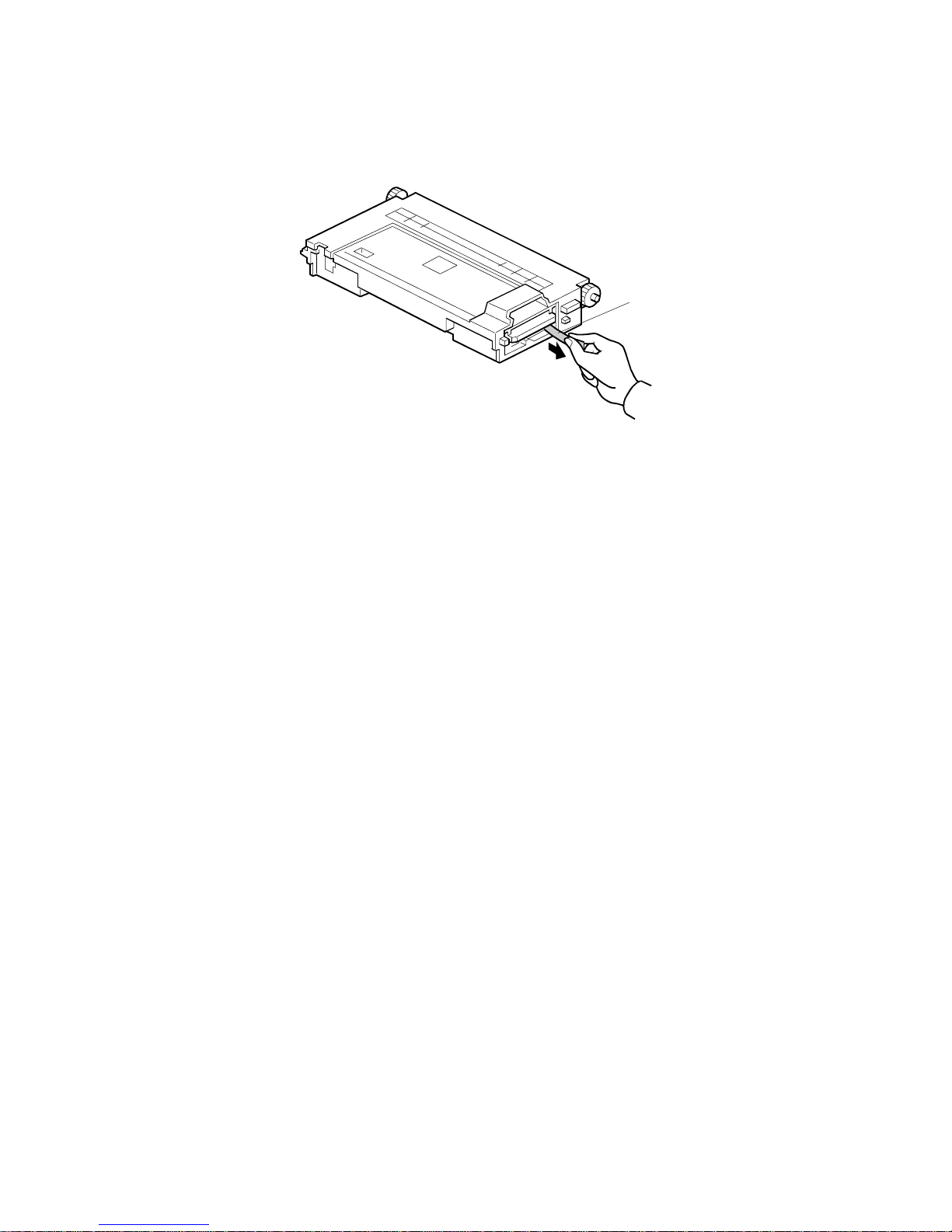

6. Peel off the toner cartridge seal [A].

7. Reinstall the toner cartridge in the development unit.

B051I133.WMF

[A]

Page 28

26 July 2002 COPIER (B051/B052)

1-9

Installation

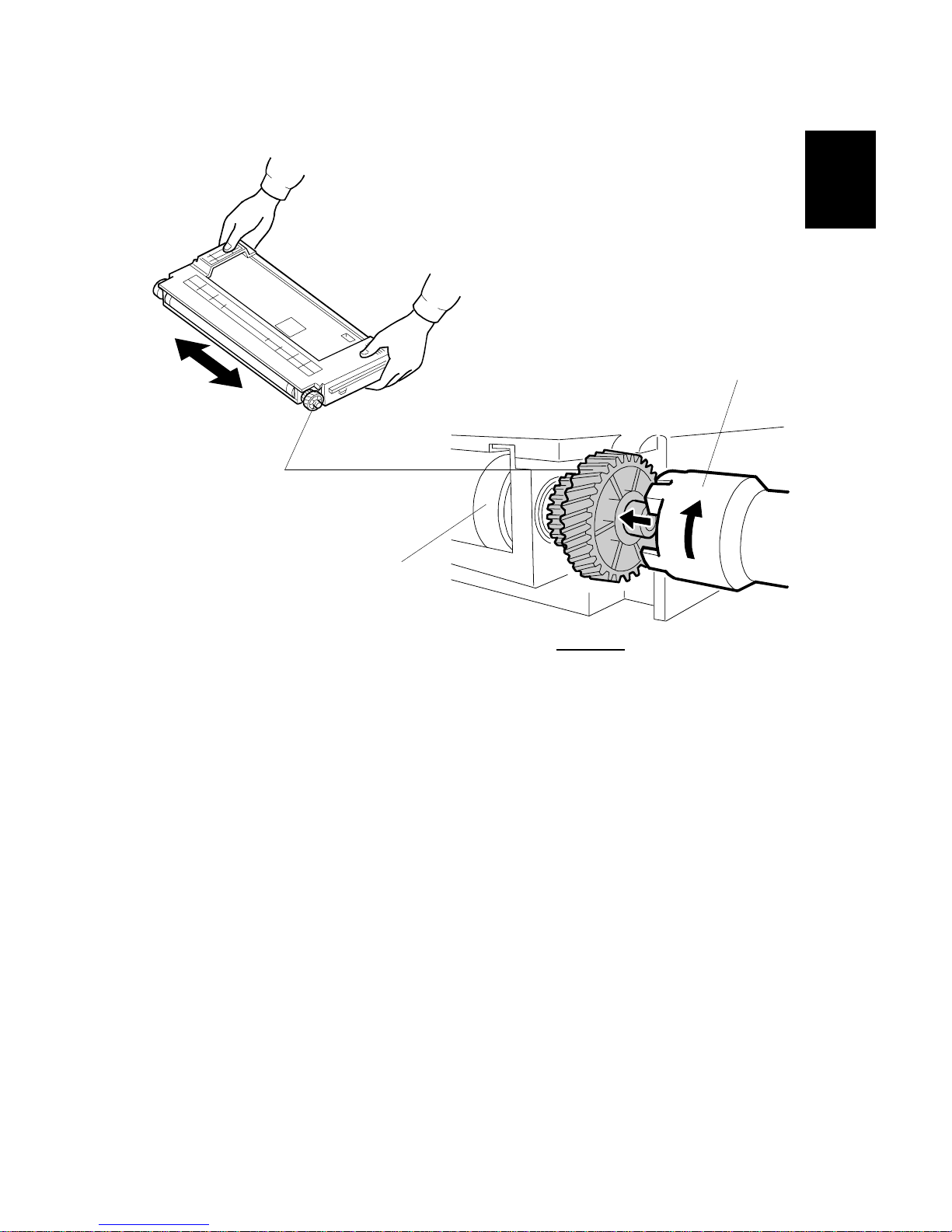

8. Keep the development unit level and shake the development unit about 10

times from side to side.

NOTE: 1) Do not touch the development roller or the development roller gear.

2) Use caution not to drop the cartridge or to damage it.

3) If the cartridge has not been shaken well, the machine takes a

longer time to initialize the development unit, or an error message or

SC350 is displayed. When either of them is displayed, turn the main

switch off and on.

9. Engage the special tool [A] (distributed with the machine) with the development

roller gear at the rear [B].

10. Turn the tool clockwise (approximately 5 times) until the toner covers the whole

area of the development roller [C].

NOTE: If the toner does not cover the whole area of the development roller,

redo step 8 to 10.

B051I315.WMF

B051I409.WMF

[A]

[C]

Rear view

[B]

Page 29

COPIER (B051/B052) 26 July 2002

1-10

11. Reinstall the development units, and close the left cover.

NOTE: A white line or band may appear on one end of the paper if a

development is incorrectly installed. To correct this, pull out the

development unit partially (about 30 mm) and slowly reinstall it.

12. Remove the oil tank cover [A] (1 clip), and fill the oil tank to the maximum line.

NOTE: Do not fill the oil tank past the arrow [B].

B051I135.WMF

[A]

[B]

Page 30

26 July 2002 COPIER (B051/B052)

1-11

Installation

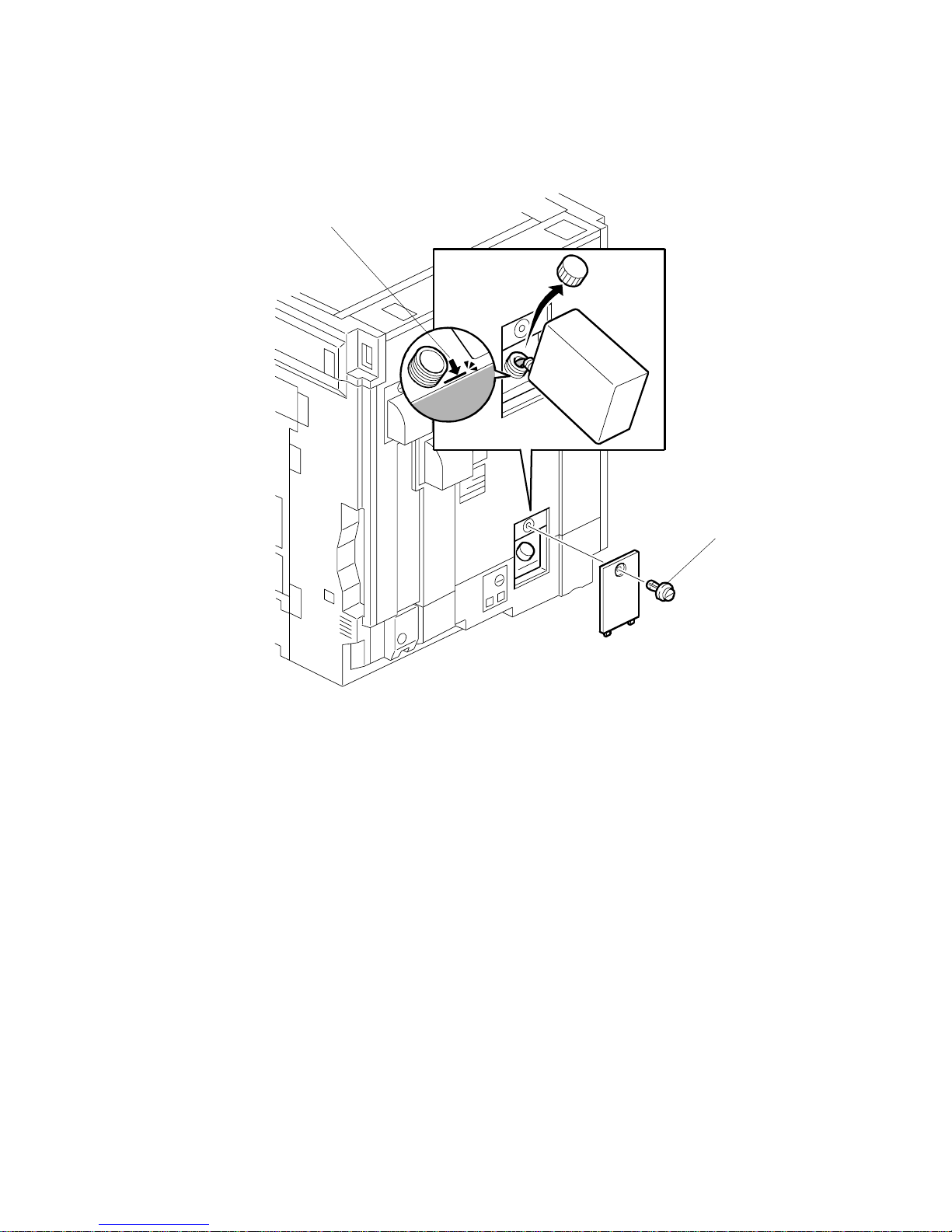

13. Install the filters [A] and ducts [B] as shown.

14. Attach the appropriate model name decal [C] to the front cover.

15. Pull the paper tray out, and adjust the side guides and end guide to match the

paper size.

NOTE: To move the side guides, first pull out the tray fully, then push down the

green lock at the rear inside the tray.

16. Attach the appropriate paper tray number decals [D] to the paper trays.

NOTE: Paper tray number decals are also used for the optional paper tray or

the optional LCT. Keep any remaining decals for use with these

optional units.

B051I137.WMF

B051I128.WMF

B051I131.WMF

[A]

[B]

[A]

[A]

[D]

[C]

Page 31

COPIER (B051/B052) 26 July 2002

1-12

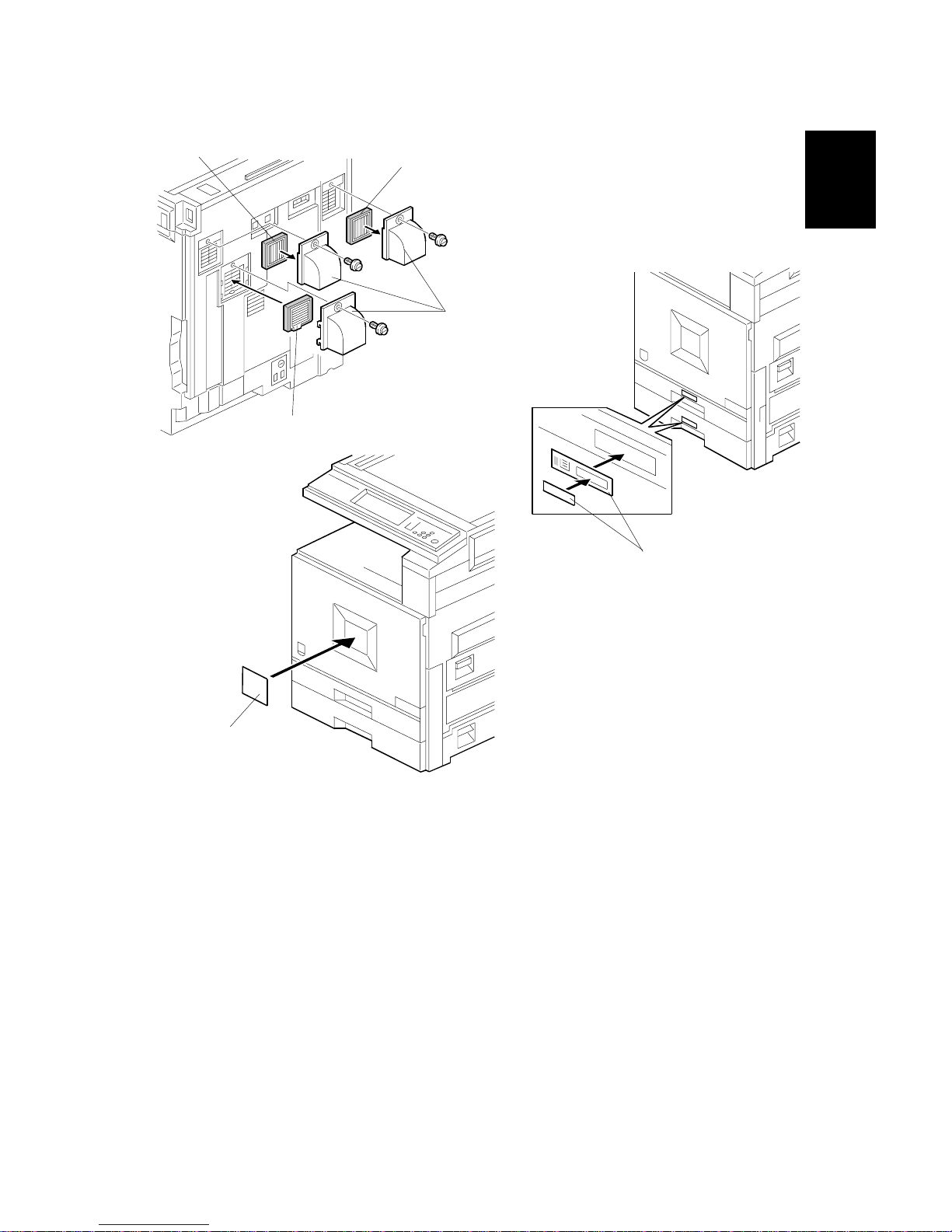

17. If the optional bridge unit will not be installed: Swing the sensor feeler [A]

out.

18. Install the optional ARDF or the optional platen cover (see ARDF Installation or

Platen Cover Installation).

19. Plug in the machine and turn the main power switch on. The machine

automatically performs the initialization procedure. After this has finished, the

Start button LED turns green.

20. Make copies of image samples (text, photo, and text/photo modes).

21. Perform Automatic Color Calibration (ACC).

NOTE: Since this machine has been subject to color adjustment using

Automatic Color Calibration (ACC) at the factory, there is no need to

make automatic color calibration again if the customer is satisfied with

the image sample. If the customer is not satisfied, do the following.

1) Print the ACC test pattern (UP mode – Maintenance – ACC – Start).

2) Place the printout on the exposure glass.

3) Place 10 sheets of white paper on top of the test chart. Then, close

the ADF or platen cover.

4) Press “Start Scanning” on the LCD panel. The machine performs the

ACC.

22. Make sure that the sample image has been copied normally.

23. After installing the machine and all options, and making all test copies, initialize

the total counter (SP 7-825) if required by the service contract.

B051I129.WMF

[A]

Page 32

26 July 2002 PAPER TRAY UNIT (B456)

1-13

Installation

1.3 PAPER TRAY UNIT (B456)

1.3.1 ACCESSORY CHECK

Check the quantity and condition of the accessories against the following list.

No. Description Q’ty

1 Right Stand Bracket 1

2 Left Stand Bracket 1

3 Securing Bracket 2

4 Front Stand 1

5 Rear Stand 1

6 Screw - M4x10 4

7 Knob Screw 2

8 Stepped Screw 2

1.3.2 INSTALLATION PROCEDURE

!CAUTION

Unplug the machine power cord before starting the following procedure.

1. Remove the strips of tape.

B456I001.WMF

B456I002.WMF

1

2

3

4

5

6 7 8

Page 33

PAPER TRAY UNIT (B456) 26 July 2002

1-14

2. Remove the paper trays [A] from the paper tray unit and remove the shipping

retainers.

3. Install the front stand [B] (! x 2).

4. Install the rear stand [C].

5. Attach two stand brackets [D] (! x 1 each).

B456I103.WMF

B456I104.WMF

[A]

[B]

[D]

[C]

[D]

Page 34

26 July 2002 PAPER TRAY UNIT (B456)

1-15

Installation

6. Set the copier [A] on the paper tray unit [B].

7. Remove the paper trays [C] from the copier and secure the paper tray unit

(! x 2).

8. Attach a securing bracket [D] to each side of the paper tray unit (! x 1 each).

B456I105.WMF

B456I102.WMF

B456I106.WMF

[A]

[B]

[C]

[D]

[D]

Page 35

PAPER TRAY UNIT (B456) 26 July 2002

1-16

9. Reinstall the paper trays and attach the appropriate paper tray number decal

[A] to the paper tray.

NOTE: The paper tray number decal is in the accessory box for the main

copier.

10. Load paper into the paper trays.

11. Turn on the main switch.

12. Check the machine’s operation and copy quality.

B456I004.WMF

[A]

Page 36

26 July 2002 LCT (B457)

1-17

Installation

1.4 LCT (B457)

1.4.1 ACCESSORY CHECK

Check the quantity and condition of the accessories against the following list.

No. Description Q’ty

1 Right Stand Bracket 1

2 Left Stand Bracket 1

3 Securing Bracket 2

4 Front Stand 1

5 Rear Stand 1

6 Screw - M4x10 4

7 Knob Screw 2

8 Stepped Screw 2

1.4.2 INSTALLATION PROCEDURE

!CAUTION

Unplug the machine power cord before starting the following procedure.

1. Remove the strips of tape.

B457I151.WMF

B457I001.WMF

1

2 3

4

5

6 7 8

Page 37

LCT (B457) 26 July 2002

1-18

2. While pressing the stopper [A] attached to the guide rail, pull out the large

capacity tray [B].

3. Install the front stand [C] (! x 2).

4. Install the rear stand [D].

5. Attach two stand brackets [E] (! x 1 each).

B457I003.WMF

B457I104.WMF

[A]

[B]

[E]

[D]

[E]

[C]

Page 38

26 July 2002 LCT (B457)

1-19

Installation