Page 1

Model J-P3

(Machine Code: G106)

SERVICE MANUAL

Subject to change

20 February 2004

Page 2

!IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the printer and peripherals,

make sure that the printer power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

4. The printer drives some of its components when it completes the warm-up

period. Be careful to keep hands away from the mechanical and electrical

components as the printer starts operation.

5. The inside and the metal parts of the fusing unit become extremely hot while

the printer is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

Toner and developer are non-toxic, but if you get either of them in your eyes by

accident, it may cause temporary eye discomfort. Try to remove with eye drops

or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The printer and its peripherals must be serviced by a customer service

representative who has completed the training course on those models.

2. The NVRAM module (option) installed on the controller has a lithium battery

which can explode if replaced incorrectly. Replace the NVRAM only with an

identical one. The manufacturer recommends replacing the entire NVRAM.

Do not recharge or burn this battery. Used NVRAM must be handled in

accordance with local regulations.

3. The optional fax and memory expansion units contain lithium batteries,

which can explode if replaced incorrectly. Replace only with the same or an

equivalent type recommended by the manufacturer. Do not recharge or burn

the batteries. Used batteries must be handled in accordance with local

regulations.

Page 3

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly

when exposed to an open flame.

2. Dispose of used toner, the maintenance unit which includes developer or the

organic photoconductor in accordance with local regulations. (These are

non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

5. Dispose of used fusing oil in accordance with local regulations.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

!WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

!WARNING

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Optics Housing Unit section. Laser

beams can seriously damage your eyes.

CAUTION MARKING:

Page 4

Trademarks

Microsoft

®

, Windows®, and MS-DOS® are registered trademarks of Microsoft

Corporation in the United States and /or other countries.

PostScript

®

is a registered trademark of Adobe Systems, Incorporated.

PCL

®

is a registered trademark of Hewlett-Packard Company.

Ethernet

®

is a registered trademark of Xerox Corporation.

PowerPC

®

is a registered trademark of International Business Machines

Corporation.

Other product names used herein are for identification purposes only and may be

trademarks of their respective companies. We disclaim any and all rights involved

with those marks.

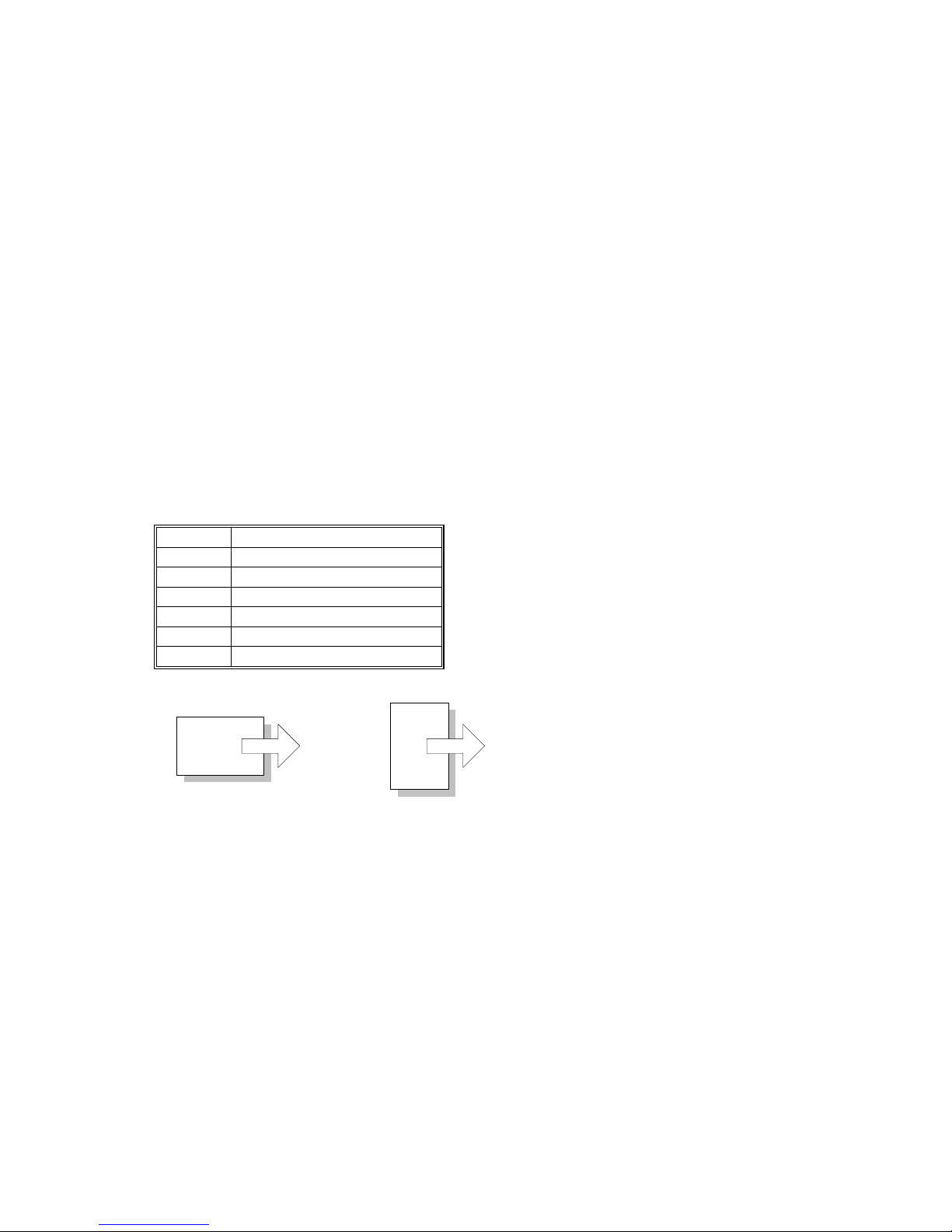

Symbols and Abbreviations

This manual uses the symbols and abbreviations shown below.

Symbol Meaning

☛

Refer to section number

!

Clip ring

"

Screw

#

Connector

SEF Short Edge Feed

LEF Long Edge Feed

Long Edge Feed (LEF)Short Edge Feed (SEF)

Page 5

i

TABLE OF CONTENTS

1. INSTALLATION........................................................................... 1-1

1.1 INSTALLATION REQUIREMENTS........................................................... 1-1

1.1.1 ENVIRONMENT .............................................................................. 1-1

1.1.2 MACHINE LEVEL ............................................................................ 1-1

1.1.3 MACHINE SPACE REQUIREMENT................................................ 1-2

Printer .................................................................................................. 1-2

Printer and Finisher.............................................................................. 1-2

1.1.4 POWER REQUIREMENTS.............................................................. 1-3

1.2 OPTIONAL UNIT COMBINATIONS.......................................................... 1-4

1.3 PRINTER.................................................................................................. 1-5

1.3.1 POWER SOCKETS FOR PERIPHERALS....................................... 1-5

1.3.2 INSTALLATION FLOW CHART....................................................... 1-6

1.3.3 INSTALLATION AND SETTINGS.................................................... 1-7

1.3.4 MOVING THE MACHINE................................................................. 1-8

1.3.5 TRANSPORTING THE MACHINE................................................... 1-9

After Machine Test............................................................................... 1-9

Transporting Used Machine................................................................. 1-9

Necessary Adjustment ......................................................................... 1-9

Preparing the Printer.......................................................................... 1-10

1.4 OPTIONAL UNIT .................................................................................... 1-12

1.4.1 TWO-TRAY FINISHER.................................................................. 1-12

Accessory Check ............................................................................... 1-12

Installation Procedure ........................................................................ 1-12

1.4.2 PUNCH UNIT................................................................................. 1-18

Accessory Check ............................................................................... 1-18

Installation Procedure ........................................................................ 1-19

1.4.3 BOOKLET FINISHER .................................................................... 1-22

Accessory Check ............................................................................... 1-22

Adjusting the Height........................................................................... 1-23

Main Body .......................................................................................... 1-24

1.4.4 OPTIONAL PUNCH UNIT.............................................................. 1-27

Accessory Check ............................................................................... 1-27

Installation Procedure ........................................................................ 1-27

2. PREVENTIVE MAINTENANCE................................................... 2-1

2.1 USER MAINTENANCE............................................................................. 2-1

Maintenance Kit ................................................................................... 2-1

PM Alert Display................................................................................... 2-1

New Unit Detection .............................................................................. 2-1

PM Table.............................................................................................. 2-2

2.2 SERVICE MAINTENANCE....................................................................... 2-3

PM Counter Reset................................................................................ 2-3

PM Table.............................................................................................. 2-3

Page 6

ii

3. REPLACEMENT AND ADJUSTMENT........................................ 3-1

3.1 MODEL J-P3 AND MODEL J-P2.............................................................. 3-1

3.2 SPECIAL TOOLS ..................................................................................... 3-1

3.3 LASER OPTICS........................................................................................ 3-2

3.3.1 CAUTION DECAL LOCATIONS ...................................................... 3-2

3.3.2 LASER OPTICS HOUSING UNIT.................................................... 3-3

3.3.3 POLYGON MIRROR MOTOR ......................................................... 3-7

3.3.4 POLYGON MIRROR MOTOR DRIVE BOARD................................ 3-8

3.3.5 LASER SYNCHRONIZING DETECTOR BOARDS ......................... 3-8

3.4 PAPER FEED........................................................................................... 3-9

3.4.1 REGISTRATION SENSOR AND RELAY SENSORS ...................... 3-9

3.4.2 BY-PASS FEED CLUTCH ............................................................. 3-10

3.4.3 PAPER FEED MOTOR.................................................................. 3-10

3.5 TRANSFER AND PAPER TRANSPORT UNIT ...................................... 3-11

3.5.1 TRANSFER UNIT .......................................................................... 3-11

3.5.2 TRANSFER BELT CLEANING UNIT............................................. 3-12

3.5.3 CLEANING BLADE AND CLEANING ROLLER............................. 3-12

3.5.4 TRANSFER UNIT DRIVE MOTOR................................................ 3-14

3.6 ID SENSORS.......................................................................................... 3-15

3.7 FUSING .................................................................................................. 3-16

3.7.1 CLEANING UNIT ........................................................................... 3-16

3.7.2 PRESSURE ROLLER.................................................................... 3-17

3.7.3 FUSING UNIT FAN........................................................................ 3-19

3.8 ELECTRICAL COMPONENTS............................................................... 3-20

3.8.1 CONTROLLER AND BCU ............................................................. 3-20

3.8.2 NVRAM REPLACEMENT PROCEDURE ...................................... 3-22

NVRAM on the BCU........................................................................... 3-22

NVRAM on the Controller................................................................... 3-23

NVRAMs on the BCU and Controller ................................................. 3-24

3.8.3 HIGH VOLTAGE SUPPLY BOARD ............................................... 3-25

3.8.4 CIRCUIT BREAKER AND PSU FAN ............................................. 3-26

3.8.5 CHOKE COIL................................................................................. 3-26

3.8.6 DEVELOPMENT DRIVE MOTOR-K.............................................. 3-27

3.8.7 WASTE TONER VIBRATOR ......................................................... 3-28

4. TROUBLESHOOTING................................................................. 4-1

4.1 MODEL J-P3 AND MODEL J-P2.............................................................. 4-1

4.2 PROCESS CONTROL ERROR CONDITIONS ........................................ 4-1

4.2.1 DEVELOPER INITIALIZATION RESULT......................................... 4-1

4.2.2 PROCESS CONTROL SELF-CHECK RESULT .............................. 4-2

4.2.3 LINE POSITION ADJUSTMENT RESULT....................................... 4-3

SC Code Classification ........................................................................ 4-4

4.3 SC TABLE ................................................................................................ 4-5

4.4 TROUBLESHOOTING GUIDE ............................................................... 4-15

4.4.1 IMAGE QUALITY........................................................................... 4-15

4.4.2 COLOR SHIFT............................................................................... 4-16

Adjustment Standard.......................................................................... 4-18

Preparation......................................................................................... 4-18

Page 7

iii

4.4.3 BLACK OVER PRINT .................................................................... 4-20

Black Over Print Enabled................................................................... 4-20

Black Over Print Disabled .................................................................. 4-20

4.5 BLOWN FUSE CONDITIONS................................................................. 4-21

Main PSU........................................................................................... 4-21

Sub PSU ............................................................................................ 4-21

BCU ................................................................................................... 4-21

4.6 LEDS (BCU) ........................................................................................... 4-22

5. SERVICE TABLES...................................................................... 5-1

5.1 SERVICE PROGRAM MODE................................................................... 5-1

5.1.1 HANDLING SERVICE PROGRAM MODE....................................... 5-1

Starting SP Mode................................................................................. 5-1

Selecting a Service Program................................................................ 5-2

Changing a Setting............................................................................... 5-2

Quitting SP Mode................................................................................. 5-2

Enabling Settings ................................................................................. 5-2

Line Position Adjustment...................................................................... 5-2

5.1.2 REMARKS ....................................................................................... 5-3

Abbreviations and Symbols.................................................................. 5-3

Possible Values.................................................................................... 5-3

Process Speed..................................................................................... 5-4

5.2 CONTROLLER SERVICE MODE............................................................. 5-5

5.2.1 SERVICE MODE TABLE................................................................. 5-5

5.2.2 BIT SWITCH PROGRAMMING ....................................................... 5-7

5.3 ENGINE SERVICE MODE........................................................................ 5-8

5.3.1 SERVICE MODE TABLE................................................................. 5-8

SP1-XXX (Feed) .................................................................................. 5-8

SP2-XXX (Drum)................................................................................ 5-15

SP3-XXX (Process)............................................................................ 5-26

SP5-XXX (Mode)................................................................................ 5-33

SP6-XXX (Peripherals) ...................................................................... 5-47

SP7-XXX (Data Log) .......................................................................... 5-48

SP8-XXX (Data Log 2) ....................................................................... 5-55

5.3.2 MEMORY CLEAR/COUNTER CLEAR .......................................... 5-65

5.3.3 INPUT CHECK TABLE .................................................................. 5-66

Table 1: Paper Height Sensor............................................................ 5-68

Table 2: Paper Size Switch (Tray 2)................................................... 5-68

Table 3: Paper Size (By-pass Table) ................................................. 5-69

5.3.4 OUTPUT CHECK TABLE .............................................................. 5-70

5.3.5 TEST PATTERN (SP5-997)........................................................... 5-74

5.4 FIRMWARE UPDATE............................................................................. 5-75

5.4.1 TYPE OF FIRMWARE................................................................... 5-75

5.4.2 PRECAUTIONS............................................................................. 5-75

Handling SD Cards ............................................................................ 5-75

Upload or Download........................................................................... 5-75

Network Connection........................................................................... 5-75

Page 8

i

v

5.4.3 FILE ARRANGEMENT .................................................................. 5-76

How the Program Works .................................................................... 5-76

Example ............................................................................................. 5-76

5.4.4 UPDATING .................................................................................... 5-77

Procedure........................................................................................... 5-77

Error Handling.................................................................................... 5-78

Power Failure..................................................................................... 5-78

5.4.5 NVRAM DATA UPLOAD/DOWNLOAD.......................................... 5-79

Uploading NVRAM Data .................................................................... 5-79

Downloading NVRAM Data................................................................ 5-80

5.4.6 ERROR CODE TABLE .................................................................. 5-81

5.5 SD CARD APPLI MOVE......................................................................... 5-82

5.5.1 OVERVIEW.................................................................................... 5-82

5.5.2 MOVE EXEC.................................................................................. 5-83

5.5.3 UNDO EXEC.................................................................................. 5-84

5.6 CONTROLLER SELF-DIAGNOSTICS.................................................... 5-85

5.6.1 OVERVIEW.................................................................................... 5-85

5.6.2 DETAILED SELF-DIAGNOSTICS.................................................. 5-86

5.7 USER PROGRAM MODE....................................................................... 5-87

Starting a User Program .................................................................... 5-87

Quitting a User Program .................................................................... 5-87

Menu List ........................................................................................... 5-87

5.8 DIP SWITCHES...................................................................................... 5-88

Controller Board................................................................................. 5-88

BCU Board......................................................................................... 5-88

6. DETAILED DESCRIPTIONS ....................................................... 6-1

6.1 MODEL J-P3 AND MODEL J-P2.............................................................. 6-1

6.2 OVERVIEW .............................................................................................. 6-2

6.2.1 COMPONENT LAYOUT .................................................................. 6-2

6.2.2 DRIVE LAYOUT............................................................................... 6-3

6.2.3 BOARD STRUCTURE ..................................................................... 6-4

Overview .............................................................................................. 6-4

Descriptions ......................................................................................... 6-5

6.3 LASER EXPOSURE ................................................................................. 6-7

6.3.1 OVERVIEW...................................................................................... 6-7

6.3.2 OPTICAL PATH............................................................................... 6-8

6.3.3 LD SAFETY SWITCH ...................................................................... 6-9

6.4 PHOTOCONDUCTOR UNIT .................................................................. 6-10

6.4.1 OVERVIEW.................................................................................... 6-10

6.4.2 DRUM CHARGE AND QUENCHING ............................................ 6-11

6.4.3 DRUM CLEANING......................................................................... 6-12

6.4.4 WASTE TONER COLLECTION..................................................... 6-13

Waste Toner Path .............................................................................. 6-13

Waste Toner Vibrator ......................................................................... 6-14

6.5 PAPER FEED LINE SPEED................................................................... 6-15

6.6 IMAGE TRANSFER AND PAPER SEPARATION .................................. 6-16

6.6.1 OVERVIEW.................................................................................... 6-16

Page 9

v

6.6.2 TRANSFER BELT DRIVE.............................................................. 6-17

Drive Motor......................................................................................... 6-17

Rotation Encoder ............................................................................... 6-18

ACS (Auto Color Sensing) Mode........................................................ 6-19

6.7 FUSING .................................................................................................. 6-20

6.7.1 FUSING TEMPERATURE CONTROL........................................... 6-20

Fusing Temperatures......................................................................... 6-20

Temperature Corrections ................................................................... 6-21

Overheat Protection ........................................................................... 6-21

6.7.2 ENERGY SAVER MODE............................................................... 6-22

Level 1 Energy Saver Mode............................................................... 6-22

Level 2 Energy Saver Mode............................................................... 6-22

6.8 CONTROLLER ....................................................................................... 6-23

6.8.1 OVERVIEW.................................................................................... 6-23

6.8.2 BOARD LAYOUT........................................................................... 6-24

6.8.3 CONTROLLER FUNCTIONS......................................................... 6-25

Paper Output Tray.............................................................................. 6-25

Stapling .............................................................................................. 6-25

Punching ............................................................................................ 6-26

6.9 HARD DISK ............................................................................................ 6-27

PERIPHERALS

BOOKLET FINISHER (B602)

1. REPLACEMENT AND ADJUSTMENT..................................B602-1

1.1 REGULAR TRAY................................................................................ B602-1

1.2 COVERS............................................................................................. B602-1

1.2.1 FRONT COVER......................................................................... B602-1

1.2.2 REAR COVER ........................................................................... B602-3

1.2.3 LEFT/RIGHT TOP AND TRAY UPPER COVER........................ B602-3

1.2.4 UPPER RIGHT COVER............................................................. B602-5

1.3 SIDE GUIDE ....................................................................................... B602-6

Removal......................................................................................... B602-6

Reassembly ................................................................................... B602-6

1.4 STAPLER UNIT .................................................................................. B602-7

Removal......................................................................................... B602-7

Adjusting the Stapler Gear Phase................................................ B602-10

1.5 FOLDING UNIT ................................................................................ B602-13

Removal....................................................................................... B602-13

Adjusting the Folding Unit Gear Phase ........................................ B602-15

1.6 STACK TRAY AND JOGGER FENCE.............................................. B602-16

1.6.1 STACK TRAY UNIT................................................................. B602-16

1.6.2 JOGGER FENCE UNIT ........................................................... B602-18

1.7 STAPLER MOTOR UNIT.................................................................. B602-20

1.8 TRANSPORT.................................................................................... B602-22

1.8.1 TRANSPORT MOTOR ............................................................B602-22

Page 10

vi

1.8.2 TRANSPORT ROLLER ........................................................... B602-22

1.9 STACK TRAY ................................................................................... B602-24

1.9.1 STACK TRAY UPPER ROLLER.............................................. B602-24

1.9.2 STACK TRAY PADDLE........................................................... B602-25

1.9.3 STACK TRAY LOWER ROLLER ............................................. B602-27

Removal....................................................................................... B602-27

Reassembly ................................................................................. B602-29

1.10 CIRCUIT BOARD............................................................................ B602-30

1.10.1 CONTROLLER BOARD......................................................... B602-30

1.10.2 STAPLER HOME POSITION SENSOR BOARD ................... B602-30

1.11 PUNCH UNIT, MOTORS, AND CONTROLLER ............................. B602-32

1.11.1 PUNCH UNIT AND PUNCH UNIT MOTOR........................... B602-32

1.11.2 REGISTRATION MOTOR...................................................... B602-34

1.11.3 CONTROLLER ...................................................................... B602-35

1.11.4 PHOTO SENSOR BOARD .................................................... B602-35

1.11.5 LED BOARD .......................................................................... B602-36

1.11.6 CHAD BOX FULL SENSOR BOARD AND LED BOARD ...... B602-37

1.11.7 ADJUSTMENT AND INITIALIZATION................................... B602-38

Sensor Voltage............................................................................. B602-38

Punch Type.................................................................................. B602-39

EEPROM...................................................................................... B602-39

2. SERVICE TABLES..............................................................B602-40

2.1 DIP SWITCH SETTINGS.................................................................. B602-40

Punch Controller Board................................................................ B602-40

3. DETAILED DESCRIPTIONS ...............................................B602-41

3.1 GENERAL LAYOUT ......................................................................... B602-41

3.2 DRIVE............................................................................................... B602-42

3.3 CONTROLLER ................................................................................. B602-43

3.4 STACK TRAY ................................................................................... B602-44

3.4.1 SIMPLE OUTPUT.................................................................... B602-44

Mechanism................................................................................... B602-44

Stack-Tray Belt............................................................................. B602-44

3.4.2 SORT....................................................................................... B602-45

3.4.3 STACK..................................................................................... B602-46

Paddle.......................................................................................... B602-46

Stack-Tray Stopper ...................................................................... B602-46

Stack-Tray Guide Mechanism...................................................... B602-47

Stack-Tray Guide Mechanism...................................................... B602-48

Home Position.............................................................................. B602-48

Stapler Switch .............................................................................. B602-48

Safety Feature.............................................................................. B602-48

3.4.4 JOGGER FENCE..................................................................... B602-49

Action ........................................................................................... B602-49

Drive............................................................................................. B602-49

Home Position.............................................................................. B602-49

Paper Position.............................................................................. B602-50

Page 11

vii

3.4.5 PAPER OUTPUT..................................................................... B602-51

Mechanism................................................................................... B602-51

Stack-Tray Belt Home Position .................................................... B602-51

3.5 STAPLING........................................................................................ B602-52

3.5.1 OVERVIEW.............................................................................. B602-52

3.5.2 STAPLER................................................................................. B602-53

Mechanism................................................................................... B602-53

Stapler Switch .............................................................................. B602-53

Sensors........................................................................................ B602-53

3.5.3 POSITIONING ......................................................................... B602-54

Action and Drive........................................................................... B602-54

Home Position and Ready Position.............................................. B602-54

Staple Position ............................................................................. B602-55

3.6 REGULAR TRAY.............................................................................. B602-57

Action and Drive........................................................................... B602-57

Ready Position............................................................................. B602-57

Paper Sensor ............................................................................... B602-58

Paper Full..................................................................................... B602-58

Fail Safe Feature.......................................................................... B602-58

3.7 SADDLE STITCH ............................................................................. B602-59

3.7.1 OVERVIEW.............................................................................. B602-59

3.7.2 STACK TRAY .......................................................................... B602-60

3.7.3 STAPLER................................................................................. B602-60

3.7.4 PAPER TRANSPORT.............................................................. B602-61

3.7.5 PAPER OUTPUT..................................................................... B602-62

Folding Plate Mechanism............................................................. B602-62

Folding Plate Home Position........................................................ B602-62

Folder Rollers Mechanism ........................................................... B602-63

Folder Rollers Home Position....................................................... B602-63

Shape of Folder Rollers ...............................................................B602-64

3.8 PUNCH UNIT (OPTIONAL) .............................................................. B602-65

3.8.1 REGISTRATION...................................................................... B602-65

Slide Unit...................................................................................... B602-65

Home Position.............................................................................. B602-65

Registration.................................................................................. B602-65

3.8.2 PUNCH .................................................................................... B602-67

Types of Punch Unit..................................................................... B602-67

Drive............................................................................................. B602-67

Home Position.............................................................................. B602-67

Two Holes and Four Holes........................................................... B602-68

Two or Three Holes...................................................................... B602-69

SPECIFICATIONS

1. GENERAL SPECIFICATIONS.............................................................SPEC-1

2. SUPPORTED PAPER SIZES..............................................................SPEC-3

2.1 PAPER FEED ..............................................................................SPEC-3

2.2 PAPER EXIT................................................................................SPEC-4

Page 12

viii

3. SOFTWARE ACCESSORIES..............................................................SPEC-5

3.1 PRINTER DRIVERS ....................................................................SPEC-5

3.2 UTILITY SOFTWARE ..................................................................SPEC-5

4. MACHINE CONFIGURATION .............................................................SPEC-6

Controller.......................................................................................SPEC-7

Others ...........................................................................................SPEC-7

5. OPTIONAL EQUIPMENT ....................................................................SPEC-8

5.1 500-SHEET TRAY .......................................................................SPEC-8

5.2 1000-SHEET TRAY .....................................................................SPEC-8

5.3 2000-SHEET LARGE CAPACITY TRAY .....................................SPEC-8

5.4 TWO-TRAY FINISHER & PUNCH UNIT......................................SPEC-9

5.5 BOOKLET FINISHER ................................................................SPEC-10

Page 13

20 February 2004 INSTALLATION REQUIREMENTS

1-1

Installation

1. INSTALLATION

1.1 INSTALLATION REQUIREMENTS

1.1.1 ENVIRONMENT

1. Temperature Range: 10°C to 32°C (50°F to 89.6°F)

2. Humidity Range: 15% to 80% RH

3. Ambient Illumination: Less than 2,000 lux (do not expose to direct sunlight)

4. Ventilation: 3 times/hr/person or more

5. Avoid exposing the machine to sudden temperature changes, which include:

1) Direct cool air from an air conditioner

2) Direct heat from a heater

6. Avoid installing the machine in areas that might be exposed to corrosive gas.

7. Install the machine at a location lower than 2,500 m (8,200 ft.) above sea level.

8. Install the machine on a strong, level base (☛ 1.1.2).

9. Avoid installing the machine in areas that may be subjected to strong vibration.

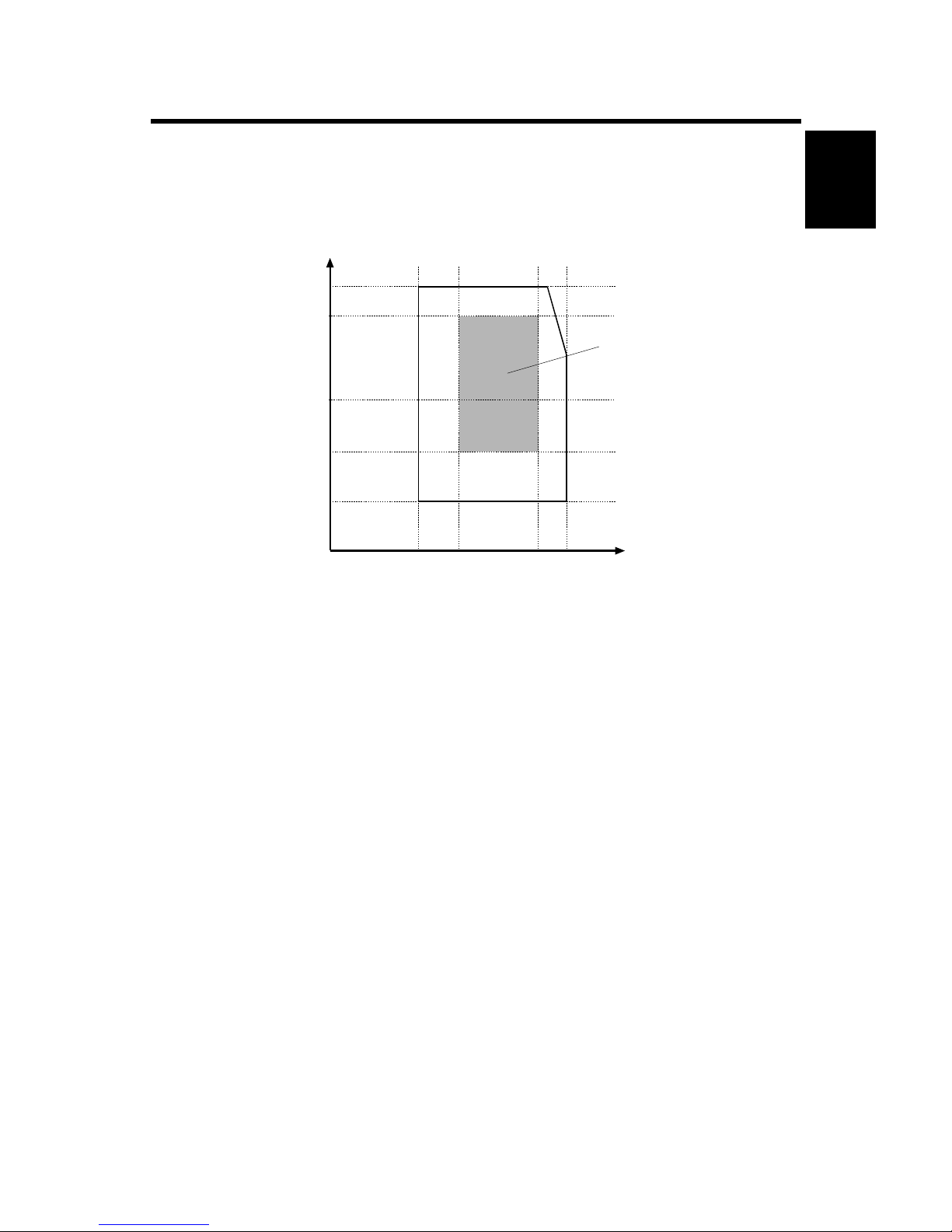

1.1.2 MACHINE LEVEL

Front to back: Within 5 mm (0.2")

Right to left: Within 5 mm (0.2")

G106I900.WMF

Ambient Humidity (%RH)

80%

70%

54%

30%

10°C 15°C25°C 32°C

15%

Recommended conditions:

15 to 25°C

30 to 70%RH

Page 14

INSTALLATION REQUIREMENTS 20 February 2004

1-2

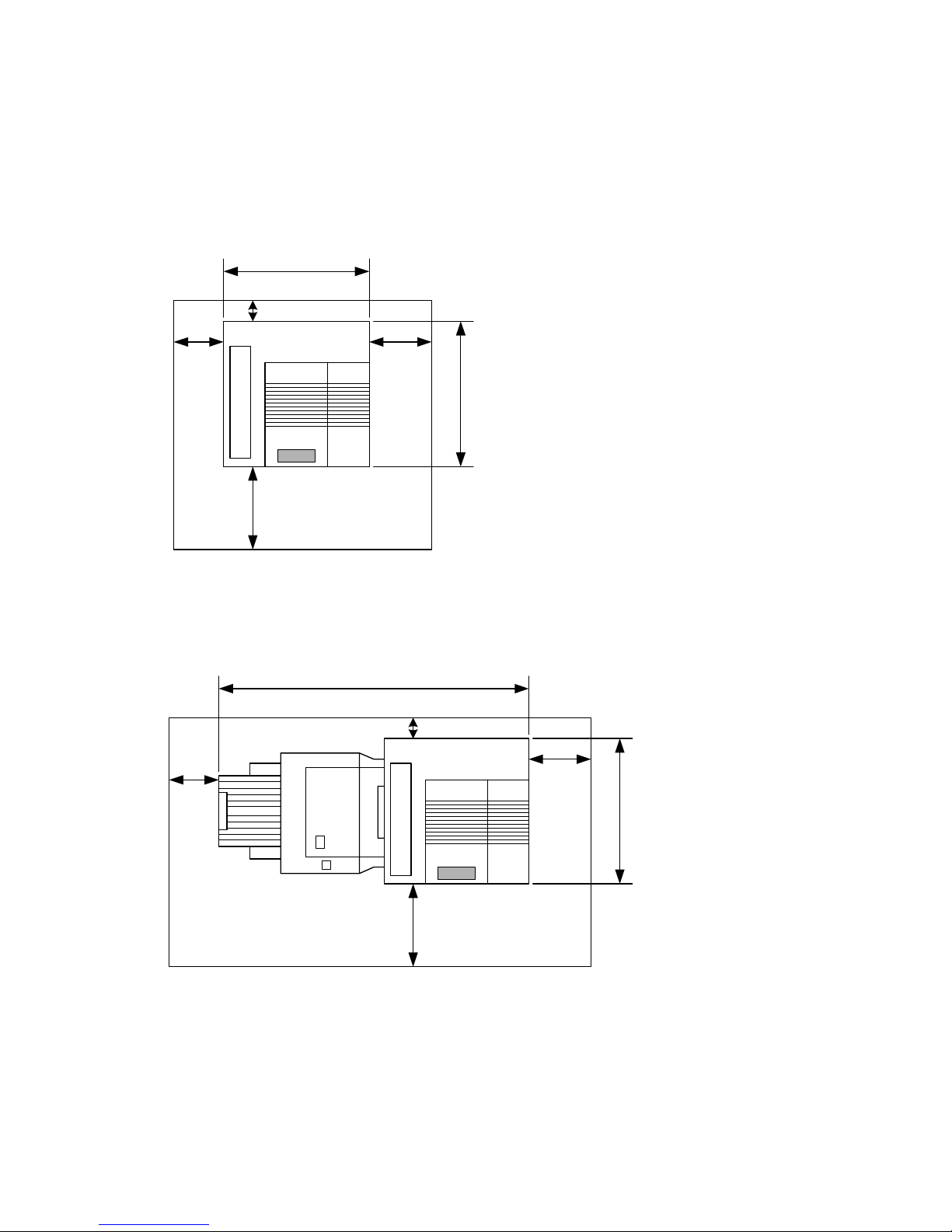

1.1.3 MACHINE SPACE REQUIREMENT

Install the machine near the power source. The diagrams show the necessary

space.

Printer

Printer and Finisher

[A]: Over 460 mm (18")

[B]: Over 100 mm (4")

[C]: Over 550 mm (22")

[D]: Over 700 mm (28")

!

!

!

!

!

!

!

!

!

!

!

!

B

D

C

A

575mm

678mm

G106I901.WMF

!

!

!

!

!

!

!

!

!

!

!

!

B

D

C

A

1450mm

678mm

!

!

G106I902.WMF

A

: Over 460 mm (18")

B: Over 100 mm (4")

C: Over 550 mm (22")

D: Over 700 mm (28")

Page 15

20 February 2004 INSTALLATION REQUIREMENTS

1-3

Installation

1.1.4 POWER REQUIREMENTS

!CAUTION

1. Insert firmly the plug in the outlet.

2. Avoid using an outlet extension plug or cord.

3. Ground the machine.

1. Input voltage level: 120 V, 60 Hz: More than 12 A

220 V ~ 240 V, 50 Hz/60 Hz: More than 7 A

2. Permissible voltage fluctuation: ±10%

3. Do not put or place anything on the power cord.

Page 16

OPTIONAL UNIT COMBINATIONS 20 February 2004

1-4

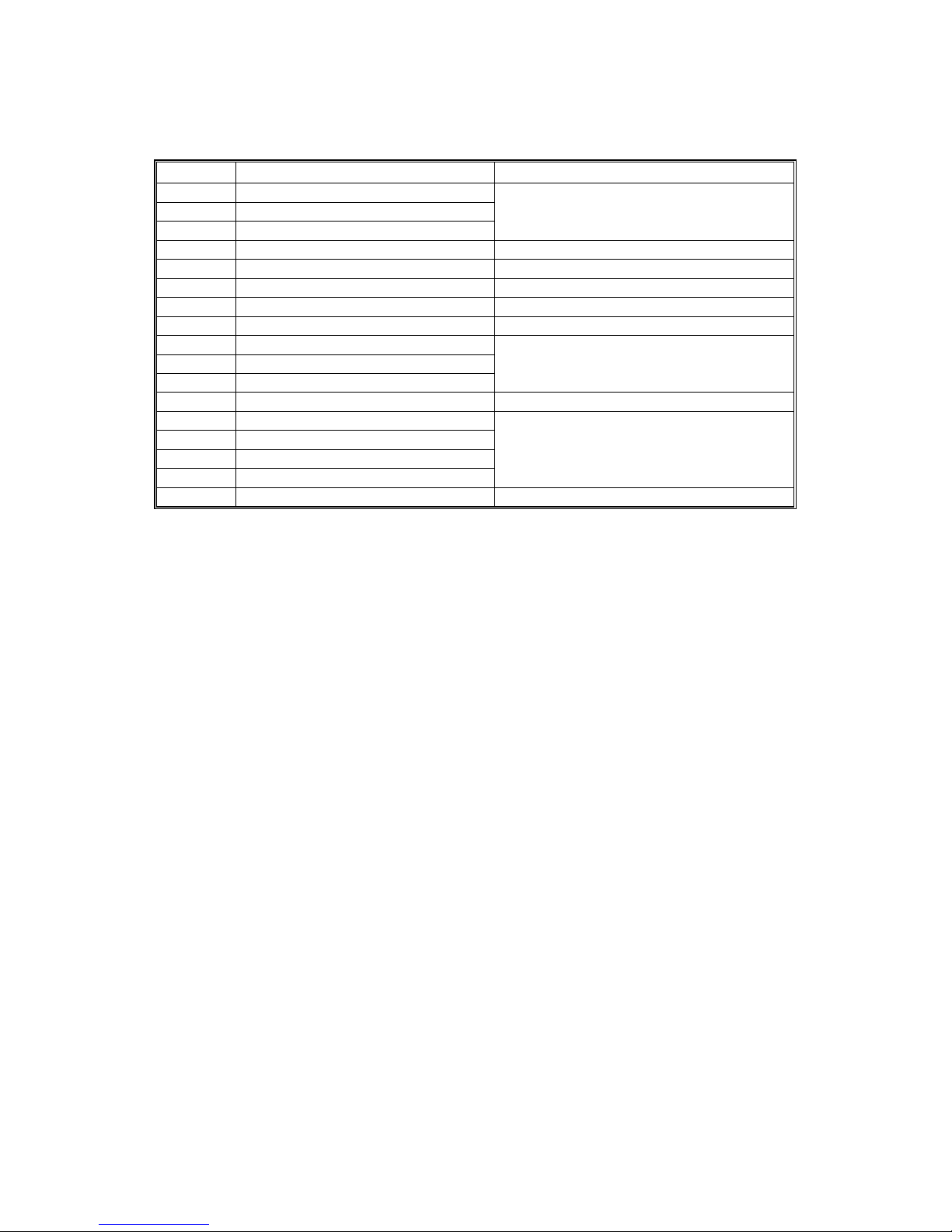

1.2 OPTIONAL UNIT COMBINATIONS

No. Options Remarks

1 One-tray paper feed unit

2 Two-tray paper feed unit

3 Large capacity tray

You can install one of these three

4 Two-tray finisher One from No. 4 and No. 6; No. 8 necessary

5 Punch kit (3 types) No. 4 necessary; One of the three types

6 Booklet Finisher One from No. 4 and No. 6; No. 8 necessary

7 Punch unit (4 types) No. 6 necessary; One of the four types

8 Duplex unit

9 64 MB memory

10 128 MB memory

11 256 MB memory

You can install one of these three

12 40 GB HDD unit

13 IEEE 1284

14 IEEE 1394

15 IEEE 802.11b

16 Bluetooth

You can install one of these four

17 NVRAM memory

Page 17

20 February 2004 PRINTER

1-5

Installation

1.3 PRINTER

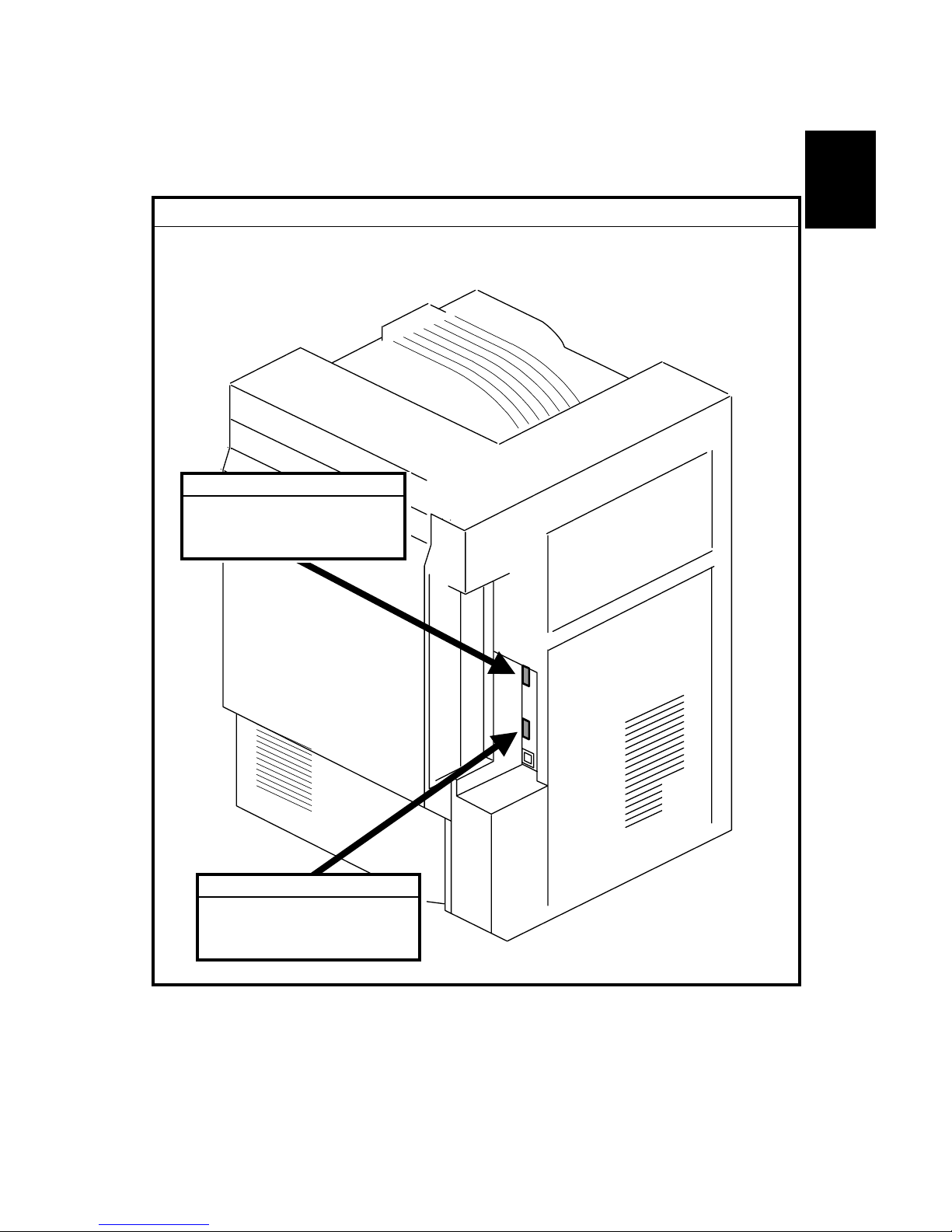

1.3.1 POWER SOCKETS FOR PERIPHERALS

!CAUTION

Rating voltage for peripherals.

Make sure to plug the cables into the correct sockets.

G106I903.WMF

1. Duplex unit

Rating voltage output

connector for accessory

Max. DC24V

2. Finisher

Rating voltage output

connector for accessory

Max. DC24V

Page 18

PRINTER 20 February 2004

1-6

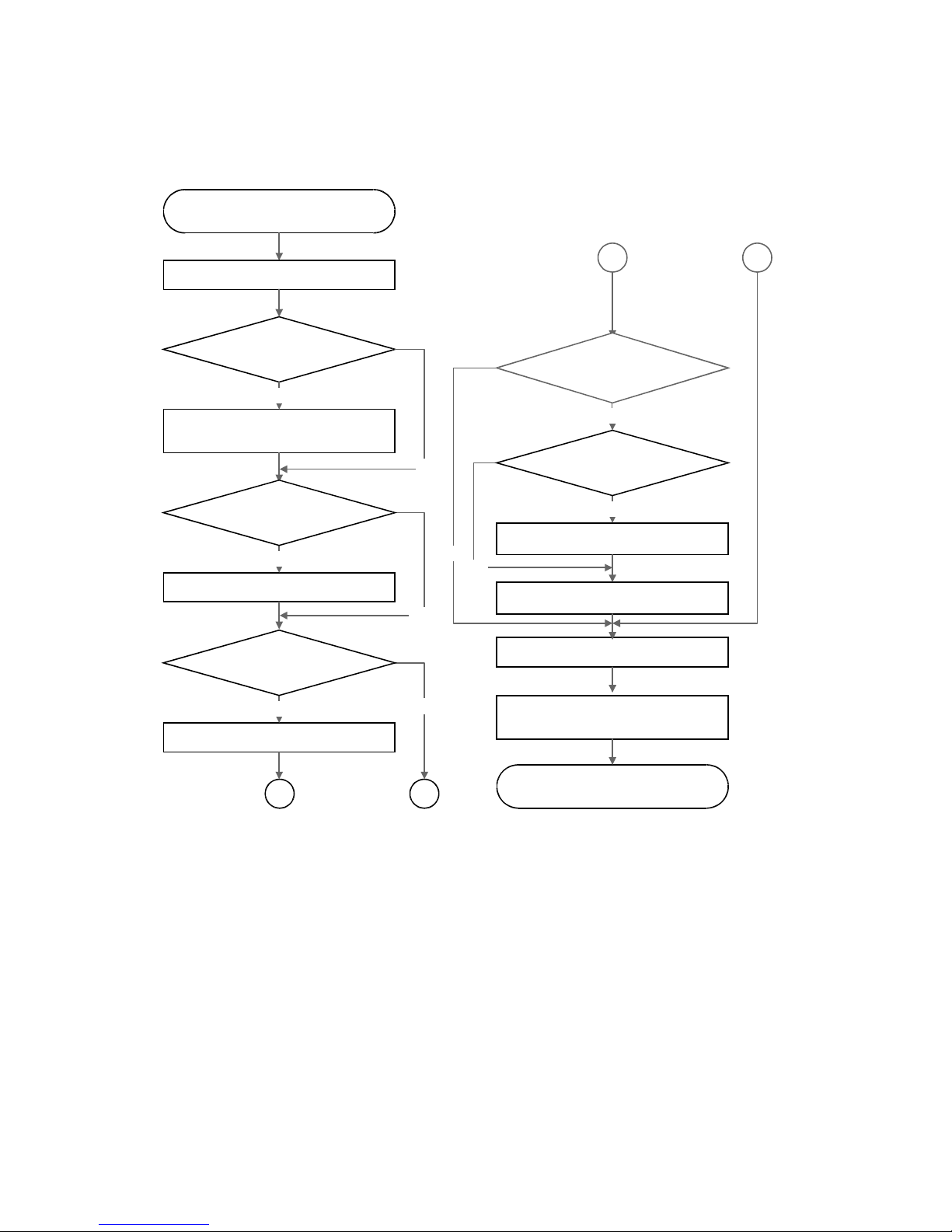

1.3.2 INSTALLATION FLOW CHART

The flow chart shows the installation procedure.

The two-tray finisher and the booklet finisher require ➀ the duplex unit and ➁ an optional paper

tray unit or the LCT. Each punch unit is dedicated to the two-tray finisher or the booklet finisher.

Start

The paper feed

unit or LCT to be installed?

Place the printer on the paper feed unit or

LCT, and install it.

Install the controller options.

Install the punch unit.

Install the printer.

Yes

Yes

No

No

Specify the settings relevant to the

contract (see section 1.3.3).

Unpack the printer.

End

A

A

No

Yes

Yes

Install the finisher.

No

The controller options to be

installed?

The two-tray finisher

or booklet finisher to be

installed?

The punch unit to be installed?

Install the duplex unit.

No

Yes

The duplex unit to be installed?

B

B

G106I904.WMF

Page 19

20 February 2004 PRINTER

1-7

Installation

1.3.3 INSTALLATION AND SETTINGS

For the installation procedure, see the Operating Instructions. After you install the

printer, make the settings that are necessary for the service contract. When you

make the settings, use caution:

1. Check the contract type carefully before you do steps 2 and 3. If you make the

wrong settings, you cannot change some settings back again.

2. You must enable Meter Charge (SP5-930-001) for any meter click counter

contract. The default is “OFF” (disabled).

3. If you set Meter Charge to “ON”, you must set Counter Methods (SP5-045)

(developments/prints) in accordance with the contract (☛ 5.3.1). If you change

the setting from “Prints” (default) to “Developments,” you cannot change the

setting back again.

The table shows the SP Mode settings related to service contracts.

Service Program Function

Meter Charge > ON/OFF

(SP5-930-001)

Enables or disables the Meter Charge. (Default: OFF

[Disabled])

When enabled:

• The Counter menu appears immediately after you push

the Menu key. The Counter Method (SP5-045) sets the

type of the counter.

• You can print the counter from the Counter menu.

• When the ACS mode is on, a monochrome page is

counted as such even if it follows a color page.

When disabled:

• The Counter menu is not displayed.

• The total counter starts from 0 (zero).

• When the ACS mode is on, a monochrome page is

counted as a color page if it follows a color page.

Meter Charge > Menu (SP5930-003)

Enables or disables the PM Alert for the PCUs, development

units, and fusing unit. (Default: Click 1 [Enabled])

When the PM Alert is enabled, a message is displayed

when one of the units needs to be replaced.

Meter Charge > Paper

Transfer (SP5-930-005)

Enables or disables the PM Alert for the transfer unit and

transfer cleaning unit. (Default: No Alert [Disabled])

Counter Method (SP5-045)

Tells the counter when to count (each development or each

print). (Default: 1 [Prints])

Double Count (SP5-104)

Specifies whether the counter increase by +1 or by +2 when

the paper size is A3 or 11" x 17". (Default: OFF [by +1])

Telephone Number Setting >

Service (SP5-812-001)

Shows or sets the telephone number of the service

representative.

Telephone Number Setting >

Fax Telephone Number

SP5-812-002

Shows or sets the fax number of the service station. The

number is printed on the counter list when the Meter Charge is

enabled. The user can send a fax message with the counter

list.

Page 20

PRINTER 20 February 2004

1-8

1.3.4 MOVING THE MACHINE

!CAUTION

Make sure that the transfer belt is in its correct position before moving the

printer, otherwise the transfer belt and the black PCU may be damaged.

NOTE: This section assumes that you manually move the machine to a different

floor in the same building. When using transportation equipment, see

section 1.3.5.

The supports on the paper feed unit or LCT make it difficult to move the machine.

You can remove them as necessary.

1. Check that the transfer belt is in the

correct position.

2. Remove the supports [A] from both

sides (! x 2 for each).

CAUTION: After moving the machine, reinstall the supports. Without them, the

machine may tip over when you draw out a paper tray or while you

work on the printer.

G106I905.WMF

[A]

Page 21

20 February 2004 PRINTER

1-9

Installation

1.3.5 TRANSPORTING THE MACHINE

Read this section when you use transportation equipment to move the machine.

When you manually move the machine to a different floor in the same building, see

section 1.3.4.

After a Machine Test

If you install the machine in your office to do a test before you send the machine to

the user, do these steps.

1. When you do your tests

• Do not use the oil supply unit that comes as an accessory with the machine.

2. When you send the machine after the tests:

• Remove the oil supply unit that you used for the tests.

If you keep the oil supply unit installed in the machine, the oil supply roller in the

fusing unit can move up and down during transportation. As a result, the oil

supply roller constantly supplies oil to all the fusing mechanism. This oil can

cause damage to the fusing mechanism, especially to the holder at the bottom of

the unit.

Transporting a Used Machine

When you move a used machine to a different location, you must discard the oil

supply unit (☛ After a Machine Test). After you install the machine at a new

location, install a new oil supply unit.

Necessary Adjustment after Transportation

After you install the machine at a new location, do the Line Adjustment (SP5-993-

002) or the Auto Adjustment (Menu > Maintenance > Color Regist. > Auto Adjust).

When you do one of these programs, make sure that the tray fences are set

correctly. If not set correctly, tray fences can make color images shift.

Page 22

PRINTER 20 February 2004

1-10

Preparing the Printer

!CAUTION

Make sure that the transfer belt is in its correct position before moving the

printer, otherwise the transfer belt and the black PCU may be damaged.

1. Check that the transfer belt is in its correct position.

2. Remove the supports (☛ 1.3.4).

3. Remove the toner bottles to prevent toner from flowing into the toner supply

tubes during transport. This may cause the tube to be clogged with toner.

4. Put air packing into the toner cartridge holders to shield the toner supply

entrances. This prevents toner from flowing out to the toner cartridge holders.

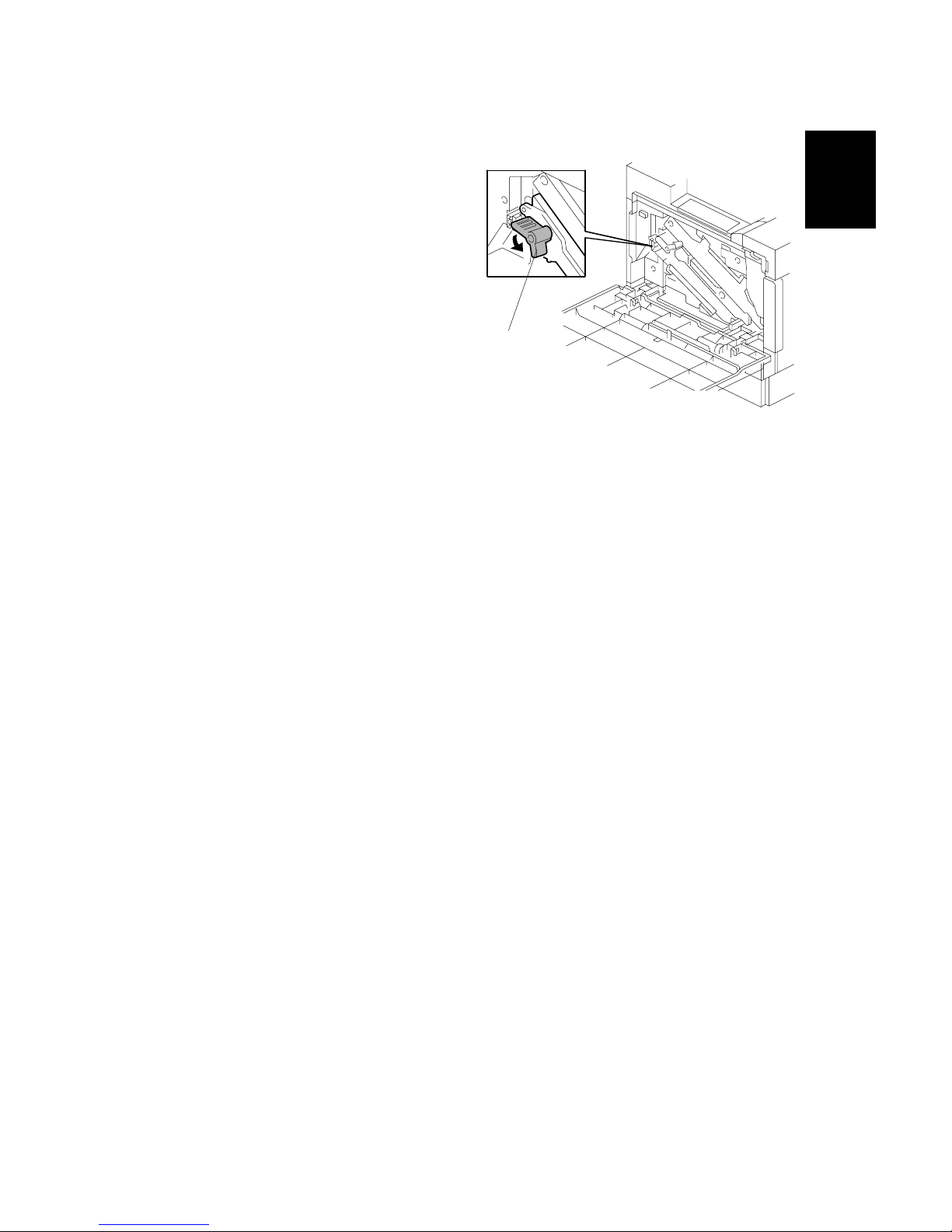

5. Set the lock pin [A] (which comes

with the machine) in the transfer

belt unit.

NOTE: The lower end of the

transfer belt moves. The

surfaces of the belt and

PCU may be damaged by

the friction between them if

you transport the machine

without locking the belt.

6. Make sure there is no paper left in the paper trays and fix down the bottom

plates with a sheet of paper and tape.

7. Empty out the waste toner bottle and attach securing tape to prevent the bottle

from coming out.

8. Empty out the waste oil bottle and attach securing tape to prevent the bottle

from coming out.

G106I906.WMF

[A]

Page 23

20 February 2004 PRINTER

1-11

Installation

9. Turn the release lever [A]

counterclockwise to its lowermost

position. (The lever does not stay in

this position if you do not hold it.)

Stick the lever in this position with

tape.

NOTE: The release lever lifts the

transfer belt up and presses

it against the black PCU.

The surfaces of the belt and

PCU may be damaged by

the friction between them if

you transport the machine

with the two units in this

position.

10. Attach shipping tape to the covers and doors, or shrink-wrap the machine

tightly.

G106I907.WMF

[A]

Page 24

OPTIONAL UNIT 20 February 2004

1-12

1.4 OPTIONAL UNIT

1.4.1 TWO-TRAY FINISHER

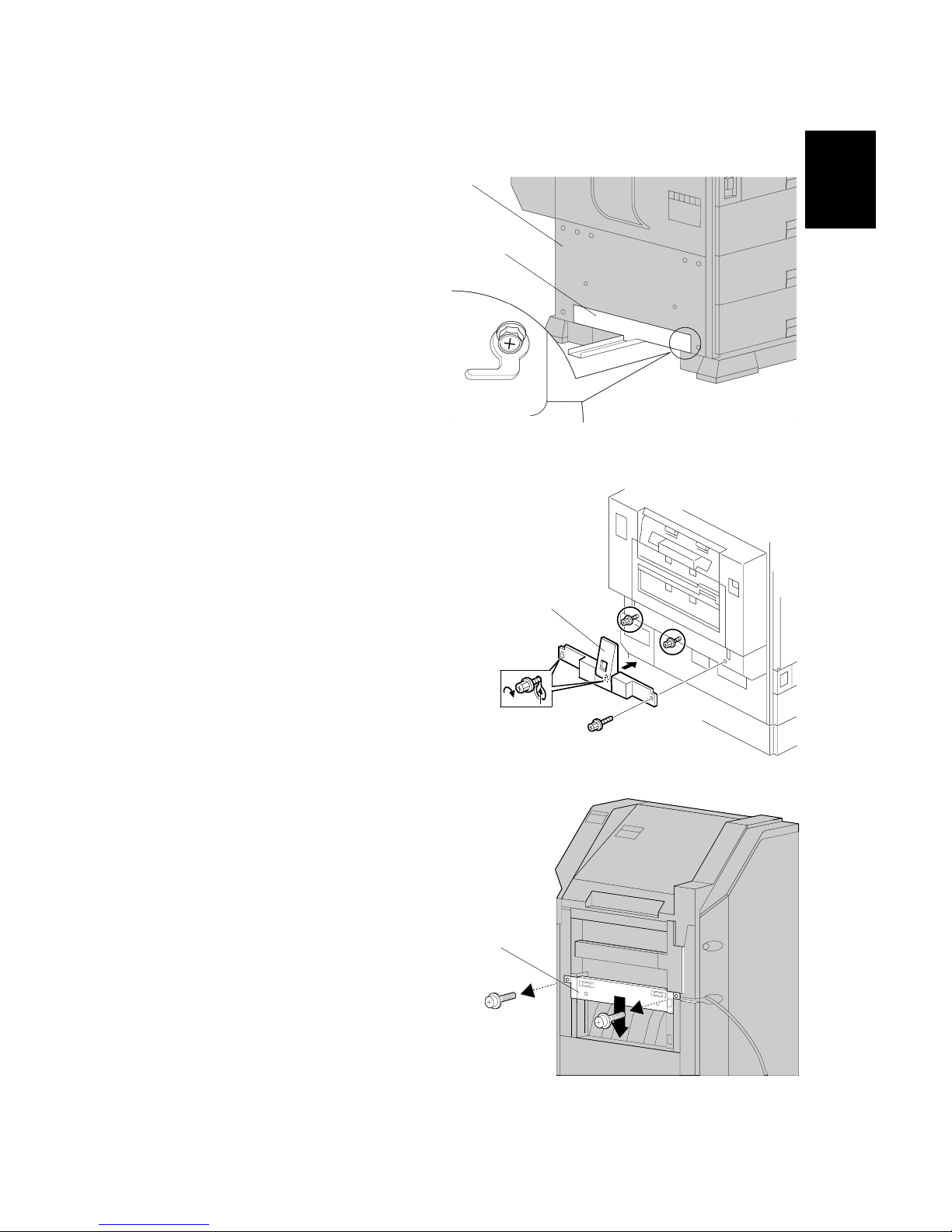

Accessory Check

Check the quantity and condition of the accessories.

Description Q’ty

1. Tray.............................................................................................2

2. Link-rail holder.............................................................................1

3. Screw M4 x 8 ..............................................................................2

4. Screw M4 x 12.............................................................................6

5. Link rail........................................................................................1

6. Duplex-unit support .....................................................................1

Installation Procedure

!CAUTION

Turn off the main switch of the printer and unplug its power cord before

starting the installation procedure.

G106I908.WMF

1

2

3

4

5

6

Page 25

20 February 2004 OPTIONAL UNIT

1-13

Installation

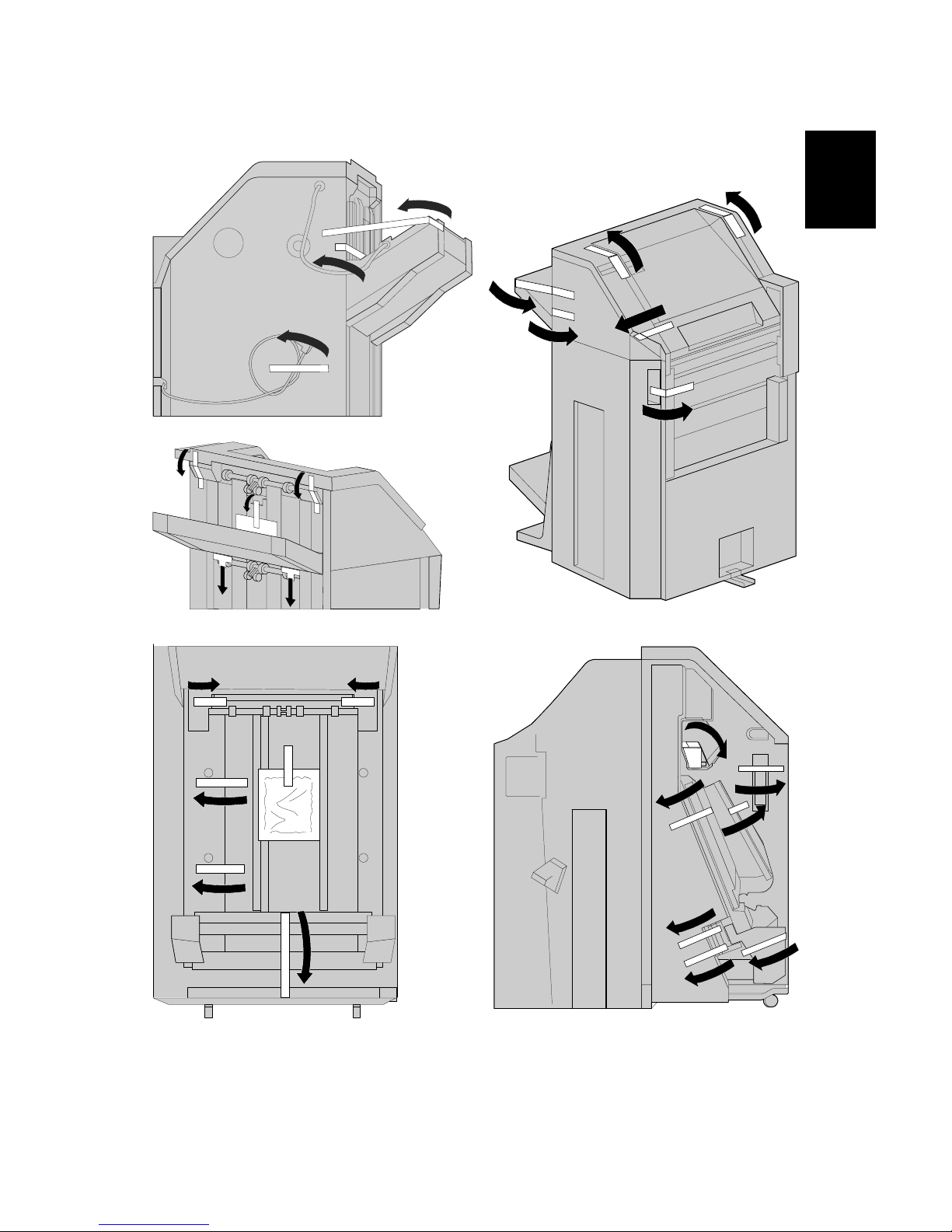

1. Remove all tape and packing materials.

G106I912.WMF

G106I909.WMF

G106I910.WMF

G106I911.WMF

G106I913.WMF

Page 26

OPTIONAL UNIT 20 February 2004

1-14

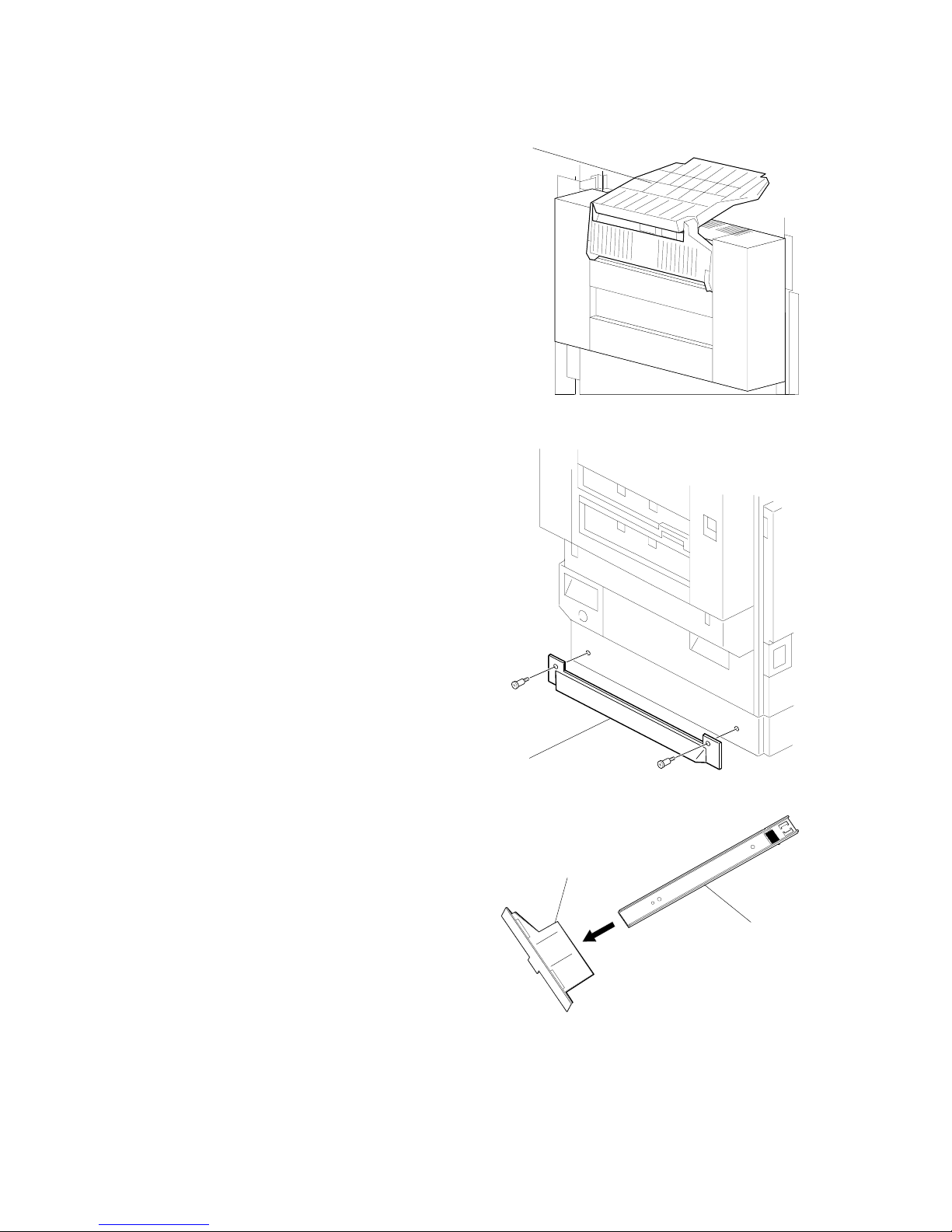

2. Fold the external tray [A].

3. Remove the support on the left side

[B] (! x 2).

4. Set the link rail [C] on the link-rail

holder [D].

G106I914.WMF

G106I916.WMF

G106I917.WMF

[A]

[C]

[D]

[B]

Page 27

20 February 2004 OPTIONAL UNIT

1-15

Installation

5. Install the link-rail holder (with

the link rail) [A] on the printer

[B] (! x 2).

6. Install the duplex-unit support [C] on

the duplex unit (! x 3).

7. Adjust the position of the connection

bracket [D] as necessary (! x 2):

• Upper position for the printer with

the two-tray paper feed unit or

LCT.

• Lower position for the printer with

the one-tray paper feed unit.

G106I918.WMF

G106I919.WMF

G106I920.WMF

[C]

[A]

[B]

[D]

Page 28

OPTIONAL UNIT 20 February 2004

1-16

8. Attach the rail [A] to the finisher [B]

(! x 1).

9. Connect the finisher [C] with the printer [D].

10. Connect the finisher cable to the connector of

the printer.

11. Install the two trays [E]

(! x 1 for each).

G106I921.WMF

G106I922.WMF

G106I923.WMF

[A]

[B]

[C]

[D]

[E]

Page 29

20 February 2004 OPTIONAL UNIT

1-17

Installation

12. Extend the external tray [A] of the

printer.

13. Turn on the main power switch

and check the operation.

G106I924.WMF

[A]

Page 30

OPTIONAL UNIT 20 February 2004

1-18

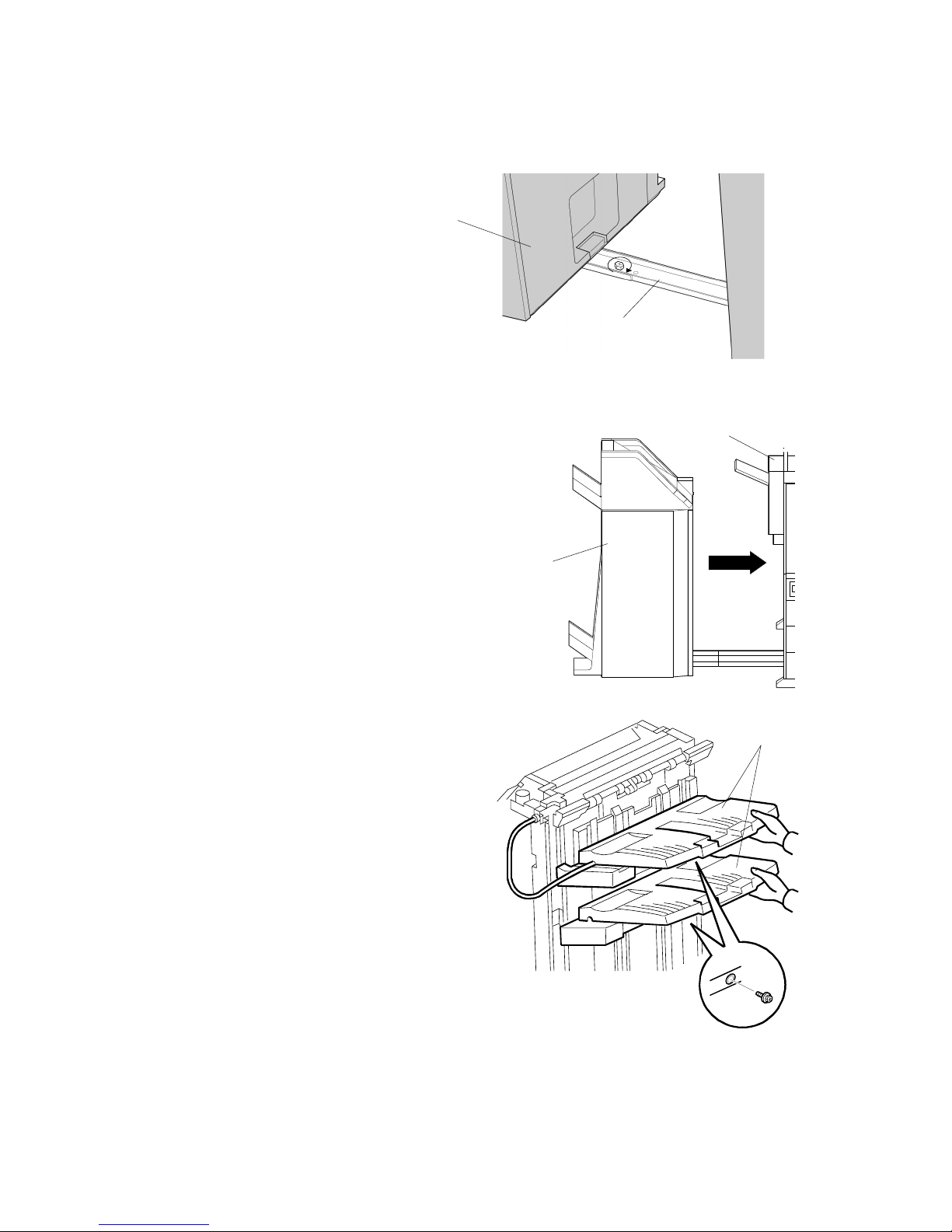

1.4.2 PUNCH UNIT

Accessory Check

Check the quantity and condition of the accessories.

Description Q’ty

1. Punch unit........................................................................... 1

2. Sensor arm ......................................................................... 1

3. Spring.................................................................................. 1

4. Screw M3 x 6 ...................................................................... 2

5. Step screw .......................................................................... 2

6. Hopper ................................................................................ 1

7. Spacer (2 mm) .................................................................... 1

8. Spacer (1 mm) .................................................................... 2

G106I925.WMF

1

2

3

4

5

6

7

8

Page 31

20 February 2004 OPTIONAL UNIT

1-19

Installation

Installation Procedure

!CAUTION

Switch off the main machine and unplug its power cord. If the two-tray

finisher has been installed, disconnect it and pull it away from the machine.

1. Unpack the punch unit and remove all tapes and shipping retainers.

2. Open the front door and remove the rear cover [A] (! x 4).

3. Remove the bracket [B] (! x 2) and paper guide [C] (stepped ! x 1).

G106I926.WMF

G106I927.WMF

[A]

[B]

[C]

Page 32

OPTIONAL UNIT 20 February 2004

1-20

4. Remove the hopper cover [A] (! x 2).

5. Install the sensor bracket [B] (stepped ! x 1).

6. Install the spring [C].

7. Install the 2 mm spacer [D].

8. Install the punch unit [E] (! x 2, stepped ! x 1).

G106I928.WMF

G106I929.WMF

[A]

[B]

[C]

[D]

[E]

Page 33

20 February 2004 OPTIONAL UNIT

1-21

Installation

9. Connect the harnesses [A] and clamp them as shown.

10. Slide in the hopper [B].

11. Fasten the two 1-mm spacers [C] to the rear frame for future adjustment.

NOTE: The spacers are used to adjust the horizontal positioning of the punch

holes.

12. Reassemble the finisher and check the punch operation.

G106I930.WMF

G106I931.WMF

[B]

[A]

[C]

Page 34

OPTIONAL UNIT 20 February 2004

1-22

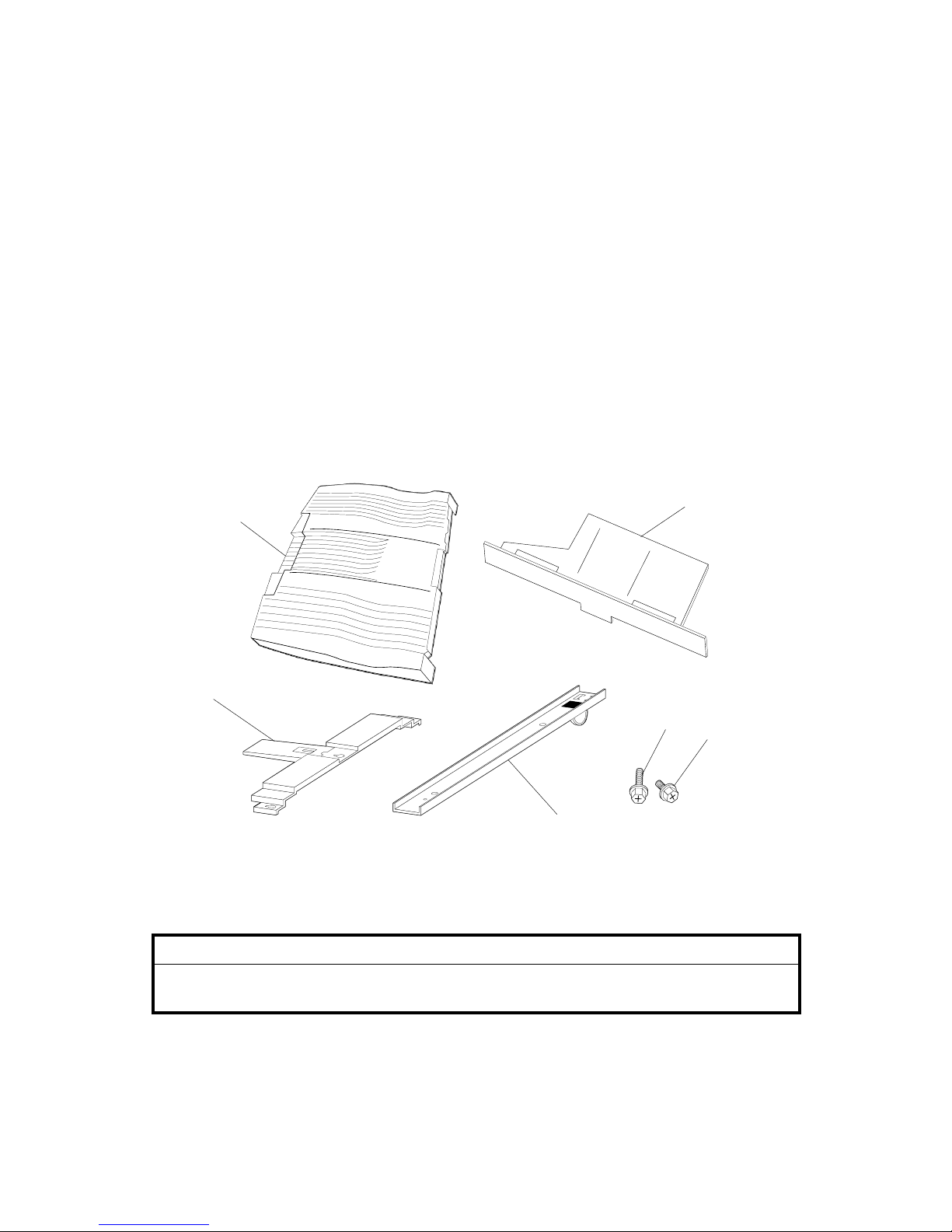

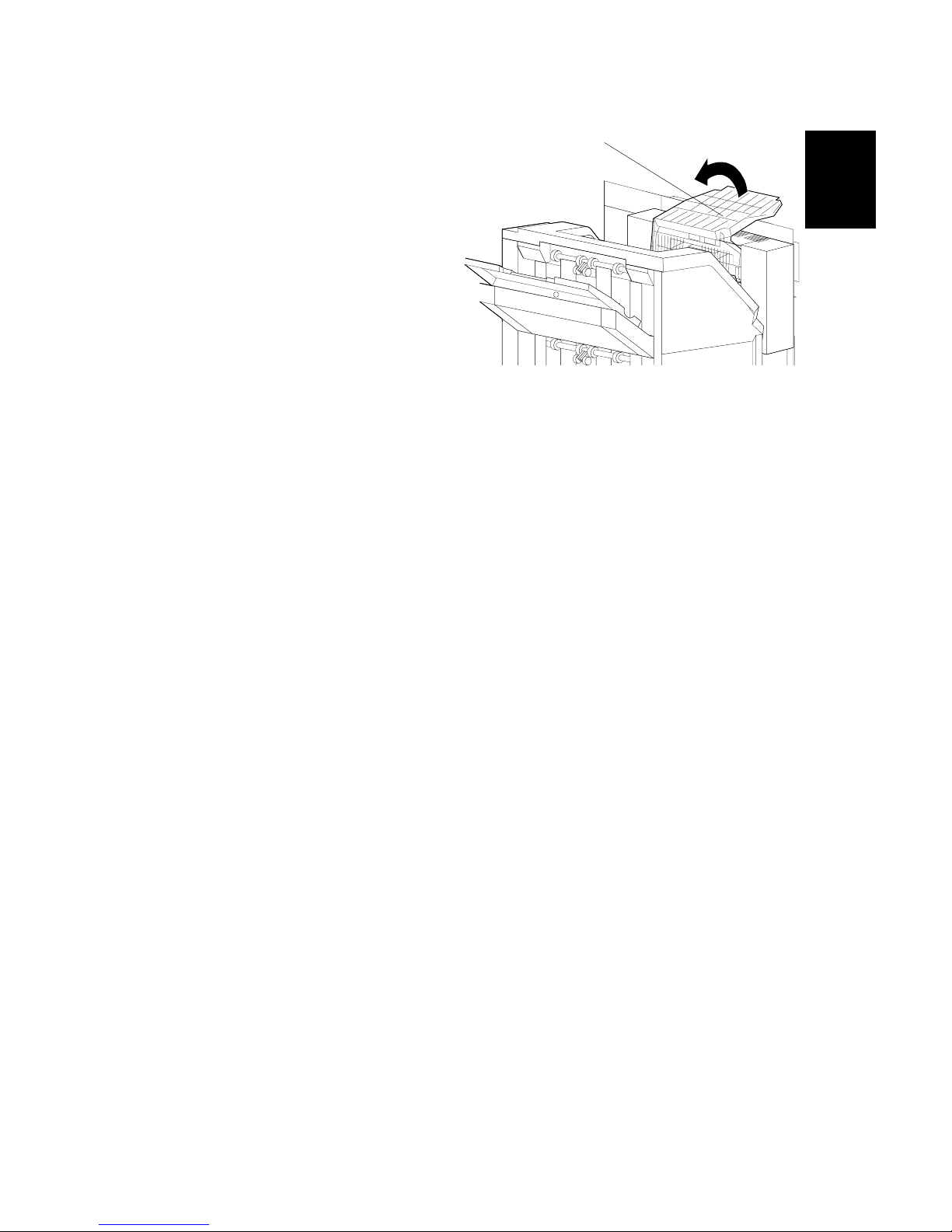

1.4.3 BOOKLET FINISHER

Accessory Check

Check the quantity and condition of the accessories.

Description Q’ty

1. Regular tray.................................................................................1

2. Rail holder................................................................................... 1

3. Magnet catch–rear ......................................................................1

4. Magnet catch–front......................................................................1

5. Duplex-unit support .....................................................................1

6. Rail joint ......................................................................................1

7. Screw M4 x 12.............................................................................6

8. Screw M4 x 6 ..............................................................................8

9. Screw M3 x 14.............................................................................4

10. Rail............................................................................................1

11. Stapler unit................................................................................ 1

12. Staple cartridge .........................................................................1

13. Pad............................................................................................3

NOTE: Make sure that you retain the pads. The pads are white and made of

Styrofoam.

G106I932.WMF

10

11

12

13

1

2

3

4

5

6

7

8

9

Page 35

20 February 2004 OPTIONAL UNIT

1-23

Installation

Adjusting the Height

1. Check the type of the optional paper tray:

• If the optional two-tray paper feed unit or the optional LCT is installed, go to

step 2.

• If either of them is not installed, go to “Main Body.”

2. Tape the pads [A] to the right-hand side of the machine.

3. Lay the machine on its right-hand side.

4. Remove the adjuster plates [B] (! x 2).

5. Change the height [C].

6. Reinstall the adjuster plates [D].

7. Take out the machine from the box and stand it up.

8. Check that the height is correct, and remove the pads.

G106I934.WMF

G106I933.WMF

[B]

[C]

[D]

[A]

Page 36

OPTIONAL UNIT 20 February 2004

1-24

Main Body

1. Remove all tape and padding.

2. Remove the screw cover [A].

3. Install the rail joint [B] (! x 4).

4. Reinstall the screw cover.

5. Install the regular tray [C] (! x 4).

G106I935.WMF

G106I936.WMF

G106I937.WMF

[C]

[B]

[A]

Page 37

20 February 2004 OPTIONAL UNIT

1-25

Installation

6. Install the magnet catches [A][B]

(! x 2 for each).

7. Install the duplex-unit support [C] (! x 3).

8. Remove the support on the left side [D] (!

x 2).

9. Set the rail [E] through the rail holder [F].

10. Install the rail holder (with the rail) to the

printer (! x 2).

G106I938.WMF

G106I939.WMF

G106I940.WMF

[A]

[B]

[C]

[E] [F]

[D]

Page 38

OPTIONAL UNIT 20 February 2004

1-26

11. Connect the booklet finisher unit to

the printer (! x 1).

12. Install the stapler unit [A].

13. Turn the knob [B] clockwise until the

staple-cartridge holder [C] reaches the

front-most position.

14. Install the staple cartridge [D] firmly to

the staple-cartridge holder.

15. Turn on the main switch and check the operation.

G106I941.WMF

G106I942.WMF

G106I943.WMF

[A]

[D]

[B]

[C]

Page 39

20 February 2004 OPTIONAL UNIT

1-27

Installation

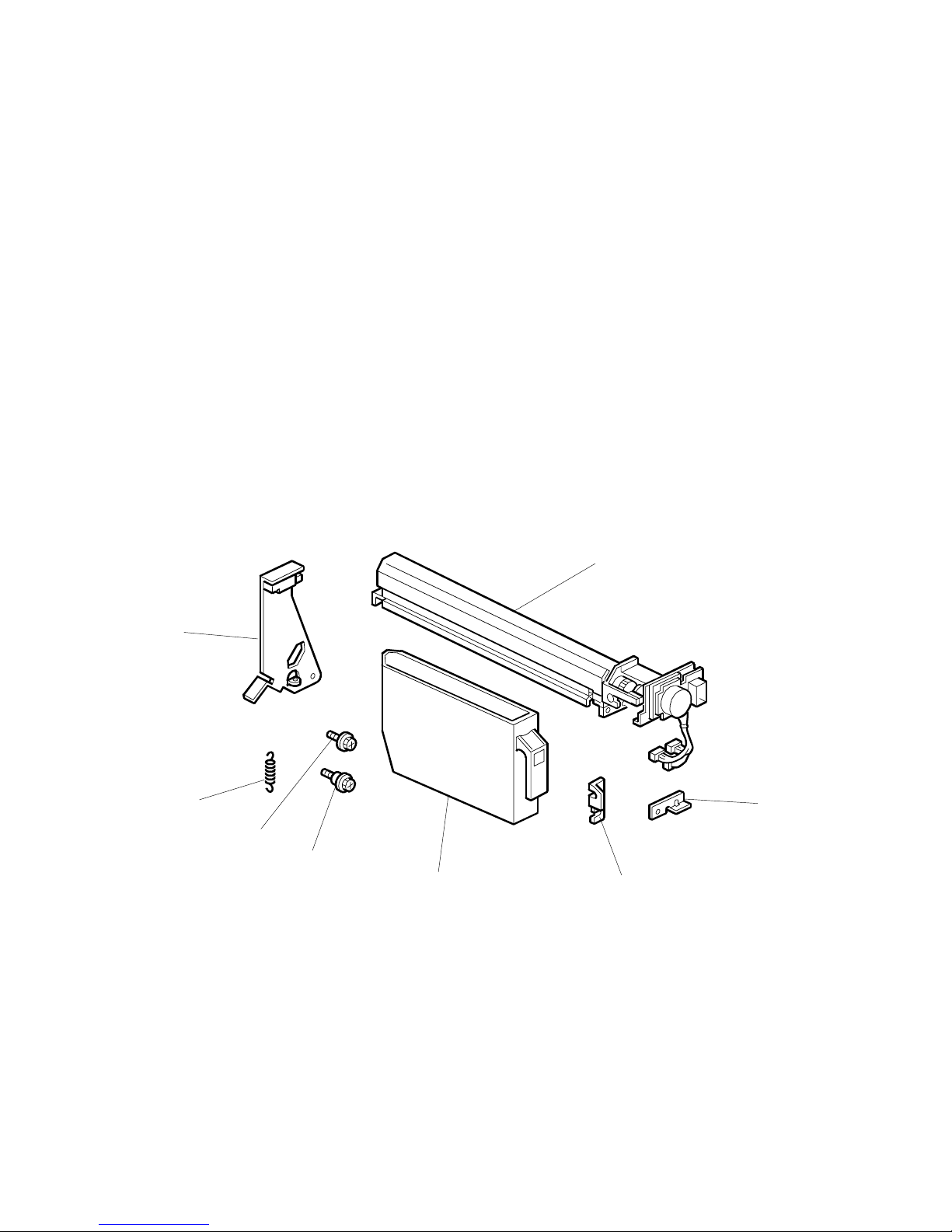

1.4.4 OPTIONAL PUNCH UNIT

Accessory Check

Check the quantity and condition of the accessories.

Description Q’ty

1. Punch unit........................................................................... 1

2. Decal................................................................................... 1

3. Screw M4 x 6 (with the base).............................................. 1

4. Cable................................................................................... 2

Installation Procedure

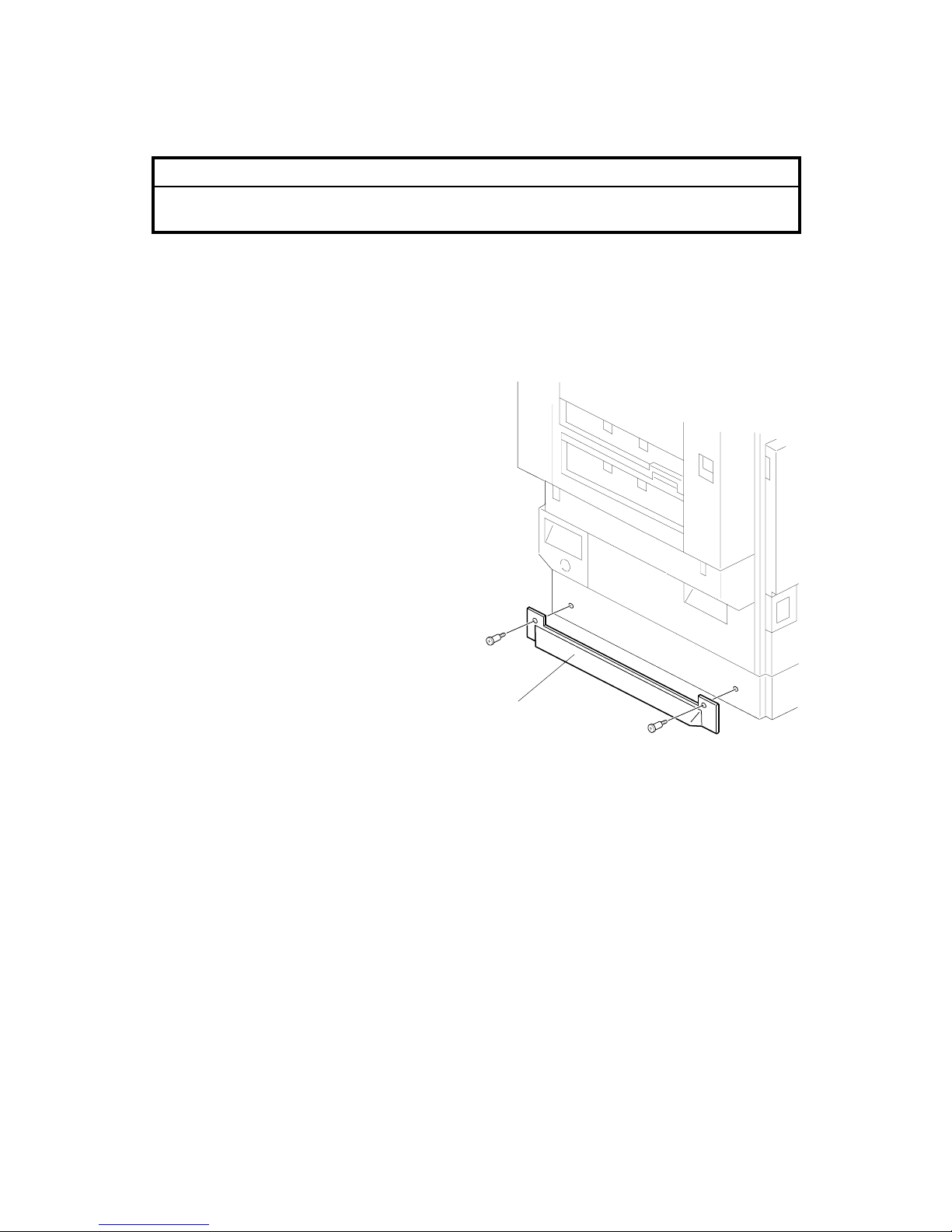

1. Remove the front lower cover

[A] (! x 2).

G106I944.WMF

G106I945.WMF

1

2

3

4

[A]

Page 40

OPTIONAL UNIT 20 February 2004

1-28

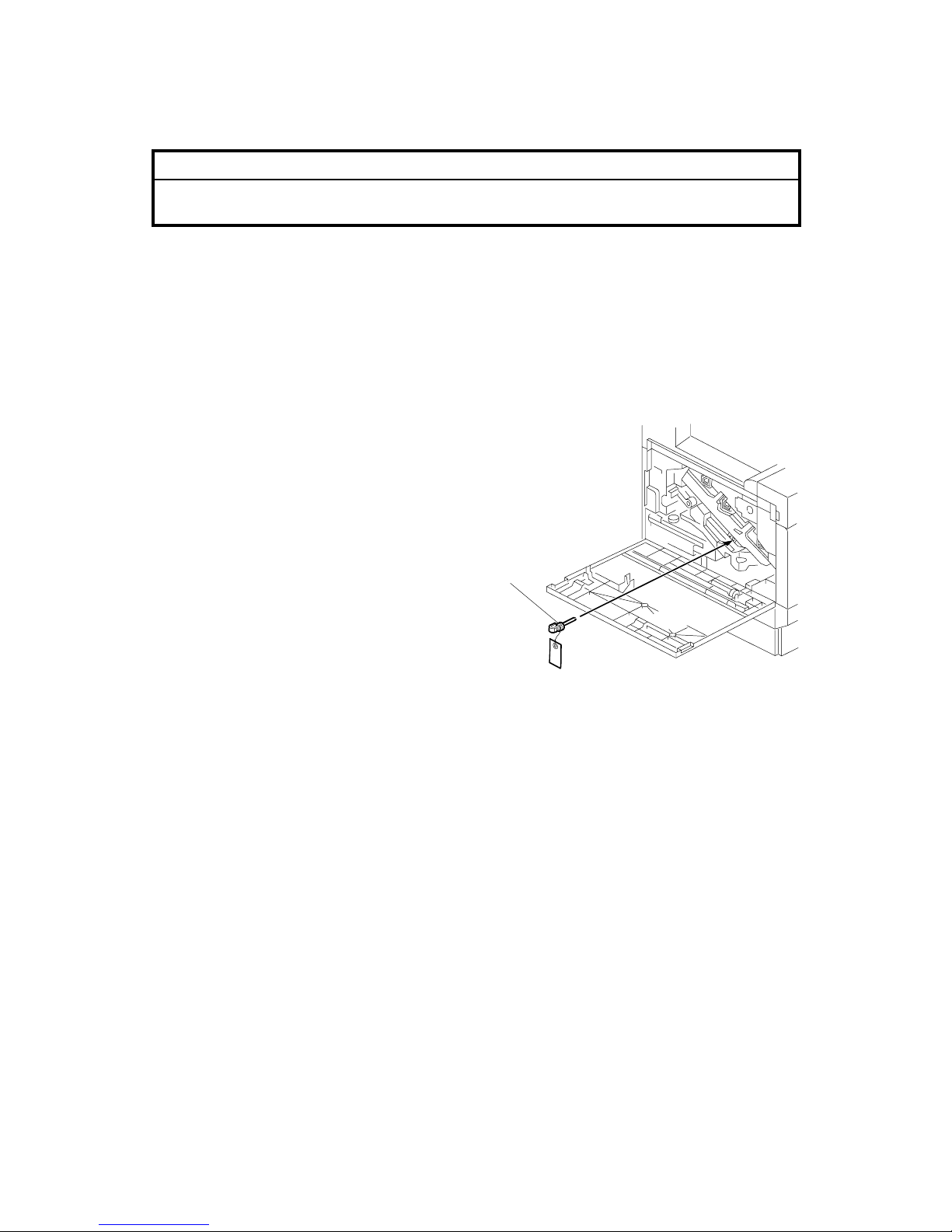

2. Remove the joint guard [A] (! x 2).

3. Open the front door [B].

4. Release the stopper and remove the knob [C].

5. Remove the front cover [D] (! x 4).

6. Remove the rear cover [E] (! x 3).

NOTE: Do not damage the Mylar when you remove the screw.

7. Remove the right top cover with the paper entrance cover [G] (! x 4).

G106I946.WMF

[A]

[D]

[E]

[G]

[C]

[B]

Page 41

20 February 2004 OPTIONAL UNIT

1-29

Installation

8. Remove the right top cover [A] from

the paper entrance cover [B].

9. Install the punch unit [C] (! x 2,

1 screw with the base [D])

10. Install the right top cover [E] (! x 2).

G106I947.WMF

G106I948.WMF

G106I949.WMF

[A]

[B]

[E]

[C]

[D]

Page 42

OPTIONAL UNIT 20 February 2004

1-30

11. Install the cable to the connectors as follows:

• J1003 (punch unit) [A] to CN12 (booklet finisher unit) [D]

• J1004 (punch unit) [B] to CN14 (booklet finisher unit) [C]

12. Fasten the cable with the clamps.

13. Reassemble the booklet finisher unit.

NOTE: Check that the side guide and the front cover correctly join with each

other [E].

14. Attach the decal [F].

15. Turn on the main switch and check the punch operation.

G106I950.WMF

G106I951.WMF

G106I952.WMF

[A]

[B]

[D]

[C]

[E]

[F]

Page 43

20 February 2004 USER MAINTENANCE

2-1

Preventive

Maintenance

2. PREVENTIVE MAINTENANCE

2.1 USER MAINTENANCE

Maintenance Kit

The table shows the maintenance kits for the user.

Kit Component Expected Yield (Prints)

A Color PCU (3 PCUs for CMY) 50k

B Color Development Unit (3 units for CMY) 100k

C Fusing Unit (without Oil Supply Unit) 100k

D Black Development Unit and Dust Filter 100k

E Waste Toner Bottle 50k

F Black PCU 50k

G Oil Supply Unit 30k

NOTE: The yield is calculated for these conditions: A4 (LT) LEF, 5% image

coverage ratio, 5 prints per job.

PM Alert Display

Model J-P3 can show a PM Alert (an error message) when a unit or component

must be replaced. The table shows the SPs related to PM Alerts.

Service Program Function

Meter Charge > Menu (SP5-930-003) Enables or disables the PM Alert for the PCUs,

development units, and fusing unit.

Alert Display > Waste Oil: Full (SP7-905-

010)

Sets the number of revolutions the development

drive motor-K can make after “Waste Oil Bottle is

Almost Full”, is shown.

Alert Display > Oil: Alert: Page (SP7-905-

014)

Sets the number of sheets the printer can output

after the fusing oil gets to the near end condition.

Model J-P3 stops operation if the user does not replace the waste toner bottle or

the oil supply unit when the machine tells the user to do this.

New Unit Detection

When the user replaces a unit or component that is a part of a maintenance kit,

Model J-P3 automatically detects the unit or component. The related counter(s)

(one or some of SP7-803-001 to 049) will be set to zero.

Page 44

USER MAINTENANCE 20 February 2004

2-2

PM Table

Symbol key: C: Clean, R: Replace, L: Lubricate, I: Inspect

Main Unit

Item 30K 50K 100K 150K EM Remarks

Black PCU R

Color (Y/M/C) PCU R

Black Development Unit R

Color (C/M/Y) Development Unit R

Fusing Unit R

Oil Supply Unit R

Waste Toner Bottle R

Dust Filter R

Circuit Breaker I At least once a month

Punch Kit

Item 10K EM Remarks

Chads I Discard chads.

Page 45

20 February 2004 SERVICE MAINTENANCE

2-3

Preventive

Maintenance

2.2 SERVICE MAINTENANCE

PM Counter Reset

Reset the related PM Counter after you replace a unit or component that is not a

part of a maintenance kit (☛ 2.1). To do this, use PM Counter Reset (SP7-804).

The table shows the service programs that you must use.

SP7-804-011 By-pass Tray Feed Roller SP7-804-015 Paper Feed Tray 4 Feed Roller

SP7-804-012 Paper Feed Tray 1 Feed Roller SP7-804-017 Transfer Unit

SP7-804-013 Paper Feed Tray 2 Feed Roller SP7-804-018 Transfer Cleaning Unit

SP7-804-014 Paper Feed Tray 3 Feed Roller

PM Table

Symbol key: C: Clean, R: Replace, L: Lubricate, I: Inspect

Main unit

Item 100K 150K 500K 1,000K 3,000K EM Remarks

Transfer Unit R

Transfer Cleaning Unit R

By-pass Feed Roller R

By-pass Pick-up Roller R

By-pass Separation Roller R

Waste Oil Bottle R

Pick-up Roller R

Feed Roller R

Separation Roller R

One-tray Paper Feed Unit (500 sheets x 1)

Item 100K 150K 500K 1,000K 3,000K EM Remarks

Relay Roller C Damp cloth

Bottom Plate Pad C Damp cloth

Pick-up Roller R

Feed Roller R

Separation Roller R

Two-tray Paper Feed Unit (500 sheets x 2)

Item 100K 150K 500K 1,000K 3,000K EM Remarks

Relay Roller C Damp cloth

Bottom Plate Pad C Damp cloth

Pick-up Roller R

Feed Roller R

Separation Roller R

Page 46

SERVICE MAINTENANCE 20 February 2004

2-4

LCT (2000 sheets)

Item 100K 150K 500K 1,000K 3,000K EM Remarks

Relay Roller C Damp cloth

Bottom Plate Pad C Damp cloth

Pick-up Roller R

Feed Roller R

Separation Roller R

Two-tray Finisher

Items 100K 150K 500K 1,000K 3,000K EM Remarks

Rollers C Damp cloth

Discharge Brush C Dry cloth

Sensors C Blower brush

Jogger Fences I Replace if required.

Page 47

20 February 2004 MODEL J-P3 AND MODEL J-P2

3-1

Replacement

Adjustment

3. REPLACEMENT AND ADJUSTMENT

!CAUTION

Turn off the main power switch and unplug the printer before removing any

part of the printer.

3.1 MODEL J-P3 AND MODEL J-P2

While reading this chapter, keep Model J-P2 Service Manual at hand. This chapter

frequently refers to Model J-P2.

Model J-P3 and Model J-P2 have common features and components. Model J-P2

Service Manual gives you the information on these features and components. This

chapter illustrates the features and components that are supported only by Model

J-P3.

Symbols in this chapter:

☛: See Model J-P3 Service Manual

☛ [P2]: See Model J-P2 Service Manual

!: Screw

": Connector

#: Clip ring

$: E ring

3.2 SPECIAL TOOLS

Part Number Part Name Q’ty

B6455010 SD Card 1

B6456700 PCMCIA Card Adapter 1

B6456800 USB Reader/Writer 1

A029 9387 Digital Multimeter–FLUKE87 1

G021 9350 Loop-back Connector–Parallel 1

C401 9503 20X Magnification Scope 1

A2579300 Grease Barrierta–S552R 1

52039501 Silicon Grease G-501 1

Page 48

LASER OPTICS 20 February 2004

3-2

3.3 LASER OPTICS

!

WARNING

Turn off the main power switch and unplug the printer before beginning

any of the procedures in this section. Laser beams can cause serious eye

injury.

3.3.1 CAUTION DECAL LOCATIONS

Caution decals are attached as shown below.

! WARNING

Be sure to turn off the main power switch and disconnect the power plug

from the power outlet before beginning any disassembly or adjustment of

the laser unit. This printer uses a class IIIb laser beam with a wavelength

of 655 nm and an output of 7 mW. The laser can cause serious eye injury.

G106R927.WMF

G106R901.WMF

G106R928.WMF

Page 49

20 February 2004 LASER OPTICS

3-3

Replacement

Adjustment

3.3.2 LASER OPTICS HOUSING UNIT

CAUTION: 1) Before installing a new laser optics housing unit, remove the sponge

padding and the tag from the new unit.

2) Do not remove the polygon mirror from its base. If you do this, the

lubricant on the shaft can leak out after you reassemble the printer.

Steps 1 through 4 refer to the

procedure for a newly supplied unit

that replaces the old one.

1. Top cover of the laser optics

housing unit [A] (! x 4)

2. Sponge padding [B]

3. Tag [C]

4. Reinstall the top cover.

5. Rear cover, upper rear cover

(☛ [P2] 3.3.1)

6. Paper exit tray (☛ [P2] 3.3.2)

7. Right cover, upper right cover

(☛ [P2] 3.3.3)

8. Operation panel

(☛ [P2] 3.3.6)

9. Black PCU cooling fan [D]

(" x 1, ! x 1)

G106R905.WMF

G106R924.WMF

[B]

[C]

[A]

[D]

Page 50

LASER OPTICS 20 February 2004

3-4

10. Securing screws for the toner

supply unit [A] (! x 4)

11. Securing screws for the laser

optics housing unit [B] (! x 2)

12. Lift the toner supply unit [C]

➀,

and

lower it ➁.

NOTE: The pins on the front side

[D] and the rear side hold

the toner supply unit.

G106R903.WMF

G106R908.WMF

[C]

[D]

[A]

[A]

[B]

Page 51

20 February 2004 LASER OPTICS

3-5

Replacement

Adjustment

13. Connector cover [A] (! x 1)

14. Four flat cables [B]

15. Connector [C]

16. Flat cable bracket [D] (! x 1)

17. Release the cable from the clamps

[E].

G106R904.WMF

G106R936.WMF

[E]

[D]

[A]

[B]

[C]

Page 52

LASER OPTICS 20 February 2004

3-6

18. Duct [A]

19. Securing screws for the laser optics housing unit [B] (! x 2)

NOTE: When reassembling, attach the ground cable [C].

20. Put a sheet of paper [D] between the laser optic housing unit and the machine

rear frame.

NOTE: This ensures that the cables are not caught by the brackets when you

lift the laser optics housing unit.

21. Hold the unit with both hands and lift it up slowly, making sure that the flat

cables from the laser diode board are not caught by the brackets.

NOTE: If you roughly remove the unit, the cables can be caught by the

brackets and the laser diode board may be damaged.

22. Do SP5-993-002 (Line Adjustment > Execute) or Auto Adjustment in the User

Tools (Maintenance > Color Regist. > Auto Adjust. > Now).

G106R906.WMF

[A]

[D]

[C]

[B]

Page 53

20 February 2004 LASER OPTICS

3-7

Replacement

Adjustment

3.3.3 POLYGON MIRROR MOTOR

1. Laser optics housing unit

(☛ 3.3.2)

2. Top cover [A] (! x 4)

3. Flat cable on the polygonmirror-motor drive-board [B]

4. Eight connectors [C] on the

four LD boards

5. Upper cover [D] (" x 9, ! x 6)

NOTE: Two of the nine

connectors are on the

opposite side of the

upper cover.

6. Air-current rectifier [E] (! x 3)

7. Polygon mirror motor [F] (! x 4)

G106R921.WMF

G106R922.WMF

G106R923.WMF

[A]

[B]

[C]

[D]

[F]

[E]

Page 54

LASER OPTICS 20 February 2004

3-8

3.3.4 POLYGON MIRROR MOTOR DRIVE BOARD

1. Laser optics housing unit

(☛ 3.3.2)

2. Polygon mirror motor drive

board [A] (! x 2, " x 1,

1 flat cable)

3.3.5 LASER SYNCHRONIZING DETECTOR BOARDS

1. Laser optics housing unit

(☛ 3.3.2)

2. Synchronizing detector boards

[A] (! x 1, " x 1)

G106R907.WMF

G106R937.WMF

[A]

[A]

Page 55

20 February 2004 PAPER FEED

3-9

Replacement

Adjustment

3.4 PAPER FEED

3.4.1 REGISTRATION SENSOR AND RELAY SENSORS

1. Right door unit (☛ [P2] 3.6.4)

2. Lift the registration guide [A]

(! x 2)

NOTE: It is not necessary to

fully lift the registration

guide. You can get

access to the screw of

the registration sensor

bracket when you lift the

guide half the distance.

3. Registration sensor bracket [B]

(! x 2)

4. Registration sensor [C]

(! x 1, " x 1)

NOTE: When you reassemble,

make sure that the

connector does not

come off.

5. Relay sensor bracket [D] (! x 1)

NOTE: Remove the registration

sensor bracket first. You

have easier access to

the relay sensor bracket.

6. Relay sensor [E] (" x 1)

G106R909.WMF

G106R938.WMF

[A]

[B]

[C]

[D]

[E]

Page 56

PAPER FEED 20 February 2004

3-10

3.4.2 BY-PASS FEED CLUTCH

1. Right door unit

(☛ [P2] 3.6.4)

2. By-pass tray cover [A]

(! x 1, 1 hook)

3. Upper guide plate [B]

(! x 4)

NOTE: It is not necessary

to remove the

connectors on the

bottom side of the

upper guide plate.

4. Support plate [C] ($ x 2)

5. Relay gear [D]

6. By-pass feed clutch [E] (" x 1)

3.4.3 PAPER FEED MOTOR

1. Rear cover (☛ [P2] 3.3.1)

2. Swing out the high voltage

supply unit. (☛ [P2] 3.10.2)

3. Sub power supply unit

(☛ 3.8.3)

NOTE: The cable of the paper

feed motor goes

behind the sub power

supply unit.

4. Paper feed motor [A] (! x 3,

" x 1)

NOTE: The connector is

CN604 on the driver

board [B].

G106R910.WMF

G106R939.WMF

[A]

[B]

[D]

[C]

[E]

[A]

[B]

Page 57

20 February 2004 TRANSFER AND PAPER TRANSPORT UNIT

3-11

Replacement

Adjustment

3.5 TRANSFER AND PAPER TRANSPORT UNIT

3.5.1 TRANSFER UNIT

NOTE: When removing or installing the transfer unit, grasp the grip on the front

frame and the center of the rear frame. Do not touch the transfer belt [A].

Do not damage the entrance Mylar [B].

1. Turn the release lever counterclockwise (☛ [P2] 3.5).

2. Pull out the transfer unit [C] until the entire unit is visible (! x 2).

3. Grasp the handle on the front frame and the center of the rear frame, and lift

the unit to remove it.

After replacing the transfer unit:

• Reset the maintenance counter, SP7-804-017

• Remove all the PCUs.

• Do the transfer belt idling with SP5-804-066 for 1 minute.

• Install the PCUs.

• Perform forced line position adjustment (SP5-993-002 or Menu > Maintenance >

Color Regist. > Auto Adjust).

• Print the 1-dot grid pattern on A3/11" x 17" paper and check the color shift level

(☛ [P2] 4.4.3).

G106R940.WMF

[A]

[C]

[B]

Page 58

TRANSFER AND PAPER TRANSPORT UNIT 20 February 2004

3-12

3.5.2 TRANSFER BELT CLEANING UNIT

CAUTION: Push the lever [A] and hold it there while you remove or install the

transfer belt cleaning unit. The blade [B] can cause damage to the

transfer belt if you do not continue to push the lever.

While pushing the lever [A], pull out

the transfer belt cleaning unit (! x 1).

Adjustment and Setting

After replacing the transfer belt

cleaning unit, reset the maintenance

counter (SP7-804-018).

After replacing the transfer belt

cleaning unit, do the forced line

position adjustment (SP5-993-002 or

Menu > Maintenance > Color Regist.

> Auto Adjust).

3.5.3 CLEANING BLADE AND CLEANING ROLLER

1. Transfer belt cleaning unit

(☛ 3.5.2)

2. Cleaning blade [A] (! x 2)

G106R941.WMF

G106R950.WMF

[A]

[A]

[B]

Page 59

20 February 2004 TRANSFER AND PAPER TRANSPORT UNIT

3-13

Replacement

Adjustment

3. 3 gears [A] ($ x 1)

4. Lever [B]

5. Gear box [C] (! x 1)

6. Cleaning brush gear [D]

($ x 1)

7. Bushing [E]

8. Cleaning brush [F]

Setting

After replacing the cleaning blade, do the forced line position adjustment (SP5-993002 or Menu > Maintenance > Color Regist. > Auto Adjust).

G106R913.WMF

G106R912.WMF

[A]

[C]

[B]

[F]

[D]

[E]

Page 60

TRANSFER AND PAPER TRANSPORT UNIT 20 February 2004

3-14

3.5.4 TRANSFER UNIT DRIVE MOTOR

1. Pull out the transfer unit

(☛ 3.5.1).

2. Transfer belt cleaning unit

(☛ 3.5.2)

3. Release lever [A] (! x 1)

4. Front cover [B] (! x 3)

5. Front plate [C] (! x 5, " x 1,

Timing belt x 1)

6. Transfer unit drive motor [D]

(! x 2, " x 1)

Reassembling

Before you attach the screw at the

left end [E], check that the timing

belt [F] is sufficiently tight. The

screw [E] adjusts the position of the

roller [G]. This roller pushes the

timing belt [H], to make sure that the

belt tightly engages with the drive

motor [I] and the drive gear [J].

G106R943.WMF

G106R944.WMF

G106R932.WMF

[A]

[B]

[C]

[D]

[E]

[G]

[H]

[I]

[J]

[F]

[E]

Page 61

20 February 2004 ID SENSORS

3-15

Replacement

Adjustment

3.6 ID SENSORS

1. Transfer unit (☛ 3.5.1).

2. Fusing unit (☛ [P2] 3.9.1)

3. Black PCU (☛ [P2] 3.5)

4. ID sensor bracket [A] (! x 2, " x 1)

Reassembling

Check that the ID sensor bracket receives the drum-positioning plate correctly.

G106R945.WMF

[A]

Page 62

FUSING 20 February 2004

3-16

3.7 FUSING