Page 1

HS2P

(Machine Code: G407/G408/G410/G411)

Service Manual

Issued on 22nd December 1998

Ricoh Co., Ltd

Page 2

IMPORTANT SAFETY NOTICES

1. Before disassembling or assembling parts of the scanner and peripherals,

make sure that the scanner power cord is unplugged.

2. The wall outlet should be near the scanner and easily accessible.

3. The output voltage of the PSU (Power Supply Unit) can be either 100 ~ 120

Vac or 220 ~ 240 Vac, without any adjustment. Make sure that the above

voltage is used.

4. The power cord should be an approved type, in accordance with the

regulations for the country in which the scanner is used.

5. The use of cables other than the shield I/O cables or equivalent specified will

invalidate the certification of this scanner and may cause interference levels

which exceed the limits established for this equipment.

Maintenance Information

The user’s manual explains how to use and maintain the scanner. Before

performing the maintenance, read the user’s manual.

Warning concerning copyright

Many documents are copyrighted. Such documents may not be reproduced by

scanning or in any other form without the express permission of the copyright

holder.

Notice

The contents of this manual are subject to change without notice.

Page 3

TABLE OF CONTENTS

1. OVERALL MACH INE INFORMATION ........................................1-1

1.1 SPECIFICATIONS..................................................................................... 1-1

1.1.1 MAIN BODY......................................................................................1-1

1.1.2 ENDORSER .....................................................................................1-2

1.2 COMPONENT LAYOUT............................................................................1-3

1.2.1 FRONT VIEW...................................................................................1-3

1.2.2 REAR VIEW......................................................................................1-4

1.2.3 ADF ..................................................................................................1-5

1.3 DRIVE LAYOUT........................................................................................1-6

1.3.1 SCANNER........................................................................................1-6

1.3.2 ADF ..................................................................................................1-7

1.4 ELECTRICAL COMPONENT LAYOUT.....................................................1-8

1.4.1 SCANNER........................................................................................1-8

1.4.2 ADF ..................................................................................................1-9

2. DETAILED SECTION DESCRIPTIONS.......................................2-1

2.1 INITIALIZATION........................................................................................2-1

2.2 SCANNER MECHANISMS........................................................................2-3

2.2.1 BOOK MODE....................................................................................2-3

2.2.2 ADF MODE.......................................................................................2-7

2.3 PAPER MISFEED DETECTION..............................................................2-14

2.4 IMAGE PROCESSING............................................................................2-16

2.4.1 OVERVIEW ....................................................................................2-16

2.4.2 SBU................................................................................................2-17

2.4.3 IPU (IMAGE PROCESSING UNIT).................................................2-18

2.5 REVERSE SIDE SCANNING..................................................................2-21

2.5.1 OVERVIEW ....................................................................................2-21

2.5.2 CIS (CONTACT IMAGE SENSOR) UNIT.......................................2-22

2.5.3 IMAGE SCANNING........................................................................2-23

2.6 ENDORSER UNIT...................................................................................2-24

2.6.1 OVERVIEW ....................................................................................2-24

2.6.2 ENDORSER UNIT..........................................................................2-25

2.7 LOW POWER MODE..............................................................................2-26

2.8 MAIN PCBs AND THEIR FUNCTIONS ...................................................2-27

2.8.1 BOARD STRUCTURE....................................................................2-27

2.8.2 SCU (SCANNER CONTROL UNIT) ...............................................2-28

2.8.3 IOB (INPUT/OUTPUT BOARD)...................................................... 2-29

2.8.4 ADU (ADF DRIVE UNIT) ................................................................2-30

i

Page 4

3. INSTALLA TION...........................................................................3-1

3.1 ENVIRONMENT........................................................................................3-1

3.1.1 PRECAUTIONS................................................................................3-1

3.1.2 ENVIRONMENTAL CONDITIONS ...................................................3-1

3.1.3 MACHINE LEVEL.............................................................................3-1

3.1.4 MINIMUM SPACE REQUIREMENTS...............................................3-1

3.1.5 POWER REQUIREMENTS ..............................................................3-2

3.2 SCANNER INSTALLATION.......................................................................3-2

3.3 IPU UNIT INSTALLATION.........................................................................3-2

3.4 ENDORSER UNIT INSTALLATION...........................................................3-3

3.4.1 ACCESSORY CHECK......................................................................3-3

3.4.2 INSTALLATION PROCEDURE ........................................................3-4

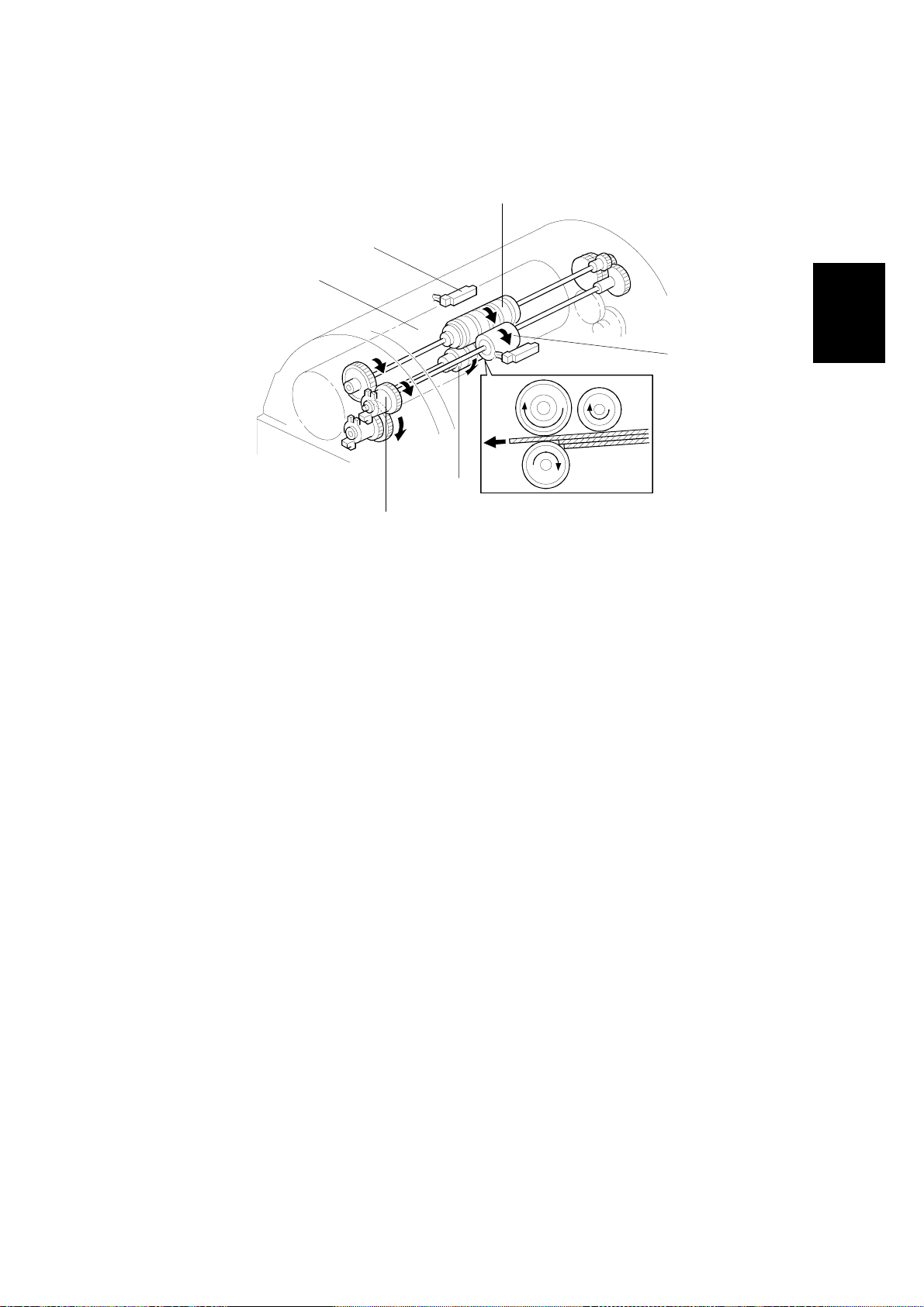

3.4.3 STAMP DENSITY ADJUSTMENT PROCEDURE............................3-6

3.5 RED LAMP UNIT INSTALLATION.............................................................3-7

3.5.1 ACCESSORY CHECK......................................................................3-7

3.5.2 INSTALLATION PROCEDURE ........................................................3-8

4. SERVICE LEVEL FUNCTIONS...................................................4-1

4.1 DIP SWITCH SETTINGS...........................................................................4-1

4.2 LEDs/TEST POINTS.................................................................................4-6

4.2.1 LEDs.................................................................................................4-6

4.2.2 TEST POINTS..................................................................................4-6

4.3 SPECIAL TOOLS ......................................................................................4-6

5. REPLACEMENT AND ADJUSTMENT........................................5-1

5.1 COVERS ...................................................................................................5-1

5.1.1 ADF EXTERIOR...............................................................................5-1

5.1.2 ADF COVER.....................................................................................5-2

5.1.3 SCANNER EXTERIOR/OPERATION PANEL..................................5-3

5.2 ADF AND UPPER SIDE............................................................................5-4

5.2.1 DOCUMENT SENSOR.....................................................................5-4

5.2.2 SEPARATION UNIT.........................................................................5-4

5.2.3 DOCUMENT TABLE ASSEMBLY ....................................................5-5

5.2.4 CIS....................................................................................................5-5

5.2.5 SCANNING GUIDE PLATE..............................................................5-6

5.2.6 FEED SENSOR................................................................................5-6

5.2.7 READ SENSOR................................................................................5-7

5.2.8 FEED-OUT SENSOR.......................................................................5-7

5.2.9 PAPER TRANSPORT DRUM...........................................................5-8

5.3 ADF AND RIGHT SIDE .............................................................................5-9

5.3.1 PAPER FEED MOTOR.....................................................................5-9

5.3.2 EDU..................................................................................................5-9

5.3.3 ENDORSER SOLENOID................................................................5-10

5.3.4 RELAY SENSOR............................................................................5-10

5.4 ADF AND LEFT SIDE..............................................................................5-11

5.4.1 ADU/PAPER TRANSPORT MOTOR..............................................5-11

ii

Page 5

5.4.2 DOCUMENT TABLE POSITION SENSOR.....................................5-11

5.4.3 PICK-UP CLUTCH/DOCUMENT TABLE LIFT CLUTCH................5-12

5.5 SCANNER...............................................................................................5-13

5.5.1 EXPOSURE GLASS.......................................................................5-13

5.5.2 EXPOSURE LAMP.........................................................................5-14

5.5.3 SBU/LAMP STABILIZER/SCANNER MOTOR/PSU.......................5-15

5.5.4 IOB .................................................................................................5-16

5.5.5 SOP................................................................................................5-17

5.5.6 HOME POSITION SENSOR...........................................................5-17

5.5.7 ADF INTERLOCK SWITCH............................................................5-18

5.5.8 SCANNER WIRE............................................................................5-19

5.6 PCB.........................................................................................................5-22

5.6.1 SCU/RCU/IPU ................................................................................5-22

6. TROUBLESHOOTIN G.................................................................6-1

6.1 SELF-DIAGNOSTICS................................................................................6-1

6.2 CHECK ITEMS..........................................................................................6-1

6.2.1 ITEMS CHECKED DURING INITIALIZATION..................................6-1

6.3 ERROR INDICATION................................................................................6-2

6.3.1 USER LEVEL ERROR INDICATION................................................6-2

6.3.2 TECHNICIAN LEVEL ERROR INDICATION....................................6-2

6.4 TROUBLESHOOTING PROCEDURES....................................................6-3

6.4.1 USER-VISIBLE ERROR CONDITIONS............................................6-3

6.4.2 SERVICE CALL ERRORS (SYSTEM ERRORS) .............................6-8

6.5 INDICATION WHEN A CONNECTOR IS OUT OF POSITION................6-14

6.5.1 SCANNER......................................................................................6-14

6.5.2 ADF ................................................................................................6-15

6.6 BLOWN FUSE CODITIONS....................................................................6-16

7. OPTION.......................................................................................7-1

7.1 IPU (IMAGE PROCESSING UNIT)............................................................7-1

7.1.1 OVERVIEW ......................................................................................7-1

7.2 IMAGE PROCESSING PATH....................................................................7-2

iii

Page 6

22 December 1998 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

1.1.1 MAIN BODY

Scanning method: Flat-bed with ADF

Book scan: Horizontal: Max. 298 mm [11.7"]

Vertical: Max. 432 mm [17.0"]

ADF: Document size:

Width: 69 ~ 298 mm [2.7" ~ 11.7"]

Length: 120 ~ 2,000 mm [4.7" ~ 78.5"]

All pages in a document must be the

same width

Document weight: 41 ~ 128 g/m2 [11 ~ 34 lb.]

ADF capacity:

150 sheets (64 g/m2 [20 lb.])

110 sheets (105 g/m2 [24 lb.]/A4, A5, LT, HLT)

80 sheets (105 g/m2 [24 lb.]/A3, DLT)

Stack height must be less than 15 mm [0.6"]

Scanning resolution: Simplex mode:

Main scan: 100 ~ 800 dpi (in 1 dpi steps)

Sub scan: 100 ~ 800 dpi (in 1 dpi steps)

Duplex mode:

Main scan: 100 ~ 600 dpi (in 100 dpi steps)

Sub scan: 100 ~ 600 dpi (in 100 dpi steps)

Overall

Information

Grayscales: 8 bits/pixel

Initialization time: About 15 seconds

Scanning speed: 0.65 s/200 dpi (A4, binary picture mode)

Scanning throughput: Simplex mode: 55 ppm/200 dpi

(A4, binary picture mode)

Duplex mode: 86 ipm/200 dpi

(A4, binary picture mode)

(Counted from the second page)

Interface: SCSI-2

Power: 1) 102 to 138 V ac (45 to 65 Hz)

2) 187 to 276 V ac (45 to 65 Hz)

Power consumption

(without all possible options):

Simplex model Standby: 50 W Max.

Scanning: 90 W Max.

Low power mode: 12 W Max.

Duplex model Standby: 80 W Max.

Scanning: 120 W Max.

Low power mode: 12 W Max.

1-1

Page 7

SPECIFICATIONS 22 December 1998

Operating environment:

Temperature: 10 to 32°C [50 to 90°F]

Humidity: 20 to 80% RH

Weight: Simplex Model: Less than 25 kg [55.1 lb.]

Duplex Model: Less than 26 kg [57.3 lb.]

(Add 1 kg [2.2 lb.] when the Endorser is installed.)

Dimensions (W x D x H): 470 x 677 x 278 mm [18.5" x 26.7" x 10.9"]

1.1.2 ENDORSER

Number of printable characters: 19 characters (max)

Character set: 43 characters

0123456789#./-:,’AB ····Z

Character size: 1.6 (W) x 2.8 (H) mm

Character pitch:

Printable lines: 1 line (main scan direction)

Inking: Ink roll type

2.4 mm ± 20%

Ink refill: Ink roll exchange

Ink color: Purple

Print position:

a: 7 ± 4 mm

b: 0 ± 5 mm

Document Feed Direction

Document

front side

a

1-2

b

G411V506.WMF

Page 8

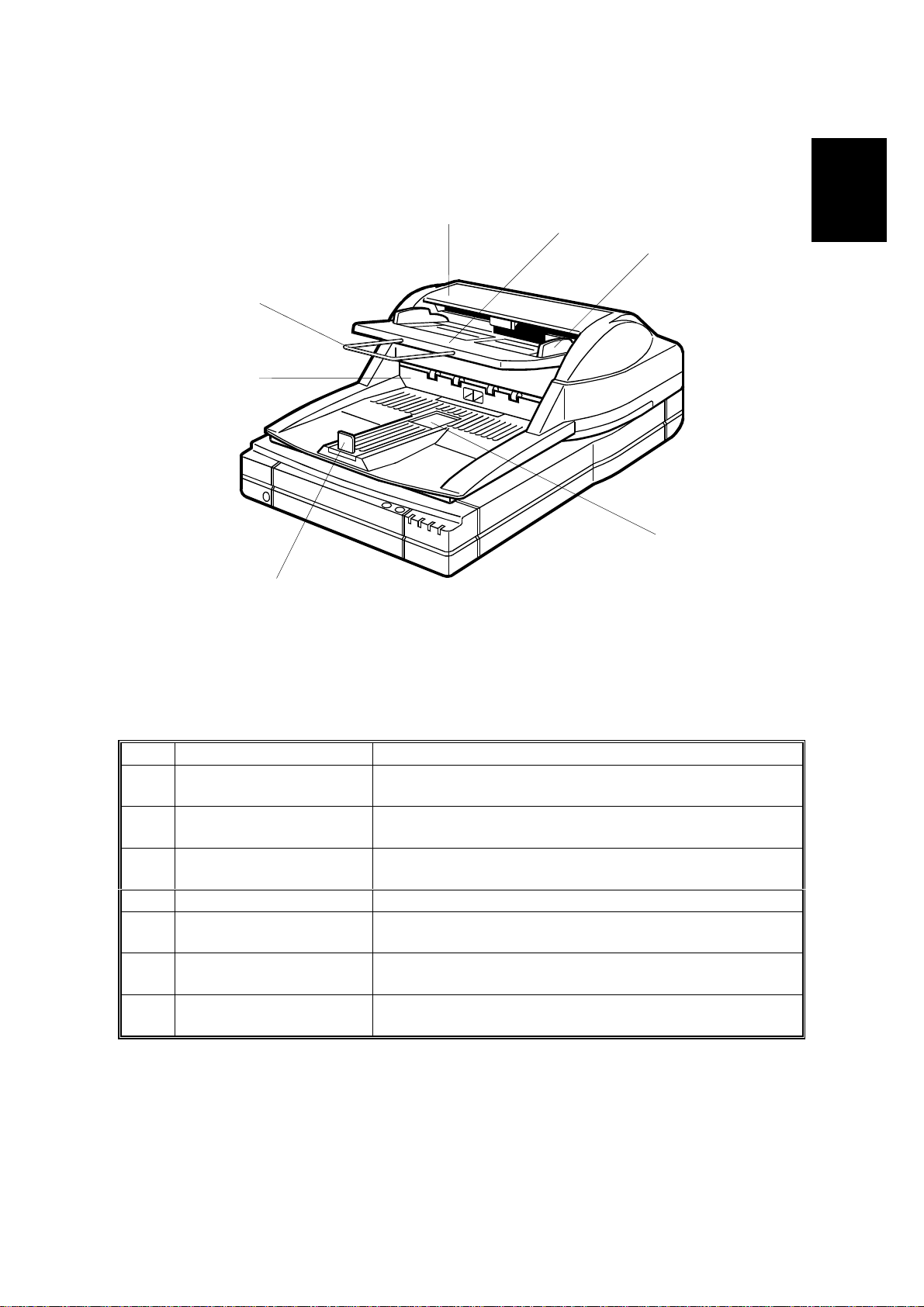

22 December 1998 COMPONENT LAYOUT

1.2 COMPONENT LAYOUT

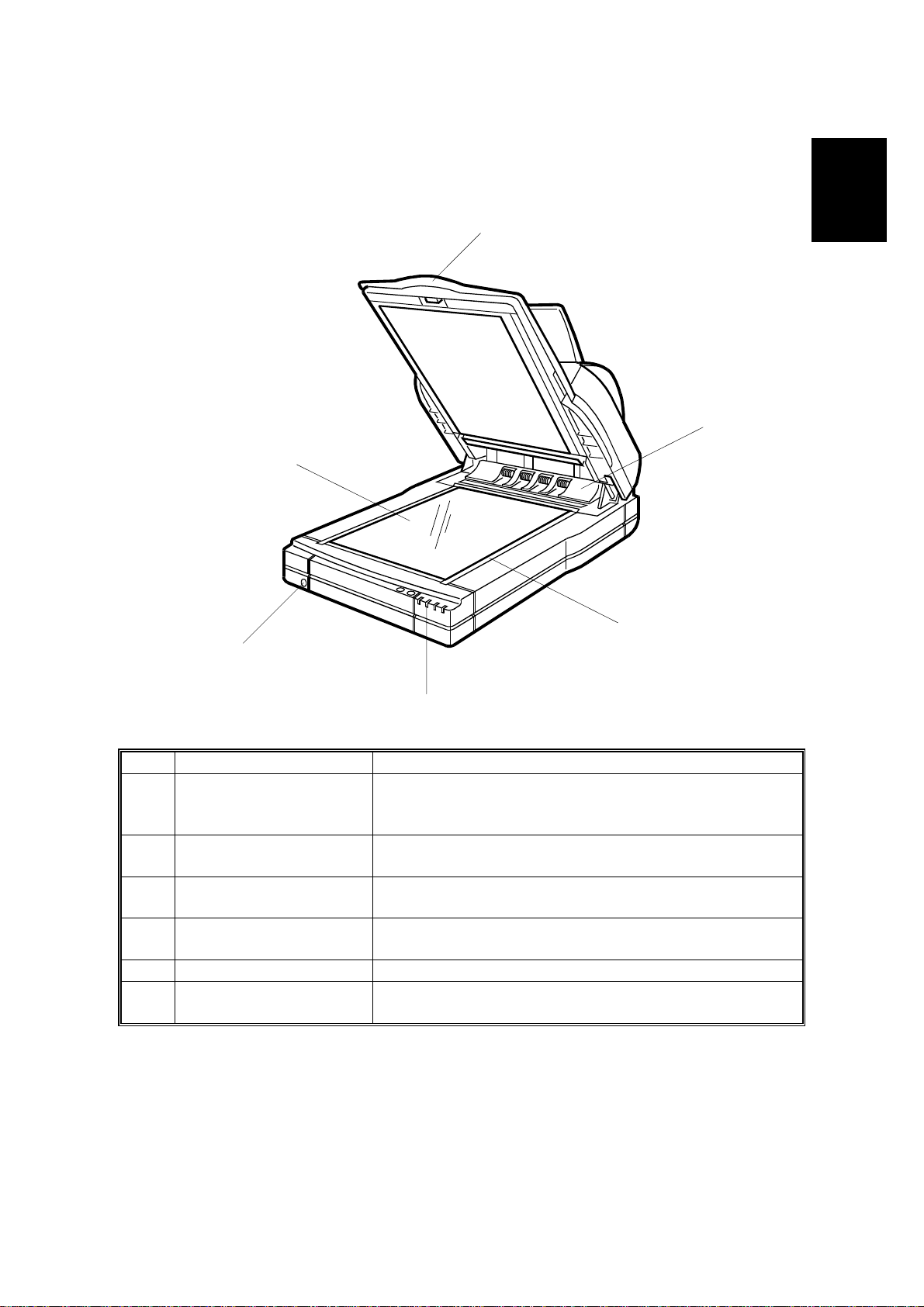

1.2.1 FRONT VIEW

1

2

6

Overall

Information

3

5

4

No. Name Function

Platen cover

1

ADF exposure cover

2

Scale Used for positioning a document when placing it on the

3

Scanner indicator lamps T he green and red lights indicate the condition of the

4

5 Power switch Turns the power on and off.

Main exposure glass A document to be scanned in book mode is placed face

6

Covers the document and serves as a neutral

background for documents placed on the main

exposure glass.

Covers the scanner and closes the ADF exposure

cover interlock switch. Also contains an exposure glass.

exposure glass.

scanner.

down on this glass.

G411V500.WMF

1-3

Page 9

COMPONENT LAYOUT 22 December 1998

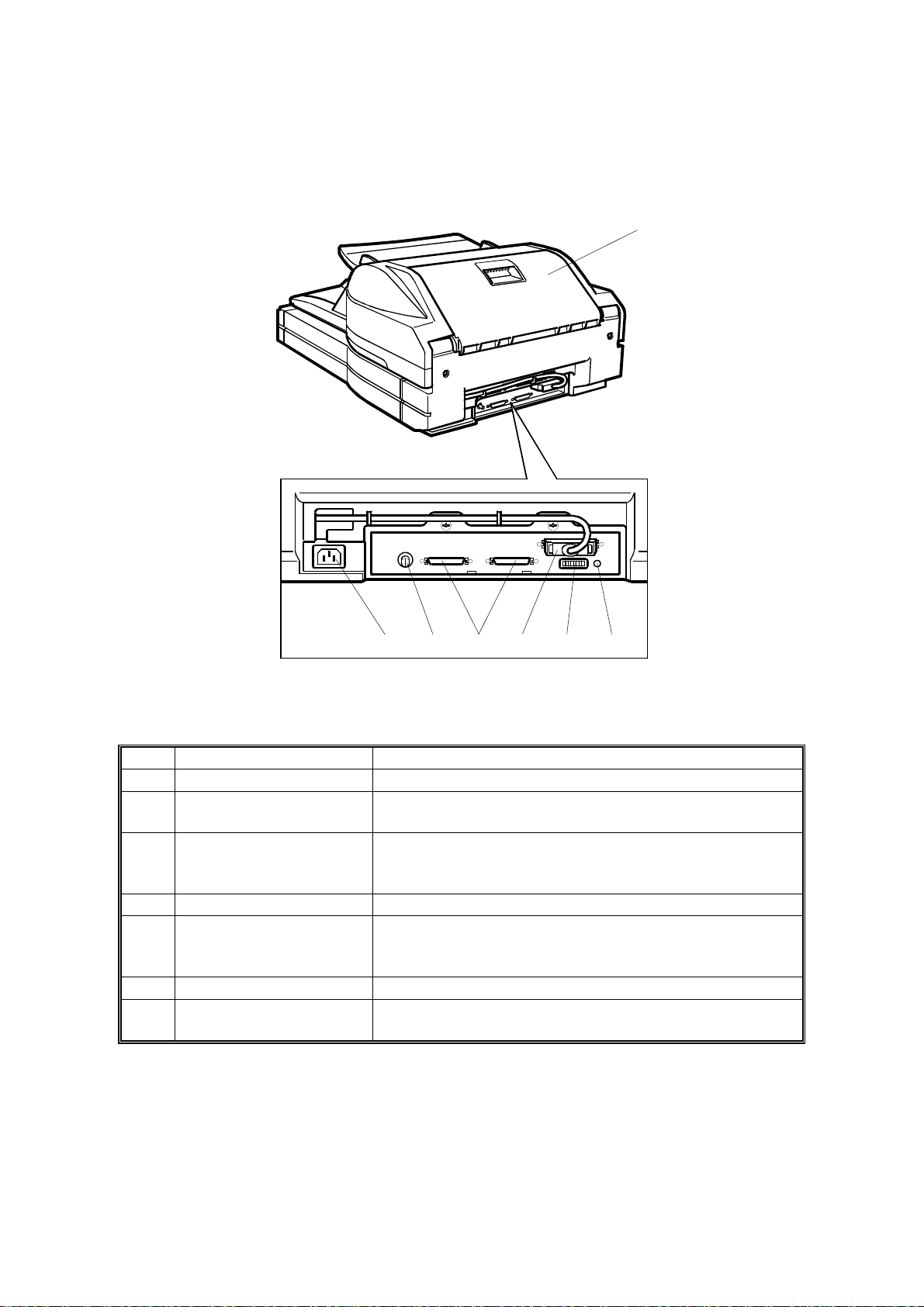

1.2.2 RE AR VIEW

13

101112 789

G411V501.WMF

No. Name Function

7 Reset switch If this is pressed, the machine is reset.

DIP switches

8

Interface for reverse side

9

scanning

(Duplex model only)

10 SCSI connectors For connecting the SCSI cables.

SCSI ID rotary switch

11

12 Power plug inlet For connecting the power cord.

ADF cover Open this cover to clear paper jammed at the input

13

Used to select various scanning modes and test

modes.

Interface for the video signal during reverse side

scanning.

Used to select the SCSI ID and to select diagnostic

tests. Note that positions 8 and 9 are interpreted as

SCSI ID 7.

side.

1-4

Page 10

22 December 1998 COMPONENT LAYOUT

1.2.3 ADF

20

19

18

14

15

G411V502.WMF

Overall

Information

16

17

No. Name Function

ADF Autom atically f eeds multi-page documents into the

14

Document table

15

Document guides Used to properly align the documents placed in the

16

17 Exit table Receives documents fed by the ADF after scanning.

Exit table extension This holds the documents output from the ADF; it can

18

Endorser cover

19

Document support wire If long documents are placed in the input tray, this helps

20

scanner.

Documents to be scanned using the ADF are placed

here.

input tray.

be extended to support long documents.

Open this cover to clean the endorser or replace the

ink.

to feed them correctly.

1-5

Page 11

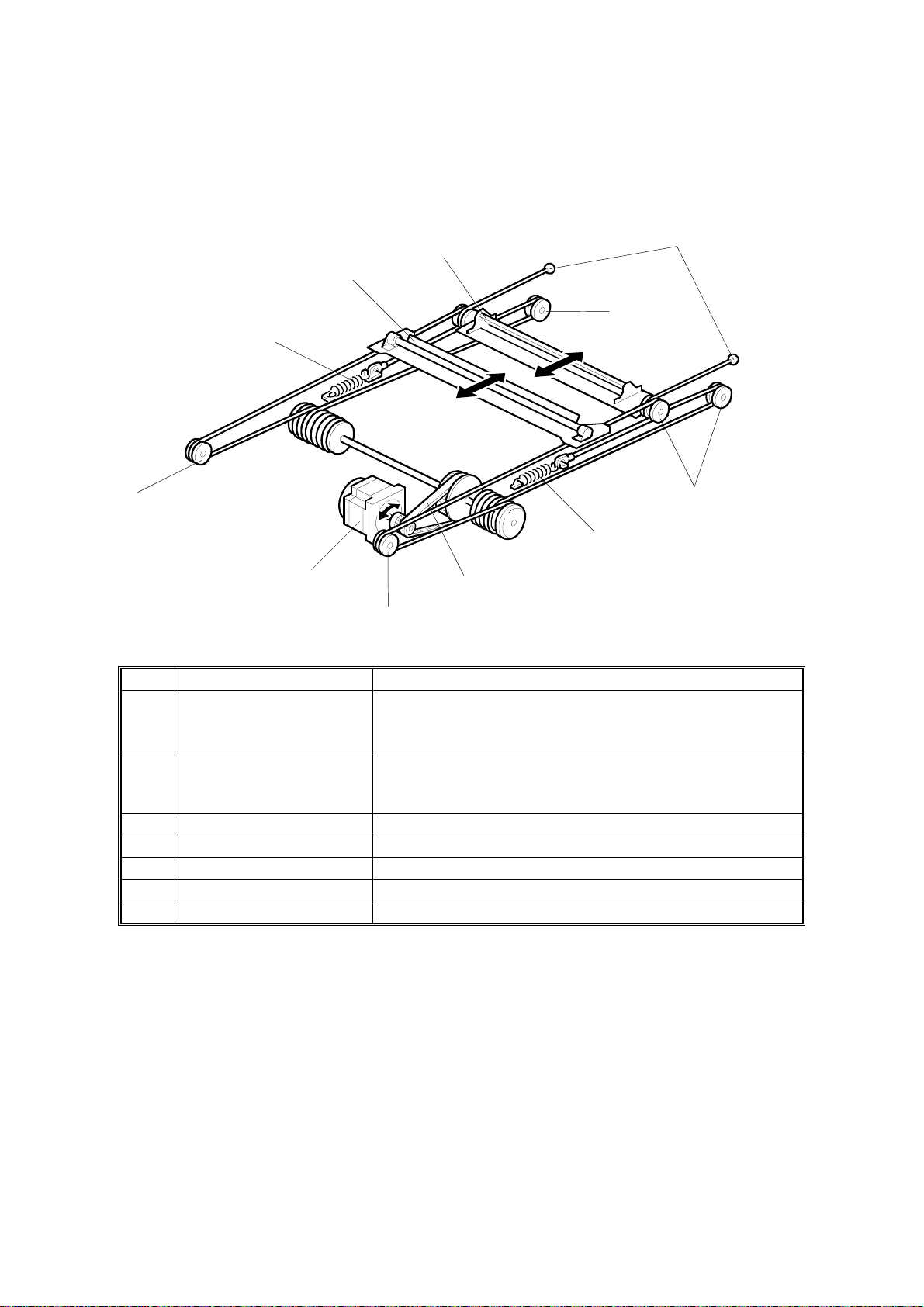

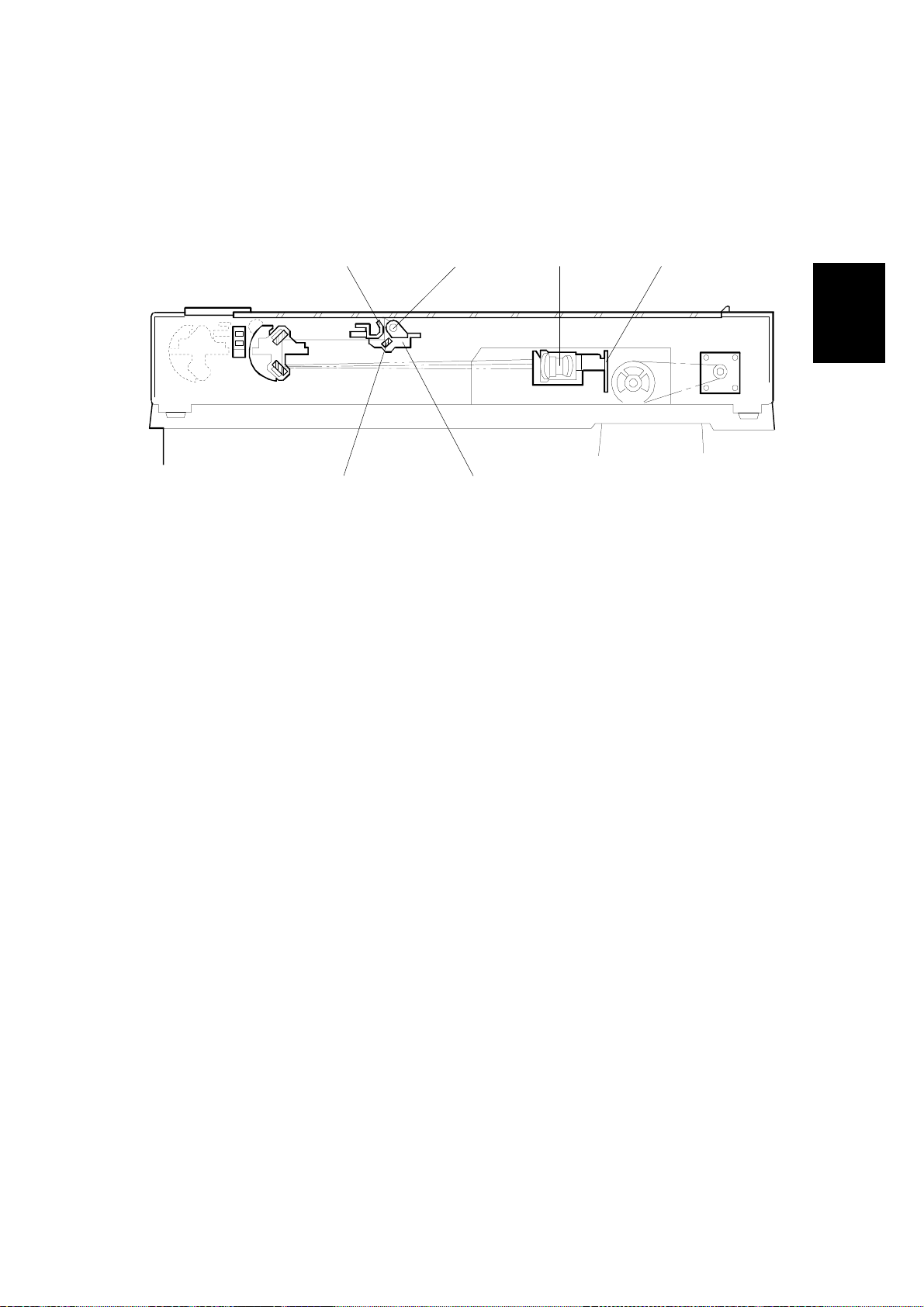

DRIVE LAYOUT 22 December 1998

1.3 DRIVE LAYOUT

1.3.1 SCANNER

2

3

1

7

4

7

7

4

6

5

7

No. Name Function

First scanner Moves the exposure lamp along the document and

1

Second scanner

2

3 Scanner drive wires Transmit motor power to the 1st and 2nd scanners.

4 Wire springs Tighten the scanner drive wires.

5 Motor belt Transmits motor power to the scanner drive wires.

6 Scanner motor Drives the scanners.

7 Pulleys Hold the scanner drive wires.

sends the light reflected from the document to the 2nd

scanner by means of a mirror.

Moves to keep the distance between the exposure lamp

and the CCD constant, and sends light reflected from

the 1st scanner to the CCD.

G411V503.WMF

1-6

Page 12

22 December 1998 DRIVE LAYOUT

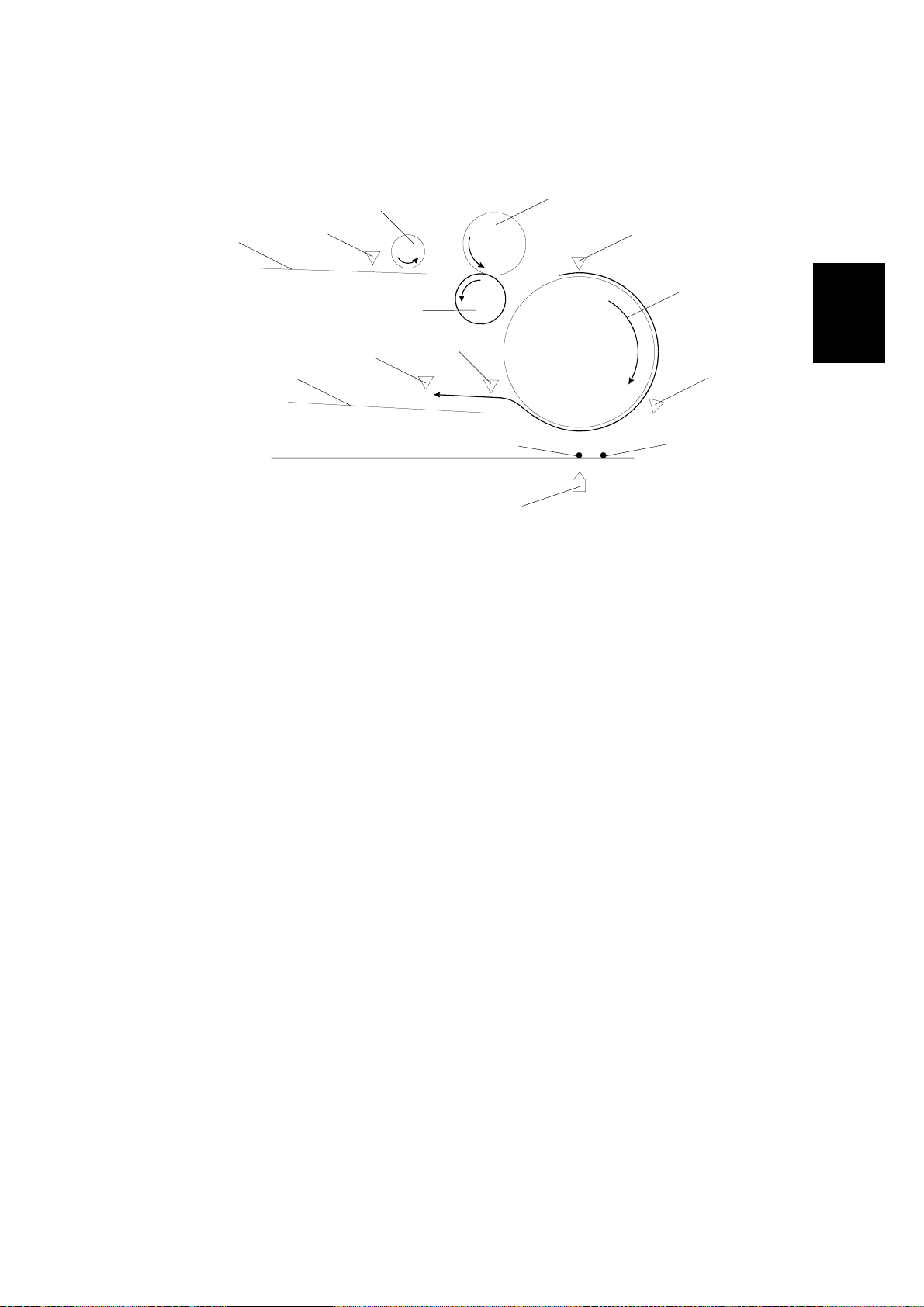

1.3.2 ADF

13

14

8

9

Overall

Information

10

11

12

G411V507.WMF

No. Name Function

8 Feed roller Feeds the top page of the original into the ADF.

Pick-up roller

9

Separation roller Stops the lower pages of the original while allowing the

10

White roller

11

(Duplex model only)

12 Feed-out rollers Feed the scanned original onto the exit table.

13 Paper transport drum Transports the original to the scanning position.

14 Paper transport rollers Hold the original against the paper transport drum.

Picks up and transports the top page of the original on

the document table.

top one to pass.

Allows the machine to correct for variations in the white

level of the CIS.

1-7

Page 13

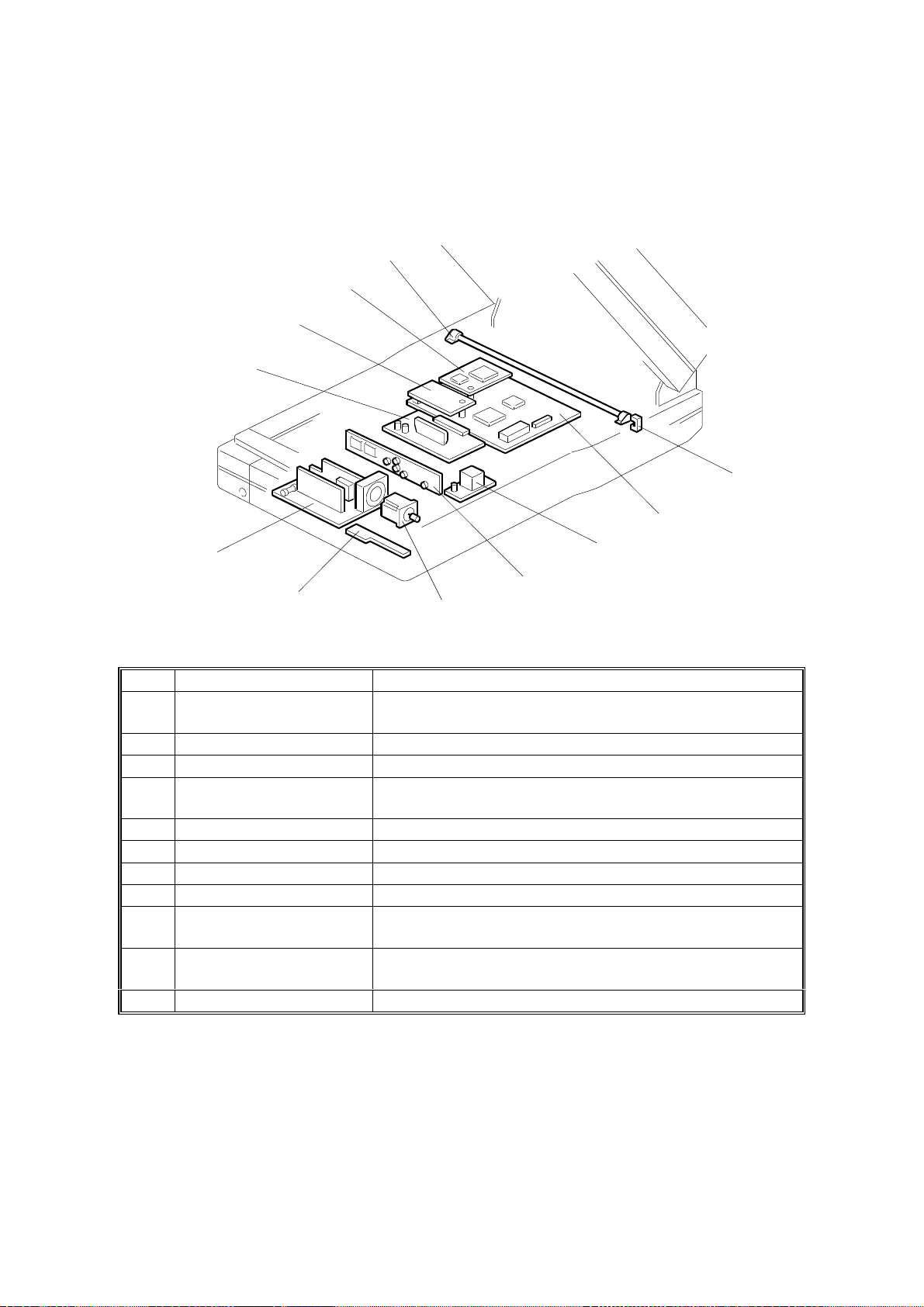

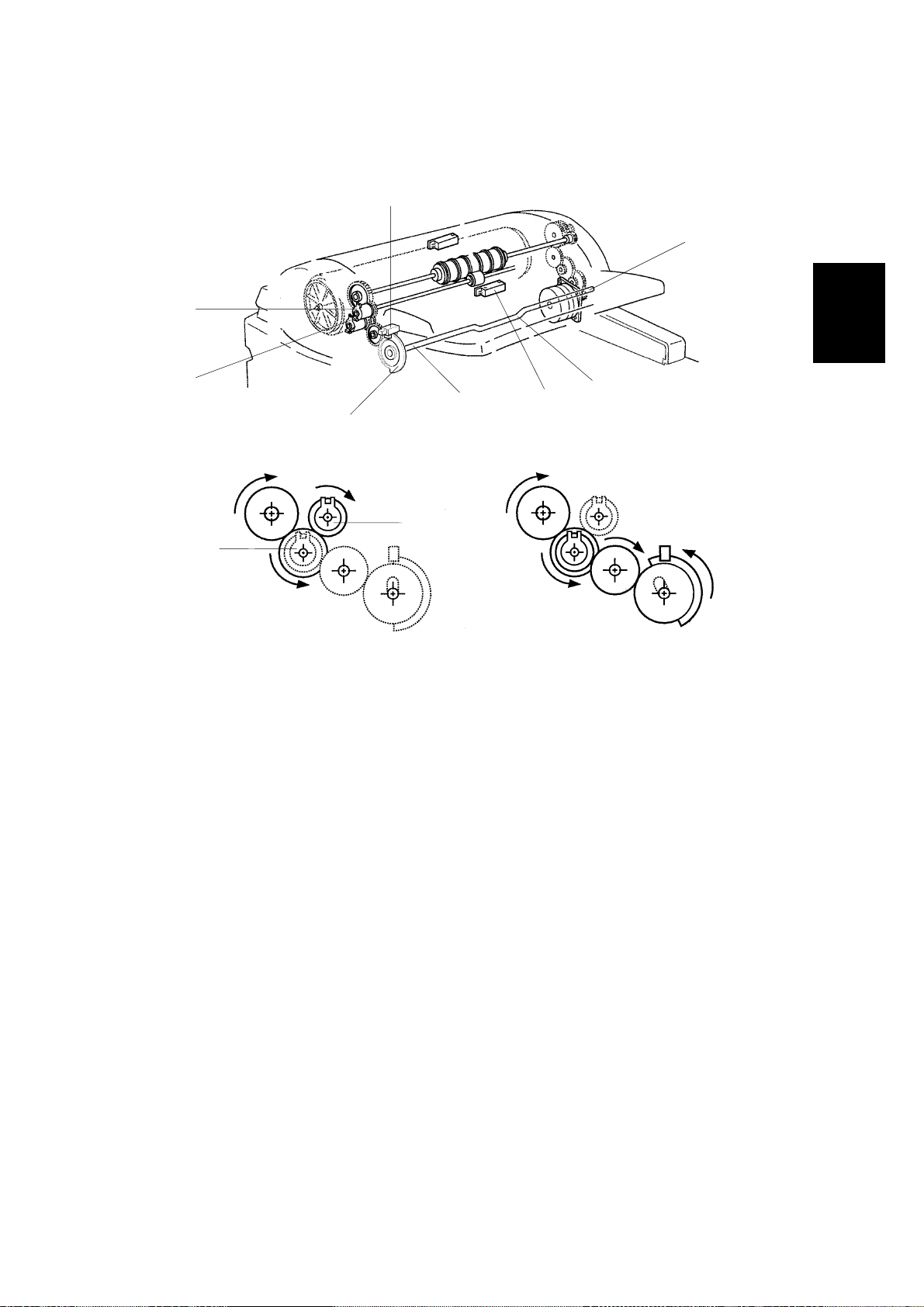

ELECTRICAL COMPONENT LAYOUT 22 December 1998

1.4 ELECTRICAL COMPONENT LAYOUT

1.4.1 SCANNER

11

10

9

8

1

2

7

3

4

6

5

No. Name Function

Home position sensor

1

2 SCU Controls the overall scanner function.

3 Lamp Stabilizer Provides ac power to the exposure lamp.

SBU Cont ains t he CCD, and outputs a video signal to the

4

5 Scanner Motor Drives the scanners.

6 SOP This contains the scanner indicator lamps.

7 PSU Provides dc voltages to the system.

8 IOB Controls the mechanical parts of the scanner.

IPU Board (Option) Performs automatic text/image separation, dynamic

9

RCU

10

(Duplex Model only)

11 Exposure lamp Illuminates the original for exposure.

Detects whether the first scanner is at the home

position.

SCU.

threshold, section area, and document size detection.

Outputs a video signal of the reverse side of the original

to the SCU.

G411V504.WMF

1-8

Page 14

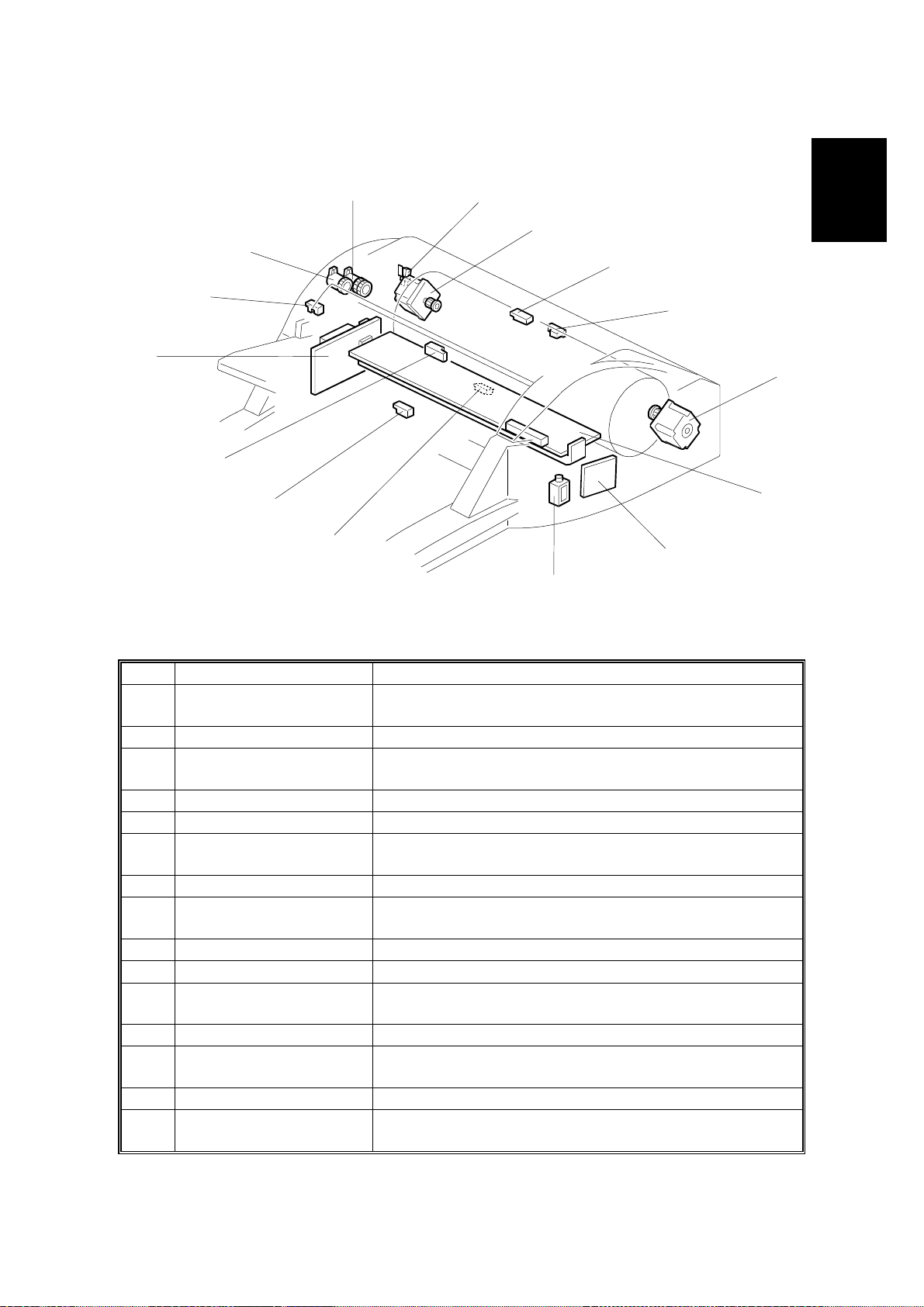

22 December 1998 ELECTRICAL COMPONENT LAYOUT

1.4.2 ADF

23

24

22

25

21

20

26

12

13

19

Overall

Information

14

15

16

17

18

G411V505.WMF

No. Name Function

ADF interlock switch

12

13 Paper transport motor Drives the paper transport drum.

Feed sensor

14

15 Read sensor Synchronizes the original exposure timing.

16 Paper feed motor This drives the pick-up and feed rollers.

CIS (Duplex model only) Contains t he CCDs and LEDs that scan the reverse

17

18 EDU (Option) Controls the mechanical parts of the endorser.

Endorser solenoid

19

(Option)

20 Relay sensor Checks for original misfeeds.

21 Feed-out sensor Detects when a document is at the feed-out position.

Document sensor Detects when a document is placed on the document

22

23 ADU Controls the mechanical parts of the ADF.

Document table position

24

sensor

25 Pick-up clutch Controls pick-up roller rotation.

Document table lift

26

clutch

Detects whether the ADF cover and platen cover are

open or closed; cuts the power supply to the machine.

Detects when a document is just before the feeding

position.

side of the original.

Moves the paper holding plate to hold the original at the

endorser’s printing position.

table.

Detects if the document table is at the feed position or

not.

Switches on to lift the document table up or down.

1-9

Page 15

22 December 1998 INITIALIZATION

2. DETAILED SECTION DESCRIPTIONS

2.1 INITIALIZATION

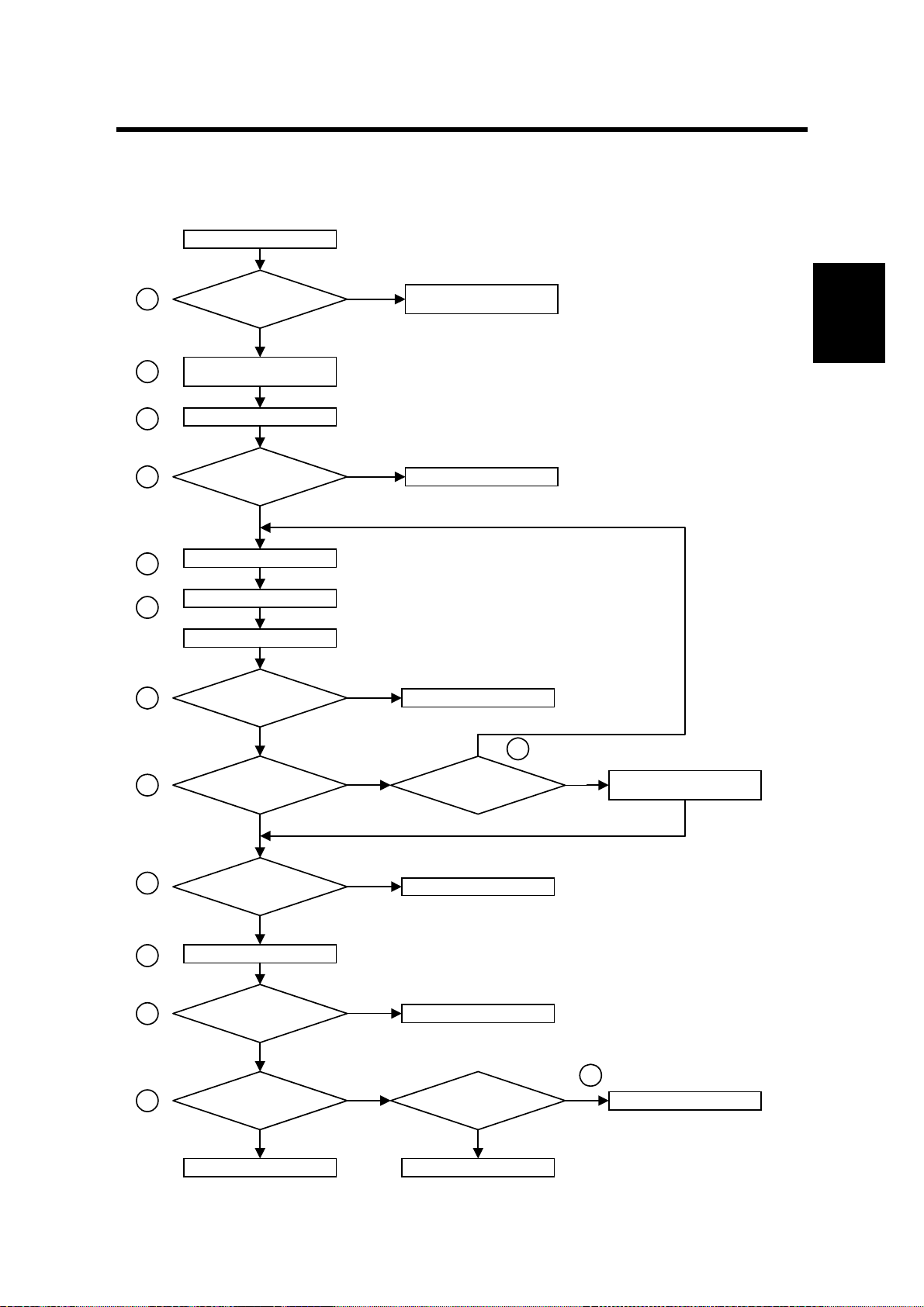

Power on

1

Is the memory OK?

Yes

No

User Level: System error

User Level: System error

Service Level: Memory error

Service Level: Memory error

Detailed

Descriptions

2

3

4

5

6

7

8

Initialize the I/O port, E2PROM,

IPU, and memory controller

Initialize the scanner motor

Is the

home position check

OK?

Yes

Adjust the black level

Turn on the lamp

Scan the white plate

Is the

white level within specified

value?

Yes

Were there any

shading, or lamp, errors?

No

No

No

Yes

Home position error

Lamp error

No

Has the

initialization procedure been

tried three times?

14

Use the default value of the white

Yes

and black levels

10

11

12

9

Endorser motor turns on for 0.1s

one of the feed, read, or feed-

Are the

ADF or the document feeder

cover closed?

Yes

Is any

out sensors on?

No

Is there

any paper on the document

table?

Yes Yes

Detects document

No

Yes

No No

ADF open error

Paper jam

Is the document

table working properly?

READY

2-1

13

Document table error

G411D503.WMF

Page 16

INITIALIZATION 22 December 1998

During power-up initialization, the scanner performs the following steps (refer to the

flow chart on the previous page).

1. Tests the ROM checksum and makes a RAM read/write test. If the CPU cannot

test these, the CPU determines that a memory error has occurred.

2. Initializes the I/O port, E2PROM, and gate arrays (IPU and memory controller).

3. Initializes the scanner motor driver.

4. Checks the home position sensor signal timing while moving the scanners. If

the CPU does not detect a signal change within the specified period, it

determines that a home position error has occurred.

5. Adjusts the difference between the even and odd black levels and total black

level.

6. Turns the exposure lamp on.

7. Adjusts the white level, and checks the peak level of the auto gain control. If the

CPU cannot adjust them to the specified levels, the CPU determines that a

lamp error has occurred.

8. If the black level or the white level cannot be adjusted properly during the

above initialization process, the scanner retries the initialization up to three

times. If the CPU detects an abnormal condition at the third time (step 14), the

CPU stores the default values of the black and white levels into the NVRAM on

the SCU.

9. Checks the ADF interlock switch signal. If the CPU detects that the switch is

open, it determines that an ADF open error has occurred.

10. When the endorser unit has been installed, the endorser moto r turns on for 0.1

second.

11. Checks the signals from the feed, read, and feed-out sensors. If any of them

are on, the CPU determines that there is a paper jam.

12. Checks the document sensor signal. If the CPU detects a document on the

document table, check #13 is not made until the document is removed.

13. Checks the document table position sensor signal timing while lifting and

lowering the document table.

14. See step 8.

2-2

Page 17

22 December 1998 SCANNER MECHANISMS

2.2 SCANNER MECHANISMS

2.2.1 BOOK MODE

Overview

[B][C][A][E]

Detailed

Descriptions

[F] [D]

G411D521.WMF

The exposure lamp (a xenon lamp in this model) [A] illuminates the original. The

image is reflected onto a CCD (charge coupled device) [B] via the 1st, 2nd, and 3rd

mirrors, and through the lens [C].

The 1st scanner [D] consists of the exposure lamp, a reflector [E], and the 1st

mirror [F].

The exposure lamp is energized by an ac supply to avoid uneven light intensity

while the 1st scanner moves in the sub scan direction (down the page). The entire

exposure lamp surface is frosted to ensure even exposure in the main scan

direction (across the page).

The light reflected by the reflector is of almost equal intensity in all directions, to

reduce shadows on pasted originals.

2-3

Page 18

SCANNER MECHANISMS 22 December 1998

Scanner Drive

[G]

[B]

[C]

[F]

[G]

[A]

[D]

[E]

G411D522.WMF

The scanner drive motor [A] (a stepper motor) drives the 1st and 2nd scanners [B,

C] through the timing belt [D], scanner drive pulley [E], scanner drive shaft [F], and

two scanner wires [G].

The IOB board drives the scanner drive motor. The scanning speed depends on

the scanning resolution. The returning speed depends on the distance from the

home position sensor.

2-4

Page 19

22 December 1998 SCANNER MECHANISMS

Basic Scanning Procedure

When the scan command is received from the host computer, the scanner starts

scanning as explained in the following steps.

Initialization

[E]

[A]

[D]

[F]

[G]

[B]

Detailed

Descriptions

[C]

G411D524.WMF

The scanner checks the home position, scanner cover, and memory. If an error is

detected, the scanner motor will stop.

The scanner scans the white plate [A] on the underside of the ADF exposure cover

to perform the shading funct i on.

Image Scanning

The scanner starts to scan the image area at the designated position [B]. The

scanner stops after scanning the designated image area [C]. The arrows indicate

that the scan start position and image area depend on the settings input by the

user.

Scanner Reversing

After the image has been scanned, the scanners return to the home position [D].

The scanners are stopped when the first scanner activates the home position

sensor [E]. If the scanner home position sensor is not activated within a certain

time, a home position sensor erro r will occu r.

2-5

Page 20

SCANNER MECHANISMS 22 December 1998

Optional Steps (Optional IPU Board)

Size Detection

If selected, this is done after the ‘Initialization’ step.

1) Main Scan Direction (Document Width)

The first scanner moves to the book mode standard position ([F] on the previous

page). Then, the scanner scans 5 mm from the book mode standard position.

The scanner determines the document width in the main scan direction from the

output signal level. The edge of the document is detected by the difference

between the level of the document data and the background signal which is

provided by the silver plate [G] attached to the platen cover across the main scan.

If there is a gap at the leading edge, such as a tear (or a black stripe), extending

more than 1 mm across the paper and more than 5 mm down the paper, the

machine cannot detect the document width past this gap. In this case, an error

message may appear, and scanning is impossible. . Disable this feature to allow

the machine to scan this document.

2) Sub Scan Direction (Document Length)

The scanner detects the document size only in the main scan direction, and the

scanner driver determines that the document length is the same as for a standard

paper size of the same width.

NOTE:

The scanner always assumes the paper is in a lengthwise orientation (i.e.,

the main scan is the short side). Also, in USA models, if Letter width is

detected, the paper is always assumed to be Letter size (this means that

the last few inches of a Legal-size original will not be scanned).

Read Size Command

If selected, this is done after the ‘Initialization’ step.

1) Read Size Command

If the scanner receives the Read Size command in book mode, it detects the size

in the main scan direction as described above.

The scanner sends the width data to the host computer.

After detecting the document size, the scanner scans the detected area.

Abort Command

This can occur at any time during the basic scanning procedure.

If the Abort command is received during scanning, the scanner motor is stopped.

Then the scanner returns to the home position ([D] in the previous diagram).

If this command is received while the scanner is reversing or checking the home

position, the operation is not interrupted.

2-6

Page 21

22 December 1998 SCANNER MECHANISMS

2.2.2 ADF MODE

Overview

[D]

[F]

[G]

[H]

[A]

[N]

[B]

[C]

[M]

[E]

[L]

Detailed

Descriptions

[J]

[K]

G411D517.WMF

[I]

When the originals are pl aced on the do cument table [ A], the document sensor [B]

detects them. The pick-up roller [C] picks up the originals and transports them to

the feed roller [D]. The separation roller [E] turns in the opposite direction to the

feed roller. As a result, just one original is sent to the paper transport drum [G]. The

feed sensor [F] detects whether the original has reached the transport drum or not.

Then the original turns with the transport drum through the read sensor [H]. While

the original passes over the ADF scanning position [J], the scanner [K] reads the

original. After reading, the original goes to the exit table [N]. The feed-out sensor

[M] detects whether the original is fed out or not. The relay sensor [L] detects when

an original is jammed in the area between the read sensor and the feed-out

sensor. This sensor is monitored at all times except when the ADF is feeding a

document.

2-7

Page 22

SCANNER MECHANISMS 22 December 1998

Basic Scanning Procedure

When the scanner receives t he ADF scanning command, the scanner scans the

original as described below.

1) ADF Mode

The scanner performs the home position check and the shading process. If a home

position error is detected, the scanner [K] will stop imme diately. If an ADF cover

open error or memory error is de tec ted, the scanner will stop after returning to the

home position.

The first carriage moves to the ADF scanning position [J] from the scanner home

position [I]. Then the paper transport motor starts.

2) SADF Mode

The scanner waits until the designated time for the originals to be placed on the

document table [A].

When the originals have b een placed on the document table, the sa me procedure

as for ADF mode is carried out.

2-8

Page 23

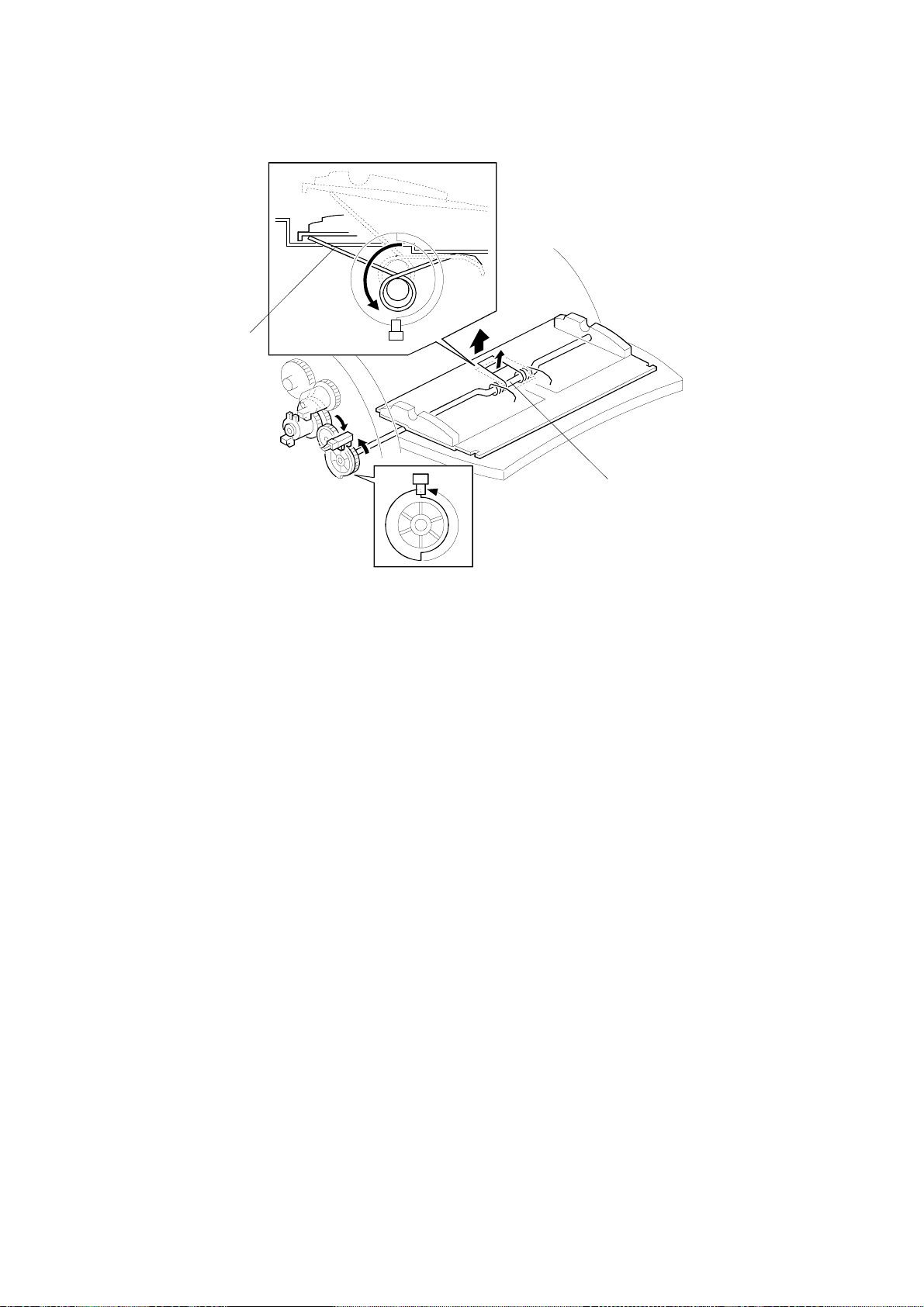

22 December 1998 SCANNER MECHANISMS

Document Table Lift

[C]

[G]

[F]

Detailed

Descriptions

[A]

[B]

[E]

[H]

[D]

[F]

[A]

G411D518.PCX

The lift mechanism consists of the document table lift clutch [A], the lift shaft [B],

the document table position sensor [C], and the sensor actuator on the gear [D].

In standby mode, the bend in the lift shaft [H] is pointing downwards and the

actuator is just inside the sensor.

When an original is placed on the document table, the document sensor [E] is

activated. Then the paper feed motor [G] turns on. At the same time, the document

table lift clutch [A] turns on to rotate the lift shaft.

At this time, the actuator starts to turn anticlockwise, and the flat part of the spring

[I] that is loosely attached to the bend in the lift shaft pushes up the document table

(see the next page for a diagram).

When the top of the document stack is pushed up against the pi ck-up roller, it can

rise no more. However, the mechanism continues to push up against the tray until

a half-turn of the shaft has been completed (i.e., until the actuator leaves the

document table position sensor). At that time, the document table lift clutch and the

paper feed motor turn off. If the actuator does not leave the sensor within a certain

time, a document table error will occur.

The feed motor turns on again at a motor speed which depends on the scanning

resolution, and the pick-up clutch [F] turns on to feed the top sheet of the original

(see Original Feed and Separation).

2-9

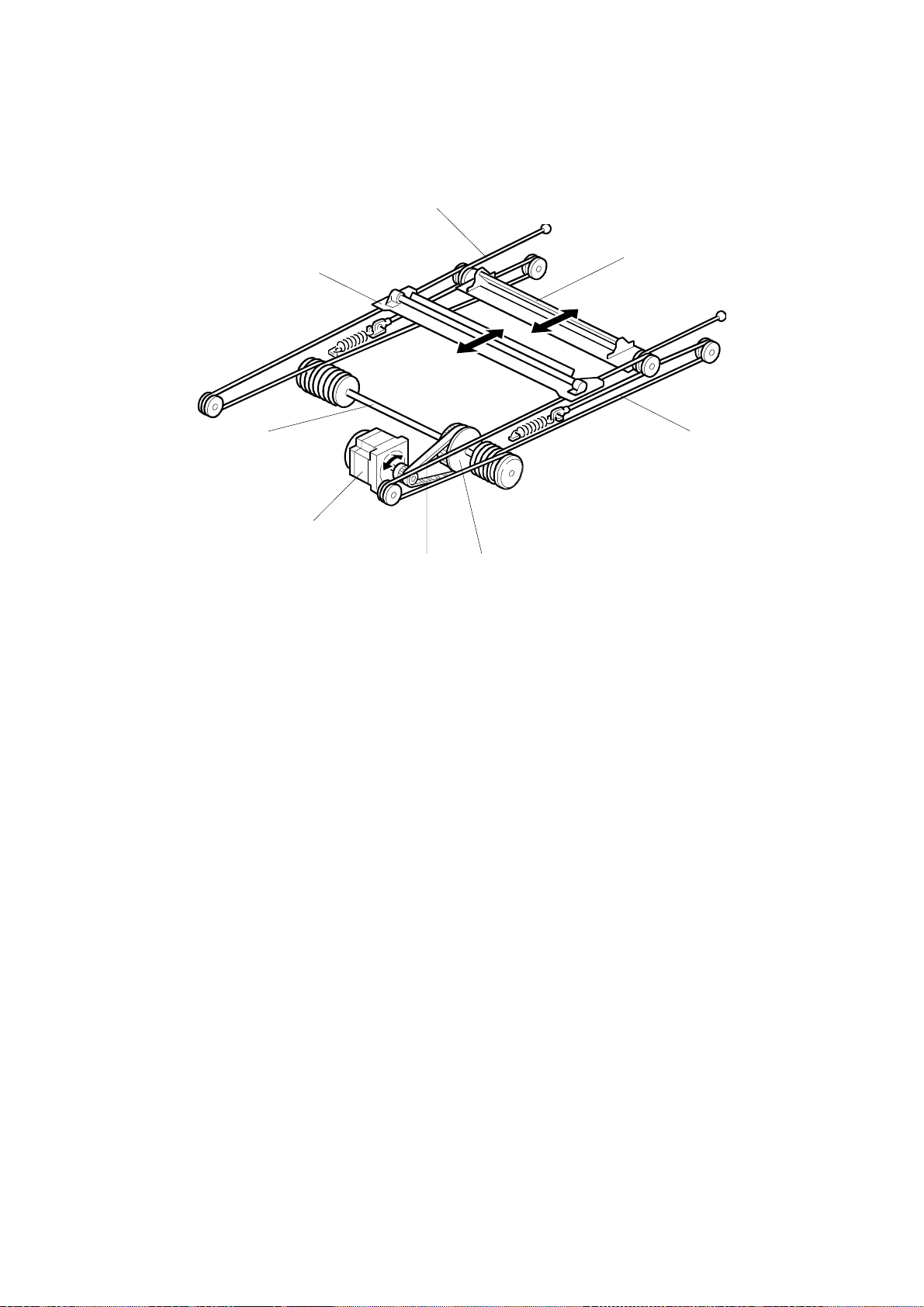

Page 24

SCANNER MECHANISMS 22 December 1998

[I]

[H]

G411D519.WMF

When the first original is being fed, the bend in the lift shaft is pointing up, and the

spring is at maximum compression. As sheets of the document are scanned, the

spring pushes the document table upwards so that the top of the stack is always

against the pick-up roller.

When all page s of the original have been fed out of the ADF, the document table

lift clutch and paper feed motor are energized to lower the tray. They turn off when

the document table sensor is deactivated. If the sensor is not deactivated within the

designated time, a document table error will occur.

2-10

Page 25

22 December 1998 SCANNER MECHANISMS

Original Feed and Separation

[D]

[E]

[F]

[A]

[C]

Detailed

Descriptions

[B]

G411D520.WMF

To feed the original, the paper feed motor and the paper transport motor (which

drives the paper transport drum) turn on. The paper feed motor drives the pick-up

roller [A] through a train of gears and the pick-up clutch [B]. The pick-up clutch

turns on to feed the top sheet of the original. If the pick-up roller feeds multiple

pages of the original, the separation roller [C] and the feed roller [D] separate these

pages (the separation mechanism is friction-based).

When the leading edge of the original ac tivates the feed sensor [E], the paper feed

motor and the pick-up clutch turn off, then the paper transport drum [F] feeds the

original to the scanning position.

Image Scanning

The scanner starts to scan the image when the leading edge has passed the read

sensor by a certain distance (measured by motor pulses).

When the CP U has fed the trailing edge of the original 30 mm past the f eed-out

sensor, the transport motor turns off.

2-11

Page 26

SCANNER MECHANISMS 22 December 1998

Optional Steps

Size Detection

[A]

[B]

[D]

G411D523.WMF

[C]

If selected, this is done after document table lift/paper feed.

1) Main Scan Direction (Document Width)

This function will be available when the optional IPU board is installed.

First of all, the original is fed to the scan ready position between the read sensor

[B] and the size detection position [C]. Then the first scanner moves to the size

detection position [C] from the ADF scanning position [D]. After that, the original is

fed to the ADF scanning position.

As a result of the above operation, the original is fed 5 mm past the first scanner.

Then the CPU detects the original width. The edge of the document is detected by

the difference between the level of the document data and the background level,

which is provided by the black bracket located over the ADF exposure cover.

If there is a gap at the leading edge, such as a tear (or a black stripe), extending

more than 1 mm across the paper and more than 5 mm down the paper, the

machine cannot detect the document width past this gap. In this case, an error

message may appear, and scanning is impossible. Disable this feature to allow the

machine to scan this document.

After finishing the above operation, the first scanner returns to the ADF scanning

position.

2) Sub Scan Direction (Document Length)

The length of the original is calculated by counting the motor pulses while the feed

sensor [A] is on. (The length is detected during scanning.)

2-12

Page 27

22 December 1998 SCANNER MECHANISMS

Read Size Command

If selected, this is done after document table lift/paper feed.

If the scanner receives a Read Size command in ADF mode, it detects the

document size in the main scan direction as described on the previous page.

The scanner sends the width data to the host computer.

Abort and Unload Commands

These can occur at any time during the basic scanning procedure.

When the CP U receives the Abort or the Unload command during paper transport,

the scanner feeds out any original that is in the ADF.

Detailed

Descriptions

2-13

Page 28

PAPER MISFEED DETECTION 22 December 1998

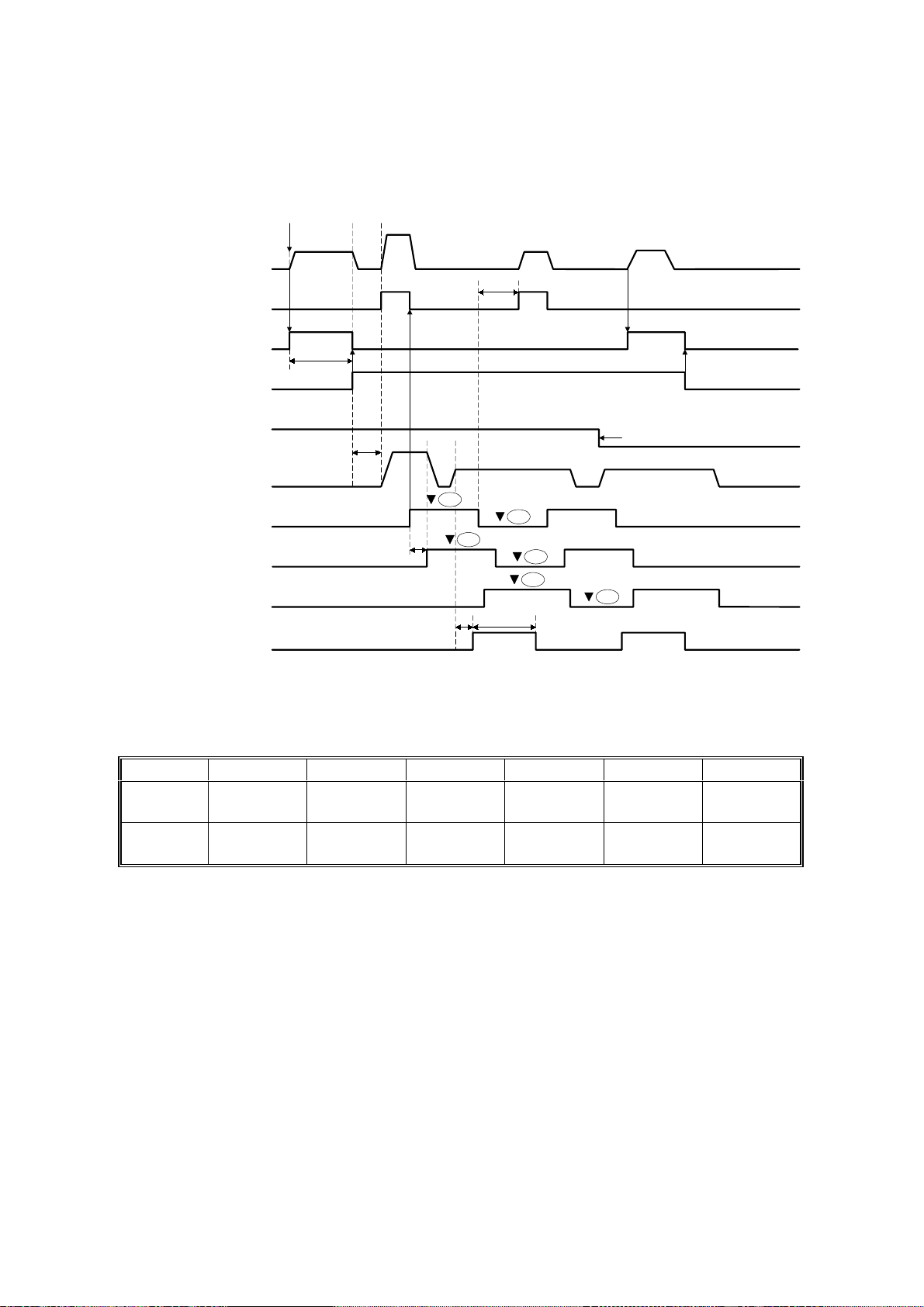

2.3 PAPER MISFEED DETECTION

Start

MAX

READ

Paper Feed Motor

Pick-up Clutch

OFF

Document Table

Lift Clutch

Document Table

Position Sensor

Document Sensor

MAX

Paper Transport

Motor

Feed Sensor

Read Sensor

Feed-out Sensor

FGATE

FGATE: When this signal is high, scanned data is valid

READ

OFF

t1

t2

t1 t2 t3 t4 t5 t6

200 dpi

400 dpi

Within

3,000

Within

3,000

210 205 44 24.64

210 205 88 172.04

Original End

J1

J4

t3

J2

J5

J3

J6

t5 t6

G411D527.WMF

Unit: milliseconds

L x 0.011

x 200

L x 0.011

x 400

2-14

L: Document length (mm)

Page 29

22 December 1998 PAPER MISFEED DETECTION

J1: The leading edge of the original does not reach the feed sensor within the time

required for feeding the distance between the pick-up roller and the feed sensor

+ 150 mm after the pick-up clutch turned on.

J2: The leading edge of the original does not reach the read sensor within the time

required for feeding the distance between the feed sensor and the read sensor

+ 150 mm after the feed sensor was activated.

J3: The leading edge of the original does not reach the feed-out sensor within the

time required for feeding the distance between the read sensor and the feed

out sensor + 30 mm after the read sensor was activated.

J4: The trailing edge of the original doe s not pass through the feed sensor within

the time required for feeding the maximum original length (2 m) + 60 mm after

the feed sensor was activated.

J5: The trailing edge of the original doe s not pass through the read sensor within

the time required for feeding the original + 75 mm after the read was activated.

J6: The trailing edge of the origin al does not pass through the feed-out sensor

within the time required for feeding the original length + 75 mm after the feedout sensor was activated.

If an original jam or an original non-feed is detected, the paper transport motor,

paper feed motor, and the exposure lamp turn off. Then, the appropriate LEDs

inform the user of the machine’s status.

Detailed

Descriptions

If an original remains in the ADF, the original is fed out and the paper transport

motor stops.

2-15

Page 30

IMAGE PROCESSING 22 December 1998

2.4 IMAGE PROCESSING

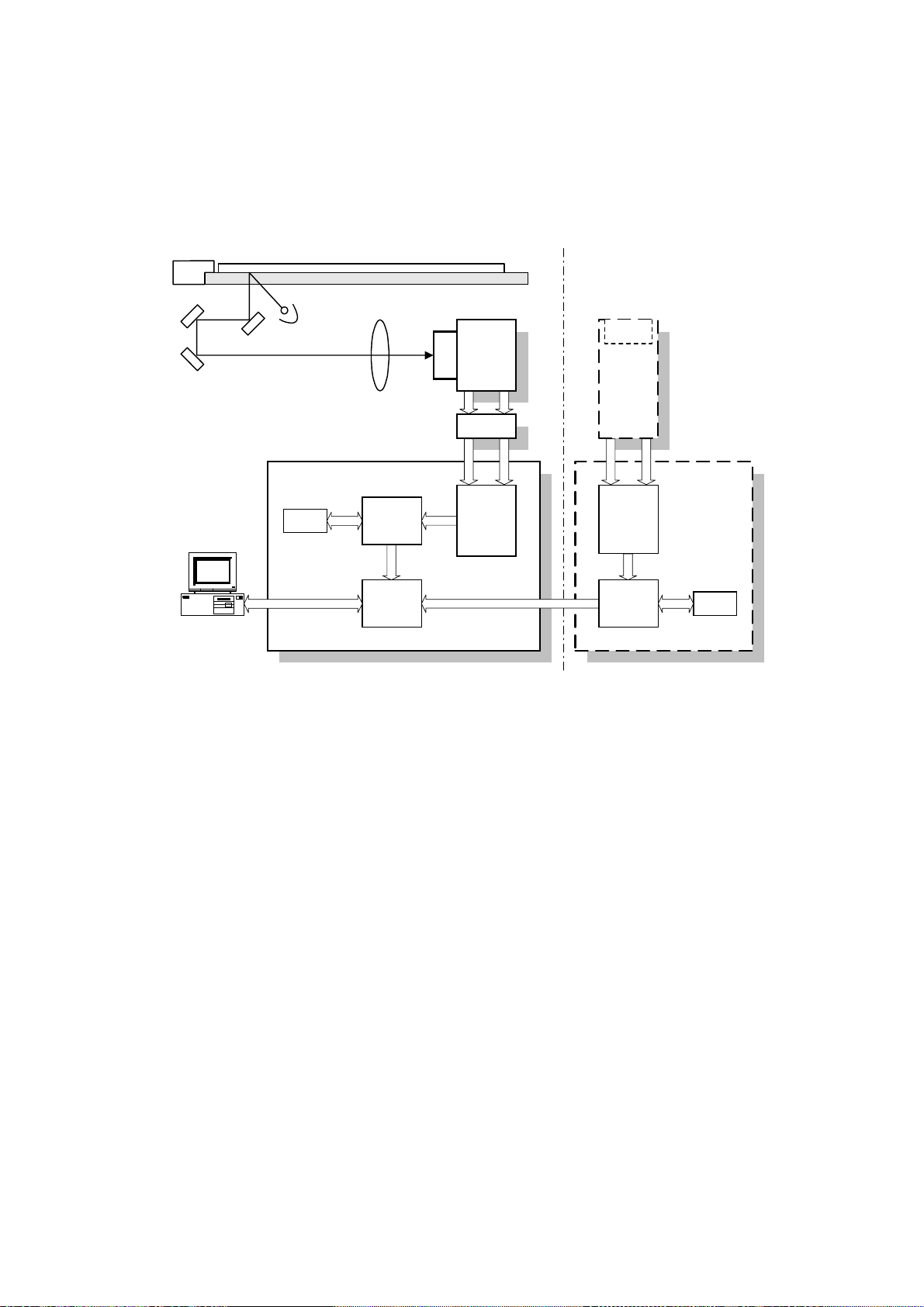

2.4.1 OVERVIEW

(Duplex model only)

CCD

SBU

CCD

IOB

CIS

SCU

DRAM

Memory

Control

IC

SCSI

Control

IC

IPU

IPU

Memory

Control

IC

RCU

DRAM

G411D508.WMF

The CCD generates two analog video signals. The SBU (Sensor Board Unit)

converts these analog signals to 8-bit digital signals, then it sends these digital

signals to the SCU (Scanner Control Unit) board through the IOB board. The IPU

(Image Processing Unit) IC on the SCU does the image processing, then the image

data goes to the computer through the Memory Control IC and the SCSI controller.

The CIS (Contact Image Sensor) unit in the duplex model for reverse-side

scanning outputs two digital signals. The IPU on the RCU (Reverse Control Unit)

board does the image processing, then the image data goes to the computer

through the SCU.

2-16

Page 31

22 December 1998 IMAGE PROCESSING

2.4.2 SBU

SBU

SCU

IOB

O

Analog

Processing IC1

A/D 1

8 bit data

IPU

CCD

E

Analog

Processing IC2

A/D 2

8 bit data

G411D507.WMF

The CCD converts the light reflected from the do cument into an analog signal. The

CCD line has 5,000 pixels and the resolution is 400 dpi (15.7 lines/mm).

The CCD has two output lines, for odd and even pixels. Each of these has an

analog processing IC. The analog processing IC performs the following operations

on the signal from the CCD.

1. Z/C (Zero Clamp)

Adjusts the black level reference for even pixels to mach the odd pixels.

Detailed

Descriptions

2. Signal Amplification

Operational amplifiers in the AGC (Auto Gain Control) circuit amplify the analog

signal. The CPU on the SCU board controls the maximum gains of the

operational ampli fiers .

After the above processes, the analog signals are converted to 8-bit digital signals

by the A/D converters. This gives a value for each pixel on a scale of 256 grades.

Then these signals go to the SCU board.

2-17

Page 32

IMAGE PROCESSING 22 December 1998

2.4.3 IPU (IMAGE PROCESSING UNIT)

Overview

Opional

IPU

IPU

C

C

D

Analog

Processing

IC 1

Analog

Processing

IC 2

AD

AD

Odd

8

Even

8

IPU

Selector

8

SCUSBU

8

Memory

Controller

8

SCSI SCSI

G411D505.WMF

The image data from the SBU goes to the IPU IC on the SCU board, which carries

out the following processes on the image data.

1. Auto shading

2. Magnification

3. Mirror processing

4. Filtering (MTF and smoothing)

5. γ (gamma) correction

6. Grayscale processing

7. Binary picture processing

8. Error diffusion

9. Dithering

10. White/black conversion

The image data then goes to the memory controller IC.

2-18

Page 33

22 December 1998 IMAGE PROCESSING

Image processing path

The following image processing is for the scanner (simplex model), not including

the optional IPU. The image processing for each of these units is explained in

separate sections. However, when the optional IPU is installed, the IPU IC on the

SCU only does the shading.

1. Without Optional IPU

SBU

Shading

correction

Magnification/

Mirror Process

2. With Optional IPU

Filtering

SBU

SCU

IPU

correction

γ

SCU

IPU

Shading

correction

Memory

Controller

Dither/

Error Diffusion

Optional

IPU

Binary process

White/black

conversion

G411D500.WMF

Detailed

Descriptions

Shading Correction

The machine scans the white plate opposite the ADF exposure glass to make a

white waveform. Shading correction prevents uneven images caused by

fluctuations in scanned data due to changes in light intensity and CCD sensitivity.

Magnification

Reduction and enlargement in the sub scan direction are done by changing the

scanner motor speed or paper transport motor speed in the ADF. However,

reduction and enlargement in the main scan direction are done by the IPU.

Mirror Processing

A mirror image of the original must be made for output.

Filtering

There are two software filters: the MTF filter and the smoothing filter. The MTF filter

emphasizes sharpness, and is used with text-only documents or documents that

contain text and photo areas. The smoothing filter is used for photo-image

documents.

2-19

Page 34

IMAGE PROCESSING 22 December 1998

Gamma (γγ) Correction

The gamma curve corrects the response of the CCD to grayscales in the original.

Grayscale Processing

This process generates up to 256 image density levels for each pixel.

Dithering

Dither processing produces good quality grayscale images of photo originals.

Error Diffusion

The error diffusion process reduces the difference in contrast between light and

dark areas of a halftone image. Each pixel is corrected using the difference

between it and the surrounding pixels. The corrected pixels are then compared with

a matrix table.

Binary Picture Processing

Each video signal level is converted from 8-bit to 1-bit (black and white image data)

in accordance with a threshold value.

White/Black Conversion

Inverts the image (converts from white to black and vice versa).

After video processing, the data goes to the host computer through the memory

and SCSI controllers.

2-20

Page 35

22 December 1998 REVERSE SIDE SCANNING

2.5 REVERSE SIDE SCANNING

2.5.1 OVERVIEW

[A]

Detailed

Descriptions

[B]

G411D516.WMF

The CIS (Contact Image Sensor) unit [A], which is in the document exit area, scans

the reverse side of the document.

The front side of the document is scanned first. Then the document goes to the

reverse side scanning area. The white roller [B] pushes the document against the

CIS unit for scanning and feeds the document to the exit area.

The position of the CIS unit is fixed in the scanner, and cannot be adjusted in the

field.

2-21

Page 36

REVERSE SIDE SCANNING 22 December 1998

2.5.2 CIS (CONTACT IMAGE SENSOR) UNIT

[A]

[B]

[D]

[C]

G411D513.WMF

[C]

G411D528.WMF

The CIS unit consists of the LED array (68 chips/line x 2 lines) [A], rod lens array

[B], five CCDs [C], and the CIS drive board [D] (this contains the CCD drive circuit,

analog processing circuit, A/D converter, shading correction IC, and LED drive

circuit). The CIS unit scans 4800 pixels in the main scan direction at a resolution of

400 dpi (15.7 lines/mm).

There is a row of LEDs on each side of the CCD so that the light is of almost equal

intensity in all directions. This reduces shadows at the edges of documents.

The five CCDs are arranged as shown above (viewed from directly above the

original feed path). The CCDs have dummy pixels at the ends, so to get a

continuous scan across the page, the CCDs have to overlap. However, as a result,

a continuous line cannot be scanned across the page at the same time. Data is

held in memory and combined later.

In book mode when scanning the front side, the scanner may stop if the buffer fills

up. This may happen if the data is complex. Scanning may not start again in

exactly the same place, due to mechanical inaccuracies. This is not a big problem

when scanning the front side. However, for the reverse side, because a complete

scan line is not scanned at the same time, it could mean loss of data.

Because of this, reverse side scanning is only enabled at 6 reproduction ratios

(expressed in the driver as dpi: 100, 200, 300, 400, 500, and 600 dpi). This is

because there is not enough memory to buffer the data and calculate the pixels for

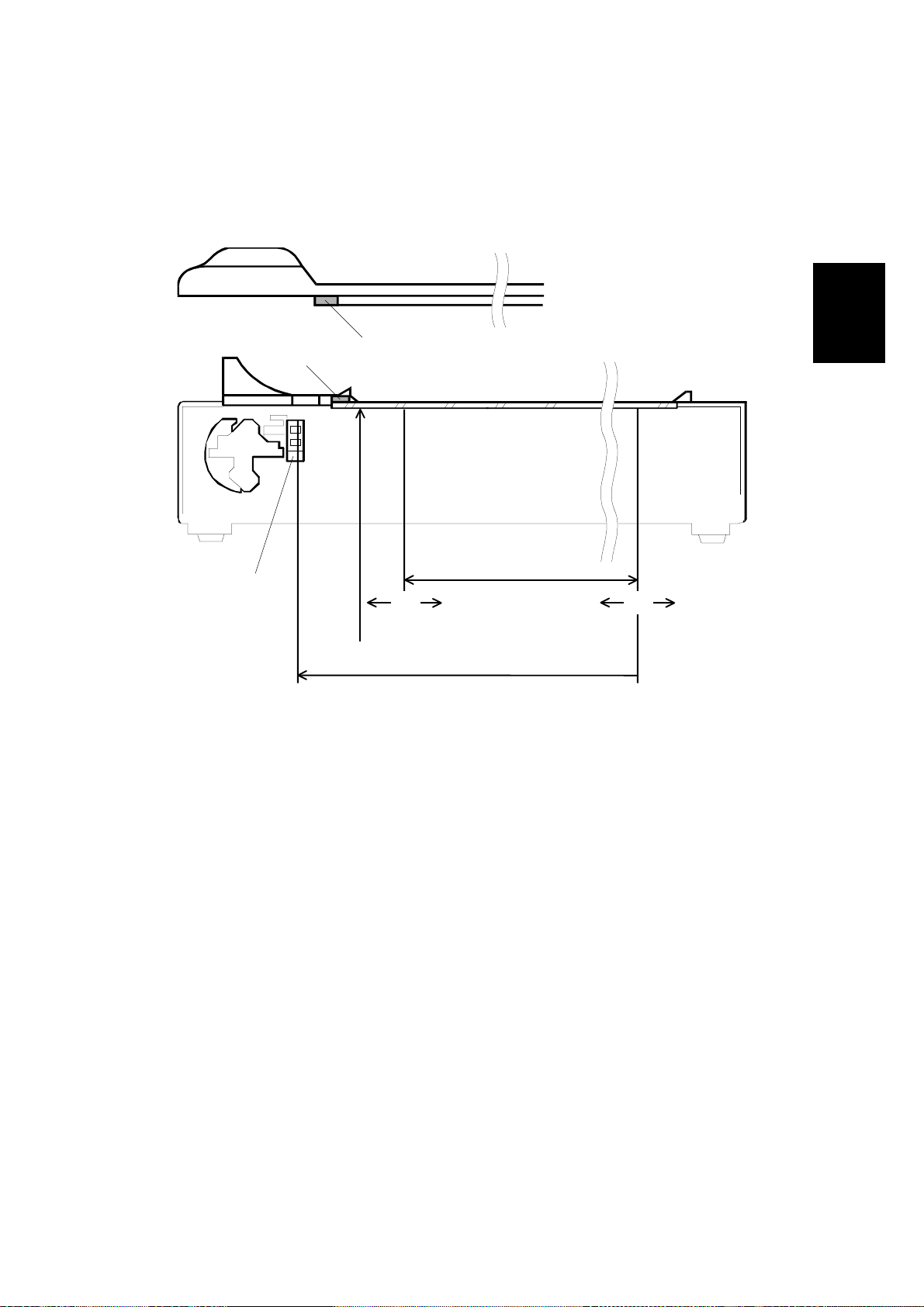

the resulting image at other resolutions without stopping the scanner.

2-22

Page 37

22 December 1998 REVERSE SIDE SCANNING

2.5.3 IMAGE SCANNING

Analog

Processing

Circuit

Analog

Processing

Circuit

C

L

E

D

C

D

Analog

Processing

Circuit

Analog

Processing

Circuit

Analog

Processing

Circuit

AD

AD

AD

AD

AD

Shading

Correction

Odd

Even

CIS

8

8

RCU

IPU

RCU

8

Memory

Controller

SCU

SCSI SCSI

8

G411D504.WMF

Detailed

Descriptions

CIS

Shading

correction

Magnification/

Mirror Process

Filtering

correction

γ

IPU

Error Diffusion

Dither/

Binary Process

Memory

Controller

White/black

conversion

G411D526.WMF

As explained on the previous page, the CIS unit contains five CCDs. The analog

signal from each CCD goes to an analog processing IC. The function of the analog

processing circuit is the same as for the SBU. After this, the analog signal is

converted to a digital signal by the A/D converter. Then, the data goes to the

shading circuit for correction. After shading, the data is divided to two signals: Odd

and Even. Then, these go to the IPU on the RCU board.

The RCU board contains the IPU and memory controller ICs for image processing.

The image processing in the IPU is the same as for the IPU in the SCU except for

the shading correction.

After image processing, the data goes to the PC through the SCSI controller on the

SCU.

2-23

Page 38

ENDORSER UNIT 22 December 1998

2.6 ENDORSER UNIT

2.6.1 OVERVIEW

[D]

[B]

G411D516.WMF

[A]

[C]

[D]

[A]

G411D514.WMF

The endorser unit [A] is located just before the exit roller [B]. The endorser unit

prints up to 19 characters (which are input using the scanner driver) at the trailing

edge of the document.

The endorser operates as follows.

1. The user inputs characters and enables the endorser function using the

scanner driver.

2. The scanner operates in the normal ADF mode.

3. The paper transport motor stops at a certain time after the leading edge of the

paper passes through the feed-out sensor.

4. The endorser motor turns on.

5. The endorser solenoid [C] is energized and the paper holding plate [D] goes

down to hold the original.

6. The endorser prints the characters.

7. After printing, the endorser motor turns off.

8. The endorser solenoid is de-energized and the paper holding plate goes up to

release the original.

9. The paper transport motor turns on ag ai n, and the original is fed to the original

tray.

2-24

Page 39

22 December 1998 ENDO RSER UNI T

2.6.2 ENDORSER UNIT

[D]

[C]

[F]

[E]

[A]

[B]

G411D515.WMF

The endorser unit consists of the endorser motor [A], clutch [B], character belt [C],

hammer unit [D], and ink roller [E].

Detailed

Descriptions

The endorser motor drives the character belt and hammer unit and operates the

hammer [F].

The clutch controls the print timing.

The ink roller always contacts the character belt and always supplies ink to the belt.

When the ink is used up, the customer replaces only t he ink roller.

2-25

Page 40

LOW POWER MODE 22 December 1998

2.7 LOW POWER MODE

W

15 min.

12 W

t

Operation Stand-by mode Low power mode

G411D525.WMF

When the scanner has been idle for 15 minutes (this interval cannot be adjusted),

the scanner automatically enters low power mode. However, the scanner cannot

enter low power mode when a document jam or system error exists.

NOTE:

The scanner can enter low power mode if the ADF cover and/or platen

cover is open or paper remains on the document table.

When the scanner enters low power mode, the PSU cuts the +24 V, +12 V, –12 V

and +5 Vs supplies, and continues to supply +5VE only. As a result, the scanner

consumes less than 12 W. The operation panel indicates that the machine is in low

power mode with the following LEDs.

LED Status

Power on Blinking

Machine busy Off

Document in place Off

Error Off

The scanner returns to stand-by mode when the ADF cover and/or platen cover is

opened and closed, or when the user places a document on the document table, or

when a Read command is received from the computer.

2-26

Page 41

22 December 1998 MAIN PCBS AND THEIR FUNCTIONS

2.8 MAIN PCBs AND THEIR FUNCTIONS

2.8.1 BOARD STRUCTURE

Endorser Unit

CIS Unit

RCU

SCU

ADU

IOB

Clutches

Sensors

Motors

SBU

Operation

Panel

Scanner

Motor

H.P Sensor

Lamp

Stabilizer

ADF

Main

Frame

Exposure

Lamp

Detailed

Descriptions

Optional IPU

PSU

Cooling

Fan

G411D509.WMF

For the main function of each PCB, refer to the Electrical Component Layout

section.

2-27

Page 42

MAIN PCBS AND THEIR FUNCTIONS 22 December 1998

2.8.2 SCU (SCANNER CONTROL UNIT)

Optional IPU RCU

SCU

Odd

Even

IOB

SEL

Memory

Controller

OSC

SCSI

Controller

SCSI 1SCSI 2

EPROM

4 Mbit (x16)

IPU

OSC

SRAM

256 kbit (x8)

Image data Signal line

E2PROM

2 kbit

Reset IC

CPU Bus

DRAM

16 Mbit (x16)

CPU

OSC

EIO

SCSI

Terminator

DIP SW

SCSI ID

Rotary

SW

G411D512.WMF

This is the main board. The functions of each component are as follows.

CPU: HD6413002F

•

Scanner sequence control

•

Clock/timer control

•

DMA control

IPU (Image Processing Unit):

•

Shading correction

•

Image processing (Mirror image, reproduction ratios, MTF correction, binary

picture processing, edge extraction, and so on)

Memory Controller:

•

Stores the image data from the IPU in the memory (DRAM 32 Mbytes x 2).

•

Address contro l whe n re calling the data from the memory.

SCSI controller: SCSI interface controller.

SRAM: Work area (32 kbytes)

EPROM: Contains the program.

Enhanced I/O (EIO):

•

Extension for the I/O port.

•

DIP switches (mode selection), rotary switches (SCSI ID setting), and a push

switch (reset button) are connected.

E2PROM: Holds the book, ADF, and lamp counter values.

2-28

Page 43

22 December 1998 MAIN PCBS AND THEIR FUNCTIONS

2.8.3 IOB (INPUT/OUTPUT BOARD)

IOB

SBU

PSU

Interlock

Switch

SCU

+ 5V

+ 12V

+ 24V

+ 24V ADU

Scanner

Motor Driver

Driver

Driver

Driver

Scanner

Motor

H.P Sensor

Lamp

Stabilizer

Exposure Lamp

Operation

Panel

ADU

Detailed

Descriptions

G411D510.WMF

The IOB contains the drive circuits for the scanner motor and the exposure lamp.

The control signals such as drive and rotation direction, and drive current for the

scanner motor come from the SCU. Also, the control signal for the exposure lamp

comes from the SCU.

The image signals from the SBU go through this board to the SCU.

2-29

Page 44

MAIN PCBS AND THEIR FUNCTIONS 22 December 1998

2.8.4 ADU (ADF DRIVE UNIT)

ADU

Motor Driver

Paper

Transport

Motor

IOB

+ 5V

+ 24V ADU

+ 12V

- 12V

+ 24V ADU

+ 5V

+ 5V

+ 12V

- 12V

+ 15V

Motor Driver

Paper

Feed

Motor

Clutches

Sensors

EDU

CIS Unit

G411D511.WMF

The ADU drives the motors and clutches in the ADF unit. Also, it informs the

sensor status to the SCU.

The SCU generates the control signals for each electrical component and the

endorser, then these are sent to the ADU through the IOB. The drivers on the ADU

convert the control signals into drive pulses for the motors.

2-30

Page 45

22 December 1998 ENVIRONMENT

3. INSTALLATION

3.1 ENVIRONMENT

3.1.1 PRECAUTIONS

Please observe the following precautions in order to ensure safe operation of the

scanner and to realize its full performance.

• Ambient illumination must be less than 2,000 lux (do not expose to direct

sunlight).

• Do not use the scanner in any location that is exposed to frequent vibration.

• Do not expose the scanner to dusty or corrosive atmospheric conditions.

• Ensure that the area in which the scanner is used is well ventilated (30

m3/hr/person).

• Make sure that the surface on which you place the scanner is stable and level.

3.1.2 ENVIRONMENTAL CONDITIONS

Installation

Temperature: 10°C to 32°C (50 to 90°F)

Humidity: 20 to 80 %

3.1.3 MACHINE LEVEL

1. Front to back: Within 5 mm (0.2") of level

2. Right to left: Within 5 mm (0.2") of level

3.1.4 MINIMUM SPACE REQUIREMENTS

Place the scanner near a power source, providing clearance as shown.

A: 10 mm (0.2") B: 30 mm (1.2") C: 600 mm (23.7")

A

D

CB

G411I500.WMF

3-1

Page 46

SCANNER INSTALLATION 22 December 1998

3.1.5 POWER REQUIREMENTS

CAUTION

1. Be sure to ground the scanner.

2. Make sure the plug is firmly inserted in the outlet.

3. Avoid multi-wiring.

1. Input voltage level:

• 102 to 138 V ac (45 to 65 Hz)

• 187 to 276 V ac (45 to 65 Hz)

2. Permissible voltage fluctuation: ± 10%

3.2 SCANNER INSTALLATION

Please refer to the scanner user’s manual for details.

3.3 IPU UNIT INSTALLATION

Please refer to the scanner user’s manual for details.

3-2

Page 47

22 December 1998 ENDORSER UNIT INSTALLATION

3.4 ENDORSER UNIT INSTALLATION

3.4.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Endorser Unit ......................................................................... 1

2. Solenoid Ass’y........................................................................ 1

3. EDU Board ............................................................................. 1

4. Harness.................................................................................. 1

5. Ink Roller ................................................................................ 1

6. Decal...................................................................................... 1

7. Screw - M3 x 6 ....................................................................... 2

8. Card Spacer ........................................................................... 1

9. Installation Procedure............................................................. 1

Installation

3-3

Page 48

ENDORSER UNIT INSTALLATION 22 December 1998

3.4.2 INSTALLATION PROCEDURE

1. Open the ADF cover [A]. Remove the

ADF upper cover [B] (2 screws), ADF

right cover [C] (1 screw), and the

endorser cover [D].

NOTE:

Remove the right cover by

carefully lifting it from the rear.

2. Install the spacer [E] and the EDU

board [F] (2 screws).

[C]

[B]

[A]

[D]

G514I501.WMF

[F]

3. Route the cable [G] as shown.

NOTE:

Ensure that the end of the

cable with the large connector

[H] is toward the inside of the

machine.

3-4

[H]

[G]

[E]

G514I502.WMF

G514I503.WMF

Page 49

22 December 1998 ENDORSER UNIT INSTALLATION

4. Install the solenoid assembly [I] as

shown (3 screws).

G514I504.WMF

[K]

5. Install the clamp [J] and connect the

[L]

three cables [K] to the EDU board [L].

[I]

Installation

6. Install the core [M].

7. Open the platen cover. Install the

endorser unit [N], as shown (1

connector).

8. Attach the decal [O].

[J]

[M]

G514I505.WMF

[O]

[N]

9. Reinstall the endorser, right, and upper covers.

3-5

G514I506.WMF

Page 50

ENDORSER UNIT INSTALLATION 22 December 1998

3.4.3 STAMP DENSITY ADJUSTMENT PROCEDURE

1. Open the ADF cover [A]. Remove the

ADF upper cover [B] (2 screws), ADF

right cover [C] (1 screw), and the

endorser cover [D].

NOTE:

Remove the right cover by

carefully lifting it from the rear.

2. Remove the solenoid assembly screw

[E] from the hole [F] and replace it in

hole [G]. Do not tighten the screw yet.

3. Loosen the screw [H] and adjust the

height of the bracket [I].

NOTE:

To reduce the stamp density,

raise the bracket. To increase

the density, lower the bracket.

[C]

[B]

[A]

[D]

G514I501.WMF

[F]

[I]

[G]

4. Tighten the assembly screw [E] to

secure the bracket in the new position.

5. Reinstall the endorser, right, and upper

covers.

[H]

[E]

G514I507.WMF

3-6

Page 51

22 December 1998 RED LAMP UNIT INSTALLATION

3.5 RED LAMP UNIT INSTALLATION

3.5.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Exposure Lamp ...................................................................... 1

2. Installation Procedure............................................................. 1

Installation

3-7

Page 52

RED LAMP UNIT INSTALLATION 22 December 1998

3.5.2 INSTALLATION PROCEDURE

1. Remove the rear cover [A] (3 screws).

[A]

G514I500.WMF

2. Remove the stopper brackets [B].

3. Remove the pins [C].

[B]

[C]

[B]

G514I510.WMF

3-8

Page 53

22 December 1998 RED LAMP UNIT INSTALLATION

[D]

4. Open the platen cover and remove

the lamp cover [D] (2 screws).

G514I508.WMF

Installation

5. Remove the exposure lamp [E] (1

[E]

screw).

G514I509.WMF

6. Install the red lamp (1 screw, 1 connector) in the place of the exposure lamp.

7. Reinstall the lamp cover, the pins, the stopper brackets, and the rear cover.

3-9

Page 54

22 December 1998 DIP SWITCH SETTINGS

4. SERVICE LEVEL FUNCTIONS

4.1 DIP SWITCH SETTINGS

The factory default position of the dip switches is indicated in the diagram below.

After changing a dip switch setting, either switch the power off and then on again,

or press the reset switch.

OFF

1234 6758

ON

G411M500.WMF

Dip Switch Setting Table

Dip Switch Item Contents

SCAM function

switch

1234 6758

ON

SCSI synchronous

transfer switch

1234 6758

ON

Internal SCSI

terminator switch

1234 6758

ON

Do not adjust switch 4. This is for factory use only.

Service level test modes

Various tests for the scanner are carried out using dip switches 5 to 8.

Within each test mode, tests are selected by turning the SCSI ID rotary

switch, and the machine's condition is indicated by the four LEDs on the

covers.

ON

1234 6758

Note the position of the SCSI ID rotary switch before you change it.

To return to normal operation mode after testing, switch dip switches 5 to 8

all off, return the SCSI ID rotary switch to its operating position, then press

the reset button.

Demonstration mode

1234 6758

ON

OFF: SCAM function enabled

ON: SCAM function disabled

OFF: SCSI synchronous transfer enabled

ON: SCSI synchronous transfer disabled

OFF: Internal SCSI terminator on

ON: Internal SCSI terminator off

Scanner demonstration in book and ADF modes;

Refer to Table A later in this section.

ON

Tables

Service

Component test

mode

1234 6758

ON

Sensor test mode Each sensor can be tested; refer to Table C later in

1234 6758

ON

Self diagnostic mode Results of the diagnosis are indicated through a

1234 6758

ON

Each component can be tested; refer to Table B later

in this section.

this section.

combination of the LEDs on the covers; refer to Table

D later in this section and “Troubleshooting” in

section 6.

4-1

Page 55

DIP SWITCH SETTINGS 22 December 1998

g

y

Dip Switch Item Contents

ADF counter

indication

1234 6758

ON

Book mode counter

indication

1234 6758

ON

Exposure lamp on

time indication

1234 6758

ON

CIS on time

indication

1234 6758

ON

The number of pages scanned in ADF mode is

indicated throu

h a combination of the SCSI ID rotar

switch position and the LEDs; refer to Table E later in

this section.

(Unit = 1 sheet, Max. value = 2,500k sheets)

The number of pages scanned in book mode is

indicated in the same way as described above for

ADF mode; refer to Table E later in this section.

(Unit = 1 sheet, Max. value = 1,000k sheets)

The total illumination time of the lamp is indicated in

the same way as above.

(Unit = 1 hour, Max. value = 3,000 hours)

The total illumination time of the CIS is indicated in

the same way as above.

ADF counter

indication

1234 6758

ON

(Reverse side)

Endorser character

counter indication

1234 6758

ON

The number of pages scanned in ADF mode is

indicated in the same way as above.

(Unit = 1 sheet, Max. value = 2500 k sheets)

The number of endorser characters is indicated in the

same way as above.

Counter reset mode After the dip switches are set to on, and the Start

button is held down for more than 3 seconds, all

LEDs are turned off, all counters which are stored in

2

PROM are cleared.

1234 6758

ON

the E

(These counters are the ADF mode, book mode,

exposure lamp, CIS and endorser character

counters.)

NOTE:

If you change the position of the SCSI ID rotary switch during these tests,

be sure to put it back to the original position after you have finished.

Table A: Demonstration Mode

SCSI ID Rotary Switch No. Contents

0 200 dpi scan in book mode

1 400 dpi scan in book mode

2 200 dpi scan in ADF mode

3 400 dpi scan in ADF mode

4 200 dpi scan in endorser mode

5 400 dpi scan in endorser mode

6 200 dpi scan in duplex mode

7 400 dpi scan in duplex mode

8ADF free run *

9 Not used

1

*1: The scanner drives the ADF without any documents.

NOTE:

During the demonstration, the LEDs indicate the machine status as usual.

But if an error occurs during the demonstration (e.g. mis-feed, jam, etc.),

the scanner stops, and the LEDs indicate the error condition.

4-2

Page 56

22 December 1998 DIP SWITCH SETTINGS

Table B: Component Test Mode

SCSI ID Rotary Switch No. Contents

0 All components off

1 Exposure lamp on/off *

2 Document table lift clutch on/off *

3 Pick-up clutch on/off *

4 CIS LEDs on/off *

5 Endorser solenoid *

1

1

1

1

1

6 Cooling fan motor on/off

7 Not used

8 Not used

9 Not used

*1: When the Start button is pressed to start the test, the component turns on and

off repeatedly.

Table C: Sensor Test Mode

SCSI ID Rotary Switch No. Contents

0 Home position sensor

1 Read sensor

2 Document table position sensor

3 Document sensor

4 ADF cover interlock switch

5 Feed sensor

6 Feed-out sensor

7 Relay sensor

8 Not used

9 Not used

If the selected sensor is on, all LEDs turn on. If the selected sensor is off, all LEDs

turn off.

Tables

Service

4-3

Page 57

DIP SWITCH SETTINGS 22 December 1998

Table D: Self Diagnostic Mode

During the self-diagnostic mode, the scanner performs the following tests.

1) Home position error check

2) Exposure lamp error check

3) White level error check

4) Document table error check

5) SCU error check

6) RCU error check

7) IPU error check

8) CIS LEDs error check

9) Memory error check

If the scanner detects errors, the first error that occurred is indicated by a

combination of four LEDs.

LEDs

Error Items

SCU error Blinking — — Blinking

RCU error Blinking — On Blinking

IPU error Blinking On — Blinking

Home position error Blinking Blinking Blinking On

Exposure lamp error Blinking Blinking On On

White level error Blinking Blinking — —

CIS Leds error Blinking Blinking On Blinking

Memory error (Simplex) Blinking — — —

Memory error (Duplex) — Blinking — —

Power On

(Green)

Machine

Busy (Green)

Document in

Place (Green)

Error

(Red)

On: LED on Blinking: LED blinking —: LED off

Table E: Counter Indication Mode

Rotary Switch Table

SCSI ID Rotary Switch No. Contents

0 Not used

1Units

2 Tens

3 Hundreds

4 Thousands

5 Ten thousands

6 Hundred thousands

7 Millions

8 Not used

9 Not used

4-4

Page 58

22 December 1998 DIP SWITCH SETTINGS

LED Indication Table

LEDs

Counter Value

0————

1———On

2——On—

3——OnOn

4—On——

5—On—On

6 — On On —

7 — On On On

8On———

9On——On

Power On

(Green)

Machine Busy

(Green)

Document in

Place (Green)

Error

(Red)

On: LED on —: LED off

Use the rotary switch to select a digit of the counter. The value of the selected digit

is indicated by a combination of the four LEDs. For the LEDs, “ON” represents a 1

and “OFF” represents a 0. The four LEDs are read off as a four-bit number.

Example:

Rotary switch no LED condition

1 (units) (ON, OFF, OFF, OFF) = 1000 = 8

2 (tens) (OFF, OFF, ON, ON) = 0011 = 3

3 (hundreds) (OFF, ON, OFF, ON) = 0101 = 5

4 to 7 (OFF, OFF, OFF, OFF) = 0000

>>> Total counter value = 538 sheets

Tables

Service

4-5

Page 59

LEDS/TEST POINTS 22 December 1998

4.2 LEDs/TEST POINTS

4.2.1 LEDs

SCU/LEDs

Number Monitored Signal

LED1 +5VS

LED2 +5VE

LED3 CPU clock

4.2.2 TEST POINTS

ADU

Number Monitored Signal

TP301 +24 V

TP302 –12 V

TP303 +12 V

TP304 COM

TP305 +5VE

TP308 +5VS

TP309 COM

4.3 SPECIAL TOOLS

Part Number Part Name

A0069104 Scanner Positioning Pin (4 pcs/set)

G4049003 RS-13 Chart (A5)

G4049005 RS-13 Chart (A4)

G4049004 RS-13 Chart (A3, 55 kg)

G4049006 RS-13 Chart (A3, 90 kg)

H2039114 RS-12 Chart (A3)

4-6

Page 60

22 December 1998 COVERS

5. REPLACEMENT AND ADJUSTMENT

CAUTION

Before starting disassembly, be sure to turn off the main switch and

disconnect the power cord and interface cable(s) for safety.

5.1 COVERS

5.1.1 ADF EXTERIOR

[B]

[A]

[D]

G411R500.WMF

1. Open the ADF cover [A].

2. Remove the ADF upper cover [B] (2 screws).

3. Remove the ADF right cover [C] (1 screw).

NOTE: Remove the ADF right cover by carefully lifting it from the rear.

4. Remove the ADF left cover [D] (1 screw).

[C]

Adjustment

Replacement

5-1

Page 61

COVERS 22 December 1998

5.1.2 ADF COVER

[A]

[B]

G411R501.WMF

G411R502.WMF

1. Remove the ADF upper and ADF right cover (see ADF Exterior).

2. Remove the rear cover (see Scanner Exterior/Operation Panel).

3. Open the platen cover vertically (see Exposure Glass).

4. Remove the spring [A].

5. Remove the pin [B] (1 screw).

6. Remove the ADF cover [C] (1 connector).

[C]

5-2

Page 62

22 December 1998 COVERS

5.1.3 SCANNER EXTERIOR/OPERATION PANEL

[C]

[B]

[D]

[A]

G411R503.WMF

1. Remove the operation panel [A] (1 screw).

2. Remove the front cover [B] (3 screws).

3. Remove the left cover [C] (2 screws).

4. Remove the right cover [D] (2 screws).

5. Remove the rear cover [E] (3 screws).

G411R504.WMF

[E]

Adjustment

Replacement

5-3

Page 63

ADF AND UPPER SIDE 22 December 1998

5.2 ADF AND UPPER SIDE

5.2.1 DOCUMENT SENSOR

[A]

G411R505.WMF

1. Remove the ADF upper cover (see ADF Exterior).

2. Remove the document sensor [A] (1 connector, 2 screws).

5.2.2 SEP ARATION UNIT

[A]

G411R506.WMF

1. Remove the ADF upper, ADF left, and ADF right cover (see ADF Exterior).

2. Remove the separation unit [A] (3 connectors, 4 screws).

5-4

Page 64

22 December 1998 ADF AND UPPER SIDE

5.2.3 DOCUMENT TABLE ASSEMBLY

[A]

G411R507.WMF

1. Remove the separation unit (See Separation Unit).

2. Remove the document table assembly [A] (3 screws).

5.2.4 CIS

[B]

[A]

Adjustment

Replacement

G411R508.WMF

1. Remove the document table assembly (See Document Table Assembly).

2. Remove the stopper bracket [A] (1 screw).

3. Remove the ADU (See ADU/Paper Transport Motor).

4. Remove the CIS [B] (2 connectors, 1 screw).

5-5

Page 65

ADF AND UPPER SIDE 22 December 1998

5.2.5 SCANNING GUIDE PLATE

[A]

G411R509.WMF

1. Remove the ADF upper, ADF left, and ADF right cover (See ADF Exterior).

2. Remove the scanning guide plate [A] (2 screws).

5.2.6 FEED SENSOR

[C]

[A]

[B]

G411R510.WMF

1. Open the ADF cover [A].

2. Remove the feed cover [B] (2 screws).

3. Remove the feed sensor [C] (1 connector, 1 screw).

5-6

Page 66

22 December 1998 ADF AND UPPER SIDE

5.2.7 RE AD SENSOR

[A]

G411R511.WMF

1. Remove the rear cover (See Scanner Exterior/Operation Panel).

2. Remove the read sensor [A] (1 connector, 1 screw).

5.2.8 FEED-OUT SENSOR

[B]

[A]

Adjustment

Replacement

G411R512.WMF