Page 1

RUSSIAN-SC

(Machine Code: G412)

Service Manual

Issued on 27th December 2000

Ricoh Co., LTD

Page 2

!

IMPORTANT SAFETY NOTICES

1. Before disassembling or assembling parts of the scanner and peripherals,

make sure that the scanner power cord is unplugged.

2. The wall outlet should be near the scanner and easily accessible.

3. The output voltage of the PSU (Power Supply Unit) can be either 100 ~ 120

Vac or 220 ~ 240 Vac, without any adjustment. Make sure that the above

voltage is used.

4. The power cord should be an approved type, in accordance with the

regulations for the country in which the scanner is used.

5. The use of cables other than the shield I/O cables or specified equivalents

will invalidate the certification of this scanner and may cause interference

levels which exceed the limits established for this equipment.

6. When keeping used lithium batteries in order to dispose of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat buildup.

Lithium Batteries (Memory Back-up)

!

CAUTION

The danger of explosion exists if a battery of this type is incorrectly

replaced.

Replace only with the same or an equivalent type recommended by the

manufacturer. Discard used batteries in accordance with the

manufacturer’s instructions.

Maintenance Information

The user’s manual explains how to use and maintain the scanner. Before

performing the maintenance, read the user’s manual.

Warning concerning copyright

Many documents are copyrighted. Such documents may not be reproduced by

scanning or in any other form without the express permission of the copyright

holder.

Notice

The contents of this manual are subject to change without notice.

1

Page 3

TABLE OF CONTENTS

1 INSTALLATION PROCEDURE.................................................... 1-1

1.1 INSTLLATION REQUIRMENTS................................................................1-1

1.1.1 ENVIRONMENT...............................................................................1-1

1.1.2 MACHINE LEVEL.............................................................................1-1

1.1.3 MINIMUM SPACE REQUIRMENTS.................................................1-1

1.1.4 POWER REQUIRMENT...................................................................1-1

1.2 MAINFRAME AND OPTION INSTALLATION PROCEDURES.................1-2

1.2.1 ACCESSORY CHECK......................................................................1-2

mainframe.............................................................................................1-2

IEEE1394 I/F (OPTION).......................................................................1-2

Network interface kit (OPTION)............................................................1-3

OIPUB (OPTION)..................................................................................1-3

Memory Card (Memory unit type B)......................................................1-3

2 PREVENTIVE MAINTENANCE SCHEDULE ............................... 2-1

2.1 USER MAINTENANCE .............................................................................2-1

3 REPLACEMENT AND ADJUSTMENT......................................... 3-1

3.1 SPECIAL TOOLS......................................................................................3-1

3.2 REPLACEMENT........................................................................................3-1

3.2.1 EXTERIOR.......................................................................................3-1

3.2.2 EXPOSURE GLASS.........................................................................3-2

3.2.3 INNER COVER 1..............................................................................3-2

3.2.4 ORIGINAL LENGTH 1/2 SENSORS.................................................3-3

3.2.5 SCANNER HP SENSOR AND DF POSITION SENSOR..................3-3

3.2.6 SENSOR BOARD UNIT (SBU).........................................................3-4

3.2.7 INNER COVER 2..............................................................................3-4

3.2.8 ORIGINAL WIDTH SENSOR............................................................3-5

3.2.9 EXPOSURE LAMP STABILIZER .....................................................3-5

3.2.10 SCANNER MOTOR........................................................................3-6

3.2.11 EXPOSURE LAMP.........................................................................3-7

3.2.12 AUTO DOCUMENT FEEDER (ADF)..............................................3-8

3.2.13 SCANNER FRAME.........................................................................3-8

3.2.14 SCANNER WIRE............................................................................3-9

3.2.15 POWER SUPPLY UNIT (PSU).....................................................3-10

3.2.16 SCANNER CONTROL UNIT (SCU).............................................3-10

3.2.17 VIDEO AND I/O CONTROL BOARD (VIOB)................................3-11

3.2.18 SCANNER OPERATION PANEL (SOP)......................................3-11

3.2.19 SWITCH BOARD (SWB)..............................................................3-12

3.3 ADJUSTMENT ........................................................................................3-13

3.3.1 SCANNER WIRE............................................................................3-13

Parallelism Adjustment.......................................................................3-13

Adjust points:......................................................................................3-13

i

Page 4

4 TROUBLESHOOTING................................................................. 4-1

4.1 LED FUNCTION MODE............................................................................4-1

4.1.1 NORMAL LED FUNCTION TABLE...................................................4-1

Order of priority.....................................................................................4-2

4.1.2 SELF DIAGNOSTIC MODE..............................................................4-2

LED function table ................................................................................4-2

Descriptions..........................................................................................4-3

4.1.3 BLOWN FUSE CONDITIONS ..........................................................4-4

4.1.4 IEEE1394 BOARD (OPTION)...........................................................4-4

5 SERVICE TABLES....................................................................... 5-1

5.1 DIP SWITCH FUNCTION..........................................................................5-1

5.1.1 DIP SWITCH COMBINATIONS........................................................5-1

DIP switch setting table (Normal mode)................................................5-1

DIP switch setting table (service level test mode).................................5-2

5.1.2 NORMAL MODE ..............................................................................5-2

5.1.3 ADF COUNTER, BOOK MODE COUNTER AND EXPOSURE LAMP

ON-TIME ....................................................................................................5-3

SCSI ID rotary switch............................................................................5-3

LED values ...........................................................................................5-3

Example: ...............................................................................................5-3

5.1.4 SENSOR TEST MODE.....................................................................5-4

5.1.5 FIRMWARE UPDATE PROCEDURE...............................................5-5

5.1.6 FLASH-ROM UPLOAD MODE.........................................................5-6

5.1.7 WHITE BALANCE ADJUSTMENT MODE........................................5-6

5.1.8 BOOK SIZE CHECK MODE.............................................................5-7

5.1.9 DEMONSTRATION MODE ..............................................................5-7

5.1.10 SELF DIAGNOSTIC MODE............................................................5-8

5.1.11 COMPONENT TEST MODE ..........................................................5-8

5.1.12 ADF SIZE CHECK MODE..............................................................5-8

5.1.13 EEPROM CLEAR MODE ...............................................................5-9

5.2 SERVICE PROGRAM MODE (WITH NIB OPTION) ...............................5-10

5.2.1 THE SP MODE DESCRIPTION .....................................................5-10

Entering the service mode..................................................................5-10

Density setup sample:.........................................................................5-10

Example: .............................................................................................5-10

5.3 NETWORK SETUP(WITH NIB OPTION)................................................5-11

5.3.1 NIB SETUP TABLE........................................................................5-11

Scanner function/Network table..........................................................5-11

Scanner function/configuration table...................................................5-11

5.3.2 NIB ERROR LOG DESCRIPTIONS...............................................5-11

rapp.....................................................................................................5-11

nas......................................................................................................5-12

SC related to the network interface card.............................................5-12

ORIGINAL SIZE SENSOR COMBINATION TABLE...........................5-13

ii

Page 5

6 DETAILED FUNCTION DESCRIPTIONS..................................... 6-1

6.1 MACHINE OVERVIEW..............................................................................6-1

6.2 CONTOROL SYSTEM BLOCK DIAGRAM................................................6-2

6.3 SCANNING................................................................................................6-3

6.3.1 OVERVIEW......................................................................................6-3

6.3.2 SCANNER DRIVE MECHANISM.....................................................6-4

6.3.3 IMAGE PROCESSING.....................................................................6-5

SBU and VIOB......................................................................................6-6

RIPU on SCU........................................................................................6-6

Line skipping correction........................................................................6-6

Scan line correction..............................................................................6-7

Black and white conversion..................................................................6-7

Gamma (γ) correction ...........................................................................6-7

Color resolution.....................................................................................6-7

Filtering.................................................................................................6-7

Magnification.........................................................................................6-8

Scale processing ..................................................................................6-8

Erasure of Irregular Dots.......................................................................6-8

OIPUB...................................................................................................6-8

Auto binary processing.........................................................................6-8

Auto image area separation..................................................................6-9

Manual image area separation .............................................................6-9

6.4 NEWORK INTERFACE.............................................................................6-9

6.5 IEEE1394 INTERFACE...........................................................................6-10

6.5.1 IEEE1394 .......................................................................................6-10

6.5.2 BLOCK DIAGRAM..........................................................................6-11

iii

Page 6

PERIPHERALS

ARDF

1 REPLACMENT............................................................................. 1-1

1.1 SPECIAL TOOLS......................................................................................1-1

1.2 REPLACEMENT........................................................................................1-1

1.2.1 LEFT COVER...................................................................................1-1

1.2.2 PAPER FEED UNIT..........................................................................1-2

1.2.3 SEPARATION ROLLER...................................................................1-2

1.2.4 PICK-UP ROLLER............................................................................1-3

1.2.5 FEED BELT......................................................................................1-3

1.2.6 ORIGINAL SET/ORIGINAL REVERSE SENSOR............................1-4

ORIGINAL LENGTH, WIDTH SENSOR BOARD..................................1-5

1.2.8 DF EXIT TABLE AND COVERS.......................................................1-6

1.2.9 FEED COVER SENSOR..................................................................1-6

1.2.10 REGISTRATION SENSOR.............................................................1-7

1.3 CLUTCH/SOLENOID/MOTORS................................................................1-8

DF Feed Clutch.....................................................................................1-8

Pick-up Solenoid...................................................................................1-8

Junction gate solenoid..........................................................................1-8

Transport Motor....................................................................................1-8

DF Feed Motor......................................................................................1-8

2 DETAILED FUNCTION DESCRIPTION....................................... 2-1

2.1 MACHINE OVERVIEW .............................................................................2-1

2.1.1 MECHANICAL COMPONENT LAYOUT...........................................2-1

Mechanical component layout ..............................................................2-1

Drive layout...........................................................................................2-2

2.1.2 CONTROL SYSTEM........................................................................2-3

2.2 DETAILED FUNCTION .............................................................................2-4

2.2.1 ORIGINAL SIZE DETECTION..........................................................2-4

2.3 SERVICE TABLE ......................................................................................2-5

2.3.1 ORIGINAL SIZE SENSOR AND BOARD COMBINATION...............2-5

2.3.2 PICK-UP AND SEPARATION ..........................................................2-7

2.3.3 ORIGINAL TRANSPORT AND EXIT................................................2-8

Single –sided originals..........................................................................2-8

Double-side originals ............................................................................2-9

2.3.4 TIMMING CHARTS........................................................................2-10

Single-sided mode (not pre-feed, not thin paper)................................2-10

Single-sided mode (pre-feed, not thin paper)......................................2-11

Single-sided mode (pre-feed, thin paper)............................................ 2-12

Double-sided mode (not pre-feed)......................................................2-13

Jam Conditions...................................................................................2-14

iv

Page 7

SERVICE TOOL

1 OVERALL INFORMATION ..............................................................1

1.1 OPERATIVE CONDITIONS .........................................................................1

1.2 INITIAL SETTINGS ......................................................................................1

1.2.1 SCSI ID................................................................................................1

1.2.2 HOST ADAPTER ID............................................................................2

1.3 CHART SETTING POSITION.......................................................................3

1.3.1 RICOH GRAY SCALE.........................................................................3

1.3.2 RS-13 ..................................................................................................3

2 SCAN...............................................................................................4

2.1 SIMPLE SCANNING ....................................................................................4

2.1.1 OVERVIEW.........................................................................................4

2.1.2 SCANNING..........................................................................................5

2.1.3 SCANNING A SELECTED AREA........................................................7

2.2 SCANNING BY MANUAL SETTING ............................................................8

2.3 CONTINUOUS SCANNING..........................................................................9

3 SCANNING ADJUSTMENT...........................................................10

3.1 OVERVIEW................................................................................................10

3.2 SCAN COUNTER.......................................................................................10

3.3 REGISTRATION.........................................................................................11

3.4 WHITE AND GRAY BALANCE...................................................................12

3.4.1 WHITE BALANCE.............................................................................12

Manual adjustment ................................................................................12

Automatic adjustment............................................................................13

3.4.2 GRAY BALANCE ADJUSTMENT......................................................14

3.5 DESTINATION ...........................................................................................16

4 IMAGE EVALUATION....................................................................17

4.1 OVERVIEW................................................................................................17

4.2 REGISTRATION.........................................................................................18

4.2.1 PROCEDURE....................................................................................18

4.2.2 SPECIFIED VALUE...........................................................................19

Book mode.............................................................................................19

ADF mode(front side).............................................................................19

ADF mode(reverse side)........................................................................19

4.2.3 CONDITION ......................................................................................19

4.2.4 METHOD...........................................................................................19

Main scan ..............................................................................................19

Sub scan................................................................................................19

4.3 SKEW.........................................................................................................20

4.3.1 PROCEDURE....................................................................................20

4.3.2 SPECIFIED VALUE...........................................................................20

Book mode.............................................................................................20

ADF mode..............................................................................................20

4.3.3 CONDITION ......................................................................................21

v

Page 8

4.3.4 METHOD...........................................................................................21

Main scan ..............................................................................................21

Sub scan................................................................................................21

4.4 ACTUAL IMAGE SIZE................................................................................22

4.4.1 PROCEDURE....................................................................................22

4.4.2 SPECIFIED VALUE...........................................................................22

Book mode.............................................................................................22

ADF mode..............................................................................................22

4.4.3 CONDITION ......................................................................................23

4.4.4 METHOD...........................................................................................23

Main scan ..............................................................................................23

Sub scan................................................................................................23

4.5 JITTER.......................................................................................................24

4.5.1 PROCEDURE....................................................................................24

± 45 degrees..........................................................................................24

0 degree.................................................................................................25

4.5.2 SPECIFIED VALUE...........................................................................26

4.5.3 CONDITION ......................................................................................26

4.5.4 METHOD...........................................................................................26

± 45 degrees..........................................................................................26

0 degrees...............................................................................................26

4.6 PARTIAL IMAGE STRETCH......................................................................27

4.6.1 PROCEDURE....................................................................................27

4.6.2 SPECIFIED VALUE...........................................................................27

Book mode.............................................................................................27

ADF mode..............................................................................................27

4.6.3 CONDITION ......................................................................................28

4.6.4 METHOD...........................................................................................28

5 TROUBLESHOOTING...................................................................29

5.1 ERROR MASSEGE ....................................................................................29

5.1.1 ON START UP ..................................................................................29

5.1.2 ADJUSTMENT AND SCANNING......................................................30

5.1.3 IMAGE EVALUATIONS.....................................................................30

5.2 SCSI CONDITION CODES........................................................................31

5.2.1 SENSE KEY CODES.........................................................................31

5.2.2 ADDITIONAL SENSE CODES AND QUALIFIRE..............................31

vi

Page 9

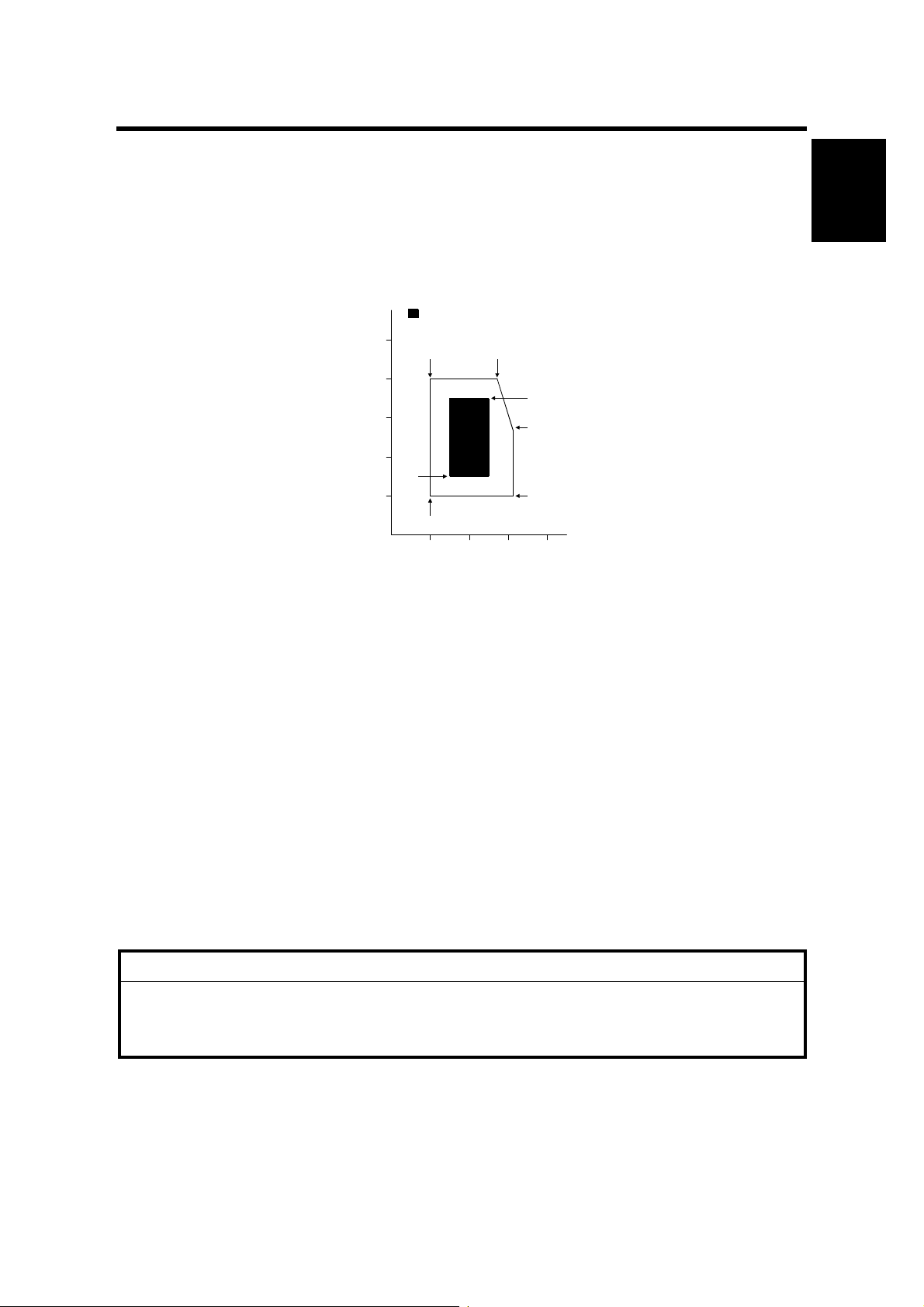

28 December, 2000 INSTLLATION REQUIRMENTS

1. INSTALLATION PROCEDURE

1.1 INSTLLATION REQUIRMENTS

1.1.1 ENVIRONMENT

Use this machine at optimum temperature and moisture.

: Optimum temperature and moisture range

100

10°C 80% 27°C 80%

80

25°C 70%

60

Moisture [%]

40

20

15°C 30%

10°C 20%

10 20 30 40

Temperature [°C]

32°C 54%

32°C 20%

G412I500.WMF

1.1.2 MACHINE LEVEL

Front to back within ±5 mm of level

Right to left ±5 mm of level

Installation

1.1.3 MINIMUM SPACE REQUIRMENTS

Right clearance: Over 0 mm

Left clearance: Over 100 mm

Back side clearance: Over 0mm

Top clearance: Over 660 mm

1.1.4 POWER REQUIRMENT

!

CAUTION

1. Make sure the plug is firmly inserted in the outlet

2. Avoid multi-wiring.

3. Be sure to ground machine.

North America: Input voltage AC102V to 138V, less than 4.0A, 45 to 65Hz

Europe: Input voltage AC187V to 276V, less than 2.0A, 45 to 65Hz

Do not set anything on the power cord.

1-1

Page 10

MAINFRAME AND OPTION INSTALLATION PROCEDURES 28 December, 2000

1.2 MAINFRAME AND OPTION INSTALLATION PROCEDURES

1.2.1 ACCESSORY CHECK

NOTE: NA is North America. EU is Europe.

mainframe

NA EU

Product code G412-17 G412-27

Terminator Yes (Internal) Yes (Internal)

SCSI Cable No No Note1)

Power Cable Yes Yes (C Type)

Screwdriver Yes Yes

Installation Procedure/ packaging contents Yes Yes

Safety instruction sheet (19 languages) No Y es

Safety instruction sheet for US Yes No

CD-ROM

Operating instruction for SCSI and

IEEE1394 (7 languages)

TWAIN Driver SCSI I / F (7 languages) Yes Note 3) Yes Note 3)

TWAIN Driver IEEE1394 I/F

(7 languages)

DeskTopBinder V2 Lig ht (14 languages) Yes Note 4) Yes Note 4)

DeskTopBinder V2 Lig ht Manual

(PDF file)

Yes Note 2) Yes Note 2)

Yes Note 3) Yes Note 3)

Yes Yes

NOTE: 1) SCSI cable is removed from 220V model.

2) Operating instruction will be provided with PDF format. No paper

manual is bundled.

3) TWAIN driver will be generic.

4) Schedule for releasing bundled drivers and utility is mentioned in the

cause of “ Schedule”.

IEEE1394 I/F (OPTION)

NA/EU

Product code G562-17

IEEE1394 board Yes

IEEE1394 cable Yes

Screws (2 pieces) Yes

Installation procedure Yes

1-2

Page 11

28 December, 2000 MAINFRAME AND OPTION INSTALLATION PROCEDURES

Network interface kit (OPTION)

NA/EU

Product code G558-17

Network interface Yes

Operation panel + Screw s Yes

Screw (2 Pieces) Yes

Installation procedure (7 lang uages) Yes

CD-ROM

TWAIN driver for Network I/F by

Ricoh (7 languages)

Scanrouter V2 (5 languages) Yes

Operating instructions Yes

Aficio manager Yes

Aficio manager for client Yes

WebStatusMo nit or He lp Yes

Yes

OIPUB (OPTION)

NA/EU

Product code G514-21

Installation procedure Yes

Installation

NOTE: Use for Image processing unit to following processing. (monochrome

image only)

• Auto binary processing

• Auto Image area separation

• Manual Image area separation

Memory Card (Memory unit type B)

NA/EU

32M SDRAM G578-17

64M SDRAM G579-17

128M SDRAM G580-17

NOTE: Increases the data capacity. Faster image reading.

1-3

Page 12

28 December, 2000 USER MAINTENANCE

2. PREVENTIVE MAINTENANCE SCHEDULE

2.1 USER MAINTENANCE

Clean the following parts at every EM.

Item Remarks

Feed belt Wipe out wet cloth at alcohol or w at er.

Pick-up roller Wipe out wet cloth at alcohol or water.

Separation roller Wipe out wet cloth at alcohol or wat er.

Preventive

Maintenance

2-1

Page 13

28 December, 2000 SPECIAL TOOLS

3. REPLACEMENT AND AD JUSTMENT

!

CAUTION

Turn off the main power switch and unplug the machine before attempting

any of the procedures in this section.

CAUTION: To prevent injury, do not change the position of bule screw. They are

used in position where customer may touch them.

This manual uses the following .

☛: See or Refer to !: Screw ": Connector

3.1 SPECIAL TOOLS

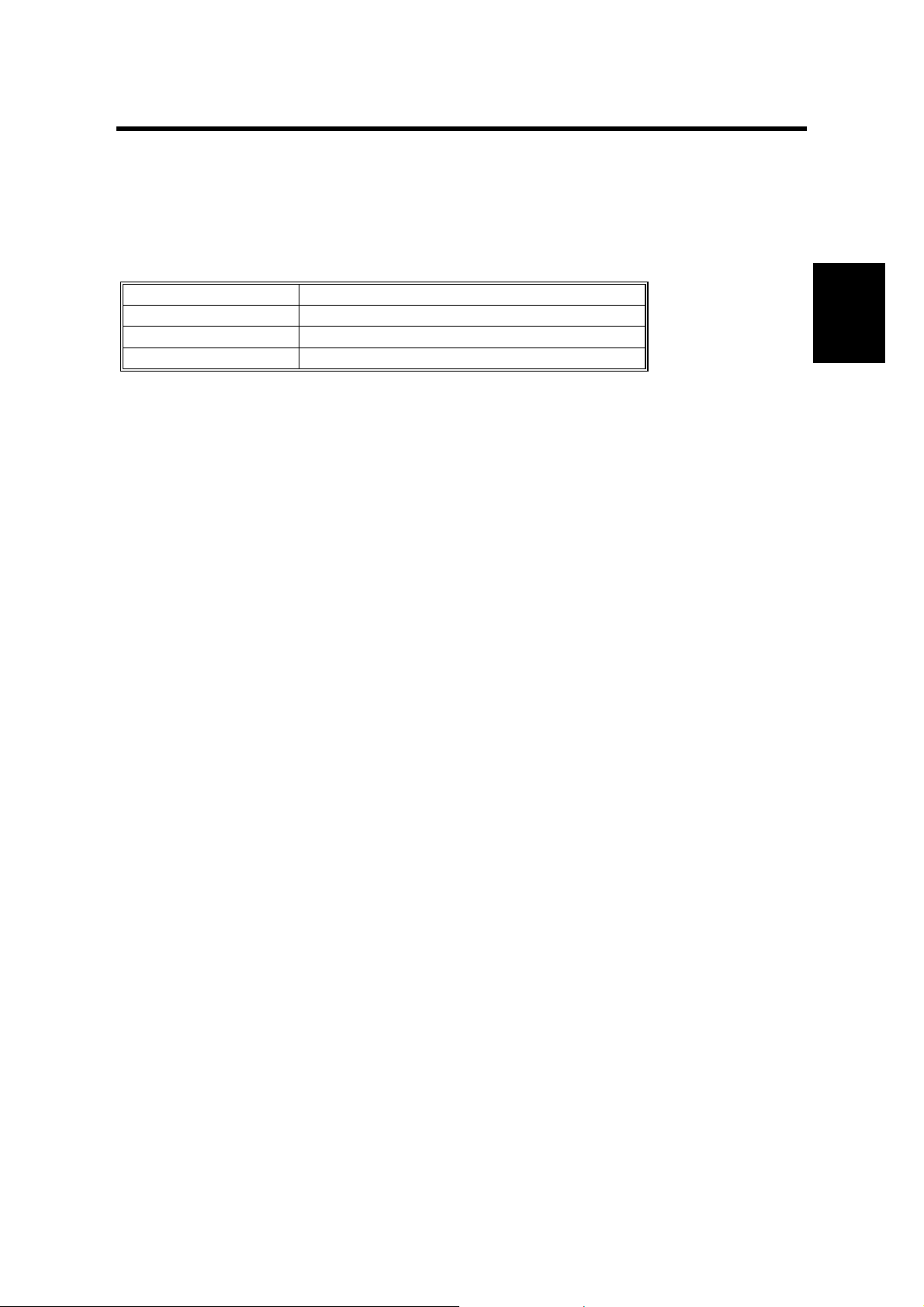

Part number Description Description section Qty

A0069104 Scanner position pin (4pcs/set) 3.3.1 SCANNER WIRE 1

A2309350 Flash memory card 4MB

G4129310 Ricoh Gray Scale SERVICE TOOL 1

G4049004 RS-13 A3 55kg

3.3.2 FIRM WARE U PDATE

PROCEDURE

3.2.6 SENSOR BOARD UNIT,

3.2.11 EXPOUSURE L AMP

3.2 REPLACEMENT

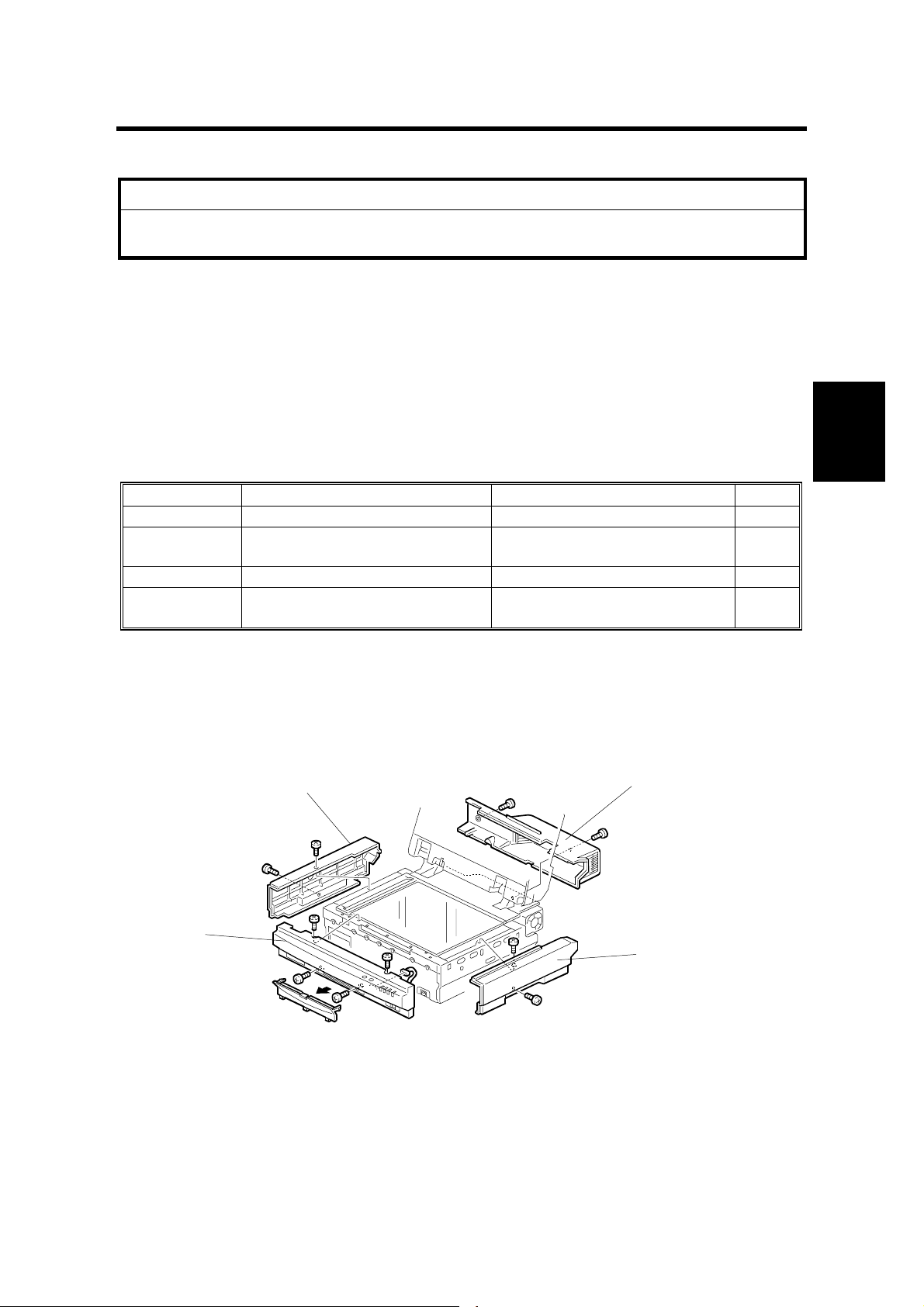

3.2.1 EXTERIOR

[B]

[D]

Adjustment

Replacement

1

1

[A]

[A]: Front cover (!x4, "x1)

[B]: Left cover (!x2)

[C]: Right cover (!x2)

[D]: Rear cover (!x2)

[C]

G412R001.WMF

3-1

Page 14

REPLACEMENT 28 December, 2000

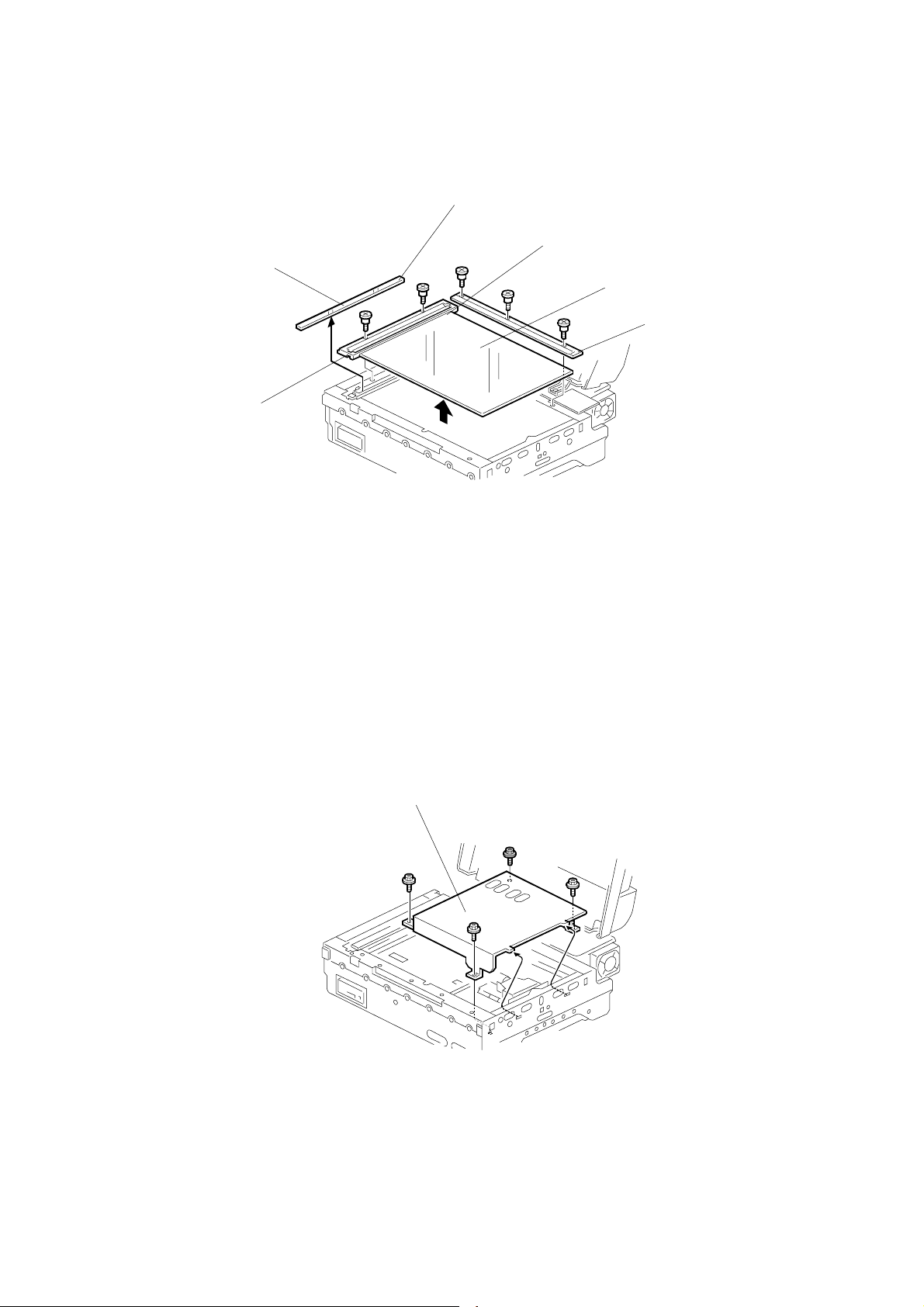

3.2.2 EXPOSURE GLASS

White Mark

Red Mark

[D]

[C]

[A]

[B]

G412R002.WMF

[A]: Rear scale(!x3)

[B]: Left scale (!x2)

[C]: Exposure glass

[D]: ADF exposure glass

CAUTION: 1) Use caution when placing the red mark position on the exposure

glass [C].

2) Use caution when placing the white mark position on the ADF

exposure glass [D].

3.2.3 INNER COVER 1

[A]

G412R003.WMF

Exposure glass (☛ 3.2.2)

[A]: Inner cover (!x4)

3-2

Page 15

28 December, 2000 REPLACEMENT

3.2.4 ORIGINAL LENGTH 1/2 SENSORS

[C]

[B]

[A]

G412R500.WMF

Adjustment

Replacement

Exposure glass (☛ 3.2.2)

Inner cover 1 (☛ 3.2.3)

[A]: Original Length 1 sensor (!x1, "x1)

[B]: Original Length 2 sensor (!x1, "x1)

[C]: Original Length sensor bracket (!x1)

3.2.5 SCANNER HP SENSOR AND DF POSITION SENSOR

[B]

[A]

A193R015.WMF

Left and Rear cover (☛ 3.2.1 EXTERIOR)

Motor cover (☛ 3.2.10 SCANNER MOTOR)

[A]: Scanner HP sensor ("x1)

[B]: DF position sensor ("x1)

3-3

Page 16

REPLACEMENT 28 December, 2000

3.2.6 SENSOR BOARD UNIT (SBU)

[A]

G412R007.WMF

Exposure glass (☛ 3.2.2)

Inner cover 1 (☛ 3.2.3)

Original Length 1/2 sensors (☛ 3.2.4)

[A]: SBU (!x4,"x1)

CAUTION: Do not dismantle this unit. Take out the screw at the bracket only.

NOTE: After SBU has been replaced, adjust the registration using Scan-Probe (the

PC utility software for this machine) if necessary.

3.2.7 INNER COVER 2

[A]

G412R005.WMF

Exposure glass (☛ 3.2.2)

Inner cover 1 (☛ 3.2.3)

Original Length 1/2 sensors (☛ 3.2.4)

SBU (☛ 3.2.6)

[A]: Inner cover 2 (!x3)

3-4

Page 17

28 December, 2000 REPLACEMENT

3.2.8 ORIGINAL WIDTH SENSOR

Exposure glass (☛ 3.2.2)

Inner cover 1 (☛ 3.2.3)

Original Length 1/2 sensors (☛ 3.2.4)

SBU (☛ 3.2.6)

Inner cover 2 (☛ 3.2.7)

[A]: Original Width 3 Sensor (!x1)

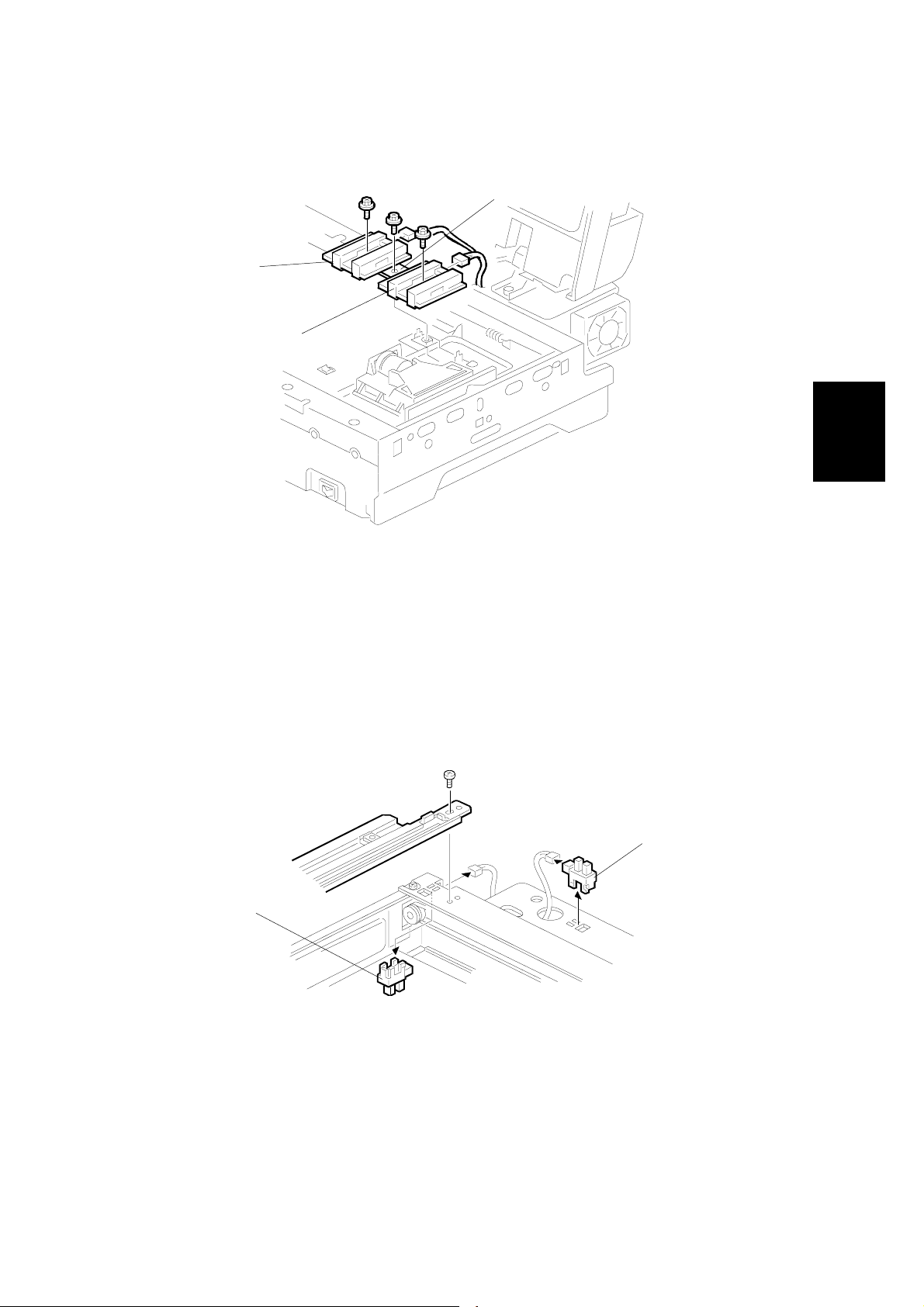

3.2.9 EXPOSURE LAMP STABILIZER

Exposure glass (☛ 3.2.2)

Inner cover 1 (☛ 3.2.3)

Original Length 1/2 sensors (☛ 3.2.4)

[A]

[A]

G412R006.WMF

Adjustment

Replacement

SBU (☛ 3.2.4)

Inner cover 2 (☛ 3.2.7)

Original Width sensor (☛ 3.2.8)

[A]: Exposure lamp stabilizer (!x2, "x2)

G412R021.WMF

3-5

Page 18

REPLACEMENT 28 December, 2000

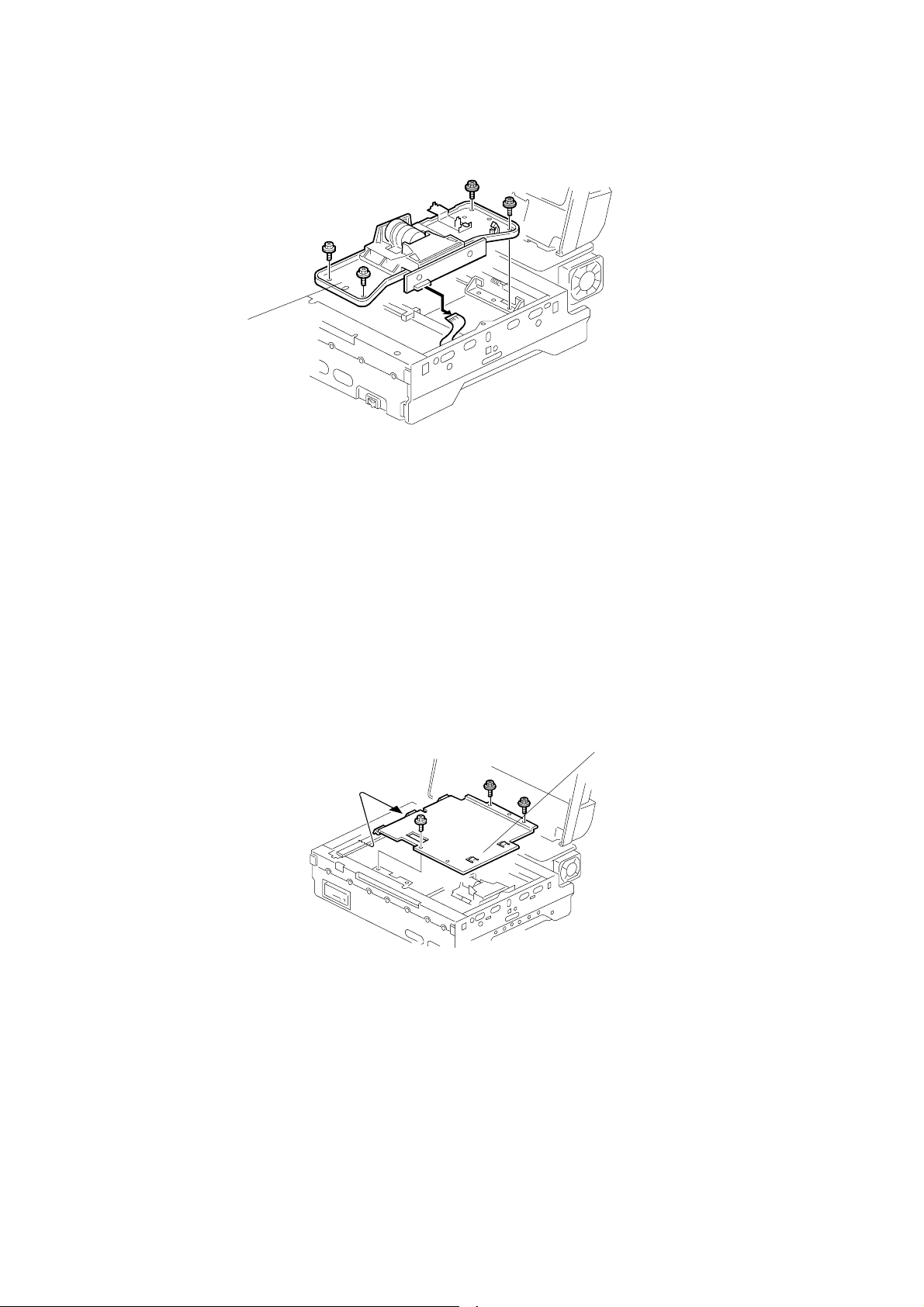

3.2.10 SCANNER MOTOR

[A]

G412R008.WMF

[B]

[D]

[A]: Motor cover (!x2)

[B]: Scanner motor bracket(!x2,"x2)

[C]: Timing belt (!x1)

[D]: Scanner motor (!x2)

[C]

G412R009.WMF

3-6

Page 19

28 December, 2000 REPLACEMENT

3.2.11 EXPOSURE LAMP

[A]

G412R006.WMF

Adjustment

Replacement

[B]

G412R013.WMF

Front cover (☛ 3.2.1 EXTERIOR)

Exposure glass (☛ 3.2.2)

Move carriage to the notch [A] on the front frame.

[B]: Exposure lamp (!x1, "x1)

NOTE: After replacing the exposure lamp, adjust the scanning image using Scan-

Probe (the PC utility software for this machine) if necessary.

3-7

Page 20

REPLACEMENT 28 December, 2000

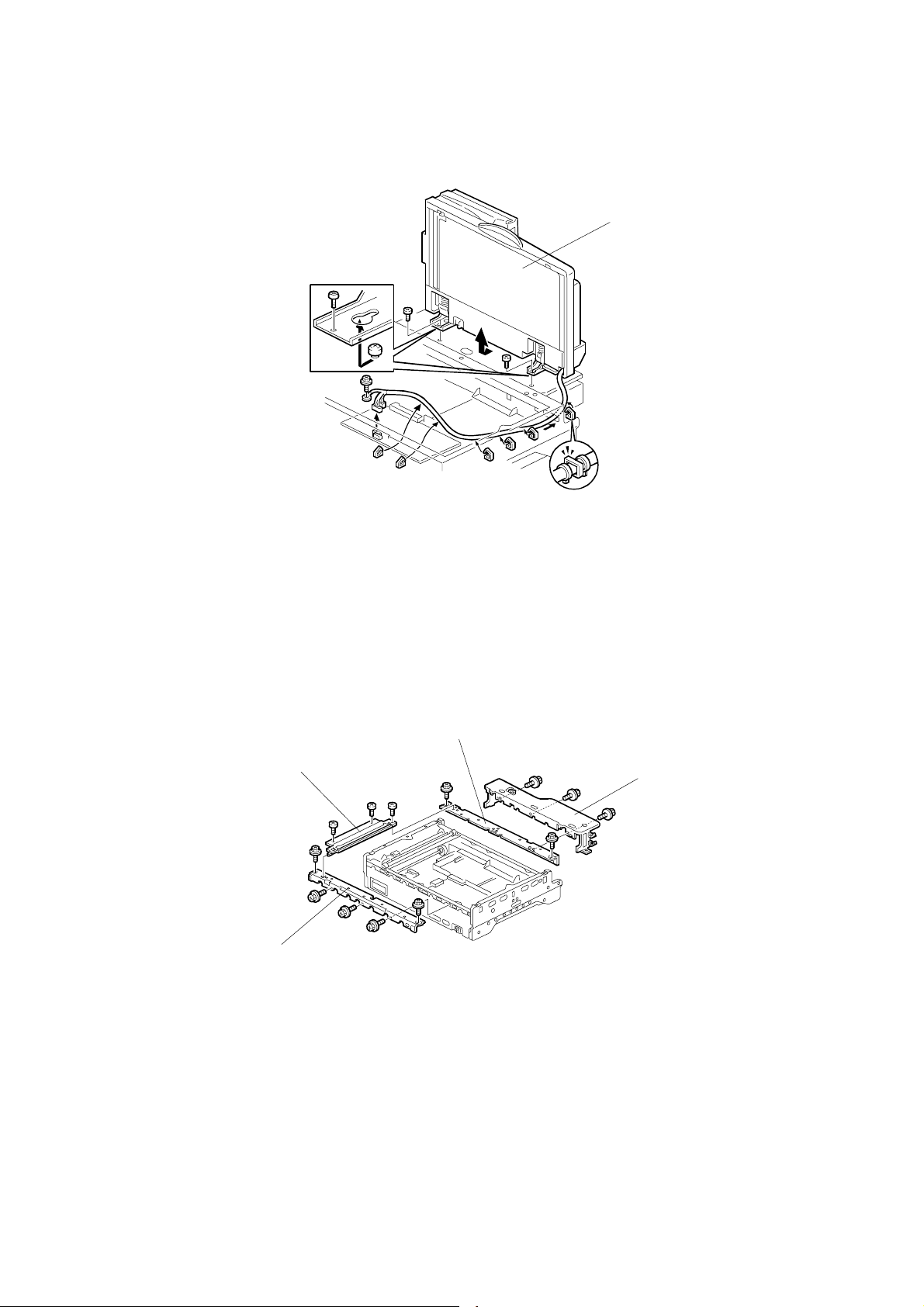

3.2.12 AUTO DOCUM ENT FEEDER (ADF)

[A]

G412R010.WMF

Exposure glass (☛ 3.2.2)

Inner cover 1 (☛ 3.2.3)

Original Length 1/2 sensors (☛ 3.2.4)

SBU (☛ 3.2.6)

[A]: ADF (!x2, "x3,earth wirex1)

3.2.13 SCANNER FRAME

[A]

[B]

[D]

[C]

G412R012.WMF

Front cover (☛ 3.2.1 EXTERIOR)

Exposure glass (☛ 3.2.2)

[A]: Left frame (!x3)

[B]: Front frame (!x5)

[C]: Hinge (!x3)

[D]: Rear frame (!x2)

3-8

Page 21

28 December, 2000 REPLACEMENT

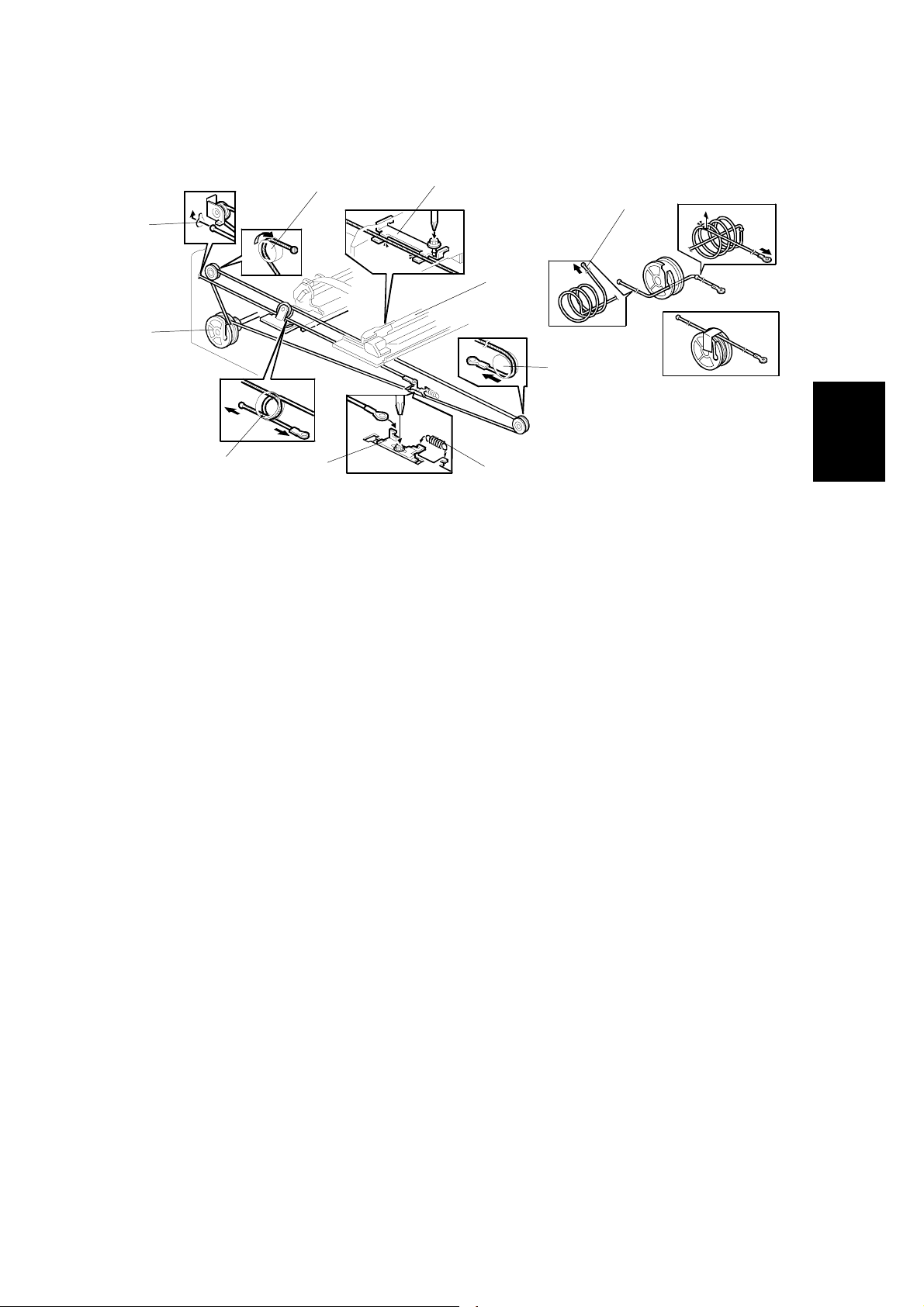

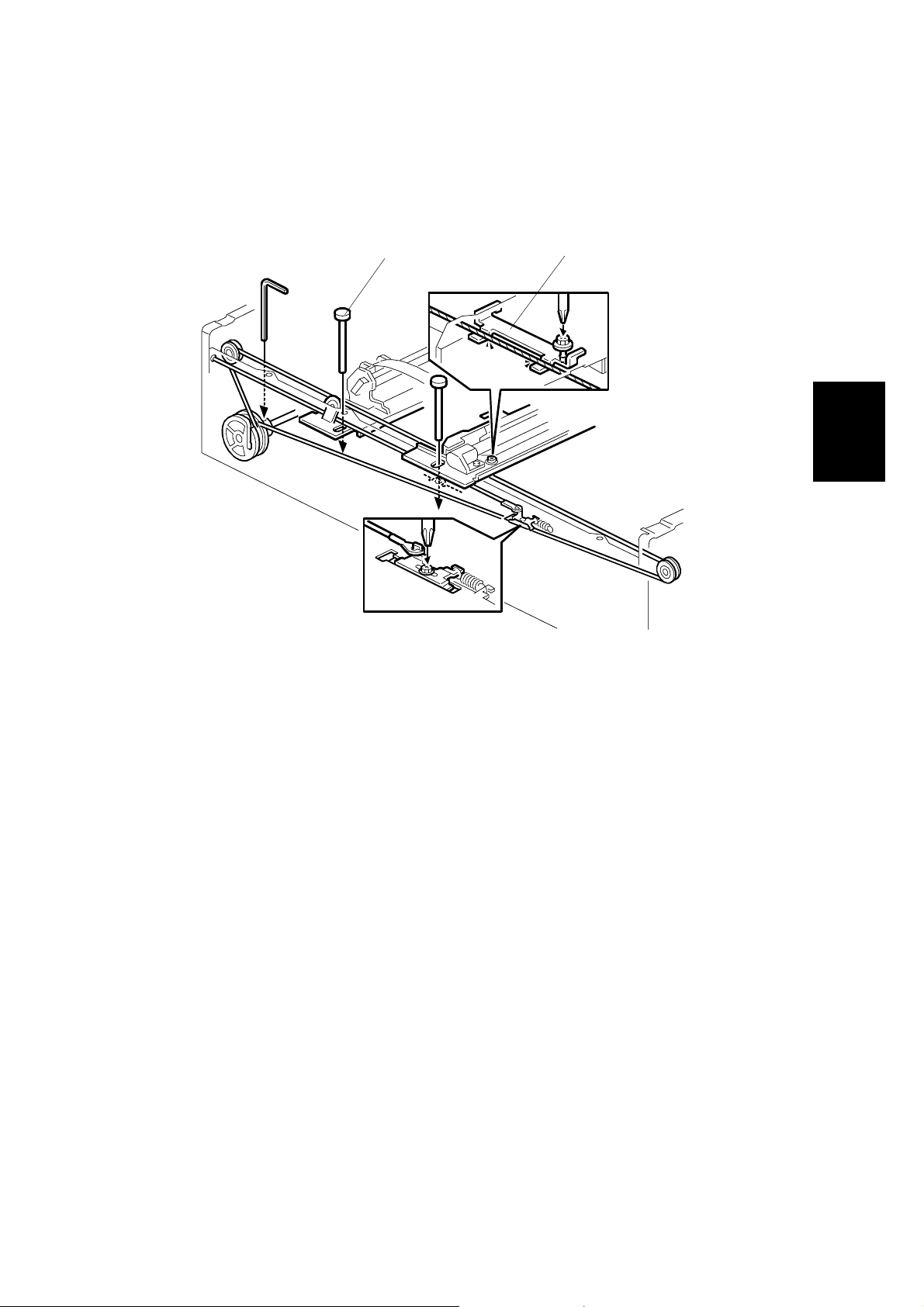

3.2.14 SCANNER WIRE

[F]

[H]

[D]

[G]

G412R504.WMF

[A]

Exterior covers (☛ 3.2.1)

Exposure glass (☛ 3.2.2)

ADF (☛ 3.2.12)

Scanner frames (☛3.2.13)

[B]

[J]

[C]

[I]

[E]

G412R015.WMF

Adjustment

Replacement

Uninstall:

[A]: Right or left scanner wire tension bracket (!x1)

[B]: Wire stopper bracket (!x1)

[C]: Tension spring

[D]: Scanner wire and scanner drive pulley (allen screw x1)

Install:

Wind the new scanner wire around scanner drive pulley in the correct direction, as

shown [E].

Wind the new scanner wire with the ball around the upper left pulley as shown [F].

Wind the new scanner wire with the ball through the central pulley as shown [G].

Hook the wire ball to the frame [H].

Wind the new scanner wire with the ring around the right pulley as shown [I].

Attach the new scanner wire to the scanner [J] .(!x1)

Wind the new scanner wire with the ring through the central pulley as shown [G].

Install the tension spring [C] on the wire tension bracket [A].(!x1)

Adjust scanner frame wire (☛ 3.3.1 SCANNER WIRE)

Tighten the wire tension bracket [A].

3-9

Page 22

REPLACEMENT 28 December, 2000

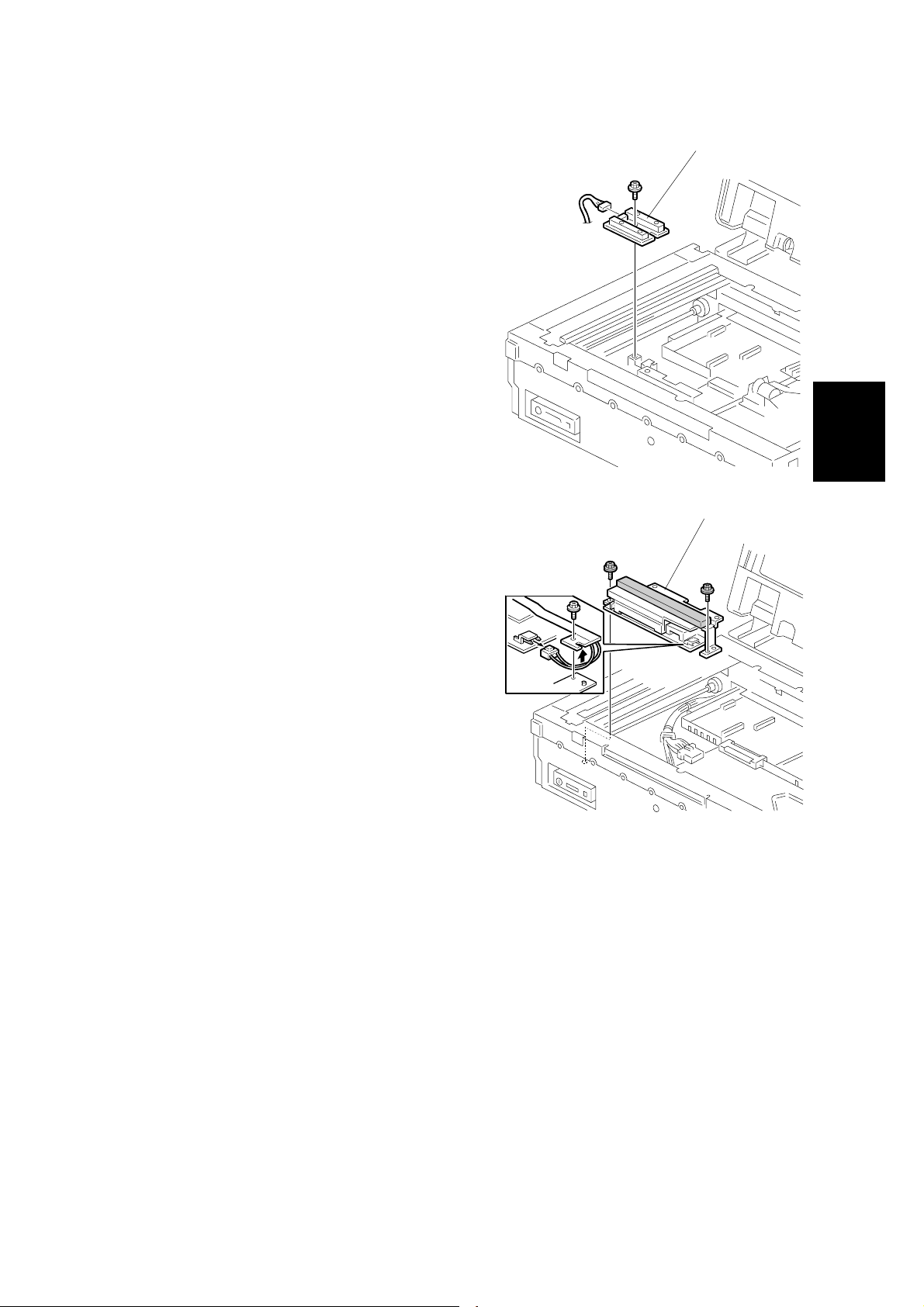

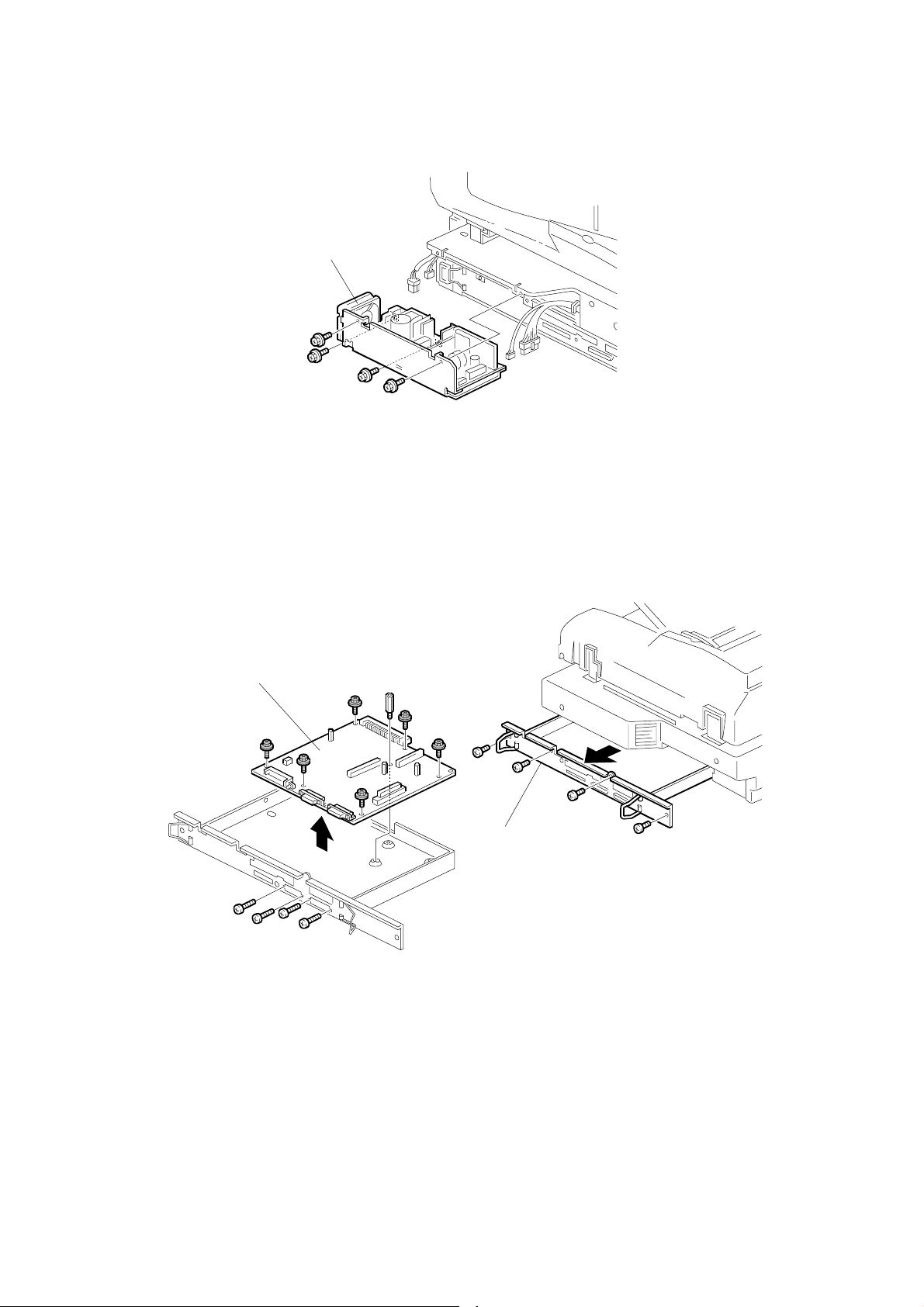

3.2.15 POWER SUPPLY UNIT (PSU)

[A]

G412R011.WMF

Rear cover (☛ 3.2.1 EXTERIOR)

[A]: PSU (!x4, "x4)

3.2.16 SCANNER CONTROL UNIT (SCU)

[B]

[A]

G412R019.WMF

G412R018.WMF

[A]: SCU assembly (!x4)

[B]: SCU (!x10, spacerx4)

NOTE: 1) Check the connection with the VIOB, if necessary.

2) After the SCU has been replaced, remove the EEPROM from the old

board and put on the new board.

3-10

Page 23

28 December, 2000 REPLACEMENT

3.2.17 VIDEO AND I/O CONTROL BOARD (VIOB)

[A]

G412R020.WMF

Exposure glass (☛ 3.2.2)

Inner cover 1 (☛ 3.2.2)

Original Length 1/2 sensors (☛ 3.2.4)

SBU (☛ 3.2.4)

Inner cover 2 (☛ 3.2.6)

[A]: VIOB (!x6, "x11)

NOTE: Check the connection with the SCU, if necessary.

3.2.18 SCANNER OPERATION PANEL (SOP)

[A]

Adjustment

Replacement

Front covers (☛ 3.2.1 EXTERIOR)

[A]: SOP (!x1)

G412R023.WMF

3-11

Page 24

REPLACEMENT 28 December, 2000

3.2.19 SWITCH BOARD (SWB)

[B]

[A]

Front covers (☛ 3.2.1 EXTERIOR)

[A]: Gird cover (!x1)

[B]: SWB (!x1,"x1)

NOTE: Keep following setting.

• SCSI ID

• Dip switch

• SCSI/IEEE1394 Switch

G412R022.WMF

3-12

Page 25

28 December, 2000 ADJUSTMENT

3.3 ADJUSTMENT

3.3.1 SCANNER WIRE

Parallelism Adjustment

[A]

[B]

G412R014.WMF

Adjustment

Replacement

Exterior covers (☛ 3.2.1)

Exposure glass (☛ 3.2.2)

ADF (☛ 3.2.12)

Scanner frames (3.2.13)

[A]: Set scanner positioning tools (P/N A0069104)

If scanner position tool does not install smoothly, it needs adjusting.

Adjust points:

1) Check the scanner drive pulley position.

2) Check the wire stopper bracket.

3) Adjust the scanner frame wire.

3-13

Page 26

28 December, 2000 LED FUNCTION MODE

4. TROUBLESHOOTING

4.1 LED FUNCTION MODE

4.1.1 NORMAL LED FUNCTION TABLE

Conditions Contents

Machine

initialization

Stand-by

Scanning Normal mode

User-visible

error

conditions

Service-call

error

Low power

mode

Flash-ROM

download

Flash-ROM

upload

Flash-ROM

download

error

Flash-ROM

upload error

Overall

machine check

Normal mode

Scan wait

mode

ADF cover switch open On

Document jam On

Document misfeed On

Option error Blinking Blinking On Blinking

Originals

on the

ADF

-OnOnOnOn

No On Off Off Off

Yes On Off On Off

No On Off Blinking Off

Yes On Off Blinking Off

No On On Off Off

Yes On On On Off

- Blinking Blinking Blinking Blinking

-BlinkingOff

- NOTE 2)

- NOTE 3)

- Off Off Blinking Blinking

- Off Blinking Blinking Blinking

Power on

(Green)

Machine

NOTE 4)

NOTE 4)

NOTE 4)

LEDs

busy

(Green)

On

On

On

Document

in place

(Green)

Off On

Blinking On

On On

Off

NOTE 1)

Error

(Red)

Off

Trouble-

shooting

On: LED on Blinking: LED blinking Off: LED off

NOTE: 1) When the mode changes to the scan wait mode, it starts blinking.

2) On LEDs scroll to the left.

3) On LEDs scroll to the right.

4) When the scanner moves back to ho me position, it turns off.

4-1

Page 27

LED FUNCTION MODE 28 December, 2000

Order of priority

1) Flash-ROM upload error

2) Flash-ROM download error

3) Flash-ROM upload

4) Flash-ROM download

5) Service-call error

6) User-visible error - ADF cover switch open

7) User-visible error - Document jam

8) User-visible error - Document misfeed

9) User-visible error - Op tion error

10) Machine Initialization

11) Stand-by - Scan wait mode

12) Stand-by - Originals on the ADF

13) Low power mode

14) Stand-by - Normal mode

4.1.2 SELF DIAGNOSTIC MODE

By setting the proper DIP switch, you can view the specific error when a service

call error is received. (☛ 5.1 DIP SW ITCH FUNCTION)

LED function table

LEDs

Conditions

Power on

(Green)

Memory error Blinking Off Off Off

IEEE1394 3.3V error Blinking On Blinking Blinking

VIOB 3.3V error Blinking Off Blinking Blinking

OIPU 3.3V error Blinking On Off Blinking

SCU 2.5V error Blinking Off On Blinking

SCU 3.3V error Blinking Off Off Blinking

Lamp failure error Blinking Blinking On On

Home position error Blinking Blinking Blinking On

NIC SC error Blinking Blinking Blinking Blinking

On: LED on Blinking: LED blinking Off: LED off

Machine

busy

(Green)

Document

in place

(Green)

Error (Red)

NOTE: 1) When t wo or more errors occu r, the LEDs display t he first error.

2) This is in self-diagnosis mode only. In normal use, any of these errors

cause all the LEDs to blink.

4-2

Page 28

28 December, 2000 LED FUNCTION MODE

Descriptions

Conditions Symptoms Possible cause

Memory error

IEEE1394 3.3V

error

VIOB 3.3V error

OIPU (Option

Image Processor

Unit)3.3V error

SCU 2.5V error

SCU 3.3V error

Lamp failure

error

SRAM or DRAM erro r

1. Ram reading or writing error,

when power is applied

2. DRAM reading or writing error,

during self-diagnosis.

3. Memory read error

Supply voltage error.

3.3V current not found.

Supply voltage error.

3.3V current not found.

Supply voltage error.

3.3V current not found.

Supply voltage error.

2.5V current not found.

Supply voltage error.

3.3V current not found.

White level is less than the

specified value.

1. Checked while the machi ne

automatically adj ust s t he white

level. The light int ensity is less

than the specified amount.

2. When machine start scanning,

white level value less than

specified value.

• Replace the SCU.

• Replace the VIOB.

• Check the harnesses betwee n

the PSU and the VIOB.

• Replace the IEEE1394 board.

• Replace the SCU.

• Replace the VIOB.

• Check the harnesses betwee n

the PSU and the VIOB.

• Replace the VIOB.

• Check harnesses between th e

PSU and VIOB.

• Replace the OIPU.

• Replace the SCU.

• Replace the VIOB.

• Check the harnesses betwee n

the PSU and the VIOB.

• Replace the SCU.

• Replace the VIOB.

• Check the harnesses betwee n

the PSU and the VIOB.

• Replace the SCU.

• Replace the VIOB.

• Check the harnesses betwee n

the PSU and the VIOB.

< Exposure lamp is turned on at

initial settings. >

• Clean or replace the white plate.

• Replace the SBU.

• Replace the VIOB.

• Check the harnesses betwee n

the PSU and the VIOB.

< Exposure lamp is not turned on at

initial settings. >

• Replace the exposure la mp.

• Replace the stabilizer for the

exposure lamp.

• Check harnesses between th e

stabilizer and VIOB.

• Check harnesses between th e

stabilizer and the exposure

lamp.

Trouble-

shooting

4-3

Page 29

LED FUNCTION MODE 28 December, 2000

Conditions Symptoms Possible cause

The sensor does not detect the

scanner.

When the switch on the machine

is turned on

1. The sensor is off and it will not

turn on—even if the scanner

moves to the left of the 472

mm mark.

Home position

(HP) error

NIC SC error SC error at NIC ☛ 5.2.2 NIC Error log descriptions

2. The sensor is on and will not

turn off. Even if the scanner

moves to the right of the

115.6 mm mark.

When the machine usually works.

1. The sensor does not turn off,

even if the scanner is

scanning a document in AD F

mode.

2. The sensor does not turn off,

even if the scanner is

scanning a document in boo k

mode.

3. The sensor does not turn on,

even if the scanner is moved

back to the home position.

• Check the scanner lock.

• Replace the HP sensor.

• Replace the scanner motor.

• Check the scanner wire.

• Check the harnesses betwee n

the VIOB and the HP sensor.

4.1.3 BLOWN FUSE CONDITIONS

Fuse

120V 220-240V

Rating

Power supply unit

F001 5A/125V 3.15A/250V No response

Symptom when turning on the

main switch

4.1.4 IEEE1394 BOARD (OPTION)

If there are problems scanning using the IEEE1394 interface, check the following.

• Use Windows 2000 with service pack 1.

• Check to see if there is a loop some where in the network. IEEE1394 networks

must be a chain or branched chain.

4-4

Page 30

28 December, 2000 DIP SWITCH FUNCTION

5. SERVICE TABLES

5.1 DIP SWITCH FUNCTION

5.1.1 DIP SWITCH COMBINATIONS

After changing the DIP switch setting, either switch the power on and off, or press

the reset switch.

If you change the position of the SCSI ID rotary switch during these tests, be sure

to put it back to the original position once you have finished.

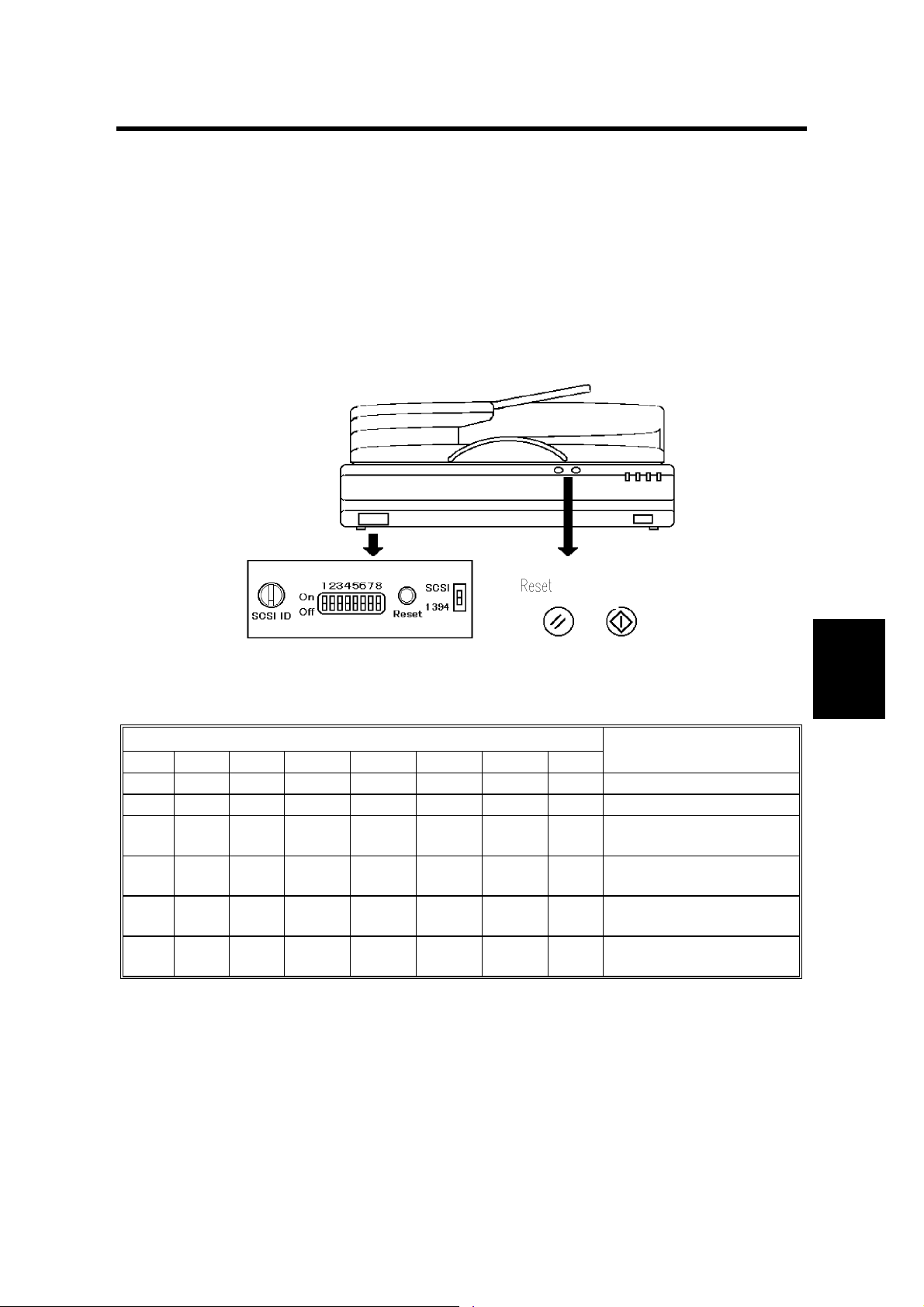

StartClear Modes

G412R501.TIF

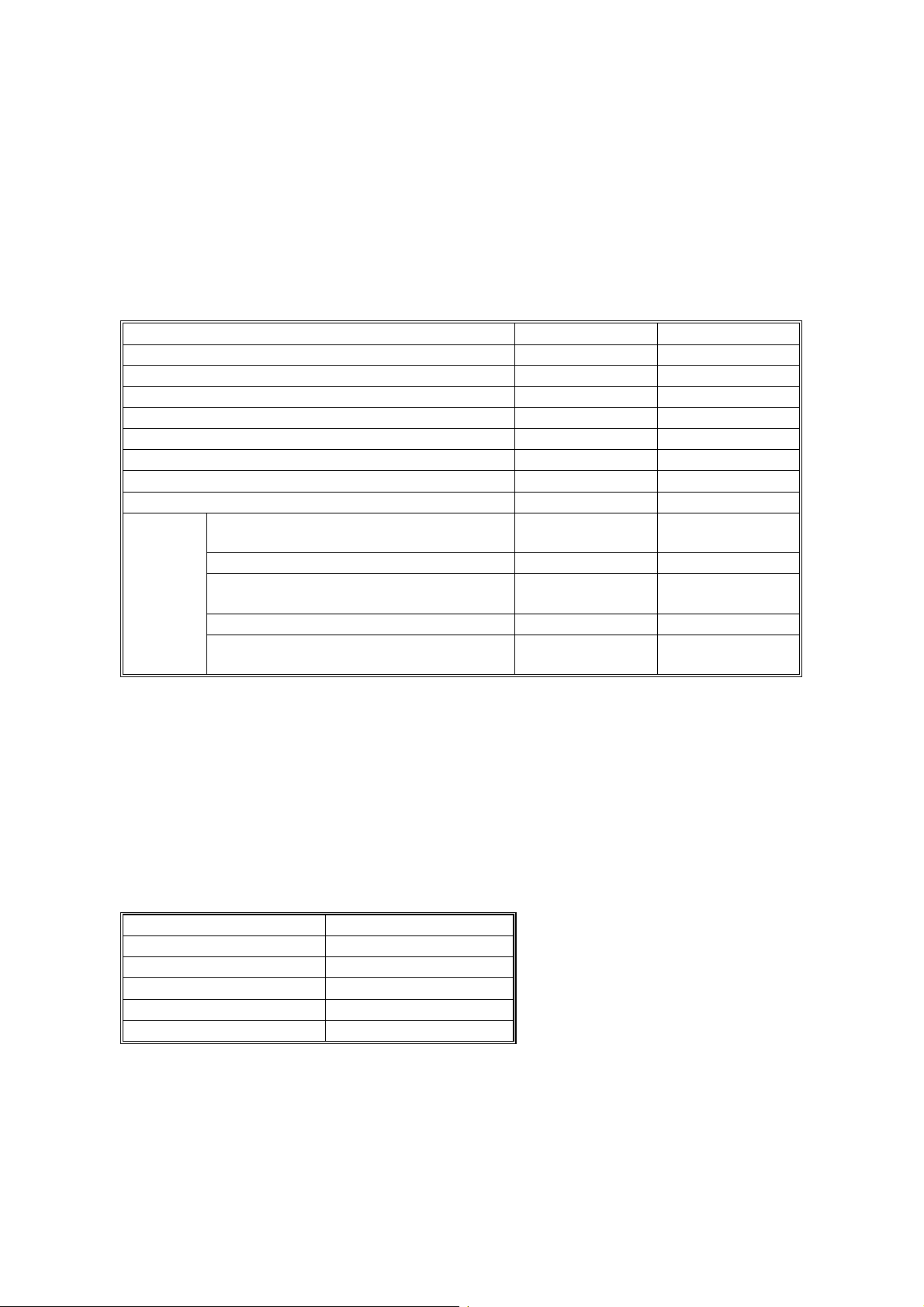

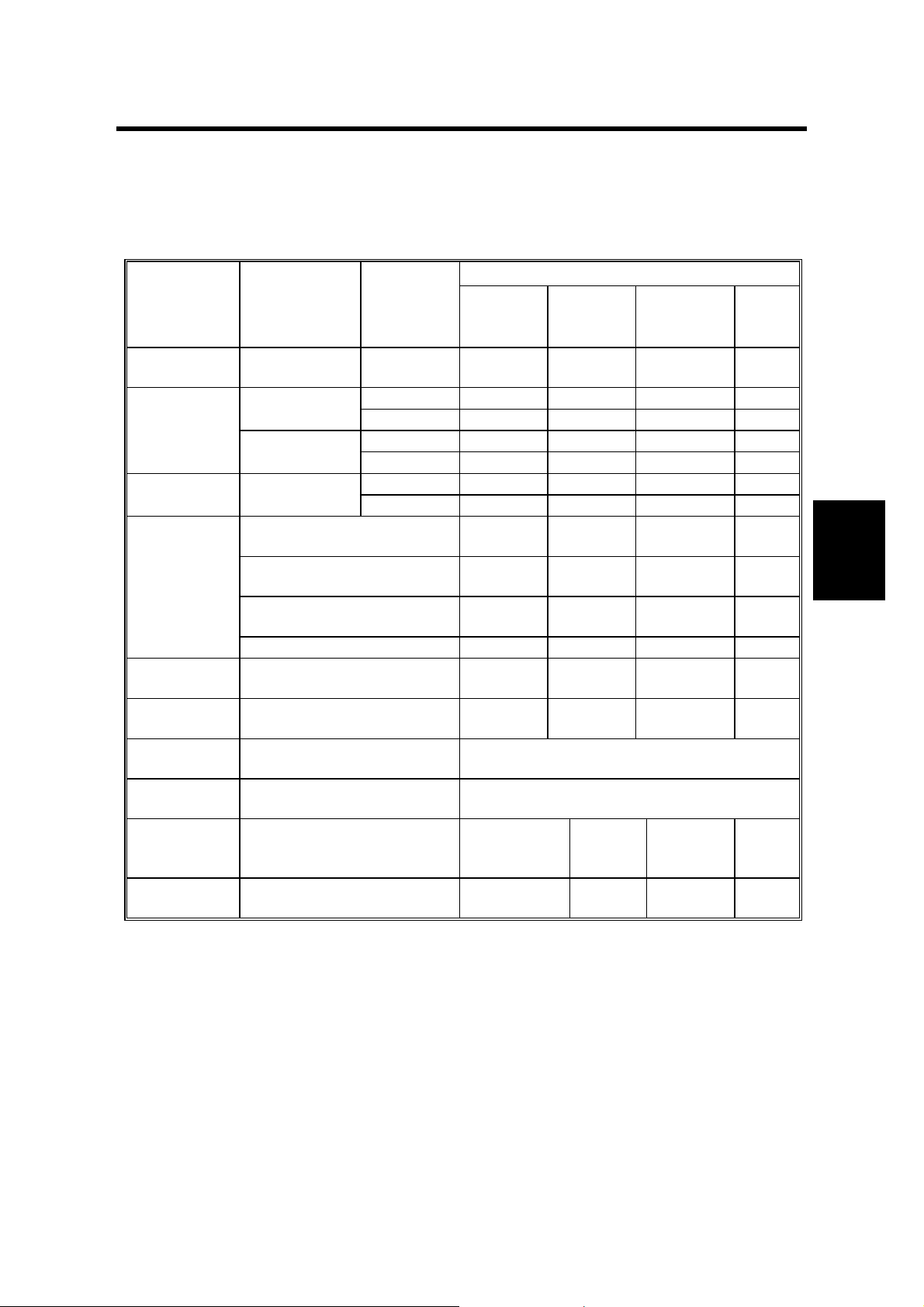

DIP switch setting table (Normal mode)

DIP switch

SW1 SW2 SW3 SW4 SW5 SW6 SW7 SW8

0 - - - 0 0 0 0 SCAM function disabled

1 - - - 0 0 0 0 SCAM function enabled

-0- - 0 0 0 0

-1- - 0 0 0 0

--0 - 0 0 0 0

--1 - 0 0 0 0

SCSI synchronous

transfer enabled

SCSI synchronous

transfer disabled

Internal SCSI

termination on

Internal SCSI

termination off

Item

0: Off, 1: On, -: Don’t care

NOTE: When SCAM function is enabled, this machine is automatically given an

SCSI ID. This prevents you from daisy-chaining other peripherals with the

scanner. If you wish to attach multiple components, disable SCAM and set

the SCSI ID at the SCSI rotary switch (☛ Table A: Normal mode).

Tables

Service

5-1

Page 31

DIP SWITCH FUNCTION 28 December, 2000

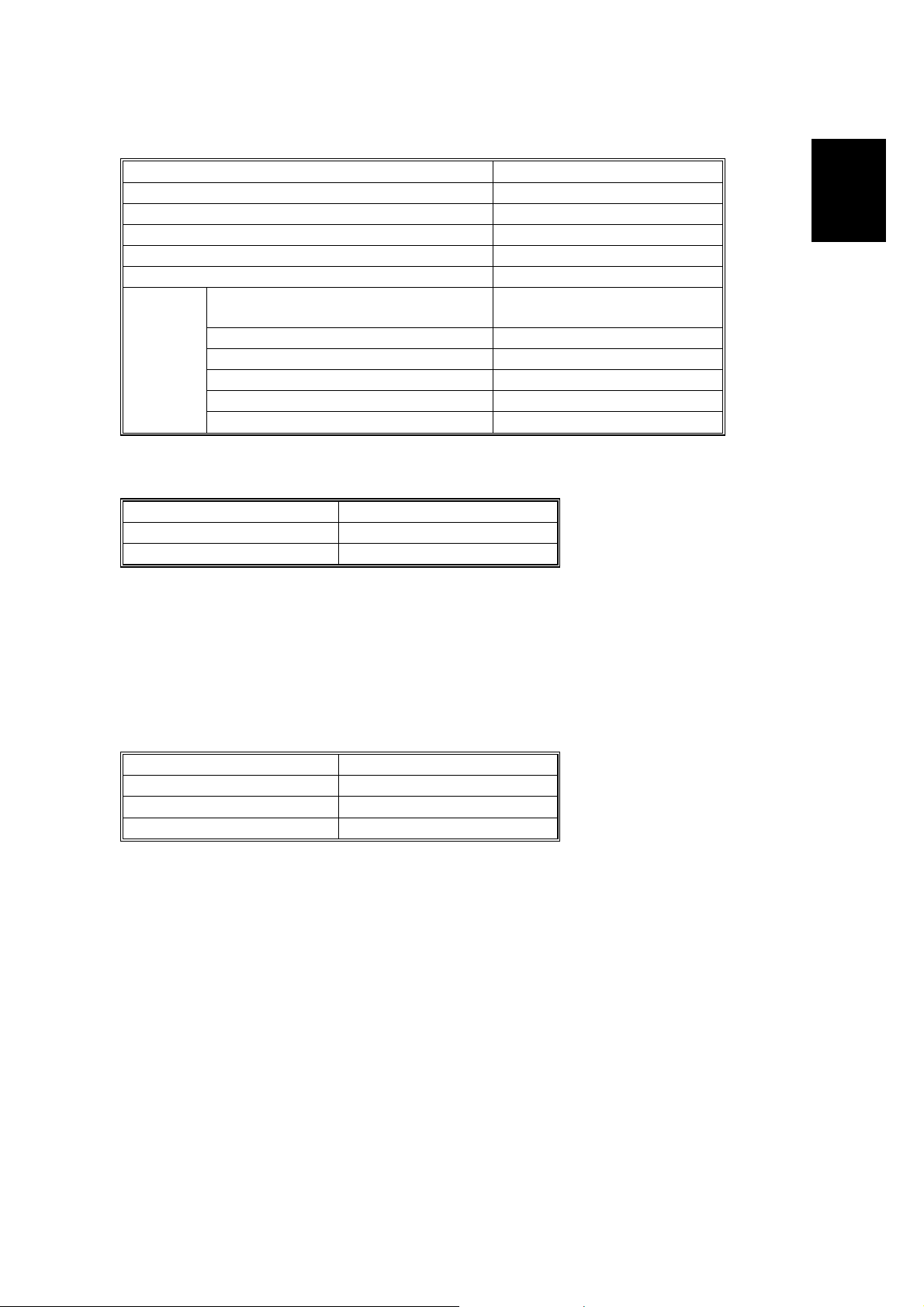

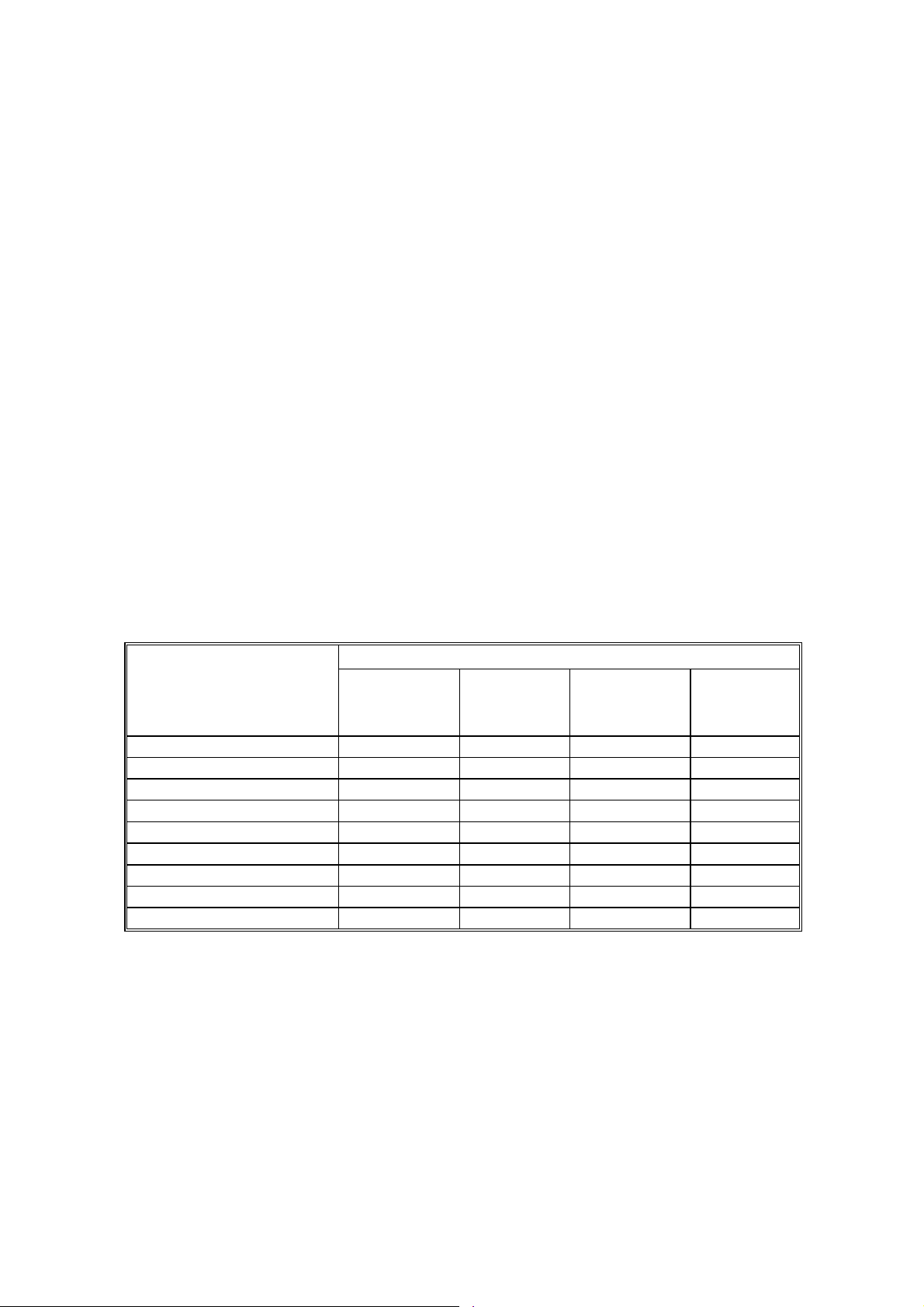

DIP switch setting table (service level test mode)

DIP switch

SW1 SW2 SW3 SW4 SW5 SW6 SW7 SW8

--- - 1 0 0 0

--- - 0 1 0 0

--- - 0 0 1 0

--- - 1 0 1 0

--- - 0 1 1 0

--- - 1 1 1 0

--- - 0 0 0 1

--- - 1 0 0 1

--- - 0 1 0 1

--- - 0 0 1 1

--- - 1 0 1 1

--- - 0 1 1 1

--- - 1 1 1 1

5.1.2 NORMAL MODE

SCSI ID Rotary

switch number

0 SCSI ID 0

1 SCSI ID 1

2 SCSI ID 2

3 SCSI ID 3

4 SCSI ID 4

5 SCSI ID 5

6 SCSI ID 6

7 SCSI ID 7

8 Not used

9 Not used

Contents

Item

ADF counter

Sensor test mode

Flash ROM upload

Exposure lamp on-time

White balance

adjustment mode

Book size check mode

Demonstration mode

Book mode counter

Self-diagnosis mode

Component test mode

Aging mode (Factory

use only)

ADF size check mode

EEPROM clear mode

NOTE: Only enabled when the SCAM function is disabled.

5-2

Page 32

28 December, 2000 DIP SWITCH FUNCTION

5.1.3 ADF COUNTER, BOOK MODE COUNTER AND EXPOSURE LAMP ON-TIME

SCSI ID rotary switch

SCSI ID Rotary

switch number

0 Not used 5 Ten thousands

1 Units (ones) 6 Hundred thousands

2 Tens 7 Millions

3 Hundreds 8 Not used

4 Thousands 9 Not used

Contents

SCSI ID Rotary

switch number

Contents

LED values

Number

0 Off Off Off Off

1 Off Off Off On

2 Off Off On Off

3Off Off On On

4 Off On Off Off

5 Off On Off On

6 Off On On Off

7 Off On On On

8 On Off Off Off

9On Off Off On

Power on

(Green)

Machine busy

(Green)

Document in

place (Green)

Error (Red)

NOTE: You must check the counts one digit at a time. Use the rotary switch to

select the digit. The value is indicated by a combination of the four LEDs.

The four LEDs are read as a four-bit, binary number.

Tables

Service

Example:

When the rotary switch is set for 1, the LEDs display the units (from the SCSI ID

Rotary switch table).

If the LEDs display (On, Off, Off, On), Counter value equals nine (from the LED

values table).

Rotary switch is 1 (units) (On, Off, Off, On)= 9

2 (tens) (On, Off, Off, Off)= 8

3 (hundreds) (Off, On, On, On)= 7

4 (Thousands) (Off, Off, Off, Off)= 0

5 (Ten thousands) (Off, Off, Off, Off)= 0

6 (Hundred thousands)(Off, Off, Off, Off)= 0

7 (Millions) (Off, Off, Off, Off)= 0

>>>Total counter value = 789 sheets (or hours)

5-3

Page 33

DIP SWITCH FUNCTION 28 December, 2000

5.1.4 SENSOR TEST MODE

SCSI ID rotary

switch number

0 Home position sensor

1 Registration sensor

2 ADF position

3 Original setting

4 Feed cover

5 Original reverse

6 Original exit

7 Not used

8 Not used

9 Not used

Contents

NOTE: If the selected sensor is on, all LEDs turn on. If the selected sensor is off,

all LEDs turn off.

5-4

Page 34

28 December, 2000 DIP SWITCH FUNCTION

ode

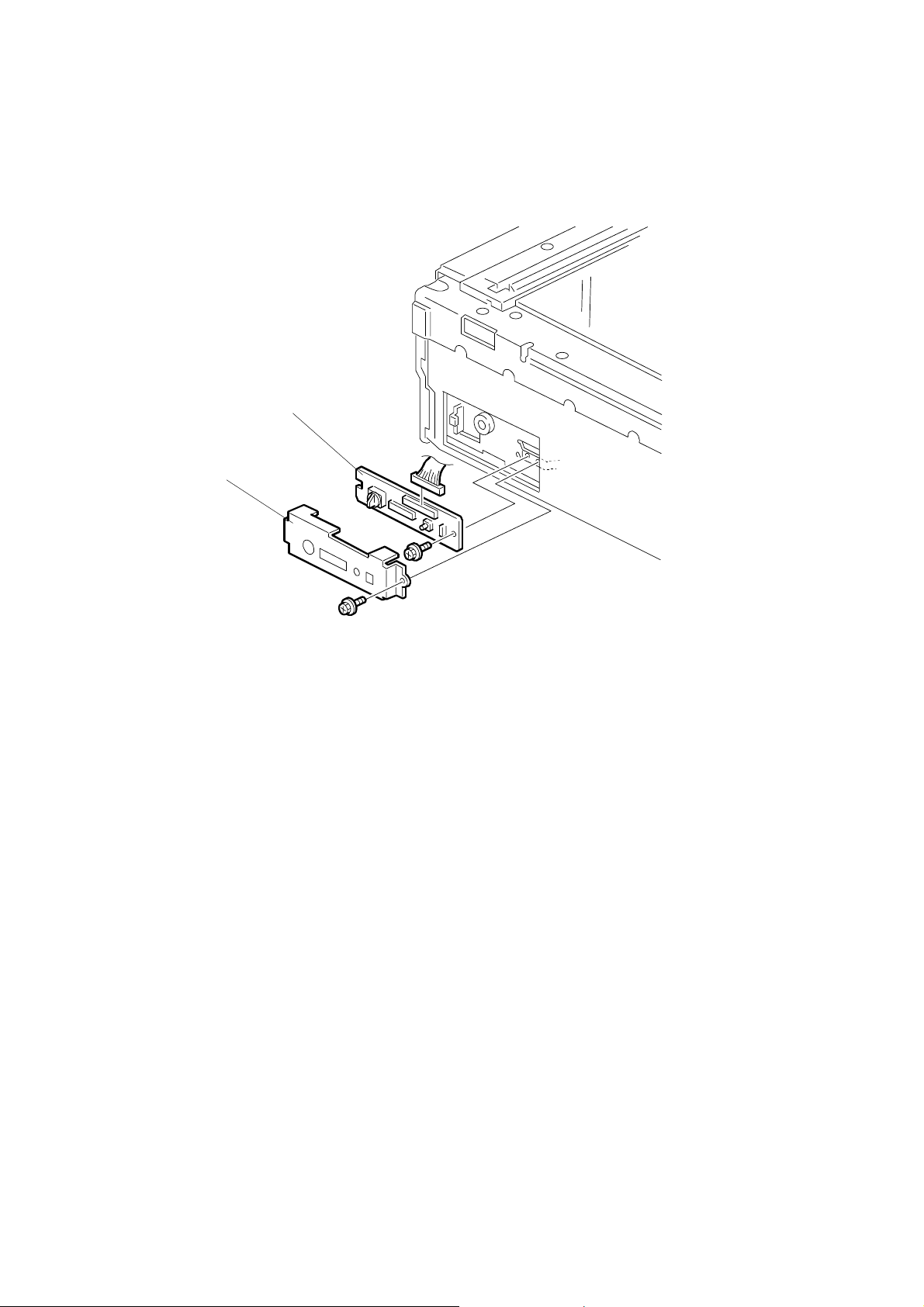

5.1.5 FIRMWARE UPDATE PROCEDURE

This procedure is for updating the firmware of the machine.

!

CAUTION

Do not turn off the machine while downloading the firmware.

IC Card Slot for Network m

l

[C]

[A]

IC Card Slot for SCSI model

[B]

G412R502.WMF

Scanner

Prepare an IC card that contains the required firmware.

Turn off the machine and remove the cover. (!x1)

[A]: Insert the IC card into the IC card slot.

Turn on the machine while pressing the start key. The update starts automatically.

NOTE: If you have installed the network option, this step is slightly different.

Since the new operation panel covers the start key, turn on the

machine while pressing switch [B] instead.

The status is indicated on the LCD.

Tables

Service

When it finishes, turn of f the machine and remove the IC card, then turn it back on.

NIB

Prepare an IC card that contains the required firmware.

Turn off the main switch and remove the cover (!x1)

[C]: Insert the IC card IC into the IC card slot.

Turn on the machine.

Select “Install” key on the operation panel.

The status in displayed on the operation panel.

Turn off the main switch and remove the IC card.

5-5

Page 35

DIP SWITCH FUNCTION 28 December, 2000

5.1.6 FLASH-ROM UPLOAD MODE

G412R502.TIF

Prepare an IC card that contains the required firmware.

Turn off the machine and remove the cover. (!x1)

Insert the IC card into the IC card slot.

Set the DIP switch. (☛ 5.1.1 DIP Switch Setting Table (Service level test mode))

Turn on the machine. The update starts automatically.

Status indicated in the LCD.

Turn off the machine, and turn it back on.

5.1.7 WHITE BALANCE ADJUSTMENT MODE

NOTE: Only when EEPROM is replaced to new one, this procedure is required.

After this adjustment, gray balance adjustment is required. (See ScanProbe manual)

Lay 10 sheets of Type 6200 paper chart on the exposure glass.

Set the DIP switch.

Turn on the main switch.

White balance automatically adjusted.

NOTE: This adjustment also can be done using Scan-Probe.

5-6

Page 36

28 December, 2000 DIP SWITCH FUNCTION

5.1.8 BOOK SIZE CHECK MODE

When a paper is laid down on the exposure gla ss, the book size sensor is active.

All LEDS is blinking.

SCSI ID Rotary

switch number

0 Not used

1 Book size sensor 1 (Original width 1)

2 Book size sensor 2 (Original width 2)

3 Book size sensor 3 (Original width 3)

4 Book size sensor 4 (Original width 4)

5 Book size sensor 5 (Original lengt h 1)

6 Book size sensor 6 (Original lengt h 2)

7 Not used

8 Not used

9 Not used

Contents

5.1.9 DEMONSTRATION MODE

SCSI ID Rotary

switch number

0 Scan in book mode (A3, 210m m/s)

1 Scan in book mode (A3, 70mm/s)

2 Scan in book mode (A3, 11.67 m m/s)

3 Scan in ADF mode (210mm/s) NOTE1)

4 Scan ADF mode (70mm/s) NOTE1)

5 Scan mode (11.67/mm/s) NOTE1)

6 Scan in ADRF mode (210mm/s) NOTE1)

7 Scan in ADRF mode (70mm/s) NOTE1)

8 ADF free running NOTE2)

9 ADRF free running NOTE2)

Contents

Tables

Service

NOTE: 1) The scanner drives any documents in the ADF.

2) The scanner drives the ADF without any document.

3) While feeding the document, the LEDs indicate the machine status as

usual. But, if an error occurs (e.g. misfeed, jam, etc), the scanner stops,

and the LEDs display the error condition.

5-7

Page 37

DIP SWITCH FUNCTION 28 December, 2000

5.1.10 SELF DIAGNOSTIC MODE

By setting this DIP switch, you can perform the following tests (☛ 4.1.2 Selfdiagnostic).

5.1.11 COMPONENT TEST MODE

SCSI ID Rotary

switch number

0 All components off

1 Exposure lamp on/off

2 Pick-up solenoid on/off

3 DF feed clutch on/off

4 Junction gate solenoid on/ of f

5 Not used

6 Not used

7 Not used

8 Not used

9 Not used

Contents

NOTE: 1) When the start but ton is presse d, the selected component turns on and

off repeatedly.

2) If the selected sensor is off, all LEDs turn off. If the selected sensor on,

all LEDs turn on.

5.1.12 ADF SIZE CHECK MODE

SCSI ID Rotary

switch number

0 Not used

1 Original width sensor (Posit i on 1)

2 Original width sensor (Posit i on 2)

3 Original length sensor 1

4 Original length sensor 2

5 Not used

6 Not used

7 Not used

8 Not used

9 Not used

Contents

5-8

Page 38

28 December, 2000 DIP SWITCH FUNCTION

5.1.13 EEPROM CLE AR MODE

Push the start button, and hold it down for three seconds.

All the LEDs turn on.

When all the LEDs turn off, the EEPROM is cleared.

The following data is cleared:

a) ADF counter data

b) Book mode counter data

c) Exposure lamp on-time data

The following data is not cleared:

a) Destination data

b) Optimal tune data

c) Registering tune data

Tables

Service

5-9

Page 39

SERVICE PROGRAM MODE (WITH NIB OPTION) 28 December, 2000

5.2 SERVICE PROGRAM MODE (WITH NIB OPTION)

5.2.1 THE SP MODE DESCRIPTION

Entering the service mode

Push the " button.

Push the # button.

Push the $ button.

Push the % button.

Hold the & button down for three seconds.

Service

Class

1

mode

number

001 FTP port Sets the FTP port number

002 Version Displays the firmware version

003 Lot No. Displays the machine lot number

004 Error log Displays the service call number (SC)

005

006 Initialize all data Initialize all SP mode data

007 Initialize SCAN-NIC Data Data related to the network is initialized.

008 Density Setup1

009 Density Setup2

010 Density Setup3

011 Density Setup4

012 Density Setup5

013 Density Setup6

014 Density Setup7

015 Flash ROM disc format Format the flash ROM

016 Binary color

Initialize SCAN-data Initialize SP mode data (SPNo.006 is not

Description Function

removed)

Adjust Density1. [0-255/40/1]

Adjust Density2. [0-255/70/1]

Adjust Density3. [0-255/100/1]

Adjust Density4. [0-255/130/1]

Adjust Density5. [0-255/160/1]

Adjust Density6. [0-255/190/1]

Adjust Density7. [0-255/220/1]

Select binary color [Yes or No/No]

NOTE: The setting range is in brackets and the default setting is in bold.

Density setup sample:

Case 1: Density fluctuations are small.

Case 2: Increases document density.

Case 3: Reduces density.

Example:

Case

1 85 100 115 130 145 160 175

2 70 100 130 160 190 220 250

3 10 40 70 100 130 160 190

Density

setup 1

Density

setup 2

Density

setup 3

Density

setup 4

Density

setup5

Density

setup 6

Density

setup 7

NOTE: It is reference value. Adjust this value by the scanning image condition.

5-10

Page 40

28 December, 2000 NETWORK SETUP(WITH NIB OPTION)

5.3 NETWORK SETUP(WITH NIB OPTION)

5.3.1 NIB SETUP TABLE

Scanner function/Network table

Item No Setting name Function

1 Scanner IP address Setup IP address [011.022.033.044]

2 Subnet address Setup Subnet addr ess [ 000.000.000.000]

3 Gateway address Setup Gateway address [000.000.000.000]

4

5 Access mask Setup Access mask [000.000.000.000]

6

7

8 MAC address Non-enterable field

9 Ftp port number Setup Ftp port no. [ 03670]

10

Access control

address

Network boot

Delivery scanner

address

Transmission speed Select transmission speed

Setup Access control address [000.000.000.000]

Select Network boot [ None or ARP+PING or A RP+PING

/RARP+TFTP or RARP+TFTP/BOOTP or RARP+TFTP

or RARP+TFTP/ BO OTP or BOOTP or DHCP/None]

Setup Delivery scanner ad dress [000.000.000.000]

[auto or 10base or 100base/auto]

NOTE: The setting range is in brackets and the default Setting is in bold.

Scanner function/configuration table

Item No Setting name Function

2

Scanner/TWAIN

connection timeout

Indicate Scanner/TWAIN connection timeout [0-30]

5.3.2 NIB ERROR LOG DESCRIPTIONS

rapp

0104-0000 A compulsory reset occurrence.

0104-0001 By the CosScanOpen() function, error. (Indicate SC4005)

0104-0002 By the CosScanRead() function, error. (Indicate SC4005)

0104-0003 By the CosScanExec() function, error.

0104-0004 By the CosMShareAt() function, error.

0104-0005 By the CosMShareAt() function, error.

0104-0006 By the CosMShareAt() function, error.

0104-0007 By the CosMShareAt() function, error.

0104-0101 Connection idle for five minutes.

0104-0102 Resource release error

Tables

Service

5-11

Page 41

NETWORK SETUP(WITH NIB OPTION) 28 December, 2000

nas

0108-1xxx

0108-2002 File communication protocol is abnormal. (Indicate SC4004)

0108-3001

0108-3002 Cannot connect to the LINF. (no resp onse f r om the NIB) (Indicate SC4004)

0108-4001 No response TCP/IC at NIB

0108-4002 TCP/IC at NIB, error.

NIC initialization failure. xxx is a diagnost ic error co de fr om the NIC. (Indicate

SC4004)

Cannot connect to the LINF. (no response from the scanner) (Indicate

SC4004)

SC related to the network interface card

SC4001 Extended memory error.

SC4002 Flash ROM check-sum error

SC4003 No battery on NIB

SC4004 NIB error

SC4005 Application error

5-12

Page 42

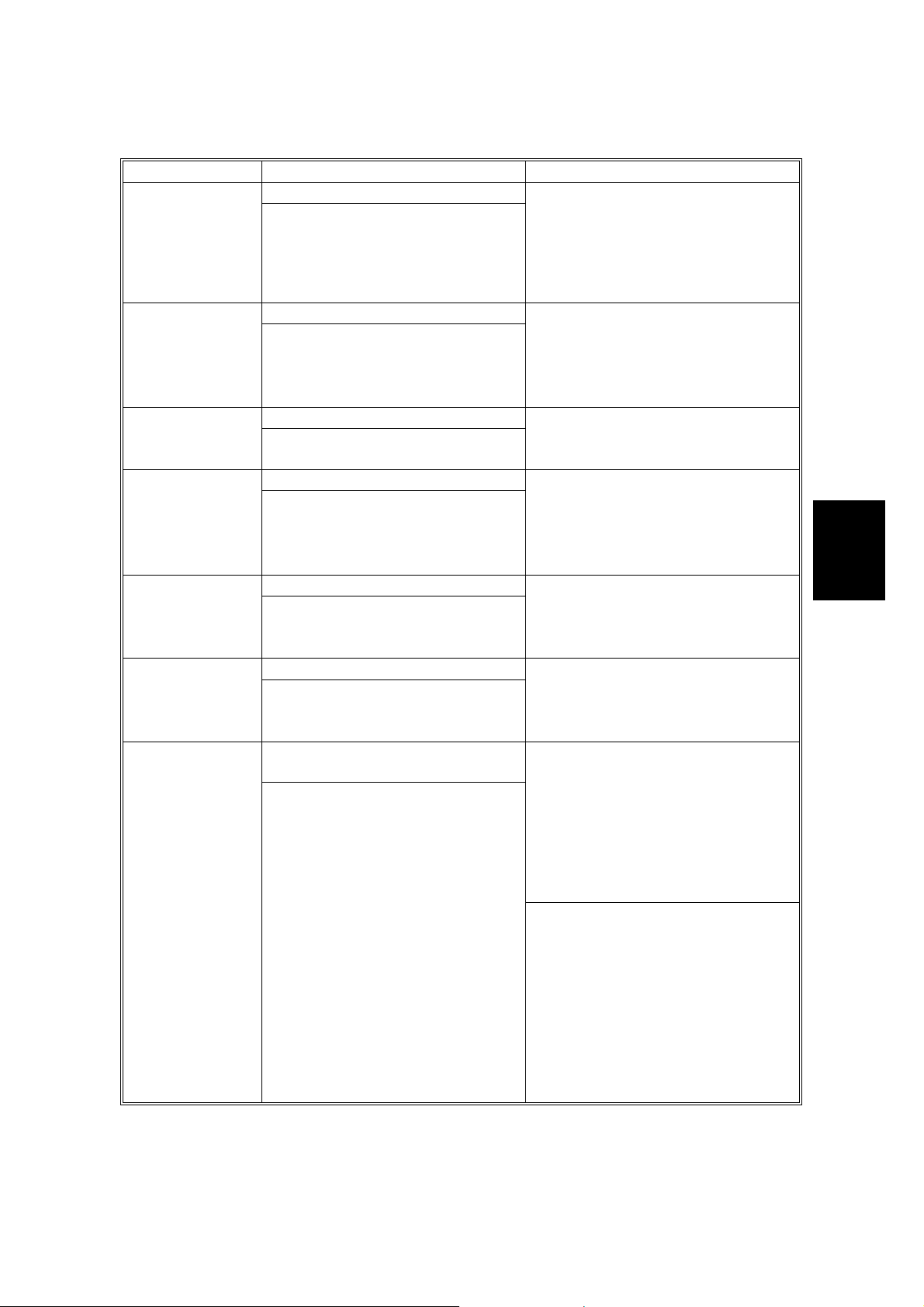

28 December, 2000 O RIGINAL SIZE SENSOR COMBINATION TABLE

5.4 ORIGINAL SIZE SENSOR COMBINATION TABLE

[A]

L1-1 L1-2 L2-1 L2-2

W1

[C]

W2

No. US EU W

[B]

G412S500.WMF

1

W

[A]: Original Length Sensor 1

[B]: Original length Sensor 2

[C]: Original Width Sensor

2

L1-1 L1-2 L2-1 L2-2

1 A3 Lengthwise X O ON ON ON ON – –

2 B4 Lengthwise X O ON – ON ON – –

3 A4 Lengthwise X O – – ON ON – –

4 A4 Sideways X O ON ON – – – –

5 B5 Lengthwise X O – – ON – – –

6 B5 Sideways X O ON – – – – –

7 11” x 17” (DLT) O X ON ON ON ON ON ON

8 11” x 15” O*

1

X ONONONONONON

9 10” x 14” O X ON – ON ON ON ON

10 8.5” x 14” (LG) O X – – ON ON ON ON

11 8.5” x 13” (F4) X O – – ON O N ON –

12 8” x 13” (F) X O*

2

– – ON ON ON –

13 8.5” x 11” (LT) O X – – ON O N – –

14 8.5” x 11” (LT) O X ON ON – – – –

15 10” x 8” O X – – ON – – –

Tables

Service

*1: Detects as DLT *2: Detects as F4

5-13

Page 43

28 December, 2000 MACHINE O VERVI EW

6. DETAILED FUNCTION DESCRIPTIONS

6.1 MACHINE OVERVIEW

[A] [B] [C] [D] [E] [F] [G] [H] [I]

[A]: Scanner HP Sensor

[B]: DF Exposure Glass

[C]: 2nd Mirror

[D]: 2nd Scanner

[E]: Exposure Glass

[F]: Exposure Lamp

[G]: 1st Scanner

[H]: Lens

[I]: CCD

[J]: Original Length Sensor 2

[K]: Original Length Sensor 1

[L]: 1st Mirror

[M]: Scanner Motor

[N]: 3rd Mirror

[O]: Original Width Sensor

[J][K][L][M][N][O]

G412D500.WMF

Detailed

Descriptions

6-1

Page 44

CONTOROL SYSTEM BLOCK DIAGRAM 28 December, 2000

6.2 CONTOROL SYSTEM BLOCK DIAGRAM

ARDF

Original Length Sensor 1

Original Length Sensor 2

Original Width Sensor

Scanner Home Position

SBU

Exposer Lamp

Stabilizer

STM3

CN207CN209 CN202 CN204 CN208

CN205 CN206CN212

VIOB

CN203 CN204

CN3 CN4

CN2

CN1

PSU

CN5

CN204CN210

NIC Operation Panel

CN211

OIPU NIB

CN102

CN101

CN201

FAN

ADF Interlock Sensor

SOP

SWB

CN1038

CN103

SCU

CN105

IEEE1394

3000DC

Option

G412R504.WMF

The SCU controls this machine. Its CPU checks all sensors and manages the SCSI

I/F, NIB I/F, IEEE1394 I/F and VIOB. The SCU has EEPROM and DRAM. It also

contains the image processing ASIC, which processes images from the CCD.

The VIOB controls several sensors and control boards and ARDF.

6-2

Page 45

28 December, 2000 SCANNING

6.3 SCANNING

6.3.1 OVERVIEW

[A]

[C]

• The exposure lamp (a xenon lamp in this model) [A] illuminates the original. The

image is reflected onto a CCD (charge coupled device) [B] via the 1st, 2nd, and

3rd mirrors, and through the lenses [C].

• The scanner scans the white plate [A] on the underside of the ADF exposure

cover to perform the shading function.

• The scanners stop when the first scanner activates the home position sensor [E].

• If the scanner home position sensor is not activated within a certain time, a home

position sensor error will occur.

[B]

G412D500.WMF

6-3

Detailed

Descriptions

Page 46

SCANNING 28 December, 2000

6.3.2 SCANNER DRIVE MECHANISM

Scanner Motor

Scanner drive Relley

Scanner Drive Shaft

Scanner Wires

1st Scanner 2nd Scanner

G412D501.WMF

[F]

[B]

[C]

[E]

[D]

[A]

[G]

G412R017.WMF

6-4

Page 47

28 December, 2000 SCANNING

6.3.3 IMAGE PROCESSING

• The CCD generates three analog video signals.

• The SBU (Sensor Board Unit) converts these analog signals to 12-bit digital

signals.

• It sends these digital signals to the SCU (Scanner Control Unit) board through

the VIOB board.

• The RIPU (Image Processing Unit) IC on the SCU processes the image, and

then the image data is sent to the computer through the Memory Control IC and

the SCSI controller.

OIPUB IEEE1394

OIPUB

ISIC

SBU VIOB

E

R

R

G

G

CCD Shading

B

BO

O

E

O

E

Analog

Processor

Analog

Processor

Analog

Processor

A/D

Converter

A/D

Converter

A/D

Converter

12bit

12bit

12bit

DRAM

RIPU

Output

Selector

8 bit

8 bit

8 bit

VIDEO I/F

8 bit

Video

Selector

NIC

SIBC2

SCU

SCSI

NIB

G412R505.WMF

LAN

Detailed

Descriptions

6-5

Page 48

SCANNING 28 December, 2000

SBU and VIOB

The CCD converts the light reflected f rom the o rigin al into an analog signal.

The CCD has an odd and an even output line for each of the three colors. Each

color also has an analog processing IC. The analog processing IC performs the

following operations.

1. Z/C (Zero Clamp)

Adjusts the black level reference for even pixels to match the odd pixels.

2. Signal Amplification

Operational amplifiers in the AGC (Auto Gain Control) circuit amplify the analog

signal. The CPU on the SCU board controls the maximum gain.

After the above processes, the analog signals are converted to 12-bit digital signals

by the A/D converters. Each pixel is given a value from the 256-grade scale. The

shading function then corrects those signals. Shading correction prevents uneven

images caused by fluctuations in scanned data due to changes in light intensity

and CCD sensitivity.

RIPU on SCU

The RIPU is the image processor on the SCU. It handles the following:

1. Line skipping correction

2. Scan line correction

3. Black and white conversion

4. Gamma (γ) correction

5. Color resolution

6. Filtering

7. Magnification

8. Scale processing

9. Erasure of Irregular Dots

Line skipping correction

Ideally, this machine would scan at a constant speed. However, when the data

transfer speed slows down, the 1st scanner must also slow down to match. If the

1st scanner must stop to wait on the client or server, duplicate lines may be

scanned. These can create a visible seam between the scanned sections. Line

skipping correction erases duplicate image lines, ensuring a smooth final image.

6-6

Page 49

28 December, 2000 SCANNING

Scan line correction

The CCD consists of three lines of elements, one for each color (red, green and

blue). Since there is a slight gap between the lines, each line is scanning a slightly

different part of the image. To produce the final image, these three outputs need to

be synchronized. Since the deviation between the lines varies with the scanner

speed, a deviance value must be calculated in proportion to the speed.

Black and white conversion

When the machine scans a color original in the black and white mode, the RGB

information needs to be converted into a grayscale image. Black and white

conversion provides four different methods.

1. RGB data: All three colors are combined into the grayscale.

2. R data mode: Only the data from the red CCDs are used. This 256-grade data

is used directly as a 256-grade grayscale. Since green and blue data is not

collected, those colors appear black in the final image.

3. G data mode: As R data but only using green.

4. B data mode: As R data but only using blue.

Gamma (

) correction

γγγγ

There should be a linear relationship between the original image density and the

CCD output.

Gamma correction adjusts for deviations from this ideal. It includes both brightness

and contrast corrections.

Color resolution

Because of the differences in color space, the color observed by a person, and the

color value sensed by the CCD can vary. Color resolution corrects the color data

gathered by the CCD. It uses a color table that adjusts for the way particular colors

are displayed on specific CRTs. This allows a more-natural representation of the

scanned image.

Filtering

There are two software filters: the MTF (Modulation Transfer Function) filter and

the smoothing filter. The MTF filter emphasizes sharpness, and is used with

documents that contain both text and photo areas. The smoothing filter is only

used for photo-image documents.

Detailed

Descriptions

6-7

Page 50

SCANNING 28 December, 2000

Magnification

The RIPU enlarges or reduces the image data in the scan direction.

Reduction and enlargement in the sub scan direction are done by changing the

scanning speed, using LIFO (last in, first out).

Scale processing

This process generates image densities of up to 256 levels for each pixel. It uses

simple binary, dithering, and error diffusion processing.

Simple binary processing sets the level based on a threshold value. There are no

shades of gray. The output is black or white only.

Dither processing is used to reproduce originals with continuous tones, such as

photographs on machines that cannot output true grayscales. It produces different

shades of gray by creating patterns of black and white dots. There are no gray

dots.

The error diffusion process reduces the difference in contrast between light and

dark areas of a halftone im age. Each pixel is corrected using the difference

between it and the surrounding pixels. The corrected pixels are then compared with

a matrix table. Error diffusion is often used in text/photo mode. It is a good

compromise because it reduces the contrast between light and dark areas of

halftone images, while having no effect on letter areas.

Erasure of Irregular Dots

When the CCD output is converted to a simple b i nary image, slight variations

(noise) may result in individual pixels being incorrectly classified as either black or

white. This process compares each pixel with its neighbors, using a matching

technique to identify and remove these irregular dots.

OIPUB

The OIPUB is an optional image-processing unit. It improves the processing of

black and white images using the following features:

1. Auto binary processing

2. Auto Image area separation

3. Manual Image area separation

Auto binary processing

When making simple binary scans of a light original (e.g. gray text on a white

background), the threshold level is adjusted. This allows the lighter shades to

appear in the final image (in the above example, as black text on a white

background).

6-8

Page 51

28 December, 2000 NEWORK INTERFACE

Auto image area separation

When a sca nned document contains both text and photo areas, the machine

searches for the outlines of the text. Based on these outlines, it separates the

image into text and photo areas. Text areas use simple binary processing. Photo

areas use dithering and error diffusion.

Manual image area separation

Here, the user separates the text and photo areas by hand (Use the TWAIN

software). Image processing is the same as in auto image area separation.

6.4 NEWORK INTERFACE

The following network scanning options are available:

1. Network Transmission scanning

This scanner transmits the scanning image data to the scanner server. The

scanner server then transmits the data to a client PC.

2. Network TWAIN scanning

The client PC sends scanning commands directly to the scanner. The scanner then

sends the scanning image data back to the client PC.

Detailed

Descriptions

6-9

Page 52

IEEE1394 INTERFACE 28 December, 2000

6.5 IEEE1394 INTERFACE

6.5.1 IEEE1394

IEEE1394, also known as FireWire (a name patented by Apple), is an easy-to-use

peer-to-peer networking technology, allowing speeds of up to 400 Mbps.

The current standard contains the following features, which are supported in most

devices:

• Hot swapping (cables can be connected and disconnected while the

computer and other devices are switched on)

• Peer-to-peer networking (no hub required)

• No terminator or device ID is required, unlike SCSI

• Automatic configuration of devices upon start-up (plug and play).

• Real-time data transfer at 100, 200, and 400 Mbps

• Common connectors for different devices

1394 I/F

1394 I/F

G056D513.WMF

The cable length is limited to 4.5 m (15ft). However, up to 16 cables and 63

devices can be connected to an IEEE1394 network.

IEEE1394 cables can be either 4-pin (data only) or 6-pin (data and power).

However, this machine only uses the 6-pin connectors. The machine has two 6-pin

ports.

6-10

Page 53

28 December, 2000 IEEE1394 INTERFACE

6.5.2 BLOCK DIAGRAM

IEEE1394 Board

EEPROM

1394 I/F

IBM Compatible

1394 I/F

PHY

TSB 412V02

• PHY: Physical layer control device

• LINK: Link layer control device

• EEPROM: 256-byte ROM

LINK

TSV43LV81

SCU

Option I/F

G412R503.WMF

6-11

Detailed

Descriptions

Page 54

AUTO REVERSE DOCUMENT FEEDER

Page 55

28 December, 2000 SPECIAL TOOLS

1. REPLACMENT

!

CAUTION

Turn off the main power switch and unplug the machine before attempting

any of the procedures in this section.

This manual uses the following .

☛: See or Refer to !: Screw ": Connector #: Snap ring $:E-ring

1.1 SPECIAL TOOLS

Part number Description Description section Q ty

G0049668 Silicone grease (KS-660) ☛1.2.7 ORIGINAL LENGTH, WIDTH

SENSOR BOARD

1

1.2 REPLACEMENT

1.2.1 LEFT COVER

[B]

[A]

A859R110.WMF

Front and rear covers. (☛ 1.2.1 DF EXIT TABLE AND COVERS)

[A]: Lower left stay unit (!x2).

[B]: Left cover.

Peripherals

1-1

Page 56

REPLACEMENT 28 December, 2000

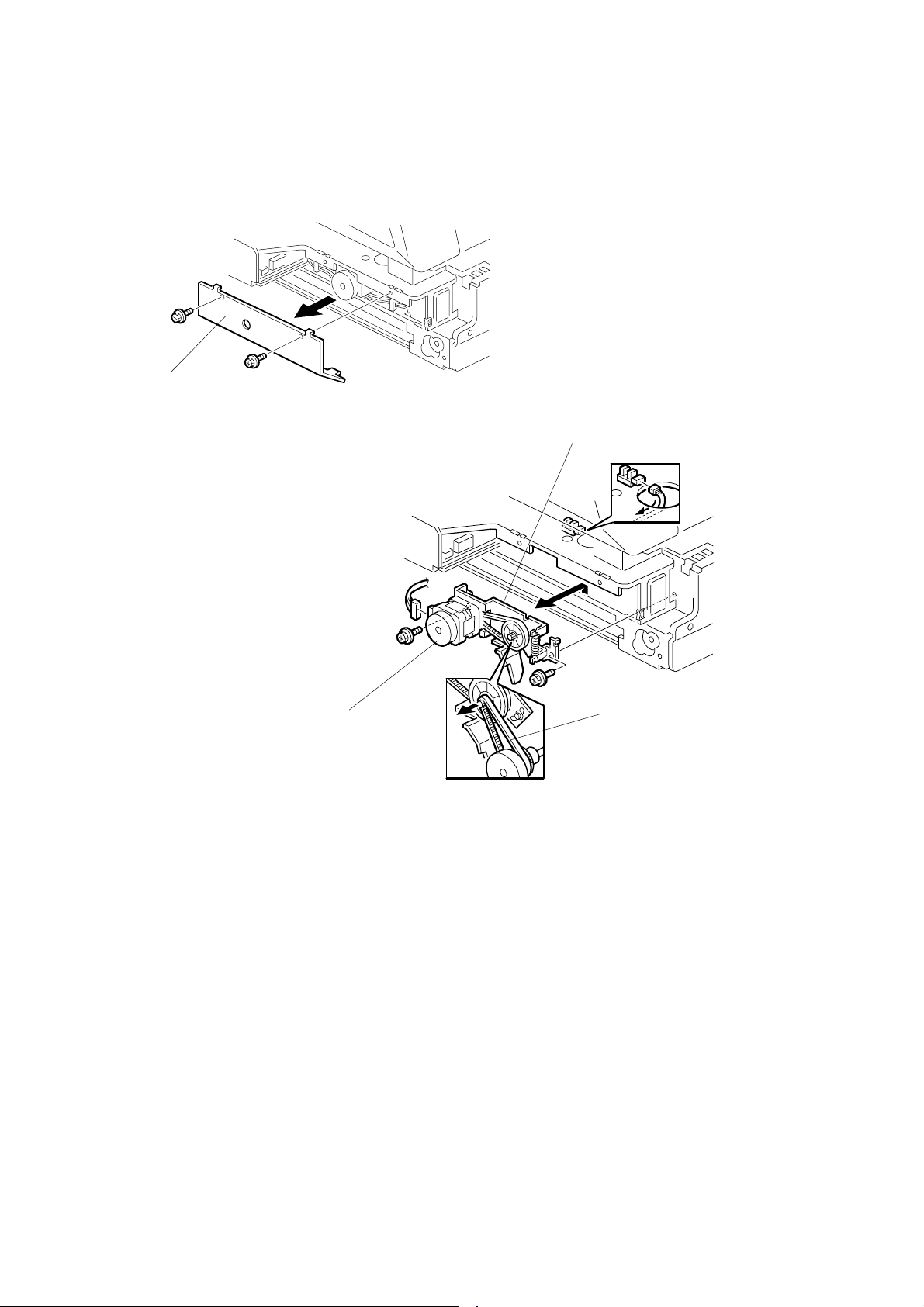

1.2.2 P APER FEED UNIT

[B]

[A]

A859R102.WMF

[A]: Open the left cover

[B]: Detach the paper feed unit by sliding it toward the front of the machine

(spring-loaded side) and then lifting the far side.

1.2.3 SEPARATION ROLLER

[A]

[C]

[A]: Open Left cover

[B]: Lift the original feed guide

[C]: Separation roller cover

[D]: Separation roller

[B]

A859R105.WMF

1-2

Page 57

28 December, 2000 REPLACEMENT

1.2.4 PICK-UP ROLLER

[B]

[A]

A859R103.WMF

[A]: Original feed unit

[B]: Pick-up roller (# x1)

1.2.5 FEED BELT

[B]

[A]

A858R204.WMF

[C]

Peripherals

[D]

Open the left cover

[A]: Paper feed unit (☛ 1.2.2 PAPER FEED UNIT)

[B]: Open the paper feed guide

[C]: Belt holders

[D]: Feed belt

1-3

A858R205.WMF

Page 58

REPLACEMENT 28 December, 2000

1.2.6 ORIGINAL SET/ORIGINAL REVERSE SENSOR

[A]

[C]

[B]

A858R201.WMF

Open the left cover

[A]: Open the original feed guide plate while pushing the left and right pawls

[B]: Original set sensor ("x1)

[C]: Original reverse sensor ("x1)

1-4

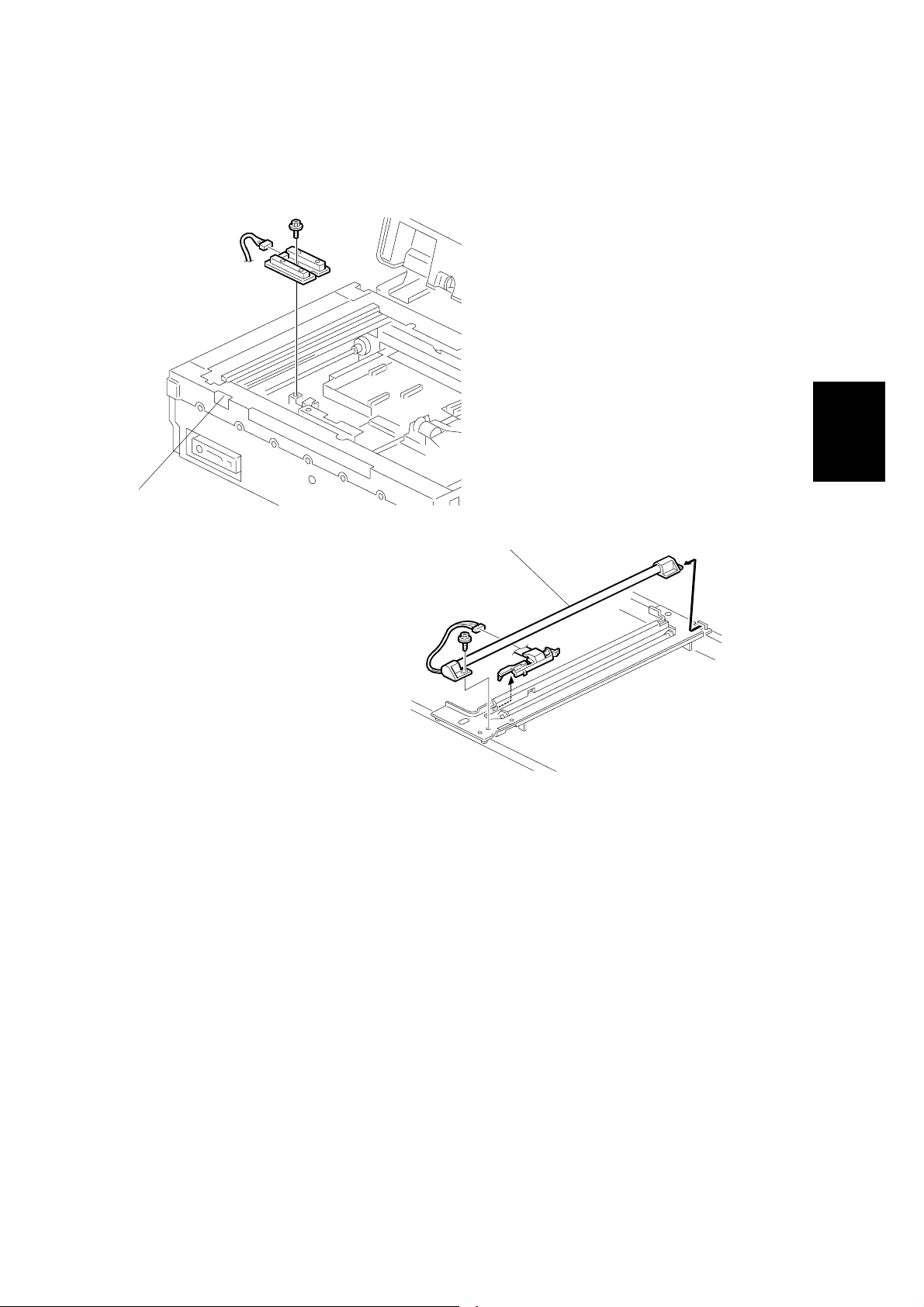

Page 59

28 December, 2000 REPLACEMENT

1.2.7 ORIGINAL LENGTH, WIDTH SENSOR BOARD

[A]

[B]

[C] [D]

A859R107.WMF

A859R108A.WMF

[A]: Open the original table

[B]: Upper part of the table (!x3).

[C]: Width sensor board (!x3, "x1)

[D]: Length sensors ("x1)

A859R113.WMF

NOTE: To ensure proper detection of paper size, after wiping the sensor board and

terminal plate with a dry cloth (or cloth with alcohol), apply silicone grease

(KS-660) to the terminal plate.( ☛1.1 SPECIAL TOOLS)

Peripherals

1-5

Page 60

REPLACEMENT 28 December, 2000

1.2.8 DF EXIT TABLE AND COVERS

[A]

[C]

[A]: Open the feed cover

[B]: Open the reverse table

[C]: Front cover (!x2)

[D]: Rear cover (!x2)

[E]: DF exit table (!x3)

1.2.9 FEED COVER SENSOR

[D]

[B]

[E]

A859R101.WMF

[A]

Rear cover. (☛ 1.2.1 DF EXIT TABLE AND COVERS)

[A]: Feed cover sensor

G412R511.WMF

1-6

Page 61

28 December, 2000 REPLACEMENT

1.2.10 REGISTRATION SENSOR

[B]

[A]

A859R111.WMF

Front and rear covers. (☛ 1.2.1 DF EXIT TABLE AND COVERS)

[A]: Transport guide plate.

[B]: Registration sensor. ("x2).

1-7

Peripherals

Page 62

CLUTCH/SOLENOID/MOTORS 28 December, 2000

1.3 CLUTCH/SOLENOID/MOTORS

[B]

[C]

[F]

[D]

[E]

Rear cover. (☛: 1.2.1 DF EXIT TABLE AND COVERS)

Then follow the instructions below for each part:

DF Feed Clutch

[A]: Clutch ($x1, "x1).

Pick-up Solenoid

[B]: Pick-up solenoid (!x3, #x1, "x1).

Junction gate solenoid

DF exit table (☛1.2.8 DF EXIT TABLE AND COVERS)

[C]: Junction gate solenoid (!x2, #x1, "x1)

Transport Motor

Remove the pick-up solenoid (!x3, #x1, "x1).

[D]: Bracket (!x2).

[E]: Transport motor (!x2, "x1).

[A]

A858R202.WMF

DF Feed Motor

Remove the pick-up solenoid (!x3, #x1, "x1).

Bracket [D](!x2).

[F]: DF feed motor (!x2, "x1).

1-8

Page 63

28 December, 2000 MACHINE O VERVI EW

2. DETAILED FUNCTION DESCRIPTION

2.1 MACHINE OVERVIEW

2.1.1 M ECHANICAL COMPONENT LAYOUT

Mechanical component layout

[B] [C] [D]

[A]

[Q]

[P]

[O]

[A]: Separation Roller

[B]: Paper Feed Belt

[C]: Pick-up Roller

[D]: Original Set Sensor

[E]: Original Width Sensor Board