Page 1

Model:

Haokan-P1T

Machine Code:

J089/J098/J099

Field Service Manual

July, 2017

Page 2

Page 3

Important Safety Notices

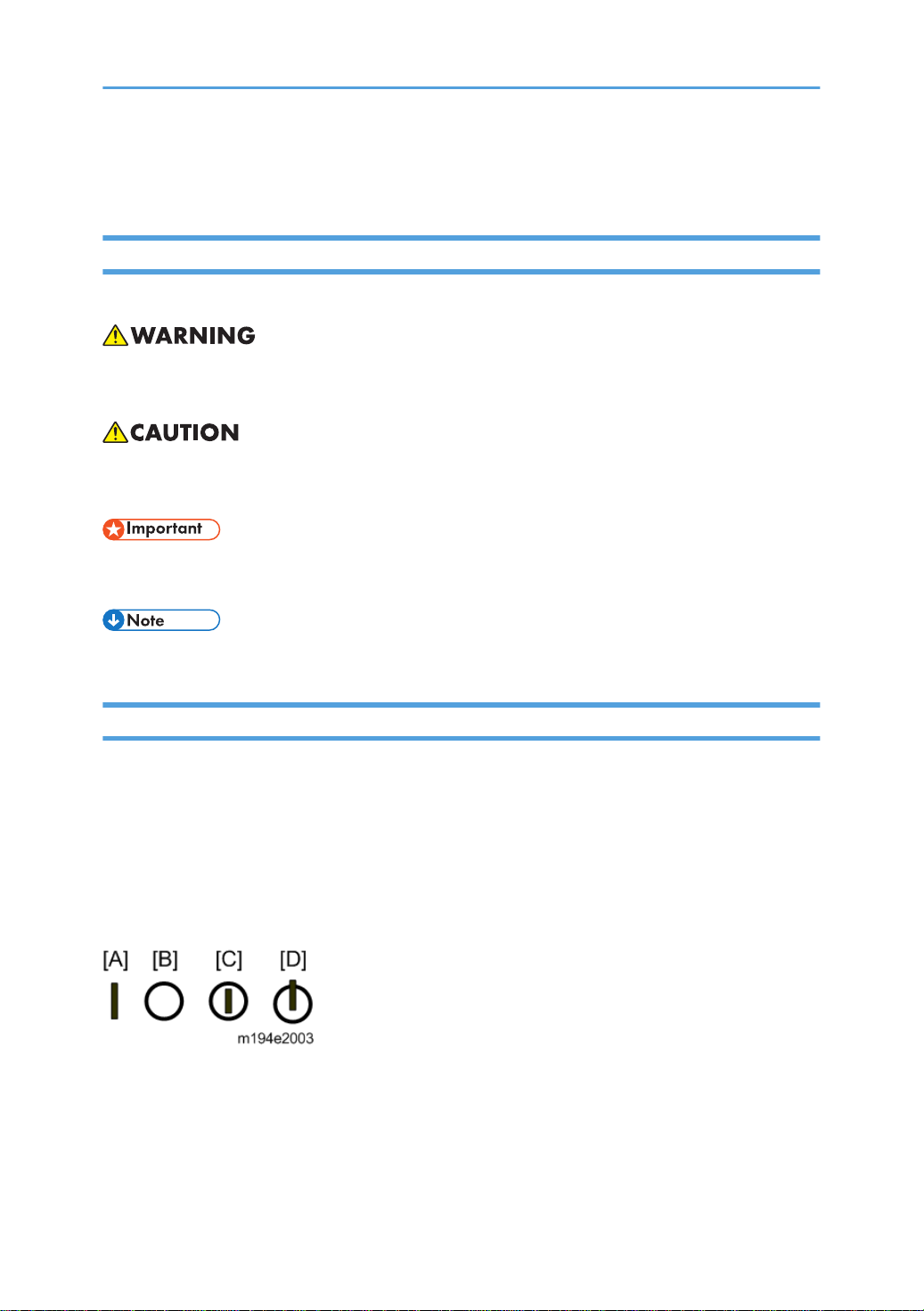

Warnings, Cautions, Notes

In this manual, the following important symbols and notations are used.

• A Warning indicates a potentially hazardous situation. Failure to obey a Warning could result in

death or serious injury.

• A Caution indicates a potentially hazardous situation. Failure to obey a Caution could result in

minor or moderate injury or damage to the machine or other property.

• Obey these guidelines to avoid problems such as misfeeds, damage to originals, loss of valuable

data and to prevent damage to the machine.

• This information provides tips and advice about how to best service the machine.

General Safety Instructions

For your safety, please read this manual carefully before you use this product. Keep this manual handy

for future reference.

Safety Information

Always obey the following safety precautions when using this product.

Safety During Operation

In this manual, the following important symbols and notations are used.

[A]: ON

[B]: OFF

[C]: Push ON/Push OFF

[D]: Standby

1

Page 4

Switches and Symbols

Where symbols are used on or near switches on machines for Europe and other areas, the meaning of

each symbol conforms with IEC60417.

Safety

Prevention of Physical Injury

1. Before disassembling or assembling parts of the machine and peripherals, make sure that the

machine and peripheral power cords are unplugged.

2. The plug should be near the machine and easily accessible.

3. Note that some components of the machine and the paper tray unit are supplied with electrical

voltage even if the main power switch is turned off.

4. Always unplug the power cord from the power source before you move the product. Before you

move the machine, arrange the power cord so it will not fall under the machine.

5. Disconnect all peripheral units (finisher, LCT, etc.) from the mainframe before you move the

machine.

6. If any adjustment or operation check has to be made with exterior covers off or open while the

main switch is turned on, keep hands away from electrified or mechanically driven components.

7. The machine drives some of its components when it completes the warm-up period. Be careful to

keep hands away from the mechanical and electrical components as the machine starts operation.

8. The inside and the metal parts of the fusing unit become extremely hot while the machine is

operating. Be careful to avoid touching those components with your bare hands.

9. To prevent a fire or explosion, keep the machine away from flammable liquids, gases, and

aerosols.

10. Do not use flammable sprays or solvent in the vicinity of the machine. Also, avoid placing these

items in the vicinity of the machine. Doing so could result in fire or electric shock.

11. To avoid fire or explosion, never use an organic cleaner near any part that generates heat.

12. Never remove any safety device unless it requires replacement. Always replace safety devices

immediately.

13. Never do any procedure that defeats the function of any safety device.

14. Modification or removal of a safety device (fuse, switch, etc.) could lead to a fire and personal

injury. Always test the operation of the machine to ensure that it is operating normally and safely

after removal and replacement of any safety device.

15. For replacements use only the correct fuses or circuit breakers rated for use with the machine. Using

replacement devices not designed for use with the machine could lead to a fire and personal

injuries.

2

Page 5

16. When using a vacuum cleaner around the machine, keep others away from the cleaner, especially

small children.

17. NEVER touch the AC circuits on the PSU board, to prevent electric shock caused by residual

charge. Residual charge of about 100V-400V remains in the AC circuits on the PSU board for

several months, even when the board has been removed from the machine after turning off the

machine power and unplugging the power cord.

Observance of Electrical Safety Standards

1. The machine and its peripherals must be installed and maintained by a customer service

representative who has completed the training course on those models with exceptions on some

machines where the installation can be handled by the user.

Safety and Ecological Notes for Disposal

1. Dispose of replaced parts in accordance with local regulations.

2. When keeping used lithium batteries in order to dispose of them later, do not put more than 100

batteries per sealed box. Storing larger numbers or not sealing them apart may lead to chemical

reactions and heat build-up.

3. The danger of explosion exists if a battery of this type is incorrectly replaced. Replace only with the

same or an equivalent type recommended by the manufacturer. Discard used batteries in

accordance with the manufacturer’s instructions.

Safety Instructions for Ink Cartridges

Accidental Exposure To Ink

1. If ink gets on the skin, wash the affected area immediately with soap and cold running water.

2. If ink gets into the eyes, immediately flush the eyes with cold running water. If there are signs

of irritation or other problems, seek medical attention.

3. If ink is swallowed, drink a strong solution of cold water and table salt to induce vomiting.

Seek medical attention immediately.

4. Ink is difficult to remove from fabric. Work carefully to avoid staining clothing when

performing routine maintenance or replacing cartridges.

3

Page 6

Handling and Storing Ink Cartridges

• Ink is flammable. Never store ink cartridges in a location where they will be exposed to high

temperature or an open flame.

1. Always store ink cartridges out of the reach of children.

2. Always store ink cartridges in a cool, dry location that is not exposed to direct sunlight.

Ink Cartridge Disposal

1. Attach the caps to empty ink containers for temporary storage to avoid accidental spillage.

2. Return empty ink cartridges to a local dealer who can accept such items for collection and

recycling or disposal.

3. If the customer decides to dispose of empty ink cartridges, make sure that they are disposed of

in accordance with local laws and regulations.

4

Page 7

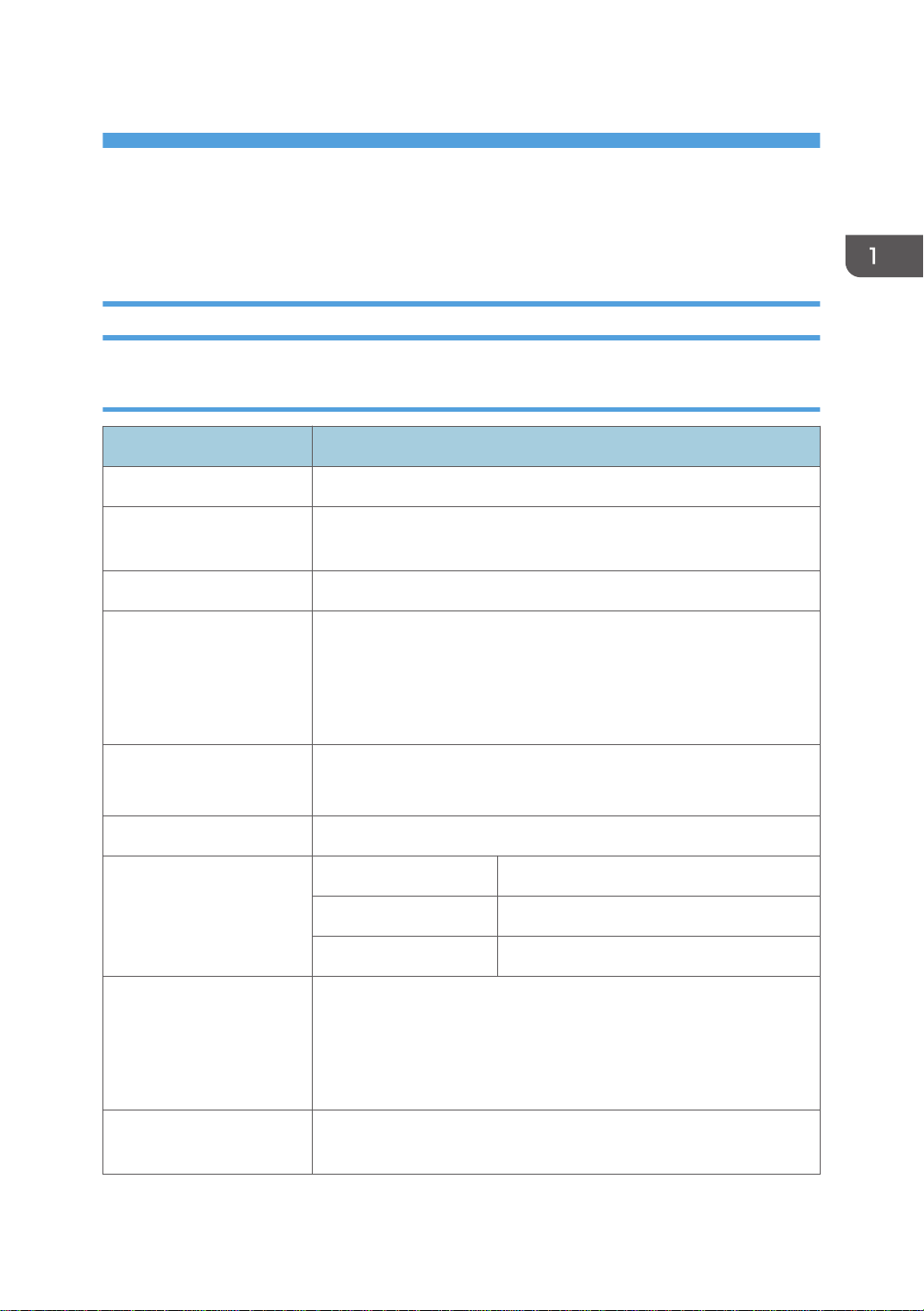

Conventions Used in this Manual

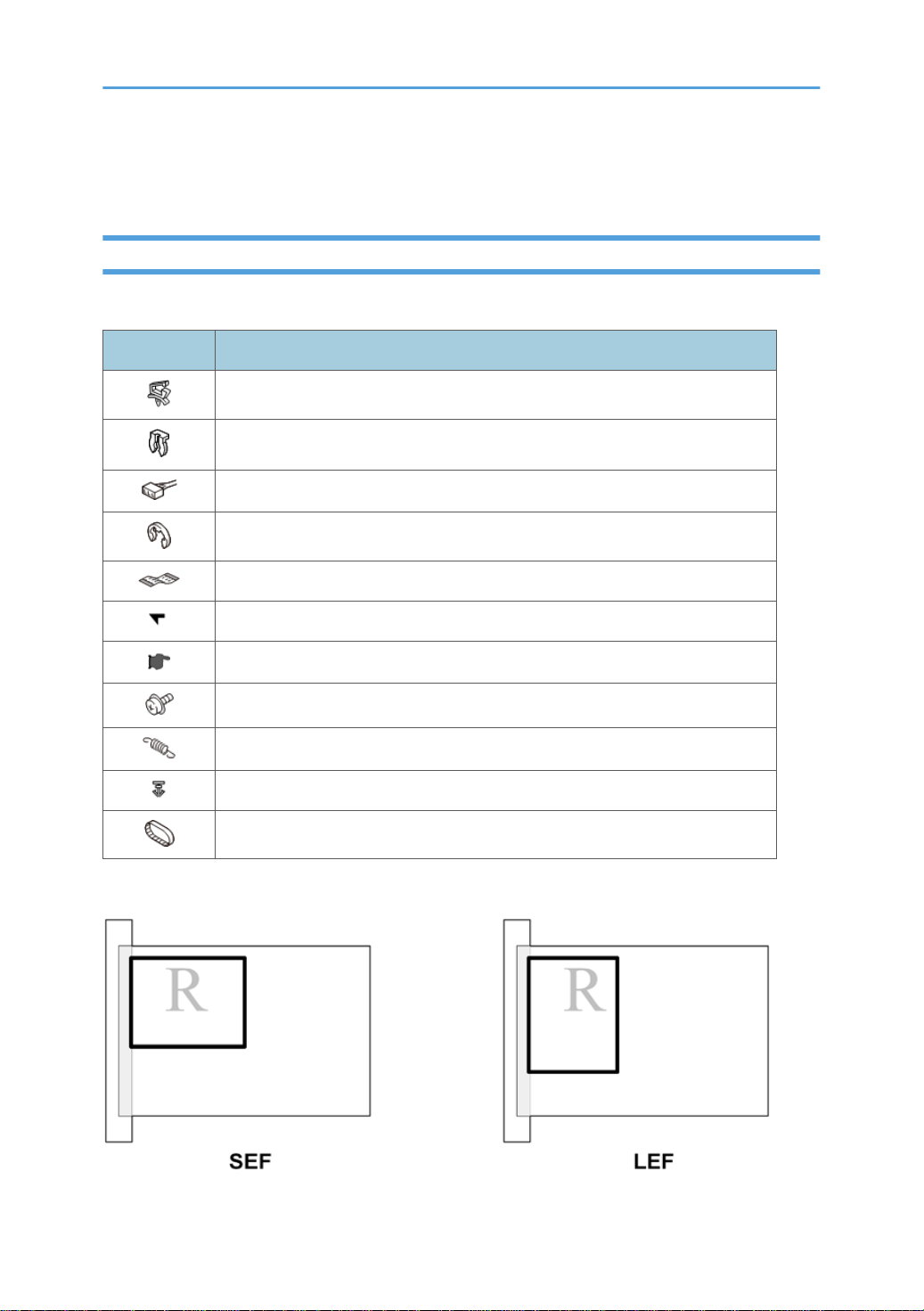

Symbols and Abbreviations

This manual uses several symbols.

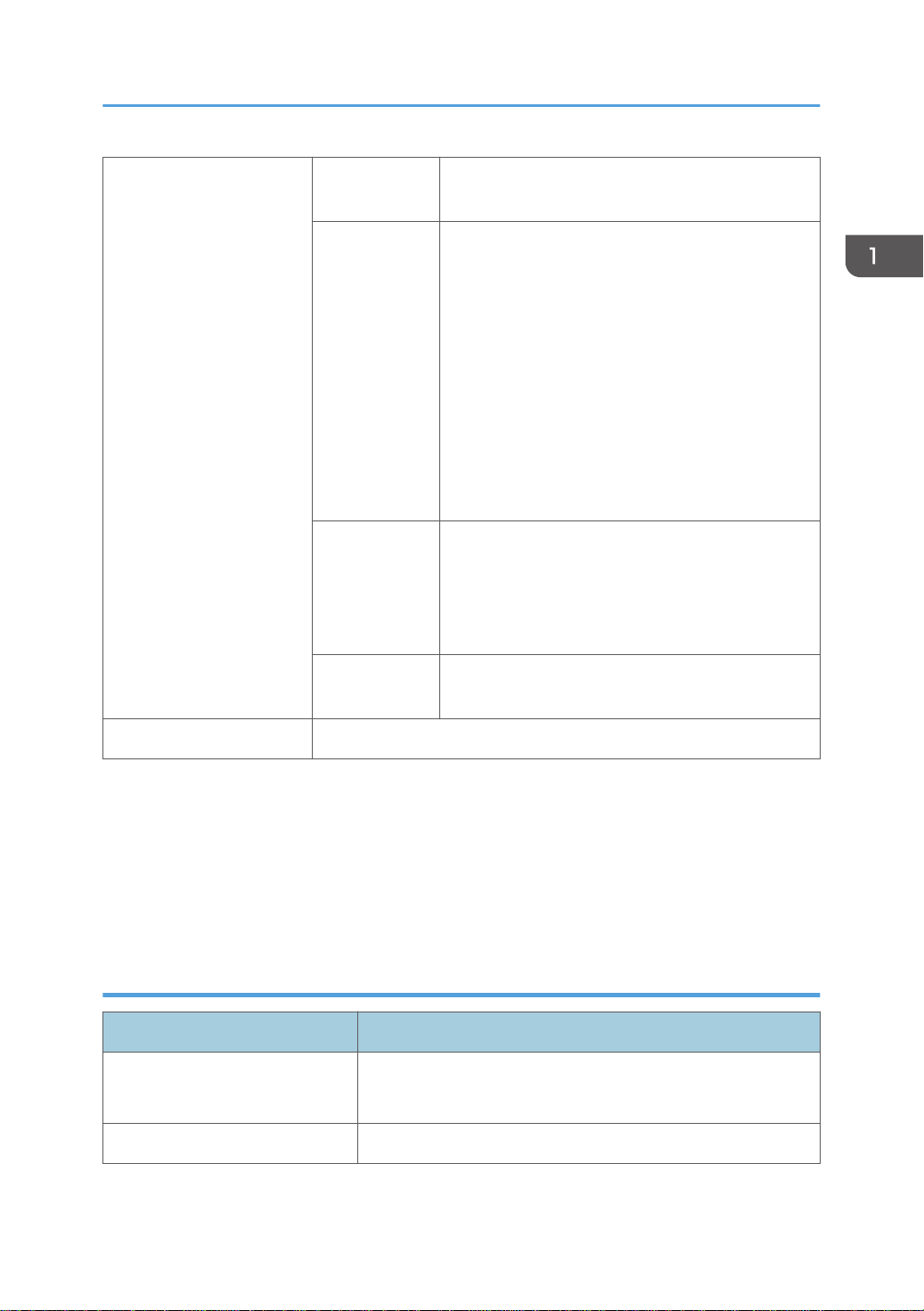

Symbol What It Means

Clamp

Clip ring

Connector

E-ring

FFC (Flat Film Connector)

Hook

Pointer (cross-reference to another manual section)

Screw

Spring

Standoff

Timing Belt

This manual uses the following abbreviations.

5

Page 8

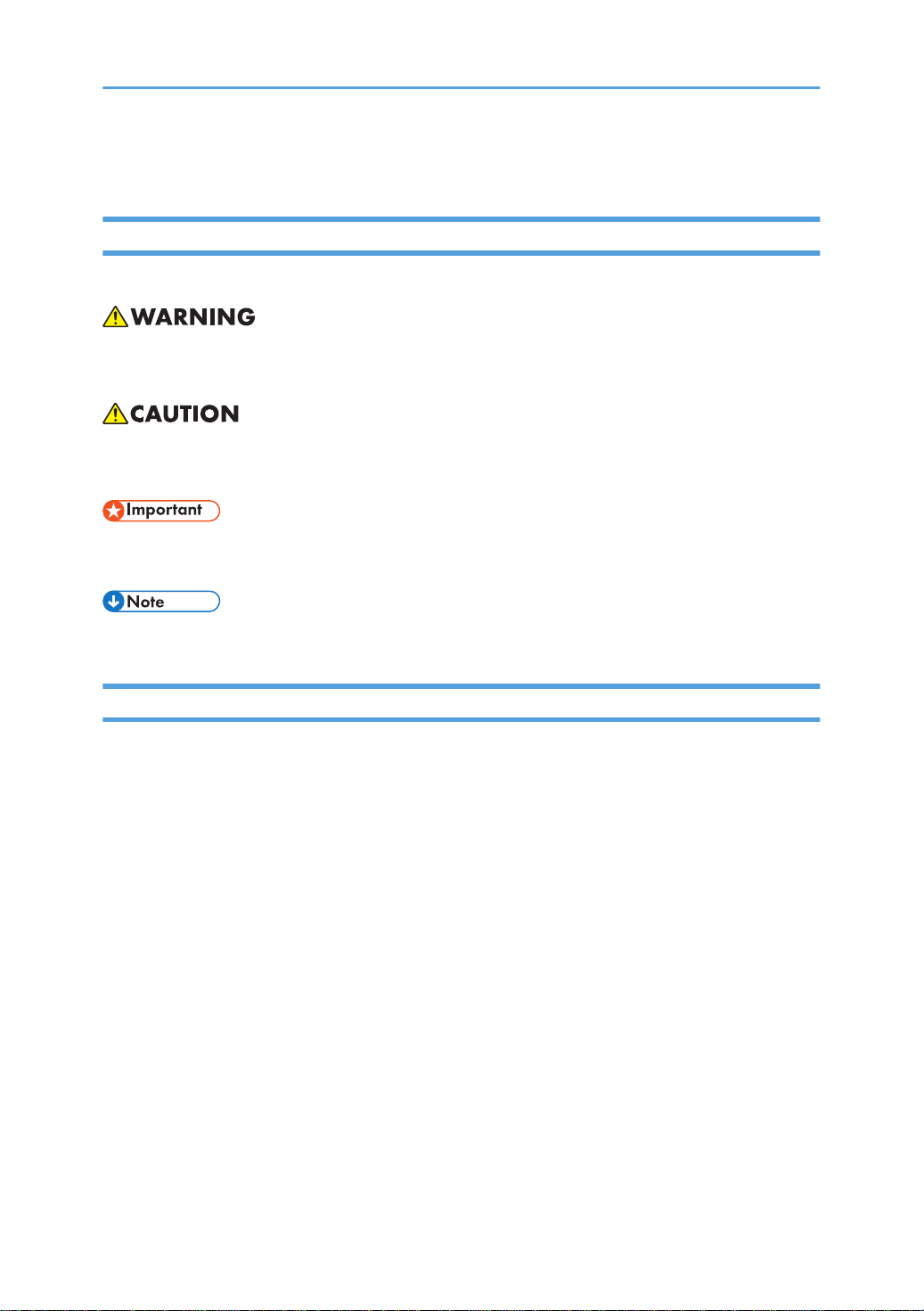

Throughout this service manual, "SEF" denotes "Short Edge Feed" and "LEF" denotes "Long Edge Feed".

Warnings, Cautions, Notes

In this manual, the following important symbols and notations are used.

• A Warning indicates a potentially hazardous situation. Failure to obey a Warning could result in

death or serious injury.

• A Caution indicates a potentially hazardous situation. Failure to obey a Caution could result in

minor or moderate injury or damage to the machine or other property.

• Obey these guidelines to avoid problems such as mis-feeds, damage to originals, loss of valuable

data and to prevent damage to the machine

• This information provides tips and advice about how to best service the machine.

Trademarks

• Apple, AppleTalk, Bonjour, ColorSync, Leopard, Macintosh, Mac OS, Power Mac, Safari and

TrueType are trademarks of Apple Inc., registered in the United States and other countries.

• Citrix, Citrix Presentation Server and Citrix XenApp are either registered trademarks or trademarks

of Citrix Systems, Inc. Firefox® is a registered trademark of the Mozilla Foundation.

• Intel and Intel Core are registered trademarks of Intel Corporation or its subsidiaries in the United

States and other countries.

• Microsoft®, Windows®, Windows Server®, and Internet Explorer® are either registered

trademarks or trademarks of Microsoft Corporation in the United States and/or other countries.

• Monotype is a registered trademark of Monotype Imaging Inc.

• PowerPC® is a registered trademark of International Business Machines Corporation in the United

States and other countries, or both.

• UNIX is a registered trademark in the United States and other countries, licensed exclusively

through, X/Open Company Limited.

• The proper name of Internet Explorer 6 is Microsoft® Internet Explorer® 6.

The proper names of the Windows operating systems are as follows:

• The product names of Windows 7 are as follows:

6

Page 9

Microsoft® Windows® 7 Home Premium

Microsoft® Windows® 7 Professional

Microsoft® Windows® 7 Ultimate

Microsoft® Windows® 7 Enterprise

• The product names of Windows 8.1 are as follows:

Microsoft® Windows® 8.1

Microsoft® Windows® 8.1 Pro

Microsoft® Windows® 8.1 Enterprise

• The product names of Windows 10 are as follows:

Microsoft® Windows® 10 Home

Microsoft® Windows® 10 Pro

Microsoft® Windows® 10 Enterprise

Microsoft® Windows® 10 Education

• The product names of Windows Server 2008 are as follows:

Microsoft® Windows Server® 2008 Standard

Microsoft® Windows Server® 2008 Enterprise

• The product names of Windows Server 2008 R2 are as follows:

Microsoft® Windows Server® 2008 R2 Standard

Microsoft® Windows Server® 2008 R2 Enterprise

• The product names of Windows Server 2012 are as follows:

Microsoft® Windows Server® 2012 Foundation

Microsoft® Windows Server® 2012 Essentials

Microsoft® Windows Server® 2012 Standard

• The product names of Windows Server 2012 R2 are as follows:

Microsoft® Windows Server® 2012 R2 Foundation

Microsoft® Windows Server® 2012 R2 Essentials

Microsoft® Windows Server® 2012 R2 Standard

• The product names of Windows Server 2016 are as follows:

Microsoft® Windows Server® 2016 Datacenter

Microsoft® Windows Server® 2016 Standard

Microsoft® Windows Server® 2016 Essentials

Microsoft® Windows Server® 2016 MultiPoint Premium

7

Page 10

Other product names used herein are for identification purposes only and might be trademarks of their

respective companies. We disclaim any and all rights to those marks.

8

Page 11

TABLE OF CONTENTS

Important Safety Notices................................................................................................................................... 1

Warnings, Cautions, Notes...........................................................................................................................1

General Safety Instructions............................................................................................................................1

Safety...............................................................................................................................................................2

Prevention of Physical Injury................................................................................................................. 2

Observance of Electrical Safety Standards.........................................................................................3

Safety and Ecological Notes for Disposal...........................................................................................3

Safety Instructions for Ink Cartridges ........................................................................................................... 3

Accidental Exposure To Ink.................................................................................................................. 3

Handling and Storing Ink Cartridges...................................................................................................4

Ink Cartridge Disposal...........................................................................................................................4

Conventions Used in this Manual......................................................................................................................5

Symbols and Abbreviations...........................................................................................................................5

Warnings, Cautions, Notes...........................................................................................................................6

Trademarks..................................................................................................................................................... 6

1. Product Information

Specifications....................................................................................................................................................17

Basic Specifications..................................................................................................................................... 17

Main Machine.....................................................................................................................................17

Optional Dryer for Garment Printer (RICOH Rh 100).....................................................................19

Optional Cassettes..............................................................................................................................20

RICOH Design Software (T-shirt Designer).......................................................................................20

RPCS Raster Printer Driver.................................................................................................................. 20

Print Volume, Service Life....................................................................................................................21

Operation Specifications.............................................................................................................................21

Printing Operation...............................................................................................................................21

Print Speed and Resolution.................................................................................................................22

Control Boards.............................................................................................................................................22

Controller............................................................................................................................................. 22

Supported Utilities........................................................................................................................................23

Overview.......................................................................................................................................................... 25

Machine Codes and Peripherals Configuration........................................................................................25

Main Machine.....................................................................................................................................25

9

Page 12

Options................................................................................................................................................ 25

Diagram............................................................................................................................................... 26

Consumables................................................................................................................................................26

Ink Cartridges...................................................................................................................................... 26

Ink Collector Unit.................................................................................................................................27

Others...................................................................................................................................................28

Names of Components................................................................................................................................28

2. Installation

Preparation....................................................................................................................................................... 31

Environment..................................................................................................................................................31

Choosing a Location....................................................................................................................................31

Minimum Space Requirements................................................................................................................... 33

Power Source............................................................................................................................................... 33

Precautions when Moving the Machine.................................................................................................... 33

Using the Operation Panel.............................................................................................................................. 35

Printer Display Summary............................................................................................................................. 36

Operation Panel: Cartridge replacement indicator......................................................................... 36

Operation Panel: Waste Ink Full Indicator........................................................................................37

Display Menu Summary..............................................................................................................................38

User Menu Mode................................................................................................................................38

Access to menus during an error........................................................................................................45

Installation.........................................................................................................................................................46

Accessory Check..........................................................................................................................................46

Important Information...................................................................................................................................... 49

Checklist before Moving the Printer........................................................................................................... 49

If the Printer Is Not Used Frequently…........................................................................................................49

3. Preventive Maintenance

PM Table...........................................................................................................................................................51

Service Call Procedures.............................................................................................................................. 51

4. Replacement and Adjustment

Before Replacing Parts.....................................................................................................................................53

Covers............................................................................................................................................................... 54

Cover Names...............................................................................................................................................54

10

Page 13

Order of Cover Removal.............................................................................................................................55

Front Right Cover......................................................................................................................................... 55

Right Lower Cover........................................................................................................................................56

Right Cover...................................................................................................................................................56

Re-assembly.........................................................................................................................................58

Port Cover.....................................................................................................................................................60

Left Lower Cover.......................................................................................................................................... 60

Left Cover......................................................................................................................................................60

Canopy Cover............................................................................................................................................. 61

Front Cover, Operation Panel Board.........................................................................................................62

Re-assembly.........................................................................................................................................65

Rear Top Cover............................................................................................................................................67

Rear Transport Cover.................................................................................................................................. 67

Rear Cover, Top Cover............................................................................................................................... 68

Top Cover Only...................................................................................................................................71

Front Lower Cover....................................................................................................................................... 71

Right Guide Rail Cover................................................................................................................................72

Left Guide Rail Cover...................................................................................................................................75

Cassette Stand............................................................................................................................................. 78

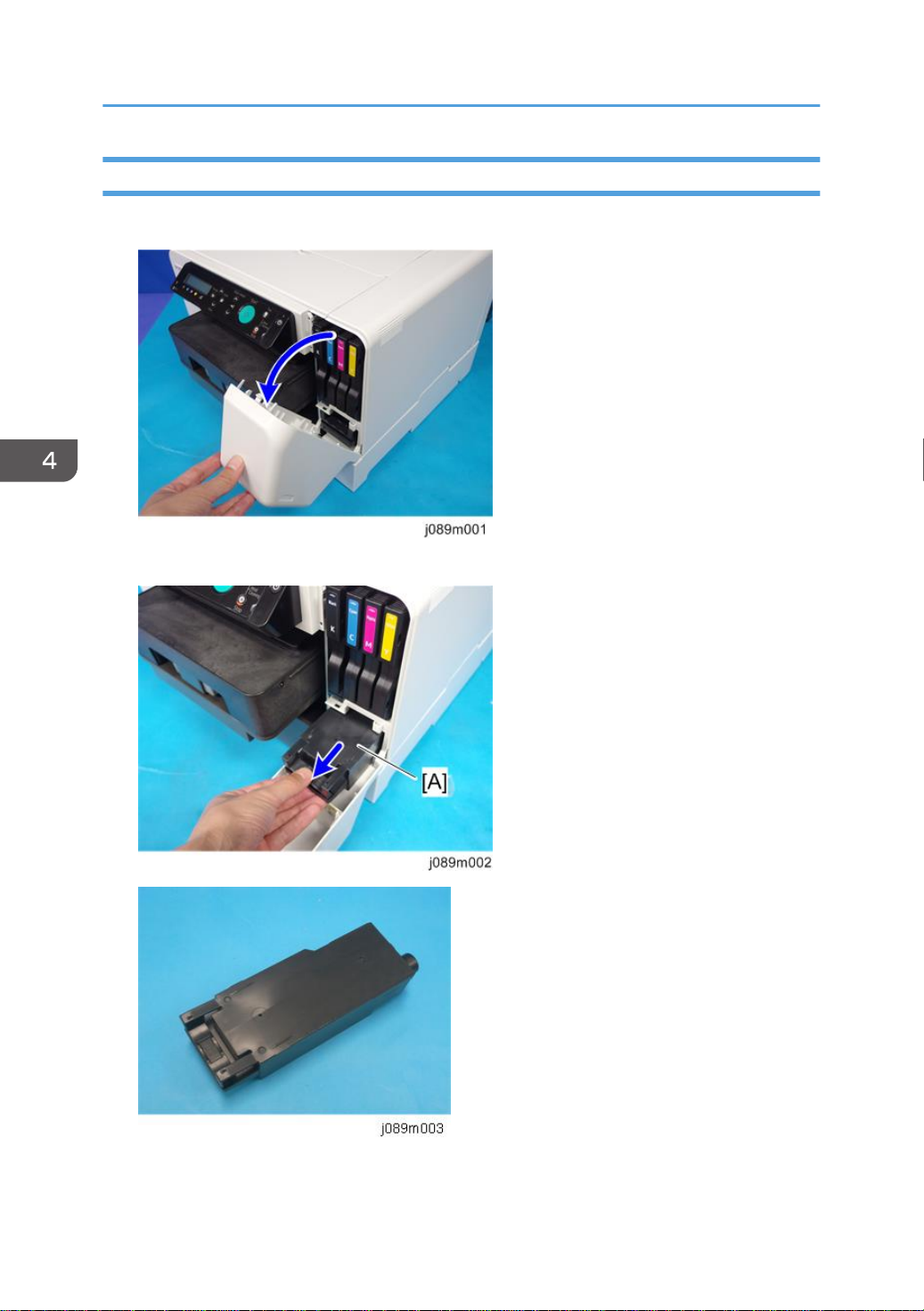

Ink Collector Unit..............................................................................................................................................81

Before You Begin......................................................................................................................................... 81

Replace the Ink Collector Unit.................................................................................................................... 82

Maintenance Unit, Right Ink Sump................................................................................................................. 84

Maintenance Unit........................................................................................................................................ 84

Right Ink Sump..............................................................................................................................................86

Encoders........................................................................................................................................................... 88

Vertical Encoder Wheel.............................................................................................................................. 88

Horizontal Encoder Strip.............................................................................................................................92

Reinstallation........................................................................................................................................94

Boards...............................................................................................................................................................99

PSU................................................................................................................................................................99

Printer Engine CTL Board.......................................................................................................................... 100

Before Replacement......................................................................................................................... 100

11

Page 14

CTL Board Replacement...................................................................................................................101

After Replacement............................................................................................................................ 103

Wireless LAN Board................................................................................................................................. 105

Relay Board............................................................................................................................................... 106

Lift Board.................................................................................................................................................... 107

Motors............................................................................................................................................................ 114

Horizontal Motor.......................................................................................................................................114

Vertical Motor............................................................................................................................................115

Lift Motor Unit............................................................................................................................................ 117

Applying Grease When Installing the Lift Motor........................................................................... 120

Fan.................................................................................................................................................................. 122

Sensors, Switches.......................................................................................................................................... 123

Vertical Encoder Sensor............................................................................................................................123

Ink Level Sensor......................................................................................................................................... 123

Air Purge Detection Switch....................................................................................................................... 126

Top Cover Switch...................................................................................................................................... 127

Front Right Cover Switch...........................................................................................................................128

Temperature/Humidity Sensor.................................................................................................................129

Interlock Switch..........................................................................................................................................129

Cassette Size Sensor.................................................................................................................................130

Height Sensor ........................................................................................................................................... 132

Cassette Carriage HP Sensor (Front).......................................................................................................133

Cassette Carriage HP Sensor (Rear)....................................................................................................... 133

Lift Tray HP Sensor ....................................................................................................................................134

Carriage Unit................................................................................................................................................. 136

Removing the Carriage Unit..................................................................................................................... 136

Ink Supply Unit...........................................................................................................................................136

Installing the Ink Supply Unit............................................................................................................139

Ink Tube Guide.......................................................................................................................................... 141

Carriage.....................................................................................................................................................142

Installing the Carriage Unit.............................................................................................................. 144

Lock the Carriage............................................................................................................................. 147

After Replacing the Carriage Unit............................................................................................................148

12

Page 15

Print Head Cleaning and Adjustment...........................................................................................................150

Preparing for Test Printing.........................................................................................................................150

Nozzle Check............................................................................................................................................151

Color Demo Print....................................................................................................................................... 152

Print Head Cleaning..................................................................................................................................153

Print Head Flushing....................................................................................................................................154

Head Position.............................................................................................................................................155

Registration................................................................................................................................................ 157

Cleaning......................................................................................................................................................... 159

Height Sensor Cleaning............................................................................................................................159

Horizontal Encoder Sensor Cleaning .....................................................................................................160

Preparation........................................................................................................................................161

Cleaning............................................................................................................................................162

Clean Internals...........................................................................................................................................163

When cleaning of the interior fails.................................................................................................. 166

Adjusting the Height of the Cassette manually............................................................................................168

Refurbishing....................................................................................................................................................170

Clean the Machine....................................................................................................................................170

5. System Maintenance Reference

Service Mode and Engine Maintenance Mode......................................................................................... 171

Service Mode............................................................................................................................................ 171

Entering/Exiting Service Mode.......................................................................................................171

Engine Maintenance (SP) Mode..............................................................................................................175

Entering/Exiting SP Mode............................................................................................................... 175

Using SP Mode Menus.................................................................................................................... 175

Bit Switch Settings......................................................................................................................................177

SP Mode Service Tables............................................................................................................................... 180

SP Table Key..............................................................................................................................................180

SP1-XXX (Feed)......................................................................................................................................... 181

SP2-XXX......................................................................................................................................................184

SP3-XXX (Process)..................................................................................................................................... 184

SP4-XXX......................................................................................................................................................187

SP5-XXX (Mode)....................................................................................................................................... 187

13

Page 16

SP6-XXX......................................................................................................................................................191

SP7-XXX (Data Log).................................................................................................................................. 191

SP8-XXX......................................................................................................................................................199

SP9-XXX (Others)...................................................................................................................................... 199

Status Reports.................................................................................................................................................201

1. Page Counter........................................................................................................................................ 202

2. Config. List (System Summary).............................................................................................................203

3. Service Summary.................................................................................................................................. 204

4. Engine Summary Chart.........................................................................................................................204

Firmware Updates......................................................................................................................................... 209

Operating Environment and Other Requirements.................................................................................. 209

Update Cautions....................................................................................................................................... 210

Preparation................................................................................................................................................ 211

Firmware Update (Bidirectional-Enabled).............................................................................................. 212

Firmware Update (Bidirectional-Disabled)............................................................................................. 214

How to check the current firmware version.................................................................................... 214

How to Update the Firmware When Bidirectional Communication is Disabled......................... 215

6. Troubleshooting

Image Problems............................................................................................................................................. 219

Basic Check Points and Specifications.................................................................................................... 219

Problems and Solutions.............................................................................................................................221

Error Codes.................................................................................................................................................... 229

Operation Panel Display.......................................................................................................................... 229

Operation Panel Messages......................................................................................................................231

Service Call Conditions.............................................................................................................................235

SC code display patterns and how to clear them..........................................................................235

Service Call Code Tables......................................................................................................................... 236

Jam Codes................................................................................................................................................. 266

Jam Codes.........................................................................................................................................266

Jammed garment location................................................................................................................267

Status Monitor Messages......................................................................................................................... 268

7. Detailed Description

Electrical Components...................................................................................................................................273

14

Page 17

Parts Layout................................................................................................................................................273

Electrical Component Summary...............................................................................................................275

Print Heads..................................................................................................................................................... 281

Print Head Configurations........................................................................................................................ 281

Print Head Detailed Configuration...........................................................................................................281

Cassette/Cassette Carriage Movement......................................................................................................283

Basic Operation........................................................................................................................................ 283

Initialization when Turning on Power (Preparation for Mounting Cassette).........................................284

Detecting Height (Unevenness due to Wrinkles and Bulges) of Printing Media.................................. 285

Printing........................................................................................................................................................286

15

Page 18

16

Page 19

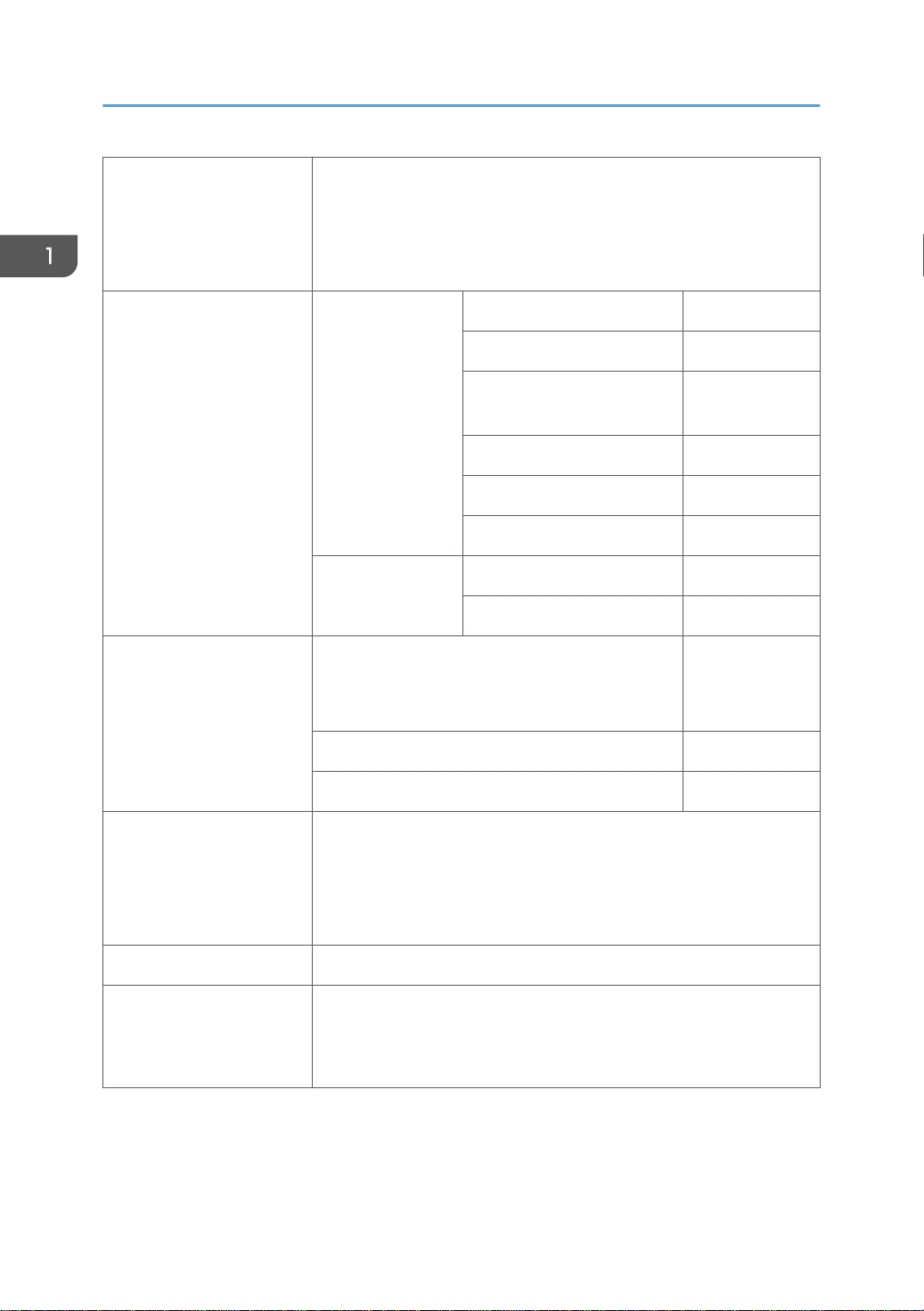

1. Product Information

Specifications

Basic Specifications

Main Machine

Items Specifications

Configuration Desktop

Printing Method On-Demand piezo inlet GEL JET Ink Printing Technology with pigment-

base ink (4 colors)

Resolution (dpi, bit/pixel) Max. 1200x1200dpi equivalent

Print Speed (when printing

the whole A4 area in black)

Nozzles • Black: 192 nozzles

Warm-up Time Less than 35 sec.

Printable area A4 standard tray 291 × 204 mm (11.5 × 8.0 inches)

Fabric thickness • A4 standard tray and A5 tray (option)

Number of loadable

cassettes

• Speed priority mode

1 minute 20 seconds or less (after pressing the Start button)

• Quality priority mode

2 minutes 30 seconds or less (after pressing the Start button)

• Cyan, magenta, and yellow: 192 nozzles per color

A5 tray (option) 204 × 142 mm (8.0 × 5.6 inches)

Multi tray*3 (option) 291 × 204 mm (11.5 × 8.0 inches)

7 mm (0.27 inches)

• Multi tray (option)

35 mm (1.37 inches)

1 cassette

*3

17

Page 20

1. Product Information

Power source • EU/Asia/China

220-240 V: 50/60 Hz 0.6 A (with all options installed)

• NA

100-120 V: 60 Hz 1 A (with all options installed)

Power consumption*1 With consumables Ready (EU/Asia/China) 9.0W

Ready (NA) 9.2W

During printing (EU/Asia/

China)

During printing (NA) 18.1W

Maximum (EU/Asia/China) 47W

Maximum (NA) 47W

With all options

Maximum (EU/Asia/China) 47W

installed

Maximum (NA) 47W

Energy Saver mode Reduced power consumption in Energy Saver

mode*2

Time to switch into Energy Saver mode 5 min.

Time to switch out from Energy Saver mode*2 2.9 sec.

External dimensions

(W × D × H)

• Standby:

399 × 698.2 × 292.5 mm (15.7 × 26.9 × 11.5 inches)

• During printing:

17.7W

1.8W (EU/

Asia/China)

1.7W (NA)

18

399 × 760.3 × 292.5 mm (15.7 × 29.9 × 11.5 inches)

Weight 22 kg (45.5 lb.) or less

Interface • USB 2.0 high speed

• Ethernet (10Base-T, 100Base-TX)

• Wireless LAN (IEEE 802.11 b/g/n)

Page 21

Specifications

Wireless LAN Transmission

Specification

Data Transfer

Speed

Frequency

Range

Transmission

Mode

Based on IEEE 802.11b/g/n

Auto select from the following speeds:

• 802.11b

1, 2, 5.5, 11 (Mbps)

• 802.11g

6, 9, 12, 18, 24, 36, 48, 54 (Mbps)

• 802.11n

6.5, 7.2, 13, 13.5, 14.4, 15, 19.5, 21.7,26,

27, 28.9, 30, 39, 40.5, 43.3, 45, 52, 54,

57.8, 58.5, 60, 65, 72.2, 81, 90,108, 120,

121.5, 135, 150 (Mbps)

• EU/Asia/China:

2412 to 2472 Mhz (1 to 13 Channels)

• NA:

2412 to 2462 Mhz (1 to 11 Channels)

Infrastructure mode

Printer language RPCS Raster

To avoid unnecessary power consumption, disconnect the power plug from the wall outlet. (Unplug the

*1:

power plug only after making sure the power lamp is off.) Power Consumption may differ depending on the

conditions and environment of the machine.

The time it takes to switch out from energy saving functions and power consumption may differ depending on

*2:

the conditions and environment of the machine.

*3: RICOH Tray for Multi Purpose Type 1 (J364)

Optional Dryer for Garment Printer (RICOH Rh 100)

Items Specifications

Power source

Power consumption 1,000 W

EU/Asia/China: 220-240 V: 50/60 Hz

NA: 110-127 V: 50/60 Hz

19

Page 22

1. Product Information

Items Specifications

External dimensions (W × D × H) 399 × 600 × 200 mm (15.8 × 23.7 × 7.9 inches)

Weight 16.5 kg (approx. 36.4 lb.)

Optional Cassettes

Items Specifications

• A5 tray

External dimensions (W × D ×

H)

Weight

242.2 × 409.2 × 97.9 mm (9.5 × 16.1 × 3.9 inches)

• Multi tray

242.2 × 409.2 × 84.9 mm (9.5 × 16.1 × 3.3 inches)

• A5 tray

2.13 kg (4.7 lb.)

• Multi tray

1.62 kg (3.6 lb.)

RICOH Design Software (T-shirt Designer)

Items Specifications

Supported device

Supported operating system

Windows tablets (with 10-inch touch panel)

Device with Mac OS (iMac, MacBook, Mac mini, etc.)

Windows 10 (32-bit version)

Mac OS X 10.10 and later versions

RPCS Raster Printer Driver

Items Specifications

Available Operating Systems

20

Windows: Windows 7/8.1/10 and Windows Server 2008/2008

R2/2012/2012 R2/2016

Macintosh: Mac OS X 10.8 and later versions

Page 23

Print Volume, Service Life

Duty 3,000 prints

Monthly Volume Ave. 200 prints

Estimated Service Life 5 years, or 60K prints

Operation Specifications

Printing Operation

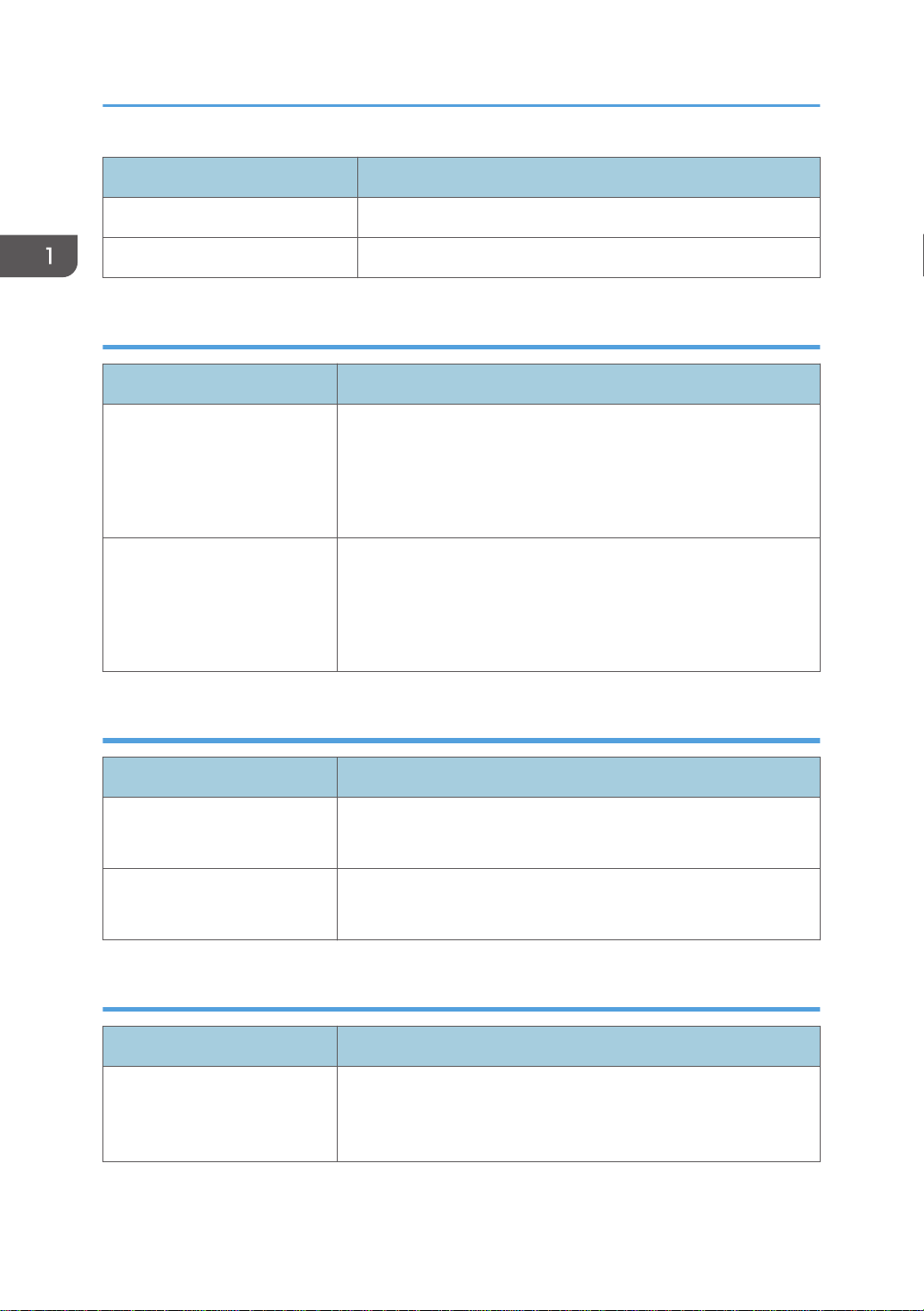

Print Area

Specifications

a. Front of the Cassette

b. Printable Area

c. Windows: 3 mm (0.12 inches), Mac: 3 mm (0.12 inches)

The printing ranges of each cassette are as follows:

• A4 standard tray: 291 × 204 mm (11.5 × 8.0 inches)

• A5 tray: 204 × 142 mm (8.0 × 5.6 inches)

• Multi tray: 291 × 204 mm (11.5 × 8.0 inches)

Functions that can be adjusted with the driver

• It is possible to select [Fine], [Speed], and [Vivid] in Print Quality for each print media

21

Page 24

1. Product Information

• Garment Settings (Size, Fit to Garment Size, Portrait/Landscape, Garment Type)

• Color/Monochrome selection

• Adjust images (Adjust Photographs, Smooth Low Resolution Images)

• Number of copies

• Advance settings for image quality (Brightness, Contrast, Saturation, RGB Revision, etc.)

• Color Profile Settings (Type, On/Off)

• Printable Area Settings (3 mm margin)

Print Speed and Resolution

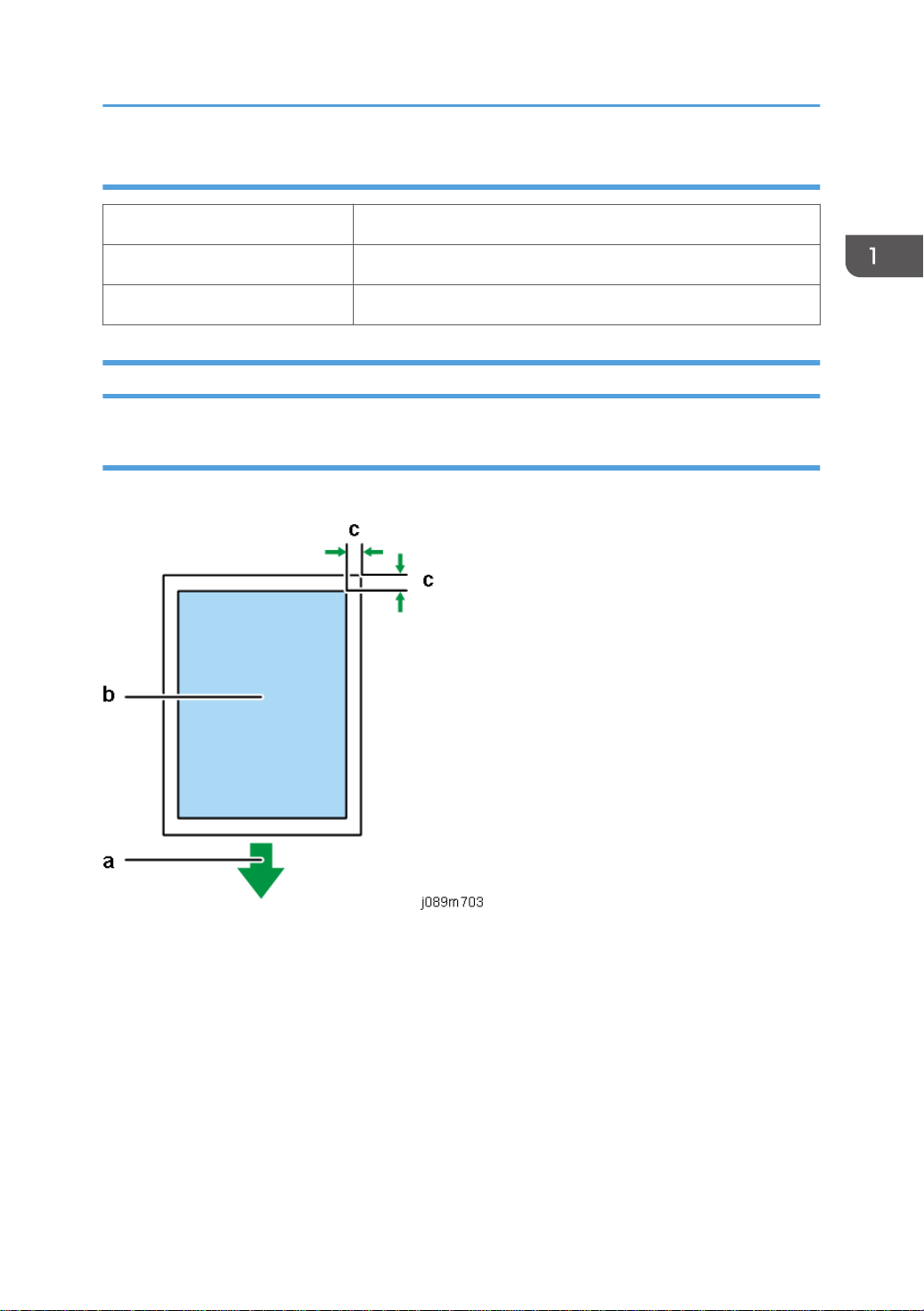

Print Mode dpi RPCS–R Diver

Fine mode 1200 x 1200 1 minute 20 seconds or less

Speed mode 600 x 600 2 minutes 30 seconds or less

Vivid mode 600 x 600 NA

*1: When printing the whole A4 area in black.

*2: After pressing the Start button.

Control Boards

Controller

CPU SH2A

SoC ZICO

RAM SDRAM: 32MB

Program ROM On Board: 4MB

*1, *2

*1, *2

22

Font ROM None

EEPROM 4KB

Optional EEPROM slot None

PDL RPCS Raster

Page 25

Connectivity

Specifications

Host Interface(Std) USB 2.0 High Speed, 10Base-T/100Base-TX

Network Protocol TCP/IP

MIB Support Private:

Ricoh Original

Standard:

RFC1213 (MIB-II)

RFC1514/RFC2970 (Host Resource MIB)

RFC1759 (Printer MIB)

RFC3412 (MPD-MIB)

RFC3413 (Target-MIB, Norification-MIB)

RCF3414 (USM-MIB)

RFC3415 (VACM-MIB)

RFC3584 (COMMUNITY-MIB)

Printer Working Group Candidate Standard 5107.1-2005

(Printer Port Monitor MIB 1.0)

Networking Operating Systems • Windows: Windows 7/8.1/10 and Windows Server

2008/2008 R2/2012/2012 R2/2016

• Macintosh: Mac OS X 10.8 and later versions

Note: Mac driver included on CD-ROM (The supported languages are English, French, German and

Japanese.).

Supported Utilities

Bundled T-shirt Designer

Software for designing and printing on T-shirt and tote bag

fabric.

Web The following software can be downloaded.

• Smart Device Monitor for Admin

• Smart Device Monitor for Client

23

Page 26

1. Product Information

Optional • Remote Communication Gate S Pro

• Smart Device Monitor for Admin Accounting Report

Package

• Desk Top Binder Lt

24

Page 27

Overview

Overview

Machine Codes and Peripherals Configuration

Main Machine

There are 3 different models. However, they each have the same product name. There are absolutely no

differences in functionality, as the only difference is the exterior color.

Machine

Code

J089 RICOH Ri 100 White Not supported Supported

J098 RICOH Ri 100 Pink Not supported Supported

J099 RICOH Ri 100 Green Not supported Supported

Product Name Exterior color Printing on paper NIC

Options

Code Product Name Remarks

Dryer for garment printer.

J361 RICOH Rh 100

J362 RICOH Tray for Standard Size Type 1

J363 RICOH Tray for Small Size Type 1 A5 tray

J364 RICOH Tray for Multi Purpose Type 1

A heat press for fixing printed images

onto fabric.

Same as the supplied standard (A4)

tray.

This tray is for fabrics on which

printing cannot be performed with

the A4 standard tray and A5 tray.

25

Page 28

1. Product Information

Diagram

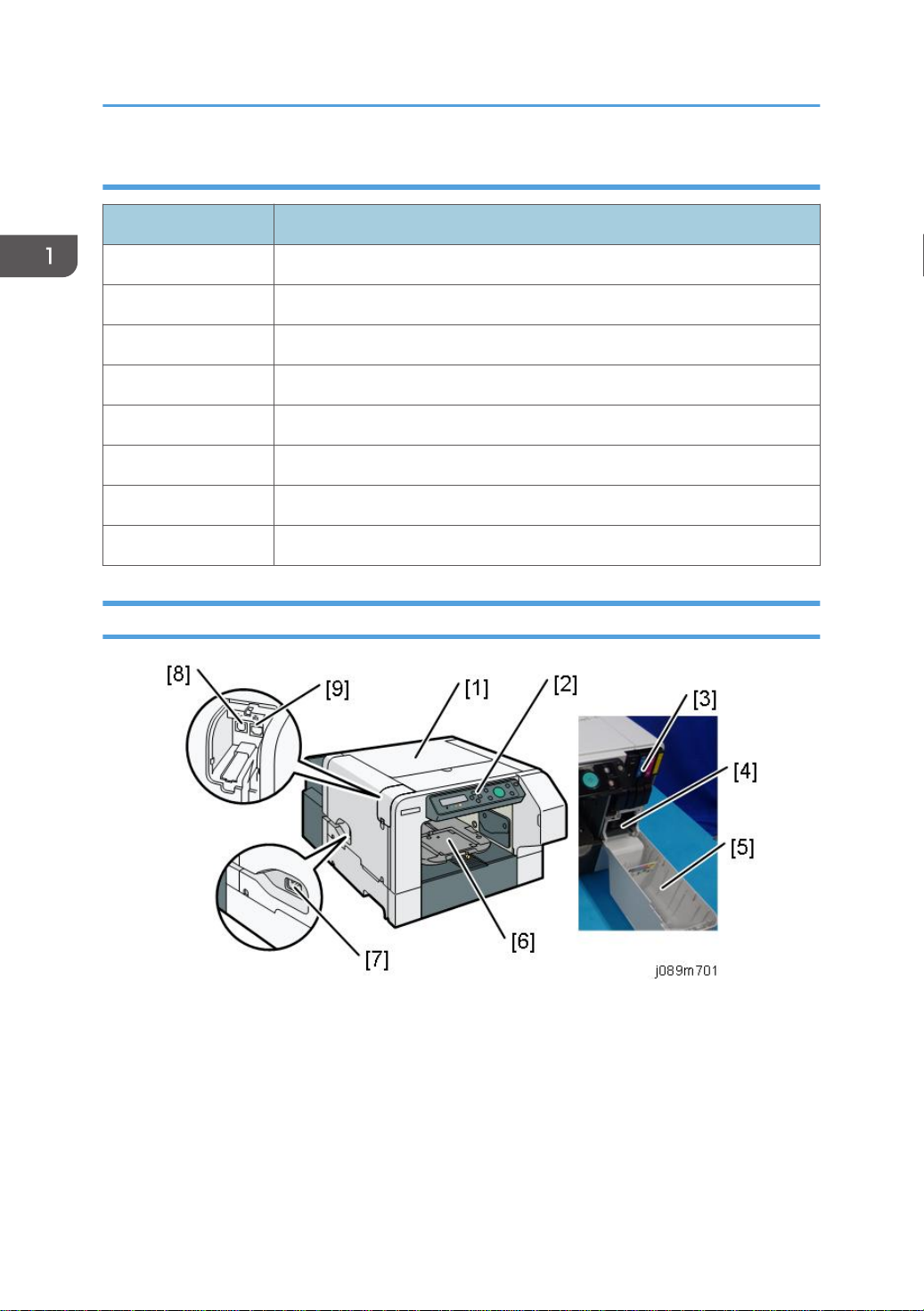

[1]: RICOH Tray for Standard Size Type 1 (standard/optional)

[2]: RICOH Tray for Small Size Type 1 (optional tray)

[3]: RICOH Tray for Multi Purpose Type 1 (optional tray)

[4]: RICOH Rh 100 (optional dryer for garment printer)

Consumables

Ink Cartridges

Always use the starter cartridges shipped with the machine to initialize ink supply at installation. Never

install used ink cartridges to initialize ink supply at installation.

26

Page 29

Code Product Name Remarks

Overview

J922-08

J922-24 (for China)

J922-09

J922-25 (for China)

J922-10

J922-26 (for China)

J922-11

J922-27 (for China)

J922-12

J922-28 (for China)

J922-13

J922-29 (for China)

J922-14

J922-30 (for China)

J922-15

J922-31(for China)

RICOH Garment Ink Cartridge K (Hi Yield) Type 1

RICOH Garment Ink Cartridge C (Hi Yield) Type 1

RICOH Garment Ink Cartridge M (Hi Yield) Type

1

RICOH Garment Ink Cartridge Y (Hi Yield) Type 1

RICOH Garment Ink Cartridge K Type 1

RICOH Garment Ink Cartridge C Type 1

RICOH Garment Ink Cartridge M Type 1

RICOH Garment Ink Cartridge Y Type 1

These are mediumsize cartridges.

These are small-size

cartridges.

Ink Collector Unit

The ink collector unit is installed on the right side of the machine behind the right front door below the ink

supply unit.

Code Product Name

J923-00 RICOH Ink Collection Unit Type 1*

*This ink collector unit is only for this machine. The units for SG 3110DN / SG 3110DNw, or the other

Geljet machines have the same appearance, but they are incompatible with this machine due to a

software detection.

27

Page 30

1. Product Information

Others

Code Product Name

J924-00 RICOH Heat Resistant Paper Type 1

J922-36 RICOH Cleaning Cartridge K Type 1

J922-37 RICOH Cleaning Cartridge C Type 1

J922-38 RICOH Cleaning Cartridge M Type 1

J922-39 RICOH Cleaning Cartridge Y Type 1

J927-00 RICOH Cleaning Tool Type 1

J928-00 RICOH Cleaning Absorber Type 1

J929-00 RICOH Cleaning Stick Type 1

Names of Components

1. Top cover

Open to remove the fabric or foreign object, or to clean the maintenance unit.

2. Operation panel

Operation keys and the 2-line LCD.

3. Ink cartridges (K), (C), (M), (Y)

28

Supply ink to the print heads.

Page 31

4. Ink collector unit

Pull out the ink collector unit when it needs to be replaced, or before servicing the printer.

5. Front right cover

Covers the ink cartridges and the ink collector. Open only when installing or replacing ink

cartridges, or when pulling out the ink collector unit. Otherwise, this door should remain closed. A

small switch detects when this cover is open and closed. The door must be closed for the printer to

operate.

6. Cassette stand

The cassette is set here. The cassette is fed to the inside of the main unit when printing.

7. Power inlet

The connection point for the power cord. Use only the detachable power cord provided with the

printer. Make sure you ground (earth) the head of the plug at the power source.

8. USB port

This is the connection point for the USB cable from the PC.

9. Ethernet port

Overview

The port for the Ethernet cable. The NIC is mounted on the controller board.

29

Page 32

1. Product Information

30

Page 33

2. Installation

Preparation

Environment

• White area: Permissible Range

• Blue area: Recommended Range

Set up the machine in a location that meets these minimum requirements:

Temperature Range: 10°C to 45°C (50°F to 113°F)

Humidity Range: 5% to 90% RH

Ambient Illumination: Less than 2,000 Lux (never expose to direct sunlight).

Choosing a Location

1. Always install the machine:

• On a sturdy, level surface.

• Where it will not become damp.

31

Page 34

2. Installation

2. Make sure the machine is never exposed to:

• Extreme changes from low to high temperature or high to low temperature.

• Cold or cool air directly from an air conditioner.

• Heat from a space heater.

3. Never install the machine in areas near:

• Dust, lint, or corrosive fumes.

• Strong vibration.

4. Do not use the machine at any location higher than 2,500 m (8,200 ft) above sea level.

5. Set up and use the machine on a sturdy, level surface.

• Place a carpenter's level on the machine front-to-back, and side-to-side and confirm that it is

level.

• Variations between the front/back and left/right level readings should be less than 2

degrees.

Required Software Environment

Software • Microsoft Windows 7/8.1/10

• Microsoft Windows Server 2008/2008 R2/2012/2012 R2/2016

• Mac OS X 10.8 and later versions

• PC/AT-compatible computer with USB or network interface

• Macintoshes that are PowerPC G3 or higher with USB port or network port

Hardware

• Macintoshes that are Intel Core Duo or higher with USB port or network port

• 80-100 MB of HDD space available

Note: Mac driver included on CD-ROM (The supported languages are English, French, German and

Japanese.).

32

Page 35

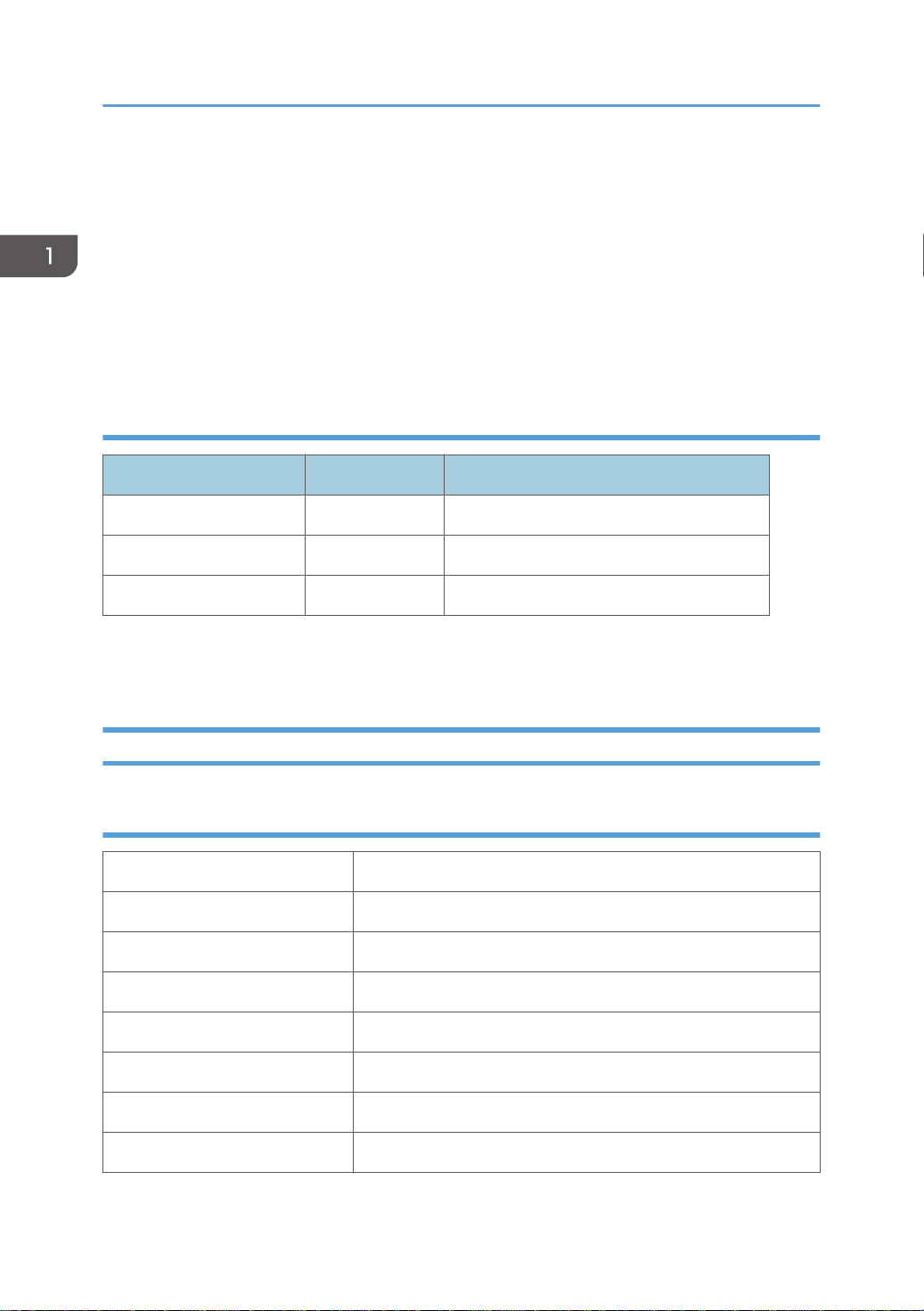

Minimum Space Requirements

a. At least 27 cm (10.7 inches)

Preparation

b. At least 10 cm (4 inches)

c. At least 45 cm (17.8 inches)

d. At least 3 cm (1.2 inches)

e At least 0 cm (0 inches)

Power Source

North America 100-120V: 60Hz 1.0A (when all options are installed)

Europe 220-240V: 50/60Hz 0.6A (when all options are installed)

Precautions when Moving the Machine

• The machine weighs around 22kg (48.5lb.).

• Two or more people are required to lift the printer.

33

Page 36

2. Installation

• When moving the printer, lift it slowly so that you do not strain yourself. Lifting the printer forcibly or

handling it roughly will risk injury to yourself and damage to the printer.

Be cautious of the following points when moving the machine for repairs or transferring it to a repair

facility etc.

• Make sure the ink cartridges remain set in position.

• Make sure that the cover and tray do not open or come off by sealing them down with tape.

• Do not tilt or apply shocks to the machine. If the machine is tilted, ink may spill out of the machine.

• After moving the machine, check the quality of images by performing a test print, and clean the

machine if necessary.

34

Page 37

Using the Operation Panel

Using the Operation Panel

Here is a brief description of how to use the keys on the printer operation panel. This information is

provided as a quick summary of important information described in the Operating Instructions.

Key Summary Table

Key/Indicator What It Does

1 Display Displays the current machine status and messages.

2 Escape Press this key to return to the previous condition on the display.

3 , /Menu Use these keys to increase or decrease values on the display when

making settings.

Keep the key pressed to quicken scrolling, and increase or decrease

values on the display in units of 10. To apply this function: under

[Maintenance], set [Key Repeat] to [On].

4 #Enter Press this key to execute menu items selected on the display.

5 Start Start printing. LED of the [Start] key lights up when the machine is ready

to start printing and flashes when it is printing.

6 Tray Press this key to move the cassette forcibly to the front.

7 Power lamp Lights up when the power is on.

Flashes when the machine is receiving data from a computer or if there

is data to be printed.

8 Alert indicator Lights up or blinks whenever a machine error occurs.

If the red light is on, follow the instructions that appear on the display.

35

Page 38

2. Installation

Key/Indicator What It Does

9 Cartridge

replacement

indicator

10 Waste ink full

indicator

11 Adjust Height /

Adjust Height

12 Stop When the machine is online, press this key to cancel an ongoing print

13 No-Fuss Head

Cleaning

14 Power Press this key to turn the power on. To turn the power off, press and

Each color corresponds to an ink cartridge.

K, C, M, and Y indicate black, cyan, magenta, and yellow,

respectively.

The amount of ink remaining in each ink cartridge is indicated on the

six-level display.

The amount of waste ink is indicated on the six-level display. A message

appears when it is time to replace the ink collector unit.

Move the height of the cassette up and down to adjust the height.

Holding down the key, you can adjust the height of the cassette quickly.

To apply this function, set [Key Repeat] to [On].

job.

When the machine is in standby mode, press the [Stop] and [Tray] keys

at the same time to perform head cleaning for all colors.

hold down this key for one second.

Printer Display Summary

Operation Panel: Cartridge replacement indicator

36

Page 39

Using the Operation Panel

The printer shows a multi-level dynamic display that keeps the operator informed about the status of the

ink levels in the tanks. The example below for Black (K) shows the progression in the display from full on

the left to completely empty on the right.

A software count determines when the ink cartridge is has less than 20% ink remaining. The 0% and Ink

Out display begin flashing alternately at 3 sec. intervals. This is the near-end alert.

When the cartridge is empty the machine issues the ink-end alert and printing stops.

If the ink runs out during printing, the machine may eject the cassette while printing is performed or leave

nothing printed.

Operation Panel: Waste Ink Full Indicator

The amount of waste ink in the ink collector unit is indicated on a six-step scale, namely 0, 20, 40, 60,

80, and 100%. It is reset to 0% if a new ink collector unit is installed. If it reaches 100%, printing cannot

37

Page 40

2. Installation

be done. A message prompting the user to replace the unit appears on the panel display. A message

prompting the user to replace the ink collector unit appears also if it is not mounted.

The amount of waste ink can be displayed also on the Status Monitor and Web Image Monitor.

On the other hand, "Ink C.U. Space" in the machine's menu on the control panel displays the available

storage space left in the ink collector unit. (It is reset to 100% if a new ink collector unit is installed.)

Display Menu Summary

Here is a summary of the function menus. Items needed for printer maintenance or troubleshooting are

marked in the left column with an asterisk (*).

User Menu Mode

Menu/Menu Item Function

Counter Displays or prints the number of pages printed in B&W and full color.

Show Counter Displays the counters on the LCD ("Black", "Color")

Print Prints the "Page Counter" report that lists: the machine serial number, Total

Full Color, Total Black, and total amount (%) of ink used for the each color

option (Coverage Count.) It also lists Coverage ratio information.

List/Test Print

38

Page 41

Menu/Menu Item Function

Config.Page(*) Prints information that tells you the current configuration of the printer.

• System Reference. Lists printer version, attached options, name of print

language, amount of ink remaining for each ink cartridge.

• Maintenance

Maintenance Information. Lists the settings of the Maintenance menu

• System

System Information. Lists the settings of the System menu

• Host Interface, Interface Information. Lists the settings of the Host

Interface menu

• Language

The selected language in the Language menu

Color Demo Page Prints a color sample.

Error Log Prints a list of most recent errors.

Using the Operation Panel

Maintenance

Nozzle Check(*) Prints the cross-hatch test pattern so you can visually confirm whether inks

are ejecting correctly from the print head.

Head-cleaning(*) Cleans the print head. Clean the print head when certain colors are missing

or printing faintly. Head cleaning consumes ink.

Head-flushing(*) Cleans the print head more thoroughly than "Head-cleaning". Flushing

consumes more ink. Use this function only after "Head-cleaning" fails to solve

the problem.

Head Position(*) Adjusts the alignment of the print head if the Nozzle Check test pattern

shows broken vertical lines, or if printed images are blurred.

Registration Adjust the print start position of the fabric.

Use the Nozzle Check test pattern as reference.

Date/Time Allows setting current date/time.

Key Repeat Enables/disables repetition of a key pushed and held down on the

operation panel.

Feed Test(*) Confirms the operation of the cassette. Printing is not performed on the

fabric.

39

Page 42

2. Installation

Menu/Menu Item Function

Move Prnt-Heads(*) Moves the print head to allow you to easily remove foreign objects stuck in

the right edge. Once all operations have completed, turn the power back on

and print a [Nozzle Check] test pattern.

Height Adjust(*) Adjusts the height of the cassette manually.

Clean Maint Unit(*) Moves the maintenance unit to a position where cleaning can be carried

out.

Auto Head Maint. (*) Cleans the print head nozzles automatically.

Clean Internals(*) The internal compartments are cleaned automatically. Clean the interior if

you do not use the machine for a long time.

System

Energy Saver Switches the energy saving function on/off. When this function is on, the

printer will automatically shut down some of its functions automatically after

it remains idle for the prescribed amount of time.

The "E. Saver Timer" can be set for 5, 15, 30, 45, 60 min.

Once the printer enters the energy save mode, it will require some time to

recover full operation once it receives a print job.

Notify by Email Determines whether a notification is sent to a specified email address when a

printer error occurs. Be sure to cycle the printer off/on after doing this

setting.

Unit of Measure Determines the units of measure ("mm" or "inch")

Default:

NA: inch

EU,AS, and CH: mm

Uni-direct Prt. You can configure the machine to eject ink only when the head is moving in

a particular direction.

If you select [Always], printing is performed unidirectionally regardless of the

fabric type. If you select [Auto Detect], printing is performed according to the

settings of [Garment Type:] specified in the printer driver.

Default: [Auto Detect]

Img Recov. Error Specify whether or not [Page Recovery Error] is reported.

40

Default: [Display]

Page 43

Menu/Menu Item Function

Ink C.U. Space Displays the current status of the ink collector unit. The number means the

amount of space remaining. (100% means the unit is empty.)

Host Interface

I/O Timeout Determines how long the printer waits for the interface to respond. After the

specified time elapses, the printer can receive data from another interface. If

the specified time is too short, a timeout might occur while a data transfer is

in progress. If this occurs, the print job will be interrupted by a new job from

another interface. Default: 15 sec.

Using the Operation Panel

41

Page 44

2. Installation

Menu/Menu Item Function

Network Setup Use to do the network settings.

Setting

Machine Name Default

Host Name Display only

Domain Name Display only

IPv4 DNS Specify the DNS server settings under IPv4.

If DHCP is off, enter the IPv4 addresses for the

primary and secondary DNS servers in the format

"xxx.xxx.xxx.xx"(where each x represents a digit).

Default: [0.0.0.0]

IPv4 DDNS Specify the setting to update the host or domain

name.

Default: [On]

DHCP Specify whether or not to use DHCP in an IPv4

environment.

Default: [Off]

IPv4 Address Specify the IPv4 address. When the DHCP is set to

On, the IP Address cannot be changed. To change

it, set DHCP to Off.

Default: [11.22.33.44]

Pv4 Subnet M Specify the subnet mask. When the DHCP is set to

On, the setting cannot be changed. To change it, set

DHCP to Off.

Default: [0.0.0.0]

IPv4 Gatewy. Ad Specify the IPv4 gateway address. When the DHCP

is set to On, the setting cannot be changed. To

change it, set DHCP to Off.

Default: [0.0.0.0]

IPv6 DDNS Specify the setting to update the host or domain

name.

42

Default: [On]

Page 45

Menu/Menu Item Function

Network Setup IPv6 DNS Specify the DNS server settings under IPv6.

If DHCP is off, enter the IPv6 addresses for the

primary and secondary DNS servers in the format

"xxxx: xxxx: xxxx: xxxx: xxxx: xxxx:

xxxx:xxxx"(where each x represents a digit).

Default: [::]

DHCPv6 Specify whether or not to use DHCP in an IPv6

environment.

Default: [Off]

IPv6 Statlss Ad Select whether to enable or disable IPv6 stateless

address auto configuration.

Default: [On]

IPv6 Address Specify the machine's IPv6 address.

Using the Operation Panel

IPv6 Gatewy.Ad. Specify the IPv6 gateway address.

Default: [::]

Active Protocol Select the protocol by setting the IPv4, IPv6, HTTP

(IPv4), HTTP (IPv6), and Web protocol to [Active] or

[Not Active].

Default: [Active]

IPsec Specify the machine's IPsec function active /not

active.

Default: [Off]

MAC Address Displays the machine's MAC address.

Ethernet Speed Set the access speed for network.

Default: [Auto Select]

Prmt SNMPv3 Com Select SNMPv3 communication for managing the

machine using MIB.

Default: [Cleartext]

43

Page 46

2. Installation

Menu/Menu Item Function

Network Setup Pmt SSL/TLS Com Set SSL/TLS communication under IPv4 and IPv6 to

[Active] or [Not Active].6for managing the machine

using MIB. This communication mode will be used

when you specify machine settings using a Web

browser.

Default: [Active]

Restore Default Reset the network settings to their defaults.

Wireless LAN SSID Display or specify an SSID.

Security Method Specify the dncription of the wireless LAN.

Default: [Not Active]

Easy Setup Configure the wireless LAN's settings automatically.

Select either [PBC Method] or [PIM Method] that is

correct to network connection via the access points

you can use.

MAC Address Displays the wireless LAN's MAC address.

USB Setting USB Speed Auto: 480 Mbps or 12 Mbps automatically

adjusted

Full Speed: 12 Mbps fixed

Default: Auto. Normally, this setting does not require

changing.

Port Setting Specifies communication settings for a USB

connection.

Default: Off

44

Page 47

Menu/Menu Item Function

Language You can select which language the menu is displayed in.

The "Language" menu will be displayed in English.

• NA model

Japanese, English, French, German, Italian, Spanish, Dutch,

Norwegian, Danish, Swedish, Finnish, Portuguese (Default: English)

• EU model

English, French, German, Italian, Spanish, Dutch, Norwegian, Danish,

Swedish, Finnish ,Portuguese, Czech, Polish, Hungarian (Default:

English)

• AS/CH model

Japanese, English, French, German, Italian, Spanish, Dutch,

Norwegian, Danish, Swedish, Finnish, Portuguese, Czech, Polish,

Hungarian (Default: English)

Using the Operation Panel

Access to menus during an error

In previous models, menus could not be accessed during an error. However, this model allows access to

user menus by pressing the [ /Menu] key.

However, functions that require printing, such as the printing of the counter, cannot be executed during

an error.

Example:

• Counter. The counts can be displayed but not printed.

• List/Test Print. No selections are available.

Even without computers, you can specify settings, such as the time and date, on the machine's control

panel.

• Menus cannot be accessed while the printer is busy.

45

Page 48

2. Installation

Installation

These machines and all peripherals are installed by the customer.

The installation procedures are in the operating instruction manuals issued to the customer with purchase

of the main machine or peripheral unit.

Accessory Check

No. Description Q’ty Remarks

1 Power cord 1

2 Cassette (A4 Standard Tray) 1

3 Cassette cover 1

4 Manual pocket 1

5 Dropper 1

6 Cleaning tool 1

7 Protective glasses 1

8 Cleaning cloth 12

9 Protective gloves 12 sets

10 Absorbent material 24

11 Cleaning stick 100

12 Disposal bag 1

13 Cleaning liquid 1

- CD-ROM (Operating Instructions) 1

- CD-ROM (Drivers) 1

- Manual: Safety Information 1

- Manual: User's Guide 1

46

- Manual: Setup Guide 1

- Manual: Quick Installation Guide 1

Page 49

Installation

No. Description Q’ty Remarks

- Manual: Maintenance Guide 1

- Manual: Notes for Wireless LAN Users 1

- Manual: Replacing the Ink Collector Unit 1

- Sheet: Notes for Wireless LAN (only for China) 1

47

Page 50

2. Installation

48

Page 51

Important Information

Important Information

Make sure that the customers understand the following points about moving, storing, and using the

printer.

Checklist before Moving the Printer

1. Turn the printer off. Disconnect the power cord.

• Never disconnect the power cord without first turning off the printer.

2. To lift the printer, grip it at the center of each side by the hand recesses provided.

3. Make sure the covers and trays are closed. Secure them with tape. Attach the tape at the same

area you removed at the time of installation.

4. Disconnect the power cord. Tape the power cord to the back of the printer.

5. Do a test print to confirm that the printer operates correctly after you move it to another location. Do

the cleaning procedures with the printer driver, if necessary.

6. The ink cartridges should remain in the printer. It is not necessary to remove the before transporting

the printer. However, ink must be purged from the print head tanks before the printer is transported.

(See the procedure below.)

• To avoid ink spillage, always hold the printer level when you move it.

• Work carefully to avoid dropping it or colliding with other objects in the work area.

If the Printer Is Not Used Frequently…

1. Turn the power off, disconnect the USB cable, and unplug the power cord.

2. To prevent the print nozzles from drying out, periodically print something.

3. Turn the printer on for a few minutes once a month.

4. After storage or a long period of disuse, use the printer driver to print a nozzle check text pattern

and clean the print head nozzles if necessary.

49

Page 52

2. Installation

50

Page 53

3. Preventive Maintenance

PM Table

There are no PM Parts in this machine.

Service Call Procedures

The procedures listed below should be done by the service technician. For more details about how to do

these procedures, please refer to "page 159 "Cleaning"".

Description At Service Call, or As Required

External Covers Damp cloth.

Maintenance Unit Damp cloth. Always use a tightly wrapped damp cloth to remove the ink

that has hardened around the suction cap and wiper blade when you

replace the ink collector unit.

Printer Operation, Print

Quality

Print a Nozzle Check Pattern and check the results. Clean the print heads if

necessary. For more, see "Print Head Cleaning and Adjustment" in section

"4. Replacement and Adjustment".

51

Page 54

3. Preventive Maintenance

Description At Service Call, or As Required

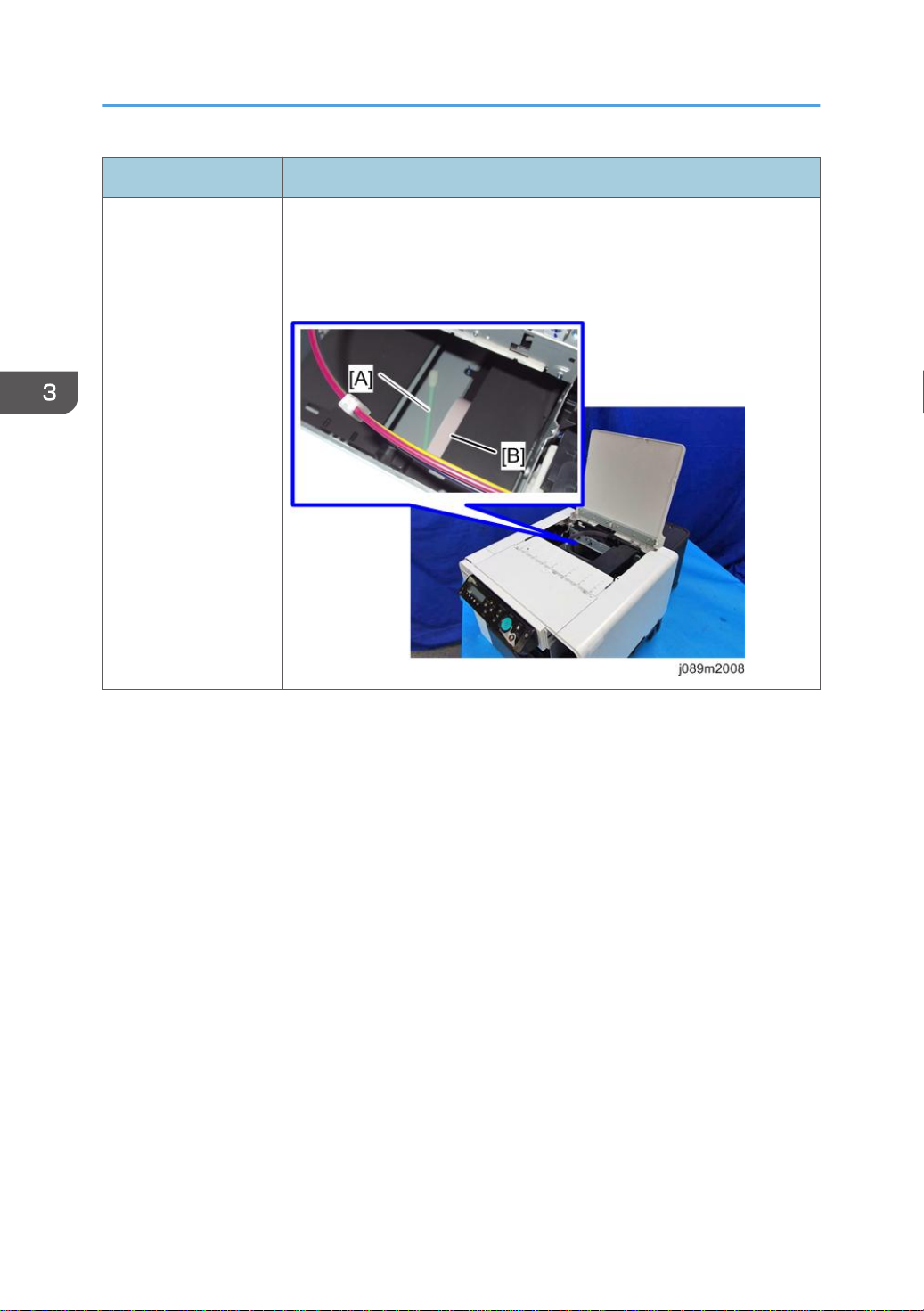

Internal Inspection Open the top cover and check whether there are any foreign materials

(particularly from when cleaning with a cotton swab [A]) inside. If there are

any foreign materials, remove them.

Make sure not to damage the FFC [B] at this time.

52

Page 55

4. Replacement and Adjustment

Before Replacing Parts

• When reassembling the machine, be sure to attach the screws to their original positions. Especially,

the blue screws are assigned to particular screw holes.

53

Page 56

4. Replacement and Adjustment

Covers

Cover Names

54

[A] Top Cover [K] Port Cover

[B] Canopy Cover [L] Left Cover

[C] Operation Panel [M] Left Lower Cover

[D] Cassette [N] Right Cover

[E] Front Cover [O] Right Lower Cover

[F] Front Right Cover [P] Rear Cover

[G] Cassette Stand [Q] Rear Top Cover

[H] Left Guide Rail Cover [R] Rear Transport Cover

Page 57

[I] Right Guide Rail Cover

[J] Front Lower Cover

Order of Cover Removal

It is very important that you understand how to remove and reinstall the covers before doing

replacement procedures. Here is a general summary of the order of removal.

Covers

Front Right Cover

1. Open the front right cover [A].

55

Page 58

4. Replacement and Adjustment

2. Disengage the latch and remove the front right cover.

Right Lower Cover

1. Remove the right lower cover [A].

56

Right Cover

1. Remove the right lower cover. (page 56 "Right Lower Cover")

Page 59

2. Open the front right cover [A], and remove all ink cartridges [B].

3. Open the top cover.

Covers

4. Remove 2 screws.

57

Page 60

4. Replacement and Adjustment

5. Remove the right cover [A].

Re-assembly

When re-attaching the right cover, check the following points.

1. Check that the harness and ink tube are secured with the tabs.

2. Check that the maintenance unit is locked.

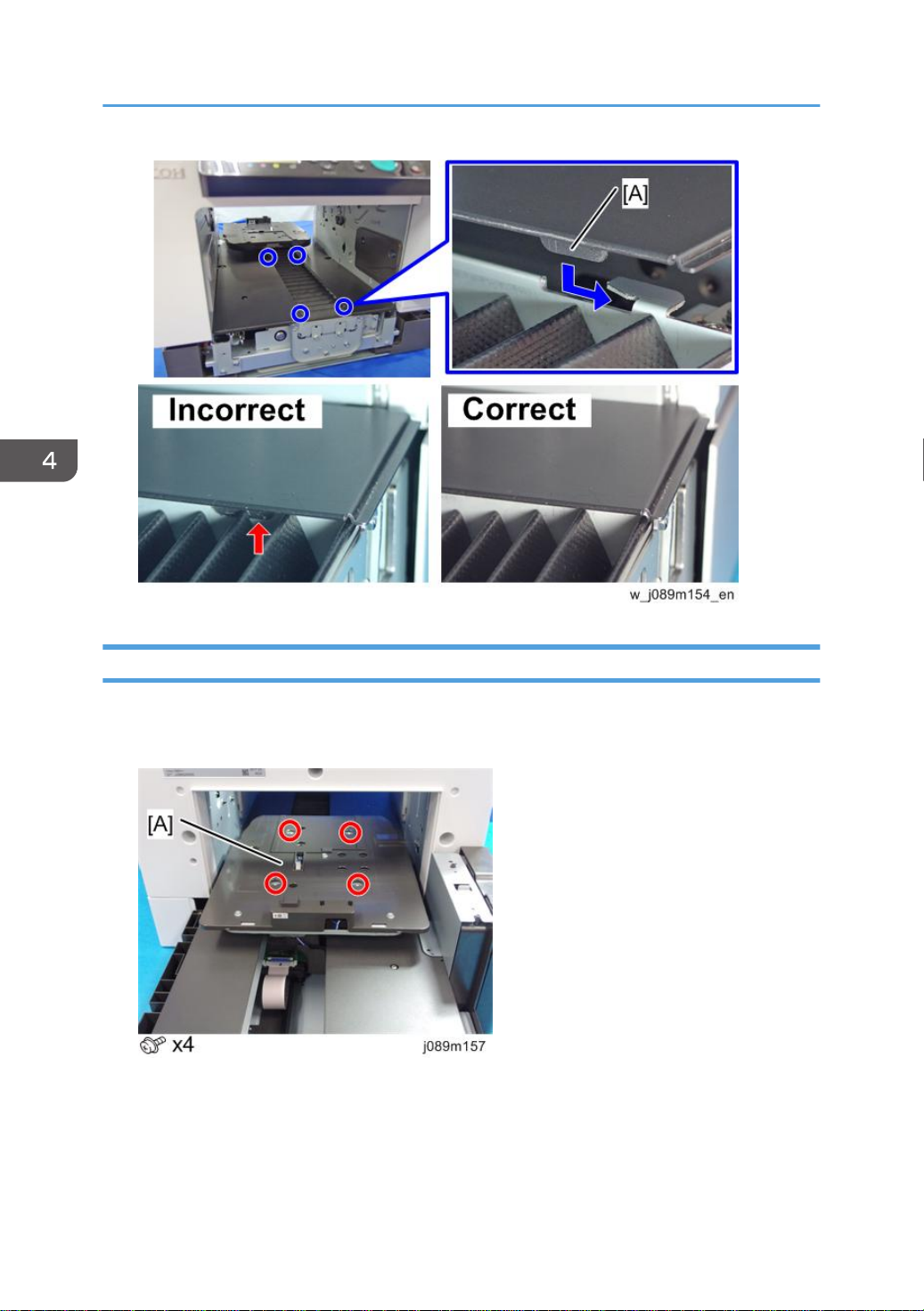

• If the triangles are aligned tip-to-tip as shown at [A], this means the carriage is unlocked (not

ready for operation) and can be moved manually.