Page 1

Reissued on April 30, 1991

Technical Bulletin No. RTB-003

SUBJECT: Corona Casing Cleaning DATE:April 30,1991

PAGE: 1 of 1

PREPARED BY: M. Kitajima

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

This bulletin gives information on cleaning the corona casing.

CLEANING

Section Action at EM/PM

Casing Clean with water first and with alcohol if

toner still remains.

End Block Clean with a blower brush and then with

alcohol.

EXPLANATION

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: General

The corona discharge causes ammonium nitrate (NH4NO3) to accumulate on the corona

casing.

NH4NO3 functions as an insulator that reduces the corona discharge to the casing. The

power pack responds by increasing the voltage to the corona wire in order to maintain a

constant current output. (The power pack is a constant current type.)

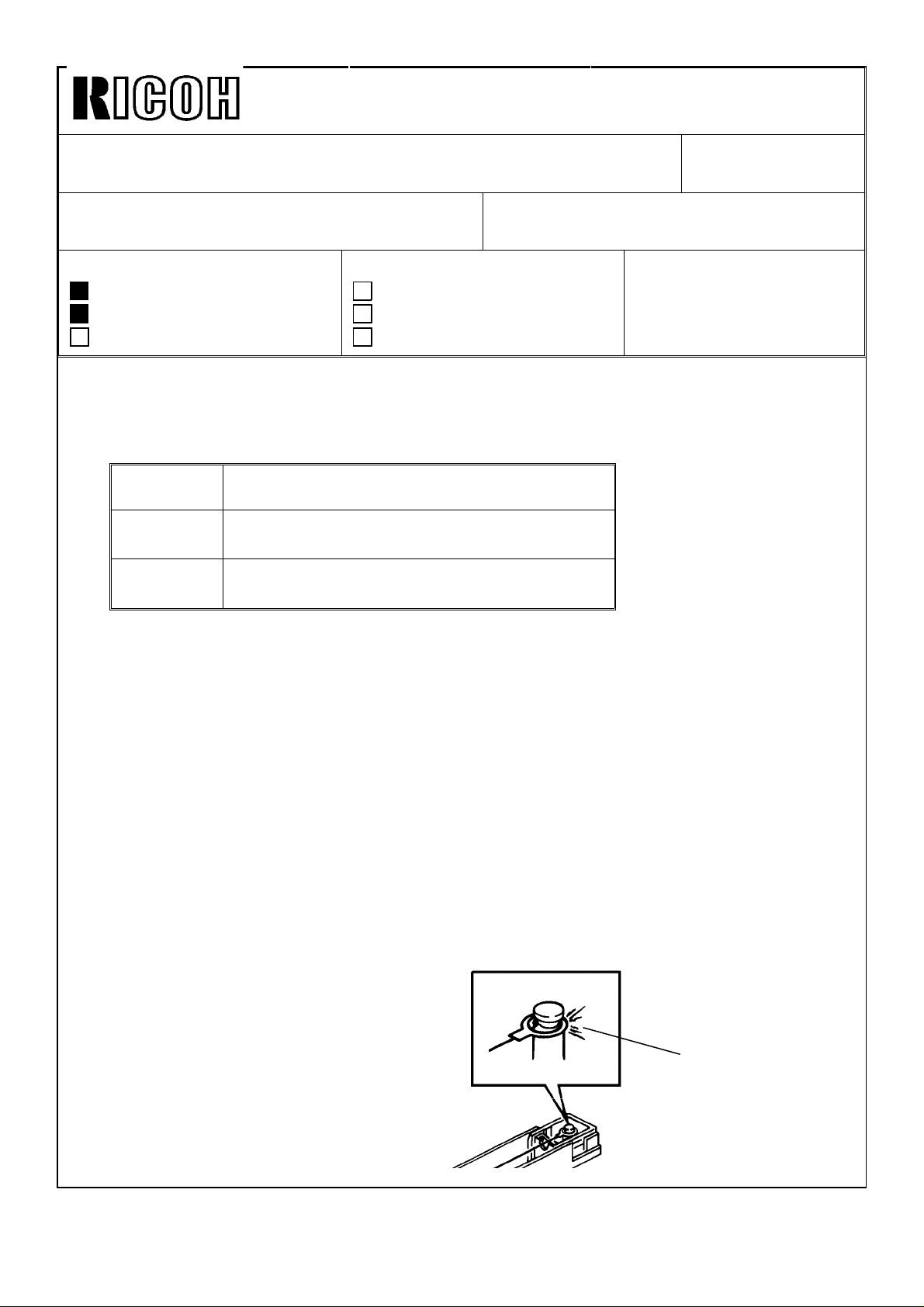

If toner or some other material accumulates inside the corona end block especially inside

the hook groove [A], it may cause an electrical leak under humid conditions.

NH4NO3 can be easily removed with water but not with alcohol. Toner can be easily

removed with alcohol but not with water.

Therefore, be careful to use the proper cleaning method for each corona unit section.

[A]

Page 2

Technical Bulletin No. RTB-005

REVISED ON APRIL 15, 1991

SUBJECT: Cleaning Solutions DATE: Dec. 30, ’90

PAGE: 1 of 1

PREPARED BY: T. OKAJIMA

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Based upon the request from the market, three type of cleaning solution have been

registered as service parts. Please order them from the parts center as usual. The details

are as follows:

Revision of service manual

Information only

Other

FROM: International Q.A. Center

MODEL: General

1. EXTERIOR COVER CLEANER (NET. 220 cc)

P/N: A0129530

Purpose: 1) To clean the exterior covers

2) To remove spilt silicone oil from the floor

Procedure: 1) Shake well and spray onto the soiled cover or on the floor.

2) After 10 seconds, wipe cleaner using a soft cloth.

2. DF BELT CLEANER (NET. 180 cc)

P/N: A0129531

Purpose: To clean document feeder belts.

Procedure: 1) Dampen a soft cloth with the cleaner, and wipe the belt.

2) Repeat until the belt is clean.

3. Optics Cleaner (NET. 190 cc)

P/N: A0129532

Purpose: To clean mirrors, lenses, exposure glasses, and paper feed rollers

Procedure: Dampen a soft cloth with the cleaner, and wipe the soiled parts.

CAUTION

Since these three type of cleaning solution are FLAMMABLE, pay attention to the

following caution:

1. Do not spray onto bare skin.

2. Keep away from heat and open flame.

3. Store in a cool place.

4. Keep away from children.

5. Do not dispose of the cleaner by burning it, by applying heat to it, or by any

means that might cause it to ignite.

6 Comply with all local regulations for disposal.

Page 3

Technical Bulletin No. RTB-006

SUBJECT: New Tri-flow Lubricant DATE: Jan 15, 91

PAGE: 1 of 1

PREPARED BY: N. Takai

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

To protect the environment, the tri-flow lubricant (P/No. 52159533) that uses CFC aerosol

propellants has been discontinued. A new tri-flow that uses LPG as the propellant is now

being supplied.

NOTE: CFC (chlorofluorocarbon) gasses are believed to contribute to the depletion of the

earth’s ozone layer.

New Tri-flow: P/No.: 52159539 (Volume: 27 ml)

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: General

Page 4

Technical Bulletin No. RTB-008

SUBJECT: Ground Sheet DATE: Mar 31,’91

PAGE: 1 of 1

PREPARED BY: M. Ninomiya

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

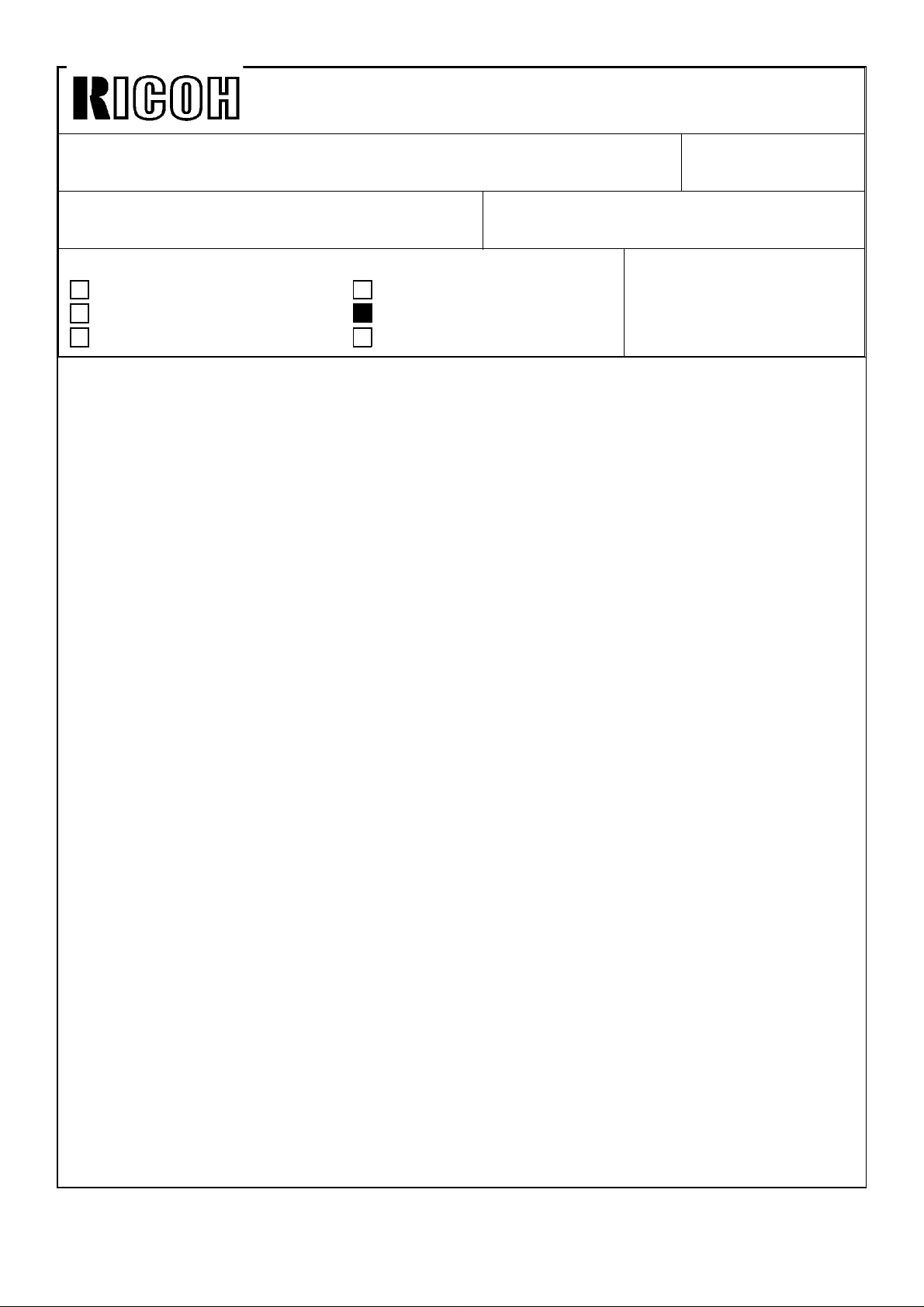

Two different sizes of ground sheets have been registered as service parts.

These sheets help keep the customer’s floor clean by catching any toner, oil, etc, that

may fall to the floor while customer engineer is servicing a copier.

800 mm

Revision of service manual

Information only

Other

FROM: Copier Technical Support Sec.

MODEL: General

650 mm

1200

mm

920

mm

Small(Green) (P/N A0099019)

Large (Gray) (P/N A0099017)

Page 5

Technical Bulletin No. RTB-009

SUBJECT: Service Parts Package Improvement DATE: Mar. 31, ’92

PAGE: 1/1

PREPARED BY: N. Takai

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

The earth is a closed environment with limited resources. People need a good

environment, where they can live safely and comfortably. We, Ricoh as a manufacturer,

believe that protecting the environment and passing on a better environment to posterity is

one of the most important duties of every living being.

In live with the above concept, we are improving not only the machines, but even the

packages for the service parts to help preserve the environment as follows:

Schedule for improvement of service parts packaging

Step 1: Elimination of plastic made from Polyvinyl chloride (PVC) Feb. ’92

Revision of service manual

Information only

Other

Item From (target)

FROM: Copier Technical Support Sec.

MODEL: General

Step 2: Elimination of glueing different materials together Aug. ’92

(i.g. styrofoam and cardboard)

* This is to facilitate segregating the waste by material.

Step 3: Reduction of usage of cardboard(10% less) Sep. ’92

* This is to reduce wasting resources.

This bulletin covers all package changes for service parts related to the preservation of the

environment. We will not inform you of the changes for individual parts packages.

Page 6

RICOH Technical

Bulletin

PAGE: 1/4

Model:

Subject:

From:

Classification:

Some service tools were set up as service parts decades ago for cases where appropriate

field service tools could not be obtained locally. These tools will no longer be available at

the SPC.

This is because all types of service tools are now available across the world. Also, some

tools are no longer needed for servicing recent Ricoh products.

The target service tools are listed on the following pages.

General

Service Tools

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

30-Sep-98

Prepared by:

No.:

1

M.Mimura

Action required

Service manual revision

Retrofit information

Page 7

RICOH Technical

Bulletin

PAGE: 2/4

Model:

General

Date:

30-Sep-98

No.:

1

TOOL LIST – 115V (54199 901)

Item Part No. Description Q’ty Item Part No. Description Q’ty

1. 54199600 Tool Case (Aluminum) 1 31. 54199630 Screw Driver Long Shawk “+” 75mm 1

2. 54199601 Tension Gauge 0-2Kg 1 32. 54199631 Voltage Checler-100V 250V 1

3. 54199602 Wrench 1 33. 54199632 Cleaner-Solder Iron 1

4. 54199603 Thickness Gauge 1 34. 54199633 Solder 1

5. 54199604 File 1 set 35. 54199634 NT Cutter 1

6. 54199605 Parts Case 1 36. 54199635 Tester 1

7. 54199606 Oiler 2 pcs. 37. 54199636 Solder Sucker 1

8. 54199607 Bond 1 38. 54199637 Electric Torch-Pen type 1

9. 54199608 Crimping Plier 1 39. 54199638 Retaining Ring Holder-1.5mm 1

10. 54199609 Wire Stripper 1 40. 54199639 Retaining Ring Holder-2.0mm 1

11. 54199610 Magnetic Screw Driver 1 41. 54199640 Retaining Ring Holder-2.5mm 1

12. 54199611 Nipper 1 42. 54199641 Retaining Ring Holder-3.0mm 1

13. 54199612 Cutting Plier-Radio Type 1 43. 54199642 Retaining Ring Holer-4.0mm 1

14. 54199613 Cutting Plier 1 44. 54199643 Retaining Ring Holder-5.0mm 1

15. 54199614 Plier 1 45. 54199644 Retaining Ring Holder-6.0mm 1

16. 54199615 Tweezers 1 46. 54199645 Retaining Ring Holder-7.1mm 1

17. 54199616 Allen Erench-1.5mm 1 47. 54199646 Retaining Ring Holder-8.1mm 1

18. 54199617 Allen Wrench-2.0mm 1 48. 54199647 Scale-150mm 1

19. 54199618 Allen Wrench-2.5mm 1 49. 54199648 Crescent Wrench 1 set

20. 54199619 Allen Wrench-3.1mm 1 50. 54199649 Insulating Tape-Black 1

21. 54199620 Allen Wrench-4.0mm 1 51. 54199650 Insulating Tape-Red 1

22. 54199621 Allen Wrench-5.0mm 1 52. 54199651 Double Coated Tape 1

23. 54199622 Allen Wrench-6.0mm 1 53. 54199652 Silicon Cloth 1

24. 54199623 Allen Wrench-8.0mm 1 54. 54199653 Spring Hook 1

25. 54199624 Screw Driver ”-“ 120mm 1 55. 54199654 Test Chart-B4 size 1

26. 54199625 Screw Driver “+” 120mm 1 56. 54199655 Test Chart-A3 size 1

27. 54199626 Screw Driver “+” 125mm 1 57. 54199656 Solder Tip 1

28. 54199627 Stubby Screw Driver “-“ 1 58. 54199657 Solder Iron –115V 1

125mm

29. 54199628 Stubby Driver “+” 1 59. 54199706 Clip Ass’y-Large 1

30. 54199629 Screw Driver Long Shawk 1 60. 54199707 Clip Ass’y-Small 1

“-“ 125mm

61. 54086001 Service Mat 1

Page 8

RICOH Technical

Bulletin

PAGE: 3/4

Model:

General

Date:

30-Sep-98

No.:

1

TOOL LIST – 220V (54199 902)

Item Part No. Description Q’ty Item Part No. Description Q’ty

1. 54199600 Tool Case (Aluminum) 1 31. 54199630 Screw Driver Long Shawk “+” 75mm 1

2. 54199601 Tension Gauge 0-2Kg 1 32. 54199631 Voltage Checler-100V 250V 1

3. 54199602 Wrench 1 33. 54199632 Cleaner-Solder Iron 1

4. 54199603 Thickness Gauge 1 34. 54199633 Solder 1

5. 54199604 File 1 set 35. 54199634 NT Cutter 1

6. 54199605 Parts Case 1 36. 54199635 Tester 1

7. 54199606 Oiler 2 pcs. 37. 54199636 Solder Sucker 1

8. 54199607 Bond 1 38. 54199637 Electric Torch-Pen type 1

9. 54199608 Crimping Plier 1 39. 54199638 Retaining Ring Holder-1.5mm 1

10. 54199609 Wire Stripper 1 40. 54199639 Retaining Ring Holder-2.0mm 1

11. 54199610 Magnetic Screw Driver 1 41. 54199640 Retaining Ring Holder-2.5mm 1

12. 54199611 Nipper 1 42. 54199641 Retaining Ring Holder-3.0mm 1

13. 54199612 Cutting Plier-Radio Type 1 43. 54199642 Retaining Ring Holer-4.0mm 1

14. 54199613 Cutting Plier 1 44. 54199643 Retaining Ring Holder-5.0mm 1

15. 54199614 Plier 1 45. 54199644 Retaining Ring Holder-6.0mm 1

16. 54199615 Tweezers 1 46. 54199645 Retaining Ring Holder-7.1mm 1

17. 54199616 Allen Erench-1.5mm 1 47. 54199646 Retaining Ring Holder-8.1mm 1

18. 54199617 Allen Wrench-2.0mm 1 48. 54199647 Scale-150mm 1

19. 54199618 Allen Wrench-2.5mm 1 49. 54199648 Crescent Wrench 1 set

20. 54199619 Allen Wrench-3.1mm 1 50. 54199649 Insulating Tape-Black 1

21. 54199620 Allen Wrench-4.0mm 1 51. 54199650 Insulating Tape-Red 1

22. 54199621 Allen Wrench-5.0mm 1 52. 54199651 Double Coated Tape 1

23. 54199622 Allen Wrench-6.0mm 1 53. 54199652 Silicon Cloth 1

24. 54199623 Allen Wrench-8.0mm 1 54. 54199653 Spring Hook 1

25. 54199624 Screw Driver ”-“ 120mm 1 55. 54199654 Test Chart-B4 size 1

26. 54199625 Screw Driver “+” 120mm 1 56. 54199655 Test Chart-A3 size 1

27. 54199626 Screw Driver “+” 125mm 1 57. 54199656 Solder Tip 1

28. 54199627 Stubby Screw Driver “-“ 1 58. 54199658 Solder Iron –220V 1

125mm

29. 54199628 Stubby Driver “+” 1 59. 54199706 Clip Ass’y-Large 1

30. 54199629 Screw Driver Long Shawk 1 60. 54199707 Clip Ass’y-Small 1

“-“ 125mm

61. 54086001 Service Mat 1

Page 9

RICOH Technical

Bulletin

PAGE: 4/4

Model:

General

Date:

30-Sep-98

No.:

1

TOOL LIST – 240V (54199 903)

Item Part No. Description Q’ty Item Part No. Description Q’ty

1. 54199600 Tool Case (Aluminum) 1 31. 54199630 Screw Driver Long Shawk “+” 75mm 1

2. 54199601 Tension Gauge 0-2Kg 1 32. 54199631 Voltage Checler-100V 250V 1

3. 54199602 Wrench 1 33. 54199632 Cleaner-Solder Iron 1

4. 54199603 Thickness Gauge 1 34. 54199633 Solder 1

5. 54199604 File 1 set 35. 54199634 NT Cutter 1

6. 54199605 Parts Case 1 36. 54199635 Tester 1

7. 54199606 Oiler 2 pcs. 37. 54199636 Solder Sucker 1

8. 54199607 Bond 1 38. 54199637 Electric Torch-Pen type 1

9. 54199608 Crimping Plier 1 39. 54199638 Retaining Ring Holder-1.5mm 1

10. 54199609 Wire Stripper 1 40. 54199639 Retaining Ring Holder-2.0mm 1

11. 54199610 Magnetic Screw Driver 1 41. 54199640 Retaining Ring Holder-2.5mm 1

12. 54199611 Nipper 1 42. 54199641 Retaining Ring Holder-3.0mm 1

13. 54199612 Cutting Plier-Radio Type 1 43. 54199642 Retaining Ring Holer-4.0mm 1

14. 54199613 Cutting Plier 1 44. 54199643 Retaining Ring Holder-5.0mm 1

15. 54199614 Plier 1 45. 54199644 Retaining Ring Holder-6.0mm 1

16. 54199615 Tweezers 1 46. 54199645 Retaining Ring Holder-7.1mm 1

17. 54199616 Allen Erench-1.5mm 1 47. 54199646 Retaining Ring Holder-8.1mm 1

18. 54199617 Allen Wrench-2.0mm 1 48. 54199647 Scale-150mm 1

19. 54199618 Allen Wrench-2.5mm 1 49. 54199648 Crescent Wrench 1 set

20. 54199619 Allen Wrench-3.1mm 1 50. 54199649 Insulating Tape-Black 1

21. 54199620 Allen Wrench-4.0mm 1 51. 54199650 Insulating Tape-Red 1

22. 54199621 Allen Wrench-5.0mm 1 52. 54199651 Double Coated Tape 1

23. 54199622 Allen Wrench-6.0mm 1 53. 54199652 Silicon Cloth 1

24. 54199623 Allen Wrench-8.0mm 1 54. 54199653 Spring Hook 1

25. 54199624 Screw Driver ”-“ 120mm 1 55. 54199654 Test Chart-B4 size 1

26. 54199625 Screw Driver “+” 120mm 1 56. 54199655 Test Chart-A3 size 1

27. 54199626 Screw Driver “+” 125mm 1 57. 54199656 Solder Tip 1

28. 54199627 Stubby Screw Driver “-“ 1 58. 54199659 Solder Iron –240V 1

125mm

29. 54199628 Stubby Driver “+” 1 59. 54199706 Clip Ass’y-Large 1

30. 54199629 Screw Driver Long Shawk 1 60. 54199707 Clip Ass’y-Small 1

“-“ 125mm

61. 54086001 Service Mat 1

Page 10

RICOH Technical

Bulletin

PAGE: 1/1

Model:

Subject:

From:

Classification:

This bulletin is a general service reminder.

Do not do any of the following in the field under any circumstances.

1. Disable safety devices such as thermofuses and thermistors.

2. Use the wrong safety devices such as thermofuses and thermistors.

General

General Service Remarks for Safety

GTSS Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

CAUTION

Part information

Electrical

Transmit/receive

Date:

31-Dec-98

Prepared by:

M. Mimura

Action required

Service manual revision

Retrofit information

No.:

2

3. Swap different types of fusing units across different models.

If the wrong type of fusing unit is used, the thermofuse may not work properly.

These points all affect product safety.

Please always use the correct parts as shown in the parts catalog for the product.

Page 11

RICOH Technical

Bulletin

PAGE: 1/1

Model:

Subject:

From:

Classification:

The new FCC regulations will be applied to products produced after December 19, 1999.

The following features will be affected by these changes and the firmware changed accordingly.

- Redialing -

Limited to only one time if the machine cannot detect the busy and re-order tones.

- Transmission Deadline function (TRD) -

The maximum number of times for redialing is limited to 14. Therefore, this function will not be

available.

- Affected machines -

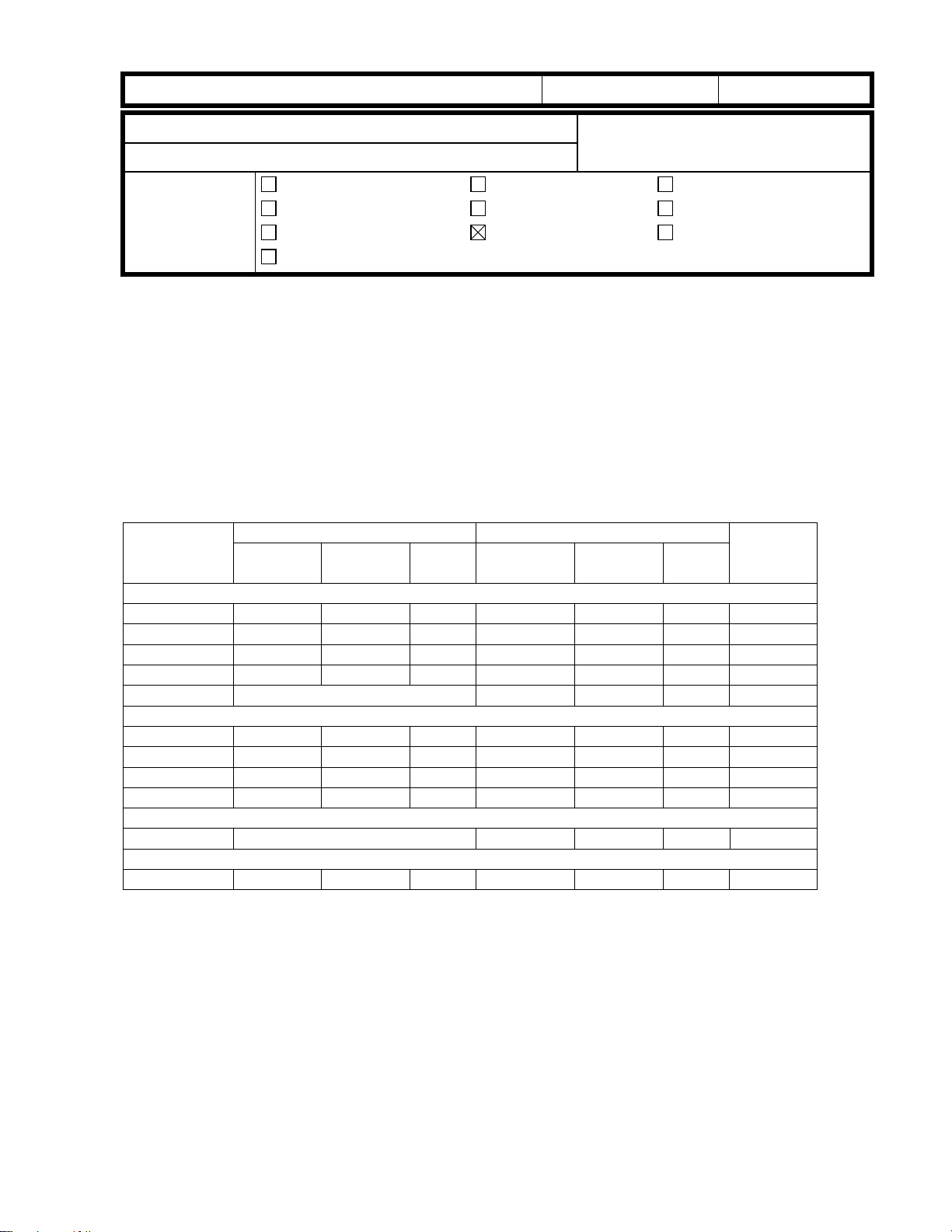

Product

Fax

LFO NO 4 NO NO 1 NO

FR6, FR4 NO 4 YES NO 1 NO

Schmidt3 YES 4 YES YES 4 NO

Schmidt1 NO 1 NO NO 1 NO

Kaiser1 No production YES 4 NO *1, *3

Digital PPC

NAD NO 4 YES NO 1 NO

Stinger-C1 NO 1 YES YE 4 NO

Russian-C1 NO 1 NO YES 4 NO *3

GF10B NO 2 NO NO 1 NO *2

Digital Color

Lilac2 No production NO 1 NO *1

Option

S G3 Option NO 4 - NO 1 NO *3, *4

Note:

*1: The change will be applied from the first lot of mass-production.

*2: No memory transmission is available.

*3: When this option is installed, redialing from the main frame is also limited to one time.

*4: TRD is controlled by the main frame.

For details of these changes, please refer to the MB or RTB that will be issued for each model.

Products with FAX function (US version)

For New FCC Regulations

Technical Servers Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Before change After change

Tone

detection

Redialing TRD Tone

Part information

Electrical

Transmit/receive

detection

Date:

30-Nov-99

Prepared by:

Redialing TRD

Action required

Service manual revision

Retrofit information

No.:

Y. Okunishi

Note

RGene003

Page 12

T

echnical

B

ulletin

PAGE: 1/17

Model:

Subject:

From:

Classification:

The new software will be released for the CiG4 unit to provide new functions for ISDN

comunication. This RTB clarifies the new switches and their software version.

Please note that the CiG4 unit is being used in the FX4 and FR4 fax machines, and in the

Adam, NAD, Stinger-C , and Russian-C copiers.

NOTE:

The software versions which enable each switch are listed in the “NOTE” column.

Otherwise, functions are available from the first production of the G4 unit for the above

machines.

Release date:

Version 0B: ’97. November (at the same time as the fax FR4 release)

Version 0F: ’00. March

General

CiG4 Switches and Software Versio n

Technical Services Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

31-Jan-00

Prepared by:

No.:

RGene004

K. Misugi

Action required

Service manual revision

Retrofit information

WARNING

Do not adjust a bit switch that is described as "Not used", as this may

cause the machine to malfunction or to operate in a manner that is not

accepted by local regulations.

Important:

In the CiG4 unit, after changing any of the bit switches, turn off the machine, wait for 5

seconds or more, and turn it back on, so that the new settings take effect.

1. G4 Internal Switches

Bit Switch 00

FUNCTION COMMENTS NOTE

Country code

Bit 4 3 2 1 0 Country

0

0 0 0 0 1 Germany (1TR6 mode)

to

0 0 0 1 0 Universal (Europe Euro ISDN)

7

1 0 0 0 1 USA

1 1 0 1 1 Taiwan

Note:

In Germany, use the Universal setting for the Euro ISDN lines.

In Taiwan, use the Taiwan setting for firmware version 0D or later.

Bit switches 01 and 02 are not used. Do not change the settings.

Page 13

T

echnical

B

ulletin

PAGE: 2/17

Model:

Bit Switch 03

1-7

Bit Switch 04

0-2

6-7

General

Amount of protocol dump data

in one protocol dump list

0:

0

3

4

5

Last communication only

1:

Up to the limit of the

memory area for protocol

dumping

Not used Do not change the settings.

Not used Do not change the settings.

Auto data rate change for

transmission

(64 kbps to 56 kbps)

0:

On

1:

Off

Auto data rate change for

reception (64 kbps to 56 kbps)

0:

Off

1:

On

RCBCTR

0:

Not valid

Not used Do not change the settings.

Date:

FUNCTION COMMENTS NOTE

Change this bit to 0 if you want to have a

protocol dump list of the last communication

only.

This bit is only effective for the dump list D +

Bch1.

FUNCTION COMMENTS NOTE

0:

The machine automatically changes the

transmission data rate from 64 kbps to 56

kbps after 3 s if the other end did not accept

the call. This is to cope with 56 kbps

networks in the USA.

Normally, keep this bit at 0.

1:

The machine automatically changes the

reception data after 6 s.

Change this bit to 1 only when there is a

communication error where the other terminal

informs 64 kbps in the SETUP signal

although it is actually 56 kbps.

This bit is used in Germany; set it to 1 for

1:

Valid

German FTZ approval tests.

1:

RCBCTR counts consecutive R:RNR

signals. If the counter reaches the value of

N2, the link is disconnected.

31-Jan-00

No.:

RGene004

Bit Switch 05

0

Not used Do not change the settings.

Logical channel number (LCN)

0:

Not controlled

1

1:

Fixed at 01

Protocol ID check

2

0:

Yes

3-7

Not used Do not change the settings.

FUNCTION COMMENTS NOTE

Keep this bit normally at 0. However, some

networks may require a fixed LCN. In such

cases, this bit should be 1, and you may have

to set a different value for the LCN using G4

Parameter Switch A.

The Protocol ID is in the CR packet.

1:

No

Page 14

T

echnical

B

ulletin

PAGE: 3/17

Model:

Bit Switch 06

2-7

Bit switch 07 and 08 are not used.

Bit Switch 09

2-7

General

FUNCTION COMMENTS NOTE

Inclusion of the DTE address

in the S:CR packet

0:

0

Calling and called DTE

addresses

1

0:

Not used Do not change the settings.

0

Not used Do not change the settings.

New session within the same

call

1

0:

1:

Not used Do not change the settings.

1:

No

Not used

Not accepted

Accepted

Yes

1:

FUNCTION COMMENTS NOTE

Used

Date:

Normally, do not change the setting.

When the CR packet format matches

ISO8208 protocol, some networks may

require this bit to be set at 1.

This bit is only effective if bit 0 of G4

Parameter switch 6 is at 0.

Normally, do not change the setting.

This is only for packet networks. The CR

packet should contain the rx side's DTE

address, but does not have to include the tx

side's; it can include it as an option.

0:

If a new R:CSS is received, the machine

sends back S:RSSN.

1:

If a new R:CSS is received, the machine

sends back S:RSSP. Set this bit to 1 for

German PTT (FTZ) approval tests.

31-Jan-00

No.:

RGene004

Bit switches 0A to 0F are not used. Do not change the settings.

Page 15

T

echnical

B

ulletin

PAGE: 4/17

Model:

Bit Switch 10

4-5

General

0

Not used Do not change the settings.

Layer 1 T3 timer

Bit 2 1 Time

1

0 0 5 s

0 1 29 s

2

1 0 10 s

1 1 Not used

Layer 1 T4 timer

3

0:

Not used

Not used Do not change the settings.

INFO1 signal resend

0: Resend

6

1: No resend

Loop back 4 mode

7

0:

Disabled

Date:

FUNCTION COMMENTS NOTE

This should be kept at 5 s (both bits at 0) for

normal operation.

Set this bit to 1 for French PTT approval

1:

Used

1:

Enabled

tests.

0: Some DSUs may not reply to the INFO1

signal with INFO2, if there is noise in the

INFO1 signal accidentally. Try changing this

bit to 0, to resend INFO1 before the machine

displays “CHECK INTERFACE”.

Normally, keep this bit at 0.

31-Jan-00

No.:

RGene004

Bit Switch 11

FUNCTION COMMENTS NOTE

0

Not used Do not change the settings.

Type of TEI used

0:

Dynamic TEI

1

1:

Static TEI

Static TEI value

2

7

This is normally fixed at 0. However, some

networks such as the Northern Telecom

ISDN may require this bit to be set at 1 (see

below). In this case, you may have to change

the values of bits 2 to 7.

This is used in the USA with the DMS100

(Northern Telecom ISDN) exchanger.

Store the lowest bit of the TEI at bit 7 and the

highest bit of the TEI at bit 2.

Example:

3 and 4 to 1 and bits 2, 5, 6, and 7 to 0.

If the static TEI is 011000, set bits

Bit switch 12 is not used. Do not change the settings.

Page 16

T

echnical

B

ulletin

PAGE: 5/17

Model:

Bit Switch 13

0-1

General

Not used Do not change the settings.

Attachment of calling ID

0:

No

2

Attachment of the Lower Layer

Capabilities

3

0:

No

Attachment of the Higher

Layer Capabilities

4

0:

Yes

Attachment of the channel

5

information element (CONN)

0:

No

Attachment of the Higher

Layer Capabilities for ISDN G3

transmission

0:

Same as the bit 4 setting

6

1:

Not attached

Condition for fallback from G4

to G3

0:

Refer to the CPS code

setting

1:

7

Fallback in response to any

CPS code

Date:

FUNCTION COMMENTS NOTE

Normally, this bit should be at 0, because

1:

1:

1:

1:

Yes

Yes

No

Yes

most networks add the calling ID to the

SETUP signal to the receiver.

However, some networks may require the

machine to add this ID. Only in this case

should this bit be at 1.

This bit determines whether Lower Layer

Capabilities are informed in the [SETUP]

signal.

Keep this bit at 0 in most cases.

This bit determines whether Higher Layer

Capabilities are informed in the [SETUP]

signal or not.

Keep this bit at 0 in most cases.

Keep this bit at 0 in most cases.

This bit determines whether Higher Layer

Capabilities are informed in the [SETUP]

signal for ISDN G3 transmission. This switch

is effective in coping with communication

problems with some types of T/A and PBX

which do not respond to Higher Layer

Capability “G3.”

When this bit is set to 0, the setting depends

on the setting of bit 4.

0:

Fallback occurs when a CPS code is the

same as the CPS code settings specified by

G4 internal switches 17, 18, 1A, 1B, and 1C.

If you wish to enable fallback when any CPS

code is detected, set this bit to “1.”

This switch is effective in coping with fallback

problems where the CPS code does not

match those specified in the ITU-T

recommendation.

31-Jan-00

No.:

RGene004

Ver. 0B

Ver. 0F

NOTE:

CiG4 software version 0F will be released from ’00. March production.

Page 17

T

echnical

B

ulletin

PAGE: 6/17

Model:

Bit Switch 14

1-2

General

ISDN G3 information transfer

capability

0:

3.1 kHz audio

1:

0

3

4

5

6

7

Speech

Not used Do not change the settings.

Channel selection in [SETUP]

in tx mode

Bit 4 3 Setting

0 0 Any channel

0 1 B1 channel

1 0 B2 channel

1 1 Not used

Called ID mapping

0:

Called party number

1:

Keypad facility

Numbering plan for the called

party number

0:

Unknown

1:

E.164

Subaddress coding type

0:

IA5 (NSAP)

1:

BCD (ISO8348)

Date:

FUNCTION COMMENTS NOTE

In tx mode, this determines the information

transfer capability informed in the [SETUP]

message.

In rx mode, this determines the information

transfer capability that the machine can use

to receive a call.

Set this bit to 1 if the ISDN does not support

3.1 kHz audio.

Any channel:

exchanger, the exchanger will select either

B1 or B2.

0:

Called ID is mapped to the called party

number.

1:

Called ID is mapped to the keypad facility.

On the 5ESS network (USA), set it to 1.

E.164:

AXE10 exchanger is fitted with old software,

and in Australia.

Unknown:

This is normally kept at 0. However, some

networks require this bit to be at 1.

This may be used in Sweden if an

When this is informed to the

This is the normal setting.

31-Jan-00

No.:

RGene004

Page 18

T

echnical

B

ulletin

PAGE: 7/17

Model:

Bit Switch 15

1-3

6-7

General

Action when receiving a

[SETUP] signal containing no

called subaddress, if the

0

subaddress was programmed

in the dialed number

0:

A reply is sent

1:

No reply is sent

Not used Do not change the settings

Action when the received

Higher Layer Capabilities is

Tel or Bearer Capabilities is

4

Speech

0:

Do not respond to the call

1:

Respond to the call

Global call reference

0:

Ignored

5

1:

Global call number is used

Not used Do not change the settings.

Date:

FUNCTION COMMENTS NOTE

This bit depends on user requirements. If it is

at 1, communication will be halted if the other

terminal has not input the subaddress.

1:

This switch is effective in coping with

communication problems when the received

Higher Layer Capabilities is Tel or Bearer

Capabilities is Speech for ISDN G3

communication.

Global call reference means 'call reference

value = 0'. This bit determines how to deal

with such an incoming call if received from

the network.

Keep this bit at 1 for Germany 1TR6.

31-Jan-00

No.:

RGene004

Ver. 0B

Page 19

T

echnical

B

ulletin

PAGE: 8/17

Model:

Bit Switch 16

3-4

General

Answer delay time

Bit 1 0 Setting

0 0 No delay

0 1 1.0 s delayed (1TR6)

1 0 0.5 s delayed

1 1 Not used

0

1

Action when receiving a

[SETUP] signal containing

user-specific called party

subaddress

0:

2

5

6

7

Ignores the call

1:

Receives the call

Not used Do not change the settings.

Indicated bearer capabilities

0:

56 kbps

Not used Do not change the settings.

Transfer capabilities (SI)

informed in 1TR6 ISDN G3

transmission

0:

G3 Fax

1:

Analog

Date:

FUNCTION COMMENTS NOTE

For Germany 1TR6, a time delay for

answering calls is required.

In other countries, use this switch as follows:

If the machine is connected to the same bus

from the DSU as a model K200 is connected,

the machine receives most of the calls

because the response time to a call is faster

than the K200.

If the customer wants the K200 to receive

most of the calls, adjust the response time

using these bits.

If the customer does not want one machine to

receive most of the calls, use subaddresses

to identify each terminal.

Normally, the 3rd octet of called party

subaddress information in the [SETUP] signal

is set to NSAP. However, some networks

may add a “user-specific” subaddress to the

[SETUP] signal, and as a result the machine

won't answer the call if a subaddress is

specified.

So, change this bit to 1 to let the machine

receive the call if the machine is connected to

such a network.

1:

64 kbps calling is indicated in the Bearer

1:

64 kbps

Capabilities, but communication is at 56 k.

Use this bit if the machine is connected to a

network which does not accept a 56 kbps

data transfer rate as a bearer capability.

This bit determines the transfer capabilities

informed in the Service Indicator for 1TR6

ISDN G3 transmission. This switch is

effective in coping with communication

problems with some types of T/A and PBX.

31-Jan-00

No.:

RGene004

Page 20

T

echnical

B

ulletin

PAGE: 9/17

Model:

Bit Switch 16

0-6

General

Condition for fallback from G4 to G3

Bits 0 to 6 of bit switch 17 contain a CPS code, and bits 0 to 6 of bit switch 18

contain another CPS code. If a CPS code is received which is the same as

either of these, communication will fall back from ISDN G4 mode to ISDN G3

mode.

The CPS codes must be the same as those specified in table 4-13 of CCITT

recommendation Q.931.

Examples: Bit 6 5 4 3 2 1 0

For the codes in bits 0 to 6 of bit switches 17 and 18 to be recognized, bit 7 of

bit switch 17 must be 1. Also, bit 0 of the Communication Switch 07 must be at

0, or Fallback from G4 to G3 will be disabled.

This bit determines whether fallback from G4 to G3 occurs on receipt of one of

the CPS codes programmed in bit switch 17 or 18, or on receipt of a certain

standard code.

0:

Fallback occurs on receipt of any of the following CPS codes:

7

Universal (Euro ISDN) - #3, #18, #57, #58, # 63, # 65, #79, #88, and #127

Germany 1TR6 mode - #3, #53, #58, and #90

Others - #3, #65, and #88

1:

Fallback from G4 to G3 occurs on receipt any of above CPS codes or one of

the CPS codes programmed in bit switch 17, 18, 1A, 1B, or 1C

Date:

FUNCTION COMMENTS NOTE

1 0 0 0 0 0 1 CPS code 65

1 0 1 1 0 0 0 CPS code 88

31-Jan-00

No.:

RGene004

Bit Switch 18

FUNCTION COMMENTS NOTE

Condition for fallback from G4 to G3

0-6

See the explanation for bits 0 to 6 of bit switch 17

This bit helps to choose the CPS code set for G4 to G3 fallback.

0:

Fallback occurs on receipt of the CPS code set which is specified by the

country code setting.

7

1:

Fallback occurs on receipt of the Universal CPS code set (#3, #18, #57, #58,

# 63, # 65, #79, #88, and #127) even if another country code is programmed.

If bit switch 17 bit 7 is “1”, fallback occurs on receipt of the Universal CPS code

set or one of the CPS codes programmed in bit switches 17, 18, 1A, 1B, or 1C.

G4 to G3 fallback

Bit 0 of Communication Switch 07 must be at 0, or fallback from G4 to G3 will be disabled.

The CPS codes for which fallback occurs are decided as follows.

G4 bit switch 17, bit 7 - If set to “0”, fallback occurs on receipt of a code from a set that

•

depends on the country code. If set to ”1”, fallback occurs for the 5 CPS codes

programmed in bits 0 to 6 of G4 bit switches 17, 18, 1A, 1B, and 1C, in addition to the

country code set.

Page 21

T

echnical

B

ulletin

PAGE: 10/17

Model:

Bit Switch 19

2-7

Bit Switch 1A: CPS Code Used for G4 to G3 Fallback - 3

0-6

Bit Switch 1B: CPS Code Used for G4 to G3 Fallback - 4

0-6

General

FUNCTION COMMENTS NOTE

Permanence of the link

0:

0

1

7

7

Set/released each LAPD

call

1:

Permanent

Channel used in ISDN L2

(64k) mode

0:

B1 1: B2

Not used Do not change the factory settings.

FUNCTION COMMENTS NOTE

Condition for fallback from G4 to G3

See the explanation for bits 0 to 6 of bit switch 17.

Not used Do not change the factory settings.

FUNCTION COMMENTS NOTE

Condition for fallback from G4 to G3

See the explanation for bits 0 to 6 of bit switch 17.

Not used Do not change the factory settings.

Keep this at 1 in the USA. In other areas, this

bit is normally 0, depending on network

requirements.

When making an IDSN L2 back-to-back test,

you can select either the B1 or B2 channel

with this bit switch.

Date:

31-Jan-00

No.:

RGene004

Bit Switch 1C: CPS Code Used for G4 to G3 Fallback - 5

FUNCTION COMMENTS NOTE

Condition for fallback from G4 to G3

0-6

See the explanation for bits 0 to 6 of bit switch 17.

7

Not used Do not change the factory settings.

Bit switches 1D to 1F are not used. Do not change any of the settings.

Page 22

T

echnical

B

ulletin

PAGE: 11/17

Model:

General

2. G4 Parameter Switches

Parameter Switch 00

FUNCTION COMMENTS NOTE

0

Network typ e

Bit 2 1 0 Type

1

x 0 0 Circuit switched

ISDN

2

Other settings: Not used

3-7

Not used Do not change the default settings.

Parameter Switch 01

FUNCTION COMMENTS NOTE

Voice coding

0

0:

µ law

1:

A law

Action when a [SETUP] signal

without HLC is received

0:

1

2-3

4

5

6

7

Respond to the call

1:

Not respond to the call

Not used Do not change the default settings.

Signal attenuation level for G3 fax signals received from an ISDN line.

If an analog signal comes over an digital line, the signal level after decoding by

the TE is theorically the same as the level at the entrance to the digital line.

However, this sometimes causes the received signal level to be too high at the

received end. In this case, adjust the decoded signal's attenuation level using

these switches.

The values in the “Codec” column below show the attenuation level at the G4

interface board. The values in the “Modem” column show the actual attenuation

level at the modem, because the signal is attenuated again on the MFCE by 6dB.

Bit 6 5 4 Codec Modem (Actual attenuation level)

0 0 0 -4.5dB -10.5dB

0 0 1 -2.5dB -8.5dB

0 1 0 -0.5dB -6.5dB

0 1 1 +1.5dB -4.5dB (default sett ing)

1 0 0 +3.5dB -2.5dB

1 0 1 +5.5dB -0.5dB

1 1 0 +7.5dB +1.5dB

1 1 1 +9.5dB +3.5dB

Not used Do not change the default settings.

Date:

Do not change the default setting.

0:

This setting is used in USA.

1:

This setting is used in Europe and Asia.

If there are several TEs on the same bus and

the machine responds to calls for another TE,

the call may be without HLC information.

Identify the type of calling terminal and

change this bit to 1 if the caller is not a fax

machine.

31-Jan-00

No.:

RGene004

Page 23

T

echnical

B

ulletin

PAGE: 12/17

Model:

Parameter Switch 02

2-3

6-7

Parameter Switch 03

1-7

General

FUNCTION COMMENTS NOTE

Data rate (kbps)

0

Bit 1 0 Setting

0 0 64 kbps

1

0 1 56 kbps

Not used Do not change the default settings.

Transmission mode

4

Bit 5 4 Mode

5

0 0 CS

Not used Do not change the default settings.

FUNCTION COMMENTS NOTE

Link modulus

0:

0

Not used Do not change the default settings.

8

1:

128

Date:

Other settings: Not used

Normally, do not change the seting.

Keep this bit at 0 in most cases.

This setting determines whether protocol

frame numbering is done using 3 bits (0 to 7

then start again at 0) or 7 bits (0 to 127 then

start again at 0). Set this bit switch to match

the network's specifications.

31-Jan-00

No.:

RGene004

Parameter Switch 04 is not used. Do not change any of the settings.

Parameter Switch 05

FUNCTION COMMENTS NOTE

Link timer (D-channel layer 2

T1 timer)

0

Bit 3 2 1 0 Value

1

0 0 0 0 0 s

2

0 0 0 1 1 s

3

0 0 1 0 2 s

and so on until

1 0 1 0 10 s

B-channel T3 timer

0:

30s

4

1:

57s

5-7

Not used Do not change the default settings.

Normally, do not change the setting.

The link timer is the maximum allowable time

between sending a protocol frame and

receiving a response frame from the remote

terminal.

1:

This switch is useful when used in

combination with communication switch 07 bit

4. This is to cope with communication

problems where G4 communication fails on

the ISDN B-channel.

Ver. 0F

Page 24

T

echnical

B

ulletin

PAGE: 13/17

Model:

Parameter Switch 06

1-3

5-7

Parameter Switch 07

4-7

General

FUNCTION COMMENTS NOTE

Layer 3 protocol

0:

0

4

0

1

2

3

ISO8208

1:

T.70NULL

Not used Do not change the settings.

Packet modulus

0:

Not used Do not change the settings.

Packet size

Bit 3 2 1 0 Value

0 1 1 1 128

1 0 0 0 256

1 0 0 1 512

1 0 1 0 1024

1 0 1 1 2048

Not used Do not change the settings.

8

1:

128

FUNCTION COMMENTS NOTE

Date:

Set this bit to match the type of layer 3

signalling used by the ISDN.

The dedicated parameters have the same

setting for specific destinations.

Do not change the default setting, unless the

machine is experiencing compatibility

problems.

This value is sent in the CR packet. This

value must match the value stored in the

other terminal, or communication will stop (CI

will be returned). If the other end returns CI,

check the value of the packet window size

with the other party.

Note that this value must be the same as the

value programmed for the transport block

size (G4 Parameter Switch 0B, bits 0 to 3).

Normally, do not change the default setting.

31-Jan-00

No.:

RGene004

Parameter Switch 08

FUNCTION COMMENTS NOTE

Packet window size

0

Bit 3 2 1 0 Value

1

0 0 0 1 1

2

0 0 1 0 2

3

and so on until

1 1 1 1 15

4-7

Not used Do not change the settings.

Parameter Switch 09

FUNCTION COMMENTS NOTE

LCGN

Bit 3 2 1 0 Value

0

0 0 0 0 0

1

0 0 0 1 1

2

0 0 1 0 2

3

and so on until

1 1 1 1 15

4-7

Not used Do not change the settings.

This is the maximum number of

unacknowledged packets that the machine

can send out before having to pause and wait

for an acknowledgement from the other end.

Normally this should be kept at 7.

Keep the value of the LCGN at 0.

Page 25

T

echnical

B

ulletin

PAGE: 14/17

Model:

Parameter Switch 0A

0-7

Parameter Switch 0B

4-7

General

FUNCTION COMMENTS NOTE

LCN

Bit 7 6 5 4 3 2 1 0 Value

0 0 0 0 0 0 0 1 1

0 0 0 0 0 0 1 0 2

0 0 0 0 0 0 1 1 3

and so on until

1 1 1 1 1 1 1 1 255

FUNCTION COMMENTS NOTE

Transport block size

Bit 3 2 1 0 Value

0

0 1 1 1 128

1

1 0 0 0 256

2

1 0 0 1 512

3

1 0 1 0 1024

1 0 1 1 2048

Not used Do not change the settings.

Date:

Keep at the value of the LCN at 1.

This value must match the value set in the

other terminal. Note that this value must be

the same as the value programmed for the

packet size (G4 Parameter Switch 7, bits 0 to

3). Also, the transport block size is limited by

the amount of memory in the remote terminal.

31-Jan-00

No.:

RGene004

Parameter Switch 0C is not used. Do not change any of the settings.

Parameter Switch 0D

FUNCTION COMMENTS NOTE

Back-to-back test mode

Bit 1 0 Setting

0 0 Off

1 0 ISDN L2 test mode

0

(TE mode)

Other settings - Not used

1

2-7

Not used Do not change the settings.

When doing a back-to-back test or doing a

demonstration without a line simulator, use

these bits to set up one of the machines in

TE mode, and the other in NT mode

Please note that this machine can only be set

to TE mode.

After the test, return both bits to 0.

See "Back-to-back Testing" in the

Troubleshooting section of the srrvice manual

for full details.

Page 26

T

echnical

B

ulletin

PAGE: 15/17

Model:

Parameter Switch 0E

2-7

Parameter Switch 0F is not used. Do not change any of the settings.

General

FUNCTION COMMENTS NOTE

Troubleshooing mode - real

time status codes display

0:

0

Saving frames to the protocol

1

dump list

0:

Not used Do not change the settings.

Off

Off

1:

On

1:

On

If this is switched on, the status codes will be

displayed in the lower two lines of the LCD.

These codes are explained in the

Troubleshooting section (G4CCU Status

Codes) of the service manual.

Change this bit back to 0 after testing.

Keep this bit at 1 normally.

Date:

31-Jan-00

No.:

RGene004

Page 27

T

echnical

B

ulletin

PAGE: 16/17

Model:

General

Date:

31-Jan-00

No.:

RGene004

3. DEDICATED TRANSMISSION PARAMETERS

The following G4 communication parameter bytes have been added for each Quick Dial

and Speed Dial.

Switch 07

FUNCTION NOTE

Data rate Bit 3 2 1 0 Setting

0

1

2

3

4-7

Switch 08

0

1

2

3

4-7

0 0 0 0 64 kbps

0 0 0 1 56 kbps

1 1 1 1 As in Parameter Switch 2, bits 0 and 1

Other settings: Not used

Not used. Do not change the settings.

FUNCTION NOTE

Link modulus Bit 3 2 1 0 Setting

0 0 0 0 Modulo 8

0 0 0 1 Modulo 128

1 1 1 1 As in Par ameter Switch 3, bit 0

Other settings: Not used

Not used. Do not change the settings.

Switch 09

Layer 3 pr otocol Bit 3 2 1 0 Setting

0

1

2

3

4-7

Not used. Do not change the settings.

FUNCTION NOTE

0 0 0 0 IS.8208

0 0 0 1 T.70 NULL

1 1 1 1 As in Parameter Switch 6, bit 0

Other settings: Not used

Page 28

T

echnical

B

ulletin

PAGE: 17/17

Model:

General

Date:

31-Jan-00

No.:

RGene004

4. OTHER RELATED SWITCHES

The following switches have been added to the mainframe switches (or fax board switches

for MFPs), in relation to ISDN G4 communication.

Communication Switch 07

FUNCTION COMMENTS NOTE

0:

Fallback from G4 to G3

reflected in programmed

Quick/Speed dials

3

0:

Fallback enabled (Default)

1:

Always start with G4

Fallback from G4 to G3 when

G4 communication fails on the

4

ISDN B-channel

0:

Fallback disabled (Default)

1:

Fallback enabled

If a communication falls back from G4 to

G3, the machine will always start

transmission with G3 from the next

communication.

1:

The machine will always start to transmit

with G4.

1:

Enable this switch only when G4

communication errors occur because the

exchanger connects G4 calls to the PSTN.

This problem only occurs with some types

of exchanger.

See the

following

table

Software versions for each machine

Communication Switch 07

FUNCTION FX4 FR4 Adam NAD

Fallback from G4 to G3

reflected in programmed

3

Quick/Speed dials

0:

Fallback enabled (Default)

1:

Always start with G4

Fallback from G4 to G3 when

G4 communication fails on

4

the ISDN B-channel

0:

Fallback disabled (Default)

1:

Fallback enabled

N/A: Function is not available

N/A

N/A

Availa-

ble

Availa-

ble

Stinger Russian

N/A N/A Available Available

Ver.

1.75

or later

Ver.

5.01 or

later

Available Available

Page 29

!"#$% M

odification Bulletin

PAGE: 1/1

Model:

Modified Article:

From:

Reason for

Modification:

General

Barrierta JEF552

Technical Service Dept., GTS Division

Parts catalog correction

To facilitate assembly

Part standardization

Old part

number

A0289300 Grease Barrierta JFE55/2 1 - 0

New part

Description Q’ty Int Page Index Note

number

A2579300 Grease Barrierta S552R 0 - 1

Date:

23-May-00

Prepared by:

Vendor change

To improve reliability

Other

O/O Refer to the Special

No.:

MGenM001

T. Itoh

To meet standards

( )

Tools section

The vendor of Grease Barrierta has produced a new type that has no scent. A new part

number has been assigned to this new type.

Page 30

odification Bulletin

M

PAGE: 1/1

Model:

Modified Article:

From:

Reason for

Modification:

General

Silicone Oil

Technical Services Dept., GTS Division

Parts catalog correction

To facilitate assembly

Part standardization

Old part

number

54209550 - Silicone Oil 1-0 O/O - -

- A2579100

- A2579550

New part

number

Description Q’ty Int Page Index Note

Silicone Oil Type SS (Ricoh

Brand)

Silicone Oil Type SS (Generic

Brand)

Date:

05-Jun-00

Prepared by:

Vendor change

To improve reliability

Other

0-1 O/O - -

0-1 O/O - -

No.:

MGenM002

H. Matsui

To meet standards

( )

The part number for the silicone oil has been changed. The difference between the two

new parts (A2579100 and A2579550) is the design of the bottle label. The label for

A2579100 contains the "RICOH" brand name and the label for A2579550 contains no

brand name (generic use).

See

Note

See

Note

NOTE

The interchangeability is O/O for all models except for the Cattleya A257/A269. The old

type of silicone oil (54209550) should NOT be used for the Cattleya A257/A269. Please

refer to RTB #RA257001 and MB #MA257001.

Page 31

!"#$% T

Reissued: 24-Jul-00

echnical Bulletin

PAGE: 1/3

Model:

GENERAL

Date:

14-Jul-00

No.:

RGene005a

RTB Correction

The items in bold italics have been corrected or added.

Subject:

From:

Test Chart

Technical Services Dept.k, GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

M. Tsuyuki

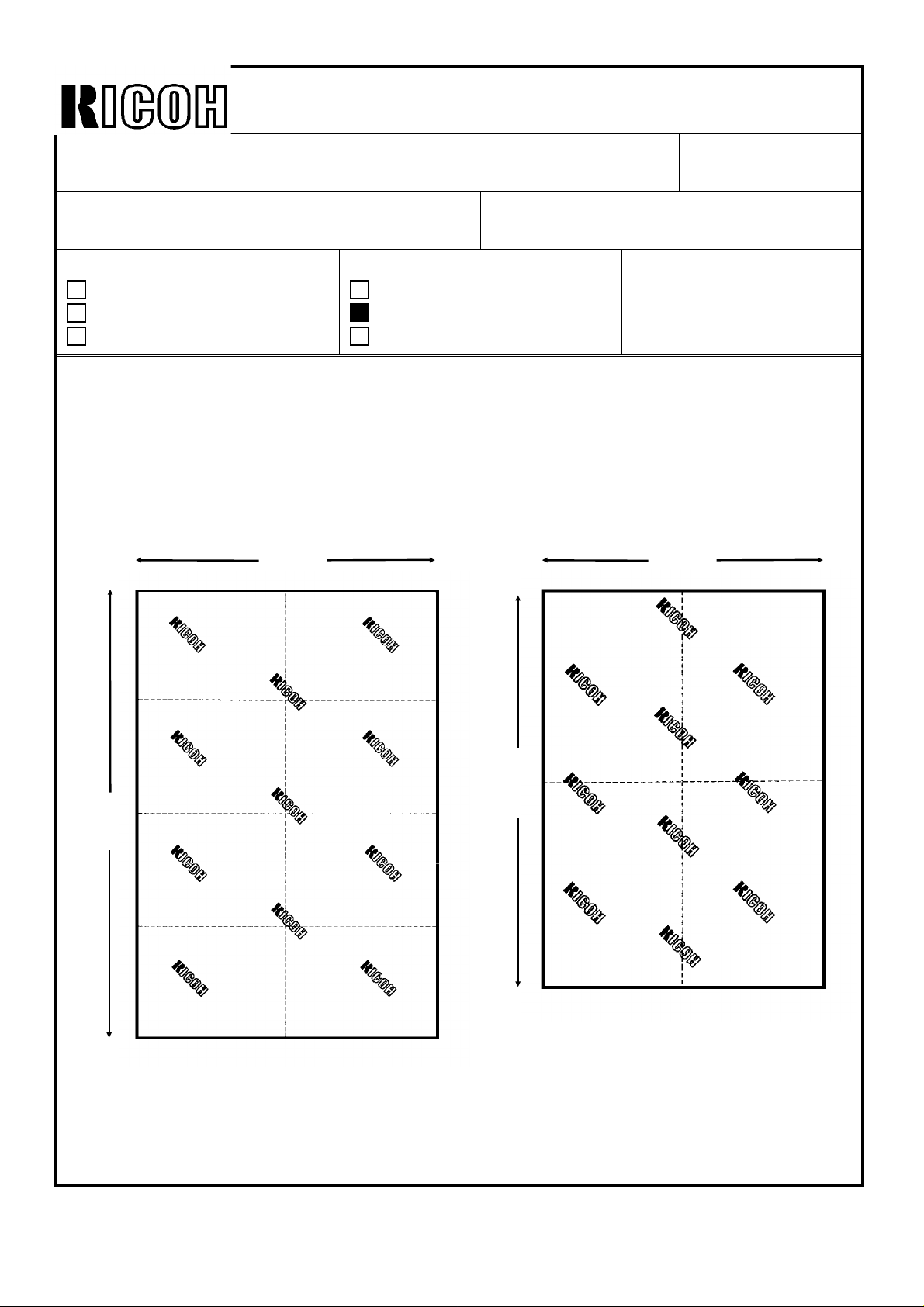

The following new test chart has been released for black-and-white copiers. This chart can

be used in place of chart 54209516 (Test Chart - OS - A3 (10pcs/set)) and 52149500 (Test

Char - OS – A4 (10pcs/set)). Its part number and description are shown below.

Part Number Description

A2929500 Test Chart – S5S (10 pcs/set)

54209516 and 52149500 have been discounted and are available until stock runs out.

For your reference, the following pages explain the items in the test chart.

Page 32

!"#$% T

Reissued: 24-Jul-00

echnical Bulletin

PAGE: 2/3

Model:

B

GENERAL

M

G

Date:

A

V

K

N

E

F H

14-Jul-00

J

I

No.:

RGene005a

W

L

M

B

B,C

E,U

D

P

O

R

T

P

S

Q

Page 33

!"#$% T

Reissued: 24-Jul-00

echnical Bulletin

PAGE: 3/3

Model:

A: Leading edge registration (Max. A3/DLT size copier)

B: Side-to-side registration/Skew (Max. A3/DLT size copier)

C: Leading edge registration (Max. A4/LT size copier)

D: Side-to-side registration/Skew (Max. A4/LT size copier)

E: Jitter (Max. A3/DLT size copier)

F: White line(s) in halftone areas (Max. A3/DLT size copier)

G: White line(s) (Max. A3/DLT size copier)

H: Main scan/horizontal magnification (Max. A3/DLT size copier)

I: Sub scan/vertical magnification (Max. A3/DLT size copier)

J: Solid black areas

K: Photo image

L: Scanning bit error (Max. A3/DLT size copier)

N: Letter

GENERAL

Date:

14-Jul-00

No.:

RGene005a

M: Uneven image density (Max. A3/DLT size copier)

O: Jitter (Max. A4/LT size copier)

P: Uneven image density (Max. A4/LT size copier)

Q: White line(s)

R: Sub scan/vertical magnification (Max. A4/LT size copier)

S: Scanning bit error (Max. A4/LT size copier)

T: Main scan/horizontal magnification (Max. A4/LT size copier)

U: White line(s) in halftone areas (Max. A4/LT size copier)

V: ID balance of solid black areas

W: Resolution

Page 34

echnical Bulletin

T

PAGE: 1/1

Model:

Subject:

From:

General

ROM History (Eland 99: Network Interface Board)

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

13-Mar-01

Prepared by:

No.:

H. Someya

Action required

Service manual revision

Retrofit information

Firmware history for Eland 99 (Network Interface Board).

The software versions listed below can be used for the NIBs of the following models:

Product Name Product Code

for Mainframe

Product Code

for Controller/NIB

Stinger-C1/C1L A250 B307

Russian-C1 A265/A267 B307

Russian-P G038

FresaWIN G024-57/-67 G678-14

PomeloWIN G033 G678-13

Color Controller

RC-200

A258/A259/A260

(Iris/Lilac)

G528

RGene006

File No.

G6785839 (G678Rxxx) Version Check Sum Production

B 001 3.7.5 1st release

C 002 3.7.7 600F February Prod. ‘99

D 003 3.8.6 7DF6 March Prod. ‘99

E 004 3.8.7 00BB April Prod. ‘99

F 005 3.8.8 6339 June Prod. ‘99

G 006 3.9.2 9605 July Prod. ‘99

H 007 3.9.8 5A35 October Prod. ‘99

J 008 4.0.0 6E2A November Prod. ‘99

K 009 4.0.2 FF9C April Prod. 2000

L 010 4.0.6 4B87 October Prod. 2000

M 011 4.0.7 C027 February Prod. 2001

Symptom Corrected (latest ones only)

Classless InterDomain Routing(CIDR) is supported.

DHCP of Solaris 2.6 is supported.

M

M

Page 35

echnical Bulletin

T

PAGE: 1/1

Model:

Subject:

From:

General

ROM History (Ferret 99/00: Network Interface Board)

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

13-Mar-01

Prepared by:

No.:

H. Someya

Action required

Service manual revision

Retrofit information

Firmware history for Ferret 99/00 (Network Interface Board).

The software versions listed below can be used for the NIBs of the following models:

Product Name Product Code

for Mainframe

Product Code

for Controller/NIB

FresaWIN+ G047/G048 G678-20

Russian-P2 G062

Color Controller

RC-210

B017/B018

(Iris2/Lilac2)

G549

RGene007

Suffix Version Check Sum Production

G6785847

D 4.8.2 4088 1st release

E 5.0.2 77A9 September Prod. 2000

F 5.0.4 C96E October Prod. 2000

G 5.0.7 0AF9 February Prod. 2001

Symptom Corrected

DHCP of Solaris 2.6 is supported.

The spelling of the command "retern" in the UNIX install shell has

been corrected to "return".

Classless InterDomain Routing(CIDR) is supported.

First release for Russian-P2 and Color Controller RC-210

G

F

E

E

Page 36

odification Bulletin

M

PAGE: 1/1

Model:

Modified Article:

From:

Reason for

Modification:

General

Flash Memory Card

Technical Services Dept., GTS Division

Parts catalog correction

To facilitate assembly

Part standardization

Old part

number

A2309351 N8031000 Case – Flash Memory Card O/O 1

A2309352 N8036701 Flash Memory Card O/O 1

New part

number

Description Q’ty Int Page Index Note

Date:

25-Jun-01

Prepared by:

Vendor change

To improve reliability

Other

No.:

MGenM003

M. Matsuda

To meet standards

( )

Refer to SPECIAL

TOOLS section.

Due to a vendor change, the part numbers of Case – Flash Memory Card and Flash

Memory Card have been changed.

Loading...

Loading...