Page 1

DUAL JOB FEEDER

(Machine Code: A376)

Page 2

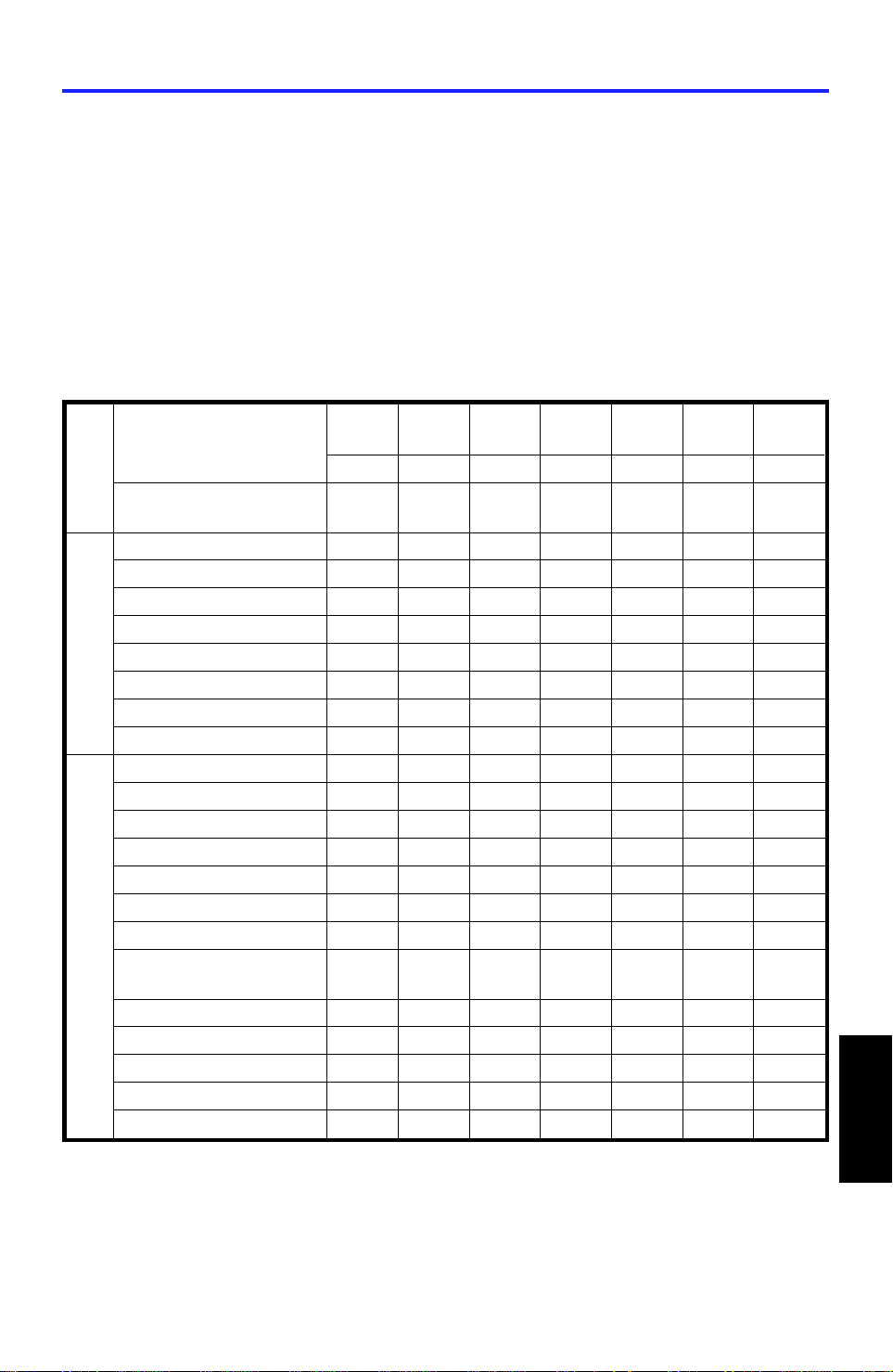

23 April 1993 SPECIFICATIONS

1. SPECIFICATIONS

Original Feed Mode: Automatic document fee d mod e

Automatic reverse document feed mode

Semi-automatic docume nt fee d mode

Mixed sized mode

Pasted original mode

Preset mode

Combine originals mode

Original Size, Weight and

Table Capacity:

40.7

Paper Weight

Maximum number of

originals to be set

A3 lengthwise ❋❋●●●❍❋

A4 lengthwise ❋❋●●●❍❋

A4 sideways ❋❋●●●❍❋

A5 sideways ❋❋❍❍❍❍❋

B4 lengthwise ❋❋●●●❍❋

B5 lengthwise ❋❋●●●❍❋

A4/A3 version

LT/DLT version

●: Mixed Original mode

❍: ADF mode, ARDF mode, SADF mode

❋: ADF mode, SADF mode

B5sideways ❋❋●●●❍❋

F (8" x 13") lengthwise ❋❋●●●❍❋

11" x 17" lengthwise ❋❋●●●❍❋

8

1/2 x 14" lengthwise ❋❋●●●❍❋

8

1/2 x 11" lengthwise ❋❋●●●❍❋

1/2 x 11" sideways ❋❋●●●❍❋

8

5

1/2" x 81/2" lengthwise ❋❋❍❍❍❍❋

5

1/2" x 81/2" sideways ❋❋❋❋❋❋❋

8" x 13" (F) lengthwise ❋❋●●●❍❋

81/2 x 13" (F4)

lengthwise

8" x 10

Preset mode

ADF mode (1 sided originals mode)

ARDF mode (2 sided original(s) mode)

SADF mode

1/2" lengthwise ❋❋●●●❍❋

8" x 10" lengthwise ❋❋●●●❍❋

8" x 10" sideways ❋❋●●●❍❋

10" x 14" lengthwise ❋❋●●●❍❋

11" x 15" lengthwise ❋❋●●●❍❋

g/m

11 lb 12.5 14 17 22 28 34

50 50 50 50 50 30 25

❋❋●●●❍❋

46.5 52.8 64.0 81.4 104.7 128.0

2

Feeder

Dual Job

1

Page 3

SPECIFICATIONS 23 April 1993

Original Standard Position: Rear left

Original Separation: Fe ed and friction belt

Original Transport: One flat belt

Power Source: DC24V from the copier, 2.0A (ave rage)

Power Consumption: 70W

Dimensions (W x D x H): 680 x 508 x 116mm

(26.8" x 20.0 " x 4.6")

Weight: 13kg (28.7lb)

2

Page 4

1

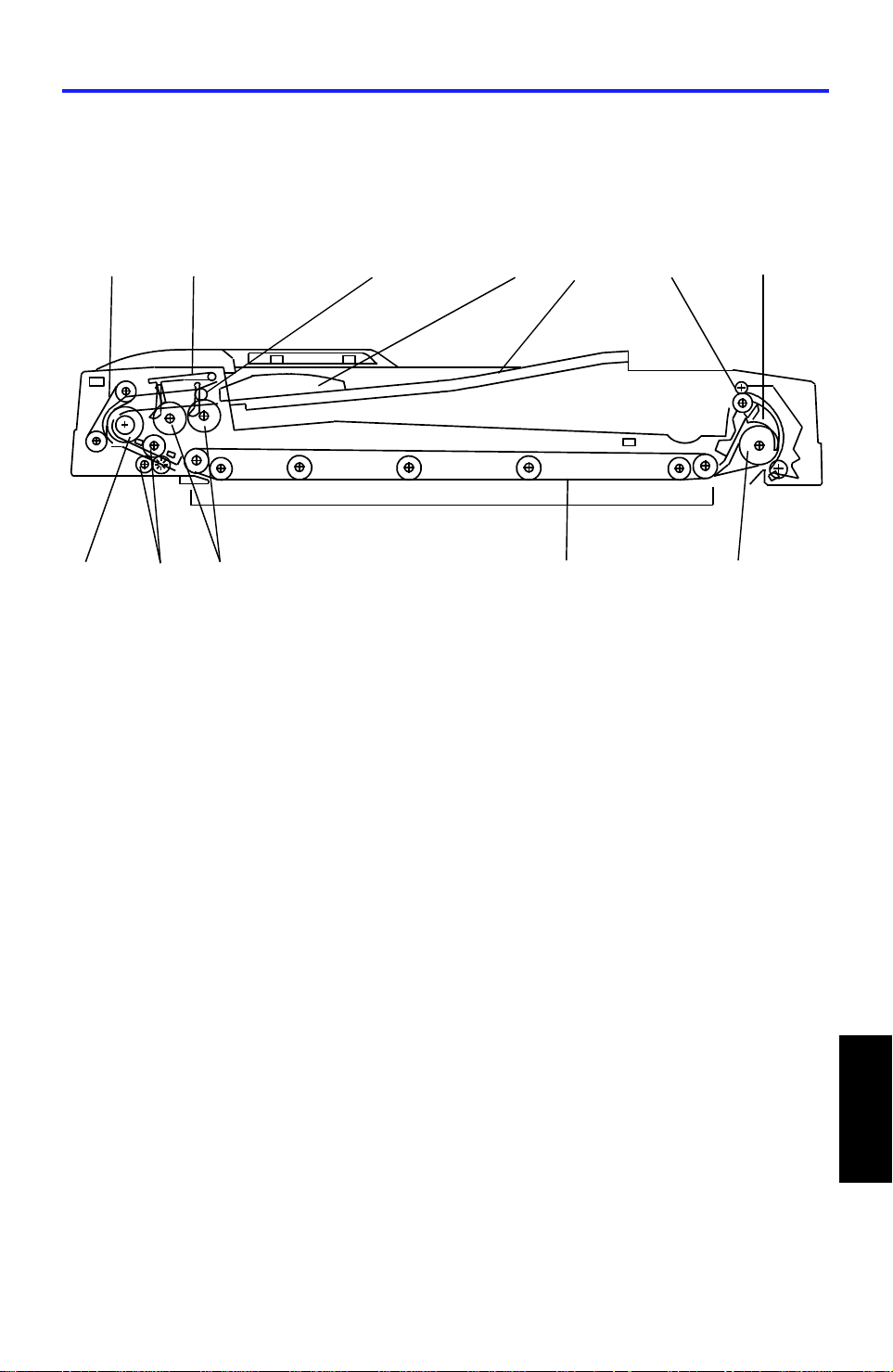

23 April 1993 COMPONENT LAYOUT

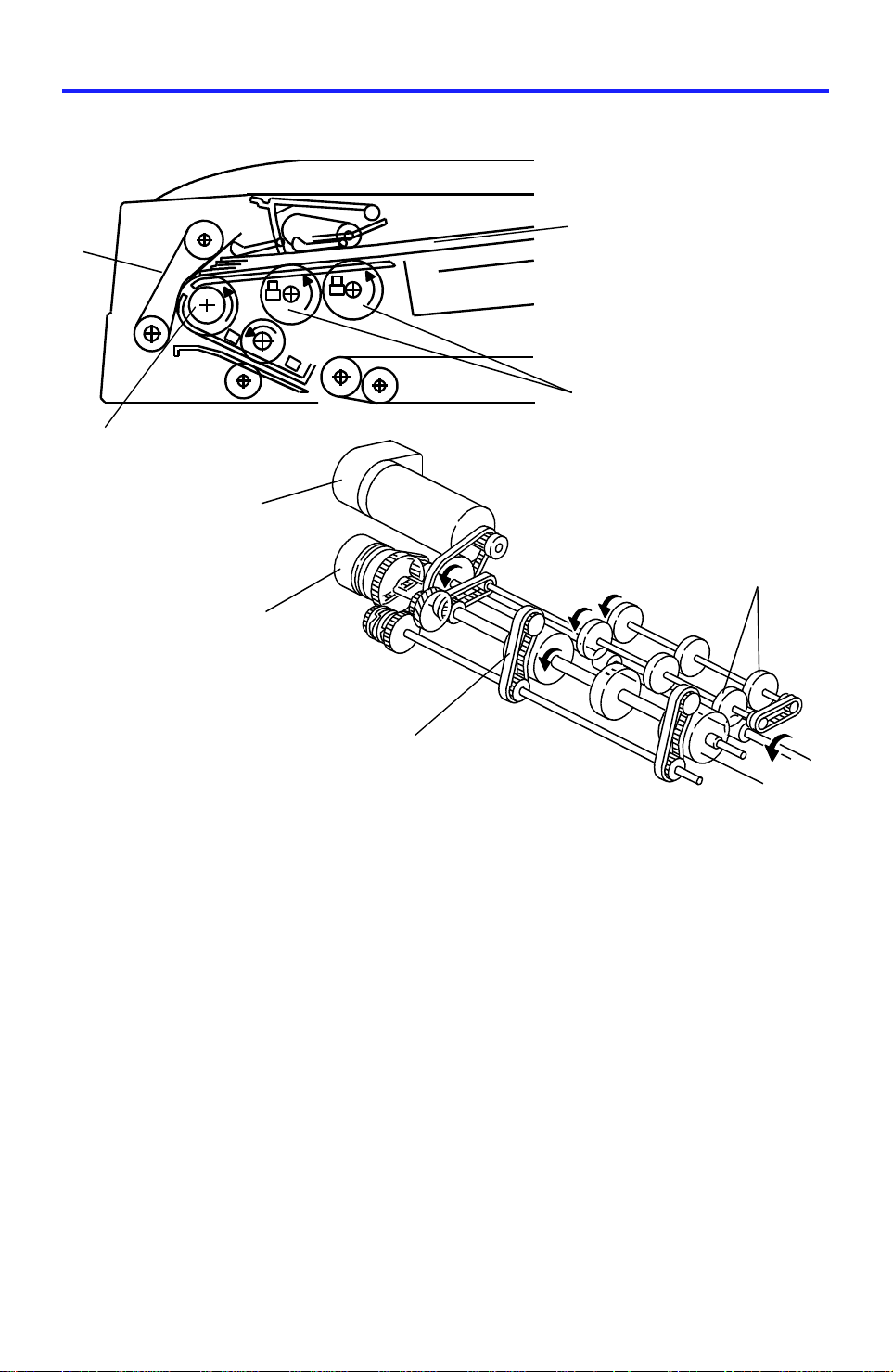

2. COMPONENT LAYOUT

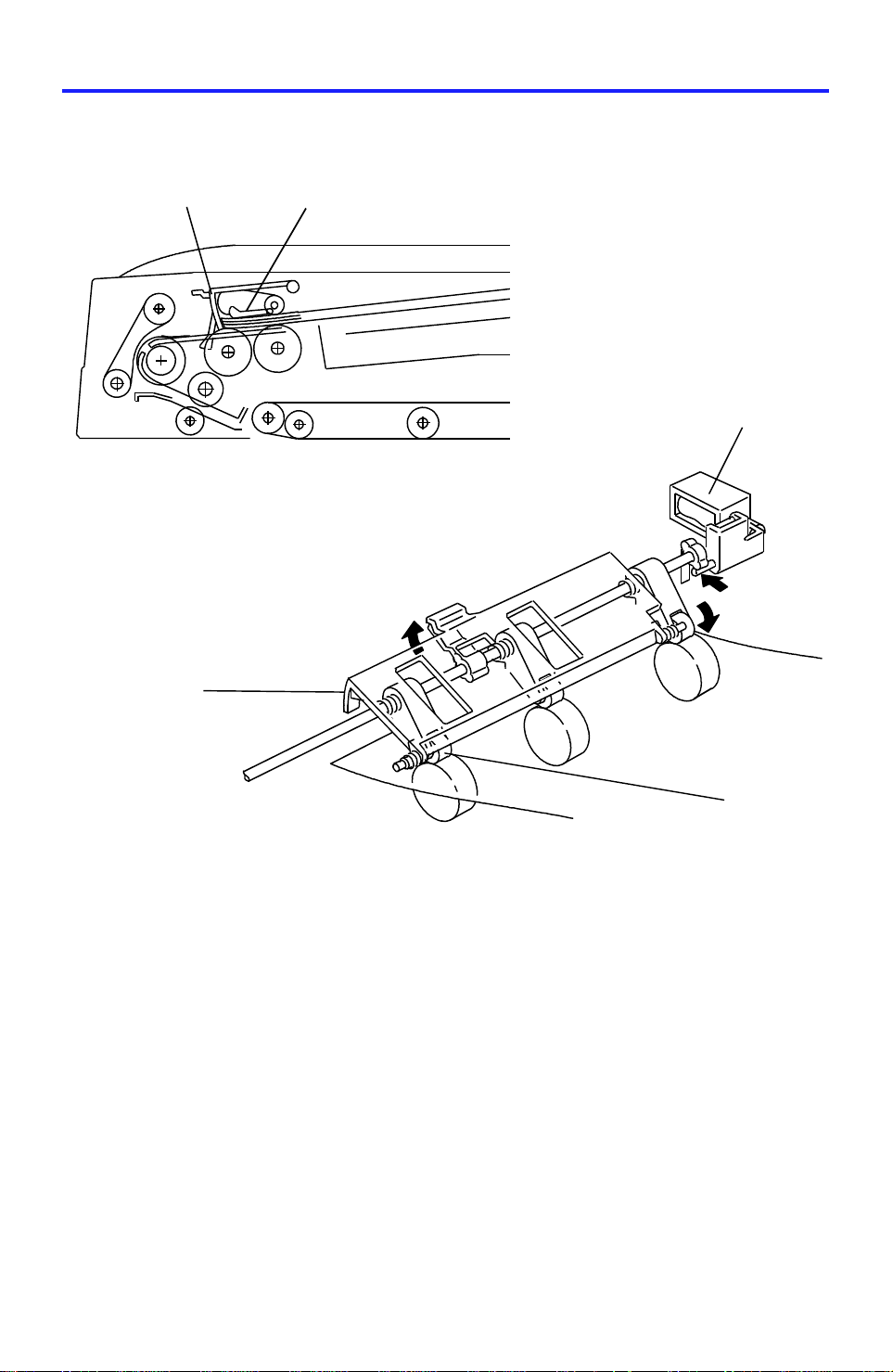

2.1 MECHANICAL COMPONENT LAYOUT

12

1. Friction Belt

2. Original Stopper

11

10

3

4

7. Inverter Pawl

8. Inverter Roller

5

9

6

72

8

3. Press Roller

4. Side Fence

5. Original Table

6. Exit Roller

9. Transport Belt

10. Pick-up Rollers

11. Pull-out Roller

12. Feed Roller

3

Feeder

Dual Job

Page 5

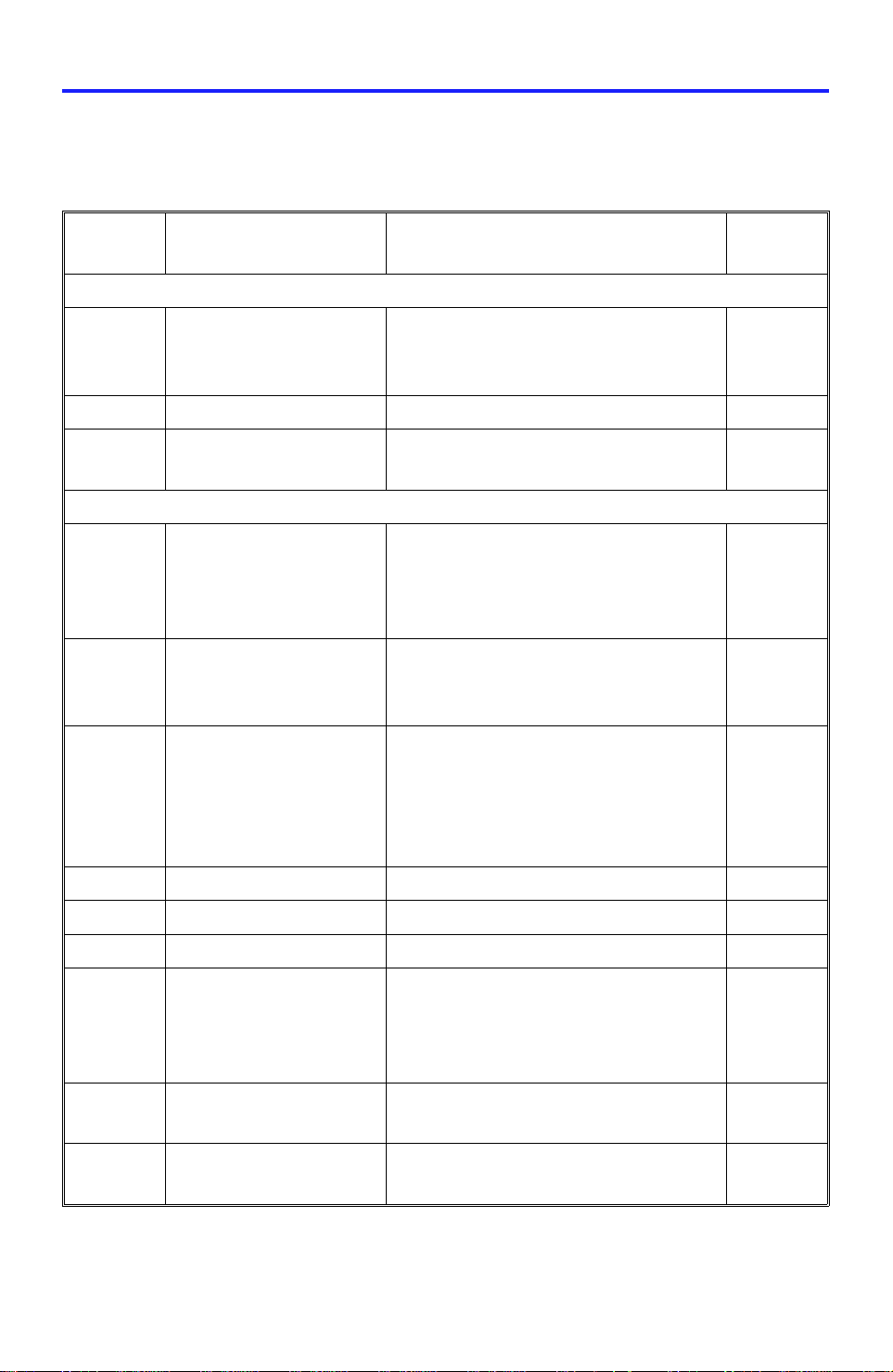

ELECTRICAL COMPONENT DESCRIPTION 23 April 1993

3. ELECTRICAL COMPONENT DESCRIPTION

Refer to the electrical compone nt layou t on the reverse side of the att ach ed

Point to Point for symbols and ind ex numbers.

Symbol Name Function Index

No.

Motors

M1 Feed-in Drives the feed-in system

(pick-up, feed, pull-out rollers,

separation belts)

M2 Belt Drive Drives the transport belt. 2

M3 Feed-out Drives the feed-out and the

inverter system.

Sensors

S1 DF Position Informs the CPU when the DJF

is being closed so that original

size detection sensors can

check the original size.

S2 Feed-out Checks for original misfeeds and

sets original stop timing when in

auto-reverse mode.

S3 Registration–2 Detects the leading edge of the

original to turn off the feed-in

clutch and to change the feed-in,

belt drive motors speed. Also

detects the original length.

1

5

7

8

10

S4 Original Width–3 Detects the original width. 11

S5 Original Width–1 Detects the original width. 12

S6 Original Width–2 Detects the original width. 13

S7 Registration–1 Detects the trailing edge of the

original to change the belt-drive

motor speed. Also, detects the

original length and original jam.

S8 Original Feed Detects if the originals reach the

feed roller or not.

S9 Original Set Detects if the originals are set on

the feed table.

4

14

15

16

Page 6

23 April 1993 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function Index

No.

S10 Pulse Count Counts the pulses generated by

the pulse generator disc to

determine the original length.

Solenoids

SOL1 In vert er Energizes to invert th e orig inal

when copying two sided

originals.

SOL2 St oppe r Lifts the original stopper and

lowers the press roller to feed

the set of originals to the feed

roller.

SOL3 Separation Transmits drive to the separation

belts.

PCBs

PCB1 DF Main Board Controls all DJF functions. 3

PCB2 Indicator Panel

Contains operator indicators. 21

Board

19

4

9

18

Switches

SW1 Lift Informs the CPU when the DJF

is lifted and also serves as the

jam reset switch for the DJF.

SW2 Feed Cover Detects if the fe ed cover is

closed.

Clutches

MC1 Feed-in Transmits the feed-in motor

drive to the pick-up and feed

rollers, and to the separation

belts.

6

17

20

Feeder

Dual Job

5

Page 7

BASIC OPERATION 23 April 1993

4. BASIC OPERATION

4.1 ONE-SIDED ORIGINAL FEED

[A]

[A]

[B]

[C]

[D]

When an original is set on the DJF feed table, th e lea din g edge is stopp ed by

the stopper [A], and the feele r [B] activa te s the origin al set senso r. The Insert

Original indicator light goes out an d the DJF informs the copie r’s CPU that

the originals have been set.

When the Start key is pressed, the copier’s CPU sends the feed-in signal to

the DJF. On receipt of this signal, th e sto pp er sole no id [C] activa tes to raise

the stopper to allow the originals to be fed in, and to lower the press rollers

[D] to press the originals against the pick-up rollers as sho wn.

6

Page 8

[B]

23 April 1993 BASIC OPERATION

[A]

[C]

[E]

[D]

[F]

[D]

[F]

[B]

[G]

[E]

The feed-in clutch [A] activat es when the DJF receive the feed-in signal.

200ms after the feed-in clutch act ivate, the feed-in motor feeds all originals to

the feed roller [B].

When the originals reach the fee d rolle r, th e sto pp er sole no id [C]

de-activates to lower the original sto pper [D] and to lift up the origina l press

rollers [E].

When the originals pass through (be twe en the sepa rat ion belt [F] and feed

roller), only the lowest orig ina l is sep ara te d an d fe d on to the exposure glass.

Until then, the feed-in motor rotates slowly (372mm/sec) to ensure prop er

original feeding. When the lea ding edge of the original activates regist rat ion

sensor - 2 [G], the feed-in clutch [A] turns off to reduce the mechanical load

and prevent the next original fro m f eeding. Also, the feed motor rotat es more

quickly (1250mm/sec).

Feeder

Dual Job

7

Page 9

[A]

BASIC OPERATION 23 April 1993

[C][B]

When the leading edge of the original reaches the exposure glass, the

original is transported by the tra nsport belt [A] (belt drive motor turns on 200

ms after the start key is pressed).

When the trailing edge of the orig ina l passes through registration sen sor - 1

[B], the feed-in mot o r tu rns off. When the trailing edge of the original passes

through registratio n sen sor - 2 [C], the belt drive mot or gra du ally de crea ses

its speed to stop the origin al at the proper place on the exposure glass.

200ms after the belt drive motor turns off, the feed -in mot or tu rns on until the

next original activates reg istra tion sensor - 1 [B], the next original waits until

the first original copy jobs comple te . This op era tio n red uces the original feed

in time.

When the scanner reaches the return position, the copier’s CPU sends the

feed-out and feed-in signals to the DJF CPU in order to exchange the original

for the next original.

When the DJF receives the feed -out signal, the belt drive and fe ed -ou t

motors turn on.

When the scanner reaches the return position after scanning the last original,

the copier’s CPU sends only the fe ed-out signal to feed-out the last orig inal.

If the original is smaller than A4 sideways, the origina l just copied is

transported to the rig ht sid e of the expo sure glass then waits until the next

original copying is completed . The n the previous original is delivered . This

operation also reduces the original fe ed-in time .

8

Page 10

23 April 1993 BASIC OPERATION

4.2 TWO-SIDED ORIGINAL FEED

[A]

[B]

Unlike one-sided original feed, the back side of the original must be copied

first to keep the originals and copies in the correct order.

During original feed-in, the sequence is the same as fo r one-side d feed ;

however, the belt drive motor con tin ue s rota ting until the original reaches the

inverter section. The DJF CPU also energize the feed-out motor and the

inverter solenoid [A] fo r a short time.

After the inverter mechanism inverts the original (10 pulses after the feed-out

sensor [B] activates), the belt drive mot or reve rses an d th e orig inal is fed

towards the original scale. It is stoppe d at the correct posit ion on the

exposure glass, and the DJF CPU sends th e cop y start signal.

When the scanner reaches the return position, the copier’s CPU sends the

invert original signal to the DJF CPU in order to ma ke a cop y of th e fro nt sid e.

The original is inverted in the same way as for back side copying.

Feeder

Dual Job

9

Page 11

BASIC OPERATION 23 April 1993

4.3 PRESET MODE

[E]

[B]

[D]

[C]

[F]

[A]

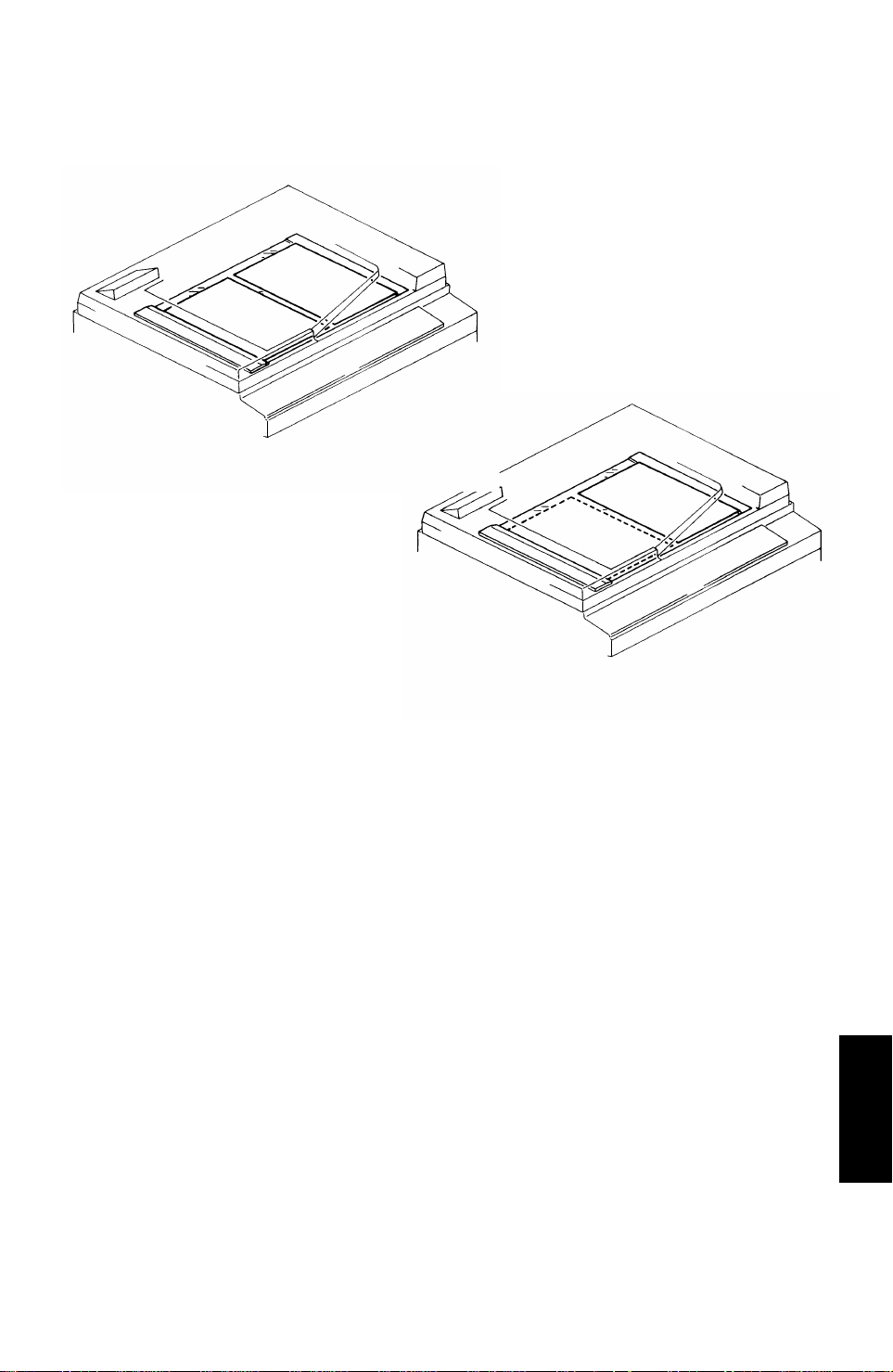

Two sets of originals for independen t cop y jobs can be set on the original tray

at the same time.

While the first set of originals [A] remains on the origin al tra y, bo th the origin al

set sensor feeler [B] and origin al fe ed senso r fee ler [C] are actuated. If the

second set of origina ls [D] ha s bee n set (st oppe d by the original stopper [E] )

and the first set of originals [A] are all fe d-in , th e orig ina l set sensor feeler [B]

is still actuated and only the original feed sensor is deactuated. There fo re,

the copier’s CPU recognizes tha t th e first jo b is comple ted.

If the second job is alrea dy pre set, the second set of originals is a ut oma tically

fed to the feed roller [F] in the same manner as the first set of origina ls was.

10

Page 12

[Fig.2]

23 April 1993 BASIC OPERATION

4.4 COMBINE 2 ORIGINALS MODE

4.4.1 Overview

[Fig.1]

2 originals are fed onto the exposure glass at once in the comb ine 2 origin als

mode as shown in figure 1. This allows copying 2 originals onto one sheet of

paper automatically either in the full size mod e or in the red uction mode. If it

is used together with the dup lex mod e, 4 originals can be copied on a single

sheet of paper automatically.

If odd numbered originals are place d on the origin al ta ble, the first original is

placed on the exposure glass as sho wn in fig ure 2.

Only 1-sided originals can be used, and Auto Pa per Select (APS) and Auto

Reduce/Enlarge mod es cannot be used with this mode.

Feeder

Dual Job

11

Page 13

BASIC OPERATION 23 April 1993

4.4.2 Operation

Figure 1

Figure 2

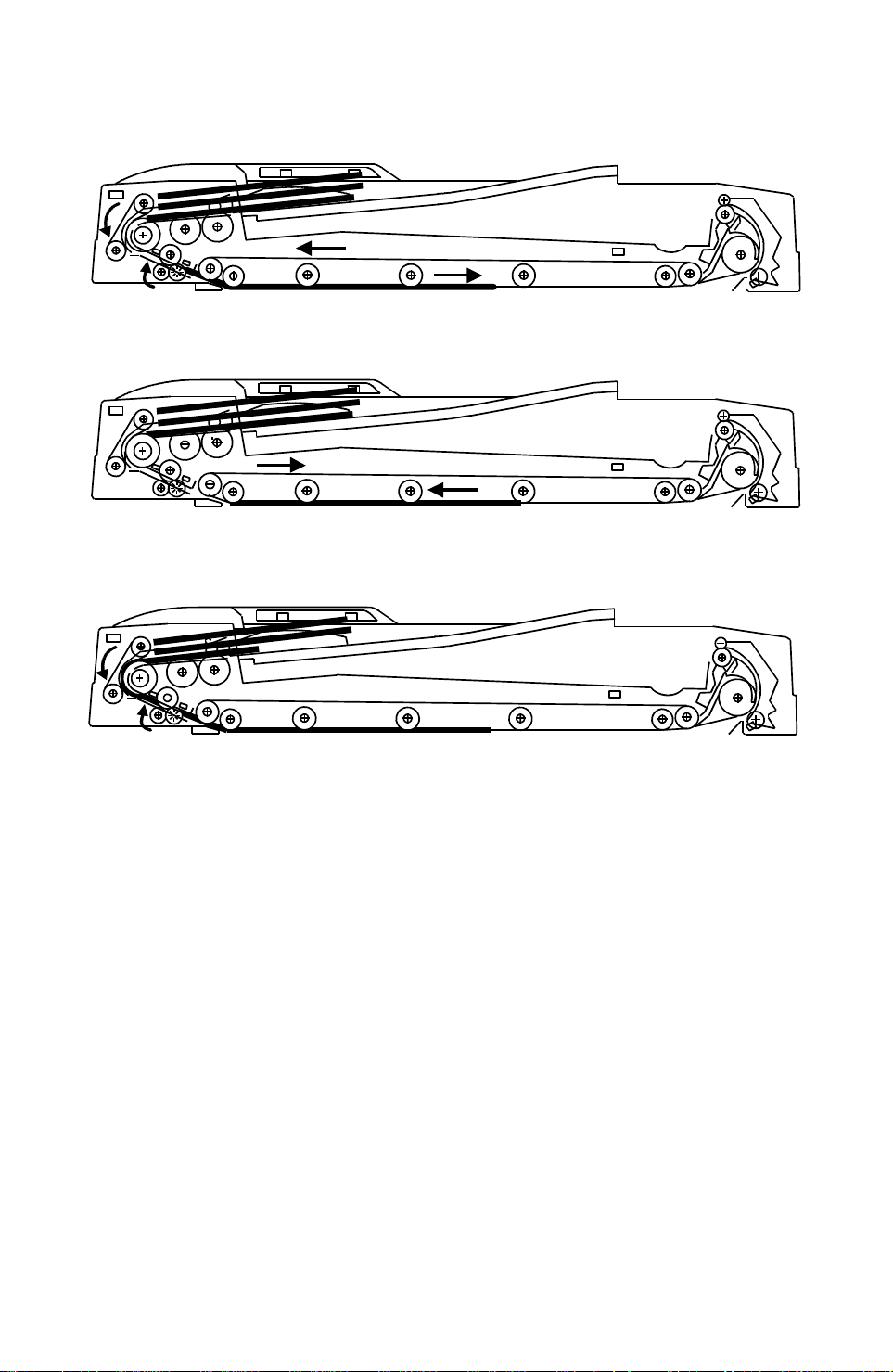

The DF operation in the combine 2 original mode is as follows:

[Figure 1]

The first original is fed in the same manner a s the one -side d orig ina l

mode. When registration sensor-2 det ect s the trailin g edge of the first

original, the feed-in and the belt drive motors sto p once and the feed -in

clutch turns on again to pre pa re for the second original fee d.

[Figure 2]

As soon as the feed-in and the belt drive motor turn off, the belt drive

motor starts rotatin g in reve rse to align the first original against the

original scale. Then the belt drive mo tor t urn s off .

[Figure 3]

50ms after the feed-in motor turns off, the feed -in mot or tu rns on again at

a lower speed (372mm/sec) to feed the secon d orig ina l.

A few pulses (0 ~ 14 pulses: depends on the SP mode adjust men t) after

the registration senso r-2 is a ctiva ted by the leading edge of th e seco nd

original, the feed-in motor and the feed-in clutch turn off.

Figure 3

12

Page 14

23 April 1993 BASIC OPERATION

Figure 4

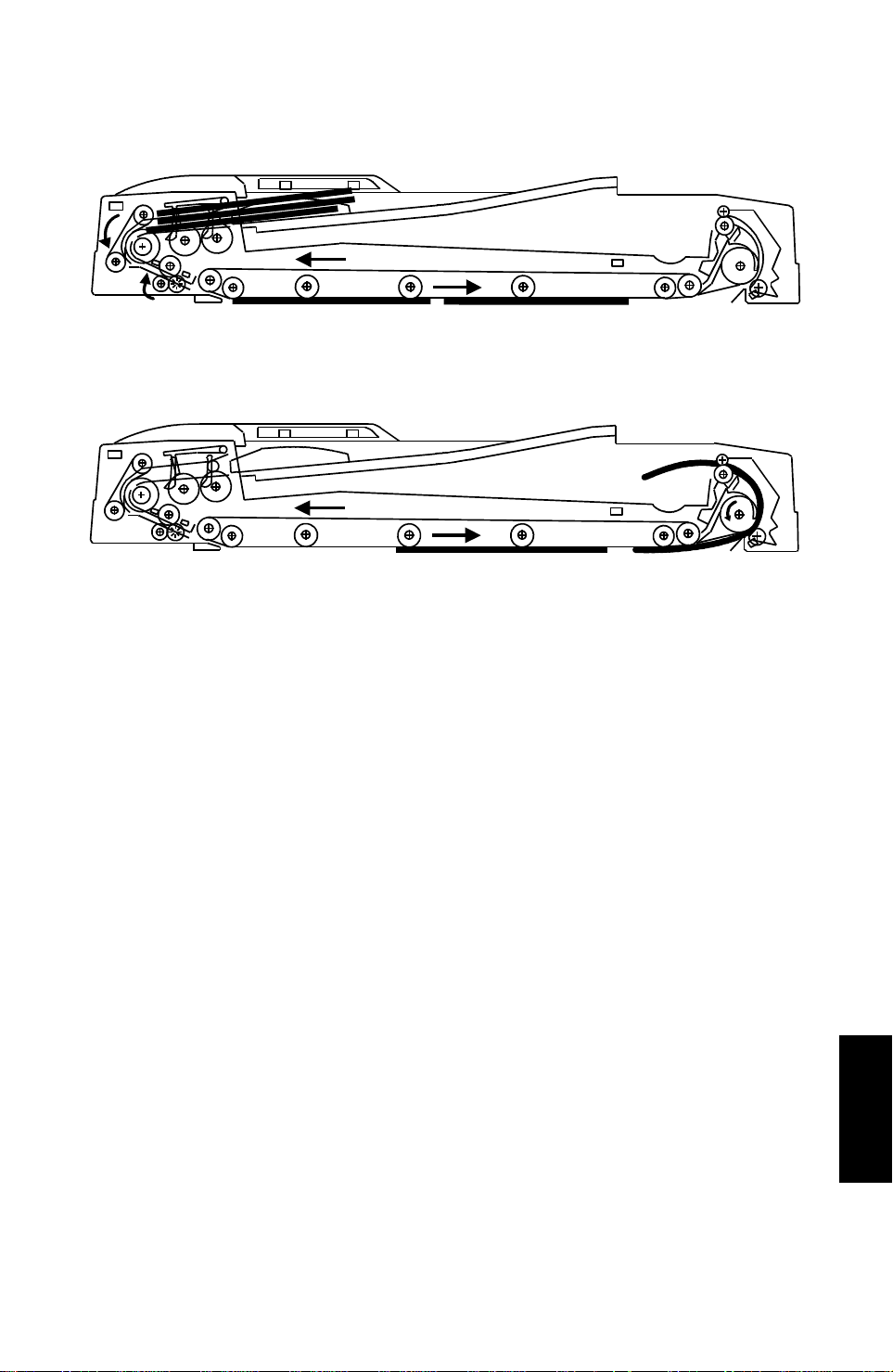

[Figure 4]

Soon after the feed-in motor turns off, both the feed-in and the belt drive

motors turn on again at the lower speed (372mm/sec).

After registration sen sor-2 detects the trailing edge of the seco nd origin al,

the feed-in and the belt drive motors turn off and gradually th e belt drive

speed reduces to sto p the original at the pro pe r p lace on th e exposure

glass.

[Figure 5]

After the copying of th ese origin als is f inish ed , the belt drive motor and

the feed-out moto r t urn on to fee d ou t th e originals. 50mm before the

trailing edge of the first original de-activates th e feed-ou t sen sor, both the

belt drive and the feed-out motor rotate at the lower speed to improve

original stacking.

48 pulses after, the belt drive motor turns off and 60 pulses after the

feed-out sensor d et ect the trailing edge of the second original, the

feed-out motor turns off.

Figure 5

13

Feeder

Dual Job

Page 15

ORIGINAL SEPARATION 23 April 1993

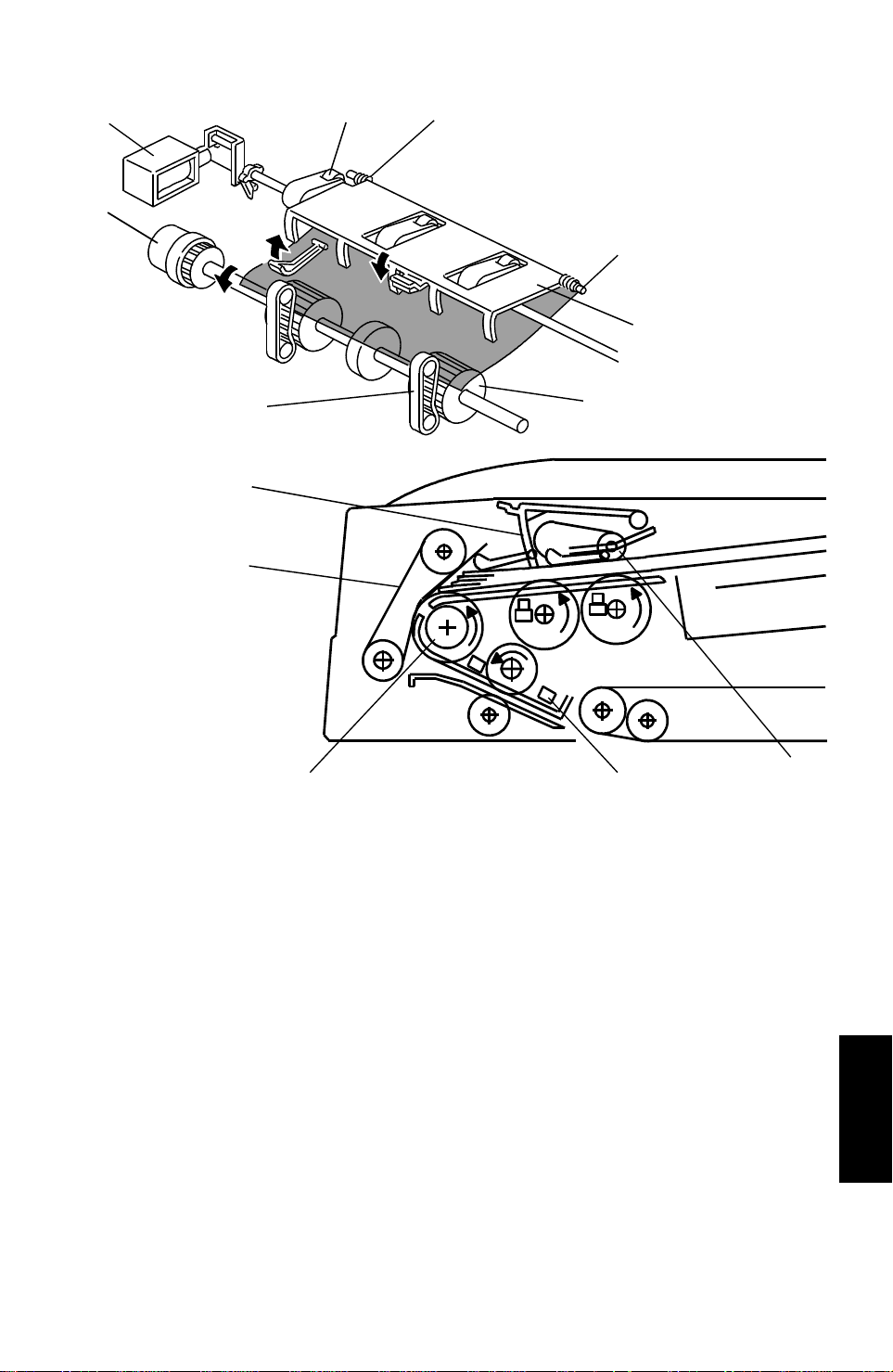

5. ORIGINAL SEPARATION

[E]

[F]

[B]

[C]

[A]

[B]

[D]

[E]

[C]

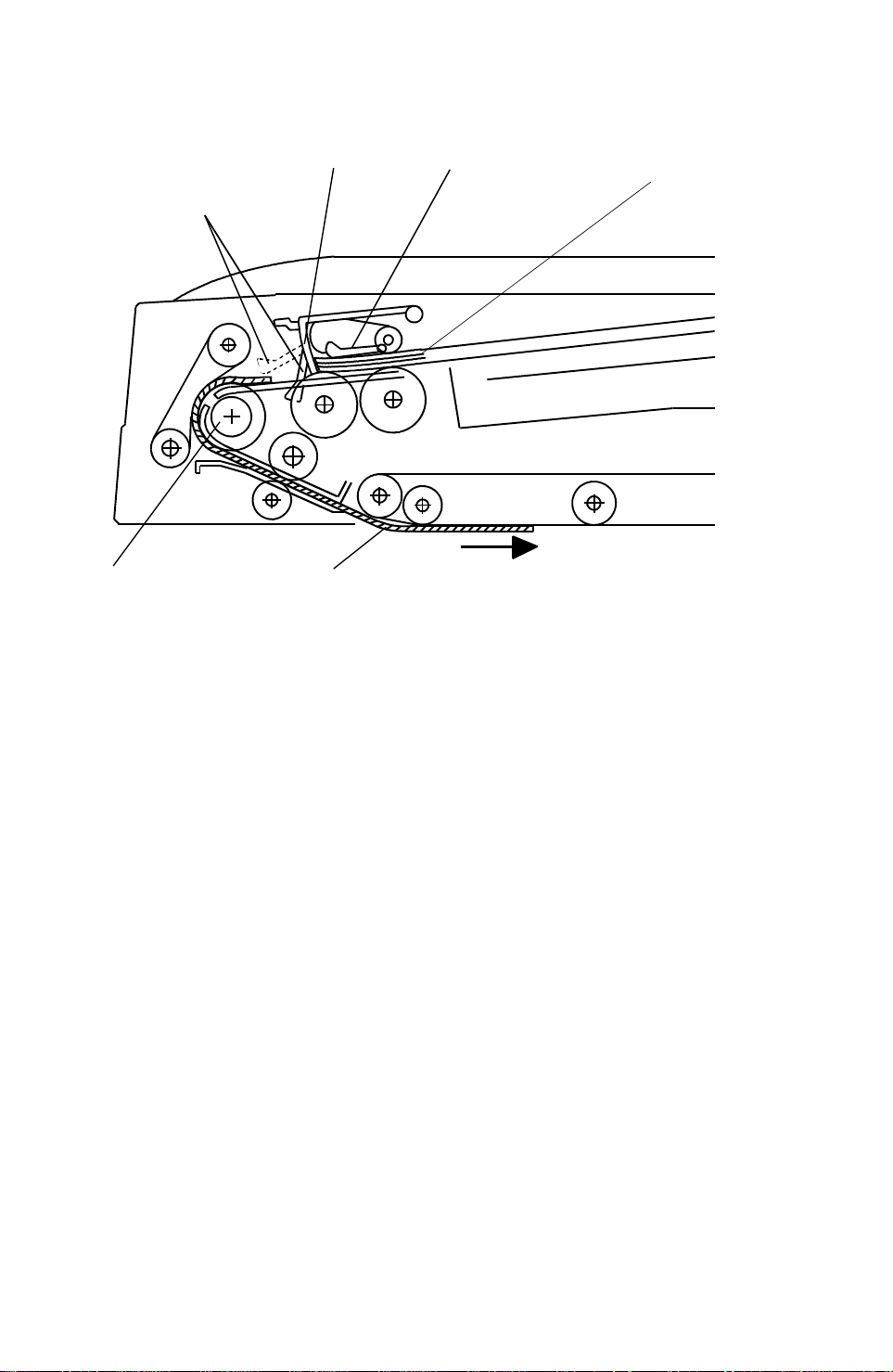

The drive from the feed-in motor [A] is transmitt ed to the pick-u p rollers [ B]

and the feed roller [C] through the feed-in clutch [D] as shown. The feed roller

and the friction belts [E] are used to feed -in and sep ara te the origin als [F] .

Only the bottom original is fed because the friction belt prevents any other

original from feeding.

Original feed starts when the feed roller starts turning and advances the

bottom original of the stack. The feed roller moves the original past the

separation belt because the driving force of the feed roller is greater than the

resistance of the friction belt . The friction belt prevents multiple fee ds

because the resistance of the frict ion belt is great er th an the frictio n be twe en

original sheets.

14

Page 16

[B]

[C]

23 April 1993 SEPARATION BELT DRIVE MECHANISM

6. SEPARATION BELT DRIVE MECHANISM

[D]

[A]

Normally the separation belt is not driven . Whe n the cop y jo b is comple te d,

the separation solenoid [A] activates for 100ms. to transmit the drive from the

feed-in motor [B] to th e sep aration belts [C] as shown.

By this operation, the part of th e frict ion belt that contacts the feed roller [D]

or the original changes to prevent multiple feeding .

When the pasted original mode is selected, the separa tio n solenoid turns on

to drive the separation belt in the same dire ction as the feed rollers.

This disables the separa tion function to reduce the frictio n be tween the

original surface and the separation belt.

Feeder

Dual Job

15

Page 17

THIN / THICK ORIGINAL MODES 23 April 1993

7. THIN / THICK ORIGINAL MODES

This document feed er ha s two dif ferent ways of stopping orig ina ls a t th e

correct position on the exposu re gla ss. They are called the thin original mode

and the thick original mode. The mode used is dete rmined by using the

copier’s User Tool No.12.

1. Thin Original Mode

The original is stopped at the corre ct po sitio n on the expo sure glass

based on encoder pulse count. The belt drive motor stops shortly after

the original trailing edge passes registration sensor - 2. (Exact timing

depends on registration adju stme nt .)

In the pasted original mode, the DJF automatica lly se lect s this mod e.

2. Thick Original Mode

When thick original mode is selecte d, the belt drive mot or rema ins

energized to carry the original approximately 10 mm pass the left scale.

Then, the belt drive motor pauses and reverses to feed th e orig inal back

against the original scale. This forces th e orig ina l aga inst the left scale

and thus aligns the trailing edge of the original with the scale.

Thick original mode is selected at the factory.

16

Page 18

[E]

[E]

23 April 1993 ORIGINAL SIZE DETECTION

8. ORIGINAL SIZE DETECTION

[F]

The DJF detects original widt h through the on/off combination of the three

original width sensors -1 [A], -2 [B] , -3 [C] , it also detects the original length

through the use of the registration sensors -1 [D], -2 [E] and the pulse count

sensor [F].

[D]

[C]

[G]

[A]

[B]

The DJF CPU counts the pulses between regist rat ion sensor - 2 [E] on timing

and registration senso r - 1 [D] off timing.

Based on this pulse count, the CPU dete rmine the origin al len gt h.

The reason for using two registration sensors are:

1) Registration sensor -2 [E] is used to sto p the pre -fed original to wait until

the previous original is fed out. For p recise cont rol, the origin al sto p

position must be after the pull out rollers [G ]. Therefore, registration

sensor -2 is placed after the pull-out roller.

2) Registration sensor -1[D] checks the trailin g edge of the origina l. This

check is used to place the orig inal on the exposure glass.

Enough distance is required bet ween the sensor and the orig ina l scale.

Therefore, registration sensor -1 is placed 34.9 mm before sensor -2.

The original size is determine d by the combination of the det ect ed origin al

width and the length.

17

Feeder

Dual Job

Page 19

➁

➂

LIFT MECHANISM 23 April 1993

9. LIFT MECHANISM

➀

[A]

[D]

➁

➂

➀

[C]

[B]

When the DJF is opened, the lift springs [A ] pro vide enough force to ensure

that the DJF does not fall onto the expo sure glass. When the DJF is closed,

points "➀", "➁", and "➂" are aligned and no upward force is provided to the

DJF.

The lift switch [B] is actuated when the DJF is closed . The copie r t hen shif ts

to the document feeder mo de. The lift switch also serves as the reset switch

for DJF misfeeds.

When a book or thick (maximum thickness 60 mm) original is copied, the DJF

acts as a cover for the original as sh own in the figu re [C] . The lift switch is

turned off during th is co ndition, so the DJF does not function. The tension of

spring [D] returns the DJF to the norma l condition after copying a thick

original.

18

Page 20

➃

23 April 1993 ORIGINAL MISFEED DETECTION

10. ORIGINAL MISFEED DETECTION

Registration sensor -1 and the feed-o ut sensor are used for misfeed checks

to light the original misfeed ind icat or.

1. One sided original

➀

Registration

Sensor – 1

➂

➁

Feed-out Sensor

Feed-in Motor

Feed-out Motor

➄

Copying

➀: If registration sensor -1 does not activate within 150 pulses after the

feed-in motor starts turning , the CPU dete rmine s that th e origina l will not

arrive (ON check).

➁: If registration sensor -1 does not de-activate within 120 pulses, the CPU

determines that the original is still there (OFF check).

➂: If the current paper size data is 40mm lon ger o r 80mm sho rter than the

previous original size data (this ch eck is disab led in the mixed size

original mode).

➃: If the feed out sensor does no t activate within 125 pulses after the

feed-out motor starts turning , th e CPU determine s tha t the orig ina l will not

arrive (ON check).

➄: If the feed-out senso r doe s not de-activate within 60 pulses after the feed

out motor slows down, the CPU determines that the orig ina l is still there

(OFF check).

19

Feeder

Dual Job

Page 21

⑤

2nd Copying

ORIGINAL MISFEED DETECTION 23 April 1993

2. Two sided original

Registration sensor -1 and the feed-o ut sensor are used for misfeed checks

to light the original misfeed ind icat or.

Registration ON/OFF ch eck is the same as for one-sided originals.

①

②

Feed-out

Sensor

Feed-out

Motor

③

④

Forward

Belt Drive

Motor

Reverse

1st Copying

➀: If the feed-out sensor does not activate within 130 pulses after the

feed-out motor starts turning , th e CPU determine s tha t the orig ina l will not

arrive (ON check).

➁: If the feed-out sensor does not de-activate within 200 pulses, the CPU

determines that the original is still there (OFF check).

➂: If the feed-out sensor does not activate within 130 pulses after the

feed-out motor starts turning , th e CPU determine s tha t the orig ina l will not

arrive (ON check).

➃: If the feed-out sensor does not de-activate within 200 pulses, the CPU

determines that the original is still there(OFF ch eck).

➄: If the feed out sensor does no t activate within 125 pulses after the

feed-out motor starts turning , th e CPU determine s tha t the orig ina l will not

arrive (ON check).

⑥

➅: If the feed-out senso r doe s not de-activate within 60 pulses after the feed

out motor slows down, the CPU determines that the orig ina l is still there

(OFF check).

20

Page 22

11. TIMING CHART

Feed-out

11.1 DJF Timing Chart (1 sided origina l mode)

RXD

TXD

Original Set SN

Stopper SOL

Feed-in MC

Original Feed SN

Registration-1

Registration-2

Feed-Out SN

Separation SOL

Feed-in M (M1)

Feed-in

Original set

200 ms

390 ms

480 ms

200 ms

M1: 10 pls

Size

Pulse Count

Original stop

150 ms

M1: 5 pls

200 ms

Feed-out

Feed-in

No original

Size

Original

stop

M1: 5 pls

Feed-out

Feed-out

Feed amount:

M1: 3.7 mm/pls

Belt Drive M (M2)

Feed-out M (M3)

M2: 2.0 mm/pls

M3: 2.7 mm/pls

Registration-1ON

check (within 150 pls)

M3: 60 pls

Feed-out sensor OFF check (within 60 pls)

Feed-out SN ON check (within 125pls)

Incorrect Original Size check

(If more than 40 mm longer or more than 80 mm shorter than previous original).

Registration-1 OFF check (within 200 pls)

21

M3: 60 pls

Page 23

11.2 DJF TIMING CHART (COMBINE 2 ORIGINALS MODE )

Feed-out

Trailing Edge

RXD

TXD

Original Set SN

Stopper SOL

Feed-in MC

Original Feed SN

Registration-1

Registration-2

Feed-out SN

Separation SOL

Feed-in

Motor (M1)

Original set

Combine: Feed-in

390 ms

480 ms

200 ms

M1:5pls

50 ms

NOTE: 1

0 ~ 14 pls

Combine: Feed-out

Original StopSize

Feed-out

M1: 3 pls

M3: 48 pls

Belt drive

Motor (M2)

Feed-out

Motor (M3)

NOTE: Adjustable (0 ~ 14 pls) by DIP SW102

M3: 60 pls

22

Page 24

23 April 1993 INSTALLATION

12. INSTALLATION

12.1ACCESSORY CHECK

Check the accessories accord ing to the following list:

Description Q’ty

1. Installation procedure.............................................................1

2. Stepped screw........................................................................2

3. Philips screw with flat washer - M5 x 10.................... ............ .2

4. New equipment condition report

(for – 17, – 27 machines only)....................... ............ ............ .1

5. Envelope (for – 17 machine only) ................................. .. .. .....1

23

Feeder

Dual Job

Page 25

INSTALLATION 23 April 1993

12.2INSTALLATION PROCEDURE

[A]

CAUTION: When installing the Dual Job Feeder (DJ F), ma ke sure that

the copier is unplugged.

1. Remove the tape strips and the cushion.

2. If present, remove the senso r [A] from th e copier (1 screw).

NOTE: Sensor [A] is not installed on copie rs ju st out of their box.

Sensor [A] is an accessory of th e platen cover (option).

24

Page 26

[A]

23 April 1993 INSTALLATION

[B]

[B]

[C]

[E]

[D]

[B]

[B]

[F]

3. Install the cover [A] with the screw supplied as an accessory of th e cop ier.

4. Install two stepped screws [B] to hook the DJF.

NOTE: There is one screw hole available on the left side fo r one of th e

stepped screws. However there are two screw hole s available on

the right where the ste pp ed screw is to be inst alle d. Install the

stepped screw into the inner screw hole [C] as sho wn in th e

illustration.

5. Mount the DJF to the two stepped screws [B] by alignin g the holes in th e

DJF hinge [D] and the stepped screws, then slide the DJF to the front as

shown.

6. Secure the DJF to the copier (2 screws - M 5 x 10).

7. Remove a small cap on the upper rear cover of the copier then connect

the connector [E] an d th e fiber optic cable connector [F].

CAUTION: Locate the fiber optic cable [F] over the electrical cable[E ]

so as not to bend the fiber optic cable[F] while opening

and closing the DJF.

Feeder

Dual Job

25

Page 27

INSTALLATION 23 April 1993

[C]

[D]

[A]

[B]

[F]

[E]

8. Adjust the height of the DJF by usin g th e ad justing dials [A]. Repeat the

following procedure for each adjustment dial.

1) Close the DJF.

2) Confirm whether or not the copier upper cover [B] and all four stoppers

[C and D] are in contact.

3) If not, loosen the lower dial [E ] (rotate counterclockwise) and adjust the

height of the DJF by rotating the upper dial [F].

NOTE: 1. First, adjust the DJF height so that the two fro nt stoppe rs [C ]

contact the upper cove r, then adjust the DJF height so tha t all

four stoppers [C and D] contact the upper cover [B].

2. Rotate the right adjusting dial clockwise to lower th e left fro nt

side of the DJF (black arrow in the illustration).

3. Rotate the left adjusting dial clockwise to lower th e righ t fro nt

side of the DJF.

4. If the height adjustment is not correct, then original skew will

occur.

26

Page 28

23 April 1993 INSTALLATION

[D]

[C]

[A]

[B]

4) Lock the adjusting (upper) dials [A] by fully rotating the lock (lower)

dials [B] clockwise.

NOTE: Mostly, height will be proper when the gap [C] is 2 mm. If the

height adjustment is not comple te d eve n if the gap [C] is smalle r

than 2 mm loosen four truss head screws [D], and tighten.

Then adjust the height again.

9. Plug in the copier and turn on the main switch.

NOTE: The copier automatically recognizes that the DJF has been

installed.

10. Make copies using the DJF a nd conf irm t he copy imag e.

27

Feeder

Dual Job

Page 29

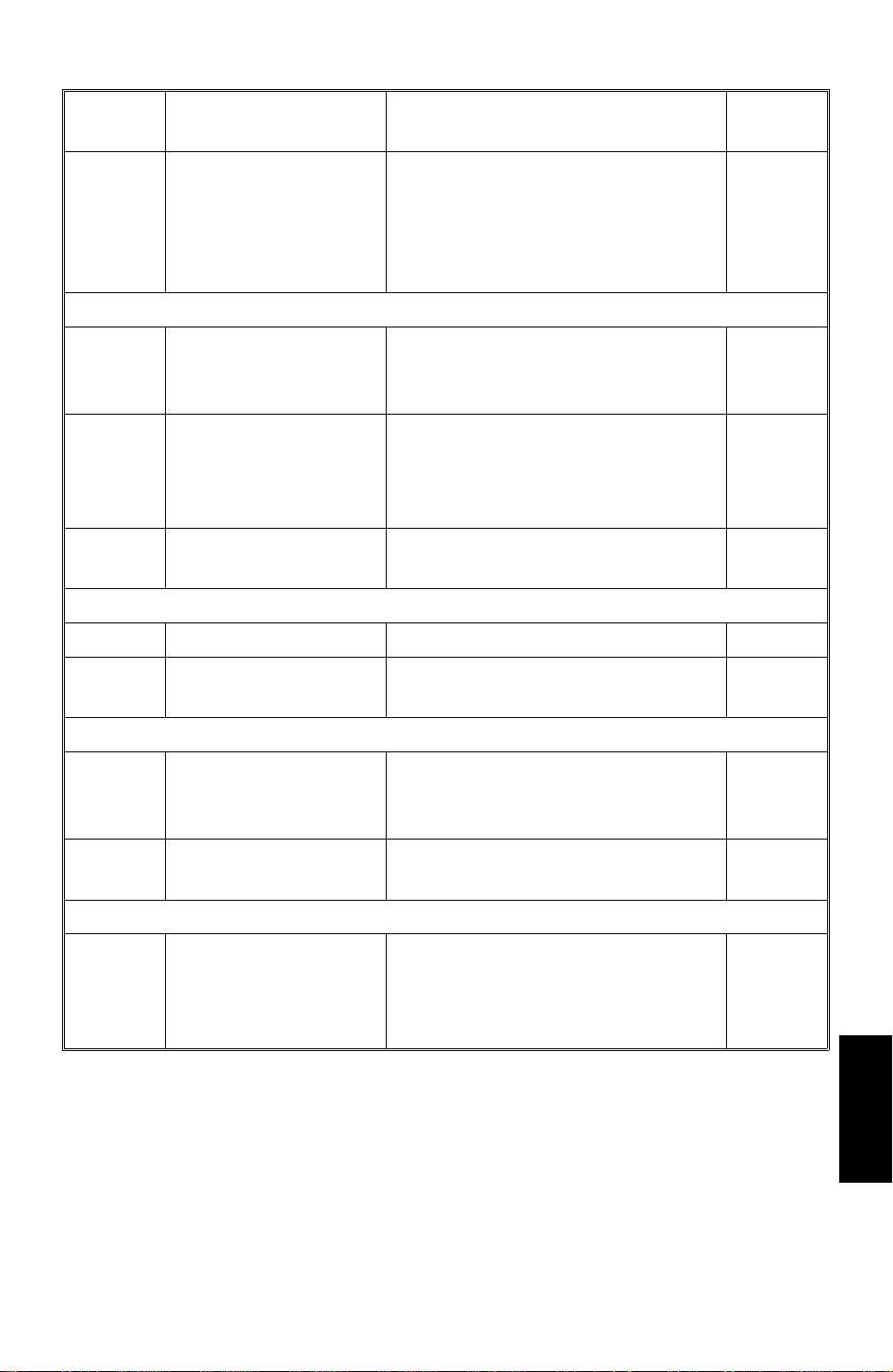

SER VICE T ABLES 23 April 1993

13. SERVICE TABLES

13.1 DIP SWITCHES AND SWITCHE S

0: OFF 1: ON ↓ : P u sh

Modes

Motor ON

(speed Adj.)

MC, SOL

Test

Original

Feed

(Registra-

tion A dj.)

Free run

with original

Free run

Original

Distance

Adj.

(Combine

Originals)

Standard 00000 00 00 0Standard setting

DPS101 DPS102 SW

12341234101102

11011000– –Feed-in motor activates

11010100– –Belt drive motor activates

11010010– –Feed-out motor activates

0 0 1 1 1 0 0 0 0 0 St opper solenoid activat es

001101000 0Separation solenoid activates

001100100 0Feed clutch activates

001100010 0Reverse solenoid activates

01010000↓ 0 Feeds the original (thick mode)

01010001↓ 0 Feeds the original (thin mode)

01010000/10↓Delivers the original

01011000↓ 0 Fe eds t he or iginal (2 sided mode )

010110000↓

01010100↓ 0

010101000↓

10010000↓ 0 Thick / 1 sided original mode

10010001↓ 0 Thin / 1 sided original mode

10011000↓ 0 Thick / 2 sided original mode

10011001↓ 0 Thin / 2 sided original mode

10010100↓ 0 Thick / mixed size original mode

10010101↓ 0 Thin / mixed size original mode

1001001–↓ 0 Combin e 2 origin als mode

1001––––0↓Stops the free run

01100000↓ 0 Starts th e free ru n

011000000↓Stops the free run

00001000– –Shift value +3.5 mm

00000100– –Shift value +7.0 mm

00001100– –Shift value +10.5 mm

00000010– –Shift value +14.0 mm

00001001– –Shift value –3.5 mm

00000101– –Shift value –7.5 mm

00001101– –Shift value –10.5 mm

00000011– –Shift value –14.0 mm

R everses the original / Exits the

original

Feeds the original (pasted

origi nal mode)

Exits the original (paste d original

mode)

Function

28

Page 30

23 April 1993 SERVICE TABLES

13.2 VARIABLE RESISTORS

VR NO. FUNCTION

101 Adjusts the registration in 1 sided original mode

102 Adjusts the registration in 2 sided original mode

103 Adjusts feed-in motor speed

104 Adjusts belt drive motor speed

105 Adjusts feed-out motor speed

13.3 LEDs

LED NO. FUNCTION

101 Monitors the motor speed (too fast)

102 Monitors the motor speed (normal)

103 Monitors the motor speed (too slow)

13.4 FUSEs

FUSE NO. FUNCTION

101 Protects the 5 V line

102 Protects the 12 V line

103 Protects the 24 V line from feed-in motor failure

104 Protects the 24 V line from belt drive motor failure

105 Protects the 24 V line from feed-out motor failure

29

Dual Job Feeder

Page 31

R EPLAC EMENTS AND AD JUSTME NTS 23 April 1993

14. REPLACEMENTS AND ADJUSTMENTS

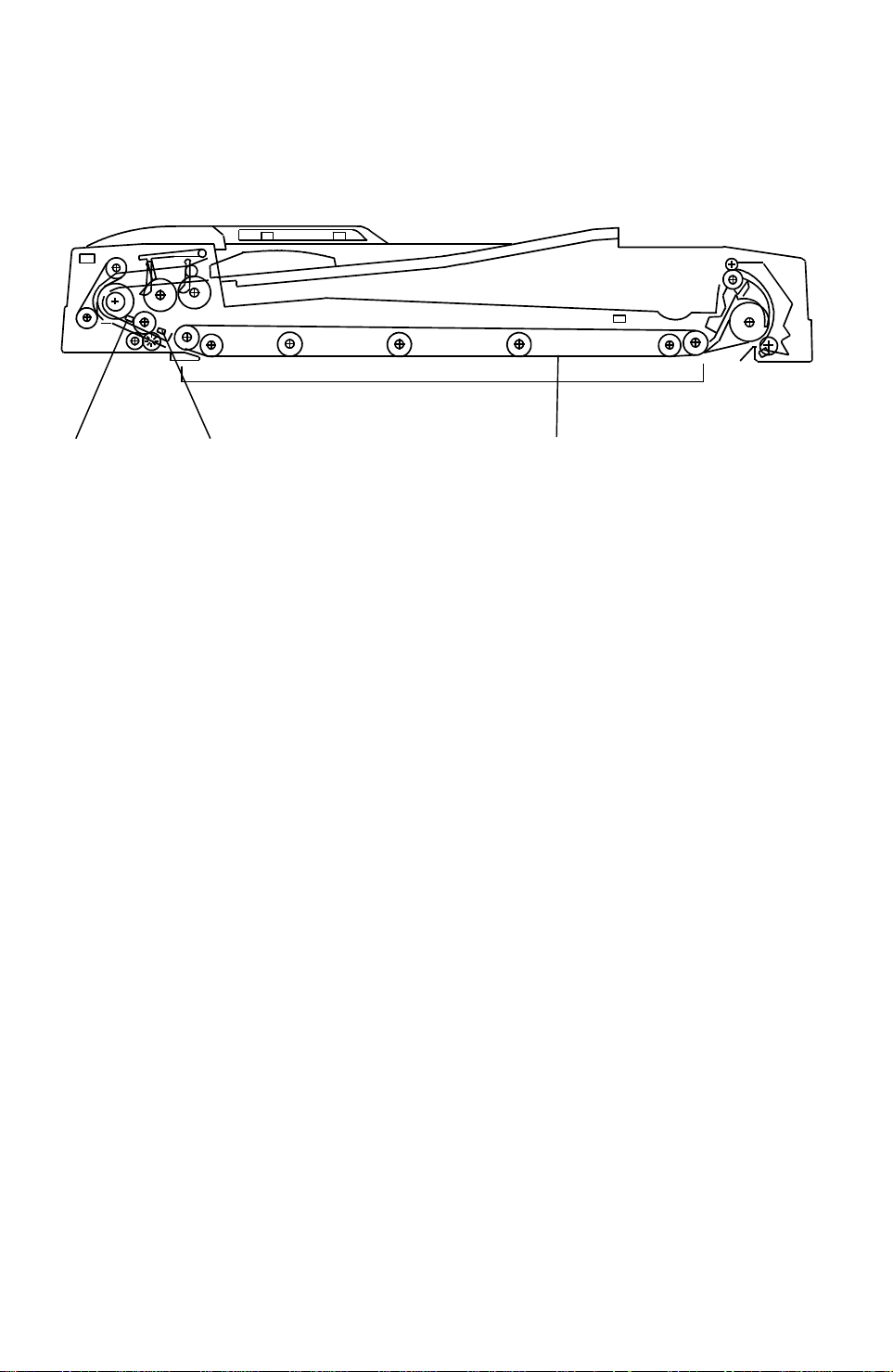

14.1 TRANSPORT BELT REPLACEMENT

[B]

[A]

[C]

[D]

1. Turn off the copier’ s main switch.

2. Fully raise the DJF, then remove the front cover [A] (loosen 4 screws).

3. Remo ve the four screws fixing the transport belt guide assembly [B].

4. Fold the stay [C] as shown.

5. Remove the transport belt [D].

30

Page 32

23 April 1993 REPLACEMENTS AND ADJUSTMENTS

[A]

[B]

[D]

6. Install the new belt to the belt guide assembly [A].

[C]

NOTE: When setting the new belt, set the belt between the belt

guides [B].

7. While opening the original guide [C], install the belt guide assembly to the

DJF (4 screws).

8. Install the front cover [D].

9. Confirm the DJF height. (Refer to step 9 of the installation procedure.)

31

Dual Job Feeder

Page 33

[A]

R EPLAC EMENTS AND AD JUSTME NTS 23 April 1993

14.2 FEED ROLLER REPLA CEMENT

M4 x 8

M4 x 6

[D]

[E]

[F]

[C]

[B]

[H]

[G]

1. Turn off the main switch then open the feed cover [A].

2. Remove the stopper screw [B] then open the original stopper [C].

3. Remove the original table [D] (5 screws).

[H]

[G]

NOTE: When installing the original table, be sure to set t he ho ok [E] in

the hole [F].

4. Befo re removing the original guide [G], measure and remember th e

distance between the original guide and th e rear frame [H] as s hown.

This is to keep the same original side-to-side registration after the

re-installation.

32

Page 34

23 April 1993 REPLACEMENTS AND ADJUSTMENTS

[A]

[C]

[B]

[D]

[D]

[D]

[GOOD]

[NO GOOD]

5. Remove the original guide [A] (3 screws).

6. Slide the feed roller assembly [B] to the front, then remove it as shown.

7. Remove the five snap rings [C], then remove the feed rollers.

8. Install the new feed rollers, then re-assemble the machine.

NOTE: 1. When working around the feed rollers, be careful not to

damage the guide mylars [D], and set the guide mylars

correctly as shown.

2. When installing th e feed roller, be sure that the one way

bearing (silver color) is loc ated in the front side (the roller must

rotate only counter-clockwise when the shaft is fixed).

3. Do not touch the roller surface with oily hands.

4. After this replacement, adjust the side-to-side original

registration if necessary.

Dual Job Feeder

33

Page 35

R EPLAC EMENTS AND AD JUSTME NTS 23 April 1993

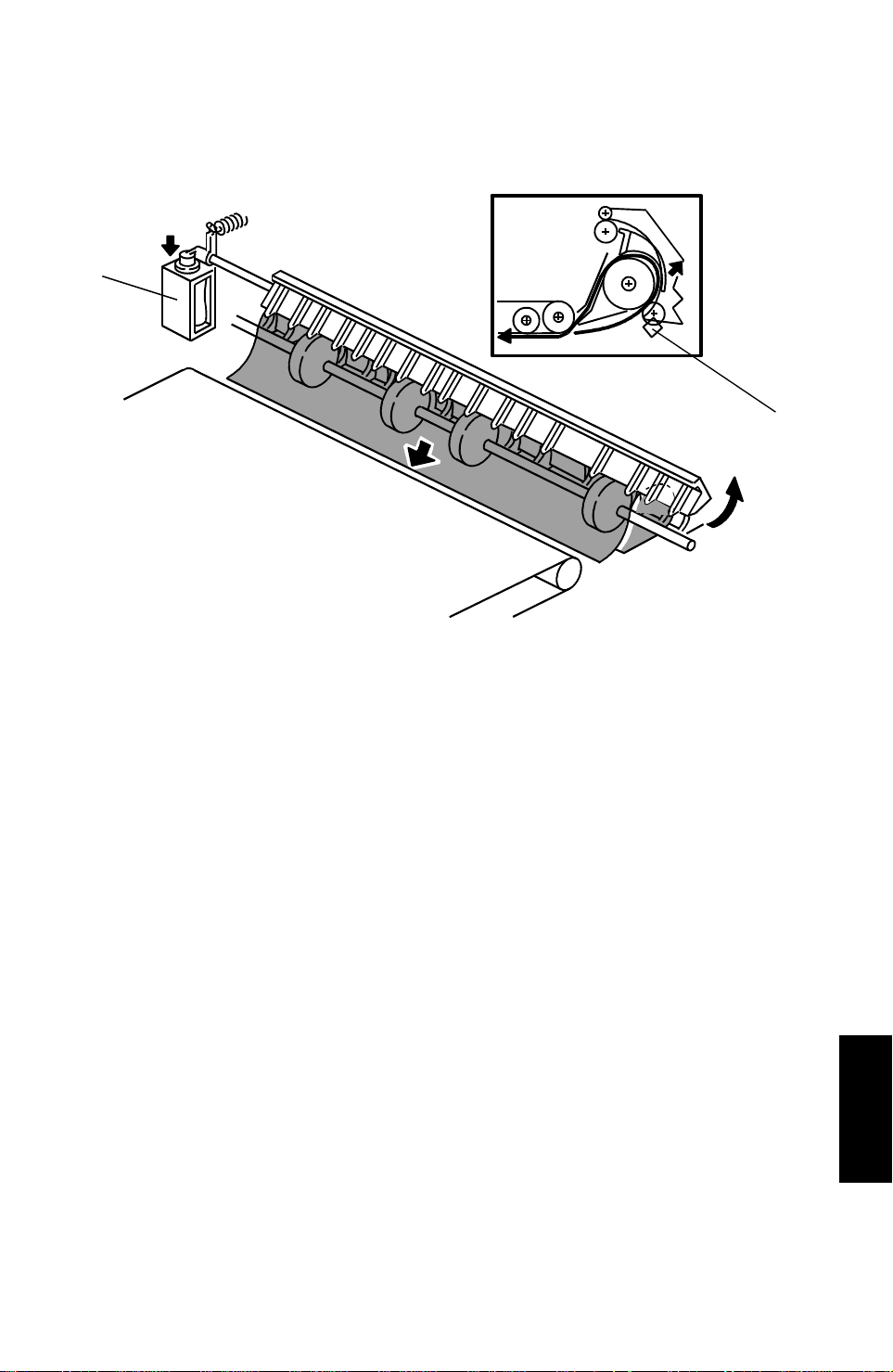

14.3 SEPARATION BELT REPLACEMENT

[C]

[B]

[A]

[E]

[D]

1. Turn off the main switch.

2. Fully raise the DJF, then remove the front cover [A] (loosen 4 screws).

3. Remove the screw [B], then remove the feed cover [C].

4. Remove the bracket [D] (1 screw).

5. Remove the four snap rings [E].

34

Page 36

23 April 1993 REPLACEMENTS AND ADJUSTMENTS

[A]

[C]

[D]

[B]

6. Slide the separation belt assembly [A] to the front and remove them.

7. Remove the bushings [B].

8. Remove the pulley [C].

9. Replace the separation b elts [D].

NOTE: Do not touch the separation belt with oily hands.

Dual Job Feeder

35

Page 37

R EPLAC EMENTS AND AD JUSTME NTS 23 April 1993

14.4 FEED-OUT MOTOR (FEED-OUT UNIT) REMOVAL

[B]

[C] [D]

[A]

[B]

[E]

[F]

[E]

[E]

1. Fully raise the DJF then remove the front cover. (Refer to Transport Belt

Replacement.)

2. Remove the right cover [A] (4 screws).

3. Remo ve the two screws [B] fixing the transport belt assembly, then fold

the transport belt stay [C] as shown.

4. Open the original guide [D].

5. Disconnect the four connectors [E].

6. Remove the five screws [ F].

[F]

36

Page 38

[F]

[B]

23 April 1993 REPLACEMENTS AND ADJUSTMENTS

[A]

[G]

[C]

[D]

[H]

[E]

7. Remo ve the feed-out unit [A] as shown.

8. Remove the spring [B].

9. Remove the bracket [C] with the feed-out motor from the feed-out unit (3

screws).

NOTE: When re-installing the bracket, be sure t o set the arm [D] on the

plunger pin [E].

10. Remove the pulley [F] (1 Allen screw [G]).

11. Remove the feed-in motor (4 screws) [H].

Dual Job Feeder

37

Page 39

[D]

[E]

R EPLAC EMENTS AND AD JUSTME NTS 23 April 1993

14.5 INVERTER SOLENOID REMOVAL AND ADJUSTMENT

[B]

OFF

[C]

[A]

ON

OFF

1. Remove the feed-out unit. (Refer to Feed-out Motor Removal.)

2. Remove the inverter solenoid [A] (2 screws).

NOTE: When installing the inverter solenoid, confirm the following:

ON

1) The arm [B] must b e set on the plunger pin [C].

2) Manually pull th e inverter solenoid plunger and confirm that

when the inverter solenoid d oes not activate (OFF), the

inverter guide [D] is insid e the outer inverter guide [E] and

when the inverter s olenoid activates (ON), the inver ter guide

is outside the outer inverter guide, as shown.

38

Page 40

23 April 1993 REPLACEMENTS AND ADJUSTMENTS

14.6 BELT DRIVE MOTOR REPLACEMENT

[A]

[B]

[C]

[D]

1. Remove the DJF from the copier (2 screws, 2 connectors, 2 hooks) and

place it on a stable place.

CAUTION: Before disconnecting the connectors, turn off the main

switch of the copier.

2. Remove the motor cover [A] (4 screws).

3. Remove the DF main control board cover [B] (4 screws).

4. Remove the transport belt. (Refer to the The Transport Belt Replacement.)

5. Remove the right cover [C] (4 screws).

6. Remove the belt guide assembly [ D] (6 screws).

NOTE: After re-installing the belt guide ass embly , confirm the DJF height

(Refer to the procedure 9 of the Installation Procedure.)

39

Dual Job Feeder

Page 41

R EPLAC EMENTS AND AD JUSTME NTS 23 April 1993

[A]

[D]

[C]

[B]

[F]

[E]

7. Remove the left hinge stay [A] ( 4 screws, 3 connectors).

NOTE: When re-installing the hinge stay, be sure not to pinch the

harness.

8. Remove the two connectors [B].

9. Remove the two screws [C] fixing the belt drive motor br acket.

10. While unhooking the pin [D] from the hole on the feed-in motor bracket,

remove the bracket [E] with the belt drive motor [F].

11. Remove the drive pulley (1 Allen screw) then replace the belt drive mo tor

(4 screws).

40

Page 42

23 April 1993 REPLACEMENTS AND ADJUSTMENTS

[C]

[B]

[D]

[A]

12. Re-assemble the machine.

NOTE: 1) Before installing the belt guide assembly [A] to the DJF, set

the timing belt [B] on the drive pulley [C] .

2) Make sure that the timing belt does not touch any harness.

3) Do not bend the anti-static brush [D].

41

Dual Job Feeder

Page 43

R EPLAC EMENTS AND AD JUSTME NTS 23 April 1993

14.7 FEED-IN CLUTCH (FEED-IN UNIT) RE MOVAL

[B]

[A]

[D]

[C]

1. Remove the following parts:

1) Original table [A] (refer to Feed Roller Replacement),

2) Feed cover [B] (refer to Separation Belt Replacement),

3) Left h inge stay [C] (refer to Belt Drive Motor Replacement).

2. Remove the table bracket [D] (2 screws).

42

Page 44

23 April 1993 REPLACEMENTS AND ADJUSTMENTS

[B]

[A]

[D]

[E]

[D]

[C]

[E]

3. Disconnect the connectors [ A].

4. Remove the feed-in unit [B] (4 screws).

5. Replace the feed-in clutch [C] (1 Allen screw).

NOTE: When installing the clutch on the shaft [D], align the sur fa ce of

the clutch stopper [E] and the head of the shaft [D], as shown.

Dual Job Feeder

43

Page 45

R EPLAC EMENTS AND AD JUSTME NTS 23 April 1993

14.8 STOPPER SOLENOID REPLACEMENT

[C]

[D]

[B]

[A]

[C]

[D]

1. Remove the feed-in unit. (Refer to Feed-in Clutch Replacement)

2. Remo ve the bracket [A] with the stopper solenoid (2 screws).

3. Replace the stopper solenoid [B] (2 screws).

NOTE: When installing the stopper solenoid, pay atten tion to the

following points:

1) The spring [C] must be correctly hooked to the stopper [D],

as shown.

2) Manually pull the stopper solenoid plunger to confirm that the

press rollers firmly contacts the pick-up rollers. When the

pick-up r ollers are manually rotated, the press rollers also

rotate. If not, adjust the stopper solenoid position.

44

Page 46

0 ~ 2 mm

23 April 1993 REPLACEMENTS AND ADJUSTMENTS

14.9 VERTICAL REGISTRATION ADJUSTMENT

14.9.1 One Sided Original Mode

[C]

[A]

[B]

1. Remove the small cover at the rear sid e on the upper DJF cover.

2. Turn on DIP-SW No. 101-2, 4 and 102-4.

3. Set a sheet of A4 / 8 1/2" x 11" (53 ~ 80 g/m2 / 14 ~ 22 lb)sideways

paper on the original table.

4. Push SW 101 [A].

5. After the original stop on the exposure glass, gently raise the DJF so that

the original d oes n ot move.

6. Confirm that the ga p be tween the trailing edge of the paper and the

original left scale [B] is within 2 mm.

7. It the gap is larger than 2 mm, adjust the registration by using the copier

SP mode ( SP Adjustment - PAGE 6).

1

NOTE: 1. Before setting the original on the original table again, open and

close the feed unit cover [C].

2. After completing the adjustment, return the DIP switches to the

origin al condition.

Dual Job Feeder

45

Page 47

R EPLAC EMENTS AND AD JUSTME NTS 23 April 1993

14.9.2 Two Sided Original Mode

[A]

[C]

[B]

10 ± 2 mm

1. Remove the copier’s left scale [A] (2 screws).

2. Remove the small cover at the rear sid e on the upper DJF cover then turn

on DIP SW 101-2, 101-4 and 102-1.

3. Set a sheet of A4 / 8 1/2" x 11" (53 ~ 80 g/m2 / 14 ~ 22 lb) sideways

paper on the original table.

4. Push SW 101 [B].

5. After the original stops on the exposure glass, gently raise the DJF so

that the original does not move.

6. Confirm that the gap between the trailin g edge of the paper and the left

edge [C] of the original rear scale is 10 ± 2 mm.

7. It the gap is not within specification, adjust the registration by using the

copier SP mode ( SP Adjustment - PAGE 6).

1

NOTE: 1. Before setting the original on the original table again, open and

close the feed unit cover [C].

2. After completing the adjustment, return the DIP switches to

their original condit ion.

46

Page 48

23 April 1993 REPLACEMENTS AND ADJUSTMENTS

14.9.3 Combine 2 Originals Mode

1. Make a copy in combine 2 originals mode.

2. Adjust the gap between the first original and the second original. It should

be as small as possible. (Do this by changing the DIP SW 102

combination, 3.5mm/step, as shown in the t able)

NOTE: Factory settings are all "0" (OFF).

If DIP SW 102-4 is "0" (OFF), the distance between the 1st and

2nd copies is wider (+ ).

102-4 102-3 102-2 102-1 Shift value

00000

0001+ 3.5 mm

0010+ 7.0 mm

0011+10.5 mm

0100+14.0 mm

1001- 3.5 mm

1010- 7.0 mm

1011-10.5 mm

1100-14.0 mm

47

Dual Job Feeder

Page 49

R EPLAC EMENTS AND AD JUSTME NTS 23 April 1993

14.10 SIDE TO SIDE REGISTRATION ADJUSTMENT

[D]

[A]

[C]

5 ± 2 mm

1. Remove the small cover at the rear sid e on the upper DJF cover.

2. Turn on DIP SW 101-2 and 101-4.

3. Set a sheet of A4 / 8 1/2" x 11" (53 ~ 80 g/m2 / 14 ~ 22 lb) sideways

paper on the original table.

4. Push SW 101 [A].

[B]

5. After the original stops on the exposure glass, gently raise the DJF so

that the original does not move.

6. Confirm if the gap between the rear edge of the paper and the original

rear scale is 5 ± 2 mm.

7. If the gap is not within the specification, adjust the registration by using

copier’s SP mode ( SP Adjustment - PAGE 4).

1

8. It the gap is not within specification by using SP mode, loosen the eight

sc rews fixing the original table [B] and the original guide [C] and shift the

original table and the original guide position accordingly.

NOTE: Before setting the original on the original table again, open and

close the feed unit cover [D].

48

Page 50

VR104

VR105

VR101

DPS102

23 April 1993 REPLACEMENTS AND ADJUSTMENTS

14.11 MOTOR S PEE D ADJUSTMENT

DPS101

VR103

VR102

[A]

[B]

[C]

LED101

LED102

LED103

SW101

SW102

1. Close the DJF and r e move the small cover at the rear side on the upper

DJF cover.

2. Turn on DIP-SW No. 101-1, -2 and -4.

3. Turn on the appropriate DIP switch corresponding to the adjusting motor

to be adjusted (see the table below).

4. Rotate the appropriate VR (see the table below) so that LED102 (green )

[A] lights.

NOTE: If the motor rotat ion speed is too high, LED101 (red) [B] lights

and if too slow, LED 103 (red) [C] lights.

5. Return the DIP switches to their original condition.

Motor DIP SW VR

Feed-in 102-1 103

Belt drive 102-2 104

Feed-o ut 102-3 105

Dual Job Feeder

49

Loading...

Loading...