Page 1

SECTION 1

OVERALL MACHINE

INFORMATION

Page 2

23 April 1993 SPECIFICATIONS

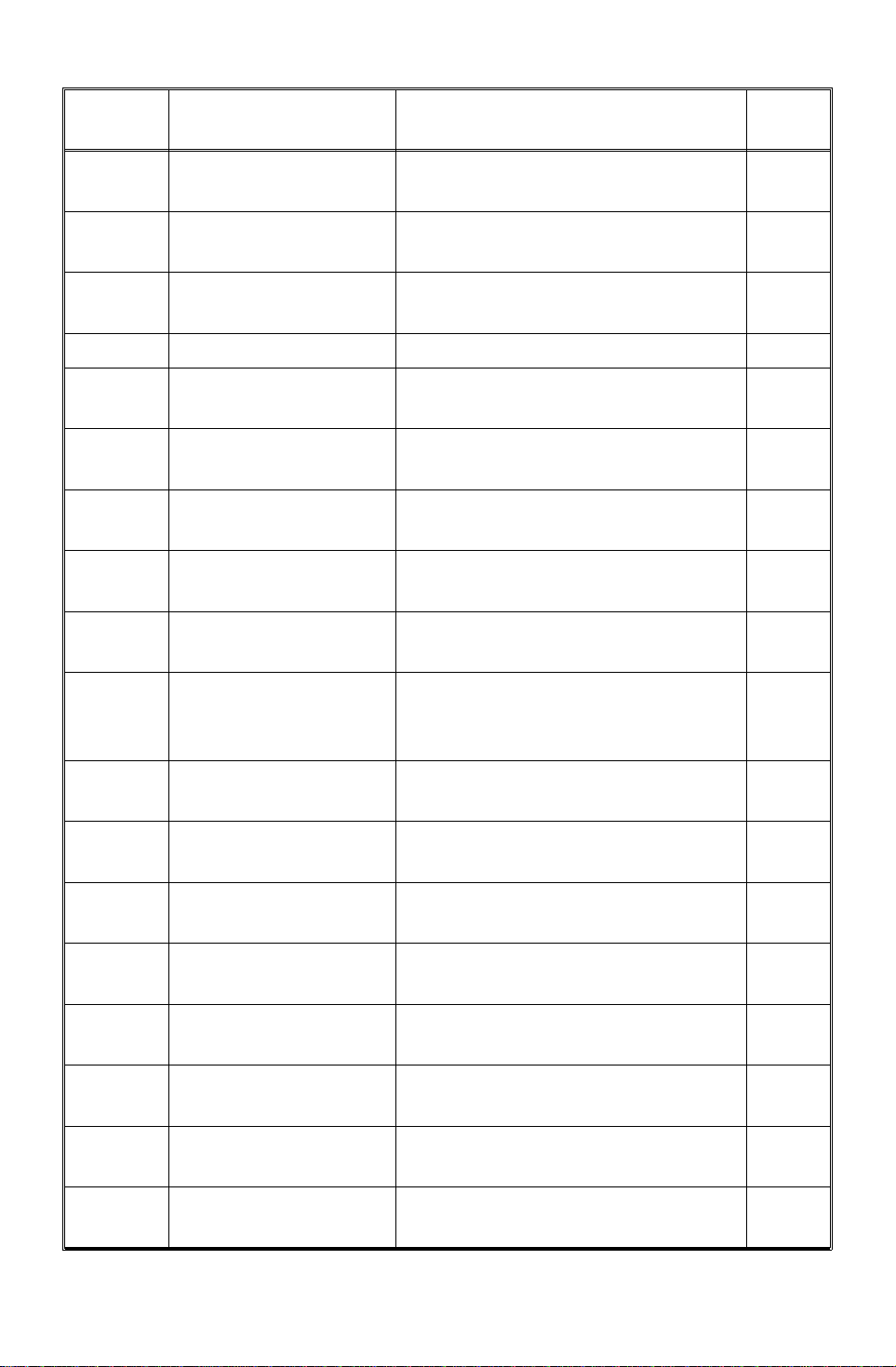

1. SPECIFICATIONS

Configuration: Console

Copy Process: Dry electrostatic transfer system

Toner Supply Control: Fuzzy Control

Photoconducto r: OPC drum

Originals: Sheet/Book

Original Size: Maximum A3/11" x 17"

Original Alignment: Left rear corner

Copy Paper Size: Maximum A3/11" x 17"

Minimum A5/51/2" x 81/2" (Tray)

B5/81/2" x 11" (1.5K LCT)

A6/51/2" x 81/2" (By-pass)

Duplex Copying: Maximum A3/11" x 17"

Minimum A5/51/2" x 81/2" (sideways)

Copy Paper Weight: Paper tray: 52 ~ 128 g/m2, 14 ~ 34 lb

Bypass feed table: 52 ~ 157 g/m2, 14 ~ 42 lb

Duplex copying: 64 ~ 104 g/m2, 17 ~ 24 lb

Overall

Information

Reproduction Ratios: 4 Enlargement and 6 Red uction

A4/A3 Version LT/LDG Version

Enlargement 200%

141%

122%

115%

Full Size 100% 100%

Reduction 93%

82%

75%

71%

65%

50%

200%

155%

129%

121%

93%

85%

77%

74%

65%

50%

1-1

Page 3

SPECIFICATIONS 23 April 1993

Power Source: 115V, 60Hz, more than 20A (for N.A)

220 ~ 240V, 50Hz/60Hz, more than 10A (f or EU

and AA)

Power Consumption: A095 and A096 copiers

Copier only Full system*

Warm-up 0.9 kVA 0.9 kVA

Stand-by 0.25 kVA 0.25 kVA

Copying 1.2 kVA 1.3 kVA

Maximum 1.45 kVA 1.5 kVA

*Full System:

• Mainframe with dual job feeder, compact

sorter stapler and 3,500-she et la rge capa city

tray

• Mainframe with dual job feeder, floor type

sorter stapler and 3,500-she et la rge capa city

tray

Noise Emission:

sound pressure level:

The measurements are

made according

to ISO7779

• Mainframe with recirculating document

handler, finisher and 3,500-sh ee t larg e

capacity tray

Copier only Full system*

Copying 55 dB (A) 61 dB (A)

Full System:

• Mainframe with dual job feeder, compact

sorter stapler and 3,500-she et la rge capa city

tray

• Mainframe with dual job feeder, floor type

sorter stapler and 3,500-she et la rge capa city

tray

• Mainframe with recirculating document

handler, finisher and 3,500-sh ee t larg e

capacity tray

1-2

Page 4

23 April 1993 SPECIFICATIONS

Dimensions: 690 x 690 x 980 (W x D x H Mainframe only)

1280 x 690 x 1020 (W x D x H Mainframe with

copy tray, platen cove r )

Weight: Copier only:(Without the optional platen cover

= Approximately 2 kg)

A095 copier: Approximately 151 kg

A096 copier: Approximately 163 kg

Zoom: From 50% to 200% in 1% steps

Copying Speed:

A4/LT (sideways) A3/DLT B4/LG

A095 copier 45 23 27

A096 copier 55 28 35

Warm-up Time: Less than 5 minutes (20°C)

First Copy Time: 3.1 seconds (A4/81/2" x 11" sideways from the

1st feed station)

Copy Number Input: Numbe r keys, 1 to 999 (count up or count down)

Manual Image Density

7 steps

Selection:

Overall

Information

Automatic Reset: 1 minute standard se tt ing; can also be set from 1

second to 999 secon ds or no auto reset.

Copy Paper Capacity: • By-pass feed table: ap pro ximat ely 50 shee ts

• Paper tray: approximately 550 sheets

• Tandem tray: approximately 500 sheets

• Large capacity tray: approximately 1500

sheets

1-3

Page 5

SPECIFICATIONS 23 April 1993

Toner Replenishment: 1,100 g/cartridge

Optional Equipment: • Platen cover

• Dual job feeder

• Recirculating document handler

• 20 bin sorter stapler (Floor type)

• 20 bin compact sorter stapler

• Finisher

• 3500-sheet Large capacity tray

• Receiving Tray

1-4

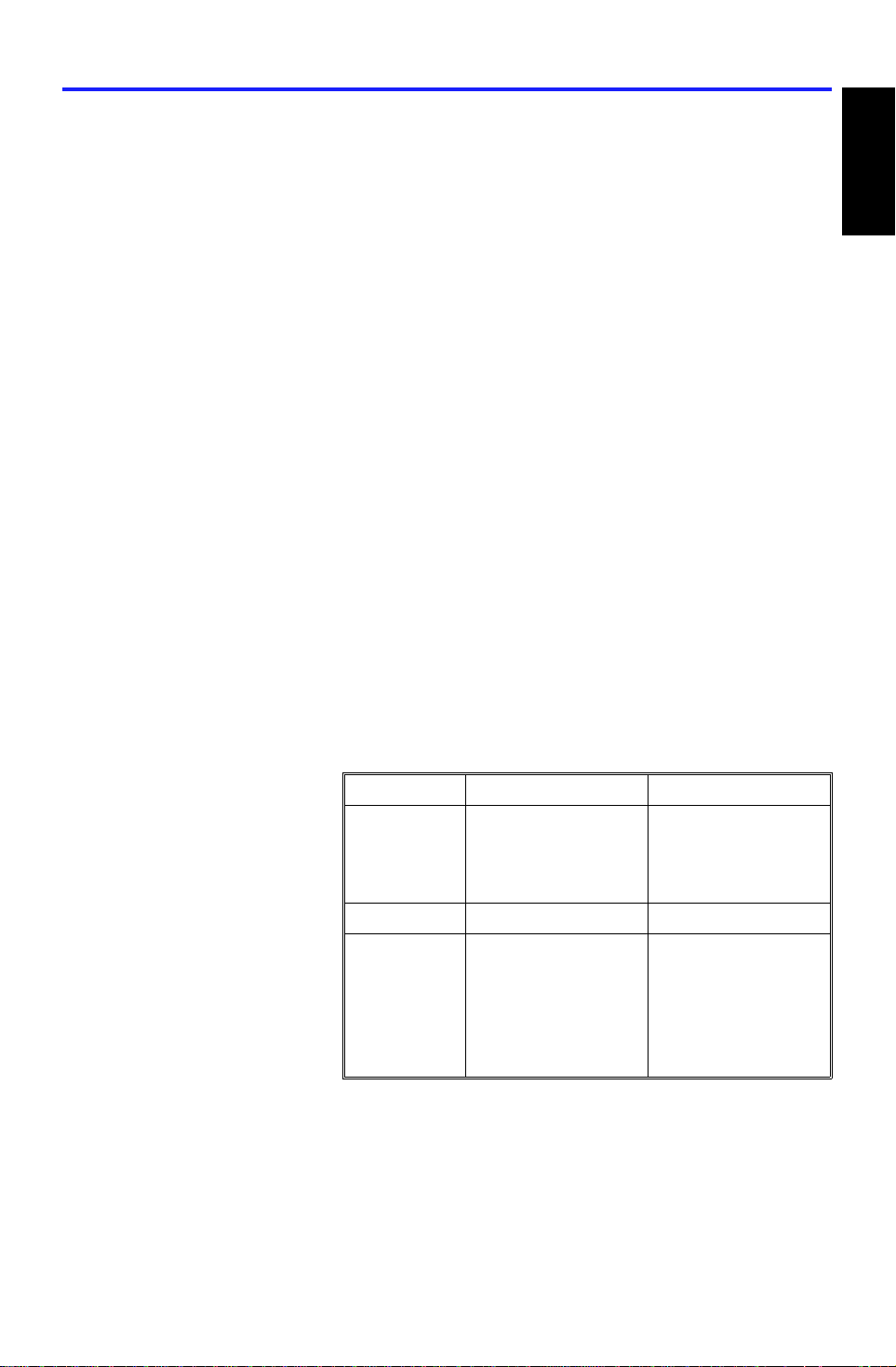

Page 6

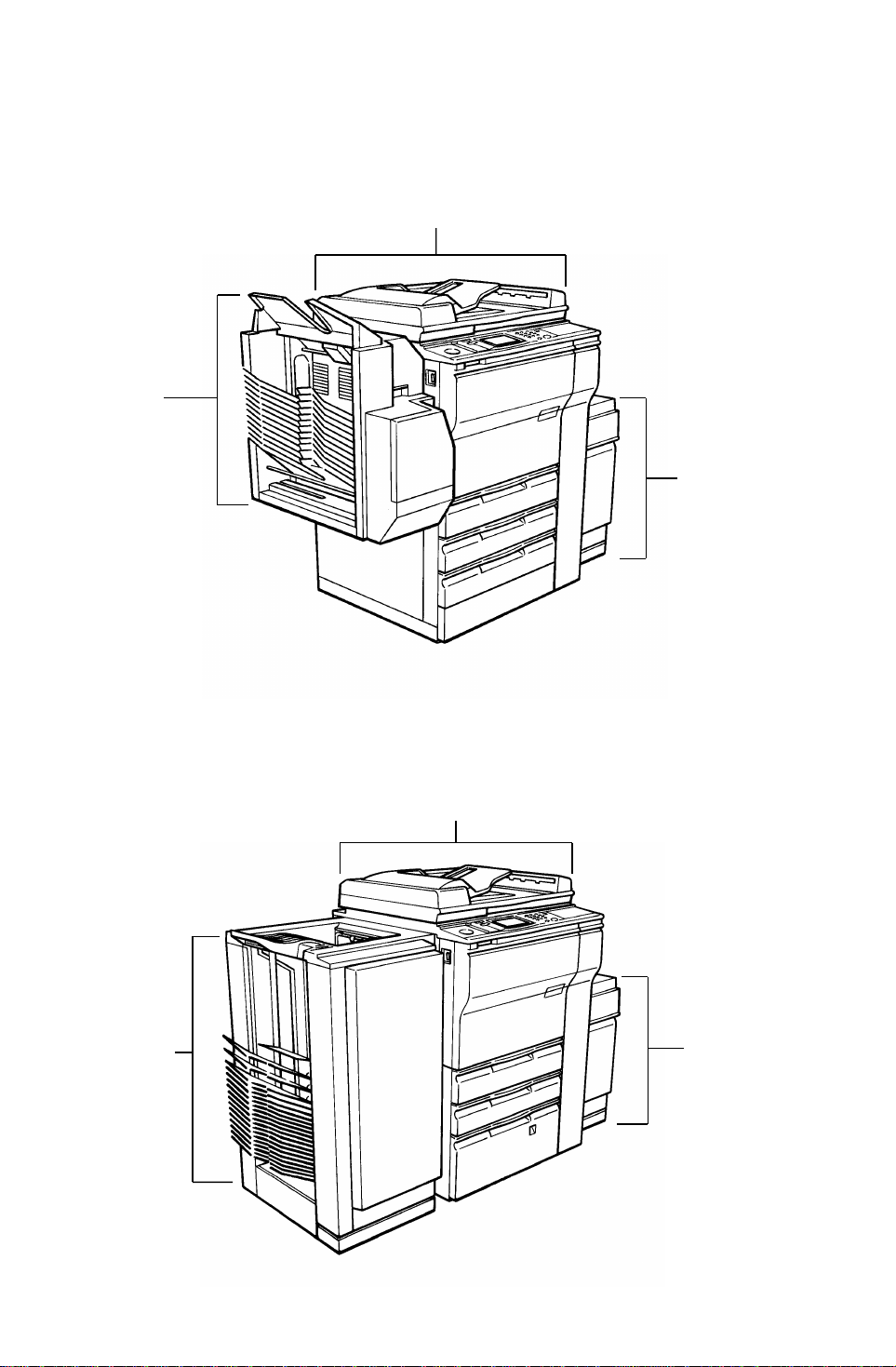

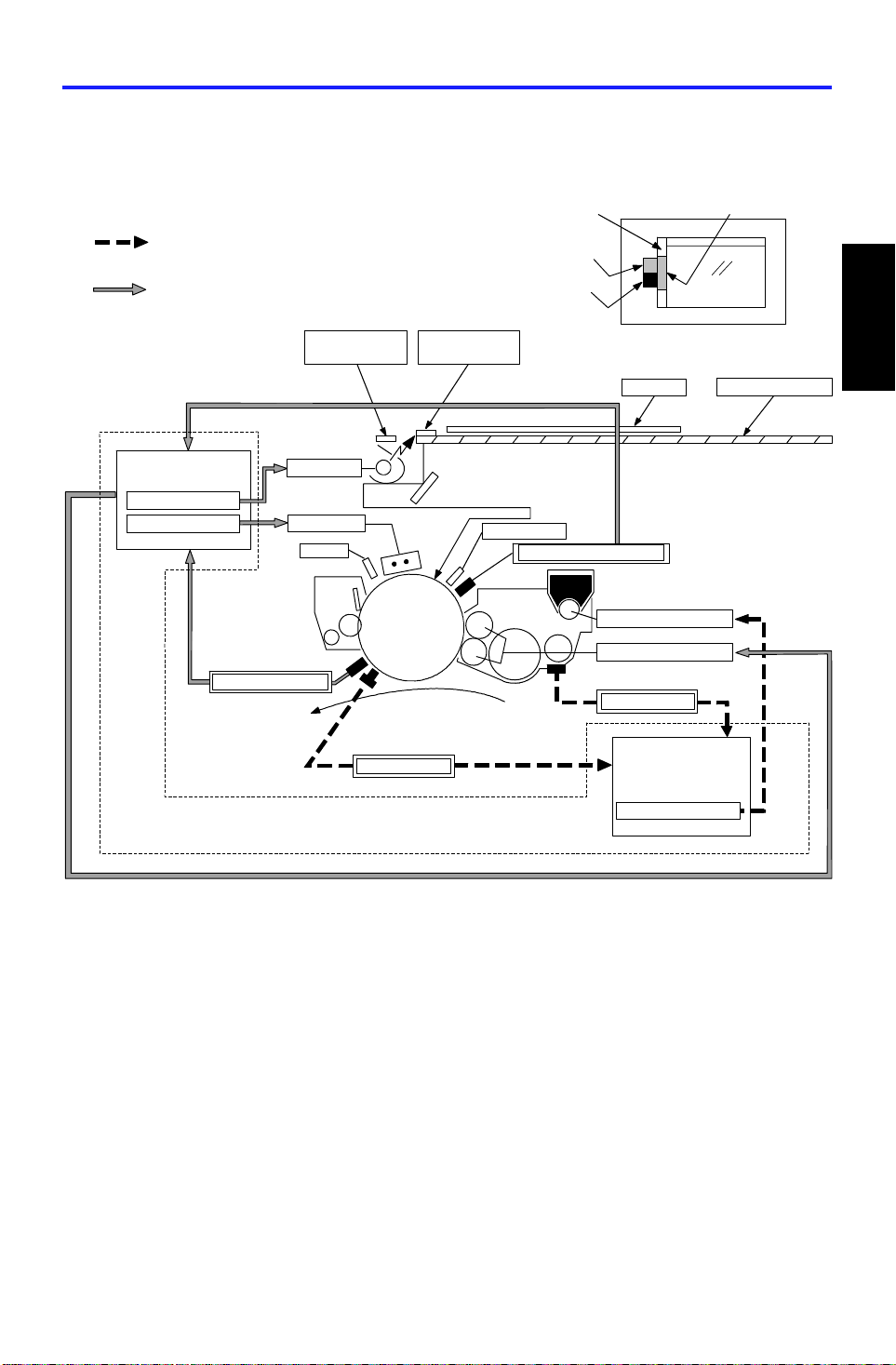

23 April 1993 MACHINE CONFIGURATION

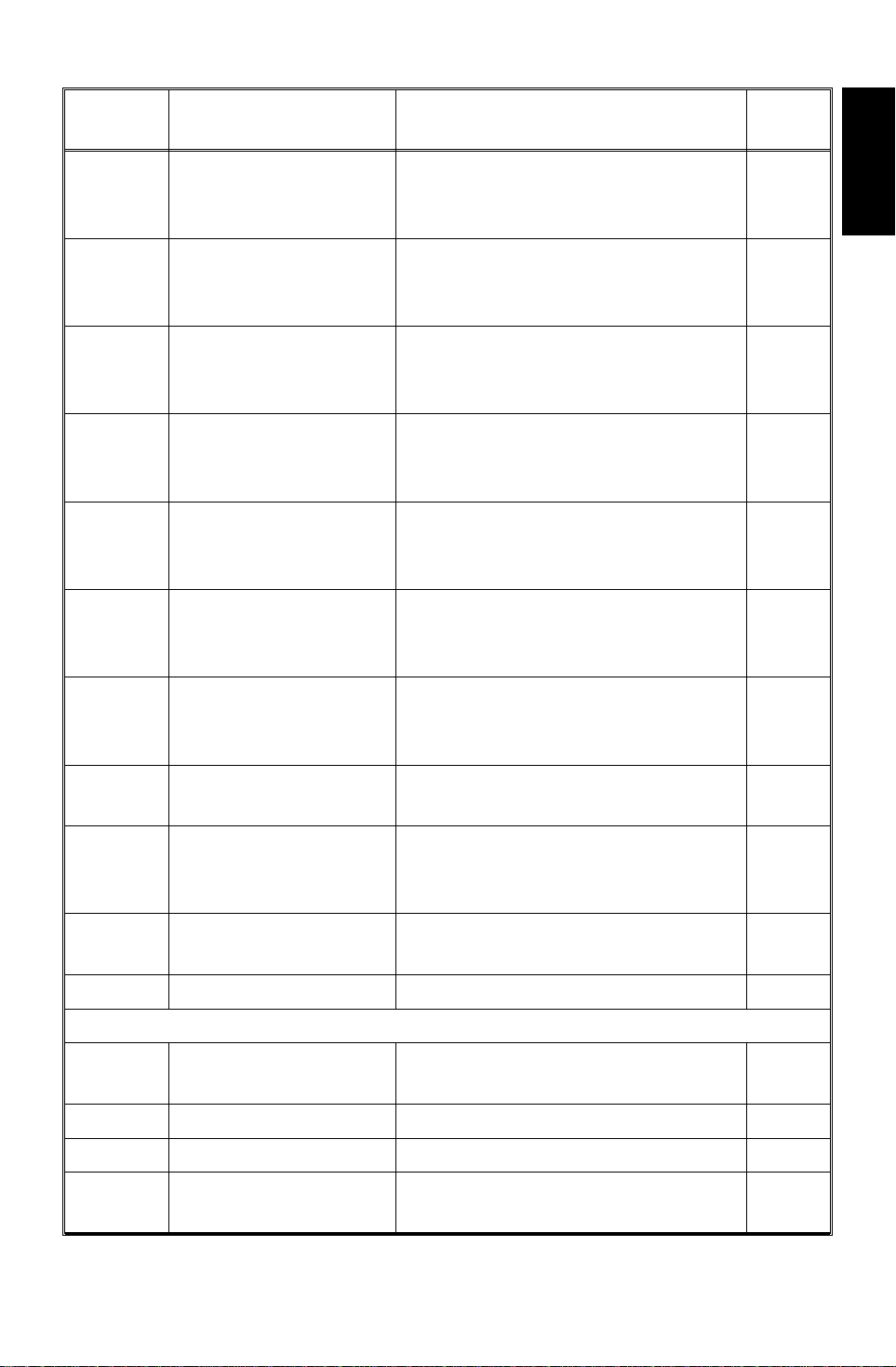

2. MACHINE CONFIGURATION

2.1 COPIER OVERVIEW

There are two types of mainfra me.

A095 copier

Three 550-sheet paper trays

Optional 3,500-sheet large capacity tray

Overall

Information

550

550

550

A096 copier

500 x 2 or 500

550

(3,500)

Tandem paper tray

(including two 500-sheet paper tray)

One 550-sheet paper t ray

1,500-sheet built-in large capa city tra y

Optional 3,500-sheet large capacity tray

(3,500)

1,500

1-5

Page 7

3,500-sheets

large capacity

tray (A380)

3,500-sheets

large capacity

tray (A380)

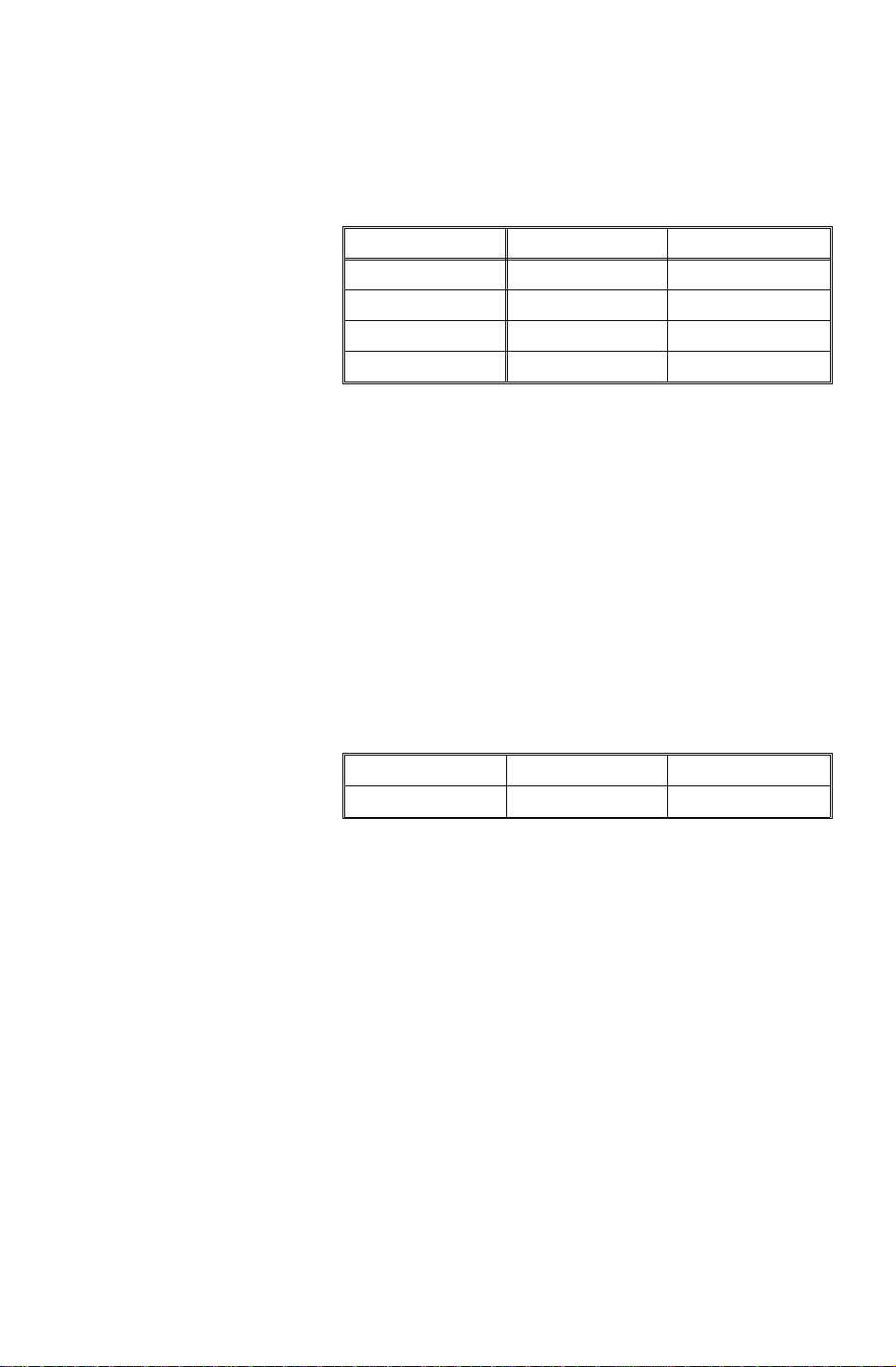

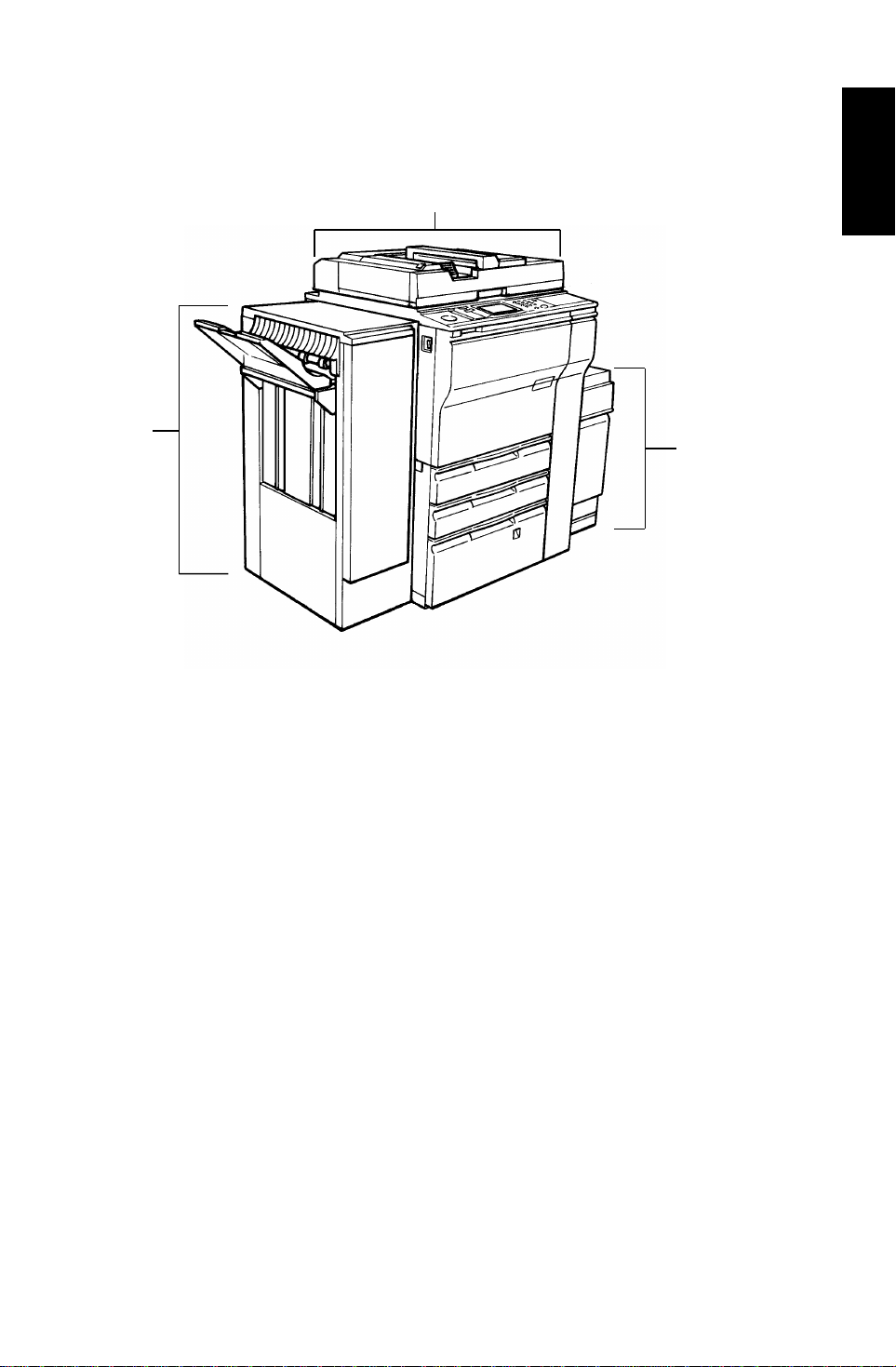

MACHINE CONFIGURATION 23 April 1993

2.2 SYSTEM OVERVI E W

System A

(The mainframe (A095) with du al job fee der and compa ct sorter stapler)

Dual job feeder (A376)

Compact

sorter stapler

(A374)

System B

(Mainframe type (A095/A096) with dual job feeder and floor type sorter

stapler. The mainframe in the illustrat ion belo w is the A096.)

Dual job feeder (A376)

Floor type

sorter stapler

(A377)

1-6

Page 8

3,500-sheets

large capacity

tray (A380)

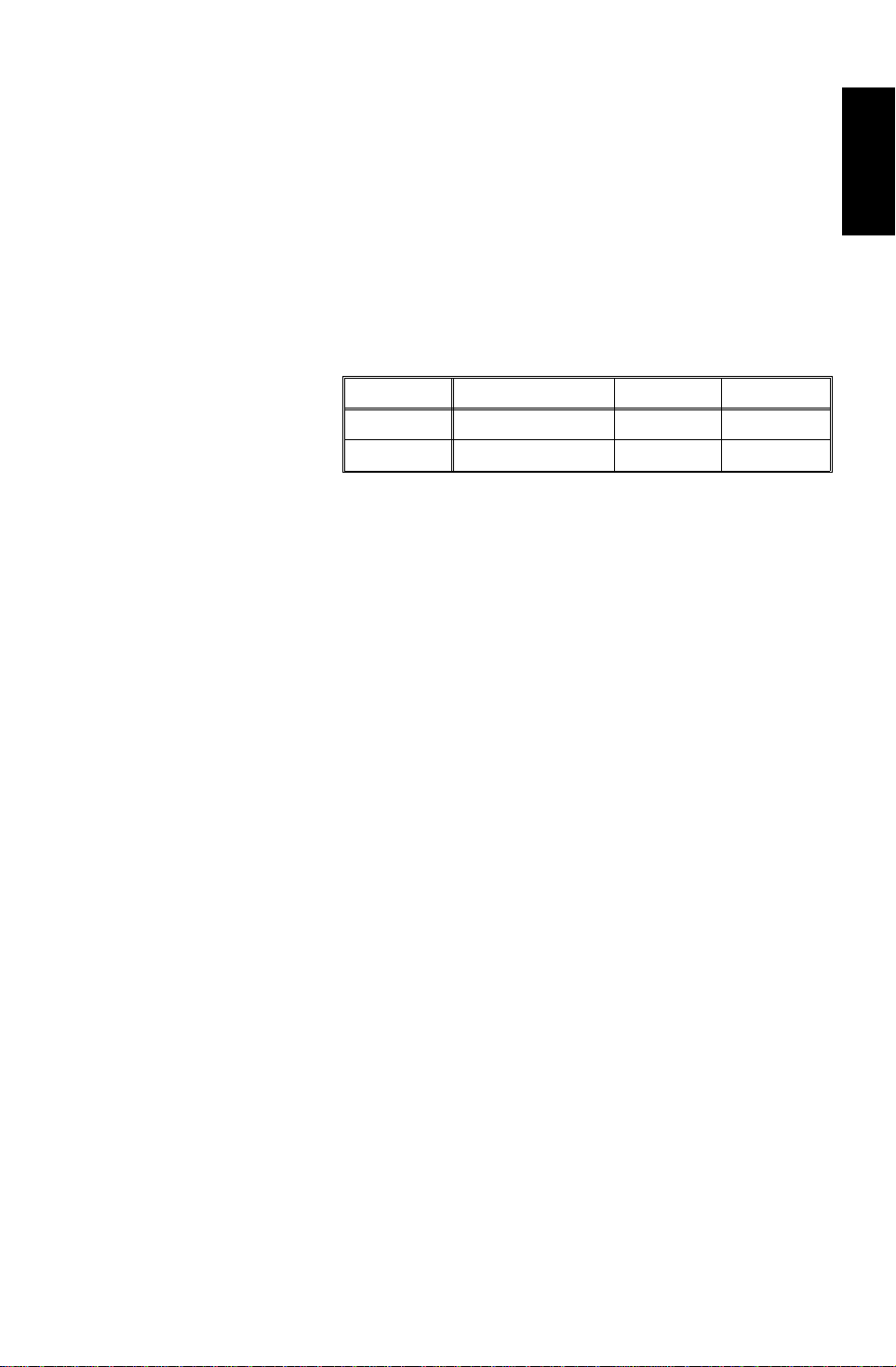

23 April 1993 MACHINE CONFIGURATION

System C

(The mainframe (A096) with recircu lating document handler and fin isher)

Finisher

(A379)

Recirculating document hand ler (A3 78 )

Overall

Information

1-7

Page 9

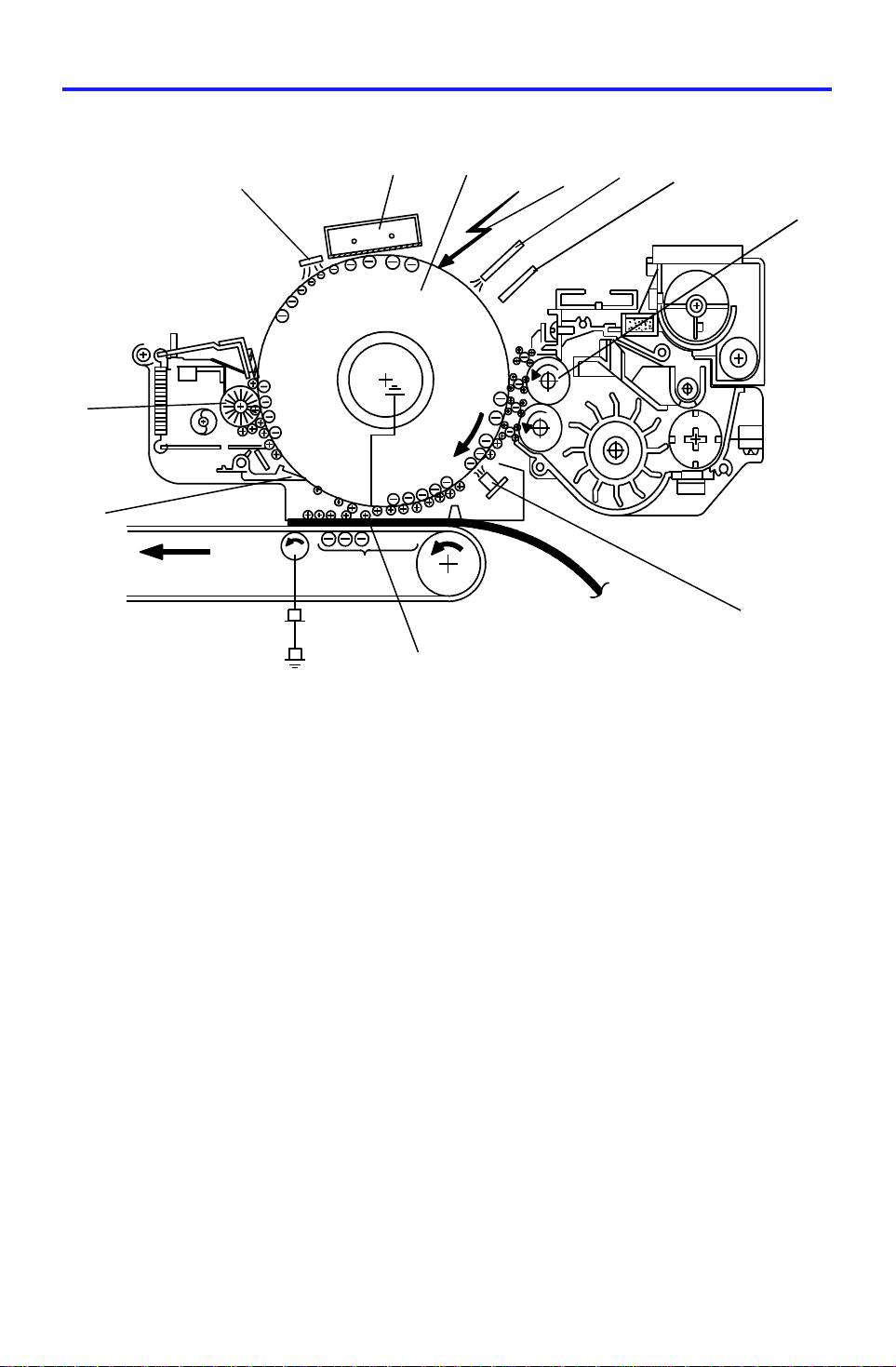

3

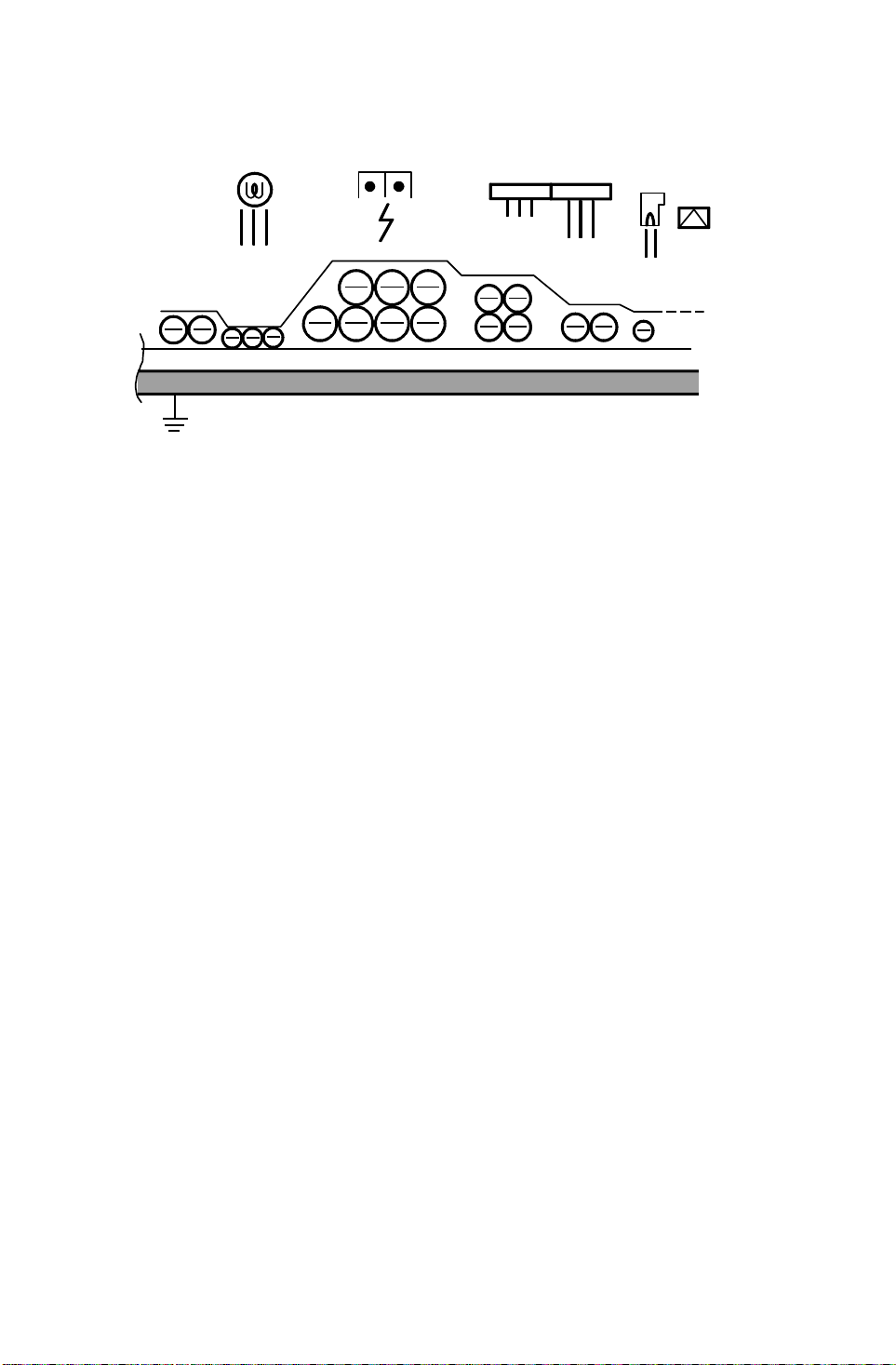

COPY PROCESS AROUND THE DRUM 23 April 1993

3. COPY PROCESS AROUND THE DRUM

10

11

12

9

8

4

5

6

7

1. OPC DRUM

The organic photo conductive (OPC) drum (10 0 mm diame te r) has hig h

resistance in the dark and low resistance under light.

2. DRUM CHARGE

In the dark, the charge corona unit gives a uniform negative ch arg e to the

OPC drum. The charge remains on the surfa ce of the drum. The amo unt of

negative charge on the drum is propo rtio na l to the ne gative grid bias voltage

applied to the grid plat e on the charg e coro na unit .

3. EXPOSURE

An image of the original is reflected to the OPC drum surfa ce via th e optics

section. The charge on the drum su rfa ce is dissipated in direct proportion to

the intensity of the reflected light, thus producing an electrical late nt ima ge on

the drum surface.

The amount of charge remainin g as a laten t imag e on the drum depe nds on

the exposure lamp intensity controlled by the exposure lamp voltage.

4. ERASE

The erase lamp illuminates the areas of th e cha rge d dru m su rfa ce th at will

not be used for the copy image. The resistance of drum in the illuminated

areas drops and the charge on those areas dissipates.

1-8

Page 10

23 April 1993 COPY PROCESS AROUND THE DRUM

5. DRUM POTENTIAL SENSOR

The drum potential sensor detects the electric potential on the drum to

compensate image processing elements.

6. DEVELOPMENT

Positively charged toner is attra cte d to the negat ively charged areas of the

drum, thus developing the latent ima ge. (The posit ive trib oe lect ric charg e of

the toner is caused by friction between the carrier and toner particle s.)

The development bias volt ag e ap plied to the developmen t rolle r shaft

controls two things:

1) The threshold level if tone r is attracted to the drum or toner remain s on

the development ro ller.

2) The amount of toner to be attracted to the drum.

The higher the negative develo pme nt bias volt ag e is, th e less toner is

attracted to the dru m surface.

7. PRE-TRANSFER LAMP (PTL)

The PTL illuminates the drum to remove almost all the negative charge from

the exposed areas of the dru m. This makes image transfer easier.

8. IMAGE TRANSFER

Paper is fed to the drum surface at the prop er timing so as to align the copy

paper and the develope d image on the drum surface. Then, a neg at ive

charge is applied to the reverse side of the copy paper by th e transfer belt,

producing an electrical force which pulls the toner particles from the drum

surface onto the copy paper. At the same time, the copy paper is electrically

attracted to the tra nsf er be lt.

Overall

Information

9. PAPER SEPARATION

Paper separates from the OP C drum by th e ele ctrica l att raction between the

paper and the transfer belt. The pick-o ff pawls help to separate the paper

from the drum.

10. CLEANING

The cleaning brush remo ves toner remaining on the dru m after image

transfer and the clean ing blade scrapes off all the rema ining toner.

11. QUENCHING

Light from the quenching lamp electrically neutralizes the charge pot ential of

the drum surface.

1-9

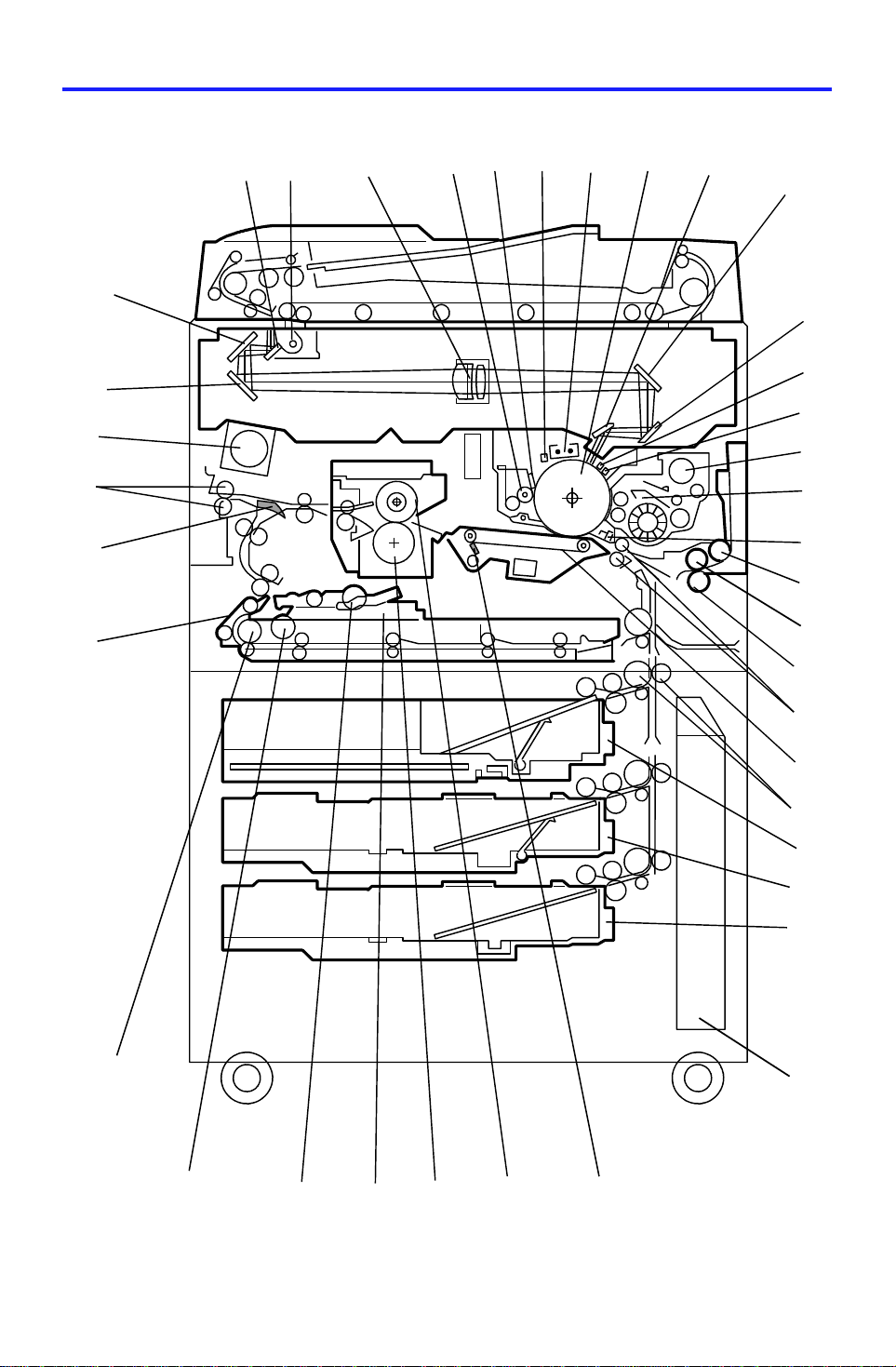

Page 11

11

29

30

8

MECHANICAL COMPONENT LAYOUT 23 April 1993

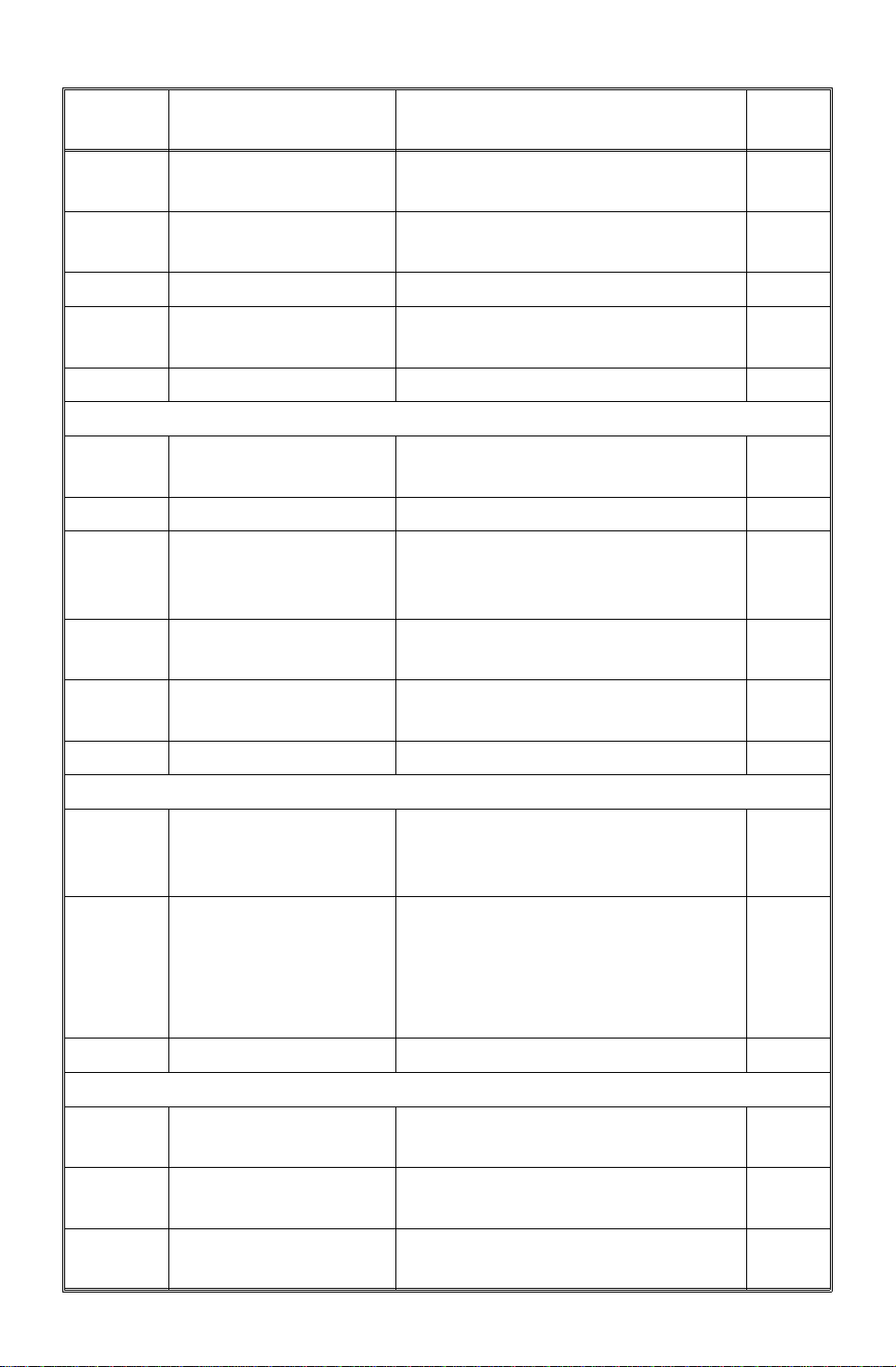

4. MECHANICAL COMPONENT LAYOUT

1

39

38

37

36

7

3

4

2

5

6

10

9

12

13

14

15

16

17

18

19

20

21

35

34

33

32

22

23

24

25

26

27

28

31

1-10

Page 12

23 April 1993 MECHANICAL COMPONENT LAYOUT

1. 3rd Mirror

2. 2nd Mirror

3. 1st Mirror

4. Exposure Lamp

5. Lens

6. Cleaning Brush

7. Cleaning Blade

8. Quenching Lamp

9. Charge Corona Unit

10. OPC Drum

11. 6th Mirror

12. 4th Mirror

13. 5th Mirror

21. Separation Roller

22. Registration Rollers

23. Transfer Belt

24. Vertical Transport Rollers

25. Tandem Tray (A096 copier)

550-sheet Tray (A095 copier)

26. Universal Tray

27. 1500-sheet LCT (A096 copier)

550-sheet Tray (A095 copier)

28. Toner Collection Bott le

29. Transfer Belt Cleaning Blade

30. Hot Roller

31. Pressure Roller

32. Jogger Fences

Overall

Information

14. Erase Unit

15. Drum Potential Sensor

16. Toner Hopper

17. Development Unit

18. Pre-Transfer Lamp

19. Pick-up Roller

20. Feed Roller

33. Duplex Positioning Roller

34. Duplex Pick-up Roller

35. Duplex Feed Roller

36. Separation Belt

37. Junction Gate

38. Exit Rollers

39. Optics Cooling Fan

1-11

Page 13

1

7

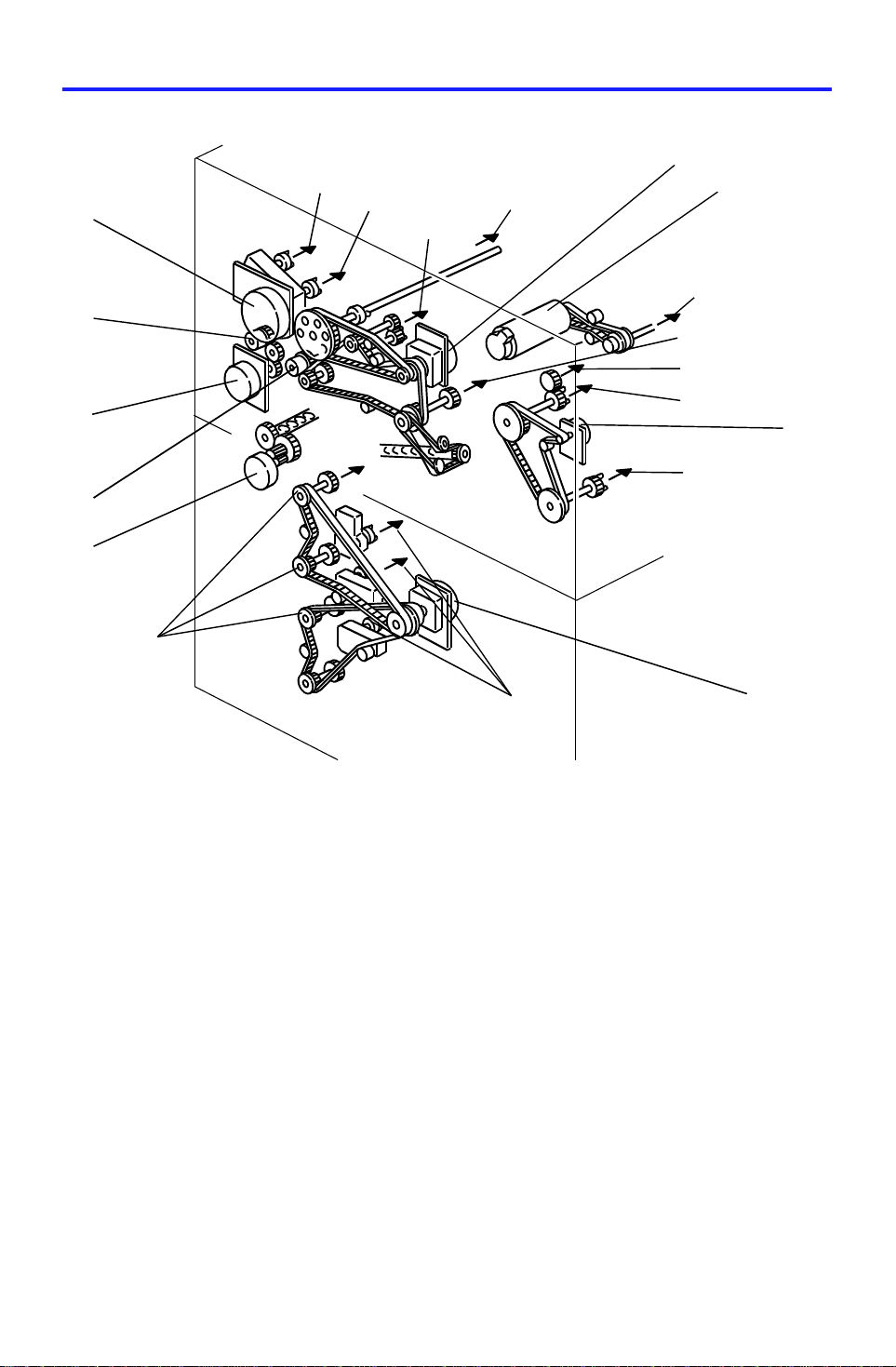

DRIVE LAYOUT 23 April 1993

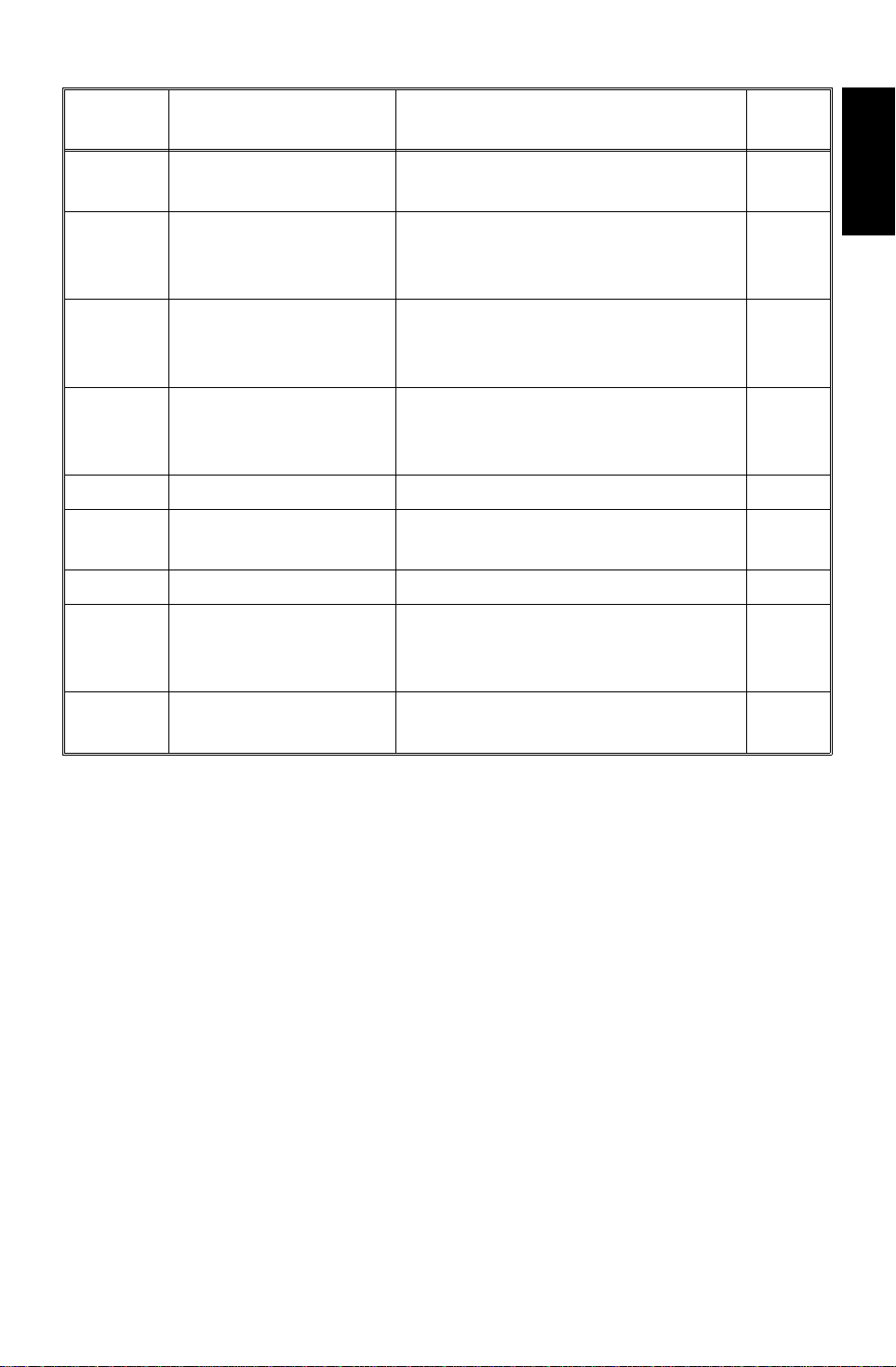

5. DRIVE LAYOUT

❾

❽

❼

❻

❺

❶

9

10

11

❷

2

3

4

5

❸

6

8

❹

❶ Main Motor

❷ Scanner Drive Motor

❸ Fusing/Duplex Drive Motor

❹ Paper Feed Motor

❺ Toner Collection Motor

❻ Registration Clutch

❼ By-Pass Feed Motor

❽ BY-Pass Feed Clutch

❾ Development Drive Motor

1. OPC Drum

2. Scanner Unit

3. Transfer Belt Unit

4. Paper Exit Unit

5. Fusing Unit

6. Duplex Unit

7. Paper Trays

8. Paper Feed Units

9. Toner Hopper

10. Development Unit

11. Cleaning Unit

1-12

Page 14

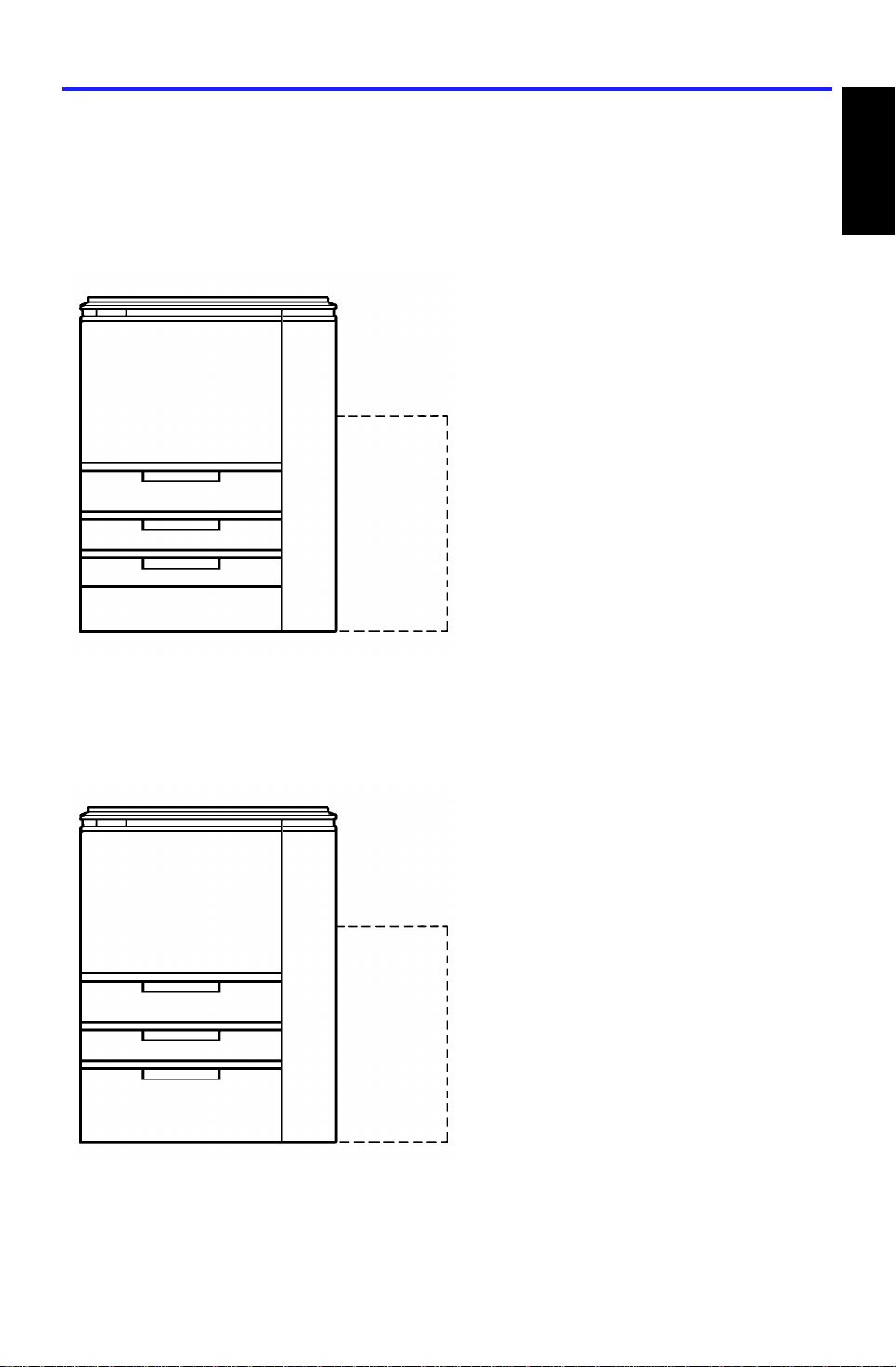

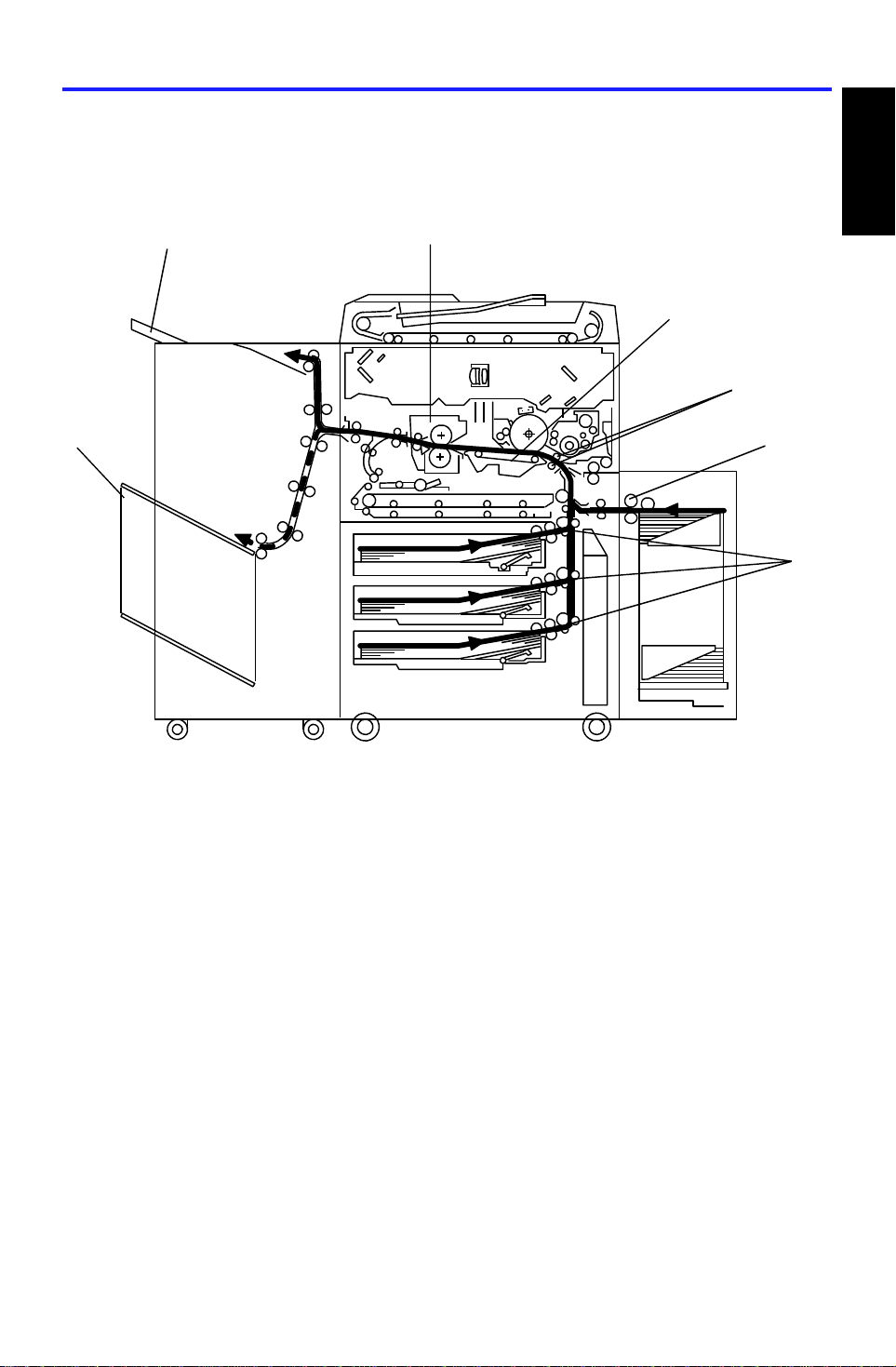

23 April 1993 PAPER PATH

6. PAPER PATH

6.1 STANDARD COPYING

[F]

[D]

[C]

[B]

Overall

Information

[E]

Paper feed begins from the exte rior LCT, by-pa ss fee d ta ble or pap er fe ed

stations in the paper tray unit . The copy pa pe r the n follows on e of two path s

inside the copier. The path fo llowe d depe nd s on which mode the operator

has selected. For copy processing, all sheets follow the same pat hs fro m t he

paper feed mechanism [A] through the registration rollers [B ], transfer belt

[C], and fusing unit [D] . Af ter that, copies are delivere d to the sorter bins [E]

or proof tray [F], however, 2 sided copie s are diverted for further processing.

[A]

[A]

1-13

Page 15

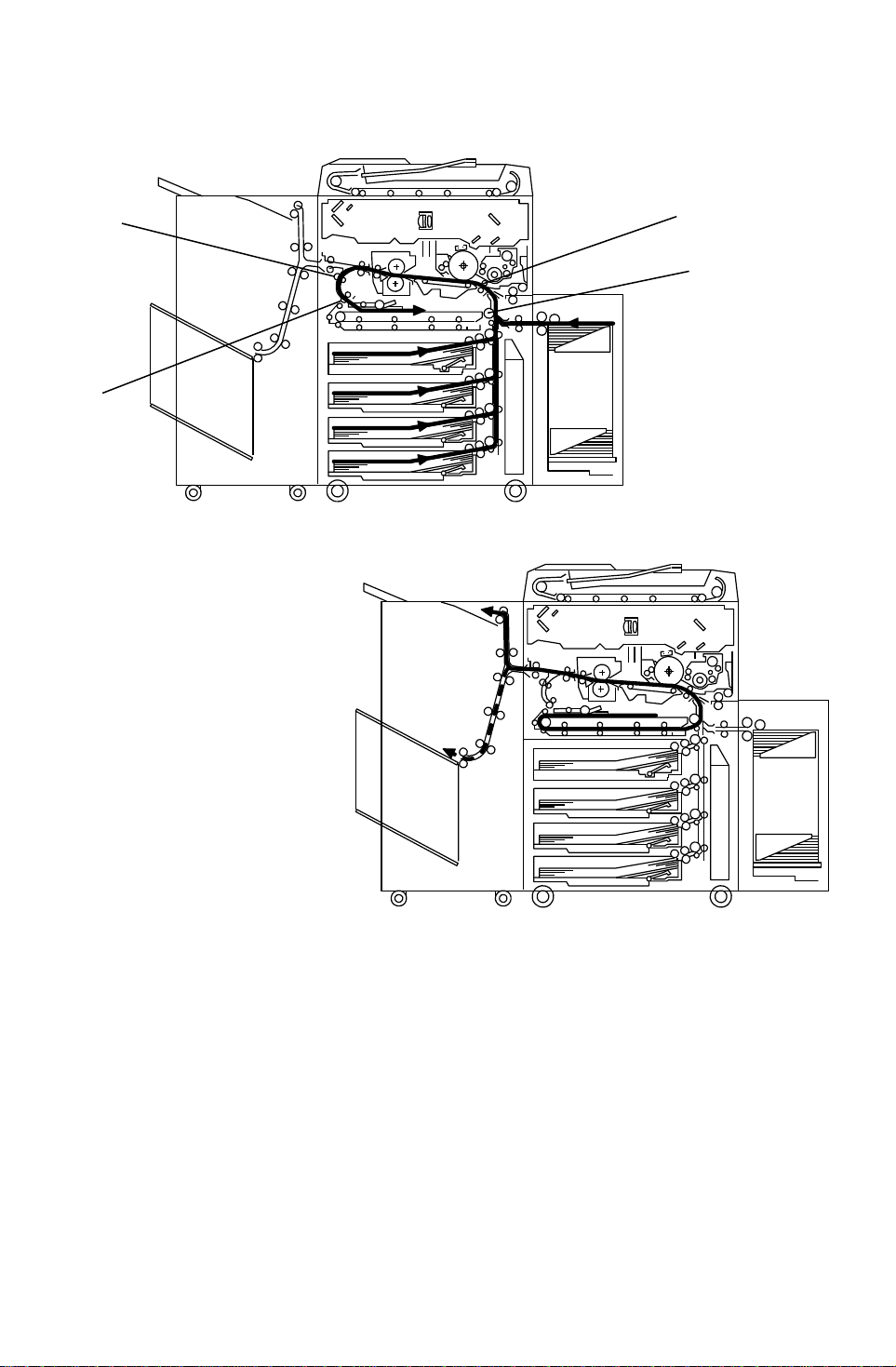

PAPER PATH 23 April 1993

6.2 MULTIPLE 2-SIDED CO PYING

a. Front Side

[B]

[A]

[D]

[C]

b. Rear Side

In this mode the junction gat e [A ] directs sheets exiting th e fu sing unit to the

duplex tray entrance. Aft er that, all sheets follo w the pat h th rou gh the dup lex

entrance rollers [B].

After all front side cop ying is comp let ed , the sheets on the duple x tray are fed

in order from the bottom to the top and follow the path throu gh the duplex

feed mechanism and vertical transport rollers [C] to the registration rollers

[D]. After that , th ese sheets follow the same pat h as sta nd ard copying from

the registration rollers to the sorter.

1-14

Page 16

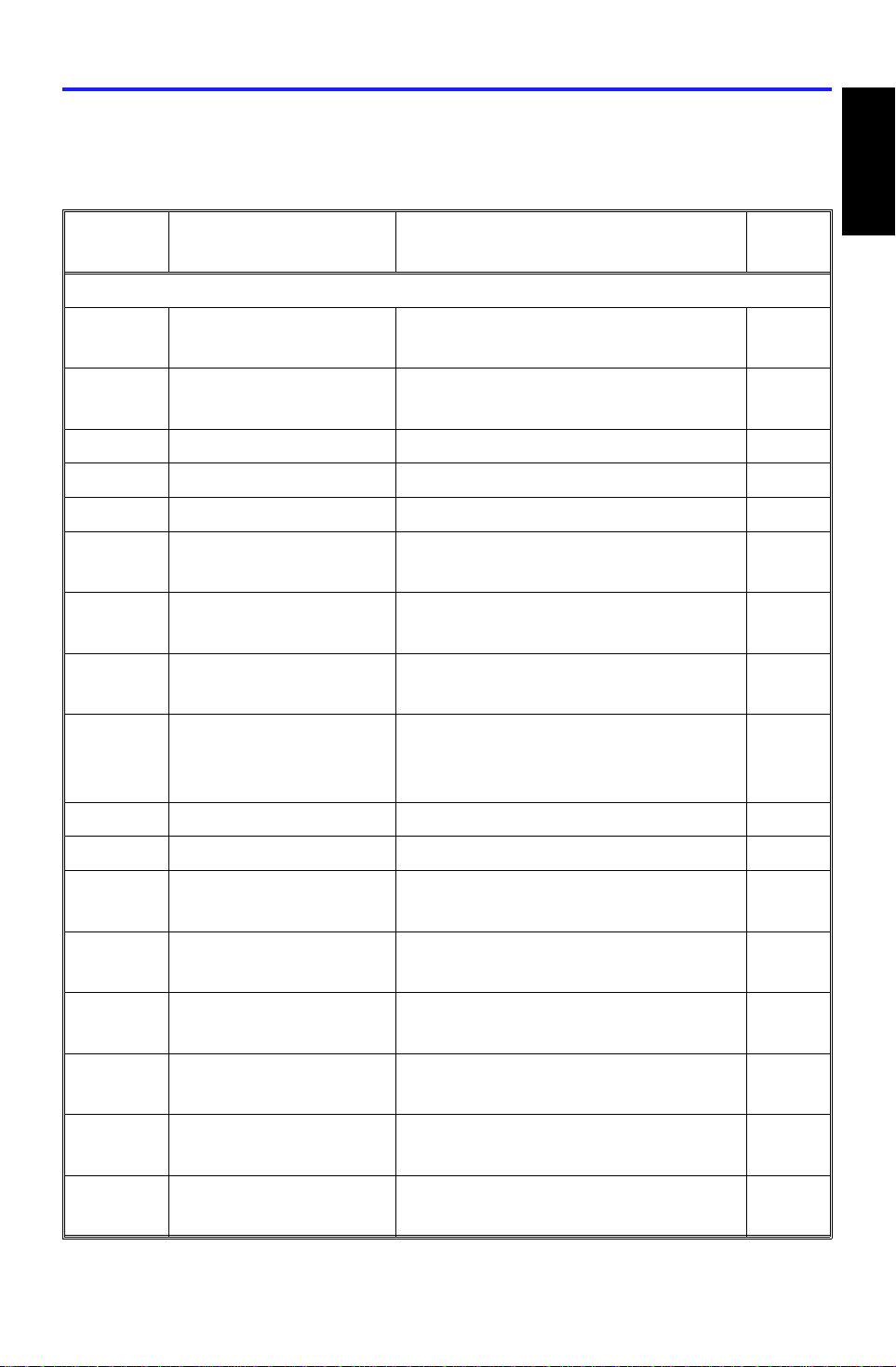

23 April 1993 ELECTRICAL COMPONENT DESCRIPTION

7. ELECTRICAL COMPONENT DESCRIPTION

Refer to the electrical compone nt layou t on the reverse side of the att ach ed

Point to Point for symbols and ind ex numbers.

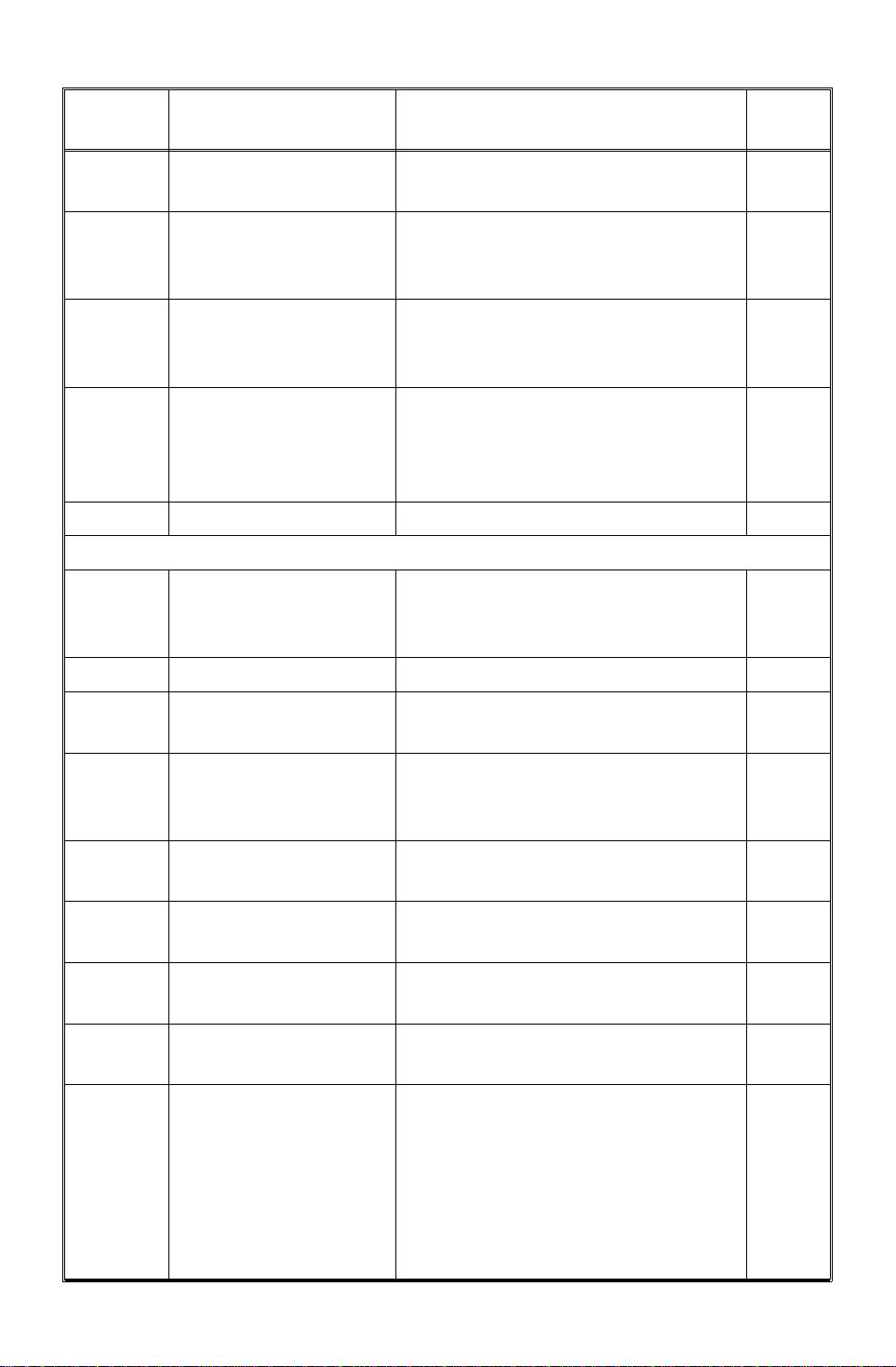

Symbol Name Function Index

No.

Motors

Overall

Information

M 1 Scanner Drive Drives the 1st and 2nd scanne rs

(dc servo).

M 2 Exhaust Fan Removes the heat from around

the fusing unit.

M 3 Main Drives the main unit components. 44

M 4 Development Drive Drives the development unit. 45

M 5 By-pass Feed Drives the by-pass feed rollers. 46

M 6 3rd Scanner Drive Drives the 3rd scanner (dc

stepper)

M 7 Toner Bottle Drive Rotates the toner bottle to supply

toner to the toner hopper.

M 8 Charge Wire Cleaner

Drive

M 9 Jogger Drives the jogger fences to

M10 Lens Horizont al Drive Shifts the lens horizontal position. 51

M11 Lens Vertica l Drive Shifts the lens vertical position . 52

Drives the main charge wire

cleaner to clean the charge wire.

square the paper stack in th e

duplex tray (dc stepper).

42

43

47

48

49

50

M12 Optic Cooling Fan Removes heat from the optics

unit.

M13 Fusing/ Duplex Drive Drives the fusing unit, the duplex

unit, and the paper exit rollers.

M14 Paper Feed Drives all feed and transport

rollers in the paper tray unit.

M15 1st Lift Raises the bottom plate in the 1st

paper tray.

M16 2nd Lif t Raises the bottom pla te in the

2nd paper tray.

M17 Toner Colle ction Transport s the collect ed toner to

the toner collection bott le.

1-15

53

54

90

91

92

93

Page 17

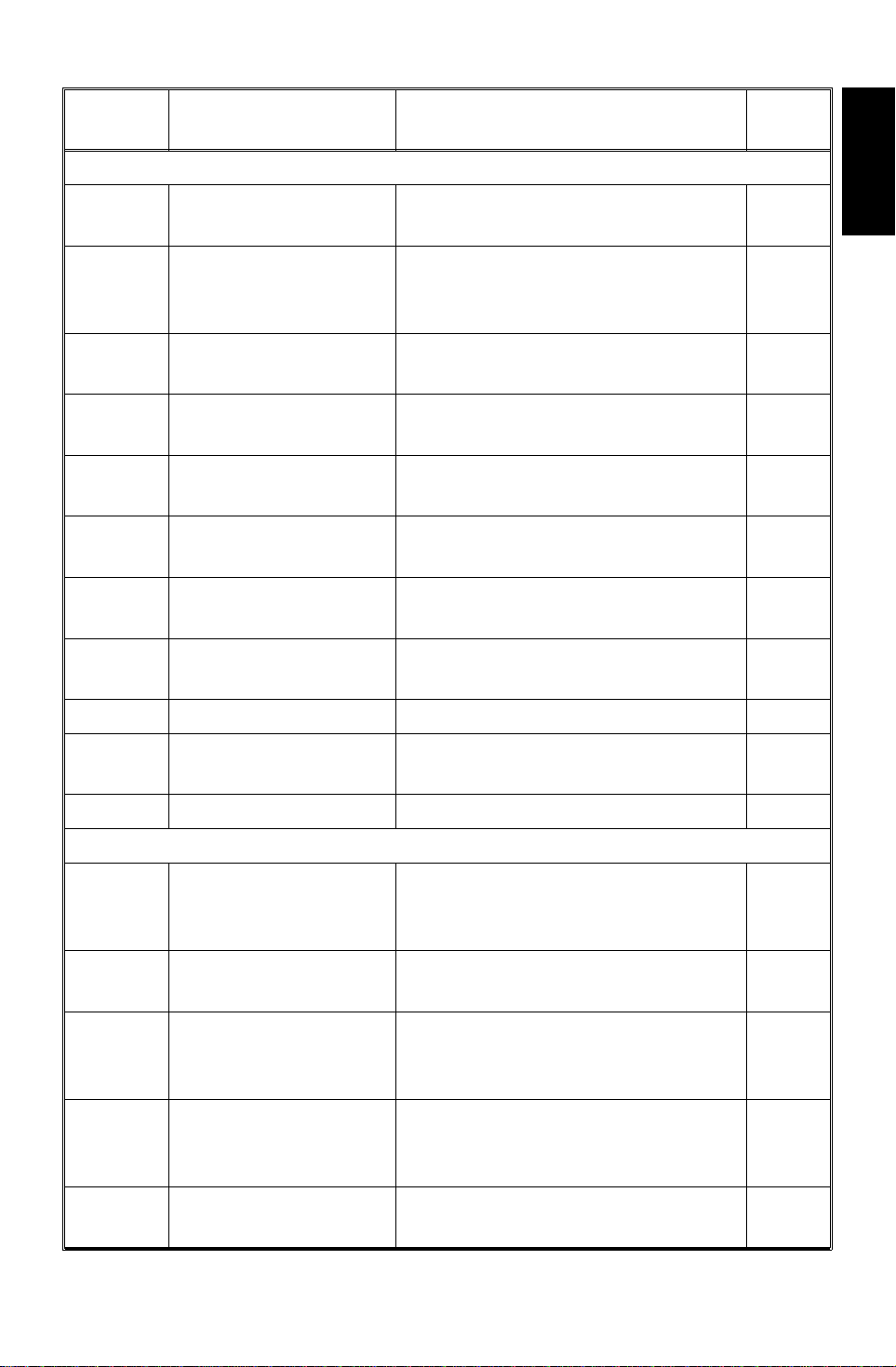

ELECTRICAL COMPONENT DESCRIPTION 23 April 1993

Symbol Name Function Index

No.

M18 3rd Lift

(A095 copier only)

M19 Side Fen ce Drive

(A096 copier only)

Raises the bottom plate in the 3rd

paper tray.

Opens and closes the front and

the rear side fences of the

tandem tray.

M20 Rear Fence Drive

(A096 copier only)

Moves the papers stacked in the

left tandem tray to the right

tandem tray.

M21 LCT Motor

(A096 copier only)

Lifts and lowers the LCT bottom

plate to bring paper to the feed

position and allow loading of the

paper.

Magnetic Clutches

MC1 Toner Supply Turns the toner supply roller to

supply toner to the development

unit.

MC2 Registration Drives the registration rollers. 58

94

95

96

127

57

MC3 By-pass Feed Starts paper feed from the

by-pass feed table.

MC4 Duplex Transport Drives the duplex tra nsport rollers

to transport the paper to the

vertical transport rollers.

MC5 Duplex Feed S tarts pa per fee d from the duplex

tray to the duplex transport rollers.

MC6 1st Feed Starts paper fee d from the 1st

feed tray.

MC7 2nd Feed Starts paper feed from the 2nd

feed tray.

MC8 3rd Feed Starts paper feed from the 3rd

feed tray.

60

64

65

99

101

104

1-16

Page 18

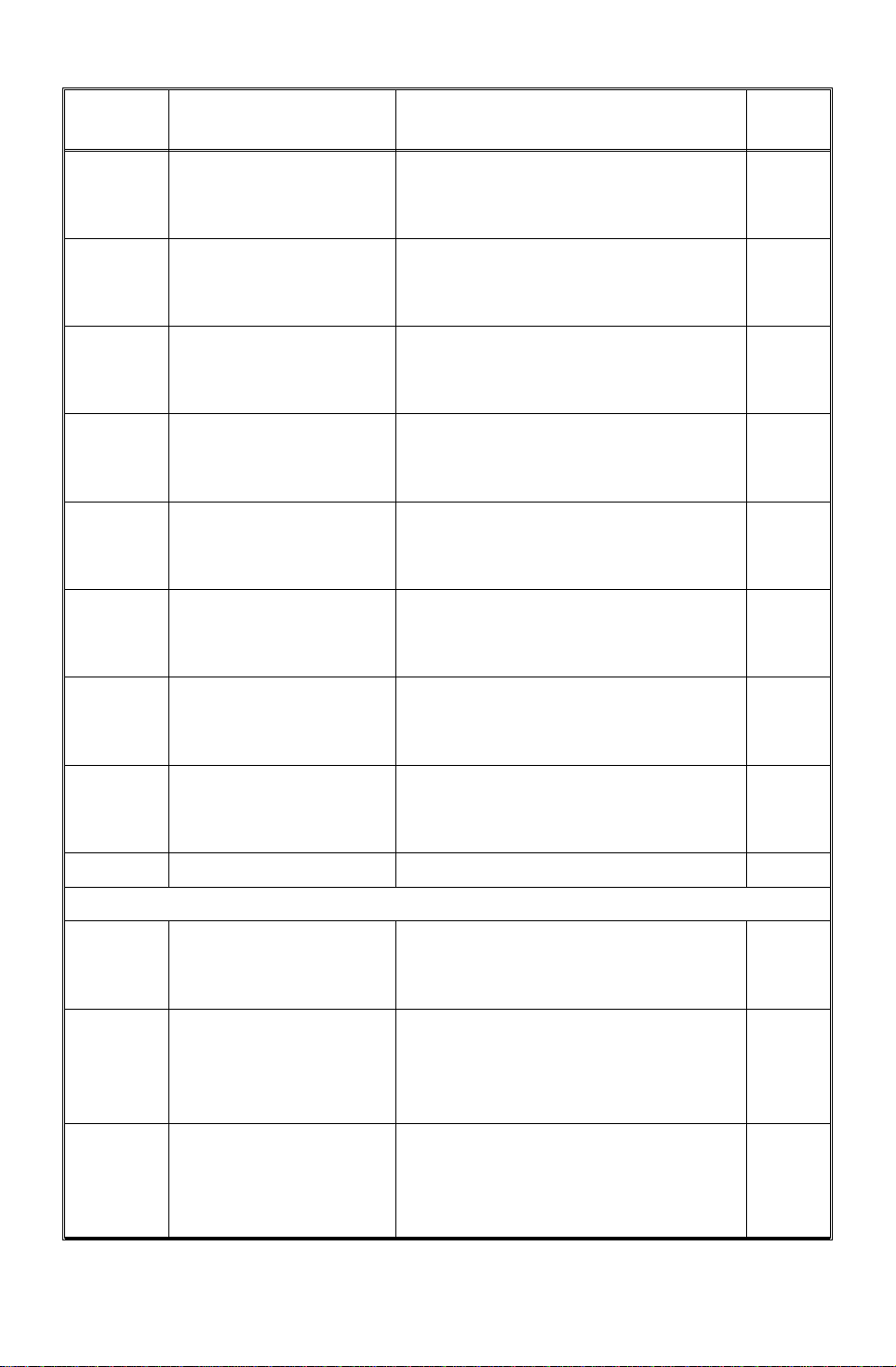

23 April 1993 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function Index

No.

Switches

SW1 By-pass Table Detects if the by-pass feed tab le

is open or closed.

SW2 Front Door Safety Cuts the ac power line and

detects if the front door is open or

not.

SW3 1st Tray Set

Detects if the 1st tray is set or no t. 66

(A095 copier only)

SW4 2nd Paper Size Determines what size paper is in

the 2nd (universal) paper tray.

SW5 Toner Overflow Detects when the toner collection

bottle is full.

SW6 Toner Collection

Bottle Set

SW7 Lower Front Door

Safety

SW8 3rd Tray Set

Detects if the toner collection

bottle is set or not.

Detects if the front door is open

or not.

Detects if the 3rd tray is set or no t. 84

(A095 copier only)

25

29

67

75

77

83

Overall

Information

SW9 Main Provides power to the copier 122

SW10 Tray Down

Lowers the LCT bottom plate. 126

(A096 copier only)

Solenoids

SOL 1 Junction Gate Moves the junction gate to dire ct

copies to the duplex t ray or to the

paper exit.

SOL 2 Duplex Positioning Controls the up-down move ment

of the positioning roller.

SOL 3 By-pass Pick-up Controls the up-down movemen t

of the pick-up roller for by-pass

feed.

SOL 4 Guide Plate Opens the guide plate when a

paper misfeed occurs around this

area.

SOL 5 Transfer Belt

Positioning

Controls the up-down movement

of the transfer belt un it.

55

56

59

61

62

1-17

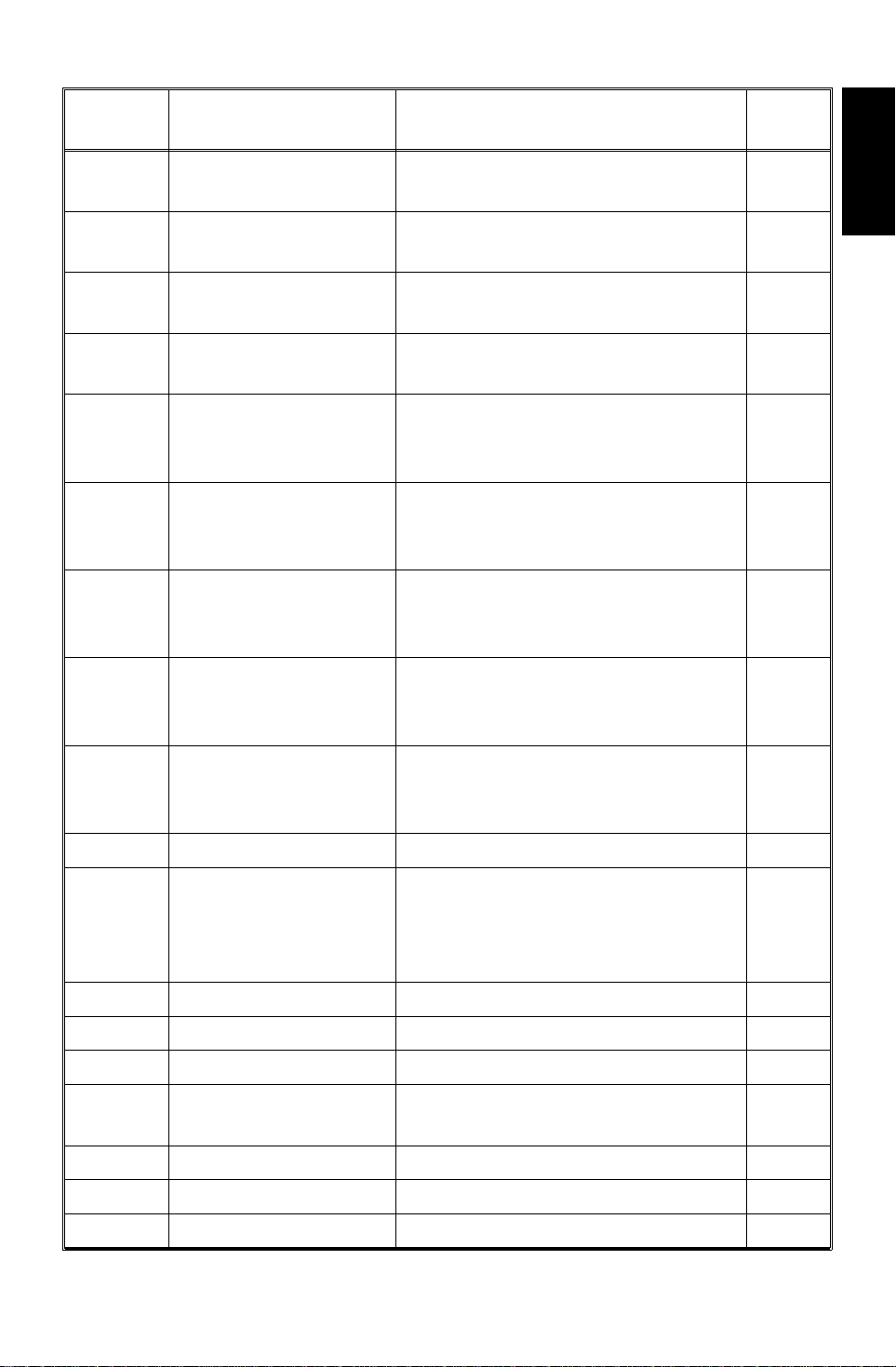

Page 19

ELECTRICAL COMPONENT DESCRIPTION 23 April 1993

Symbol Name Function Index

No.

SOL 6 Pressure Arm Presses the paper on the duplex

tray against the duple x fee d

rollers.

SOL 7 Tandem Lock Locks the left tandem feed tray

and separates the righ t an d lef t

tandem trays.

SOL 8 1st Pick-up Controls the up-down movemen t

of the pick-up roller in the 1st

feed station.

SOL 9 1st Separation Roller Controls the up-down movement

of the separation roller in the 1st

feed station.

SOL10 2nd Pick-up Controls the up-do wn movement

of the pick-up roller in the 2nd

feed station.

SOL11 2nd Separat ion Roller Controls the up-down movement

of the separation roller in the 2nd

feed station.

SOL12 3rd Pick-up Controls th e up -do wn movement

of the pick-up roller in the 3rd

feed station.

63

97

98

100

102

103

105

SOL13 3rd Separa tio n Rolle r Controls the up-down move men t

of the separation roller in the 3rd

feed station.

Sensors

S 1 Scanner HP Informs the CPU when the 1st

and 2nd scanners are at the

home position.

S 2 Platen Cover

Position–1

Informs the CPU that the platen

cover is in the up or down

position (related to APS/ARE

function).

S 3 Platen Cover

Position–2

Informs the CPU that the platen

cover is in the up or down

position to detect if th e original

has been removed or not.

106

1

2

3

1-18

Page 20

23 April 1993 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function Index

No.

S 4 Lens Vertical HP Informs the CPU that the lens is

at the full-size position.

S 5 Lens Horizontal HP Informs the CPU that the lens is

at the horizontal home position.

S 6 3rd Scanner HP Informs the CPU when the 3rd

scanner is at the home position.

S 7 By-Pass Paper End Informs th e CPU that there is no

paper in the by-pass feed tab le.

S 8 Guide Plate Position I nforms th e CPU if the

registration guid e pla te is closed

or not.

S 9 Jogger HP Detects if the duplex jogg er

fences are at the home position

or not.

S10 Vertical Transport Detects the leading edge of the

paper to determine the paper

feed timing of the next sheet.

S11 Duplex Exit Detects the leading edge of the

paper to determine the duplex

transport clutch on timing .

4

Overall

Information

5

6

7

8

9

10

11

S12 Duplex Entrance

Sensor

Detects the leading edge of the

paper to determine the duplex

12

feed clutch off timing.

S13 Duplex Paper End Detects paper in the duplex tray. 13

S14 Duplex Transport Detects the lea din g ed ge of th e

14

paper to control the jogger motor

and the positioning solenoid on

timing.

S15 Exit Detects misfeeds. 15

S16 Fusing Exit Detects misfeeds. 16

S17 Paper Guide Detects misfeeds. 17

S18 Auto Image Density Senses the ba ckgro un d de nsit y

20

of the original.

S19 Original Length–1 Detects original length. 21

S20 Original Length–2 Detects original length. 22

S21 Original Width Detects original width. 23

1-19

Page 21

ELECTRICAL COMPONENT DESCRIPTION 23 April 1993

Symbol Name Function Index

No.

S22 By-Pass Paper Size Informs the CPU what size pape r

26

is in the by-pass feed table.

S23 Toner Density Senses the amount of toner in th e

27

black developer.

S24 Registration Detects misfeeds and controls

28

registration clutch off-on timing.

S25 Toner End Detects toner end cond itio n. 30

S26 Auto-Response Returns the display fro m the

34

screen saver.

S27 Drum Potential Detects the drum surface

39

potential.

S28 Image Density Detects the density of the ID

41

sensor pattern on the drum.

S29 1st Paper End Informs the CPU when the 1st

68

cassette runs out of paper.

S30 1st Paper Near End Informs the CPU when the 1st

69

cassette is in near end condition.

S31 1st Paper Feed Controls the 1st paper feed clutch

70

off/on timing and the 1st pick-up

solenoid off timing.

S32 2nd Paper Near End Informs the CPU when the 2nd

cassette is in near end condition.

S33 1st Lift Detects the correct fe ed heig ht of

the 1st cassette.

S34 2nd Paper End Informs the CPU when the 2nd

cassette runs out of paper.

S35 Toner Collection

Motor

Detects the toner co llect ion motor

operation.

S36 2nd Lift Detects the correct fe ed heig ht of

the 2nd cassette.

S37 3rd Lift Detects th e correct feed height of

the 3rd cassette.

S38 3rd Paper Near End

(A095 copier only)

Informs the CPU when the 3rd

cassette is in near end condition.

S39 3rd Paper End Informs the CPU when the 3rd

cassette runs out of paper.

71

72

73

74

76

78

79

80

1-20

Page 22

23 April 1993 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function Index

No.

S40 3rd Paper Feed Controls the 3rd paper feed

clutch off/on timing and the 3rd

pick-up solenoid off timing.

S41 2nd Paper Feed Controls the 2nd paper feed

clutch off/on timing and the 2nd

pick-up solenoid off timing.

S42 Base Plate Down

(A096 copier only)

Detects when the bottom plate is

completely lowered to stop the

1st lift motor.

S43 Side Fence

Positioning

Informs the CPU when the

tandem tray side fences are open.

(A096 copier only)

S44 Rear Fence Return

(A096 copier only)

Informs the CPU when the

tandem tray rear fence is in the

return position.

S45 Rear Fence HP

(A096 copier only)

Informs the CPU when the

tandem tray rear fence is in the

home position.

S46 Left Tandem Paper

End

Informs the CPU when the left

tandem tray runs out of paper.

(A096 copier only)

81

Overall

Information

82

85

86

87

88

89

S47 LCT Near End

(A096 copier only)

S48 Tray Down

(A096 copier only)

Detects the paper nea r e nd

condition.

Detects when the tra y is

completely lowered to stop the

LCT motor.

S49 Tray Paper Set

(A096 copier only)

Informs the CPU when the paper

is set on the LCT bottom tray.

PCBs

PCB 1 AC Drive Provides AC power to the

exposure lamp and fusing lamp.

PCB 2 Main Controls all machine fun ctio ns. 109

PCB 3 Optic Control Controls all optics components. 110

PCB 4 High Voltage Con tro l Controls the output of both power

packs and development bias.

123

124

125

108

111

1-21

Page 23

ELECTRICAL COMPONENT DESCRIPTION 23 April 1993

Symbol Name Function Index

No.

PCB 5 Paper Feed Cont rol Controls all components in the

paper bank.

PCB 6 DC Power Supply

Provides DC power. 113

Unit

PCB 7 Guidance Controls the guidance displa y. 120

PCB 8 Operation Panel Controls the LED matrix, and

monitors the key matrix.

Lamps

L1 Exposure Applies high intensity light to the

original for exposure.

L2 Fusing Provides heat to the hot roller. 32

L3 Quenching Neutralizes any charge remaining

on the drum surface after

cleaning.

L4 Erase Discharg es th e drum outside the

image area.

L5 Pre-transfer Reduces the charge on the dru m

surface before transfer.

112

121

18

37

38

40

Power Packs

PP1 Transfer Provides high voltage for the

transfer belt and controls the

transfer belt positioning solenoid.

PP2 Charge Provides high voltage for the

charge corona wires, and the grid

plate. Controls QL, PTL, and

charge wire cleaner motor

functions.

Others

TS1 Optics Thermoswitch Opens the exposure lamp circuit

if the optics unit overheats.

TF1 Fusing Thermofuse Opens the fu sing lamp circuit if

the fusing unit overhe at s.

TH1 Fusing Thermistor Senses the temperat ure of the

hot roller.

117

119

19

33

24

1-22

Page 24

23 April 1993 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function Index

No.

TH2 Optics Thermistor Monitors the temperature of the

36

optics cavity.

TH3 Drum Thermistor

(Located on the ID

Monitors the tempe rature of the

OPC drum.

41

Sensor Ass’y)

H1 Transfer

Anti-Condensation

Turns on when the main switch is

off to prevent moisture from

31

forming on the transfer belt.

H2 Optics

Anti-Condensation

Turns on when the main switch is

off to prevent moisture from

35

forming on the optics.

RA1 Main Power Relay Controls main power. 107

CO1 Total Counter Keeps track of the total number of

114

copies made.

NF1 Noise Filter Removes electrical noise. 115

CB1 Circuit Breaker Provides back-up high current

116

protection for the electrica l

components.

Overall

Information

LA1 Lightening Arrestor Removes current surg es fro m the

AC input lines.

118

1-23

Page 25

SECTION 2

DETAILED SECTION

DESCRIPTIONS

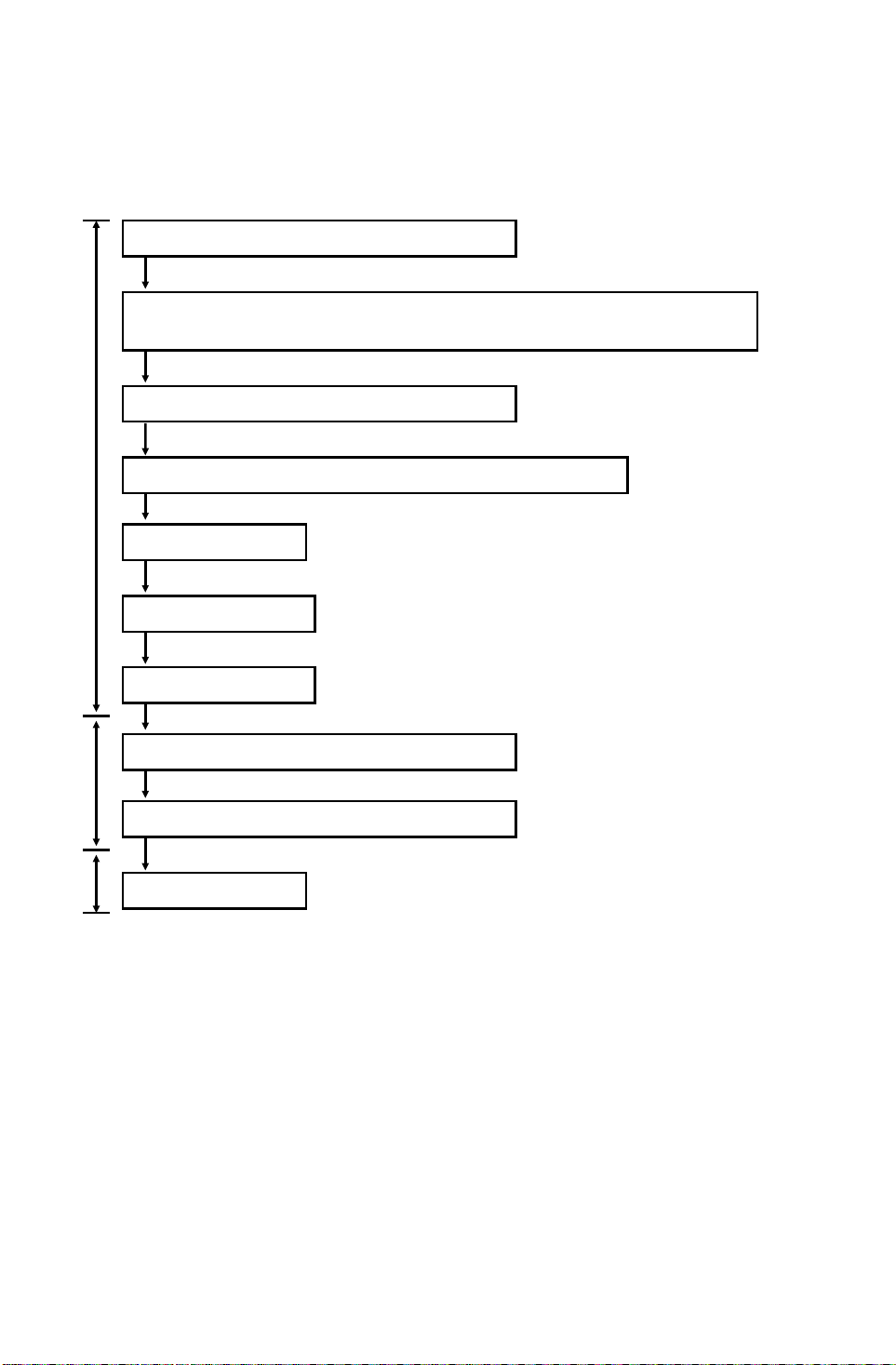

Page 26

VL Pattern

Original

Toner Supply On time

Development. Bias

TD Sensor

Image Density Control

23 April 1993 PROCESS CONTROL

1. PROCESS CONTROL

1.1 OVERVIEW

Original Scale

Image Density Control

(Fuzzy Control)

Latent Image Control

ADS Pattern

VD Pattern

Latent image Control

Exposure Control

Charge Control

Temperature Sensor

Main PCB

Lamp Voltage

Grid Voltage

Paper

VD Pattern

QL

ID Sensor

VL Pattern

Erase Lamp

Drum Potential Sensor

(Fuzzy Control)

Toner Supply Control

Exposure Glass

Detailed

Descriptions

This model uses two process control methods. One compensates for

variation in the drum potential (latent image control) and the othe r con tro ls

the toner concentratio n an d tone r supply a mou nt (image density control).

2-1

Page 27

Erase

VD

PROCESS CONTROL 23 April 1993

1.1.1 Latent Image Control

QL

Charge

Vo

Exposure

Black White

VL

Potential

Sensor

VR

Drum

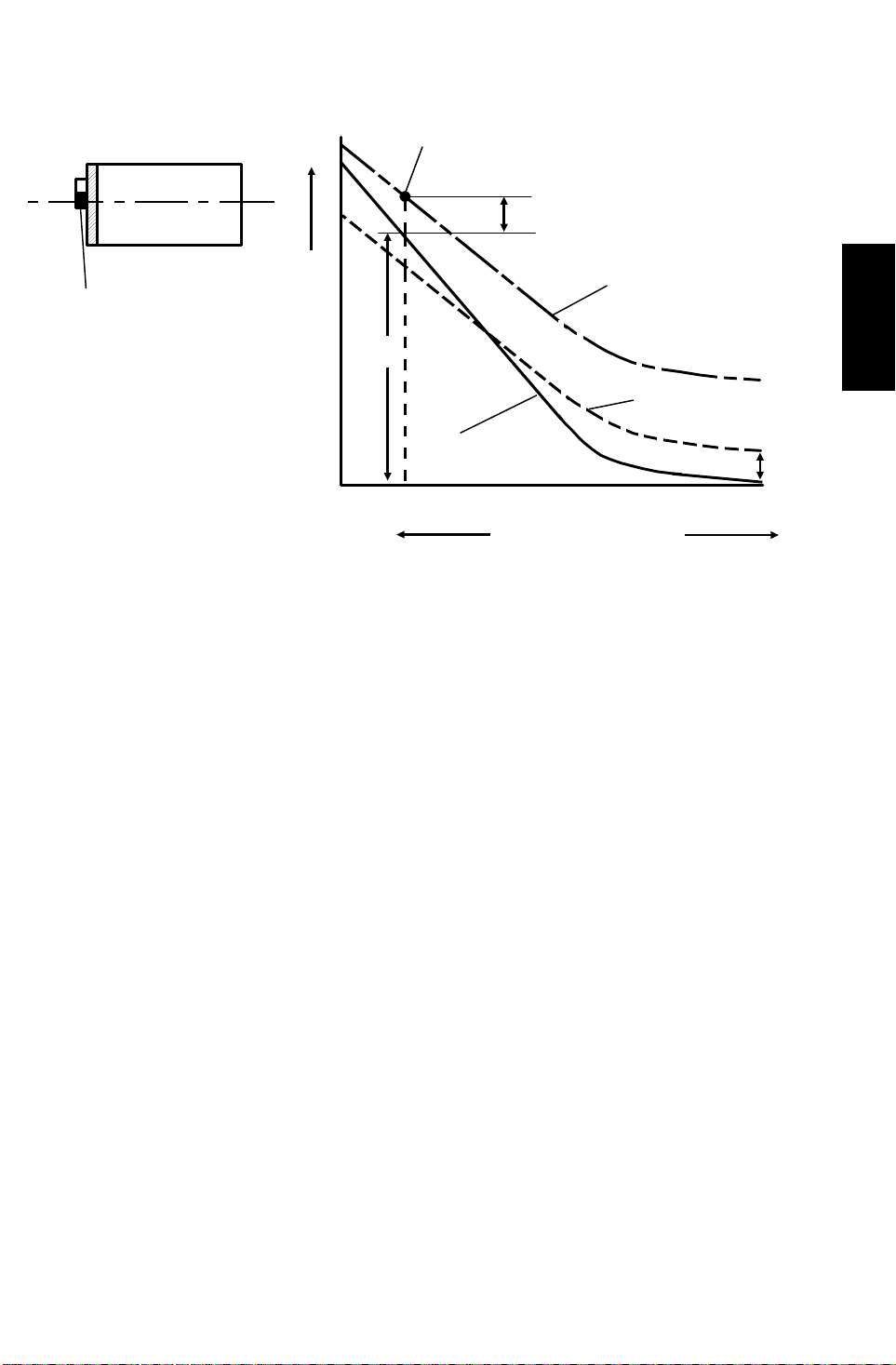

The figure shows the changes of the drum pote nt ial du ring the copy process.

Vo: The drum potential just afte r charg ing the drum.

VD (Dark Potential): The drum potential just after exposing the black

pattern (VD pattern)

VL (Light Potential): The drum potential ju st af ter exposing the white

pattern (VL pattern)

VR (Residual Voltage ): The drum potential just after t he expo sure of the

erase lamp.

After long usage following installation or a PM, drum potentia l will gra dually

increase due to the following factors:

Dirty optics or exposure lamp deterioration

Dirty charge corona wire and grid plate

Change of the drum sensitivity

In this copier, th e change in drum potential is detected by the drum potentia l

sensor and the following it ems are cont rolle d to maint ain goo d cop y quality.

The grid bias voltage

The exposure lamp voltage

The development bias voltage.

A drum thermistor detects the drum tempera ture an d this data is also use d to

control the above voltages. It is impossible to explain simply because it is

controlled by methods developed in our laboratories using an artificia l n eural

network.

2-2

Page 28

23 April 1993 PROCESS CONTROL

1.1.2 Image Density Control

Image density is controlled by the following sensors:

Toner density sensor (TD sensor)

Image density sensor (ID sensor)

Data from the TD sensor is used to keep the toner con centration in the

developer at a constant level. However, the image on the OPC drum varies

due to the variation of toner charge ab ility (inf luenced by the environment)

even if the toner concentration is constant. By the ID sensor compensation,

toner concentratio n is change d to keep the ima ge den sity on the OPC dru m

constant.

The following items are contro lled to main ta in a con sta nt copy imag e density:

Toner supply clutch on time

Detailed

Descriptions

Toner supply level data (VREF) of the TD sensor

2-3

Page 29

PROCESS CONTROL 23 April 1993

1.2 PROCESS CONTROL DATA INITI AL SE TTI NG

The following flow chart shows all the steps that will be perf orme d whene ver

the machine is turned on while the hot ro ller te mpe rature is below 100°C.

This initializes all the process control sett ings.

Main SW On (Fusing Temp. < 100°C)

Charge wire cleaning (if more than 5 K copie s are mad e since

last cleaning

Drum Potential Sensor Calibration

①

Drum Conditioning Start (Fusing Temp . = 180° C)

VSG Adjustment

VR Measurement

VD/VL Correction

TD Sensor Detection

②

ID Sensor Detection/Correctio n

③

ADS Adjustment

① : See Latent Image Control section (Page 2-5) for details.

② : See Image Density Control section (Pa ge 2-12 ) for deta ils.

③: See Optics section (Page 2-3 9) for details.

2-4

Page 30

23 April 1993 PROCESS CONTROL

1.3 LATENT IMAGE CONTROL

1.3.1 Drum Potential Sensor Calibra tion

[A]

RA601

-100 V

RA602

-800 V

Drum

[B]

Case

Sensor

Output

Amp.

Detailed

Descriptions

Main PCB

The drum potential se nso r [ A] is located just above the development unit. The

sensor has a detector which dete cts th e stre ngth of the ele ctric field from the

electric potential on the drum. The output of the sensor depends on the

strength of the electric field.

Since the output of the sensor is affected by environmental conditions, such

as temperature and humidity, the sensor outp ut is calibrat ed durin g pro cess

control data initial setting.

The High Voltage Contro l PCB [B] has two relay contacts. Usually RA 602

grounds the drum. However, during the initial setting, th e main PCB tu rns

RA601 on and RA602 off an d ap plie s t he volta ge to th e drum shaft.

By measuring the output of the drum po te ntial sensor when –100 V and –800

V are applied to the drum, the sensor output is calibrated auto mat ically.

(The machine recognize s t he re lat ionship between actua l drum po te ntial and

the potent ial sensor output.)

2-5

Page 31

VR

Light

New Drum

Used Drum

PROCESS CONTROL 23 April 1993

1.3.2 Drum Conditioning

When the fusing tempe r at ure reaches 180°C, the machin e sta rts the drum

conditioning proc ess. In th is mo de , th e main motor, main charge corona ,

erase lamp and developme nt bias are activated for about 30 second s and

drum sensitivity and residual volt age (VR) are stabilized , as in con tin uo us

copy runs.

1.3.3 VSG Adjustment

During drum conditioning , th e ID sen sor checks the bare drum’s reflectivity

and calibrates the output of the ID sensor to 4 ±0.2 V.

1.3.4 VR Measurement

Drum

Potential

[V]

[–V]

Vo

VD

VL

Original DensityDark

The above figure shows t he relationship between th e dru m pot en tia l a nd the

original density. To get consta nt copy quality, this relation ship must be

maintained.

Since this relationsh ip te nd s to cha ng e to the one represente d by th e do tted

line by various factors, compen sat ions are required.

The residual voltage (VR) cannot be compensated even if the exposure lamp

voltage is increased. Therefore, the VR change has to be compensated by

other means.

The main control board checks th e drum potential just afte r t he erase lamp

exposure by the drum pote nt ial sensor after drum conditioning. This

measured drum potential is in fact VR. This VR is used as the standard for the

VD and VL corrections.

NOTE: In the figu re ab ove, the residual voltage (VR) for the new drum is

0V. Actually, there is some re sidu al voltage even on the new

drum.

2-6

Page 32

Original Density

23 April 1993 PROCESS CONTROL

1.3.5 VD Correction

[-V] VD

Exposure

Glass

VR

VD Pattern

Drum

Potential

VD Compensated

–770

After many copies

New Drum

VR

Dark

Light

The drum potential ju st af ter the black pattern (VD Pattern) is exposed (VD:

Dark Potential) tends to lo wer during drum life due to a decrease in the

drum’s capacity to carry a charge.

To check the actual VD , th e first scanner moves to the home position and the

VD pattern (Black) stuck on the bottom side of the exposure glass bracket is

exposed on the drum.

The main control board measures VD through the drum potential sensor and

adjusts it to a target value by adjusting the grid bias voltage (V G RID).

Detailed

Descriptions

On the other hand, ther e is a chan ge of th e dru m residual voltage (VR), so

that the target VD voltage is compensa te d as follows:

Target VD Value : VD = VR + (–770)

The adjusted grid bias voltage (VGRID) is kept in memory until the next

process control data initial setting.

2-7

Page 33

PROCESS CONTROL 23 April 1993

1.3.6 VL Correction

[-V]

Exposure

Glass

VL Pattern

Drum

Potential

–770

Dark

Dirty optics and/or exposure lamp deteriora tio n decrea ses th e int ensity of the

light that reaches the drum. In addit ion to this, the drum sensitivity also

changes during the drum’s life. These factors change the drum potential ju st

after white pattern exposure (VL : Light Potential).

VD

VR

–140

VR

VL

Original Density

Only VD

Compensated

VD and VL

Compensated

New Drum

VR

Light

To check the actual VL , the first scanner moves under th e VL pattern (White)

stuck underneath th e orig inal scale. The pattern is exposed on the drum.

The main control board measures VL through the drum potential sensor and

adjusts it to a target value by adjusting the exposure lamp voltage (VLAMP).

The residual voltage (VR) change also affe cts V L, so that VL’s target voltage

is compensated as follows:

Target VL Value : V L = VR + (–140)

The adjusted exposure lamp voltage (VLAMP) is stored in memory unt il the

next process control data initial setting.

2-8

Page 34

23 April 1993 PROCESS CONTROL

1.3.7 VR Correction

[-V]

VD

Drum

VD and VL Compensated

Potential

VR

VL

Development Bias (VBB)

New Drum

–770

VR

–140

VR

Dark

Original Density

Light

Potentials (VR, VD, VL) are mon itored by the potential sensor. (This is don e

only when the fusing temp erature is less than 100°C after t he machine is

turned on.)

During the check cycle, the VD and VL patterns are exposed and the drum

potential on th e are a where exposed by each pa tt ern is checked by the

potential sensor.

Compare the curve of the VD and V L compensated drum potential with the

curve of the new drum, they are para llel but the compensated potentia l is still

higher (VR) than the new drum p oten tia l. To prevent dirty backgrounds due to

increased residual po te ntial, development bias (VBB) is applied as follows:

Detailed

Descriptions

VBB= VR + (–220)

2-9

Page 35

New VL

PROCESS CONTROL 23 April 1993

1.3.8 Initial Setting Sequence

The following graph shows the seque nce of eve nt s durin g pro cess con trol

data initial setting.

Scanner

Motor

Exposure

Lamp

Potentia l

Sensor

Output

forward

reverse

V800

V100

1. Potential

sensor

calibration

VD New VD

VL

VR

New VR

2. VR’, VD’, VL’

potential

detection

Latent Image Control

3. VD, VL

correction

for the purpose

of ADS sensor

correction

4. ID sensor

pattern

potential

detection

1. Potential sensor calibration

By measuring the output of the drum po te ntial sensor when –100 V and

–800 V are applied to the dru m , th e sensor output (V 100 and V800) is

calibrated automatically (See page 2-5 for details).

2. VR, VD, VL potential detection

After about 30 seconds of drum conditioning, VD and VL Patterns are

developed by using the previous grid bias voltage (VGRID) data and

exposure lamp voltage (V LAMP) da ta to detect the VR, VD, VL data .

The machine calculate s the new VGRID and VLAMP data using the

detected VR, VD, VL data.

2-10

Page 36

23 April 1993 PROCESS CONTROL

3. VD and VL corrections

Using the calculated VGRID and VLAMP data, VR, VD, and VL patterns are

developed again and the new VR, VD, and VL data are detected.

If both VD and VL data are within specificat ions, the new V GRID, VLAMP

and development bias (VBB) are determined based on the new VD, V L,

and VR values.

Specifications:

VD = –770 + VR ± 20 V

VL = –140 + VR ± 20 V

If VD is outside specifications, VGRID is shifte d on e step. Then the VD pattern

is measured again and VD is detected again.

The same is done for VL and VLAMP.

The above process continues until both V D and VL fall within spe cifica tions.

The graph on the previou s pag e sho ws t he examp le whe n on ly VL was

outside specifications at the first VL detection and it became within

specifications after on e V L corre ction (VLAMP is changed 0.5V/step , VGRID is

changed 20 V/step).

If V100 or V800 at drum potential sensor calibration is outsid e spe cifica tions or

if VD or VL do not fall within specificat ions after VGRID or VLAMP are shifted to

the maximum or minimum level, the machine stops VD or VL correction and

uses the previous V GRID and VLAMP values during copying.

In this case, nothing is in dica ted on the machine but the SC counter is

incremented.

Related SC codes (see troublesh oo tin g section for details):

Code Condition

361 Incomplete drum potential sensor

calibration

364 Abnormal VD detection

Detailed

Descriptions

365 Abnormal VL detection

Development bias is also de cide d by using VR as follows.

VBB = VR + (–220)

4. ID sensor pattern potential detection

This is performed to determine ID Sensor Bias Volt age. The details are

explained in the develo pment control section (se e page 2-16).

2-11

Page 37

VD (12 V)

GND

PROCESS CONTROL 23 April 1993

1.4 IMAGE DENSITY CONTROL

1.4.1 Toner Density Sensor

A: VOUT (Gain data) is high.

OUT is within the specification.

B: V

OUT (Gain data) is low.

C: V

A

B

VOUT = VIN x

New Developer

1234

Toner Weight %

= 12 x

V

IN

Main PCB

VOUT

AGC

Gain

256

Gain

256

TD

Sensor

Sensor

Output

Sensor

Output

(V)

5

C

4

3

REF

V

2

1

0

Developer consists of carrier particles (iron ) and toner particle s (re sin and

carbon). Inside th e de velo pment unit, developer passes through a magnetic

field created by coils inside the ton er de nsit y senso r. When the toner

concentration chan ge s, th e voltage output by the sensor changes accordingly.

<Toner Density Sensor Initia l Setting>

When new developer with th e sta nd ard toner concentratio n (2.0% by weight,

20 g of toner in 1000 g of developer) is installed, developer initial settin g must

be performed by using SP mod e ( SP Adjustment – PAG E 1).

1

During this setting, the outpu t volt ag e (VOUT) from the auto gain control

circuit (AGC) on the main control board PCB varies to cha nge the output

voltage from the toner density (TD) senso r. This is don e by cha ng ing the gain

data, see below.

VOUT = VIN x

Gain Data

256

= 12 x

Gain Data

256

If the data is high, VOUT becomes high, and the sen sor ou tp ut

voltage becomes high. As a result, the sensor characteristic

becomes as illustrated by curve A. If the data is low, VOUT

becomes low, and the sensor ou tput voltage becomes low. As a

result, the sensor characte ristic shifts as illustrated by curve C.

2-12

Page 38

23 April 1993 PROCESS CONTROL

By selecting the proper ga in da ta , the sensor output is set wit hin the targeted

control level (VREF, VREF = 2.5 ± 0.1 V). Now, the sensor characteristic is

illustrated by curve B and the TD sensor initial settin g is comple ted.

The selected gain data is sto red in me mory, and VOUT from the auto gain

control circuit stays consta nt during the toner senso r d et ect ion cycle.

<Toner Supply Criteria>

At every copy cycle, toner density in the deve lop er is det ect ed once . The

sensor output voltag e (VTD) during the detectio n cycle is compared with the

toner supply level voltage (VREF).

5

4

Sensor

V

Output

(V)

3

TD

Detailed

Descriptions

V

2

1

REF

0

12345

Toner Weight %

2-13

Page 39

PROCESS CONTROL 23 April 1993

<Toner Supply Clutch on Time>

To stabilize toner concentrat ion , to ne r supp ly amou nt (t oner supply clutch on

time) is controlled by referring to V REF and VTD.

The toner supply amount is calculated at every copy. The toner supply

amount is determined by using the following factors.

① VREF – VTD

② VREF – VTD’(VTD’ = VTD of the previou s copy cycle)

VTD’

Previous Copy Last Copy Next Copy

VTD

VREF

By referring to these fact ors, the machine recognizes th e difference between

the current toner concentration and the target toner concentration. The

machine also understan ds ho w much toner concentration has changed and

predicts how much the toner supply amount will probably cha nge.

By changing the toner supply amount precisely, toner concentration (image

density) is kept at a constant level.

Since the toner supply clutch on time up dating is under fuzzy control, the

relation among VTD, VTD’, VREF cannot be expressed by a simple algebraic

formula.

<VREF Correction>

The image on the OPC drum changes due to varia tio n of ton er cha rgeability

(influenced by the environment) even if the toner concentration is constant.

The image density sensor (ID sensor) direct ly checks th e image on the OPC

drum and shifts VREF data (under fuzzy control) to keep the image on the

OPC drum constant, as expla ined in the next section.

NOTE: 1. Toner end cond ition is detected by the toner en d sen sor (see the

development sect ion for de tails).

2. The toner supply clutch turns on at the inte rvals be twe en each

copy process while image develop men t is not perf ormed.

2-14

Page 40

3rd Series of

Copies (17

copies)

23 April 1993 PROCESS CONTROL

1.4.2 Image Density Sensor Dete ction

[B]

[C]

[A]

Drum

bias

V

LED

ON

SG

4 V

LED

V

ON

SP

VSG and VSP are checked by the ID senso r [A] . The ID se nso r is located

underneath the drum clea ning section.

There is no ID sensor pattern in th e optics, however, a pattern image is made

on the OPC drum by the charge corona unit [B] and the erase lamp [C].

VSG is the ID sensor output when checkin g th e era sed drum surf ace .

VSP is the ID sensor output when checking the ID sensor pattern image.

To compensate for any variat ion in light inte nsity from the sensor LED, the

reflectivity of both the erased drum surface and the pa tt ern on the drum are

checked.

Detailed

Descriptions

VSP Detection

12345678 9101112

VSG

Detection

1st Series of Copies

(8 copies)

2nd Series

of Copies

V

SG

(5 copies)

Detection

V

SP Detection

13

14 15

SG

V

Detection

V

SP Detection

29

30

VSG is detected eve ry time the machine starts copyin g.

During VSG detection, the development sleeve rollers do not rotate and no

development bias is applie d.

VSP is detected after copying is completed if 10 or mo re cop ies ha ve be en

made since VSP was last detected . Since the transfer belt must be rele ased

when checking VSP, a VSP check cannot be done during continuous copying.

2-15

31

V

SG

Detection

Page 41

PROCESS CONTROL 23 April 1993

① Potential

Sensor Detection

VP

VP

–700 V

①

②

③

② ID Sensor

Bias Level

4.0 V

③ ID Sensor Output

While developing the ID sen sor pa tt ern , ID sensor bias is applied. ID sensor

bias is determined during process control dat a init ial set tin g as follows:

Apply charge while grid voltage is –700 V to creat e th e ID sensor pa tt ern.

–300

VSP

VIDB = VP +300 (V)

Check the drum potentia l (V P) of the latent image created by the charge with

–700 V grid.

Adjust the ID sensor bia s (VIDB) so that it satisfies the following formula.

VIDB = VP – (–300) (V)

= VP + 300 (V)

Change the bias to the calculated VIDB and detect VSP. VSG detecte d du ring

VSG adjustment sequen ce in th e pro cess cont rol data initial setting and V SP

are used to determine VREF data at pro cess con trol data initial setting.

VIDB is not changed until the next process contro l d ata init ial setting is done.

<VREF correction timing>

After the series of cop ies is completed in the case that 10 or mo re cop ies

have been made, VREF is updated by referring to the previous VREF (VREF’),

VSG, VSP and the current TD sensor ou tp ut (VTD).

Since this VREF data updating is under fuzzy control, the relationship among

VREF, VREF’, VSG, VSP and V TD cannot be expressed by a simple algebraic

formula.

VREF is updated not only at the ab ove case. But also during developer initial

setting and during pro cess control data initial setting.

2-16

Page 42

23 April 1993 PROCESS CONTROL

1.4.3 Sensor Abnormal Conditions

a. ID sensor (VSG,VSP) abnormal

Whenever VSG falls under 2.5 V or VSP rises over 2.5 V, the CPU fixes th e

VREF data and toner concent ration is controlled only by using TD se nso r

output.

VSG and VSP are still detected as usual during abnorma l co nditions and if

output returns to normal levels (V SG ≥ 2.5 V, VSP ≤ 2.5 V), the CPU returns

the toner concentratio n con trol to normal mode.

b. TD sensor (VTD) abnormal

Whenever VTD rises over 4.0 V or VTD falls under 0.5 V, the CPU shifts the

toner supply to the fixed supp ly mo de. In this condition, the CPU ne ver stops

the toner supply. The fixe d toner supply amount can be chan ge d in fo ur steps

(4%, 7%, 11%, 14%) by usin g SP mode. The default fixed to ne r su pp ly

amount is 4%.

VTD is still detected as usual durin g th e abnormal condition and if its output

returns to a normal level, the CPU returns the toner conce nt rat ion cont rol to

normal mode.

Detailed

Descriptions

c. Drum Potential Sensor abnormal

Whenever V100 rises over 1. 6 V or V 100 falls under 0.1 V or whenever V800

rises over 5.0 V or V800 falls under 2.7 V, the CPU also shifts the toner

supply to the fixed supply mode, as for a TD sensor (VTD) abnormal

condition.

Related SC codes. (See troub lesh oo tin g section of details.):

Code Condition

351 Abnormal VSG Detection (VSG > 4.2 V)

352 Incomplete TD Sensor Initial Setting

353 Abnormal VSP Detection (VSP > 2.5 V)

354

Abnormal VSG Detection (VSG ≤ 2.5 V)

355 Abnormal VTD Detection (VTD > 4 V)

356 Abnormal VTD Detection (VTD < 0.5 V)

357 Abnormal VSP/VSG Detection (VSP/VSG ≥ 0.25 V)

358 Abnormal VSP/VSG Detection (VSP/VSG < 0.25 V)

361 Incomplete Drum Potential Sensor Calibration

2-17

Page 43

16

DRUM UNIT 23 April 1993

2. DRUM UNIT

2.1 OVERVIEW

12

11

10

13

9

14

7. 8

15

1

2

3

4

5

6

The drum unit consists of the components as shown in the ab ove illustration.

An organic photoconductor drum (dia met er: 100 mm) is used for th is model.

1. OPC Drum

2. OPC Drum Protective Shutter

3. Erase Lamp

4. Drum Potential Sensor

5. Pre-transfer Lamp

6. Pick-off Pawl

7. Image Density Sensor

8. Drum Thermistor

9. Cleaning Brush

10. Toner Collection Coil

11. Cleaning Blade

12. Ozone Filter

13. Cleaning Filter

14. Charge Power Pack

15. Quenching Lamp

16. Main Charge Corona Unit

2-18

Page 44

23 April 1993 DRUM UNIT

2.2 OPC DRUM CHARACTERISTICS

An OPC has the characteristics of:

1. Being able to accept a high negative elect rical charge in the dark. (The

electrical resistance of a photocon ductor is high in the absence of light.)

2. Dissipating the electrical charge when exposed to light. (Exposure to light

greatly increases the conduct ivity of a photo con du cto r.)

3. Dissipating an amount of charge in direct proportion to the inte nsity of the

light. That is, where stronger light is directed to the photoconduct or

surface, a smaller voltage remains on the OPC.

4. Being less sensitive to changes in temperature (wh en compared to

selenium F type drums).

5. Being less sensitive to changes in rest time (light fatigue). This makes it

unnecessary to compensate development bia s voltage for variations in

rest time.

Detailed

Descriptions

2-19

Page 45

DRUM UNIT 23 April 1993

2.3 DRUM CHARGE

2.3.1 Overview

[A]

This copier uses a double corona wire scorotron system for drum charge.

Two corona wires are required to give suff icien t ne ga tive charg e on the drum

surface because of a rather hig h dru m spee d (33 0 mm/se c.). The sta inle ss

steel grid plate makes th e corona charge uniform and controls the amount of

negative charge on the drum surfa ce by ap plyin g th e negative grid bias

voltage.

The charge power pack [A ] gives a constant corona curren t to the corona

wires (1100 µA) and bias voltage to the grid pla te is automat ically con tro lled

to maintain proper image den sity acco rding to the change of the OP C drum

potential due to dirty grid plate and charge corona casing.

2-20

Page 46

23 April 1993 DRUM UNIT

2.3.2 Air Flow Around the Drum

[A]

Detailed

Descriptions

[B]

The exhaust fan [A] located above the fusin g un it pro vides an air flow to the

charge corona unit to pre vent uneven built-up of negat ive ions that can cause

an uneven charge of th e drum surface as shown.

An ozone filter [B] abso rbs the ozone (O3 ) around the drum.

The exhaust fan rotates slowly during stan d-b y and rota te s quickly during

copying to keep the temperature inside the machine constant.

2-21

Page 47

DRUM UNIT 23 April 1993

2.3.3 Charge Wire Cleaning Mechanism

[A]

[C]

[A]

[C]

[B]

The flow of air around the charge corona wire may deposit tone r part icles on

the corona wires. These particles may int erfere with charging and cause low

density bands on copies.

The wire cleaner pads [A] automa tica lly clean the wires to pre ven t such a

problem.

The wire cleaner is driven by a dc motor [B]. No rmally th e wire clea ne r [C] is

located at the front end position (home position). After 5000 or more copie s

are made and fusing temperature is less than 100°C after the main switch is

turned on, the wire cleaner motor turns on to bring the wire cleaner to the

rear end and then back to the home position.

When the wire cleaner moves from the rear to the home position (black arrow

in the illustration), the wire clean er pads clean the wires.

There are no home position and retu rn po sitio n sen sors. The CPU monitors

the input voltage (5 V). When the wire clean er rea che s the end, it is stop pe d

and the motor is locked. At this time, in put voltage slightly decreases (to

about 4 V) and the CPU judges to rotate the motor in reverse.

2-22

Page 48

23 April 1993 DRUM UNIT

2.4 ERASE

2.4.1 Overview

EL

LE

SE

Detailed

Descriptions

LOES

LC

LE: Lead edge erase marg in 3.5 ± 2.5 mm

SE: Side era se margin total of both sides 3 mm or less

Lo: Original width

Lc: Charged width of drum

EL: Lead edge erase

Es: Side erase

The erase lamp unit consist s of a line of 12 3 LE Ds extending across the full

width of the drum, the width of each bein g abou t 2. 5 mm. In edit ing mo de, th e

appropriate LED’s turn on acco rdin g to the custo mer’s de sign ation.

2-23

Page 49

DRUM UNIT 23 April 1993

2.4.2 Lead Edge and Trail Edge Erase

The entire line of LEDs turns on when the main mot or tu rns on . The y stay on

until the erase margin slight ly overla ps the lead edge of the original ima ge on

the drum (lead edge erase margin). It preve nts the shadow of the original

lead edge from appearing on the copy paper. This lead erase margin is also

necessary for the lead edge of the copy pape r to sep ara te from th e hot roller.

The width of the lead edg e era se marg in can be adjusted by SP mode

1

( SP Adjustment mode: PAGE 3).

When the scanner reache s the return position, the charg e coro na , the grid

bias, and the exposure la mp tu rn off. However, the charged area on the drum

surface is a little longer than the actu al orig ina l le ngth in order to have the

entire latent image of the original.

The entire line of LEDs turn on when the trail edge of the latent image has

passed under the erase la mp un it. This p reve nts developing unnece ssary

parts of the drum surfa ce, reducing toner consump tio n an d drum cleaning

load.

The LEDs stay on to erase th e lead edge of the laten t image in the next copy

cycle. After the fina l copy, the erase lamps turn off at the same time as the

main motor.

2.4.3 Side Erase

Based on the combinat ion of copy paper size and the reproduction ratio data,

the LEDs turn on in blocks. This prevent s the shad ow of the origin al side

edge and unexposed fro nt and rear sides of the drum surface in reduction

mode from being develop ed . This red uces toner consumption an d dru m

cleaning load.

In the DJF mode, the horizontal original standard position on the exposu re

glass is 5 mm away from the rear scale.

In the RDH mode, the horizontal center of the original is aligned with the

center of the exposure glass.

On the other hand, the horizontal origin al sta nd ard posit ion on the exposure

glass in the platen cove r mode is the rear scale edge.

To erase the shadow made by th e ed ge of th e rea r sca le in pla ten cover

mode, one more LED at the fron t side turns on. This is in addition to th e

LED’s on in DJF and RDH modes.

2-24

Page 50

23 April 1993 DRUM UNIT

2.5 CLEANING

2.5.1 Overview

[A]

[C]

[B]

[D]

Detailed

Descriptions

4 mm

This copier uses the counter blade system for drum cleaning.

The blade [A] is angled against drum rotation. This counter blade system has

the following advantages:

• Less wearing of the cleaning blade edge.

• High cleaning efficiency.

Due to the high efficiency of this cleaning system, the pre-cleaning corona

and cleaning bias are not used for this copier.

The cleaning brush [B ] is used to support the cleanin g bla de .

The brush collects toner from the dru m surface and scraped by the cleaning

blade. Toner on the cleaning brush is scraped off by th e mylar [C] and falls to

the toner collection coil [D]. Ton er is transported to the toner collectio n bottle

by the toner collection coil.

To remove the accumulated toner at the edge of the cleaning blade, the drum

turns in reverse for about 4 mm a t th e en d of every copy job. The

accumulated toner is removed by the cleaning brush by this action.

2-25

Page 51

DRUM UNIT 23 April 1993

2.5.2 Drive Mechanism

[C]

[E]

[A]

[B]

[D]

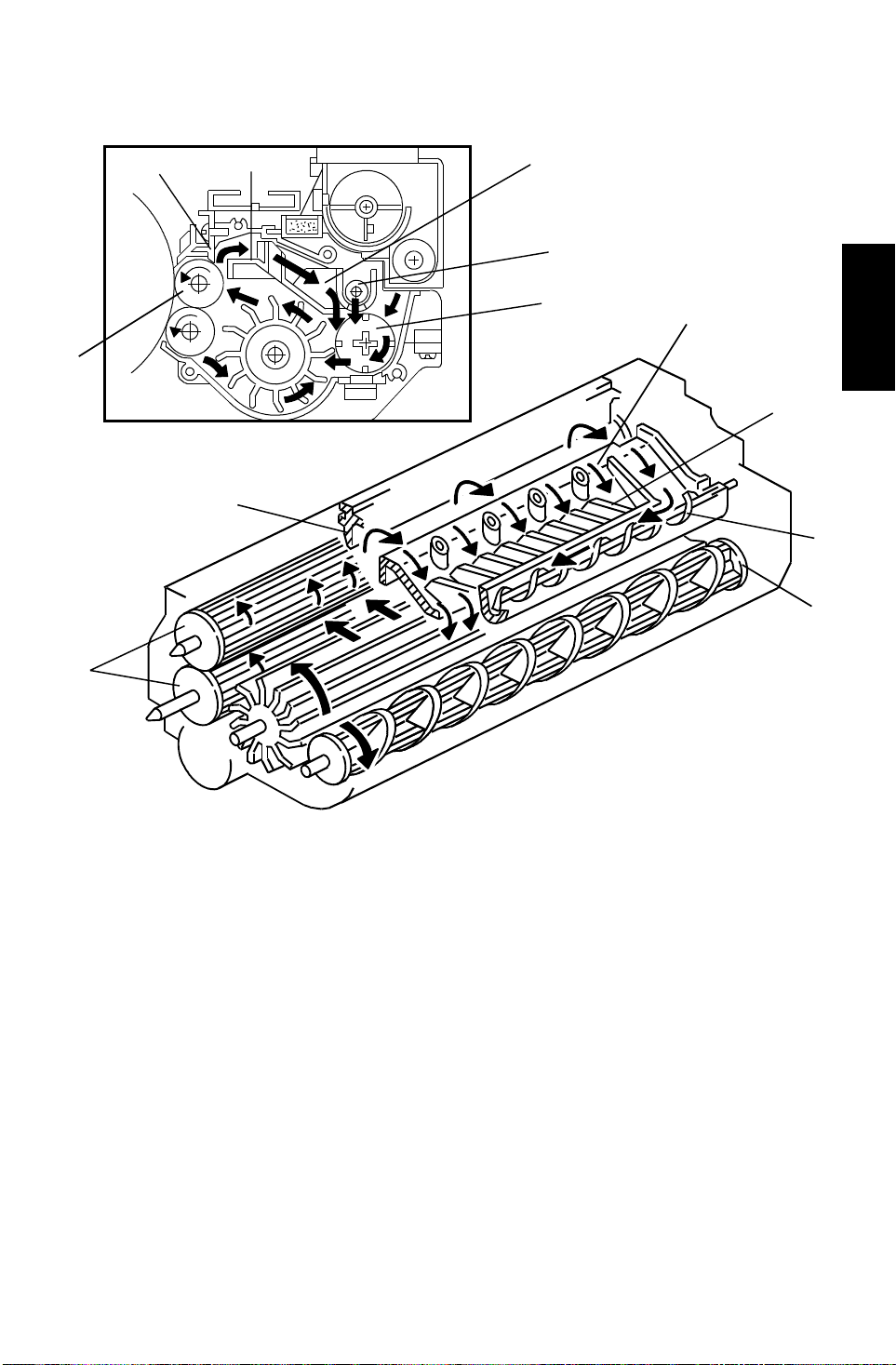

The drive force from the main motor is transmitted to the cleaning unit drive

gear via the timing belt [A] and the cleaning unit coupling [B]. The cleaning

unit drive gear [C] then transmits the force to th e fro nt side through the

cleaning brush [D]. The force at the front side is used for the toner collection

coil gear [E].

2-26

Page 52

23 April 1993 DRUM UNIT

2.5.3 Cleaning Blade Pressur e Mechanism and Side-to-Side Moveme nt

[C]

[A]

[D]

[B]

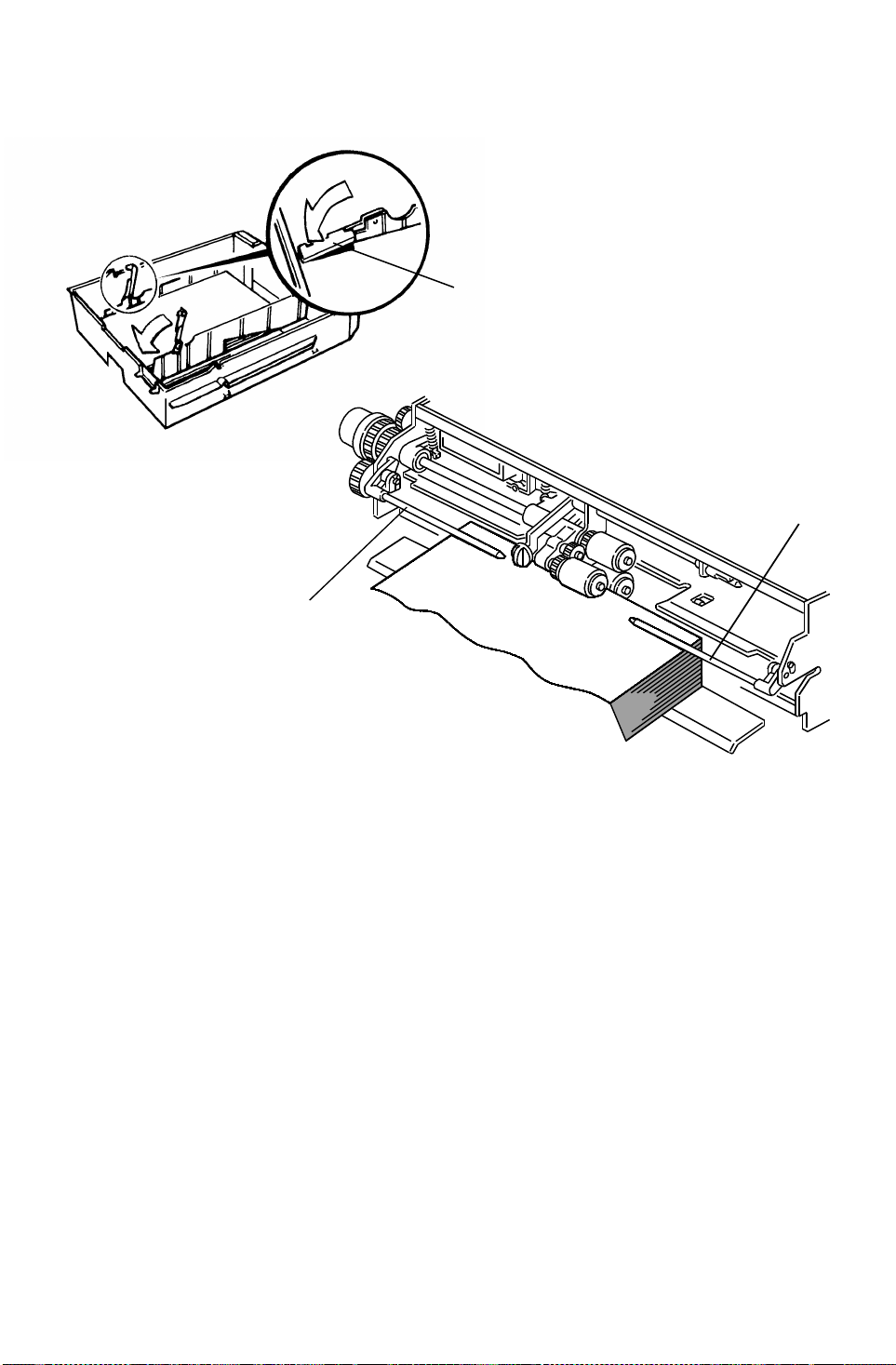

The spring [A] always push es the cleaning blade against the OPC drum. The

cleaning blade pressure can be manually released by pushing up the release

lever [B]. To prevent clean ing blade deformation durin g the transportation ,

the release lever is locked in the pre ssure release (upper) position .

The pin [C] at the rear end of the cleaning blade holder touches the cam gear

[D] which gives a side-to-side moveme nt to the blade. This movement helps

to disperse accumulated toner to prevent early blade edge deterioration.

Detailed

Descriptions

2-27

Page 53

[D]

DRUM UNIT 23 April 1993

2.5.4 Toner Collection Mechanism

[B]

[E]

[G]

[F]

[C]

[A]

Toner collected by the cleaning unit is transported to the toner collection

bottle [A] through the tone r collect ion tubes. Three helical coils are use d for

toner transport.

One coil [B] is driven by the main motor via drive belts and the other coil [C]

is driven by an independent toner collection drive motor [D].

The actuator disk [E] on the toner collection drive mot or mon ito rs the proper

rotation of the toner collectio n coil [C] to pre ven t th e coil fro m being damaged

by toner clogged in the colle ction tube. The main PCB monitors the sensor

output and increases t he mo to r sp ee d if th e sensor monitors that the to ne r

collection motor rotates at a speed lower th an norma l. Also , th e CPU will

display an SC 342 if no signal changes (ON → OFF) are detecte d for more

than 2.55 seconds while the toner collection motor is turning.

When the toner collection bottle [A] become full, the toner pressure in the

bottle increases and presses the gear [F] against the toner overflo w swit ch

[G]. After the toner ove rflo w switch is a ctiva te d, the finishing of the copy job,

or up to 100 continuou s copie s, is a llowed, then copying is prohib ite d an d the

service call "full toner collection bottle" indication is displayed on the LCD.

This condition can be cleared by de-a ctuating the toner overflo w switch while

de-actuating then actua tin g the to ner co llect ion bot tle swit ch ([C] in next

page).

2-28

Page 54

23 April 1993 DRUM UNIT

[B]

[C]

[A]

Detailed

Descriptions

2.5.5 Pick-off mechanism

The pick-off pawls are always in contact with the drum surface with weak

spring pressure. They move side to side during the copy cycle. This

movement is made via a shaft [A] and an ecce nt ric ca m [B] .

2.5.6 Toner Collection Bottle Set Detection

The toner collection bottle set switch [C] prohibits machine operation by

indicating SC343 wh ile th e toner collection bottle is not set .

2-29

Page 55

DRUM UNIT 23 April 1993

2.6 QUENCHING

[A]

In preparation for the ne xt cop y cycle , ligh t fro m t he que nch ing la mp (QL ) [A]

neutralizes any charge remaining on the drum.

The quenching lamp consist s o f a line of 16 LEDs extending across the full

width of the drum.

Yellow colored LEDs are used fo r Q L to reduce ultra violet light which would

cause light fatigue on the OPC drum.

2-30

Page 56

[D]

23 April 1993 OPTICS

3. OPTICS

3.1 OVERVIEW

[A]

[C]

[B]

[E]

Detailed

Descriptions

The optics unit reflects an image of the origin al on the expo sure glass onto

the OPC drum. This forms a latent electrical image of the origin al.

On this model a halogen lamp (85 V 23 0 W) is use d fo r t he expo sure la mp

[A]. Lamp surface is frosted to ensure even exposu re.

Six mirrors are used to make the optics unit smaller and obtain the wide

reproduction ratio ran ge (50 ~ 200 %).

The lens [B] is driven by two stepping motors for (1) vertica l direction (parallel

to the paper feed direction) an d (2) horizontal direction movement s.

To correct focal length change in reduction and enlargement modes, the third

scanner unit [C] (4th and 5th mirrors) posit ion is changed by a stepping motor.

The toner shielding filte r [ D] is gree n (a gree n filter partly absorbs red light)

to improve red original duplication.

The optic anti-condensation heate r [ E] (located on the optic base plate) turns

on while main switch is turned off to preve nt the moistu re from forming on the

optics.

2-31

Page 57

OPTICS 23 April 1993

3.2 SCANNER DRIVE

[A]

[C]

[B]

[D]

[E]

A dc servo motor is used as the scanner drive moto r [ A] . Sca nn er drive

speed is 330 mm/sec. during scanning, and 1950 mm/sec. whe n the scanner

goes back.

The scanner drive motor drives the first [B ] and second scanners [C] using

two scanner drive wires via the timing belt [D] and the scanner drive shaft [E].

The second scanner speed is half of the first scan ne r spee d.

The scanner drive wire is not directly wound around the pulley on the

scanner drive motor.

2-32

Page 58

23 April 1993 OPTICS

3.3 VERTICAL LENS DRIVE

[B]

[A]

Detailed

Descriptions

HP (100%)

ReduceEnlarge

(Enlarge → HP)

(Reduce → HP)

(Enlarge → Enlarge)

(Reduce → Reduce)

(Enlarge → Reduce)

(Reduce → Enlarge)

steps30 30 30 30

The lens vertical drive motor [A] changes the lens vertical position in

accordance with the selected re pro du ctio n rat io.

A stepping motor (approx. 0. 09 5 mm/st ep) is use d to drive th e len s thro ug h

the lens drive belt. The maximum lens vertica l shift dista nce is 290 mm (from

the position at 50% to the position at 200%).

The lens vertical home position sensor [B] detects the lens vertical position

for full size mode. The optic control PCB keep s track of the lens po sitio n

based on the number of pulse s sent to the lens vertical drive motor.

2-33

Page 59

OPTICS 23 April 1993

3.4 HORIZONTAL LENS DRIVE

[A]

40

steps

Enlarge

40

HP

Reduce

40

The original horizont al position on the exposure glass varies dependin g on

the mode (such as platen, DJF and RDH modes) for easy original handling .

However, the cente r is th e sta nd ard position for paper feed.

Therefore, the lens ho rizontal position has to be cha ng ed accord ing to paper

size, reproduction ratio, original feed modes an d th e ed it mod es (centering,

margin adjust, etc.).

A stepping motor (ap pro x. 0.07 mm/step) is used to drive the lens through the

lens drive belt.

The lens horizontal ho me position sensor [A] is used to dete ct the lens

horizontal position fo r A4/ LT side ways, in full size an d pla ten mode.

The other positions are determined by counting the number of moto r drive

pulses.

Since this model has a horizontal lens drive mechanism, side-to-side

registration adju stme nt for each feed station can be don e easily b y using SP

mode ( SP Adjustment mode: PAGE 4).

1

2-34

Page 60

23 April 1993 OPTICS

3.5 HORIZONTAL LENS POSITIONI N G

3.5.1 For Original Position

Platen

DJF

5

100%

[A]

[C]

143.5

RDH

(Center)

Horizontal

2.5

Lens Position

Copy Paper

[B]

There are three standard orig ina l positions for the platen, DJF and RDH

modes.

In platen mode, the original is align ed with both the rear [A ] an d the lef t [B]

original scales (rear left corner [C] is the standard position).

In RDH mode, the original position is the cen te r of th e left scale [B].

In DJF mode, the original position is 5 mm to front of the pla te n mod e original

position to maintain th e orig ina l t ran spo rt pa th (5 mm from the rear scale).

The above figure shows the le ns horizontal positions for each original mode

when identical size paper is used.

Detailed

Descriptions

3.5.2 For Paper Size

Original Rear Edge

Horizontal

100%

Lens Position

Copy Paper

To keep high paper feed performance, the center is assigned as the paper

feed standard position . The ref ore, the lens horizontal position is chan ged

according to the paper size.

The figure shows the lens horizont al po sitio n fo r each paper size in fu ll size

mode.

2-35

Page 61

Copy Paper

OPTICS 23 April 1993

3.5.3 For Reproduction Ratio

Original Rear Edge

100% 50%

Original

200%

100%

3rd Scanner Position

50%

200%

When the reproduction ratio is changed, the vertical position of the lens is

changed. At th e same time, the total focal len gt h ha s t o be chan ge d to adjust

the image focusing. For this focal length change , th e ho rizon tal position of the

3rd scanner is also adjusted. The maximu m 3rd mirror shif t distance is 50

mm (from the position at 100% to the position at 50, 200%).

The figure shows the lens horizont al po sitio n fo r 50, 100 and 200%.

2-36

Page 62

23 April 1993 OPTICS

3.6 3RD SCANNER DRIVE

[B]

[A]

(Initialize)

Detailed

Descriptions

(Reduce/Enlarge → HP)

(Reduce/Enlarge → Reduce/Enlarge)

(Reduce/Enlarge → Reduce/Enlarge)

(Reduce/Enlarge →Enlarge/Reduce)

40 steps 40 steps

To compensate the focus for reproduction and lens po sition changes, the 3rd

scanner (4th and 5th mirrors) position is changed.

A stepping motor [A ] (ap prox. 0.095 mm/step) is used fo r the 3rd scan ne r

drive.

The 3rd scanner home positio n sen sor [B] is used to detect the un it po sitio n

for full size mode. The optic control PCB keep s track of the unit posit ion

based on the number of motor drive pulses.

2-37

Page 63

Optic Thermistor

Scanner Drive

Horizontal Lens

Drive

Vertical Lens

Drive

3rd Scanner

Drive

Optic Cooling

Fan

OPTICS 23 April 1993

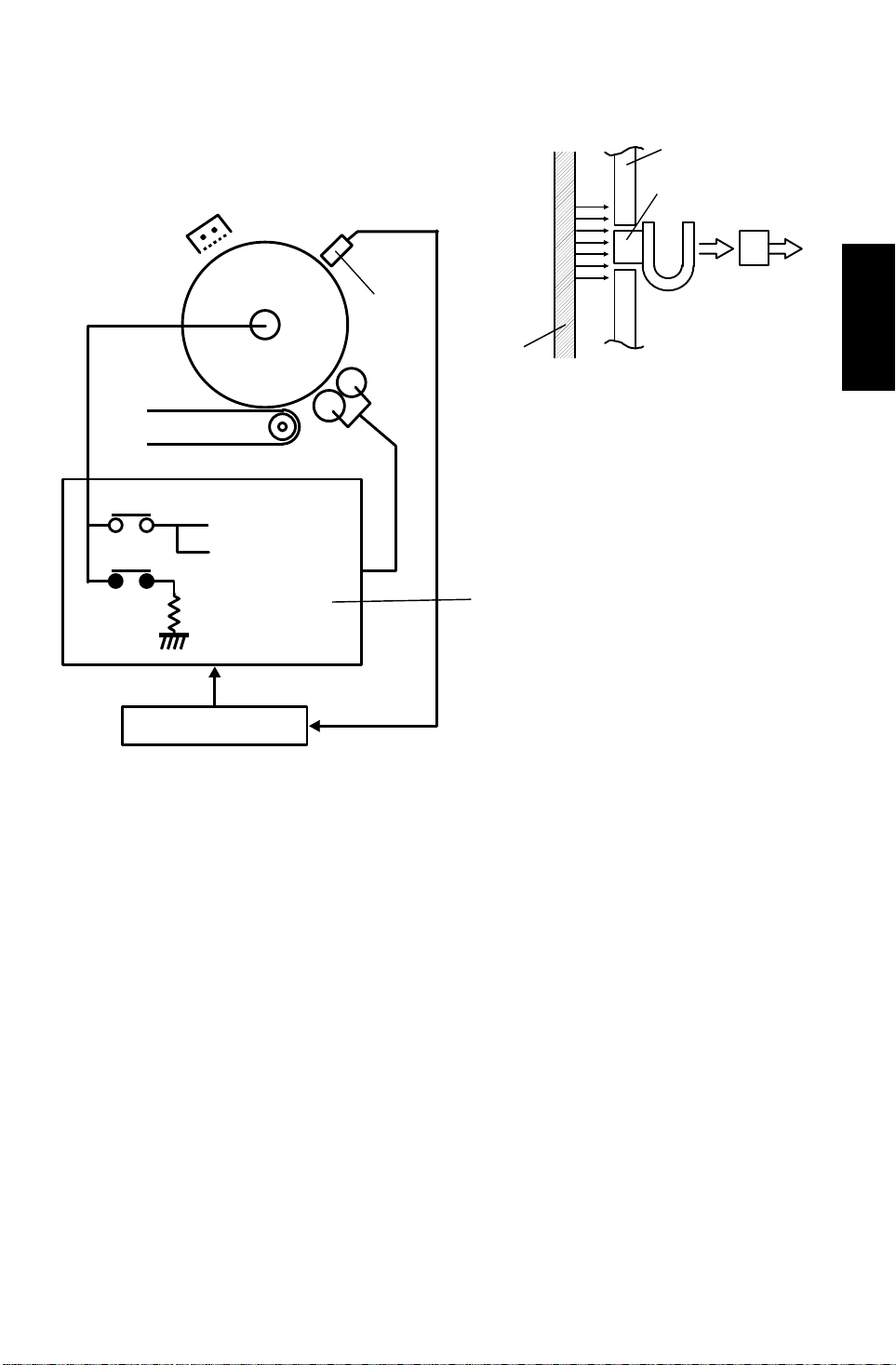

3.7 OPTICS CONTROL CIRCUIT

Main

Control

Board

Main

CPU

Sensors

Data

Bus

Optics Control Board

Optics Control

CPU

E

M

M

M

M

Encoder

M

Exposure Lamp

AC Drive

Board

The optic control board communicates with the main board through a data

bus. The optics control board mon ito rs all t he sensor signals, encoder output,

thermistor output and controls all motors in the opt ics.

At the programmed time, the main CPU sen ds a scan ne r start signal to the

optics control CPU.

The CPU generates a pulse-width modulation (PWM) signal. The PWM

signal goes to a driver circuit, which sen ds drive pulse s to th e scan ne r drive

motor.

An encoder in the scanner drive mot or ge nerates pulse signals.

A speed/direction contro l circu it mon ito rs t he sca nner speed and the direction

of the signals, and uses th is dat a to re gu lat e the motor speed.

The home position sensor mon itors the position of the scan ne r. Whe n the

main switch is turned on, the main CP U conf irms t he posit ion of the scanner

by moving the scanner out of the home posit ion and back ag ain . This da ta is

sent to the optics control CPU.

2-38

Page 64

23 April 1993 OPTICS

3.8 AUTOMATIC IMAGE DENSITY CONTROL SYSTEM (ADS)

[B]

[A]

Detailed

Descriptions

In ADS mode the original backgroun d densit y is sensed by the ADS sensor

[A] and the main CPU determines an appro pria te deve lopment bias voltage

for the original to preven t dirty backgrounds from appearing on copie s.

The ADS sensor board is moun te d on the rear side of the optics side plate.

The sensor board is covered by the sensor housing cover which has a small

hole to direct the reflected lig ht from th e orig ina l t o the ADS senso r.

The ADS sensor standard voltage is adjusted to 2.7 V when proce ss co nt rol

data initial setting is performed. The exposu re lamp turns on with ID level 4 at

the home position and the light refle cte d by th e ADS patte rn [B ] (white

painted) reache s the ADS sen sor. The main CPU adjusts the ADS gain dat a

automatically to make the out pu t 2. 7 V. This gain data is stored in the RAM

board.

2-39

Page 65

20 mm

OPTICS 23 April 1993

90 mm

9.7

A =

M

(mm)

M = 1.0 (m = 50 ~ 100)

m

M =

AB

B =

(m = 101 ~ 200)

100

8.25

x 100 (mm)

m

m: reproduction ratio

[V]

(50 ~ 200)

ADS

Sensor

Output

ADS

Original

Voltage

Peak hold

For the first scanning of an original in ADS mode, the CPU starts samplin g of

the ADS sensor output while exposing the ADS patte rn at the scann er ho me

position. Then the CPU stores th e maximu m ADS sen sor ou tp ut as a

reference voltage. This me ans tha t eve ry ADS check cycle, the first scanning

for the original, th e ADS re fe rence voltage is renewed by the la te st exposure

light reflected by the ADS pattern.

In the full size mode, th e CPU samp les the ADS sensor output whe n th e

scanner scans the original from 9.7 mm to 18 mm from th e left scale edge.

The CPU takes the maximum ADS sen sor ou tput during the sampling period

and compares it with the ADS refere nce voltage to determine the proper

development bias vo lta ge . (See development bias con tro l se ctio n for details.)

The sampling length of ADS senso r o ut pu t fo r t he original differs dependin g

on the reproduction ratio because the scanner speed is different.

2-40

Page 66

Darker

3

4

23 April 1993 OPTICS

3.9 MANUAL IMAGE DENSITY CONTROL

When the image density is set manually, th e volt ag e ap plie d to the expo sure

lamp changes as shown in the table below.

Dev. Bias

Voltage

(negative)

Exposure

Lamp Voltage

V

VBB –60

LAMP +4.5

V

V

LAMP +3.0

VLAMP +0.5

LAMP –1.5

V

LAMP –3.5

V

BB –90

VBB

V

LAMP

Lighter

Detailed

Descriptions

V

LAMP –5.5

6

7

5

21

VLAMP: Exposure lamp voltage at ID level 4.

This value is determined at process control data initial setting.

VBB: Development bias (negative) voltage at ID level 4.

This value is determined at process control data initial setting.

Manual ID

Position

2-41

Page 67

[D]

OPTICS 23 April 1993

3.10 UNEVEN LIGHT INTENSITY CORRECTION

[D]

original

[D]

exposure

intensity

illumination

Shading plate

[A] [B] [C]

distribution

[A] [B] [C]

The entire exposure lamp surface is frosted to ensu re eve n exposure.

To compensate for red uced light at the edge of the lens, a shading plate is

placed in front of the lens. The shading plate is fixed to th e lens unit.

The shading plate compensates the light intensity when the lens horizontal

position is shifted ([A] to [C]).

Also three shading mylars [D] int ercept any diffused refle cte d light from

outside the light path.

2-42

Page 68

23 April 1993 OPTICS

3.11 ORIGINAL SIZE DETECTION IN PLATEN MODE

[E]

[B]

[D]

[C]

Detailed

Descriptions

[A]

There are three reflective sensors (APS sensors) in the optics cavity for the

original size detection. Origin al widt h Se nso r [ A] is used fo r se nsin g th e

original width and Original Lengt h Sensor-1 [B] and Original Length Sensor-2

[C] sense the origina l leng th.

Inside each APS sensor, there is a n LED [D] an d th ree pho to ele ctric de vices

[E]. The light generated by the LED is broken up in three beams and each

beam scans a different point of the exp osu re gla ss. If the original or platen

cover is present over the scan ning point, the beam is refle cte d an d ea ch

reflected beam expose s a photo ele ctric de vice and act ivates it.

While the main switch is on, these sensors are active and the origin al size