Ricoh FT 5640 Service Manual

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main switch is turned off.

4. If any adjustment or operation check has to be made with exterior

covers off or open while the main switch is turned on, keep hands away

from electrified or mechanically driven components.

5. If the start key is pressed before the copier completes the warm-up

period, keep hands away from the mechanical and the electrical

components as the copier starts making copies as soon as the warm-up

period is completed.

6. The inside and the metal parts of the fusing unit become extremely hot

while the copier is operating. Be careful to avoid touching those

components with your bare hands.

HEALTH SAFETY CONDITIONS

1. Toner and developer are non-toxic, but if you get either of them in your

eyes by accident, it may cause temporary eye discomfort. Try to remove

with eye drops or flush with water as first aid. If unsuccessful, get

medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course

on those models.

2. The RAM board on the main control board has a lithium battery which

can explode if replaced incorrectly. Replace the battery only with an

identical one. The manufacturer recommends replacing the entire RAM

board. Do not recharge or burn this battery. Used batteries must be

handled in accordance with local regulations.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate the toner bottle or the used toner. Toner dust may

ignite suddenly when exposed to open flame.

2. Dispose of used toner, developer, and organic photoconductor

according to local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later,

do not put more than 100 batteries per sealed box. Storing larger

numbers or not sealing them apart may lead to chemical reactions and

heat build-up.

A204/A206/A207/A208/A210/A211

COPIER

SERVICE MANUAL

The A204 copier is based on the A153 copier.

The A206 copier is based on the A155 copier.

The A207 copier is based on the A156 copier.

The A208 copier is based on the A157 copier.

The A210 copier is based on the A159 copier.

The A211 copier is based on the A160 copier.

Only the differences from the base copiers are described in the

following pages. Therefore, this documentation should be treated

as an insert version of the base copier’s service manual, although

it has a separate binder. It should always be utilized together with

the base copier’s service manual.

31 March 1997 SPECIFICATIONS

1. SPECIFICATIONS

NOTE:

Only items marked with ✽ are different from A153, A155, A156,

A157, A159, and A160 copiers.

Configuration: Desktop

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book

Original Size: Maximum: A3/11" x 17"

Copy Paper Size: Maximum: A3/11" x17" (Paper trays)

Minimum: A5/8

A4/11" x 8

A6/5

1/2

1/2

" x 5

" x 8

1/2

" sideways (Paper trays)

1/2

" sideways (LCT)

1/2

" lengthwise (By-pass)

Duplex Copying: Maximum: A3/11" x 17"

Minimum: A5/8

1/2

✽ Copy Paper Weight: Paper tray: 52 ~ 128 g/m

By-pass: 52 ~ 157 g/m

LCT: 52 ~ 128 g/m

Duplex copying: 64 ~ 105 g/m

" x 5

1/2

" (sideways)

2

, 14 ~ 34 lb

2

, 14 ~ 42 lb

2

, 14 ~ 34 lb

2

, 17 ~ 24 lb

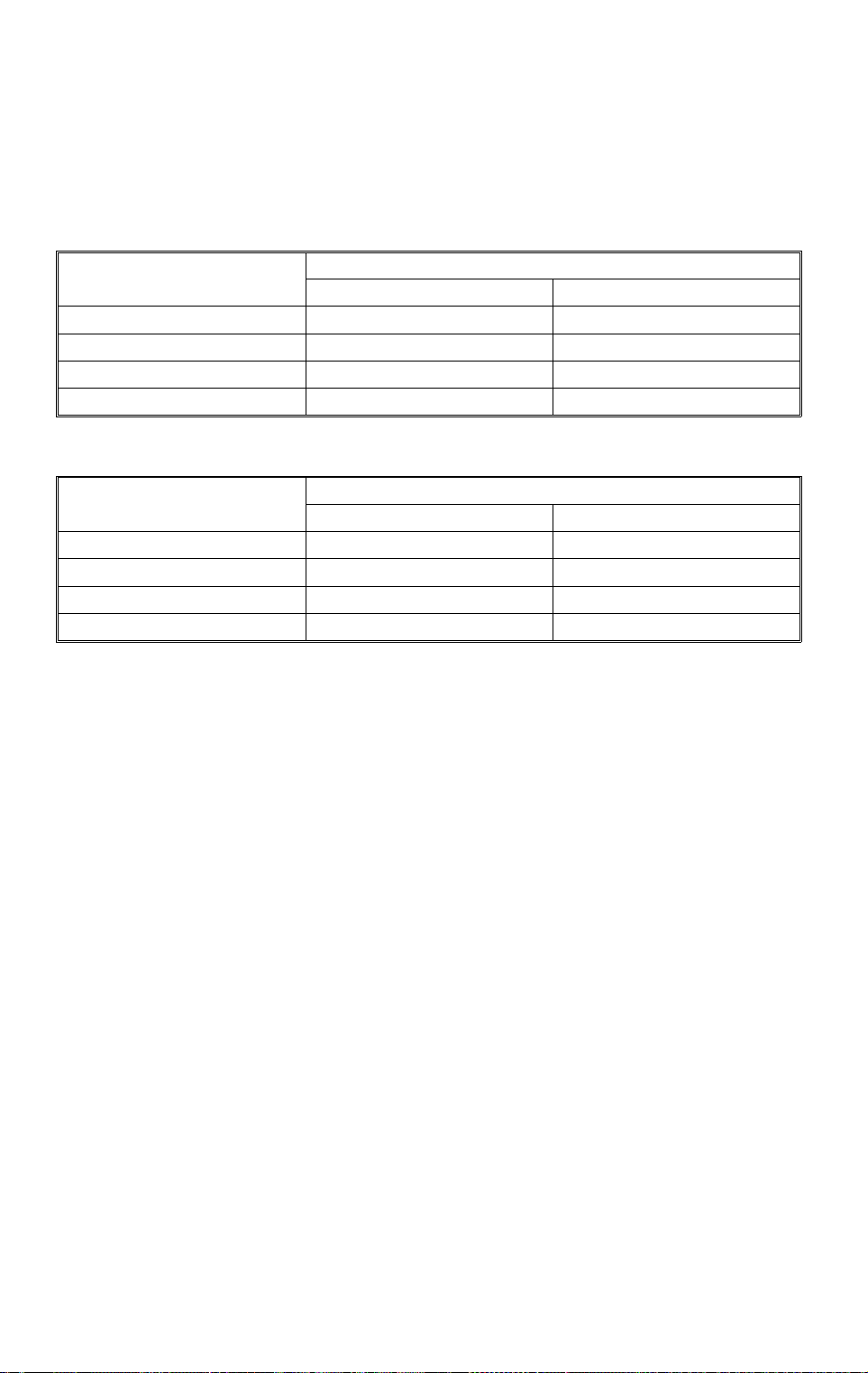

Copier

Reproduction Ratios: 4 Enlargement and 6 Reduction

A4/A3 Version LT/DLT Version

200%

Enlargement

Full size 100% 100%

Reduction

141%

122%

115%

93%

82%

75%

71%

65%

50%

200%

155%

129%

121%

93%

85%

77%

74%

65%

50%

1

SPECIFICATIONS 31 March 1997

Power Source: 120 V/60 Hz:

More than 12 A (for North America)

220 V ~ 240 V/50 Hz:

More than 7 A (for Europe)

220 V/50 Hz:

More than 7 A (for Asia)

110 V/60 Hz:

More than 13 A (for Taiwan)

220 V/60 Hz:

More than 7 A (for Saudi Arabia, Philippines)

✽ Power Consumption:

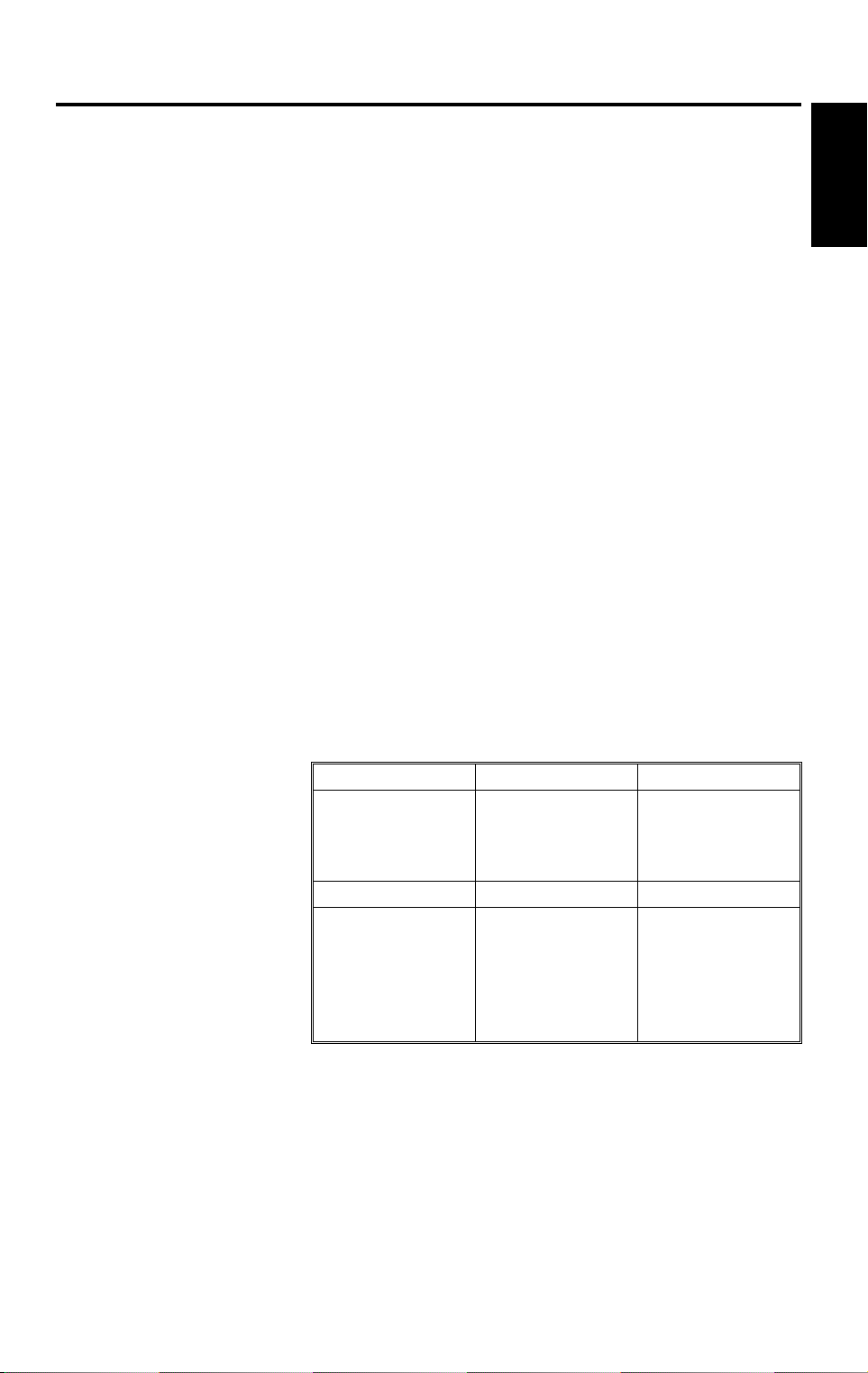

A204, A206, and A2 07 copiers A208, A210, and A21 1 copiers

Copier Only Full System Copier Only Full System

Maximum 1.35 kW 1.40 kW 1.35 kW 1.40 kW

Copying 1.15 kW 1.21 kW 0.90 kW 1.00 kW

Warm-up 1.21 kW 1.23 kW 0.98 kW 1.00 kW

Stand-by 0.18 kW 0.20 kW 0.16 kW 0.18 kW

NOTE:

– Full System –

Copier + ARDF (A663) + Paper Tray Unit (A549) + 20 Bin S/S (A664)

✽ Noise Emission:

A204, A206, and A20 7 copiers A208, A210, and A211 copiers

Copier Only Copier Only

1. Sound Pressure Level

Operator position 64 dB (A) 63 dB (A)

Standard positio n 59 dB (A) 58 dB (A)

2. Sound Power Level

Copying 70 dB (A) 69 dB (A)

Stand-by 42 dB (A) 43 dB (A)

NOTE:

The above measurements were made in accordance with ISO 7779.

2

31 March 1997 SPECIFICATIONS

Dimensions:

Width Depth Height

A204 copier 1,030 mm (40.6") 655 mm (25.8 ") 606 mm (23.9")

A208 copier 900 mm (35. 5") 655 mm (25.8") 606 mm (2 3.9")

A206 and A207 copiers 1,258 mm (49 .6 ") 655 mm (25.8") 606 mm (2 3.9")

A210 and A211 copiers 1,128 mm (44 .5 ") 655 mm (25.8") 606 mm (2 3.9")

Measurement Conditions

1) With by-pass feed table closed

2) With platen cover and copy tray attached

3) With LCT cover closed

Copier

✽ Weight:

NA EU

A204 copier 70 kg (154.3 lb) 73 kg (160.9 lb)

A206 copier 78 kg (172.0 lb) 81 kg (178.5 lb)

A207 copier 81 kg (178.6 lb) 84 kg (185.2 lb)

A208 copier 69 kg (152.1 lb) 72 kg (158.7 lb)

A210 copier 77 kg (169.8 lb) 80 kg (176.4 lb)

A211 copier 79 kg (174.2 lb) 82 kg (180.7 lb)

Weight

Zoom: From 50% to 200% in 1% steps

✽ Copying Speed (copies/minute):

A4 sideways/

11" x 8

A204, A206, and A207 copiers 40 22/21 25

A208, A210, and A211 copiers 32 17/16 19

1/2

"

A3/11" x 17" B4/8

✽ Warm-up Time: A204, A206, and A207 copiers:

Less than 250 seconds (20°C)

A208, A210, and A211 copiers:

Less than 110 seconds (20°C)

" x 14"

1/2

✽ First Copy Time:

Paper Feed Station

1st Tray 4.4 s (except for A20 7) 4.9 s (except for A211)

2nd Tray 4.9 s 5.4 s

By-pass 4.4 s 4.7 s

LCT 4.4 s 4.9 s

NOTE:

In A207 and A211 copiers, the 2nd tray in the above table is called

the 1st tray.

A4/11" x 8

A204, A206, and A20 7 copiers A208, A210, and A211 c opi er s

3

" (sideways)

1/2

SPECIFICATIONS 31 March 1997

Copy Number Input: Ten-key pad, 1 to 999 (count up or count down)

Manual Image Density

7 steps

Selection:

Automatic Reset: 1 minute is the standard setting; it can be changed

to a maximum of 999 seconds or no auto reset by

SP mode.

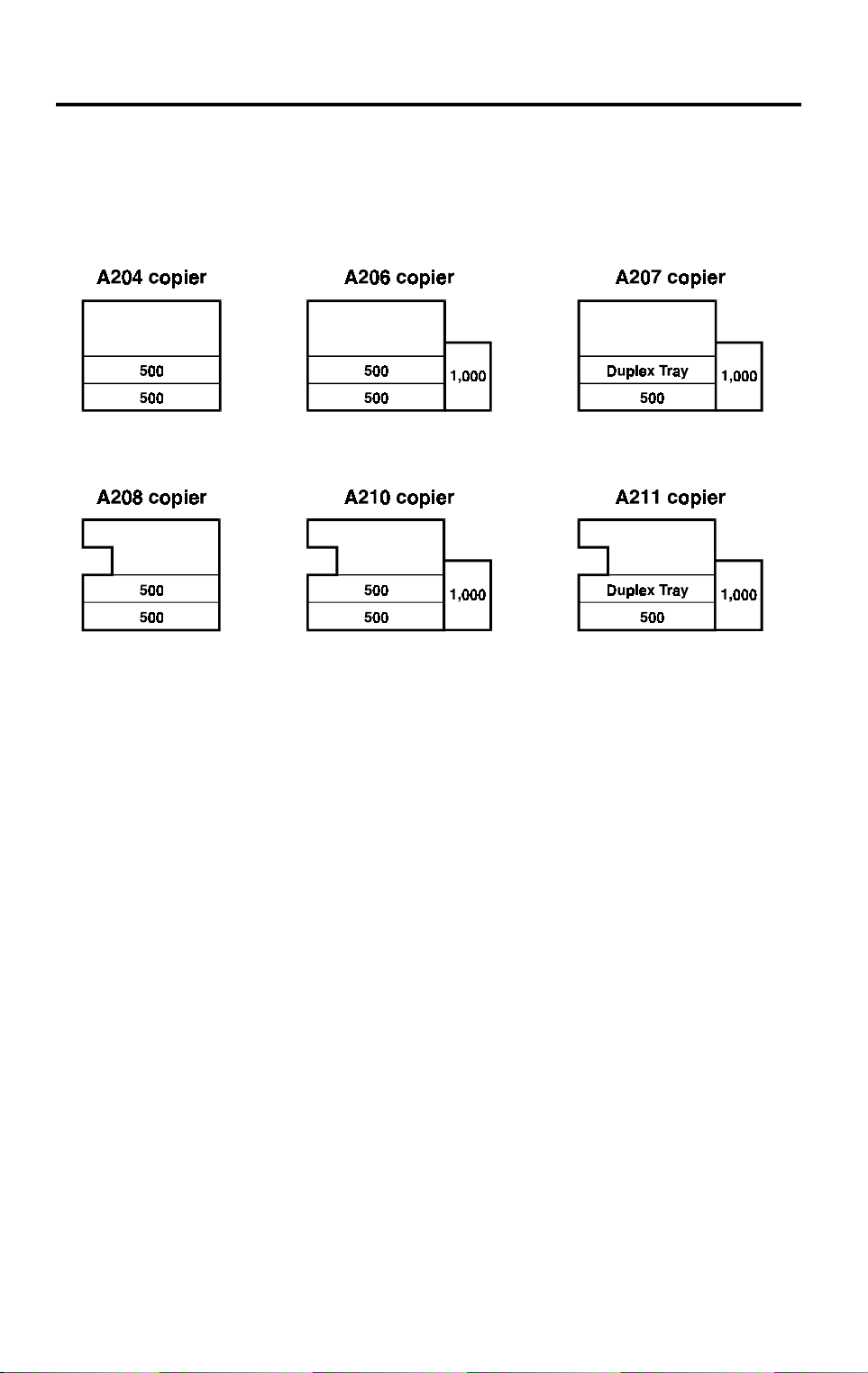

✽ Copy Paper Capacity:

Paper Tray By-pass Feed LCT

A204 copier About 500 sheets x 2 About 40 sheets —

A206 copier About 500 sheets x 2 About 40 sheets About 1,000 sheet s

A207 copier About 500 sheets x 1 About 40 sheets About 1,000 sheet s

A208 copier About 500 sheets x 2 About 40 sheets —

A210 copier About 500 sheets x 2 About 40 sheets About 1,000 sheet s

A211 copier About 500 sheets x 1 About 40 sheets About 1,000 sheet s

NOTE:

Paper tray - 500 sheets or less than 53 mm stack height

By-pass feed - 40 sheets or less than 4 mm stack height

LCT - 1,000 sheets or less than 120 mm stack height

Duplex Tray Capacity

[A207/A211]:

50 sheets (30 sheets for A3/11"x17"

81 ~ 105g/m

2

, 21.5 ~ 27.9 lb paper)

Toner Replenishment: Cartridge exchange (415 g/cartridge)

•

✽ Optional Equipment:

Platen cover

•

Document feeder

•

Paper tray unit with two paper trays

•

Paper tray unit with three paper trays

•

10 bin micro sorter (for A208, A210, and A211

copiers)

•

20 bin mini sorter

•

10 bin sorter stapler

•

20 bin sorter stapler

•

20 bin multi-position sorter stapler

•

Sorter adapter (required when installing 20 bin

mini sorter, 10 bin sorter stapler, 20 bin sorter

stapler, or 20 bin multi-position sorter stapler for

A208, A210, and A211 copiers)

•

Key counter

•

Tray heater

4

31 March 1997 SPECIFICATIONS

•

Optical anti-condensation heater

•

Original length sensor for 11" x 15" size paper

(only for LT/DLT version)

•

ADS sensor for particular types of red original

•

Specifications are subject to change without notice.

Copier

5

MACHINE CONFIGURATION 31 March 1997

2. MACHINE CONFIGURATION

2.1 COPIER

A204V500.wmf

6

31 March 1997 MACHINE CONFIGURATION

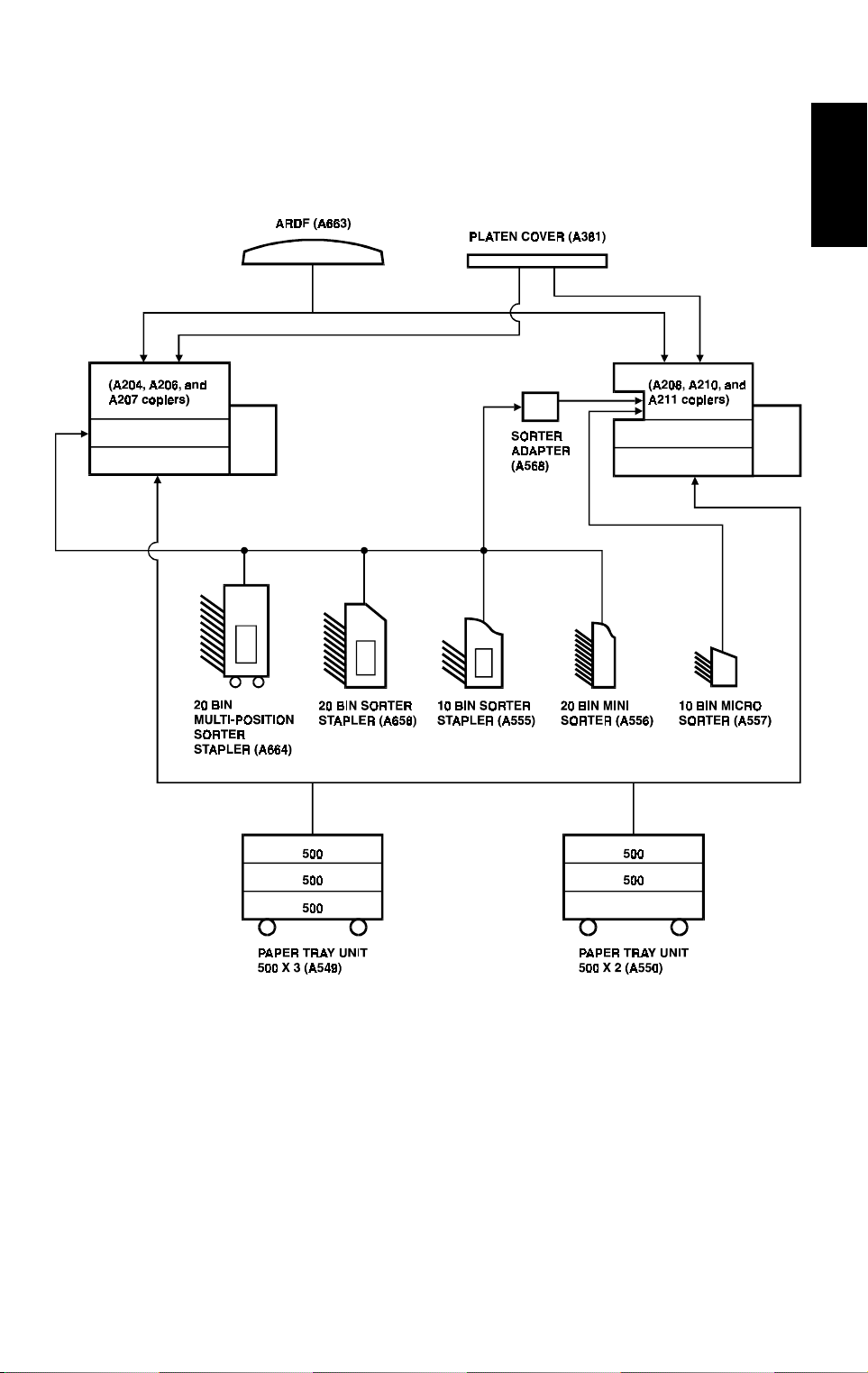

2.2 OPTIONAL EQUIPMENT

Copier

A204V501.wmf

7

MECHANICAL COMPONENT LAYOUT 31 March 1997

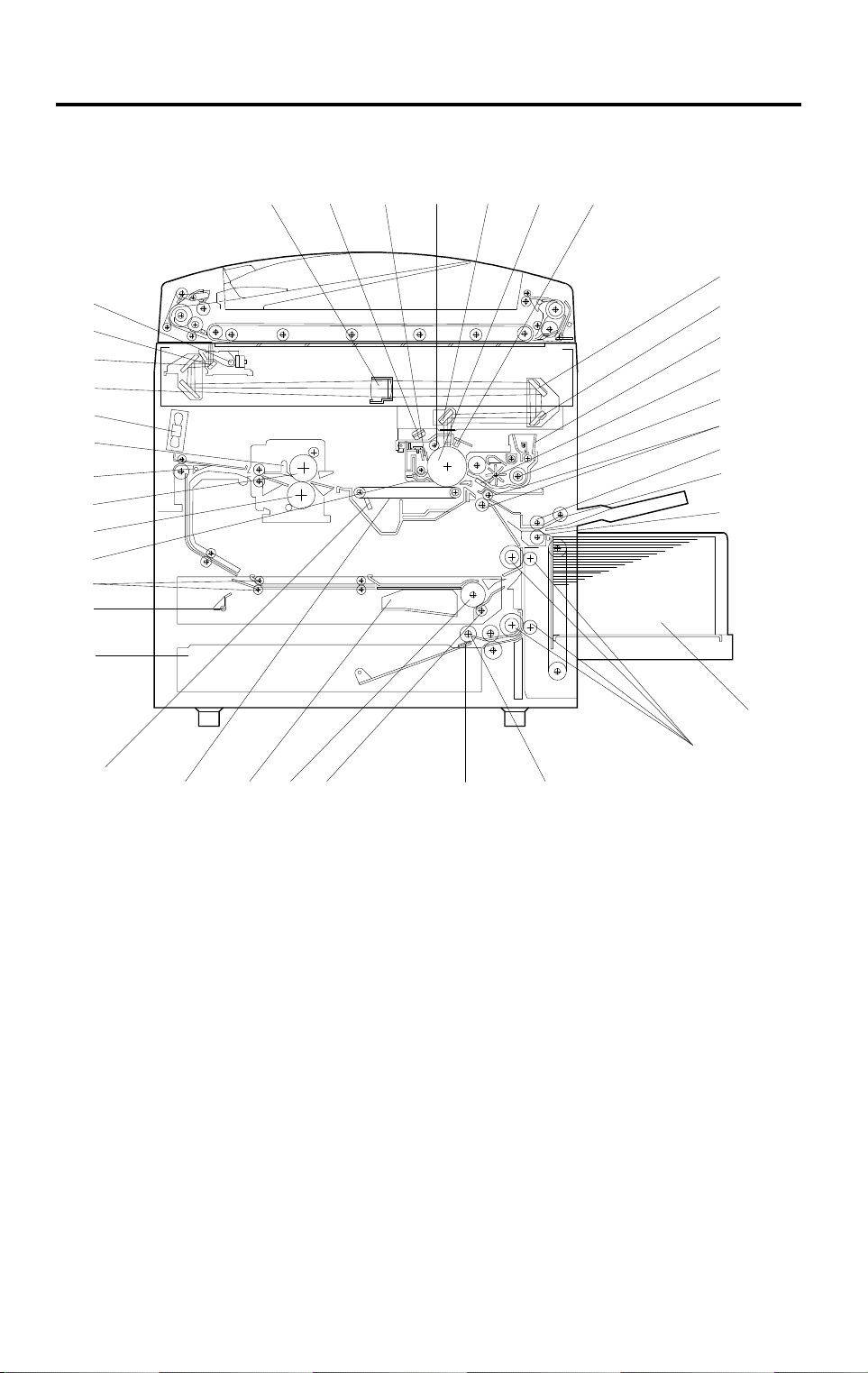

3. MECHANICAL COMPONENT LAYOUT

– A207 copier –

56 91011

4

3

2

1

38

37

36

35

34

33

32

31

87

12

13

14

15

16

17

18

19

20

30

22

29

28 27 26 25 24

23

A204V502.wmf

The fusing unit has been changed. (See Detailed Descriptions for more

information.)

NOTE:

1) The A204 copier is the same as the A207 copier except that the

A204 does not have a duplex tray or an LCT.

2) The A206 copier is the same as the A207 copier except that the

A206 does not have a duplex tray.

21

8

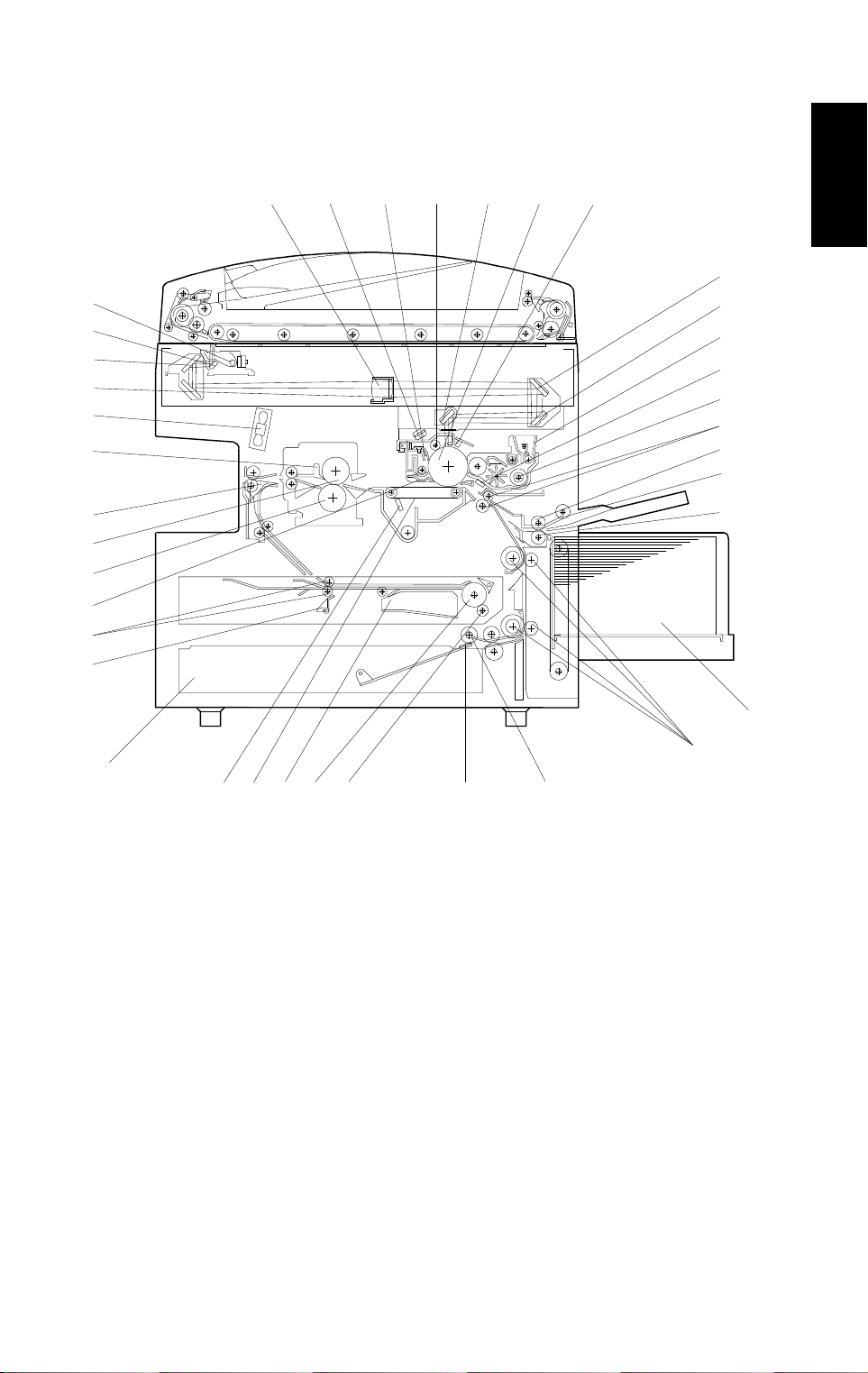

31 March 1997 MECHANICAL COMPONENT LAYOUT

– A211 copier –

4

3

2

1

38

37

36

35

34

33

32

31

56 91011

87

Copier

12

13

14

15

16

17

18

19

20

21

22

30

28 27 26 25

29

24

23

A204V503.wmf

The paper tray unit has been changed from the corner separation system to

the FRR feed system.

NOTE:

1) The A208 copier is the same as the A211 copier except that the

A208 does not have a duplex tray or an LCT.

2) The A210 copier is the same as the A211 copier except that the

A210 does not have a duplex tray.

9

MECHANICAL COMPONENT LAYOUT 31 March 1997

1. 3rd Mirror

2. 2nd Mirror

3. 1st Mirror

4. Exposure Lamp

5. Lens

6. Quenching Lamp

7. Drum Cleaning Blade

8. Drum Charge Roller

9. 6th Mirror

10. OPC Drum

11. Erase Lamp

12. 4th Mirror

13. 5th Mirror

20. Separation Roller

21. Large Capacity Tray

22. Vertical Transport Rollers

23. Paper Feed Roller

24. Friction Pad

25. Duplex Friction Roller

26. Duplex Feed Roller

27. Jogger Fence

28. Transfer Belt

29. Transfer Belt Cleaning Blade

30. Lower Paper Tray

31. End Fence

32. Entrance Rollers

14. Toner Supply Unit

15. Pre-transfer Lamp

16. Development Unit

17. Registration Rollers

18. Feed Roller

19. Pick-up Roller

33. Pick-off Pawls

34. Pressure Roller

35. Hot Roller

36. Junction Gate

37. Hot Roller Strippers

38. Exhaust Fan

10

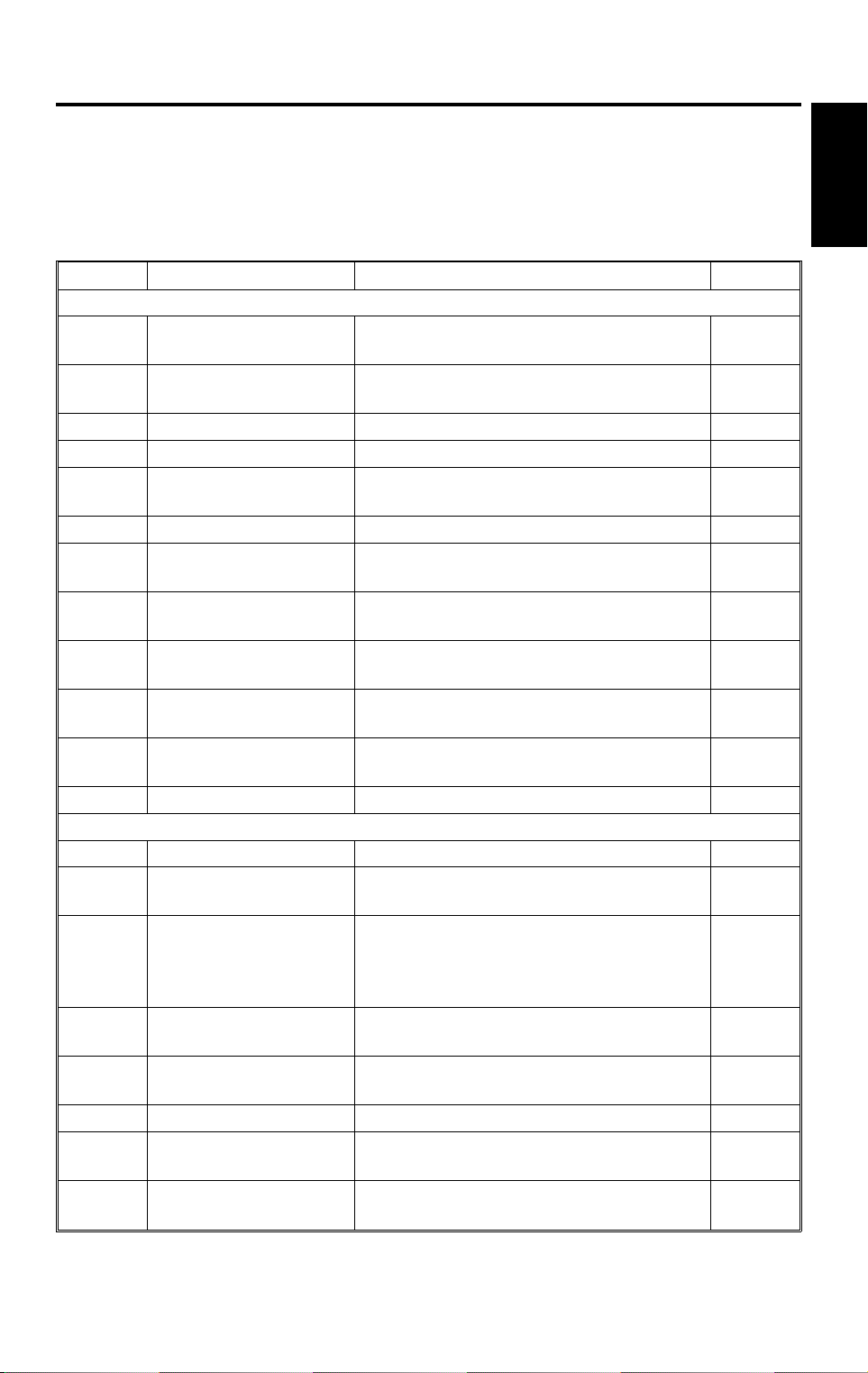

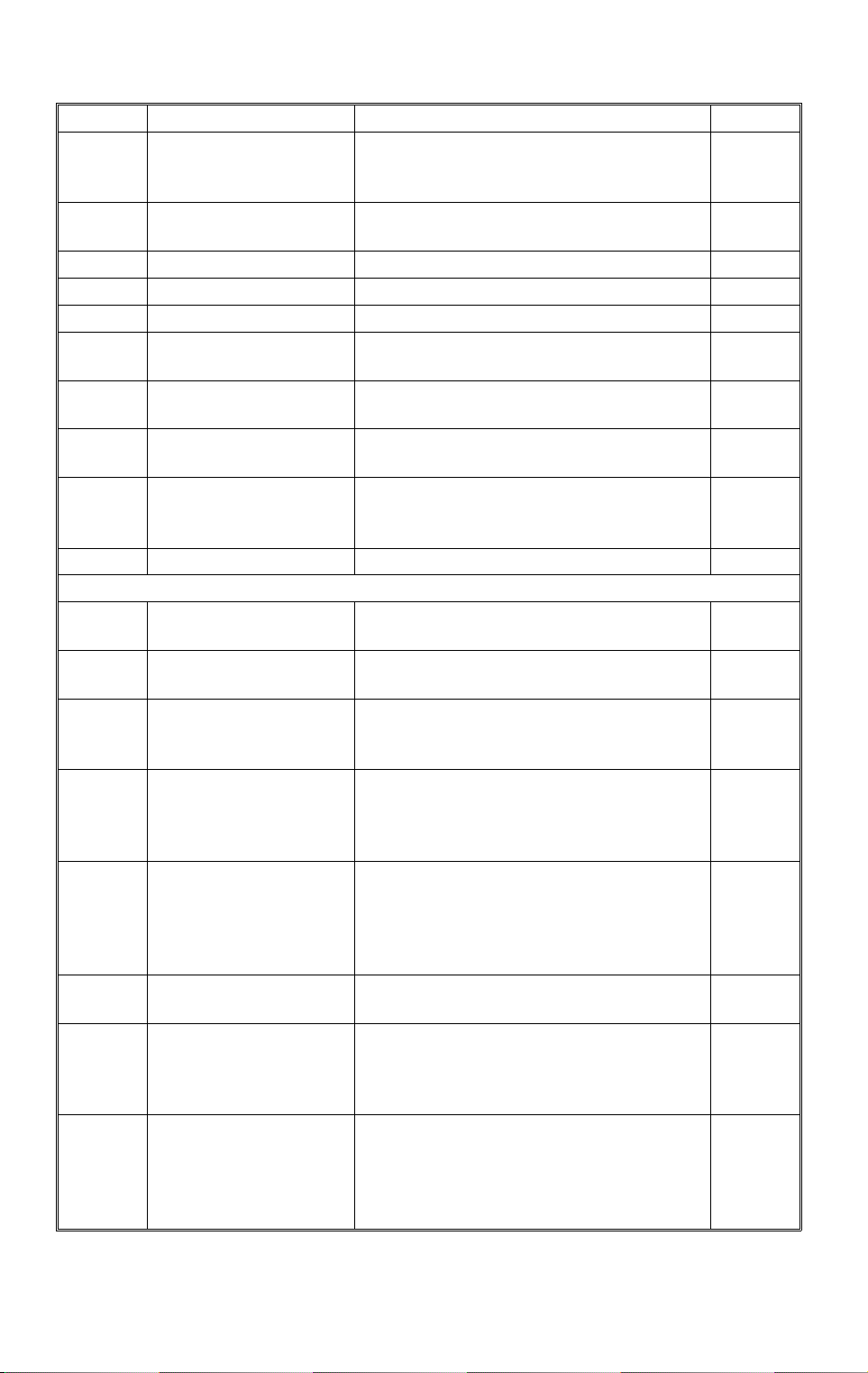

31 March 1997 ELECTRICAL COMPONENT DESCRIPTIONS

4. ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout and the point to point diagram on the

waterproof paper in the pocket for symbols and index numbers.

✽ : New or modified components

Symbol Name Function Index No.

Printed Circuit Boards

PCB1

PCB2

PCB3 DC Power Supply Provides dc power. 10

PCB4 Main Motor Co nt rol Controls the rotat ion of the main moto r. 94

PCB5

PCB6 T High Voltage Supply Supplies high voltage to the transfer belt. 52

PCB7

PCB8

PCB9

PCB10

PCB11

Main Control Controls all copier functions both directly or

through other control boards.

AC Drive Provides ac power to the exposure lamp

and fusing lamps.

CB High Voltage Supply Supplies high vo ltage to the drum charg e

roller and development roller.

Operation Pan e l Controls the LED matri x, and monitors th e

key matrix.

Noise Filter (220 ~ 240

V machines only)

Duplex Control

(Duplex mac h in es only)

Liquid Crystal Display

(A207 machines only)

LCT Interface

(LCT machines only)

Removes elect rical noise.

Controls the oper ation of the duplex tray.

Controls the gui dance dis play and displays

guidance for machine opera tion.

Interfaces the LCT control signal between

the main board and the LCT.

13

11

1

3

8

60

6

100

Copier

Motors

M1 Main Drives the ma i n uni t com ponents. 85

M2

M3

✽

M4

✽

M5

M6 Optics Cool i ng Fan 1 Removes h eat from the optics unit. 92

M7

✽

M8

Toner Bottle Drive Rotates the toner bottle to supply toner to

the toner supply u ni t .

Upper Tray Lift

(Non-duplex machines

only)

Lower Tray Lift Raises the bottom pl ate in the lower paper

LCT Lift

(LCT machines only)

Optics Cooling Fan 2 Removes h eat from the optics unit .

Exhaust Fan 1 Removes the heat from around the fusing

Raises the bottom pl ate in the uppe r paper

tray.

A204/206/208/ 210: M3 and M4 are

✽

combined into one unit

tray.

Lifts up and lower s t he LC T bottom plat e.

A208/210/211 now have two fans.

✽

unit.

11

76

95

83

97

93

87

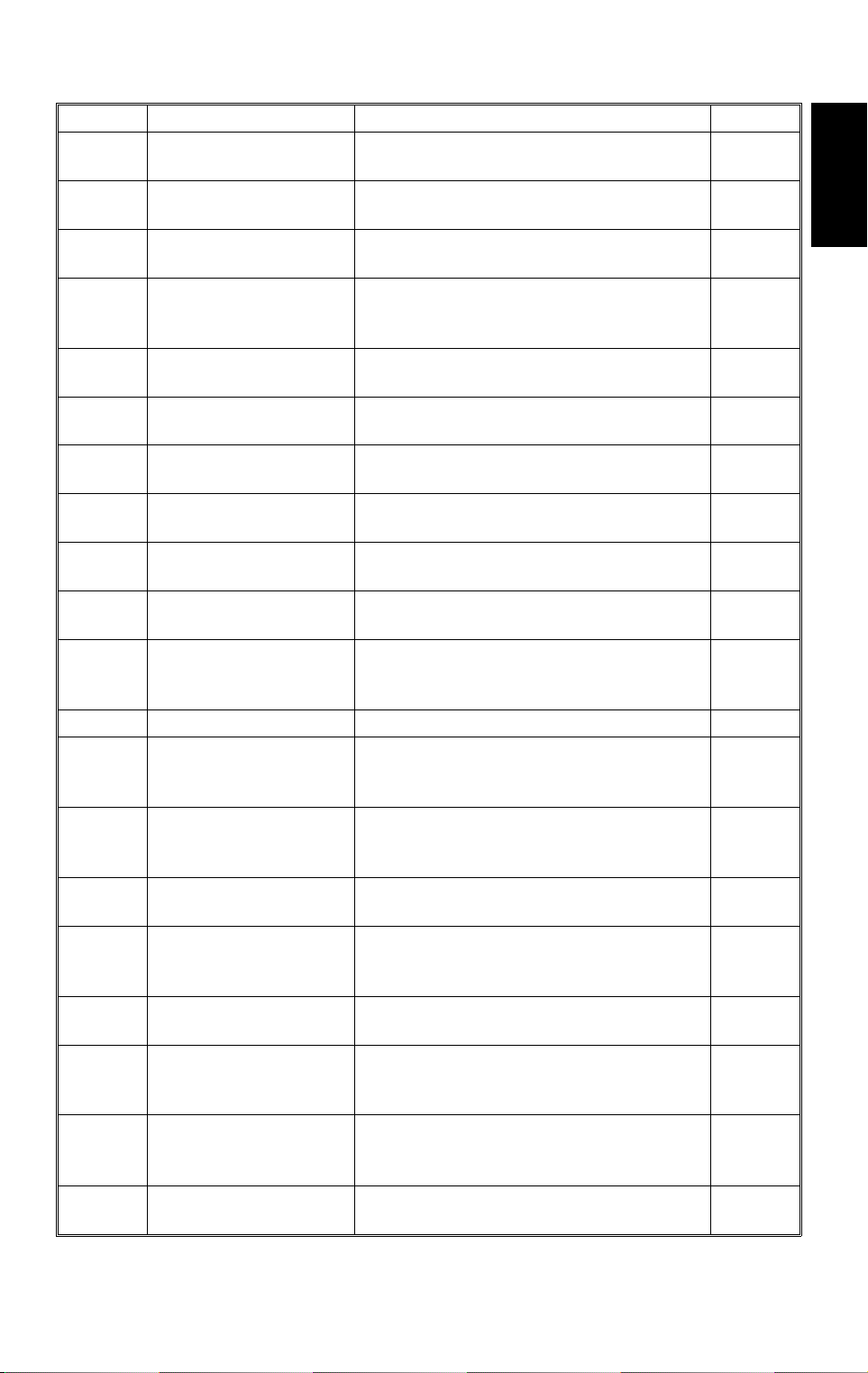

ELECTRICAL COMPONENT DESCRIPTIONS 31 March 1997

Symbol Name Function Index No.

M9

Exhaust Fan 2

(A204/A206/A207

Removes the heat fr om ar ound the fusing

unit.

88

machines only)

M10

Scanner Drive Drives the 1st and 2nd scanners (dc

stepper motor ).

90

M11 3rd Scanner Drive Drives the 3rd scanner (dc stepper motor). 75

M12 Lens Vertical Drive Shifts the lens vertical position. 84

M13 Lens Horizont al D r i ve Shifts th e l ens horizontal p osi t i on. 74

M14

M15

M16

M17

✽

Duplex Feed

(Duplex mac h in es only)

End Fence Jogge r

(Duplex mac h in es only)

Side Fence Jogger

(Duplex mac h in es only)

DC Board Cooling Fan

Motor (A204/A206/A207

Drives the feed roller and moves the

bottom plate up and down.

Drives the end f ence jogger to squar e t he

paper stack.

Drives the side f ence jogger to squar e the

paper stack.

55

58

57

Removes heat from t he dc power supply

board. 86

N. American mo del s)

Sensors

S1

S2

S3

S4

S5

✽

S6

S7

S8

✽

By-pass Feed Paper

Width

Informs the CPU what width paper is in the

by-pass feed ta bl e.

By-pass Feed Pa per End Informs the CPU that ther e i s no paper in

the by-pass tray.

Upper Tray Paper End

(Non-duplex machines

Informs the CPU wh en the upper paper

tray runs out of pap er. 48

only)

Upper Relay Detects the leadi ng edge of paper f ro m the

upper tray to dete rm i ne the stop timi ng of

the upper paper fee d clutch, and detects

misfeeds.

Upper Tray Upper Limit

(Non-duplex machines

only)

Detects the hei ght of the paper stack i n the

upper paper tray t o stop the upper tray lif t

motor.

A208/210/211 have the compone nt s

✽

needed for an FRR m echanism.

Lower Tray Paper End Informs the CPU when the l ow er paper tray

runs out of paper.

Lower Relay Detects the le ading edge of pape r from the

lower paper tray to determine the stop

timing of the low er paper feed clutch, and

detects misfeeds.

Lower Tray Upper Limit Detects the height of the paper stack in t he

lower paper tray to stop the lower tr ay l i f t

motor.

A208/210/211 have the compone nt s

✽

needed for an FRR m echanism.

26

30

105

28

49

104

29

12

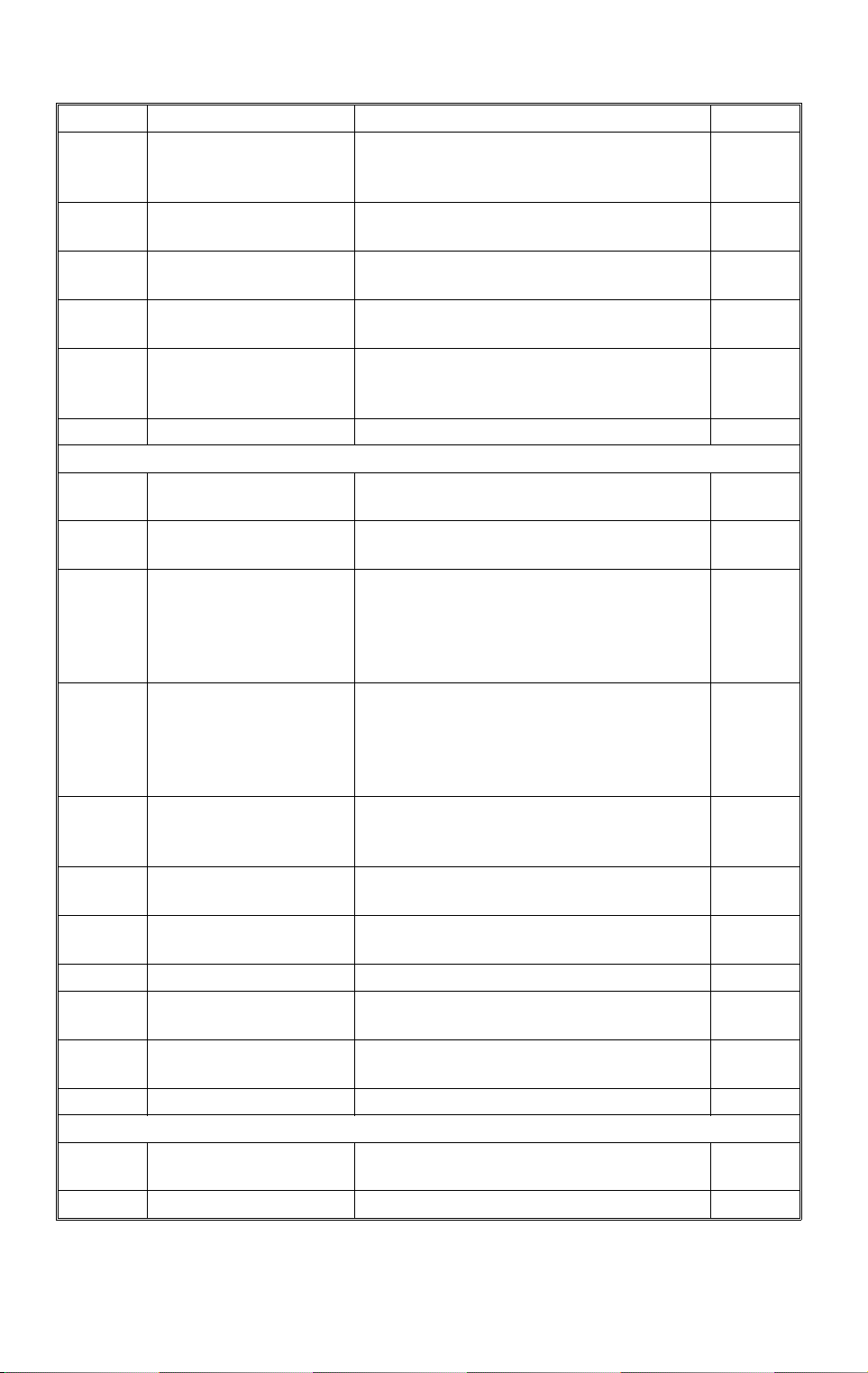

31 March 1997 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Name Function Index No.

S9

S10

S11

S12

S13

S14

S15

S16

S17

S18

S19

S20 Fusing Exit Detects mis fe eds. 42

S21

S22

S23

S24

S25

S26

S27

S28

LCT Lower Limit

(LCT machines only)

LCT Paper End

(LCT machines only)

LCT Upper Limit

(LCT machines only)

Registrati on Detects the leading edge of the copy pape r

Image Densi ty (I D) Detects the density of various patterns on

Toner Densi t y (TD) Detects the toner concentrat i on i nside the

Lens Horizont al H P Informs the CPU tha t the l ens is at the

Lens Vertical HP Informs the CPU that the lens is at the

Scanner HP Informs the CPU when the 1st and 2nd

3rd Scanner HP Informs the CPU when the 3rd scanner is

Original Length-2 Detects the lengt h of the original . Th i s i s

Platen Cover Informs the CPU whether the pl at en cover

Toner End Instructs the CPU to add toner to the toner

Auto Response Returns the operation panel display and

Transfer Belt Co nt act HP Informs the CPU of the current position of

Auto Image Density

(ADS Sensor)

Original Width Detects the width of the original. This is

Original Length-1 Detects the lengt h of the original . Th i s i s

Duplex Paper End

(Duplex mac h in es only)

Sends a signal to th e C P U to stop lowering

the LCT bottom p late.

Informs the CPU wh en the LCT runs out of

paper.

Sends a signal to th e C P U to stop lifting

the LCT bottom p late.

to determine the stop timing of the paper

feed clutch, and d et ect s misfeeds.

the drum durin g pr ocess control.

development unit.

horizontal ho me position.

full-size position.

scanners are at the h om e position.

at the home posit i on.

one of the APS (Auto Paper Select)

sensors.

is up or down (related to APS/ARE

functions). ARE: Auto R educe and Enlarge

supply unit, and detects toner end

conditions.

exits from the energy saver mode.

both the transfer belt unit and th e dr um

charge roller uni t .

Detects the background density of each

original in ADS mo de.

one of the APS (Auto Paper Select)

sensors.

one of the APS (Auto Paper Select)

sensors.

Detects paper i n t he duplex tray.

98

99

25

27

47

50

36

19

14

23

20

15

51

40

22

12

41

18

53

Copier

13

ELECTRICAL COMPONENT DESCRIPTIONS 31 March 1997

Symbol Name Function Index No.

S29

Duplex Turn

(Duplex mac h in es only)

Detects the trailing edge of the copy paper

to determine the jo ggi ng timing, an d

54

detects misfeeds.

S30

S31

S32

S33

Duplex Entrance

(Duplex mac h in es only)

Side Fence Jogger HP

(Duplex mac h in es only)

End Fence Jogge r HP

(Duplex mac h in es only)

Original Length

(Option for N. American

Detect s m i sfeeds.

Detects the hom e position of the duplex

side fence jogger.

Detects the hom e position of the duplex

end fence jogger.

Detects orig inal l ength for 11" x 15" p aper.

59

56

61

21

models)

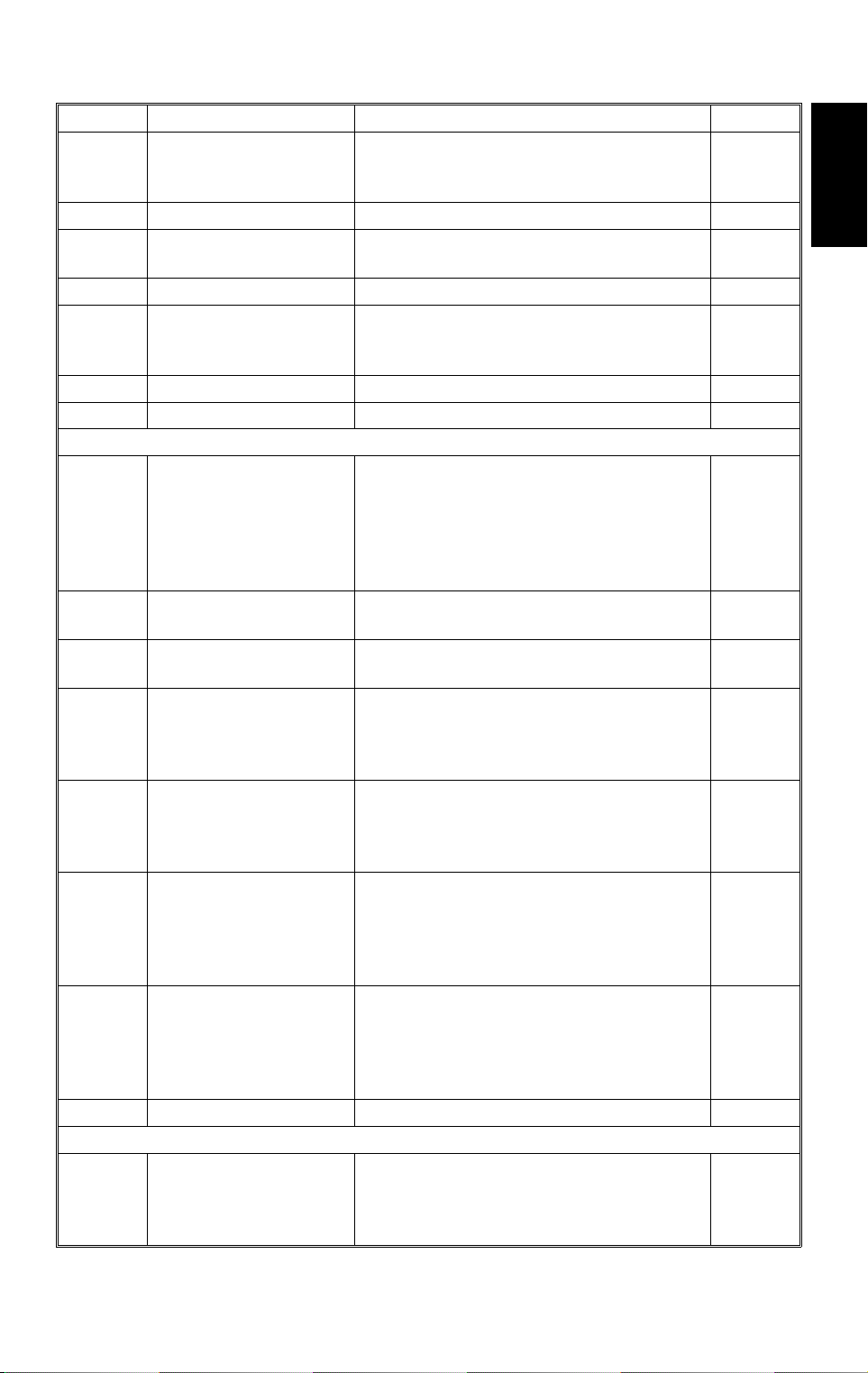

Switches

SW1

SW2

SW3

✽

By-pass Feed Table Detects whether the by-pass feed table is

open or closed.

Tray Down

(LCT machines only)

Upper Tray Paper Siz e

(Non-duplex machines

only)

Sends a signal to the CPU to lower the

LCT bottom plate.

Determines w hat si ze of paper is in th e

upper paper tray, and detects when th e

tray has been cl osed.

The upper tray swi t ch has been

✽

32

102

24

eliminated.

Lower Tray Pap er Siz e Determines what size of paper is in the

lower paper tray, and detects when the tray

SW4

✽

has been closed.

The lower tray switch has been

✽

33

eliminated.

SW5

Vertical Guide Set

(Non-LCT m achines

Detects whether the vertical gui de i s open

or not. 31

only)

SW6

SW7

LCT Cover-1

(LCT machines only)

LCT Cover-2

(LCT machines only)

Detects whether the LCT cover is ope n or

not.

Cuts the dc power l i ne of the LCT lift motor.

103

101

SW8 Main Supplies power to t he copier. 39

SW9

SW10

Front Cover Saf e t y Cuts the ac power line and detects whether

the front door is open or not.

Exit Cover Safety

(A211 machines only)

Cuts the ac power l i ne and detects whet her

the exit cover is open or not.

38

45

Magnetic Clutches

CL1

Toner Supply Turns the toner supply roller to supply

toner to the devel opment unit.

CL2 Dev elopment Drives t he develo pment roller. 68

14

69

31 March 1997 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Name Function Index No.

Transfer Belt Co nt act Controls the touch and releas e m ovement

CL3

CL4 Registration Drives the registration rollers. 70

CL5

CL6 Relay Drives the relay rollers. 73

CL7

CL8 Lower Paper Feed Starts paper feed fr om the lower paper tr ay. 82

Solenoids

SOL1

SOL2

SOL3

SOL4

✽

SOL5

✽

SOL6

✽

SOL7

✽

By-pass Feed Starts paper feed from the by-pass feed

Upper Paper Feed

(Non-duplex machines

only)

LCT machines:

LCT/By-Pass Pick -u p

Solenoid

Non-LCT machi nes:

By-pass Pick-up

Solenoid

Junction Gate

(Duplex mac h in es only)

LCT Pick-up

(LCT machines only)

Upper Tray Pick-up

(Non-duplex machines

only)

Lower Tray Pick -up Controls the up/ down movement of th e

Upper Tray Separ at i on

(Non-duplex machines

only)

Lower Tray Separation Controls the up-down movement of the

of both the transfer bel t uni t and the drum

charge roller uni t .

table or LCT.

Starts paper feed from the upper paper

tray. 81

Picks paper up from t he by-pass feed

table. When paper is fed from the LC T, this

solenoid ass i st s SO L3.

Moves the junction gate to direc t copies to

the duplex tray or to the paper exit.

Picks up paper from t he LC T.

Controls the up/down movement of the

pick-up roller i n the upper paper tray.

A208/210/211 have the compone nt s

✽

needed for an FRR m echanism.

pick-up roller i n the lower paper tr ay.

A208/210/211 have the compone nt s

✽

needed for an FRR m echanism.

Controls the up- down move m ent of the

separation rol l er in the upper pap er tr ay

feed station.

A208/210/211 have the compone nt s

✽

needed for an FRR m echanism.

separation rol l er in the lower pa per tr ay

feed station.

A208/210/211 have the compone nt s

✽

needed for an FRR m echanism.

91

71

72

89

96

77

79

78

80

Copier

Lamps

L1

✽

Exposure Applies high intensity light to the original for

exposure.

Modified - see the "O pt i cs" section for

✽

details.

15

16

ELECTRICAL COMPONENT DESCRIPTIONS 31 March 1997

Symbol Name Function Index No.

Main Fusing Provides heat to the central area of the hot

L2

✽

roller.

Modified - see the "Fusing" section for

✽

62

details.

Secondary Fu si ng Provides heat to both ends of the hot roller.

L3

✽

Modified - see the "Fusing" section for

✽

63

details.

Pre-transfer Red uces the charge re maining on the

L4

drum surface bef or e t ransfer. 4

Quenching Neutralizes any charge rem a in ing on the

L5

drum surface af te r cleaning.

5

Erase After exposure, this eliminates the charge

L6

on areas of the drum that will not be used

2

for the image.

Heaters

Drum Turns on when the main switch is off to

keep the temperature around the drum

H1

charge roller at a certain level. Also

35

prevents moisture from forming around the

drum.

H2

Optics Anti-c ondensation

(option)

Turns on when the main switch is off to

prevent moisture from forming on the

43

optics.

H3

Lower Tray (option) Turns on when the main switch is off to

keep paper dry i n th e l ow er paper tray.

34

Thermistors

TH1

Main Fusing Monitors the tem perature at the central

Secondary Fu si ng

TH2

✽

(A208/A210/A2 11

machines only)

TH3

TH4

Optics Monitors the temperature of the optics

Drum Charge Monitors the temperature of the drum

Thermofuses

TF1

Main Fusing Provides back-up overheat pro te ct i on i n

Secondary Fu si ng

TF2

✽

(A208/A210/A2 11

machines only)

area of the hot roll er.

Monitors the tem perature at the e nds of the

hot roller.

A204/206/207 have only one thermi st or.

✽

cavity.

charge roller .

the fusing unit.

Provides back- up overheat pro te ct i on i n

the fusing unit.

A204/206/207 have only one thermofuse.

✽

16

66

67

44

46

65

64

31 March 1997 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Name Function Index No.

TF3

Counters

CO1

CO2

Others

CB1

TR1

CC1 This has been eli minated from all m odels.

Exposure Lamp Opens the exposure lamp circuit if the 1st

scanner overheats.

Total Keeps t rack of the total num ber of copies

made.

Key (option) Used for co nt rol of authorized use. The

copier will not operate until it is installed.

Circuit Breaker (220 ~

240 V machines onl y)

Transformer (220 ~ 240

V machines only)

Provides back-up high current protection

for electrical components.

Steps down the wall voltage to 100 Vac.

17

37

N/A

9

7

Copier

17

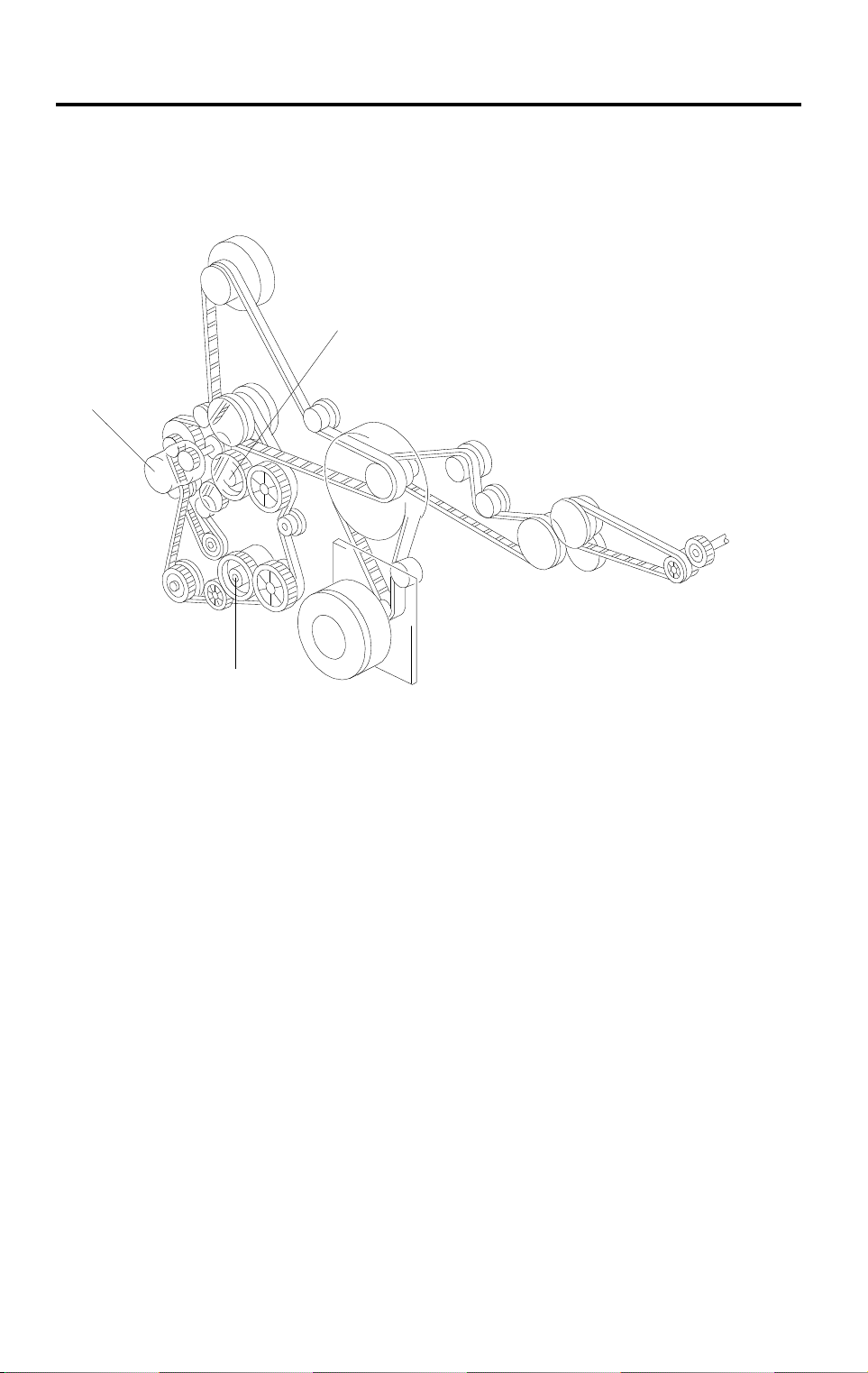

PAPER FEED DRIVE LAYOUT 31 March 1997

5. PAPER FEED DRIVE LAYOUT

5.1 A204/A206/A207/A208/A210/A211

1

3

2

A204V504.wmf

Since A208, A210, and A211 have been changed to the FRR feed system, all

models carry the same type of drive layout.

1. Upper Paper Feed Clutch Gear (A207/A211 only)

2. Lower Paper Feed Clutch Gear

3. Relay Clutch Gear

18

31 March 1997 PROCESS CONTROL

6. PROCESS CONTROL

6.1 HALFTONE MODE

This mode is newly added.

If the user selects the halftone mode function on the operation panel, the

machine reduces the size of the exposure lamp voltage, development bias,

and the drum charge voltage by the changes shown below.

•

Exposure Lamp Voltage: –1.0 V

•

Development Bias: +80 V

•

Drum Charge Voltage: +300 V

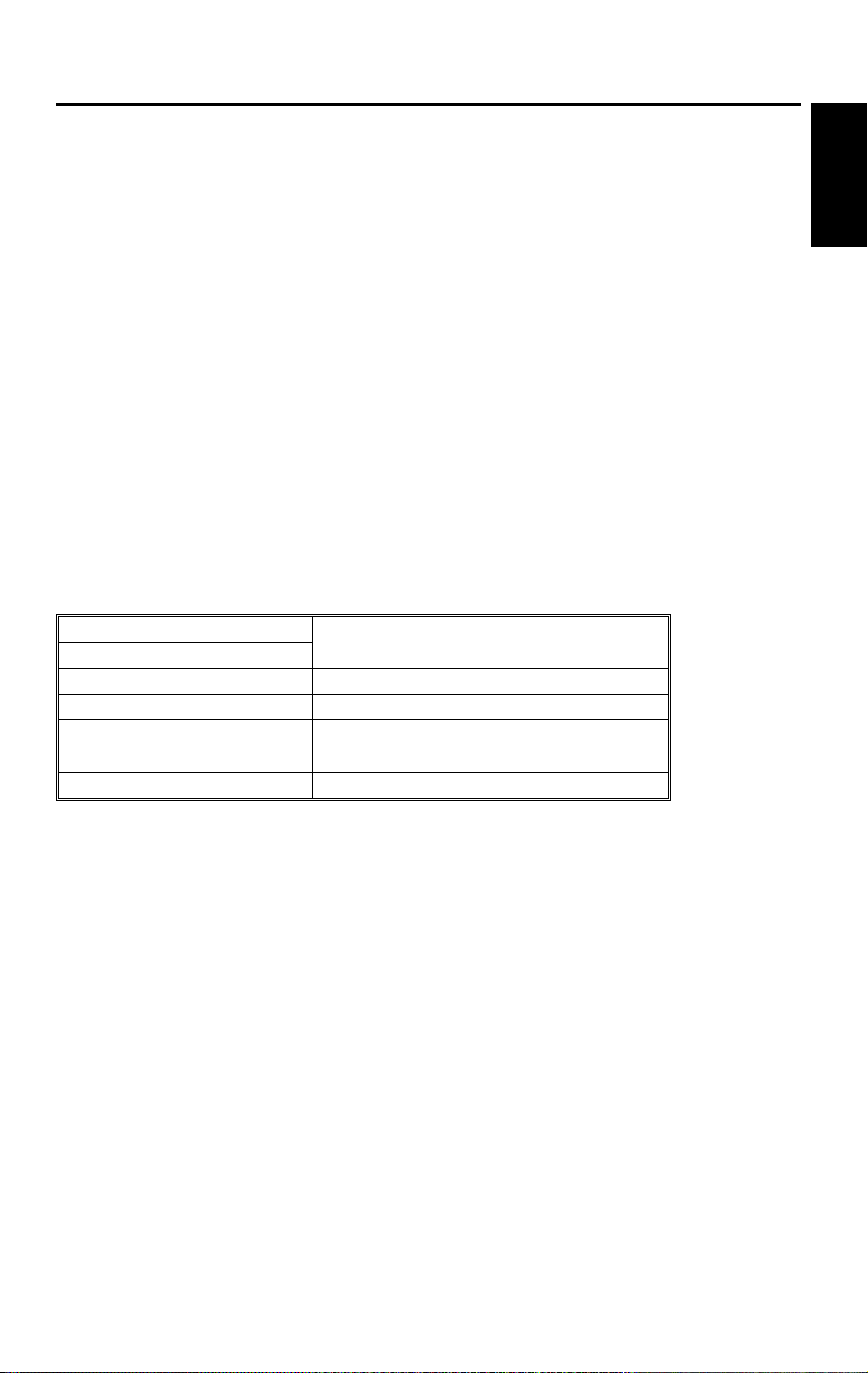

6.2 ADS CORRECTION

✽ Five possible corrections can be selected from, where the base copier has

only three.

Copier

ADS correction

ADS Density SP5-106

Setting Copy Density

0 Dar kest 816 x (AR – 0.85) + 60

✽

1 Darker 816 x (AR – 0.75)

2 Nor m al 816 x (AR – 0.85)

3 Lighter 816 x (AR – 0.95)

4 Lightest 816 x (AR – 0.85) – 60

✽

Where AR (ADS Ratio) = V

Development Bi as C orrection Voltage

ADS

(original)/V

ADS

(pattern)

19

PROCESS CONTROL 31 March 1997

6.3 TONER SUPPLY CONTROL DURING COPYING

✽ The amount of toner supplied per unit of time (TS) has been changed from

the base copier.

Toner clutch on time is calculated by the following formula.

Toner CL on time [ms] =

S x

AT x

TSC

TS

⁄⁄

100

(Formula 1)

where: S = Copy paper size [cm

AT = Amount of toner developed on the latent image per unit area

= 0.7 [mg/cm

2

] (constant)

TSC = Toner supply coefficient [%]

✽ TS= Amount of toner supplied per unit of time

= 0.217 [mg/ms] (for A204, A206, and A207 copiers)

= 0.183 [mg/ms] (for A208, A210, and A211 copiers)

2

]

20

31 March 1997 PROCESS CONTROL

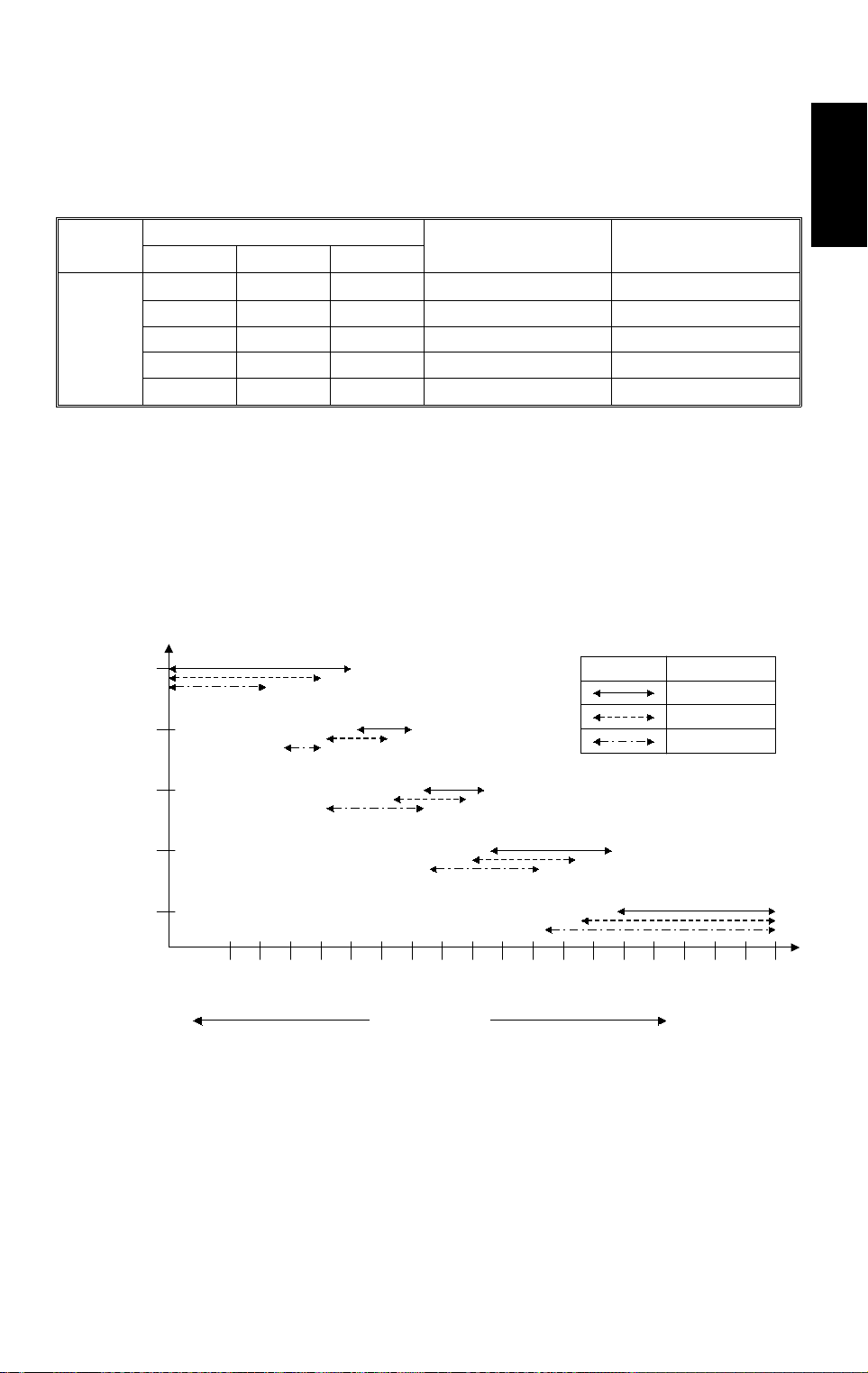

6.4 VR PATTERN CORRECTION

✽ The values in the ID correction column of the table have been changed.

R

correction

V

ID Correction

–40 V –80 V

V

RP/VRG

100 (%)

x

±±

0 V

74 ~ 100 68 ~ 100 62 ~ 100

53 ~ 73 50 ~ 67 43 ~ 61 –40 V –40 V

41 ~ 52 37 ~ 49 26 ~ 42 –80 V –80 V

31 ~ 40 26 ~ 36 19 ~ 25 –120 V –120 V

0 ~ 30 0 ~ 25 0 ~ 18 –160 V –160 V

For example, taking the ID correction to be zero for now, if VRP/V

Drum Charge Roller

Correction Voltage

0 V

±

Development Bia s

Correction Volt age

0 V

±

RG

is 45%,

the drum charge and development bias corrections will both be –80 V.

R

V

correction also depends on the current VSP pattern ID correction that is

being used. If development bias has been increased by ID correction, the V

correction may be smaller in some cases to take this into account. This is

shown by both the table above and the following diagram.

–160 V

–120 V

ID correction

0 V

–40 V

–80 V

Copier

R

–80 V

–40 V

Correction Voltage

R

V

–0 V

10080604010 20 30 50 70 90

Drum residual

voltage largel

VRP/VRG (%)

Drum residual

voltage small

A204D505.wmf

Using the same example to illustrate this, but with an ID correction of –80 V,

the corrections will both be –40 V this time.

21

PROCESS CONTROL 31 March 1997

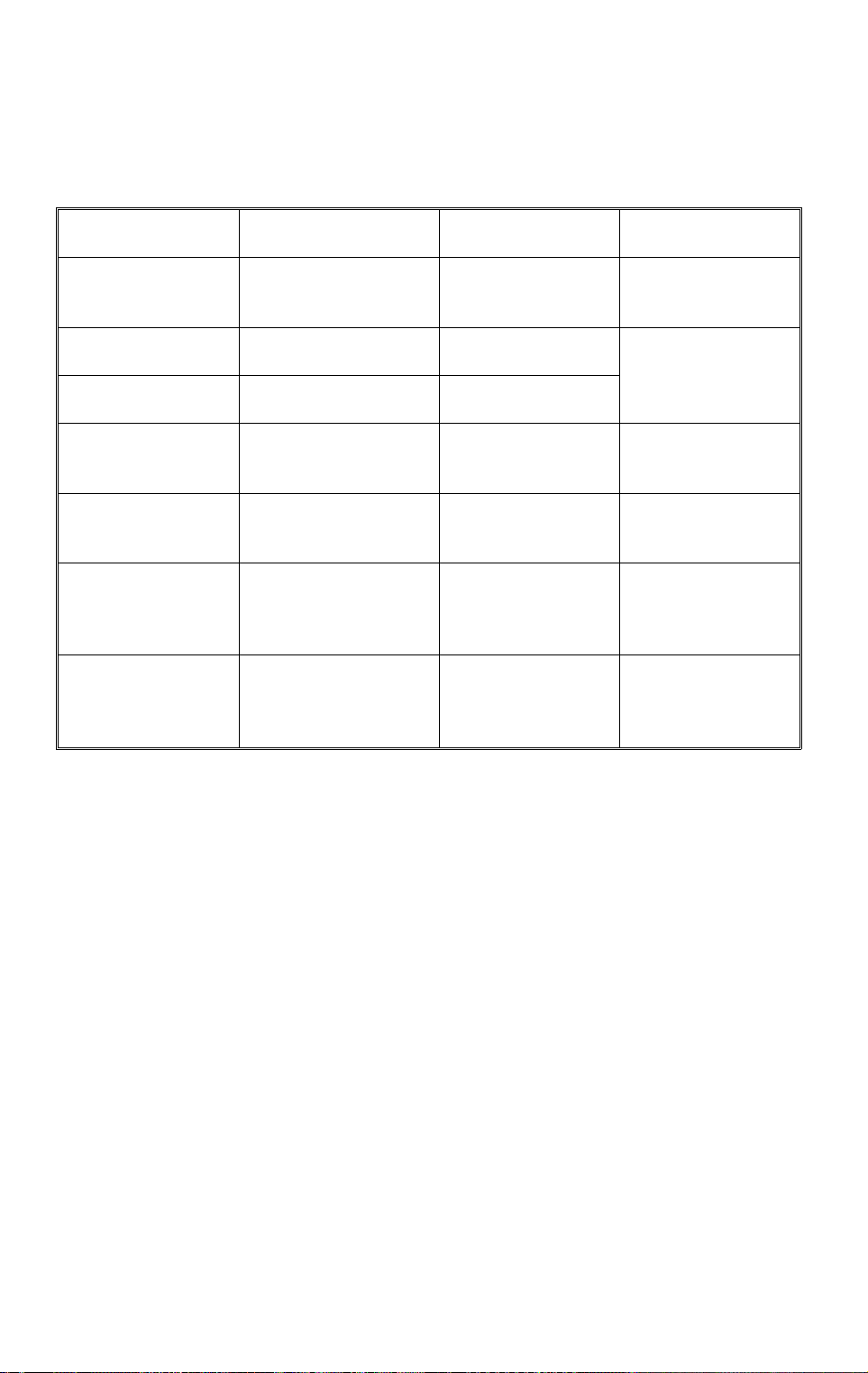

6.5 TONER SUPPLY IN ABNORMAL SENSOR CONDITIONS

If any sensor errors occur under detect supply mode, toner supply mode is

changed automatically as shown below.

Error Abnorma l Cond ition

ID Sensor

Adjustment Error

Abnormal ID Sensor

SP

)

(V

Abnormal ID Sensor

SG

)

(V

TD Sensor

Adjustment Error

TD Sensor (V

T

)

Measurem ent Error

Drum Charge

Thermistor Error

Abnormal Drum

✽

Charge Thermistor

Output

When ID senso r output

cannot be adjusted to

4.0 ± 0.2 V

SP

> 2.5 V during

If V

SP

V

detect i on.

SG

If V

< 2.5 V during

SG

detection

V

When TD sensor

output cannot be

adjust ed to 2.5 ± 0.1 V

If VT > 4.0 V or VT <

0.3 V during V

T

detection.

Temperature det ected

by the drum cha rge

thermistor is below 0°C

or above 60°C

Temperature det ected

by the drum cha rge

thermistor is between

0°C and 14°C

Fallback Toner

Supply Mode

Display on

Operation Panel

Fixed Supply Mode None

Fixed Supply Mode None

Fixed Supply Mode

Fixed Supply Mode Manual ID level or

ADS indicator blinks

Fixed Supply Mode Manual ID level or

ADS indicator blinks

Fixed Supply Mode None

TD Sensor Supply

None

Mode

NOTE:

No indication is displayed under the "abnormal drum charge

thermistor output" condition, because the machine soon recovers

due to the heat inside the machine.

22

31 March 1997 PROCESS CONTROL

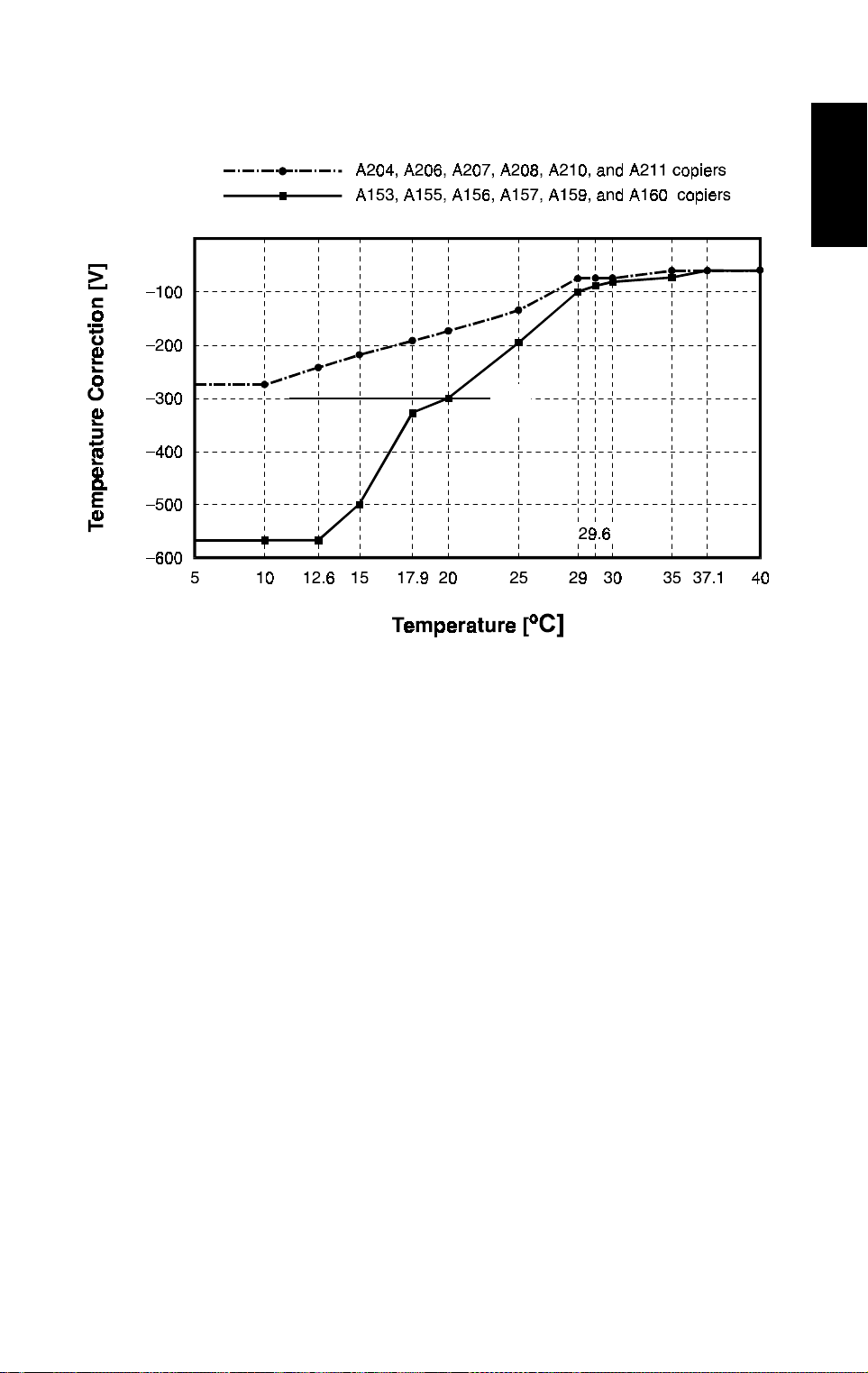

6.6 TEMPERATURE CORRECTION

[A]

Copier

A204D506.wmf

✽ The temperature correction has changed as explained below. Also, the

machine no longer does the drum rotation time correction.

The temperature correction difference between the A204, A206, and A207

copiers and the A208, A210, and A211 copiers is a result of the difference in

copy processing speed (240 mm/s for the A204, A206, and A207 copiers,

compared with 200 mm/s for the A208, A210, and A211 copiers).

The new drum charge roller needs only about half the correction voltage

used for the base copier. Also, the level of correction needed for the lowest

temperature point (5°C) is about the same as the normal room temperature

point for the base copier [A].

In the base machine, rotation time correction was only needed for low

temperatures where the temperature correction was large. In the new

machines, the temperature correction is never greater than –300 V, so the

rotation time correction has been eliminated.

23

PROCESS CONTROL 31 March 1997

The temperature corrections are as shown below.

•

Temperature Correction (Copying) - Base drum charge voltage = –1,500 V

•

Temperature Correction (VSP Pattern) - Base drum charge = –1,370 V

– A204, A206, and A207 –

Drum Charge Roller

Temperature (°C)

35.0 ≤ T

28.0 ≤ T < 35.0

10.0 ≤ T < 28.0

T < 10.0 –130.0 –295.0

– A208, A210, and A211 –

Drum Charge Roller

Temperature (°C)

35.0 ≤ T

29.0 ≤ T < 35.0

10.0 ≤ T < 29.0

T < 10.0 –120.0 –260.0

Temperature Correcti on

V

Pattern Copying

SP

+53 –57.0

–83.5 + 3.9T –211.0 + 4.4T

–217.6 + 8.7T –410.0 + 11.5T

Temperature Correcti on

V

Pattern Copying

SP

+47 –61.0

–51.0 + 2.8T –173.0 + 3.2T

–199.1 + 7.9T –3 55.5 + 9.5T

24

31 March 1997 PROCESS CONTROL

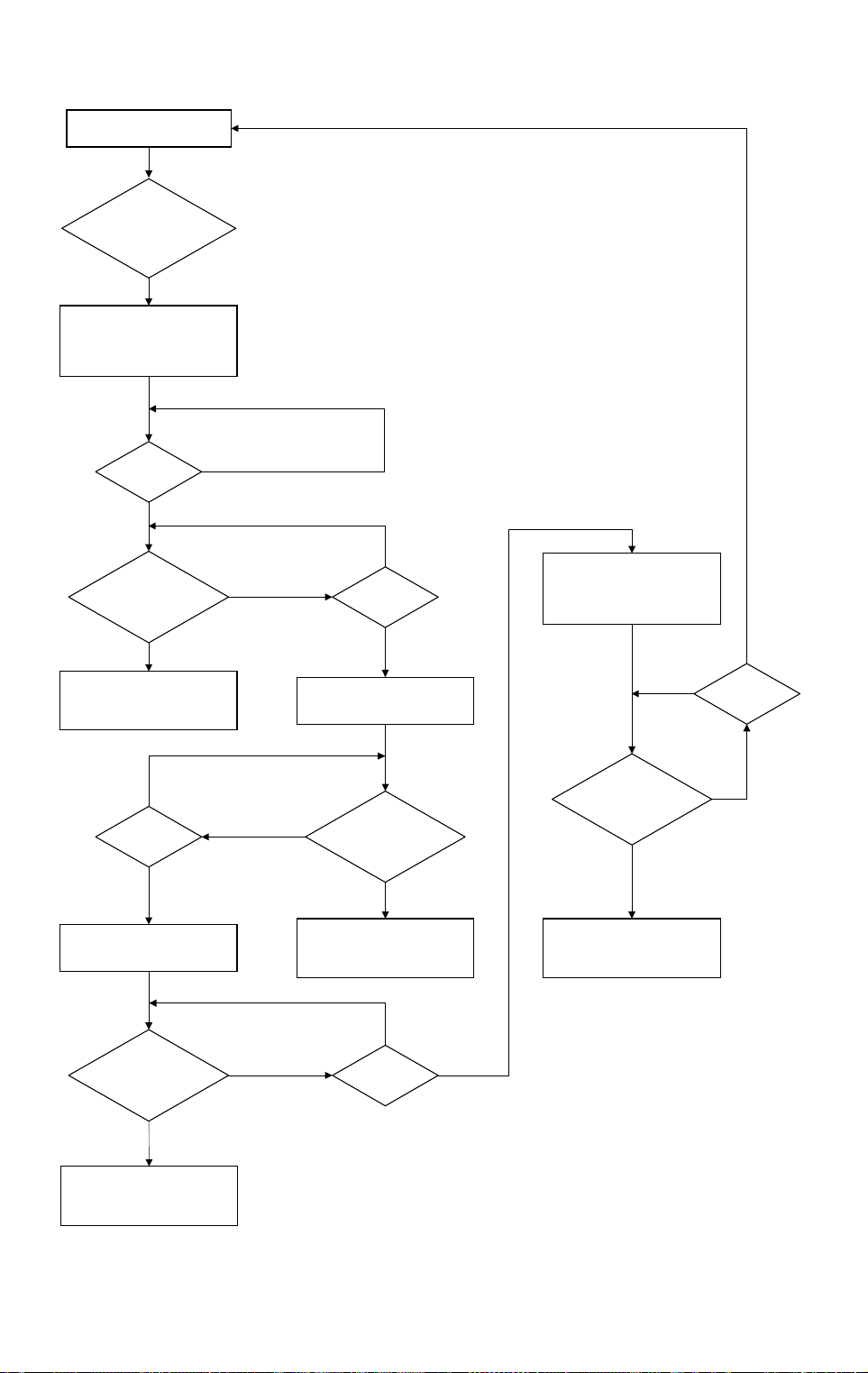

6.7 TONER END RECOVERY

If the front cover switch or the main switch is turned off and on during a toner

near-end/end condition, the machine will perform the toner end recovery

procedure as shown on the flow chart on the next page.

For the base copier, the toner end sensor checked for toner for a total of 10

seconds. The check stops when the toner supply clutch stops transporting

toner.

For the A204 series, the toner sensor checks for toner for a total of 14

seconds, stopping 2 seconds after the toner supply clutch stops. When the

toner supply clutch stops, any toner present is likely to drop into the

development unit, which will be detected during the final 2 seconds of

detection time. This will decrease the chances of a mis-detection when a new

toner bottle has been installed by the customer.

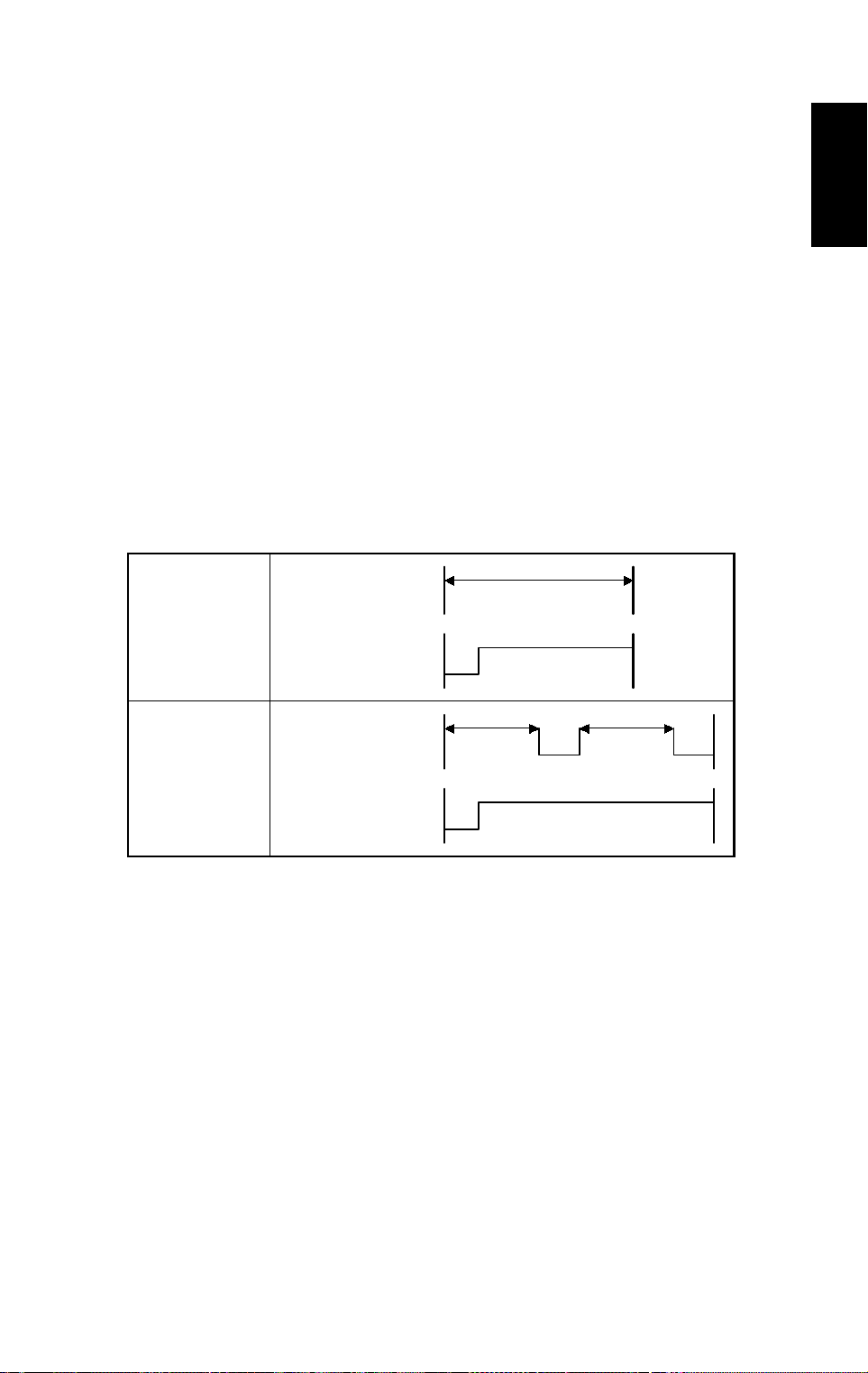

Copier

A153/A155/A156/

A157/A159/A160

A204/A206/A207/

A208/A210/A211

Toner Supply

Clutch

Toner End

Sensor

Toner Supply

Clutch

Toner End

Sensor

ON

OFF

ON

OFF

ON

OFF

ON

OFF

10

2

2 255

2

A204D516.wmf

25

PROCESS CONTROL 31 March 1997

Toner End Condition

Yes

Front

Cover Switch or Main

Switch Turned OFF/

ON?

Yes

Drum Drive, Development

Clutch, Toner Supply Clutch,

Toner Bottle Drive Motor

Turn On. t = 0s.

t ≥ 2s

Toner End

Detection. Is Toner

Present?

Components Turn Off. Toner

End/Near End Condition is

Canceled.

t ≥ 7s

Toner Supply Clutch, Toner

Bottle Drive Turn On.

No

Yes

No

Yes

No

Yes

No

t ≥ 5s

Yes

Toner Supply Clutch, Toner

Bottle Drive Turn Off.

Toner End

Detection. Is Toner

No

Components Turn Off. Toner

Present?

Yes

End/Near End Condition is

Canceled.

Drum Drive, Development

Clutch, Toner Supply Clutch,

Toner Bottle Drive Motor

Turn Off.

No

Toner End

Detection. Is Toner

Present?

Yes

Components Turn Off. Toner

End/Near End Condition is

Canceled.

No

Yes

t ≥ 14s

Toner End

Detection. Is Toner

Present?

Yes

Components Turn Off. Toner

End/Near End Condition is

Canceled.

t ≥ 12s

No

YesNo

A204D515.wmf

26

31 March 1997 PROCESS CONTROL

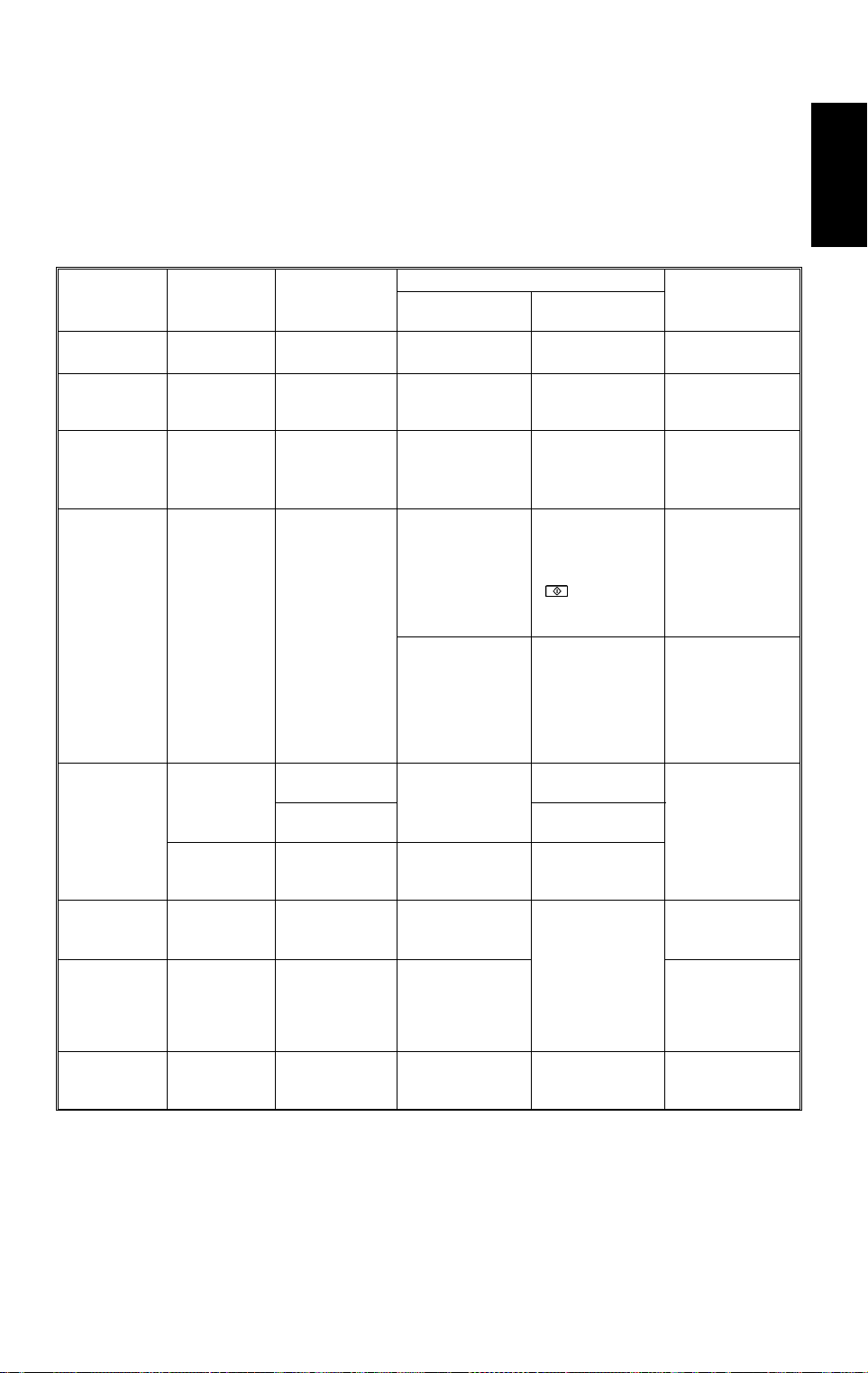

6.8 SUMMARY

NOTE:

Only items marked with ✽ are different or reviewed from A153, A155,

A156, A157, A159, and A160 copiers.

A summary of process control and correction timing is shown below.

Correction

Manual ID

correction

Reproduction

ratio

correction

✽

Halftone mode

ADS

correction

ID

correction

and

Toner density

control

R

V

correction

L

V

correction

✽

Temperature

correction

Electrical

Component

Operation

panel

Operation

panel

Operation

panel

ADS sensor

ID sensor

TD sensor VT

ID sensor V

ID sensor V

Drum charge

roller

thermistor

Sensor Output

V

ADS

V

ADS

T: (temperature) —

Used

——

——

——

Forced Correction

(pattern)

(original)

SG

V

SP

V

RP

, V

LP

, V

New exposure

lamp, ADS sensor,

after SP4- 001

(Exposure lamp

voltage

adjustment) or

optics cleaning

New drum, ID

sensor or ID

sensor cleaning

When the

developer is

changed

New drum or ID

sensor replacement

RG

New drum,

exposure lamp or

LG

after SP4- 001

(Exposure lamp

voltage adj ustment)

Correction Timing

Every copy in

manual ID mode

Every copy in

reduce/enlarge

mode

Every copy in

halftone mode

ADS Mode:

•

Once per original

—

(ARDF mode), or

once when the

! key is

pressed (Platen

mode)

Every 1,000 copies

At the start of

each copy job

About every 10

copies

Every copy

After every 1,000

copies

Every copy Drum charge roller

Automatic

Correction

Corrected Value

Lamp voltage

•

Dev. bias

•

Development bias

Lamp voltage

•

Dev. bias

•

Drum charge

•

roller voltage

Development bias

ADS

V

•

(pattern)

is stored

Dev. bias

•

Toner supply

•

clutch ON

time

Drum charge

•

roller voltage

Dev. bias

•

Lamp voltage

voltage

Copier

27

Loading...

Loading...