Page 1

I{ll(txml”

.

.

CUSTOMER SERVICE

FT505015070

FIELD SERVICE MANUAL

REV.NO.

1-

& -—- + -–—— — ——--

—. —-

— —.-———— -

.

DATE COMMENTS

5191

OrmnalPnntma

—

—.—

—.

—

1

~-. -— – .--—

L- —. —._

——

—

.

.

—-

—

“’:-1

3

PN RCFtV15050

Page 2

.

Page 3

WARNING

r

The Field Service Manual contains information

regarding service techniques, procedures,

processes and spare parts of office equipment

distributed by Ricoh Corporation. Users of this

manual should be either service trained or

certified by successfully completing a Ricoh

Technical Training Program.

Untrained and uncertified users utilizing

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property, or loss of warranty

protection.

1

mcoh corporation

J

Page 4

————

.-

Page 5

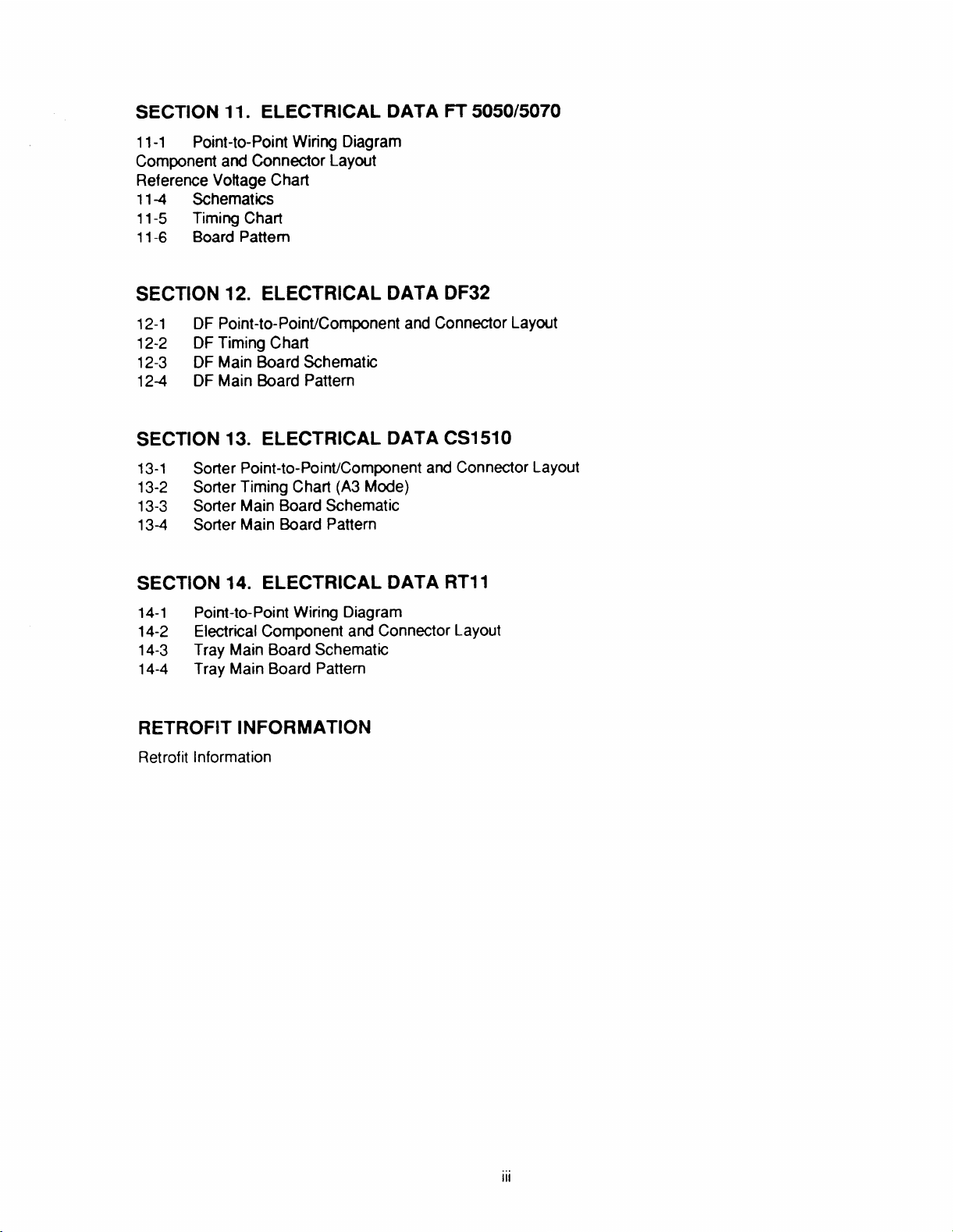

Table of Contents

SECTION 1. INSTALLATION REQUIREMENTS

1-1

1-2

1-3

1-4

Environment ..............................................................................................................

Machine Level ...........................................................................................................

Minimum Space Requirements ..................................................................................

Power Sourm ............................................................................................................

SECTiON 2. UNPACKING AND INSTALLATION

Installation-Setup Checklist

2-1

2-2 Accessory Checklist ..................................................................................................

2-3

2-4

2-5 Key Counter Holder installation ..................................................................................

2-6

Unpacking Procedure ...................................................................... .........................

Installation Procedure ................................................................................................

Cassette Modification .

Main Transformer Conversion ....................................................................................

...............................................................................................

SECTION 3. PREPARATION FOR TRANSPORTING COPIER

Pr+aratbn for Trans~fii~ the Copier ..................................................................................

SECTION 4. REMARKS

4-1

4-2 Handling the Dmm .....................................................................................................

Points to Remember ..................................................................................................

1-1-1

1-2-1

1-3-1

1-4-1

2-1-1

2-2-1

2-3-1

2-4-1

2-5-1

2-6-1

3-1-1

4-1-1

4-2-1

SECTION 5. REPLACEMENT AND ADJUSTMENT

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

Exposure Glass Removal ..........................................................................................

Or@inal Stielndkator Board Removal .......................................................................

2ti Mirror Removal ...................................................................................................

Exposure La~Replacement ....................................................................................

Ex~sure Lamp Position ............................................................................................

Scanner Drive Wire Replacement .......

Scanner Drive Motor Replacement ............................................................................

Lens Drive and2nd Scanner Drive Motor Replacement ................... .........................

........................................................... ...........

SECTION 6. SERVICE TABLES

6-1

6-2 Dip Switch Table .......................................................................... ... ............ ............

6-3

6-4 Self-Diagnostic Codes ...............................................................................................

Preventive Maintenance Schedule

6-6 Sp*ial Tmls .............................................................................................................

Adjustment Table .......................................................................................................

Defective Sensor Table ............................................................................................

I

5-1-1

5-1-2

5-1-3

5-1-5

5-1-7

5-1-9

5-1-15

5-1-17

6-1-1

6-2-1

6-3-1

6-4-1

6-6-1

Page 6

.. ..

SECTION 7. TROUBLESHOOTING

1-1

1-2

1-3

14

1-5

1-6

1-7

1-8

1-9

1-1o

1-11

1-12

1-13

7-2

2-1

2-2

2-3

2-4

2-5

2-7

2-8

2-9

2-1o

2-11

2-12

2-13

2-14

2-15

2-16

2-17

2-18

Whtie Copy ................................................................................................................

Dirty Background

Uneven Image Density ..............................................................................................

Vertical Black Line .....................................................................................................

Vertical White Line .....................................................................................................

Horizontal Black Line .................................................................................................

..........................................................................................................................

Jitter

Copy Image is Scraped Off by the Finger Due to Unfused Copy ................................

Scanner Movement is Out of Control

Toner Density is Too Hgh

Toner Density is Too Low ..........................................................................................

Distorted Copy Image ................................................................................................

Mi~ellaneous .......................................................................................................... ..

Electrical and Mechanical

Exposure Lamp Malfunction ..................................................................................... .

Lamp Reiay O~n .................................................................................................... .

Scanner Not in H. P., Delayed H.P. Signal ..................................................................

@emn Swtich ON ....................................................................................................

No Regist Start Signal ...............................................................................................

Lens H.P. Not ON, Lens H.P. Not OFF ......................................................................

2nd Scanner H.P. Not ON, 2nd Scanner H.P. Not OFF .............................................

Hgh Frequency Ender Out~t ................................................................................

Low Frequency Encoder Output ................................................................................

.......................................................................................................

.........................................................................................

Upper Lift Sensor Not ON, Lower Lift Sensor Not ON ................................................

Themtise Blown .....................................................................................................

Themistor Blown ................................................................................................ ......

Ready Sgnal Not ON ................................................................................................

Fundbnal Drive Maltindion ......................................................................................

Jogger H.P. Not ON, Jogger H.P. Not OFF ...............................................................

Counter Malfunction ..........................................................................................

Total

Optics/Main Board ltiedace Malfundion ....................................................................

.........................................................................

7-1-1

7-1-2

7-1-4

7-1-6

7-1-7

7-1-9

7-1-1o

7-1-11

7-1-12

7-1-13

7-1-15

7-1-17

7-1-18

7-2-1

7-2-2

7-2-3

7-2-4

7-2-5

7-2-6

7-2-7

7-2-8

7-2-9

7-2-10

7-2-11

7-2-11

7-2-12

7-2-13

7-2-14

7-2-15

7-2-15

..—

..-

SECTION 8. DOCUMENT FEEDER DF32

8-1 Unpacking

8-2

DF Installation Procedure ..........................................................................................

.................................................................................................................

SECTION 9. SORTER CS1510

9-1 Unpacking Procedure ................................................................................................

2-1 Instaliat.mn Procedure ................................................................................................

SECTION 10. LARGE CAPACITY TRAY RT11

10-1

10-2 Installation Procedure ................................................................................................

3-1

3-2

3-3

3-4

Unpacking Procedure ................................................................................................

Tray Down Sensor and Positioning Switch Replacement ...........................................

Paper Size Sensor Replacement ...............................................................................

Tray Wire Replacement .............................................................................................

Pa~r Volume Cod Replacement ..............................................................................

8-1-1

8-2-1

9-:-1

9-2-1

10-”-1

10-2-1

10-3-1

10-3-3

10-3-4

10-3-7

..44.

Page 7

SECTION 11. ELECTRICAL DATA FT 5050/5070

11-1 Point-to-Point Wiring Diagram

Component and Connector

Reference Vottage Chart

11-4

11-5

11-6

Schematics

Timing Chafi

Board Pattern

Layout

SECTION 12. ELECTRICAL DATA DF32

12-1 DF Point-to-Point/Component and Connector Layout

12-2 DF Timing Chart

12-3

12-4 DF Main Board Pattern

DF Main Board Schematic

SECTION 13. ELECTRICAL DATA CSI 510

13-1 Sorter Point-to-Point/Component and Connector Layout

13-2

13-3 Seder Main Board Schematic

13-4 Sorter Main Board Pattern

Sorter Timing Chart (A3 Mode)

SECTION 14. ELECTRICAL DATA RTI 1

14-1

14-2 Electrical Component and Connector Layout

14-3 Tray Main Board Schematic

14-4 Tray Main Board Pattern

Point-to-Point Wiring Diagram

RETROFIT INFORMATION

Ret refit Information

Page 8

-4 ‘

4

Page 9

SECTION 1

INSTALLATION REQUIREMENTS

Page 10

—

4

Page 11

—.

l-l

Environment

.

1.

Temperature Range

: 10°C to 30°C (50°F

to 86°F)

2.

Humidity Range : 15% to 90% RH

3.

Ambient Illumination: Less

lUXS (Do not expose

to direct sunlight)

4.

Ventilation

: Room air

turn over at least

3 times/hour.

5.

Amb~ent Dust

: Less than 0.15mg/m3

(4 x

6.

Room Size

: More

(13.4yd3)

7.

xf

the

conditioned or heated,

Where It w~ll

● ✎

installation place is

place the machine:

not be subjected to

sudden temperature changes from low to

high, or vice versa.

than

10

‘30z/yd3)

than

..-8 ., .-” -

1,500

should

10m3

air–

b. Where it will not be directly exposed

to cool air froman alr conditioner Ln

the summer.

May7,1984

Where it will not be directly exposed

c.

to reflected heat from a space heater

in winter.

8. Avo~d placing the copier in an area

filled with corrosive gas.

9. Avoid any area higher than 2,000m (6,500

feet) above sea level.

10.

Place the copier on

base.

11. Avoid any area where the copier maY be

sub]ected to frequent strong vibration.

a strong and level

1-1-1

1-1-2

Page 12

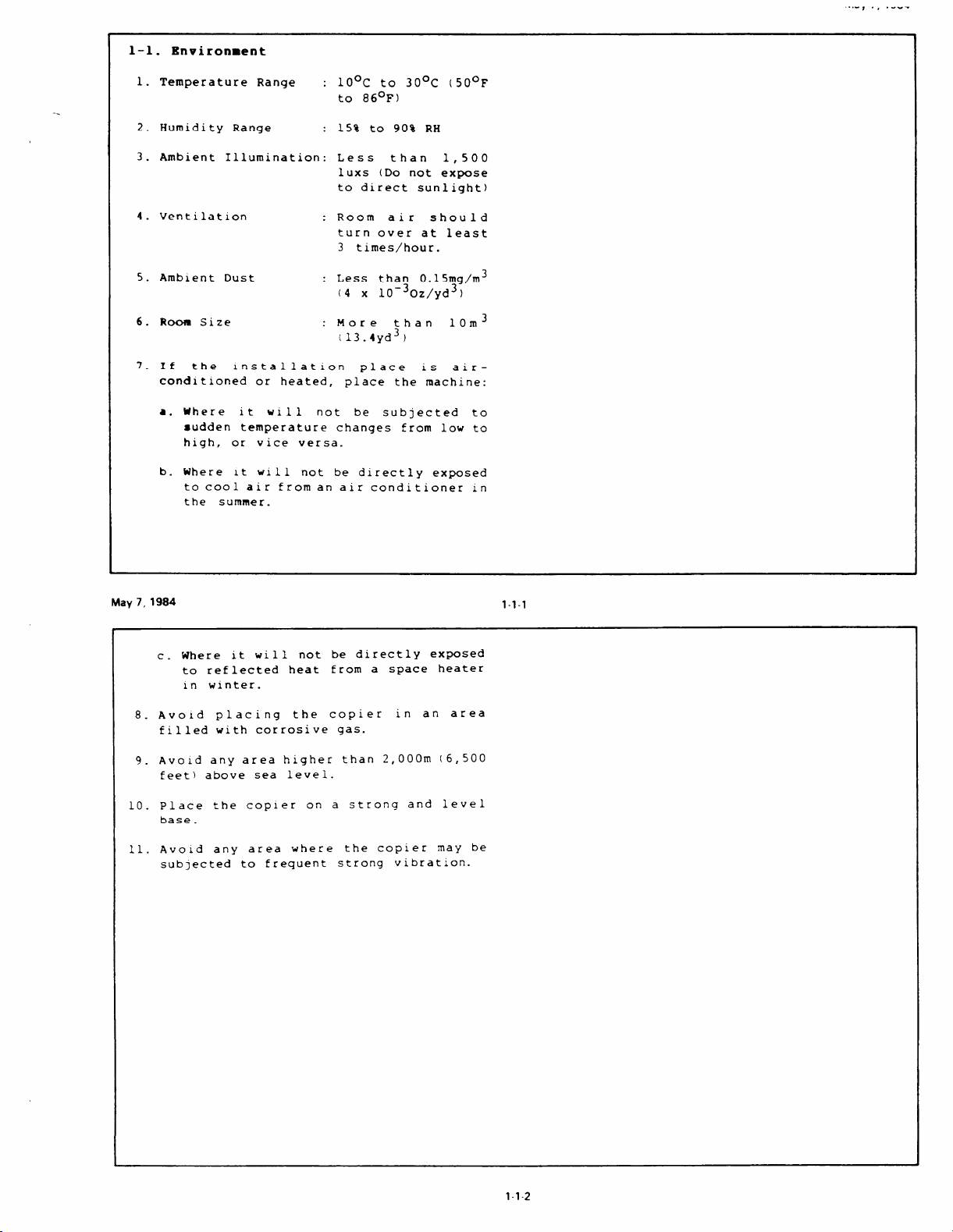

1-2. Machine Level

Front to back

1.

.,.”

., ,”.,-

t

Within 5mm (O

2.

Right to left:

Within 5mm (0.2”)

(Legs may be

the machine.

the exposure

2“)

of

level

of

level

screwed up or down to level

Set a carpenter’s level on

glass. )

—-=-

&-

l._.

+

L ,,

/1

.4 ‘

)

A

,,

,/

I

-R---

/

/

/)

‘\

~

f

May7,1984

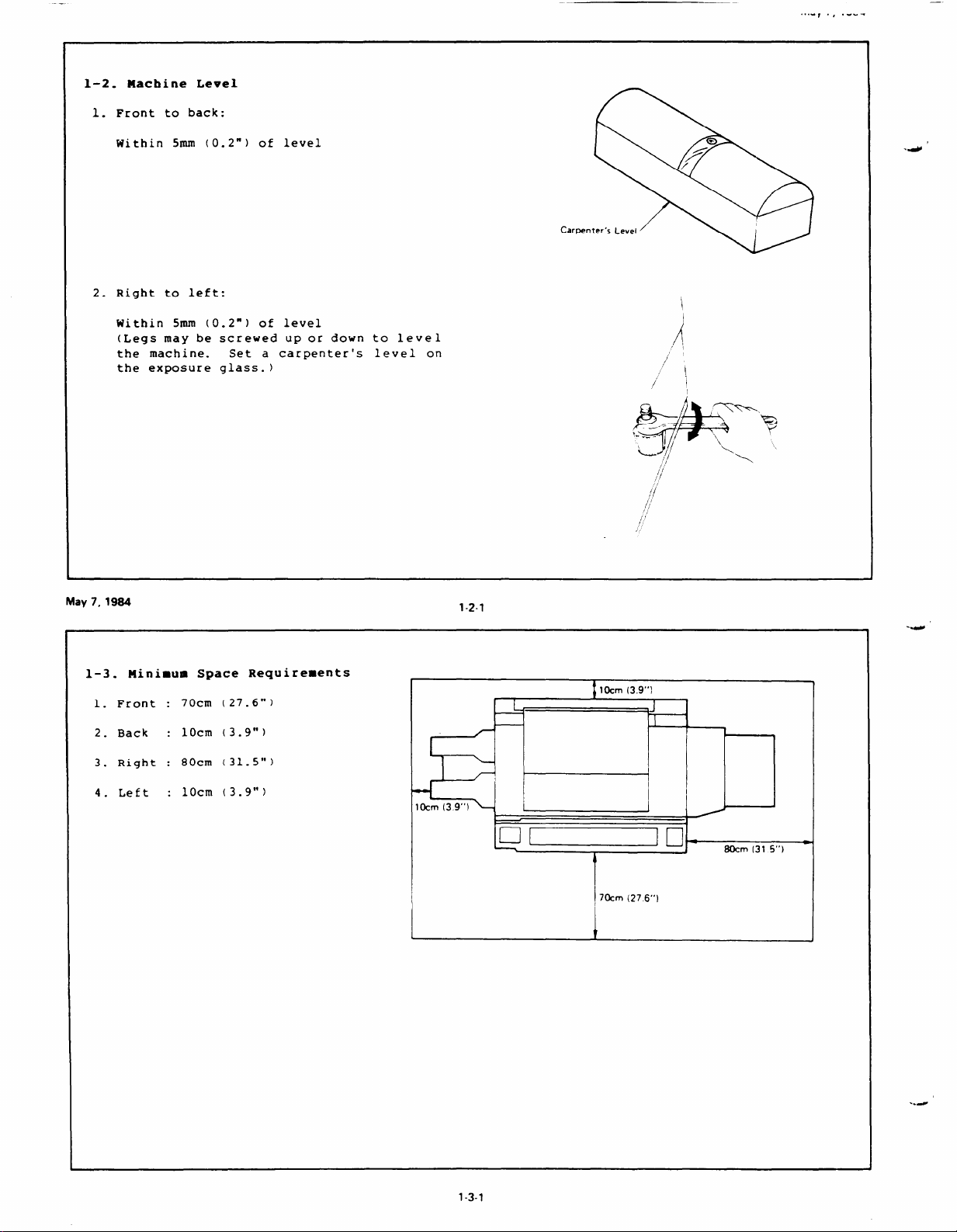

1-3.

1.

Front :

2.

Back :

3.

Right :

4.

Left :

Blinimum Space Requirements

(27.6”)

70cm

1Ocm

(3.9”)

(31.5”)

80cm

10cm

(3.9”)

1-2-1

..-

lCkm(39“)

4

I

I

~70cm(276“)

I

1

1-3-1

..-

Page 13

1-4. Power Source

1. Input voltage level

l15v/60Hz

: More than 15A

220v/50Hz : More than 7A

240vi50Hz : More than 7A

2. Permissible voltage fluctuation : flO%

3. Permissible extension cord :

At least 300V, 30A capacity and less than

5m (16.4’” long.

NOTE : 1. Be sure to ground the machine.

(Do not connect the grounding

wire to a gas pipe.)

2. Make sure the plug is

firmly

inserted ~n the outlet.

3. Avoid multl-wiring.

4. Do not set anything on the power

cord.

141

Page 14

,.-

..4

w’

../

Page 15

SECTION 2

UNPACKING AND INSTALLATION

Page 16

Page 17

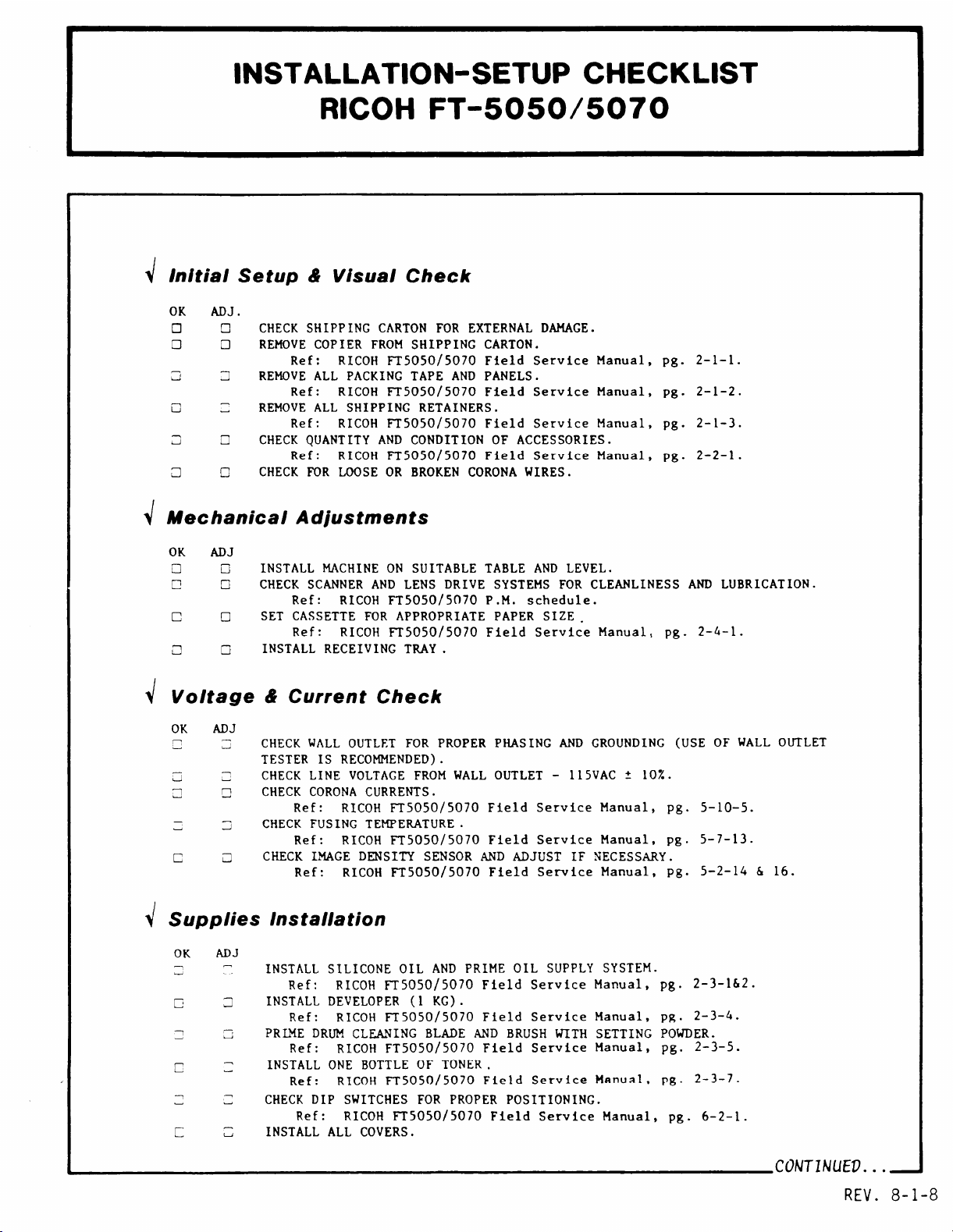

INSTALLATION-SETUP CHECKLIST

RICOH FT-5050/5070

r

~ Initial Setup& Visual Check

OK ADJ .

On

❑ ❑

CHECK SHIPPING

REMOVE COPIER FROM SHIPPING CARTON.

Ref: RICOH FT5050/5070 Field Service Manual, pg. 2-1-1.

REMOVE ALL PACKING TAPE AND PANELS.

Ref: RICOH FT5050/5070 Field Service Manual, pg. 2-1-2.

REMOVE ALL SHIPPING RETAINERS.

Ref: RICOH FT5050/5070 Field Service Manual, pg. 2-1-3.

CHECK QUANTITY AND CONDITION OF ACCESSORIES.

Ref: RICOH FT5050/5070 Field Service Manual,

CHECK FOR LOOSE OR BROKEN CORONA WIRES.

~ Mechanical Adjustments

CARTONFOR EXTERNAL DAMAGE.

pg. 2-2-1.

OK ADJ

•1 o

p

c ❑

a G

INSTALL MACHINE ON SUITABLE TABLE AND LEVEL.

CHECK SCANNER AND LENS DRIVE SYSTEMS FOR CLEANLINESS AND LUBRICATION.

❑

Ref: RICOH FT5050/5070 P.M. schedule.

SET CASSETTE FOR APPROPRIATE PAPER SIZE.

Ref: RICOH FT5050/5070 Field Service Manual, pg. 2-4-1.

INSTALL RECEIVING TIUiY.

~ Voltage& Current Check

OK ADJ

CHECK WALL OUTLET FOR PROPER PHASING AND GROUNDING (USE OF WALL OUTLET

TESTER IS RECOMMENDED).

CHECK LINE VOLTAGE FROM WALL OUTLET - 115VAC t 10%.

CHECK CORONA CURRENTS.

Ref:

CHECK FUSING

Ref: RICOH FT5050/5070 Field Service Manual, pg. 5-7-13.

CHECK IMAGE DENSITY SENSOR AND ADJUST IF NECESSARY.

Ref: RICOH

RICOH FT5050/5070 Field Service Manual, pg. 5-10-5.

TEMPEMTURE.

FT5050/5070 Field Service Manual, Pg. 5-2-14 & 16.

dSupplies Installation

OK ADJ

L-.

1

1

INSTALL SILICONE OIL AND PRIME OIL SUPPLY SYSTEM.

Ref: RICOH FT5050/5070 Field Service Manual, pg.

INSTALL DEVELOPER (1 KG).

-,

u

Ref: RICOH FT5050/5070 Field Service Manual, pg.

PRLME DRUM CLEANING BLADE AND BRUSH WITH SETTING POWDER.

Ref:

INSTALL ONE BOTTLE OF TONER.

Ref:

CHECK DIP SWITCHES FOR PROPER POSITIONING.

INSTALL ALL COVERS.

RICOH FT5050/5070 Field Service Manual, pg. 2-3-5.

RICOH FT5050/5070 Field Service Mnnual, pg. 2-3-7.

Ref: RICOH FT5050/5070 Field Service Manual, pg. 6-2-1.

2-3-162.

2-3-4.

REV. 8-1-8

Page 18

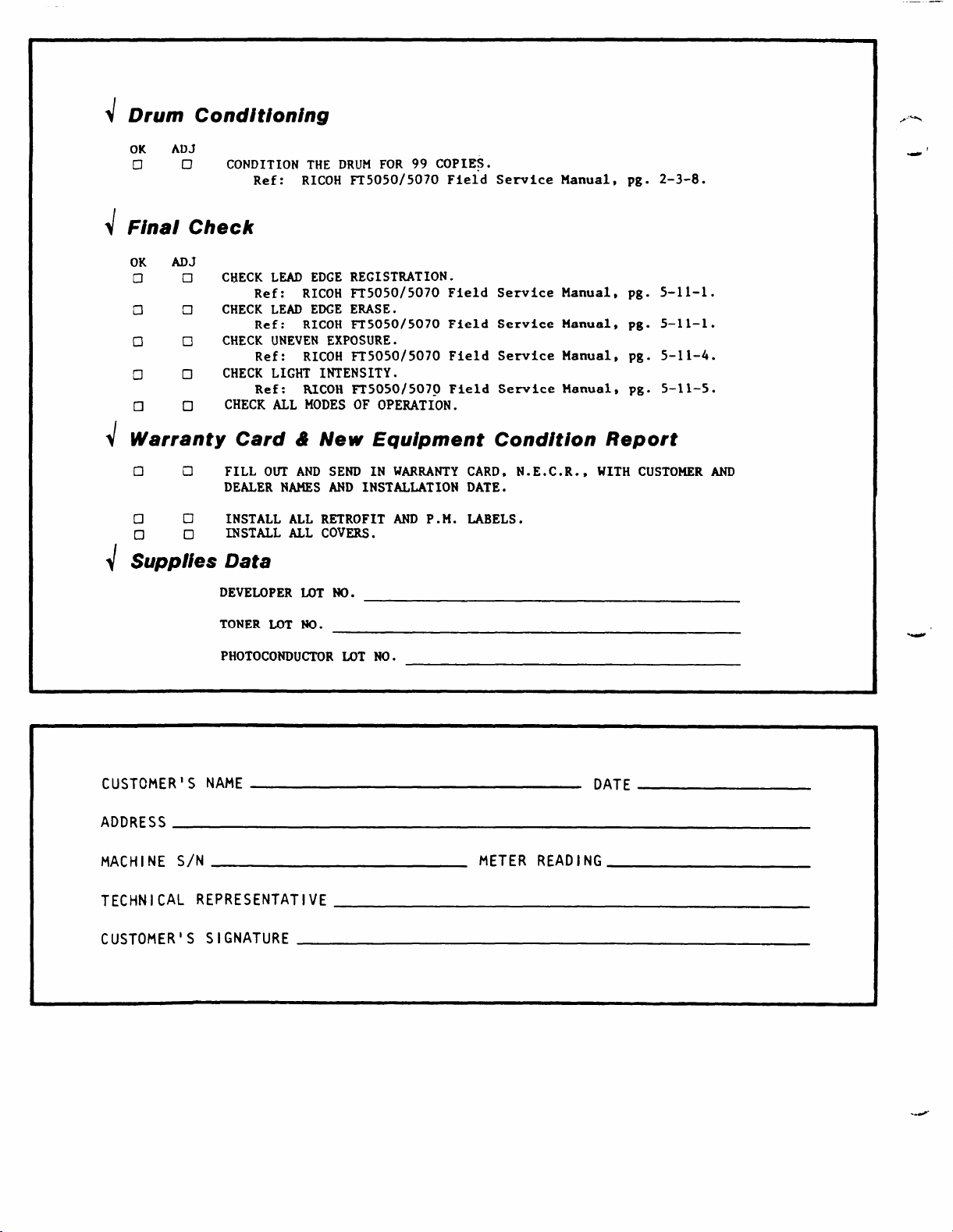

rum Conditioning

~D

OK ADJ

CID

Final Check

~

OK ADJ

c1

a •1

00

00

❑ 0

arranty Card & New Equipment Condition Report

Jw

no

•1

Lppies Data

d

CONDITION THE DRUM FOR 99 COPIES.

Ref: RICOH FT5050/5070 Field Service Manual, pg. 2-3-8.

CHECK LEAD EDGE REGISTRATION.

•1

c1 INSTALL ALL RETROFIT AND P.M. LABELS.

Ref: RICOH FT5050/5070 Field Service Manual,

CHECK LEAD EDGE ERASE.

Ref: RICOH FT5050/5070 Field Service Manual,

CHECK UNEVEN EXPOSURE.

Ref: RICOH

CHECK LIGHT INTENSITY.

Ref:

CHECK ALL MODES OF OPERATION.

FILL OUT AND SEND IN WARIW4TY CARD, N.E.C.R., WITH CUSTOMER AND

DEALER NAMES ANI) INSTALLATION DATE.

INSTALL ALL COVERS.

DEVELOPER MIT NO.

RICOH ~5050/5070 Field Service Manual,

FT5050/5070 Field Service Manual, pg. S-11-4.

pg. 5-11-1.

pg. 5-11-1.

pg. 5-11-5.

TONER LOT NO.

PHOTOCONDUCTOR LOT NO.

CIJSTCMER’S NAME

ADDRESS

MACHINE S/N

TECHNICAL REPRESENTATIVE

CUSTOMER’S SIGNATURE

I

I

DATE

METER READING

../

Page 19

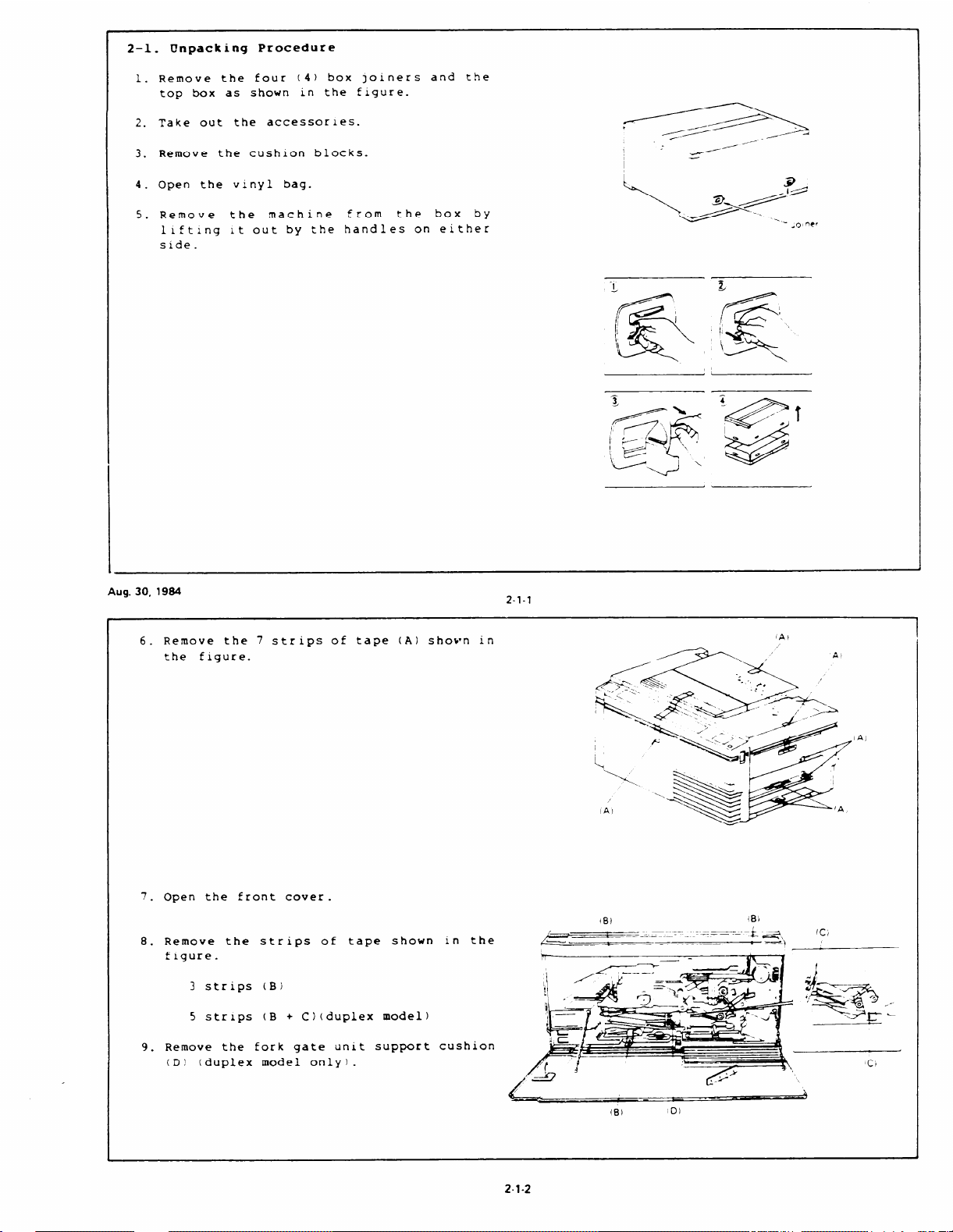

Unpacking Procedure

2–1.

1.

Remove the four (4) box ]olners and the

top box as shown in the figure.

2.

Take out the accessories.

Remove the cushion blocks.

3.

4.

Open the vinyl bag.

t

~

.-

_.

----’

___

5.

Remove the machine

llftlng lt out by the handl

side.

Aug.30,1984

Remove the 7 strips of tape (A) shotrn in

6.

the figure.

from

the box by

es on either

. . .

z-l-l

/’—9—.. .’

IAI

A

7.

Open the front cover.

8.

Remove the strips of

figure.

3 strips (B)

5 str~ps (B + C) (duplex model)

Remove the fork gate unit support

9.

(D! (duplex model only).

2-1-2

‘\.

IA)

h

\

—

——— —

—

— -k

—- m~

a,

--)

(c,

.

Page 20

--. --,..-,

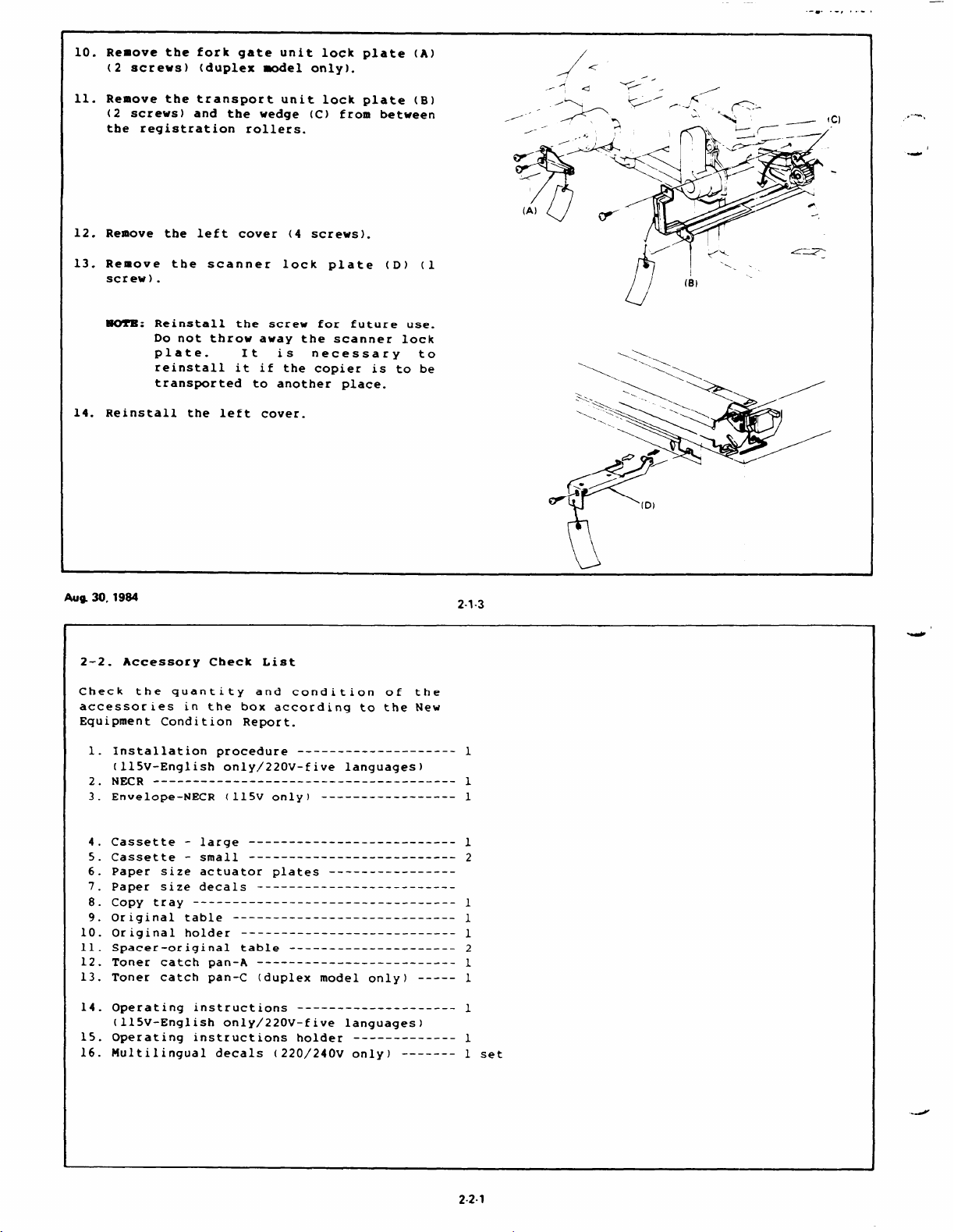

Remove the fork gate

10.

(2 screws) (duplex model only).

11.

Remove the transport unit lock

(2 screws) and the wedge (C) from between

the registration rollers.

12.

Remove the left cover (4 screws).

13.

Remove the scanner lock plate

screw) .

WU1’B: Reinstall the screw for future use.

14.

Reinstall the left cover.

Do not throw away the scanner lock

plate. It is necessary to

reinstall it if the copier is to be

transported to another place.

unit lock plate (A)

plate (B)

(D) (1

./

A

.=l~

<

-.

-< .

u

/

c)

,-%,

.4

1

AUQ 30,1984

2-2. Accessory Check List

Check the quantity and condition of the

accessories in the box according to the New

Equipment Condition Report.

Installation procedure

1.

(l15V-English only/220V-five languages)

--—_ ___________________ _______________

NECR

2.

Envelope-NECR (115V only)

3.

Cassette - large

4.

Cassette - small

5.

Paper size actuator plates

6.

7.

Paper size decals

Copy tray

8.

Original table

9.

10.

Original holder

11.

Spacer-original table

12.

Toner catch pan-A

13.

Toner catch pan-C (duplex model only)

----------- ____ ________ ________ __

-------- __________________

--__— __________ ________ ---

---------- ___________ _______

---- ________ ______ ______ ___

-------- --------- .-.

---------- -------

----- -----------

------ _________ ____ ______

------ ________ ---_-_—

______________________ ___

-----

(7

2-1-3

1

1

1

1

2

1

1

1

2

1

1

14.

Operating instructions

(l15V-English only/220V-five languages)

15.

Operating instructions holder

16.

Multilingual decals (220/240v only) ------- 1 set

----- ________ -------

------ -------

1

1

I

2.2.1

Page 21

..-,,

---

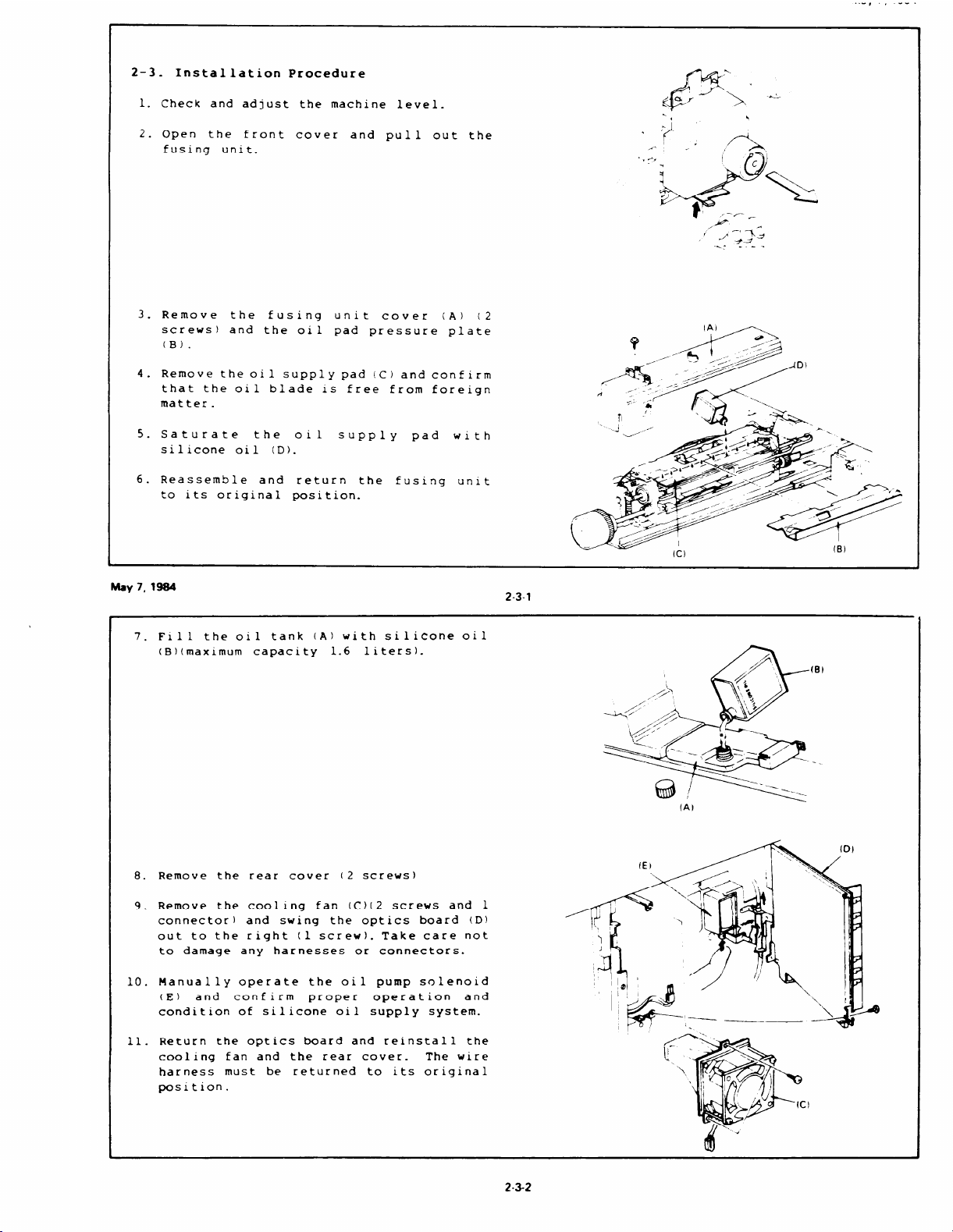

2-3.

Installation Procedure

1. Check and adjust the machine level.

2. Open the front cover and pull out the

fusing unit.

3.

Remove

screws) and the oil pad pressure plate

(B).

4.

Remove the oil supply pad (C) andconflrm

that the oil blade 1s free from foreign

matter .

5. Saturate the oil supply

silicone oil (D).

6.

Reassemble and return the fusing unit

to Ats original position.

the fusing unit cover

(A) (2

pad with

gar

.

.

..,~%

P

~ ,2A

t

,\

J >’ d

c’

.—-

,J= “a

f /-j-3

------

AD)

May 7,1984

7.

Fill the oil tank (A) with silicone oil

(B)(maximum capacity

Remove the rear cover (2 screws)

8.

Remove the coollng fan (C)(2 screws and 1

9.

connector) and swing the optics board (D)

out to the right (1 screw). Take care not

to damage any harnesses or connectors.

10. Manually operate the oil pump solenold

(E)

and confirm proper operation and

condition of silicone 011 supply system.

1.6 liters).

2-3-1

(A)

11. Return the optics board and reinstall the

cooling fan and the rear cover.

harness must be returned to its original

Position.

The wire

)

.

t!’

2-3-2

Page 22

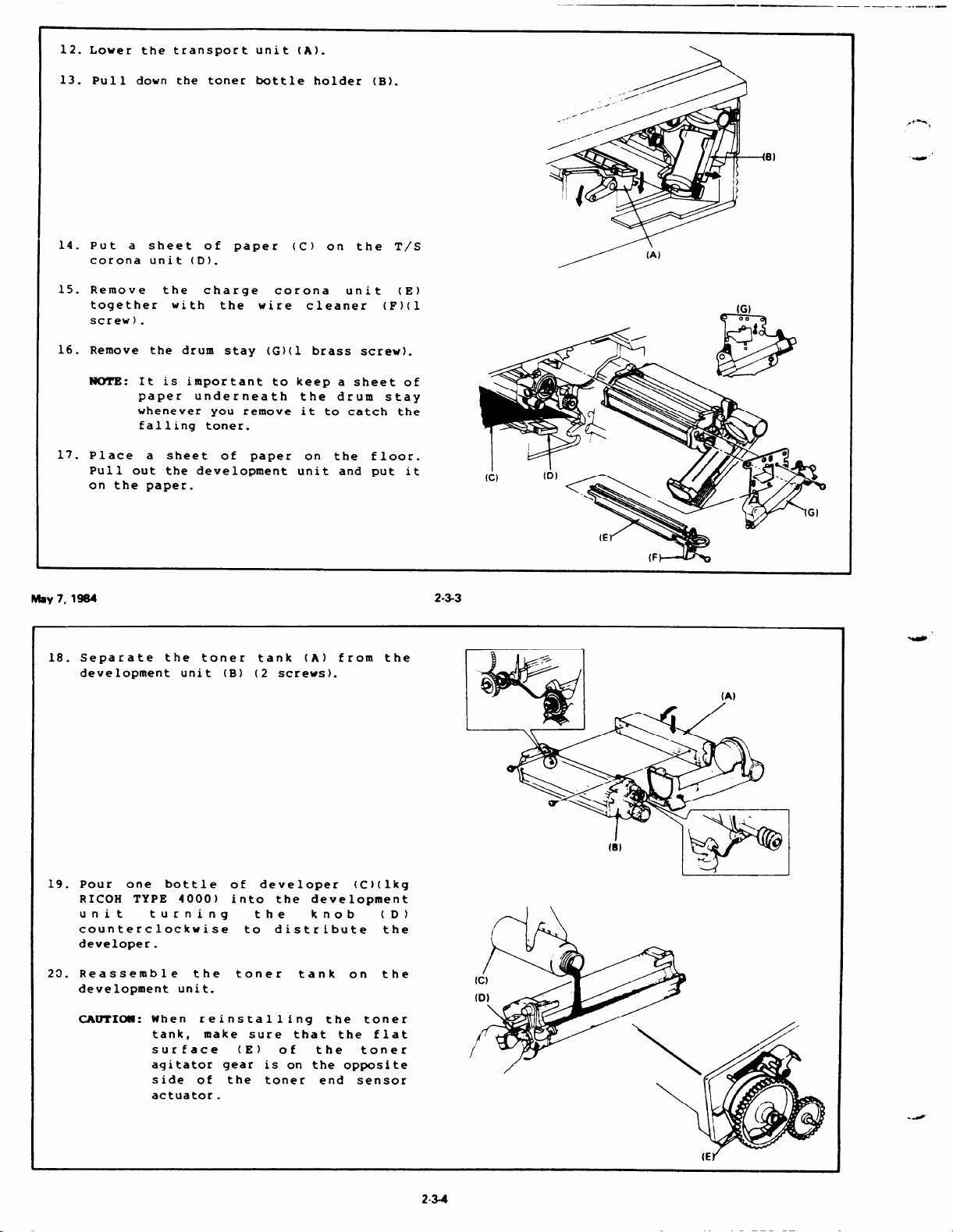

12. Lower the transport unit (A).

13. Pull down the toner bottle holder (B).

14. Put a sheet of paper (C) on the T/S

corona unit (D).

1S. Remove

together with the wire cleaner

screw) .

16. Remove the drum stay (G)(l brass screw).

the

charge corona

unit (E)

(F)(l

—.

/ ‘A)

— .—. —...—,.—

NOTB: It is important to keep a sheet of

paper underneath the drum stay

whenever you remove it to catch the

falling toner.

17. Place a sheet of paper on the floor.

Pull out the development unit and put it

on the paper.

M8y 7,1904

18. Separate the toner tank (A) from the

development unit (B) (2 screws).

2-3-3

19. Pour one bottle of developer (C)(lkg

RICOH TYPE 4000) into the development

unit turning

counterclockwise

developer.

20. Reassemble the toner

development unit.

CAUTICX@: When reinstalling the toner

tank,

surface

aqitator gear is on the opposite

side of the toner end sensor

actuator .

make sure that the flat

the knob (D)

to distribute the

tank on

(E) of

the toner

the

2-3-4

Q-i

J

Page 23

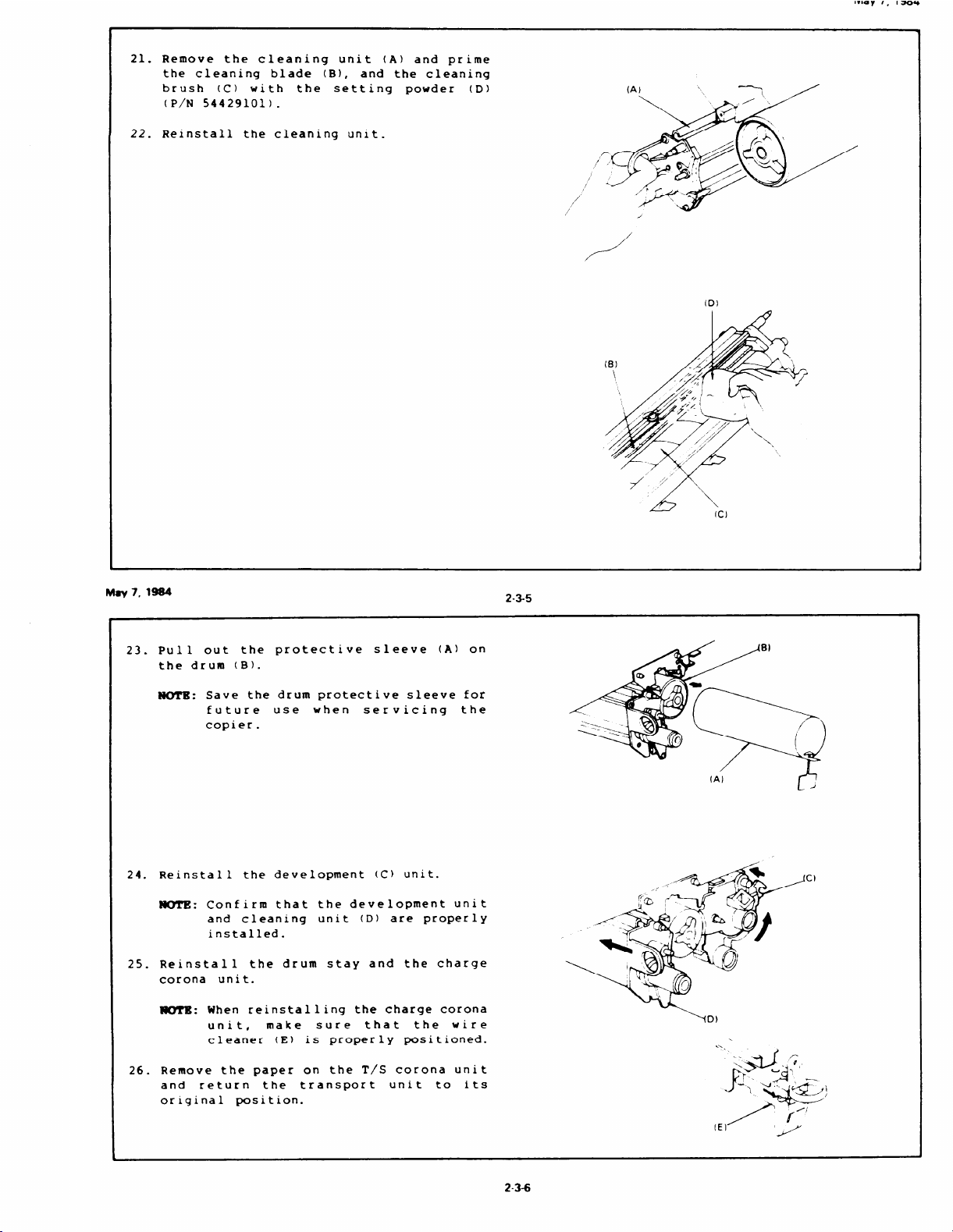

21. Remove the cleaning unit (A) and prime

the cleaning blade (B), and the cleaning

brush (C) with the setting powder

(D)

(P\N 54429101).

22. Reinstall the cleaning unit.

(A)

P

,, ,

,-

,/

/

Mav 7,1984

23.

Pull out the protective sleeve (A) on

the drum (B).

NOTB: Save the drum protective sleeve for

future use when servicing the

copier.

2-3-5

(B)

\

/4

/.//

/2

.2’

\

‘\

(c)

(A)

24.

Reinstall the development (C) unit.

lJOl’E:Confirm that the development unit

and cleaning unit (D) are properly

installed.

Reinstall the drum stay and the charge

25.

corona unit.

I@iY?15:When reinstalling the charge corona

unit,

make sure that the wire

cleaner (E) is properly positioned.

Remove the paper on the T\S corona unit

26.

and return the transport unit to its

original position.

I

/.

2-3-6

Page 24

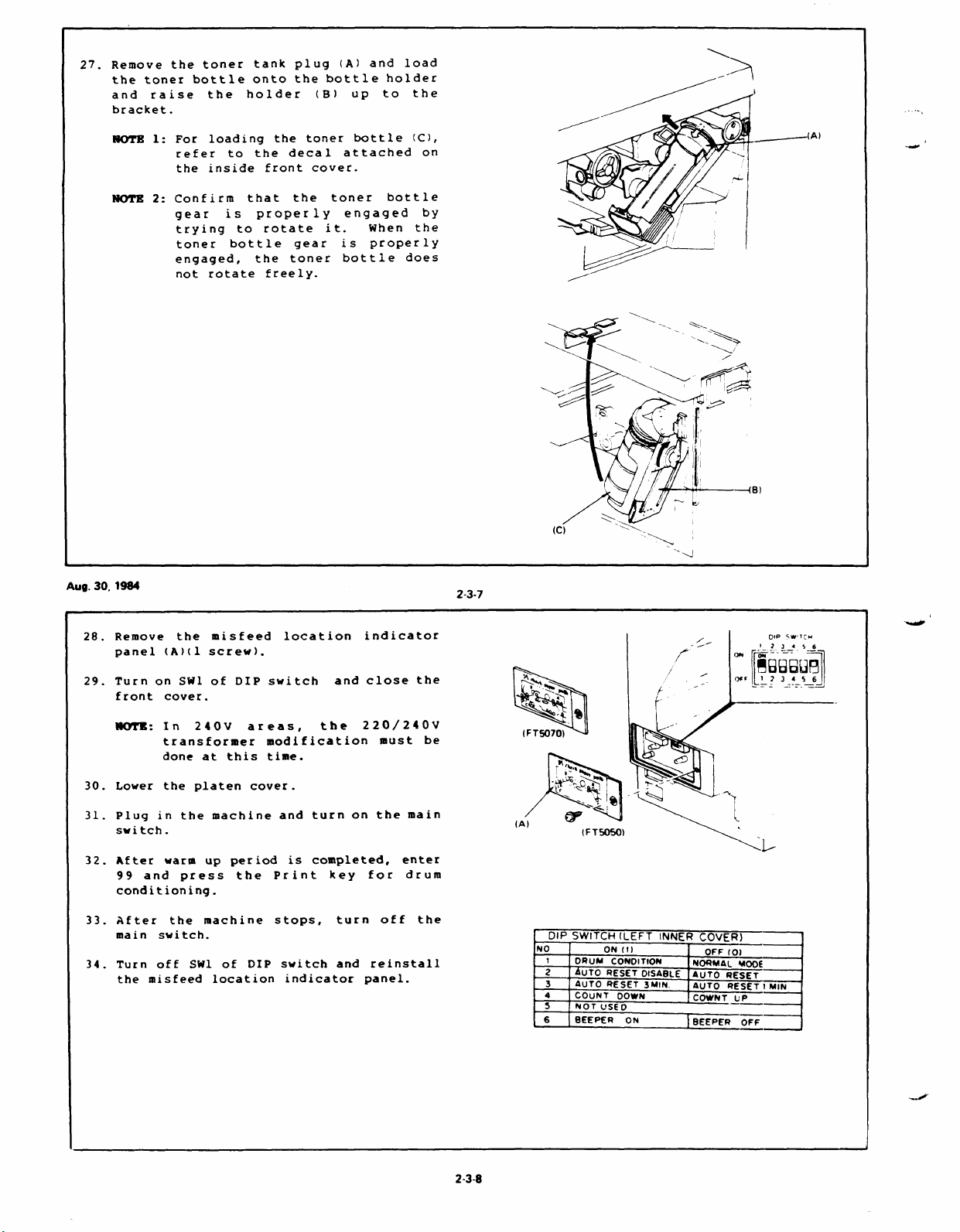

27. Remove the toner tank plug (A) and load

the toner bottle onto the bottle holder

and raise the holder

bracket.

NOTE 1: For loading the toner bottle (C),

refer to the decal attached on

the inside front cover.

(B) up to the

I

. ...

-(A)

--

Aug.30,1984

28.

29.

~ 2: Confirm that the toner bottle

gear

trying to rotate it.

toner bottle gear is properly

engaged,

not rotate freely.

Remove the misfeed location indicator

panel (A)(l screw).

Turn on SW1 of DIP switch

front cover.

~: In 240V areas,

transformer modification must be

done at this time.

is properly engaged by

When the

the toner bottle does

and close the

the 220\240v

“4

a..

OIP <W,l CU

.!_ :-;_y4 S_*

ikmw!

1 23 45 6

Im

. v. u--—.—_

<!%

‘@.*aQ

.T

%

‘ “+%< g

Q

[FT5070)

,/

/“

/

30.

Lower the platen cover.

31.

Plug in the machine and

switch.

32.

After warm up period is

99 and press the Print key for drum

conditioning.

33.

After the machine stops,

main switch.

34.

Turn off SW1 of DIP switch and reinstall

the misfeed location indicator panel.

turn on the main

completed, enter

turn off the

2-3-8

---- s--..

1 NOT USED

6 18EEPER ON

I

]COWNT UP

]BEEPER OFF

---- .

.—

.J

=3

-/’

Page 25

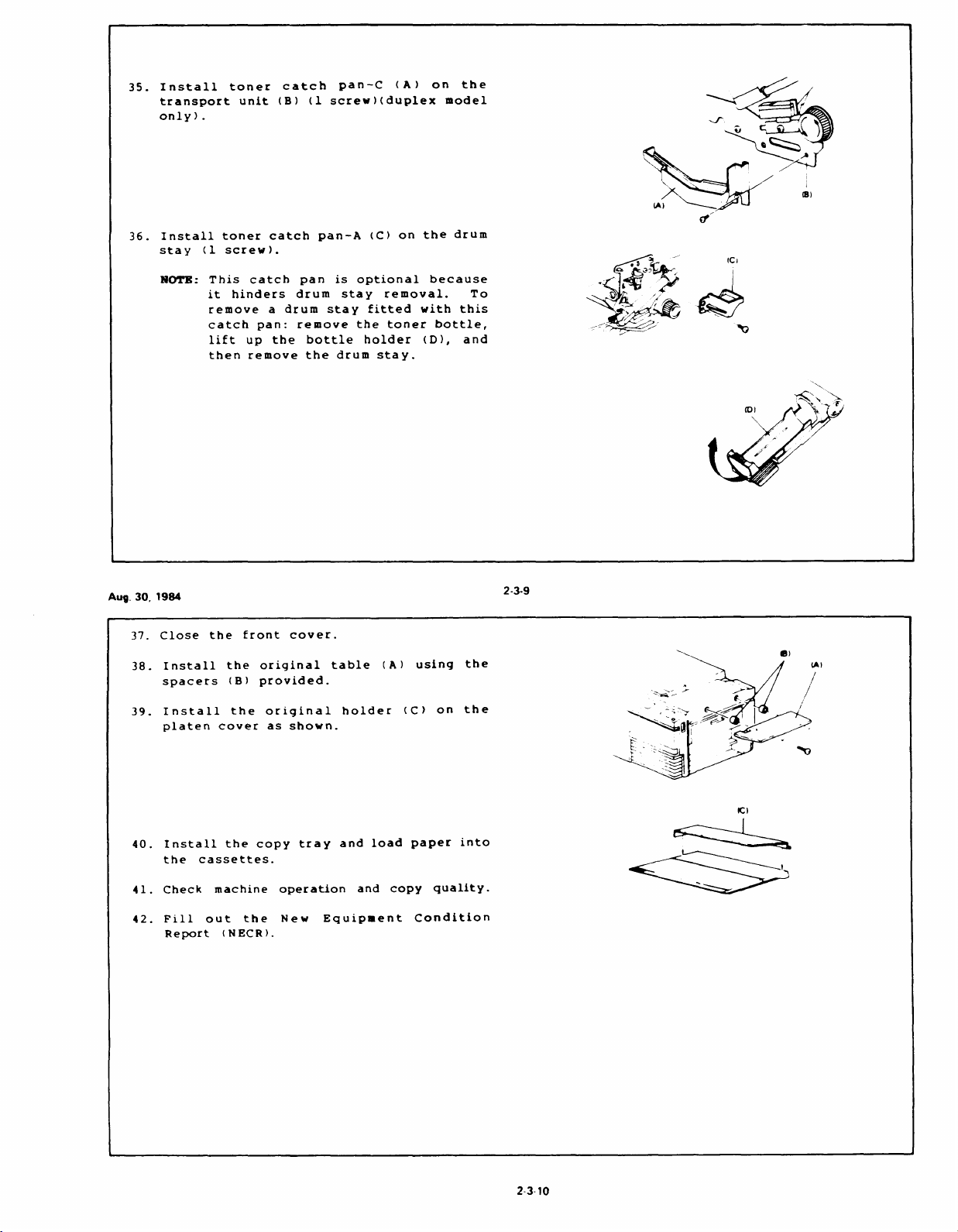

Install toner

35.

catch pan-c (A) on the

transport unit (B) (1 screw )(duplex model

only) .

Install toner catch pan-A (C) on the drum

36.

stay (1 screw).

190’1’11:This catch pan is optional because

Aug. 30, 1984

Close the front cover.

37.

Install the original table (A) using the

38.

spacers (B) provided.

it hinders drum stay removal. To

remove a drum stay fitted with this

catch pan: remove the toner bottle,

lift up the bottle holder

(D), and

then remove the drum stay.

(r’

2-3-9

39.

Install the original holder (C) on the

platen cover as shown.

40.

Install the copy tray and load paper into

the cassettes.

41.

Check machine

Fill out the

42.

Report

(NECR)

operation and copy quality.

New

Equipment Condition

2-3.10

Page 26

May 7,Iw

.—_—

2-4

.

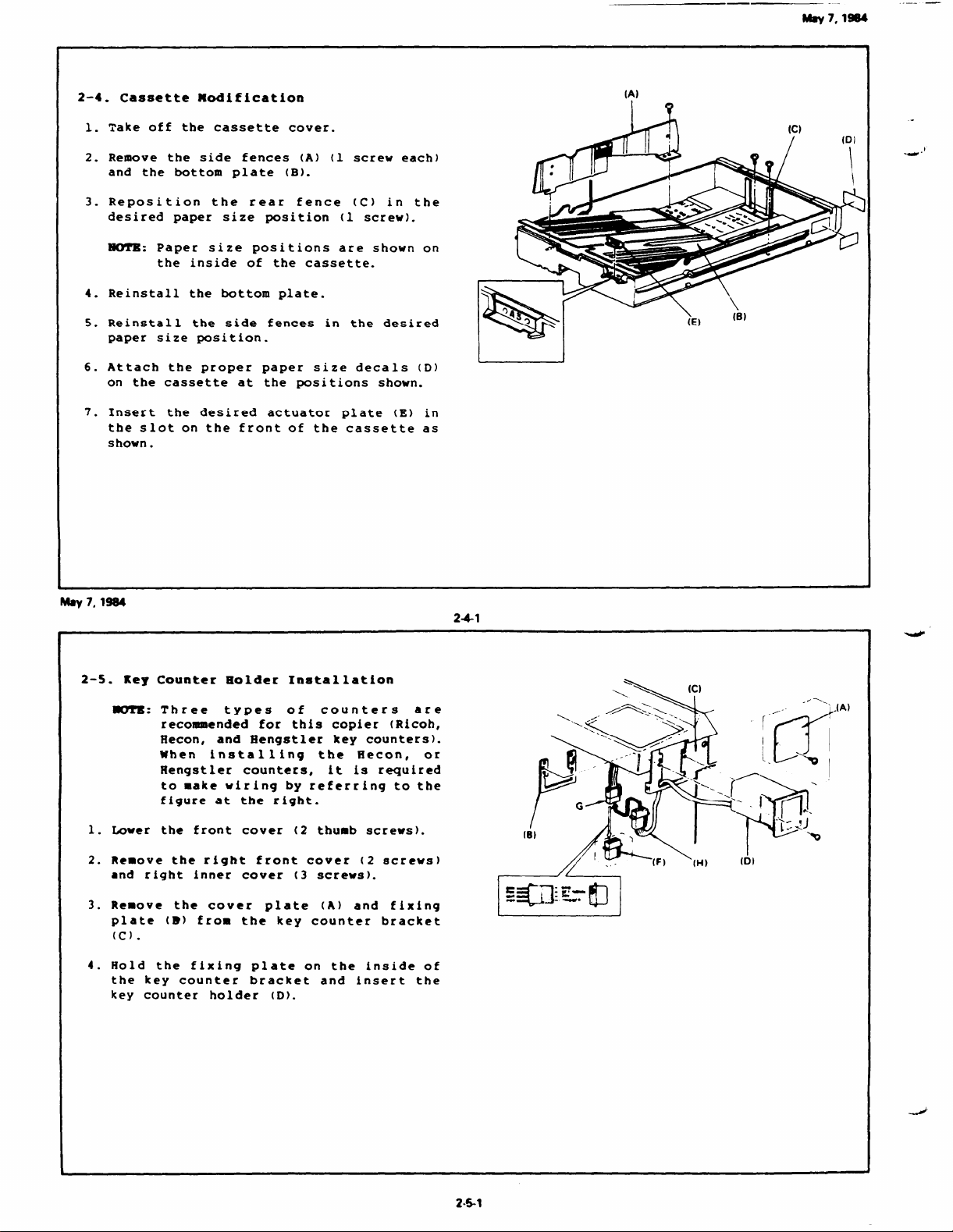

Cassette Modification

Take off the cassette cover.

1.

Remove the side fences (A) (1 screw each)

2.

and the bottom plate (B).

Reposition the rear fence (C) in the

3.

desired paper size position (1 screw).

19tEFB:Paper size positions are shown on

the inside of the cassette.

Reinstall the bottom plate.

4.

Reinstall the side fences in the desired

5.

paper size position.

Attach the proper paper size decals (D)

6.

on the cassette at the positions shown.

7.

Insert the desired actuator plate (E) in

the slot on the front of the cassette as

shown.

(A)

1?

M8y7, 1984

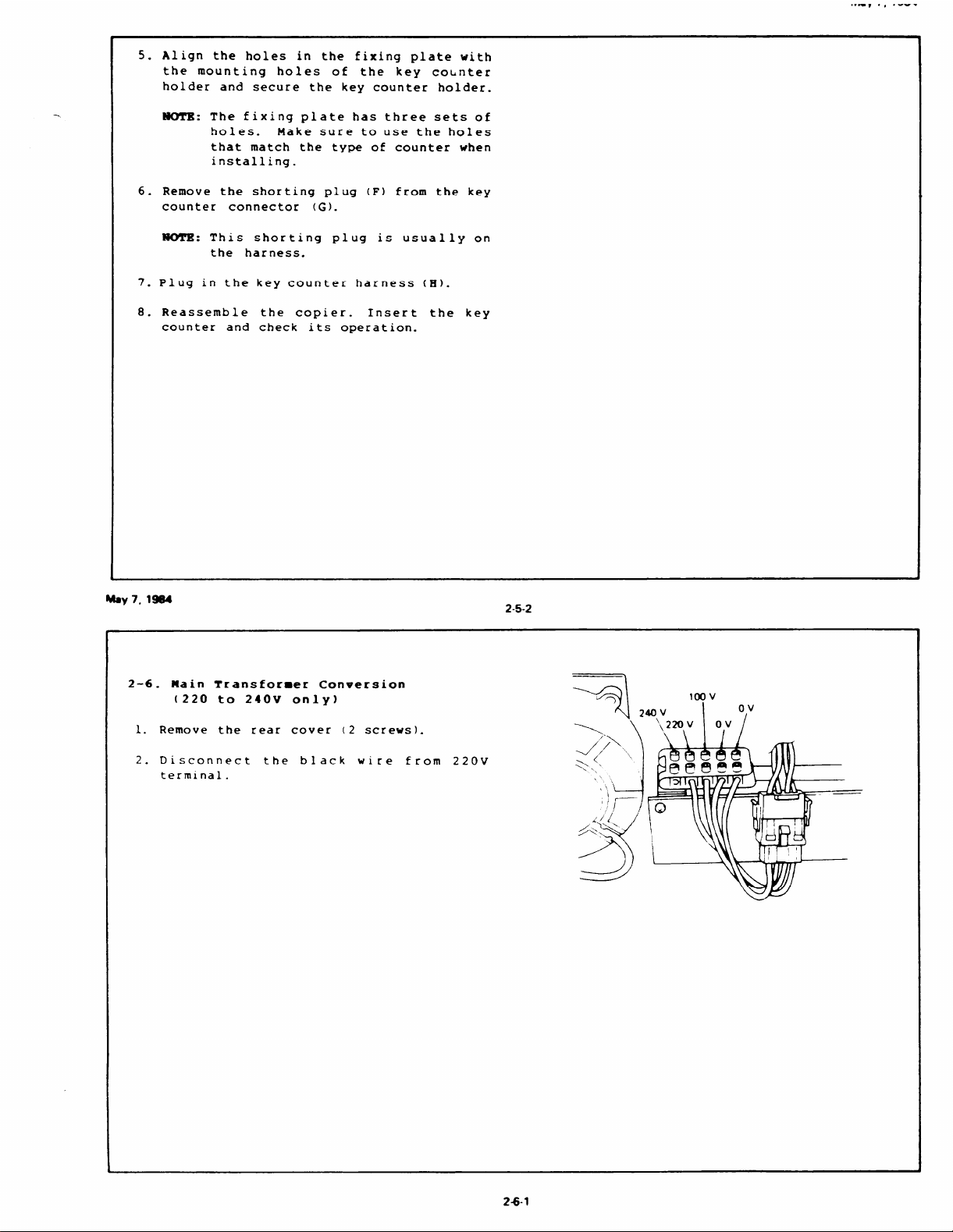

2-5. Key

MY1’E:

1.

Lowe r

Remove the right front cover (2 screws)

2.

●nd right inner cover (3 screws).

Remove the cover plate (A) and fixing

3.

plate (B) from the key counter bracket

(c).

4.

Hold the fixing plate on the inside of

the key counter bracket and insert the

key counter holder

Counter Holder Installation

Three

recommended for this copier (Ricoh,

Recon, and Rengstler

When installing the Hecon, or

Hengstler

to make wiring by referring to

figure at the right.

the front cover (2

types of counters

key counters).

counters, it is required

thumb screws).

(D).

are

the

241

E!za

2-5-1

Page 27

5.

Align the holes in the fixing plate with

the mounting holes of the key co~nter

holder and secure the key counter holder.

.,-r.,--- -

FKYl”B:The fixing plate has three sets of

holes. Make sure to use the holes

that match the type of counter when

installing.

6.

Remove the shorting plug (F) from the key

counter connector (G).

NOTB: This shorting plug is usually on

the harness.

7.

Plug in the key counter harness (H).

8.

Reassemble the copier.

Insert the key

counter and check its operation.

May 7,1904

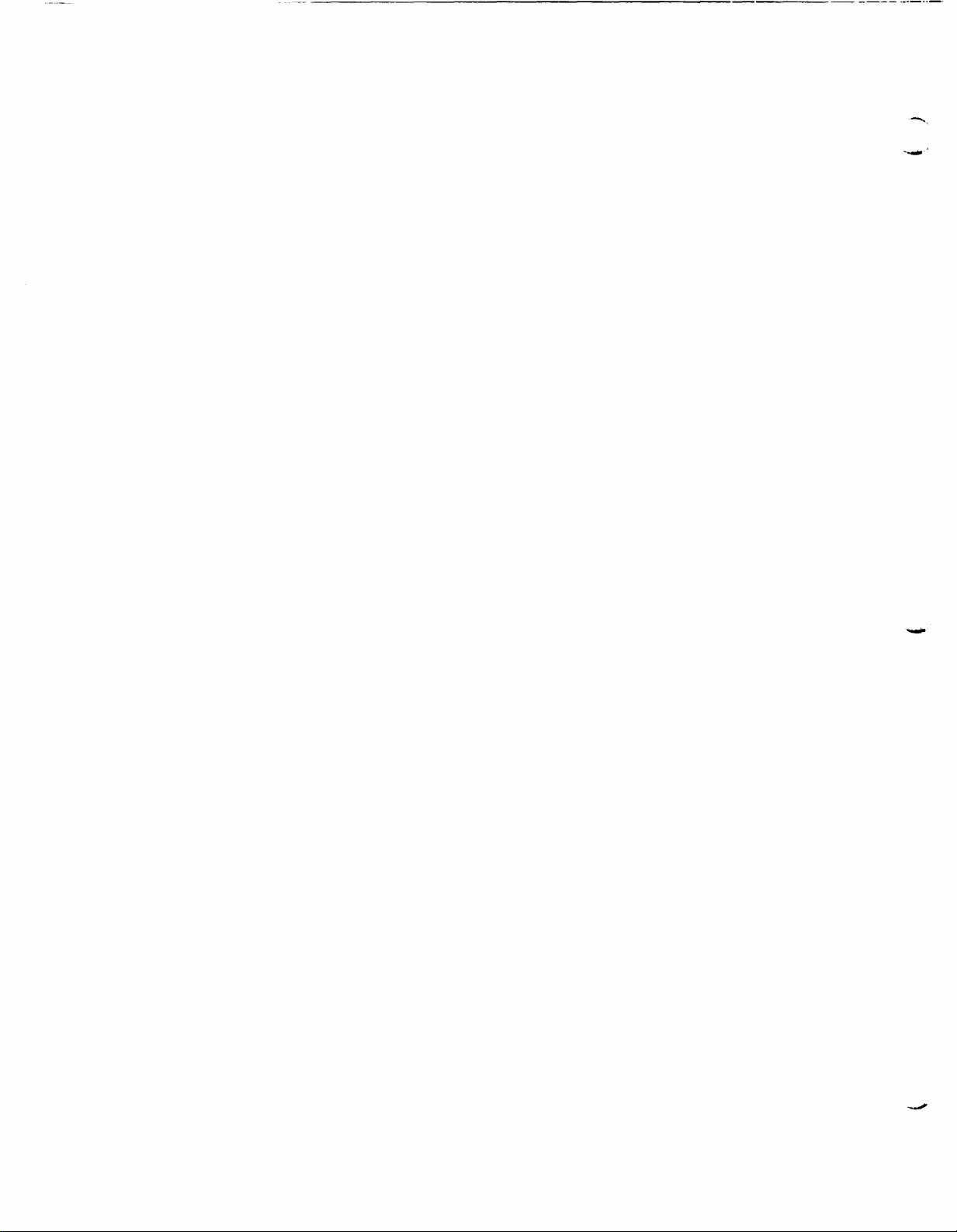

2-6. Main Transformer Conversion

(220 to 240v only)

1. Remove the rear cover (2 screws).

2.

Disconnect the black wire from 220v

terminal.

2-5-2

26-1

Page 28

—————

.... ..—.

--.,

‘

%-

Page 29

SECTION 3

PREPARATION FOR

TRANSPORTING COPIER

Page 30

-. —

Page 31

may 1, 1YU4

PRBPAIWTIOU FOR TW13SPORTIBJG THE COPIBR

Before moving the copier from its place of

installation,

transportation as follows below.

The copier may be badly damaged if it is

moved without proper preparation.

1.

Remove the developer

development unit.

Insert the drum protective sleeve.

2.

3.

Reinstall the development unit.

4.

Reinstall the drum stay and the charge

corona unit.

5.

Place a wedge between the registration

rollers.

Install the transport unit lock plate and

6.

the release lever lock plate.

7.

Install the fork gate unit lock plate.

(FT5070 only)

be sure to prepare it for

from the

1 ,6

,-”4

/

Fork GateUnit Lock Plate

v<”, /

‘/--’ /\

/ \ “’’”

$

u

Trans~rt’Unlt Lock Plate

1

-.,

.-’

\

L.A

.

May 7,1984

8.

Remove the left cover and insert the

scanner lock plate.

?WTll: Confirm that the scanner is at the

9. Secure the front cover, platen cover and

by-pass table with tape.

CAUTION: While transporting the copier by

home position.

car, always cover the copier to

avoid direct sunshine.

leave lt in the car or expose it

to extreme hot or

conditions.

Do not

cold

3-1-1

\“

(+

‘i Scanner Lock plate

\

\

\

3-1-2

Page 32

Page 33

SECTION 4

REMARKS

Page 34

.Ud#”

e“

’984

Page 35

4-1. Points to Remember

CAOTIU9: Keep hands away

●

This is to avoid possible injury when the copier starts idling at the end of warm

from mechanical drive cqnents when the copier is warming up.

up.

●

The beeper sounds five times just before starting idling.

Drum Charge

1. The corona

dry cloth.

2.

Do not touch the corona wires with oily hands.

wires should be cleaned at every service call by sliding the corona unit or with

Do not use emery paper or any solvent for wire cleaning.

3. Make sure that the corona wires are correctly positioned between the cleaner pads.

4. After cleaning the charge corona unit,

make sure that there are no threads on the casing to

avoid white lines on the copy.

Rxposure

1. Do not adjust the following parts:

a: First and second scanner height

adjusting cams (1 screw each)

b: Scanner Guide Plate (3 screws)

c: Lens Axis Adjusting

Cam (1 screw)

d: Lens Position Adjusting Screws

e: Fourth Mirror Angle Adjusting Screw

f: Lens Home Position Sensor (1 screw)

May7,1984

4-1-1

2. Lens home position sensor does not have a convenient ad]usting procedure.

sensor,

mark the position of the sensor bracket before removing it, and adjust the fine

position of the sensor by checking the copy image (horizontal magn~fication and focus).

3. Do not bend or damage the lens support plate or the mylar strip.

4.

Launa 011 or an equivalent oil should be used to lubricate or clean the following:

a. Scanner Gu~de Rod (cleanlng)

b. Scanner Guide Rod Pads (Lubrlcatlon)

c. Scanner Guide Plate (Lubrlcatlon,/Cleanlng )

CAUTION : Do not use slllcone 011 or any other kind of oil.

5. Clean the exposure glass with alcohol and water.

6. Clean the mirrors only with alcohol and,’or water and a soft cloth.

7.

Do not touch the followlng parts with bare hands:

a.

Reflectors

b. Exposure Lamp

c. Mlrros and Lens

8. Do not ad]ust the VR on the optics board.

9.

When ad)ustlng the light lntenslty, make

ten copies before proceeding to check copy image ~f

the main switch has lust been turned on.

When replacing the

4-1-2

Page 36

Development

1. Be careful not to nick or scratch the development roller sleeve.

2. Place a sheet of paper under the development unit when it is out of the copier.

-—.

3. Clean the suction duct at every EM or PM.

4. Clean the development unit guide plate before reinstalling the unit.

5. When reinstalling the toner tank to the development unit,

make sure that the flat surface of

the toner agitator gear is on the opposite side of the toner end sensor actuator.

Toner

Image density sensor should be cleaned at every EM or PM with a blower brush.

1.

2. DO not touch the sensor pattern with bare hands.

3. Image density sensor adjustment is required when:

a: The ID sensor board is replaced.

b: The main board is replaced.

c: The drum has been replaced and Vsg is out of standard.

d: Problems with toner supply have occurred and ID sensor check shows the Vsg to be out of

standard.

4. Grease the toner supply clutch with Mobil Temp 78 periodically to avoid noise and bad

operation.

.dO,’

May7,19$4

4-1-3

Transfer and Separation

1. The corona wires should be cleaned with a dry cloth at every EM or PM.

2. While the drum stay is out,

do not lift up the corona unit.

(The corona casing hits against

the drum.)

Cleaning

DO not damage the edge of the cleaning blade.

1.

2.

DO not touch the cleaning brush with oily hands.

Before pulling out the cleaning unit,

3.

4.

Be careful not to damage the drum with the pick-off pawls when pulling out or inserting the

place a sheet of paper under it.

unit.

When a new cleaning blade and/or a new cleaning brush is installed,

5.

dust them with setting

powder before reinstalling the unit.

.-

4-14

Page 37

Pusing

1. When removing the fusing unit, keep it in an up-right position so that the silicone oil does

not spill.

2. After replacement of the oil blade, oil supply pad, and the hot roller, prime with silicone

oil to the top of the OL1 blade.

3. Be careful not to damage the edge of the hot roller strippers or their tension springs.

4. Be careful not to bend the pressure roller strippers.

5. DO not touch the fusing lamp with bare hands.

6. Be sure that the fusing lamp is not in contact with the inner surface of the hot roller.

7. Be sure that the oil end sensor contacts the bottom of the oil tank.

8. When replacing a fusing temperature control board, make sure that the DIP switch on the board

is set for the correct frequency (50/60Mz).

Mav 7,1984 4-1-5

Paper Feed and Duplex

1. Grease the following parts with Mobil Temp 78 periodically to avoid noise and bad operation:

a. Slip clutches in upper, lower,

b. Worm Gears and Worm Wheels of upper and lower lift motors.

2.

Be careful not to damage the forks when removing the fork gate unit.

3. The rollers and S1lP clutch for duplex and cassette feed are not Interchangeable.

4.

Be sure that the duplex transport belts are matte-side out when replaclng them.

5. When reinstalling the support bracket,

the groove of the registration clutch stopper.

Optional Equipments

1. When servlclng the document feeder and/or sorter,

copier

1s off.

2. Before servlclng the large capacity tray,

and duplex separation rollers.

make sure that the bracket is properly engaged with

make stire that the Main switch of the

unplug the power supply cord of the tray.

4-1-6

Page 38

4-2. Handling the Drum

1. Never touch the drum surface with bare hands.

2. Store the drum in a cool dry place away from heat.

Illdv /, lYd4

3. When cleaning the drum, always use a pair of gloves.

cleaning.

Bring it back to the service depot for disposal according to local regulations.

Do not throw away cotton used for

4. Always prime the drum with setting powder after cleaning the drum, and when installing a new

drum. This should be done within one minute in a location not exposed to room light.

5. To protect the drum,

always applly setting powder to a new cleaning blade and/or a new

cleaning brush before installing them.

6. Drum conditioning is necessary when a new drum is installed. In addition, it should be done

at the following times:

1) When image density is reduced due to over-exposure of the drum.

2) After cleaning the drum.

3) When the drum is lightly scratched.

7. Always keep the drum in the protective sleeve when inserting or pulling the drum out of the

copier (except when applying setting powder).

8. Before inserting or pulling out the drum,

the cleaning unit should be pulled slightly out to

avoid drum damage by the pick-off pawls.

9. Before inserting the protective sleeve on the drum while it is in the copier, always take out

the development unit.

If the sleeve is inserted while the development unit is ir,the copier,

the edge of the sleeve will scrape off developer from the development roller.

10. Send used drums to the distributor according to standard procedure.

4-2-1

Page 39

SECTION 5

REPLACEMENT AND ADJUSTMENT

Page 40

— —

Page 41

1-1.

Bxposure Glass Removal

Take off the left scale (2 short screws).

1.

2.

Grasp the left edge of the exposure glass

and lift it up slightly.

edge

holder.

out from under the right glass

Remove the exposure glass.

Slide the other

-,. . .-”.

ShortScrew

NoTB:

When reinstalling the exposure

glass:

●

Make sure that the left edge of the

glass is flush with the sensor

pattern plate.

●

Make

sure that the right glass

holder firmly secures the exposure

glass.

sensor Pattern Plate

5-1-1

May 7,1984

1–2. Original Size Indicator Board Removal

1.

Turn off the main switch.

Take off the left scale (2 short screws).

2.

Remove the platen cover and the mounting

3.

studs.

4.

Remove the upper cover

(2 long and 6

standard screws).

5.

Open the front cover and remove the left

inner cover (4 screws and 1 thumb screw).

6.

Remove the orlglnal size indicator board

(1 connector).

&

Original Size

Lefl Inner Cover

Left Scale

I

*

Ill

Platen Cover

. 1A

5-1-2

Page 42

———

Iwdy t, Iyoq

1-3.

2nd Mirror Removal

IiOTB: This procedure is usually performed

in order to make cleaning the 3rd

mirror easier.

1.

Turn off the main switch.

2.

Remove the exposure glass.

(See Exposure

Glass Removal.)

3.

Move the 1st scanner 2/3 to the right by

pushing it at the rear side.

4.

Remove

depressing

the front spring plate by

the top of the spring and

moving the plate towards the front side

of the machine.

5.

Carefully pull the 2nd mirror towards the

front side of the machine to remove the

rear spring plate.

6.

Lift the mirror out of the machine rear

side first.

7.

Clean mirrors with alcohol followed by

water, and then dry.

[Front]

2nd Mtrror

Rear Spmg Plate

d’

- To Reinstall -

8.

Place the rear spring plate in place and

hold it with your finger.

9.

Insert the 2nd mirror into the front side

plate cut out.

10.

Insert the rear side of the mirror into

the rear spring plate.

11.

Locate the bottom of the front spring

plate and rotate the top of the spring

into position.

t90TB: Make sure that you install the

mirrors with the 1st surface facing

the lens as shown.

5-1-3

(Right)

! ~ti=&;

~—_J

““’at’?~’rs’ea~~’n’

I

surface

1St

(Wrong)

,2nd%anner&xket

May7

19a4

5-14

‘d

I

Page 43

1-4. Exposure Lamp Replacement

1. Turn off the main switch.

2. Remove the exposure glass. (See Exposure

Glass Removal.)

Move the first scanner to the position

3.

where the rear frame is cut out.

4. Remove the reflector cover (2 screws).

5. Wrap a strip of paper around the exposure

lamp as shown.

CAUTION: Do not touch the reflector or

the new exposure lamp with your

bare hands.

paper as shown.

Use a strip of

(Finger oil

marks on the lamp or reflectors

will be affected by the heat and

will result in discoloration.)

Reflector Cover

iExposure Lamp

Press the release lever on the front lamp

6.

terminal as shown and take out the lamp.

.Install

7.

paper .

a new lamp US111C3 a strip of

(Set the rear terminal first. )

NOTE: The blister on the lamp must point

toward the mouth of the reflector

as shown.

8.

Check the exposure lamp posltlon and the

liqht

intensity

(See

Exposure

Posltlon and Light Intensity Adjustment.)

Lamp

5-1-5

May7,1984

, Reflector Cover

5-1-6

Page 44

1-S. Exposure Lamp Position

Remove the exposure glass. (See Exposure

1.

Glass Removal. )

-Horizontal Adjustment-

2.

Move the exposure lamp to the center of

the copier.

3.

View the lamp filament through the sight

holes on the top of the reflector cover.

The filament should be directly beneath

the sight holes.

4.

To correct the position of the filament,

turn adjusting screws.

-Vertical Adjustment-

5.

Move the exposure lamp fully to the

right.

View the lamp filament through the

6.

ventilation

the upper cover.

slits on the right side of

The filament should be

level with the sight holeson the sideof

the reflector.

7.

To correct the position of the filament,

remove the platen cover and the upper

cover (8 screws and 2 mounting studs).

8.

Remove the reflector cover (2 screws) and

turn the adjusting

knobs until the

correct position is achieved.

~: Be sure to tighten the adjusting

knob screws after adjusting the

lamp position.

9. Check uneven exposure and light

intensity. (See Copy Image Section.)

5-1-7

Adjusting Knob ‘

/

=1

Adjust Ing Screw

May7 1984

5-1-8

Page 45

Scanner Drive Wire Replacement

1-6.

1. Turn off the main switch.

MaInBoard

1

2. Remove the platen cover,

studs,

3. Remove

and the

4.

Remove

cooling

5. Move the harnesses out of the way of the

bottom of the optics board (1 twist

clamp).

right (1 screw) and the main board to the

left (2 screws).

6. Loosen the wire clamp screw.

7.

Move

pos~tlon.

8. Unhook the tension spring and take off

the wire hook.

and the upper cover

the left scale (2 short screws)

exposure glass.

the rear cover (2 screws) and the

fan (2 screws and 1 connector).

Swing the optics board to the

the 2nd scanner to the return

Take OUY the old wire.

the mounting

(8 screws).

Scanner Drive pulley ~lre Clamp

Tension Spring

9. Remove the 2nd scanner drive pulley (1

Allen screw) by aligning the notch of the

pulley d~sk

position sensor.

10. Position the bead of the new wire on the

groove of the 2nd scanner drive pulley

and wrap the wire around the pulley with

two and half turns as shown.

11. Secure the turns of the wire on the

pulley with the ‘Jclamp (or with tape).

12. Set the 2nd scanner drive pulley on the

drive motor shaft as shown and t~ghten

the Allen screw on the flat side of the

shaft.

?un’E: ‘

●

with the 2nd scanner home

The end of the second scanner

drive pulley should be flush

with the end of the motor shaft.

The 2nd scanner home position

sensor should be positioned

between the short and long ends

of the wire.

5-1-9

second

Drive

May 7,

1984

Long

End

Second Scanner

. . -..,

.

’’’---

Drive Pulley

,

I

‘...%

4

----

\

- -.

-..

‘---

.-..

‘---

:\

“&’

5-1-1o

:A*~ati

Yi&2~b”

Long End

Second &ner ~

Home position Sensor :,:.

I

Page 46

13. Run the scanner drive wire over the

pulleys in the follow;ng order:

1 Short end should be in lower track

(WPl). (Tape the wire on the bracket. )

2 Long end should be in upper track (wP1)

3 Outer track (WP2)

4 Outer track (WP3)

5 Lower side (Wire Clamp)

6 Lower track (WP4)

7 Lower track (WPS)

8 Three and half turns from lower to

upper (Scanner Drive Pulley)

9 Upper track (WP5)

10 Lower track (wP6)

11 Inner track (WP3)

12 Inner track (WP7)

14. Remove the tape and pull the ends of the

wire together and join them with the wire

hook .

15. Push the tension pulley to the right.

Take the wire off of the pulleys in

figures 2 (WP1) and 9 (WP5) of step 12,

so that you can hook the tension spring

easily.

16. Hook the tension spring and reposition

the wire on the pulleys in steps 2 and 9 .

.,----

.-,’

5-1-11

Wire Clamp

WP3 (2nd Scanner Pulley)

10

c1

*

WI%

El

M8y7, 1984

WP6

WP2

5-1-12

L

WP7(Tens,oo Pulley)

J

Page 47

17. Remove the Q clamp.

18. Rotate the scanner drive pulley and make

sure that the scanner drive wire moves

smoothly and

there is no overlapping

around the scanner drive pulley.

WUI’B: Step 18 is

overlapping of the scanner drive

wire occurs,

A3 (11” x 17”) copies may be

reduced.

Amportant!

If

then the trail edge of

5-1-13

May 7,1984

– Rough Adjustment of Wire Clamp Position -

Move the 2nd scanner to the right (rear

19.

view)

and position it so that

the

distance between the 2nd scanner bracket

and the inner

surface of the optical

frame 1s 52mm (2.05”).

Move the first scanner to the home

20.

posltlon and make the right edge of the

wire clamp flush with the right side of

the home Position sensor.

Tighten the screw of the clamp temporarily.

21.

Ad]ust the horizontal magnification by

22.

changing the wire clamp posltlon. (See

Horizontal Magnification Adjustment.)

Wire Clamp,

—----/,” ;

.—

—++ ‘J

/

~- t+ome Position Sensor

/’

W,re Clamp

hd Scanner

Bracket ‘.

\-

‘--,

~.G6

%*

/< ,

,

— ,—Y

Flush

‘=/’ ‘<

\

T “;

\

‘ ~!.”””;.

‘./’=

~ @</’-

.

.4

NOTE lnner%rf~

I

I

I

“>(

—,. —

/

c

—P

Opticai Frame

(205”)

5-1-14

Page 48

—

1-7

. Scanner Drive Motor Replacement

..-

1.

Remove the

platen cover and the mounting

studs.

2.

Remove the upper cover

(8 screws) and the

rear cover (2 screws).

3.

the three scanner

Fix

as shown,

to hold the

pulleys with tape,

scanner drive wire

on the pulleys.

4.

Lift up

the scanner drive pulley

vertically and take it off from the shaft

of the scanner drive motor

(2 Allen

screws) .

5.

Disconnect

connectors and free them from

motor bracket.

6.

Remove

the

two scanner

scanner

the

drive motor (4

the scanner

screws) .

7.

Install a new scanner drive motor.

NO’TB: When installing the scanner drive

pulley on the motor shaft:

●

Make sure that one of the allen

screws is secured squarely on

the flat side of the motor

shaft.

motor

Scanner Drive

Motor

*

The scanner drive pulley should

be flush with the ‘>nd of the

motor shaft.

8. Remove tapes and make

scanner

drive wire is correctly

positioned on the pulleys.

sure that the

5-1-15

May 7, 1984

5-1-16

Page 49

May 1, 1354

l–8. Lens Drive and 2nd Scanner Drive Motor

Replacement

1.

Remove the platen cover and the mounting

studs.

2.

Remove the upper cover (8 screws) and the

rear cover (2 screws).

3.

Remove the left scale (2 short screws)

and the exposure glass.

4.

Remove the cooling fan (2 screws and 1

connector) .

5.

Move the harnesses out of the way of the

bottom of the optics board (1 twist

clamp). Swing the optics board to the

right (1 screw).

,,-

2nd Scanner

Drwe Puliey

1

Disconnect the two

6.

motors

screw) .

7.

Move the scanner to the return position

and put the Slclamp (or tape) on the 2nd

scanner drive pulley.

Flx the pulley (WP1) with tape as shown.

8.

9.

Loosen the Allen screw on the 2nd

drive pulley and align the notch of the

disk with the 2nd scanner home position

sensor .

10.

Take off the 2nd scanner drive pulley

from the motor shaft.

11.

Open the front cover and take out the

fusing unit (1 lock pin - orange).

Take out the motor

12.

13.

Remove the motor cover (1 screw) from the

motor

and remove the nylon clamp (1

assembly.

connectors of the

assembly (3 screws).

scanner

5-1-17

Motor \

Second Scanner

Drwe Motor

‘ear \ e

*B

‘-.

4% .

.

y+

I

/

‘%

AL

Coollng Fan

M8y 7,1984

9

“ ‘- --’---’

Loosen the Allen screw of the motor gear

14.

on the motor shaft.

from the assembly --- lens drive motor

and/or

screws each).

2nd scanner drive motor --- (2

Remove the motors

5-1-18

&&i!ii!i!6

k

&

>

‘\\

II

‘1.

MotorGver

Lens Drive

Motor

“&V.A

=&

Page 50

May 7,1984

15. Install the new motor in the motor

assembly.

Make sure that the harnesses

CAUTION :

*

are properly positioned.

—

* When installing the motor

gear, push the gear against

the motor and then

Allen screw on

secure the

the flat

surface of the motor shaft.

When installing

*

scanner motor,

drive gear so

rotate

that the flat

the

2nd

the

side of the shaft faces the

rear of the copier.

16. Reinstall the motor assembly and

reassemble the copier.

CAUTIOU: When installing the 2nd scanner

drive pulley, make sure that the

notch of the 2nd scanner drive

pulley faces the right rear

corner of the copier.

P

i/

//

2nd &ner

Home?osmon%nsor

s:tt

[Rear]

[Front]

2nd Scanner

Drive Pul[eY

5-1-19

‘-

d

Page 51

SECTION 6

SERVICE TABLES

Page 52

.-J

4

Page 53

6-1. ADJUSTMENT TABLE

[COPIER]

,.oa, ,, ,-

No.

Adjustment Item

Development Roller Magnet

Angle

1

Doctor Gap

2

Adjustment Standard

1 line right of center {Move the plate to the

left and then move it back.)

1.26 t 0.1 mm (0.050” t 0.004”)

~

ltne RIO( of Center

1

Doctor Gap

Plate

Nota

Magnet A@e

Ad~sting Rate

No.

Toner Supply Clutch

3

Image Density Sensor

4

Adjustment Itam

Adjustment Standard

O 1 mm (0.004”)

LIw *P gauge (P/N 52059101).

Grease with Mobil Temp 78

(P/N 54479078).

+4 ? 0.2 v

6-1-1

Olmm

Gao Gauge

!

I

u

ChamferedEnd

Toner Supply Roller

Drwe Sprocket

E rlnq

L

I

.“

lb

DqItaI

Multlrneter

r-—a I

:1Ilon

6-1-2

pyz~

A-’

I Po51twe Probe

Page 54

.—— — .. ----

—

——.

.- e..-,.- -.

.—.

No.

5

6

Adjustment Item

Feed Clutches

Pressure Springs

(Fusing Unit)

I

0.1 mm (0.004”)

Use

Lock nut should be flush with the end of

the adjusting screw.

[Nip Band Width]

Adjustment Smndard

gaP @u@ (P/N 52059101).

Center: 5.6 t 0.4 mm (0.22” t 0.02”)

Side to Side: Less than 0.4 mm

(0.02”)

E-ring

%il

W.NiOBandWii

,

/

GWI Gauw

PmSure

Spring

4 P-Ir9 I mw.r =

Nota

p

M@sting COh

Gap

Gauge

(Mar

,-“\

6-1-3

No. Adjustment ham Adjustment Standard

Thermistor Gap

7

Thermofuse Position As far away from the hot roller as possible.

8

0.5 ~ 0.15 mnl (0.02” * O.CMX”’)

Adjustiw ScfUW

ThermistorBad

Thermistor

.

I

,

6-14

\

M Rdlar

‘J

i

Page 55

No.

Acijuatment Item

Oil End Sensor Contacts the bottom of the oil thank.

Adjustment Standerd

Note

Metal Cvlmder

9

Pressure Roller Stripper

10

No.

1 nverter Return Solenoid

Adjustment Item

Pull each stripper down against the guide

bracket.

6-1-5

Adjustment Standerd

—

Solenoid Lever Gap –

1.5 f 0.2 mm (0.059” f 0.008”)

—

SoIenod Stroke Gap –

2.2 t 0.3 mm (0.047” ~ 0.012”)

B

‘b

%-r

/’

/

Lower Fusing Ex(t

Guide Bracket

Invener Prmure Roller

\

‘\

.

u?

-- _-

Note

1 5mm

&

,—

slot cut

O’II Tank

Pressure Roller

Stnciper

\

Guide

Bracket

\

\ —--- L

\

.—

!

8

.——.

Inverter Pressure

Rdl& Lever

se! Screw

(Allen screw)

~ %leno,d I_evpr

I

11

Inveflw SUPPOR Roller

clutch

12

0.1 mm (0.004”)

U= *P gMJge (P/N 52059101).

Clutch Gear ,

clutch Slopper

‘Add ‘“

rlw?l

1 L

Adpstlng Screw

Gap Gauge

‘-.

t’

,=

‘ Inverter Return

SoIenod

Gag Gauty

-/

Lock Collar

,

Page 56

,.-, ,, ,-

No.

13

14

AdbtnlaltMan

Dupbx pickwP Solanoii

Duplex Stopper Solenoid

Ad

matma?t St8ndwd

1.6 f 0.5 mm (0.07” t 0.02”)

Unhook the spring on the duplex stopper

5olenoid pluqpr and insert the plunger into

the solenoid.

Then adjuat.

Press the solenoid fully to the left.

Duplex Stopper Solenoid

/

-%-

Mounting Screw

1.8tO.Srnm

(0.07” t 0.02’”)

-up

May 7, 1W4

No.

15

16

Mjustment

Duplex Positioning Solenoid

ham

JoggtrHome Position

61-7

Poaition thereuand front jowarfencea8s

shown in the f~m.

Mova the aenaor toward the actuator phl

until the LED on the sanaor chacker turns

off .

Movethe sensor away fromthaactuator

plate until the LED just Ii@.

At this point ti@ten the adjusting screw.

5 ? o.5nm

(0.20 f 0.02”)

-r Home

Po6itlon

Duplex StopperSolenoid

+-

>

r=

\

.

Mounting

/

screw

61-8

Sensor C2nxker

L- J?=-

-t-’

5VTest P!n

Page 57

MO.

Mju8tmmtham

Corona Currant

Charge

Optimum

DC+57.7 tO.1 @

(Turn on SW on the witching board.)

MjustingVdua

..

17

Transfer Corona Current

18

DC+17.7t0.3LLA

(Turn on SW3 on the switching board.)

T

Drum shoa

9

Erm hp

@

●

MultiMate

Unit

May 7, 1984

No.

19

20

Adjustment

Separation Corona Current

Pre-Claaning Corona Currant

Itam

&l-g

optimum Mjusting Vdua

AC 43.1 * 0.4 PA

DC –2.2 t 0.3 AA

(Turn on SW 4 on the switching board.)

Dc+17.5io.3JlA

(Turn on SW5 on the switching board.)

Eraw bmp

Umt

“&*-

U

timetef

sed

61-10

Page 58

No.

Horizorttal Magnifmtion

(ROUGH Adjustment)

21

Adjustment ham

Adjustment standard

Distance between the 2nd scannar bracket

and the inner surface of the optical frame:

52 mm (2.05”)

The right edge of the wire clamp should be

flush with the ri*t side of the home posi-

l—

~

‘+

Wire (lamp

2nd Sanner I

Bracket

Wire clamp

\\ .- “’4/’”’- “

/ ./?

. .

.

d

f-

FlustI

Home Rxiticm m

NOTE: Inner SUrfa

l/

-: ; \ :2~#,

— –L

/.

/

.-

u. =’

0

;

.

4

~

OptIc4 Frame

-.\

r

——

.-

*

Horizontal Magnif~tion

(FINE Adjustment)

22

No.

I

Light Intensity

23

Adjustnwmt Item

t 0.5% (Full size)

Move the wire clamp position with checking

copy image.

6-1-11

1. Level 2 of the gray scale on

theOS-A3

chart should be li#rtly visible on the copy

when 2nd level of the density control is

selected.

2. Background of the COPY should be sli#ttIy dirty when the Ist level of the density

control isselected.

“ Make a test coPv without the repeat com-

pensation of the bias voltage.

Lamp

Re@ator

I

I

1

I Smaller I

Wire aamp

1st

\

Scanner

6-1-12

L

.UOd

Page 59

[IX3WWWFEEDER]

No.

Beft Unit Level

1

Mjuatnnmthorn

MjustmentStandard

Front Side

Gap betwaen the nylon spacer and the exposure glass: 0.16 mm (0.006”)

Rear Side

Distance between the pressure suppon

bracket and the exposure glass:

15.5 t 0.5 mm (0.61” f 0,02”)

Left We Magnet

\

‘\

.

‘h

‘iii—

RIOI Sde Ma(peI

N)rIon

Spacer

~ o.16mnl [0.006”)

T

\

Exposure GIas

u=z-

PrWre

RrYler SupporK

8rxket

/

15.5 f05mm

(0.61 “)

Original Stopper Solenoid

2

No.

3

Mjustment Item

Break Pressure Spring

“ Hei@t above the original feed table:

8 mm – 12 mm (0.31” – 0.47”)

● Depth below the original feed table:

3 mm – 6 mm (0.12” – 0.24”)

6-1-13

Adjustment Standard

14 mm -15 mm (0.55” – 0.59”)

(031 –0.47 )

(I)

14mm - I%nm

(o 55”-0 59”)

4

a-’2mrnw7-

3–6mm

1’” – 0.24”)

,=!5+-4

Y

-“-

“.

‘

. .

.,

Note

y“ ,/

‘2

● 4

:. ,

.

-Q? ‘“

Solen~d

Onglnai Feed Table

/

/

/

Orlgmal Stopper

A

Y

k

-~j

4

Lift Switch

Lift switch is dwctuated when the distance

between the exposure giasaand the feed belt

(front side) is 16 mm -30 mm

(0.63” – 1.18”’).

WI ~

Brake Prmsure ~rtng

L.-J

1-,fl SW! tch

/

/

, - ++q

Page 60

OF Rqiatnth Adjuatwmt

No.

- Praadjustrnant for

A3 Original -

Chanfcopy

Adiuatmant WdaWWta

ON

-2. 4

I

1

I

I

-\,,

1

To faad in, dapresa “Auto

ReducelEnbr#” key.

To fead out, depress “Auto

~ Sebct” kay.

2

– Adjustment for

Haavy/Li~t Originals –

3

A3 Haavv Chart

A3 ~ Chart

ihii!!

—ow —

DIP SW101

[Original Counter]

[Original Counter]

Heavy C Ll@t

6-1-15

l“]

p

Ix!!!El

,

N“kf!!!i

L

J

EEl

/

1

Heavy > L@t

OF Main Board

Preadjustwwnt Ran=

) F=q

I

—

‘

.*

No.

– Adjustment for

Make copies using the DF.

4

– Adjustment for

Make copies in platen mode

with flip scale and in D_Fmode

5

Procadura

Lar@rnalI Originats -

Pbten/DF Mode –

Chart/copy

AJ Tast Chan

(Either heavy or

Ii@t)

&5 Test Chan

Any Test Chart

1

ON:

OFF: 2,3,4

UWIR

—06f —

DIP SW101

[Lead Ed~ Registration]

1’

OF > PLATEN

i

I

I

I

I

1

MhntmantStandardmota

A3 > A5

I

b

J

II I

/

OF < PLATEN

--

OK

A3

n

AS

c1

/

A3 < A5

o

A3 = A5

OF

D

PLATEN

[1

3F = PLATEN

L-

6-1-16

‘.>

J

Page 61

6-2. DIP SWITCH TABLE

DIP SWITCH ( LEFT

INNER COVER)

?.L?!!z.._-

Function

1 ‘G Drum

Condlt]orung

off

-)

.

on

off

3on

——. .

off

4 on ‘-

-————. - ——-——— —

off Count Up To enable quantsty completed counter to count up from

: Normal Mode

Auto Reset

Eh.sable

Auto Reset

. ———

Auto Reset 3 Mm To specsfy 3 nunutes as the

Auto Reset 1 MI. To speafy 1 mmute as the automat]c reset tune.

Count Dowrt To

5 on ‘-—–No Auto Cassette

sh.lft

off

Auto Casaette When the sekcted cassette runs out of paper, the copier wdl

Shift

6 Ilrt Beeper On

, off

Beeper Off

To

prepare the drum surfaa for copying

To turn off Auto reset

To emble the copier to automatdly reset aIJ its settsngs and

modes to normal status after a specified tme Reproduction RAtIo

automatic reset tune.

enable quantity completed counter to count down Enter 5 copses

to zero

zero.

shift to the other cassette if the other cassette has the same

paper am and dirc~on.

To turn on beeper

To

turn off beeper

● After uistalJatson of a new drum.

● occurrence of afightcopy image.

● Occurrenceof vertical black lines.

4

<

!

1

I

I

~Normal Status

Note

Quantity Entered

Quantity Compkted

sorter OFF

Document Feeder

Special Functmns

I

press the PMt key

Quntsty

Compkced&splays

5,4, 3,2,1,0

Emter 5 coptss

Ress the Print key

Compkted dqda~.

@rtUty

0,1, 2,3,4, s.

I

I

FUIJ

sue

,. .,

OFF

OFF

OFF

1

May 7,

1984

DIP SWITCH 101 (MAIN BOARD)

I

!’ii:!?. . --

I

,lrl

,

off

on No Mtsfccd

2

, - Normal Mode -

off -

on

3

& + Idk Run On “

——..

4

on

off

——

r

5 1Must be

Free Run

NormaJ Mode

Detect ton

Idle Run Off To d:sabk warm up cyck . To check the drum current

~oIn

—+-

~_Normal Mode To dssablc cotn lock operat]on.

~m

6

7

~on

!

80n Image Derrsllv

—. . —— – ———-—

I

off

off

,

ID Sensor

1 LED On

NorrnaJ Mode

Auto Reset

NO Image Denssty To clear Image density auto reset

Auto Rewt

–– --- — .—-..--:--

—-

—— —————

‘bck “-To selectcoin lock operattorr

_.—. —

6-2-1

,

To enable the copter to run wrthout paper

.

To ckar mssfeed detectton

-—

——

—. ——

To Idle machtne for 30 scmrds at 170”C to warm up

fusing ass”y

enable warm up cycle

To

1

The ID sensor LED conturues to lsght

To return the Image density

reset

—— —.—.

————.~. -— —. -—

to setting (4) during automatic

I

T

● To check and adprst ID sensor

—-—~——————

● To check operatronwthout paper

● TO Judge whether a mrsfeed n

I

caused by a defectwc misfeed

sensor

L.———– –——– ——

;

—. —–— --

. Afler mstallatson of

Unst

1

● To adp’t the ID sensor

—4

—

— -—-----l

—

—

theCowslock

—

-– ~—-

I

I

Regsstratson Sensor

Fussng Sensor

Paper Exit ScnmI

lnverter Sensor

_

Fork Gate Sensor

Dupkx Entrance Sensor

———— ————

—-——–-—-

I

.—— ——

Note

——

6-2-2

Page 62

DIP SWITCH 102 (MAIN BOARD)

No.

On/Ou

I

1 on Fii supply Toaddatixtd

off

2 on

off

7

3

See

chart for

combination

-i-

required

5 on Iighter (Toner

off

6 on

7

Moat k

8 off

ttu~ 30, 19B4

Mode determined by the combinati of DIP SW 102-3 and 4.

Detectsupply

Mode

ID Sensor

Monitor

I NormalMode

,

-- I

Density) ; denait y check cycle, the sensor pattern is developed at the

Darker (Toner To increase the toner density on the copies during tlK image ]

‘ Density) ~ density check C@, the rensor parttern is developed at the [

To enabk automatic toner density supply. Amount is determined by the combination of DIP SW 102-3 and 4.

To diSphy the Potentiak of V= and V~P via hexadc&mk

in the Quantity Entered and the Quantity Compkted

counter respectively.

1

Freed Supply Mode

/To&crease thetoner density ortthecopies during theirnage I

2nd retting (lower bias).

I 5th setting (higher bias).

Fgnujoo

amount of toner at avery copy cyck which is.

Detect Supply Mode

6-2-3

● when supply system faih.

. To judge

I

I

wbther abnormal toner

dcnsityhabeen cauaedbyv=

and V~p or not. (See Image

- Sensor Check Section.)

. . .

.4”

I

‘MectSupplyMode20% iafact.ory

setting.

If Both5and6arc ONor OFF

-?4tixwfubeadectad.

I

i

DIP SWITCH 301 (OPTICS BOARD)

DIP SWITCH 302 (OPTICS BOARD)

No Odoff

Ion

‘ off

7

.

~ Must be

3 off

4(

5

ple~~ *

6

1 chart

7

combma-

Optics Free Run

I Normal Mode

Uading EdW

for ~Erase

i

lToti

tmn

required

81

. To adjust the kading edge erase

xanrurdrivc rnotor~.

600001111

7001-10011

8010 ~0101

.—+

I

##p

0.8 mmlsw

——.—.

F~

10 Tociwx&xmuur

-*===-).

. Leadrngedgeeraseis out of

standard.

.

Afterrepiacirrgqxksboard.

opratkm (after

Adjwtmeat standud4flmm

! fO.J6’” * 0.04’’)(fuO aizr; .

Me

Page 63

6-3. DEFECTIVE SENSOR TABLE

No.

I 1 ! Scanner Home Posltmn

I

Overrun

2

3 Lens Home Powtmn

4

] 2nd Scanner H P

~-—- -—

~ Toner End

5

GOwr L,h —

7 Uppw/Lower Paper Size

Upper/Lower Paper Volume

8

Upper/Lower Paper End

9

By-pass

10

.— —

——.

~ied

12 Imqp DerrsIty

~

Inverter

15 :

1

16 ~ Fork Gate

lx--LQ-En’ra” —

J-r Home Pcmtmn

18

I

19 ~ Duplex Paper

011 End Sensor

20

——-

——

—

—— --—— -—

M8y7, 1964

I

Mlrn Svmpt’oms

I I I

I

IS displayedduring copy cycle

! ““2d”

“22” IS dkplayed No effect

Lensdrwesto reductmn ●nd “28” ISd@a@

2nd scanner drive pulley rotates ciockwwe for 0.3 sec

and “2A” ISdasplayed.

No toner

end detectmn and poor copy CNIalIW are

Obsenred.

Lift motor overdrwes feed fse@t for 20 sec and “41”

ISdisplayti,

Wrong paper size is dtsplayed. Lift motor on, when no

cassette is Inserted.

~nt of volume display IS blank.

Add Paper indicator is

constantly dtsplayed.

By-passmodeISalways wlected.

Mtsfeeds occur aher paper feed.

toner supplled (abnormal)

No

t—

Qmstant false mlsfeeds occur during copy cycle

1

Constant false m!sfeeds occar during COPY cycle

False m!sfeeds occur durtng duplex. Mtsfeeds occur

False mlsfeeds occur during duplex.

False mlsfeeds occur during duplex.

J-r fences move to inter and “81” IS d@ayed at

povmr on.

I

1

Machine WIII not register the entrance of paper to the

duplex tray and It WIII not feed the second stale

1

WIII not detect low 011 conditmn. Damage to hot roller ~

—

“2d” ISdsplayed ●fter power on

Lensdrwesto errlar~t and “28” ISdqlayed.

2nd scanner drive pulley overshoots H P counterclock

Wiseand‘%” Isdlsdayed

Frewmt toner end

No lIti motor

Wrong paper

Itft motor is always off.

%~ent of voJume d@shy IS ●lways on

No

size IS dlspiayad and If all fwe are sh~ed,

paper end detection

No bypass mode

Mmfeeds occur

No toner IS supplied (abnormal)

Mlsfeeds ocar al power on

Misfeeds ocxur at power on

MIsfeeds occur

False misfeeds occur during duplex

Jogger f~ move to outsIde ●nd “81” IS d,splayed

●t power on

1

Second ongnal blinks at power on

Add 011 indmtor IS d@ayed constantly

●t power on

●t power on

at power on

I

I

1

&3-1

Page 64

.—. ——.

——

SELF-OIAGNOSllC~O=

S-4.

da

main switdr is turned tm, ““11””diiys

11

MdsJnction in the exposure lamp circuit: L@ts

if the lamp filament opens or if the lamp turns on

duringstmd4sy. CN701-5

-T’’zse’m” ‘ieh--i’iO”

21 Medlanical rndfumtifm in the

power up, li@sts if the servomotor rotates for more

ttm 1024 encoder pulses but the home position

sensor is not actuated. Also in copy cycle, if the

motor is tummg and the home position

-nar

sensoris&-actuated Md

22

Scanner overrun: Li@ts if the overrun sensor IS

aCtUJtd

23 I No Ra@st Start Sigwi: Li~ts when the rnam Scanner moves approx. 112 of the way then ‘“23”

~r drive: At

StWS dS-SCtUatSd.

~ board does not receive the registration stafl

siqal from the opttcs board 2.7 seconds after

the 1ssscannerhasstared to move.

!

! No Home Positron Sigal to Main 6oard; LI@rts If ~ Scanner operates normally. But “24” displays in

24

~ the main board doas not receive H .P. sigral from ~ 20 seconds.

optics board 20sec after the sewomotor sta~.

I

Lam +f.P. Sanaor rmt actuated: Liita if Whan tha

‘i

bna ia rnovrng toward

●t a low signal level longer than 3.7 aawnda.

stays

mductiom tho H.P. se-

Whenthe

within 1 second.

The lamp remainslit when the scannerreturns to

At power up - the scmner is out of home position. Mechanical

During copy cycfe - the scanner left home d

than stops.

} NOTE: In this case it can be assumed dwt the

home sensor and the servomotor are working

propedy. see

( The ~rrer is at the extreme right end of its travel

●’27 isdisplayad at povverucrwtren the-nor ~ AIO always +5V DC, shcw@d ovormn

I or

I ishorna.

“2d”.

displays. CNlm.

1) The lens always moves toward enlarymerst ●

power up and, If at ready condition, when

reproduction ratio is changed.

2) The lens

IS to the r@rt of the H.P. sensa and

the lens motor does not turn on.

———.——

I hismmw

EXPtsaura lamp. m, 0002, Iunls

n?@8tor, CN701.3 mnatant 1-, ,,

constmt l-, main bomi

Lamp Reqpslator

driw? IwIley Allen scruws.

I optics board, main board -

!~

I

Opt@ board, main board CN304 and

1

- scanner cable, ~rtrbar

I

, CN106 and CN304, main board, optws

board.

Machanicd bind or 100ss set =raw,

t

I shorted H.P. sensor, short at CN84A,

84, 302. oP’ics control bowtf, lasts

drive motor, CN302, ~.

Wy 7,19s4

9

1

1

CN102-

641

May7, 19s4

ode Oafinition

~ I bna H.P.

I

1

2A ~ 2nd Scanner H.P. sensor not actuated: LI@ts

when the 2nd scanner H.P. sensor is not actuatad

within 0.3 seconds after the 2nd scanner motor IS

turned on.

I

~-- ‘Yd”notmove

2b 2nd

when the 2nd scanner H.P. sensor remains -atad for 3 seconds after the 2nd scanner motor

seeks home position.

I

~ stays acuratod:Lightsif the brie

H.P. aenaor stays ●ta high dgnal bvel longer tf’mrs3 1

seconds whsn the lane u movmg towards enlarge