Page 1

FT5233/5433/5733

SERVICE MANUAL

Page 2

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier po wer cor d is unplu gg ed .

2. The wall outlet should be near the copier and easily accessible.

3. Note that some component s of th e copier and the paper tr ay un it ar e

supplied with electrical voltage even if the main switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers

off or open while the main switch is turned on, keep hands away from

electrified or mechanically drive n com p on en ts.

5. If the hot roller temperature is low when the main switch is turned on, the

copier starts idling automatically when the warm-up period is completed.

Keep hands away from the mechanical and th e electrical components to

avoid any injury.

6. If the start key is pressed before the copier completes the warm-up period

(Ready indicator starts blinking), keep hands away from the mechanical

and the electrical componen ts as th e cop i er starts making copies as soon

as the warm-up period is completed.

7. The inside and the metal parts of the fusin g un it be com e extr e m ely ho t

while the copier is operating. Be careful to avoid touching those

components with your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get eit her of them in your

eyes by accident, it may cause temporary eye discomfort. Try to remove

with eye drops or flush with water as fir st ai d. If unsuccessful, get medical

attention.

Page 3

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course

on those models.

2. The RAM board on the main control boar d has a lithi um ba tt er y which can

explode if replaced incorrectly. Replace the battery only with an identical

one. The manufacturer recommends replacing the entire RAM board. Do

not recharge or burn this battery. Used batteries must be handled in

accordance with local regulations.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate the toner cartridge or the used toner. Toner dust may

ignite suddenly when exposed to open flame.

2. Dispose of used toner, developer, an d or g an ic pho to conductor according

to local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do

not put more than 100 batteries per sealed box. Storing larger numbers or

not sealing them apart may lead to che m ical r eac tio ns an d he at build - up .

Page 4

SECTION 1

OVERALL MACHINE

INFORMATION

Page 5

12 February 1992 SPECIFICATIONS

1. SPECIFICATIONS

Configuration: Desktop

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book

Original Size: MaximumA3/11" x 17"

Copy Paper Size: MaximumA3/11" x 17"

Minimum B5/11" x 8

A6/5

1/2

" x 8

" - Paper tray

1/2

" (lengthwise)

1/2

-By-pass feed table

(LCT B5/A4/11" x 8

" sideways only)

1/2

(Duplex Copying)

Multiple:

Single/Overlay:

A4 and B5/8

" x 11" (sideways)

1/2

Maximum A3/11" x 17"

Minimum B5/8" x 13"

Copy Paper Weight: • 250-sheet paper tr ay an d 10 00-sheet large

capacity tray:

52 –128g/m2, 14 –34lb

• By-pass feed table:

52 –157g/m2, 14 –43lb

Overall

Information

• Duplex and overlay:

64 –105 g/m2, 17 –28lb

Reproduction Ratios: 4 Enlargement and 6 Reduction

A4/A3 Version LT/LDG Version

200%

Enlargement

Full Size 100% 100%

Reduction

Receiving Tray

Capacity:

141%

122%

115%

93%

82%

75%

71%

65%

50%

250 sheets (B4/8

100 sheets (A3/11" x 17" )

200%

155%

129%

121%

93%

85%

77%

74%

65%

50%

" x 14" and smaller)

1/2

1-1

Page 6

SPECIFICATIONS 12 February 1992

Power Source: 115V, 60HZ, more than 12A (for N.A)

110V, 60HZ, (for Taiwan)

220/230/240V , 50HZ/60HZ, more than 7A

(for EU and AA)

Power Consumption: Maximum: 1.5 KW

Warm-up: 0.77 KW

Stand-by: 0.14 KW

Copy Cycle (average): 1.2 KW

Noise Emission: Stand-by: less than 40 dB

Copy Cycle (average):

less than 57 dB (copier only)

less than 59 dB (full system)

Maximum:

less than 62 dB (copier only)

less than 63 dB (full system)

Dimensions:

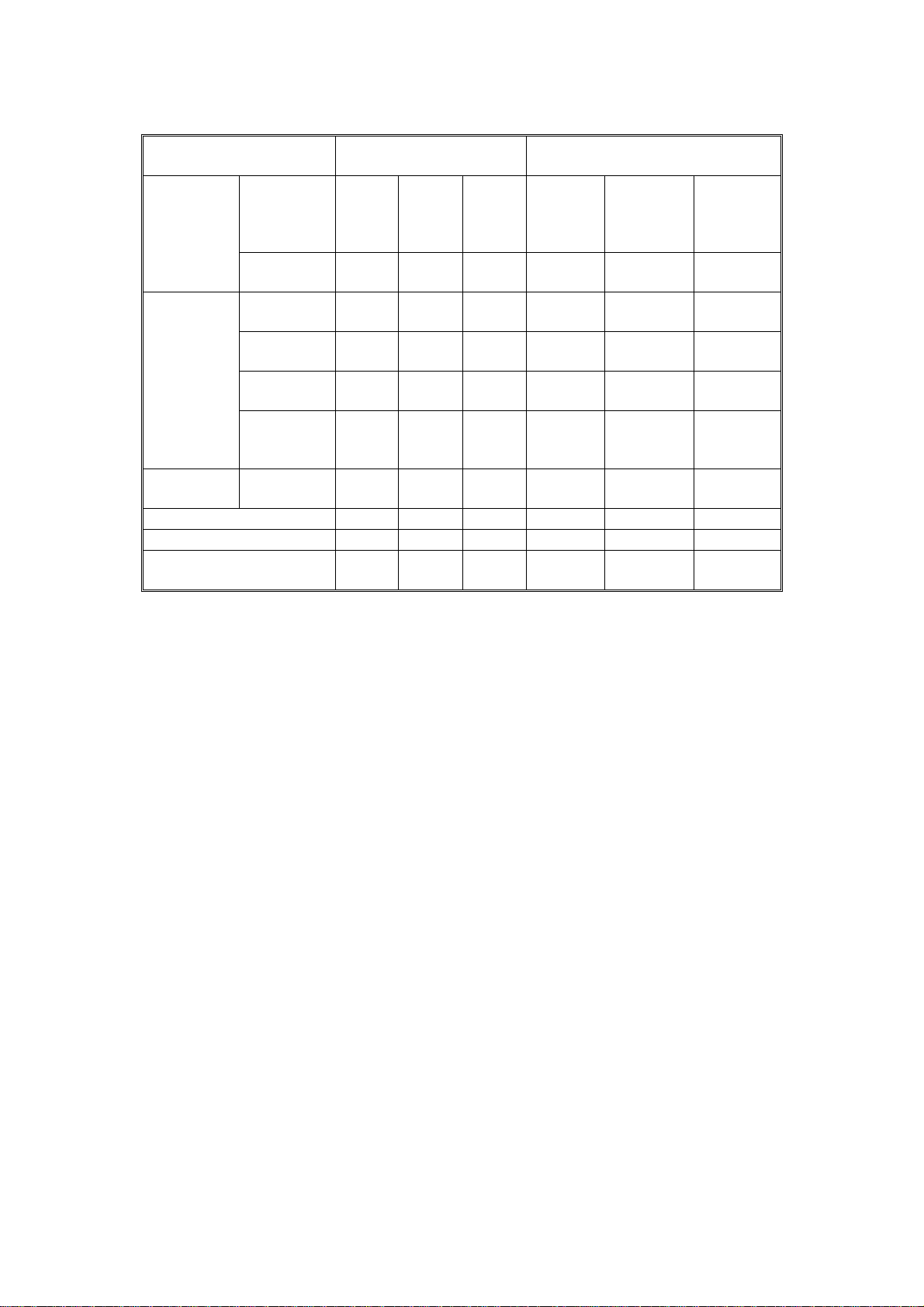

Width Depth Height

Type 1

Type 2

Type 3

697 mm (1035 mm)

27.4" (40.7")

871 mm (1075 mm)

34.3" (42.2")

871 mm (1075 mm)

34.3" (42.2")

600 mm

23.6"

600 mm

23.6"

600 mm

23.6"

542 mm (574 mm)

21.3" (22.6")

542 mm (574 mm)

21.3" (22.6")

542 mm (574 mm)

21.3" (22.6")

( ): When the by-pass feed table is opened, the copy tray is extended, and

the platen cover is installed.

Weight: Copier only (Without the opt i on al pla te n

cover=Approximately 2 kg)

Type 1: approximately 78 kg (172.0 lb)

Type 2: approximately 88 kg (194.0 lb)

Type 3: approximately 84 kg (185.2 lb)

Zoom: From 50% to 200% in 1% steps

Copying Speed: 33 copies/minute (A4/8

" x 11" sideways)

1/2

19 copies/minute (A3)

18 copies/minute (11" x 17")

Warm-up Time: Less than 110 seconds (20°C)

1-2

Page 7

12 February 1992 SPECIFICATIONS

First Copy Time: Black copy:

4.5 seconds (A4/8

" x 11" sideways)

1/2

Type 1, 3: (Upper tray feed)

4.9 seconds

Type 2: (Large capacity tray feed)

Color copy:

6.6 seconds

Type 1, 3: (Upper tray feed)

7.0 seconds

Type 2: (Large capacity tray feed)

Copy Number Input: Ten keys, 1 to 999 (count up or count down)

Overall

Information

manual Image Density

7 steps

Selection:

Automatic Reset: 1 minute standard setting; can also be set to 3

minutes or no auto reset.

Copy Paper Capacity: • By-pass feed table; approximately 20 sheets

• Paper tray: approximately 250 sheets

• Large capacity tray; approximately 1000 sheets

Toner Replenishment: Black: cartridge exchange

(320 g/cartridge)

Color: manual exchange (red, blue, & green

60 g/cartridg e)

Optional Equipmen t: • Platen cover

• Document feeder

• Paper tray unit with one paper tray

•

Paper tray unit with thre e pa per trays

• 10 bin micro sorter

• 20 bin mini sorter

• 20 bin midi sorter

•

20 bin sorter stapler

•

Sorter adapter (needed when installing the

mini or midi sorter, or the sorter stapler)

•

Interface PCB (needed when installing the

sorter stapler or the menu reader)

• Editor (only for A074)

•

Editing interface adapter (needed when

installing the editor)

1-3

Page 8

SPECIFICATIONS 12 February 1992

• Color development unit

• Key counter

•

Menu reader (except for Europe)

• A3 counter (service part)

1-4

Page 9

12 February 1992 MACHINE CONFIGURATION

2. MACHINE CONFIGURATION

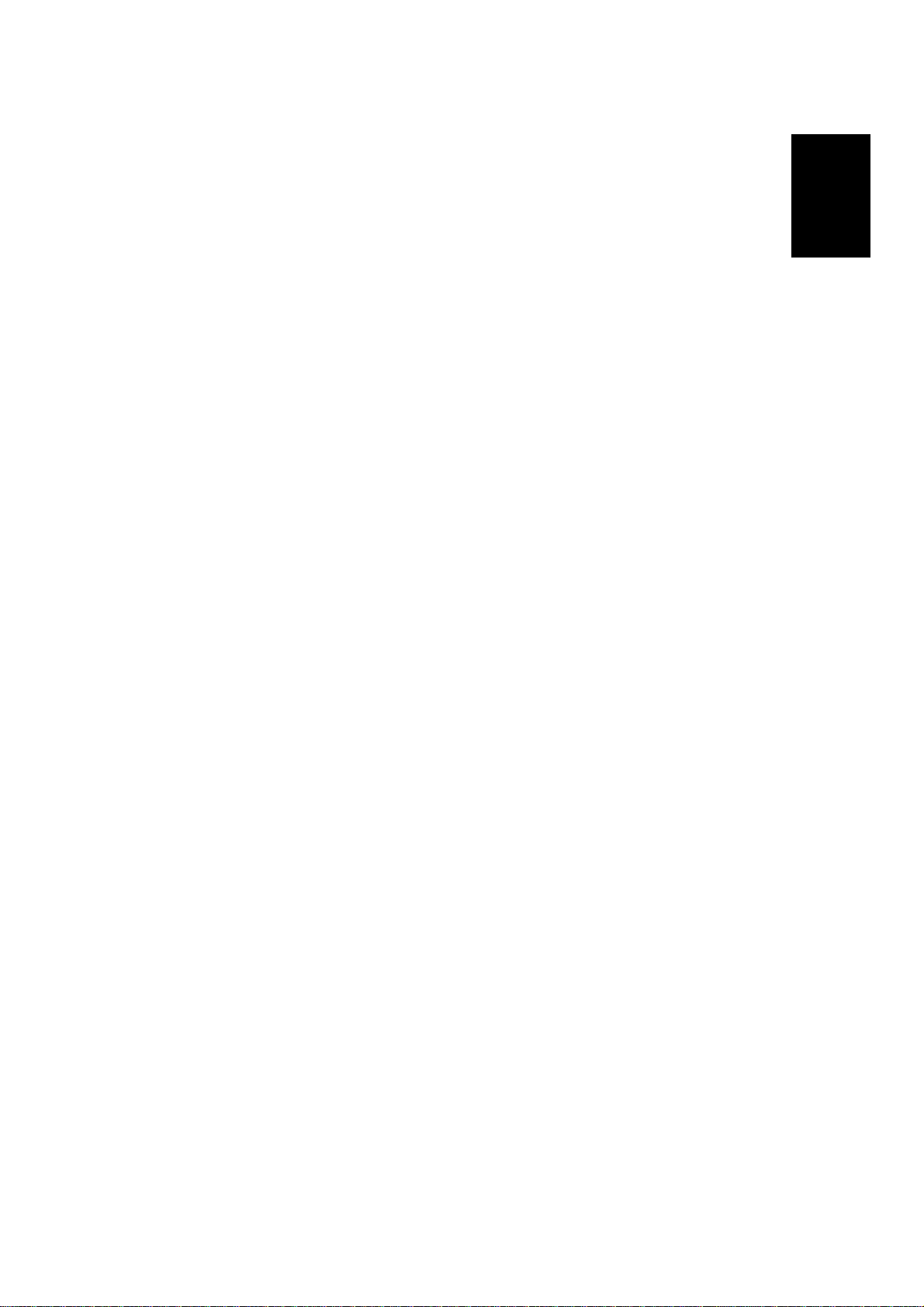

2.1 COPIER

TYPE 1 (A069) TYPE 2 (A074) TYPE 3 (A073)

UPPER TRAY 250 DUPLEX 250

LOWER TRAY 250 250 250

LCT – 1,000 1,000

2.2 OPTIONAL EQUIPMENT

10BIN SORTER (A327)

MENU READER (A952)

EDITOR (A916)

Overall

Information

20BIN SORTER

(A423)

20BIN SORTER

(A411)

ARDF (A497)

SORTER ADAPTER

(A328)

SORTER STAPLER

(A366)

PAPER TRAY UNIT PAPER TRAY UNIT

(A325)

1-5

(A326)

Page 10

MACHINE CONFIGURATION 12 February 1992

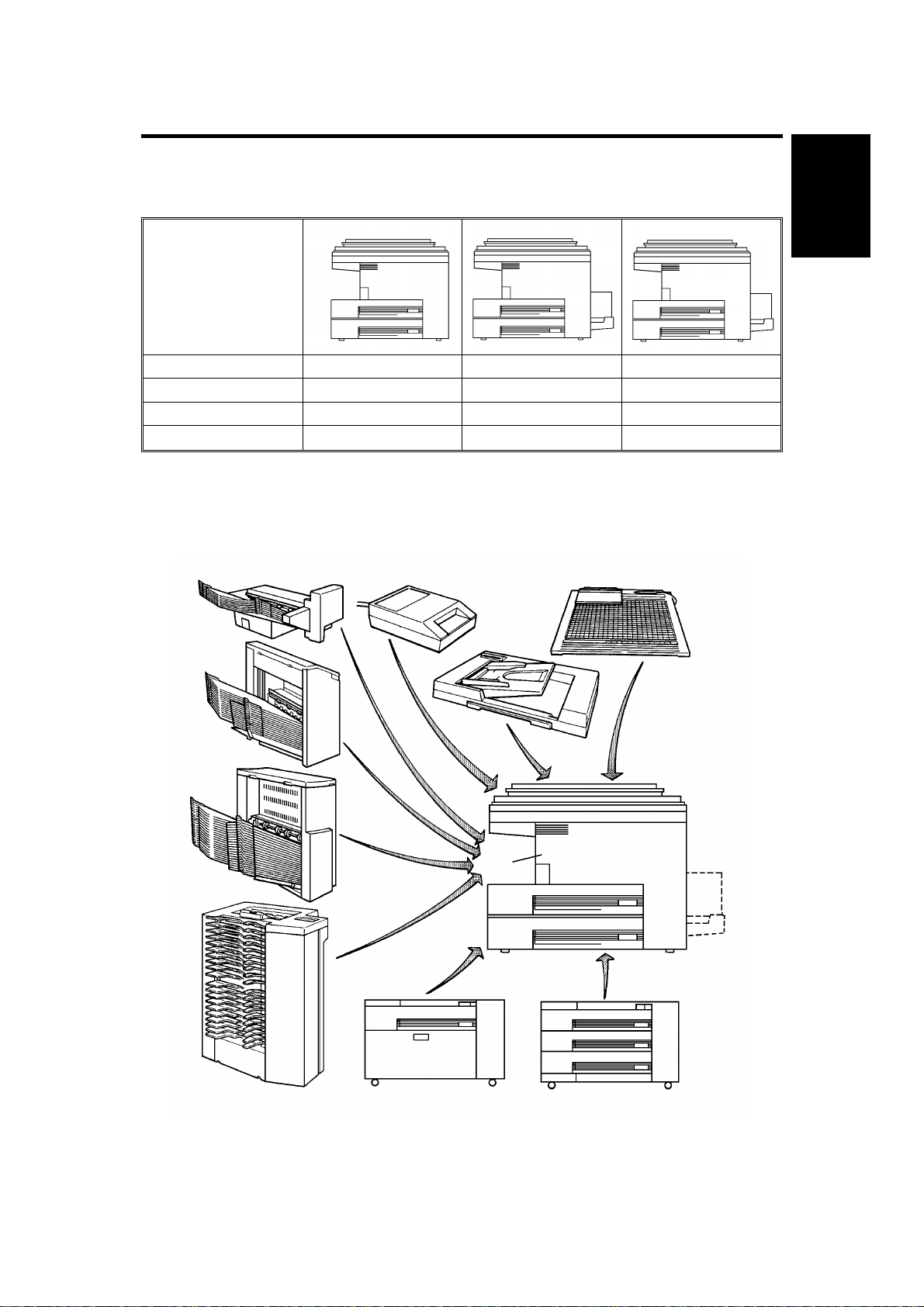

COPIER

1 TRAY

PAPER

TRAY UNIT

SORTER

DOCUMENT

FEEDER

EDITOR (A916) x o x * **

MENU READER (A952) o o o **

COLOR DEVELOPMENT

UNIT (A337)

(A325)

3 TRAY

(A326)

10 BIN

(A327)

20 BIN MINI

(A423)

20 BIN MIDI

(A411)

20 BIN

STAPLER

(A366)

ARDF

(A497)

TYPE 1

(A069)

TYPE 2

(A074)

ooo

ooo

ooo *

ooo *

ooo * **

ooo

ooo

TYPE3

(A073)

REQUIRED OPTIONAL

EQUIPMENT

SORTER

ADAPTER

(A328)

INTERFACE

PCB

(A344)

EDITING

INTERFACE

ADAPTER

(A345)

NOTE1: * The sorter adapter is required to install the 20 bin

mini sorter, 20 bin midi sort e r or sorter stapler.

* * The I/F board is required to install the sorter stapler

or Menu Reader.

** * (1) The editing interface adapter is required to install

the editor.

(2) The editing interface adapter can be installed

independently when more precise erasing is

desired.

NOTE 2: When installing the sorter stapler, the copier must be placed

on the paper tray unit or a table of exactly the same height.

1-6

Page 11

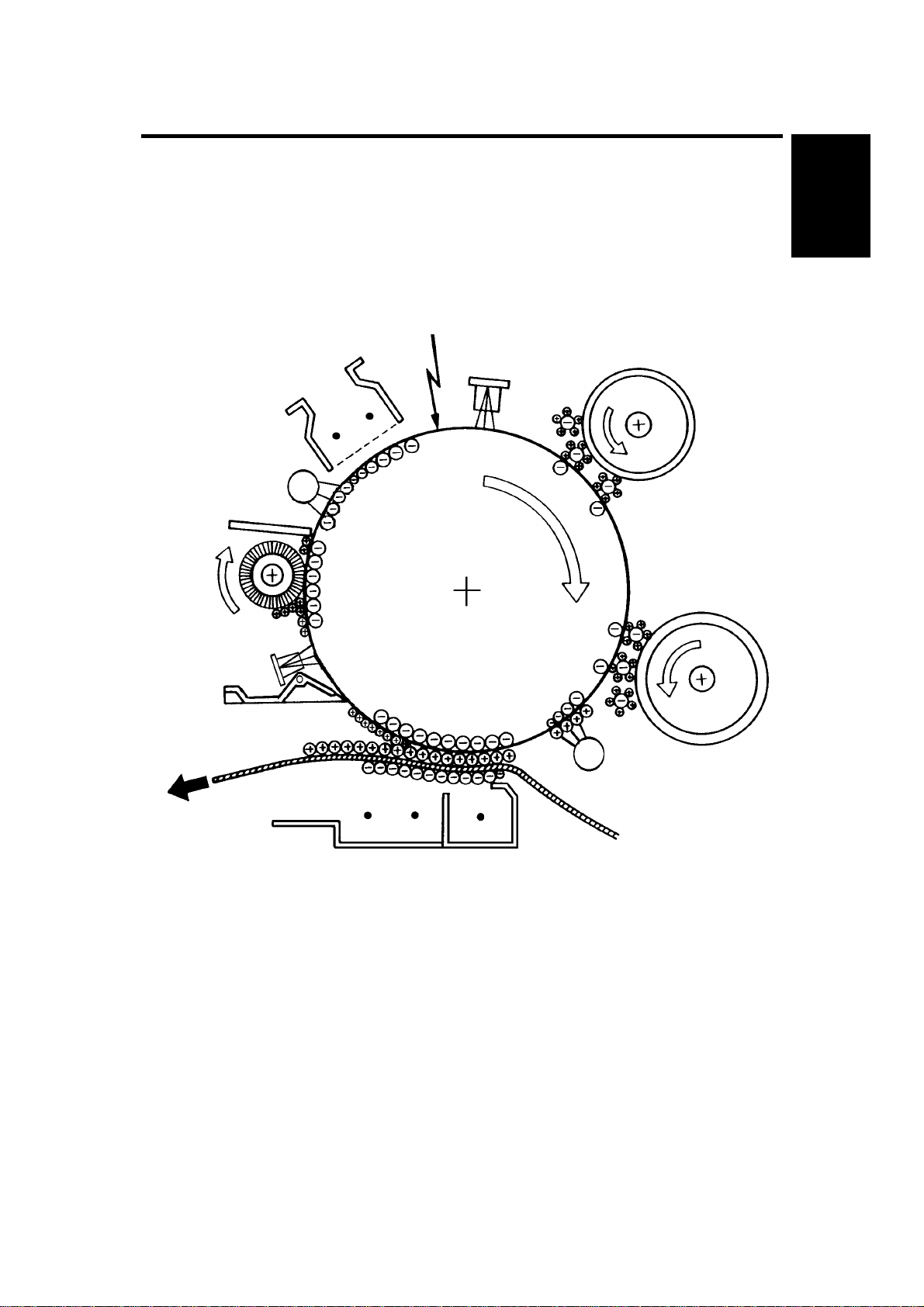

12 February 1992 COPY PROCESS AROUND THE DRUM

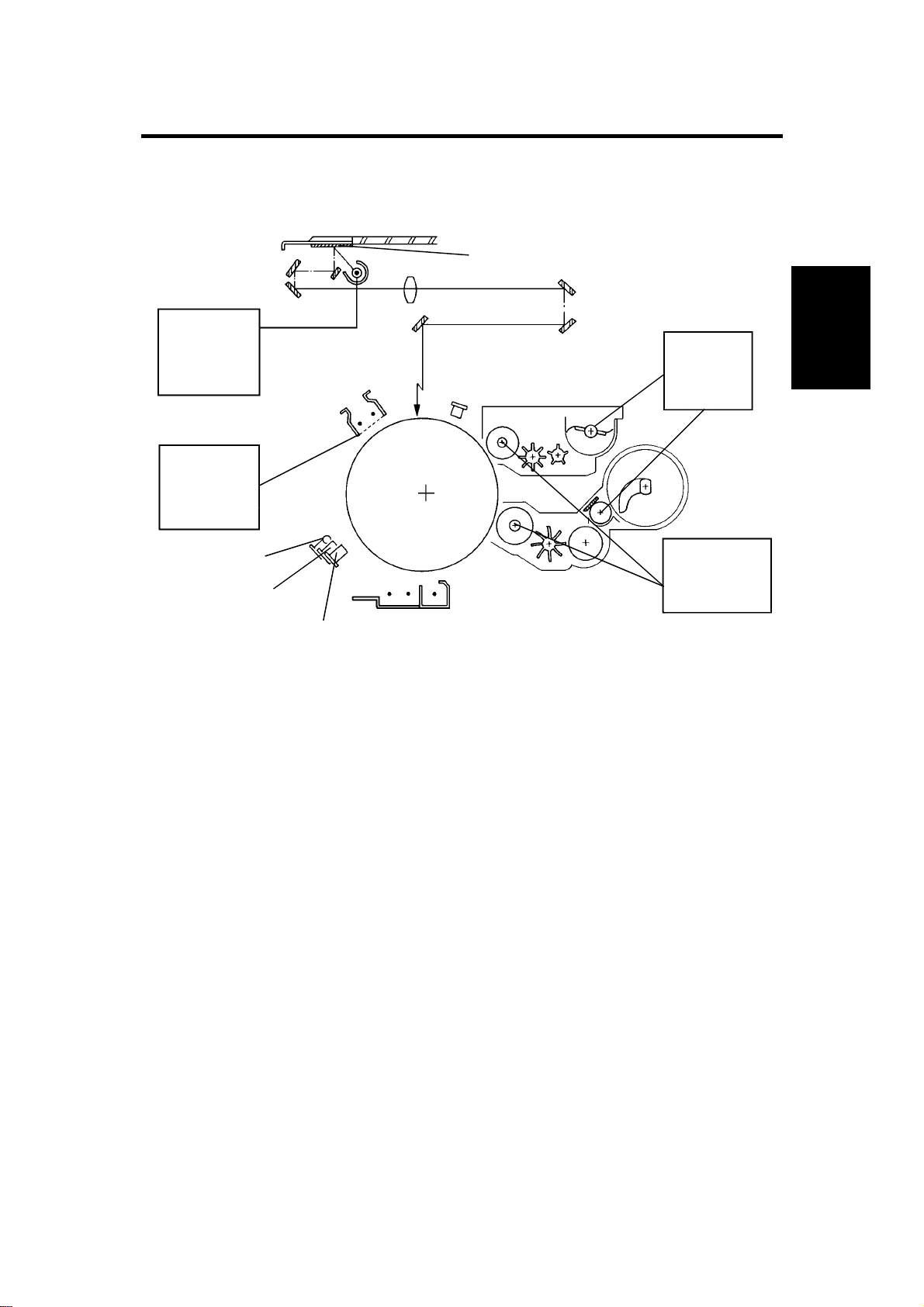

3. COPY PROCESS AROUND THE DRUM

2. EXPOSURE

4. DEVELOPMENT

9. QUENCHING

8. CLEANING

1. DRUM

CHARGE

3. ERASE

(COLOR)

Overall

Information

ID/V SENSORS

PICK-OFF

PAWLS

7. PAPER

4. DEVELOPMENT

(BLACK)

5. PRE-TRANSFER

LAMP

6. IMAGE TRANSFER

SEPARATION

1-7

Page 12

COPY PROCESS AROUND THE DRUM 12 February 1992

1. DRUM CHARGE

In the dark, the charge corona unit gives a uniform negative charge to the

organic photo conductive (OPC) drum. The charge remains on the surface of

the drum because the OPC layer has a high electrical resistance in the da r k.

The amount of negative charge on the drum is proportional to the negative

grid bias voltage applied to the grid plate on the charge corona unit.

2. EXPOSURE

An image of the original is reflected to the OPC drum surface via the optics

assembly. The charge on the drum surface is dissipated in direct proportion

to the intensity of the reflec te d ligh t, thus producing an electrical lat en t im ag e

on the drum surface.

The amount of remain ing char g e as a latent image on the drum de pe nds on

exposure lamp intensity controlled by the exposure lamp voltage.

3. ERASE

The erase lamp illuminates the areas of the charged drum surface that will

not be used for the copy image. The resistance of the drum in the illuminated

areas drops and the charge on those areas dissipates.

4. DEVELOPMENT

Positively charged toner is attr a c te d to the neg at ively cha r ge d ar e as of the

drum, thus developing the latent image. (The positive triboelectric charge is

caused by friction between th e car ri e r and ton er pa rticles.)

The development bias voltag e ap plie d to the deve lop m en t r oller shaf t

controls two things:

1) The threshold level if toner is attracted to the drum or toner remains on

the development roller.

2) The amount of toner to be attracted to the drum.

The higher the negative develo pment bias voltage is, the less toner is

attracted to the drum surface.

5. PRE-TRANSFER LAMP (PTL)

The PTL illuminates the drum to remove almost all the negative charge from

the exposed areas of the drum. This prevents the toner particles from being

reattracted to the drum surface during paper separation and makes paper

separation easier.

1-8

Page 13

12 February 1992 COPY PROCESS AROUND THE DRUM

6. IMAGE TRANSFER

Paper is fed to the drum surface at the proper timing so as to align the copy

paper and the develope d im ag e on the drum surface. Then, a strong

negative charge is applied to the reverse side of the copy paper, producing

an electrical force which pulls the ton er pa r ticle s fr om th e dr u m sur fa ce onto

the copy paper. At the same time, the copy paper is electrically attracted to

the drum surface.

7. PAPER SEPARATION

A strong ac corona discharge is applied to the reverse side of the copy

paper, reducing the negative charg e on the copy paper and breaking the

electrical attraction between the paper and the drum. Then, the stiffness and

the weight of the copy paper cause s it t o separ a te fr om th e drum surface.

The pick-off pawls help to separate pa pe r and drum .

8. CLEANING

Overall

Information

The cleaning brush removes tone r rem ain ing on th e dru m aft er image

transfer and the cleaning blade scrapes off all the remaining toner.

9. QUENCHING

Light from the quenching lamp electrically neutralizes the charge po tential of

the drum surface.

1-9

Page 14

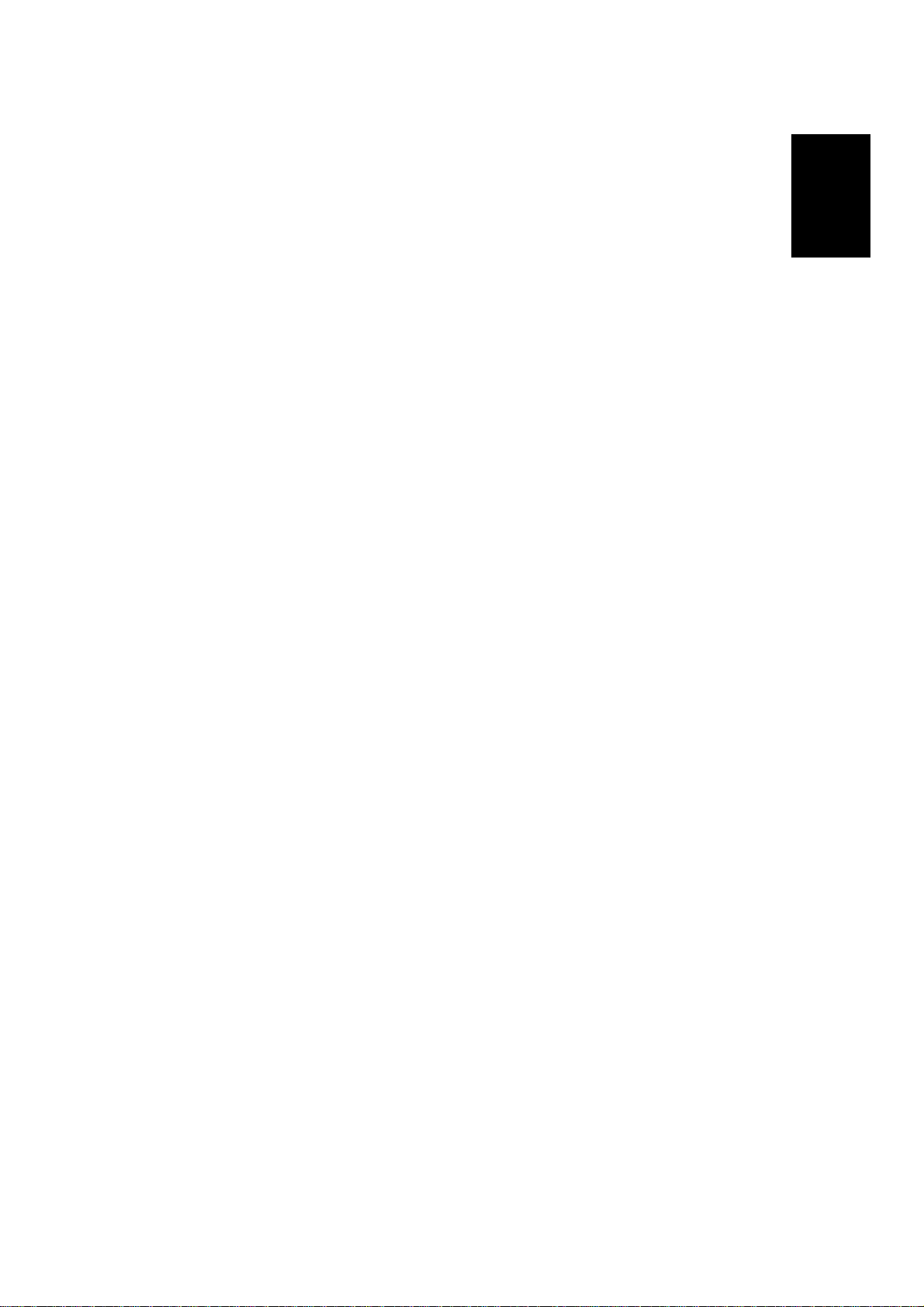

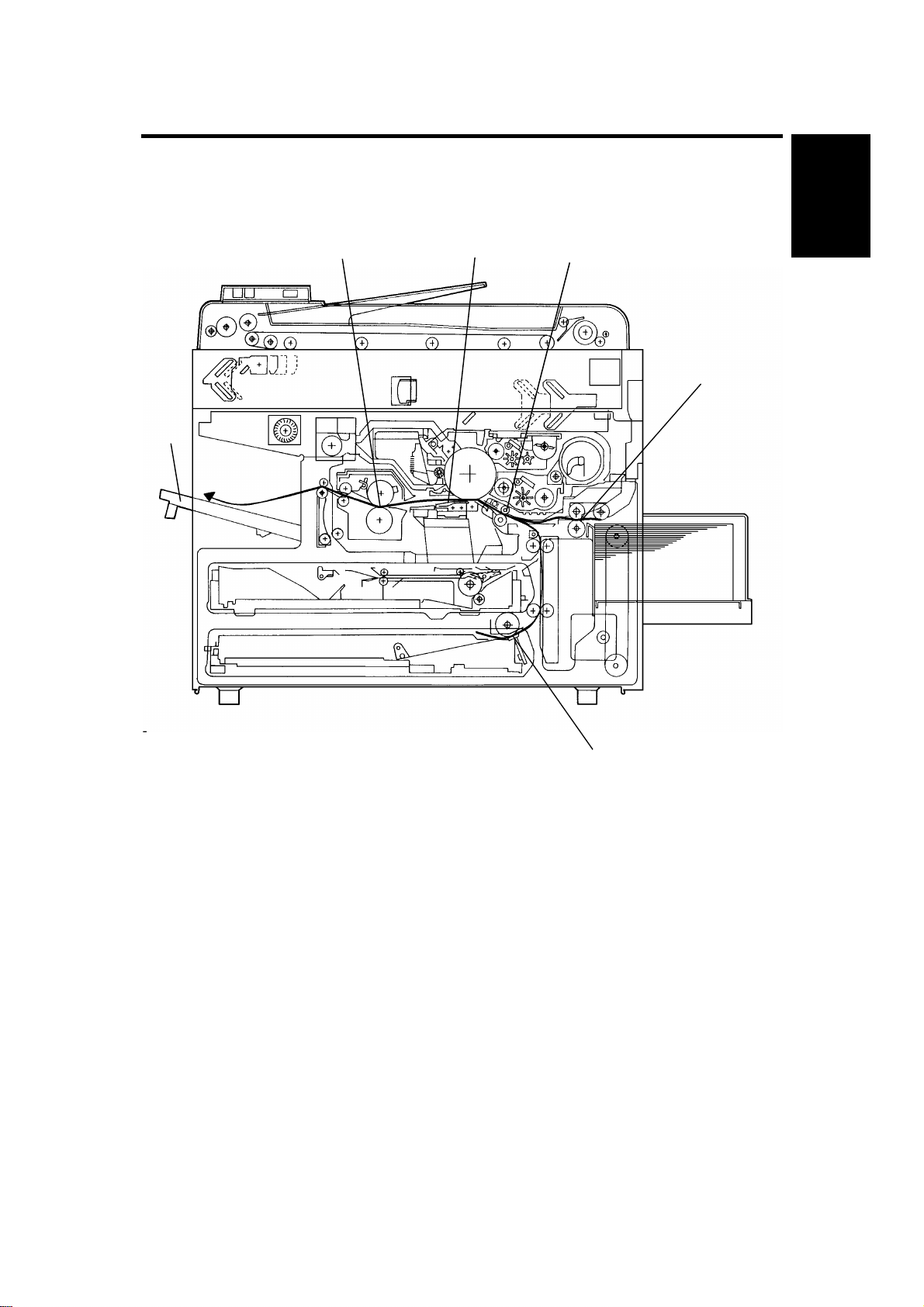

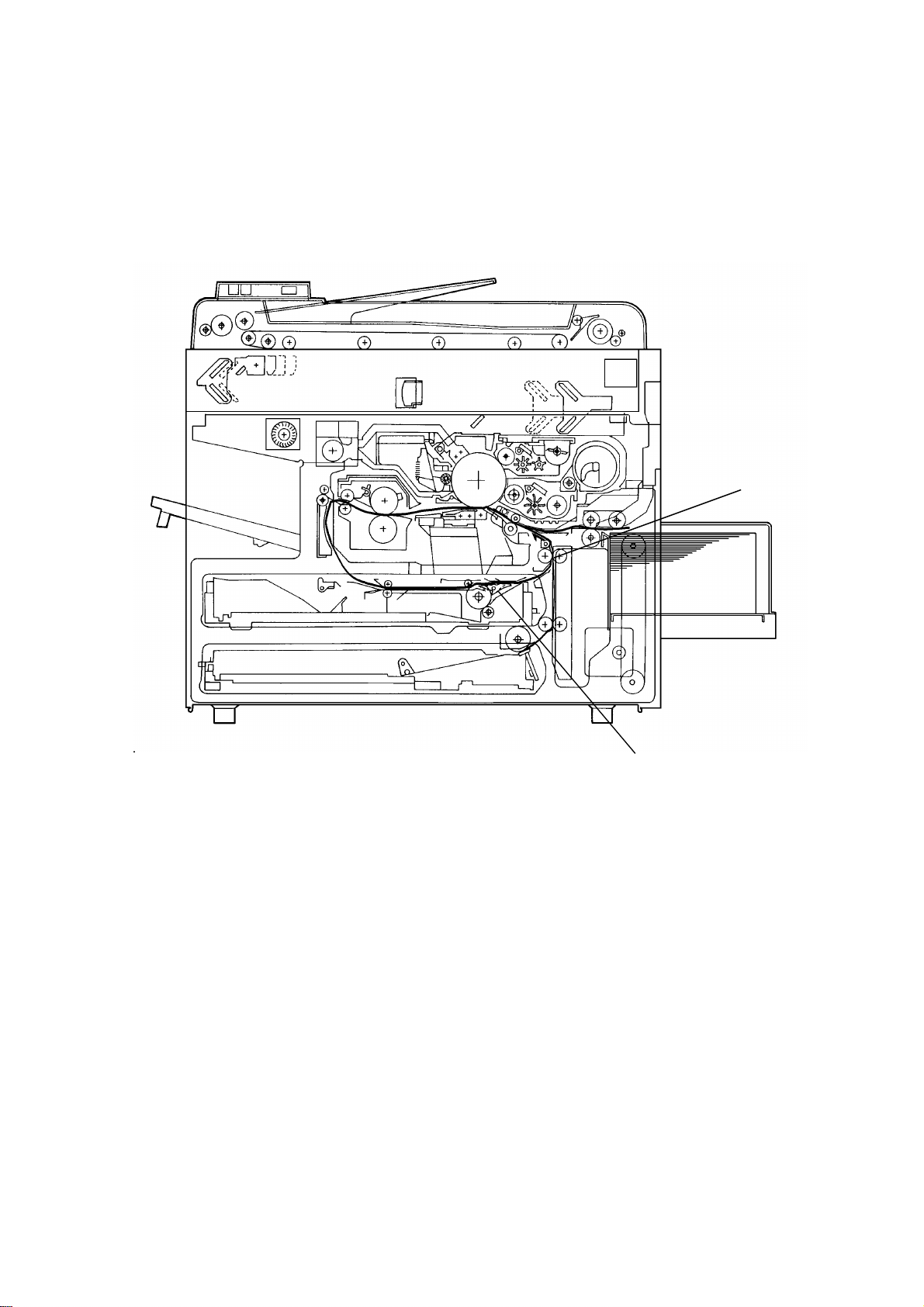

MECHANICAL COMPONENT LAYOUT 12 February 1992

4. MECHANICAL COMPONENT LAYOUT

111098765

4

3

12

13

14

2

1

424142

40

39

38

37

36

35

34

33

32 31

1. 3rd Mirror

2. 2nd Mirror

3. 1st Mirror

4. Exposure Lamp

5. Lens

6. Cleaning Brush

7. Quenching Lamp

8. Cleaning Blade

9. Change Corona Unit

10. OPC Drum

11. 6th Mirror

12. Erase Unit

13. 4th Mirror

14. 5th Mirror

15. Color Development Unit

16. Black Development Unit

17. Black Toner Supply Unit

18. Pre-Transfer Lamp

19. Feed Roller

20. Pick-up Roller

21. Separation Roller

30

15

29 28 27

26 25 24 23

22. Large Capacity Tray

23. Relay Rollers

24. Registration Rollers

25. Paper Tray Feed Roller

26. Friction Pad

27. Turn Gate

28. Duplex Friction Roller

29. Duplex Feed Roller

30. Transfer & Separati on Coron a Unit

31. Jogger Fences

32. End Fence

33. Lower Paper Tray

34. Entrance Rollers

35. Duplex Tray

36. Pressure Roller

37. Pick-off Pawls

38. Hot Roller

39. Junction Gate

40. Hot Roller Strippers

41. Transport Fan

42. Fusing Exhaust Fan

16

17

18

19

20

21

22

1-10

Page 15

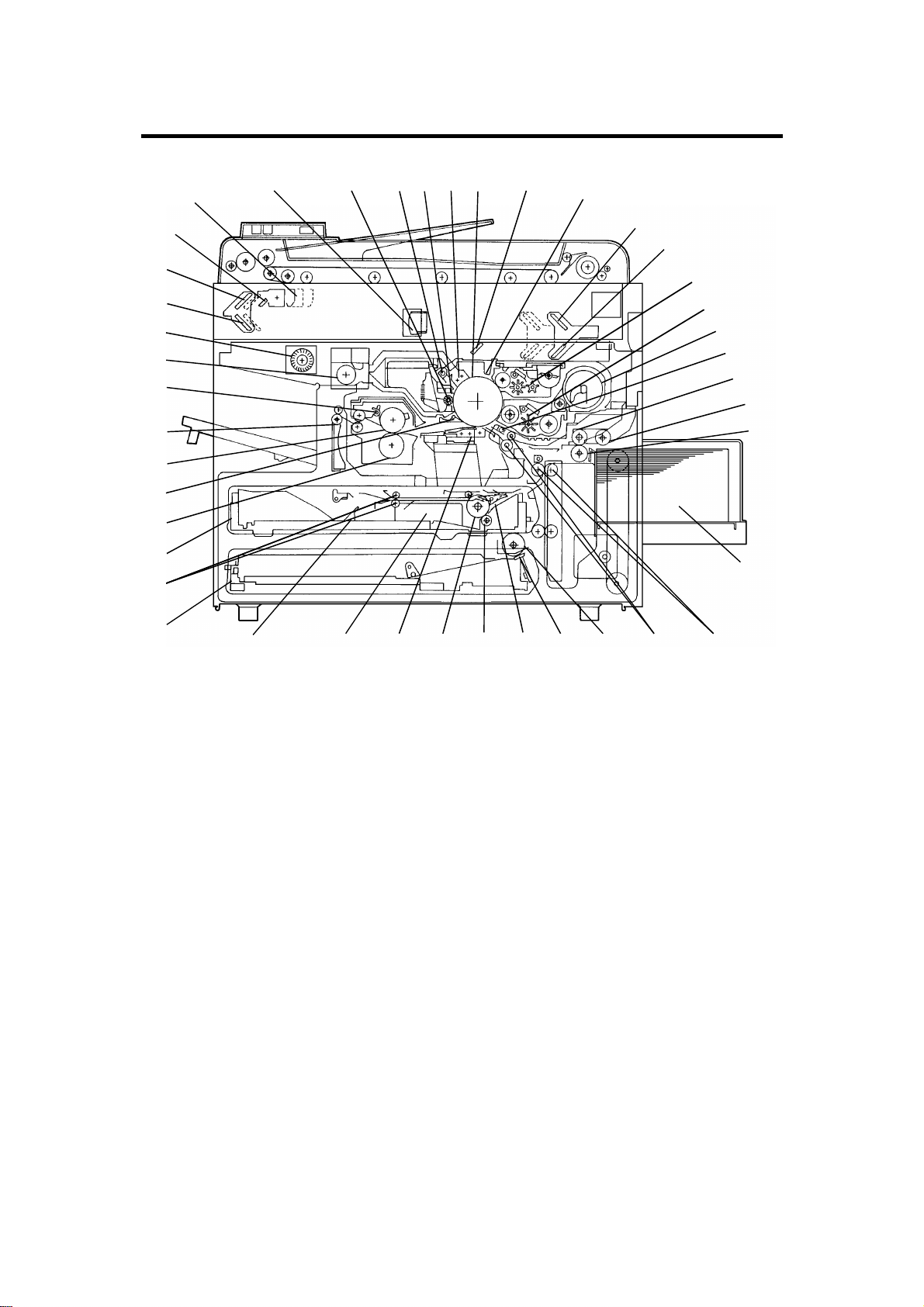

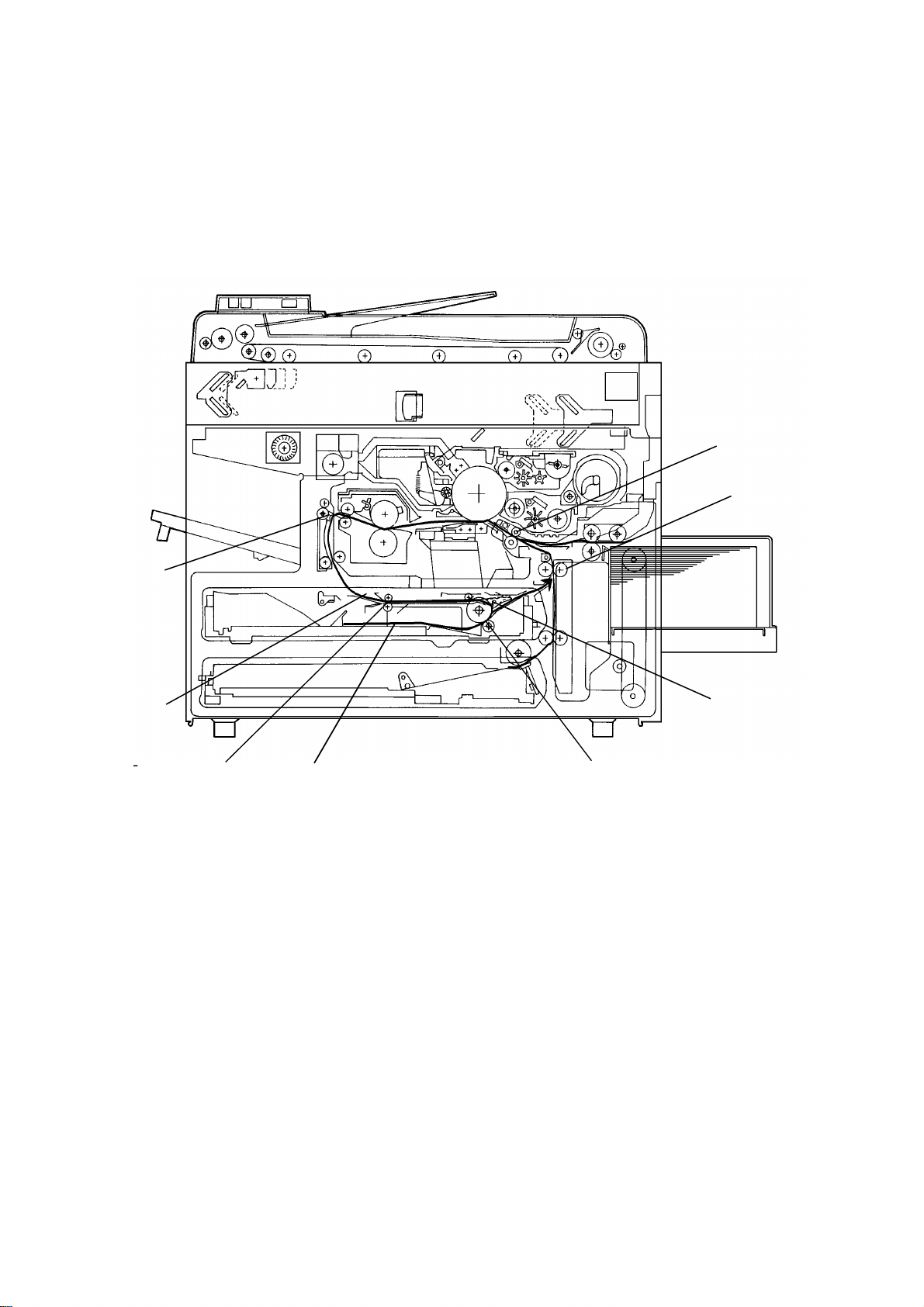

12 February 1992 DRIVE LAYOUT

5. DRIVE LAYOUT

21

20

19

18

22

13

23

12

24

11

10

25

26

1

2

Overall

Information

5

6

17

16

7

8

9

14

134

1015

1-11

Page 16

DRIVE LAYOUT 12 February 1992

1: Main Motor Pulley

3: Fusing Drive Belt 2: Drum Drive Belt

4: Drive Distribution

Gear/Pulley

23: Drive Distribution Belt Cleaning drive Gear 9: Fusing Unit Drive

12: Drive Distribution

Gear/Pulley

25: Drum Drive Pulley 24: Development Drive

Drum Development Unit

Cleaning Unit Fusing Unit

20: Toner Supply

Drive Gear/Pulley

22: Toner Supply CL

Gear

26: Development Drive

Belt

CL Pulley

Gear

6: Copier Exit

Roller Gear

7: Duplex Transport

Drive Belt

19: Paper Feed Drive

Gear/Pulley

16: Paper Feed Drive

Belt

14: Lower paper Feed

CL Gear

21: Development Unit

Shift Gears

10: Registration CL Gear

11: Upper Paper Feed CL

13: Feed Relay CL Gear

17: Relay Roller Gears

18: By-pass Feed CL

Gear

15: Tray Unit drive

Gear

8: Duplex Transport

Roller Pulley

5: Sorter Adapter Gears

1-12

Page 17

12 February 1992 PAPER PATH

6. PAPER PATH

6.1 NORMAL COPYING

[D]

[E]

[C]

[B]

[A]

Overall

Information

[A]

Paper feed begins from the LCT or paper tray unit paper feed stations. The

copy paper then follows one of tw o pa th s inside the copie r . The pat h fo llowe d

depends on which mode the operator has selected. For copy processing, all

sheets follow the same path from the paper feed mechanism [A] through the

registration [B], T & S corona [C], and fusing unit [D]. After that, normal

copies are delivered to the copy tra y [E], however, 2 sided copies and

overlay copies are diverted for further processing.

1-13

Page 18

PAPER PATH 12 February 1992

6.2 MULTIPLE 2-SIDED COPYING

[H]

[G]

[A]

[B]

[C]

[F]

Paper that is A4, B5, and 8

[E]

" X 11" sideways can be used for multiple

1/2

[D]

2-sided copying. In this mode the junction gate [A] directs sheets exiting the

fusing unit to the duplex tray entrance [B]. After that, all sheets follow the path

through the entrance rollers [C], and the turn gate [D]. The turn gate directs

paper through the duplex feed mechanism [E] to the duplex tray [F]. After all

sheets are stacked in the duplex tray, these sheets follow the path thr ough

the duplex feed mechanism and relay rollers [G] to the registration rollers [H].

After that, these sheets follow the same pat h as normal cop ying fr om th e

registration rollers to the copy tray.

1-14

Page 19

12 February 1992 PAPER PATH

6.3 SINGLE 2-SIDED COPYING

[D]

Overall

Information

[A]

[B]

[C]

Any sheet up to A3\11" x 17" but except for A4, B5, or 8

" X 11" sideways

1/2

can be used for single 2-sided copying. In this mode, the sheet follows the

same path as in multiple 2-sided copying to the duplex tray. However, the

end fence [A] of the duplex tray lowers. The sheet advances over the lowered

end fence. The sheet is stopped by the friction between the duplex feed and

friction rollers [B,C]. It is directed to the relay rollers [D] by the reversed

duplex feed roller. It stays there once. After that, the sheet follows the same

path as in multiple 2-sided copying from the relay rollers to copy tray.

1-15

Page 20

PAPER PATH 12 February 1992

6.4 SINGLE IMAGE OVERLAY COPYING

[B]

[A]

In this mode, the sheet follows the same path as in multiple 2-sided copying

to the turn gate [A]. The turn gate directs the sheet to the relay rollers [B].

The sheet stays there once. After that, the sheet follows the same path as in

multiple 2-sided copying from the relay rollers to the copy tray.

1-16

Page 21

12 February 1992 ELECTRICAL COMPONENT DESCRIPTION

7. ELECTRICAL COMPONENT DESCRIPTION

Refer to the electrical component layout on the reverse side of the Point to

Point (Water proof pap er) fo r symbols an d ind ex nu m ber s.

Symbol Name Function Index No.

Motors

M1 Main Drives the main unit components. 1

Overall

Information

M2 Exhaust blower Blows the ozone built up around the charge

section through the ozone filter.

M3 Upper tray lift

(non-duplex

machine only)

M4 Lower tray lift Raises the bottom plate in the lower paper

M5 Transport fan Provides air flow to the transport section so

M6 Fusing exhaust

fan

M7 Scanner drive Drives the 1st and 2nd scanners (dc

M8 3rd scanner drive Drives the 3rd scanner (dc stepper). 75

Raises the bottom plate in the upper paper

tray.

tray.

that paper is held on the transport guide.

Also the air flow isolates the toner

collection tank from fusing heat.

Provides air flow to the charge corona

section as well.

Removes the heat from around the fusing

unit.

stepper).

6

31

28

65

66

67

M9 Optics cooling fan Removes heat from the optics unit. 77

M10 Lens drive Positions the lens. 100

M11 Duplex feed

(duplex machine

only)

M12 Jogger (duplex

machine only)

M13 LCT lift Lifts up and lowers the LCT bottom plate. 79

Drives the feed roller and moves the

bottom plate up and down (24 V dc

stepper).

Drives the jogger fences to square the

paper stack in the duplex tray (dc stepper).

1-17

103

107

Page 22

ELECTRICAL COMPONENT DESCRIPTION 12 February 1992

Symbol Name Function Index No.

Circuit Board

PCB1 dc power supply Drives the exposure and fusing lamps and

rectifies 100 Vac or 220/230/240 Vac input

and outputs dc voltages.

PCB2 Main control Controls all copier functions both directly

and through the other control boards.

PCB3 Scanner motor

control

PCB4 Main motor

control

PCB5 Operation panel Controls the LED matrix, and monitors the

PCB6 ADS sensor Senses the background density of the

PCB7 High voltage

supply - CTBG

PCB8 High voltage

supply - D

Controls the speed of the scanner drive

motor.

Controls the rotation of the main motor. 71

key matrix.

original.

Supplies high voltage for the charge

corona, grid bias, transfer corona, and

development bias.

Supplies high voltage for the separation

corona.

44

10

69

93

90

9

8

PCB9 PTL/QL stabilizer Provides high voltage for the quenching

and pre-transfer lamps.

PCB10 Duplex control

(duplex machine

only)

PCB11 LCT interface

(LCT machine

only)

PCB12 Guidance display

control (duplex

machine only)

PCB13 Guidance display

(duplex machine

only)

Controls the rotation of the duplex feed

motor.

Interfaces the LCT control signal between

the main control board and the LCT.

Controls the guidance display board. 92

Displays guidance for machine operation. 94

73

106

80

1-18

Page 23

12 February 1992 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function Index No.

PCB14 Interface - type

G (option for

sorter stapler

and menu

reader)

PCB15 Nose filter

(230 V machine

only)

Switches

SW1 Upper paper size

- 1 (non-duplex

machine only)

SW2 Upper paper size

- 2 (non-duplex

machine only)

SW3 Upper paper size

- 3 (non-duplex

machine only)

SW4 Upper paper size

- 4 (non-duplex

machine only)

Interfaces the sorter stapler and menu

reader with the main control board.

Removes electrical noise 35

Determines what size paper is in the upper

paper tray.

Determines what size paper is in the upper

paper tray.

Determines what size paper is in the upper

paper tray.

Determines what size paper is in the upper

paper tray.

16

2

3

4

5

Overall

Information

SW5 Lower paper size

- 1

SW6 Lower paper size

- 2

SW7 Lower paper size

- 3

SW8 Lower paper size

- 4

SW9 Color detection Detects if color development unit is set or

SW10 Exit cover

(Duplex machine

only)

SW11 Platen cover Informs the CPU when the platen cover is

Determines what size paper is in the lower

paper tray.

Determines what size paper is in the lower

paper tray.

Determines what size paper is in the lower

paper tray.

Determines what size paper is in the lower

paper tray.

not and which color toner development unit

is installed.

Cuts the ac power line. 64

closed.

36

34

33

32

13

88

1-19

Page 24

ELECTRICAL COMPONENT DESCRIPTION 12 February 1992

Symbol Name Function Index No.

SW12 Front door safety Cuts the ac power line through RA1 and

detects if the front door is open or not.

SW13 Main Supplies power to the copier. 95

SW14 LCT cover - 1

(LCT machine

only)

SW15 LCT cover - 2

(LCT machine

only)

SW16 LCT down (LCT

machine only)

Lamps

L1 Quenching Neutralizes any charge remaining on the

L2 Pre-transfer Reduces the charge on the drum surface

Detects if the LCT cover is open or not. 83

Cuts the dc power line of the LCT lift motor. 84

Sends a signal to the CPU to lower the LCT

bottom plate.

drum surface after cleaning.

before transfer.

91

85

47

49

L3 Fusing Provides heat to the hot roller. 60

L4 Exposure Applies high intensity light to the original

exposure.

L5 Erase Eliminates the charge for unnecessary

areas of the image on the drum surface

before exposure.

Magnetic

Clutches

MC1 Development

drive

MC2 Toner supply Drives the toner supply roller. 14

MC3 By-pass feed Starts paper feed from the by-pass feed

MC4 Feed relay Drives the relay rollers. 19

MC5 Registration Drives the registration rollers. 20

Drives the development roller. 11

table or LCT.

99

48

17

1-20

Page 25

12 February 1992 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function Index No.

MC6 Upper paper

feed (non-duplex

machine only)

MC7 Lower paper feed Starts paper feed from the lower paper tray. 24

Solenoids

SOL1 Development

unit change

SOL2 Pick-up roller Picks paper up from the by-pass feed table

SOL3 Duplex tray lock

(duplex machine

only)

SOL4 Upper tray lock

(non-duplex

machine only)

SOL5 Lower tray lock Locks the lower paper tray in the main

Starts paper feed from the upper paper tray. 22

Changes the position of the black

development unit and color development

unit.

or LCT.

Locks the duplex tray in the main copier. 29

Locks the upper paper tray in the main

copier.

copier.

12

18

39

37

Overall

Information

SOL6 Junction gate

(duplex machine

only)

SOL7 Duplex turn gate

(duplex machine

only)

Sensors

S1 By-pass feed

table

S2 Upper tray set

(non-duplex

machine only)

S3 Lower tray set Detects if the lower paper tray is set or not. 26

S4 By-pass feed

paper end

S5 Upper tray paper

end (non-duplex

machine only)

Moves the junction gate to direct copies to

the duplex tray or to the paper exit.

Moves the duplex turn gate to direct copies

to the duplex tray or to the relay rollers.

Detects if the by-pass feed table is open or

closed.

Detects if the upper paper tray is set or not. 21

Informs the CPU that there is no paper in

the by-pass feed table.

Informs the CPU when the upper paper tray

runs out of paper.

43

105

15

53

23

1-21

Page 26

ELECTRICAL COMPONENT DESCRIPTION 12 February 1992

Symbol Name Function Index No.

S6 Lower tray paper

end

S7 Upper tray upper

limit (non-duplex

machine only)

S8 Lower tray upper

limit

S9 Lower relay Detects the lead edge of paper from the

S10 Upper relay Detects the lead edge of paper from the

S11 Registration Detects the lead edge of paper to

Informs the CPU when the lower paper tray

runs out of paper.

Detects the upper position of the paper

stack in the upper tray to stop the upper lift

motor.

Detects the upper position of the paper

stack in the lower tray to stop the lower lift

motor.

lower paper tray to determine the stop

timing of the lower paper feed clutch and

detects misfeeds.

upper paper tray to determine the stop

timing of the upper paper feed clutch and

detects misfeeds.

determine the stop timing of the feed relay

clutch and detects misfeeds.

25

30

27

51

50

52

S12 Image density

(ID)

S13 V Detects the VR and VL patterns. 58

S14 Fusing exit Detects misfeeds. 62

S15 Junction gate

(duplex machine

only)

S16 Scanner H.P. Informs the CPU when the 1st scanner is at

S17 Lens H.P. Informs the CPU when the lens is at the

S18 Platen position Informs the CPU when the platen cover is

S19 3rd scanner H.P. Informs the CPU when the 3rd scanner is in

Detects the density of the ID sensor pattern

on the drum to control the toner density.

Detects misfeeds. 63

the home position.

full-size position.

positioned. When the angle between, the

platen cover and the exposure glass is

about 30 degrees.

the full size position.

57

68

72

74

76

S20 Original length Detects the original length. 89

1-22

Page 27

12 February 1992 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function Index No.

S21 Original width Detects the original width. 96

S22 Duplex entrance

(duplex machine

only)

S23 Duplex turn gate

(duplex machine

only)

S24 Duplex paper

end (duplex

machine only)

S25 Jogger H.P.

(duplex machine

only)

S26 LCT paper end

(LCT machine

only)

S27 LCT lower limit

(LCT machine

only)

Detects misfeed. 109

Detects the trail edge of paper to determine

the reverse timing of the duplex motor and

detects misfeed.

Detects copy in the duplex tray. 102

Detects if the jogger fences are at home

position.

Informs the CPU when the LCT runs out of

paper.

Sends signal to CPU to stop lowering the

LCT bottom plate.

101

108

82

81

Overall

Information

S28 LCT upper limit

(LCT machine

only)

Heaters

H1 Drum Turns on when the main switch is off to

H2 Optics

anti-condensation

(option)

H3 Upper tray

(option)

H4 Lower tray

(option)

Thermistor

TH1 Drum Monitors the temperature around the drum. 56

TH2 Fusing Monitors the temperature of the hot roller. 59

Sends signal to CPU to stop lifting up the

LCT bottom plate.

prevent moisture around the drum.

Turns on when the main switch is off to

prevent moisture from forming on the optics.

Turns on when the main switch is off to

keep paper dry in the upper paper tray.

Turns on when the main switch is off to

keep paper dry in the lower paper tray.

78

54

97

55

87

1-23

Page 28

ELECTRICAL COMPONENT DESCRIPTION 12 February 1992

Symbol Name Function Index No.

TH3 Optics Monitors the temperature of the optics

cavity.

TH4 Duplex motor

(duplex machine

only)

Thermofuse

TF1 Fusing Provides back-up overheat protection in the

Thermoswitch

TS1 Optics Provides overheat protection in the optics

Noise filter

NF1 Removes electrical noise. 40

Fuse

FU1 Main (115 V

machine only)

Monitors the temperature of the duplex

motor.

fusing unit.

unit.

Provides back-up high current protection in

the electrical components.

98

104

61

70

42

FU2 Sorter line (115

V machine only)

FU3 DF line (115 V

machine only)

Circuit Breaker

CB1 (230 V machine

only)

Relay

RA1 Main power Controls main power. 45

Transformer

TR1 Main Steps down the wall voltage to 100 V ac. 38

Counter

CO1 Total Keeps track of the total number of copies

Provides back-up high current protection in

the electrical components of the sorter.

Provides back-up high correct protection in

the electrical components of the ARDF.

Provides back-up high current protection in

the electrical components.

made.

46

7

41

86

1-24

Page 29

SECTION 2

DETAILED SECTION

DESCRIPTIONS

Page 30

12 February 1992 PROCESS CONTROL

1. PROCESS CONTROL

1.1 OVERVIEW

ID Sensor Pattern

V Sensor Pattern

Exposure

Lamp

Voltage

(Color)

Grid

Bias

Voltage

Toner

Supply

Detailed

Descriptions

Drum Thermistor

(Black)

ID Sensor

V Sensor

Development

Bias

Voltage

As seen in section 1 the copy process around the drum and the copy image

(image and background density) are controlled by many factors.

On this copier, the following items are controlled during the copy process to

maintain good copy quality:

The exposure lamp voltage of the optics section

The grid bias voltage of the drum charge section

The development bias voltage and to ner supply of the development

section

The items above use the following electrical components:

The operation panel (manual ID selectio n and reproduction ratio), ADS

sensor, ID sensor, V sensor, drum thermistor, paper size switches,

color detection switches, and RAM board (drum rotation time and SP

mode data)

Refer to the process control table in the supplement sheet bag for the details

on which electrical component controls which controlled item.

In the following sections, we will explain briefly how the major electrical

components are controlled in the copy process.

2-1

Page 31

PROCESS CONTROL 12 February 1992

1.2 ID SENSOR CONTROL

Sensor

Pattern

Original Lead Edge

Original

ON OFF ON OFF

A B C

RAM Clear

1234567891011121314 202122

Toner Density Detection Toner Density Detection Toner Density

D E

1st

Leading Edge Erase

Detection

ID Sensor

Pattern

2nd 3rd

Low Toner Density

Toner Supply Timing

Toner Add

Toner Supply Clutch ON

(10 times)

Detection

Development

Bias

Detection

1.2.1 Overview

An ID (Image Density) sensor is used to control toner supply.

The sensor is located on the drum unit, under the cleaning unit. Placing the

sensor under the cleaning unit, instead of the development unit, reduces the

risk of scattered toner getting on the sensor.

The CPU checks toner density through the ID sensor by directly sensing the

image density on the drum. This is done every 10 copy cycles (every 5 copy

cycles for the color development unit). Turning the main switch off and on has

no effect because the count is stored in RAM. If the drum initialization is

performed (SP mode #66) or the RAM is cleared (SP mode #99), the CPU

starts counting for the toner density check from the beginning of the first copy

cycle.

The ID sensor pattern (black) is stuck on the operator side of the bott om of

the left scale bracket. During the check cycle, the ID sensor pattern is

exposed prior to exposure of the original.

2-2

Page 32

12 February 1992 PROCESS CONTROL

After the ID sensor pattern is developed, the ID sensor checks the pattern’s

reflectivity and the CPU notes it. If the reflected light is too strong, indicating

toner density is too low, toner is added to the development unit.

The toner is not added all at once. The CPU energizes the toner supply

clutch solenoid for the proper amount of time to add a calculated amount of

toner over the next 10 copy cycles (5 copy cycles for color toner).

Such toner supply control through the ID sensor is called a detect supply

mode. On this copier, this mode is used to control both black and color toner

supply.

Detailed

Descriptions

2-3

Page 33

PROCESS CONTROL 12 February 1992

1.2.2 ID Sensor Output

VSG = 4.0 ± 0.2

1/10 VSG = 0.4

(V)

LED

ON

VSG

0

Sensor

Bare

pattern

drum

LED

ON

VSP

VSG

1/10 VSG

(T)

VSP

Low image density

High image density

0

When in the toner density check cycle, the CPU receives two voltage values

directly from the ID sensor: Vsg and Vsp. Vsg is the voltage value for the

area of the drum made bare by the erase lamp unit before the ID senso r

pattern is exposed. Vsp is the voltage value for the developed ID sensor

pattern. The CPU compares these two values to monitor the image densit y

on the drum and with this controls the toner supply.

[Standard setting ] 0 to 500 copies Over 500 copies

Black toner – 220 V – 200 V

Red/Blue toner – 200 V – 180 V

Green toner – 240 V – 220 V

Vsg is the reference voltage of the ID sensor output and is automa tica lly

adjusted to 4V whenever SP mode #54 is called.

The development bias for the ID senso r pat te r n is fi xed for each toner color.

This is to avoid any influence from the m an ual ID level set tin g on ton er

density control. (See chart.)

2-4

Page 34

12 February 1992 PROCESS CONTROL

Vsg

Vsp

[Black Toner]

100% (4.0 V)

Low Density

10% (0.4 V)

High Density

Vsg

Vsp

[Color Toner]

High Density

(1) Detect supply mode

In the detect supply mode toner will be supplied under the following

conditions:

Black toner...........................Vsp/ Vsg x 100 ≥ 10

Color toner...........................Vsp/ Vsg x 100 ≥ 25

(2) Fixed supply mode

A fixed amount of toner is supplied every copy cycle when the fixed

supply mode is selected (when the data of SP mode #30 is "1").

On this copier, this mode can be selected only for black toner.

The CPU monitors Vsp and Vsg once every 10 copy cycles even in the

fixed supply mode.

To avoid over toning, the CPU stops toner supply when Vsp becomes

1/10 Vsg or less.

100% (4.0 V)

Low Density

25% (1.0 V)

Detailed

Descriptions

2-5

Page 35

PROCESS CONTROL 12 February 1992

4.0 V

2.5 V

Vsg

Vsp

[Vsg abrormal]

Vsg

Vsp

[Vsp abnormal]

(3) ID Sensor Abnormal Conditions

The following ID sensor abnormal conditions apply to both the detect and

fixed supply modes.

a. Vsg abnormal

When Vsg falls under 2.5V, the CPU stops the toner supply and

continues the ID sensor patt ern detection (every 10 copies for bla ck

and every 5 copies for color). If this abnormal value of Vsg is detected

5 times in a row under this condition (without any toner supply), the

CPU makes the call service indicator blink. Then the CPU shifts the

toner supply to the abnormal fixed supply mode. But in this condition

the CPU never stops the toner supply as it does to avoid overtoning in

the normal fixed supply mode.

b. Vsp abnormal

When [Vsp/Vsg X 100] goes to 50 or more, the CPU changes the toner

supply amount to the ID sensor abnormal level and continues toner

supply and ID sensor pattern detection. If this abnormal value of Vsp is

detected 5 times in a row, the CPU makes the call service indicator

blink. Then the CPU shifts the toner supply to the abnormal fixed

supply mode, as it does under a Vsg ab no r mal con dit ion .

100% (4.0 V)

50% (2.0 V)

NOTE: The CPU continues the ID sensor pattern detection even under

the ID sensor abnormal condition s .

For both black and color toners, if Vsg and Vsp return to the

normal range at any of the subsequent toner density check

cycles, the CPU will return the toner supply control to normal.

2-6

Page 36

12 February 1992 PROCESS CONTROL

1.3 VR PATTERN CONTROL

1.3.1 Overview

(V)

Drum

residual

voltage

Copy volume

(V)

Drum

potential

Light intensity

During the OPC drum’s life, drum residual voltage gradually increases due to

electrical fatigue. This may cause dirty backgrounds on copies. The V sensor

is used to avoid this problem.

The V sensor is located on the drum unit, on the same frame as the ID

sensor. The ID sensor is located on the non-operator side and the V sensor

is on the operator side.

The CPU checks the drum residual voltage through the V sensor by directly

sensing the VR pattern on the drum surface. This VR pattern detection is

performed after the drum initial setting (SP mode #66). After this, the CPU

will do one VR pattern detection every 200 copie s f or th e ne xt 2,000 copies,

and every 1,000 copies after that. Also when VR data correction (See 1.5

Drum Temperature Control) is applied and the drum temp erature goes over

25°C, this detection is performe d.

Detailed

Descriptions

According to the data of the VR pattern detection, the CPU ap plies V

correction to the grid bias volt ag e an d th e de velopment bias voltage.

2-7

R

Page 37

PROCESS CONTROL 12 February 1992

1.3.2 VR Pattern Detection

Image

0V Bias

Non-image

Fixed Bias

Vrg

VR Pattern

V Sensor

Vrp

The VR pattern is made on the drum befo r e th e original latent image, as in

the case of the ID sensor pattern.

During VR pattern detection, the drum surface is charged with a fixed grid

bias voltage: – 500V + VG correction (see 1.6 Drum Rotation Time Control).

At the same time all the blocks of the erase lamp unit turn on to illuminate this

charged area of the drum.

The exposed area of the drum is develop ed with a fixed bias voltage for

non-image area: – 160V + VR correction + VR Data correction (See 1.5 Drum

Temperature Control) + Bl ack Bia s cor rect ion (SP mode #37). The V sensor

checks the reflectivity of the bare area of the drum and this sensor output

voltage is called Vrg. (The meaning of Vrg is the same as that of Vsg

detected by the ID sensor.)

Just next to this bare drum area, th e dr u m is develo pe d with VR pattern bias

voltage (0V). If there is residual voltage on the drum, this are a of the drum

will attract some toner, making a VR pattern. The V sensor checks the

reflectivity of the VR pattern and this sensor output voltage is called Vrp.

The CPU notes the ratio, Vrp/Vrg. This VR pattern check is done 5 times in a

row during the copy cycle (among 5 copies) and the CPU takes their average.

During the 5 VR pattern check cycles, if color copies are made, or if a toner

density check is done, the CPU skips the VR pattern check and will do it in

the next copy cycles.

If an ID sensor abnormal conditio n occu r s, the CPU does not perform the V

R

pattern detection because toner density may not be proper.

2-8

Page 38

12 February 1992 PROCESS CONTROL

1.3.3 VR Correction

VR level Vrp/Vrg x 100(%)

0100~84

Grid bias correction

voltage

0 V

±

Development bias

correction voltage

0 V

±

1 83~58 – 40 V – 40 V

2 57~41 – 80 V – 80 V

3 40~28 – 12 0 V – 120 V

4 27~0 – 16 0 V – 160 V

When calling SP mode #54, the reference voltage of the V sensor output Vrg

is automatically adjusted to 4V at th e sam e tim e as Vsg is adjust ed .

The grid bias voltage and the de velo pm e nt bias voltage are corrected (V

R

correction) according to the ratio between Vrp and Vrg as shown in the above

table.

(ex. If there is no residual voltage on the drum, Vrp=4V and Vrg=4V. Then

the proportion is: Vr p/Vrg x 100 = 4/4 x 100 = 100%)

When the drum residual voltage increases, th e VR pattern becomes darker.

The value of Vrp decreases and also the Vrp/Vrg ratio decreases. Then the

CPU increases the negative development bias voltage to prevent a dirty

background, and simultaneo usly incr e ase s the negat i ve gr id bias voltage to

prevent low image density.

Detailed

Descriptions

,

2-9

Page 39

PROCESS CONTROL 12 February 1992

1.4 VL PATTERN CONTROL

1.4.1 Overview

I

D Sensor Pattern

V

Pattern

L

DC

PSU

Main

Board

(V)

Drum

Potential

V Sensor

Exposure lamp voltage

(V)

Dirty optics or deterioration of the exposure lamp decreases the int ensity of

the light that reaches the drum via th e op tics cavity. As more copies are

made during the drum’s life, the pho to cond uct i ve laye r get s wor n and dr u m

sensitivity drops. The drum sensitivity also drops under low temperature

condition.

VL pattern control is performed on this copier to prevent dirty backgrounds

caused by the factors mentioned above. The V sensor is also used for V

L

pattern control as well as for VR pattern control.

The VL pattern (light gray) is located on the non-operator side of the bottom

of the left scale bracket. When a copy job fi nish es in VL pattern detection

timing, the exposure lamp stays on for ab ou t 6 seco nd s while at the home

position. The VL pattern is lit and a latent image of it is made on the drum.

After this image is developed, its reflectivity is checked by the V sensor. The

CPU notes the strength of reflectivity, and if the reflected light is too weak,

the exposure lamp voltage is increased.

2-10

Page 40

12 February 1992 PROCESS CONTROL

1.4.2 VL Pattern Detection

Main SW on

data

V

R

correction

done ?

Y

Drum Temp.

> 25°C

N

N

Programmed

copy

interval ?

Y

N

VL Pattern

Y

150 mm

pattern detection

V

R

Detailed

Descriptions

N

Is copy

Job completed ?

20 mm

Y

20 mm

pattern detection

V

L

Vdat = Vlp/Vlg

VL pattern detection is done after VR pattern detection, but unlike VR pattern

detection it is done after the cop y job is fi nish ed . This m ea ns af te r the drum

initial setting (SP mode #66), ever y 20 0 cop i es fo r the fir st 2,000 copies,

every 1,000 copies af te r excee din g 2,000 copies, and when the dr um

temperature go es ove r 25°C un de r t he VR data correction condition.

When VL pattern detection starts, the exposure lamp turns on, the main

motor stays, on together with other fan motors, to rotate the drum. The

charge corona, grid bias, all the blocks of the erase lamp, the pre-transfer

lamp, and the quenching lamp turn on.

After about one revolution of the drum, the appropriate blocks of the erase

lamp turn off and on to make a VL pattern (20 x 20 mm) on the drum surface.

The drum surface is developed with non-image area bias for both the bare

drum and VL pattern.

The V sensor checks the reflectivity of the bare drum (Vlg) and that of the V

pattern (Vlp). The CPU calculates the ratio between Vlp and Vlg (Vlp/Vlg).

The VL pattern is made 4 times with 150 mm distance between each pattern .

The CPU takes the average of Vlp/Vlg (=Vdat).

2-11

L

Page 41

PROCESS CONTROL 12 February 1992

When the drum initial setting (SP mode #66) is performed and more than 7

black copies are made, the init ial VL detection is performed at the end of the

copy job and the CPU stores the VL reference value (initial Vlp/Vlg = Vref) in

memory. ID sensor patter n de te ction and VR pattern detection is done prior to

this initial VL detection.

ID sensor pattern an d VR pattern detections are performed when blac k

copies are made even in the SP mode. However, VL pattern detection is

performed when a black copy is made in enlarge or full size mode and no t in

the SP mode.

1.4.3 VL Correction

VL Level (%)

Lamp correction

voltage

151~ –1 V

101~150

±

0 V

0~100 +1 V

The V sensor output is automatically adjusted to 4V (for Vlg=Vrg) by calling

SP mode #54 as we mentione d in 1. 3.3 VR Correction.

When the VL pattern detection is performed during the operation, the CPU

compares the Vdat with the Vref. According to the ratio be twe en Vda t an d

Vref, the CPU applies the voltage correction to the exposure lamp (V

L

Correction) as shown in the above table.

Vdat/Vref x 100 = VL level (%)

The exposure lamp voltage for VL pattern detection depe nd s on all pr e viou s

correction factors, and the new VL correction factor is added to them. This

result is then applied to the exposure lamp voltage till the next VL pattern

detection.

2-12

Page 42

12 February 1992 PROCESS CONTROL

1.5 DRUM TEMPERATURE CONTROL

1.5.1 Overview

(V)

Drum

potential

Exposure lamp voltage

(V)

(V)

Drum

potential

Light intensity

Under low temperature conditions drum sensitivity drops and dru m residu al

voltage increases. This is a characteristic of the drum and may cause dirty

backgrounds on copies.

To compensate for this, a drum thermistor is installed on the ID sensor board

to monitor the temperature around the drum.

When the main switch is turned on, the CPU checks the temperature through

the drum thermistor. I f th e te m per ature is 25°C or less, the CPU applies

appropriate correctio ns to the exposure lamp voltage (low te m p. corr ect ion ) ,

to the grid bias voltage (VR data correction), and to the development bias

voltage (VR data correction).

Detailed

Descriptions

When the tempera tu r e goes over 25°C, the VR pattern detection and V

L

pattern detection are performed and the above corrections are canceled.

If the temperature is alread y over 25 °C when the ma in switch is turne d on , no

correction is applied.

2-13

Page 43

PROCESS CONTROL 12 February 1992

Low Temp.

correction

Exposure lamp

voltage

Grid bias voltage

VR Data correction

Development bias

voltage

Over 25°C No correction No correction No correction

25°C or lower Lamp voltage + 1V VR level + 1 VR level + 1

1.5.2 Low Temp. Correction

When a correction is required under low temperature conditions, the CPU

increases the exposure lamp voltage by 1V.

1.5.3 VR Data Correction

When the low temp. correction is applied, VR data correction is applied

simultaneously. The VR correction level for both the grid bias voltage and the

development bias voltage is stepped up by 1. This means the negative

voltage for the charge grid and the development bias is increased by 40V.

2-14

Page 44

12 February 1992 PROCESS CONTROL

1.6 DRUM ROTATION CONTROL

(V)

Drum

potential

Drum rotation time

(H)

Detailed

Descriptions

(V)

–600

–550

–500

–450

Grid bias

voltage

–500

0 1 2

VG Correction for Sensor

Pattern

–580

–560

–540

–520

37 63 88~(H)

Drum rotation time

(V)

–850

–800

–750

–700

Grid bias

voltage

–745

0 1 2

VG Correction for Image

–805

–785

–765

37 63 88~(H)

Drum rotation time

1.6.1 Overview

During the OPC drum’s life the photo conductive layer gets worn and this

causes a drop in drum sensitivity and a decrement in the drum potential after

the drum charge.

The CPU keeps track of the drum rotation time (main motor on time) that

corresponds to the wear of the drum surface. The grid bias voltage is

increased at set intervals (VG correction).

–825

1.6.2 VG Correction

If drum potential decreases after the drum charge, the ID sensor pattern on

the drum becomes lighter, causin g hig he r ton er con c en tr a tio n in th e

developer. Also, copy image density becomes slightly lighter.

To control toner density properly and to keep copy image density, drum

potential is maintained by increments of the grid bias voltage at set intervals.

(See graph above)

2-15

Page 45

PROCESS CONTROL 12 February 1992

The drop of drum sensitivity due to th e dr u m wear is com pe nsated by V

L

correction. VL correction is performed more often than VG correction,

therefore, VG correction is not applied to the exposure lamp voltage, only to

the grid bias voltage.

2-16

Page 46

12 February 1992 DRUM

2. DRUM

2.1 OPC DRUM CHARACTERISTICS

An OPC has the characteristics of:

1. Being able to accept a high negative electrical charge in the dark. (The

electrical resistance of a photo c on du cto r is high in the absence of light.)

2. Dissipating the electrical charge when exposed to light. (Exposure to light

greatly increases the conductivity of a photoconductor.)

3. Dissipating an amount of charge in direct proport i on to the intensity of the

light. That is, where stronger ligh t is dir ect ed to th e ph otoconductor

surface, a smaller voltage remains on the OPC.

4. Being less sensitive to changes in temperature (when compared to

selenium F type drums).

5. Being less sensitive to changes in rest time (light fatigue). This makes it

unnecessary to compensate development bias voltage fo r variations in

rest time.

Detailed

Descriptions

2-17

Page 47

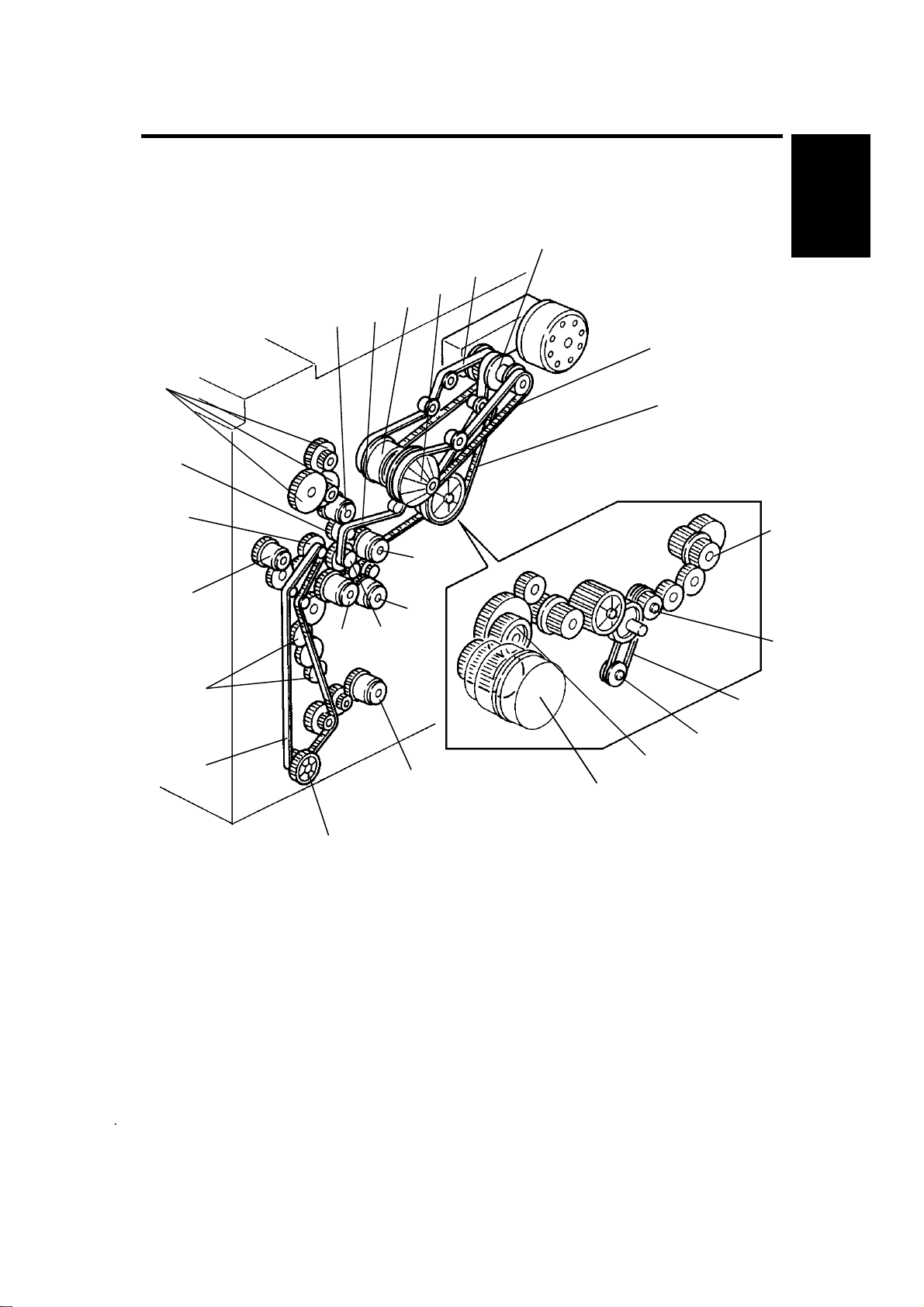

DRUM 12 February 1992

2.2 DRUM UNIT

[G]

[H]

[F]

[E]

[B]

[I]

[D]

[C]

[D]

[A]

An organic photoconductor drum is used on this model.

To prevent stress on the drum, a drum un it is used to ho ld th e dr u m witho ut a

drum shaft.

The drum unit consists of an OPC drum [A], ID sensor board with a drum

thermistor [B], V sensor board [C], pick-off pawls [D], erase lamp unit [E], and

toner shield glass.

The pick-off pawls are always in contact with the drum surface with weak

spring pressure. They move side to side during the copy cycle. This

movement is made via a worm ge ar an d an eccentric cam gear.

The ID sensor is used to control the toner density in the developer. The V

sensor is used for VR and VL pattern detections. The dru m t her m isto r is used

for drum temperature control.

A green color filter [F] is stuck just above the toner shield glass on the drum

unit top plate to decrease the sensitivity of the OPC layer against red light.

The drum is driven by the main motor [G] through a timing belt [H], an d a

drum drive shaft [I].

2-18

Page 48

12 February 1992 DRUM CHARGE

3. DRUM CHARGE

3.1 OVERVIEW

[A]

[B]

Detailed

Descriptions

This copier uses a double corona wire scorotron system for drum charge.

Two corona wires are required to give sufficient negative charge on the drum

surface because of a rather hig h drum speed (180 mm/sec.). The stai nle ss

steel grid plate [A] makes the cor o na charge uniform and controls the amoun t

of negative charge on the drum surface by applying the negative grid bias

voltage.

The high voltage supply board - CTBG [B] gives a constant corona current to

the corona wires (– 500 µA (– 5.6 kV)) and a constant bias voltage to the grid

plate (– 745 V: for image, – 500 V: fo r senso r pat te r n) . The cor o na cur ren t is

controlled by the variable resistor in the circuit and the grid bias voltage is

controlled by a PWM (Pulse Width Modulation) system.

The transport fan located above the fusing unit provides an air flow to the

charge corona unit to preven t un eve n bu ilt- u p of negative ions that can cause

an uneven charge of the drum surface.

The air around the drum is exhausted outside of the copier by the exhaust

blower located on the rear side frame. The exhaust blower assembly has two

ozone filters (ceramic type and paper type) to absorb the ozone (O3) around

the drum generated by the corona discharge.

2-19

Page 49

DRUM CHARGE 12 February 1992

3.2 CHARGE CORONA WIRE CLEANER MECHANISM

[C]

[A]

[B] [D][B]

[A]

The flow of air around the charge corona wire may deposit paper dust or

toner particles on the corona wires. These particles may interfere with

charging and cause low density bands on copies.

The wire cleaner pads [A] above an d be low th e cha r ge cor ona wir es clea n

the wires as the charge corona unit is manually slid in and out.

The cleaner pad bracket [B] rotates when the charge unit is fully extended

and the bracket is pulled up against the rear block [C]. This moves the pads

against the corona wire (see illustration). If the charge unit is not fully

extended, the pads do not touch the corona wires.

The pads move away from the wire when the charge unit is fully inser te d and

the cleaning bracket is pushed against the front block [D].

After copier installation, the key operator should be told how to use this

mechanism when white streaks appe ar on copie s.

2-20

Page 50

12 February 1992 DRUM CHARGE

3.3 GRID BIAS VOLTAGE CORRECTION

The grid bias voltage differ s depen din g on the mo de s and cor r ect ion fact or s

(see the process control section).

3.3.1 Base Grid Bias Voltage

There are two base grid bias voltages, one for image and the other for sensor

patterns (ID sensor pattern and VR pattern).

Grid bias voltage for image (Vgi): -745 V

Grid bias voltage for sensor pattern (Vgp): -500 V

The high voltage supply board - CTBG is adjust ed at th e fa cto r y to ou tp ut the

correct Vgi and Vgp. When the high voltage supply board - CTBG is replaced

in the field, the variation of the grid bias output should be corrected by

entering the grid voltage correction data in SP mode #62.

3.3.2 Manual ID Correction

Detailed

Descriptions

When the image density is selected by

the manual image density keys on the

operation panel, the grid bias voltag e is

changed as shown in the above t ab le.

The image density for each manua l I D

level is also controlled by the exposure

lamp voltage and the development bias

voltage. The manual ID correction for

the grid bias voltage is applied only to

levels 6 and 7. This is to expand the

difference of image density at levels 6

and 7 from the other manu al ID leve ls.

ID Level Grid Bias Voltage

1

2

3

4

5

6 Vgi +50V

7 Vgi +50V

NOTE:

Vgi (Grid bias voltage

Vgi ±0V

Vgi ±0V

Vgi ±0V

Vgi ±0V

Vgi ±0V

for image)= –745V

2-21

Page 51

DRUM CHARGE 12 February 1992

3.3.3 VR Correction

Grid Bias Correction Voltage

–160 V

–120 V

–80 V

–40V

V

0274057

Level

R

(4)

(3) (2)

VR Level Vrp/Vrg x 100 (%) Grid Bias Correction Voltage

83

(1)

0 100~84

1 83~58 –40V

2 57~41 –80V

3 40~28 –120V

4 27~0 –160V

(0)

100

(%)

0V

±

According to the results of the VR pattern detection, the grid bias voltage is

corrected as shown in the above table.

The VR correction is also applied to the development bias voltage.

3.3.4 VR Data Correction

Drum

Temperature

Over 25°C No correction

25°C or lower V

Grid Bias V

Correction

level +1

R

R

NOTE: VR level (max.)=4

If the temperature around the drum is 25°C or less when the main switch is

turned on, the VR data correction is applied to the grid bi as volt ag e as sho w n

in the above table.

VR data correction is also applied to the development bias voltage and the

low temp. correction is applied to the exposure lamp voltage simultaneously

under this condition.

2-22

Page 52

12 February 1992 DRUM CHARGE

3.3.5 VG Correction

Grid Bias Correction Voltage

–80 V

– 60 V

–40 V

–20 V

Detailed

Descriptions

0

37

SP100: Drum Rotation Time

63

(H)

0~1

2~36 –20V

37~62 –40V

63~87 –60V

882 Drum Rotation Time (H)

Grid Bias Correction Voltage

0V

±

According to the drum rotation time after performing SP mode #66 when a

new drum is installed, VG correction is applied to the grid bias volt age as

shown in the above table.

3.3.6 SP Mode Data Setting

SP34: ADS Density

Data Density Grid Bias Correction Voltage

0 Normal

1 Darker –50V

2 Lighter

0V

±

0V

±

When the darker setting for ADS (data "1") is selected in SP mode #34 (ADS

density), the negative grid bias voltage is increased by –50 V.

When the lighter setting is selected, the negative development bias voltage is

increased.

2-23

Page 53

DRUM CHARGE 12 February 1992

3.3.7 Total Grid Bias Voltage

The total grid bias voltage for each mode is determined by th e CPU as

follows:

(1) ADS Mode

Vgi(–745 V) + VR Correction + VR Data Correction + VG Correction +

ADS Density(SP34)

(2) Manual ID Mode

Vgi(–745 V) + Manual ID Correction + VR Correction + VR Data

Correction + VG Correction

(3) ID Sensor Pattern Detection

Vgp(–500 V) + VG Correction

(4) VR Pattern Detection

Vgp(–500 V) + VG Correction

(5) VL Pattern Detection

Vgi(–745 V) + VR Correction + VR Data Correction + VG Correction

(6) Non-Image Are a

0 V

2-24

Page 54

12 February 1992 OPTICS

4. OPTICS

4.1 OVERVIEW

[B] [A] [F] [G] [L]

[D]

[I]

Detailed

Descriptions

[E]

During the copy cycle, an image of the original is reflected onto the drum

surface via the optics assembly as follows.

Light Path:

Exposure Lamp [A]

→2nd Mirror [D]

4th Mirror [G]

→

Toner Shield Glass [J]

→

The optics cooling fan [L] removes warm air (heated by the exposure lamp)

from the optics cavity. This blower operates if the optics thermister installed

on the left scale bracket senses 40°C or more. This operation reduces the

possibility of the optics unit becoming dirty by the optics cooling fan.

The 1st scanner (lamp and 1st mirror), 2nd scanner (2nd and 3rd mirrors),

3rd scanner (4th and 5th mirrors), and the lens function together to achieve a

wide range of reproduction ratios (50 –200%).

[C]

Original [B]

→

3rd Mirror [E]

→

5th Mirror [H]

→

[K]

→

→

→

OPC Drum [K]

→

1st Mirror [C]

Lens [F]

6th Mirror [I]

[J]

→

→

→

[H]

The auto density selection (ADS) sensor board is mounted on the optics

bottom plate in the lens housing cover. The ADS sensor board collects light

reflected from the original in ADS mode. Original length and width sensors

are mounted in the optics cavity for the original size detection.

A thermoswitch (turning off at 130°C) is installed on the back of the exposure

lamp reflector as a back-up safe ty fo r preve nting the optics unit overheatin g.

2-25

Page 55

OPTICS 12 February 1992

4.2 SCANNER DRIVE

[D]

[F]

[E]

[H]

[E]

[I]

[G]

[A]

[B]

This model uses a stepper motor [A] to drive the scanners via a timing belt

[B], scanner drive pulley [C], and 2 long & short scanner drive belts [D, E].

Both ends of each scanner are dr iven to prevent skewing. The scanners

have sliders [F], which ride on guide rails.

The scanner home position is detected by the home position sensor [G]. The

main CPU sends the appropriate pulses to the scanner drive motor to

determine the scanner return position.

The first scanner [H], which consists of the exposure lamp and the first mirror,

is connected to 2 long scanner drive belts by the belt clamps. The second

scanner [I], which consists of the second and third mirrors, is connected to 2

short scanner drive belts by belt clamps.

The relay pulley moves the second scanner at half the velocity of the first

scanner. The diameter of the pulle y for th e short belts is half that for the long

belts. This is to maintain the focal distance between the original and the lens

during scanning. This relationship can be expressed as:

V1r = 2 (V2r) = VD/r

where r = Reproduction ratio

V1r = First scanner velocity (when the reproduction ratio is "r")

V2r = Second scanner velocity (when the reproduction ratio is "r")

VD = Drum peripheral velocity (180 mm/s)

[C]

2-26

Page 56

12 February 1992 OPTICS

4.3 LENS DRIVE

[G]

[E]

[D]

[G]

[C]

[A]

[B]

Detailed

Descriptions

[F]

: Reduction

[H]

: Enlargement

4.3.1 Lens Drive

The lens motor [A] (stepper motor) changes the lens [B] position through the

lens drive wire [C] in accordance with the selected repr od uct ion ra tio to

provide the proper optical distance between the lens and the dru m surface.

The rotation of the lens drive pu lley [D] moves the lens back and forth in

discrete steps. The home positio n of the lens is det ect ed by the home

position sensor [E]. The main bo ar d keep s tr ack of t he lens po sition based on

the number of pulses sent to the lens motor.

4.3.2 Shading Mechanism

The shading plates [F] are installed on the lens housing [G] and are slid open

and shut by the shading cam [H]. This shading mechanism adjusts the

horizontal light intensity, which becomes uneven in reduction mode, when the

light at the sides of the image is more int en se. The shading plates close in

reduction mode to even out the light intensity.

2-27

Page 57

OPTICS 12 February 1992

4.3.3 Lens Positioning

[C]

[A]

[B]

(Initialize)

(Enlarge → Full Size)

(Reduce → Full Size)

[D]

Lens H.P. Sensor Signal

2020

1

L

20

H

(Full Size → Enlarge

(Full Size → Reduce

(Reduce → Enlarge

(Enlarge → Reduce

(Enlarge → Enlarge

(Reduce → Reduce

pulses

1 pulse = 0.06 mm

The lens home position sensor [A] informs the main board when the lens is at

full size position (home position). The main board de te rm ine s the lens stop

position in reduction and enlargement modes by counting the number of

steps the motor makes with reference to the lens home position. When a new

reproduction ratio is selected, the lens [B] moves directly to the selected

magnification position.

The lens home position is registered each time the lens starts from or pa sses

through the lens home position sensor. As the lens moves from the

enlargement side to the reduction side, the sensor registers the home

position. This occurs when the actuator plate [C] enters the lens home

position sensor.

)

)

)

)

)

)

The lens can be seen to go back and forth when the lens moves through the

home position from the reduction side to the enlargement side. The lens is

going in the wrong direction to re gist er th e ho m e po sitio n. The len s

overshoots the home positio n by 20 pulses bef ore goin g ba ck to reg i ste r the

home position and it then overshoots it by 1 pulse before finally settling there.

The lens always stops while moving from left to right (as viewed from the

front) to minimize the er r o r cause d by m ech an ical pla y in the dr ive ge ars [D].

2-28

Page 58

12 February 1992 OPTICS

4.4 3RD SCANNER DRIVE

[B]

[A]

(Initialize)

(Enlarge/Reduce

Full Size)

→

Detailed

Descriptions

(Full Size

Enlarge/Reduce)

→

(Enlarge/Reduce

Enlarge/Reduce)

→

1

pulses

3rd Scanner

H.P. Sensor

Signal

2020

1 pulse = 0.06 mm

LH

4.4.1 Drive

The 3rd scanner drive motor (stepper motor) changes the 3rd scanner

position through the pinion gears [A] and the rack gear [B] in accordance with

the selected reproduction ratio to provide the proper optical distance between

the lens and drum surface.

4.4.2 Positioning

The positioning mechanism is similar to that for lens positioning, as shown in

the above positioning chart. The scanner always stops while moving from

right to left (as viewed from the front).

2-29

Page 59

OPTICS 12 February 1992

4.5 ORIGINAL SIZE DETECTION

[B]

[A]

[C]

There are six (for LT version) or seve n ( fo r A4 ver sio n) r ef lective sensors in

the optics cavity for the original size detection. Two of them [A] are used for

sensing the original width and the other four/five [B] are for the original length.

While the main switch is on, these sensors are active and the original size

data is always sent to the main CPU. You can recognize this by the changes

of the original size indicator when moving an original on the exposure glass.

However, the CPU checks the data only twice in platen mode for determining

the original size for actual copying in APS or AMS modes.

First check is done when the platen (or DF) position sensor [C] is activated.

At this time the angle between the platen cover and the exposure glass is

about 30 degrees. Only the sensor(s) underneath the original receive the

reflective light and output a low sign al. The other sensor(s) output a high

signal. The CPU sends an original size signal to the operation panel board

and stores this data.

[D]

A second check is done when the platen cover ( or DF) is closed and th e

platen cover switch [D] turns on. The CPU compares the second check with

the first one to confirm if the detected original size is correct or not.

2-30

Page 60

12 February 1992 OPTICS

If there is any difference between the first and second check, the CPU judges

if the original exists above the resp ect i ve sen sor or no t acco r din g to the

following table.

First data

High High Paper exists

High Low No paper

Low High

Low Low Paper exists

Second

data

Judgment

Indicates

"Check

paper size"

S21–2

S21–1

Original Width

Sensors

S20–1

S20–2

Original Length Sensors

The CPU finally determines the original size from the above judgments. The

following table shows how the original size is determined with information of

each sensor.

Sensors

Original Size

Original Width

Sensor

S21–1 S21–2 S20–1 S20–2

Original Length Sensor

(S20–3)

S20–4 S20–5

Detailed

Descriptions

S20–5(S20–3) S20–4

A3 11" x 17"OOOOOOO

B4

—8

F4 — XOOOOXX

A4 lengthwise 8

B5 lengthwise

or smaller

A5 lengthwise

A4 sideways

or smaller

B5 sideways 8

A5 sideways

or smaller

11" x 15"

10" x 14"

" x 14"XOOOOOX

1/2

" x 11" X O O O X X X

1/2

8" x 10" X O O X X X X

" x 8

5

1/2

1/2

or smaller

11" x 8

1/2

" x 5

1/2

1/2

8

" x 5

1/2

1/2

or smaller

OOOOOOX

"

XXXXXXX

"OOOXXXX

"OOXXXXX

"

XOXXXXX

O: Paper exists X: No paper

If the start key is pressed with the plat en cover open, the CPU uses the

original size data detected when the start key is pressed.

If an original is fed on to the exposure glass through th e ARDF, the CPU

uses the original size data from the ARDF.

2-31

Page 61

OPTICS 12 February 1992

4.6 AUTOMATIC IMAGE DENSITY CONTROL SYSTEM (ADS)

[A]

In ADS mode the original backgro un d de nsity is sensed by the ADS sensor

[A] and the CPU determines an appropriate development bias voltage for the

original to prevent the backgr ound fr om ap pe ar in g on copie s.

The ADS sensor board is mounted on the front side of the optics base plate.

The sensor board is covered by the lens ho usin g cove r which ha s a smal l

hole to direct the reflected light fr om th e original to the ADS sensor.

The ADS sensor standard voltage is adjusted to 1.5V when SP mode #56 is

performed. The exposure lamp turns on with 64V (fixed voltage) at the home

position and the light reflecte d by the middle part of the reverse side of the

left scale bracket (white painted) reaches the ADS sensor. The CPU adjusts

the ADS gain data automatically to make the output to 1.5V. This gain data is

stored in the RAM board .

2-32

Page 62

12 February 1992 OPTICS

35 mm

(V)

ADS

Sensor

Output

B

Peak hold

- 18

A

C

Lead Edge

- 8 0

D

Original

ADS Reference Voltage

Peak hold

5 64 (mm)

Scan Positon

A= 8 mm, B= 18 mm

C= 5 mm D= 64 mm (Full size)

ADS Original Voltage

For the first scanning of an original in ADS mode, the CPU starts sampling of

the ADS sensor output from when the scanner moves from -18mm to -8mm

from the original lead edge. Then the CPU memorizes the maximum ADS

sensor output as a reference voltage. This means that every ADS check

cycle, the first scanning for the original, the ADS reference voltage is

renewed by the latest exposure light reflected by the white left scale bracket.

Detailed

Descriptions

In the full size mode, the CPU samples the ADS sensor output for the original

when the scanner moves from 5mm to 64mm fro m the or igin al lea d ed ge .

The CPU takes the maximum ADS sensor output during the sampling period

and compares it with the ADS reference voltage to determine the proper

development bias voltage. (See ADS Data Correction in development bias

control section for the detail.)

The sampling length of ADS sensor output for the original differs depending

on the reproduction ratio beca use the scann er spe ed is diffe r en t. It also

differs when color copies are mad e be cau se the latent image on the drum

surface comes to the development point faster.

2-33

Page 63

OPTICS 12 February 1992

4.7 EXPOSURE LAMP CONTROL

The base exposure lamp voltage (Vexp) is determined by SP mode #48

according to the actual copy image when the drum initial setting (SP66) is

performed. Based on this Ve xp, the exposure lamp voltage differs depending

on the modes and correction factors.

4.7.1 Manual ID Correction

Vexp

+2

+1

±

– 2

– 2

Lamp

Voltage

0

1234 756

ID Level

ID Level

1 Vexp –2V

2 Vexp –2V

3 Vexp –1V

4

5 Vexp +1V

6 Vexp +1V

7 Vexp +2V

SP48: Lamp Voltage

Lamp

Voltage

Vexp ±0V

0~75 V=Vexp

(63V=Default

)

When an image density level is selected by the manual image density keys

on the operation panel, the exposure lamp voltage is changed as shown in

the above table.

The voltage changes ±2V within manual ID levels 1 to 7.

The grid bias voltage and the de velo pm e nt bias voltage also change to make

the appropriate image density graduation for each ID level.

2-34