Page 1

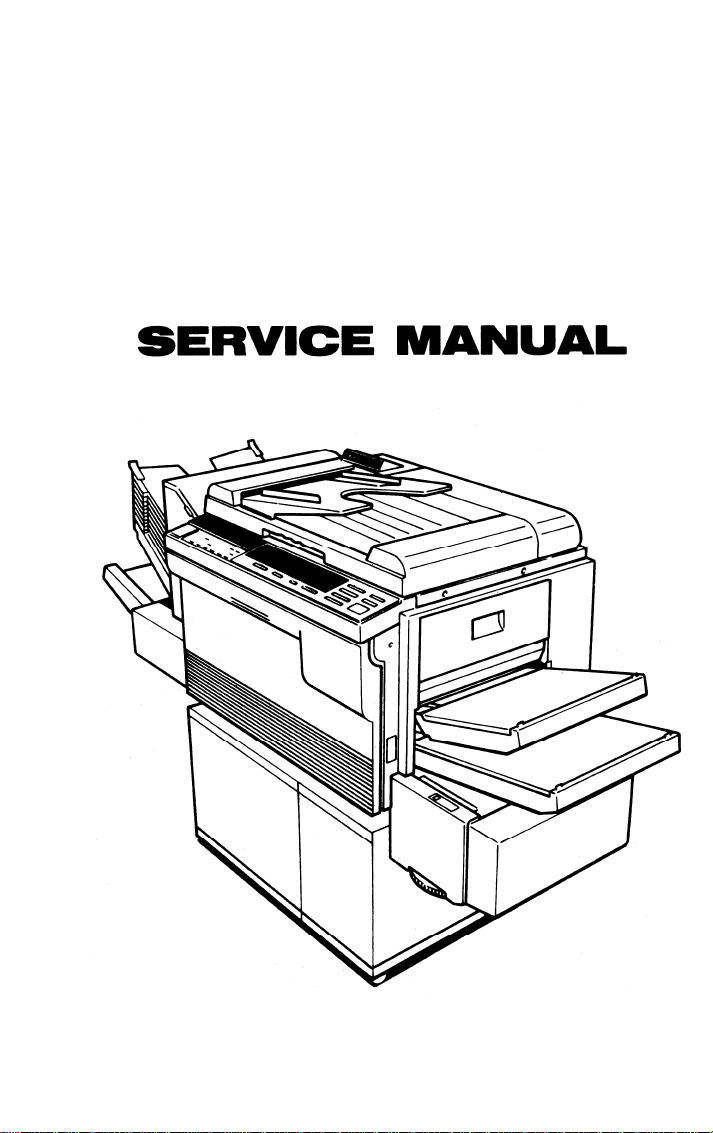

RICOH

RICOH FT4460

RICOH COMPANY, LTD.

Page 2

Table of Contents

OVERALL MACHINE INFORMATION

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.1 MAIN COPIER, FT4460 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

2. OPERATION PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

3. COPY PROCESSES AROUND THE DRUM . . . . . . . . . . . . . . . . . . . . .1-9

4. FUNCTIONAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

5. PAPER PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

5.1 PRIMARY PAPER PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

5.2 SlNGLE DUPLEX COPY PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

5.3 MULTI DUPLEX COPY PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

5.4 SINGLE OVERLAY COPY PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

5.5 MULTI OVERLAY COPY PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

6. DRIVE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

7. MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . .1-18

8. ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . .1-20

9. ELECTRICAL COMPONENT DESCRIPTIONS . . . . . . . . . . . . . .1-22

10. AC AND DC POWER DISTRIBUTION . . . . . . . . . . . . . . . . . . . . . . . .1-27

11. OVERALL MACHINE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-28

DETAILED

SECTION DESCRIPTIONS

1.2.DRUM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

1.1 OPC DRUM CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

1.2 HANDLING THE DRUM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

1.3 DRUM UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

DRUM CHARGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.2 CHARGE CORONA UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.3 CHARGE CORONA POWER PACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.4 CHARGE CORONA WIRE CLEANER MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

3. OPTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Page 3

3.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

3.2 SCANNER DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

3.2.1 1st and 2nd Scanner Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

3.3 SCANNER MOTOR DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

3.4 LENS DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

3.4.1 Lens Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

3.4.2 Shading Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

3.5 LENS POSITIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

3.6 3RD SCANNER DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

3.6.1 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

3.6.2 Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

3.7 STEPPER MOTOR CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

3.8 RED ERASE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

3.9 AUTOMATIC IMAGE DENSITY SENSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

3.10 AUTOMATIC ORIGINAL SIZE DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

3.11 EXPOSURE LAMP VOLTAGE CORRECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

3.11.1 Manual Image Density Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

3.11.2 Size Magnification Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

3.11.3 Drum Sensitivity Correction (Vr Correction) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

3.11.4 Drum Rotation Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

3.11.5 Photo Mode Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

3.11.6 ADS Correction (SP mode #34) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

3.11.7 Red Erase Mode Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

3.11.8 Pre-scan Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

3.12 EXPOSURE LAMP CONTROL ClRCUlT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

3.13 SERVICE CALL CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

4. ERASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

4.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

4.1.1 Lead Edge Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

4.1.2 Side Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

4.1.3 Special Mode Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

4.1.4 Trailing Edge Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

4.2 ERASE LAMP CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

4.3 ERASE TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28

Page 4

5. DEVELOPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

5.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . .2-29

5.2 DEVELOPMENT UNIT CHANGE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

5.3 DEVELOPMENT UNIT SUPPORT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-31

5.4 DRIVE MECHANISM (Black) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

5.5 DRIVE MECHANISM (Color) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-33

5.6 AGITATOR MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-34

5.7 TONER SUPPLY AND AGITATOR DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . .2-35

5.8 TONER DENSITY DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

5.9 TONER DENSITY CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-37

5.10 TONER END DETECTION (Black) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

5.10.1 Black . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

5.11 TONER END DETECTION (CoIor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-39

5.11.1 Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-39

5.12 ID SENSOR SUPPLY CONTROL (Black only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-40

5.13 ID SENSOR TONER SUPPLY LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-41

5.14 ID SENSOR SUPPLY CONTROL IN FIXED SUPPLY MODE . . . . . . . . . . . . . . . . . . . .2-42

5.15 TONER SUPPLY AMOUNT (FIXED SUPPLY MODE) . . . . . . . . . . . . . . . . . . . . . . . . .2-44

5.16 ID SENSOR ERROR DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-45

5.17 DEVELOPMENT BlAS CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-46

5.17.1 Manual Bias Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-46

5.17.2 Auto Image Density Bias Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-46

5.18 BIAS CORRECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-47

5.18.1 Vr Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-47

5.18.2 SP Mode Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-47

5.19 ID SENSOR BlAS COMPENSATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-48

5.19.1 Standard Bias . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-48

5.19.2 Vp Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-48

5.19.3 Developer Counter Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-49

5.19.4 Total lD Sensor Bias . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-49

6. IMAGE TRANSFER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-50

6.1 PRE-TRANSFER LAMP (PTL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-50

6.2 IMAGE TRANSFER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-50

6.3 PAPER SEPARATION AND TRANSPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-51

Page 5

6.3.1 Paper Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-51

6.3.2 Paper Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-51

6.4 PTL AND T/S CHARGE CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-52

7. ID SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-53

7.1 ID SENSOR IMAGE CORRECTION (Vr Pattern) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-53

7.2 ID SENSOR PATTERN (Vsp) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-55

8. DRUM CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-56

8.1 OVERVlEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-56

8.2 DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-57

8.3 RELEASE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-58

8.4 TONER OVERFLOW DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-59

9. PAPER FEED AND REGISTRATION . . . . . . . . . . . . . . . . . . . . . . . . . .2-60

9.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-60

9.2 FRR FEED SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-61

9.2.1 Pick-up Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-61

9.2.2 Feed and Separation Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-61

9.3 FRICTION PAD FEED SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-62

9.4 PAPER LlFT MECHANlSM (1st Feed Station) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-63

9.5 PAPER LIFT MECHANISM (2nd and 3rd Feed Stations) . . . . . . . . . . . . . . . . . . . . . . . .2-64

9.6 PAPER SIZE AND END DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-65

9.7 PAPER FEED DRlVE MECHANlSM (FRR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-66

9.8 PAPER FEED REGISTRATION DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . .2-67

9.9 MANUAL FEED TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-68

9.10 PAPER FEED TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-69

9.11 SERVICE CALL CONDITlON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-70

10. IMAGE FUSING AND PAPER EXIT . . . . . . . . . . . . . . . . . . . . . . . . . .2-71

10.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-71

10.2 FUSING DRIVE RELEASE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-72

10.3 FUSING CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-73

10.3.1 Phase Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-74

10.4 SERVICE CALL CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-75

11. DUPLEX/OVERLAY MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . .2-76

11.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-76

11.2 DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-77

Page 6

11.3 JOGGER MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-78

11.4 SlNGLE DUPLEX/OVERLAY TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-79

12. OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-80

12.1 PAPER MISFEED CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-80

12.2 SERVICE CALL CONDlTIONS (Others) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-82

13. COPIER TIMING CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-83

INSTALLATION

1. INSTALLATION REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

1.1 ENVIRONMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

1.2 MACHINE LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

1.3 MINIMUM SPACE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

1.4 POWER REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

1.5 COPIER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

1.5.1 Accessory Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

1.5.2 Removal Of Shipping Retainers And Tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

1.5.3 For Areas Where The Voltage Is 240V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

1.5.4 Developer Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

1.5.5 Cassette Modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

1.5.6 Key Counter Holder Installation (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

SERVICE TABLES

1. SERVICE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

1.1 TEST POINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

1.2 DIP SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

1.3 VARIABLE RESISTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

2. SERVICE REMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

2.1 DRUM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

2.2 CHARGE CORONA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

2.3 OPTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

2.4 DEVELOPMENT UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

2.5 TONER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

2.6 TRANSFER and SEPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

2.7 CLEANING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

2.8 FUSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Page 7

2.9 PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

2.10 DOCUMENT FEEDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

2.11 SORTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

2.12 LARGE CAPACITY TRAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

2.13 OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

3. SPECIAL TOOLS AND LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . . . .4-10

4. SERVICE PROGRAM MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.1 DIP SWITCHES TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.1.1 DIP SW 1 (Operation Panel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.2 SERVICE PROGRAM MODE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

4.2.1 Service Program Access Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

4.2.2 Change Adjustment Values or Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

4.2.3 Memory Clear Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

4.2.4 Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

4.3 SERVICE PROGRAM MODE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

4.4 SERVICE PROGRAM SP-8 DATA INPUT GUIDE TABLE . . . . . . . . . . . . . . . . . . . . . . . .4-32

4.5 SERVICE PROGRAM SP-9 DATA OUTPUT GUIDE TABLE . . . . . . . . . . . . . . . . . . . . . .4-34

4.6 USER CODE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-36

4.6.1 User Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-36

4.6.2 User Code Counter Check (SP Mode #91) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-37

4.6.3 User Code Counter Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-37

4.7 MISFEED TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-38

4.7.1 Location of Jams/Number of Jams (SP Mode #131) . . . . . . . . . . . . . . . . . . . . . .4-38

4.7.2 Sensor Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-40

5. PREVENTIVE MAINTENANCE SCHEDULE . . . . . . . . . . . . . . . . . . . .4-41

5.1 LUBRICATION POINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-45

5.2 REPLACEMENT POINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-46

5.3 ADJUSTMENT POINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-47

5.4 EXPLANATION OF REGULAR PM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-48

REPLACEMENT AND ADJUSTMENT

1. OPTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

1.1 EXPOSURE GLASS REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

1.2 1ST MIRROR REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Page 8

1.3 2ND AND 3ND MIRROR REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

1.4 4TH AND 5TH MlRRORS REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

1.5 EXPOSURE LAMP REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

1.6 AUTO SIZE/ADS FIBER OPTIC CABLE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . .5-8

1.7 THERMOSWITCH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

1.8 SCANNER DRIVE WIRE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

1.8.1 Wire Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

1.8.2 Wire Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

1.9 SCANNER MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

1.10 LENS DRIVE MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17

1.11 3RD SCANNER DRIVE MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

1.12 RED ERASE FILTER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19

1.13 EXPOSURE LAMP POSITION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-20

1.14 EXPOSURE LAMP VOLTAGE ADJUSTMENT (SP Mode #48) . . . . . . . . . . . . . . . . . .5-22

1.15 ADS ADJUSTMENT (SP Mode #58) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-23

1.16 ADS CORRECTION (SP Mode #56) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-24

1.17 APS VOLTAGE ADJUSTMENT (SP Modes #61 and #62) . . . . . . . . . . . . . . . . . . . . .5-25

1.18 APS LENGTH SENSOR ERROR CORRECTION (SP Modes #50 and #46) . . . . . . .5-26

1.19 VERTICAL MAGNIFICATION ADJUSTMENT 1 (SP Mode #43) . . . . . . . . . . . . . . . . .5-27

1.20 VERTICAL MAGNIFICATION ADJUSTMENT 2

1.21 HORIZONTAL MAGNIFICATION ADJUSTMENT (SP Mode #44) . . . . . . . . . . . . . . .5-29

1.22 3RD SCANNER HEIGHT ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-30

(Overlay and Duplex) (SP Mode #45) . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-28

2. DEVELOPMENT AND TONER SUPPLY . . . . . . . . . . . . . . . . . . . . . . .5-31

2.1 BLACK DEVELOPER REPLACEMENT (SP Mode #65) . . . . . . . . . . . . . . . . . . . . . . . . .5-31

2.2 BLACK DEVELOPMENT ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-32

2.3 DOCTOR GAP ADJUSTMENT (Black) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-33

2.4 COLOR DEVELOPER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-34

2.5 COLOR DEVELOPER CONDITIONING (SP Mode #10) . . . . . . . . . . . . . . . . . . . . . . . .5-35

2.6 COLOR DEVELOPMENT ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . .5-36

2.7 DOCTOR GAP ADJUSTMENT (Color) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-37

2.8 TONER SUPPLY CLUTCH CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-38

2.9 DEVELOPER SHIFT CLUTCH LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-39

2.10 DEVELOPMENT BIAS MEASUREMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-40

2.10.1 Measurement (Beckman) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-40

Page 9

2.10.2 Measurement (SP Mode #59) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-41

2.11 BLACK DEVELOPMENT BIAS ADJUSTMENT (SP Mode #37) . . . . . . . . . . . . . . . . .5-42

2.12 COLOR DEVELOPMENT BIAS ADJUSTMENT (SP Mode #79) . . . . . . . . . . . . . . . . .5-43

2.13 HIGHLIGHT COLOR DENSITY AMOUNT (SP Mode #86) . . . . . . . . . . . . . . . . . . . . .5-44

2.14 BLACK TONER SUPPLY ADJUSTMENT (SP Mode #30) . . . . . . . . . . . . . . . . . . . . . .5-45

2.15 BLACK TONER SUPPLY AMOUNT (ID Sensor Mode) (SP Mode #31) . . . . . . . . . . .5-46

2.16 BLACK TONER SUPPLY AMOUNT (Fixed Supply Mode) (SP Mode #32) . . . . . . . .5-47

2.17 COLOR TONER SUPPLY AMOUNT (SP Mode #70) . . . . . . . . . . . . . . . . . . . . . . . . . .5-48

3. CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-49

3.1 CLEANING UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-49

3.2 CLEANING BLADE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-50

3.3 CLEANING BRUSH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-51

3.4 BLADE SCRAPER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-52

3.5 TONER OVERFLOW SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-53

3.6 USED TONER COLLECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-54

3.7 QUENCHING LAMP REPLACEMENT/CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-55

4. PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-56

4.1 MANUAL FEED TABLE REMOVAL AND

4.1.1 Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-56

4.1.2 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-56

4.2 PAPER SIZE SWITCH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-57

4.3 1ST FEED ROLLERS REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-58

4.4 GRIP ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-60

4.5 2ND FEED ROLLER AND FRICTION PAD REPLACEMENT . . . . . . . . . . . . . . . . . . . . .5-61

4.6 3RD FEED ROLLER AND FRICTION PAD REPLACEMENT . . . . . . . . . . . . . . . . . . . . .5-62

4.7 FRICTION PAD PRESSURE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-63

4.8 PRESSURE ARM ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-64

4.9 FEED AND RELAY CLUTCH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-65

4.10 PAPER END SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-66

4.10.1 1st Feed Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-66

4.10.2 2nd and 3rd Feed Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-66

4.11 LIFT MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-67

4.12 REGISTRATION SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-68

4.13 REGISTRATION CLUTCH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-69

MANUAL FEED SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . .5-56

Page 10

4.14 UPPER REGISTRATION ROLLER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-70

4.15 LOWER REGISTRATION REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . .5-71

4.16 REGISTRATION ADJUSTMENT (SP Mode #42) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-72

4.17 UPPER RELAY SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-73

4.18 LOWER RELAY SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-74

5. TRANSPORT . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . .5-75

5.1 TRANSPORT BELT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-75

5.2 DRUM HEATER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-77

6. DRUM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-78

6.1 CHARGE CORONA WIRE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-78

6.2 CHARGE CORONA GRID REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-79

6.3 CHARGE CORONA HElGHT ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-80

6.4 TRANSFER/SEPARATION CORONA WIRE REPLACEMENT . . . . . . . . . . . . . . . . . . . .5-81

6.5 DRUM REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-82

6.6 ID SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-85

6.7 ID SENSOR Vsg ADJUSTMENT (SP Mode #54) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-86

6.8 SEPARATION PAWL REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-87

6.9 CHARGE CORONA CURRENT ADJUSTMENT (SP Mode #9-2) . . . . . . . . . . . . . . . . .5-88

6.10 GRID VOLTAGE ADJUSTMENT (SP Mode #9-2 and 3) . . . . . . . . . . . . . . . . . . . . . . .5-89

6.11 DRUM CURRENT ADJUSTMENT (SP Mode #9-5 and 7) . . . . . . . . . . . . . . . . . . . . . .5-90

6.11.1 Transfer Current Measurement (SP Mode #9-5) . . . . . . . . . . . . . . . . . . . . . . . .5-91

6.11.2 Separation Corona Current Measurement (SP Mode #9-7) . . . . . . . . . . . . . . . .5-92

7. FUSlNG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . 5-93

7.1 FUSING UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-93

7.2 FUSlNG LAMP REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-94

7.3 HOT ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-95

7.4 PRESSURE ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-96

7.5 FUSING STRIPPER PAWL REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-97

7.6 THERMAL FUSE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-98

7.7 FUSING THERMISTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-99

7.8 FUSING TEMPERATURE CHECK (SP Mode #52) . . . . . . . . . . . . . . . . . . . . . . . . . . .5-100

7.9 FUSING TEMPERATURE ADJUSTMENT (SP Mode #49) . . . . . . . . . . . . . . . . . . . . .5-101

7.10 FUSING TEMPERATURE CONTROL SELECTION

(Full Wave Control or Phase Control) (SP Mode #29) . . . . . . . . . . . . . .5-102

Page 11

7.11 NIP WIDTH MEASUREMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-103

7.12 FUSlNG PRESSURE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-104

7.13 FUSING GUIDE PLATE HEIGHT ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-105

7.14 FUSlNG EXIT SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-106

8. TRANSPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-107

8.1 TRANSPORT GUIDE UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-107

8.2 RELAY SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-108

8.3 INVERTER SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-109

8.4 DUPLEX/OVERLAY TRANSPORT MAGNETIC CLUTCH REPLACEMENT . . . . . . . . .5-110

9. JOGGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-111

9.1 JOGGER UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-111

9.2 JOGGER HOME POSITION SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . .5-112

9.3 JOGGER UNIT WIRE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-113

9.4 JOGGER MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-115

9.5 JOGGER SOLENOID ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-116

10. OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-117

10.1 OPERATION PANEL REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-117

MULTI DUPLEX/OVERLAY

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

2. COMPONENTS LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

3. ELECTRICAL COMPONENT DESCRIPTIONS . . . . . . . . . . . . . . . . . . .6-3

4. OVERALL MACHINE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

5. BASIC OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

6. PAPER STACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

7. PAPER ALIGNMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

8. PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

9. ELECTRICAL TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

10. ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

11. INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

12. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . .6-14

12.1 PAPER FEED ROLLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

Page 12

12.2 FRICTION PAD REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . .6-15

12.3 REPLACEMENT OF POSITIONING ROLLER AND ROUND BELT . . . . . . . . . . . . . . .6-16

12.4 JOGGER FENCE DRIVE WIRE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

12.5 JOGGER HOME POSITION SENSOR ADJUSTMENT (SP Mode #8-13) . . . . . . . . . .6-19

12.6 CAM CLUTCH LUBRlCATlON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-21

12.7 POSITIONING ROLLER SOLENOID ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

12.8 PAPER EXIT/PAPER END SENSORS REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . .6-23

12.9 MULTI-DUPLEX SIDE TO SIDE REGISTRATION ADJUSTMENT . . . . . . . . . . . . . . . .6-25

DOCUMENT FEEDER

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

2. COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

3. ELECTRICAL COMPONENT DESCRIPTIONS . . . . . . . . . . . . . . . . . . .7-3

4. OVERALL MACHINE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

5. BASIC OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7

6. POWER DISTRIBUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-9

7. INTERFACE CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10

8. ORIGINAL FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-11

8.1 ORIGINAL PICK-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-11

8.2 ORIGINAL SEPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-12

8.3 ORlGlNAL FEED-lN MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-13

8.4 ORlGlNAL SlZE DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-15

8.5 ORIGINAL INVERSION MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-16

8.6 ORlGlNAL FEED-OUT MECHANlSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-18

8.7 BELT DRIVE MOTOR CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-19

8.8 FEED-OUT MOTOR ClRCUlT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-20

8.9 INPUT AND OUTPUT ClRCUlTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-21

9. LIFT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-22

10. ORIGINAL MISFEED SENSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-23

11. ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-25

12. INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-26

13. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . .7-32

Page 13

13.1 FEED-lN UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-32

13.1.1 Transport Belt Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-32

13.1.2 Feed-in Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-33

13.1.3 Pick-up Roller Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-34

13.1.4 Feed-in Clutch Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-35

13.1.5 Pick-up Solenoid Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-36

13.1.6 Feed Roller Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-38

13.1.7 Feed-in Solenoid Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-39

13.1.8 Friction Belt Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-40

13.1.9 Registration Sensor and Original Width Sensor Replacement . . . . . . . . . . . . . .7-41

13.1.10 Entrance Guide Plate Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-42

13.1.11 Belt Drive Motor Speed Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-43

13.2 FEED-OUT UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-44

13.2.1 Feed-out Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-44

13.2.2 DF Main PCB Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-45

13.2.3 Inverter Solenoid Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-46

13.2.4 DF Leading Edge Registration Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-47

14. SERVICE TABLES FOR DF MAIN PCB . . . . . . . . . . . . . . . . . . . . . . .7-49

14.1 TEST POINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-49

14.2 VARIABLE RESISTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-49

14.3 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-49

14.4 DIP SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-50

15. DF TIMING CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...7-51

SORTER

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

2. MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . .8-2

3. ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . .8-3

4. ELECTRICAL COMPONENT DESCRIPTIONS . . . . . . . . . . . . . . . . . . .8-4

5. BASIC OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

5.1 CLEAR MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

5.2 SORT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

5.3 STACK MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

6. EXAMPLE OF SORT MODE OPERATION . . . . . . . . . . . . . . . . . . . . . .8-6

Page 14

7. BIN DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7

8. BINS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

9. EXIT ROLLERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-10

10. ELECTRICAL TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-11

11. ELECTRICAL CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-12

12. ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-13

13. INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-14

14. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . .8-17

14.1 EXIT ROLLER AND O-RING REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-17

14.2 PAPER SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-19

14.3 TIMING BELT TENSlON ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-20

EDITOR

1.

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . .9-2

2.

ELECTRICAL COMPONENT DESCRIPTIONS . . . . . . . . . . . . . . . . . . .9-3

3.

BASIC OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-4

4.

DETECTING METHOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-5

5.

ERROR DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-7

6.

6.1 INITIAL ERROR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-7

6.2 PARITY ERROR (Communication Error) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-7

7. ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-9

8.1 EDITOR INSTALLATION (on Platen Cover) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-9

8.2 EDITOR INSTALLATION (on Editor Table) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-12

9. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . .9-13

9.1 MAIN PCB REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-13

DATE PRINTER

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

2. OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-2

3. AUTOMATIC MAGNIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-3

9-8

Page 15

4. DATA PRINTING FUNCTION TABLE . . . . . . . . . . . . . . . . . . . . . . . . .10-4

5. TIME CORRECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-5

6. ELECTRICAL TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

7. ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-7

8. INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-8

9. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . .10-13

9.1 BATTERY REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-13

10. SERVICE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 DIP SWITCH TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-14

10.1.1 Standard Mode: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-14

10.1.2 Special Mode: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-14

10.2 DATE PRINTER PROGRAM MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-16

. . . . . . . . . .

10-14

LARGE CAPACITY TRAY

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

2. MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . .11-2

3. ELECTRICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . . .11-3

4. ELECTRICAL COMPONENT DESCRIPTIONS . . . . . . . . . . . . . . . . .11-4

5. MECHANICAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-5

5.1 DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-5

5.2 PICK-UP ROLLER MECHANlSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-6

5.3 PAPER SIZE DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-7

6. ELECTRICAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-8

6.1 DOWN OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-8

6.2 UP OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-8

7. ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..11-9

8. INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . .11-10

8.1 LCT INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-10

8.2 ADJUSTING SlDE REGISTRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-15

9. REPLACEMENT AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . .11-17

9.1 TRAY WIRE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-17

9.2 TRAY DOWN SENSOR AND POSITIONING SWITCH REPLACEMENT . . . . . . . . . . .11-19

Page 16

9.3 PAPER SlZE SENSOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-21

9.4 SIDE REGISTRATION ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-22

TROUBLESHOOTING

1. COPY QUALITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

1.1 BLANK COPY (WHITE COPY) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

1.2 DIRTY BACKGROUND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-4

1.3 UNEVEN lMAGE DENSlTY - 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-7

1.4 UNEVEN lMAGE DENSlTY - 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-8

1.5 VERTlCAL BLACKBANDS - 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-9

1.6 VERTICAL BLACKLINES - 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-10

1.7 VERTICAL WHITE LINES OR BANDS - 1 (Dull or Blurred) . . . . . . . . . . . . . . . . . . . . .12-11

1.8 VERTICAL WHITE LlNES - 2 (Half Tone Images) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-12

1.9 VERTICAL WHITE LINES - 3 (Smeared Image) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-13

1.10 VERTICAL WHITE LINES OR BANDS - 4 (Thin, Distinct) . . . . . . . . . . . . . . . . . . . . .12-14

1.11 HORIZONTAL BLACK LINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-15

1.12 JITTER - 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-17

1.13 JITTER - 2 (lrregular) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-18

1.14 MARKS AT 251MM INTERVALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-19

1.15 SKEWED (OPTICAL) COPY IMAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-20

1.16 BLACK SPOTS ON THE COPY IMAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-21

1.17 TONER DENSITY TOO HIGH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-22

1.18 TONER DENSITY TOO LOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-24

1.19 UNFUSED COPY IMAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-26

1.20 OPTlCS UNlT CONTROL FAlLURE - 1 (Initialization) . . . . . . . . . . . . . . . . . . . . . . . .12-28

1.21 OPTICS UNIT CONTROL FAILURE - 2 (Copy Cycle) . . . . . . . . . . . . . . . . . . . . . . . .12-29

1.22 SIDE REGISTRATION MALFUNCTION IN DUPLEX/OVERLAY COPY MODE . . . . .12-30

2. SERVICE CALL CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-32

2.1 CODE #11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-32

2.2 CODE #12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-33

2.3 CODE #21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-34

2.4 CODE #22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-34

2.5 CODE #23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-35

2.6 CODE #24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-35

2.7 CODES #25 AND #2E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-36

Page 17

2.8 CODE #2A AND #2B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-37

2.9 CODE #28 AND #29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-38

2.10 CODE #41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-39

2.11 CODE #53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-40

2.12 CODE #54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-40

2.13 CODE #55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-41

2.14 CODE #61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-41

2.15 CODE #81 AND #82 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-42

2.16 CODE #91 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-43

2.17 CODE #92 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-43

2.18 CODE #93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-44

2.19 CODE #94 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-44

2.20 CALL SERVlCE CONDITION #95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-45

3. OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-46

3.1 ID SENSOR MALFUNCTION (Color Copy Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-46

3.2 LOW lMAGE DENSITY (Black) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-47

3.3 SORTER PAPER STACKING PROBLEM (A3/LDG Tracing Paper) . . . . . . . . . . . . . . .12-48

3.4 DIRTY BACKGROUND (Blue Development Unit) . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-48

3.5 PAPER CREASlNG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-49

4. ELECTRICAL COMPONENT DEFECTS . . . . . . . . . . . . . . . . . . . . . .12-50

4.1 PAPER END SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-50

4.2 MANUAL FEED SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-50

4.3 1ST CASSETTE LIFT SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-50

4.4 REGlSTRATION SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-51

4.5 FUSING EXIT SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-51

4.6 INVERTOR SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-51

4.7 INVERTER RELAY SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-52

4.8 COLOR TONER END SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-52

4.9 PULSE GENERATOR SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-52

4.10 1ST SCANNER HOME POSlTION SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-53

4.11 LENS HOME POSITION SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-53

4.12 3RD SCANNER HOME POSITlON SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-53

4.13 FRONT COVER SAFETY SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-54

4.14 THERMOFUSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-54

Page 18

4.15 FUSlNG THERMISTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-54

4.16 DC POWER SUPPLY FUSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-55

4.17 SHORT ClRCUIT lN DC 5V LlNE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-55

5. CAUTIONS FOR USERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-56

5.1 PICK-OFF PAWL TRACES (Overlay mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-56

5.2 CREASlNG DURING FUSING PROCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-56

5.3 OHP MlSFEEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-57

5.4 PHOTO MODE lD LEVEL SETTlNG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-57

5.5 INCOMPLETE IMAGE TRANSFER AT TRAILING EDGE . . . . . . . . . . . . . . . . . . . . . . .12-57

5.6 LOW IMAGE DENSITY WITH RED ORIGINALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-58

5.7 LOW ID LEVEL WITH MULTIPLE SOLID COLOR COPIES . . . . . . . . . . . . . . . . . . . . .12-58

5.8 MODES CLEARED WHEN FRONT COVER OPENED . . . . . . . . . . . . . . . . . . . . . . . .12-58

5.9 INADEQUATE FUSING OF UNEVEN COPY SURFACE . . . . . . . . . . . . . . . . . . . . . . .12-59

5.10 GAP OR OVERLAPS IN OVERLAY COPYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-59

5.11 MULTIPLE PASSES THROUGH FUSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-59

5.12 PAPER EXlT ROLLER MARKS ON DIRECT IMAGE MASTERS (C & P) . . . . . . . . . .12-60

ELECTRICAL DATA

PCB-1

PCB-2

PCB-3

PCB-4

PCB-5

PCB-6

PCB-7

PCB-8

PCB-9

COPIER: I/O CONTROL BOARD . . . . . . . . . . . . . . . . . . . . . . . .13-1

COPIER: SYSTEM CONTROL BOARD . . . . . . . . . . . . . . . . . . .13-2

COPIER: DC POWER SUPPLY BOARD . . . . . . . . . . . . . . . . . . .13-3

COPIER: AD DRIVE BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-4

COPIER: PAPER FEED BOARD . . . . . . . . . . . . . . . . . . . . . . . . .13-5

DF: MAIN BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-6

LCT: MAIN BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-7

EDITOR: MAIN BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-8

DATE PRINTER: MAIN BOARD . . . . . . . . . . . . . . . . . . . . . . . . .13-9

PCB-10 SORTER: CONTROL BOARD . . . . . . . . . . . . . . . . . . . . . . . . .13-10

Page 19

SECTION 1

OVERALL MACHINE

INFORMATION

Page 20

CONTENTS

1. SPECIFICATIONS . .

1.1 MAIN COPIER, FT4460 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

2. OPERATION PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

3. COPY PROCESSES AROUND THE DRUM . . . . . . . . . . . . . . . . . . . .1-9

4. FUNCTIONAL OPERATION

5. PAPER PATH

5.1 PRIMARY PAPER PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...1-12

5.2 SlNGLE DUPLEX COPY PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

5.3 MULTI DUPLEX COPY PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

5.4 SINGLE OVERLAY COPY PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

5.5 MULTI OVERLAY COPY PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

6. DRIVE LAYOUT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

7. MECHANICAL COMPONENT LAYOUT

8. ELECTRICAL COMPONENT LAYOUT

9. ELECTRICAL COMPONENT DESCRIPTIONS . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

1-10

1-11

1-17

1-18

1-20

1-22

10. AC AND DC POWER DISTRIBUTION . . . . . . . . . . . . . . . . . . . . . . .1-27

11. OVERALL MACHINE CONTROL . .

. . . . . . . . . . . . . .

. . . . . . . . . . . .

1-28

Page 21

1. SPECIFICATIONS

1.1 MAIN COPIER, FT4460

28 February 1989

Configuration:

Copy Process:

Originals:

Original Size:

Copy Paper Size:

(DupIex/Overlay Copying)

Copy Paper Weight:

Reproduction Ratio:

Enlargement

Full Size

Reduction

Desk top

Dry electrostatic transfer system

Sheet/Book

Maximum A3/11”x17”

Maximum A3/11”x17” Minimum A6/5.5”x8.5”

Maximum A3/11”x17” Minimum A5/5.5”x8.5”

Cassette feed: 52 - 128 g/m² (14 - 34 lb)

Manual feed: 52 - 157 g/m² (14 - 42 lb)

Duplex/Overlay: 64 - 105 g/m² (17 - 28 lb)

4 Enlargement and 6 Reduction

LT/LDG Version A4/A3 Version

200% 200%

155% 141%

129%

121%

100% 100%

93% 93%

85% 82%

77%

74% 71%

65% 65%

50% 50%

122%

115%

75%

Zoom:

Copying Speed:

Warm Up Time:

From 50% to 200% in 1% steps

21 copies/minute (8½”x11” sideways)

20 copies/minute (A4 sideways)

12 copies/minute (A3/11”x17”)

120 seconds (20°C)

1-1

Page 22

28 February 1989

First Copy Time:

Copy Number Input:

Manual Image Density

Selection:

Automatic Reset:

Paper Stock:

Toner Replenishment:

Black Copy:

7.9 seconds (A4/8.5” x11” sideways)

12.3 seconds (APS mode, A4/8.5” x11”

sideways)

Color Copy:

11.6 seconds (A4/8.5”x11” sideways)

12.8 seconds (APS mode, A4/8.5” x11”

sideways)

Ten keys, 1 to 999 (count up or count down)

7 steps

1 minute standard setting; can also be set to

3 minutes or no auto reset.

Three universal cassettes (auto cassette

shift) Manual feed table Large capacity (option)

Cartridge exchange

Black: 310 g/cartridge

Color: 60 g/cartridge (red, blue, & green)

Copy Tray Capacity:

Power Source:

Maximum Power

Consumption:

Dimensions:

Copier only

Full System

250 sheets B4/10”x14”

100 sheets A3/11”x17”

110V/60Hz/15A

115V/60Hz/15A

220V/50Hz/8A

220V/60Hz/8A

240V/50Hz/8A

110/115V: 1.3kw

220/240V: 1.5kw

Width

700 600

(27.6”)

1610

(63.4”)

1-2

Depth

(23.7”)

600

(23.7”)

Height

443 mm

(17.5”)

1026 mm

(40.4”)

Page 23

28 February 1989

Weight:

Optional Equipment:

110/115V version: Approximately 86kg(190 lb)

220/240V version: Approximately 88kg(194 lb)

Document feeder (DF52)

20 bin sorter (CS2090)

Large capacity tray (RT15)

Color development unit (CU120)

Editor board (RE12)

Date printer (DP 100)

Multi duplex/overlay unit (AD 500)

Key counter

1-3

Page 24

28 February 1989

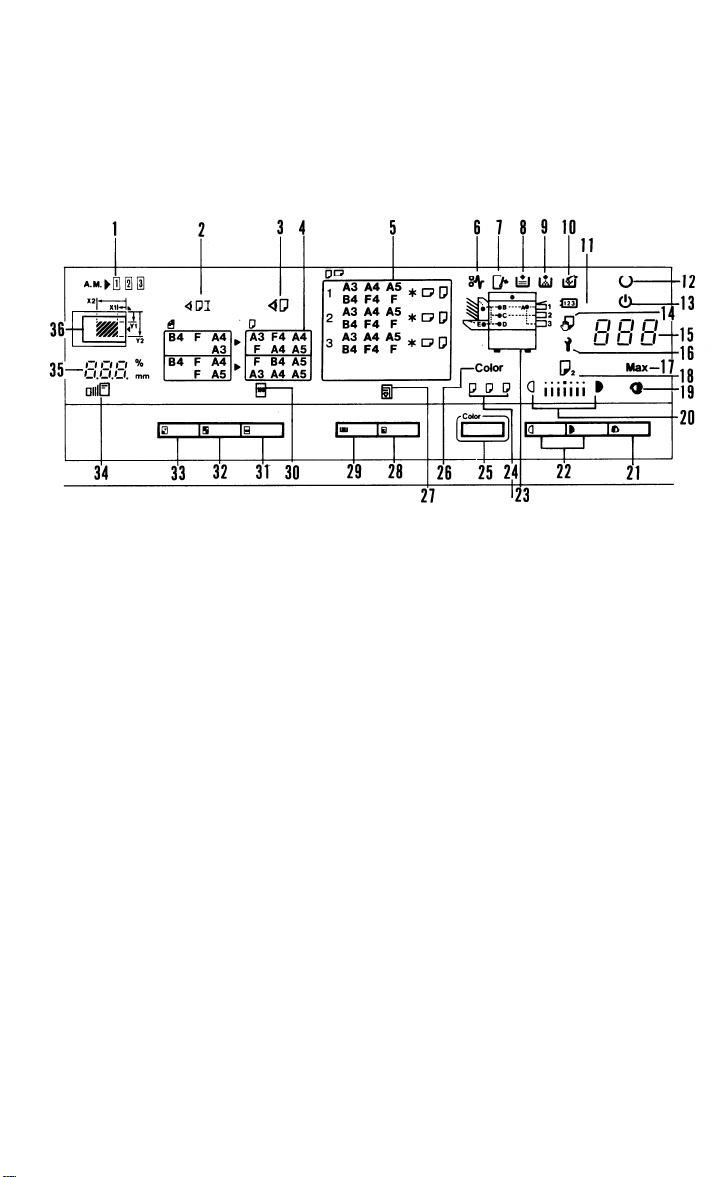

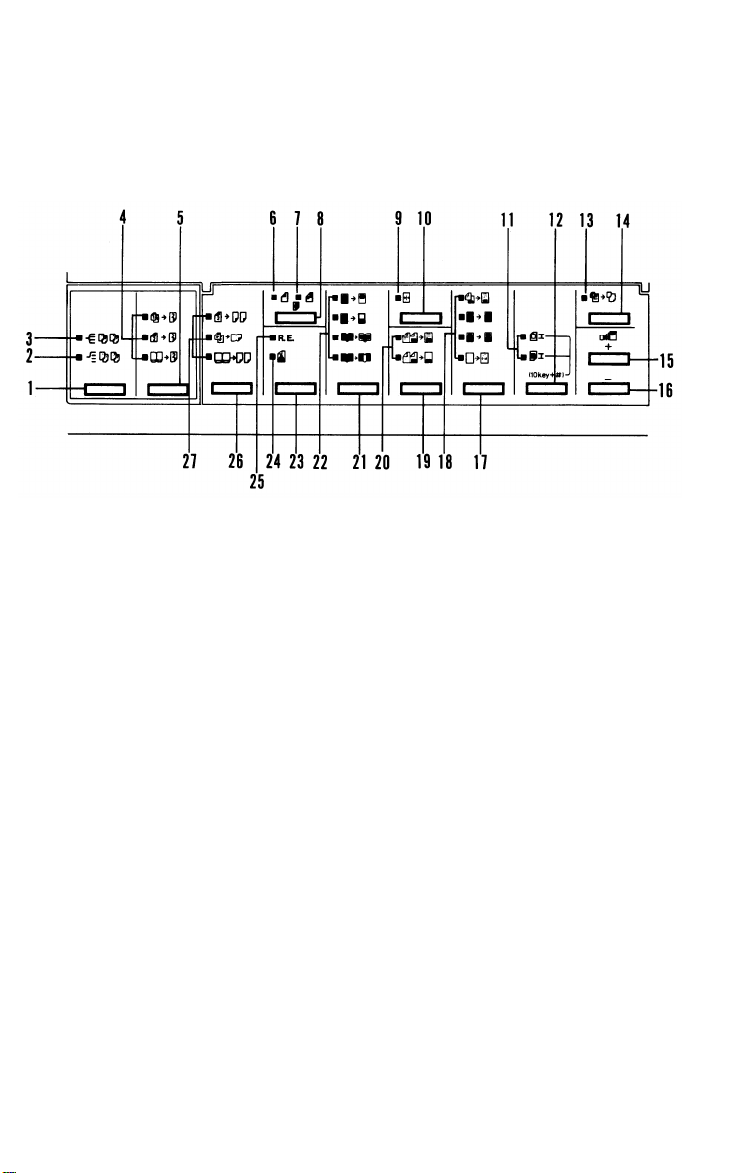

2. OPERATION PANEL

- Section A -

- LT/LDG Version -

1. Area Memory Indicator

2. Check Paper Size/Direction

3. Check Paper Size Indicator 12. Ready Indicator

4. Magnification Indicators

5. Paper Size Indicator

6. Check Paper Path Indicator

7. Close Cover Indicator

8. Load Paper Indicator

9. Add Toner Indicator

10. Used Toner Bottle Indicator

11. Set Key Counter Indicator

13. Wait Indicator

14. Manual Feed Indicator

15. Copy Counter

16. Call Service Indicator

17. Max indicator

1-4

Page 25

- A4/A3 Version -

28 February 1989

18. Second Original Indicator

19. Auto Image Density Indicator

20. Manual Image Density Indicator

21. Auto Image Density Key

22. Manual Image Density Keys

23. Misfeed Location Display

24. Color Toner Indicator

25. Color Copy Key

26. Color Copy Indicator

27. Auto Paper Select Indicator

28. Auto Paper Select Key

29.

Select Cassette Key

.

Full Size Indicator

30

.

Full Size Key

31

.

Enlarge Key

32

.

Reduce Key

33

.

Zoom Indicator

34

.

Magnification Ratio Indicator

35

.

36

Set Area Indicator

1-5

Page 26

28 February 1989

- Section B (Keys and Indicators for Special/Optional Functions) -

- LT/LDG Version -

1. Sorter Key

2. Stack Indicator

3. Sort Indicator

4. Duplex Indicators

5. Duplex Key

10.

11.

12.

6. Front Margin Adjustment Indicator 13.

7. Back Margin Adjustment Indicator

Margin Adjustment Key

8.

9.

Centering Indicator

Centering Key

Size Magnification Indicators

Size Magnification Key

Auto Reduce/Enlarge Indicator

1-6

Page 27

- A4/A3 Version -

28 February 1989

14. Auto Reduce/Enlarge Key

15. Zoom Up Key

16. Zoom Down Key

17. Overlay Key

18. Overlay Indicators

19. 2 Page Overlay Key

20. 2 Page Overlay Indicators

21. Edit Image Key

22. Edit Image Indicators

23. Tone Key

24. Photo Mode Indicator

25. Red Erase Indicator

26. 2 Single Copies Key

27. 2 Single Copies Indicators

1-7

Page 28

28 February 1989

- Section C -

- LT/LDG Version -

- A4/A3 Version -

1. Number Keys

2. Recall/Enter Key

3. Program Indicator

4. Program Key

5. Interrupt Indicator

6. Interrupt Key

7. Clear Modes Key

8. Start Key

9. Clear/Stop Key

1-8

Page 29

28 February 1989

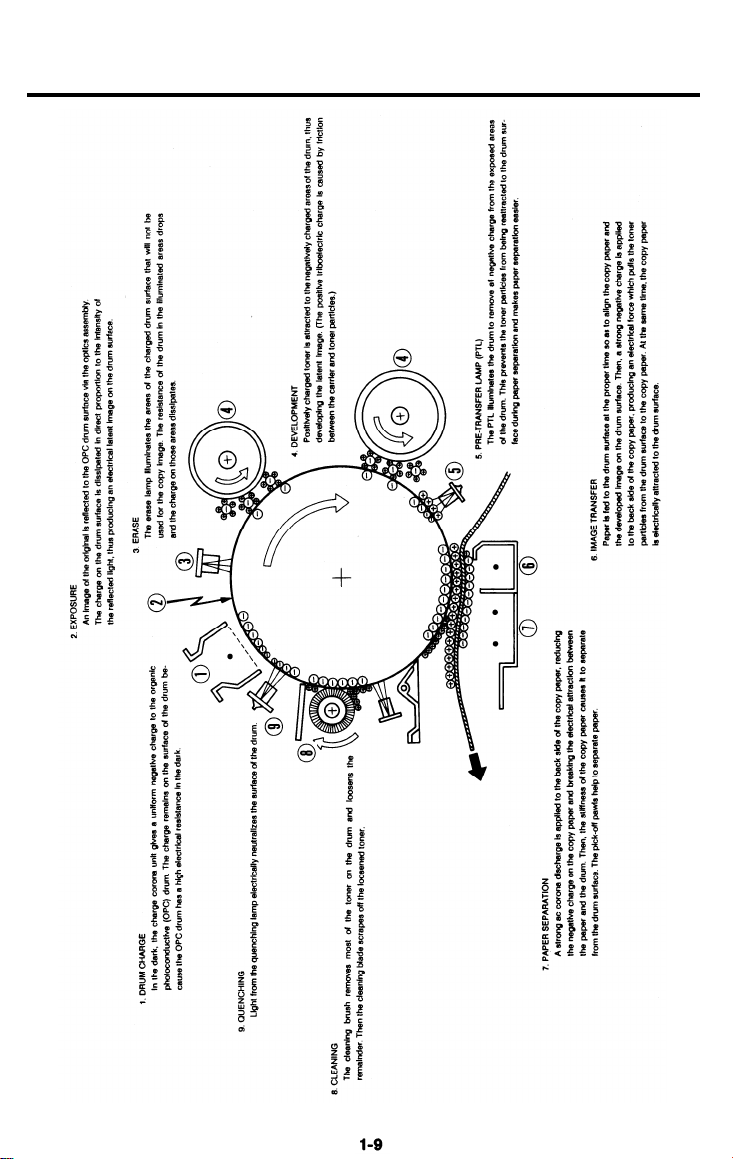

3. COPY PROCESSES AROUND THE DRUM

Page 30

28 February 1989

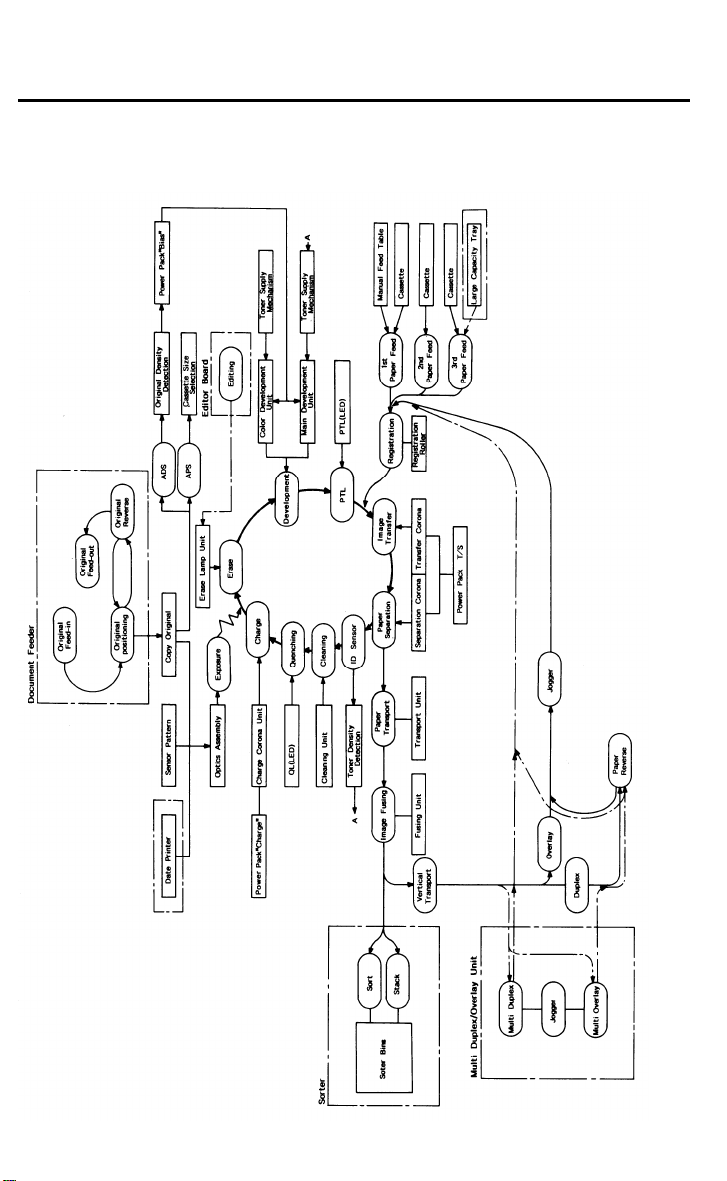

4. FUNCTIONAL OPERATION

1-10

Page 31

5. PAPER PATH

28 February 1989

The paper feed starts from one of the three paper feed

paper then follows one of two paths inside the copier.

depends on which mode the operator has selected. For copy processing, all

sheets follow the same path from the paper feed mechanism through the

fusing unit. After that, normal copies are delivered to the copy tray; however,

duplex copies and overlay copies are diverted for further processing. The fol-

lowing discussion follows the route of a single sheet of paper through a

duplex/overlay cycle.

1-11

stations. The copy

The path followed

Page 32

28 February 1989

5.1 PRIMARY

PAPER PATH

1. Paper Feed:

If paper is fed from the first station, an FRR (Feed and Reverse Roller)

mechanism separates one sheet of paper from the paper stack and feeds it to

the registration rollers. The second and third stations use a friction pad for

separation. In addition, if paper is fed from the third station, relay rollers move

the paper to the registration rollers. The registration rollers are not turning at

this time. The paper buckles slightly when the leading edge reaches the

registration rollers. Buckling seats the sheet securely between the registration

rollers and corrects any skew.

2. Registration:

At the programmed time, the registration rollers start turning to feed the paper

to the drum.

3. Image Transfer:

The toner image on the drum surface is pulled from the drum onto the pass-

ing paper by the transfer corona.

4. Paper Separation:

The electrostatic attraction between the paper and the drum is broken by the

separating corona. The suction of the vacuum fan and the weight of the paper

pulls the paper onto the transport belt. The transport belt moves the paper

with the developed copy image to the fusing unit.

5. Fusing:

The paper passes between two rollers which bond the toner image to the

paper by applying heat and pressure. At this point the copy is complete, and

the paper path splits two ways. Ordinary copies go directly through the exit

rollers to the copy tray. However, duplex copies and overlay copies are

diverted to the lower transport unit.

1-12

Page 33

5.2 SINGLE DUPLEX COPY PATH

28 February 1989

[F]:

Duplex/Overlay Transport Gate

[G]: Junction Gate

[H]: Invertor Gate

Duplex Paper Feed:

The copy paper is fed down from the fusing unit to the lower section [A],

where the paper’s leading edge passes through the inverter rollers. When the

inverter sensor detects the paper’s trailing edge, the inverter rollers [B]

reverse direction and the paper is fed to the jogger section [C]. When the

paper enters the jogger section the jogger fences move up against the paper

on both sides. Next, the transport rollers move the paper up through the vertical relay rollers [D] to the registration rollers [E]. From here on, the paper follows the same path as the first time, with the only difference being that the

reverse side now faces up to receive the image.

1-13

Page 34

28 February 1989

5.3 MULTI DUPLEX COPY PATH

Multi Duplex Paper Feed:

After the paper makes its first pass through the copier, the junction gate [A]

directs the paper to the duplex tray where jogger fences [B] move up against

the paper from both sides to correct its lateral position.

The duplex feed mechanism then feeds the paper to the jogger section inside

the copier. This time, however, the jogger fences there do not operate and

the paper is fed directly to the registration rollers.

After reaching the registration rollers, the sheet follows the same path as

when the front side was copied, with the only difference being that the

reverse side now faces up to receive the image.

1-14

Page 35

5.4 SINGLE OVERLAY COPY PATH

28 February 1989

Overlay Paper Feed:

The copy paper is fed down from the fusing unit to the lower section [A] and

sent directly to the jogger section [B]. When the paper enters the jogger sec-

tion the jogger fences move up against the paper on both sides. Next, the

transport rollers move the paper up through the vertical relay rollers [C] to the

registration rollers [D]. From here the paper follows the same path as the first

time, with the second image being placed on the same side.

1-15

Page 36

28 February 1989

5.5 MULTI OVERLAY COPY PATH

Multi Overlay Copy Feed:

After the paper makes its first pass through the copier, the junction gate [A]

directs the paper to the duplex tray, where jogger fences [B] move in from

both sides to correct the lateral position of the paper.

After this, the duplex feed mechanism feeds the paper. The inverter gate [C]

guides the paper to the inverter rollers [D]. The inverter rollers turn until the

trailing edge of the paper is detected by the inverter sensor [E]. The rollers

then reverse direction and the paper is fed to the jogger section. This time,

however, the jogger fences here do not operate and the paper is fed directly

to the registration rollers.

After the paper reaches the registration rollers, the sheet follows the same

path as when the front side was copied. However, this time the front side

faces up to make an overlay copy.

1-16

Page 37

6. DRIVE LAYOUT

28 February 1989

Gears

G1: Third Paper Feed Clutch Gear

G2: Second Paper Feed Clutch

Gear

G3: First Paper Feed Clutch Gear

G4: Toner Supply Clutch Gear

G5: Development Unit Change Drive

Gear

G6: Duplex/Overlay Transport

Clutch Gear

G7: Registration Clutch Gear

G8: Relay Clutch Gear

Sprocket

S1: Main Motor Sprocket

Timing Belt

TB1: Drum Drive Belt

Belt

B1: Exit Roller Drive Belt

Chains

C1: Main Drive Chain

C2: Duplex/Overlay Drive Chain

1-17

Page 38

28 February 1989

7. MECHANICAL COMPONENT LAYOUT

Page 39

28 February 1989

1. Exposure Lamp

2. Cleaning Unit

3. Ouenching Lamp

4. Lens

5. Charge Corona

6. 6th Mirror

7. Shield Glass

8. Erase Unit

9. Exposure Glass

10. Red Erase Unit

11. 4th Mirror

12. 5th Mirror

13. Color Development Unit

14. OPC Drum

15. Manual Feed Table

16. Black Toner Cartridge

23. Pre-Transfer Lamp

24. Registration Roller

25. Transfer Corona

26. Separation Corona

27. Pick-off Pawl

28. I.D.Sensor

29. Cleaning Brush

30. Cleaning Blade

31. Jogger Unit

32. Transport Unit

33. Main Motor

34. Pressure Roller

35. lnverter Roller

36. Inverter Gate

37. Junction Gate

38. Hot Roller

17. Black Development Unit

18. Pick-up Roller

19. Feed Roller

20. Separation Roller

21. Feed Roller

22. Friction Pad

39. Hot Roller Stripper

40. Duplex/Overlay Transport Gate

41. Fusing Exhaust Fan

42. 3rd Mirror

43. 2rd Mirror

44. 1st Mirror

1-19

Page 40

28 February 1989

8. ELECTRICAL COMPONENT LAYOUT

1. Sorter Interface Board

2. Cooling Fan Motor

3. Scanner Drive Motor

4. Main Motor Capacitor

5. Development Drive MC

6. SC Power Pack

7. Toner Supply MC

8. AC Drive Board

9. Development Unit Change SOL

10. Manual Feed Sensor

11. 1st Paper Feed MC

12. 1st Lift Motor

13. 2nd Paper Feed MC

14. Paper Feed Board

15. 1st Pick-up SOL

16. 1st Cassette Lift Sensor

17. 2nd Cassette Paper End Sensor

18. 3rd Paper Feed MC

19. I/O Control Board

20. 3rd Cassette Paper End Sensor

21. Relay Roller MC

22. Registration MC