Page 1

RICOH FT4430

SERVICE MANUAL

RICOH COMPANY, LTD.

Page 2

SECTION 1

OVERALL MACHINE

INFORMATION

Page 3

SPECIFICATIONS . .

OPERATION PANEL

SECTION A . . . . . . . . .

SECTION B . . . . . . . . .

Table of Contents

Page 4

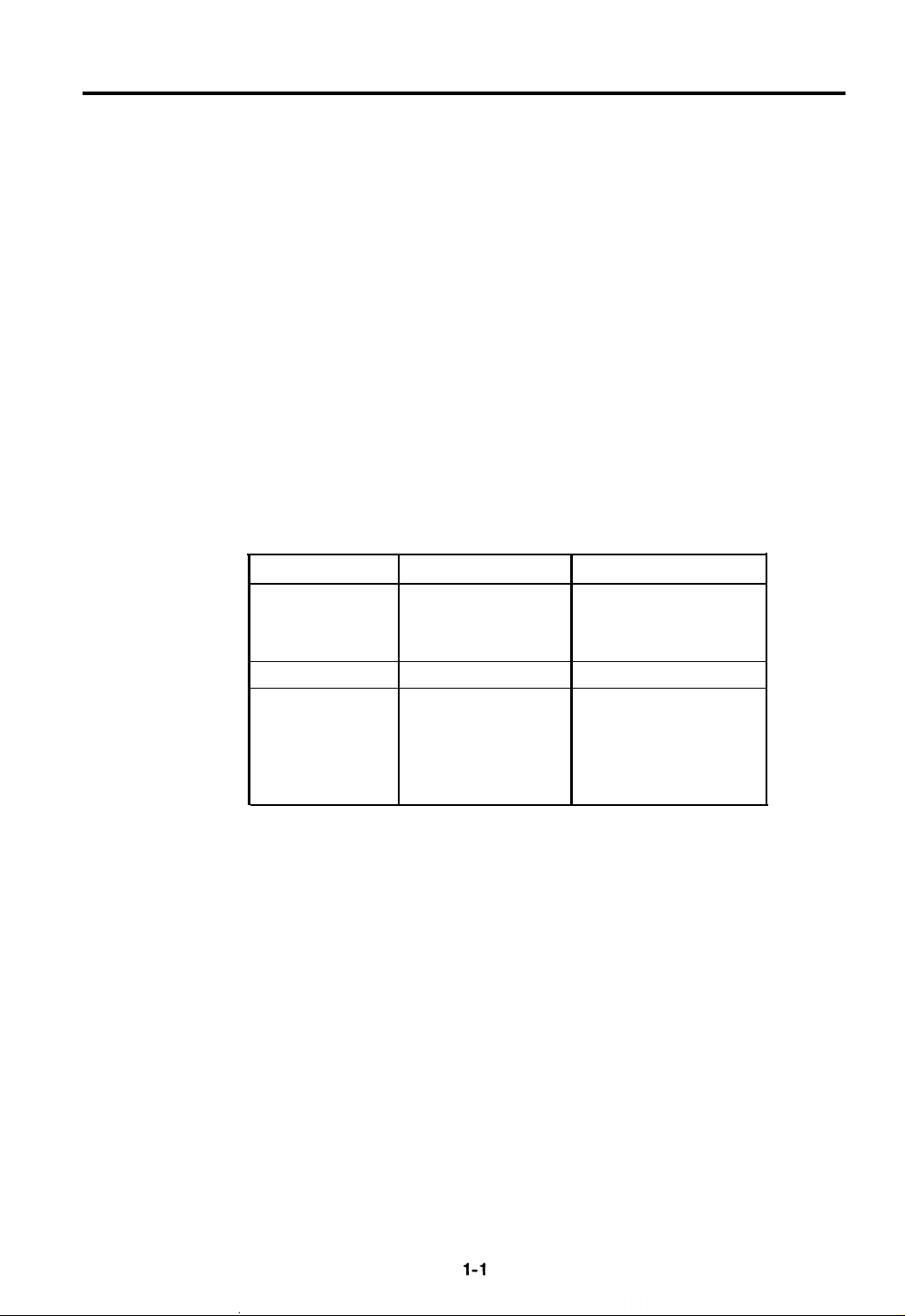

SPECIFICATIONS

16

April ’88

Configuration:

Copying Process:

Original:

Original Size:

Copy Paper Size:

Copy Paper Weight:

Reproduction Ratios:

Enlargement

Full Size

Reduction

Desk top

Dry electrostatic transfer system

Sheet/book

Maximum A3 (11“ x 17”)

Maximum A3 (11“ x 17”)

Minimum A6

(51/2" x

81/2”)

Cassette feed 52 to 128 g/m

Manual feed

52 to 157 g/m

See the following table:

v

A4 Version Letter Version

1:1.41 1:1.55

1:1.22

1:1.15

.

1:1

●

1:0 93

.

.

1:0.82

● . .

1:0.71

1:1.29

1:1.21

:G

11

.

1:0 93

●

.

1:0 77

1:0.74

1:0.65 1:0.65

2

(14 lb to 34 lb)

2

(14 lb to 42 lb)

Zoom:

From 65% to 155% in 1 % steps

Reproduction Ratio Full size - Enlargement or

Change:

Full size - Reduction in less than 5 seconds

Enlargement

- Reduction or

Reduction - Enlargement in less than 6.5

seconds

Page 5

16 April ’88

Copying Speed:

The copy speed (in copies per minute) is shown

in the following tables:

A4 Version

A3 B4 A4 B5

11

13

20 20

A4R B5R

15 15

Letter Version

LDG LG LT LT(R)

12 15

22

16

When used with document feeder, A4 (LT) speed

is 17 cpm (sideways).

First-Copy Time:

6.0 seconds (A4 or

81/2” x 11”)

Warm-Up Time: Approximately 100 seconds (23°C)

Copy Number Input:

Special Functions:

Numeral keys, 1 to 999, (count up or count down)

- Margin adjustment

- Auto size magnification mode

-2 single copies mode

- Auto paper select and auto reduce/eniarge

mode (with ADF only)

Manual Image Density

7 Steps (Development bias variable)

Selection:

Automatic Reset: 1 min. standard setting; can also be set to 3 min.

or no auto reset.

All functions canceled except cassette selection.

Quantity entered returns to “1”, and reproduction

ratio returns to full size.

1-2

Page 6

16 April ’88

Paper Feed:

- Double universal cassette feed, 250 sheets each

(auto cassette shift)

- Manual feed table

- Optional large capacity tray (LCT) at second

feed station.

Paper-Feed System: Friction-pad system

Exposure System: Slit exposure, moving optics

Lens:

Through lens, F8, f = 180mm

Light Source: Halogen lamp (85 V, 290 W)

Photoconductor:

Charge System:

Erase:

Selenium drum (F type)

Dual wire dc corona

LED lamp unit (34 LEDs)

Development System: Magnetic brush roller

Toner Density Control:

Development Bias

System:

Automatic, direct density sensing

Automatic voltage change (The control board

monitors the selected image density level, drum

temperature, and rest time.)

Toner Replenishment:

Toner Consumption:

Cleaning System:

Cartridge exchange (300 g/cartridge)

Approx. 7,500 copies/cartridge (A47% original)

Blade and brush

Quenching System: Photo-quenching

Image Transfer:

Paper Separation:

Single wire dc corona, pre-transfer lamp

Dual wire ac corona and pick-off pawls

Image Fusing:

Heat/pressure - roller type

Fusing Lamp: Halogen lamp (840 W)

1-3

Page 7

16 April ’88

Electronic Control

8-bit microprocessor

System:

Copy Tray Capacity:

250 sheets (B4 / 10” x 14”)

100 sheets (A3 / 11” x 17“)

Self-diagnostics:

19 codes, displayed in the copy counter

Power Source: 110V/60Hz....15A

115V/60Hz....15A

220V/50Hz....8A

220V/60Hz....8A

240V/50HZ....8A

Power Consumption: Warm-up:

1.0 kW

Stand-by: 0.08 kW

Copying: 0.42 kW (A4 sideways)

Dimensions:

Maximum:

Copier only:

1.22 kW

(WxDxH)

734 x 654 x 390 mm

28.9 x 25.8 x 15.4 inches

Full System:

1363 x 654 x 460 mm

53.7 x 25.7 x 14.1 inches

Weight:

65 kg (143 lb) (Copier only)

100 kg (221 lb) (Full System Without table)

Optional Equipment: Document Feeder

Sorter (20 bins)

Large Capacity Tray

Editor Board (requires editing eraser lamp)

Color Development Unit (Red, Blue, Green)

1-4

Page 8

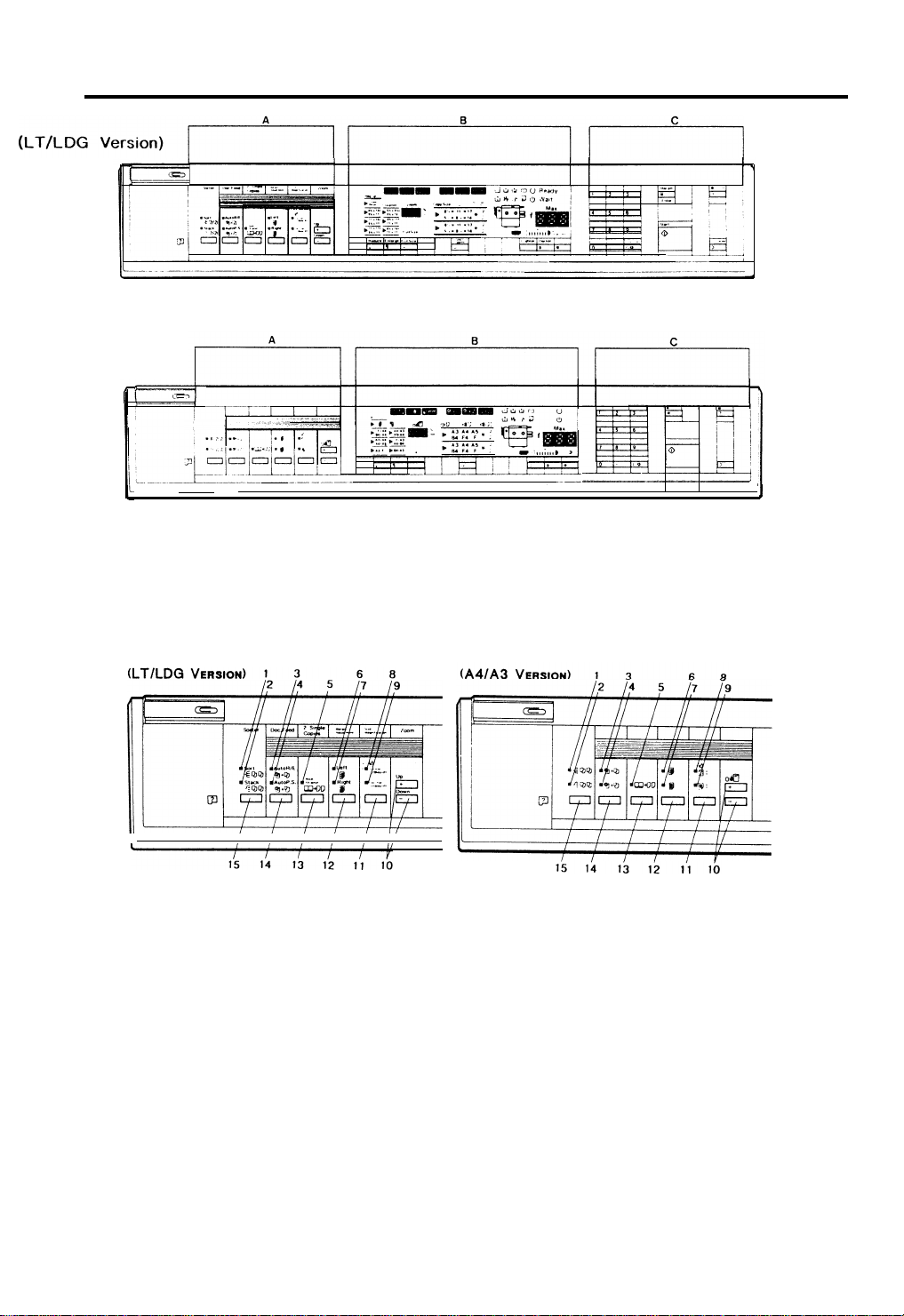

OPERATION PANEL

(A4/A3 Version)

16 April ’88

SECTION A

1. Sort Indicator

2. Stack Indicator

3. Auto Reduce/Enlarge Indicator

4. Auto Paper Select Indicator

5.2 Single Copies Indicator

6. Left Margin Adjustment Indicator

7. Right Margin Adjustment Indicator

8. Original Image Size Indicator

9. Copy Image Size Indicator

10. Zoom Keys

11. Size Magnification Key

12. Margin Adjustment Key

13.2 Single Copies Key

14. Auto Selection Key

15. Sorter Key

1-5

Page 9

16 April ’88

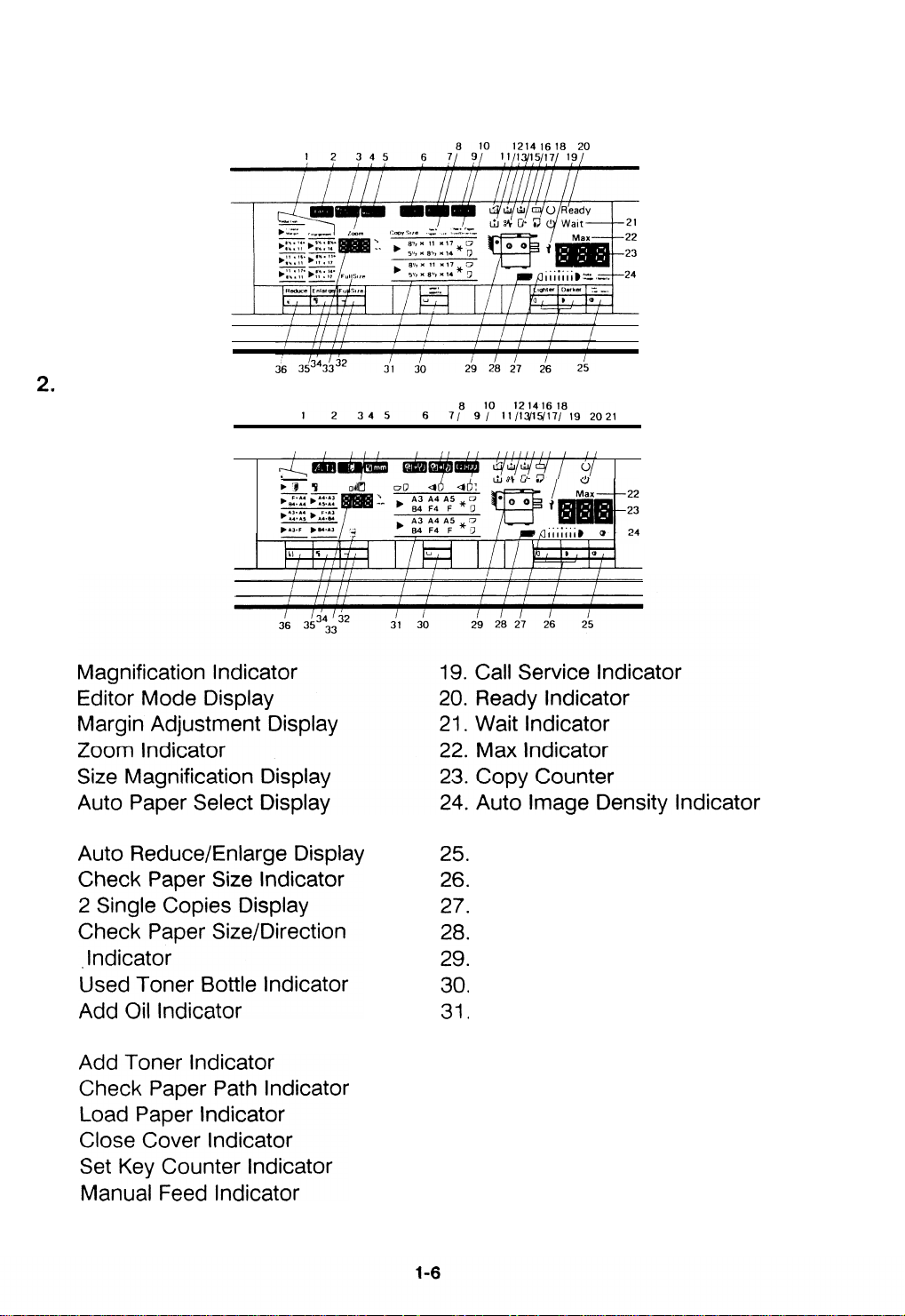

SECTION B

1. (LT/LDG Version)

(A4/A3 Version)

1,

2

3

4

5

6

7

8

9

10

11

12

13

14,

15.

16

17

18

4

<

●

.

,

.

●

Auto Image Density Key

Manual Image Density Key

Manual Image Density Indicator

Color Toner Indicator

Misfeed Location Display

Select Cassette Key

Paper Size Indicator

,

(

Full Size Key

32

Full Size Indicator

33

Magnification Ratio Indicator

34

Enlarge Key

35

Reduce Key

36

.

Page 10

16 April ’88

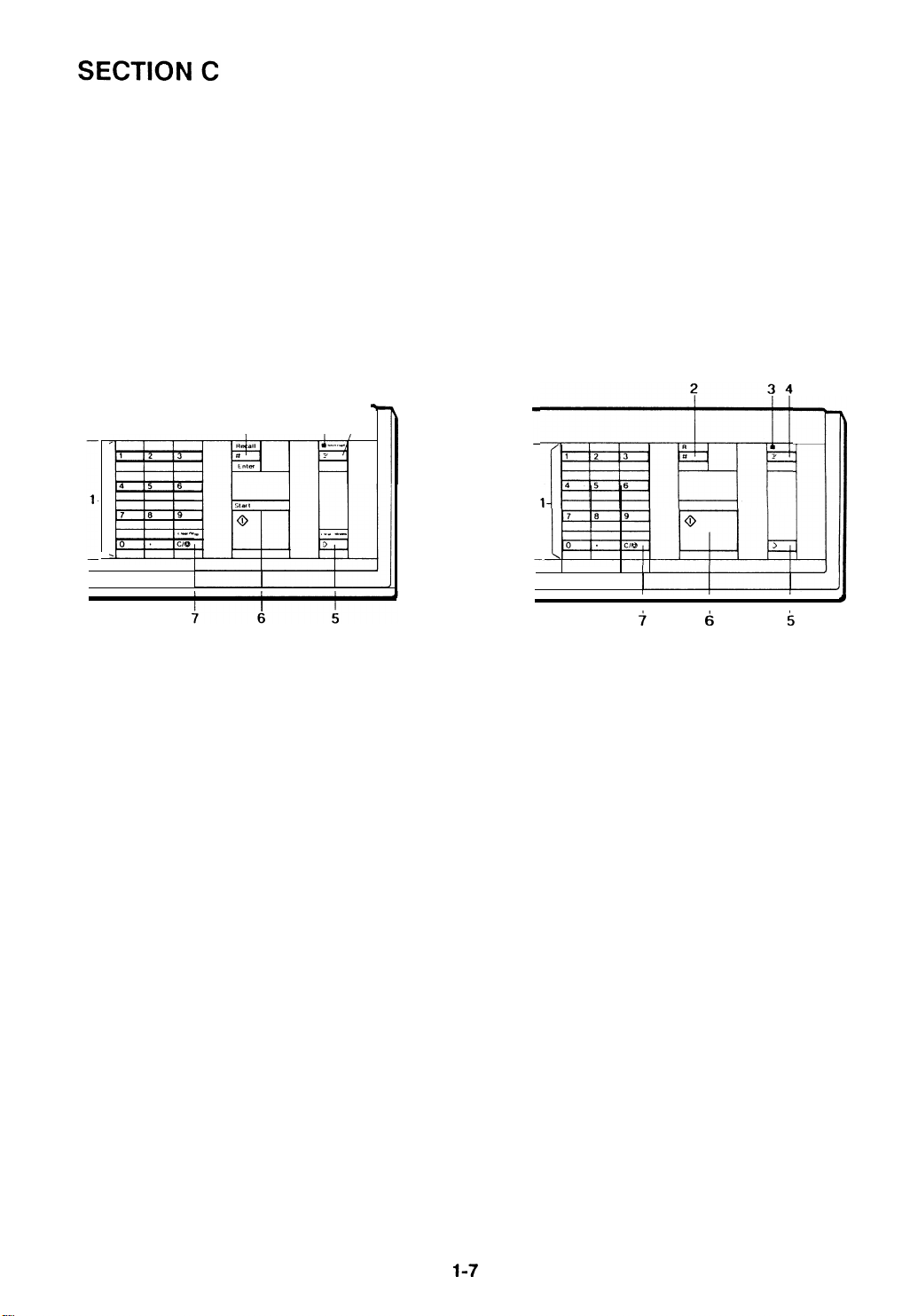

(LT/LDG Version)

-

1. Number Keys

2. Recall/Enter Key

3. Interrupt Indicator

4. Interrupt Key

(A4/A3 Version)

5. Clear Modes Key

6. Start Key

7. Clear/Stop Key

Page 11

Page 12

Page 13

16 April ’88

PAPER PATH

Paper feed starts from one of the two paper feed stations. The path followed

depends on which cassette the operator has selected. For copy processing,

all sheets follow the same path from the paper feed mechanism through the

fusing unit. After that, copies are delivered to the receiving tray.

1. Paper Feed

A friction pad and feed roller mechanism separates one sheet of paper from

the

paper stack and feeds it to the registration rollers. The registration rollers

are not turning at this time. The paper buckles slightly when the leading edge

reaches the registration rollers. Buckling seats the sheet securely between the

registration rollers and corrects skew.

1-10

Page 14

16 April ’88

2. Registration

At the programmed time, the registration rollers start turning to feed the paper

to the drum.

Image Transfer

3.

The toner image on the drum surface

is pulled from the drum onto the

passing paper by the transfer corona.

4. Paper Separation

The separation corona breaks the electrostatic attraction between the paper

and the drum. The suction of the vacuum fan pulls the paper onto the

transport belt. The transport belt moves the paper with the developed copy

image to the fusing unit.

5. Fusing

The paper passes between two rollers which bond the toner image to the

paper by applying heat and pressure. At this point the copy is complete.

1-11

Page 15

16 April ’88

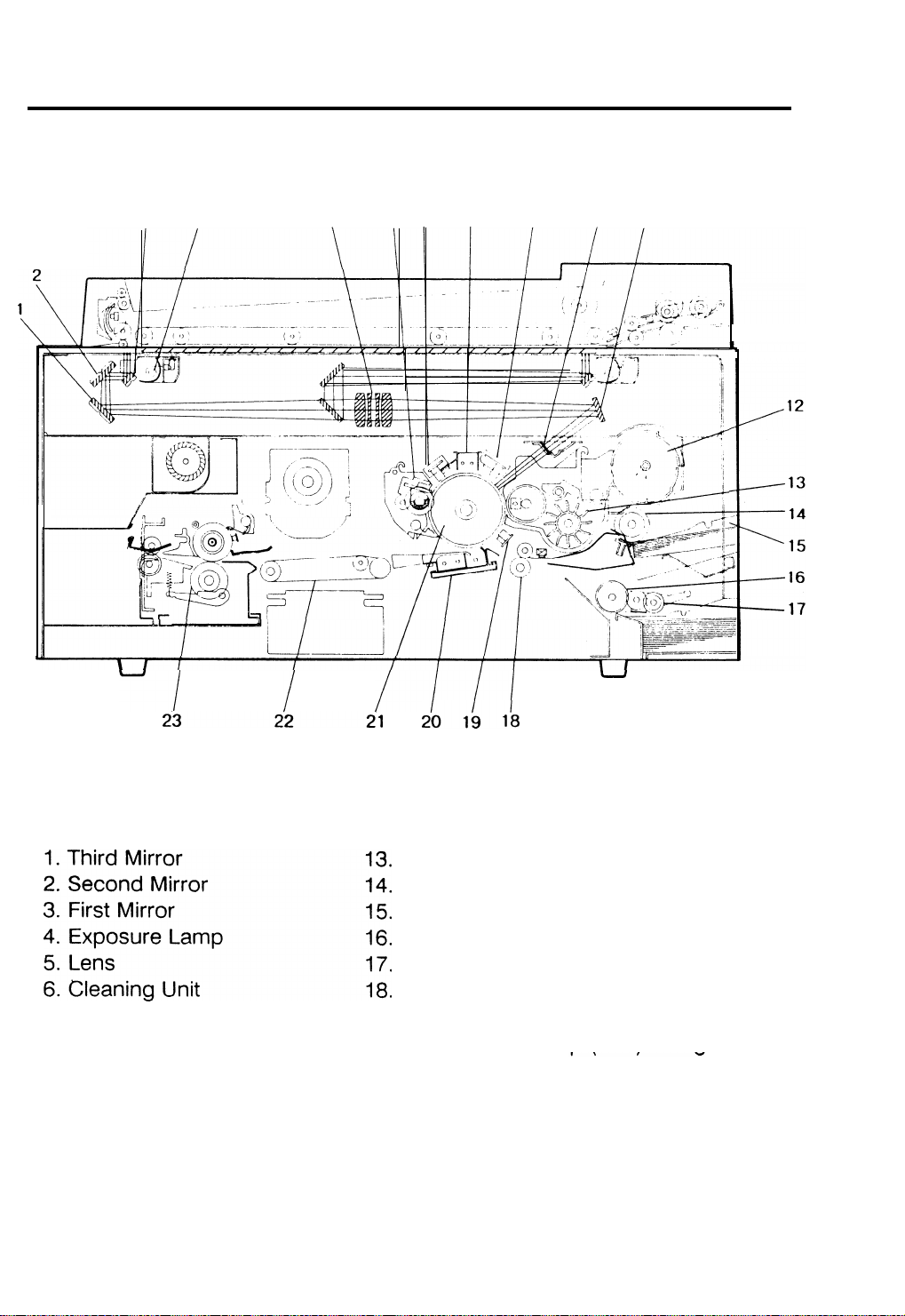

MECHANICAL COMPONENT LAYOUT

34

5

678 9

10 11

7

.

Quenching Lamp

Main Corona Unit

8

9

Erase Lamp Unit

10

Toner Shield Glass

(

11

Fourth Mirror

12

Toner Cartridge

Development Unit

First Feed Roller

First Cassette

Second Feed Roller

Pick-up Roller (LCT)

Registration Roller

19

.

Pre-Transfer Lamp (PTL) /lmaqe

Density Sensor Board

20. Transfer/Separation Corona Unit

21. Selenium Drum

22. Transport Belt

, 23. Fusing Unit

1-12

Page 16

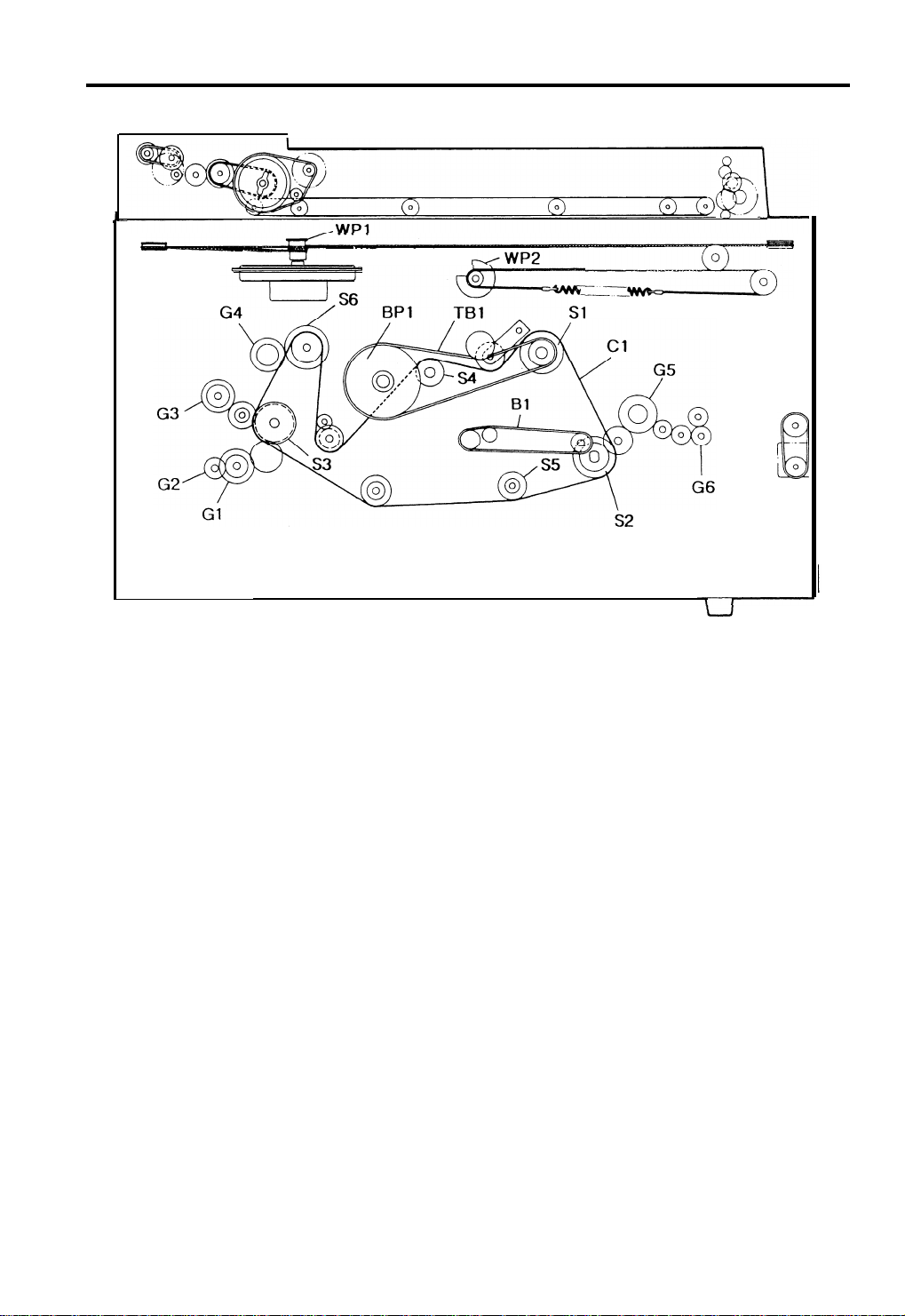

DRIVE LAYOUT

16 April ’88

Gears

G1

Second Feed Clutch Gear

Pick-up Roller Drive Gear(LCT)

G2

First Feed Clutch Gear

G3

G4

Toner Supply Clutch Gear

Hot Roller Drive Gear

G5

Exit Roller Drive Gear

G6

Sprockets

Main Motor Sprocket

S1

Fusing Drive Sprocket

S2

Feed Drive Sprocket

S3

S4

Cleaning Drive Sprocket

Toner Collection Bottle

S5

Drive Sprocket

S6

Development Drive Sprocket

Wire Pulleys

WP1 Scanner Drive Pulley

WP2 Second Scanner Drive Pulley

Timing Belt

TB1 Drum Drive Belt

Belt

B1 Transport Belt

Belt Pulley

BP1 Drum Drive Pulley

Chains

Cl Main Drive Chain

1-13

Page 17

16 April ’88

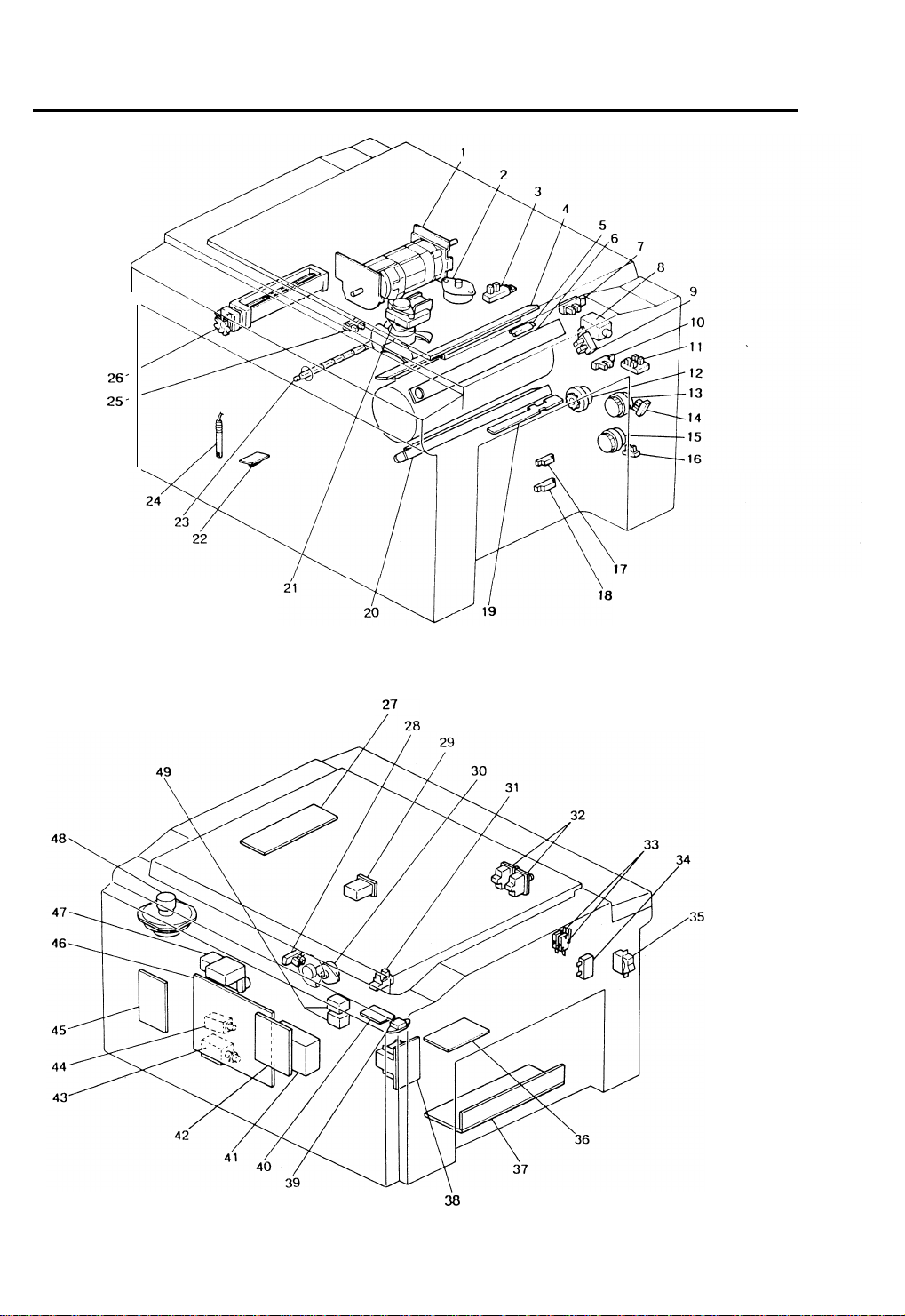

ELECTRICAL COMPONENT LAYOUT

.

1-14

Page 18

.

16 April ’88

1. Main Motor - Ml

2. Lens Drive Motor - M2

3. Lens HP Sensor - S1

4. Quenching Lamp - L1

5. Drum Heater

6. Erase Lamp - L2

7. Pulse Generator Sensor - S2

8. Toner Supply Solenoid - SOL1

9. Color Toner End Sensor - S3

10. Manual Feed Sensor - S4

11. Color Toner Sensors - S5

12. Registration MC - MCI

13. First Paper Feed MC - MC2

14. First Paper End Sensor - S6

15. Second Paper Feed MC - MC3

16. Second Paper End Sensor - S7

17. First Paper Size Sensor - S8

18. Second Paper Size Sensor - S9

19. Registration Sensor - S10

20. Pre Transfer Lamp - L3

27. Lamp Regulator PCB - PCB1

28. Second Scanner Home Position

Sensor - S12

29. Total Counter - CO1

30. Second Scanner Motor - M5

31. Scanner Home Position

Sensor - S13

32. Front Cover Safety Switch - SW2

33. Door Switch - SW1

34. Main Motor Capacitor - C

35. Main Switch - SW3

36. Relay PCB - PCB2

37. DC Power Supply Unit - PSU

38. Transformer - TR1

39. Fusing Triac - FT

40. Heater Control PCB - PCB5

41. Power Pack - T/S - P1

42. Interface Board - PCB3

43. Cleaning Solenoid - SOL2

44. Pick-off Solenoid - SOL3

21. Vacuum Fan Motor - M3

22. Toner Overflow Sensor - S14

23. Fusing Lamp - L4

24. Oil End Sensor - S15

25. Paper Exit Sensor - S11

26. Exhaust Blower Motor - M4

45. Feed Control PCB - PCB4

46. Main PCB - PCB6

47. Power Pack - C/B - P2

48. Scanner Drive Motor - M6

49. AC Drive Relay - R1

1-15

Page 19

16 April ’88

ELECTRICAL COMPONENT DESCRIPTIONS

SYMBOL

NAME

Motors

Ml

M2

M3

M4

M5

M6

Main Motor

Lens Drive Motor

Vacuum Fan Motor

Exhaust Blower

Motor

Second Scanner

Motor

Scanner Drive Motor

Magnetic Clutches

MC1

MC2

MC3

Registration MC

First Paper Feed MC

Second Paper Feed

MC

FUNCTION

Drives all main unit components

except otics unit and fans/bIowers.

(100Vac)

Positions the lens. (dc stepper)

Provides suction so that paper is

held firmly on the transport belt. (100

Vat)

Removes heat from around the

fusing unit. (100 Vat)

Positions the second scanner. (dc

stepper)

Drives the scanner. (dc stepper)

Drives the registration rollers.

Starts paper feed from the first paper

feed station.

Starts Paper feed from the second

fe1’

paper eed station.

LOCATION

1

2

21

26

30

48

12

13

15

Solenoids

SOL1

SOL2

SOL3

Switches

SW1

SW2

SW3

Sensors

S1

S2

Toner Supply

Solenoid

Cleaning Solenoid

Pick-off Solenoid

Door Switch

Front Cover Safety

Switch

Main Switch

Lens Home Position

Sensor

Pulse Generator

Energizes to supply toner.

Moves the cleaning blade against the

drum.

Brings the pick-off pawls into contact

with the drum.

Enables the Door Open indicator.

Cuts ac power to ac components.

Supplies power to the copier.

Informs the CPU when the lens is at

the full size position.

Supplies timing pulses to the main

board.

8

43

44

33

32

35

3

7

1-16

Page 20

16 April ’88

SYMBOL

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

NAME

Color Toner End

Sensor

Manual Feed Sensor

Color Toner Sensors

First Paper End

Sensor

Second Paper End

Sensor

First Paper Size

Sensor

Second Paper Size

Sensor

Registration Sensor

Paper Exit Sensor

Second Scanner

Home Position

Sensor

FUNCTION

Detects when it is time to add toner.

Detects when the manual feed table

is open.

Detects which color toner

development unit is installed.

Informs the CPU when the first

cassette runs out of paper.

Informs the CPU when the second

cassette runs out of paper.

Determines what size paper is in the

first cassette.

Determines what size paper is in the

second cassette.

Misfeed detector and ON/OFF timing.

Misfeed detector.

Informs the CPU when the second

scanner is at the home position.

LOCATION

9

10

11

14

16

17

18

19

25

28

S13

S14

S15

Scanner Home

Position Sensor

Toner Overflow

Sensor

Oil End Sensor

Printed Circuit Boards

PCB1

PCB2 Relay PCB

PCB3 Interface PCB

PCB4

PCB5

PCB6

Lamp Regulator PCB

Feed Control PCB

Heater Control PCB

Main PCB

Lamps

L1

L2

L3

Quenching Lamp

Erase Lamp

Pre-Transfer Lamp

Informs the CPU when the scanner is

at the home position.

Detects when the

full

.

Detects low

Regulates the exposure lamp voltage.

Main power relay. Provides 100 volts

ac to motors and circuits.

Interfaces the data

copier main board and the sorter

and/or DF main boards.

Contains multiplexing circuitry to

control feed components.

Controls heater switching.

Controls all copier functions both

directly and through other PCBS.

Neutralizes any charge remaining on

the drum surface after cleaning.

Discharges the drum outside of the

image area. Provides lead/traiI edge

erase and editing functions.

Reduces charge on the drum surface

before transfer.

used toner bottle is

oil condition.

between the

31

22

24

27

36

42

45

40

46

4

6

20

1-17

Page 21

16 April ’88

SYMBOL

L4

Power Packs

P1

P2

Transformer

TR1

Counter

CO1

Relays

R1

NAME

Fusing Lamp

Power Pack - T/S

Power Pack - C/B

Transformer

Total Counter

AC Drive Relay

FUNCTION

Provides heat to the fusing unit.

Provides dc voltage for the transfer

and provides ac and dc voltage for

separation coronas.

Provides high voltage power for the

charge corona and the development

roller bias.

Steps down the wall voltage to 100

Vat.

Keeps track of the total number of

copies made.

Main Power Relay

LOCATION

23

41

47

38

29

49

Others

c

FT

PSU

Main Motor Capacitor

Fusing Triac

DC Power Supply

Unit

Start capacitor

Switches fusing lamp on and off.

Rectifies 100 Vac input and outputs

dc voltages.

34

39

37

1-18

Page 22

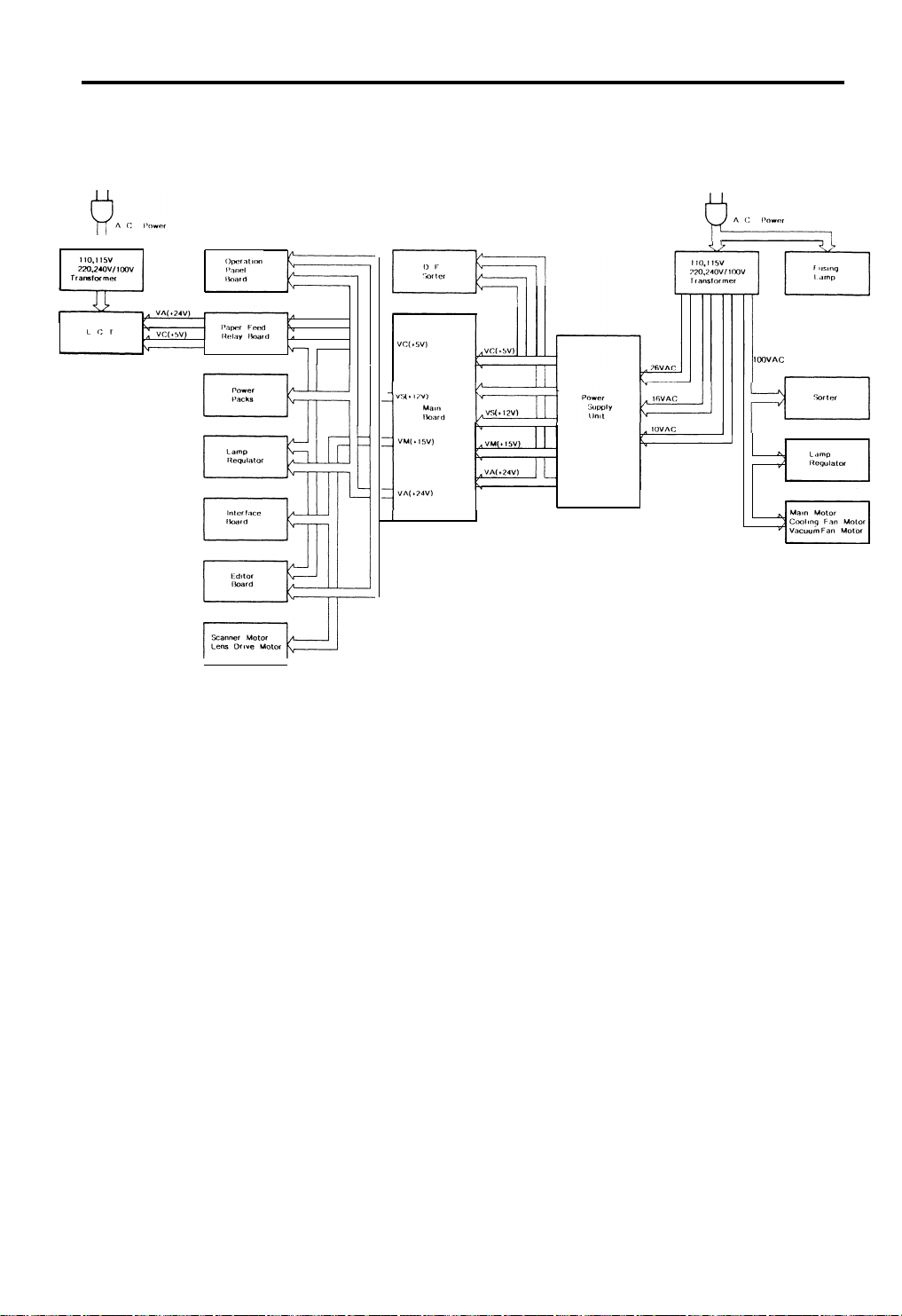

AC AND DC POWER DISTRIBUTION

16 April ’88

The ac power supply is filtered then distributed to the fusing lamp and the

main transformer. The transformer supplies 100 volts to the cooling fan,

vacuum fan, and the main motor.

The”dc power supply unit receives ac 26, 16, and 10 volts, via fuses, from the

main transformer. These voltages are rectified and regulated to 24, 15 and 12,

and 5 volts respectively and distributed to the sorter, ADF, and the copier

main board. All supplies have their own ground line.

The main board supplies voltage to all copier electrical components including:

power packs, PCBs, and relays. It also supplies the editor.

The LCT has a separate power supply.

1-19

Page 23

16 April ’88

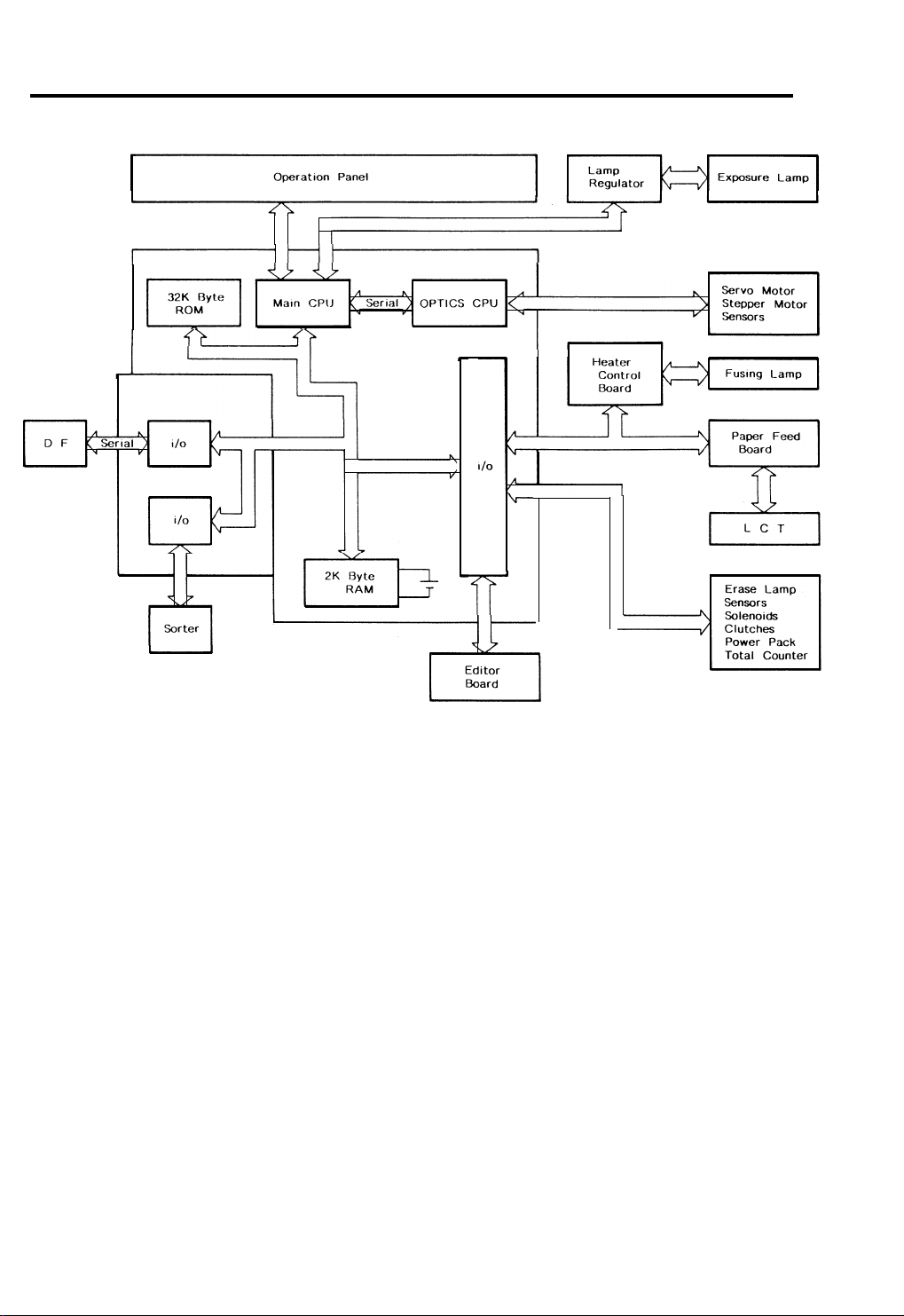

OVERALL MACHINE CONTROL

The base copier has two CPUs on the main board that control all machine

operations (the main CPU and the optics CPU).

The main CPU is the main controller of this copier. It monitors the input

signals from sensors and controls the electrical devices through program

mable 1/0 devices. The main board has a RAM (2 kilobytes) for the service

program function. A battery backs up the power to this RAM. This CPU con

trols the fusing lamp, via the heater control board, the exposure lamp, via the

lamp regulator, and motors directly from the main board.

The optics CPU controls the servomotor (15 volts) and the stepper motors

(24 volts) for the optics section.

The interface board is connected to the copier main board when the

document feeder and/or sorter are installed.

1-20

Page 24

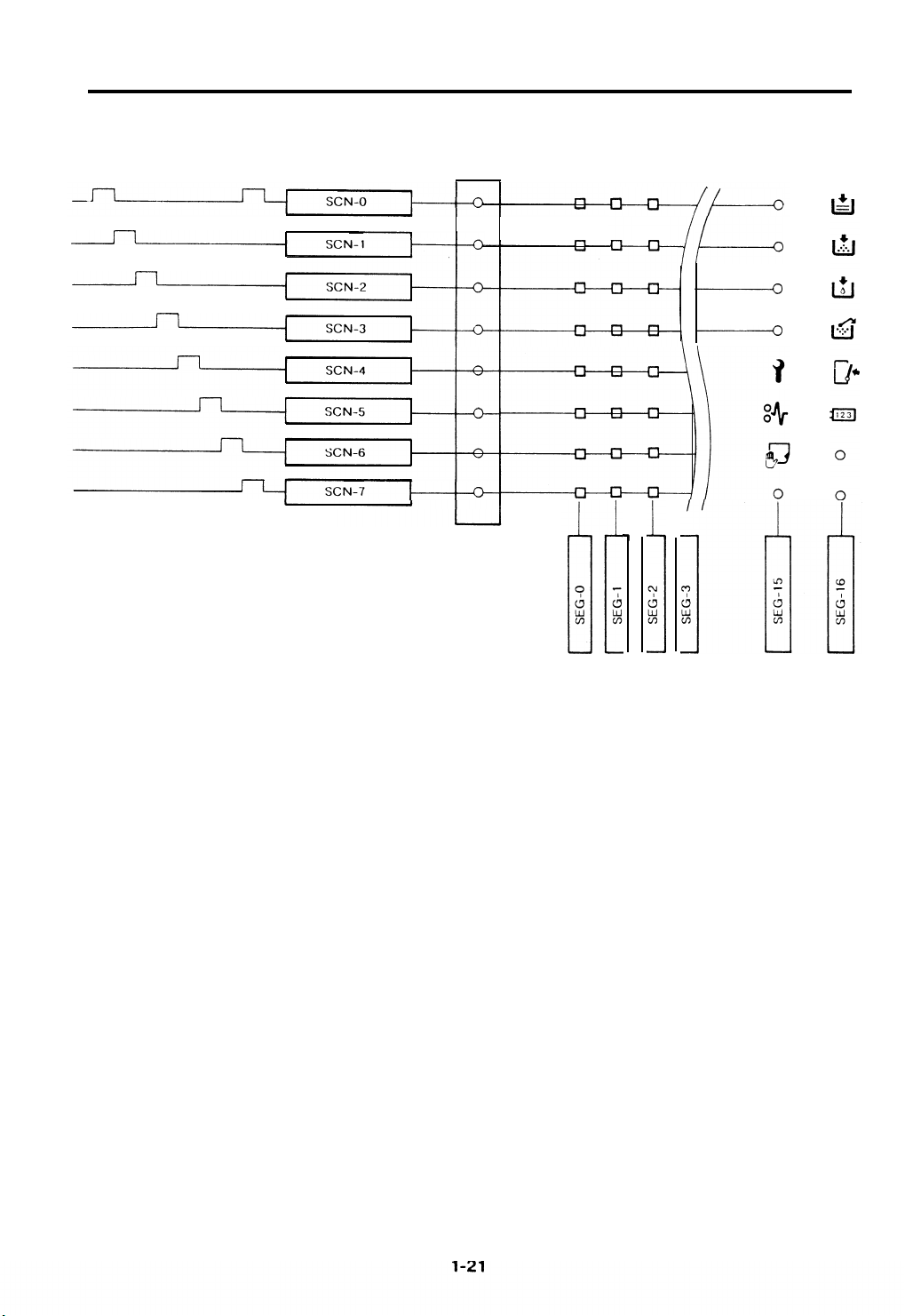

OPERATION PANEL CONTROL

16 April ’88

The CPU controls all functions of the operation panel. The CPU sends data to

programmable 1/0 devices which form a multiplexing circuit consisting of 8

scan lines and 17 segment lines, Transistors drive all the scan lines at 12 volts

to reduce effects from noise.

The multiplexing circuit lights all displays and monitors all keys of the

operation panel. The door switch is also monitored by this circuit and acts like

any other operation panel key. The counters are also controlled by the

operation panel multiplexing circuit and act like the operation panel lamps.

Page 25

SECTION 2

DETAILED SECTION

DESCRIPTIONS

Page 26

OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . : . . . . . . ...2-6

LEAD EDGE ERASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-7

SIDE ERASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-7

I. Side Erase Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-8

TRAIL EDGE ERASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-9

ERASE LAMP CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-10

OPTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . ...2-12

OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-12

SCANNER DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-13

I. Scanner Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-13

2. Scanner Motor Control

LENS/MIRRORPOSITIONING

I. Lens Drive . . . . . . . . . . .

Z. Lens Positioning . . . . . .

3. Second Scanner Drive .

4. Second Scanner Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-18

STEPPER MOTOR CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-19

AUTOMATIC IMAGE DENSITY SENSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-20

EXPOSURE LAMP CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-21

Service Call Conditi.ons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-22

DEVELOPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-23

overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-24

SEALS AND END MAGNETS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-25

CROSS-MIXING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-26

IMAGE DENSITY CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-27

1. ManualImag eDensityControl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-27

Z. Automatic Image Density Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-28

. . . . . . . . . . . . ...2-23

3. Bias Compensation Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-29

4. Rest Time Compensation (V2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-29

5. Drum Temperature Compensation (V3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

6. Total Bias (VT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-30

BIAS FOR ID SENSING . . . . . . . . . . o . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-31

BIAS CONTROL CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-32

Page 27

COLOR DEVELOPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-33

I. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-33

Z. Bias Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-33

3. Base Bias for Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-33

4. Bias for lD Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-33

5. Color Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-34

SERVICE CALL CONDITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-35

TONER DENSITY DETECTION AND TONER SUPPLY . . . . . . . . ...2-36

TONER DENSITY DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-36

TONER DENSITY CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-37

TONER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-39

I. Roller Drive Mechanism.. . . . . . . . . . . . . . . . . . . . . . . . . . , . . . . . . . . . . . . ...2-39

Z. Toner Agitator Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-40

TONER SUPPLY AMOUNT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-41

l. Detect Supply Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-41

Z. Fixed Supply Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-41

TONER END DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-42

COLORTONERDENSITY DETECTIONANDCOLOR TONER SUPPLY . . . . . . . ...2-42

l. Color Toner Density Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-42

Z. Color Toner End Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-43

3. Abnormal Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-44

SERVICE CALL CONDITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-44

IMAGE TRANSFER AND PAPER SEPARATION . . . . . . . . . . . . . ...2-45

PRE-TRANSFER LAMP (PAL).... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-45

IMAGE TRANSFER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-45

PAPER SEPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , . . . . . ...2-46

PRE-TRANSFER LAMP CIRCUIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-47

TRANSFER/SEPARATIONCORONA CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-48

PICK-OFF MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-49

l. Touch and Release Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-49

2. Side to Side Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-50

PICK-OFF CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-51

DRUM CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-52

OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-52

Page 28

.

16 April ’88

DRUM

SELENIUM DRUM

Selenium has the characteristics of:

1

.

Being able to accept a high positive electrical charge in the dark. (The

electrical resistance of selenium is high in the absence of light.)

2

.

Dissipating the electrical charge when exposed to light. (The conductivity

of selenium is greatly enhanced by exposure to light.)

.

Dissipating an amount of charge in direct proportion to the intensity of the

3

light. That is, where a stronger light illuminates the selenium surface, a

smaller voltage remains on the selenium.

The sensitivity of selenium changes slightly with variations in the surface

temperature of the drum. (Under cool conditions, the drum may be

excessively charged; this will result in background or excessive image

density.) To prevent this, the CPU monitors the temperature variations around

the drum and changes the development bias accordingly. Also, during cold

periods, the drum heater warms the drum.

Drum sensitivity also depends on how long the drum has rested between

copy runs. The copier’s CPU compensates for changes in drum sensitivity

due to rest time by changing the development bias. This prevents variations in

image density at the beginning of copy runs

The selenium drum used in this model has high sensitivity, good color

reproduction,

and good reproduction of low contrast originals (pencil

originals, etc.)

2-1

Page 29

16 April ’88

HANDLING THE DRUM

1

.

Never touch the drum surface with bare hands.

2

●

Store the drum in a CooI dry place away from heat.

.

When cleaning the drum, always wear gloves.

3

4

.

Prime the drum with setting powder only when installing a new drum.

●

Never expose the drum to light for long periods.

5

.

Drum conditioning is necessary after installing a new drum. In addition, it

6

should be done at the following times:

1 ) When image density is reduced due to over exposure of the drum

2) After cleaning the drum

3) When the drum is lightly scratched.

7

●

Always keep the drum in the protective sleeve when inserting or pulling

the drum out of the copier.

.

Before inserting or pulling out the drum, pull the cleaning unit out slightly

8

to avoid scratching the drum on the pick-off pawls.

.

Return used drums to the distributor according to standard procedure.

9

Page 30

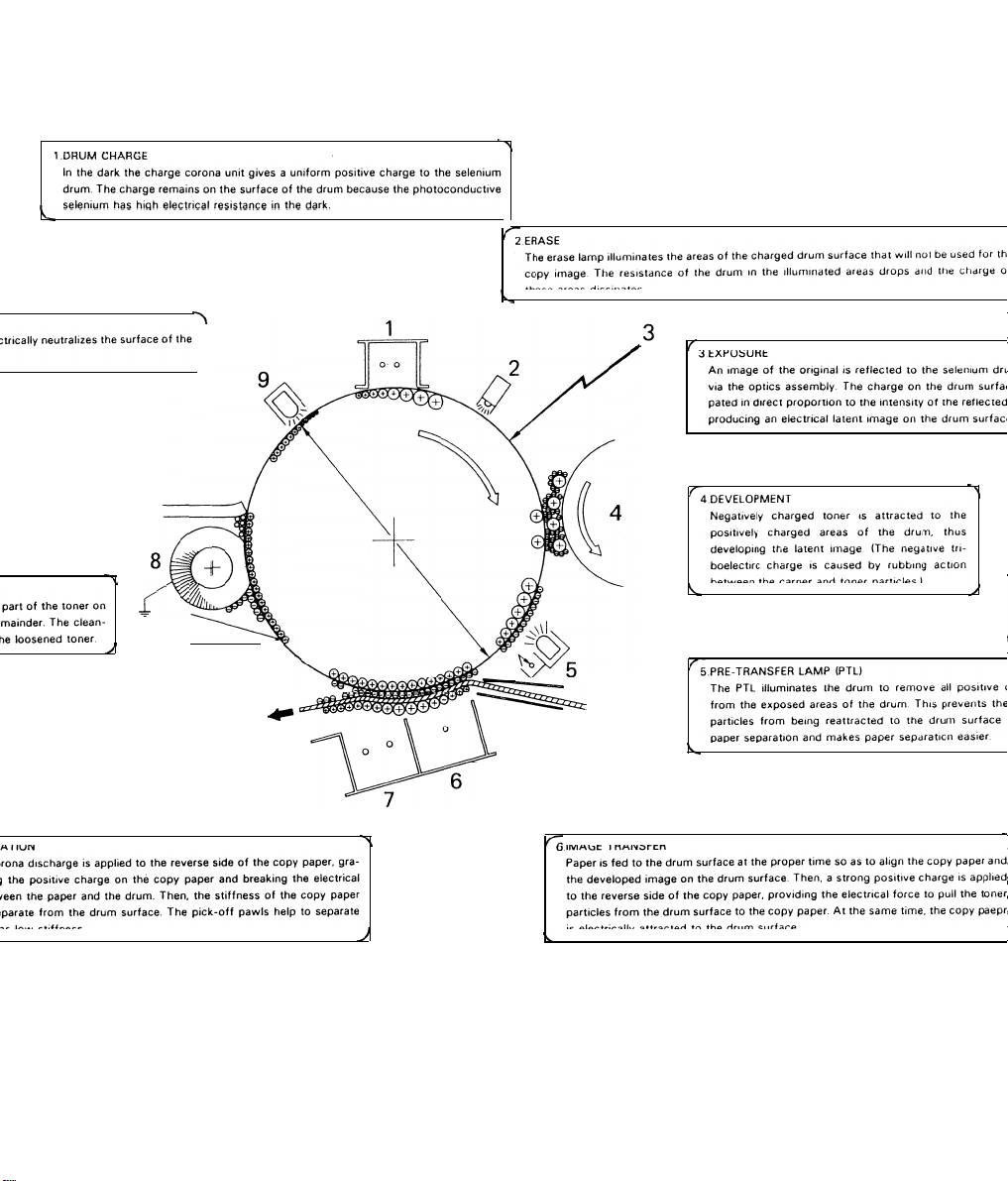

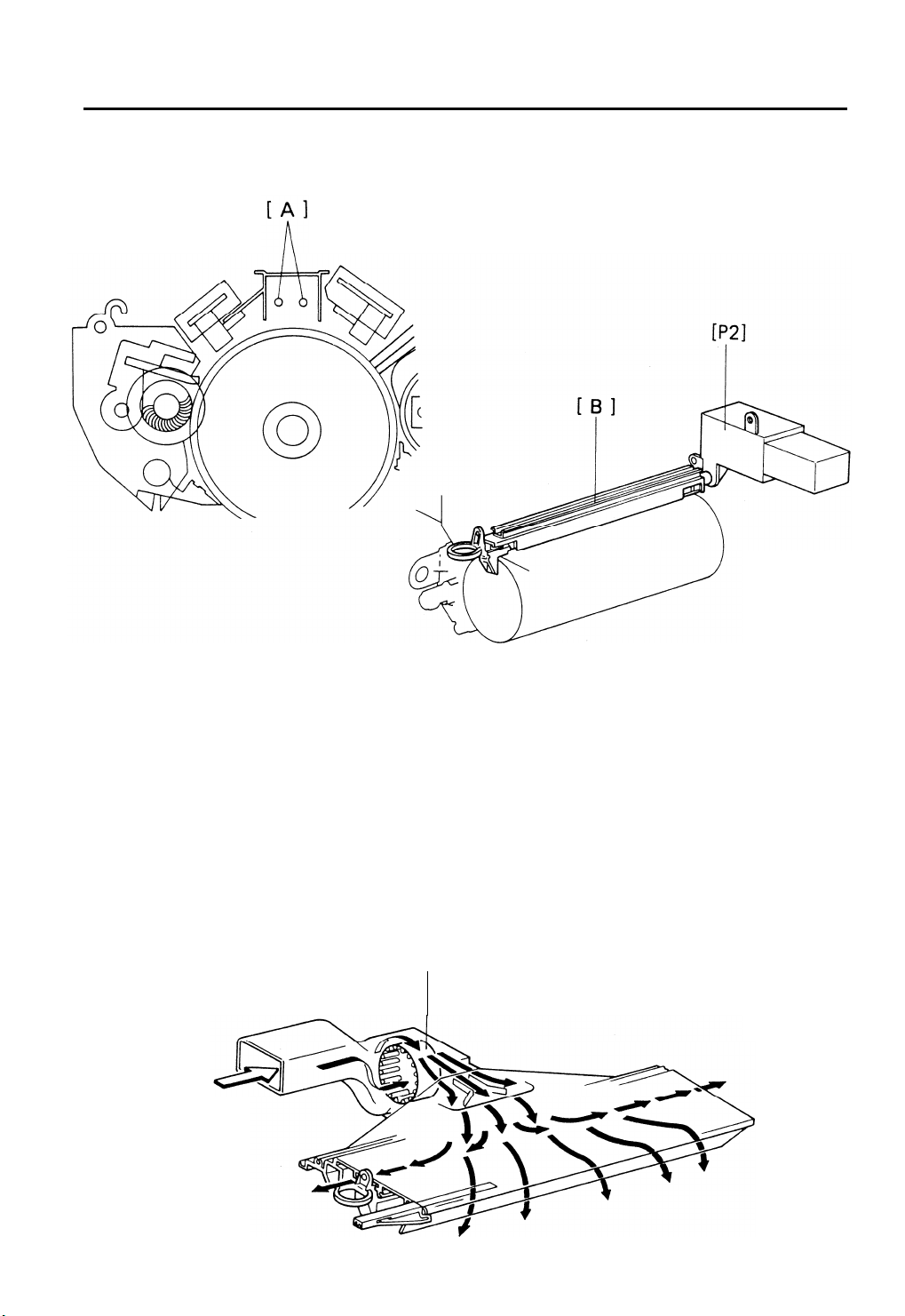

DRUM CHARGE

OVERVIEW

16 April ’88

This copier uses

drum. The corona wires generate a corona of positive ions when the charge

power pack [P2] applies a high positive voltage. The selenium coating

receives a uniform positive charge (750 t 50 volts) as it rotates

corona unit [B].

The main motor fan [C] provides a smooth flow of air to the interior of

charge corona unit to prevent uneven build-up of positive ions. (An uneven

build up of positive ions could cause uneven image density.)

a dual wire corotron [A] and a highly sensitive selenium

past

the

the

[cl

2-3

Page 31

16 April ’88

CORONA WIRE CLEANER

The flow of air around the charge corona wires [A] may deposit paper dust or

toner particles on the corona wires.

These particles may interfere with

charging and cause low density bands on copies. The wire cleaner [B] allows

the operator to correct this problem by simply pulling out and pushing in the

corona unit.

Each corona wire is held between two pads on the wire cleaner bracket [C].

The wires ride between the pads when the unit is pulled out, and the pads

clean off any particles on the wires.

2-4

Page 32

CHARGE CORONA POWER PACK

16April ’88

The circuit operation for the charge corona [A] begins with the input of +24

volts to the power pack at CN1-1. This power supply is used for the high

voltage coronas.

The charge corona turns on 0.42 second after the Start key is pressed. A

LOW

signal from the main board (at CN206-A22) energizes the power pack.

The charge corona always turns on at the same time, but the off timing

depends on paper size.

2-5

Page 33

16 April ’88

ERASE

OVERVIEW

Lead Edge Erase Margin

Side Margins -size copies, the total of both side

margins is less than

Original Image width

Charged width on the Drum

Lead Edge Erase

Side Erase

The erase lamp [A] consists of a line of LEDs extending across the full width

of the drum [B].

The erase lamp has three functions: lead edge erase, side erase, and trail

edge erase. Trail edge erase begins after the trailing edge of the copy paper;

therefore, the trailing edge of the copy will not be erased.

4 mm. )

The erase lamp unit [A] also has two thermistors: TH-I and TH-2. Both of

these thermistors detect the temperature around the drum. TH-1 selects the

proper rest time compensation, and TH-2 controls the development bias

voltage.

Page 34

LEAD EDGE ERASE

The entire line of LEDs turns on when the main motor turns on. They stay on

until the erase margin slightly overlaps the lead edge of original image area on

the drum (Lead Edge Erase Margin). This prevents the toner density sensor

pattern from being developed on every copy cycle and prevents the edge of

the original from appearing on the copy image. The width of the lead edge

erase margin can be adjusted using SP Mode # 41.

During image density detection cycles (once every ten cycles), the center

block of erase lamps turns off long enough for the sensor pattern to be

developed.

SIDE ERASE

Based on the paper size and on the reproduction ratio, the LEDs turn on in

pairs (one on either side) to discharge the drum potential on both sides. This

reduces toner consumption and drum cleaning load.

The CPU adjusts the side erase margin to be as near as possible to the actual

image size, even when using the zoom function. However, since the erase

lamp LEDs will not work in precise one millimeter intervals, the side erase

margin varies slightly depending on the reproduction ratio. The width of the

side erase margin varies from O mm to a maximum of 6 mm (total of both

sides).

2-7

Page 35

16 April ’88

1. Side Erase Operation

The tables below show which erase lamps turn off,

size and reproduction ratio selected. Note that A3 side edge erase occurs

because the charge corona end block covers stop the edges of the drum

from receiving charge.

2-8

Page 36

16 April ’88

TRAIL EDGE ERASE

Normally, the erase lamps turn on after the trailing edge of the latent image

has passed. Therefore, a trail edge erase margin cannot be observed on the

copy. Trail edge erase ON timing is the same as charge corona OFF timing.

During enlargement or reduction, the trail erase ON timing changes according

to the paper size and the reproduction ratio.

Page 37

16 April ’88

ERASE LAMP CIRCUIT

This copier uses 34 LEDs in the erase lamp unit.

Shift register drivers control the LEDs. Initially, the RESET signal (LOW active)

turns off all the shift registers. Then the main board sends erase lamp data to

the shift registers from CN203-15.

2-1o

Page 38

16 April ’88

After the RESET signal goes back to HIGH, the shift registers start accepting

data. If the data line is HIGH at the time of the CLOCK pulse (rising edge), the

shift register is set to turn the LED on; if it is LOW, the the shift register is set

to keep the LED off. The data in the shift registers is shifted right one position

at the start of each clock cycle; so, it takes 34 CLOCK pulses to set the shift

registers for all the LEDs.

After all data bits have been sent, the main board sends the LATCH signal to

turn on the erase lamp unit. The latch signal sets the shift registers which turn

on all LEDs for which data bits have been set.

The center section of LEDs turns on and off as a block, and the outer LEDs

turn on and off in pairs.

2-11

Page 39

16

April ’88

OPTICS

During the copy cycle, an image

surface

Light Path:

Exposure Lamp [A] --> Original [B] --> First Mirror [C] -->

Second Mirror [D] --> Third Mirror [E] -->

Fourth Mirror [G] --> Toner Shield Glass [H] --> Drum [1]

The cooling blower [J] circulates cool air into the optics cavity. The air flows

from the right to the left in the optics cavity and exhausts through the vents in

the top cover. This blower operates during every copy cycle.

This model has eight standard reproduction ratios: four reduction ratios, three

enlargement ratios, and full size. In addition, it has a zoom function. The user

can change the reproduction ratio in one percent steps from 65% to 155%.

Stepper motors are used to change the positions of the lens and mirrors.

Separate motors are used because of the wide range of reproduction ratios.

The scanner drive motor is a servomotor and is controlled by the optics CPU.

The scanner drive motor changes the scanner speed depending on the

reproduction ratio.

via the optics assembly as

of the original

follows.

Lens [F] -->

.

This copier has a special function: the 2 Single Copies mode, which makes

two single copies from a bound document.

2-12

Page 40

SCANNER DRIVE

16 April ’88

1. Scanner Drive Mechanism

This model uses a dc servomotor [A] to drive the scanners.

The first scanner [B], which consists of the exposure lamp [C] and the first

mirror, is connected to the scanner drive wire by the wire clamp [D]. The

second scanner [E], which consists of the second and third mirrors, is

connected to the scanner drive wire by a movable pulley (the second scanner

pulley

[F]).

The pulley moves the second scanner at half the velocity of the first scanner.

This is to maintain the focal distance between the original and the lens during

scanning. This relationship can be expressed as:

V1r = 2(V2r)

where: r =

Reproduction ratio

= VD/r

V1r = First scanner velocity (when the reproduction ratio is “r”)

V2r =

VD

—

—

Second scanner velocity (when the reproduction ratio is “r”)

Drum peripheral velocity (150 mm/s)

The wire clamp for the first scanner also works as the actuator of the home

position sensor. The CPU controls both the registration and return timing.

2-13

Page 41

SCANNER DRIVE

16 April ’88

1. Scanner Drive Mechanism

This model uses a dc servomotor [A] to drive the scanners.

The first scanner [B], which consists of the exposure lamp [C] and the first

mirror, is connected to the scanner drive wire by the wire clamp [D]. The

second scanner [E], which consists of the second and third mirrors, is

connected to the scanner drive wire by a movable pulley (the second scanner

pulley

[F]).

The pulley moves the second scanner at half the velocity of the first scanner.

This is to maintain the focal distance between the original and the lens during

scanning. This relationship can be expressed as:

V1r = 2(V2r)

where: r =

Reproduction ratio

= VD/r

V1r = First scanner velocity (when the reproduction ratio is “r”)

V2r =

VD

—

—

Second scanner velocity (when the reproduction ratio is “r”)

Drum peripheral velocity (150 mm/s)

The wire clamp for the first scanner also works as the actuator of the home

position sensor. The CPU controls both the registration and return timing.

2-13

Page 42

16 April ’88

2. Scanner Motor Control

The scanner drive motor [M6] is a servomotor, The optics CPU on the main

board [PCB6] controls the speed of this servomotor. The main CPU and the

optics CPU communicate through a serial interface bus.

At the programmed time, the main CPU sends a scanner start signal to the

optics CPU. The optics CPU then checks the drum speed by monitoring the

pulses from the pulse generator.

Based on this input, the optics CPU

determines the proper speed for the scanner drive motor. The optics CPU

sends the speed data to the timer IC which sends the motor drive pulses.

The. encoder on the servomotor has a photointerrupter that generates pulse

signals. The optics CPU monitors the scanner speed by these pulse signals

and uses this data to regulate the servomotor speed.

The home position sensor [S13] informs the optics CPU whether the first

scanner is in the home position.

2-14

Page 43

LENS/MIRROR POSITIONING

[B]

16 April ’88

[M2]

[A]

1. Lens Drive

The lens drive motor [M2] (stepper motor) changes the lens [A] position in

accordance with the selected reproduction ratio to provide the proper optical

distance between the lens and the drum surface.

The lens drive motor drives the entire lens unit through an idle gear [B]. The

rotation of the lens drive pulley moves the lens back and forth in discrete

steps.

2-15

Page 44

16 April ’88

2. Scanner Motor Control

The scanner drive motor [M6] is a servomotor, The optics CPU on the main

board [PCB6] controls the speed of this servomotor. The main CPU and the

optics CPU communicate through a serial interface bus.

At the programmed time, the main CPU sends a scanner start signal to the

optics CPU. The optics CPU then checks the drum speed by monitoring the

pulses from the pulse generator.

Based on this input, the optics CPU

determines the proper speed for the scanner drive motor. The optics CPU

sends the speed data to the timer IC which sends the motor drive pulses.

The. encoder on the servomotor has a photointerrupter that generates pulse

signals. The optics CPU monitors the scanner speed by these pulse signals

and uses this data to regulate the servomotor speed.

The home position sensor [S13] informs the optics CPU whether the first

scanner is in the home position.

2-14

Page 45

16 April ’88

2. Lens Positioning

[Enlargement]

Low

The lens home position sensor [S1] informs the optics CPU when the lens is

at the full size position (home position). The optics PCB determines the lens

stop position in reduction and enlarge modes by counting the number of

steps the motor makes with reference to the lens home position. After

changing the reproduction ratio, the lens moves directly to the selected

magnification position.

Lens home position is registered each time the lens starts from or passes

through the lens home position sensor. As the lens moves from the

enlargement side to the reduction side, it registers the home position. At

registration there is

board. This occurs

a LOW to HIGH voltage change at CN101-B3 ‘of the main

when the actuator blade enters the lens home position

sensor.

A small vibration can be observed when the lens moves through home

position from reduction to enlargement because the lens is going in the

wrong direction to register. The lens overshoots the home position by only

one step before going back to reference home position.

Page 46

3. Second Scanner Drive

16 April ’88

1

To provide the proper optical distance between the original and the lens, this

model uses a stepper motor [A] to move the second scanner. A separate

motor is used because the second scanner must travel a long distance to

accommodate the wide range of reproduction ratios. The single scanner drive

wire provides the second scanner with drive as well as correcting the second

scanner position.

When the second scanner drive pulley [B] turns to change the scanner

position, WP1 and WP2 do not turn. So, the wire clamp [C]

position and only the second scanner pulley [D] moves. When the scanner

drive pulley turns, WP3 does not rotate; however, the second scanner pulley

and the wire clamp do move.

stays at the home

As the second drive motor drives the second drive pulley directly, then the

second scanner can be positioned manually (for maintenance etc.).

2-17

Page 47

16 April ’88

4. Second Scanner Positioning

Like the lens, the second scanner is positioned by counting the number of

steps from the home position. Second scanner home position is determined

by a HIGH to LOW to HIGH change at CN101-B4 of the main board.

Actually, as this machine has horizontal magnification adjustment by changing

the position of 2nd scanner drive pulley using SP Mode # 44, the home

position may be detected when the signal goes from HIGH to LOW by

calculating the adjusted magnification data.

When moving away from the home position, the second scanner drive pulley

[A] turns clockwise and moves the second scanner directly to the selected

position. However, when moving closer to the home position (pulley turning

counterclockwise), the second scanner overshoots the selected position by 5

steps and then returns to the selected position. This takes out any

mechanical play.

2-18

Page 48

STEPPER MOTOR CONTROL

16 April ’88

Both the lens

drive

[M5] are

stepper motors. The stators of these stepper motors have four coils (labeled

A, B, A and B above), and the rotors are permanent magnets.

Pulse signals energize the four coils as shown in the above illustration. The

rotor turns in discrete steps.

2-19

Page 49

16 April ’88

AUTOMATIC IMAGE DENSITY SENSING

Leading Edge of the Original

The input for the automatic image density circuit is via a fiber optic cable [A]

that is “mounted on the first scanner. Light from the exposure lamp [B] passes

through a small hole in the reflector, reflects from the original, and is collected

by the fiber optic cable. The sampled strip starts 31.5 millimeters from the

leading edge of the original and is 8 millimeters wide and 30 millimeters long.

The fiber optic cable conducts the light to a sensor (photodiode) on the lamp

regulator. The sensor circuit converts the light intensity to a voltage level. The

detected voltage is adjustable via a variable resistor on the lamp regulator

board. A peak hold circuit keeps the maximum voltage.

The lamp regulator sends the maximum voltage value to the main board. The

CPU then computes the correct image density and adjusts the development

bias accordingly. (See the section on image density control for more

information. )

2-20

Page 50

EXPOSURE LAMP CONTROL

Lamp

ON/OFF

16 April ’88

[PCB4]

The lamp regulator board controls the exposure lamp. The voltage applied to

the exposure lamp is determined by the combination of HIGH and LOW

signals at CN204-6, -7, and -8.

The main CPU sends the lamp trigger signal 0.13 seconds after the

registration clutch turns off.

The main CPU constantly monitors CN204-5 to check whether the lamp is on

or off. If CN204-5 becomes HIGH when CN204-9 is LOW (lamp ON) or

CN204-5 becomes LOW when CN204-9 is HIGH (lamp OFF), the CPU

displays SCI 1. RAI -RA3 opens at the same time, cutting the + 24V power

*

line

.

2-21

Page 51

16 April ’88

Service Call Conditions

Self Diagnostic Code 11:

Exposure Lamp Malfunction

Code 11 is displayed if the lamp monitor voltage is detected during standby

(lamp ON), or if the lamp filament opens.

Self Diagnostic Code 21:

canner

Code 21 is displayed if the scanner home position sensor stays deactivated

for more than 2 seconds. This code is effective only when the scanner home

position is initialized.

Self Diagnostic Code 23:

O Registration Start Signal

N

Code 23 is displayed if the optics board does not send the registration start

signal to

Home Position Check

the

main board.

The main board waits 4 seconds for this signaL

Self Diagnostic Code 24:

No Scanner Home Position Signal

Code 24 is displayed if the optics board does not send the scanner home

position signal to the main board. The main board waits 20 seconds for this

signal.

Self Diagnostic Codes 28 and 29:

Lens Home Position Check

Code 28 is displayed if the lens home position sensor stays deactivated more

than 3 seconds. Code 29 is displayed if the scanner home position sensor

stays

activated more than 3 seconds.

Self Diagnostic Codes 2A and 2B:

cond S

canner

Home Position

At certain times (power ON, clear, timer) the second scanner either moves to

its home position or moves out and back. Code 2A is displayed if the second

scanner home position sensor stays deactivated longer than 2.5 seconds.

Code 26 is displayed if the second scanner home position sensor stays

activated longer than 2.5 seconds.

Self Diagnostic Codes 2C and 2D:

Scanner Motor Encod

er Frequ

encv

Code 2C is displayed if the frequency of the signal from the scanner motor

encoder is too high. Code 2D is displayed if the frequency of the scanner

motor’s signal is too low.

2-22

Page 52

DEVELOPMENT

Overview

16 April ’88

When the main motor

[B] start turning. The

transports it to the development roller. Internal permanent magnets in the

development roller attract the developer to the development roller sleeve.

The turning sleeve of the development roller then carries the developer past

the doctor blade [C]. The doctor blade trims the developer to the desired

thickness and creates backspin to the cross-mixing mechanism.

The development roller continues to turn, carrying the developer to the

selenium drum. When the developer brush contacts the drum surface, the

positively charged areas of the drum surface attract and hold the negatively

charged toner. In this way, the latent image is developed.

Positive bias is applied to the development roller to prevent toner from being

attracted to non-image areas on the drum that may have residual positive

charge. The bias also controls image density.

After turning about 100 degrees more, the development roller releases the

developer to the developer tank. The developer is agitated by the paddle

roller and the cross-mixing mechanism.

turns on, the paddle roller [A] and development roller

paddle roller picks up developer in its paddles and

Also, in this machine, rotation of the paddle roller [A] and development roller

[B] tend to cause air pressure inside the unit at point [D] to become higher

than the air pressure around the development unit.

Therefore, a hole, fitted with a filter, has been added to the top of the unit to

relieve air pressure and to minimize toner scattering. It also causes air flow

across the face of the ID sensor, which helps dislodge any toner or paper

dust which might fall on it. Also, to allow better heat transmission than earlier

machines, the bottom plate of the unit is made of aluminum.

Page 53

SEALS AND END MAGNETS

[A]

16 April ’88

Several seals prevent toner from spilling out into the copier. The upper brush

seal [A] prevents particles from scattering upward. The side seals [B] at the

ends of the development unit contact the drum-ends (out of the image area);

they prevent toner from scattering out of the sides.

Since the internal permanent magnets are shorter than the development roller

sleeve, the toner tends to scatter from both ends. To reduce this scattering of

toner, small magnets [C] are mounted under the ends of the development

roller [D]. These magnets create small magnetic fields that stop developer

particles from scattering.

.

2-25

Page 54

16 April ’88

CROSS-MIXING

This copier uses a standard cross-mixing mechanism to keep the toner and

developer evenly mixed.

It also helps agitate the developer to prevent

developer clumps from forming and helps create the triboelectric charge.

The developer on the turning development roller is split into two parts by the

doctor blade [A]. The part that stays on the development roller [B] forms the

magnetic brush and develops the latent image on the drum. The part that is

trimmed off by the doctor blade goes to the backspin plate

[C].

As the developer slides down the backspin plate to the paddle roller [D], the

mixing vanes [E] move it slightly toward the rear of the unit. Part of the

developer falls into the auger inlet and is transported to the front of the unit by

the mixing auger [F].

2-26

Page 55

16 April ’88

IMAGE DENSITY CONTROL

Image density is controlled by changing two items: (1) the strength of the bias

voltage applied to the development roller sleeve, and (2) the strength of the

voltage applied to the exposure lamp.

Applying a bias voltage to the development sleeve reduces the potential

between the development roller and the drum, thereby reducing the amount

of toner transferred. As the bias voltage becomes greater, the copy image

becomes lighter. Similarly, increasing the voltage to the exposure lamp

causes an increase in light intensity which also results in lighter copies.

The method of control is different depending on whether

manually selected or the automatic ID system is used. “

1. Manual Image Density Control

Manual Image Density Control

r

I

the image density is

When the image density is set manually, the bias depends on two factors: the

auto image density base level, and the manually selected ID level. (See the

above table. ) The exposure lamp voltage also varies as shown in the table.

NOTE: To set the auto image density base level, simultaneously press and

hold the Clear/Stop key and press the Auto ID key. Then, select the

base level using the manual ID keys.

.

2-27

Page 56

16 April ’88

2. Automatic Image Density Control

o

0

0 0

0

0

0

0

I

I

0

0

0

1 0

1

1

1 0 1 320

1

1

1

‘o

1

1

1

010

0

0

~

0

1

1 1

o

1

1

1

1

b

0

0

0

1

o

\

1

r

200

230

260

290

350

380

410

440

470

500

I

200

!

I

t

Development Bias Voltage (V)

When automatic image density control is on, the exposure lamp voltage is set

to Vo + 5 volts. A change in the bias voltage only controls the image ‘density.

The normal factory setting is the fourth column; however, this setting can be

changed for troubleshooting or to satisfy customer requirements by selecting

the Auto ID mode, holding down the Clear/Stop key, and pressing the image

density keys.

At the start of the copy cycle, the original sensing mechanism measures the

background density of the original image. It does this by measuring the

strength of the light reflected from a 30 mm strip near the leading edge of the

original. A fiber optic cable pipes the reflected light to a photodiode on the

lamp regulator board. The photodiode is the input element of the auto ID

circuit.

The CPU checks the voltage output by the auto ID circuit. This circuit has a

peak hold function. The peak hold voltage corresponds to the maximum

reflectivity of the originaL The CPU then determines the proper bias base

level, with reference to the peak hold voltage, and sends a 4-bit control signal

to the power pack. The power pack then applies the proper bias to the

development roller.

2-28

Page 57

.

16 April ’88

3. Bias Compensation

Factors

As discussed previously, either the automatic image density system or the

operator, through the image density keys, sets the bias base level (V1). The

CPU increases the bias base level as necessary to compensate for the rest

time between copy runs and the drum temperature, both of which affect drum

TD: Drum Temperature

4. Rest Time Compensation (V2)

The drum sensitivity often drops slightly over the first few cycles of a copy

run. This is because the light from the exposure lamp fatigues the drum

slightly, and it takes

a few copies for the selenium to restabilize. The amount

that the sensitivity drops depends on the drum’s temperature and the rest

time between copy runs (the longer the rest time, the greater the change).

The copier increases the bias at the beginning of each copy run to prevent

variations in the image density of the first few copies produced. The above

two tables show the amount of bias increase. If the drum temperature is less

than 10

degrees Celsius, no rest time compensation is

applied.

When the main switch is turned on, the CPU automatically selects the “greater

than two hours” rest time compensation level.

2-29

Page 58

16 April ’88

5. Drum Temperature Compensation (V3)

(v) ,

Temp

(TH-2), and it

The

CPU

22 18 15

TH Resistance

monitors drum temperature through a thermistor

increases or decreases the bias voltage to compensate for variations in drum

sensitivity that are induced by temperature changes in the drum cavity. The

temperature compensation is effective from 5 degrees to 50 degrees

(Celsius).

As shown by the “knee” in the above chart, the temperature compensation

factor depends on the temperature range. Between 5°C and 15°C, the change

in

V3 is -14 V/”C; between 15°C and 50”C, the change in V3 is -5 to -6V/”C.

6. Total Bias (VT)

The total bias applied to the development roller sleeve is the sum of the base

bias and the two compensating factors.

.

2-30

Page 59

BIAS FOR ID SENSING

16

April

’88

Scanner

Bias

600

500

400

300

200

100

!

Bias change Signal ( from Optics Board)

I

for ID

( Fixed Bias)

t

Sens’or Pattern

Drum Temp = 30”C

Rest Time = Over 2hours

Auto ID Input = 3V

for ‘Image

(Selected Bias)

for Image

I

To develop the ID sensor pattern consistently, the CPU applies a fixed base

bias level to the development roller at the beginning of each copy cycle. The

fixed base bias is 470 volts (SP Mode data selectable) after ten copies; prior

to which, it is affected by drum cavity temperature and drum rest time.

The CPU applies the ID sensor bias to the development roller about 1.12

seconds after the Start key is pressed. Just after the sensor pattern is

developed, the CPU changes the bias output to the level selected by auto ID

sensor or the operator for image development. The bias output remains at

this level until 0.22 second after the scanner starts returning.

The ID sensor bias can be changed to adjust the overall image density by SP

Mode # 33 as follows:

ID Sensor Bias (SP Mode # 33)

Data

.

● 470V

O

.

.

1

.

2

.

●

.

3

Base Bias

440V

500V

530V

Normally the data of SP Mode # 33 is “O” (factory preset).

2-31

Page 60

16 April ’88

COLOR DEVELOPMENT

1. Overview

This copier has mono-color copying capability in red, green, and blue as well

as standard black. To change colors, the development unit must be replaced.

To detect which color is used, an actuator is mounted on the development

unit. Since the reflectivity varies with the color of the toner, the toner end

detection system uses a mechanical detection system instead of an ID sensor

detection system.

2. Bias Control

Due to the differences in the characteristics of black and color toner, the CPU

changes the bias control when it detects a color development unit.

3. Base Bias for Color

4. Bias for ID Sensing

VT

Since the reflectivity of color toner varies with the color type, the ID sensor is

used only to detect overtoning. Just as for black copies, the image density is

sensed once in 10 copy cycles.

2-33

Page 61

16 April ’88

The ID sensor bias can be changed to adjust the color image density by

using SP Mode # 75 as follows:

Data ID Sensor Bias

.

.

o

.

1

.

590 volts

620 volts

Normally, the data of SP Mode # 75

is “O”. When the data is changed to “1”,

the threshold level for toner supply inhibition is increased. This causes the

toner density to become higher

(See the section on color toner density

control.)

5. Color Detection

Blue

Green

Red

Color Toner Sensors*

S-A S-B

OFF OFF

ON OFF

OFF ON

ON ON

Three actuators, each having a

between the different toner colors.

Toner

Black

Blue

Green

Red

different shape, are used to distinguish

When a color development unit is installed

in the copier, the actuator activates the color toner sensors. The CPU

determines which color unit is instaIled based on the input from these two

sensors. (See the preceding table.)

*

ON

= actuator blocking the gap of the photo-interrupter.

,

2-34

Page 62

16 April ’88

SERVICE CALL CONDITION

Self Diagnostic Code 31:

Drum Thermistor Open

Code 31 is displayed if the drum thermistor circuit becomes open.

Self Diagnostic Code 32:

PTL / ID Se

Code 32 is displayed if the PTL / ID sensor board circuit becomes open or it

is not set properly.

nsor Boaard Ope

n

2-35

Page 63

16 April ’88

.

TONER DENSITY DETECTION AND TONER

SUPPLY

TONER DENSITY DETECTION

A B c

[Low Toner]

Developed Sensor

Sensor

Original Lead Edge

DE

Edge Erase

The main CPU checks toner density by directly sensing the image density at

the beginning of the first copy cycle after the main switch is turned on, and at

every 10th

copy after that.

During the check cycles, the sensor pattern is exposed prior to exposure of

the original. After the sensor pattern is developed, its reflectivity is checked by

the image density sensor (which is a hotosensor). The CPU notes the

reflectivity. If the reflected light is too strong, indicating a too low toner density

condition, it adds toner to the development unit.

The toner is not added all at once. The CPU energizes the toner supply

solenoid for the proper amount of time to add a selected amount of toner

over the next 10 cycles.

2-36

Page 64

16 April ’88

The image density sensor checks the density of the sensor pattern image

once every 10 copy cycles. The CPU receives two voltage values directly

from the sensor: the value for the bare drum (Vsg) and the value for the

sensor pattern (Vsp). These two values are then compared to determine

whether more toner should be added.

- Detect Mode B -

is added)

When the image density is too low, the CPU activates the toner supply

solenoid to add a selected amount of toner over the next 10 copy cycles.

To maintain the image density precisely and prevent image offset, toner

supply amount is changed automatically according to the value of Vsp.

If Vsp is in condition (2), toner is added according to the supply amount

selected by SP Mode # 34. If Vsp is in condition (3), toner is added according

to the supply amount selected by SP Mode # 31.

When Vsp is less than 1/20 Vsg, toner is not supplied.

2-37

Page 65

16

April ’88

Detect mode A controls toner density as follows:

.

High image density (no toner is added)

Low image density (toner is added)

SP Mode # 35 changes the toner end detection level and the timing cycle.

The toner end detection level drops to 0.65 and the monitoring cycle is every

5 copy cycles.

SP Mode # 54 is used to turn on the LED of the sensor. VR201 adjusts the

light intensity of the sensor LED. Therefore, the photosensor Vsg can be

correctly calibrated.

Toner density control can be selected with SP Mode # 30.

If Vsg becomes less than 2.5 volts, the CPU determines that the sensed data

is abnormal. It then changes from detect mode to fixed supply mode. The

amount supplied is determined by the data of SP Mode # 32 (fixed mode). At

the same time the Service Call indicator starts blinking. However, copies can

still be made.

2-38

Page 66

TONER SUPPLY

Roller Drive Mechanism

1.

16 April ’88

The toner supply clutch gear [A] turns when the main motor is on. The

transmission

of this rotation to the toner supply drive gear [B] is controlled by

the toner supply clutch [C].

When the toner supply solenoid [SOLI ] energizes, the toner supply clutch

engages and starts turning the toner supply drive gear. The toner supply

drive gear turns the toner supply roller gear [D]. Toner catches in the grooves

on the toner supply roller [E]. Then, as the grooves turn past the opening, the

toner drops into the development unit.

The toner supply opening is the same width as A4 lengthwise

(81/2”

x 11”) and

is located at the center of the developer tank. This is to reduce toner

scattering from both the ends of the development roller even if small size

paper is used continuously.

2-39

Page 67

16 April ’88

2. Toner Agitator Drive Mechanism

The toner agitator mechanism, contained in the toner cartridge, prevents

toner from blocking.

The toner supply roller gear engages the toner agitator gear [A] through an

idle gear [B]. Therefore, the toner agitator gear turns whenever the toner

supply clutch is engaged.

Rotation passes through the toner cartridge casing to the agitator junction.

2-40

Page 68

16 April ’88

TONER SUPPLY AMOUNT

This copier has two different ways of controlling the amount of toner sup

plied. Normally, the detect supply system controls toner supply; however, a

fixed supply system can also be selected. When

unit is installed, the CPU automatically selects fixed supply mode.

a color toner development

1. Detect Supply Mode

When the data of SP Mode # 30 is “O”, the standard detect supply mode B is

selected. If a low image density condition is detected, a small amount of toner

is supplied on each of the next 10 copy cycles as determined by the setting of

the data into SP Mode # 34 and # 31.

Toner supply starts 0.52 second after the scanner motor reverses. (Toner is

supplied at this time to prevent toner scattering on the copies.) The actual

amount of toner added is determined by controlling the ON time of the toner

supply solenoid, which activates a spring clutch.

2. Fixed Supply Mode

When the data of SP Mode # 30 is “1”, or a color development unit is

installed, the fixed supply mode is selected. In this case, a fixed amount of

toner is added every copy cycle as determined by the setting of the SP Mode

# 32. When a color development unit is installed, a fixed amount of toner is

determined by the setting of SP Mode # 70. The length of time that the toner

supply solenoid is energized depends on the data set into the SP Mode # 32

(Black) or # 70 (color) and the paper size.

2-41

Page 69

16 April ’88

TONER END DETECTION

The CPU uses the image density sensor to detect a toner end condition. This

method is effective in both detect and fixed supply modes.

If Vsp becomes greater than 0.75 volt, the CPU determines that it is time to

add toner and starts blinking the Add Toner indicator.

After the indicator starts blinking, the operator can make up to 50 copies. If a

new toner cartridge is not added within that 50 copy interval, the Add Toner

indicator stops blinking (stays on) and copying is inhibited. The toner end

condition is reset by opening and closing the front cover.

COLOR TONER DENSITY DETECTION AND COLOR TONER SUPPLY

1. Color Toner Density Control

When a color development unit is used, the CPU automatically selects the

fixed toner supply mode. SP Mode # 70 determines the supply amount.

The CPU calculates the threshold level for toner

color development installation procedure is

determined by calculating the average of Vsp

developer.

Since the fixed supply system is selected when in color toner mode, it is

necessary to inhibit toner supply if the toner density becomes high to prevent

over-toning. The CPU checks Vsp once in 10 copy cycles. If Vsp becomes

lower than the threshold level, the CPU stops supplying toner. Toner supply

resumes when Vsp rises above the threshold level again.

A RAM stores the threshold level data for the three colors. The CPU selects

the correct threshold level from this RAM after checking the color signal from

the color toner sensors. The power supply for the RAM has battery backup so

the data will not be lost if the power supply is disconnected.

The RAM stores not only the threshold level data but also the number of

copies made data with each color. This data can be displayed on the

operation panel by using SP Mode # 73.

supply inhibition when the

completed.

and Vsg while using new

This level is

Page 70

2.

Color Toner End Detection

16 April ’88

[E]

[A]

[D]

[cl

[F]

[G

The toner agitator gear [A] has a cam [B] (the toner end cam) on its inner

surface, and it rotates only when toner is supplied. The cam follower on the

end of the toner end lever [C] rides on the surface of the toner end cam

(spring pressure). The opposite end of the toner end lever alternately presses

and releases the toner end arm [D] as the cam turns. The toner end plate [E],

which is in the toner hopper, is mounted on the same shaft as the toner end

arm.

When there is sufficient toner in the hopper, the toner end plate is prevented

from moving by the toner. Therefore, even when the toner end lever drops to

the lowest position on the cam (releasing the toner end arm), the toner end

arm does not move and the toner end sensor [F] is not activated.

When there is insufficient toner in the hopper, the toner end plate can move.

When the toner end lever releases the toner end arm, the toner end plate

lowers and the actuator [G] on the toner end arm moves into the toner end

sensor. The CPU receives a single pulse from the toner end sensor.

If this condition is detected by the CPU more than seven times consecutively,

the Add Toner indicator starts blinking.

After the indicator starts blinking, 50 copies can be made. If a new toner

cartridge is not added within that 50 copy interval, the Add Toner indicator

stops blinking (stays on) and copying is inhibited.

2-43

Page 71

16 April ’88

3. Abnormal Condition

If Vsg becomes lower than 3.2 volts, the machine will reduce toner supply to

half of the normal supply amount. (For example, the amount of toner supply

condition, the Service Call indicator is not displayed and the machine can be

operated.

SERVICE CALL CONDITION

Service Call Indicator Blinks (no code):

ID Sensor Abnormal

The Service Call indicator starts blinking if Vsg becomes less than 2.5 volts.

When this happens, the machine automatically shifts to the fixed supply

mode. Operation is possible.

t

.

2-44

Page 72

.

16 April ’88

IMAGE TRANSFER AND PAPER SEPARATION

PRE-TRANSFER LAMP (PTL)

After the latent image is developed but before the image is transferred to the

copy paper, the drum surface is illuminated by the pre-transfer lamp [A]. This

illumination reduces the positive potential on the drum surface. This prevents

the toner particles from being re-attracted to the positively charged drum

during the paper separation process. It also makes image transfer and paper

separation easier.

IMAGE TRANSFER

The registration rollers [B] feed the copy paper through the transfer entrance

guides to the transfer section. A high positive voltage (+5.6 kilo volts) is

applied to the transfer corona wire [C], and the corona wire generates

positive ions. These positive ions are applied to the copy paper, and the

positive charge attracts the negatively charged toner away from the drum and

onto the paper. In addition, the paper is held against the drum by the negative

counter charge on the drum.

2-45

Page 73

16

April ’88

PAPER SEPARATION

After image transfer the copy must be separated from the drum. To break the

attraction between the paper and the drum, the separation corona wire [D]

applies an ac corona (500 Hz) to the reverse side of the paper. The stiffness

and weight of the paper causes it to separate from the drum [E].

The separation corona has a small dc bias but its affect is negligible. A dc

bias is unnecessary because the separation corona is wide and diffuse. The

positive charge on the paper (from the transfer corona) is not completely

discharged until the paper is far enough from the drum that the toner will not

be reattracted to the drum. The two pick-off pawls [F] ensure that thin,

low-stiffness paper or upward curled paper separates completely.

.

2-46

Page 74

PRE-TRANSFER LAMP CIRCUIT

16 April ’88

When the Start key is pressed, the main board outputs a LOW signal to

activate the pre-transfer lamp. The pre-transfer lamp, like the erase lamp, is

an array of LEDs. However, the CPU does not control the individual elements

of the pre-transfer lamp as it does the erase lamp. Instead, all of the LEDs

turn on and off simultaneously.

2-47

Page 75

16 April ’88

TRANSFER/SEPARATION CORONA CIRCUIT

When the Start key is pressed, the main board sends LOW signals to

energize the power pack for the transfer and separation coronas. The power

pack has a dc to dc converter and a dc to ac inverter. The dc to de converter

changes +24 volts to +5.6 kilovolts for the transfer corona. The inverter

changes +24 volts to 5.0 kilovolts ac (500 Hz) with a negative dc bias (about

-90 V) for the separation corona.

2-48

Page 76

PICK-OFF MECHANISM

1. Touch and Release Mechanism

16 April ’88

The pick-off solenoid [A] energizes 1.69 seconds after the Start key is

pressed. The pick-off lever [B] rotates counterclockwise (rear view) and

pushes the pawl shaft pin [C]. Then the pawl shaft [D] rotates clockwise and

the pick-off pawls [E] touch the drum. The pawl springs [F] hold the pick-off

pawls on the shaft and prevent them from touching the drum too strongly.

When the leading edge of the paper passes the pick-off area and just before it

reaches the fusing unit, the pick-off solenoid turns off. The pick-off lever

spring then rotates the pick-off lever and moves the pick-off pawls away from

the drum.

2-49

Page 77

16 April ’88

2. Side to Side Movement

The pick-off pawls [A] do not always contact the drum in the same place but

instead move slightly to the side on each copy cycle.

The pick-off pawl shaft [B] and the cam rider [C] are joined by a one-way

bearing [D]. Each time the pick-off pawl solenoid turns on, the one-way

bearing causes the cam rider to turn together with the pick-off pawl shaft. As

the cam rider turns, it and the pawl shaft are forced to move laterally by a

cam. However, when the pawl shaft rotates the pawls away from the drum the

cam. rider does not turn.

Pawl lateral movement is 0.1 to 0.2 millimeter per copy cycle. After the pick-off

pawls move about 8 millimeters, the cam rider passes the “step” of the cam

and the pawl shaft is returned to its start position by the pawl shaft spring.

2-50

Page 78

PICK-OFF CIRCUIT

16 April ’88

I

1

Main Board

The main PCB supplies +24 volts to the pick-off solenoid at CN206-BI 2. The

CPU supplies a LOW signal at CN206-BI 1 1.69 seconds after the Start key is

pressed. This

The CPU waits 0.99 second before turning off the pick-off solenoid. The

leading edge of the paper has just passed the pick-off area at this time.

LOW

I

J

signal energizes the pick-off solenoid.

Separation Solenoid

Page 79

16 April ’88

DRUM CLEANING

OVERVIEW

[cl

B]

A]

The cleaning brush [A] and cleaning blade [B] remove any toner remaining

on the drum after the image is transferred to the paper.

The cleaning brush and drum move in opposite directions at their point of

contact. The cleaning brush removes paper dust and nearly half of the toner

from the drum surface to reduce the cleaning load placed on the blade.