Page 1

DOCUMENT FEEDER

Page 2

31 October 1995 SPECIFICATIONS

1. SPECIFICATIONS

Original Size and Weight: – Thin original mode –

Maximum A3/11" x 17"

Minimum B6/51/2" x 81/2"

Weight 41 to 128 g/m2 (11 to 34 lb)

– Thick original mode –

Maximum A3 / 11" x 17"

Minimum B6 / 51/2" x 81/2"

Weight 52 to 128 g/m2 (14 to 34 lb)

– Auto reverse mode –

Maximum A3 / 11" x 17"

Minimum B6 lengthwise /

51/2" x 81/2" lengthwise

Weight 53 to 105 g/m2 (14 to 28 lb)

Original Feed: Automatic feed — ADF mode

Manual feed one by one — SADF mode

Original Table Capacity: 35 sheets / 64 g/m2 (17 lb)

Original Insertion: Face up. First sheet on top

Original Transport: One flat belt

Copy Speed: 20 copies/minute for A4/8 1/2" x 11" sideways

Power Consumption: 20 W

Dimensions (W x D x H): 670 x 460 x 103 mm (26.4" x 18.1" x 4.1")

Weight: Approximately 9.0 kg (19.916 lb)

1

Page 3

5

COMPONENT LAYOUT 31 October 1995

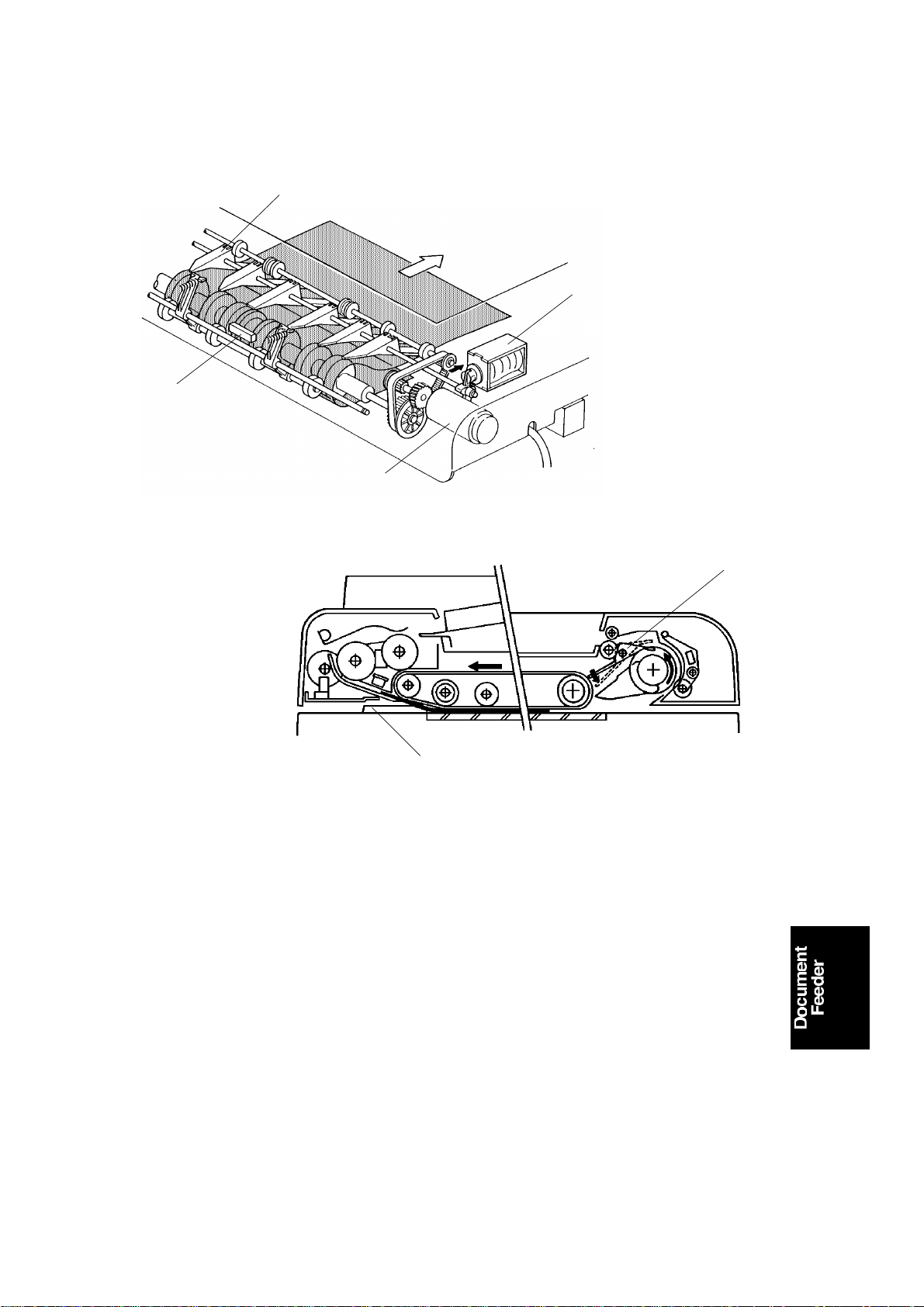

2. COMPONENT LAYOUT

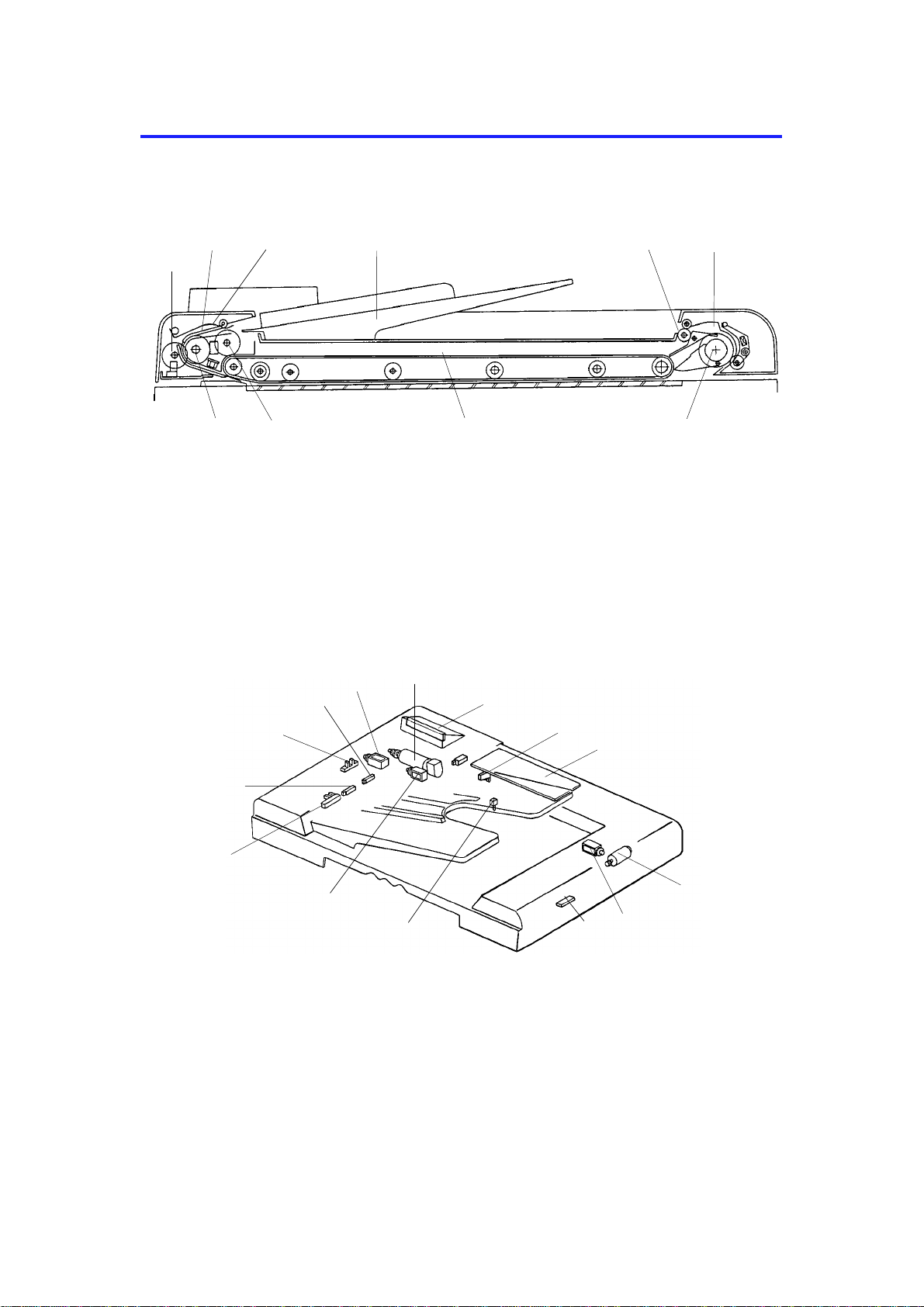

– Mechanical Components –

23

1

4

6

10

9

8

1. Pulse Generator Disk 6. Inverter Pawl

2. Friction Belt 7. Inverter Roller

3. Pick-up Lever 8. Transport Belt

4. Original Table 9. Pick-up Roller

5. Exit Roller 10. Feed Roller

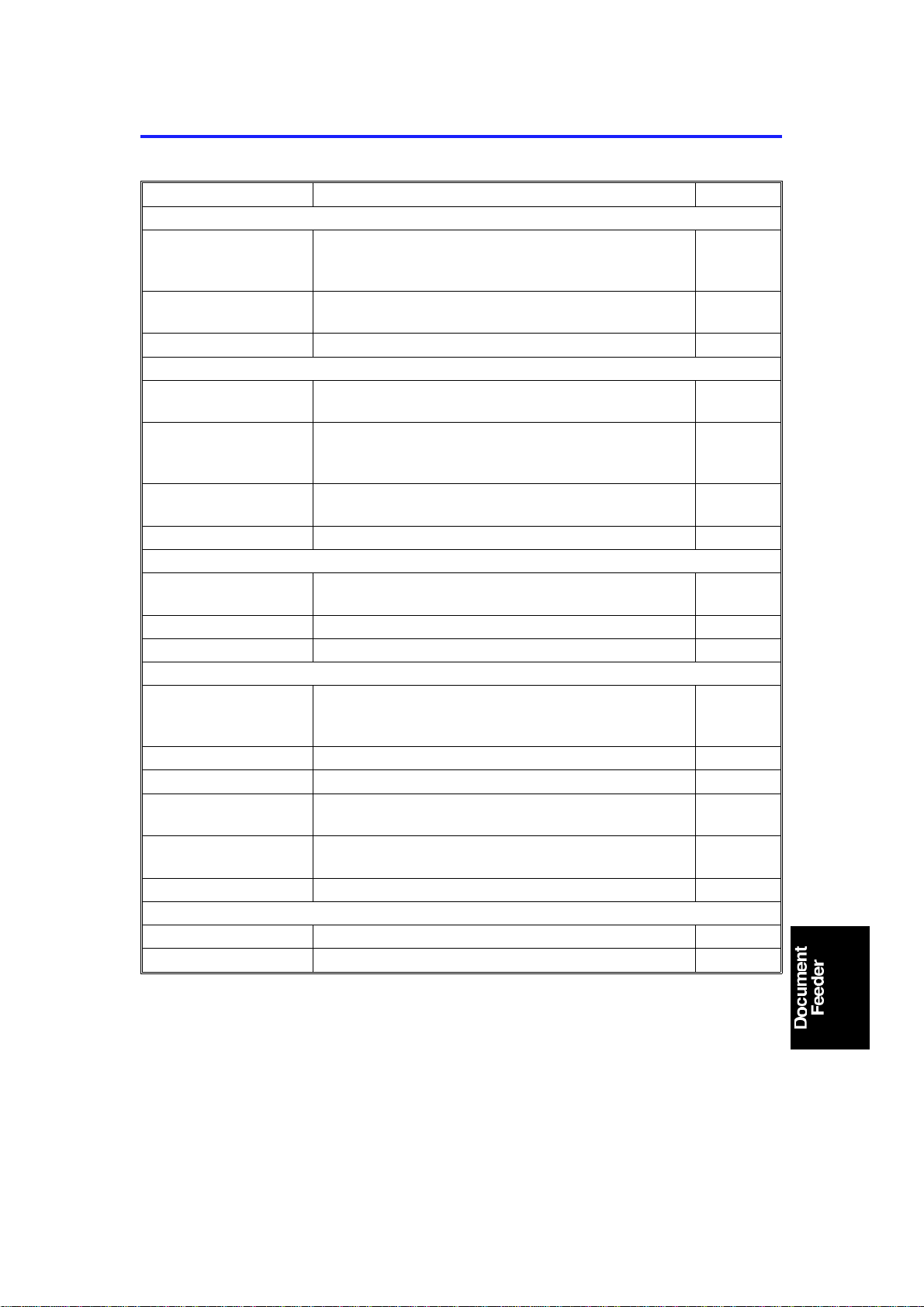

– Electrical Components –

5

4

3

6

7

8

9

2

1

7

A318V500.img

14

11

13

12

A318V501.img

1. Original Set Sensor 8. Lift Switch

2. Registration Sen sor 9. DF Main Board

3. Pulse Generator Sensor 10. Feed-out Motor

4. Original Width Sensor 11. Inverter Solenoid

5. Pick-up Solenoid 12. Feed-out Sensor

6. Belt Drive Motor 13. Original Select Switch

7. Indicator Panel 14. Feed-in Solenoid

2

10

Page 4

31 October 1995 ELECTRICAL COMPONENT DESCRIPTIONS

3. ELECTRICAL COMPONENT DESCRIPTIONS

Name Function Index No.

Motors

Belt Drive Motor A DC servomotor that drives the transport belt and

feed-in system (pick-up roller, feed roller, pull-out

roller, and relay roller).

Feed-out Motor A DC servomotor that drives the feed-out unit of the

DF.

Solenoids

Pick-up Solenoid Energizes to press the pick-up lever against the stack

of originals in preparation for original feed-in.

Feed-in Solenoid Turns on to engage the feed-in clutch so rotation is

transmitted to the feed roller, pull-out rollers, and relay

rollers.

Inverter Solenoid Energizes to invert the original when copying

two-sided originals.

6

10

5

14

11

Switches

Lift Switch Informs the CPU when the DF is lifted and also serves

as the jam reset switch for the DF.

Original Select Switch Selects thick original mode or thin original mode. 13

Sensors

Original Set Sensor Informs the copier CPU that originals have been

placed and causes the Insert Original indicator to go

out.

Registration Sensor Sets original stop timing and measures original length. 2

Original Width Sensor Determines the width of the originals. 4

Pulse Generator

Sensor

Feed-out Sensor Checks for original misfeeds and sets original stop

Printed Circuit Boards

DF Main Board Controls all DF functions. 9

Indicator Panel Board Contains operator indicators. 7

Generates pulses used to measure the original length. 3

timing when in auto reverse mode.

8

1

12

3

Page 5

OVERALL MACHINE CONTROL 31 October 1995

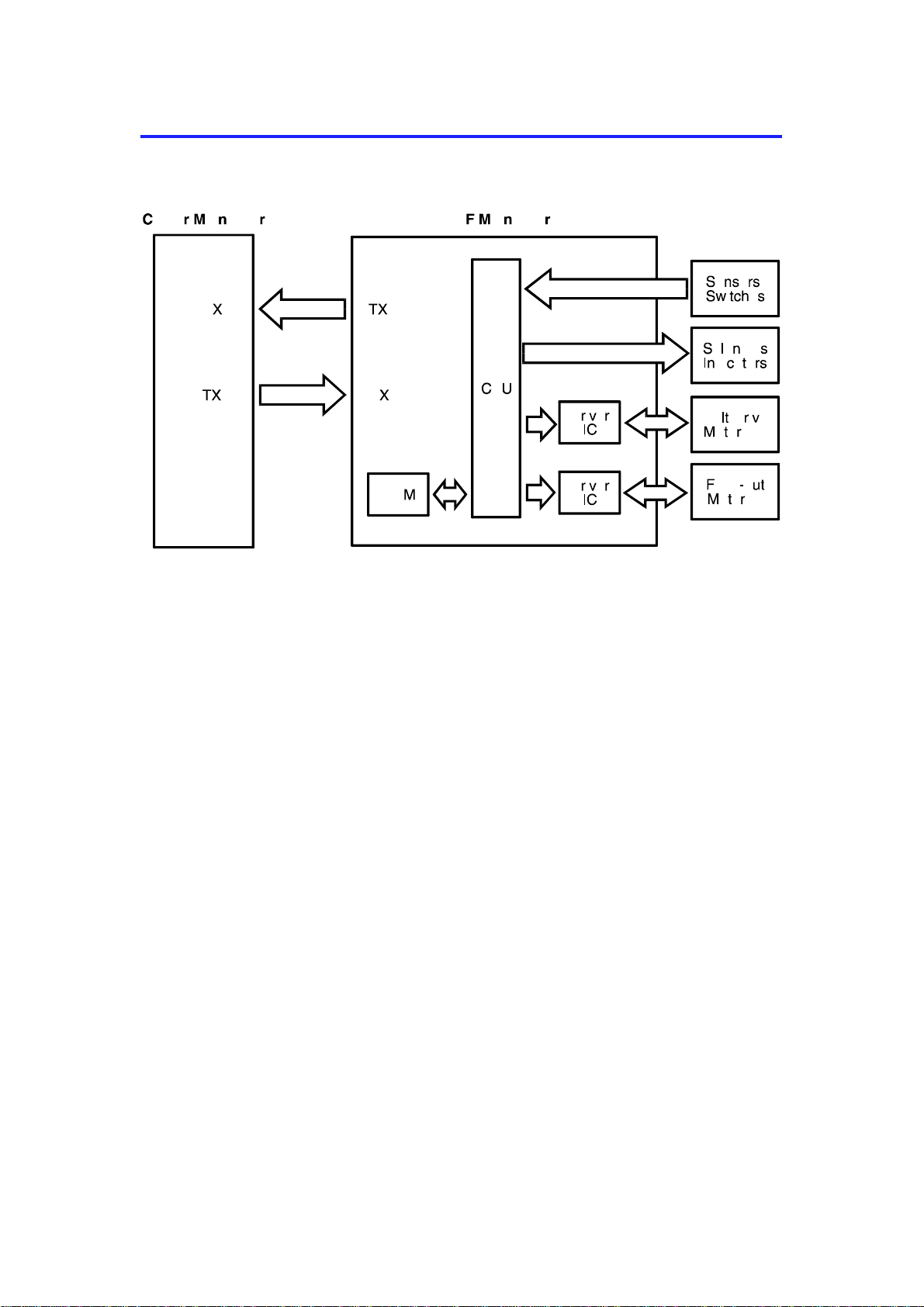

4. OVERALL MACHINE CONTROL

A318D500.wmf

The DF CPU monitors the input signals from the sensors and switch es, and

energizes the solenoids and the indicator LEDs directly. The belt drive motor

and the inverter motor are cont rolled by the DF CPU through their respective

driver ICs. The exchanged signals are shown in the tables on the next page.

4

Page 6

31 October 1995 OVERALL MACHINE CONTROL

1. DF → Copier

No. Signal Name Definition

1 Original Set Originals have been set on the original table

2 Copy Start Allows the copier to start the copy sequence

3 Lift Up The DF has been lifted

4 DF Misfeed A misfeed has occurred in the DF

2. Copier → DF

No. Signal Name Definition

1 Feed-in Requests the DF to feed in the original

2 Feed-out Requests the DF to feed out the original

3 Invert Original Requests the DF to invert the original

4 Auto Feed Shifts the DF to the auto feed mode

5 Original Stay The was attempted to use the DF but an original from the

previous copy run remains on the exposure glass

5

Page 7

BASIC OPERATION 31 October 1995

5. BASIC OPERATION

1. One-sided Original Feed

When an original is inserted face up into the DF, the Inse rt Orig inal indicator

light goes out and the DF informs the copier CPU that originals have been set.

When the Start key is pressed, the copier CPU sends the feed-in signal to

the DF. On receipt of this signal, th e DF ene rgize s the pick-up solen oid, the

feed-in solenoid, an d the belt drive motor in order to fe ed in the bot to m shee t

of the original stack onto the exposure glass. The pick-up solenoid and the

feed-in solenoid remain energized until the original’s leading edge reaches

the DF registration sensor. The belt drive moto r t urn s off short ly a ft er th e

original’s trailing edge passes the DF registration sensor.

While feeding the original, the DF registra tio n sen sor and the orig ina l width

sensor check the origina l size.

Just when the origina l trailing edge has passed the DF registra tio n sensor,

the DF CPU sends the copy start signal to th e copier.

When the scanner reaches the return position, the copier CPU sends the

feed-out and the feed-in signals to the DF CPU in order to exchange the

original with the next original. At this time, the scanner be gin s retu rnin g to the

home position.

When the scanner comes to th e ret urn position after scannin g th e last

original, the copier CPU only sen ds th e feed-out signal in order to feed out

the last original.

6

Page 8

31 October 1995 BASIC OPERATION

2. Two-sided Original Fee d

Unlike one-sided original feed, the back side of the original must be copied

first to keep the originals and copies in the correct order.

During original feed-in, the sequence is the same as fo r one-side d feed ;

however, the DF CPU also energizes the in vert er mot or an d th e inverter

solenoid a short time afte r t he origin al’s trailing edge has passed the DF

registration sensor. The belt drive motor continues to feed the origin al un til

the original’s leading ed ge passe s the fee d-out sensor. At this point the

inverter mechanism inverts the origin al, in prep aration for copying the back

side. Then the belt drive motor reve rses an d th e orig inal is fed towards the

left scale and is aligned against the sca le. The DF CPU se nds the copy sta rt

signal a short time after the origin al’s tra iling edge has passed the feed-out

sensor.

When the scanner reaches the return position, the copier CPU sends the

invert original signal to the DF CPU in order to make a copy of the front side.

The original is inverted in the same way as for back side copying.

3. Semi-automatic Document Feed

If a single original is inserte d int o the original table and cop ied , the DF shifts

to the semi-automatic feed mode and lights the Auto Feed ind icat or. The

Auto Feed indicator remains on for five secon ds after the copier main motor

stops. If another origina l is inserted within that five-second pe riod , it is

automatically fed and copied.

7

Page 9

ORIGINAL FEED 31 October 1995

6. ORIGINAL FEED

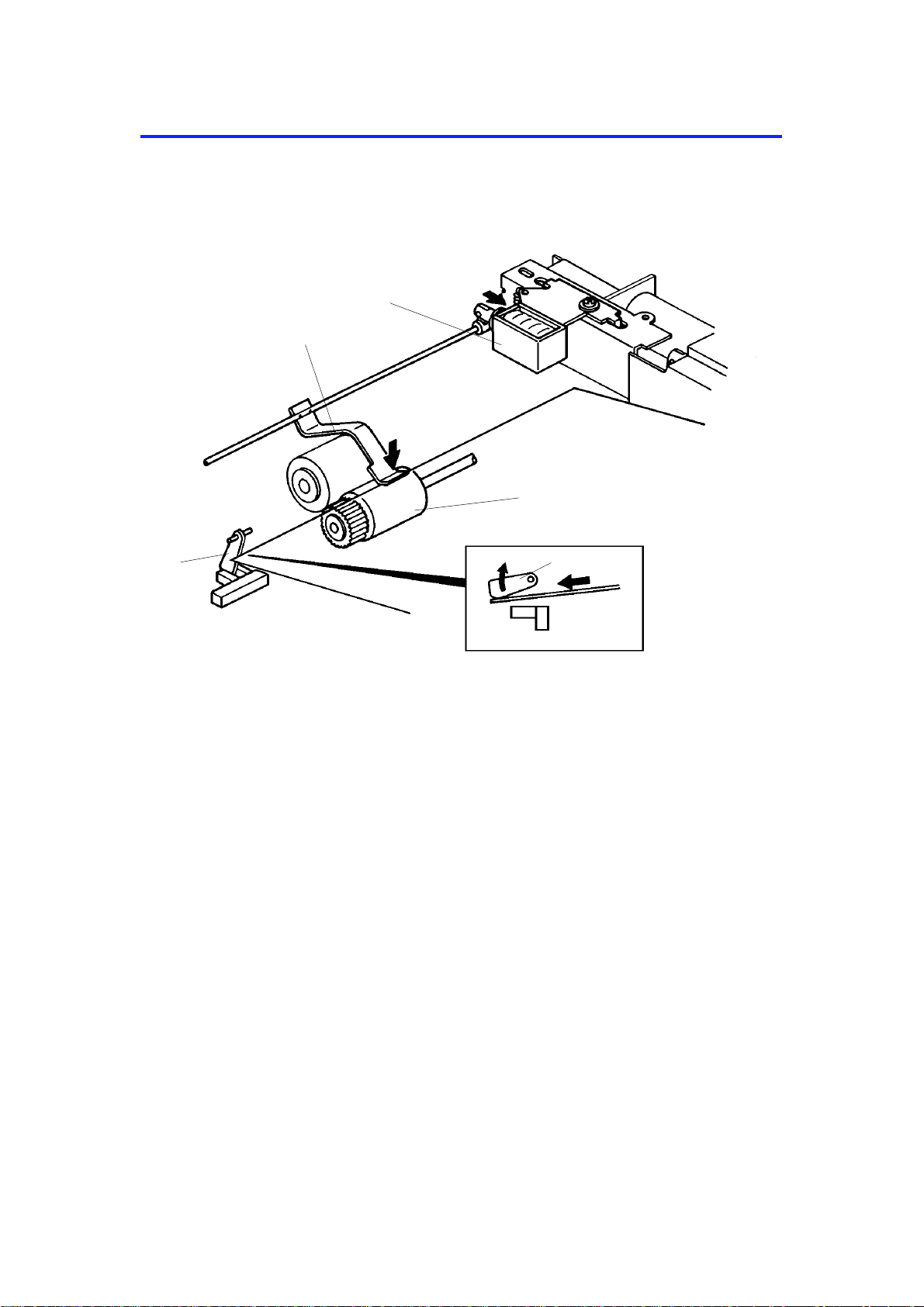

6.1 ORIGINAL PICK-UP

[B]

[C]

[D]

[A]

After the originals have been pla ced on the orig ina l t able, the originals

contact the feeler [A] of the original set sensor and cause the feeler to move

out of the sensor. The DF then sends the origin al set signa l to the cop ier

CPU to inform it that the DF will be used. When the Sta rt key is pressed, the

pick-up solenoid [B] is energized. The original stack is then pressed between

the the pick-up lever [C] and pick-up roller [D]. The rota tio n of the pick-up

roller advances the bottom original.

[A]

A318D501.img

8

Page 10

[B]

31 October 1995 ORIGINAL FEED

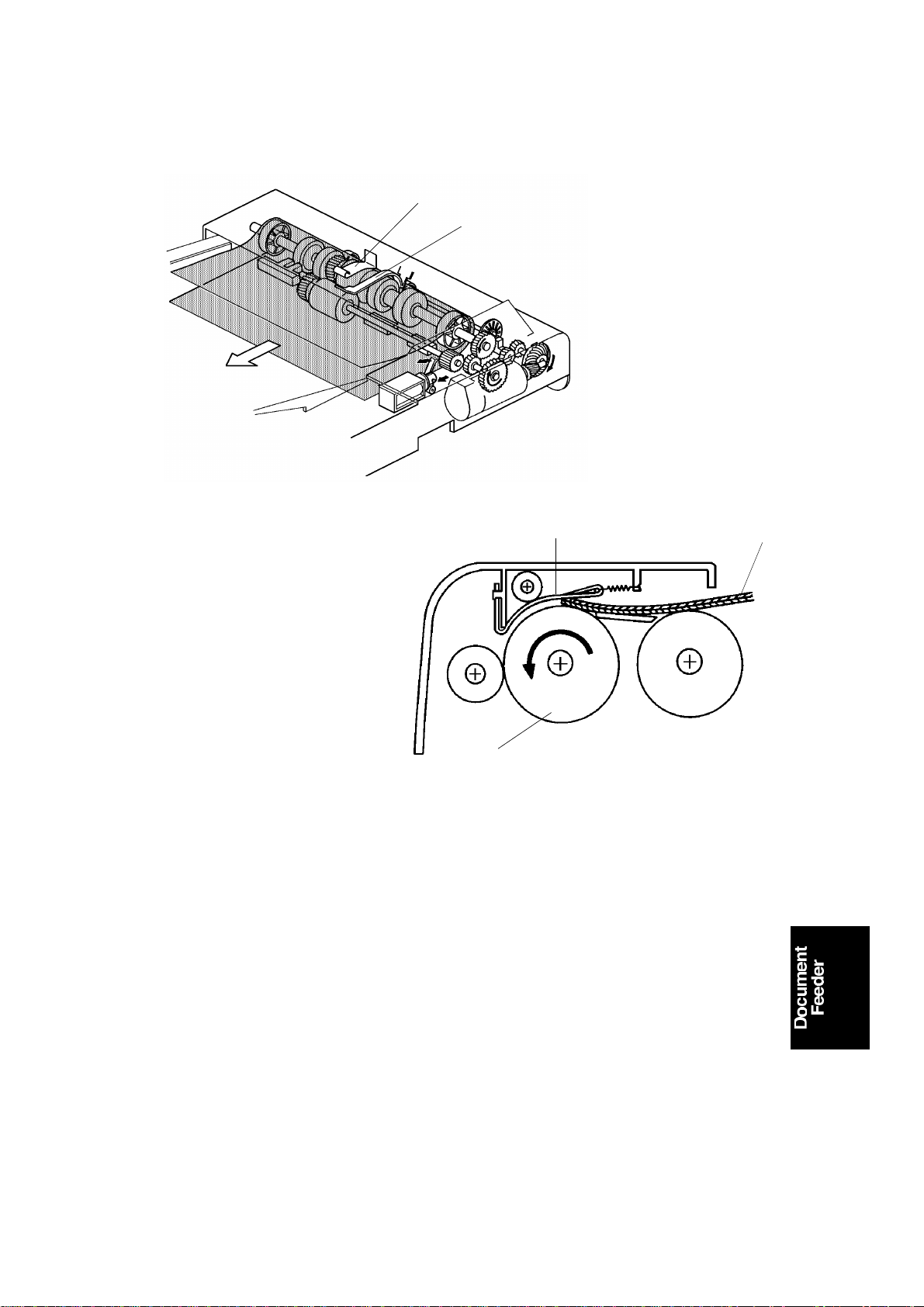

6.2 ORIGINAL SEPARATION

[B]

[A]

A318D502.img

[C]

[A]

A3618D503.img

The feed roller [A] and the friction belt [B] are use d to fee d in and sep ara te

the originals [C]. Only the bottom original is fed because the friction belt

prevents any other origin als fro m f eeding.

Original feed starts when the feed roller starts turning and advances the

bottom original of the stack. The feed roller moves the original past the

friction belt because the driving force of the feed roller is great er than the

resistance of the friction belt . The friction belt prevents multiple feeds

because the resistance of the frict ion belt is great er th an the frictio n be twe en

original sheets.

9

Page 11

[E]

[C]

ORIGINAL FEED 31 October 1995

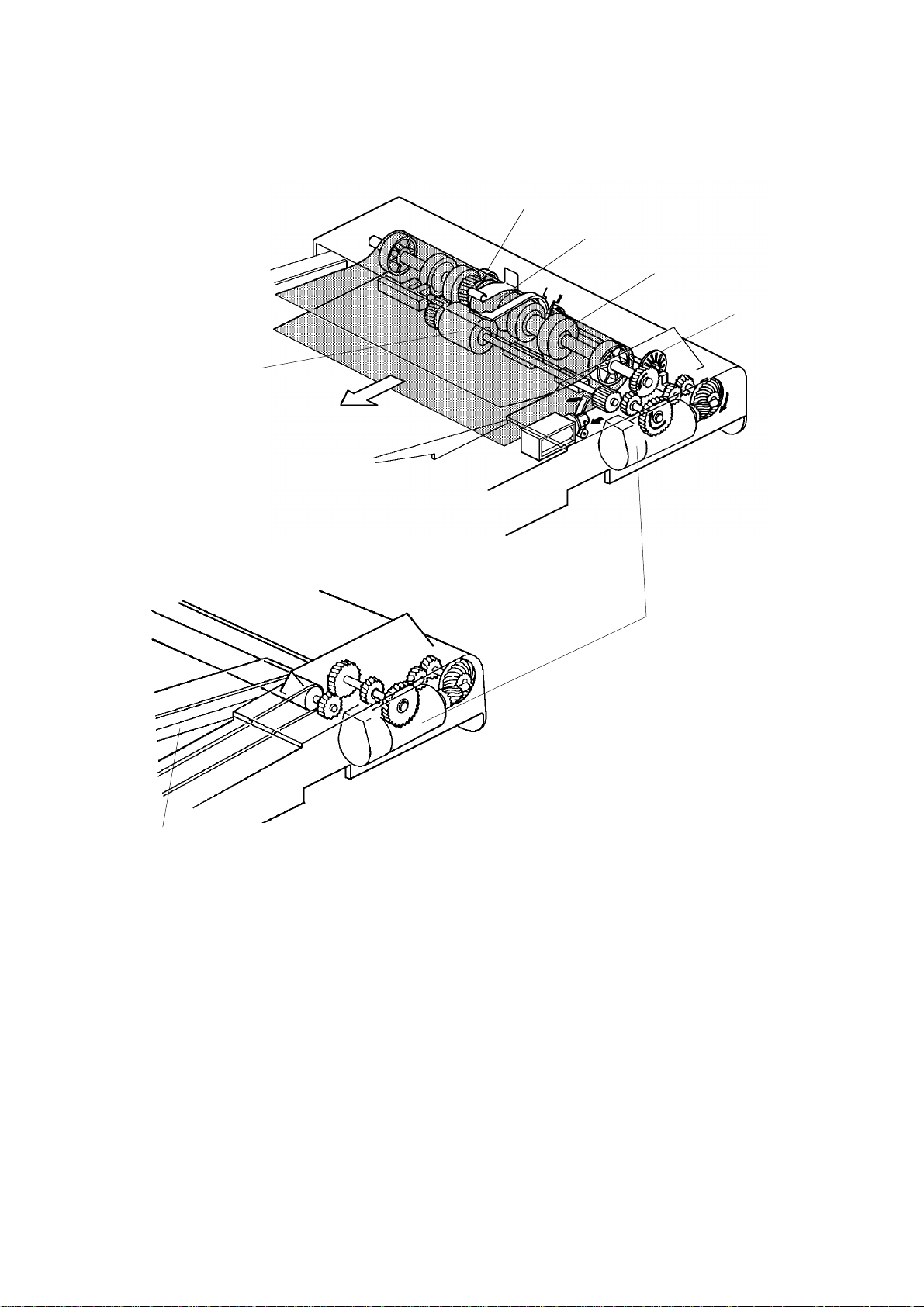

6.3 ORIGINAL FEED-IN MECHANIS M

[D]

[G]

[B]

A318D504.img

[A]

[F]

A318D505.img

The belt drive motor [A] drives the pick-up roller [B], the feed ro ller [C] , the

pull out roller [D], the relay roller [E], and tra nsp ort belt [F] via a feed clutch

and a gear train.

The pick-up and feed-in soleno ids are ene rgize d 10 0 milliseco nd s aft er th e

Start key of the copier is pressed. Then 100 milliseconds after the soleno ids

are energized, the belt drive motor starts turning. The pulse genera tor disc

[G] always turns when the belt drive motor is on.

Slightly after the original’s trailing edge passes the reg istra tio n sen sor, the

relay rollers and the transport belt sto p turnin g.

10

Page 12

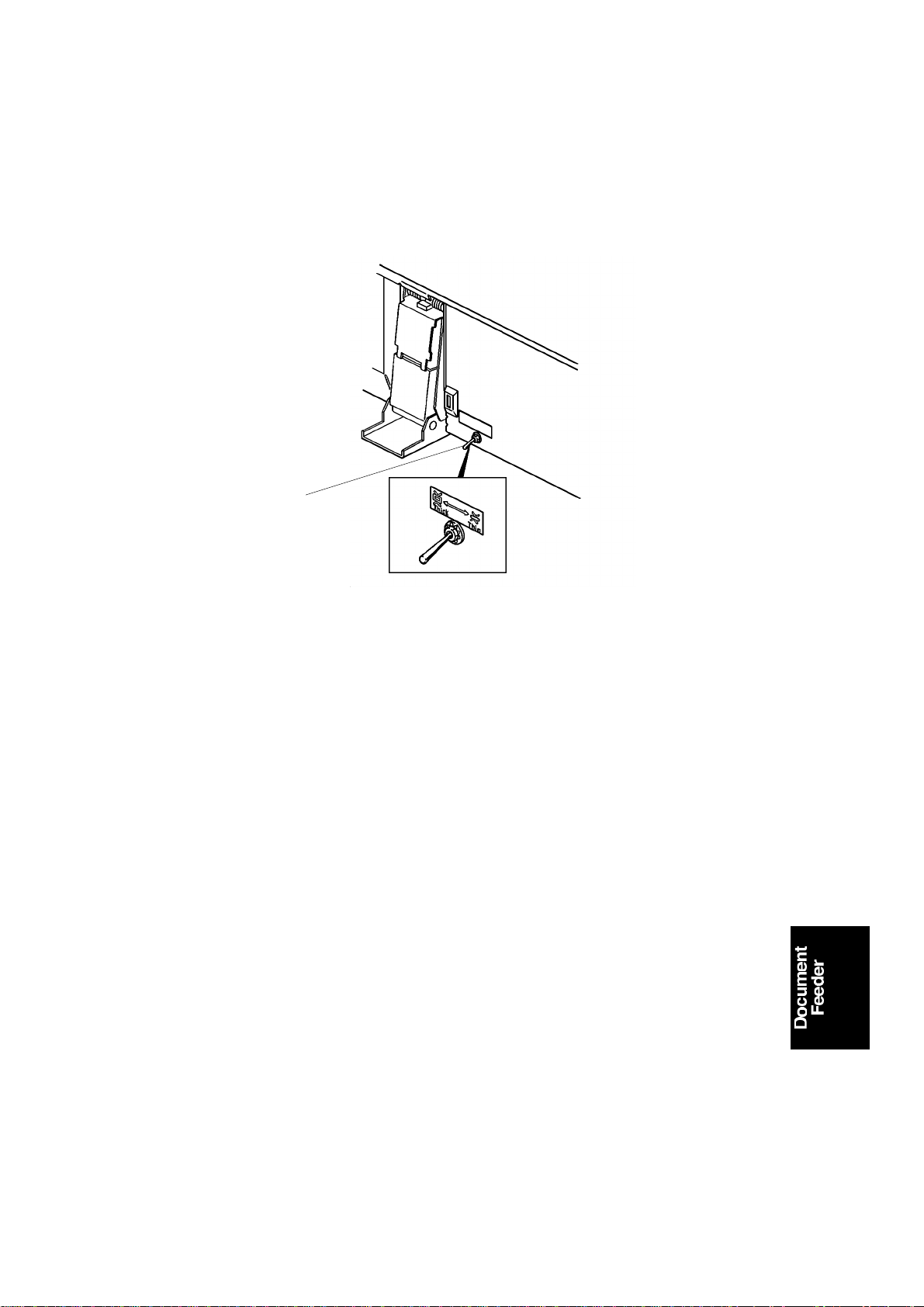

31 October 1995 ORIGINAL FEED

This document feed er ha s two dif ferent ways of stopping orig inals at the

correct position on the exposu re gla ss. They are called the "thin original

mode" and the "thick original mode". The mode used is determin ed by the

original select switch [A].

[A]

A318D506.img

– Original Select Switch –

1. Thin Original Mode

The original is stopped at th e correct position on the exposure glass ba sed

on encoder pulse count. The belt drive mot or stops shortly after the original’s

trailing edge passes the DF registra tio n sensor. (Exact timing depends on

registration adjustme nt.) Thin original mode is selected at the factory.

2. Thick Original Mode

When thick original mode is selecte d, the belt drive mot or rema ins en erg ized

for an additional 30 encoder pulses as comp ared to thin original mode. Then,

the belt drive motor pauses and reverse s f or 21 pulse s. This forces the

original against the left scale and thu s align s the edge of the origin al with the

scale.

After the exposu re cycle is completed, the copier send s the fee d-o ut signal to

the DF CPU and the belt drive and feed-out moto rs start turning. At this time,

the copied original f ee ds out an d the next original feeds in.

11

Page 13

ORIGINAL FEED 31 October 1995

6.4 ORIGINAL SIZE DE TECTI O N

[B]

[A]

A318D507.img

The DF determines original size (bot h widt h and len gt h) th rou gh the use of

the original width sensor [A], registration sensor, and pulse generat or sensor

[B]. The original’s length is calculated by counting the number of pulses from

the pulse generator while th e reg istration sensor is on.

Original size detection is necessary for the feed-in /feed-out timing of the DF.

12

Page 14

31 October 1995 ORIGINAL FEED

6.5 ORIGINAL INVERSION MECHANI SM

[D]

[C]

[E]

[B]

A318D508.img

1)

[D]

[A]

A318D509.img

Two-sided originals are inve rte d in th e fe ed -ou t un it.

1) When the copier Start key is pressed, the two-side d original is fed into the

feed-in unit, passing over th e DF re gist ration sensor [A]. The fee d-o ut

motor [B] and the inverter sole no id [C] turn on 100 milliseconds after the

original’s trailing edge passes the registratio n sen sor. When the invert er

solenoid turns on, the inverter pawls [D] rotate counterclockwise.

13

Page 15

ORIGINAL FEED 31 October 1995

2) 4)

A318D510.img

3) 5)

A318D511.img

6)

A318D512.img

2) The original passes over the exposure glass and feeds into the fee d-out

unit.

3) The original is directed onto the exposure glass again by the inverter

pawls. The belt drive motor now reve rses 14 0 milliseco nd s aft er th e

feed-out sensor [E] turns on. The transport belt then moves the original

toward the left scale . Sligh tly be fo re the original reaches th e lef t scale,

the belt drive motor drops to half speed. This is to prevent damaging the

edge of the original against the left scale.

When the original’s leading edge reach es th e lef t scale , th e belt drive

motor stops. At the same time, the feed-out mot or an d th e inverter

solenoid turn off.

4) After the reverse side of the original has been exposed, the belt drive

motor, the feed-out motor, and the inverter solenoid turn on, and the

original is fed into the inverter section. (This is the same as step 2 above.)

5) The original is fed onto the exposure glass again as in step 3 above . The

front side of the orig ina l is th en co pie d.

6) After the front side of the original has been expo sed , the original is fed

out from the DF.

14

Page 16

31 October 1995 ORIGINAL FEED

6.6 ORIGINAL FEED- OUT ME CHANI SM

[A]

[D]

[C]

[B]

A318D513.img

The exit rollers [A] are driven by the inverter motor [B]. When the document

feeder receives the feed-o ut sig nal f rom the cop ier, the transport belt and the

exit rollers start turning simulta neou sly. The tran spo rt belt carrie s the origin al

to the inverter rollers [C] and the exit rolle rs take over the original feed-out .

When the original’s trailing edge passes the feed-out sen sor [D], the feed-out

motor drops to half of its normal spee d for 2 20 millise con ds an d then stops.

The lower speed preven ts un eve n stacking of originals. For A3 or double

letter size originals, th e feed-out motor speed does n ot chan ge , because it

would take too long to feed then out at the lower speed.

15

Page 17

ORIGINAL FEED 31 October 1995

6.7 BELT DRIVE MOTOR CIRCUIT

A318D514.wmf

A dc servomotor is used as the belt drive motor. The driver IC contro ls the

speed of the belt drive motor. The CPU sen ds th e speed dat a to the driver IC.

The driver IC sends a pulse-width-modulation (PWM) signal to the driver

circuit, which sends the mot or drive pulse s.

An encoder in the servomot or ha s two magnetic sensors that genera te two

pulse signals (phase A and B). The drive r I C monitors the belt speed and

direction with these pulse sig na ls and uses th e signals to regulate the mot or’s

speed.

16

Page 18

31 October 1995 ORIGINAL FEED

6.8 FEED-OUT MOTOR CIRCUI T

A318D515.wmf

The DF CPU sends the speed data (high or low) t o th e drive r IC a nd the

motor drive circuit. The moto r drive circuit creates a PWM signal and sends

the motor drive pulses to the feed-out motor.

The frequency generato r (FG) in the fee d-o ut motor makes a very low voltage

ac signal which is fed back to the driver IC. The drive r IC mo nit ors th e

frequency of this ac signal an d it regulates the motor spee d ba sed on th is

frequency.

17

Page 19

ORIGINAL FEED 31 October 1995

6.9 INPUT AND OUTPUT CIRCUITS

A318D516.wmf

The above devices are directly con tro lled and monit ored by the CPU. The

solenoids and indica to r p anel are energized with +24 volts. The sensors and

switches are energized with +12 volts or +5 volts.

To energize a solenoid or in dica tor, the CPU drops the conne cte d trigger line

from +24 volts to LOW. The CPU monitors t he inpu t line s of th e sen sors and

switches to determine when they are activated.

18

Page 20

[B]

31 October 1995 LIFT MECHANISM

7. LIFT MECHANISM

[D]

[G]

A318D517.img

[A]

[C]

[C]

[A]

[B]

A318D518.img

[F]

[E]

A318D519.img

A318D520.img

When the document feeder is ope ne d, the lift springs [D] provide enough

force to ensure that the document feeder does not fall onto the exposure

glass. When the document fe eder is clo sed , po int s "A" , "B", and "C" are

aligned and no such force is provided to the document feed er.

The lift switch [E] is actuated when the docu men t fe ed er is closed . The copier

then shifts to the document feeder mode. The lift switch also serves as th e

reset switch for document fe ed er misfe ed s.

When a book or very thick original (maximum thickness 60 mm) is copied, th e

DF acts as a cover for the original as shown in figure [F]. The lift switch is

turned off during th is cond ition, so the DF does not function. The tension of

spring [G] returns th e DF t o th e no rmal con dition after copying a thick orig ina l.

19

Page 21

ORIGINAL MISFEED DETECTION 31 October 1995

8. ORIGINAL MISFEED DETECTION

The registration sensor and the fe ed-out sensor are used for misfeed checks.

1. One-sided original

A318D521.wmf

If the registration sensor is not actu at ed wit hin 685 millise con ds af te r the belt

drive motor starts turning, the Origin al Misfe ed indicator lights (ON check).

If the registration sensor does no t tu rn of f with in 1, 25 0 milliseco nds, th e CPU

determines that there has been an original misfeed (O FF check). The

Original Misfeed indicato r also ligh ts if the feed-out sensor is not actu at ed

within 1,250 milliseconds after the feed-out motor starts turning (ON check)

or if the feed-out sensor does not turn off within 1,250 milliseconds after the

feed-out sensor is actuate d (OFF che ck).

20

Page 22

31 October 1995 ORIGINAL MISFEED DETECTION

2. Two-sided original

A318D522.wmf

The registration ON/OFF check is the same as for one-sided originals. Th e

inverter motor and the inve rte r solen oid turn on 100 milliseconds after the

registration senso r t urn s off. If the feed-out sensor is not actuated within

1,250 milliseconds after the feed-out motor starts turning, the Original

Misfeed indicator lights (ON check). The Origin al Misfeed indicator also lights

if the feed-out sensor does not turn off within 1,250 milliseconds after the belt

drive motor reverses (OFF check).

If a previous original remains on the expo sure glass af ter manual copying

and DF feed is attempted, the original misfeed indicat or ligh ts. When the DF

is lifted and the previous original is removed, DF copying is permitted.

21

Page 23

[2]

[9]

[10]

[17]

INSTALLATION PROCEDURE 31 October 1995

9. INSTALLATION PROCEDURE

9.1 ACCESSORY CHECK

Check the accessories and their quantities against the following list:

1. Original Table ........ .......... .. .................... .. .......... .. .................... .. ......1 pc

2. DF Mounting Bracket....................................... .. .......... .. ..................1 pc

3. Angle Stopper..................................................................................1 pc

4. Lift Switch Actuator..........................................................................1 pc

5. E Plate..... .................... .. .......... .. .................... .. .......... .. ....................1 pc

6. Spacer - 0.5 mm.............. .............................. .. .......... .. ....................6 pcs

7. Spacer - 0.2 mm.............. .............................. .. .......... .. ....................4 pcs

8. DF Harness Bracket (not used)........... .. .................... .. .......... .. ........1 pc

9. Bushing (not used) ..........................................................................1 pc

10. Toothed Wash er................................ .. .......... .. .................... .. ..........1 pc

11. Ground Screw - M4 x 6...................... .. .... .. .. .. .. .. .. .... .. .. .. .. .. .. .... .. .. .. ..1 pc

12. Hexagon Head Screw - M4 x 10 .....................................................4 pcs

13. Philips Screw with Flat Wash er - M4 x 5................. ............ ............4 pcs

14. Philips Pan Head Screw - M4 x 5 (round head).................... .. .... .. ..3 pcs

15. Philips Pan Head Screw - M4 x 5 (flat head)................... .. .. ............2 pcs

16. Philips Pan Head Screw - M3 x 5....................................................1 pc

17. Philips Pan Head Screw with Washe r - M3 x 5 (not used ).......... .. ..1 pcs

18. Stud Screw........ .. .. .... .. .. .. .. .. .. .... .. .. .. .. .. .. .... .. .. .. .. .. .. .... .. .. .. .. .. .. .... .. .. ..2 pcs

19. DF Test Sheet ................. .. .......... .. .................... .. .......... .. ................1 pc

[1]

[3]

[4] [5] [6] [7] [8]

[11] [12] [13] [14] [15] [16]

[19]

[18]

A318I500.img

22

Page 24

[22]

31 October 1995 INSTALLATION PROCEDURE

[20]

[21]

[23] [24]

[25] [26] [27]

A318I501.img

20. Philips Pan Head Screw - M5 x 10 (not used).................................2 pcs

21. DF Mounting Bracket (not used) ............... ............ .. ............ .. .. ........1 pc

22. DF Bracket (not used) ............................. .. .................... .. .......... .. ....1 pc

23. Sensor Actuator (n ot used)............ ............ .. ............ .. .. ............ .. .. ....1 pc

24. Sensor Actuator (n ot used)............ ............ .. ............ .. .. ............ .. .. ....1 pc

25. Philips Pan Head Screw - M5 x 12 (not used).................................2 pcs

26. Clamp..............................................................................................1 pc

27. Philips Pan Head Screw with Flat Washer - M4 x 8 .......................1 pc

NOTE: Optional DF Interface Kit Typ e B (A6 25 ) is necessa ry to inst all a

DF57 on the A173 model. This kit includes the following parts:

DF Interface Board...................................................................1 pc

Studs.........................................................................................2 pcs

M3 x 6 Hexagon Head Screws........... .. .. .. .. .. .. .. ........................4 pcs

23

Page 25

INSTALLATION PROCEDURE 31 October 1995

[A]

A318I502.img

NOTE: Connector (3P/Brown) [A ] on the DC harne ss assemb ly is not use d

with the A173 copier.

24

Page 26

31 October 1995 INSTALLATION PROCEDURE

9.2 INSTALLATION PROCEDURE

[A]

[D]

[B]

A318I504.img

A318503.wmf

"a"

[C]

A318I506.img

CAUTION

I

Before installing the DF, check that the power cor d is unplugge d.

1. Remove the platen cover [A] (4 screws).

[D]

A318I505.img

[E]

A318I507.img

2. Remove the rear cover (4 screws) and the right cover (4 screws).

3. Secure the DF mounting bracket [B] (4 screws [12] in the acce ssorie s list ).

4. Adjust the height of the DF mount ing bracke t in th e fo llowin g ord er:

1) Set the E plate [C] on the exposure glass as shown and measure the

clearance "a" between the DF mounting bracket and the E plate using

a scale.

2) If necessary, remove the DF moun tin g bra cket and insert spacers [D]

until the clearance "a" is betwee n 0 mm and 0.3 mm.

5. Remove the strip of tape [E].

25

Page 27

INSTALLATION PROCEDURE 31 October 1995

A318I508.img

[A]

A318I509.img

6. Mount the DF on the DF mounting bracket, aligning the holes in the DF

and the pins on the mountin g bra cket, then slide the DF to the lef t as

shown.

7. Secure the DF to the DF mounting bracket (4 screws [13 ] in th e

accessories list).

8. Secure the 2 stud screws [A] as shown in the diagram.

26

Page 28

[E]

31 October 1995 INSTALLATION PROCEDURE

[A]

[C]

[F]

[B]

[D]

A318I510.wmf

9. Attach the clamp [A] as shown (1 screw [27] in the accessories list).

10. Install the DF inte rfa ce bo ard [B] on the main board (2 studs [C] and 4

screws).

11. Connect the optics fiber cable connector (2P/Black) [D] and the dc

harness connector [E] to the DF interface board .

12. Secure the grounding wire [F] (1 scre w and too th ed washer).

27

Page 29

INSTALLATION PROCEDURE 31 October 1995

[A]

A318I511.img

[C]

[B]

A318I512.img

13. Remove the DF main PCB cover [A] and turn off DIP switch 101- 2.

NOTE: Make sure that DIP switch 101 -1 is on an d th e other switches

(101-2, 3 and 4) are off.

14. Install the angle stop per [ B] (2 screws [15 ] in th e accessories list).

15. Install the origina l tab le [C] .

28

Page 30

31 October 1995 INSTALLATION PROCEDURE

[A]

A318I513.img

[C]

[B]

A318I514.img

16. Adjust the height of the magnet catch es in th e fo llowin g ord er:

1) Remove the grip cover [A] (3 screws).

2) Loosen the screws of the magnet catches [B] (2 screws each).

3) Close the document fee de r and tighten the screws of the magnet

catches when the rubber stopper [C] contacts the exposure glass.

17. Reinstall the grip cover (3 screws).

NOTE: Open and close the docume nt fee de r wh ile con firming that the

magnet catches are makin g good contact.

18. Plug in the copier and turn on the main switch.

19. Inch version machines only:

Access SP mode and change the sett ing of SP1 from 0 to 1.

20. Check the original re gist ration. (See page 30.)

21. Reassemble the copier. (The DF harne ss f its in th e cut -out in the rear

cover as shown.)

22. Check the operatio n of the DF.

23. Position the original select switch to th in pape r mode (this is the norma l

position) and explain th e function of this switch to the customer.

29

Page 31

INSTALLATION PROCEDURE 31 October 1995

[A]

A318I515.wmf

Original Registrati on Adjustm ent

1. Make a copy of the test sheet in the platen mode (A4 width).

2. Confirm that the original select swit ch is in the thin origin al mod e and

make a copy in DF mode (A4 width).

3. Compare the registration of the copy in platen mode with that of DF

mode, and check that the difference is within 2.5 mm.

4. If the difference is more than 2.5 mm, remove the DF main PCB cover [ A]

(1 screw) and adjust VR102 to change the origina l-sto p timing.

NOTE: Turning VR102 clockwise results in the original sto pping later.

5. Make a copy of the test sheet in DF two-sided original mode.

NOTE: a) The test sheet should stop presse d ag ain st the left scale in DF

two-sided original mode.

b) The position of the original select swit ch does no t mat te r .

6. Compare the registration of the copy in platen mode with that of DF

two-sided original mode, and check that the difference is within 2. 0 mm.

7. If the difference is more than 2.0 mm, remove the DF main PCB cove r

and adjust VR103 to change the orig ina l-sto p timin g.

NOTE: a) The test sheet should stop presse d ag ain st the left scale in DF

two-sided original mode.

b) Turning VR103 clockwise results in the original sto pp ing later.

30

Page 32

[A]

31 October 1995 PREPARATION FOR TRANSPORTATION

10. PREPARATION FOR TRANSPORTATION

IMPORTANT

Before moving the document feeder, be sure to prepare it for

transportation as follows. The docume nt fe ede r ma y be badly dam age d

if it is moved without proper preparation.

[B]

1. Remove the original table [A].

[B]

A318I516.img

2. Secure the document feeder with strips of ta pe [B] as shown in the

illustration.

31

Page 33

REPLACEMENT AND ADJUSTMENT 31 October 1995

11. REPLACEMENT AND ADJUSTMENT

11.1 FEED-IN UNIT

11.1.1 Transport Belt Replacement

[C]

[A]

[D]

[B]

A318R500.img

1. Turn off the main switch and remove the grip [A] (3 screws).

2. Remove the DF main PCB cover [B] (1 screw, 1 connector).

3. Open the entrance guide [C] and remove the tran sport belt assembly [D]

(5 screws).

32

Page 34

31 October 1995 REPLACEMENT AND ADJUSTMENT

[C]

[B]

[A]

A318R501.img

4. Remove the 2 tension springs [A] and pull off the transport belt [B].

NOTE: a) When installing the tra nsport belt, make sure the belt lies

between the belt guide spacers [C].

b) When installing the tra nsport belt assembly, make sure th e

positioning pin correctly fits in the DF frame, and hold open the

exit guide to prevent the mylar strip from be comin g damaged.

33

Page 35

REPLACEMENT AND ADJUSTMENT 31 October 1995

11.1.2 Feed-in Unit Removal

[B]

[A]

A318R502.img

1. Turn off the main switch.

2. Remove the transport belt assembly. (See Transport Belt Replacement.)

3. Remove the belt drive motor cover [A] (4 screws).

4. Remove the feed-in unit [B] (4 screws, 8 connectors).

34

Page 36

31 October 1995 REPLACEMENT AND ADJUSTMENT

11.1.3 Pick-up Roller Replacement

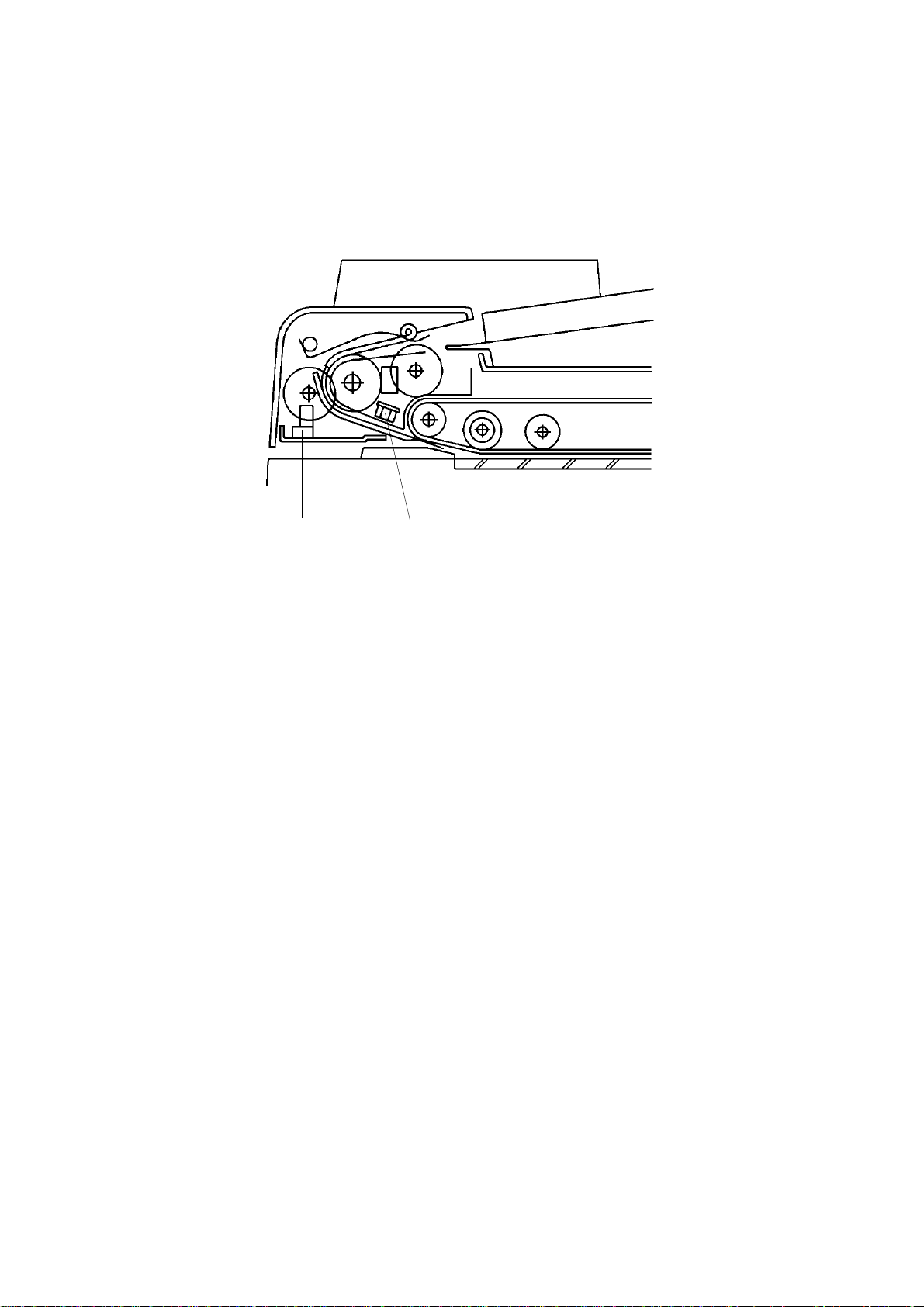

[A]

[B]

[C]

[D]

A318R503.img

1. Turn off the main switch.

2. Remove the feed-in unit. (See Feed-in Unit Removal.)

3. Remove the lower entrance guide [A] (2 screws).

4. Remove the original set sensor assembly [B] (1 screw, 1 connector).

5. Remove the pick-up roller [C] (3 E-rings, 1 bushing, 1 gear).

NOTE: a) Be careful not to loose the pin [D].

b) When installing the roller, make sure the positioning pin is

correctly inserted in the cut-out of the roller.

c) When installing the gear, make sure th e fla t side of the gear is

facing away from the roller.

35

Page 37

REPLACEMENT AND ADJUSTMENT 31 October 1995

11.1.4 Feed-in Clutch Lubrication

[B]

[D]

[C]

[A]

A318R504.img

1. Turn off the main switch.

2. Remove the original set sensor assembly. (See Pick-up Roller

Replacement.)

3. Remove the feed-in solenoid lever spring [A].

4. Remove the pick-up roller assembly [B] (2 E-rings, 2 bushings).

5. Disassemble and lubricate the feed clutch [C] (1 E-rin g) with Mobil Temp.

78.

NOTE: a) Be careful not to loose the pin [D].

b) When installing the fe ed clutch, make sure the positionin g pin is

correctly inserted in the cut-out of the clutch.

36

Page 38

[D]

31 October 1995 REPLACEMENT AND ADJUSTMENT

11.1.5 Pick-up Solenoid Adjustment

[B]

[F]

[E]

A318R505.img

[C]

[A]

A318R506.img

1. Turn off the main switch.

2. Place several sheets of paper [A] over the expo sure glass area.

3. Lower the feed-in unit (see Fee d-in Unit Removal) without disconnecting

the eight connecto rs.

4. Turn on the main switch.

NOTE: When the main switch is turned on, the DPS1 01 setting on the

DF main PCB must be as follows:

1 = ON 3 = OFF

2 = ON 4 = OFF

This is so that the initial check sequence can take place.

37

Page 39

REPLACEMENT AND ADJUSTMENT 31 October 1995

5. Turn off DPS101-1 and 2, then turn on DPS101-3 and 4 [B].

6. Loosen the screw fixing the pick-up solenoid [C].

7. Place the 0.15 mm thickness gauge [D] between th e plu ng er an d the

solenoid.

8 While holding the solenoid , press SW101 [E] on the DF main PCB to

engage all DF solenoids.

9. Holding the solenoid securely, move it slowly towards the left , un til th e

plunger is attracted to the solenoid. Just at th is point, tighten the screw.

NOTE: Make sure the pick-up lever is touch ing the pick-up roller during

this adjustment.

10. Press SW 102 [F] to turn of f th e solenoids.

11. Turn off DPS101-3 and 4, then turn on DPS101-1 and 2.

12. Turn off the main switch and reassemble the DF.

13. Check the original feed-in operation.

38

Page 40

31 October 1995 REPLACEMENT AND ADJUSTMENT

11.1.6 Feed Roller Replacement

[C]

[A]

[B]

A318R507.img

1. Turn off the main switch.

2. Remove the lower entrance guide. (See Pick-up Roller Replacement.)

3. Loosen the front bracket [A] (2 screws).

4. Release the feed roller shaft [B] from the front bracket (1 E-ring, 1

bearing).

5. Remove the feed roller [C] (3 E-rings, 1 side roller, 1 pull-out roller).

NOTE: a) Take care not to lose the pin s.

b) When installing the fe ed roller, make sure the gear side of the

roller faces the front (see illustration).

c) When installing the side and pull-ou t rolle rs, make sure the pins

are correctly inserted in the cut -ou ts of the rollers.

39

Page 41

[D]

REPLACEMENT AND ADJUSTMENT 31 October 1995

11.1.7 Feed-in Solenoid Adjustment

[B]

[C]

[A]

A318R508.img

1. Turn off the main switch.

2. Place several sheets of paper [A] over the expo sure glass area.

3. Lower the feed-in unit (see Fee d-in Unit Removal) without disconnecting

the eight connecto rs.

4. Check that DPS101 is set for the normal mode (1 = ON, 2 = ON, 3 =

OFF, 4 = OFF).

5. Turn on the main switch.

6. Turn off DPS101-1 and 2, then turn on DPS101-3 and 4 [B].

7. Loosen the 2 screws securing the feed-in solenoid [C] .

8. Press SW101 on the DF main PCB (to engage all DF solenoids) and

adjust the position of the solen oid until the gap [D] (see illustration) is

within 1.0 – 2.0 mm.

9. Press SW102 on the DF main PCB to turn off all DF solenoids.

10. Turn off DPS101-3 and 4, then turn on DPS101-1 and 2.

40

Page 42

31 October 1995 REPLACEMENT AND ADJUSTMENT

11.1.8 Friction Belt Replacement

[A]

[B]

[C]

A318R509.img

[D]

1. Turn off the main switch.

2. Remove the seal cover [A] on top of the DF cover.

3. Remove the friction belt assembly [B] (1 screw).

4. Remove the friction belt [C] (2 springs, 1 pin).

NOTE: a) When installing the friction belt assembly, make sure the

friction roller [D] is set in the corre ct position (see illustration).

b) If the seal cover becomes dirty or def orme d, replace it with a

new one.

41

A318R510.img

Page 43

[A]

REPLACEMENT AND ADJUSTMENT 31 October 1995

11.2 FEED-OUT UNIT

11.2.1 Feed-out Unit Removal

A318R511.img

[C]

[B]

A318R512.img

1. Turn off the main switch.

2. Remove the DF grip [A] (3 screws).

3. Remove the feed-out motor cover [B] (4 screws).

4. Remove the feed-out unit [C] (4 screws, 3 connectors).

42

Page 44

31 October 1995 REPLACEMENT AND ADJUSTMENT

11.2.2 Inverter Solenoid Adjustment

[A]

[B]

[C]

[D]

A318R513.img

1. Turn off the main switch.

2. Place several sheets of paper [A] over the expo sure glass area.

3. Lower the feed-out unit (See Feed-out Unit Removal) without

disconnecting the th ree connectors.

4. Check that the DPS101 is set for the normal mode (1 = ON, 2 = ON, 3 =

OFF, 4 = OFF).

5. Turn on the main switch.

6. Turn off DPS101-1 and 2, then turn on DPS101-3 and 4 [B].

7. Loosen the screw securing the inverter solenoid [C].

8. Press SW101 on the DF main PCB (to engage all DF solenoids), and

adjust the position of the solenoid until the gap [D] (Se e illustrat ion) is

within 1.5 ± 0.5 mm.

9. Press SW102 on the DF main PCB to turn off all DF solenoids.

10. Turn off DPS101-3 and 4, then turn on DPS101-1 and 2.

43

Page 45

REPLACEMENT AND ADJUSTMENT 31 October 1995

11.2.3 DF Leading Edge Registration Adjustment

[A]

A318R514.img

1. Using the DF test chart, make a copy in the platen cover mode (A4 width).

2. Confirm that the original select switch [A] is in the thin mode and again

using the test chart, make a copy in the DF mode (A4 width).

3. Compare the leading edge registration of both copies, and check tha t th e

difference betwee n the two copies is within 2.5 mm.

4. If the difference is more than 2.5 mm, remove the DF main PCB cover (1

screw) and adjust VR102 on the DF main PCB until the leading edge

registration is within specifica tio n.

NOTE: Turning VR102 clockwise results in stoppin g the origina l la ter.

5. Using the DF test chart, make a copy in the DF two sided-o rigin al mode.

(Insert the origina l face down.)

6. Compare the leading edge registration with that of the plate n cover mode

copy, and check that the diff erence between the two copies is within 2.00

mm.

7. If out of specification , ad just VR10 3 on the DF main PCB un til the

leading edge registration is correct.

NOTE: a) The test sheet stops pressed against the left scale in DF

two-sided original mode.

b) Turning VR103 clockwise results in the original sto pp ing later.

44

Page 46

[B]

31 October 1995 REPLACEMENT AND ADJUSTMENT

11.3 BELT DRIVE MOTOR SPEED ADJUSTMENT

Normal

Setting

[A]

A318R515.img

[C]

A318R516.img

NOTE: The belt drive speed adjustment is require d whe n th e main board is

replaced.

1. Turn off the main switch.

2. Check that DIP switch 101 is set for the normal setting as follows:

101-1 101-2 101-3 101-4

ON OFF OFF OFF

3. Turn on the main switch and DIP switch 101-2 and -4.

4. While turning on the lift switch manually, adjust th e belt drive moto r speed

using VR101 [A] so that both the Insert Origin al ind icator [B] and Auto

Feed indicator [C] tu rn off.

NOTE: a) When the Insert Original indicator ligh ts, turn VR10 1 clockwise

to reduce the motor speed.

b) When the Auto Feed indica tor lights, turn VR101

counterclockwise to increase the motor speed.

c) Confirm that both indicators remain off for approximately 5

seconds in order to stabilize the mot or spe ed .

5. Turn off DIP switch 101-2 and -4.

NOTE: Do not use VR106. This variab le reg ister is for adjusting feed-out

motor speed. This is preset by th e ven do r.

45

Loading...

Loading...