Page 1

SECTION 1

OVERALL MACHINE

INFORMATION

Page 2

1 July 1991

1. SPECIFICATIONS

Configuration:

Desk top

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book

Original Size: Maximum A3/11"x17"

Copy Paper Size: Maximum A3/11"x17"

Minimum A6/5 1/2" x 8 1/2" (lengthwise)

(Duplex Copying) A4 and B5/8 1/2" x 11" (sideways)

Copy Paper Weight: Cassette feed: 52 to 157 g/m2 (14 to 42 lb)

Paper tray feed: 64 to 90 g/m2 (17 to 22 Ib)

Manual feed: 52 to 157 g/m2 (14 to 42 lb)

Duplex: 59 to 104 g/m2 (16 to 27 lb)

Reproduction Ratio: 2 Enlargement and 3 Reduction

A4/A3 Version LT/LDG Version

Enlargement

Full size 100% 100%

Reduction

Zoom: From 50% to 200% in 1% steps

Copying Speed: 18 copies/minute (A4 /8 1/2" x 11" sideways)

10 copies/minute (A3/11" x 17")

Warm-Up Time: 60 seconds (at 20oC)

First Copy Time: 5.9 seconds (A4/8 1/2" x 11" sideways)

Copy Number Input: Ten keys, 1 to 99 (count up)

141%

122%

93%

82%

71%

155%

129%

93%

74%

65%

Manual Image Density

Selection:

7 steps

1-1

Page 3

1 July 1991

Automatic Reset: 1 minute standard setting; can also be set to 3

minutes or no auto reset.

Paper Capacity: Cassettes: 500 sheets

Paper tray: 250 sheets

Manual feed table: 50 sheets

Toner Replenishment: Black: Cartridge exchange (370 g/ cartridge)

Color (red, blue, & green): Cartrid ge excha ng e

(310g/cartridge)

Copy Tray Capacity: 250 sheets (B4/8 1/2" x 14" and smaller)

100 sheets (A3/ 11" x 17")

Power Source: 110V / 60 Hz/ 15A (for Taiwan)

115V/ 60Hz/ 15A (for N.A.)

220V/ 50Hz/ 8A (for EU.)

220V/ 60Hz/ 8A (for EU.)

240V/ 50Hz/ 8A (for EU.)

(Refer to the serial number plate (rating plat e) to

determine the power source required by the

machine.)

Power Consumption: Maximum: 1.2 kw

Warm-up: 0.72 kw (average)

Ready: 0.16 kw (average)

Copy cycle: 0.81 kw (average)

Dimensions:

Width Depth Height

Copier only

Full system

672 mm

(26.5")

1149 mm

(45.3")

600 mm

(23.7")

600 mm

(23.7")

Weight: Copier only: 52 kg (114.7 Ib)

Full system: 71 kg (156.6 Ib)

Optional Equipment: Document feeder

10 bin sorter

Duplex unit

Color development unit

Key counter

Universal Cassette

410 mm

(16.2")

513 mm

(20.2")

•Specifications are Subject to cha ng e withou t no tice .

1-2

Page 4

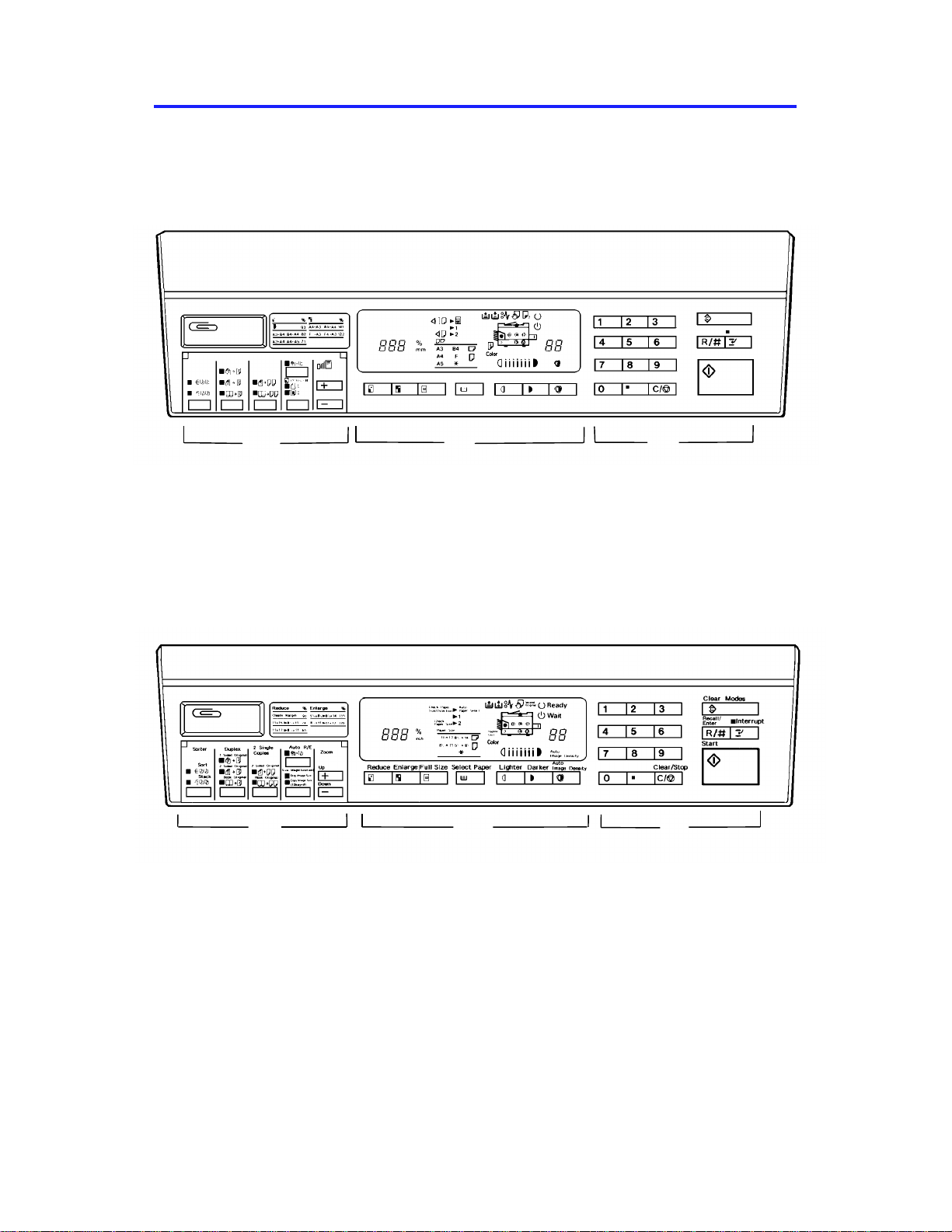

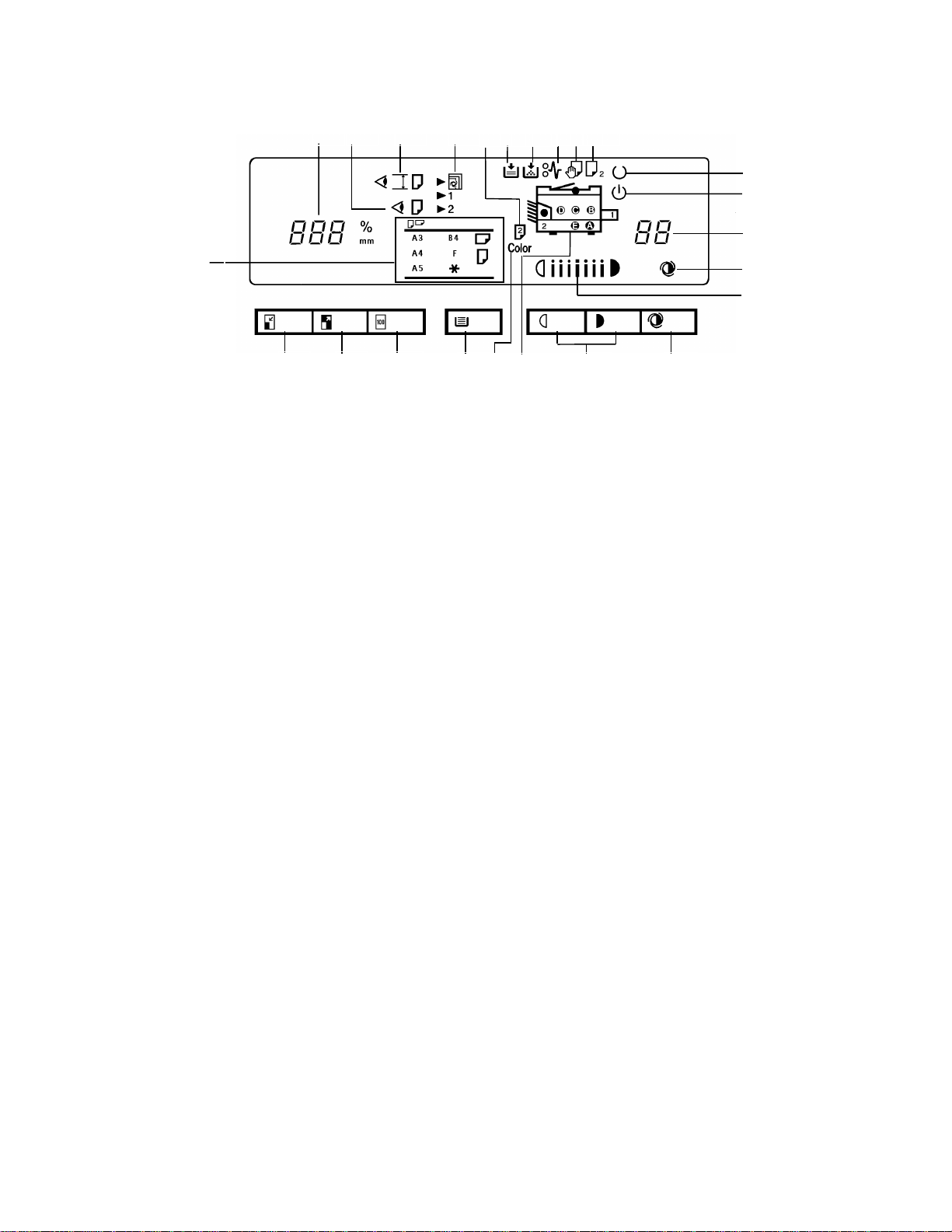

2. OPERATION PANEL

— A4/A3 Version —

C B A

1 July 1991

— LT/LDG Version —

Section A: See page 1-4.

Section B: See page 1-5 or 1-6.

BC

A

Section C: See page 1-7 or 1-8.

1-3

Page 5

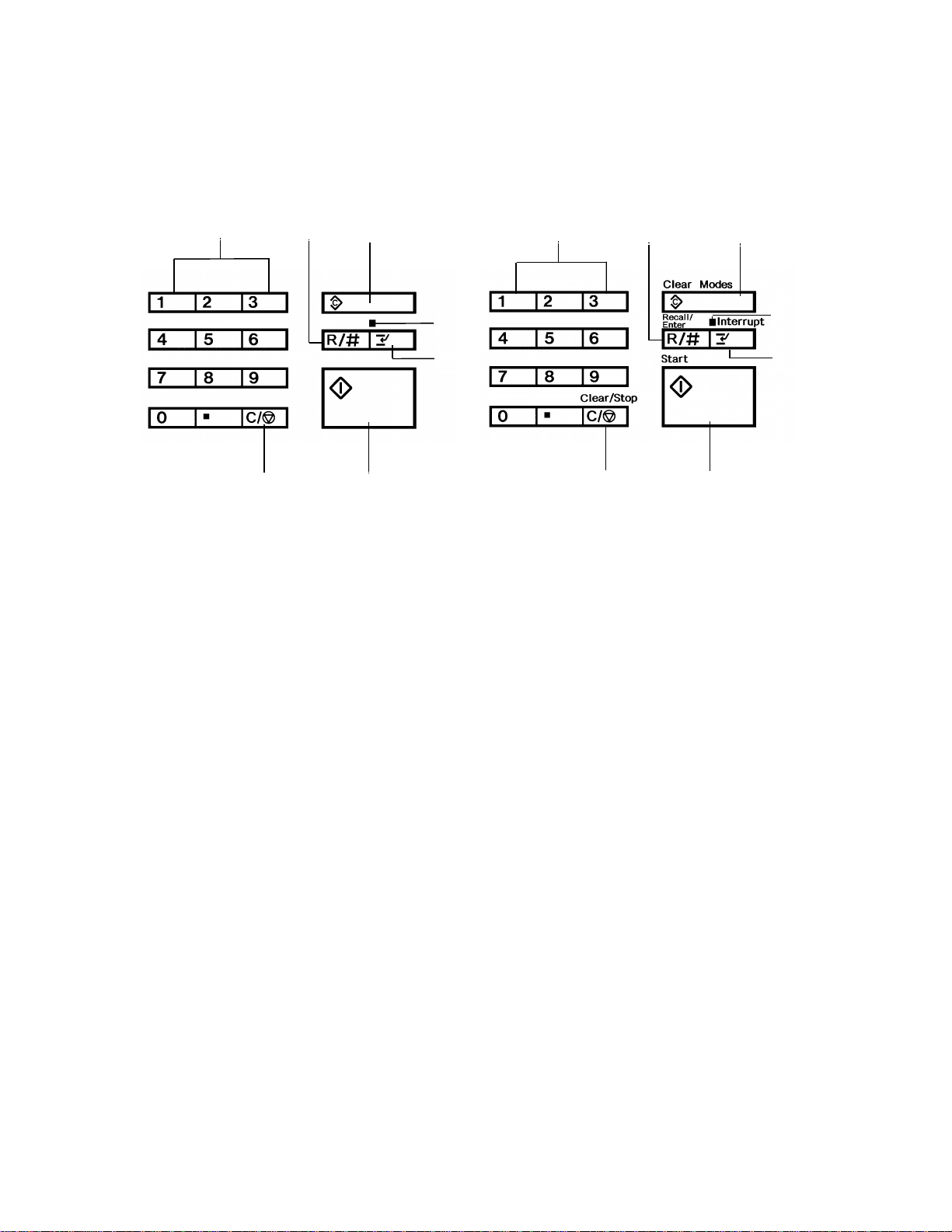

2

1 July 1991

Section A —

— A4/A3 Version —

1

2

7

— LT/LDG Version —

3

4

5

6

1

3

4

5

7

6

1. Number Keys

The number keys are used to

enter the desired numb er of

copies. They are also used to

input the sizes of the original

and the copy image when in size

magnification mode.

2. Recall/Enter Key

Press to display the number of

copies entered. Also use to

enter or change da ta when in

size magnification mode.

3. Clear Modes Key

Press to clear all previously

entered settin gs and modes.

4. Interrupt Indicator

Lights when interrupt mode is

selected.

5. Interrupt Key

Press to make interrupt copies

during a copy run.

6. Start Key

Press to start copying.

7. Clear/Stop Key

Press to cancel the copy

number entered. While cop ying ,

press to stop copying.

1-4

Page 6

— Section B —

1

— A4/A3 Version —

1

2 3 4

5

6 7

1 July 1991

8 9 10

11

12

13

14

15

212223

1. Magnification Ratio Indicator

Shows the selected

reproduction ratio and data for

the Size Magnificatio n mod e.

2. Check Paper Size Indicator

Lights when improper paper

size is selected in the book

original mode or the duplex

mode. (Copying is impossible.)

3. Check Paper Size/Dir ection

Indicator

Blinks when the original size

do es not mat ch with the pap er

size or directio n. This indicator is

functional only wit h th e do cume nt

feeder. (Copying is possible.)

4. Auto Paper Select Indicator

Lights when auto paper select

mode is selected. This mode is

an optional feature with the

document feeder.

5. Duplex Unit Indicator

Lights when the duplex unit is

installed.

6. Load Paper Indicator

Lights when the cassette or the

paper tray in use runs out of

paper.

20

1819

1617

7. Add Toner Indicator

Blinks when it is time to change

the toner cartridge. When it is

continuously lit, the copier

cannot be used unt il a new

cartridge is installed.

8. Check Paper Path Indicator

Lights if there is a misfeed

within the machine.

9. Manual Feed Indicator

Lights when the manual feed

table is open.

10. Second Original Indicator

Lights when it is time to position

the second original on the

exposure glass when making

duplex copies.

— Light ON —

If copying has been completed,

press duplex key to cancel the

duplex mode and press start

key to eject copies.

— Light Blinking —

Press start key to eject copies.

11. Ready Indicator

Lights when the machine is

ready to make copies.

1-5

Page 7

24

1 July 1991

— LT/LDG Version —

1

2 3 4

5

6 7

8 9 10

11

12

13

14

15

212223

12. Wait Indicator

Lights when that the ma chin e is

not ready to copy.

13. Copy Counter

Displays the number of copies

entered. While copying, it shows

the number of copies made.

14. Auto Image Density Indicator

Lights when the copier is

automatically controlling image

density. If this indicator blinks,

refer to page 55.

15. Manual Image Density

Indicator

Shows the manually selected

image density. If this indicator

blinks, refer to page 55.

16. Auto Image Density Key

Press to select/cancel the

automatic image density mode .

20

1819

1617

18. Misfeed Location Displa y

Shows the location(s) of misfed

paper.

19. Color Copy Indicator

Lights if a color toner

development unit is insta lled .

20. Select Paper Key

Press to select the cassette or

the paper tray for paper feed, or

press to cancel auto paper

selection mode when the

document feeder is insta lled .

21. Full Size Key

Press to make copies the same

size as the originals.

22. Enlarge Key

Press to make enlarged copies.

23. Reduce Key

Press to make reduced cop ies.

17. Manual Image Density Keys

Use to cancel the automatic

image density mode and

manually select the image

density level.

24. Paper Size Indicator

Shows the size and direction of

the paper in use.

1-6

Page 8

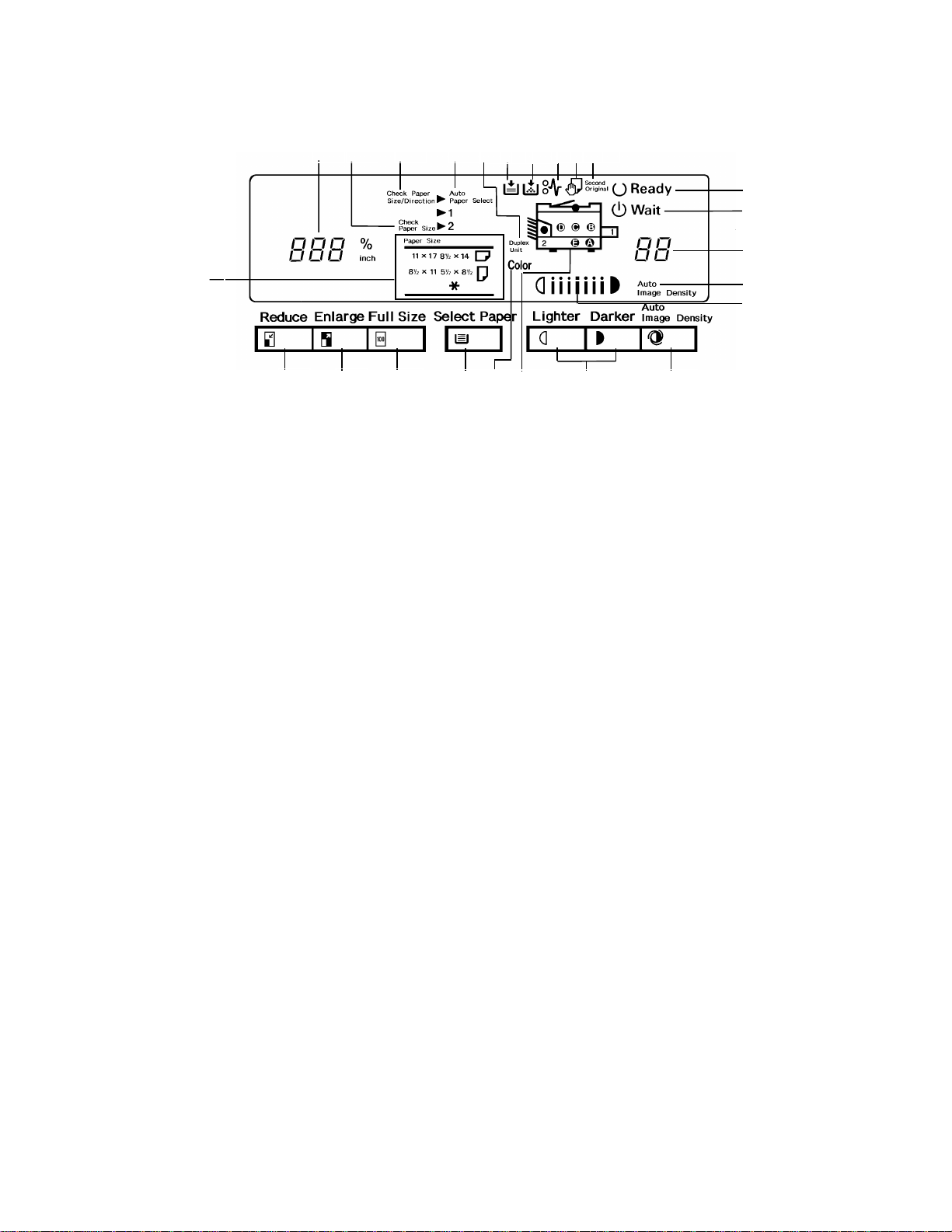

— Section C —

— A4/A3 Version —

5 4 6 7

1 July 1991

3

2

1

13

1. Sorter Key

Press to select the sort or stack

mode. The sort mode and stack

mode are optional feature s requ iring

a sorter.

2. Stack Indicator

Lights when in the stack mode.

3. Sort Indicator

Lights when in the sort mode.

8

9

1112

10

5. Duplex Indicators

Show which duplex copying mode is

selected.

6. Auto Reduce/Enlarge Indicator

Lights when in the auto

reduce/enlarge mode. This mode is

an optional feature requiring a

document feeder.

4. Duplex Key

Press to select one of three du plex

modes. These modes are optional

features requiring a duplex unit.

1-7

Page 9

2

1 July 1991

— LT/LDG Version —

5 4 6 7

3

1

7. Auto Reduce/ Enl arge Key

Press to select the auto

reduce/enlarge mode. This

mode is an optional feature

requiring a document feeder.

8. Zoom Up Key

Press to increase the

reproduction ratio in 1% step s.

9. Zoom Down Key

Press to reduce the

reproduction ratio in 1% step s.

10. Size Magnification Key

Press to select the size

magnification mode.

1213

11

10

11. Size Magnification Indicators

Lights when in the size

magnification mode; shows

when to enter the original size

and copy size data.

12. 2 Single Copies Key

Press to select one of two 2

single copies modes. The 2

Sided Original mode is an

optional feature requiring a

document feed er.

13. 2 Single Copies Indicators

Show which the 2 single cop ies

mode is selected.

8

9

1-8

Page 10

1 July 1991

1-9

Page 11

1 July 1991

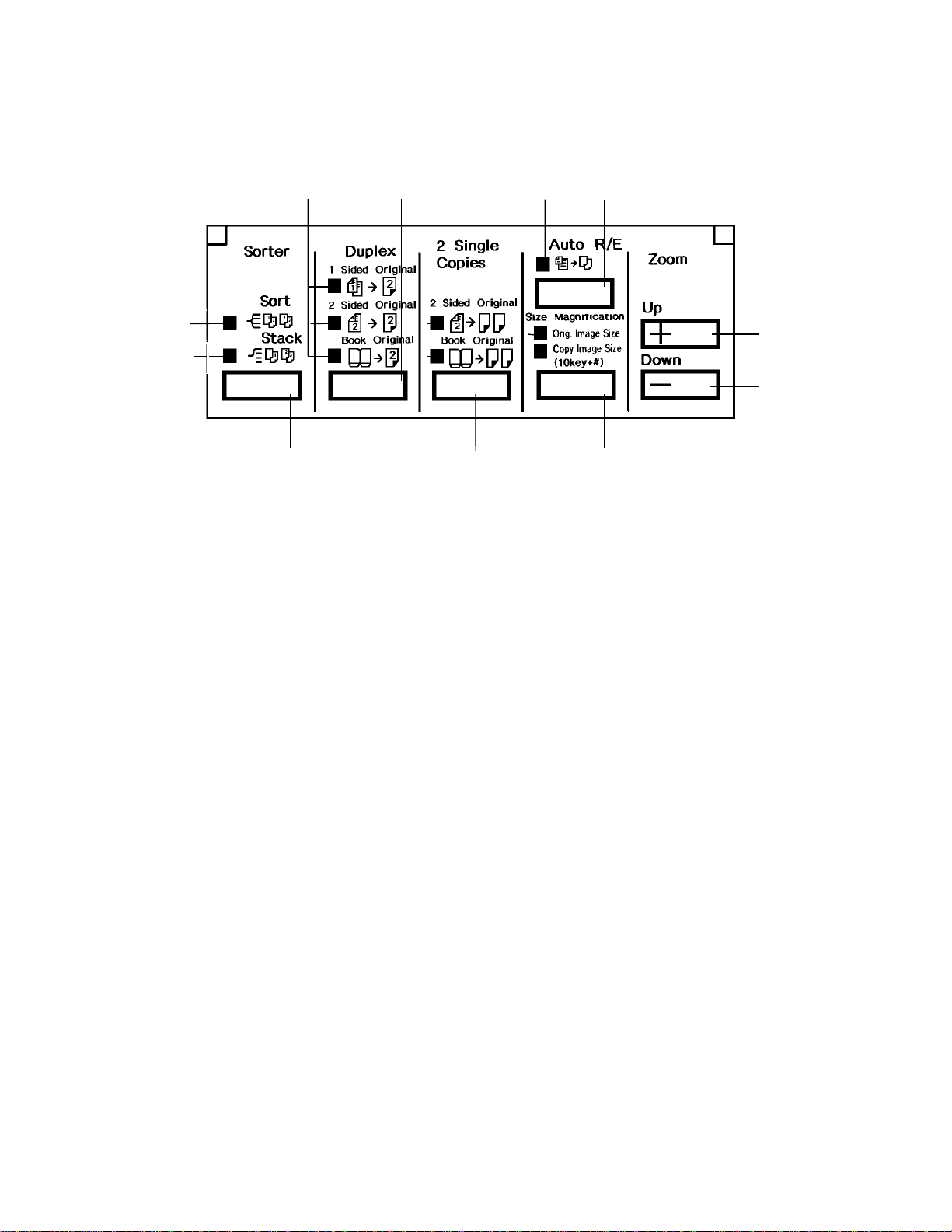

3. COPY PROCESSES AROUND THE DRUM

2. EXPOSURE

1. DRUM CHARGE

3. ERASE

9. QUENCHING

4. DEVELOPMENT

8. CLEANING

7. PAPER

SEPARATION

5. PRE-TRANSFER LAMP

(PTL)

6. IMAGE TRANSFER

1-10

Page 12

1 July 1991

1. DRUM CHARGE

In the dark, the charge corona unit gives a uniform negative charge to the organic

photoconductive (OPC) drum. The charge remains on the surface of the drum because the

OPC drum has a high electrical resistance in the dark.

2. EXPOSURE

An image of the original is reflected to the OPC drum surface via the optics assembly. The

charge on the drum surface is dissipated in direct proportion to the intensity of the reflected

light, thus producing an electrical latent image on the drum surface.

3. ERASE

The erase lamp illuminates the areas of the charged drum surface that will not be used for

the copy image. The resistance of the drum in the illuminated areas drops and the charge on

those areas dissipates.

4. DEVELOPMENT

Positively charged toner is attracted to the negatively charged areas of the drum, thus

developing the latent image. (The positive triboelectric charge is caused by friction between

the carrier and toner particles.)

5. PRE-TRANSFER LAMP (PTL)

The PTL illuminates the drum to remove all negative charge from the exposed areas of the

drum. This prevents the toner particles from being reattracted to the drum surface during

paper separation and makes paper separation easier.

6. IMAGE TRANSFER

Paper is fed to the drum surface at the proper time so as to align the copy paper and the

developed image on the drum surface. Then, a strong negative charge is applied to the back

side of the copy paper, producing an electrical force which pulls the toner particles from the

drum surface to the copy paper. At the same time, the copy paper is electrically attracted to

the drum surface.

7. PAPER SEPARATION

A strong ac corona discharge is applied to the back side of the copy paper, reducing the

negative charge on the copy paper and breaking the electrical attraction between the paper

and the drum. Then, the stiffness of the copy paper causes it to separate from the drum

surface. The pick-off pawls help to separate paper.

8. CLEANING

The cleaning brush removes most of the toner on the drum and loosens the remainder. Then

the cleaning blade scrapes off the loosened toner.

9. QUENCHING

Light from the quenching lamp electrically neutralizes the surface of the drum.

1-11

Page 13

1 July 1991

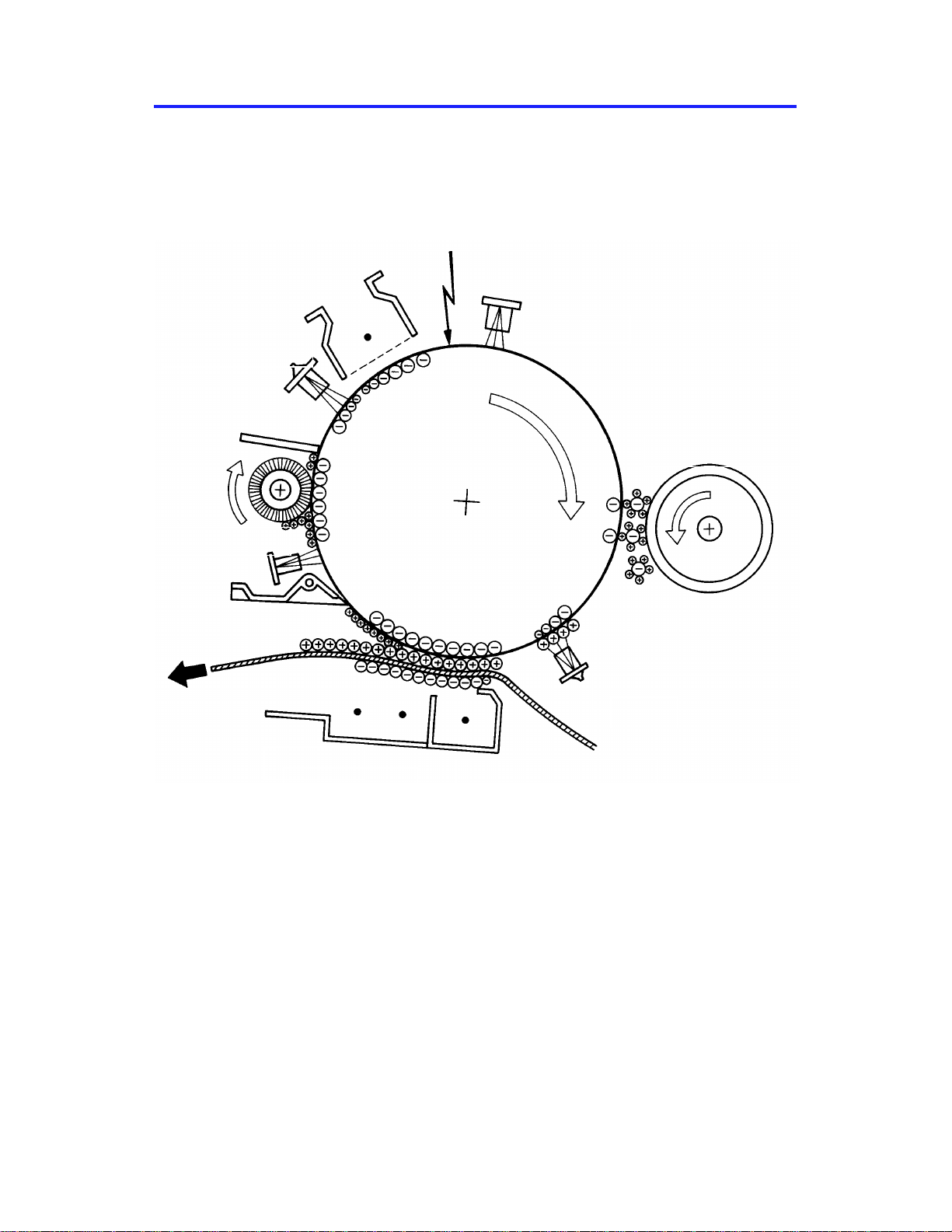

4. FUNCTIONAL OPERATION

1-12

Page 14

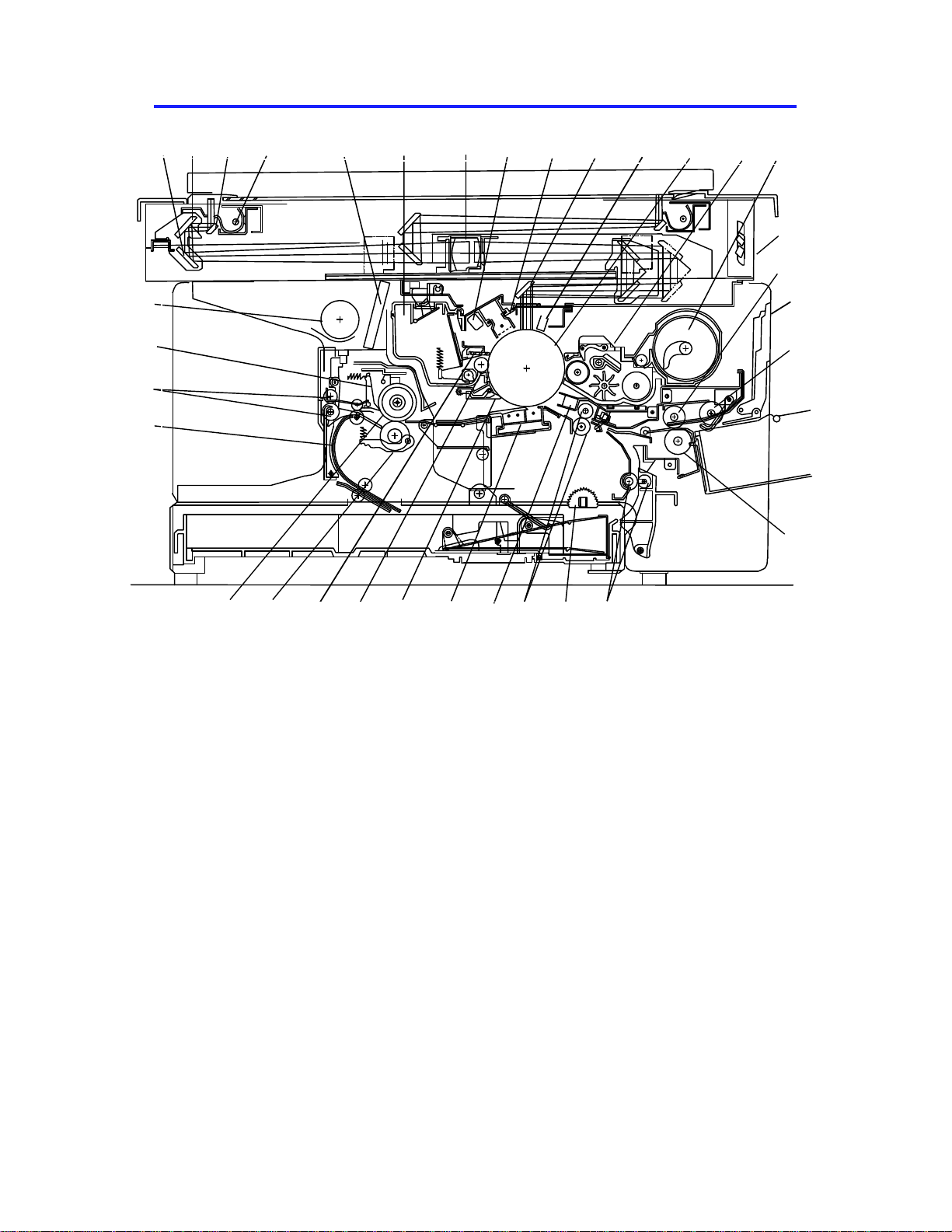

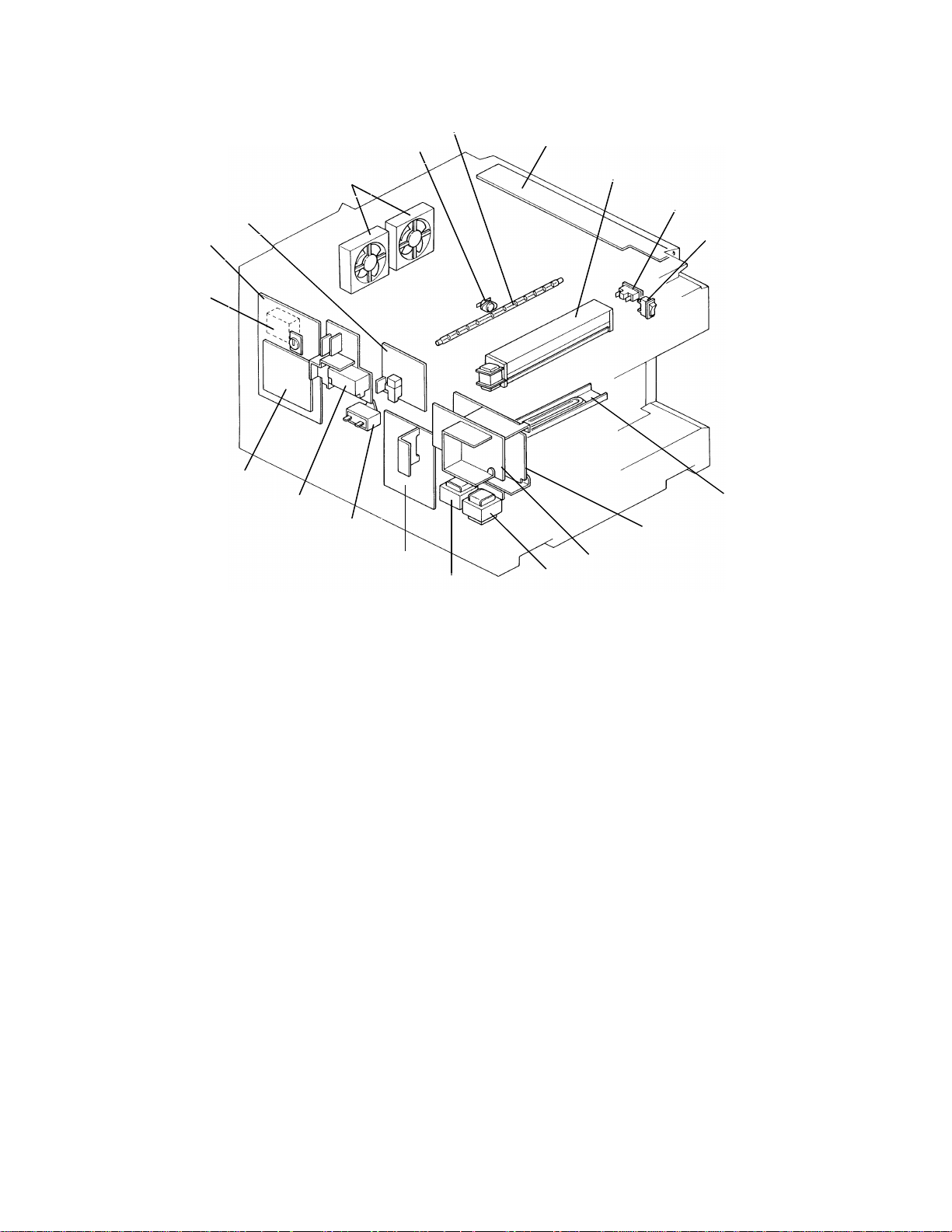

5. MECHANICAL COMPONENT LAYOUT

11

12

1

2 3

4

5

6 7

8 9 10

1 July 1991

13 14

15

16

33

32

31

30

29

1. Third Mirror

2. Second Mirror

3. First Mirror

4. Exposure Lamp

5. Ozone Filter

6. Cleaning Unit

7. Lens

8. Quenching Lamp (QL )

9. Charge Corona Unit

10. Sixth Mirror

11. Erase lamp (EL)

12. OPC Drum

13. Development Unit

14. Toner Supply Unit

15. Optics Cooling Fans

16. Feed Roller

17. Manual Feed Table

18. Pick-up Roller

17

18

19

20212224 2325262728

19. Separation Roller

20. Relay Rollers

21. Semi-circular Feed Rollers

22. Registration Rollers

23. Pre-transfer Lamp (PTL)

24. Transfer and Separation Corona

Unit

25. Pick-off Pawls

26. Cleaning Brush

27. Cleaning Blade

28. Pressure Roller

29. Hot Roller

30. Duplex Turn Guide (Option)

31. Exit Rollers

32. Hot Roller Strippers

33. Exhaust Blower

1-13

Page 15

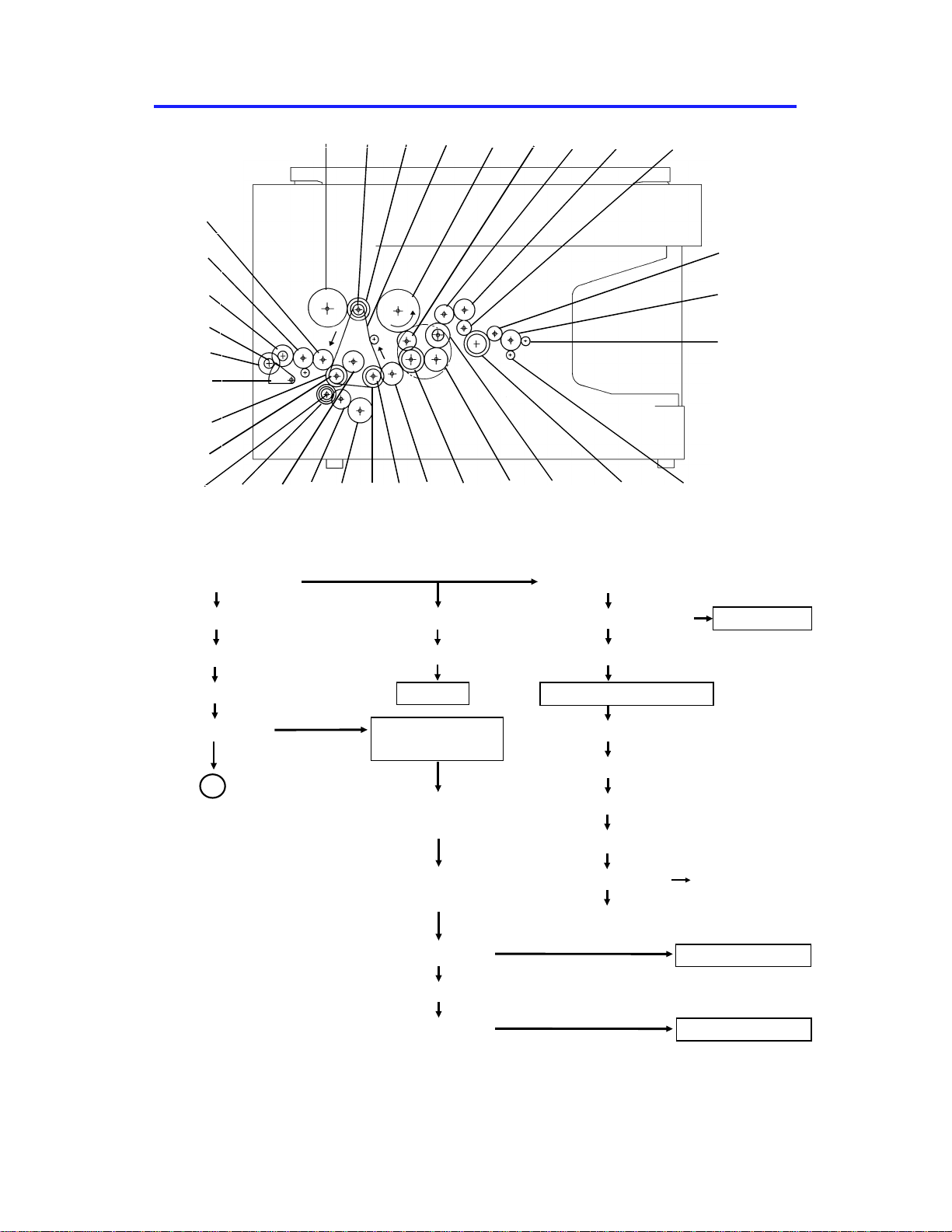

G24

G29

1 July 1991

6. DRIVE LAYOUT

G17 BP2 G16 TB1 G19 G18

G5

G6

G7

G9

G8

G10

G4

BP3

G11G12G13

G14

G1: Main Motor Gear G20: Relay Gear

G3BP1G15

G22 G23

G25G21G20G1G2

G26

G27

G28

G2: Relay Gear G18: Relay Gear G21: Cleaning Drive Cleaning Unit

G3: Timing Belt Drive Gear G19: Drum Drive Gear G22: Relay Gear

BP1: Timing Belt Pulley Drum Fusing and Exit Section

TB1: Timing Belt Development G23: Relay Gear

Section

G24: Relay Gear

A

BP2: Timing Belt G25: Hot Roller Gear

Pulley

G26: Relay Gear

G16: Development G27: Relay Gear G29: Duplex Transport

CL Gear Gear (Option)

G28: Exit Roller Gear

Development CL Development Unit

G17: Toner Supply CL Gear

Toner Supply CL Toner Supply Unit

1-14

Page 16

1 July 1991

A

Paper Feed Section

BP3: Timing Belt Pulley

G11: Registration CL Gear G4: Relay Gear 2nd Feed Station

Registration CL G5: Relay Gear G12: Relay Roller

CL Gear

Registration Roller

1st Paper Feed CL G6: 1st Paper Feed CL Gear Relay Roller CL

1st Paper Feed CL G7: Relay Gear Relay Roller

G13: Relay Roller Gear

1st Paper Feed Rollers G8: Paper Lift CL Gear G14: Relay Gear

G15: 2nd Paper Feed

Paper Lift CL CL Gear

G9: Paper Lift Gear 2nd Paper Feed CL

G10: Sector Gear 2nd Paper Feed Roller

1-15

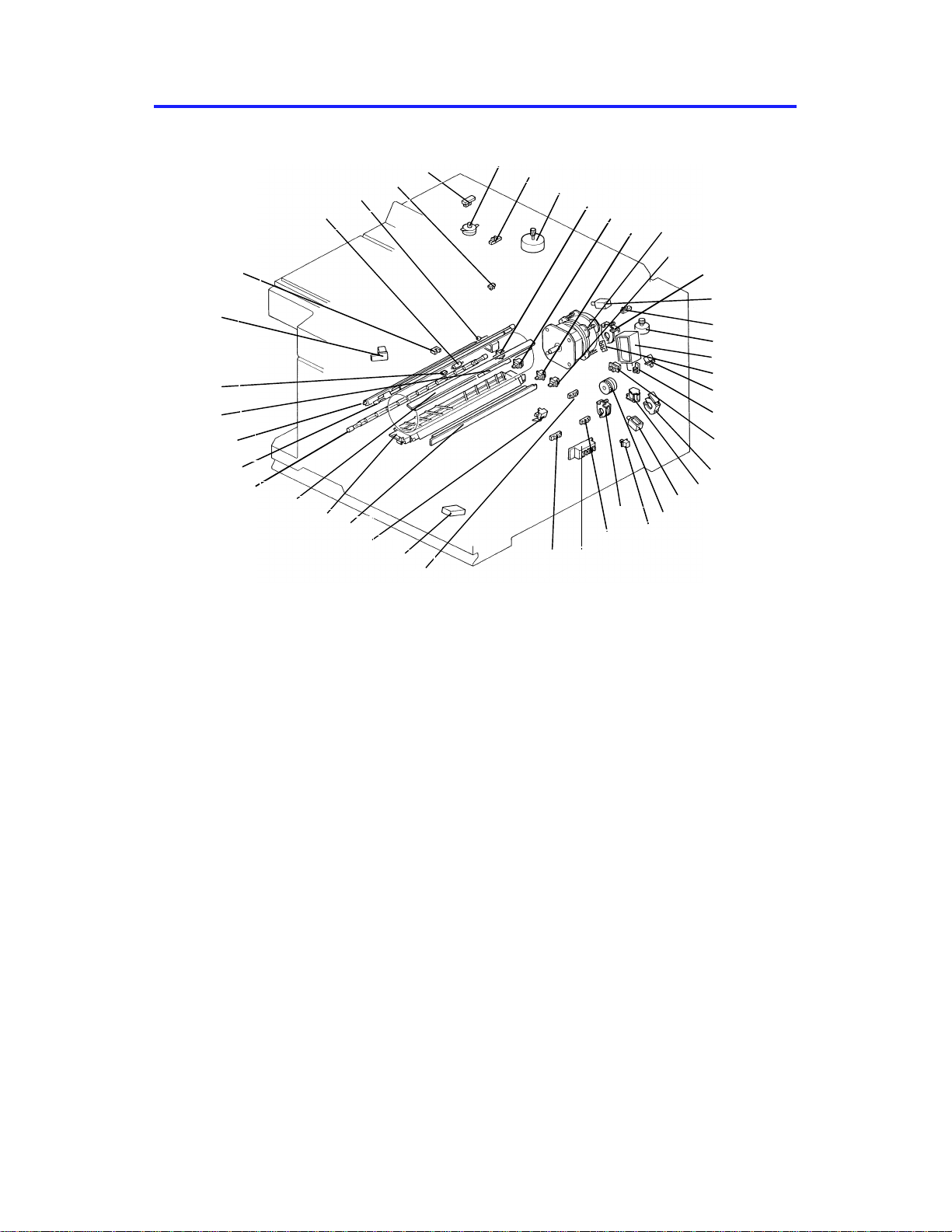

Page 17

789

10

2122242325

27

1 July 1991

7. ELECTRICAL COMPONENT LAYOUT

39

41

32

40

38

36

37

34

42

35

43

31

30

1

4

3

5

6

13

11

12

15

16

14

17

18

19

20

2

26

33

29

28

1. Scanner H.P. Sensor

2. Lens Motor

3. Lens H.P. Sensor

4. Exit Sensor

5. Scanner Motor

6. 2nd Paper Size SW-1 (SW4)

7. 2nd Paper Size SW-2 (SW5)

8. 2nd Paper Size SW-3 (SW6)

9. 2nd Paper Size SW-4 (SW7)

10. Main Motor

11. Development CL Sol.

12. 4th/5th Mirror H.P. Sensor

13. Toner Supply CL Sol.

14. Toner End Sensor

15. 4th/5th Mirror Motor

16. Pick-up Roller Release Sol.

17. Manual Feed Table SW

18. Development Unit Set Sensor

19. Color Switch

20. Paper Lift CL Sol.

21. 1st Paper Feed CL Sol.

22. Relay Roller CL Sol.

23. Right Cover SW

24. Registration Clutch

25. 2nd Paper Feed CL Sol.

26. 1st Paper Size SW

27. 1st Paper End Sensor

28. 2nd Paper End Sensor

29. Cassette Lift Sensor

30. Registration Sensor

31. Pre-transfer Lamp (PTL)

32. ID Sensor

33. Total Counter

34. Erase Lamp (EL)

35. Transfer and Separation Corona Unit

36. Charge Corona Unit

37. Fusing Lamp

38. Quenching Lamp (QL)

39. Auto ID Sensor

40. Toner Overflow Sensor

41. Fusing Thermistor

42. Fusing Thermofuse

43. Tray Lock Sol.

1-16

Page 18

55

1 July 1991

49

50

48

51

47

52

46

45

53

44

62

61

60

44. Key Counter (Option)

45. Main Board

46. CC/Grid/Bias Power Pack

47. Optics Cooling Fan Motors

48. Optics Thermoswitch

49. Exposure Lamp

50. Operation Panel Board

51. Exhaust Blower Motor

52. Cover Safety SW

53. Main SW

59

56

58

54. Drum Anti-condensation Heater

55. Main DC Power Supply Board

56. Optional DC Power Supply Board

(Option)

57. Optional Transformer (Option)

58. Main Transformer

59. AC Drive Board

60. Main Motor Capacitor

61. TC/SC Power Pack

62. Interface Board (Option)

57

54

1-17

Page 19

1 July 1991

8. ELECTRICAL COMPONENT DESCRIPTIONS

SYMBOL NAME FUNCTION INDEX

NO.

Motors

M1 Main Motor Drives all the main unit components except

for the optics unit and fans.

(115/220/240Vac)

M2 Scanner Motor Drives the scanners (1st and 2nd). (dc

stepper)

M3 Lens Motor Moves the lens position according to the

selected magnification. (dc stepper)

M4 4th/5th Mirror Mo-

tor

M5 Optics Cooling

Fan Motor-1

M6 Optics Cooling

Fan Motor-2

M7 Exhaust Blower

Motor

Move the 4th/5th mirror position according

to the selected magnification. (dc stepper)

Prevents built up of hot air in the optics

cavity. (24 Vdc)

Prevents built up of hot air in the optics

cavity. (24 Vdc)

Removes heat from around the fusing unit

and blower the ozone built up around the

charge section to the ozone filter.

Magnetic Clutch

MC1 Registration

Clutch

Drives the registration roller. 24

Solenoid

10

5

2

15

47

47

51

SOL1 Toner Supply

Clutch Solenoid

SOL2 1st Paper Feed

Clutch Solenoid

SOL3 2nd Paper Feed

Clutch Solenoid

SOL4 Pick-up Roller

Release Solenoid

SOL5 Paper Lift Clutch

Solenoid

SOL6 Tray Lock Sole-

noid

SOL7 Development

Clutch Solenoid

SOL8 Relay Roller

Clutch Solenoid

Drives the toner supply roller via the toner

supply spring clutch.

Starts paper feed from the first paper

station.

Starts paper feed from the 2nd paper

station.

a) After the paper is fed, releases the

pick-up roller from next paper. b) When the

manual feed table is used, releases the

pick-up roller from the table.

Lifts paper to the appropriate feed position. 20

Locks the paper tray/duplex unit. 43

Drives the development unit. 11

Drives the relay roller for the 2nd cassette

station.

1-18

13

21

25

16

22

Page 20

1 July 1991

SYMBOL NAME FUNCTION INDEX

NO.

Switches

SW1 Main Switch Supplies power to the copier. 53

SW2 Cover Safety

Switch

SW3 1st Paper Size

Switch

SW4 2nd Paper Size

Switch-1

SW5 2nd Paper Size

Switch-2

SW6 2nd Paper Size

Switch-3

SW7 2nd Paper Size

Switch-4

SW8 Color Switch Determines which color development unit is

SW9 Manual Feed Ta-

ble Switch

SW10 Right Cover

Switch

Cuts the ac power line. 52

Determines what size paper is in the first

cassette.

Determines what size paper is in the paper

tray.

Determines what size paper is in the paper

tray.

Determines what size paper is in the paper

tray.

Determines what size paper is in the paper

tray.

installed.

Detects when the manual feed table is

open.

Detects when the right cover is open. 23

Sensor

S1 Scanner Home

Position Sensor

Informs the CPU when the 1st scanner is at

the home position.

26

6

7

8

9

19

17

1

S2 Lens Home

Position Sensor

S3 4th/5th Mirror

Home Position

Sensor

S4 Registration

Sensor

S5 Exit Sensor Detects misfeeds. 4

S6 1st Paper End

Sensor

S7 2nd Paper End

Sensor

S8 Toner End

Sensor

S9 Toner Overflow

Sensor

S10 Paper Lift

Sensor

Informs the CPU when the lens is at the

home position (full size position).

Informs the CPU when the 3rd scanner

(4th/5th mirrors assembly) is at the home

position (full size position).

Detects misfeeds. 30

Informs CPU when the first cassette runs

out of paper.

Informs CPU when the paper tray runs out

of paper.

Detects when it is time to add toner. 18

Detects when the used toner tank is full. 40

Detects the correct feed height of the

cassette.

1-19

3

12

27

28

29

Page 21

1 July 1991

SYMBOL NAME FUNCTION INDEX

NO.

S11

S12 Development

Image Density

(ID) Sensor

Unit Set Sensor

Detects the density of the image on the

drum to control the toner density.

Sensors whether or not the development

unit is properly set.

Printed Circuit Board

PCB1 Main Board Controls all copier functions both directly

and through the other PCBs.

PCB2 AC Drive Board Drives all ac motors, the exposure lamp,

fusing lamp, quenching lamp, exhaust

blower motor.

PCB3 Main DC Power

Supply Board

PCB4 Auto Image

Density Sensor

(ADS)

PCB5 Optional DC

Power Supply

Board

PCB6 Interface Board Interfaces between the copier main board

PCB7 Operation Panel

Board

Rectifies 26 and 10 Vac input and outputs

dc voltages.

Senses the background density of the

original.

Rectifies 26 and 10 Vac input and outputs

dc voltasges.

and all the optional equipment’s main board.

Informs the CPU of the selected modes

and displays the situations on the panel.

32

18

45

59

55

39

56

62

50

Lamps

L1 Exposure Lamp Applies high intensity light to the original for

exposure.

L2 Fusing Lamp Provides heat to the hot roller. 37

L3 Quenching Lamp Neutralizes any charge remaining on the

drum surface after cleaning.

L4 Erase Lamp Discharge the drum outside of the image

area. Provides leading/trailing edge erase.

L5 Pre-transfer

Lamp

Reduces charge on the drum surface

before transfer.

49

38

34

31

Power Packs

P1 CC/Grid/Bias

Power Pack

P2 TC/SC Power

Pack

Provides high voltage for the charge

corona, grid, and the development roller

bias.

Provides high voltage for the transfer and

separation corona.

46

61

1-20

Page 22

1 July 1991

SYMBOL NAME FUNCTION INDEX

NO.

Heaters

H1 Drum Anti-

condensation

Heater

H2 Optics Anti-con-

densation Heater

Option

Counters

CO1 Total Counter Keeps track of the total number of copies

CO2 Key Counter

(Option)

Prevents moisture around the drum. 54

Prevents moisture from forming on the

optics.

made.

Used for control of authorized use. Copier

will not operate until installed.

Transformer

TR1 Main Transformer Steps down the wall voltage to 26 Vac and

10 Vac.

TR2 Optional

Transformer

Steps down the wall voltage to 26 Vac and

10 Vac for the document feeder and duplex

unit.

Others

TH Fusing

Thermistor

Monitors the fusing temperature. 41

N/A

33

44

58

57

TF Fusing

Thermofuse

TS Optics

Thermoswitch

C Main Motor Ca-

pacitor

Provides back-up overheat protection in the

fusing unit.

Provides back-up overheat protection

around the exposure lamp.

Start capacitor 60

42

48

1-21

Page 23

1 July 1991

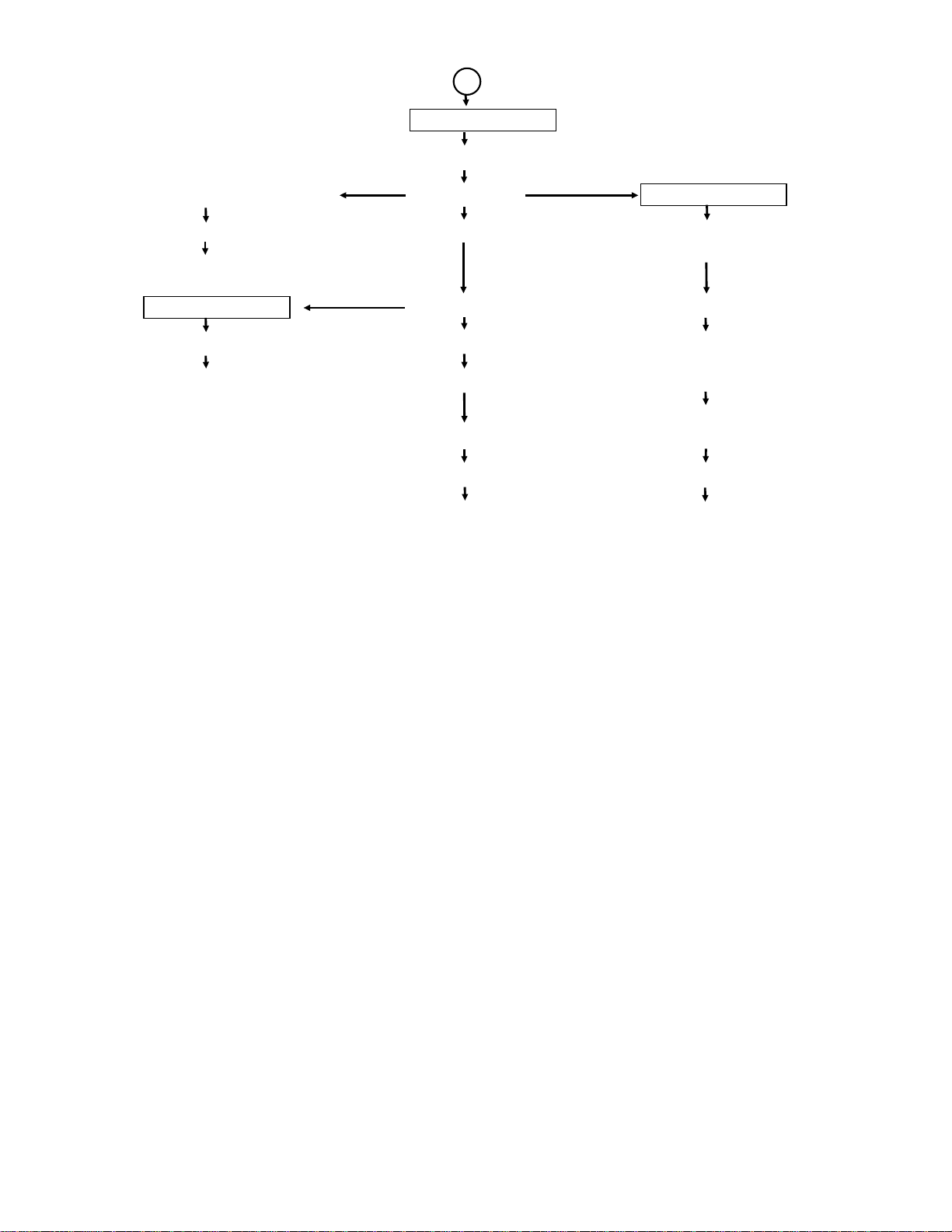

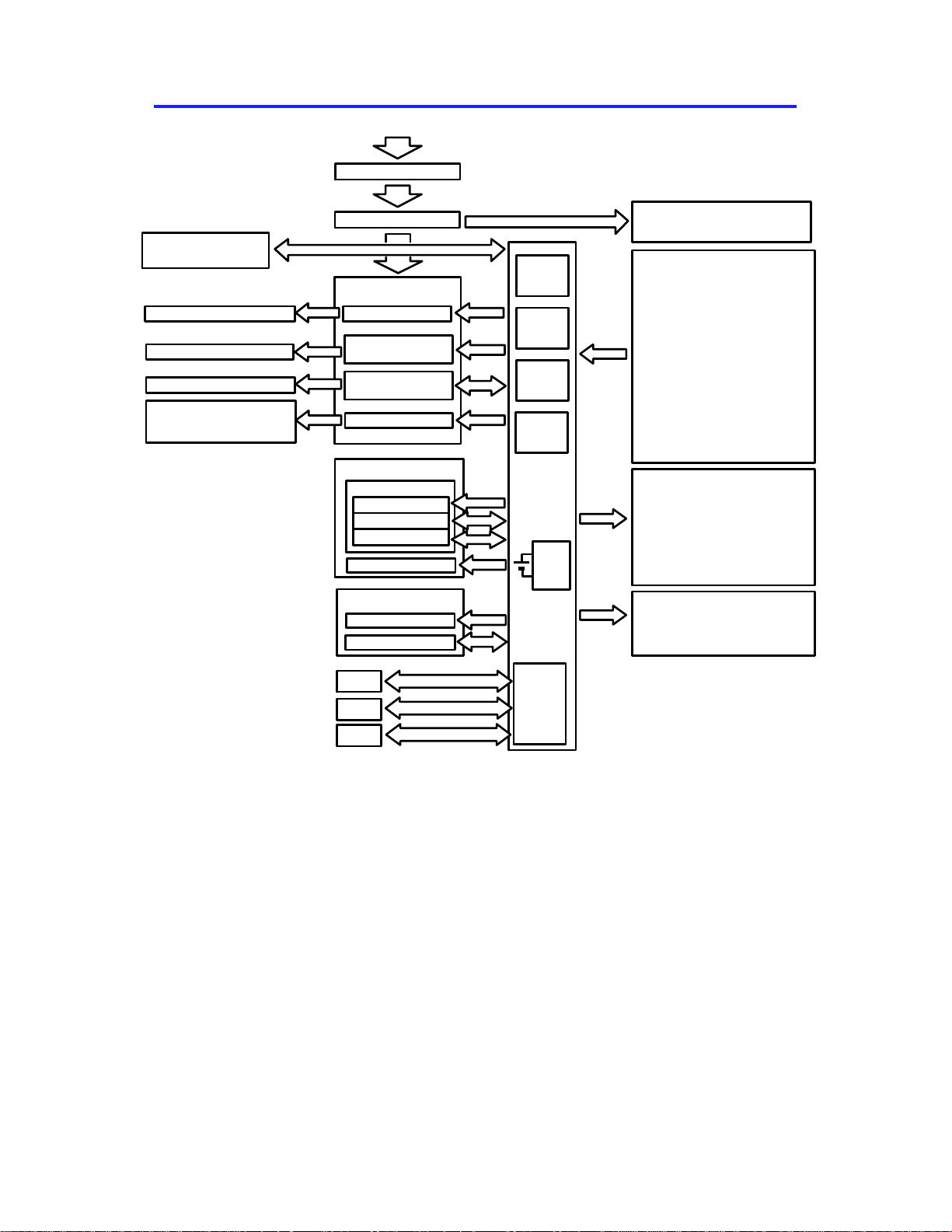

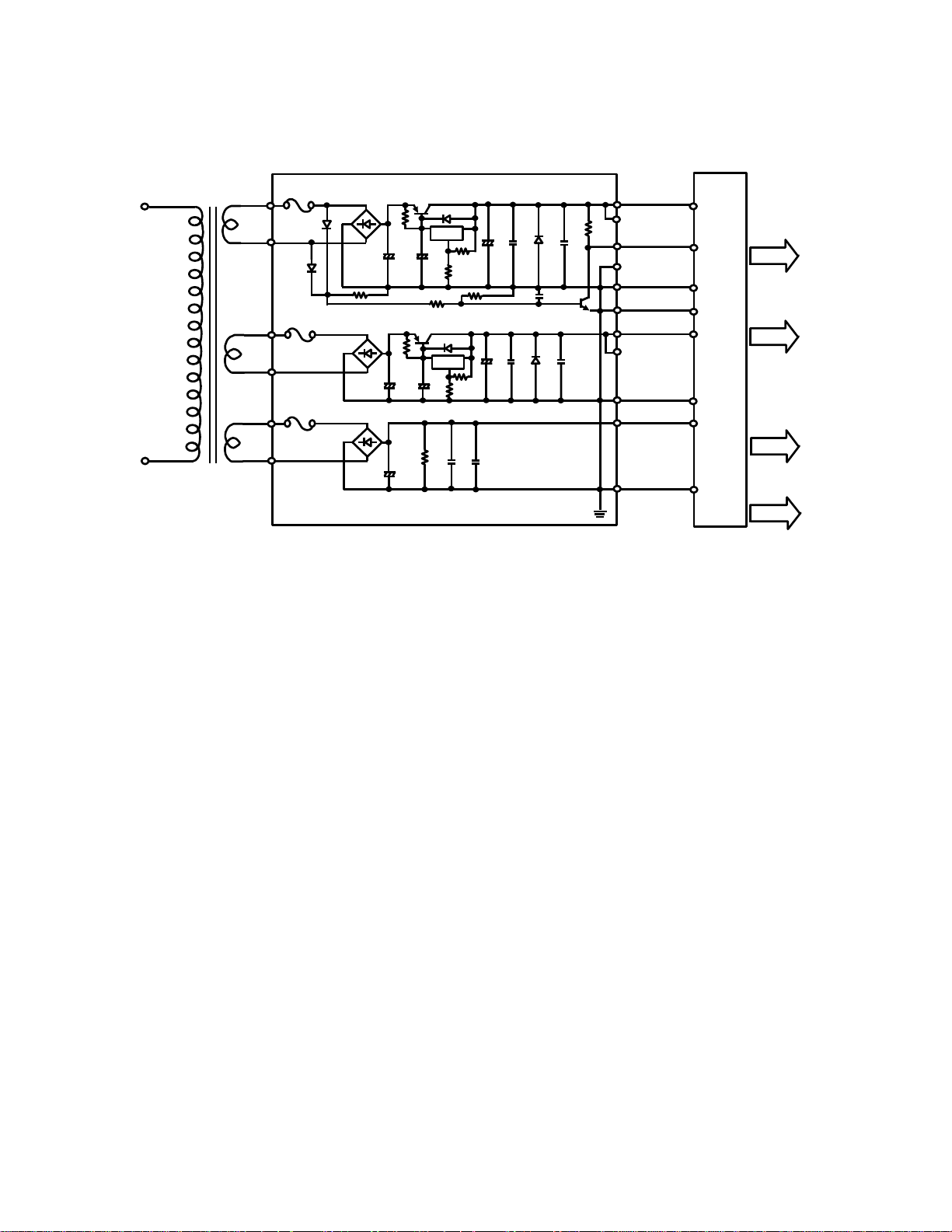

9. OVERALL MACHINE CONTROL

AC Power (115V or 220/240V)

Cover Safety Switch

Operation

Panel Board

Exhaust Blower Motor (L)

Fusing Lamp

Exposure Lamp

Main Motor

Quenching Lamp

Exhaust Blower Motor (H)

Main Switch

AC Drive Board

Power Relay

Fusing Lamp

Drive Circuit

Exposure Lamp

Drive Circuit

Main Motor Relay

Power Packs

CC/Grid/Bias P.P.

Charge Corona

Grid Voltage

Dev. Bias

TC/SC P.P.

Counters

Total Counter

Key Counter

IC 123

CPU

IC 105

I/O

IC 124

I/O

IC 111

ROM

Main Board

RAM

Board

Anti-condensation Heater

Sensors/Switches/Thermistor

Image Density Sensor

Registration Sensor

Cassette Lift Sensor

Exit Sensor

Auto ID Sensor

Scanner HP Sensor

Lens HP Sensor

4th/5th Mirror HP Sensor

Toner Overflow Sensor

Toner End Sensor

Color Switch

1st/2nd Paper Size Switches

1st/2nd Paper End Sensors

Right Cover Switch

Manual Feed Table Switch

Fusing Thermistor

Solenoids/Clutches

Pick-up Roller Release Sol.

Cassette Lift CL Sol.

1st/2nd Paper Feed CL Sol.

Relay Roller CL Sol.

Registration Clutch

Tray Lock Sol.

Development Drive CL Sol.

Toner Supply CL Sol.

Motors

Scanner Motor

Lens Motor

4th/5th Mirror

Optics Cooling Fan Motor

-Drum

-Optics

ARDF

Duplex

Sorter

Serial

Serial

Interface

Board

NOTE: The interface board is

connected to the copier main

board when the ARDF, duplex

unit and/or sorter is installed.

The above diagram shows the cont rol syste m of th is copie r in block form. The

CPU (IC123) on the main board controls the timing of all copie r’s ope rat ion

based on the CPU’s internal clock. The CPU monit ors the inp ut signals from

all sensors and controls the dc comp on ents directly or through two I/O chips

(IC 105 and IC 124). It also con tro ls a c components such as the fusing lamp,

exposure lamp, main motor qu en chin g lamp , an d exh au st blo wer motor (High

speed) directly via the ac drive board. The exh au st blo wer motor (Low speed)

is controlled via the I/O chip (IC 124) an d ac drive board. The cha rge corona,

grid voltage and development bias are powered by the same power pack

(P1) but are controlled separa te ly a s shown above. The main board has a

RAM board for the service program mode and misfeed recovery. A battery

backs up the power to the RAM board.

1-22

Page 24

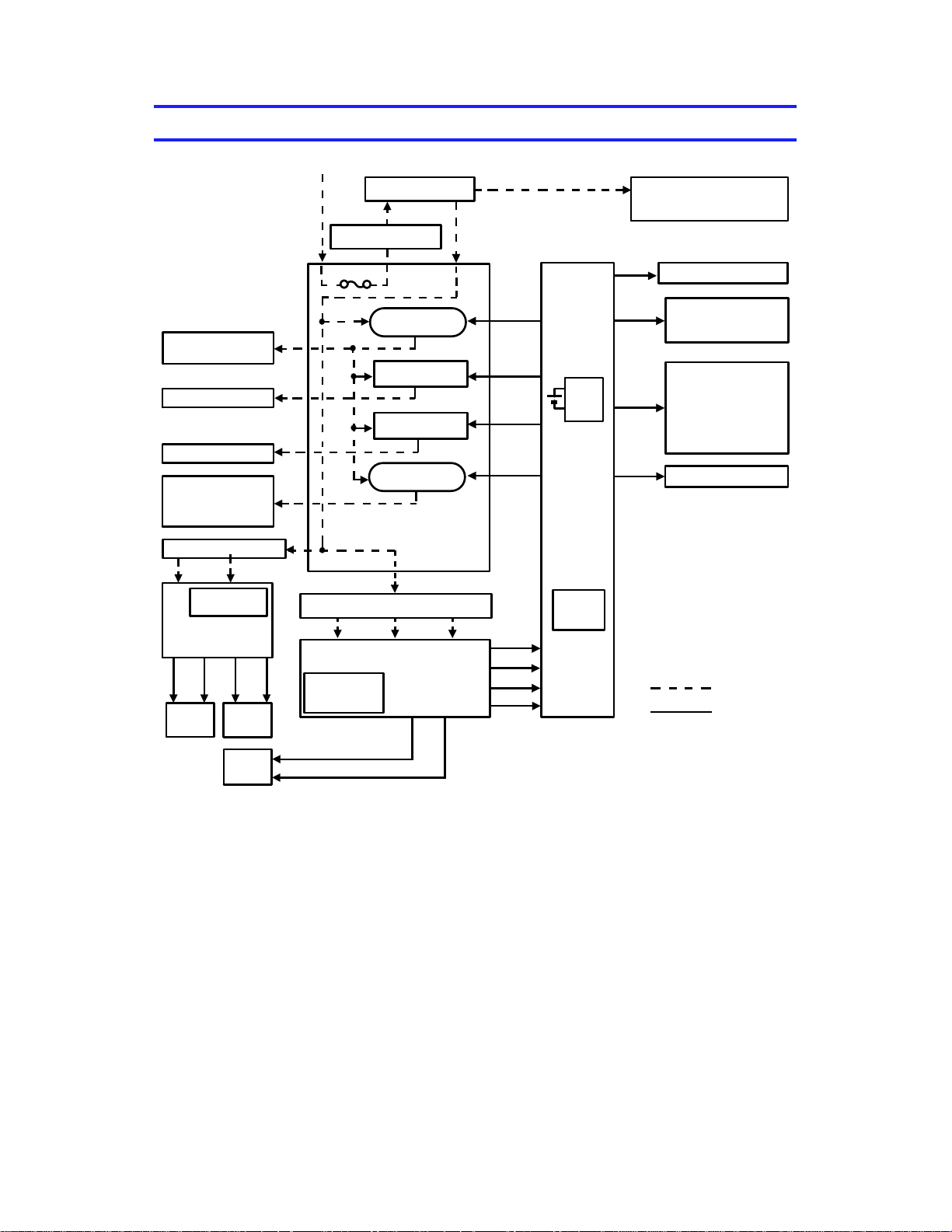

10. AC POWER AND DC POWER

DISTRIBUTION

AC Power (115V or 220/240V)

Main SW

Cover Safety SW

1 July 1991

Anti-condensation Heater

-Drum

-Optics (Option)

Exhaust Blower

Motor (L)

Fusing Lamp

Exposure Lamp

Main Motor

Quenching Lamp

Exhaust Blower

Motor (H)

Optional Transformer

26V AC 10V AC

FU100 (5V)

FU101 (24V)

Optional

DC Power Supply

Board

24V

(VA)5V(VC)

ARDF

24V

(VA)5V(VC)

Duplex

Fuse

Power Relay

(RA401)

Fusing Lamp

Drive Circuit

Exposure Lamp

Drive Circuit

Main Motor

Relay (RA402)

AC Drive Board

Main Transformer

10V AC 26V AC 26V AC

Main DC Power Supply Board

FU100 (5V)

FU101 (24V)

FU102 (30V)

24V (VA)

24V (VA)

24V (VA)

24V (VA)

30V (VM)

24V (VA)

5V (VC)

Zero

Cross

RAM

PCB

Main

Board

Interface

Board

Scan

Operation Panel Board

Signal

5V (VC)

Solenoids

Clutches

24V (VA)

30V (VM)

Power Packs

Lens Motor

4th/5th Mirror Motor

Optics Cooling Fan

Scanner Motor

Sensors

Switches

Interface Board

Motors

ac power

dc power

24V (VA)

Sorter

5V (VC)

When this copier is plugged in and the main switch is turned off, ac power is

supplied via the ac drive board to the anti-co nd ensation heater. When the

front cover and/or the exit cove r is open, the cover safety switch complete ly

cuts off power to all ac and dc components. The RAM board has a back up

power supply (dc battery) for the service program mode and misfeed job

recovery.

When the main switch is turned on, the ac power sup ply to the

anti-condensation heat er is cut of f an d ac power is supp lied to the ac drive

board. The main transformer receives wall outlet ac power through the ac

drive board and outputs 10 volts ac and 26 volts ac to the main dc power

supply board.

1-23

Page 25

1 July 1991

The main dc power supply board converts the 10 volts ac input to +5 volts

and a zero cross signal. There are two 26 volts ac inputs. The dc power

supply board converts them t o +24 volts an d +30 volts.

The +5 volts and +24 volts are supplied to both th e copier main board and

the sorter main board. The zero cross signal and +30 volts are supplied to

the copier main board.

The copier main board supplie s dc powe rs to all cop ier dc components. All

sensors, and switches plus the inte rfa ce bo ard ope rat e on +5 volts. The

scanner motor operate s on +30 volts. All other dc componen ts inclu ding the

power relay (RA401) and the main motor relay (RA 402) operate on +24 volts.

The ARDF and the duplex unit have a separat e dc power sup ply.

When the main board receives power, it act ivat es th e power rela y (RA401)

which then supplies ac power to the fusin g lamp drive circuit, and the

exposure lamp drive circuit on the ac drive board. The exhaust blower motor

begins rotating at low speed. The fusing lamp drive circuit receives a trigger

signal from the main board an d the fusing lamp lights. The exposure lamp

does not turn on until the main boa rd send a trigger pulse to the exp osure

lamp drive circuit.

When the Start key is pressed, the main bo ard ene rgize s the main mot o r

relay (RA402). Then, the ma in mot or an d the quenching lamp turn on an d th e

exhaust blower starts rotating at high speed.

When the main switch is turned off, power is cut off to the main board an d to

RA401, and the drum and optional anticondensa tio n he at ers are turned on.

The exposure lamp and the fusing lamp power lines are completely

disconnected from the lin e volt ag e.

1-24

Page 26

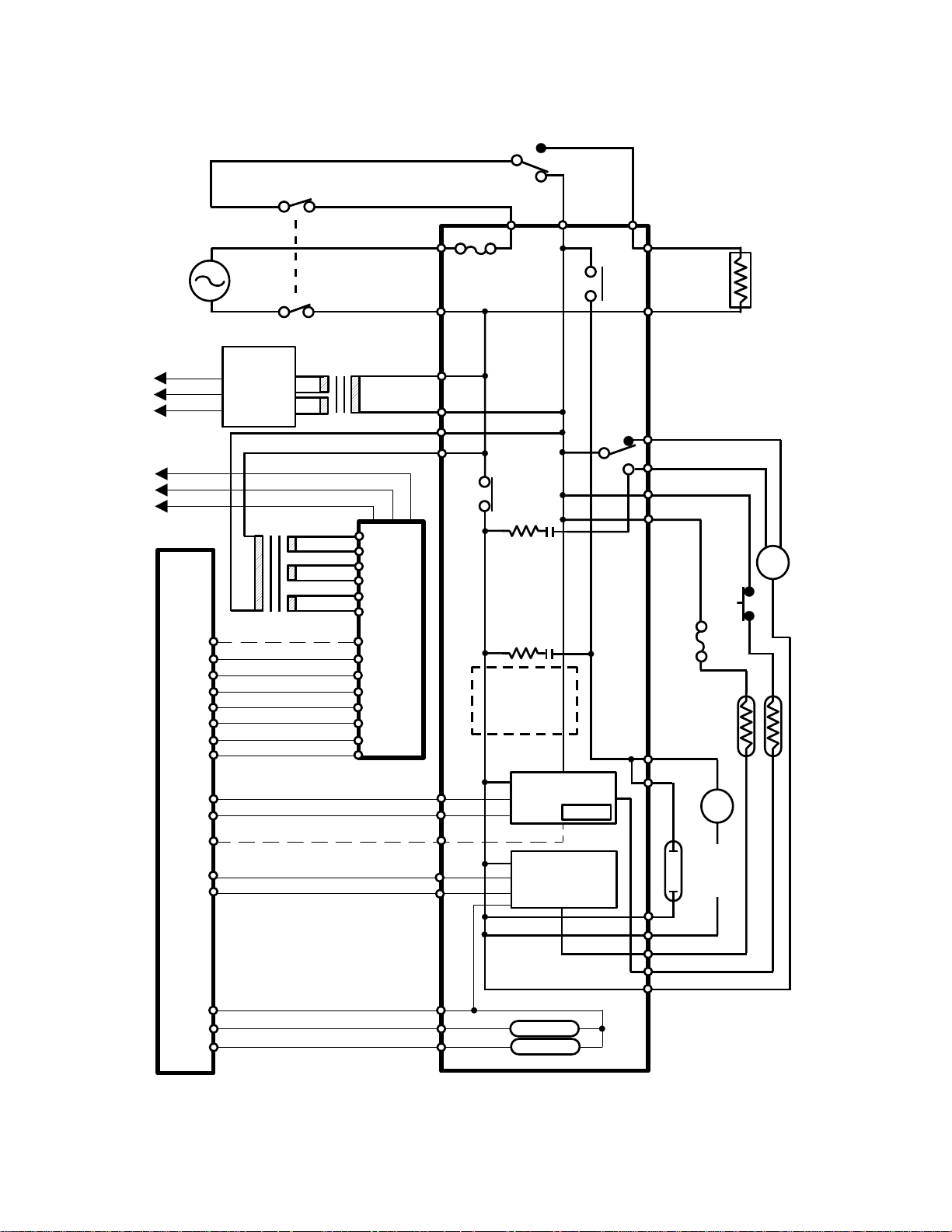

10.1 AC POWER DISTRIBUTION

Main SW

(SW1)

115V

220/240V

To DF and Duplex

[24] VA

[5] VC

[0] GND

To Sorter

[24] VA

[5] VC

[0] GND

ZERO

CROSS

[0] GND

[0] GND

[30] GND

[0] GND

[24] VA

[0] GND

[5] VC

Main

Board

(PCB1)

CN108-1

CN108-2

CN107-1

CN107-2

CN107-3

CN107-4

CN107-5

CN107-6

CN122-7

CN122-6

CN122-10

CN122-14

CN122-9

Optional

DC Power

Supply

Board

(PCB5)

TR1

Cover

Safety

SW (SW2)

10V AC

26V AC

CN103-1

CN103-2

CN103-3

CN100-1

CN100-2

CN100-3

CN100-4

CN100-5

CN100-6

CN102-2

CN102-1

CN101-1

CN101-2

CN101-3

CN101-4

CN101-5

CN101-6

TR2

T404

Fuse

T407

CN418-1

CN418-3

CN417-3

CN417-1

26V AC

26V AC

10V AC

DC

Power

Supply

Board

(PCB3)

CN401-8

CN401-9

CN401-5

CN401-1

CN401-6

T403 T401T402

RA401

AC

Drive

Board

(PCB2)

Noise Filter

Circuit

(220/240V

Only)

Exposure

Lamp Drive

Circuit

Fusing

Lamp Drive

Circuit

RA402-1

RA402-2

CN421

(220/240V

Only)

1 July 1991

CN411-1

CN411-2

Drum

Anti-condensation

Heater (H1)

CN420-3

CN420-2

Exhaust Blower Motor

CN419-1

Exposure Lamp

T405

Fusing

Lamp

Thermoswitch

Thermo-

fuse

169 C

(TF)

CN413-1

Main

Motor (M1)

CN415-1

(TS)

o

(L1)(L2)

M

Quench-

ing

Lamp

(L3)

LH

M

(M7)

CN122-13

CN122-12

CN122-11

CN401-2

CN401-3

CN401-4

Main Motor Relay

1-25

Power Relay

RA401

RA402

CN415-2

CN413-2

T406

CN419-2

CN420-1

Page 27

1 July 1991

10.2 DC POWER DISTRIBUTION

CN417

-1

115V

220/240V

CN417

-3

CN100

10VAC

CN100

CN100

26VAC

CN100

CN100

26VAC

CN100

DC Power Supply Board

FU100

-5

ON

-6

D101

FU101

-3

-4

FU102

-1

-2

ST100

D100

R104

ST101

ST102

R100

+

C100

R107

+

+

C110

Q100

R105

+

C101

Q102

+

C107

R108C110

D102

IC100

D104

IC101

R101

R102

R106

C114C111

C103+C104

+

C109 D105 C113

C108

D103

R103

C112

Q101C105

CN101-6CN107

CN103

-2

CN102

-2

CN103

-1

CN101

-5

CN102

-1

CN101

-4

CN103

-3

CN101-3CN107

CN101

-2

CN101

-1

(

(

(

Sorter

CN108

Sorter

CN107

CN108

CN107

Sorter

CN107

CN107

Main Board

-6

To

)

-1

To

)

-5

-2

-4

To

)

-3

-2

-1

[5]Vc

Zero

Cross

[0]GND

[0]GND

[24]VA

[0]GND

[30]VM

[0]GND

[24]VA

[5]VC

[30]VM

[0]GND

1-26

Page 28

SECTION 2

SECTIONAL DESCRIPTION

Page 29

1 July 1991

1. DRUM

1.1 OPC DRUM CHARACTERISTICS

An OPC has the characteristics of:

1. Being able to acce pt a high negat ive ele ctrical charge in the dark. (The

electrical resistance of a photoco nd uct or is high in the absence of light.)

2. Dissipatin g the ele ctrica l ch arg e whe n exp ose d to light . (Exp osu re to lig ht

greatly increases the conductivity of a photocond uctor.)

3. Dissipating an amount of charge in direct proportion to the intensity of the

light. That is, where stronger light is directed to the photoconductor

surface, a smaller voltage remain s on the OP C.

4. Being less sensitive to changes in temperatu re (whe n compared to

selenium F type drums). This makes it unnece ssary to monitor and

control the drum temperature.

2-1

Page 30

[F]

[D]

[E]

1 July 1991

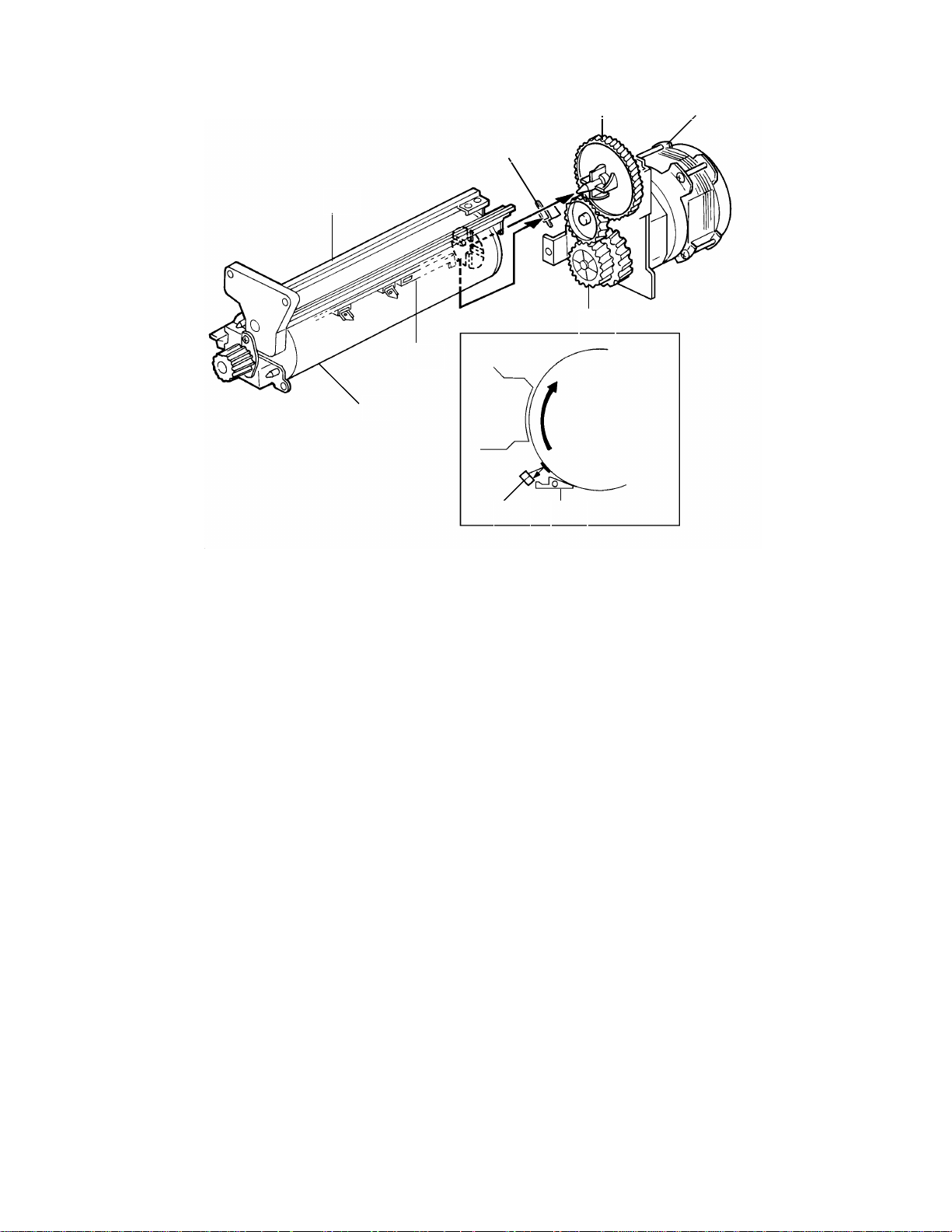

1.2 DRUM UNIT

[H]

[G]

[B]

[C]

[A]

[C]

An organic photoconducto r drum [A] is used on this model.

A drum unit [B] is used to hold the drum to pre ven t stress on the drum. The

drum unit consists of an OPC drum, ID sensor [C] and pick-off pawls [D].

When the drum is replaced, and/or th e pick-o ff pawls an d/ or the ID sen sor

are cleaned, the drum unit must be removed from the copier as a unit.

The drum is driven by the main motor [H] through the main mot o r ge ar [E ], a

relay gear and the drum drive gear [F]. The pick-off pawls [ D] are always in

contact with the drum surfa ce. The ID sen sor is elect rically connected to the

ID sensor connector [G].

2-2

Page 31

1 July 1991

1.3 HANDLING THE DRUM

The organic photoconductor drum is compa ratively more sensitive to light

and ammonia gas than a selenium drum.

1. Never expose the drum to direct sunlight.

2. Never expose the drum to direct light of more than 1,000 Lux for more

than a minute.

3. Never touch the drum surface with bare hands. Wh en the drum surf ace is

touched with a finger or beco mes dirty, wipe with a dry cloth or clean with

wet cotton. Wipe with a dry clot h after cleaning with wet co tt on .

4. Never use alco ho l to clea n th e dru m; alcohol dissolves the drum surface.

5. Store the drum in a coo l, dry pla ce away from heat.

6. Take care not to scra tch the drum as th e dru m la yer is thin and is easily

damaged.

7. Never expo se th e drum to corrosive gases such as ammonia gas.

8. Always keep the drum in th e pro te ctive shee t whe n inserting or pulling the

drum unit out of the copier to avoid exposing it to bright light or direct

sunlight. This will protect the dru m from light fatigue.

9. Before inserting or pulling out the drum unit, the follo wing shou ld be

performed to avoid damaging the drum:

a) Remove the cleaning unit.

b) Remove the development unit.

c) Remove the charge corona unit.

d) Release the transport unit.

10. Before pulling out the drum unit, place a sheet of paper under the drum to

catch any dropped toner.

11. Drum initial setting (SP #66) must be performe d whe n a new drum is

installed.

NOTE: This is not necessary at installation of a new machine as the drum

initial setting is performed at the factory.

12. Dispose of the used drum acco rdin g to local regulations.

2-3

Page 32

1 July 1991

2. DRUM CHARGE

2.1 OVERVIEW

[A]

[C]

[C]

[B]

[A]

This copier uses a single wire scorotro n and a highly sensitive OPC drum [A].

The corona wire [B] genera tes a corona of negative ions wh en the CC/B/G

power pack applies a high voltage . A sta inless steel grid plate [C] makes the

corona charge uniform. The dru m coat ing receives a uniform negative charge

as it rotates past the corona unit.

The exhaust blower, locat ed abo ve the cop y exit, causes a flow of air from

the upper area of the deve lopment unit through the charge corona unit. This

prevents uneven build -up of negative ions that ca n cau se un eve n image

density. The exhaust blower runs at half speed when in the stand-by

condition and runs at fu ll sp ee d while copying.

The exhaust blower has an ozone filte r (a ctive carbo ns) which adsorbs ozone

(O3) generated by th e coro na discharge. The ozone filter de crea ses in

efficiency over time as it adsorbs ozo ne. The ozone filter should be replace d

at every 60,000 copies.

The flow of air around the charge corona wire may deposit paper dust or

toner particles on the corona wire . The se pa rticle s may in te rfe re with

charging and cause low density ba nds on cop ies. The wire cleaner cleans

the corona wire when the op erator slides the corona unit in and out .

2-4

Page 33

2.2 CHARGE CORONA WIRE CLEANER MECHANISM

[B]

[A]

1 July 1991

[D]

[C]

Pads [A] above and below th e charge corona wire clean the wire as the

charge unit is manually slid in and out.

The cleaner pad bracket [B ] rotates when the charge unit is fully extended

and the bracket is pulled up against the rear block [C]. This moves the pads

against the corona wire (see illustra tio n). If the charge unit is not fully

extended, the pads do not tou ch th e corona wire.

The pads move away from the wire when the charg e unit is fu lly inse rte d an d

the cleaning bracket is pushed against the front block [D].

After copier installatio n the key operator should be instructe d ho w to use this

mechanism when copies have whit e stre aks.

2-5

Page 34

1 July 1991

2.3 CHARGE CORONA CIRCUIT

VA [24]

VC [5]

CC Trig [ 24]

Grid Trig (PWM) [ 0 0/5]

Grid FB

GND [0]

CN112-8

CN112-7

CN112-6

CN112-5

CN112-4

CN112-3

CN112-2

CN112-1

CN1-1

CN1-2

CN1-3

CN1-4

CN1-5

CN1-6

CN1-7

CN1-8

CC/Grid/Bias

Power Pack

(P1)

TC

TG

TB

Charge

Corona Wire

Grid

Development

Roller

Main Board (PCB 1)

The main board supplies +24 volt s to th e CC/G rid/Bias power pack at CN1-1

as the power supply source. About 0.44 seconds af te r t he Sta rt key is

pressed, the CPU drops CN1-3 fro m +24 volts to 0 volts. This energizes the

charge corona circuit within th e CC/G rid/Bias power pack, which applies a

high negative voltage of approximately –5.6 kv to the charge corona wire.

The corona wire then generates a negative corona charge.

The grid limits the charge voltage to ensu re th at the charge does not fluctuate

and an even charge is applied to the drum surf ace .

The grid trigger pulse applied to CN1-5 is a pulse width modulated signa l

(PWM signal). This signal is not only a trigger signal; it also chan ges the

voltage level of the grid. As the width of the pulse ap plie d incre ases, the

voltage of the grid also increase s. The CPU monitors the grid voltage at

CN1-7 and controls the wid th of th e grid trigger pulses based on this

feedback.

2-6

Page 35

1 July 1991

2.4 GRID VOLTAGE CORRECTION

There are two grid voltage correction factors. These correct fo r increases in

the drum residual voltage (Vr). The first such fact or, Vr correct ion, is done

every 1,000 copies. Vr correction is based on the data of the dru m coun te r

(SP #69) and the Vr correction ratio (L) (SP #67). The second factor, Vp

correction, corrects for changes in the photo con ductor’s chargeability. (The

chargeability of a new OPC drum may change after inst alla tio n, but this

stabilizes at around 2,000 copie s.) Vp correction is based on the drum

counter. The counter re set s to "0" whe n dru m initia l se tt ing (S P mod e #66) is

performed.

Both correction factors are applied to the copy pro cess as fo llows:

1. Image area

Grid Voltage = –920 volts

+

Vr Correction Factor.

Vr Correction Factor

L = Vrp/Vsg x 100 (Vr correction ratio)

2. Non-image are a

Grid Voltage = 0 volts (Fixed)

L Change of Grid Voltage

100 to 89 (%)

88 to 76 (%)

75 to 62 (%)

61 to 45 (%)

44 to 0 (%)

±0 (volts)

–40 (volts)

–80 (volts)

–120 (volts)

–160 (volts)

Vrp: ID sensor output for Vr correction pattern

Vsg: ID sensor output for bare drum

2-7

Page 36

1 July 1991

3. ID sensor pa tt ern area

Grid Voltage = –620 volts

Vp Correction Factor

+

Drum Counter

0 to 999 (copies)

1,000 to 1,999 (copies)

Over 2,000 (copies)

4. Vr correction pattern area

Grid Voltage = –500 volts (Fixed)

Vp Correction Factor

Black Color

±0 (volts)

–20 (volts)

–40 (volts)

±0 (volts)

±0 (volts)

–20 (volts)

2-8

Page 37

3. OPTICS

3.1 OVERVIEW

1 July 1991

[C] [B] [A] [E] [H] [F]

[D] [I] [G]

During the copy cycle, an image of the original is reflecte d onto the drum

surface through the optics assembly as follows.

Light Path:

Exposure Lamp [A] → Original → First Mirror [B] → Second Mirror [C]

→ Third Mirror [D] → Lens [E] → Fourth Mirror [F] → Fifth Mirror [G]

→ Sixth Mirror [H] → Drum [I]

[J]

The two optics cooling fans [J] draw cool air into the optics cavity. The air

flows from the right to the left in the optics cavity and exhausts through the

vents in the left cover. These fans operate during the copy cycle.

This copier has six standard reprod uct ion ratios: Three reduction ratios, two

enlargement ratios, and full size. It also has a zoom fun ctio n. The operator

can change the reproduction ratio in one perce nt steps from 50% to 200%.

Stepper motors are used to cha nge th e positio ns of the le ns and mirrors.

Separate motors a re use d be cause the wide range of reproduction ratios

makes it mechanically difficult fo r one moto r t o positio n both the lens and

mirrors. A stepper motor is also used to drive th e scanner. This motor

changes the scanner spe ed according to the reproduct ion ratio.

The thermoswitch opens at 130 oC and removes ac power to the exposure

lamp to prevent overh eating. The thermoswitch can be reset ma nu ally whe n

the exposure lamp area cools.

2-9

Page 38

[F]

1 July 1991

3.2 SCANNER DRIVE

[B]

[D]

[E]

[C]

[A]

[G]

3.2.1 1st and 2nd Scanner Drive Mechanism

This model uses a stepping moto r [A] to drive the scanners. Both ends of

each scanner are driven to pre vent skewing. The scanners have slid ers [B ],

which ride on guide rails.

The scanner home position is detected by the home position sensor [C]. The

scanner return position is determine d by cou nt ing the scann er mot or drive

pulses.

The first scanner [D], which consists of the exposu re lamp and the first mirror,

is connected to the scanner drive wire by the wire clamps [E]. The second

scanner [F], which consists of th e seco nd and third mirro rs, is conn ect ed to

the scanner drive wire by movable pulleys (the second scann er pulley [G ]).

The pulley moves the second scanne r at ha lf th e velo city of the first scanner.

This is to maintain the focal distance between the original and the lens during

scanning. This relationship can be expressed as:

V1r = 2 (V2r) = VD/r

where r = Reproduction ratio

V1r = First scann er velo city (whe n the reproduction ratio

is "r")

V2r = Seco nd scann er velo city (whe n the reproduction ratio

is "r")

VD = Drum peripheral velocity (12 0 mm/s)

2-10

Page 39

3.3 LENS DRIVE

: Reduction

: Enlargement

[D]

1 July 1991

[C]

[E]

[B]

[G]

[A]

[F]

3.3.1 Lens Drive

The lens motor [A] (stepper motor) changes the lens [B] position through the

lens drive wire [C] in accordance with the selected rep rod uction ratio to

provide the proper optical distan ce between the lens and the drum surface.

The rotation of the lens drive pulley moves the lens back and forth in discrete

steps. The home position of the len s is dete cte d by th e home position sensor

[D]. The main board keeps track of the lens position based on the number of

pulses sent to the lens mo to r.

3.3.2 Shading Mechanism

The shading plate s [E] are installed on the lens housin g [F] and are slid open

and shut by the shading cam [G]. This shading mechanism adju sts the

horizontal light inten sity, which be come s une ven in redu ctio n mode, when the

light at both edges is more intense. The shading plates close in reduction

mode to even out the ligh t int en sity.

2-11

Page 40

(100% → 141/155%)

(141/155% → 71/65%)

(71/65% → 93%)

(71/65% → 141/155%)

(141/155% → 122/129%)

(122/129% → 100%)

(100% → 71/65%)

(71/65% → 100%)

1 July 1991

3.3.3 Lens Positioning

[A] [C]

Home Position (100%)

[D]

[B]

(93% → 71/65%)

Reduction SideEnlargement Side

The lens home position sensor [A] informs the main board when the lens is at

full size position (home position). The main board dete rmine s the lens sto p

position in reduction an d en largement modes by countin g the number of

steps the motor makes with reference to the lens home position. When a new

reproduction ratio is select ed , th e lens [B] moves directly to the selected

magnification position.

The lens home position is registe red each time the lens starts from or passes

through the lens ho me posit ion sensor. As the lens moves fro m t he

enlargement side to the reduction side, the sensor registers the home

position. This occurs when the actu at or plate [C] enters the lens home

position sensor.

A small vibration can be observed when the lens moves through home

position from the red uct ion side to the enlargemen t side because the lens is

going in the wrong direction to register the home positio n. The len s

overshoots the home position by on ly one pulse before going back to register

the home position.

The lens always stops while moving from lef t to rig ht (as viewed from the

front) to minimize the erro r cause d by mechanical play in the drive gears [D].

2-12

Page 41

[A]

(71/65% → 100%)

1 July 1991

3.4 4TH AND 5TH MIRROR DRIVE

Home Position (100%)

[B]

(100% → 141/155%)

(141/155% → 71/65%)

(71/65% → 93%)

(93% → 71/65%)

(71/65% → 141/155%)

(141/155% → 122/129%)

(122/129% → 100%)

(100% → 71/65%)

3.4.1 Drive

The 4th/5th mirror drive motor (stepper motor) changes the 4th/5th mirror

assembly position throug h th e pin ion gears [A] and the rack gear [B] in

accordance with the selected reproduction ratio to provide the proper optical

distance between the lens and drum surf ace .

3.4.2 Positioning

The positioning mechanism is similar to that of lens po sitio ning, as shown in

the above positioning chart. The scanner always stops while moving from

right to left (as viewed from the fron t).

2-13

Page 42

1 July 1991

3.5 STEPPER MOTOR CONTROL CIRCUI T

Scanner

H.P. Sensor

(S1)

Lens

H.P. Sensor

(S2)

4th/5th

Mirror

H.P. Sensor

(S3)

CN122-3

CN122-4

CN122-5

CN102-7

CN102-8

CN102-9

CN102-10

CN102-11

CN102-12

CN806-3

CN806-2

CN802-1

CN824-3

CN824-2

CN824-1

CN826-3

CN826-2

CN826-1

[0] GND

[ 5]

Scanner H.P.

[5] VC

[0] GND

[ 5] Lens H.P.

[5] VC

[0] GND

[ 5] 4th/5th

Mirror H.P.

[5] VC

A [ 30 0/30]

A [ 30 0/30]

B [ 30 0/30]

B [ 30 0/30]

A [ 24 0/24]

A [ 24 0/24]

B [ 24 0/24]

B [ 24 0/24]

A [ 24 0/24]

A [ 24 0/24]

B [ 24 0/24]

B [ 24 0/24]

Main Board (PCB1)

VM [30]

VM [30]

VA[24]

VA[24]

VA[24]

VA[24]

CN105-1

CN105-2

CN105-3

CN105-4

CN105-5

CN105-6

CN102-1

CN102-2

CN102-3

CN102-4

CN102-5

CN102-6

CN106-1

CN106-2

CN106-3

CN106-4

CN106-5

CN106-6

CN825

6

5

4

3

2

1

Scanner

Motor

(M2)

1

2

3

4

5

6

Lens

Motor

(M3)

4th/5th

Mirror

Motor

(M4)

Step 1 2 3 4 5 6 7 8

A

B

A

B

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Com.

1

2 3 4

A

A

B

Com.

6

5

B

The scanner motor, th e len s mo to r, an d the 4th/5th mirror motor are all

stepper motors. The scanner mot or op era te s on +30 volts. Bot h the len s

motor and the 4th/5th mirror motor operate on +24 volt s. The stat ors of these

stepper motors have four coils (labeled A, B, A, B above), and th e rotor is

made of permanent magnets. Pulse signals energize the four coils as shown

in the above illustration. The roto rs o f these motors turn in discrete steps, and

48 steps are required for on e revo lution.

2-14

Page 43

1 July 1991

The lens motor and the 4th/5th mirro r moto r move at a const an t spe ed , bu t

the scanner motor speed varies acco rdin g to the reproduction ratio. The CPU

changes the pulse rate (pulse per second) to adjust the speed for the

selected reproduction ratio.

HP sensors inform the main board when the first scanner, lens, and 4th/5t h

mirror assembly reach their respective home positions. The main board

determines the stop position by count ing the numb er of steps the moto r

makes with reference to the home position.

2-15

Page 44

[A]

[C]

40 mm

1 July 1991

3.6 AUTOMATIC IMAGE DENSITY DETECTION

[B]

Sampled area

70 mm

A

B

Light from the exposure lamp is reflected from the original and tra vels to the

lens [A] via the mirrors. The auto ID senso r [B] , a phot odiode, is mounted on

the upper front frame. The sensor cover [C] has a hole in it to allow light to

fall directly onto the sensor. Sampling starts 10 millimete rs from th e leadin g

edge of the original and continued to 40 millimeters from the lead ing edge of

original in full size mode.

The length A and B in each rep roduction ratio are calcu lat ed as follows:

A=

10 mm

Reproduction Ratio (%)

x100

B=

Reproduction Ratio (%)

x100

The photosensor circuit converts the light intensity to a voltage. The dete cte d

voltage is amplified and sent to the main PCB. The CPU stores the voltage of

each sampled point in RA M. It the n comp utes the image density of th e

original from the maximum sample volt ag e and changes the development

bias accordingly. (See page 2-3 0 for d et ails. ) The exposure lamp voltage is

constant regardless of the image density of the origin al. (See page 2-1 8 for

details.)

2-16

Page 45

1 July 1991

3.7 EXPOSURE LAMP VOLTAGE CONTRO L

The main board controls the expo sure lamp voltage through the ac drive

board. The exposure lamp voltage is based on the base lamp voltage and

various correction factors. The exposure lamp data settin g dete rmine s the

base lamp voltage. The followin g table gives th e appro ximate lamp voltage

for each data setting.

Exposure Lamp Data/Voltage Reference Table

Exposure Lamp Voltage

Exposure

Lamp Data

100 57.1 105.9 126 71.9 133.4

101 57.6 106.9 127 72.5 134.5

102 58.2 108.0 128 73.0 135.5

103 58.8 109.1 129 73.6 136.6

104 59.3 110.1 130 74.2 137.6

105 59.9 111.2 131 74.7 138.7

106 60.5 112.2 132 75.3 139.8

107 61.1 113.3 133 75.9 140.8

108 61.6 114.4 134 76.5 141.9

109 62.2 115.4 135 77.0 142.9

110 62.8 116.5 136 77.6 144.0

111 63.3 117.5 137 78.2 145.1

112 63.9 118.6 138 78.7 146.1

113 64.5 119.6 139 79.3 147.2

114 65.0 120.7 140 79.9 148.2

115 65.6 121.8 141 80.5 149.3

116 66.2 122.8 142 81.0 150.4

117 66.8 123.9 143 81.6 151.4

118 67.3 124.9 144 82.2 152.5

119 67.9 126.0 145 82.7 153.5

120 68.5 127.1 146 83.3 154.6

121 69.0 128.1 147 83.9 155.6

122 69.6 129.2 148 84.4 156.7

123 70.2 130.2 149 85.0 157.8

124 70.8 131.3 150 85.6 158.8

125 71.3 132.4

115V machine

(Standard)

220/240V

Exposure

Lamp Data

machine

Exposure Lamp Voltage

(Standard)

115V machine

220/240V

machine

NOTE: Exposure lamp rating: 100V machine : 85V/300W

115V machine: 97V/300W

220/240V machine: 180V/330W

2-17

Page 46

1 July 1991

The exposure lamp voltage consist s of th e followin g 3 factors:

Exposure lamp voltage = Base lamp voltage factor

+

Reproduction ratio correction factor

+

Drum wear correction factor

3.7.1 Base Lam p Voltage Factor In Manual Image Densi ty Control

Darker Lighter

Manual ID Level 1234567

Exposure Lamp Data Vo –4

Vo ±0 Vo ±0 Vo ±0

Vo +4 Vo +8 Vo +12

The above table shows changes in the expo sure la mp data in manual image

density mode.

SP mode #48 sets the expo sure lamp da ta for level 4 (Vo) of manual imag e

density mode. A value from 100 to 150 can be select ed .

3.7.2 Base Lamp Voltage Factor In Auto Image Density Contr ol

In auto ID mode, the CPU selects the level 4 (Vo) exposu re lamp dat a

regardless of the input from the auto image density sensor. When the auto

image density level is set to lighter in SP mod e #34, the expo sure lamp da ta

changes to that of man ua l ID level 5 as sho wn be low. When the auto image

density level is set to darker, the develop men t bias shifts +40 volts. Only the

development bias varies acco rding to the input from the auto imag e density

sensor. (See page 2-30).

Auto Image Density Level (SP mode #34)

Auto Image Density

Level

Normal 0

Darker 1

Lighter 2

SP Data

(SP mode #34)

Exposure Lamp Data

Same as level 4

(Vo ±0)

Same as level 4

(Vo ±0)

Same as level 5

(Vo +4)

Development Bias

Shift

±0 volts

+40 volts

±0 volts

2-18

Page 47

3.7.3 Reproduction Ratio Corr ection Factor

Exposure

Lamp

Data

+10

+5

+0

-

1 July 1991

Lighter

50 100

62

140 150 160 180 200 (%)

Reproduction Ratio

For the reduction and en larg ement reproduction ratios the light path is longe r

than for the full size reproduct ion ratio. For this reason, the expo sure lamp

voltage is increased whe n red uction or enlargemen t is selected. The above

chart shows the exposu re lamp data at various reprodu ctio n ratios.

2-19

Page 48

1 July 1991

3.7.4 Drum Wear Correction Factor

Exposure

Lamp

Data

+10

(Max)

SP #61 = 0

+5

+0

-

0 10203040 60708090 110 (Hours)

50 100

SP #61 = 1

Main Motor On Time

To compensate for OPC drum wea r ca use d by con ta ct with the cleaning

brush, the exposu re lamp voltage is increased at set intervals of main motor

ON time. When SP mode #61 is set to 0, exp osu re lamp dat a is increa sed 1

at 10-hour intervals. When SP mode #61 is set to 1, the dat a is increa sed 1

at 20-hour intervals. The total increase cannot excee d 8.

2-20

Page 49

3.8 EXPOSURE LAMP CONTROL CIRCUI T

Main Board (PCB1) AC Drive Board (PCB2)

1 July 1991

CN108-1

Zero

Cross

240V

T402

CN419-1

Thermo-

SW (TS)

Exposure

Lamp

(L1)

CN419-2

T407

A

D

AC115V

AC220V

AC240V

B

CPU

(EXPO)

E

Feed back signal

+24V

TP111

0V

CN122-7

CN122-6

CN122-13

CN401-8

CN401-7

CN401-2

VR401

R403

R401

C

24V

0V

Trigger Pulse

CN122-10

AC power

Zero cross

Trigger pulse

Lamp power

Feedback

signal

CN401-5

A

B

C

D

E

PC401

R404

R404

C401

ZD

401ZD402

ZD

403ZD404

R411

TRC401

D401

R406

R413

DB401

CR401

L401

L402

CN421

220V

220V Only

TR401

C411

Feedback

The main board sends lamp trigger pu lses to the ac drive board from

CN122-10. PC401 activates TRC401, which provid es ac power to the

exposure lamp, at the trailing edge of each trigger pu lse.

The voltage applied to the expo sure lamp is also provided to the fee db ack

circuit. The feedback circuit steps down (TR401), rectif ies (DB401), and

smoothes (zener diodes and capacitors) the lamp voltage. The CPU monit ors

the lowest point of the smoot he d wave (f eedb ack sign al), which is directly

proportional to the actu al lamp voltage.

The CPU changes the timing of the trigger pulses in response to the

feedback voltage. If the lamp voltage is too low, the CPU sends the trigg er

pulses earlier so that more ac power is applie d to the expo sure lamp. This

feedback control is performed instantly; so, the lamp voltage is always sta ble

even under fluctuating ac power conditions.

The voltage applied to the expo sure lamp can be changed with SP mode #48

(Light Intensity Adjustment). The ADS voltage ad just ment (SP mode #56)

must be done whenever the light intensity adjust men t is done.

2-21

Page 50

1 July 1991

3.9 SERVICE CALL CONDITIONS

Service Code 11: Exposure Lamp Error

The feedback signal becomes high er th an 4.2 volts (r.m.s.) for 1.0

second when the exposure lamp is on, or it becomes higher than 1.0

volt (r.m.s) for 1.0 second when the exp osu re lamp is off.

Service Code 12: Exposure Lamp Error

The feedback signal falls belo w 0.5 volt (r.m. s.) fo r 1.0 second when

the exposure lamp is on, or th e exp osure lamp stays on for longer tha n

10 seconds.

Service Code 13: Zero Cross Signal Error

The CPU does not receive the zero cross signal with in 0.56 second.

Service Code 21: Scanner Home Position Error

The scanner home position sensor rema ins off (LOW) 8 seconds after

the main switch is turned on.

Service Code 22: Scanner Home Position Error

The scanner home position sensor is still on (HIGH) 1.0 secon d afte r

the scanner starts.

Service Code 28: Lens Home Position Error

The lens home position sensor remains of f (LO W) 3 .5 seconds after the

lens moves to the home position.

Service Code 29: Lens Home Position Error

The lens home position sensor is still on (HIGH) 3.5 secon ds afte r the

lens leaves the home position.

Service Code 2A: 4th/5th Mirror Home Position Error

The 4th/5th mirror home position sensor is still on (HIGH) 2.5 seconds

after the 4th/5th mirror assembly moves to the home position.

Service Code 2B: 4th/5th Mirror Home Position Error

The 4th/5th mirror home position sensor is still off (LOW) 2.5 seconds

after the 4th/5th mirror assembly leaves the home position.

2-22

Page 51

4. ERASE

Lo

Lc

4.1 OVERVIEW

1 July 1991

LE

EL

SE

ES

LE: Lead edge erase margin 2.5 ±1.5 mm

SE: Side erase margin 2.0 ±2.0 mm on each side;

total of both sides 4 mm or less

LO: Original width

LC: Charged width of drum

EL: Lead edge erase

ES: Side erase

The erase lamp [A] consist s of a line of LE Ds extending across the full width

of the drum [B].

The erase lamp has three functio ns: lead ing edg e era se, side era se, and trail

edge erase. Trail edge erase begins after the trailing edge of the copy paper;

therefore, the trailing edge of the copy will not be era sed .

2-23

Page 52

1 July 1991

abcd e f g h f e d bac

4.1.1 Lead Edge Erase

The entire line of LEDs turns on when the main mot or tu rns on . The y stay on

until the erase margin slight ly overla ps the lead edge of the original ima ge

area on the drum (Lead Ed ge Erase Ma rgin ). This prevents the toner den sity

sensor pattern fro m being developed every copy cycle and the shadow of the

original edge from being deve loped on the paper. At this point, side erase

starts. The width of th e lead edge erase margin can be adju sted using SP

mode #41.

During the image density detection cycle (once eve ry ten copy cycles), a

block of erase lamps (labele d "h" ab ove ) t urn s off long enough for the senso r

pattern to be developed.

The entire line of LEDs turns on when the re sidu al volt ag e on the OPC dru m

is being detected (Vr correction).

4.1.2 Side Erase

Based on the combinat ion of copy paper size and the reproduction ratio data,

the LEDs turn on in blocks (labeled "a" – "h" above ). This reduces toner

consumption and drum cleaning load.

2-24

Page 53

1 July 1991

The following table shows which erase lamp LEDs turn on.

Blocks On Paper Size Reproduction Ratio (%)

None

a

a – b

a – c

a – d

a – e

a – f

a – f, g

All

A3, A4 sideways

11" x 17", 11" x 8 1/2

B4

8 1/2" x 11", 8 1/2" x 5 1/2"

A4 lengthwise

B5 lengthwise

A5 lengthwise, 5 1/2" x 8 1/2"

98 – 200

92 – 97

86 – 91

80 – 91

71 – 79

61 – 70

50 – 60

For ID sensor pattern

For Vr correction

4.1.3 Trailing Edge Erase

The entire line of LEDs tu rns on aga in to erase the trailing edge aft er th e

latent image has passed. This prevents the trailing edge from appearing on

the copy. The LEDs stay on to era se th e leading edge of the laten t image in

the next copy cycle. After th e final copy, the erase lamps t urn off at th e same

time as the main motor.

2-25

Page 54

1 July 1991

5. DEVELOPMENT

5.1 OVERVIEW

[E]

[A] [D]

[C][B]

[F]

When the main motor turns on, th e pa ddle roller [A] development roller [B]

the auger [C], and the agitator [D] start turnin g. The paddle rolle r picks u p

developer in its paddles and transports it to the development roller. Internal

permanent magnets in the development roller attract the developer to the

development roller sleeve .

The turning sleeve of the deve lop ment roller then carries the developer pa st

the doctor blade [E]. The doct or blade trims the developer to the desired

thickness and creates backsp ill to th e cross-mixing mechanism.

The development roller con tin ue s to tu rn, carrying the deve lop er to the OPC

drum. When the developer bru sh con ta cts th e dru m surface, the negatively

charged areas of the drum surfa ce at tra ct an d hold th e positive ly ch arg ed

toner. In this way, th e lat en t imag e is d eve loped.

The development roller is given a negat ive bia s to pre ven t toner from being

attracted to non-image areas on the drum that may have resid ual neg ative

charge. The bias also controls image density.

After turning abou t 10 0 de gre es more, the development roller rele ases the

developer to the deve loper tank. The develope r is agita te d by the paddle

roller, agitator [D], an d th e cross-mixin g mechanism.

Rotation of the pad dle roller and development ro ller te nd to cau se air

pressure inside the unit to become hig he r tha n the air pre ssure arou nd the

development unit. A hole, fitted with a filter [F], has been added to the top of

the unit to relieve air pressure and to minimize toner scattering.

2-26

Page 55

5.2 DRIVE MECHANISM

[I]

[H]

[J]

1 July 1991

[G]

[E]

[B]

[F]

[D]

[A]

[C]

When the main motor turns, the rota tion is transmitted from the develo pment

drive gear [A] to the deve lop ment roller gear [B] throug h the development

clutch [C]. (The rotation is transmitted to the development drive gear wh en

the development sole no id [D] is de-energized.) Then, the rotation is

transmitted from the develo pment roller gear to the paddle roller gear [E]

through the idle gea r [ F].

A gear [G] on the front end of the paddle roller shaft drives the auger gear [H]

and the agitator gear [I]. The padd le rolle r shaf t ha s a knob [J] on the fron t

end so that it can be turned manually to exchange toner. The knob has a

one-way clutch inside. The one-wa y clutch prevents the developmen t roller

from turning in the wrong direction.

The development clutch solenoid energizes each copy cycle after image

development is completed. This stops the rollers, reducing developer fatigue.

2-27

Page 56

1 July 1991

5.3 CROSS-MIXING

[F]

[A]

[B]

[E]

[D]

[C]

This copier uses a standard cross-mixing mechanism to keep the toner and

developer evenly mixed . It also he lps ag ita te the developer to prevent

developer clumps from forming and help s create the trib oelectric charge.

The developer on the turnin g de velo pment roller is split into two parts by the

doctor blade [A]. The part tha t stays on the development roller [B] forms the

magnetic brush and develops the latent image on the drum. The part that is

trimmed off by the doctor blade goes to the backspill plate [C].

As the developer slides down the backspill plate to the agit ator [D], the mixing

vanes [E] move it slightly toward the re ar of the unit . Pa rt of the developer

falls into the auger inlet and is transported to the fro nt of the unit by the auge r

[F].

The agitator moves th e de velo pe r slig ht ly t o th e fro nt as it turn s, so the

developer stays level in th e de velo pment unit.

2-28

Page 57

1 July 1991

5.4 DEVELOPMENT BIAS FOR IMAGE DENSITY CONTRO L

Image density is controlled by chan gin g two it ems: (1) the strength of the bias

voltage applied to th e de velo pment roller sleeve, and (2) the stren gth of the

voltage applied to th e exp osure lamp.

Applying a bias voltage to the development sleeve reduces the potential

between the develo pment roller and the drum, th ereby reducing the amoun t

of toner transferred. As the bias voltage beco mes greater, the copy image

becomes lighter. Similarly, incre asing the voltage to the exposure lamp

causes an increase in light intensity which also results in lighter copies.

The method of control is different dependin g on whethe r the ima ge density is

manually selected or the au tomatic ID mode is used.

The development bias ap plie d to the development rolle r sleeve has the

following three factors:

Development bias voltage = Base bias volta ge fact or

(Manual or automatic image density control)

+

Base bias voltage adjustmen t fa ctor

+

Vr correction factor

The base bias voltage for non-image areas is –200 volts (Fixed ).

5.4.1 Base Bias Voltage Factor In Manual Ima ge Dens ity Control

Darker Lighter

Manual ID Level1234567

Base Bias Voltage –120 –120 –160 –200 –200 –240 –280

Exposure Lamp Data Vo –4 Vo Vo Vo Vo +4 V o+8 Vo+12

In manual ID control mode, the base bias volt ag e depe nds on th e man ually

selected ID level. The voltag e applied at each ID level is shown in the above

table. The base exposu re lamp voltage also varies dependin g on the ma nual

ID level as shown in the table. (See pa ge 2-18 for more in formation.)

2-29

Page 58

1 July 1991

5.4.2 Base Bias Vol tage Factor In Automatic Image Density Control

In automatic image density contro l mode , th e base exp osure lamp voltage is

fixed to Vo. (See page 2-18 for more information.) Image density is cont rolle d

by changing only the base bias voltage.

The base bias voltage depends on the backg round image density of the

original, which is measured using the origin al ID sen sor. (See page 2-18 for

more information.)

The CPU checks the voltage output from the automa tic ID circuit . This circuit

has a peak hold function. The peak hold volta ge corresp on ds to the

maximum reflectivity of the original. The CPU then det ermin es the pro per

base bias level with refere nce to th e pe ak ho ld voltage.

The following table gives th e ba se bias voltages at each ADS outpu t leve l.

When the automatic density level is set to darker by SP mode #34, the base

bias voltage shifts +40 volts as shown in th e following table.

Base Bias Voltage

K

K ≥ TH1

TH1 > K ≥ TH2

TH2 > K ≥ TH3

TH3 > K

Normal or Lighter

(SP mode #34 = 0 or 2)

–200 volts

–260 volts

–320 volts

–380 volts

Darker

(SP mode #34 = 1)

–160 volts

–220 volts

–280 volts

–340 volts

ADS Output Voltage (Peak Hold Voltage )

K =

ADS Adjusted Voltage (SP #56)

TH1 to 3: Threshold level (Se e the following table.)

To maintain the correct image density, the lamp da ta is incre men te d whe n

the reproduction ratio is changed and/or dru m wear correction is done. This

increment in the lamp data increases the intensity of lig ht re fle cted from the

original. Therefore, the ADS output voltage also changes.

In order to maintain a const an t volt ag e for the same original when the lamp

data is incremented, the th reshold levels are shifted with each incre ment in

the lamp data as shown in the following table.

Increase of

lamp data

TH1 0.70 0.75 0.80 0.85 0.89 0.94 0.98 1.03 1.08 1.12

TH2 0.66 0.70 0.74 0.78 0.83 0.87 0.91 0.96 1.00 1.04

TH3 0.29 0.31 0.33 0.35 0.37 0.39 0.41 0.43 0.45 0.48

+0 +1 +2 +3 +4 +5 +6 +7 +8 +9

2-30

Page 59

5.4.3 Base Bias Vol tage Adjustment Factor

Base Bias Adjustment

(Black toner: SP mode #37, Colo r Toner: SP mode #79)

1 July 1991

Image Density

SP Data

(SP mode #37 or #79)

Change of

Base Bias Voltage

Normal 0 ±0 volts

Darkest 1 +40 volts

Darker 2 +20 volts

Lighter 3 –20 volts

Lightest 4 –40 volts

The base bias voltage can be changed in SP mode #37 for black toner or

#79 for color toner to adju st the image density level. The ab ove tab le gives

the base bias voltage fo r each SP mod e setting. This adjustme nt shou ld be

done only when the exposure lamp volt age ad just ment (SP mode #48) fails

to achieve the desired image density.

5.4.4 Vr Correction Factor

As the OPC drum is used, drum residual voltage (Vr) gradually increases. Vr

correction compensate s fo r resid ua l volta ge on the dru m. Vr corre ctio n is

done every 1,000 copies based on the dat a of the drum cou nter (SP mode

#69) and the Vr correction ratio (L) (SP mode #67). The following chart

shows how the bias voltage changes depe nding on the Vr correction ratio (L).

Vr Correction Factor

L Change of Bias Vo ltage

100 to 89 (%)

88 to 76 (%)

75 to 62 (%)

61 to 45 (%)

44 to 0 (%)

±0 (volts)

–40 (volts)

–80 (volts)

–120 (volts)

–160 (volts)

NOTE: L = Vrp/Vsg x100 (Vr Correction Ratio)

Vrp: ID sensor output for Vr corre ctio n pa tt ern

Vsg: ID sensor output for ba re drum

When the Vr correction is made every 1,0 00 copie s, all blocks of erase lamps

turn on and the development bias becomes 0 volts to deve lop the Vr

correction pattern.

2-31

Page 60

1 July 1991

5.5 DEVELOPMENT BIAS CIRCUI T

VA [24]

VC [5]

Bias Trig (PWM) [ 0 0/5]

Bias FB

GND [0]

CN112-8

CN112-7

CN112-6

CN112-5

CN112-4

CN112-3

CN112-2

CN112-1

CN1-1

CN1-2

CN1-3

CN1-4

CN1-5

CN1-6

CN1-7

CN1-8

CC/Grid/Bias

Power Pack

(P1)

TC

TG

TB

Charge

Corona Wire

Grid

Development

Roller

Main Board (PCB 1)

The main board supplies +24 volt s to th e CC/G rid/Bias power pack at CN1-1

as the power supply source. When the Start key is pressed , th e CPU starts